EXCELLENCE

www.PatersonCooke.com

Tailings & Mine Waste

Long-distance Pipelines

Mine Backfill

Mineral Processing

Mine Services

Bulk Water Supply

Dredging & Marine Pipelines

Laboratory & Test Work

Engineering Services

As leading experts, our holistic solutions balance many competing requirements, such as geotechnical stability, geochemical stability, water conservation, social license to operate, people at risk, emissions, operational risks, and cost. Our solutions are site specific and focus on each of the processing, transportation, and deposition challenges, as well as the client’s needs.

With over 30 years of experience designing overland pipeline systems, we are global leaders in this field. Our expertise includes conventional tailings pipelines, thickened and paste tailings disposal systems, and long-distance ore and concentrate pipelines.

Our engineers have solved some of the most complex backfill challenges while testing and designing hydraulic, paste and cemented rock fill (CRF) projects all over the world. We remain leaders in the design, execution, and ongoing management support of mine backfill systems.

OFFICE BEARERS AND COUNCIL FOR THE 2024/2025 SESSION

President E. Matinde

President Elect

G.R. Lane

Senior Vice President

T.M. Mmola

Junior Vice President

M.H. Solomon

Incoming Junior Vice President

S.J. Ntsoelengoe

Immediate Past President

W.C. Joughin

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk M.C. Munroe

Z. Fakhraei S.M. Naik

B. Genc G. Njowa

K.M. Letsoalo S.M. Rupprecht

S.B. Madolo A.T. van Zyl

M.A. Mello E.J. Walls

K. Mosebi

Co-opted Council Members

A.D. Coetzee

L.T. Masutha

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

G.R. Lane – TP Mining Chairperson

Z. Botha – TP Metallurgy Chairperson

K.W. Banda – YPC Chairperson

C.T. Chijara – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC K.T. Kekana (Interim Chairperson)

Johannesburg N. Rampersad

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West Vacant

Pretoria P.G.H. Pistorius

Western Cape Vacant

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

Editorial Board

S.O. Bada

R.D. Beck

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

R.T. Jones

W.C. Joughin

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

C. Musingwini

P.N. Neingo

S.S. Nyoni

M. Onifade

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

T.R. Stacey

International Advisory Board members

R. Dimitrakopolous

R. Mitra

S. Ndlovu

A.J.S. Spearing

E. Topal

D. Tudor

F. Uahengo

D. Vogt

Editor /Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31 Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

VOLUME 125 NO. 5 MAY 2025

Journal Comment: Think small by D. Vogt

President’s Corner: Engineers dividend and the African mine of the future by E. Matinde

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2025 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys Auditors

Genesis Chartered Accountants Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za

ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Comparison of Denver and Leeds laboratory flotation cells: Effect of particle size and hydrodynamics by

M.P. Tshazi, L.S. Leal Filho, N. Naude

.............................................................................

In this paper, the authors performed experiments in the Denver and Leeds laboratory flotation devices1 at the University of Pretoria using various particle sizes to evaluate the performance of the devices. These findings highlighted the influence of particle size on flotation recovery. For all experiments, the Denver laboratory flotation cell outperformed (defined by higher recovery) the Leeds device, while still operating at a lower impeller speed.

The impact of junior miners on the global supply of high-purity manganese sulfate monohydrate for the electric vehicle battery market by

K. Fichani, L.S. Teseletso, J. Kaavera, T.K. Dintwe, E. Shemang, B.I. Matshediso

In this paper, the high-purity manganese sulphate monohydrate project pipeline and projected production volumes with C1 cash costs were researched for six projects in the southern part of Botswana. The results showed that, while the estimated C1 cash costs would place the K.Hill project as the second highest cost producer, it would nonetheless have healthy profit margins due to the high projected price of high-purity manganese sulphate monohydrate. The study recommended policy options, which if implemented, could further encourage the exploitation and value addition of battery metals in Botswana.

The potential of 4IR technologies to mitigate risk in mine residue management by G.M.

Rohde, C. Bester

The fourth industrial revolution (4IR) is impacting society due to increased interconnectivity, processing speed, and automated technologies. This paper explores whether 4IR technologies have the potential to mitigate risks associated with tailings dams. Experts in the field of tailings dam operational management were surveyed to determine their viewon the risks associated with tailings dams and the potential of 4IR technologies to mitigate these risks. The survey found that a majority of experts believe that certain 4IR technologies have the potential to reduce the risks associated with tailings dam failures.

Improving spatial mine-to-plan compliance at an open pit mine through enhanced short-term mine planning by T.J. Otto, T. Mkhatshwa, T.J. van Heerden, C.H. Cloete

The Sishen open pit iron ore mine (Sishen) strives to continuously improve spatial compliance to the business plan. The enhanced short-term mine planning process focuses on detailed tactical sequence designs per mining pushback, the health of value chain buffers, spatial plan-to-plan reconciliation, and the associated management routines. This led to improved spatial mine-to-plan compliance. These results indicate that the application of short-term mine planning can contribute positively to improving the level of spatial execution against the business plan.

and recovery of

and aluminium

272 by M. Kruger, H. Krieg, D. van der Westhuizen

This study aimed to optimally separate cobalt and aluminium from the spent Fischer-Tropsch synthesis catalyst for potential use in the agricultural sector. It leverages the OLIÒ database to predict metal speciation during solvent extraction to aid with experimental planning. The investigation revealed the pivotal role of the aqueous pH yielding effective separation. Equipment design analysis for a targeted separation efficiency of 87% dictated the necessity of two mixer stages and a settler.

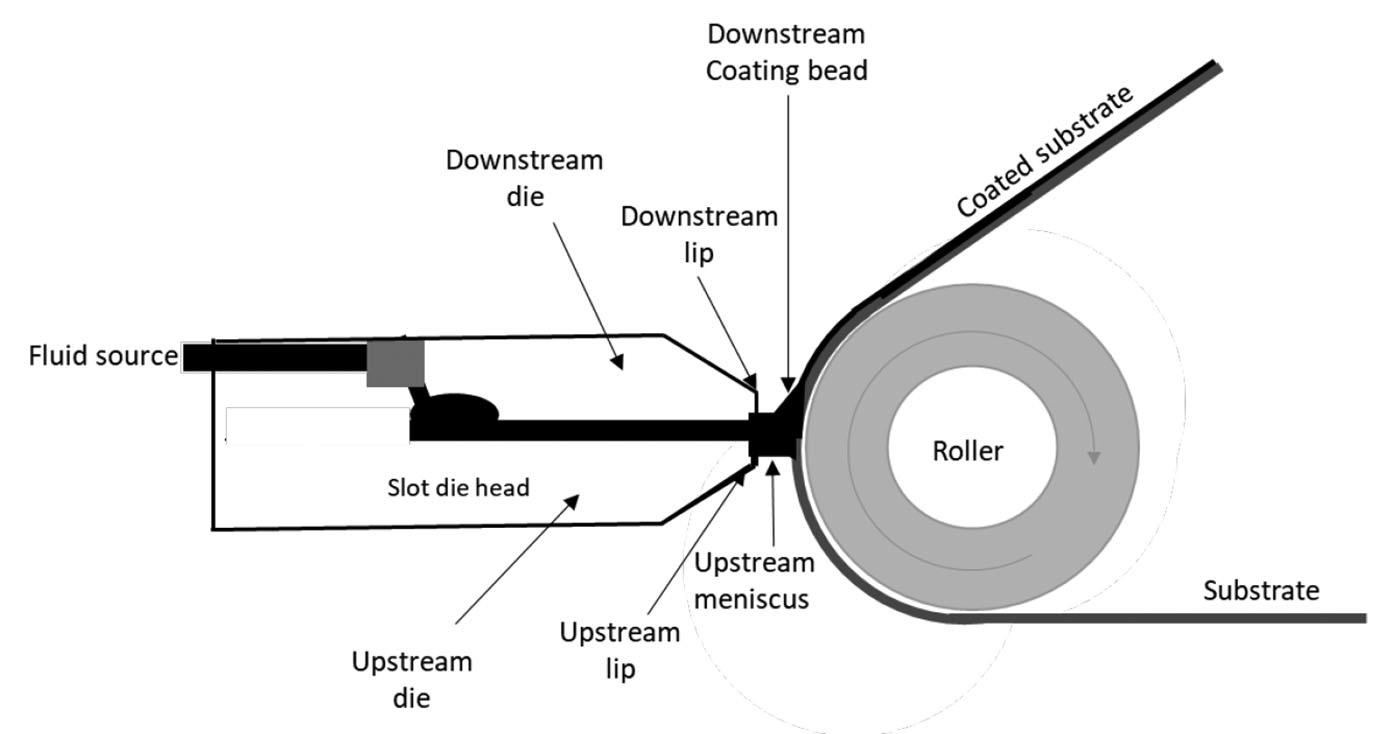

by C. Felix, O. Barron

In 2023, polymer electrolyte membrane fuel cell membrane electrode assemblies accounted for about 62% of the global fuel cell market share and this demand is expected to grow. The membrane electrode assembly is crucial and represents a significant cost to polymer electrolyte membrane fuel cell manufacturing. Roll-to-roll is a continuous coating process with speeds of 10 m/min being achieved. In this work, MicrogravureTM and slot-die coating methods have been adopted and have shown promising outcomes. An overview of the MicrogravureTM and slot-die coating methodologies is provided, and a discussion on preliminary results and challenges are presented.

ining is big business. For many commodities, the orebodies are big and the best way to exploit them for maximum profit is on a large scale.

