WRITING THE NEXT CHAPTER

A one-off paver purchase has transformed into a quarter of a century-long partnership

Secret in the soil

Brand new research is transforming what’s commonly found beneath our feet

Building blocks

A new delivery and storage method is ensuring bitumen supply for projects

The Most Innovative Paver Technology!

VÖGELE SUPER 1700-3(i) / SUPER 1703-3(i)

VÖGELE SUPER 2000-3(i) / SUPER 2003-3(i)

The number one paver manufacturer on the global market

Equipped with state-of-the-art Cummins engines available in either Tier 3 or Tier 4 Final / Euro Stage V emission standards, are the perfect choice for any application in the Universal (2.5m) and Highway (3.0m) paver classes. Thanks to the easy-tounderstand ErgoPlus 3 operating system which is common across all VÖGELE products both paver and screed operators can handle all VÖGELE pavers simply and safely. These machines are also available with vibrating screeds or high compaction tamping & vibrating screeds for those critical jobs. In combination with advanced optional features, such as VÖGELE EcoPlus, AutoSet Plus and Navitronic Plus 3D, these models are the stars of any road construction site.

COVER STORY

16 Writing the next chapter

State Asphalt Services has long placed its faith in Astec machinery for its equipment requirements.

ROADS REVIEW

20 This month, we asked the industry’s decision-makers, ‘What factors can help the industry build up more capability to deliver the current pipeline of construction work?’

INNOVATION

22 Transport’s tick of approval

NTRO Certification is expected to set a new standard for evaluations on the proficiency, sustainability and efficiency of products, processes and people.

TECHNOLOGY

25 Integral telematics

Geotab is shifting to an all-in-one telematics platform, providing fleet managers with the best foot forward when it comes to safety and reliability.

PROJECT REPORT

28 Everywhere you go

Works on the Hobart Airport have signified a shift in best practice when it comes to the delivery, storage and application of polymer-modified bitumen.

MACHINERY AND EQUIPMENT

32 The cherry on top

The expansion of the company’s hire division has signified a new direction for Matthews Brothers Engineering, with more solutions and support on the way.

34 Moving on up

Wirtgen is expanding, moving into two new facilities across two key states and markets. So, what does these movements means for customers?

37 Bring on the Bell

The Bell Motor Grader range will be hitting Australian shores sooner rather than later.

40 Total crushing and screening

ALLU has launched its Asphalt Bucket to complement the existing ALLU Screener/ Crusher bucket range.

RESEARCH PROJECTS

42 From clothing to concrete

A new trial from Victoria University is evaluating the potential inclusion of recycled high-visibility vests to create sustainable concrete.

44 Everyday clay the answer

The performance of low-grade clay, as an alternative and sustainable substitute to cement in concrete production, is being assessed as part of new research.

ASSOCIATION SECTION

46 Sydney Gateway: Precision precast powers a pivotal transport link

The Sydney Gateway project represents a defining step forward in modernising Sydney’s transport infrastructure.

48 Beyond Hard Hats: Systemic Solutions for Road Worker Safety

The Australian Flexible Pavement Association is rethinking how procurement and strategic funding can transform safety outcomes.

EVENTS

50 Counting down to CONEXPO-CON/AGG CONEXPO-CON/AGG has unveiled its expanded Next Level Awards and New Exhibit Design Awards for 2026.

52 Highways AU 2025: Real Solutions for Australia’s Transport Future

Highways AU, Australia’s flagship event for roads, transport, and mobility, returns to Sydney this October.

54 Trailblazers galore

Breaking down the latest iteration of the Women in Industry Awards, which recognised and celebrated trailblazers from the construction and transport industries.

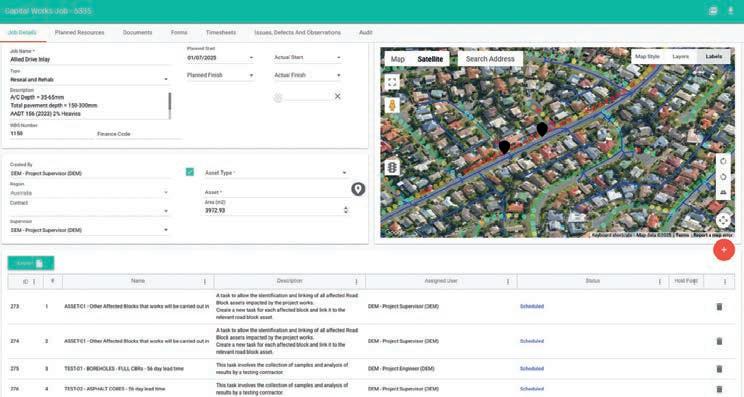

56 Converge: Diversifying into new markets

Converge Expo exhibitor Asset Vision touches on how its diversifying its offerings to cater for growing and emerging markets.

57 Pipes aplenty at No-Dig Down Under

The 2025 edition of No-Dig Down Under is set to hit Melbourne in September, and it will not be short of pipeline innovations to see and learn about.

CONTRACTS AND TENDERS

58 Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market across the Australian infrastructure sector.

Image: Logan City Council

CEO

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Courtney Burton courtney.burton@primecreative.com.au

CLIENT SUCCESS MANAGER

Sabrina Zor sabrina.zor@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia

p: +61 3 9690 8766 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

REVOLUTION IN RESEARCH

MEASURING COST AGAINST ENVIRONMENTAL IMPACT is a common point of contention when justifying the use of sustainable materials. It’s a topic which has appeared again in this edition of Roads & Infrastructure magazine.

It has long been advocated that sustainable alternatives should – and must – be used in every single instance where applicable. But even after clear communication around the short-term and long-term benefits by suppliers, some in the industry are still prioritising cost over environmental impact. That being said, it’s important to note that the financial aspects of project delivery continue to be a significant challenge.

So, how do we as an industry find the perfect balance between cost and the environment?

Hard work is being done in the background to ensure that markets for sustainable materials can continue to grow and be supported.

Research is leading the way, and our chat with RMIT University is a perfect example of the impact of studies and development. RMIT is just one of a number of universities and industry bodies that make up Transformation of Reclaimed Waste Resources to Engineered Materials and Solutions for a Circular Economy (TREMS). TREMS brings together top scientists and industry experts from nine Australian universities and 36 state, industry, and international partners to minimise waste and repurpose reclaimed materials for the construction sector.

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE Astec

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The TREMS team has recently been investigating the performance of low-grade clay as an alternative and sustainable substitute for cement in concrete production. The progress so far has been overwhelmingly positive, with the study justifying the potential creation of a brand-new market within the sustainable materials segment.

Another university that continues to turn heads is Victoria University. Previously, we discussed the fantastic work that Malindu Sandanayake, Victoria University Associate Professor, Built Environment – College of Sport, Health and Engineering, has been doing in the material science field. In this edition, Sandanayake takes Roads & Infrastructure inside the university’s research into the recycling and repurposing of discarded high-visibility vests. Similar to the aforementioned low-grade clay research, this project is hoping to transform an everyday item in the construction industry into a blended composite material, which could act as an alternative to virgin cement.

For our cover story, we sat down with State Asphalt Services. In just the past few years, the company has invested heavily in expanding and improving its machinery fleet, particularly equipment from Astec.

Astec’s Roadtec machinery range has been with the company since the very beginning –a Roadtec asphalt paver was one of the first pieces of machinery purchased. That purchase solidified a now 25-year partnership, and there’s even more on the way, with State Asphalt Services set to welcome a brand new RP195Fx highway class asphalt paver to its evergrowing fleet.

This and more, in this edition of Roads & Infrastructure.

Happy reading!

Tom O’Keane

TOM O’KEANE – EDITOR

NEW DEAL SEALED FOR 2032 BRISBANE OLYMPICS INFRASTRUCTURE

The Queensland and Federal governments have inked a new deal that will refine and reallocate funding for priority projects necessary for the 2032 Brisbane Olympic and Paralympic Games, while also ensuring the suitability and longevity of infrastructure post-games.

