ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY ASIATIC & PACIFIC EDITION INTERNATIONAL MAGAZINES .it 20222023 Supplemento a TecnAlimentaria N° 11 Novembre 2022 Poste Italiane SpA - Spedizione in Abbonamento Postale D.L. 353/2003 (conv. in L. 27/02/2004 n. 46) art. 1 comma 1 NE/TV - Anno 27 N°11 - 2022 - ISSN 2498-9541

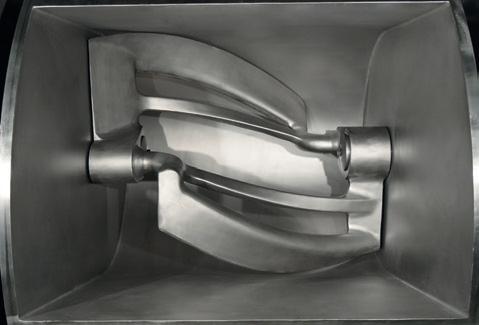

TWO ARMS MIXER IBT SERIES 45 kg up to 160 kg Via Tretti Marotti, 4 Grisignano di Zocco 36040 (VI) - Italy T +39 0444 414735 F +39 0444 414719 E info@teknostamap.com PLANETARY MIXER TK 2

TecnAlimentaria

November 2022 Year XXVII

Publisher: Fabiana Da Cortà Fumei

Editorial Staff & Design redazione@tecnalimentaria.it Sabrina Fattoretto Claudia Bosco Elena Abbondanza

Marketing and Advertising Anita Pozzi anita.pozzi@edftrend.com Franco Giordano franco.giordano@edftrend.com

Management, Editorial Office

Editrice EDF Trend srl Corso del Popolo, 42 31100 Treviso – Italy Tel. +39 0422 549305 Fax +39 0422 591736 www.tecnalimentaria.it www.edftrend.com

Printing: L’Artegrafica Srl

Autorizzazione Tribunale di Forlì n. 5 del 19.01.1996 N° iscrizione ROC: 22054 (Registro degli Operatori di Comunicazione) In questo numero la pubblicità non supera il 45% Sped. in abbonamento postale 45%Art. 2 Comma 20/B Legge 662/1996 DCI-TV All right reserved.

Reproduction in whole or in part without written permission is prohibited. The Publisher is not responsible for any materials, nor for writers’ nor contributors’ expressed or implied opinions. Informativa ex D.lgs 196/03 Ai sensi dell’art.2 comma 2° del Codice Deontologico dei giornalisti si rende nota l’esistenza di una banca dati di uso redazionale presso la sede di Corso del Popolo, 42 - Treviso. Responsabile del trattamento dati è il direttore responsabile a cui ci si può rivolgere presso la sede di Treviso - Corso del Popolo, 42 per i diritti previsti dalla legge 675/1996.

Member of:

ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY ASIATIC & PACIFIC EDITION INTERNATIONAL MAGAZINES .it 20222023 Supplemento a TecnAlimentaria N° 11 Novembre 2022 Poste Italiane SpA - Spedizione in Abbonamento Postale D.L. 353/2003 (conv. in L. 27/02/2004 n. 46) art. 1 comma 1 NE/TV - Anno 27 N°11 - 2022 - ISSN 2498-9541

N°11

supplement

TecnAlimentaria is a magazine by INTERNATIONAL MAGAZINES .it TECNOLOGIE PER L’INDUSTRIA DEGLI ALIMENTI E MANGIMI PER ANIMALI FOOD ET ANIMAL FEED & TECHNOLOGY D.L. 353/2003 (conv. L. 27/02/2004 n. 46) art. comma NE/TV Anno 24 N° 4/2019 ISSN 2498-9541 Plastics Rubber &

EDITRICE EDF TREND SRL INTERNATIONAL MAGAZINES year XXVI INTERNATIONAL MAGAZINES .it INTERNATIONAL MAGAZINES.it Supplemento TecnAlimentaria Agosto/Settembre Poste Italiane Spedizione in Abbonamento Postale D.L. 353/2003 (conv. in L. n. 46) art. 1 NE/TV N°8/9 2022 2498-9541 2022/2023 ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY FOOD INDUSTRY Technology for the Food Industry - International magazine in Italian/English www.tecnalimentaria.it N°10 Ottobre / October 2022 Italiane SpA Abbonamento D.L. 353/2003 (conv. in L. 27/02/2004 46) art. comma NE/TV Anno N°10/2022 ISSN ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY TECNOLOGÍA ITALIANA PARA LA INDUSTRIA ALIMENTARIA AMERICAS EDITION Supplemento TecnAlimentaria Luglio/July 2022 Italiane SpA Spedizione Abbonamento D.L. 353/2003 in L. 27/02/2004 46) NE/TV N°7 2498-9541 MAGAZINES .it 2022/2023

www.edftrend.com - www.tecnalimentaria.it www.petfoodtechnology.com www.tecnaplastics.com

