As Australia’s largest supplier and extruder of aluminium, Capral is committed to supporting Australian manufacturing with high-quality, locally produced aluminium extrusions. Our stateof-the-art facilities provide precision-engineered solutions for industries nationwide, from construction, to transport, and marine.

Choosing Capral is an investment in reliable supply, shorter lead times, and a stronger Australian manufacturing sector.

When you need Australian-made aluminium, Capral can do.

manmonthly.com.au

Chairman: John Murphy

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Jack Lloyd jack.lloyd@primecreative.com.au

Design: Alejandro Molano

Head of Design: Blake Storey

Sales/Advertising: Emily Gorgievska Ph: 0432 083 392 emily.gorgievska@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST) Overseas prices apply Ph: (03) 9690 8766

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 11.01, 201 Miller St, North Sydney, NSW 2060

Printed by: The Precision Group

83-89 Freight Drive. Somerton Vic 3062 Ph: (03) 9794 8337

Welcome to the August edition of Manufacturers’ Monthly

For this edition’s Manufacturer Focus, NIOA CEO, Australia and New Zealand, Ben James, discussed the company’s growing footprint in ammunition and weapon system manufacturing. Additionally, in RSM Australia’s Manufacturing Playbook, Richard Quaine examines how real-time financial reporting can bridge the gap between operations and finance in manufacturing.

Finally, this issue features two Decision Maker columns, with pharmaceutical perspectives from Glen Fleming, CEO at Ego Pharmaceuticals, and defence insights from James Heading, director and general manager of Missiles and Fire Control for Lockheed Martin Australia.

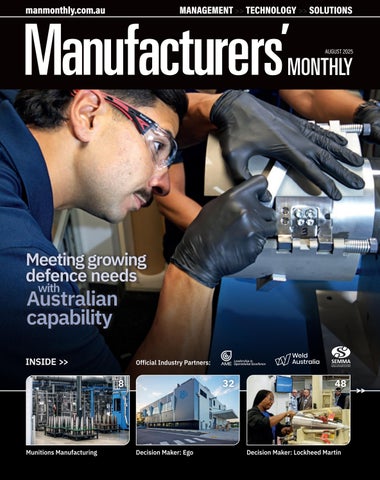

As a standout of our industry in 2025, Australian defence manufacturing is rapidly expanding in sovereign capabilities. Under the Defence Industry Development Strategy, the Federal Government is investing between $16 and $21 billion over the next decade, including major guided weapons and munitions projects.

According to the ABS, the defence industry added $11.9 billion in gross value to the economy in 2023–24 – a 12.4 per cent increase on the previous year – with employment rising 9.1 per cent to 69,400 people. Small and medium enterprises are playing an increasingly important role, supported by the $170 million Defence Industry Development Grant program to 2028, which aims to boost capability and security. This growth is underpinned by organisational reforms stemming from the Defence Strategic Review, targeting workforce shortages and shifting strategic needs.

The volume of announcements reflects the sector’s rising momentum. Key examples include a record $61.6 million contract for DroneShield, $480 million for shipbuilding and the AUKUS workforce, $262 million to strengthen the AUKUS supply chain, and a $569 million Boeing Defence contract.

Among these developments is the announcement of a new missile manufacturing complex in partnership with Lockheed Martin Australia. The facility aims to produce 4,000

missiles annually by 2029. As featured in this month’s edition, Lockheed Martin Australia’s director and general manager of Missiles and Fire, James Heading, outlines how the company is helping build Australia’s sovereign weapons capability. Beginning with assembly of GMLRS components, the program is scaling to full local manufacturing by decade’s end. With government investment of up to $21 billion, the initiative also includes local SME partnerships and the use of cutting-edge automation and digital technologies to strengthen supply chains, workforce skills, and long-term defence readiness.

Local defence manufacturer NIOA is another key player. With operations in Queensland and Victoria, NIOA produces everything from artillery shells to weapon systems. CEO Ben James underscores the company’s focus on expanding domestic capability through global partnerships and next-gen defence technology.

While defence is a central theme this edition, other sectors are equally vibrant. Ego Pharmaceuticals CEO Glen Fleming shares how the company is investing in local manufacturing, automation, and workforce development to build a future-ready business capable of meeting global demand and adapting to technological change.

Representing the medical technology space is the Australian Medtech Manufacturing Alliance (AMMA), featured for the first time in this issue. The alliance is calling for stronger support from

government and industry and is working to improve procurement systems and boost local demand through initiatives like the Pathways to Market program. While Australia’s medtech manufacturers create world-class products, many still struggle to sell locally due to fragmented systems. The Alliance seeks to close those gaps and elevate medtech as a national economic and healthcare asset.

We also spotlight the story of Naomi Elliot –general manager of Concept Labs and founder of Suncoast Biochem – whose leadership has transformed her family business into a futurefacing, sustainable manufacturer. A Women in Industry Award winner, Elliot is a champion for automation, growth, and empowerment in the skincare and cosmetics space.

This month’s Engineering Focus reports on a breakthrough from a global research team led by UNSW and the ARC Centre of Excellence for Carbon Science and Innovation. The team has created a featherlight calcium-intercalated graphene oxide aerogel that absorbs over three times its weight in water from humid air. This material offers a low-energy, high-efficiency solution to global water scarcity affecting more than 2.2 billion people.

Whether through sovereign defence programs, advanced pharmaceuticals, medtech breakthroughs, or climate-resilient technologies, our industry continues to aim for a future that is skilled and strategically self-reliant.

GEOFF CRITTENDEN, CEO, WELD AUSTRALIA

While Australia’s productivity is stagnating,

the solution lies in reforming licensing, strengthening

standards,

and focusing on real-world competency, says Geoff Crittenden.

Australia’s productivity growth is at its lowest level in 60 years, according to data from the Business Council of Australia (BCA). Despite decades of dialogue around reform and investment, we continue to fall behind our global competitors.

Productivity is one of the most powerful levers we have to improve living standards and control inflation. Yet, growth has stagnated at just 0.5 per cent over the past year. To match the already modest gains of the last decade, we’d need to quadruple that rate to around 2 per cent annually by 2030.

This downward trajectory is eroding our economic prosperity, placing pressure on national infrastructure programs, and weakening real wages and living standards. It doesn’t have to be this way.

Productivity isn’t a mystery. It’s a policy choice. And right now, some of our choices are holding us back. Among them, fragmented occupational licensing schemes and a patchwork of standards that add cost and complexity without clear benefit.

As Australia’s national authority on welding, Weld Australia recently made a submission to the Productivity Commission’s National Competition Policy Review. In it, we highlighted two key opportunities that could drive real, lasting productivity gains across construction, fabrication, manufacturing, and engineering: a unified national licensing framework for tradespeople, and greater clarity and consistency in the application of Australian and international standards.

licensing paradox

Across the trades, Australia’s licensing arrangements are inefficient at best and dysfunctional at worst. For example, bricklayers must be licensed. Electricians can become licensed straight out of TAFE. Yet every state and territory applies different rules, overseen by different bodies, often with inconsistent competency benchmarks.

The Productivity Commission has rightly identified occupational licensing as an area ripe for reform. In theory, licensing protects safety and quality. In practice, it’s a broken system that delivers neither. There is little assurance that licensed individuals meet real-world competency expectations, and virtually no national consistency.

In welding, we’ve taken a different path: an industry-led approach to certification. For decades, Weld Australia has overseen certification of welders to recognised Australian and international standards, ensuring they are competent to carry out high-risk, high-consequence work. This process is robust, auditable, and backed by accreditation bodies like JAS-ANZ and the International Institute of Welding (IIW).

