a better future through youth empowerment and skills developed

through youth empowerment and skills development

64

71

teachers mentored and 3 300 grade 12 learners supported awarded in local communities

graduate interns hired youth participants in sport initiatives

97 bursaries and 144 learnerships + 7 000

We are committed to investing in young talent and nurturing future leaders.

OFFICE BEARERS AND COUNCIL FOR THE 2025/2026 SESSION

President G.R. Lane

President Elect

T.M. Mmola

Senior Vice President

M.H. Solomon

Junior Vice President

S.J. Ntsoelengoe

Incoming Junior Vice President

M.C. Munroe

Immediate Past President

E. Matinde

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk M.A. Mello

A.D. Coetzee K. Mosebi

Z. Fakhraei M.J. Mothomogolo

B. Genc S.M. Naik

F. Lake G. Njowa

K.M. Letsoalo S.M. Rupprecht

S.B. Madolo A.T. van Zyl

Co-opted Council Members

K.W. Banda

M.L. Wertz

Past Presidents Serving on Council

N.A. Barcza W.C. Joughin

R.D. Beck C. Musingwini

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

M.L. Wertz – TP Mining Chairperson

W. Broodryk – TP Metallurgy Chairperson

C.T. Chijara – YPC Chairperson

T.S. Ndlela – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC Vacant

Johannesburg A. Hefer

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West T. Nsimbi

Pretoria P.G.H. Pistorius

Western Cape M.H. Solomon

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

E. Matinde (2024-2025)

Editorial Board

S.O. Bada

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

P.N. Neingo

S.S. Nyoni

M. Onifade

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

Past President’s serving on the Editorial Board

R.D. Beck

R.T. Jones

W.C. Joughin

C. Musingwini

T.R. Stacey

S. Ndlovu*

*International Advisory Board member International Advisory Board members

R. Dimitrakopolous

R. Mitra

A.J.S. Spearing

E. Topal

D. Tudor

F. Uahengo

D. Vogt

Editor/Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31 Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

Journal Comment: The art of rock engineering design and the need for research by F. Malan ....................................................................

President’s Corner: Our responsibility to develop future industry leaders by G.R. Lane ...................................................................

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2025 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys

Auditors

Genesis Chartered Accountants

Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Barriers and drivers towards the approval and implementation of new technology in mining: A dilemma and exit strategies framework by

B. Emwanu, R.A. Raju

The mining industry faces a persistent investment paradox wherein financiers demand feasibility studies grounded in conventional, validated methodologies, while emerging technologies require extended operational validation before being deemed bankable. This constraint inhibits capital flow into innovative mining solutions, perpetuating a cycle of underinvestment. As resource accessibility declines, technological innovation becomes increasingly critical for maintaining operational sustainability and competitiveness. Over the past decade, the sector has recognised the potential of advanced technologies to reduce costs, mitigate environmental impacts, enhance mineral recovery, and improve production efficiency. Addressing the techno-economic barriers and enablers of adoption is essential for successful implementation. This paper proposes a strategic framework to resolve the investment dilemma and facilitate the integration of novel technologies into mainstream mining operations, thereby supporting long-term industry resilience.

Development of mining industry in Tanzania: A review by B.F.

Giyani, A. Salama

...............................................................................................

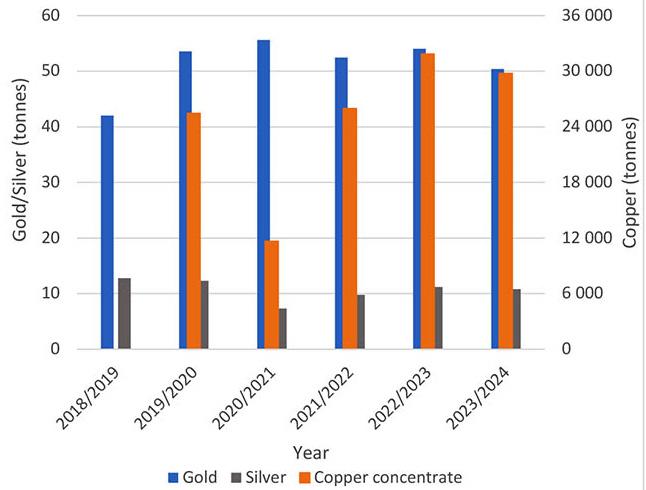

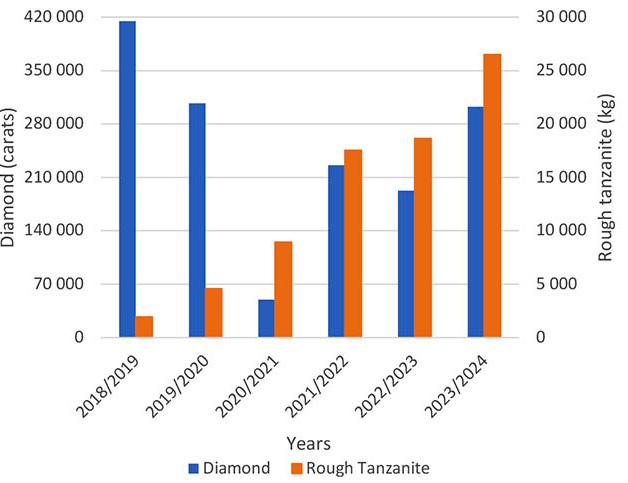

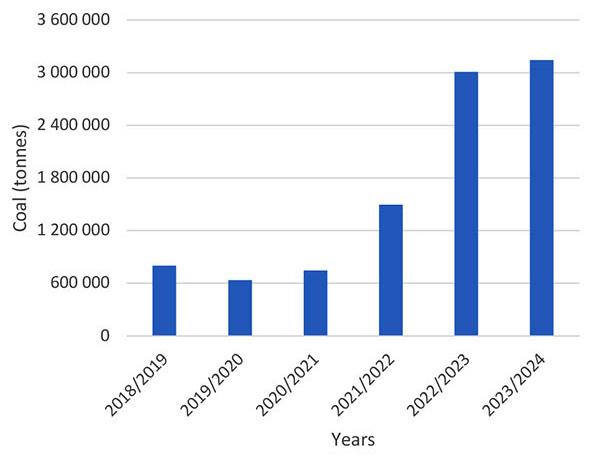

Tanzania hosts diverse mineral resources, including metallic ores, gemstones, industrial minerals, mineral fuels, and critical minerals. This study presents a comprehensive overview of the country’s mining legal framework, mineral occurrences, production trends, sectoral challenges, and government interventions. Gold production, for instance, rose from 42 tonnes in 2018/2019 to approximately 50 tonnes in 2023/2024, reflecting positive growth. However, the sector faces persistent challenges such as limited geological data, inadequate infrastructure in remote regions, informal artisanal mining, and mineral smuggling. In response, the Tanzanian government has initiated high-resolution airborne geophysical surveys, formalised artisanal and small-scale mining operations, established mineral trading hubs, and promoted domestic mineral beneficiation. These measures aim to enhance resource governance, attract investment, and improve sectoral sustainability. The findings underscore Tanzania’s potential for expanded mining investment, contingent on continued regulatory rand infrastructural improvements.

