CODES:

Reusable Container

KMRGN750

Reusable Lid

KMRGNLID

An effective and innovative alternative to traditional single-use plastic, this simple and stackable solution is compliant with government regulations.

Developed specifically for commercial caterers, the Regen container meets the demands of professional kitchens. Its construction prioritises durability without compromising on material efficiency; robust enough to withstand daily use without succumbing to cracks or breaks. Crafted from clear plastic mono polymer (polypropylene), readily recycled at the end of its lifecycle. Approved by the Australian Packaging Covenant Organisation (APCO).

Reusable Food Container

Comes with optimised wall strength to ensure it doesn’t break or crack, maintaining the desired materials efficiency.

Commercial

Dishwasher Safe

Can sustain temperatures of 75°C and maintain its shape when exposed. Microwaveable and fridge/freezer safe.

Leak resistant due to the embedded seal in the lid.

Ensuring safe handling of hot food and avoiding food loss. simple and stackable solution for kitchens and catering.

Recyclable in Co-Mingled Recycling

Easily disposed of in co-mingled recycling. Can be collected, sorted and recycled in practice and at scale in Australia and New Zealand. Made with polypropylene so can be recycled when reaches its end of life.

SManaging Editor: Mike Wheeler

ustainability is a word that you are going to be hearing a lot more of over the next 18 months. It is a word that is doing the rounds in many industries, not just in the food and beverage sector. One dictionary definition is “avoidance of the depletion of natural resources in order to maintain an ecological balance”.

How is this going to affect our industry? Well, the greatest impact will probably be felt in the packaging sector.

As readers are aware, we have a regular contribution to the magazine from the Australian Institute of Packaging. You’ll note that column after column over the past two to three years has been dedicated to sustainable packaging, how to design better packaging, or has celebrated a range of awards won by those who are introducing such innovations to the industry.

The federal government enacted the National Waste Policy Action Plan (NWPAN) in 2019, whereby it set a target of all waste streams having a recycling return rate of 80 per cent by 2030. On current trajectory, a large number of these waste streams won’t make it for a variety of reasons – lack of infrastructure, education and sometimes political will.

However, that doesn’t mean this industry shouldn’t be doing its part. And in some cases, it is. Take Bunzl, for instance. The company saw a gap in the market when it comes to sustainability in the food space and released a range of containers aimed at consumers that can be used more than 700 times before they reach the end of their life.

It’s not only how the range is designed that is interesting, but how the company got there. Not satisfied with just making a product that might be reused every now and then, they went a few steps further.

First, it partnered with Genfac Plastics, which, as the name suggests, specialises in plastics manufacturing – but not just any plastics. Its goal is to produce products that not only leave a low carbon footprint but are also recyclable. The company manufactured Bunzl’s Katermaster Regen range with that in mind. As well as being able to be recycled via kerbside collection at the end of its life, the innovation won it a Gold at the 2025 Australasian Packaging Innovation and Design Awards (PIDA) in the Sustainable – Reuse and Refill category.

The likes of Bunzl are getting on the front foot with these kinds of innovations, not only because it is the right thing to do, but because it is becoming an expectation from the public at large. The younger generation especially is becoming more discerning in its choices around different ecological matters. Manufacturers are beginning to see that making a great product is now only part of the process – if the competition is making a great product and packaging it sustainably, then that is becoming a competitive advantage.

Companies like Bunzl and Genfac are on the front foot when it comes to meeting consumer demands in this space. Hopefully, in the near future, it will become the norm. F

Chairman: John Murphy

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Ph: (02) 9439 7227

mike.wheeler@primecreative.com.au

Art Director: Michelle Weston

michelle.weston@primecreative.com.au

Sales/Advertising: Joanne Davies

Ph: 0434 785 611

joanne.davies@primecreative.com.au

Production Coordinator: Justine Nardone

Ph: (03) 9690 8766

justine.nardone@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109119

2 year subscription 189 199 209 For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

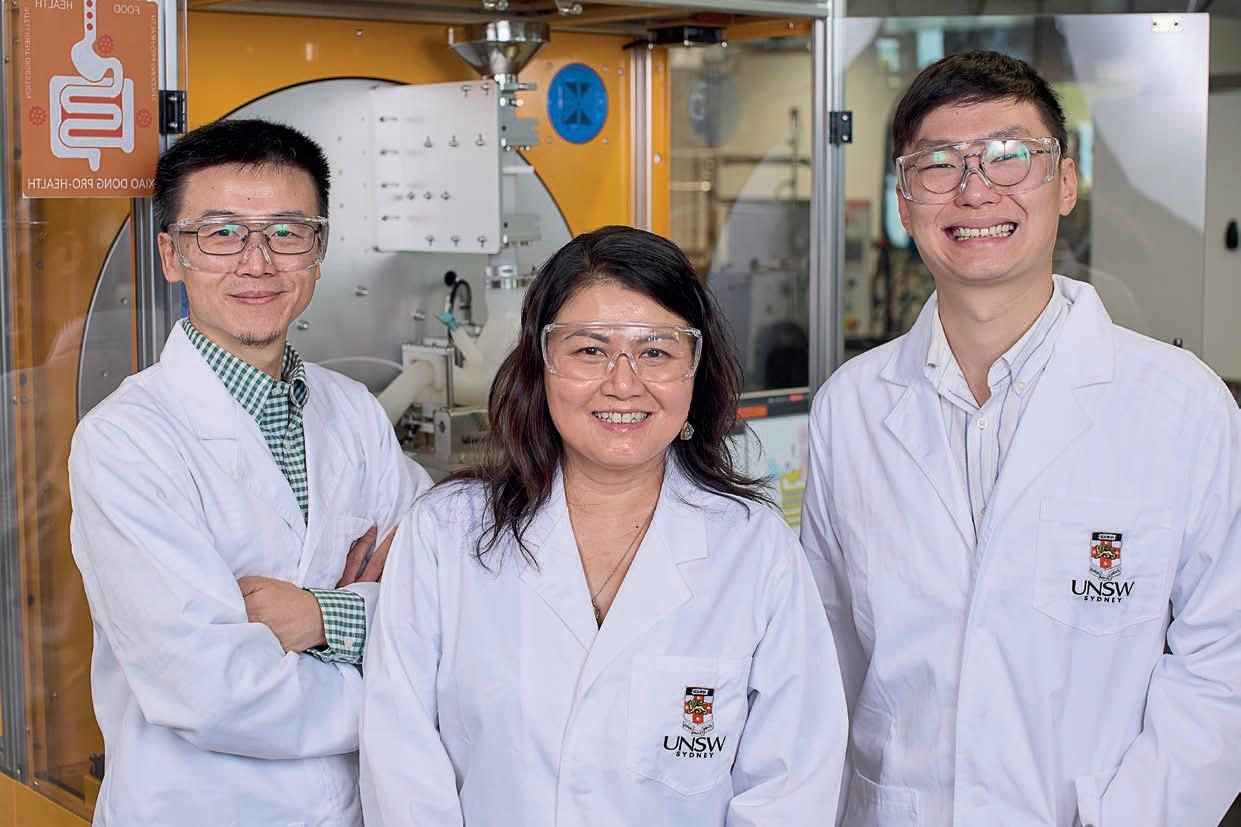

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Cover

Image: Atlas Copco

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite 11.01, 11th Floor

201 Miller St North Sydney, NSW 2060, Australia

Printed by: Precision Group

83-89 Freight Drive, Somerton Vic. 3062

Ph: (03) 9490 1500

6 News

10 Meet the Manufacturer: Alchemy Cordial Obsessed with flavour, the founder of a cordial company turned values into reality.

14 Meet the Manufacturer: Barnes and Brown

Creating flavourful non-alcoholic spirits for non-drinkers.

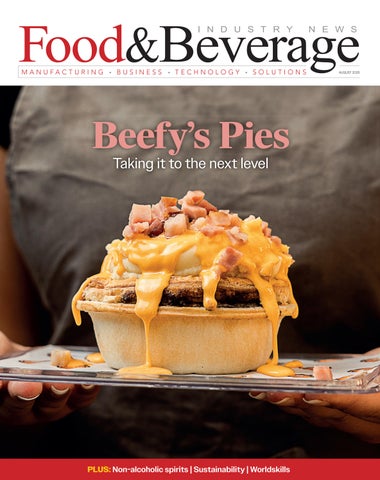

18 Meet the Manufacturer: Beefy’s Pies

Starting as a local bakery, a national brand aims to elevate Aussie meat pies.

22 Bunzl

In packaging, end of life is just as important for sustainability.

24 APS Manufacturing Centre

APS’ facility is designed around the principles of digitalisation and customisation.

