5 minute read

Prototyping

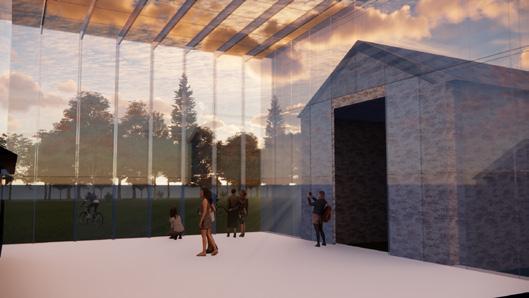

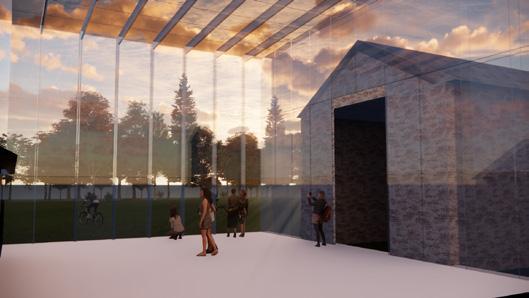

glazing glazing glazing glazing glazing

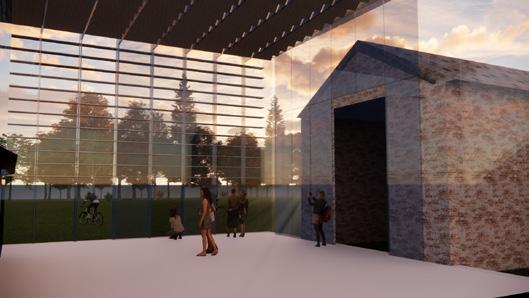

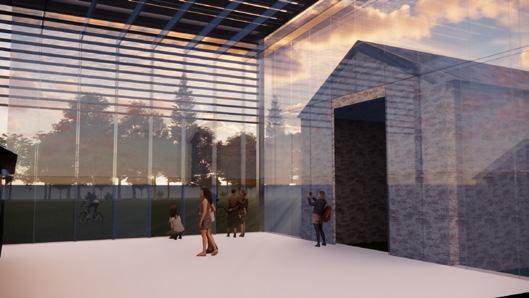

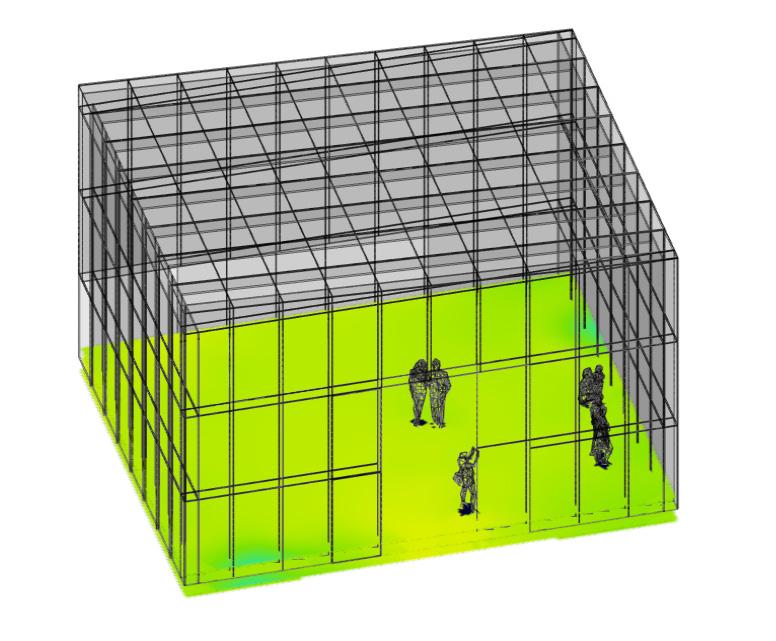

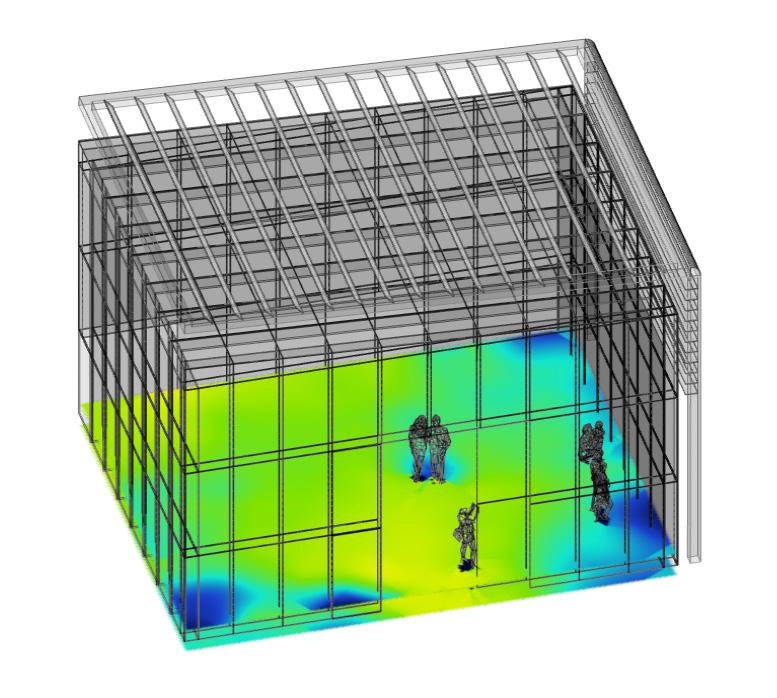

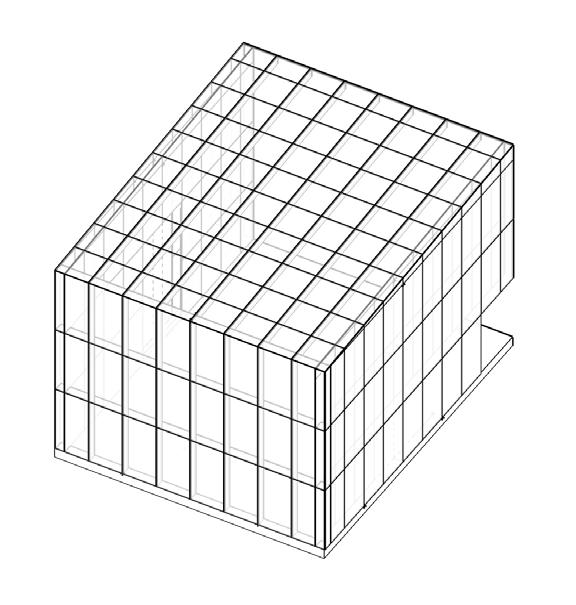

The first iteration is a fully glazed facade with no solar shading devices.

Advertisement

TEST 2: ENERGY USE & LIGHTING

58

Expected results

A fully glazed facade with no shading devices means that the building will heat up too fast, requiring a higher usage of artificial cooling and heating.

Observed results

Surprisingly, the annual energy use met the target which could be because of the double skin, but the building receives too much light.

Energy use:

