This is a celebration of success — thanks to your hard work and our dedication to you.

Together, we’ve achieved 1 million tyres sold and shaped 1 million stories.

A million more are waiting to be written. Try Agri Star II and start creating your story now!

12 Smart farming starts with Dieci, thanks to a two-in-one machine which combines the best of telehandlers and wheel loaders

Farming

6 Legacy planning and wool industry promotion inspiring Bridgitte Brooks

26 Achmea Farm Insurance impacting Australian agriculture

17 Locally-made platforms from Midwest Fabrications transforming harvest

20 A ordable luxury and tailored service driving Wattz lighting

24 CFMOTO introduces brand’s rst electric UTV

30 Rata Equipment Power Claw makes farmer’s timber clean up easy

34 Bobcat telehandlers a winning mix for Queensland business

38 AVR potato harvesters a key

Editor Lincoln Bertelli

lincoln.bertelli@primecreative.com.au

Journalist Jackson Haddad

Contributors Omika Upadhayay, Gary Northover

Design Danielle Harris, Jacqueline Buckmaster

Art Director Daz Woolley

Managing Editor Eugene Du y

Cover image Dieci

product for Vin Rowe Farm Machinery

40 Maxam tyres giving high performance and cost savings

44 John Berends Implements ying the ag for local manufacturing

48 Tractor sales stabilised in the month of June, the Tractor & Machinery Association says, with two states and two size categories seeing a welcome boost

50 Nepalese migrant Omika Upadhayay, who is working with WAFarmers, highlights the need to emphasise regional jobs along with South Asia’s importance to Australian agriculture

54 Extra drought funding for Victorian farmers

54 Regional tech hub grants to help connectivity

55 Additional drought support in South Australia

55 CEA expands into new Queensland locations

56 Tasmania produces winegrape growers guide

56 evokeAG host city announced

57 Nu eld Scholars to descend on Adelaide

58 New South Wales extends AgSkilled program

59 Research into oating solar panels on damssoil health bene ts

4 Editor’s note

52 Calendar of upcoming events

74 List your item for sale!

Hire25 showcased the latest machinery that the industry has to o er

Another month ticks by, and in the midst of a busy events season it is easy to get caught up in the excitement of how much is going on.

Fresh from attending FarmFest and Hort Connections during June, our team was at both the Tractor and Machinery Association annual conference and the Renewables in Agriculture conference last month.

Coverage from both of these events will feature in our September edition, along with some of our coverage from the always-anticipated AgQuip in New South Wales.

This edition showcases the broad depth of machinery which is needed to make an Australian farm tick over, while also telling stories from around the country.

Our cover story this month focuses on Dieci’s Agri Pivot T70, a unique machine which arrived in Australia earlier this year and which combines the bene ts of telehandlers and wheel loaders in one impressive package.

Telling the stories of farmers actively using the machinery is something we love doing –and this month’s selection includes a Victorian farmer using a Rata Equipment Power Claw, plus a Queensland farmer who owns multiple Bobcat telehandlers.

There are several brands showcased who have not featured in our pages for a while.

One of these is CFMOTO - which has just launched a new electric UTV – and another is the AVR potato harvester available through Vin Rowe Farm Machinery.

There is also a piece on Maxam tyres and why they are suited to Australian agricultural needs, while telling the story of Achmea Farm Insurance and its e orts to go above and beyond for local farmers.

We celebrate Australian manufacturing by highlighting both Midwest Fabrication and John Berends Implements, both of which are building products designed speci cally for local conditions.

In a challenging economic climate, Wattz emphasises the value of its lighting package and describes how it is an a ordable way of boosting productivity.

We also love celebrating the work and achievements of those who keep Australian farming moving forward.

This month we pro le Western Australia’s Bridgitte Brooks, who has recently launched a clothing label that aims to highlight Australia’s wool industry while also discussing the importance of succession planning for farming families.

Plenty of industry news also graces these pages, including the Queensland expansion of CEA along with details of this year’s Nu eld Australia conference and next year’s evokeAG location.

Happy reading!