FOOD INDUSTRY INDEX

FIELD PAGES WEBSITE COMPANY

4G GHIDINI SRL www.4gghidini.it 10-11 Food Industry

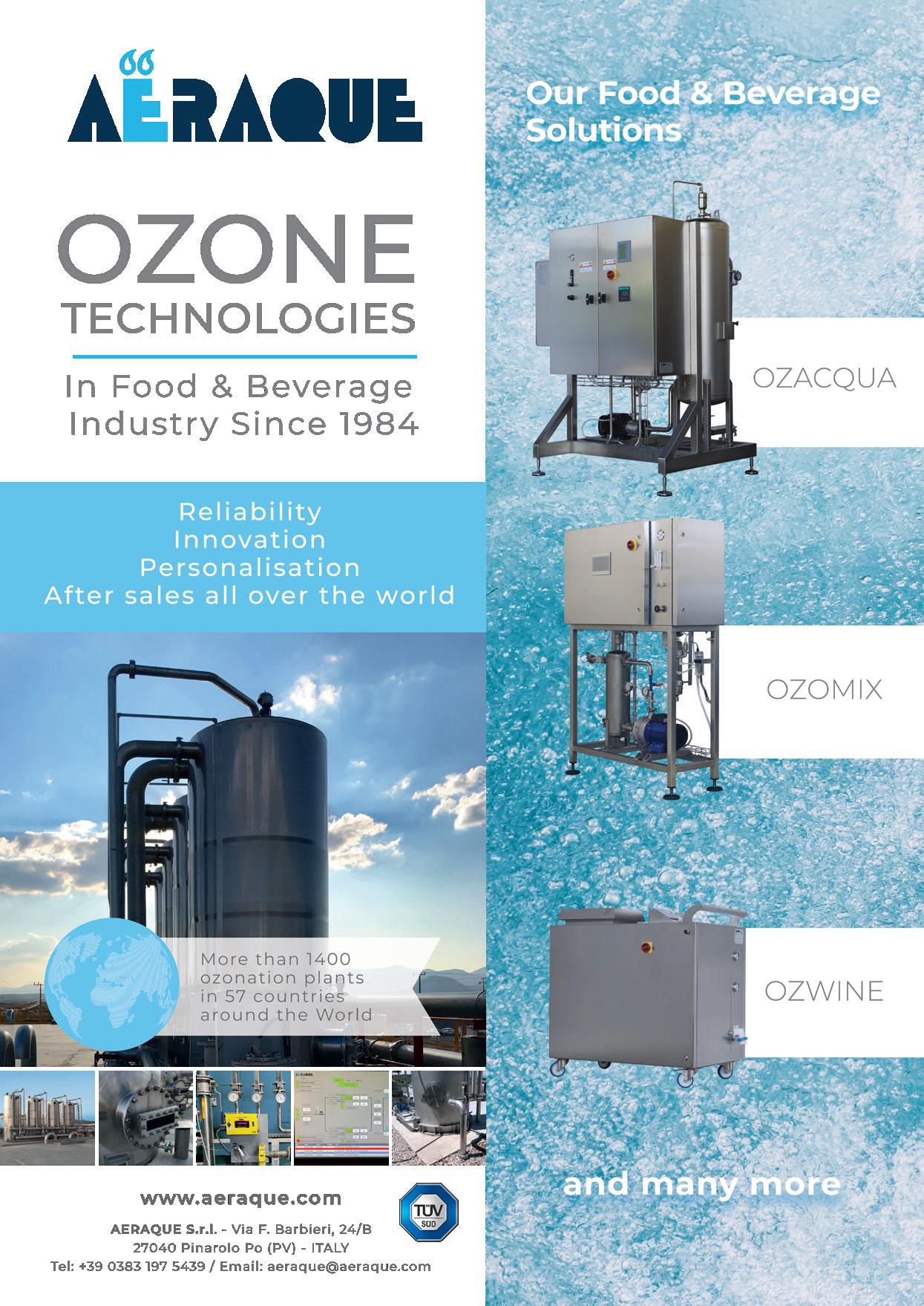

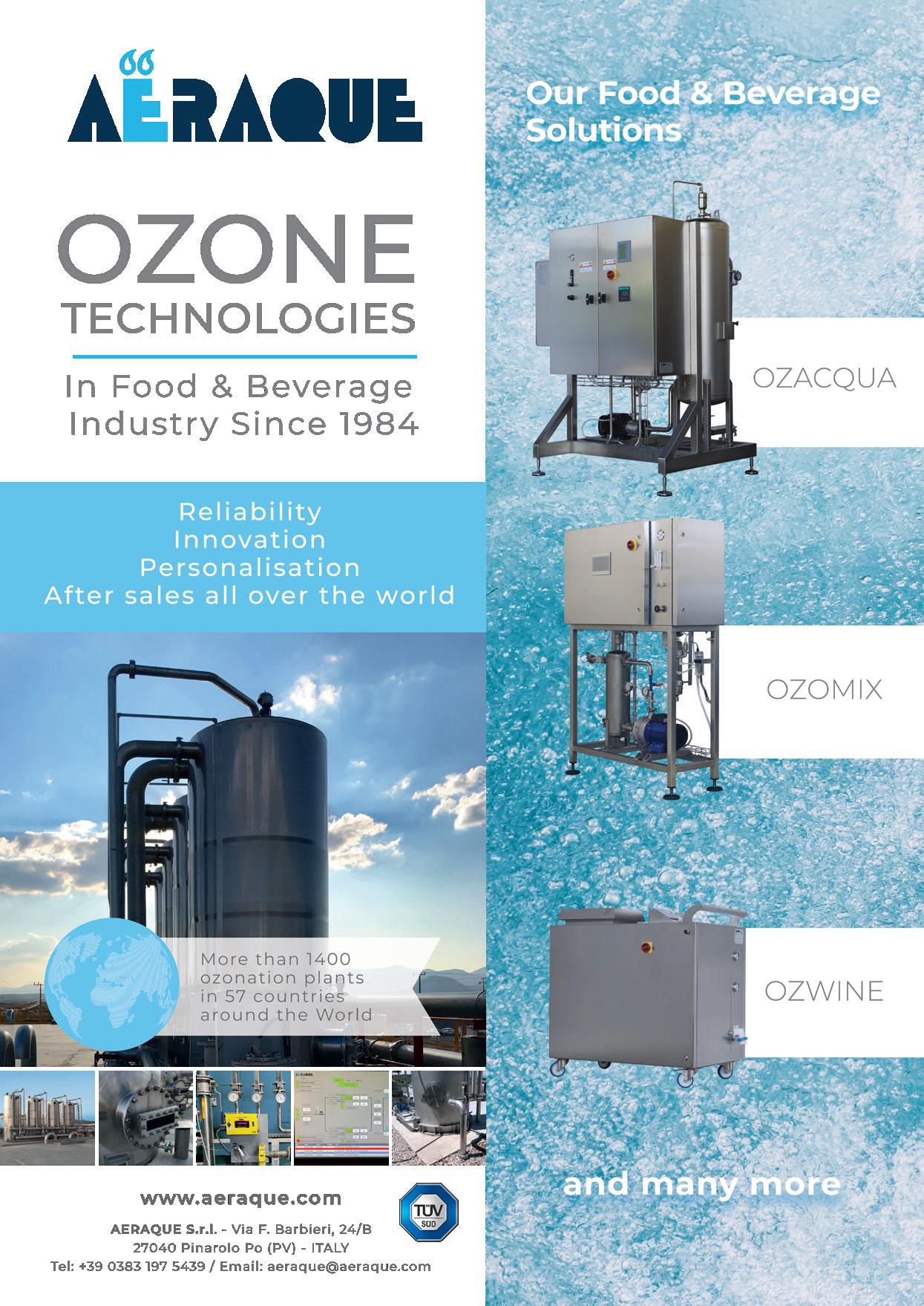

AERAQUE SRL www.aeraque.com 9 Food & Beverage Industry

AZ GOMMA SRL www.azgomma.it 61 Food Industry

BELLINTANI ZENO www.bellintani.it 12-13 Food Industry

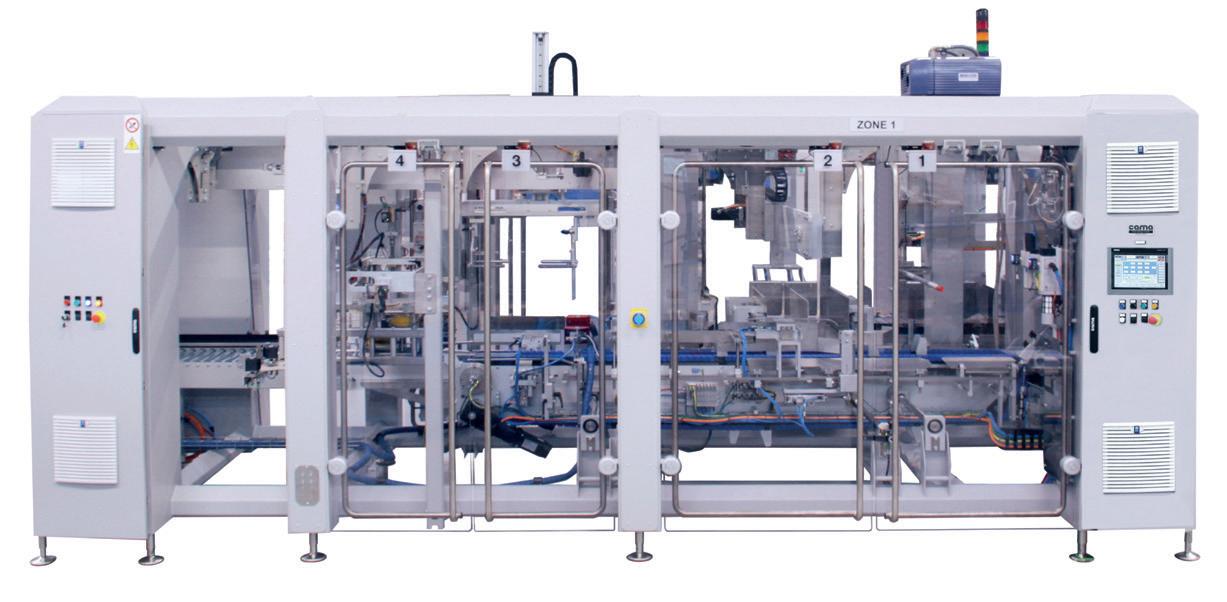

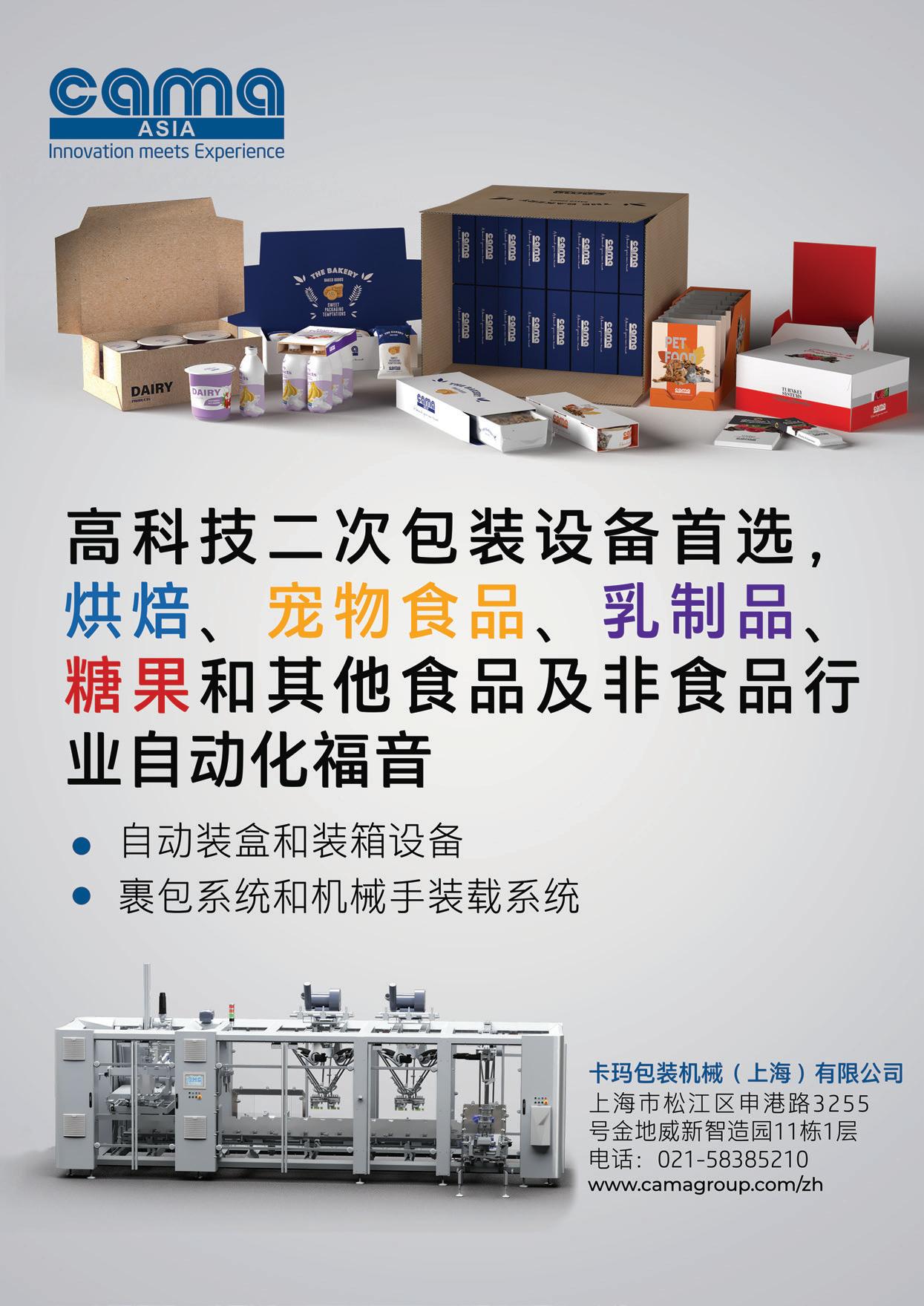

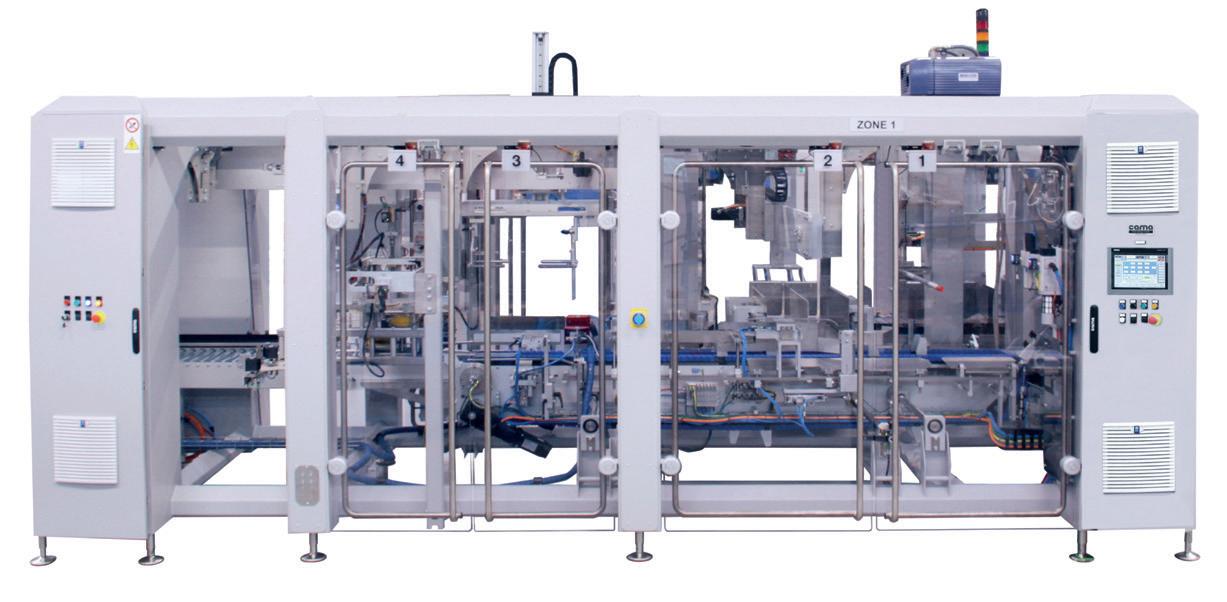

CAMA GROUP www.camagroup.com 17-19 Food Industry

CM TECHNOLOGIES www.cm-technologies.biz 15 Food Industry

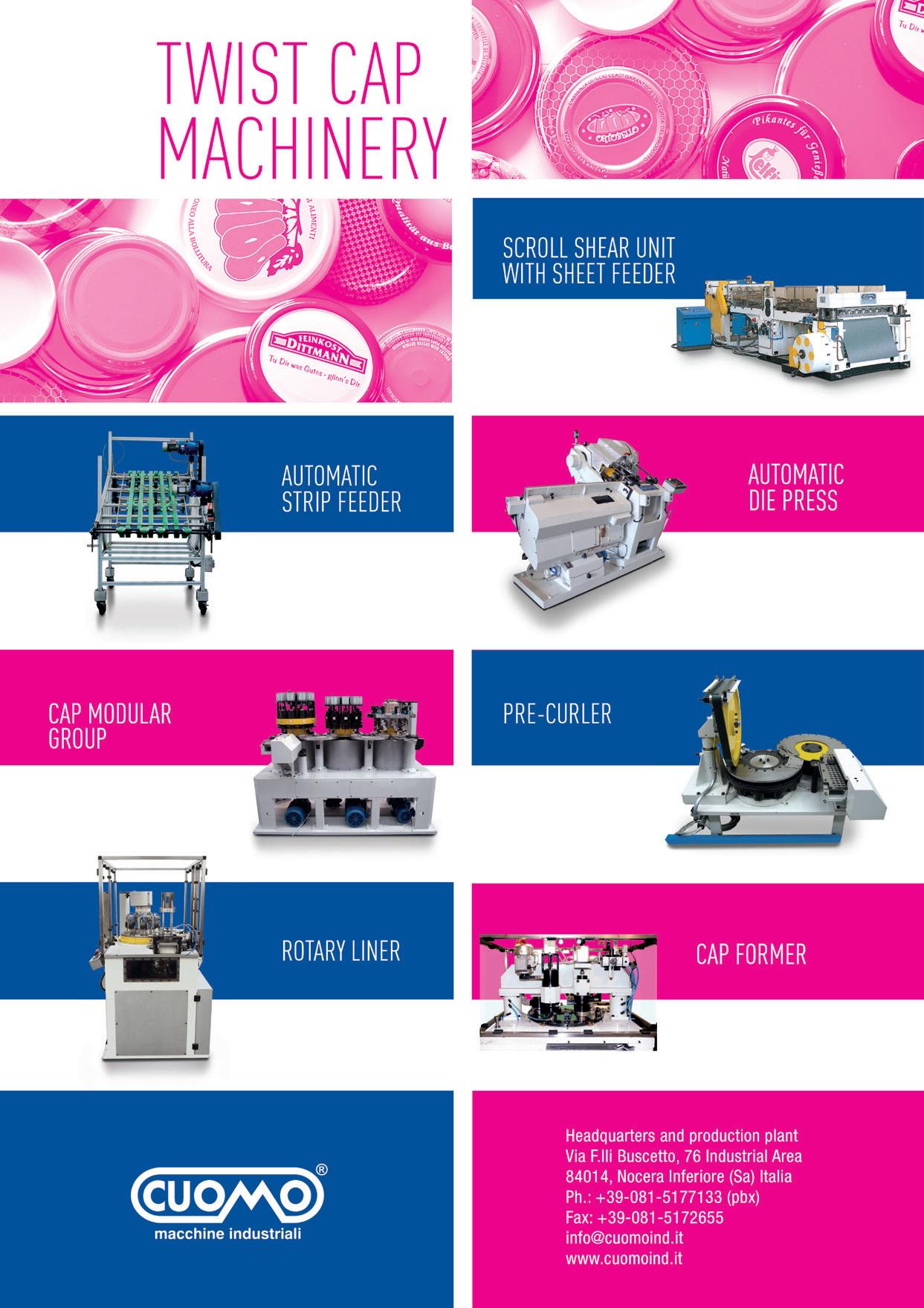

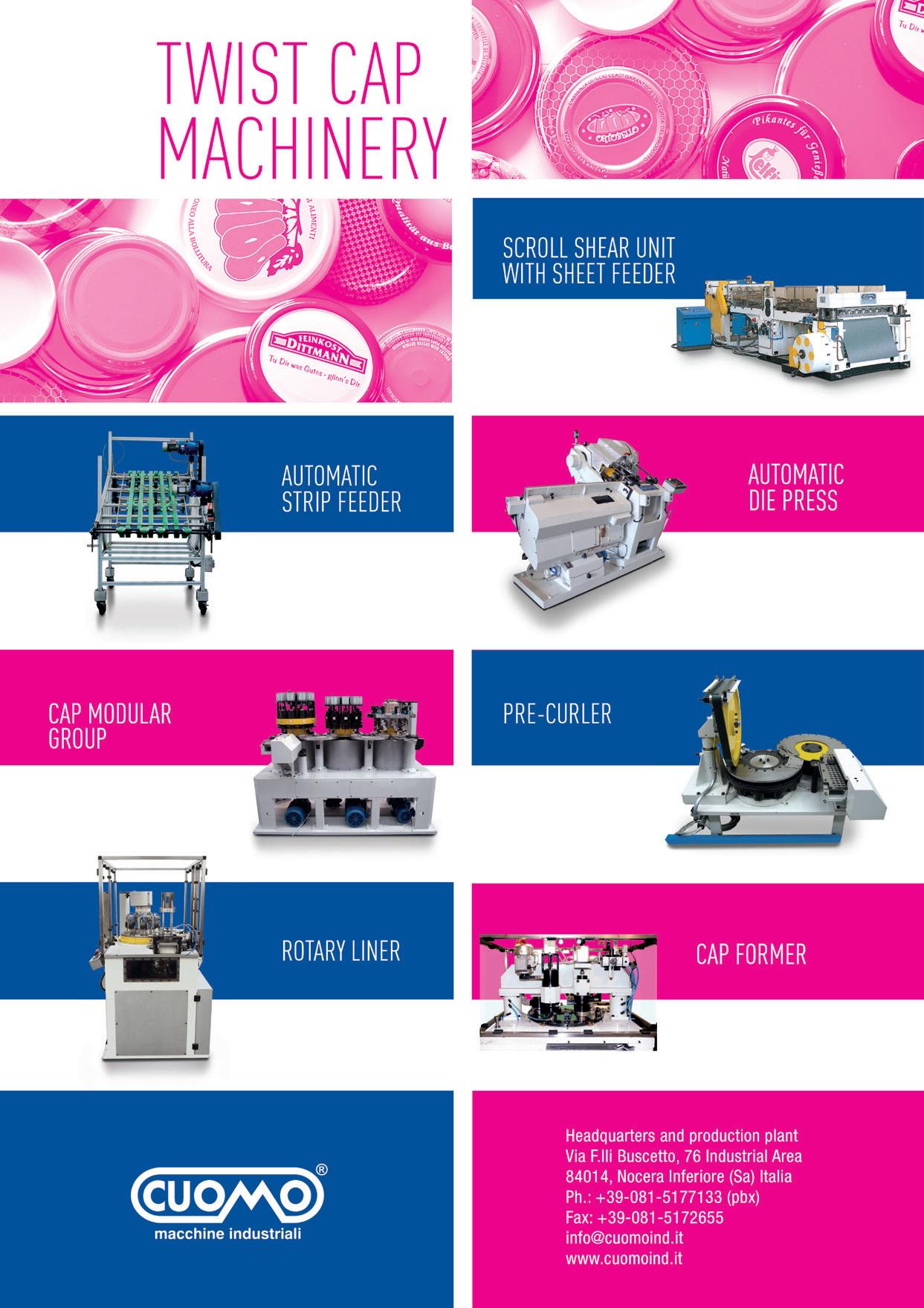

CUOMO F.LLI www.cuomoind.it II^ Cover, 20-23 Food Industry

DEFINO & GIANCASPRO SRL www.defino-giancaspro.com 24-25 Food Industry

ELVEM SRL www.elvem.it 8 Food & Beverage Industry

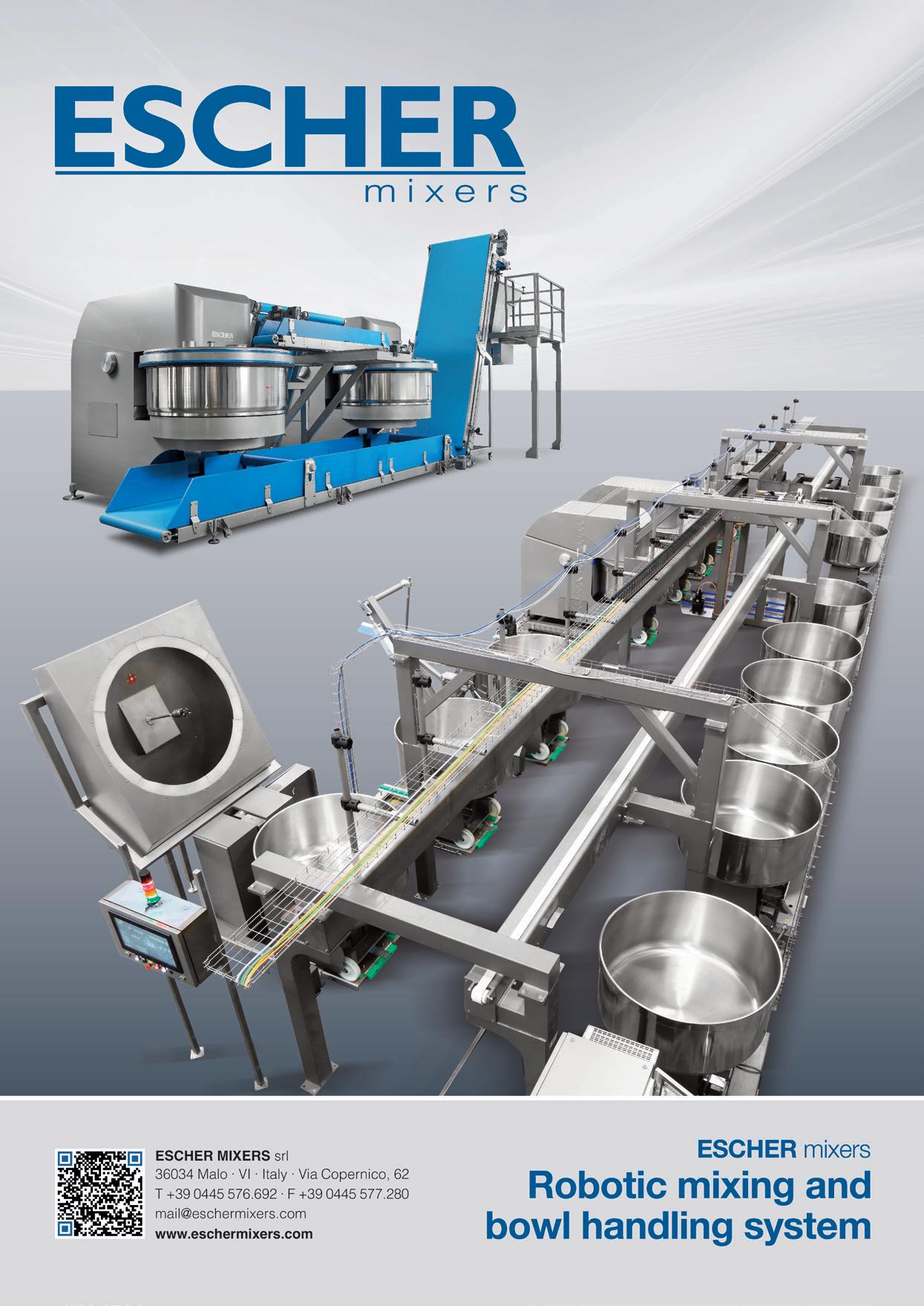

ESCHER MIXERS SRL www.eschermixers.com 26-27 Food Industry

EUROPA SRL www.europa-zone.com 28-29 Food Industry

FAVRIN SRL www.favrinsrl.com 30-31 Food Industry

FIC SPA www.fic.com 32-33 Food Industry

G.MONDINI SPA www.gmondini.com 35-37 Food Industry

GENERAL SYSTEM PACK SRL www.gsp.it 74-75 Food Industry

IFP PACKAGING SRL www.ifppackaging.it 74-75 Food Industry

INOX MECCANICA SRL www.inoxmeccanica.it 40-41 Food Industry

ITALPAN www.italpan.com 38-39 Food Industry

KMP SRL www.kmp.srl 5, 42-43 Food Industry

LANDUCCI SRL www.landucci.it 44-45 Food Industry

LCZ SRL www.lcz.it 46-47 Food & Beverage Industry

METALMONT SRL www.metalmont.it 48-49 Food Industry

MILK ITALY SRL www.milkitaly.com 50-51 Food Industry

MILLENNIUM ENGINEERING SRL www.me-foodsolutions.com 52-53 Food Industry