As part of this agreement, the Federal Government has announced changes to the structure and breakdown of its $3.435 billion contribution to the $7.1 billion Games Venue Infrastructure Program.

Both the State and Federal governments will now work together to update 17 new and upgraded venues across Queensland. This includes works on the main Games stadium, as well as the National Aquatic Centre.

The main stadium at Victoria Park will become the new, world-class, 63,000 seat home to AFL and cricket in Queensland and attract major national and international events, leaving a lasting legacy for 2032 and beyond. It will host the opening and closing ceremonies, as well as the athletics events.

The new agreement has been reached following project validation work, which determines the Federal Government’s final investment, assessing that these projects can be delivered on time and on budget, represent a good use of taxpayer dollars, and will benefit Queensland for decades to come.

As part of the agreement, the Minor Venues Program has also been revised and

includes new projects such as a National Aquatic Centre, a Toowoomba Equestrian Centre, a dedicated para-sport facility and an expanded Queensland Tennis Centre.

Minor venue procurement has launched for work to commence at four key Games venues across the state: Logan Indoor Sports Centre, Moreton Bay Indoor Sports Centre, Barlow Park Stadium upgrade and Sunshine Coast Stadium upgrade.

CHAIR APPOINTED TO MELBOURNE AIRPORT RAIL STEERING COMMITTEE

The Melbourne Airport Rail Link (MARL) project has appointed Merren McArthur as the independent Chair of the MARL Steering Committee.

McArthur’s appointment follows a Memorandum of Understanding (MoU) being reached between the Federal Government, Victorian Government and Melbourne Airport earlier this year in which all three parties committed to establishing a Steering Committee led by senior officials from each organisation to progress the project.

As chair, McArthur will foster a collaborative and constructive environment, enabling the parties to work together to develop a clear and effective pathway for the successful delivery of the MARL.

McArthur is a Non-Executive Director and Chief Executive Officer with significant governance experience in the aviation, rail and broader transport and freight sectors.

Her experience includes leading Tiger Airlines, Virgin Australia Regional Airlines and Virgin Australia Cargo, as well as being a Non-Executive Director of Airport Development Group and National Intermodal Corporation, an Executive Director and Chair of the People and Safety

Committee of Queensland Rail, and a legal advisor to governments on commercial governance issues.

The Victorian Government said McArthur’s experience makes her well placed to navigate the complexities of this major urban infrastructure project.

Merren McArthur will lead Melbourne’s Airport Rail Project. Image: stock.adobe. com/oleksandr

Key projects for the new infrastructure include a new Brisbane stadium at Victoria Park, a national aquatic centre, and upgrades to venues like the RNA Showgrounds and the Queensland Tennis Centre. Image: stock.adobe.com/Richie Chan

SRE’s telescopic bitumen sprayers or our newly developed 8m fixed wing bitumen sprayers are available for mid 2026 delivery.

Fully compliant with all Australian regulations our sprayers meet all Austroads performance requirements for bitumen sprayers and are ready to go straight to work.

$10.7B INFRASTRUCTURE INVESTMENT REVEALED IN WA BUDGET

The Western Australian 2025/26 State Budget has allocated $10.7 billion investment in transport infrastructure over four years. Image: stock.adobe. com/Michael

Road Safety Program that aims to rollout upgrades on local government roads ($250 million). Upgrades to the Wanneroo Road Corridor will also receive $36 million worth of funding.

More funding ($107 million) will also support the expansion of the current ferry service on the Swan River, on top of a further $103 million to deliver a full transition of buses to an electric fleet.

This transition will also benefit from a $83 million investment into the production of electric buses and ferries in Western Australia.

The Western Australian Government’s 2025/26 State Budget includes a $10.7 billion investment in transport infrastructure over the next four years, aiming to increase connectivity and accessibility, all while reducing congestion.

Key road upgrades that will receive new or additional funding include works to widen and upgrade the Kwinana Freeway ($700 million), the Reid Highway-Erindale Road Grade Separation ($450 million), as well as more funding to support the Regional

EXTRA $600M ANNOUNCED FOR LOGAN AND GOLD COAST FASTER RAIL

The Queensland Government has announced an additional $600 million in funding for the $5.7 billion Logan and Gold Coast Faster Rail, which will support upcoming pre-construction works on the project.

This funding from both the Federal and State governments ($300 million each) will help the ActivUs consortium to deliver the Rail Package in this mega infrastructure project, following the finalisation of its Design and PreConstruction contract on the project a few months ago.

The project will see the number of tracks between Kuraby and Beenleigh

doubled from two to four, significantly improving service frequency and reliability for commuters. It also includes the removal of five level crossings; upgrading stations; and improving access and connectivity along the 20-kilometre project corridor.

The rail line between Kuraby and Beenleigh is a key capacity bottleneck on the network, where trains share a single track in each direction. During peak periods, all-stop Beenleigh trains need to be held to one side to allow Gold Coast express trains to pass through.

The Logan and Gold Coast Faster Rail project aims to unlock this bottleneck,

Further funding for improvements to the South Coast Highway ($25 million), Northam Pithara Road realignment ($25 million) and new SufCAT bus service ($18 million) was also announced.

Public transport was also a winner, with $152 million going towards the delivery of the Suburban Flat Fare, as well as $10 million to keep public transport free for students in 2026.

$152 million was also announced to establish the new suburban flat fare across the Transperth and Transregional public transport networks.

making it easier for commuters to access high frequency rail services.

This funding forms part of the 2025/26 Queensland State Budget.

The Logan and Gold Coast Faster Rail project is a key investment to support the Brisbane 2032 Olympic and Paralympic Games. Image: stock. adobe.com/Castigatio

INDUSTRY

INVITED TO DELIVER $2.24B WESTERN SYDNEY UPGRADES

Three major arterial roads in Western Sydney will be transformed as the region braces for an airport boom, with the State Government calling on industry to deliver critical upgrades worth $2.24 billion.

The infrastructure investment is expected to deliver safer, faster journeys for Western Sydney communities as new employment zones drive unprecedented growth, and comes as the Western Sydney International (Nancy Bird Walton) Airport nears completion.

The State and Federal governments are each providing half of the committed funding.

Transport for NSW is inviting experienced contractors to register their interest in designing and constructing upgrades to Elizabeth Drive, Mamre Road Stage Two, and Garfield Road East – key arterial routes that will transform connectivity.

Elizabeth Drive is a $800 million transformation which will deliver a two-lane dual carriageway to priority sections between Devonshire Road and Western Road.

As well as upgraded intersections providing

CONSTRUCTION KICKS OFF ON NSW CENTRAL COAST HIGHWAY

Main construction works to upgrade the Central Coast Highway-Tumbi Road intersection have started.

Work has officially begun to replace the existing roundabout with modern traffic lights and expand the highway to two lanes in each direction, to the project boundary.

This upgrade will address the bottleneck and improve traffic flow and safety on the Central Coast Highway between Wamberal and Bateau Bay.

The $65.5 million upgrade is being jointly funded by the Federal and New South Wales governments, with the Federal Government contributing $52.4 million, and the New South Wales Government investing $13.1 million.

The transformation is expected to slash travel times, improve safety, and boost the local economy with 125 construction jobs

The New South Wales Government has called on the industry to deliver critical upgrades worth $2.24 billion. Image: stock.adobe.com/Pawel Pajor

safer access to Kemps Creek, Badgerys Creek, Luddenham and the emerging Bradfield city.

Mamre Road Stage Two will continue following the work on Stage One.

This $1 billion investment will upgrade the road from Erskine Park Road through to Kerrs Road.

This will support the rapidly expanding employment zones along this critical corridor.

Investigation works are already underway between Erskine Park and Kerrs Road.

The Garfield Road East $440 million project is a key sub-arterial route between Piccadilly Street and Windsor Road.

It will be converted to a two-lane dual carriageway, improving amenity for communities in the North West Growth Area as housing development accelerates.