81

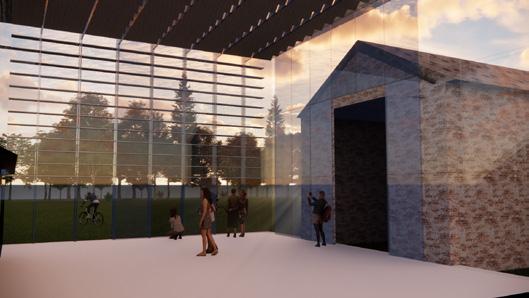

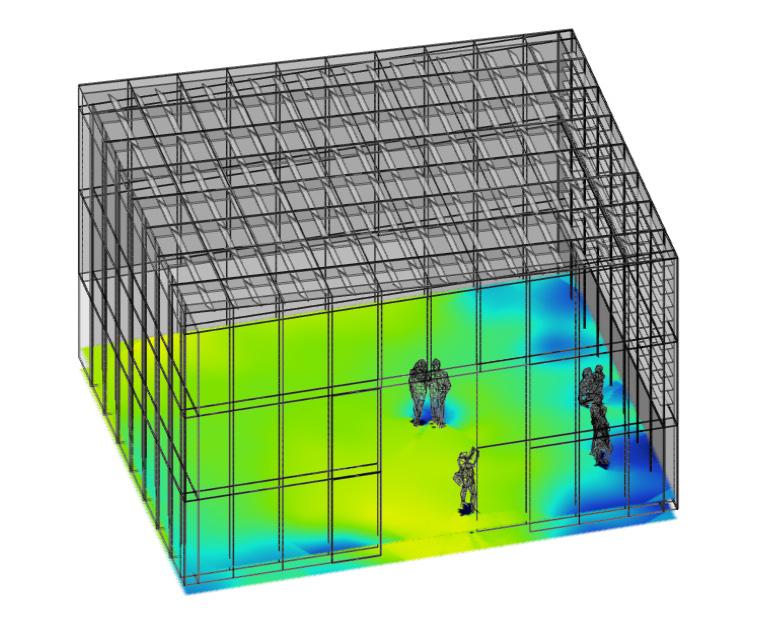

19 brise soleil brise soleil glazing

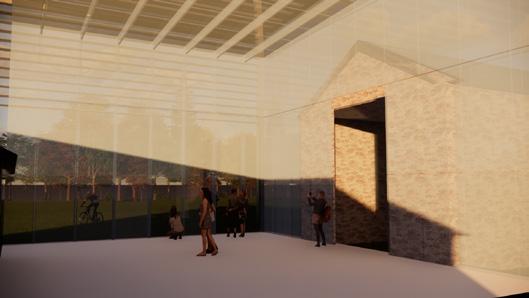

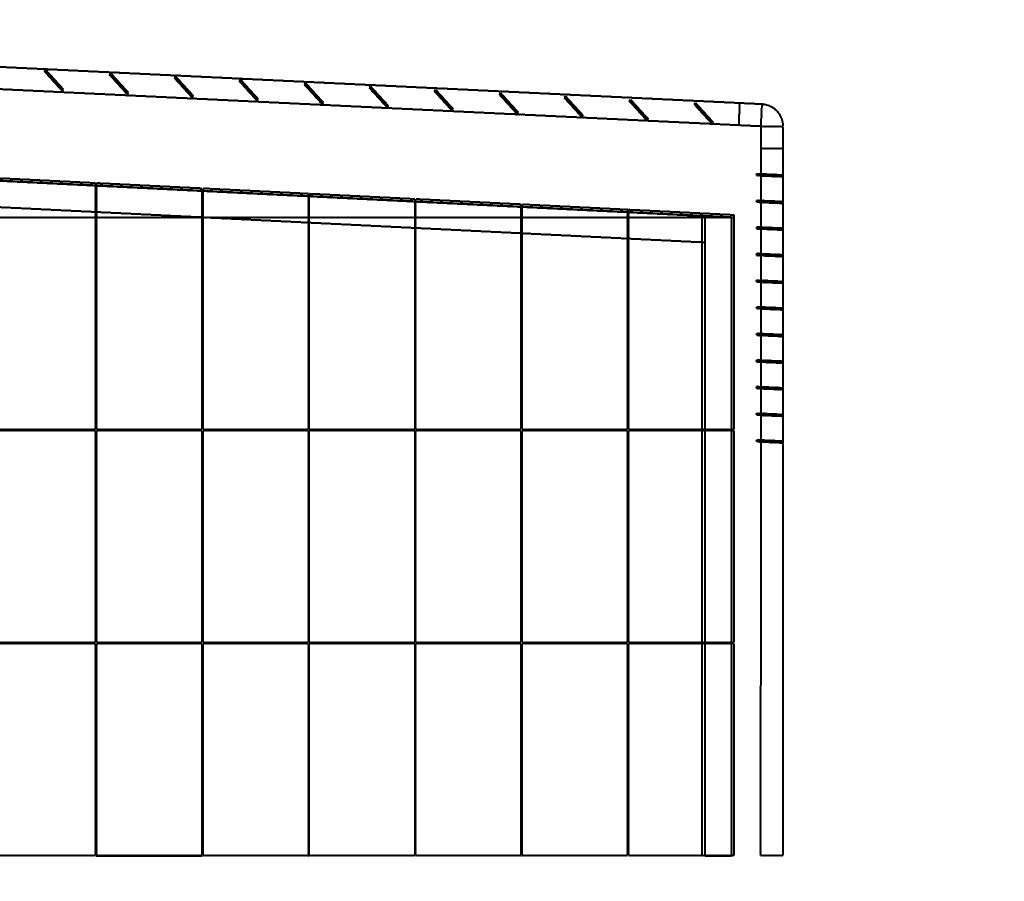

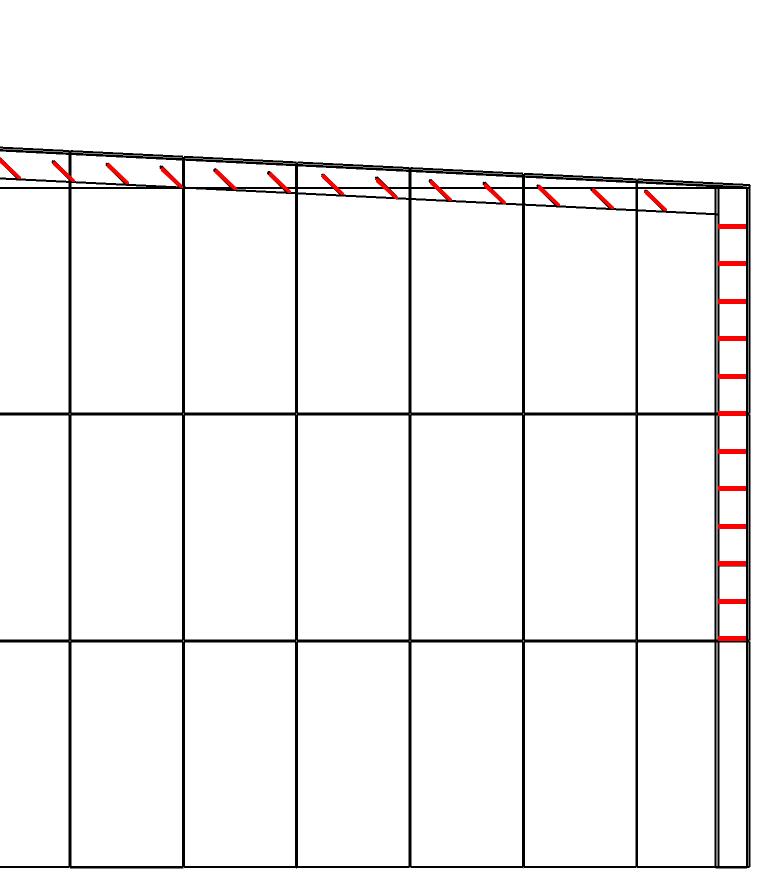

The second iteration is a fully glazed facade with internal brise soleil between the glazed roof panels and the glass panels on the south facing side.

Expected results

The brise soleil in the interior would reduce the annual energy use and control daylighting.

Observed results

As expected, a lower energy use value than the first iteration and the building is well-lit.

TEST 3: ENVIRONMENTAL EVALUATIONS

Pros: maximum solar gain with heating benefits during the winter

Cons: direct sunlight which requires operable glazing or mechanical ventilation to moderate temperatures and lighting conditions

From the results of the tests conducted, it can be deduced that a fully glazed facade with no solar shading devices means that there is no way to control daylighting and heat build up. This would create an internal environment that is extremely over-lit, hot and will require lots of energy for cooling. Thus, this iteration is the least suitable.