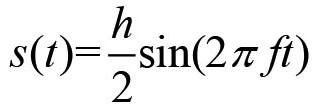

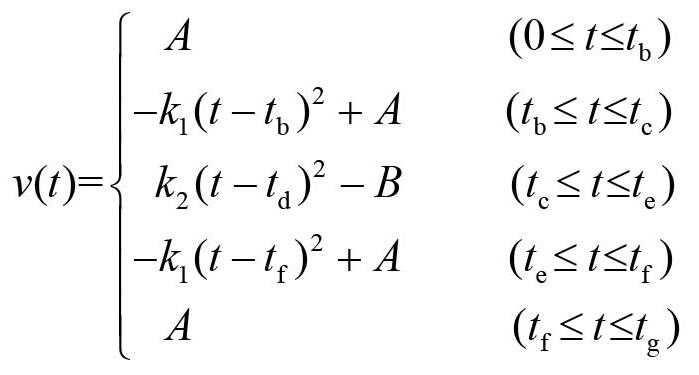

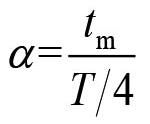

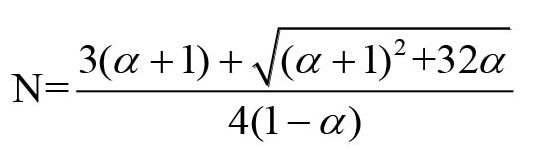

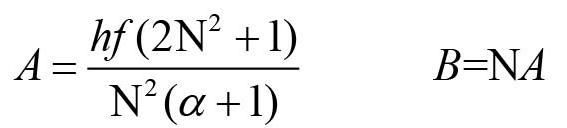

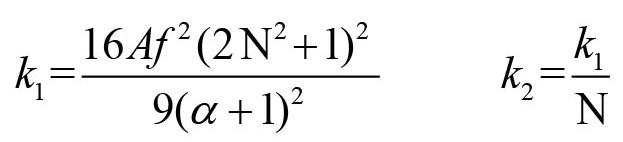

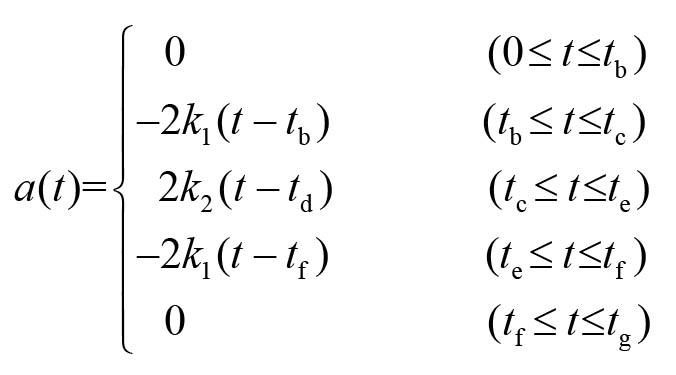

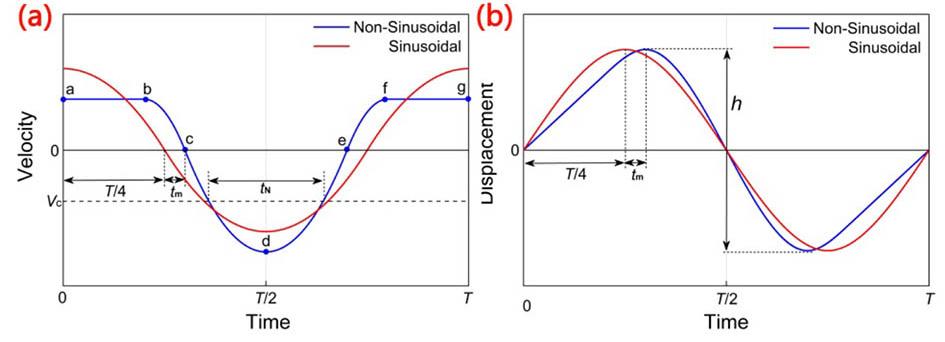

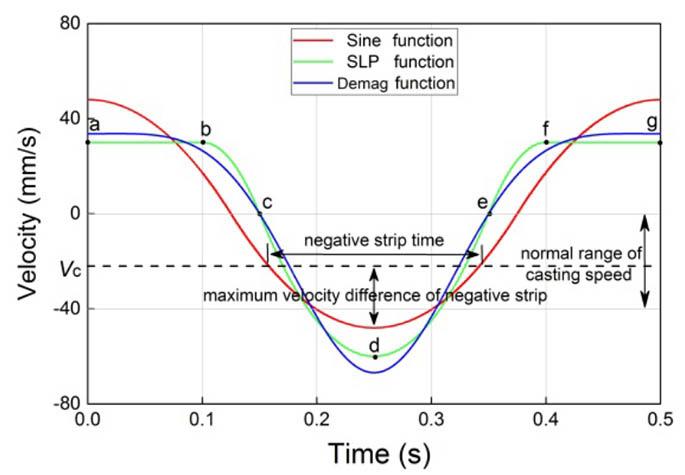

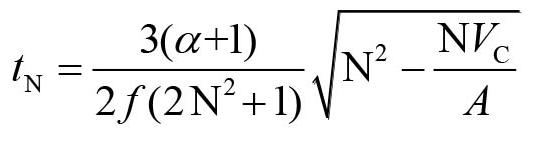

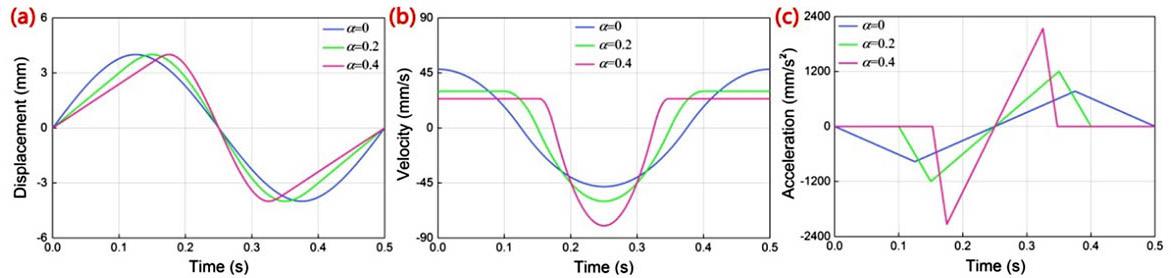

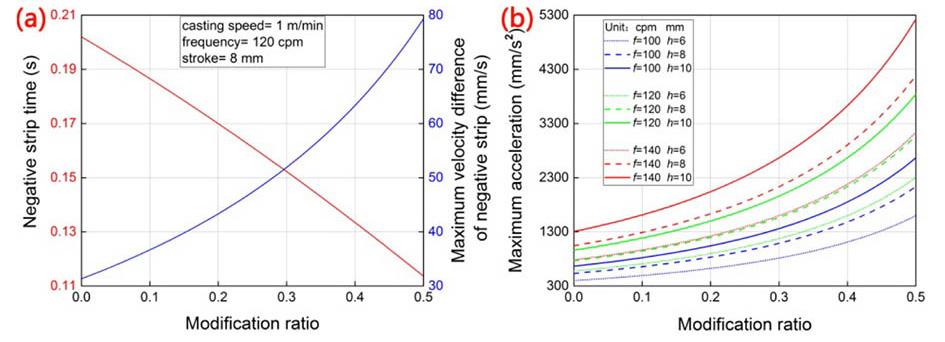

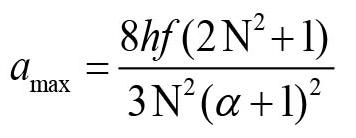

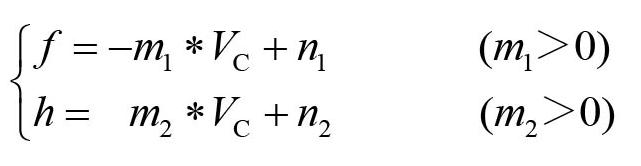

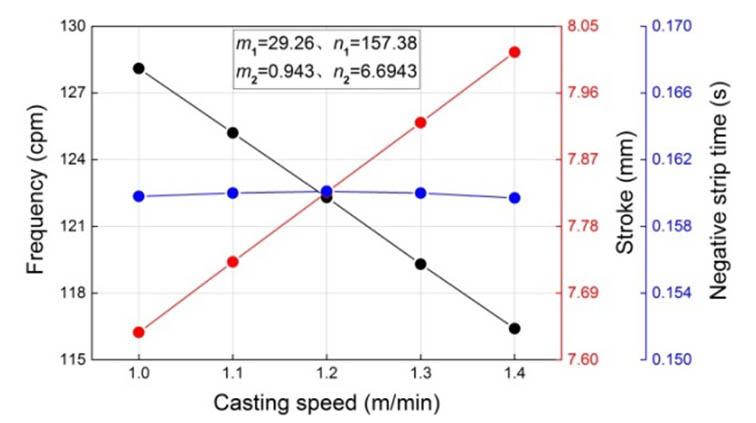

Investigation of waveform construction and dynamic characteristics for mould non-sinusoidal oscillation by

K.H. Zhang, Q. Li, J.C. Ma, J.Q. Zhao, Y.P.

Gao 593

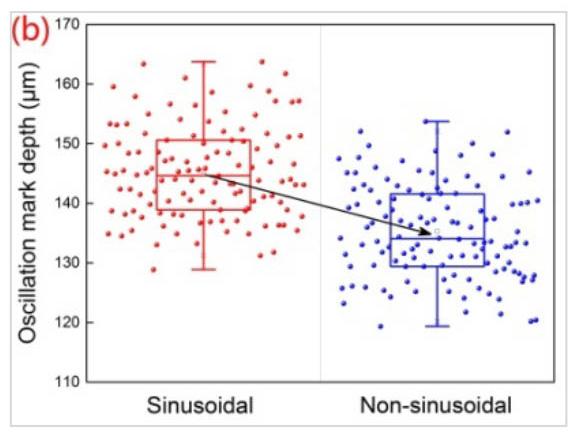

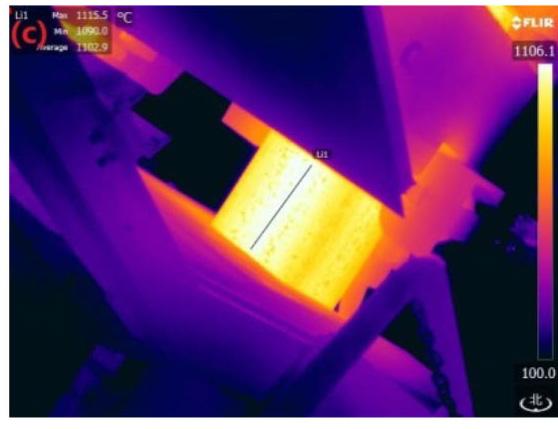

This study introduces a novel non-sinusoidal mould oscillation waveform for high-efficiency continuous casting, characterised by segments of straight lines and parabolas. Compared to traditional sinusoidal oscillation, the proposed waveform improves dynamic control and process adaptability. Quantitative analysis shows a 15.9% reduction in negative strip time, a 38.3% increase in maximum negative strip velocity difference, and a 27.8% decrease in maximum positive strip velocity difference. The oscillation process parameters are analytically derived, and isoplethic curves are constructed to evaluate multi-parameter interactions. Negative strip time decreases with increasing modification ratio, frequency, and casting speed, but increases with stroke. To stabilise negative strip time, an oscillation synchronous control model is developed for parameter optimisation. Practical implementation demonstrates improved surface quality, with oscillation mark depth reduced by 10.1 μm and flux consumption increased from 0.37 kg/t to 0.45 kg/t, meeting industrial production requirements.

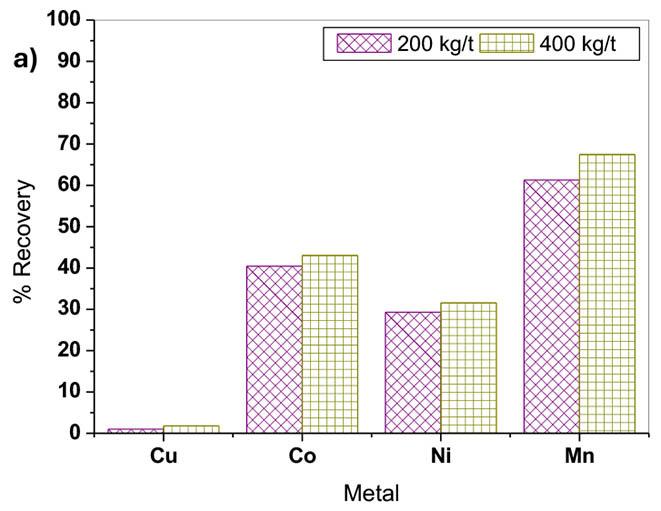

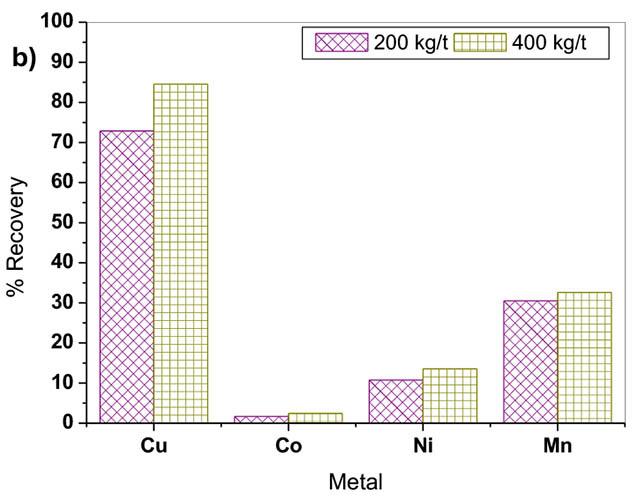

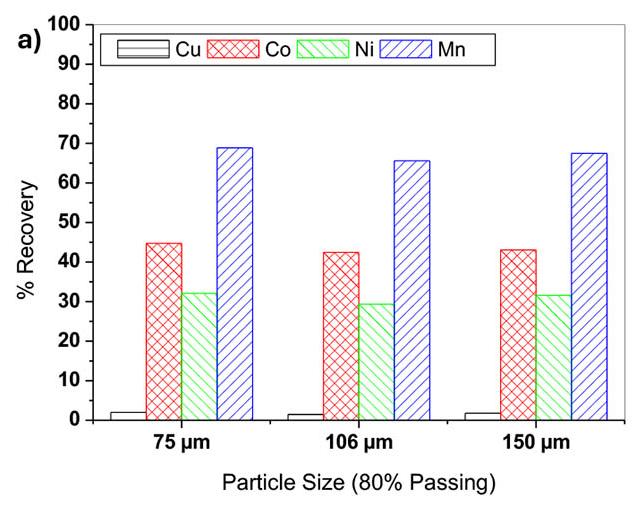

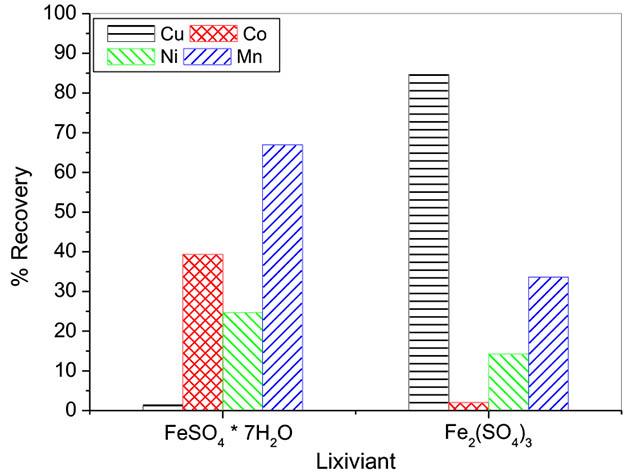

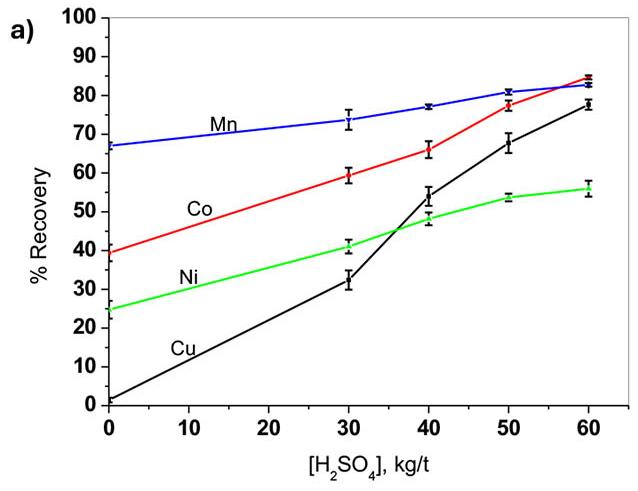

Effects of acid and reductants on iron salt leaching of copper-cobalt oxide ore: A case study from Zebesha Mine, Zambia by F.D.L. Uahengo, Y.R.S. Hara, O. Bazhko

