The year’s big industry opportunity

2024 Collision Repair Expo brings learning to you

Smart. Simple. Streamlined.

Built by repairers, PartsCheck & FlexiQuote revolutionises quoting with two simple solutions that truly ‘Make Your Business Flow’. It’s more than just software, it’s a tailored solution for your workshop’s unique challenges.

Experience seamless integrations, intuitive functionality, and enhanced profitability, streamlining your workshop through PartsCheck & FlexiQuote.

The new innovative quote builder simplifies the estimating process, allowing you to create accurate quotes quickly.

Quickly submit parts, vehicle details and photos to your preferred suppliers straight from your quote.

Advanced Inventory Management with Parts Control Manage orders, receipt and credit parts giving you clear visibility on parts status in one easy-to-view screen.

Simplifies how you allocate resources and schedule jobs.

Use our data’s potential to your advantage with new reporting tools to get a deeper insight that can help increase your workshop’s profitability.

These are just a few of the many features & benefits available now! Excited? So are we. Scan the QR code to learn more.

www.partscheck.com.au

www.flexiquote.com.au

Ph: 1300 140 292

CEO

John Murphy

john.murphy@primecreative.com.au

COO

Christine Clancy

christine.clancy@primecreative.com.au

SALES

Brad Buchanan

bradley.buchanan@primecreative. com.au

0413 672 403

EDITOR

Eugene Duffy

eugene.duffy@primecreative.com.au

0412 821 706

BUSINESS

Kerri McCauley

kerri.mccauley@primecreative.com.au 0404 898 362

PUBLISHED BY

379 Docklands Drive, Docklands, VIC 3008 03 9690 8766

www.primecreative.com.au

Articles

Head

April is shaping up to be a big month for the collision industry.

The National Collision Repairer magazine is proud to be a media partner with the Australian Automotive Aftermarket Association for the combined expos that create such a splash for the industry every two years.

The Collision Repair Expo, held on April 11-13, will bring together hundreds of industry experts and thousands of those involved in the automotive industry under the expansive roof of the Melbourne Exhibition Centre.

The AAAA has wisely rescheduled the event this year to avoid the Grand Prix in Melbourne which means all those visiting can take in its vast array of products, services and ideas in a more relaxed manner.

This year, not only does the expo promise to be a gathering of the latest products and services but provides some fascinating and hopefully inspirational learning opportunities.

For any repair workshop that has been tentative about the advent of new technology that is just around the corner, such as the making a workshop EV compliant or investigating the complexities about ADAS calibration, this could be the big opportunity to take a major step forward.

Extensive reading or trolling endless YouTube ‘How to’ videos can only deliver part of the important information. The expo will provide not only carefully crafted learning sessions but also offer business owners the opportunity to ask questions and interact with the experts in these fields. This includes both the equipment specialists who can give honest estimations about what a workshop needs to invest in, business advice on how to take the next step and consultation from the very latest in high-tech service

providers who are eager to partner with businesses.

And this highlights another element to the expo that is worth looking forward to; a chance to meet and catch up with the diverse range of people who make the industry tick.

The frenetic daily bustle of a repair business often doesn’t allow it, but these three days could also be a great opportunity to relax and get to know the many faces behind the suppliers and services which are a great support to the industry.

And on the subject of people, what better way to celebrate the industry’s greatest asset, its people, than by attending the NCR Lifetime Achievement Awards.

These will be held on the eve of the industry’s biggest expo and will be celebrated with a Gala Night on April 10 at Showtime Events, also in Melbourne.

It is also exciting to announce that the night will be compered by sporting legend and media celebrity Dermott Brereton.

The National Collision Repairer ’s awards nights will be additionally special this year because it now includes three great awards: the Lifetime Achievement Award, the Woman in Automotive and the Next Generation Leader.

The Lifetime Achievement Award is one of the industry’s most prestigious awards and celebrates those involved in the sector for more than 20 years who have made outstanding contributions to the wider industry.

The new Women in Automotive award gives recognition to women in repair businesses and the Next Generation Leader award showcases the valuable contributions made by up-and-coming achievers in the industry.

All three are worthy of honouring and celebrating because they highlight the depth of talent and dedication that makes the collision repair industry so passionate and dynamic.

Registration for the Expo is free and open to anyone in the automotive trade. Tickets for the NCR awards night are on sale now.

So, all busy repairers need to do is take a little time out of their schedule to ensure April is a month worth remembering.

Eugene Duffy Editor The National Collision Repairer

Car-O-Liner have taken their innovative approach to great workshop solutions and trusted quality, and incorporated them in a range of lifting devices that may rapidly become indispensable to the efficient repair body shop.

The CDS 35 is an indispensable aid for all work requiring the vehicle to be lifted, including damage diagnosis, cosmetic dent repair and mechanical checks in general. It is a compact double-scissor lift designed to fit into any collision repair workshop.

Car-O Liner’s renowned attention to design ensures it will fit into most workshops and can add to efficient repair processes. The CDS 35 can be used to perform diagnostics, light cosmetic repair or service operations with the opportunity to shorten cycle times and maximise workshop turnover and profitability.

The compact double-scissor lift is space saving and takes less room than a standard 2-post lift. Its profile allows the technician to drive or roll any vehicle over it for fast mounting and efficient workshop routines. When surface mounted the lift platform is only 116 mm over the floor surface or even with the

floor if flush mounted, giving a faster start-up to the repair process.

The rugged steel construction makes CDS 35 one of the strongest double scissor lifts in the market, with powerful hydraulics that can lift vehicle weights of up to 3500 kg. The lifting platforms with locking ramps adjust from 1.480 to 2.140 mm to accommodate longer wheelbase vehicles.

The CDS 35 can also be part of an integrated total solution for collision repair workshops and works well together with other Car-O-Liner solutions. CDS 35 offers a wider variety of quick repair services, and if pulling is needed the vehicle can quickly be driven off the lift and onto a bench. Combined with a PointX II diagnostic measuring tool or the CDR1 Cosmetic Dent Repair Workstation, it forms a specialised workplace, where complete repairs are performed quickly and efficiently.

It also features a compact console control station that protects key electrical components, hydraulic power pack and hydraulic synchronization controls.

To meet the increasing and specialised demand of EVs in workshops, Car-OLiner have also developed flexible and portable lifting solutions. Since the battery is the largest and most expensive single component of the vehicle, battery maintenance requires a robust lift table and is essential for safe service. The BT 1800 delivers a convenient, portable double-scissor table lift, ideal for EV service and battery pack replacement.

The strong and rugged steel, double scissor offers more stability than a single-scissor structure with 1800 kg of lifting power. The BT 1800 hydraulic mobile lifting table is designed to handle EV batteries but can also be used for lifting engine, gearbox, drive axle, fuel tank, suspension and chassis components of traditional vehicles.

It is also highly portable with a rechargeable 12-volt DC power supply provides full flexibility around the workshop, as no power supply cable is required. Learn

To celebrate our 50-year milestone, we are offering unbelievable ‘Special 50-year Promotion Deals’ on all Car-O-Liner Benches and Car-O-Tronic Measuring Equipment ... and you also receive our normal ‘Trade-in Deal’ which is still available.

This Special Offer is 50-years in the making.

Invest in your equipment to improve productivity and technician retention!

A truly universal and versatile addition to any bodyshop –the BenchRackTM systems are designed to hold and lift virtually any type of unibody or full frame vehicle. From small cars to light trucks, vans and SUVs.

Global coatings leader Axalta may have more than 150 years of past experience in the coatings industry, but its pursuit of innovation in beautiful and sustainable coatings solutions means it is always looking to the future.

This includes preparing the repair industry for the next wave of technology as Advanced Driver Assistant Systems (ADAS) become increasingly common in modern vehicles.

Axalta has added radar compliant colour formulas to its global online colour databases - ChromaWeb, Phoenix and Standowin iQ - to be prepared for future radar requirements for the repair of cars equipped with ADAS systems.

“Some estimates predict the ADAS market to double from a valuation of US$30.9 billion in 2022 to US$65.1 billion by 2030 due to the number of vehicles being equipped with some form of ADAS.

“ADAS-supporting equipment is often located behind painted plastic surfaces

on cars and can be a major concern for the automotive refinish business since the coating layers can directly influence the signal emitted and received by the ADAS sensors,” says Jim Iliopoulos, Product and Technical Manager for Axalta Australia and New Zealand.

Radar sensors are especially sensitive to the thickness and composition of coating layers, resulting in potential interference with critical safety systems, including pedestrian detection, collision avoidance, adaptive cruise control, automatic emergency braking and blind spot detection.

“We can identify and test colours that we know will interfere with radar sensors during the colour development process, such as those with high concentrations of aluminium flakes. For colours where the radar transmission loss exceeds the threshold set by the OEM, we can develop a compliant colour formula that passes these specifications,” says Iliopoulos.

The radar compliant colour formulas,

Formulas in Cromax Pro, Spies Hecker Permahyd Hi-TEC and Standox Standoblue, will ensure correct repairs of vehicles equipped with radar sensors. Bodyshops can easily recognise these radar compliant colour formulas thanks to a special icon that identifies that the formulas have passed OEM radar specifications.

“For the repair of painted surfaces that cover radar sensors, refinishers should always choose the radar compliant colour formula and strictly follow the OEM repair guidelines to ensure an accurate repair,” Iliopoulos says.

Once the formula has been chosen, a message will also be displayed to indicate it is mandatory to follow the OEM repair guidelines for the repair and for testing ADAS before the vehicle is put back into service.

