e inaugural year of Blue Phoenix’s incinerator bottom ash plant marks a signi cant milestone in resource recovery.

Australian technology company mapping the PFAS landscape.

From op shop origins to a national revolution.

Mapping Australia’s leachate landscape.

Is it time for a Waste Chain of Responsibility?

Breakthrough PFAS remediation technology from the University of Queensland.

A unique ‘Waste Safari’ transforms a suburban land ll.

A look at the inaugural year of Blue Phoenix’s incinerator bottom ash plant.

“WE ARE NOT SAYING THERE IS A SILVER BULLET FOR THIS CHALLENGE, BUT THERE IS A BIG KNOWLEDGE GAP AND WE ARE ABLE TO BRIDGE THAT GAP WITH SCIENCE.”

Saasha Callaghan, Technical Solutions Manager, OLEOLOGY

A single TANA shredder has sparked a circular economy revolution.

Inside the latest Australian Organics Recycling Association report.

Spotlight on Aerated Static Pile compost systems.

Spotlight on safety within the waste and recycling sector.

Making an impact on Australia’s circular economy.

LiuGong Australia establishes exclusive agship dealerships.

From AWRE and Circularity to ReGen, Sydney expo has its nger on the pulse.

44 NOMINATIONS OPEN

Waste Innovation and Recycling Awards: Recognising industry heroes. 46 BATTERY CIRCULARITY

Dissecting the challenges of a battery circular economy. 48 SELFLESS, STRONG AND SETTING THE STANDARD ree businesswomen share their journeys, challenges and achievements. 52 THE NEXT LEVEL

Trade show expands its award program for 2026.

e persistent challenge of PFAS (per- and poly uoroalkyl substances) contamination continues to loom large, yet recent actions by the Australian Government o er a beacon of hope for a cleaner future.

From July 1, 2025, restrictions have come into e ect under the Industrial Chemicals Environmental Management Standard (IChEMS), banning the import, manufacture, and use of three key PFAS chemicals: PFOS, PFOA, and PFHxS. is decisive move aligns with Australia’s commitments under the Stockholm Convention and underscores a growing national resolve to curb the spread of these “forever chemicals”.

While legislative bans are a critical step, the true victory lies in e ective remediation. is is where the ingenuity of Australian companies like OLEOLOGY comes to the fore.

OLEOLOGY has achieved success in treating PFAS-contaminated water, boasting the ability to reduce these pervasive substances to non-detectable levels. In this edition’s cover story, we examine how the company’s technology is o ering a compact, e cient, and environmentally sound solution.

Contamination is something Australia’s organics recycling industry is also all too familiar with.

Recyclers currently face escalating costs and operational headaches due to “waste in the system” – everything from general plastics and metals to more insidious substances such as PFAS and asbestos.

We speak with Christopher Malan, Chief Operating O cer at SOILCO, who lays bare the challenges the industry is facing and calls for industry-wide collaboration to create a “Waste Chain of Responsibility”.

It’s a timely discussion as the Australian Organics Recycling Association releases its latest report, which also reveals the need for a harmonised policy. You can read the key ndings and a state-by-state breakdown of recycling rates in this edition.

We also bring you some more success stories, including a look back at the rst year of operation of Blue Phoenix’s incinerator bottom ash plant, the launch of a new plant to permanently retire mercury, and how a single piece of equipment has sparked a revolution for one New South Wales council.

Happy reading!

CEO Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN

Laura Drinkwater

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia P: +61 3 9690 8766

enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. e rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COVER Cover image: OLEOLOGY

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

At EcoBatt, we are driving real change through our nationwide Battery Collection Service, which is designed to significantly reduce the number of batteries ending up in landfill. With approximately 7,000 collection units located across Australia in partnership with major retailers, we are making battery recycling more convenient and accessible than ever before.

Improper battery disposal can have serious consequences. From fires in waste trucks and landfill sites to toxic chemicals leaking into soil and waterways, the risks to our environment, wildlife and community health are far-reaching.

Recycling batteries correctly is a simple yet powerful way to protect what matters. By working together, we can create a cleaner, safer future and preserve valuable resources for generations to come.

What’s recyclable through EcoBatt’s Smart Bins?

Button cell batteries

Mobile phones

Easily removable batteries

Rechargeable batteries under 5kg

Regular AA & other household batteries

For organisations grappling with substantial battery waste, EcoBatt offers tailored solutions. From battery recycling bins ranging from 2L to 120L to our larger-scale Mixed Battery Safety Bins available in 600L and 800L capacities, we’ve got you covered.

Reach out to us at 1300 32 62 92 to connect with one of our battery recycling specialists who will craft a bespoke solution to suit your needs. Because protecting what matters starts with all of us working towards a cleaner, greener tomorrow, join with EcoBatt today.

From op shop origins to a national revolution. Waste Management Review looks at the enduring power of reuse.

For Australians, the humble op shop is an iconic institution, deeply ingrained in the fabric of communities across the country. What many might not realise, however, is that the very term “op shop” itself has its roots in Melbourne, dating back a century to 1925.

Born from a desire to raise funds for St Vincent’s Hospital’s X-ray department, the rst “stores of opportunity” – or “magasins d’occasion” as they were known in Paris – were pioneered by Lady

Millie, seeking a more appealing name than thrift or charity shop.

While organisations such as Vinnies and Salvos (part of the Salvation Army) have been operating for even longer, this marked the beginning of a uniquely Australian phrase, embodying a centurylong tradition of reusing goods for social good.

Fast forward to today, and this grassroots movement is undergoing a transformation, with reuse gaining recognition within Australia’s waste

hierarchy. At the forefront of this shift is Charitable Reuse Australia (CRA), an organisation championing the role of charitable reuse in building a more circular economy.

e importance of reuse, which sits directly below reducing consumption in the waste hierarchy, cannot be overstated.

As Omer Soker, Chief Executive O cer of Charitable Reuse Australia, states, “Reuse, for us, is really the act of reusing an item in its original form.”

“It’s not recycling, it’s not repurposing,”

For John Gertsakis, Director of the Product Stewardship Centre of Excellence, reuse is the rst responder to waste prevention, conserving resources

“Reuse enables consumers to take control and make conscious decisions to look after their products and keep them circulating in their households, their communities, and the economy more

Both agree the environmental bene ts are clear – the more things we reuse, the

For many years, quantifying the impact of reuse proved challenging. However, groundbreaking work by Charitable Reuse Australia, in partnership with Monash University and funded by an Australian Research Council grant, led to the development of the national reuse

is framework has enabled the quanti cation of reuse’s triple bottom line impact – environmental, social and economic.

e ndings show reuse is providing substantial nancial relief to households, highlighting the vital role that op shops and second-hand goods play in reducing expenses, while also delivering job opportunities (6300 full-time jobs including for people facing barriers), and fundraising for charity social programs to support Australians in need (charities reinvested $180 million from op shops into social programs).

Reuse is also accelerating Australia’s transition to a circular economy, saving 1.4 million tonnes of carbon dioxide emissions – equivalent to removing 585,000 passenger vehicles from the road.

New South Wales, lauded by Omer as a leader in the circular economy, was the rst State Government to fund a comprehensive study on the impact of reuse.

Omer says the ndings are compelling. Reuse in New South Wales generates 25 times more jobs than recycling per tonne of materials handled. e study also found 343,000 tonnes of carbon emissions saved and $432 million in community savings, directly impacting the cost of living for residents.

Similar studies are now underway in other states, with Tasmania showing an even greater impact, creating 34 times more jobs per tonne through reuse.

is data underpins the Charitable Reuse Conference, an annual event that has grown in recent years. What began with about 60 attendees in 2018 has expanded to more than 280 delegates across two streams in 2024, re ecting a growing industry and government interest in reuse.

Omer says the conversations at the conference have evolved from basic waste discussions to encompass complex topics such as the circular economy.

“It’s grown quite tremendously,” he says, highlighting that the event now features two streams, including a dedicated one for shop managers to educate, empower and inspire up-and-coming people.

He attributes the surge in interest to several factors, including Charitable Reuse Australia’s strategic decision to change its name from Charitable Recycling Australia to better re ect its core mission.

Omer says the term recycling was a broader umbrella, but as the nuances of the waste hierarchy became clearer, the time was right to champion “reuse”.

“I think the governments are also starting to become more nuanced as well,” he says, referencing the shift from waste policies to incorporating circular economy and, increasingly, reuse and repair strategies.

John says that while knowledge about reuse is relatively high among those who understand the bene ts, there’s a need to clarify how it compares to recycling, especially for

29-30 October 2025

Melbourne Convention & Exhibition Centre

100+ Exhibitors from over 10 Countries 100+ Speakers Delivering over 50 Sessions Across 3 Stages Network with 3,000+ Peers

the general public. He believes consumers are “increasingly savvy about reuse being central to waste prevention, while recycling, as important as it is, has a focus on managing the symptoms of overproduction and over-consumption”.