But do large mines mean large equipment? At the moment, the answer is yes. Ramps can only handle a limited number of trucks per day and removing that obstacle is very expensive; more or wider ramps, a larger pit to hold them, and a lower extraction ratio. We deal with the problem of optimising ramps by making our trucks as large as possible. This also means we can manage with fewer drivers and, as is common knowledge, drivers are an ongoing expense.

If we look at air travel, we have seen the same move to larger equipment over time. A route like Johannesburg to London is like a ramp. It cannot take many more aircraft than it already does, because airports are constrained to accept a limited number of aircraft per day. The limit is safety; aircraft cannot land more frequently because of fear of collision. The result is a longterm trend to larger and more fuel-efficient aircraft.

But aviation is changing. We are seeing developments in local flight like the Lilium air-taxi: electric power and vertical take-off enables quiet ‘air taxis’ that can fly directly from your house to the nearby airport, from where you can catch a plane to anywhere.

For both mine haulage and aircraft, a constraint is a driver. While aviation is becoming steadily more automated, it is unlikely that we will see pilotless planes for a while yet, more because we cannot stomach the idea of a computer flying the plane in which we sit than because it is going to be less safe. For mine haulage, we already have automated trucks, and their safety record is better than that of human-driven trucks.

In mining, it is unlikely that anyone is going to switch to many small trucks in a large operation, although there is evidence that their flexibility might make them a more costeffective option. But then again, automating small trucks in a small operation makes sense. For example, a planned mine nearby can only work during the day, due to concerns about noise from its neighbours. In their application, a small, autonomous electric haul truck would be able to operate at night because it is silent, and in this case, would travel downhill loaded and uphill empty, and subsequently may be able to achieve its task without consuming any diesel.

With time, perhaps we will see many smaller trucks in large pits, rather than a few larger trucks, running on electricity rather than diesel, respectively. If we are serious about geometallurgy, we need to handle ore in smaller packages, and just the improvement in grade control could make the switch possible. With the widespread introduction of renewable energy, it also allows mines to lower their diesel bills and be seen to be greener.

At a time of tariffs and uncertainty, anything that can reduce risks and lower costs appears good. General automation of the mining fleet is at the point where it can solve problems and make mines at all scales more efficient, and therefore, more viable when prices collapse.

D. Vogt

he mining industry has experienced massive metamorphic and irreversible structural changes in the recent past. In addition to the recent unpredictable geopolitical conditions, the major challenges affecting the actors in the mining industry are intricately shaped by structural constraints such as geological, technological, and market conditions. Complexity in the geometallurgical properties of the individual ore bodies, for example, is irreversibly shaped by the geological conditions that existed billions of years ago. The grade and mineralisation properties of the ore bodies also have a significant impact on the choice of mining and processing technologies adopted, the economics of production, and the location of the mining operations. In addition, the mining industry also continues to face operational pressures to cut costs and increase productivity, while simultaneously navigating other challenges such as competition for high end skills, and meeting increasingly strict governance requirements and stakeholder expectations.

Due to the nature of mining as a business, it is clear that these inherent challenges are here to stay, and thus, the future of the industry depends on the ability to learn and adapt. The first, and perhaps most important priority for any mining operation, would be to strengthen its operational and cashflow resilience to enable it to weather the obvious challenges, such as geopolitical disruptions and cyclical downturns. Second to strengthening the economic position, the focus of a future looking mining operation would be to elevate its social licence to operate, achieved mostly through long term investments in human capital and environmental, social, governance, and sustainability KPIs. In fact, investing in talent and leadership has been considered a key variable to building a sustainable mining operation, as the mine of the future will be highly automated and will require highly skilled personnel capable of operating sophisticated systems and technologies. Establishing and strengthening economic linkages with other sectors of the economy is also critical to building value chain resilience and mitigating against the cyclical impact of the commodity markets.

In my October 2024 article, I introduced a controversial and yet highly ambitious proposition that critical minerals can result in sustained technological and economic catch-up. My hypothesis still remains unchanged, and I am convinced that it is possible to utilise the vast experience in complex mining systems and technologies on the African continent to build a vibrant manufacturing economy capable of providing value-added products and services to the rest of the world. I also highlighted that the ability to catch up is driven by deliberate efforts to build value-add competencies. Traditionally, the number of science, technology, engineering, and mathematics (STEM) skills active in the economy was used as a proxy measure of technological capabilities, however more recently, interesting terms such as ‘engineer dividend’ are being introduced to broadly describe the nature and quantum of STEM skills that are required to drive and sustain technological innovation.

Borrowing from investment economics, the term ‘engineer dividend’ was introduced in a recent Bloomberg article to refer to a phenomenon whereby countries with a large and diverse skilled engineering workforce naturally develop competitive advantage in areas leading to technological advancement and industrial development (Bloomberg, available at https://www.bloomberg.com/opinion/articles/2025-03-24/china-s-engineer-dividendis-paying-off-big-time). Case in mind is China, which, according to Bloomberg, invested intensely in STEM education and managed to increase its number of engineers by close to 12 million in the period between 2000 and 2020. In this context, engineer dividend was described as an internal rate of return on investment in engineering competencies to create a concentrated community of experts and strong network of engineering skills capable of driving innovation in multiple fields. Although dependent on other factors to succeed, the high concentration of multidisciplinary and specialised engineering expertise fosters both competition and collaboration, leading to improved sector productivity and industrial competitiveness.

In conclusion, there is no doubt that resource-rich countries on the continent can leverage on the extensive experience in designing and operating complex mining systems and operations to build a robust manufacturing and value-added services economy. With all conditions remaining the same, would it be plausible to consider the ‘engineer dividend’ concept as a viable skills investment concept to derisk the future of African mining industry and, if so, which areas should we focus on?

E. Matinde President, SAIMM

Affiliation:

1University of Pretoria, South Africa

2Universidade de São Paulo, Brazil

Correspondence to:

M.P. Tshazi

Email: mfesane.tshazi@up.ac.za

Dates:

Received: 25 Aug. 2022

Revised: 29 Nov. 2024

Accepted: 27 Mar. 2025

Published: May 2025

How to cite:

Tshazi, M.P., Leal Filho, L.S., Naude, N. 2025. Comparison of Denver and Leeds laboratory flotation cells: Effect of particle size and hydrodynamics. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 5, pp. 225–232

DOI ID:

https://doi.org/10.17159/2411-9717/2289/2025

ORCiD:

M.P. Tshazi

http://orcid.org/0009-0001-6389-1547

L.S. Leal Filho

http://orcid.org/0000-0001-8501-1857

N. Naude

http://orcid.org/0000-0002-9615-0243

by M.P. Tshazi1, L.S. Leal Filho², N. Naude1

Abstract

In this paper, the authors performed experiments in the Denver and Leeds laboratory flotation devices1 at the University of Pretoria at various particle sizes to evaluate the performance of the devices. Quartz was used in a single mineral system at discrete sizes fractions, -25 µm, +2545 µm, +45-75 µm, and +75-106 µm. Hydrodynamic analysis, based on dimensionless power and Reynolds numbers, indicated that the Leeds cell required higher power input to achieve comparable flow conditions. Specifically, the Leeds cell exhibited an average power number of 1.03, whereas the Denver cell averaged 0.77 within the same impeller speed range of 1000 rpm–1500 rpm. For comparative flotation performance, impeller speeds were calibrated, resulting in operating speeds of 1200 rpm for the Denver cell and 1400 rpm for the Leeds cell. The cells performed similarly at two coarser-sized fractions. However, some deviations were observed in the finer particle size range. The -25 µm (fine) fraction initially achieved a recovery of only 15%. An additional reagent dosage was required to enhance the recovery of this fraction significantly. These findings highlighted the influence of particle size on flotation recovery. For all experiments, the Denver laboratory flotation cell outperformed (defined by higher recovery) the Leeds device, while still operating at a lower impeller speed. This advantage can be attributed to its impeller-stator design and air dispersion features, effectively overcoming slurry resistance and resulting in superior flotation performance compared to the Leeds cell.