Lincoln Bertelli Editor

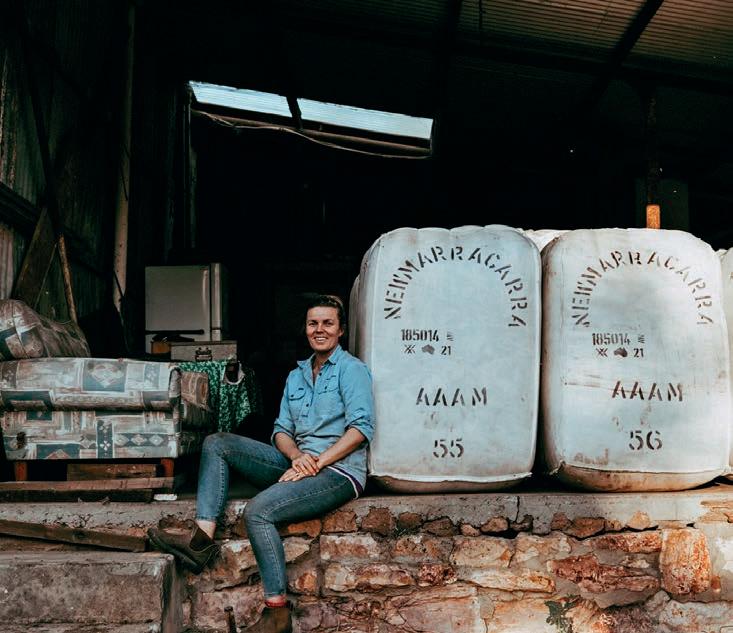

Bridgitte Brooks wants to help both Australia’s wool industry and farming families to thrive, using her knowledge and passion to promote positive change

Australian farming features endless daily jobs to complete, and so much routine and process involved in looking a er either the crop or livestock to ensure things keep ticking over and the income stream can be maintained.

Amid all this, and the focus being on the day-to-day requirements, it is understandable that the long term or bigger picture can be pushed to the side.

One woman on a mission to change this is Western Australia’s Bridgitte Brooks.

Determined to “leave the industry in a little bit better position than what it is”, Bridgitte is passionate about three things in agriculture: positive succession planning, celebrating rural women, and promoting Australian wool.

Having been born into farming and then marrying a cropping farmer, she is based at Yuna near Geraldton in WA’s mid-west and has become a prominent advocate for her areas of interest.

Bridgitte launched her own Merino wool active and leisure wear brand earlier this year, while also helping to steer succession planning – or ‘legacy planning’ as she prefers to call it – on her family farm. Her story speaks to the evolving roles

of women in agriculture, the need to successfully navigate legacy planning, and the power of advocating for your industry and community to create a greater good.

Her father farmed with his brother – and still does – and growing up as one of four children with cousins around meant Bridgitte’s earliest memories are both joyful and tied to rural Western Australia.

When it came time to select her university pathways while at high school, WA was battling a major drought and Bridgitte wondered if having an o -farm career option would be sensible in case future droughts occurred.

She studied occupational therapy, still helping on the family farm while at university, before embarking on a career that took her to multiple regional areas across the state.

A er meeting her now-husband – a dry land cropping farmer – Bridgitte moved back to the land but was determined to break stereotypes about the role of women in agriculture.

“There are still such societal expectations about, dare I say it, the farmer’s wife

being at home and baking cakes,” she says.

“People forget that farming businesses can be medium to large size businesses and there is a lot that goes into the back end of a business.

“Even though you’re not necessarily out at operations, it’s quite signi cant what you contribute to agriculture.

“That’s probably a reason why I started the brand too, I wanted rural women to feel seen and celebrated and know how special they are.

“They’re integral to the vibrancy of rural communities and for agriculture to keep going because when things go down, it’s usually women who are nurturers and keep everything ticking along.”

Bridgitte’s clothing label – Homestead Road – was about four years in the making before properly launching this March.

All pieces are made from Australian Merino wool and are simultaneously “a dedication to the wool industry and celebrating rural women”.

Acutely aware of the challenges facing Australian sheep farmers, she hopes the label can help to make a small di erence

by getting more consumers interested in Australian wool and connecting them back to that heritage.

Admitting she had “no clue about fashion” prior to starting the journey, much of the research that led to Homestead Road’s creation occurred while feeding her babies.

Initially planning to create Merino wool baby blankets, she instead spotted a gap in the market for both active wear and leisure wear.

“The performance qualities of wool are unbelievable really and there are some ex-

cellent scienti c tests to back it up,” Bridgitte says.

“I set about creating designs that were attering, comfortable and multifunctional so you could exercise in them, or you could wear them with jeans to see the bank manager or socialise in.

“It’s been an absolute challenge, and not that di erent to farming to be honest with all the bumps in the road, but it’s been a great learning curve.”

More than simply being a business, Bridgitte hopes Homestead Road can be part of a movement to promote both the

Australian wool industry and the role which rural women play.

“There’s still such a disconnect between where people’s food and bre comes from so I hope Homestead Road can be an extension of education and connecting people,” she says.