“ e reality is we need a better balance of interventions, investment and action across the waste hierarchy with more emphasis in the top half, i.e. avoid, reduce, reuse and repair,” he says.

e potential impact of widespread reuse is immense, as demonstrated by a hypothetical scenario explored by Charitable Reuse Australia. If every person in New South Wales bought all their clothes second-hand for just one year, it could divert 125,000 tonnes from land ll, save 1.3 million tonnes of carbon emissions, conserve 68,000 megalitres of water (equivalent to 27,000 Olympicsized swimming pools), provide $3.9 billion in cost-of-living relief, and raise $740 million for social welfare.

Omer says this powerful illustration underscores that even “one little change can make a huge impact”.

To amplify that impact, Charitable Reuse Australia is advocating for three key policy changes – more accessible grants tailored to charities, recognising their long-standing work and signi cant impact in land ll diversion, emissions

savings, job creation, and social welfare; encouraging more people to donate usable items to charity shops or commercial reuse enterprises; and see reuse integrated into government policy, with targets set that will drive necessary interventions and funding.

“Doing more stu higher up the waste hierarchy– whether it’s repair, reuse, or refurbishing – will be better for all of us,” he says.

However, signi cant challenges hinder reuse at scale.

e single biggest challenge, according to John, is “over-production and overconsumption, backed in by aggressive sales and marketing campaigns by brands and retailers to update, upgrade and keep purchasing new products”.

“ is is further compounded by planned and premature obsolescence by some manufacturers and brands, despite claimed commitment to circularity and ESG (environmental and social governance) objectives,” he says.

“ e design and production of shortlife products is also a major barrier to reuse, repair and the ability to give products a second and third life.”

In addition to more e ective consumer education, he says the need for smart regulations is overdue in Australia.

In its nal report in 2024, the Circular Economy Ministerial Advisory Group (CEMAG) recommended the creation of a Circular Economy Act, providing a clear framework for setting design rules for products and labelling their performance, like the European Union’s Ecodesign for Sustainable Products Regulation.

ese design rules should enable the establishment of circular economy requirements for products, including those related to durability, repairability, recyclability, and the presence of chemicals of concern.

France has led the way with its Repairability Index, which e ectively drives product redesign and requires brands to provide consumer

information and labelling that indicates a repairability score or ‘star’ rating.

e French have also introduced laws that ban the destruction of unsold goods by requiring brands to donate or reuse products.

John says that despite these challenges, there are clear successes, led by Charitable Reuse Australia.

“I’m always impressed with their foresight and the practical work of their members and volunteers, especially when it comes to the reuse of clothing, homewares and small appliances,” he says.

He also highlights the role of local councils, serving as ambassadors of reuse, who do what they can to promote reuse, including the operation of tip shops and similar facilities.

And while not yet widespread, some manufacturers are incorporating reuse, refurbishment, and repair into their business models for major appliances.

“ is is usually limited to refurbishing warranty returns but provides a glimpse of what could be possible at scale if all whitegoods and small appliance brands moved beyond recycling end-of-life products as part of a more comprehensive product stewardship approach,” John says.

He stresses that product reuse should not be limited to just household consumers, but also for government agencies and businesses, advocating for the inclusion of reuse and secondhand goods in government and business procurement.

“We increasingly talk about the circular economy, but we need to get serious about honouring the waste hierarchy as an essential bus-stop on the way to a more restorative and regenerative economy that is environmentally positive, not just ‘less bad’.”

e 2025 Charitable Reuse Conference will be held in Sydney at the UTS Aerial Function Centre on October 13-14. It will be a special “Once in a Century” event celebrating 100 years of the term Op Shop.

Blue Phoenix brings world-leading expertise in IBA processing to Australia, transforming waste into high-quality aggregates and recovered metals. By recovering these materials from IBA, we're reducing landfill reliance and enabling sustainable solutions for civil construction.

ith operations across the globe, we lead in developing end mar ets and wor ing with regulators to enable responsible reuse, preserve resources, and drive the circular economy rivin policy an circular solutions

Why one company is mapping Australia’s leachate landscape.

Australia’s waste management sector faces a monumental task: Navigating the complex and increasingly stringent regulations surrounding per- and poly uoroalkyl substances (PFAS) contamination.

While the industry grapples with the perceived di culty of meeting these demands, one company is taking a proactive approach by conducting an Australia-wide research and collection program of leachate water.

Saasha Callaghan, Technical Solutions Manager at OLEOLOGY, says it’s a boots-on-the-ground e ort to understand the full spectrum of contamination and to prove that e ective, commercially viable treatments are not only possible but

“ e reality for waste facilities and councils is that leachate management

“We get a lot of clients telling us it’s really hard to meet regulations surrounding PFAS levels. However, when OLEOLOGY examines the requirements, it hasn’t been that hard.

“We are not saying there is a silver bullet for this challenge, but there is a big knowledge gap and we are able to

PFAS are a group of man-made chemicals that have been used in various products since the 1950s because of their ability to resist heat, stains, grease, and water. ey’ve been dubbed “forever chemicals,” because of their persistence

Products containing PFAS are often disposed of in land lls. As the waste decomposes and leachate forms, PFAS seeps into the liquid, contaminating it.

collection initiative is a chance to fully understand the spectrum of contamination – the good, the bad

It’s driven by a desire to quantify the challenges faced across the country

and take practical steps to tailor e ective solutions.

She cites a case study from Western Australia that demonstrates the direct bene ts of the research. A client dealing with signi cant leachate problems, including o ensive odours and leaching into local waterways, was advised that reverse osmosis (RO) was its “silver bullet”.

OLEOLOGY’s analysis revealed the client’s leachate fell into “the real ugly” category, with large ammonia levels accompanied with PFAS.

Rather than advocating for an expensive, energy-intensive system, OLEOLOGY demonstrated that its technology could handle both ammonia and PFAS within the same treatment system.

To further demonstrate the system’s e cacy and cost-e ectiveness, OLEOLOGY proposed a novel approach – conducting a trial at its own facility.

“Conducting a trial on site is a huge expense,” Saasha says. “Instead, we recommended the client send us a sample every few weeks and we conducted the trial for them. It’s much more cost-e ective and reassuring for every stakeholder that this system is going to do what we say it’s going to do.

“ e technology and the advancement that OLEOLOGY has provided to the industry as a commercially viable solution for PFAS treatment and other co-contaminants is solidi ed in more than 13 years of research, data collection and execution out in the eld.

“ ese are not pilot trials. ese are working systems.”

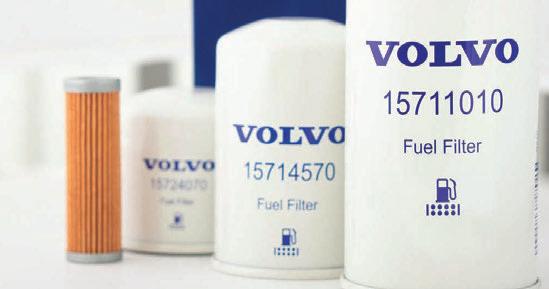

Recognised as a leader in water treatment, the core of OLEOLOGY’s success is in its technology, which diverges from conventional treatment methods such as carbon and resins, instead focusing on permanent contaminant removal and minimal waste generation.

Its proprietary MyCelx technology, a polymer developed through extensive research and development since 2006, operates on a principle of molecular cohesion, where the polymer permanently binds with contaminants such as PFAS and oil at a molecular level. is ensures that the contaminants are not only separated but also irreversibly bound to the media, preventing their release back into the water.

e treatment process involves a multi-stage ltration sequence

designed to remove various contaminants in layers.

“We speci cally ensure that all cocontaminants are gradually removed from the water stream throughout the system,” Saasha says.

“We have multiple stages to avoid bottlenecks, which also reduces operational intervention. At the polishing end, our nal stage, reaching PFAS guidelines of below levels of detection is not a problem for us.”

She says this robust technology is the secret to OLEOLOGY’s cost e ciency, with sites down to just 0.0002 cents of the dollar spent on treating each litre of water. is saving is factored into operational costs such as power and lters (which are the only consumables).

e system is also self-sustaining, regenerating clean water produced within the system, thereby eliminating the need for harsh chemicals.

Beyond the cost-per-litre bene t, OLEOLOGY’s technology o ers advantages in waste management. Unlike conventional treatment methods that generate problematic sludge waste, the OLEOLOGY system produces a dry, solid waste.

“Because of this, we only need to replace the lters and sometimes its only one or two at a time,” Saasha says. “Chemically bound to that lter is the PFAS and other hydrocarbons and organic materials. You can simply put the lter back into the box it came in for disposal.

“ ere’s no need for expensive and disruptive suction vacuum trucks and extensive operator downtime for media changes.”

e disposal of the dry waste is also simpli ed – incineration, which completely destructs contaminants, and certi ed waste disposal sites.

Critically, Saasha says the United States EPA has proven that this

technology does not leach, meaning the PFAS is chemically bound to the media and will not release into the environment. As a result, the lters can be sent to a waste depot.

e widespread impact of PFAS is undeniable. Saasha highlights its presence in various sectors beyond traditional waste, including the shing industry, salmon production, oyster production and the agricultural and horticultural sector. Even the construction industry often fails to factor in PFAS treatment costs.

OLEOLOGY’s broad client base, which includes major liquid waste contractors, civil construction and dewatering companies, Defence locations and airport maintenance facilities, underscores the pervasive nature of the challenge to eradicate PFAS.

e company’s focus extends beyond leachate to PFAS in drinking water.