For more information, please contact your local Axalta representative or Axalta distributor.

For workshops looking for a combined polishing system that will help deliver the best outcomes with less effort and lower overheads, the upcoming Collision Repair Expo could provide the perfect learning opportunity. Saint-Gobain will be showcasing the innovative Farécla system as part of its exhibition stand in April with a special demonstration area for the G Plus Electric Rotary Polishing Machine and the complete G360 Super Fast Polishing System.

The G Plus Electric Rotary Polishing Machine from Farécla is a tool that can deliver the precision and power that are important to any automotive workshop.

Farécla has crafted the innovative polisher for professionals with a host of features. One standout is the light weight of the tool, coming in at 2.2kgs. With its well-balanced design this ensures fatigue-free operation during extended polishing sessions. It also features cool running technology that helps maintain consistent performance without overheating, especially for tackling large-scale polishing projects.

The G Plus is driven by a low noise 80dba high-torque 800-watt motor, purpose-built to accommodate G Mop 6” (150mm) and 8” (200mm) pads. This pairing is aimed at giving technicians an exceptional polishing experience. The thumb-operated speed dial, with variable speed control ranging from 700 to 2500 RPM, also gives the technician the flexibility to adapt to different surfaces and applications, while a five-metre power cord adds to freer movement and eliminates constant repositioning.

The soft-start motor has low vibration 1.7 m/s2 function, reducing product splash during start-up and enhancing

www.nationalcollisionrepairer.com.au

The light weight of the G Plus Electric Rotary Polishing Machine is a major benefit for technicians.

Images: Saint-Gobain

user control. The speed stabilization mechanism gives a steady and constant speed output, also enhancing control.

Farécla have designed the G Plus Electric Rotary Polishing Machine with engineering excellence and user-centric features to make it the tool of choice for technicians who want to produce the best results every time.

Farécla’s G360 Super Fast Polishing System can require between 30 and 50 per cent less compound being used on a job compared to other brands, saving the workshop on product costs as well as reducing clean-up time. This system also eliminates the need for expensive P3000 discs. The ability to compound after P1500 rapidly speeds up the

process time, saving money in product usage and labour time.

The speed of the G360 System cuts polishing times but also less electricity cost per job, with increased productivity and throughput. Reduced polishing time also has the EHS benefit of reduction in the risk of operator exposure to Hand Arm Vibration risk. Farécla’s G360 System’s performance has been further improved with the upgrade to the formulation of its optional step 2 product, Farécla G360 Finish swirl and hologram remover. The new formulation provides a deeper gloss, faster wipe-off, and noticeably quicker flawless finish on blacks and dark colours.

More information is available at SaintGobain Australia 1300 007 650

In 2023 full battery EVs made up more than seven per cent of all new vehicles purchased in Australia. These numbers are expected to increase as new cheaper models come onto the market and innovation increasingly overcomes range issues. As this happens repair workshops are likely to see more coming though their doors and with training and an investment in equipment, businesses can be ready to mee this transition.

Leading power accessory supplier Projecta has further expanded its range of quality EV charging cables and accessories to meet this demand.

The Projecta Chargers include both Type 1 and Type 2 cables providing safe and reliable charging for most late and earlier model electric vehicles. Along with cables and chargers, Projecta’s product offering in the EV space also extends to adaptors and storage solutions, positioning Projecta as a one-stop solutions provider for all EV charging needs.

Included in the range is the EVC2KW 2.4KW EV Portable EV Charger, which allows owners to daily or emergency charge their vehicles at the home or in the garage by plugging into a regular

mains socket. The charger features an ergonomic design for comfortable use, and an LCD screen displays charging information.

Also available are the EVCBT2T2 and EVCBT2T2-3P 7.2KW and 22KW EV Charging Cables which are suitable for charging Type 2 vehicles at a Type 2 charging station; these chargers come with a choice of either single or threephase cables. For owners with older Type 1 vehicles, the EVCBT2T1 Type 1 EV Charging Cable is a must-have, allowing them to charge their car at a Type 2 charging station.

All chargers are ergonomically designed, are weatherproof and built to endure high frequency use; they also feature caps that prevent water and dust ingress and are certified to IK10 ratings for impact resistance to ensure durability. For safe and convenient storage and transportation, the charging cables come with a hardwearing EVA case.

Projecta also offers a selection of convenient charging adaptors, including the EVAPT1T2 Type 1 to Type 2 Adaptor for charging a Type 2 vehicle at a Type 1 charging station, and the EVAPT2T1 Type 2 to Type 1 Adaptor for

charging a Type 1 vehicle at a Type 2 charging station.

Projecta Senior Brand Manager, James Pearson, says the expanded Projecta provided charging solutions for just about all electric vehicles.

“With four different charger cables available to suit both Type 1 and Type 2 cars along with an emergency charger and a selection of adaptors and accessories, the Projecta Chargers range has most EV cars – both old and new – covered,” James said.

“Along with this product breadth, prospective buyers can also rest assured that they are purchasing these important components from an extremely reputable manufacturer whose core business is power management. The range is designed, engineered and manufactured to Projecta’s industry-leading standards, ensuring safe, reliable and durable operation for the long term.”

For full details on Projecta’s EV Chargers range, visit: www.projecta. com.au/categories/battery-chargers/evchargers-accessories These products are available from leading automotive outlets nationwide.

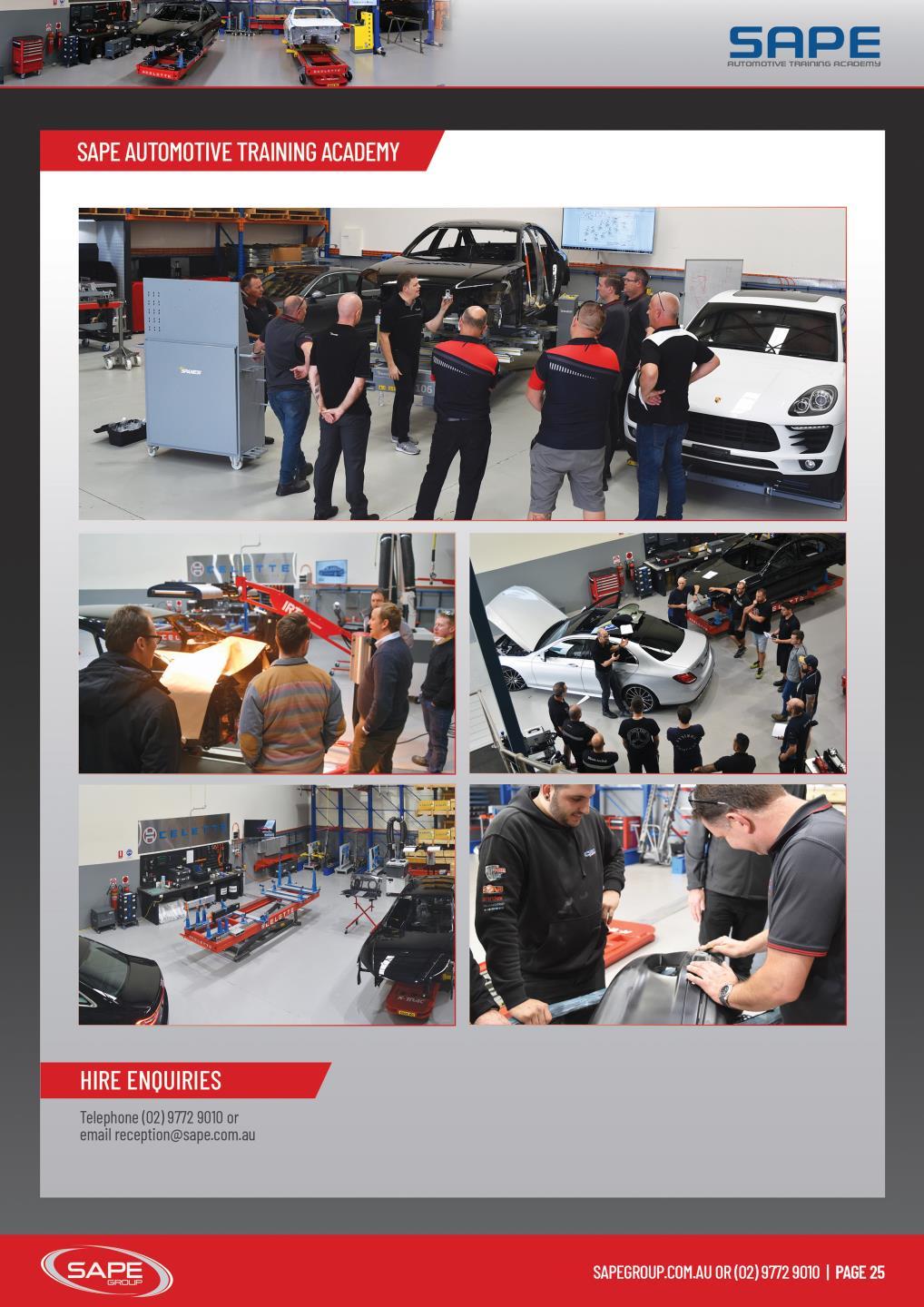

The 2024 Collision Repair Expo launched with the special theme ‘The Future is Here’. Plans for the April event have followed up this focus with a range of educational opportunities not only making this future accessible but offering practical solutions that can make real differences to repair businesses.

When it comes to preparing for the future, one of the best opportunities to learn so much under one roof will be at the unmissable 2024 Collision Repair Expo where a strong educational focus hopes to inspire and energise repair businesses in a diverse range of areas.