It works – and more importantly, it works across borders. Certification to ISO 9606 or AS/NZS ISO 1554 ensures a welder is job-ready anywhere in the country. A national licensing scheme should adopt this same philosophy: assess competency, not just coursework; enable mobility, not bureaucracy; and demand rigour, not red tape.

The current system enables a person fresh from TAFE to undertake complex electrical

work, while simultaneously requiring licensed trades in areas where competency has not been adequately tested. This lack of consistency not only compromises safety and quality but stifles productivity. Employers must navigate a maze of licensing bodies, pay duplicate fees, and absorb unnecessary delays in project delivery.

We support a national licensing scheme, but only if it puts competency first. It must be tied to practical, standardised assessments that are recognised across jurisdictions. Otherwise, we’re simply reshuffling the deck chairs on a ship that’s already listing.

Weld Australia recommends the following:

1. State-based licensing should be replaced by a national licensing system run by the appropriate trade body.

2. Qualification and certification must be mandatory for all trades.

3. Trade training must include a test to standard.

4. Uncertified tradespeople must not work unsupervised.

The Productivity Commission also asked whether Australia should abandon national standards in favour of international alternatives. Our view is clear: the idea is not only impractical, but deeply misguided.

There’s no doubt that harmonising certain standards can support trade, particularly in regulated product markets. But to suggest we abandon Australian standards altogether is to misunderstand their value. Our standards are

designed for Australian conditions, be they environmental, industrial, or economic. They reflect decades of experience in construction, engineering, and manufacturing under our unique regulatory and climate settings.

Weld Australia collaborates closely with Standards Australia and international bodies like ISO. Many of our national welding standards are already aligned with ISO equivalents where appropriate. But adopting international standards wholesale would introduce unnecessary complexity, especially when those standards are bureaucratic, inconsistent, or irrelevant to Australian industry practice.

What’s more, the real issue isn’t which standards we use – it’s whether they’re being complied with. Right now, many imported fabricated steel components enter the Australian market without meeting any recognised standard, Australian or international. This not only creates a safety risk but undermines compliant Australian businesses that are doing the right thing.

The priority for reform should not be a switch to ISO for the sake of appearances. Instead, we need to strengthen compliance mechanisms, invest in quality assurance, and ensure fair competition by holding all market participants to the same bar, regardless of origin.

The overarching problem in both licensing and standards is fragmentation. Every state and territory runs its own licensing agenda.

Every procurement agency seems to interpret compliance differently. The result? Costly inefficiencies, lost productivity, and a national workforce that struggles to move where it’s needed most.

Consider this: in the construction industry, while the number of workers has increased in the past decade, output per worker has reduced. On average, people are working two hours less per year with 25.4 per cent lower output – calculated as construction work completed divided by the number of workers. For example, worker output in 2023 was $180,100, compared with $196,800 in 2018. With demand for skilled workers continuing to outpace the available supply, greater productivity is key to raising worker output.

Skilled labour shortages persist, yet our systems prevent qualified people from moving between jurisdictions or gaining recognition for their skills.

The solution isn’t another layer of policy. It’s simplification. A national licensing system, based on real competency. A clear framework for standard adoption, focused on outcomes, not politics. Stronger enforcement of quality expectations, not weaker ones. And training systems that prepare workers for real jobs, not just hand out certifications on paper.

Weld Australia is leading by example. We’ve proposed a new productivity-based training scheme that gives fabrication businesses the resources to train staff internally, supported by our advanced learning modules and instructor

accreditation. We are also fast-tracking certification for production welders so businesses can access qualified workers in weeks, not years. At the same time, we’re conducting research into welder productivity across jurisdictions. Our findings suggest that Australian welders average just two hours of arc-on-time per day, compared to five hours in Germany or the US. We’re investigating how technology, such as collaborative robots (cobots) and Trades Assistants, can help overcome bottlenecks in materials handling and prep work, freeing qualified welders to focus on highvalue tasks.

These are tangible, grassroots solutions, designed by industry, for industry. If we truly want to lift Australia’s productivity, we need to move beyond theoretical policy debates and start acting on what works.

The Productivity Commission’s review is an important opportunity. But it must be more than just another report. If we are serious about revitalising productivity, we need bold action. That means unifying trade licensing around demonstrated competency. It means safeguarding Australian standards where they serve us best. And it means enforcing compliance to protect local jobs and communities.

The reforms we need aren’t radical – they’re rational. But they require leadership, collaboration, and a willingness to put practical outcomes ahead of politics. The future of Australian industry depends on it.

NIOA CEO, Australia and New Zealand, Ben James, sat down with Manufacturers’ Monthly’s Jack Lloyd to unpack the company’s growing footprint in ammunition and weapon system manufacturing across the country.

Headquartered in Brisbane, NIOA is an Australian-owned supplier of firearms, ammunition, and weapon systems across defence, law enforcement, and commercial sectors. Notably, the company bolsters Australia’s sovereign defence manufacturing capabilities through its involvement in munitions plants in Victoria and Queensland.

Despite investments in advanced facilities and partnerships with government and global OEMs, NIOA remains family-owned by Group CEO Robert Nioa, a key advocate for building a strong, domestic defence industry. Nioa inherited the business from his parents, Bill and Barbara Nioa, who sold firearms while running service stations on the Fraser Coast and up toward Townsville in the 1970s.

“Bill was a keen shotgun shooter, and over time they began selling firearms alongside their service station operations,” said Ben James, CEO of NIOA Australia and New Zealand. “After the Port Arthur tragedy in 1996 and the major gun law reforms that followed, a lot of businesses exited the industry – but Bill and Rob decided to double down.

“They held a family meeting and made the call to

expand, purchasing several businesses and moving into wholesale. That’s when things really started to grow.”

While the company’s roots lie in the commercial sporting side of the firearms business in 1973 – an aspect still maintained across Australia and New Zealand – by the late ‘90s, NIOA had diversified into government, particularly law enforcement and defence. Its first major distribution agreements were with Nico Pyrotechnic – now part of Rheinmetall –and Saco Defence.

“Today, most of our revenue comes from the defence side – firearms, ammunition and the services that go along with that – but the sporting side still remains a significant part of what we do,” said James.

Flashing forward to the present, NIOA Group is now split into four main operating units that span several countries including Australia, New Zealand, the United States, and most recently, the UK.

• T he largest unit, NIOA Australia and New Zealand, is directly managed by James and includes the Brisbane headquarters, technical centre, and a facility near Christchurch on New

Zealand’s South Island. It employs around 140 people.

• T he second unit reflects NIOA’s global ambition, focusing on Barrett Manufacturing in Murfreesboro, Tennessee – a renowned name in large-calibre, long-range precision shooting and now a wholly owned subsidiary.

• T he third is a Joint Venture with Rheinmetall in Maryborough, Queensland, (Rheinmetall Nioa Munitions) producing 155mm artillery ammunition with the German defence company.

• T he fourth, the Australian Missile Corporation, provides advisory and staff support to Defence, particularly in guided weapons and explosive ordnance.

NIOA’s global projects often overshadow the fact that the company still has manufacturing projects here in Australia. This manufacturing largely occurs on two sites, the first of which is the Joint Venture with Rheinmetall (RNM – Rheinmetall NIOA Munitions) in Rob Nioa’s hometown

manufacturing in Benalla, Victoria under contract at a government-owned, commercially operated facility. NIOA operates about half the tenancy at Benalla, where it manufactures a range of munitions and weaponry.

“This includes 120mm tank ammunition for the Abrams tanks, and medium-calibre ammunition used by armoured vehicles, the Joint Strike Fighter, and eventually the Apache helicopters when they arrive,” said James. “That site also produces fuses for grenades, primary energetics for primers, and pyrotechnics.