“So many people are focusing on the three main PFAS analytes – PFOA, PFHxS and PFOS challenges. But when you just focus on the three, you are missing out on the other 37 that are testable.”

Saasha Callaghan Technical Solutions Manager at OLEOLOGY

“Personally, I don’t want to have to consume PFAS, any level of PFAS,” Saasha says, re ecting a concern that resonates widely.

She says the US EPA has stringent drinking water standards that are driven by the availability of e ective technologies. OLEOLOGY’s technology has been approved for drinking water treatment and has contributed to reducing allowable PFAS levels.

Saasha hopes to see similar proactive measures in Australia. She says OLEOLOGY’s commitment to water quality stems from a core ethical principle instilled by the company’s founder, Paul Callaghan.

“Paul actually cares and has always had a motivation to make a di erence in the community,” Saasha says.

“We see PFAS as an immediate need right now because, unfortunately, we’re seeing a lot of people get burned, and we want to right the wrong in the market. We want to x the root cause of the problem.

“People are coming to us with other challenges. We don’t necessarily have all the answers, but we will go away with our innovation team and actively seek solutions to those challenges, even those not yet seen in Australia.”

e Australia-wide leachate collection, initiated in October 2024, is a testament to this ethos.

Saasha says the research aims to create an understanding and identify solutions for not just PFAS, but also co-contaminants that unexpectedly emerge. “So many people are focusing on the three main PFAS analytes, PFOA (per uorooctanoic acid), PFHxS and PFOS (per uorooctanesulfonic acid)

challenges. But when you just focus on the three, you are missing out on the other 37 that are testable,” she says.

“We’ve always been able to keep ahead of the curve. For the past 13 years, we’ve been able to remove all of those and the precursors to non-detectable levels, as cost-e ectively as possible, with the lowest risk to the end user.”

While global e orts to halt PFAS production are crucial, managing existing legacy contamination, particularly in land lls and a ected waterways, remains a signi cant task for OLEOLOGY.

e company’s cost-e ective, scalable, and environmentally sound technology o ers a pathway for Australian waste management to address the PFAS challenge head-on. OLEOLOGY encourages all councils and industries with PFAS challenges to be part of the nationwide leachate review and email pfasfree@oleology.com.au.

For more information, visit: www.oleology.com.au

Contamination is costing the organics processing industry millions and hindering a circular economy. I ’s hie perating cer hristopher alan says industry-wide collaboration is needed to create a “Waste Chain of Responsibility”.

Australia’s waste management industry stands at a pivotal juncture, particularly concerning organics.

Christopher Malan, Chief Operating O cer at SOILCO, says Food Organics and Garden Organics (FOGO) mandates, while vital for environmental sustainability, also bring challenges that demand a shift in how the entire supply chain operates.

He says it’s time for every stakeholder, from households to regulators, to step back and collectively rethink the approach to organics collection and processing.

“We all have to partner together to try and achieve an optimal outcome. As far as I see it, the waste supply chain is not there yet,” he says.

“I’m calling for all of the players to come together and consider how we can shift from an adversarial relationship to a partnership relationship, to achieve best possible outcomes for our communities and the environment.”

Christopher joined SOILCO, a prominent organics recycling business with a signi cant presence across the East Coast, in January, bringing a decade of experience running ELB Equipment in Australia and New Zealand, a major supplier of waste processing and recycling equipment.

His long-standing association with SOILCO and prior work with other key players in the organics recycling sector has given him a unique perspective on the industry’s intricacies.

Christopher’s professional drive is rooted in “organising the kinks in businesses and getting them to work more uidly, e ciently and at scale,” particularly the human element of leading a team on a journey to achieve signi cant goals.

is passion is now focused on supporting SOILCO’s mission to expand its operations and cement its position as one of the largest organics recycling businesses in the country.

“Getting the team excited to achieve something signi cant is what motivates me,” he says. “Here, I absolutely love

that I can pair that with a business focused on the circular economy and that we’re doing a fundamentally good thing for the environment – manufacturing products that enhance the health and productivity of soil and contribute to more sustainable communities.”

He says that vision also requires buy-in from the entire supply chain, including households, businesses, packaging manufacturers, transporters, processors, local government, and regulatory bodies such as Environmental Protection Authorities (EPAs).

Christopher is emphatic that his call is not a critique of any individual player, but rather an invitation for collective introspection. He points to the transformations in workplace safety and transport safety (chain of responsibility) over the past two decades as examples of industries that recognised the futility of an adversarial system.

In those models, every entity within the supply chain holds an obligation to the entire chain, making transparent, best-practice decisions rather than simply shifting liability. is proactive, shared

responsibility, he argues, is lacking in the current waste supply chain.

“I do think that we all collectively need to step back and rethink our approach to liability and our approach to contracting,” he says. “Currently, various players in the supply chain are absolutely looking to contract away their liability. ey are looking to contract away transparency and create a situation in which they can simply say, ‘not my problem’.

“I think that we need a new framework in which such behaviour is not generally accepted and, quite frankly, not allowed.”

He highlights recent draft contracts from some councils that e ectively divorce them from the consequences of their waste streams once materials are picked up, even if problematic materials are later discovered.

While experienced players such as SOILCO would propose alternative terms that share risk and encourage all parties to work collaboratively to reduce contamination, others lacking the same experience might accept them, potentially leading to

is on a

situations where they are forced to choose between commercial and environmental outcomes.

“We, as much as possible, don’t want any of the players in the supply chain to be confronted by that choice,” Christopher says. “We need them to always be picking the environmental outcome, but we can’t do that if the terms, under which they’ve contracted, back them into a corner.

“Everybody in the supply chain has an obligation to make the best decisions with the things that are under their control and to communicate quite transparently, because if any one of those players fails to do that, they simply push liability to some other player.”

e consequences of this fragmented approach are tangible and costly. In the absence of practical management solutions and risk-based thresholds, processors are left with contaminated

products and are forced to land ll thousands of tonnes of otherwise recyclable material that would have contributed to the circular economy.

Legal, consulting and disposal fees quickly add up to millions of dollars.

Contamination of input material is now equal second as a critical obstacle to organics recycling according to the Australian Economic Advocacy Solutions (AEAS) Industry Capability Assessment 2022-2023 prepared for the Australian Organics Recycling Association (AORA).

is “waste in the system,” as Christopher calls it, diverts critical resources that could otherwise be invested in infrastructure to meet the increasing volume demands of the New South Wales mandate requiring all households to have a FOGO collection service by 2030.

is narrative, he believes, is not unique to SOILCO but is mirrored across the country’s organics and other recycling sectors, with contamination leading to signi cant nancial and environmental burdens. And the problem has the potential to escalate with increased FOGO adoption if there is no change.

“As it stands today, compared to garden organics only, an average load of FOGO contains higher physical contamination, and the complexity of light and rigid plastics introduced by food waste leads to lower product yield,” Christopher says.

“Not only do we need to invest substantially in more capacity, which SOILCO is doing, but we have to invest very substantially in better technologies to be able to deal with a more complex contamination stream.

“We are currently looking at a project that’s going to cost upwards of ve million dollars to deliver better decontamination results at a single site. It’s not just about sifting o some light plastics anymore. If we nd the wrong materials in the wrong place, everything grinds to a halt.”

Christopher says the burden of managing those wrong materials and increasingly complex and contaminated waste streams, including PFAS and asbestos often found in mixed waste organic outputs (MWOO), falls disproportionately on recyclers, despite having minimal control over the waste’s initial composition or how it’s collected. e industry is e ectively caught between the tightening regulatory frameworks and the rising expectations for resource recovery, all while being expected to deliver contaminant-free products with little ability to in uence upstream factors.

He says many councils exhibit a risk-averse approach in their waste contracts, which often leads to contracts that permit alarmingly high contamination rates, sometimes as high as 20 per cent, or lack clear penalties for contaminated loads.

While seemingly protecting councils from risk, these clauses undermine the entire organic recycling process.

“ ey force processors to accept poor-quality feedstocks, leading to inferior end products that may ultimately end up in land lls, thus doing a disservice to the industry’s goals of resource recovery and environmental stewardship,”

Christopher says. “ is creates a disconnect where the party best positioned to manage the risk (the council, through community education and proper contracting) o oads it onto the processor, who has limited means to address the contamination once it arrives at their facility.

“Processors cannot a ord to stay in business if pressures from both regulator and increasingly contaminated supply chains continue to push from all directions.”

As the national peak body for the Australian organics recycling industry, AORA is actively advocating for the elimination of hazardous materials

and contaminants from all feedstock streams, highlighting it as a crucial factor for the success of recycling and the circular economy.

Supporting a national target of less than two per cent physical contamination in source-separated FOGO and commercial food wastes, the association has repeatedly emphasised that responsibility for contamination should not solely rest with organic processors, but rather, should be addressed at the source of the contamination – the beginning of the supply chain.

