VOLUME 125 NO. 7 JULY 2025

VOLUME 125 NO. 7 JULY 2025

OFFICE BEARERS AND COUNCIL FOR THE 2024/2025 SESSION

President E. Matinde

President Elect

G.R. Lane

Senior Vice President

T.M. Mmola

Junior Vice President

M.H. Solomon

Incoming Junior Vice President

S.J. Ntsoelengoe

Immediate Past President

W.C. Joughin

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk M.C. Munroe

Z. Fakhraei S.M. Naik

B. Genc G. Njowa

K.M. Letsoalo S.M. Rupprecht

S.B. Madolo A.T. van Zyl

M.A. Mello E.J. Walls

K. Mosebi

Co-opted Council Members

A.D. Coetzee

L.T. Masutha

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

G.R. Lane – TP Mining Chairperson

Z. Botha – TP Metallurgy Chairperson

K.W. Banda – YPC Chairperson

C.T. Chijara – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC K.T. Kekana (Interim Chairperson)

Johannesburg N. Rampersad

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West Vacant

Pretoria P.G.H. Pistorius

Western Cape Vacant

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

Editorial Board

S.O. Bada

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

P.N. Neingo

S.S. Nyoni

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

Past Presidents Serving on Editorial Board

R.D. Beck

R.T. Jones

W.C. Joughin

C. Musingwini

T.R. Stacey

International Advisory Board members

R. Dimitrakopolous

R. Mitra

S. Ndlovu

M. Onifade

A.J.S. Spearing

E. Topal

D. Tudor

F. Uahengo

D. Vogt

Editor /Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31 Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

VOLUME 125 NO. 7JULY 2025

Journal Comment: Finding the needle in the haystack by Q.G. Reynolds iv

President’s Corner: South Africa’s green hydrogen strategy: Challenges and opportunities by E. Matinde ..................................................................

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2025 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys Auditors

Genesis Chartered Accountants Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za

ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Fatigue performance improvement using laser shock peening in high strength ductile metallic materials by S.L. George, R. Tait, A. Becker, A. Carlisle

Surface treatments like laser shock peening (LSP) significantly increase the potential impact on materials prevalent in the automotive and aerospace sectors. Through extensive fatigue testing and fractography investigations, it was determined that LSP resulted in a fatigue life increase of over five times for aluminium alloy AA7075-T6, 1.7x for titanium Ti-6Al-4V, and was also noted in AISI316 stainless steel. While fatigue life in all cases improved, the efficacy of LSP was shown to be material dependent.

Comparison of remote sensing techniques in mapping hydrothermal alteration associated with Ovacik epithermal gold-silver mineralization by C. Kwang, H. Uygucgil

There is a need to explore the potential of new robust remote sensing and geographic information system techniques in the field of mineral exploration. In this study, the argillic alteration associated with epithermal gold-silver mineralisation was mapped. Of the two methods used in mapping out the argillic alteration zones associated with gold-silver mineralisation, the Crósta technique produced the optimal argillic alteration. The study demonstrates the analytical capabilities of Google Earth Engine in image processing and analysis for mineral exploration.

Premature ageing of a blast furnace taphole clay containing resole resin and liquid pitch as binder by

A.M. Garbers-Craig, I. Cameron, S. Ramjee

The cause of reduced workability and increased ageing of a blast furnace taphole clay was examined. The workability and Marshall extrusion pressure of the clay samples were evaluated to assess the extent of ageing of the clay. The analyses confirmed a chemical interaction between the resole resin and liquid pitch. Upon ageing of the resin-pitch mixtures, the resin underwent premature cross-linking, causing earlier onset of curing. This was identified as the primary cause of reduced workability, accelerated ageing, and increased Marshall extrusion pressure of the taphole clay.

The use of soundless chemical demolition agents in large scale in situ rock breaking applications in the mining industry by I. Maubane, P.L. Ngwenyama

Soundless chemical demolition agents (SCDAs) are proving to be the future of sustainable and environmentally-friendly mining. This study evaluated whether soundless chemical demolition can break large volumes of in situ rock. This was done by conducting five trials using Nex-Pand soundless chemical demolition agents in four different surface mining sites. These trials proved that soundless chemical demolition agents can replace explosives in areas closer to sensitive infrastructure and communities. This will ultimately enable mines to unlock value and access deposits in these areas.

Evaluating the creditworthiness of a viable artisanal and small-scale mining operation by O.D. Eniowo, M. Onifade, H. Grobler, A.F. Mulaba-Bafubiandi, O.S. Otuogbai

This study looks at how artisanal and small-scale miners can attract formal funding, which will help them take the leap from artisanal state to a sustainable small-scale mining operation. This study evaluates the creditworthiness of artisanal and small-scale mining operators in Nigeria, using key credit risk parameters identified in the literature and through primary investigation. The results show that being a member of a mining cooperative society improves the chances of access to formal financing for miners within the sample group.

Light detection and ranging-based georeferencing of underground mining ground-penetrating radar data by T. Kgarume, M. van Schoor, M. Mpofu, H. Grobler

The South African mining industry has committed to achieving a state of zero harm for its workforce. Among the major safety concerns are falls of ground, a leading cause of injuries and fatalities. This study presents a comprehensive georeferencing methodology. The potential for integrating diverse datasets to construct insightful models of the underground mining environment is illustrated. This potential is likely to offer a holistic understanding of the mining environment, providing essential information to decision-makers.

347

355

361

371

385

393

n the course of our engineering work on mining and metallurgical plants we are often called upon to evaluate the merits of different choices in process flowsheets, operating parameters and philosophies, raw material selection, and many others. The phenomenological complexity of the minerals industry usually means that each of these aspects is parameterised by a large number of variables, and there are also strong coupling effects between them – one changes a feed-rate setting here, and even though it fixes the immediate production problem over here, it also affects several other things over there in ways that one did not expect.

In the digital age we have access to powerful process and systems models, which can create virtual analogues (or “digital twins” if one prefers catchy jargon) of our real-world plants, which can make decision-making easier. However, in the pursuit of improved accuracy these models often start to become as impenetrable and confusing a black box as the actual thing they are trying to simulate. This is especially true when data-centric artificial intelligence and machine learning methods are included in the mix. Manually exploring such systems models by making basic changes using oversimplified fundamental principles, can very quickly turn into an endless game of whack-a-mole to mitigate the cascade of unintended consequences.

To better manage this problem, two formal mathematical concepts are becoming increasingly useful as interface layers over complex systems models. Uncertainty quantification tracks the propagation of errors through a system from inputs to outputs, and sensitivity analysis identifies how strongly outputs are affected by changes in the inputs. In combination, these tools can help guide design or process optimisation studies to find small changes that yield large improvements while minimising undesirable side effects. They are well worth investigating to help us find the needles in our metallurgical haystacks.

Q.G. Reynolds

Significant global efforts have been dedicated to mitigate the man-made impacts of climate change and environmental degradation. However, recent policy shifts by some of the major economic jurisdictions, such as the United States, to focus on prioritising domestic economic growth, potentially at the expense of climate change, and stricter environmental regulation is a major cause for concern. For example, the US’s policy changes to truncate the roll-out of electric vehicle incentives and subsidies, among other roll-backs on clean energy transition initiatives, will provide interim fiscal relief but may inadvertently undermine climate change mitigation measures in the long term. In addition, the emerging geoeconomic order and tariff regimes will also have a disproportionate impact on both the demand-side and supply-side of climate-neutral technology cooperation and financing mechanisms. Consequently, this will delay the deployment of nascent interventions required to reduce emissions from energy- and greenhouse gas intensive industries. Obviously, the impact is disproportionately high in critical but hard-to-abate industries such as cement clinker production, iron and steel manufacturing, and public transportation, of which their global CO2 emissions are estimated to be roughly 8%, 7-9%, and up to 14%, respectively.