OCRIM SPA www.ocrim.com 2-3, 54-57 Food Industry

OLI SPA www.olivibra.com 58-59 Food Industry

OLOCCO SRL www.olocco.eu 62-63 Food Industry

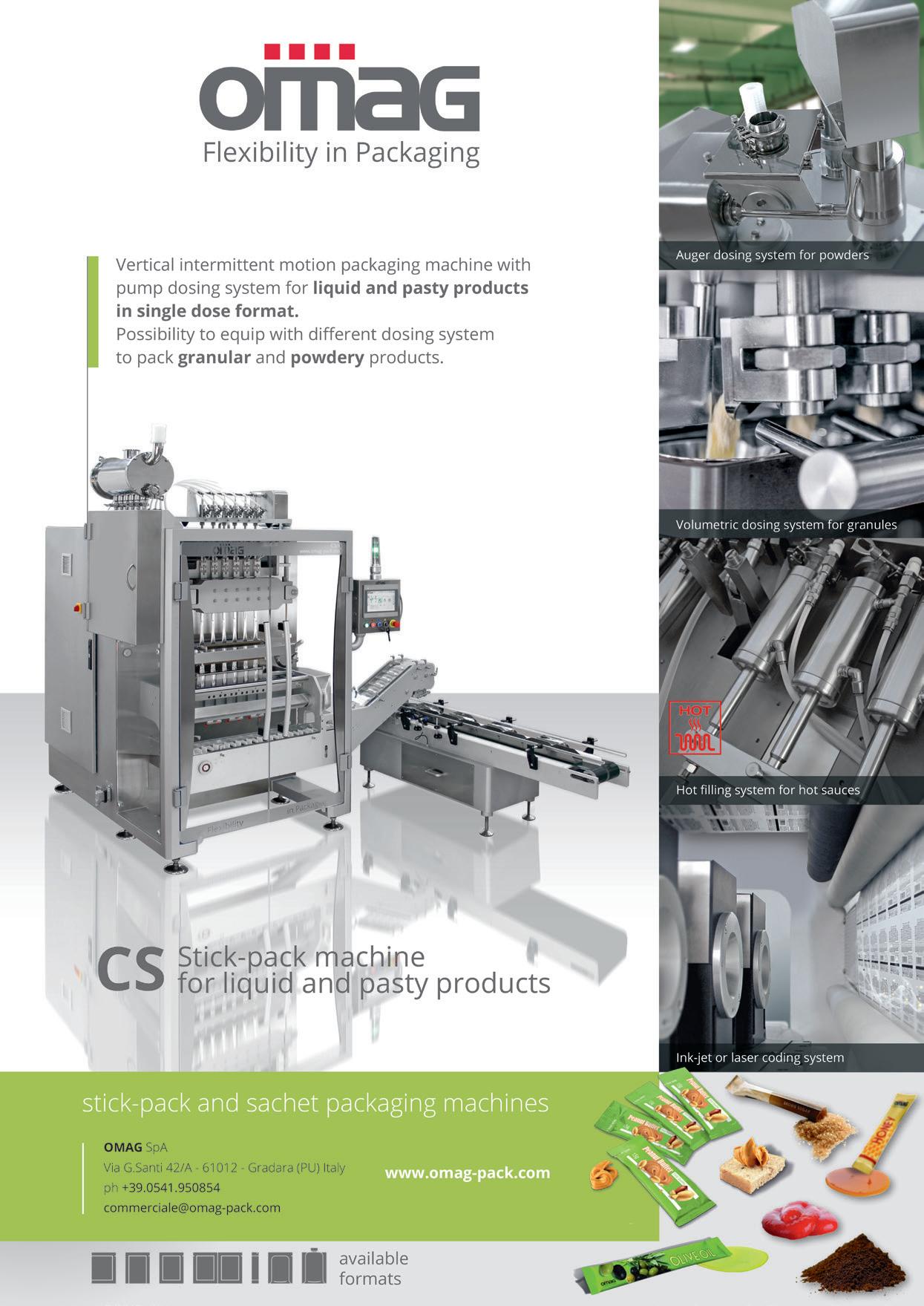

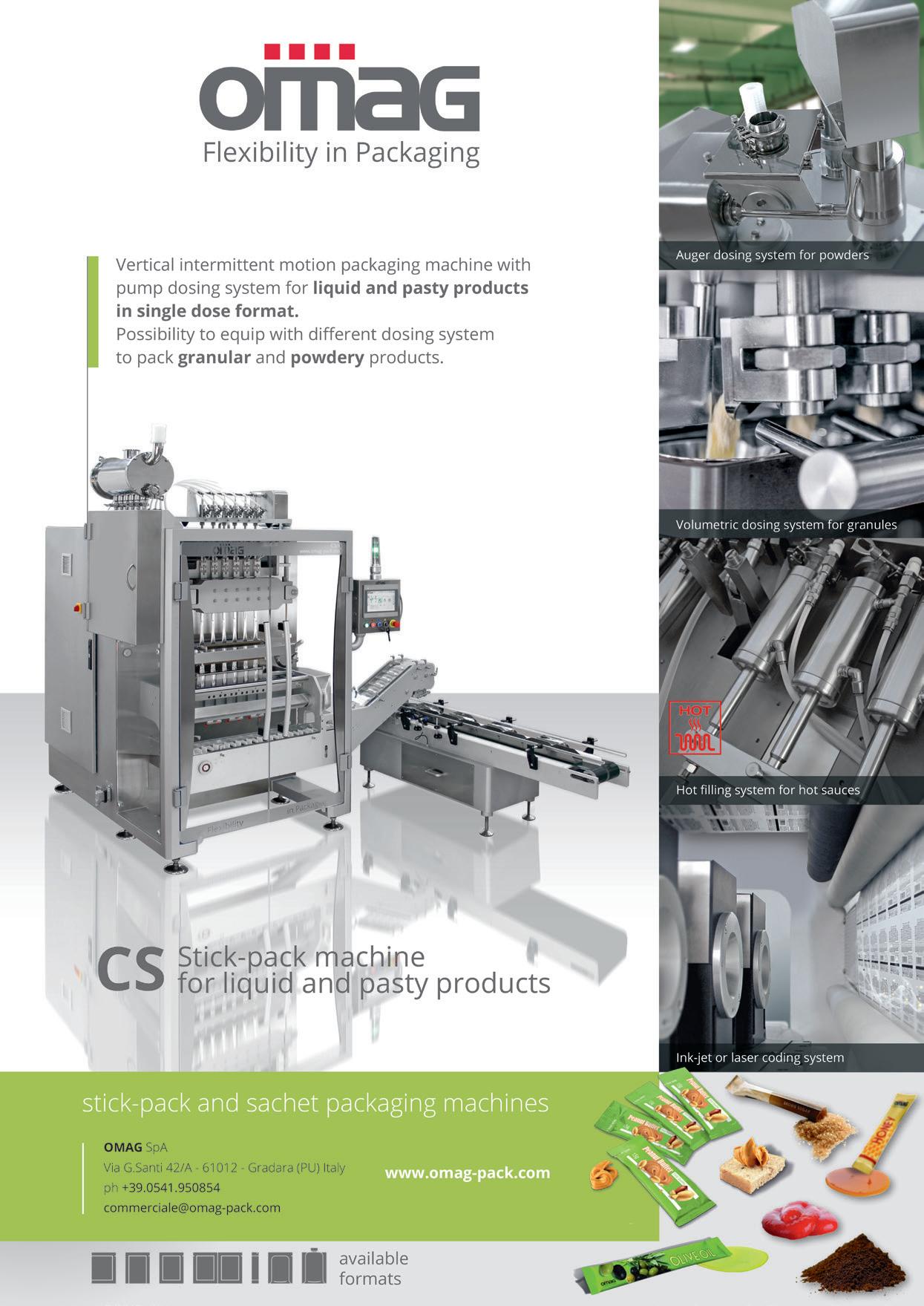

OMAG SPA www.omag-pack.com 64-65 Food Industry

PND SRL www.pndsrl.it 66-67 Food Industry

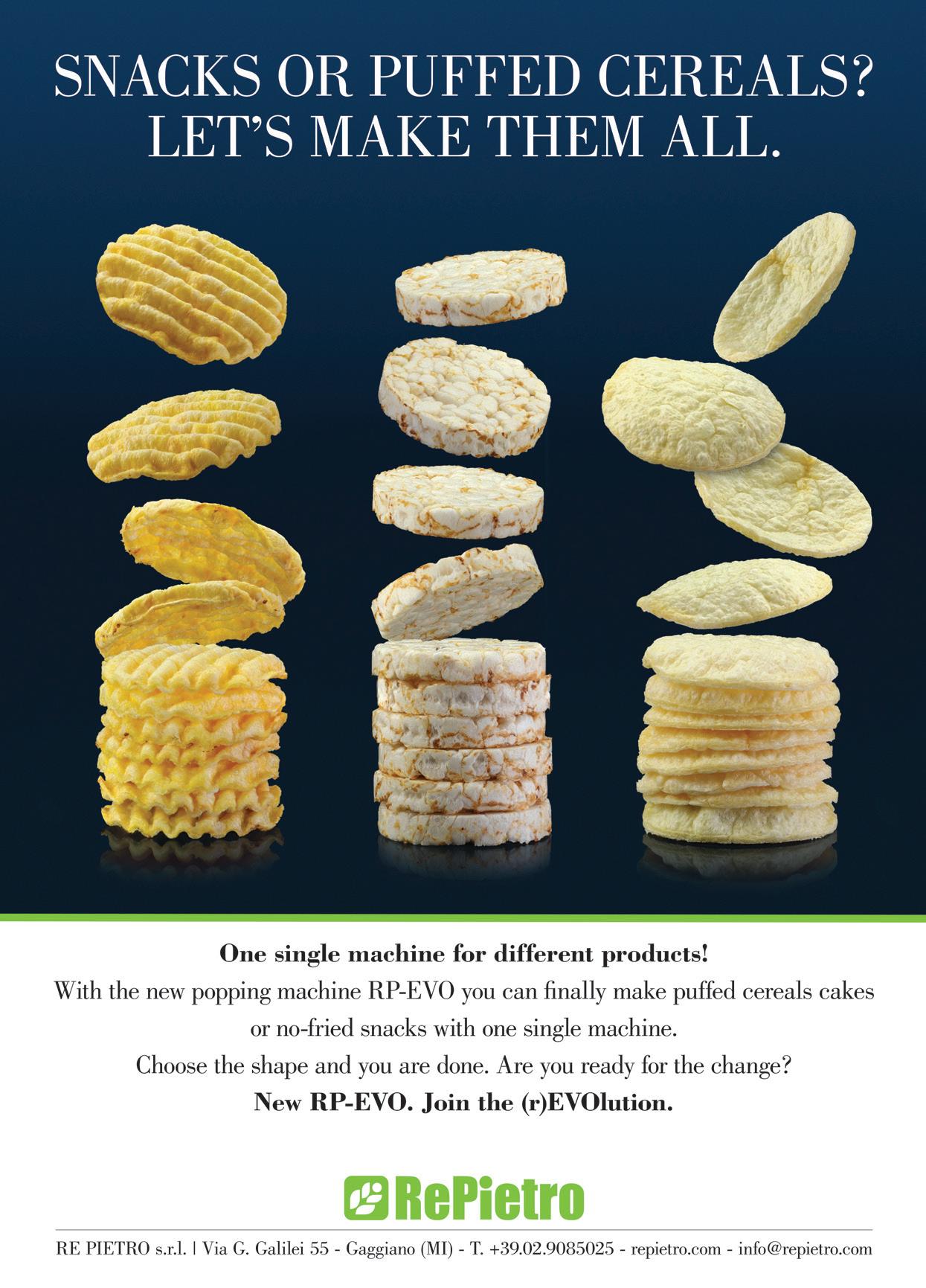

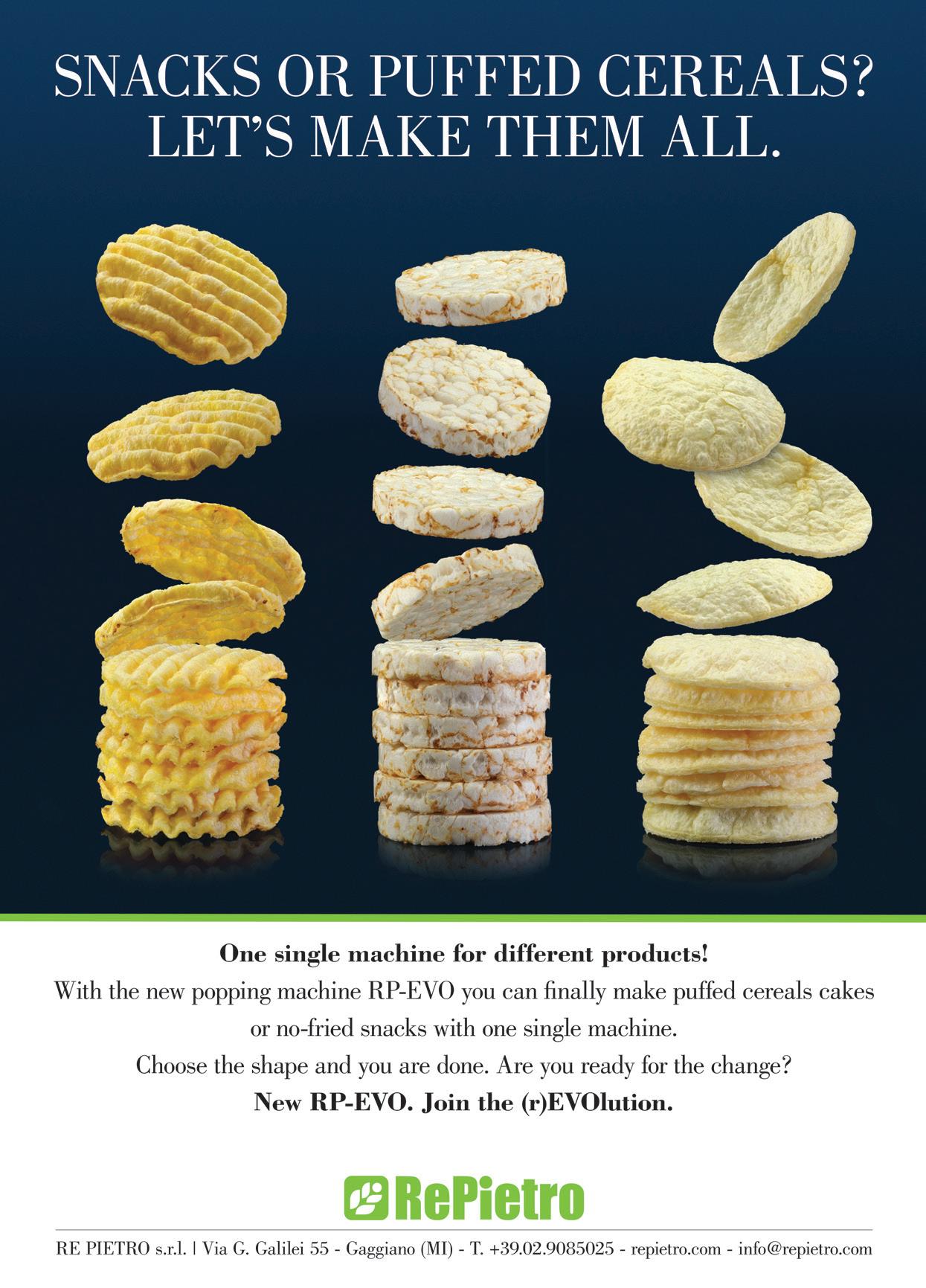

RE PIETRO SRL www.repietro.com 68-69 Food Industry

SILVESTRI SRL www.impastatricisilvestri.it 70-71 Food Industry

SITEC SRL www.sitecsrl.it 72-73 Food Industry

TECNO PACK SPA www.tecnopackspa.it 74-75 Food Industry

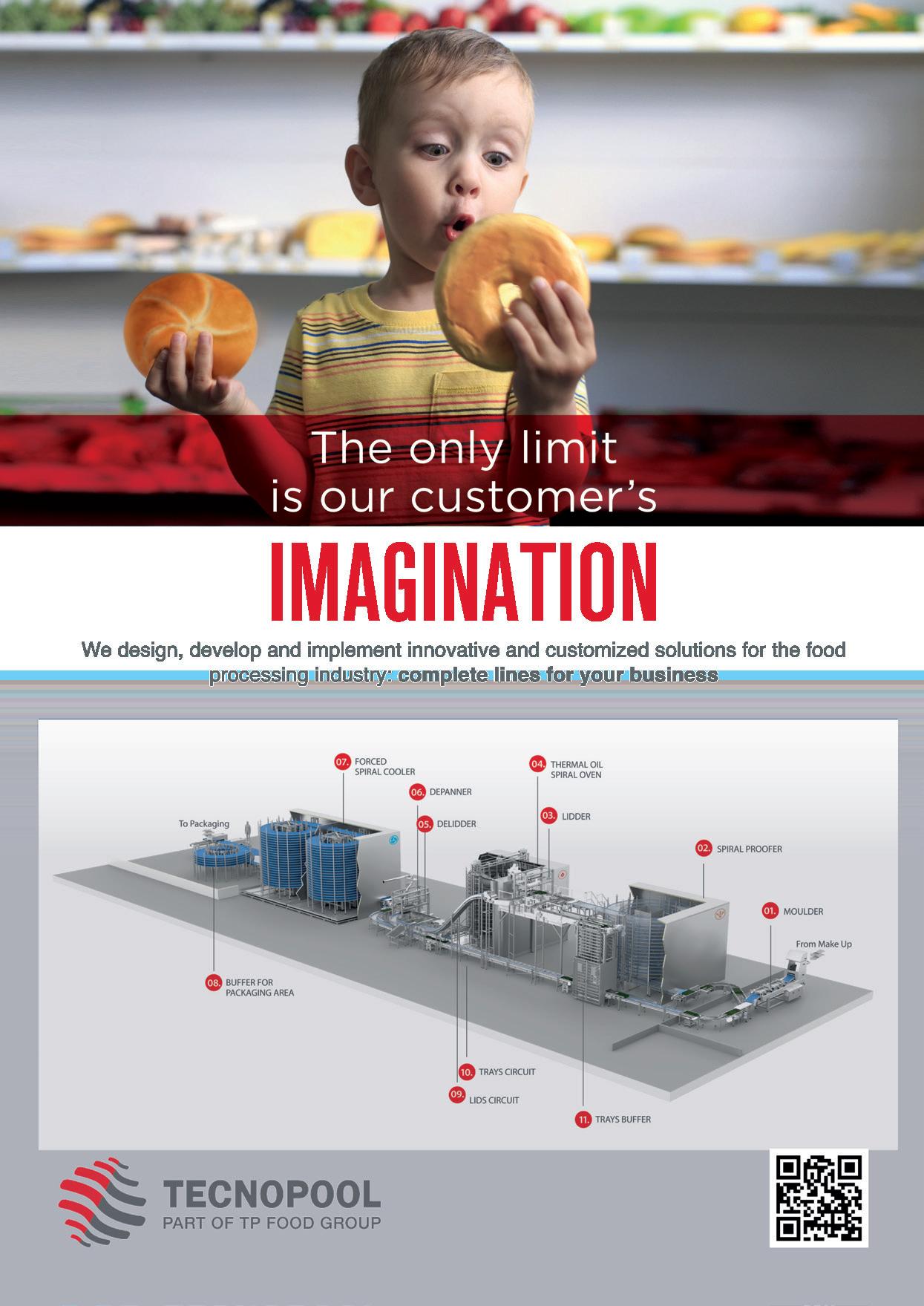

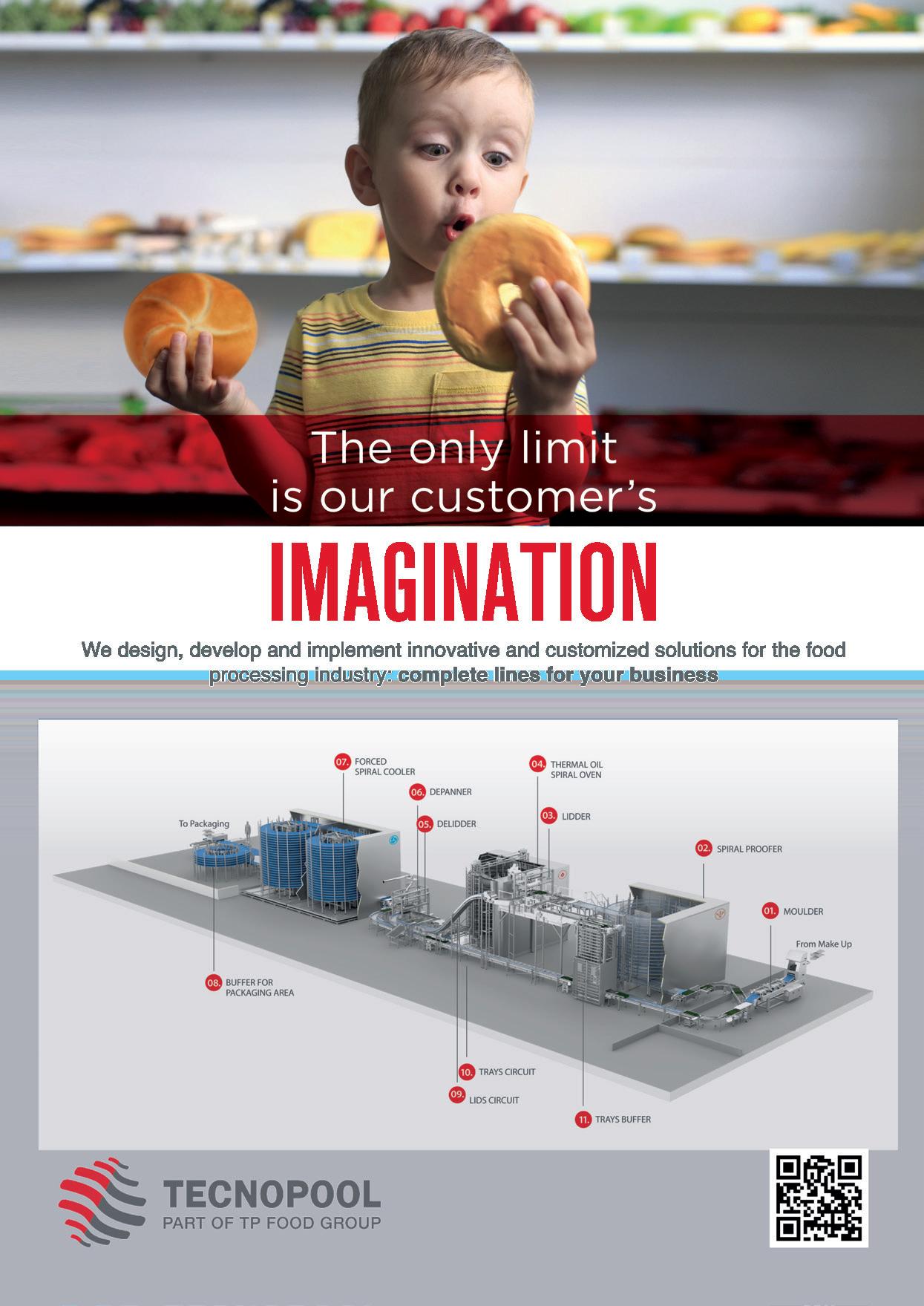

TECNOPOOL SPA www.tecnopool.it 4 Food Industry

TEKNO STAMAP SRL www.teknostamap.eu 1, 78-79 Food Industry

TREESSE PROGETTI SRL www.treesseprogetti.it 76-77 Food & Beverage Industry

Z MATIK SRL www.zmatik.com 80-81 Food Industry

ZANIN F.LLI SRL www.zanin-italia.com 82-83 Food Industry

4G Ghidini Srl is specialized in producing stainless steel ball valves and fittings

4G Ghidini was founded in 1978 by the 4 Ghidini brothers. The company, with over 40 years of experience, has always set the product and service quality as its main objective. Product quality is ensured by using raw materials exclusively sourced in the European Union and by processing them entirely in the production site located

Ruca, 400 (Z.I) - 25065 Lumezzane (Brescia) Italy Tel. +39 030 892 59 53 info@4gghidini.it - www.4gghidini.it

in Lumezzane, Brescia. Service quality relies on prompt stock availability of all the proposed items, added value in terms of offer and timely deliveries.

