INDUSTRY NEWS ENERGY INDUSTRY 4.0 THE JOURNAL OF ALUMINIUM PRODUCTION AND PROCESSING www.aluminiumtoday.com March/April—Vol.36 No.2 ALUMINIUM INTERNATIONAL TODAY MARCH/APRIL 2023 VOL.36 NO2 FURNACE TECHNOLOGY Serving the Aluminium industry for 50 years

#turningmetalsgreen

At SMS group, we have made it our mission to create a carbon-neutral and sustainable metals industry. We supply the technology to produce and recycle all major metals. This gives us a key role in the transformation towards a green metals industry.

Volume 36 No. 2 – March/April 2023

Editorial

Editor: Nadine Bloxsome Tel: +44 (0) 1737 855115 nadinebloxsome@quartzltd.com

Editorial Assistant: Zahra Awan Tel: +44 (0) 1737 855038 zahraawan@quartzltd.com

Production Editor: Annie Baker

Sales

Commercial Sales Director: Nathan Jupp nathanjupp@quartzltd.com

Tel: +44 (0)1737 855027

Sales Director: Ken Clark kenclark@quartzltd.com

Tel: +44 (0)1737 855117

Advertisement Production

Production Executive: Martin Lawrence

Managing Director: Tony Crinion

CEO: Steve Diprose

Circulation/subscriptions

Jack Homewood

Tel +44 (0) 1737 855028

Fax +44 (0) 1737 855034 email subscriptions@quartzltd.com

Annual subscription: UK £257, all other countries £278. For two year subscription: UK £485, all other countries £501. Airmail prices on request.

Single copies £47

Cover picture courtesy of MECHATHERM INTERNATIONAL LTD

ALUMINIUM INTERNATIONAL TODAY is published six times a year by Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey, RH1 1QX, UK. Tel:

CONTENTS 1 www.aluminiumtoday.com

International Today March/April 2023 2 LEADER 2 NEWS

Aluminium

COVER

+44 (0)

+44

Today (USO No; 022-344) is published bi-monthly by Quartz Business Ltd and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. POSTMASTER: send address changes to Aluminium International c/o PO Box 437, Emigsville, PA 17318-0437. Printed in the UK by: Pensord, Tram Road, Pontlanfraith, Blackwood, Gwent, NP12 2YA, UK © Quartz Business Media Ltd 2023 ISSN1475-455X Supporters of Aluminium International Today SEARCH FOR ALUMINIUM INTERNATIONAL TODAY 12 45 15 35 22 INDUSTRY NEWS ENERGY INDUSTRY 4.0 THE JOURNAL OF ALUMINIUM PRODUCTION AND PROCESSING www.aluminiumtoday.com March/April—Vol.36 No.2 ALUMINIUM INTERNATIONAL TODAY MARCH/APRIL 2023 VOL.36 NO2 FURNACE TECHNOLOGY Serving the Aluminium industry for 50 years 39 THE ALUMINA CHRONICLES 7 Technology innovations in Aluminium Production Processes IAI ANNIVERSARY 22 50 Years of the IAI - Thank you! FURNACE TECHNOLOGY 27 Decarbonisation of secondary aluminium melting 35 Optimising efficiency in aluminium recycling: Delacquering furnaces 39 Playing the numbersWhen to repair or replace a bricking machine RECYCLING 45 Q&A with Andy Doran, Chairman of Alupro ENERGY 12 Where will green energy come from? INDUSTRY 4.0 15 Aluminium towards Industry 4.0 FOCUS ON HFQ 17 HFQ Technology: Enabling ultra-high strength and sustainable aluminium structures SUSTAINABILITY 48 The sustainability ratings are in!

1737 855000 Fax:

(0) 1737 855034 Email: aluminium@quartzltd.com Aluminium International

SPRING INTO ACTION

It feels like a long time since the news pages were filled with stories of investment, partnership and strategic planning.

With the last few years very much in ‘survival mode’, the recent developments and announcements from a number of primary aluminium producers shows a significant shift in how the industry is looking ahead.

The restart of the Alcoa San Ciprián smelter is just one example of where investment is being made to protect such an asset and a workforce.

The announcement of a partnership between Rio Tinto and BMW also highlights the continued demand for low-carbon primary aluminium into automotive products, keen to drive a sustainable future (forgive the pun!)

It’s interesting to see where these kinds of investments are having the biggest impact and how the industry is making substantial changes to the upstream and primary manufacturing areas in a move towards more sustainable supply chains and future-proofing.

This issue includes a selection of articles, all centred around where the most development is being applied - within digital manufacturing, furnace technologies and the green energy transition.

In an exclusive article by Tim Murray, CEO of Cardinal Virtues Consulting, the discussion of what really constitutes green energy is raised and where will this energy needed for such a transition really come from...

There is all of this, as well as an interview with the new Chairman of Alupro, Andy Doran and a reflective article from the IAI, following their 50th anniversary.

nadinebloxsome@quartzltd.com

Alcoa Plans Restart at San Ciprián Aluminium Plant for 2023

The Alcoa Corporation have announced that a majority of the workers at its San Ciprián complex in Spain have agreed to an improved plan for the restart of the aluminum smelter in 2024.

In December 2021, Alcoa announced a two-year curtailment to work on plans for a stronger smelting facility, which had faced exorbitant energy prices that threatened its viability. In 2022, the Company announced the signing of two long-term wind power purchase agreements (PPA)

to secure up to approximately 75 percent of the smelter’s needs at full capacity. The supply of energy will depend on the permitting and development of the windfarms.

The updated agreement with the workforce provides a detailed schedule that will commence the restart process in phases beginning in January 2024. The agreement also includes increased investments in the facility and protections for the workforce.

“With this latest agreement, we have additional flexibility and

a clear direction for the future as we continue to work constructively with our workforce and other stakeholders to begin the restart process in 2024, supported by wind-based power agreements and increased investments designed to improve the smelter’s viability,” said Alcoa President and CEO Roy Harvey.

“We will continue to work cooperatively with the regional and national governments in Spain as we move forward with these plans.”

Ma’aden announces major new venture and strategic partnerships

During the Future Minerals Forum 2023, the Saudi Arabian Mining Company (Ma’aden) announced a major new venture with the Public Investment Fund (PIF). A new, jointly owned company will make significant investments internationally into upstream strategic minerals opportunities, securing value chains critical to industrial development and energy transition in the Kingdom.

Ma’aden has also signed strategic partnerships with leading mining companies, Ivanhoe Electric (IE) and Barrick Gold Corporation (Barrick) to develop globally signif-

icant strategic mineral resources in the Kingdom to fuel the development of the sector internationally. These agreements will play an important role in unlocking value from Ma’aden’s extensive exploration and development portfolio, expanding Ma’aden’s international reach and bringing new skills and technology into the sector in Saudi Arabia.

Ma’aden has also signed more than 20 agreements and MOUs with globally leading organisations to increase exploration and technical capabilities in mining operations.

Alba commissions FCN

Potlines 4 and 5

Aluminium Bahrain B.S.C. (Alba)’s Chairman of the Board of Directors Shaikh Daij bin Salman bin Daij Al Khalifa along with the Chief Executive Officer Ali Al Baqali celebrated the successful commissioning of the Forced Cooling Network (FCN) Project at Potlines 4 and 5. Alba Executives, respective area Directors and Managers as well as concerned teams were also present during the commissioning of the FCN Project.

Managed in-house by the Operations and Engineering teams, the FCN Project has enabled Alba to creep-up the amperage to 410 kA

Robert Wilt, CEO of Ma’aden, commented: “By attracting new partners to Saudi Arabia and increasing the commitment of our existing partners, we are introducing new technologies into our operations, diversifying our upstream product mix and accelerating the development of our exploration portfolio. This will create opportunities for knowledge and technology transfer that will deepen the talent pool in Saudi Arabia and open up new opportunities to develop the Kingdom’s abundant mineral resources.”

Project at

in Potlines 4 and 5 which would ultimately lead to increasing Alba’s production capacity by approximately 17,000 metric tonnes per annum.

Commenting on this occasion, Alba’s Chairman Shaikh Daij bin Salman bin Daij Al Khalifa stated:

“By chasing operational efficiency, we will attain excellence as

we journey to the future.

Devised as a focus area within Alba’s 5-year business strategy, the FCN Project started as one step outside our comfort zone since it was executed while Potlines 4 & 5 were fully operational -- and that speak volumes about the technical and operational expertise of our people.”

COMMENT 2

March/April 2023 TOP STORIES

Nexans and Trimet improve the eco-balance of power cables

Aluminium producer Trimet and Nexans have laid the groundwork for improving the eco-balance of power cables. In a joint breakthrough development project, the two companies have developed a material with recycled aluminium content for the production of aluminium rod used in electrical cables.

Trimet and Nexans have developed a new product able to meet the high technical requirements on the mechanical properties and conductivity of the alloy while reducing the product’s carbon footprint. Until now, power cables have been manufactured exclusively on the basis of primary aluminium.

Melting and recycling of aluminium scrap requires only a fraction of the energy needed to produce primary aluminium. However, recycled aluminium contains impurities that adversely affect the material’s specific properties.

The collaborative project between Nexans and Trimet aimed to coordinate optimised raw material supply and innovative material development. For example, Nexans has refined the sorting of aluminium scrap at its production sites in Europe through RecyCâbles, a Nexans-Suez joint venture,

while gearing its collection to recycling for electrical cables. Trimet has closed the material cycle with its recycling concept and used the scrap obtained to develop a high-quality alloy that meets the full range of quality requirements for mechanical and electrical performance.

Road to a Greener Future: Rio Tinto Partners with BMW Group

Gone are the days when premium car buyers simply looked for speed, style, and luxury. Today, there’s increasing interest in the origin, sustainability and emissions profile of the materials used to build their cars.

The new mantra for the highend auto industry is “green is the new black.” From the leather used for upholstery to the metals used for engine parts, premium car buyers are increasingly demanding vehicles made from responsibly sourced materials.

This fundamental shift in the automotive market has led to the creation of a new, innovative partnership between Rio Tinto and the BMW Group, leaders in their respective industries who share a

common goal of developing more responsible, sustainable, traceable and secure supply chains.

Under this new partnership, Rio Tinto plans to provide responsibly sourced aluminium to the BMW Group’s vehicle production plant in Spartanburg, South Carolina, for use in body components from 2024.

Low-carbon primary aluminium from Rio Tinto’s hydro-powered operations in Canada, combined with recycled content, could generate a reduction of up to 70 percent in CO2 emissions compared to the BMW Group’s benchmark for aluminium.

The two companies have signed a Memorandum of Understanding (MoU) which will see technical experts working together on how to

embed these low-carbon solutions into the BMW Group’s supply chain while ensuring the highest standards of vehicle quality are maintained. The partnership provides for the use of aluminium produced using ELYSIS™ on BMW production vehicles. ELYSIS™ is the world’s first carbon free smelting technology for aluminium as it enables the production of aluminium metal without direct carbon dioxide emissions during the smelting process, instead emitting pure oxygen.

Rio Tinto and the BMW Group will also work to deploy START from Rio Tinto. START provides supply chain traceability to customers and consumers with information about provenance and ESG standards.

EGA and Microsoft to collaborate on Industry 4.0

Emirates Global Aluminium (EGA) have announced that they are to collaborate on Industry 4.0 and broader digital transformation, aiming to set global best practice for the aluminium industry while improving the sustainability of EGA’s computing operations.

Under the new agreement, the two companies will work together to progress EGA’s Digital Roadmap, which is already transforming EGA’s operations through digital capabilities such as artificial intelligence and big data.

Calderys becomes a standalone company

Calderys has announced it has become an independent company encompassing the full scope of the High Temperature Solutions business (HTS) area formerly under Imerys. The new company is owned by US-based Platinum Equity following the successful completion of regulatory approvals and customary closing conditions.

Hydro and Wave Aluminium to recover minerals from bauxite residue

Hydro Alunorte and Wave Aluminium have signed a contract to build a plant in Brazil to process bauxite residue. Using a new combination of disruptive technologies, the planned bauxite residue processing plant will initially have the capacity to process 50,000 tonnes of bauxite residue per year.

3 NEWS IN BRIEF March/April 2023 NEWS Aluminium International Today

EGA welcomes nuclear energy

to supporting the UAE’s growing intermittent renewable sources, which generate during daylight hours. Nuclear energy generated electricity is particularly important for decarbonizing heavy industries, which need large volumes of continuous electricity to power industrial processes, like aluminium smelting. ENEC supplies electricity to EWEC through a long-term agreement, which EWEC sells on for dispatch.

March

30th March - 1st April

METEF

Expo of customised technology for the aluminium, foundry castings & innovative metals industry. New opportunities for the downstream sector generated by the synergies between Metef and MECSPE.

Held in Bologna, Italy www.metef.com/en/

EGA has announced a strategic initiative with TAQA, Dubal Holding and EWEC to divest its natural gas-fired power plants and instead source its electricity needs via the grid from EWEC, including an increasing proportion of clean energy.

This would make EGA the largest single customer on the grid. ENEC’s Barakah plant is already the largest source of clean, zero-carbon

electricity in the UAE and wider Arab World, with two of the four 1400MW units already commercially operational, the third unit due to commence commercial operations shortly and the fourth unit gearing up for operational readiness later this year. Nuclear energy is an important source of baseload electricity, meaning it generates significant volume 24/7, which is fundamental

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said, “The UAE’s ambitious energy transition provides the largest single opportunity for decarbonisation at EGA. Alongside solar, nuclear power will be a major part of EGA’s energy mix over the decades ahead, enabling us to provide the low-carbon aluminium the world needs to make modern life possible.”

Hydro to increase aluminium recycling capacity in UK

Hydro plans to develop remelt scrap ingot production at its plant in Wrexham, UK to increase recycling of post-consumer scrap, providing European customers with more low-carbon aluminium.

“We see increasing interest from forward leaning customers across Europe to buy Hydro’s low-carbon aluminium, particularly within the automotive, transport, and buildings and construction segments,” says Ingrid Guddal, Head of Recycling in Hydro Aluminium Metal.

Hydro is planning an investment in its UK Wrexham plant, increasing the aluminium recycling capacity to a total of around 103,000 tonnes per year.

The remelt scrap ingot (RSI) production in Wrexham will strengthen Hydro’s position in the UK market and enable the plant to

process and recycle a wider range of post-consumer aluminium scrap. The planned investment to increase the capacity is currently estimated to be GBP 25-35 million and will provide around 30 full time jobs.

“We are eager to increase our capacity here in Wrexham to meet increased customer demand for low-carbon aluminium. Every year, around one million tonnes of aluminium scrap leaves Europe. This investment will ensure that more

Fast Forward Zero

FAST FORWARD ZERO has launched its services and website to help businesses to transform to NET ZERO, circular and inclusive operating models.

Leveraging over 25 years of experience, Chief Executive Officer, Jerome Lucaes, works with a network of well-established experts and institutions to develop

post-consumer scrap is kept in the loop and processed here at home. The remelt scrap ingot will then be turned into new, low-carbon aluminium products that contribute to Europe’s green transition,” says Wayne Clifton, Hydro’s plant manager in Wrexham.

Hydro has an overall ambition to double its recycling of post-consumer scrap by 2025 and the project in Wrexham is one of several investments made to reach this target.

MAY

10th - 12th

Future Aluminium Forum

The Forum will return in a live format to Québec City, a region where the aluminium industry has existed for more than a century and is now seeing rapid change and collaboration between manufacturers, processors, suppliers and OEMs.

Held in Québec City, Canada www. futurealuminiumforum. com

16th - 18th

CRU: World Aluminium Conference 2023

The Conference will allow attendees to make valuable connections with industry peers and build their professional network in a business social environment. www.events.crugroup. com/aluminium

JUNE

12th - 16th

METEC

International buyers, users, experts and decision-makers from the metallurgy, thermal engineering and casting industry meet here at these four events at the same time and place.

Held in Düsseldorf, Germany www.metec-tradefair.com

relevant and applicable solutions that inspire sustainable transformations to leverage unique competitive advantages.

For a full listing visit www.aluminiumtoday.com/ events

Aluminium International Today www.aluminiumtoday.com

2023 DIARY

4

March/April 2023 GREEN NEWS

+44 (0121) 684 0175 info@mqpltd.com mqpltd.com The next dimension in grain refinement... Contact us today to discuss your refinement needs. made with low carbon aluminium 125% relative efficiency 5:1 125 5:1 125

ST. LOUIS, MISSOURI, USA 800 325 7075 | www.gillespiepowers.com | 314 423 9460 ✓SINGLE CHAMBER / MULTI CHAMBER FURNACES ✓SCRAP DECOATING SYSTEMS ✓TILTING ROTARY MELTING FURNACES ✓SCRAP CHARGING MACHINES ✓LAUNDER SYSTEMS ✓CASTING / HOLDING FURNACES ✓HOMOGENIZING OVENS ✓COOLERS ✓SOW PRE-HEATERS ✓REPAIR & ALTERATIONS

Technology Innovations in Aluminium Production Processes

By Richard McDonough*

Like many other industries, the aluminium industry is in transition. Efforts are underway by a number of firms to reduce carbon emissions, enhance sustainability, improve logistics and supply-chain operations, and utilise tools and technologies that reduce costs.

“In an effort to streamline production, many metals manufacturers have recently found significant value in re-examining their core business processes and fundamental operations for inefficiencies,

vulnerabilities, and redundancies to align with industry best practices,” said Joe Velez, Managing Director of Client Services at Ultra Consultants. “We’ve seen aluminium refineries, smelters, and fabricators roll out sweeping changes that are supported by industry-specific enterprise resource planning (ERP) software with updated shop-floor technology. This inside-out approach creates a foundation on which new tech can be supported and innovation encouraged and tracked.”

Mr. Velez began his career at ALCOA, according to his biography, and then worked at Rio Tinto’s ALCAN division. For the past eight years, he has worked for Ultra Consultants, a firm focused on ERP consulting and implementation services. The business indicated that it “…works with aluminium manufacturers headquartered in North America, whose operations are often global.”

“Many aluminium manufacturers are on a system they’ve been patchworking

THE ALUMINA CHRONICLES 7 Aluminium International Today March/April 2023

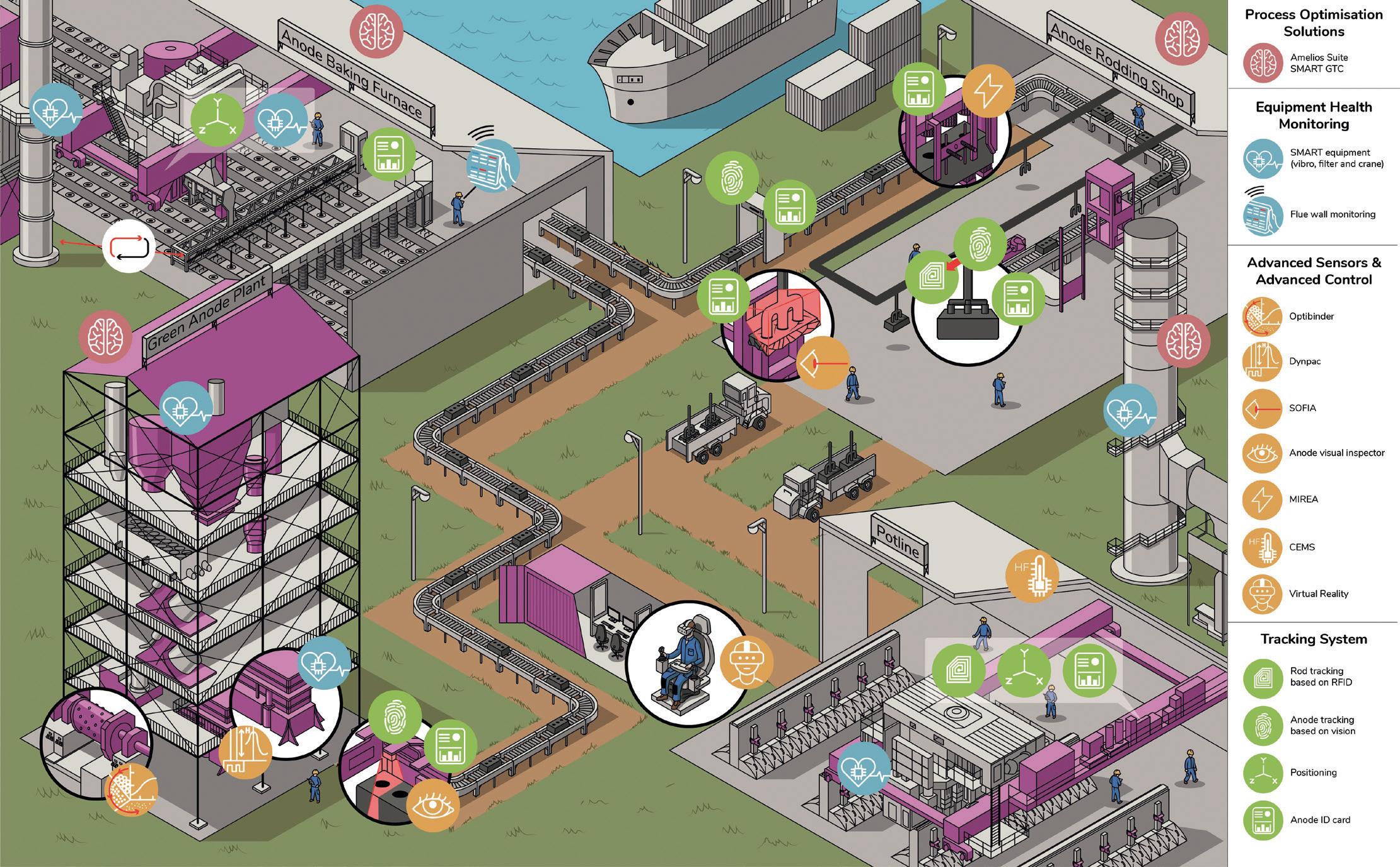

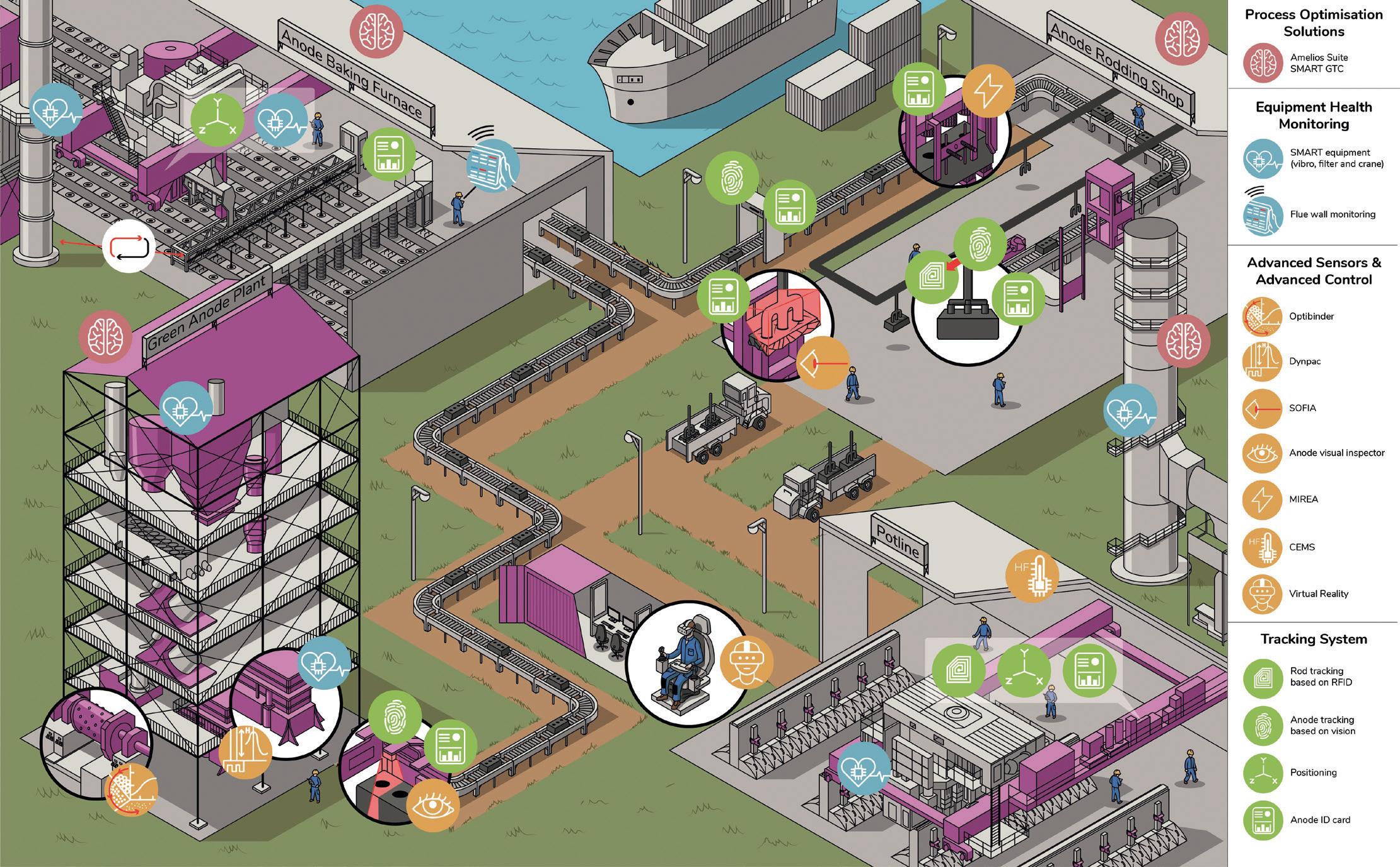

This illustration shows digital solutions for the aluminium industry from Fives for equipment monitoring process optimisation and emission control. (The illustration was provided courtesy of Fives.)

