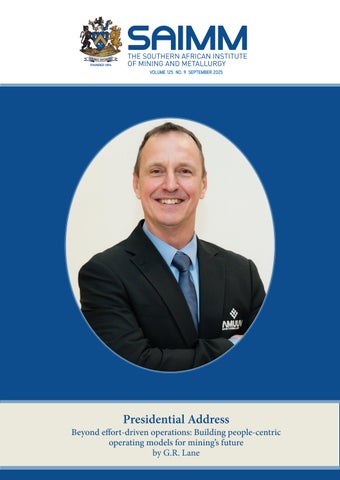

Presidential Address

Beyond effort-driven operations: Building people-centric operating models for mining’s future by

G.R. Lane

Beyond effort-driven operations: Building people-centric operating models for mining’s future by

G.R. Lane

Gary Lane was born in Queenstown in the Eastern Cape in 1968. He matriculated from Randpark High School in 1986, where he served as head boy. A talented sportsman, he played rugby and excelled in athletics, winning the victor ludorum in the 100-metre event on several occasions.

With the support of an Anglo American Scholarship, Gary studied Civil Engineering at the University of the Witwatersrand, graduating with a Bachelor of Science degree in 1990. After completing his compulsory national service, he began his professional career with Anglo American in projects, contributing to several major capital developments. These included serving as Resident Engineer for the construction of Namakwa Sands on South Africa’s West Coast, Project Engineer for the Sadiola Hill Gold Mine in Mali, Project Manager for the Bulk Acid Handling Facility at the Jwaneng Aquarium for Debswana in Botswana, and Project Engineer for the Combined Treatment Plant for De Beers in Kimberley.

After a decade in these technical roles, Gary broadened his expertise by completing a Master of Business Administration through Bond University in Australia in 2001. That same year, he transitioned into entrepreneurship and co-founded Cyest Corporation (now BSC Global), where he established and built the mining practice. His work focused on mine optimisation, scenario planning, techno-economic modelling, value driver trees, and software development. He also led a pioneering syndicate driven development programme to develop an innovative top-down mine planning solution.

In 2016, Gary co-founded the Vuuma Group of Companies with Harry Sinko. Guided by systems thinking and a people-centred philosophy, the group developed a comprehensive service offering encompassing business improvement skills and capability development using a physical mining value stream simulation, rapid operational improvement using Lean Six Sigma and theory of constraints, and the design of people-centric operating models across industries worldwide.

Throughout his career, Gary has drawn inspiration from industry leaders and diverse leadership styles, which have shaped his own approach. He is particularly passionate about developing young professionals and remains committed to mentorship and leadership development.

Gary has also provided significant service to the Southern African Institute of Mining and Metallurgy (SAIMM). He became a member in 2004, contributing actively to conference organising committees and presenting more than ten technical papers. In 2016, he was elected to the SAIMM Council, and the following year he was appointed Chairperson of the Technical Programmes Committee for Mining, a role he held until 2025.

Beyond his professional commitments, Gary is an enthusiastic mountain biker who has competed in stage races across South Africa.

He also enjoys road trips and outdoor adventures, with highlights including kayaking on Yellowstone Lake, exploring the swamplands of Louisiana in the United States and a 5-day unsupported rafting trip down the orange river with his daughter Chloe, who is currently training to become a field guide.

OFFICE BEARERS AND COUNCIL FOR THE 2025/2026 SESSION

President G.R. Lane

President Elect

T.M. Mmola

Senior Vice President

M.H. Solomon

Junior Vice President

S.J. Ntsoelengoe

Incoming Junior Vice President

M.C. Munroe

Immediate Past President

E. Matinde

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk M.A. Mello

A.D. Coetzee K. Mosebi

Z. Fakhraei M.J. Mothomogolo

B. Genc S.M. Naik

F. Lake G. Njowa

K.M. Letsoalo S.M. Rupprecht

S.B. Madolo A.T. van Zyl

Co-opted Council Members

K.W. Banda

M.L. Wertz

Past Presidents Serving on Council

N.A. Barcza W.C. Joughin

R.D. Beck C. Musingwini

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

M.L. Wertz – TP Mining Chairperson

W. Broodryk – TP Metallurgy Chairperson

C.T. Chijara – YPC Chairperson

T.S. Ndlela – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC Vacant

Johannesburg A. Hefer

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West T. Nsimbi

Pretoria P.G.H. Pistorius

Western Cape M.H. Solomon

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

E. Matinde (2024-2025)

Editorial Board

S.O. Bada

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

P.N. Neingo

S.S. Nyoni

M. Onifade

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

Past President’s serving on the Editorial Board

R.D. Beck

R.T. Jones

W.C. Joughin

C. Musingwini

T.R. Stacey

S. Ndlovu*

*International Advisory Board member International Advisory Board members

R. Dimitrakopolous

R. Mitra

A.J.S. Spearing

E. Topal

D. Tudor

F. Uahengo

D. Vogt

Editor/Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31

Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

Journal Comment: Safety and the human dimension by M. Onifade ..................................................................

Profiles of the Branch Chairpersons

Presidential Address: Beyond effort-driven operations: Building people-centric operating models for mining’s future by G.R. Lane ...................................................................

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2025 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys

Auditors

Genesis Chartered Accountants Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Thermochemical evaluation of elemental phosphorus recovery from sewage sludge by A. Kotze, D. Messina, Y. Cryns, E. Nagels, S. Arnout ...................................................................

The FlashPhos process aims to recover white phosphorus (P4) from sewage sludge by drying, flash combustion/gasification, and carbothermic refining steps. This study evaluates the material behaviour of sewage sludge ash melting and reduction in a refining furnace for the novel FlashPhos process. A clean slag is produced in the process free of heavy metals making it suitable to be used as a cement-like binder material. The main heavy metals that co-evaporate with the phosphorus are Zn, Pb, As, Sb, and Sn. Additional processing steps will be required to remove these to produce a pure P4 product.

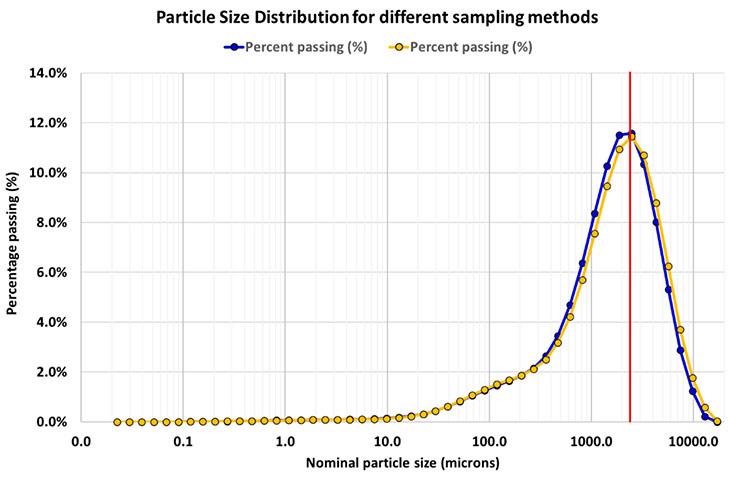

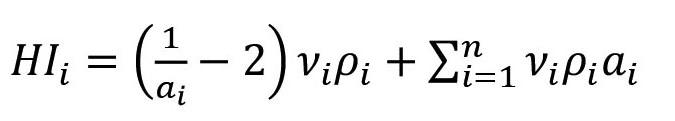

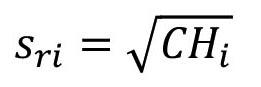

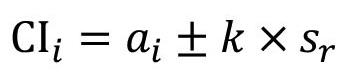

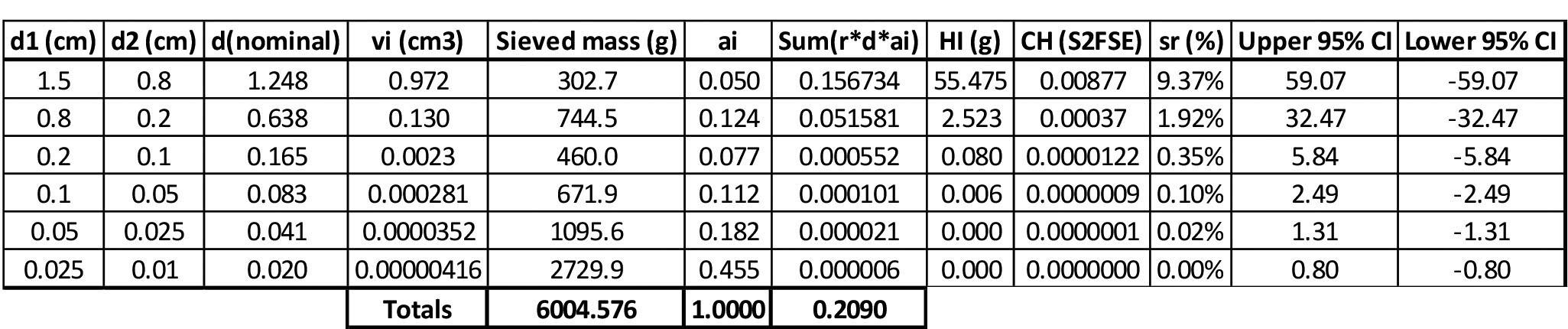

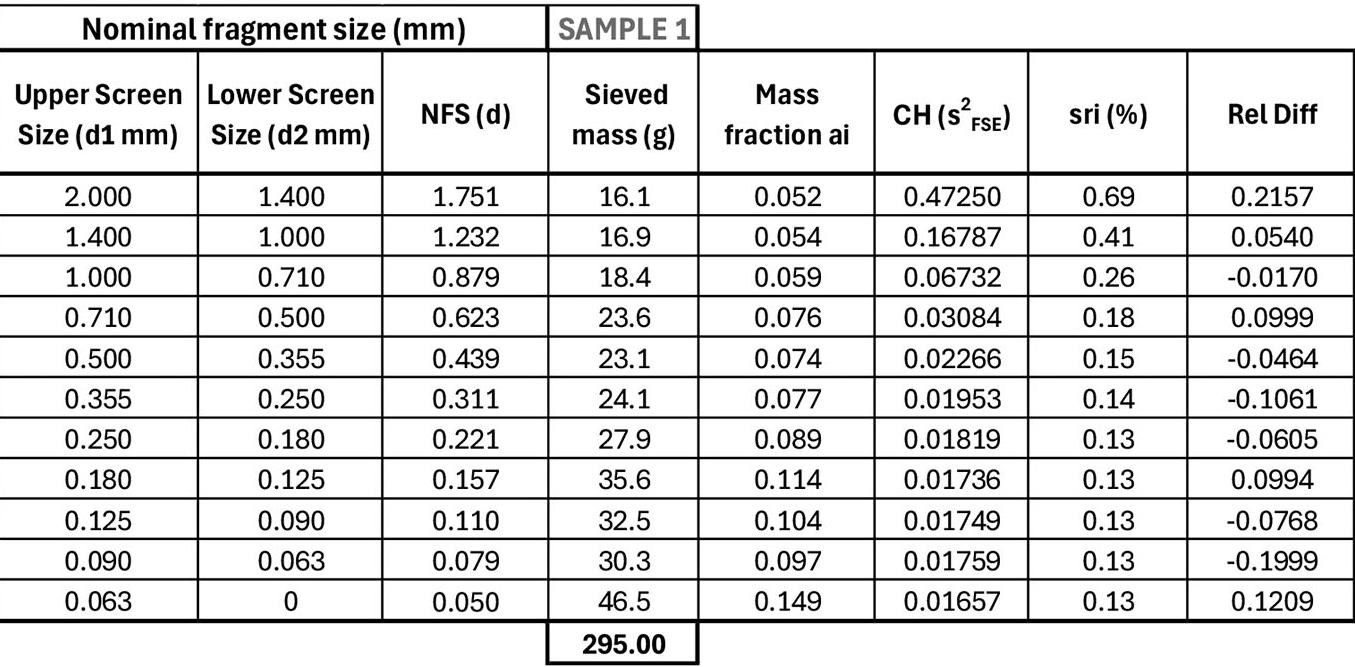

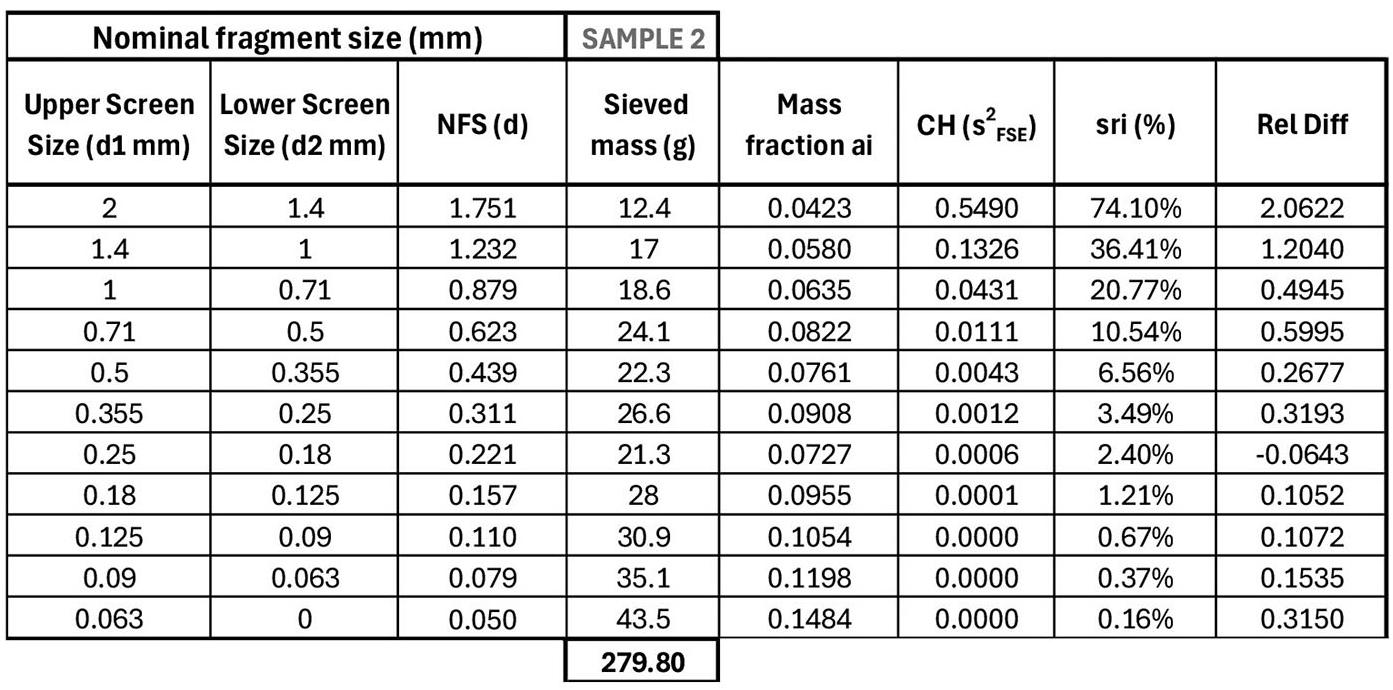

Testing sample representivity using particle size distribution by R.C.A. Minnitt, P. Minkkinen ......................................................................................

