Flexible purchasing options

Flexible purchasing options

High-pressure compressors

Class zero oil-free air

Chillers (process cooling)

Monitoring & control and comprehensive service

Onsite Nitrogen & Oxygen generation

Low pressure blowers Energy recovery systems Heat pumps

CO2 compressors

Optimise your air compressor operations and ensure food-grade air quality, while improving your bottom line.

Diagnostic & Maintenance Service Program

Experience unparalleled efficiency, innovation, and support with Atlas Copco’s full suite of solutions tailored to meet all your food and beverage needs.

1. Class zero oil-free air: for a sanitary air supply

2. Onsite nitrogen and oxygen generation: assist in your process and packaging

3. CO2 compressors: recover carbon monoxide for your processes eg. Breweries

4. Low pressure blowers: for your industrial wastewater treatment

5. Energy recovery systems: reduce your carbon footprint with our innovative solutions

6. Heat pumps: efficiently recover waste heat with our advanced technology

7. Monitoring & control and comprehensive service: optimise your energy usage with our advanced solutions and remote monitoring. Our dedicated team is here to meet your needs with a range of service agreements tailored to you

8. Chillers (process cooling): provide precise cooling to maintain product quality and safety in the food and beverage industry

9. Flexible purchasing options such as AIRPlan, to integrate seamlessly with your OPEX

10. High pressure compressors: for specialised packaging, including PET Bottling

▪ Design Risk Assessment (DRA)

▪ Machine Risk Assessment (RA)

▪ Security Risk Assessment (SRA)

▪ Safety Concept (SC)

▪ Safety Requirements Specification (SRS)

▪ Safe Design (SD)

▪ Post-Measures Risk Assessment (PMRA)

▪ Safety Validation / Safety Verification (SV)

▪ Compliance with Local and International

Legislations & Regulations (e.g. CE Marking, AS/NZS

▪ Site Audit (MSE)

▪ Machine Risk Assessment (RA)

▪ Security Risk Assessment (SRA)

▪ LOTO Assessment (LA)

▪ Safety Concept (SC)

▪ Safety Requirements Specification (SRS)

▪ Safe Design (SD)

▪ Functional Safety Management (FSM)

▪ Project Management (PM)

▪ Engineering Services (ES)

▪ Post-Measures Risk Assessment (PMRA)

▪ Safety Validation / Safety Verification (SV)

▪ PilzCare Annual Support

▪ Stop-Time measurements

▪ Force and Pressure testing for Collaborative Robot applications

▪ Periodic Inspection Services

(e.g. functional checks)

▪ Compliance with Local

& Regulations (e.g. AS/NZS 4024)

Through research and innovation, climate-resilient and mildew-resistant grapevines have been newly introduced in South Australia’s Coonawarra wine region.

To future-proof Australia’s $45 billion wine industry, national science agency CSIRO and Treasury Wine Estates (TWE) have partnered to develop and trial the new vines. The first of the new progeny were recently planted at Wynns Coonawarra Estate.

Mildew costs the Australian wine sector an estimated $160 million annually in management expenses and production losses. The new mildewresistant traits were developed through years of selective breeding by CSIRO.

“Using traditional breeding methods, we introduced two distinct genes to the Wynns heritage vines, which give resistance to downy mildew and

powdery mildew,” said CSIRO research scientist and project lead, Paul Boss.

“These are from CSIRO-developed breeding lines that confer robust disease resistance and other quality traits onto their progeny.

“Having resistance genes for both powdery and downy mildew makes these plants more robust as it is unlikely the pathogens can break both sources of resistance with a single mutation.”

The mildew-resistant genetics were integrated with TWE’s heritage vines, which have demonstrated strong climate resilience after decades of exposure to extreme weather.

“Creating mildew resistant vines that are also able to withstand climatic variation means we’re setting up our vineyards to continue producing worldfamous wine for generations to come,” said chief supply and sustainability

adding to the sustainability benefits.

The new grapevines are expected to require fewer inputs, such as fungicide sprays, helping to reduce carbon emissions from diesel-powered tractors,

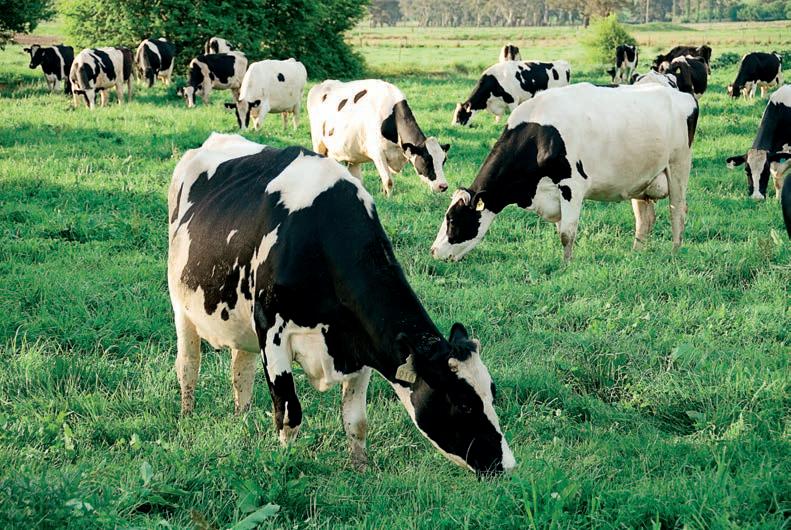

Australian beef as a sustainable protein has been recognised at the World Expo 2025, Japan.

This Expo is a global event that runs for 184 days from April to October 2025. With expectations to attract up to 28 million visitors, Australian beef was named the only ‘sustainable

“It stands out as the only protein globally to receive this certification.”

supplier’ at the Expo.

Held in Osaka, Australia was able to achieve this status by meeting the Expo’s ‘Code of Sustainable Procurement’, which includes:

• transparency and compliance.

“After working with Expo officials, Australian beef has met all the criteria to be recognised as a sustainable supplier,” said MLA’s regional manager for Japan

By addressing both climate variability and disease threats, scientific innovation is helping secure a resilient and sustainable future for Australia’s wine industry. F

“Having the industry certified allows all of us to promote and share this point in our discussions, negotiations and promotions where sustainability is an ever-increasing factor in buying and purchasing decisions.”

In 2024, Japan was the second largest beef export market for Australia, importing $2.07 billion worth of beef. Outside of Australian beef, lamb is also gaining attention in Japan.

“The Expo is an incredible opportunity to showcase the very best of Aussie Beef and Lamb to over 12,000 daily visitors to the Australian pavilion,” said MLA managing director, Michael Crowley. “This recognition at the Expo, and the work of the MLA team highlighting the product, strengthens the bond between Australia and Japan. It highlights Australia’s credentials in sustainable food production.”

Japan is the third largest importer of beef globally and is one of Australia’s long-running trading partners. F

The ACCC has released a new Food and Grocery Code of Conduct making it mandatory for Australia’s largest supermarkets and grocery wholesalers.

The code sets the rules for how supermarkets and wholesalers negotiate and contract with their suppliers.

Requirements of the new code include:

•Have a written supply agreement in place.

•Act lawfully and in good faith towards their suppliers.

•Ensure that suppliers are not penalised for exercising their rights under the code.

The ACCC has also launched a new online portal for people to make anonymous reports about potential contraventions of the code. Supermarkets and wholesalers may now face penalties for going against the new code.

The code is mandatory for all retailers and wholesalers that earned over $5 billion from their supermarket or grocery wholesaling businesses in the

Fiona Harrison is mixing her passion for chocolate with Indigenous bush food to create a blend that is uniquely Australian.

Fiona Harrison, a proud Wiradjuri woman from Central West NSW, always knew she was meant to break barriers. Even as a child, she felt a deep determination to rise above the trauma and hardships she endured. An Indigenous Australian woman, she faced a world that often overlooked the voices and talents of her people. But Harrison was not one to accept limitations. Her journey led her to create Chocolate on Purpose, a certified Social Enterprise that blends ethically sourced cacao with traditional Indigenous bush foods. And

her purpose for starting the enterprise was not just to delight taste buds but also to share cultural knowledge with the wider community.

