Dematic guides strategic, data-led warehouse automation decisions. RETHINKING WAREHOUSE AUTOMATION

PROLOGICAL APPOINTS DIRECTOR

Prological appoints Sean Ledbury to lead automation.

Dematic guides strategic, data-led warehouse automation decisions. RETHINKING WAREHOUSE AUTOMATION

PROLOGICAL APPOINTS DIRECTOR

Prological appoints Sean Ledbury to lead automation.

Argon & Co guides AI-driven warehouse optimisation.

As a global leader in temperature-controlled logistics, Americold understands the importance of keeping operations moving. Partnering with the Connected Workforce Solutions (CWSTM) division at Dematic, they modernised their cold chain operations in Australia, upgrading wireless connectivity, voice-picking systems, and RF devices.

The transformation signi cantly boosted ef ciency, accuracy, and productivity. Dematic’s robust solution included meticulous planning and mapping to ensure seamless WiFi coverage and device connectivity, maintaining smooth operations, even in sub-zero conditions.

Learn more at dematic.com/americold

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

Chairman: John Murphy

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Phillip Hazell

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Danielle Harris, Jacqueline Buckmaster

Client Success Manager: Caitlin Pillay

FOR ADVERTISING OPTIONS

Contact: William Jenkin

william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (11 issues) for $99.00 2yrs (22 issues) for $179.00

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

From automation breakthroughs to infrastructure reform and the legacy of a logistics titan, this month’s edition captures a defining moment for the supply chain and logistics industry – one where innovation and investment converge to shape a more efficient, resilient, and sustainable future.

In Melbourne, two milestone projects signal the direction forward. Röhlig Logistics has opened an 18,500 sqm warehouse near Tullamarine, purpose-built with sustainability and visibility at its core. Meanwhile, Synnex Australia’s $150 million Oakleigh South headquarters – complete with a 35-metre-high ASR facility – reflects the increasing role of automation and data in shaping modern warehousing operations.

This spirit of transformation is reflected nationally. The NSW Government’s new freight reform roadmap, outlined at the Property Council’s Sydney summit, maps a path toward $131.5 billion in economic uplift and 235,000 new jobs by 2061. That vision hinges on coordinated investment in land, ports, and intermodal infrastructure – the arteries of our supply chain.

It comes at a time when the third-party logistics sector is undergoing major expansion. New forecasts suggest Australia’s 3PL market will nearly double to around $66.87 billion by 2033. Key drivers? A digitising economy, the rise of eCommerce, and growing demand for integrated, value-added services. Smart operators are already adapting – embracing automation, modern WMS platforms, and advanced analytics to meet rising expectations.

We also spotlight the latest addition to our Australia’s Most Sustainable Warehouses column: Hellmann Worldwide Logistics’ new contract logistics centre in Truganina, Melbourne. Officially opened on July 1st, the purpose-built facility doubles Hellmann’s Melbourne capacity and is targeting a 5-star Green Star As-Built rating. Sustainability features include a 200-kW solar PV system, rainwater harvesting, EV charging infrastructure, and advanced warehouse management systems to optimise energy use and reduce emissions.

Finally, we pause to reflect on the passing of Frederick W. Smith, founder of FedEx and a true pioneer of global logistics. His visionary approach – fusing speed, scale, and service – laid the foundations for the modern supply chain. His legacy lives on in the continued pursuit of excellence that drives our industry forward.

TRUSTED TOYOTA MANUFACTURING

*System of Active Stability available only on selected Toyota Forklifts. our

For over 60 years Toyota has been at the forefront of the materials handling market. From our patented System of Active Stability™ safety technology to our exclusive I_Site telematics system, our spirit of innovation drives our continuous improvement. We’re also proudly committed to a sustainable future with one of Australia’s most comprehensive ranges of zero operating emissions forklifts designed to be up to 99% recyclable, and that’s just part of the Toyota Forklift Advantage.

PROUDLY DISTRIBUTED BY TOYOTA MATERIAL HANDLING

12 Argon & Co shows how AI enhances intralogistics through datadriven optimisation, automation, and strategic maturity.

19 Prological appoints Sean Ledbury to lead automation-focused supply chain consulting.

34 EnerSys supports verifiable forklift sustainability with data-driven electric power solutions.

26 TMHA helps Drake Group enhance safety and operational efficiency.

23 Adaptalift launches Hyster XTLG electric range after ANZ acquisition.

38 SICK supports safe, efficient cobot integration at Tait Communications’ production line.

30 Dematic outlines strategic framework for successful warehouse automation implementation.

EVENTS, SPECIAL FEATURES AND REGULARS

03 Ed’s letter

06 Industry News

40 MegaTrans 2026

42 Australia’s Most Sustainable Warehouse

46 Industry Report

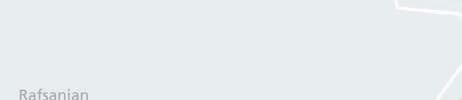

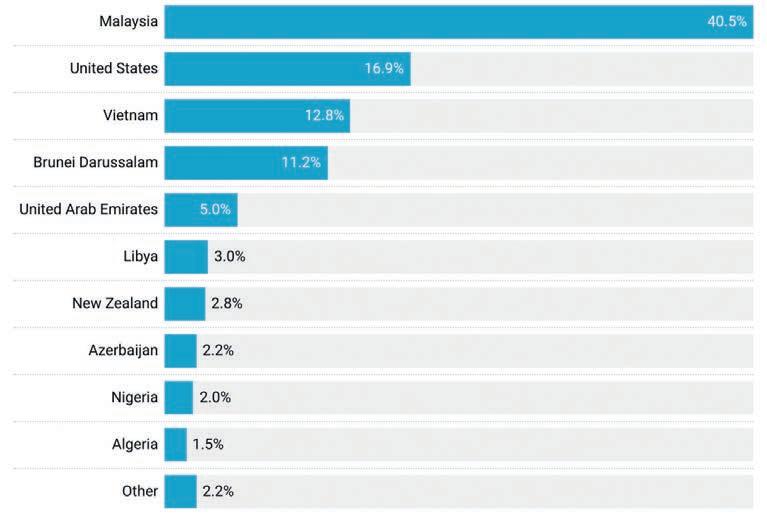

48 Special Feature: Strait of Hormuz

52 People on the Move

54 ASCI

56 SCLAA

Argon & Co outlines how AI is transforming intralogistics by enhancing flow management, slotting, and inventory accuracy – shifting operations from manual oversight to intelligent, real-time optimisation.

Röhlig Logistics has opened its new, purpose-built warehouse in Melbourne, marking a milestone in the company’s commitment to delivering faster, tailormade, and sustainable logistics solutions across Australia.

Located near Melbourne Airport, the facility includes 18,500 sqm of advanced warehousing space and 1,000 sqm of modern office space, purpose-built to support growing international trade and evolving supply chain needs.

With capacity for 17,500 pallet positions, the facility offers improved flexibility and supply chain visibility – all managed

through Röhlig’s global network.

Key green features include rooftop solar panels, electric vehicle and MHE

charging stations, sustainable water and waste management systems. It has achieved a 4-Star Green Star rating. ■