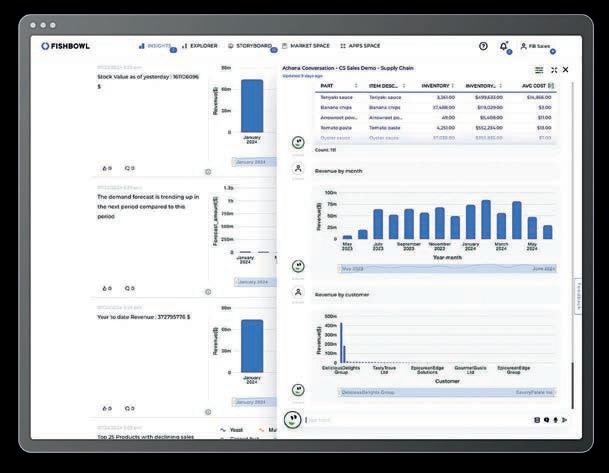

26 Fishbowl

With tailored services, Fishbowl provides smart inventory solutions with flexibility.

28 Endeavour Awards

For the first time, the 2025 Endeavour Awards will have a food innovation award.

29 Krones

From single machinery to complete turnkey lines, Krones offers flexible solutions.

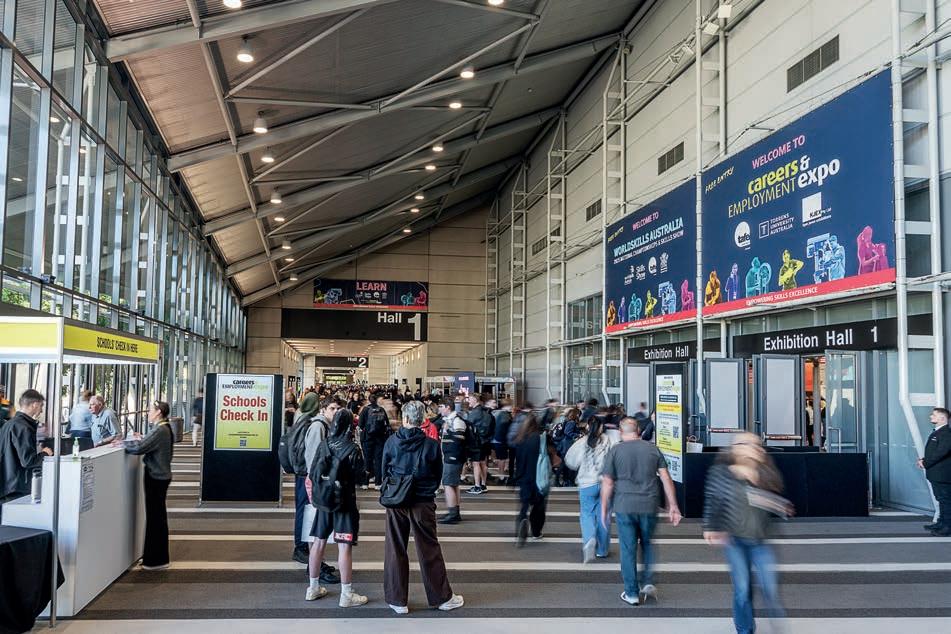

30 WorldSkills

Being the third gold medal winner in his family, William Nickl shares his experience.

32 MICE

The coffee expo saw a rising discussion surrounding innovative packaging solutions.

34 Australian Wine Research Institute

The global grapevine nursery industry is reliant on clones for consistent quality.

36 Food partnership

Mars Food Nutrition Australia and Foodbank partners to deliver truckloads of pasta sauces.

38 Instrumentation

To meet the standards of accurate measurement, VEGA provides solutions for the industry.

42 Food security

SecondBite gets creative with warehousing and logistics to feed hungry Australians.

44 AIP

Box-bottom paper bags stole the stage at the recent PIDA Awards.

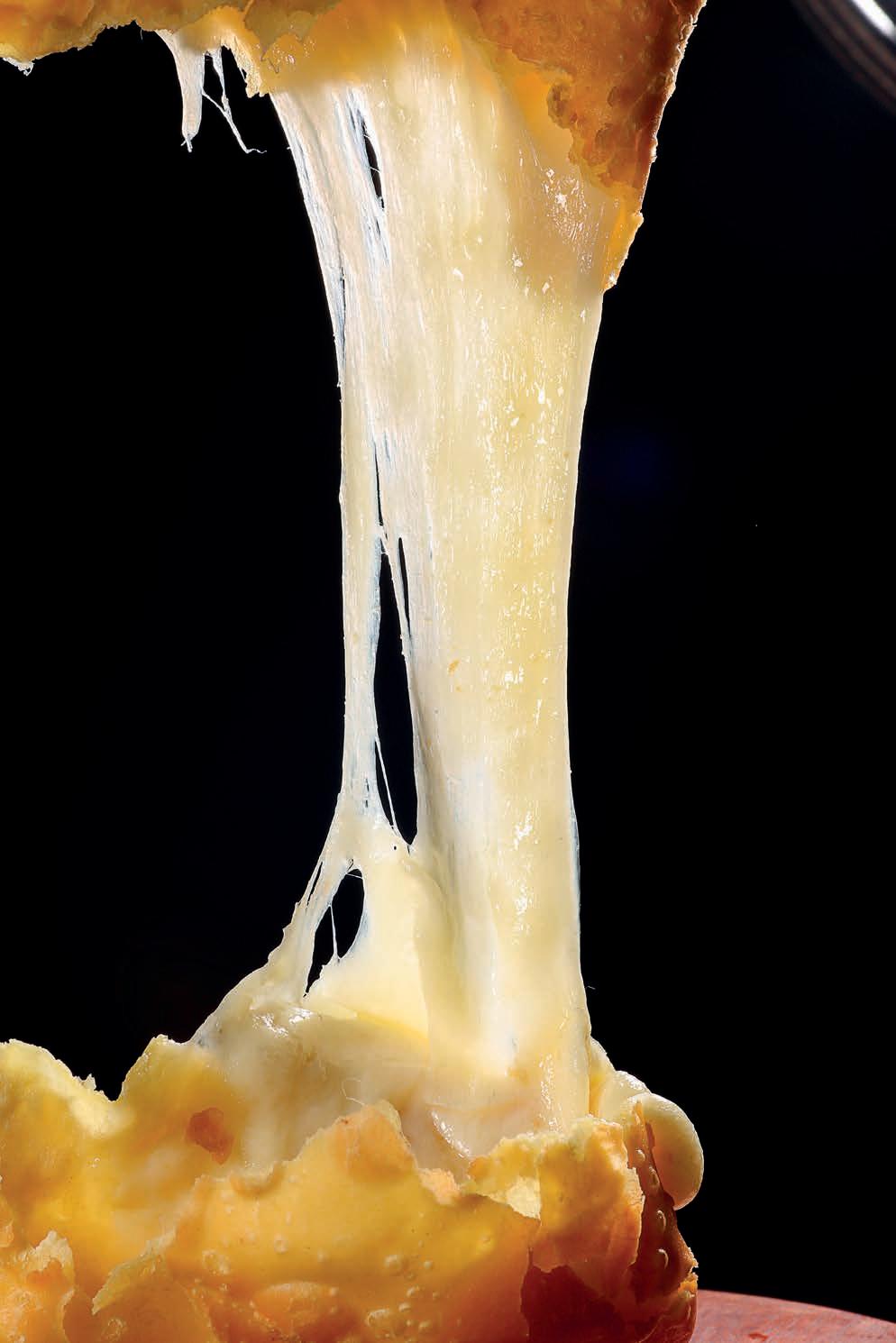

46 Plant-based cheese

Researchers make fake cheese that stretch and melt like the real thing.

49 New Products

Beverage company Suntory has opened its $400 million facility in Swanbank, Queensland, alongside the official launch of its $3 billion multibeverage business, Suntory Oceania, to support growth in the beverage sector.

To grow the beverage sector across Australia and New Zealand, Suntory Oceania has created the region’s fourth-largest multi-beverage group, responsible for a portfolio of spirits, alcoholic beverages, juice, water, soft drinks, coffee and energy drinks.

Chief executive officer at Suntory Beverage & Food Oceania, Dai Minato, addressed the potential for growth in Australia.

“Our team has delivered incredible results in just over two years – the transformation of a greenfield site to a $400M state-of-the-art, carbonneutral facility and the establishment of a new supply chain and commercial model,” said Minato.

“We have grown our Oceania family to 1500 people, including new Licensed RTM and Advocacy teams.”

The new beverage facility in Queensland can produce 20 million cases per annum at start-up, with the capacity to expand to 50 million cases in the future.

“The Australian beverages market is one of the most energetic and innovative in the world. Suntory Oceania gives us the platform to truly ignite the industry,” said managing director at Suntory Global Spirits –

Oceania, Mark Hill.