“I experienced trauma in my life,” Harrison said. “And I think that when you experience trauma, your life gets thrown up into the air, and the pieces land in a very different order to what they were before. And within that comes realisations.”

One of those realisations was the healing power of plants. Harrison’s journey of self-discovery led her to study

aromatic medicine, where she learned how essential oils and natural botanicals could influence emotional and physical well-being.

“Through the trauma I experienced, my greatest push to healing was through essential oils,” she said.

This sparked a lifelong curiosity about the power of plants and their ability to create wellness. As she delved deeper into her cultural roots, Harrison discovered a new way to share this wisdom with the world: chocolate. It started as a personal passion – learning

the craft of chocolate making for her own enjoyment. But a transformative moment during a chocolate-making class ignited a larger purpose.

“The teacher said we were going to make a dark chocolate with raspberry and black pepper,” she said. “I just looked at my friend Jo and said, ‘Oh my gosh, that’s an essential oil! Maybe this is the universal language’.

“Most people love chocolate, and so we started to sort of brainstorm the superfoods we could put into a bar.”

From that moment, everything

clicked. Harrison realised she could combine her Indigenous heritage, her knowledge of plants, and her love of chocolate to create something truly special.

“I had this clanger of an idea: ‘I’m going to use bush food’,” she said. “Because that’s what my ancestors have been using for over 60,000 years. That was the day Bush Food Chocolate came into being.”

She didn’t stop there. A few days later, another realisation struck her, which became the name of her company.

“Chocolate on Purpose,” she said. “Chocolate would be the driver to deliver the message. It started as a way to share the power of native botanicals and the ancient wisdom of Aboriginal and Torres Strait Islander peoples.”

Her chocolates are not simply a treat; they are a cultural experience, she said. She selects native ingredients, then considers their aromatic profiles and how they interact with the chocolate.

“I don’t just stick the chocolate and the plant together,” Harrison said. “I look at the aromatic triad and what will blend best to create depth of flavour. That’s what I’ve created – chocolate with depth.”

Through research and experimentation, Harrison developed unique flavour combinations that highlight the complexity of native ingredients. Her dark chocolate infused with Rosella flower and native mountain pepper berry, for example, unfolds in layers.

“For me, it’s the cacao notes first, then the fruitiness, and finally the warming sensation of the mountain pepper,” she described. “It’s not a punchy heat like black pepper; it’s a warming on your palate – like deliciousness followed by comfort.”

But Harrison’s passion for chocolate extends beyond taste. She is also committed to ethical sourcing. Early in her business journey, she became aware of the injustices within the cacao supply chain, including modern slavery and deforestation.

“Farmers often don’t own their land, and their income is limited not only by trade prices but also by how much cacao they can grow,” she explained.

To counteract these issues, Harrison partnered with Cocoa Horizons, ensuring her cacao is ethically and sustainably sourced. Her cacao beans are a blend sourced from Ghana, the Ivory Coast, and Ecuador. She chose the blend because she wanted a smooth chocolate that wouldn’t overpower the native

“I had this clanger of an idea: I’m going to use bush food. Because that’s what my ancestors have been using for over 60,000 years. That was the day Bush Food Chocolate came into being.”

ingredients. Sustainability is central to every aspect of her business.

“Palm oil was another issue I had to tackle,” Harrison said. “Even sustainable palm oil is problematic because of the damage it causes to the peat moss that cools the Earth. That’s why I chose to source chocolate with no palm oil.”

Beyond ethical chocolate, Harrison is an advocate for Indigenous representation in the bush food industry.

“Less than two per cent of the Australian native botanical industry is represented by Indigenous people, even though these industries were built on our cultural and intellectual property,” she said.

Harrison actively seeks Indigenous suppliers for her ingredients and aims to bring more Indigenous women into her business. She said that, traditionally, women are the matriarchal holders of plant knowledge systems. She wants to honour that legacy and empower Indigenous women to reclaim their leadership. Despite her success, Harrison faces ongoing challenges.

“Chocolate prices are punishing, and I have to innovate to make my business sustainable,” she said.

Gobeyondtraditionalpeakand off-peakcontractsbyaccessing cheaper,cleanerenergy availableduringdaytimehours.

Shiftenergy-intensive operationstotimesoflow electricityprices.Smallchanges canleadtosignificantsavings.

Viewenergyinsightsand controlyourconsumptioninreal timeviaourcustomerportal andhardwareinstalledonsite.

Reduceyourrelianceongrid energybygeneratingand storingyourownelectricitywith rooftopsolarandbatteries.

Sayg’daytoourfriendlyteamatFoodTech,GoldCoast-19-20June

TalktoFlowPoweraboutcuttingcosts,boosting operationalefficiencyandstayingaheadof risingenergypricesandelectrification-allwhile drivingtowardamoresustainablefuture.

More than 50 speakers will join us over two days to discuss the challenges –and opportunities – in municipal

17–18 SEPTEMBER 2025

Atlas Copco’s Oil-Free Air product manager Tim Van Driessche explains how compressed air is a crucial ingredient in the food and beverage processing space.

In the food and beverage industry quality and safety aren’t only priorities – they’re essential. Every production must be in strict compliance with air quality standards. That’s where Atlas Copco’s Class 0 certified compressed air systems make a difference. These systems deliver guaranteed oil-free air ensuring a client’s end products are safe and contamination-free. Atlas Copco oil-free solutions help a business maintain the highest production standards.

Compressed air plays a critical role in food and beverage production.

It often comes into direct contact with ingredients, packaging and final products. That’s why meeting air quality standards is non-negotiable.

The most important of these is ISO 8573-1 (ed. 2010), which classifies air quality based on three contaminants: moisture, oil, and particles. The highest purity level is Oil Class 0. This requires lower contamination levels than Class 1.

“It should also be noted that some applications may call for different air quality classes for the various contaminants. For example, the required air quality may be Class 1-2-2, meaning

it must meet Class 1 standards for solid particles and Class 2 standards for both oil and water,” said Tim Van Driessche, Atlas Copco Oil Free Air product manager

Atlas Copco compressors are ISO 8573-1 Class 0 certified, meaning zero risk of oil contamination. This certification ensures that its products won’t compromise a company’s hardwon professional reputation due to oil contamination. These compressors provide the highest quality compressed air, preventing contamination and safeguarding your reputation.

Then there is the low cost of ownership. Reducing production costs is crucial for increasing profitability in the food and beverage industry.

Atlas Copco’s oil-free compressors are designed with low energy consumption and efficient monitoring systems, delivering a low total cost of ownership. Atlas Copco’s Variable Speed Drive and SMARTlink monitoring systems allow users to plan maintenance, minimising downtime and maximising production efficiency.

This range of compressors is compliant with the ISO 22000 food safety management system, ensuring they are built to perform in food and beverage factories. As the first compressor manufacturer to be awarded ISO 22000 certification for its Oil-free Air Division production facility, Atlas Copco guarantees quality and transparency to its customers.

Atlas Copco offers a range of compressed air solutions tailored to meet the diverse needs of the food and beverage industry. Its portfolio includes oil-free screw compressors, centrifugal compressors, low-pressure screw compressors, rotary screw blowers, and scroll compressors. Each of these oil-free solutions is designed to provide the highest standards of safety and efficiency.

The company also provides specialised solutions for compressed gases, ensuring reliability and efficiency in various applications. These solutions include reciprocating gas compressors, CO2 compressors, and nitrogen generators and oxygen generators, all of which offer maximum energy savings and a low cost of ownership.

To ensure the highest air quality, Atlas Copco offers a range of dryers and filters. Its rotary drum dryers, twin tower desiccant air dryers, refrigerated

air dryers, and coalescing filters are designed to provide a constant supply of high-quality dry air with low power consumption. These solutions are suitable for critical processes, including oil-free applications, ensuring the highest standard of air purity.