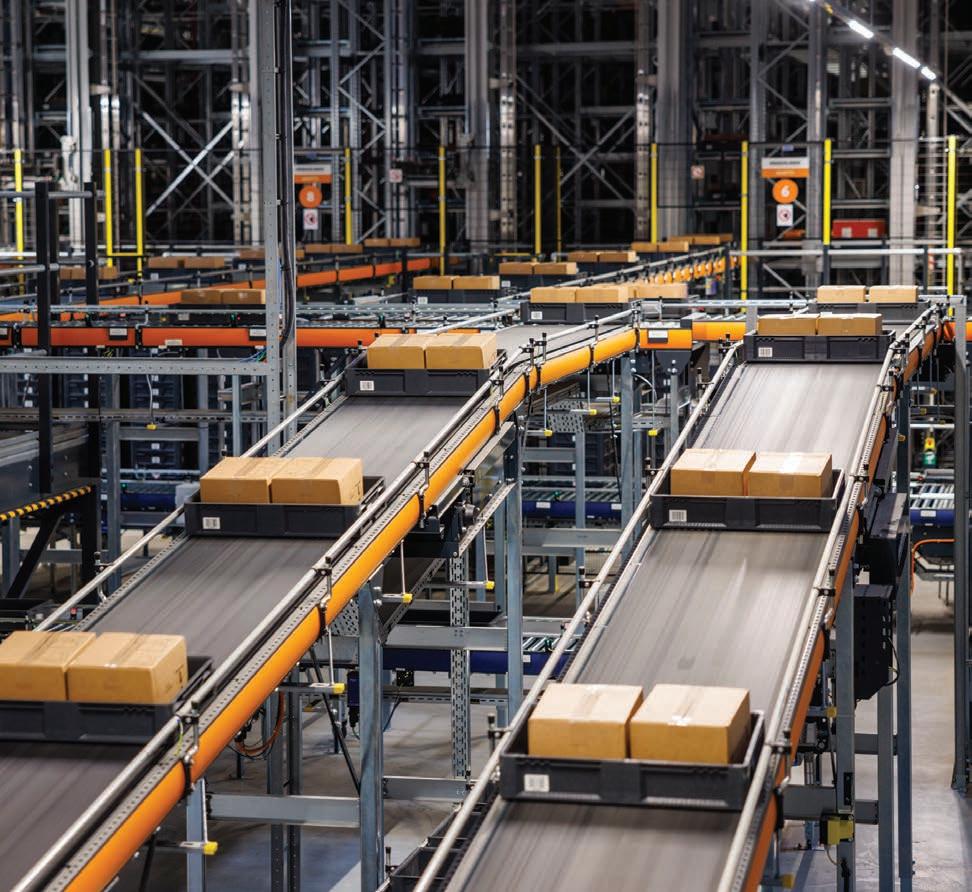

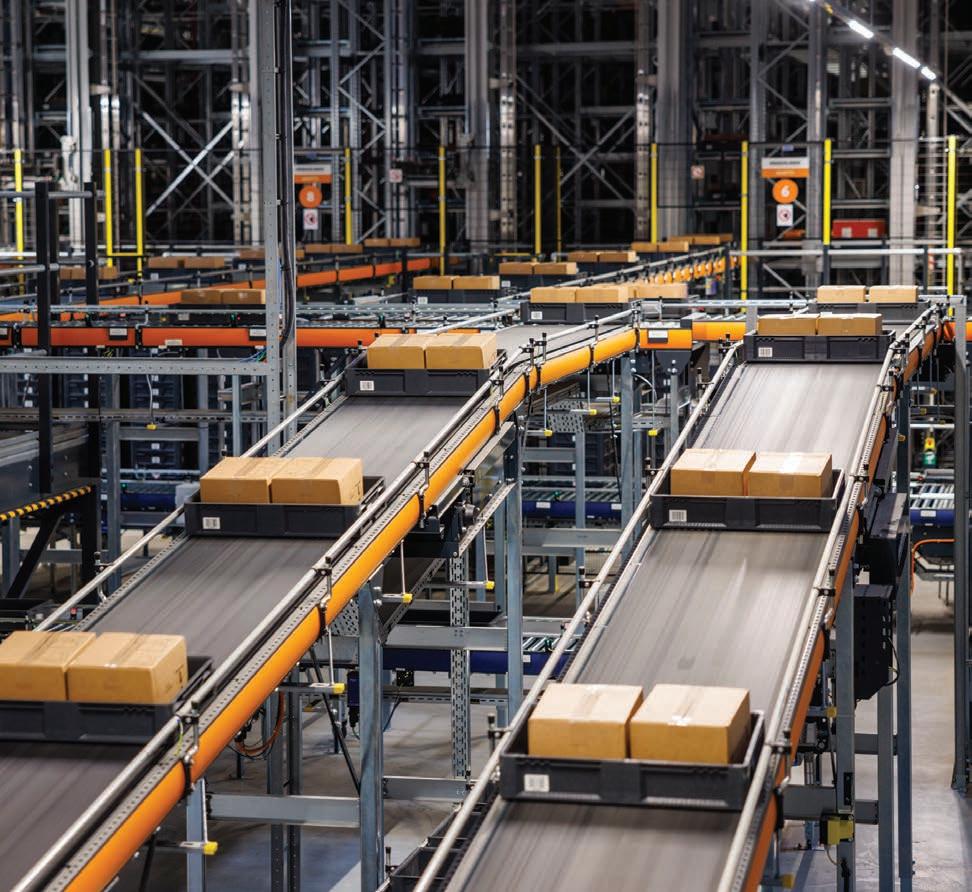

Synnex Australia has unveiled its new $150 million headquarters and logistics facility in Oakleigh South, Melbourne – marking a step in the company’s long-term investment in Australia’s technology and distribution infrastructure.

Spanning 44,000 square metres, the purpose-built site includes a 22,000pallet capacity and a 35-metre-high, 4,283 sqm high-bay warehouse fitted with a state-of-the-art Automated Storage and Retrieval System (ASR).

With more than a kilometre of conveyors and 25,280 sqm of conveyor

infrastructure, the system enables fast, accurate pallet handling across all levels. The site also features one of the largest rectangular sprinkler tanks in the country at 800,000 litres, alongside an 8,500-head fire protection system and an architecturally designed threelevel office complex.

“This project represents not just our commitment to technology, investment, and sustainable growth in Australia, but a reflection of the dedication of the people behind it,” says Arthur Gimisis, CEO of Synnex ANZ. “It pushed the boundaries of what we thought was possible in terms of coordination, planning, and execution.”

Construction began in 2020, with access to the site restricted prior to completion. In response, Synnex’s team relied on 3D simulations, real-time monitoring, and their MIS system to coordinate a complex relocation operation. Over the 2025 Easter weekend, more than 600 containers and

7,200 pallets were moved in four days –with no disruption to business operations.

“This was one of the boldest, most fearless projects we’ve seen in the local logistics industry,” noted an Australian equipment supplier, while a Japanese automation partner described the execution as “exceptional”.

Alex Lin, General Manager of Synergy Intelligent Logistics, called the operation “meticulous yet tough – a true test of our capabilities from end to end”. Jacky Chen, Senior Logistics Manager of Synnex Australia, added, “What stood out was the unwavering teamwork, with every detail executed with precision.”

Operating alongside Synnex’s Sydney facility, the new site enhances national logistics capability and supports the company’s USD$2.5 billion in annual regional revenue. It also forms part of a broader global network of 26 logistics centres. ■

Our trucks, software solutions and services are engineered to support our customers in achieving their sustainability targets. Through a detailed analysis of your operational priorities and environmental objectives, we can identify and recommend the most suitable trucks and energy systems to help you achieve measurable, long-term results.

Australia’s 3PL sector is expanding rapidly, driven by e-commerce, automation, and integrated logistics services. Image: WS Studio 1985/stock.adobe.com

Australia’s third-party logistics (3PL) sector is forecast to grow from USD$24.03 billion in 2024 to USD$44.32 billion by 2033, according to new research from IMARC Group.

The report projects a compound annual growth rate (CAGR) of 7.04 per cent, underpinned by rising e-commerce activity, supply chain digitisation, and increasing demand for value-added services.

It also identifies manufacturing and healthcare as key drivers of growth, as businesses seek to streamline logistics while focusing on core operations. Technological advancements, particularly in automation and warehouse management systems (WMS), are also playing a central role in

improving efficiency and scalability.

According to IMARC Group, 3PL providers are increasingly offering integrated services such as inventory management, transportation, customs brokerage, and last-mile delivery. This has allowed them to cater to shifting customer expectations around faster, more transparent, and cost-effective logistics.

Geographically, the report notes that New South Wales and Victoria remain dominant markets due to higher population density and industrial activity. However, infrastructure investments are accelerating demand in regions such as Queensland and Western Australia.

Other sources, including research by

Expert Market Research, echo similar trends and highlight the entrance of global technology providers – such as Softeon’s 2024 launch in Australia and New Zealand – as a signal of increased regional competition and sophistication.

Major players in the Australian 3PL landscape include Toll Holdings, Linfox Australia, DB Schenker, Kuehne + Nagel, and CEVA Logistics, among others. These firms are investing in automation, sustainability, and integrated IT platforms to meet evolving market demands.

As consumer and B2B expectations around logistics continue to shift, analysts suggest the Australian 3PL market is positioned for sustained longterm growth. ■

The property, infrastructure and logistics sectors came together in Sydney recently at the Property Council of Australia’s Navigating the Future of Freight Infrastructure Breakfast to chart the next wave of investment across New South Wales’ freight network.

Property Council NSW Executive Director, Katie Stevenson, says the event came at a pivotal moment, following the release of the NSW Government’s new freight roadmap, Delivering Freight Policy Reform in NSW, which outlines a potential $131.5 billion economic uplift and 235,000 new jobs by 2061.