Pros: good control of lighting and atmospheric conditions, environmentally beneficial, minimised use of artificial lighting and heating, connects to BMS

Cons: requires maintenance and operation brise soleil brise soleil

From the results of the tests conducted, it can be deduced that a fully glazed facade with internal brise soleil between the glass panels would be the most suitable option. They provide the best daylighting and heat control between all the iterations. This design would also require less maintenance and cleaning as the louvres are not exposed to external environment.

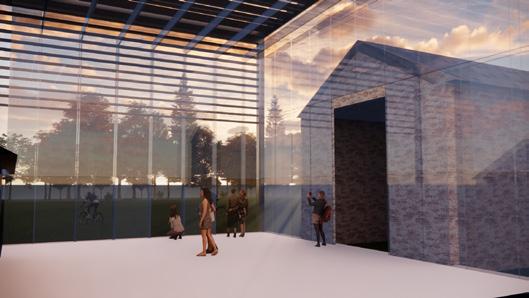

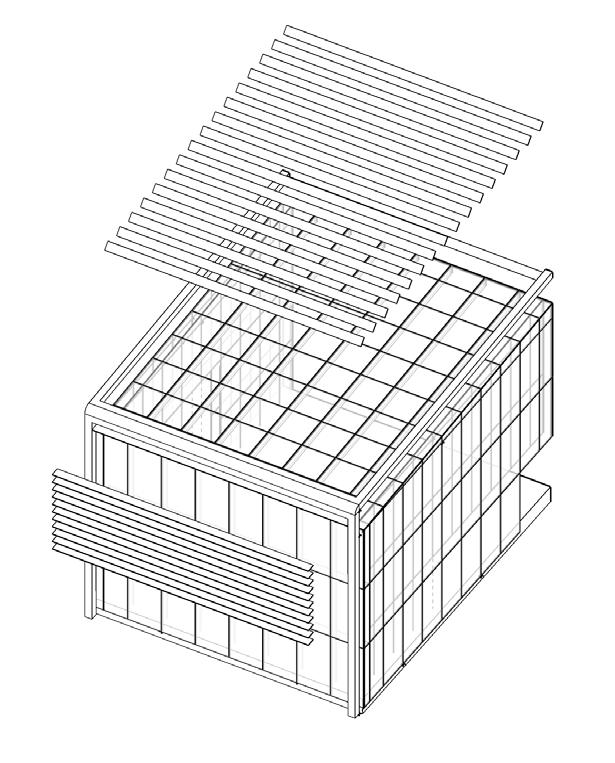

The third iteration is a fully glazed facade with a external steel frame that has brise soleil attached onto it, similar to that of a gazebo/canopy.

Well-lit: 85

Over-lit: 15

Expected results

With brise soleil on an exterior frame, I expect the lowest value of energy use and a very well-lit space.

Observed results

The energy use value was higher than expected but the space is still well-lit.