“Our Queensland facility complements our global production footprint – which includes distilleries and bottling sites across North America, Europe, and Japan – and

will produce more of the drinks Australians love, like those from the rapidly growing RTD category.”

The multi-beverage business in the New Zealand market will be launched in January 2026. F

Backed by the Australian government, Farm Foods Australia’s manufacturing plant in Breakwater has expanded its production capacity, creating new jobs and installing new equipment.

As part of a $45 billion investment by the government to create more local jobs and support community projects and infrastructure, the Geelong-based business upgraded

its food processing plant with advanced manufacturing technology and equipment, providing 24 new jobs for locals.

“We’re supporting regional Victorian businesses to take the next step, growing commercial confidence and helping make our regional towns and cities more resilient and better places to live, work and invest,” said minister for regional development Jaclyn Symes.

Farm Foods Australia specialises in pre-packaged meat products. The upgraded machinery enables an increase in production from 20 to 30 trays per minute, helping the business boost sales.

Starting small in Birregurra as a shop selling handmade meat products, wine, cheese and condiments, the business moved into food manufacturing in 2013.

Farm Foods Australia is now a

supplier to major retailers across Australia.

“Continuing the integration of cutting-edge technology is critical and has not only facilitated higher production output but has also contributed to improvements in both consistency and quality,” said managing director at Farm Foods Australia Greg Hughes.

“The investment has also led to the creation of new product formats and sales into new market channels.”

With government support, the expansion will help meet growing demand for Australian meat products while securing jobs for the local community.

“We’re excited to support Farm Foods Australia as the business continues to grow and invest in regional Victoria, and create more jobs in our community,” said state member for Geelong Christine Couzens. F

The Australian Competition and Consumer Commission (ACCC) has not opposed Lactalis’ proposed acquisition of Fonterra’s consumer and food service businesses.

Given Lactalis’ reputation and the demand for high-quality dairy products in Australia, the ACCC cited minimal concerns about competition.

Lactalis and Fonterra both source raw milk directly from dairy farmers in Victoria and Tasmania, where they process and supply various dairy products across Australia.

Additionally, Lactalis and Fonterra have different product focuses, which reduces concerns about competition or overlap in the acquisition.

“While we acknowledge the concerns raised by some representative bodies, after careful consideration we have determined that the acquisition is unlikely to result in a substantial lessening of competition,” ACCC deputy chair Mick Keogh said.

The ACCC found that in the regions of Gippsland, the Murray and Western Victoria, the presence of alternative buyers of raw milk would continue to limit Lactalis’ market power if the acquisition proceeds.

The ACCC concluded that the transaction was unlikely to substantially lessen competition in the wholesale supply of dairy

products such as drinking milk, cream, cheese, chilled yellow spreads, and dairy ingredients like milk powder. It stated that the differing

production focus of Fonterra and Lactalis meant there was limited overlap between the two in the supply of these products. F

Alexia Horley has been appointed as the new chief executive officer for PepsiCo Australia and New Zealand Foods.

Currently serving as general manager of Australia Foods for PepsiCo, her new role as CEO commenced on 21 July 2025.

“Alexia’s strong strategic mindset, relentless consumer focus and deep expertise in the ANZ retail landscape position her perfectly to lead the business forward,” said CEO APAC Foods Anne Tse.

“She’s a highly respected and dynamic leader and I’m looking forward to partnering with her as we continue to build momentum and shape the future of ANZ Foods.”

As GM of Australia Foods, Horley played a critical role in transforming the business through product innovation across new formats,

guided by her focus on consumers.

Under her leadership, PepsiCo Australia’s manufacturing footprint has expanded, including investment in multipack capabilities and an additional production line for Red Rock Deli to support continued growth.

“I’m honoured to step into the role of CEO and excited to lead such a passionate and talented team,” said Horley.

“I’m committed to building on our strong foundations and driving sustainable growth across every part of the ANZ Foods business, and most importantly, continuing to deliver the best snacks to Aussie and Kiwi consumers under our iconic portfolio of brands.”

Current CEO Kyle Faulconer has been appointed SVP, PepsiCo North America Commercial. F

The Central Highland Iona Project has been officially declared a prescribed project by the Queensland government. The facility is designed to process up to 200,000 head of cattle each year, strengthening Queensland’s beef industry and supporting regional economic growth.

Located in Emerald, the Iona Project will include a state-of-the-art beef processing facility incorporating advanced technologies such as robotics, automation and artificial intelligence.

The development is expected to create 188 jobs during the construction phase and a further 427 ongoing operational roles.

“Queensland is Australia’s greatest cattle producer and the LNP is backing our graziers and beef industry by partnering with the private sector to further grow the industry,” said deputy premier and minister for state

development, infrastructure and planning Jarrod Bleijie.

“The Iona Project has the potential to enhance Queensland’s beef processing capabilities while creating economic development opportunities across regional Queensland.”

Minister for primary industries Tony Perrett reinforced the government’s commitment to growing the sector, reiterating its target to increase the value of primary industries to $30 billion by 2030.

Assistant minister for primary industry development and member for Gregory Sean Dillon also welcomed the declaration, emphasising its significance for the agricultural industry and local economies.

“This project represents a significant opportunity to boost productivity and profitability across our beef supply chain while ensuring

Queensland’s producers remain globally competitive,” said Dillon.

“By taking advantage of innovative technologies, the Iona Project could

A new $10 million funding package has been announced by the Victorian government to help food, dairy and beverage manufacturers switch to electric alternatives.

This funding is part of a $15 million program aimed at reducing gas pollution on farms and in food manufacturing facilities. Based on a successful project in Aotearoa New Zealand with the Fonterra dairy

co-operative, the initiative enables food and beverage manufacturers to replace gas boilers and heating systems with electric alternatives.

The program aims to demonstrate that electrification can reduce emissions while saving manufacturers thousands in gas costs. Implementing clean energy practices in gasreliant sectors is expected to propel the broader food and beverage

manufacturing sector towards improved efficiency.

“The Greens are proud to have negotiated this innovative $15 million climate project to help farms and food manufacturers get off gas and go all-electric, saving huge amounts of emissions and saving thousands off farmers’ energy bills,” said leader of the Victorian Greens Ellen Sandell.

Drawing on New Zealand’s Rewiring

help future-proof Queensland’s beef industry and open the door to new markets and greater export opportunities.” F

Aotearoa initiative, the remaining $5 million will support farmers to transition to electric heat pumps, solar panels and battery storage.

The funding is part of a broader $40 million climate and electrification package secured in the recent state budget and tax bills. It is expected to assist five to ten food manufacturing sites and 20 farms in transitioning to electric alternatives. F

Popular family-owned chocolate maker Haigh’s Chocolates has announced the retirement of chief executive officer Alister Haigh, who has led the company for 30 years.

Current chief operating officer Peter Millard will step into the role, marking the first time someone outside the Haigh family has been appointed as CEO in the business’s 110-year history.

The transition comes at a significant time for the company, with the upcoming completion of a $130 million manufacturing facility in Salisbury South and the opening of its seventh store in Broadway, Sydney.

Alister Haigh, who plans to continue championing the legacy of Haigh’s, welcomed Millard into the leadership of the family-owned business.

“Peter has been integral to our success here at Haigh’s, responsible for the businesses day-to-day operations while proudly spearheading the development of our Salisbury South facility alongside a high-performing team,” said Haigh.

“His work ethos is a testament to the Haigh’s values of contribution, determination and trust.

“I feel confident knowing that the business will continue to thrive and grow under his exceptional leadership.”

Millard has been involved with the company for 19 years. His past four years as COO were preceded by a long tenure as supply chain manager.

He expressed his passion and gratitude.

“Having had the privilege to work closely with Alister for nearly two decades, I have been inspired by his ambitious, humble and personable leadership,” he said.

“Alongside the family I remain passionate about preserving the enduring quality of Haigh’s premium chocolate to delight generations of chocolate lovers for years to come.”

According to board chair Carolyn Mitchell, Millard underwent an extensive interview process that included an external panel to assess his suitability for the role. She stated

that his passion, determination, and aligned vision were decisive in his appointment.

Over the past 30 years, Alister Haigh has expanded the company’s operations, which now produce more than 1,000 tonnes of chocolate each year. He will remain on the board alongside fourthgeneration family members Simon Haigh and Sara Fitzgerald.

As part of a $10 million investment into new manufacturing hubs announced in the 2025–26 Budget, the Queensland government is backing the Sunshine Coast’s establishment of a new manufacturing hub.

The Sunshine Coast Manufacturing Hub will provide targeted support to boost the region’s manufacturing sector. It aims to help local manufacturers modernise while creating jobs.

According to minister for manufacturing Dale Last, the broader Sunshine Coast region is home to more than 4,000 manufacturing businesses. Employing more than 33,000 workers, he said the hub will drive industrial growth in the state.