“The freight sector keeps goods moving, cities functioning, and businesses growing,” Katie says.

“The NSW Government’s reform agenda shows what’s possible when we get the policy settings right – across land use, infrastructure, investment and planning.”

She says the report reflects many of the Property Council’s long-standing advocacy priorities, including urgent action to address Sydney’s industrial land shortage and improve connections between freight precincts, ports, intermodals, and the future Western Sydney International Airport.

“Unlocking land and investment for freight infrastructure is central to NSW’s economic future,” she says.

Speakers at the event included:

• Marika Calfas, CEO, NSW Ports

• Steven Woodlands, Executive Manager – Cargo & Commercial,

Western Sydney Airport

• Andrew Simons, Head of Development – Industrial & Logistics, Charter Hall

• Scott Falvey, General Manager NSW, ESR Australia

• Jacqueline Parker, Director, Urbis Katie says coordinated planning and investment in freight infrastructure would be key to enabling long-term growth and improving the efficiency of freight movements.

“The challenge is moving more goods, more efficiently – reducing congestion, cutting emissions, and supporting urban development,” she says. “Our ports, airports and freight corridors are the arteries of the NSW economy. This discussion was about ensuring they’re equipped for the decades ahead.” ■

Frederick W. Smith, the founder of FedEx and a pioneer of modern express delivery, has died at the age of 80. He passed away from natural causes on June 21 in Memphis, Tennessee – the city where he built one of the world’s most recognised logistics companies and shaped the future of global commerce..

Smith, who served as FedEx CEO for nearly 50 years before becoming Executive Chairman in 2022, was widely credited with inventing the overnight delivery industry. His original vision – conceived while studying economics at Yale University – transformed into a global network that today moves more than 17 million packages per day across 220 countries and territories.

“Frederick W. Smith pioneered express delivery and connected the world, shaping global commerce as we know it,” said FedEx President and CEO Raj Subramaniam. “His legacy of innovation, leadership, and philanthropy will continue to inspire future generations.”

Born in Mississippi in 1944 and raised in Memphis, Smith founded Federal Express in 1973 with just 14 aircraft. Drawing on his experience as a decorated U.S. Marine Corps officer – including two tours in Vietnam –Smith applied military precision and

entrepreneurial drive to logistics, introducing the world’s first integrated air-to-ground delivery network.

Under his leadership, FedEx grew into the largest express transportation company in the world, supporting over 500,000 employees and moving an estimated $2 trillion in goods annually. Beyond operational scale, Smith cultivated a customer-centric culture known as the “Purple Promise,” focused on reliability, respect, and service excellence.

Even after stepping down as CEO,

Smith remained closely involved in FedEx’s direction, advising on innovation, sustainability, and public policy initiatives. His influence was also felt well beyond the company. He held leadership roles with organisations including the Business Council, the U.S., China Business Council, and the International Air Transport Association, and supported a range of philanthropic causes, from education and healthcare to veterans’ affairs and environmental sustainability.

Smith’s impact was especially profound in Memphis, where he championed economic development, job creation, and civic renewal. Through FedEx and personal philanthropy, he played a major role in reshaping the city’s trajectory.

He is survived by his wife Diane, eight children, 31 grandchildren, and two great-grandchildren. He was preceded in death by his daughter Windland Smith Rice.

Frederick W. Smith leaves behind a company – and an industry – built in his image: fast-moving, innovative, and globally connected. His legacy endures in every shipment delivered, every community served, and every boundary pushed in the world of logistics. ■

At Vanderlande, we’re helping customers lead the shift toward low-impact, high-performance warehousing. What does that mean in practice?

> Future-ready automation

> Energy-conscious system design

> Reuse and circularity built in

> Meet growing regulatory and customer sustainability demands

Our warehouse automation solutions are designed to reduce energy use, minimise emissions, and extend equipment life through circular principles like reuse, remanufacture and recycle. From low-friction conveyors to predictive maintenance and energy modelling tools, we empower your operations to meet environmental goals without compromising e ciency. Together, we can future-proof your supply chain while contributing to a healthier planet and stronger bottom line.

Learn more at www.vanderlande.com/about-vanderlande/sustainability

Argon & Co shows how AI transforms intralogistics from manual oversight to intelligent, data-driven optimisation.

Distribution centres have been under pressure for years. Labour shortages, rising SKU counts, and changing customer expectations have forced logistics operators to invest in greater levels of automation. But the next frontier in intralogistics isn’t mechanical – it’s cognitive.

That’s the view from management consultancy Argon & Co, which works with businesses across ANZ to improve warehouse performance. While many organisations have invested heavily in conveyors, shuttles and robots, most are still relying on traditional, manual approaches for day-to-day decisionmaking. The real value of AI, the firm says, lies in filling that gap.

The challenge: complexity meets constraint

Richard Mahoney, Associate Partner at Argon & Co, specialises in distribution centre (DC) design and project engineering. He says that despite decades of automation progress, many DCs still struggle to match physical flow with operational intent.

“There’s a perception that warehouses are mainly about storage,” Richard says. “But in reality, they’re about flow – and specifically about what is flowing, when, and in what sequence. Coordinating that across hundreds of thousands of transactions in real time is extremely difficult.”

He points to a growing disconnect between physical and digital operations. While WMS platforms and ERP systems provide a baseline level of control, they often fail to capture critical context –especially in highly tailored, servicesensitive environments.

Warehouses often rely on institutional knowledge – like knowing a particular 2pm truck needs to be loaded a certain way to meet a specific customer preference. But as Richard points out, without formalising that kind of insight within a system, it’s impossible to scale or automate effectively.

“There’s often a person deep in the warehouse who just knows that one customer needs pallets arranged a certain way,” he says. “That insight might never be documented but is essential to how that operation works day to day. Institutional knowledge like this becomes a barrier to automation unless captured and codified.”

Richard notes that this challenge intensifies in multi-client DCs or operations with specialised service levels.

“One client may require cartons stacked by SKU, another by order. Those nuances require systems that are intelligent enough to adapt.”

Adding to the challenge is poor data quality.

“Transactional data, like weights and dimensions, is often incomplete or inconsistent,” he says. “You can’t make intelligent optimisation decisions when your underlying data isn’t accurate.”

Traditional methods: active management, manual fixes For many operators, the go-to response has been what Argon & Co calls ‘active management’: the constant human oversight of operations via dashboards, spreadsheets, and control towers.

Jeff Triantafilo, a Partner at the firm, says these traditional approaches are increasingly being pushed to their limits.

“Most DCs are still relying on historical data to make forward-looking decisions,” Jeff says. “A person might be sitting in a control room with a Power BI dashboard, trying to adjust

flow rates or assign labour based on what they think will happen. That’s inherently limited.”

Jeff outlines three core areas where manual intervention remains common – and problematic.

First is flow management: coordinating mechanical and logical flows through a site in a way that optimises cost per unit.

“As sites grow more complex, it becomes harder for individuals to manage all the interdependencies,” Jeff says.

Second is data governance.

“Inventory accuracy is still a massive challenge,” Jeff says. “You’ve got teams spending hours each day reconciling stock between systems – WMS, ERP, inventory snapshots. It’s labourintensive, error-prone, and ultimately reactive.”

Third is slotting.

“Slotting is often done once, properly, then left to go stale,” he explains. “Without dynamic inputs, slotting becomes ‘set and forget’ – and that leads to inefficiencies.”

The broader issue, Jeff says, is that traditional methods simply don’t scale with the complexity of modern operations.

“We’ve hit the ceiling of what people can manage manually. That’s where AI becomes necessary – not just as a niceto-have, but as an enabler of continued performance improvement,” he said.

From mechanisation to cognition

Enter artificial intelligence. For Argon & Co, the next wave of intralogistics optimisation is about embedding intelligence into decisions – particularly those that need to be made in real time, under uncertainty, or at scale.

Aiden Heke, Adviser at Argon & Co ANZ, says the firm has spent the past few years developing AI tools that address precisely these gaps.

AI’s strength lies in its ability to make accurate predictions even in uncertain conditions – an ability that makes it particularly valuable in the logistics space, Aiden explains.

“When your data is incomplete or your environment is constantly shifting, traditional tools break down,” he says. “But AI can help extract insight and drive decisions – even with partial information or information that has traditionally been hard to predict behaviour like seasonality.”