*Do you have questions about the aluminium industry? Governmental regulations? Company operations? Your questions may be used in a future news column. Contact Richard McDonough at aluminachronicles@gmail.com. © 2023 Richard McDonough

for twenty-plus years, and they have no idea what they’re missing out on,” noted Mr. Velez. “Today’s cloud-based ERP solutions with advanced analytics, machine learning, and statistical models provide always-on transparent oversight of the entire supply chain and shop floor, predicting when shipments will be late and when equipment is likely to fail, whilst digital imaging, spectroscopy, and nondestructive testing techniques provide seamless quality control.”

“Aluminium refineries, smelters, fabricators, manufacturers, distributors, and recycling facilities all benefit by the increased efficiencies and advanced data integration of ERP systems,” Mr. Velez continued. “…We’ve seen three main external forces that have affected companies’ decisions to optimise technologies: raw material cost fluctuations, increased environmental regulations, and the globalisation of competition in the aluminium industry. Each of these has played a role in companies’ decisions to adopt digital transformation initiatives to increase redundancies and visibility in the supply chain, adopt more energy-efficient and environmentally friendly practices, and optimise their production processes to stay ahead of the competition.”

Throughout the world, a number of businesses are working on technology innovations in the aluminium production processes. This news columns highlights efforts by several of these firms, including Fives, PSI Metals, RIA Cast House Engineering, and Rockwell Automation.

Fives

“As a pioneer in decarbonising industry for over 15 years, Fives now has a clear technical edge when it comes to the energy transition,” said Sébastien Gauguier, President of Fives – Aluminium Division. “The energy crisis only confirms the daring choices we made: working towards an industry that combines performance with energy and environmental efficiency.”

“We must continue to innovate to reduce aluminium industry’s carbon emissions and ensure its digital transformation: 80% of the patents we file concern solutions aimed at reducing our customers’ environmental footprint,” Mr. Gauguier continued. “More than ever, Fives is committed to a mutually responsible and virtuous industry.”

Fives indicated that given the goals of many to increase aluminium production and the tendency to be carbon neutral, the firm expects an increasing demand over the next few years for production “creeping” projects on existing aluminium smelters.

“Investment profitability, time to

market, and performance risks being the key drivers,” stated Frederic Pereira, Head of Marketing at Fives Aluminum. “For several years, we have been working on solutions to assist aluminium smelters in their net-zero programmes.”

“At Fives, we are convinced that Industry 4.0 will play a central role in the transformation of the global aluminium industry in the years to come and will support their road map to netzero,” continued Mr. Pereira. “That’s why to support our customers in their transition towards green production of aluminium we have introduced successful innovative solutions aiming at optimising CO2 emissions per tonne of aluminium produced, reducing energy consumption and polluting emissions whilst improving working conditions.”

Mr. Pereira said that “in the carbon sector, digitalisation across the whole anode production process with Amelios Suite allows optimised carbon consumption and better monitoring of anode quality. It potentially reduces the amount of CO2 emitted per tonne of aluminium produced by 35 to 70 kg, whilst also reducing anode production costs by 2.5%. Consequently, our Amelios Suite solution has been selected by the Solar Impulse Foundation as one of the #1000 Solutions to change the world.”

“The Helios Advanced Firing Control System (FCS) offers clean and efficient combustion in the anode baking furnace,” Mr. Pereira continued. “When converting plants to natural gas, Fives supports its customers in the modernisation of their anode baking systems by providing an optimised injection system to reduce NOx emissions at the source. The integration of the anode baking module of the Amelios suite also allows data analysis and provides key performance indicators to monitor and optimise the baking process.”

He also indicated that “in the reduction lines, CAFD Eco2 (Crust Alumina and Feeding Device) contributes to reducing anode effect and the compressed air consumption of the smelter. The Fives’ SMART GTC (Gas Treatment Centre) allows for enhancing smelter environmental performance and reducing operating costs through constant monitoring of emissions and equipment. The Ozeos filtering unit together with Cascade feeding system offers to Fives’ GTC a level of HF (Hydrogen Fluoride) emissions and energy consumption unmatched on the market.”

“In addition, the 4.0 road maps of our customers will drive the demand for control platforms, connectivity, and automation,” explained Mr. Pereira. “We are already in these different digital segments, with machine monitoring

software, online advanced scoring sensors and advance control, and a range of remote service mobilising a comprehensive set of technologies and experts.

“That’s why our main target is to continue to develop innovative digital tools to help our customers to improve their productivity,” stated Mr. Pereira. “These include easy access to operational information, everywhere at any time, preventing security concerns with their IT systems, improving operational efficiency thanks to data mining and analytics, switching maintenance from reactive to predictive, and elimination of physically demanding tasks (generating heat stress for example).”

“We also have deployed OEM to customer interfacing tools such as the online portal Fives Connect providing privileged access to numerous digital services,” continued Mr. Pereira. “We continue to expand the functionality of our machine health monitoring system, SMARTCrane, which following its successful introduction continues to be connected to increasing numbers of special process cranes across smelter sites. We have recently launched SMARTVibro for the vibro compactor unit (anode forming) within the green anode plant, and developments continue on the SMART filter for GTC. And we anticipate expanding our portfolio applications such as virtual reality applications for PTM (Pot Tending Machine) training as we are also leveraged by multiple stakeholders to provide it.”

PSI Metals

“Sustainability and digitalisation are two factors that are key in the coming years,” stated Gunther Schober, Sales Manager at PSI Metals Non Ferrous GmbH. “Our generation has the responsibility to pass on an ecologically-friendly environment to the future generations. This makes sustainable production indispensable.”

“Digitalisation offers huge potentials,” Mr. Schober continued. “AI-based software solution powered by a Service Platform (SP) optimises production plants, using smart services that network like a team of agents. An SP enables a collaboration of local and global optimisation tools. But it is not just the planning solutions that work together; the supply chain is equally optimised and becomes fully transparent, with additional flexibility.”

His biography detailed that “Gunther Schober, is a global expert in aluminium with a background in Metallurgical Engineer, focusing on industrial and energy economics. He has held diverse roles as a Senior Consultant, Project Manager and Sales Manager. His expertise in metals and international experience in process development and supply chain

Aluminium International Today March/April 2023 THE ALUMINA CHRONICLES 8

management is highly sought after. With more than fifteen years of experience in production management solutions encompassing supply chain management and planning, product design, quality management, production execution and logistics, he has become a recognised expert in these areas.”

PSI Metals describes itself as combining “…the metals expertise within the PSI Software AG and is the world’s largest provider for software solutions in production management for the metals industry.” The firm indicated that it has its solutions running at more than 260 customer plants.

Mr. Schober said that the “efficiency of the production plants is also a core of digitalisation as our solution allows aluminium producers to structure how best to produce, the ideal time to produce, the optimised yield, and reduced material movements. The result is savings in cost across all levels – production costs, energy costs, material costs, handling costs, and increased overall equipment effectiveness. Digitalisation of the production plant has a direct impact on sustainability. We promote sustainability by even decreasing material usage and optimising energy. Put simply, save costs in order to save the environment.”

One of the key facets cited by Mr. Schober are smart and collaborative pieces of software.

“Smelting aluminium consumes a vast amount of energy,” stated Mr. Schober. “Software will not change the process, but it can optimise the energy consumption and thus help reduce CO2 emissions. Even if aluminium producers have a CO2 – neutral power supply, energy peaks may have to be met by fossil fuel-based electricity. These peaks may not originate in their plant only. There are waves of electric energy consumption. Intelligent software can predict such events and flatten power consumption in a broader perspective. Further, wind, hydro, and solar power depend on weather conditions. Smart software can integrate the weather forecasts and the anticipated wind force for example to balance the estimated consumption with the predicted supply of energy.”

“There is giant potential to use the flexibility of the process,” he continued. “The technology to use the aluminium bath as a battery is already there. With intelligent software solutions, producers can make the most out of it and optimise the entire production process.”

Mr. Schober said that an important software service is alloy optimisation.

“Aluminium producers use it to optimise the input for their casters,” he said. “The system knows all available input and

alloying materials and the corresponding costs. The result is an optimised use of scrap, that is ideal from an energy standpoint as well as from the CO2 perspective.”

“Aluminium producers may want to support the use of a particular material and hold their own scrap sale, or they want to limit a popular material and avoid cherry-picking,” Mr. Schober continued. “Liquid material and the sump can be considered like any other material. They set the target and the system finds the best way there.”

He noted that moving to the next steps downstream – towards extrusion or rolling, “dynamic order dressing (rule-based and characteristic-based) give aluminium producers the required flexibility. In a

determine the measures. Another step towards reducing CO2 by increasing the first time right rate.”

He indicated that an additional option to reduce excessive material is dynamic order combination.

“Based on the existing order book and material units – planned and real –an order/material combination tool will nest different orders optimised into the material units,” according to Mr. Schober. “Multilevel combinations become reality and the smart software fully supports a ‘Make to Stock, Finish to Order’ strategy to optimise production and material requirements. Combined with order dressing, they get the optimised route along with the specific production instructions for emissions by eliminating

matter of seconds, they have all the details on qualitative and quantitative material requirements, test and sampling instructions, process instructions and time demand for planning and costs. Further, they can calculate the carbon footprint for each production step and later compare with the actual. A production order optimised and designed for their customer’s request. The time for defining a new article can be reduced from two weeks to two hours.”

In the area of predictive quality, Mr. Schober stated that “intelligent software can predict defects and thus help to avoid them. We’re not there yet to avoid them completely – at least not yet. Nevertheless, the results of existing projects show a 50% reduction in defects. This is, based on our experience, equal to an increase of production output by 2% with no additional CO2 emissions.”

“Software would not only predict errors; it can also help aluminium producers find the root cause,” Mr. Schober continued. “If they want to avoid an error, they must first find the cause, then they can

defective material, right the first time.”

“Collecting a lot of data together with smart analytics can offer a prediction of maintenance too,” Mr. Schober continued. “Producers can change parts including anodes right on the spot. They don’t waste money by replacing parts that have not reached the end of their live cycle nor do they risk production stops or quality issues by worn out parts. This increase of productivity has a significant impact on the sustainability of production.”

Whilst technological innovations will be important as the aluminium industry moves into the future, Mr. Schober stated that “…experienced human operators still make most critical production decisions. These operators launch fully automated procedures that have a predefined mostly rule-based non-adaptive behaviour. If this automation behaviour needs adaption, it will require ‘re-programing’ or ‘reconfiguring.’ Unfortunately, production conditions evolve, requiring regular adaptions. This adaptability is one of the main challenges for the next generation of Production Management Systems

THE ALUMINA CHRONICLES 9 Aluminium International Today March/April 2023

“Sustainability and digitalisation are two factors that are key in the coming years,” stated Gunther Schober.

Gunther Schober, Sales Manager at PSI Metals Non Ferrous GmbH. (The photograph was provided courtesy of PSI Metals.)

(PMS) solutions. We will need production automation that will be able to self-adapt its behaviour to changing production conditions. To this effect, PSI Metals is taking the lead in finding the solution to this current and futurist challenge and deeply involved in research projects.”

Among on-going research projects cited by Mr. Schober, some focused on the future of PMS automation; decarbonisation and CO2 tracking; optimising efficient energy scheduling to energy availability; and online heat scheduler and cast house scheduler for the upstream production and order scheduler for the downstream production.

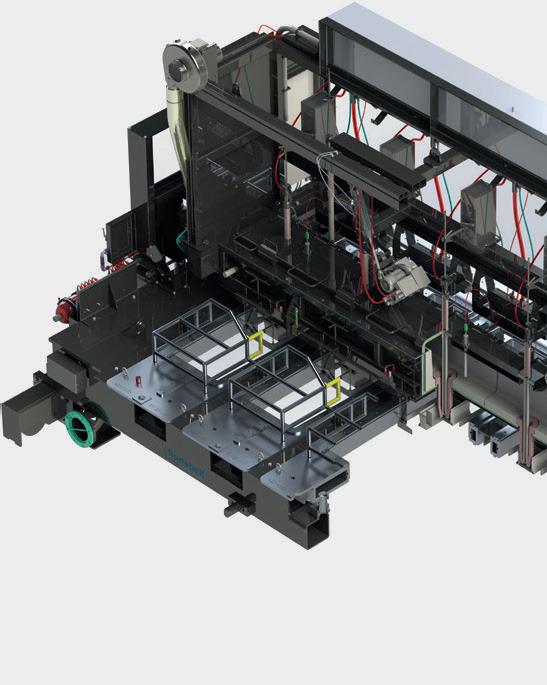

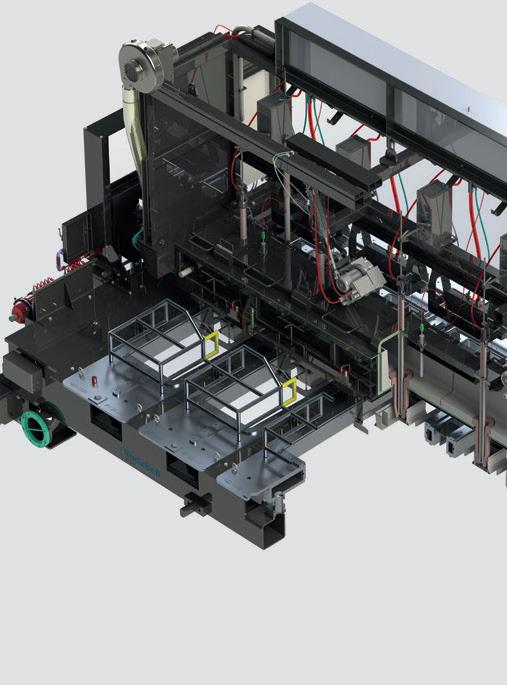

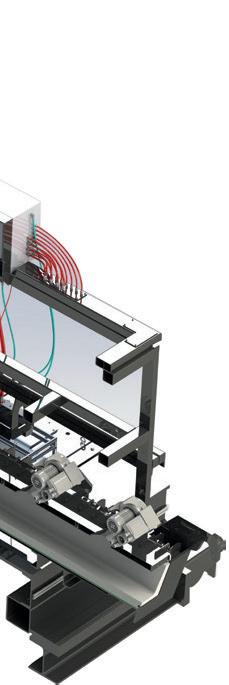

RIA Cast House

“RIA Cast House Engineering (RIA) provides rail-mounted precision cast house-proven charging and skimming machines for aluminium cast houses worldwide,” said James Tomkinson, Sales and Marketing Manager at RIA Cast House Engineering GmbH. “The design and development of all RIA machines take reliability, durability, maintenance, and occupational safety into account. RIA has supplied over seventyfive furnace charging and skimming machines, all rail-mounted and capable of charging up to 30 metric tonnes in less than 90 seconds or skimming a furnace faster than a traditional forklift truck or wheeled furnace tending vehicle, but with more repeatable results and without damaging the refractory lining.”

He indicated that key customers of RIA include Hydro, Constellium, Kaiser, and Matalco, among others: “Several clients have multiple machines in the same cast house or across multiple sites and territories. One client alone has implemented more than thirty RIA machines in ten different countries.”

“In recent years, in conjunction with our exclusive partner Fioscope GmbH, RIA added the innovative capability of AI [Artificial Intelligence] smart camerabased decision making to our machines to offer fully autonomous operation and therefore removing the requirement to have operators on or even near our machines,” noted Mr. Tomkinson. “RIA’s Managing Director, Michael Rockstroh, also became Managing Director of Fioscope GmbH in February 2022, helping to drive the continuous development of RIA’s AI enabled autonomous machines and assuring our growing customer base that RIA equipment is not only suitable for today, but also tomorrow and beyond.”

Mr. Tomkinson stated that “in typical operations, melting and holding furnaces are skimmed by either a wheeled vehicle or a rail mounted machine. Typically, both are driven by an operator present on board the machine to give them a direct

view in to the furnace to locate the dross to skim from the melt surface.”

“The above process presents two main concerns for the aluminium cast house,” he continued. “The first concern being that operators have to be on board the machine, exposed to the heat and potential dangers of molten aluminium. Secondly, operator-driven wheeled vehicles typically have long skim booms that move with little control or precision when skimming the furnace. Often, this causes unnecessary damage to the refractory lining within the furnace leading to the earlier replacement of refractory walls and the furnace sill and lintel. Not only does this incur the cost of replacing the refractory lining more frequently, but also the lost production time with the furnace being down to conduct the necessary repairs, often for several weeks.”

He said that Fioscope’s air-cooled smart cameras that RIA has installed on board its skimming machines help to manage the radiant heat from furnaces, thus reducing the exposure to operators.

“Camera images are relayed to the operator pulpit and the operator can watch the skimming cycle from a safe

Mr. Tomkinson summarised the benefits of using this technology: “Smart cameras reduce unnecessary door openings, shortening cycles, and saving energy. These systems can increase safety and potentially avert accidents. Smart cameras also allow the melt cycle to be optimised, ensuring charging can take place safely, at the first opportunity. Furnace monitoring systems allow playback, trouble-shooting and diagnostics. It is believed that in the future all new furnaces will incorporate infurnace cameras.”

Rockwell Automation

“Aluminium companies need to adapt to an ever-changing environment,” stated

location, away from the furnace,” Mr. Tomkinson stated. “Through precise position measurement and control, it is possible to follow a pre-determined skimming pattern, lane-by-lane, to remove the dross from the furnace, without contacting or damaging the refractory nor the need for an operator to be onboard the machine. However, the machine will skim the entire surface of the bath regardless of the location of the dross, or if the dross moves into an already clean and previously skimmed lane, the machine was effectively blind and would not react. The solution was to install smart cameras on the skimming machine that have a view of the bath surface. The cameras identify the difference between dross and a clean surface and drive the skim blade to the location of the dross and remove it from the furnace.”

Steffen Zendler, Europe, the Middle East and Africa (EMEA) Strategy and Marketing Manager – Heavy Industry at Rockwell Automation. “Current market conditions are characterised by excess production capacity, oversupply of raw materials, constantly changing raw material and energy costs, growing demand for new products, and evolving workforce demographics.”

“Considering that energy costs can account for up to 50% of costs associated with aluminium production, the global energy crisis contributes to the challenges for this industry,” Mr. Zendler noted.

Aluminium International Today March/April 2023 THE ALUMINA CHRONICLES 10

“Aluminium companies need to adapt to an ever-changing environment,”

stated Steffen Zendler

Steffen Zendler, EMEA Strategy and Marketing Manager –Heavy Industry, Rockwell Automation. (The photograph was provided courtesy of Rockwell Automation.)

“Rockwell Automation’s powered end-to-end systems integration and scalable analytics facilitate better decision-making thanks to both supply chain and smelter-to-market visibility. The Connected Enterprise provides real-time guidance on the digital way forward, whilst prioritising secure networks and workforce safety simultaneously, creating an infrastructure that enables operators to reduce downtime and maximise efficiency, with the help of predictive and prescriptive maintenance across processes and infrastructure.”

“Smart data analytics and insights help to improve process efficiencies, quality of end products, and timely management of supply chains,” he continued. “In the context of smelter digitalisation, smart sensor technology enables the tracking of materials, manpower, consumables, and emissions. Further, the application of the relevant layers of technology such as digital twins and simulation models helps drive operational efficiency, better throughput and higher profitability by managing validation costs using simulation and allowing for the testing of engineering ideas before implementation.”

Mr. Zendler stated that “artificial intelligence and machine learning offerings facilitate the seamless transfer of knowledge and skills, where augmented reality and virtual reality are useful in improving collaboration across different project locations and making operations safer, where new talent and workers are onboarded.”

Rockwell Automation is engaged in a number of efforts to streamline production in the aluminium industry.