The specialist’s chiller and cooler range is an effective all-in-one solution to maintain precise temperatures in various food production processes. These chillers are designed to ensure consistent and optimal cooling environments, supporting the production of high-quality food and beverage items. Selecting correctly sized chillers tailored to specific food and beverage production requirements is essential. Atlas Copco’s experts can help clients determine the ideal chiller size for their needs. Alternatively, chillers can be sized to supply cooling water to Atlas Copco’s oil-free, water-cooled

compressors, which in turn can be offered with an energy recovery module. This range of oil-free compressed air solutions are versatile and essential for various applications within the food and beverage industry including:

•Automation air – controls valves and actuators in automated lines for filling, packaging, and bottling, preventing jamming and ensuring product safety.

•Pneumatic conveying – pushes powdered milk or cocoa powder along pipes, maintaining powder purity by avoiding oil contamination.

•Cleaning air – cleans bottles, packaging, and moulding prior to filling, preventing contamination and health hazards.

•Air blowing and aeration – boosts oxygen content in liquids, essential for fish farming and fermentation processes.

•Fermentation – supplies oxygen to bacteria during fermentation, ensuring high-quality food ingredients.

•Food storage – preserves foods using nitrogen generated from oil-free compressed air, maintaining product integrity.

•Cooling and spraying – cools baked goods post-oven, preventing spoilage and production losses.

For more information on how Atlas Copco’s compressed air solutions can benefit your food and beverage production, contact its experts. Discover the difference oil-free compressor systems can make in ensuring the highest quality and safety standards for your products.

Atlas Copco is committed to providing innovative and reliable compressed air solutions that meet the highest industry standards. F

From a small office in Sydney’s west, to building state-of-the-art food and beverage facilities, Total Construction has come a long way in the past three decades.

As a construction and fit out partner to the Food & beverage Industry, Total Construction this year celebrates 30 years servicing the building sector and providing advice, guidance and construction services to clients both large and small as they have grown and expanded their businesses.

Steve Taylor and Bill Franks started Total Construction in 1995 from a small office located in Wetherill Park NSW. From the get-go Total was positioned to be a specialist builder focusing on select clients that were looking for a builder that would provide more than just construction services.

constructing special-purpose facilities. Knowledge gained in constructing self-storage facilities, in particular, was invaluable. Understanding the process flow of people and materials expected in the finished facilities was critical when reviewing designs and delivering projects.

Total entered the food and beverage sector in 2008 with the same vigour and focus it had displayed in the self-storage construction space; by understanding that to service the sector effectively it would need industry specialists in house. Employing in-house food literate process engineers with a wealth of knowledge

construction in the food and beverage sector, would pay off, and successfully won its first major food and beverage project, which was at George Western Foods’ facility located at Gateshead NSW.

The project scope was to build an extension to house a new bread line, and required some smart thinking around how the building itself enveloped the proposed new line and ensuring the correct services were in place without hindering GWF’s current operation. The project went to plan, and the learnings Total gained was the beginning of a long phase of knowledge

Over 17 years, the team has delivered transformative projects for some of the most recognisable names in the industry, including Arnott’s, Cadbury, Coca-Cola, Alpha Flight Catering (now Dnata), Goodman Fielder, Woolworths, Peters Ice Cream, Schweppes, and Asahi. Most recently, they began construction on an innovative indoor farm for Stacked Farm, a leading agritech business.

One of the most valuable lessons Total Construction has learned over the past 17 years working on F&B projects is the importance of early involvement in the project. Traditionally, clients would design their process, order equipment, and only then engage a builder to adapt an outdated or incompatible building design – often leading to costly compromises. Total Construction takes a different approach: an “inside-out” methodology. By first understanding and optimising the process flow, the building is then designed to wrap around the equipment – not the other way around. After all, it’s the production process that generates revenue, not the structure itself. Poorly planned layouts can lock in inefficiencies for the life of the facility, impacting overall

Total Construction’s first major food and beverage project was George Western Foods’ facility in

To achieve a smooth project progression and to avoid potential glitches in delivery, Total has learned the best scenario is for a client to involve a builder early in the process and review the layout against the buildability of the building. This detailed review can reveal any roadblocks, issues, and/or clashes in the building’s proposed design with the client’s proposed production processes. Drawing from this experience, Total has developed a unique Early Contractor Involvement (ECI) model. In addition to the standard elements of design, costing, and value engineering, Total’s F&B ECI process incorporates detailed process flow evaluation, equipment services planning, and tailored construction methodology – all developed in collaboration with the client’s operational, safety, and management teams. This front-end planning approach has consistently

delivered seamless outcomes for food and beverage projects across the country.

If a client is looking to move into a Brownfield site (an existing building such as a warehouse requiring a food and beverage fit out), Total can, as part of the feasibility stage, review the proposed facility. Total is looking for such things as adequate power and gas availability, as well as check the building’s structure to confirm it can carry heavy loads such as evaporators and equipment services. Total will also review the building’s design against proposed process flows and operational movements and advise of any potential bottlenecks that may occur due to the building’s design limitations.

Total’s extensive food and beverage industry knowledge and experience gained in working within the industry, has seen it grow from strength-tostrength and become a well-respected construction partner for the industry. F

“Fishbowl

operate as a unified whole”

Gosling - Co-Founder - COYO

“This insight and overall higher level of reassurance for our reporting is invaluable”

Lisa Coller - Company Accountant

powerful when brought together. An integrated system combining energy demand response, storage, renewable generation, and real-time market data gives businesses maximum flexibility and unlocks value across multiple fronts.

For example, charging batteries when renewable energy is abundant and prices are low, then discharging during peak pricing, helps reduce costs and support grid reliability. When this approach is connected to on-site solar or EV charging infrastructure, the result is a highly efficient energy system.

MacLachlan emphasised that adopting this approach isn’t about choosing one piece of technology; it’s about building a holistic, long-term energy strategy.

“The tools are already available –monitoring, automation, storage, market insights. What matters is integrating them in a way that supports broader business objectives, whether that’s managing costs, meeting sustainability targets, or improving operational resilience,” he said.

Traditionally, energy management was limited to procurement, signing a contract and revisiting it every few years. That model no longer fits today’s dynamic environment. What’s needed now is a more proactive, hands-on approach.

That’s why Flow Power is helping businesses implement whole-ofbusiness energy strategies. These plans

embed energy thinking into everyday operations, from scheduling production to planning maintenance. Energy is no longer just an overhead; it’s a lever for performance and growth.

More companies are also connecting their energy use to wider priorities like decarbonisation, compliance, and brand perception. Investors and customers are paying closer attention to environmental performance, and observing how a company manages energy as a key indicator of progress.

By taking a more active role in their energy strategy, manufacturers can better manage rising costs, stay ahead of shifting expectations, and uncover new opportunities for efficiency, innovation, and long-term growth.

The path forward for Australian manufacturers will be shaped by how well they adapt to the changing energy environment. As the national grid continues to incorporate more renewables, the ability to manage energy will affect a company’s bottom line.

For businesses willing to invest in smart systems and rethink their relationship with power, the benefits are clear. Lower costs, improved sustainability, and a stronger competitive position await those who treat energy as a strategic asset.

Flow Power’s work with companies like Snack Brands and Riverina Oils demonstrates that this isn’t a vision for the future – it’s already happening. And as more manufacturers make the leap, the manufacturing sector will move closer to a cleaner, more efficient, and more resilient energy future.

To understand what this transformation looks like in practice, two manufacturers – Snack Brands and Riverina Oils– have embraced flexible energy management with help from Flow Power.

Snack Brands is one of the largest suppliers of snack foods in Australia, including the iconic Aussie nibble, Cheezels.

With strong aims to create positive impact one snack at a time, Snack Brands is using its smart energy contract to offset its emissions, and its influence to help build an ethical, sustainable food system that supports better futures for everyone involved. Since entering into a long term corporate renewable PPA with Flow Power in 2019, Snack Brands has been supplied with green energy allocations linked to Bomen Solar Farm and Sapphire Wind Farm.