The firm’s early investments were in data quality engines for spend analytics, which it has since adapted for broader applications including warehouse and inventory contexts.

“We often start with a data quality assessment,” Aiden says. “It’s the foundation. You can’t layer intelligence on top of a broken data set.”

From there, the consultancy applies AI to specific challenges – such as stocktake automation.

“In one case, a client is looking for intelligent alternatives to manual warehouse stocktaking,” Aiden says. “We’re now working on a solution using drone technology and Vision Language Models (VLMs) to scan inventory barcodes and reconcile stock positions automatically.”

Aiden says that VLMs – an evolution of large language models like ChatGPT – can match images and text to validate inventory against WMS records in real time. He said that this isn’t hypothetical. These models are already being tested in client environments, and they’re seeing encouraging results. Aiden also highlights a newer frontier: using AI to process unstructured data.

“We now have the ability to plug in unstructured data sources – Slack messages, meeting transcripts, comments from team collaboration tools – and use AI to extract useful insights from them,” he says. “That’s a huge leap from what we could do even a couple of years ago. These were

blind spots – conversations, team decisions, process workarounds. Now they’re sources of intelligence. The more complete your picture of what’s actually happening in the warehouse, the smarter your AI-driven decisions can be.”

Slotting has also become a focus area for Argon & Co’s AI team. Using a trained language model specific to supply chain and warehouse environments, the firm is experimenting with AI-generated slotting permutations based on SKU profiles, order frequency, and space constraints.

“Think of ChatGPT as a giant generalist brain,” Aiden says. “We’ve trained our own model on demand planning, and we’re now applying that to slotting – basically asking the model to generate optimal layouts based on dynamic data inputs.”

Aiden emphasises that these tools are not meant to replace human operators, but to augment them.

“AI doesn’t eliminate the need for domain knowledge,” he says. “If anything, it makes it more valuable. The best results come when smart people train the model with real operational insight.”

Why strategy – and maturity – matter

Despite the promise, the consultants agree that AI isn’t a silver bullet. Success depends on starting from the right place.

“Many businesses jump into AI because it’s a board-level priority,” Jeff says. “But unless you understand your maturity – your data readiness, your systems landscape – you can waste a lot of time and budget.”

To that end, Argon & Co has developed an AI maturity framework and diagnostic tools to help clients assess where they are on the journey.

“Sometimes less is more,” Jeff says. “You don’t need to boil the ocean. Pick a use case where you can prove value quickly – like inventory reconciliation or automated slotting. Get a win, then scale.”

Aiden adds that a clear AI and data strategy is essential. “Most businesses don’t have a robust data strategy, let alone an AI strategy,” he says. “That has to change. You need a roadmap, not a series of disconnected experiments.”

Levelling the playing field

While large enterprises are often first to experiment with AI, Aiden believes the technology could ultimately be a leveller.

“Australia and New Zealand have a large middle band of subscale businesses,” he says. “These businesses don’t have global footprints, but they still face global expectations – faster fulfilment, lower cost, better visibility. AI gives them a chance to compete.”

Aiden observes that international players are increasingly leveraging AI to lower their cost to serve and speed up fulfilment. Without adopting similar levels of sophistication, he warns, local operators risk falling behind on service. However, he stresses that the entry barrier isn’t as high as some may think.

“It’s not about building an in-house AI lab,” Aiden says. “It’s about selecting the right partners and platforms and applying them to your unique context.”

Jeff agrees.

“AI helps smaller teams do more with less. It removes grunt work, improves accuracy, and allows your people to focus on what really matters – managing exceptions and improving outcomes,” Jeff says.

Richard says that as delivery windows shrink and DCs become more servicedriven, the case for AI will only strengthen. Increasingly, warehouse operators are no longer just picking and packing boxes – they’re assembling custom orders in real time while managing multiple constraints.

“No human – even the best operator –

can manage all of that fast enough,” he says. “You need systems that think, not just systems that move.”

Looking ahead, the Argon & Co team believes that DCs must start viewing AI not as a future project, but as a core enabler of present-day performance.

“Whether it’s continuous flow optimisation, demand-driven slotting, or real-time inventory visibility, AI will be central to how the best warehouses operate,” Aiden says. “It’s already happening at the cutting edge – and the tools are increasingly accessible.”

The takeaway? AI is not a silver bullet, but it is a scalable advantage. As warehousing complexity grows, businesses that build intelligence into

their operations today will be best placed to lead tomorrow.

Asked what the future holds, the team shares a cautious optimism. The shift to intelligent intralogistics won’t happen overnight – but when it does, it will feel abrupt.

“There’s a saying in economics: things happen slower than you think, and then faster than you expect,” Richard says. “That’s AI in supply chain. One day it will feel niche, the next day it will be everywhere.”

Aiden agrees. “It’s when a competitor comes in with a new model – cheaper, faster, smarter – that the market really shifts. And those who haven’t prepared will be playing catch-up.” ■

Australia is making history with the debut of its first-ever container-unloading robots,The RockyOne.

This groundbreaking innovation marks a new chapter in logistics, redefining how goods move through the supply chain. It’s a turning point for the industry. innovation

Combining internal combustion-like power with clean energy, the Hyster XTLG Outdoor Electric Forklift Series delivers the performance, durability, and reliability you’ve come to expect from Hyster — now powered by integrated lithium technology. Available in capacities from 2 to 7 tonnes, it’s the sustainable solution that doesn’t sacrifice strength, speed, or uptime.

Sean Ledbury joins Prological, bringing years of automation experience to drive strategic supply chain consulting.

Prological has announced the appointment of Sean Ledbury as Director, bringing with him more than 35 years of global experience in logistics automation. The appointment marks a pivotal moment for the consultancy as it scales up in response to increasing demand for independent, technology-agnostic advice across the supply chain.

Sean joins Prological after a career with some of the world’s most recognised automation companies, including Swisslog, Dematic, and Packsize. Most recently, he served as Head of Sales and Consulting at

Swisslog ANZ. His early years in the industry began with Colby Engineering, now part of Dematic, and have included roles in Australia, Europe, the United States, and China.

“I’ve seen a lot of change in this sector,” says Sean. “But never more so than in the last three to five years. New technologies are emerging rapidly, and businesses are grappling with how to apply them effectively. That’s what drew me to Prological – the chance to guide companies toward the right outcomes, not just the right products.”

Sean says his move to Prological was motivated by a desire to work beyond

the bounds of a single vendor and instead work with clients to achieve the best possible outcome for their supply chain and logistics automation challenges, regardless of technology offering.

“Having worked with some of the biggest global providers, I understand the strengths and limitations of different systems,” he says. “But as a consultant, I’m now able to tailor solutions based entirely on what’s best for the client, not what’s in a particular provider’s catalogue.”

Prological, now in its 15th year, works with clients including The Iconic,

BlueScope, and Electrolux, delivering projects spanning warehouse design, transport planning, network strategy, and automation. The business recently relocated to new headquarters at the University of Wollongong’s Innovation Campus, positioning it closer to emerging talent and research.

Direct investment vs. consultation

Sean says he was particularly excited by the opportunity to work with a consultancy known for delivering deeply integrated solutions that extend beyond automation.

“What makes Prological unique is the breadth of its advisory capabilities. We’re not just about deploying a robot or a shuttle system. We look at property, we look at transport network and infrastructure, we look at how the entire supply chain functions. That holistic view is what makes our work so impactful.”

According to Sean, the rise of low-cost automation options has created both opportunity and risk. While entrylevel automation technologies like AMRs (Autonomous Mobile Robots) are more accessible than ever, he warned that many businesses are rushing into implementation without proper planning.

“I often say that successful automation isn’t about the technology – it’s about knowing your operation.

What outcomes are you trying to achieve? How will people interact with the system? If you can’t answer those questions, you’re setting yourself up for failure.”

Sean added that Prological is increasingly being approached by businesses that have tried to automate without support and now face costly rework.

“You can’t afford to get it wrong. The cost of failure often far outweighs the investment in getting it right the first time,” he said.

His experience spans everything from ASRS systems, parcel and postal sortation, airport baggage and cargo systems to automated packaging and AI-powered fulfilment. In addition to his technical credentials, Sean brings a people-first mindset to automation projects.

“At the end of the day, logistics is still about people. My motivation is always to make their jobs easier, safer, and more rewarding,” says Sean.

As for immediate priorities, Sean says his focus will be on helping more organisations understand and access Prological’s services.