Keywords quartz, particle size, hydrodynamics, impeller speed, recovery

Introduction

Froth flotation

Froth flotation is commonly used to concentrate valuable minerals. This process depends on adequate surface exposure, i.e., the extent of liberation of the mineral, and selective hydrophobicity of the desired mineral(s). Froth flotation is regarded as a complex system, with many influencing factors and interdependent interactions. These factors and interactions are summarised as a flotation system, which is comprised of three categories of components namely: chemistry, equipment, and operation components. Each component is subdivided into many variables, such as particle size, collectors, and airflow, as shown in Figure 1. These flotation variables significantly influence flotation performance. Laboratory flotation tests have made a considerable contribution to industrial process development and troubleshooting (Newcombe et al., 2012; Ross, 2019). The validity of correlation of laboratory batch froth flotation data to an industrial application is historically somewhat poor (Newcombe et al., 2012). This poor correlation has been linked to differences in equipment and operational variables between the laboratory and plant configurations.

A comparison of the Denver and Leeds laboratory cells was conducted over 40 years ago (Liddell, Dunne, 1984). However, the unique characteristics of these cells, like their structure, impeller, and air intake mechanism, were not explored. The study aimed to compare laboratory flotation cells, Denver and Leeds, across varying particle size ranges and hydrodynamic conditions to provide insight into how particle size and cell characteristics influence flotation performance under identical experimental conditions.

1All references to devices in this document refer to those used at the University of Pretoria.

Figure 2 (left) illustrates a Denver D-12 laboratory flotation cell, which is widely used for conducting laboratory test work. Figure 2 (right) illustrates the Leeds laboratory flotation cell. As introduced by Professor C. Dell of the University of Leeds, this cell aimed to increase reproducibility of results and reduce operatordependent factors. (Liddel, Dunne, 1983). Flotation tests performed in laboratories are usually dependent on the operator because froth scraping is generally done manually. The scraping areas of the cells differ, with the Denver cell having the impeller in the centre, which obstructs scraping, while the Leeds cell has no obstruction. The Leeds cell features a froth crowder-like shape at the rear. The Leeds flotation cell is designed as a complete unit and parts are not easily interchangeable, whereas the Denver allows for much more flexibility as the cell size and/or impeller design can be changed easily without a significant redesign.

One of the biggest differences between the two cells is their impeller design (Figure 3): The Denver design has four equally sized holes from which the air is sheared as it is introduced into the cell; in the Leeds cell, air is introduced just above the impeller to be sheared. Some air is forced into the impeller and sheared to smaller equally sized bubbles, and some air bypasses the impeller to enter the cell. These differences cause different bubble flow patterns.

In froth flotation, minerals are concentrated based on three main principles: true flotation, entrainment, entrapment, or a combination of these processes (Wills, Finch, 2015). True flotation is governed by three mechanisms: collision, attachment, and detachment. A brief description of true flotation is that a particle needs to collide with an air bubble, the two entities become attached, and then this unit must remain stable as it moves through the cell and into the froth zone until it is discharged via the cell lip. This is a chemically activated process (Wills, Finch, 2015). Entrainment is the result of water-suspended minerals deporting to the concentrate launder (Wang, 2016). The entrainment mechanism is non-selective as particles are not attached to air bubbles but are instead carried upward by the flow of water or by the wake created by bubble-particle aggregates (Smith, Warren, 1989). This mechanism can affect both valuable and gangue mineral particles. Wang et al. (2015) and Zheng et al. (2006) further observed that entrainment typically favours particle sizes below 50 μm, while entrapment occurs when minerals are trapped between air bubbles because of a non-draining froth phase. This mechanism primarily affects coarse particles (> 106 μm) more than fine particles (Zheng

et al., 2006). Like entrainment, entrapment can concentrate both valuable and gangue minerals, leading to reduced selectivity in the flotation process.

The floatability of a mineral is determined by its particle hydrophobicity (water repellence) and the hydrodynamic conditions that promote particle–bubble collisions, adhesion, and transport from the pulp to the froth. High floatability is typically observed in particles with large contact angles and high collection efficiency (Ek), which is expressed by Equation 1: [1]

where Ec is efficiency of particle–bubble collision; Ea is efficiency of adhesion; Ep is efficiency of preservation of the particle–bubble aggregate.

In Trahar’s (1981) study, it was highlighted that although particle size was recognised as a crucial factor in froth flotation, its practical advantages in the design and plant operations have been limited. This gap is expected to close to meet the challenges of processing increasingly complex ores. Particle size plays a crucial role in the efficiency of bubble-particle attachment (Rao, 2004), and flotation recovery is significantly influenced by the size of mineral particles (Jameson, 2012). Norori-McCormac et al. (2017) further demonstrated that even small changes in particle size distribution can significantly impact froths stability.

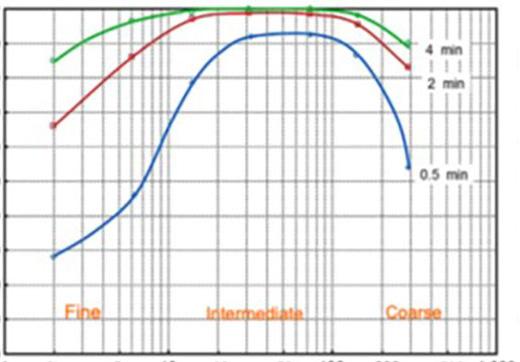

In addition to the influencing factors recorded in Figure 1, the effect of particle size on flotation recovery is highlighted in Figure 4, categorising particle sizes into three regions: fine, intermediate, and coarse. The specific boundaries of these regions depend on the mineral type and its properties. It is generally accepted that there is an ideal size range (intermediate) where recovery is maximised. Consequently, particles outside of a particular range will be compromised when floated and it is difficult to achieve optimum recoveries (Trahar, 1981).

Pease et al. (2006), expounded on Trahar’s findings, demonstrating the benefits of floating fine particles separately to maximize recovery (Figure 5). The study emphasised the importance of narrow size distribution in flotation operations, suggesting that both fine and coarse materials can be floated optimally if the kinetics associated with each size fraction are fully understood and controlled.

Fine particles suffer from poor collision efficiency, thus resulting in poor overall recovery (Nguyen, 2007; El-Rahiem, 2014). The main factors affecting this are bubble size, energy input, and pulp rheology, and therefore the recovery performance can be tuned by adjusting either one of those inputs. Moreover, due to the larger surface area of fine particles, higher reagent dosages are often required to render them hydrophobic (Pease et al., 2006). On the other hand, coarse particle flotation is decreased by the detachment of particles from bubbles (Wills, Finch, 2015). The main factors affecting this are hydrophobicity and energy input. Coarse particle recovery can be optimised by focusing on these inputs; however, it should be noted that fine and coarse particle recovery often react in an opposing manner (Safari et al., 2016). For instance, increasing energy input will benefit fine particle recovery while decreasing coarse particle recovery, and careful consideration should be used when optimising recovery of a certain size fraction.

Finer particles generally exhibit slower flotation rates compared to larger particles under conditions of low turbulent energy dissipation, as observed by Pyke et al. (2003). As a result Pyke et al. (2003) and Changunda et al. (2012), observed that kinetic rate (k) increases almost linearly with particle size. This phenomenon is related to the efficiency of particle-bubble collision.

Further research by Murhula, Hashan, and Otsuki (2022) demonstrated that flotation recovery is influenced by the interaction between solid concentration, particle size, and mineral type. In quartz flotation, for instance, higher recovery rates are typically achieved with higher solid concentrations and smaller particle size fractions, highlighting the role of entrainment, whereas more dilute pulps tend to enhance bubble loading efficiency while minimising entrainment (Ramlall, 2008).

Hydrodynamics

Hydrodynamics (fluid flow) within the flotation system are primarily influenced by the impeller (Shabalala et al., 2011; Souza Pinto et al., 2018). Hydrodynamic behaviour is typically characterised by hydrodynamic parameters and dimensionless numbers (Souza Pinto et al., 2018). These parameters and numbers account for the complex interactions and behaviours observed in the flotation system, as illustrated in Figure 1. Key dimensionless numbers include the power number (NP), Reynolds number (NRe), and Froude number (NFr), amongst others.