Due to the high costs of technology development and complexity of integration into existing systems, global cooperation in the development and financing mechanisms for sustainable climate-friendly technologies, such as green hydrogen, carbon capture, and storage technologies, has immense benefits to mankind. Green hydrogen, in particular, is considered to be one of the most promising energy carriers with immense environmental benefits. According to the Green Hydrogen Organisation (https://gh2.org/what-green-hydrogen), green hydrogen is produced via an electrochemical process to split water into hydrogen and oxygen using renewable sources of energy. Several technologies to produce green hydrogen at scale have been developed and/or are at different stages of development and commercialisation. However, each technology regime is characterised by its own inherent challenges and opportunities in terms of interoperability, efficiency, costs and availability. With substantial support from industry, policymakers and the public, the roll-out of green hydrogen technologies has been touted as a gamechanger, with massive global strategic efforts being deployed towards technology development and establishment of infrastructure and special economic zones, supported by the promulgation of targeted industrial policies as well as support with tax incentives and subsidies.

As part of the dual drive to attain both economic and energy sovereignty, South Africa launched an ambitious green hydrogen strategy to leverage the country’s abundant renewable energy resources, both for domestic use and for export. The Hydrogen Society Roadmap was launched in 2021 to support the implementation of the country’s green hydrogen economy, and its implementation is anchored on the attainment of four strategic outcomes, viz, (1) creating an export market for the country’s green hydrogen and allied products, (2) greening the power generation, (3) decarbonising the transportation and heavy industries and, (4) localising the green hydrogen supply chains. According to the Hydrogen Society Roadmap (https://gh2.org/countries/south-africa), the country aims to produce approximately 500,000 tonnes per annum of green hydrogen by 2030, achievable by 10 GW of electrolysis capacity in the Northern Cape special economic zones by 2030, and up to 15 GW by 2040. In addition, the Hydrogen Roadmap targets the deployment of 100 hydrogen-powered buses and trucks by 2025 and up to 500 buses and trucks by 2030, with the opportunity to create and sustain up to 30,000 jobs annually by 2040. According to a report by National Business Initiative (https://www.nbi.org.za/green-hydrogen-presents-theopportunity-as-the-fuel-for-the-future/), South Africa has the potential to produce green hydrogen for USD1.60 per kg by 2030, one of the lowest costs worldwide. These ambitious energy transition targets are applaudable, despite the challenges to achieve them being the stated timelines and current technoeconomic landscape. In

addition, there is an urgent need to revisit the assumptions used to formulate the stated impact targets, if one is to take into account the unprecedented number of bankruptcies by green hydrogen technology startups and established global companies due to inhibitive development costs and complexity of the associated systems and technologies.

Indeed, green hydrogen is going to be a game-changer due to its potential to drastically reduce greenhouse gas emissions and drive innovations in sustainable technologies. However, it is evident that the suite of technologies to produce green hydrogen are emerging technologies, which are disproportionately prone to failure due to the high costs of electrolyser technologies, complexity of integration, and intermittency of renewable energy storage systems, among other challenges. Synergistic to bottlenecks from the complex technology systems is the valley of death faced by green hydrogen technologies due to misallocation of financing, and the “Lindy effects” arising from sunk costs and perceived performance of established fossil fuel-based technologies. Although the challenges in the roll-out of green hydrogen technologies is a global phenomenon, reliance on imported technologies, high cost, and availability of climate finance, further increases vulnerability for countries in the global south, South Africa included.

I had the privilege of listening to a keynote address by the Chairperson of SAIMM Limpopo Branch, Mr Steven Zulu, at the branch event held at the University of Limpopo earlier this month. In his opening address, Mr Zulu highlighted the need to develop sustainable technologies based on endogenous technology learning capabilities as a sovereign strategy to mitigate against perpetuation of external dependency, a phenomenon he referred to as “technology colonialism”. In particular, Mr Zulu highlighted some basic implementation strategies to attain technology sovereignty, such as building sustainable R&D and technology development skills. Furthermore, he emphasised the importance of developing home-grown technology alternatives, drive down technology costs, and unlock the ability to reverse engineer existing technologies to suit the domestic market requirements.

In conclusion, there is no doubt that green hydrogen can be a game-changer for South Africa and the region. However, the attainment thereof, together with the Green Hydrogen Roadmap impact targets, risk being wishful thinking unless collective efforts are channelled towards intensifying technology development initiatives to drive down costs and reduce dependency on imported technologies and components. Most importantly, openminded approaches are required to take advantage of emerging geoeconomic dynamics, so as to establish genuine collaborations with all leading green hydrogen technology developers globally. As the SAIMM, we commit to continue supporting the dissemination of technical knowledge required to sustain the localisation of technology know-how in this highly contested domain.

.

E. Matinde President, SAIMM

Affiliation:

1Centre for Materials Engineering, Department of Mechanical Engineering, University of Cape Town, South Africa

2Department of Mechanical Engineering, University of Cape Town, South Africa

Correspondence to:

S.L. George

Email: sarah.george@uct.ac.za

Dates:

Received: 13 May 2021

Revised: 20 Aug. 2022

Accepted: 25 Apr. 2025

Published: July 2025

How to cite:

George, S.L., Tait, R., Becker, A., Carlisle, A. 2025. Fatigue performance improvement using laser shock peening in high strength ductile metallic materials.

Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 7, pp. 347–354

DOI ID:

https://doi.org/10.17159/2411-9717/1619/2025

ORCiD: S.L. George

http://orcid.org/0000-0002-6084-6361

by S.L. George1, R. Tait2, A. Becker2, A. Carlisle2

Abstract

Surface treatments like laser shock peening (LSP) induce residual stresses penetrating up to 1 mm deep, surpassing traditional methods, thus significantly increasing the potential impact on materials prevalent in the automotive and aerospace sectors. Through extensive fatigue testing and fractography investigations, it was determined that LSP resulted in a fatigue life increase of over five times for aluminium alloy AA7075-T6 and titanium Ti-6Al-4V. Increased fatigue life was also noted in AISI316 stainless steel, which showed increases in fatigue life of 1.7x. While fatigue life in all cases improved, the efficacy of LSP was shown to be material dependent.

Keywords

laser shock peening, compressive residual stress, fatigue performance, AA7075-T6, Ti-6Al-4V, AISI 316

Introduction

Fatigue failure is one of the most common failure mechanisms in industry where cyclic loading is experienced, contributing to an estimated 80% of all mechanical service failures (ASM International, 2008). Many such failures result from fatigue cracks initiating at stress concentration sites found on the surface of components (ASM International, 2008). The fatigue life of a component comprises fatigue crack initiation as well as crack propagation, with initiation commonly being related to the surface condition of the component, such as surface finish and the presence of surface or sub-surface defects. To prolong the fatigue life of components, surface treatments can be utilised. Surface treatments aim to achieve one or more of the following: reduction of local stress concentrations, removal or neutralisation of existing defects, or reduction of tensile residual stress through the introduction of compressive residual stress (CRS), (Cui, 2002). Such residual stresses are introduced into the surface layers of the component to increase the number of cycles associated with the crack initiation stage These local residual stresses (normally compressive) counteract applied stresses (often tensile in nature), thereby delaying the onset of crack initiation. Residual compressive stresses at crack tips and surrounding material can reduce fatigue crack propagation rates, resulting in an overall increase in the fatigue life of the component (Montross, et al., 2002). One of the most effective and widely used surface modification processes is shot peening (SP), which is a cost-effective and robust process. Studies have been conducted into how the shot peening process affects the residual stress (Peyre, 1996; Hammond, 1990). Magnitudes of residual stresses produced by a shot peening process are at least as great as tensile strength of the material being peened (Metal Improvement Company, 2005). However, the SP process itself has limitations (Montross, et al., 2002; Kulekci, Esme, 2014), such as deterioration of surface finish and limited penetration depth of the compressive residual stresses. LSP CRS layer is typically 4-5 times deeper that the depth achieved through traditional SP (Gupta et el., 2017). The laser shock peening process introduces a slightly rougher surface finish to the sample, when compared to SP (Montross, et al., 2002). Surface roughness plays a critical role in the crack initiation stage of the fatigue testing (Montross, et al., 2002). Therefore, it can be important to eliminate surface roughness as a contributing factor to facilitate a direct comparison between laser shock peened (LSP) samples and non-laser shock peened (non-LSP) samples. The induced roughness can be removed before the peened components can be put into service, but Montross, et al. (2002) raised a concern regarding the offset of shot peen induced benefits through the removal of some of the residual stress in the surface layer in the context of SP where the CRS layer is relatively thin. Liu et al. (2017) determined that the benefit of improved surface quality from post LSP polishing may be considered as overriding the disadvantage of a reduced CRS layer thickness if the penetration depths are great enough.