In the agricultural hub of Bomen, NSW, Riverina Oils operates a canola oil processing facility with high energy demands. Recognising the need for a more sustainable and cost-effective energy strategy, Flow Power built a dedicated solar farm to help Riverina Oils power its daytime operations.

The project includes 2.8 MW of solar PV and a 2.6 MVA inverter to provide a direct behind-the-meter electrical supply to the neighbouring Riverina Oils manufacturing plant, via an underground 11 kV feeder. It is one of the largest behind-the-meter installations to a manufacturing operation in Australia. This was made possible through power systems studies with the local electricity distributor. The addition of multiple reactive power units ensures stable performance across a range of conditions.

By generating its own solar power, Riverina Oils has reduced the carbon intensity of its production, which is an important step for a company that produces more than 80,000 tonnes of refined vegetable oil and 120,000 tonnes of canola protein meal each year. This move also helps the business shield itself from price spikes and strengthens its commitment to sustainability. F

BOGE has a range of oil-free compressed air solutions for the food and beverage manufacturing industry.

With more than 118 years engineering, BOGE can provide an efficient one-stop solution for a company’s compressed air requirements. Whether for process air, plant air, packaging, or other applications, it has the solutions that consumers need. It offers dedicated Class 0 certified compressor air systems for the food and beverage industry.

BOGE products are guaranteed oil-free air for safe and high-quality end products, with a low total cost of ownership.

Compressed air and nitrogen play an important function in food and beverage production across different stages, ensuring product excellence and safety.

From dairy and baked goods to beverages and snacks, one common thread runs through it all – the need for uncompromised air purity. For critical applications within food and beverage plants, ISO 8573-1 Class 0 oil-free air is needed to ensure the highest standards of quality and safety. Every aspect of production, from the processing of raw materials to packaging, is subject to scrutiny.

ISO 8573-1 (ed.2010) is the most important standard that needs adhering to as it is an internationally recognised air quality standard that is divided into air quality classes for the three main types of contaminants (moisture, oil and particles).

It serves as a guide that helps operators determine how clean their air is for manufacturing operations. It defines how many contaminants the air may contain at a specific point in the compressed air system.

BOGE offers oil-free piston, screw, scroll and turbo compressors along with downstream air treatment components. It has high-pressure boosters for PET bottling, which is an integral part of food and beverages packaging.

BOGE bluekat produces Class 0 quality oil-free compressed air from oil lubricated compression, while eliminating expensive condensate disposal. The principle is safe and is a suitable solution for oil-free compressed air, especially for sensitive industrial applications.

There are numerous ways in which compressed air and nitrogen are involved in food and beverage manufacturing.

In the case of nitrogen it is important that contact with oxygen is avoided in various production steps in the manufacture of beverages such as fruit juice or beer.

This is because there is a risk of microbial infections as well as oxidative and enzymatic reactions.

Traditionally, companies sourced the required nitrogen for their production processes from external suppliers, delivered in bulky containers that required storage space. Yet, there is a better alternative.

On-site N2 generation makes the operations independent of an external gas supply and, due to the latest technology, ensures low generation costs. In addition, the environmentally friendly technology reduces CO2 emissions and thus protects the climate and environment.

On-site nitrogen generation brings an array of benefits, such as:

• Cost efficiency;

• customised purity;

• streamlined operations;

• continuous supply;

• enhanced safety; and

• environmental impact.

Food packaging is also often made in the presence of a shielding gas.

This increases durability for transport and extends the use by date. Packaging under a modified nitrogen atmosphere keeps food fresh and durable for longer without the addition of preservatives. This MAP method (Modified Atmosphere Packaging) is mainly used for oxygensensitive foodstuffs such as meat, fish, nuts, yoghurt, cheese, pasta, bread, salad and vegetables.

Another example of nitrogen’s use in the food industry is for blanketing rollers and jet mills. These are used in food production.

The grinding processes in the production of flour, cocoa and other dry, dust-like foodstuffs can lead to fires and explosions.

This is especially true in combination with frictional heat and oxygen. Using nitrogen as an inert gas can prevent such fires and explosions.

If you need an integrated solution for your food and beverage plant, BOGE offers an in-house built range of oil-free and oil-injected air compressors; desiccant, and refrigerant dryers; nitrogen and oxygen generators; filtration solutions; and central control systems. F

Safety is a key concern in any food or beverage processing plant, which is why BEGA harnessed Pilz’s expertise when assessing its various production sites.

Bega Group, a prominent name in the Australian dairy and food industry, is known for products like Bega Cheese, Vegemite, and Peanut Butter. Established in 1899, Bega has become a household name. In 2020, Bega expanded its production sites from 9 to 21, presenting new challenges in standardising and ensuring safety across all plants.

Most Bega products are milk-based. The production process involves several intricate steps with a high level of automation. Let’s take the famous Bega Cheese for example.

The process starts with raw milk intake, followed by pasteurisation, curdling, cutting, cooking, moulding, and ageing (6-18 months). The key concern lies in the packaging stage, where complex machinery is involved, posing safety risks.

To enhance safety, Bega partnered with Pilz for plant assessments across its 21 sites. Pilz conducted thorough evaluations, identifying hazards and recommending improvements.

On average, 150 assets per site were assessed, resulting in thousands of safety recommendations. Following these assessments, the Bega team underwent several training sessions on machinery safety conducted by Pilz, with more ongoing. Key training courses including the MachineSAFE Comprehensive course and CMSE (Certified Machinery Safety Expert) training.

These programmes enhance safety expertise, ensuring compliance and reducing accident risks. By prioritising safety, Bega continues to uphold its reputation for quality and reliability, ensuring its products remain trusted by

“The Pilz team’s knowledge and expertise live up to the brand promise,” said Neil Roberts, group risk engineer, Bega Group. “It’s what you expect. Their detailed assessments gave us valuable insights from both a business and practical standpoint. We discovered numerous hazards that we were previously unaware of. Having experts in the field conduct these assessments improved hazard awareness, especially for those in operations. Plus, their support didn’t stop after the assessments – they were always available to help.”

Getting a water treatment system installed is just the beginning for those that deal with Aerofloat. Food & Beverage Industry News explains why.

Wastewater compliance doesn’t end with commissioning – it’s an ongoing journey that requires trusted partnerships and responsive support. For food and beverage manufacturers like Priestley’s Gourmet Delights, having a team they can rely on makes all the difference.

Delivering more than just a system

When Priestley’s Gourmet Delights sought a treatment system that would tick both sustainability and compliance boxes, Aerofloat’s bespoke plant design delivered. But it’s the continued relationship, long after installation, that’s left a lasting impression.

“The After Care program that I signed up with has been second to none,” said Edi Amstad, maintenance manager at Priestley’s. “When there is a hiccup,

Aerofloat’s the first one to make sure that we’re being looked after.”

Aerofloat’s After Care team supports more than 60 clients across Australia, offering a full suite of services – from regular servicing and emergency callouts to remote monitoring and chemical supply.

For food and beverage businesses, wastewater isn’t just a by-product – it’s a regulatory challenge. Aerofloat’s After Care servicing and chemical supply ensures long-term compliance with authorities.

The service includes support and optimisations, as well as the option of chemical supply, remote servicing and

and remote monitoring to ensure smooth operations, to fast chemical deliveries, even for long-lead items,” said Michael Anderson, general manager of Aerofloat.

“We don’t just fix issues – we train and support on-site teams, so they feel confident managing the system day-to-day.”

Amstad agrees, the support from Aerofloat’s After Care team is secondto-none.

“The service techs that Aerofloat send out are thorough and very knowledgeable,” said Amstad. “They’re able to take my team members out here and train them on what should be done, what shouldn’t be done.”

allowed to interfere with production.

“Due to the way that the plant has been designed, we have quite a bit of storage, and we are able to move water around the plant to make sure production isn’t hindered by things that aren’t quite working correctly,” said Amstad.

That reliability stems from a clear understanding of both the client’s process and the wastewater profile. Aerofloat’s team designed the system with fats, oils, dyes, and sugar-heavy loads in mind, and its After Care team keeps the plant optimised to maintain performance.

