OFFICE BEARERS AND COUNCIL FOR THE 2024/2025 SESSION

President E. Matinde

President Elect

G.R. Lane

Senior Vice President

T.M. Mmola

Junior Vice President

M.H. Solomon

Incoming Junior Vice President

S.J. Ntsoelengoe

Immediate Past President

W.C. Joughin

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk M.C. Munroe

Z. Fakhraei S.M. Naik

B. Genc G. Njowa

K.M. Letsoalo S.M. Rupprecht

S.B. Madolo A.T. van Zyl

M.A. Mello E.J. Walls

K. Mosebi

Co-opted Council Members

A.D. Coetzee

L.T. Masutha

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

G.R. Lane – TP Mining Chairperson

Z. Botha – TP Metallurgy Chairperson

K.W. Banda – YPC Chairperson

C.T. Chijara – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC K.T. Kekana (Interim Chairperson)

Johannesburg N. Rampersad

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West Vacant

Pretoria P.G.H. Pistorius

Western Cape Vacant

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

Editorial Board

S.O. Bada

R.D. Beck

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

R.T. Jones

W.C. Joughin

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

C. Musingwini

P.N. Neingo

S.S. Nyoni

M. Onifade

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

T.R. Stacey

International Advisory Board members

R. Dimitrakopolous

R. Mitra

S. Ndlovu

A.J.S. Spearing

E. Topal

D. Tudor

F. Uahengo

D. Vogt

Editor /Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31 Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

Journal Comment: Complexity of Slope Stability by R. Armstrong ................................................................

President’s Corner: Final reflections and future considerations by E. Matinde ..................................................................

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2025 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys

Auditors

Genesis Chartered Accountants

Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za

ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Stability design of slopes in carbonatite complexes characterised by brecciation by D. Moses, J.A. Onyango ......................................................................................... 401

In this contribution, a numerical simulation using phase2 v 7.0 was carried out to investigate the influence of in situ rock damage on the stability of mine pit walls. The results reveal that the existence of breccia in the competent rock mass has the capability to reduce the slope stability performance. From a series of analyses, the ratio of 1:5 between the breccia distance from slope toe and pit depth should be implemented to counter its impact. If the breccia is within or close to the pit limit, it should be mined out.

Evaluating the triaxial strength of Misis fault breccia using artificial neural networks analysis by S. Kahraman, M. Alber, O. Gunaydin, M. Fener..................................................................... 413

The purpose of this study is to develop some predictive models for the differential stress (Δσ) based on physical and textural properties of fault breccias. Artificial neural networks were used to analyse data related to Misis fault breccia. It can be concluded that artificial neuron networks analysis provides a reliable indirect method for predicting the differential stress of Misis fault breccia.

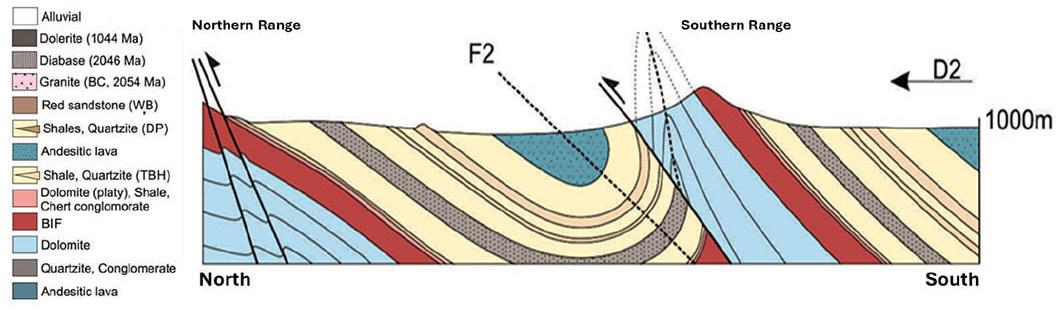

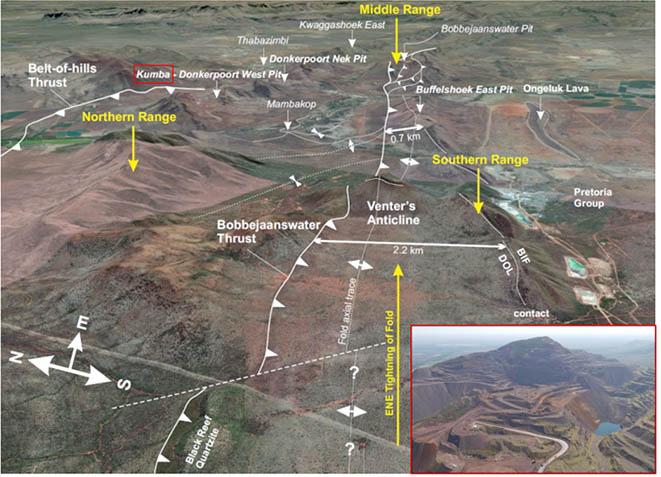

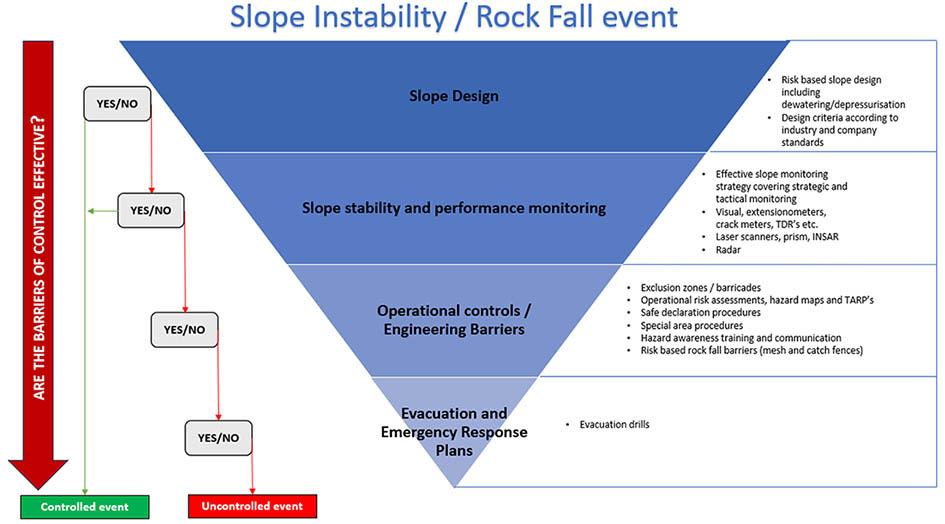

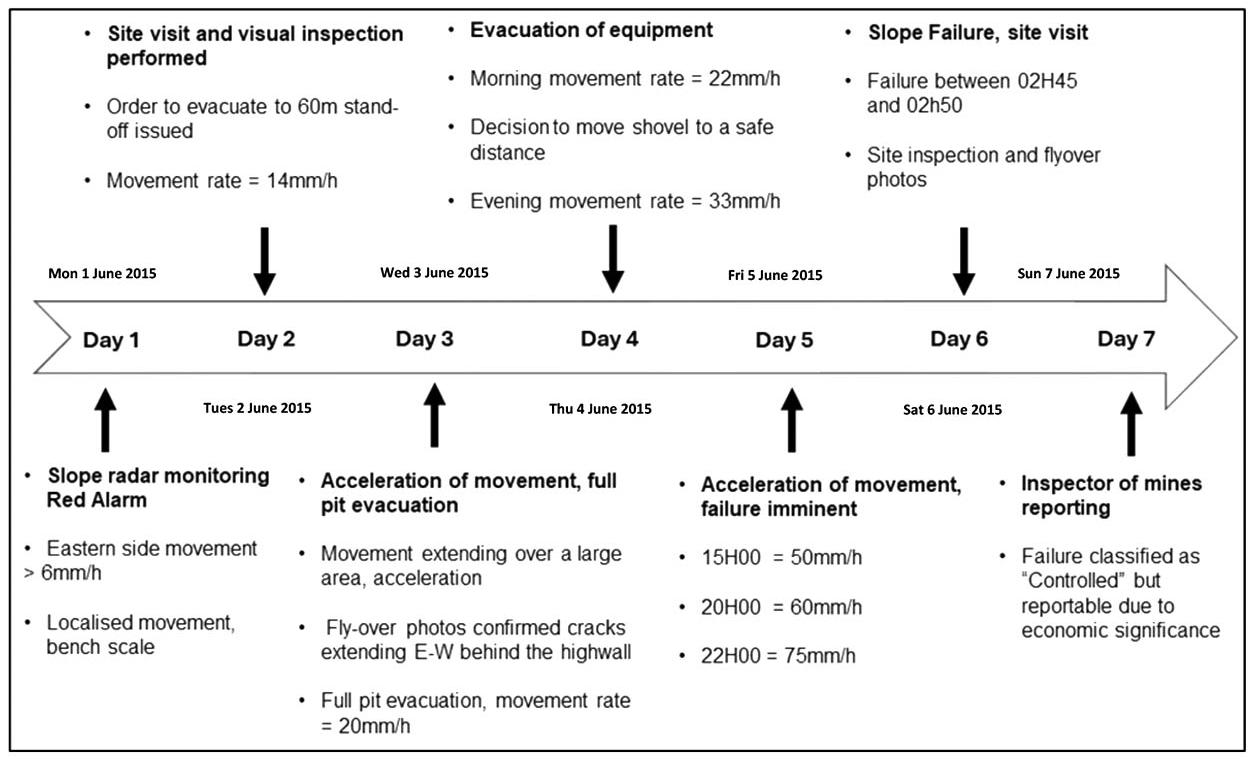

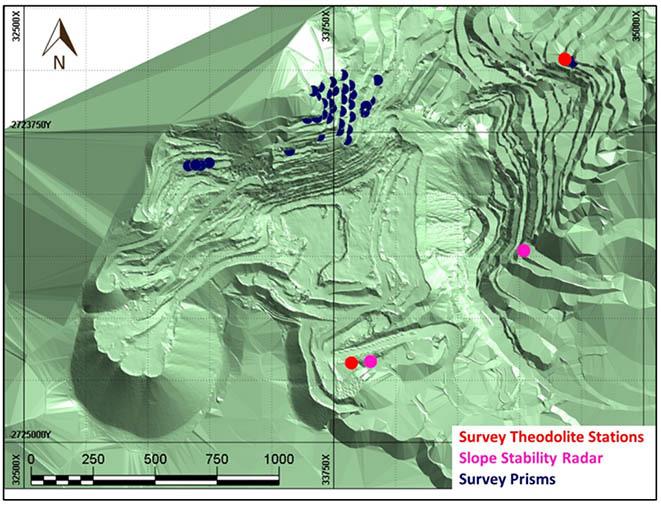

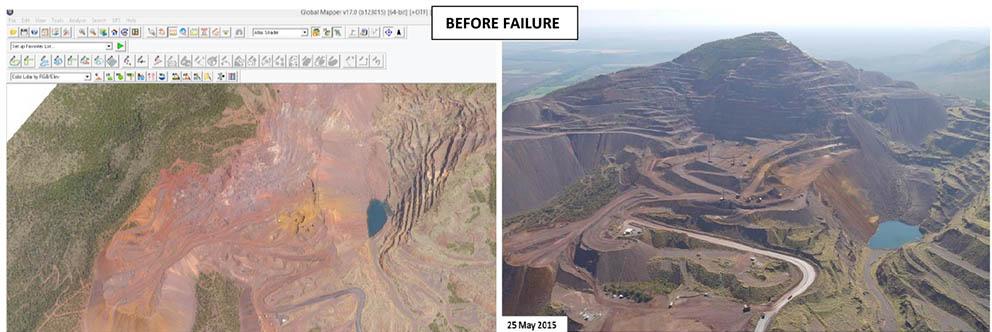

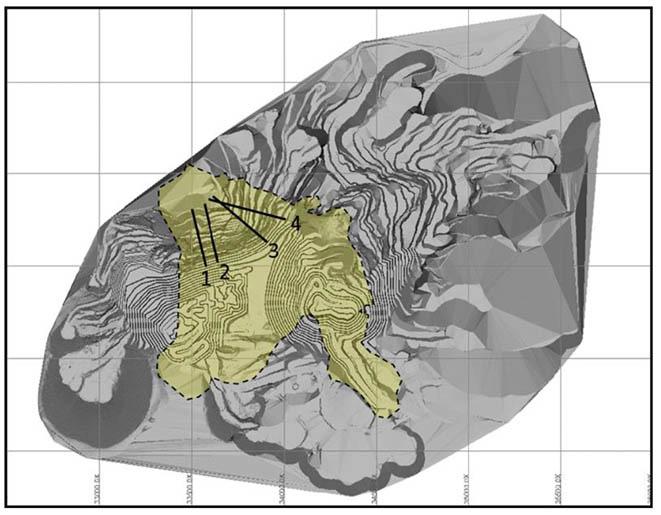

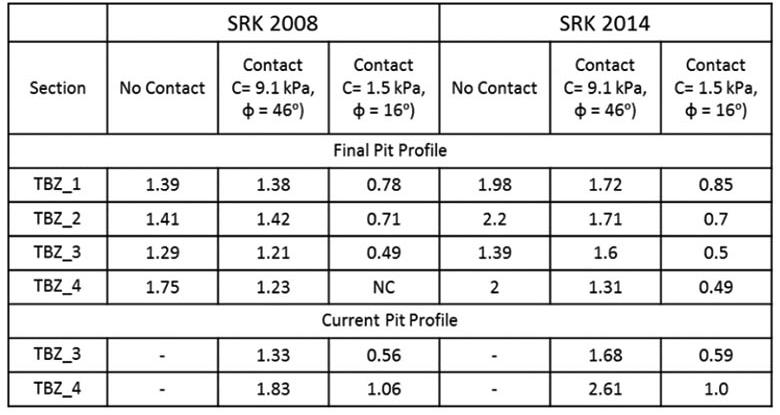

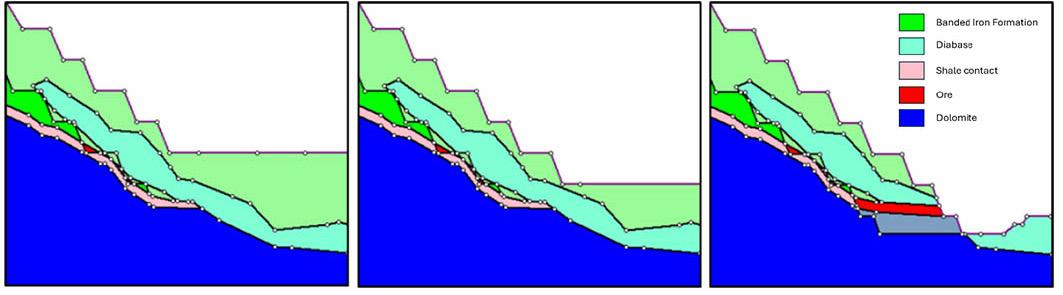

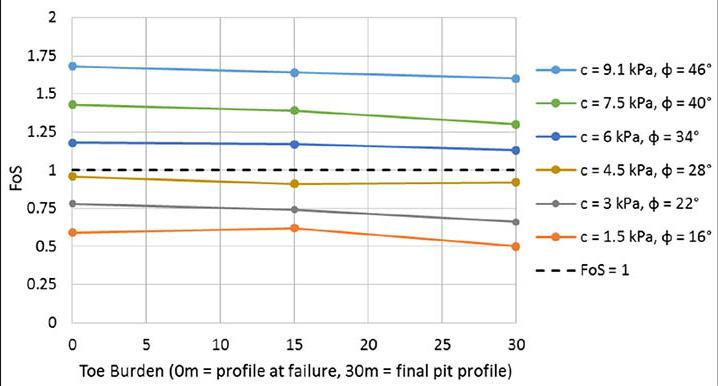

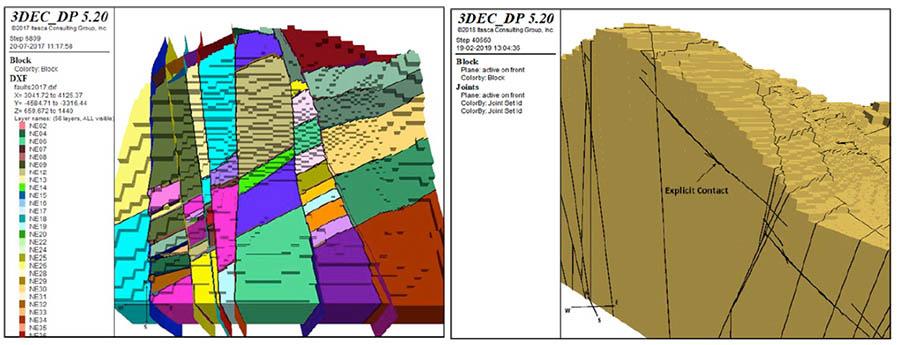

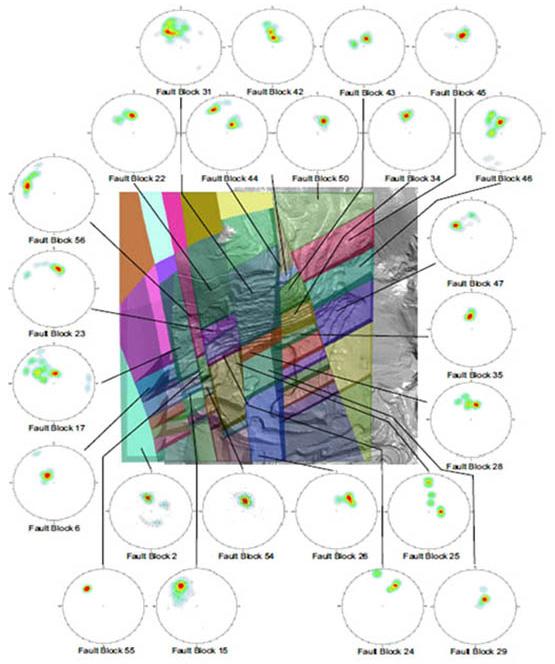

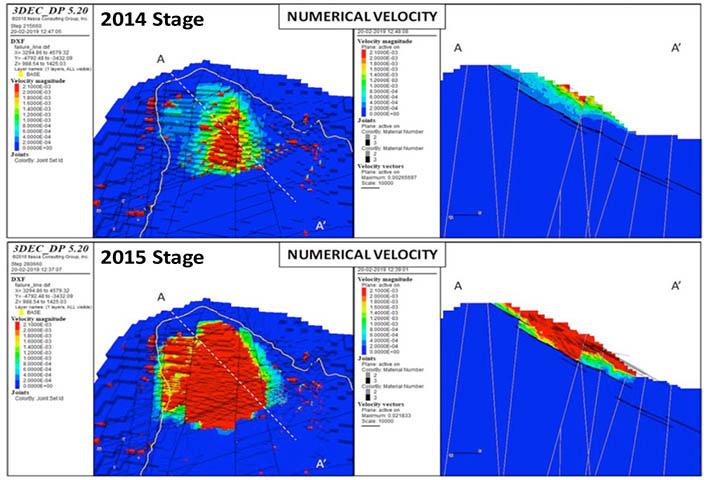

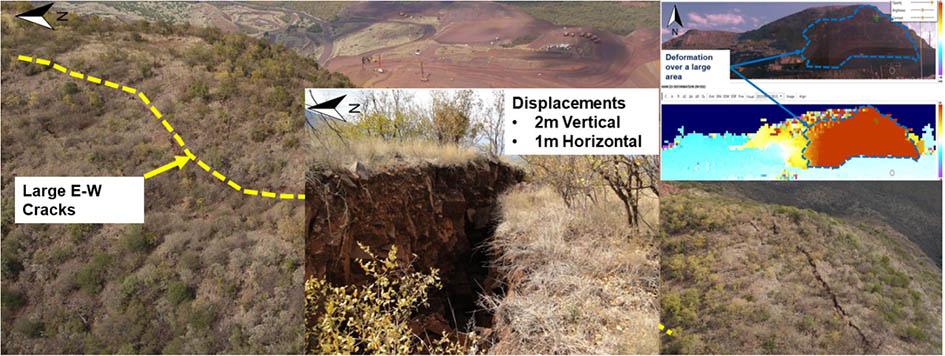

Risk-based slope design: Insights from the Thabazimbi failure by M. Bester, T. Dlokweni, I. Basson, C. Koegelenberg

This contribution presents the slope failure in Thabazimbi Mine’s Kumba pit as a case study in the context of a risk-based approach to slope design as well as the importance of implementing geotechnical controls to effectively manage slope instability risk. A comprehensive back-analysis was performed to gain insights into the failure mechanism. Lessons learnt demonstrated the importance of following a risk-based approach in slope design to effectively manage safety and financial risk in open pit mines.