Dimensionless hydrodynamic numbers are valuable for benchmarking the performance of impellers and flotation cells (Rodrigues et al., 2001). Key dimensionless numbers, such as the NRe, NFr, and NP, are derived from operational variables (e.g., impeller rotational speed, volumetric airflow, pulp specific gravity, and dynamic viscosity) or geometric parameters (e.g., impeller diameter). These dimensionless numbers facilitate the analysis of fluid flow characteristics within a flotation cell. Table 1 provides a comprehensive summary of these parameters, including their formulas and typical ranges, enabling researchers to quickly assess fluid dynamics.

Characterisation of flotation hydrodynamics with dimensionless numbers related to impeller characteristics (from Fuerstenau et al.,

(Wang, Liu, 2021)

Describes solids suspension and characterisation of mixing intensity (Nelson, Lelinski, 2000)

Describes

and how the impeller draws power (Tabosa et al., 2016b)

where P is power drawn by impeller (W); N is impeller rotational speed (s-1); D is impeller diameter (m); ρ is specific gravity (kg/m3); μ is dynamic viscosity at a given temperature (kg/m.s); g is gravity acceleration (m/s2).

NP represents the net power drawn for both pumping and shearing, quantifying the resistance imposed by the slurry on the impeller blades, also known as the drag coefficient (CD). A higher NP signifies greater fluid displacement (Arbiter, Harris, 1962), which is advantageous for fine particles due to their low collision efficiency. NP varies with the slurry flow regime and is typically plotted against the Reynolds number (NRe), as shown in Figure 6. In laminar flow, NP decreases steadily, whereas in highly turbulent conditions (NRe > 10⁴), commonly observed in mechanical flotation cells, it remains constant (Harris, 1976; Harris, 1986; Leal Filho et al., 2002).

The dynamic viscosity of water at different temperatures is well-documented in literature. At 27°C, it is reported to be 0.8509 × 10-³ Pa·s (Ma et al., 2020). To estimate the dynamic viscosity of a slurry system, the Krieger–Dougherty Equation (5) is commonly used, particularly for monodisperse systems. The maximum packing fraction (φm) generally falls between 0.6 and 0.7, with a value of 0.63 often used for randomly packed spheres. Furthermore, for spherical particles, the intrinsic viscosity ([η]) is typically 2.5, as noted by Abo Dhaheer et al. (2015).

where μ and μ0 are the dynamic viscosities of the slurry and water (Pa s), respectively; φ is volume fraction of the dispersed solid.

Experimental Laboratory flotation cells

[5]

(medium), and +75–106 µm (coarse). Each fraction was separately blended and split with a rotary splitter to ensure that representative samples were used for the flotation tests. The cell operations were characterised in such a way that comparable kinetic results could be obtained. This was achieved by manually calibrating the impeller speeds of the cells, resulting in optimised speeds of 1200 rpm for the Denver cell and 1400 rpm for the Leeds cell. All tests were performed at 17 mass% solids in a 25 g/t Flotigam EDA ether amine collector, with a 2-minute conditioning time. This collector exhibits frothing properties and therefore no frother was added during the experiments. The pulp was adjusted to a pH of 9.5 with the aid of NaOH. An air flow of 2 L/min was employed. Three to four concentrates were collected every minute after manual scraping at a 10-second interval. It was necessary to conduct further tests on the –25 µm fraction at 50 and 175 g/t collector dosages of Flotigam EDA to improve recovery. Consequently, seven concentrates were collected from the higher collector dosed -25 µm fraction. In general, flotation continued until no froth was recoverable. The concentrates were filtered, oven dried, and weighed. All experiments were carried out repeatedly, with a variability limit of up to a maximum of 5% standard deviation.

The power consumption of Denver and Leeds laboratory cells was measured using an Efergy Classic Wireless Energy Monitor. Tests were conducted at impeller speeds between 1000 rpm and 1500 rpm with increments of 1000 rpm. Testing was conducted under three conditions: an empty cell, a cell filled with 3 L of water with an air flow rate of 2 L/min, and a slurry mixture containing approximately 17 mass% quartz solids with an air flow rate of 2 L/min. The power draw was calculated by subtracting the power consumed under loaded conditions (water or slurry) from that recorded in the no-load (empty) condition.

All tests were conducted using the Denver and Leeds laboratory flotation cells with nominal volumes of 3.5 L, both made of Perspex. Each cell was equipped with a distinct tachometer for adjusting the impeller speed. A centralised flow meter was employed to regulate the flow of air supplied from a compressed dry air cylinder, ensuring consistent and controlled aeration across the experiments. The Denver and Leeds cells had impeller diameters of 0.07 m and 0.074 m, respectively. The effect of particle size distribution was evaluated in the Denver and Leeds laboratory flotation cells, while maintaining all other variables (given in Figure 1) constant.

Experimental conditions and procedures

A 40 kg sample of 99.9% quartz was used. Quartz is classified as a strongly hydrophilic mineral (Wills, Finch, 2015) and therefore requires chemical activation. The material was wet-milled in a rod mill and thereafter wet-sieved to produce four narrow size fractions: −25 µm (fine), +25–45 µm (intermediate), +45–75 µm

This section presents the results and discussions from a comparative study of Denver and Leeds cells at different particle size fractions. The study was conducted using a single mineral system, namely quartz, ensuring consistent mineralogy and resulting in uniform hydrophobicity.

The flotation of four particle size fractions was evaluated under optimised conditions. Figure 7 illustrates the average cumulative recoveries over time for the two larger size fractions: (medium) +45–75 µm, and (coarse) +75–106 µm. Both flotation cells performed similarly for the +45–75 µm fraction, achieving recoveries of approximately 80%. Whereas, for the +75–106 µm fraction, the Denver cell recorded a recovery of 74%, outperforming the Leeds cell by approximately 3%. The difference in performance between the two cells for the coarsest fraction could be attributed to the effect of turbulence, which is better dampened in the Denver cell compared to the Leeds cell. As a consequence of turbulence, which can disrupt particle–bubble aggregates, particularly when coarse particles are present, lower flotation efficiency is the result. (Yao et al., 2021). The recovery of both size fractions was completed within 2.5 minutes, which aligns with expectations, since these fractions fall mostly within the ideal flotation range of +25–106 µm (as shown in Figure 5). These recoveries were aided by the formation of stable and voluminous froths during flotation.

The kinetic constants were approximately the same for both cells for flotation of the intermediate (+45−75 µm) and coarse (+75−106 µm) size fractions, although the values for the Denver cell were slightly higher, aligning with the same trend as the recovery rates.

Figure 7—Comparison of Denver (dotted lines) and Leeds (solid lines) cells for kinetics curves for flotation of the medium (+45−75 µm and coarse (+75−106 µm) size fractions of silica, with corresponding rate constant in the legend label

Figure 8 presents the results for the smaller size fractions: fines (−25 µm) and intermediate (+25–45 µm). Recovery of the fine fraction (−25 µm) was very low for both cells, though the Denver cell achieved a slightly higher recovery of 15%. To support this, the Denver cell demonstrated nearly double the kinetic rate (0.32 min-¹) compared to the Leeds cell (0.18 min-¹), suggesting that the Denver impeller enhanced collision efficiency (Ec). The low recovery of the finest particles (−25 µm) can be largely attributed to the low collector dosage (25 g/t), which significantly hindered their flotation performance. Additionally, fines typically have a higher specific surface area (cm²/g), leading to lower collision efficiencies between particles and bubbles. As Pease et al. (2006) showed, fines can achieve good flotation performance, but only when flotation conditions are specifically tailored to treat this fraction in a narrow size distribution range.

For the intermediate size fraction (+25–45 µm), the Denver cell outperformed the Leeds cell, with recoveries of 74% and 63%, respectively. This suggests that the Denver cell provided more favourable hydrodynamic conditions for particle–bubble collisions, a conclusion supported by the higher flotation rates of 0.65 min-¹ for the Denver cell compared to 0.44 min-¹ for the Leeds cell.

Moreover, both the fine (−25 µm) and intermediate (+25 –45 µm) size fractions required an additional 90 seconds to reach completion compared to the larger fractions. This finding is consistent with the conclusion of Pease et al. (2006) that finer particles generally require longer residence times in flotation processes than coarser particles.

