STUDIO 3.2

Reborn Spirits: CloughBank Farm Distillery

Tamar Lang

20103625

1 STUDIO 3.2

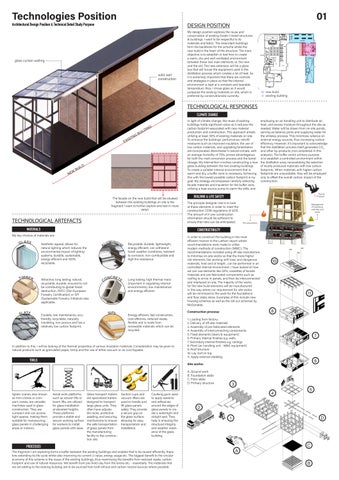

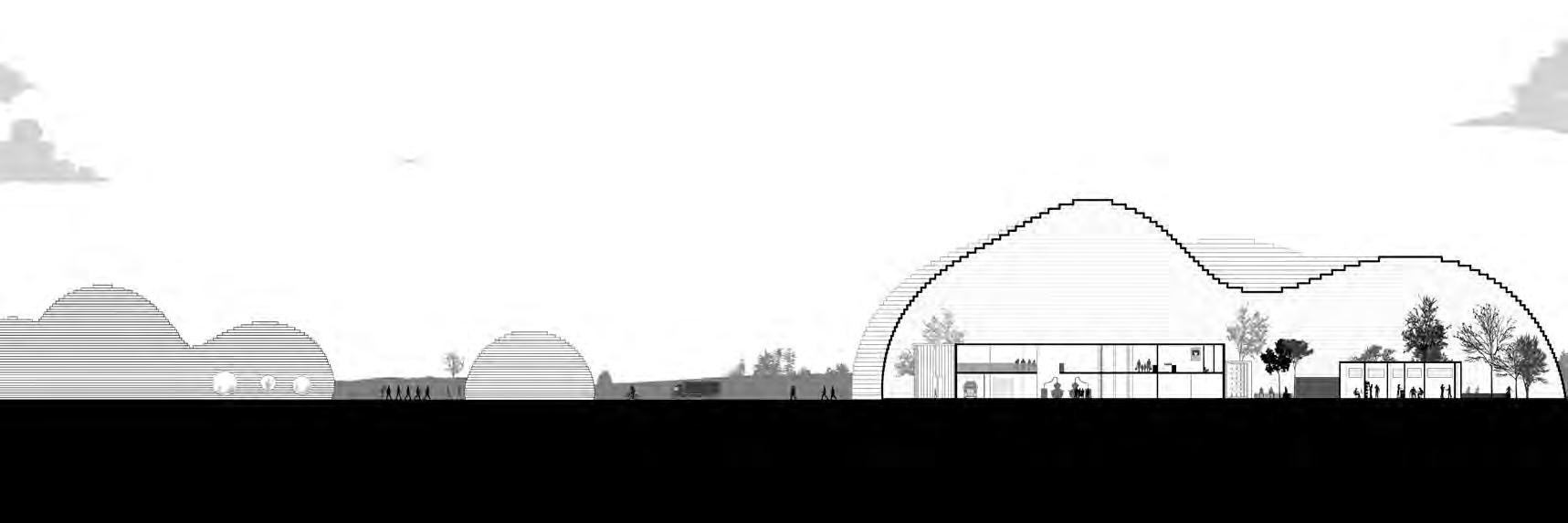

Continuing the development into phase 3.2, the focus shifts towards enhancing the spatial qualities and addressing technical aspects of the design. To create a more well-lit and playful space, several changes can be considered:

RETROFIT FIRST

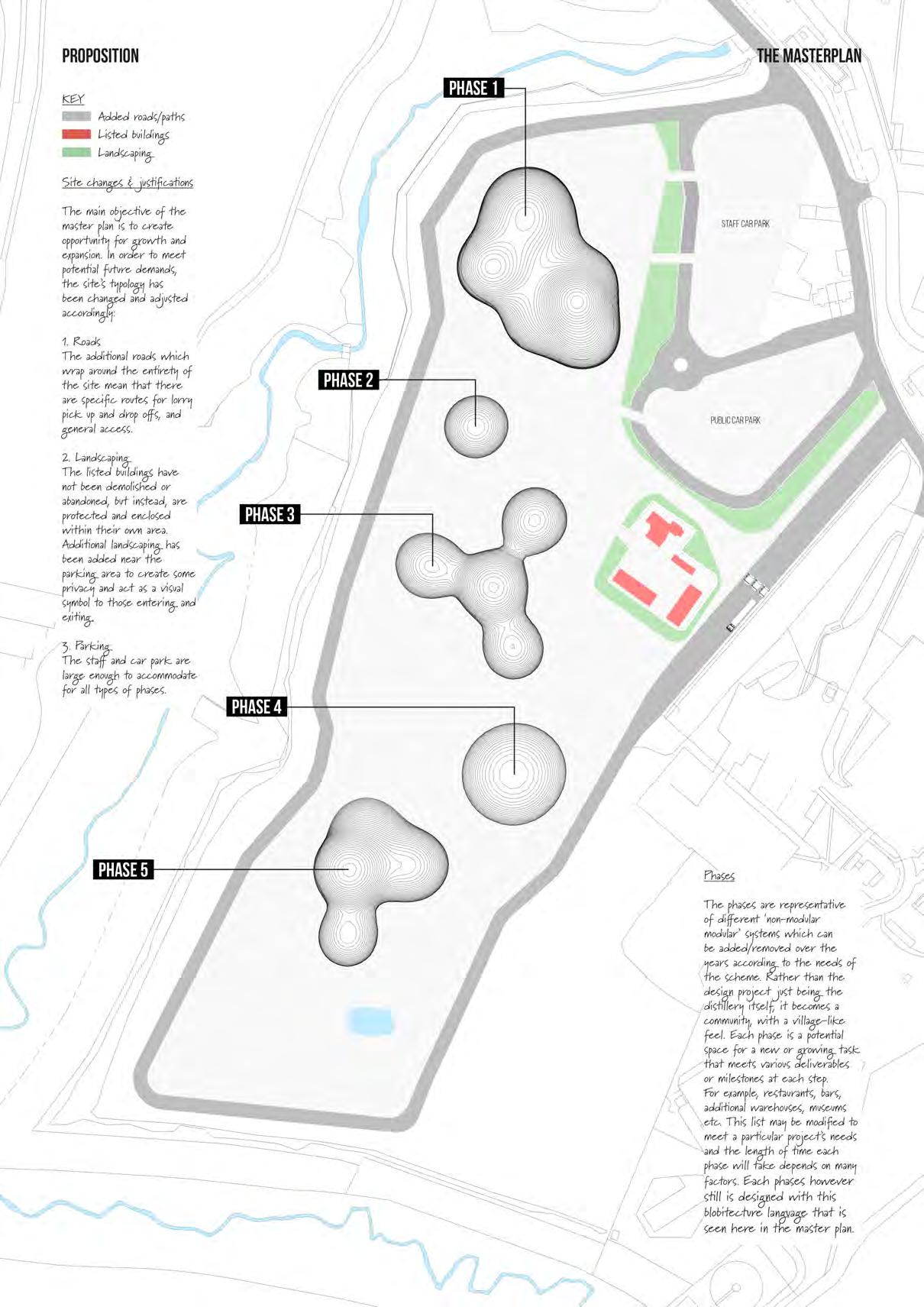

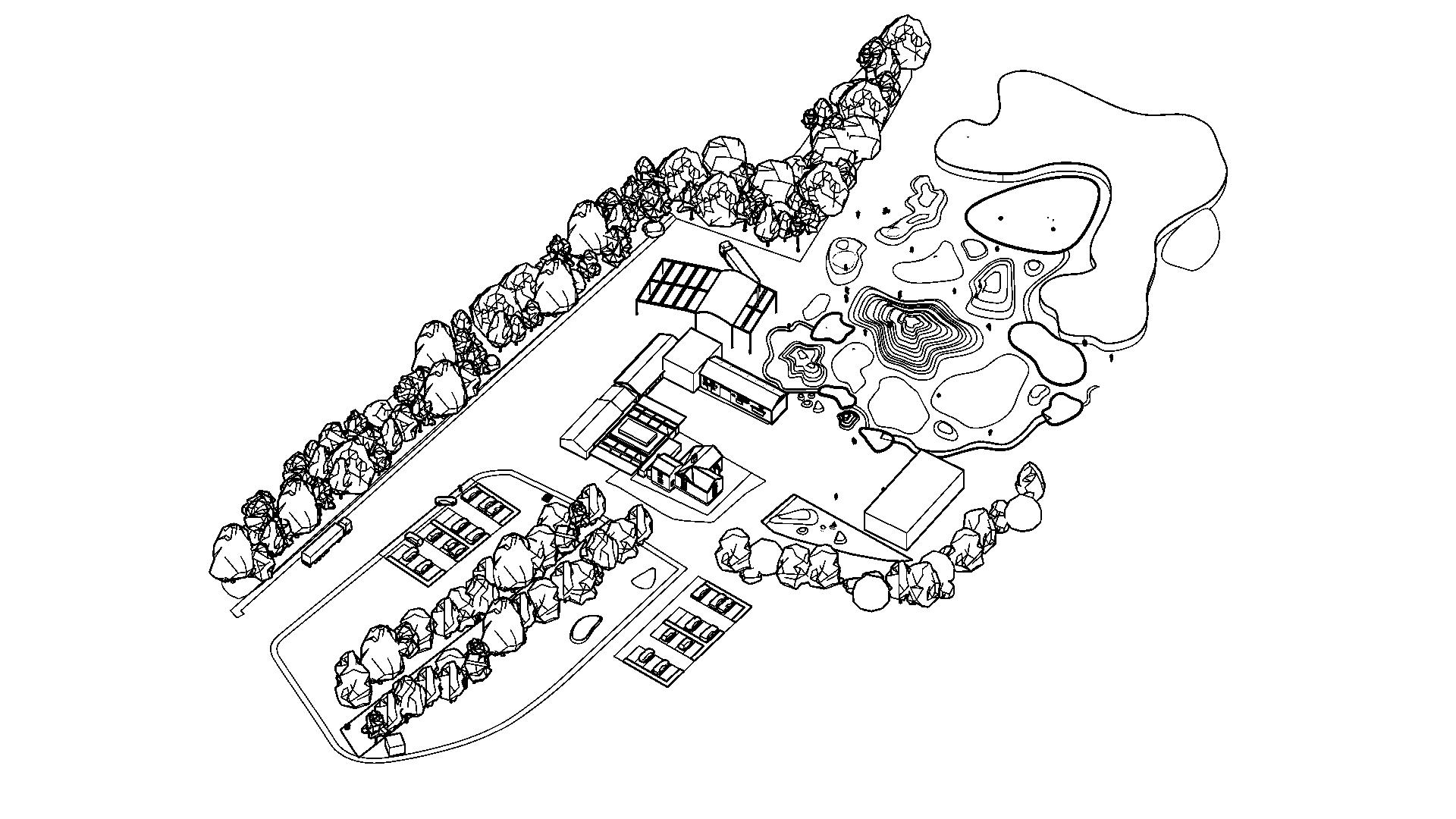

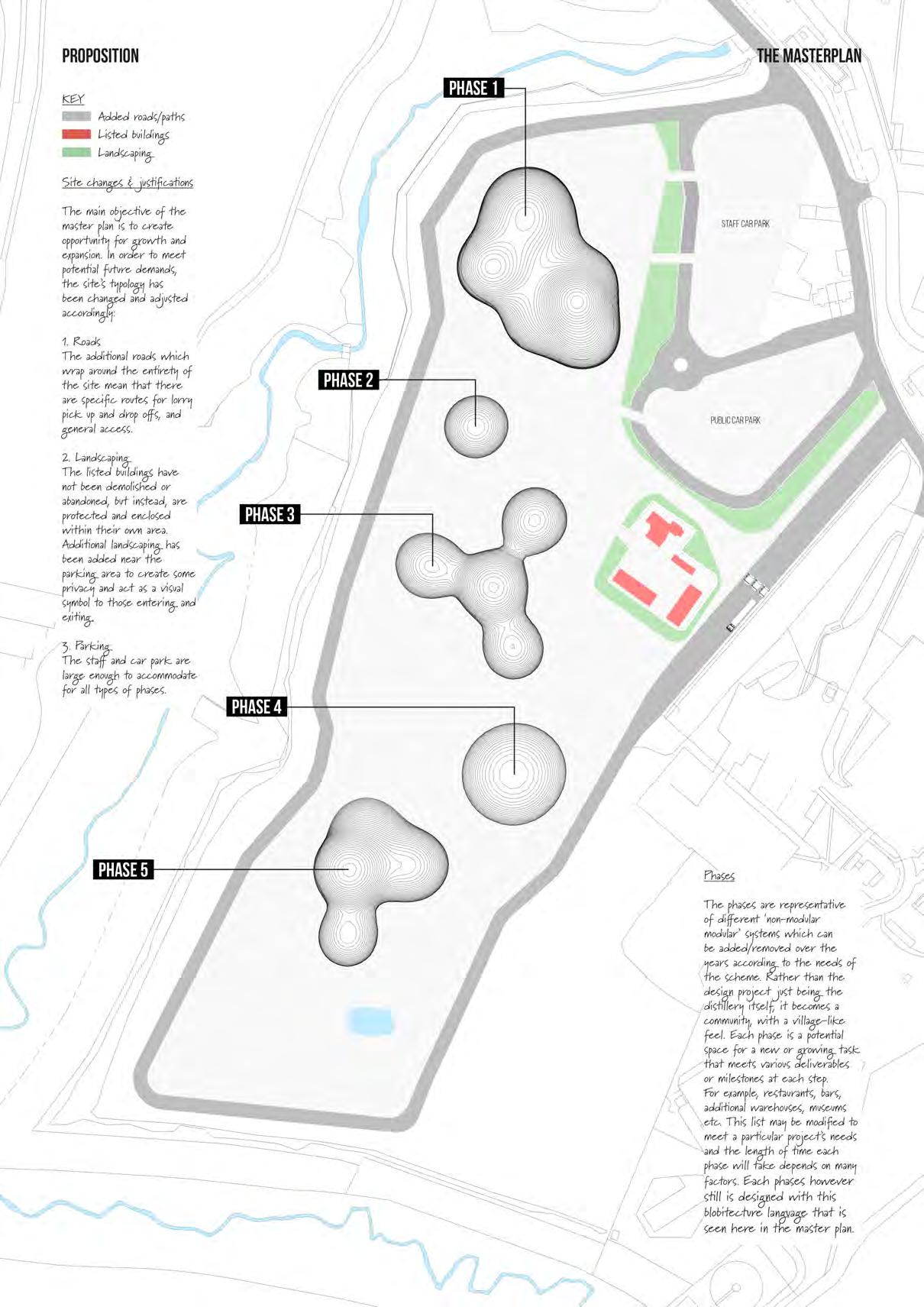

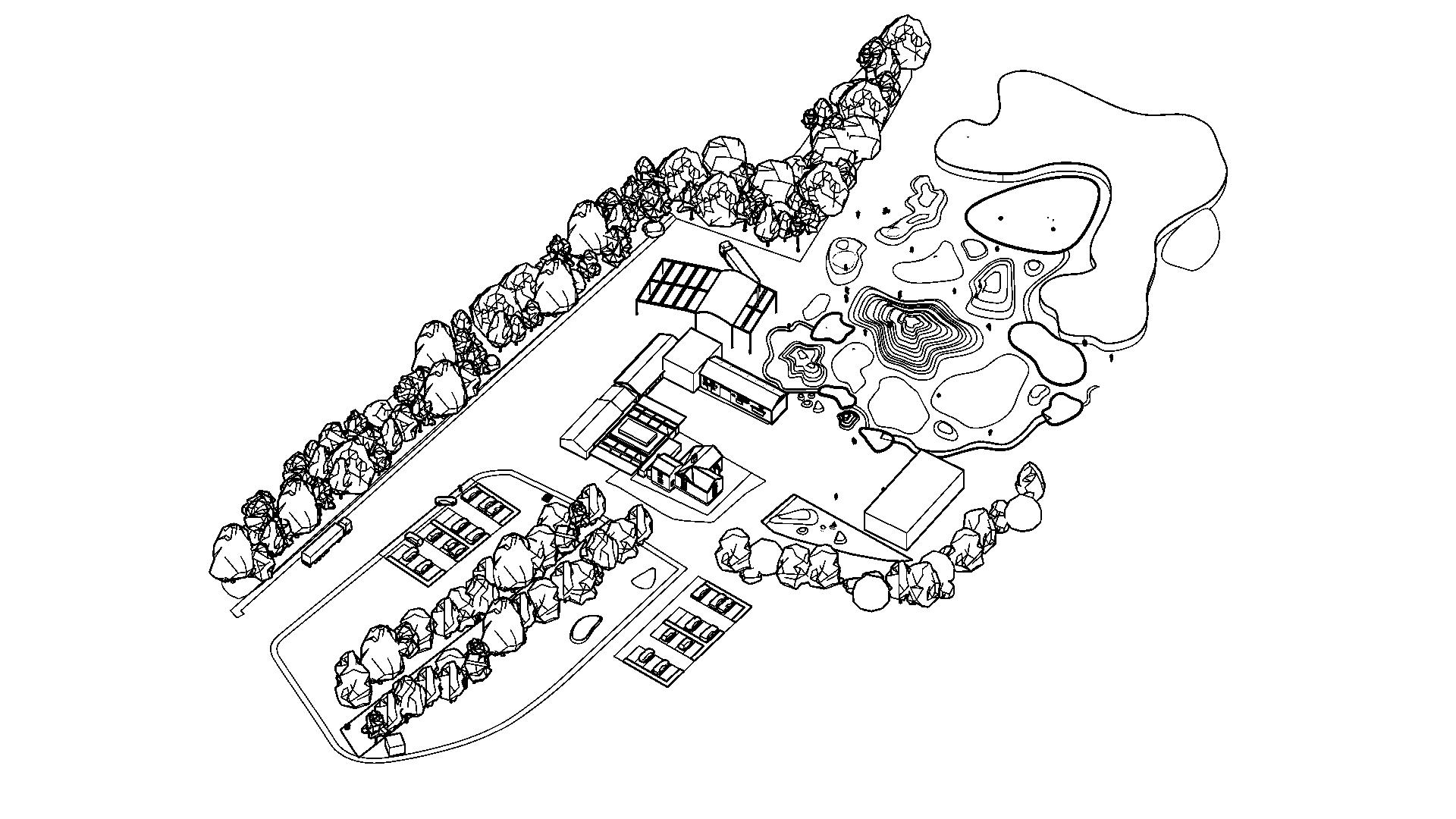

This brief presents an opportunity for the revitalization of CloughBank Farm and the creation of new Distillery building. Situated next to Manchester Airport, which has undergone significant redevelopment in recent years, the development site offers immense potential.

Clough Farm comprises four distinct buildings, encompassing approximately 428 m of former agricultural structures alongside a charming farmhouse.

Through meticulous review and extensive discussions, the project brief underwent a transformative evolution, incorporating the following key requirements:

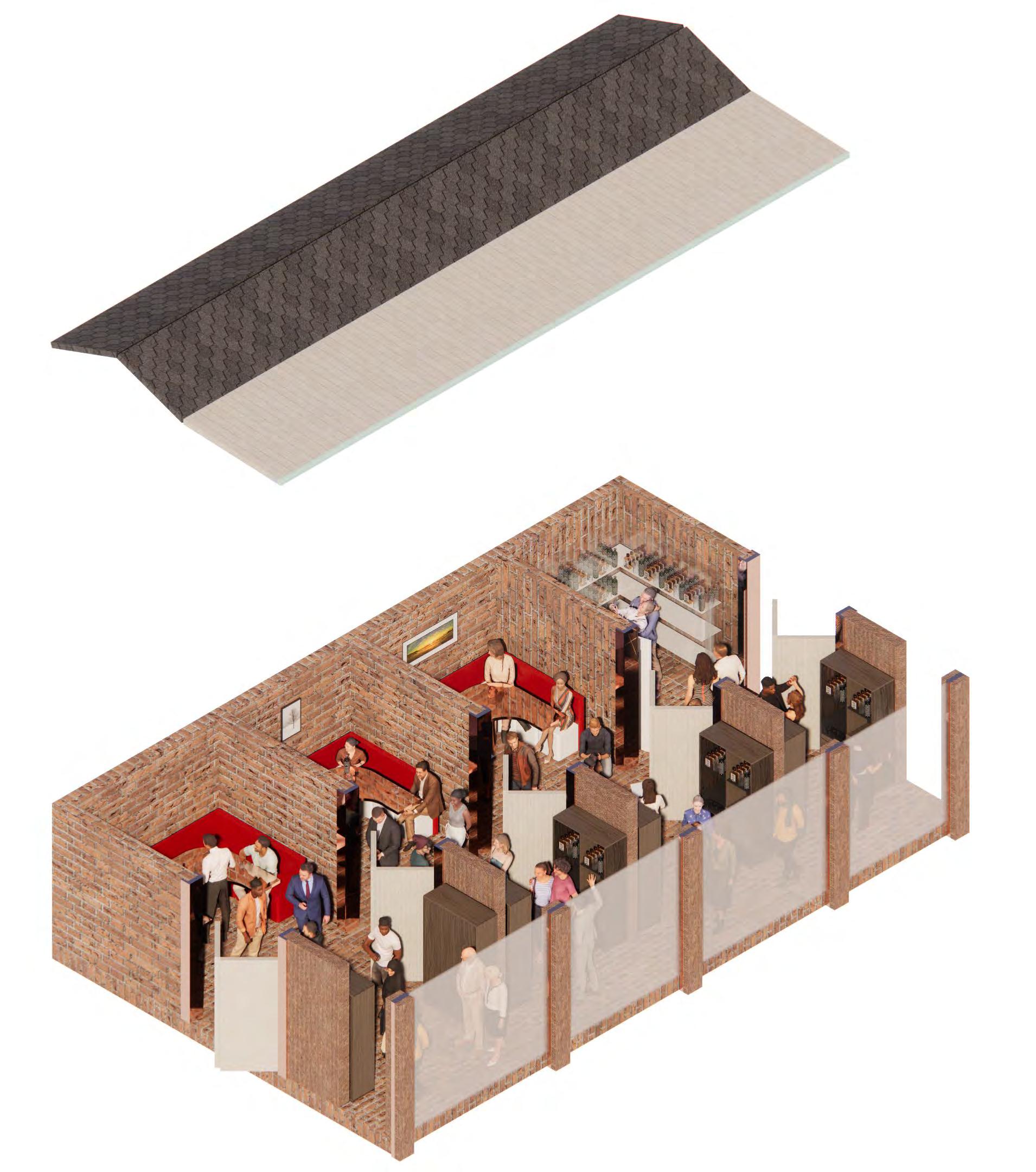

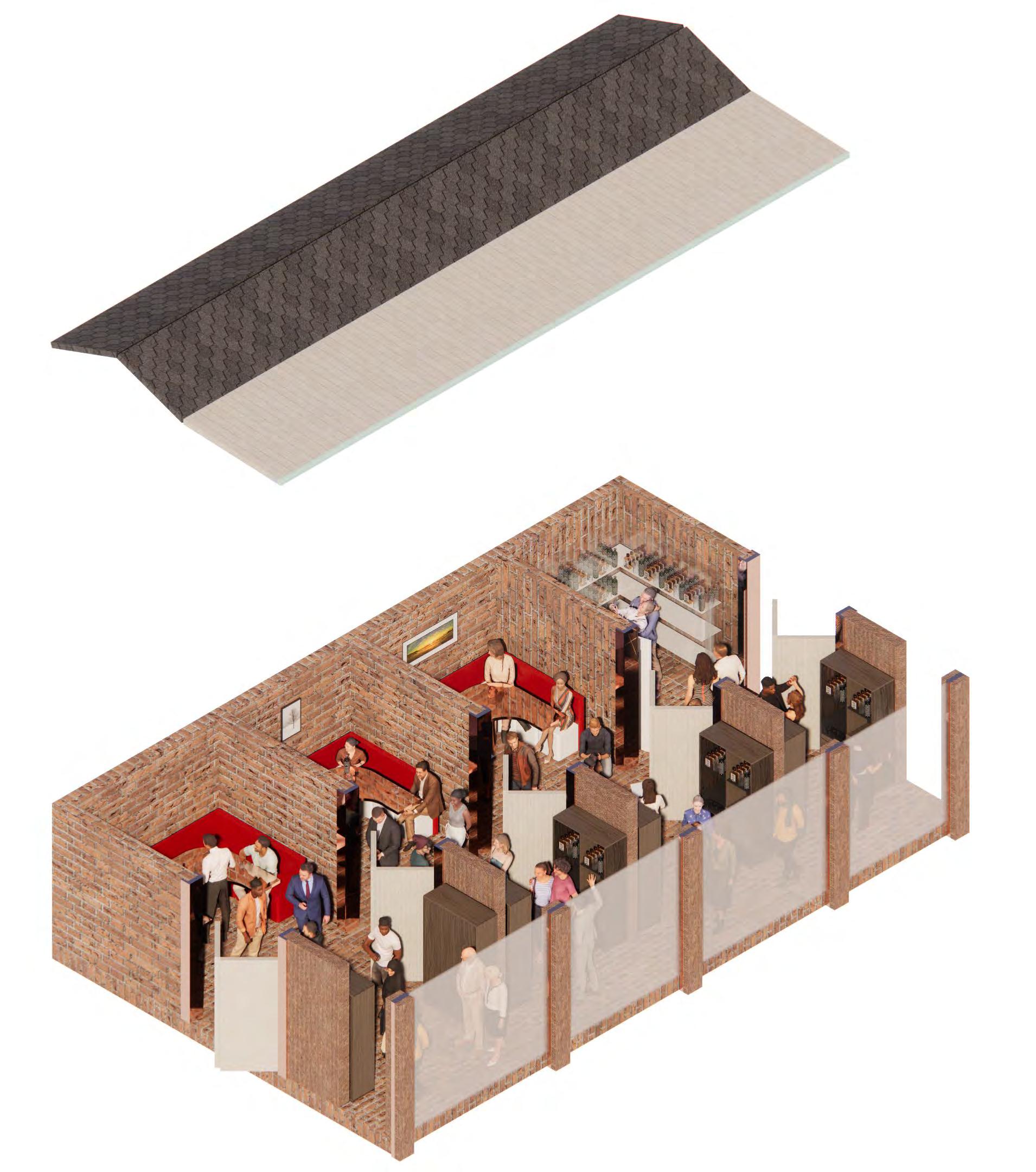

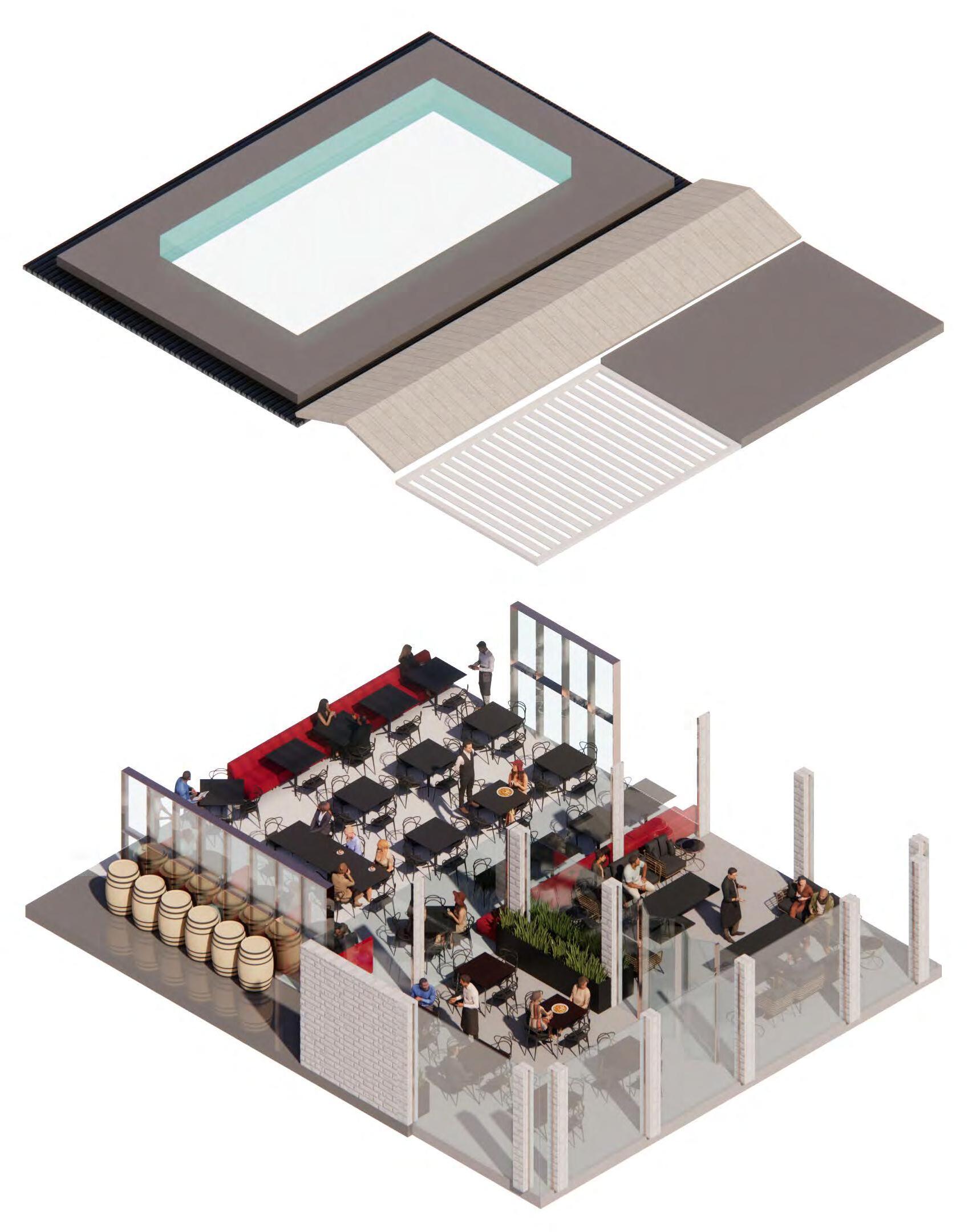

Distillery buildings encompassing shop and restaurant/ bar facilities.

Precise definition and refinement of the Farm Yard area.

Development of a captivating and well-designed public realm that complements CloughBank Farm.

Situated in a locale popular among local cyclists, the project presents an exciting opportunity to establish a destination catering to their needs and preferences, as well as appealing to wider audience.

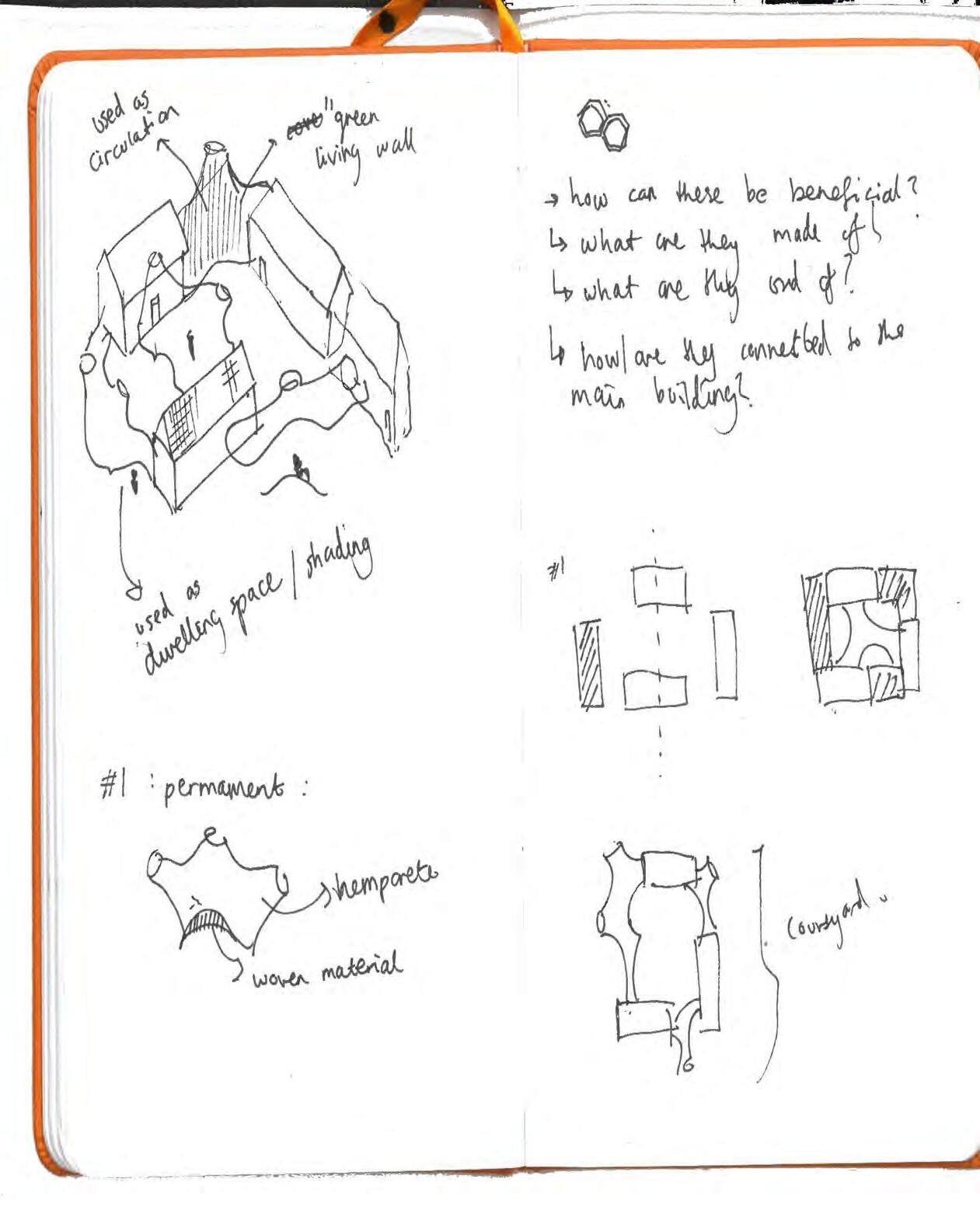

Increased Fenestration: Incorporate more windows, skylights, and glazed elements to maximize natural light penetration and create a brighter interior ambiance. This will enhance the visual connection with the surroundings and create a vibrant atmosphere.

