Helixes & Nozzles

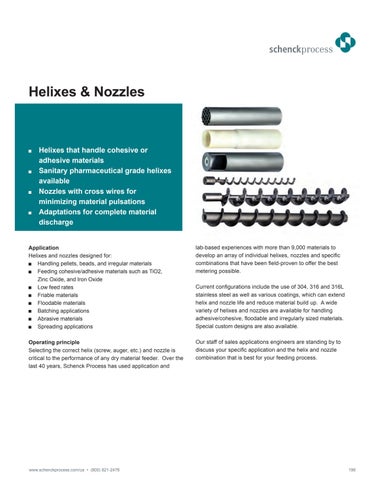

Helixes that handle cohesive or adhesive materials Sanitary pharmaceutical grade helixes available Nozzles with cross wires for minimizing material pulsations Adaptations for complete material discharge Application Helixes and nozzles designed for: Handling pellets, beads, and irregular materials Feeding cohesive/adhesive materials such as TiO2, Zinc Oxide, and Iron Oxide Low feed rates Friable materials Floodable materials Batching applications Abrasive materials Spreading applications

lab-based experiences with more than 9,000 materials to develop an array of individual helixes, nozzles and specific combinations that have been field-proven to offer the best metering possible.

Operating principle Selecting the correct helix (screw, auger, etc.) and nozzle is critical to the performance of any dry material feeder. Over the last 40 years, Schenck Process has used application and

Our staff of sales applications engineers are standing by to discuss your specific application and the helix and nozzle combination that is best for your feeding process.

www.schenckprocess.com/us • (800) 821-2476

Current configurations include the use of 304, 316 and 316L stainless steel as well as various coatings, which can extend helix and nozzle life and reduce material build up. A wide variety of helixes and nozzles are available for handling adhesive/cohesive, floodable and irregularly sized materials. Special custom designs are also available.

196