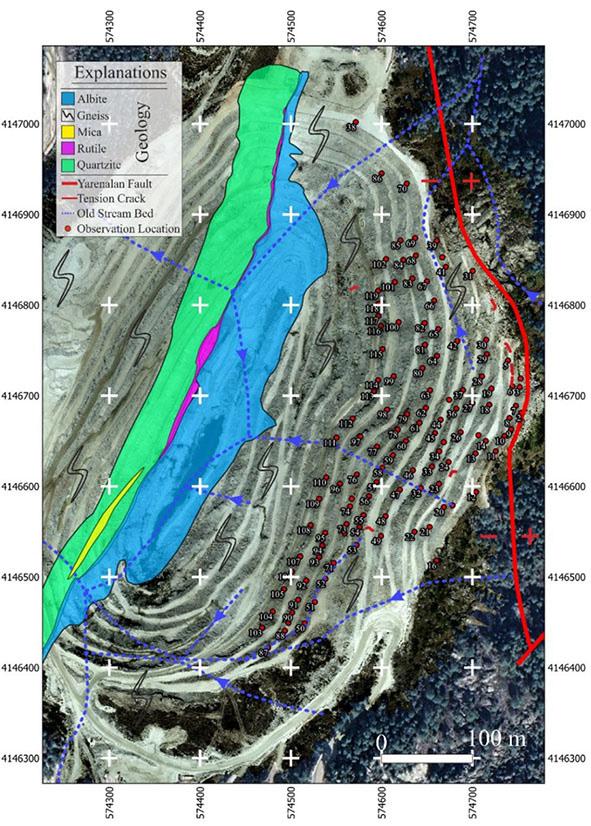

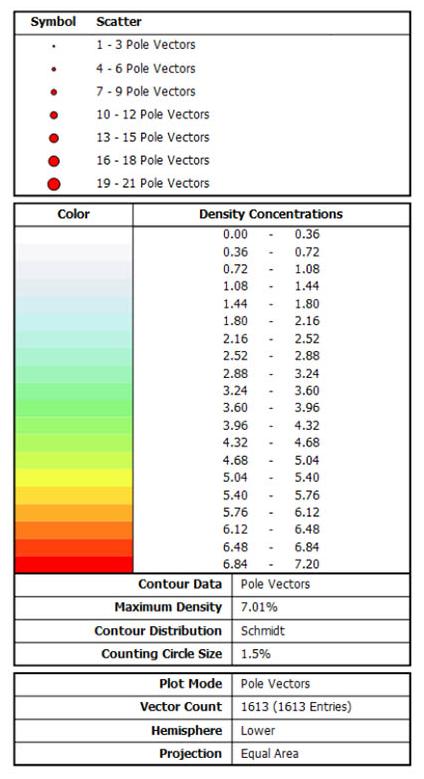

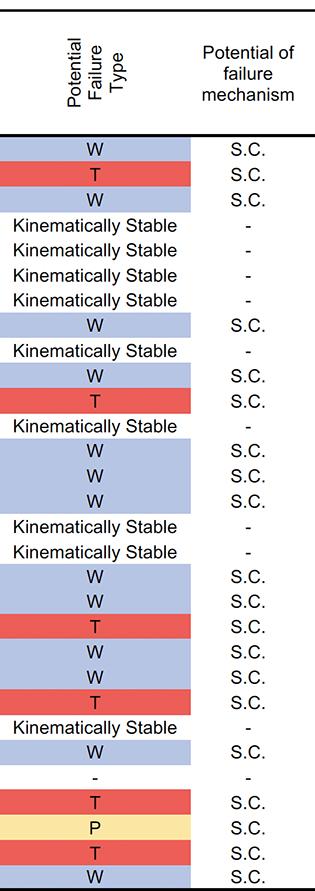

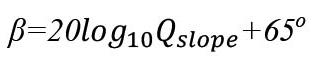

Slope stability evaluation of Gneiss rock slopes using slope mass rating (SMR) and QSlope by E. Kalhan, C. Kincal

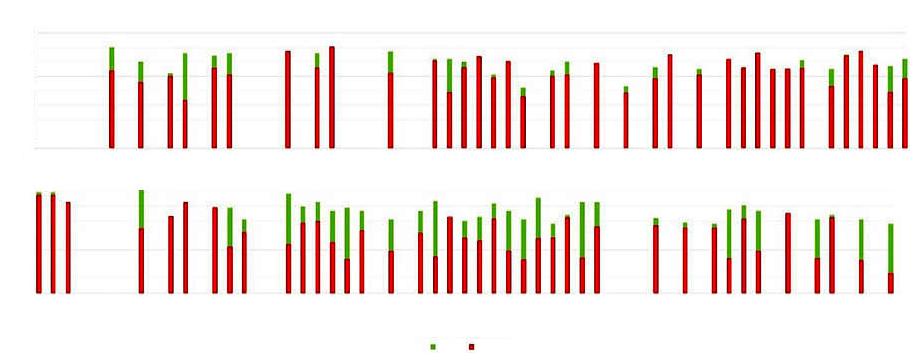

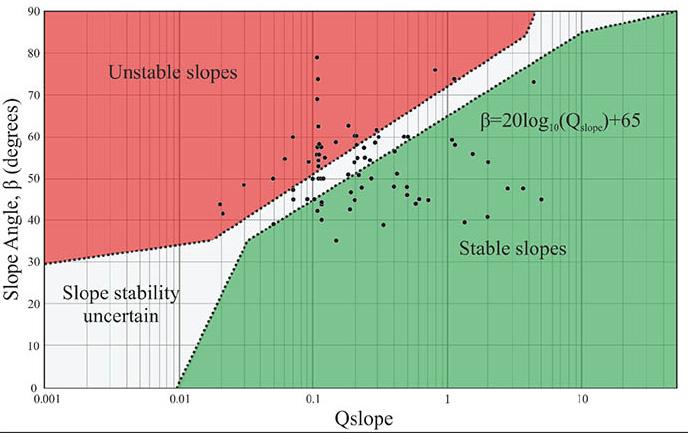

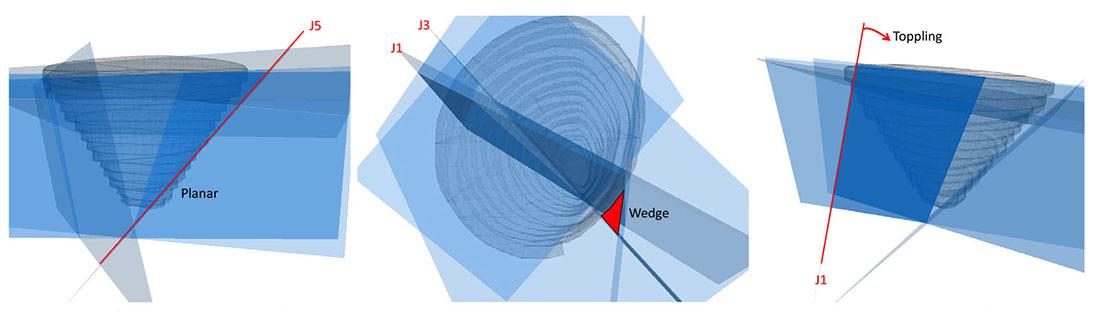

In this research, the slope stability of rock slopes in a mine opened in a gneiss geological unit was studied. To assess slope stability, detailed discontinuity surveys were carried out on bench faces. Subsequently, kinematic and numerical analyses were employed to identify geometries that are expected to maintain stability. Based on these classification systems, potential unstable rock slopes were identified, and thematic maps were created using geographic information systems.

Learnings from development of an underground sub-level open stope mine below an open pit by K.B. Le Bron, M.C. van Eeden, R. Vermeulen

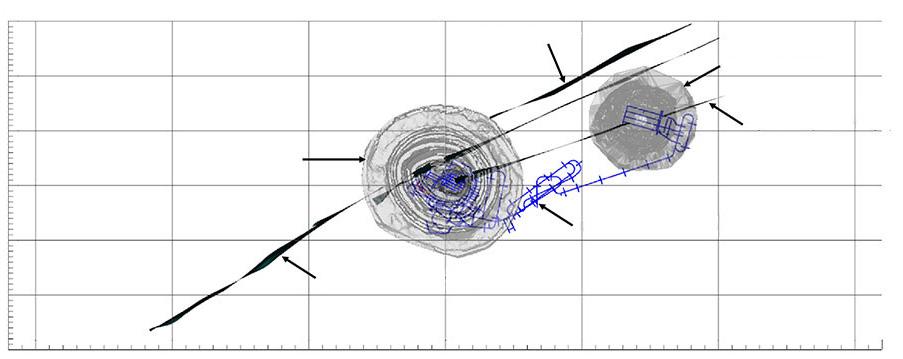

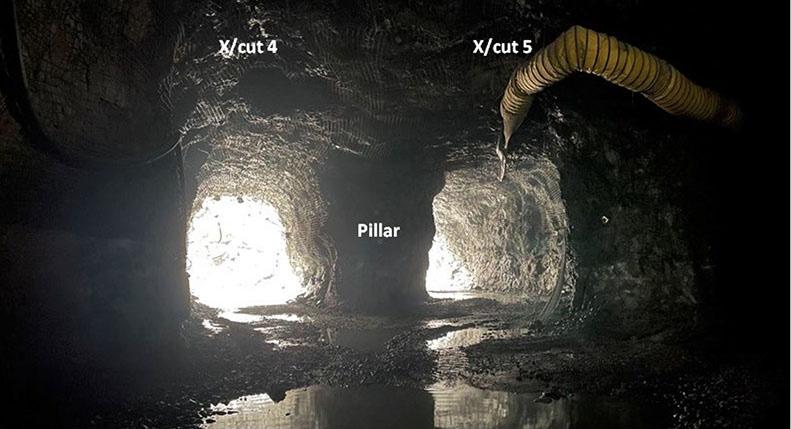

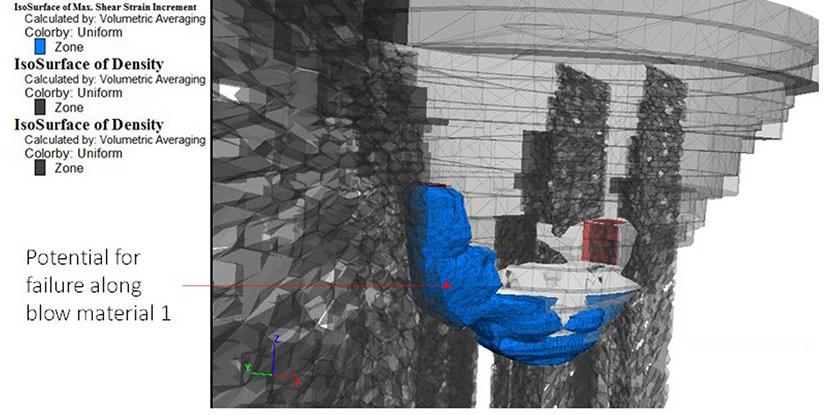

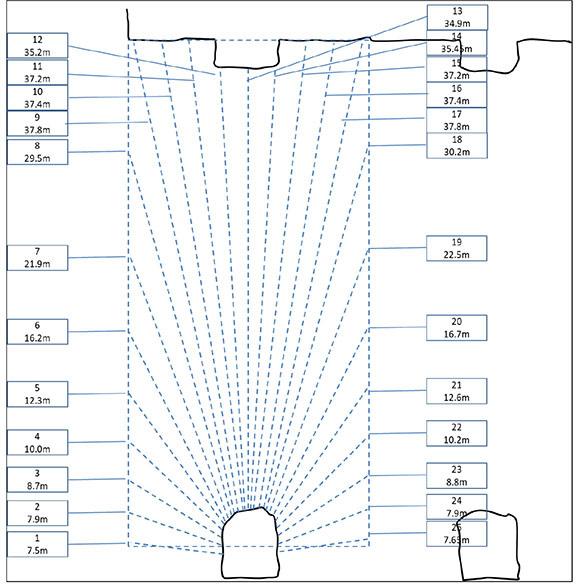

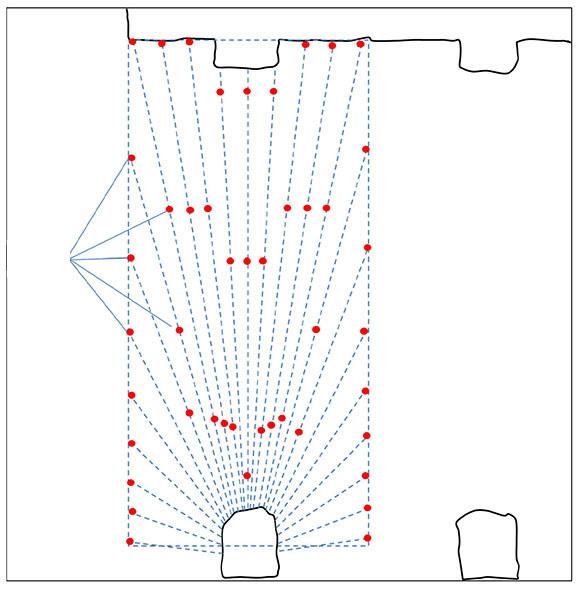

This paper presents the lessons learnt during the transition from an open pit method to a sub-level open stoping method at the Koidu Limited kimberlite pipe. Predictive geotechnical stability modelling was successfully applied to highlight potential failure zones, which allowed modification and enhancement of the mining layouts and quantification of the potential dilution of the kimberlite from indicative instabilities.