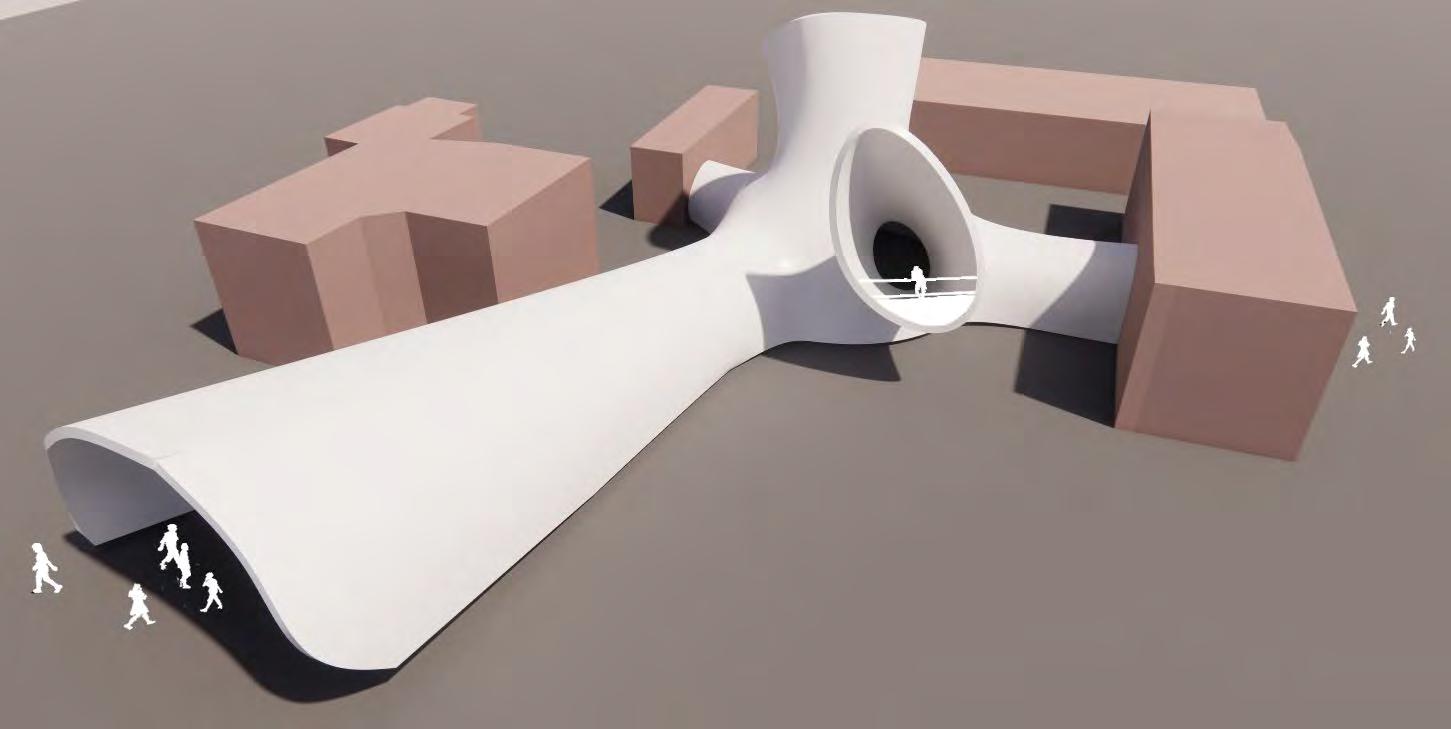

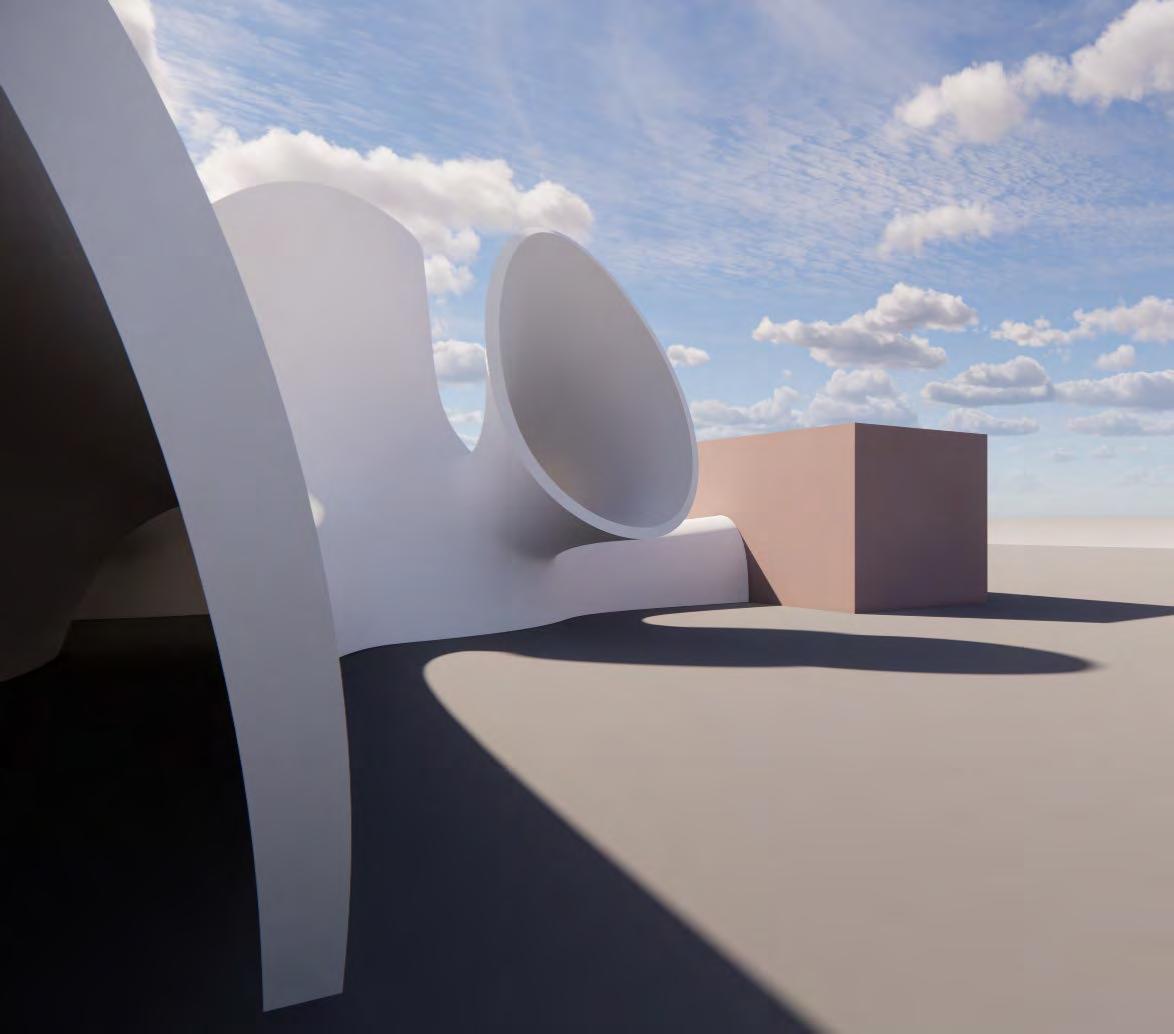

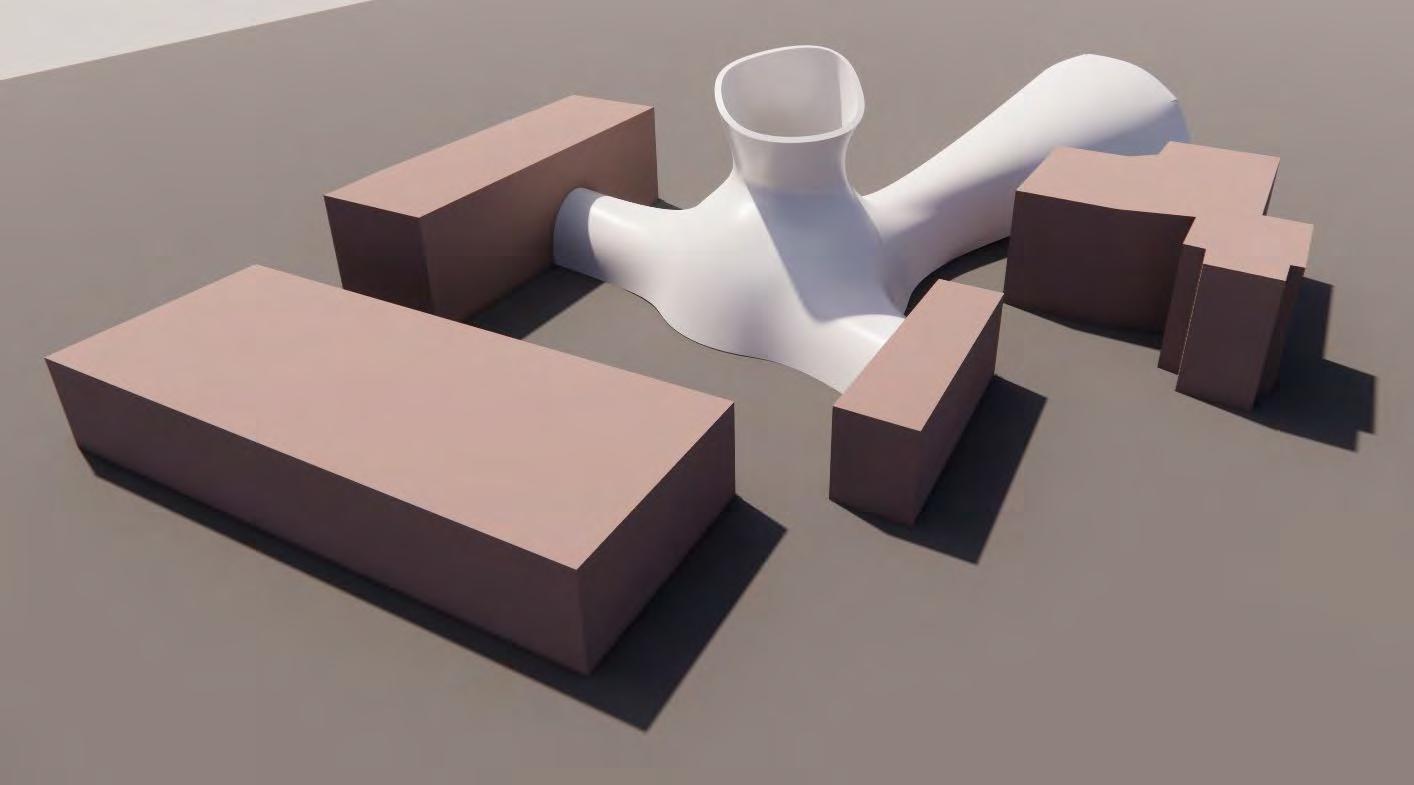

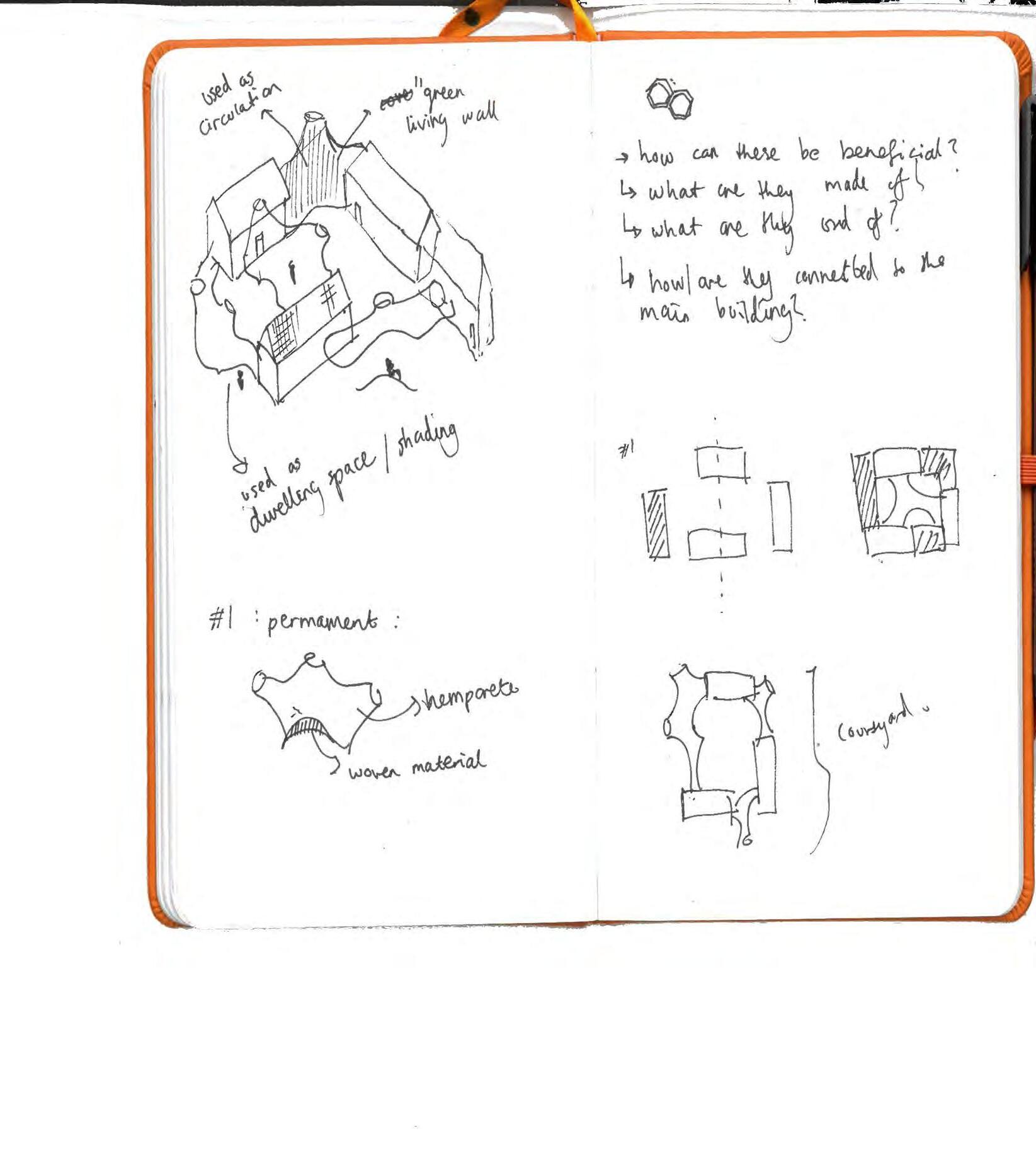

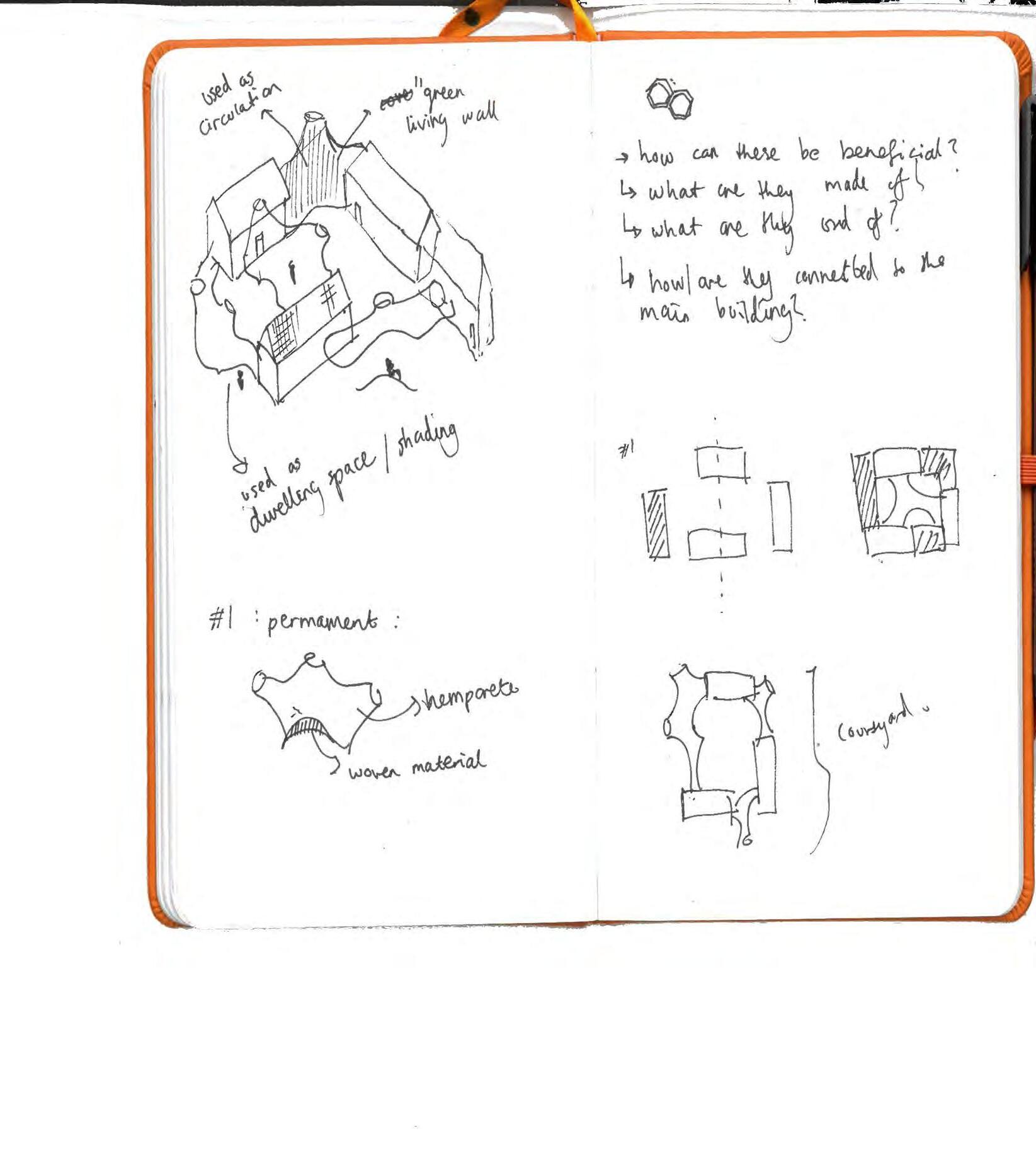

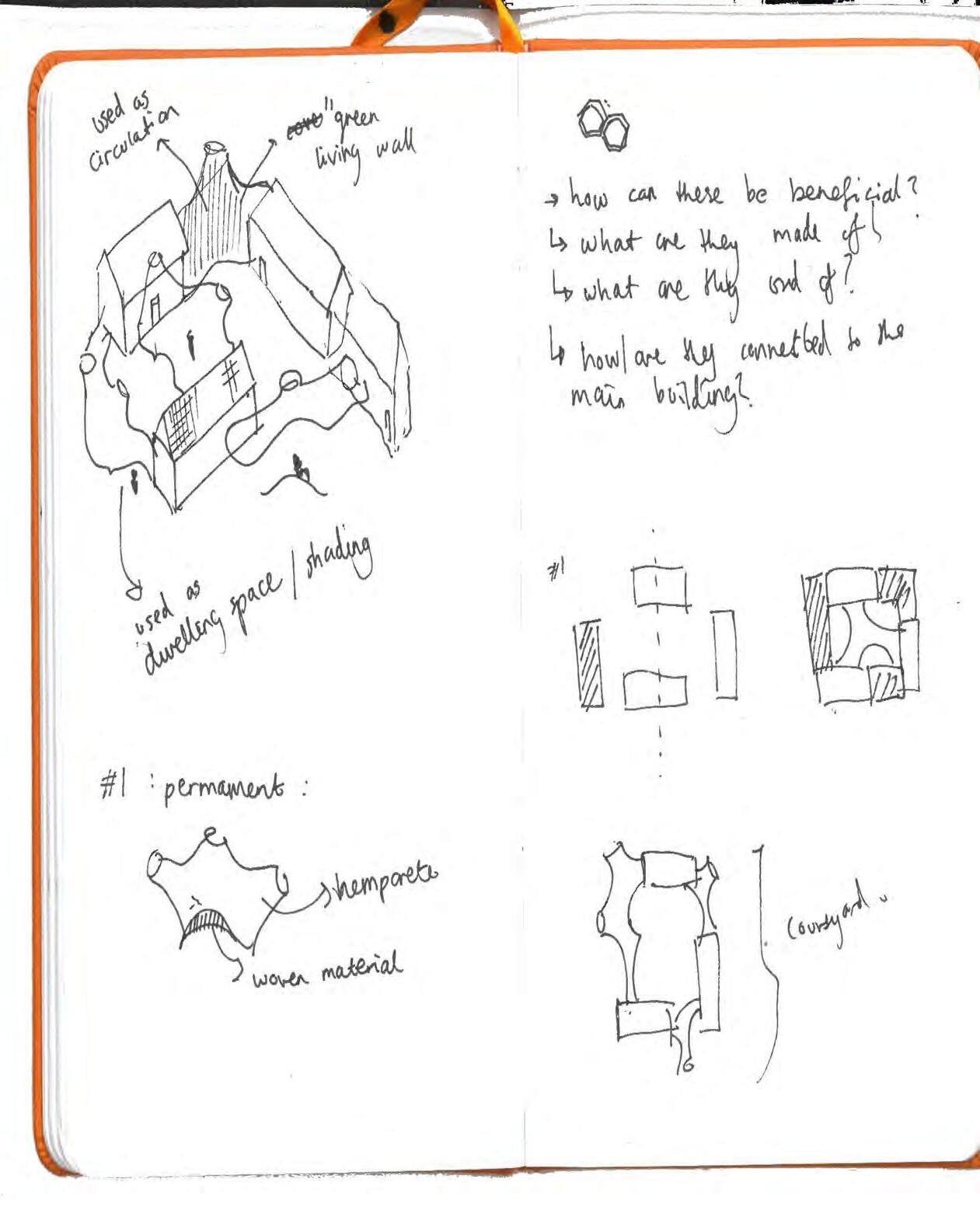

Introduce Nodes: Incorporate strategically placed nodes or focal points within the space to encourage interaction, socialization, and playful engagement. These nodes can be designed as multi-functional elements, serving as seating areas, gathering spots, or even sculptural installations.

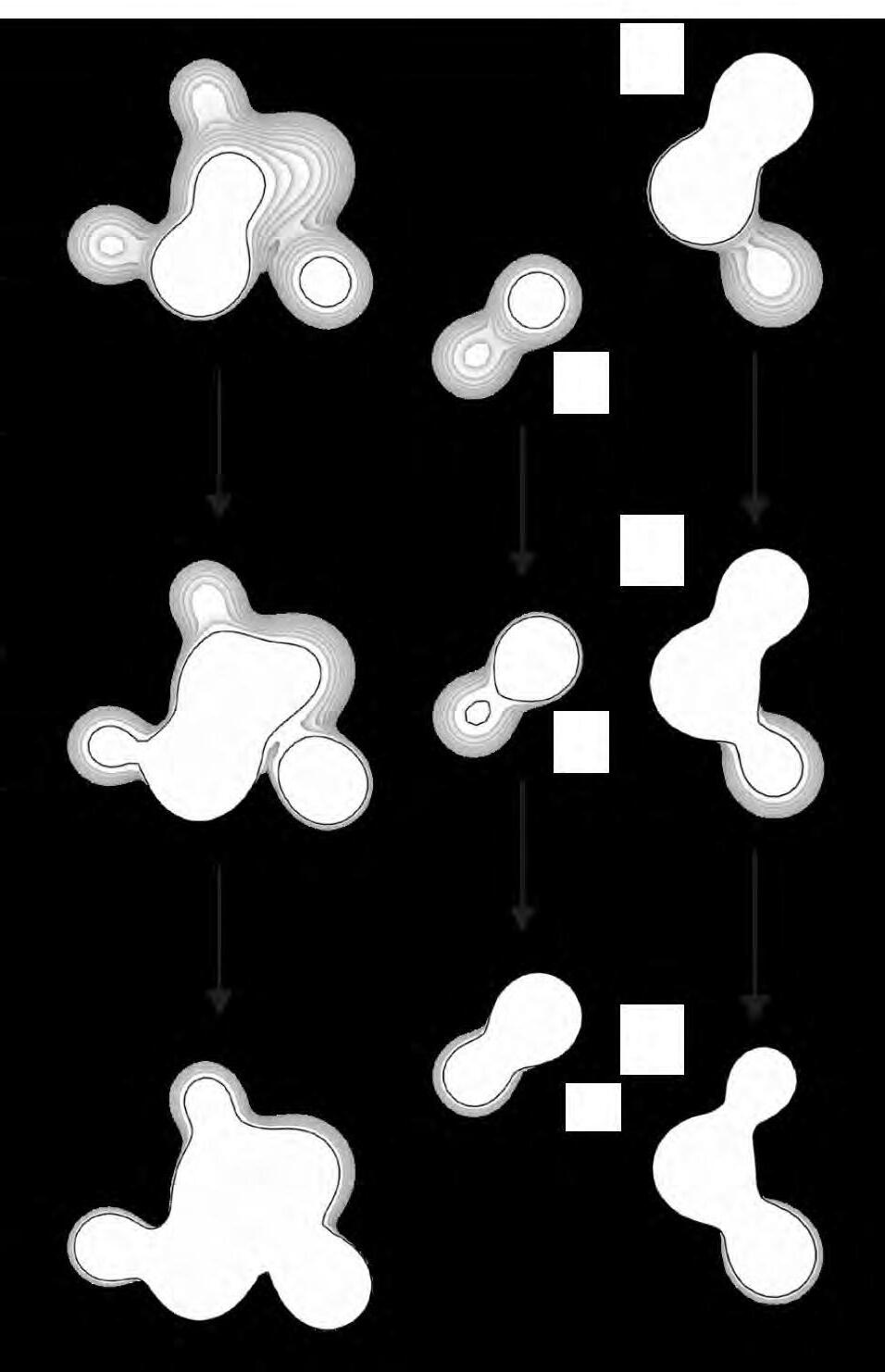

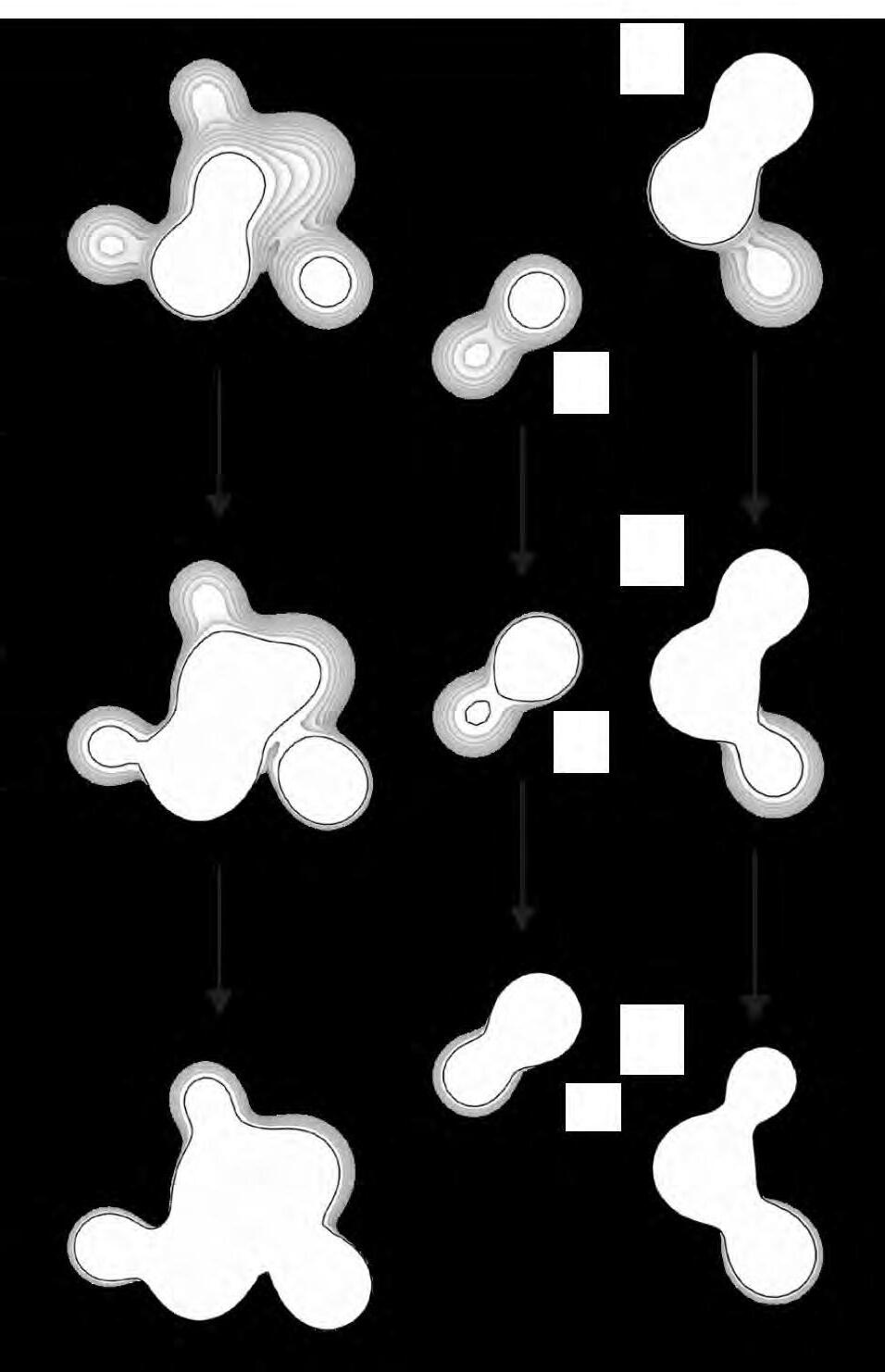

Structural Mechanism: Develop a flexible structural mechanism or frame that connects and detaches the “blobs” as the plan evolves. This will allow for adaptable and reconfigurable spaces, enabling the circulation routes to expand and contract based on the desired spatial arrangement.

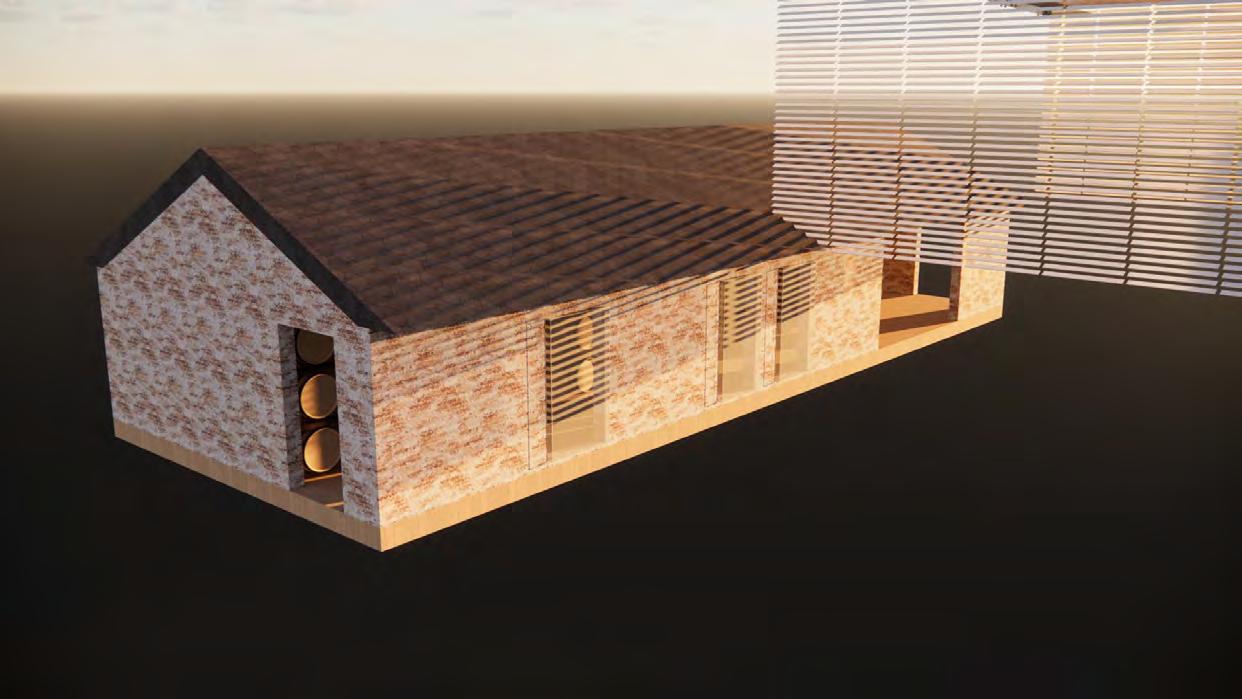

Explore the integration of undulating structures for barrel storage, creating visually intriguing spaces that reflect the fluidity and organic forms found in the overall design concept.

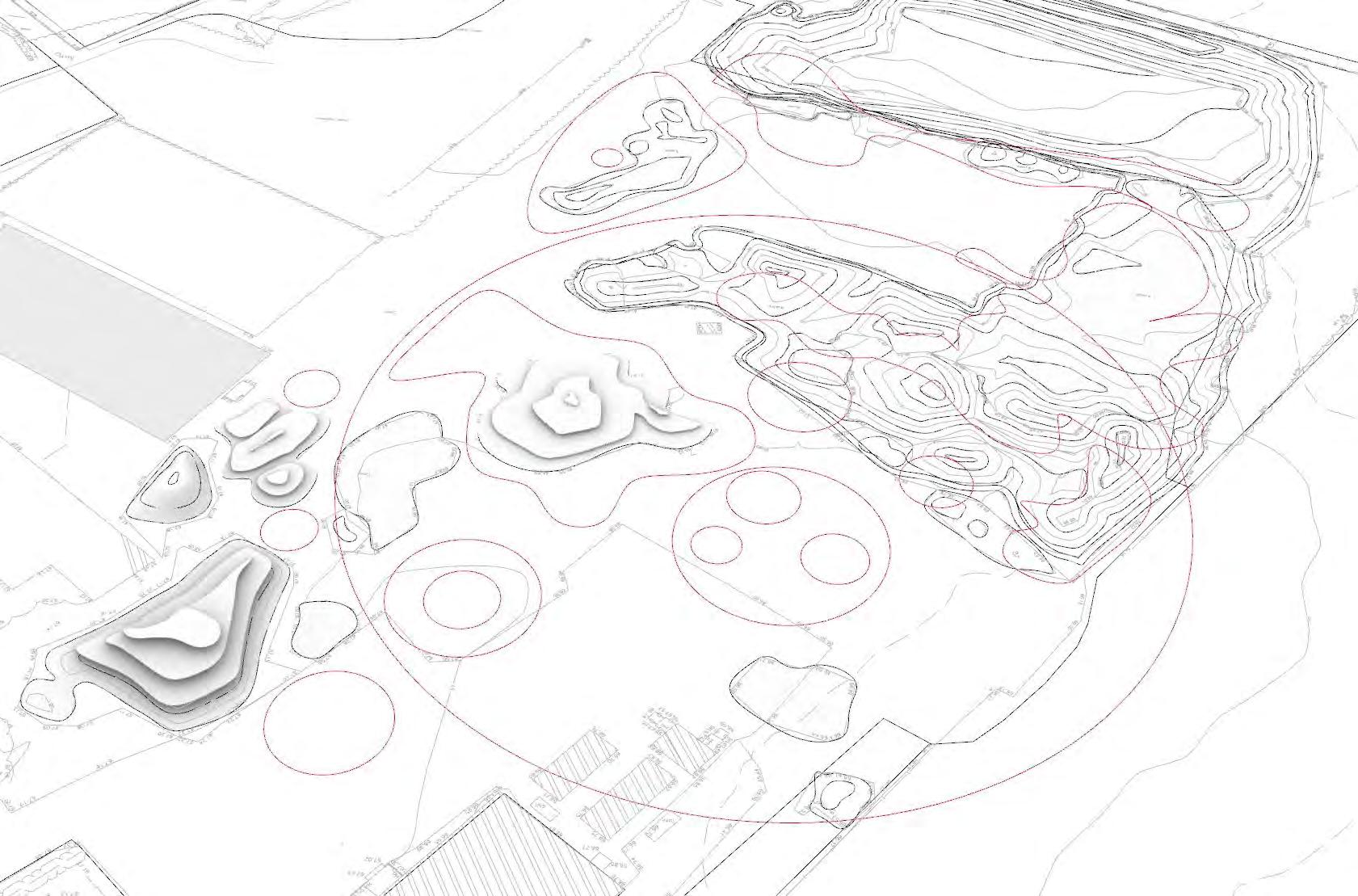

The site displays several important constraints; acknowledged in the landscape design strategy and building concept adopted. The constraints are:

1. Pedestrians routes

2. Active Street Frontage & Suitable Location

3. Vehicular routes Access for fire engines, parking, bike stop

4. Existing Buildings and Structure

5. Established Trees and Water features

6. Scale of Buildings

7. Site History And listed Structure

8. Site Opportunities

Creation of an inviting border along the airport, harmoniously aligned with the enchanting treelined hidden brook.

Integration of mounds and ponds within the public realm to offer leisure opportunities and recreational spaces.

Adaptive reuse of former industrial structures, prioritizing sustainable design and ensuring high-quality outcomes.

Key Drivers:

Identifying and accommodating site constraints, establishing fixed reference points for design exploration.

Applying a logical linear grid system to create hierarchy of routes, guiding movement and circulation throughout the site.

Integrating smaller routes and rest spaces, ensuring a harmonious balance between connectivity and opportunities for relaxation.

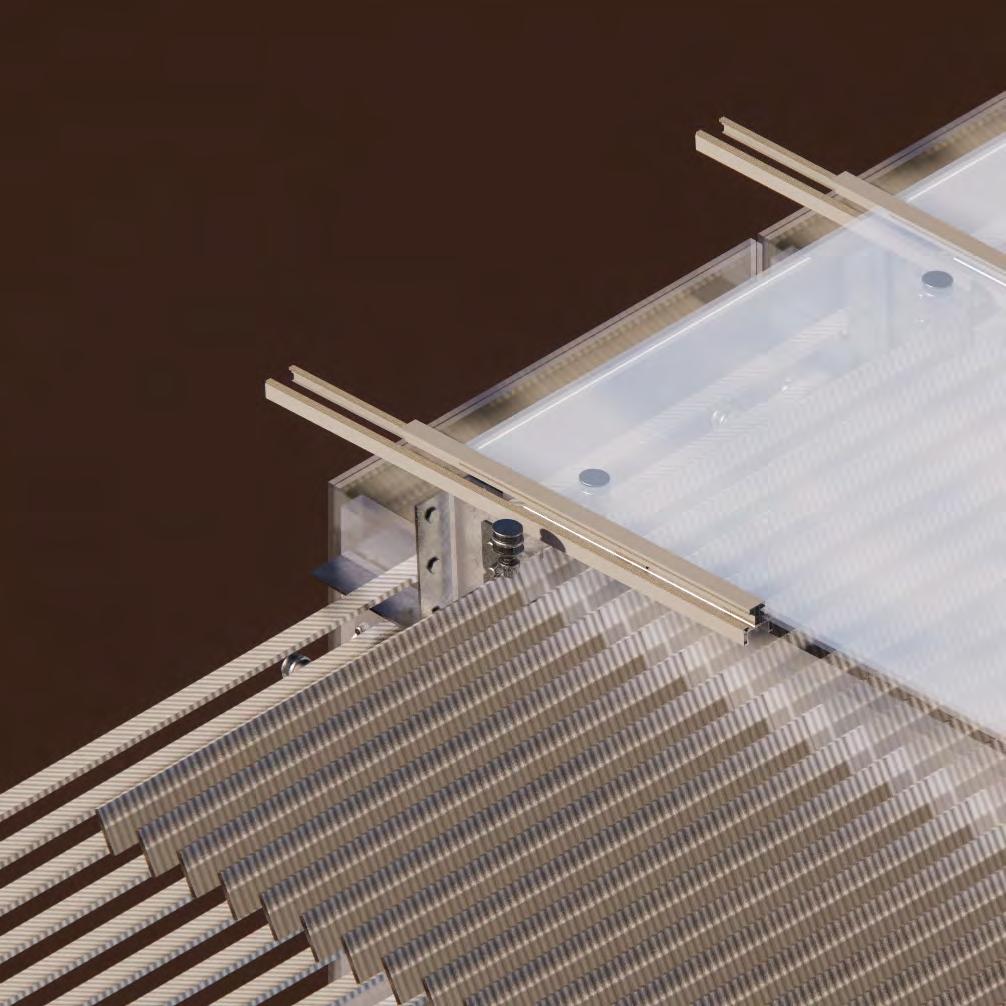

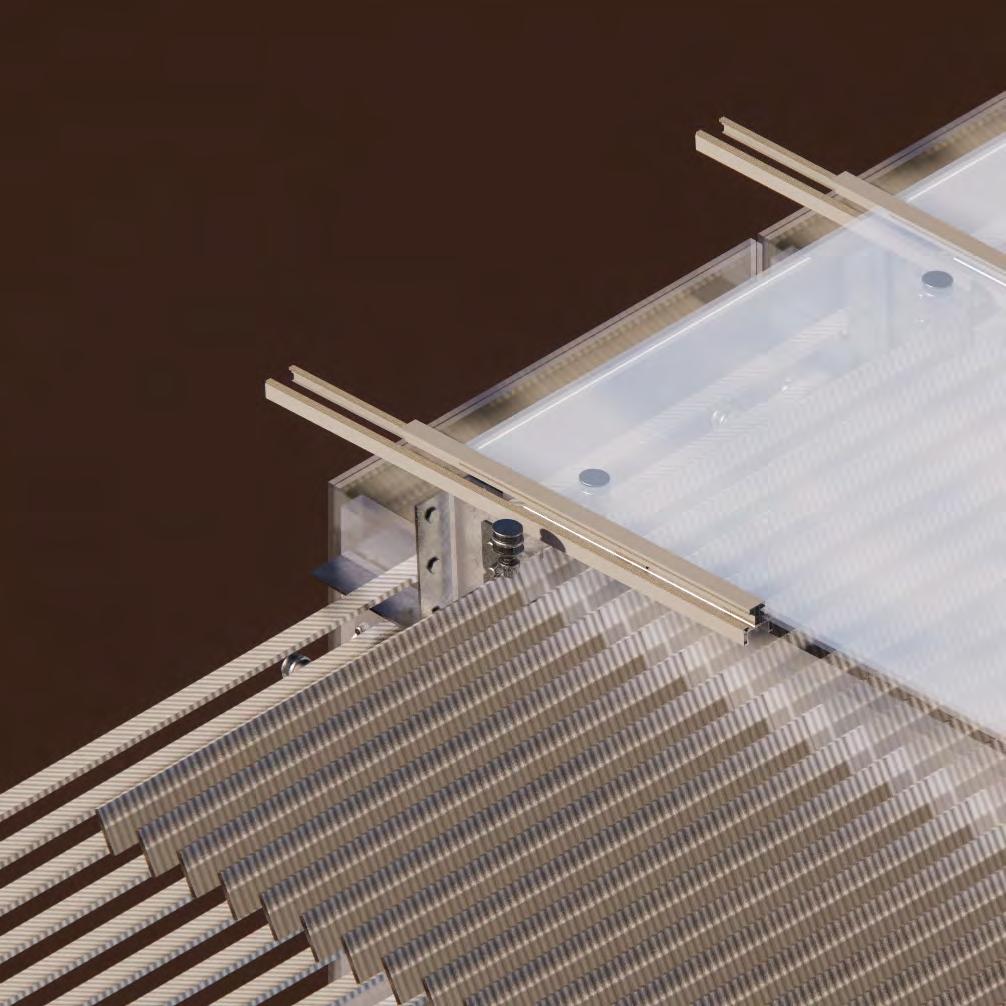

Address technical details such as the cleaning of the building and efficient rainwater drainage systems. Incorporate appro

priate access points and maintenance strategies to ensure the longevity and cleanliness of the structure.

Investigate additional ventilation strategies to effectively manage and dissipate hot air emanating from the distillery. This may involve the integration of natural ventilation systems, mechanical ventilation systems, or combination of both.

