AGILIUM®

AGILIUM®

Light weight cast iron drainage system

In 2023, the construction industry generates 39% of the greenhouse gas emissions: every saving counts in reducing the environmental impact of construction.

In response, we developed Agilium® , our first cast iron solution designed through eco-design principles. Agilium® achieves lower CO2 emissions than our traditional ranges. This performance is verified by the comparison of our new Environmental Product Declaration (EPD) with the previous version published on the Environdec platform (www.environdec.com), confirming its contribution to more sustainable building projects.

30% LIGHTER 20% LESS CO2 99% RECYCLED MATERIAL & FULLY recyclable FOR PLUMBERS

• Easier to carry with a weight reduction of 30% compared to our standard range

• Faster to install with less time spent on pipe handling FOR DESIGN OFFICES

• More agility with a space-saving in increasingly more constrained spaces FOR PROJECT OWNERS

• Better environmental compliance with a 20% reduction in carbon emissions

AGILIUM®

Technical features

Pam Building launches a new drainage solution that reduces its environmental impact and facilitates the daily work of installers. An innovation that is part of our eco-design approach.

Recommended use

Domestic use: wastewater, rainwater, runoff water, hot effluents

• Commercial, public and residential buildings, particularly medium- to high-rise buildings which require robust and safe solutions for basements and lower levels to vertical risers: offices, shopping centers, housing, airports, hotels, public builidings, stadiums

Certified performance

• Compliant with standard EN 877

• Guaranteed performances by quality marks delivered by third party

Easy maintenance & installation

30% weight reduction of the pipes and 15% for the fittings compared to standard range: a 3m Agilium® DN100 pipe weighs just 17 kg, compared to 24 kg for the standard range.

Due to their exceptional mechanical properties, cast iron drainage systems prevent the worry of untimely and costly repairs.

Possibility to:

• Mix Agilium® pipes with standard range fittings

• Mix pipes of the standard range with Agilium® fittings

• Use most standard couplings

• Keep most of the reservations for standard range with Agilium®

Fire safety

• Reaction to fire: Euroclass A1

Vs our standard range

• Fire resistance: up to 240 minutes depending on the configuration (generally requires no special fire protection saving time and costs)

Acoustic comfort

• LSC,A ≤ 13 dB(A) & La,A = 46 dB(A) according to EN 14366 with flow rate of 2l/s