The kinetic rate (k) was very low for the fine fraction (−25 µm) and increased with particle size, a trend consistent with the findings of Pyke et al. (2003) and Changuada et al. (2008). Particle size significantly affects the recovery rate, as highlighted by several researchers, including Trahar (1981), Rao (2004), and Jameson (2012). The maximum value of k was observed for the +45−75 µm fraction, but it decreased for the coarsest size fraction (+75 −106 µm). This behaviour can be attributed to the particle–bubble collection efficiency (Ek), which is determined by the product of collision efficiency (Ec), adhesion efficiency (Ea), and the preservation efficiency of the particle–bubble aggregate (Ep). Fine particles have low Ek due to poor Ec (i.e., limited particle–bubble collisions), while very coarse particles show reduced Ek because turbulence in the flotation cells tends to destroy the particle–bubble aggregates.

Pease et al. (2006) also demonstrated that finer particles require higher reagent dosages due to their larger specific surface area (cm²/g). To improve the recovery of fines to levels comparable to

Figure 8—Comparison of Denver (dotted lines) and Leeds (solid lines) cells for kinetics curves for flotation of the intermediate (+25−45 µm) and fine (−25 µm) size fractions of silica, with corresponding rate constant in the legend label

Figure 9—Effect of collector dosage on flotation recovery of fines (−25 µm) using the Denver (dotted lines) and Leeds (solid lines) cells, with corresponding rate constant in the legend label

those of the +25 µm size fractions, higher reagent dosages were investigated. The collector dosage was initially doubled, then further increased to 175 g/t. Figure 9 illustrates the impact of these increased dosages on fines recovery.

Despite doubling the dosage, recovery levels still fell short of those achieved for the +25 µm fractions. However, when the dosage was raised to 175 g/t of Flotigam EDA, a significant improvement in flotation response was observed, with recovery levels becoming comparable to those of the larger size fractions. Also, notably so, this required up to nine minutes to reach completion. As previously mentioned, finer particles typically require longer flotation times. This increase in reagent dosage enhanced overall flotation rates and potentially contributed to greater particle stabilisation, resulting in higher fines recovery from the froth.

Despite a significant increase in reagent dosage for the finest size fraction (−25 µm), the average k values remained relatively low at 0.34 min-¹ for the Denver cell and slightly lower at 0.23 min-¹ for the Leeds cell. This suggests that the Leeds impeller was less effective in promoting particle–bubble collisions compared to the Denver impeller, as all other conditions were kept constant. The observed increase in recovery rates can be attributed to the higher reagent dosage, which aligns with the findings of Pease et al. (2006).

Figure 10 presents the results for the water-only system, showing a general trend of decreasing power number with increasing Reynolds number. This aligns with Westhuizen’s (2004) findings that the presence of air reduces the power number by decreasing the density effect around the impeller. The Leeds cell exhibited slightly higher turbulence intensities (higher Re) and power inputs than the Denver cell, except at 1000 rpm. Furthermore, increased turbulence

intensity (higher NRe) and power input enhance bubble-particle collisions, especially for finer particles, leading to more efficient flotation, although excessive turbulence can potentially disrupt bubble-particle adhesion. These findings suggest that the Leeds cell is better suited for applications requiring higher turbulence intensity.

Figure 11 illustrates impeller performance in a slurry. The Leeds cell produced results similar to those in the water-only system, whereas the Denver cell maintained a stable power number of approximately 0.77 across the 1000 rpm–1500 rpm range. This stability highlights the Denver cell’s ability to generate sufficient turbulence while consuming less power.

In the absence of solids (Figure 10), both cells operated in the transitional region between laminar and turbulent flow, as evidenced by fluctuations in power numbers, suggesting the presence of large eddy vortices. However, in slurry conditions (Figure 11), the Denver impeller demonstrated a greater ability to overcome resistance from solid particles, with its power number rapidly approaching the fully turbulent regime. In contrast, the Leeds impeller did not exhibit this behaviour under the experimental conditions. These results indicate that the Denver cell produced more consistent fluid fields while operating with greater power efficiency.

Additionally, the Denver and Leeds cells had similar Froude numbers (2 < NFr< 4.5 and 2.1 < NFr < 4.7, respectively), indicating comparable solid suspension capabilities.

This study compared the performance of the Denver and Leeds laboratory flotation cells based on various particle size fractions and hydrodynamic characteristics to achieve comparable kinetic results. Hydrodynamic characteristics included dimensionless numbers such as power and Reynolds numbers, which revealed that these cells require different operating conditions in the presence and absence of particles. Leeds demonstrated higher power numbers under both conditions, indicating greater resistance to movement imposed by water and slurry due to a unique impeller-stator design. As a result, the Leeds impeller must dissipate more power to facilitate particle and bubble dispersion and promote particle–bubble collisions.

Consequently, the cells needed to be operated at different rotational speeds, 1200 rpm for the Denver cell and 1400 rpm for the Leeds cell, to achieve similar performance. The difference in operating speeds required to obtain similar results can be linked to hydrodynamic characteristics, which influence the manner of air

bubble creation in the cells and mineral recovery. These operating conditions were used for testing at narrow size fractions. The cells performed similarly at the coarser fractions, but there were some differences in the lower particle size range. This suggests that the impact of cell design, particularly impeller efficiency, becomes more pronounced at smaller particle sizes. The Denver cell reported higher recovery rates across all test ranges with faster kinetic rates.

The study emphasises the importance of cell design in flotation efficiency and highlights the critical role of particle size in flotation recovery. Fine particles require more reagents and longer flotation times (due to their larger surface area) to obtain optimum recoveries. Process efficiency will increase as a result of knowing how to optimise particle size distribution.

The results demonstrate that the Denver cell outperformed the Leeds cell, as the Leeds cell required a higher impeller speed to achieve similar recoveries. Overall, the Denver cell exhibited marginally superior performance, which can be attributed to its more versatile hydrodynamic characteristics, making it better suited for handling a broader range of particle sizes.

The authors wish to thank Anglo American for financial support and the University of Pretoria for use of the laboratory for this research. English editing of this manuscript was carried out by Prof. K. C. Sole.

References

Abo Dhaheer, M.S., Al-Rubaye, M.M., Alyhya, W.S., Karihaloo, B.L., Kulasegaram, S. 2015. Proportioning of self-compacting concrete mixes based on target plastic viscosity and compressive strength: part i - mix design procedure. Journal of Sustainable Cement-Based Materials, vol. 5, no. 4, 199–216. https://doi.org/10.1080/21650373.2015.1039625

Arbiter, N., Harris, C.C. 1962. Flotation machines. In: D.W. Fuerstenau (Editor). Froth Flotation 50th Anniversary Volume, Pap. 14. The American Institute of Mining, Metallurgical, and Petroleum Engineers, New York.

Changunda, K., Harris, M., Deglon, D.A. 2008. Investigating the effect of energy input on flotation kinetics in an oscillating grid flotation cell. Minerals Engineering, vol. 21, nos. 12–14, pp. 924–929. https://doi.org/10.1016/j.mineng.2008.03.015

El-Rahiem, F.H.A. 2014. Recent trends in flotation of fine particles. Journal of Mining World Express, vol. 3, pp. 63–79. https://doi.org/10.14355/mwe.2014.03.009

Fuerstenau, M.C., Jameson, G.J., Yoon, R. H. 2007. Froth flotation: a century of innovation. Littleton, Colo.: Society for Mining, Metallurgy, and Exploration.

Harris, C.C. 1976. Flotation machines. In: Fuerstenau, M.C. Flotation: A.M. Gaudin Memorial Volume. AIME, New York, vol. 2, p. 788.

Harris, C.C. 1986. Flotation machines design, scale up and performance: data base. In: Somasundaran, P. (ed), Advances in mineral processing. Symposium honoring Nathaniel Arbiter on his 75th birthday, New Orleans. Littleton, p. 618–635.

Jameson, G.J. 2012. The effect of surface liberation and particle size on flotation rate constants. Minerals Engineering, 36-38, pp. 132–137. https://doi.org/10.1016/j.mineng.2012.03.011

Klimpel, R.R. 1984. Use of chemical reagents in flotation. Chemical Engineering, vol. 91, no. 18, pp. 75–79.

Leal Filho, L.S., Rodrigues, W.J., Ralston, J. 2002. Importance of hydrodynamics in coarse particle flotation. In: Ralston, J., Miller, J., Rubio, J. (eds). Flotation and flocculation: from fundamentals to applications. Snap Printing, Medindie (Australia), p. 203-212.