There are increasing demands for lower operational costs, higher safety measures, and better lifetime performance characteristics in industry. As such, significant pressure has been placed on the manufacturing systems and surface processing technologies to produce components that are ’near flawless’ and require as few processing steps as possible before completion. One of the surface treatment techniques that has been developed recently, in response to these demands, is laser shock peening (LSP). LSP utilises high-speed and high-energy neodymium lasers to focus short-duration coherent energy pulses onto the surface of the component. A high amplitude stress wave propagates into the material, thereby causing the surface layer to yield in compression, and plastically deform.

This localised plastic deformation produces both strain hardening and residual compressive stress at the surface of the laser peened component and extends below the surface of the material (Clauer, 1997), up to a depth of approximately 1 mm (Clauer, 2001) or more. LSP is reported to have a limited minimal effect on the surface roughness of the material (Zhang, 2010; Schubnell, 2023) compared to SP. The extent of roughness changes is directly related to the laser process parameters and the use of a protective coating layer during the LSP process (Zhang, 2010; Schubnell, 2023). The LSP process can be applied to the finished surface of a part or before the final finishing step. Regions inaccessible to SP, such as small fillets and notches, can be treated by being considered for treatment using LSP. The application of LSP to parts where line-of-sight access is available is very straightforward, making it an easy process to use in industry (Holmes, 2013). LSP has been shown to significantly improve the fatigue performances of engineered components (Montross, et al., 2002; Ren et al.).

Over and above the benefits to fatigue life, laser shock peening can result in improved performance in wear, corrosion, and stress corrosion cracking for a variety of materials, (Montross, et al., 2002; Abdullahi, 2014). The fatigue life of stainless steel has been investigated by various researchers (Peyre, 1996; Bikdeloo, et al., 2020) and has been shown to improve the fatigue life of components. Bikdeloo et al. (2020) showed that AISI 316L stainless steel exhibits approximately 125% increase in fatigue life with single LSP layers and 170% with a second layer. Other materials, such as carbon steels, aluminium alloys, titanium alloys, and nickel-based super-alloys have also shown improved fatigue life through the application of LSP, where scanning parameters were investigated in detail (Abdullahi, et al., 2014; Adu-Gyamfi, et al., 2018; Sano, et al., 2006; Correa, et al., 2015]). Other considerations regarding the efficacy of LSP are related to crystal structure and stacking fault energies of the material, as deformation mechanisms differ, thus, affecting the CRS and the microstructure evolution in the affected layer (Deng et al., 2023).

The scanning pattern has a marked effect on the efficacy of LSP on fatigue life enhancement. FEM simulations and experimental results by Adu-Gyamfi et al., (2018) have shown that the CRS layer is strongly affected by the LSP scanning patterns in aluminium alloy AA2024 (Adu-Gyamfi, et al. 2018). Three scanning patterns were investigated. While all scanning patterns showed an increase in fatigue life, the highest increase in fatigue life experienced with an L-spiral scanning pattern (Adu-Gyamfi, et al. 2018). While in LSP of AA7075 notched samples in bending fatigue (Peyre et al., 1996), it has been shown that there is a dramatic improvement in the fatigue life with clear differences in the early and later stages of crack growth, where the fatigue life improvements from LSP can be separated into a seven-fold increase in the early crack growth

stage and only a three-fold increase in the later propagation stage. For AISI 316L stainless steel, Correa et al. (2015) found that a fatigue enhancement from LSP can be increased from 166% to 471% by optimising the pulse sequence and scanning pattern, and that greatest improvements were seen when the crack propagation direction is perpendicular to the fatigue load (Correa et al., 2015).

The aim of this work is to assess the effect of LSP on the fatigue life extension for three different high strength, high toughness materials, namely aluminium alloy AA7075, Ti-6Al-4V, and AISI316 stainless steel. These materials represent a variety of structures and characteristics, namely a face centred cubic (FCC) material with a high stacking fault energy (SFE), a material with an HCP structure, and an FCC material with a low SFE, respectively. These characteristics will influence the efficacy of the LSP in each case. Therefore, the penetration depth of the LSP induced case hardened layer and its effect on the crack initiation zone are quantified for each material. Through this, the relative material specific efficacy of LSP for fatigue life improvement can be evaluated.

Selected materials and fatigue testing set-up

The three materials selected for this investigation were AA7075 aluminium alloy in the T6 condition, Ti-6Al-4V titanium alloy, and AISI 316 stainless steel alloy. The material was sourced in extruded rod form with varied diameters. To standardise the sample geometry, surface finish and properties, all samples were turned on a lathe to a final diameter of 12 mm and were partitioned to 80 mm in length. Circular cross section samples were chosen to eliminate the effects of laser pulse area overlap (Zhao et al.,2017). During bending fatigue, the specimen span was equivalent to four times the diameter (i.e., S = 4D), which corresponds to dimensions suggested in both the ASTM E1290-02 (ASTM Standard E1290-02, 2002) and E399-90 standards (ASTM Standard E399-90, 1990) for fracture toughness testing, although no Standard specifically makes use of un-notched, cylindrical bend test specimens for fatigue testing.

Laser shock peening and sample surface roughness

The laser shock peening process parameters are shown in Table 1. The laser shock peening parameters for each material were tested on typical Almen strips to determine the correct saturation intensity.

The non-LSP samples were polished for 10 seconds with 1200 grit paper, where the samples were rotated relative to the grinding media. The samples were polished to a surface finish corresponding to Ra of 0.2 micron prior to testing using diamond impregnated lubricant and cloth on a rotating sample. The surface roughness values were determined using a profilometer. The LSP process, performed on polished samples, introduces shallow, homogeneous dimples onto the surface of the specimen, related to the laser parameters. These dimples produced an Ra of 2.28 micron. To eliminate the effects of surface roughness on the fatigue life data,

Table 1

Laser peening parameters

Power intensity

Number of pulses

Wavelength

Water confinement

4.9 GW/cm2

800 spots per cm2

1064 nm

Spray nozzle

a number of the LSP samples were briefly polished after peening, to achieve a surface finish Ra of 0.2 micron. This small amount of polishing was assumed to contribute negligible surface hardening on the samples relative to the LSP process and was thus, not included as part of the case hardening investigation. AA7075-T6 samples were used to evaluate the effect of surface finish on fatigue life, and fatigue testing was performed on three conditions: (i) aspolished, non-LSP, (ii) LSP and, (iii) LSP-polished. For the titanium and stainless-steel samples, the tests were performed on as-polished non-LSP and LSP-polished (where the surface was polished to achieve a surface roughness of the order of 0.2 micron).

LSP penetration depth: hardness profiles and fracture surface analysis

The depth of penetration of the LSP and the CRS layer thickness was determined from a combination of hardness testing and fracture surface analysis. Incremental micro hardness measurements were taken at increasing surface depths on unfatigued specimens through successive polishing and indentations to obtain a hardness profile for increasing depth from the surface. Longitudinal sections of the test specimens, of a length L (between 15 mm and 20 mm) were mounted in resin with their surfaces parallel to their cylindrical axes exposed from the resin and incrementally polished, removing a surface layer of nominally 3 μm thick per polish step. A schematic of this process is shown in Figure 1. This process of polishing the surface of the specimen, measuring the thickness of the mount, and then making several HV indents on the surface, using the full length of the mounted specimen is used to increase the number of indents for each depth to improve statistical uncertainties in HV number. This increase in polishing depth is repeated until the total depth of polishing is approximately 1 mm, or where a sudden decrease in hardness was achieved consistently, indicating the end of the LSP penetration depth.