Thriving leisure destination, drawing visitors seeking relaxation, recreation, and enjoyment.

Strongly pedestrianoriented environment, promoting accessibility and encouraging exploration on foot.

This iterative approach allowed for the refinement and evolution of the project’s concept, resulting in a site plan and layout that optimizes functionality, aesthetics, and user experience.

need to evaluate the material's characteristics, effects, and flexibility in achieving the desired design scheme. Assess its structural viability, construction methods, and potential for disassembly and reconfiguration, ensuring it aligns with the overall design intent.

By incorporating these ideas and conducting in-depth research, the project can progress towards a more welllit, well-circulated, and playful space that embraces innovative architectural language and technical considerations.

-

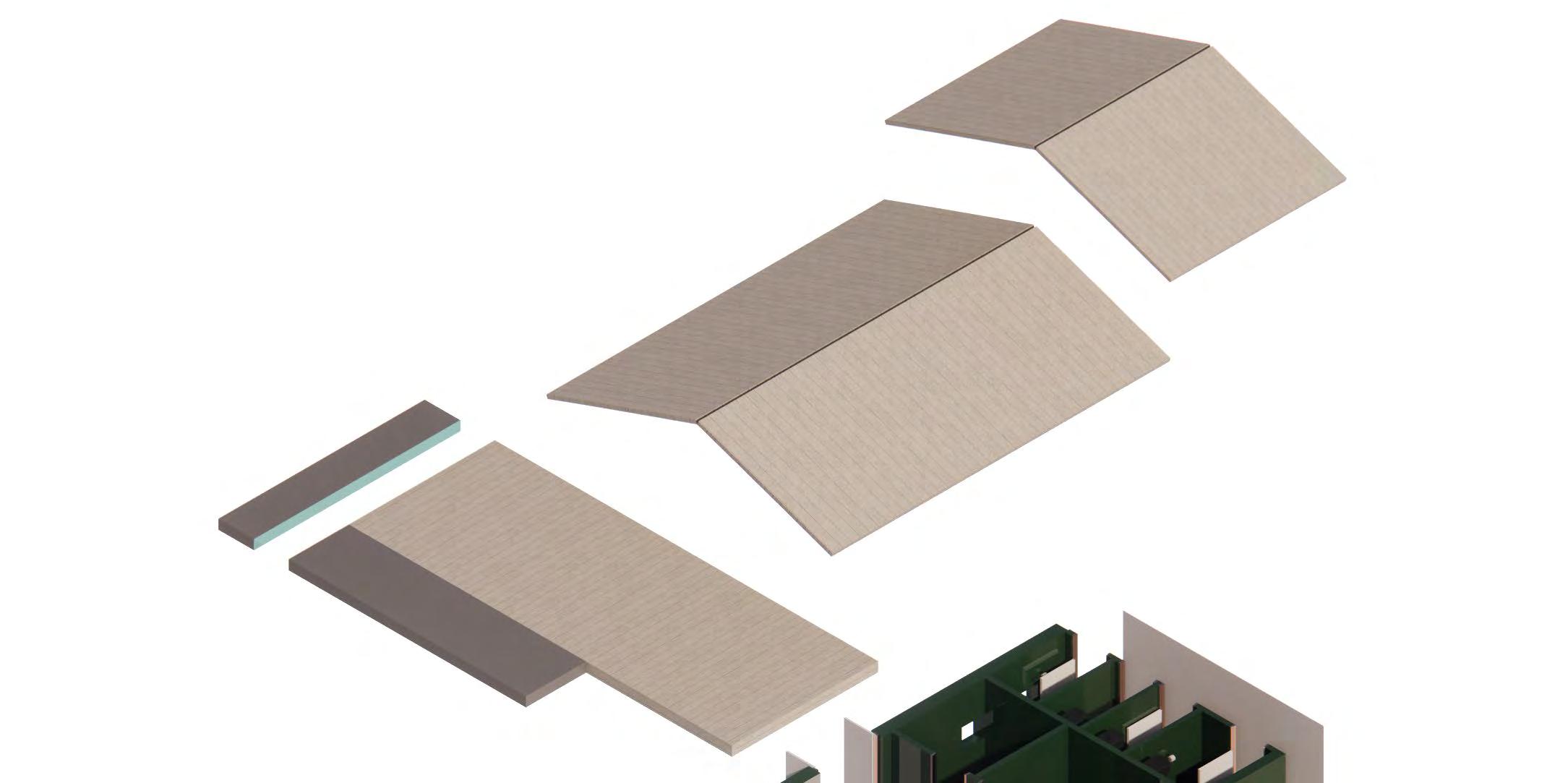

STUDIO 3.2 2 3 STUDIO 3.2 Resolution Proposition & Position Resolution A Recap Of 3.1 The Farmhouse The Hay barn The Warehouse The Barn Area: 36m Area: 131m Area: 132m Area: 129m 12m 18.1m 20m 3m 7m 6.1m

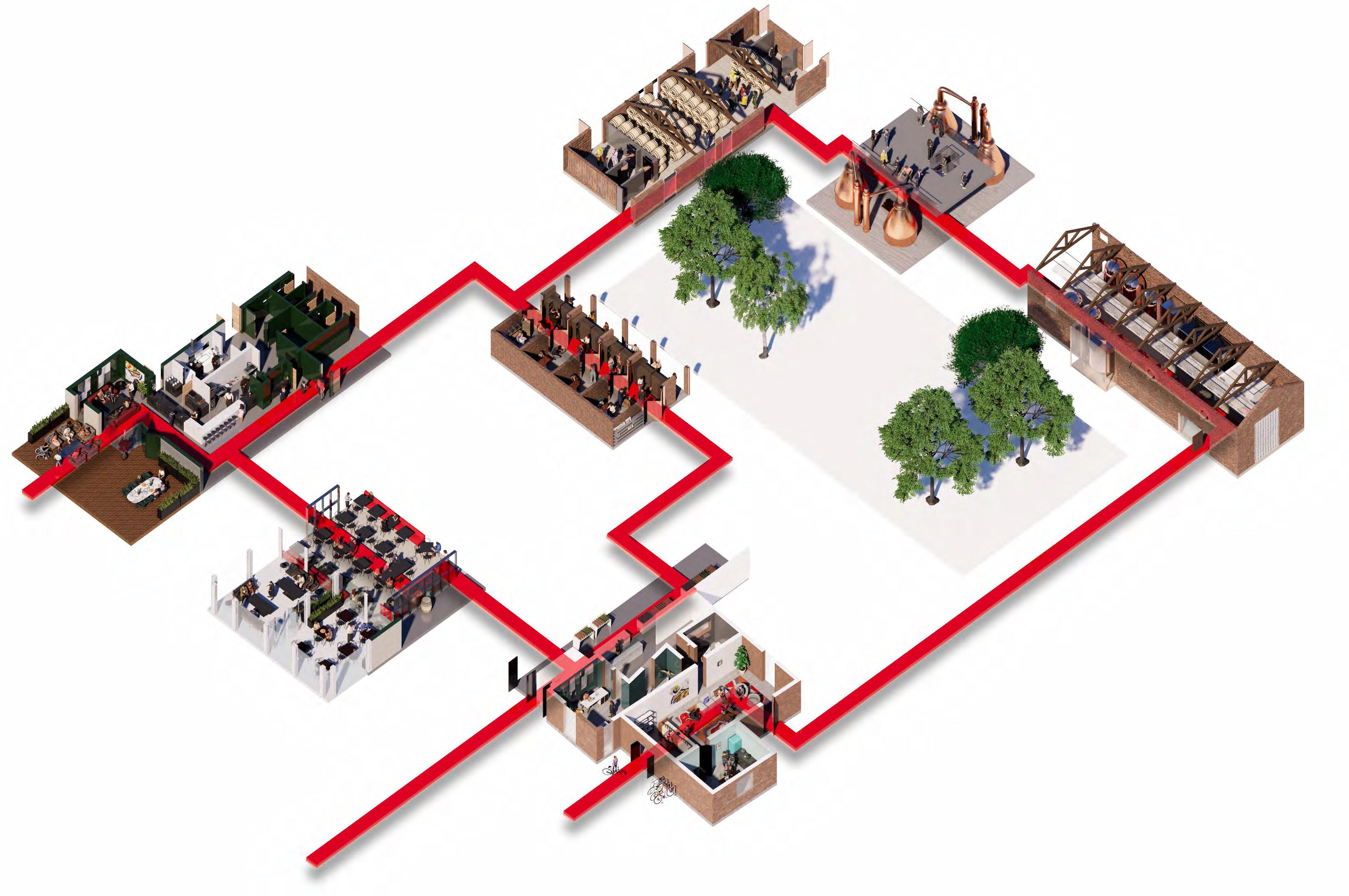

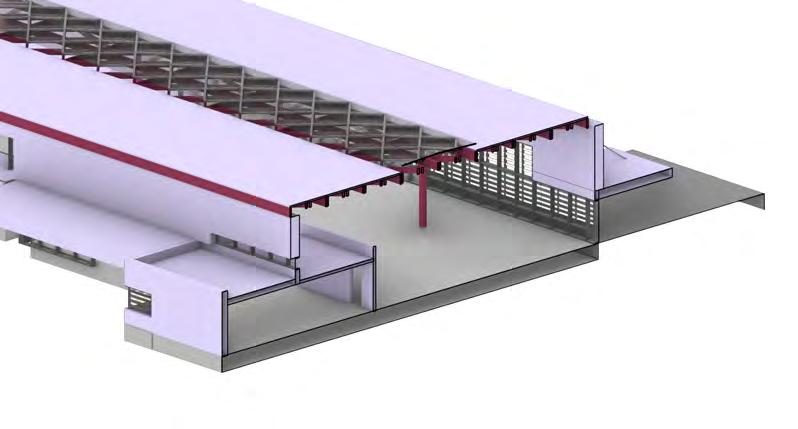

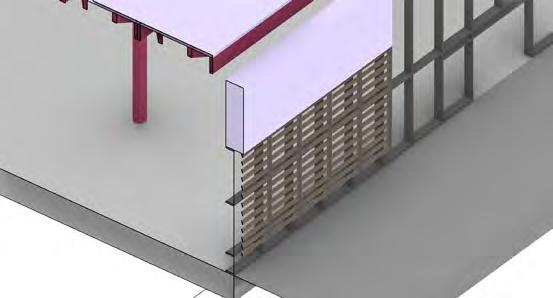

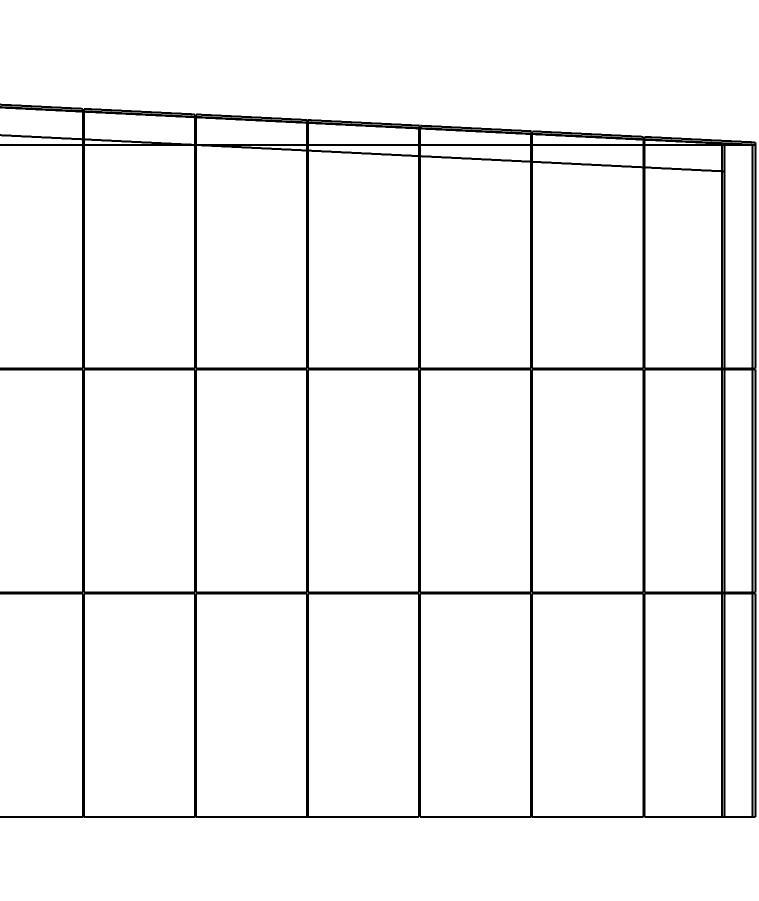

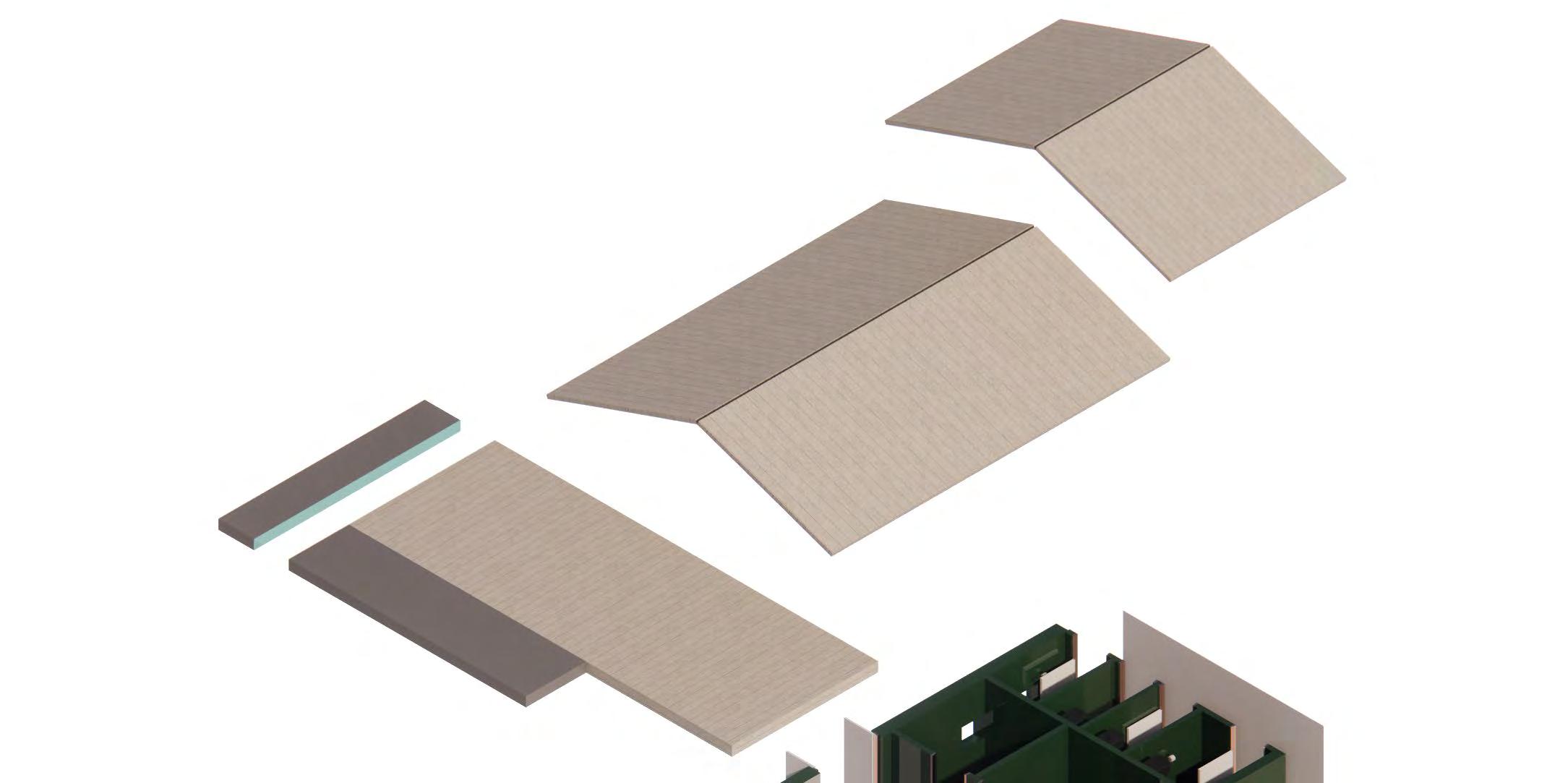

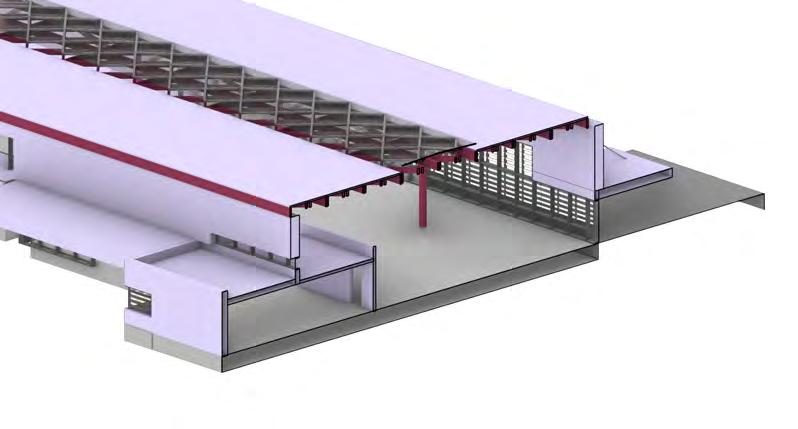

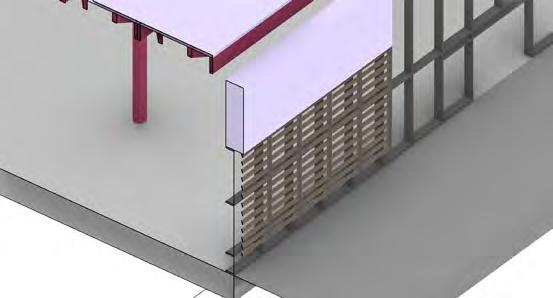

STUDIO 3.2 4 5 STUDIO 3.2 Resolution Roof Plan Resolution Ground Floor Plan 5x2.5 m 5x2.5 m 4 10 11 12 13 14 15 16 17 18 19 20 21 23 22 24 25 26 6 27 28 29 30 31 32 33 35 36 34 37 38 39 40 41 42 43 N BUILDING A 1. our Entrance 2. Dis. W/C 3. Boiler Room 4. Malting 5. Mashing 6. ermentation 7. Escape BUILDING B 8. Distillation 9. Viewing Mezzanine BUILDING C 10. Escape 11. Barrel Storage 12. Staff Rm & Changing 13. Cls. Store BUILDING D 14. Dis. W/C 15. W/C 16. Clns 17. Escape 18. Whiskey Display & Store 19. Tasting Seating Area 20. Display BUILDING E 21. Restaurant Entrance 22. Dining Seating 23. Bunket Seating 24. Outdoor Seating BUILDING F 25. Beer Store 26. Sta 27. Deliveries & Refuse Store 28. Store 29. K itchen 30. Bar Server Area 31. Bar Entrance/Exit 32. eating 33. Outdoor Seating BUILDING G 34. Shop 35. L ink Corridor 36. O ffice Meeting Room 37. Dis. W/C 38. Waiting Area 39. Entrance Lobby 40. K itchen 41. Courtyard 42. ‘Drunken’ Gardens 43. orry Drop Off & Pick Up Decking Paving Grass 5x2.5 m 5x2.5 m 5x2.5 m 5x2.5 m 5x2.5 m 5x2.5 m 5x2.4 m 5x2.5 m 5x2.5 m 5x2.5 m 5x2.5 m Sarnafil Single Ply Blackened Timber Glass Timber Pergola Slate Gutter EPDM Rubber N

MATERIAL SCHEDULE

01Brick Wall, Painted White Finish, RAL Colour TBC.

02Powder Coated Aluminium Railings, RAL Colour TBC.

03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03.

04Entrance Doorsets, refer to Window Schedule and Specification.

05Timber Windows, refer to Window Schedule RAL Colour TBC.

06Obscured Glazing Timber Windows,

14Proprietary Powder Coated Capping

RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02.

Rainwater Goods uPVC RAL Colour TBC.

Soffits uPVC Borad RAL Colour TBC.

Facias to match Single Ply Grey Colour TBC.

to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02.

Rainwater Goods uPVC RAL Colour TBC.

Soffits uPVC Borad RAL Colour TBC.

to match Single Ply Grey Colour TBC.

2.40m

level 5.40m

4m -

1m

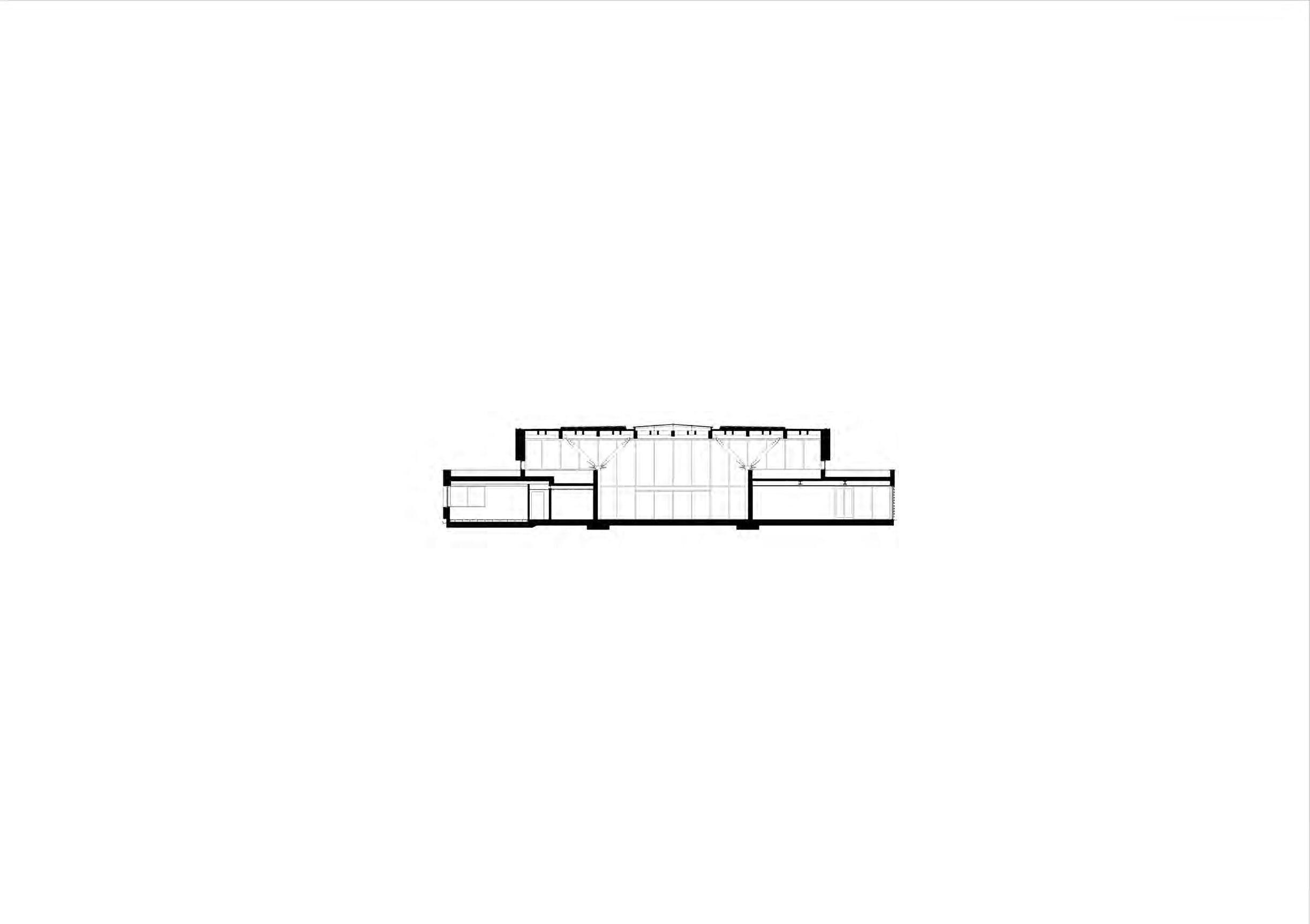

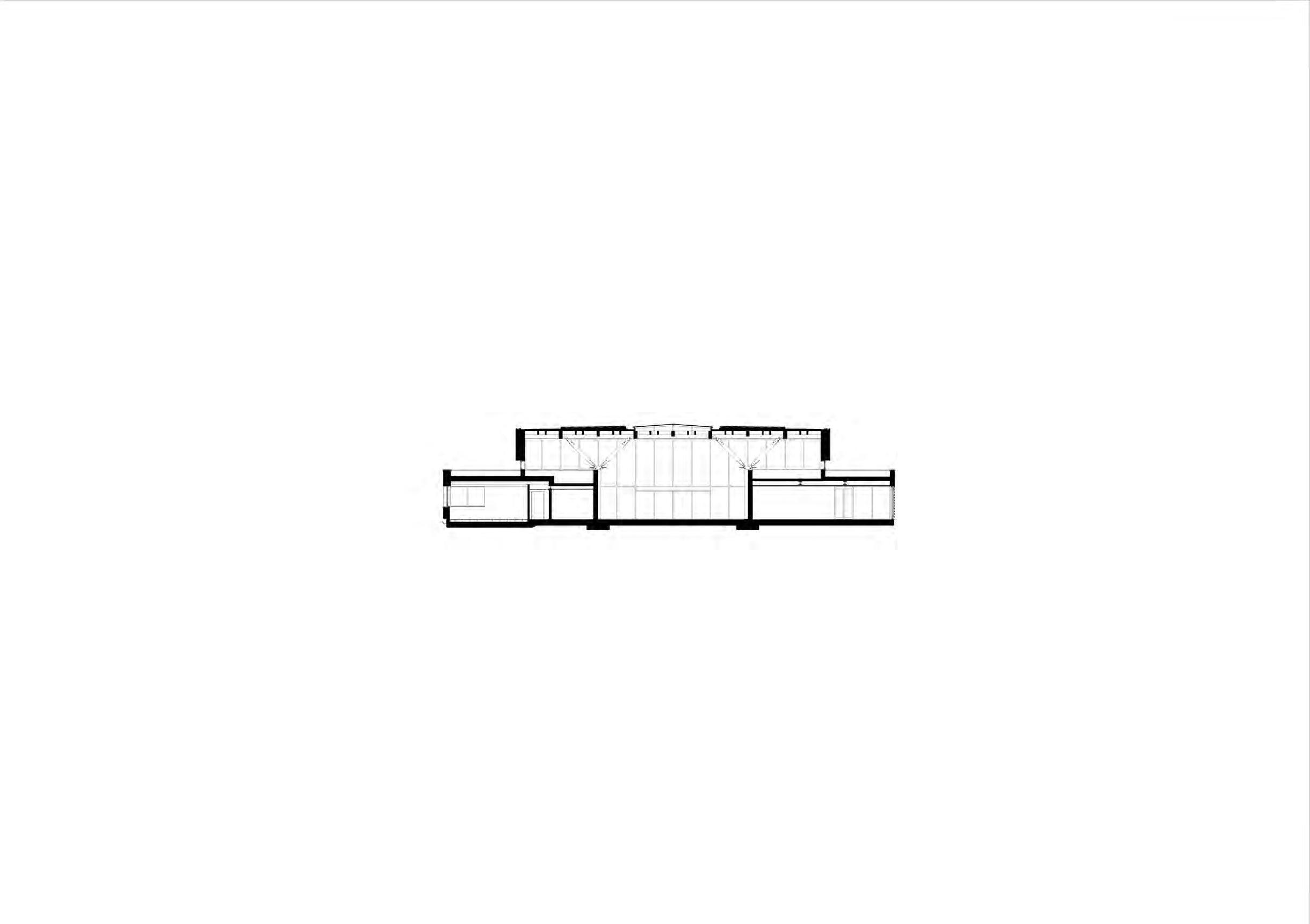

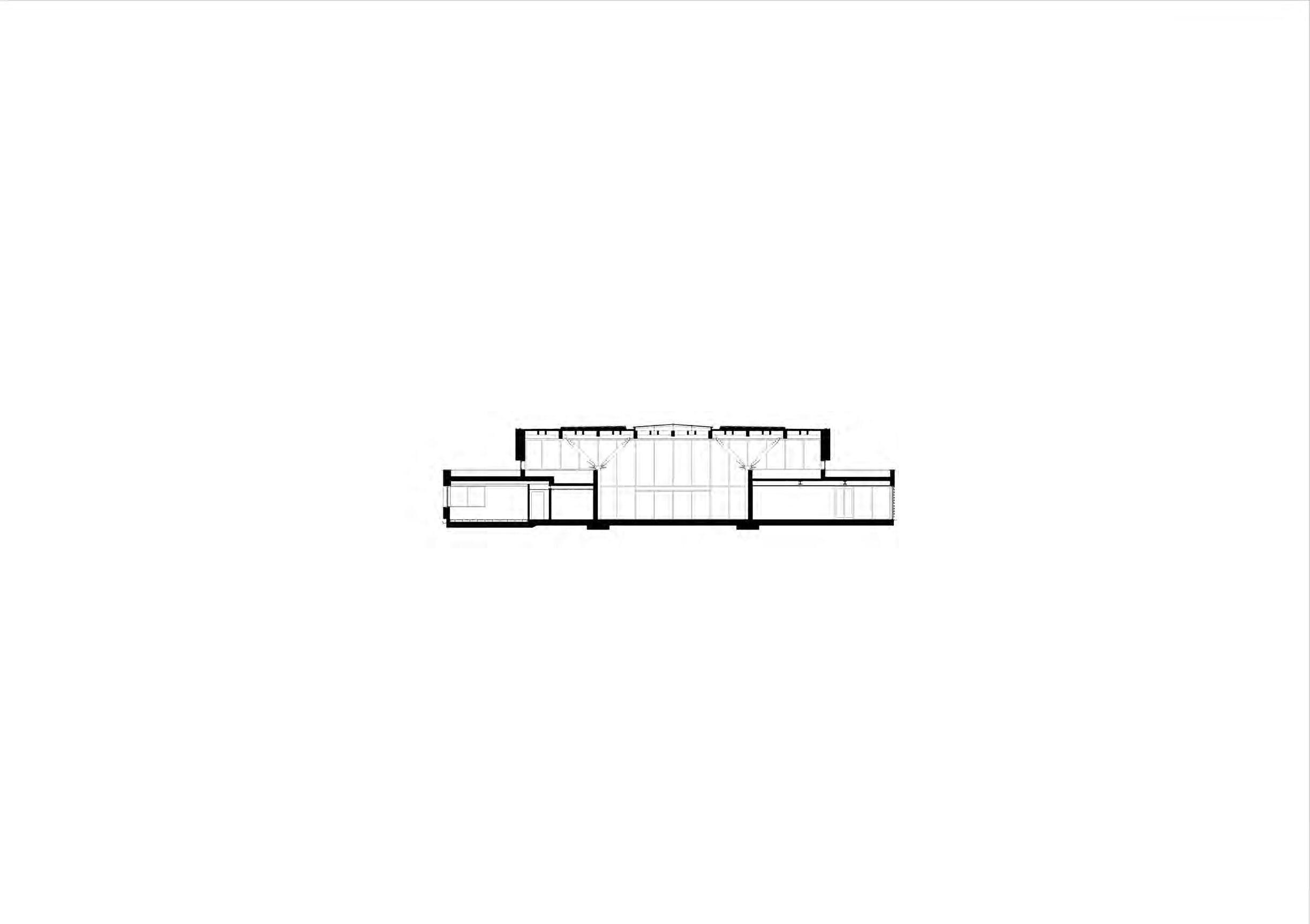

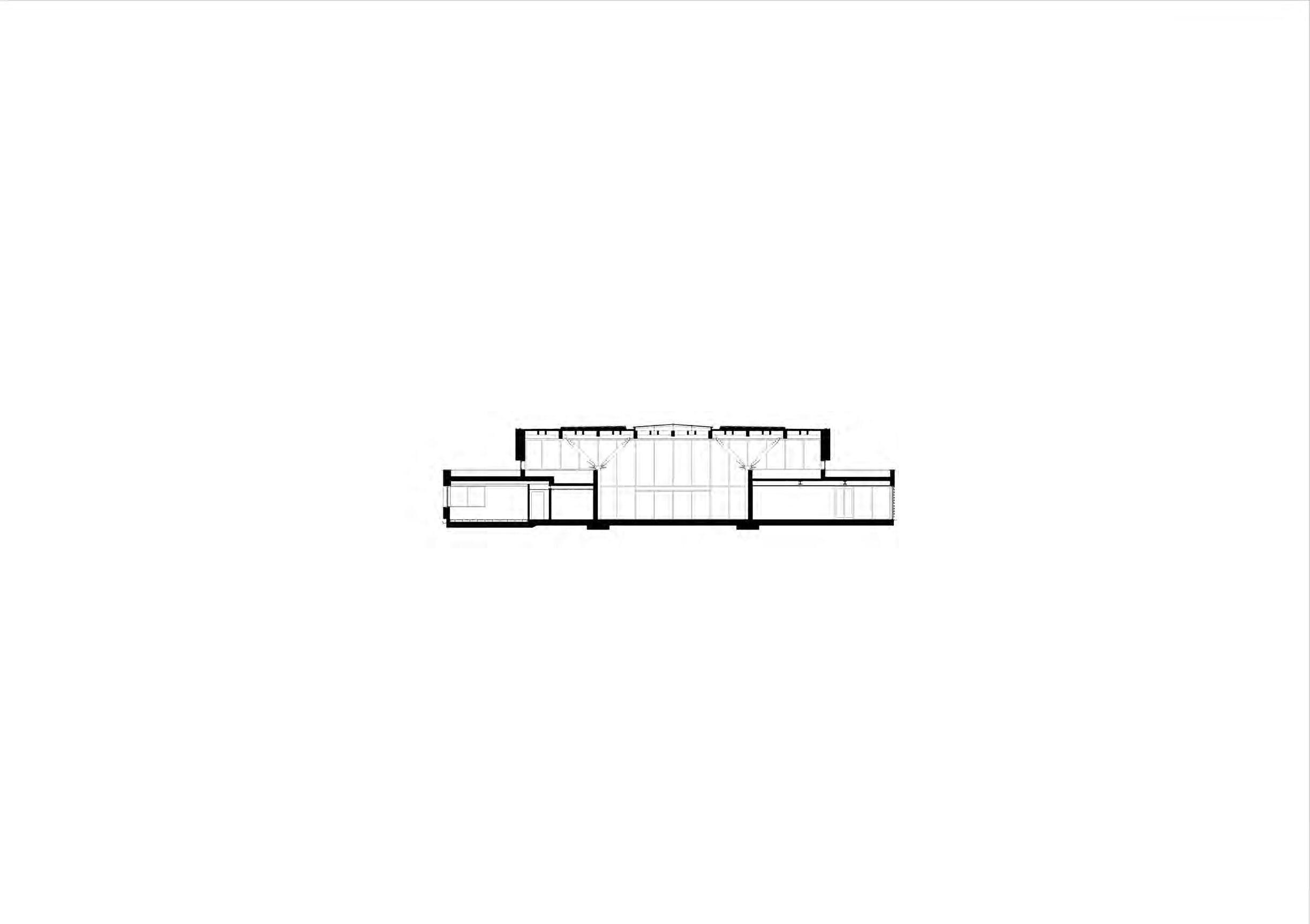

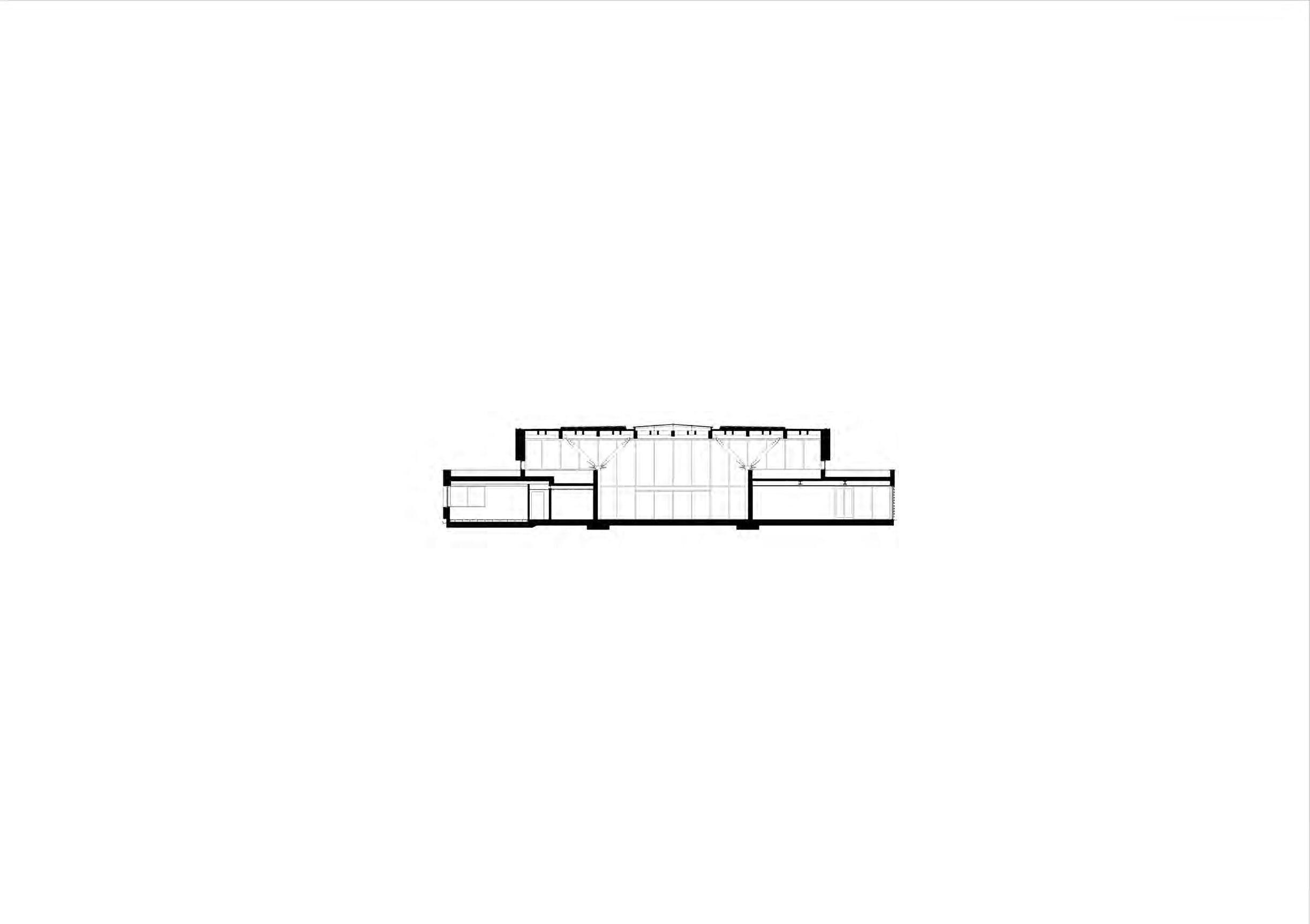

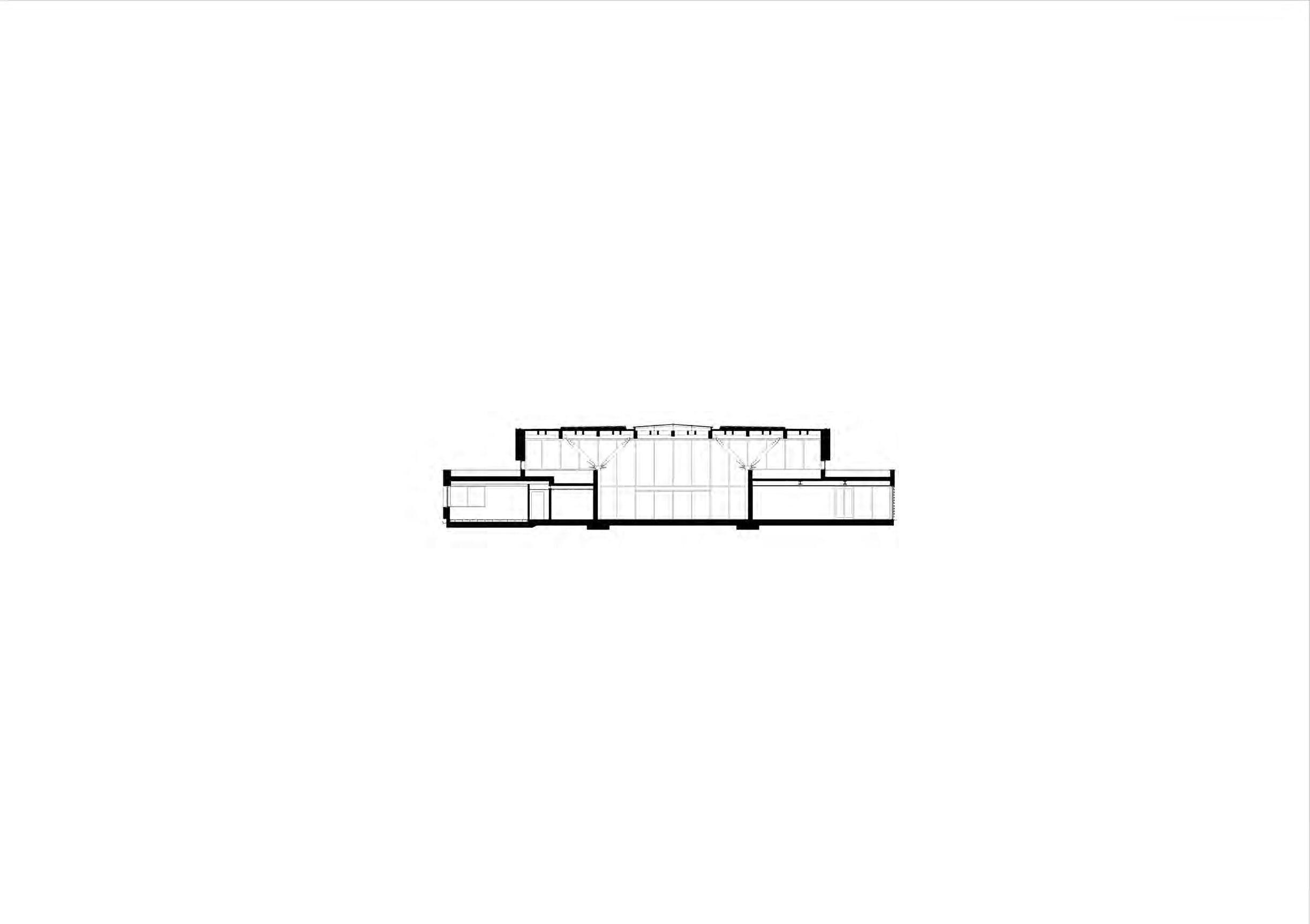

3-3 SECTION p r o p s e d s e c t i o n 1:200

3-3 SECTION

level 5.40m

ground floor

2.40m

1m

-

ground floor

MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC.