“The Crisafulli government is focused on growing Queensland’s manufacturing capabilities and giving regions like the Sunshine Coast a fresh start by backing the industries that will shape our future,” said Last.

“This is a smart, future-focused investment in a region that already has a strong track record in innovation.”

“Reflecting on my time, it’s incredible to think how far we have come over the years with more than 300 chocolate varieties, 900 employees, 21 stores and grown tenfold all while remaining true to the heritage and quality Haigh’s is known for,” he said.

The transition will become official from 4 August 2025. F

Member for Caloundra Kendall Morton mentioned that food and beverage production was one of the key industries the hub will support to drive the Sunshine Coast’s economic future.

“The Sunshine Coast is one of the largest manufacturing regions in Queensland, and it’s important we invest in the industries that create secure, skilled jobs close to home,” said Morton.

“This new manufacturing hub will focus on supporting the unique strengths and needs of the Sunshine

Coast, including its growing capabilities in food and beverage, health and medical products, aviation and aerospace, and building materials.

“Our region already leads the way, and this hub will give local businesses the support they need to innovate and grow.” F

From beverage business to café supplier, a founder of a beverage manufacturing company focuses on quality and flavour in every aspect of the business. This is his story.

It all started with chilli cordial.

Founder of Alchemy Cordial Company, Michael Bishop, had no idea that a bold leap taken 30 years ago tasting his friend’s lemon and chilli cordial would change the course of his life.

Bishop recalled his initial reluctance when his friend persistently offered the family recipe, which he referred to as a “combination of fire and water”. After finally giving in and trying the unique drink, his mind was blown, sparked with fireworks of ideas, spiralling into experimentation, including mixing it with vodka.

Taken over by the flavour until 3 o’clock in the morning, Bishop and his friend knew what they needed to do.

“We decided we were going to make the world’s first chilli soft drink,”

he said. “That was our destiny.”

Although their passion and dedication soared above all doubts, they soon met the realities of the beverage business.

“The soft drink business is massive and led by multinationals,” he said. “It’s intensely competitive because you’re fighting for just that little bit of shelf space on the supermarket shelf.”

Eighteen months later, Bishop’s friend, who was also his business partner, returned to his old job after the business struggled with financial realities. However, Bishop could not let go of the flavour. While he adored the taste, he understood the limitations of becoming a soft drink baron and made a key realisation about the wider demographic who might enjoy that flavour.

“That chilli and lemon cordial tasted amazing, but it only appealed to blokes who like ginger beer,” said Bishop. “There was nothing there for those that wanted a more ethereal or beautiful experience.”

After researching the market, Bishop repositioned the brand as a cordial and syrup supplier, evolving into a company that enables efficient beveragemaking in cafés and homes alike.

Alchemy

Cordial’s obsession with flavour reflects a commitment to delivering consistency through creativity and joy for the palate. While skilled café baristas prioritise taste, Bishop noted they often lack the processes or resources to reproduce the same drink every time.

Rather than requiring baristas to add multiple ingredients into each drink, Alchemy Cordial offers syrups that combine these components, condensing them into a single bottle for direct and convenient use.

Bishop explained that the company uses only plant-based products. All products are free from gluten, dairy and allergens, and contain no artificial colours or flavours. He also highlighted the benefits of using concentrated products.

“Alchemy Cordial’s syrups and concentrates are shelf stable and can sit on a bench in a café for 18 months to two years,” he said.

For cafés and baristas seeking flavour consistency these long-life products offer a distinct advantage. According to Bishop, a 750ml bottle of concentrated syrup can make

up to 50 drinks. This, he explained, is part of a broader commitment to the food service industry, and in particular cafés, by providing a solution to satisfy increasingly complex beverage orders in a way that is easy to execute, full of flavour and profitable.

Over the years, the company has grown, leading to expansions and larger facilities. For the past 15 years, all manufacturing and processing has taken place at its fifth and latest facility in Cleveland, Queensland.

Discussing the plant-based products and facility, Bishop explained how the company’s longterm vision for sustainability has shaped its operations since the early days. Long before sustainability became a mainstream business focus, Alchemy Cordial was already

“Alchemy Cordial’s syrups and concentrates are shelf stable and can sit on a bench in a café for 18 months to two years.”

working to reduce its environmental impact by using plant-based alternatives instead of animal-based or synthetic ingredients.

However, as sustainability gained traction across industries, Bishop had to make the company’s practices more visible to customers and clients.

Bishop said Alchemy Cordial operates under the British Retail Consortium (BRC) food safety system, which is a recognised Global Food Safety Initiative (GFSI) standard, with the facility certified as plant-based and gluten-free. These certifications support safer

there’s no dairy, there’s no gluten. People who buy our products can do so without risk or fear as there’s nothing that is going to cause a problem.”

The business is also certified carbon neutral under the Climate Active program, a governmentbacked initiative to reduce emissions across Australia. Bishop said the three-year certification supports the company’s responsibility to meet rising sustainability expectations from both customers and clients.

As younger generations and end consumers become increasingly and Europe are more advanced in sustainability practices than Australia. To work with multinational partners such as Blank Street and Black Sheep Espresso, where sustainability is standard practice, Alchemy Cordial must be prepared

to share its footprint and green initiatives.

“In between the corporates and the end consumer, a lot of Australian businesses lack commitment to the cause,” said Bishop. “Even though our contribution might be considered a drop in the ocean, we’re committed to reducing the footprint that we have on this planet.”

He continued by sharing several examples of the company’s creative eco-friendly practices.

Alchemy Cordial uses recycled PET bottles for all its products, reducing reliance on new plastics and supporting a circular economy. All cardboard used in the business is recycled and repurposed for packaging. Even 44-gallon flavour drums that are no longer functional are collected and reused as fire pits.

Bishop emphasised that these practices require almost no energy, which helps lower both emissions and operational costs.

One of the most unique ways Alchemy Cordial supports sustainability is through the

“Anything that comes from Alchemy Cordial, you’re safe. There are no allergens, there’s no dairy, there’s no gluten. People who buy our products can do so without risk or fear as there’s nothing that is going to cause a problem.”

product itself. While industry standards require four bottles to make 50 drinks, Alchemy Cordial’s concentrated formula achieves the same with one.

“We don’t produce any singleuse products. Instead, we focus on beverage concentrates, which offers a much higher product-to-packaging ratio,” Bishop added.

By delivering consistent flavour through concentrated syrup, the company reduces the number of PET bottles needed. On top of this, their 750ml and 1.47L bottles are made from 100 per cent recycled PET, meaning no new plastics are introduced in the production cycle. He explained that sustainability is not just about the product, but also about the actions surrounding it, such as inefficient transport costs and excess emissions.

Through involvement in the government’s Climate Active program and adherence to BRC, Alchemy Cordial aims to support environmental responsibility through strategies unique to its business.

“We really try to think about our footprint and all we can do to reduce it,” said Bishop. “You don’t just think about it, you have to measure it every year.”

To sustain passion, businesses must adopt strategies for longterm security. While the company has grown into a forward-thinking operation, Bishop still carries the same youthful enthusiasm that sparked his journey.

“When organisations get to a certain size, they tend to make

a lot of their decisions on Excel spreadsheets,” he said.

In the pursuit of cost-cutting or efficiency, Bishop warned, companies risk losing valuable human connection. Reflecting on his own journey, Bishop affirmed that Alchemy Cordial’s obsession with flavour has never wavered. The brand continues to focus on quality, natural ingredients and customer value –especially within the café sector.

“Alchemy Cordial is creating, making and marketing better beverages for the global café industry – that’s our vision,” added Bishop. He ended with a message of encouragement to the broader coffee and beverage industry. In the face of financial pressure and structural issues, businesses must nurture their passion and use it to create positive change.

Although external threats are beyond their control, Bishop said businesses can improve the things within their reach. Excellent customer service and quality products are always worth the investment.

“When you do that, the business side of it takes care of itself,” said Bishop. F

“Fishbowl is an invaluable asset to our entire organisation. We now operate as a unified whole”

Sandra Gosling - Co-Founder - COYO

“This insight and overall higher level of reassurance for our reporting is invaluable”

Lisa Coller - Company Accountant

Barnes & Brown is a rising force in the non-alcoholic spirits industry. Co-founder Tim Brown discusses how the brand began, where it’s heading, and why the sector is maturing.

When Tim Brown set out to create Barnes & Brown, it wasn’t because he had a background in beverage manufacturing. In fact, it was quite the opposite. He had worked in retail and distribution, selling alcoholic drinks, before discovering the scale of the opportunity in the non-alcoholic space. Brown saw a clear market gap: high-end nonalcoholic spirits that weren’t simply sugary mixers but could stand tall on their own, emulating the flavour complexity of alcohol-based spirits

What began as an observation turned into a mission.