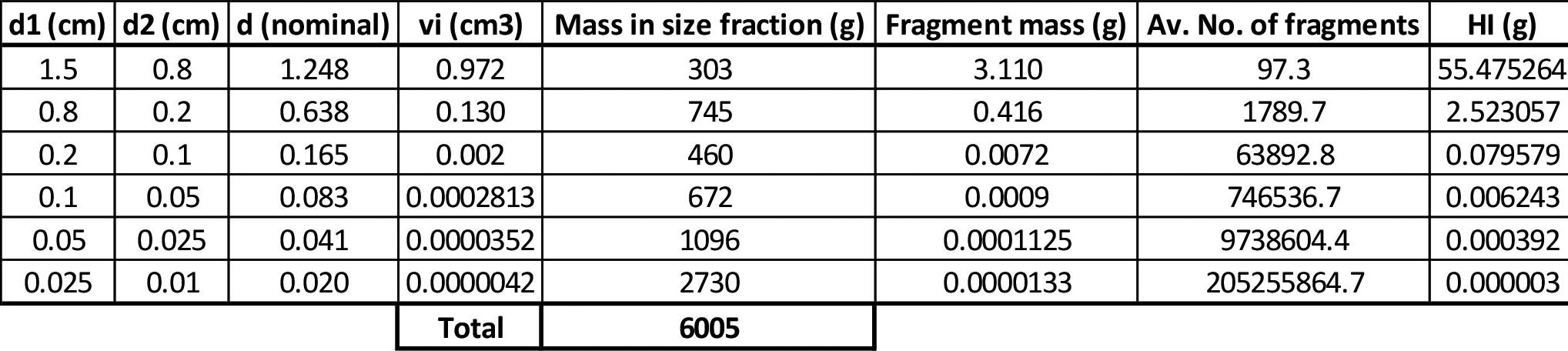

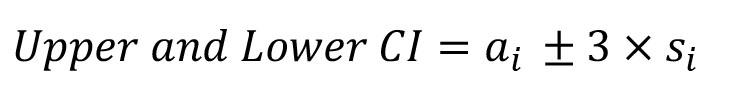

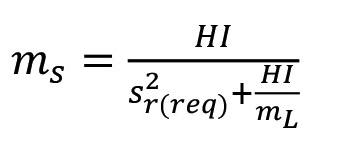

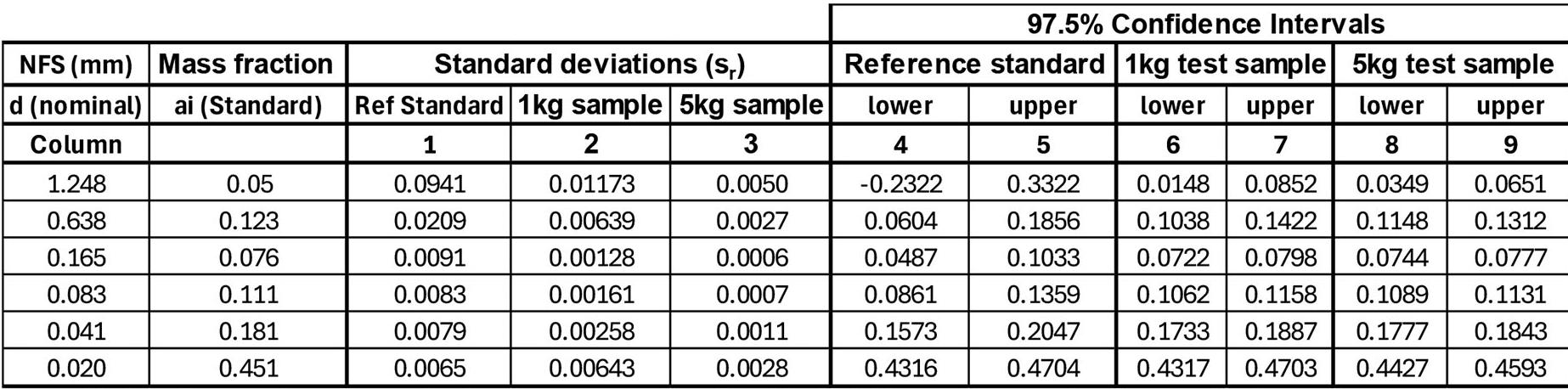

Sampling blasthole cuttings poses challenges due to large material volumes, segregation, and uneven settling of particles in dense gold bearing ores. Commonly used sampling methods, such as spear or sectoral sampling, may lack representativeness. A case study demonstrates this approach by using a 6.005 kg benchmark sample to assess two additional samples (1 kg and 5 kg), highlighting particle size distribution’s role in detecting sampling errors and refining protocols. An example of three test samples collected from reverse circulation drill cuttings compared to a standard reference sample is presented to illustrate a quality assurance/quality control procedure for reverse circulation drilling.

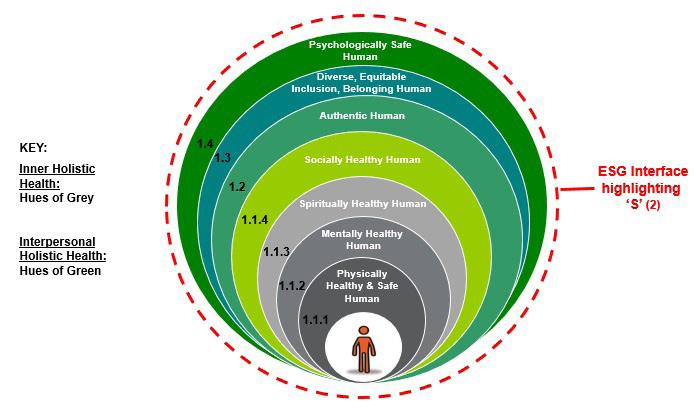

Novel integrated holistic healthy human framework: A special lens on the minerals industry by V. Morar, U. Govender, B. Genc, G.L. Smith ..........................................................................

This paper presents a novel holistic healthy human framework for C-suite executives and senior leaders in the minerals industry. The value-add of the framework centres around the integration of inner holistic health and interpersonal holistic health to support and enhance environment, social, and governance transformation, with a focus on the social enterprise. Insights were gleaned from interviews with 10 C-suite executives, each with over twenty years of experience in mining or business leadership.

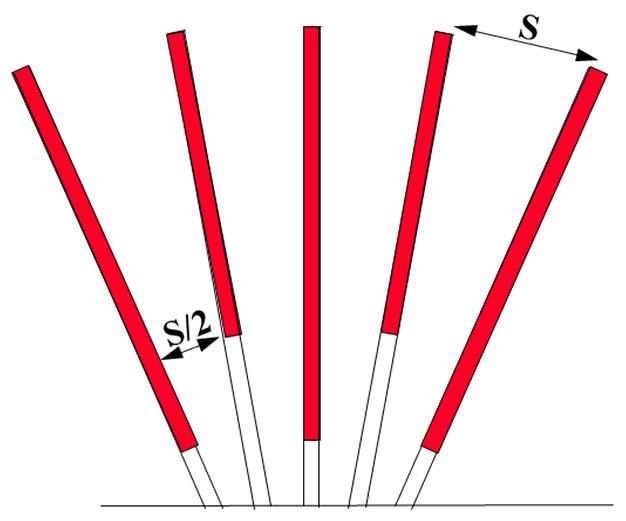

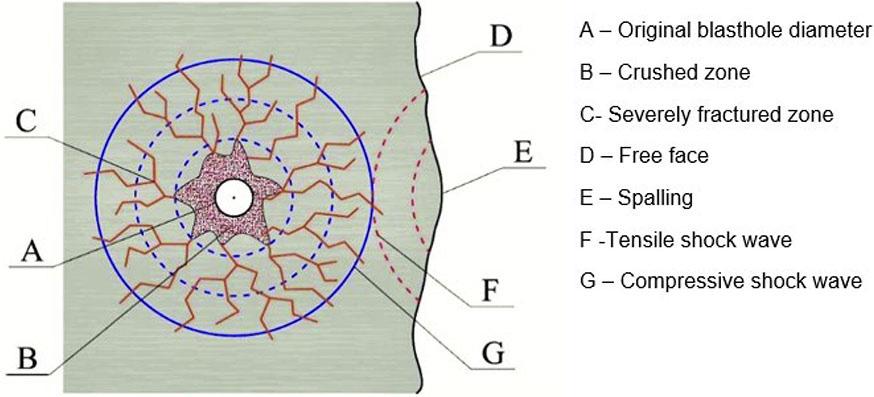

Using the Aegis underground drill and blast analyser to optimise drill patterns: A case study by M.J. Nong, E. Uludag, P.J.K Leeuw

This study investigated persistent fragmentation problems at a longhole stoping operation that suffered from simultaneous oversized rock blockages in 300 mm × 300 mm grizzlies and excessive fines. Fifty-one muckpile images from five blasted stopes were analysed with Split-Desktop. Existing drill patterns were then evaluated with the Aegis underground software. The methodology illustrates how integrated image analysis and modelling software can effectively diagnose and address fragmentation issues, particularly in underground longhole mining where challenging blasting conditions require a balance between achieving optimal fragmentation and maintaining stope stability. This approach offers a cost-effective pathway to improving comminution performance in deep-level mines.