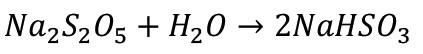

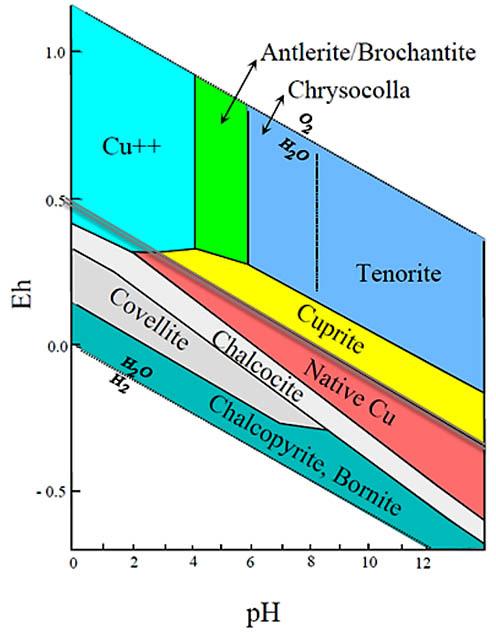

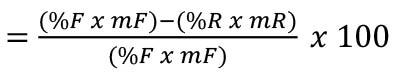

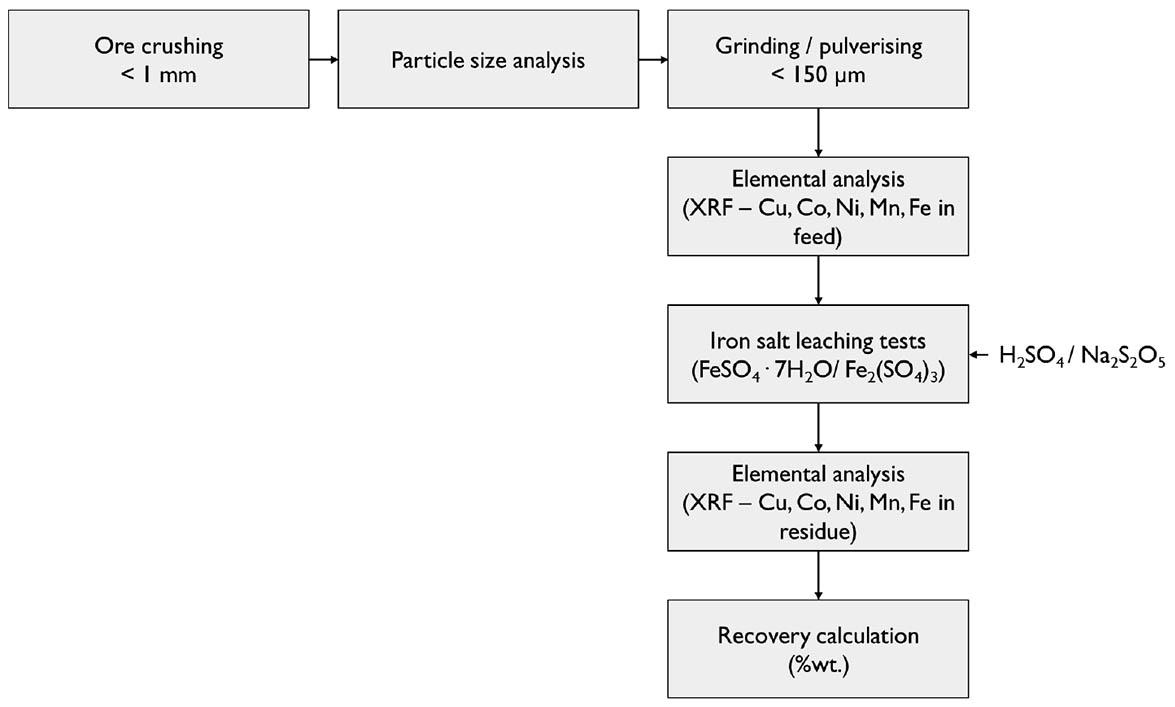

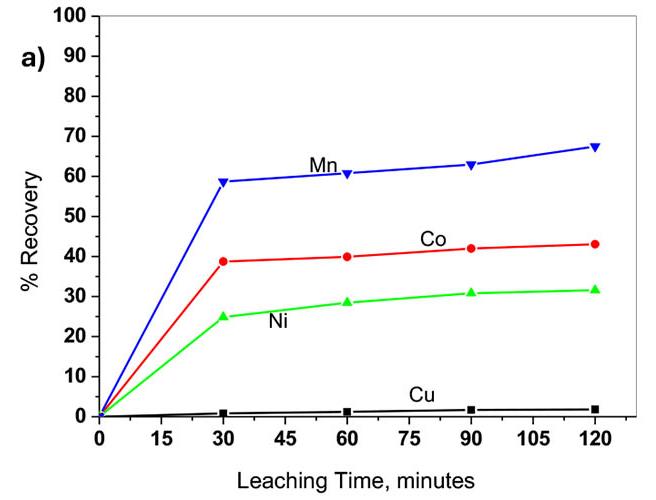

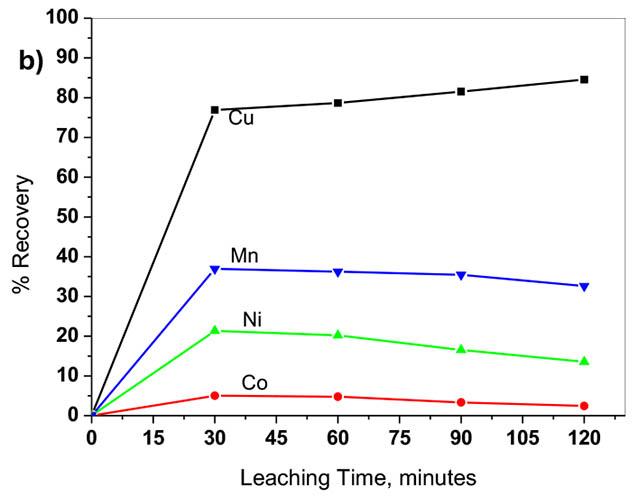

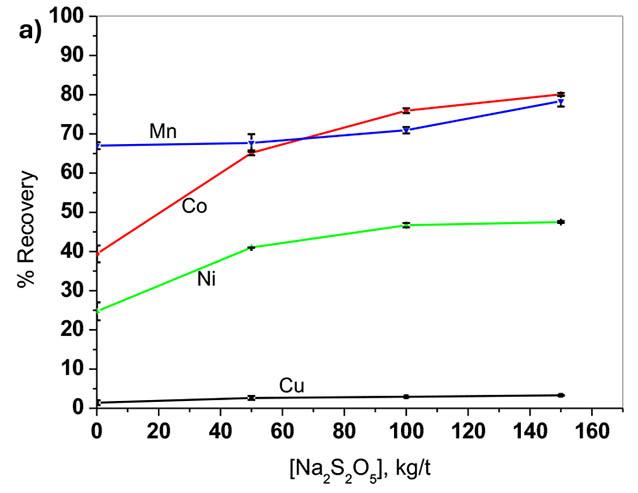

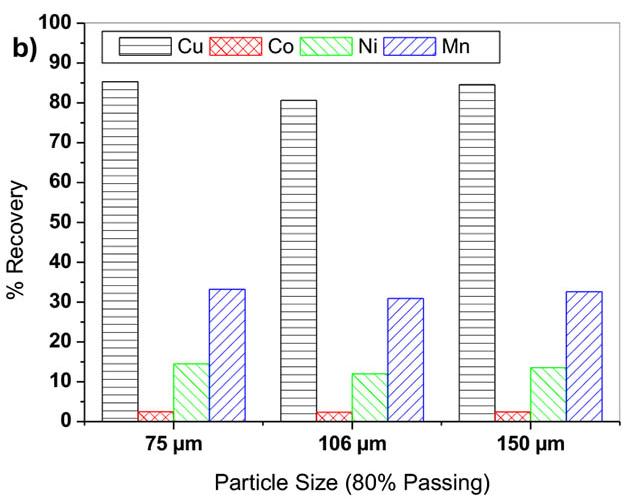

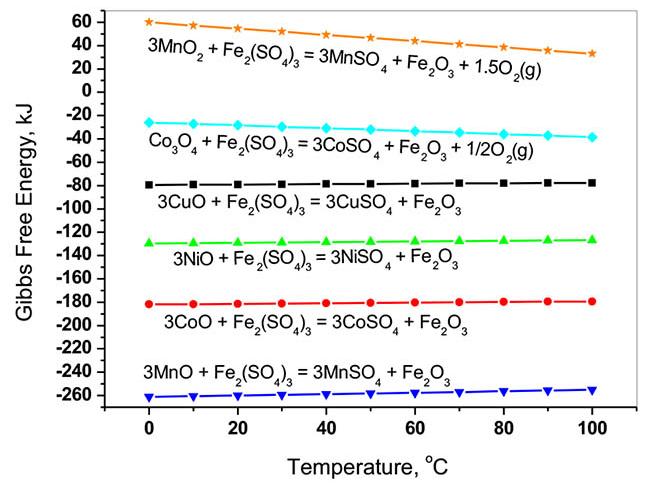

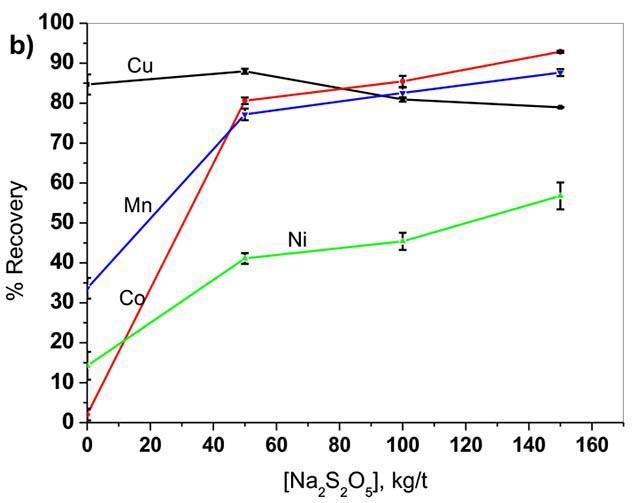

This study investigates the leaching behavior of copper (Cu) and cobalt (Co) from Zebesha Cu–Co oxide ore using ferrous sulphate heptahydrate (FeSO₄·7H₂O) and ferric sulphate (Fe₂(SO₄)₃) as lixiviants, with sodium metabisulphite (Na₂S₂O₅) and sulphuric acid (H₂SO₄) as additives. Leaching experiments conducted at ambient temperature revealed that Na₂S₂O₅ significantly enhances Co recovery in the FeSO₄·7H₂O system, reaching 80% at 150 kg/t, while Cu recovery remained below 5%. In contrast, Cu recovery peaked at 92% with 60 kg/t H₂SO₄ in the Fe₂(SO₄)₃ system, whereas Co, Ni, and Mn recoveries remained below 40%. The results demonstrate that Na₂S₂O₅ is more effective for selective Co extraction with FeSO₄·7H₂O, while H₂SO₄ improves Cu recovery in Fe₂(SO₄)₃. These findings provide insights into optimising reagent combinations for enhanced hydrometallurgical performance in Cu–Co oxide ore processing.

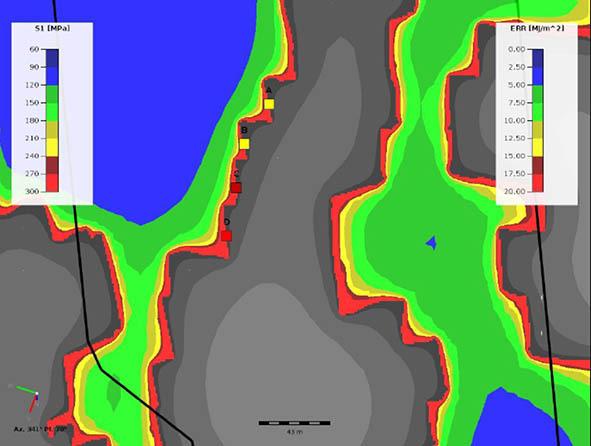

The practicality of using rock mass classification in a narrow tabular orebody at depth extracting the Ventersdorp Contact Reef by R. van Heerden, T.R. Stacey 609