“Rural women are also quite an undervalued market, but they should never be underestimated because they’ve got so many skills from their previous life that they bring to their communities and the farm business which people don’t know about - I think we should celebrate that.

Bridgitte has been involved in farming since she was born

“I’m only this tiny fashion brand, but hopefully I can get the word out and leave the industry in a little bit better position than what it is.

“Australia once thrived on the back of sheep, but the sheep farmers are hurting at the moment so I hope I can make a di erence to them.”

As the mother of four young children all born quite close together, it was the time spent feeding them as babies which enabled her mind to develop the Homestead Road idea.

It was not the only place her mind went though, with thoughts around the legacy she wanted to leave and the need for smooth legacy planning.

This is a process Bridgitte has been through twice – the rst instance was with her husband’s family, although she chose to stay out of the nitty-gritty out of respect.

“I supported my husband but the formalities were between him and his family because it’s not my asset or my business to tell people what to do, but that was still an incredibly challenging experience,” she says.

“It was highly emotive with concerns about mental wellbeing and I just saw how the family unit can break down without good planning and good communication skills, and there is a chance that you can lose a family farm.

“The thing with farming is once that asset has gone, it’s very hard to get back into it unless you win lotto.”

Bridgitte’s average week involves spending one day at her family’s farm, which is located about an hour’s drive away.

Premium LED lights, custom designed to your tractor.

She describes herself as the self-appointed CEO, although she jokes that her father may not agree with that title, and helps in the farm’s operations – which now involves legacy planning.

Having recently witnessed rst-hand the impact of this process not going well for a nearby family, Bridgitte’s passion to succeed has only grown – knowing that this will not only bene t her family but also her wider community.

“Succession planning is something I’m super passionate about because the ow-on e ects for rural communities are signi cant too,” she says.

“We’re from a tiny community, and it’s really sad but we just had a family leave because their succession planning, which I like to call legacy planning, wasn’t successful or wasn’t even there, so they had to make a difficult choice to leave.

“That’s now one less family in our play group, one less family in our school, one less person to do a community role.

“When you get a small community, everything falls on the same few people which can get a bit fatiguing as well.

“I think it’s really important for the industry and that’s why we changed the phrasing to legacy planning because it’s acknowledging all the contributions that the previous generations made so the next generation can get an opportunity to keep farming and keep the legacy going.”

In a changing landscape where farmland is increasingly being bought by international corporates where “nobody volunteers or stays for long”, Bridgitte knows that keeping as many family farms as possible thriving is crucial towards ensuring the communities can as well.

Bridgitte believes successful legacy planning requires two things –starting early and maintaining good communication.

“I’ve got a mate on a farm in Mukinbudin and he said ‘for people that are turning over millions of dollars, the lack of communication skills is crazy. You would never see that in any other business or any other board’, which is quite true,” Bridgitte says.

“Quite o en the younger generation want to know what’s going on - have they got security, especially when they have families and should the wife give up her permanent position because we’re out on the farm?

“They ask those questions, but then it might be viewed as an angle of entitlement too.

“It’s a business risk strategy as well be-

cause even while working things out now with our family farm, there are no o -farm assets or money pot we can use, so I think starting early is de nitely going to help the process.”

A further complication can be when family members not working on the farm see it only as an asset amount and believe they are entitled to an equal share of its worth.

“That amount is only realised if you sell the farm most of the time - so how do we nd a way that people see it as fair and equitable?” Bridgitte says.

“I think it really comes down to whether you want to keep the family farm or not, because o -farm siblings in all my experience will say ‘you’ve got that so I’m entitled to this’, but I see it as an opportunity.

“Quite o en we come in with a signicant amount of debt and we get given an asset, but there’s a lot of liabilities that no one talks about or thinks about, so I think there probably needs to be more education around the sustainability of the farm too.”

Having used succession consultants, which she believes were not particularly helpful, Bridgitte believes that authoritative information around succession planning needs to come from a respected industry body to ensure it is taken

seriously and the information provided is consistent.

“Initially I think it should be a national industry body like the National Farmers Federation or someone trickling that information down so by the time it gets to the ground, it’s discussed on a grassroots level so people know the process is what everyone does and that it’s essential to keep Australian agriculture going,” she says.

Bridgitte believes a central information website could be useful, particularly around starting the thought process for the older generation in an environment free from any hostility or tension.

“Say the 65-year-old gru dad doesn’t want to have the conversations with the kids, but at least if he thinks about it, he can go in his own time at night while he’s having a cuppa and just learn a bit about it himself in his own time without feeling like he’s getting confronted,” she says.