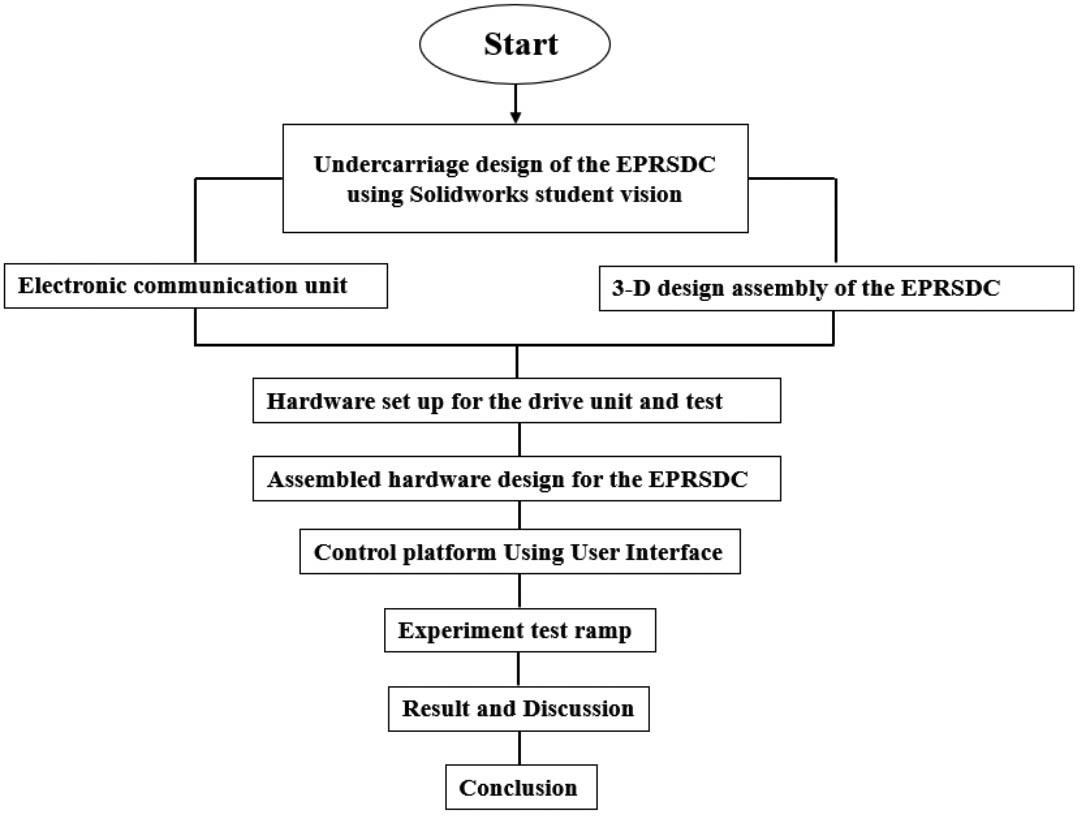

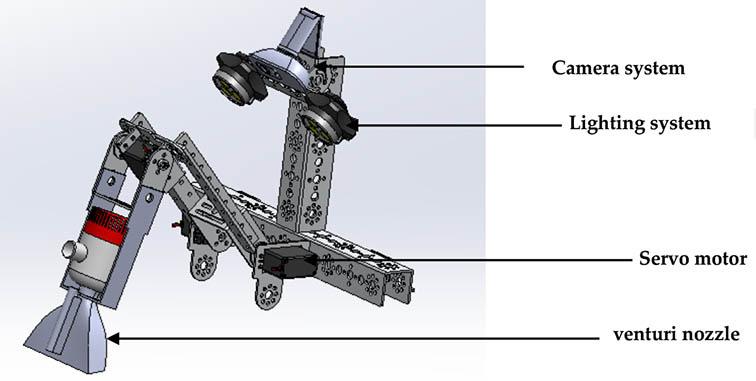

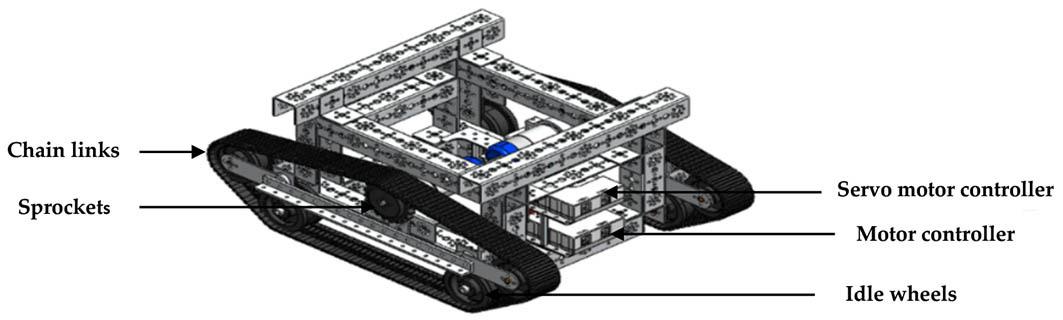

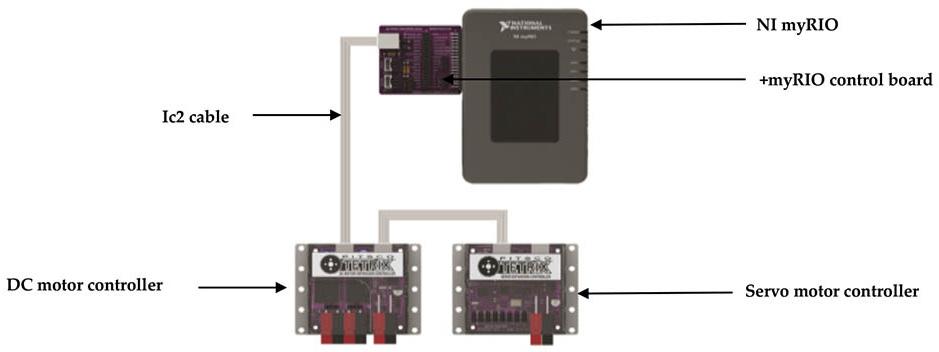

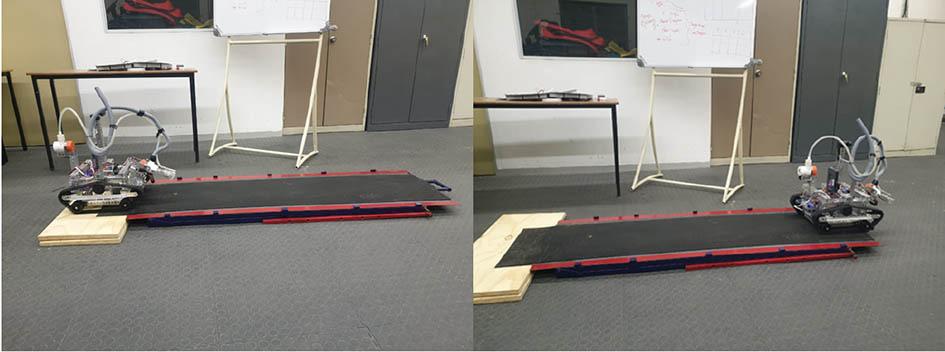

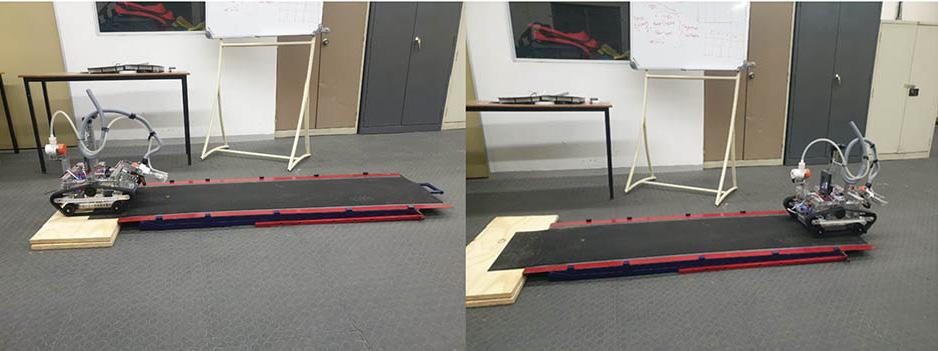

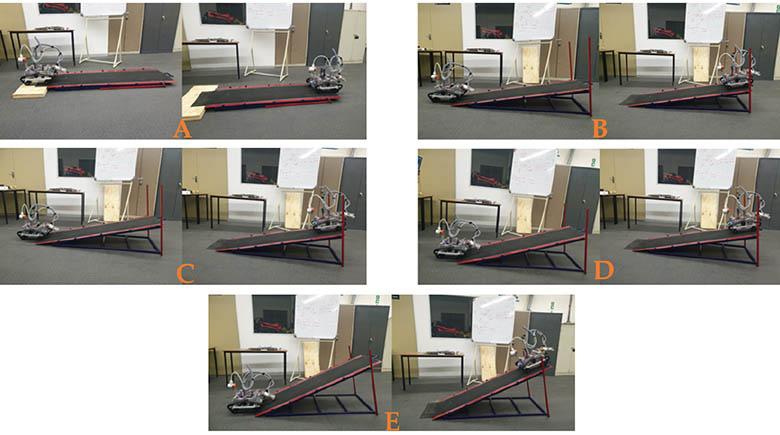

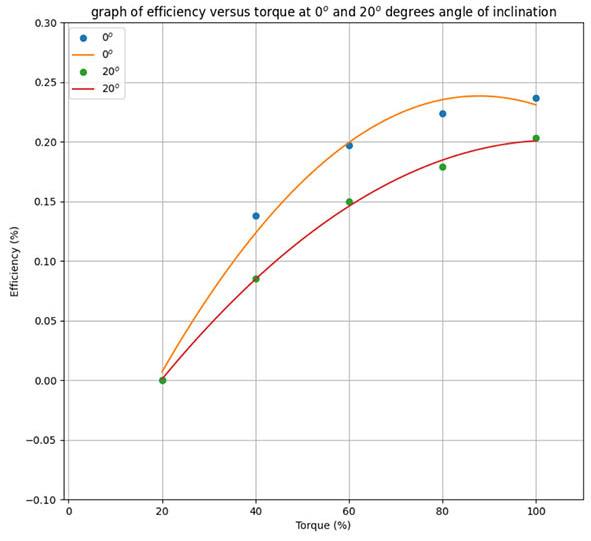

Enhancing performance metrics of an electrical-powered subsea robotic dredging crawler across varied inclination angles by M.O. Ojumu, A.K. Raji, E.F. Orumwense

This research paper introduces a novel passive method for ocean mining using an electric-powered robotic subsea dredging crawler designed to operate in various subsea conditions. The experiment aimed to determine the maximum velocity, torque, and efficiency of the crawler at different angles of inclination. The results of this study demonstrate a quadratic relationship between driving performance and inclination angle. This can be used to optimise the electric-powered robotic subsea dredging crawler’s performance for future ocean mining robot drive applications.