All the products are designed, manufactured and 100% tested before being marketed, following a correct certified construction practice and with the aid of highly advanced machinery to guarantee end-users a highlevel product.

The company is UNI EN ISO 9001:2015 certified. Product traceability is guaranteed throughout the entire production process, from the entry of raw materials to subsequent processing, up to the finished product. 4G Ghidini product is 100% Made in Italy, no import particulars are used.

4G Ghidini products are used in the most varied industrial applications, including pharmaceutical, biotechnological and cosmetic industry; food and beverage;

chemistry, process, water treatment and energy production.

Ball valves with enveloping seals, which prevent fluid deposits inside them, are the ideal product for the pharmaceutical industry.

The valve, easily removable, guarantees better cleaning and quick maintenance; the external polish finish offers a treated in details product.

4G Ghidini can provide various specific solutions for the food industry, including arrangements for washing and Pig passage; in addition, all its valves are also available with heating jacket, ideal for use in the production of chocolate.

All our products comply with MOCA regulation (1935/2004/EC)

For the chemical industry, the valves and fittings made entirely in Aisi 316L from bar ensure maximum compatibility with the most aggressive fluids and the most critical conditions of use. Ball valves are ATEX II 2 G-D T4 certified

Products also comply with the technical regulation EAC TR CU 010/2011 and EAC TR CU 032/2013

The different types of connections allow 4G Ghidini to customize ball valves according to customer’s needs, making them suitable for installation on any system.

Strengthened of the past and present challenges, 4G Ghidini is ready for the future ones.

4G Ghidini Srl

Via

FOOD INDUSTRY 10 ASIATIC EDITION

Via Schiappa, 64 Località San Siro

46027 San Benedetto Po (Mantova) Italy

Tel. +39 037 66 12 180 - Tel. +39 037 66 12 147 info@bellintani.it - www.bellintani.it

of raw materials to the transport and packaging of the final product, supplying electrical and automation equipment for turnkey delivery of the plant.

The Bellintani company, operating in the pet food field since 1954, owes its success to the long experience built up in the sector and the continuous technological updating to provide its customers with the best-customized solutions. The results of this commitment, which has lasted for more than 65 years, are reflected in a wide range of processing plants of various products with the guarantee of conservation of nutritional qualities and chemicalphysical characteristics of food.

Equipment and machinery suitable for food and non-food, pharmaceutical, confectionery, chemical, mechanical, etc. sectors, are the ideal solution to transform raw materials and products from other processes, for reuse and reduction of waste.

By focusing on the grinding and mixing phases, Bellintani directly produces mills and mixers of various models that place at the basis of complete systems. They are used in a variety of actions, from the storage

The wide range of combinations, accessories and customizations offered allows Bellintani to satisfy the most varied requests not only for the type of machine but also for the logistics of the plant.

A test room available to test Bellintani machines on the user’s products allows you to develop the technical characteristics more closely to the customer’s needs.

The search for raw materials and highend components are the guarantee of a made in Italy that meets the needs of the most demanding customers.

The company’s activity is completed by a wide range of after-sales services like a line of customer-care with direct contact with Bellintani specialized technicians, allowing the request of information and the possibility to provide solutions in real-time.

Moreover, the supply of spare parts is always available for the customer to accompany the purchased machines and equipment as well as the service of ordinary and extraordinary maintenance and the customer assistance that continues at the user with timely interventions by Bellintani technical staff.

FOOD INDUSTRY 12 ASIATIC EDITION

Bellintani Zeno

TRANSFORMS FOR YOUR PET

Pasta-flour processing machine

Mills and mixers

Horizontal mixer with container and greasing machine

Pasta-flour processing machine

Mills and mixers

Horizontal mixer with container and greasing machine

Faultless high-velocity packaging essential to keep pace with growing demand

Evolving markets require proven solutions in order to gain greater economies. Noodles may be basic, but their packaging demands certainly are not. Convenience foods are an international phenomenon, with new variants and markets appearing all the time. Many are based on short-term fads, but there are some that have stood the test of time – for decades indeed – including the humble instant noodle.

Forming a staple meal and/or snack across countless regions and multiple demographics, they are just so easy to make, and with so many flavours and spice packets, you could probably eat a different variety every day of the year. The latest pandemic has also proved how important tasty, easy-to-make comfort food has been for populations everywhere, with some figures pointing to a doubling of consumption.

“There is a massive array of market maturities all over the globe,” explains Alessandro Rocca, Sales Engineering Director at Cama Group. “Some markets are well established, such as Japan and China, but we are seeing rising demand in India and Malaysia too, both of which are overtaking China in terms of volume. Major growth is anticipated in Africa and the Philippines too.

“Although diverse geographically,” he continues, “all of these markets have something in common; and that is the need to introduce further economies by exploiting automation in their packaging regimens. The mature markets are already well served, but the growing markets – especially now companies have secured a foothold – are starting this modernisation journey, hunting for greater efficiencies.

“For some multinationals, it is a natural progression,” Rocca adds, “comprising a ‘technological cut-and-paste’ of operations from an established region to a growing region. We are fortunate to be on the supplier lists of many of these larger companies in their established markets, so are, as a result, trusted by them to learn from these current installations and repeat our successes elsewhere! We have a mentality and personality that makes us attractive to smaller companies too, so we are seeing a noodle-driven expansion in quite few different regions.”

In a recent project, Cama was tasked with developing a new secondary packaging solution for one of the worlds’ largest food

1st Floor, Building 11, Gemdale Viseen Songjiang Intelligence Park, n. 3255, Shengang Road, Songjiang District, Shanghai City cama-CN@camagroup.com

and confectionary suppliers, at a brand-new greenfield site in India. The customer, seeing a 30% increase in noodle demand even before the pandemic, was eager to start exploiting the capabilities and flexibilities that automation would deliver and called upon Cama to bring its expertise to the project.

“This was a big project,” Rocca explains. “The market in India started livening up in 2018 and, based on our experiences with the customer – for whom we installed the first noodle line 15 years ago in another country – we were asked to develop a solution for its new site. Part of the reasoning from both sides being that we could bring all of our experiences and technological evolution over the past 15 years and deploy them in this new site.

“There are two approaches to this type of application,” Rocca elaborates. “The question is do you side load, or do you top load? Our solution specified sideloading for a number of reasons, but primarily because in this application you gain better control of the product, especially considering the throughput levels. The customer had also experienced mis-packing problems from a competitor’s top-loading machine at another group plant, so was not eager to face the same issues.”

Cama’s solution comprised two of its Breakthrough Generation (BTG) IN Series case packers, each of which would be fed by three high speed in-feed lines. The important figures being an infeed of 990 packs per minute and an output of 11 RSC cases per minute.

“Not everyone can package cleanly and successfully at this rate,” Rocca enthuses. “Space was a key consideration too. We had to combine multiple loaders feeding one machine quite a limited bit of real estate. With such a prodigious in feed rate – being

handled by the machine’s triple independent loaders – we also had to design in a buffer to prevent microstops. Typical buffers would be built for 20 to 30 seconds, this one had to be 60 seconds!”

In operation, each infeed supplies products at the rate of 330 per feed. The product packages are turned on their edge and enter a racetrack, which creates the first batch configuration. These then feed into a stacking device, which assembles the product stacks. Once the packaging configuration completed all products are transferred into mono-axis conveyor, which takes production from each in feed (with a slot for each) and, once full, advances them to the case packer, where a pusher pushes the noodle collations into the pre-assembled carton. The cartons are sealed using glue, tape or both before being checked for integrity and passed to the outfeed.

“We developed a special pusher system to push the noodle packs into the cases,” Rocca explains. “Insertion of 96 packs

Cama Group FOOD INDUSTRY 18 ASIATIC EDITION

Cama Group

or more has to be handled very carefully, otherwise the product losses that afflict top loaders can occur. The key to truly lexible noodle packaging is the ability to package both single and multipacks (up to 6) in the same case, with very little intervention. As a rule of thumb, multi in-feed machines do not normally like product variation, but our IN Series solution can actually handle anything from 40 to 100 packs in same case style. We have also developed a way to very quickly adjust the loaders, keeping a complete changeover down to just 32 minutes, which, in anybody’s books is a very quick time, especially for a machine with three in feeds AND a case packer!”

Cama’s Breakthrough Generation (BTG) concept is setting the standard in secondary packaging. Machines deliver modular, scalable frameworks that offer easy entry and access, coupled to a hygienic machine

design. Within this framework, contemporary automation solutions, including advanced rotary and linear servo technology, is tightly coupled to in-house-developed robotics, to deliver the all-important flexibility and adaptability required by modern packaging operations.

“Automation and Industry 4.0 capabilities were another important facet to this project,” Rocca explains. “Our customer is front runner in the deployment of connected manufacturing solutions and, it could be argued, its size and global reach means it also dictates the direction that many other companies follow.

“In this instance,” he concludes, “Augmented Reality capabilities were part of the wish list, something that has really been bought to the

fore over the last few months, with social distancing and travel restrictions bringing almost all correspondences online. Our deployment of contemporary automation solutions means that these Industry 4.0 capabilities are in easier reach for customers and we have seen really positive real life results recently, where they have proved vital for FATs, training, maintenance and operation, all delivered and performed virtually!” www.camagroup.com https://www.camagroup.com/zh/

FOOD INDUSTRY 19 ASIATIC EDITION

1st Floor, Building 11, Gemdale Viseen Songjiang Intelligence Park, n. 3255, Shengang Road, Songjiang District, Shanghai City cama-CN@camagroup.com

Via F.lli Buscetto, 76 - 84014 Nocera Inferiore (Salerno) Italy

Tel. +39 081 517 71 33 - Fax +39 081 517 26 55 info@cuomoind.it - www.cuomoind.it

CUOMO is a family-run company specializing in design and production of metal packaging and food processing machinery. Founded in 1964 by three brothers, CUOMO is headquartered in Nocera Inferiore, Salerno, and run by its founders’ sons.

The company’s production range includes the following:

• Food processing machinery

• Twist cap machinery

• Metal packaging machinery

Food processing machinery

Machines, complete lines and equipment for primary and secondary packing suitable for any food (vegetables, meats, fishes, oils, milks, etc.). This kind of machinery carry out packing process of food, including thermal treatment of the filled container and final packing of filled containers in accordance with the market requests. The keystone of those production lines is the filling-closing automatic groups, where containers are automatically filled – by gravity either vacuum or volumetrically – by double seamers. The food processing machinery range allows to cover production speeds from 60 up to 1.000 cpm, for can sizes ranging between 70 gr and 5 Kg. (from 202 to 603 can size AS).

Twist cap machinery

Machinery and complete lines for production of metal lug caps, twist-off type, for glass jars. This division is dedicated to suit any need of glass packing (bottles, jars) industry

of foodstuff such as jams, legumes, tuna fish, ketchup, sauces, etc. Lug caps manufacturing line based on a double die strip feed press, served upstream by a scroll shearing line and, downstream, by operational machines all rotary type, with production speeds up to 1.000 caps per minute. Fully automatic manufacturing process which allows to save on production costs.

Metal packaging machinery

Fully Automatic machines and lines for tinplate cans. Complete lines for end/shell starting from the tinplate sheet. All machinery has been individually designed for a new generation of can making lines, allowing to reach production speeds of up to 900 cpm. Independent operational machines or multimachine groups are available, for can body

making lines, to suit customers’ particular needs.

The company’s range of machinery also includes the Automatic telescopic filler Made of stainless steel AISI 304 and in compliance with EC rules, the machine is suitable for volumetric filling of a wide range of solid products into metal cans, glass jars, plastic container, cartons, etc.

The complete filling process is performed by the most advanced technologies for they guarantee filling accuracy. The machine allows fast changeover of container sizes and easy access for cleaning and maintenance operations.

On request, the machine can be also manufactured with container tangential exit; the machine can handle a range of different diameters up to 5 Kg.

F.lli Cuomo Sas di Alfonso e Carmine Cuomo

FOOD INDUSTRY 20 ASIATIC EDITION

Via F.lli Buscetto, 76 - 84014 Nocera Inferiore (Salerno) Italy

Tel. +39 081 517 71 33 - Fax +39 081 517 26 55

info@cuomoind.it - www.cuomoind.it

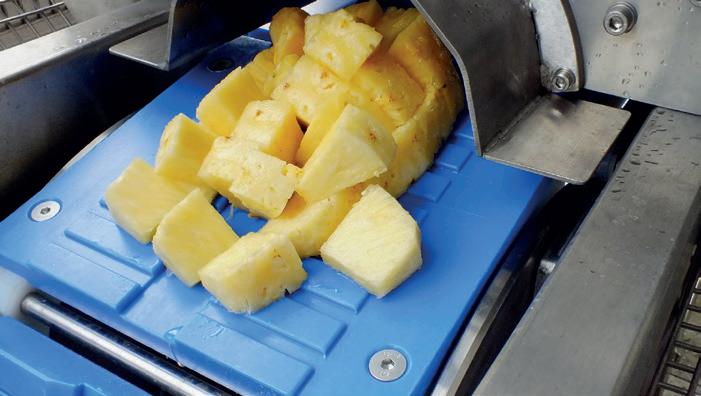

This automatic telescopic filling machine is suitable for filling the following products: tomato (whole and cubes), olives (whole and sliced), legumes, sweet corn, vegetables (sliced and diced), artichokes (hearts), onions, mushrooms, picked vegetables, seafood, pet food, fruits (whole, sliced and diced), hazelnuts, nuts and peanuts. Depending on product and container size, the machine can run at speeds from 40 to 1200 cpm.

Among the Cuomo machines, we can also find the Automatic Seamer Mod. A480; it is a machine with 10 seaming heads, rotary can type, adjustable height tower, for seaming metal lids to cylindrical, filled, cans.

F.lli Cuomo Sas di Alfonso e Carmine Cuomo

This sturdy and steady machine offers outstanding performances. It is specially designed for closing filled cans (any type of product) by utilizing the most up-to-dated technologies. All machine parts getting into contact with product, are made of stainless steel.

It is also worth highlighting that Cuomo grants customers the best after-sales, technical and any kind of assistance, in Italy and abroad,

and that has always been the company’s main target, on which trust in the future is grounded and toward which the company is heading to, knowingly and with its usual inherent strength.

The engineering of state-of-the-art machinery has enabled the company to deal with complex technological issues concerning sectors such as metal packaging and metal twist-off capsules, with spirit of innovation and cutting-edge technology.

FOOD INDUSTRY 21 ASIATIC EDITION

Via Archimede, 27/33 - 70024 Gravina in Puglia (Bari) Italy

Tel. +39 080 326 61 96 - Fax +39 080 326 58 54

info@defino-giancaspro.com - www.defino-giancaspro.com

Defino & Giancaspro “has its roots in the time of mills made by wood”. The company was founded in 1965 in Gravina in Puglia (Bari-Italy) thanks to some craftsmen, whose main occupation was the assembling of milling plants and whose only capital was the work of their hands and their commitment to the world of wheat and cereals.

The master-fitter Vito Antonio Giancaspro, the father of the current General Manager, had many skills in various fields such as carpentry, mechanics, plants and food technology. This “artisan” disposition, after more than 50 years, remains the cornerstone of the company philosophy and is one of its strengths. The company continues nowadays to provide its customers with all the experience and expertise of over one hundred employees with the same passion and enthusiasm.

The goal of the Defino &Giancaspro is not to simply offer a machine or a plant, but to supply all the technologies and means to adapt them to the customer’s requirements.

Just like a high-quality tailored dress, the product meets the customers’ needs but always respect the company style with the unmistakable Made in Italy quality. Engineering, prototyping, research and continuous development ensure always the best solution to the customer. In Defino & Giancaspro design is meant with the overall conception of work planning, with the aim to turn ideas into product specification through the precious and constant sharing of information between young engineers and expert workers.

The company is a specialist in realization of carbon and stainless steel spouting and accessories, has a pool consisting of more than fifty types of machines in various sizes

and operates construction and assembly of structures and silos. Its success lies in the precision and accuracy of working, always realized within their own workshop, and in the use of forefront machinery and certified welding techniques, which offer an excellent finishing and quality.

The service does not end at the delivery of the supply, the relationship with the customer continues through the optimization and the implementation of the new product, ensuring support, maintenance and constant assistance, namely a complete turnkey product.

Plants and machines manufactured and assembled by Defino & Giancaspro are requested and appreciated all over the world. Almost daily and constant are collaborations not only in Italy and Europe, but also with Russia, the United States, Mexico and North Africa.

Proud of their work, everywhere, from the offices to the workshop, all the departments work daily to improve and expand the range of products and services to satisfy both historical and new customers.”