“It’s a highly capable part of Australia’s strategic manufacturing enterprise, with latent capacity to support pressing warheads for loitering munitions and guided weapons, among other capabilities.”

by James as non-negotiables for forging steel and manufacturing projectiles the size and weight required for artillery. These technologies operate alongside Schuler presses and CNC machines to ensure a precise manufacturing production line.

“The machinery itself is incredibly impressive, with robotic arms moving the shells through the production line via conveyor belts and CNC systems,” said James. “You’ll see banks of CNC machines that give the rounds their precise shape and finish, along with balancing machines to ensure the projectile’s properties meet exact specifications.

“The forge itself in Maryborough is built around a massive Schuler press, which shapes the steel billets into the core form of the projectile.”

of Maryborough, QLD. Here, James said the workforce – including more than 100 of NIOA’s own – manufactures 155mm artillery projectiles for export markets and potentially for use by the ADF.

“Essentially, we’re taking steel billets and turning them into artillery projectiles – non-explosive components – which are then exported to Germany at a rate of around 45,000 rounds a year,” he said. “Once they arrive in Germany, the projectiles are filled with explosives, fitted with fuses and a propelling charge, and prepared for use in artillery systems.”

Alongside this facility, NIOA also has 16 staff

While 16 may seem like a small workforce, Benalla are already producing rounds in the tens of thousands to meet existing demand, with scope to grow and expand operations.

“We have clear plans to expand both the number and types of ammunition we manufacture at Benalla, and there’s potential to extend that site to support production of solid rocket motors for Defence’s high-priority guided weapons program,” said James. “If those proposals gain traction, we’d expect the headcount to grow substantially.”

Supplementing NIOA’s workforce at both sites is robotic and automated processes, systems described

Alongside an innovative production line, NIOA also scrutinises the quality control measures of its defence products to ensure performance and safety. James said this particularly shines in Maryborough, where the workforce has developed unique Quality Assurance and Quality Control (QAQC) processes.

“They’ve implemented ways to test whether the metal has the right hardness, tensile and impact strength, giving the necessary fragmentation properties, and has developed a balancing process to ensure each round performs with the right dynamic flight characteristics,” he said. “It’s a really skilled and thoughtful workforce in Maryborough, with a strong sense of initiative and engineering know-how.”

At the Benalla facility, a large part of the quality control and overall manufacturing mission is to ensure the ammunition performs as it should. This includes testing through pressure gauges and different environmental conditions. James emphasised the impressiveness of the team of engineers who put ammunition and weapons systems through tests at sub-zero temperatures, dragging them through sand, mud, and silt.

“When we manufacture medium calibre ammunition, for example, we test it in cannons using pressure gauges to ensure it won’t exceed safe specifications in the breach,” said James. “We also test fragmentation, muzzle velocity, and ballistic performance – not just to make sure the ammunition does its job for soldiers, but that it’s safe to use under extreme environmental conditions.”

Past direct manufacturing initiatives, NIOA also does its share in growing a skilled local workforce with people that previously had little to no experience in the defence industry. In Maryborough, experience in manufacturing artillery projectiles was low, with the regional city having a very strong manufacturing and maritime history. Despite this, James said NIOA utilised the area’s industrial heritage to create a widely skilled workforce within the facility.

“Maryborough is where the train carriages for the Brisbane Olympics are being built. There’s a deep industrial heritage in the region,” he said. “While the employees in the forge didn’t have experience in making artillery projectiles, they’ve brought broad skills from parallel industries to producing this critical ammunition for the ADF and for export.”

The Benalla facility has seen similar initiatives as it utilised a local skill base drawn from industries like solar and concreting and applied it to the demands of ammunition manufacturing.

“Whether it’s working with raw materials from Germany, components from Northrop Grumman in the US, or producing small arms primers with partners elsewhere, the key is to identify a skilled, motivated workforce,” said James.

James said that in both NIOA’s locations, if you help a workforce understand the importance of the industry they’re contributing to, encourage a strong sense of initiative, and back it up with the right values, the rest tends to “take care of itself”.

Alongside manufacturing facilities dedicated to enhancing Australia’s Defence Industry capabilities, NIOA has direct involvement in projects in and

outside of Australia. Within Australia, an example of this is involvement in the ADF’s LAND 300 and LAND 1508 projects.

LAND 300 – targeted at what Defence calls the ‘Close Combat Family of Weapons’ – began as a program to replace all the Australian Defence Force’s small arms including pistols, assault rifles, machine guns, grenades, and lethality systems. This has since expanded to cater to modern combat.

“NIOA has been the prime contractor delivering that Program of work, and when we bid for the tender, we told Defence: we won’t just offer you a standalone sniper rifle – we’ll build you a complete, best-of-breed system,” said James. “We’re concluding the delivery of the first tranche of those systems, which includes everything from pistols and personal defence weapons to specialised weapons such as the Barrett M107A1 Anti-Material Sniper System.”

This commitment to the best rifle, optic, ammunition, surveillance and thermal systems –even the best carry case, firing support implements, bipods and integrated platform – sees NIOA test all equipment for this project – and others – extensively.

“We test everything here at our 100-metre indoor range in Brisbane – gel block testing, drop

testing, environmental and drag testing – to ensure these systems meet every specification required by Defence,” said James. “Once we complete delivery, we’ll move into sustainment –maintaining those systems at unit level – which is a pretty exciting evolution of the program.”

Land 1508 is a separate program with its own budget and a more agile, flexible scope. It allows NIOA to turn things around faster – from identifying a requirement from a specific user community to testing and bringing a capability into service. This might include modifying an existing weapon system – swapping out an upper or Picatinny rail – or even introducing a completely new system like loitering munitions or armed drones.

“We’re constantly learning, evolving, and adapting our manufacturing processes,” said James. “Those loitering munitions, for example, carry small warheads, and we’re looking at how we might integrate that capability into our tenancy at Benalla as well.”

A project that is more international facing is NIOA’s acquisition of long-range, large-calibre 50-calibre sniper system specialist, Barrett Firearms, based in Murfreesboro, Tennessee USA. After having a long-term relationship with Barrett through a distribution arrangement, NIOA acquired the company in 2023 and has since embarked on

an expansion program to broaden its product lines and increase capacity.

“Barrett has an extraordinary history and manufacturing footprint in Tennessee and, like NIOA, is evolving from a company with an idea into a broader, next-level capability provider,” said James. “We’re working closely with both the Tennessee State Government and the Federal Government to expand the factory.”

One such project that Barrett Firearms is leading – alongside ammunition manufacturer AMTEC Corporation and other US companies – is the US

Army’s Precision Grenadier System (PGS). This involves moving beyond long-range precision fire to develop a 30mm, shoulder-fired precision grenade system, designed as a Squad Support Rifle System. In May 2025, after a competitive testing phase, the team led by Barrett was announced as the winner of the US Army xTech Soldier Lethality prize. xTech is a US Army run program that stimulates innovation and served as a precursor to the PGS program of record.

“This is a big leap. 30mm rounds are normally fired from vehicles or aircraft, but this system will be portable by individual soldiers,” said James. “These

As a leading defence consulting firm, Systematiq has the experience & expertise to navigate the complexities across the

Our experience, attention to detail and knowledge of industry-leading practices ensure our clients achieve their strategic goals.

Talk to us about how we can support your entry into the defence industry and moving your projects forward.

30mm precision grenades are highly relevant for countering unmanned aerial systems (UAS) and can be proximity-fused, which is proving important in conflicts.”

Alongside these projects, the commercial sporting side of the business is still very much in action.