“Our solutions for the metals and mining industries employ data capture, integration and processing capabilities of the Connected Enterprise, leveraging analytics for better and faster decisionmaking,” explained Mr. Zendler. “Streamlining production in the aluminium industry is one of the many benefits of the Connected Enterprise. A connected aluminium smelter converges plant-level and enterprise networks, securely connecting people, processes, and technologies.”

“The information revolution has created a huge opportunity for metals companies to fundamentally change their business – to become more productive, agile, profitable and safe,” he continued. “Across the globe, Rockwell Automation technologies are focused on driving effective outcomes with solutions built for optimisation, by helping aluminium producers harness their manufacturing and production data to improve operations and influence business decisions.”

Rockwell Automation has operations, Mr. Zendler stated, in 44 manufacturing units across 11 countries on four continents, with a multi-cultural workforce of approximately 36,000 across the globe.

He cited a few challenges facing the aluminium industry in the years ahead: “The need to upskill new workers against the backdrop of retiring workforce and the advent of new technology offerings; increased capital and operational costs; limited access to resources or pricing instability (raw material, water, energy); market volatility as a new normal (energy and other commodities pricing); and the need for all industries to transition to sustainable models.”

To meet some of these challenges, Mr. Zendler stated that “Rockwell Automation is committed to working with aluminium companies, and the wider metals industry, helping them achieve their business and sustainability objectives, bringing the Connected Enterprise to life. With this integrated and holistic solution, producers can gain situational awareness of single or several operations from any location; deep contextual insights across the value chain, including energy, emissions, and asset efficiency; the ability to benchmark operations from different sites for operational improvement; and real-time operational plant-control systems whilst providing an enhanced user experience.” �

Preparation Technology for Carbon Paste

Choose the Eirich solution:

• Low investment costs

• Low operating and maintenance costs

• Simple and swift commissioning

• Optimum mixing and cooling conditions

• Excellent paste quality

• Maximum plant availability

• All key machinery is manufactured in our own workshops

• Reliability for more than 150 years

eirich.com

THE ALUMINA CHRONICLES 11 Aluminium International Today March/April 2023

Where will Green energy come from?

Where will Green energy come from?

By Tim Murray*

By Tim Murray*

Today sustainability and going “Green” are of paramount importance to the world. For the world to make this transition it will need to wean itself of its never-ending thirst for fossil fuels. However, this is MUCH easier said than done, given the vast majority of today’s installed power generation capacity is based upon fossil fuels.

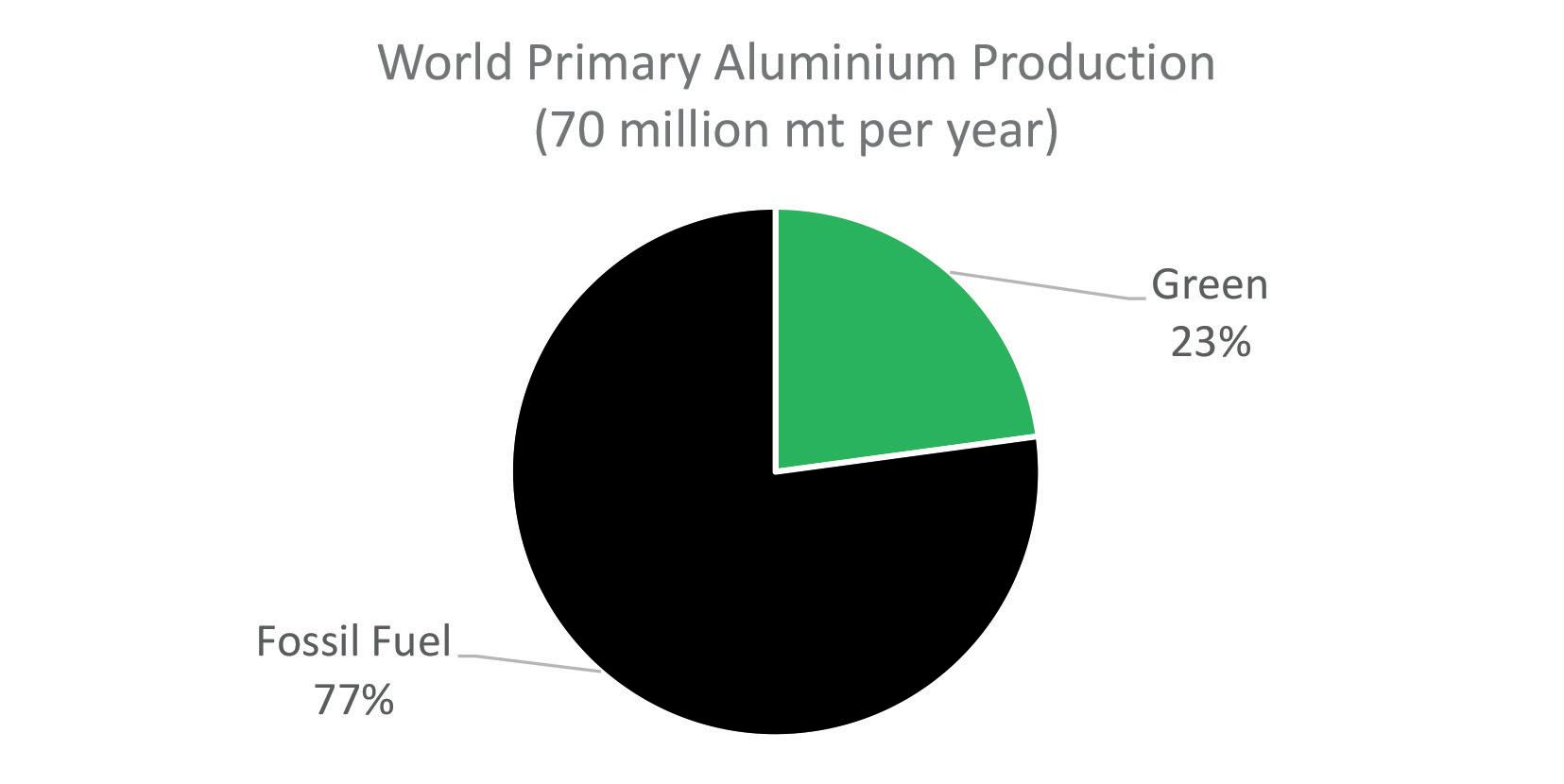

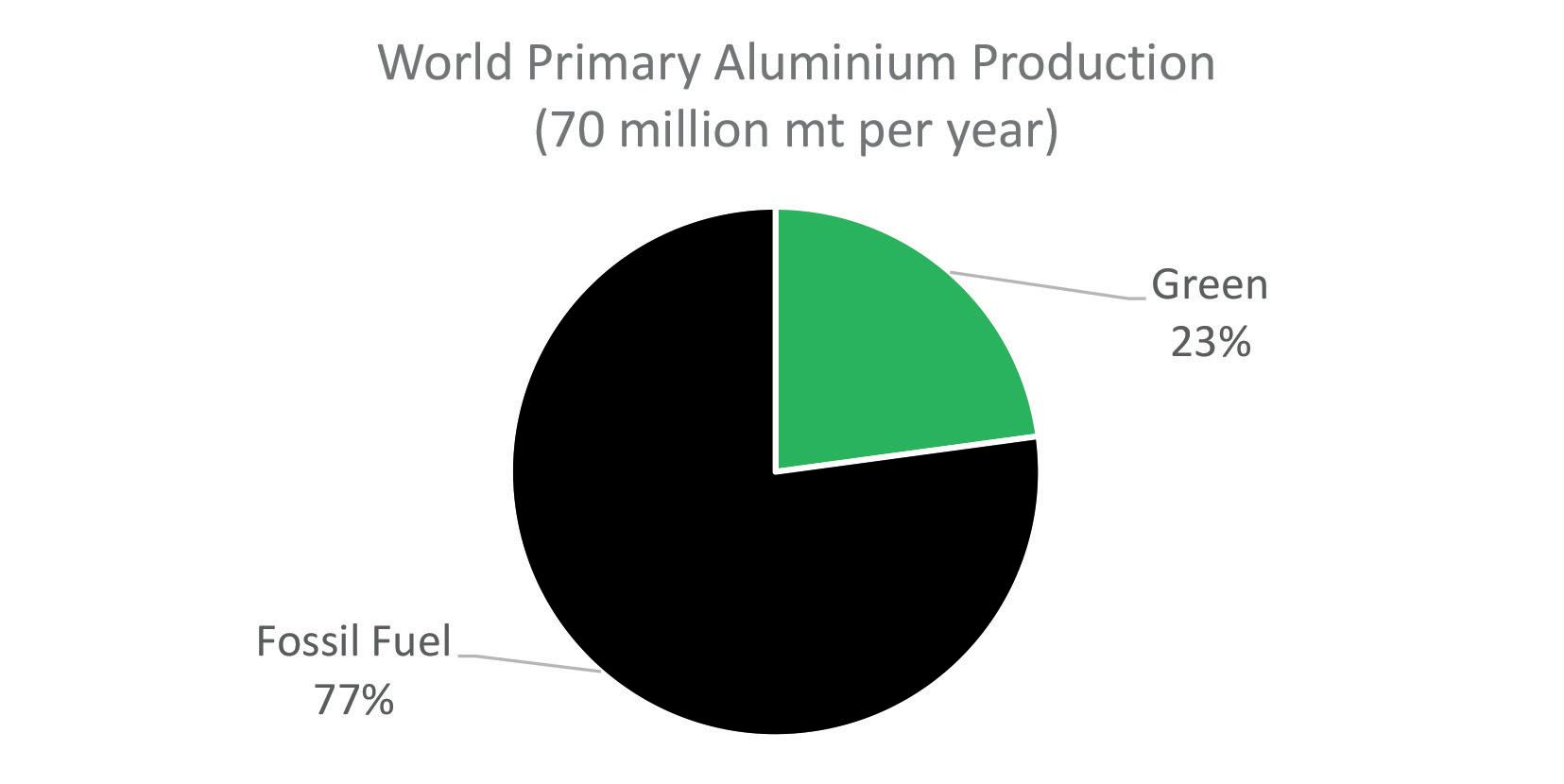

Nowhere is this more evident than in the highly power intensive aluminium industry. In 2022 the world production was approximately 70M mt of which 77% was from fossil fuel power generation. In terms of green energy (Wind, Solar, Hydro and Nuclear) only 23% coming from green energy. I know many people will say that Nuclear is not truly green but I think we have to be practical and acknowledge that nuclear is a highly efficient form of carbon free energy.

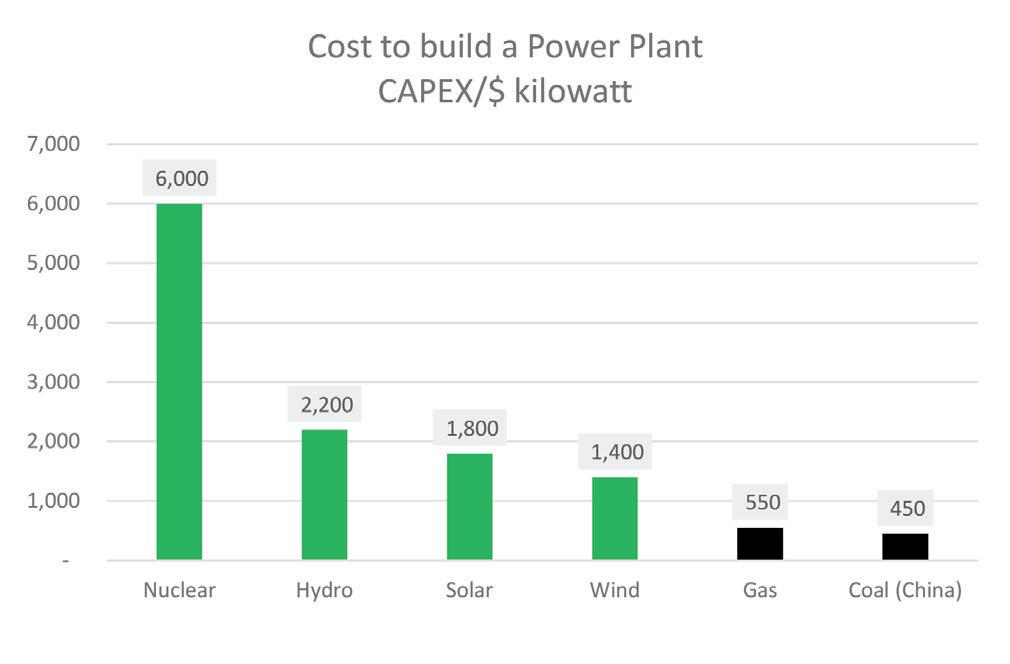

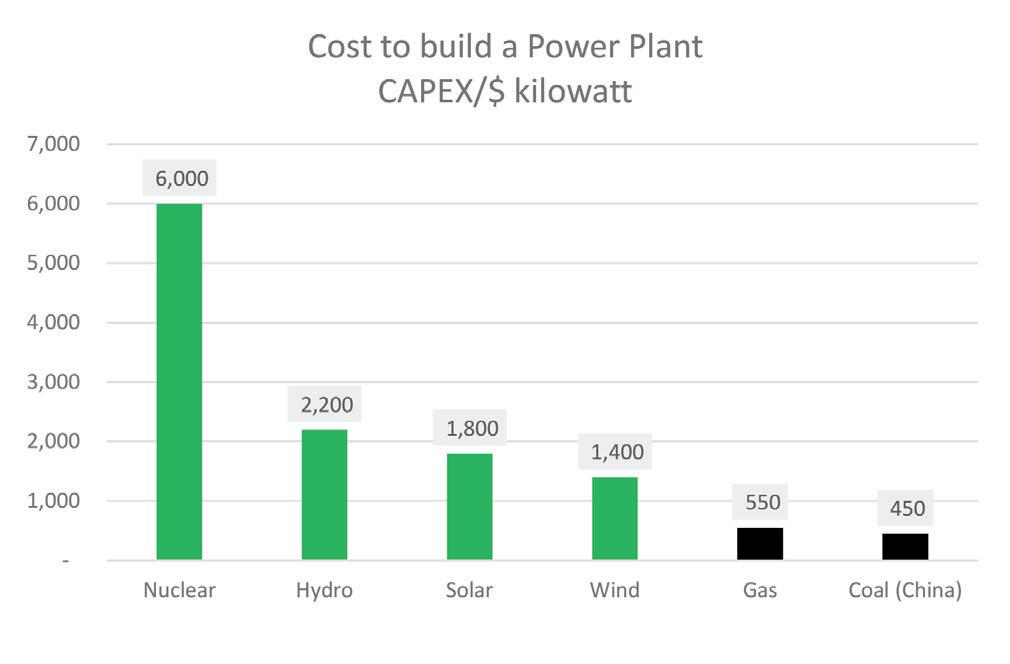

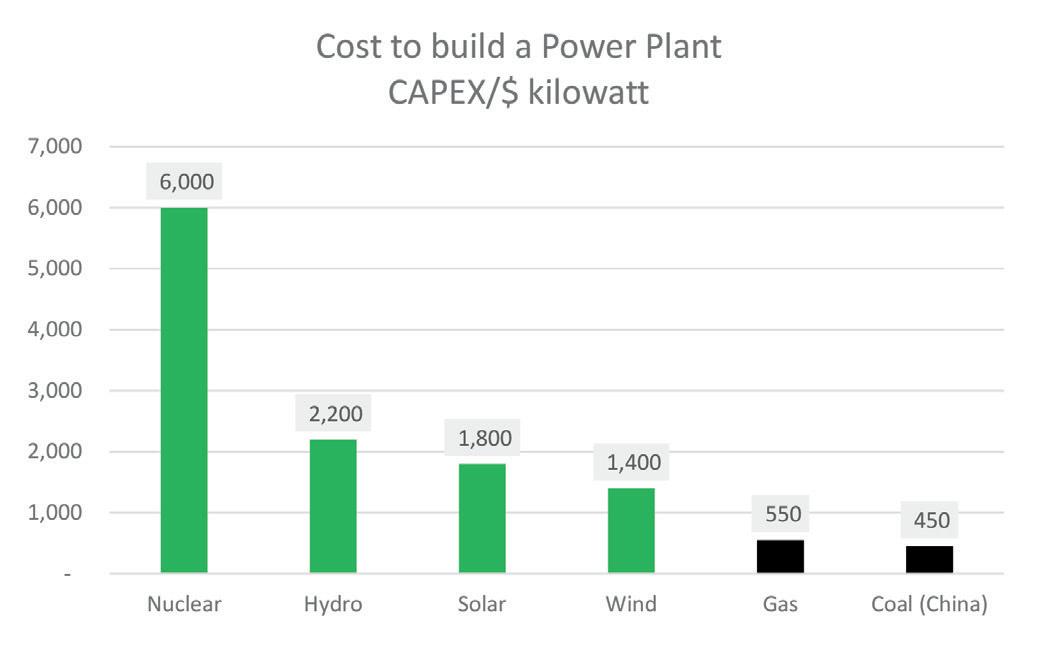

In terms of green energy the capital cost to build such plants is much higher than a fossil fuel plant. In addition, the time to construct green energy projects also takes longer given the significant amount of government regulations. As you can see in the charts below green energy is clearly more expensive and time consuming. Only in the case of solar is the time to construct comparable to fossil fuels.

In terms of the cost to build a green

energy plant power station if we average the green columns in the chart above, we come out with $2,850 per kilowatt of installed capacity versus $500 per kilowatt for fossil fuels.

Also, the time to build a green power plant is much longer with the average being five years whereas a fossil fuelbased plant is around 2.5 years. So, it is obvious there is a financial disadvantage to building a green energy plant versus the alternative of a cheaper/faster fossil fuel plant.

We need Governments to work in a more coordinated fashion to expediate new projects and reduce the red-tape. In

addition, Governments need to provide more financial incentives such as subsides and/or loan guarantees to fund large scale projects. We cannot assume that private companies will invest capital where there is a financial disadvantage or not a clear payback on their investment. The transition to more green energy needs to be a partnership between industry and government.

In conclusion the road to a “Green Energy” is going to be long and expensive. We as a society need to embrace this transition however there must be a practical give and take to make this transition a reality. �

Aluminium International Today March/April 2023 ENERGY 12

*CEO of Cardinal Virtues Consulting

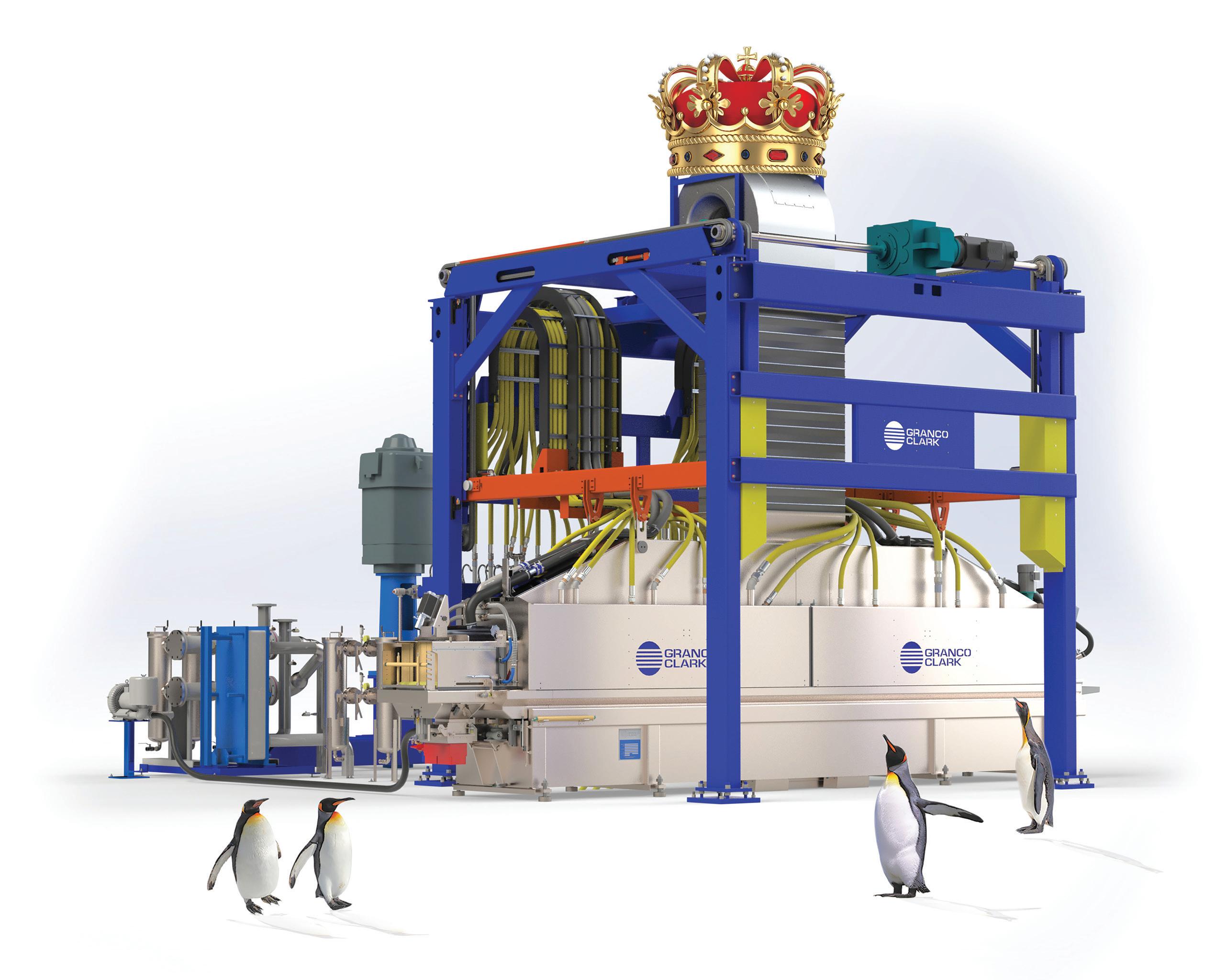

KING OF COOL Performance Driven Our high-performance, high-impact quenching systems are unmatched. Excellence is our standard. +1-800-918-2600 | gcinfo@grancoclark.com | www.grancoclark.com THE Scan: Impact quench data