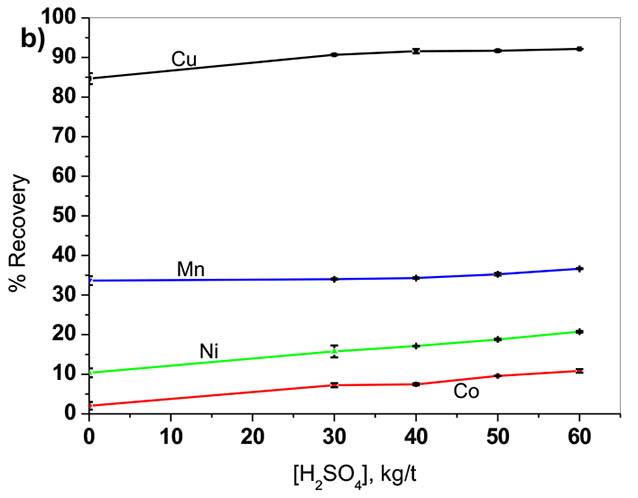

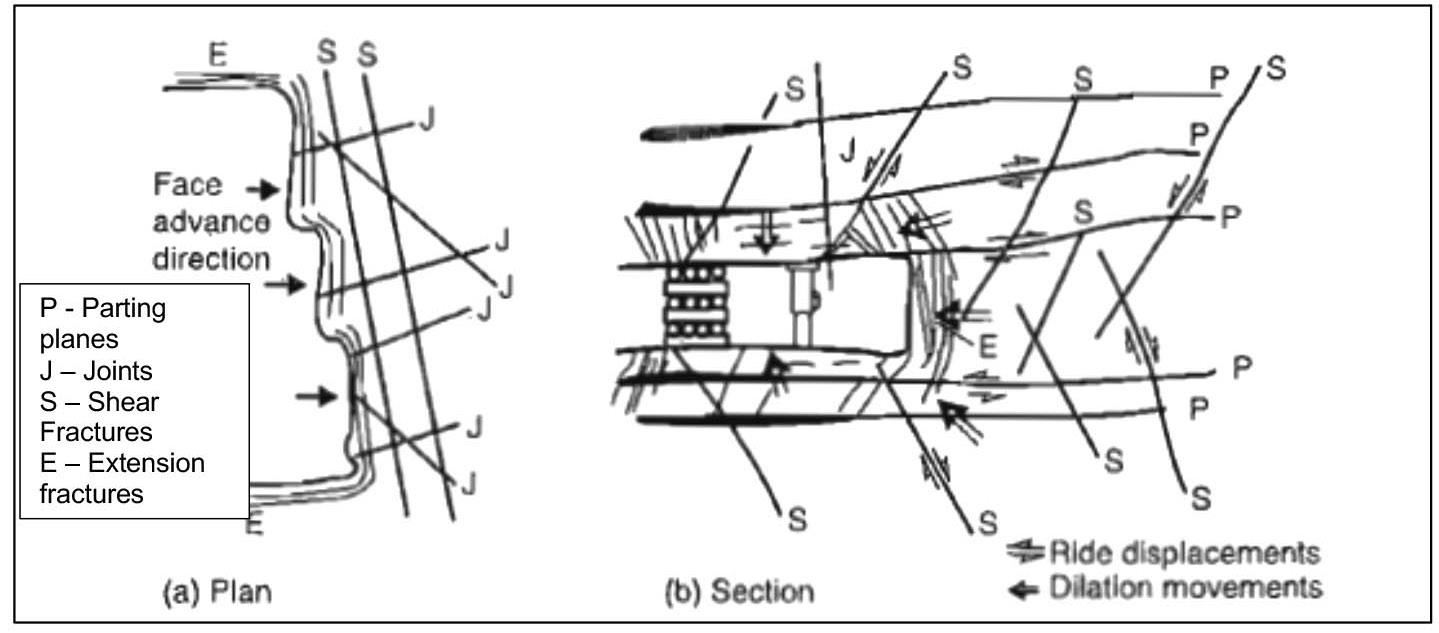

In deep-level, narrow tabular gold mines of South Africa, rock mass classification offers a potential method for predicting geotechnical hazards and optimising support systems. This study assesses the applicability of existing classification methods, emphasising the Mining Rock Mass Rating (MRMR) system, which is adapted for high-stress conditions. Fieldwork at Kusasalethu Mine included underground mapping and analysis of the 2020/2021 fall-of-ground database. The modified MRMR system was tailored to site-specific geological and operational conditions, offering a simplified and practical tool for rock engineering personnel. Results demonstrate its effectiveness in quantifying rock mass conditions and guiding proactive mining decisions. The system enhances understanding of rock mass behaviour and significantly reduces rockfall and collapse risks. Continued refinement and broader application of the MRMR system are recommended to improve safety and operational efficiency in deep-level mining contexts

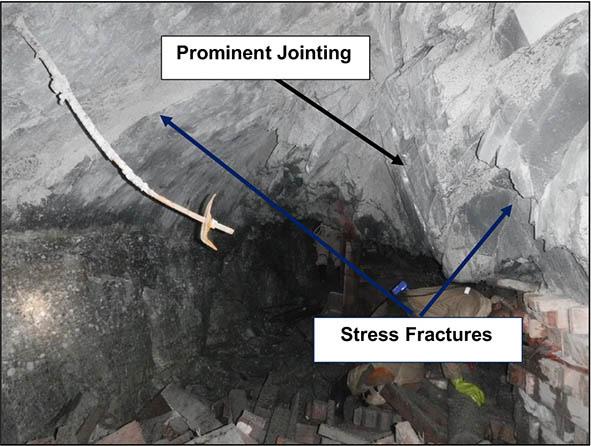

RThe art of rock engineering design and the need for research

ock Engineers and mine personnel frequently disagree on design aspects. These disagreements can lead to poor designs or failures. A number of large collapses have occurred in the bord and pillar mines and open cast mines in the Southern Africa region in the last two decades. Can we learn from the decision-making that led to these collapses and improve? Philosophy offers the opportunity to adopt a reflective learning approach.

ChatGPT gave an interesting insight into this aspect of mine design. Rock engineering is less of an exact science than other engineering disciplines and it is suggested that rock engineering design is best described as a “science-based art”.

The science provides the foundation and design is based on aspects such as rock mechanics principles (e.g., stress-strain behaviour, and failure criteria), empirical methods (e.g., Q-system, and RMR), numerical modelling (e.g., finite element, distinct element, and boundary element methods), monitoring and instrumentation (e.g., extensometers and stress cells) and geological and geotechnical data (e.g., boreholes, core logging, and lab tests). The designs are never purely scientific owing to reasons such as natural variability of the rock mass, the geology is complex and discontinuous, the uncertainty caused by incomplete or generalised data, decisions must often be made with partial information, when conditions change the designs must evolve, and balancing performance, cost, and safety is not purely technical.

Based on these considerations, it implies that “industry standard” criteria for design neither are always the best technical solutions, nor does it imply these criteria are correct. Davide Elmo and his co-workers explored this topic and examined rock engineering using a philosophical approach (Elmo et al., 2022) in Examining Rock Engineering Knowledge through a Philosophical Lens. Geosciences. They noted that rock engineering designs are shaped by cognitive biases, which over time have created a dogmatic barrier to innovation. Almost no attention has been given to the impact that subjectivity, human factors, and lack of scientific replicability have on the empirical design methods used in this field.

As a complicating factor, the modelling methodologies and constitutive codes typically used are difficult to calibrate and represent a universal challenge for the application of rock engineering models. As more complex numerical models are developed for the improved simulation of observed rock mass behaviour, more onerous requirements of model calibration and user expertise are required. This applies to boundary element models, finite element, and finite difference codes. Elmo et al. (2022) made the following important observation: “It is evident generally that if older and simpler solutions have a clear advantage in terms of durability and/or efficiency, even if this advantage is restricted to a limited purpose, they continue to exist and evolve.” In his 2003 Presidential Address: Rock engineering – good design or good judgement, T.R. Stacey recognised this problem and noted that rock masses are so complex that realistic modelling, even with sophisticated methods, is impossible. Simple elastic models with good engineering judgement may therefore continue to exist as one of the practical rock engineering tools.

As a first step to mitigate the uncertainty in rock engineering and the challenge described in this note, Elmo et al. (2022) emphasised that for research, critical thinking needs to be applied and the foundations of rock engineering as an empirical science should be questioned. Furthermore “replication” research should be conducted as a more rigorous form of review compared to the traditional peer review. A recent example of replication research is given by the Le Roux and Malan paper (2024). Researchers need to provide full information to allow others to replicate their work. Very often the assumptions used for numerical modelling of layout design are not given in design reports and these need to be included in the reports.

F. Malan

t a recent conference, a young professional asked me: “What do I do if my boss won’t give me the time to get involved in SAIMM Young Professionals Council activities and events?”

This question cuts to the heart of a broader issue: What is our responsibility as leaders to guide, coach, and prepare the next generation to take our place?

I remember being a young graduate, fresh out of university, unaware of what I did not yet know. It is easy to get consumed by the demands of a day job and neglect the time needed for personal and professional development.

Fortunately, I had the benefit of learning from some exceptional leaders in the industry who encouraged me to look beyond my immediate role. Their guidance helped me understand the importance of contributing to the broader mining community and part of my career and personal development.

While many companies offer formal management and leadership training, this is only one piece of the development journey. My own journey with the SAIMM began 20 years ago, when a respected industry leader encouraged me to join, get involved, and give back.

Over time, my involvement in the SAIMM has significantly contributed to my professional growth and confidence. I have learned how to present ideas clearly through technical papers and conference presentations, built skills through chairing conference organising committees, and gained insight into the value of collaboration across the industry. Serving as Chairperson of the Technical Programme for the past eight years has further strengthened my ability to lead, facilitate dialogue, and shape the Institute’s value proposition.

Now that I have taken on the role of the SAIMM President in 2026, I recognise how deeply this involvement has shaped my leadership capabilities—and how critical it is that we create the same opportunities for others.

Serving on the SAIMM Council provides professionals with exposure to governance responsibilities, often for the first time. It acts as a valuable stepping stone into board-level thinking and decision-making. The SAIMM is, without doubt, a vital platform for developing the future leaders of our industry.

But it only works if we, as the current leaders, support it. That means setting clear expectations for the professionals in our teams and explaining the value—to the company, the individual, and the industry—of dedicating time beyond day-to-day responsibilities.

In our company, every young professional is expected to become a SAIMM member, join the Young Professionals Council, and participate in conference organising committees. As they gain experience, they are encouraged to submit abstracts and contribute papers to conferences.

We have seen the results: Our Operations Director served as Chairperson of the Young Professionals Council, is now a member of the SAIMM Council, and has become a Certified Director. Connie Chijara— another one of our own—is now the chairperson of the Young Professionals Council, the first female to take on this role.

We give them the time because we have seen the benefit—not just to them, but to the industry and to our company. These young professionals are not just contributors today. They are the leaders of tomorrow.

G.R. Lane President,

SAIMM

INTERNATIONAL CONFERENCE 2026

Foundations of Competitiveness and Sustainability

The South African metallurgical industry is facing significant obstacles: Rising production costs, the closure of key service providers like refractory suppliers, and increasing pressure globally for the industry to transform. To face these challenges, it is important for different areas of the industry to work together.

26-28 MAY 2026

CSIR INTERNATIONAL CONVENTION CENTRE, PRETORIA, SOUTH AFRICA

25 May 2026 – Workshops 26-28 May 2026 – Conference 29 May 2026 – Technical Visits

The Southern African Institute of Mining and Metallurgy (SAIMM) invites you to the 2026 Pyrometallurgy International Conference, taking place from 25 to 29 May 2026. The conference will bring together professionals and experts from the fields of pyrometallurgy, furnace tapping, and refractories under the theme: Foundations of Competitiveness and Sustainability. This theme challenges us to collaborate in finding answers to the difficult questions we are faced with and to develop sustainable solutions to safeguard the future of our industry. We are confident that through collaborative research, innovative technology development and operational excellence, we can transform the industry and secure a greener future for the next generation of pyrometallurgists.

By integrating these three key focus areas, we aim to create a platform for strategic thinkers, policymakers, researchers, and economic influencers to share insights, challenge assumptions, and collaborate on practical solutions for the future of the industry.

• Professionals and researchers focused on pyrometallurgy, furnace tapping and refractories

• Industry leaders

• Academics

• Students

DAY 1: WORKSHOPS

• The Future of Pyrometallurgy in South Africa

• Pyrometallurgy in SA Under Pressure – What Next?

• Tapped In – The Future of Sustainable Furnace Tapping

• Quo Vadis, Refractories?

• To Be Confirmed

CALL FOR PAPERS, PRESENTATIONS AND POSTERS

Papers, presentations or posters are invited on any topic related to the conference and can be submitted to any of the three Symposia.

Prospective authors are invited to submit titles and abstracts of their papers in English. The abstracts should be no longer than 500 words and submitted via the SAIMM Abstract Portal.

Acceptance of papers for publication in the SAIMM Journal will be subject to peer review by the Conference Committee and SAIMM Publications Committee pre-conference.

The conference will include a student poster session where students will be given an opportunity to prepare a poster and a 5 minute presentation on their research projects. Students are requested to indicate during the submission that their abstract is for the student poster session. The best student poster will be offered an award.

• Abstract submission deadline: 17 October 2025

• Paper submission deadline: 24 November 2025

• Workshops: 25 May 2026

• Conference: 26-28 May 2026

• Technical Visits: 29 May 2026

• Advanced Tapping and Refractories Gugu Charlie, Conferences and Events Coordinator FOR FURTHER INFORMATION, CONTACT: E-mail: gugu@saimm.co.za Tel: +27 11 530 0238 Web: www.saimm.co.za

Affiliation:

1School of Industrial Engineering, University of the Witwatersrand, South Africa

2Technology Development, Anglo American, South Africa

Correspondence to:

R.A. Raju

Email: ralph.raju@angloamerican.com

Dates:

Received: 14 Feb. 2024

Revised: 13 May 2025

Accepted: 11 Sept.2025

Published: October 2025

How to cite:

Emwanu, B., Raju, R.A. 2025.