James himself is really excited about where things are headed, especially off the back of a substantial expansion of NIOA’s sporting distribution. He believes this side of the business is going from strength to strength with high-quality products.

“We have partnered with a European manufacturing company called the Czechoslovak Group or CSG, which owns premium shotgun brands like Perazzi, as well as ammunition brands like Fiocchi, Lyalvale Exopress and Baschieri & Pellagri (B&P),” he said. “We are now the sole exclusive representative for those brands in the Australian sporting market.”

Looking ahead, James insists that NIOA is still pushing hard for new programs of work in defence, responding to the fact that the “we’re living in an

increasingly rough neighbourhood in the IndoPacific, with some serious muscle flexing going on”. He noted that Benalla is a key site for these new programs aimed at expanding manufacturing capability.

“Australia has to think differently about defence, and we’re working to help meet that challenge by developing new capabilities, including components for guided weapons like solid rocket motors, propulsion systems for missiles, and the associated warheads,” he said. “We have proposals with Defence and are working closely on how industry can partner to bring those capabilities to Australia quickly, both to support our National security requirements, and to support allies and coalition partners and their forward deployed troops.”

James emphasised that this strong approach to domestic capability is off the back of recent global lessons that taught Australia that it needs to be able to manufacture more here at home. He believes as a nation we can’t just rely on global supply chains during crises, whether health pandemics or supply chain disruption.

“We’re strongly advocating for increased domestic manufacturing in weapons and munitions,” James said. “We have significant planning underway to meet today’s defence needs and to prepare Australia’s defence industry for tomorrow.”

As a part of preparing the industry for the future, NIOA is also investing in cutting-edge technologies to maintain an edge.

“Additionally, we’re breaking new ground in capabilities such as loitering munitions and counterUAS technologies,” James said. “These are no longer just future battlefield technologies – they’re here now, and we have to move fast and be agile to keep up.”

NIOA is expanding its capabilities and facilities, not just to meet current defence demands but to position Australia as a sovereign manufacturing force in the global defence landscape. From guided weapons to next-generation battlefield systems, James makes it clear the company is focused on strategic, homegrown solutions that will help safeguard the nation in an increasingly volatile region.

NIOA’s Brisbane headquarters is a state-of-theart facility supporting Australia’s defence and commercial firearms industries.

RSM Australia’s Richard Quaine examines how real-time financial reporting can bridge the gap between operations and finance in manufacturing.

In today’s manufacturing environment, split-second decisions can have long-term financial impacts. Yet despite rising inflation, ongoing supply chain disruptions and increasing operational complexities, many manufacturers still depend on outdated, retrospective financial reports to guide planning. Monthly or quarterly reporting no longer meets standards.

This reality first struck Richard Quaine, director of Audit and Assurance at RSM Australia, after seeing several family-owned manufacturers acquired by multinationals – only to be caught off guard by the unexpected level of oversight and reporting rigour required by global head offices.

“When those companies are sold to multinationals, suddenly they’re reporting to boards overseas – in the US or Europe – and the way they’ve been running things for 20 or 30 years is no longer fit,” said Quaine.

To remain competitive, Quaine believes manufacturers need real-time financial insights to enable quicker responses to risk, improve operational efficiency, and support better strategic decisions.

“Across all levels of the business, from the shop floor to the executive suite, real-time reporting is no longer optional, but essential,” he said.

The need for real-time reporting stems from a disconnect between the financial and operational sides of a business. Quaine said that while many manufacturers have digitised operations – robotics on the production line, real-time logistics tracking, and automated inventory systems – finance often remains reactive.

“One of the most common disconnects is timing – operations are dealing with real-time issues like production delays or supplier disruptions, while finance is often working with data that’s weeks or even months old,” said Quaine. “Without a shared reporting platform, decisions tend to be reactive rather than strategic.”

Another issue is the difference in granularity. While operations may track performance down to a specific machine or product batch, finance often focuses on high-level management accounts. This disconnect can lead to delayed visibility across cost overruns, inaccurate pricing decisions, and inefficient working capital management due to outdated accounts receivable and payable balances.

“The result is missed opportunities, preventable errors, and slower response times at exactly the moment when operational agility matters most,” he said.

Quaine emphasised that real-time reporting isn’t about more data, but better data – available at the right time and in the right format. In a manufacturing context, this means continuous or daily financial insights that mirror operational performance, helping the finance department to shift from scorekeeper to strategic partner.

When production and finance systems are integrated, manufacturers gain a shared source of truth linking daily activity to long-term direction.

“It connects production, sales, inventory, and finance into a single view, so that leaders can understand the financial impact of decisions as they happen,” said Quaine. “All of this allows management to make course corrections on the fly, whether that’s reordering materials, adjusting labour, or reviewing pricing strategies.”

ERP platforms such as SAP, NetSuite, or Microsoft Dynamics 365 are key tools for the enablement of real-time reporting. Properly integrated these systems / tools can consolidate data across departments to provide instant visibility into performance. Examples include:

• Live dashboards tracking COGS, gross margin, and WIP by product line.

• Rolling cash flow forecasts based on current receivables, payables, and pipeline.

• Automated alerts for raw material thresholds to trigger timely procurement.

• Daily variance analysis comparing actual vs standard job costs.

• Real-time margin tracking by job or project.

“Inventory management becomes more precise, production planning more agile, and the entire operation becomes more responsive and lean,” said Quaine. “You can reroute jobs, adjust batch sizes, or shift labour in line with current margin and demand data.”

According to Quaine, ERP systems are further enhanced with automation and AI. These features allow for automated reconciliations and workflows that reduce manual error; predictive analytics for costing, pricing, and forecasting; and dynamic dashboards linking operations, sales, and finance.

1. Stronger strategic decisions – Monitor margins, demand trends, and labour efficiency in near real-time to inform pricing and planning decisions.

2. Improved cash flow – Daily updates on receivables and payables enable better collections, timing of payments, and capital allocation or investment decisions.

3. Operational efficiency – Link finance and production data to detect cost blowouts early and optimise supplier negotiations or resourcing.

4. Enhanced governance – Flag budget variances or compliance issues sooner to improve audit readiness and risk management.

Despite its benefits, Quaine acknowledged the path to real-time reporting can be difficult. Integration remains one of the biggest challenges, especially for businesses using legacy ERPs or siloed systems. Implementation costs and resourcing are also key concerns, but Quaine suggested that staged rollouts can make the process more manageable.

“Many mid-sized manufacturers find success by starting with high-impact areas like inventory, margin reporting, or cash flow visibility,” he said. Data integrity is another hurdle. If input data is inconsistent or flawed, the insights generated will be unreliable. Quaine emphasised that clean, structured, and reconciled data is essential; without it, real-time reporting can potentially amplify existing errors.

Equally important in Quaine’s mind is overcoming cultural resistance, as adopting real-time reporting requires a fundamental shift in mindset – from periodic reviews to

continuous performance monitoring. It is not merely a systems upgrade; finance must evolve from retrospective scorekeeping to real-time performance management.

The good news is that these challenges are solvable. RSM Australia’s ERP Consulting and Digital Advisory team specialises in systems transformation and real-time reporting enablement. As businesses seek to streamline operations, reduce reporting lags and improve data accuracy, the firm is seeing growing demand for ERP modernisation, automation and dashboarddriven insights.

While Quaine’s role as an external auditor focuses on financial reporting integrity and evaluating controls relevant to the audit, he works closely with the ERP & Digital Advisory team to keep up to date with these evolving trends. This collaboration allows him to bring timely and practical insights to audit clients, helping them strengthen governance, enhance transparency, and improve decisionmaking.