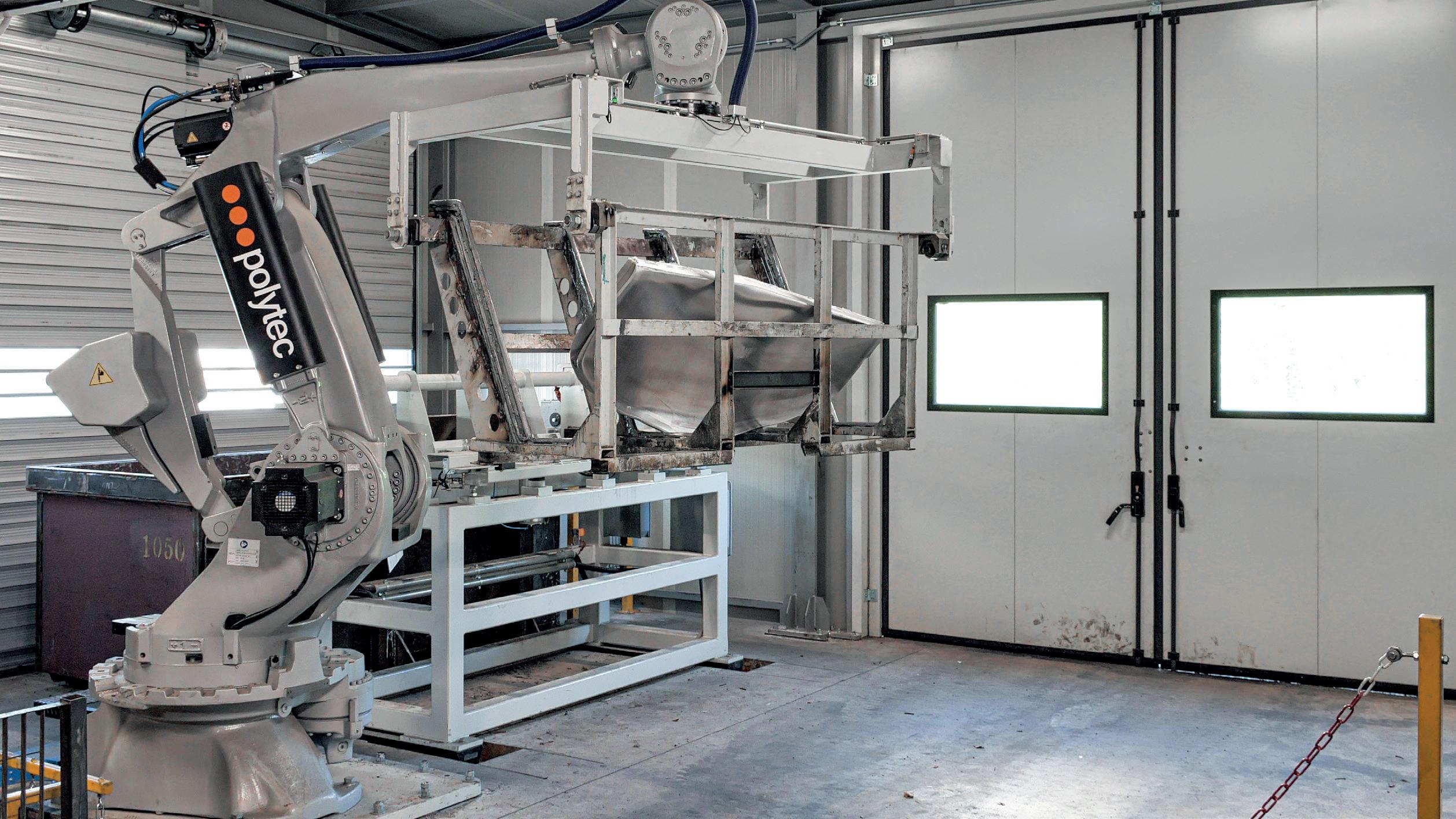

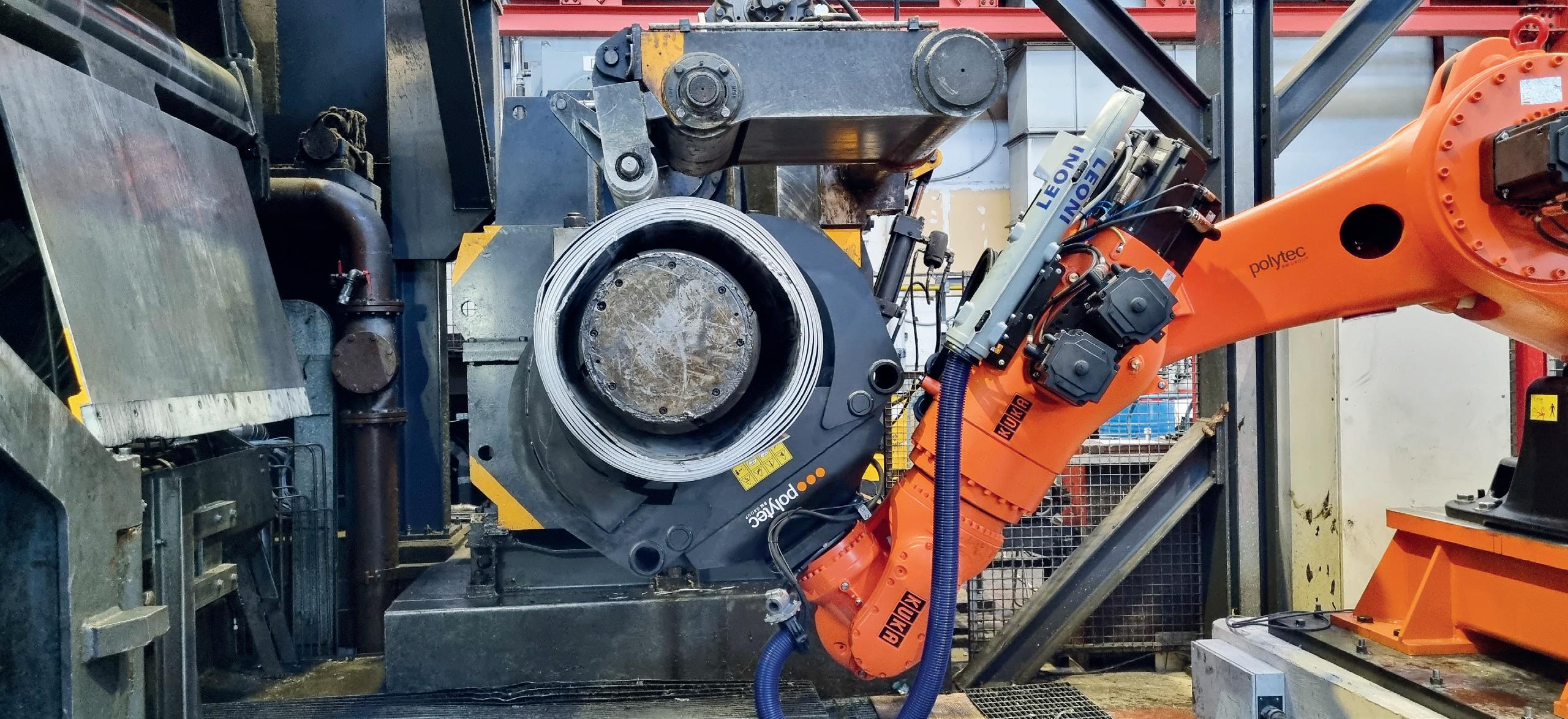

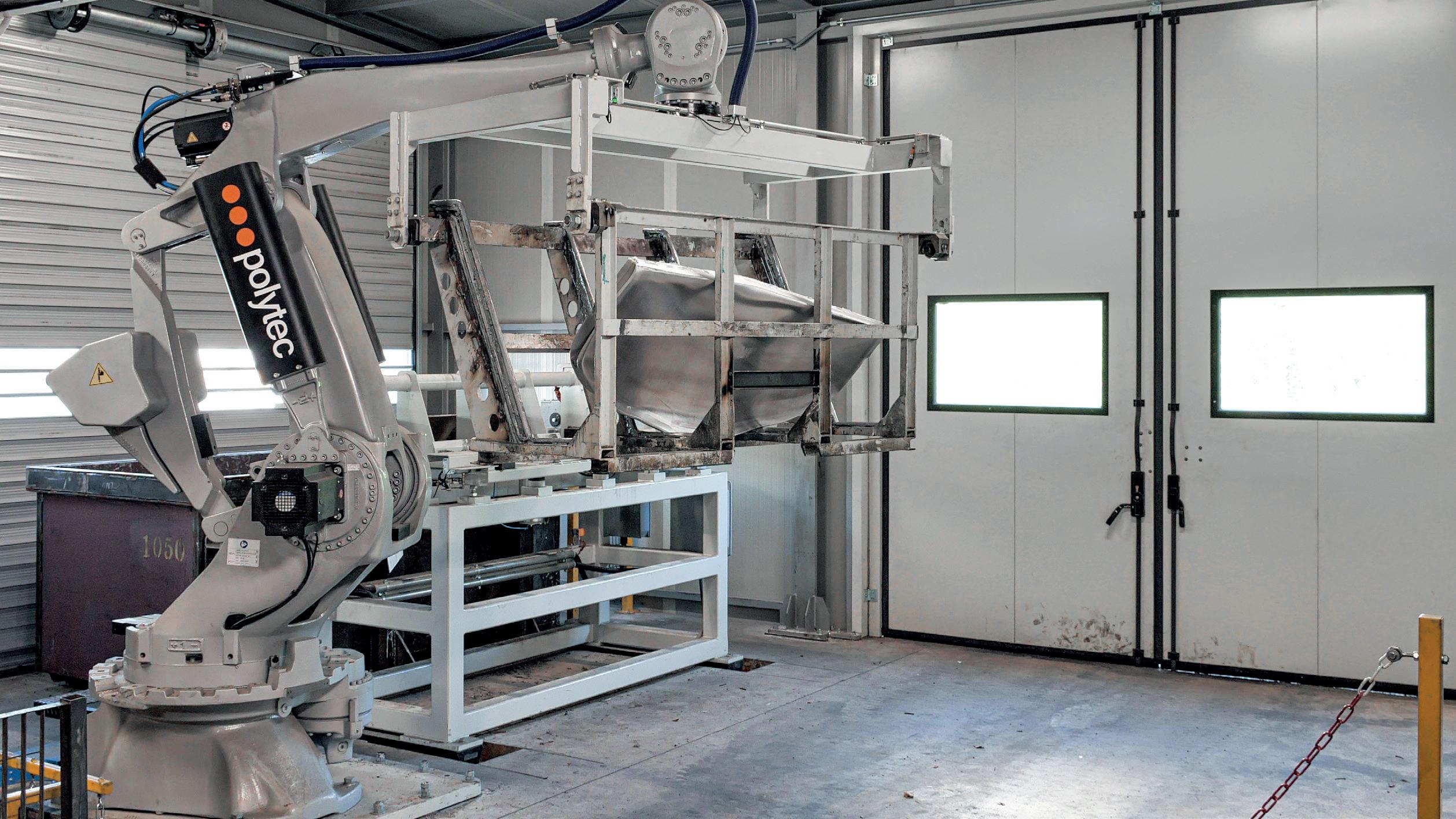

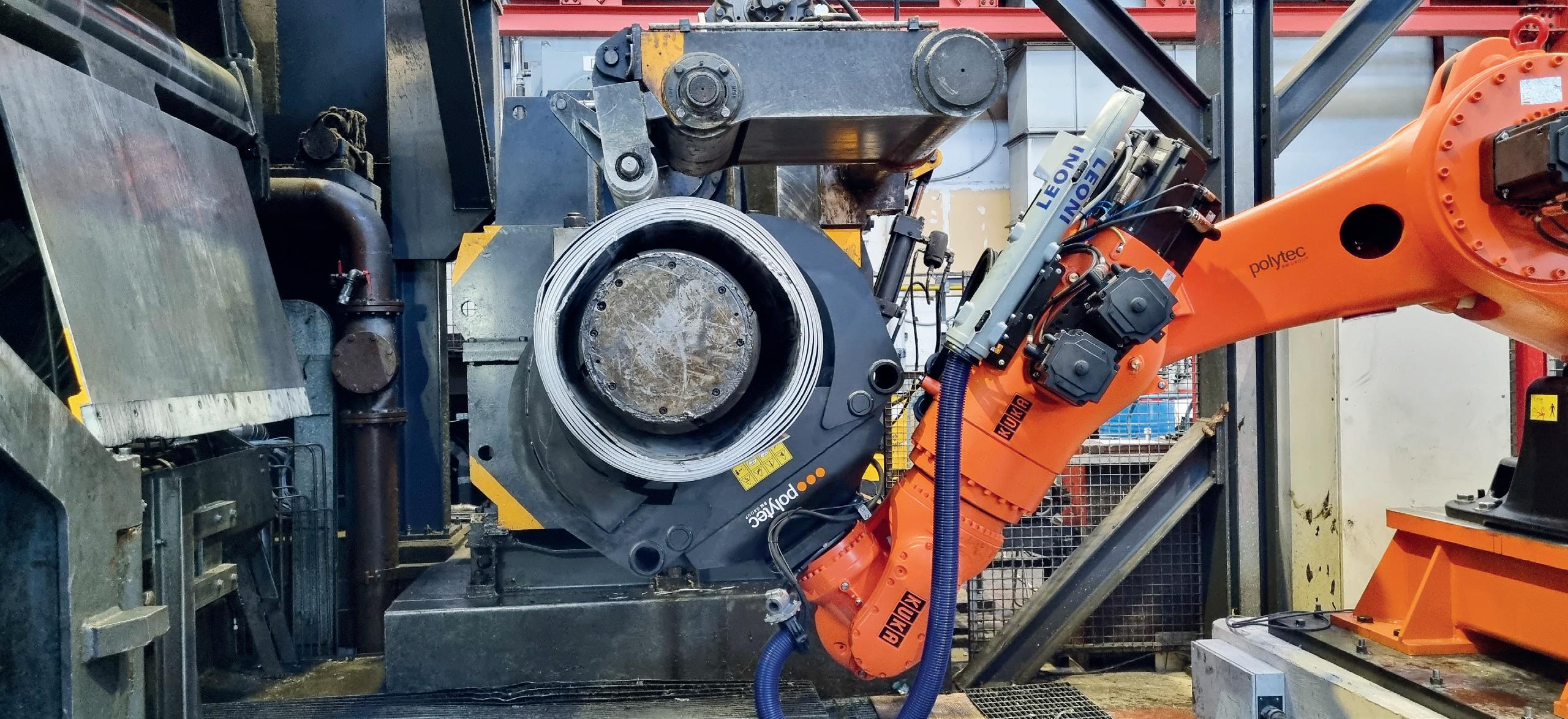

TAILOR-MADE ROBOTIC SOLUTIONS

▪ Plate removal and replacement in the ceramic foam filter

▪ Coil waste removal from the rolling mill unwinder

▪ Strap cutting and removal

▪ Machine tending for aluminum components

▪ Ingots handling and palletizing

▪ Coils marking and tagging

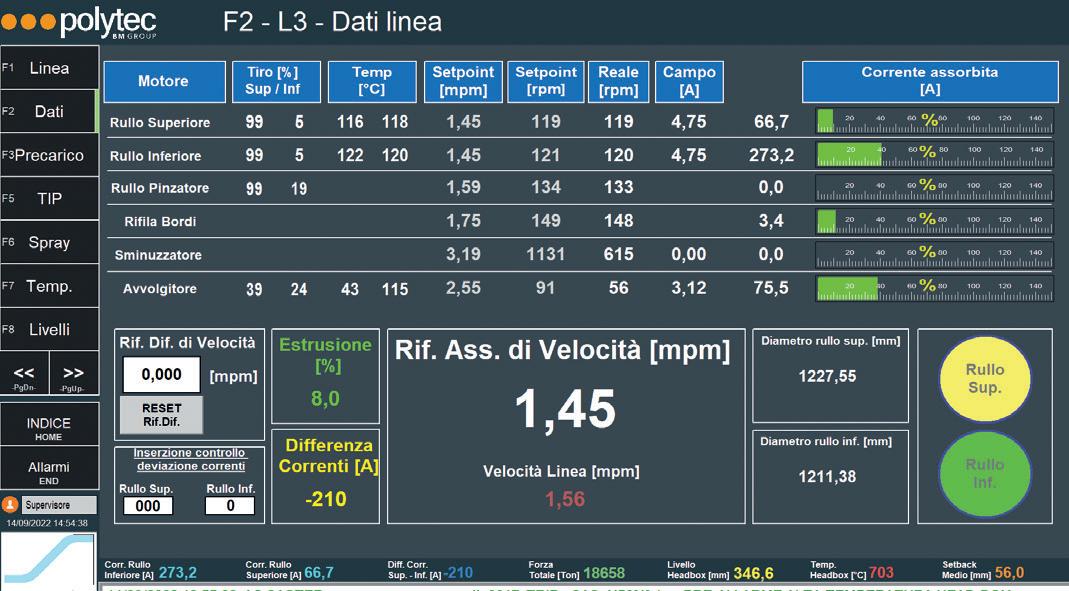

ALUMINUM PLANT UPGRADING AND RETROFITTING

By introducing digital technologies, aluminum producers can notice a significant leap in productivity, while offering a better control over the production process and customer reach. This also provides better safety and environmental sustainability.

OUR EXPERTISE

Automation and Process Control, Electrical Engineering, Distribution Systems HV/MV/LV, MCC and Drive Panels, Safety Management, PLCs & Drives, DCSs, HMIs & SCADA, Data Management, Cloud & IIoT.

polytec.bmgroup.com

sales@bmgroup.com

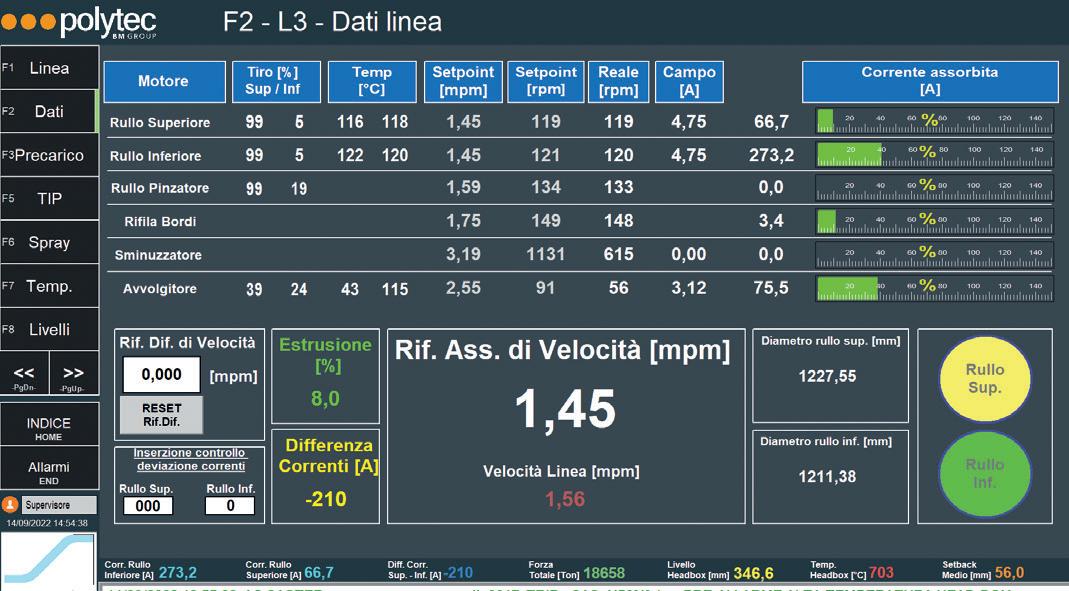

Aluminium towards Industry 4.0

By introducing digital technologies and Industry 4.0 automation, aluminium producers can record a significant leap in productivity while offering a better control over the production process and customer’s reach out. This approach also provides better safety and environmental sustainability. The combination of digital and automation systems, industrial internet and big data, makes smart factories a reality.

Our mission is to introduce breakthrough technologies that rapidly adapt to new situations and to anticipate the concept of “lean production”, while supporting the customer on the path of change towards a continuous improvement culture.

Electrical equipment and automation retrofitting

After melting, the semi-finished products undergo other processes including hot rolling to be transformed into flat products and subsequently into coils. Polytec provides automation and control by providing process control technology systems based on real-time platforms.

The cold rolling of aluminium flat strips requires quick, efficient and easy-tomanage controls. Process optimisation to reduce scrap is essential and the basis of our control software. Polytec is able to carry out the entire automation for complete control of the rolling process on roughing and intermediate rolling mills. Stands cylinders regulation and compensation algorithms and reel motors internally, allow to guarantee excellent performances in terms of thickness stability and reaction speed of the entire hydraulic AGC system in reaching the target of desired thickness reducing the coils’ scraps (heads/tails). Tailored regulation of these processes is

essential to meet customer’s needs and satisfaction.

An area of production of aluminium products uses extrusion presses and machines to reshape the profile of the extrusions (stretching machines). Polytec is able to supply automation systems based on PLCs complete with software entirely designed in-house, active remote units, supervision and management systems capable of completely controlling the plant from Level 0 up to interfacing with the MES.

Smart robotics tailored to aluminium production process

The automation and electrical equipment upgrade projects carried out for important manufacturers in the sector, have allowed Polytec to deepen the knowledge of the production process and to imagine the integration of robotics, which presence is still scarce in this sector.

In just a few years, Polytec has been able to engineer and commission robotic cells that provide great advantages in terms of workers safety and liability reduction while improving production with solutions that provide error-free product identification, downtime minimisation and overall productivity improvement. The robotic solutions developed resist both environments in which temperatures are high and in the presence of acids, replacing humans in high-risk tasks.

Following the flowchart we engineered multiple solutions, an automatic robot for managing the Plate removal and replacement in the Ceramic Foam Filter can be integrated in the melting area, while numerous robotic solutions for handling, palletizing, marking and tagging are

available to be integrated throughout the complete production process (ingots, coil products..).

Specific automatic robots have been engineered and supplied answering customer’s critical issues such as strap cutting and removal, coil waste removal from the rolling mill unwinder and for the machine tending for aluminium components.

“Big data” and images collection support producers in the production predictive analysis to better control operations and to improve process management. Machine learning lets machines access data and learn for themselves, to operate independently. By integrating artificial vision with robotics, it is possible to achieve products’ and production’s data, improving traceability and reporting to aluminium producers a “product data sheet” that certificates its quality.