543

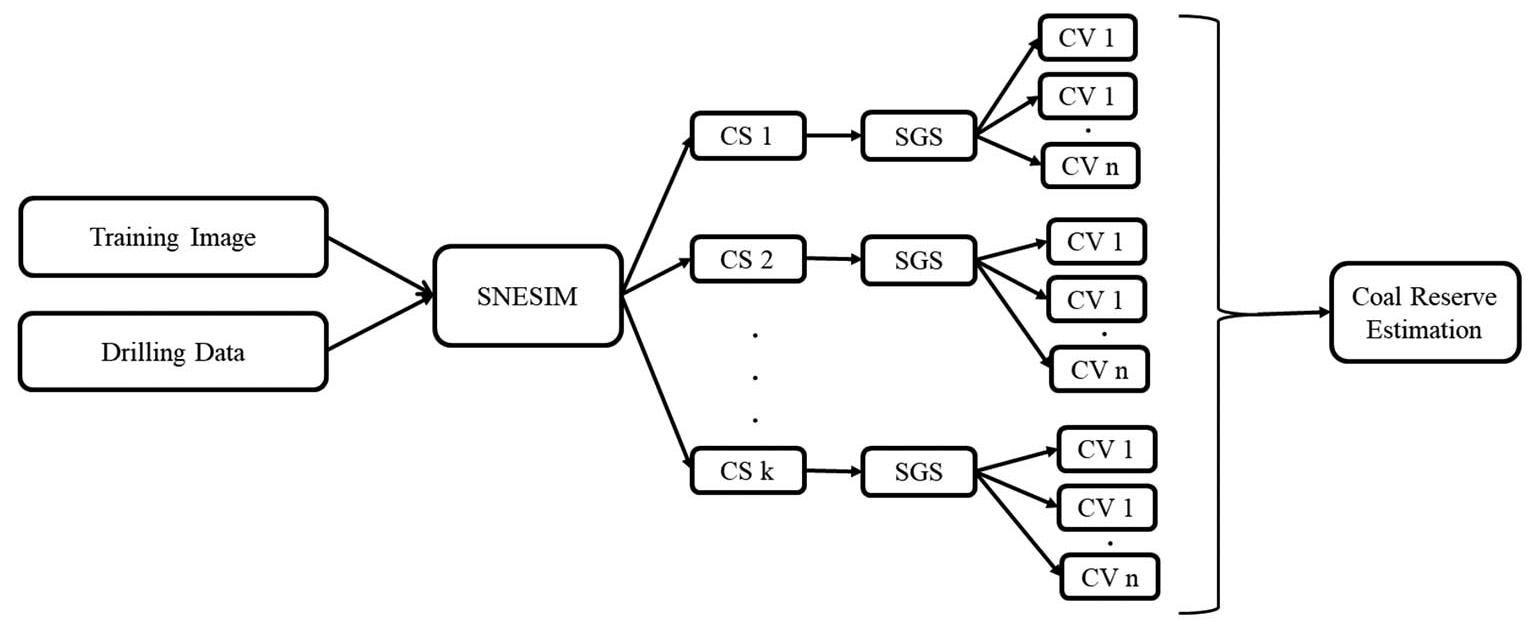

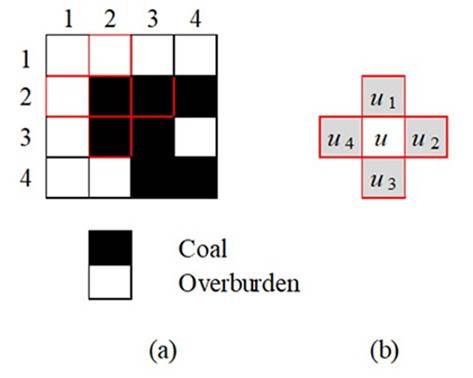

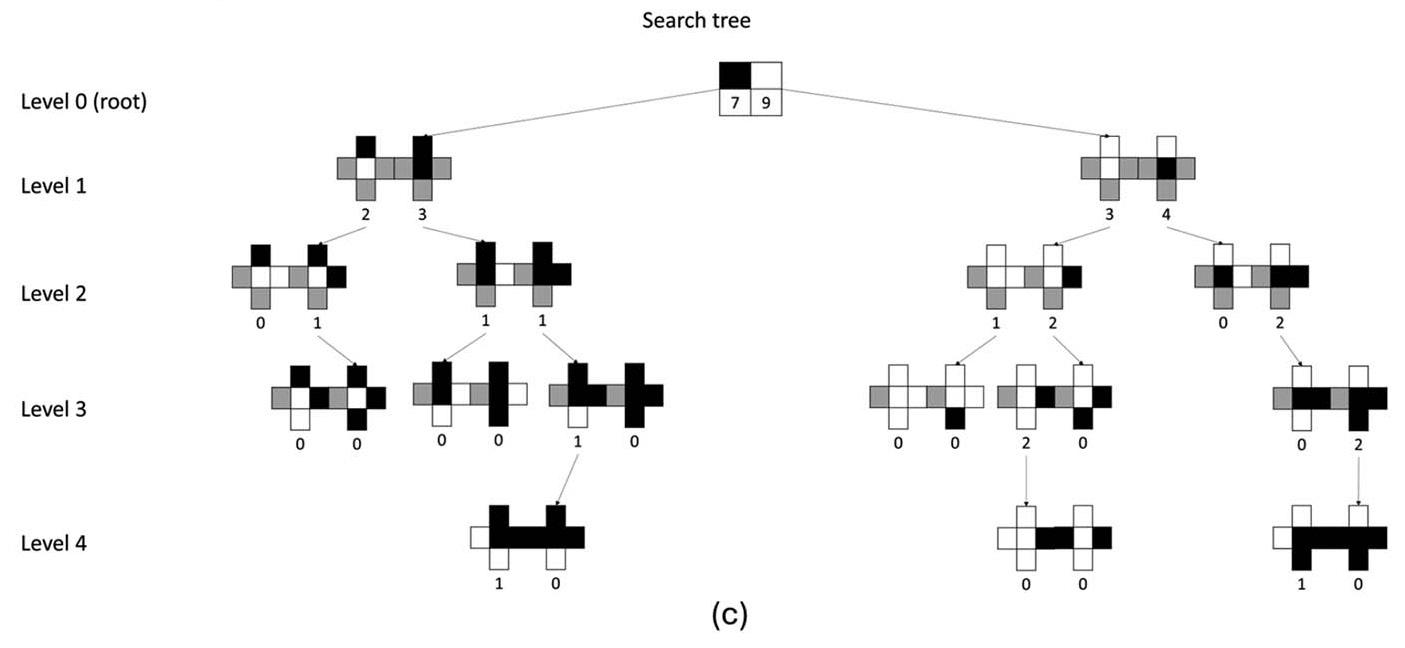

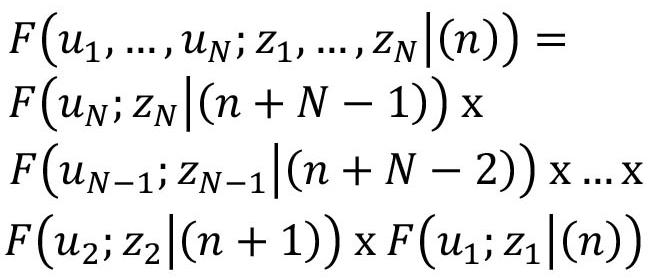

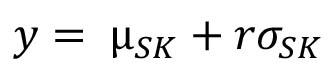

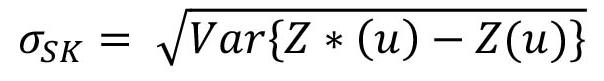

Minable coal reserve estimation by incorporating tonnage and calorific value uncertainties by suc-cessive multiple-point and two-point geostatistical simulation algorithms by F. Suparno, A. Paithankar, S. Chatterjee 555

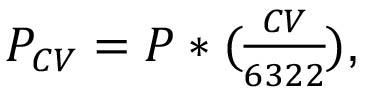

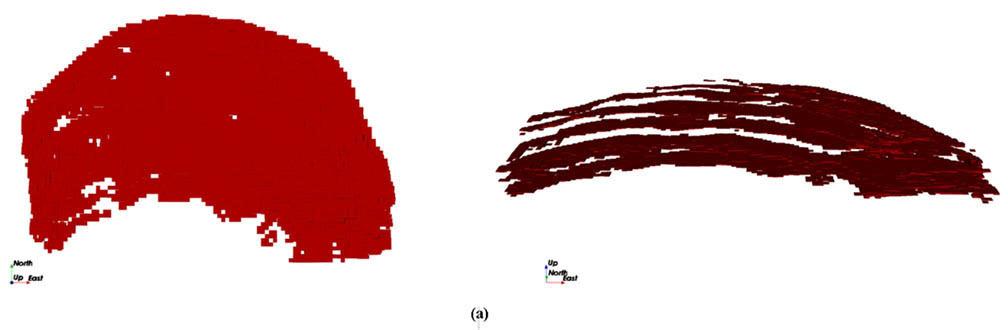

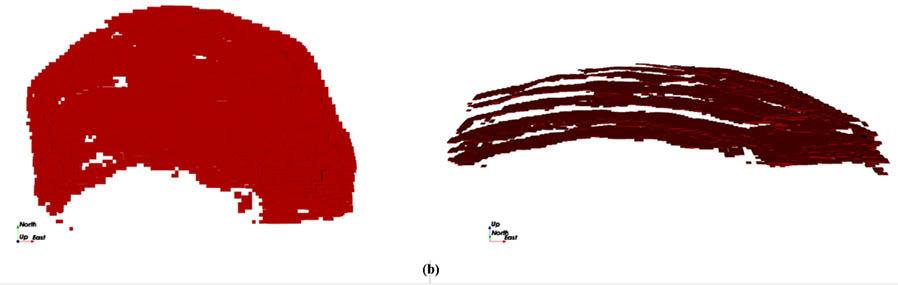

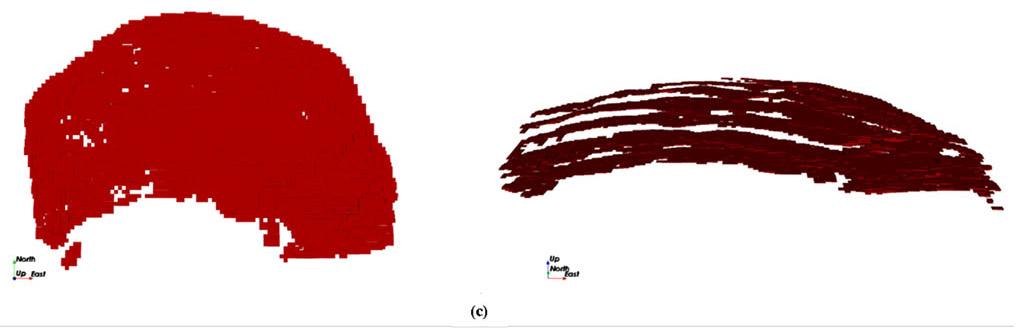

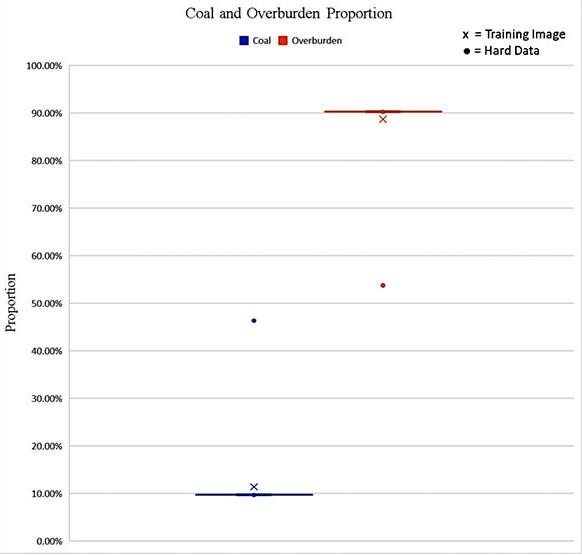

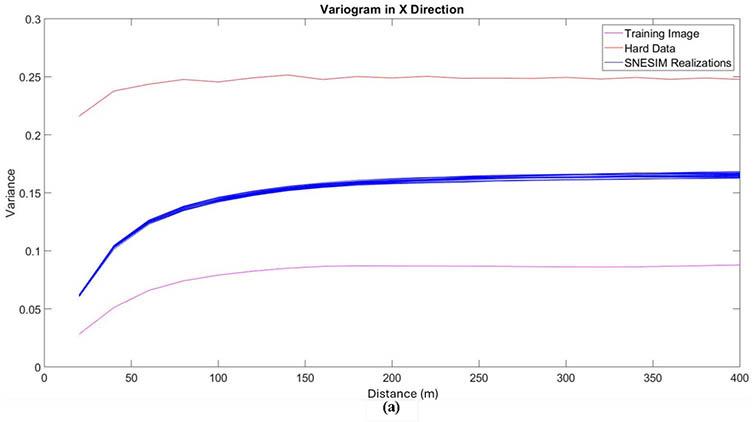

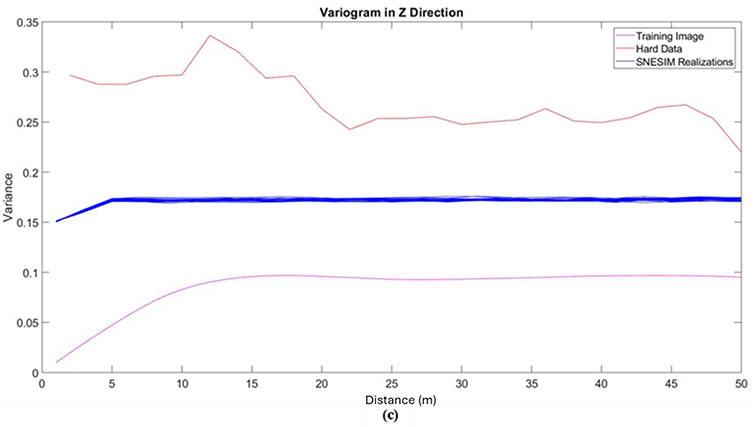

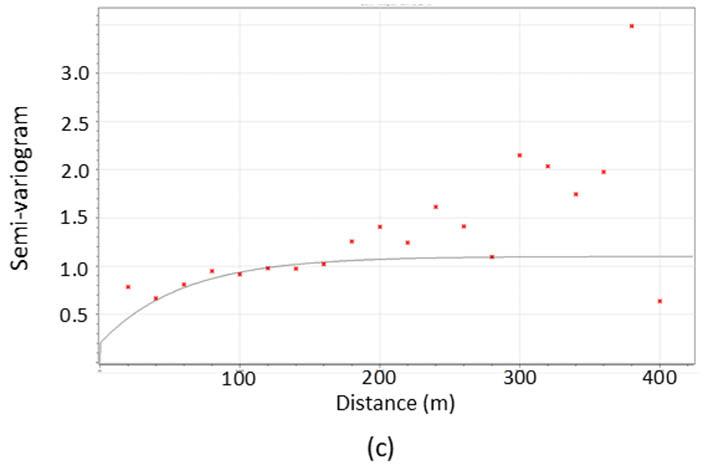

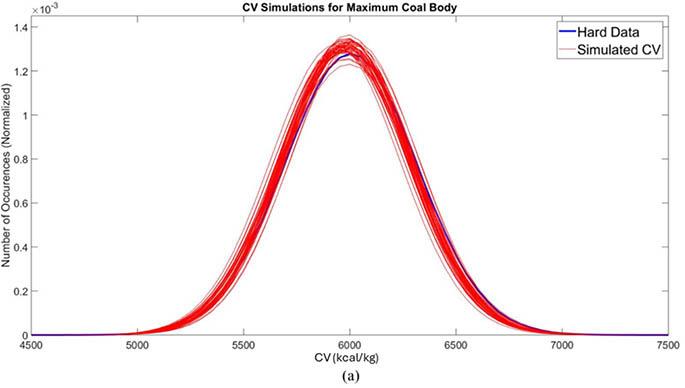

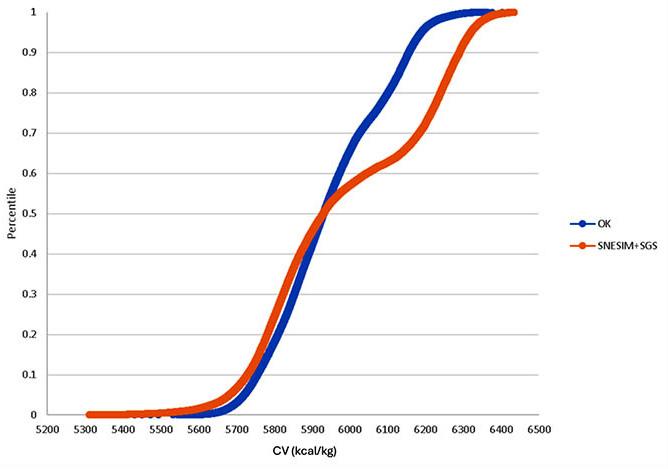

This research delves into the domain of geological uncertainties, with a specific focus on calorific value, aiming to numerically characterise resources and reserves within an open-pit coal mine situated in Indonesia. To quantify resources, the coal seam geometry underwent simulation via a multi-point geostatistical technique. To simulate CV, 50 realisations were generated for each simulated coal seam. Within this final pit, the average stripping ratio was 1.62, coupled with a CV value of 6,019.66 kcal/kg. When juxtaposed with the deterministic model, the findings underscore that the stochastic ultimate pit delineates a more expansive excavation, accompanied by a heightened undiscounted cash flow.

ining has historically been one of the most hazardous industries, a reality that has shaped the sector’s reputation for high risks and low margins of safety. Despite decades of progress in mechanisation, automation, improved ventilation, and the widespread adoption of personal protective equipment, accidents and occupational diseases remain serious and persistent concerns. Underground mining poses unique challenges because workers are confined to narrow spaces where they are exposed to unpredictable geological conditions, poor visibility, high temperatures, and dangerous gases. Beyond these acute risks are chronic health conditions that develop over time, including silicosis from prolonged inhalation of respirable dust, occupational hearing loss from exposure to high levels of noise, and musculoskeletal disorders resulting from heavy manual handling. The persistence of these problems highlights the complexity of mining safety and health, showing that technological improvements alone cannot eliminate them.

What is particularly striking is that many of these hazards are not new. Historical records show that mine heat stress, for instance, was a well-recognised occupational hazard in South African gold mines by the mid-twentieth century, where deeplevel mining exposed workers to extreme geothermal heat. Decades later, despite significant research into mine cooling systems, refrigeration, and ventilation optimisation, heat stress remains a major challenge in ultra-deep mines worldwide. Likewise, dust-related diseases such as silicosis and pneumoconiosis were documented as early as the nineteenth century, yet miners in jurisdictions with strict regulation, including Australia and the United States, continue to suffer from such conditions. In some coal mining regions, cases of “black lung” have even re-emerged after being thought nearly eradicated. This persistence suggests that while engineering controls and medical surveillance programmes are critical, they cannot succeed without rigorous enforcement of standards, strong occupational health policies, and most importantly, a cultural commitment to safety.