Environmental assessments for all projects will be publicly displayed later this year, with construction expected to commence following community consultation.

Industry submissions must be submitted to Transport for NSW.

The Central Coast Highway provides an important connection between the M1 Pacific Motorway and Gosford, from Gosford to Erina and The Entrance through to Doyalson. Image: stock.adobe.com/Rok

supported throughout the build. Upgrades include traffic lights replacing the roundabout, highway widening to two lanes each way north of the intersection, two right-turn lanes from Tumbi Road onto the highway, a right turn lane onto Tumbi Road from the Central Coast Highway southbound and extended left-turn capacity into Tumbi Road.

Other works include upgraded footpaths

and cycling infrastructure and relocated bus stops for better passenger access, with two existing northbound bus stops moved to a common location north of the intersection. Following extensive community consultation in 2021-2022 and preparatory works in 2023, Daracon Pty Ltd was awarded the construction contract in March 2025.

The project is expected to be completed in 2027.

Creating, connecting, and caring for communities

Fulton Hogan delivers high-quality infrastructure to improve the lives of people in Australia and New Zealand, every day.

We’re a growing, forward-looking and family-oriented business that’s investing in the talent of tomorrow.

Come and join our team.

Explore opportunities to join the team at at fultonhogan.com

PREFERRED ALLIANCE NAMED FOR PERTH PRECINCT DELIVERY

The preferred alliance team has been named to deliver the design, development, site investigations and early works preparation for the Perth Entertainment and Sporting Precinct.

The preferred alliance consists of Seymour Whyte Constructions, Civmec Construction & Engineering and Aurecon Australasia.

The Perth Entertainment and Sporting Precinct will comprise of a multi-purpose entertainment precinct that will boost the region’s capacity to host a range of arts,

cultural and sporting events.

The project includes a new amphitheatre with a capacity for 15,000 to 20,000 people, complementing nearby existing venues and entertainment infrastructure, such as Crown Perth and Optus Stadium. The precinct will host and support official events, while also being open to the community year-round.

Consultation with community and stakeholders has already delivered hundreds of ideas, which will help to inform

the final design for the precinct.

Concept development will consider facilities to support live music and sporting events, including an annual Supercars event, cycling criterium racing and paralympic racing.

Further stakeholder and community input will be invited as the design progresses in the coming months. Early works will commence later this year, with construction works on the precinct expected to be completed in 2027.

WORK COMMENCES ON $19 MILLION TRAFFIC SOLUTION IN NSW

Works on a $19 million upgrade to several key intersections across the Woy Woy Peninsula in New South Wales have commenced.

The upgrades will transform three key chokepoints and cut travel times for the 22,000 vehicles that travel on Blackwall Road corridor every day.

Transport for NSW said the upgrades will future-proof the Peninsula’s critical transport spine as the Central Coast continues to grow.

On Blackwall Road and McMasters Road, new pedestrian-activated traffic lights on the south side of the intersection will be installed, as well as a new right-turn bay on the northern leg to reduce congestion. Both sides of McMasters Road will become left turn only onto Blackwall Road for improved safety on Memorial Avenue, Maitland Bay Drive and Barrenjoey Road.

Other works will include the installation

of dual right-turn lanes from Maitland Bay Drive to Memorial Avenue and the separation of left and right-turn lanes for motorists exiting Gallipoli Avenue.

The intersection of Blackwall, Allfield and Farnell Roads upgrade is currently being reviewed.

Transport for NSW will update the community when this has been finalised and will start consultation if required. The upgrade of this intersection will be the final stage of work for the project which is expected to be complete within two years.

The Perth Entertainment and Sporting Precinct (PESP) is a project focused on delivering a multi-purpose entertainment and sporting hub at Burswood Park. Image: stock.adobe.com/Michael Evans

LOGANLEA ROAD WORKS KEEP MEADOWBROOK ON THE MOVE

As the City of Logan writes, drivers are now enjoying smoother and safer travel along Loganlea Road in Meadowbrook, following the completion of a major road upgrade.

Logan City Council’s multi-million dollar upgrade of Loganlea Road between the Logan Hospital and the M1 on-ramp at Slacks Creek is complete. The $81 million project was funded by the Federal Government and Logan City Council.

A 2.5-kilometre stretch of Loganlea Road from the Logan Motorway overpass (just north of the hospital) to the M1 was widened to six lanes as part of the works.

Major works were carried out to improve vehicle and pedestrian access through intersections, while wider road shoulders north of Queens Road have made it easier for drivers to pull over safely.

New stormwater infrastructure and kerbing was installed to minimise the impacts of heavy rainfall along the roadway.

A new shared northbound pathway and improvements to the southern pathway have also made it easier to get around the area on foot, or by bike.

The project is the largest Council road

upgrade delivered in the city’s history.

Mayor Jon Raven said its completion was a major step towards improving safety and traffic flow along one of the city’s most important thoroughfares.

“Loganlea Road is one of the busiest roads in our city, carrying more than 42,000 vehicles every day and serving as a critical link between the M1, the

The opening of the road upgrade is already providing safer and more efficient journeys for locals.

Logan Hospital, and our newest areas of housing in the south of the city,” he said. “Improving traffic flow and the safety of the area was vital, but we also needed to deliver something that would service our growing city into the future. Teaming up with the Federal Government has helped us to deliver the upgrade our community deserves while also getting

An aerial image looking south on Golf Course Drive. Images: Logan City Council

more people from the hospital to the highway, every day.”

Other improvements made as part of the project include the construction of a new northbound lane and shared footpath along the Ray Hodgson Bridge over Slacks Creek. These works included the lifting and placement of 36 pre-cast concrete bridge decks, using a 300-tonne mobile crane.

Work have also delivered extended vehicle turning lanes in each direction at the intersection with Ellerslie Road and University Drive, new traffic lights at Queens Road and extended U-turn space for vehicles travelling north to the M1, a dedicated left turn lane onto the M1 at the Nujooloo Road intersection, as well as on-road 1.5 metre-wide cycle lanes (commencing at Queens Road).

New and upgraded bus stops, and fauna protection fencing from Queens Road along Slacks Creek Environmental Park, to minimise wildlife movement along the roadway, have also been delivered.

Member for Rankin Jim Chalmers said the Federal Government was partnering with Council to deliver the infrastructure Logan needs and deserves.

“This is a great example of how we’re working with the council to make Logan City an even better place to live and work,” he said. “I use this road regularly, so I know how important it is for the local hospital, university, TAFE and shops, which is why I’m so enthusiastic about delivering this upgrade in our area.

“We’re upgrading Loganlea Road to

get people home quicker and safer and to ease congestion, but also to cater for growth in our community. Projects like this one are important for local jobs and the local economy but also for future proofing Logan City – ensuring we continue to create more jobs and more opportunities for more people in our community.”

Priority access will still be given to emergency vehicles, including ambulances, travelling along Loganlea Road.

Transponders in emergency vehicles can send a signal to the road’s traffic control system, which will hold a green

light to ensure faster movement through busy intersections.

Mayor Raven said this can cause extra waiting time on side roads, but encouraged drivers to be patient.

“Once an emergency vehicle has passed through, the traffic lights will return to their normal sequencing after a couple of cycles,” he said.

“I know local drivers will work with us to ensure ambulances can get where they need to be, and do their lifesaving work.”

More information on the project is available at: logan.qld.gov.au/loganlearoad-upgrade

add two powders at once up to 60 TPH of powder

option of adding two liquids

Logan City Council Mayor Jon Raven at the Loganlea Road bridge installation.

WRITING THE NEXT CHAPTER

STATE ASPHALT SERVICES HAS LONG PLACED ITS FAITH IN ASTEC MACHINERY FOR ITS EQUIPMENT REQUIREMENTS, WITH LONG-TERM RELIABILITY, CONSISTENT EQUIPMENT PERFORMANCE, AND STRONG CUSTOMER SUPPORT TURNING A ONE-OFF PURCHASE INTO A QUARTER OF A CENTURY-LONG PARTNERSHIP.