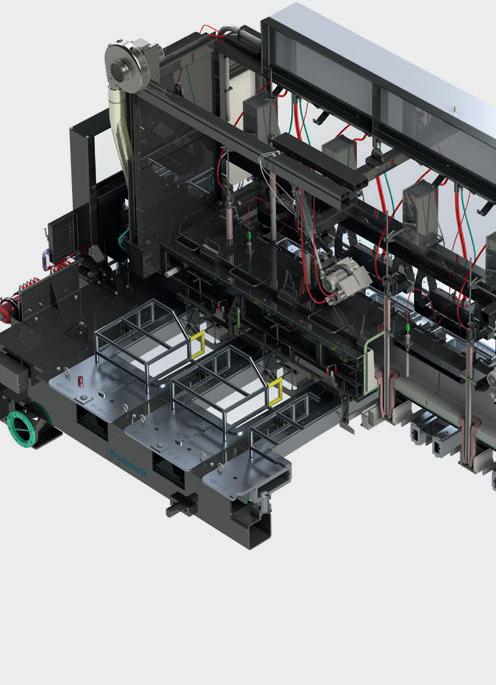

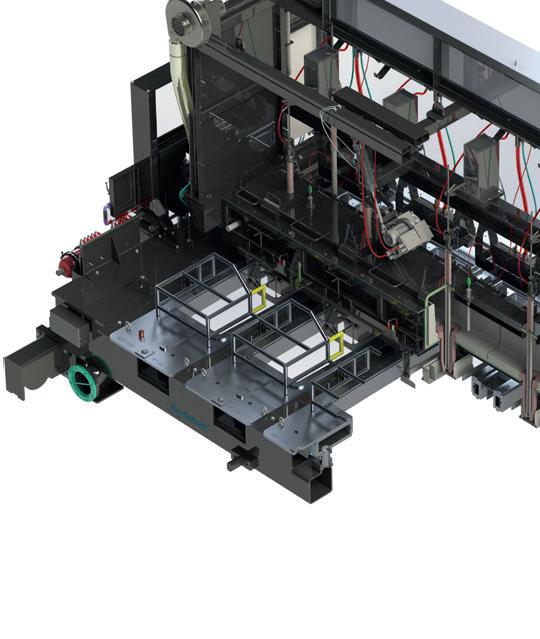

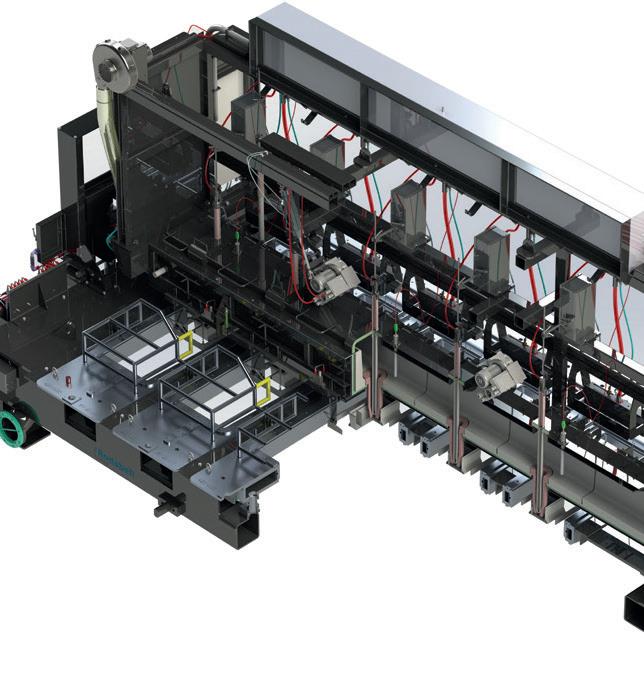

Automonous mobile robots for a smart warehouse management

Automated Guided Vehicles (AMR) are an active part to manage the warehouse smartly.

For logistics and operations like picking, handling and shipping preparation AMRs help to process more orders in “busy” warehouse’ environment, to increase capex and maintain customer satisfaction. Autonomous mobile robots work collaboratively with warehouse operatives by transporting batches to the next stage of processing, allowing workers to move on to their next task.

Many materials can be moved and placed within the warehouse by AMRs, placing-related capabilities allow them to move pallets, carts, shelving and racking without the need for a human operator.

INDUSTRY 4.0 15 Aluminium International Today March/April 2023

By operating autonomously, AMR’s move seamlessly within an existing warehouse layout without major disruption to existing operations. On-board sensors, maps, and processing systems allow them to plan routes and adapt dynamically to changes

in their surroundings. AMRs can move stock within a warehouse or between facilities, programming can be flexible. This obligatory route towards a new approach seeks in the continuous improvement of quality and production

efficiency. The strategic key to remain competitive in a global market while paying attention to the issue of sustainability. �

Contact: Polytec.bmgroup.com

| sales@bmgroup.com

Stub Heaters for Primary Aluminium Production

• Supports all Anode Stub Layouts

• Guard Plates to Increase Coil Durability

• For Drying and Heating Pre-Straightening

• Efficient Heating Reducing Downtime

• Tailored to Stub Diameter and Material

• Further Customisability for the End User

Aluminium International Today March/April 2023 INDUSTRY 4.0 16

Call +44 (0)1256 335 533 Email: info@inductothermhw.co.uk www.inductothermhw.com AIT 2020 AD 5.indd 1 18/12/2019 10:01:26

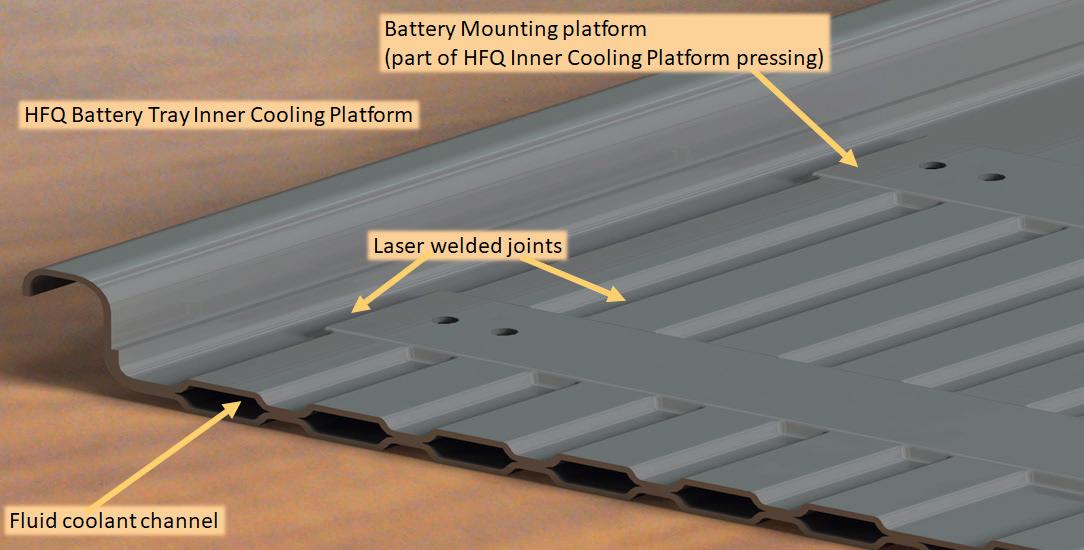

HFQ Technology: Enabling ultra-high strength and sustainable aluminium structures

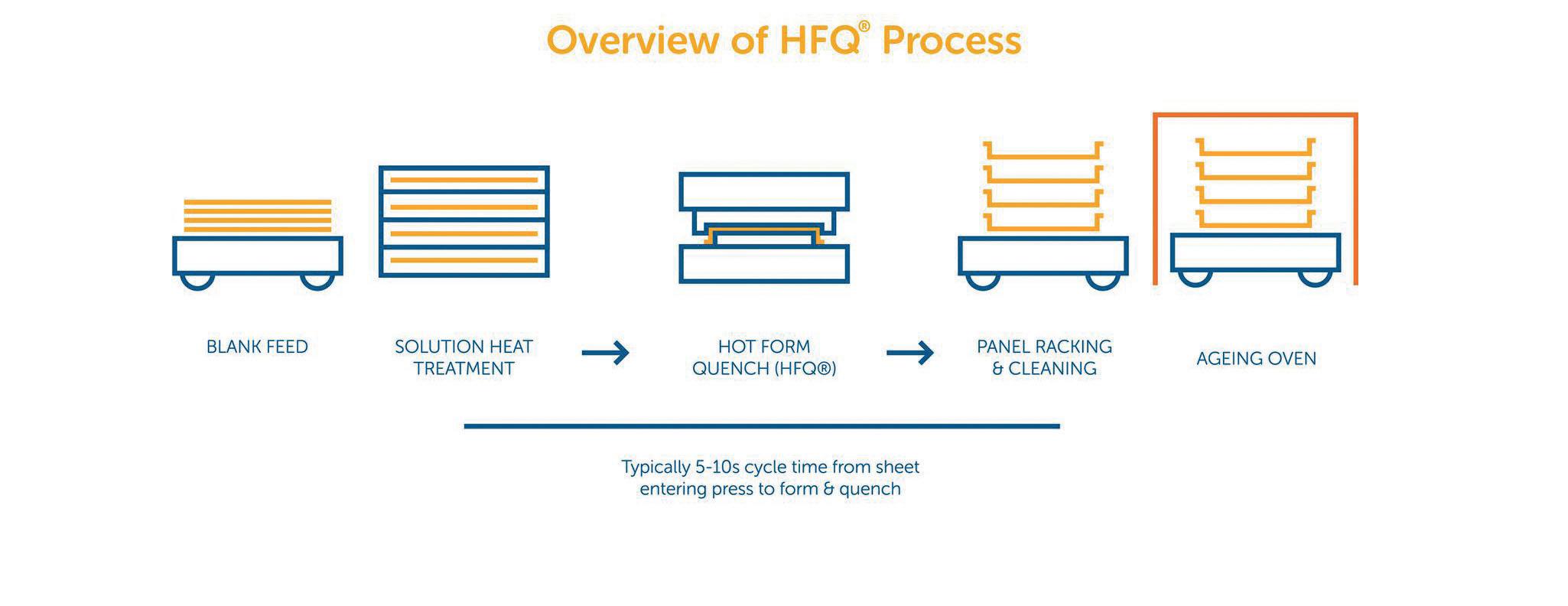

WHAT IS HFQ?

Hot Form Quench (HFQ®) is a novel hot forming process for the production of deep drawn, tight tolerance and complex geometry high strength and ultra-high strength aluminium (UHSAL) sheet components. With many similarities to the press hardening of ultra-high strength steels, but with significant metallurgical mechanism differences, HFQ exploits aluminium viscoplasticity at temperatures , typically, in the 400-550°C range. This allows the rapid production of complex lightweight structures without the problems of spring-back or multiple operations and the option to replace steel, composites, castings, extrusions, stretchformed parts or multiple cold formed pressings.

This hot forming process for high strength aluminium sheet (usually between 0.8 to 4.5mm), in 2x, 6x and 7x series alloys, was researched in the early 2000s by Professors Jianguo Lin and Trevor Dean at the University of Birmingham, and then at Imperial College London. Late in 2012, Impression Technologies Limited (ITL), a lightweighting technology company based in Coventry, UK, was formed with exclusive commercialisation rights for HFQ and the associated intellectual property. ITL has since developed its own additional know-how and rights in this domain, particularly in relation to

advanced forming simulation, aluminium alloy characterisation and the production of serial production parts across a range of alloys and in high volume. Candidate applications span a wide range of sectors including automotive body-in-white, aerospace flying surfaces, seating, ground transportation and consumer goods.

HFQ component manufacture

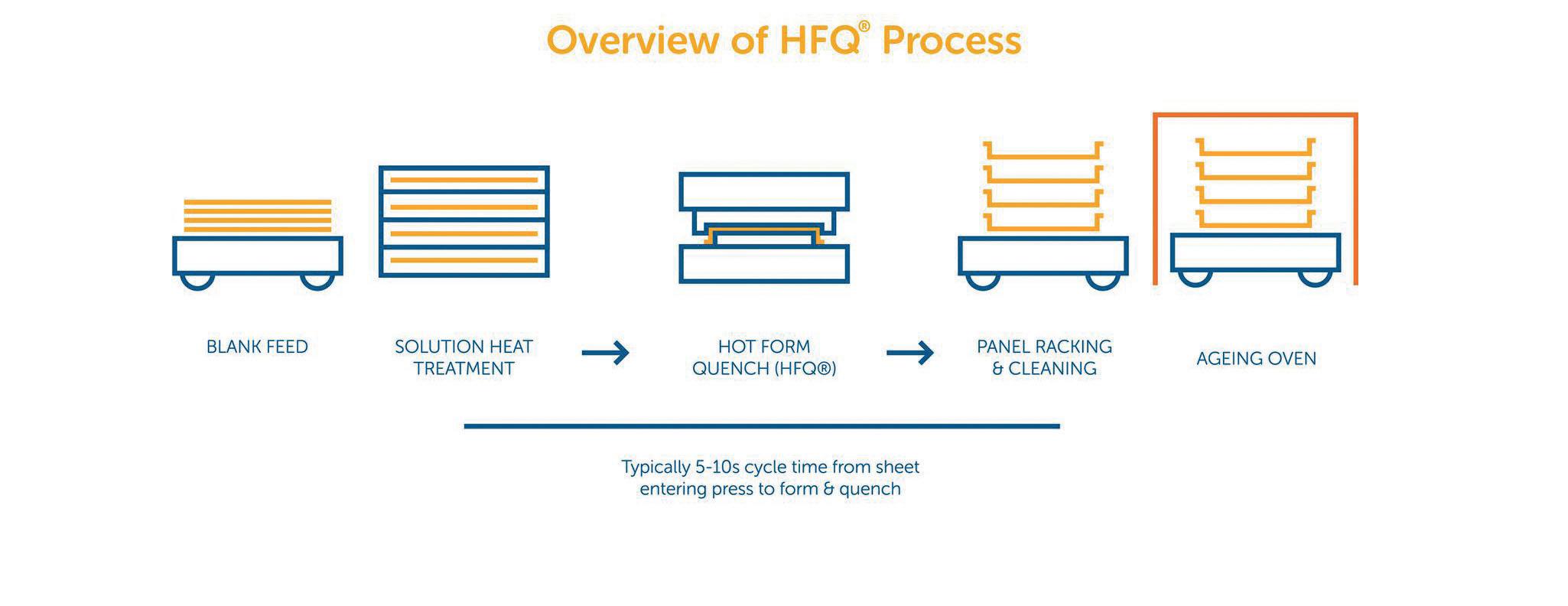

HFQ forming of aluminium comprises four stages as represented in (Fig 1): solutionising, transfer, quenching + forming, and artificial aging. The pressing operation is carried out in a high speed hydraulic, servo-hydraulic or servo press in which the forming tool is cooled to create

FOCUS ON HFQ 17 Aluminium International Today March/April 2023

Fig 2. of fischer production line in Germany

Fig 1. summarising process steps

the necessary quenching to maintain the alloying elements in supersaturated solid solution. The subsequent ageing process enables precipitation and increases the strength of the components to the required level, typically 300 to 500MPa yield, depending on the aluminium alloy used. Customised proprietary ageing processes have been developed to optimise corrosion performance and downstream joining, such as self-pierce riveting. Following the HFQ process, parts can be in-die trimmed or laser trimmed before downstream coating and joining.

Cycle times for the HFQ forming stage can match those for hot forming (press hardening) of steel and are mostly depending on the throughput capacity of the solutionising ovens and sophistication of the process automation feeding the press. Low volume lines for aerospace parts may expect cycle times of 60-90 seconds; whereas for high volume automotive components cycle times per set of parts could be below 15 seconds, with the potential for even faster production with optimised cooled tool designs, process control and automation. Ageing is carried out on batches of parts over a duration of 90-120 minutes for typical applications, the size of the furnace is sized to correspond with the cycle time of the press line. (Fig 2)

Because of the global and cross-sector applicability of HFQ Technology, ITL has adopted a technology franchising model to create a growing global network of accredited manufacturing tiers to serve OEMs. (ITL estimates that the market for UHSAL parts for automotive alone could be several hundred million parts per annum, which could require well over 100 dedicated forming lines.) Aside from its own production facility in Coventry, UK, ITL has licensed automotive tier partners in Germany (fischer group) and China (Jet Wagon) with another dozen tier 1 producers in discussion covering automotive, industrial and aerospace component supply in North America, China, India and Europe. All accredited HFQ manufacturers are trained and supported in HFQ design and manufacture and have access to all future innovations; and ITL works proactively to acquire new applications with OEMs for the tiers in their chosen markets. There is also the possibility for OEMs to adopt HFQ hot

stamping internally where appropriate. ITL supports new tiers with the specification and sourcing of forming lines, with certain equipment providers accredited against the HFQ process.

Applications and design optimisation for USAL components using HFQ HFQ is used where light-weighting and high levels of part integration are required, and where aluminium sheet is considered a suitable technical and economic proposition. In the automotive sector a target premium of $3-5 per kg saved is deemed to be the target when replacing steel structures; and studies have shown that HFQ can meet this for appropriate applications. The economics of production of HFQ components are driven in descending order by input material cost, material/design optimisation and then cycle time.

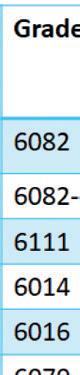

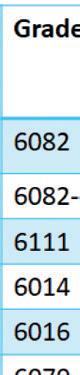

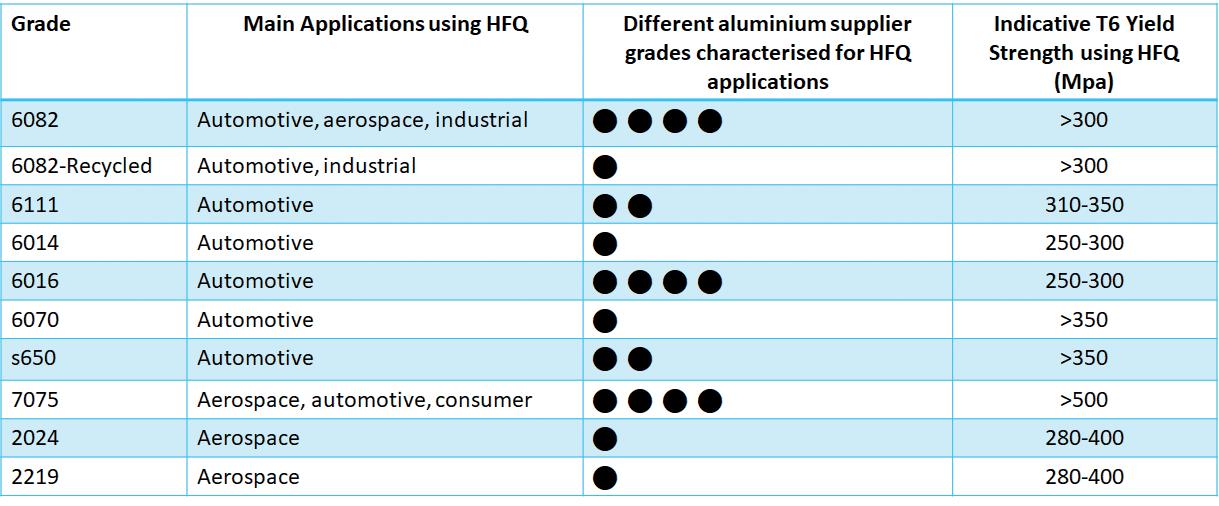

For the automotive sector typical HFQ applications target body-in-white (BIW) structures and closures including A and B pillars, door rings, cross members, sills, dash panels, rear quarter inners, door inners, tailgate inners and under shields Recently there has been significant interest in the use of HFQ for battery lids and casings for electric vehicles (EVs). Currently there are 39 parts in serial production for the automotive OEMs across Europe, China and the US, with many more in development. Alloys used for these applications include the 6x series grades such as 6111, 6082 and 6016 with new project evaluations in 7x series grades..

Aerospace applications are being developed that include lip skins, nacelles, fairings, wing ribs and seats with Boeing recently confirming the economic proposition for aluminium structures formed by HFQ following a joint evaluation with ITL. Transportation sector applications also include electric bicycles, motorcycles, and rail structures. In other sectors, HFQ has been considered to replace heavy castings and machined components, currently made from aluminium where

light-weighting or material utilisation are critical factors. (Fig 3)

HFQ’s main advantage for designers is superior formability for ultra-high strength aluminium alloys, that would otherwise split, excessively wrinkle or suffer from spring-back (or dimensional non-conformity) during conventional cold forming. This leads to greater design freedom for part form, including extremely deep drawn parts (which can exceed 300mm), sharp radii (r/t of 0.8 has been demonstrated) and high levels of part integration versus cold formed pressings. In addition, HFQ enables the manufacture of parts from high and ultra-high strength aluminium, which for strength-prioritised applications facilitates significant weight reductions of 20-30% versus some lower strength cold formed aluminium alloys. Secondary benefits of HFQ include the ability to use lower cost and more widely available F Temper alloy feedstocks and even use highly recycled alloys.

HFQ developments during 2023

There has been an unprecedent number of enquiries for using HFQ to reduce weight, cost and achieve part integration or eliminate dimensional quality issues. Most applications are for EVs with aerospace enquiries growing rapidly. The major trends shaping the evolution of the HFQ Technology are sustainability, continued cost pressures and transport electrification.