Indeed, the evidence shows that accidents and diseases in mining often result from organisational and systemic failures as much as from technical limitations. For example, lapses in enforcement, inadequate training, or production pressures can undermine the effectiveness of safety measures. Worker participation is therefore vital; miners must not only be protected by technology but also empowered to identify risks, report unsafe practices, and influence decision-making without fear of reprisal. A culture of safety must be nurtured at every level, from corporate leadership down to the underground face worker. Without this cultural shift, even the most advanced safety systems risk becoming superficial or poorly implemented.

The rise of automation and digital technologies in mining presents a new chapter in this long struggle between hazard and safety. On one hand, the deployment of autonomous haulage systems, remote-controlled drilling equipment, and advanced real-time monitoring systems offers unprecedented opportunities to remove workers from high-risk zones. Technologies such as wearable sensors can track miner fatigue, monitor gas levels, and even detect hazardous movements, thereby reducing accidents. Drones and robotic inspection devices can be sent into dangerous areas before humans, minimising exposure to unknown risks. These developments, if integrated with strong safety systems, have the potential to revolutionise mining health and safety.

On the other hand, these same technologies introduce new challenges. Automation can displace traditional jobs, leading to unemployment or underemployment in mining-dependent communities. The shift toward digital mining requires new skill sets, including expertise in programming, data analysis, and systems management, which many mining regions, especially in developing countries, are not equipped to provide. Without adequate reskilling programmes and community investment, technological advances may exacerbate social inequality, leaving behind the very workers they were meant to protect. Furthermore, automation can introduce new categories of risks, such as cybersecurity vulnerabilities in mine control systems or over-reliance on complex technologies that can fail under certain conditions.

Safety in mining, therefore, cannot be considered in isolation from broader social justice concerns. Protecting workers underground must go hand-in-hand with protecting the wellbeing of mining communities on the surface.

Social sustainability to ensure that workers have meaningful employment, access to healthcare, education, and economic opportunities remains central to the true advancement of mining safety. Ultimately, while technology can reduce exposure to hazards, it is strong regulatory enforcement, cultural transformation, and inclusive community engagement that will determine whether the mining industry can overcome its long history of danger and fulfill its responsibility to both workers and society.

M. Onifade

Botswana Branch

K. Mosebi

Kabelo Mosebi is a Mining Engineer by profession, Managing Director of Blue Horizon Resources (Pty) Ltd., and Director of both Pineshare (Pty) Ltd and Broad Horizon Group. Mr. Mosebi is married to Mrs. Ludo Mosebi and the father of three daughters. He identifies his personal purpose as being a helper and possessing a very strong belief system. The person purpose forms part of a strong personal philosophy that has influenced Mr. Mosebi’s success in both professional and social aspects of life.

Mr. Mosebi holds a Bachelor of Applied Science (BASc) Degree in Mineral Engineering (Mining) from the University of Toronto, Canada, and graduated in 2010. He has more than thirteen years working experience in the mining industry. He previously worked for Debswana Diamond Company and AECI Mining at Jwaneng Mine from 2010 to 2021. During that time, he participated in the Final Wall Control Project, which improved the final wall compliance score from approximately 20% to 90%. He was appointed as a Mining Engineer at Debswana, Jwaneng Mine in 2015 and rose through the different ranks to the position of Mining Manager at the same time he left to establish his own firm. He was part of the execution of the Dip Slope Mining Project, which ensured the stability of the Cut 8 Slopes, which is viewed as one of the unique mining methods. He was part of the team that presented a technical paper for publication on Dip Slope Mining to a worldwide audience at the Slope Stability Symposium, which was held in Spain in April 2018. Preceding that, he was involved in a project to re-design Cut 8 and optimize the slopes, the results of which saved the Cut 8 business case at Jwaneng Mine.

While studying in Canada, thirteen years ago, Mr. Mosebi developed a deep desire to plough back into the community, following his involvement with community activities like several on-campus clubs. This involved being a Vice-President of the National Society of Black Engineers (NSBE) for the University of Toronto chapter in 2009 – 2010.

Back home in Botswana, he shared his vision with friends, and they founded a society called the Youth Empowerment Society (YES), which was registered with the Botswana Registrar of Societies in April 2008. YES targets youth (aged 13 to 35) in and outside of school communities to address the declining educational performance, a decline in employability skills, an increase in youth violence, and a concerning number of youth infected and affected by HIV and AIDS in Botswana.

Mr Mosebi has developed a great desire to address these issues and that is why he is here to speak up and make a difference in the lives of those who have potential to lead the nation, both today and tomorrow. He is Council member of The Southern African Institute of Mining and Metallurgy (SAIMM) and a member of the Australasian Institute of Mining and Metallurgy (AusIMM). u

Johannesburg Branch

A. Hefer

Amanda Hefer is a metallurgical engineer with over two decades of experience, particularly in metallurgical laboratories and refineries in precious metals. She currently serves as the Senior Manager of Metallurgical Services at Rand Refinery (Pty) Ltd, where she has held various positions since July 2008. Throughout her tenure, she has reached numerous milestones, including the establishment of a stateof-the-art metallurgical laboratory. She aimed to set up a comprehensive facility that encompasses all fields of metallurgy related to refining, fabrication and smelting processes. Her efforts in implementing cuttingedge equipment and technologies led to higher technical standards and accelerated understanding in these areas.

While continually contributing to the industry, Amanda is busy completing her MSc thesis at the University of Witwatersrand. Additionally, she actively participates in industry conferences and research, shares her knowledge and insights with peers, and mentors the next generation of engineers. Amanda is dedicated to fostering a technologically advanced and collaborative environment in the workplace and building relationships with tertiary institutions for technical and academic input within the metallurgy field. u

Limpopo Branch

M. S. Zulu

Steven Zulu is an accomplished Metallurgical Technical Manager with extensive expertise in extraction metallurgy and technology management. He holds a National Diploma and a B.Tech. in Extraction Metallurgy from the University of Johannesburg, BSc (Hons) and M.Sc. in Technology and Innovation Management from the University of Pretoria, B.Com Economics and B.Com Economics (Hons) from Unisa. Currently, he is pursuing a Ph.D. in Management of Technology & Innovation.

Steven’s career is marked by significant contributions to the mining and metallurgical sectors. As a legal appointee for Safety, Health, and Environmental compliance, he has overseen critical operations including production, metal accounting, budgeting, human capital, tailings dam management and cost reduction initiatives. His leadership in metallurgical optimisation and recovery improvement projects has yielded substantial results, including the successful design and commissioning of the MIG and Chrome Recovery Plants at Modikwa Concentrator.

In academia, Steven is deeply involved in mentoring and supervising graduate students, chairing career development panels, and collaborating with various academic institutions. He has organised multiple colloquia and symposia for professionals in the mining and metallurgy fields.

His research interests have culminated in several published papers, focusing on the strategic competitiveness of the South African mining industry in the context of the Fourth Industrial Revolution and digital transformation technological innovations. Steven’s publications highlight the importance of organisational capabilities in adopting new technologies and advancing the sector.

A member of multiple professional organisations, including the South African Institute of Mining and Metallurgy and the Mine Metallurgical Managers Association, he currently serves as the Chair of the SAIMM Limpopo Branch. Steven’s commitment to professional development is evident in his active participation in workshops, courses, and conferences.

With a strong foundation in metallurgy and a keen understanding of technology management, Steven Zulu continues to be a leading figure in his field, dedicated to innovation and excellence in metallurgical practices. u

T. Aipanda

Tomas boasts more than 12 years’ experience in open-pit hardrock mining. He has led in various capacities within mining, spanning areas such as drilling, blasting, planning (short and long term), and production management. He is currently serving as a production superintendent at Swakop Uranium, where he is responsible for leading and managing a sizable team comprising of various disciplines within the mining operation. u

T. Nsimbi

Thandekile Nsimbi is an accomplished Performance Improvement Manager at Impala Platinum’s PGM smelter with nearly two decades of experience in mining and metallurgy. She is a qualified Metallurgical Engineer with extensive expertise in production management, operational excellence, process optimisation, and continuous improvement.

Her career spans leadership roles across leading organisations such as Impala Platinum, Jubilee Metals, Afarak Mogale, Samancor, and Arcelor Mittal, where she has successfully driven strategic initiatives, resource optimisation, and efficiency improvements in smelter and plant operations.

She has served in committee and council roles including the Furnace Council Committee, FRCP Steering Committee (Hazardous Materials Champion), and the Process Improvement Council, reflecting her strong industry presence and contribution to advancing metallurgical practices.

Thandekile holds a BSc (Hons) Applied Science in Metallurgy (University of Pretoria), a BTech in Metallurgical Engineering (TUT), and a National Diploma in Extraction Metallurgy (UJ), complemented by executive training at GIBS and professional certifications such as Six Sigma Green Belt. She is currently studying towards a Postgraduate Diploma in Business Administration at GIBS, further strengthening her strategic management and leadership skills.

Recognised for her leadership, problem-solving ability, and technical expertise, she is passionate about fostering a culture of excellence, safety, and sustainability in metallurgical operations. Her vision is to drive innovation and deliver long-term value in the mining and metals sector.

Pretoria Branch

P.G.H. Pistorius

Pieter Pistorius was born in, what is now known as Modimolle, in the Limpopo Province. He studied at the University of Pretoria and at Sheffield University. He attained a PhD degree in Phase Transformation Behaviour of 12% Cr Steels at the University of Pretoria. He held various positions in the manufacturing industry before joining the Department of Materials Science and Metallurgical Engineering at the University of Pretoria for a second time in 2015. He is responsible for undergraduate, and postgraduate teaching and research in welding engineering. He is a Fellow of the SAIMM, a registered professional metallurgical engineer, and an international welding engineer. u

Zambia Branch

N.M. Kazembe

Nathan Mukulakasuba Kazembe is a seasoned Mining Engineer and senior executive with over 15 years of experience driving excellence in mining project engineering and operations management across Africa. He currently serves as the Country Manager for Zambia at Rolls-Royce Solutions Africa , leveraging his extensive industry background to deliver high-impact power solutions. Nathan is also a dynamic entrepreneur, acting as Director and Co-founder of K-Squared, a project engineering startup.

His professional stature is demonstrated by his fellowships and memberships, including being a Fellow of the Engineering Institute of Zambia (EIZ), a member of the Chartered Institute of Arbitrators (CIArb), and current Branch Chair for Zambia for the Southern African Institute of Mining and Metallurgy (SAIMM) .

Nathan holds a BEng in Mining Engineering and an MBA from the University of Zambia (UNZA), complemented by a Postgraduate Diploma in Project Management from the University of Stellenbosch Business School. He is currently advancing his expertise through a Doctor of Business Administration (DBA) program. u

Zimbabwe Branch

L. Shamu

Lloys is a professionally qualified Process Engineer with over 30 years’ experience in Mineral Processing, Pyrometallurgy, and Hydrometallurgy. He is currently employed as Head Processing at Mimosa Platinum Mine in Zimbabwe. His experience spans across project management, metallurgical testing, flowsheet/ process development, plant design, starting up of new mining projects, expanding and commissioning of new mining operations, and managing existing ones. Lloyd has occupied different operational and technical roles, from plant/concentrator/projects/process leadership, up to executive roles.

He has gained excellent experience in the extraction of precious metals, base metals, and chrome smelting from working at mines, smelters, and being part of new projects. His management skills have been enhanced by having to manage across disciplines and in multicultural environments, both locally and regionally.

Lloyd serves on a few industrial boards for tertiary institutions in Zimbabwe, and is currently the Board Chairperson for the National University of Science and Technology (NUST) Zimbabwe, Department of Chemical Engineering.

He is a member of the Zimbabwe Institution of Engineers, member of SAIMM, and a registered professional engineer with the Engineering Council of Zimbabwe.

Lloyd is married to Tracy, and they have three boys, Leon Nicholas, Lennon Takudzwa and Ryan Kudzaiishe. u

by G.R. Lane

Affiliation:

1Vuuma Collaborations, South Africa

Correspondence to:

G.R. Lane

Email: glane@vuuma.com

Dates:

Received: 31 Oct. 2024

Revised: 8 May 2025

Accepted: 21 Jul. 2025

Published: September 2025

How to cite:

Lane, G.R. 2025. Presidential Address: Beyond effort-driven operations: Building people-centric operating models for mining’s future. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 9, pp. 495–500

DOI ID: https://doi.org/10.17159/2411-9717/2025/2025

My opportunity to serve as President of the prestigious Southern African Institute of Mining and Metallurgy (SAIMM) was made possible by an Anglo American scholarship 39 years ago—a pivotal moment that set me on a career path spanning various roles and start-up ventures in the mining industry. Over the past decade, I have been privileged to broaden my experience by consulting across diverse industries globally. This exposure revealed something profound: what I had previously considered mining-specific challenges are, in fact, universal across many sectors. At its core, a mining operation is a complex system of interconnected activities—from exploration through mining operations like drill and blast, load and haul, to beneficiation, and outbound logistics. My cross-industry work has clearly shown that diverse sectors, such as chocolate manufacturing, tissue paper production, toilet paper converting facilities, labgrown diamonds, or high-tech equipment lifecycle management, all rely on value streams of interconnected activities to transform products. The objective is to maximise throughput while effectively managing performance variability. The primary difference lies solely in the specific technical expertise required for each industry, such as chemical, mining, processing, or metallurgical engineering.