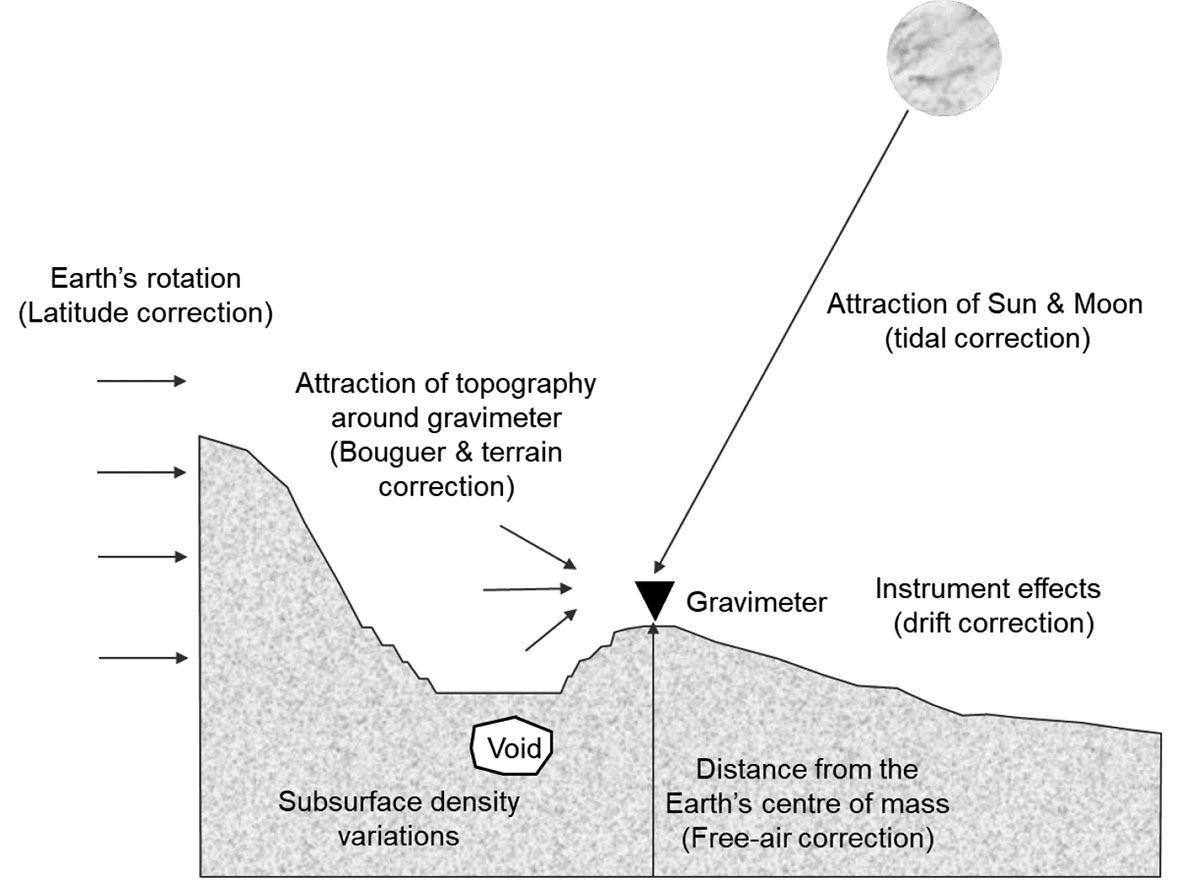

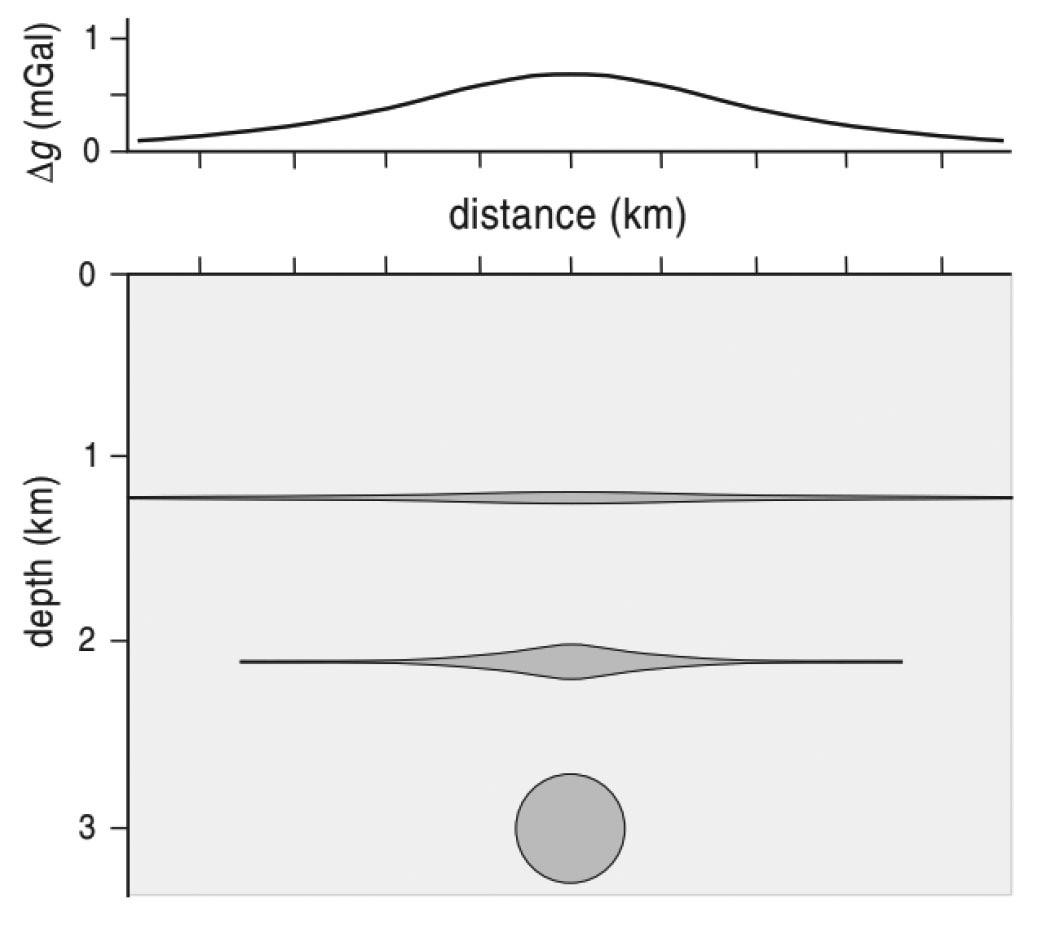

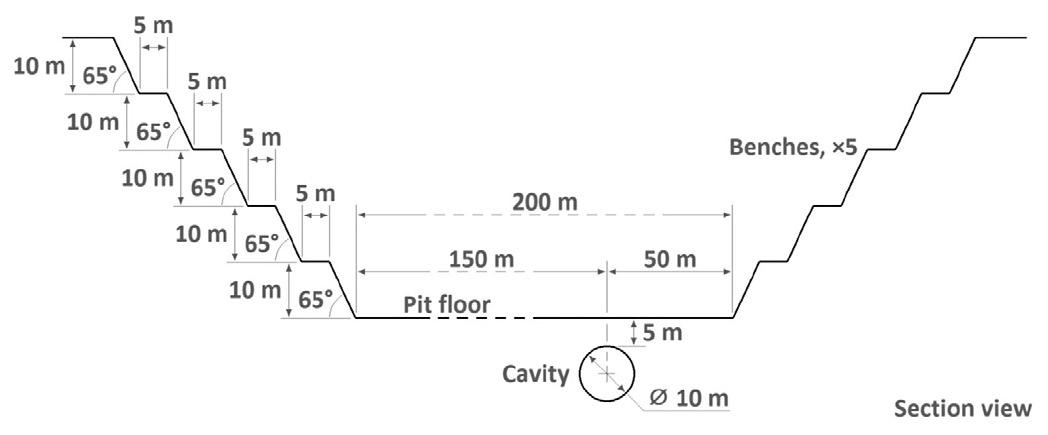

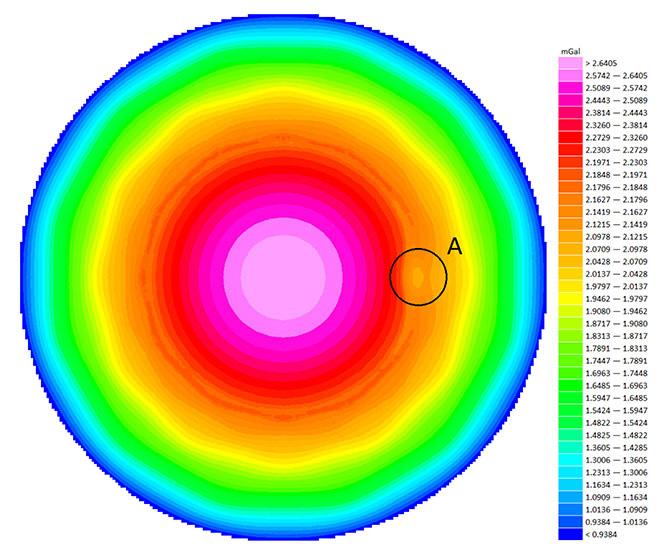

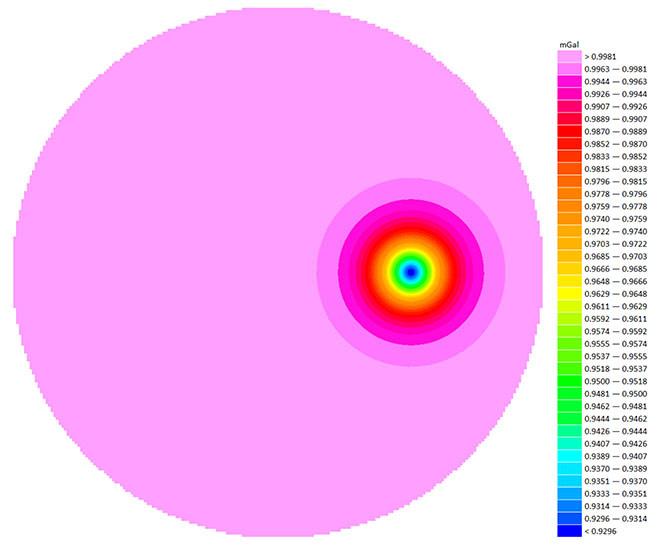

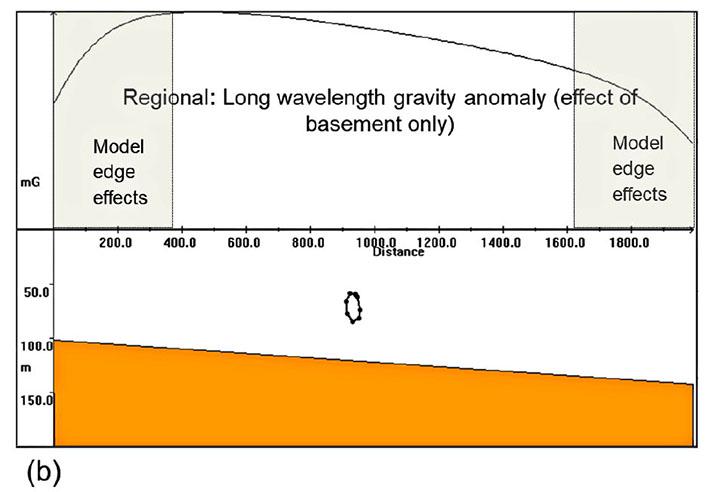

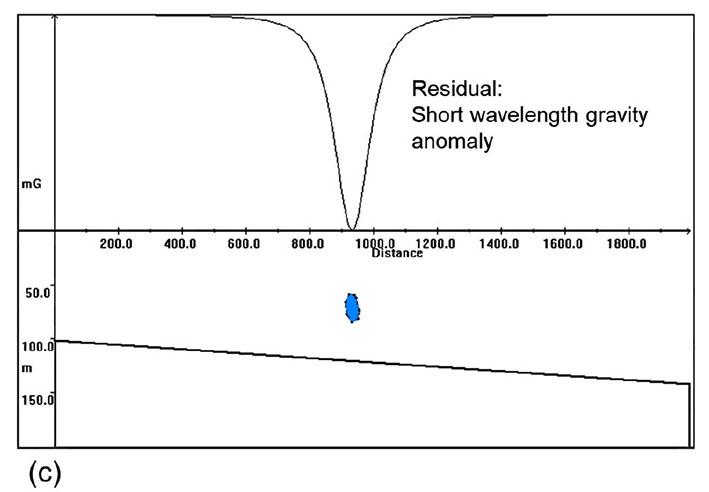

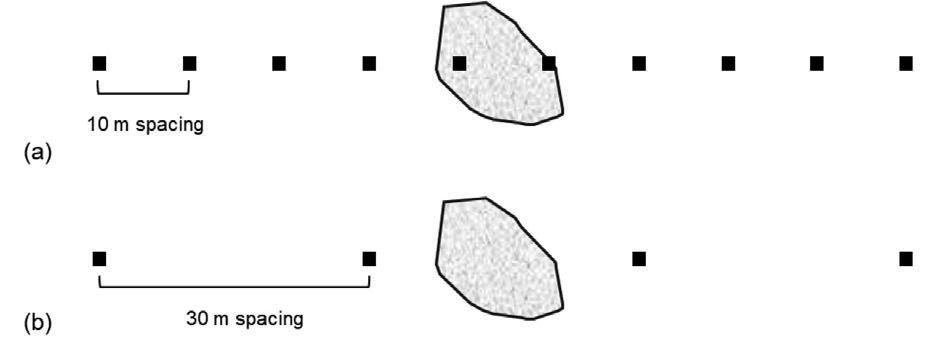

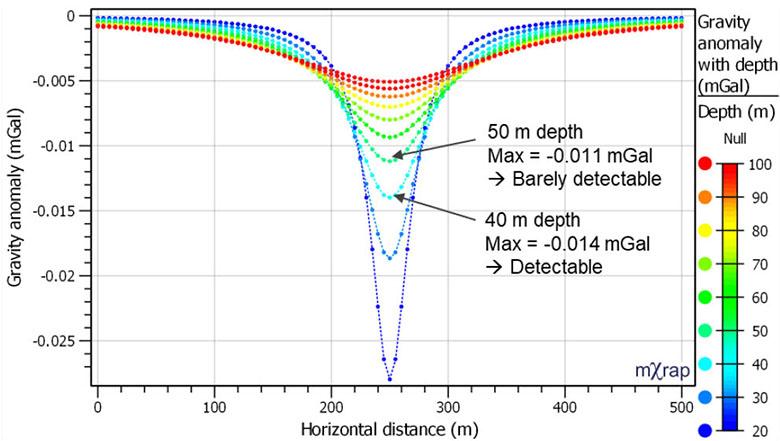

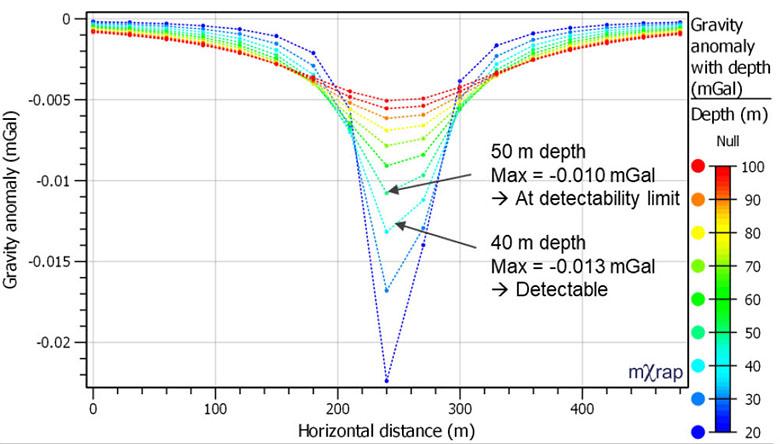

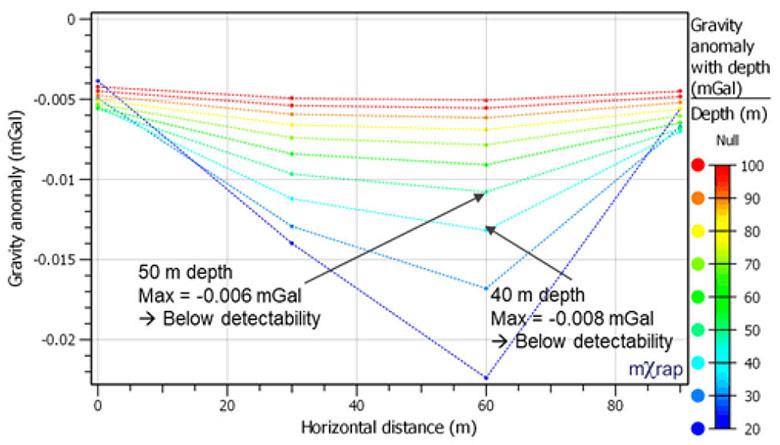

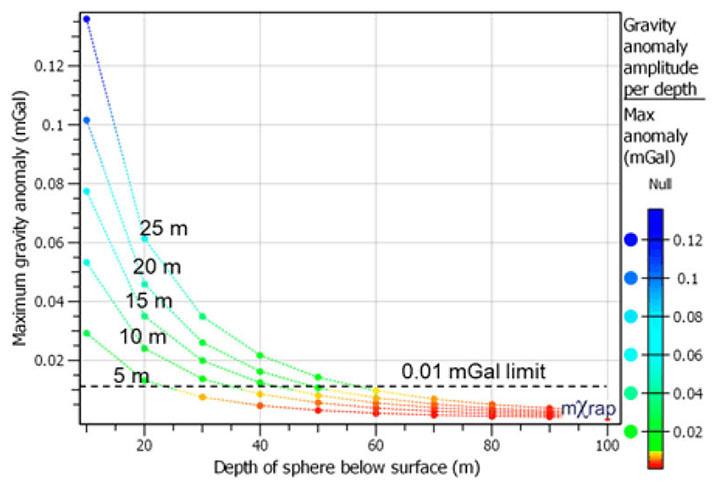

Guide to using gravity in the detection of underground voids by L.M. Linzer, P. Linzer

This paper aims to explain how to apply the gravity method correctly to mining and geotechnical problems, specifically in the detection of subsurface cavities. It discusses various factors to assist with optimising the acquisition of gravity data and its processing in order to maximise the practical value of gravity surveys. The gravity surveying specifications prescribed in SANS 1936 omit some key requirements for optimal survey outcomes, and this paper is intended to fill those gaps.

Calibrate rock mass shear strength for open pit slopes by J. Venter, C. Banff, E.C.F. Hamman.

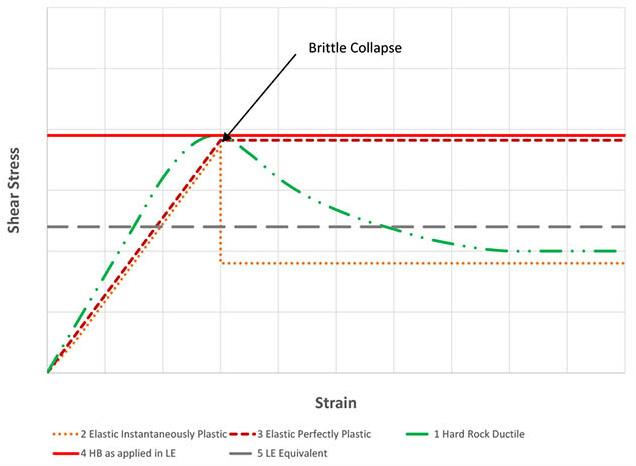

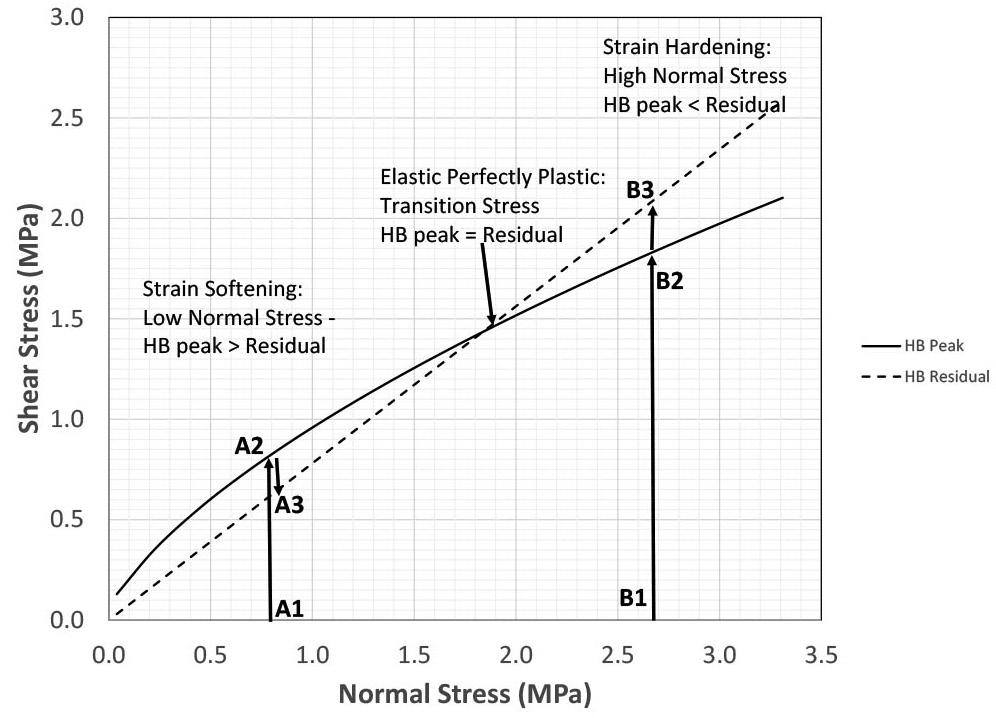

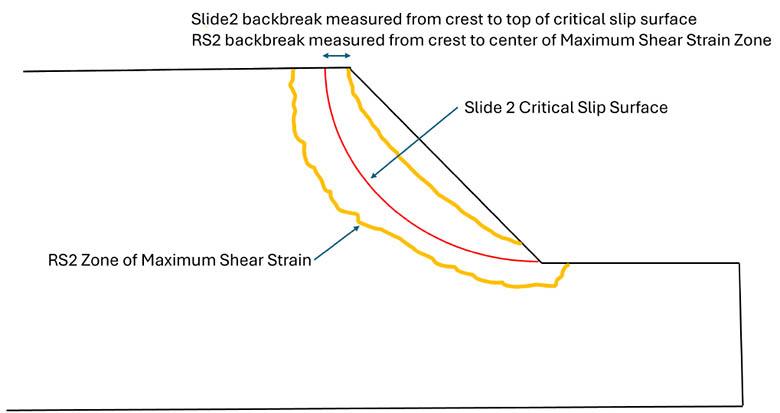

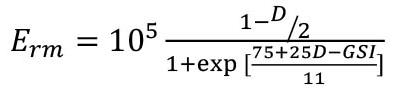

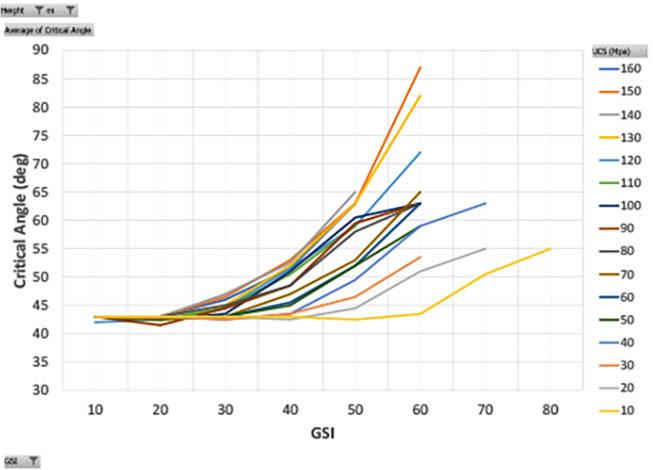

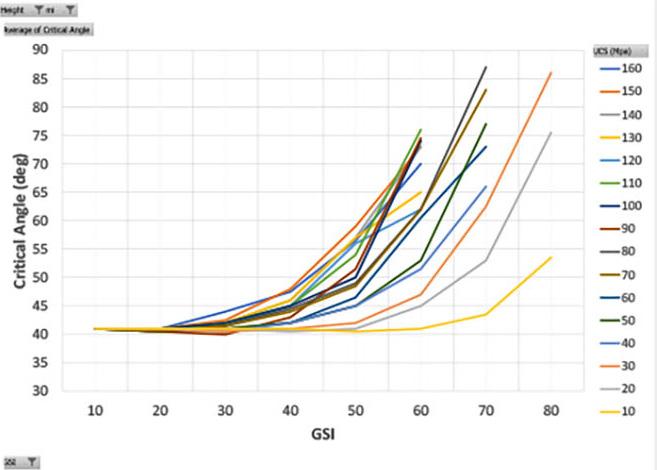

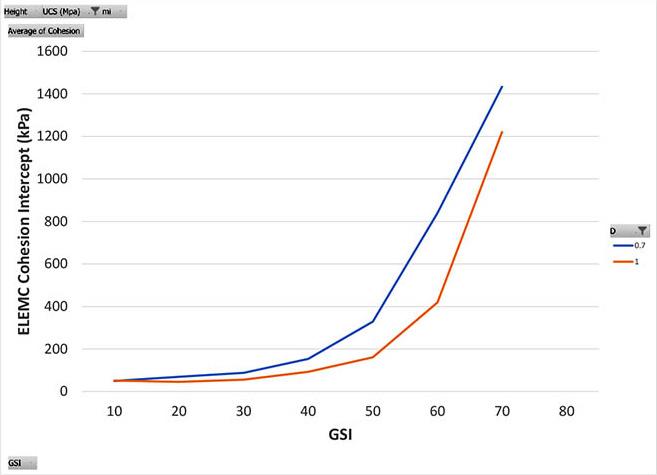

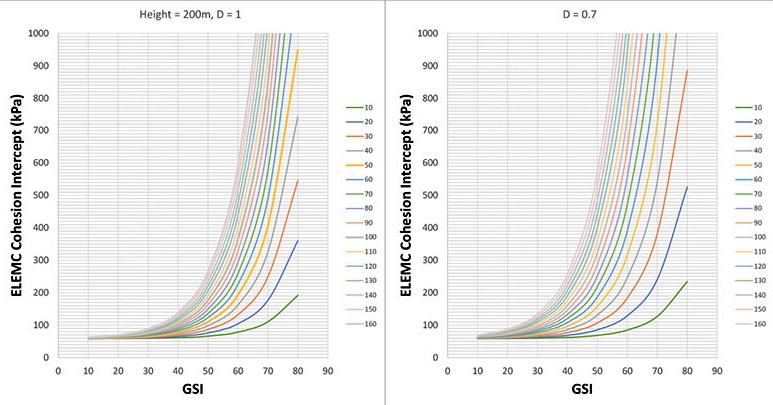

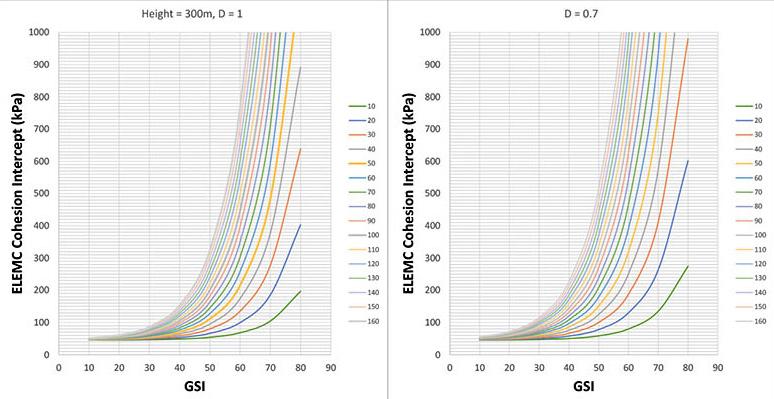

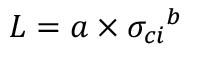

This paper investigates the differences between limit equilibrium and elastic linearly plastic slope stability analysis based on the Hoek-Brown failure criterion for open pit slope stability analyses. The investigation consisted of a comparison of 3840 RS2 finite element analysis models completed with strain softening, and 216 Slide2 limit equilibrium models. The results compare well with older empirical shear strength estimates, however, a detailed calibration of the results against case studies will need to be carried out.

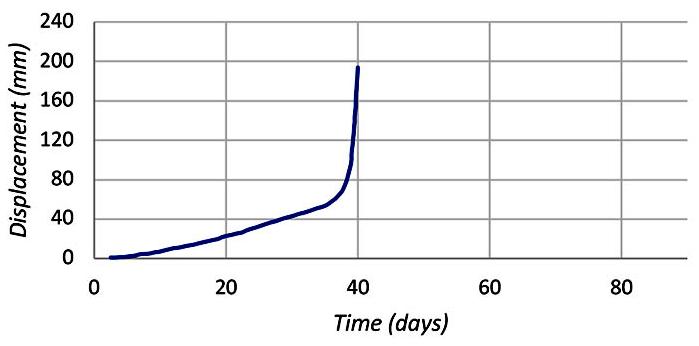

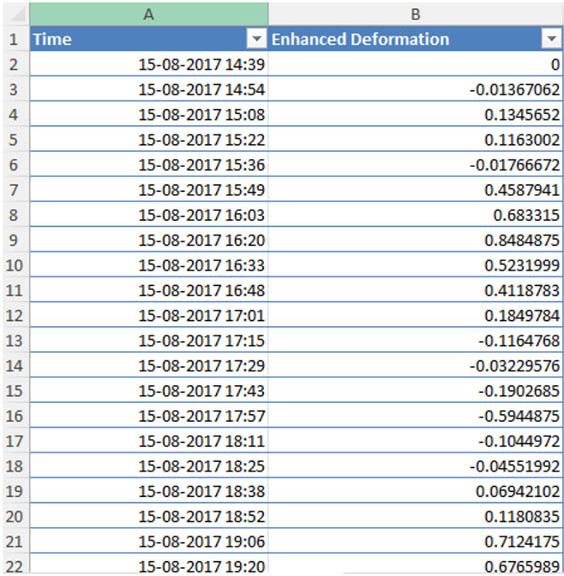

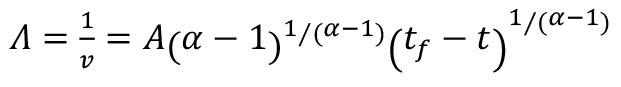

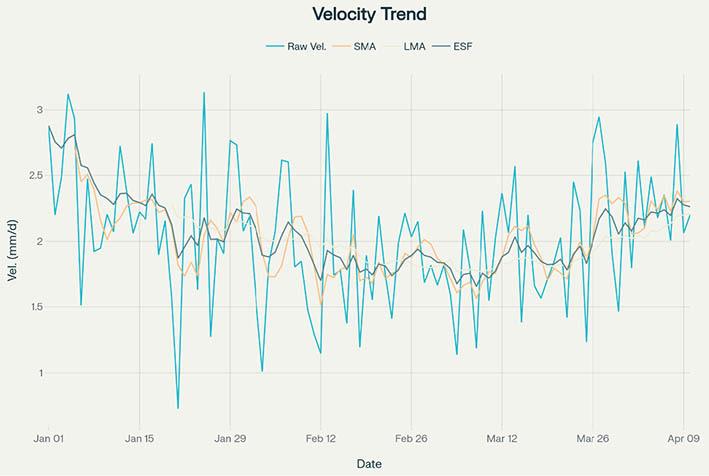

Development of a filtered inverse velocity method analyser: A comparative study of smoothing filters in surface mines for optimisation of slope failure predictions by M.M. Masood, T. Verma, G.Y. Raju ...............................................................................