SOILCO remains heavily involved with industry associations and is increasing engagement with regulatory bodies including councils and EPAs to initiate the conversations needed for a paradigm shift. Christopher recognises that a shift requires a united vision and a mass of in uential gures across the entire waste industry.

e goal is to develop a “Waste Chain of Responsibility” framework, ensuring that all parties are educated, committed to the ultimate outcome, and incentivised to promote environmentally sound practices. Such a framework, he says, must be sustainable and create a “win-win for everybody”.

“ is means fostering an environment where every participant understands and actively mitigates risks, ensuring that valuable resources are not squandered on rectifying preventable issues,” he says.

“I’m looking for more partners that can zoom out from their own patch of the waste management industry, that can look at it broadly and ask the question, How can we collectively come together, not as adversaries, but as partners to drive the best outcomes in total?”

For more information, visit: www.soilco.com.au

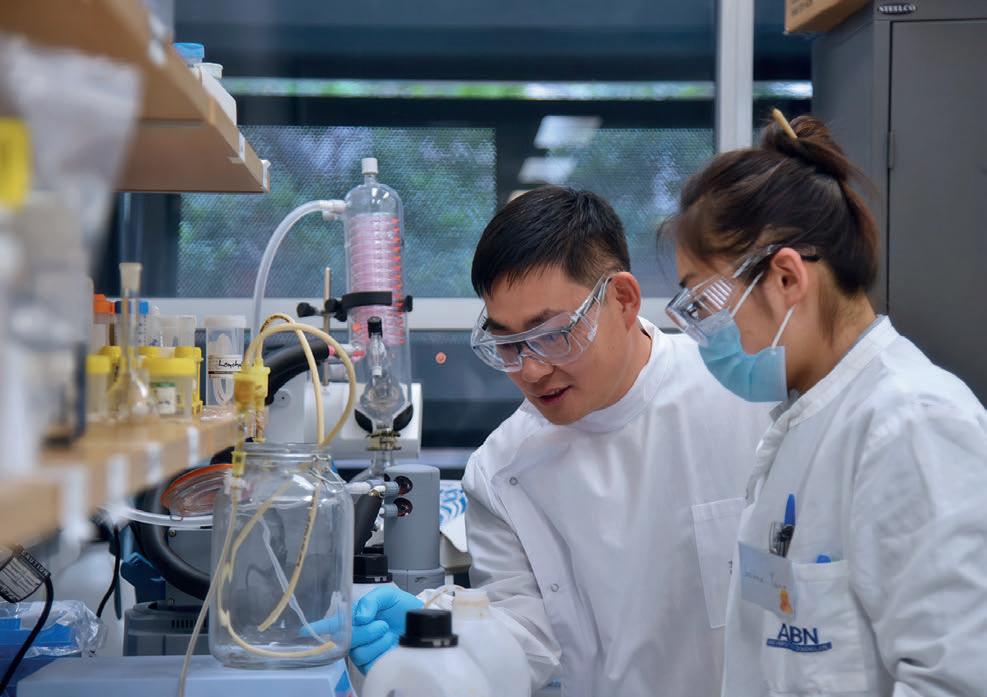

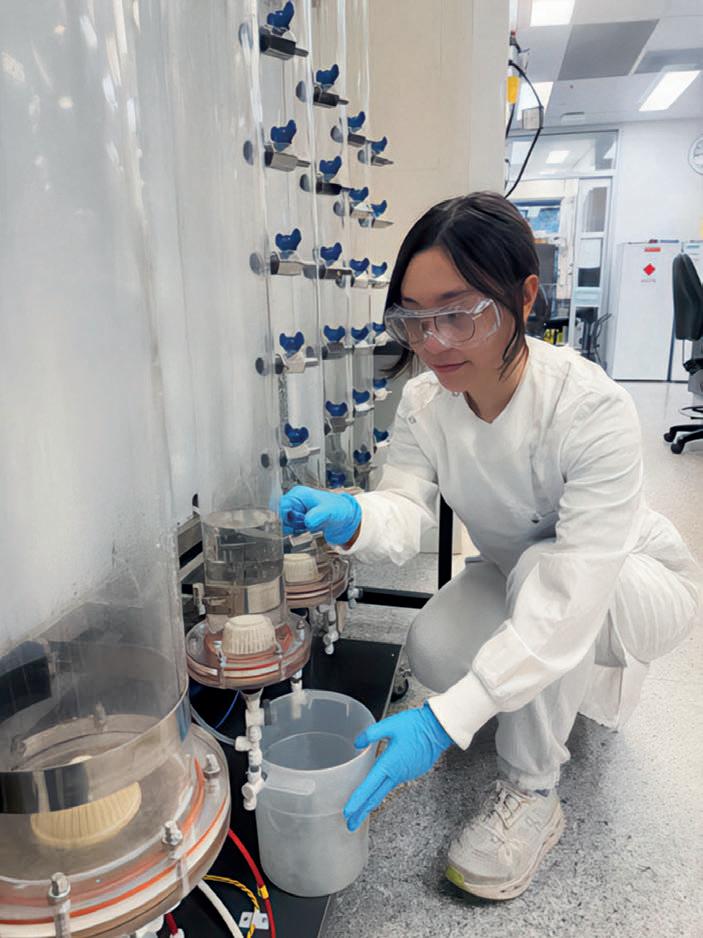

Breakthrough technology from the University of Queensland promises a revolution in PFAS remediation.

Per- and poly uoroalkyl substances, or PFAS, have earned the ominous moniker “forever chemicals” for good reason: their persistent nature in the environment and human body poses a complex challenge for waste management and public health alike.

e presence of PFAS in water sources, land lls, and even biosolids demands innovative solutions that move beyond conventional approaches.

e urgency is underscored by the recent move from the Australian Government to include short-chain PFAS such as per uorobutane sulfonic acid (PFBS) in drinking

water guidelines. It’s a development that Dr Zicheng Su, Senior Research O cer at the University of Queensland’s Australian Institute for Bioengineering and Nanotechnology, hails as a great progress for the PFAS regulatory framework.

Led by Dr Cheng Zhang, Zicheng and Dr Xiao Tan are spearheading research into a novel magnetic sorbent designed to tackle PFAS contamination head-on.

e sorbent is a round-beaded, ion-exchange resin that has undergone specialised surface modi cation. Zicheng says it’s this modi cation that

is the key to its enhanced capabilities, allowing it to e ciently trap PFAS from even highly contaminated sources, and to target ultra-short chain PFAS – a notoriously di cult class of compounds to remove.

She estimates the sorbent is about 10 times more e cient and ve times more cost-e ective than the currently available commercial PFAS sorbents in the market.

Furthermore, its regenerable nature promises to lower the operational costs for the users, addressing what Zicheng says is a signi cant hurdle in widespread PFAS remediation.

e true breakthrough, however, is this laboratory innovation is now on the cusp of real-world application.

e university team is synthesising the polymer sorbent at kilogram levels in the lab in preparation for its rst pilot deployment at Brisbane Airport. Zicheng says this pilot will speci cally target ground leachate contaminated by re ghting foams, a challenging and relevant source of PFAS.

She’s “quite con dent” the pilot stage will be successful.

“As with most eld pilots, I expect there might be engineering challenges during deployment, but we’re not concerned about the science – the sorption performance and mechanism have been rigorously validated in the lab,” she says.

e pilot is planned to run in stages, with initial data collection over three months, followed by a six-month phase, generating reports for industrial partners at each stage.

Dr Zhang has been working on the PFAS treatment for more than seven years. Taking the treatment from the lab to the eld was honed through the Commonwealth Scienti c and Industrial Research Organisation (CSIRO) On Prime program, designed to help research teams understand the potential of their research and develop pathways to impact.

“I think the greatest experience from that program is that we connected with more than 100 people in the industry related to PFAS treatment, including policy makers, researchers, industrial solution providers, and the treatment users,” Zicheng says.

“ is helped us understand what the pain points for the industry are, and what the PFAS policy is moving to. It was a great opportunity to listen to what the industry needs.

“In the lab, we focus on how e cient our solvent is, what it can do, what the variables are. rough On Prime, we learned to listen rather than simply touting the sorbent’s laboratory e ciencies.”

is extensive engagement revealed several pain points that Zicheng says existing commercial solutions struggle to address.

e rst is the challenge of very dirty, contaminated sources such as land ll leachate which often contain

elevated concentrations of both PFAS and co-contaminants that can reduce the e ciency of conventional sorbents. Biosolids present a similar dilemma. e second pain point is short chain and ultra-short chain PFAS.

ese shorter chain compounds are increasingly used as substitutes for legacy PFAS but signi cantly harder to remove.

Finally, a practical concern for industrial application was “the clogging issue” associated with early versions of the university team’s sorbent, which were ne, irregularly shaped powders unsuitable for existing

e team has addressed these challenges with ongoing research and surface modi cation techniques.

Zicheng hopes success at the Brisbane Airport pilot, with its highly contaminated ground leachate, will set a strong precedent for the treatment’s application across a spectrum of industries, including water treatment and general land ll leachate management.

“In the short term, success for the pilot program is the most important, because it’s a great leap forward in demonstrating our technology to the industry,” she says.

“For the medium to long-term, we are expecting to commercialise the technology through licensing or establishing a dedicated startup for PFAS treatment.”

She says initial responses from industry have been encouraging. Lab data consistently shows promising results for treating contaminated sources, and companies are expressing interest in integrating the university’s sorbent into their operations.