Barriers and drivers towards the approval and implementation of new technology in mining: A dilemma and exit strategies framework.

Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 10, pp. 571–580

DOI ID:

https://doi.org/10.17159/2411-9717/3288/2025

ORCiD:

B. Emwanu

http://orcid.org/0000-0001-9906-7245

R.A. Raju

http://orcid.org/0000-0002-5440-556X

by B. Emwanu1, R.A. Raju1,2

Abstract

The implementation of new technology in mining can be likened to a paradoxical situation or dilemma, where, on one hand, major mining projects are not able to solicit investor funding unless it is proven that the business cases were developed using tried and tested mining methods. On the other hand, new and innovative mining technology and mining methods need first to demonstrate and prove themselves under real production conditions over a reasonable period before they can be considered bankable feasibility studies in the mining industry. This dilemma locks new mining technology investments in a continuous cycle of underinvestment. Technological innovations are particularly relevant to the mining industry, which deals with the challenges of depleting access to resources, requiring new solutions to remain sustainable and competitive. In the last decade, the mining industry has come to realise that technological innovations can directly contribute to its sustained competitive advantage (Sanchez, Hartlieb, 2020), helping to reduce costs, lessen environmental impact, increase production, and improve mineral recovery. While understanding barriers and drivers for technology adoption is important for the success of technology implementation efforts and the sustainability of the mining sector (Muduli et al., 2013), this paper suggests strategies to exit the dilemma, proposing a preliminary framework.

Keywords new technology development, hard rock cutting, barriers and drives for new technology adoption

Mining can be seen, from a basic perspective, as involving breaking in situ rock and hauling the broken rock out of the mine while ensuring the health and safety of all key stakeholders, profitability, and sustainability of the operation. Presently, mine operators are exploring ways to achieve both net zero and net profit to stay sustainable. Since the early 1900s, a relentless search has been underway for new and innovative mining technologies that can improve health, safety, environmental conditions, and productivity (Vogt, 2016). From a historical perspective, mining extraction technology has evolved over time and includes milestones such as the invention of the safety lamp, the safe use of explosives for fragmentation, the safe use of electrical energy, the development of continuous miners for cutting coal, the invention of rock bolts for primary and secondary support, open-pit mining technology for mining massive low-grade deposits, the introduction of longwall coal mining, and recently, in situ mining, automated mining, and robotic mining systems (General Kinematics, 2019). Through these achievements, it became apparent in the earlier years that integrating technological innovation into mining practices can result in reduced costs, increased productivity, and improved worker safety. It later became apparent that the mining sector needs to foster innovation to remain competitive.

New mining technology adoption barriers

Understanding barriers and drivers for technology adoption is important for the success of technology implementation efforts and the sustainability of the mining sector. Numerous past studies conducted on technology adoption have focused mainly on organisations in the manufacturing and service sectors. When companies in the mining industry identify new technologies that could make step changes in performance, these companies are often faced with organisational resistance because the organisational incentives set up for production output, work against them (Deloitte, 2016). One would expect operations to jump at the new technology, but if companies are incentivising operational personnel

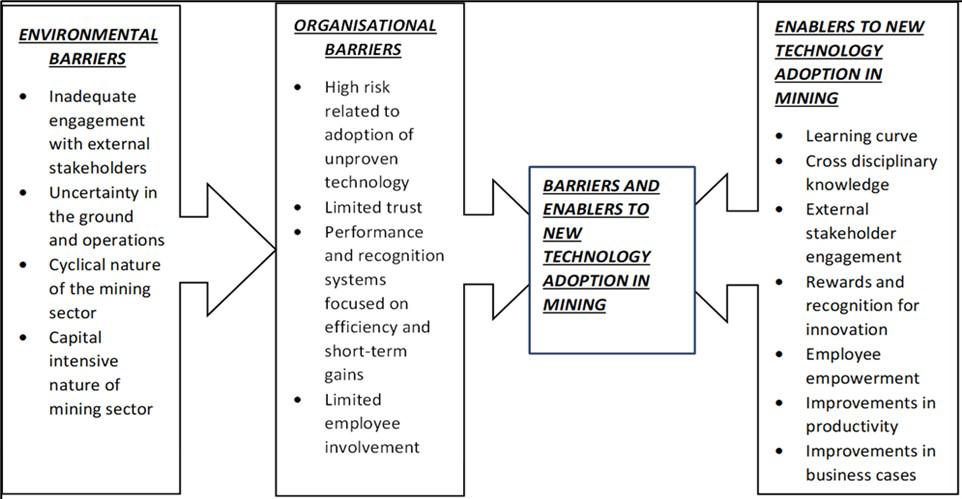

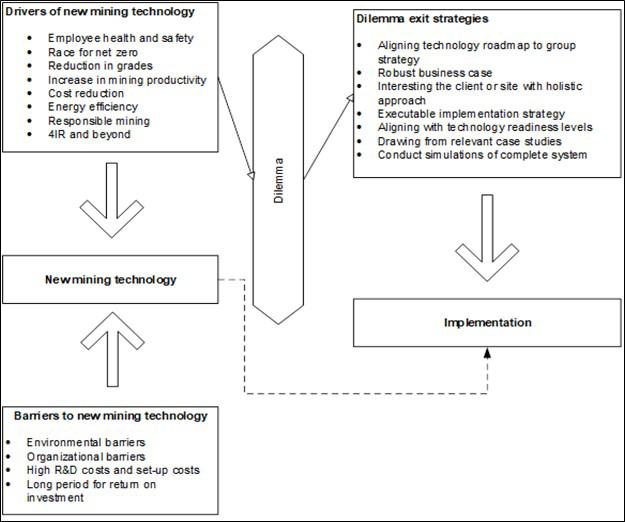

for short-term production performance (Deloitte Monitor,2016), the risk inherent in the technology adoption works against the industry (Deloitte, 2016). The mining industry, in general, relies on third parties to take the lead in the development of new mining technologies. These third parties, such as original equipment manufacturers (OEMs) of mining equipment, are very reluctant to change as this would impact their existing equipment offerings, such as drill rigs, bolters, load haul dumps (LHDs), and dump trucks, among others (Olvera, 2021). The study conducted by Ediriweera and Wiewiora (2021) on barriers and enablers of technology adoption in the mining industry, revealed the following findings, as shown in Figure 1.

Mining projects are very capital-intensive, and mining methodology is locked in once access excavations start (Nanda, Kumar, 2013). Operational procedures become entrenched, and it may be complex to implement new technologies when they involve disruption to these existing operational routines (Nuur et al., 2018). Additionally, and to a greater extent than in other industries, mining operations are often undertaken in geographically remote and isolated areas, adding further challenges (Hall, 2017). These mining operations have a tremendous direct and indirect effect on communities and the environment, posing specific requirements in terms of their operations and approach to climate and social responsibility matters (Fordham et al., 2017). These aspects are also reflected in the emergence of the concept of 'social licence to operate', describing the requirement for civil society to accept and approve mining projects (Prno, Slocombe, 2012). The more miningrelated drivers and barriers of innovation suggest that primitive models, or typical tried and proven methods of value-creating innovations, will deter the diffusion of innovation (Soderholm, Svahn, 2015). Successful demonstration projects help to make the benefits of an innovation visible and tangible, which can positively affect its diffusion (Stewart, Malatji, 2018).

This is significant given the large capital and operational investment costs associated with mining operations (Olvera, 2021). In addition, operational demands can present both drivers and barriers for the diffusion and adoption of innovation. If a technology that was previously used, like drill and blast, becomes obsolete or local conditions require other solutions, this may be a driving factor for the adoption of innovation (Amadi-Echendu et al., 2011). On the other hand, the complexity involved in

implementing an innovation at a potentially remote mine site may result in considerable barriers to its adoption (Nanda, Kumar, 2013). Corporate and social responsibility (CSR) motivates the implementation of new technology due to the imperatives mining companies face to create benefits in terms of safety, sustainability, or reduced emissions (Nasirov, Agostini, 2018).

One of the most dominant drivers for new technology development in the mining industry noted in the literature is employee health and safety (Deloitte, 2016). This includes the pursuit of safety goals, health concerns, and companies striving for environmental and social improvements, all of which may drive the adoption of innovations that have the potential to improve organisational health and safety standards. The second most common driver for the development of new technology noted in the literature is the aim to increase productivity (Olvera, 2021). Hard rock mining presently is a batched process, using drill and blast systems (Vogt, 2016), which leaves room for improvement such that any anticipated productivity improvements triggered by the adoption of new technology is an important motivator for fast-tracking new technology rollout. Thirdly, sustainability, mainly characterised by environmental concerns (Ediriweera, Wierwiora, 2021), has the potential to drive the adoption of innovation in the mining environment. Other frequently noted drivers include increasing efficiency (Gruenhagen, Parker, 2020), the availability of human capital (Macfarlane, 2001), cost reductions (Deloitte, 2016), collaboration (Ediriweera, Wiewiora, 2021), and market pressure (Gruenhagen, Parker, 2020).

Several major mining companies are aligned with global climate goals, which have been agreed upon in international pacts such as the Paris Agreement. A number of these significant mining companies that have committed to supplying the raw materials required to build the low-carbon future have declared their own targets to reduce carbon dioxide emissions by 30% to 40% by 2030 and net zero by 2050 (Lasley, 2022). This is because mining investors, manufacturers that buy metals to build their products, and the public that use those goods are increasingly demanding that minerals and metals be produced with the highest environmental, social, and governance standards (Lasley, 2022). This implies

that mining companies need to investigate innovative ways of maximising value and minimising waste. Moreover, it suggests that for a company striving towards zero-footprint mines, this should be a prerequisite embedded in its strategy. For instance, by electrifying the mobile fleet (IntelliSense.io, 2022), increasing remote operations (International Institute for Sustainable Development, 2021), smart tracking (Institute for Sustainable Development, 2021), and optimised extraction methods (Institute for Sustainable Development, 2021), much of the environmental degradation seen in mining operations could be avoided.

Mining depletes the natural mineral resources and in a strict sense is therefore inherently unsustainable. One can argue, for instance, that there is only a finite amount of copper in the Earth's crust, and each unit of copper extracted increases the fraction of the total copper depleted from the ground.

This reduction in rich mined ore grades means that more low-grade ore needs to be processed to produce the same amount of metal, leading to a rise in energy requirements and, thus, greenhouse gas emissions (Norgate, Haque, 2010). This implies that use of innovation in search for new minerals increases in importance over time as humanity demands for more materials to satisfy its growing needs and strategic minerals become increasingly exhausted, with ore grades rapidly declining.

Requirement for the increase in mining productivity

During the height of the mining boom (Eleven, 2021), recordbreaking commodity prices notionally supported the development of marginal, high-cost, low-productivity mineral deposits (Jacobs, 2016). As commodity prices dropped over the past few years, companies responded by slashing costs, a traditional response to this ever-shifting market cycle (Eleven, 2021).

Productivity is about maximising throughput per unit of time, per unit of quality, and per unit of cost (Macfarlane, 2001). Mining companies may wish to apply a better use of technology to achieve these goals. To do so, they need to seek out innovative technologies capable of unlocking deposits and improving productivity on the mine site.

Miners cannot control the vagaries of the world economy that shift currencies and commodity prices; however, they can control how they operate. As mining companies refocus on becoming lowest-quartile cost producers, they will need to move away from reactionary cost-cutting and towards sustainable cost management programmes. To prevent this constant cycle of cost reduction and high cost creep, miners must go beyond traditional cost-cutting measures. Labour productivity in mining is often measured by output per mining company employee over a given period, such as a year (Vogt, Hatting, 2016), where output typically is the content of the main metal product contained in the ore. Miners need to raise productivity before companies can reclaim shareholder support and deliver bottom line value. Mine operators could scale operations to suit individual projects. Furthermore, they could build stronger funding practices by better understanding the difference between a project's value and the price the market sets.

Energy efficiency improvement programmes in mining are widespread and target all aspects of mining. These include

capturing waste heat, managing electricity demand, mine drainage, ventilation, and generating energy from by-products (Levesque et al., 2014). Hence, opportunities for energy efficiency in mines can be explored in specific mines using innovative ways. However, comminution and material handling (including loading and hauling) operations have been identified to have the highest potential for energy efficiency improvements (BSC Incorporated, 2007). In a study by the Department of Energy in the United States, grinding and diesel equipment used in material handling were identified as the operations presenting the greatest energy savings potential (BSC Incorporated, 2007).