“I think having a central website with objective info would be great, but I do think we need those industry bodies to push it as well so it’s seen as normal and essential.

“It’s a very complex area but I think education is the start.

“Legacy planning is so important because it’s the way of honouring those on the land, their legacy and all the hard work they’ve done.”

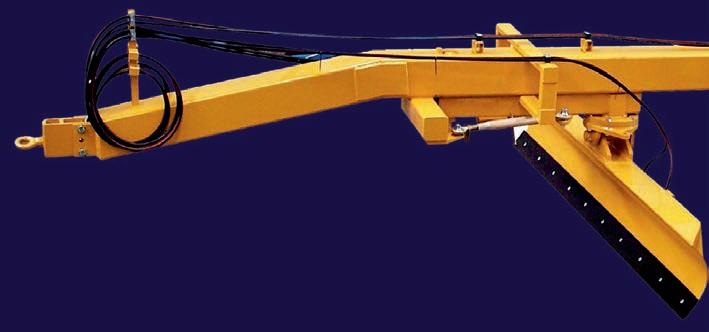

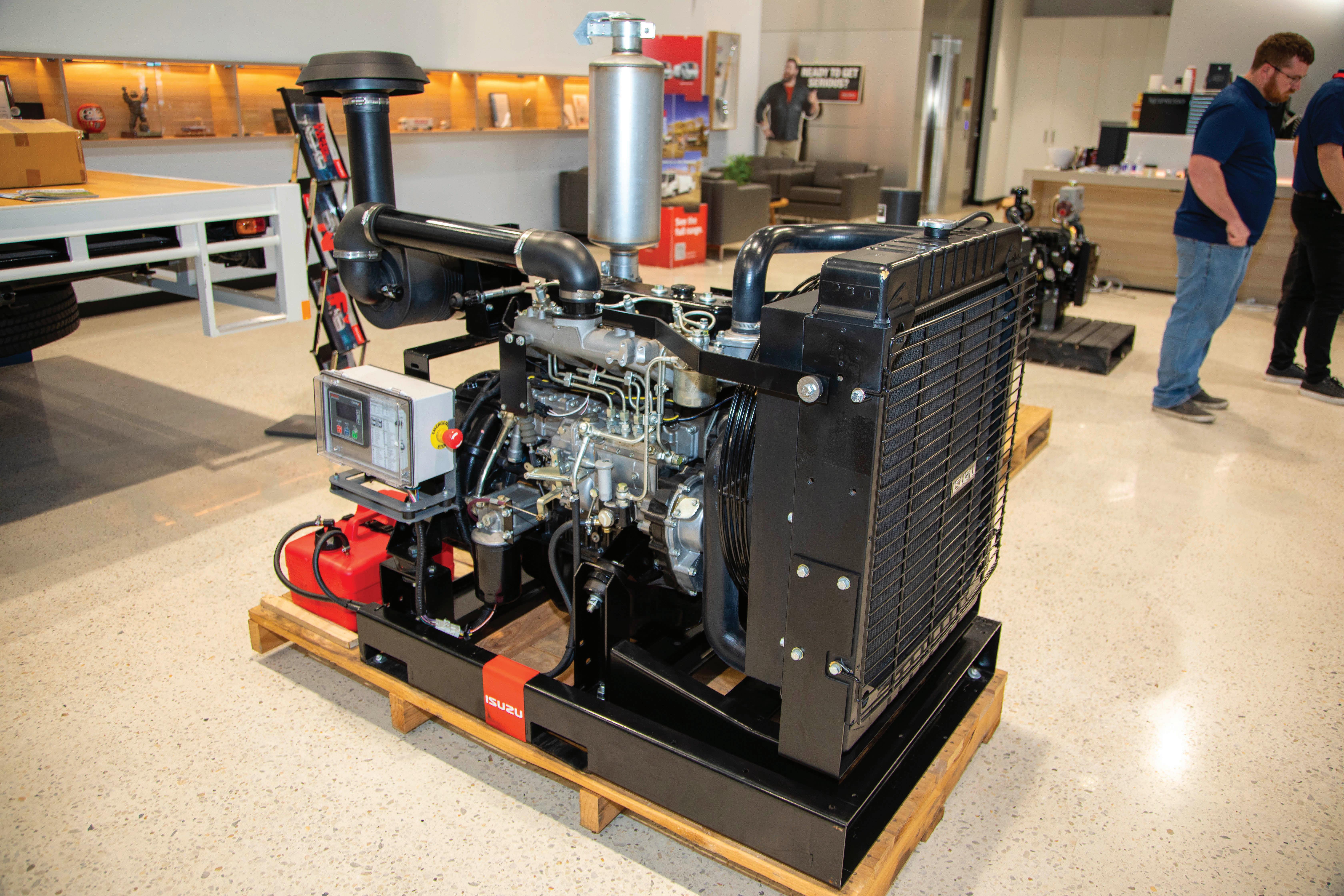

Dieci’s latest agricultural machine is already earning a reputation as a dependable workhorse.