“I think a lot of people are surprised when they find out I don’t come from a distilling background,” Brown said. “But that worked in our favour. We weren’t tied to the old way of doing things.”

He spoke candidly about the moment the idea crystallised. Having visited a number of cocktail bars and bottle shops, he realised that while beer and wine alternatives were becoming more available, nonalcoholic spirits were still in their

Determined to approach things differently, he assembled a team of food scientists and mixologists who could help reverse-engineer the sensory characteristics of traditional spirits. Their goal was to build something credible, not just in terms of flavour but also branding. They wanted a product that bartenders would want to work with, not something that sat on the shelf gathering dust, Brown said. From day one, Barnes & Brown was designed as a premium option. Packaging, formulation, and flavour notes were all

Building a non-alcoholic spirit isn’t as simple as removing alcohol from an existing formula. It’s about rethinking the very structure of a drink. Brown explained that one of the major hurdles is replacing the mouthfeel and complexity that ethanol typically provides. Alcohol isn’t just an intoxicant, it’s a carrier for flavour and aroma. Without it, many ingredients fall flat.

The Barnes & Brown approach involved layering botanical extracts in a way that mimicked the complexity of spirits. Brown said it was an iterative process, involving constant trial, tasting and refinement. Early versions, he admitted, weren’t always successful. He even openly admits that some of the first ones we made were “terrible”. They were either too bitter, too thin, or just plain weird. Over time, the team developed what Brown describes as “a new language of flavour” – one not anchored to alcohol, but still capable of evoking the same emotions and experiences. He is quick to point out that its drinks are not designed to trick the palate or replicate a specific brand. Instead, they aim to create something that feels grown-up and well-rounded. Brown said their most popular product has juniper and citrus notes but also includes earthy and peppery tones that make it feel familiar yet new.

The company’s core market might seem obvious; people who don’t drink. But Brown said that isn’t entirely accurate.

“The majority of our customers still drink alcohol,” he explained. “They’re just choosing not to drink all the time.”

For Barnes & Brown, the sweet spot is the so-called “moderation movement”; consumers who enjoy the ritual of drinking but want a break from booze. Brown said he sees this in the diversity of their customer base. From young professionals trying to reduce mid-week drinking, to older customers seeking better health, to pregnant women and designated drivers, the brand has found resonance across demographics. Brown believes it is about inclusion and that everyone should be able to enjoy a good drink, regardless of what’s in it.

The hospitality industry, he said, has also evolved. Whereas once nondrinkers were fobbed off with soda water or sugary mocktails, venues are now recognising the value of premium alcohol-free options.

“It’s about giving people a reason to stay,” Brown said. “If someone’s not drinking, they shouldn’t feel like a second-class guest.”

Retailers, too, are beginning to change their layouts. Barnes & Brown is often stocked not in the soft drink aisle, but in the spirits’ section. Brown believes this signals that this is a serious product. He said it deserves to sit alongside gin, vodka, and rum. That positioning has helped the brand appeal to bartenders and serious home mixologists alike.

The journey from prototype to national brand wasn’t straightforward. Brown described the early days as “chaotic”, making small batches,

testing them with friends, and tweaking the formula. The breakthrough came when they partnered with a co-manufacturing facility that understood the sensitivity of their ingredients and could handle the process at scale.

“Our production methods are very specific,” Brown said. “We use a combination of heat and cold extraction, and the order in which we add ingredients really matters. Scaling that up was no small feat.”

Finding the right supply chain partners was essential. Barnes & Brown now works with a network of producers, designers and logistics providers, each aligned with the brand’s mission.

The business remains independent and founder-led, something Brown sees as a major strength.

“We’re small, but we’re agile,” he said. “If we want to make a change to a recipe or try a new product, we can do that quickly.”

While some non-alcoholic

brands are funded by large alcohol companies, Barnes & Brown has stayed lean and focused.

Distribution is now growing steadily.

The brand has listings in major bottle shops and is featured on the menus of several well-regarded cocktail bars. Brown said that while they’ve had international interest, their focus remains domestic for now. It wants to make sure it can serve the Australian market properly before it gets too far ahead of itself.

Brown believes that the nonalcoholic industry is only just getting started. Although there’s been a flurry of new brands and growing consumer interest, he said the category is still young and evolving fast. He thinks the industry is where craft beer was 20 years ago and there’s a lot of excitement, but also a lot of confusion.

One challenge is defining what

non-alcoholic spirits actually are. Unlike beer or wine, which have clear reference points, many consumers still don’t know what to expect from a non-alcoholic gin or rum. Brown said education is key. He and his staff spend a lot of time talking to bartenders and customers, helping them understand how to use the product.

He also believes that better standards and clearer labelling will help. At present, definitions vary from country to country, and not all products are truly alcohol-free.

“It’s important for us that someone can drink our product and not worry about hidden alcohol content,” Brown said.

That transparency has helped build trust, especially among customers with health or religious reasons for avoiding alcohol. Brown said it also makes the brand more appealing to venues (and countries for that matter) with strict policies.

“For Barnes & Brown, the sweet spot is the so-called ‘moderation movement; consumers who enjoy the ritual of drinking but want a break from booze.”

Barnes & Brown is not standing still. Brown hinted at new products on the horizon, including limited-edition seasonal releases and a more experimental range designed for cocktails. He also said they’re exploring sustainable packaging innovations and working on new ways to engage directly with customers.

“We want to be more than just a brand on a shelf,” he said. “We want to be part of people’s rituals.”

To that end, the company has invested in events and collaborations with venues that support mindful drinking. Pop-up bars, tasting nights and education sessions are all part of the brand’s future strategy. Brown also reflected on the broader social changes that have helped the brand grow. He said people are asking more questions about what they consume. They’re looking for quality, for meaning, for balance. He believes the best non-alcoholic brands aren’t just copying alcoholic ones – they’re forging their own identities.

While growth is important, Brown is cautious about overextending.

“We don’t want to be everything to everyone,” he said. “We want to stay true to what we do best.”

That means sticking to their commitment to flavour, authenticity and design, and continuing to treat non-drinkers with the same respect as drinkers. In many ways, Barnes & Brown’s success reflects a cultural turning point. As the line between alcohol and non-alcoholic blurs, and as consumers become more intentional, brands like this one are helping redefine what it means to enjoy a drink. For Brown, that’s the whole point.

“We’re not anti-alcohol,” he said. “We’re prochoice.” F

We attach great importance to combatting climate change, feeding the world’s population and using packaging responsibly by ensuring resource-economical production and offering ecofriendly packaging solutions and efficient recycling innovations.

Beefy’s Pies, once a humble Sunshine Coast bakery, is now a growing national brand under Retail Food Group, with CEO Matt Marshall outlining plans for expansion.

Beefy’s Pies began in 1997, founded by Ron and Shirley Hobbs on Queensland’s Sunshine Coast. Originally operating under the name Sunrise Bakery at the Aussie World precinct, the business focused on delivering traditional Australian pies with an emphasis on quality and locally sourced ingredients. Over time, it evolved into Beefy’s Pies and became a local institution.

The founders’ son, Mark Hobbs, inherited the business and continued its expansion across the Sunshine Coast. He also extended the product range, building an award-winning gluten-free portfolio in both savoury and sweet categories. In December 2023, Beefy’s was acquired by Retail Food Group (RFG), the parent company of well-known food brands such as Donut King and Crust Pizza.

Since joining the RFG portfolio, the business has extended into new territories, with stores opening in Ballina in Northern New South Wales, Newtown in Toowoomba, and Brisbane’s Cannon Hill and Capalaba. According to Retail Food Group CEO Matt Marshall, the acquisition

of Beefy’s represented a strategic investment in a brand with deep community ties and a proven track record of customer loyalty.

The Hobbs family, in launching Beefy’s, recognised an opportunity to do more than simply make pies. They saw the potential to elevate the Aussie meat pie by focusing on consistency, generosity, and premium Australian ingredients.

Marshall said the family’s commitment to sourcing local produce and delivering hearty, authentic flavours had long made Beefy’s popular. He described the business as “resonating with consumers seeking genuine meals grounded in Australian tradition” and praised the founding family for staying true to that vision over more than two decades.

Beefy’s success has not gone unnoticed. In 2020 and again in 2021, its Gluten Free Steak, Bacon & Cheese Pie was named Australia’s Best Gluten Free Pie at the Official

Great Aussie Meat Pie Competition.

“These accolades are a testament to the brand’s dedication to meeting the evolving needs of customers without compromising on taste or quality,” said Marshall.

The business has continued to invest in its gluten-free product line, which has become a hallmark of the brand.