FOOD INDUSTRY 24 ASIATIC EDITION

Defino & Giancaspro Srl

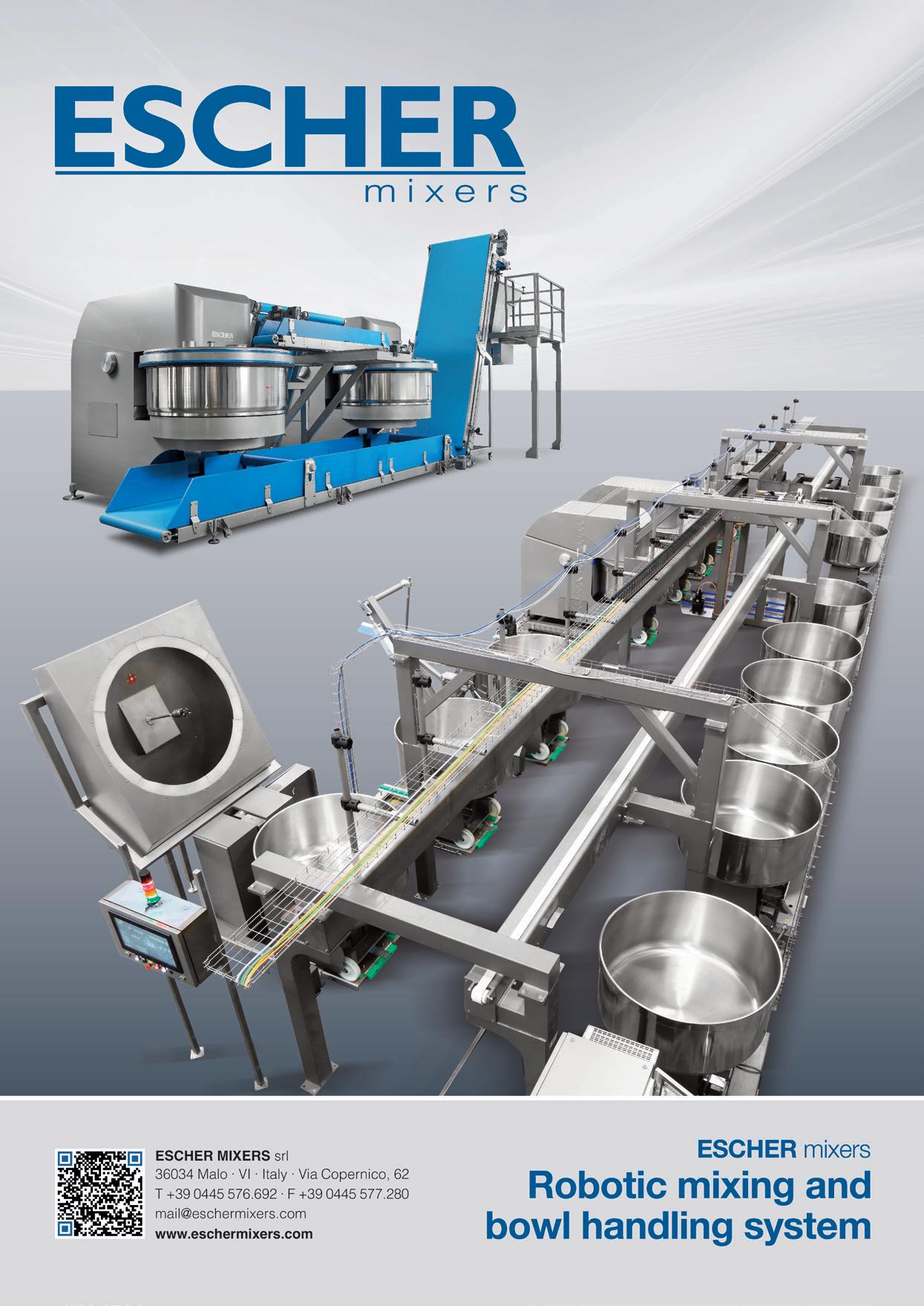

Via Copernico, 62 36034 Malo (Vicenza) Italy Tel. +39 0445 57 66 92 Fax +39 0445 57 72 80 mail@eschermixers.com www.eschermixers.com

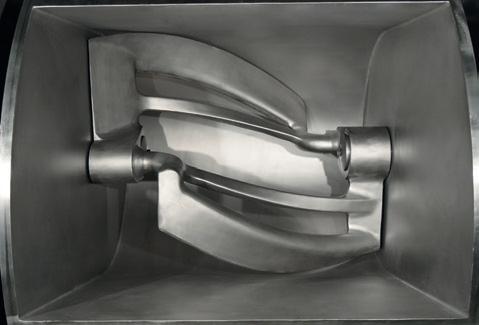

Escher Mixers specializes in the production of mixing machinery for the bread and pastry-making sectors.

Over the years, Escher Mixers has gained specialized knowledge that has allowed this company to develop machines and solutions to meet the needs of a variety of clients and different types of markets.

Escher Mixers machines are renowned for their sturdiness, durability, accurate finishes, and for the quality of the dough they produce.

Bakery equipment

Escher Mixers proposes Spiral and Wendel mixing concepts. Both solutions can be with removable bowl through a patented® bowl locking and motion system MR-MW Line or bottom discharge system MD-MDW Line with conveyors belts or bowl lifters which can be matched with automatic solutions with linear system and storage of the resting bowls in vertical or linear storages, rotating automatic systems-carousel, scraps recovery systems, transverse hopper systems and star-cutting/guillotine/roller with guillotine and other customized solutions.

Pastry equipment

The range of planetary mixers with double tool for the pastry industry is characterized by the lack of oil lubrication systems, improving hygiene and reducing machine maintenance. A wide range of interchangeable tools is available for different uses and doughs. For industrial productions, Escher Mixers has

developed the PM-D Line with independent tool movement, with individual speed regulation and the possibility to reverse the motion. While the PM-DB Line with the bridge structure allows automatic insertion

of the ingredients, air insufflation to reduce mixing times and increase volume, dough processing with negative/positive pressure and cleaning through CIP washing system. Various bowl discharge options are available.

FOOD INDUSTRY 26 ASIATIC EDITION

Escher Mixers Srl

Via del Lavoro, 53 - 36034 Malo (Vicenza) Italy

Tel. +39 0445 63 74 44 - Fax +39 0445 63 74 55 europa@europa-zone.com - www.europa-zone.com

For more than 30 years, EUROPA has been selling professional ovens to a large number of bakeries, pastry and pizza shops, hotels and supermarket chains, exporting to more than 70 Countries worldwide.

Established in 1990, the brand EUROPA has become synonymous with reliability and innovation, specializing in the production of commercial ovens and equipment for bread, pastry and pizza baking. The company grew and expanded in a very short time, leading the business over the main international markets. This could happen thanks to a dynamic team, characterized by a professional and fresh approach. The management group has always been supported by a qualified and experienced technical staff, ready to understand market’s requirements and to meet customers’ needs. Experimentation and research, in fact, have always represented the primary purpose of this company.

Over the years, EUROPA has consolidated world-wide its own position, thanks to a constant renewal of its range with increasingly more

advanced products. It continues to grow year by year, consolidating its presence both in Italy and abroad, relying on a strong mark, which means quality and modernity. The wide range of products offered by EUROPA is divided in 2 main product lines: the BLACK line and the GREEN line.

The BLACK line offers a large number of ovens and provers suitable for artisan bakers, industrial bakery/pastry/biscuits productions and supermarket chains. In this line, you can find rack ovens, electric deck ovens, steam tube deck ovens, multi-loading deck ovens and provers. A special mention is needed for GALILEO rack ovens. Through the years, this oven has become even more complete, sophisticated and modern. Its strong points are COMPACT dimensions and solid structure, joining together refined design and functionality. GALILEO has been studied to simplify the cleaning and the ordinary maintenance. Besides, the improved combustion chamber, completely renewed with innovative technologies, has allowed to reach a very high efficiency, with surprising recovery times and very low average consumptions.

Europa Srl

FOOD INDUSTRY 28 ASIATIC EDITION

GALILEO new edition Rotary rack ovens for bread and pastry products. Designed both for craft and industrial bakeries specifically tested for heavy non stop baking cycles. EUROPA SRL Società unipersonale Via del Lavoro, 53 • 36034 Malo (VI) Italy Tel. +39 0445 637444 • Fax +39 0445 637455 • www.europa-zone.com • europa@europa-zone.com ORIGINAL PRODUCTS PATENTED BREVETTATO Follow us on: Europa Srl Europa s.r.l. #europaovens

Via del Pian 3 - 31049 Bigolino di Valdobbiadene (Treviso) Italy

Tel. +39 0423 98 03 34

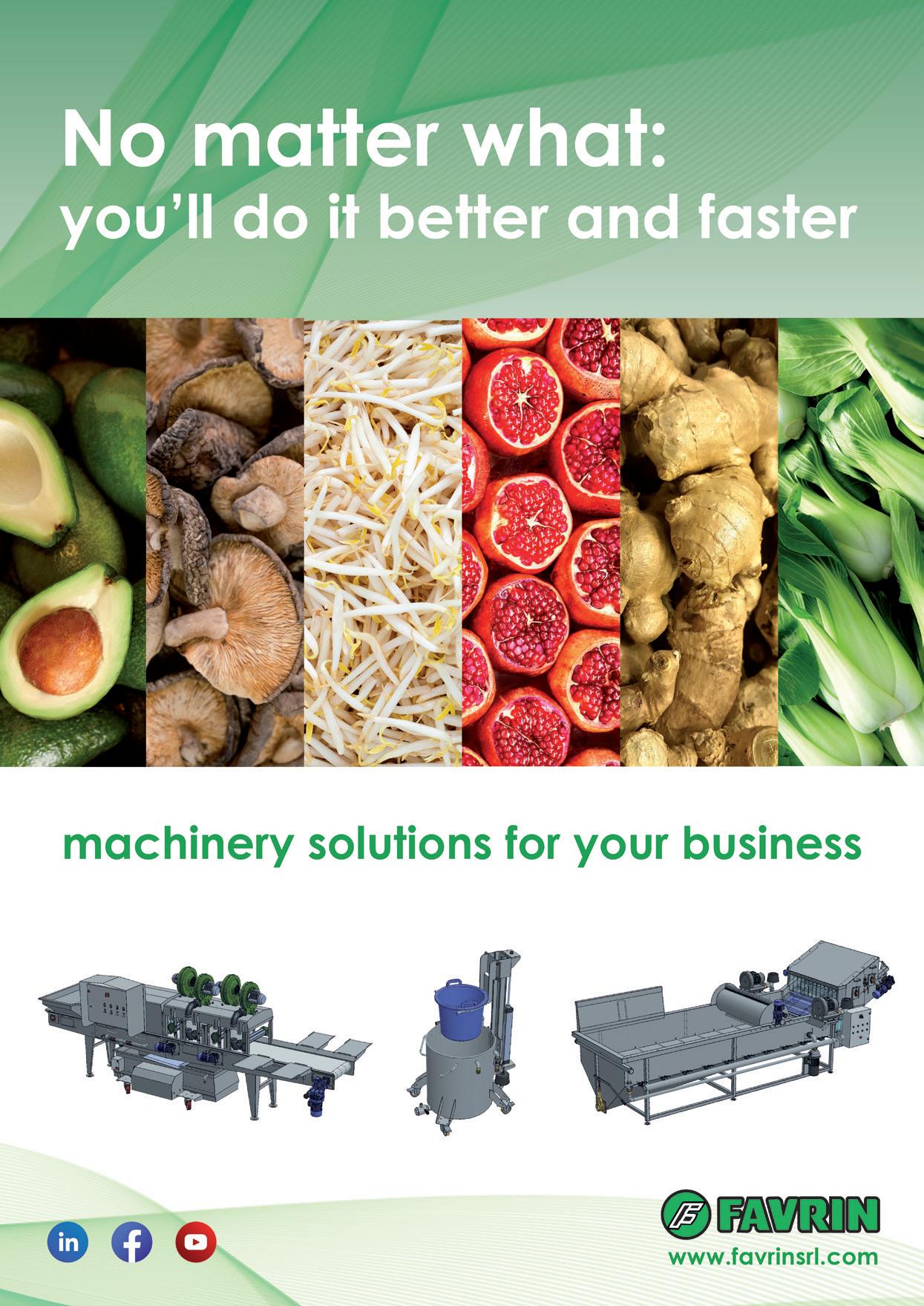

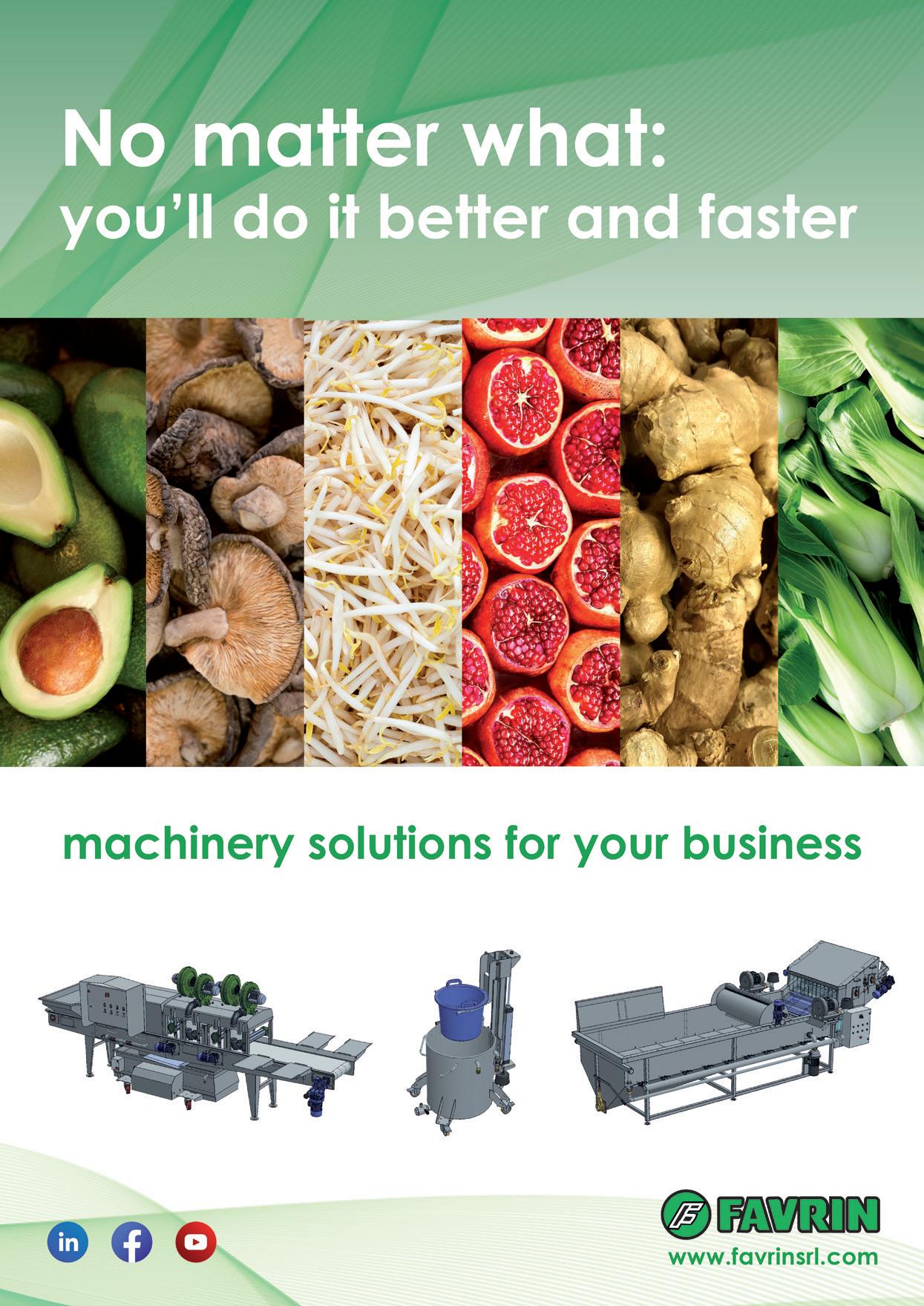

commerciale@favrinsrl.it - www.favrinsrl.com

Favrin S.r.l. was born in the early 1970s, from the idea of Franco Favrin, as a company for sheet metal processing and for the construction of livestock facilities. After years, thanks to the experience it evolves in the processing of stainless steels, building machines for the wine and food sectors, with particular regard to the processing lines for fruit and vegetables.

All Favrin machines are designed and built within its headquarters in Valdobbiadene (TV).

The specific focuses that identify Favrin products are: the easy way of use, the high value for money and the possibility, cooperating with its clients, to find always the best possible solution, from small artisan productions to large industrial processing installations.

This allows Favrin to continuously expand its gamma of machinery, developing new versions or starting with completely new projects. In this way Favrin has day by day

the possibility to offer new technologies to its clients.

Favrin main products are:

• Basket washing machine for small productions

• Washing tank with extraction belt or with processing, selection and packing belt

• Washing machine with bubbling tank system and high pressure tunnel

• Washing, drying and sorting tunnel for bulk product or in boxes

• Crates washing tunnel

• Complete washing systems for “ready to eat” products

• Air blades dryer

• Vibrating doser (also for bins discharge)

• Belt or vibrating sorting table

• Product processing, selection and packing belts

• Conveyor belts and elevators certified for use in food sector

• Conveyors, elevators and screw tanks

All Favrin machines are:

“Plug and play”, immediately ready without any installation

Designed and made entirely in Italy

Customizable in every detail to adapt to specific needs

Fully electromechanical (unless requested by the customer), so extremely reliable and strong

Certified according to the safety and health standards required by the EU

Covered by Favrin 24 month warranty

“Inspired by the past looking to the future”

FOOD INDUSTRY 30 ASIATIC EDITION

Favrin Srl

Via Trivulzia, 54 - 23020 Mese (Sondrio) Italy

Tel. +39 0343 410 51 fic@fic.com - www.fic.com

Chilled water cooling – is it the right system for you?

With more than 70 years of innovation and a strong presence on international markets, FIC is the perfect partner when ice water is used in a cooling process. Water is considered the safest cooling media in the food industry and the possibility to take advantage of its PCM properties (phasechanging material), makes it more convenient than ever, especially with rising energy bills. FIC can offer a complete range of ice banks, from small compact sizes to container size.

FIC ice banks

With FIC ice banks you can reduce your peak power load. Because ice is built up overnight, you may be able to take advantage of offpeak power rates. The advantage is even bigger if you consider it vital to have a cold energy reservoir during blackout times. FIC offers a complete range from 45 kWh to 2500 kWh. All FIC equipment is carefully tested with different methods to guarantee extended functionality and the customers’ success.

FIC falling film chillers

For mega farms, dairies, industrial bakeries and large plants running 24/7, FIC can supply ice water solutions for instant cooling down to 0.5°C. This technology is widely used in some of the most innovative dairies, thanks to its consistency and scalability. This system is very compact and can be adopted when the available space is limited. In this case, FIC can propose a fully customized range of falling film chillers. The number of plates and modules can be increased according to the customers demand, to meet actual and future flexibility requirements.

Falling film and ice banks can be integrated to maximize the benefits of both technologies

Fic Spa FOOD INDUSTRY 32 ASIATIC EDITION

Via Trivulzia, 54 - 23020 Mese (Sondrio) Italy

Tel. +39 0343 410 51

fic@fic.com - www.fic.com

RED for large installations

RED plate banks for instant cooling

In some applications and industries, plate banks are popular for their flexibility and outstanding performances. FIC has it all: From compact machines (10 kW) up to 1500 kW, used in dairies, industrial bakeries, ice cream and breweries.

