8 minute read

Helixes & Nozzles

Helixes that handle cohesive or adhesive materials Sanitary pharmaceutical grade helixes available Nozzles with cross wires for minimizing material pulsations Adaptations for complete material discharge

Application

Advertisement

Helixes and nozzles designed for:

Handling pellets, beads, and irregular materials

Feeding cohesive/adhesive materials such as TiO2,

Zinc Oxide, and Iron Oxide

Low feed rates

Friable materials

Floodable materials

Batching applications

Abrasive materials

Spreading applications

Operating principle

Selecting the correct helix (screw, auger, etc.) and nozzle is critical to the performance of any dry material feeder. Over the last 40 years, Schenck Process has used application and lab-based experiences with more than 9,000 materials to develop an array of individual helixes, nozzles and specific combinations that have been field-proven to offer the best metering possible.

Current configurations include the use of 304, 316 and 316L stainless steel as well as various coatings, which can extend helix and nozzle life and reduce material build up. A wide variety of helixes and nozzles are available for handling adhesive/cohesive, floodable and irregularly sized materials. Special custom designs are also available.

Our staff of sales applications engineers are standing by to discuss your specific application and the helix and nozzle combination that is best for your feeding process.

Helixes

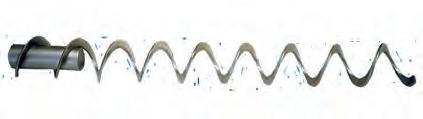

Full Pitch Open Flight Helix – A standard helix used for most applications. The helix pitch equals the diameter of the helix.

Half Pitch Open Flight Helix – Used when you need the larger diameter flights to get cohesive materials to drop into the flights, but has reduced output compared to a full pitch open flight helix. The helix pitch is one half the size of the helix diameter. Full Pitch Open Flight Helix with End Stub – Used with an over size nozzle with end bushing on pellets, beads, and irregular materials. Provides a clearance between the helix and nozzle adapter to prevent binding.

Full Pitch Helix with Center Rod – The center rod is used for added strength in smaller diameter helixes and to reduce possible flooding. Cannot be used with adhesive/cohesive materials.

Double Pitch Open Flight Helix – The increased spacing between the flights promotes filling of the flights on very cohesive materials. The helix pitch is two times the size of the helix diameter.

Double Open Flight Helix – Helix has two discharge flights and is used in batching applications to reduce the deviation caused when the flight stops and a small amount of material drops off the end.

Full Pitch Open Flight Helix with Stirring Rods

– Promotes flight filling of smaller diameter helixes on light density materials that do not easily fill the flights.

Machined Sanitary Full Pitch Helix with Center

Rod – Polished, machined, stainless steel bar stock that is typically used for food and pharmaceutical applications.

Knife-Edged Open Flight Helix – Used with a tight fit poly nozzle adapter for adhesive/cohesive materials such as TiO2, Zinc Oxide, and Iron Oxide. The helix continuously cleans the nozzle walls to prevent material build up. Twin Screw Helix – Excellent for adhesive/ cohesive materials like TiO2 and Calcium Carbonate. The reduction of material build up and pulsing is also realized with a twin screw system.

Nozzles

Stainless Nozzle – A standard nozzle used in most applications.

Poly-Lined Nozzle – Used in applications where materials cannot come into contact with metal. A tight fit version of the nozzle with a knife-edge helix is available for feeding adhesive/cohesive materials.

Nozzle with End Bushing – Primarily utilized with an end stub helix for pellet, bead, and irregular shaped material feeding applications. The design provides clearance between the helix and nozzle adapter to prevent binding.

Total Hopper Cleanout Nozzle – Typically used in sanitary applications for the food and pharmaceutical industries. The nozzle allows complete material discharge minimizing residual material left in the feeder. Nozzle with End Screen/Cross Wires – The screen or cross wires are used to break up the material as it comes out of the nozzle. Used in continuous or batching applications for reducing deviations by not allowing the material to “extrude” out the end of the nozzle. The nozzle also minimizes material pulsations by providing back pressure, which promotes fuller flights.

Vinyl Nozzle – For adhesive/cohesive materials that have a wide range of particle size distribution or materials that cannot come into contact with metal.

Side Discharge Nozzle – Used for free flowing materials. For batching applications the nozzle offers a positive material flow cut off reducing deviations. Provides back pressure for promoting fuller flights.

Spreading Nozzle – Discharges a curtain of material across a given width. Typically used in applications where spreading materials across a belt or on to a tumble drum is required.

Helixes & Nozzles

HELIXES:

(1) Full Pitch Open Flight Helix (2) Half Pitch Open Flight Helix (3) Double Pitch Open Flight Helix (4) Double Open Flight Helix (5) Knife-Edged Open Flight Helix (6) Full Pitch Open Flight Helix with End Stub (7) Full Pitch Helix with Center Rod (8) Machined Polyethylene Helix with Center Rod (9) Full Pitch Open Flight Helix with Stirring Rods (10) Machined Sanitary Full Pitch Helix with Center Rod (11) Twin Screw Helix

NOZZLES:

(12) Stainless Nozzle (13) Poly Nozzle (14) Nozzle with End Bushing (15) Total Hopper Cleanout Nozzle (16) Nozzle with End Screen/Cross Wires (17) Vinyl Nozzle (18) Side Discharge Nozzle (19) Spreading Nozzle

NOTE: This is a random sample of the materials Schenck Process has experience feeding. Please contact our sales department for information on your specific application. Avicel is a registered trademark of FMC Corporation, Borax is a registered trademark of U.S. Borax, Inc., and Irganox is a registered trademark of CIBA Specialty Chemicals Corporation.

Materials 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Activated Carbon X X X X X X X Aluminum Oxide X X X X X X X X Aspartame X X X X X X X X Avicel® X X X X X X X Borax® X X X X X X X X Cabosil X X X X Calcium Carbonate X X X X X X X X X Calcium Stearate X X X X X X X Carbon Black X X X X X X X X X Cellulose X X X X X X X X Citric Acid X X X X X X X X X X X X Coffee X X X X X Corn Meal X X X X X X X Diatomaceous Earth X X X X X X X X X X Egg Powder X X X X X X X X Floculant X X X X X X X X X X Flour X X X X X X X X X X X X Flux X X X X X Fly Ash X X X X X X X X X X X Graphite X X X X X X X Guar Gum X X X X X X Irganox® X X X X X X X X X X X X X Iron Oxide X X X Lactose X X X X X X X X Lime X X X X X X X X X X X Magnesium Oxide X X X X X X X X X X Manganese X X X X X X X X Nylon Powder X X X X X X X X X X Phenolic Resin X X X X X X X X X X Phosphor X X X X X X X Polyethylene Resin X X X X X X X X X X X X Polypropylene Resin X X X X X X X X X X X X PVC Compound X X Salt X X X X X Sap X X Silica Sand X X X X X X X Soda Ash X X X X X X X X Sodium Bicarbonate X X X X X X X X X X X Sodium Perborate X X X X X X X X X X X X X Solka Floc X X X X X X X Spices X X X X X X X X X X X Starch X X X X X X X X X X Stearic Acid X X X X X X X Talc X X X X X X X X X X TiO2 X X X Toner X X X X X X X X X X Tungsten Carbide X X X X X X X X Whey Powder X X X X X X X Wood Flour X X X X X X X X Zeolite X X X X X X X X Zinc Oxide X X X Zinc Powder X X X X X X X X X