Regularity. It’s what many organisations in the infrastructure and construction spaces are striving for when it comes to their project pipeline.

Achieving regularity is easier said than done, but for some, it’s the result of a clear vision, as well as staying true to one’s philosophy.

It’s these factors that are best used to explain the continual and rising success of Sydney-based State Asphalt Services.

Jeffery Sherriff, Chief Operating Officer – State Asphalt Services, says the company is anchored by forward thinkers, complemented by a team that doesn’t

run away from a challenge.

“We are the largest independent asphalt producer in the market,” he says. “We pride ourselves on being able to have that full chain of custody, from the moment we make the asphalt, to the last stage of practical completion.”

The privately-owned company is particularly focused on major government and private sector infrastructure projects, providing holistic solutions across a variety of projects segments and disciplines.

But this wasn’t always the case.

In fact, the beginning of what is now a 25-year-old partnership can be traced back

to the company’s first steps, with one of State Asphalt Services’ first-ever pieces of machinery being a Roadtec RP150 paver from Astec.

As Sherriff explains, this kick-started things for the company in a serious way.

“When I started in the contracting business, I’d heard nothing, but good words said about Roadtec equipment,” he says. “And if you talked about asphalt placement in the industry, Roadtec was the first product range that people would mention.”

The RP150, complete with a Carlson screed, quickly found a companion in a second RP180, with both units holding the fort as

State Asphalt Service’s job and contract size continually increased.

With more work came a need to constantly upgrade the company’s fleet, leading to a number of additional Astec purchases over time.

Brant Volner, Project Coordinator – State Asphalt Services, has virtually been with the company since its inception. As he recalls, jumping on an Astec unit was a far cry from other equipment he’d used previously.

“When I got here and operated a Roadtec for the first time, it was like Christmas and your birthday had come at once,” he says.

“Straight away, the way that the machine was laid out and set was quite impressive. It was a great first impression.”

STRUCTURE OF STRENGTH

Although its foundation can be linked back to 2000, State Asphalt Services is actually a vertically integrated business that forms part of the Kypreos Group of companies.

Launched in 1970 by George Kypreos, the collection of companies is focused on delivering civil engineering and infrastructure services across Sydney. This includes asphalt production and contracting, spray seal, traffic management, plant hire and road profiling.

State Asphalt Services acts as the contracting division and has benefitted from a strong focus on self-sufficiency and growth, while keeping most processes in-house by reducing its reliance on sub contracting.

“George had a strong vision to be a selfdependant service provider, consistent with

that vertical integration,” Sherriff says. “We’ve had a lot of projects that have been around 100 million dollars or above. Now that we have a full suite of capabilities around road surfacing, we’re looking for more.”

The bulk of these connections have been established and cemented through word of mouth, quality project outcomes, as well as the vast experience of State Asphalt Services team. As Volner explains.

“We’ve had some great people work across the company who’ve been in the industry for a long time. That’s been a big factor in our strong relationships with some of those big contacts across tier ones and government,” he says.

State Asphalt Services’ relationship with Astec is no different.

MACHINERY REQUIREMENTS

In total, State Asphalt Services’ fleet now consists of 10 Astec units. This comprises an RP170ex, an RP175ex and three RP190ex pavers, as well as four SB2500 MTV (material transfer vehicles), along with one SB1500 MTV.

A number of these units have worked on several challenging jobs in challenging conditions. Regardless, each unit has shown no signs of slowing down.

“Some of our machines are north of 10,000 hours and are still going strong,” Sherriff says. “The first buggy we bought, we’ve still got, and that’d be about 18 years old. We still use it to this day.

“The feedback that we hear is that they’re well-balanced machines when you consider

Images:

Astec

State Asphalt Services will soon welcome yet another Astec unit to its fleet, in the form of the RP195Fx highway class asphalt paver.

The Astec and State Asphalt Services partnership has grown stronger with each machinery acquisition.

State Asphalt Services is building up a strong project pipeline for the remainder of 2025 and beginning of 2026.

the usability and user-friendliness. They’ve been able to perform through some of the hardest jobs and sub-bases.”

He adds that Astec’s constant introduction of new equipment, as well as the company’s efforts to mould and react to industry needs, means State Asphalt Services has gotten what it’s needed – when it’s needed it.

“They’ve certainly evolved their equipment over the years. It’s that commitment to development and moving with the times that has certainly been a reason for us coming back,” Sherriff says.

Despite these constant updates, Astec’s stamp can be felt on each and every unit.

“It’s almost like buying a new model of a car every year,” Sherriff says.

“You get a bit more advancement, but ultimately the machine still behaves the

same, and that’s because we’ve got such a thorough understanding on how to use and get the best out of them.”

As well as the quality and reliability of its equipment, another significant box that’s been ticked for State Asphalt Services has been after-sales support.

Between parts, training, and constant communication to check in, Volner says he and the rest of the State Asphalt Services’ team has well and truly felt a part of the Astec family.

“Whenever we need parts, they’re on our doorstop within 24 hours. I can probably count on one hand the number of times where that hasn’t happened,” he says.

“One of the biggest things for us is that we’re never treated like we’re just another client. Astec’s always focused on helping us

out, so much so that at times you feel like you’re their only customer.”

GEARING UP

FOR THE FUTURE

State Asphalt Services’ will soon add yet another Astec – Roadtec unit to the fleet, this time in the form of the new F Series (RP195Fx) tracked highway class asphalt paver.

With a 360-degree view, swing-out operator platforms, automatic lubrication, hydraulic pressure sensors, as well as its Astec and Carlson screed versions available, the RP195Fx is a heavy hitter in the Roadtec range, aimed at larger transport and construction works.

Sherriff says the purchase of the RP195Fx is part of a clear strategy to upgrade and expand the company’s fleet, to enable tendering of a larger scope and volume of projects.

“We’ve got a requirement at the moment to really start to renew the fleet,” he says. “The RP195Fx is likely the first of a few that we’ll need to purchase to deliver on that strategy.

“This unit in particular will be a good step forward for us, and we see a lot of benefits in Astec’s new series of tracked pavers.”

Greater visibility is just one benefit that Sherriff specifies as an advantage over previous units, as well as other options in the market.

“The RP195Fx is a lot lower set and has a lower profile, meaning it’s going to be much easier for our operators to get a good view of the site,” he says. “It’s really going to help us with our ability to do all sorts of different jobs.”

“In an industry where project overruns are commonplace and practices have remained largely unchanged since the middle of last century, Octant AI’s predictive capability is revolutionary.” Bent Flyvbjerg, Saïd Business School, Oxford University

ROADS REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, WHAT FACTORS CAN HELP THE INDUSTRY BUILD UP MORE CAPABILITY TO DELIVER THE CURRENT PIPELINE OF CONSTRUCTION WORK?

RAQUEL RUBALCABA, A/DEPUTY SECRETARY, INFRASTRUCTURE PROJECTS AND ENGINEERING –TRANSPORT FOR NSW

The NSW Government through Transport for NSW is providing certainty for industry through a programme of major projects, both in delivery and in the pipeline. Most recently, Transport for NSW is calling for industry EOIs to design and construct more than $2 billion worth of upgrades along Elizabeth Drive, Mamre Road (2) and Garfield Road East. It comes as a major tender was awarded to Seymour Whyte Construction Pty Ltd to design and construct an alternate exit to the Hume Highway from the M5 at Moorebank. Transport for NSW strives to work closely with construction partners to foster trust and reliability. Some of this work includes working with industry in a pre-tender stage to identify potential issues and find solutions before formal tendering takes place. By providing this confidence, our construction partners can better train workforces and offer their workforces better employment security and incentives to invest in modern technologies and capital equipment.