Determination of penetration depth through fracture surface analysis was performed through fractography on the fracture surfaces themselves and through crack path analysis on crosssections through samples after failure. The fractography analysis included the identification of ductile and brittle features, crack initiation sites (surface or sub-surface). For crack path analysis, samples representing a section through the fracture surface (i.e., perpendicular to the fracture surface) of the failed samples were cut, mounted, ground, and polished to a colloidal silica finish in preparation for viewing using light microscopy with a Nomarski prism. Rounding of the polished edges is due to the polishing process resulting in poor edge retention between the sample edge

and the mount resin, but this did not affect the interpretation of the crack path. Light micrographs allowed for the analysis of the crack path in the various materials and conditions. A deviation in the crack path is expected at a point corresponding to a sudden change in residual stress, such as the limit of the LSP penetration depth on the crack initiation side and the final fracture side of the samples.

Fatigue performance

The fatigue performance of the various test specimens was evaluated under cyclic loading using a 100 kN electro-servo hydraulic fatigue machine (ESH) at the University of Cape Town, Centre for Materials Engineering. Test specimens of all materials, in both the LSP and non-LSP conditions, were fatigued to failure using a 3-point bending system at a constant amplitude bending stress. The testing frequency was set at 10 Hz using a sinusoidal wave at a stress ratio (R) of 0.1.

For the AA7075-T6 material, the initial stress estimate used to calculate the required load for the fatiguing of the test specimens in the T6 material condition was determined by looking at stresses used to generate S-N curves for AA7075-T6 found in literature. An incremental bending fatigue approach was then implemented to adjust incrementally the stress level to a level at which crack initiation occurred at a desirable cycle count of approximately 30 000 cycles. Based on the superimposed curve, a fatigue life of 30 000 cycles could be achieved somewhere in the applied stress range of 482 MPa to 551 MPa, achieved through incremental increases in the fatigue testing stress level. A final stress of 585 MPa was found to result in specimens failing at approximately 30 000 cycles, and this stress was kept constant for the test specimens in their respective material conditions regardless of the surface treatment that they had received. The stress level of 1080 MPa was used for Ti-6Al-4V and 1150 MPa for AISI 316 stainless steel, both calculated using Equation 1.

Where d is the diameter of test specimen, L is the span length and σ is 90% of ultimate stress (σUTS). This consistent equivalent stress level allowed the effects of the varying surface treatments on the fatigue lives of the test specimens to be determined.

Microstructure observations and fractography

The cross section through the fracture surface of the failed samples was viewed to analyse the crack path in the different materials using light microscopy, where any changes in the crack path direction

in the region corresponding to the CRS and LSP penetration depth was evaluated. The study did not focus on crack initiation sites. Fractography was performed using an FEI NovaNano SEM scanning electron microscope (SEM) to examine the fracture surfaces of the samples in the LSP and non-LSP conditions. Characteristic features identified on the fracture surfaces during fractography were related to the failure modes and the influence of the laser peened layer of material at the surface.

Laser shock peening penetration depth for all materials

The hardness results from the longitudinal sections of the test specimens were plotted. The schematic in Figure 1 describes the experimental approach for hardness mapping. In the AA7075-T6 condition, the surface hardness was 185 HV, with a drop-off to 167 HV after 1.2 mm depth. In the Ti-6Al-4V the hardness was 334 HV at the surface that extended to a depth of 0.2 mm, a subsequent decrease to approximately 320 HV until 0.95 mm, and a drop to 309 HV beyond 1 mm. For the AISI 316, the hardness gradually increased from 281 HV at the surface to 294 HV at a depth of 0.65 mm, and then rapidly decreased to a hardness of 275 HV at a depth of 1 mm. The normalised hardness is defined here as the change in hardness value (∆HV) relative to the measured hardness of the parent material, where the parent material hardness is the hardness unaffected by the LSP. The normalised hardness profiles are presented in Figure 2. The penetration depth for all three materials is of the order of 1 mm, and this result is consistent with results documented by Clauer (1997; Clauer 2001). The penetration depth would be expected to increase with an increasing number of passes of the laser peening, as was shown by Zhou et al. (2023) in the case of AA7075 over a range of laser process parameters and passes (ASTM Standard E399-90, 1990).

The fracture surface cross section of the failed samples was studied to identify the presence of crack path. Directional changes were attributable to a change in the properties of the material. This property change is directly related to the transition between

the LSP-affected material and the parent material. Figure 3 shows the cross section through a failed Ti-6Al-4V sample, while Figure 4 shows an equivalent AISI316 stainless steel sample. The image shows the fast fracture edge of the samples (as opposed to the crack initiation side) as the effect of a property change was more pronounced on the side of the sample. The non-perpendicular angle of the fracture surface to the surface edge is a result of the compression curl (Quinn et al. 2005). There is a noticeable deviation in the crack path for both the Ti-6Al-4V and the AISI 316 samples, as shown in Figure 3 and Figure 4, respectively. The crack path deviation typically corresponds to the change in properties at the transition of the case depth of the LSP. The measured depth at the step in the crack path is approximately 1 mm in both cases. This indicates a change in the residual stress of the material attributed to the residual stresses associated with the penetration depth of the LSP. These depths correspond to the depth measured with hardness results as illustrated in Figure 2. Similar depths of penetration for AA7075 are reported by Zhou et al. (2023), for Ti-6Al-4V by Dyer et al. (2024) and for stainless-steel by Wu et al. (Wu, et al., 2023).

Fatigue performance

Aluminium AA7075 – Effect of laser peening on fatigue life

The results of the fatigue testing for AA7075 in four different conditions can be seen in Figure 5. The four different conditions represent the effect of laser peening on polished AA7075-T6 samples and the effect of laser peening on unpolished samples. From these results we can determine the effect of laser peening on the fatigue life of AA7075 in the T6 aged condition.

The AA7075 samples in the non-laser shock peened condition (non-LSP) failed after an average of approximately 39 000 cycles, while the samples that had undergone laser shock peening achieved a maximum of approximately 211 000 cycles. This is an improvement of more than five times with the application of laser shock peening. These results are for samples with the same equivalent surface roughness value, Ra, of approximately 0,2. This was achieved by polishing the samples before and after laser shock peening.

Table 2

Surface roughness values for AA7075-T6 samples and the number of cycles to failure for each condition

non-LSP / polished

AA7075: LSP / as peened

with 2.08 decrease in Ra AA7075: LSP / polished

AA7075: LSP / intermediate polished (0.74 Ra) 0.74

Aluminium AA7075 – Effect of surface roughness on fatigue life

The effect of surface roughness is determined by identifying the number of cycles to failure in the fatigue test results on laser shock peened and non-laser shock peened samples in the polished and unpolished conditions. The results are also shown in Figure 5. The surface roughness values are shown in Table 2. The table also shows the number of cycles to failure associated with each condition and the calculated improvement in fatigue life with the improved surface roughness owing to polishing.

For samples that have not been exposed to laser peening, there is an improvement of approximately 1.2 times in the fatigue life with a decrease in Ra from 0.74 to 0.22. For samples that have been laser shock peened, in the as-peened condition there is a surface roughness of 2.28, which results in a fatigue life of 102 700 cycles. After peening followed by surface polishing to improve the Ra to 0.2, there is an improvement of the fatigue life in the order of about twice the fatigue life. This shows that surface roughness does play a very important part in the fatigue life, but also shows that the change in surface roughness does not fully account for the improved fatigue life after laser shock peening, where, for the

equivalent roughness values, the un-peened material exhibits an 18% improvement, while the peened exhibits a 44% improvement.