The ADAS Technology Zone will showcase ADAS calibration demonstrations and answer important questions about this emerging and crucial component of automotive repair.

Another Expo highlight for 2024 is the Expo Electrified Zone, which will offer unique opportunities to learn about EV and hybrid service and repair with hands-on and practical demonstrations, including live testing of EV motors and generators.

Expo training will be about a lot more than just technology, with a wide range of sessions including international experts on how you can improve your businesses as well as special insights on recruitment.

Presented by the Australian Automotive Aftermarket Association the exhibition will be held at the Melbourne Convention and Exhibition Centre across April 11-13.

If 2024 is the year when collision repair workshops plan to take the bold step into ADAS calibration, then there is one more reason to make the Collision Repair Expo an unmissable event.

The AAAA has added a new ADAS Technology Zone, exploring Advanced Driver Assistance Systems and the skills needed for ADAS calibrations as part of its learning experience at the major April event.

The zone will showcase the latest

www.nationalcollisionrepairer.com.au

ADAS equipment and calibration techniques from suppliers, provide ADAS calibration demonstrations, training and specialist advice focused on best practice. The zone is tailored specifically for collision repairers, automotive repairers and those working in vehicle modification.

The ADAS Technology Zone has been created by the AAAA in partnership with a leader in the field ADAS Solutions Australia.

AAAA director of membership, marketing and events Tiffany Conway says the zone will be a valuable new feature at an Expo focussed on the future.

“The ADAS Technology Zone will address the important questions repairers and modifiers have about incorporating ADAS calibration into their service offering, either inhouse or outsourced to a business partner, and the business implications

The expo will provide great learning opportunities about the growing demands of ADAS systems. Image: AAAA

of both options,” Conway says.

“This Zone will be the most comprehensive opportunity for attendees to get-up-close-and-personal with ADAS equipment, learn what’s best for their business, and get all the answers they need from ADAS industry experts.

“The AAAA is very proud to be partnering with ADAS Solutions Australia to bring this vitally important subject matter to life. Together, we will provide attendees with equipment demonstrations, peer networking opportunities, and access to ADAS calibration experts, to help attendees to better understand and navigate the complexities of ADAS calibration.”

ADAS Solutions Australia are industry leaders in ADAS technology, equipment, and training; utilising a variety of ADAS equipment to educate and also provide calibration services.

“Almost every passenger vehicle sold in Australia today has some form of

ADAS,” ADAS Solutions Australia director, Adrian Parkes says.

“As such, it is vitally important that the automotive and collision repair industry understands the systems and components commonly used by manufacturers, and what these systems and components are designed to do, as well as the repair requirements and processes of the ADAS’ commonly found on passenger vehicles today.

“Covering ADAS fundamentals, components, calibration and providing live demonstrations with ADAS technicians, we will provide attendees with the chance to improve their knowledge base, ask questions and discuss real world issues and scenarios they face in the industry,” Parkes says.

The ADAS Technology Zone builds on the 2022 Expos’ Workshop of the Future concept, by providing a dedicated space which focuses on this rapidly growing segment of the market.

The Expos are packed with additional training opportunities, including an exclusive Collision Repair Training Program with leading international experts Dirk Fuchs and Robert Snook and a comprehensive Business Education Program.

The big names are lining up at the collision industry’s biggest expo, making for even more reasons not to miss the April event.

The three-day event will deliver a comprehensive, free-to-trade, Business Education Program.

Auto Care Association president and CEO, Bill Hanvey, is the latest addition to headline the array of experts-leading the business education program at the Australian Auto Aftermarket Expo & Collision Repair Expo in Melbourne.

Hanvey, highly sought after globally for his industry knowledge and insights – will speak exclusively to attendees on the important topics of global aftermarket trends, right to repair, and skills shortages.

“Education is a crucial mechanism to ensure our industry is sustainable and continues to grow. I am looking forward to contributing my insights and knowledge to the comprehensive education program being offered at the Expo, and to once again meet with many Australian and international industry leaders at Expo,” Hanvey says.

Joining the list of speakers at the exclusive Business Education Program will be a list of automotive leaders who steer many of Australia’s major automotive organisations. They include Wayne Bryant, CEO Automotive Division of GPC; Steve Drummy, EGM Trade at BAPCOR; Lesley Yates, Director Government Relations and Advocacy at AAAA; Adam Gillick, Group Marketing Manager at Pedders; Adam Pay, CEO of mycar Tyre & Auto; Bradley Gannon, CEO Automotive of Capricorn Society and Stuart Charity, CEO of the Australian Automotive Aftermarket Association.

The new line-up adds to the announcement of special guests Dirk Fuchs from the US who will provide EV systems and EV workshop fit-out training

Leading consultant Robert Snook will also bring his industry experience to the business program.

AAAA CEO, Stuart Charity says the tailored program sessions to equip attendees with the insights they need to best prepare their business for the future, amidst a rapidly evolving industry and economic landscape.

“It is our goal to provide trade visitors to the Expos with the tools and knowledge they need to make wellinformed decisions for their businesses. We couldn’t be more excited to be delivering this all-encompassing program, which will help visitors increase their business profitability, understand future trends, and take advantage of workplace efficiencies,”

Session topics will include global aftermarket trends, local area marketing, right to repair, demonstrating the motor vehicle information scheme, finding and keeping great employees amidst a skills shortage, preparing your workshop for electrification, improving work life balance and increasing business profitability.

For any repair business tentative about the big move into the world of EV repairs and maintenance, this year’s expo offers the ideal place to take the first step.

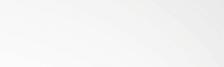

The ‘Expo Electrified’ feature zone at April’s Collision Repair Expo will ensure attendees can get up close to EV/Hybrid service and repair on a whole new scale.

The exciting new Expo Electrified

Zone will offer unique opportunities to learn about EV and hybrid service and repair with hands-on and practical demonstrations including live testing of EV motors and generators, all delivered by the experts from The Automotive Technician’s (TaT) EV & Hybrid Network.

The expo co-located with the Australian Auto Aftermarket Expo is free to attend and the only comprehensive trade show for the nation’s automotive repair and service industry.

Designed to give attendees exposure to the latest in EV technology and techniques, the Zone will also feature the latest in EV tools and workshop equipment, EV Personal Protective Equipment (PPE), and display a Ford F-150 Lightning EV, provided by the Auto Innovation Centre (AIC).

“The value of getting ready for the EV evolution has never been clearer, and excitement around this new and rapidly evolving technology is building quickly,” AAAA Director of membership, marketing and events, Tiffany Conway says.

“As such, we are very excited to offer the Expo Electrified Zone to technicians and workshop owners wanting to get ahead of the curve, and seeking the chance to learn from awesome teachers

and state-of-the-art equipment at Expo.”

TaT Technical Editor and Director, Jeff Smit, says Expo Electrified is a must for anyone looking to make sure they can best service their clients in this emerging space.

“Electrified vehicles are currently transforming from a trend to the mainstream, reshaping the roads and the way we can service our customers. We are excited to bring real hands-on component testing to the Expo Electrified Zone, giving an opportunity for you to carry out real tests on real EV and Hybrid motors,” Smit says.

Focused solely on EVs and Hybrids, Expo Electrified follows the popular Workshop of the Future feature area which ran at Expo in 2022.

“Such is the pace of technological advancement in the EV and Hybrid space, and with vehicles increasingly Hybrid or EV powered – accounting for seven percent of new car sales in 2023 – the time is right for this growing and dynamic field to have its own dedicated space at our Expo,” Conway says.

“Whether you want to learn about EVs and Hybrids for now or for the future, Expo Electrified is a great way to gear up for effective and safe service and repair

of these vehicles in your workshop.”

The combined Expos will showcase more than 400 leading brands plus international exhibitors and guests showcasing the latest equipment, technology, parts, and accessories, and this new zone further ensures the Australian Auto Aftermarket Expo and Collision Repair Expo are ‘not to be missed.’

The Collision Repair Expo also features a dedicated Training Program led by international experts Dirk Fuchs and Robert Snook. Attendees at the special program will be able to supercharge their EV collision repair skills, plus learn important business improvement strategies.

To find out more about the ADAS Technology Zone, Expo Electrified Zone or to register for the Business Education Program, or any other training and features of the Expo, and to get your free tickets,visit www.collisionrepair.com.au

The Collision Repair Expo is free-toattend for all members of the automotive trade, register at the website.

The Expo will take place 11 – 13 April 2024 at the Melbourne Exhibition & Convention Centre.

The 2024 Collision Repair Expo will bring together under one roof some of the market leading service providers in new areas of technology, offering businesses the ideal opportunity to see what is on offer to help them improve and grow. One of these market leaders is Repairify and its cutting-edge diagnostic services will be on show.

Repairify provides market-leading remote automotive diagnostic services across North and South America, Canada and Europe, with strong long-term relationships with a wide range of OEM’s and in 2023 it made its exciting launch in Australia. Repairify has brought its unique and world-leading advanced tools and remote OEM diagnostic, programming and calibration services to Australian workshops.

This is the specialist support many workshops are looking for as they tackle more technical vehicle repairs.

So, April’s Collision Repair Expo offers an unmissable chance to learn up-close more about Repairify Australia and its new products.

At the Repairify stand, technicians will be available to show visitors the innovative Repairify products, explaining how the products work to make it quicker and easier to repair vehicles in house, removing the need to return vehicles to the dealer and reduce key-to-key times.