The Agri Pivot T70 only arrived in Australia earlier this year, but its unique design which combines the bene ts of a telehandler and wheel loader means it has already caught the eye.

It o ers the 5.2m reach and 3,000kg load capacity which farmers expect from a telehandler, along with the agility and movement associated with a wheel loader.

Seeing the machine already excelling for local farmers has Dieci Australia’s national sales manager Bob Mules excited.

“The Agri Pivot T70 is fast becoming a favourite on Aussie farms,” he says.

“Operators value how it simpli es jobs that once needed two machines.

“Farmers appreciate machinery that works as hard as they do - and the Agri Pivot T70 is earning a reputation as a dependable workhorse on properties across the country.

“In a tough farming economy, the T70 is a smart investment.”

Dieci’s Agri Pivot T70 has been developed to use a variety of attachments including buckets, forks, shredders and li ing hooks, with Mules saying it is ideal for tasks which require precise placement of load into a bucket.

A standard telehandler allows for side shi but not typically swivelling of the bucket, he says, however the Agri Pivot

T70’s front positioning of the arm means it can be rotated to align the bucket precisely with where the load is being placed.

As a result, the T70 is ideal for common farm jobs such as animal feeding plus moving and dumping sand and soil, Mules says.

Accurate placing of the feed also leads to cost savings through reduced waste, he adds.

The Agri Pivot T70’s bene ts extend far beyond just combining a telehandler and

wheel loader, with plenty of thoughtful and valuable design features both inside the cabin and out.

It features a double-joint articulated chassis, which helps to ensure stability, strength and manoeuvrability in all the machine’s movements.

Further versatility is provided thanks to the 80-degree steering angle, something that enables e cient operation in even the tightest of spaces required during animal feeding.

An electronic accelerator and inching pedal help to provide accurate and controlled movement at any speed, even when the boom is operating at full power.

The rear oscillating axle makes the Agri Pivot T70 adaptable to all types of ground, guaranteeing four support points and maximising stability.

It also features a 45 per cent di erential

lock, something which is standard across the Dieci range.

A swing kinematic mechanism, which is speci cally designed to increase the service angle, is something Dieci says will be particularly appreciated when the bucket in moved to the ground and when it is unloaded at the maximum height.

Mules also highlights two additional features which help to guarantee safety while using the Agri Pivot T70.

“The advanced Load Limiter Device constantly analyses stability, ensuring the machine won’t perform movements beyond safe threshold,” he says.

“The patented single compensation cylinder improves boom balance and control, therefore raising the bar on safety and performance.”

Mules also describes the Agri Pivot

T70 as delivering “big results in a midsized frame”.

The unit is powered by a 115hp (86kW) Perkins engine, has a pull-out force of 6,000 daN, towing force of 6,650 daN and a maximum speed of 40km/h.

Functionality and operator comfort have also been heavily considered by Dieci with the design.

The rst example of this comes from the Shi on Fly transmission, which allows for gear changes to occur without the machine stopping – thereby spending less time on manoeuvres.

Dieci has added an Eco function which reduces both noise emissions and fuel consumption, even while the Agri Pivot T70 is travelling at its maximum speed of 40km/h.

There is also a creeper function that provides a constant engine speed and oil ow rate to e ectively use equipment such as sweepers, while another function automatically limits the speed when the boom is raised.

Four advanced controls have also been added to the high-tech boom – shake, wall, memory and oating – and each of these make an aspect of daily operations easier, by doing everything from facilitating materials release during unloading through to allowing the equipment’s position to be memorised.

Being able to e ectively and seamlessly use these functions requires an intuitive, well-designed cabin and this is something else which Dieci has put plenty of thought into.

Those four advanced controls, along with the transmission and travel direction,

It has been described as a ‘dependable workhorse’

are controlled exclusively by the new joystick.

“This is intuitive, ergonomic, and precise, putting full boom and directional control in the palm of your hand,” Mules says.

“The cabin’s climate control system, improved visibility, and 360-degree eld of view also make long days feel shorter and more comfortable.”

Crucially, this 360-degree vision is maintained even when the boom is raised thanks to its central positioning.