3-3 SECTION p r o p o s e d s e c t i o n 1:200 4m -

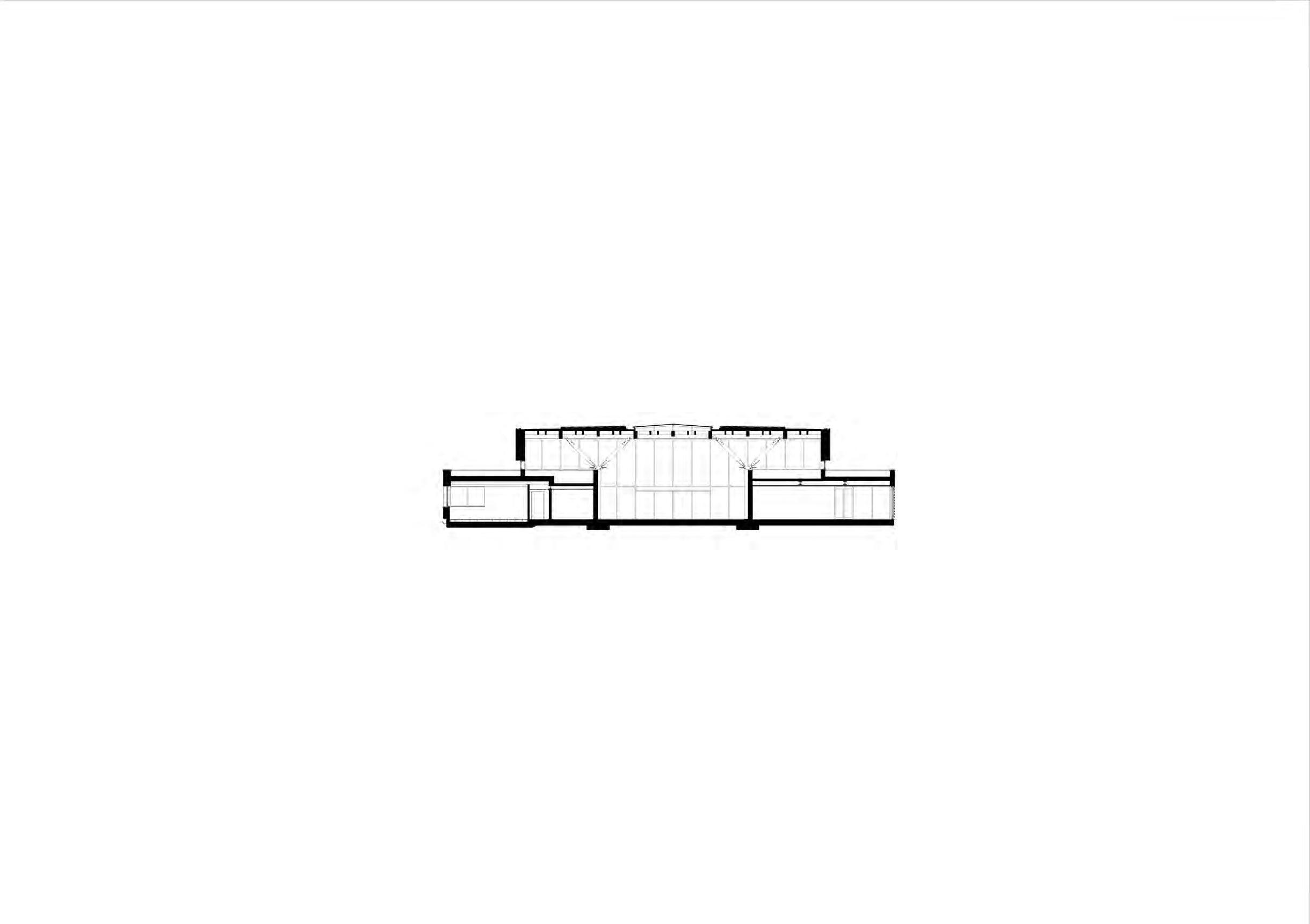

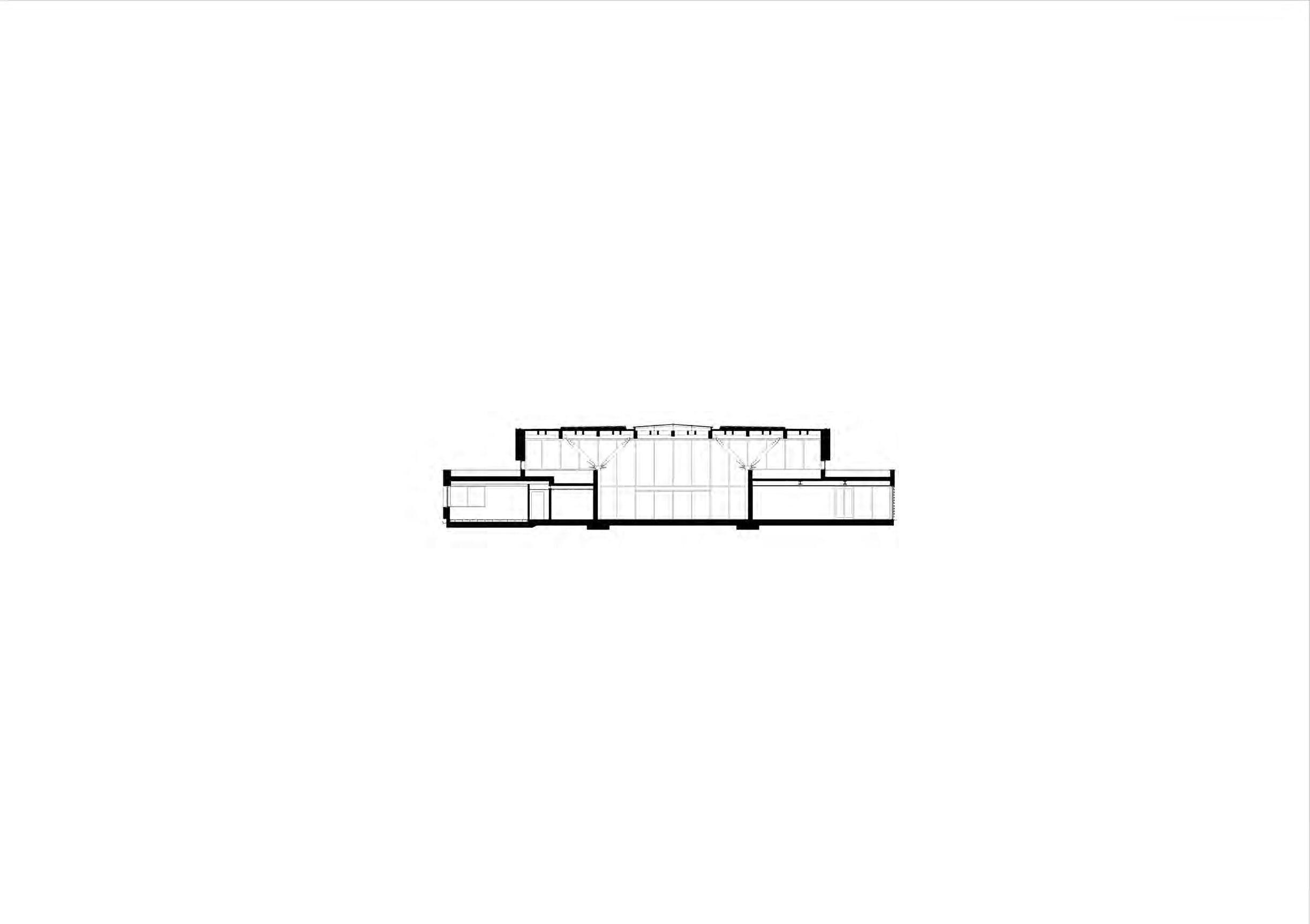

2-2 SECTION 1-1 SECTION

2.40m

ground floor

2-2 SECTION 1-1 SECTION 2-2 NW SECTION

STUDIO 3.2 6 7 STUDIO 3.2 Resolution 1:200 Sections & Elevations level 6950 5400 5100 2500 2300 ceiling ceiling heads 1m 10m window ceiling window ff level level gf level00 01 ext 03ground floor level 2.40m 5.40m level 2.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer

All

All

p r o p o s e d s e c t i o n 1:200 SECTION SECTION 7800 8400 8100 level 6950 5400 5100 2500 2100 ceiling heads ceiling window heads 1m 10m window ceiling window heads ff level level gf level00 01 ext 03ground floor 5.40mground floor level 2.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC. SECTION p r o p o s e d s e c t i o n 1:200 SECTION SECTION 7800 8400 level 5400 5100 2300 2100 ceiling ceiling window 1m 10m window ceiling heads ff level level gf level00 01 ext 03ground floor level 2.40mground floor 5.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC. SECTION e d s e c t i o n 1:200 SECTION SECTION 7800 8400 8100 tf level 6950 5400 5100 2500 2100 ceiling heads ceiling window heads 1m 10m window ceiling window heads level rf level gf level00 01 ext 03ground floor 1m level 5.40mground floor 1m level 2.40m

All Facias

RAL Colour TBC.

refer to Window Schedule

07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification.

Finish,

Finish, TBC.

09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey

refer to Specification. 12Textured White Through Colour Render

13Recessed Textured White Through Colour Render Finish, TBC.

All

1-1 NE SECTION p r o p o s e d s e c t i o n 1:200 1-1 NE SECTION 1-1 NE SECTION 5x2.5 NORTH EAST COURTYARD ELEVATION NORTH EAST COURTYARD SECTION NORTH EAST ELEVATION 4mground floor 1m level 5.40m 4mground floor 2.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC.ground floor 1m 2.40m level 5.40m

Piece,

All

All

p r o p o s e d s e c t i o n 1:200 7800 8400 8100 tf level 6950 5400 5100 2500 2100 ceiling heads ceiling window heads 1m 10m window ceiling window heads level rf level gf level00 01 ext 03ground floor 1m level 5.40mground floor 1m level 2.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC. 1-1 NE SECTION p r o p o s e d s e c t i o n 1:200 1-1 NE SECTION 1-1 NE SECTION 5x2.5 NORTH WEST COURTYARD ELEVATION NORTH WEST COURTYARD SECTION NORTH WEST SECTION 4mground floor 1m 2.40m level 5.40m 4mground floor 1m 2.40m level 5.40m MATERIAL SCHEDULE 01Brick Wall, Painted White Finish, RAL Colour TBC. 02Powder Coated Aluminium Railings, RAL Colour TBC. 03Boxed Window Powder Coated Aluminium White Finish, RAL Colour TBC. Refer to 3077(SK)03. 04Entrance Doorsets, refer to Window Schedule and Specification. 05Timber Windows, refer to Window Schedule RAL Colour TBC. 06Obscured Glazing Timber Windows, refer to Window Schedule RAL Colour TBC. 07Timber Panel, siberian larch refer to Specification. 08Facing Brickwork, refer to Specification. 09Recessed Facing Brickwork, refer to Specification. Refer to 3077(SK)04. 10White Through Colour Render Finish, refer to Specification. 11Single Ply Membrane Roof Grey Finish, refer to Specification. 12Textured White Through Colour Render Finish, TBC. 13Recessed Textured White Through Colour Render Finish, TBC. 14Proprietary Powder Coated Capping Piece, RAL Colour TBC. 15Timber Fencing, refer to Specification. 16something nice 17Balcony Detail. Refer to 3077(SK)01. 18Entrance Detail. Refer to 3077(SK)02. All Rainwater Goods uPVC RAL Colour TBC. All Soffits uPVC Borad RAL Colour TBC. All Facias to match Single Ply Grey Colour TBC. 4mground floor 1m level 5.40m

2-2 SECTION 1-1 SECTION 2-2 NW SECTION

Resolution 1:200 Sections & Elevations

Part A Structure Part B Fire Safety Part C Site preparation and resistance to contaminates and moisture Part D Toxic Substances Part F Ventilation Part G Sanitation, hot water safety and water efficiency Part H Drainage and waste disposal Part M Access to and use of buildings Resolution Materiality & Structural Strategy

GOODS & GARDENS

Sustainability lies at the core of good design and is an integral part of my holistic approach when developing the design. Having considered a broad range of environmental factors, the building is developed in an environmentally responsible manner. One of the key areas focussed on is meeting the requirements set by Part L, which govern energy use and CO2 emissions reduction.

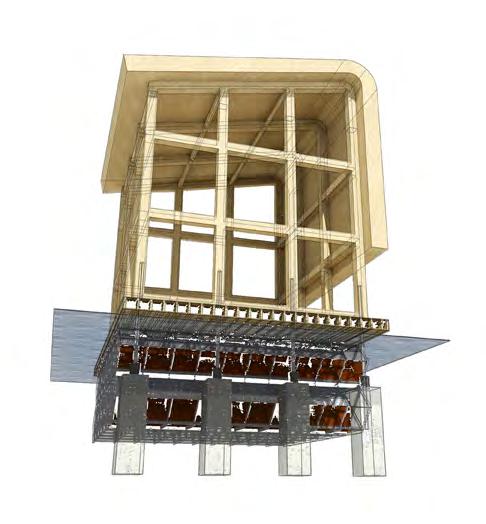

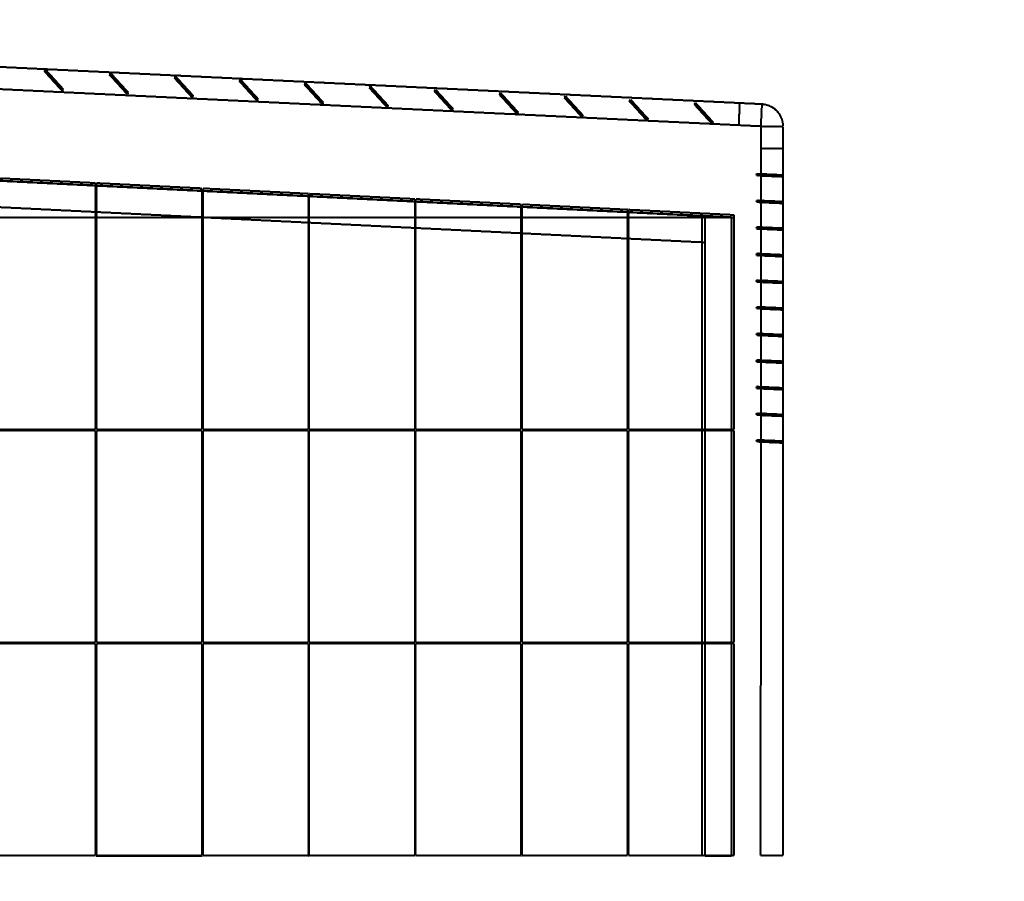

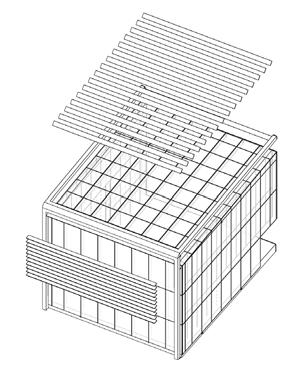

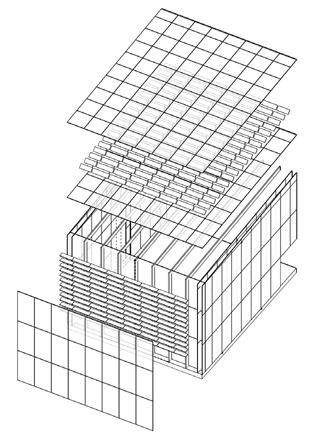

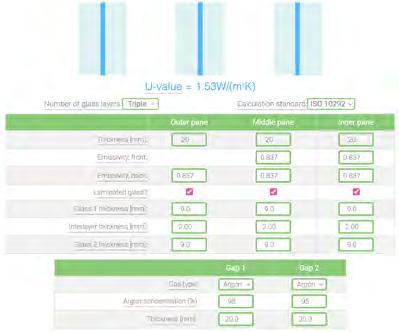

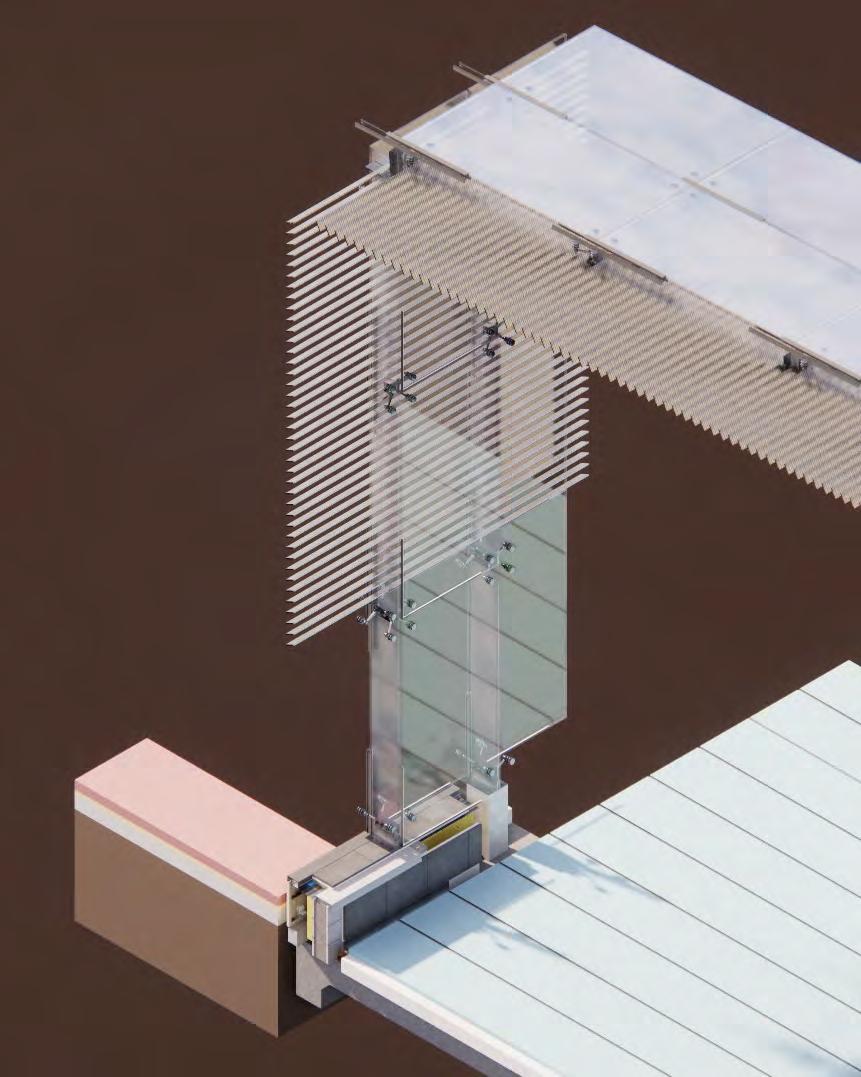

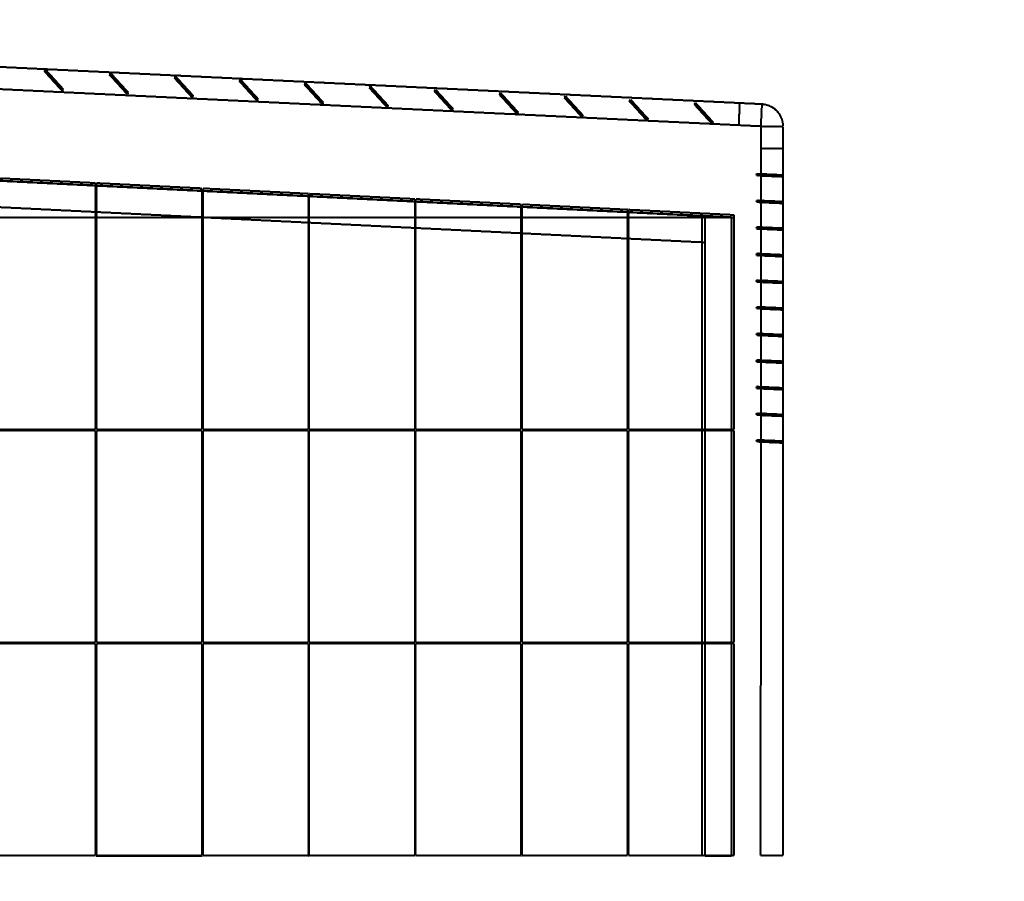

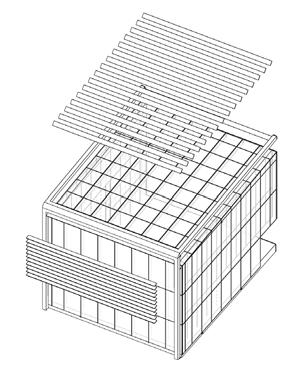

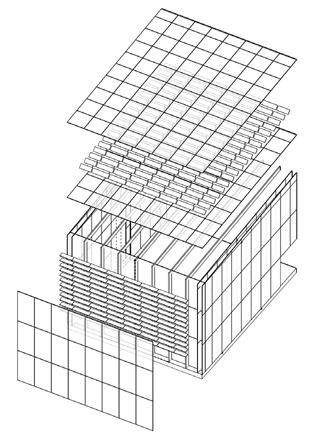

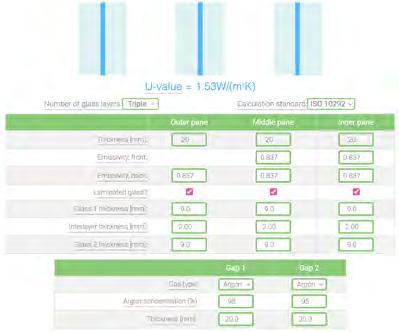

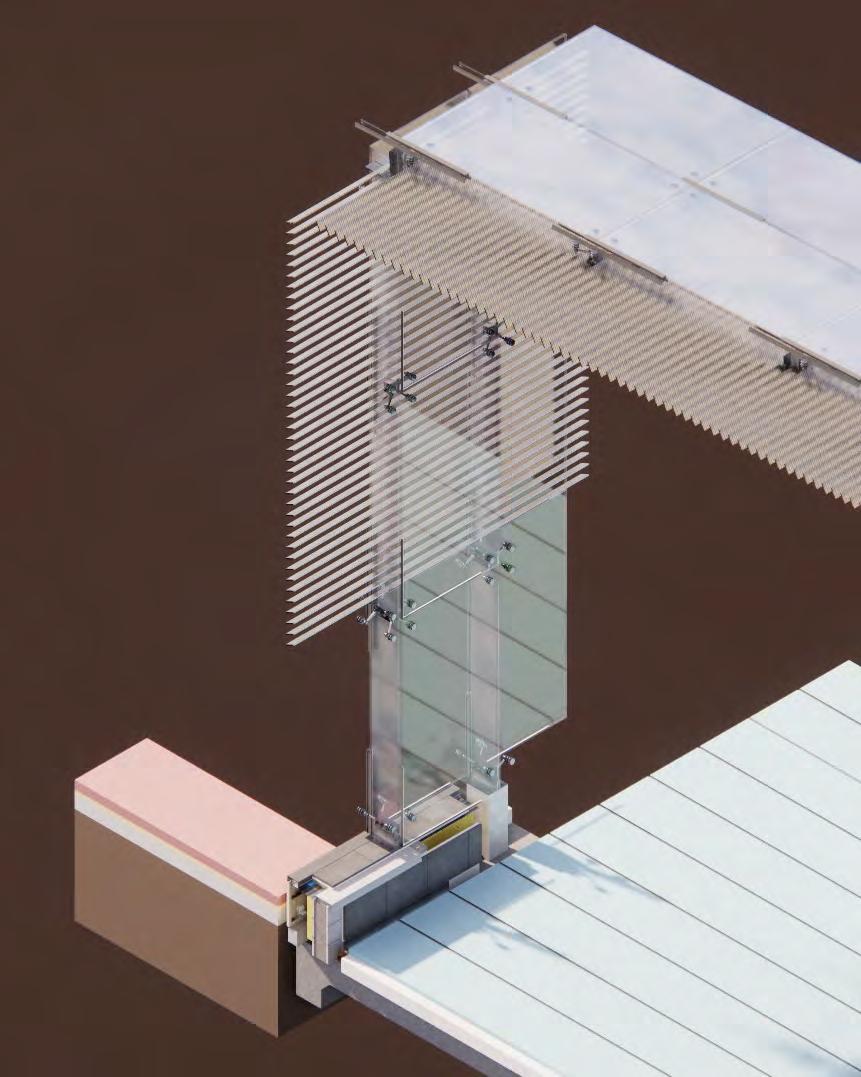

To surpass the recommended percentage improvement requirements, carefully considered the targets the building needs to achieve. aimed to enhance the building fabric, going beyond the standards outlined in approved Document L2A. By doing so, improving the U values of the external envelope, exceeding the requirements of Part L. Another important target is preventing excessive solar gain during summer months to minimize the reliance on cooling systems. This is achieved through solar control coatings on the glass, which allow for good light transmission while mitigating solar heat gain. Additionally, timber slats on the perimeter frame contribute to shading coefficient. In collaboration with the proposed method of renewables and low and zero-carbon (LZC) technologies suggested by DSA, my design aims to make substantial improvement beyond the target emissions rate (TER).

In terms of air tightness, wanted to set high standards for the scheme, which are facilitated by utilizing off-site fabrication techniques and the modular nature of the building. This helps ensure that the desired level of air tightness is easier to achieve.

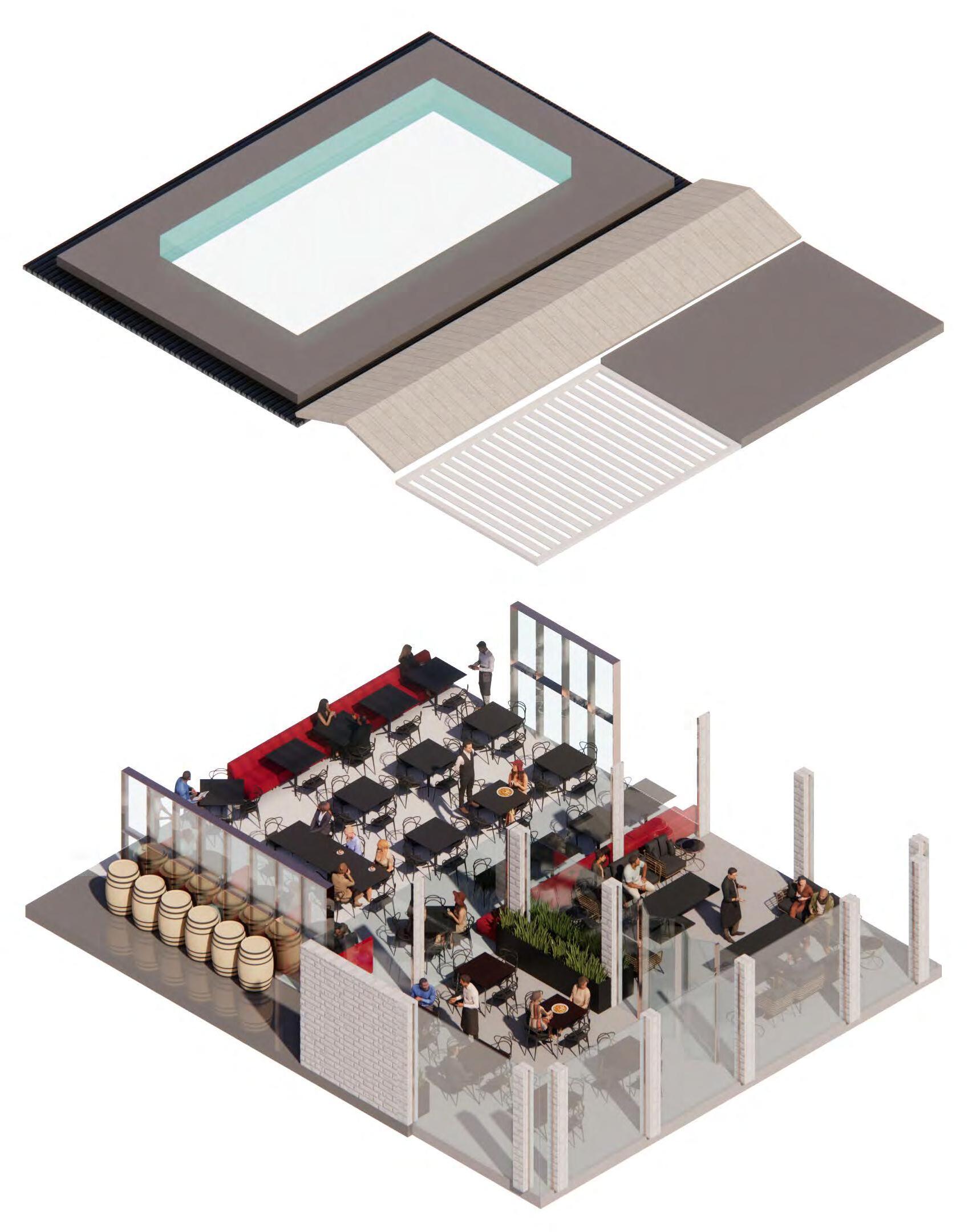

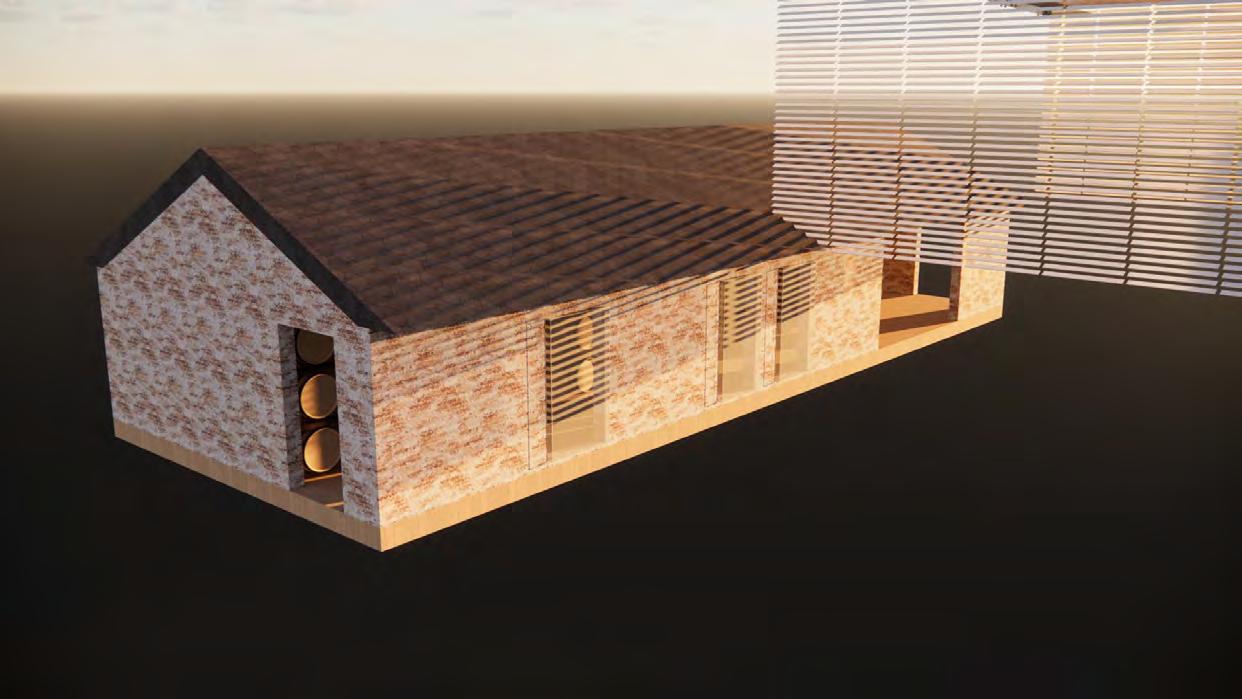

Timber has been chosen as the primary material for the cladding and main frame of the Restaurant and Bar due to its natural characteristics and inherent beauty. Unlike imitation materials such as porcelain or laminate, timber accurately represents the charm and character of a genuine natural product. The processing methods employed maintain the original grain and texture of the timber, emphasizing its authenticity.

The restaurant building will feature glulam and cross-laminated timber floor slabs, creating serene and immersive environment reminiscent of farmstead holidays and rural architecture. The transition from the interior timber structure to the outside should evoke excitement and intrigue. To protect the external timber from weathering, method of darkening the material has been proposed, which will both preserve its appearance and create a harmonious palette with other building materials.