The Repairify team will be on hand at the Repairify Expo Stand showcasing the products and services, including our All-in-One solution. This is a device that enables the technician to both work

locally on the car via a tablet and, where scans can’t be completed locally, connect with Repairify’s Remote Services team to complete the scan remotely using OEM tools. When the scan is completed, a detailed report is emailed to the workshop. This service gives repairers access on a pay per use basis to an extensive and ever-expanding range of OEM tools.

Newly appointed General Manager of Repairify Australia Tristan Sender is looking forward to exhibiting the Repairify solutions at the Collision Repair Expo.

“In an increasingly complex vehicle repair environment, our solution makes it easier for you to complete safe and proper repairs,” Sender says.

“The power of our All-in-One solution and Digital ADAS is the combination of workshop based tools and access to an extensive OEM tool stack through our Remote Services offering. This enables businesses to keep vehicles onsite and generate new revenue streams.”

“We’re particularly excited to be at this year’s Collision Repair Expo as it’ll give businesses the opportunity to see what the Repairify solution looks like, how it works and allow them to experience the benefits for themselves. I encourage anyone interested in finding out more to come and say hello to the team”.

Visit the Repairify stand to see how they can help reduce job turnaround times and support workshops in keeping jobs in house. Their services aim to reduce the need for workshops to take vehicles back to the dealer or wait for a subcontractor to visit their workshop to complete more complex repairs. For more information go to repairify.com.au or to register for the Collision Repair Expo for free, visit www.collisionrepair.com.au

The Sheen Group has a prominent history in Victoria’s repair industry but also makes an extraordinary philanthropic contribution. It fosters a culture of giving that is not only part of the wider company ethos but is helping to build stronger communities at a workshop level.

The Sheen Community Fund expects to make donations of more than $300,000 this year both to much loved charities like Variety and the Royal Children’s Hospital but also to a wide range of lesser-known causes. What the causes have in common though, is the determination to change people’s lives for the better.

Manager of the Sheen Community Fund David Whitehead said while they work with the Lord Mayor’s Charitable Foundation to ensure it meets all appropriate levels of governance and accountability; their independence and flexibility gives them the ability to also look at numerous individual causes.

“We’re identifying where there’s a need, where people fall between the gaps,” Whitehead says.

“For instance, there are people whose kids turn 16 or 17 on the NDIS and the funding drops away and they need to get a replacement wheelchair. There’s always a gap and we aim to fill that.”

In 2023 they worked with charity Friend in Me to identify gaps in these resources and those people whose less publicised need means they could miss out on funding. One project they are focused on in 2024 is raising $30,000 at a golf day to purchase an assistance dog for a child with high needs. Whitehead explains that it is often in these lower-key cases where the generosity of participants can have the most demonstrable effect.

“In the case of a child who has high needs, the result of an assistance dog to comfort the child can be life changing for an individual but also for the whole family,” he says.

“Not only does it give the child massive emotional and physical support, but it also means the parents can take a break without having to take the child with them. Parents can go to the shops without experiencing the separation anxiety of the child. The ripple effect of that dog is amazing. That’s what we look

for because these parents just aren’t going to get funding for someone to baby sit their child.”

Apart from the feel-good factor of all those who help to change a family’s life, Whitehead explains these causes have a powerful networking effect at bringing groups and businesses together.

“It’s our first ever golf day. We put that out in October expressions of interest, and we sold out in about two weeks. That’s how good our network is. We didn’t have to convince anyone, there was no hard sell; everyone jumped on board and paid their money to sponsor it. And all those people will do the

Projects like raising funds for an assistance dog can have life-changing results. All Images: Sheen Group

golf day and they’ll do more, they’ll donate in terms of cash or services to the community.”

Whitehead explains that giving begets more giving as the natural momentum of charity and networks grows. One of their big events of the year is their longrunning involvement in the charity Grand Final Luncheon for Variety.

“Crown Casino has a 120-table capacity and last year, we had 35 tables in that room. Of those 35 tables, a lot of those people we invited as a guest once. Now they bring their own guests. So instead of inviting two people, they now book a whole or two tables of ten

and all that funding goes to Variety.”

The long history of philanthropy began with Martin Stone’s involvement with Variety as a charity of choice more than 30 years ago, where he sat on the board and was a major contributor, both from a business and a personal point of view. This grew as the Sheen Group founder extended the philanthropy to support a wider range of individuals and organisations. The group then began to look for a longer-term view so they could set up a legacy they could pass on inperpetuity. This led to them adopting the Lord Mayor’s Charitable Foundation to make the administration of the fund more efficient.

Even more important is how the culture of giving back is developed throughout the company, both in supporting the Sheen Community Fund but also in the focus on community support from the 27 workshops for their own local causes and organisations.

“This goes beyond just the Community Fund,” Whitehead says. “I think the

The flexibility of the Sheen Community Fund enables it to support a wide range of causes from Variety to bike building.

managers and the staff understand the value of the good feel (of giving) because they’re all doing their own little thing.

“The manager’s kids may be involved, for instance, in the local footy club so there’s a reason for that shop to be invested into that footy club or netball

club or whatever it is. Because it has meaning to that family and creates community and it’s not always about the top end of town. And that’s where the foundation, probably this year more than ever, will get shops involved at the grassroots on the ground.

“We will do things like some bike building in a couple of shops. They will pick a suitable applicant in their area, a school or community, and they will go and buy some bikes, do the build and a handover to the kids who need them. It has an impact on the community and it’s meaningful at a shop level. It’s easy to hand over money but to participate in the solution when the opportunity arises is another thing. It’s tangible; I mean to see a kid with a fresh new bike!”

These community links in turn create individual small communities from the group of 10 people on average employed in each Sheen Group workshop, who then embrace the philanthropic culture.

“As a family business we look after our

staff like family and we try to treat them with family values, so they get it. I think whenever we do something charitable it is quite meaningful, and they know that’s coming from our DNA. We’re wired that way.

“They understand we do not sponsor something for a sticker on the front page. We’re not looking for return on investment, we’re looking out for the contribution we can make, whether it’s a solid funding contribution or public contribution.”

These local communities in turn have the power to strengthen bonds with customers.

“And quite often, we might get a request from a customer telling us they

are involved with this person or group and with a good customer, we might jump on board with support. The shop is actually further engaging this customer.”

Whitehead himself has seen the generosity of the Stone family, from Sheen Group’s founder Martin to its current generation and is motivated by a passion to continue that legacy through the company.

“I’ve seen the good stuff that Martin and Blair Denys have done over 20 plus years of fundraising. The people we’ve touched, whether it’s the people who have come to us for advice, those who come to us to get their cars fixed: it’s about the personal relationships. I’ve seen we’ve touched a lot of people’s hearts. You don’t need any convincing, you look at that and know it works.”

Whitehead says the great stories to tell can influence and connect the newest and youngest staff even if the culture of the Sheen Group is new or unusual to them.

“I think if we’re doing more events or activities, if you get them involved you take them on the journey. It doesn’t seem as foreign to them if people can have an experience with the end user (of the giving). If some of our people could get to meet the recipient of the assistance dog and see the difference it makes, I’m sure they will end up in tears. It has that effect. The more of that we do, the more relevant giving becomes.”

The Future Leaders series run by The National Collision Repairer is a showcase of individuals in the industry who display outstanding future potential and growth.

We would like you to consider nominating people who fit this description.

It is a great opportunity to recognise emerging talent and leadership and give some high-profile recognition to your exceptional staff through our magazine and website.

To nominate someone, send us a name, contact details and a brief synopsis of their achievements to: eugene.duffy@primecreative.com.au or call 0412 821 706 for more detail.

Like the customer waiting for their vehicle to be returned, most collision repairers want to turn a repair around as soon as possible. A crucial part of that is having the necessary parts delivered correctly and efficiently. ACM Parts are finding new ways to make it happen.

At first glimpse the task is daunting; over 40,000 SKUs, 200,000 pieces, four warehouses, four cities, dozens of delivery vans, and hundreds of drop-off points. Then there is the four separate ranges ACM Parts offers, Genuine, Aftermarket, Reclaimed and a core range of Consumables to be considered. Somehow, this system needs to get the right part delivered to the individual business, where possible on the same day, so that customer can be kept satisfied.

For ACM Parts’ General Manager Warehouse Operations, Enzo Ciano, this complex logistical task can be simplified to the principle of having as much of what the client wants, when and where they need it.

“We have a massive range of core items in stock. If it’s a front collision, we’ve got a bumper bar, we’ve also got headlights, grills, fenders,

and reinforcements,” Ciano says.

“We’re managing over 35 shipping containers coming inbound per month and hundreds and hundreds of deliveries going outbound to our customers, plus inbound parts from the 600 vehicles we dismantle per month.

“From a local delivery point of view, we have seven vans out of Queensland, seven out of New South Wales, one out of Perth and 11 out of Victoria.

“We’re doing two to three deliveries a day to our customers, with 10 to 15 drops per run. When you multiply that out by five days a week and however many weeks we work, it is a significant number of deliveries going out of the door.”

For Ciano, speed and efficiency are all about delivering on the service guarantee to workshops.

“Our service promise is if you place an order for a local delivery before our cut off time, you’ll get it that same day.

If it’s after cut-off, then it’ll be delivered the next day.”

Even for regional customers outside the capital cities, where ACM Parts uses external couriers, it is important to offer certainty to repair businesses customers.

“If it’s a customer where we use the third-party freight provider if it’s before cut-off, we’ll dispatch it that day and it’ll either be delivered the next day or the day after, depending on where they’re located.