Libii, J.N. 2010. Using wind tunnel tests to study pressure distributions around a bluff body: the case of a circular cylinder.

Liddel, K.S., Dunne, R C. 1983. An evaluation of the Leeds laboratory-scale flotation cell. Council for Mineral Technology (Mintek), Randburg, South Africa.

Ma, Y., Li, S., Zhang, L., Li, H., Liu, Z. 2020. Numerical simulation on heat extraction performance of enhanced geothermal system under the different well layout. Energy Exploration & Exploitation, vol. 38, no. 1, pp. 274–297. https://doi.org/10.1177/0144598719880350

Murhula, E., Hashan, M., Otsuki, A. 2022. Effect of Solid Concentration and Particle Size on the Flotation Kinetics and Entrainment of Quartz and Hematite. Metals. vol. 13, no. 53, pp. 1–21. https://doi.org/10.3390/met13010053

Nelson, M.G., Lelinski, D. 2000. ‘Hydrodynamic Design of SelfAerating Flotation Machines’, Minerals Engineering, 13(10), 991–998. doi:10.1016/S0892- 6875(00)00085- 6

Newcombe, B., Bradshaw, D., Wightman, E. 2012. Development of a laboratory method to predict plant flash flotation performance. Minerals Engineering, vol. 39, pp. 228–238. https://doi.org/10.1016/j.mineng.2012.07.008

Nguyen, A.V. 2007. Flotation, Encyclopedia of Separation Science, pp. 1–27. https://doi.org/10.1016/B0-12-226770-2/00071-5

Norori-McCormac, A., Brito-Parada, P.R., Hadler, K., Cole, K., Cilliers, J.J. 2017. The effect of particle size distribution on froth stability in flotation. Separation and Purification Technology, vol. 184, pp. 240–247. https://doi.org/10.1016/j. seppur.2017.04.022

Pease, J.D., Curry, D.C., Young, M.F. 2006. Designing Flotation Circuits for High Fines Recovery. Minerals Engineering, vol. 19, no. 6, pp. 831–840. doi:10.1016/j.mineng.2005.09.056

Pyke, B., Fornasiero, D., Ralston, J. 2003. Bubble particle heterocoagulation under turbulent conditions. Journal of Colloid and Interface Science, vol. 265, no. 1, pp. 141–151. https://doi.org/10.1016/S0021-9797(03)00345-X

Ramlall, N.V. 2008. Development and modelling of a semi-batch. dissertation.

Rao, S.R. 2004. Flotation Kinetics and Fine Particle Flotation. In: Surface Chemistry of Froth Flotation. Springer, Boston, MA. https://doi.org/10.1007/978-1-4757-4302-9_14

Rodrigues, W.J., Leal Filho, L.S., Masini, E.A. 2001. Hydrodynamic Dimensionless Parameters and Their Influence on Flotation Performance of Coarse Particles. Minerals Engineering, vol. 14, no. 9, pp. 1047–1054. doi:10.1016/S08926875(01)00110-8

Ross, V. 2019. Key aspects of bench flotation as a geometallurgical characterization tool. Journal of the Southern African Institute of Mining and Metallurgy, vol. 119, no. 4, pp. 361–367. https://doi.org/10.17159/2411-9717/605/2019

Shabalala, N.Z.P., Harris, M., Leal Filho, L.S., Deglon, D.A. 2011. Effect of slurry rheology on gas dispersion in a pilot-scale mechanical flotation cell. Minerals Engineering, vol. 24, no. 13, pp. 1448–1453. https://doi.org/10.1016/j.mineng.2011.07.004

Safari, M., Harris, M., Deglon, D., Leal Filho, L., Testa, F. 2016. The effect of energy input on flotation kinetics. International Journal of Mineral Processing, vol. 156, pp. 108–115. https://doi.org/10.1016/j.minpro.2016.05.008

Smith, P.G., Warren, L.J. 1989. Entrainment of Particles into Flotation Froths. Mineral Processing and Extractive Metallurgy Review, vol. 5, nos. 1–4, pp. 123–145. https://doi.org/10.1080/08827508908952647

Souza Pinto, T.C., Braga, A.S., Leal Filho, L.S., Deglon, D.A. 2018. Analysis of key mixing parameters in industrial wemco mechanical flotation cells. Minerals Engineering, vol. 123, pp. 167–172. https://doi.org/10.1016/j.mineng.2018.03.046

Tabosa, E., Runge, K., Holtham, P., Duffy, K. 2016. Improving flotation energy efficiency by optimizing cell hydrodynamics. Minerals Engineering, vol. 96–97, pp. 194–202. https://doi.org/10.1016/j.mineng.2016.05.002

Trahar, W.J. 1981. A rational interpretation of the role of particle size in flotation. International Journal of Mineral Processing, vol. 8, no. 4, pp. 289–327. https://doi.org/10.1016/03017516(81)90019-3

Wang, L. 2016. Entrainment of fine particles in froth flotation, Thesis: Doctor of Philosophy, University of Queensland, Australia.

Wang, D., Liu, Q. 2021. Hydrodynamics of Froth Flotation and Its Effects on Fine and Ultrafine Mineral Particle Flotation: A Literature Review. Minerals Engineering, vol. 173. doi:10.1016/j.mineng.2021.107220

Westhuizen, A.P.P. 2004. The evaluation of solids suspension in a pilot scale mechanical flotation cell. Master dissertation. University of Cape Town, Cape Town, page 25.

Wills, B.A., Finch, J.A. 2015. Wills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery. 8th edn., Oxford: Butterworth-Heinemann.

Yao, N., Liu, J., Sun, X., Liu, Y., Chen, S., Wang, G. 2021. A Rational Interpretation of the Role of Turbulence in Particle-Bubble Interactions. Minerals, vol. 11, no. 9, p. 1006. https://doi.org/10.3390/min11091006

Zheng, X., Johnson, N.W., Franzidis, J.-P. 2006. Modelling of Entrainment in Industrial Flotation Cells: Water Recovery and Degree of Entrainment. Minerals Engineering, vol. 19, no. 11, pp. 1191–1203. doi:10.1016/j.mineng.2005.11.005 u

Mining operators are seeing an increased demand for minerals and ores. Operators must now consider the costs of pump maintenance and replacement as well as the cost-benefit of utilizing fewer larger pumps versus several smaller pumps to perform the same work.

Mining operators are seeing an increased demand for minerals and ores. Operators must now consider the costs of pump maintenance and replacement as well as the cost -benefit of utilizing fewer larger pumps versus several smaller pumps to perform the same work.

The KSB GIW® MDX pump line delivers proven results in the harshest hard rock mining applications.

The KSB GIW® MDX pump line delivers proven results in the harshest hard rock mining applications. W: www.ksb.com/en-za T: +27-11-876-5600

W: www.ksb.com/en-za T: +27-11-876-5600

Affiliation:

Botswana International University of Science and Technology

Correspondence to: K. Fichani

Email: fichanik@biust.ac.bw

Dates:

Received: 20 Nov. 2023

Revised: 8 Apr. 2024

Accepted: 25 Mar. 2025

Published: May 2025

How to cite:

Fichani, K., Teseletso, L.S. Kaavera, J. Dintwe, T.K., Shemang, E., Matshediso, B.I. 2025. The impact of junior miners on the global supply of high-purity manganese sulfate monohydrate for the electric vehicle battery market. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 5 pp. 233–242

DOI ID:

https://doi.org/10.17159/2411-9717/3196/2025

ORCiD: K. Fichani

http://orcid.org/0000-0001-9364-8217

LS. Teseletso

http://orcid.org/0000-0002-3984-4089

J. Kaavera

http://orcid.org/0009-0007-6878-5851

T.K. Dintwe

http://orcid.org/0000-0002-2739-624X

E. Shemang

http://orcid.org/0000-0003-2865-4148

B.I. Matshediso

http://orcid.org/0009-0001-2465-6114

by K. Fichani, L.S. Teseletso, J. Kaavera, T.K. Dintwe, E. Shemang, B.I. Matshediso

Abstract

The minerals sector continues to draw attention from policy makers who would want to see both old and new mineral projects add value to the minerals in the host country. The current technological development in the leaching of manganese oxide ores to produce a high-purity manganese sulphate monohydrate, a compound that is used in the manufacture of batteries for electric vehicles or long-life storage cells for the renewable energy market, has led to junior mining companies spearheading this technology in new projects across the globe. In this paper, we researched the high-purity manganese sulphate monohydrate project pipeline and used projected production volumes and C1 cash costs to construct the industry supply curve for six projects, including the K.Hill project owned by Giyani Metals Corporation near Kanye, in the southern part of Botswana. The aim was to determine the ideal conditions that would provide a comparative advantage for further local value addition to high-purity manganese sulphate monohydrate and to the end user product. The results showed that while the estimated C1 cash costs would place the K.Hill project as the second highest cost producer from among five projects, it would nonetheless have healthy profit margins due to the high projected price of high-purity manganese sulphate monohydrate. The study recommended policy options, which, if implemented, could further encourage the exploitation and value addition of battery metals in Botswana.