Across all these industries, I have observed a consistent pattern, that is, performance is primarily driven by individual efforts, where people react and work diligently as situations unfold in real-time. General managers and their teams often operate tactically, focusing on explaining yesterday’s poor performance rather than proactively setting up operations for success. This often resembles an ‘‘under-7s soccer match’’, with everyone chasing the ball. The common response to issues is to add more ad hoc meetings. This effort-driven organisational behaviour persists regardless of whether operations are greenfield digital manufacturing facilities, advanced digital mines with advanced process control, or operations run on paper and Excel spreadsheets for data acquisition. Paradoxically, more real-time data can lead to increased data noise, greater indecision, and sometimes, lower performance. Despite value streams often operating significantly below capacity, organisations continue to invest heavily in additional equipment or in ‘‘glossy brochure promises’’ of Industry 4.0 digital technology and real-time data solutions, which frequently fail to deliver value.

This leads to a critical question: Have we underinvested in our most valuable resource— people? Even Tesla faced this challenge with their underperforming fully automated Model X facility. We must shift our focus to designing the ecosystem, or operating model, of our organisations. This extends beyond the traditional triad of people, process, and technology, and moves beyond simplistic views of change management. Artificial Intelligence (AI) has the potential to add significant value, but it also introduces another layer of complexity into designing the organisation of the future.

My full presidential address below at the SAIMM AGM discussed the symptoms of an effort-driven organisation and covered the fundamental building blocks and requirements of an operating model, including recommendations on implementing a people-centric approach.

Keywords

people-centric, operating model, value stream optimisation, mining, technology, change management, Mine4Future

Introduction

My journey to this perspective

I share this perspective as it is important to our young professionals as they are the future leaders and their career journey and choices along the way shape their experience and capabilities.

My career in mining began with an Anglo American scholarship in 1985, leading to a BSc in Civil Engineering in 1990. I started as a bright-eyed, bushy-tailed engineer with plenty of theory but

little practical experience. For 10 years at Anglo American, I was fortunate to be involved in project management of multiple new mine developments across Africa, even building a multi-million dollar mine in Mali with only satellite phones and fax machines and no email. After a decade, I pursued an MBA, which broadened my understanding beyond engineering and led me to co-found a mining consulting start-up. This venture grew to over one hundred people and focused on mine optimisation, techno-economic modelling, BI dashboarding, and software development, aiming to add value through top-down and advanced scenario planning and economic modelling. However, I reached a point where I questioned if we were truly adding sustainable value. We saw value while our consultants were on site when we directly used the technology, but it was not sustainable. This prompted a critical question: ‘‘What am I missing and what are other industries doing that we can learn from?’’

My research in 2016 revealed that despite sophisticated solutions, global mining productivity (multi-factor productivity, or MFP) had declined by as much as 50% over the preceding decade, even with innovative technologies and sophisticated software systems. In contrast, the motor industry saw a 300% increase in MFP, with Toyota leading the way through its Total Productive Maintenance (TPM) methodology, which emphasises systems thinking and an integrated understanding of the value stream. This stark contrast was a pivotal point for me, leading me to delve deeper into skills development, systems thinking, Lean Six Sigma, Theory of Constraints, and the concept of integrated operating models.

Over the past decade, I have had the privilege to work across multiple industries globally, gaining insights into challenges that are not unique to mining.

The pervasive challenge: The effort-driven organisation At its core, a mining operation, much like any other industry, is a value stream of interconnected activities, such as drill, blast, load, haul, crush, screen, and process. The goal is to maximise

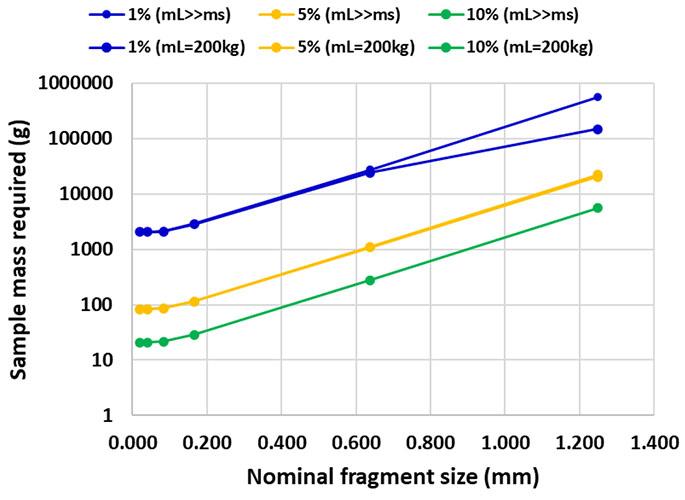

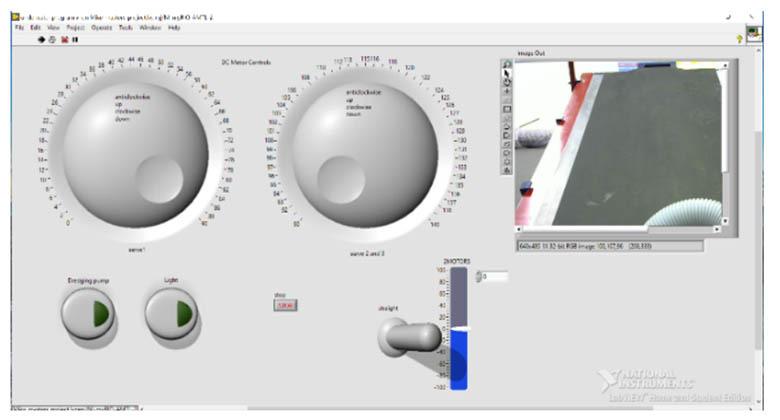

the flow of material through that value stream at the minimum cost. Despite the availability of vast amounts of data, advanced business improvement tools to identify the value stream constraint and improve performance, and sophisticated decision-making technologies, including AI, we often fail to achieve sustainable performance improvements. In fact, more real-time data can sometimes lead to increased data noise, greater indecision, and even lower performance. This is because technology alone cannot solve the fundamental challenges rooted in how people interact within the system (Figure 1).

Despite all this data, business improvement tools and sophisticated decision-making technology, we often find ourselves in what I call an ‘‘effort-driven organisation’’.

Common characteristics of an effort-driven organisation include:

➤ People working below their pay grade, where individuals across all levels of the operation are working tactically.

➤ General managers focusing on explaining yesterday’s poor performance rather than looking forward to setting up the operation for success.

➤ Too many meetings that add no value, becoming a curse in all our organisations, with no clear purpose or outcomes.

➤ Initiative overload, where organisations pursue numerous projects and initiatives without prioritising those that address the true constraints of the system.

➤ A prevalent reactive/firefighting/tactical approach to managing daily operations with poor or no rigorous forwardlooking planning.

➤ Unclear roles and responsibilities, often leading to duplication of efforts and a lack of clarity.

➤ Key performance indicators (KPIs) not linked to business outcomes.

➤ A lack of accountability management, which results in fingerpointing and obfuscation.

➤ Burnout, low morale, and high staff turnover.

My experience while consulting across various global industries over the past 10 years has revealed that these challenges are not unique to mining. They are identical across sectors like:

➤ Chocolate manufacturing: A connected set of activities where teams aim to maximise chocolate flow through the system.

➤ Tissue and toilet paper production: Similar interconnected activities with engineering and production efforts to maximise flow.

➤ High-tech equipment lifecycle management: From research and development through manufacture and support, often characterised by throwing prototypes directly into production without effective stage-gate reviews and pre-production processes.

➤ IT function of a multinational: Like an engineering function dealing with service requests, planned maintenance and capital project pipeline to improve capability.

While each industry demands unique technical/engineering expertise—be it metallurgical, mining, chemical, processing, or mechanical engineering—the process of managing these interconnected activities and the human challenges faced by engineers and production teams are remarkably similar. The maturity of digitisation, automation and robotics, and advanced process control does not change these fundamental people challenges; in some digital operations, they are even exacerbated by data overload.

The solution: A people-centric operating model

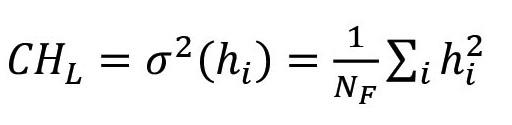

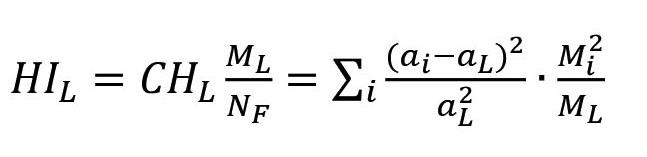

Since technology, data, and capital investment alone are not delivering sustainable value, we must recognise that people are at the heart of the system. It is people who make decisions and act on insights. Therefore, the focus must shift to building a people-centric operating model. An operating model is not just about the typical triad of people, process, and technology; it is about designing the entire organisational ecosystem so that all work is orchestrated to deliver the outcome consistently and confidently. Here are the fundamental building blocks and requirements of such a model (Figure 2):

➤ Strategic direction and sense of purpose: Leaders must clearly and consistently communicate the business objectives.

➤ Create psychological safety for the teams: This is most critical for fostering an environment where individuals can speak up, take accountability, continually learn, and perform without fear of blame. It is about clear ‘rules of the game’ where an individual can thrive and perform with a clear understanding of roles and responsibilities, and accountability.

➤ Ask questions that focus the team on what is important: Directing efforts toward the most impactful areas, such as the system’s constraint.

➤ Drive the development, adoption, and continual improvement of an operating model: Co-creation and continual improvement of the operating model with the teams in the business drive the change management required.

➤ Drive accountability management

➤ Coaching and development of the teams.

➤ Leaders in the organisation break operating models: By asking the wrong questions of teams breaks the consistent and deliberate ways of work in an operating model.

➤ A structured business-level information model: Linked directly to what is required for effective decision-making, owned by the business, not filled with IM jargon.

➤ Value driver trees: The organisation must develop a mental model of metrics and leading indicators that influence outcomes in their respective areas.

➤ Unambiguous definitions and a glossary of terms: Essential to prevent confusion and ensure data credibility.

➤ Credible and accessible data: Data easily accessible by business users and not IM only.

Skills and capability

➤ Effective meeting planning and leadership: This is a critical skill often overlooked and is why we all sit in many hours of

meetings each week that add no value. Meetings must have a clear purpose, defined outcomes, and planned steps to achieve the outcomes.

➤ Data skills: Even in this digital age, with access to terabytes of data, the most basic data skills are lacking, and the ability to use data to ‘tell a story’ for decision-making is limited.

➤ System flow and impact of variability: Understanding system flow and the impact of variability is crucial, drawing from methodologies like Theory of Constraints, Lean Six Sigma, and systems thinking.

➤ Graphical tools for decision-making: Using tools like capability histograms and control charts, which simplify complex data and aid effective decisions, rather than basic bar or line charts.

➤ Decision-making tools: Employing structured tools within meetings to drive to a decision.

➤ Levels of work linked to cascading performance measures: This defines who is responsible for what, from strategic (years ahead) down to tactical (hourly achievement), with KPIs and leading indicators mapped to each level.

➤ Structured management routines: An effectively designed meeting system is the tool for leaders to manage the system and drive continuous improvement.

➤ Functional processes:

- Strategic planning: An annual drumbeat and defined process for setting expectations and targets for the business.

- Operational planning (capability management):

Focusing on what is required to deliver on expectations, understanding current performance versus target, and driving improvement projects using a structured BI approach and tools. This includes critical aspects

like asset maintenance strategy to ensure equipment availability meets the required targets for net operating hours.

- Work management (stability management): A confident system for planning, scheduling, resourcing, and executing work with low variability and a feedback loop for improvement.

➤ Real-time escalation process and criteria: Clear processes for managing real-time emergent events and schedule adherence.

➤ Standard work procedures (SWP): Visual and easily accessible work procedures to ensure work is done consistently to the same quality, regardless of the team member.

➤ Tools and software: Effective design, implementation and adoption of technology aligned to the people-centric operating model requirements and business objectives.

➤ Feedback loops: A structured and deliberate process for continuous improvement of the operating model and processes (Figure 3).

A compelling example from an international manufacturing facility demonstrates the power of a people-centric approach. A manufacturing facility had invested millions in a full manufacturing execution system (MES) implementation, digitising the shop floor to get all equipment data into a production database with Power BI dashboards. Management had access to all dashboard metrics and held daily stand-up meetings, yet there was no improvement in total lead time (the time from when an order enters production until it leaves) over a two-year period. Sales orders that needed to be delivered in three days were taking 12 to 14 days. By adopting a people-centric approach, engaging shop floor personnel, identifying the value stream constraint, understanding the value stream

capacity, and implementing a very simple work management system—including shift planning, capacity planning, simple production work order scheduling, and a performance review feedback loop—they achieved a significant improvement. Crucially, the management dashboards were rebuilt to measure leading indicators directly impactful to shop floor personnel. This resulted in average lead times dropping from 12 days to 2.8 days, a sustained improvement over a year with a simple, yet effective, people-centric work management process.

Walking our talk: Building the SAIMM operating model

The SAIMM is committed to practising what we preach. Our management team is actively building the SAIMM operating model. With numerous volunteers on our council and committees, and a secretariat handling events, membership, marketing, journal, and finance, it is vital to effectively integrate all these elements and roles, to deliver repeatable and reliable service to our members, our corporate partners, and the industry. This is not a one-year focus but will be a continuous process of improvement of our operating model as we learn and the needs of our members and industry change into the future. When issues arise, the focus shifts from ‘‘who messed up’’ to ‘‘what in our system has resulted in this unwanted outcome,’’ fostering a culture of learning.