“There’s a real hunger out there for independent advice,” he says. “With the market now flooded with different vendors

and options, customers want someone they can trust to help them make the right decision. That’s what we do.”

Reflecting on the state of the industry, Sean says logistics and supply chain now have a much louder voice in Australian boardrooms.

“Twenty years ago, supply chain wasn’t on the radar. Now it’s got a seat at the table,” he says. “The challenges of the past few years have really highlighted the importance of resilience, planning, and smart investment.”

With the industry embracing change at an accelerating pace, Sean believes Prological is well-positioned to help businesses navigate complexity.

“We’re seeing growing pressure on labour, rising property costs, and increasing service expectations. Companies want to get more out of their existing footprint. That means optimising what they have, not always building new. That’s where we come in.”

Sean officially joined Prological in July and is already working closely with clients on a number of new automation and optimisation projects. He says he looks forward to helping the Prological team enter its next phase of growth.

“It’s a great time to be in this industry,” he says. “There’s real momentum for change, and I’m thrilled to be part of a business that’s helping shape what comes next.” Ledbury’s

Addverb's versatile carton shuttle, Quadron, automates storage and retrieval of cartons, crates, and totes up to 50 kg. Its adjustable forks can handle tote widths up to 800mm with ease. With vertical lifts and specialised racking, it enables high throughput and storage density. Double-deep storage allows efficient buffering, sequencing, and improved warehouse productivity.

AHyster’s lithium-ion XTLG range is built for allweather outdoor performance, handling wet and uneven surfaces. Images: Adaptalift Group

Adaptalift and Hyster unveil the XTLG outdoor

electric range, offering internal combustion-like performance with all-electric benefits.

s the industrial sector continues its transition toward decarbonisation, one longstanding challenge remains: how to replace diesel and LPG-powered forklifts with electric alternatives that can perform in tough outdoor conditions.

Earlier this year, Adaptalift Group announced its acquisition of the exclusive Hyster New Zealand Dealer, extending its dealership footprint for Hyster beyond Australia. The move makes Adaptalift the exclusive distributor of the Hyster brand in the region, enabling tighter integration across sales, service, and product delivery. It also allows Adaptalift to respond more rapidly to local market demands while ensuring continuity for existing Hyster customers.

According to Mark Chaffey, Area Business Director – Pacific at Hyster, the new XTLG Outdoor Electric series is developed to replicate the power and

ruggedness of a traditional IC truck, but without the emissions.

“We basically took an internal combustion truck and turned it into an electric truck,” Mark says. “It gives customers IC-like performance by fitting a battery, motor and controller in place of a transmission and diesel or LPG engine.”

Designed for demanding outdoor applications, the XTLG range features advanced traction capability and enhanced handling, addressing a gap in the market where conventional electric forklifts have historically struggled –especially on uneven ground or sloped surfaces.

“In the past, Class 1 electric trucks were built around large lead-acid battery boxes,” Mark explains. “Those machines weren’t well suited to outdoor work – they’d wheel spin easily due to smaller diameter tyres and bog down on loose ground. With the XTLG, you’ve got a true outdoor-capable truck.”

A step forward in Hyster’s sustainability roadmap

The launch of the XTLG range forms part of Hyster’s broader electrification strategy, which includes research into hydrogen-powered vehicles and electrified port equipment. The company’s long-term goal is to provide viable alternatives for customers looking to reduce their operational carbon footprint.

“Almost every customer we speak to now is looking to electrify,” says Adam Duncan, General Manager of Sales at Adaptalift Group. “This range gives them a product that performs like an IC truck but with a green tick. It’s a pathway for customers that want to switch to battery electric.”

“We’re also seeing customers commit to sustainability targets through their boards and public reporting,” Adam adds. “Many are now acting on those commitments – including large bluechip clients who are planning full

transitions to electric fleets over the coming years.”

Hyster’s battery-electric trucks are designed for flexibility, with minimal infrastructure requirements. According to Mark, all that’s needed to operate the vehicle is a standard three-phase power supply for the charger – no hardwiring or extensive electrical upgrades required.

“It’s a standard charger setup,” he says. “If you’ve got three-phase power, you can plug in and go. We also offer both 20-amp and 32-amp options depending on your facility. Run time is at least five hours per charge, with some expected degradation over a fiveyear period. “We account for battery life in our planning, but the system is built to deliver consistent performance within that cycle. Of course, there is the added advantage of top up charging for longer run times during a shift.”

Proven handling and performance

One of the key value propositions of the XTLG range is its ability to exhibit comparable performance as IC trucks on lifting speed, travel speed, and terrain performance. The vehicles are engineered to provide a like-for-like experience for operators, reducing the learning curve and making fleet transition easier.

According to Mark, the machine is designed to behave just like an engine-powered truck from the driver’s perspective, ensuring a familiar operating experience.

“It’s been programmed to operate with the same responsiveness and lifting speed. Customers can lift, drive, and handle loads the way they always have.”

The XTLG range is also highly customisable. Customers can configure

trucks with attachments, safety systems, and features commonly found on IC machines – from pedestrian detection systems and cameras to minilever armrests and wet brakes.

“Pretty much anything you can add to an internal combustion machine, you can add to this,” Adam says. “It’s a true replacement. Nothing is lost in the shift to electric – and in many cases, you gain extra features.”

The series covers a range of lift capacities from 2.0 tonnes to 7 tonnes, with distinct categories that reflect operational needs: 2.0–3.5 tonne, 4–5 tonne, and 5–7 tonne models.

Adaptalift have received their first orders for stock and have started delivering the XTLG units to customers, interest has been strong across Australia and New Zealand. The range is already available across Adaptalift’s national branch network, and stock is on the ground for demonstrations.

“We’ve got machines available now for trial and demo. Customers can get real-world feedback before they make a fleet-wide commitment,” says Adam.

He adds that many businesses –especially those building new premises – are factoring electric vehicle charging into their infrastructure design. The switch to electric can be seamless if customers plan accordingly.

“Some clients are building in the power capacity as part of their new sites,” he says. “And even with older facilities, the cost of installing chargers isn’t prohibitive. It just needs to be considered as part of the process.”

“We’ve even had some customers make the switch without doing a real-

world trial – just based on internal analysis. But we always encourage customers to do a demonstration and proof of concept where possible.”

As with any fleet transition, operator comfort and familiarity are critical for uptake. Hyster’s approach to design puts ergonomics front and centre, incorporating proven IC layouts and enhancements made possible by electrification.

Mark says the XTLG builds on years of experience designing internal combustion trucks, with the electric platform enabling further enhancements beyond what traditional IC models offer.

“You’ll see features like wet brakes, automatic park brakes, and electric control levers integrated into armrests – things that are only available on our high end IC trucks,” he says.

These details not only enhance comfort but also help to ensure operator safety and reduce fatigue – particularly important in longer shifts and outdoor applications.

A national solution

With a footprint across every major capital city in Australia, Adaptalift is positioned to supply, support, and service the XTLG range nationwide. Demonstration units are already being deployed, and additional stock is expected to arrive in the months ahead.

“This isn’t a Sydney or Melbourneonly story,” Adam says. “It’s a solution available to customers across the country, and we’re ready to support trials wherever they’re needed.”

As the push for electrification gains momentum, Hyster’s XTLG range arrives at a critical time for the logistics and material handling sector. By delivering performance without compromise, it offers a practical, scalable alternative for businesses navigating the transition to cleaner, more efficient operations.

“This range gives customers the best of both worlds,” Adam says. “The familiarity of a diesel or LPG truck, and the environmental and operational benefits of electric.”

With zero tailpipe emissions and no compromise on performance, the XTLG range stays true to what Hyster stands for: Zero Emissions. Zero Compromise. ■

The Drake Group boosts safety and efficiency with tailored Toyota forklifts and TMHA equipment at its Wacol manufacturing site.

Afamily-owned trailer manufacturing company has enhanced the efficiency of its business operations with the help of Toyota Material Handling Australia (TMHA) equipment, due to a range of tailored forklift and material handling solutions chosen to suit its specific needs. The Drake Group is an Australian-owned trailer manufacturer based in Wacol, Queensland, who builds and sells a range of bespoke trailers

to customers both locally and abroad. The company has grown to around 430 employees in 2024, and along with Drake Trailers it also includes O’Phee Trailers and Dalzell & Bagley Engineering under its brand umbrella.