Furthermore, while Part does not cover all aspects of the building’s design, paid careful attention to the materials used. My selection process focuses on choosing materials with high scores in the BRE Green Guide, prioritizing their environmental impact. And place an emphasis on the responsibility within the supply chain and contractor’s role, requiring products to come from a BES 6001 certified supply chain and ISO 14001 accredited manufacturer. Additionally, raw timber would be sourced from FSC and PEFC certified sources. Responsible sourcing is a crucial consideration in both the glazed and timber frame specifications. The principal environmental benefit of using massive timber is that (when considering the embodied energy per weight of timber, together with the weight of material used per unit area of floor) has the lowest embodied carbon of any construction material.

Assumed weight of structure

Embodied Energy MJ/Kg

Embodied Carbon Kg Co2e/kg

Assumed total energy MJ

STEEL GLULAM

63 tonnes

21.5

140 tonnes 12 0.42 fos + (0.45 bio)

1,680,000

96,390

58,800

EED

EPDM

RETROFIT NEWBUILD NEWBUILD RETROFIT LAMINATEDGLASS STUDIO 3.2 8 9 STUDIO 3.2

A

Resolution Materiality & Structural Strategy

F

CHARRED TIMBER

RUBBER CLTFLOORSLABS

ENTERTAIN

RRIVAL

DRINK CELLAR BLEND

Assumed total carbon Kg Co2e 1.53

1,354,500

Careful attention will be given to the detailing of the cladding rain screen boards to ensure their robustness and longevity. Various processing techniques will be explored to achieve the desired aesthetic, and the mounting of the cladding boards will be carefully executed. Overall, the aim is to create visually stunning and durable timber-clad structure that seamlessly integrates with its surroundings while preserving the natural beauty of the material throughout the building’s lifespan.

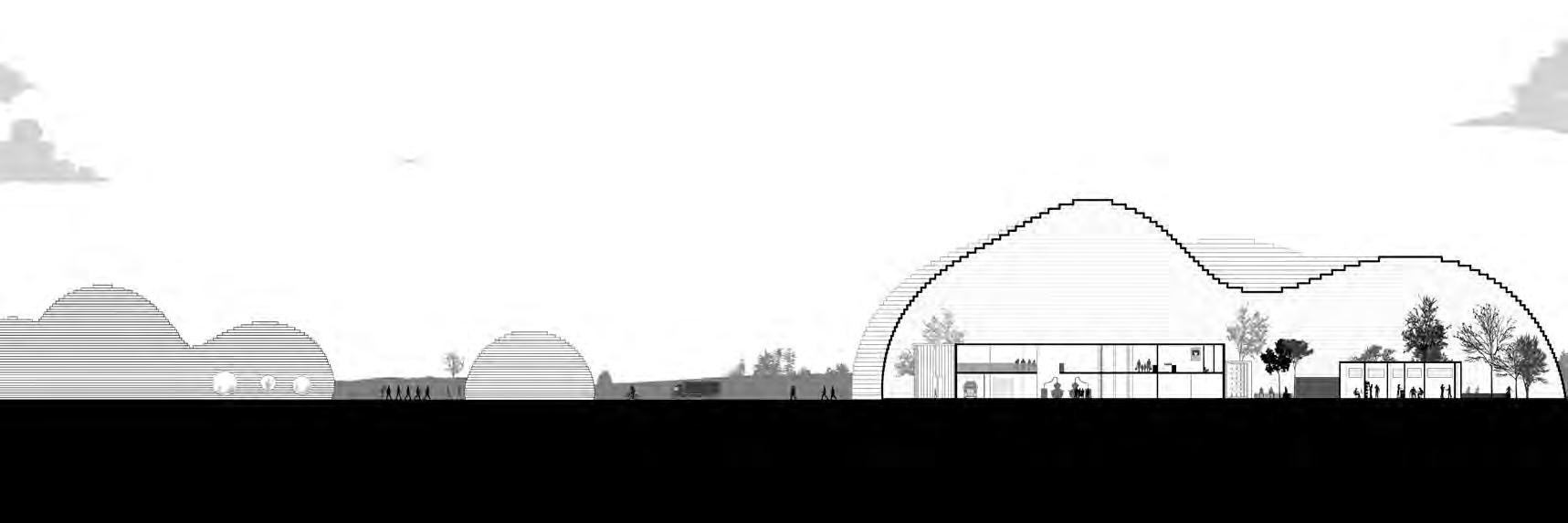

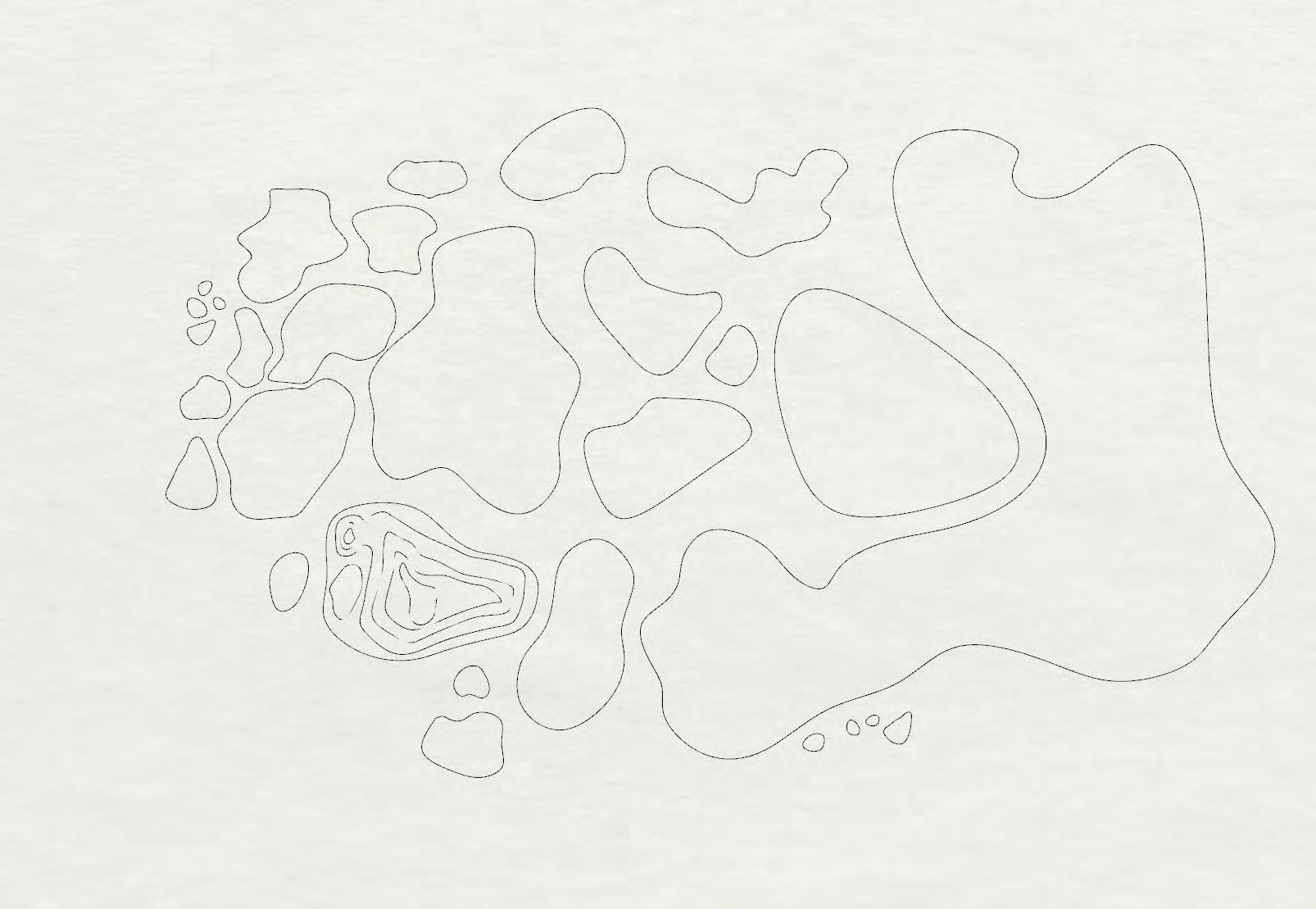

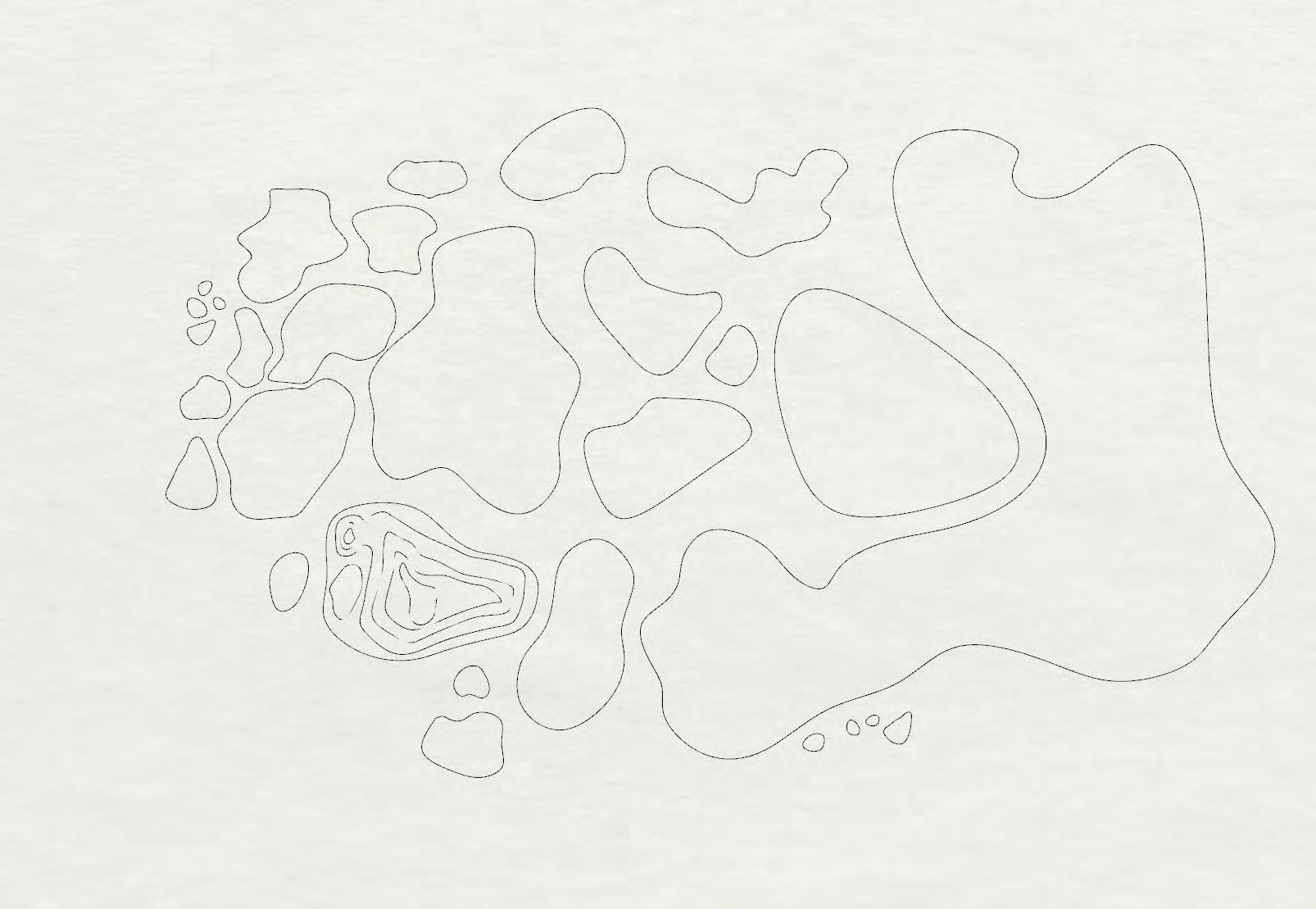

THE ‘DRUNKEN’ GARDENS

The main building exhibits distinct linear and orthogonal design, prompting my inclination to introduce fluid and organic shapes that deviate from its prevailing regularity within the landscape. Currently, the site features neglected and scattered mounds comprised of soil and waste, so instead of wasting energy on dismantling and disposing of these elements, propose more resourceful approach: recycling these materials to construct sizable, abstract forms that not only foster a visually captivating environment but also offer leisurely spaces within the garden and enhance biodiversity.

The meandering pathways, adorned with gentle curves, lead visitors around the hills, presenting them with idyllic spaces to gather, unwind, and revel in the breathtaking views. It is noteworthy that select paths have been thoughtfully crafted to ensure accessibility, catering to the needs of wheelchair users and further fostering inclusivity within the garden’s design. In this haven, the gardens take on an enchanting ambiance, reminiscent of a kids playground, despite their adultoriented exclusivity.

Fundamental to the success of the proposed master-plan is the creation of a strong sense of place as a natural extension of the rural landscape.

A key guiding principle has been to learn from the existing vernacular and reference the historic site use and the mounds of earth and rubble created during the demolition of the former structures of the site. The forms including the river bank and farm yard courtyard have been used to inform the character of the development. The existing spatial and functional typologies have been studied and scales compared.

These studies have influenced the design principles and concepts that are concerned with the flow of people and vehicles around the site, culminating in key strategy of shared space and pedestrianisation.

This strategy includes the creation of an access for all landscape:

Open Spaces Drunken Gardens River walk Formal Garden Treelined approach

Mounds and Ponds combine landscape and sustainability

Pedestrianised zones throughout the sites

Shared interplay of traffic and pedestrian movement

New vistas to key destinations

Integrated way-finding

Public amenity space to support and involve local community

New cycling pathways that are safe for all

The development of new strategic pedestrian and cycle infrastructure, together with the existing cycle network, will connect the various separate neighbourhoods of the Proposed Development, bringing them into the existing local centre. The new pathways have been designed to respond to the natural scale of the new buildings and work in harmony to promote ease of navigation and encouragement of explorations across the campus.

PLANTING

The mix of plant species selected will ensure there are flowering species for a long period, from early spring to late autumn, thus establishing a place that is beautiful and a much-needed habitat for wildlife

The variety of trees and shrubs will create a landscape across the campus that looks ordered and enhances the character of the site.

SEATING

Seating is a fundamental part of the design, for this is how most people will choose to spend time in space. There are places for people to sit as a group in the summer, or protected from the wind on a cold day in winter. There are places for groups to lay down and others to work quietly amongst beautiful planting.

In the interests of enhancing biodiversity, ecological links will be provided to connect local habitats into viable network across the site. The Proposed Development will include series of landscape areas which will function as SUDS corridors, areas that will create and integrate network of habitat and ecological corridors and biodiversity and provide space for informal recreation and play spaces. These ponds also contribute to the visual aesthetics of the overall landscaping, lending captivating and harmonious element to the surroundings.

BIODIVERSITY

The use of native species, which are found within the locality, is essential in the establishment of any new landscape areas. Existing sparse hedgerows will be interspersed with native species to encourage varied mix of habitat typologies.

In some recent buildings badly designed courtyards have often degenerated into unused, sterile spaces. However in this proposal the courtyard is the active heart of the scheme with the main circulation space and key function rooms opening directly onto it. The courtyard is seen as the heart of the scheme, mature trees will sit at the centre with mixture of planting, hard landscaping and grassed areas providing a variety of external surfaces and textures to enjoy.

GREEN CORRIDORS

The green corridors that run around the gardens provide access and help provide long distance views from within and across the Site.

The proposal ensures that existing topographical features are integrated and retained within the proposed new landscape setting. The overall objective is to secure and integrate existing landscape assets while enhancing ecology and biodiversity.

The shared spaces are connected by series of mounds and ponds that provides a more intimate environment for people to go where new seating has been placed within the planting.

Access to the Proposed Development is intended to reflect the following principles:

1) Create high quality public realm for the Development.

2) The creation of a pedestrian, cyclist and public transport friendly development.

3) Integrate built development, movement corridors, public realm, open land, recreational areas and wildlife habitat.

4) Ensuring that pedestrian movement corridors are designed to meet requisite DDA and inclusivity standards.

5) The vision of development is sensitive to its environment yet has its own prestigious, high quality character.

6) Retain important trees and species rich hedgerows.

7) Ensuring that measures to avoid pedestrian/ vehicle conflict are managed in such a way as to maintain free movement but to give pedestrian appropriate priority.

8) The desire to incorporate renewable energy infrastructure into the fabric of the landscape.

9) Integrate playful areas and open fields with informal landscape.

10) Enabling cross site pedestrian and cycle corridors to be well related to topographical features to meet secured by design standards and to reflect natural desire lines.

STUDIO 3.2 10 11 STUDIO 3.2

COURTYARD A B C A B C SUDs Natural Daylighting Deliveries Underground Pipes Plant Room Cold Water Hot Water Bore Holes Retrofitted Buildings AHU Heat Recovery EXTRACTION WASTE DISPOSAL

BOTTLING PLANT & WATER FILTRATION Resolution Landscaping Plan Resolution Environmental Strategies

The design approach integrates the field type and built form, ensuring cohesive narrative. Each built mass is developed based on the character area it belongs to, adhering to established principles that strengthen the concept while meeting functional requirements.

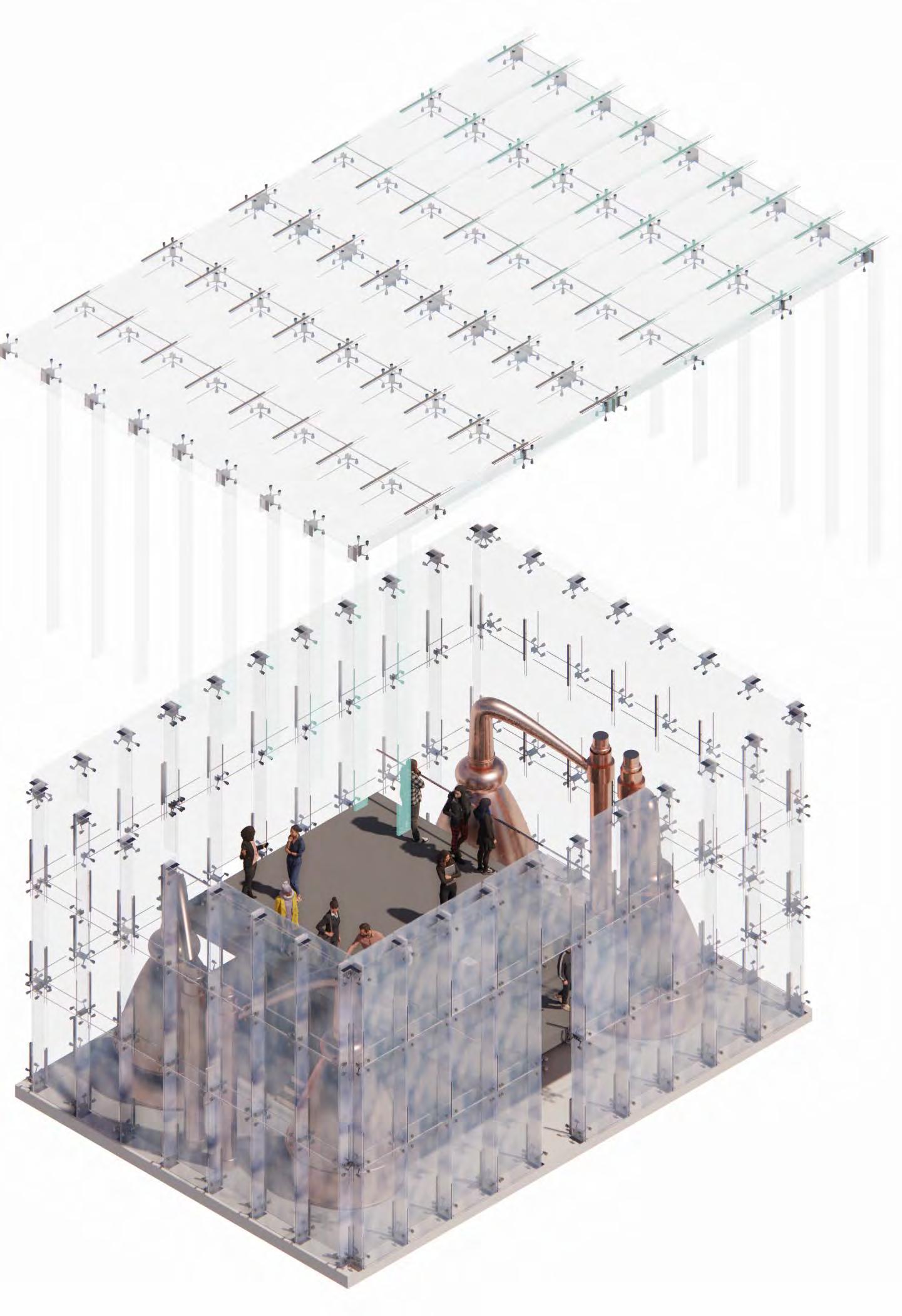

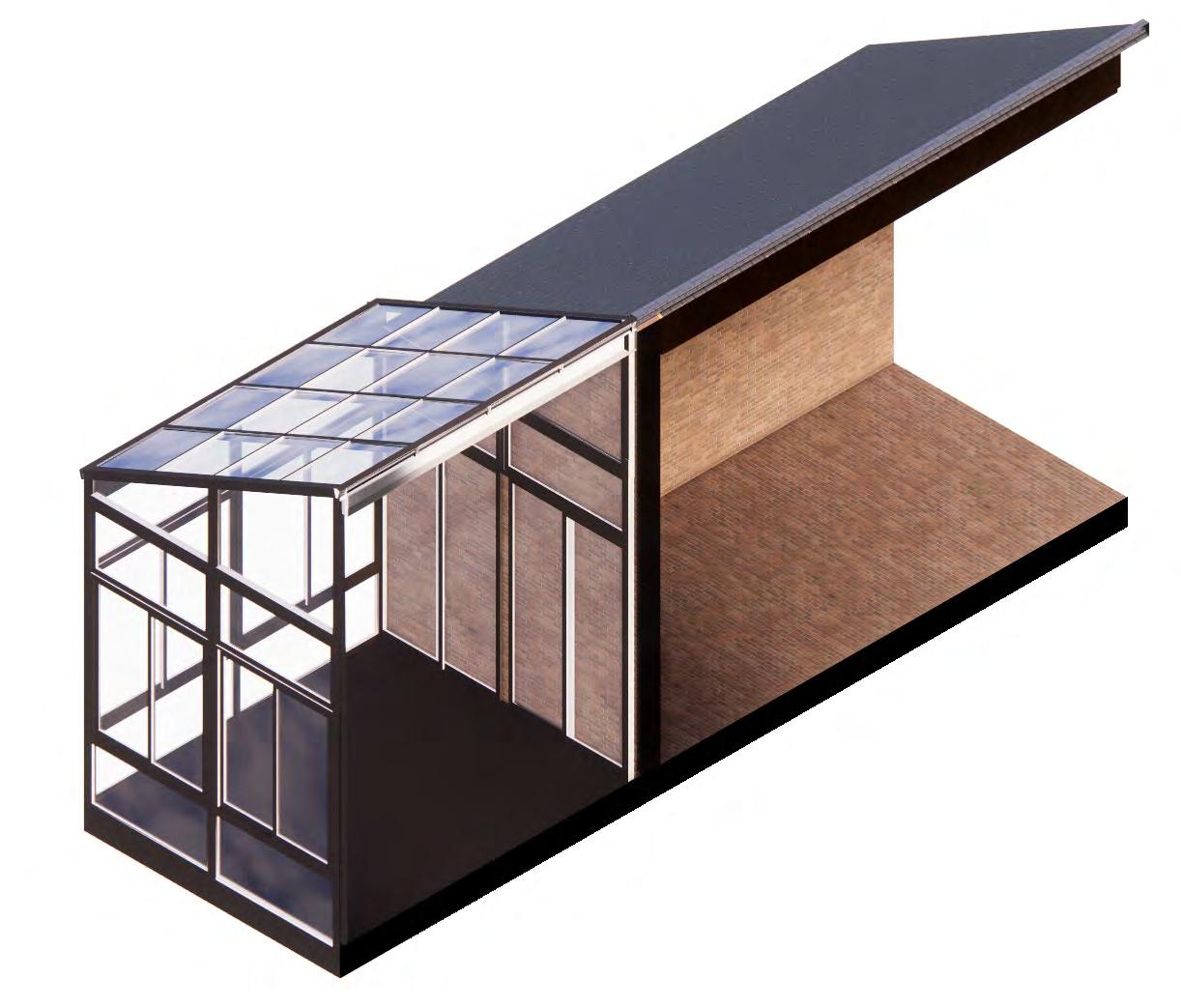

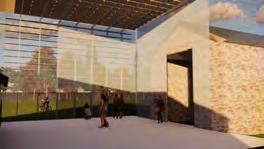

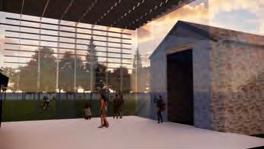

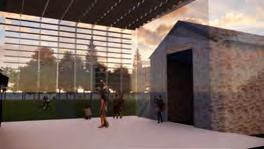

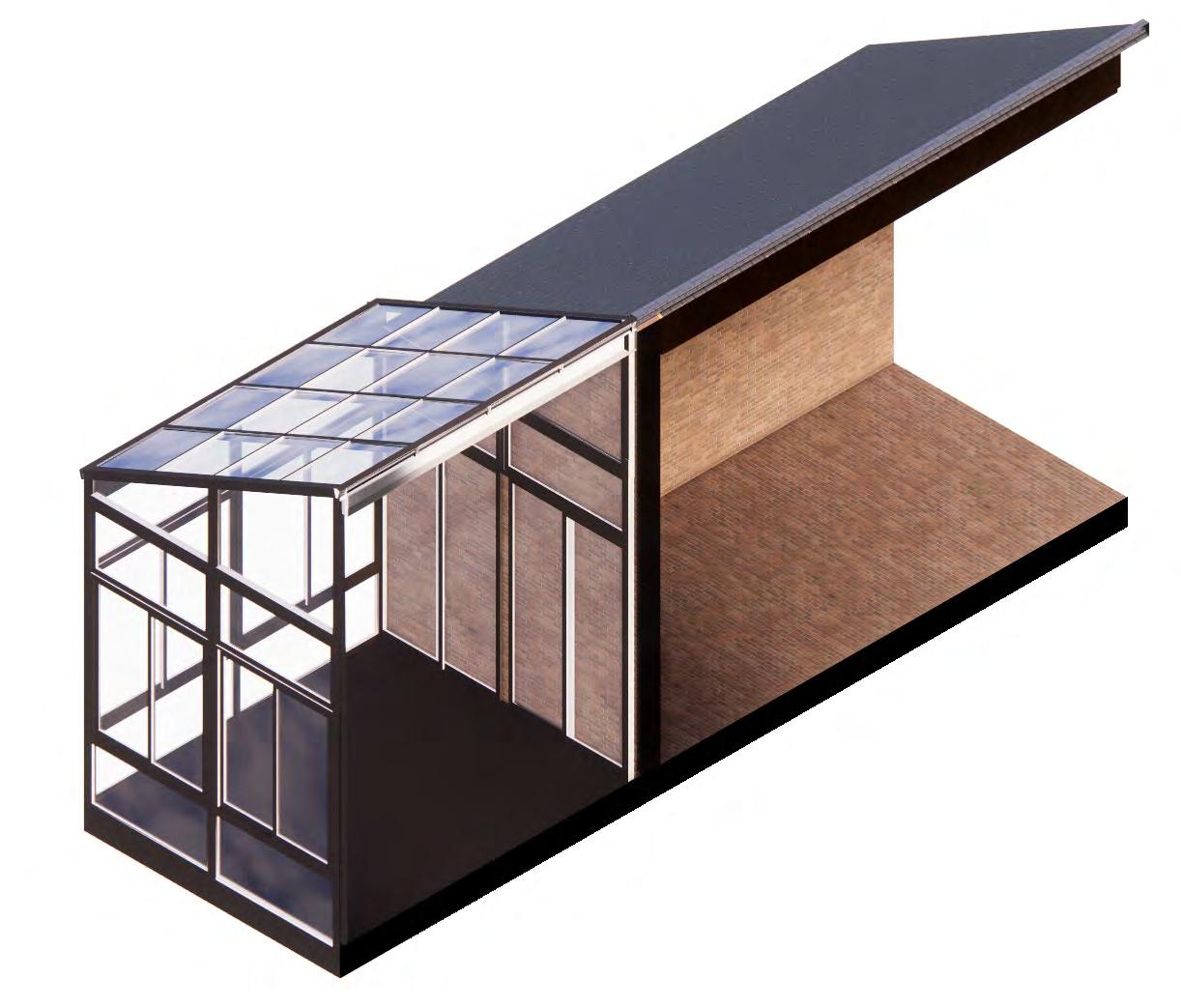

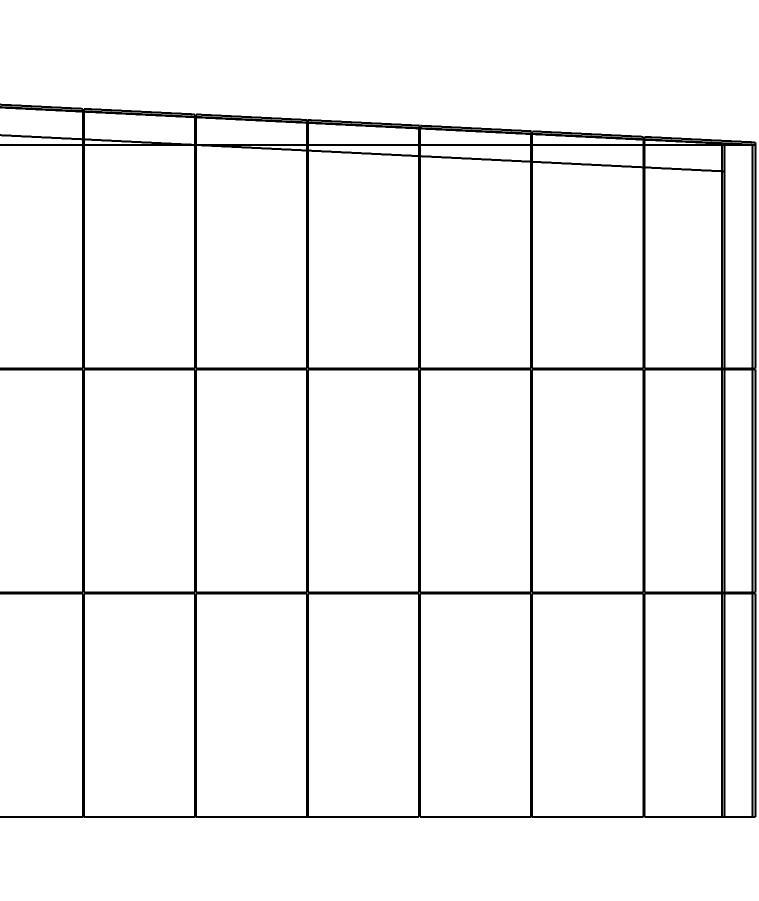

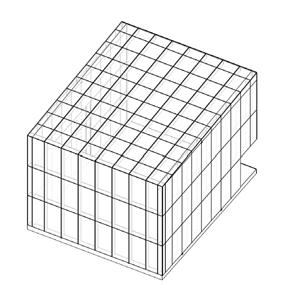

Environmental sustainability is a priority, with responsible sourcing of materials for both landscape and buildings in alignment with MCC CO2 reduction policies. Reusing existing hard landscaping is a key objective. The new buildings take inspiration from the former farm, employing a rigid grid to generate form and recreate the central courtyard. The largest new structure, the "Still Box," contrasts the listed brick buildings with its transparent glass construction, expressing the new grid overlaid on the site. Consideration is given to access to direct sunlight and controlling overheating in the "box" during periods of direct sunlight.

Intimatebarwithanexpertlycuratedwhiskeycollection

Viewingbalconyoverlookingthedistillationprocess

Gastronomyrestaurant

Goods&Gardens

Whiskeyshopandaccesstothe‘drunkengardens’

The relationship between built form and landscape is carefully considered, and plant selection plays crucial role in maintaining high-quality environment. Rather than strictly adhering to the grid as proportioning tool, the design opts for loose-fit landscape with undulating characteristics, breaking the square form of the buildings and creating green space leading to the brook. Waste materials on-site are re-purposed to create mounds, paths, and leisure areas within the landscape.

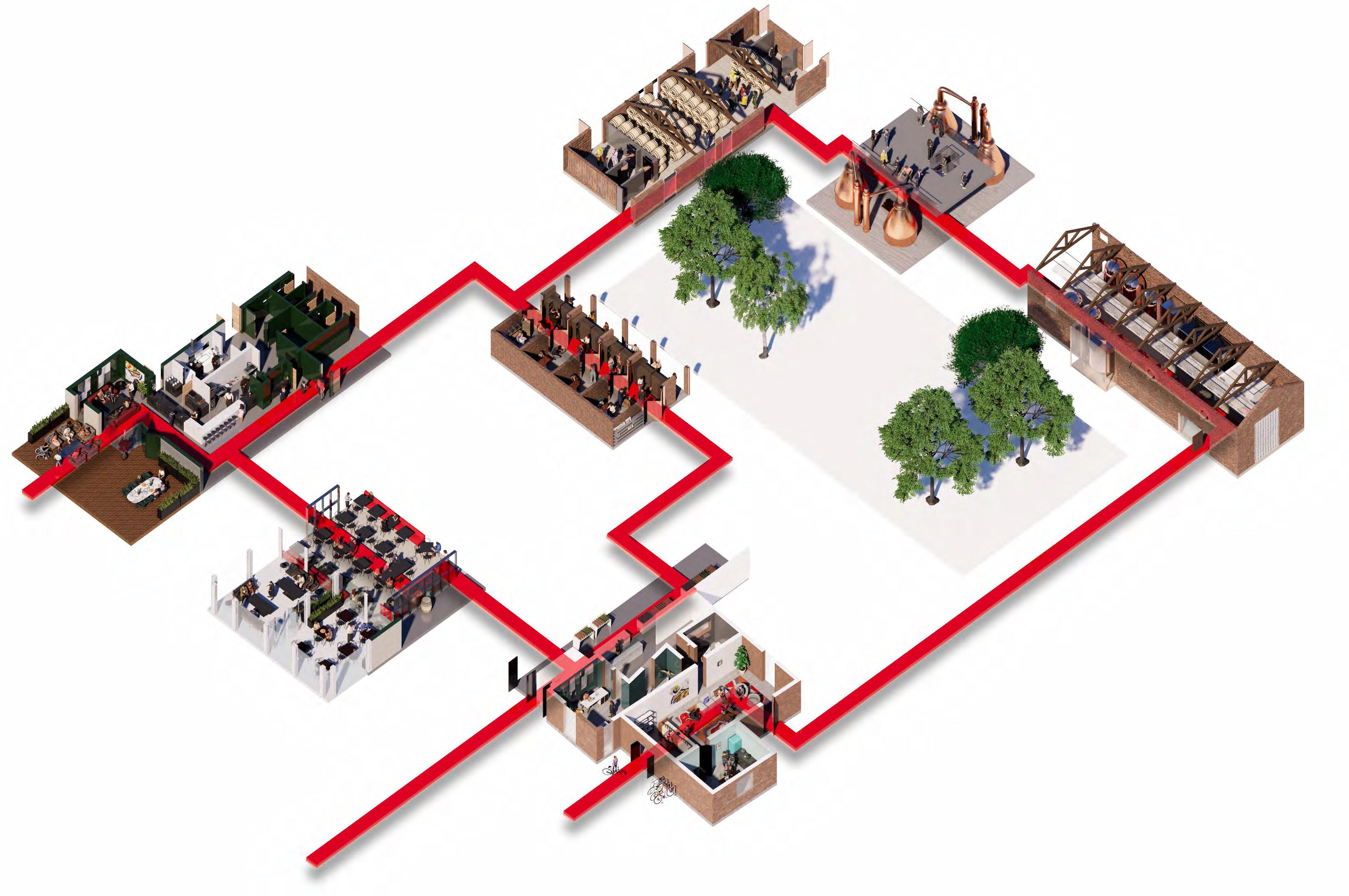

The envisioned space is branded as a destination for city dwellers to relax, offering outdoor seating, bars, and restaurants. By incorporating leisure elements, is expected to transform the utilization of the square. The different building elements, including The Field, The Pavilion, The Barn, The Farmhouse, and The Still Box, contribute to the overall aesthetic. The restaurant is specifically designed around the former Hay Barn, incorporating elements that break down the solidity of the facade.