This study applies and evaluates three filtering techniques to velocity time series data to enhance predictive accuracy to improve slope failure forecasting in surface mining operations. A refined prediction framework is proposed. The results demonstrate that filter selection plays a crucial role in optimising failure time predictions, offering valuable insights for geotechnical monitoring and early warning systems in surface mines.

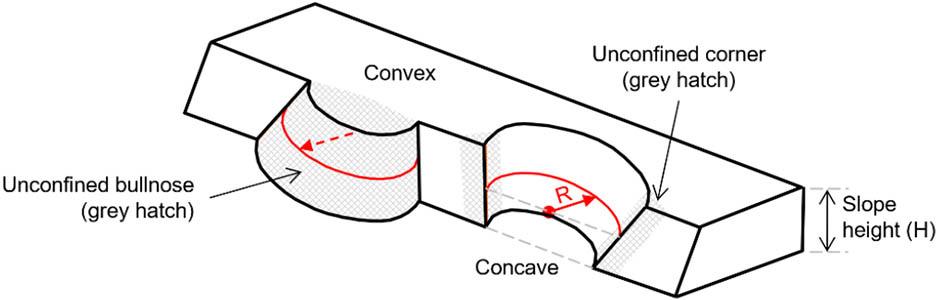

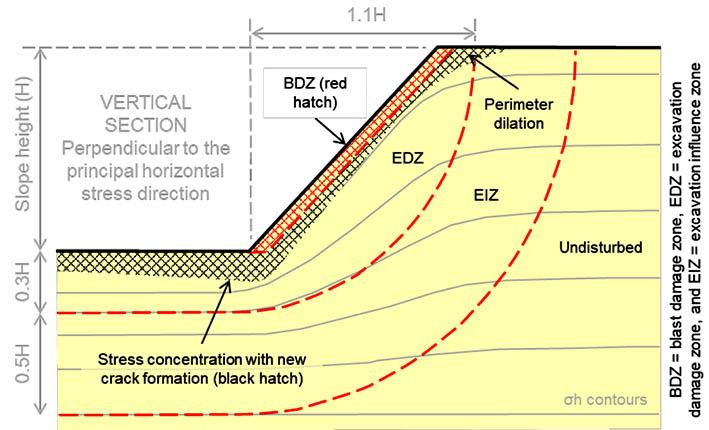

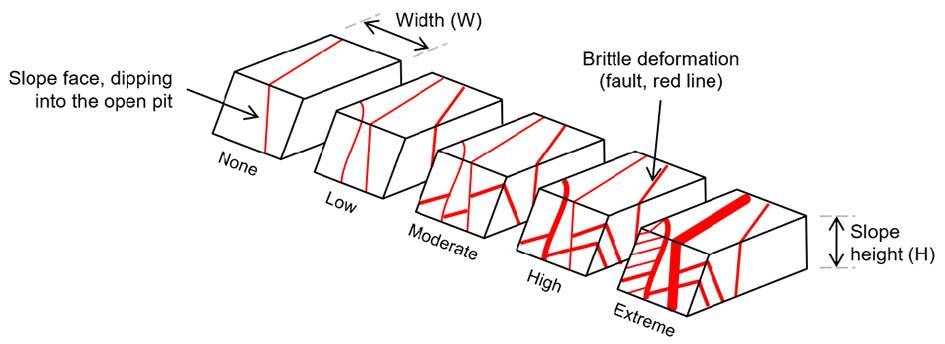

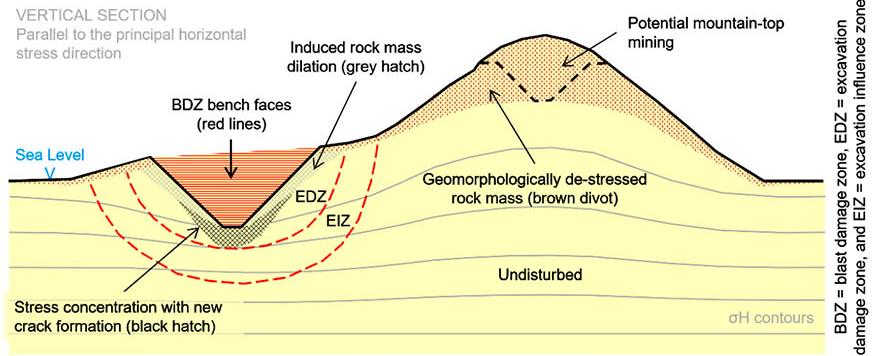

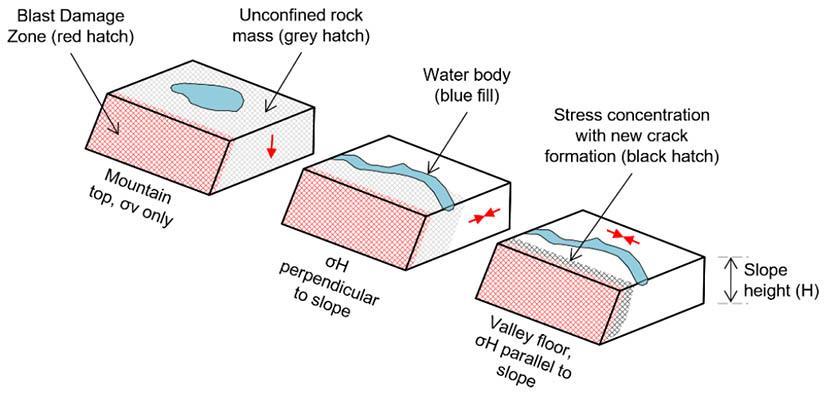

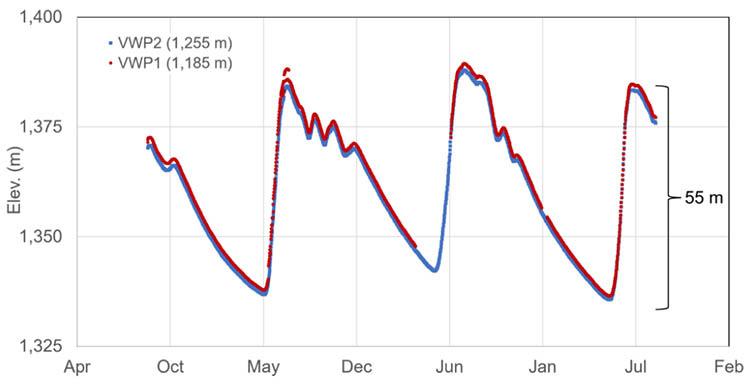

Rock mass damage and induced passive depressurisation around open pits by A. Bloem, M. Royle, R. Uken

Rock mass damage induced by mining increases the fracture frequency and joint aperture width in pit walls and rock mass behind open pit mine slopes. This investigation has resulted in the development of a method to adjust initial hydraulic conductivity values used to estimate transient pore pressure conditions found in rock masses exposed in different pit morphologies within the open pit mine. The changes in K values and pore pressures can be used to determine hydrogeological influence more accurately on future pit slope stability.

he South African mining industry is well known for the advancements in underground, especially ultra-deep, mines. But it has also made significant contributions to open pit mining and the stability of slopes. The SAIMM hosted a symposium on slope stability as early as 1970 (book S2 in the symposium series), which was conceptualised by the SAIMM because open pit mines were getting bigger and deeper, and the sharing of knowledge and experience from the industry was required. Over 300 local and international delegates attended the symposium, including technical, industry, and academic leaders in open pit mining and rock mechanics. Incidentally, two of the speakers would go on to found two international mining consulting firms. Again, recognising that pits were being planned much deeper than ever before, The SAIMM planned the first International Symposium on Stability of Rock Slopes in Open Pit Mining and Civil Engineering in 2006, which has since been held 10 times in 8 different countries (now informally referred to as simply The Slopes Conference). This symposium was again organised by the SAIMM in 2015. This special edition of the journal serves as a further commitment to the development of the science and engineering of rock slopes, with the very high response of papers dealing with some interesting and pertinent developments. Topics covered include: slope stability analyses, groundwater interactions with slopes, forecasting of failure, detection of underground cavities, and the back analysis of a very large slope failure.

Significant developments have taken place in the last two decades in monitoring and numerical modelling of rock slopes. These often overshadow the importance of understanding the actual mechanics of big slopes, and how to reliably design them. Many advances in technology have provided the tools to aid in this, but there is a long way to go in understanding the complex interplay of the geological complexity (including varying rock types, geological structure, alteration, and weathering), complex groundwater systems (often grossly over simplified), strength properties, appropriate failure criteria, slope geometries, blasting, et al. These complexities are impossible to include in any single analysis or model, so the design and understanding of large slope behaviour still require contextualising multiple over-simplified models and determining how their interaction results in the limitation of slope equilibrium. Furthermore, how to manage all of that in the implementation of big slopes. This complexity means that slopes require the inputs from many specialists and an understanding of the limitations of their science and models. So much more is needed in the development of rock slope engineering.

R. Armstrong

his month’s article will be my last contribution to the SAIMM President’s Corner. It has been a very interesting and rewarding twelve months as President of the SAIMM and I am thrilled to hand over the baton to my colleague Gary Lane as the newly inaugurated SAIMM President. As part of my communication strategy during the last twelve months, I deliberately selected a few, but very critical, areas of engagement affecting our mining industry. I also chose to structure my article contributions through the lens of a Socratic approach. Of course, any reasonable mind is bound to ask: Why the Socratic approach?

Originally attributed to the ancient Greek philosopher Socrates (c.a. 470-399 BCE), the Socratic method is a form of logical argumentation used to uncover hidden assumptions, challenge beliefs, and achieve deeper understanding of complex and contentious issues through a set of continual probing questions. As opposed to the conventional didactic, and often positional discussions based on perceived factual knowledge, the Socratic approach is a self-discovery method that encourages participants to explore complexities and plurality around sensitive topics by forcing them to evaluate issues from multiple perspectives. In my view, the challenges affecting our industry are way too complex, and indeed too complicated, to solve them through a positional and/or zero sum mindset. Case in point is the discussions around retrenchments and layoffs amid market disruptions precipitated by the turbulent global geopolitical environment.

In my first article I made a bold proposition that, with the right technological, economic, and policy conditions, critical minerals and metals can act as key levers for industrial development, leading to sustained technological and economic catch-up. My hypothesis still remains unchanged, particularly in the context of astronomical demand for critical raw materials that are needed to drive the clean energy transition. In essence, the clean energy economic epoch naturally presents windows of opportunity for technological upgrading and industrialisation through value-added manufacturing and localisation of value-added manufacturing activities. Although the role of mineral endowment in the technological and economic catch-up framework is still poorly understood, I support the urgent calls to increase the level of beneficiation of mineral resources in host communities. In my view, this call to action should be universal if we are to address the extractivist curse that has epitomised the mineral resources sector in the global south for centuries.

Obviously, I am not naive to the fact that developing and sustaining manufacturing capabilities is not a trivial endeavour. However, I remain convinced that, with the right economic incentives and policy enablers, such capabilities and competencies can be developed and nurtured for the long-term benefits of our industry and members. If value-addition and beneficiation is a mission, then all that we need are mission-oriented industrial policies and corporate strategies to drive the innovation and technological upgrading in our industry. As an avid reader on this subject, I would like to refer our readers to explore the interesting dimensions of mission-oriented policies presented in the work published by Prof. Mariana Mazzucato (open access article is available here: https://academic.oup.com/icc/article/27/5/803/5127692).

I also made reference in one of my articles to China’s deliberate efforts to industrialise its economy through strategic support of SMEs and SMMEs (they call them little giants due to their unique capabilities and positioning to grow into national champions) in critical industries. Despite the global contestations on the perceived methods used, the Made in China 2025 policy framework is a noteworthy sovereign strategy that provided the driving force required to catalyse innovation and drive the competitiveness of the value addition and beneficiation supply chains for Chinese enterprises. Germany’s SME-centric Industrie 4.0 strategic initiative, supported by a strong vocational education and training system, also provides a comprehensive template for the global south to learn from. Obviously, there are insurmountable challenges and complexities that we have to overcome before we can achieve some of these desired outcomes. I am looking forward to opportunities to engage further on this complex subject beyond my tenure as President of the SAIMM.

It was an honour that my tenure as SAIMM President coincided with the publication of the Critical Minerals and Metals Strategy for South Africa. The timing of the strategy document is profound in that it comes at a time when we have strong convergence on the need to intensify the local beneficiation of our minerals. The bold declarations to improve the regulatory stability and regulatory flexibility, including deliberate efforts to address other critical bottlenecks, are well received and appreciated. Once again, I would like to reiterate the importance of alignment of the strategy to the broader socio-political economy for us to achieve meaningful economic transformation.

The contribution of mining to the fiscuses and economic development of host countries should never be questioned. However, it would be folly to ignore the negative externalities our industry presents to host communities in the form of potential environmental damage from mine residues, mine impacted water, and airborne emissions. In one of my monthly articles, I highlighted the challenges of legacy mine residues emanating from the historical closure of mining sites and smelters long before the nascent environmental practices came into effect. The environmental potency is obviously exacerbated by the fact that these mine residues are formed ex situ with the potential to undergo physical, chemical, and/or thermal alteration over a period of time, making their long-term geochemical behaviour unpredictable. Additionally, the absence of real-time monitoring data, including limited availability of historical data sets in open access platforms, complicates our understanding of the long-term environmental impact of these legacy challenges. Despite our best efforts, the production and accumulation of mine residues is unfortunately inevitable if humanity is to continue enjoying the same level of affluence and economic development. However, I am convinced that our technical programmes will continue to provide non-zero sum platforms designed to share knowledge and best practices that are required to minimise the environmental footprint of mining activities.

Finally, I would like to take this opportunity to emphasise the need for homegrown technological solutions to transform our industry. With collective effort to develop endogenous technological capabilities, I strongly believe that we can achieve technology sovereignty and mitigate against external technological dependency. To achieve this, we need to strengthen collaborations while continuously investing in building and sustaining multidisciplinary engineering and vocational skills to drive innovation and upgrade productivity and industrial competitiveness. I am optimistic about the future impact from the industry drive to fund artisanal, enterprise, and postgraduate qualifications in the mining industry through the various public and private sector initiatives. In particular, I would like to encourage our young professionals to aggressively pursue any self-learning opportunities available to them, which includes exploring the pursuance of postgraduate qualifications through the various platforms available to support personal growth in the industry.

In conclusion, I would like to thank all those who took their time to read my articles over the past year. I acknowledge the fact that it takes an insurmountable amount of patience to read articles on Greek mythologies, but at this juncture our industry needs to demonstrate hope, resurrection, and renewal, similar to the immortal phoenix bird that cyclically regenerates itself by rising from the ashes of its predecessor.

Capaci occasio.

E. Matinde President, SAIMM

Affiliation:

1Department of Geography and Earth Sciences, School of Applied Science, University of Malawi, Malawi

2Department of Mining, Materials and Petroleum Engineering, Jomo Kenyatta University of Agriculture and Technology, Kenya

Correspondence to: D. Moses

Email: dmoses@unima.ac.mw

Dates:

Received: 3 Jan. 2022

Revised: 7 Mar. 2022

Accepted: 10 Jul. 2025

Published: August 2025

How to cite:

Moses, D., Onyango, J.A. 2025. Stability design of slopes in carbonatite complexes characterised by brecciation. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 8, pp. 401–412

DOI ID:

https://doi.org/10.17159/2411-9717/1972/2025

ORCiD:

D. Moses

http://orcid.org/0000-0002-9387-4094

J.A. Onyango

http://orcid.org/0000-0002-5558-4125

by D. Moses1, J.A. Onyango2

Abstract

Carbonatites are generally competent rock masses with rock mass rating class II rating 60–74. In spite of their competency, they tend to be affected by weak features like manganese-iron veins and/or in situ rock damage due to brecciation associated with carbonatite complexes. Rock slope failure in such hard rocks is complex since such structures within the rock mass form weak links that could potentially control slope instability. In this contribution, a numerical simulation using phase2 v 7.0 was carried out to investigate the influence of in situ rock damage on the stability of mine pit walls. The outcome reveals that, the existence of breccia in the competent rock mass has the capability to reduce the slope stability performance particularly at gentle dipping angles of emplacement in close range to the slope toe. However, as the emplacement position of breccia moves away from the pit wall, the stability performance increases at gentle dipping angle <50º. On the contrary, at the dipping angle of 50° the performance of slope reduced, and at steeper angles >50° the impact becomes negligible. Thus, from a series of analyses, mine design in brecciated rock masses, the ratio of 1:5 between the breccia distance from slope toe and pit depth should be implemented to counter its impact, and if the breccia is within or close to the pit limit, a deliberate effort must be made to mine it out.

Keywords Songwe Hill, carbonatite, finite element method, in situ rock damage, breccia

Introduction

In recent years, the significance and applications of the rare earth elements (REE) for modern technologies, particularly for the permanent magnets used in the generators of wind turbines and the motors of electric vehicles, have led to an increased research focus on alkaline rocks and carbonatites (Goodenough et al., 2021). Carbonatites, which are igneous rocks containing more than 50% modal primary carbonates and less than 20 wt. % SiO2 (Simandl, Paradis, 2018; Woolley, Church, 2005; Xu et al., 2015), are generally competent rock masses with rock mass rating class II rating 60-74 (Moses et al., 2020). However, carbonatite complexes are highly affected by the later stage hydrothermal and carbo-hydrothermal phases where expelled fluids in fissures lead to the formation of new weak features like manganese-iron (Mn-Fe) veins and/or damage of the rock. Thus, rock slope failure in these hard rocks is complex since structures within the rock mass form weak links that could potentially control slope instability. Stead and Wolter (2015) highlighted instances of the significant impacts of sheeting, exfoliation, and joints on slope stability. Generally, when considering structurally controlled stability in hard rocks, emphasis is given to the role of discontinuity persistence, orientation, and intensity. But the complexity of failure mechanisms in rock slopes is when a combination of pre-existing geological weak planes and failure of intact rock induce instability. Intact rock can be subjected to physical damage of different forms as discussed by Brideau et al. (2009) presented in a summarised form in Table 1.

The concept of damage of intact rock and rock mass relates to the degradation of their strength properties. The physical damage usually takes place in planes of weakness ranging in scale from microcracks to faults. Atkinson (1987) articulates that the formation of planes of weaknesses occurs through three basic modes of fracture: opening, sliding, and tearing.The ultimate effect of the damage processes is the degradation of the intact rock properties towards damaged rock mass and the rupture in intact rock is regarded as the accumulation of the damage (Brideau et al., 2009).

The determination of the rock damage condition has mostly been made possible through rock mass classification systems. Among sundry classification schemes, Geological Strength Index (GSI) has proven to be pivotal in the rock damage characterisation process with respect to stability analysis. A number of

Table 1

Types of rock slopes damage (Brideau et al., 2009)

Type of damage Process

Brittle Initiation, comminution

Ductile Rigid block overlying soft rocks.

Creep Sub-critical crack growth.

Fatigue Low/high frequency loading/unloading cycles (glaciation, isostasy, pore water pressure fluctuation, freeze–thaw, wet/dry, seismicity).

Thermal Heating and cooling cycles.

Tectonic Preconditioned damage due to faults, folds and in situ stress.

Anthropogenic Excavation, blasting.

Physio-chemical Hydrothermal alteration, weathering, corrosion.

Geomorphic Stress induced damage associated with valley formation, cambering, erosion, thermal cycling.

studies have investigated the control of folds and faults, shearing, and clay-infill of joints on the stability of rock slopes. A study by Bye and Bell (2001) revealed that steep dipping and persistency of the joints at Sandsloot open pit in South Africa were principal causes of the slope instability at the mine, triggering failure.

Faults and fault damage have also been recognised to compromise the performance of the slopes by affecting the regional geology, rock mass, and stress conditions in large open pits. The impact of fault characteristics are directly linked to stress heterogeneities created by the interaction between the faults and the mining induced stresses generated during excavation, leading to localised high plastic shear strain and high extensional strain around the fault (Severin, 2017; Stead, Wolter, 2015). Additionally, Stead and Wolter (2015) demonstrated that structural features, such as folds, bedding planes, faults, and discontinuities commonly affect hydrogeological conditions, a crucial factor in slope stability, acting as either water conduits or aquitards. Simulated models that incorporated groundwater showed a tremendous slope instability due to groundwater pressures.