Widening alloy choice and offering fully recycled alloy options is a major focus area for HFQ development. With expertise in characterising UHSAL sheet for hot forming, ITL has now established HFQ material cards for high fidelity simulation, matched to the HFQ standard process, for over 18 alloys covering suppliers across the globe. The use of F Temper, enabled by HFQ, also widens the choice for OEMs. With alloys characterised to a standard, OEMs can be confident that simulations for different alloys for a given geometry will be accurate; and they then benefit from choice of supply. In addition to standard commercial grades

Aluminium International Today March/April 2023 FOCUS ON HFQ

Fig 3. Photo of HFQ part - automotive

Fig 4. alloy availability table

TOGETHER TOWARDS PERFORMANCE

NOW IS THE TIME TO ACT REEL is on a journey contributing towards a net-zero Aluminium Industry.

reelinternational.com

REEL Aluminium is a major solution provider dedicated to reduce the carbon footprint in the Aluminium industry. Both internal and external partnership, new ways of understanding and innovative technological investments in the development of net-zero solutions for the Aluminium industry are the best conditions for REEL‘s goals to work together on its path to decarbonization and to green Aluminium future.

of 2x, 6x and 7x grades, ITL has recently demonstrated the forming of automotive structures using 100% recycled 6x sheet, including a batch of 6082 recycled alloy with ~40% post-consumer content supplied by Gränges. Recycled HFQ parts attract significant interest from OEMs because of the potential for reducing embedded carbon by up to 95%. During 2023, a full technical summary will be published on the recycled demonstration programme, followed by the creation of industrialisation partnerships to progress fully recycled aluminium towards serial production. (Fig 4)

Aerospace seating is potentially an ideal application for HFQ, where the technology offers process step simplification, design flexibility and part integration with low cycle times. ITL has recently produced its first seat back demonstrator in fully recycled 6082 alloy, creating a structure that is inherently

stiff, cost-effective and sustainable; and the same structure could be produced in higher strength 7075 alloy. It offers a compelling alternative to composite structures, with the prospect of much reduced cost, superior environmental credential and a competitive weight. During 2023, ITL will engage with aircraft seat manufacturers in all regions to secure applications for serial production. (Fig 5)

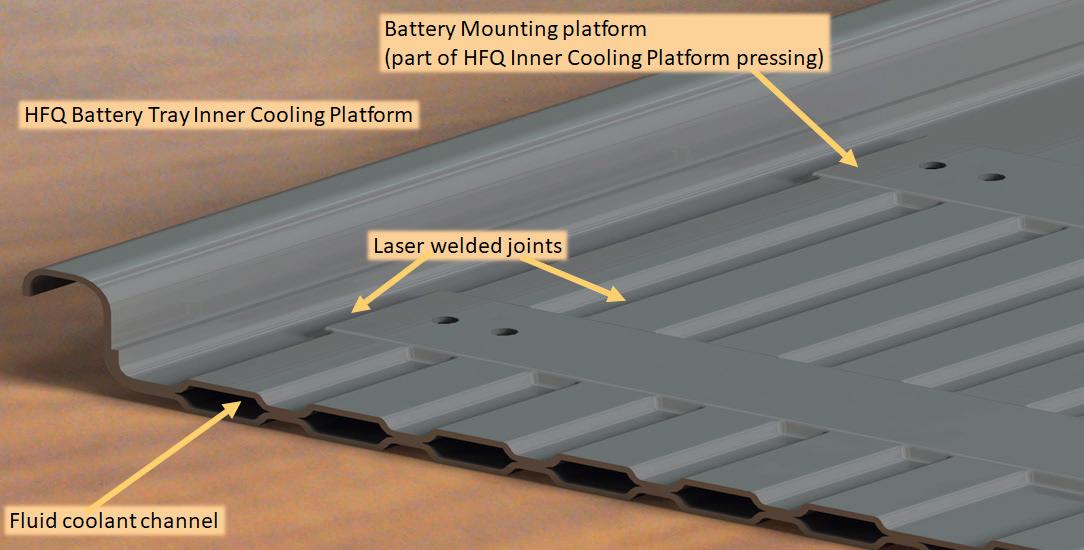

Battery pack trays and lids for EVs may be made from aluminium, steel or composites. For aluminium parts, cold pressings, welded extrusions or castings have been used; all of which are costly to manufacture. With the projected rapid increase in EV production, car makers are searching for innovations that drive down cost of battery packs; whilst tier suppliers are seeking short cycle times and compact production footprints to minimise capital expenditure. With its inherent short cycle time and ability to minimise part count

and joining operations, HFQ is now being considered by tiers, OEMs and design consulting companies as an additional option for high volume battery enclosures. In addition, a confidential development programme, exploiting the full potential of HFQ is currently in progress with a leading automotive consulting player with publication of results due in the second half of 2023. (Fig 6)

In conclusion, HFQ, in serial production since 2016, is now starting to take hold in the automotive and aerospace markets as an enabler of cost-effective and sustainable UHSAL sheet components. Given the scale of the opportunity, the full potential is achievable only via the close collaboration within a global supply ecosystem, supported by the aluminium sector, which stands to gain from a technology that increases the appeal of the material in its quest to be the preferred choice for lightweight structures. �

Aluminium International Today March/April 2023 20

Fig 6 .battery concept photo

Fig 5. Photo of HFQ aircraft seat back

THE BRIQUETTE. The Original. www.briquetting.com More information RUF_M_10_AIT_216x108_GB_oM_neu.indd 1 09.03.21 09:50

Reliable briquetting machines from the world market leader

FOCUS ON HFQ

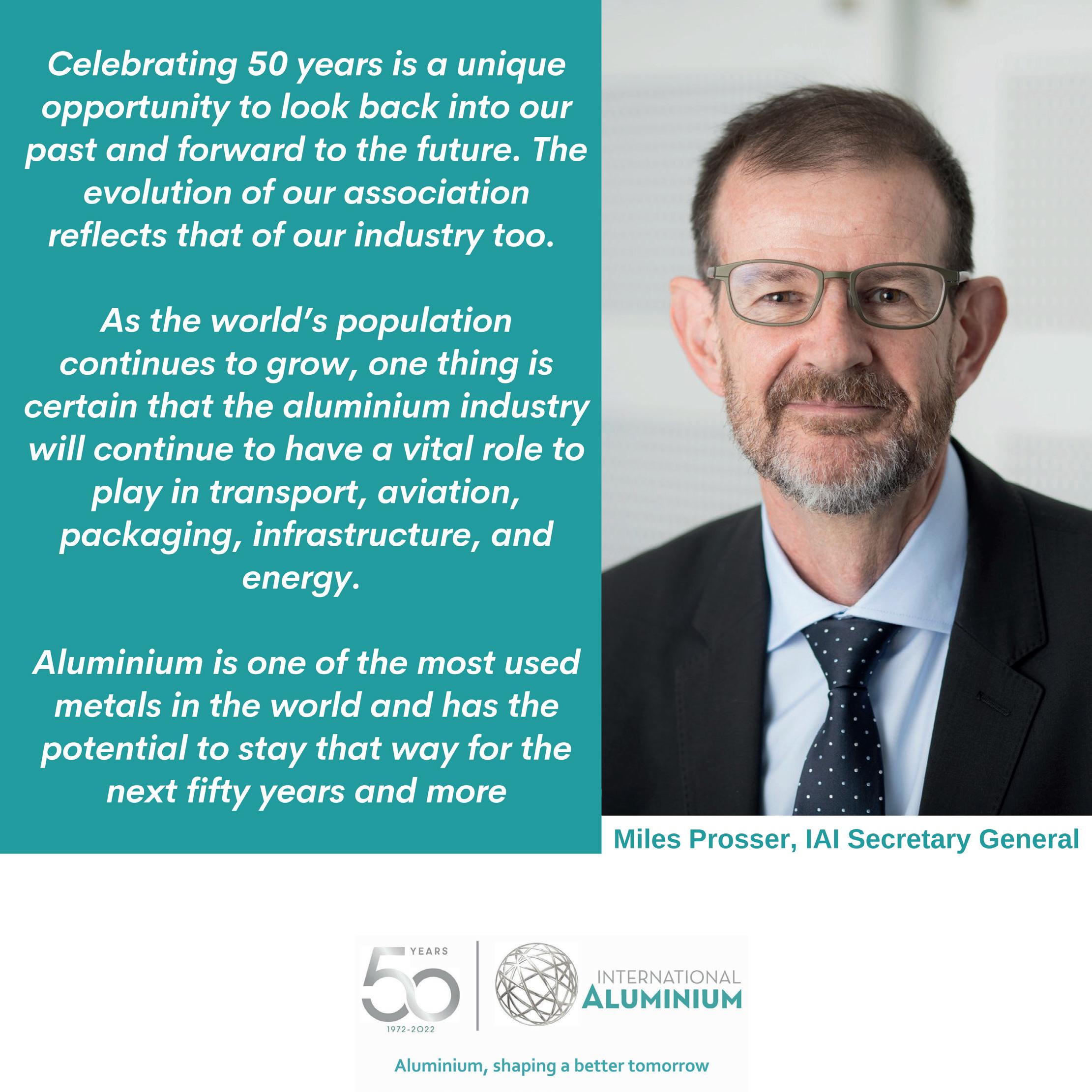

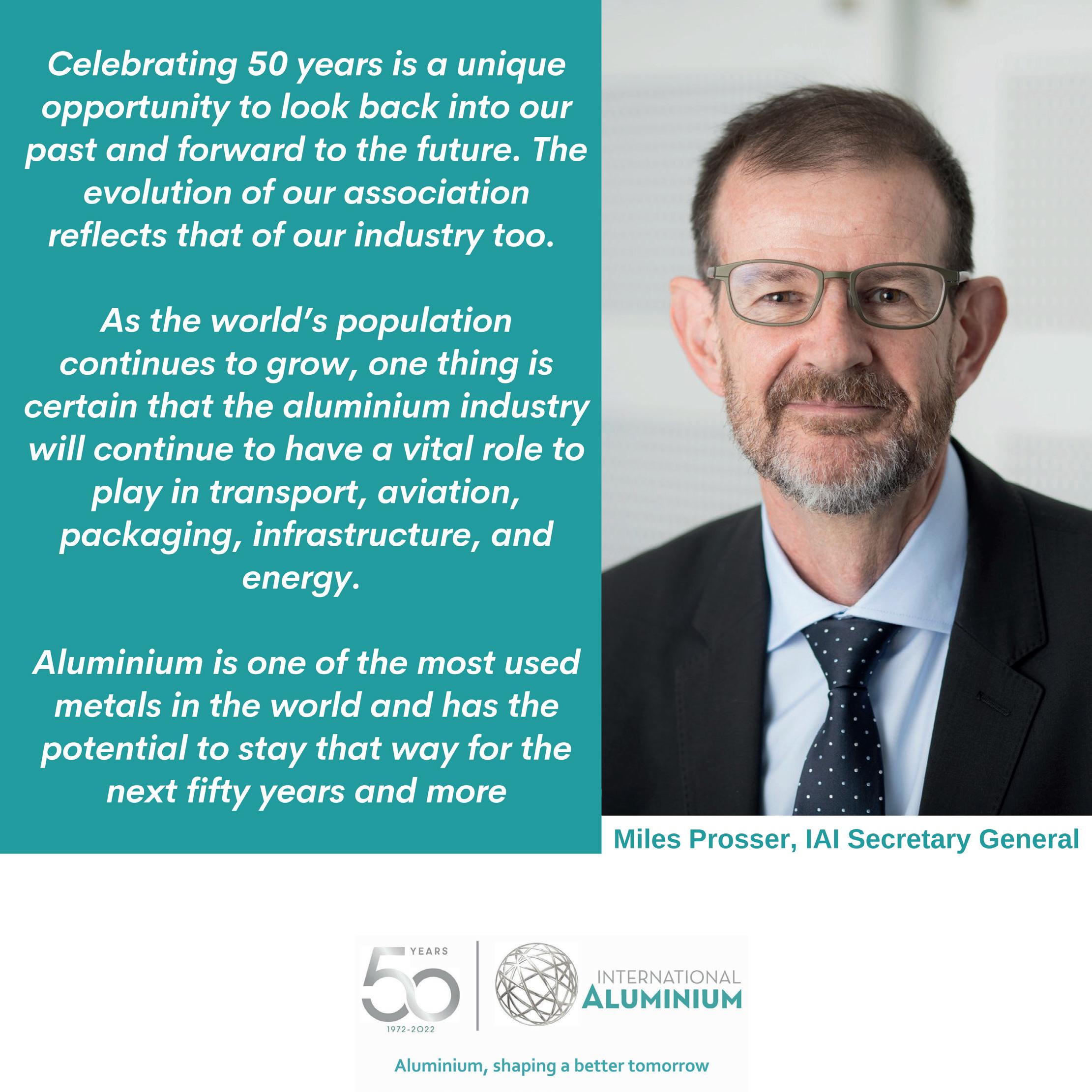

50 Years of the IAI – Thank you!

By Miles Prosser*

By Miles Prosser*

Aluminium International Today March/April 2023 IAI ANNIVERSARY 22

on our past and looking forward to shaping a better tomorrow.

Reflections

*IAI Secretary General

Throughout 2022, the International Aluminium Institute (IAI) marked the 50th Anniversary of its founding and its role in representing the global primary aluminium industry on a sustainable journey. As part of the celebrations, the IAI shone a spotlight on the industry’s people, essential products made from aluminium, and the defining moments in our sector’s history.

The IAI was established in 1972 primarily to foster industry collaboration with a focus on collecting and publishing statistical data – and this remains one of the IAI’s core priorities.

Over the past 50 years, the IAI has been a leading voice for the aluminium industry, providing solid data which is widely acknowledged as credible and robust with statistical and analytical expertise honed over several decades.

The Anniversary has been a unique opportunity to reflect on our past and look forward.

We recognised just some of the trailblazers, milestones, events, and essential products that have played a vital role in shaping society today and contributing to meeting tomorrow’s challenges.

50 People

The 50th Anniversary of the IAI provided us with an enormous opportunity to celebrate the diversity of people who have contributed and continue to contribute to the progress and development of aluminium and the industry.

From engineers to directors, we all work towards a common goal: continuing to grow aluminium’s contribution, while promoting sustainability. What a breadth of diversity of the people who make up the aluminium industry!

As we remain focused on progress and development, we recognise the continued efforts of the people who give their time, energy, and heart to this industry. The aluminium industry is vital in our society – thanks to the creativity, ingenuity, and resourcefulness of everyone who is working hard to help shape a better tomorrow.

50 Products

Aluminium has evolved beyond our expectations over the past 150 years, and it continues to be used in new and innovative ways. From everyday essentials such as ladders, buses and electric cabling to less visible but still essential uses, such as industrial heat exchangers, aluminium remains incredibly versatile and fundamental in technology, transport, sustainability and more.

In trucks, for example, aluminium allows the truck itself to be lighter and

use less fuel: this not only allows for a higher freight load with each trip, but it also reduces CO2 emissions from fuel consumption. We can all be proud of the contribution aluminium is making to lowering society’s environmental impact. As transport moves to an electric basis, aluminium’s light weight and recyclability will see it continue as a material of choice for performance vehicles, family transport, and goods transport.

Aluminium is everywhere in our daily lives. Look around your kitchen: utensils, dishes, coffee pods, foil and more will be made from aluminium. Quite literally, aluminium is the essential to all aspects of our society. We use it for buildings, bridges and medical equipment, and, most importantly, it is an instrumental player in sustainability and renewable energy. For wind turbines and solar panels, for instance, aluminium’s ability to withstand the harshest climate makes it a long-term, durable solution.

The closer we look, the more we see just how much aluminium surrounds us. This

formidable metal improves every aspect of our life. From technological advances to creative outlets, its countless qualities have made it the metal of choice in numerous industries.

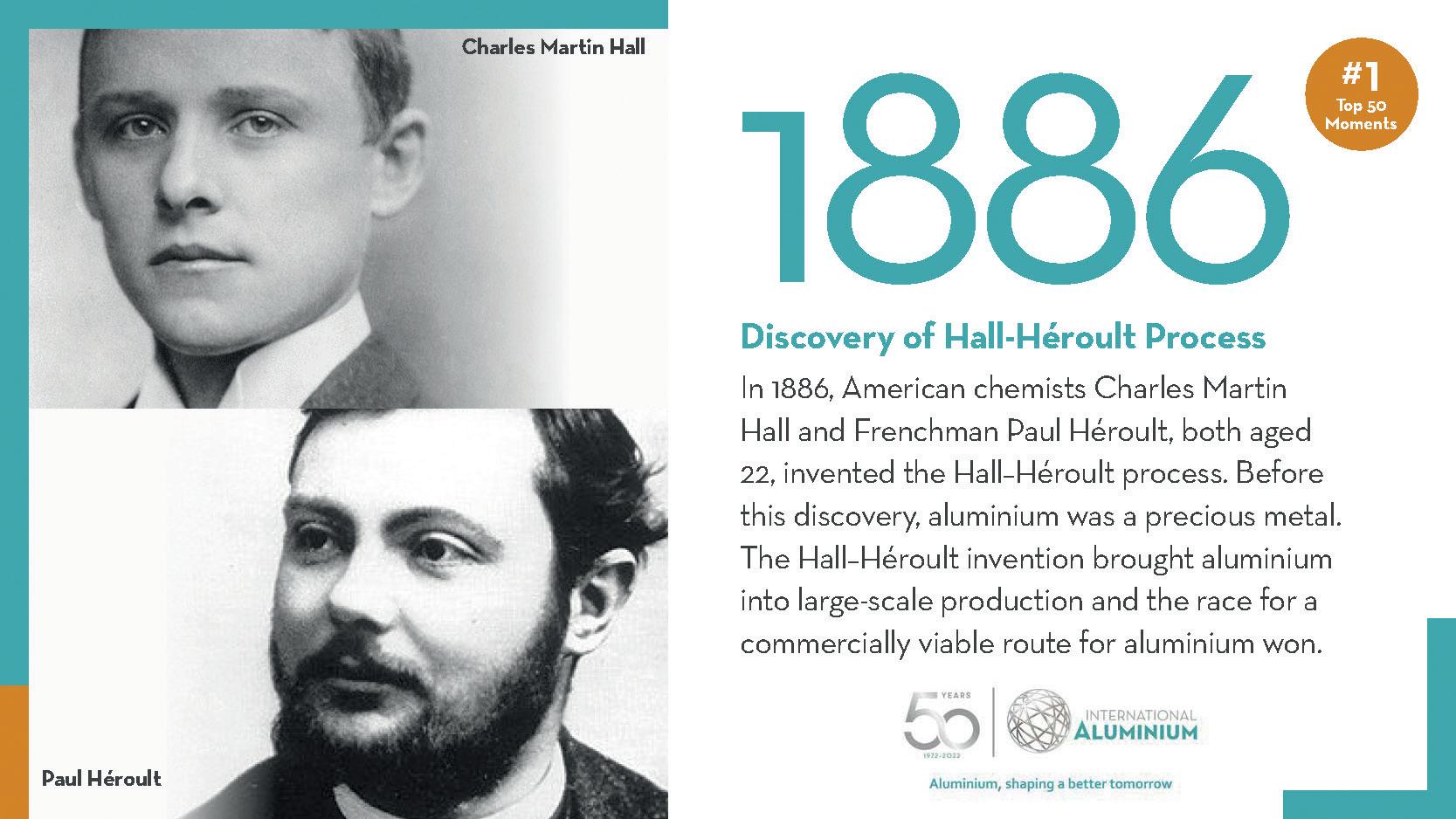

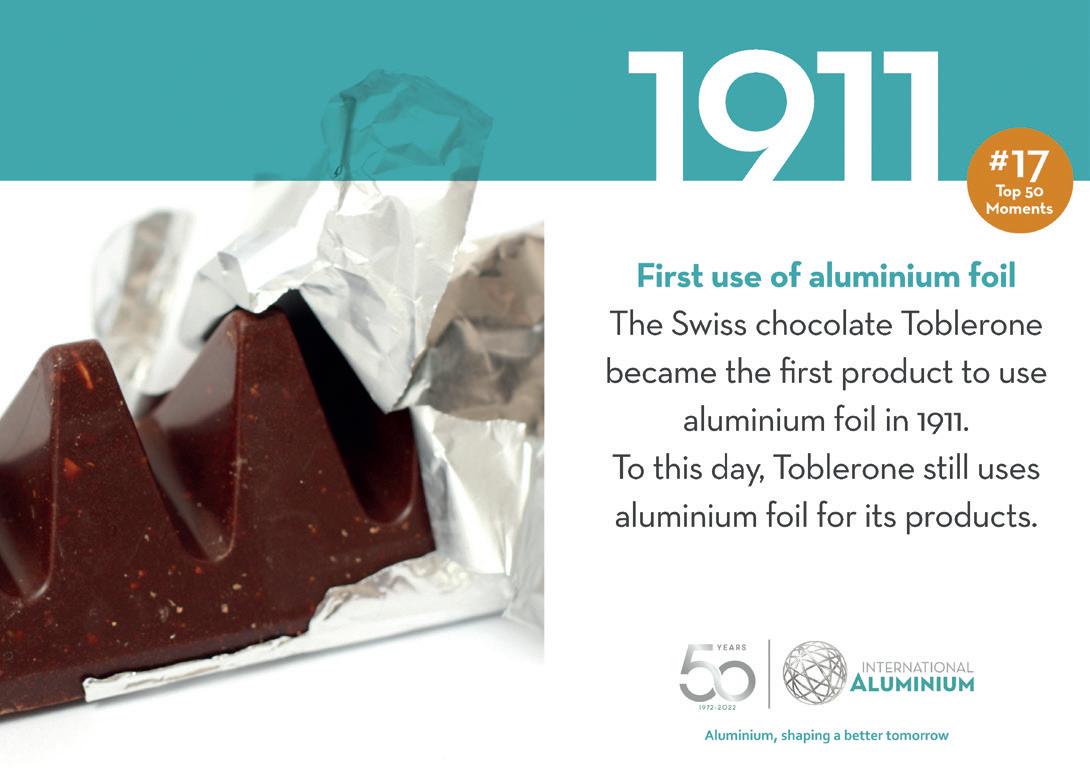

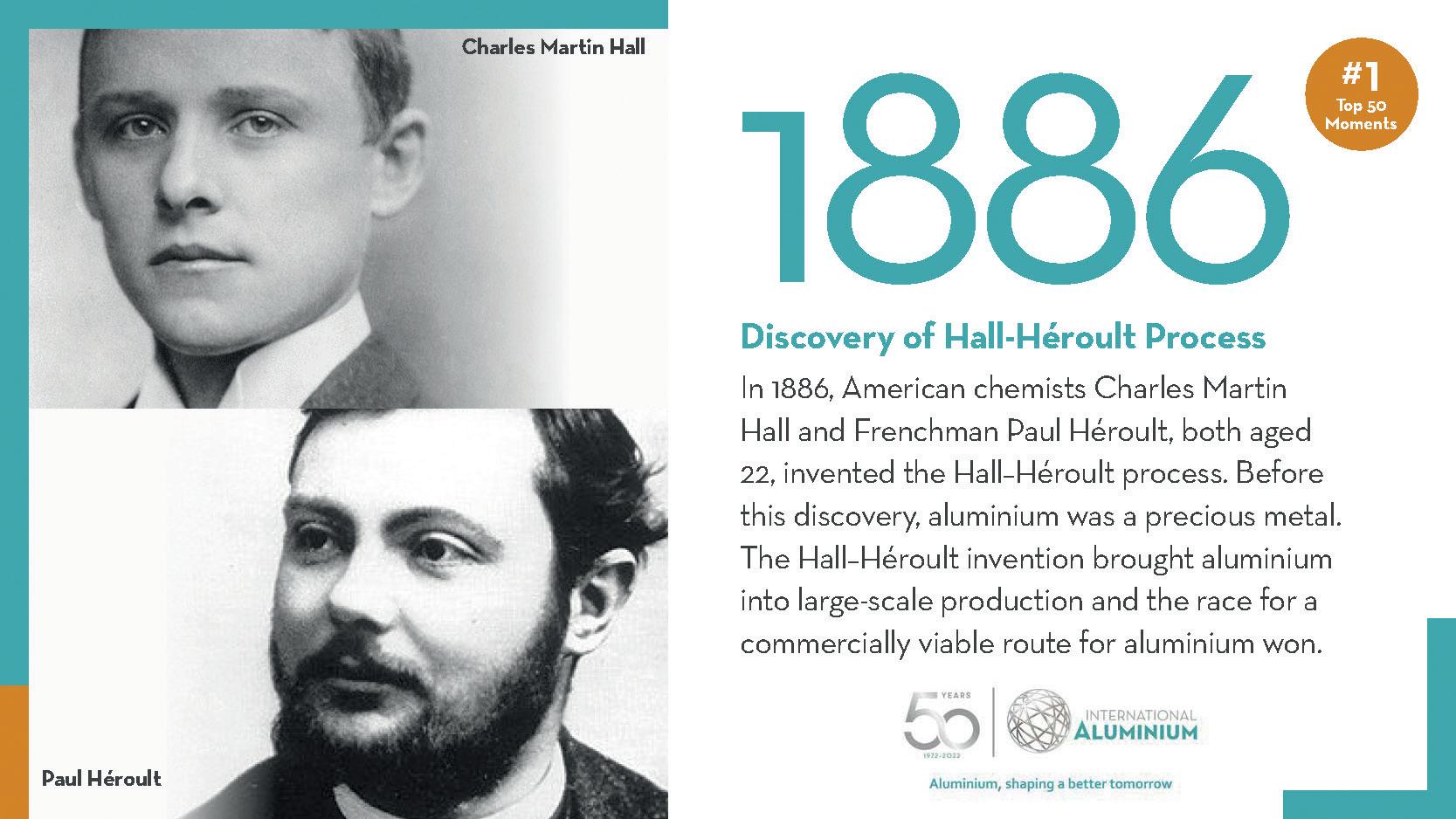

50 Moments

While celebrating our 50th Anniversary, it was imperative that we considered our role in the context of the extended story of aluminium. Going back to 1808, the year of its discovery, aluminium has coloured many moments in our history – just a few of which are listed here.