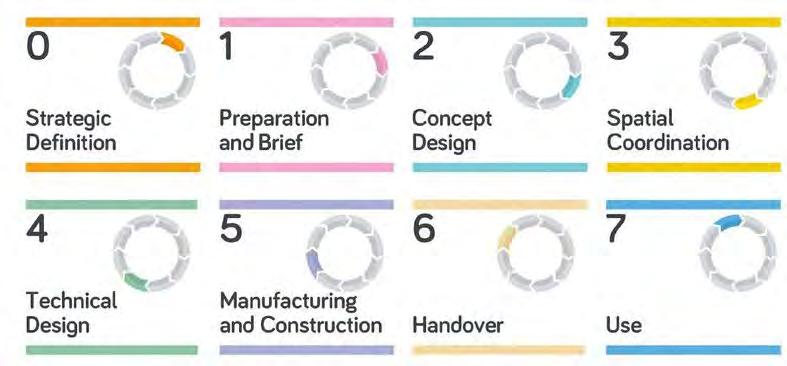

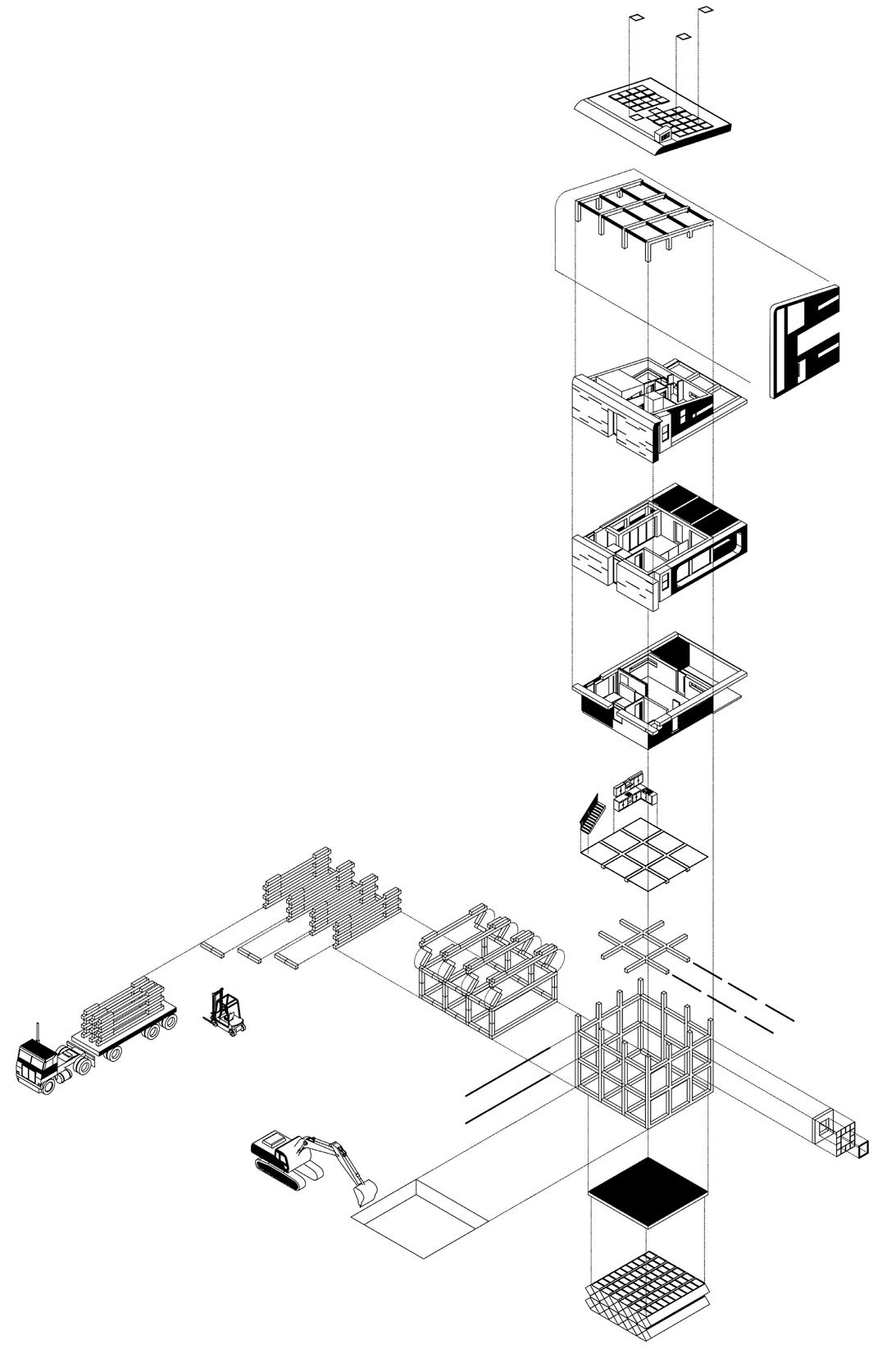

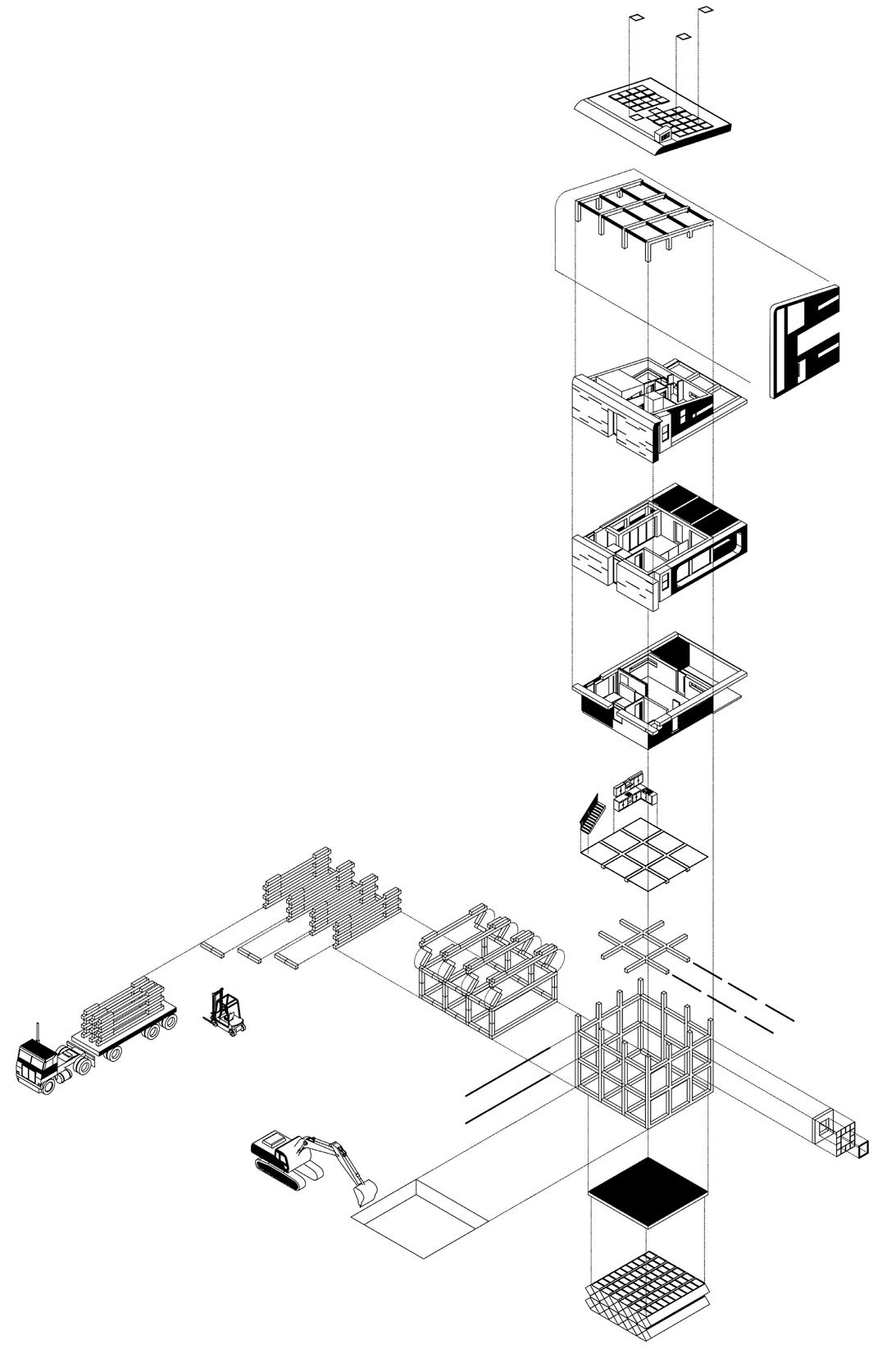

The construction process is divided into these steps, with the addition of building phasing.

1. Mobilisation.

2. Demolition.

3. Site clearance.

4. Set Up site facilities

5. Setting out.

6. Excavation.

7. Installation of foundations. 8. Frame construction. 9. Cladding installation. 10. Fitting out. 11. Landscaping and highways.

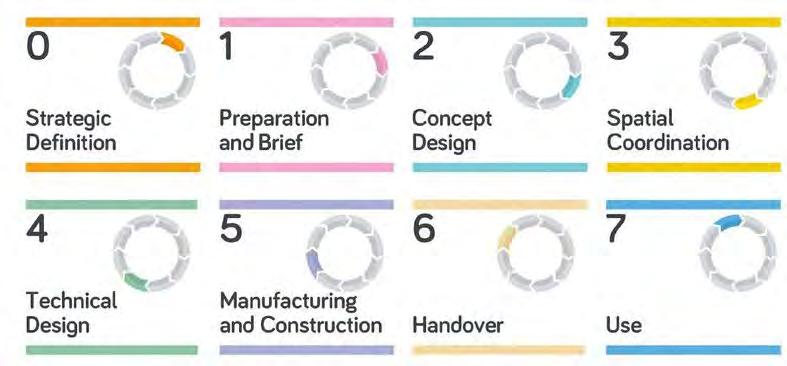

In terms of the work stages of the RIBA Plan of Work, the construction process can be said to start at stage 5 and finish at the end of stage 6, as shown below.

and brief.

DEMOLITION MOBILISATION STUDIO 3.2 12 13 STUDIO 3.2

Construction. Handover and

7 In use.

Strategic definition. Preparation

2 Concept design. Developed design. Technical design.

close out.

SET UP SITE FACILITIES SETTING OUT MOBILISATION DEMOLITION SITE CLEARANCE EXCAVATION FOUNDATIONS BUILDING FABRIC FITTING OUT LANDSCAPING HIGHWAYS Fireplace WAITING MEETING ENTRANCE AREA Traditional construction with secondary internal insulation RETROFIT LOBBY Fireplace shop Stair WAITING Installation of new windows, roof and suspended block and beam floor Intervention and repair of barn REUSE 22mm Plywood LOBBY Fireplace shop Stair WAITINGground Modular construction of glass cassettes and glass frame REINVENT ROOF LEVEL GROUND FLOOR Fireplace ENTRANCE WAITING ENTRANCE LOBBYExtending barn with timber construction W/C & back of house REPAIR Detail through the shop & placement of flat roof REDEVELOP

SITE CLEARANCE

STARTOFTOUR

ARRIVAL BLEND

D

E

CELLAR

RINK

NTERTAIN FEED

Resolution User Experience Technical Detail Construction Sequence

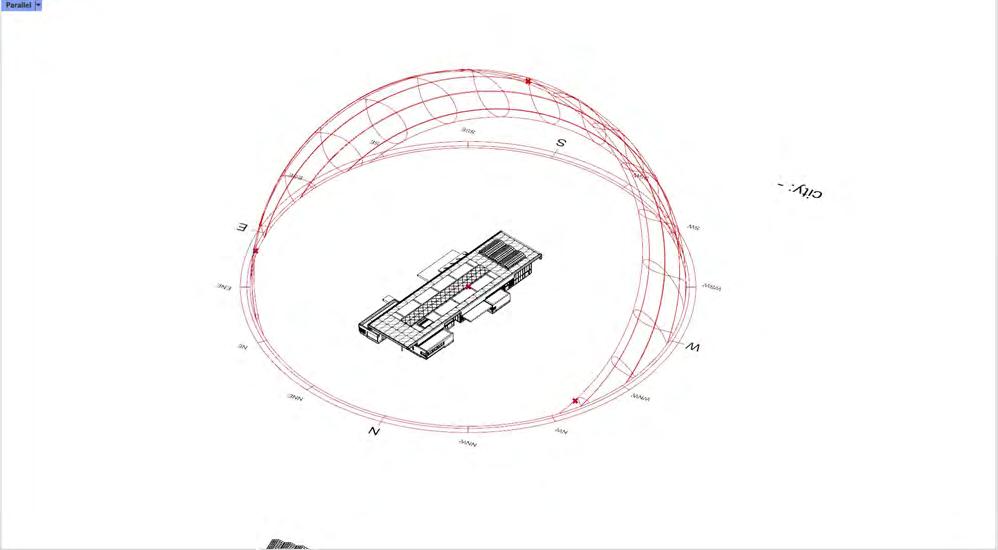

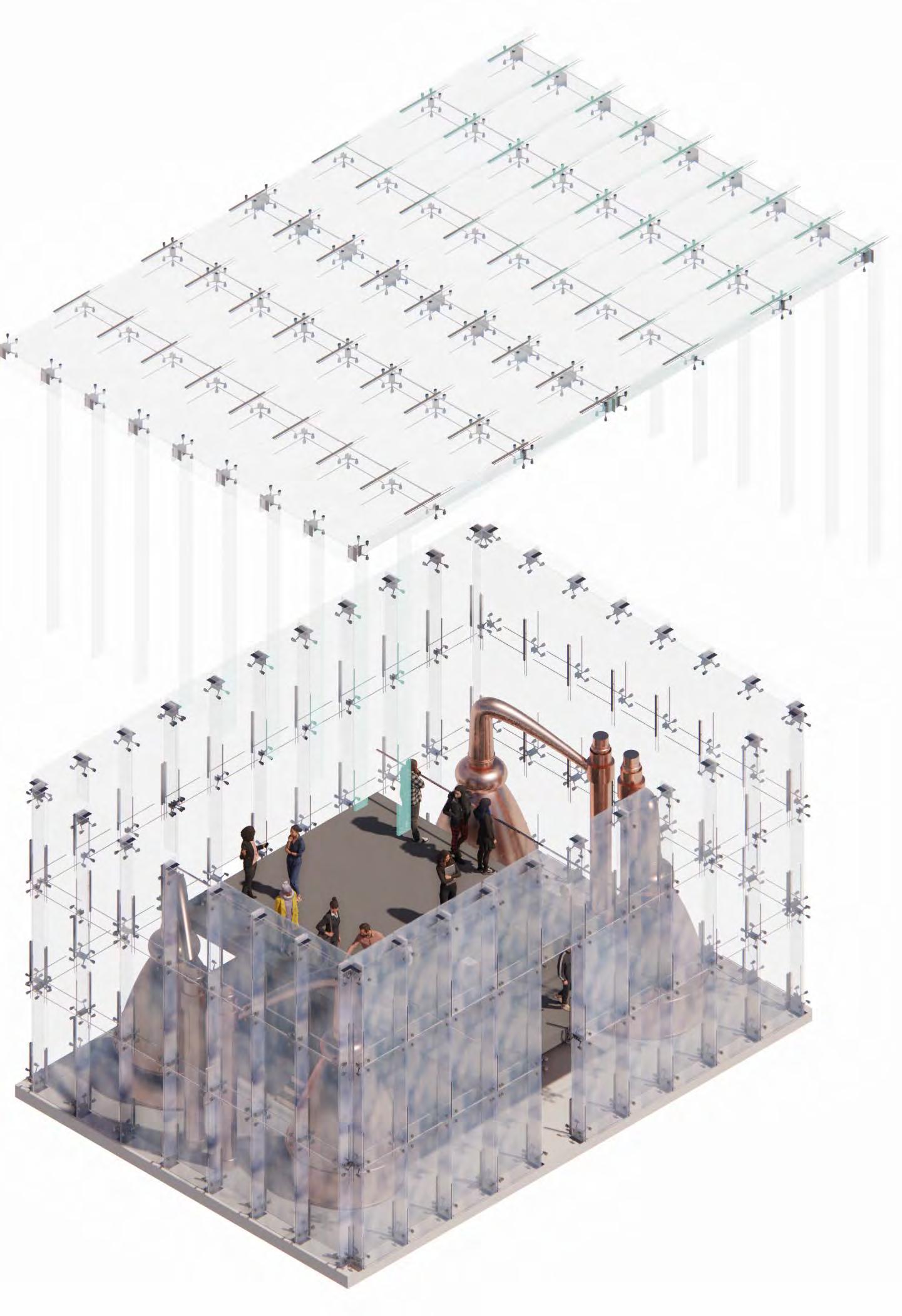

Environmental sustainability is a priority, with responsible sourcing of materials for both landscape and buildings in alignment with MCC CO2 reduction policies. Reusing existing hard landscaping is a key objective. The new buildings take inspiration from the former farm, employing a rigid grid to generate form and recreate the central courtyard. The largest new structure, the “Still Box,” contrasts the listed brick buildings with its transparent glass construction, expressing the new grid overlaid on the site. Consideration is given to access to direct sunlight and controlling overheating in the “box” during periods of direct sunlight.

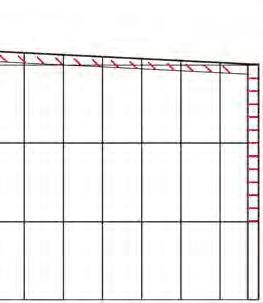

Windows are an important feature of any listed building, epresenting an integral part of their historical fabric They are the single element which most serves to establish the character of the building. Recognizing the value of preserving and enhancing the existing window roundels, which hold medium significance in the building’s heritage, propose an innovative solution. The introduction of an operable, revolving pivot window would not only retain the original features but also provide a practical means of ventilation, which holds utmost importance for this particular building type. This thoughtful approach ensures the harmonious integration of modern functionality while honouring the building’s historical integrity.

STUDIO 3.2 14 15 STUDIO 3.2 Technical Detail 1:20 Section 5x2.5 underlay carried into gutter 50mm overhang max. Tilting fillet Eaves and under eaves battens Slates Slate battens Air flow Roof space insulation omitted for clarity Ventilation spacer Wall plate Cavity closer Cavity insulation Soffit ventilation 10mm gap 1 Air flow Air flow Proprietary inline ventilator Underlay protector Cut slating batten and underlay to locally to accommodate ventilator Additional battens many be required locally 2 Ridge Shoulder course Top course maintaining gauge Code lead flashing fixing 3

30° 30°

Technical Detail 1:5 Tactile Elevation & Section

500mm 100mm200mm300mm400mm 100mm 1:5

REFLECTION

1. Embracing Materiality and Spatial Experience: Through the atelier position, have actively explored and valued the qualities of materials, materiality, and spatial experiences within architectural design. By considering the immersive nature of architecture and the built environment, have sought to create designs that engage and enrich the experiences of users and occupants.

STUDIO 3.2 16 Design Journal A Reflection On 3.1

EXHIBITION Reflection Exhibition & Conclusion

PRECEDENT STUDY

HUTONG

BUBBLE

Architects: MAD Architects

Year: 2019

Location: Beijing, China

The Hutong Bubble 218 project is design concept that aims to revitalize traditional Beijing hutongs, which are narrow alleyways lined with courtyard residences. The project proposes the construction of transparent bubble-like structure, known as the “Hutong Bubble,” within one of the hutongs, providing a unique and contemporary space for communal activities.

The Hutong Bubble 218 seeks to preserve the cultural heritage of the hutongs while introducing modern elements. The transparent structure serves as a public space that connects multiple courtyards, creating a gathering place for residents and visitors. It acts as a flexible hub for cultural events, exhibitions, workshops, and social interactions, fostering community engagement.

The design of the Hutong Bubble incorporates sustainable principles, utilizing solar panels to generate electricity and rainwater harvesting systems to promote eco-friendliness. The transparent material allows natural light to permeate the space, reducing the need for artificial lighting during the day.

Overall, the Hutong Bubble 218 project envisions a harmonious blend of traditional hutong architecture and contemporary design, revitalizing these historic neighbourhoods and promoting community cohesion.

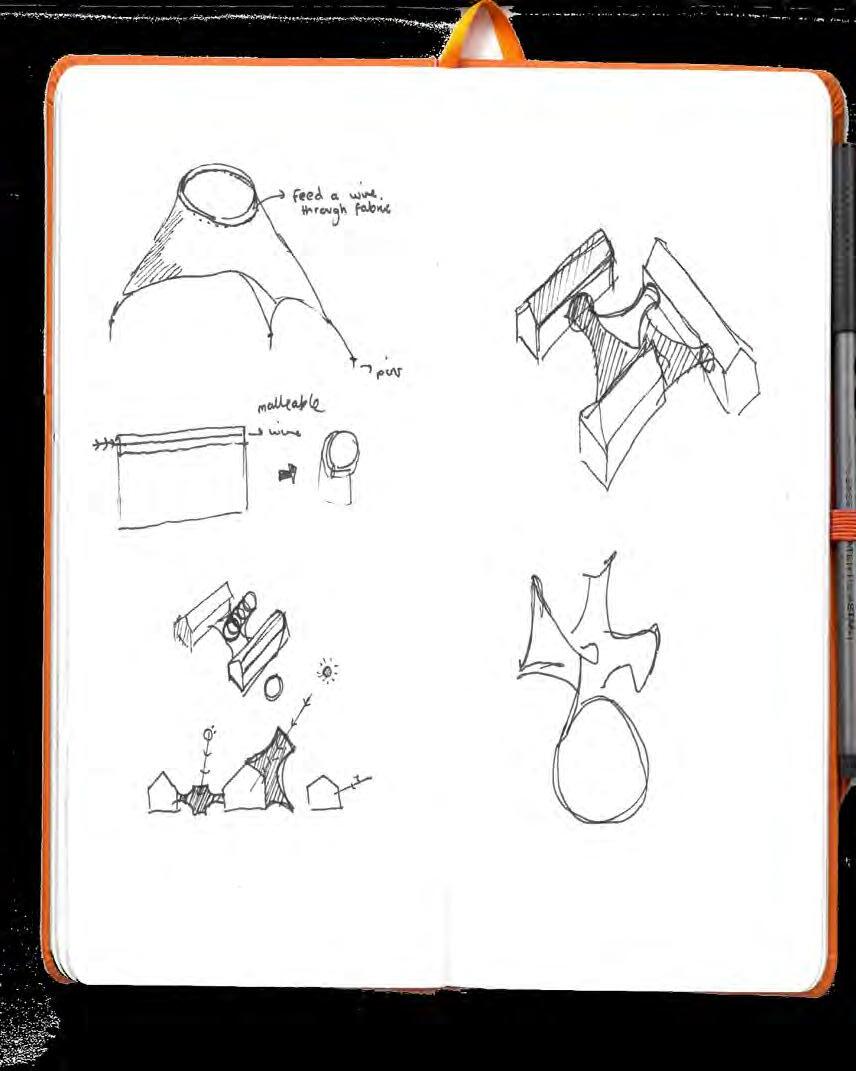

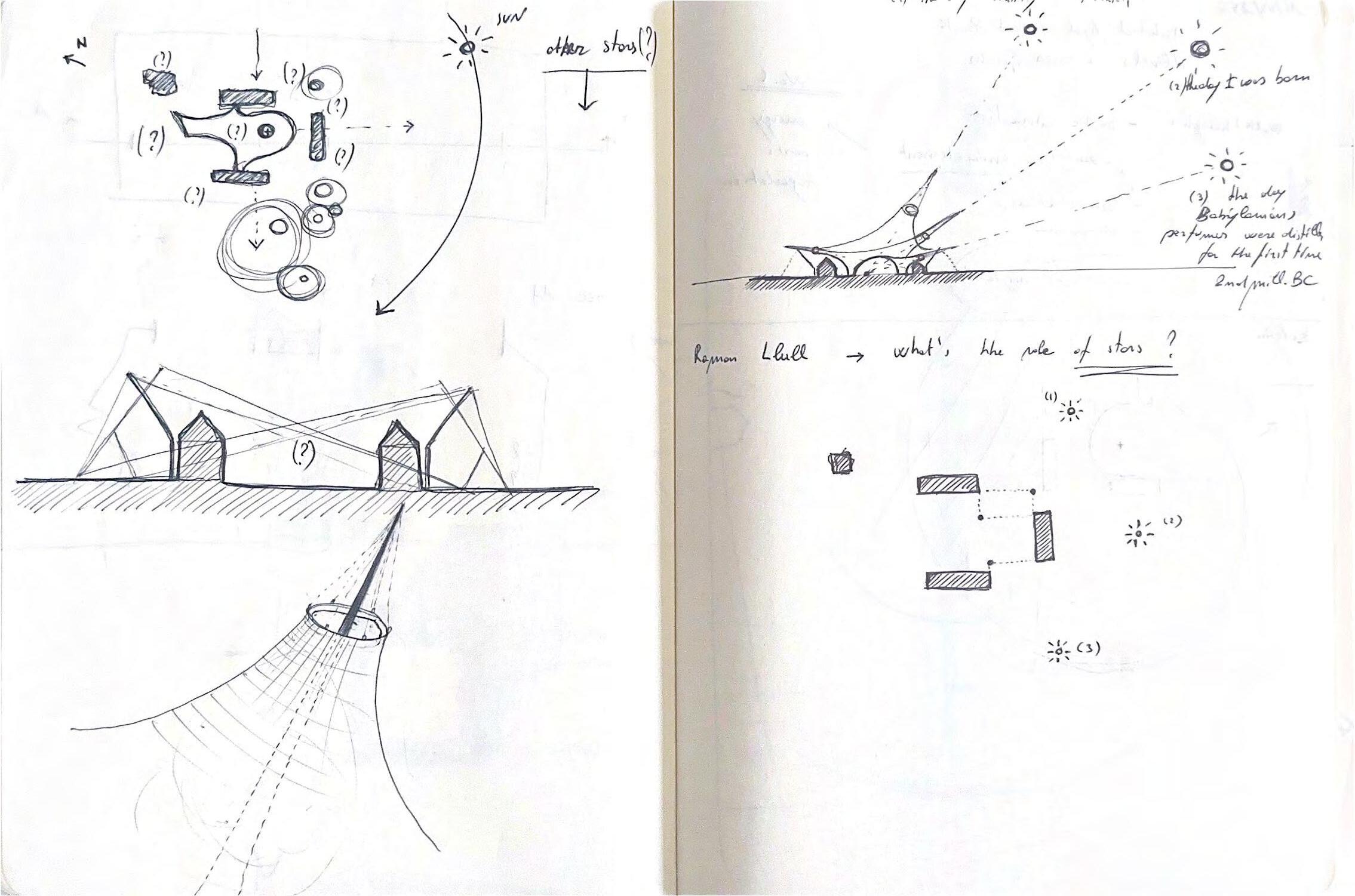

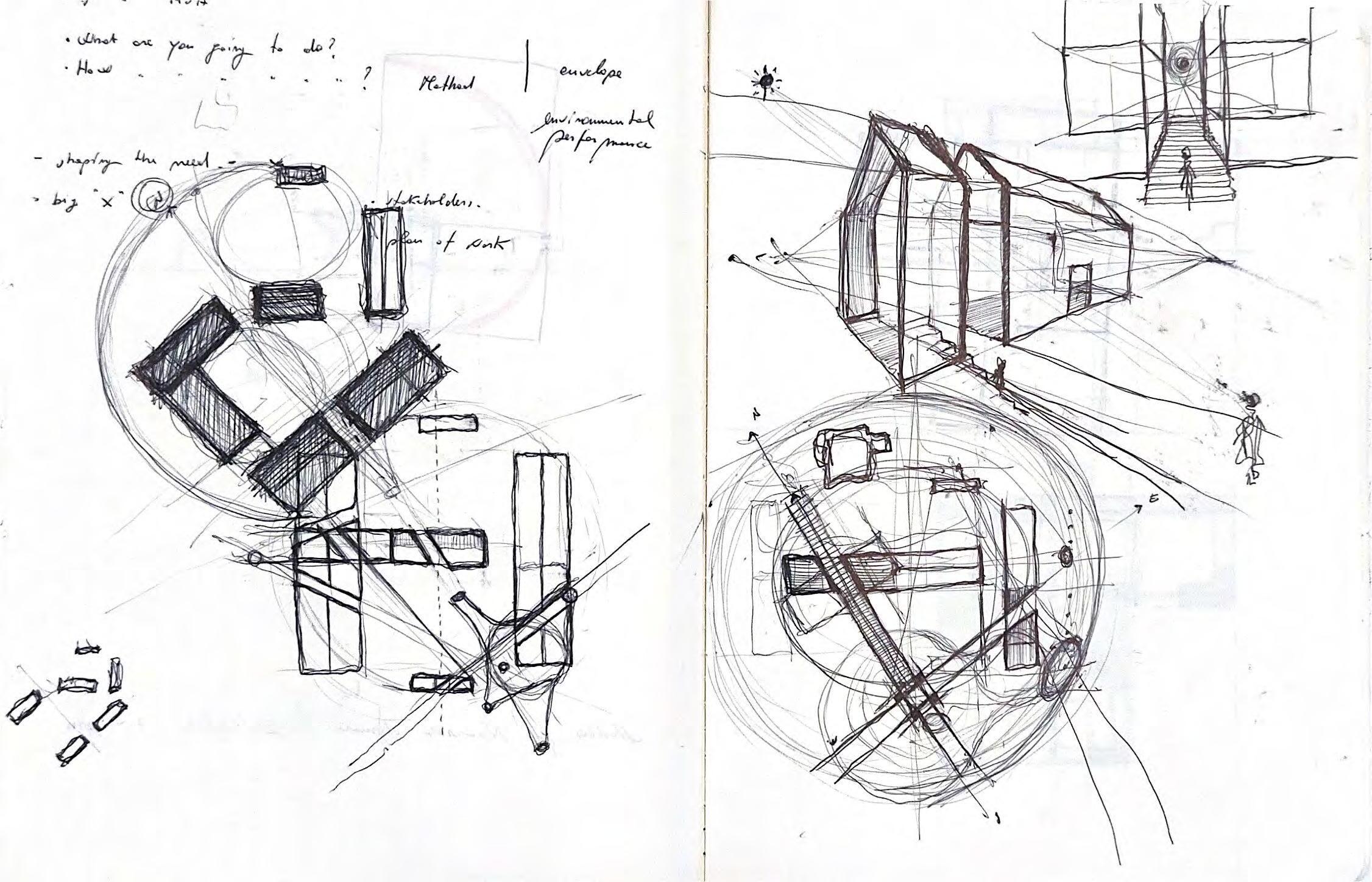

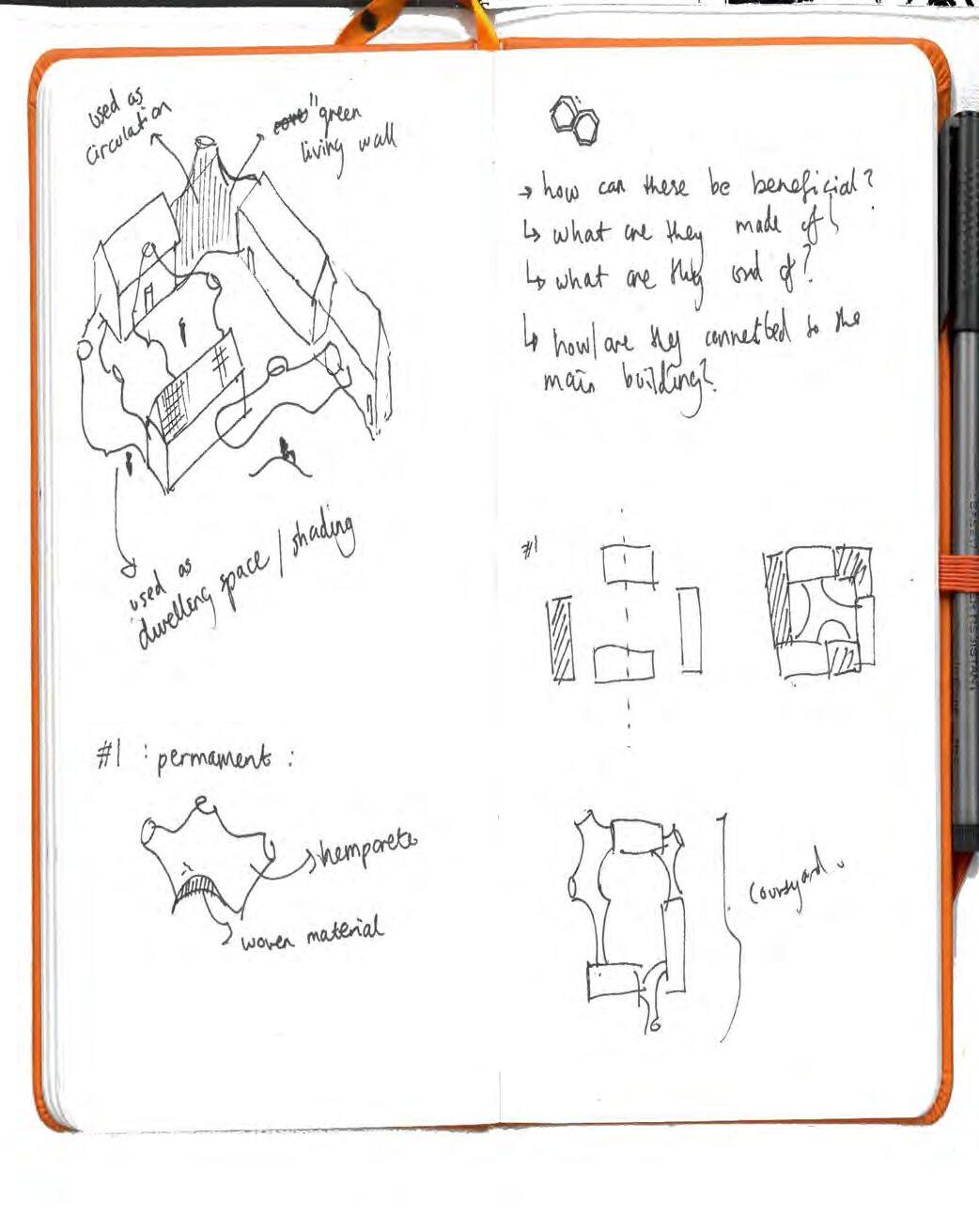

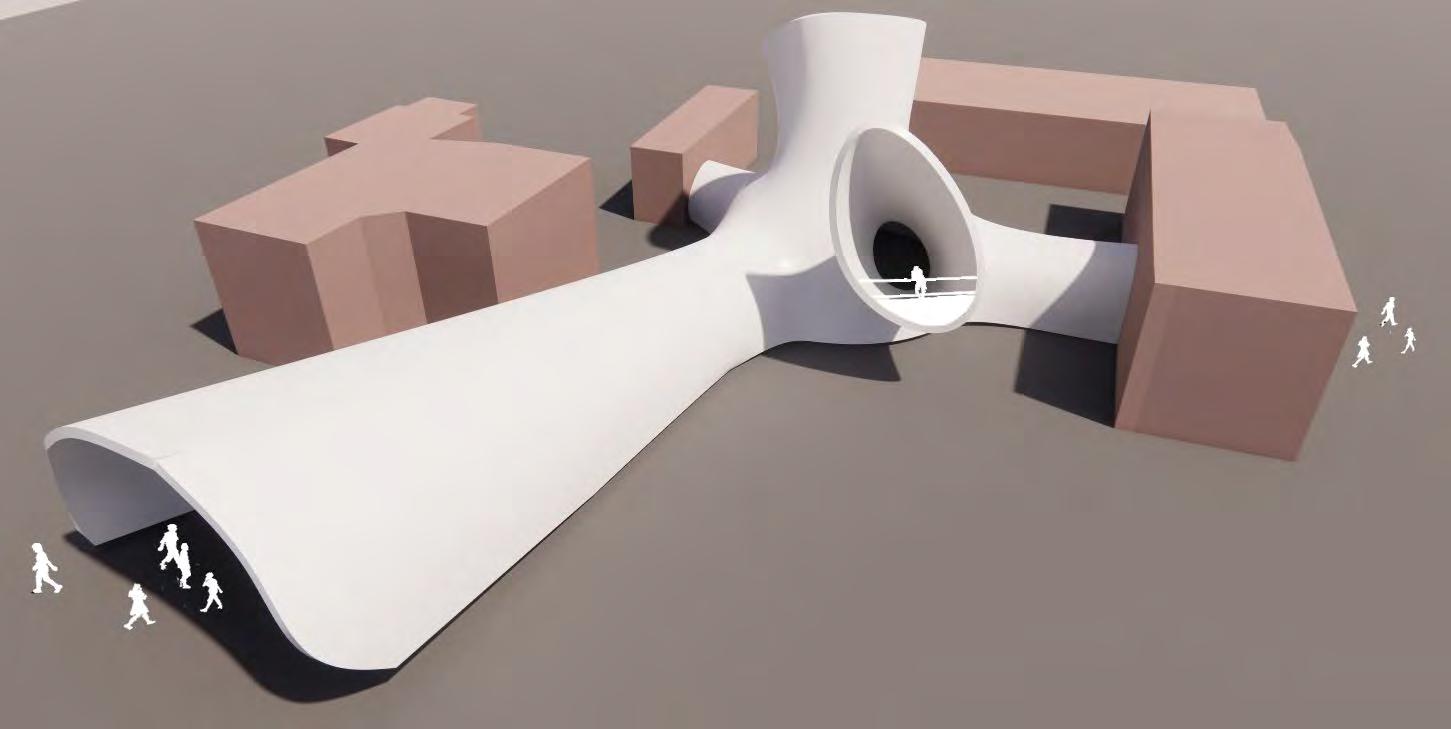

Returning to previous drawing from 3.1, was motivated to push its boundaries and move beyond standalone structure on the site. Inspired by the concept of parasitic architecture, embarked on an exploration of new possibilities. The idea was to create a network of interconnected tubes that would cleverly attach themselves to the existing buildings, serving as circulation paths, entrances, and potentially even housing the program within them. By embracing this approach, the tubes not only establish a unique relationship with the site’s surroundings but also unlock myriad of benefits. The strategic placement