“I’ve seen how they help clients in multiple ways, like assessing and modernising their ERP architecture, automating data flows to reduce errors, and developing dashboards aligned to business drivers,” he said. “They also provide the training and change management needed to embed these tools effectively.”

Several manufacturers have already seen tangible results from adopting automation and real-time reporting tools. In one case, a food and beverage manufacturer halved its month-end close timeline from 15 days to seven by automating journal entries, variance analysis, and stock reconciliations.

“This freed up Finance staff to provide business partnering support during the month,” Quaine said. “Management had access to near-final numbers by day six or seven, enabling more agile decisions on pricing and promotions.”

In another example, an industrial manufacturer reduced stock obsolescence by over 20 per cent after implementing a live inventory dashboard that linked production and sales data. The system flagged low raw material levels in real-time, enabling proactive procurement and smoother production scheduling.

“This allowed them to avoid production delays and fulfil orders – ultimately strengthening both service levels and cost control,” Quaine said.

Quaine believes traditional month-end reporting will still exist in the future, but will eventually take on a different role – more of a compliance -function than a management tool. The real shift will be in how finance supports operations between reporting cycles, using daily insights and predictive analytics.

“Finance teams that embrace real-time reporting will spend less time bookkeeping and more time driving performance. In short, finance is moving from the back office to the front line of strategic decision-making,” he said.

For making the business case, Quaine advises finance leaders to focus on outcomes that matter to operational decision-makers: faster forecasting, better working capital management, less waste, and closer alignment between pricing and profitability.

“It’s not just a finance tool – it’s a business enabler that empowers operations to make smarter, data-backed decisions,” he said.

How AVT helped Street Furniture Australia transform operations with Oracle NetSuite – an integrated ERP solution driving precision, confidence, and scalable growth for Australian manufacturers.

Founded in 1986, Street Furniture Australia designs and manufactures vibrant, durable public furniture for streets, parks, campuses and transport hubs. With more than 30,000 installations worldwide – including projects for Google Campus in Washington, the Long Island Railroad in New York, and Sydney Trains – the company is recognised for its design-led ethos, local manufacturing, and commitment to public space activation.

But despite a loyal customer base and a strong design reputation, the company’s internal systems were straining under pressure. Street Furniture Australia was relying on an array of disconnected and manual spreadsheets that led to missed deadlines, unprofitable products going undetected, and staff uncertainty over critical business data. These fragmented systems, sprawling spreadsheets, and production inconsistencies were creating operational headaches, threatening customer satisfaction and holding the team back. This is when Street Furniture Australia began its search for a system overhaul that would eventually lead it to a fruitful partnership with AVT.

“We had the growth. What we needed was control and process automation,” explains CEO, Street Furniture Australia, Blair Saddington. “Centralising on one platform gave us that control and the ability to move fast. AVT, with their deep understanding of NetSuite, manufacturing, process improvement and integration skills, were the perfect partner for us.”

Prior to implementing NetSuite, Street Furniture Australia’s on-time delivery rate hovered around 50 per cent. Inventory errors, quoting, and production led to costly rework and miscommunication. The business had simply outgrown its original setup –and even its premises. A move to a larger facility in Sydney signalled readiness for scale, but not without the right operational foundation.

“If you don’t have information, you can’t make good decisions,” said Saddington. “We could make furniture, we could talk to customers, we could sell. But putting it all together and making the timing just right was very difficult when you don’t have the information. Data is everything.”

To support its transformation, Street Furniture Australia selected NetSuite after reviewing four ERP platforms. The deciding factor was a fast return on investment and a strong partnership with AVT, which had already built trust through its collaborative approach and manufacturing acumen.

“Moving from multiple systems to one NetSuite system that had all our information. We finally had real, reliable data and could make confident decisions. It made a big difference,” said Saddington.

For Head of Operations, Street Furniture Australia, Chris Morgan, the impact of NetSuite was immediate and foundational. He said that NetSuite is now embedded in Street Furniture Australia’s operations so much so that it’s now referred to as SPOT (single point of truth)” for all processes.

“All the data from finance, manufacturing, warehousing, sales and marketing is contained in one system,” he said. “Everything is linked. Everyone can see where everyone else is working. If you need a bit of information, you can follow it from a sales order

all the way to a purchase order. It’s become the way we live.”

This seamless integration has powered end-to-end visibility and improved reliability. Once plagued by surprise shortages and two-week stocktakes, Street Furniture Australia now operates with less than one per cent variance in inventory – and no reported stockouts on high-volume runs.

“We’d come in the morning and find two parts we never ordered, and jobs would sit for months while we air-freighted castings or parts at a huge cost,” says Morgan. “Now we have a clean, accurate warehousing system that is reliable. We’re looking at moving to just one stocktake per year thanks to cycle counting and built-in controls.”

The shift to NetSuite has also delivered benefits across engineering, sales and customer service. Head of Engineering, Quality and Business Systems, Mahsa Hirbod, said that NetSuite has helped improve the business coding process with speed and accuracy.

“Products get quality checked better because there are fewer mistakes when transferring data from sales to operations,” she said. “Reporting and analytics allow us to make better decisions, like identifying top-performing products or improving cost efficiency.”

Quoting speed and accuracy have also improved, supported by a new product configurator that

standardises sales language and production specifications to reduce friction between departments. Additionally, order fulfilment has become a point of pride, with Street Furniture Australia recently completing its largest-ever order of 800 seats for Sydney Trains in just eight weeks without stockouts or dispatch delays. Customer complaints have declined, and the business now proactively alerts clients to any potential delays, enabled by real-time visibility across operations.

Street Furniture Australia’s success story speaks to the broader digital maturity journey within Australian manufacturing. ERP systems like NetSuite are no longer just finance tools – they serve as the operational backbone of modern, data-driven businesses. Saddington sees the transformation as pivotal for smaller manufacturers navigating complexity and margin pressure.

“You can’t run this in Excel anymore,” he said. “ERP lets you scale, but more importantly, it gives you clarity. When you know your margins, your capacity and your stock position, you can make the right investments in people, machines and projects.”

NetSuite has helped Street Furniture Australia align its manufacturing, inventory and customer engagement around shared data, enabling faster

launches and more consistent performance. Staff no longer second-guess the system, they trust it.

With more than a decade of understanding Street Furniture Australia’s operations, AVT’s role in the transformation was described as “part of the team, not contractors”.

“AVT helped us deploy streamlined processes robustly and efficiently to meet our change and improvement needs,” said Hirbod.

Tyre-derived rubber is already being used in Australian-made products with proven success across defence infrastructure. It’s local, durable and ESG-aligned.

Explore suppliers already using tyrederived rubber in their manufacturing. If yours doesn’t — ask why not.

As the company looks ahead, its integrated ERP platform gives it the confidence to keep growing, not just in size, but in service quality, innovation and manufacturing precision.

For Australian manufacturers seeking to grow without compromising control, Street Furniture Australia offers a clear example: clarity is real-time visibility from a single source of truth, which in turn fosters sustainable growth with trusted data.

Manufacturers’ Monthly explores the longstanding relationship between Albert Smith Signs and one of its key material suppliers, Capral Aluminium.

Founded in 1875, Albert Smith Signs is an Australian manufacturer specialising in the design, production and installation of signage solutions for national and international brands. Before evolving into a large-scale operation, the business began with the humble craft of rubber stamp manufacturing.

“My great-grandfather went to New Zealand to start the business but returned to Australia and set up shop in Brisbane,” said Rodney Smith, CEO of Albert Smith Signs. “My grandfather joined him making rubber stamps and stencils, and then just before the war, my father came on board.”