Pros: provides good shading, cheap solution, low operational maintenance

From the results of the tests conducted, it can be deduced that a fully glazed facade with brise soleil placed along an external steel frame would be a suitable option, but not the best. The brise soleil would require maintenance, cleaning and replacement often as it is likely to corrode and fade as it would be exposed to rain, snow and sun. ITERATION

Having tested three options for the overall design of the new build, I have concluded that the second iteration is the best. I want to look further into other factors such as materials and the u-values of different glazing build ups in order to come up with a final design that would perform accordingly and ensure the best internal environment for the distillation process.

MATERIAL STUDY: GLAZING & BRISE SOLEIL Brise soleil

Glazing

FLOAT GLASS Advantages: durable, affordable and easy to produce in large quantities.

Disadvantages: not very strong and can easily break.

TEMPERED GLASS Advantages: four times stronger than regular glass, less likely to shatter into dangerous shards and able to withstand high temperatures.

Disadvantages: difficult to cut or modify once tempered.

LAMINATED GLASS Advantages: highly durable, able to withstand impact, provides sound insulation and protection against UV radiation.

Disadvantages: expensive.

INSULATED GLASS Advantages: highly energy-efficient so able to reduce heating and cooling costs and provides sound insulation.

Disadvantages: can be expensive.

WIRE GLASS Advantages: highly durable and able to withstand high temperatures, protection against fire and impact.

Disadvantages: not very transparent and can obscure views.

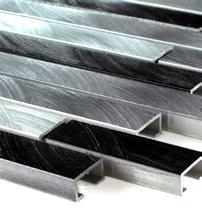

ALUMINIUM Advantages: lightweight, durable, and easy to install, and resistant to corrosion.

STEEL

Disadvantages: expensive.

Advantages: strong, durable, and inexpensive.

Disadvantages: heavy and may require extra structural support.

GL ASS Advantages: attractive, allows natural light to pass, can be treated to be reflective or tinted.

Disadvantages: expensive, fragile and difficult to clean.

WOOD Advantages: renewable, sustainable and natural.

Disadvantages: requires regular maintenance to prevent rot or warping.

FABRIC Advantages: lightweight and cost-effective

Disadvantages: not as durable as other materials and can be difficult to clean.