Blind tests conducted by two external companies have yielded “quite positive results”.

uni ue aste a ari event trans ormed a suburban landfill site into a amily un day success a showpiece or modern operation and building community trust.

Aland ll site isn’t typically the rst place that springs to mind for a family fun day, but for Heidelberg Materials, it has proven to be a successful base for fostering community connection and environmental education.

A recent “Waste Safari” event at its Wollert Resource Park on the northern fringe of Melbourne de ed expectations, turning a working land ll and quarry into an engaging, interactive experience for hundreds of visitors.

Rachael Quinlan, Development Project Manager at Heidelberg Materials, says the initiative was aimed at strengthening a relationship with the community.

“We really wanted to open our gates and encourage the community to come and have a look at what we’re doing,” Rachael says.

“Not often people get to come into a waste management facility and actually see where their waste goes. I think it was really important, as an educational piece, and for raising

community awareness about what happens when they put their waste in the bin.”

e day was an undeniable triumph – despite uncooperative weather – with 346 people registered, reaching 87 per cent capacity.

Attendees embarked on 30-minute bus tours hosted by “Resource Rangers”, o ering a visual learning experience through the site. e renewable energy section, that generates land ll gas to power a data centre, was a crowd favourite.

An exhibitor hall including collaborations with community groups, local council, and industry associations such as the Victorian Waste Management Association, created “a real buzz around the place” with many environmental synergies.

Families enjoyed interactive mobile plant displays, a jumping castle, a simulator, face painting, and even received branded high-vis vests and activity guidebooks.

Rachael says post-event feedback was overwhelmingly positive, with a 4.7 out of 5-star rating from participants.

“We sent out a feedback survey following the event, and there was only one negative comment – and that was that the day had nished too soon,” she says.

More than 75 per cent of visitors were local residents, 91 per cent said they would attend again, and nearly a third were children – a key demographic for waste education.

Rachael says the day achieved its objectives.

“We drove up our community contact database, we enhanced engagement in terms of people feeling like they can come and talk to us directly if there’s an issue or concern, and I think we built our social license to operate.

“Overall, I would say it was a success.”

e Wollert Resource Park is no ordinary site. Formerly known as the Wollert Quarry and Renewable Energy Land ll, owned and operated

by Hanson, it was rebranded in 2024 following the company’s acquisition by Heidelberg Materials in 2007.

It currently has a quarrying operation, a land ll, and a biogas power facility.

e quarry supplies basalt products for a variety of uses, including the construction of roads and houses, and concrete for infrastructure projects. It’s been operating since the late 1970s.

e land ll started operating in 2000 and accepts thousands of tonnes of waste each year including municipal, commercial and industrial, and construction and demolition.

e cells are in previously quarried parts of the site and are designed to help contain leachate.

A capped portion of the land ll site has been transformed into a solar farm, and the operators have pioneered phytocapping in Australia – a process that uses deep beds of locally sourced soils, planted with indigenous grasses, bushes and trees to rehabilitate and improve biodiversity of former land ll cells.

Rachael says that despite the site’s long history, it’s important to continue to build trust and social license.

Opening the gates to the site for public viewing helps to demystify operations and foster community con dence, particularly as urban areas encroach on long-standing sites and given the waste industry’s historical reputation.

“If we want to operate to the best of our ability, we need the community to be on board and to trust us as operators,” Rachael says.

“We just really wanted to build that trust with the community and allow them to come onto our site and see rsthand how we operate, and that we do care about the environment.

“Environmental compliance is extremely important to us, and that’s something we’re very proud of.”

Heidelberg Materials plans to host future Waste Safaris, and encourages private tours for community organisations and schools, ensuring ongoing dialogue and transparency around the “dynamic site”.

In an era of increasing environmental scrutiny and urban expansion,

compliance is no longer just good practice – it’s essential for maintaining public con dence.

And public con dence is key for Evan Kyriakopoulos, Operations Manager at Heidelberg Materials, Australia.

He says some common misconceptions about land lls and waste sites, are fuelled by outdated imagery.

“Whenever you see land lls portrayed in media, they’re showing ird World sites. ey’re not showing a site that’s well managed and operated,” Evan says.

“ e Waste Safari, for us, is not only about making people a bit more aware of waste management and their impact, but also their understanding that this facility exists and that there are no big secrets.

“First and foremost, we want them to understand who we are and that we’re actually a good operator, that we’re someone that can be trusted. at’s the biggest thing for us.”