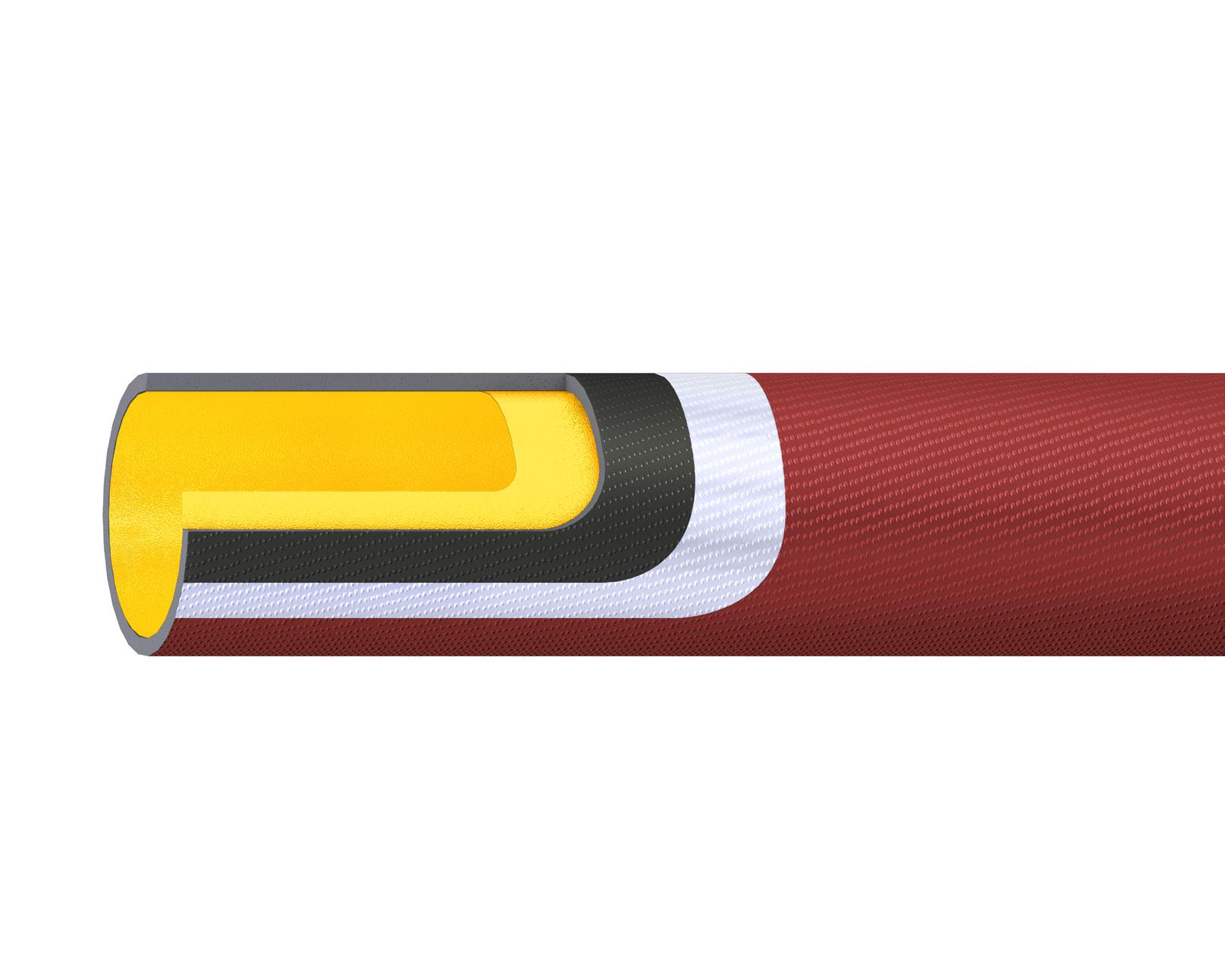

Coatings

• External coating: Red-brown, acrylic primer paint, average dry film thickness 40 μm