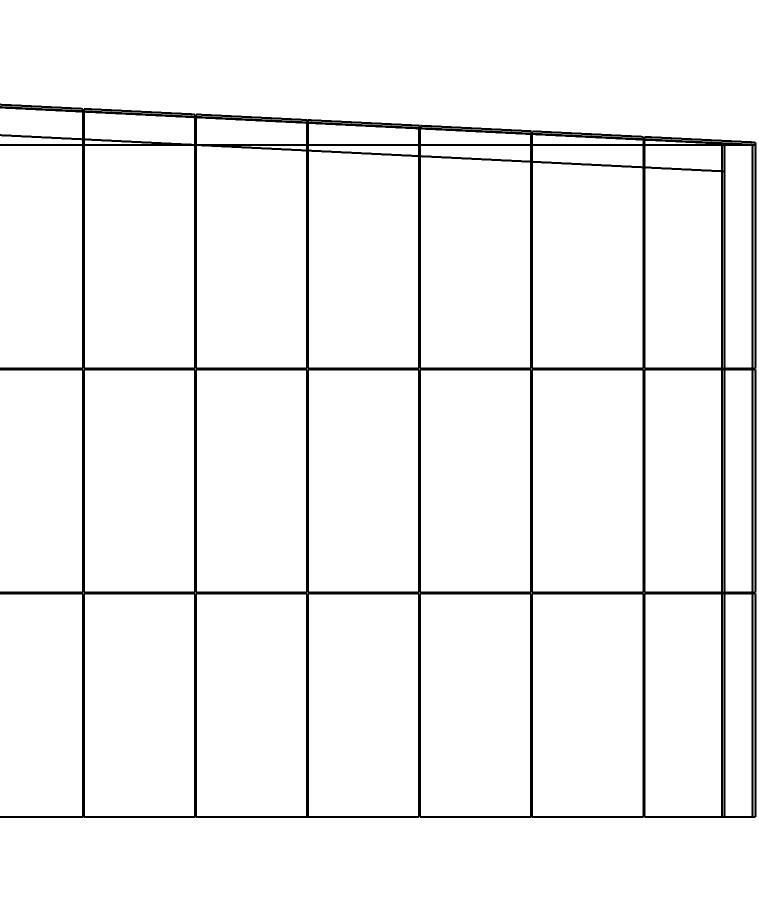

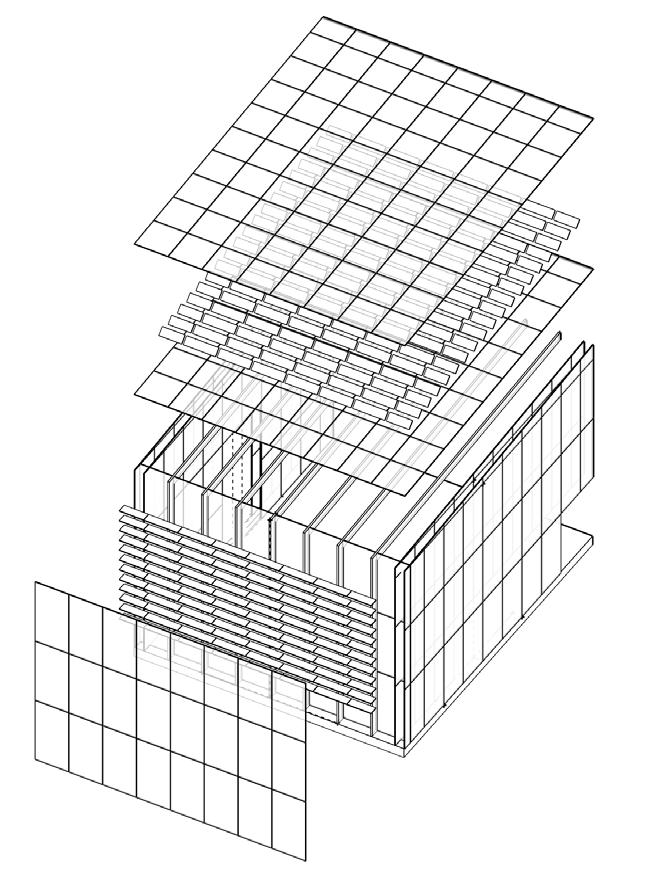

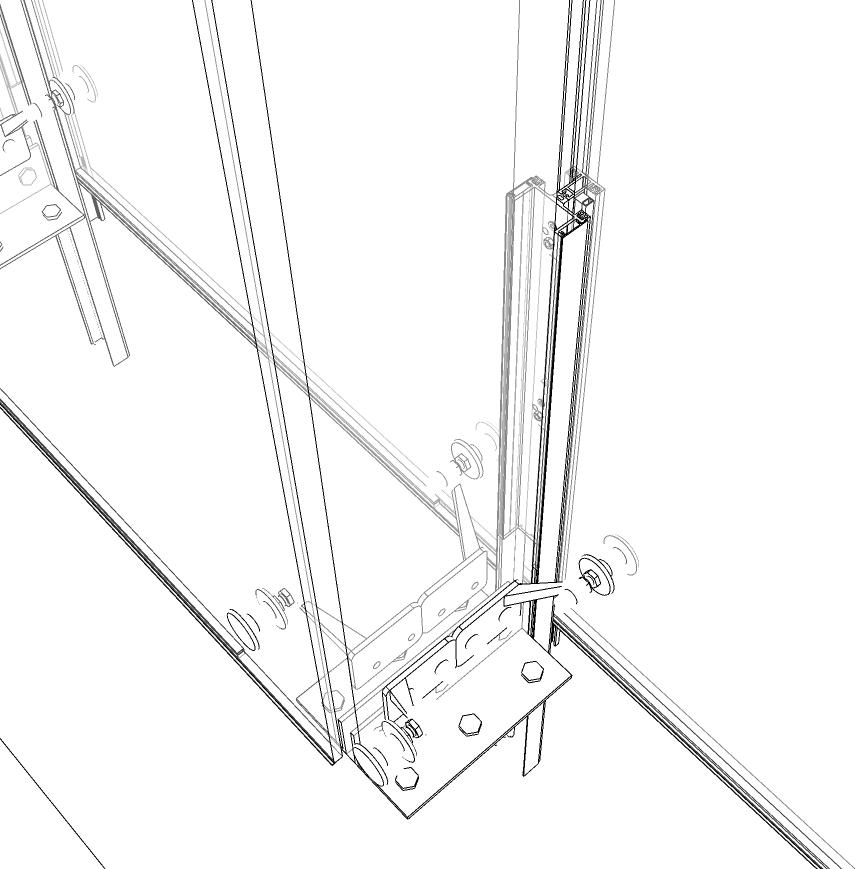

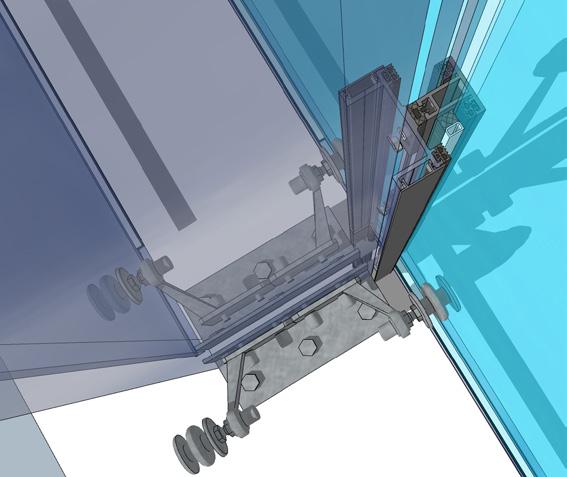

Reflections On Constructibility

My final proposed solution offers innovation and aesthetic appeal while minimizing material usage. However, it is worth noting that the technology for this approach is still under development, and only a few companies currently produce and construct curtain glazing in this manner. Considering the whiskey business is an expensive one, cost implications are unlikely to be a significant concern. After examining different glass types and their properties, I explored various system options, including a dual-clad rain screen system, a single glazing system, and a hybrid cassette. The chosen system of a hybrid one offers advantages such as off-site manufacturing, simplified on-site construction, and reduced construction time. Moreover, it is an integrated system that minimizes the risk of failure, making the integration of a brise soleil feasible. However, there are some drawbacks to consider, including challenges in procurement, limited availability of specialized contractors, high costs, the need for exceptional craftsmanship, and the requirements for cleaning and maintenance. With the ongoing construction boom in Manchester, a solution that is quick, efficient, and requires minimal labour while potentially leveraging skilled workers from afar is desirable. Hence, adopting Modern Methods of Construction (MMC), as highlighted in the Latham report, becomes a viable option. Through the exploration of retrofit options, I discovered that using cassettes, whether made of timber or glass, is a common practice when working with old buildings. Initially considering a standard curtain walling system and later exploring the hybrid rain screen system, I ultimately chose to utilize structural glazing in a cassette form, as depicted in the diagram on page one.