STUDIO 3.2 19 STUDIO 3.2 Design Journal Precedent Study

Design Journal Parasitic Architecture

CONCEPTUAL PLANS

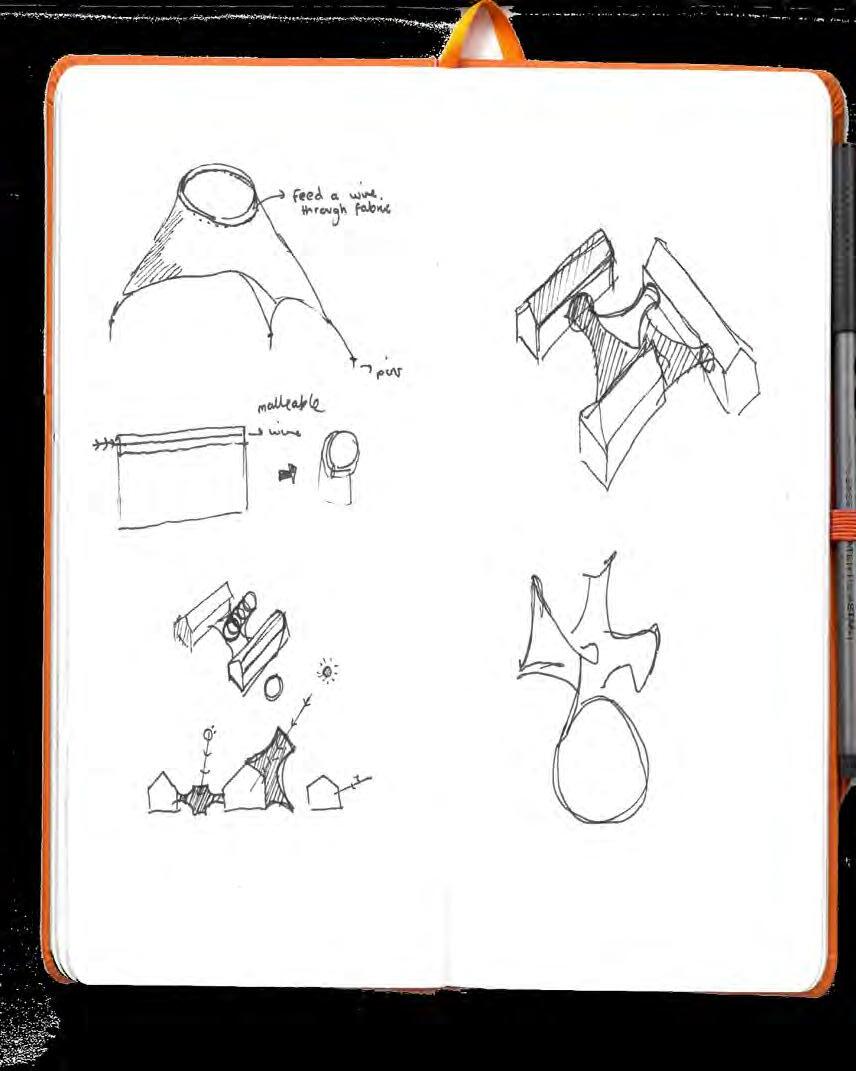

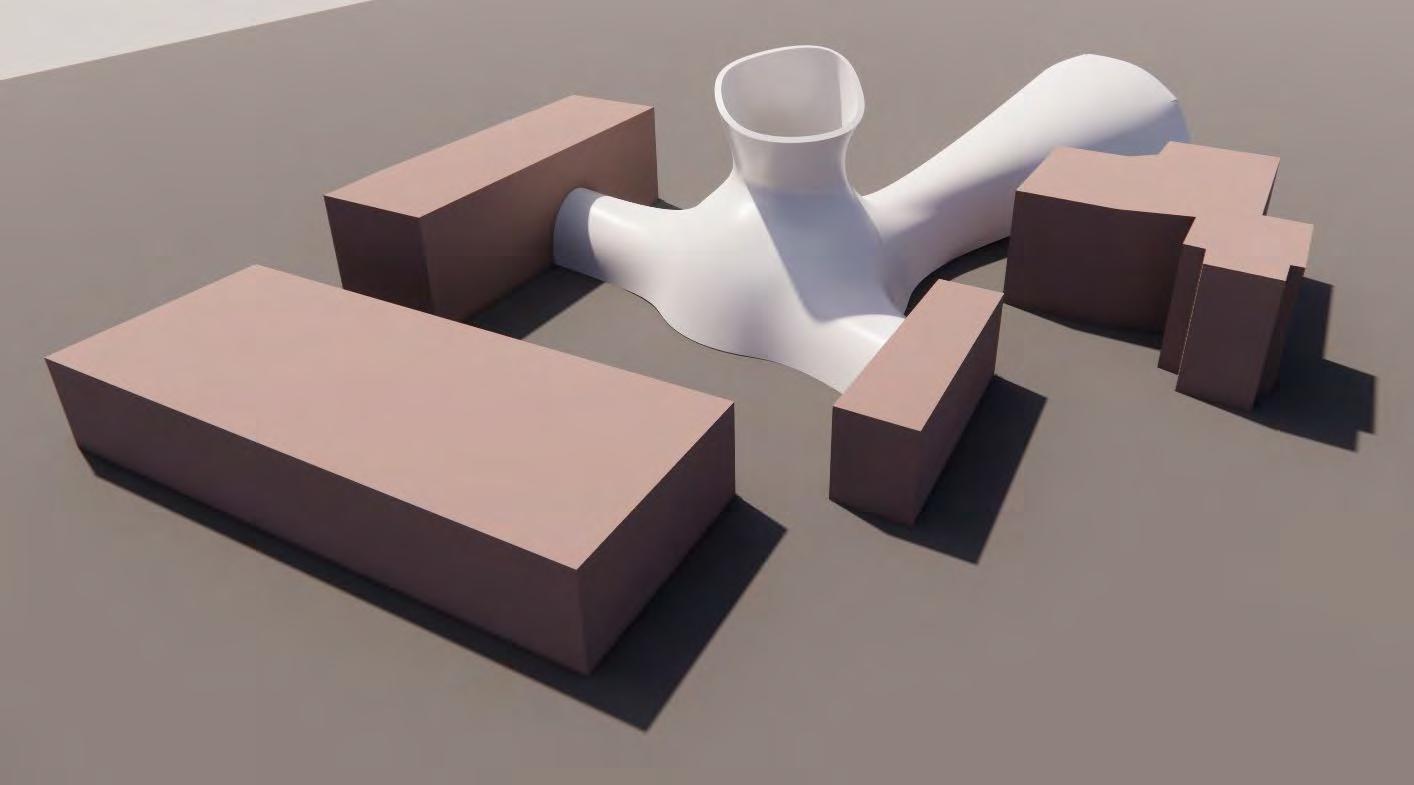

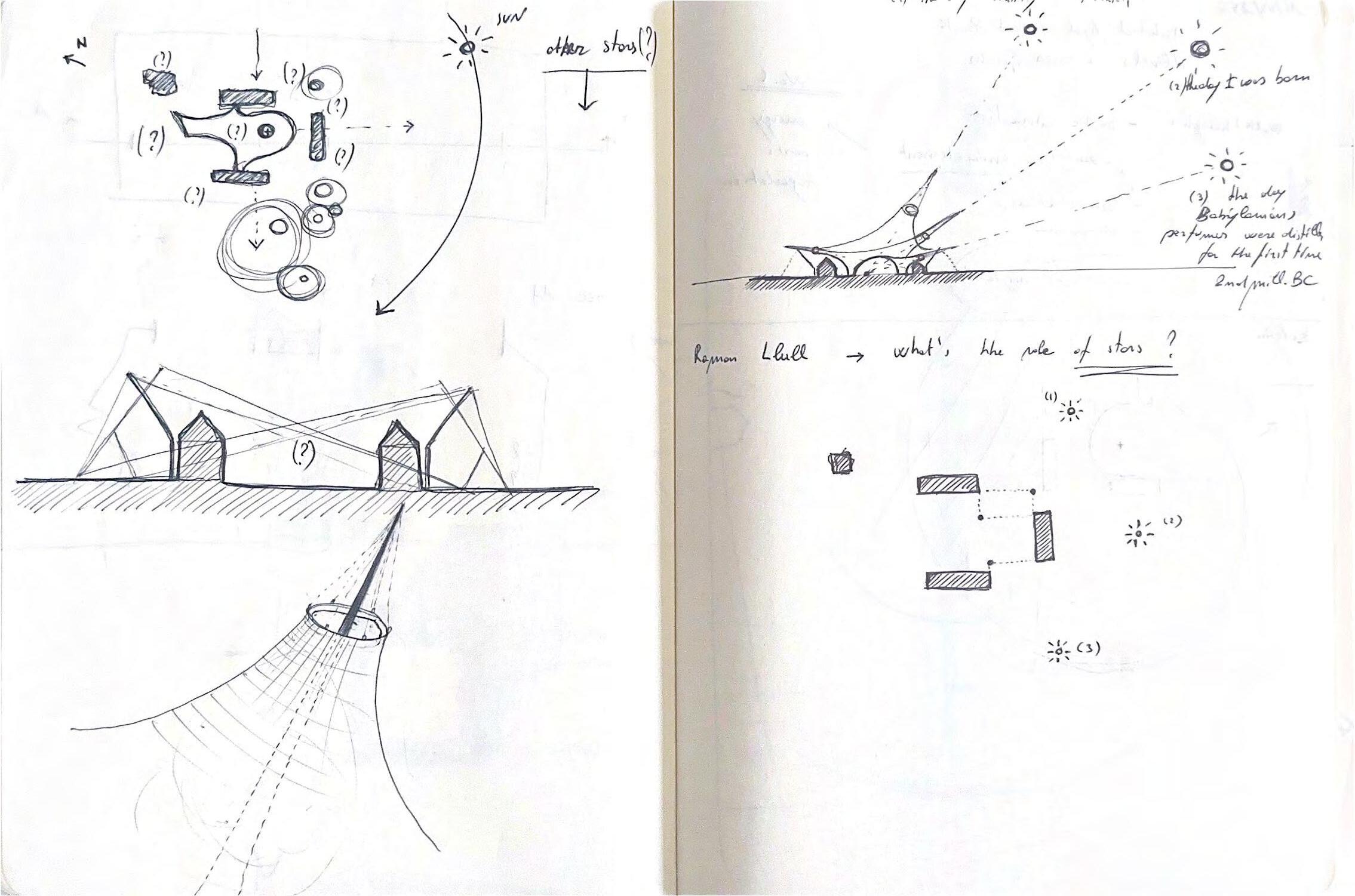

After thorough exploration of the initial intervention, found myself grappling with the structural challenges it presented. Even the structural engineers who visited raised questions about its feasibility, compelling me to seek alternative solutions. was during this phase of reconsideration that delved into the realm of tensile structures. Tensile structures, with their ability to assume organic shapes, emerged as a compelling option. Not only could they seamlessly integrate ventilation, daylighting, and other desired features, but they also offered the advantage of delicately balancing themselves along the edges of the existing buildings. This innovative approach allowed for the creation of an inner courtyard, a tranquil oasis that would be shielded from external elements. By embracing the concept of the tensile structure, found a more harmonious solution that preserved the distinctive silhouette of the site. It offered a structurally viable approach, addressing the concerns that had surfaced with the previous design. Moreover, this new direction promised to bring forth an enhanced architectural experience, where the interplay of light, form, and functionality would intertwine to create a captivating space.

STUDIO 3.2 20 STUDIO 3.2 key Public entrance/exit Staff entrance/exit Public circulation Staff circulation

4 2 3

2.

3.

4.

6000mm 19200mm 3200mm 11000mm 9700mm 28000mm

1. Reception

Warehouse

Museum

Distillery

Design Journal Opportunites and Constraints Design Journal Drafting

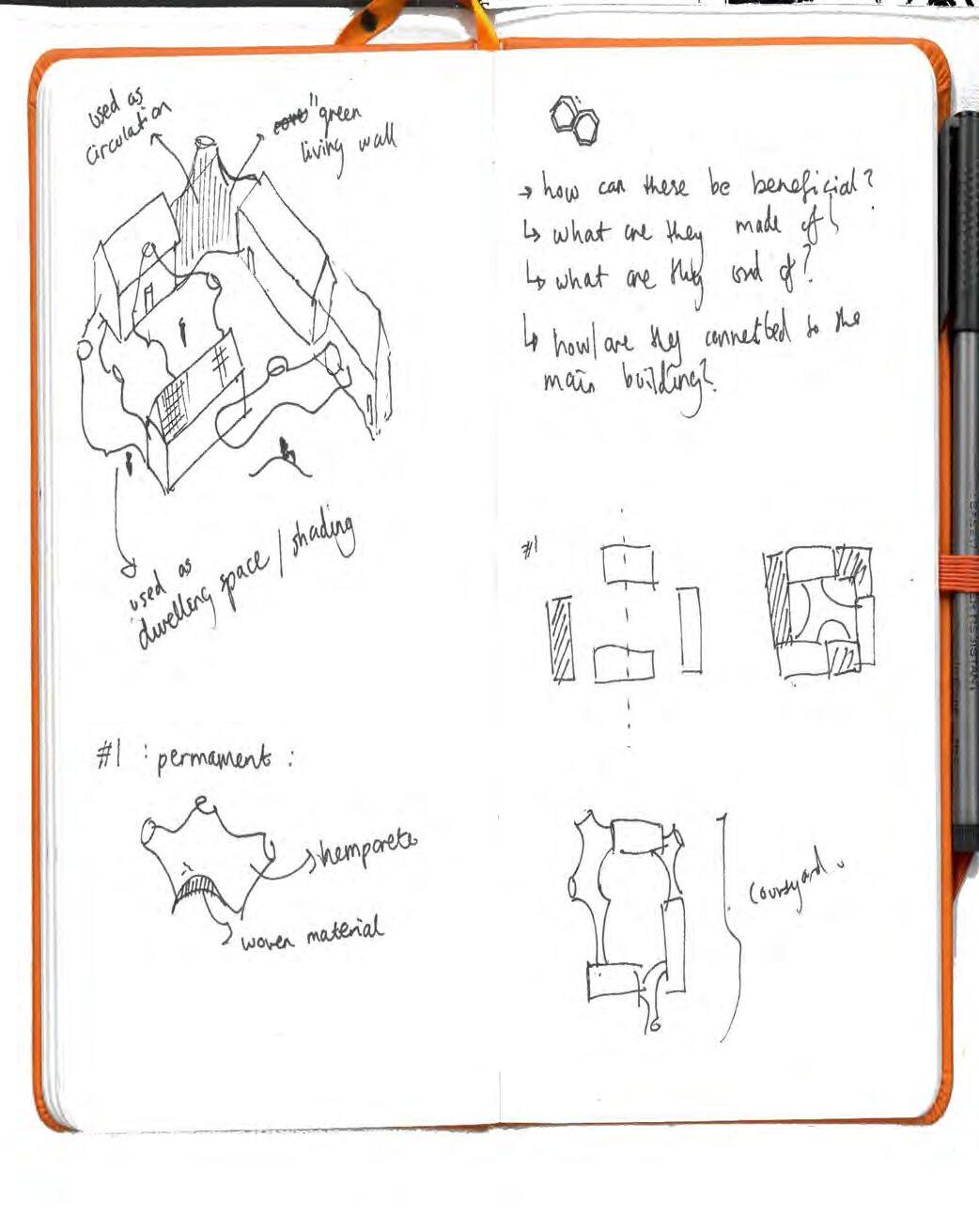

After exploring the possibilities offered by tensile structures, realized the importance of refocusing on the project brief. recognized that had deviated from the original path and needed to reassess how the distillery would function as whole: its program, spatial organization, the interplay between different areas, and the overall impact on the public realm.

To realign my approach, decided to re-frame the organic forms as canopies, understanding that their role should be primarily to provide shade and shelter.

With this in mind, shifted my attention towards retrofitting and re-purposing the existing buildings on the site. My aim was to re-imagine how the program could be accommodated within these structures and to envision the journey that visitors would experience.

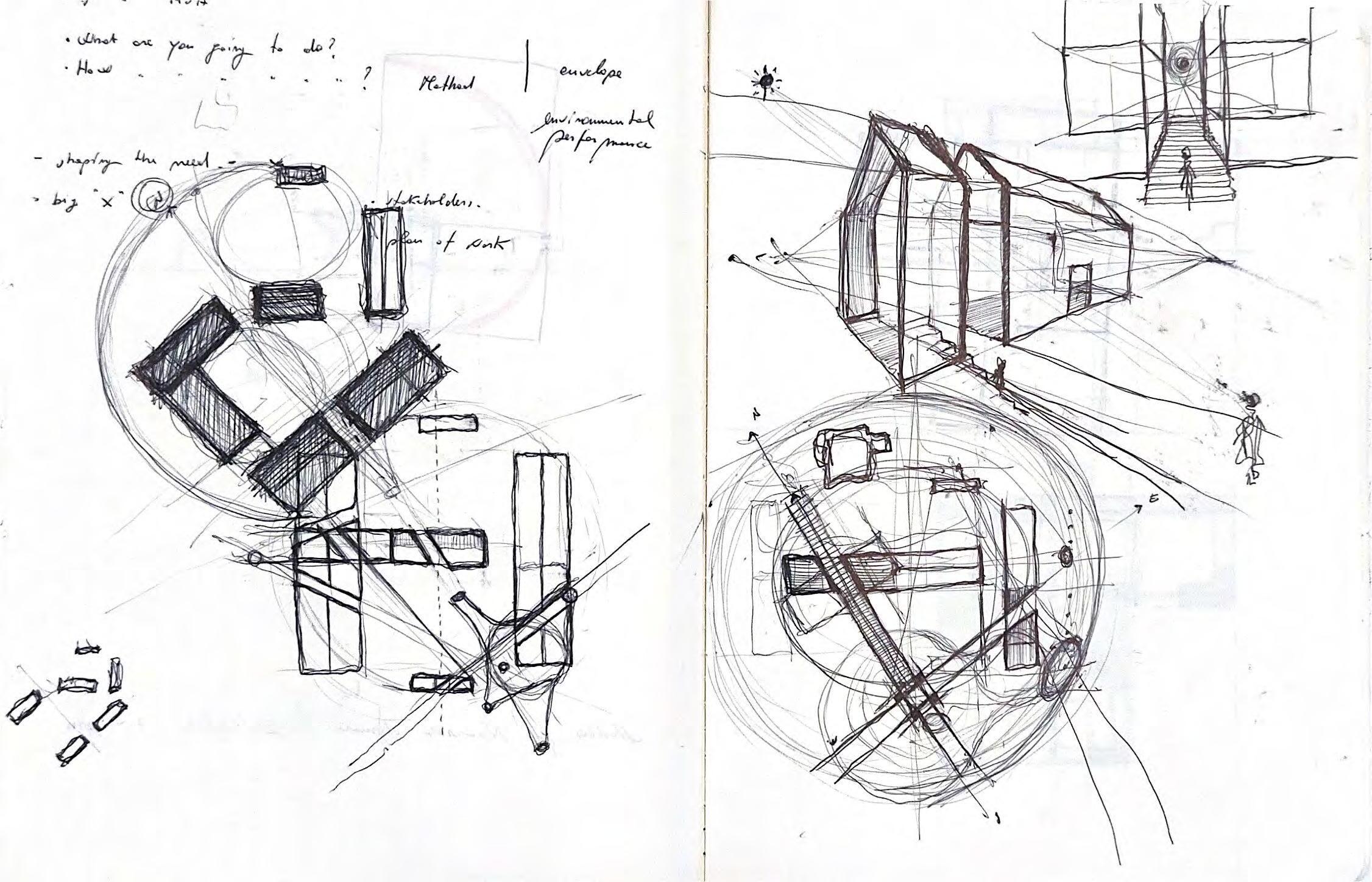

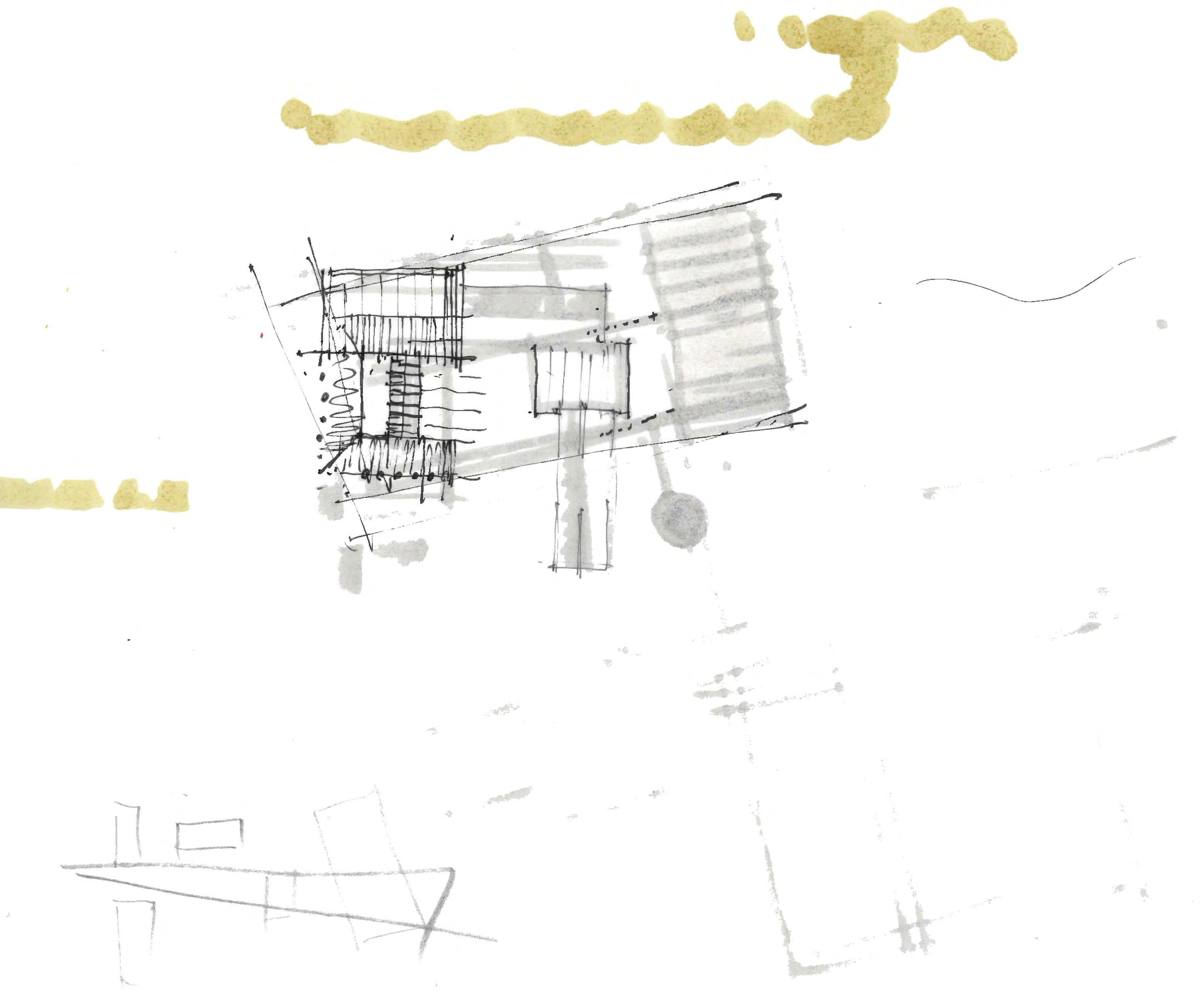

Through series of sketching sessions, explored various iterations, constantly experimenting with different layouts and versions. This process allowed me to play with the composition of spaces, considering how could break them up or selectively add or remove elements to align with the project brief. Each sketch served as a stepping stone, guiding me towards finding the optimal arrangement that would best fulfil the requirements of the distillery.

By immersing myself in this iterative design process, sought to uncover innovative ways to enhance the existing buildings, ensuring they harmonized with the project’s goals and aspirations. The goal was to create an engaging and functional environment that would captivate visitors and seamlessly integrate the distillery’s program into the site’s fabric.

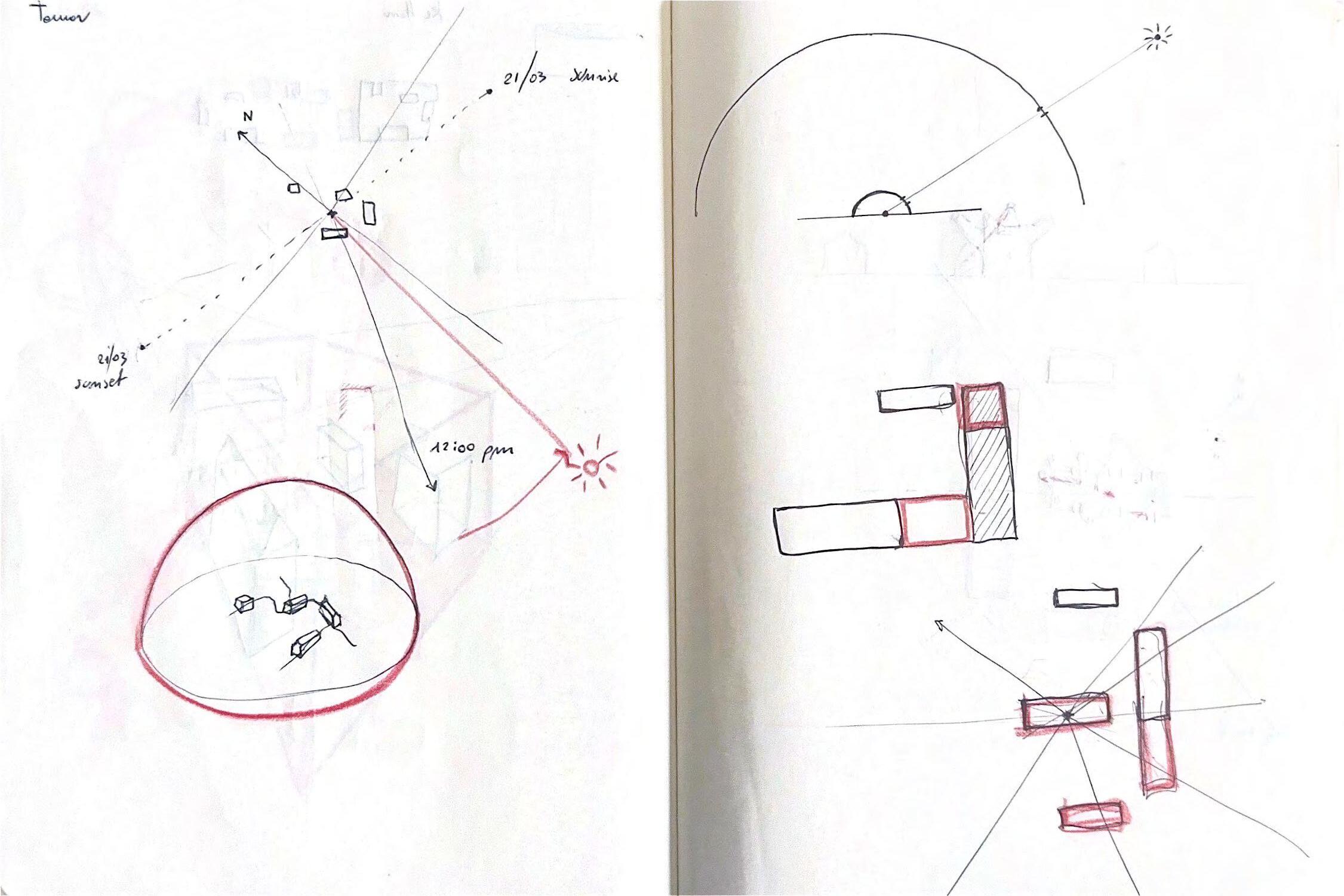

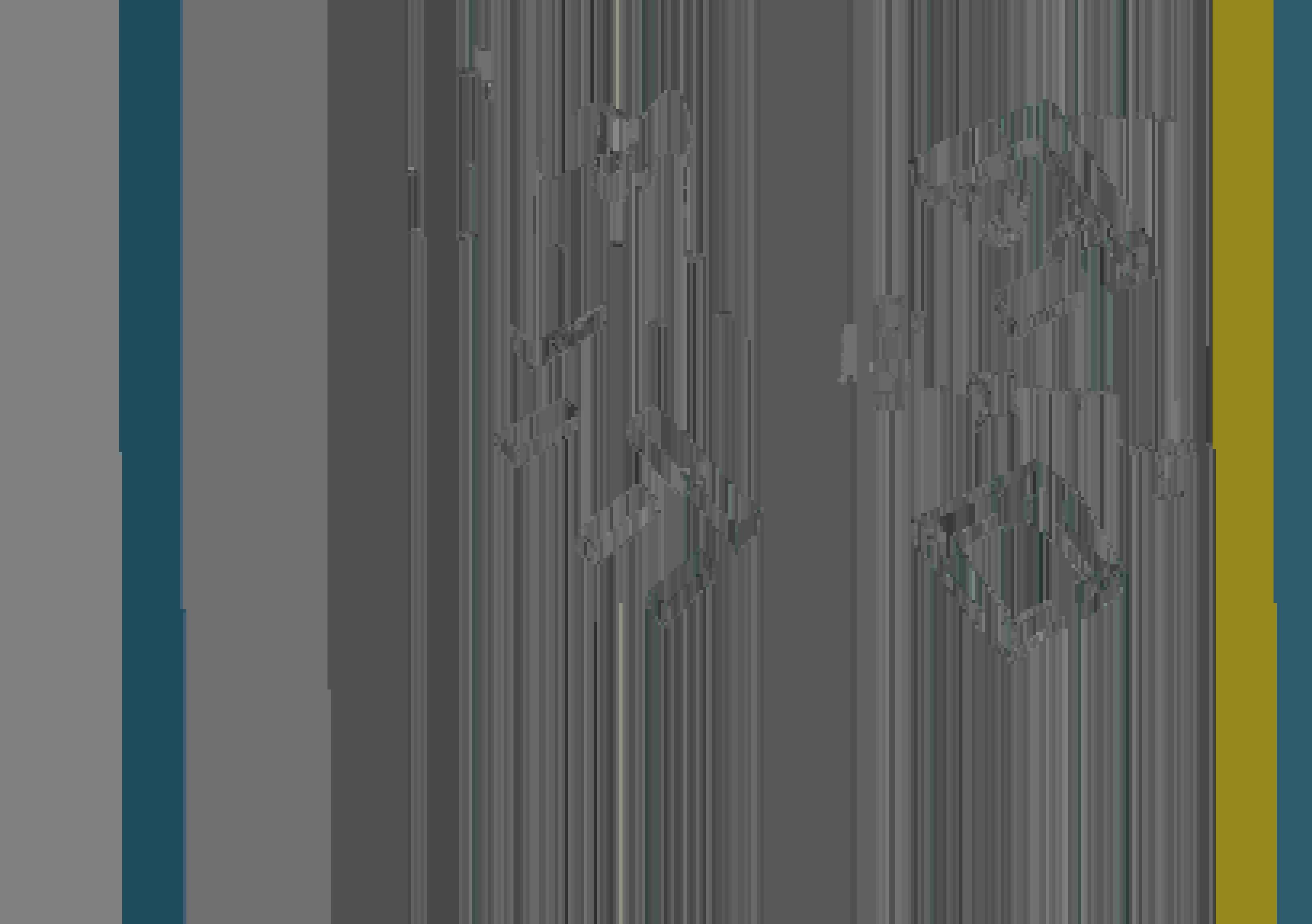

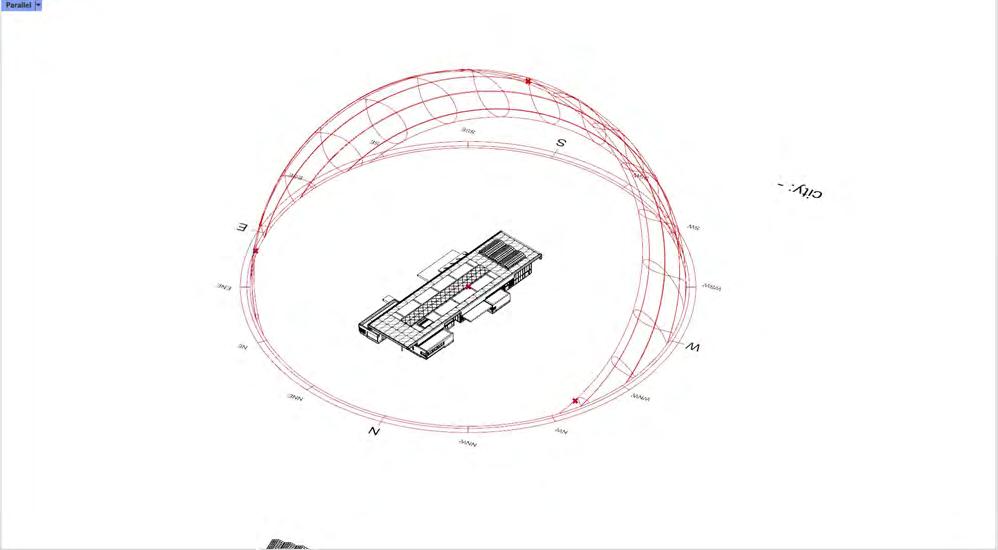

In my pursuit to accommodate the desired program within the existing site buildings, realized that additional extensions would be necessary. It became evident that relying solely on the original structures would limit the possibilities. To explore this avenue further, embarked on sketching numerous variations of layouts, focusing on the relationships between the buildings and considering influential factors such as sun paths, circulation patterns, and key vistas.

By incorporating extensions, aimed to seamlessly connect the different structures, ensuring a cohesive flow and optimal utilization of space. These extensions became an opportunity to create transitional zones and forge meaningful connections between the existing buildings, enhancing the overall functionality and aesthetic appeal of the distillery.

Throughout the sketching process, carefully considered the interplay between the new and existing elements, seeking balance that would seamlessly integrate the extensions while preserving the unique character of the site. paid particular attention to how the sun’s path would interact with the spaces, ensuring ample natural light and creating pleasant environments for visitors.

Additionally, examined circulation patterns, strategically designing pathways that would guide visitors through the distillery, highlighting key features and fostering a sense of exploration. The consideration of key vistas allowed for the framing of captivating views, ensuring that the architecture harmonized with the surrounding landscape.

By meticulously studying and iterating upon these factors, endeavoured to create cohesive design that not only fulfilled the program requirements but also responded sensitively to the site’s context, resulting in a captivating and well-integrated distillery experience.

STUDIO 3.2 22 23 STUDIO 3.2

Design Journal Spatial Agency Design Journal Retrofit

THE JOURNEY

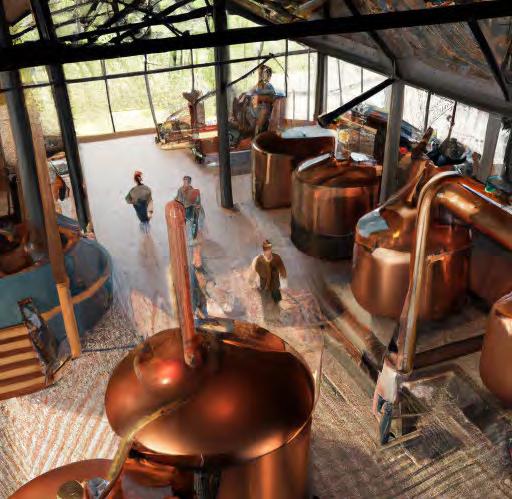

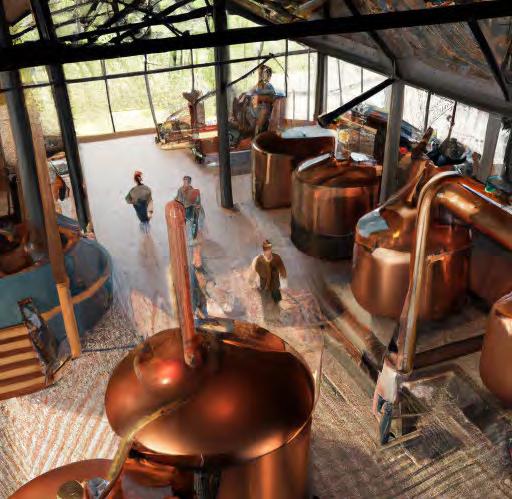

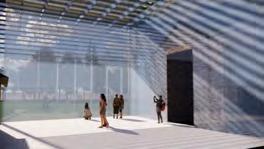

As you walk along the glass balcony, you’re treated to a captivating view of the distillery below. The balcony offers vantage point overlooking the gleaming copper stills, where the magic of whiskey distillation takes place. The rhythmic movements of the stills catch your eye, their polished surfaces reflecting the ambient light in mesmerizing patterns.

Nestled within the cozy confines of the intimate whiskey bar, you find yourself immersed in realm of flavors waiting to be discovered. Surrounded by like-minded enthusiasts and guided by knowledgeable staff, the tasting experience becomes an engaging and enlightening conversation.

A road stretches ahead, flanked on both sides by a beautiful boulevard of trees. The road is lined with lush greenery and a canopy of branches, creating a serene and inviting atmosphere. On this road, there are cyclists and pedestrians enjoying a leisurely stroll, walking towards the entrance of a distillery that resembles a French château house.

The ambience within the space exudes unique tranquility and serenity. The combination of the soft lighting, the gentle creaking of wood, and the comforting scent creates an atmosphere that invites you to pause, reflect, and appreciate the craftsmanship and artistry that goes into every barrel of whiskey.

As you stroll along the orderly rows of whiskey barrels, a mesmerizing scene unfolds before you. Sunlight streams through the expansive windows, casting warm beams of light that illuminate the space and create a play of shadows among the barrels. The gentle interplay of light and darkness enhances the allure of the surroundings, enticing you to immerse yourself in the experience.

STUDIO 3.2 24 25 STUDIO 3.2

Design Journal Vignettes

Design Journal Iterative Development

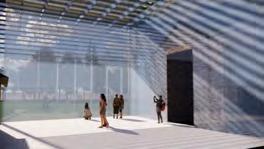

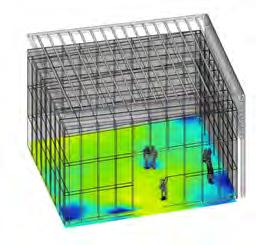

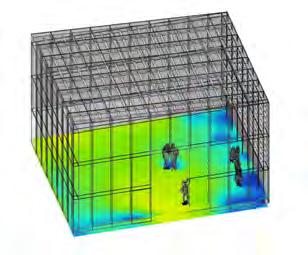

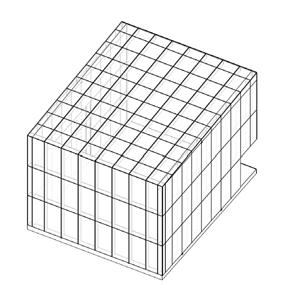

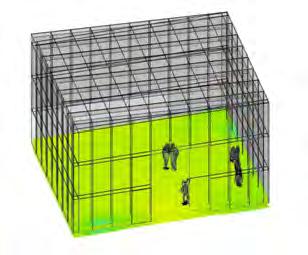

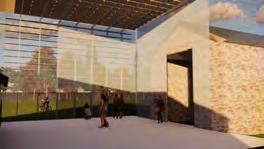

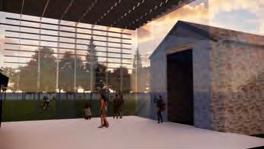

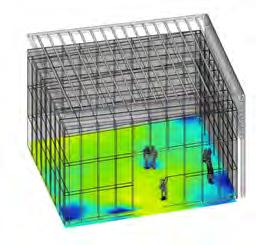

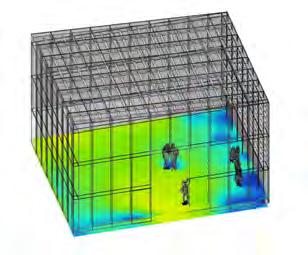

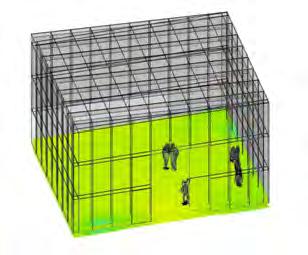

The primary goal is to create a well-ventilated and comfortable environment that seamlessly connects the new and old elements. To house the heat-producing distillation equipment, a glass extension is chosen, emphasizing the need for meticulous controls and strategies to maintain a constant and pleasant internal temperature.

PRECEDENT STUDY

Carlo Scarpa's work was characterized by his meticulous attention to detail, innovative use of materials, and a deep understanding of the historical context and craftsmanship of the Venetian region. He sought to create harmonious and poetic spaces that seamlessly integrated modernist principles with traditional architectural elements.

One of Scarpa’s key focuses was the exploration of spatial relationships. He carefully considered how people would experience and move through his buildings, paying attention to the flow of spaces and the interaction between indoor and outdoor environments. His designs often featured interconnected courtyards, intimate gardens, and carefully framed views that enhanced the overall sensory experience.

Scarpa was also known for his innovative use of materials. He had deep understanding of their properties and capabilities, and he employed them in unique and unexpected ways. He combined traditional Venetian materials, such as marble, terrazzo, and glass, with modern materials like concrete and metal, creating a dialogue between the old and the new.

Scarpa’s work can be characterized as unique blend of modernist design principles, traditional Venetian craftsmanship, and deep sensitivity to the spatial experience. His designs continue to inspire and influence architects and designers today, and his buildings are recognized as masterpieces of 20th-century architecture.

STUDIO 3.2 26 27 STUDIO 3.2

Carlo Scarpa

“creating a dialogue between the old and the new.”

“modernist principles with traditional architectural elements.”