That focus has helped grow Beefy’s into a destination for customers

As the company expanded, the need for reliable, high-volume production became clear. In 2002, Beefy’s moved into a manufacturing facility at Kunda Park on the Sunshine Coast. Since then, the site has been expanded and modernised to accommodate increased demand. While the exact details of equipment used remain proprietary, the business operates with the kind of high-

mixers, pastry sheeters, and pieforming machines,” said Marshall. “These tools are essential for maintaining consistent quality across multiple sites while still ensuring the signature Beefy’s texture and taste.”

That balance, between scale and craftsmanship, is one Marshall believes sets the brand apart. He said the facility’s layout and investment in technology allow it to “produce at scale without losing the handcrafted company’s sourcing philosophy. From the beginning, the business has prioritised working with local farmers and suppliers. Meats and produce are selected based on freshness, traceability, and regional sourcing. This not only supports Australian agriculture but also strengthens the brand’s integrity.

Marshall noted that this commitment is especially relevant in today’s market.

“Customers increasingly want to know where their food comes from. Beefy’s has always been ahead of the curve in offering that transparency,”

In the face of market pressures, Beefy’s has remained resilient. The bakery and QSR (quick-service restaurant) sector continues to be competitive, particularly with the rise of boutique independent bakeries. Despite this, Beefy’s has maintained a loyal following, something Marshall attributes to the company’s focus on quality and generous portion sizes. He acknowledged that the current business landscape poses a range of

manufacturers, we’re seeing increased pressure on beef pricing due to international demand, especially from China,” Marshall said. “At the same time, labour shortages and rising employment costs are impacting every part of the supply chain, from production to frontline

Marshall explained that while these pressures are mounting, Beefy’s is committed to working closely with suppliers to maintain quality

The business has also adopted a more agile approach to its menu and operations. Innovation, such as rotating limited-time product offers, which has helped counteract rising costs while offering something new

Digital channels have also become a growth driver. The brand has experienced consistent demand through food delivery platforms like Uber Eats and DoorDash, as well as its own online ordering system. These platforms allow Beefy’s to reach new customers without the immediate overheads of a physical store. Marshall said this model

of “strategic digital expansion” is becoming increasingly important to the company’s long-term strategy.

What the sector must do next

Looking more broadly at the Australian foodservice and franchising sector, Marshall believes there are opportunities to do better. He pointed to the need for continued innovation in product offerings. Plant-based items, gluten-free lines, and allergen-friendly choices are increasingly important for modern customers and offer growth potential for brands willing to invest.

He also touched on the value of upgrading production technologies.

“Investing in modern manufacturing equipment can enhance both consistency and efficiency,” he said. “This allows

Beefy’s Pies continues to invest in its gluten-free product line.

“Customers increasingly want to know where their food comes from. Beefy’s has always been ahead of the curve in offering that transparency.”

businesses to scale effectively without compromising on quality.”

But beyond product and operations, Marshall stressed the importance of policy settings. He said the franchising sector, which plays a vital role in economic growth, job creation and small business ownership, requires a stable and fair regulatory environment.

“There’s been a lot of uncertainty in franchising over recent years,” Marshall said. “We need a balanced framework that protects franchisees while also encouraging innovation and commercial viability. That balance is essential if we want to see continued

growth and investment in this sector.”

His comments reflect the broader goals of RFG, which seeks to create an environment where each of its brands, whether pizza, doughnuts, or pies, can scale sustainably and support local ownership.

Since the acquisition by RFG, Beefy’s has been moving quickly but carefully. The new stores in Ballina, Toowoomba, and Brisbane reflect a growing appetite for the brand in regional and metro areas alike. Each opening has been supported by local promotions and community engagement, including pie drives and special offers, which are designed

to introduce new customers to the Beefy’s experience.

While expansion will continue, Marshall is focused on measured growth. Future locations will be guided by customer feedback, sales data, and demographic insights.

The company is also looking at ways to enhance its drive-thru model and experiment with digital loyalty programs.

Marshall described Beefy’s as a brand with “enormous potential” that still feels close to its roots. He said the plan is not to reinvent the business but to support it and therefore help extend its reach while preserving its identity.

“We’re not here to change what makes Beefy’s special,” he said. “We’re here to provide the support and scale needed to take it to more customers.” F

True sustainability in packaging demands a full-circle approach, from production to reuse to responsible disposal.

Over the years, the food industry has seen a shift towards a more sustainable future. While efforts contributing to a healthier food industry have shown positive results, there are gaps in the process that industries often overlook – packaging.

When it comes to packaging, industries remain reliant on singleuse plastic. Beyond affordability and functionality, research and product development to replace plastic has been slow.

For example, wooden cutlery has become more common in fast food restaurants and supermarkets. While this is a step in the right direction, phasing out problematic, single-use materials is still taking time, according to Nasim Aflatoon, sustainability manager at Bunzl Asia Pacific.

She addressed the gap in recycling infrastructure as one of the barriers to progressing towards a sustainable future.

“Infrastructure for reusable and circular systems are emerging in Australia,” said Aflatoon. “Although some options are available in the market, lack of accessible collection points can present challenges.”

However, this is not to say that the efforts by individuals, governments, organisations and industries dedicated to sustainability are futile.

Australia has seen improvements by lowering its carbon footprint and emissions, reducing food waste, and innovating low-impact technologies to produce food efficiently without further harming the environment.

Bunzl takes it further by not only applying sustainable practices

internally but also extending them to its products, partner industries and consumers.

While every individual has a role in sustaining the planet, industries have a responsibility to inform their customers and encourage participation.

From material traceability and data collection to navigating regulatory frameworks, various challenges continue to stunt the growth of sustainability in Australia. According to head of marketing and ecommerce at Bunzl Australia and New Zealand, Fiona Corsie, inconsistent requirements across states create confusion for customers.

“Our colleagues on the

sustainability side spend a lot of time informing the customer as to what those government frameworks actually mean for them in their location,” said Corsie.

Working closely with governments and government bodies, the team addresses queries from customers trying to navigate labelling, recycling, low-impact materials and solutions, with the goal of reducing overall waste.

Bunzl’s reusable and recyclable Katermaster Regen food container aims to support this mission by offering environmental benefits through consumer-friendly features.

Katermaster Regen is Bunzl Australia and New Zealand’s food service solution brand. Its products cater to customers seeking durable kitchen

The Katermaster Regen is cost-efficient, reusable, and recyclable.

and food service options.

It is a locally manufactured product that received gold at the 2025 Australasian Packaging Innovation and Design (PIDA) Awards for Sustainable – Reuse and Refill.

The reusable container withstands up to 700 commercial washes and is designed for long-term use. However, longevity is only the beginning. While durability is a key selling point, it should not be the sole factor when selecting materials.

Aflatoon explained that the team assessed every stage of the product’s lifecycle. She noted the container’s microwaveable and refrigerable features, and its kerbside recyclability when it reaches end of life.

“Manufacturers often design a product without thinking how it will be recycled or disassembled,” said Aflatoon. “They use multiple materials within a product, which makes it difficult to separate and recycle.”

“Bunzl looks for products that have a good start of life story all the way through to the end of life, making sure it’s the easiest to repurpose, reuse, and recycle,” added Corsie.

The Katermaster Regen is made from polypropylene (PP) monomaterial, which is integral to its lightweight, heat-resistant, and

“Bunzl looks for products that have a good start of life story all the way through to the end of life, making sure it’s the easiest to repurpose, reuse, and recycle.”

food-safe properties. PP is also cost-effective for high-volume manufacturing, making it a preferred choice for streamlining supply chains.

Combined with its affordability and durability, it offers a practical alternative for customers transitioning from single-use products.

The container includes the Australian Recycling Label (ARL), which provides clear instructions for proper disposal – helping consumers adopt better recycling habits and reduce the environmental impact of food packaging.

With increased use and user feedback, Bunzl hopes to continue developing innovative packaging solutions that support a more sustainable future.

By informing customers and selecting PP monomaterials, Bunzl’s Katermaster Regen ticks off the

boxes of processes that feed into the broader picture of sustainability.

Bunzl collaborates with local Australian manufacturers, aiming to make a positive contribution to the environment and the broader food industry.

Genfac Plastics is an Australianowned plastic food packaging manufacturer. The business has 30 years of experience with the goal to deliver low carbon footprint and quality recyclable products, such as the Katermaster Regen.

With aligning ethical values, the partnership between the two companies helped nurture the growth of environmentally conscious decisions and products.

“Genfac Plastics generates 15 per cent of production electricity needs from its roof-top solar farm,” said Aflatoon. “By working with local suppliers, you’re not just supporting the Australian manufacturing industries and jobs, you also reduce international transport emissions, lead times and

risk of supply chain disruptions.”

Aflatoon noted that transport emissions are among the highest contributors to global emissions. Local material sourcing and production can help reduce emissions associated with transport. Due to the locality of the business, quality control can also be managed easier.

Bunzl has a unique role in the supply chain, Corsie added. While most manufacturing companies find limitations caused by fixed machinery, Bunzl has an advantage to flexibly source sustainable packaging solutions that customers are after.