Bachmann et al. (2004) also examined the influence on slope stability of both damage due to weathering and the presence of large-scale fractures using three-dimensional scaled analogue physical models. The experimental results demonstrated that the introduction of a weathered material on the surface of the rock mass controlled the ease, depth, and extent of the slope failure. However, the presence of large scale fractures had little effect on slope stability. Based on the findings by Bachmann et al. (2004), the fractures controlled the lateral extent of the slope failures. Recently, Qian et al. (2017) investigated the influence of rock mass disturbance caused by blasting on rock slope stabilty and found that the thickness of blasting damage zone substantially lowers the rock slope stability. A similar study was conducted by Zheng, et al. (2018) but the focus was on comparing limit equilibrium (LE) approach against numerical approach. Further from confirming findings by Qian et al. (2017), the results revealed only 5.6% discrepancy between the LE and numerical analyses results. In this contribution,

a consideration is given to in situ rock damage in a brittle form as a result of a unique phenomenon of brecciation associated with carbonatite complexes and its role in preconditioning instability on mine pit walls.

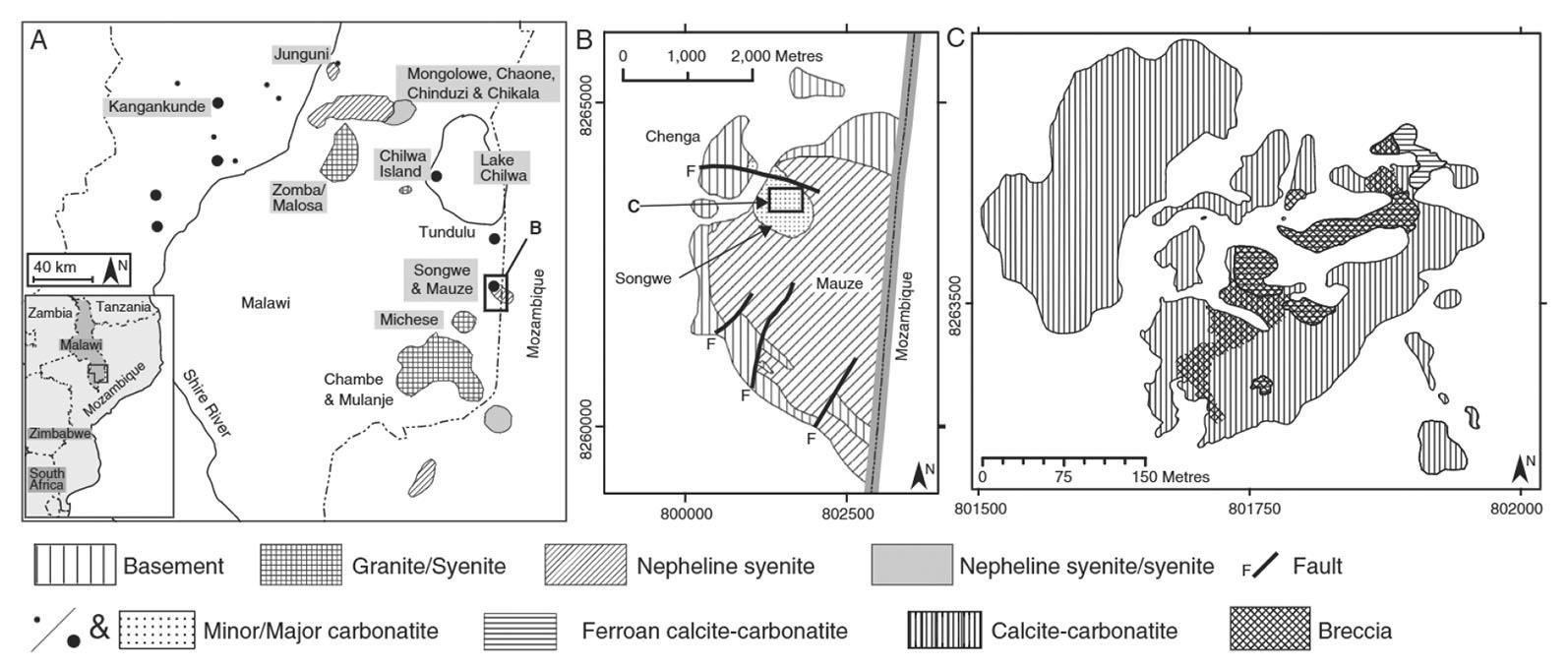

Location and geology of the study area

Songwe Hill is situated in Phalombe district in the South-eastern region of Malawi. On international borders, Malawi shares boundaries with Tanzania to the north, Zambia to the west and Mozambique surrounds the country from east to west. The study area of Songwe Hill is adjacent to Mozambique separated by the syenitic intrusion of Mauze Mountain (Figure 1a). In terms of regional geology, the area is underlain by crystalline rocks of Precambrian to lower Palaeozoic age referred to as the Malawi Basement Complex, which is intruded by alkaline intrusive bodies (Garson, Smith, 1965; British Geological Survey, 2009). The emplacement of these alkaline intrusions occurred during the Late Jurassic – Early Cretaceous Period, which affected an area approximately 300-400 km in diameter in the south of Malawi and in Mozambique. At various localities, the basement complex is overlain by a sequence of Permo-Carboniferous to lower Jurassic sedimentary rocks of the Karoo super-group and superficial Tertiary to recent Karoo sediments. The local geology of the study area is principally composed of carbonatite and fenite surrounded by a massive intrusion of syenite.

Carbonatite, which is the ore hosting rock, occurs in three categories namely: coarse-grained calcite carbonatite (sovite); fine-grained carbonatite (alvikite); and Fe-rich ferroan calcite carbonatite. Fenites form an aureole around the carbonatite intrusion. It is postulated that the carbonatite intrusion never reached the surface since the fenite is continuous with only rare carbonatite veinlets (Broom-Fendley, et al., 2017). In terms of the texture, the fenites are of a coarse-grained equigranular igneous texture, strongly suggesting an igneous protolith. Structurally, Songwe Hill lies within the active tectonic environment of the Malawi Rift System (MRS), which is part of the main East African Rift System (EARS). Thus, faulting and development of joints may not be an uncommon phenomenon but the structural disruptions at the site are not reflected on a macro scale, except for a mappable fault at the foot of the hill as shown in Figure 1b.

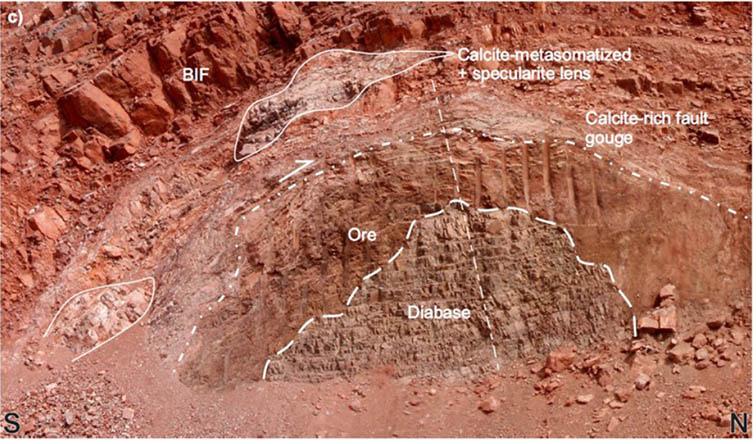

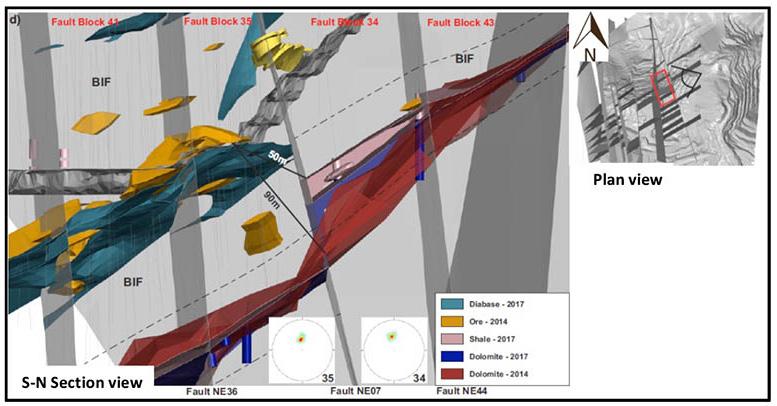

Witley et al.(2019) attempted to present subtle evidence of structural deformation, which they argued to be reflected in sharp lithological breaks across the area. They concluded that the lithological breaks that corresponded to the faults were interpreted from the ground magnetic fields. However, it must be admitted that the fault traces were considered as an approximation, given that the resolution of the magnetic image was low at the scale of the geological map. One exceptional phenomenal feature of interest is the in situ damage of the rock mass due to brecciation (Figure 1c) revealed from the geological and geotechnical logging of the diamond drill core.

Brecciation mechanism

Breccia (Bx) is a term commonly used for an enigmatic rock group that comprises a variety of discrete broken fragments of rocks, every so often angular and bound together by a fine grained matrix and occasionally vitreous matrix, which may or may not resemble the composition of rock fragments (Shukla, Sharma, 2018). Woodcock and Mort (2008) made an effort to classify breccias using a criterion that can easily be applied in the field. These rock masses can be identified in different geological settings mostly associated with

various ore types. In carbonatite complexes, breccia is a common structural feature. Shukla and Sharma (2018), Sibson (1986), and many other authors have discussed mechanisms of brecciation in different geological environments, including the volcanic setting. Among many mechanisms of brecciation, this study reveals two phenomena that can be attributed to be the occurrence of the breccia at the study site of Songwe Hill, namely: hydro-fracturing and tectonic forces along a pre-existing plane of weakness. The hydro-fracturing process for brecciation involves highpressure fluids. This hydrothermal process readily affects carbonaterich rocks. In this process, the pre-existing rock interacts with water-rich hydrothermal solutions that increase the fluid pressure within a fissure, and the effective pressure decreases leading to fracture propagation (see Figure 2a). Elliott et al. (2018) explain that the occurrence of breccias at several carbonatite complexes corroborates the explosive release of fluids and volatiles from an evolving magma underneath. For Songwe carbonatite, BroomFendley, et al. (2021) stress that based on the angular nature of the clasts and the comminuted groundmass, the breccia formed by in situ rapid volume expansion, most likely as a result of subsurface explosive release of volatiles from the proposed underlying carbonatite bodies. Thus, the explosive hydrothermal brecciation and the metasomatic action of hydrothermal fluids can indeed be considered to be responsible for the generation of the breccia. On the other hand, tectonic disturbances resulting from fault movements can also account for the brecciation as the area is located in a rifting setting with potentially high stresses acting along the weak plane causing rock comminution but the certainty of it is not fully verified at the study site. Accordingly, the brecciation associated with the fault system forms due to the grinding action of rock blocks along a plane of weakness.

Methods and model construction

For decades, most slope stability analyses have been performed using limit equilibrium methods (LEM). The underlying concept of the LEM is that the rock mass behaves as a rigid material and that the shear strength is mobilised at the same time along the entire failure surface (Brideau et al., 2009). Based on this assumption, LEM can only be adequate for analysing simple failure modes and small-scale analyses. However, demand for mineral resources has seen surface mining operations expanding to greater depths in order to meet the needs of growing industries. This trend requires modelling that covers complex conditions found in rock masses

like nonlinear stress-strain behaviour, anisotropy, and changes in geometry. Thus, the development of numerical codes over the last decades has revolutionised rock mass modelling, thereby superseding the traditional methods. Numerical modelling has now been described as a valuable tool to enhance the understanding of the response of rock masses to excavation (Hart, 2003). Currently, there are numerous methods; continuum, discontinuum, and hybrid continuum/discrete methods that have been developed in an effort to represent the characteristics and behaviour of rock masses. Regardless of the method selected based on the nature of the problem to be addressed, parameters like material properties, intact rock discontinuities, boundary conditions, hydrogeological regime, and permeability are considered in evaluating the stability of the excavations. In this study numerical method of continuum is applied in simulating the rock slope stability using finite element method (FEM) codes.

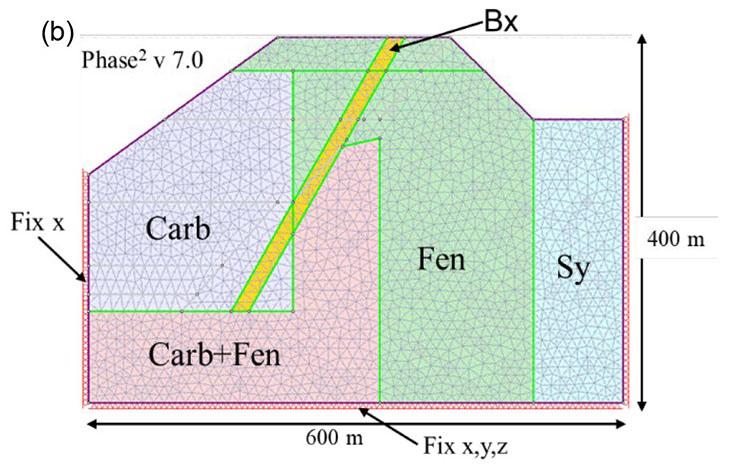

To carry out the analysis, conceptual models were built in Phase2 v 7.0. The dimensions of the model measured 600 m in length and 400 m vertical extent from the highest reduced level (RL) mimicking the hill. Two main conceptual cases were generated with respect to pit height. In the first scenario, shear strain behaviour on the pit-slope was investigated at the current planned depth of 250 m, which is the depth within the bounds of the proven ore reserve, hence the geological confidence is high. The second scenario is for the global slope height (GSH) of 300 m. At this depth, the geological confidence is relatively low since less than 10% of the drilled holes reached 300 m. In both cases, the analysis was conducted at different pilot overall slope angles (OSA) that could be practical in the design. Thus, OSA was varied from 45° to 40°. The excavation of the stack benches (dimension 15 m height and 7.5 m width) was carried out in three sequential stages as depicted in Figure 3.

Three cases were generated with respect to the conceptual extent of the brecciated rock section. In the first case, shear strain behaviour on the pit slope was investigated without including the brecciated section. The second scenario incorporates the 10 m brecciated rock section and the last case having a 20 m thickness of brecciation (Figure 4). According to the field survey, the 10 m brecciation thickness is considered the closer representation of the brecciated zone for the study site. The emplacement of the breccia is estimated to be dipping at ≥ 50° and as Broom-Fendley, et al. (2021) established, the breccia grades down into an underlying carbonatite body at great depth. To cater for uncertainties, the emplacement angle was varied for parametric analysis from 30° to 70° at an equal interval of 10°.

In carrying out the study, the material properties were obtained from uniaxial compressive strength (UCS) tests, triaxial compressive strength tests (TCS), and literature.

Mechanical properties of the rock units

*Based on empirical values (Katz et al., 2000; Croll, et al., 2014)

The material properties used in this simulation are given in Table 2

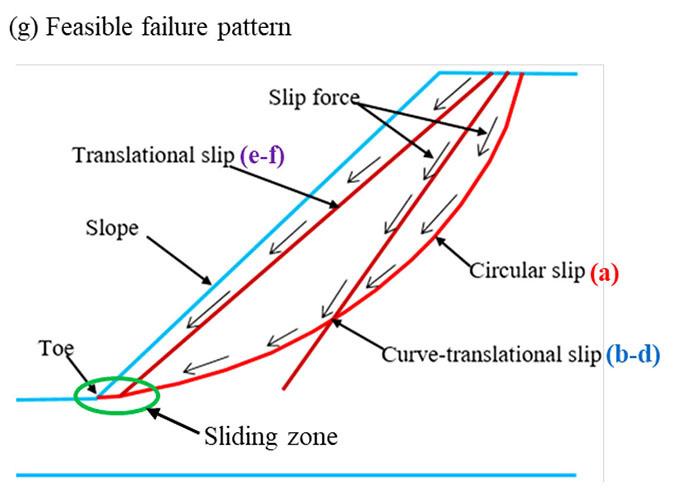

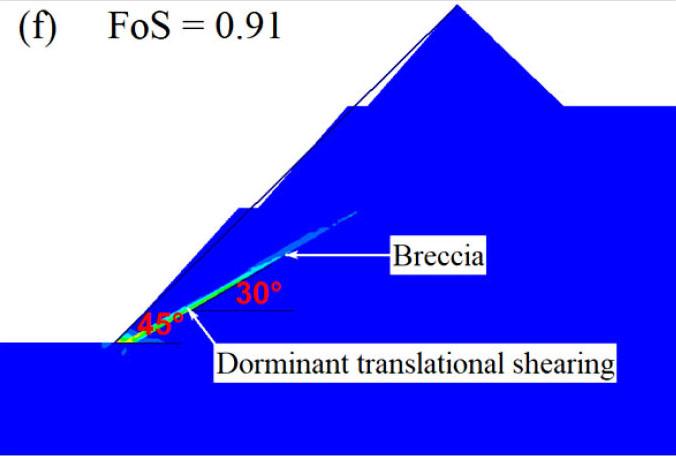

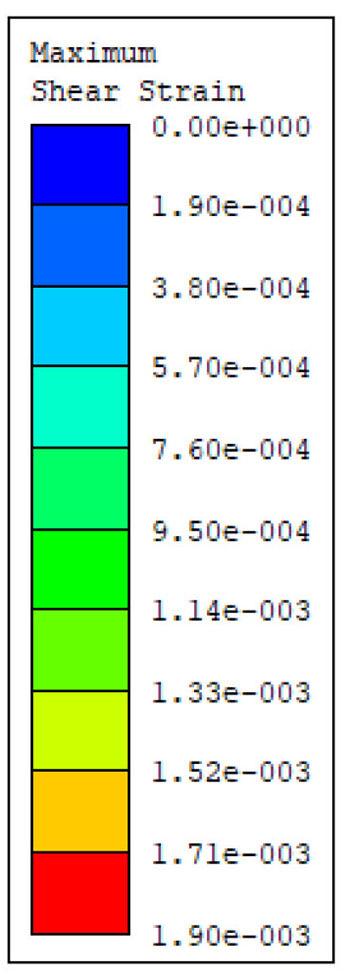

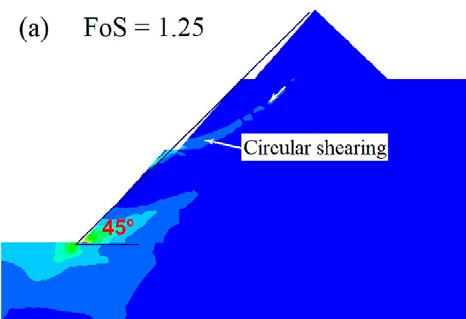

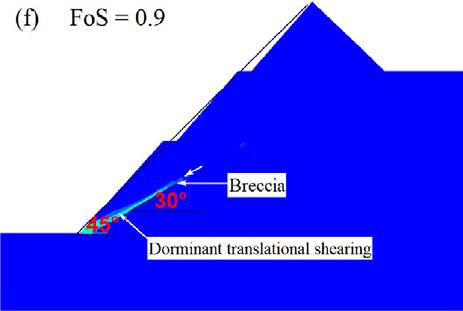

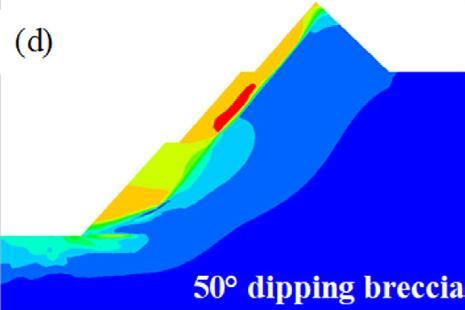

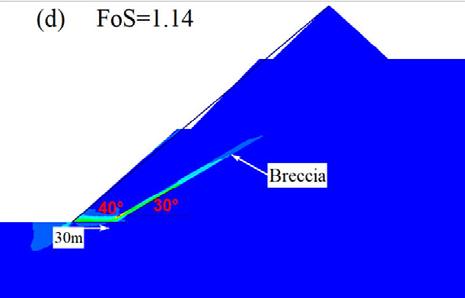

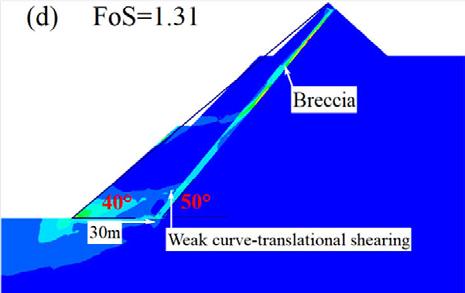

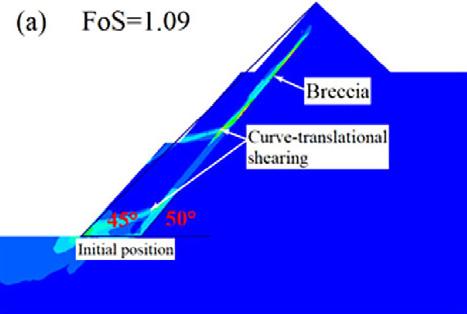

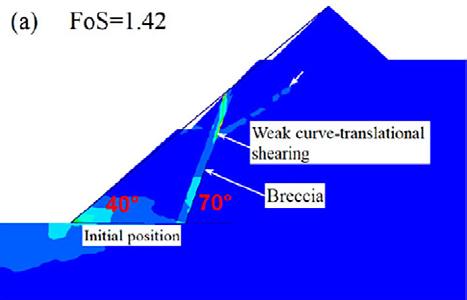

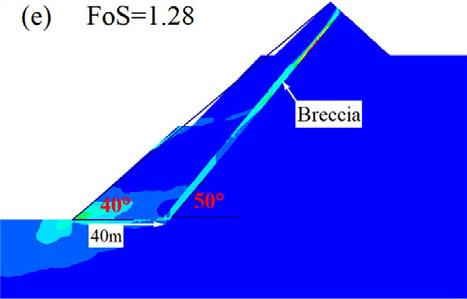

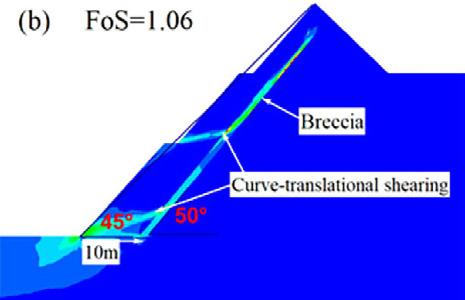

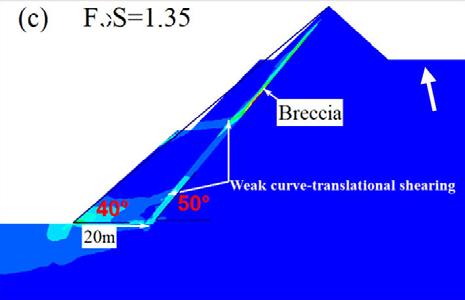

The principal objectives of the open pit slope stability analyses are: to investigate the pit slope stability conditions, probable failure mechanism, slope sensitivity or vulnerability, and to design optimum pit slope angles in terms of safety, reliability, and economic lucrativeness. Generally, stability of open pit slopes depends on geometry of slope, rock mass characteristics, and shear strength behaviour of the joints (Soren et al., 2014). In slope stability analysis, factor of safety (FoS) is used as an index to determine the stability conditions. The factor of safety is a ratio between shear strength and shear stress to determine the stability of excavated sections. The basic minimum requirement for stability assurance when assessing the performance of excavated sections is that FoS should be equal to 1, which is a state of plastic equilibrium. However, in mines, the minimum requirement is > 1. Generally, the benchmark value varies by region and mining guidelines enforced by different countries. After a compilation of data from numerous open pit mines (OPM), Adams (2015), Read and Stacey (2009) and Sullivan (2013) established that the minimum criterion for safety assurance in OPM is for FoS to be ≥ 1.2. In this work, since the results are based on a 2-D numerical modelling in an out of the plane mode, the benchmark FoS tolerable has been pegged at 1.3. To vividly comprehend the influence of brecciation, the research object of the qualitative analysis presented only covers the GSH of 300 m at a slope angle of 45°. On the other hand, the quantitative analysis caters for all the pit heights and slope angles. From Figure 5, one notices a significant change in the shear failure path prior to and after the inclusion of breccia, in which case there is a rotational/ circular and translational potential failure respectively. The circular

failure path prior to the inclusion of brecciated rock develops at inter-ramp level in the second excavation, and then the shearing strain concentrates at the slope toe.