Image: Transport for New South Wales

SARAH BACHMANN, CHIEF EXECUTIVE OFFICER – NATIONAL PRECAST CONCRETE ASSOCIATION AUSTRALIA

With record infrastructure investment across every Australian state, the challenge is no longer a lack of projects, but the capability to deliver them. Precast concrete plays a growing role in this pipeline, from bridges and tunnels to stations and noise walls. For the first time, targeted micro-credentials (MCs) about precast are available nationwide for workers manufacturing or working with precast. Whether on major transport builds or local upgrades, industry now has a scalable solution to lift capability, safety and quality. It’s a practical step forward and one the entire sector can benefit from. Details at nationalprecast.com.au

Image: National Precast

PETER ALI, CHIEF EXECUTIVE OFFICER – MUNICIPAL WORKS AUSTRALIA

To meet Australia’s growing construction pipeline, the industry must increase workforce capacity, update practices, and build resilience. Addressing the skilled labour shortage is essential. Procurement reform is also crucial. Clearer project pipelines, fairer risk-sharing, and collaborative contracts will give the industry the confidence to invest and achieve better outcomes. Other challenges include adopting new technology and sourcing sustainable materials, which will reduce reliance on imports and help control costs. Together, these changes will build the capacity needed to deliver Australia’s infrastructure future.

Image: Municipal Works Australia

MARK PIORKOWSKI, EXECUTIVE DIRECTOR, QLD/NT – AUSTRALIAN FLEXIBLE PAVEMENT ASSOCIATION

Building capability starts with clarity. As governments, particularly those in Queensland, invest record amounts in infrastructure, industry needs timely, structured visibility of upcoming work to plan with confidence. Forward-looking delivery programs – backed by transparent, geographic, and staged funding information – allow companies to retain skilled staff, align resources, and respond competitively when opportunities arise. When project pipelines are visible and predictable, industry can invest in training, grow local capacity, and deliver with greater speed and certainty. Whether for major transport builds or local maintenance upgrades, strategic visibility drives industry confidence and capability retention. It’s not just good planning – it’s nation-building.

Image: Australian Flexible Pavement Association

MATTHEW BERENI, CHIEF EXECUTIVE OFFICER – TRAFFIC MANAGEMENT ASSOCIATION OF AUSTRALIA

Delivering Australia’s record transport infrastructure pipeline demands more than funding. We must grow capability by attracting and keep a diverse workforce; embracing innovation and real-time data to lift safety and productivity; harmonising specifications across jurisdictions so skills are transferable; and forming genuine partnerships with government, contractors, suppliers and communities to share innovation.

Image: Traffic Management Association of Australia

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2025, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

Enhance fleet management through innovation and sustainability

As a global leader in IoT and connected transportation, Geotab processes and analyses data from over 4 million connected vehicles, generating over 75 billion data points per day. It’s a huge amount of data, and it is most powerful when we have the right tools to securely and efficiently manage it. That’s why we have partnered with Google to leverage Google Cloud’s data analytics and machine learning solutions.

Championing

Innovation and Sustainability

Geotab has been awarded two Google Cloud Customer Awards for its achievements in the transportation sector. Recognition in both the Cross Industry and Sustainability categories underscore Geotab’s successful use of Google Cloud’s analytics to innovate and drive sustainable practices in fleet management.

Kirsten Kliphouse, the President of Google Cloud Americas says that the Awards are an opportunity to recognise the most innovative, technically advanced, and transformative cloud deployments across industries globally built on their platform.

In her congratulatory message to Geotab, she acknowledged Geotab’s role in “serving as an innovator for the industry”, which also highlights Geotab’s innovative integration of data to revolutionise the transportation sector, leading to transformative impacts across organisations and customers around the world.

Empowering sustainable transportation

As the world’s premier EV telematics provider, Geotab has demonstrated its commitment to reducing emissions through its Electric Vehicle Self-Assessment (EVSA) tool, which won Google Cloud’s Award for Sustainability.

The tool provides tailored EV recommendations to support businesses and governments in transitioning to electrified fleets. For two consecutive years, Geotab was also identified as a Cross-Industry winner impactful transformation facilitated by Google Cloud. The award also acknowledges the launch of the Intelligent Transportation Systems (ITS) and its flagship transportation analytics platform Altitude.

Altitude has been pivotal in supporting government agencies by offering actionable, privacyconscious data insights for city planning and transportation network enhancements.

Strong synergy of Geotab and Google Cloud show great potential

As a valued partner in the Google Cloud Ready - Sustainability validation program, Geotab plays a crucial role in accelerating sustainability programs and informing strategic decisions for future developments.

Geotab’s collaboration with Google Cloud delivers significant benefits, including real-time improvements in driver safety and behavior, advancement of sustainability goals, enhanced productivity and significant cost savings.

This partnership not only redefines fleet management standards but also illustrates the impactful role of technology in fostering a more sustainable and efficient transportation industry.

An industry-leading solution

Geotab’s partnership with Google demonstrates the company is at the forefront of leveraging data analytics and machine learning to enhance fleet management, drive sustainability and create safer transportation systems worldwide.

By integrating Google Cloud’s advanced analytics with its telematics expertise, Geotab is confident of continuing its lead in the development of sustainable transportation solutions, demonstrating the profound impact that innovative technology can have on the transportation system today.

OF APPROVAL TRANSPORT’S TICK

NTRO

(NATIONAL TRANSPORT RESEARCH ORGANISATION) CERTIFICATION IS EXPECTED TO SET A NEW STANDARD FOR EVALUATIONS ON THE PROFICIENCY, SUSTAINABILITY AND EFFICIENCY OF PRODUCTS, PROCESSES AND PEOPLE IN THE TRANSPORT SECTOR.

The knowledge gap between different generations of engineers, operators, builders and more continues to be a pressing issue throughout the transport and infrastructure sectors.

Michael Caltabiano, Chief Executive Officer – National Transport Research Organisation, says Australia’s national transport infrastructure requires – and thrives on –technical excellence. An important aspect that he fears may be diluted by such a knowledge gap.

“When you’re dealing with natural materials, as you are in a transport environment, you need on-site and hands-on skills. You need a depth of knowledge and an understanding of how natural materials operate under load,” he says.

“The public sector used to run that skills training. People would then migrate from the public sector into the private sector, with those skills in tow. As a result, the whole industry would improve. But that’s now stopped, and it’s been stopped for a long, long time.”

Caltabiano says that, in the three decades that have passed since the disappearance of such a pathway, few programs have been developed to take its place.

The result: an accelerated sector-wide and inter-generational knowledge gap.

“It’s the absence of such training, plus the overlay of privatisation of both maintenance and capital works, that’s led to this skills deficit,” Caltabiano says.

After identifying a need for change, the NTRO began looking at how such a program could be implemented effectively in the current landscape, as well as the skills that would need to be included in such a program.

It’s here that NTRO Certification was conceived.

NTRO Certification aims to address these gaps by providing structured, multi-level training that covers theoretical and practical

aspects of infrastructure construction, as Caltabiano explains.

“The NTRO has a core obligation as a publicly-owned enterprise to undertake knowledge transfer,” he says. “We created NTRO Certification because there was a gap, and as a result, the private sector had no avenue to get innovation done and implemented. But most of all, we created NTRO Certification as a one-stop shop for industry, as well as the public and private sectors, to certify products, people and processes.”

PRODUCTS

NTRO Certification works across these three key levels to offer a variety of evaluation services, each tailored to the application.

The product section of the certification focuses on validating product performance against current standards, while also ensuring that products do what they claim.

Covering materials, tools and technologies, the product arm of the certification aims to create new pathways for innovative products, while also potentially influencing and creating new standards that could be

for local road authorities and state governments, but it also helps to create stricter control around the variability of quality.

Using bitumen as an example, Caltabiano says an NTRO Certification is a stamp that assures product quality.

“The sources of bitumen have changed fundamentally over the past 20 years,” he says. “We don’t refine any more in Australia; everything’s fully imported. So, what does that mean for quality? What does it mean for performance in the field?