All FIC products are available for different refrigerants, to meet the highest standards and different local regulations. Feel free to contact FIC and become the promoter of advanced cooling technologies in your Country!

Fic Spa FOOD INDUSTRY 33 ASIATIC EDITION

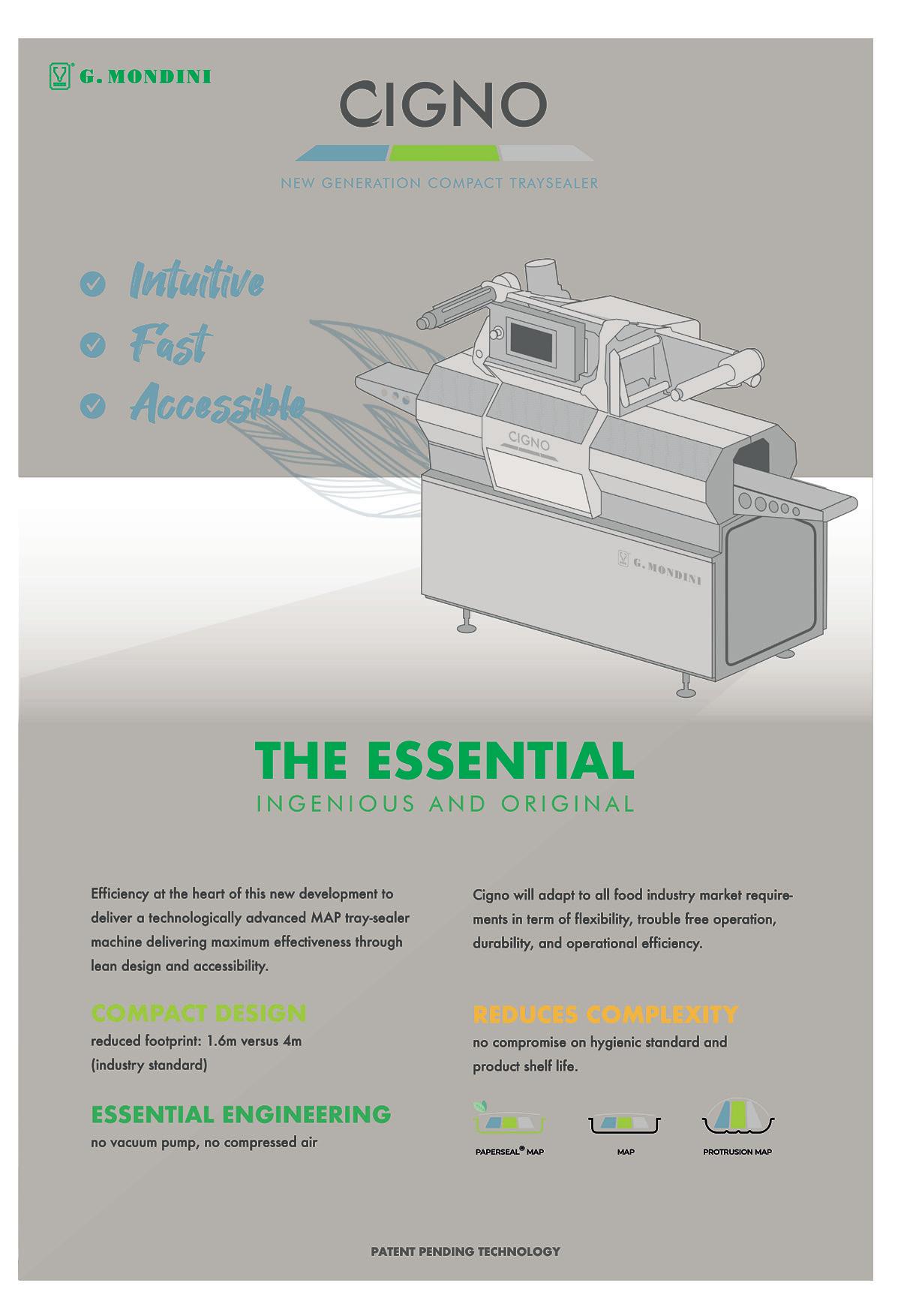

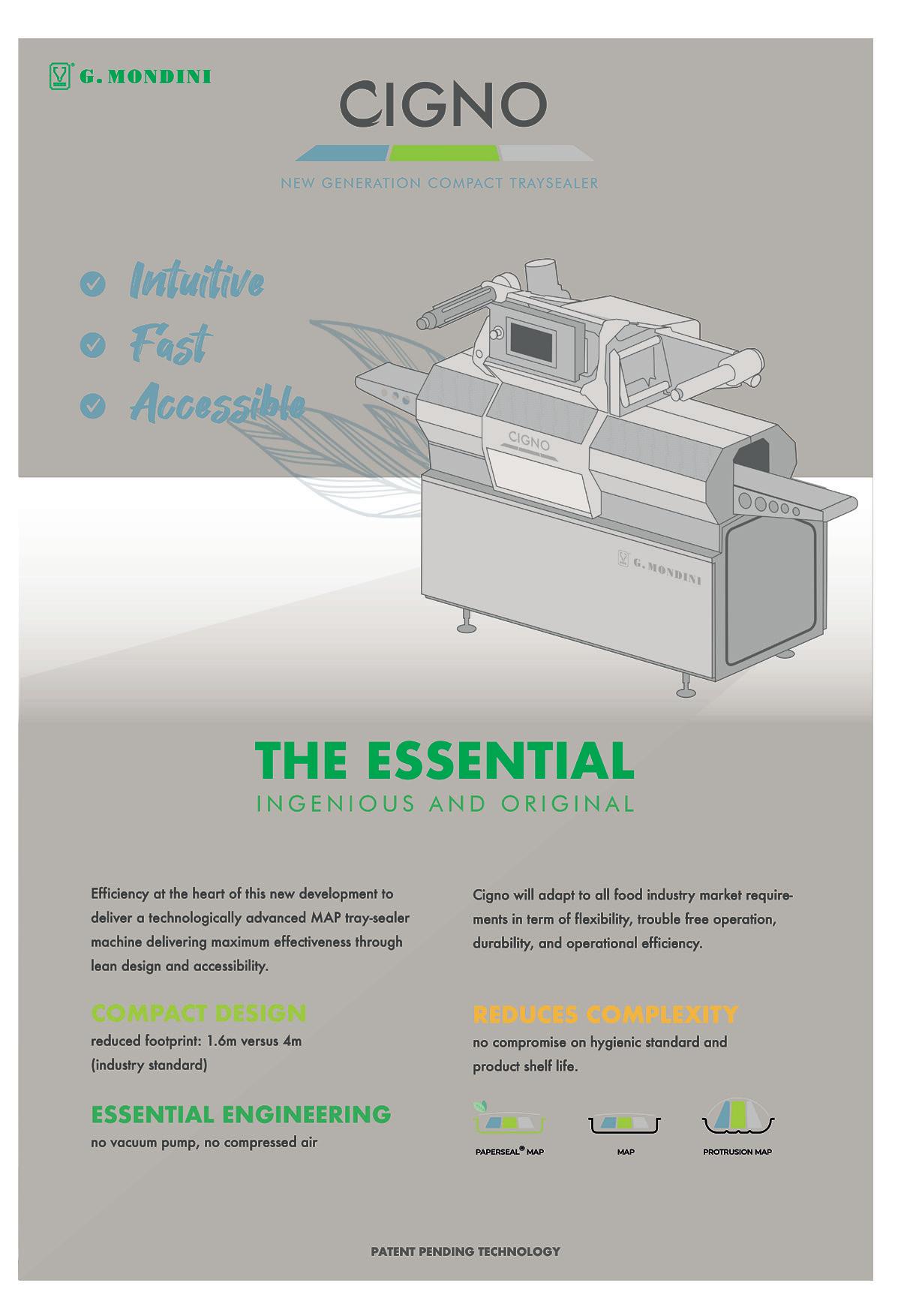

G.Mondini Spa

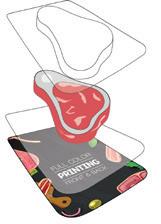

Building on the success of SLIMFRESH®, this new system was developed and launched to bring the benefits of using flat cardboard supports to sensitive sliced products packaged in MAP® such as meat and cheese.

• Increased consumer convenience in reclosable version to help in reduction of consumer food waste.

• Digital printing all over the pack with easy design change to increase consumer communication

• Thinner pack with increased rigidity that expands opportunities for retail merchandising.

• Flexibility to run on Trave® Trays Sealers through simple tool changes.

Via Brescia, 5/7 - 25033 Cologne (Brescia) Italy

Tel. +39 030 70 56 00 - Fax +39 030 70 56 250 info@gmondini.com - www.gmondini.com

G.Mondini

SUSTAINABLE PACKAGING SYSTEMS

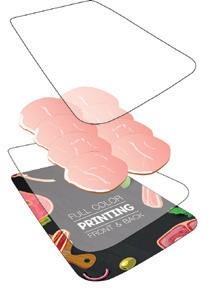

Sustainable paper board materials are central in G.Mondini new range of VSP and MAP systems to improve their acceptability, increase performance and enhance product security due to perfect sealing technology.

First of its kind launched by Mondini, SLIMFRESH® reduces plastic content by up to 80% in the vacuum skin market. Combining a fully printed flat cardboard support with a thin

high barrier liner, opening new opportunities in pack styling, merchandising and communication.

Whilst maintaining all the benefits of the vacuum skin process it delivers:

• Flat cardboard support designed to be recyclable giving consumer possibility to easily separate the liner from the cardboard and place into suitable waste recovery stream.

• Combined with Skin technology to extend shelf life reducing food wastage.

• Fully printable cardboard support extends communication and merchandising.

• Flexibility to run on Trave® Trays Sealers through simple tool changes.

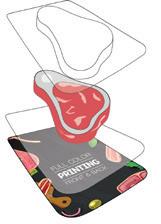

This new system expands the opportunities to replace MAP and VSP plastic trays with barrier lined cardboard. The process operates by fabricating a MAP tray from a pre-cut flat cardboard, which is formed and a barrier liner automatically applied in one step process. The system is based on the same benefit stream as Thermosealer® technology where the fabricating of trays is conducted directly before the tray sealing process.

Through value engineering and clever pack design G.Mondini spa has constructed a cardboard tray system that is straightforward to integrate into current packaging lines giving:

FOOD INDUSTRY 36 ASIATIC EDITION

Via Brescia, 5/7 - 25033 Cologne (Brescia) Italy

Tel. +39 030 70 56 00 - Fax +39 030 70 56 250 info@gmondini.com - www.gmondini.com

• Safety. Unique process to generate perfect sealing surface. Guaranteed state of the art seal integrity equal to traditional plastic packaging.

• Flexibility. Availability of different liners and paperboards offers technical solutions to suit any product. Presented for Top Seal, Modified Atmosphere and Vacuum Skin formats. Recommended for cheese, fresh meats, processed meats, ready-made products, frozen foods, snacks, salads and fruit.

• Full branding. 360° communication on all surfaces of the package. High quality graphics for premium branding design. Flexibility on communications format – Printing and/or labelling.

• Less plastic. It reduces plastic content by up to 80%. Liner forming station with ZERO® technology eliminates all process waste. Easy separation of liner and paperboard for simple and efficient recycling at end of life.

• Minimum size maximum skills. Trays delivered as flat boards significantly reduce distribution and storage costs vs premade trays; liner forming with ZERO® waste technology optimises cost of final package. Reduced inventory with availability of smaller purchase quantities.

G.Mondini Spa

PaperSeal® Dual Compartment Tray PaperSeal® Cook Mac Cheese

PaperSeal® Cook pasta fish PaperSeal® MAP Cod Fillet

PaperSeal® MAP fresh chicken PaperSeal® MAP fresh salad PaperSeal® MAP fruit

PaperSeal® MAP fresh pasta

PaperSeal® SKIN Salmon PaperSeal® Slice Cheese PaperSeal® Wedge Cheese

PaperSeal® MAP Salad

FOOD INDUSTRY 37 ASIATIC EDITION

Via Braglio, 68 - 36015 Schio (Vicenza) Italy

Tel. +39 0445 31 42 36 - Fax +39 0445 31 42 37 info@italpan.com - www.italpan.com

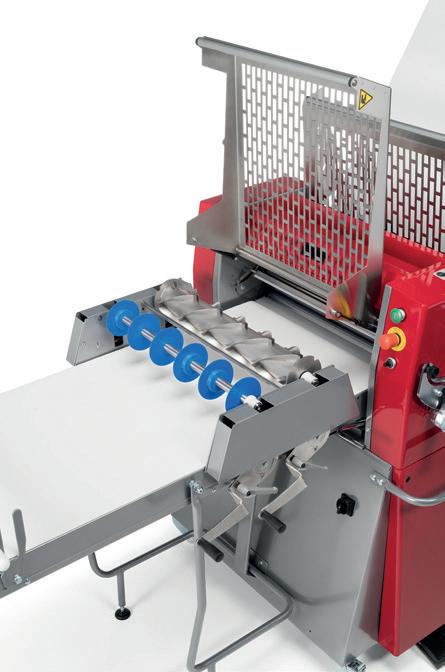

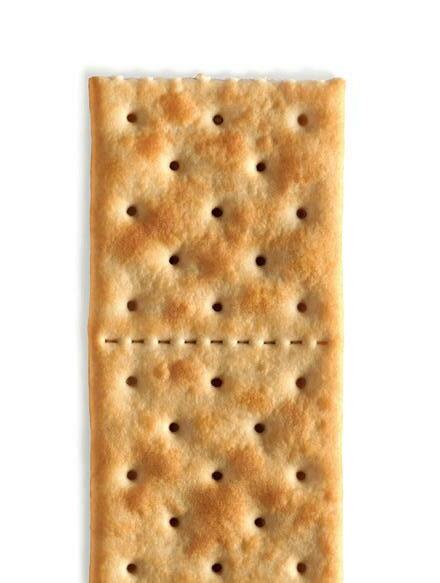

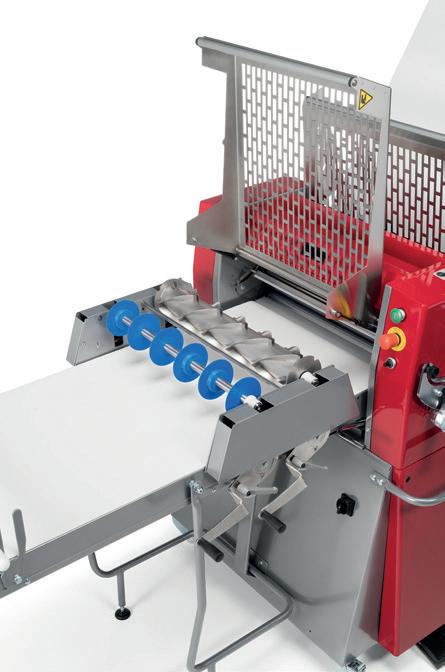

The success of Italpan is based on its attention to its clients’ needs and its ability to transform them into advanced technical solutions, as well as its great flexibility of operation. Growth has been constant since the company was founded in 1977, and the range of products it now offers on the market is further proof of its dynamism: machines for bread sticks and taralli, taralli boilers, loaf moulders and rollers, dough sheeters, bread cutters, flour sifters, crumbers and fully automatic lines for the production of bread sticks.

The Automatic Grissini Machine MOD. GR/25-A is a mass-supplied with adjustable press so as to make even the thickness of dough when entering in the die. The cut of dough can be carried out by manual electric control or through programming by timer for continuous duty. All surfaces in touch with dough are in Stainless Steel. Output can achieve 50 kg per hour. The Automatic Grissini Machine MOD. GR/25-L is a mass-supplied with adjustable press so as to make even the thickness of dough when entering in the die. The cut dough can be carried out by manual or electric control or through programming by timer for continuous duty. All surfaces in touch with the dough are in Stainless Steel, Teflon or treated through “Nihar Process” (American patent replacing the chromothickness). Output can achieve 50 kg/h.

Dies are easily interchangeable with the intervention of two knobs. The speed of the exit belt is adjustable to be adapted to every type of product in order to avoid stretching or accumulation of the dough. The assembling system on the trolley has been studied to take a minimum amount of space in a rest position.

The Sheeter Moulder I.T.P. 500/600 - Painted steel sheet bedplate, mounted on castors. Anodized aluminium sides. Ball bearings with double seal on all rotating parts. Ground and thickness chrome-plated steel rollers. A simple device stops the upper belt and the machine becomes a roll unit for the upper belt and the machine becomes a roll unit for the rolling of small quantities of dough. The machine is supplied with infeed belt for the automatic feed of the dough into the rollers.

Italpan

FOOD INDUSTRY 38 ASIATIC EDITION

Tel. +39 0376 60 82 82 - Fax. +39 0376 60 81 80 info@inoxmeccanica.it - www.inoxmeccanica.it

Research, development, and technology are at the core of Inox Meccanica’s projects, aiming to strengthen and preserve its region’s traditions and history.

Inox Meccanica’s dream has become reality thanks to a life dedicated to an ongoing pursuit of simplicity, quality and constructive efficiency. That’s a fruitful marriage increasing speed in production processes. Here they are the driving forces shaping this company’s industrial automation concept.

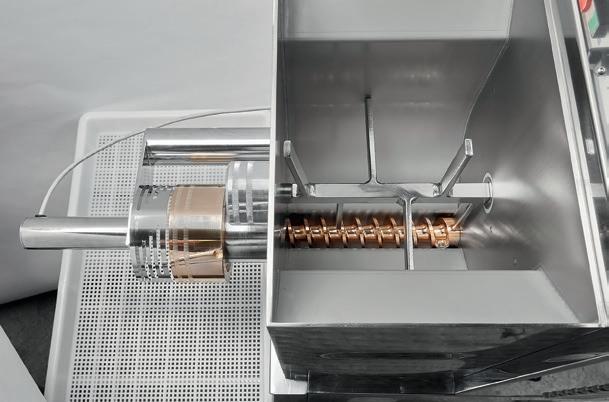

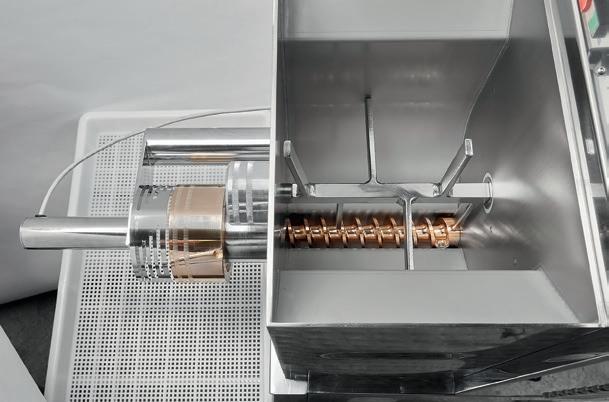

As a global market leader since 1975, Inox Meccanica designs and manufactures machinery for meat processing and packaging, focusing on sausage products. Thanks to the experience developed over the years, Inox Meccanica jumped into a diametrically and complementary field; it fully immerged into the world dedicated to washing and sanitation of all sorts of production tools and containers, finding the sector cleverly cross-cutting. 1968 is the year of its first patent; a date opening the door to a pride that has persisted for almost fifty years. With the desire to satisfy customers’ most peculiar and diversified requests, Inox Meccanica has achieved around 50 commercial partnerships which allow it today to cover almost 60 countries all over the world.