A redesigned dashboard, clear instrument panel, advanced diagnostic system and new monitors provide a step up in accessibility for operators, while the seat has also been moved slightly back to o er increased legroom.

All of this combines to create a machine which has proven to meet the needs of

farmers since its local launch earlier this year.

“The T70 is loaded with innovations that increase output and reduce fatigue,” Mules says.

“With its rugged build and Australian-ready specs, it is doing exactly what local farmers need - reducing downtime, li ing productivity, and handling tough terrain with ease.

“It is versatile enough for every season and durable enough for every challenge.

“The T70 delivers cost-e ciency, performance, and peace of mind – all of which are qualities which every Australian farmer values.”

Dieci Australia’s Agri Pivot T70 is accessible nationwide through the brand’s agship branches located in Sydney, Brisbane, Melbourne and Perth.

The Australian-built platforms from Midwest Fabrication have been transforming harvest e ciency across the country

For nearly three decades, Midwest Fabrication has been setting the benchmark in harvesting innovation with Australian-made harvest platforms that thrive in the most rugged eld conditions.

As AgQuip rolls into Gunnedah this August, Midwest returns once again and will be bringing their leading Midwest platform.

Whether you’re harvesting wheat on the Western Downs or canola in the Riverina, Midwest platforms are designed to do more with less; less wear, less fuel, less downtime, while delivering more e ciency, more control, and more value per hectare.

Overall, that means fewer headaches during harvest and more money in your back pocket.

In a market crowded with imported machinery, Midwest Fabrication remains unapologetically local.

Every platform is engineered, fabricated, and assembled right here in Australia.

That means lightning-fast production times, local and easily accessible parts, and service you can actually get on the phone.

But being Australian-made is about more than location. It’s about understanding our elds, our crop types, our soil, and the

conditions that change from hour to hour.

Midwest’s engineering team works side by side with local farmers and dealers to continuously improve platform performance where it counts, on the ground.

The result? A platform that’s not just built tough, but built smart.

Flat crop? Midwest will still cut and deliver a good harvest. Melon holes? No problem. Mung beans? It can get razor close to the ground for maximum crop haul.

At the centre of Midwest’s range are two models and one commitment to harvesting smarter.

The Legacy and Durus models are both built for peak performance but tailored to di erent needs.

Purpose-built for the John Deere X9, 10 and 11 Series combines, the Legacy is the latest evolution in Midwest’s premium range.

Designed for high-output harvesting, it delivers smoother crop ow, reduced grain loss, and even lower operating costs.

It features an upgraded frame and centre mount designed to handle greater loads delivered by larger Deere combines, while preserving balance and agility in the eld.

With its high resale value and streamlined features, the Legacy is ideal for contractors and large-scale operators ready to level up.

Tried and tested across numerous Australian harvests, the Durus is Midwest’s workhorse.

Available in sizes up to the 60 feet width (18.3m) – and Midwest was proudly the rst to engineer to 60 feet wide – it is a favourite among farmers chasing e ciency over multiple crop types.

Mechanically driven with minimal electronics, the Durus delivers consistent performance without the headache.

It’s also fully compatible with major combine brands including John Deere, Case IH, New Holland, Claas, Gleaner and Fendt.

Both platforms o er smart harvesting solutions like fully integrated cross

augers for u y crops, and exceptional ground-following performance, even in melon hole and contoured country.

Ask any Midwest operator why they made the switch, and you’ll hear the same thing: simplicity, reliability, and return on investment.

It o ers the lowest operating costs in class, the company says, with fewer wearing components and better crop ow meaning Midwest platforms reduce maintenance and fuel bills.

Stronger frames, Australian manufacturing standards, and dealer support give Midwest platforms a second-hand edge thanks to their exceptional resale value.

They are built for every crop and every condition. From pulses to cereals to canola, Midwest platforms are designed to handle crop diversity without constant adjustments.

With a growing national dealer network and dedicated local support team, help is never far away.

Optional extras like cross augers and

extension kits are purpose built and designed in-house for seamless integration.

Rather than just focusing on features that look good in a brochure, Midwest says it keeps its focus on function.

New product improvements are driven by farmer feedback and trialled in real eld conditions.

Recent developments include hydraulic tilt on feeder house, high-capacity belt systems to minimise stoppages, enhanced flotation kits for uneven fields, and updates to frame design for even stronger platform integrity.

This practical innovation is why Midwest platforms continue to outperform others, the company says, especially in harsh or high-yielding environments where downtime is not an option.