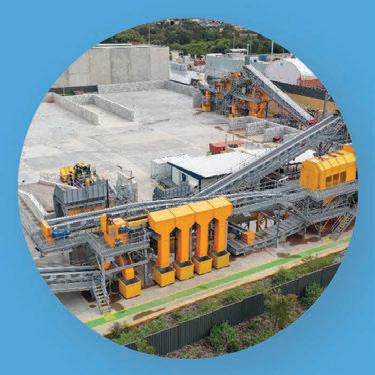

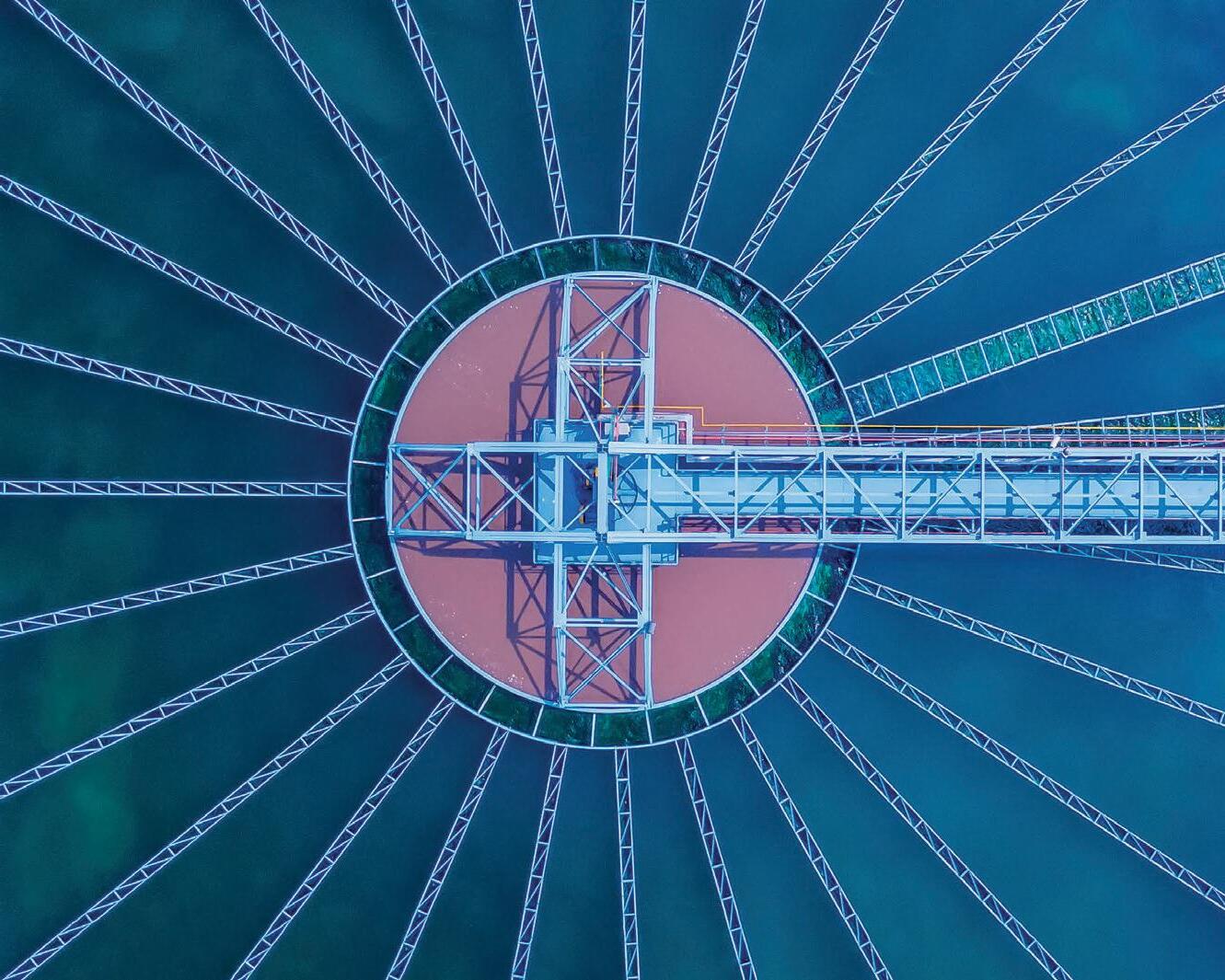

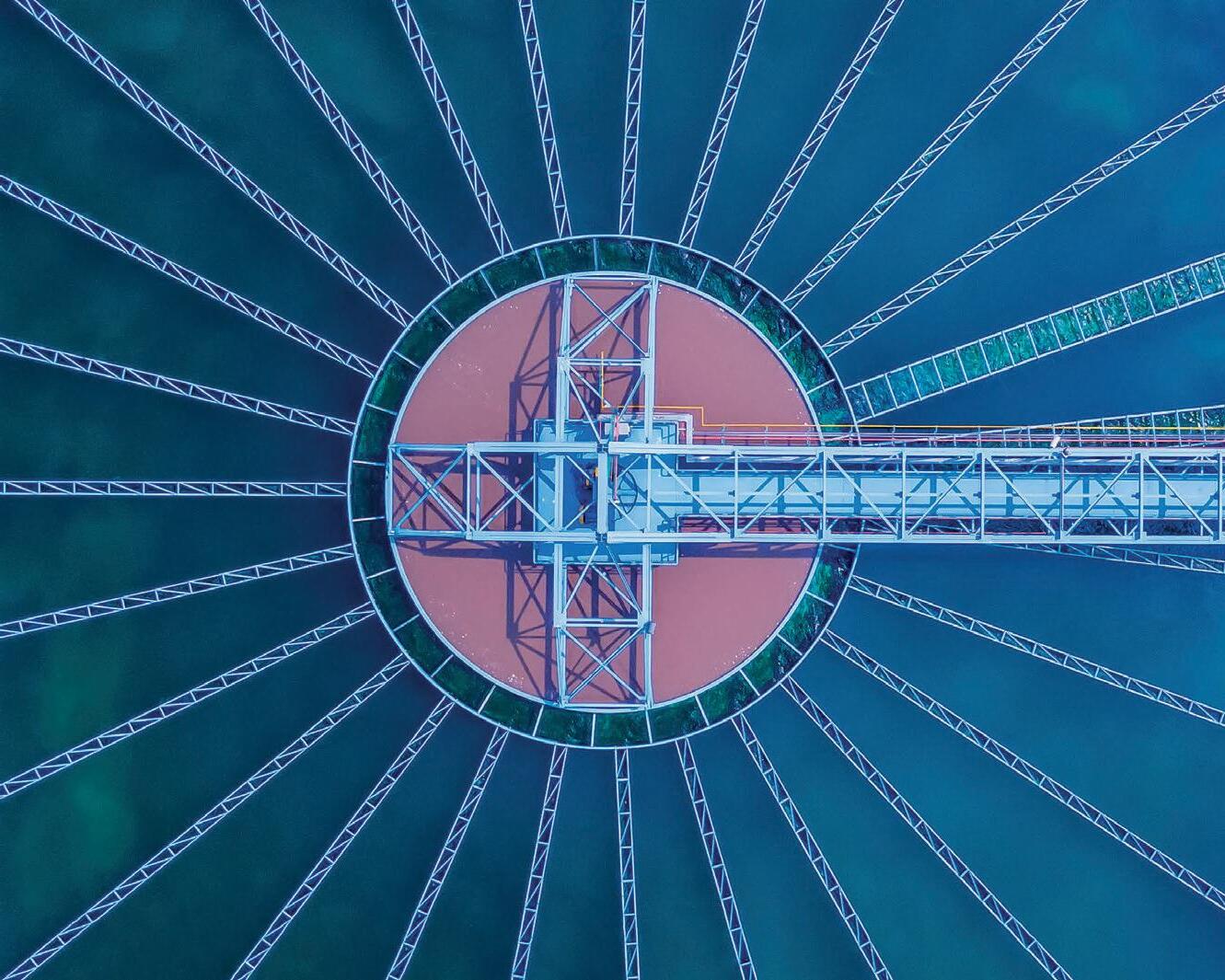

The inaugural year of Blue Phoenix’s incinerator bottom ash plant marks

Chris Gee, Blue Phoenix Australia Site Manager, describes the rst year of operation for the company’s incinerator bottom ash (IBA) plant in Western Australia as “incredible.”

In its rst 12 months, the plant has processed 100 per cent of all IBA received, achieving a 95 per cent recovery rate – none of the processed material has gone to land ll – and the team is already planning upgrades to the processing plant, particularly to enhance the extraction of stainless-steel and aluminium, ensuring a cleaner nal product.

Chris says the plant’s success represents a signi cant stride toward sustainability and the circular economy.

“We’re now a big part of the circular economy and driving sustainability,” he says. “We are recovering and reusing those materials that would otherwise go to land ll. To be a part of that is absolutely fantastic.”

e facility, the rst of its kind in the Southern Hemisphere, was o cially opened in October 2024. It processes IBA from energy-from-waste partner Acciona, transforming it into valuable secondary materials such as aggregates, for use in the civil construction industry.

Chris says the plant completed commissioning and achieved optimum running for material recovery relatively quickly.

Recognising that production e ciency required early intervention, the team identi ed and engineered out crucial downtime issues inherent in the initial build, establishing a maintenance program that ensures consistent operation. is allows the plant to run production four days a week, with the fth day dedicated entirely to maintenance.

e transition, however, was not without its unique challenges,

particularly those presented by the Australian climate. e relentless high temperatures of the Western Australia summer, with consistent high 30s and 40s, posed an operational hurdle.

“Heat a ects the material, causing it to dry out into a ne, dusty state,” Chris says.

It’s a stark contrast to the European experience, where summer heat is eeting. Now entering its rst winter, the plant faces the opposite problem: wet material causing blockages and operational issues.

Chris says managing this material consistency requires constant attention and adaptation, but the team has Blue Phoenix’s global knowledge and decades of experience to draw on.

“We’ve seen probably 90 to 95 per cent of the issues at other plants over the years,” he says. “It’s nothing di erent to what we’ve done before, and we’ve had some great tools on site.”

Personnel training also proved tough. Many new employees, some fresh out of school, had never seen a processing plant before, let alone one speci c to IBA. Teaching new personnel how to maintain, clean, and recognise issues unique to the Blue Phoenix patented technology was a de nite challenge.

Despite these operational hurdles, the plant’s performance metrics in its rst year have been remarkable. Chris says the response from industry and the local community has also been positive.

Blue Phoenix has actively engaged with local businesses, providing education on its processes and the material it recovers. ere have also been several industry tours of the facility.

“We had the Blue Phoenix Chief Executive O cer here in October, and when he saw the product we were producing after commissioning, he was shocked,” Chris says.

“We’ve made some pretty amazing material to go back into sub-base and road materials.”

e Blue Phoenix facility in Western Australia is not just an operational success; it is viewed as a global benchmark and is expected to serve as a blueprint for future Blue Phoenix projects worldwide, continuously improving with each new iteration.

“It’s certainly the best plant I’ve ever worked on,” Chris says.

“I thought the rst year would be a lot

Australia site and bid for new contracts, potentially bringing in an additional 50,000 tonnes.

“We’ve noticed an increase in stainless-steel and aluminium,” Chris says. “We want to upgrade the plant to extract this metal and have a cleaner and better product at the end of the process.”

For more information, visit: www.bluephoenix-group.com

SEQUENCED FILTRATION:

REMOVAL TO "NON-DETECT"

1,000,000 LITRES /DAY (SHOWN ABOVE)

PROVEN REMOVAL ALL PFAS

REMOVES FUTURE LIABILITY

SAFE AND FAST: INSTALLATION MAINTENANCE

REDUCE SITE COSTS:

DRY WASTE

REMOTE CONTROLLED SAVE OPERATOR TIME

SMALL FOOTPRINT

EcoCycle leads Australia’s push for safer mercury disposal, launching a new encapsulation plant to permanently retire this persistent toxic legacy.

Mercury may be a naturally occurring element, but its impact on human health and the environment is anything but natural.

From old thermometers and dental llings to industrial gauges and button cell batteries, mercury lingers in many corners of modern society.

Now, as international attention turns to the upcoming sixth Conference of the Parties (COP-6) to the Minamata Convention on Mercury (an international treaty designed to protect human health and the environment from the adverse e ects of mercury), Australia faces a timely question: are we doing enough to deal with this toxic legacy?

For EcoCycle, Australia’s most experienced mercury recycler, the answer is clear.

EcoCycle has long been at the forefront of mercury recovery, o ering end-to-end solutions to safely collect, treat, purify, and retire mercury from a wide range of sources.

With momentum building ahead of COP-6 the company is urging stronger national regulation, tighter compliance standards, and a more coordinated approach to mercury waste management.

Mercury has historically been used in a wide array of household, medical and industrial products – compact uorescent lighting, thermostats, mercury switches, sphygmomanometers

(used to measure blood pressure), button cell batteries and dental amalgam are among the most common.

While many of these items are slowly being phased out, thousands of tonnes of mercury-containing waste still circulate in the economy and environment.

According to Nick Dodd, General Manager at EcoCycle, the issue is not just historical.

“Even today, many dental clinics still use amalgam for restorative procedures. Amalgam llings, often referred to as silver llings, will remain present in the population for decades to come,” he says.

“As these are gradually removed or replaced it is essential to prevent mercury-bearing waste from entering our sewer systems, waterways, and harming the environment.

“Mining, oil and gas operations also continue to generate mercury as a by-product, and older infrastructure remains a ticking time bomb. e problem hasn’t gone away – it’s just changed form.”