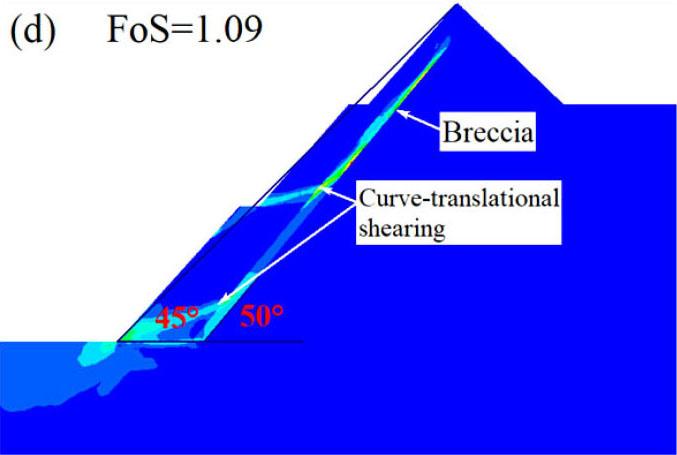

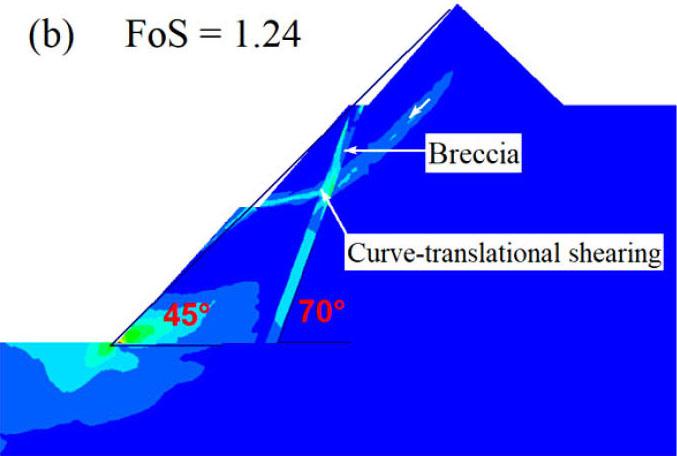

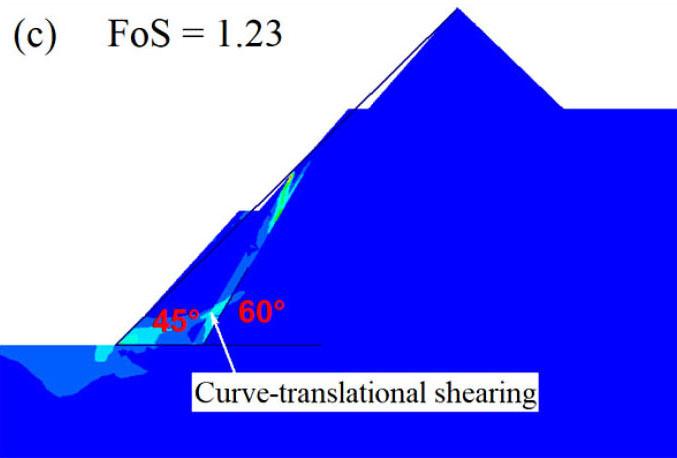

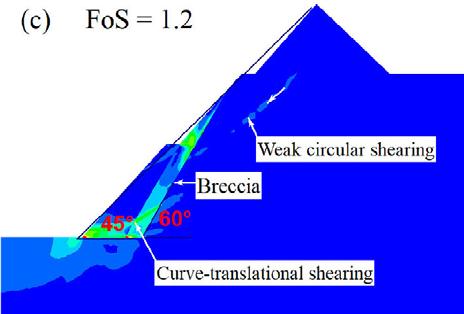

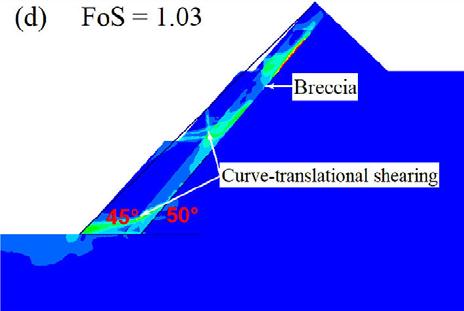

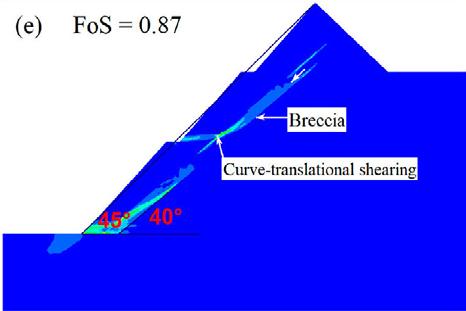

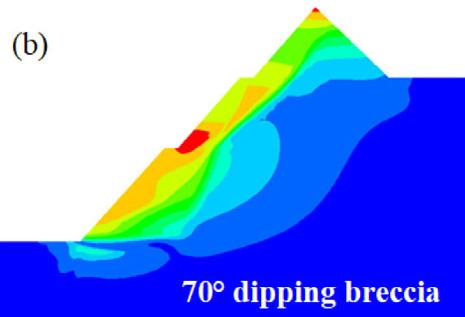

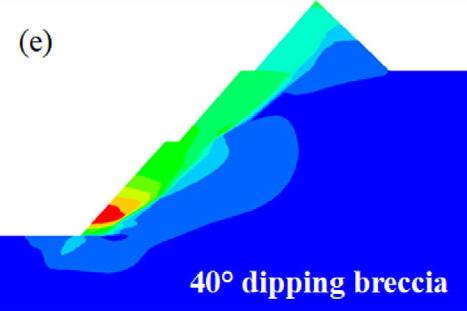

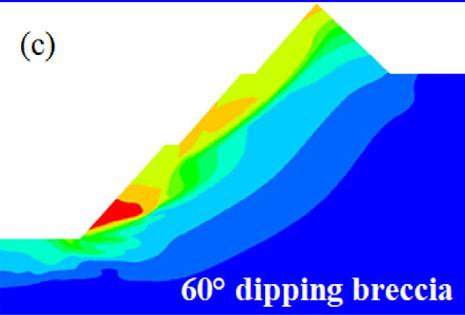

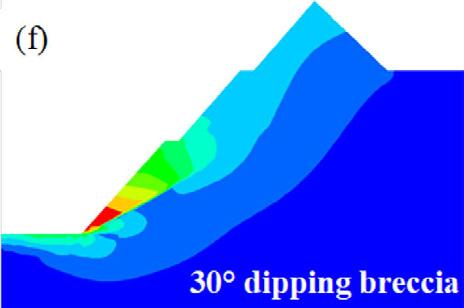

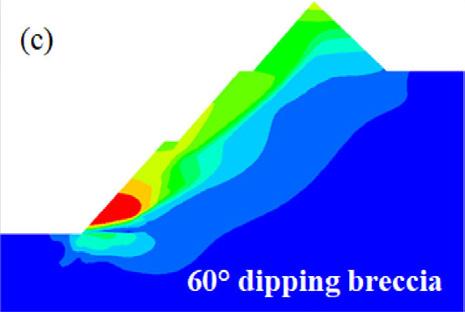

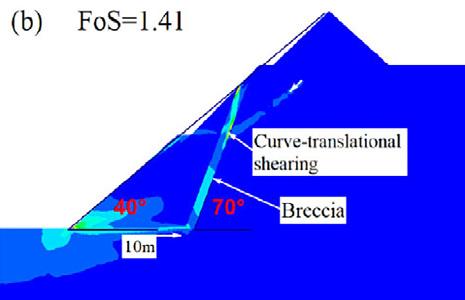

On the other hand, the translational failure path is well developed at gentle angles of emplacement of the breccia, especially at 40° and 30°. The performance of the slope at these angles is critically low since the overlying block is supplied with a failure plane characterised by low cohesion and friction resistance along the in situ damage section. At a relatively steep emplacement angle of the brecciated rock, that is, 50° and 60°, the failure plane is characterised by a combination of circular and translational shearing. That is, the circular shearing failure plane joins the translational shearing failure plane induced in the breccia. At a much steeper angle of say 70°, the failure path is almost identical to the condition prior to inclusion of brecciated rock, implying a negligible influence, which is reflected in the FoS being almost equal.

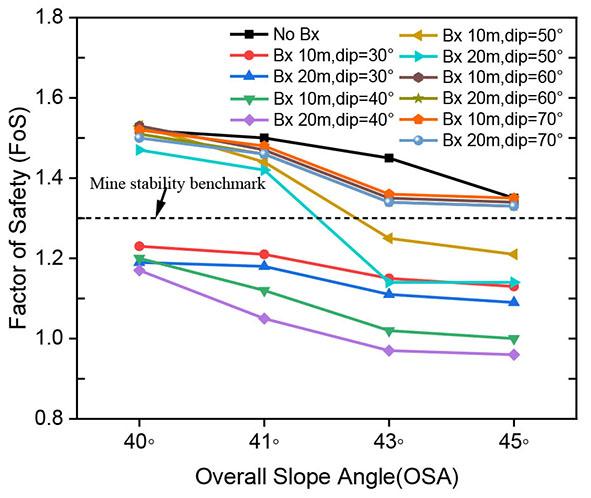

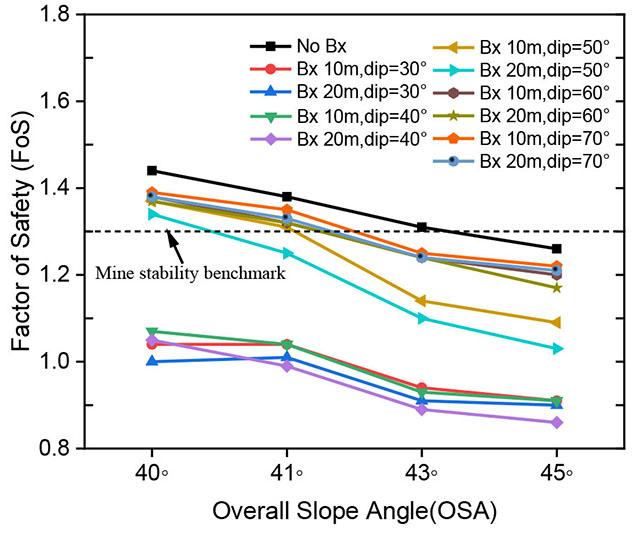

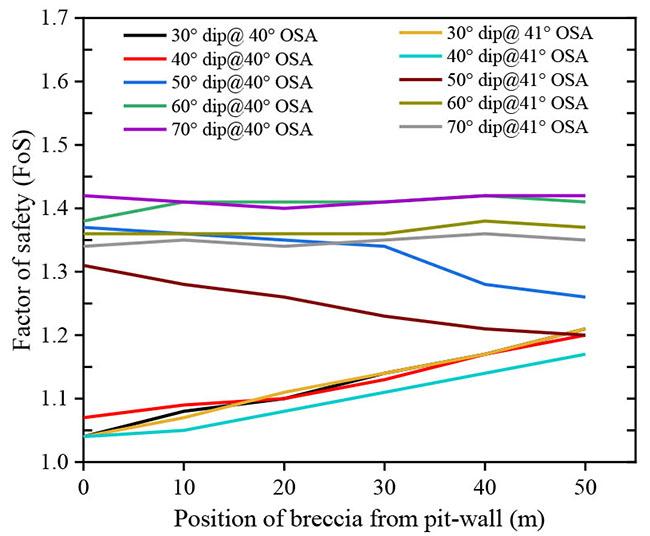

The emplacement of the breccia into the carbonatite complexes is of interest to understand how it would have a bearing on the stability of the pit wall. From the quantitative analysis results, regardless of the angle at which the breccia is orientated, its mere existence reduces the stability performance of the pit wall but as the dip angle of the breccia gets gentler, the impact becomes enormous. At the dip angles of 70°, 60° and, 50° the FoS slightly reduces at OSA of 40° and 41° with the 70° orientation having almost the same FoS value as prior to the inclusion of the brecciated rock section (see Figure 6). However, at steep slope angles, that is to say 43° and 45°, the stability performance of the pit-wall significantly reduces with the 50° orientation registering a sharper drop, and the FoS values fall

further below the threshold at all simulated pit heights. When the breccia is emplaced at gentler angles, i.e., 30° and 40°, the stability of the pit-wall falls below the benchmark value of mine stability at all slope angles (40°– 45°). Thus, to attain a good performance of the slope in this condition it would require safeguarding the slope toe against the breccia position by ensuring that there is an optimal buffer zone.

The thickness of the brecciated rock appears to have an equivocal influence. On a steep slope angle (45°), at breccia dipping angles of 60°, 70° and 30°, the thickness has a fair influence because the slope stability value reduces, though not quite prominent. However, at dip angles between 50° - 40°, the impact on the pit slope performance becomes significant (see Figure 7). This can be ascribed to the increased weak surface area within the translational failure plane trajectory, which adjoins the nascent circular shearing trajectory. However, on gentle slope angles, that is to say 40° and 41°, the impact of breccia is negligible at all dipping angles of the breccia as shown in Figure 7. We can thus deduce that thickness of the brecciated rock has a considerable impact at moderately gentle angles of the emplaced breccia with steep angles, in this case study at 43° and 45°, otherwise it would not have a significant influence on the stability performance of the appropriately optimised gentle slopes, that is, 41° for this study case.

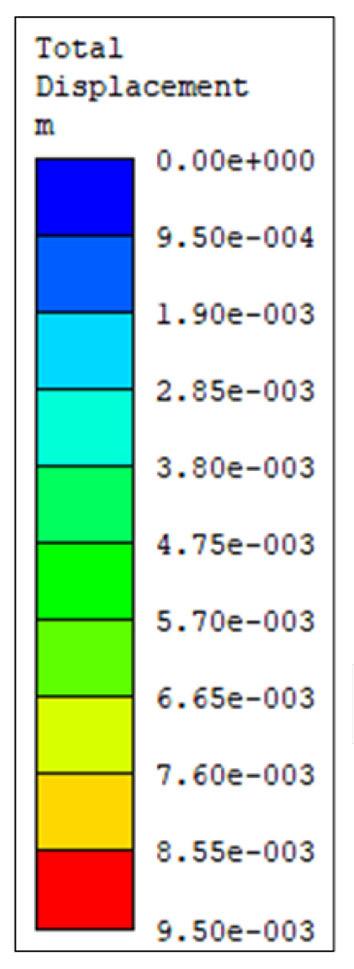

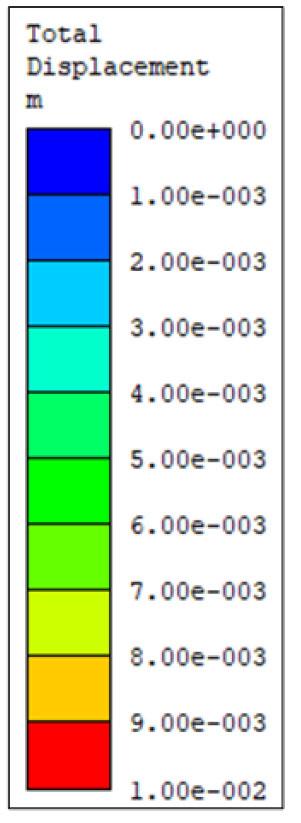

Displacement pattern

The study also assessed the influence of brecciation on pit wall displacement. In this case, the 45° OSA at 300 m was used as a research case study. The trend of total displacement is presented in Figure 8 and Figure 9.

It can be seen from the Figures 8 and 9 that the orientation of the breccia has an apparent control on the movement of the geological materials on the slopes. Prior to the introduction of the breccia, the peak displacement is in the last excavation phase close to the toe of the slope where the shearing stress and strain is concentrated. When the breccia is introduced, the peak displacement at steep dipping angle of breccia locates in the upper section of the slope where the brecciated section is emplaced. This phenomenon can be identified at 50°, and 70° but in the case of 60° the peak displacement is down to the slope toe due to minimal impact of the breccia at an intersection with the slope face. At gentle dip angles of the breccia where translational shearing strain is predominant, the peak displacement is at the slope toe with an evident trajectory provided by the brecciated zone. With respect to brecciation extent, the change in the thickness of the breccia to 20 m (Figure 9) slightly changes the impact area but the section of the peak displacement remains the same with 10 m breccia thickness (Figure 8). From the analysis, it can be deduced that the displacement trajectory of materials on the pit walls is controlled by the orientation of the brecciated section in the rock mass rather than the thickness.

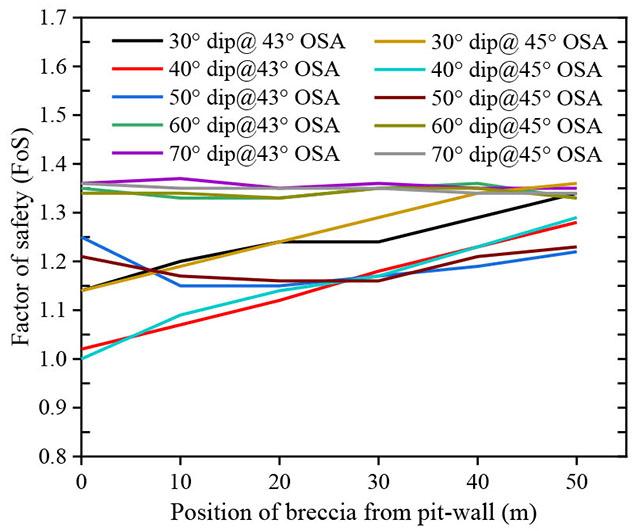

As a parametric analysis, the study evaluated the impact of the position of the breccia and the pit wall with reference to the slope toe. In this regard, the position of the breccia was changed from the initial position by a factor of 10 from 10 m to 50 m. The initial positions of the breccia with respect to the angle of orientation were 10 m at the most gentle dip angle and 90 m at steeper dip angles, respectively.