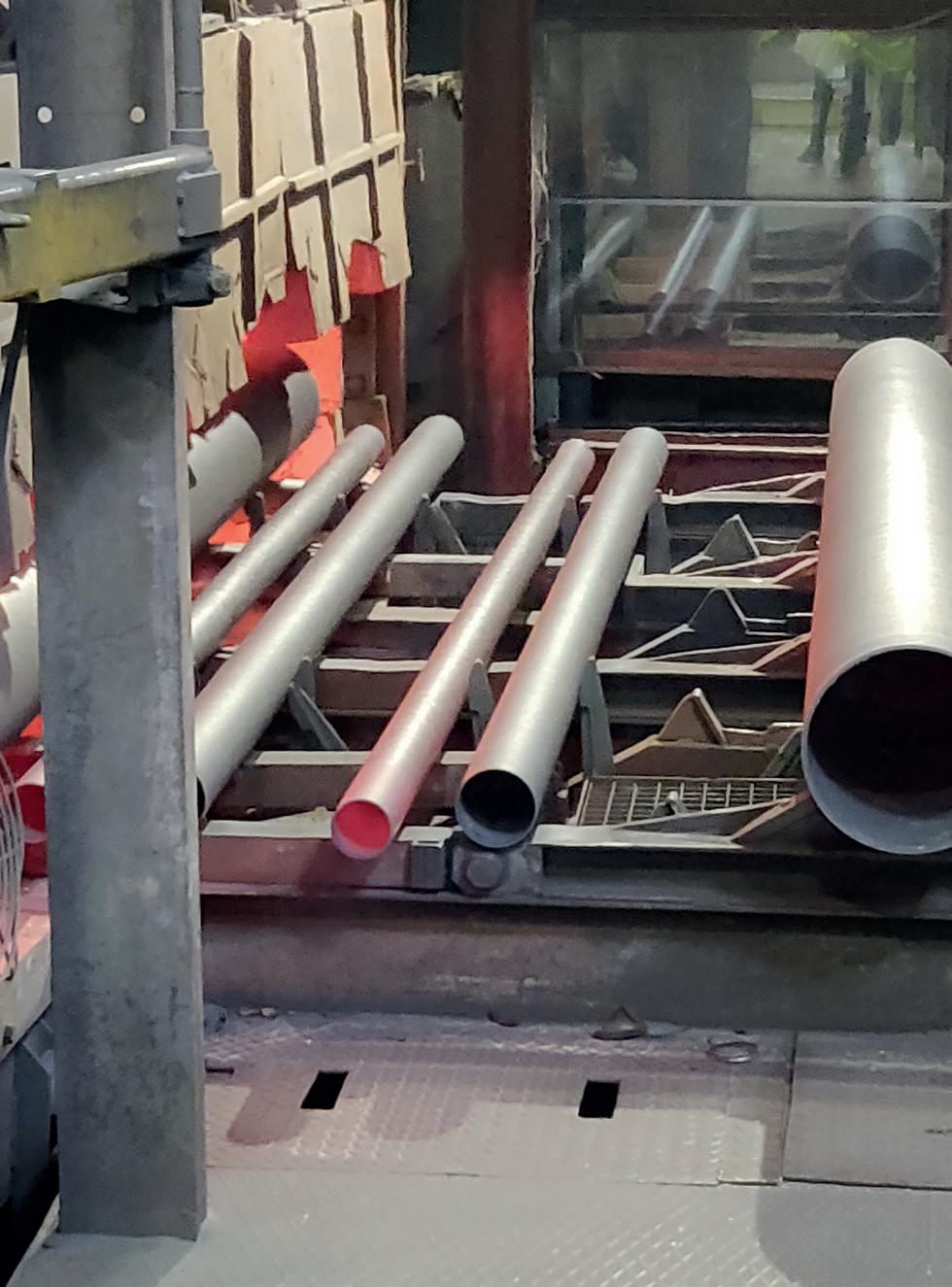

• Cast iron Made with the de Lavaud process

• Internal coating Two-component ochre-coloured epoxy coating, average dry film thickness of 130 μm

AGILIUM®

A complete range adapted to all your projects

150

200

250

300

FITTINGS

Shorter than the standard

• Reduced sealing zone at the ends,

• External diameter maintained,

• Weight reduction*

In the example above the footprint is reduced by 2.3 cm.

Contact us for other configurations.

The de Lavaud process

A unique manufacturing process, optimized for Agilium partly supported by the Grand Est region. In the de Lavaud process, the liquid metal is poured into a bare steel shell and undergoes very rapid cooling. A graphitization annealing process, followed by ferritization, results in pipes with exceptional mechanical properties.

AGILIUM® Performances

Agilium® complies with the EN 877 standard and maintains equivalent performance to our current cast iron drainage solutions.

FIRE SAFETY

Pipes are the arteries of a building.

In the event of a fire, the risk is that these pipes will sustain and spread the fire throughout the building. Choosing Pam Building cast iron systems means ensuring the safety of people and property.

Reaction to fire

• Reaction to fire is the propensity to ignite and to feed the fire,

• Agilium® drainage systems are A1 fire rated and completely non-combustible. They do not generate smoke or droplets in case of fire.

The Euroclasses establish a classification of reaction to fire harmonized throughout Europe that can be used to compare materials and product performance.

EUROCLASSES

Fire resistance

• The fire resistance of a product is its ability to resist fire for a given time and not transmit the fire to an adjacent room,

• Agilium® cast iron is a non-combustible metallic material with a melting point higher than 1000°C.

SMOKE production

sub-classification

s1: Low smoke production

s2: Medium smoke production

s3: High smoke production

FLAMING DROPLETS

sub-classification

d0: No flaming droplets

d1: Flaming droplets that persist for less than 10 s

d2: Flaming droplets

Classes other than E-d2 and F

AGILIUM® Performances

Fire resistance test results

Following fire resistance tests carried out by Efectis on slab and wall penetrations, multiple firewall solutions are considered:

• In the vast majority of cases, no protection is necessary,

• Optimization of the thickness of the slab by adding concrete blocks at the level of the crossing,

• In some cases, because the fire resistance classification implies a limitation of the heating on the side opposite the fire, insulation in the area of the penetration is necessary, carried out by the use of mineral wool shells.