According to the 2022 Responsible Mining Index report, 94% of the mine sites assessed scored an average of less than 20% on the fifteen fundamental economic, environmental, social and governance or EESG issues (Responsible Mining Index, 2022). This demonstrates little evidence of companies translating their lofty corporate commitments into action plans by applying thorough due diligence processes and tracking the effectiveness of implementation. The result has been more verbal promises than action, if any, on responsible mining. However, mining has the potential to innovate and support a more sustainable future through responsible mining. Companies could do this through a range of deliberate actions to ensure that mines remain environmentally sustainable and provide social profitability to the local communities.

Part of responsible mining includes empowering and supporting communities in closing and reclaiming mine sites (Responsible Mining Index, 2022). Even after the closure of a mine, it can present significant harm to surrounding communities and the environment, as processing often uses harmful chemicals. It is apparent that opportunities exist for miners to innovate in this area. However, with the closure of the Responsible Mining Foundation (Responsible Mining Index, 2022) and reluctance by miners to act on these issues, it is doubtful that over the near term (five years ahead), there will be a marked improvement.

The Fourth Industrial Revolution (4IR) is characterised by technologies, and the combination of technologies, such as artificial intelligence, analytics, cloud computing, the internet of things, and other dynamic attributes (Ntsoelengoe, 2021), all of which have enormous potential to grow the industry while improving workplace safety. Modernisation of the mining industry can lead to the required transformation and return to productivity. In the context of 4IR, this should mean that the minerals and metals required to move the globe towards a circular economy can be extracted in less environmentally destructive ways. At the same time, some minerals, such as coal, and hydrocarbons should be left in the ground. The implication is that modernisation of the mining industry can lead to the required transformation and return to productivity.

If investment costs are high, it prevents an innovation from being adopted, as some mining companies lack the necessary financial resources. Many mining companies still struggle to embrace high-tech solutions, as discerned by Filippou and King (2011), who indicate that mining companies have spent, on average, a lower share of their operational expenditure in the development

of technologies compared to other sectors. Between the 1990s and 2000s, the research and development (R&D) intensity of mining companies, measured as R&D expenditure as a percentage of total revenues, was on average only approximately 0.5% (Filippou, King, 2011), significantly lower than sectors such as information and communication technology (ICT) or pharmaceuticals, where the level of R&D spending was 24.7% and 25.1%, respectively, in 2015 (Sanchez, Hartlieb, 2020).

The following are suggested strategies supported by literature for exiting the paradoxical trap, culminating in a preliminary conceptual framework.

Align technology roadmap with group strategy

A company’s success or failure is reliant on the development and adoption of a business strategy that provides guidelines on how it operates and the approved options available to exercise in reaching its long-term objectives (Jordaan, Hendricks, 2009). A technology roadmap is meant to be used as a strategic planning tool in the field of innovation and new technology development. It provides a visual representation and comprehensive plan for the development, adoption, and integration of technologies within an organisation or industry. The purpose of a company’s technology strategy is to gain a sustainable technological advantage that offers a competitive advantage (Du Plessis, 2017). A common problem in the mining division of companies is the lack of aligned business and technology strategies. Mining companies need clear mandates and objectives to guide them in selecting the technologies required for them to achieve their objectives. Khalil (2000) suggests that the first step in developing a business technology strategy is to establish the mining companies’ core competencies. The mining companies' portfolios must be strategically aligned; this would mean that all their projects are ‘‘on strategy’’ and that their breakdown of spending across projects, areas, markets, etc., must mirror their strategic priorities (Schilling, 2017).

Develop a robust business case

Mine development cannot progress without observing positive economic evaluation results, which are the potential profitability of a future mine. According to the discounted cash flow (DCF) method being the most widely used method in mining (Bhappu, Guzman, 1995), net present value is generally calculated as an indicator of project profitability. However, in the case of new technology mining projects, the information required for the economic calculations input data is problematic to generate (Raju, 2021). This is due to the specific features of these projects, which complicate their economic evaluation. The objective of any investment within a firm is to create value for its owners and shareholders. The purpose of allocating money to a division or project is to generate a cash flow substantially more significant than the amount invested in the future. Investors have alternative uses for their funds (Fagan, 2020), and they, therefore, have an opportunity cost if money is invested in a corporate project. The investor opportunity cost is the sacrifice of the return available on the foregone alternative.

Investors are comfortable investing their money in projects that will generate risk-free returns. In the mining sector, the project teams that are tasked to compile bankable feasibility studies are compelled to use tried and tested benchmarks to compile their business cases (Olvera, 2020). When confronted with the transition of new mining technology from demonstration to validation and then into a bankable production system, one needs to follow

a similar rigour as when compiling bankable mining business cases (Nel, Burks, 1999). The team needs to first ensure they have access to an orebody that has all the approved levels of geological, geotechnical, and mineral grade information to develop a bankable study (Nel, Burks,1999).

Find an interested client (site)

Mining used to be a business primarily focused on the technical aspects of getting value out of the ground and extracting the minerals in a metallurgically efficient way (Humphreys, 2020). Without denying the importance of these skills, a narrow focus on technical cases is no longer sufficient to guarantee success, even in rich orebodies. Skills in economics is an essential partner to technical skill in every step of the mining process (Runge, 2015).

While planning for the development, implementation and embedding of new technology within a mining operation, the organisation must have a quantifiable purpose and benefit to the business, whether in terms of economics, environment, or health and safety (Nicholas, Steyn, 2010). Moreover, this analysis must take account of the total value chain of the mining operation. Such a proposed techno-economic analysis should consider the holistic system in which the technology operates as opposed to the standalone benefits of the new device or process (Sanchez, Hartlieb, 2020), which addresses the holistic concerns of prospective clients.

From an overall stakeholder perspective, the optimum mining method will always be the one that maximises the economic returns (Mackenzie, Cusworth, 2007) while keeping the environmental impacts within acceptable levels (Bitarafan, Ataei, 2004), maintaining acceptable working conditions (especially regarding levels of safety risk) for employees (Lane, 2016), and statutory obligations (Bitarafan, Ataei, 2004) including resources recovery stipulations. Collectively, these goals will also satisfy the objectives of the use of these mineral resources and, hence, become attractive to potential clients.

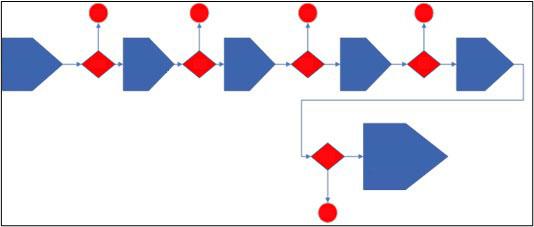

Mining companies usually adopt new technology development processes in-house, and although systematic, new technology development phases can typically be stopped at any time as the process progresses through the development stages, as depicted in Figure 2.

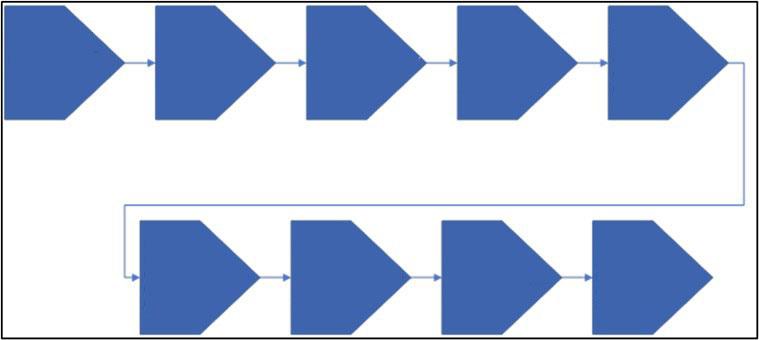

Borrowing from best practices in other industries, this paper proposes the use of a technology readiness levels (TRL) approach to guide the technology development process in mining companies. TRL is a type of measurement system used to assess the maturity level of a particular technology (Beck, 2013). The new mining technology development project (NMTDP) is evaluated against the parameters for each technology level and is then assigned a TRL rating based on the NMTDP progress (De Villiers, 2013). There are generally nine technology readiness levels. TRL 1 is the lowest, and TRL 9 is the highest, as illustrated in Figure 3.

When a technology is at TRL1, scientific research of a concept will begin, and those outcomes will be translated into future research and development. TRL2 occurs once the basic principles have been studied and practical applications can be applied to those initial findings. When active research and design begin, a technology is elevated to TRL3. Generally, both analytical and laboratory studies are required at this level to see if a new mining technology is viable and ready to proceed further through the development process. Often, during TRL3, a proof-of-concept

model is constructed. Once the proof-of-concept technology is ready, the technology advances to TRL4. During TRL4, multiple component pieces are tested with one another. Simulations should be run in environments that are as close to realistic as possible. Once the testing of TRL5 is complete, a technology may advance to TRL6. A TRL6 technology has a fully functional prototype or representational model. TRL7 technology requires that the working model or prototype be demonstrated in a mining environment. TRL8 technology has been tested and operationally qualified, and it is now ready for implementation in an already existing mining system. Once a technology has been operationally proven over an agreed time span, it can be called TRL9, or it is operational ready as a bankable technology or mining system.

Following this approach, a more progressive perspective is suggested, where companies need not stop and abandon their projects entirely every time there is a major challenge (see Figure 2). Rather, they should assess their level of readiness and the stage they are at in relation to the overall pathway and anticipate the next steps that need to be taken to eventually reach the final goal. Using this perspective, it should be possible for a given company to pause the progression of technology development at the current stage for a while without abandoning the project entirely and prepare for the next step in the technology development pathway.

Develop an executable technology implementation strategy

The technology implementation strategy should be developed for the specific mining operation and not be considered as one solution that fits all (Jacobs, 2016). For an appropriate technology implementation methodology, it is reasonable to consider the task as a project and draw from best practices in project management

and general management, as these are tried and tested management systems applied during the implementation of projects of all types. Following project management best practices (Nickolas, Steyn, 2010), when engaging with mining operations, one needs to compile a technology charter (Nel, Burks, 1999). When the technology charter is completed and agreed upon by the various key stakeholders, it must be signed off. This signed-off document will mandate that the technology implementation team have access to the target orebody and mining operation.

The team should then compile a detailed scope of work (Nickolas, Steyn, 2010) for the specific new mining technology execution. This detailed scope of work must also be signed off by the key stakeholders at the operations, stating what is in the new mining technology (NMT) implementation teams' scope and what would be in the scope of the operations and should also include the OEM's task assignments. The NMT target site must be considered a mining section, comprising an organisation's structure with names, titles, and legal appointments clearly stating reporting lines.

Once the detailed scope of work is approved by the technology development teams and the mining operational team, the tender process for the appointment of engineering, procurement, and construction management (EPCM) can begin; it must be clearly stated to the shortlisted EPCMs that this scope will undergo continuous development as the implementation progresses. The EPCM will develop a detailed project schedule and estimate to monitor and control the work packages and specific activities.

New mining technology case studies highlighting major challenges

Several mining companies, in joint agreements with original

equipment manufacturers, have funded large investments to develop new technology to excavate hard rock (Ridley, 2020). These investments mainly focused on developing mechanical complex rock-cutting machines to invent and implement continuous mining technologies (Macfarlane, 2001). One of the most dominant drivers in pursuing these investment programmes was the quest to achieve higher production rates, reduce operational costs, and transition away from the batch, unsafe aspects of drill and blast mining systems (Vogt, 2016).

Many of these joint development agreements (JDA) focused on adapting the existing dominant designs, such as tunnel boring machines, to develop mine access tunnels more quickly (Herrenknecht, 2011). Some companies have developed new cutting techniques, such as undercutting. These are improvements made to mechanical cutting techniques. This cutting system caused tensile rock failure to enhance production rates. While the art of mechanical cutting was optimised, engineers also investigated various material technologies to develop more efficient and wearresistant cutting tools for hard rock excavation (Herrenknecht, 2011).

Some of the outcomes of the early development of mechanical excavation technologies included the mobile miner, continuous miner, mini full-facer, disc boom miner, oscillating disc cutter, activated disc cutting, narrow reef miner, mini mole, mini-disc drum cutterhead, roadheader, tunnel boring machine (TBM) for underground mining, and the mechanical surface miner for surface mining (Hartman,1992; Luxner et al., 2013; Karas’, Wach, 2014). Some of these development efforts have been halted or entirely abandoned by the development teams, including the mobile miner, mini full-facer, the disc boom miner and the mini mole (Hassani, 2008).