Keywords high-purity manganese sulfate monohydrate, battery metals, industry supply curve, electric vehicle

The global supply of manganese, as estimated by the US Geological Survey for 202,1 was 20 million metric tonnes (Schnebele, 2022). A brief analysis of the US Geological Survey’s mineral commodity summary for manganese demonstrates the following: approximately 80% of manganese production during 2021 was from four countries, being South Africa (37%), Gabon (18%), Australia (16.7%), and China (6.5%). In terms of the distribution of known reserves, approximately 61% of these reserves occur in Africa, with South Africa accounting for the largest share, estimated at 42.7%, followed by Gabon and Ghana at 4.1% and 0.9%, respectively. Other countries with estimated significant shares of global manganese reserves are Australia and China at 18% and 4%, respectively. The characterisation and classification of manganese ores is based mainly on the manganese content, iron, and other impurities. Metallurgical ore contains more than 35% Mn, ferruginous ores and manganiferous ores contain 15% – 25% Mn and 5% – 10% Mn, respectively. Another common classification for manganese ore is high (>44% Mn), medium (30% – 44% Mn), and low (<30% Mn) (Ratshomo, 2013; Indian Bureau of Mines, 2014a). It is estimated that 90% of the global supply of manganese ore is used in ferrous and non-ferrous metallurgical applications for production of steel and ferroalloys (Indian Bureau of Mines, 2014b). In the ferrous metallurgical applications, approximately 30% of manganese ores are used in the steelmaking process itself as reactants in the de-oxidation and desulfurisation stages, with the remainder being used as ferroalloys in the steel product (Indian Bureau of Mines, 2014a). In steel making, the ferroalloys impart the requisite properties of strength and workability to the steel, a property for which no substitutes for manganese currently exist (Steenkamp et al., 2020). The non-ferrous metallurgical application is based on the production of high-purity electrolytic manganese metal (EMM) and electrolytic manganese dioxide. The former is used in the production of some alloys of non-ferrous metal like aluminium, copper, magnesium, and nickel (Van Zyl et al., 2016; Indian Bureau of Mines,

2014b). The main grades of alloys are high-carbon ferromanganese (HCFeMn: 65% – 80% Mn), medium-carbon ferromanganese (MCFeMn) and silicomanganese (SiMn: 50% – 74% Mn). The HCFeMn and SiMn require high-grade ores with over 44% Mn and low-grade ores at 33% – 35% Mn, respectively (Indian Bureau of Mines, 2014b). The remaining 10% of the global supply of manganese ore is used in non-metallurgical applications such as dry cell batteries, the glass industry, and a wide range of applications in the chemical and health industries (Van Zyl et al., 2016, Indian Bureau of Mines, 2014b).

In Botswana, the historical mining of manganese at Kgwakgwe Hill, which is currently referred to as K.Hill by the project owners, Giyani Metals Corporation, started in the pre-independence period and lasted fifteen years (from 1957 to 1972). The mining was focused on both the metallurgical and high-grade manganese oxide ores. Over the fifteen years of operation, the K.Hill area exported about 195 743 t of manganese ores (SRK Consulting UK Limited, 2020). In a Press Release dated April 6, 2023, Giyani Metals Corporation indicated that it had submitted an Environmental Impact Assessment (EIA) statement to the Department of Environmental Affairs of Botswana. The press release further states that the EIA statement, if approved, would lead to the company being granted a mining license for up to 25 years (Giyani Metals Corporation, 2023). The prospect of developing the K.Hill deposit into a manganese mine has generated interest from policy makers, as the government of Botswana issued an expression of interest in 2022, inviting possible joint venture partners for its electric mobility (e-mobility) programme under which the country intends to set up a factory for the manufacturing of electric vehicles (EV) (Kuhudzai, 2022). The K.Hill project would produce a precursor product, a high-purity manganese sulphate monohydrate (HPMSM), for the manufacturing of batteries for the EV market. The project will further provide some assurance about security of supply of the HPMSM to future local manufacturers of batteries for EVs. The other metals required in the lithium-ion batteries are nickel and cobalt. The Botswana Institute for Technology Research and Innovation (BITRI) and Process Research ORTECH (PRO) in Canada would carry out a study, which, if successful, would result in the setting up of a 30 000 t/a plant that would produce highgrade nickel and cobalt salts. This plant would be used to produce raw materials required to facilitate the production of EV and large energy storage batteries in Botswana (BITRI, 2022).

In this paper, we review the literature on publicly available information regarding the capacity and estimated unit costs to produce HPMSM by new or planned projects. This information is then used to construct the HPMSM industry supply curve to determine the likely competitiveness of the proposed K.Hill project. A further search of the literature is carried out to determine the ideal conditions that would provide a comparative advantage for further local value addition of the HPMSM beyond the precursor compound, manganese sulfate, and to the end user product, the battery or long-life storage cell for the EVs, and renewable energy markets. We conclude by providing policy options, which, if adopted, would further encourage the exploitation of battery metals in Botswana.

Geology, deposit size and mine production capacity

In this section, the major manganese mines in the world’s top three producer countries, i.e., South Africa, Australia, and Gabon, are compared to establish any similarities in ore types, size of resources, and manganese beneficiation processes as well as the end product at

the mine gate. Selected new manganese projects are also reviewed to determine if any influence exists on the extraction technology resulting from the expected growth in the future demand for manganese in the EV battery market.

In South Africa, manganese ore is mined from the Kalahari Manganese Field that is located in the Northern Cape. This field is a banded iron formation with inter-bedded units of manganese ore, and it contains over 90% of South Africa’s manganese resources. Globally, this field represents approximately 80% of land-based global resources of manganese ore. The field is estimated to host 4.2 Bt of manganese ore resources (Beukes et al., 2016). The overburden cover is shallow on the eastern side of the field and therefore amenable to exploitation by open-pit methods, such as at the Mamatwan mine, while it is deep seated on the western side, up to 1400 m. The depths of underground workings are estimated at approximately 400 m at the Wessels and Nchwaning mines (Beukes et al., 2016). The Kalahari Manganese Field covers an area that is approximately 15 km by 35 km in the EW and NS directions, respectively. There are two major ore types present. The first is a low-grade primary sedimentary-type ore rich in carbonates, primarily calcites, and dolomite with braunite (2Mn2O3MnSiO3; 64.3% Mn) as the main manganese-bearing mineral. The second ore type is a high grade, structurally-controlled hydrothermal ore comprised mostly of oxides, mainly braunite and braunite II (Ca(MnFe)14SO24), some hausmannite (Mn3O4; 72% Mn), bixbyite ((Mn,Fe)2O3), and hematite (Fe2O3) which is found in the northern part of the deposit (Tsikos et al., 2003; Ratshomo, 2013).

Manganese ore production in Australia is mainly concentrated in the Groote Eylandt deposits, Gulf of Carpentaria in the Northern Territory, and in the Woodie Woodie mine, eastern Pilbara Craton in Western Australia (NSW Department of Primary Industries, nd). The geology of Groote Eylandt is described as Early to Middle Cretaceous Mullaman beds (sandstone, claystone, pebble gravel, and manganese marl), unconformably overlain by lateritic Tertiary conglomerate. At the Groote Eylandt mine, the mineralised zones average 3 m in thickness, approximately 150 km2 in areal extent, and the overburden cover ranges from 3 m – 12 m. The Groote Eylandt deposit is thought to have formed as a shallow water marine sedimentary deposit on a Proterozoic basement with postenrichment processes. Conversely, the Woodie Woodie mine ores are thought to have formed from both supergene enrichment of manganiferous sedimentary rocks and filling of cavities and fissures in dolomite and fault zones. The ores consist mainly of pyrolusite (MnO2; 60% – 63% Mn), cryptomelane (KMn8O16; 59.8% Mn), and minor manganite (Mn2O3H2O; 62.5% Mn), and trace amounts of other manganese minerals (NSW Department of Primary Industries, nd).