“With Katermaster Regen, around 18 months of work went into finding a manufacturer that could meet the requirements of what we were after, work with the material that we were after and provide the end of life we required,” said Corsie.

As packaging demands grow alongside advancements in food technology, it is imperative to research and develop solutions that take a full-circle approach — including the end-of-life stage of the product.

Bunzl’s approach serves as a catalyst for advancing Australian manufacturing and guiding the food and beverage sector toward a sustainable future. F

To stay competitive in the food and beverage manufacturing market, futureproofing a business is encouraged. To make this a possibility, a modern and innovative manufacturing site is imperative.

APS Industrial has announced a new agency agreement with engineering software provider Eplan. Eplan develops software solutions that support integrated design processes in electrical, automation and mechatronic disciplines.

This strategic partnership enables APS to incorporate Eplan’s capabilities into its own operations and to offer these tools to Australian food and beverage manufacturers. Customers will benefit from design accuracy, enhanced documentation, and efficient communication throughout project lifecycles.

The partnership is directly enabled through APS’ facility that supports digitalisation, efficiency and customisation.

APS Industrial’s Manufacturing Centre in Adelaide is raising the bar for advanced manufacturing in Australia through value-added services and tailored solutions for the Australian food and beverage sector. Purpose-built to streamline delivery and enhance product customisation, the facility exemplifies what modern manufacturing can achieve when innovation, efficiency and local capability are prioritised. In today’s competitive climate, where speed and adaptability are crucial for success, APS’ facility shows how an integrated manufacturing approach can respond to market demands without compromising quality or service.

Through the combination of advanced hardware and sophisticated software technologies, APS delivers high-performance outcomes across a range of services. These include air circuit breaker (ACB) adaptation, precision printing, terminal rail cutting and automated panel assembly. Every element is designed to reduce production time, cut costs, and empower local food and beverage manufacturers to grow with confidence.

A key strength of the Centre is its ability to support Australia’s local industries in managing their energy needs. The centre is not just a warehouse or an assembly line – it is a technology hub where digitalisation plays a role in optimising efficiency and output. Through data-driven

processes and a commitment to excellence, APS continues to raise expectations in local manufacturing.

In an industry that relies on highspeed production and operational consistency, the ability to deliver high-quality components quickly and reliably is essential. APS has developed its facility to minimise delivery timeframes while providing flexible, customised components built to exacting standards.

For example, by reducing reliance on overseas production and delivery cycles, APS helps local producers respond more quickly to shifting demand. This is especially valuable for food and beverage businesses

that operate on tight schedules and rely on dependable, uninterrupted energy supplies

Through a strong partnership with Siemens, APS has made contributions to South Australia’s Advanced Manufacturing Strategy. This includes bringing to life a local adaptation centre for Siemens air circuit breakers, which serves both Australian and New Zealand markets. The company’s manufacturing capability extends beyond the basics, delivering end-to-end solutions that are faster, smarter and more efficient.

Air circuit breakers are a critical component in ensuring reliable electricity supply across many sectors, particularly in manufacturing, mining, commercial property and infrastructure. ACBs not only prevent electrical overloads and equipment damage but also contribute to the energy transition by supporting stable and secure power networks.

APS’ facility includes a Siemenscertified Adaptation Centre – the first of its kind globally outside of Siemens

itself. This centre allows APS to locally adapt and assemble Siemens SENTRON ACBs, reducing typical delivery times by up to 50 per cent. This faster turnaround benefits local switchboard builders and electrical contractors who depend on consistent and immediate access to high-performance power protection systems.

By supporting the ACB lifecycle from assembly to local service and support, APS improves cost control, reduces lead times, and gives customers access to critical infrastructure without the delays typically associated with international supply chains.

APS also provides a complete suite of custom-designed distribution boards (DBs), developed with a deep understanding of the needs of the Australian food and beverage industry. These DBs are built to deliver durability, compatibility and convenience.

The APS ‘DB family’ range is designed to work seamlessly with Siemens circuit breakers, providing a

reliable, high-performance electrical solution for complex production environments. The flagship ‘DB Ultimate’ range features a removable, one-piece internal frame that allows assembly and wiring independent of the enclosure itself.

This design allows for greater flexibility during installation, servicing, commissioning and retrofitting, making it suitable for evolving production environments where equipment upgrades and reconfiguration are common. The range supports modular thinking and long-term efficiency for end users.

The Centre is more than just a production site – it is a blueprint for the future of advanced manufacturing in Australia. Every process, from machining to assembly to software integration, reflects the company’s mission to empower local industries with premium technology and reliable service.

By offering local access to Eplan’s digital engineering solutions, APS

is setting a precedent for smarter, software-enabled manufacturing in Australia. This collaboration gives food and beverage businesses the opportunity to harness advanced engineering tools without navigating the complexity of multiple systems or offshore support networks.

By building its facility around the principles of digitalisation, efficiency and customisation, APS is helping Australian food and beverage manufacturers stay competitive in a fast-changing global economy. This commitment ensures that customers receive not only high-quality products, but also the long-term support and service needed to thrive in the years ahead.

The centre showcases what is possible when local capability is aligned with global standards and backed by partnerships with Siemens and Eplan. F

To learn more about APS Industrial’s Manufacturing Centre and its contribution to Australian manufacturing, visit: https://apsindustrial.com.au/ manufacturing-centre.

With tailored support and smart technology, Fishbowl helps food and beverage businesses navigate inventory challenges.

In the food and beverage sector, meeting industry compliance needs is becoming more demanding as businesses try to juggle and balance other operational and ancillary tasks. When asked about the current challenges food and beverage businesses face, managing director of Fishbowl Inventory Asia Pacific Simon Jupe described the poor systems surrounding inventory in warehousing.

“If you don’t have a good inventory system, the subsequent reporting

requirements that you need to be compliant in the food and beverage industry becomes hard to meet,” he said.

For many food and beverage manufacturers, inventory management is often a behind-thescenes function, but it plays a critical role in efficiency, compliance and customer service.

Whether businesses are supplying to big or small retailers or simply trying to meet basic hazard compliance, efficient processes need to be set in place to build quality control and a

strong reporting framework.

Fishbowl, a software company specialising in inventory and manufacturing systems, helps food and beverage businesses navigate compliance, traceability and operational challenges. Founded in the United States in 2001, the company launched into the Australian and New Zealand market in 2011. Working closely with a range of industries including food and beverage for more than two decades, Fishbowl focuses on making inventory and manufacturing operations more streamlined.

As Fishbowl provides an off-the-shelf inventory package, businesses in the food and beverage industry look for assistance in traceability. Traceability is one of Fishbowl’s core strengths. In highly regulated sectors like food and beverage, being able to track products and ingredients across the supply chain is vital.

For the food and beverage sector, the work that goes into inventory costing and operational requirements around inventory can be challenging.

Fishbowl aims to help businesses meet regulatory compliance standards while improving accuracy and efficiency. One of the issues food manufacturers face is working with spreadsheets. Many begin with manual tracking systems that gradually become elaborate collections of Excel files.

Over time, these tools can become inconsistent. Jupe explained that spreadsheets often create problems.

“While spreadsheets are brilliant in business, they are brittle,” he said.

Technical issues caused by version control, broken formulas, inconsistent data, absent staff or incorrectly updated systems are all variables that leave consequential gaps in business inventory systems.

Fishbowl addresses these issues by providing a centralised system where purchasing, production and sales processes are managed in one place. This eliminates duplication and fragmentation. All information flows through a single system, allowing real-

time reporting and visibility.

“Fishbowl brings all the operations from purchasing, production and sales into one system,” said Jupe.

While Fishbowl offers an offthe-shelf inventory package, it has reporting functionality tooling enabling the building of both custom forms and templates directly in the software.

By streamlining processes into one system, Fishbowl enables manufacturers to deliver accurate reports and respond quickly to quality control issues.

“The value comes from having one standardised central repository of the whole business operations, rather than bits and pieces coming from multiple sources,” he added.

The software covers a range of users, from sales and operations teams to warehouse staff and production managers. It handles quoting, order processing, picking, packing and shipping, while also managing procurement and manufacturing workflows.

Another advantage is the flexibility Fishbowl offers in its service approach. While the software itself is off the shelf, the implementation and support services are tailored to each business. For complex industries like food and beverage, face-to-face interaction remains valuable.

In Jimba Lamb’s case, a brand of premium Australian lamb, the company required assistance to solve a unique inventory challenge.

As a new division of United Meat Co, Jimba Lamb was building its system from scratch. In order to find a solution, it required a collaborative approach.

Compared to other businesses that invoice before picking and packing, Jimba Lamb has a process where it sells by the box and charges per kilogram. As every box weighs differently, an invoice could only be determined after the inventory is picked. To tackle this issue, the company had to search for customisable solutions that allowed seamless integration with Xero to keep their financial reporting consistent.