The started out from a small workshop in Brisbane in 1958 and continues to build all of its products locally. The company recently looked to upgrade its fleet of material handling equipment by reaching out to several

manufacturer. The reliability, aftersales service, broad model range and competitive pricing of TMHA proved to be the most compelling forklift manufacturer for the company.

“Price-wise Toyota was really competitive – also in the reliability, [and] the aftersales service,” says Buchanan Pinder, Drake Group Maintenance Supervisor.

The Drake Group purchased a range of machinery to suit the needs of their manufacturing facility in Wacol, including six TMHA LHE150 electric pallet jacks, two TMHA Leonardo elevated work platforms, three Toyota 8FG25 counterbalance forklifts and a Huski 5SDK5 skid-steer loader. TMHA Major Account Manager Chevy Date and Buchanan worked together to determine which machines would best suit The Drake Group’s needs, such as the Huski skid steer loader, which has made it much easier to clean up its blast booth.

Previously, the company would fit an attachment onto a forklift to scrape up the sand and debris from the floor of the blast booth, however the harsh usage would eventually break the forklifts, leading to additional downtime and maintenance costs. The Huski skid steer loader is suited to tough environments, and provides a more tailored solution for the business while also doing a better job of cleaning up the blast booth.

Likewise, using the two Leonardo elevated work platforms has made the fabrication process both easier and safer for the welders who work on trailer manufacturing.

“When we build our trailers, we turn them 360 degrees when we weld them out,” Buchanan says. “When they’re on their side we used to use scaffolding, and the welders would climb the scaffolding and do their work on that. Now we use these scissor lifts to take the welder and the wire feeder up the unit and they can use that instead of having to climb up and down scaffolding, so it’s a lot safer and a lot more user-friendly.”

Chevy helped to make the purchase and aftersales process as simple and pain-free as possible and has further helped tailor the fleet to suit the company’s needs, such as fitting a louder reversing alarm on the new forklift to suit the noisy warehouse environment.

A Drake Group employee uses a TMHA Leonardo HD elevated work platform, improving safety and ease of access during fabrication tasks.

After using different brands of forklifts in previous years, Buchanan says the performance of the Toyota forklifts has quickly turned the operator of the new machine into a fan.

“The forklift we received is actually only operated by one person – he is our oldest and longest-employed forklift driver and has been there 30-plus years,” Buchanan says. “He was a bit reluctant to get on the new Toyota but about a week later he came up to me and I’ve never seen him take so much pride in his forklift since he got this new machine. He washes it every week, he takes really good care of it; he’s very happy with it.”

The Drake Group’s forklift operator isn’t the only one who has been happy with the switch to TMHA, with Buchanan saying that having Chevy handle his order has been a breeze. He has kept an open dialogue and assisted in helping find the right specification of equipment for the company.

“It’s been second-to-none – it’s been awesome to deal with TMHA,” Buchanan says. “For example, we put fork positioners on all the forklifts, but I wanted a specific type. It was so easy – I told Chevy what I wanted, he sent me a list of options, I picked the option I wanted, and it was done. There were no questions, I knew exactly what was going on.

“There were a few changes where I had to call Chevy and say, ‘I want to change this to that.’ He was awesome – more than happy to help in any way. One of the biggest things that stuck out to me was when I called him with a question and he says, ‘Ask a hundred –that’s what I’m here for’.” ■

For more information freecall Toyota Material Handling Australia on 1800 425 438 or visit toyotamaterialhandling.com.au

www.prologicalconsulting.com

info@prologicalconsulting.com

Dematic’s Pas Tomasiello provides insights on strategic planning, data, and partnerships for successful warehouse automation.

The pressure on supply chains and distribution centres to deliver goods swiftly and accurately has never been greater. Rising labour costs and shortages, limited real estate, and growing customer demands for speed and accuracy are pushing businesses to rethink how they move products through their operations. The growth of e-commerce and rapid stock keeping unit (SKU) proliferation add to this complexity, leading many companies to realise that manual processes can no longer keep pace with demand.

The shift towards automation

Businesses are increasingly embracing automation to alleviate supply chain pressures, while looking for the best

way to implement it effectively. With a range of technologies like robots, conveyors, and automated storage and retrieval systems on the market, identifying the best-fit solution requires a strategic approach.

At the core of most distribution centres is order picking, whether for direct-to-consumer shipments or retail fulfilment. Despite years of technological advancements, many warehouses still rely on manual processes, leading to inefficiencies and excessive worker travel time. In a market where speed and accuracy are crucial, businesses must evaluate their current workflows and identify where automation can deliver the most impact.

Understand the landscape before diving in

With numerous factors at play, the most critical starting point to implementing automation is undertaking a thorough assessment. Mapping out the entire operational landscape, both external (geopolitical, economic, and consumer trends) and internal (warehouse layout, order profiles, data accuracy, and corporate objectives), is foundational. Without this holistic view, it’s easy to be swayed by a single flashy solution that addresses only one segment of the overall challenge.

When performing this assessment, businesses should weigh each variable according to its importance. Is land cost the biggest pain point, making

high-density storage critical? Is speed of delivery the key competitive differentiator, placing throughput above other criteria? Or is cost the greatest concern, necessitating a strict capital expenditure limit? Ranking each factor clarifies priorities and helps filter through the range of technologies on offer.

The framework: a four-step approach

Although no plan ever goes exactly as intended, following this four-step approach will increase the likelihood of success:

1. Orientation and scoping

Start by outlining the project’s scope at a high level, establishing its key

Dematic’s Multishuttle system in action, showcasing high-throughput tote handling and precise sequencing across multi-level racking for advanced split-case picking.

objectives and boundaries. If possible, visit other automated sites and start having discussions with technology providers. The goal here is to develop a preliminary sense of requirements and constraints.

2. Establish a design level

Set a target timeframe and define what success looks like for that horizon. This “design level” approach asks businesses to envision future requirements for storage capacity, throughput, and flexibility. While forecasts are never 100 per cent accurate, setting a benchmark provides a foundation for modelling potential solutions.

3. Examine alternatives

Cast a wide net. Explore multiple

automation technologies like shuttles, robotic picking solutions, autonomous mobile robots (AMRs), and even hybrid setups. As there’s no ideal single solution for all use cases, thorough evaluation is essential. The range of options should be systematically narrowed down to a shortlist that warrants deeper investigation.

4. Detail and validation

Once the shortlist has been refined, a more in-depth analysis should be conducted. This includes mapping out processes, confirming technical specifications, calculating capital and operating costs, and thoroughly modelling the return on investment. At this stage, data accuracy is

Autonomous mobile robots (AMRs) operate within the AutoStore grid system, streamlining goods retrieval and boosting order fulfilment speed.

crucial, as incomplete or inaccurate information can result in a design that falls short of real-world requirements. Close collaboration between internal teams and the technology supplier is essential to account for the unique complexities of the operation.

The importance of good data should not be underestimated. Data on SKU profiles, order volumes, peak demand periods, and travel distances drive decisions about picking methods, storage media, and throughput requirements. However, many organisations discover their operational data is less clean and comprehensive than they thought. Rectifying data inconsistencies requires collaboration between internal stakeholders who understand the business nuances, and external experts who can interpret and structure data for automation modelling.

Four key solutions for split-case picking

Within the warehouse automation landscape, there are four solutions specifically designed for split-case picking (where items are picked as eaches). These include:

1. AMR shelf-to-picker systems –

AMRs that transport shelving units with SKUs to picking workstations, streamlining order fulfilment. These systems enhance accuracy, efficiency, and flexibility in warehouses by automating inventory retrieval and reducing cycle times.

2. AMR bin-to-picker – Robots that automatically lift and transport product SKUs in totes to and from workstations. This method offers flexibility and can integrate well with conveyors for higher-speed operations.

3. AutoStore – an advanced automated storage and retrieval system (AS/ RS) designed for high-density, highthroughput warehouse operations. Its modular grid structure, combined with fast-moving robots, maximises space, accelerates inventory retrieval, and adapts to changing needs, even in cold storage environments.

4. Shuttle-based systems (Multishuttle) – Here, shuttles operate on rails within storage racks, where they store, buffer and sequence products between bulk stock and other functions such as picking and order assembly. The system can increase speed, storage density, accuracy and throughput in warehouses, factories or distribution centres.

None of these solutions stand alone

as universally perfect; each solves different problems more or less efficiently. In many cases, a hybrid approach, combining multiple solutions, can yield the best results, especially for facilities that handle a range of product velocities.