The production of manganese ores is also widespread in West Africa, with Gabon hosting the most significant resources outside South Africa. The manganese deposits in Gabon are supergene manganocrete that developed on relatively unmetamorphosed and undeformed manganese-bearing black carbonaceous shale of the Francevillian Supergroup that overlies the Archaean basement in the northwestern part of the Congo Craton. The deposits are large and shallow and therefore exploited by open pit mining. The manganese resource is estimated to be 325 Mt at 49% Mn in the washed product, with a regional potential in the order of 100 Mt – 200 Mt. The ore minerals in the Franceville area consists of cryptomelane and pyrolusite with some nsutite and lithiophorite set in a goethitic, clay, and quartz matrix (Beukes et al., 2016).

The preceding three descriptions are examples of large-scale manganese deposits that are exploited by companies based in the world top three manganese ore-producing countries. Jupiter Mines, which is a 49.9% shareholder in the Tshipi é Ntle Manganese Mining Proprietary Limited (Tshipi) located in the Kalahari Manganese Field in the Northern Cape, RSA, is already a major manganese ore producer with target production of 3.6 Mt of manganese ore of which 600 kt is low grade (30% Mn). The low-grade ore would be supplied to a proposed HPMSM facility to be located in either Canada, USA, or Europe (Jupiter Mines Ltd, 2024). It joins a list of five other HPMSM projects at different project study stages, such as the Giyani Metals Corporation’s K.Hill project in Botswana (Giyani Metals Corporation, 2022; Keating, 2023), Canadian Manganese’s Woodstock manganese project in New Brunswick, Canada (Sprott Capital Partners Equity Research, 2022), Manganese X Energy Corporation’s Battery Hill project near Woodstock, New Brunswick (Manganese X Energy Corp., 2022), Euro Manganese’s Chvaletice Manganese project, Chvaletice, Czech Republic (Tetra Tech Canada Inc., 2022), and the Butcherbird project by Element 25 in Western Australia, of which the project will produce manganese concentrates to be sold under an off-take agreement to the company’s HPMSM facility in Louisiana (Element 25 Limited, 2022). The common business objective of these projects is to produce HPMSM for the expected high demand in the EV battery market.

Manganese extraction technologies

One of the key factors influencing the choice of extraction

technology for manganese between pyrometallurgical approaches employing reduction smelting in either blast furnace or submerged arc electric smelting furnaces (SAF), or hydrometallurgy involving leaching followed by solvent extraction and electrowinning, is the size of the deposit. Table 1 indicates that, for the major manganese ore producers, there is very limited production of ferroalloys in their home countries apart from China, which is the world’s leading producer of steel and manganese ferroalloys such as SiMn and HCFeMn. It is therefore apparent that the manganese value chain for large or world class deposits follows the pyrometallurgical route as depicted in Figure 1.

Source: Compiled by the authors based on (Steenkamp et al., 2018; Van Zyl, et al., 2016)

Figure 1—A simplified value chain for manganese for world class deposits

Recent ore reserves or resources and production from selected major manganese ore producing countries

Mine, company and country

Mamatwan, Hotazel Manganese Mines, Northern Cape, South 32 Limited, RSA.1

Tshipi é Ntle Manganese Mining Pty Ltd (Tshipi), Jupiter Mines Ltd, Northern Cape, RSA.2

Groote Eylandt Mining Company, South 32 Limited Northern Territory, Australia.1

Moanda mine, ERAMET (Comilog), Gabon.3

Source:

As of June 2022: Proven and probable-45Mt @ 36.2% Mn; Total resources-72 Mt @ 35% Mn; LoM as at Jan 2022-14 years.

As of February 2022: Measured –129.21 Mt @33.85% Mn; Indicated – 70.15 Mt @ 33.28% manganese and inferred – 225.80 Mt @ 32.77% Mn. Total mineral resources – 425 Mt @ 33.18% Mn.

As of June 2022: Proven and probable- 35 Mt @ 43% Mn and 4.8 Mt Sands @ 40% Mn; Total resourses- 138 Mt @ 43% Mn and 9.0 Mt sands @ 19.5% Mn; LoM as at Jan 2022-3.9 years.

Company webpage attributes 25% of global reserves and grades at 30% Mn.2

1Compiled by the authors from (South32 Limited, 2022)

Ore production in 2022 was 2.069 Mt.1

Ore production capacity is 3.6 Mtpa. In 2023, it was 3.34 Mt down from 3.68 Mt in 2022.

Washed lump ore, and Sinter for SAF smelting locally and for export.

Washed lump ore and future HPMSM product for EV batteries.

Ore production in 2022 was 3.363 Mt.1

Washed lump ore and fines all exported.

Estimated ore production is 4.0 Mt but it is projected to increase to 7.0 Mtpa.2

2Compiled by the authors from (Jupiter Mines Ltd, 2024; Jupiter Mines Ltd, 2023)

3Compiled by the authors from (Comilog, n.d.)

Lump ore, sinter and ferroalloys (silico manganese) for the export market.

The manganese project pipeline is presented in Table 2. It is apparent that these projects are at different stages of study, ranging from scoping studies or preliminary economic assessment to feasibility studies. The K.Hill project in Botswana is at the feasibility study stage but due to a recent fourfold increase in its Indicated Mineral Resources from 2.0 Mt to 8.6 Mt, the company is planning to conduct a preliminary economic assessment to consider this improvement in resources and possibly increasing the life of mine to beyond 25 years (Keating, 2023). The Butcherbird project, has completed a feasibility study to produce HPMSM from manganese

concentrates. For the five other projects, which consist of two projects in Canada, one each in the Czech Republic and Botswana, it will produce HPMSM. Lastly, the HPMSM project by Jupiter Mines Ltd is at the scoping study stage and its HPMSM facility may be located in either Canada, the US, or Europe.

The processing methods of the ore would depend on the ore type with direct leaching of ores or concentrates using dilute sulfuric acid applied in manganese carbonate ores while reduction leaching is applied in oxide ores (Manganese X Energy Corp, 2021; Tetra Tech Canada Inc, 2019). If the ores are manganese oxides,

Preliminary and advanced stage manganese projects for producing HPMSM for the EV battery market

Project, company and country Manganese ore minerals Resources / reserves Ore

Battery Hill, Manganese X Energy Corp., Canada1

Butcherbird HPMSM project, Element 25, Australia2

Manganese carbonate and manganese carbonatesilicate-oxide.

Manganiferous shale (Pyrolusite).

Chevaltice, Euro Manganese, Czech Republic3

K.Hill, Giyani Metals Corp., Botswana4

Tshipi é Ntle Manganese Mining Pty Ltd (Tshipi), Jupiter Mines Ltd, Northern Cape, RSA5

Tailings from old pyrite mines; 81% of ore is manganese carbonate and the rest manganese carbonate-silicates.

Manganiferous shale, that occurs in layers 3–4 m thick and are high grade manganese oxides, Pyrolusite (MnO2)

Low grade - primary sedimentary-type ore rich in carbonates High grade – oxides, mainly braunite and braunite II

Woodstock project, Canadian Manganese Company Inc., New Brunswick, Canada6

Manganese carbonates, mainly Rhodochrosite.

Source: Compiled by the authors from:

1(Manganese X Energy Corp., 2022)

2(Element 25 Limited, 2022)

3(Tetra Tech Canada Inc., 2019)

Measured –11.26 Mt @6.75% Mn; Indicated – 23.60 Mt @ 6.26% Mn and Inferred – 25.91 Mt @6.66% Mn.

Measured – 16.0 Mt @11.6% Mn; Indicated – 41Mt @10% Mn, and Inferred – 206 Mt @ 9.8%.

Indicated – 464 kt @7.85% Mn; Measured – 26.496 Mt @7.32% Mn.

Indicated Resource of 8.6 Mt ore at 15.2 MnO at a cut-off grade of 7.3% MnO. Inferred Resource of 6.1 Mt at 14.1% MnO.

As at February 2022: Measured – 129.21 Mt @33.85% Mn; Indicated – 70.15 Mt @ 33.28% Manganese and Inferred –225.80 Mt @ 32.77% Mn. Total mineral resources – 425 Mt @ 33.18% Mn.

Direct leaching of RoM ore at 365kt per annum to produce 68 kt/a HPMSM in year 3 from project start date.

1.3 Mtpa RoM beneficiated to produce lump ore fines concentrates; HPMSM future project based on concentration feed.

Direct leaching of RoM ore at 1,1 Mtpa starting in year 4 from project start date to produce 120 -150 kt / year a HPMSM.