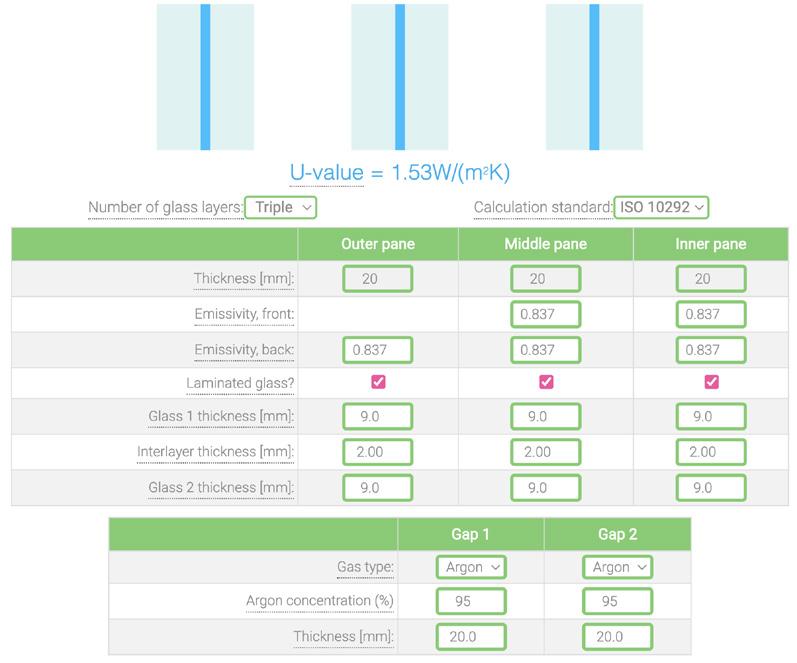

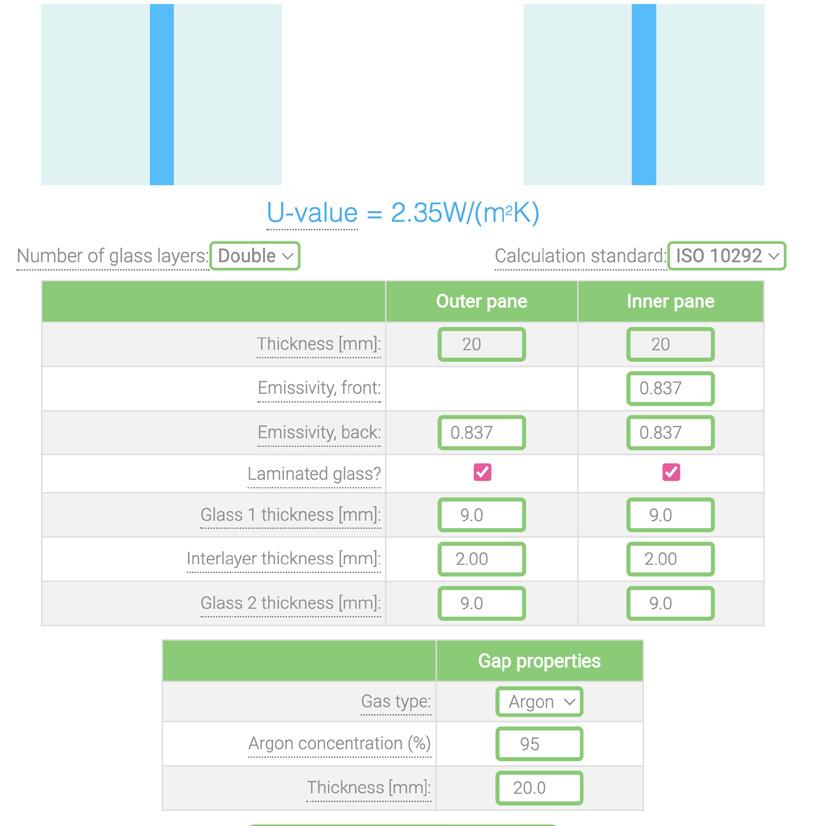

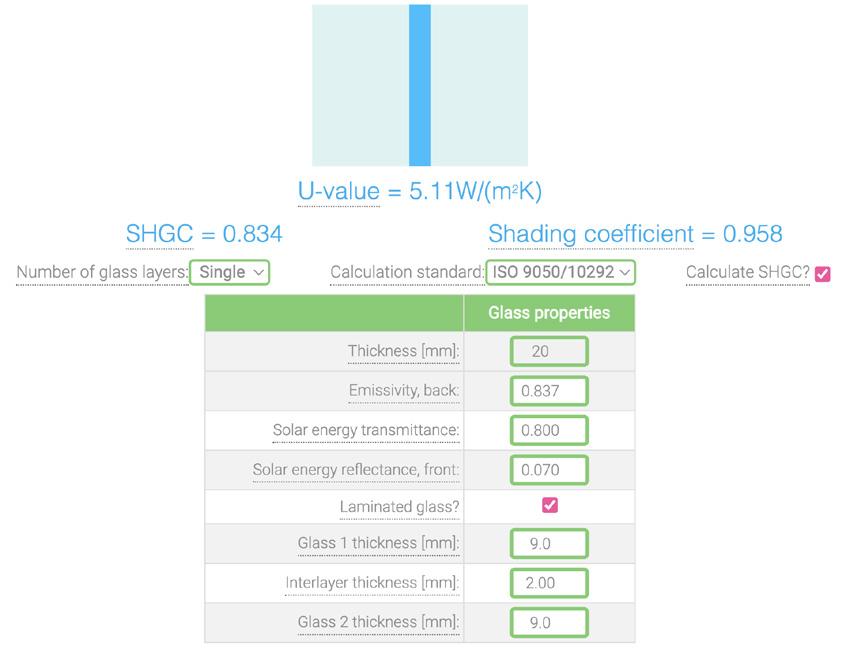

I have tested three types of glass: single, double and triple and opted to use triple glazing for the roof, and a structural cassette which is a combination of single and double glazing to achieve a better U-value for the building. I will be using a proprietary mullions and transoms which incorporate seals that provide a thermal break to stop cold bridging.

Reflections On Building And Life Safety

The glazing process requires precision and attention to detail to ensure that the glass is properly sealed and structurally sound. Overall, constructing a glazed curtain walling system is a complex process that requires a high level of expertise and experience. It is important to work with a qualified team of professionals who have experience in designing, fabricating, and installing these types of systems to ensure that the project is completed successfully and meets all necessary building codes and standards. The combination of structural facade glass panels, the point support system (spider cladding) and the stack structural wall system all use vertical glass designed to resist wind, seismic forces and snow. As recommended, toughened and laminated glass ensures that should any of the glass panes break in the roof, the glazing would fail but no glass with fall internally. The laminate (using PVB) within the inner pane holds the glass together and in place. While ordinary glass may shatter or break when exposed to high temperatures, fire-rated glass is designed to withstand fire for a specified duration, acting as a barrier against smoke, flames, and heat transfer. It helps in limiting the spread of fire and provides occupants with more time to evacuate safely. Also, in choosing a prefabricated system, there is less likelihood of failure at junctions, which helps building and life safety. Safety glazing standards, such as those outlined in building codes, ensure that glass installations meet specific criteria to minimize the risk of injury. For instance, safety glazing is required in areas prone to impact, such as doors, shower enclosures, and glass partitions. Compliance with safety glazing regulations is essential for protecting occupants from potential hazards. This section of the building is a single compartment, as it is the highest point in all of the structures across the site - it will incorporate smoke vents, smoke detection and an automatic fire suppressant system. Attention must be paid to the building safety act 2020 by the new building safety regulator.