Midwest Fabrication says it is more than a manufacturer. It’s a business that exists to support Australian farming communities through job opportunities, local investment, and machinery that actually makes harvesting easier.

From humble beginnings in Queensland to becoming a global pioneer in 60 feet platforms and now leading the way in innovative harvest platforms that improve harvest operations and pro tability, Midwest’s journey has always been rooted in one simple goal: to help Aussie farmers harvest smarter.

If you’re heading to AgQuip this August, make time to stop by the Midwest stand.

You can see the platforms up close, chat with the team, ask the hard questions, and nd out why more growers are backing Australian-made.

Visit www.midwest.net.au or call (07) 4662 2137 to speak with the Midwest team, or follow Midwest on social media for field day updates and o ers.

AGRI PIVOT T70, the articulated telehandler designed to meet diverse needs. Resembling a wheel loader with a telescopic boom, this telehandler excels in confined spaces, offering high performance at a low operating cost. Its articulated chassis with double-pivot central articulation ensures stability, strength, and manoeuvrability in all directions.

Max Capacity: 3,000 kg Max Lift Height: 5.2 m

Weight: 7,150kg Max Power: 85.9 kW (115 hp)

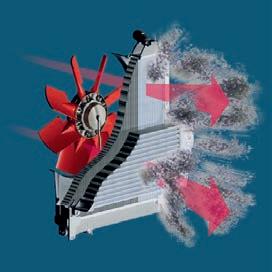

Providing a ordable luxury and tailored service is how lighting provider Wattz wants to be seen in the Australian market

Luxury without the high-end price tag is something which people can usually only dream of.

Whether it is the next machinery purchase or something else in life like the next holiday, getting a top-quality experience without a huge nancial cost can be dicult to achieve.

Blending these two attributes – and combining it with a customer service experience that treats farmers as family – is the philosophy which guides lighting supplier Wattz.

“We come from farming, so our team is knowledgeable about all farming operations,” Wattz founder and Victorian farmer Andre Meyer says.

“Our product provides a luxury level of quality at a portion of retailers’ prices.

“That is not where the value stops though, because it is not just about the lights being brighter or stronger than others on the market – it is also about the service and quality promise included when customers purchase from us.”

Wattz rst entered the Australian market

earlier this year with the goal of providing this value and quality for local farmers.

Thanks to its partnership with major European lighting brand Crawer, it means customers can deal with Wattz knowing they have access to a huge selection of top-quality LED lights which can signicantly improve their farming operations at a fraction of the cost of alternatives.

The lights provide up to 400 per cent more brightness than factory- tted options, Meyer says.

This means farmers can comfortably work in otherwise challenging lighting conditions such as dawn and dusk, while also getting a product that is designed speci cally for their model of tractor, does not alter the factory look and is easy to install.

Providing a quality product is just one part of Wattz’s philosophy though.

The company is not simply a middleman selling the lights to customers, with Meyer and the Wattz team being embedded in Australian farming and having a

genuine investment in their customers’ success.

“We want to o er unmatched service and quality and we view our customers as being customers for life,” Meyer says.

“We personally follow up purchases with calls to check in and to have an honest chat.

“The relationship does not end when they check out – we want to continue providing service beyond the purchase, even if they just have a question.

“We see farmers as the pillars of the community and we will support, listen to, advise and assist our farmers seven days a week.”

This desire to support customers means Wattz is prepared to tailor its operations to suit what farmers need, help anybody who is not satis ed with their product, and maintain these ongoing relationships long a er the transaction has been completed.

A ordability is at the forefront of all its products, with Meyer aware that farmers around the country are facing economic hardship due to factors such as drought.

This has acted as motivation for Wattz to not only provide a solution that was a ordable, but to provide service which exceeds expectations and make the investment even more worthwhile.

“Our lights are not only a ordable and priced according to the everyday farmer, but they are an investment,” he says.

“It’s a small upfront cost that could save you thousands. How much does an accident cost you? If you drive into a fence line or stump you can’t see, or get fatigue from dull lights, how much does that cost you?

“How much does it cost you if you’re spraying a crop at night and you have blocked nozzles?”

Wattz also aims to go above and beyond by providing customised solutions tailored to individual needs, rather than just supplying an o -the-shelf product which farmers need to adapt.

“Being farmers ourselves, we have the in-depth knowledge of what each industry would require, and this advice and expertise assists the farmer when purchasing,” Meyer says.

“The products themselves are as universal as possible while being as speci c as possible. We also have di erent solutions or options to suit their needs, so it may be the same model of tractor but two farmers will have di erent needs.