“We’ve created a service matrix; our customer service team knows what the cut-off times are for each of the states and what the transit times are as well. It is reassuring for businesses, and we’ve partnered with good third-party carriers to make sure we’ve got the shortest transit time as possible, and we also work to ensure these partners are reliable and consistent with their delivery times.”

One of the enemies of delivery drivers is congestion and this is where location of facilities can play a major part.

The large-scale relocation of ACM Parts in Queensland to Hemmant, closer to the port and free of the worst bridge traffic, meant the introduction of multiple new delivery runs per day. The sheer size of the new Hemmant facility also allows for more stock lines and in turn better customer service, Ciano says.

“The growth and sales out of there has been fantastic since we’ve consolidated into that one larger facility. It’s given us the opportunity to be much more efficient. And I think the opportunity for us now is to place more inventory and we have an opportunity to sell and create further growth and sales from that place.”

A similar focus has been made on the established sites in Melbourne and Sydney about how to best utilise the locations to deliver the best outcomes for customers.

“Our Somerton facility has excellent access to the main freeways, the ring road and the Hume. We’re not too far from the airport and we’re really not too far from the wharfs either.

“In New South Wales it is hard to find good warehousing space at the best of times, but our Smeaton Grange location suits our operations and customer base. It isn’t as large as the Victorian and Queensland warehouses, but we utilise the space well with narrow racking and the appropriate equipment to go along with it.”

One of the recent big steps for ACM

Parts in Victoria, where it has a large customer base, is to bring the delivery service in-house with a fleet of high-roof long wheelbase Mercedes Benz delivery vans that are further adding to the efficiency and reliability ACM Parts can deliver to customers.

“Our Victorian facility at Somerton has a full in-house, van and truck setup and that’s been a successful process not just for ACM but for our customers,” Ciano says.

“We’re now starting to introduce that same methodology in the Queensland facility and the New South Wales facility. By mid-March we’ll be getting our fleet of ACM Parts vehicles, so they won’t be outsourced or contracted drivers anymore.

“We are seeing huge customer service

benefits from that, not only from a cost point of view, but they’ll all have an ACM employee turning up in an ACM branded vehicle. There will be a huge service improvement when our vans hit Queensland and New South Wales.

“We can manage route optimisation, who we are delivering to first and last. We can manage loading and unloading to reduce damages and correct delivery as well.”

Ciano explains that while the trend among many businesses is to outsource services, the specialised role of their own fleet means better results for repair businesses.

“I think when you’ve got employees, they’ve got a bit of skin in the game, which means an even better experience for our customers. It means that the delivery team and the warehousing teams are genuinely aligned to ensure the best experience for our customers.” Ciano says.

In addition to providing a great delivery experience, ensuring that the right parts are available is also important.

“Our supply team does a really good job in reviewing demand and ordering the right parts,” he says.

“The way that we structure our business in terms of what stock we keep, ensures a level of safety stock we hold which looks after some of these inconsistencies or any irregularity that occur in our supply chain.”

Whatever might occur at a global level affecting the supply chain, Ciano and his team at ACM Parts are working to deliver on their service promise to Australian repair workshops.

The Capricorn Rising Stars Award is the confidence boost every apprentice needs and nominations are now open for the 2024 crop of next-generation talent.

Role models for young people embarking on automotive careers are one thing the industry cannot have too many of. The Capricorn Society has long been at the forefront of highlighting and celebrating rising stars. These people not only showcase some of the best talent in the business but also act as a great reminder of the rich career paths that lie ahead for potential recruits.

Mark Smith, an auto-electrician with The Battery Terminal in Belconnen, Canberra, was the first-ever winner of the Capricorn Rising Stars Award, in 2018.

At the time, his prizes included an all-expenses-paid trip to the Gold Coast to watch the Supercars race and a customer service training package from The Workshop Whisperer for The Battery Terminal— his parents’ business. But the real prize was something far less tangible.

“I got a lot more respect from a lot of peers and from the businesses that we deal with,” Mark says.

“But the main thing for me was just the confidence from knowing that everyone had respect for me at such a young age. It allowed me to learn off a lot of other people who wouldn’t normally talk to an apprentice from another business. Business owners of other mechanical shops were actually talking to me about electrical problems, rather than always going straight to Dad.

“So, that’s one of the biggest things Rising Stars gave me—just the confidence. Now I’m sort of second in charge, and in charge when Dad’s not there, and it’s definitely given me the confidence to do that.”

It’s a boost Mark said every business owner can give their apprentice by nominating them for this

year’s Capricorn Rising Stars Award. Nominations are now open for 2024.

The prestigious achievement award recognises talented apprentices who show initiative, thirst for knowledge and commitment. The competition is open to all Capricorn Members.

Capricorn Group CEO David Fraser is proud of the competition.

“Encouraging and acknowledging future leaders is an important part of growing and supporting the automotive industry.

“We know that finding and keeping apprentices is one of the big challenges for the industry. By celebrating apprentices like Mark, we hope to encourage more to join, and stay, in the industry,” David says.

Over $27,000 shared cash and prizes is up for grabs for the top five apprentices, overall winner and nominating workshops. Capricorn thanks long-term program sponsors Castrol, Repco and The Workshop Whisperer for taking part in this most valuable automotive aftermarket industry recognition program.

Mark was nominated for the Capricorn Rising Stars by his parents, Capricorn Members Steve and Julie Smith, of The Battery Terminal.

If you’d like to nominate your apprentice and give them the kind of confidence boost Mark talks about, visit cap.coop/stars.

2024 Capricorn Rising Stars Terms and Conditions apply, visit cap.coop/tc

“RECOGNISING INDIVIDUALS WHO HAVE MADE A MEANINGFUL IMPACT TO THE INDUSTRY.”

The National Collision Repairer Lifetime Achievement Awards ceremony is held annually to induct recipients and acknowledge each individual for their outstanding service to the collision repair industry.

Proudly presented byIn partnership with Sponsored by

MELBOURNE

10 APRIL 2024 FINALIS

ncrlifetimeawards.com.au

2024 will be a big year for one of the most important documents governing the relations between insurers and repair businesses. Repairers can expect a Motor Vehicle Insurance and Repair Industry code that is more relevant and easier to understand.

Action on the MVIRI Code of Conduct continues to gather momentum following a review completed in 2023 that outlined key weaknesses in the code and made 15 recommendations to help make it more relevant and effective.

The reviews principal criticisms were that in an industry that represents 45 per cent of Australia’s 3.9 million insurance claims, “the number of parties using the code appears to have declined significantly”. It also found “There was a widespread perception that the code is not currently well promoted or known, and that levels of knowledge about its contents and its achievements are not well understood by either industry members or external bodies.”

But the MVIRI Code Administration Committee led by chair Stephen Jenkins is determined to turn this around and has already embarked on the recommendations, targeting three key areas; a re-write of the code, corporate governance and the need for education and promotion of the code.

The National Collision Repairer magazine sat down with Stephen Jenkins to discuss the complex but critical work of rewriting the code.

National Collision Repairer: Can you give any details or parameters of the brief for the rewrite?

Stephen Jenkins: The rewrite will be centred around the recommendations of the Schaper Review, with a particular focus on cleaning up the language to be simple and accessible. The recommendations of Dr Schaper were in accordance with the Terms of Reference which covered five areas of concern by the Committee in relation to the Code. The Terms of Reference were agreed to by both the MTAA and ICA.

NCR: What can the motor repair industry

expect from the rewrite in 2024?

SJ: A more simplified Code that spells out in plain English which matters are disputable under the Code and which matters are more appropriate for commercial negotiations between individual insurers and repairers (e.g. pricing for repairs). The CAC will also be looking to uplift the website to support greater accessibility and engage with regulators to support more awareness of the MVIRI as a tool for repairers. The Code will address the current difficulty which the Industry has in skills shortages, in particular in relation to Assessors and Estimators. In addition, the Code will streamline the Dispute Resolution process to provide certainty and closure for the industry participants.

NCR: How do you anticipate these changes will help in the compliance of both insurers and repair businesses?

SJ: A more precise and clearer to understand Code will enable repairers to better understand what is disputable and what to expect from a dispute. It would also enable both insurers and repairers to understand what their obligations are under the MVIRI Code. It will provide Insurers with clear guidance as to how they engage with the Industry and also provide visibility to Regulators on how the Industry is performing in its delivery of service to the consumer.

NCR: How will the new code help with dispute resolution? Has the committee agreed on sanctions?

SJ: It will enable repairers and insurers to understand what is disputable and what is not under the MVIRI Code – this would help streamline dispute resolution process as both parties to a dispute will be better informed as to what to expect in the process. The Committee

is still having ongoing discussions regarding the potential of including sanctions, however, the priority is to improve accessibility and awareness of the Code. As the Code will be voluntary in a number of states across the Commonwealth the jurisdictional issues on imposing sanctions upon industry participants is being worked through. The Committee wish to see the standards across the industry continue to improve and therefore implementing enforcement upon industry participants is a goal of the Committee.

NCR: Should more states adopt the code as compulsory and what other steps could help with a higher level of uptake or gain more signatories?

SJ: The South Australian experience will be instructive as to the merits of a mandatory MVIRI Code being rolled out across all jurisdictions. While there are benefits in knowing that a code is enforceable under law, there is evidence that mandatory codes can result in additional compliance costs as well as more drawn-out dispute resolution processes noting that additional costs are ultimately born by the end user – the customer having their car fixed under an insurance policy. Having said this, it is clear that the higher the uptake of industry participants onto a single code the better for the industry and the end consumer. It removes the ability

for differing regimes of rules and obligations to apply across the industry which only leads to confusion and delays for consumers in their dealings with the Collision Repair Industry. A focus on greater education and awareness, in our view, would provide the best return on investment in terms of promoting update in terms of increasing uptake of the Code.