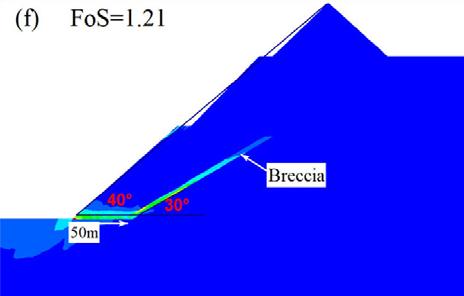

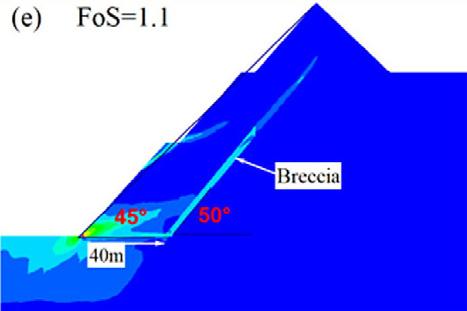

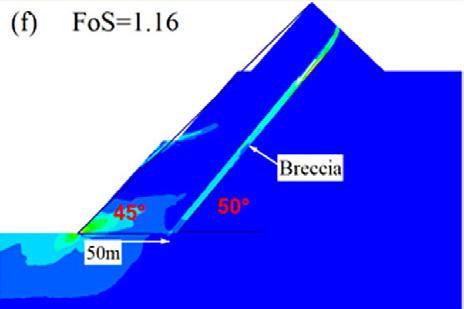

For qualitative analysis, four scenarios were identified when the position of the breccia was changed. The first scenario is when the dip of the breccia is at an angle of 30° as presented in Figure 10. As would be anticipated, as the emplacement position of breccia is increased away from the pit wall, the stability performance of the slope increases. At an increase of 10 m, the FoS was observed to be 1.08 and at 50 m increase the FoS improved to 1.21 representing a 12% change in FoS. Basically, moving the dipping brecciated section minimises the effect of translational shearing strain within the breccia because the buffer zone between slope toe and breccia increases. This trend was similar to the 40° dip angle of the breccia. On the contrary, in the second case where the dip angle of breccia is 50°, the stability trend is dissimilar.

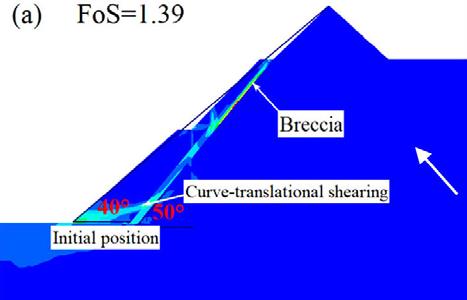

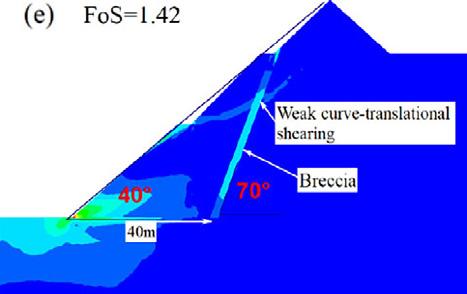

As shown in Figure 11, when the position of the breccia is moved 10 m away from the slope, the performance of the slope begins to decline and at 50 m increase, the stability further declines. The FoS after a 10 m increase is 1.36 from the initial 1.39, and at 50 m the FoS reduced to 1.26. The reason for this trend is that the breccia wholly locates immediately behind the pit wall, thereby creating an extended plane of translational shear failure plane, which weakly joins up with the circular shear failure plane. This was observed only for gentle slope angles of 40° and 41°. However, at relatively steep slope angles, i.e., 43° and 45°, the pit wall stability performance improved as the position of breccia increases away from the pit wall.

In this third scenario, it can be observed that when the slope angle is steepened, the breccia locates closer to the pit wall. This provides the conditions for the curve-translational potential slip as the circular shearing failure path combines with the translational shearing failure path. When the breccia is moved further away from

the initial position, especially at ≥ 30 m, the circular shearing failure path and the translational shearing failure path become disjointed, as shown in Figure 12.

This phenomenon reduces the combined circular and translational shearing impact in the pit wall, which implies a discrete influence of the shear paths and the stability performance of the slope is enhanced.

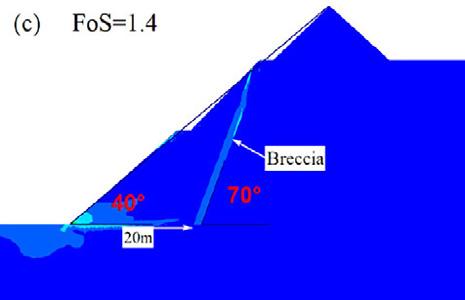

In the fourth scenario, which is shown in Figure 13, it can be noted that a steep dip angle of the breccia at 70° barely has an effect on the stability of the pit wall when the position of the breccia is

changed. Quantitative results presented as a summary in Figure 14 show a similar pattern at 60° dip angle of the breccia. In both cases, the safety factor remained almost the same. Thus, it can be deduced that in steeply dipping breccia, the translational shear impact within the damaged rock section is minimal and also at the designed slope angle part of the breccia is truncated.

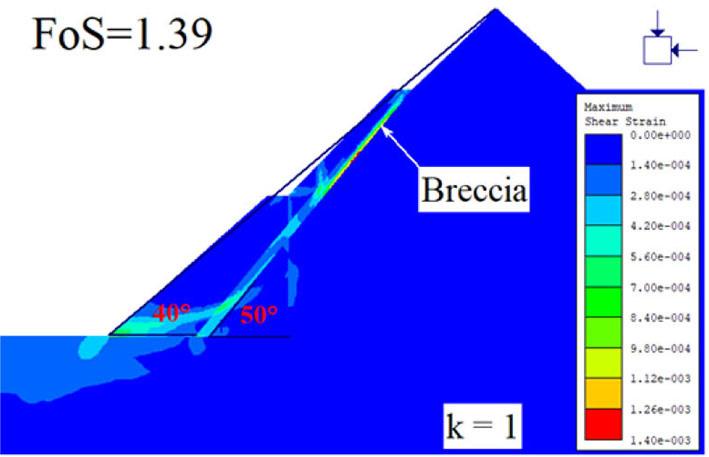

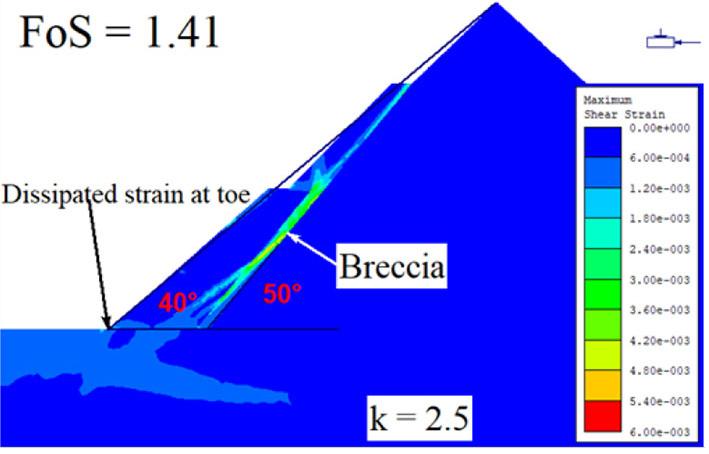

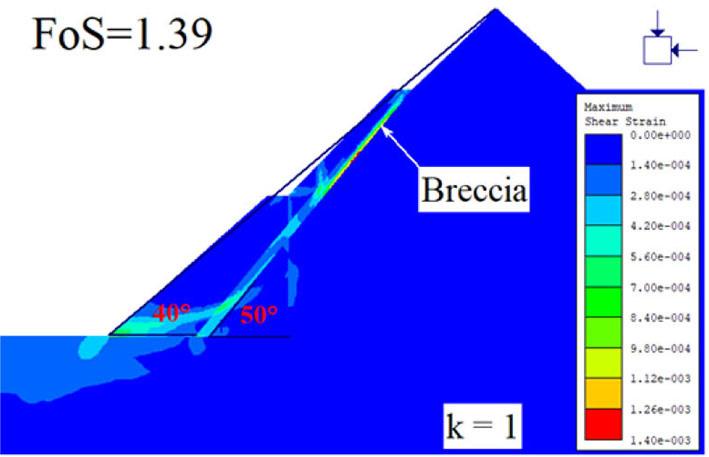

In situ stress regimes and brecciation Rock masses are inherently inhomogeneous and geological features such as breccias can greatly change the stress field, which can have

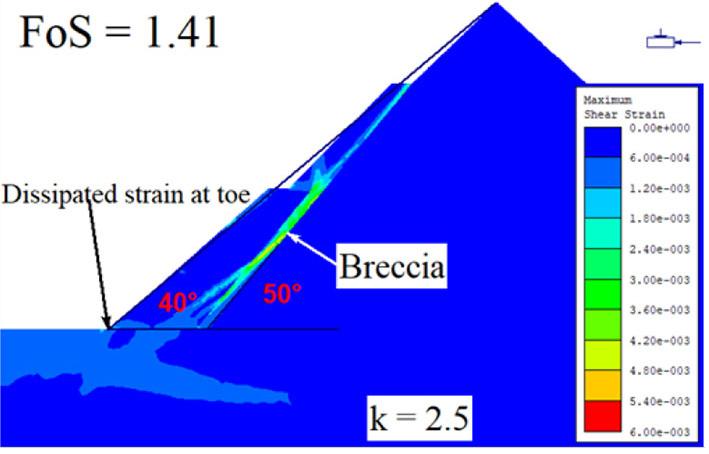

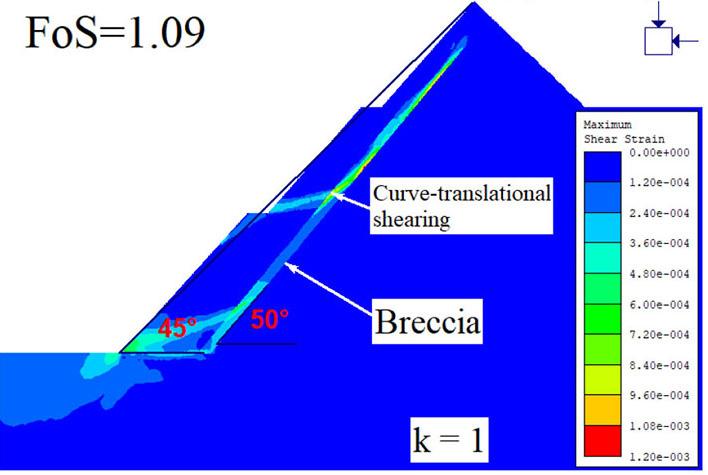

a bearing on the stability of the excavation. To comprehend the impact of the interactions between the stress regimes and breccia, simulations were undertaken at different stress ratios. The analyses involved scenarios of high horizontal and vertical stress regimes. The research case studies for analyses were selected at slope angles of 40° and 45° with the dip of the breccia at 50° at a GSH of 300 m. The results of high horizontal stress ratio are presented in Figure 15 and Figure 16. It would be anticipated that high horizontal stress could lower the performance of the pit wall as the induced stress gets redistributed to the excavated section. However, the existence of the breccia close to the slope appears to increase the performance of the slope. As shown in Figure 15 and Figure 16, stress magnitudes

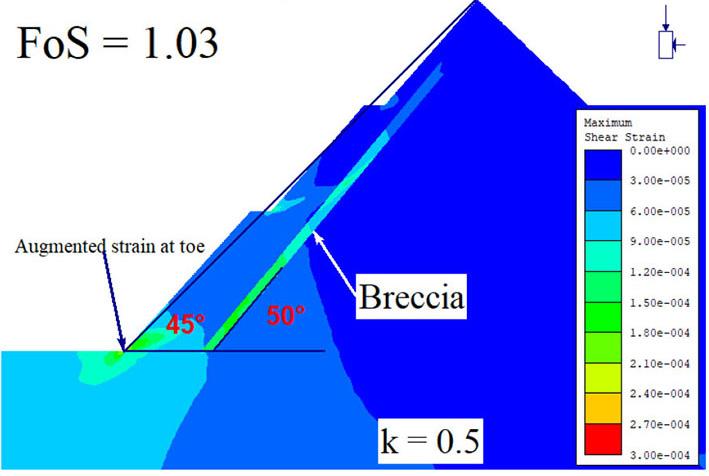

tend to be greatly dissipated, and stress orientations rotate as much as the dip angle of the breccia on crossing it. The changing of the direction of stress is manifested in the shear strain failure path along the breccia. At a stress ratio of k=1, the shear strain is concentrated at the toe of the slope and there is a weak adjoining of circular and transformational shear path. This combination evidently lowers the stability performance of the pit slope. However, when the vertical stress is reduced as horizontal stress increases, the horizontal stress gets redistributed and changes its orientation and aligns with the breccia dip. Thus, the breccia acts as a buffer to the slope and the shear strain at the slope toe is dissipated rendering the slope performance enhanced.

14—Summary of stability conditions of the pit wall with respect to the position of the breccia

On the contrary, a high vertical stress regime slightly reduces the slope stability performance as shown in Figure 16. The FoS at a gentle slope angle of 40° reduced from 1.39 to 1.38 and at a steep angle of 45° the FoS decreased from 1.09 to 1.03. However, it must be noted that the mechanisms leading to low stability performance of the pit slopes is different at gentle and steep angles. On gentle slopes, it can be observed that the mechanism involves adjoining of the circular and translational shear failure paths, which causes potential curve-translational failure. On the other hand, at steep slope angles, the mechanism does not involve adjoining of circular and translational shearing failure path but rather distinct translational failure path and the intensification of shear strain at the toe of the pit slope. The concentration of the strain at the toe basically minimises the bearing capacity of the toe to the overlying burden, hence reduced stability performance. Although, the African average regional stress is determined to be at k = 1.5 as presented in the work of (Stacey, Wesseloo, 1998), the regional tectonic stresses may vary from one area to another depending on structural setting. Thus, the results of k = 0.5 are significant to anticipate this phenomenon in normal faulting predominated areas.

Countermeasures

In general, it is noted that the existence of the breccia poses a threat to the stability of the pit slope and an intervention is necessary to counter its impact. A range of innovative and effective methods of rock reinforcement and artificial support have been widely used in civil engineering and underground mining applications but hardly in open pit mines (Martin, 1987). The stabilisation of slopes in mining presents a distinct range of issues and challenges from those in civil engineering. Read and Stacey (2009) articulate that in mining, the economics and practicality of artificial support are affected by the larger volumes of rock to be supported. Generally, the length and height of slopes in mining are often much greater, and the service life of artificial support is often short, especially where a number of different cutbacks are to be undertaken. Experience from different projects (Martin, 1987) has demonstrated that slopes approximately 100 m high were the maximum that could be artificially supported with 30 m long cable bolts but reported subsequent failure of a large number of anchors due to tension. Beyond the 100 m height, failure occurs behind the supported volume, creating larger, deeper seated masses, which are more difficult to control (Read, Stacey, 2009). From this background,

in large open pits, for global wall reinforcement to attain stable slopes with aggressive wall angles could be challenging, if not unachievable.

Thus, from a series of analyses executed and presented in a summarised graph in Figure 14, a pattern of failure with respect to the slope toe was observed and an approach is suggested to deal with the breccia in slope design. The proposal is based on the relationship of FoS, excavation depth, and the position of the in situ damaged rock. In this proposition, it is recommended that for OPM design in brecciated rock masses, the ratio of at least 1:5 between the breccia distance from slope toe of the pit limit and pit depth should be adopted to counter the impact of the breccia. For instance, at the pit depth of 100 m, a distance of 20 m between the slope toe and breccia should be left as a buffer, while at 250 m, the pit limit should be designed such that the slope toe is 50 m from the breccia and at 300 m pit depth the slope toe should be at 60 m.

If the brecciated unit is within or close to the pit limit, a deliberate effort must be made to mine out or truncate the breccia because it has the capability to cause instability when there is a load above it. The ultimate intention is to increase the resisting forces along the translational shear plane generated within the damaged rock section. Furthermore, the traditional approach of making the slope gentle could be a more pragmatic remediation that could be applied in the event of the shallow angle emplaced breccia in the rock mass. Based on this case study, the stable performance of the pit slopes at the GSH of 300 m would be assured at 38° and 36° OSA for a breccia emplaced in the pit wall at 40° and 30°, respectively. The intervention obviously implies an increase in the stripping ratio for the mine, but it can prove a necessary step if undesirable risks, which could render operations utterly uneconomical, were to be sidestepped.

Conclusion

In this study, the stability conditions and deformation behaviour of the geological units on the pit slopes were evaluated by considering the existence of breccia. This was achieved by numerical methods carried out with a finite element code using Phase2 v 7.0 software. The analyses were performed in elasto-plastic state with a MohrCoulomb constitutive model and failure criterion. The analysis shows that the competency of the carbonatites can permit the overall slope designs to be developed at steep angles, 45º - 50° at shallow depth ≤ 250 m, but caution has to be taken at greater depth

and when weak rock sections due to brecciation are considered. Basically, as observed, the existence of breccia in carbonatite complexes has the capability to reduce the stability performance of the excavated pit wall and the enormity of the impact increases at the gentle dip emplacement angle in close proximity to the slope toe, hence, slope angle optimisation could aid in finding a poise between safety and mining economic benefits. In the case of the study area, the OSA of 41° is recommended as an optimal design at a GSH of 300 m. Regarding the breccia, the ratio of 1:5 between the breccia distance from slope toe of the pit limit and pit depth is advocated to counter the impact of breccia and if breccia is within or close to the pit limit, a deliberate effort must be made to mine out or truncate it. However, this conservative design could be adjusted to a flexible design in the course of operations as more geotechnical and geological data regarding the breccia is collected. Furthermore, the traditional approach of making the slope gentler could be a more pragmatic remediation that could be applied in the event of the gentle dip angle of emplaced breccia in the rock mass.

Conflict of interest

The authors declare no conflict of interest regarding the publication of this paper.

Acknowledgement

The authors express their sincere gratitude to Mkango Resources Company for providing the data for the study to materialise.

References

Adams, B.M. 2015. Slope Stability Acceptance Criteria for Opencast Mine Design. New Zealand: Golder Associates (NZ) Limited. Atkinson, B.K. 1987. Fracture mechanics of rock. London: Academic Press.

Bachmann, D., Bouissou, S., Chemenda, A. 2004. Influence of weathering and pre-existing large scale fractures on gravitational slope failure: insights from 3-D physical modelling. Natural Hazards and Earth System Sciences, vol. 4, pp. 711–717.

Brideau, M.-A., Yan, M., Stead, D. 2009. The role of tectonic damage and brittle rock fracture in the development of large rock slope failures. Geomorphology, vol. 103, pp. 30–49. doi:10.1016/j.geomorph.2008.04.010

British Geological Survey. 2009. Malawi Potential of Malawi Zomba: Malawi Government.

Broom-Fendley, S., Brady, A.E., Horstwood, M.S., Woolley, A.R., Mtegha, J., Wall, F., Gunn, G. 2017. Geology, geoche mistry and geoch ronology of the Songwe Hill carbonatite, Malawi. Journal of African Earth Sciences, pp. 11–23.

Broom-Fendley, S., Elliott, H.A., Beard, C.D., Wall, F., Armitage, P.E., Brady, A.E., Dawes, W. 2021. Enrichment of heavy REE and Th in carbonatite-derived fenite breccia. Geological Magazine, pp. 2025–2041. doi:https://doi.org/10.1017/S0016756821000601

Bye, A.R., Bell, F.G. 2001. Stability assessment and slope design at Sandsloot open pit, South Africa. International Journal of Rock Mechanics & Mining Sciences, vol. 38, pp. 449–466. doi:10.1016/S1365-1609(01)00014-4

Croll, R., Swinden, S., Hall, M., Brown, C., Beer, G., Scheepers, J., Trusler, G.E. 2014. NI 43-101 Pre-feasibility Report. Johannesburg, South Africa: MSA Group (Pty) Ltd.

Elliott, H.A., Wall, F., Chakhmouradian, A.R., Siegfried, P.R., Dahlgren, S., Weatherley, S., Deady, E. 2018. Fenites associated with carbonatite complexes: A review. Ore Geology Reviews, pp. 38–59. doi:https://doi.org/10.1016/j.oregeorev.2017.12.003

Garson, M.S., Smith, C.W. 1965. Carbonatite and Agglomeratic Vents in the Western Shire Valley. Zomba: Geological Survey Department.

Goodenough, K.M., Deady, E.A., Beard, C.D., Broom-Fendley, S., Elliott, H.A., Van den Berg, F., Öztürk, H. 2021. Carbonatites and Alkaline Igneous Rocks in Post-Collisional Settings: Storehouses of Rare Earth Elements. Journal of Earth Science, pp. 1–27. doi:https://doi.org/10.1007/s12583-021-1500-5

Hart, R. 2003. Enhancing rock stress understanding through numerical analysis. International Journal of Rock Mechanics and Mining Sciences, vol. 40, pp. 1089–1097. doi:10.1016/S1365-1609(03)00116-3

Katz, O., Reches, Z., Roegiers, J.C. 2000. Evaluation of mechanical rock properties using a Schmidt Hammer. International Journal of rock Mechanics and Mining sciences, vol. 37, no. 4, pp. 723–728.

Martin, D.C. 1987. Application of Rock Reinforcement and Artificial Support in Surface Mines. 6th ISRM Congress. Montreal, Canada: ISRM.

Moses, D., Shimada, H., Sasaoka, T., Hamanaka, A., Dintwe, T.K., Wahyudi, S. 2020. Rock Slope Stability Analysis by Using Integrated Approach. World Journal of Engineering and Technology, vol. 8, pp. 405–428. doi:https://doi.org/10.4236/ wjet.2020.83031

Qian, Z.G., Li, A.J., Lyamin , A.V., Wang, C.C. 2017. Parametric studies of disturbed rock slope stability based on finite element limit analysis methods. Computers and Geotechnics, vol. 81, pp. 155–166. doi:10.1016/j.compgeo.2016.08.012

Read, J., Stacey, P. 2009. Guidelines for open pit slope design Australia: SCIRO Publishing.

Severin, J.M. 2017. Impact of Faults and Fault Damage in Large Open Pit Slopes. University of British Columbia: Doctor Thesis, 1-168.