After World War II, Smith’s father brought back knowledge gained during his time in the air force, helping to launch what Rodney called “an acrylic revolution” in the business. Transitioning from simple products like house nameplates and brass plaques, the company moved into plastic signage as technologies evolved. Rodney Smith joined the business at age 16 and soon witnessed a national expansion beginning in the 1970s.

“We moved into vacuum forming and expanded nationally through major clients like Shell, Kmart and Woolworths,” he said. “That national expansion saw us set up in every state across Australia.

“It was a gradual evolution, driven by innovation and opportunity, from rubber stamps to largescale plastic fabrication. We’ve come a long way

from our humble beginnings – but it’s been a very natural and progressive journey.”

With national expansion paving the way for an international presence, Albert Smith Signs delivers solutions to a broad client base across and beyond Australia. Having traditionally served oil companies – most of which now import signage –the business has shifted its focus to new sectors.

“As manufacturers, we build boutique products tailored to each customer’s needs in colour, size and style,” said Smith. “We do a wide range of work – major shopping centre signage, Westfield identification signs, directional signage in malls and car parks and signs for Hungry Jack’s, KFC, Subway. Sometimes I forget how much we still build until I look at our website.”

Smith said projects range in value from a few dollars to multi-million-dollar undertakings.

“We’ve done everything from a toilet sign to a $400,000 or $500,000 sky sign to several projects around the $25 to $30 million mark, all manufactured here in Australia with Australian components and Australian people,” he said. “Offshore, we did another $30-$40 million for a major oil brand across Asia Pacific, Hong Kong and all of Australia.”

The company has also created public art pieces, much of it in aluminium.

“I often see our work on TV and think, ‘wow, that is pretty cool’,” Smith said. “It takes a huge amount of time and skill to get it right – artists might create something out of cardboard, and then we replicate it in aluminium.”

With manufacturing facilities in Australia, China and the Philippines, the company has produced hundreds of millions of dollars’ worth of signage.

“We’ve probably made somewhere in the vicinity of $300-$400 million worth of signs in Australia alone over the past couple of decades,” Smith said. “Our factories in China and the Philippines would’ve built another $200-$300 million worth of signage each.”

This scale hasn’t come without challenges, including competing with global offshore-owned companies early on. But Smith credits innovation, persistence, and expertise as key to survival.

“Technology has moved forward so much in the last 20 years that it opened the door to many more competitors,” he said. “At the same time, corporate standards for branding have lowered –what used to be a detailed, high-quality process is now often just a flat sheet of plastic with a vinyl decal.

“This increase in competition and the lowering of standards has made life much more challenging for us.”

Despite its scale, Albert Smith Signs retains the spirit of a family business – proud of its

history and dedicated to reliability, support and uniqueness.

“We’ve never let anyone down on what we promised – we’ve always delivered. If something goes wrong, we try to figure out why and fix it,” Smith said. “I believe it’s this uniqueness that we’ve been able to deliver competitively, combining quality and strong warranty support.

“We’ve consistently supported our warranty and never failed to back our products, which has been a major factor in our longevity and reputation.”

A relationship bonded behind the signs

Behind the signs seen in supermarkets and on highways, is a technical manufacturing process that requires not only crafty people but also people with high computer skills. These people make up both design and assembly teams that bring everything together.

“It’s a different craft to the old days, but craftsmanship remains at the core of what we do,” said Smith.

A crucial part of Albert Smith Signs’ operations is maintaining the quality of materials used. Alongside plastics and steel, aluminium has played a key role since the late 1960s and ’70s – a time when it was less commonly used than it is today.

“Aluminium was difficult to get, expensive, and couldn’t always be sourced, but it offered a lot more versatility because we could run extrusion dies to make any shape we wanted,” Smith said. “We then built forming dies to be able to form and bend aluminium.”

As technical expertise evolved, the quality of aluminium grades gave the company greater versatility. One thing that didn’t change however, was its supplier in Capral Aluminium. With a national network of extrusion facilities and distribution centres, Capral has supplied high-quality aluminium

“Capral carries the whole range, including extrusions and proprietary extrusions, with the bulk of these historically made by them,” said Smith. “We also roll form a lot of products using coils and sheets of different thicknesses and tempers, such as soft and hard tempers.”

More than just a supplier, Smith credits Capral with helping the company succeed through its technical expertise and reliable service.

“Capral has been a supplier for a long time, and its service has always been impeccable,” Smith said. “We’ve never had any issues with the quality of their product whatsoever. I’ve never had to question or query the quality because I’m confident in what they deliver.

“We couldn’t have done what we did without the technical expertise from Capral back in the day. It was very important to ensure we can deliver what we promise.”

Smith added that Capral’s commitment to innovation, sustainability, and support for Australian manufacturing aligns with his own values.

“I always look for reliability and quality before price – that’s always been my priority,” said Smith. “Capral never lets me down. Its service is brilliant, and whatever I need, whenever I need it, the company supports me.”

Smith insisted that these trustworthy suppliers – like Capral – helped the company’s supply chain stay strong through challenging times like COVID 19.

“When COVID hit, the supply chain became critical. If you don’t have a strong supply chain, those with better relationships always get first pick,” he said. “We have a fantastic supply chain. Many of the people who are supplying us today were supplying us 30, 40 years ago.

“I’ve stayed loyal to my suppliers because I want them to stay loyal to me through thick and thin, and they have.”

Smith’s journey has taken him around the globe, seeing his company’s signs light up city skylines from Hong Kong to Hobart. Yet, he remains grounded by the same principles that built the business.

“I still get a thrill seeing our signs out there,” he reflected. “It’s a quiet pride – no need for a neon sign shouting ‘We made this’ – we just feel it.”

And while his role continues to evolve, retirement isn’t on the cards just yet.

“I’m still passionate about what we do,” he said. “This industry has shaped my life, and I’m thankful every day. With a fantastic team, strong partners, and projects that stand the test of time, what more could anyone ask for?”

Heath Roberts from Camfil explains why the control of airborne contaminants in metalworking facilities is essential for safe, efficient and sustainable operations.

Airborne contaminants are a common yet often underestimated byproduct in Australian metalworking environments. Generated during processes such as cutting, grinding, and welding, these pollutants – primarily dust, fumes, and mist – can impact worker health, safety, and productivity if left unaddressed.

“Dust typically comes from dry processes like grinding, cutting or sanding; fumes are produced by high-heat processes like welding, laser or plasma cutting; and mist is generated by operations using oils or coolants, such as CNC machining,” said Heath Roberts, Air Pollution Control (APC) sales manager at Camfil.

Although invisible to the eye, these poor air quality contaminants present clear risks including shortand long-term health issues among workers, which directly correlates with absenteeism and lower business productivity.

“Poor indoor air quality can lead to serious health issues like asthma, chronic respiratory conditions and skin irritations,” said Roberts. “Long-term exposure is harmful to the lungs and affects productivity, with increased absenteeism and reduced focus among workers.”

Given these factors, Australia enforces stringent workplace health and safety regulations to reduce the risk of exposure and prevent explosive or combustible incidents. Regulatory frameworks like Safe Work WHS, CoSHH, WEL limits, and standards including ATEX and NFPA, all play a role in guiding workplace practices.

“In Australia, we follow Safe Work WHS regulations, with workplace exposure standards that are very similar to international limits,” said Roberts. “There are clear definitions around exposure and combustion risks under Workplace Australia guidelines.

“Combustible dusts like aluminium, magnesium, and titanium present serious risks, particularly in metalworking environments. Explosion hazards are a major concern in these settings, so it’s essential to have systems specifically designed to control and mitigate those dangers.”

Helping metalworking companies stay compliant, safe and efficient is Camfil Australia, a provider of clean air and industrial filtration solutions.