Where to start: Reviewing your meetings

For any leader managing teams, businesses, or functions, the most impactful place to start is by reviewing all your meetings. Your meeting system is your primary management tool to effectively manage and continuously improve the performance of your operating model. The key is to:

➤ Define the purpose: Clearly state why the meeting is being held.

➤ Define the outcomes: What tangible results do you want to achieve from this meeting? This also helps determine who truly needs to attend.

➤ Define the results: What individual steps or items need to be covered to achieve the stated outcomes.

➤ Plan the approach: How will the meeting achieve its results (e.g., brainstorming, specific decision tools, presentations)?

➤ Incorporate ‘‘plus delta’’ feedback at the end of each meeting: This involves each participant briefly stating one positive aspect (‘‘plus’’) and one area for improvement

(‘‘delta’’). This non-judgemental feedback mechanism allows both the meeting facilitator and participants to learn and improve for future meetings.

Planning an agenda effectively can take as much time as the meeting itself. This systematic approach to meetings, driving clear agendas with purpose, outcomes, results, and performance metrics, is a foundational step toward repeatable and reliable execution, supported by an appropriate technology stack and a capable workforce. This journey of continual learning and the systematic development of a people-centric operating model is how we will truly maximise the performance of our value streams in mining and beyond.

To effectively transition from ‘‘effort-driven’’ operations to sustainable performance, organisations must prioritise the deliberate design and continuous improvement of a peoplecentric operating model. This model should be built upon four fundamental pillars, which are, empowering leadership to define business expectation and foster psychological safety, a structured information model that provides credible and accessible data for rigorous decision-making, robust skills and capability development (especially in data literacy, business improvement tools, and meeting effectiveness), and a clearly defined operating model framework with levels of work, cascading performance measures, structured management routines, and functional work processes with the supporting digital architecture and systems.

The most impactful starting point for any leader is to systematically review and reform the overload of existing meetings to free up leadership time through the organisation. This involves defining the purpose, desired outcomes, agenda results and approach for each meeting, and eliminating meetings that do not add value. Concurrently, invest in developing the human skills essential for optimising and managing complex value stream systems and interpreting data effectively for effective decision making, and cultivate an environment of psychological safety where teams are empowered to identify and resolve systemic issues without fear of blame. This foundational shift in how work is managed and decisions are made, rooted in a ‘‘system-first’’ rather than ‘‘people-blaming’’ mindset, will unlock sustained improvements in productivity and overall performance. u

13 October 2025 Technical Workshops

14-15 October 2025 Conference

16 October 2025 Technical Visits

Venue: Glenburn Lodge and Spa, Muldersdrift

(1-hour drive from O.R. Tambo International Airport, Johannesburg, South Africa)

ECSA and SACNASP Validated CPD ActivityCredits = 0.1 per hour attended

Ore heterogeneity and metallurgical complexity continue to rise, while sustainability occupies an ever-prominent role. Geometallurgy offers a refined, multidisciplinary pathway to improve the value of ore deposits.

Future-Ready Geometallurgy examines strategies to generate trustworthy data through the steady application of machine learning, novel sensors, digital twins, and Industry 4.0 technologies in mining. Reliance on dependable data and innovative tools empowers the industry to make more timely and discerning decisions for mine planning and metallurgical plant optimisation.

Following the success of past SAIMM Geometallurgy conferences, the third conference in this series provides a platform to explore the latest progress in geometallurgy and to celebrate the success of its integration into the mining value chain.

• Sampling and sensor-based core logging

• Practical tools and methodologies for ore characterisation and testing

• Standardised methods for reporting to generate trusted data

• Geostatistics, data integration, smart workflows, and modelling

• Incorporation of predictive mining, processing, and environmental models into resource modelling

• Project and operational geometallurgy case studies

• 17 June 2025 - Submission of short abstracts

• 29 July 2025 - Submission of extended abstracts for peer review

• 13 October 2025 – Technical workshops

• 14-15 October 2025 - Conference

• 16 October 2025 - Technical visits

FOR FURTHER INFORMATION CONTACT: Gugu Charlie, Conferences and Events Coordinator E-mail: gugu@saimm.co.za | Tel: +27 11

Geomet Advisor & Business Development Manager, Datarock, Australia

Wendy Ware

Chief Metallurgist, Transmin Metallurgical Consultants, United Kingdom

Adam Johnston

Prospective authors are invited to submit short abstracts of not more than 500 words to: Conferences and Events Co-ordinator, Gugu Charlie, e-mail: gugu@saimm.co.za Authors of accepted abstracts will be required to submit extended abstracts for peer review and publication in the conference proceedings. Following the conference, full papers can be submitted to the journal for peer review and publication in an SAIMM Journal Special Issue.

Affiliation:

1InsPyro NV, Belgium

Correspondence to: A. Kotze

Email: andrea.kotze@inspyro.be

Dates:

Received: 2 Sept. 2024

Revised: 9 Jun. 2025

Accepted: 8 Jul. 2025

Published: September 2025

How to cite: Kotze, A., Messina, D., Cryns, Y., Nagels, E., Arnout, S. 2025. Thermochemical evaluation of elemental phosphorus recovery from sewage sludge. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 9, pp. 501–508

DOI ID: https://doi.org/10.17159/2411-9717/3556/2025

by A. Kotze1, D. Messina1, Y. Cryns1, E. Nagels1, S. Arnout1

Abstract

The FlashPhos process aims to recover white phosphorus (P4) from sewage sludge by drying, flash combustion/gasification, and carbothermic refining steps. This study evaluates the material behaviour of sewage sludge ash melting and reduction in a refining furnace for the novel FlashPhos process. Thermodynamic modelling in FactSage 8.2 is combined with experiments from a tube furnace to determine the possible phosphorus recovery and minor element behaviour. For the two studied sludges, a yield of 40% and 75% white phosphorus is achieved after 1 hour at 1600°C, corresponding with a 60% and 25% loss to the metal phase. This is slightly above the calculated equilibrium yield of 28%–73%, which depends mainly on the Fe/P ratio of the sludge. Temperature is found to have a significant influence on the final phosphorus yield when leading to incomplete melting of the ash. A clean slag is produced in the process free of heavy metals making it suitable to be used as a cement-like binder material. The main heavy metals that co-evaporate with the phosphorus are Zn, Pb, As, Sb, and Sn. Additional processing steps will be required to remove these to produce a pure P4 product. The metal alloy consists of mostly Fe and P with smaller amounts of other components such as Mo, Cr, Cu, Mn, Sn, Sb, and V. The final slag consists of CaO, SiO2, MgO, and Al2O3 with virtually complete removal of P and heavy metals.

Keywords sewage sludge, phosphorus recovery, sustainability, refining process

Introduction

Phosphorus is classified as a critical raw material by the European Commission due to its importance in the agricultural, pharmaceutical, and electronic sector. The current and expected increased demand for phosphorus far exceeds the phosphorus reserves available (Salkunić, et al., 2022). Europe is currently fully dependent on imports for elemental phosphorus (European Commission, 2022). Currently, the main source of phosphorus is primary phosphate rock. Alternative secondary phosphorus sources are therefore critical to ensure the sustainable supply of this resource. Sewage sludge is one potential resource of phosphorus, which is currently only exploited to a limited extent. A country loses approximately 50% of its phosphorus through wastewater (Salkunić et al., 2022). It is estimated that 323 kt/a phosphorus can be recovered from sewage sludge in the EU (Nättorp, et al., 2015). This is enough phosphorus to meet the entire EU demand for elemental phosphorus, which is estimated to be around 100–130 ktP/y (European Sustainable Phosphorus Platform, 2020).

Typically, municipal wastewater is treated to remove particles and precipitate out phosphates and other harmful components from the water before returning it to the environment as clean water (Prasad, Smol, 2023). The solids produced in the treatment process are referred to as sewage sludge. Apart from organic matter, sewage sludge also contains heavy metals and other unwanted components such as pathogens and bacteria from the wastewater (Boniardi, 2018). There are various ways in which the sewage sludge is disposed of or re-used, such as landfill, landscaping, or incineration. The sludge is a sink for most of the impurities and contaminants, such as heavy metals and micropollutants (e.g., pharmaceuticals) in the wastewater (Košnář et al., 2023), which are harmful to the environment. Historically, the primary method of sewage sludge disposal has been landfilling (Inglezakis et al., 2014), which leads to the loss of valuable phosphorus resources and poses environmental risks, such as heavy metal contamination of soil and water. In the EU, landfilling of sewage sludge is no longer permitted under EU Directive 86/278/EEC (Council Directive, 1986). Beyond landfilling, other common sludge management practices include incineration and land application, each presenting its own challenges. Incineration destroys organic matter and limits the options for phosphorus recovery, while land

application risks introducing heavy metals and excess nutrients into water systems, exacerbating eutrophication. Given that sewage sludge can contain significant phosphorus concentrations, its management is critical for both environmental protection and resource recovery. It is therefore expected that landfilling or soil applications of this material will soon be more restricted across the world (Inglezakis et al., 2014). This means that most of the material will be incinerated (Cohen et al., 2019). Although costly, this provides the opportunity to recover energy from the combustion of the sludge and produce an inorganic ash. The produced ash will still require further processing for nutrient recovery and safe disposal, as it contains a significant amount of phosphorus along with other contaminants, such as heavy metals.

Sewage sludge is therefore a crucial waste stream that could aid significantly in the phosphorus supply and global sustainability goals. In line with the importance of phosphorus and the high losses in wastewater sludge, some EU countries are implementing limits on wastewater treatment plants to ensure the recovery of phosphorus. Germany is enforcing mandatory phosphorus recovery from 2029 for sewage sludges containing more than 20 g P/ kg dry sludge. In Switzerland, phosphorus recovery from sewage sludge is mandatory from 2026 (Sichler et al., 2022). Furthermore, limits are placed on using sewage sludge directly as fertiliser without further treatment due to the high heavy metal content and pathogens present. Table 1 provides the limits being implemented in Germany and Switzerland (Hermann, Schaaf, 2019). The main focus of these regulations is to ensure phosphorus recovery and removal of heavy metals from the material. If used directly in agriculture without purification, there is a high risk of contamination with heavy metals.

The phosphorus can be recovered at various points in the whole wastewater treatment cycle, each with its advantages and disadvantages. From the wastewater itself, roughly 50% phosphorus removal is possible through a precipitation process. The pH is typically increased to between 8–10 and the phosphorus can be precipitated from the water. Depending on the conditions and reagents used, different phosphorus precipitates are formed. In most precipitation treatment routes, the main product is struvite, which can be used as a fertiliser to some extent. Some heavy metals or other contaminants present in the water are precipitated along with the struvite (Salkunić et al., 2022).

During the production of sludge in the wastewater treatment process, using biological or chemical processes to precipitate phosphorus, the removal can be up to 90%–95% (Salkunić et al., 2022). Typically, the chemicals added are Fe and to a lesser extent Al chloride salts, which increase the metals present in the sewage sludge and the chloride content in the wastewater. To bring the phosphorus in the resulting sewage sludge (or ash after its incineration) to use, a separation process is necessary. Currently, a number of processes are being developed to recover phosphorus from sewage sludge and ash. The two main strategies are wetchemical and thermochemical (Canziani et al., 2023).

Table 1

The wet-chemical methods involve leaching the phosphorus from the sludge/ash using an acid or alkaline solution (Egle et al., 2015). Phosphorus can then be precipitated out or concentrated in different forms. In some cases, the phosphorus is kept in solution to produce phosphoric acid. Purification steps are often included to separate contaminants from the product. The wet-chemical process has a higher cost compared to the thermochemical process as well as other challenges to ensure efficient separation of heavy metals and other contaminants (Canziani et al., 2023).

Thermochemical processes involve heating the sludge or ash to higher temperatures (1000 °C–1600°C). In some cases, Cl or S is added to aid in separating the heavy metals from the phosphorus. In these processes, the phosphorus is kept in the slag to produce a fertiliser product (Canziani et al., 2023). Typically, some of the heavy metals (As, Pb, and Zn) will be found in the gas phase due to their high volatility. Others, such as Ni, Cr, Cu, etc., remain in the slag product. As a consequence, these processes cannot completely remove the heavy metals from the final P-product.

A limit in many of the processes (precipitation of e.g., struvite, thermochemical and wet-chemical) is the removal of heavy metals. As the heavy metals content in the wastewater is highly variable, the final phosphorus product may not always meet the criteria to be used directly as fertiliser, or for other purposes such as phosphoric acid (Egle et al., 2015). This makes the processes less robust towards different feed compositions. Nevertheless, these routes allow to recover P in a fertiliser or as phosphoric acid and may cover parts of the largest P applications. However, no route is available for high purity phosphorus products, which typically rely on thermal white phosphorus.

FlashPhos is a novel thermochemical process being developed to recover phosphorus from dried sewage sludge. Unlike the mentioned processes, this process is designed to recover highquality white phosphorus from sewage sludge. While the FlashPhos process also recovers some phosphorus in a ferrophosphorus alloy, its primary output is high-value P4. A pilot plant is currently being developed by an international consortium in the FlashPhos project (Flashphos, 2024). Figure 1 provides the flowsheet of the process.

Sewage sludge is first dried and ground to a fine powder. The material is then fed into a flash furnace to gasify and partially combust the material. The combustion energy is used to melt the material in the furnace. Municipal sludge contains between 23%–60% organic material, which can generate an amount of energy of between 8–21 MJ/kg through combustion (Prasad, Smol, 2023), which could significantly contribute to the energy required for the process. The molten material is then reduced with carbon in a refiner furnace to produce phosphorus gas, slag, and a ferrophosphorus alloy. The iron present in the sewage sludge is partly from the wastewater itself as well as from the chemicals (typically, FeCl3) added to precipitate out the phosphate in the water treatment process. White phosphorus is recovered from the gas phase by condensation. The process achieves a better separation of

Heavy metal limits for (recycled) fertiliser in Germany and Switzerland (Hermann, Schaaf, 2019)

heavy metals compared to other processes, as many metals remain in the alloy or slag material. Volatile metals, such as arsenic and zinc, that report to the gas phase along with P4 can be efficiently removed before P4 condensation, due to their higher condensation points, and different reactivities.