EcoCycle provides collection and processing services for mercurycontaining waste from a range of sectors, including dental surgeries, hospitals, laboratories, mines and industrial facilities. It also services local councils and state governments tasked with managing public dropo programs.

ere are a variety of amalgam traps and ltration systems designed to capture mercury-bearing waste generated during dental procedures, particularly from the drilling of old amalgam llings.

EcoCycle supplies and services the full range of approved products available on the market, including its own ECOASO4 unit which, Nick says, for about $800 per year represents an a ordable and e ective solution to safeguard the environment and ensure compliance with best practice waste management.

At the heart of EcoCycle’s future o ering is a mercury encapsulation plant currently under development at the company’s site in Kwinana Beach, Western Australia.

Scheduled for commissioning by the end of 2025, the facility will incorporate proven German technology, enhanced with local innovations to deliver a world-class mercury retirement operation for Australia.

Once operational, the system will chemically bind liquid elemental mercury with sulphur in a controlled, vacuum-sealed environment, forming mercury sulphide (cinnabar) a non-toxic

and environmentally stable compound. e resulting product will be safe to transport and store, eliminating the risk of mercury vapour exposure or leakage.

Nick sees this as a transformative step.

“With the new encapsulation plant in Western Australia, we’ll have a permanent, best-practice solution for the retirement of mercury. It’s an investment in national capacity, designed to reduce risk, ensure compliance, and support Australia’s obligations under international conventions.”

Globally, mercury is regulated under the Minamata Convention on Mercury

use in dental amalgam. At COP-5 in 2023, delegates agreed that instead of immediately phasing out amalgam, parties must submit national plans outlining how they intend to reduce its use. ese plans will be reviewed at COP-6, to be held in Geneva in November 2025.

Australia’s Department of Climate Change, Energy, the Environment and Water (DCCEEW) has indicated that formal consultations on the national submission will begin in August 2025.

Until then, responsibility for enforcing correct amalgam disposal lies with state environmental regulators and health departments, with the Australian

mandated ban or regulatory framework that requires the collection and safe disposal of all mercury waste, including dental amalgam, would align Australia with best international practice, and what’s now being practiced in the United States, United Kingdom and European countries.”

As of 2023-24, there are more than 19,800 general dental practitioners in Australia, according to the Australian Health Practitioner Regulation Agency (AHPRA).

While some have transitioned to mercury-free alternatives, many still

and collection services across all states and territories.

e company also supports government e orts to prepare for stricter international obligations, providing technical input into draft policies and participating in industry consultations.

e 2024 Progress Report from the Minamata Convention Secretariat emphasises the importance of Best Available Techniques (BAT) and Best Environmental Practices (BEP) for mercury release control. At COP-5, parties adopted comprehensive guidance on mercury releases to land and water, including speci c measures for dental amalgam waste management.

While not all elements are mandatory, they o er a strong benchmark. e

guidance calls for mercury separators compliant with ISO 11143, sta training in waste minimisation, and the use of approved transport and recycling services.

“ at’s where EcoCycle already excels,” says Nick. “We’re ahead of the curve on containment, transport and compliance. e technology is coming. e capacity is coming. What we need now is the policy framework to make it universal.”

As COP-6 approaches, the focus will turn to how countries are meeting their commitments and what additional steps are needed. For Australia, Nick says this could mean setting national collection targets, introducing mandatory product stewardship, or banning mercury use in certain applications.

For the private sector, it’s also a moment to lead. EcoCycle is calling

on industry groups, waste generators and policymakers to collaborate on creating a coherent mercury recovery system, backed by data, infrastructure and regulation.

“ e days of turning a blind eye to mercury are over,” says Nick. “We know the risks. We know the solutions. COP-6 is our chance to get serious and protect future generations from a toxic legacy that never should have lasted this long.”

He says that as EcoCycle continues to invest in infrastructure and policy engagement, the pathway to national mercury retirement becomes clearer. With the right commitment and coordination, Australia can ensure mercury remains where it belongs – safely contained, and rmly in the past.

For more information, visit: www.ecocycle.com.au

A single TANA shredder has sparked Liverpool City Council’s pioneering Circular Economy Centre and micro-factory.

In the world of local government waste management, a single piece of equipment rarely sparks a revolution.

Yet, for Liverpool City Council,

Tim Pasley, Liverpool City Council’s Resource Recovery Manager. is initiative wasn’t born from an environmental mandate alone, but from a pragmatic assessment of investing in the infrastructure to manage the waste internally.

Historically, Liverpool City Council collected and land lled thousands of illegally dumped mattresses annually. e practice was expensive – up to $137 for each mattress – and unsustainable with land ll in the Sydney basin expected to expire by 2032. e cost of having mattresses taken away by a private contractor for recycling was close to $800,000 a year.

But what began as an investment in a shredder, quickly evolved into a vision to close the loop on mattress waste. e council successfully secured an Environment Protection Authority grant and implemented a localised waste strategy, which was quietly executed over four years. On November 16, 2023, the council unveiled its latest weapon in land ll diversion – the TANA Shark.

A ectionately known as “the Croc”, the TANA Shark provided the mechanical capacity, shredding mattresses and liberating the ock – a mix of textiles and foam – that was previously unusable. is material is now the feedstock for a groundbreaking micro-factory established at the Cowpasture Road facility, poised to become the region’s Circular Economy Centre.

e micro-factory is transforming mattress ock into high-value products through an innovative partnership with the University of New South

Wales (UNSW). Using UNSW’s intellectual property, Liverpool Council is embedding the ock into Green Ceramics and working on developing new technologies that aim to incorporate a higher percentage of mattress content.

e ultimate aim is to embed the circular economy directly into the council’s operations and infrastructure.

e council plans to use the Green Ceramic tiles – made from recycled mattress content – in its own capital works projects.

Tim says the rst application is a new education centre at the 600 Cowpasture Road site, where 160 square metres of the tiles will be installed.

“Visitors to the centre will be literally walking on the product, providing a tangible example of the council’s commitment,” he says.

He says the success of the TANA shredder and the resulting micro-factory has resonated across the region.

While Liverpool City Council is not a private company focused on business

development, its vision and the science behind its operations have drawn interest from neighbouring councils.

“We’ve got Wollondilly, Penrith, and Campbelltown signed up, and a number of private companies, sending mattresses to us for processing,” Tim says.

“When people use our mattress recycling facility, they are actively contributing to the circular economy which aligns with state government targets of 80 per cent diversion from land ll by 2030.”

e council is actively connecting residents, particularly school groups and families with the facility, allowing them to see where their mattresses are going.

Tim hopes this unique approach will help build community pride and foster understanding of the circular economy in action.

Looking ahead, the vision for the Circular Economy Centre is ambitious.

e current facility processes up to 78,000 mattresses annually, but the council is aiming to eventually

process up to one million mattresses a year with the addition of two more TANA shredders. It is working to lift development application restrictions to maximise processing capacity.

e collaboration extends beyond manufacturing; Liverpool Council is co-funding research and providing a unique learning experience for UNSW PhD students and local trainees, hoping to create jobs of the future.

“We’re trying to do things a little bit di erently here,” Tim says.

“ e TANA Shark pretty much unlocked all of this. We were aiming just for the shredder to begin with, and then once we had it, all these other opportunities started to come forward.

“ e Croc is the bridge in the recycling process: We collect the waste; we process it, and then the Croc’s the bridge to the manufacturing hub that we’ve created.”

For more information, visit: www.tana.com.au

The latest Australian Organics Recycling Association report reveals the states’ performance and highlights the need for harmonised policy and infrastructure investment to meet the growing volume of organics.

Unless the industry can continue to grow at a faster rate than population growth, organics material recycling rates will continue to decline,” says John McKew, National Executive O cer of the Australian Organics Recycling Association (AORA).

“ ere is a profound need to ensure the Australian organics recycling industry can continue to grow and keep pace with the growing volume of feedstock, either via existing operators expanding or attracting new entrants,” he says.

“Unless this occurs, the diversion of organics away from land lls cannot keep pace with the material being generated.”

He paints a picture of caution for the Australian Organics Recycling Industry (AORI), following the release of the third edition of e Economic Contribution of the Australian Organics Recycling Industry (2023-24) report.

Produced by Australian Economic Advocacy Solutions (AEAS), the report assesses the organics industry’s economic impact and capacity to meet increasing recycling targets.

As with previous editions, this report was produced to determine the economic and environmental bene ts of the organics recycling industry to the Australian and all state economies.

It shows that with national population growth, driven predominantly by immigration coupled with interstate migration, organics recycling rates have, albeit marginally, declined.

South Australia had the highest organics recycling rate at 78.8 per cent, followed by the ACT at 68.1 and New South Wales (57).

Victoria was the next best with a recycling rate of 49.5, followed by Queensland (38.2), Tasmania (37.8)

and Western Australia (33.6). e Northern Territory had the lowest organics recycling rate at 19.0 per cent.

In comparison, in 2021-22, South Australia’s recycling rate was 79.4 per cent, the ACT sat at 68 per cent, followed by New South Wales (57.9), Victoria (50.3), Queensland (39.2), Tasmania (34.8), Western Australia (34.5) and Northern Territory (19.7).

Tasmania is the only state to have recorded an increase in organics recycling in the past nancial year.

John says some actions can be taken by governments to support the industry.