Fast response times and proactive communication make a difference, especially when minor issues could snowball into major downtime. For Amstad, Aerofloat’s responsiveness stood out.

“The office staff have been exceptional,” he said. “Turnaround on service people and chemicals I would say has probably been the best I’ve had to deal with for a long time. We get chemicals within about five days of ordering – even long lead items.”

That level of service isn’t limited to one site. Aerofloat’s national reach, remote capabilities, and growing After Care team mean even regional clients get metro-level service.

Aerofloat’s After Care plans are built for evolving businesses.

“Our client’s systems aren’t just monitored –they’re optimised over time as processes change and production scales,” said Anderson.

That flexibility is critical in an industry where waste streams change depending on production cycles, seasonal ingredients, or product innovation.

“Aerofloat’s ability to adapt, improvise, take on feedback willingly, and overcome those issues has just been phenomenal,” Amstad agreed.

Priestley’s is already thinking about what’s next – and it’s planning to do it with Aerofloat.

“We will be looking to work with Aerofloat again in the future regarding how we can expand,” Amstad said. “One of those expansions would be a bioreactor, so that we can make sure that we’re removing all of our biochemical demand.

“Aerofloat is definitely a company in the water treatment industry that I would recommend to anyone that I thought needed the professional advice, as well as great after service care.”

For food and beverage manufacturers, ongoing wastewater compliance and operational reliability aren’t luxuries – they’re essentials. Aerofloat’s After Care program offers exactly that: a partnership that evolves with a business and keeps a company one step ahead of issues, regulations, and downtime.

When a site’s wastewater has as much variety as a dessert menu, you need more than a good design – you need long-term care that performs. F

Hygienic flooring is a must when it comes to food and beverage facilities. That’s why it’s important to have experts on hand to deliver the right solution.

ROXSET’s flooring solutions meet the strict regulations around HACCP compliance.

For companies searching for a flooring solution that offers both durability and cleanliness then ROXSET HACCP Health and Safety Epoxy Flooring Solutions might be the answer. Suitable for a variety of settings, such as large food processing factories, abattoirs, wineries and mining facilitates, these floors are designed to minimise contamination while providing a seamless finish that is easy to maintain.

ROXSET has been operating in Australia for more than 30 years and is the largest applicator to the food and beverage industry in Australia.

ROXSET has worked with many key players in the Australian food manufacturing sector such as Bulla Ice-Cream, Norco Milk, Goodman Fielder, Nestle Foods, Steggles Chicken and Bega Cheese.

Key features

It is critical in all food facilities – both large and small – to meet the strict regulations around HACCP compliance and to adhere to safety and hygiene at times. Hygienic epoxy flooring is more than just a surface; it is a flooring solution built to withstand heavy foot

traffic and harsh conditions. This flooring option is water-resistant, allowing for easy cleaning and preventing the growth of harmful bacteria. With this epoxy flooring system, users can maximise hygiene levels while maintaining a sleek and modern aesthetic in the surrounding space.

First and foremost, these epoxy flooring solutions feature a non-porous surface that does not trap dust, dirt, or allergens, making them suitable for environments where safety and cleanliness are paramount. Furthermore, the hygienic nature of this flooring contributes to overall health by minimising the risk of slip and fall accidents, as well as preventing the spread of germs in shared spaces.

Many food facilities suffer from badly maintained floors containing cracks coming from old concrete and dated tiles. ROXSET can provide a range of repairs and upgrades with screeding and jointing to ensure the floor is properly prepared prior to the epoxy coating. These flooring solutions are built to withstand the rigorous demands of

any food and beverage environment. With features like resistance to spills, chemicals, and heavy foot traffic, the specialised coatings ensure that flooring maintains its integrity over time. Available in various textures and colours, clients can achieve the aesthetic they desire while not compromising on quality. A facility deserves flooring that can handle temperature fluctuations and damp conditions without compromise.

Installation of Hygienic Epoxy Coating solutions will be both efficient and straightforward. ROXSET’s professional in-house team, who can mobilise from its NSW base or QLD facility, will ensure that the new floors are installed to the highest standards, minimising disruptions to daily operations. Once installed, the maintenance of the flooring is straightforward – with a commercial scrubber for large areas, or just regular sweeping and occasional mopping is enough to keep floors looking new.

Installation of the flooring will be both efficient and straight forward, minimising disruptions to daily operations.

ROXSET’s colour range can be tailored to match a brand or logo. The company can also assist with line marking and delineation areas to contain product or various traffic conditions within a factory.

In conclusion, these floors are designed to meet the demands of hightraffic and sanitary environments, as well as provide a blend of durability, ease of use, and cleanliness.

Transform a food and beverage processing facility now and experience the difference with high-quality food grade epoxy flooring. F

ContiTech sees FoodTech as a gateway to educating food manufacturers on why hoses play an important part in the manufacturing process.

ContiTech is set to debut some of its latest hose solutions at FoodTech 2025 in Brisbane this June. According to Lee Cranswick, head of distribution for Australia and New Zealand, the company sees this event as a crucial stepping stone leading up to 2026’s

a milestone in the company’s ongoing commitment to delivering high-quality solutions. Cranswick emphasised that FoodTech is an important opportunity to showcase their premium products and reinforce their position as a trusted supplier, especially in the beverage space.

over the last 150 years.”

Cranswick said one area he has seen rapid growth over the past few years is in microbrewing despite increasing government taxation.

“Microbreweries are where you get your wins,” Cranswick notes. “They’re

microbreweries often face challenges when it comes to sourcing equipment that balances cost, quality, and efficiency. This is where ContiTech sees an opportunity to provide real value. The company’s premium hoses are designed to minimise downtime and ensure efficient operations,

microbreweries need solutions that will ultimately help them offset operational expenses.

“Being an election year, you never know what changes might be introduced,” Cranswick said. “But what we do know is that reducing downtime and improving efficiency is key to staying profitable, no matter what happens with government policies.”

And what kind of hoses are popular and provide security for those not only in the brewing sector now, but thinking of starting a small business?

“Our Microban technology is a real game-changer,” Cranswick explains. “It prevents bacterial growth on the hose cover, reducing the risk of cross-contamination. That means a single hose can be used across multiple sections of a plant, cutting costs and improving efficiency.”

Additionally, ContiTech also has sanitary-grade fittings to complement their hoses.

“You can’t just use any fitting with food-grade hoses,” says Cranswick. “We work with top partners to provide

At FoodTech, ContiTech will showcase an array of specialised food and beverage hoses, including:

• Vintner Hose – Designed specifically for winemakers, featuring a crush-resistant poly filament helix that maintains shape even in tight spaces.

• ExtremeFlex Blue and Red Beverage Hoses – Highly flexible and durable, ideal for beverage production facilities.

• Fortress Blue and Yellow Washdown Hoses –Featuring Microban antimicrobial technology to inhibit bacterial growth, ensuring safer, more hygienic washdown processes.

“Food manufacturers are looking for products that are reliable, easy to clean, and resistant to bacteria buildup,” says Cranswick. “That’s exactly what we

Cranswick points out another feature of ContiTech’s hose technology – its design helps businesses improve efficiency by reducing strain on

“Some of our hoses, like the ExtremeFlex, are designed with a corrugated surface, making them easier to drag across the floor,” he says. “That small feature makes a big difference in day-to-day operations.

“If you’ve got a smooth hose, you’ve got 100 per cent of the product on the floor, and it can be hard to drag. But if you’ve got a corrugated hose, you’ve only got that little section dragging across the ground, which means it’s less force to pull and less force to bend.”

Another key focus is shifting market perception.

“When people hear ‘Continental,’ they think tyres,” said Cranswick. “We’re working to change that. ContiTech is a major player in industrial solutions, including the food and beverage sector, and trade shows like FoodTech help us reinforce that message.”

Cranswick also said that ContiTech is actively optimising its supply chain to ensure customers receive high-quality products efficiently.