“Camfil designs systems that help businesses remain safe, productive and compliant as standards evolve,” said Roberts. “Staying ahead of regulatory changes is key to delivering long-term, reliable air filtration solutions.”

As a division of the Stockholm-headquartered Camfil Group, Camfil Australia draws on more than 25 years of experience supporting manufacturers with high-quality, energy-efficient filtration systems. Its range – spanning HVAC filters, HEPA filters, molecular filters, dust collectors and air purifiers –aims to protect both people and processes.

“Clean air contributes to healthier, more productive workplaces – it’s a win for both sustainability and worker wellbeing,” said Roberts. “Clean air leads to fewer sick days, greater focus, and better overall productivity.”

Next to worker safety, energy efficiency is a key pillar in Camfil’s design ethos. Its systems are engineered to provide sustained efficiency with low pressure drop, allowing air to move more freely while using less energy. This reduces electricity use and extends the life of HVAC systems, delivering reliable performance over the long term.

“Our systems help minimise waste and lower overall energy consumption,” said Roberts. “HemiPleat filters are designed to last longer, clean more effectively, and reduce the frequency of replacements. They also ease the load on HVAC systems, helping customers maintain performance while cutting operating costs.

“This helps facilities meet their energy efficiency targets while maintaining clean air standards.”

Camfil’s solutions for the metalworking industry include both wet and dry filtration systems, each suited to specific applications and contaminants. To determine the most suitable filtration setup, Camfil begins with an on-site evaluation of plant layout, worker proximity, compliance requirements and operational goals. The outcome is a tailored air filtration solution specific to each facility’s risks and needs.

“Dry filtration is the most common type of system we offer, typically using cartridge-style collectors ideal for general dust and fume applications like grinding, welding and cutting,” said Roberts. “Wet filtration is usually recommended for combustible dusts or processes that generate sticky or sparkprone particles. When you’re polishing magnesium or laser cutting materials like titanium or aluminium, wet systems are the safer option.

“It’s never one-size-fits-all, each system is customised to suit the environment and the risks involved.”

Additionally, Camfil offers value-added services like free dust hazard analyses. In this process, approximately 150 millilitres of collected dust is tested at a Camfil lab, with results presented in a four-to-five-page report.

“The report includes details like particle size distribution, particle weight and other key characteristics of the dust,” said Roberts. “This

analysis helps us determine the most suitable filtration system and guides decisions around indoor air quality assessments.”

Putting words into action

One example of Camfil’s approach comes from a recent project with a large metal fabrication company in Queensland. The site faced compliance challenges and frequent complaints about poor air quality. With six to ten welding bays operating regularly, Camfil

conducted a full site audit before implementing a source capture solution using dry filtration and HEPA filters.

“After installation, the workplace was noticeably better – air felt clearer and the environment more vibrant,” said Roberts. “There was an improvement in employee comfort and retention following the upgrade. The system brought the facility into full compliance with Safe Work

The solution for in-line measuring metal content in electroplating baths or liquids!

• Market-leading precision. Combination of measuring cell and software ensures best measuring performance and safety.

• Maximum service life. High availability of 1 year due to innvative design and material selection.

• Intelligent self-monitoring. Fully automatic, preventive purging, monitoring and calibration processes ensure maximum uptime.

• One instrument for everything. Measure all metallic solutions such as zinc, nickel zinc/nickel, gold, chromium, palladium or rhodium.

• Safety in real-time. Live measurement results as well as simple and fast documentation of these.

• Up to 4 channels. Separate supply lines to the measuring cell prevent contamination.

• No time-consuming spot checks and information gaps. Stay continuously in the picture about your electroplating process.

Australia standards and dramatically reduced airborne particles.”

Roberts believes cases like this highlight why air quality should be treated as more than a compliance box-tick.

“At Camfil Australia, we believe clean air is a human right, and we’re here to help lead the industry in that direction,” he said. “It’s a strategic investment in your workforce, your reputation and your bottom line.”

A

new automated XRF-based liquid analyser is transforming electroplating bath monitoring by delivering real-time and accurate metal concentration measurements.

Within the demanding world of electroplating – a manufacturing process that uses an electric current to deposit a thin layer of metal onto the surface of a material for improved appearance, durability, or corrosion resistance – precision, consistency, and speed are paramount.

From the jewellery sector to heavy industrial applications, achieving coating quality hinges on the control of bath composition. Traditional methods like wet chemistry or inductively coupled plasma optical emission spectrometry (ICP-OES) offer accuracy, but are often hindered by high costs, laborious sample preparation, and time lags. To address these challenges, the Fischerscope Xan Liquid Analyzer by Helmut Fischer is transforming electroplating solution analysis with its automated, inline X-ray fluorescence (XRF) technology. It delivers precise, real-time measurement of metal concentrations in liquids to ensure consistent process control and quality assurance.

Lastek, a distributor of advanced analytical equipment, plays a pivotal role in bringing the device to manufacturers across Australia and New Zealand. With decades of experience supporting industrial sectors, Lastek ensures access to Fischer’s technology is backed by expert local support,

training, and service. The company’s understanding of regional manufacturing needs allows it to tailor solutions for a range of applications.

A smart alternative

Electroplating processes depend heavily on maintaining strict tolerances in bath composition. Even minor deviations can compromise the thickness and quality of the coating, resulting in inconsistent finishes and material waste. For industries such as jewellery manufacturing – where metallic coatings like AuCuCd, RhRu, or AuCuIn must be evenly applied for aesthetic uniformity –such inconsistencies are unacceptable.

Traditional methods such as titration or atomic absorption spectroscopy (AAS) typically involve manual sampling one to two times per day. These approaches introduce a lag between measurement and correction, limiting the capacity for real-time process control. They are also costly and often require consumables like purified water or specialty gases such as argon.

The analyser answers this need with an automated, inline system capable of continuously measuring metal concentrations in electroplating baths. Built to withstand the harsh conditions of industrial environments – including extreme pH levels, salt

content, solvents, and particulate matter – the device requires no sample preparation and functions within existing plating lines.

At the heart of this innovation is a robust, temperature-independent measuring cell that, when coupled with Fischer’s WinFTM software, delivers increased measurement performance. This software-enabled platform offers intelligent selfmonitoring with preventive purging, calibration, and diagnostic checks, ensuring the instrument remains operational with minimal maintenance for over a year in most cases.

The system supports up to four independent channels, allowing it to monitor multiple baths simultaneously without risk of cross-contamination. Each bath is connected to a dedicated flow cell, eliminating the need for complex valve switching and reducing potential downtime.

One of the most prominent features of the analyser is its precision. In comparative studies with traditional titration methods, the system demonstrated exceptional repeatability.

Measurements of zinc at 6.82 g/l yielded a coefficient of variation (COV) of just 0.26 per cent over a 10-second analysis window. Nickel measurements at 1.26 g/l recorded a COV of 0.71 per cent – results that validate the system’s accuracy and reliability for

both short-term and long-term monitoring.

In another test spanning 48 hours of continuous operation, the system maintained consistency in readings, highlighting its potential for long-duration, unattended analysis. This not only enhances productivity but also reduces the risk of human error and missed deviations.

Another key feature of the device is its integration with high-level control systems. Measurement data can be displayed both locally on the instrument and remotely at the electroplating line, offering operators

immediate insights into bath status. This real-time visibility enables instant process adjustments, reducing waste and increasing yield.

Such responsiveness is critical for zinc-nickel (ZnNi) coatings, which are used for their corrosionresistant properties. These baths are prone to fluctuation, requiring up to four measurements per hour to ensure optimal performance – a frequency impractical with manual methods but feasible with Fischer’s automated system.