Two cases are selected to illustrate typical challenges encountered when introducing new technology developments in mines where the technology is initially embraced with enthusiasm and even progresses to implementation but later gets abandoned. The first example involves one of the joint development agreements

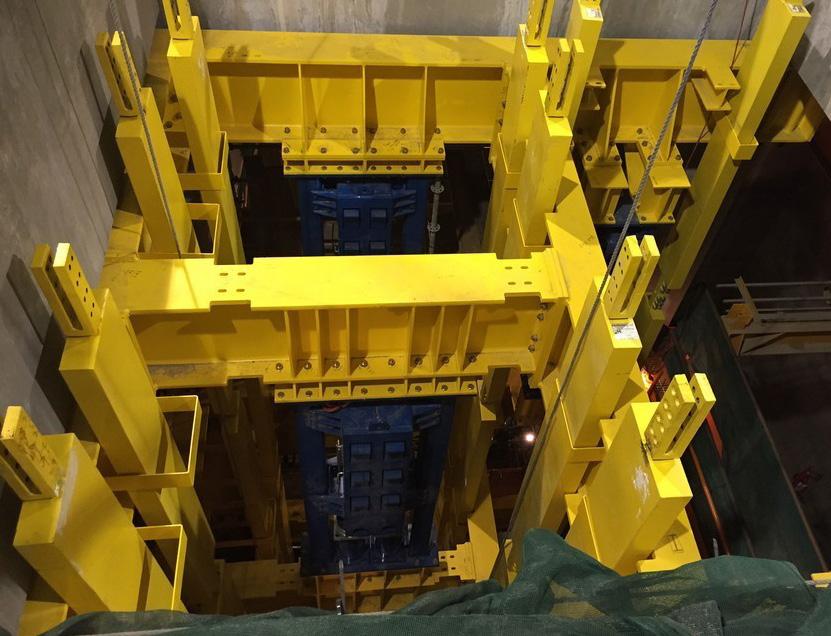

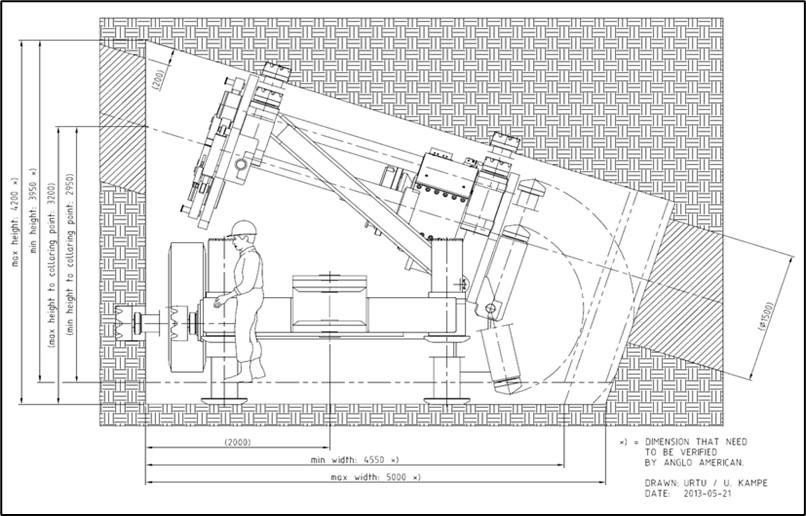

(JDA), which included OEM mining equipment and a major platinum miner. These companies pulled all the stops to develop and test some of these technologies. This equipment aimed to achieve two objectives, namely, rapid access and rapid stoping. The JDA partners designed and developed a slot boring system, Figure 4, which adopted a raise boring technology that used TBM-styled steel discs as a cutting system, as stated by Janicijevic and Valicek (2015). The rock collection system was pneumatic rather than hydraulic to minimise water-related problems with the platinum ore.

The slot boring system was designed to cut slots of 1.5 m dia at a rate of 11.4 m/h. The machine would be set up in haulage, as shown in Figure 5. The haulage needed to be drilled and blasted as a shanty back layout, as shown, 4.5 m high x 5 m wide. The pipes were fed into the machine from the bottom, pushing the cutter head into the reef, and the extracted material would be vacuumed out of the stope via a pneumatic extraction system, as shown in Figure 6. The improvement and advantage expected in using this equipment compared with existing drill and blast have many advantages, such as continuous mining can be much faster if set up correctly, safer as operators can be moved away from the mining face, and excavations are much more stable in the stope as no blast-induced fracturing is propagated into the surrounding rock mass.

The system underwent a testing period but was later abandoned in 2018 after drilling six holes over a period of six months of testing. Some of the major shortfalls revealed from these tests were that the mine design and the drill and blast development were not considered a complete system, the machine experienced excessive vibration, excessive dust was experienced, the pneumatic system was under-designed, the extracted ore could not be loaded onto the strike belt system, material spill over into the adjacent slots occurred, and extreme flexing of push rods occurred. Due to the magnitude of the setup costs and the system not achieving its planned key performance indicators (KPIs), the project was abandoned, and the machine was scrapped.

The second case involves the voestalpine reef miner, the ARM 1100, illustrated by Figure 7, which was developed for the South African platinum mining industry in 2001. The project was a joint development between voestalpine and a consortium of South African platinum mining companies (Moxhan, 2004). The reef mining machine went through several iterations from its inception in 2001 up until 2018, when it was eventually abandoned due to the age of the machine and the added cost of rehabilitation.

During the period of 2001 up until 2018, the machine underwent several modifications and upgrades. The dominant design of this machine was based on undercutting technology but with many cutting tool developments. The other modifications included the ore handling system, machine tramming, bolting,

electrical cable handling system, and the steering system (Ramezanzadeh et al., 2010). These tests of the various systems were carried out as standalone tests as and when issues were noticed on these systems.

The final reef mining machine called the MN220, was abandoned in mid-2018 after the machine was tested using a pneumatic system for the extraction of the cut ore from the face to a test separator and filter system. Following this, a joint development agreement was initiated between an OEM and a major mining company to develop the next generation of this reef mining system. The lessons learnt over the almost twenty years of testing this machine were used as input to the new version of this stoping system, which not only considered the technical aspects of the stoping system but an entirely new mining layout to cater for this system. Although this system has been in development for over twenty years, it is still not regarded as a bankable technology or stoping system in the platinum mining industry. This is because the system can only be regarded as a bankable mining system once it has been vetted by a major mining company. These selected cases highlight the fact that major technology development in mining can take several years, involve major partnerships and protocols, and be costly to set up, and yet mining companies will be slow to adopt the new technology, or in the worst-case scenario, as often happens, it becomes abandoned.

The drivers of new mining technology build on traditional ones, such as productivity and cost reduction, and feature both technological, social, and competitive related issues like net zero, responsible mining and 4IR, among others. Barriers to mining technology are largely those identified by Ediriweera and Wiewiora (2021), augmented by experience from case studies in South Africa that highlight high R&D and setup costs, and long periods of return on investments.

There is a dilemma in implementation, as mines are reluctant to adopt unproven mining technology until the technology is proven in an actual operation, where it can prove its planned KPIs over a set period. Nevertheless, a significantly small number of these technologies, which are either less costly to set up and implement or initially accompanied by high enthusiasm and substantial buy-in from stakeholders, are approved and implemented even if later abandoned. A substantial portion of the new mining technology, however, faces the dilemma of reluctance to be tried out and requires either robust return on investment or exit strategies, as shown in Figure 8, that can convince decision makers to take the risk of implementation. This hesitation is further compounded by operational inertia, regulatory uncertainty, and the high capital intensity of mining projects, which make experimentation on unproven technologies a costly option.

Additionally, the fragmented nature of mining operations often spread across geographies and governed by varying local policies creates inconsistencies in technology adoption. On the other hand, drivers such as increasing pressure for sustainability, digital transformation mandates, and competitive advantage through efficiency gains are beginning to shift the narrative. Technologies that align with ESG goals or demonstrate clear productivity enhancements are more likely to gain traction. Therefore, the dilemma is not merely technical but deeply strategic, requiring a framework that balances innovation with risk mitigation and provides clear exit pathways should the technology fail to deliver as expected.

Conclusion

This article notes key barriers and drivers for the implementation of new technology in the mining industry and proposes that a standardised technology development pathway applicable to other industries is adaptable to the mining sector. However, although lessons can be drawn by comparing the parallel features and similarity of pathways with other industries, the paper concludes that the mining industry has an outstanding characteristic to be confronted with, which may lead to a different outcome from others. Due to the capital-intensive nature and long periods before the return on investment (ROI) of mining investments can be realised, mining companies are reluctant to adopt new mining technology, as illustrated by the case studies discussed. The cost and time considerations, among others, are significant barriers to the adoption of new technology in mining. The article argues that for developers of new technology in mining, the approach used to present the business case to decision makers should incorporate both an economical and holistic perspective in addition to technical viability for a better chance of adoption. Such an approach is proposed in this paper as a preliminary conceptual framework to guide stakeholders on key areas to consider when presenting new technology to mining decision makers. As an initial framework, more work is required to test and pilot the concepts proposed.

Referencesw

Amadi-Echendu, J., Lephauphau, O., Maswanganyi, M., Mkhize, M. 2011. Case studies of technology road mapping in mining, Journal of engineering and technology management

Beck, D.F. 2013. Technology development life cycle processes, Fuzing and instrumentation technologies, Sandia national laboratories.

Bhappu, R.R., Guzman, J. 1995. Mineral investment decision making, Engineering and Mining Journal, vol. 7, pp. 36–38. Bitarafan, M.R., Ataei, M. 2004. Mining method selection by multiple criteria decision making tools, The Journal of The South African Institute of Mining and Metallurgy

BSC Incorporated. 2007. Mining Industry Energy Bandwidth Study, U.S. Department of Energy, Industrial technologies program Deloitte. 2016. Innovation mining Australia 2016, Monitor Deloitte. Available at: https://www.deloitte.com/content/dam/assetsshared/legacy/docs/gx-au-en-innovation-in-mining.pdf

De Villiers, R. 2013. Technology Development Handbook, Anglo American Plc.

Du Plessis M.J. 2017. Evaluation of Technology Strategy Application in the South African Mining Industry, researchgate.net/ publication/274364033

Ediriweera, A., Wiewiora, A. 2021. Barriers, and enablers of technology adoption in the mining industry. Resources Policy, vol. 73.

Eleven. 2021. Technological Innovation - A challenge worthy of the mining industry available at: https://eleven-strategy.com/ technological-innovation-a-challenge-worthy-of-the-miningindustry/

Fagan, D. 2020. Real life examples of opportunity costs. Open vault blogs. Available at: Stlouisfed.org/open-vault/202/january/reallife-exmples-opportunity-costs

Filippou, D., King, M.G. 2011. R&D Prospects in mining and metals industry, Resource Policy, vol. 36, no. 3, pp. 276–284.

Fordham, A.E, Robinson, G.M, Blackwell, B.D. 2017. Corporate social responsibility in resource companies – opportunities for developing positive benefits and lasting legacies. Resource Policy vol. 52, pp. 366–376.

General Kinematics. 2019. A brief history of mining: the advancement of mining techniques and technology. Available at: https://www.generalkinematics.com/blog/a-brief-history-ofmining-and-the-advancement-of-mining-technology/

Gruenhagen, J.H., Parker, R. 2020. Factors driving or impeding the diffusion and adoption of innovation in mining: A systematic review of the literature. Resources Policy, Elsevier.

Hall, H. 2017. Exploring innovation in Northern Canada with insights from mining innovation systems in greater Sudbury, Ontario. The Northern Review, vol. 45, pp. 33-56. Available at: https://doi.org/10.22584/nr45.2017.003

Hartman, H.L.1992. SME Mining Engineering Handbook, 2nd edition, vol 2.

Hassani, F. 2009. Review of explosive free rock breakage technologies and expertise, Final report submitted to: The technical committee of the explosive-free rock breakage initiative. Submitted by McGill University Department of Mining and Materials Engineering

Herrenknecht, A.G. 2011. Utility Tunneling, Traffic Tunneling, March.

Humphreys, D. 2020. Mining productivity and the fourth industrial revolution. Mineral Economics Journal

IntelliSense.io. 2022. An alternative approach to winning the race to net zero, available at: https://www.intellisense.io/2022/07/analternative-approach-to-winning-the-race-to-net-zero/ International Institute for Sustainable Development. 2021. New Tech, New Deal: Mining policy options in the face of new technology. The Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development (IGF), August.

Jacobs, J. 2016. Creating a technology map to facilitate the process of modernisation throughout the mining cycle. M.Eng (Mining Engineering) thesis, Department of Mining Engineering, University of Pretoria, South Africa.

Janicijevic, D., Valicek, P. 2015. A review of hard-rock cutting equipment technology development at Anglo American and Anglo Platinum. Proceedings of MPES 2015, Mine Planning and Equipment Selection, ‘Smart Innovation in Mining’, Sandton Convention Centre, Johannesburg, South Africa. Southern Institute of Mining and Metallurgy, Johannesburg.