Design Journal Technology Design Journal Precedent Study

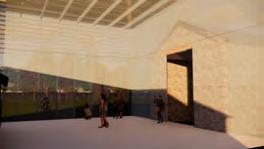

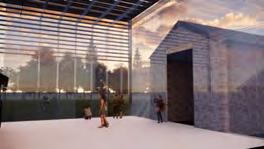

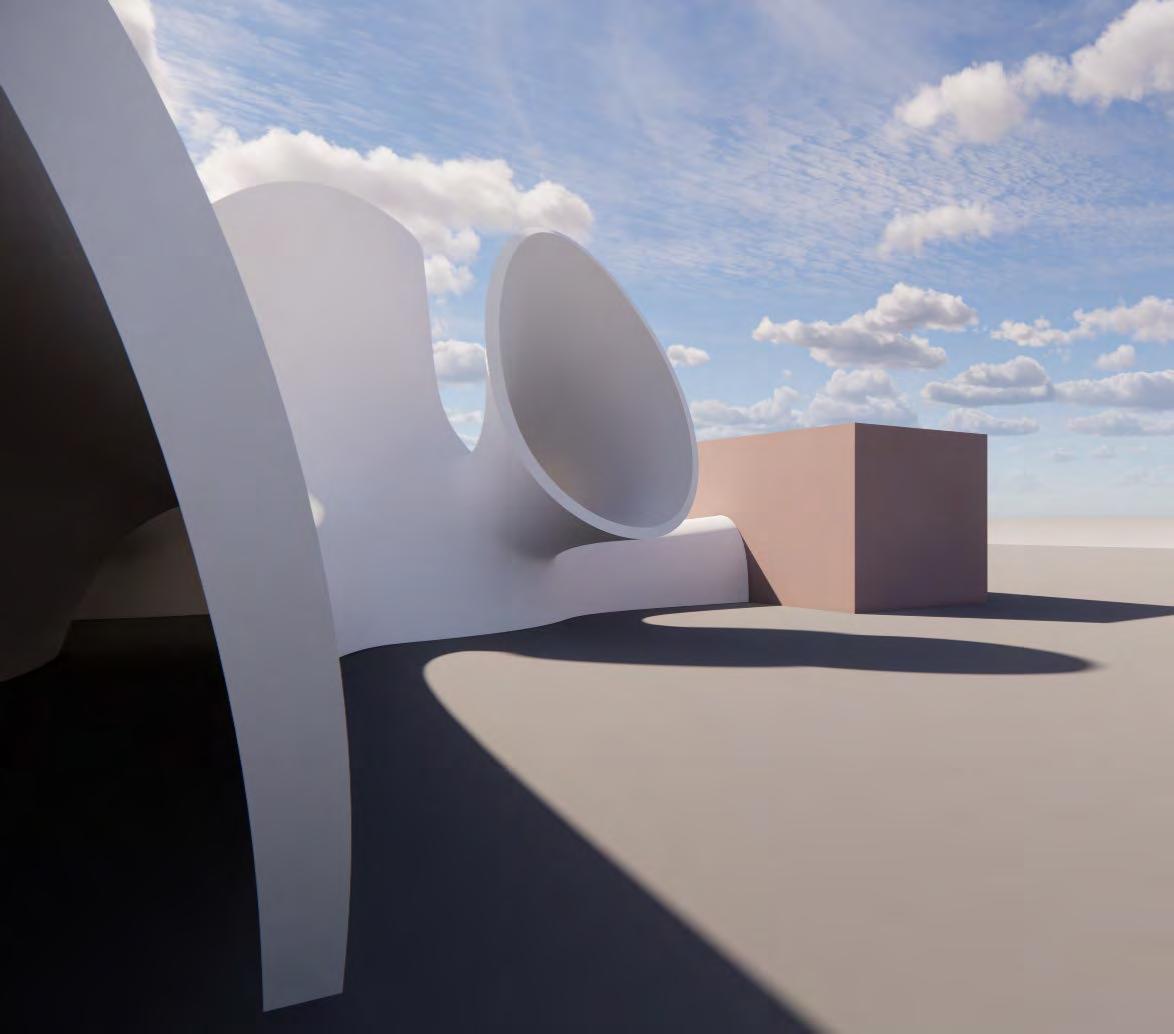

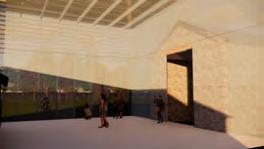

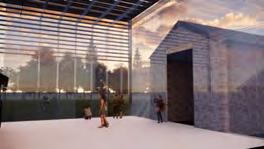

In order to gauge the visual impact and the interplay of elements, conducted tests and created renders that showcased the proposed forms and new additions to the existing buildings. These renders allowed me to explore how light would interact with the spaces and helped me determine the most suitable materials to enhance the overall aesthetic.

One particular focus was the introduction of a glass box that gracefully protruded between the two adjacent buildings. This architectural feature aimed to create a dynamic visual statement, drawing attention to the harmonious fusion of old and new. Through the renders, sought to capture the captivating image that this juxtaposition would generate, immersing viewers in a visual narrative that celebrated the integration of contemporary design within the existing context.

Light played pivotal role in these renders, as it revealed the intricate play of highlights and shadows, emphasizing the sculptural qualities of the glass box. carefully considered how natural light would filter through the transparent surfaces, casting mesmerizing reflections and illuminating the surrounding spaces. The interplay between light and the architectural elements became key factor in shaping the desired ambiance and the overall mood of the environment.

Materials also took centre stage in the rendering process, as they greatly influenced the visual impact and tactile experience. explored various options, contemplating how different textures, finishes, and colours could complement the existing buildings and create a cohesive visual language. By experimenting with materials, aimed to strike a balance between continuity and contrast, seamlessly integrating the new glass box while respecting the historical fabric of the surroundings.

Through these visualizations, sought to transcend the realm of imagination and bring the proposed design concepts to life. The renders allowed me to immerse myself and others in vivid representation of the envisioned interplay between old and new, unveiling a captivating image that conveyed the essence of the architectural transformation.

STUDIO 3.2 28 29 STUDIO 3.2

Design Journal Testing With Renders Design Journal Development Sketches

PRECEDENT STUDY

Lady Of The North

Northumberlandia, also known as the “Lady of the North,” is a unique and iconic land sculpture located in Northumberland, England. Designed by renowned artist Charles Jencks, Northumberlandia is an ambitious earthwork creation that merges art, landscape architecture, and environmental conservation.

The sculpture takes the form of a reclining female figure, measuring approximately 100 feet in height and spanning over 1,300 feet in length. It is sculpted from the surrounding landscape, utilizing around 1.5 million tons of earth and rock to shape the contours of the figure. The land form is carefully crafted to mimic the shape of a reclining woman, with undulating curves and contours that create a sense of graceful elegance.

Northumberlandia serves as a striking symbol of the region’s rich heritage and celebrates the beauty of the natural landscape. Visitors are encouraged to explore the sculpture by walking along designated pathways that wind through the various mounds and valleys, providing different perspectives and viewpoints of the artwork.

Beyond its aesthetic appeal, Northumberlandia also serves an important ecological purpose. The site includes a carefully designed network of ponds, wetlands, and woodlands, providing a habitat for a diverse range of plant and animal species. The sustainable landscaping techniques implemented during its construction prioritize conservation and biodiversity.

The architecture of Northumberlandia is unique in its blend of artistry and environmental consciousness. It represents an innovative approach to land art, where the landscape itself becomes a canvas for artistic expression. By combining natural and man-made elements, the sculpture creates an immersive experience that engages visitors with the surrounding environment.

Northumberlandia has become a popular visitor attraction, drawing people from near and far to appreciate its beauty and explore the surrounding parkland. The site offers a tranquil setting for leisurely walks, picnics, and enjoying panoramic views of the surrounding countryside.

Overall, the architecture of Northumberlandia showcases the potential of blending art, nature, and sustainability in a harmonious and captivating way, leaving a lasting impression on all those who encounter this magnificent land sculpture.

Drawing inspiration from the intriguing precedent of Northumberlandia and its integration with the natural landscape, embarked on my own creative endeavor. Instead of removing the existing dirt mounds found on the site, which disrupted the environment, envisioned a unique approach that would harness their potential to enhance the landscaping and prioritize conservation and biodiversity.

My design concept involved carving out the shapes of these preexisting mounds, transforming them into purposeful elements that contribute to the overall aesthetics and functionality of the site. By carefully sculpting the mounds, aimed to create visually engaging forms that seamlessly blend with the surrounding environment, while simultaneously serving as habitats for various plant and animal species.

Incorporating principles of sustainable landscaping, envisioned the introduction of playful gardens within the carved-out mounds. These gardens would offer a delightful experience for visitors, providing spaces for relaxation, exploration, and interaction with nature. Each garden area would be carefully curated, showcasing a diverse array of plant species, native flora, and possibly even sculptures or installations that harmonize with the natural surroundings.

By repurposing the existing mounds and integrating them into the overall design, sought to strike a balance between environmental preservation and human enjoyment. The playful gardens would not only enhance the aesthetic appeal of the site but also encourage visitors to engage with the landscape in a meaningful and sustainable way.

Moreover, the integration of these carved-out mounds would contribute to the conservation and biodiversity goals of the project. The varied topography, combined with strategic planting schemes, would create microhabitats that support a range of plant and animal life, fostering ecological resilience and promoting a healthy ecosystem.

In this way, my design aimed to build upon the spirit of Northumberlandia while offering a fresh interpretation that showcases the potential of repurposing existing elements for environmental enhancement. By preserving the site’s unique features, incorporating playful gardens, and prioritizing conservation and biodiversity, my vision sought to create a harmonious and immersive experience that celebrates the beauty of nature and engages visitors in a sustainable and enjoyable manner.

STUDIO 3.2 30

“sustainable landscaping techniques implemented during its construction prioritize conservation and biodiversity.”

Design Journal | Landscaping Strategy

Overall Massing & Form:

The building is a single storey, long and narrow rectangular building with protruding blocks and large cantilevers along the north, NE and south sides. The NE-SW orientation is crucial in ensuring maximised sunlight infiltration and solar gain.

The East-West orientation to avoid heat lossminimal north facade.

During hotter seasons, the shorter sides receive the most light thus reducing the chance of overheating via passive solar gain.

Arrangement:

Open floor plan with pods catered to specific programmes. There is accessibility to all these spaces. The building is designed predominantly as one open space, allowing visitors to flow between the various uses: ticketing, learning, retail, plant sales, and café.

WINTER THERMAL COMFORT (DAY) SUMMER THERMAL COMFORT (DAY)

ELECTRICAL SYSTEMS

Services containment rises centrally through the 16 columns and via the mullions. From here it runs along channels concealed in the underside of the glulam beams to serve the lighting, WiFi and CCTV and provide future flexibility. Ambient lighting is achieved with a combination of up- and down-light luminaries mounted on the structural columns. To minimise electrical containment, there is wireless technology and an embedded slimline wiring containment system into the soffit. Natural light permeates the building either through Siberian Larch louvred curtain walling or filters through the diagrid roof via two roof lights, one running centrally 6 metres wide x 54 metres long and one 18 metres wide x 12 metres long creating a glasshouse environment.

PLUMBING SYSTEMS

HEATING, COOLING & VENTILATION

To preserve the clean lines of sight across the space, there is a mechanical ventilation and heat pump system plant above the appropriate pods. To meet the 1m height limit needed to preserve the view outdoors along the main retail area, they had to design bespoke plant solutions. With respect to the view of the building from the surrounding landscape, the use of a ground source heat pump system, rather than roof-mounted condensing units, permitted a wild flower green roof which is a key part of the design. The head pump leads to bore holes in the car park which avoid the need for flues or other elements to the plant room There is also underfloor heating to have a cleaner look vs. ducting strategies.

Thermal control: the main challenge is in achieving maximum thermal performance as the large proportion of glazing will result in higher rates of heat loss.

1. Passive strategy: thermal mass, double-skin glazing, airtightness and continuous insulation.

2. Active strategy: underfloor heating, brise soleil. T building embraces environmental considerations with ground source heat pumps providing 80% of requirements.

Daylight control: challenge in controlling daylight with a glazed facade and a large central roof light. The brise soleil modulates the light so that it does not create glare for users. They diffuse and reflect light to reduce overheating, which rise to a maximum angle of 62 degrees in the UK.

Evaluations:

Provide rainwater and grey water recycling: The building rainwater capture and storage system. This water is used for irrigation purposes within the garden. Also, a greywater recycling system that collects and treats water from handwashing facilities, showers, and other non-toilet sources. This treated water is then reused for flushing toilets.

Design spaces that are inclusive and universal accessible: There are incorporated accessible design features, such as ramps, lifts, and accessible toilets. There is step free access throughout, including the private staff areas, with all public doors meeting or exceeding building regulation requirements.

Fine tune internal environment with efficient mechanical systems: There are implemented energyefficient systems such as LED lighting, building management systems, and efficient heating and cooling systems to reduce energy consumption.

SUSTAINABLE WATER CYCLE

Provide low flow fittings and appliances: The building has water-efficient taps, showers, and toilets to reduce the amount of potable water required.

GOOD HEALTH AND WELL-BEING

Design spaces with good indoor air quality: Sustainable and non-toxic materials, such as low VOC (volatile organic compound) paints and finishes, to promote healthy indoor air quality.

NET ZERO OPERATIONAL CARBON

Demonstrate additionality of off-site renewables: the building has a PPA (power purchase agreement) with a renewable energy supplier. Under the PPA, the building’s

Provide spaces with strong visual connection to outside: There various elements biophilic design that create such as plants, natural light, views of the surrounding greener, and the garden which can help improve the indoor environment’s quality, reduce stress, anxiety and promote feelings of well-being.

The building features a rainwater harvesting system that collects waters rainwater from the roof and stores it for land use. The harvested rainwater is then filtered and treated before being reused for non-potable purposes such as toilet flushing and irrigation. The system consists of a large underground storage tank, which has a capacity of 300,000 litres. The rainwater is collected from the roof through a series of gutters and pipes which are directed to the tank. Once full, the excess water is discharged into the nearby lake. Siphonic drainage is also hidden along the perimeter, dropping to the ground behind the cladding. In comparison to traditional gravity drainage systems which create a whirlpool effect that allows water and air to enter the pipe, a siphonic drainage system prevents air from entering the downpipes. This allows higher volumes of water to drain more quickly from flat roofs, which means fewer, smaller diameter downpipes are required.

WINTER THERMAL COMFORT (NIGHT)

The cold winds during the night provide passive cross ventilation. Less thermal mass stored in the concrete slab during the day, so less energy is released back into the space. The building is unoccupied so the high-level windows could be opened to cool the building.

The new 4750m lake is equipped with a pumping chamber backup to the existing lake provides facility for fire fighting.

1) More efficient as each gutter only requires one or two smaller diameter downpipes, which can be located at the ends of the building. This frees up floor space and eliminates the need for internal underground drainage and significantly reduces the requirement for external underground drainage.

2) Fewer roof outlets and downpipes

3) Shorter pipe lengths takes up less space and reduces installation costs

4) Bracketing system is unaffected by pipe elongation resulting from temperature change resilient

SUMMER SOLSTICE

Sunrise: 04:47 Midday Sunset: 21:28

Evaluation During the winter, although sunlight is weaker, it is more direct due to lower sun angle. This results in dimmer natural light, however a deeper penetration into the main space. The angle of the brise soleil itself means that more light is able to penetrate though, which is advantageous during colder seasons when thermal insulation is necessary. Artificial lighting is required throughout the day, most importantly in the afternoon and evening. The darkest areas are those divided into the pods (i.e. kitchen, office, classroom etc.) because of the lack of glazing and position of interior walls. It may be assumed that artificial lighting supplements these areas. During the summer, the higher angle means that the lighting is somewhat inconsistent, however, due to the large central skylight and orientation, the building is well lit (especially at midday).

1) Theory & Strategy

2) Environmental Design Strategies

energy needs are met by renewable energy that is generated off-site.

responsive local controls: a BMS (building management system) allows for centralized control and monitoring of systems e.g. heating and lighting. The HVAC system uses sensors and controls to adjust ventilation rates based on occupancy levels and air quality, ensuring a comfortable environment whilst minimizing energy use.

Provide

Long section showing horizontal and vertical distribution of services

Lake

Sunrise: 08:01 Midday Sunset: 15:55

06:24 Midday Sunset: 18:12

Sunrise:

SPRING EQUINOX

s s s s s s Create Sustainable Urban Drainage that supports natural aquatic habitats and human amenity: The drainage infrastructure is based around SuDS principles, including a permeable car park construction, filter strips, swales, and a storm water attenuation pond designed to contain on-site the rainwater. Electrical wires Lighting locations Wifi Receiver CCTV Smoke Detector S Column head section showing services containment system Countersunk fixings Light fitting fixed to integrated bracket Galvanised steel strap to support wifi point Galvanised steel fixing plates Polished insitu concrete column Cast in containment Galvanised steel column head Structural timber branches

DETAILED ENVELOPE STUDY Electrical wires Lighting locations Wifi Receiver CCTV Service trench Rooms needing water Cold water Greywater Hot water Heat pump system Underground storage tank Rain Cooling HVAC Plant room Heat pump system Service trench Heating Borehole Reflected ground ceiling plan ii) General Arrangement Services Distribution Service voids: siphonic drainage 394 50 50 Service voids: service trench in slab Winter solstice Summer solstice co2 TAMAR LANG

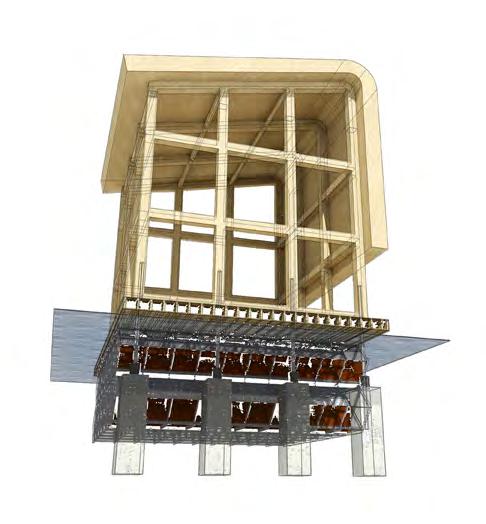

Detailed Assembly/Building Fabric:

With landscape renewal and sustainability at its heart, the project embodies post-pandemic offerings for social engagement and well-being through an intelligently delivered solution to amenity.

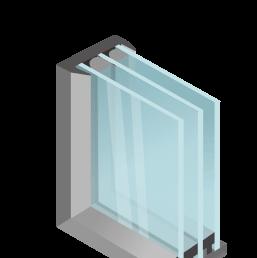

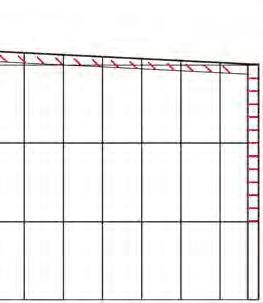

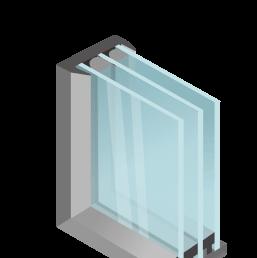

The structural properties of the roof allow for the enclosing elements of the project to be largely ‘infill’ in nature. It provided the opportunity for the wall and roof forms to fold along their edges, responding to site context and uses. Shading canopies extend out, blurring the edge between building and landscape. A triple-glazed roof-light is supported off the roof with mill-finished aluminium curtain wall frames following the diagrid below. Glazing extends from floor to roof to provide glimpses out. This curtain wall structure provides the support, via a series of brackets, for warm Siberian larch cladding and brise soleil, located in response to thermal modelling, site orientation and uses. These glazing areas also allow for high and low-level opening lights to achieve natural cross-ventilation.

The timber roof and extensive timber cladding provide a constant reminder of the environmental aims as well as sequestering about 350 tonnes of carbon in the roof, and a further 27 tonnes in the Siberian larch board cladding. Externally, the cladding to the main body of the building boxes out its horizontal form. It is cut out around entrance glazing or dips down in a lip to provide shading at the end, breaking down the bulk and length of the building, but it also permits glimpses through to the garden and landscape beyond.

A key component of the design was to ensure sustainability was seamlessly integrated into the building using basic ‘fabric first’ principles, with lots of natural light, a green roof and rainwater harvesting complemented with technology controlled through the BMS. Ground source heat pumps fed from boreholes within the car park provide 80 per cent of the building’s heat and some summer cooling, benefiting the RHS with a low-maintenance and visually unintrusive energy source.

The building had to offer the RHS flexibility, hence the an open plan structure which can adapt to changing needs with a mix of retail, catering and welcome facilities all having the ability to expand and contract. Great attention to detail was given to services distribution to be discreetly integrated into the fabric of the structure, which provides conduit and duct runs for retrofitting lighting, communications and power throughout. Additional foundations were included to allow expansion of the structure as visitor numbers rise.

Change Over Time:

Maintenance and replacement:

The rain screen cladding provides many benefits for the entire building. Without it, it is likely that structural repairs will be required on a much more frequent basis, and the extent of damages would be more severe. In the event that there is structural damage to some of the walls (mould, cracks, damp) then individual panels can bee removed to grant access to problem areas. The cladding itself has very low maintenance. If replacement is need, it is very lightweight and can be easily installed quickly without causing a lot of interior disruption. The Siberian Larch has good drilling properties, takes fixings well and has good machining and gluing qualities, making changes to be the brise soleil, internal/external cladding or the decking much easier. The timber is a golden-yellow wood, so if left untreated, it will eventually weather to a silvery-grey. However, this species is incredibly low maintenance so it doesn’t strictly need any treatment or sealing before being installed. The concrete floors will require little maintenance or replacement due to its strong, durable properties. Unless for aesthetic purpose, there is no requirement for coating or painting concrete to protect it against weathering.

Adaptation and Reuse:

Its open floor plan make it adaptable to different uses and allows for greater flexibility with the space. Additional foundations were also included to allow expansion of the structure as visitors rise. The building currently operates efficiently and effectively in use and coping with higher-than-expected visitor demand, testing the robustness of finishes as well as the mechanical and electrical systems. However, the integrated and concealed services may pose an inconvenience if within the 100 year life span they are in need of an upgrade with new and more efficient technologies.

Longevity and Resilience:

The rain screen cladding helps to protect the exterior walls of the building by giving it extra protection against the elements and extending the façade’s durability. It also acts as an in tumescent cavity barrier which greatly reduces the spread of vertical fire. As a result of its extreme native climate, Siberian larch grows extremely slowly. These inhospitable growing conditions make this type of timber very useful and practical particularly for exterior projects. It has greater density than many hardwoods, is highly resistant to knocks, bumps and scrapes, suiting it ideally to exterior applications such as cladding and decking. With fewer abrasions, there are also fewer areas for moisture to penetrate the wood which is very important as Manchester receives a lot of rain. However, snow, ice and UV will eventually damage the wood so the building may benefit from a protection being applied as there currently is none. With the right treatment, this larch could last for over 50 years, and even up to 100 years. Concrete is very resilient, often lasting for many decades without reconstruction work being needed. It also has the ability to store energy, therefore helping to moderate temperatures within the building. As such, heating and cooling demands will reduce, subsequently saving energy costs. Compared to wood, it is also better at resisting the adverse effects of water. Although chemicals in the water can lead to the gradual erosion of the reinforced concrete, which may pose an issue in the future, especially due to its near proximity to the lake.

However, the material can withstand plain water without serious deterioration. Concrete is also quite fire-resistant and stores heat from the environment while withstanding against it for around 6 hours, so in case of a fire, it can allow sufficient time for rescue operatives to arrive.

building can adapt to changing needs and requirements over its lifetime, reducing the need for costly renovations and refurbishments.

Measure energy costs: The building used BIM to create a digital model of the building and apply IES dynamic thermal modelling. By doing this, the architects were able to establish ventilation needs by understanding the combined effects of solar gain alongside the high internal heat gain from lighting and occupancy.

NET ZERO EMBODIED CARBON EMISSIONS

Minimise

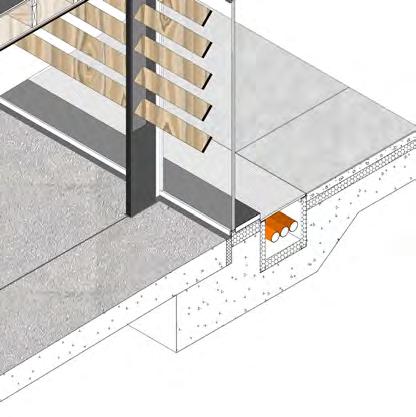

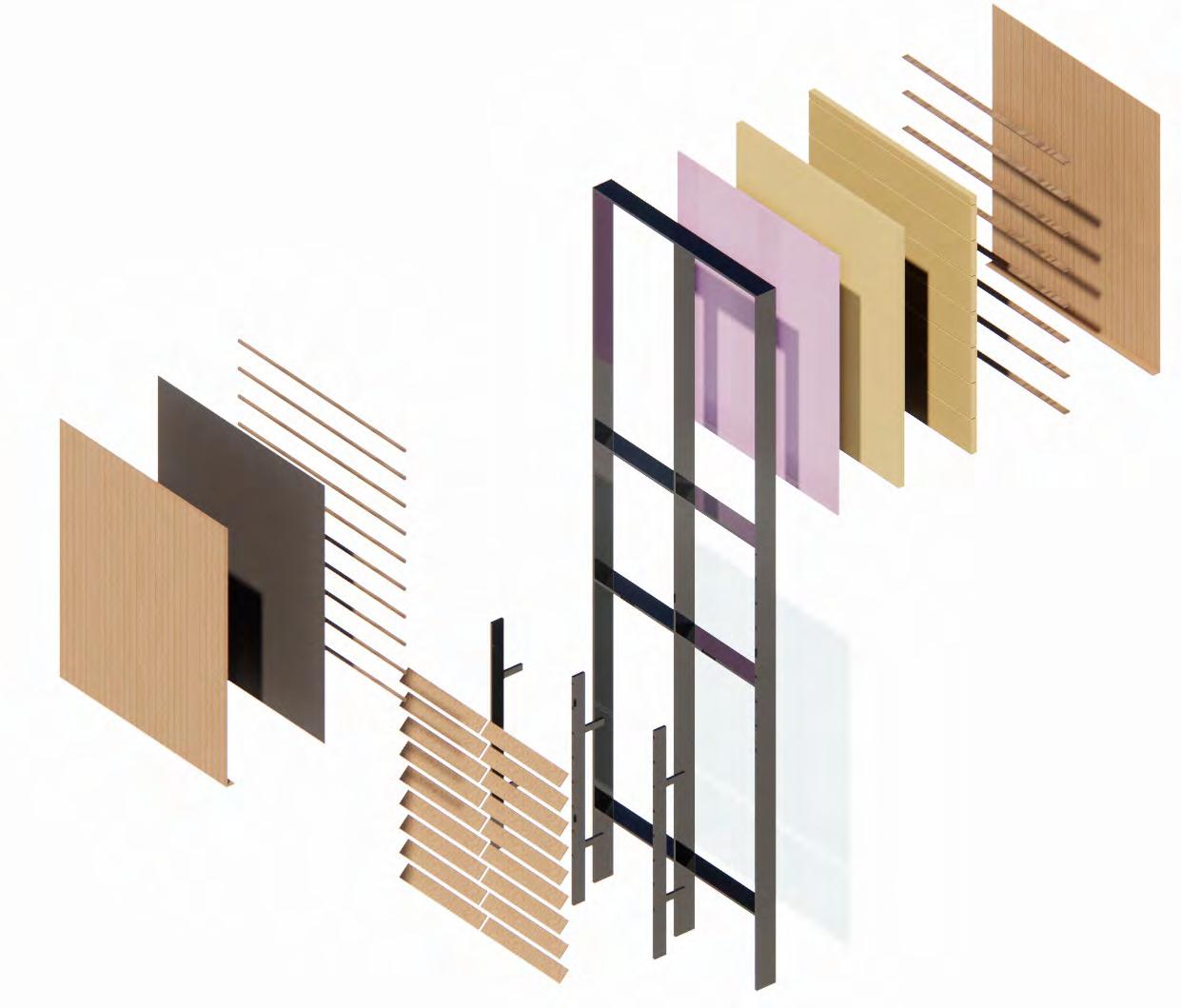

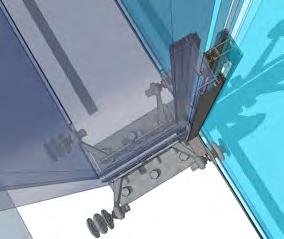

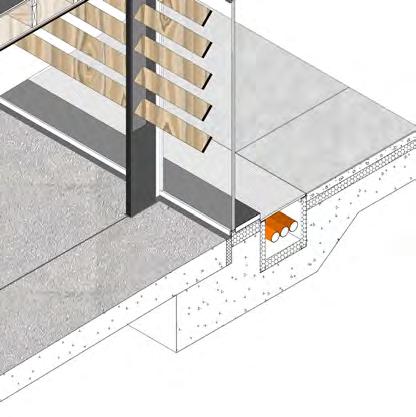

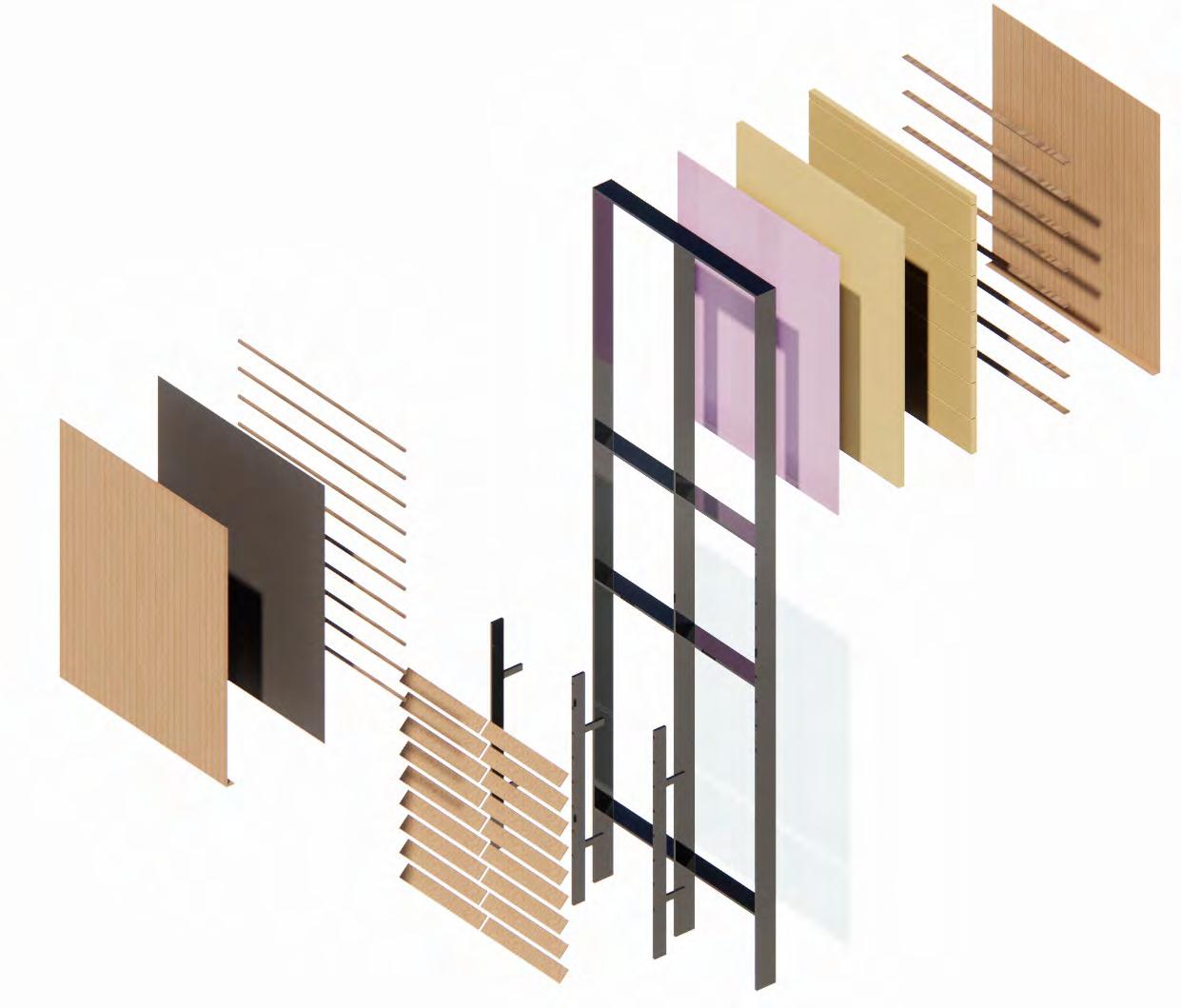

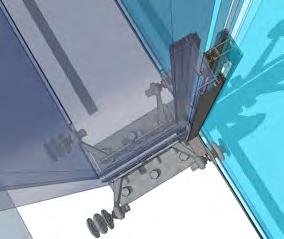

1.Soft joint between timber cladding and roof

2. SFS system between C/W mullion brackets

3. Timber battens

4. Vertical Siberian larch rainscreen cladding

5. Siphonic drainage system

6. Black insect mesh

7. Breather membrane

8. Rigid insulation

9. Canopy primary structure

10. C/W mullion bracket

11. Aluminium clad insulated C/W infill panel 12. Vertical Siberian larch cladding

13. Perimeter timber rafter

14. Grillage roof

1. Curtain walling transom

2. Inward opening window

3. Double glazing

1 SFS (Structural Framing System)

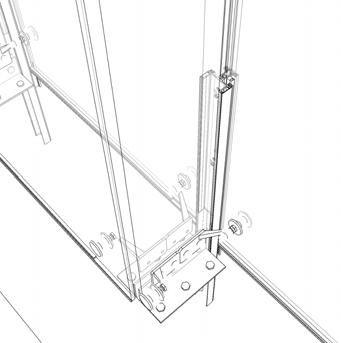

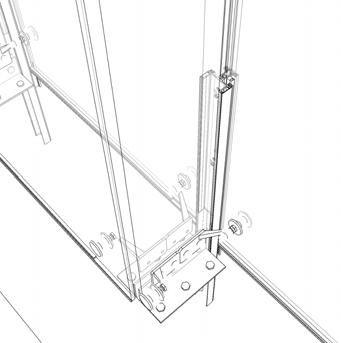

The frame is constructed first by placing the base track along the floor which serves as the starting point for the steel framing. The base track is fixed to the floor using anchors or screws. Steel studs are installed vertically with specific spacing determined by the design specifications. The head track is placed along the top of the wall to support the top of the studs and is then fixed to the ceiling. The horizontal channels are installed.

5

2 Softwood timber battens

Rigid insulation Insulation is then added for thermal protection and as an air and moisture barrier. By placing the insulation on the exterior it has an added advantage of containing the thermal mass of the blocks within the conditioned space.

3 4 180mm acoustic insulation

Acoustic insulation adds mass to stop noise from passing through the structure which is very important in creating a comfortable and healthy interior environment. They are placed prior to the insulation so they can carry the cladding battens directly.

Timber battens are fitted to support the interior timber cladding boards to create a drained and ventilated cavity separating the outer lead from the structural substrate. Softwood is also fairly resistant to bacteria, fungi, termites and moisture, making them ideal for this building which is susceptible to attack. It is also a renewable resource, extremely economical, flexible and versatile, which bolsters their benefits in terms of workability

6 Siberian larch cladding (internal)

Vertical Siberian larch cladding boards are placed for the interior cladding. This type of wood is seen throughout the structure, creating a visual harmony between all the elements.

7 Softwood timber battens Timber battens are fitted to support the exterior timber cladding boards, and to create airflow and water drainage in the cavity.

8 Black insect mesh

Insect mesh is added after to cap off the battens and prevent anything building up in the crucial air flow gap behind the cladding, without restricting any of the airflow It is lightweight and easy to work with, making it an ideal product for keeping insects out too.

9 Siberian larch cladding (external)

Vertical Siberian larch cladding boards are placed for the exterior cladding. This type of wood is stable, so their is minimal movement. Its high density makes it a very durable material for exterior cladding. It also has a high content of natural non-reactive resin, which gives it excellent resistance to rot and decay something which is very important due to the rainy climate in Manchester.

Double glazing:

Double glazed curtain wall is added to reduce the condensation on the inside. The air gap inside the double glazing sandwich helps to keep the internal pane of glass closer to room temperature. Less energy is used to heat or cool a room so it is much more energy efficient, which is extremely important in this building which is mostly glass. Another advantage is noise pollution, such as not letting in outdoor noise and improving the overall security of the building.

12 Siberian larch brise soleil Brise soleil is added last once the main structural elements have been constructed. It averts glare and mitigates overheating - making it more comfortable for occupants inside.

Insect mesh: Important to protect timber cladding as it is susceptible to insect attack which could cause problems such as warping, splitting, rot and decay Siberian larch cladding: Non-combustible and can resist temperatures above 1,000’c, making it ideal fire-retardant for a timber-clad building which is flammable.

Black Insect mesh behind cladding 17. Timber framework 18. Insulated panel glazed in to curtain wall 19. 180mm mineral fibre acoustic insulation 20. Timber framework 21. Siberian larch cladding (internal) 22. Double glazed curtain wall with 40mm T profile cap 23. Single ply membrane to canopy 24. Canopy joists between steel structure 25. Siberian larch soffit 26. Siberian larch brise soleil 27. Canopy steel PPC 28. Movement joint 29. Pandomo Loft cementitious resin floor finish 30. Screed with underfloor heating pipework 31. 80mm rigid insulation 32. 300mm concrete slab 33. Perimeter service trench with rigid insulation to sides and bottom 34. Anodised aluminium grille to service trench 35. Mineral fibre insulation to base curtain wall 36. Double glazed curtain wall with 40mm T profile cap 37. Isolation joint 38. Grey exposed aggregate rocker slab 1. Vegetation 2. Growing medium 3. Water retention fleece 4. Drain mat 5. Root barrier 6. Roof membrane 7. Rigid tapered insulation 8. CLT roof deck 9. European Spruce glued laminated timber roof grillage 10. Siphonic drainage outlet leading to perimeter pipe 11. Steel angle 12. Aluminium roof capping 13. Siberian larch cladding (external) 14. Mineral fibre to head 15. Double glazed curtain wall with 40mm T profile cap

16.

2 6 7 10 11 12 1 5 15 8 9 14 13 3 4

18 17 19 21 22 23 24 25 26 16 20 FLOOR SLABDETAIL 27 28 30 32 33 29 35 37 38 36 34 31 1) Synthesis & Argument ENERGY

3) 1:10 Junction Details ii) Envelope

Thumbnails)

Carry out whole life cycle analysis of key building systems: A whole-life cost analysis was conducted to consider the cost implications of the building’s design, construction, and operation over its lifetime. This analysis ensures that sustainability measures are cost-effective over the building’s entire life cycle. Measure management and maintenance costs: Durable and low-maintenance materials and finishes were used. Also, flexible design features were included to ensure that the

ROOF TO WALLDETAIL

EXTERNAL WALLDETAIL

& ENVIRONMENT

Assembly (Sequential

SUSTAINABLE LIFE CYCLE COST

low embodied carbon and healthy materials: The building has incorporated low-carbon materials, such as sustainably sourced timber and recycled content products, in the building’s construction to reduce the embodied carbon emissions associated

building.

Prioritise

with the

materials with high embodied

impacts: 80 per cent of

heating from 20 ground source

pumps. Further power comes from a 75kW biomass boiler. Consider modular off-site construction systems: With much of the structure fabricated off-site – the in-situ concrete column bases being the most obvious exceptions –there is less waste and fewer greenhouse gases.

energy

its

heat

2) Integrated 3D Envelope Study 1 2 3 4 5 9 8 7

10 11 12 i) Isometric

6

10

WINDOW DETAIL

1 2 3 1 2 3 4 5

6 7 8 9 10 11 12 13 14 1. Softwood timber framed fixed to C/W mullion 2. Acoustic insulation

canopy

2.

rainscreen

3. Siberian larch rainscreen cladding on the underside of canopy 4. Diameter cable 5. Reinforced bitumen cold roof 6. Plywood deck 1 2 3 4 5 6 1 2 1. Siberian larch brise soleil 2. T-profile cap 3. Double glazing 4. Curtain

transom 5. Outward

low level window 6. Canopy primary steelwork 7. Roll up grill anodised aluminium finish 8. Insulated service trench formed in slab 9. Siberian larch decking 10. Insulation 11. Polished concrete 12. Screed 13. Rigid insulation 14. Raft foundation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 11 C/W mullion with T profile cap Vertical bars are placed to divide the glazing from one another. They also define the outer edges of the curtain wall. WALL TO ROOF INTERFACE CANOPY DETAIL CANOPY TO WALL SLAB DETAIL EXTERNAL WALL TO GROUND SLAB DETAIL TAMAR LANG

1.Timber joist to form

parept upstand

Vertical Siberian larch

cladding

walling

opening

Technologies Position

Architectural Design Position & Technical Detail Study Purpose

DESIGN POSITION

solid wall construction