NCR: What are the next steps to make the code and its benefits wider known among the respective industries?

SJ: Improving the website functionality and uplifting engagement with regulators. The Committee is working through a business plan on a roll out of the education and engagement for the code across the country. The combined efforts of the ICA and the MTAA will assist in the greatest amount of engagement with the industry as well as encouraging the update of industry participants in the Code.

NCR: What content do you anticipate publishing on the website? Will that include adjudications?

SJ: Discussions are still ongoing amongst the CAC regarding the design and content of the website, however the underpinning principle would be to maximise accessibility and engagement with the MVIRI.

NCR: What developments have there

been under the code on how it can help the industry utilise and cover new technology, particularly AI’s use in insurance assessment and estimation?

SJ: The MVIRI is not intended to be an exhaustive manual for managing every conceivable dispute between insurers and repairers, however, but certainly insurers and repairers alike recognise the growing potential for AI to impact on the MVIRI Code. There may be a role for the MVIRI to ensure fairness and transparency of repair estimation processes as adoption of these technologies become more widespread. Potential area for further exploration is the development of defined standards and guidance for the use of AI-assisted assessment and repair as part of the MVIRI would help address potential concerns around the use of these technologies when they become more available. This issue was part of the Terms of Reference provided to Dr Schaper. Therefore, both the ICA and the MTAA recognize the challenges that new technology will bring to the Industry. The challenge for the Collision repair Industry in Australia is the plethora of makes and models being imported and the lack of guidance from some OEM’s on repair methodologies. The Committee consider that the Code can be adapted to cover the future proofing of the Industry and we look forward to assisting the Industry in dealing with its challenges.

The growth of interest in forming or becoming part of a network, whether it is an MSO, franchise or repairer group, leaves a tantalising question for small independent repairers looking to secure their future within the ever-evolving repair industry.

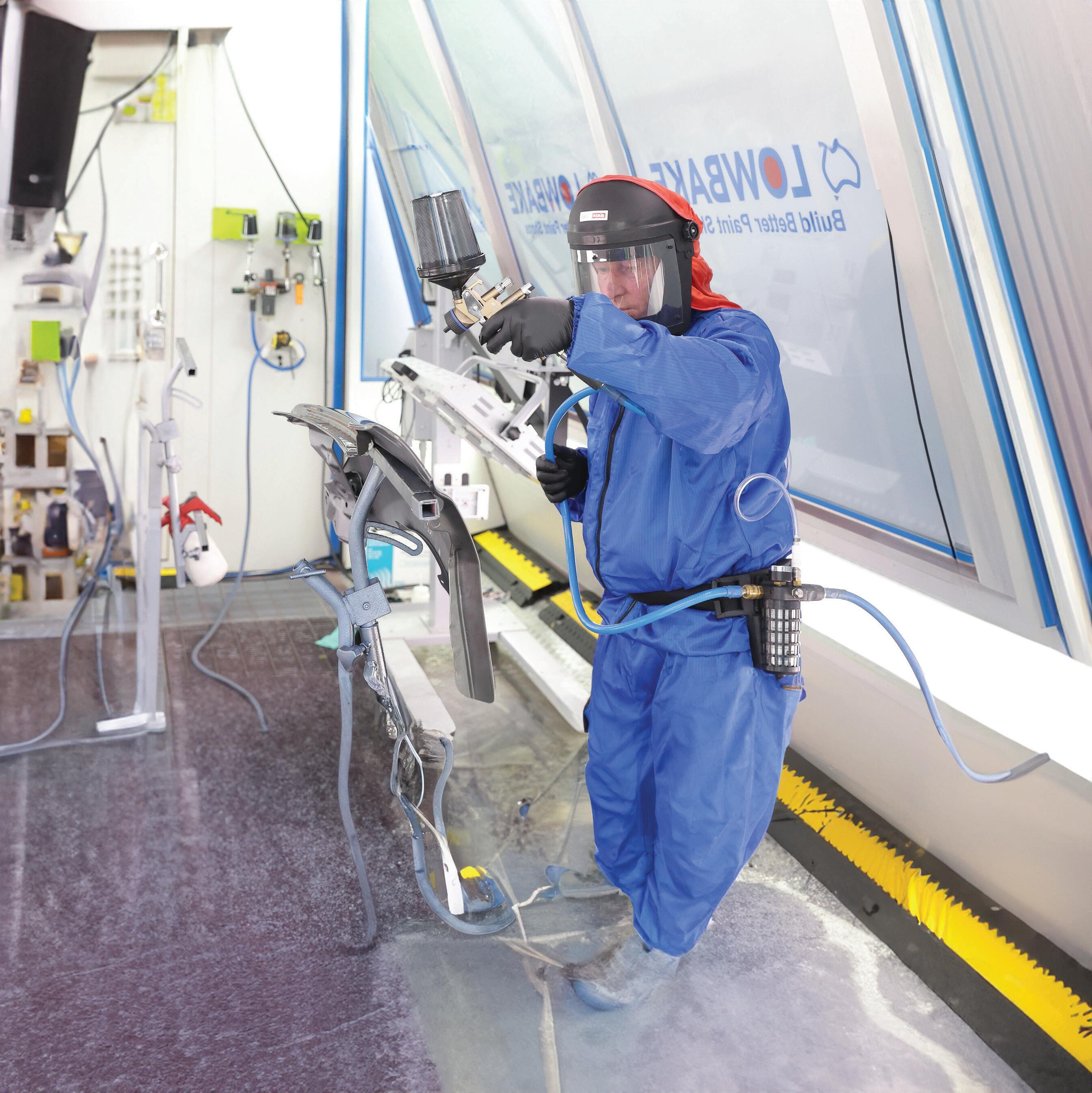

There are many who will argue that there is no need to train, or that they have no time to train.

For the independent smaller repairer, there is a strong bond with their clientele that has been built up over years of doing business and providing quality service and repairs. The big challenge in this area is to continue to provide quality repairs that are complete and safe as technology evolves.

There is a growing requirement by all insurers to follow OEM procedures and what is now becoming prevalent is the impact of ADAS on complete repairs. There seems to be an ongoing negative attitude to training as a burden on a business and while the management or owners of a business believe there is no

benefit, then there will be no investment in training now or into the future. It is only when something goes wrong that training may be considered. But what will that have already cost?

The loyal customer may not be overjoyed that the vehicle they have purchased based on its looks, the colour and most importantly the safety features provided is not working as it was designed to. Many businesses have their refinishers trained regularly to ensure maximum productivity within the refinish section which is admirable. Admittedly the finish of the vehicle is the first thing a customer notices, but let’s be real, nobody was ever seriously injured by a shiny paint job!

However, improper repairs, such

as uncalibrated ADAS systems and unscanned pre and post-repair checks are a greater concern. These are the things an owner does not see, and some repairers still believe that certain materials can be heated, sectioned or repaired regardless of how advanced it is. The fact remains that incorrect repair methods on advanced materials compromise the design of vehicle structures. Once a structure is compromised then the safety features built into the vehicle also become compromised.

Timing of Supplemental Restraint Systems (SRS) may be affected, misalignment of structures, however small, affect radars and cameras when they are travelling at speed. Imagine

travelling at 100km/h down the highway and camera and radars have not been calibrated and an incident occurs whereby the traffic stops dramatically. There is a potential that the ADAS system will not recognise the incident outside of its sensing parameters and the vehicle will slow down later and as a result, become involved in the incident and causing more damage to the vehicle, a late deployment of SRS and potential injury to the occupants.

Worst case scenario, yes! However, there comes a time where, as an industry, we recognise that this is why OEMs are building vehicles with technology to ensure damage is minimised and most importantly that occupants are protected in motor vehicle incidents, regardless of the size of the incident.

So, what affect does this have on a repairer involved in this situation? This can vary depending on the significance of the incident to the occupants. The concerning thing is that minor repairs can have larger more significant outcomes if repairs are not performed correctly. There could be large financial ramifications ($40,000,000 in the US for one such outcome) or if there are only smaller problems it means reworking the repair.

What is the cost of rework within your business? Does it affect cycle times and other customers vehicles? More importantly, having to deal with an unsatisfied customer who was once-upon-a-time an advocate for your business. In the future, will they still be advocates for your business?

Back to the question of ‘is training a

cost you can afford?’

Playing the percentages in collision repair and hoping that your repairs are complete, safe and of quality, needs to be understood. The need to invest in you or your technicians, regardless of the experience within the industry, is going to be a part of doing business into the future. The technology will continue to evolve and challenge the way repairs are to be done.

There is a significant attitude in this industry that the way repairs have always been done is still correct or that many repairers believe they are doing the repairs correctly based on their ‘experience’. But new materials challenge old concepts as they are highly advanced in their making and as a result there may be limitations in the correct methodology, that may be completely opposite to a technician or estimators understanding.

The line between complete and incomplete repairs is becoming more pronounced except in the minds of

untrained technicians. It’s not like eating a meat pie today as compared to eating one ten years ago, pies haven’t changed. A modern vehicle however has changed significantly at every level, so if you believe that training is unnecessary in repairing modern vehicles, and your repair is found to be a resulting factor in an incident, that may be a cost you cannot afford.