ISOVER Ultimate® Solution

ISOVER U Protect® Pipe Section Alu2 u171 "ISOVER ULTIMATE® concentric mineral wool shells aluminum coated, allowing a fireproof passage for cast iron networks".

DURABILITY AND MECHANICAL STRENGTH

Reduced maintenance costs due to the mechanical properties of cast iron.

Aging behaviour: cast iron is characterized by a long life span of 70 years, in particular thanks to the stability of its mechanical properties, in comparison with the aging of polymers and their deterioration.

Resistance of Agilium® cast iron to impacts occurring in parking lots and basements in technical rooms (cellars, garbage rooms...).

Process Other processes (not Pam Building)

Fire resistance tests carried out by Efectis.

Concrete blocks at the level of the slab crossing.

ACOUSTIC COMFORT FOR THE OCCUPANTS

Agilium® reaches the acoustic performance with an airborne sound insulation of La,A 46dB(A) according to the EN 14366 standard, for a discharge flow of 2.0 l/s. (Test report P-BA6/2021E, tests performed at the Fraunhofer Institute).

Unlike other materials, the acoustic performance of Agilium® cast iron is guaranteed:

• Without technical advice,

• Without addition of specific parts,

• Without specific assembly (gluing, welding, etc...).

ENVIRONMENTAL IMPACT

Agilium® is our first eco-design, in line with our environmental roadmap.

=

Our solution is made from recycled materials and is fully recyclable.

Less CO2 emissions compared to our current ranges

The plumbing package represents less than 5% of a building’s C02 emissions (data from life cycle analysis), according to a sensitivity study conducted in France by the Bastide Bondoux, Pouget and Tribu design offices, on a 4-story office building (4,000 m2).

This performance is validated by comparing our new Agilium® Environmental Product Declaration (EPD) with the one previously available on the environdec database (www.environdec.com).

AGILIUM Zn ®

Ideal for external agressions

Agilium® Zn is recommended for applications in coastal areas, directly or indirectly exposed to climatic stresses, polluted atmospheres or confined areas such as cellars, cellars or crawl spaces.spaces.

AGILIUM® Zn

Technical features

High-performance solution designed to withstand external stresses due to climate exposures (ultraviolet radiation, saline mist, condensation, freezing-thawing cycles and pollution).

Recommended use

Domestic use: wastewater, rainwater, runoff water, hot effluents

• Coastal areas, directly or indirectly exposed to climatic stresses polluted or confined atmospheres (cellars, crawl spaces), exposition to external aggressions during manufacturing processes and condensation.

Certified performance

• Compliant with standard EN 877

• Guaranteed performances by quality marks delivered by third party

Easy maintenance & installation

• Long-lasting operational safety thanks to the robustness and stiffness (around 700 kN.m) of cast iron and the use of flexible mechanical couplings

• Ease of installation due to mechanical couplings assembled with simple tools

Coatings

• External coating: Red-brown, acrylic primer paint, average dry film thickness 40 μm

• Anti-corrosive layer: flame-applied zinc metal coating of 260 g/m2 on average

• Cast iron: Made with the de Lavaud process

• Internal coating: Two-component ochre-coloured epoxy coating, average dry film thickness of 130 μm

Fire safety

• Reaction to fire: Euroclass A1, s1-d0

• Fire resistance up to 240 minutes depending on the configuration (generally requires no special fire protection,saving time and cost)

Chemical & corrosion resistance

• Hot water resistance: 24 h at 95°C

• Thermal cycle resistance: 1500 cycles between 15°C and 93°C

• Chemical resistance for 2 ≤ pH ≤ 13: up to 80°C (check resistance for more than 30 different effluents in the tables on p.56 and 57)

• External coating corrosion resistance test to neutral salt spray according to standard NFEN ISO 9227_2017: 3500 hours.

Acoustic comfort

L < 10 dB (A) & L = 46 dB(A) according to EN

Fittings: Externally and internally coated in red epoxy to an average thickness of 70 μm.

INDUSTRIAL EXPERTISE FOR SAFETY AND DURABILITY

Cast Iron, a long lasting and noble material

Our services to professionals

Our service portfolio is fully aligned with the new expectations of MEP consultants and contractors working on safe, comfortable and durable building projects.

If you have any questions, you can ask our experts on the following topics:

• Acoustics

• Fire protection

• Technical and functional advice (see “Design & Recommendations” section)

• Environmental building certifications.