Inox Meccanica manufactures more than eighty machines for industrial plants each year, entirely handmade in Italy, in a workplace covering more than ten thousand square meters. However, the beating heart of its headquarters consists of almost 100 employees divided between production, warehouse, technical/electrical department, administration and sales. Staff to whom Inox Meccanica provides an on-going training to ensure a highly competent workforce. So far, its meticulousness has assured the attribute “quality” to Inox Meccanica branded products which, together with a selected dealer network and strategic business partnerships, have ranked the company at the peak of the national and international market. The distinctive quality note associated with the Italianness of Inox Meccanica AISI 304 stainless steel products, coupled with its after-sales service, make global expansion visible, reaching all the way to the Americas and Australia.

The sales procedure is inclusive, on request, of tests, if the customer feels the need to put Inox Meccanica machines to a trial with specific needs and their own food recipes.

Thanks to an exclusive Pilot Plant, Inox Meccanica can test industrial production, both for the development of new products and for the optimisation of traditional production processes. However, the testing does not just end with the packaging procedure. After that, the food can also be evaluated from a microbiological aspect in the new laboratory, and from an organoleptic and taste angle in a modern, purposeequipped tasting room.

Strada Solarolo, 20/B-C-D - 46044 Solarolo di Goito (Mantova) Italy

Meccanica Srl FOOD INDUSTRY 40 ASIATIC EDITION

Inox

(Vicenza) Italy

TeL. +39 0445 63 72 22 info@kmp.srl - www.kmp.srl

Avancini, Kemplex and La Pastaia. Three Italian excellences serving Ho.Re.Ca. professionals, since 1963

Avancini, Kemplex and La Pastaia are the excellences of Made in Italy in production of professional food machinery: a comprehensive range of spiral mixers, planetary mixers, sheeters and fresh pasta machines, produced and distributed by KMP, that fully meet the requirements of restaurants, pizzerias, pastry shops and bakeries.

Avancini has been in the food machine sector since 1963; it combines technological innovation, high-quality material, and Italian design flair to create a wide range of mixing machines that meet the bakery sector’s any requirement.

MOMA and MIDI are two spiral mixers that emerge in Avancini product portfolio: synthesis of sturdiness, aesthetics, and noiselessness, they guarantee maximum comfort and high performances, also with high-hydration dough.

Kemplex has been highly renowned since 1986 as a sound and reliable brand for the pastry sector. Sheeters are its flagship product, but its range also includes planetary mixers: all those products are characterized by excellent quality/price ratio, manufactured with selected materials and resulting from technological research that put efficaciousness and user-friendliness first. Reliable, sturdy, and efficient, Kemplex sheeters are designed and produced to guarantee easy and functional use, fully complying international safety standards. All models fully meet the requirements of restaurants, hotels, pastry shops, and small and medium-sized bakeries.

La Pastaia is the brand specializing in fresh pasta making machines. An all-round Italian excellence that grants technology and reliability to restaurants, gastronomy,

artisan pasta factories, and the community, enhancing pasta’s creativity, tradition and flavour.

TR machines, with mixers and extrusion screw, are available with an extensive range of equipment and, depending on the model, stainless steel structure, capacity from 2,5 Kg/h of the smallest to 80 kg/h of the biggest models.

Via del Lavoro, 45 - Z.I Molina di Malo - 36034 Malo

KMP Srl FOOD INDUSTRY 42 ASIATIC EDITION

Via Landucci, 1 - 51100 Pistoia, Italy

Tel. +39 0573 53 25 46 - Fax +39 0573 53 30 67

landucci@landucci.it - www.landucci.it

Landucci has always meant tradition and high technology; a combination formed during a century of experience combined with the ability to understand the present and innovate by developing new technologies, accepting the challenges that an increasingly qualifying market imposes. It offers solutions capable of increasing production performance qualitatively and quantitatively, it is at the side of its customers to bring their production to the best levels obtainable by developing synergies with common objectives.

Lancucci’s work is based on extremely specialized skills and on strong investments in technology and research: the recent acquisition of Zamboni company, a brand of excellence for pasta Bologna, represents an important step within its development project and an expansion of technologies available to customers. It is in fact the attention to their needs that guides Landucci, that inspires important innovations and that leads to the registration of patents, each of which represents a technological goal.

Landucci’s production organization is able to offer a wide range of complete solutions in the field of pasta formation, covering needs ranging from cutting equipment for short pasta to Bologna pasta processing machines, from accessories for pasta waste recovery to cleaning and hygiene of dies and sticks for long pasta. Landucci is a company with a vision, and which has been able to constantly evolve.

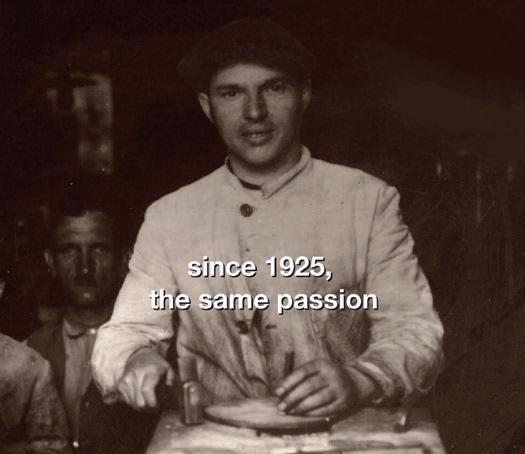

It is from the refined technique of creating dies that Landucci began its journey in 1925, distinguishing itself for the quality, reliability

and originality of the proposals, immediately becoming a strategic partner for the most important industries of pasta production.

It has always offered a unique support service to the customer for the development of the desired shapes: pasta formation designers and dynamics experts work side by side with the customer in order to obtain a perfect realization of the product, whatever the shape and leaving full freedom to creativity. Landucci’s results derive from the union of high technology and human touch: a powerful synergy that manages to go where technique could not without experience. Landucci combines the design and the perfect realization with the best materials the market can offer, to guarantee precision and duration of the die, consistency and tolerances of one hundredth of a millimetre. This precision allows Landucci to deliver inserts that always have the same yield, which can complement existing supplies or replace worn out elements.

Perfectly complementary to the dies, Landucci pasta forming machines represent the maximum technological evolution available to the pasta factory. This company has invested years in the development of the revolutionary Twin Flow cutting unit: fluiddynamic studies on the behaviour of the air inside the dies and of the pasta transport, design optimization to offer total control of production with maximum efficiency; Twin Flow guarantees the customer an alwaysoptimized regulation of the airflows according to any production need.

But every goal achieved is only a starting point for Landucci, innovation is continuous

and global change brings the attention towards wider horizons, towards farreaching commitments that embrace the optimization of resources, water saving and energy: Landucci has patented die cleaning systems that use half of the standard water and energy resources, obtaining exceptional results. Landucci wants innovation to be sustainable.

The values in which Landucci reflects are part of its most authentic tradition, Landucci is proud to be in the fourth generation of the family to lead the company towards the future. Being a family-run company makes it extremely involved in the production far beyond the commercial terms: all the passion, the desire to create something new, useful, really better for the production of pasta drives Landucci to ask all the company, collaborators, suppliers extra attention; a commitment to create together something always better than the previous day.

For anyone at Landucci, business is not only a job: they feel part of a project in which customers are an active part, they feel driven exclusively to excellence, since the company’s foundation, since 1925.

Landucci Srl FOOD INDUSTRY 44 ASIATIC EDITION

Via Canvelli, 21 - 43015 Noceto (Parma) Italy Tel. +39 0521 25 87 23/4 - Fax +39 0521 25 87 17

info@lcz.it - www.lcz.it

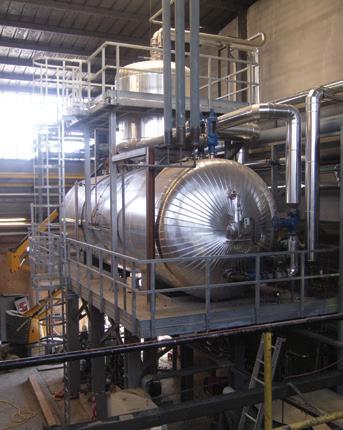

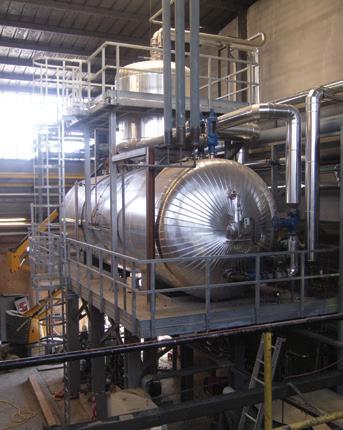

Since 1971, LCZ has been proposing fire-tube steam boiler with high performance for current needs.

Welcome to LCZ, dedicated to design, manufacturing, installation, service and maintenance of industrial boilers for standard and special applications since 1971: plug in solutions, package solutions, site erected plants.

Over the years, LCZ has been able to adapt the proposal to market evolutions, thanks to constant and continuous improvement, regarding the product as well as the fabrication processes, without forgetting the hallmark: careful analysis of customer’s requirements by its technical department aimed at drawing up the most focused, customized and detailed answer.

A manufacturing system, organized in two manufacture plants both in Italy and one of these with a covered area of more than 40.000sqm, is well-characterized by automated welding processes, nondestructive tests (X-rays-L.P.), a home production of the furnaces FOX (corrugated) all supported by management using software as SAP ERP. These are some evidences of capacity and productive process that allow LCZ to be one of the best manufacturers of boilers worldwide. Its internal technical department provides process and mechanical design in compliance to PED, TS-TR and ISO 9001 certifications; according to European standards.

One of the products, pride of the company, is the fire tube steam boiler model “CS” completely “Made in Italy”. This boiler is characterized by:

- Three effective smoke turns, - Semi-fixed, - Wet bottom,

- Furnace FOX model,

- Steam production from 350kg/h up to 25Ton/h (higher on demand),

- Pressure up to 20bar (higher on demand),

- Steam water ratio 98% (higher on demand),

- Efficiency up to 96% with economizer (up to 105% in several applications),

- Available to use gaseous and liquid fuels, - Superheated steam on demand.

The fields of application of this type of boiler could be food and beverage (main focus on canning and milk companies), pharmaceutical, tyre, tobacco, gas&oil, etc.

The main advantages of the fire-boiler LCZ mod. “CS” are:

- High-efficiency reducing consumption, - Long lifetime,

- Steam high-quality fulfilling sudden demands of steam, - Low Nox emission.

- LCZ boiler model “CS” can be configured with efficiency up to 96% (in specific application up to 105%) and for operating without continuous supervision up to 72 hours and/or with a global control system of the plant or the whole boiler room by a PLC or a multichannel electronic control device.

In one of the most important companies of Italy’s canning industry, with the aim of extending the supply to the whole site, LCZ has provided its best technologically advanced configuration plant able to grant the minimum impact on running expenses, by reducing power, gas and water consumption down to the minimum.

Steam boiler CS12000 for steam production of 20 t/h and 15 bar, is characterized by yield up to 96%; it is managed by an automatic control system that enables the plant to run safely as long as 72 hours without requiring constant supervision of operators.

LCZ carried out in house engineering and manufacture of the boiler, and steam distribution collector; moreover, it also supplied boiler water treatment, as follows: inverse osmosis plant to produce 10mc/h of osmotized water pressurized thermophysic degasser LCZ also provides its customers with customized solutions to help them exploit process and combustion residual heat as much as possible, by building condensation

water recovery systems, pre-heating system for edible water, chimney heat recovery for process water production.

The system enables to get efficiency up to 105%, granting the optimization of temperature of flues into the atmosphere and producing saturated steam and hot water to be used in the process.

LCZ also acts on steam plants and boilers already in use, examining the possibility of operating interventions that improve overall system performances, reducing emissions and consumption.

In addition to energy audit, the technicians also analyze the operation parameters of the plant to work out a proposal of interventions to get significant:

- Fuel saving; - Energy saving; - CO2 emission reduction; - Covering of investments on White Certificates.

LCZ’s commitment extends to the management of processing waters, for which it provides water treatment turnkey plants: from process water pretreatment to discharged water recovery, with the optimization of the percentage of recycled water.

As regards process waters, the company also supplies the best technology for demineralization processes (ionic exchange, inverse osmosis, etc.) and degassing (atmosphere degassers and pressurized thermophysic plants).

L.C.Z. Srl FOOD INDUSTRY 46 ASIATIC EDITION

Via Marconi, 92 - 31020 Revine Lago (Treviso) Italy

Tel. +39 0438 56 20 28 - Fax +39 0438 56 20 23

info@metalmont.it - www.metalmont.it

METALMONT is an Italian company that has been operating in the storage field of grains since 1995. The company helps farmers, agro-industrial companies, millers, grain traders and feed producers from more than 20 Countries around the world to choose the most suitable solution for the storage of their products.

The main activity of METALMONT is designing, manufacturing and marketing handling and pre-cleaning equipment used for the mechanization of silo plants, as well as the automation of flat storage warehouses.

The METALMONT equipment is designed to work perfectly with bulk products such as grains, oil seeds and pulses, as well as products that tend to cake, such as soybean meal.

The main goal of METALMONT is to help operators of the agroindustrial field:

• to choose the most cost-effective solution for grains storing (silos or flat storage warehouses, in a variety of configurations);

• to minimize grain losses before, during and after storage;

• to simplify the process of meals storage, ensuring the safety of the staff;

• to minimize operating costs and maximize revenues

FOOD INDUSTRY 48 ASIATIC EDITION

Metalmont Srl

Milk Italy is specialized in plants to process milk and all its by-products. Milk Italy has been established after a strong thirty-year experience gained in some of the major dairy firms.

Milk Italy produces complete units for processing the milk starting from Raw and/or Powder Milk.

The company’s plants are mainly designed to produce: Pasteurised milk; UHT milk; Yoghurt; Laban; Cheese; Cream & Iced Cream; Powder milk plant; Butter & Margarine (from vegetable oil).

The company’s strength points are: High engineering level of the solutions proposed; Knowledge and experience in this industry; Quality of product offered; Customer care and Customer support; Excellent ratio quality/price.

Milk Italy follows the client from the beginning, in order to understand his specific needs and to propose its advise, until the start-up of the plant. Milk Italy can also provide warranty on site.

Via Copernico, 62 - 36034 Malo (Vicenza) Italy

Tel: +39 0445 57 66 92 - Fax: +39 0455 57 72 80 info@milkitaly.com - www.milkitaly.com

Milk Italy has production solutions from the small needs 150 lt./h up to 40.000 lt./h of milk.

Due to the similarity of the plants and the equipment, it also makes units for juices, ice-cream and units for eggs pasteurisation process.

The experience gained on many international markets has enabled the company to have remarkable knowledge of products and local dairy production techniques. In addition to this Central Europe markets, the company also operated very-well also in the following markets: East European Countries & Russia; Africa; Middle East; South America.

Check the following website: www.milkitaly.com

Write to info@milkitaly.com

Contact the company directly in order to study the best solution for your needs.

Milk Italy Srl

100%

FOOD INDUSTRY 50 ASIATIC EDITION

Mini dairy plant Mini laiterie 100% Made in Italy www.milkitaly.com

Made in Italy www.milkitaly.com

Via Copernico, 62 I-36034 Malo (VI) T +39.0445.576.692 F +39.0445.577.280 info@milkitaly.com www.milkitaly.com

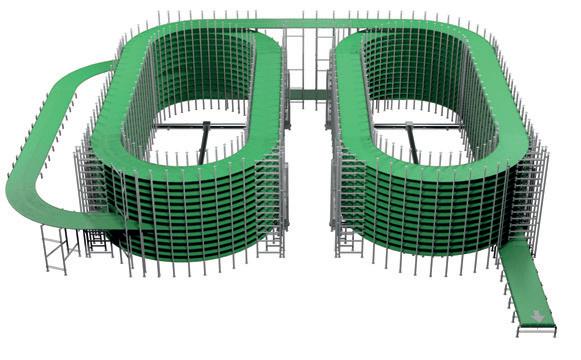

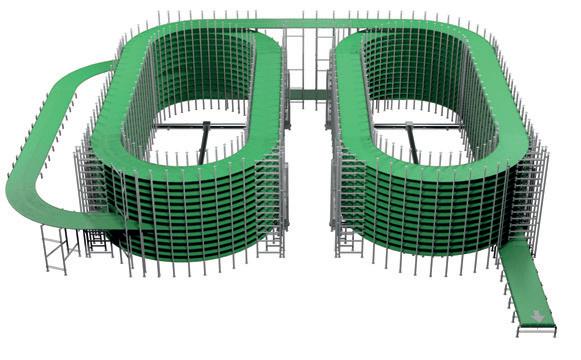

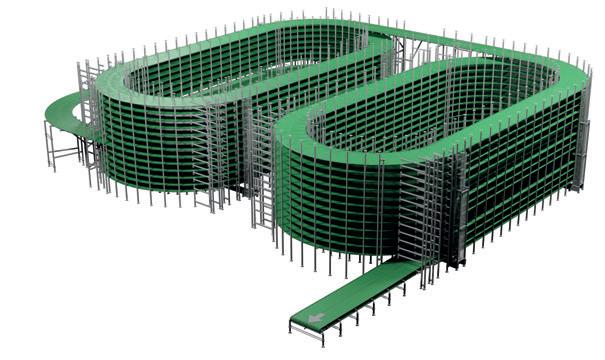

ME Food Solutions: Beyond to where none has gone before 1996-2021. Millennium Engineering celebrates its 25th anniversary in the name of 3 keywords: Passion, Projects, and People, inspiring performance circularity and stemming from Eng. Luca Priore’s expertise and strong guidance.

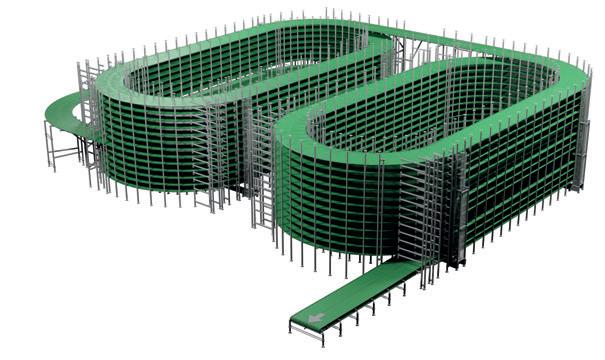

ME Food Solutions is therefore the brand that conveys the ability to understand every specific food processing requirement with flexibility, innovation, customized design and remarkable professional helpfulness, guaranteeing efficient, tested solutions that can optimize two highly sensible parameters: cost control and space management. Headquartered in the Province of Padua and with a network of dealers all over the world, ME Food Solutions is acknowledged as a sound benchmark especially in the bakery sector, thanks to its ability to manage all processing stages, from leavening to cooling and freezing.