Members of the industry voted for their favourites, and the results may be quite surprising. While more mainstream moments were featured, such as the creation of aluminium beverage cans and the construction of the Empire State Building, the top spots were taken by two fundamental operational moments: the discovery of the Hall-Héroult Process in 1886; and the discovery of the Bayer Process two years later.

These two processes are, in a way,

IAI ANNIVERSARY 23 Aluminium International Today March/April 2023

the foundation of the industrial life of aluminium and the reason it is now such a widespread material used all around the globe. It is wonderful to see two moments from the 19th century feature so highly –a testament to the enduring mastery of our industry’s pioneers.

This poll showcased that our members truly value the history of this product, not merely as a feature of our lives, but as an incredible scientific achievement.

From its role in landing the first man on the moon to the first all-metal flight, its contributions to science are invaluable. Another core value celebrated in this poll is sustainability. We are proud of the progress the aluminium industry has made in minimising its impact on the environment, and we are eager to continue improving. The widespread recycling of aluminium, the launch of the Greenhouse Gas Pathways and the creation of closed-

loop recycling are only a few of the pivotal milestones featured in this poll. Global, sustainable and versatile, these top 50 moments celebrate the qualities that make aluminium more than just a metal.

If you missed any of our 50th Anniversary communications, you can find them on our website, LinkedIn, and under the features section on the Aluminium International Today website. �

SLAB CASTING EQUIPMENT

CASTING LAUNDER / CASTING TABLE:

- Automated casting launder (hands-free casting)

- Integrated preheating equipment

- Automatic lids

- Fused silica refractories (low density)

METAL FLOW REGULATION:

- Laser sensor technology for metal level control

- Pin position actuators

actu

- Centralized electrical outlet

Improved control software

- Cooling system to prevent bending/distorsion

- Thermocouples integrated for Temp. monitoring seat

CASTING CONSUMABLES:

- Pin and spouts

- Spout s

- Heated pin package available

- Ring retainer (FRR Fiber Reinforced Refractory)

- Combo bags (Thermo-Formed & regular version)

CASTING TOOLING:

- Platform & Bottom block support

- Bottom blocks & Plugs machining

- Casting table (tilt-able or powered travel bogie systems)

- Casting molds

- Tooling spare parts

Aluminium International Today March/April 2023 IAI ANNIVERSARY 24

More Info:

www.rodabell.com

ventas@rodabell.com

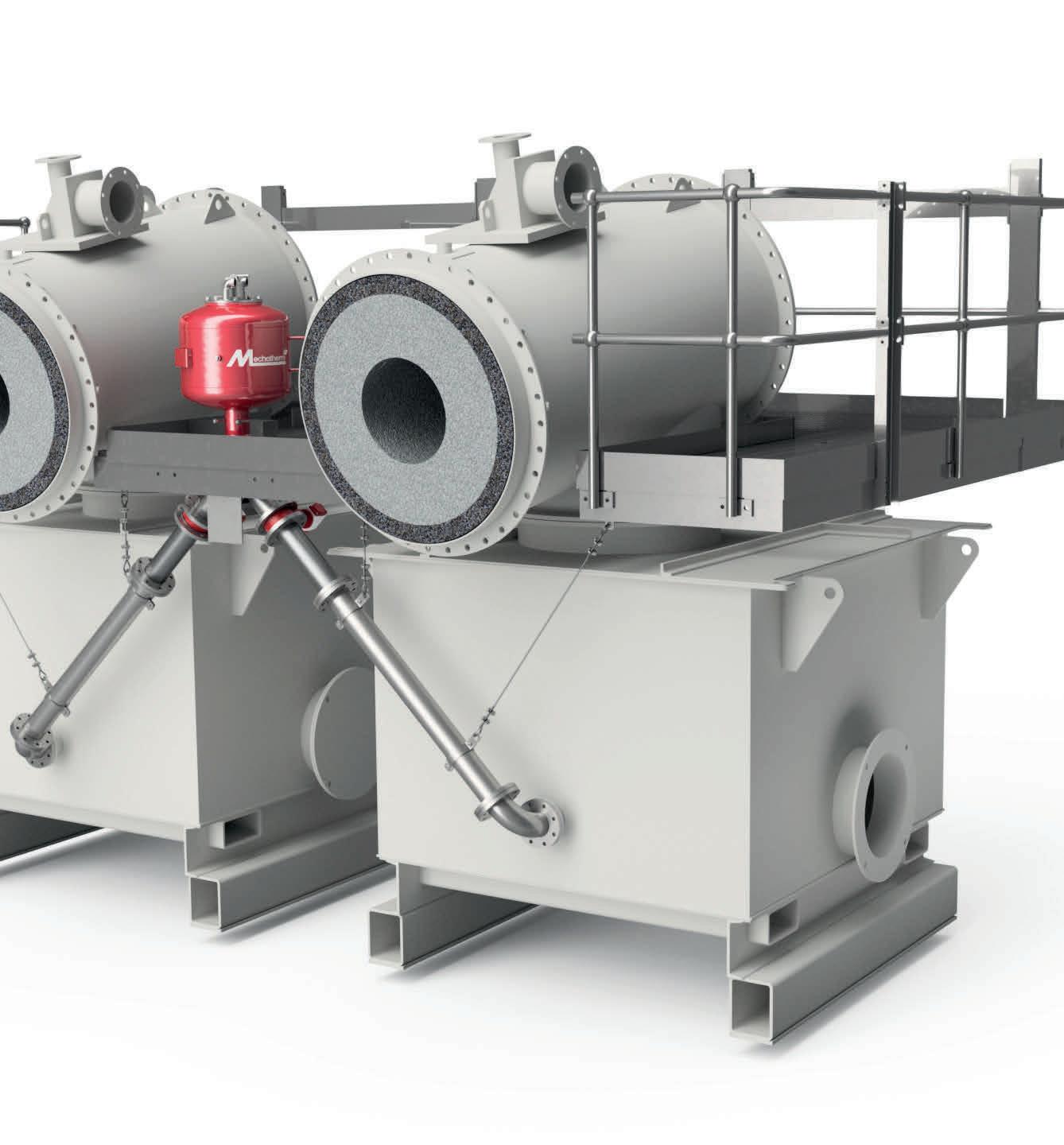

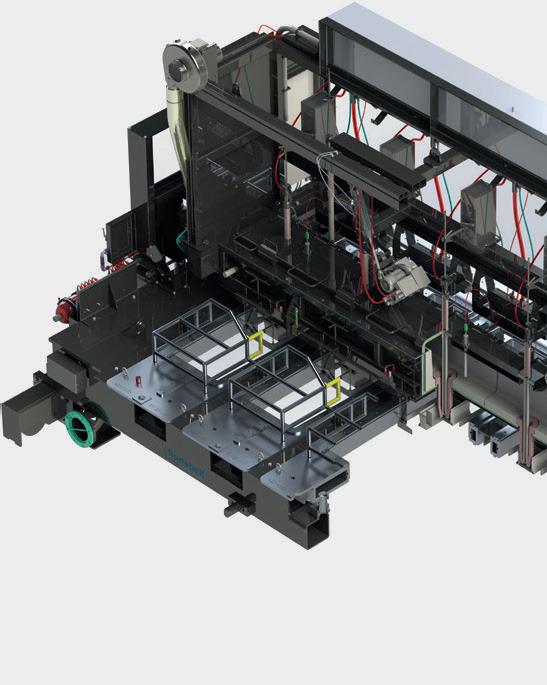

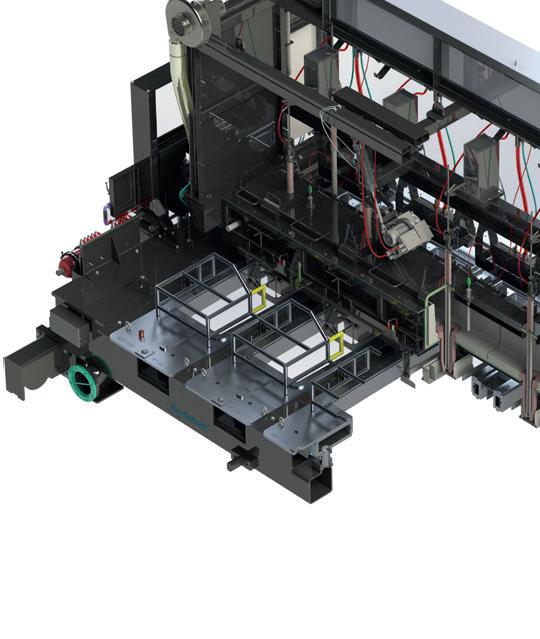

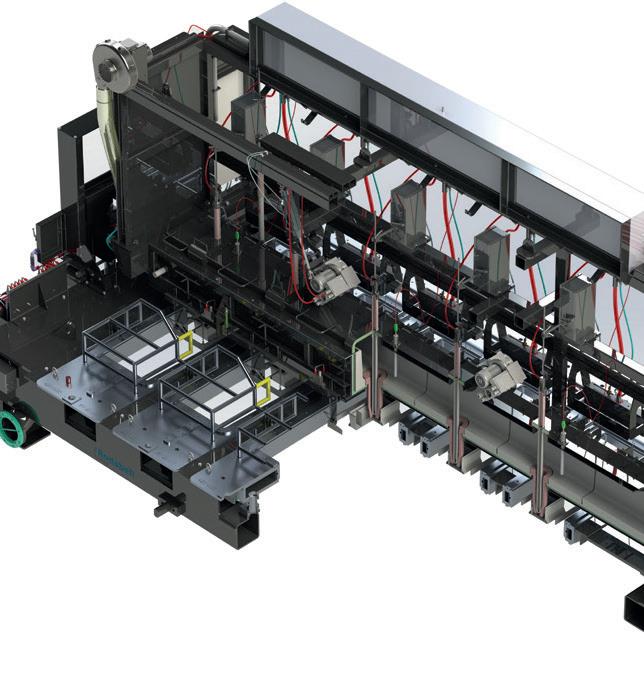

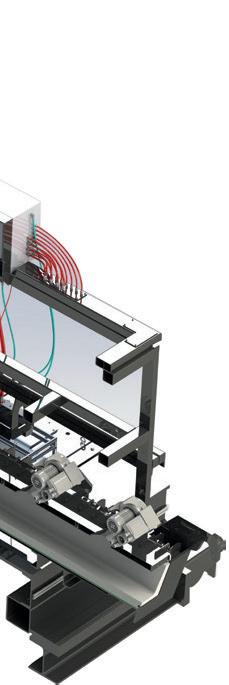

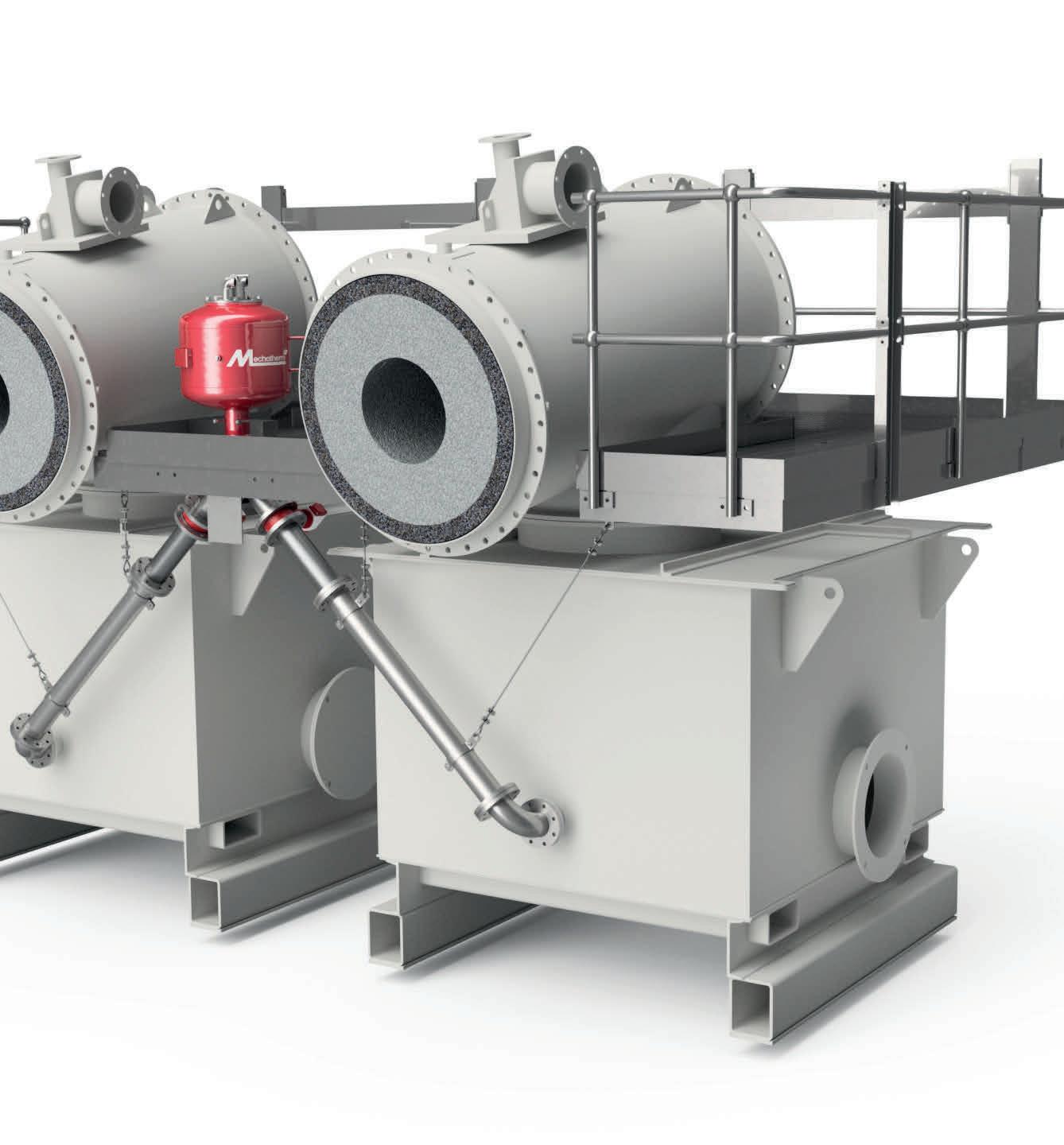

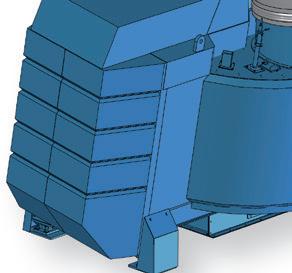

Mechatherm’s licenced Air Cannon technology Improves media bed performance in regenerative burner systems by delivering bursts of air at regular intervals during the melting process, breaking through media bed blockages and agitating the media balls to ensure efficiency is maintained.

The entire process is fully automated, can be easily integrated into your current regenerative burner set up, and reduces media bed changes from days to months*

*Dependant on scrap contamination levels

AUTONOMOUS CHARGING & SKIMMING MACHINES

Decarbonisation of secondary aluminium melting

Oxy-fuel combustion and low-carbon intensity fuels

By Anand Makwana*, Xiaoyi He*, Russell Hewertson* and Martin Lawrence*

Introduction

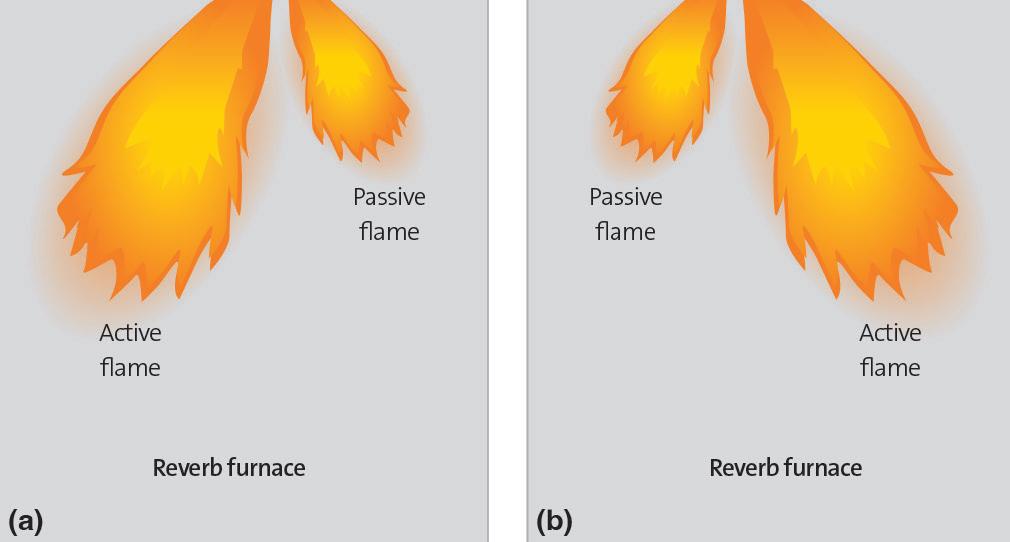

Reverb or secondary melting furnaces are an effective way to achieve a global circular economy for aluminium supply. The recycling of aluminium uses up to 95% less energy compared to the primary production route, and global production of secondary aluminium has increased by 86% from 2000 to 2015.1 In 2015, the total amount of secondary aluminium produced accounted for about 22% of the total global aluminium production.1 This increasing trend in secondary aluminium production will continue to grow in the future as more aluminium becomes available through old scrap metal and aluminium manufacturers are pushed to reduce their carbon footprint to move towards net-zero goals. The increase in the secondary aluminium market size, along with the global effort towards decarbonisation, creates pressure on producers to find innovative ways to decarbonise their operations.

The need for decarbonisation of high temperature melting furnaces has bolstered interest in the use of oxy-fuel combustion systems and low-carbon intensity fuels. Both options provide a pathway to decrease the carbon footprint of new and existing furnaces, as they are suitable for retrofit. The use of oxy-fuel combustion helps to increase the overall thermal efficiency and production rate of a furnace.2 This increase in efficiency helps to reduce the specific fuel consumption and, hence, helps to lower the carbon footprint of the furnace operation.

Additionally, use of low- or zerocarbon intensity fuels like hydrogen is another route to reduce carbon dioxide (CO2) emissions from furnace operations. It is important that the hydrogen is produced from a source that has a lowcarbon intensity. The next generation of

burners needs to be flexible so that they can operate using traditional fuels (e.g., natural gas) and mixtures of traditional and low-carbon intensity fuels (e.g., hydrogen, ammonia, etc.).

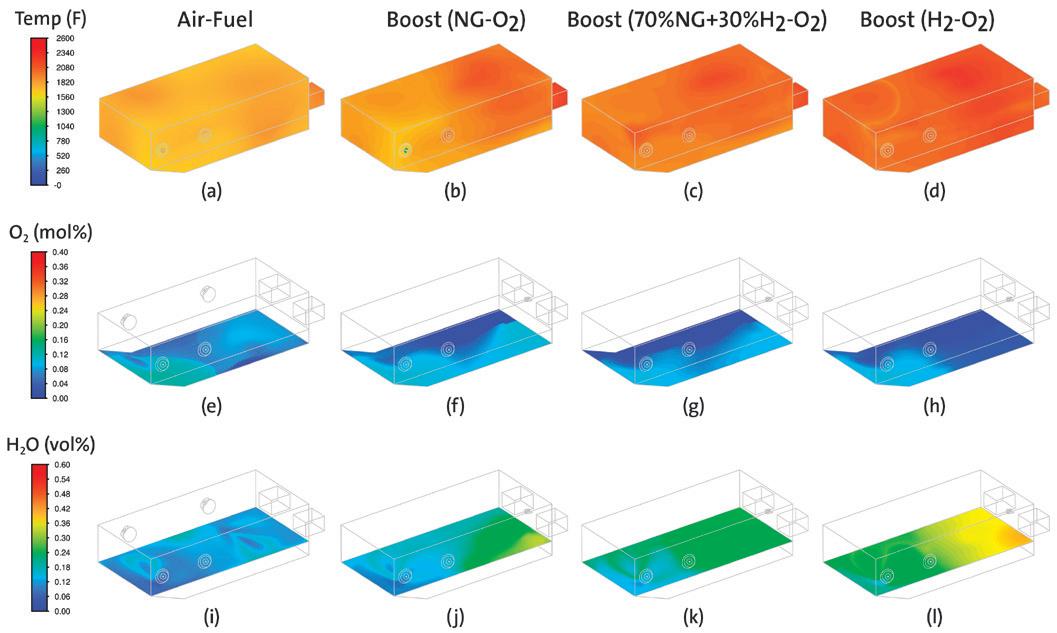

This paper focuses on the performance of the patent pending Horizontal Transient Heating Burner (HTHB) technology developed by Air Products. It discusses using oxy-fuel burner performance using conventional fossil fuels and mixtures of conventional and low-carbon intensity fuels in an industrial scale combustion furnace. Additionally, this paper presents results from computational fluid dynamics (CFD) simulations, demonstrating how the use of oxy-fuel combustion and the use of hydrogen as a fuel impacts the melting performance of a furnace. Theoretical and experimental data on CO2 savings and the impact of furnace atmosphere composition on refractory, performance, and aluminium quality using oxy-fuel systems (commercial installation results) and low-carbon intensity fuels (with CFD results) are also presented to enable manufacturers to choose the optimal solution to move towards decarbonisation for secondary melting furnaces.