Fishbowl works closely with clients, iterating and expanding the software’s use as the business grows. Once that foundation is in place,

businesses often move on to explore more advanced features.

“Engaging in more complex industries or requirements like food and beverage, it is advantageous for us to actually have face-to-face contact,” said Jupe.

Using Fishbowl’s legacy ERP product, Jimba Lamb was able to co-develop a solution that could generate invoices and picking slips simultaneously tailored to its box-to-kilo process. Also, due to the locality of Fishbowl, Jimba Lamb was able to evolve into using newer technology such as Fishbowl’s AI reporting platforms to boost visibility across the entire team from sales to transport crew.

customer expectations and efficiency demands, Fishbowl’s tools provide clarity and control. Whether the goal is to reduce waste, improve costing, or ensure consistent quality, having the right systems in place is essential.

As each company has its own set of needs and processes, Fishbowl dives deeper into those industries to provide flexible services with fixed products.

Jupe spoke about a yoghurt company that uses Fishbowl’s software. He described that the way they utilise the software differs from other companies such as meat manufacturers based on their factory layout, staffing or resourcing availability.

He emphasised that while Fishbowl does not use a “one-size-fits-all” approach, it customises its service, which allows them to work with customers long-term.

As manufacturers continue to face pressures from compliance,

While food and beverage companies approach Fishbowl for its expertise surrounding traceability and compliance standards, Jupe addressed how they uncover other avenues to grow through its products. By witnessing the value of the products that can assist with production costing and analysis, Fishbowl then collaborates with customers through in-person or remote offerings to optimise their warehouse processes.

For companies like Jimba Lamb, working with Fishbowl has meant more than just software. It has been a journey of operational transformation supported by local consultants and a system that grows with the business. F

As Australian manufacturing continues to embrace innovation, the 2026 Endeavour Awards will highlight the companies and individuals driving change in the food and beverage sector.

Awards and certificates are not just displays to be placed on bookshelves or hung on walls to collect dust. They mark milestones, passion, and growth from the innovative minds who pour their efforts into the shared goal of building communities. From technologies to manufacturing capabilities, it is important to pause and show appreciation, celebrating achievements and acknowledging how far businesses have come.

Specifically in the food and beverage sector, manufacturing capabilities are being modernised to align with the digital landscape. Winning the Best Technology Application Award and Australian Manufacturer of the Year at the 2024 Endeavour Awards, MEQ celebrated its efforts to boost Australia’s food sector.

Presented annually by Manufacturers’ Monthly, the Endeavour Awards are the premier national awards programme recognising outstanding achievement in the Australian manufacturing industry.

MEQ builds solutions across both production and processing by generating data through its advanced hardware.

With a focus on animal protein and the global red meat industry, the company aims to deliver new insights through customer data.

Remo Carbone, chief executive officer and co-founder of MEQ, expressed the team’s pleasure in celebrating their success at the Awards.

“It was great recognition for the team,” he said. “Everyone was super pleased to be there and be a part of it.” The award submission was based on MEQ LIVE, an agriculture-focused technology that allows breeders, farmers, feedlot operators and sale yards to measure the meat quality and yield of a live animal while reducing carbon emissions within the industry.

MEQ LIVE can unlock blind spots in livestock production systems. Its solution allows producers to predict end processes for managing animals as far as 400 days in advance.

Although the company has been operating for nine years, the first six were focused purely on research and development. Carbone acknowledged the challenging beginnings of building revolutionary technology from scratch.

“We had to find a way to build hardware that had never existed before,” he said.

Carbone described the difficulty of combining different types of hardware and software at a machine learning level while proving the product’s value to the market.

Nevertheless, the company’s clear direction and perseverance kept the team committed. Recognising a blind spot within the engineering and entrepreneurial communities regarding animal protein production, Carbone described not only the technical but also the commercial challenges of building a categorydefining business in a largely overlooked space.

One of the most effective ways to catalyse growth in Australian manufacturing, according to Carbone, is through interactions between creative problem solvers who are striving to make a meaningful impact.

With determination and vision, the business evolved into a thriving operation with a growing deployment base and activity in six countries.

“It has been quite a journey,” said Carbone. “Australia may have a high cost of labour relative to other countries, but we have all the ingredients to double down on advanced manufacturing.”

With events like the Endeavour Awards, Carbone emphasised the importance of recognising and supporting companies in their early stages as they take bold steps toward innovation.

Connecting with other advanced manufacturing leaders, both within and outside the food and beverage sector, gave the MEQ team the opportunity to step beyond its internal focus and engage with a broader, appreciative community.

Staying aware of each other’s progress and remaining engaged in these peer networks can lead to new opportunities and collaborative efforts.

The Endeavour Awards Gala is a celebration of innovation, resilience, and excellence across the manufacturing sector.

“I’d love to see more companies being present at the Endeavour Awards,” Carbone concluded. “We’re trying to help build the ecosystem in relation to advanced manufacturing in Australia.”

For the first time in the award’s history, there will be a dedicated Innovation in Food Manufacturing Award. This new category celebrates innovations that enhance food and beverage production and is open to

businesses developing new solutions in processing, packaging, automation, or sustainability.

Now more than ever, it is essential to support and champion local food manufacturing. This is an opportunity to acknowledge those making a real impact, whether by driving innovation, supplying vital products or services, or leading their organisations with vision and determination.

Next year’s award categories include Technology Application Award (Sponsored by Weld Australia); Innovation in Aerospace; Innovation in Health Technology; Innovation in Food & Beverage Manufacturing; Innovation in Transport; Outstanding Start-Up Award; Leader of the Year (Sponsored by BDO Australia); Manufacturer of the Year.

To be eligible, innovations must be newly introduced to the market or significantly advanced within the two years prior to the nomination closing date. F

Technology group Krones is working closely with customers to deliver future-ready production lines and technologies tailored to every step of the beverage process.

In the diverse food and beverage industry, every operation has its own set of unique processes and needs. Some businesses work with complete turnkey lines, while others operate with single machines or partial systems.

Depending on these requirements, most beverage products go through several processing stages. For businesses working with in-built systems, the challenge lies in finding automated and integrated solutions to streamline operations and meet production targets.

Krones is helping food and beverage producers modernise their operations while staying competitive in high-cost markets such as Australia and New Zealand. It offers a range of solutions, from standalone machines to integrated turnkey production lines.

Founded in 1951, the familyowned company has evolved into a global technology group with tailored solutions for every stage of production. With nearly 20,000 employees worldwide, Krones has built a strong reputation in beverage manufacturing.

In this sector, flexibility and customisation are essential. Krones delivers tailored factory planning

services that enable partial or full upgrades, based on each client’s specific needs.

From container production, filling and packaging to recycling, the company can provide solutions for individual components such as blow moulders, palletisers and fillers, or full processing and packaging lines.

Reducing downtime and cutting production costs are key goals in manufacturing. By improving output through smarter systems, workflows can be optimised without the need for excess inventory. Storage space is preserved, and resources can be used more efficiently.

With a focus on staying responsive to market trends, Krones integrates new technologies and digital tools into its offering. Franz Kirchberger, head of sales at Krones Pacific, said the company’s systems are designed with flexibility and future readiness in mind.

“Krones has a lot of AI solutions that are being offered to make machines more reliable,” said Kirchberger.

He noted that customers across Australia and New Zealand are embracing automation as they recognise the cost pressures of local manufacturing. To achieve optimal

results, businesses are increasingly adopting automation in their packaging lines, particularly in PET systems.

While trends differ across regions, PET continues to grow in the AsiaPacific, driven by population growth and rising demand. Krones supports this demand with equipment suited to a variety of packaging formats, including PET and aluminium cans.

New tools powered by artificial intelligence are helping improve machine reliability, reduce the need for manual intervention, and increase overall production efficiency. The upcoming drinktec 2025 exhibition in Munich, Germany, will showcase the best of what Krones has to offer.

“Automation is being considered in many areas where automation wasn’t considered before,” said Kirchberger. “Artificial Intelligence is making its way into packaging to make machines more reliable.”

He pointed out that automation is especially relevant in Australia, where high labour costs continue to influence capital investment decisions. He believes the local market is not far behind Europe when it comes to adopting digital and automated manufacturing solutions.

In addition to flexible systems for single machines or complete lines,

Krones puts a strong emphasis on building relationships with its customers.

“The customers are at the centre of our attention,” Kirchberger said. “Krones is focused on partnerships, rather than just transactional relationships.”

The company takes a partnershipbased approach by offering aftersales services, operator training, and access to spare parts through its online shop. Its local footprint is supported by a team of 20 service technicians across Australia and New Zealand, ensuring responsive and consistent support.