“Leading those actions is a determination to harmonise regulations across states and improve the planning process for new or expanding facilities.

“Further, ensuring we do not overburden the industry with regulation

it has little or no control over, speci cally contamination of forever chemicals such as per- and poly- uoroalkyl substances (PFAS).”

Organic material recycling is driven by a number of factors, including population growth, economic growth, technological change, access to recycling markets, local government collection changes and commonwealth and state government waste and carbon reduction policies.

Across the decade, AORI’s recycled material has grown by 0.9 per cent each year and compares to Australia’s average population growth rate of 1.5 per cent over the same period.

In 2023-24, Australia is estimated to have produced 14.9 million tonnes of organic waste (about 550 kilograms per person) of which, 5.7 million tonnes was sent to land ll, 7.7 million was recycled and 1.6 million tonnes recovered through energy.

According to the report, Australia’s overall organic material recycling rate in 2023-24 was 51.4 per cent, (7676 kilotons of recycled organic material) compared to 52.3 per cent in 2021-22.

John says the drop re ects a higher number of tonnes recycled but a comparatively higher amount of organic material generated.

He says the National Waste Policy

“AORA plans, as part of the next edition of its Australian Organics Recycling Industry Capacity Assessment in 2025-26 to undertake additional analysis on progress toward the NWPAP target,” he says.

“If, as is evidenced from the third edition of e Economic Contribution of the Australian Organics Recycling Industry (2023-24) report, organics recycling rates have largely declined, we need to understand the reasons for this and the potential strategies to mitigate the situation.

“We know population growth is contributing to greater volumes of organic material being available for recycling and that situation will continue as long as population growth remains.”

John says it is highly likely that as food organics, garden organics (FOGO) services continue to be rolled out by local councils around the country that also will result in an increase.

“ e question then is how do we meet that growth in organic material,” he says.

John says the Federal Government’s Interim report, Australia’s circular economy: Unlocking the opportunities released by the Productivity Commission in March 2025, provides relevant considerations to this question.

e report suggests harmonising waste classi cations, kerbside recycling

regulations, either through improved interjurisdictional arrangements or a new body.

It also states governments could work with industry associations, research bodies and/or community organisations to coordinate initiatives. is could include o ering information on existing services, trialling new platforms, or facilitating connections between businesses for circular opportunities.

e Productivity Commission is seeking further input on how governments can use place-based circular policies to support economic, social and/or environmental objectives such as reducing regulatory burdens, linking circular objectives to precincts or regions with related objectives (net zero) or service delivery (waste management and recovery).

e Productivity Commission is proposing that an expanded set of indicators could include environmental and economic outcomes from circular activities, so that the data can be used to identify opportunities and measure improvements made.

John says all suggestions are “worthy pursuits”.

“AORA has long championed a need for greater harmonisation of policy and regulation across states,” he says.

“Especially as we begin to see an increasing number of organics processing businesses continue to grow across jurisdictional borders.”

He says it’s essential to improve planning processes to facilitate timely and less burdensome infrastructure investment across all states.

“Without ongoing investment by the AORI to grow the industry to meet the increasing growth in organics material, recycling rates will continue to decline and that is harmful for both the economy and the environment.”

For more information, visit: www.aora.org.au

As Australia aims for ambitious organics diversion goals; the spotlight is on innovative composting. Aerated Static Pile (ASP) systems, enhanced with engineered covers, are revolutionising the future of FOGO composting.

Halving the amount of organic waste sent to land ll and to roll out food organics and garden organics (FOGO) collection services to all metropolitan households and businesses by 2030 is a key component of Australia’s National Waste Policy Action Plan.

But as the 2030 deadline looms, pressure is mounting to adopt scalable, reliable composting technologies for FOGO.

Scott Woods, Founder and Chief Executive O cer of Sustainable Generation, says concrete tunnels and anaerobic digestion often fall short due to their complexity, high capital costs, and operational challenges.

Aerated static pile (ASP) composting has emerged as a practical, cost-e ective, and high-performing solution.

ASP BASICS

ASP composting relies on forced aeration to maintain aerobic conditions and optimise biological activity. ere are two primary methods: negative

aeration, which uses simple timed motors to pull air through the pile and exhaust through a bio lter; and positive aeration with temperature feedback. Developed in the 1980s, this method pushes air into the pile and uses real-time temperature monitoring to regulate blower activity, improving process consistency.

Both approaches typically require a biolayer cap – 250 millimetres or more of woodchips or nished compost – to manage odours and retain heat.

Scott says this traditional approach adds operational complexity and does not always deliver consistent results.

e latest evolution in ASP systems involves engineered membrane covers that are semi-permeable, waterproof, and breathable.

“ ese advanced systems o er invessel performance without the cost and complexity of enclosed facilities, consistently outperforming basic biolayer cap systems when evaluated on a true apples-to-apples basis,” he says.

Biolayer caps are labour- and equipment-intensive. Applied on top of the compost mix recipe pile as a 250-to-500-millimetre layer, it provides insulation and odour control but requires a consistent application and frequent watering.

Inconsistent cap thickness, improper application, or failure to apply the cap altogether can lead to odour problems and ine cient composting.

Brian Fuchs, Global Business Specialist at W.L. Gore & Associates, says engineered covers o er a visible, physical barrier that is easy to deploy and remove.

He says that with a more than 25-year track record, GORE Covers provide superior odour control, separate stormwater from leachate, regulate pile temperature, retain moisture, reduce greenhouse gas emissions, and improve compost quality – all while simplifying operations and reducing risk.

Two biolayer-based ASP designs – low tech ASP with aerated oors using above grade piping, and extended mass bed ASP’s using in-ground sparger or trenching systems – are currently used for FOGO processing.

Brian says both can face performance limitations.

“ ey can only handle up to less than 15 per cent food organics, digestate, or biosolids by weight before odour complaints arise and require roofs to separate stormwater and leachate,” he says.

“Moisture loss through the cap demands a dedicated watering system, and the cap reduces pile volume (thus capacity), consumes nished compost that could otherwise be sold, and introduces ongoing labour and operational costs.

“Uniformity in cap application is di cult to monitor, and inconsistencies compromise performance and emissions compliance.”

Brian says recent failures at FOGO facilities using aerated oor and mass bed ASPs reveal several recurring mistakes including:

Underestimating feedstock complexity – assuming ASPs can handle high food organics concentrations without adequate odour control.

Inadequate cap application –skipping the cap or applying insu cient depth (250 millimetres compared to the required 500 millimetres).

Ine ective moisture management – watering systems fail to penetrate the pile, drying out the core and requiring frequent turning.

High energy consumption – negative ASPs and single-blower manifold mass bed systems run continuously, consuming signi cant power and requiring complex components such as

actuators, and variable frequency drives, increasing maintenance risks.

Not all engineered fabric covers are the same. e performance of the GORE Cover system, supplied by Sustainable Generation, is setting a new standard.

Scott says proven reproduceable outcomes include 90-99 per cent odour reduction for a recipe mix of up to 50 per cent (by weight) of food, biosolids, digestate, and other di cult feedstocks such as animal waste and mortalities. e results are backed by third-party, independent air emission studies.

“ e GORE Cover does not require a roof for separation of stormwater from leachate, delivering lower capital costs when compared to other ASP systems,” Scott says.

Among other bene ts, the cover prevents the spread of litter from feedstock contamination. Because the cover is sealed to the surface, pressurization occurs and prevents channelling and anaerobic pockets, delivering additional performance.

Sustainable Generation’s positive aeration with oxygen control and monitoring also provides energy e ciency by turning the blower on

and o to meet the oxygen demand of the microorganisms that perform the composting process.

Because the GORE Cover is waterproof, moisture in the pile carries through the process, eliminating the need for a watering system.

ere are currently more than 400 installations of the GORE Cover worldwide, with an annual processing capacity of more than four million tonnes.

Scott says that as Australia’s FOGO mandates rapidly approach, councils, operators, and project developers must invest in proven, scalable composting technologies.

“ASP systems with engineered covers – particularly those incorporating the GORE Cover and positive aeration with oxygen control – are the clear frontrunners,” he says.

“ ese systems o er unmatched performance, reliability, and cost-e ciency, making them the ideal foundation for Australia’s next-generation organics recovery infrastructure.”

For more information, visit: www.sustainable-generation.com

On 17 September, the Waste Contractors and Recyclers Association of NSW (WCRA) will host the 2025 National Safety Summit in Sydney – the only conference dedicated solely to safety within the waste and recycling sector.

Safety must be more than a compliance exercise; it’s the foundation of every successful and sustainable waste and recycling business,” says Brett Lemin, Executive Director of the Waste Contractors and Recyclers Association (WCRA) of New South Wales.

“ e National Safety Summit is about coming together as an industry to share knowledge, challenge ourselves, and drive real improvements that protect our people every single day.”

Brett says at a time when the waste and recycling industry faces growing risks, from lithium-ion battery res to heavy vehicle incidents, manual handling, and the rise of psychosocial injuries, the National Safety Summit provides a critical forum to address these challenges head-on.

e summit brings together frontline workers, supervisors, managers, regulators, and safety professionals to collaborate, learn, and share best practices that help keep people safe and the industry moving.