“We manufacture in the US and, to a lesser degree, in Germany,” he says. “But we’ve also got manufacturing capabilities in Canada, which helps us navigate tariffs and streamline distribution.”

As ContiTech prepares for its first-ever appearance at FoodTech, the company remains committed to innovation and customer satisfaction.

“At the end of the day, we’re here to provide highquality solutions that help businesses operate more efficiently,” Cranswick said. “That’s what we’ve done for over a century, and that’s what we’ll continue to do.” F

Fishbowl has helped an array of food and beverage companies streamline processes and enact efficiencies that have helped with their bottom lines. Here are a few examples.

Green Beacon Brewing has risen to prominence with support from Fishbowl Inventory’s management software. The partnership began in 2018, marking a turning point for the Brisbane-based craft brewery.

Following the opening of a high-tech facility in Geebung in 2017 – featuring a centrifuge, reverse osmosis water filtration system, and “hot rocket” –the company tripled production and expanded interstate, even securing a partnership with Singapore Airlines. However, outdated manual systems hampered its growth, offering little control over production and costing.

“Fishbowl has been a game-changer for us,” said Lisa Coller, finance lead at Green Beacon. “Before, batch costing was guesswork. Now, we have detailed insights that meet Asahi’s rigorous standards.”

With Fishbowl, Green Beacon gained real-time visibility into inventory, production, sales, and reporting. The integration streamlined logistics and enabled smarter decisions.

“If we want to know what’s sold by rep, state, or SKU, we have it instantly,” said Collier.

“Green Beacon’s success shows the value Fishbowl brings to accurate costing, standardised processes, and reporting tailored to business needs,” said Jupe.

In 2019, Green Beacon’s rapid growth attracted industry heavyweight Asahi, who acquired the brewery.

Today, Green Beacon has continued to innovate under Asahi’s craft portfolio.

The Fishbowl-Green Beacon partnership exemplifies how the right tools and teamwork drive success in an evolving market.

In March 2025, the Federal Government committed $3.5 million to the Feeding Australia initiative – designed to strengthen supply chains and reduce food price volatility.

But the food industry isn’t waiting. Many businesses are already turning to AI to boost efficiency, reduce waste, and manage supply chain disruptions.

inventory,” added Tsai. “We’re more agile, efficient, and prepared for demand changes.”

AI is proving to be a key tool not just for tackling current challenges, but for building a more resilient food industry long-term.

“Businesses that don’t keep up with AI risk being left behind. As the technology continues to mature, it will become even more indispensable for maintaining efficiency and staying competitive in the market.”

A March 2025 Food Engineering Reviews report highlights how AI is transforming food manufacturing with smarter, faster processes.

“The government’s investment in food security aligns with broader industry momentum,” said Jupe. “AI is arriving at a critical time, helping businesses overcome operational challenges and boost efficiency.”

Fishbowl’s AI-powered tools are already showing results. Hodo Foods, a plant-based food producer, faced supply chain issues and frequent stockouts

before adopting Fishbowl’s AI Insights.

“Our old system was slow and reactive. Fishbowl changed that,” said Hodo Foods founder Minh Tsai. “We now use real-time data to make smart decisions, reduce waste, and improve operations.”

Since implementing Fishbowl, Hodo Foods has cut stockouts by 35 per cent and inventory costs by 28 per cent, while reporting is now 70 per cent faster, allowing for quicker decision-making and better forecasting.

“AI has transformed how we manage

Australia’s premium food sector is booming. CSIRO projects demand for luxury and novel food products will reach $2.8 billion by 2030, with exports growing from $1.1 billion to $1.7 billion.

For ambitious food manufacturers, now is the time to scale up and go global as long as the right infrastructure is in place.

Pic’s Peanut Butter is an example of this. Exporting worldwide, the company turned to Fishbowl to support its rapid growth and streamline operations.

Founded in 2012, Pic’s built a reputation for quality, but success has also brought complexity.

With growing demand, the team struggled to manage raw material imports, production, and distribution, relying heavily on spreadsheets for inventory. This led to inefficiencies, manual errors, and a lack of visibility.

“Before Fishbowl, we used Excel spreadsheets to manage inventory across multiple locations,” said Heath Bowman, operations manager at Pic’s. “It meant lots of manual entries and hours chasing errors.”

Its existing accounting software couldn’t keep up with inventory demands. There was no integrated purchasing system, making cost tracking and order management difficult. Implementing Fishbowl changed the game.

The system seamlessly integrated with their existing software, managing everything from purchase orders to sales and work orders. It brought visibility, accuracy, and efficiency.

“An unexpected benefit was how Fishbowl immediately exposed where we were cutting corners,” Bowman added. “It helped tighten our systems.”

With Fishbowl in place, Pic’s now manages stock across multiple locations with ease. The system has freed up time for growth and allowed the team to focus on strategy and expansion.

For food makers looking to scale up, Pic’s story shows that passion and product quality are just the start. With powerful tools like Fishbowl, global success is within reach. F

There is an array of solutions – both big and small – that can be provided by CAPS’ offerings.

CAPS specialises in making sure its customers achieve their operational outcomes. Here’s how.

Arange of industries have a lot riding on the quality of compressed air utilised in their operations. Determining the right way for your business to go when selecting a compressed air solution is often a balance between capital investment, overall efficiency and risk mitigation.

Oil contamination can result in a damaged or contaminated product, so going oil-free at the point of compressing the air negates the need for several air-treatment processes downstream to clean and dry the air. By using a true oil-free compressor, the long-term benefits associated with less ancillary equipment and servicing, combined with the reduction of risk, can more than offset the initial investment cost and potential impacts to your operations.

Choosing the right compressed air or power solution is more than just delivering the required performance outcomes that your operations need, and CAPS Australia has been providing the necessary service and support to customers across the country for more than 45 years. Any inefficiency or downtime has a costly impact. CAPS Australia offers multiple ways

to successfully achieve operational outcomes and also keep things performing at their optimum.

Delivering compressed air and power generation solutions across Australia, CAPS has a range of products and brands to deliver solutions that are suitable for local operating requirements. Partner brands such as Ingersoll Rand, AIRMAN, Mitsubishi Heavy Industries, Sauer, Pedro Gil, Next Turbo Technologies and more feature in CAPS designed solutions.

Whether companies are looking for a reciprocating, rotary screw, oil-free rotary screw, portable diesel or centrifugal air compressor, these flexible solutions are engineered around a customer’s needs with a commitment to delivering low-cost, best-in-class industrial air compressors that are built tough and engineered to last.

The manufacturing, food and pharmaceutical sectors require a range of specialised ‘Class Zero’ air quality compressors, meeting standards according to ISO 8753-1:2010. This standard generally requires systems that are

specifically designed and configured to the end user application. CAPS’ compressed air solutions supply clean, dry air to comply with safety, quality and hygiene standards. This requirement is met by CAPS with its range of ISO Class 0 oil-free compressors, guaranteeing 100 per cent oil-free air for industrial applications.

For larger scale applications, CAPS has a range of oil-free centrifugal compressors as well as rotary screw compressors from 37kW to 355kW in either fixed or variable speed. These machines are versatile and tailor-made, so there are many factors to weigh up when choosing the right compressor.

On a smaller scale, CAPS can offer scroll compressors in an all-in-one solution with a dryer, storage tank and compressor in a single unit, keeping the real estate of the system as compact as possible. This smaller footprint translates to higher efficiency, a key component when choosing the right compressed air system, particularly as energy prices continue to climb. Offered as single phase from 1.5kW-2.2 kW, or three phase from 3.7kW to 7.5kW, this integrated solution is suitable for smaller applications requiring oil-free air.

Air dryers are essential in meeting the air quality requirements that are critical throughout the manufacturing sector. Air dryers help to remove moisture from compressed air systems, decreasing the humidity and preventing bacteria from growing, as well as warding off rust and extending the life of the machine. Desiccant air dryers are popular for industrial applications and processes that require extremely dry air between -40 to -70 ˚ C, where a desiccant material such as silica gel, molecular sieve or activated alumina is housed in a chamber through where the compressed air passes, absorbing the moisture.