Choosing the right partners, including technology providers, consultants, and internal stakeholders, is one of the most critical decisions in any automation journey. Effective implementation requires collaboration between technical teams, software developers, and operational staff who understand dayto-day challenges.

Large-scale automation is an investment. Ensuring a strong return goes beyond choosing the right technology, it’s about seamless execution and adaptability as business needs evolve. The right partnership provides guidance from initial planning to long-term optimisation, ensuring the system delivers lasting value. Success ultimately comes down to aligning technology with a clear vision for the future of warehouse and distribution centre operations. With the right partners, businesses can navigate the transition smoothly and unlock the potential of automation. ■

our solutions for your challenges

Automation of manual processes, warehouse optimisation and safety solutions for innovative logistics

Consumers increasingly demand sustainability from products and services they buy, even if they may be a little vague on what ‘sustainability’ means. To the surprise of many companies, 62 per cent of consumers say they “always or often” seek products to purchase because they are sustainable. They just want to trust their brands to be “doing the right thing”.

A YouGov survey in 2023 found that 55 per cent of global consumers are sceptical of the sustainability claims of most brands. While this figure is roughly representative of the US and Canada, it is less than the 64 per cent in the UK, 63 per cent in Germany and 68 per cent in France, where consumers seem to be far more critical.

Much of this doubt is likely due to “greenwashing” by companies trying to take advantage of consumer brand preference and additional profit margins without taking measures to be

more sustainable. Similarly, a Deloitte poll has found 57 per cent of consumers don’t believe most sustainability claims, and 46 per cent are not willing to pay extra because they struggle to differentiate between greenwashing and genuine sustainability benefits.

This issue has also spread beyond consumer-facing brands and retailers. The increasingly sophisticated sustainability debate has evolved past initial assessments of greenhouse gas (GHG) emissions, the use of petrochemicals or even how food and other natural materials are grown. It now challenges all aspects of sustainability in the supply chain; manufacturing processes, logistics, even construction, operational facilities and assets – through multiple tiers of supply and distribution.

Major global corporations reporting on their sustainability efforts are expected to not just report on their own operations but include those of their

suppliers and partners. This includes the roughly 67 per cent of companies intending to hold their supply responsible for sustainability.

There are also other stakeholders. A study by IBM recently found 68 per cent of workers are more inclined to accept a job with an environmentally sustainable company. Ethical investment funds and activist groups are taking a forensic look at corporate sustainability claims, and governments are getting involved with legislation, taxes and penalties as well.

This year, an amendment was attempted to the Digital Markets, Competition and Consumer Bill in the UK Parliament – giving the Competition and Markets Authority (CMA) powers to fine companies up to 10 per cent of global turnover for ‘greenwashing’, defined as making sustainability claims that can’t be verified by a Court.

The UK’s CMA is already examining controversial sustainability claims

in the fashion industry, and Sarah Cardell, CEO of the CMA, has made it clear she is prepared to look beyond consumer markets. As noted in a recent speech, she said that it was, “important that law enforcers take action where firms could be making unfounded [sustainability] claims or presenting products and services in a way that could mislead”.

Above the Greenwash

While sustainability claims and reporting may happen at the corporate level, it is critical for operating facilities to be part of both achieving sustainability goals and subsequently reporting on their progress. As mentioned earlier, 62 per cent of consumers say they “always or often” seek products to purchase because they are sustainable, so it does not matter whether your customer is an endconsumer or another business.

Processes within warehousing and manufacturing facilities are largely designed around scalability and repeatability. This makes opportunities to achieve sustainability goals within those facilities more readily identifiable versus administrative- or corporatetype facilities where processes are less consistent and routine.

This process consistency also helps make most of the sustainability improvements more accurately quantifiable (i.e. they would meet the aforementioned ‘verifiable by a Court’ test) and there is far less subjective guesswork on what sustainability measures achieved in terms of realword improvements.

It highlights two often overlooked yet easily implemented sustainability improvements.

The first is converting your combustion forklifts to electric equivalents. The second is ensuring you have the optimal power solution for

Genuine sustainability means using technologies that deliver verifiable gains in emissions, energy use, and water consumption across the supply chain. Image: Image Alchemy/stock.adobe.com

your electric forklift equipment.

What many do not realise is that battery technologies have multiplied and charger technologies have advanced – providing a range of combinations matched only by the variety of operational conditions they can support. While each electric technology has its own unique characteristics, finding and switching to an optimal batterybased solution for an application offers environmental and sustainability gains over sub-optimal systems.

Reduced harmful emissions –depending on how their energy is produced, battery-powered forklifts offer a CO2 emissions reduction of up to 57 per cent compared to propane / LPG and up to 63 per cent reduction versus hydrogen. And unlike combustionpowered forklifts, electric equipment doesn’t create disposal issues for contaminated lubricants, transmission fluids, and filters. Electric equipment also eliminates other potentially

EnerSys uses power studies and simulation tools to help businesses match battery and charger technologies with sustainability and operational goals. Image: TStudious/ stock.adobe.com

harmful exhaust emissions such as oxides of nitrogen, which can be especially concerning in closed, indoor operating areas.

Extensive recyclability – most battery materials are readily recyclable. For lead-acid batteries the recovery rate is around 99 per cent, while lithium-ion batteries from EnerSys can achieve a recovery rate of up to 95 per cent. The recovery of these raw materials can reduce the environmental and human impacts of mining for raw materials and help keep the supply chain for these materials domesticated.

Improved energy efficiency – there are a couple of ways batteries can also reduce energy consumption, even between different technologies. When it comes to your goals for an optimal solution and the energy capabilities needed to support your application, certain battery technologies can reduce energy consumption per recharge by up to 17.3 per cent.

Reduced water consumption – while efforts for sustainability were previously focused on energy and emissions, the projected 40 per cent shortfall in global fresh water supply by 2030 has quickly drawn attention to needed reductions in water consumption – making it part of critical sustainability efforts in many companies.

But in efforts to conserve water, many operations overlook that their traditional “flooded” lead acid battery can use up to 13 gallons (49 litres) of water per week. While this does not sound like much, it grows rapidly when multiplied by the number of batteries in your fleet and operating weeks per year.

balances supporting your application’s needs with your sustainability goals requires two crucial elements – a broad selection of available battery and charger technologies coupled with datadriven approach to selecting the optimal combination of them, based on your specific objectives.

Compared to combustion equipment, batteries also offer basic improvements from a daily practice perspective. An example is when an operator dismounts combustion-powered equipment for a quick task such as moving an empty pallet or clearing an aisle. They frequently leave the engine idling – burning fuel (and emitting GHGs and other pollutants). In contrast, when an operator dismounts battery-powered equipment, it stops using energy almost entirely.

If reducing water usage is part of your sustainability requirements, there are maintenance-free battery technologies, such as thin-plate pure lead (TPPL) and lithium-ion (li-ion), that are sealedeliminating the need to top up with distilled water altogether. Depending on your sustainability goals regarding water savings, it is often much easier, quicker and less costly to upgrade the batteries in your forklift equipment than it is to have all new water-saving plumbing and related fixtures installed in your facility.

These are all real sustainability measures that are readily quantifiable using established methodologies that stand up to scrutiny.

But finding the optimal solution that

EnerSys is one company in the material handling power stakes that combines both elements. We start with power studies of your existing equipment to determine the energy needs of your application and then use our exclusive EnSite modelling software to simulate your application across one of the broadest portfolios of battery and charger technologies in the industry to find an optimal solution.

This optimal solution also includes predictive modelling of both energy and CO2 emissions reductions for any conversion from a combustion to an electric power source, ensuring that ample power is available when needed for smoothly running operations without overpaying for unneeded energy capacity.

Sustainability gains from switching your forklift equipment to electric power, or even upgrading your existing battery system, are well worth achieving, documenting and highlighting to internal stakeholders as well as external customers – with almost no fear of being accused of “greenwashing”. ■

MEGATRANS is Australia’s largest integrated conference and exhibition for the logistics industry. It brings together leading companies showcasing advanced technologies and services, all focused on enhancing and supporting a sustainable supply chain through innovation and collaboration.

Tait Communications integrates SICK sensors to safely deploy collaborative robot applications in shared workspaces, boosting efficiency and safety.

As manufacturers look to boost productivity through automation, safety remains a central consideration – particularly when humans and machines share the same workspace. For Tait Communications, the introduction of a collaborative robot (cobot) raised questions not just about technical feasibility, but about how to manage safety in an environment not originally designed for human-machine interaction.