The fatigue life data for Ti-6Al-4V can be found in Figure 6. The fatigue life for Ti-6Al-4V with no laser peening was approximately 27 000 cycles, while after laser peening the fatigue life improved by more than five times, to approximately 143 300 cycles. This shows that titanium alloy Ti-6Al-4V responds very well to laser peening in the context of fatigue life extension, with a 5.3 times larger fatigue (81%). This is a far greater increase than the 22.2% increase documented by Zhang et al . (2010). The discrepancy between this work and Zhang may be due to a number of contributing factors, namely, the surface roughness, which is not explicitly stated in the work by Zhang et al. (2010), the testing parameters of the different tests, where the load fatigue force ratio was 0.3 as opposed to the 0.1 from this present work, or the underlying microstructure of the material, which had been specially heat treated to provide a bi-modal starting structure by Zhang et al. (2010). The difference in fatigue life increase owing to LSP may also be a result of a combination of the afore-mentioned effects.

The fatigue life data for AISI 316 stainless steel can be found in Figure 6. The non-laser peened fatigue life was found to be approximately 32 400 cycles, while after laser peening this improved by 1.63 times to nearly 53 000 cycles. A similar investigation by Stamm et al. (1996) into the high cycle fatigue behaviour of austenitic stainless steel AISI 316L showed an increase in the fatigue life of 1.2 times. This is slightly lower than the 1.6 increase seen in this present investigation. This difference may be attributed to the fact that Stamm et al. (1996) did not polish the as-peened surface prior to fatigue testing. The increase in the fatigue life does indicate the relative effectiveness of laser shock peening on stainless steel. The reduced impact of LSP on fatigue life in FCC materials with low SFE has been highlighted by Deng et al., 2023 and is associated with dislocation mobility and twinning mechanisms in low SFE austenitic stainless steels.

The fracture surfaces of the as-received and the laser shock peened tested samples were analysed and compared. For each tested sample and processing regime, images were captured in the crack initiation region; the crack propagation region within 1 mm of the edge of the specimen; the crack propagation region beyond the LSP case depth; and finally, within the fast fracture region.

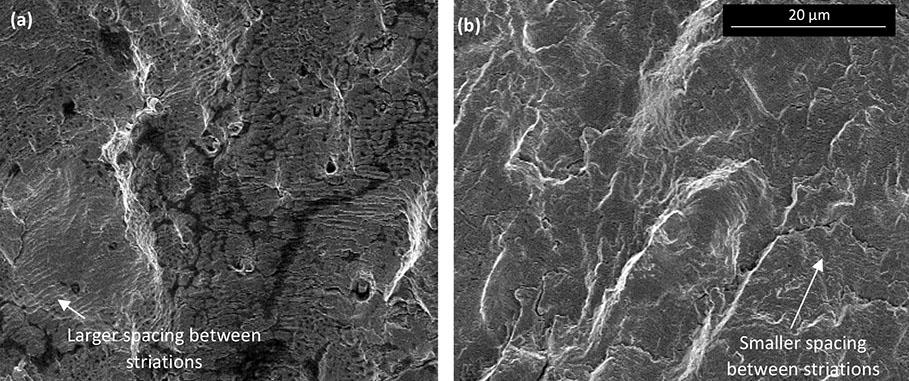

The fractographic images revealed that the specimens subjected to LSP were indeed more brittle in the LSP zone than the non-LSP

specimens, as can be seen in Figure 7. This was indicated by brittle fracture characteristics, such as cleavage facets in Figure 7(b) for the non-LSP specimenAA7075-T6 and a smoother fracture surface. The spacing between fatigue striations on the fracture surfaces in the as-received specimens appear to be far greater than the spacing between fatigue striations in the LSP specimens, as seen in Figure 8(a) and Figure 8(b), respectively. The difference in fatigue striation spacing is in agreement with the results of Ren et al, (2013).

Measuring the distance between striations, it was found that the spacing in the as-received 7075-T6 is approximately 1.1 μm, while the spacing in the LSP 7075-T6 is approximately 0.4 μm. The smaller spacing implies a more brittle material that develops because of compressive residual stress and the reduced dislocation mobility owing to LSP (Ren et al., 2013). A similar trend can be seen in Figure 9 for AISI 316 where, by performing an approximate measurement of the distance between fatigue striations on the micrograph, it was found that the measured spacing between striations in the as-received specimen is approximately 0.7 μm, whereas the measured spacing between the striations in the LSP specimen is approximately 0.3 μm. Thus, the specimen that has been subjected to LSP is more resistant to crack growth than the as-received specimen, indicating that there is greater residual stress in the LSP zone.

The fractography in Figure 10 (a) shows an AA7075-T6 sample where the crack initiation site is sub-surface, at 0.3 mm away from the surface (the annotations A, C, and D represent crack initiation

site, cleavage and dimpled fracture surface (ductile tearing), respectively). The applied bending stress combines with the peening induced residual stress, creating a resultant stress profile, where the highest tensile stress on the profile is just below the surface hardened layer, as shown in Figure 10 (b). The schematic diagram in Figure 10 (b) illustrates the combined residual LSP stress and pure bending stress, two triangles across the bending section representing tension on the side opposite the load point of 3-point bending, and compression on the opposite face. The schematic also indicates the presence of the residual stress from peening, which is compressive but is limited to a narrow subsurface depth. The LSP CRS layer tapers away deeper, but still within a confined layer close to the surface, into the material towards the neutral axis, where the tensile bending stress begins to dominate. The resultant of the two stresses reduces the surface tensile stress substantially and puts the peak tensile stress at some point inside the surface from which the crack initiates and radiates. After some fatigue loading, there is no evidence of a surface crack, as it is growing radially from this highest stress regime sub-surface. Suddenly the crack breaks through the surface and at this point, the sample goes from having no noticeable surface crack to having a visible surface crack driven by the growth of an internal crack of between 5 mm to 10 mm long, showing that it grew from the inside radially in all directions and finally broke through the surface.

Figure 11 (b) shows that, in the aluminium LSP specimens, crack initiation occurred just beneath the surface of the specimen, as opposed to at the surface in the non-LSP sample in Figure 11 (a), where the crack initiation point is clearly at the surface and would be the result of typical persistent slip banding as part of the initiation process. In Figure 11 (b), the chevron marks point to the crack initiating at the edge of the transition area where there is a change in the residual stress in the material, which corresponds to approximately 0.8 mm. The expansion of the initiation region after LSP indicates that for samples that have been exposed to laser shock peening, many fatigue cycles are spent on the crack initiation phase before crack propagation occurs in a steady state manner. Figure 6 shows features on the fracture surface within the

crack initiation region for AA7075-T6 and highlights the change in the material because of the LSP process. The LSP sample exhibits cleavage facets on the fracture surface, which are features associated with brittle materials, while the non-LSP sample exhibits dimples, which are typical ductile features. This same trend was seen in both the Ti-6Al-4V and the AISI 316. However, in the titanium and stainless steel the crack initiation region was smaller than that of the aluminium alloy. The change in depth of the transition region is also illustrated in the hardness profiles in Figure 2. This indicates that materials have different susceptibilities to the effects of the LSP process. The susceptibility is related to the crystal structure and the SFE of the material, which dictates the slip planes available for deformation and the mobility of the dislocations under load.

Laser shock peening (LSP) significantly enhances the fatigue performance of various materials. The efficacy of LSP is approximated by the relative increase in fatigue life for the peened versus non-peened conditions. Three materials were considered, aluminium AA7075-T6, an FCC material with a high SFE, AISI 316 austenitic stainless steel, an FCC material with a low SFE and Ti-6Al-4V, and an HCP and BCC two-phase structure. All three materials are considered ductile, high strength materials with good corrosion resistance properties. The results indicate that aluminium AA7075-T6 with an FCC structure and a high SFE responds best to LSP and shows the greatest increase in fatigue life in the LSP condition.

The main findings of the work are summarised below:

➤ In the case of aluminium alloy AA7075-T6, LSP extended fatigue life by more than five times when the surface roughness was polished to an R_a of 0.2 microns, matching that of the non-LSP sample.

➤ For as-LSP treated AA7075-T6, the surface roughness was measured at 2.28 microns, and this untreated roughness still resulted in a 4.1-fold increase in fatigue life. When the surface roughness was equalised at 0.2 microns, LSP improved the fatigue life of AA7075-T6 by 5.4 times. This indicates that

11—AA7075-T6

reducing the surface roughness—without compromising the LSP-induced case depth—is key to maximizing fatigue life across different materials.