Now dry, the air must also be cleaned before it can be compliant with relevant standards. Specialised filters use a variety of technologies, including coalescing and adsorption, to remove dust, oil, and other contaminants from compressed air systems. Reliable and customisable, they are available in various sizes and configurations to meet your specific needs.

The at-scale generation of nitrogen

to support operational needs is a challenge that CAPS Australia has efficient solutions for. Experienced in delivering engineered nitrogen (N2) generation systems, CAPS can configure the equipment needed to support a client’s on-site demands with dependable and economical supplies.

CAPS Australia has been entrusted to provide reliable power for a range of applications such as manufacturing, healthcare, data centres, water treatment, landfills and independent power stations, underpinned by high performance and fuel-efficient equipment. As a supplier of AIRMAN products, and the official Australian distributor for the Mitsubishi Generator Series (MGS), CAPS can deliver the power generation solution needed to maintain a company’s operations.

AIRMAN is one of the world’s largest manufacturers of diesel compressors and generators. Designed, engineered and manufactured in Japan, this range of portable power generators are precision engineered, reliable and fuel efficient.

Partnering with Mitsubishi Heavy Industries Engine System Asia (MHIES-A), the Mitsubishi Generator Series (MGS) delivers reliable and excellent performance, supplying power during emergencies and acting as a backup for critical operations. Crafted in Japan with Mitsubishi Engines, Mitsubishi Turbochargers, advanced control systems and a top quality brand of alternators, the MGS exemplifies quality and performance.

CAPS delivers complete solutions, designed and developed by its in-house engineering team and supported through its Australian ISO9001 accredited manufacturing facility. The custom-built systems are matched to clients’ requirements. This expertise also enables CAPS, where possible, to integrate new technology into existing installations, enhancing the operational performance and life of equipment and infrastructure.

Founded in Western Australia in 1980, CAPS joined the Ingersoll Rand family in 2024, expanding its access to Ingersoll Rand’s global offering of innovative and missioncritical air, fluid, energy and medical technologies, which enhance industrial

productivity and efficiency.

With 10 branches nationwide, the CAPS team delivers service, expert advice, support and spare parts. Its 24/7 maintenance and breakdown service ensures customers’ operations run smoothly and reliably.

The support continues throughout the equipment’s operational life, with CAPS CARE providing clients with ongoing warranty, parts and service plans, ensuring the greatest value for managing assets. Scheduled air compressor maintenance, as well as using predictive analytics, helps prevent unexpected interruptions in production. CAPS CARE maximises

equipment uptime and takes any hassle out of equipment maintenance.

CAPS can also get clients operational without big capital costs by delivering its competitively priced, turnkey rental solutions. Keeping operations running smoothly all year round, CAPS offers short- and long-term rental of compressors and generators across Australia.

CAPS delivers global technology, suited to Australian conditions, backed by local service.

Utilising quality products with proven reliability and the best technologies across:

•Rotary screw and centrifugal air compressors.

•Portable diesel air compressors.

• Power generators.

• Industrial filtration.

• Air blowers.

•Gas generators (oxygen and nitrogen).

•Air treatment equipment including custom built heavily engineered vessels.

•Engineered packages to suit customer’s needs and location.

• Parts and accessories. F

CAPS provides flexible air compressor solutions that are built tough and engineered to last.

Business partnerships are a key to help businesses grow. Krones and Nu-Pure are a great example of how teamwork makes both companies stronger.

Founded in 2005 as a small family business, Nu-Pure’s mission has been to provide healthy hydration with a commitment to deliver quality, service and value for the Australian beverage market. Fast-forward to 2024, and Nu-Pure has expanded, accelerating its market growth opportunities. Now, it’s opted for a new ErgoBloc L, which will catapult their production to new high-speed records.

For 15 years, Nu-Pure has partnered with Krones, which has been vital to Nu-Pure’s growth. It began with a compact line with equipment from Kosme and evolved into a strategic collaboration with the Krones Group, characterised by trust and loyalty.

new ground with the ErgoBloc L

In January 2024, Nu-Pure ordered a groundbreaking 100,000-bottles-perhour (bph) line. Its centrepiece: the high-speed version of the ErgoBloc

L – the first of its kind in Australia and the Asia-Pacific region. This milestone represents the culmination of years of collaboration and mutual growth.

Nu-Pure’s decision was a logical consequence when looking at its core values: Its commitment to manufacturing efficiency and providing high-quality beverages for nearly 27 million Australians has driven its demand for state-of-the-art equipment. And since the product portfolio is primarily 600-millilitre PET bottles, it is only logical to invest in a dedicated line for exactly this bottle size, which will perfectly fit alongside an existing 60,000 bph PET line.

The decision to purchase a 100,000bph line was not made lightly. Initial discussions considered speeds of 60,000 to 72,000 bottles per hour, but a larger line emerged as the best option for performance and efficiency.

This high-speed line aligns with Nu-Pure’s vision of maximising efficiency and achieving economies of scale. In December 2023, the company celebrated a milestone – producing one billion bottles in a single year, most of which were filled using Krones equipment. After thorough evaluation, Krones was again selected as the supplier, solidifying its place in the industry with this ErgoBloc technology, now for the first time breaking the 100,000 mark.

The success of this project hinges on a strong partnership between Nu-Pure and Krones, founded on trust and mutual respect, as Sid Raghu, national engineering manager from Nu-Pure said. “Our 15-year partnership with Krones has been instrumental to our success and growth in the Australian beverage market. When it comes to high-speed equipment, Krones offers unmatched turnkey solutions that seamlessly integrate innovation, reliability, and

efficiency. Their ErgoBloc L technology and exceptional support services consistently exceed expectations, making them a trusted partner in delivering our vision for quality and sustainability.”

By September 2025, the new line will be operational, greatly increasing Nu-Pure’s production capacity to meet rising demand

This marks the seventh Krones line for Nu-Pure, showcasing its journey from a compact system to high-speed production. F

(Financial Market Infrastructure and Other Measures) Bill 2024 will make climate-related disclosures mandatory for large businesses in Australia. Food and beverage producers will need to demonstrate energy and water efficiency, emissions reductions, and environmental responsibility.

And then there’s food safety, which is an ever-present concern. A single contamination incident can trigger product recalls, legal consequences, and lasting reputational damage.

A recent industry study found that 38 per cent of Australian F&B leaders cited food safety as their primary concern, underscoring the need for preventative solutions.

The role of IO-Link in modern manufacturing

To tackle these varied challenges, many producers are embracing digitalisation with IO-Link emerging as a key enabler. Developed as a standardised, open technology (IEC 61131-9), IO-Link facilitates bi-directional communication between field devices – like sensors and actuators – and control systems, unlocking real-time process insight. Where traditional analogue systems are limited by noise, complex wiring, and minimal feedback, IO-Link offers:

• Seamless integration with existing PLCs, fieldbuses, and control systems. •Greater accuracy in data collection, including temperature, pressure, flow, and level.

• Simplified installation and maintenance due to standardised, unshielded cables.

• Remote configuration and diagnostics, reducing the need for physical intervention.

“IO-Link allows you to turn your sensors into intelligent data sources. It helps businesses meet strict quality, safety, and environmental standards while making their processes leaner and more resilient,” said Freddie Coertze, national IoT business manager at ifm Australia.

One of the advantages of IO-Link is the ability to capture and utilise realtime data.

Whether it’s monitoring refrigeration temperatures in a dairy plant, tracking flow rates in a beverage bottling line, or measuring the pressure in a meat processing facility, IO-Link provides immediate insight.

This enables plant managers

to respond proactively rather than reactively. For instance, if a valve begins to drift out of range, IO-Link sensors can detect the change and trigger an alert before the issue escalates. This supports predictive maintenance, one of the most valuable tools for reducing unplanned downtime and improving asset reliability.

The addition of Y-Path technology – a communication route allowing process and service data to be accessed simultaneously – further enhances visibility.

This dual-channel setup allows for condition monitoring while production continues uninterrupted, a boost for continuous processing industries.