With training and technology in mind, the Collision Repair Expo is happening again from 11-13 April at the Melbourne Convention and Exhibition Centre.

There will of course be a huge selection of equipment to browse through, as well as many demonstrations to assist the industry to further improve processes, productivity and of course quality. It is astonishing to see the level of sophistication in everything from paint to technology, measuring through to welding machines.

Sometimes the shiniest of machines, or the latest of equipment, may not provide your business with the biggest return, invest in your people and the value will be there.

I-CAR will have our amazing team at the expo during the three days to answer any questions you may have on our training courses and the addition of a virtual welding machine for visitors to try their welding skills on. We will also have two guests from I-CAR (USA) with us for the three days and they will also be presenting and detailing what to look for when static ADAS calibration fails.

We look forward to seeing you all at the Collision Repair Expo 2024 and please drop by stand AA24 to see what’s new at I-CAR Australia.

For more information on I-CAR or to see their full training schedule go to i-car.com.au

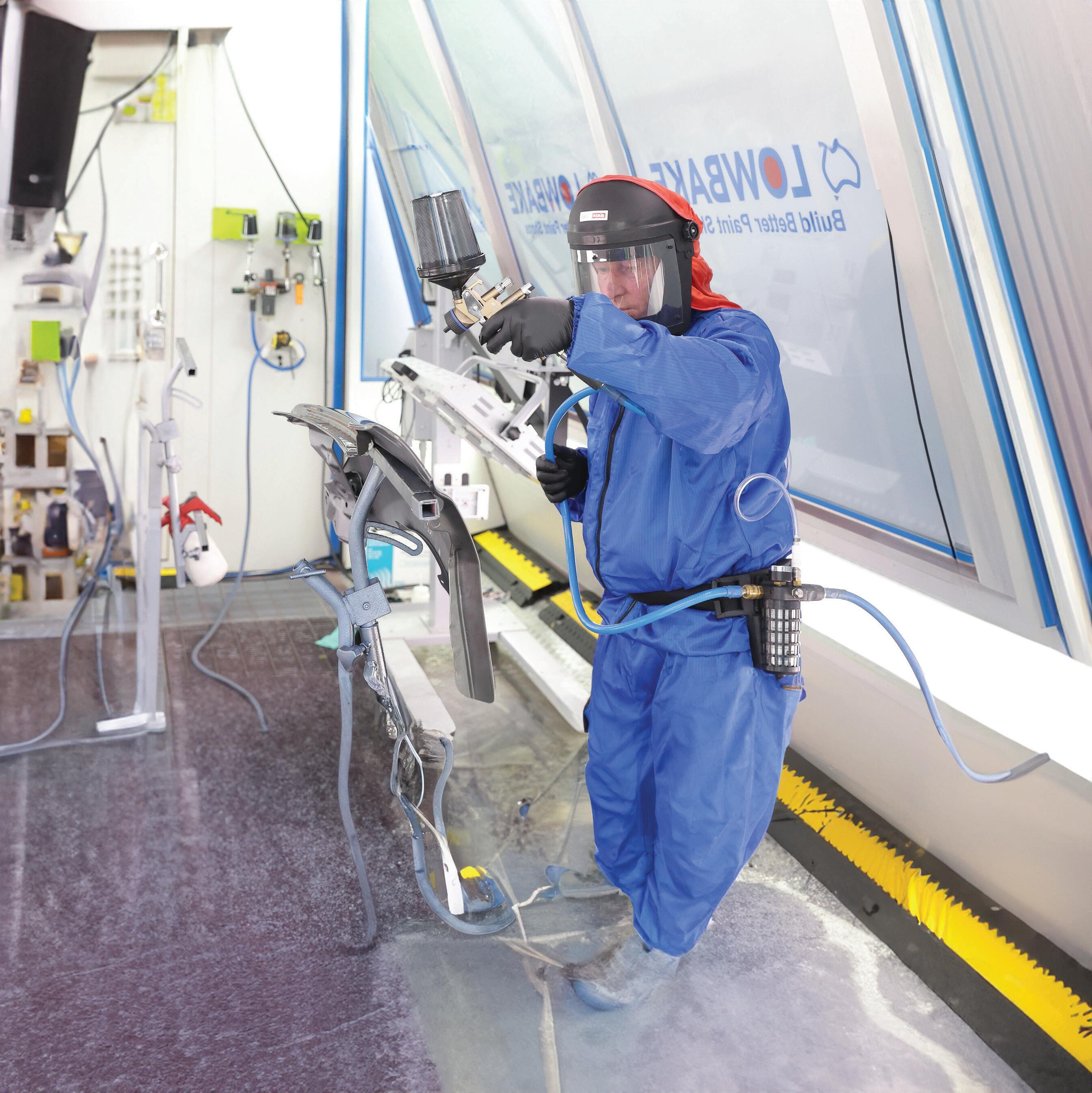

While it might have been a backyard project and a lot of curiosity that drew Lois Pagana into the repair industry, it is the support of his mentors and a love of cars that keeps him excelling.

For Pagana, it began with that familiar and memorable experience of his first car. He was one of many young people who, on leaving school, think their destiny lies through the portals of a university but Pagana quickly learned that passion is sometimes a better guide to a career path.

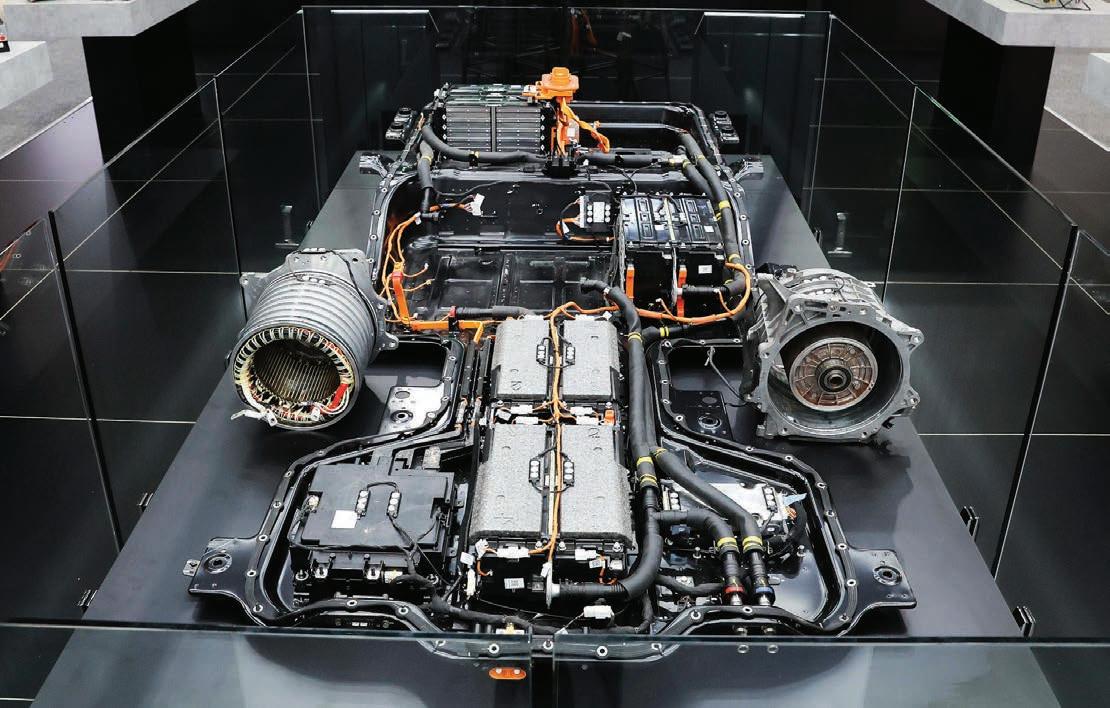

“I actually got into the industry because I bought my first car with my brother and we spray painted that car with rattle cans,” the fourth-year apprentice spraypainter says.

“I wasn’t really heavily into cars then. I went to uni as well and I was studying aeronautical engineering, but I found that it was a bit too much theory for me and I wanted to do some hands-on work.

“And then in 2020, I was buying and selling (restored) cars and I got a Honda Integra Type A and did a lot of work on that, fixing it up.”

The pleasure of restoration became the slow revelation for him.

“I really enjoy working on cars and I thought; I want to do that full time and that’s when I applied for TAFE,” he says.

“I wasn’t sure what to do exactly, so I simply applied for spray painting. When I went to TAFE for the first time, I remember there was an alternative GTR that was getting painted there and I was amazed. This was so cool, and I said, I want someday to be able to work on cool cars like that and learn to work on it properly, so that you know your stuff.”

His passion for learning was backed up not only at TAFE but at Fix Auto Morley where he was first employed.

“I really enjoy learning and when I went into that workshop, I told the bosses I just wanted to learn, and I wanted to keep growing as a person, to learn everything

to do with spray painting and even the actual business as well. I wanted to learn how to quote and other roles like that.”

He has done his first three years as an apprentice and looks forward to completing his final unit in fourth year.

“I didn’t find it hard. Obviously, there’s some challenges with the work-life balance, but I never thought of work as a burden because I always really enjoyed it.”

Pagana believes it is important to

be driven by a pride in his work and a passion to get progressively better.

“It’s just an incredible feeling after you finish the job, and you just look at it and you have that, “I did that!” kind of feeling. It’s not just simply finishing a job, it’s because you want to perfect the job.”

Part of this for him is to take an approach of continuous learning, something he was well supported in at Fix Auto Morley.