The design of the measuring cell underscores Fischer’s focus on operational efficiency. Made from chemical-resistant materials and equipped with an automatic rinsing system, the cell eliminates the need for frequent replacements. The entire setup is user-friendly and requires no specialised training, enabling in-situ analysis by production staff.

The launch of the analyser comes with a shift in how electroplating baths are monitored and controlled.

goods manufacturing.

Consumables are minimal – limited to reusable plastic rings and Mylar foils used in optional benchtop setups – and there are no additional costs for purified water or inert gases, which are commonly required in alternative analysis methods.

Beyond ZnNi baths, the analyser is compatible with a range of metallic solutions, including gold, chromium, palladium, rhodium, and nickel. This makes it a versatile tool suitable for diverse industries, from electronics and aerospace to automotive and luxury

With the launch of the analyser, Helmut Fischer has delivered more than just an upgrade – it has introduced a shift in how electroplating baths are monitored and controlled. By automating the measurement process, reducing operational costs, and enabling real-time adjustments, this system empowers manufacturers to meet the rising demand for quality, consistency, and sustainability.

In an industry where every micron matters, Fischer’s inline solution delivers a timely and transformative advantage. Through its partnership with Helmut Fischer, Lastek empowers businesses across Australasia to optimise their electroplating processes with confidence, efficiency and proven technical reliability.

As Test Machines Australia nears an industry milestone, managing director Paul Cibotto joined Manufacturers’ Monthly to reflect on the company’s impact on Australia’s materials testing sector.

Marking 25 years in business and 10 under its current name, Test Machines Australia traces its roots to general manager

Paul Cibotto’s earlier career. After working for a company that showed little interest in expanding its successful materials testing division, Cibotto stepped in to separate and revive the operation with his own initiative and financial backing. He described this as his “sink or swim” moment and a chance to back his own ideas without limitation.

“They wanted to go in a different direction,” said Cibotto. “All the knowledge, all the customer relationships and supplier connections were with me. Nothing stopped me from continuing. I spoke with the company, and they were supportive. I bought the division off them, rebranded it, and made it my own. It was a very peaceful transition.”

Now, Test Machines serves almost all manufacturing industries, as well as universities and defence departments. It manufactures testing equipment for quality control departments. The company also repairs other brands of testing equipment, refurbishes older machines with new technology, and calibrates and services all brands. As the company has evolved, its focus has broadened beyond manufacturing universal testing machines to include specialised solutions tailored to the needs of the local market.

“In Australia, with only 25 million people, we need machines tailored to our standards and requirements. It is a small market, so we must adapt, and offer things that others do not,” said Cibotto. “We’re a bit removed from the rest of the world, and that’s not a bad thing – it gives us the freedom to do things differently.”

This adaptation presents itself through Test Machines’ customer-made solutions that allow customers to obtain a machine that suits their own particular needs. Cibotto said this differs from larger testing machine companies who are not interested in custom-made single enquires. He said that the company’s machine engineers thrive in applying expertise to understanding what the customer needs – and why they need it.

“This is our skill. Quite often the machine a customer needs doesn’t even exist,” he said. “Because we’re a smaller manufacturer, we can take the time to build exactly what the customer wants – whether that means a wider or taller frame, different load cells, or even fully customised software.”

While this niche has facilitated growth within the company, Cibotto admits that he has purposely kept this growth controlled to maintain the company’s quality service and support. He insisted this is born out of the reality that if you have a bad product but excellent support, it’s redeemable. But if you’ve got a great product and no support, no warranty, no service – it’s useless.

“I deliberately kept it controlled – we have a reputation for excellent service and support, and I didn’t want to lose that,” he said. “You can’t always control cost or production – but you can 100 per

Test Machines Australia manufactures testing equipment – including the 10T UTM with an environmental chamber –for quality control departments.

cent control service and support. They’re the least expensive parts of any project but make the biggest difference.”

Test Machines Australia offerings

• Tensile testers

• Torsion testers

• Spring testers

• Strain gauges

• Melt flow index machines

• Load cells

• Coefficient of friction tester

• Pressure and displacement transducers

• Impact testers

• Data acquisition and displays

• ASTM cutting dies

• Concrete compression testing machines

• Testing machine accessories

• Repairs and servicing

Taking a moment to celebrate

Test Machines has enabled Cibotto to fully realise his vision, and he said seeing the company grow into what it is today makes him proud. Professionally, it has given him and his team the opportunity to develop and deliver products that didn’t – and still don’t – exist elsewhere in the market. He attributes this success to his unwavering ‘glass-half-full’ attitude.

“With risk comes reward. A lot of people think, ‘What if it fails?’ But I’ve always had a ‘What if it succeeds?’ attitude,” said Cibotto. “It’s been my baby, and it’s let me put my ideas into motion. Not every one of them worked, but the positives far outweigh the negatives.”

Though the journey has been far from easy, he

Test Machines serves almost all manufacturing industries, as well as universities and defence departments. Pictured: Pipe stiffness testing machine.

“We’ve been expanding into machine repairs and upgrades, but we’re doing it slowly and carefully,” said Cibotto. “It would be easy to put people in every state and set up workshops, but if they start overpromising or making mistakes, it damages the brand.”

The company also brought all calibration and servicing in-house after external providers failed to meet standards. Committed to protecting its reputation, Test Machines now offers a fast turnaround service to help reduce downtime.

“We’re now doing calibrations and services not just across Australia, but internationally. We aren’t chasing that work – it’s coming to us. That tells me the name has weight now,” said Cibotto.

Test Machines is also preparing to expand into the civil engineering sector, after identifying a gap in the market for testing machines that meet compliance standards. This expansion will go in line with the company’s same values; if it carries the brand, it must be perfect.

insists he still loves what he does every single day. For Cibotto, the real reward lies in seeing customers using the machines that Test Machines has crafted. “If you enjoy what you do, it doesn’t feel like work. Yes, I work seven days a week and odd hours – but I don’t mind, because I enjoy it,” he said. “You’re designing, creating, building. I can see why people who build bridges or buildings feel so proud.”

Expanding alongside industry demands

Recently, the company’s repairs division has grown substantially due to financial constraints across many industries. Now doing a lot more repairs and refurbishments using Australian-made products, Test Machines can get customers back up and running much faster.

Test Machines’ custom-made solutions allow customers to obtain a machine that suits particular needs. Pictured: Metallic wire torsion testing machine.

“We’ve been doing a lot of repairs and service work on civil engineering machines, and we’re finding many of them don’t actually meet the relevant standards,” said Cibotto. “We can make machines that meet the standards, that output data simply, that are automated, easy to use, and mistake-proof. Close enough’ doesn’t cut it for us.”

Test Machines is now applying for Australian Made certification, as part of a renewed focus on local manufacturing. While economics have meant that some machines are manufactured overseas to Test Machines’ designs, Cibotto is committed to increasing the Australian-made content.

“We’ve always believed in Australian-made. Sometimes economics or customer expectations make it difficult, but if we can make it here, I prefer to – I’m a toolmaker by trade, and I enjoy it,” he said.

“It’s also more efficient. The design and drawings are done here, so we can go straight to the workshop and have it built in hours or days, instead of dealing with delays or mistakes from overseas.

“A lot of our fixtures and custom setups are now made in-house in Melbourne.”

Another key project that stands out for Cibotto is Test Machines’ work in partnership with the United Nations. This involved setting up a testing lab for the Tanzania Bureau of Statistics.

“The lab included more than 20 different machines, and we were responsible for setting up the equipment and training their staff. It’s something I’m quite proud of,” he said.