“Similarly with the focus on green cement, how is it produced and what are the performance characteristics? When can it successfully be used?

“We’ve spent a lot of time thinking through the current issues with variable material quality in the bitumen, asphalt and concrete sectors. NTRO Certification aims to give State Government, road owning authorities and contractors greater confidence when they’re answering these questions.”

NTRO Certification has been developed by engineers and experts in the industry.

It’s the NTRO’s hope that the certification program will lead to the development of higher quality transport infrastructure.

PEOPLE

Comprehensive skills development and knowledge transfer is the name of the game for NTRO Certification’s peoplecentric evaluations.

“The ‘people’ certification is all about development and certifying core competencies,” Caltabiano says. “It enables people to ask themselves, ‘Can I do a spray seal design? Can I lay asphalt? Do I understand how to deliver effective drainage on a construction site?’ ”

But how do you build a program for differing experience levels and backgrounds?

NTRO delivers training through three knowledge levels: “introductory knowledge” (level one), “foundation knowledge” that teaches how standards are applied (level two) and “applied knowledge” for complex scenario handling (level three).

“Introductory knowledge” is an online training module, focusing on establishing a fundamental understanding of basic concepts. “Foundation knowledge” that teaches how standards are applied is a mix of online and in-person training and teaches individuals about applying knowledge to current industry standards in a more practical setting.

The last level, “applied knowledge” is conducted fully in person and instructs participants on how to deal with real-world challenges, such as unpredictable weather, assessing material quality on-site and critical decision making in other variable scenarios and conditions.

For those who have been in the sector for some time, the option is available to skip straight to level three. For those new to the

sector, the program provides a cross-section of essential skills, once complete.

Caltabiano says the long-term impacts of this training and development shouldn’t be underestimated, particularly its potential impact on retaining and encouraging skilled individuals in the transport sector.

“Building capacity means more than just upskilling. It means enlivening the next generation of engineers who want to be a part of the transport infrastructure space,”

Above: An NTRO Certification is highly regarded as an independent stamp of approval.

one of the core responsibilities of the organisation itself.

The NTRO hopes that a specific focus on processes would help to streamline practices that encourage efficiency and compliance.

Just one example is better supporting local government to understand what data needs to be collected, and how it can be used effectively, to measure infrastructure conditions.

The NTRO will also soon launch a suite of standards and specifications aimed at local government, once again reaffirming the role the NTRO plays in establishing and improving standards to guide positive progress and innovation across all transport modes nationally.

“We’re also globally connected as an enterprise,” Caltabiano says. “We’re regularly looking to, and hearing from, our partners globally to make sure that we’re on top of best practice, in line with what’s happening in the rest of the world.

“BY HAVING HIGHLY TRAINED PEOPLE WHO UNDERSTAND THE PERFORMANCE OF NATURAL MATERIALS AND HAVE ACHIEVED THIS CORE COMPETENCY, WE’LL ALL BE ABLE TO LIVE AND USE HIGHER QUALITY INFRASTRUCTURE.”

he says. “If they get excited and enticed through that knowledge development, then they’ll likely remain in the sector for the long-term.”

Therefore, creating benefits for all.

“By having highly trained people who understand the performance of natural materials and have achieved this core competency, we’ll all be able to live and use higher quality infrastructure,” Caltabiano says.

“That means more value for money, more innovative processes, and ultimately enabling the community to do more, with less.”

PROCESSES

The ‘process’ segment of NTRO Certification relates to the development of standards and specifications for the transport sector,

“The NTRO has spent a lot of time thinking through who’s doing what really well, and how we can adopt that. Just one example is the International Road Federation, which is excellent in road safety auditor training. It’s a global standard that’s proven to be successful, so we should be looking to simply adopt it. We don’t need to invent something for Australia.”

It’s a constant game of push and pull, but Caltabiano says today’s hard work will lay the foundation for the next generation of transport innovators.

“We need to be continuing to develop and keep up to date – and in some cases –be slightly ahead of where the industry is, in order to point it in the right direction,” he says.

“That is, and has always been, a key driver for the NTRO.”

THE POWER TO GRADE SMARTER

BUILT FOR THE WORK THAT MATTERS

Transformed through evolution, the ultimate species delivers more power, productivity and precision than ever before.

The BELL Graders

Built for performance where it matters most – on construction sites, council roads and out in remote mining zones. Powered by a quiet, e cient Cummins engine and smooth ZF transmission, Bell Graders deliver the control, comfort and durability needed for tough grading work.

With advanced grading technology, a rugged build and full nationwide support, Bell Graders are ready to take on your toughest jobs.

Hitachi Construction Machinery

Geotab’s Marketplace has a range of dashcam’s available for customers.

TELEMATICS INTEGRAL

GEOTAB IS SHIFTING TO AN ALL-IN-ONE TELEMATICS PLATFORM, PROVIDING FLEET MANAGERS WITH THE BEST FOOT FORWARD WHEN IT COMES TO SAFETY AND RELIABILITY.

As transport and data industries continue to modernise technology, one tool in particular has proven to transform roads worldwide: all-in-one telematics platforms.

At the forefront of this evolution is Geotab, one of the global leaders in connected transportation solutions, which is now rolling out its integrated safety platform across Australia.

The shift to an all-in-one video and telematics system can redefine how fleet operators manage safety, risk, and efficiency.

The all-in-one system forms Geotab’s holistic approach to move from reactive to proactive when it comes to safety and maintenance.

It combines video footage, AI- (Artificial Intelligence) driven analytics, and engine diagnostics, providing fleet operators with a full picture of every drive.

In the unfortunate case of an incident, Geotab’s all-in-one integrated system will not only capture what happened on the road, but also helps to uncover why it happened.

Alkan Ciftci, Business Development Manager for Geotab, says Geotab saw a gap in the market.

“Fleet managers are no longer satisfied with simply knowing there was a harsh braking event. They want to understand why it occurred,” he says.

Traditional telematics systems provide data on isolated events, such as harsh braking or engine faults, but without

video footage or AI, there is room for misinterpretation.

“Harsh braking could occur because the driver was distracted and wasn’t aware of what was in front of them,” says Ciftci. “Or it could have occurred because another road user cut in front of their vehicle, and they hit the brakes to protect themselves and that driver.

“So was the driver distracted or were they avoiding a collision with another vehicle?”

The all-in-one platform uses a mix of forward-facing, driver-facing and external cameras, depending on the clients’ operational needs. And these aren’t just standard dashcams.

Using AI technology, the system can also detect potential distractions

Images:

Geotab

Geotab’s all-in-one telematics platform is ideal for fleet managers looking to have all of their safety and maintenance needs monitored in one place.

such as fatigue, phone use and even eating. Ciftci says the program will alert the driver if it notices any of these distractions.

However, it’s important that the alert doesn’t disrupt them further. Therefore, finding a balance is key.

“You have to be careful with driver prompts, if a driver gets audible alerts it could add to their distraction level,” says Ciftci.

In the instance where an incident has occurred, Geotab’s model can once again use AI to scour through the footage in the lead-up to the collision.

Ciftci says reviewing hours of footage is something humans will never have the capacity or patience to do, and therefore the tool is a time and cost saver.

“It’s not big brother style where the whole trip is constantly being watched. In the case of an incident, the footage can be reviewed,” he says.

“If a truck has a driver facing camera, the program can look at an incident and determine the cause leading up to it.

“It will look at things like the driver’s head and position of their eyes. For example, if their eyes are downcast, there is a good chance they were either falling asleep or looking at a phone.”

With this technology, Ciftci says risky behaviour can be coached, and good

communicate with a driver on a rural road, as they had to rely on satellite phones to communicate.

“Even though we have mobile phones now, cellular coverage is still a problem around some parts of the nation,” Ciftci says.

With improved connectivity, fleet managers can identify and respond to incidents even in areas with limited coverage.

With Australia’s long-standing expertise in both vehicle technology and telematics,

Geotab expects the region to be a leader in the global roll out of integrated fleet safety systems.