Nuttelex, a Melbourne-based manufacturer of plant-based spreads, is one example of an Australian business embracing digital transformation with IO-Link.

With a commitment to allergenfree production and high-quality standards, Nuttelex turned to ifm for sensor automation solutions. IO-Linkcompatible sensors were deployed across various parts of the plant, streamlining data collection and improving repeatability.

“We needed more control over our processes, more visibility into our machines, and less downtime. ifm’s technology, especially the IO-Link system, has helped us achieve that while future-proofing our operations,” said Mitchell Johnstone, systems engineer at the company.

As environmental legislation tightens, manufacturers must do more than meet production goals, they must measure and minimise their environmental impact.

IO-Link sensors can monitor energy usage, water flow, temperature changes, and machine efficiency in real time. This data can be aggregated to produce emissions reports, assess water efficiency, and inform maintenance strategies that reduce waste.

With automatic data logging, IO-Link also supports regulatory compliance. Accurate, traceable records simplify audit processes and demonstrate proactive environmental stewardship.

“Sustainability is no longer just good practice – it’s a business imperative. IO-Link delivers the transparency businesses need to hit their

targets and show measurable progress,” said Coertze.

From raw ingredient handling to final packaging, food safety is non-negotiable. IO-Link sensors can provide precise, consistent monitoring of process-critical values such as temperature, humidity, pressure, and cleanliness.

Any deviation can trigger an immediate alert or corrective action. In one example, a meat processing plant used IO-Link to ensure temperature thresholds in refrigerated storage were never breached.

This level of precision helps eliminate human error and supports HACCP (Hazard Analysis and Critical Control Point) compliance.

Additionally, IO-Link’s compatibility with hygienic design standards and IP-rated devices makes it suitable for washdown environments, common in food processing.

The future of IO-Link is wireless. IO-Link Wireless eliminates the need for physical cabling between sensors and masters, expanding the technology’s use in rotating, mobile, or hard-to-reach applications.

This innovation is already making headway in intralogistics and warehouse automation, but its potential in food

manufacturing is vast, from robotic arms on packing lines to mobile cleaning systems.

There’s also a growing trend towards integrating functional safety directly into IO-Link devices. This convergence will simplify control architectures, reduce wiring complexity, and strengthen plant-wide safety protocols.

“We’re heading towards fully connected, intelligent plants. IO-Link is the gateway to that reality, bringing together efficiency, compliance, and innovation,” said Coertze.

For Australia’s food and beverage manufacturers, digitalisation is more than a competitive advantage, it’s a necessity. IO-Link technology provides a cost-effective and scalable path to smarter operations, improved safety, and sustainability compliance.

By enabling real-time monitoring, predictive maintenance, and seamless integration with existing systems, IO-Link is helping producers navigate a complex landscape with confidence and clarity.

Whether you’re a small producer or a large-scale manufacturer, investing in smart sensors and communication protocols like IO-Link is a step towards future-ready operations. F Have questions or interested to learn more about how IO-Link might benefit your operation? Come see ifm are at FoodTech, on stand #H2.

RMR think differently when it comes to processing facilities and how they are built.

When Peter Taitoko walks into a food manufacturing site, he doesn’t see walls and ceilings, he sees production lines, process flow, and possibilities. As the founder and director of RMR Process, Taitoko has made it his mission to help food and beverage companies rethink how they approach building or upgrading their facilities.

“We’re not a construction company,” Taitoko said. “We’re a company that focuses on the processes of manufacturing. We don’t focus on a new factory. For us, it’s all about how you make your products.”

The distinction matters. At a time when building costs are surging and manufacturers are under pressure to scale sustainably, Taitoko’s approach is saving clients time, money, and longterm headaches.

RMR Process starts with questions: What are you making? How do you make it? What’s your output now, and what will it be in five years?

It’s a reverse-engineered approach that places manufacturing and process design at the heart of the project. Only after those needs are mapped out does the facility itself begin to take shape around them.

“Most people start with the building,” Taitoko said. “But we start with the process. Because if you get that right, the building works itself out around it.”

It’s a subtle but necessary shift in mindset. In traditional factory development, builders and architects often lead the design, with the process team brought in later to fit equipment and flow into an already established space. The process-first approach results in tighter layouts, smarter material movement, and more efficient use of automation – all of which help drive down capital costs.

Taitoko’s background is rooted in the manufacturing world. That pedigree shows in RMR Process’s DNA. From ready meals to petfood to beverages, Taitoko and his team have worked across a range of categories, and they’re attuned to the pressures that food manufacturers face.

Not every RMR Process project involves building a new facility. In many cases, the company helps clients retrofit or repurpose existing infrastructure, which helps them minimise capital expenditure and avoid unnecessary downtime.

“Often, people think they need to build new because their current facility feels constrained,” Taitoko explains. “But when you look at the process, sometimes it’s not the space that’s the problem, it’s the layout, or the way the product is being moved, or the level of automation.”

Taitoko decided to set up RMR having spent years in the industry and seeing that he could save manufacturers a lot of time and money utilising his methods.

“I grew up building food factories and was on the tools as a fitter and welder,” he said. “I was lucky enough to get a job in an engineering fabrication business in NSW that worked with companies such as Mars and Nestle. Then I started studying at night for project management and business management.”

He then decided to start his own company, doing things his way. He gives an illustration of the types of insights he sees that a lot of other companies miss.

“When you’re process focussed, you’re thinking about how the operational staff will use the factory, how the utilities will be integrated, how much automation is required to gain efficiencies to minimise labour and energy costs,” he said. “Combine this with a design that achieves a costeffective execution strategy, and the

“When you base the facility design around the process, you avoid the trap of overbuilding or underbuilding. You make more informed decisions about the level of automation you need, and that has a massive impact on the cost.”

client will get a much better operational and capital cost outcome.”

By auditing existing processes and identifying pinch points, RMR can recommend upgrades that deliver exponential gains without major overhauls. That could mean repositioning a filler line, adding a conveyor, or rethinking cleaning-inplace systems to reduce downtime between product runs.

Taitoko is acutely aware of the pressure manufacturers face to control costs while keeping pace with demand. Construction, he notes, is one of the biggest capital outlays a food business will make, and one of the hardest to get right.

“When you base the facility design around the process, you avoid the trap of

overbuilding or underbuilding,” he says. “You make more informed decisions about the level of automation you need, and that has a massive impact on the cost.”

This strategic restraint is appealing in a climate of rising material and labour costs. By focusing on how to make the product as efficiently as possible, rather than simply building for scale, RMR helps clients avoid investing in redundant infrastructure. Taitoko gives an example.

“We helped build a food factory in Western Sydney,” he said. “I think they paid $6 million for the site, and we did the project for $13 million. That’s $19 million for a world-class, state-of-the-art food facility that took eight months to build. The project had been cancelled before we got involved as they were told it would cost in excess of $30 million.

“They went to the building construction companies to find out how much it would cost for a new building. We told them, ‘Why not get an older building and just retrofit it?’ And that’s what we did.”

Taitoko said one of the main reasons the company wanted new premises was to build in redundancy as the business grew. This is where Taitoko’s process mindset came into play.

“I said to them, ‘Okay, we don’t know what the future looks like, but instead of building a bigger factory, why don’t we just incrementally replace your equipment and buy faster equipment?’” he said. “They might have a filler that can do 120 packs a minute. As capacity upscales, we can replace it with a filler that takes up no additional real estate but can do 300 packs a minute? It sounds simplistic but that’s the point, and it works.”

To guide clients through the journey, RMR starts with feasibility and ends with full commissioning support. Each

phase builds on the last, establishing clear goals, reducing guesswork, and keeping project budgets and timelines on track.

The early phases are focused on understanding the client’s product, production method, and volumes. From there, RMR develops process concepts, identifies critical equipment, and defines the plant layout based on product flow, utilities, cleaning protocols, and quality systems. Only after the process design is optimised does the building design follow.

With each phase validated and scoped, surprises are minimised when it comes time to procure equipment or integrate services.