➤ For titanium alloy Ti-6Al-4V and AISI 316 stainless steel, LSP increased fatigue life by 5 times and 1.7 times, respectively. This demonstrates that titanium alloy Ti-6Al4V and aluminium alloy AA7075-T6, both ductile at room temperature, are far more responsive to LSP than AISI 316 stainless steel.

➤ Results indicate that the improvement in fatigue life can be attributed to the residual compressive stresses induced by LSP (although not quantified in this work), rather than the penetration depth, which was approximately 1 mm for all three materials tested.

➤ LSP samples exhibited a notable expansion in the crack initiation zone for all materials and a sub-surface crack initiation point, as evidenced by the features on the fracture surfaces.

Future work in this area must include quantification of the compressive residual stress in each material and the dislocation structures in the CRS layer that are linked to crystal structure and dislocation mobility.

In conclusion, LSP is an effective method for improving the fatigue life of components made from aluminium AA7075-T6, titanium Ti-6Al-4V, and AISI 316 stainless steel. However, the degree of improvement varies between materials, with some being more susceptible to the benefits of LSP-induced compressive residual stress, which penetrates up to 1 mm into the material.

Acknowledgments

Acknowledgments to Daniel Glaser at the National Laser Centre (NLC) at the Council for Scientific and Industrial Research (CSIR) in South Africa for the laser peening of the investigated samples, and to the Electron Microscope Unit (EMU) at the University of Cape Town for the use of the electron microscopes and operator guidance by Miranda Waldron.

References

Abdullahi, K., GujbaK., Medraj, M. 2014. Materials vol. 7, pp. 7925–7974.

Adu-Gyamfi, S., Ren, X.D., Larson, E.A., Ren, Y., Z. Tong, Z. 2018. Optics and Laser Technology, vol. 108, pp. 177–185.

ASM International. 2008. Elements of Metallurgy and Engineering

Alloys, Becker , A. 2016. MSc Thesis , UCT.

ASTM Standard E1290-02 (2002).

ASTM Standard E399-90 (1990).

Bikdeloo, R., Farrahi, G.H., Mehmanparast, A., Mahdavi, S.M. 2020. Theor Appl Fract Mec, vol. 105, p. 102429, Clauer, A. 1997. Laser shock peening for fatigue resistance.

Clauer, A., D. Lahrman, D. 2001. Key Engineering Materials - Key Eng Mat 197, pp. 121–144.

Correa, C., Peral, D., Porro, J.A., Díaz, M., Ruiz de Lara, L., GarcíaBeltrán, A., J.L. Ocaña, J.L. 2015. Optics & Laser Technology, vol. 73, pp. 179–187.

Cui, W. 2002. Journal of Marine Science and Technology. pp.43–56.

Deng, W., Wang, C., Lu, H., Meng, X., Wang, Z., Lv, J., Luo, K., J. Lu, J. 2023. Int. J. Mach. Tools Manuf., vol. 191, p. 104061.

Dyer, K., Ghadar, S., Zulić, S., Rostohar, D., Asadi, E., Molaei, R. 2024. Coatings, vol. 14.

Gupta, K., Jain, N.K., Laubscher, R. 2017. (Eds.), Advanced Gear Manufacturing and Finishing. Academic Press, pp. 127–165.

Hammond, D.W., Meguid, S.A. 1990. Engineering Fracture Mechanics, vol. 37, pp. 373–387.

Holmes, T. 2013. MSc Thesis, University of Cape Town, Cape Town Kulekci, M.K., Esme, U. 2014. The International Journal of Advanced Manufacturing Technology vol. 74 pp. 1551–1565.

Liu, Z.G., Wong, T.I., W. Huang, W. 2017. Acta Metall. Sin. (Engl. Lett.), vol 30, pp. 630–640.

Metal Improvement Company. 2005. Shot Peening Applications Ninth Edition. Ed. by Unknown. pp. 4–6.

Montross, C.S., Wei, T., Ye, L., Clark, G.,Mai, Y.-W. 2002. International Journal of Fatigue vol. 24, pp.10218–1036.

Peyre, P., Fabbro, R., Merrien, P., Lieurade, H.P. 1996. Materials Science and Engineering: A 210 pp. 102–113.

Quinn, J.B., Quinn, G.D., Robert Kelly, J., Scherrer, S. 2005. Dental Materials, vol. 21, pp. 920–929.

Ren, X.D., Zhang, Y.K., Yongzhuo, H.F., Ruan, L., Jiang, D.W., Zhang, T., Chen, K.M. 2011. Materials Science and Engineering: A, vol. 528, no. 6, pp. 2899-2903.

Ren, X.D., Zhan, Q.B., Yang, H.M., Dai, F.Z., Cui, C.Y., Sun, G.F., Ruan, L. 2013. Materials and Design, vol. 44pp. 149–154. Sano, Y., Obata, M., Kubo, T., Mukai, N., Yoda, M., Masaki, K., Ochi, Y. 2006. Materials Science and Engineering: A 417, pp. 334–340. Schubnell, J., Carl, E.-R., Sarmast, A., Hinterstein, M., Preußner, J., Seifert, M., Kaufmann, C., Rußbüldt, P., J. Schulte, J. 2023. Materials, vol. 16, p. 6769.

Stamm, H., Holzwarth, U., Boerman, D.J., Marques, F.d.S., Olchini, A., Zausch, R. 1996. Fatigue and Fracture of Engineering Materials and Structures, vol. 19, pp. 985–995.

Wu, J., Ding, W., Zhai, Y., Qiao, H., Zhao, J., Mao, Z., X. Chen, X. 2023. Wear 522. p. 204836.

Zhang, X.C., Zhang, Y.K., Lu, J.Z., Xuan, F.Z., Wang, Z.D., Tu, S.T. 2010. Materials Science And Engineering A-Structural Materials Properties Microstructure And Processing vol. 527, pp. 3411–3415.

Zhang, X.C., Zhang, Y.K., Lu, J.Z., Xuan, F.Z., Wang,Z.D., Tu, S.T. 2010. Materials Science and Engineering: A 527 pp. 3411S.T.3415.

Zhao, J., Dong, Y., C. Ye, C. 2017. International Journal of Fatigue, pp. 407–417

Zhou, L., Zhu, C., Yuan, H., Mei, X., Jiang, J., Lu, Z. 2023. Opt. Express vol. 31, pp. 18039–18049. u

Affiliation:

1Department of Geography and Resource Development, University of Ghana, Accra, Ghana

2Institute of Earth and Space Sciences, Eskisehir Technical University, Eskisehir, Turkey

Correspondence to:

C. Kwang

Email: ckwang@ug.edu.gh

Dates:

Received: 30 Sept. 2021

Revised: 3 May 2025

Accepted: 15 May 2025

Published: July 2025

How to cite:

Kwang, C., Uygycgil, H. 2025. Comparison of remote sensing techniques in mapping hydrothermal alteration associated with Ovacik epithermal gold-silver mineralization. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 7, pp. 355–360

DOI ID:

https://doi.org/10.17159/2411-9717/1775/2025

ORCiD:

C. Kwang

http://orcid.org/0000-0003-3545-1429

H. Uygucgil

http://orcid.org/0000-0003-3100-0129

by C. Kwang1, H. Uygycgil2

Abstract

The use of remote sensing and geographic information system techniques in mineral exploration is still underutilised. There is a need to explore the potential of new robust remote sensing and geographic information system techniques in the field of mineral exploration. In this study, we mapped the argillic alteration associated with epithermal gold-silver mineralisation. A band ratio of band5/band6 and Crósta technique on Advanced Spaceborne Thermal Emission and Reflection Radiometer within the Google Earth Engine Environment was applied. The bands 5 and 6 were selected for the band ratio after critically analysing and comparing the illite spectral extracted from the Advanced Spaceborne Thermal Emission and Reflection Radiometer image and the illite spectral obtained from the United States Geological Survey spectral library. The band ratio and Crósta technique identified and mapped the Ovacik goldmine and other argillic alteration zones. Even though both methods mapped out the argillic alteration zones associated with gold-silver mineralisation, the Crósta technique produced the optimal argillic alteration. The study demonstrates the analytical capabilities of Google Earth Engine in image processing and analysis for mineral exploration, such as discovering hydrothermal alteration associated with mineralisation.