“Travis Arnold, my manager, gave me

IAG’s ongoing support and sponsorship of these awards is greatly appreciated, as is the support from I-CAR Australia, who donates two training courses valued at over $500 to each Future Leader of the Industry.

a lot of support and he was really helpful for me at every opportunity; if I wanted to paint more, he just let me paint, if I wanted to learn other stuff, he just let me do that.

“Then I got an opportunity to work at a BMW repairer. Travis was really supportive of that, even though it was a bit hard to leave that workshop. It’s always sad.

“But I wanted to be able to go into the office and learn about estimating and

other things in order to one day own my own business and I told Travis and that’s why he’s was so supportive.”

Pagana has since started working at Autobody and Paint, Osborne Park whose expertise in repairing BMWs has ignited another level of passion for his craft.

“It’s pretty cool and it’s almost scary at the same time, working on new BMWs, working on cars I’ve never knew even existed. It’s just a different level.”

He is appreciative of all the support

he has gained and his advice for young people, is that with the right attitude to learning, repair is an industry that can help fulfill career dreams.

“I really want to get to that next step. And hopefully, will have my own business in about five years or so,” he says “Learn as much as you can. Just keep learning and just enjoy the learning.”

Do you know someone who is a future leader in the industry? The Future Leaders series run by The National Collision Repairer is a showcase of individuals in the industry who display outstanding future potential and growth. NCR extends the invitation to organisations and businesses to nominate people who fit this description. NCR believes this is a great opportunity to promote the best of people in collision repair and create role models for other up-and-coming staff. This series is not limited to young people but anybody within the industry who has demonstrated a level of excellence and displays a potential for growth and leadership. Send the National Collision Repairer magazine a name and a few lines on what they do and why you think they qualify as a future leader.

Email eugene.duffy@primecreative. com.au

Be part of this unmissable April evening that celebrates the repair industry with three great awards; the Lifetime achievement Award, the Woman in Automotive and the Next Generation Leader.

The National Collision Repairer’s awards will be celebrated with a Gala Night on April 10 at Showtime Events, Melbourne, and will be compared by well-known media personality and football legend Dermott Brereton.

After a decade at the peak of Australian Rules Football, playing for Hawthorn, where he kicked 427 goals, ‘Dermie’ then went onto one of the highest profile careers in the sports media in Australia, first at the Nine Network and now with Foxtel.

NCR’s Lifetime Achievement Award is one of the industry’s most prestigious awards and celebrates those involved in the sector for more than 20 years who have made outstanding contributions to the wider industry.

M1 Autobody director Peter Ruggeri, who won in 2022 said it was a special highlight in his career.

“After 40 years in the business, to get an award from an industry that I have loved so much was very special to me. After all those years, I was really chuffed and it recognises the efforts you put into that industry and the respect it deserves,” Ruggeri says.

Another worthy winner from 2022, Michelle Morgan, Head of Channel at Saint-Gobain also spoke of her joy at receiving the award.

“The Lifetime Achievement Award is a significant honour,” Morgan says.

“Being acknowledged by industry peers within the field I love and have dedicated my entire career to is incredibly humbling and a milestone achievement of which I am very proud.”

These awards have the gained the sponsorship and support of some of the biggest names in the industry.

Repairify Australia says it was thrilled to a be a platinum sponsor of this year’s Lifetime Achievement Awards.

“The collision industry wouldn’t be the innovative, cutting-edge industry it is today without the people in it,” Tristan Sender, GM of Repairify Australia says.

“We’re proud to support the prestigious Lifetime Achievement Award and celebrate the outstanding work and meaningful impact of long-serving industry experts,” Sender said.

Global coatings giant PPG is also a Gold Sponsor with PPG sales director Australia John Hristias saying the awards were an important recognition of outstanding figures in the repair industry.

“Today’s robust, tech savvy collision repair industry has been made possible by people across the country who have literally put their blood, sweat and tears into it,” Hristias says.

“To help recognise that, PPG is proud to support the National Collision Repairer Lifetime Achievement Awards. As one of the longest serving suppliers to the local industry, PPG has built its success on establishing long term relationships and that has brought us

HELD ANNUALLY, THE RECIPIENTS OF NCR’S LIFETIME ACHIEVEMENT AWARDS ARE INDUCTED AND HONOURED FOR THEIR OUTSTANDING SERVICE TO THE COLLISION REPAIR INDUSTRY.

The night will be compared by AFL legend Dermott Brereton.

Image: enhanceentertainment

into contact with individuals who have dedicated themselves to making the industry stronger. Whether these industry achievers are front and centre or operate quietly in the background, the National Collision Repairer Lifetime Achievement Awards provide a valuable way to recognise them.”

They are also particularly special awards for Capricorn – Australia’s largest automotive cooperative, which has more than 26,000 members across the nation.

“Capricorn are thrilled to be a sponsor of the Lifetime Achievement Awards in 2024,” Capricorn Group CEO David Fraser says. “These awards recognise some of the most experienced individuals in collision repair and we are proud to play a part in acknowledging the contribution they have made to the industry.”

Tickets are currently on sale for the gala night.

Scan here:

Proudly Sponsored by:

Platinum Sponsor

Evening Sponsors

2007 Richard Nathan

2007 David Weatherall

2008 Terry Flanagan OAM

2008 Marshall Duncan

2008 Graham Winter

2008 Jeff Hendler (Int)

2009 Max Chanter

2009 John Howes

2009 Robert Renwick (Int)

2009 David Newton-Ross

2010 Wayne Phipps

2010 Richard Pratt

2010 Bob Rees

2011 Lance Weiss

2011 Mark Brady

2011 Don Wait OAM

2012 Tony Farrugia

2012 Bob Christie

2012 John Zulian

Platinum Sponsors

2013 Tom Vukelic

2013 Robin Taylor

2013 Ray McMartin

2013 Colin Edwards

2014 Ian Wilkinson

2014 Julie Thomas

2014 Brian Johnson

2014 Terry Feehan

2015 Owen Webb OAM

2015 Phil Nixon

2015 Trevor Parkes

2016 Tony Warrener OAM

2016 Brenton Abbott

2017 Michael Killen

2017 Carl Tinsley

2017 Per Madsen (Int)

2017 Rex Crowther (Int)

2018 Garry Clear

2018 Cec Simpson

2018 Michael Wilkinson

2019 Mark Czvitkovits

2019 Martin Stone AM

2019 Julie Wadley

2019 Walter Zuber (Int)

2020 Brad Franklin

2020 Jim Vais

2020 Jeff Williams

2021 Steve Economidis

2021 Garry Maher

2021 Peter McMahon

2021 Rob Mildenhall

2022 Tony Cafasso

2022 Michelle Morgan

2022 Peter Ruggeri

2022 Darren Wales

2023 Ben Chesterfield

2023 Scott Donnelly

2023 Morry Corvasce

Industry bodies are examining the details of the long-awaited fuel efficiency standard to see what impact it could have on the automotive industry.

The federal government’s policy, released last month, will limit the average emissions of each carmaker over their fleet of new cars in Australia and was met with mixed reactions.

The federal government has promised a greater choice in fuelefficient cars and electric vehicles under the pollution limits that it hopes will save drivers $1000 in fuel a year.

Under the new standard, which will be open for consultation, car makers will be required to lower average vehicle emissions across their fleets by 61 per cent by 2029.

Grams of carbon emitted per kilometre will need to drop form 141 grams per kilometre in 2025 to 58 grams by 2029.

Australia currently has emissions on average of 170 grams of carbon dioxide per kilometre travelled, 20 per cent higher than the US and 40 per cent higher than the European Union.

The Electric Vehicle Council has welcomed the proposed New Vehicle Efficiency Standard, saying it was critical to bring Australia in line with over 85 per cent of the global car market that already has these standards.

“The government’s proposed New Vehicle Efficiency Standard will drive down fuel bills for Australians while improving the choices consumers have to purchase more efficient petrol, diesel, hybrid and electric vehicle models. It also aligns with Australia’s 2030 emissions reduction target.”

However, the standard has called into question the future of highemitting cars such as larger ICE vehicles and reignited a political debate, capitalising on Australia’s love affair with large utes, which

make up four out of five of the top new cars.

Total EV sales in 2023 amounted to 7.2 per cent of new vehicles, which combined with hybrids equal about 15 per cent of cars sold. The idea behind the limits is car manufacturers will need to offset their higher emitting ICE range with more EVs and low emitting vehicles, prompting more models in their range.

The Federal Chamber of Automotive industries argues the standard must continue to ensure the affordability and mobility of Australian consumers.

FCAI Chief Executive Tony Weber says the automotive industry has been seeking a fuel efficiency standard in a united effort to combat high emissions, but this should not be at the expense of choice.

“Most important is that Australian families and businesses can continue to access the style of vehicle that suits their needs for work and recreation,” Weber said in a statement.

“On the surface, the targets seeking a 60 per cent improvement in emissions are very ambitious, and it will be a challenge to see if they are achievable taking into

account the total cost of ownership.”

“The preferred option suggests that Australia considers adopting the type of targets that are currently in place in the United States. The targets in that country are supported by significant financial incentives yet the discussion paper makes no reference to any additional incentives to support the uptake of low emission vehicles,” he says.

“There is a great deal of further analysis to do, and we look forward to continuing to work with the government on the development of a standard that is right for Australia and supports Australian consumers.”

Australian Automobile Association managing director Michael Bradley says the government must ensure vehicles remain affordable and called on the government to release modelling including its forecasted fuel bill savings.

“The government should be commended for pursuing this regulatory change,” Bradley says.