The New Zealand-based manufacturer of radio communications equipment is currently trialling its first collaborative robot application as part of a larger effort to modernise its production

line. The robot, a Techman TM5-900, is being introduced to address a bottleneck at the end of one of Tait’s surface mount technology (SMT) lines. The objective is to increase throughput while reducing reliance on an ageing test station that has become a frequent source of downtime.

James Coleman, a test engineer at Tait, says the deployment marks a shift for the company’s approach to automation.

“We’ve got some traditional robotic systems, but they’re fully enclosed, behind fencing,” he says. “This is the first time we’ve introduced a robot that will be operating in the

same space as our people.”

The new setup required a fresh approach to workplace safety. Unlike traditional industrial robots, which are isolated from human workers by physical guards, the automated solution introduced at Tait is designed to operate in closer proximity to people, This shift enables greater flexibility on the production line, reduces the need for large, isolated work zones, and allow operators and robotic system to share tasks more effectively. However, working in a shared environment also introduces new safety challenges.

To manage these risks, Tait worked with advanced sensing and safety

technology company SICK to design a safety system ensuring productivity gains don’t come at expenses of workers protection. The companies have been collaborating on a setup that uses both 3D vision and photoelectric sensing to support both safety and precision in this application.

Eduardo Speranza, Market Product Manager for Industrial Safety at SICK, says the approach draws on safety standards designed for machinery in shared workspaces.

“We worked closely with the team at Tait to understand the application and determine the appropriate performance level for the system,” he says. “Based on that, we were able to recommend a solution aligned with ISO 12100 and AS/ NZS 4024.1.”

At the core of the setup is SICK’s SafeVisionary2, a 3D time-of-flight camera used to monitor a defined hazard zone around the robot system. The camera is configured to enforce two safety-rated fields: a warning field and a protective field. If someone enters the warning field, the system triggers a predefined safety reaction - the robot’s speed slows down; if they move into the protective field, the robot comes to a complete stop.

“Slowing the robot down when someone walks past – rather than stopping it altogether – prevents unnecessary interruption to workflow,” James says. “But the system will still stop completely if someone comes too close.”

The fields are defined volumetrically, allowing for three-dimensional monitoring and control over how the robot behaves depending on the position and movement of people nearby. The SafeVisionary 2 camera

is programmed to recognise typical patterns of activity in the space, triggering graduated safety responses depending on proximity.

In addition to the 3D camera, photoelectric sensors were deployed to manage the robot’s interaction with testing stations. These sensors ensure that a Printed Board Assembly (PBA) is only placed onto an unoccupied surface, preventing collisions or placement errors that could disrupt the production flow. The decision to trial the robotic solution was driven in part by the need to replace an ageing automated test station that had become increasingly unreliable and a source of frequent downtime.

“The current tester frequently fails and is difficult to maintain,” James says. “We needed something more reliable, and the robotic system allows us to run multiple test cases in parallel.”

While the system has not yet been fully deployed, internal trials suggest that the new system will significantly improve capacity.

“Right now, the automated tester can handle one product at a time,” he says. “This new system can manage three simultaneously, as well as support a second product variant- the one is currently manually loaded onto a test station.”

The move towards collaborative robotics has prompted Tait to rethink its approach to workplace design and safety documentation. James says the team has been building its own checklist and review process to ensure the system complies with applicable standards.

“It’s been a steep learning curve,” he says. “We’re building a framework from the ground up – everything from hardware integration to design review

and safety validation.”

From SICK’s perspective, the collaboration demonstrates how safety solutions can be adapted to meet specific industrial needs.

“Every site has different requirements,” Eduardo says. “The SafeVisionary2 is flexible enough to be tailored to those specifics, but it still needs to be part of a broader safety plan that takes into account the type of work, the movement of people, and the expected performance of the equipment.”

He notes that the same technology has been applied in other settings across New Zealand, including in the health and medical manufacturing sector, where minimal human contact is preferred due to contamination concerns.

While the project is still ongoing, Tait expects the integration of the robotic system to reduce unplanned downtime and support broader efforts to modernise its production processes. The company is already considering exploring additional applications.

“We’ve got a couple of legacy robots doing glue application,” James says. “They’re more than 20 years old. If this robotic system setup works well, we’re looking at replacing those older systems too – with greater flexibility and improved safety, supported by the SICK SafeVisionary2 camera technology.”

Ultimately, James explained that having direct input from SICK was instrumental in navigating the new safety requirements.

“We weren’t exactly sure how to approach it at first, but having someone come on-site, see our setup, and collaborate with us directly made a huge difference,” James says. “We’ve been able to get up to speed quickly on the safety side by working with SICK.” ■

The robot’s movements are regulated by safety-rated fields defined by the SafeVisionary2, ensuring protection without halting workflow unnecessarily.

As Australia’s freight sector braces for long-term growth, MegaTrans 2026 offers a chance to take stock of where the industry is heading – and where the conversation needs to go next.

Australia’s freight and logistics sector is steadily evolving, shaped by growing demand, shifting consumer expectations, and the realities of constrained infrastructure. With supply chains under increasing strain, industry attention is turning to new strategies for improving performance – and ensuring the system can meet future demand.

The upcoming MegaTrans event, set for 16–17 September 2026 in Melbourne, provides a space for operators, suppliers, and technology providers to engage with these challenges. While the format includes an exhibition, the focus is just as much on connection: on bringing together people working at different ends of the supply chain to share lessons and look ahead.

Matt Edgar, Product Marketing Manager at Allotrac, believes this kind of gathering is timely.

“The real challenge in freight today isn’t just volume – it’s complexity. As the industry grows, the systems supporting it need to become more connected, more scalable, and more collaborative,” Matt says. “Events like MegaTrans are critical because they bring the whole industry together –from business owners and operators to tech providers, government, and the thought leaders shaping what comes next. It’s one of the few forums where strategy meets execution, and where the conversations that shape the next decade of freight actually take place.”

Allotrac will be among the technology providers at the event, highlighting its transport management platform. With a growing emphasis on digitisation and real-time coordination across freight operations, software tools are increasingly part of conversations

about efficiency, compliance, and sustainability.

“At MegaTrans 2026, we’ll be showcasing Allotrac.io – our nextgeneration platform built to simplify operations, reduce manual work, and help transport businesses scale with structure,” Edgar says. “Our focus is practical digitisation. We’re not selling a distant vision – we’re giving operators the tools to modernise their day-to-day. Whether it’s automating dispatch, replacing paper runsheets, or improving subcontractor visibility, Allotrac.io helps businesses run leaner, faster, and with more control.”

For Matt, part of the value in an event like MegaTrans is its ability to bring different parts of the logistics community into the same space – from major infrastructure owners to tech startups, and from fleet managers to government agencies. That diversity

Graham Bringham, Co-Founder of Priority Integrated Systems presents during the SCLAAhosted conference session on trust, leadership, and collaboration in supply chain environments.

helps surface questions that aren’t always explored in more segmented industry settings.

“What sets MegaTrans apart is that it brings the full ecosystem together – not just tech partners, but solution providers, operators, government, infrastructure, and education – all under one roof,” he says. “For Allotrac, the value goes beyond visibility – it’s the quality of conversations and the decision-makers in the room.”

The sector’s longer-term outlook adds context to this year’s event. According to Infrastructure Australia, freight volumes are expected to grow by over 26 per cent by 2050 – growth that will not only demand more capacity, but better use of what’s already in place. For companies like Allotrac, that means staying active in the broader industry conversation.

“From a visibility perspective, it puts

our brand directly in front of the people making decisions across transport, logistics, technology, and the broader supply chain,” Edgar says. “It’s not just about numbers – it’s the quality and relevance of the people in the room. We’re engaging with leaders who are actively looking to solve problems, form partnerships, and move their businesses forward.”

While events like MegaTrans offer a platform for products, Edgar says the more valuable part of the experience is the exchange of ideas – particularly when it comes to how different parts of the logistics chain are responding to similar challenges in different ways.

“We’re looking forward to honest conversations about what’s still slowing people down – whether it’s rekeying job details, chasing subcontractors, managing compliance manually, or reconciling finance across disconnected systems,” he says. “We want to speak directly with the people running transport day-to-day – dispatchers, schedulers, subcontractors, and finance teams – and hear where the friction really is.”

When asked about the key technologies that could help prepare the sector for the years ahead, Edgar points to automation and digitisation – but also notes that their success depends on implementation strategies, internal buy-in, and how well they integrate into day-to-day operations.