Keywords band ratio, Crósta technique, argillic alteration, epithermal gold-silver deposit

Introduction

Minerals and metals are vital for the sustainability of humanity on Earth and are used in innumerable and diverse applications, for instance, from building aircraft to producing ornaments for human use. Economically, mineral resources contribute to gross domestic product and offer employment opportunities. According to Creamer (2012), mining's contribution to the world's gross domestic product is approximately 45 per cent. Thus, sustainable mining of minerals and metals remains paramount. in most instances, mining usually only commences after extensive mineral exploration.

Despite the benefits, mineral exploration is one of the highest risk ventures in recent times in terms of the associated cost and failure (Gandhi, Sarkar, 2016). Modern technologies, such as remote sensing and geographic information systems (GIS), have been used as an alternative approach for mineral prospecting to reduce the cost and failure of new minerals' discovery. Remote sensing and GIS have yielded many successful mineral exploration works (Ninomiya et al., 2006; Chen et al.; 2007; Tangestani et al., 2011; Hede et al., 2015; Salehi et al., 2017; Rajendran, Nasir, 2017; Wang et al., 2017). Therefore, the objective of the study was to use Google Earth Engine as a working environment for the identification and mapping of the argillic alteration zones associated with epithermal gold-silver deposits in Izmir, Turkey.

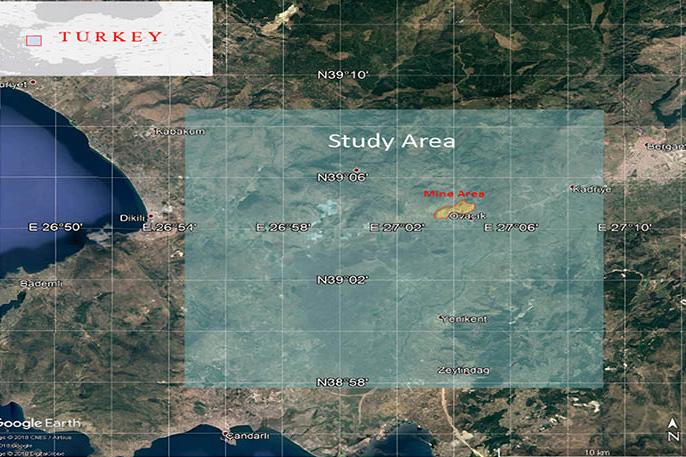

The Ovacik gold mine is located in the northern part of Izmir in Turkey, lying adjacent to the eastnortheast (ENE) trending Bergama graben (Figure 1).

The first economic epithermal deposit found in Turkey using modern exploration technology is the Ovacik gold-silver deposit (Yilmaz, 2002). The principal rock types within the Ovacik mine and its environment include limestones, palaeozoic metamorphic rocks, and intrusive andesitic rocks (Yilmaz, 2002), as illustrated by Figure 2. The main minerals associated with the argillic alteration of the Ovacik epithermal deposit are illite, interlayered illite/smectite, illite/chlorite, adularia, smectite, chlorite, and chalcedonic quartz (Yilmaz, 2002). This study area also confirms illite minerals as one of the main argillic alteration minerals in Ovacik.

Material and methods

The materials used in this study include an Advanced Spaceborne Thermal Emission and Reflection Radiometer (ASTER) image, a geological map of the Ovacik Mine, and Google Earth Engine Application Programming Interface (API). In order to identify and map the argillic alteration associated with gold-silver mineralisation within the study area, Google Earth Engine API was used to extract the image spectra, perform the band ratio, and the Crósta technique was applied to the image. Google Earth Engine has reduced the burden of downloading satellite images before performing image processing and analysis. Google Earth Engine can process broad coverage areas image analysis faster and easier than most commercial remote sensing and GIS software (Gorelick et al., 2017).

The Ovacik gold mine was selected because its characteristics are similar to the other gold-silver mineralisation locations in Turkey. The ASTER image captured on 23 September 2006, was first loaded on the Google Earth Engine environment. Owing to its diagnostic characteristics and predisposition to clay minerals detection and mapping, shortwave infrared bands were selected. In brief, the image was transformed from radiance to reflectance using gain and offset values of bands of the image before the band ratio operation was performed. The geological map of the Ovacik gold mine was also imported to Google Earth Engine, and sample points were extracted from known mineralised locations. Sample points extracted from the known mineralised locations in the geological map were used to obtain image spectra from the ASTER image. The illite mineral spectra obtained from the United States Geological

Band 7 Reflectance 0 0.5 1 1.5 2 2.5 3 3.5 Wavelength (mm)

Illite (USGS spectral library)

Point 1 (Extracted ASTER image spectral)

Point 2 (Extracted ASTER image spectral)

Illite (USGS spectral library)

Diagnostic AlOH absorption ASTER Bands

Point 1 (Extracted ASTER image spectral)

Point 2 (Extracted ASTER image spectral)

(a) (b)

Survey (USGS) spectral library was compared with that of the spectra acquired from the ASTER image, as illustrated in Figure 3. The extracted image spectrum shows the diagnostic characteristics of the illite mineral, which is a known mineral of argillic alteration. In Figure 3, the illite mineral showed high reflectance in Band 5 and strong absorption, or low reflectance in Band 6, which were vital diagnostic characteristics for its identification and mapping using the band ratio method.The presence of argillic alteration characterised by illite mineralisation was also identified by performing the Crósta technique using bands 1, 3, 5, and 6, as suggested by Crósta et al. (2003). All the processed images were exported from the Google Earth Engine as Geographic Tagged Image File Format (GeoTIFF) images for map creation.

Band ratio

Minerals and rocks do not show similar reflectance responses at different ranges of spectral wavelengths (Chandrasekar et al., 2011). Band ratio operation can be easily performed to map hydrothermal alteration by using the spectral diagnostic characteristics exhibited by rock and minerals. For instance, in 800–1000 nm, iron oxide minerals portray high absorption features and high reflectance in other wavelength regions (Pontual et al., 2008). In mapping hydrothermal alteration zones associated with mineralisation, the most common techniques applied are the band ratio and principal component analysis (PCA) (Yajima, 2014). There is a reduction in the effect of the seasonal changes, slope shadows, and the elimination of sunlight angles effect when band ratio analysis is applied on satellite imagery (Jensen, 1986).

Crósta technique

The Crósta technique is a modified version of the standard PCA, and it utilises four image bands (Loughlin, 1991). The Crósta technique uses the linear combinations of the PCA to determine which principal component (PC) image best describes the theoretical spectral response of the mineral under investigation (Loughlin, 1991). The Crósta technique has the advantage of determining whether the target feature type has been enhanced in the previous principal component image as dark or bright pixels. Other image analyses, such as band colour combination and band ratio, were performed to decide the band that could best show the

argillic alteration within the study area before choosing the bands for the Crósta technique.

Results and discussion

The short-wave infrared (SWIR) bands offer a moderate spatial and spectral resolution for detecting and identifying clay and hydrous minerals. Within the SWIR bands, the clay and hydrous minerals reveal diagnostic spectral characteristics. In the SWIR region of the electromagnetic spectrum, illite minerals portray different absorption features. The wavelengths of distinct absorption features identified within the SWIR include 1.900 µm (water absorption), 2.180-2.228 µm (AlOH), 2.342 µm, and 2.435 µm (Pontual et al. 2008). Field studies of the hydrothermal alteration of the Ovacik gold deposit reveal the abundance of illite minerals and its association with epithermal gold-silver mineralisation. The image spectra, as shown in Figure 3, revealed the diagnostic feature of illite mineral as 2.180-2.228µm (AIOH) after being critically examined. At a wavelength of 2.185-2.225µm, the AI-OH molecular vibration process obtained the high AIOH absorption feature (Pontual et al., 2008) corresponding to band 6 of the ASTER image.