Jordaan, J.T., Hendricks, C. 2009. The challenge of technology adoption and utilisation in the mining industry – A focus on open pit mining technologies. SAIMM, Base Metals Conference

Karas, H., Wach, M. 2014. New mechanization and automation roads in continuous mining – KGHM’s experience and future steps. Rapid Development Conference, Krakow, pp. 29–30 September.

Khalil, T. 2000. Management of Technology – The Key to Competitiveness and wealth creation, McGraw-Hill International Editions, pp 1–3; pp. 192 – 195; pp. 207–216.

Lane, A. 2016. Innovation state of play, Africa mining edition, Mining Indaba and Monitor Deloitte study

Lasley, S. 2022. Mining sector races to net zero by 2050. Available at: https://www.metaltechnews.com/story/2022/08/10/miningtech/mining-sector-races-to-net-zero-by-2050/1030.html

Levesque, M., Miller, D., Paraszczak, J. 2014. Energy and mining the home truths. Journal of Cleaner Production ,vol. 84, no. 1, pp. 233–255.

Luxner, T., Deen, J., Koske, M. 2013. Use of tunnel boring machines at the still water mining company’s underground PGM mines. Rapid Development Conference, Sydney.

Macfarlane, A.S. 2001. The implementation of new technology in southern African mines: Pain or panacea. Journal of the South African Institute of Mining and Metallurgy, vol. 101, no. 3, pp. 115–126

Mackenzie, W., Cusworth, N. 2007. The use and abuse of feasibility studies, Project evaluation conference, Melbourne Victoria. Enthalpy, available at: enthalphy.com.au

Moxam, K.A. 2004. A hard rock narrow reef mining machine— ARM 1100. International Platinum Conference ‘Platinum Adding Value’, The South African Institute of Mining and Metallurgy. Muduli, K., Govindan, K., Barve, A., Geng, Y. 2013. Barriers to green supply chain management in Indian mining industries: a graph theoretic approach, Journal of Cleaner Production, vol. 47, pp. 335-344.

Nanda, N.K., Kumar, S. 2013. Developments in mining machinery and systems, both surface and underground, for meeting the future challenges. Journal of Mines, Metals and Fuels, vol. 61, no. 7–8, pp. 163–169.

Nasirov, S., Agostini, C.A. 2018. Mining experts’ perspectives on the determinants of solar technologies adoption in the Chilean mining industry. Renewable and Sustainable Energy Reviews, vol. 95, pp. 194–202.

Nel, l., Burks, S. 1999. The bateman approach towards achieving economic and financial requirements for feasibility studies. Journal of the Southern African Institute of Mining and Metallurgy, pp. 303–315

Nicholas, J.M., Steyn, H. 2010. Project management for business, engineering, and technology principles and practices, 3rd edition, Butterworth-Heinemann.

Norgate, T., Haque, N. 2010. Energy and greenhouse gas impacts of mining and mineral processing operations. Journal of Cleaner Production.

Ntsoelengoe, B. 2021. Mining 4.0 – Modernization of mining in the fourth industrial revolution. Publication of CSIR Sciencescope, vol.17, no1.

Nuur, C., Gustavsson, L., Laestadius, S. 2018. Capability creation in the natural resource-based sector: experience from Swedish mining. Innovation and Development, vol.8, no. 1, pp. 103–123.

Olvera, B.C. 2021. Innovation in Mining: what are the challenges and opportunities along the value chain of Latin American suppliers, Mineral Economics, vol.3 5, pp. 35–51.

Prno, J., Slocombe S.D. 2012. Exploring the origins of ‘social license to operate’ in the mining sector: perspectives from government and sustainability theories Resources Policy, vol. 37, no. 3, pp. 346–357.

Raju, R.A. 2021. Comparison of the Business Case between Explosives and Non-Explosives Mining Methods for Underground Platinum Mining Projects, Research Gate, 2021.

Ramezanzadeh, A., Wood, M. 2010. A state of the art review of mechanical rock excavation technologies, International Journal of Mining and Environmental Issues, vol 1 no1.

Responsible Mining Index. 2022. RMI Report, available at: https://2022.responsibleminingindex.org/en

Ridley, M. 2020. How the innovation works, 4th Edition, Estate London.

Runge, P. 2015. Minimum Engineering Requirements, Minarco Perspectives, Issue 128.

Sanchez, F., Hartlieb, F. 2020. Innovation in mining industry: Technological trends and a case study of the challenges of disruptive innovation, Mining, Metallurgy and exploration.

Schilling, M.A. 2017. Strategic management of technological innovation, 5th Edition, McGraw Hill Education.

Soderholm, P., Svahn, N. 2015. Mining, regional development and benefit sharing in developed countries, Resources Policy, vol. 45, pp. 78–91.

Stewart, J.M., Malatji, S.M. 2018. Development of the MOSH leading practice adoption system – a science-based system for managing behaviour change, Journal of Southern African Institute of Mining and Metallurgy, vol. 118, no. 3, pp, 259–277.

Vogt, D. 2016. A review of rock cutting for underground mining: past, present, and future. Journal of The South African Institute of Mining and Metallurgy, vol. 116, no. 11, pp. 1011–1026.

Vogt, D., Hattingh, T. 2016. The importance of people in the process of converting a narrow tabular hard-rock mine to mechanization, Journal of The South African Institute of Mining and Metallurgy, vol. 116, no. 3, pp. 265–274. u

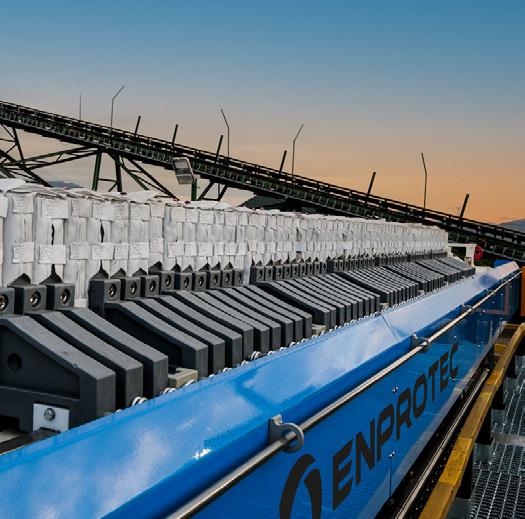

Introduce advanced solutions to improve thickener and filtration efficiencies amid changing ores

Date: 24-25 June 2026

Venue: Mintek, Johannesburg

We are excited to invite you to an exclusive seminar collaboratively hosted by technical experts from Solenis, ENPROTEC and Mintek.. This seminar will focus on addressing key challenges in thickener and filtration operations operations, including optimising performance amid variable ore characteristics, enhancing water recovery through innovative dewatering techniques, implementing sustainable tailings management practices, and leveraging automation and advanced control systems to boost overall process efficiency.

As the mining industry embraces increasingly complex mineral deposits and adapts to evolving ore grades, there is a growing opportunity to leverage innovation and advanced technologies to boost efficiency and sustainability. Dewatering systems stand at the heart of this transformation, playing a crucial role in optimising dewatering processes and enabling responsible tailings management. By enhancing thickener and filtration performance, mining operations can achieve greater productivity while meeting their environmental stewardship commitments.

In recognition of these opportunities, this seminar will provide a comprehensive platform to explore cutting-edge technologies, share practical insights, and foster collaboration aimed at operational excellence and sustainability in mineral processing.

KEY TOPICS TO BE COVERED:

• Impact of ore variability on dewatering performance

• Innovative dewatering and water recovery technologies

• Sustainable tailings deposition practices

• Automation and advanced control systems to enhance thickener and filtration reliability and efficiency

Participants will gain valuable knowledge and actionable strategies to optimise thickener and filtration operations amid changing ore conditions.

Join us for an engaging, solutions-oriented workshop designed for professionals seeking to improve thickener and filtration reliability, maximize water reuse, and ensure responsible tailings management.

FOR FURTHER INFORMATION, CONTACT:

Gugu Charlie,

Conferences and Events Coordinator

E-mail: gugu@saimm.co.za

Tel:011 538 0238

Web: www.saimm.co.za

Affiliation:

1The University of Dar es Salaam, Mining and Mineral Processing Engineering, School of Mines and Geosciences, Tanzania

Correspondence to:

B.F. Giyani

Email: giyani.baker@udsm.ac.tz

Dates:

Received: 24 Dec. 2024

Revised: 14 Aug. 2025

Accepted: 27 Aug. 2025

Published: October 2025

How to cite:

Giyani, B.F., Salama, A. 2025. Development of mining industry in Tanzania: A review. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 10, pp. 581–592

DOI ID:

https://doi.org/10.17159/2411-9717/3629/2025

ORCiD:

B.F. Giyani

http://orcid.org/0009-0009-3140-2380

A. Salama

http://orcid.org/:0000-0001-6210-978X

by B.F. Giyani1, A. Salama1

Abstract

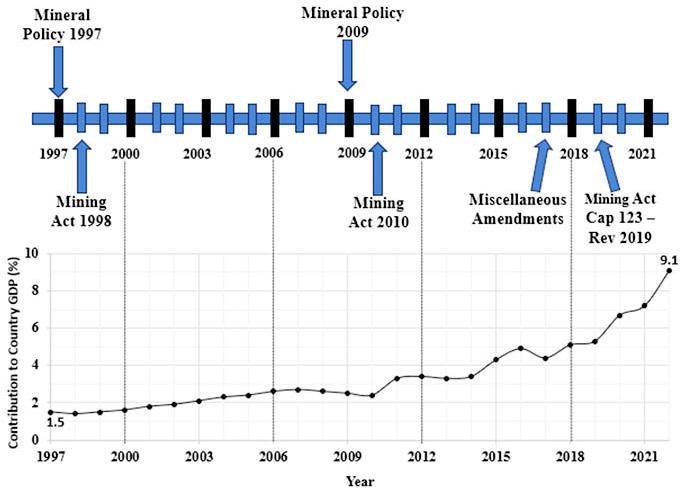

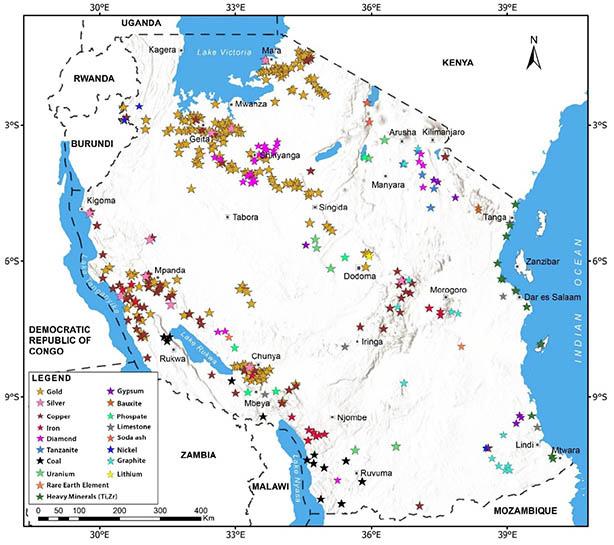

Tanzania is a country with a variety of mineral deposits, including metallic minerals, gemstones, mineral fuels, industrial minerals, and critical minerals. This study provides an overview of mining legal framework, mineral occurrence and production, challenges in the mining sector, and government initiatives. The aim is to demonstrate the development of the mining sector in Tanzania and explore the potential for further mining investment in the country. The mineral production data showed generally increasing trends over the years, for example, gold production increased from 42 tonnes in 2018/2019 to around 50 tonnes in 2023/2024. Despite the growth, the mining sector encounters several challenges, including a lack of detailed geological information on mineral deposits, inadequate infrastructures in some remote mining sites, the existence of informal artisanal miners, and mineral smuggling. The Tanzanian government has introduced several initiatives to address these challenges, including carrying out the highresolution airborne geophysical survey to increase geological information in some areas, the formalisation of artisanal and small-scale mining, establishing mineral markets to combat mineral smuggling, and encouraging mineral value addition within the country.

Keywords mineral commodities, critical minerals, rare earth elements, mineral occurrence, artisanal and small-scale miners, mining legal framework

Introduction

The global demand for mineral commodities has increased rapidly in recent years due to technological advancement, industrial development, and a growing world population. Currently, mining operations worldwide extract about 70 billion tonnes of ore and waste materials from the ground each year (Vidal et al., 2021). The global decline of ore grades also accelerates the mineral demand as higher-grade deposits are mined and exhausted over time (Calvo et al., 2016). For instance, the global copper head grades dropped from about 4.0% in 1900 to around 0.65% in 2015 (Flores et al., 2020), and recently (2022), it has dropped to less than 0.52% (Holden, 2023). This means larger volumes of low-grade ores must be mined and processed to keep up with the increasing metal demand. In addition, mining companies are increasing their production in the existing deposits and searching for new mineral resources across the world, including Tanzania.