Belt width 1,4 m Belt length 1,340 km Work temperature

80°C Motor power 5+5 kW Height of the structure 5.8 m Footprint 730 m2 Sliding components 68.000 pz Weight AISI304

Via Martin Luther King, 12 - 35010 - Curtarolo (Padova) Italy

ME Food Solutions exceeds itself one more time

Millennium Engineering Srl FOOD INDUSTRY 52 ASIATIC EDITION

used 55

With the new line, it goes beyond the limits reached so far. A new pasteurization plant where 1,600 Kg/product are processed at 90°C. sets the bar even higher and breaks down another barrier. Today, it can say to be able to build spiral plants with belt width up to mm1400. In the table, some figures to fully understand the size. (Tab. 1) The pasteurization system has been installed on the premises of the most important salty snacks producer of Northern Europe. Owing to its size, all plants are assembled and pre-tested (FAT) either on the Curtarolo premises, Padua, or at the new facilities in San Martino di Lupari, Padua, of 10,000 sqm. The customer and its technicians examined and verified the new solutions adopted for the plant’s particular size, and the temperature it will undergo. Great satisfaction for the smooth motion of the belt also at very low speed, less than 1m/min (< 39 inch/min). The goal has been hit once again with no lubrication, crucial condition to guarantee hygiene and absence of product contamination with lubrication particles. Research on increasingly modern and advanced technopolymers has enabled ME Food Solutions to always guarantee, also at extreme temperatures, high performance and absolute reliability. That has been belt

000 Kg Useful

surface 1876 m2 Electric equipment Allen Bradley Software ME FOOD 3.2

Tab. 1

Tel. +39 049 96 24 258 - Fax +39 049 96 23 823 info@me-foodsolutions.com - www.me-foodsolutions.com

Via Martin Luther King, 12 - 35010 - Curtarolo (Padova) Italy

Tel. +39 049 96 24 258 - Fax +39 049 96 23 823

info@me-foodsolutions.com - www.me-foodsolutions.com

possible thanks to accurate durability and reliability tests, where the components used for manufacturing the plant have undergone significant stress tests, passed with widely safety margin to get spiral’s reliability. This allows offering a safe and functional system in demanding work conditions of 2/3 work shifts for 6/7 day/week. With the washing systems consisting of 2 KARCHER pumps, whose working pressure is 120 bar, a double-row of rotating nozzles is fed. One row is above the belt and the other

below. In addition to this, a dosing system enables detailed detergent distribution before washing. The same system is also used for the distribution of the sanitizing solution when detergent, washing and drying phases are complete. This solution guarantees unmatched cleaning of the surface where the products to be treated are placed. Once again, ME Food Solutions stands out as market leader in thermal processes for food products, with flexible and reliable solutions. Where other producers cannot succeed.”

Millennium Engineering Srl FOOD INDUSTRY 53 ASIATIC EDITION

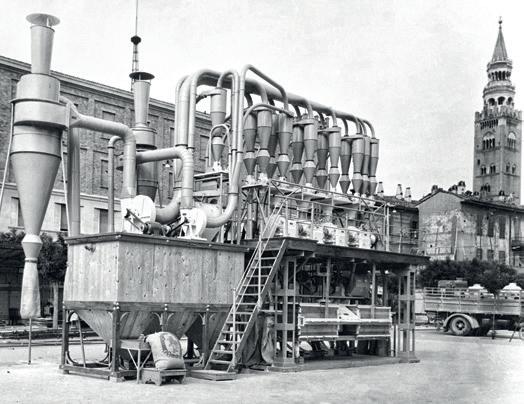

The company OCRIM of Cremona is renowned all over the world as a reliable partner for the construction and supply of milling, feed, and cereal processing plants, and end-of-line plants. Its important commitment in research, customer care, training and communication has always been an incentive for innovative and productive teamwork.

OCRIM boasts two sites in the city of Cremona: The original headquarters in Via Massarotti, which houses offices and parts of its production factories, and the premises at the canal port for some important production and logistics departments, and also for the Milling Hub (created jointly with Bonifiche Ferraresi), which includes the new Milling Hub Masterclass school.

Turnkey projects are one of OCRIM’s strong points, supplied in tailor-made solutions, increasingly welcomed by international customers who decide to rely on a single partner who can guarantee a high professional level and respect programmed time.

OCRIM is an irreplaceable partner also for the supply of machines only and in milling plant upgrade/modernization.

Since 2017, thanks to the OCRIMFBC department, the company has also manufactured end-of-line plants for palletization and packaging of bags and other packing, supplied turnkey and personalized upon customer’s requirements.

Since 2021, Fluting Hub - a new department for process and treatment of milling rollers

Via Massarotti, 76 - 26100 Cremona - Italy

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92

info@ocrim.com - www.ocrim.com

has been open and where it will be possible to manage fluting, grinding and balancing stations as well as an innovative system for coating the rolls in titanium.

Hence, internalizing all processes and therefore completing the industrial chain, OCRIM can guarantee a traced, controlled, and certified Italian Made product.

OCRIM’s versatility and reliability are also evidenced by the strategic alliance, officially signed on in June 2021, with AGCO - global leader in the design, manufacture and distribution of agricultural machinery and precision ag technology.

Thanks to Cimbria’s and GSI’s expertise in material storage, processing and handling, AGCO and OCRIM aim to be the players of a constructive change, for a highly sustainable global food industry, by offering intelligent and innovative solutions from one single partner

OCRIM’s versatility is also evidenced by an important agreement reached with Italian company Molitecnica Srl at the beginning of 2019, to build nixtamalized flour plants for tortilla, snacks and chips production.

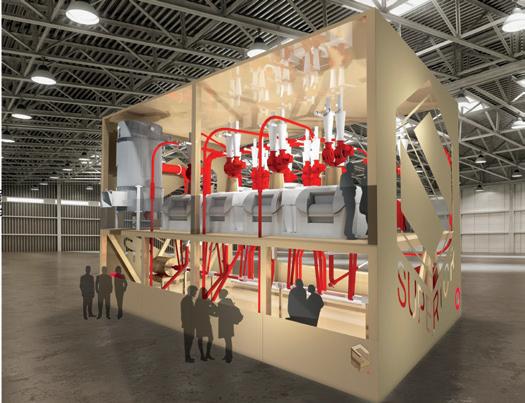

Inside the Milling Hub – plansifters floor

Ocrim Spa

Milling hub

FOOD INDUSTRY 54 ASIATIC EDITION

Manufacturing and logistical headquarters

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92 info@ocrim.com - www.ocrim.com

These products are mainly part of Central and Southern America’s food culture, but also highly appreciated and consumed all over the world. The best OCRIM process machines, which are highly renowned for their performances fully responding to the targets to hit, are installed in these plants.

OCRIM’s target is supplying its customers with long-lasting milling plants and efficient high-quality services. With this goal, innovative sanitization solutions have been introduced to reduce energy consumption and to minimize operating and maintenance costs.

As for maintenance strategies and management, OCRIM has developed the Modular Mill Concept, a truly innovative technology that enables stopping some parts of the grinding section, for any reason, while letting others run, thus granting certain output. The benefits deriving from that are clear and easily definable,

since it is a solution already chosen and highly appreciated by many customers.

Also in the automation sector, Ocrim knows to be a direct reference and that is the reason why the company does not rely on external bodies to study and create plant management systems.

The general automation package @mill (which offers many application packets), the innovative @rollermills, which enables controlling the mills remotely via tablet, and the Immersive Reality and its resonance and important feedback all over the world, are futuristic systems created to improve and simplify the work activities of those who live the mill.

OCRIM’s Italian Made brand is synonymous with quality, design and accuracy, since it is evidence of the production and logistic process that is carried out in Italy only, based

Inside the Milling Hub – roller mills floor

OCRIM-FBC department

Inside the Milling Hub – roller mills floor

OCRIM-FBC department

Via Massarotti, 76 - 26100 Cremona - Italy

Ocrim Spa

Conference hall

FOOD INDUSTRY 55 ASIATIC EDITION

Historical and manufacturing headquarters

on research in quality and design, which are true conventions of Italian business culture.

Grounding on Italian Made feeling and thanks to the partnership with Bonifiche Ferraresi, the biggest Italian agro-food business reality, OCRIM is acknowledged as a sound partner in The Italian AgriFood Chain Choice, a project strongly wanted and carried out by OCRIM and Bonifiche Ferraresi jointly with other renowned Italian companies.

This ambitious project, connected with the food chain, has inspired the study and creation of Milling Hub, a company that aims at building and managing the different milling plants on OCRIM’s premises in Cremona canal port. The Milling Hub aims to strengthen Italian agri-food sector, giving the food industries without their own milling plant the chance of having a customized one and benefitting from OCRIM team’s technical and technological skills. They will be granted a traced and certified product, thanks to accurate control by the agri-food chain, The Italian Agri-Food Chain Choice. In addition to this, thanks to the great training experience, proved by the OCRIM International School of Milling Technology which has been training technicians and technologists since 1965, and in line with the Milling Hub project, the Milling Hub Masterclass has been created to give education a new vision.

Only a limited number of previously trained technicians, with a well-defined experience, can access the Masterclass in order to guarantee a high-degree training. 360° advanced training focusing on the knowledge of seeds, through cereal and pulses processing, to finished product sales.

On account of this corporate positive development, OCRIM’s R&D department has experimented such new strategies and state-ofthe-art projects to be broadly acknowledged as unique in the milling sector and in full harmony with the novelties the company has been experiencing. The partnership between OCRIM and some Italian universities, whose contribution is crucial to get valuable results to gain benefits for the milling sector in general, continues and is increasingly efficacious.

Via Massarotti, 76 - 26100 Cremona - Italy

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92 info@ocrim.com - www.ocrim.com

OCRIM’s various communication instruments to convey its orientation have been greatly changed in such a way as to finetune the company’s language to the new trends. In fact, the company boasts considerable visibility through both national and international sector publications, via its LinkedIn profile, Ocrim S.p.A. | LinkedIn, and its three internet websites: the corporate website www.ocrim.com, one dedicated to the company’s museum www.ocrimcore.com, one dedicated to the blog www.ai-lati.com strongly wanted by OCRIM as a real information provider for the entire The Italian Agri-Food Chain Choice chain, and therefore for its member companies.

In addition to this, in 2020, the company’s media department was highly developed with the start of highly technical-scientifical Webinars into the milling world.

Customized machines for its customers, events such as “Wheat, flour and…” and the hospitality of hO (Home OCRIM), events and projects created to provide a close-up view of a company that is continuously and constantly evolving.

OCRIM Core Museum

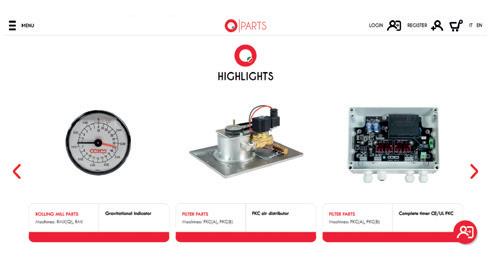

OPARTS: Ocrim’s world is just a click away

On May 2022, the company launched a new platform www.opartsshop.com, an e-commerce portal with interactive catalogues where spare parts for milling plants can be bought.

The entire website has been designed with the customer in mind. The aim is to ensure the best user experience in terms of ease of navigation, speed, and intuitiveness.

The is available worldwide and allows customers to directly purchase milling products 24 hours a day via certified international payment circuits.

The portal is structured in two parts: a B2B e-commerce platform for the immediate and direct purchase of milling plant articles and a customised section for loyal customers with interactive catalogues. In the latter area, the user’s machine catalogues will be uploaded for browsing, with the relevant serial number, table, and bill of materials so that users can find and order both specific and custom-made spare parts.

The reserved area has been specifically designed both for new and long-standing customers. We truly wanted to optimise the flow of information and improve our customer service when purchasing specific spare parts for Ocrim machines. Customers can browse the various catalogues in several ways, making the ordering process easier and quicker, thus minimising the chance of error when searching for a specific component. With Oparts, the user can buy spare parts with just a few clicks, choose and order spare parts by selecting them directly from the table, view dedicated promos and keep track of requests and orders at all times.

For more information visit www.oparts-shop.com or write an email to info@ocrim.com.

Ocrim Spa

FOOD INDUSTRY 56 ASIATIC EDITION

Via Massarotti, 76 - 26100 Cremona - Italy

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92

info@ocrim.com - www.ocrim.com

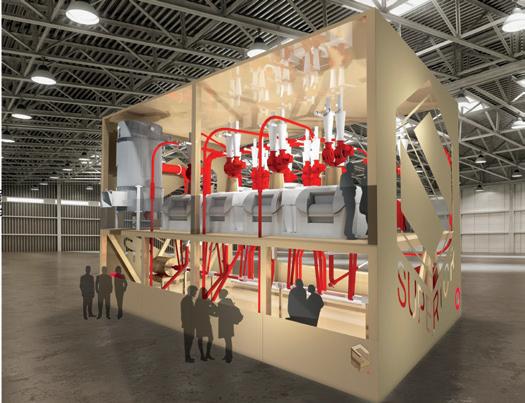

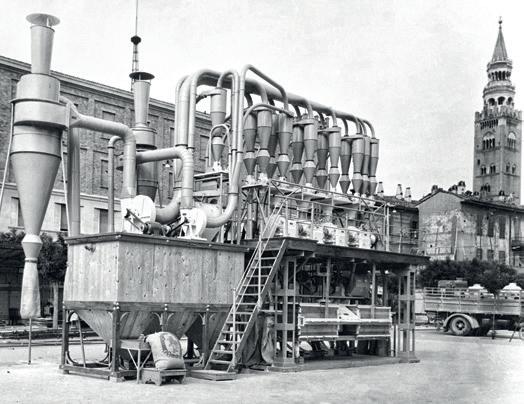

Superior is back! The OCRIM compact mill

Superior is a compact mill representing a strategic and smart investment that offers safe and versatile productive solutions for an excellent final product. Pre-assembled at OCRIM warehouse, Superior just needs final installation in an industrial shed, thus reducing the costs of a dedicated multi-level building and bureaucracy expense for urbanization works. Superior offers high energy performance for reduced production and management costs.

Superior has been thought and studied for customers with different goals and entrepreneurial courses. It is for people approaching the milling world for the first time as well as for those who are already working in the agro-food sector and want a compact plant in short time to extend or diversify their offer, to satisfy specific or niche markets, without revolutionizing or replanning their industrial production.

The first compact mill Superior stemmed from a pioneering idea in the 1950s and would be undisputed icon for almost 20 years. Its state-of-the-art engineering has highly contributed to

Superior today

OCRIM’s industrial development, making the name OCRIM resound across the globe, from Italy to Centre and South Americas. A compact and smart grinding mill for wheat only, for different capacities depending on the composition of the model requested. High degree of customization of technical and technological equipment, and design are the innovative features of the new compact mill.

Superior will represent and interpret, also harmonically, the needs, style and culture of customers and Countries where it is accomodated in, starting from one of the four different solutions available: Passion, Natural, Gold, and Style.

Superior is back to OCRIM home in a futuristic elegant shape, from the technological and design points of view.

After the great interest generated and significant demand, OCRIM has dedicated Superior an Internet website – www. ocrimsuperior.com – with all information, and e-mail address to write for requests – info@ocrimsuperior.com, as well as a brochure whose content and design fully convey the usability and elegance of this compact mill.

Ocrim Spa

Superior 1948

FOOD INDUSTRY 57 ASIATIC EDITION

Brochure dedicated to Superior

Via Sparato, 14 - 41036 Medolla (Modena) Italy

Tel. +39 0535 41 06 11 - Fax +39 0535 41 06 50

info@olivibra.it - www.olivibra.com

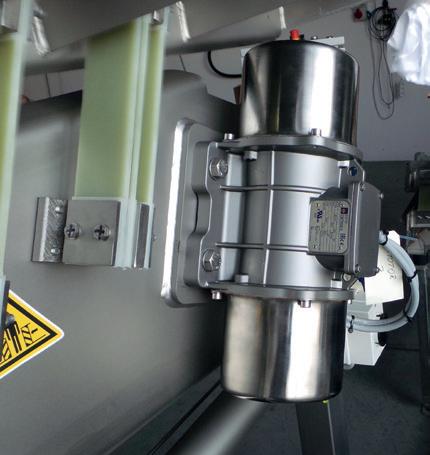

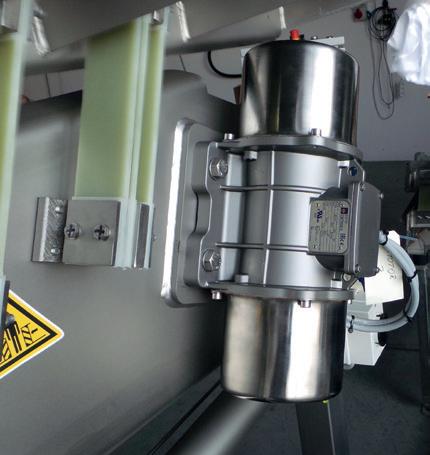

OLI, 60 years of constant growth

OLI has been a market leader in the sale of industrial vibrators for years. In 2021, it celebrated 60 years of history and inaugurated the new headquarters in Medolla (province of Modena).

It can boast an extensive sales and customer service network: 25 commercial branches and 36 warehouses on 5 continents, supplied by 3 production plants, two of which in Italy (Medolla and Parma).

Originally born to produce vibrators intended for vibrating concrete, OLI has grown at a constant pace, becoming a world reference point in all sectors.

The wide range of products, designed and certified to meet all market demands, combines competitiveness, reliability, and a globally certified quality management.

With its technical expertise and valuable knowledge of the market, OLI is a credible partner when it comes to finding the solution that best suits the needs and of each individual customer.

As proof of its continuous growth, in recent years OLI has implemented

and completed the range of vibrators, designed specifically for purifiers and for the food sector. MVE Milling and MVE Stainless Steel immediately convinced the markets, which year after year have increased requests.

Even in the packaging sector, OLI confirms to be a strategic partner thanks to the multiplicity of solutions offered, ranging from electric vibrators, even small ones, pneumatic vibrators, hammers, passing through “metal detector” fluidification systems, used to avoid any contamination of the food powders.

That’s not all, customers who turn to OLI can count on a single partner for the supply of:

• Industrial vibrators: electric vibrators for vibrating equipment and machines.

• Flow facilitators: complete range of electric and pneumatic vibrators to solve any problem of smoothness.

• Concrete consolidation: complete systems for concrete vibration.

• Elastic elements

To find out more about the world of products offered by OLI, visit the website: www.olivibra.com

OLI Spa

FOOD INDUSTRY 58 ASIATIC EDITION