Table1 shows eigenvector loadings, eigenvalues, the percentage variances of individual principal component images of the bands used in the Crósta technique, and statistics of individual bands used to calculate the eigenvector of the Crósta technique. Each of the individual principal components (PC) in Table1

Table 1

The eigenvector loadings, eigenvalues, and percentage variance of bands (1, 3, 5, and 6)

has a corresponding principal component image. The principal components in Table1 indicate the numeric values of argillic minerals. Principal component images display spectral information of the argillic minerals as grey in colour. Principal components, which contained the argillic alteration characterised by illite mineralisation were based on Loughlin's (1991) criterion, which states that "PC that contains the target spectral information shows the highest eigenvector loadings from the image bands, coinciding with the target's most diagnostic features, but with opposite signs (+ or -)". Based on Loughlin's criterion, PC3 was selected as it has the highest value with high opposite loadings values. The PC3 has

a high eigenvector loading value for bands 5 (0.4) and 6 (-0.76). The high and negative eigenvector loading of band 6 and the low positive value of band 5 are the main reasons why argillic alteration zones in Figure 4 appeared as dark rather than bright pixels. In order to display the argillic alteration zones as bright pixels, the spectral values of PC3 were multiplied by negative 1 (Tangestani, Moore, 2000). Figure 3 shows high absorption of illite in band 6 and high reflectance in band 5.

A threshold value of 1.08, calculated by using the mean plus twice the standard deviation, was applied at a 95% significance level on the image processed with the Crósta technique method to

separate altered from non-altered argillic zones.The orange colour in Figure 5 shows zones with reflectance values above the threshold value, and these are the most likely argillic zones associated with gold-silver mineralisation. When the argillic alteration zones extracted from the band ratio of band 5/band 6 were overlaid with alteration zones produced from the Crósta technique, most of the argillic alteration zones from band ratio did not coincide with alteration zones of the Crósta technique. The argillic alteration zones obtained from the band ratio were affected by vegetation cover, while in the Crósta technique, the effect of vegetation was suppressed. Suppression of the vegetation effect helped enhance spectral reflectance of the illite mineral.

The spectral characteristics of minerals are not vastly distinctive, and this must be considered when mapping hydrothermal alteration. Although the wavelength for reflectance bands may vary, many clay minerals' diagnostic absorption features fall within almost the same wavelengths. This suggests that the same band ratio index may not produce optimal hydrothermal alteration zones in all geographic locations. Band combinations can aid in selecting suitable bands for hydrothermal alteration identification and mapping. By comparing the argillic alteration zones produced from two methods, the Crósta technique produced better alteration results than the band ratio method. However, both the band ratio and Crósta technique identified the Ovacik goldmine within the argillic alteration zones.

Conclusion

This study demonstrates the use of Google Earth Engine (GEE) for detecting and mapping argillic alteration zones associated with gold-silver mineralisation in Izmir using the band ratio and Crósta techniques. Despite its potential for handling large geospatial datasets efficiently, the use of GEE in mineral exploration remains limited.

The study evaluated methods for identifying and mapping argillic alteration zones linked to epithermal gold-silver mineralisation. Specifically, it assessed the performance of Landsat bands 5 and 6 for band ratio analysis and bands 1, 3, 5, and 6 for the Crósta technique. The findings indicate that the Crósta technique outperformed the band ratio method, as it leverages spectral bands associated with alteration minerals, providing greater accuracy and reliability in delineating areas with potential gold-silver deposits.

Furthermore, this study underscores the transformative potential of Google Earth Engine as a powerful geospatial tool for advancing mineral exploration. Its ability to process and analyse large-scale satellite imagery enhances the efficiency and precision of remote sensing-based mineral prospecting, offering a valuable approach for future exploration initiatives.

References

Aydal, D., Arda, E., Dumanlilar, Ö. 2007. Application of the Crosta technique for alteration mapping of granitoidic rocks using ETM+ data: a case study from eastern Tauride belt (SE Turkey). International Journal of Remote Sensing, vol. 28, pp. 3895–3913.

Chandrasekar, N., Mujabar, P.S., Rajamanickam, G.V. 2011. Investigation of heavy-mineral deposits using multispectral satellite data. International Journal of Remote Sensing, vol. 32, pp. 8641–8655.

Chen, X., Warner, T.A., Campagna, D.J. 2007. Integrating visible, near-infrared and shortwave infrared hyperspectral and multispectral thermal imagery for geological mapping at

Cuprite, Nevada. Remote Sensing of Environment, vol. 110, pp. 344–356.

Creamer, M. 2012. Global mining drives 45%-plus of world GDP – Cutifani. http://www.engineeringnews.co.za/article/globalmining-drives-45-plus-of-world-gdp-cutifani-2012-07-04 [accessed 9 October 2018]

Crósta, A.P., De Souza Filho, C.R., Azevedo, F., Brodie, C. 2003. Targeting key alteration minerals in epithermal deposits in Patagonia, Argentina, using ASTER imagery and principal component analysis. International Journal of Remote Sensing, vol. 24, pp. 4233–4240.

Gandhi, S.M., Sarkar, B.C. 2016. Essentials of Mineral Exploration and Evaluation, Elsevier, Candice G. Janco.

Gorelick, N., Hancher, M., Dixon, M., Ilyushchenko, S., Thau, D., Moore, R. 2017. Google Earth Engine: Planetary-scale geospatial analysis for everyone. Remote Sensing of Environment, vol. 202, pp. 18–27.

Hede, A.N.H., Kashiwaya, K., Koike, K., Sakurai, S. 2015. A new vegetation index for detecting vegetation anomalies due to mineral deposits with application to a tropical forest area. Remote Sensing of Environment, vol. 171, pp. 83–97.

Jensen, J.R. 1986. Introductory Digital Image Processing: A Remote Sensing Perspective. Prentice-Hall, Englewood Cliffs, New Jersey, USA.

Loughlin, W.P. 1991. Principal Component Analysis for Alteration Mapping. Photogrammetric Engineering & Remote Sensing, vol. 57, pp. 1163–1169.

Pontual, S., Merry, N., Gamson, P. 2008. Spectral interpretation - Field manual. GMEX. 2008. Spectral Analysis guides for mineral exploration: AusSpec International Pty. Ltd., 189.

Ninomiya, Y., Fu, B., Cudahy, T.J. 2006. Corrigendum to "Detecting lithology with Advanced Spaceborne Thermal Emission and Reflection Radiometer (ASTER) multispectral thermal infrared "radiance-at-sensor" data" Remote Sensing of Environment, vol. 101, p. 567.

MTA 2018. Jeoloji Haritalari [Online]. Available: http://www.mta.gov.tr/v3.0/hizmetler/jeoloji-haritalari [Accessed 9 October 2018].

Rajendran, S., Nasir, S. 2017. Characterisation of ASTER spectral bands for mapping of alteration zones of volcanogenic massive sulphide deposits. Ore Geology Reviews, vol. 88, pp. 317–335. Salehi, S., Rogge, D., Rivard, B., Heincke, B.H., Fensholt, R. 2017. Modelling and assessment of wavelength displacements of characteristic absorption features of common rock-forming minerals encrusted by lichens. Remote Sensing of Environment, vol. 199, pp. 78–92.

Tangestani, M.H., Jaffari, L., Vincent, R.K., Sridhar, B.B.M. 2011. Spectral characterisation and ASTER-based lithological mapping of an ophiolite complex: A case study from Neyriz ophiolite, SW Iran. Remote Sensing of Environment, vol. 115, pp. 2243–2254.

Tangestani, M.H., Moore, F. 2000. Iron oxide and hydroxyl enhancement using the Crosta Method: a case study from the Zagros Belt, Fars province, Iran.Communication. JAG, vol. 2, pp. 140–146.

Wang, G., Du, W., Carranza, E.J.M. 2017. Remote sensing and GIS prospectivity mapping for magmatic-hydrothermal base- and precious-metal deposits in the Honghai district, China. Journal of African Earth Sciences, vol. 128, pp. 97–115.