Contact our technical support at tc@pambuilding.com

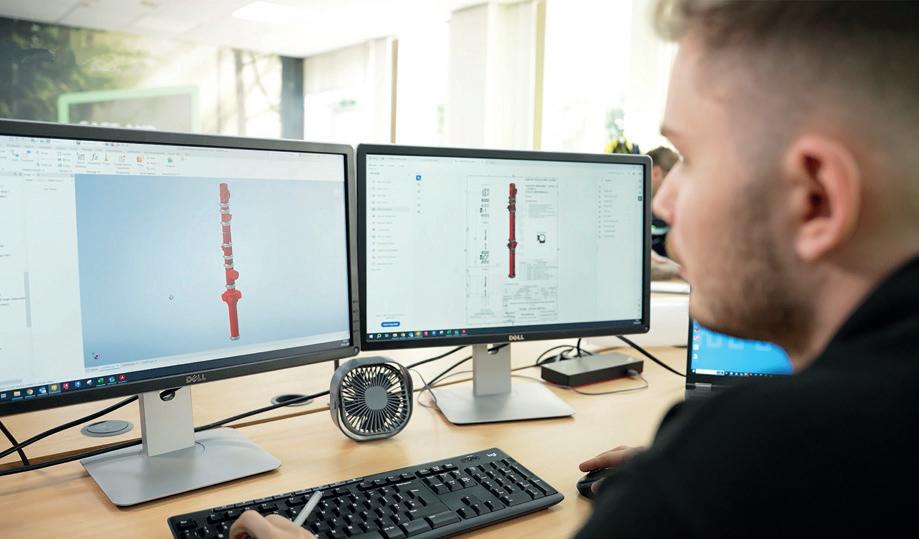

Pam Building helps you optimize your BIM workflow with two complementary libraries designed for different project stages.

• Our EN 877 Generic Cast Iron Library is ideal for early design phases. It includes a full range of parametric fittings with simplified geometry and essential data only. Lightweight files (under 500 KB) make early-stage modelling faster and easier, without overloading your system.

• For detailed design and execution, our Pam Building Cast Iron Library provides complete product data for our S, Plus, and epams® ranges. It includes real geometry, coupling zones, and full specifications to support precise planning and smooth coordination with contractors.

By combining these two libraries, you speed up design, improve accuracy, and simplify data sharing throughout your project.

Discover our complete BIM offer at www.pambuilding.com/bim-services

For 150 years, we have been designing, manufacturing and supplying high-quality drainage systems for residential and commercial buildings and engineering structures.

We work exclusively with cast iron, a noble and durable material, of which we are a specialist and leader.

As a leading manufacturer, we claim excellence in our processes, products and services.

As a responsible manufacturer, we are at the forefront of sustainable performance to help reduce the carbon footprint of the construction sector.

As an innovative manufacturer, we put all our creative audacity into developing new, more specific and more efficient technologies, to deliver better products for your future needs

Over 400 employees

Sales in more than 50 countries

2 manufacturing sites for our products:

• Bayard sur Marne in France

• Telford in England

1st business in the cast iron industry to have published a third-party validated Environmental Product Declaration (EPD)

35% female managers 1/3 internships and work- study contracts converted to full employmacontracts

Committed to reducing our impact on the environment

Our mission: the safety and durability of buildings

Our cast iron solutions and systems contribute to ensure the comfort, safety and durability of the most demanding residential and commercial buildings. Their characteristics allow them to contribute to HQE, BREEAM, LEED and other international environmental certifications.

Recycling of metal waste

Our products are made of 99% recycled materials (mainly scrap metal), which can be recycled indefinitely. Cast iron is a simple and sustainable material that allows a smart reuse of materials. Resistant, reliable and durable, cast iron has a bright future ahead of it. In 2021, we recycled the equivalent of of21,000 cars.

Our ambitious goals for 2028-2030

Reducing carbon emissions directly linked to the cast iron pipe manufacturing process: a project for a electric furnace, a low-carbon energy source in France, was opened in 2024 for commissioning by 2028-2030 at our Bayard-sur-Marne site. A key step in pursuing the company’s ambitions in terms of circular economy and environmental responsibility