In addition to connectivity, fleet operators around the country are experiencing challenges getting deliveries to destinations on time and having drivers meet their maintenance schedules.

behaviour can be rewarded. “Using this system, we can predict risk or know with a lot of certainty why an incident occurred, based on the information we have,” says Ciftci.

“Ideally the driver could get help before an incident occurs.”

Prior to Geotab integrating the all-inone model, Ciftci says the team noticed a rise in drivers installing their own cameras as a safety net.

Ciftci says Geotab provides rich engine data that allows fleet managers to address potential maintenance requirements ahead of time, avoiding breakdowns on the road.

This information can be accessed through two of Geotab’s platforms: its centres for Safety and Maintenance.

With data from over 4.8 million connected vehicles, fleet managers can benchmark their operations and see how their fleet compares on risk and vehicle health.

“IT WILL LOOK AT THINGS LIKE THE DRIVER’S HEAD AND POSITION OF THEIR EYES. FOR EXAMPLE, IF THEIR EYES ARE DOWNCAST, THERE IS A GOOD CHANCE THEY WERE EITHER FALLING ASLEEP OR LOOKING AT A PHONE.”

“Drivers want to have the footage there in the case of an incident to prove they weren’t in the wrong,” he says.

“It can be used to exonerate the innocent and of course identify the cause if the driver was at fault.”

LOCAL CHALLENGES

Ciftci expresses that although the shift towards all-in-one communications is global, Australia presents unique challenges.

“We are a huge continent and therefore connectivity can be challenging,” he says.

Ten years ago, it was difficult to

The Maintenance Centre provides fleet managers with the critical maintenance information for the fleet, including track codes, upcoming service needs and potential breakdown risks.

Alternatively, the Safety Centre provides driver risk levels, allowing managers to address behaviours and reinforce safety policies.

Ciftci says that together, these tools form a proactive management system designed to reduce downtime, improve delivery reliability, and enhance driver wellbeing.

EVERYWHERE YOU GO

WORKS ON THE HOBART AIRPORT HAVE SIGNIFIED A SHIFT IN BEST PRACTICE WHEN IT COMES TO THE DELIVERY, STORAGE AND APPLICATION OF POLYMER-MODIFIED BITUMEN. SUPPLIER SAMI BITUMEN TECHNOLOGIES AND HEAD CONTRACTOR DOWNER REFLECT ON THE CHALLENGES AND SUCCESSES OF THE PROJECT.

For rural and remote road, highway and airport works, bitumen supply and transport can often be a logistical challenge.

Proximity to binder manufacturing facilities, duration of the project, as well as environmental factors can dictate what is and isn’t possible when it comes to bitumen transport.

That is, until now.

Brad Richards, State Manager Southern Region – SAMI Bitumen Technologies, says the company now has a solution that can deliver on demand high-quality binders, wherever the customer wants it.

“SAMI goes above and beyond to make sure we meet our client’s needs, and then we go the extra mile to make sure that we make the process as stress-free, easy, and streamlined as possible,” he says.

To deliver on this promise, SAMI has established a line of bitumen containers, each equipped to maintain bitumen at a specific temperature, ensuring product quality throughout transportation and storage.

These 32,000 litre capacity containers, which are able to cater for multiple material types and specifications, mean contractors no longer need to be concerned about extended truck waiting times or complicated

The container setup means contractors can have product that’s up to temperature and readily available onsite, when bitumen tankers aren’t viable.

logistics. The containers provide a flexible, reliable storage solution.

This solution has already proven successful on challenging projects, showing its potential to transform how bitumen is transported and managed in infrastructure development.

A NEW FRONTIER

As Daniel Anile, Project Director – Hobart Airport Upgrade Project, from the Downer Specialised Pavements and Projects (SPP) team explains, recent highly technical works in Tasmania have been enabled through the collaborative partnership between SAMI and Downer. Breaking new ground in the material transport and quality control of regional and remote projects.

“The project aimed to upgrade Hobart Airport to accommodate larger, widebody aircraft, unlocking tourism and trade opportunities for Tasmania,” he says.

“This required a strengthening of the main runway, widening of some taxiways, construction of a brand-new taxiway, as well as upgrades to the existing parking stands and construction of a Code E concrete parking bay. The project had to be completed within 12-months, requiring work to begin quickly and continue year round without disrupting aircraft operations or compromising quality.”

One glaring test was the transport and storage requirements to ensure availability of enough premium PMB (polymer-modified bitumen) to cater for the works. As Riaan Van Dyk, Construction Project Manager – Downer SPP explains.

“One of the biggest challenges we faced was that in Tasmania, high spec polymer modified binders are not commonly used. Standard grade binders are typically preferred due to the local supply chain limitations, colder climate and challenging logistics,” he says.

“So, we knew from the outset that getting premium quality binder on site was going to be a significant challenge in its own right.”

With no binder manufacturing facilities and traditional stationary tankers proving ineffective due to the project’s timeline and remote location, the team needed to think

SAMI’s bitumen container solution can cater for projects of all scopes, environments and regions.

outside the box to guarantee a suitable bitumen supply.

Accordingly Downer joined forces with SAMI Bitumen Technologies, to develop a unique and optimised solution to overcome one of the project’s largest challenges.

“Adding to the challenge, PMB products have a relatively short shelf life. With this in mind, Downer needed an experienced and capable partner. SAMI proposed the establishment of a purpose-built mobile bitumen storage facility located on the Hobart Wharves, consisting of 33-tonne capacity containers, each capable of storing, transporting and conditioning of either straight bitumen or PMB.”

Arranged in rows comprising 10-12 containers each, this provided a heated and transportable option, leading to greater flexibility. All the while enabling precise temperature management during both transportation and storage.

Each of these containers was loaded in Melbourne before being processed, shipped and delivered to Hobart where they were then transported to site.

Each of these containers held SAMI’s highest quality airport-grade A10E binder, a product that Richards says has already become a highly regarded offering in the market.

“SAMI has a fantastic reputation in the industry of having quality binders,” he says.

“So whenever there’s a special project, or even a challenging project, people reach out to SAMI because they know that the quality is going to be second to none.

“SAMI and Downer did a lot of joint research prior to the start of the project to optimise the properties of the binder that SAMI manufactured, so that it could survive the trip and the reheating process and ensure it comfortably exceeded the exacting airport specification requirements. Pleasingly, with over 5000 tonnes of product delivered to Downer’s site, all were delivered with specification and all were delivered on schedule and as per plan.”

From the customer’s perspective, Van Dyk adds that regular communication and alignment on safety values between the two

Constant communication was key throughout the delivery of the project, enabling all involved to stay up to date with project requirements.

companies played an essential role in the safe and successful delivery of the project.

“SAMI had live information obtained from Downer’s daily bitumen testing, and based on that information, they could make tweaks to the formulation back in the factory,” he says.

“SAMI was great in understanding our requirements and how to best modify the binder to get the best possible results.”

Regular project meetings were held between Downer Construction Manager Billy Clark and SAMI Project Manager Samuel Wright, reviewing the technical, safety and delivery performance to date, along with weekly, monthly and a whole of project look ahead programs, providing both immediate and long-term forecasts, and ensuring that

Images:

Downer

all project stakeholders were across project progress and future requirements.

HAND IN HAND

Samuel Wright, Project Manager – SAMI is part of a wider project team that’s specifically focused on delivering works where SAMI’s container solution is best suited.

The team’s primary responsibility is to create efficient, adaptable storage facilities that can be quickly deployed in remote or challenging locations. The team handles the entire logistics chain, from container preparation and heating to transportation across multiple modes, such as trucks, boats, and trains.

They work closely with clients to manage project requirements, providing real-time communication and rapid problemsolving capabilities.

Wright says the team’s expertise lies in their ability to handle complex logistical challenges, with a small, highly skilled group that can quickly adapt to changing project needs. All the while supporting a solution that enables significant cost savings by allowing transport vehicles to quickly deliver, rather than being stuck on-site for extended periods.