Shukla, M.K., Sharma, A. 2018. A brief review on breccia: it's contrasting origin and diagnostic signatures. Solid Earth Sciences, vol. 3, pp. 50–59. doi:10.1016/j.sesci.2018.03.001

Sibson, R.H. 1986. Brecciation processes in fault zones: Inferences from earthquake rupturing. PAGEOPH, vol. 124, pp. 159–175. doi:https://doi.org/10.1007/BF00875724

Simandl, G.J., Paradis, S. 2018. Carbonatites: Related Ore Deposits, Resources, Footprint, and Exploration Methods. Applied Earth Science, vol. 127, no. 4, pp. 123–152. doi:10.1080/25726838.201 8.1516935

Soren, K., Budi, G., \Sen, P. 2014. Stability Analysis of Open Pit Slope by Finite Difference. International Journal of Research in Engineering and Technology, pp. 326–334.

Stacey, T. R., Wesseloo, J. 1998. In situ stresses in mining areas in South Africa. The South African Institute of Mining and Metallurgy, pp. 365–368.

Stead, D., Wolter, A. 2015. A critical review of rock slope failure mechanisms: The importance of structural geology. Journal of Structural Geology, vol. 74, pp. 1-23. doi:10.1016/j.jsg.2015.02.002

Sullivan, T. D. 2013. Pit Slope Design and Risk – A View of the Current State of the Art. The South African Institute of Mining and Metallurgy, pp. 51–80.

Witley, J.C., Swinden, S., Trusler, G., Dempers, N. 2019. Songwe Hill Rare Earth Elements (REE) Project, Phalombe District, Malawi. South Africa: MSA Group.

Woodcock, N.H., Mort, K. 2008. Classification of fault breccias and related fault rocks. Geol. Mag, vol. 145, no. 3, pp. 435–440. doi:10.1017/S0016756808004883

Woolley, A.R., Church, A.A. 2005. Extrusive Carbonatites: A brief review. Lithos, vol. 85, pp. 1–14. doi:10.1016/j.lithos.2005.03.018

Xu, C., Wang, L., Song, W., Wu, M. 2015. Carbonatites in China: A Review for Genesis and Mineralization. Geoscience Frontiers, vol. 1, pp. 105–114. doi:10.1016/j.gsf.2010.09.001

Zheng, H., Li, T., Shen, J., Xu, C., Sun, H., Lu, Q. 2018. The effects of blast damage zone thickness on rock slope stability. Engineering Geology, pp. 1–25. u

13 October 2025 Technical Workshops

14-15 October 2025 Conference

16 October 2025 Technical Visits

Venue: Glenburn Lodge and Spa, Muldersdrift

(1-hour drive from O.R. Tambo International Airport, Johannesburg, South Africa)

ECSA and SACNASP Validated CPD ActivityCredits = 0.1 per hour attended

Ore heterogeneity and metallurgical complexity continue to rise, while sustainability occupies an ever-prominent role. Geometallurgy offers a refined, multidisciplinary pathway to improve the value of ore deposits.

Future-Ready Geometallurgy examines strategies to generate trustworthy data through the steady application of machine learning, novel sensors, digital twins, and Industry 4.0 technologies in mining. Reliance on dependable data and innovative tools empowers the industry to make more timely and discerning decisions for mine planning and metallurgical plant optimisation.

Following the success of past SAIMM Geometallurgy conferences, the third conference in this series provides a platform to explore the latest progress in geometallurgy and to celebrate the success of its integration into the mining value chain.

• Sampling and sensor-based core logging

• Practical tools and methodologies for ore characterisation and testing

• Standardised methods for reporting to generate trusted data

• Geostatistics, data integration, smart workflows, and modelling

• Incorporation of predictive mining, processing, and environmental models into resource modelling

• Project and operational geometallurgy case studies

• 17 June 2025 - Submission of short abstracts

• 29 July 2025 - Submission of extended abstracts for peer review

• 13 October 2025 – Technical workshops

• 14-15 October 2025 - Conference

• 16 October 2025 - Technical visits

FOR FURTHER INFORMATION CONTACT: Gugu Charlie, Conferences and Events Coordinator E-mail: gugu@saimm.co.za | Tel: +27 11

Geomet Advisor & Business Development Manager, Datarock, Australia

Wendy Ware

Chief Metallurgist, Transmin Metallurgical Consultants, United Kingdom

Adam Johnston

Prospective authors are invited to submit short abstracts of not more than 500 words to: Conferences and Events Co-ordinator, Gugu Charlie, e-mail: gugu@saimm.co.za Authors of accepted abstracts will be required to submit extended abstracts for peer review and publication in the conference proceedings. Following the conference, full papers can be submitted to the journal for peer review and publication in an SAIMM Journal Special Issue.

Affiliation:

1Hacettepe University, Mining Engineering Department, Ankara, Türkiye

2Ruhr University-Bochum , Applied Geology Department, Bochum, Germany

3Adiyaman University, Civil Engineering Department, Adiyaman, Türkiye

4Ankara University, Geological Engineering Department, Ankara, Türkiye

Correspondence to: S. Kahraman

Email: sairkahraman@yahoo.com

Dates:

Received: 24 Mar. 2024

Revised: 19 May 2025

Accepted: 16 July 2025

Published: August 2025

How to cite:

Kahraman, S., Alber, M., Gunaydin, O., Fener, M. 2025. Evaluating the triaxial strength of Misis fault breccia using artifical neural networks analysis. Journal of the Southern African Institute of Mining and Metallurgy, vol. 125, no. 8, pp. 413–420

DOI ID:

https://doi.org/10.17159/2411-9717/3337/2025

ORCiD:

S. Kahraman

http://orcid.org/0000-0001-7903-143X

M. Alber

http://orcid.org/0000-0003-2488-7817

M. Fener

http://orcid.org/0000-0002-0464-5194

O. Gunaydin

http://orcid.org/0000-0001-7559-5684

by S. Kahraman1, M. Alber2, O. Gunaydin3, M. Fener4

Abstract

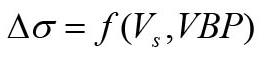

Falling into the weak rocks category, fault breccias have extremely poor engineering properties. These pebbles typically cause issues with slopes, subterranean construction, and building projects. Professionals will benefit from the creation of some predictive models for fault breccia triaxial strength, as smooth specimen preparation is typically challenging and timeconsuming. The purpose of this study is to develop some predictive models for the differential stress (Δσ) based on physical and textural properties. Artificial neural networks were used to analyse data related to Misis fault breccia. Initially, models with moderate (noticeable, but not good) correlation coefficients were created using multiple regression analysis. After that, the regression models and three distinct artificial neuron network models were contrasted. Regression models are weaker and less trustworthy than artificial neuron network models, as demonstrated by this comparison. Pointed out is the practicality and ease of use of the artificial neuron network model with S-wave velocity and volumetric block proportion. Ultimately, it can be concluded that artificial neuron networks analysis provides a reliable indirect method for predicting the differential stress of Misis fault breccia.

Keywords Misis fault breccia, triaxial strength, ultrasonic velocity, artificial neural networks

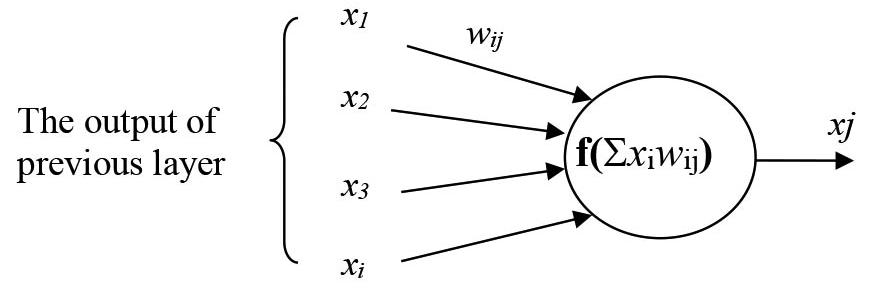

Introduction

Non-linear multivariable problems are typical in the geosciences. Regression analysis and conventional expert systems can occasionally fail to provide satisfactory solutions for such issues. Artificial neural networks (ANNs) are therefore frequently employed in the geosciences (Yuanyou et al., 1997; Yang, Zhang, 1998; Singh et al., 2001; Kahraman et al., 2005; Sonmez et al., 2006; Zorlu et al., 2008; Gunaydin et al., 2010, Dagdelenler et al., Marais, Aldrich, 2011, Sayadi et al., 2013; Khoshjavan et al., 2013; Basarir et al., Kahraman, 2016, etc.). Numerous geoscience studies have used ANNs, and the results have shown that ANN models perform well when solving multivariable problems. Typically, fault breccias cause issues in applications involving rock engineering since they belong to a weak rock group. In order to solve the issues that arise when carrying out projects, it is crucial to understand or estimate the geomechanical properties of fault breccias. To prepare smooth specimens for standard tests, on the other hand, requires a lot of time, effort, and money, and fault breccias are typically not suitable for this. Deriving a few predictive models for the geomechanical characteristics of fault breccias will be beneficial because of this. Many researchers (Chester, Logan, 1986; Medley, 1994; Medley, Goodman 1994; Lindquist, Goodman, 1994; Ehrbar, Pfenniger, 1999; Goodman, Ahlgren, 2000; Buergi et al., 1999; Medley, 2001; Medley, 2002; Habimana et al., 2002; Laws et al., 2003; Sonmez et al., 2004; Sonmez et al., 2006; Coli, 2011; Afifipour, Moaref, 2014; Mahdevari, Maarefvand, 2017; Lu et al., 2019; Festa et al., 2019; Avsar, 2020; Caselle et al., 2024; Gayathridevi, Ray, 2025) have studied the characteristics of geologically complex rocks such as melanges and fault rocks. On the Ahauser fault breccia (Germany), Kahraman and Alber (2006; 2008) as well as Alber and Kahraman (2009) conducted the first study on the geomechanical properties of fault breccias. Later on, Kahraman et al. (2008) and Slatalla et al. (2010) assessed the geomechanical characteristics of the breccia from the Misis fault. Kahraman et al. (2010) examined how well the Cerchar abrasivity index worked in predicting the uniaxial compressive strength (UCS) and Young’s modulus € of the Misis fault breccia.

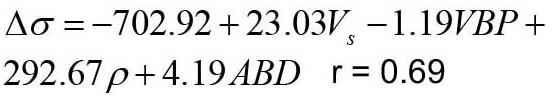

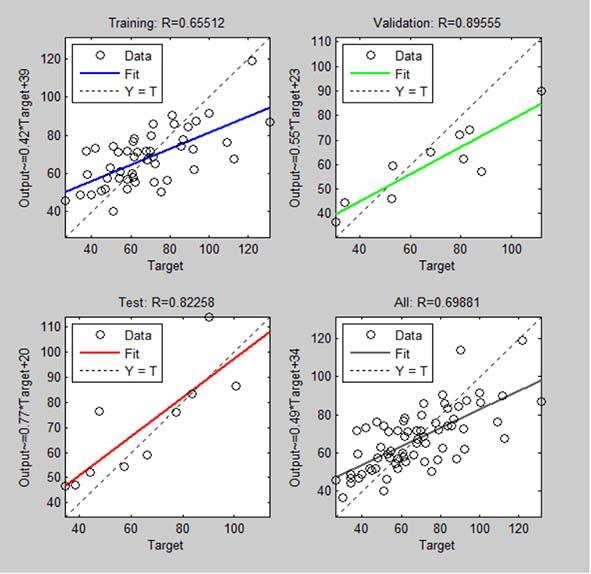

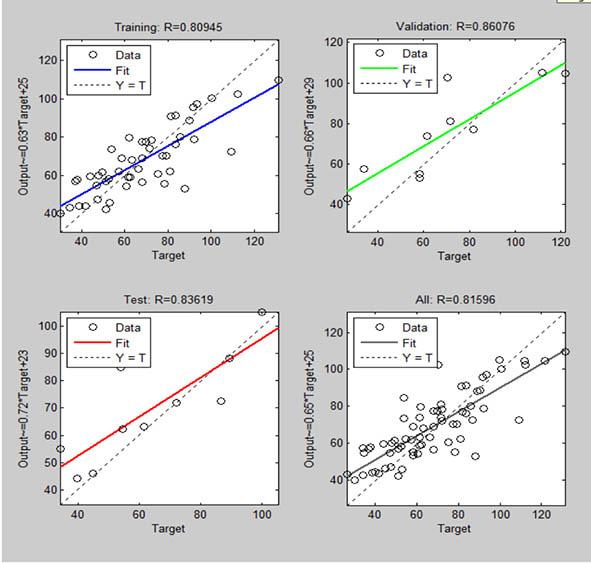

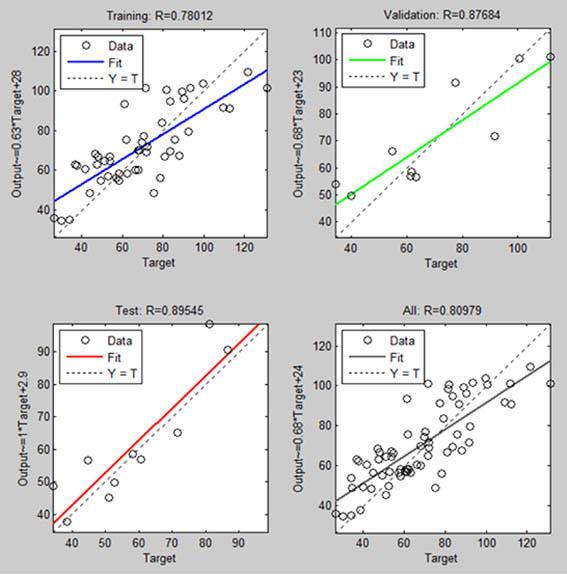

Kahraman et al. (2008), investigated the triaxial strength of Misis fault breccia and developed an estimation equation for the differential stress (Δσ) using multiple regression analysis. However, the

correlation coefficient for this relationship was weak. In this work, artificial neural networks (ANNs) were utilised to analyse the triaxial strength of Misis fault breccia with the goal of creating more robust models. Fifty specimens were added to this study in addition to the eighteen from the previous investigation.

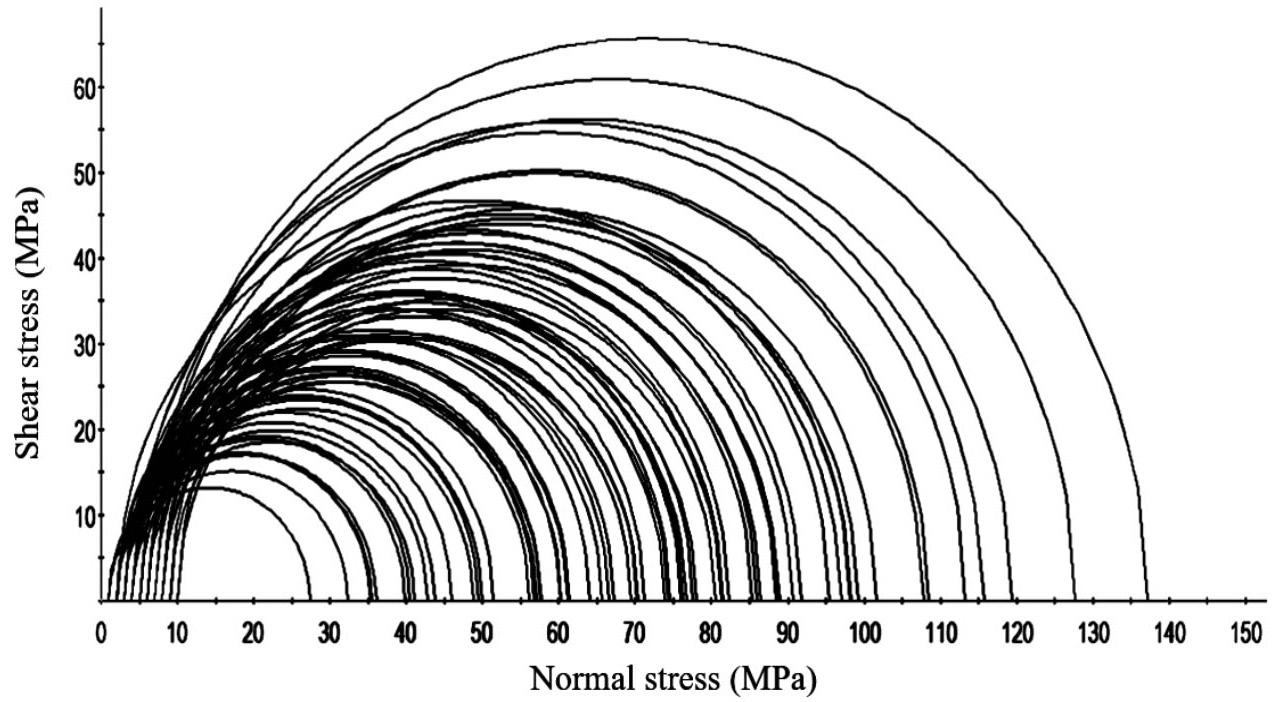

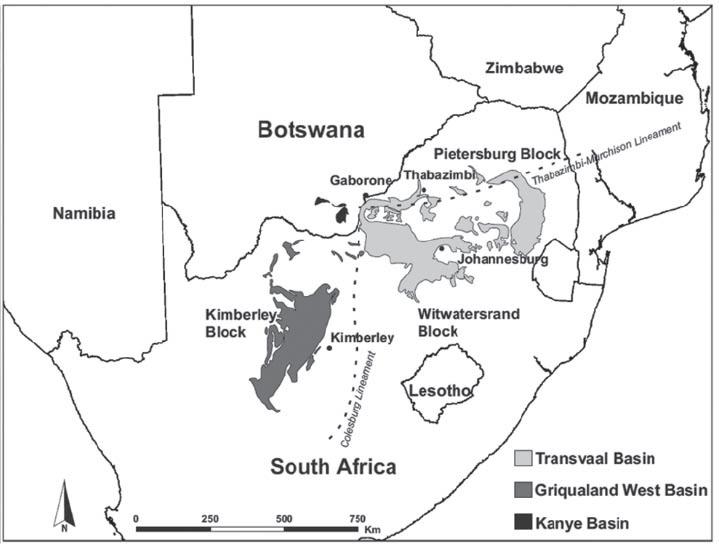

For the experimental investigations, large blocks were taken from the Misis fault breccia (Ceyhan-Adana, Türkiye). The Misis fault's location map is displayed in Figure 1. Dolomitic limestone blocks embedded in a finely grained matrix of red claystone containing clay rich in iron make up the Misis fault breccia. From the large blocks in the lab, 68 test samples in total were cored. The test samples have a 61 mm diameter and a 2-2.5 length-to-diameter ratio (Figure 2).

Determination of textural properties

Each core sample's circumferential surface was scanned with the DMT CoreScan II to produce digital images. Using image analysis software, the volumetric block proportion (VBP), average block diameter (ABD), aspect ratio, and roundness of the blocks were calculated from the scanned images of the cores.

Estimation of volumetric block proportion

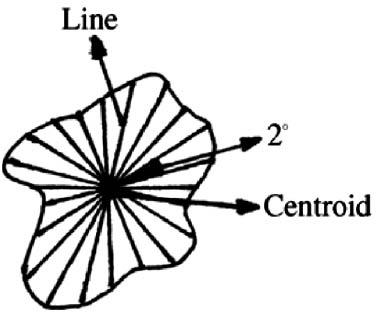

The volume of block partition (VBP) is calculated by dividing the volume of blocks or grains by the volume of rock mass. A few researchers have explained the VBP prediction methods and the uncertainties in predicting three-dimensional block size distributions from one- or two-dimensional measurements (Medley, Goodman, 1994; Goodman, Ahlgren, 2000; Medley, 1997; Medley, 2002; Haneberg, 2004). Blocks from the matrix are typically very difficult to separate, even though sieve analysis is the best technique. This is why it is common practice to estimate VBP using one- or

two-dimensional methods like scanlines, geological mapping, and image analysis, or drill core/block intersection lengths. The circumferential surface scan images of the cores were processed and used to estimate VBP in this study. Figure 3 displays a sample's raw and processed images.

The length of the line that passes through each block's 2° centroid was used to estimate the two-dimensional diameter, which was assumed to be the same as the three-dimensional diameter (Figure 4). ABD values were then calculated by averaging these lines.

Aspect ratio of blocks

The length of the major and minor axes of an ellipse with an area equal to that of the block is called the aspect ratio, which characterises the elongation of blocks. Every block in the sample had its aspect ratio measured, and the average value was determined.

Form factor is another way to define roundness. For a perfect circle, roundness equals 1. The roundness decreases as the shape moves away from circularity. Each block's roundness value in the sample was found, and the average value was computed. This is the roundness formula.

where R is roundness, A is the area of shape (mm2), and p is the perimeter of shape (mm).

Table 1

Descriptive statistics of textural properties

Table 2

Descriptive statistics of test results

Experimental studies

Prior to conducting triaxial compressive strength tests, each core sample underwent a density test and an ultrasonic test.

Density test

Density was calculated using samples of smooth core. Averaging multiple calliper readings allowed for the calculation of the specimen volume. A balance that could weigh the specimens precisely to within 0 points of the sample mass was used to determine their mass. The specimen mass to volume ratio was used to calculate the density values.

Ultrasonic test

To test the samples' elastic qualities, the USG 40 ultrasonic generator, made in Pirna, Germany, by Geotron GmbH, was employed. For the measurements, a 250 kHz ultrasonic transducer was employed. The ultrasonic tests yielded P- and S-wave velocities.

Triaxial compressive strength test