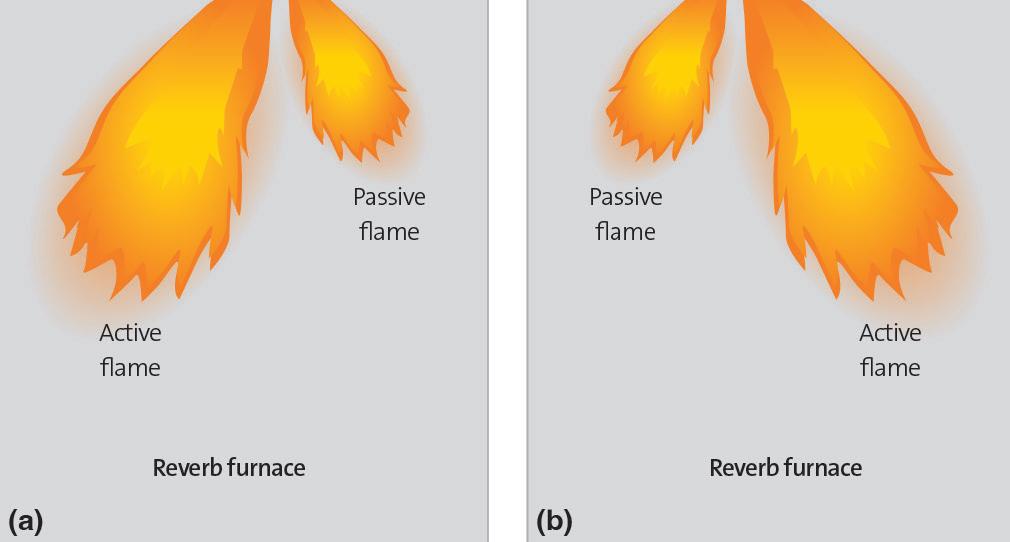

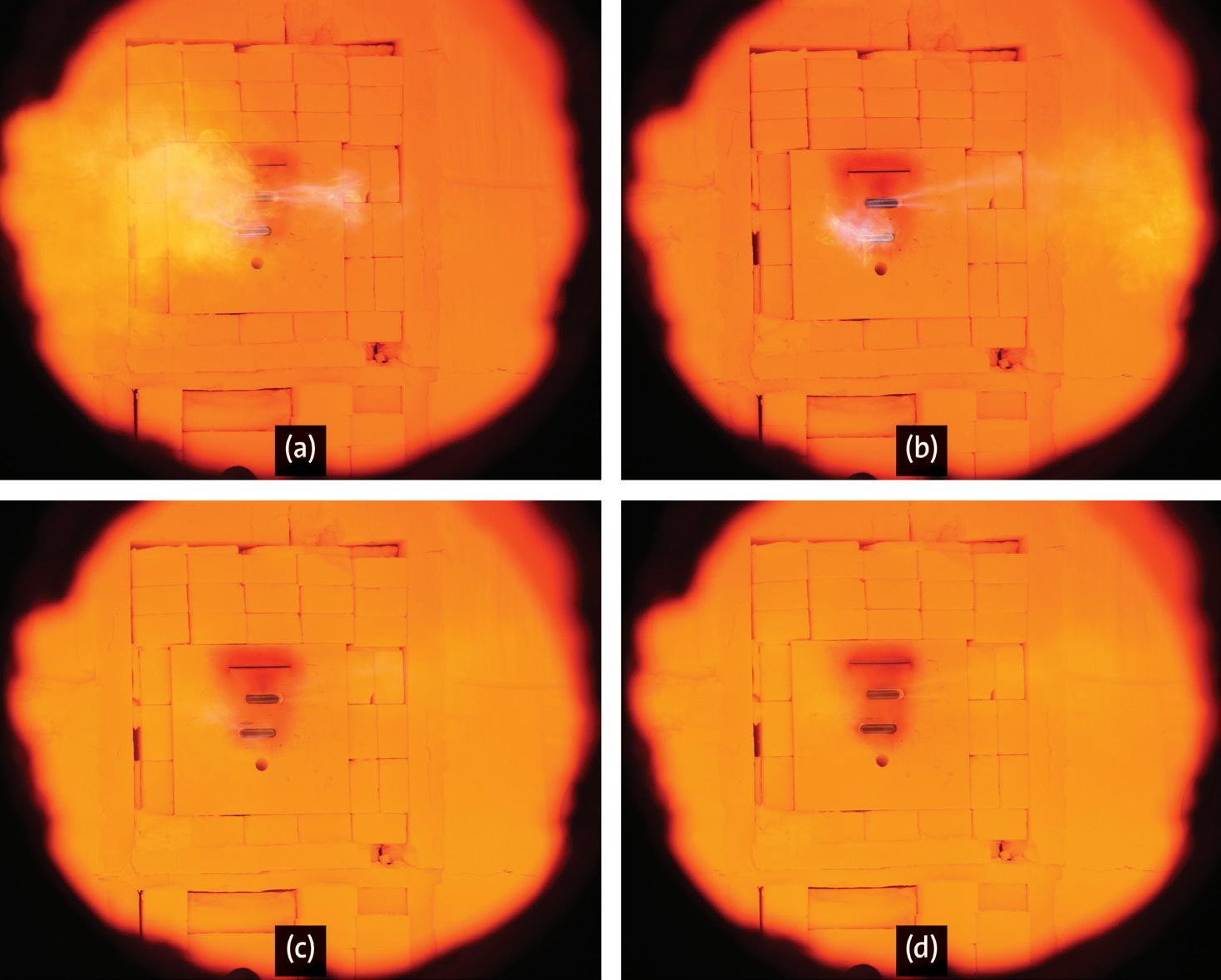

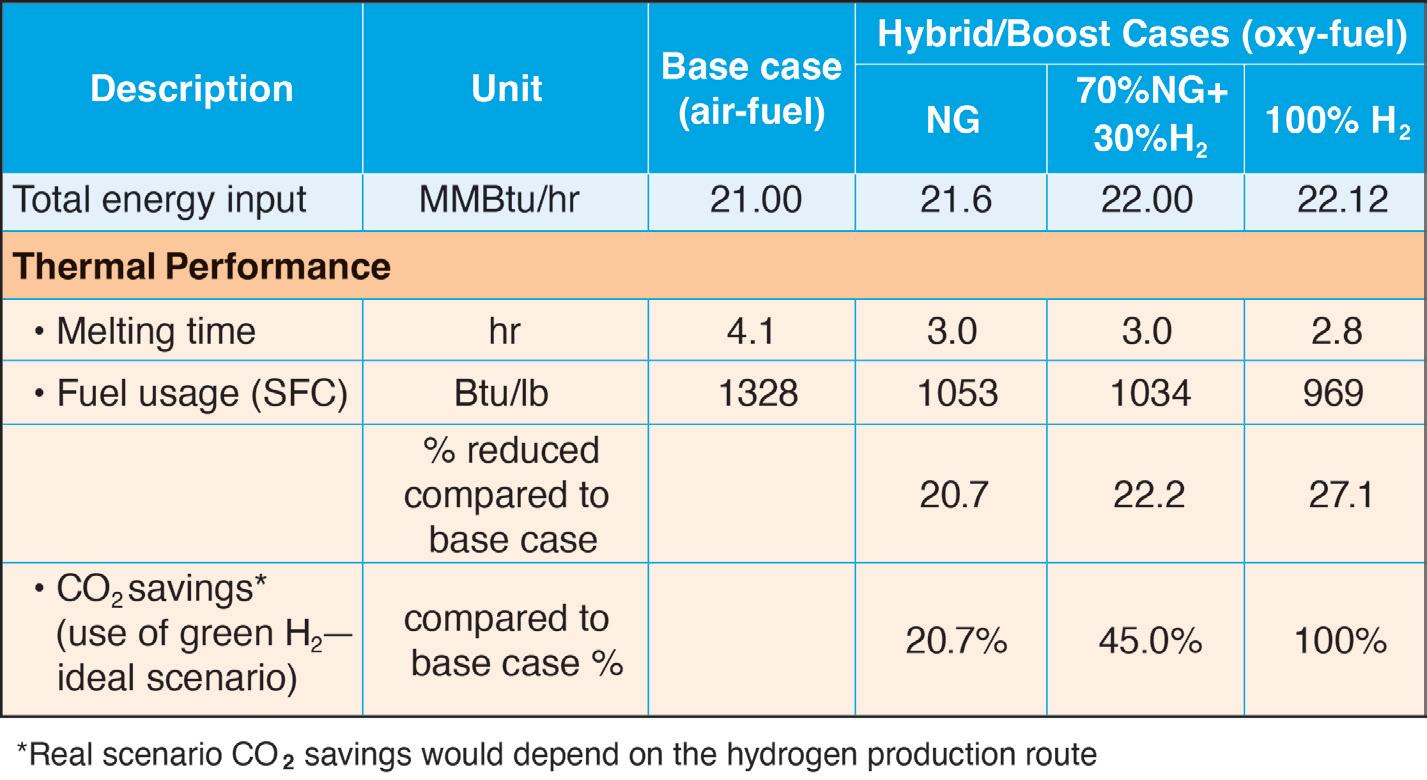

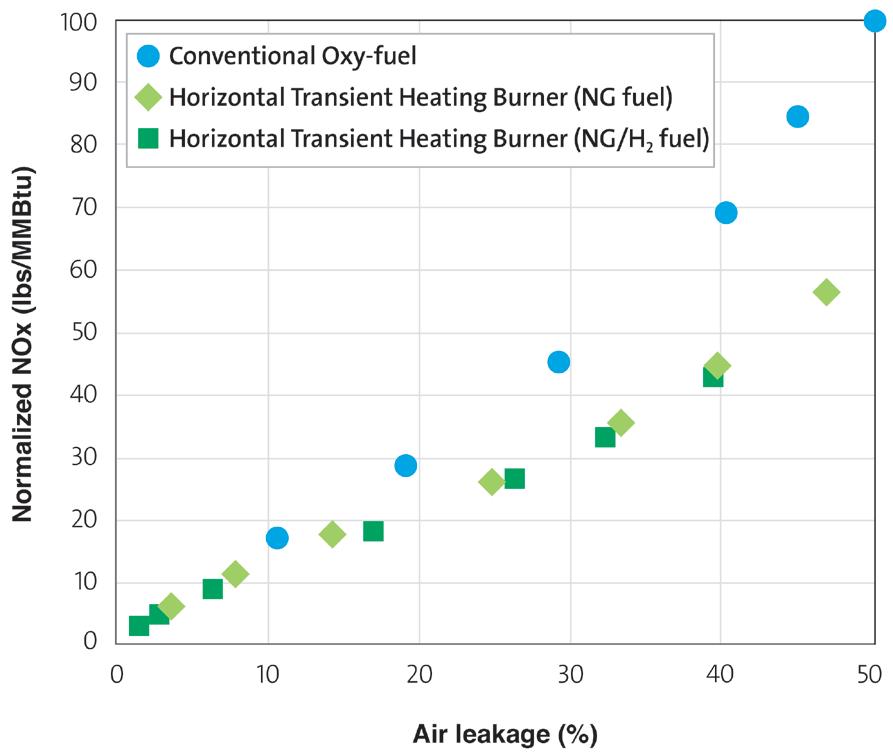

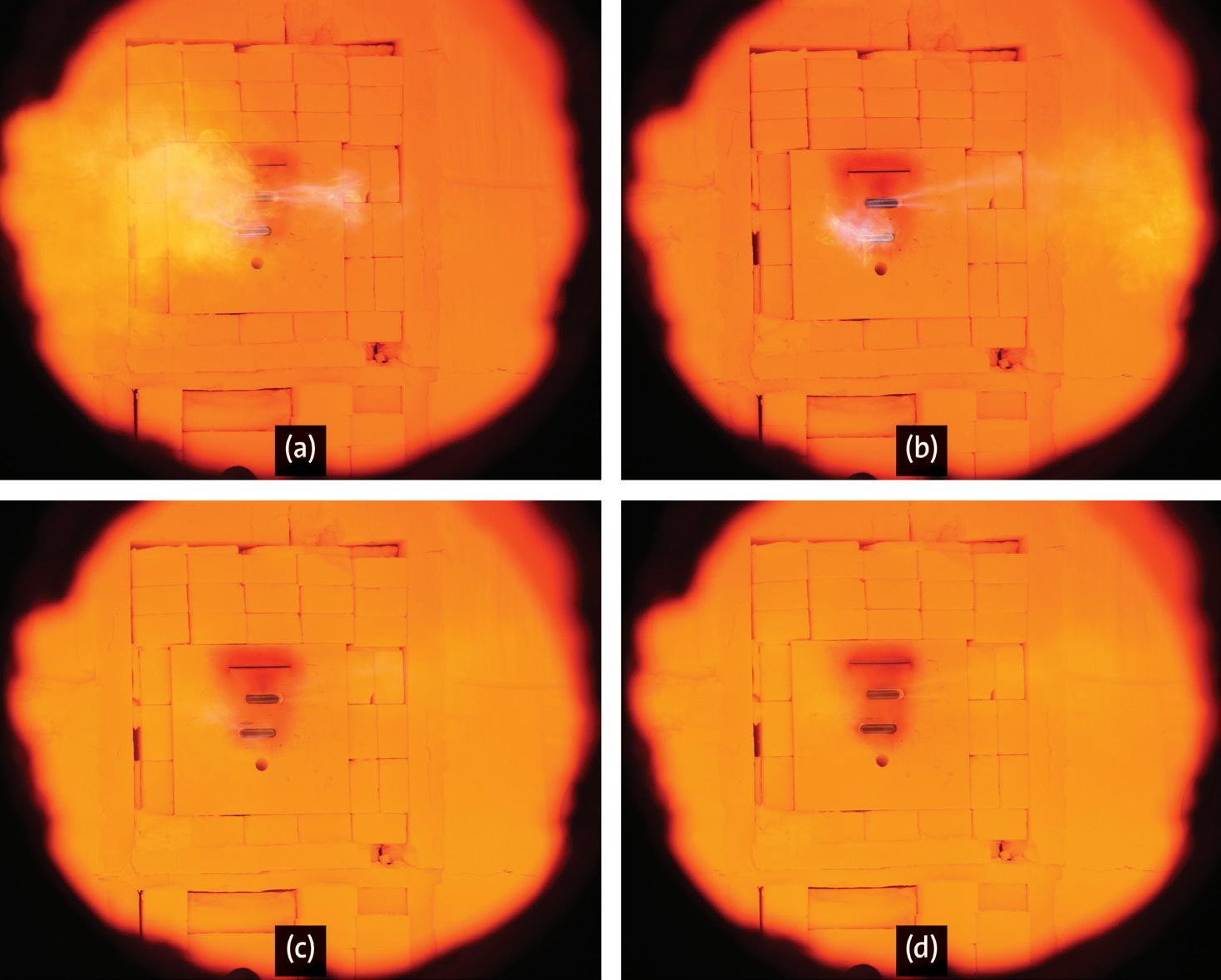

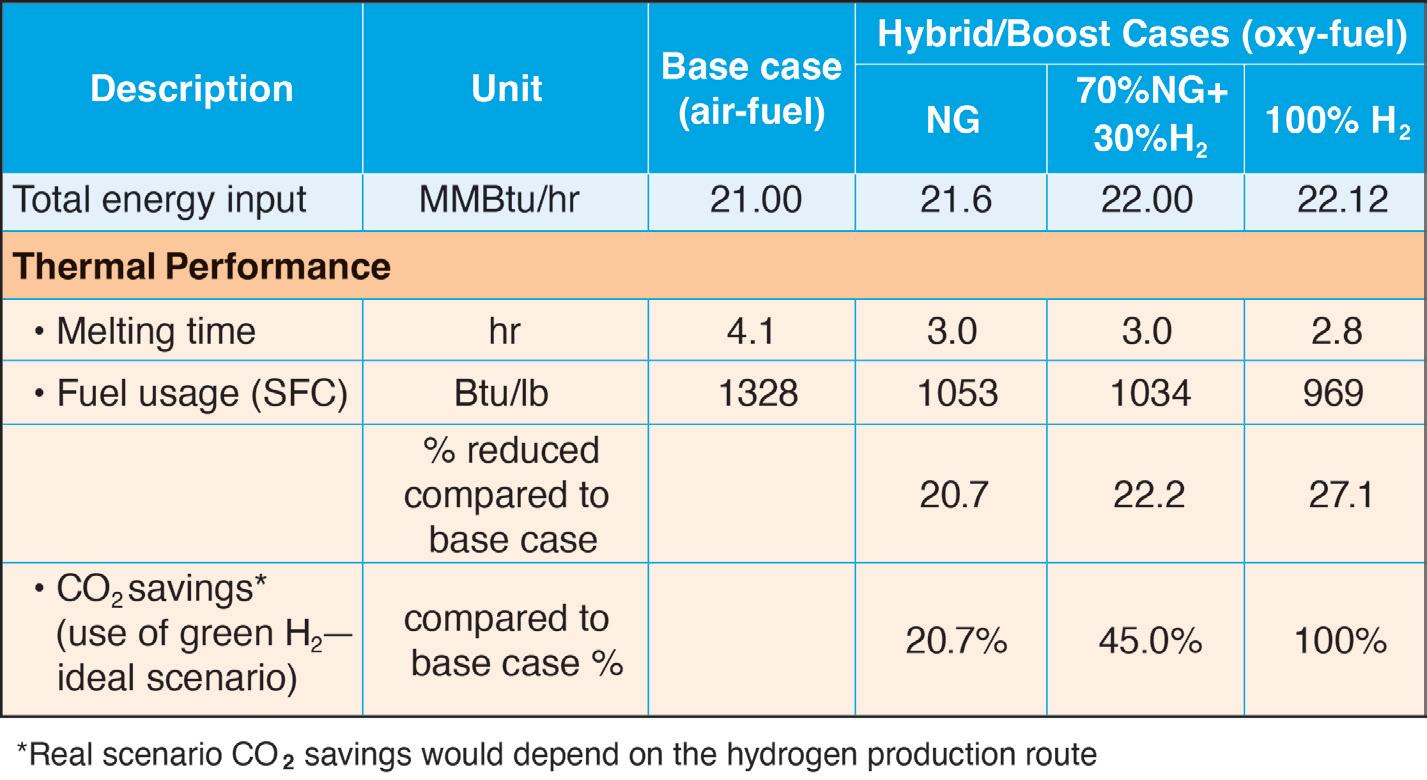

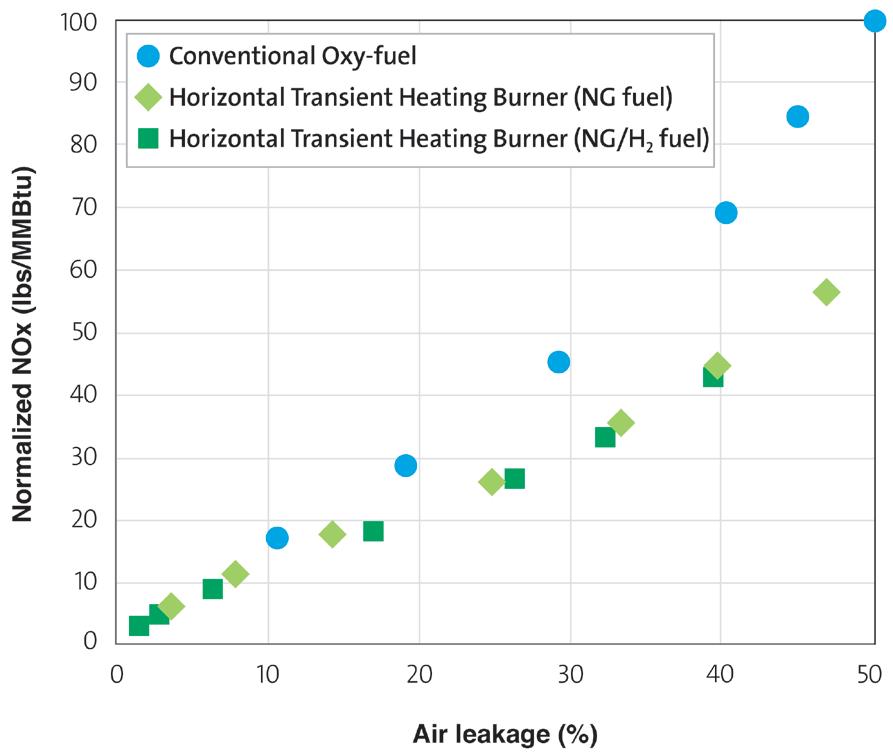

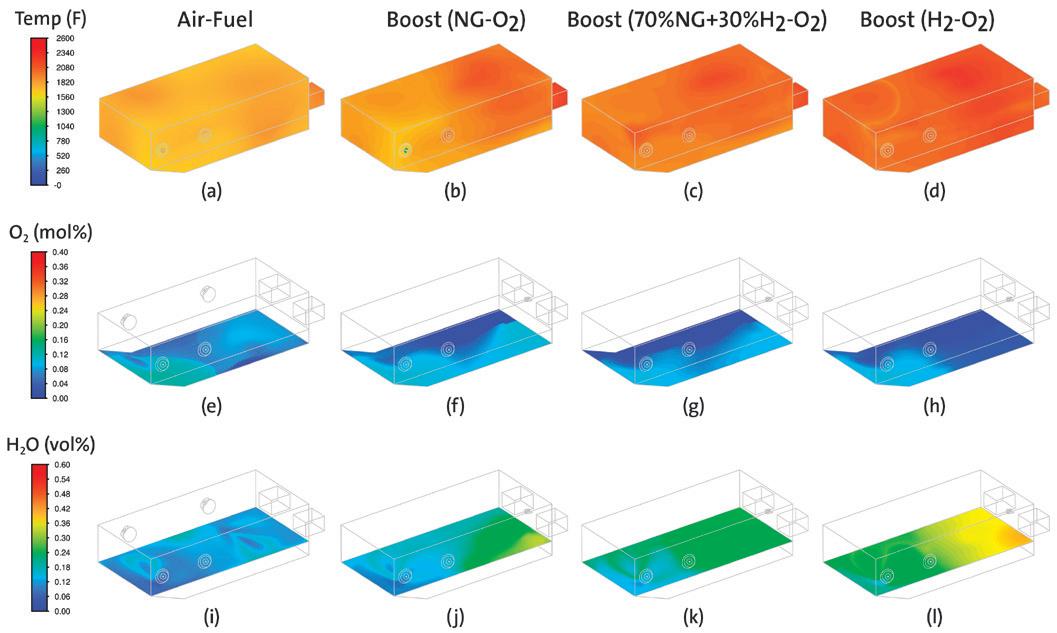

Laboratory test results