He says it’s a growing aspect of SAMI’s operation, and one that he sees as a key contributor to best practice project delivery in the future.

“When we were halfway through the project, it became relatively easy because

everyone knew what had to happen, we had our routine and our meetings, and we were constantly in touch with each other,” he says.

At every step a SAMI representative was co-located with the project team, providing on-site expertise and guidance to site coordinator Jeffrey Burnet, responsible for offloading bitumen to Downer storage tanks.

“It didn’t matter what company was on your shirt, it was just ‘let’s work together to get the job done’. When it comes to that communication, I can confidently say it was one of the best projects I’ve come across, especially for a project where we had to deliver 5000 tonnes of bitumen.

“We finished two weeks early with the bitumen supply on a project that a lot of big names said couldn’t be done, and we went into it knowing that it was going to be a challenge. At the end of the day, everything went to plan and everyone was happy.”

By offering a scalable, innovative solution, SAMI’s project team is not just providing a service, but also fundamentally transforming how bitumen logistics can be managed in infrastructure projects, creating new possibilities for transportation and storage.

Richards adds that all project stakeholders were satisfied with the outcome, a reflection of the “great” collaboration and communication between the different parties.

“It’s rare that you get a project where everyone who’s worked on it can walk

“IT’S RARE THAT YOU GET A PROJECT WHERE EVERYONE WHO’S WORKED ON IT CAN WALK AWAY AND COMFORTABLY SAY ‘THAT WAS A REALLY SUCCESSFUL PROJECT’. IT’S EVIDENT HOW SUCCESSFUL YOU CAN BE WHEN YOU WORK TOGETHER.”

away and comfortably say ‘that was a really successful project’. It’s evident how successful you can be when you work together,” he says.

Feedback from Downer has been overwhelmingly positive, with SAMI’s container division also benefitting from additional offers and tenders off the back of these works.

Reflecting on the works, Van Dyk says the container method is one that Downer will likely consider for some of its future projects, yet another milestone in what continues to be a growing professional relationship between Downer and SAMI.

“Downer and SAMI have both proven that it’s possible to take on difficult projects, especially regional and remote projects, and deliver high-quality outcomes, even when the use of bitumen tankers simply wasn’t feasible,” he says.

“It opens up a lot of confidence and possibility with a method like this, being able to show that you can successfully deliver in a logistically challenging place like Tasmania, where you don’t have the local refineries or blending plants to meet the bitumen supply requirements.”

For SAMI’s bitumen container line, Richards believes this is just the beginning.

“We’re really looking to open up new markets in Australia and make them more accessible to having high quality binders on demand, where the customer wants it,” he says.

“It’s really opened some big doors for our customers, to allow them to target projects that they wouldn’t normally go for, because

Downer is considering using the mobile bitumen containers for works in the near future.

ALLU ASPHALT BUCKET – BUILT FOR RAP. DESIGNED FOR RESULTS.

Unlock the full potential of reclaimed and coldmilled asphalt with the ALLU Asphalt Bucket – a next-generation hybrid screening solution engineered for maximum efficiency and sustainability.

One-step processing – crushes and screens simultaneously

High productivity – up to 250t per hour

Hybrid blade tech – superior material separation in a single pass

Robust build – reinforced for heavy-duty asphalt applications

Fits your fleet – suits 25–45t excavators and 15–30t wheel loaders

Launching in Australia Q4 2025. Register your interest today with your local ALLU dealer: The hybrid blade setup – a mix of screening and crushing blades – enables the bucket to crush clumps, screen fines and separate oversized particles all in a single pass, eliminating the need for pre-crushing or secondary equipment.

THE CHERRY ON TOP

THE EXPANSION OF MATTHEWS BROTHERS ENGINEERING’S HIRE DIVISION HAS SIGNALLED THE START OF A NEW DIRECTION FOR THE COMPANY, WITH MORE SOLUTIONS AND SUPPORT ON THE WAY.

Across Australia, federal, state, territory and local governments spend about $30 billion annually on road works (Bureau of Infrastructure and Transport Research Economics). This comprises expansions, upgrades and maintenance.

The Safer Local Roads and Infrastructure Program – established by the Federal Government to deliver safer and more productive roads nationally – offers at least $200 million annually for such works, creating significant opportunity for local players in the sector.

For some, purchasing new bitumen sprayers to cater for these works isn’t always financially feasible, and bitumen sprayer hire is limited.

This is a space that Matthews Brothers Engineering is successfully navigating.

The bitumen sprayer, road tanker, tack coater, melting tank and aggregate spreader manufacturer’s hire division is far from new. In fact, its origins can be traced back to 1972, when the company filed its Certificate of Incorporation of Proprietary Company submission.

Since that time, Matthews Brothers Engineering has grown into a household name, but this is not the case with its hire division.

It’s for this reason that the company is looking to grow its already strong range of bitumen spraying equipment, specifically for hire. As Sally Rolfe, Operations Manager –Matthews Brothers Engineering explains.

“There is really no one else actually hiring out bitumen sprayers in the market today,” she says.

“But this is more than just filling a gap in the market. It’s about showing the best that we have to offer.

“It’s predominantly to service short-term client needs.”

Whether a contractor is taking on extra work, a new project type, or hoping to cover for a downed unit, this short-term solution is more than just a temporary fix. Instead, it’s a “get out of jail free card”, that Rolfe says has been curated to satisfy industry and operator requirements.

Equipped with a high-quality unit, with the latest technological, safety and efficiency features, contractors can be effective on-site with dry hire. This is thanks to the ease of operation and control provided by Matthews Brothers Engineering’s sprayer units, an ideal combination when paired with an experienced operator.

Matthews Brothers Engineering will soon welcome additional units to its existing hire range.

All of which is supported by a team headed up by Jake Hally, Matthews Brothers Engineering’s Service and Maintenance Coordinator.

Hally is responsible for overseeing and ensuring technical support for customers during the hire period, including diagnosing and fixing issues as they pop up.

Each unit also receives a pre-hire equipment inspection, as well as an equipment verification to make sure all features are operational.

The team also offers a walk-around the equipment to familiarise operators with sprayer functions, with operational guidance tailored to different experience levels.

Once the unit has been returned following its hire period, the team, under Hally’s supervision, also conducts thorough servicing across hydraulic functions, valve replacements, air actuator maintenance and more, making sure it’s ready to go for the next job.

Hally says that every equipment hire is in many ways a first impression, one of the main reasons why the team takes great pride in providing fully-functional and highperforming spraying units.

“We want to offer our hire clients the best possible version of ourselves,” he says. “It’s about making sure that we can provide the highest-performing gear, as frequent as possible.”

A big part of this mission is constantly updating the division’s capacity and

capability, one of the reasons why Matthews Brothers Engineering will soon add two new 6000-litre units to its existing range.

Sporting a Scania P320 chassis and single rear axle for greater manoeuvrability, these 6000-litre capacity spraying units are well suited to metropolitan and regional jobs alike.

“The better turning circle and greater accessibility are the main reasons why the 6000s have been popular in metro areas,” Hally says.

“It’s also less daunting for operators who aren’t full-time truck drivers.”

Hally says these are the first steps in Matthews Brothers Engineering’s gradual fleet replacement strategy, which will include additional 10,000-litre units in the near future.

Standardisation is also the goal, with the company’s control systems, diesel package burners, temperature control functionality and safety standards to be consistent across all units.

“We want to simplify and improve the customer experience, that’s why we’re looking to standardise features like the classic control system,” Hall says. “Importantly, it gives potential customers a taste of what to expect from some of our wider range.”

WHAT TO EXPECT

With these new spraying units in tow, as well options for a chip sealer, Matthews

Brothers Engineering’s hire division is not an alternative to purchasing, rather a backup option that can answer the call, should circumstances dictate.

With a growing wait list, there’s plenty of operators and contracts already in line, but Rolfe says the more the merrier.