Arnout and others (2023) previously discussed the material behaviour in the flash furnace. Based on this work, a detailed CFD model could be developed to simulate the process discussed by Ortner et al. (2023). Another important aspect is the design and operation of the refiner process. For this reduction process, it is important to understand the chemical behaviour of phosphorus and the relevant impurity elements in sewage sludge, in order to determine the expected phosphorus yield as well as the quality of phosphorus, slag, and alloy. The current work aims to improve this knowledge using a combination of thermodynamic modelling and lab-scale experiments. This work builds on the previous work, which focused on phosphorus behaviour with limited experimental work (Arnout, Nagels, 2016).

Approach and methodology

This study aims to provide insight into the expected efficiency of the refining process, specifically reaction equilibria, component distribution, and product yields. The material reduction behaviour is first studied using thermodynamic calculations. This enables an understanding of the carbon requirement of the process to achieve maximum phosphorus recovery. In addition, the theoretical phosphorus yield and component distribution, including heavy metals, are determined and can be compared with experimental results. For experimental verification of the potential phosphorus yield, 40 g scale experiments are conducted in a tube furnace.

The raw materials used in the study are two types of dry sewage sludge (sourced from Germany and Belgium), which are comprised of organic material, volatiles, and 50% ash. The exact composition is a result of the wastewater characteristics and the nature and efficiency of the treatment operations, as well as the geology of the area. Ash is produced from the sludge by heating the sludge at 1000°C for 24 h in an air atmosphere during which all the organic material is combusted. Table 2 provides the ash composition quantified as oxides analysed with XRF. It is expected that these oxides will be present in combined compounds such as phosphates, however, in the thermochemical calculations the mineralogy of the feed material has no effect on the equilibrium phases.

Thermodynamic calculations

Thermodynamic calculations are carried out with FactSage 8.2 (Bale et al., 2016) using the FactPS, FToxid, FSsteel databases for the gas, slag, and metal phases. The FactPS database is included as it contains all the pure compounds. The FToxid data base is selected to represent the oxide phases and the FSsteel to represent the iron phosphate phase in the process.

Table 3

Tube furnace experiments

In the thermodynamic assessment, the reduction progress is evaluated as a function of reductant addition. It also allows the study of the phosphorus yield and the component distribution over the different phases formed. A further parameter considered is the temperature of the process. This provides a better understanding of the expected onset temperature of the reduction process. The calculated results are compared with experimental findings to understand kinetic limitations.

Tube furnace experiments

A set of experiments is completed in a vertical tube furnace (GERO HTRV, model 100-250/18) using graphite crucibles of 45 mm inner diameter. This setup allows for a 40 g sample size. It enables the analysis of the final products and to determine the product yield. The influence of basicity and temperature as process parameters are experimentally evaluated. The formed products are analysed with XRF (Malvern – PANanalytical with OMNIAN software), XRD (Bruker D2 phaser), and ICP-MS (iCAP RQ IFC from Thermo Scientific).

Samples are heated at 5°C/min and kept at high temperature for 60 min, then cooled at 5°C/min. All steps are conducted in an inert Ar atmosphere. Table 3 provides a summary of the samples prepared for evaluation. To increase the basicity, samples 2–7 are prepared by mixing the ash with CaO.

Results and discussion

Thermodynamic calculations

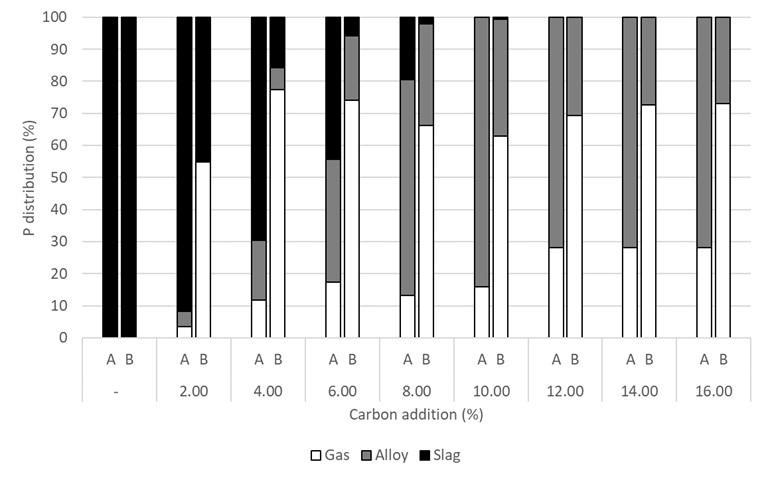

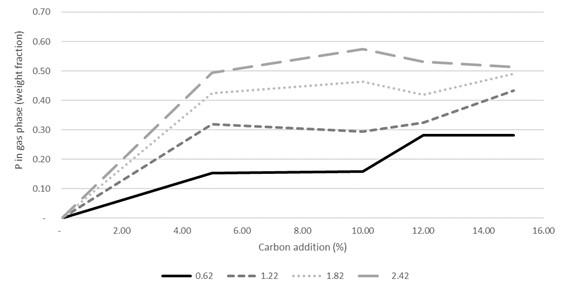

Figure 2 shows the calculated phosphorus distribution as a function of carbon addition for ash A and B at 1600°C. This will allow determination of the required amount of carbon to ensure maximum recovery of phosphorus. As expected, with a higher carbon addition, more phosphorus can be reduced and subsequently evaporated. With 12% carbon addition, 28% and 69% phosphorus yields are theoretically possible for ash A and B, respectively. Increasing the carbon addition further does not improve the phosphorous recovery. The remainder of the P forms a metal alloy with Fe, and only a very small amount of phosphorous is expected to remain in the slag. For ash B the losses to metal are expected to be smaller, this is investigated in more detail in the following section. These results are in line with previously reported calculation results (Arnout, Nagels, 2016).

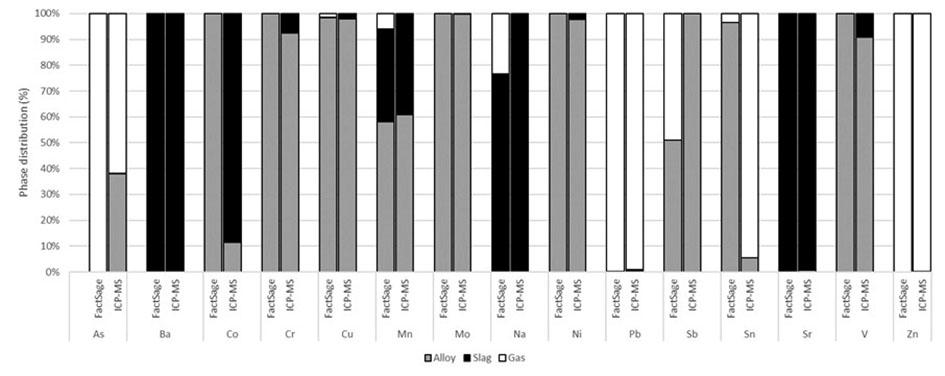

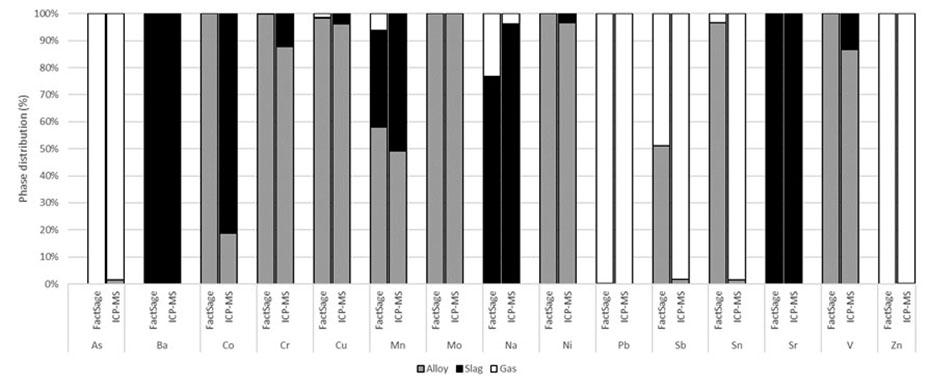

The maximum phosphorus yield for ash A is achieved at 12% carbon addition, which is defined as the carbon saturation point. Adding additional carbon does not improve the recovery. Figure 3 gives the full elemental distribution at 1600°C with 12% carbon addition for ash A. The following can be concluded: Pb, As, and Zn report to the gas phase (depicted by the white bars). Elements

such as Co, Cr, Cu, Fe, Ni, Sn, and V report to the metal phase (grey bars). Al, Ba, Ca, Mg, and Sr remain in the oxidic slag phase (black bars). K, Na, S, and P distribute over metal and gas phase, and Mn, Ti, and Si distribute over slag and metal.

Thus, the main contaminants expected in the final phosphoruscontaining gas stream are As, Zn, and Pb. These are all components with high volatility and will evaporate at these temperatures into the gas phase once reduced. To obtain a clean end product, these elements are to be removed from the gas phase before the final condensation of phosphorus. The final slag contains mainly SiO2, CaO, and Al2O3 and is expected to have a low remainder of heavy metals (only barium tends to remain in slag). Potential for the use of this material as a cement-type binder has been shown in experiments (Arnout et al., 2023).

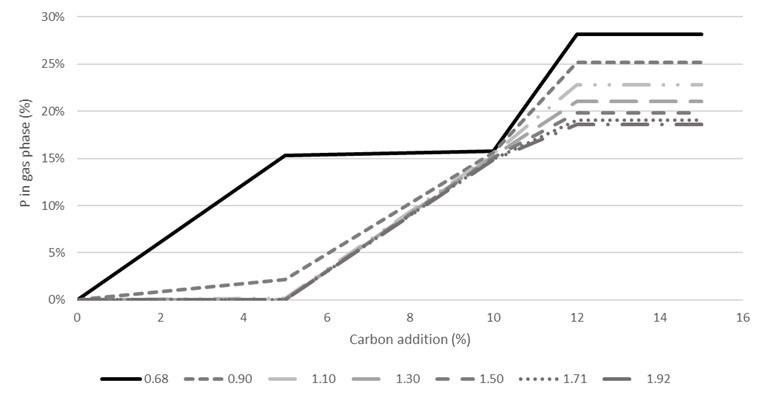

Based on the results it could be seen that the formation of a ferrophosphorus metal alloy limits the potential yield of the process. The formation of the metal alloy consumes reductant, and it captures a substantial amount of P, which can no longer be evaporated. This phenomenon is observed for both Ash A and Ash B. A much higher P recovery is achieved with Ash B due to a higher P2O5:Fe2O3 ratio compared to Ash A. The influence of the P2O5:Fe2O3 ratio was further evaluated in Figure 4. It can be seen that the P2O5:Fe2O3 weight ratio of a sludge or ash is an important parameter for the P-recovery potential (Arnout, Nagels, 2016). As shown in Figure 4, a higher iron content in the ash increases the phosphorus remaining in the metal and subsequently limits the amount of recovered phosphorus. From a P recovery standpoint, it could therefore be beneficial to use biological processes or aluminium salts for P removal from the wastewater (ESPP, 2025).

Liquid slags are often characterised by their basicity (CaO/ SiO2 ratio) as this has a large influence on the properties of this slag (e.g., melting point, viscosity, activity coefficient) (Verein Deutscher Eisenhüttenleute, 1995). As these properties may influence the reaction extents and kinetics, an experimental validation is needed. In light of this, the influence of basicity on the phosphorus recovery is evaluated in Figure 5 with thermochemical calculations. This is verified experimentally and reported in the next section. The basicity was adjusted by addition of CaO to the feed material in increasing amounts. Based on the calculated theoretical value, a lower basicity achieves the highest phosphorus recovery. However, this is in contrast to experimental work where the recovery is largely independent of the basicity.

The tube furnace experiments allow a better understanding of the material behaviour and final product quality. Experiments were run with both types of ashes: Ash A, which had a low P₂O₅:Fe₂O₃ ratio of 0.4, and Ash B, which had a higher and more favourable ratio of 1. As the output gas composition was not measured, the amount of phosphorus that evaporated (as product) is obtained from the difference between the phosphorus in the input and the phosphorus remaining in the slag and alloy at the end of the experiment. A yellow residue was formed at the bottom of the tube furnace. The collected quantity was insufficient for detailed evaluation, but a qualitative evaluation with XRF indicated that it was phosphorusrich with minor amounts of volatile elements Na, K, Zn, Sn, and S. This corroborates that phosphorus evaporated during the experiment and then condensed at the cold surface in the furnace

together with the other volatile components. More details on the phosphorus product can be expected when larger amounts are produced in the pilot plant.

Table 4 and Table 5 show the comparison between the experimental analysis and the calculation results (FactSage) at carbon saturation (12% C) of Sample 2. Sample 2 is close to the expected operating parameters of the FlashPhos process and therefore provides insight into the suitability of the industrial scale application. Good alignment is found between the analysis and the calculation results. The Si and P calculated percentage differ from the measured results by +4.2% and -6.3%, respectively. This is due to excess carbon present reducing more Si and increasing the P activity. It is clear that this point is not reached in the experiment despite the abundance of carbon from the crucible. This could be due to basicity or incomplete melting.