“For example, we can provide a spotlight to help them look further if they are doing work with hay, or a ood beam if they are doing anything at low speed.”

Wattz can provide three di erent beam angles to suit a speci c light, while also

The JCB 542-70S Loadall is the ultimate tool for a wide range of tasks with unmatched versatility. This isn’t just a telehandler; it’s an investment in your farm’s efficiency and output.

Why buy the 542-70S?

•Increased Productivity: Move more, lift higher, and stack smarter with 4.2-tonne lift capacity and 7-meter reach.

•Enhanced Safety: Superior visibility, stability, and control keeping your operators safe and your operations running smoothly.

•Fuel Efficiency: Advanced engine technology and hydraulics mean more work for less fuel.

•JCB Reliability: Backed by industry-leading support and parts availability, ensuring your machine is always ready for work.

D

Don’t compromise on performance, speak to your nearest JCB CEA dealership today!

providing an extra set of screws to help any product t on a variety of tractors.

Wattz can provide a wide range of di erent connectors to make up a custom wiring loom if a farmer wanted to t a light where it is not normally tted .

“If you want to put a spotlight where there is not meant to be one, we can make it t,” Meyer says.

In seeking to balance a ordability and quality, Wattz has found the sweet spot.

With its LED lights providing up to 400 per cent more brightness than factory- tted options, they o er a signi cant increase in functionality.

Additional lumens could be added to make the lights even brighter, Meyer adds, but this would compromise the style and

pricing of the lights and therefore not make them as accessible to Australian farmers.

The lights are primarily aimed at tractors and harvesters, but Wattz can also provide solutions for everything from sprayers to implements.

Within each machine type, tailored lights are available for an extensive list of brands and for speci c models meaning everything from headlights, work lights, spray lights to shed lights can be replaced with Wattz products.

This extensive product range and versatility means Wattz is well placed to cater to any machinery lighting needs – no

matter how speci c – and to do so without breaking a farmer’s budget.

“We hope that Wattz becomes a household name and the go-to one stop shop for any and all of your lighting needs,” Meyer says.

“If you’re spending hundreds of thousands on new machinery it should come with great lights, unfortunately that is not the case unless you pay a fortune at the dealer for their LED upgrade.

“We wanted to provide a solution, which is to provide a better quality product at a tenth of the price with one-on-one tailored service.”

The full product range can be viewed online at www.wattz.com.au

CFMOTO’s rst pure-electric utility terrain vehicle (UTV) has been launched to the Australian market, o ering several bene ts for farmers around the country

Global manufacturer of ATVs, side-by-side vehicles and motorcycles CFMOTO is no stranger to hard-working vehicles, having sold over 50,000 units in Australia, with a large majority acquired by farmers.

Having been distributed in Australia since 2005, CFMOTO has also been a household name in the global powersports industry since 1989, selling a full suite of durable vehicles suited to the agricultural landscape, including the popular and ever-evolving UFORCE utility terrain vehicle range.

The o -road capability of these vehicles makes them the perfect partner in crime for farmers driving through rugged terrain, and now CFMOTO is proud to o er an electric model, eliminating engine fumes and operating with minimal noise.

CFMOTO recently launched its rst pure-electric UTV, the UFORCE U6 EV, marking a new chapter in its commitment to practical innovation and environmental responsibility.

The new model comes following the strong reception of the electric concept both locally and overseas, with the UFORCE U6 EV designed to deliver robust performance, everyday reliability, and real-world versatility – all in a package that’s both practical and a ordable.

“We are very excited to release CFMOTO’s rst 100 per cent electric UTV, fresh o the production line, giving Aussie farmers even more choice when it comes to selecting the right UTV for their farm,” CFMOTO o road vehicle marketing manager Stephen Carrington says.

“We have been showcasing the new UFORCE U6 EV at eld day events, prior to launch, and have been getting great feedback from interested customers.

“I feel that there will be a strong adoption for a large variety of farming operations –big or small – and even new commercial opportunities where silent operation and no engine fumes are game changing in the UTV space.”

The near-silent operation of the U6 EV is complemented by low rolling resistance

tyres and no engine vibration, making it ideal for sensitive environments and early morning starts, which can be particularly bene cial for farms with livestock.

Carrington recently spoke with a Victorian sheep farmer who reinforced the suitability of electric-powered UTVs on-farm.

“The key standout was the silent operation during lambing season,” he says.

“It was a blessing in disguise, no longer startling mobs of sheep, easily conducting stock checks and the ability of doing all the other jobs in between.”

Feature packed

A 35kW (46.9hp) Permanent Magnet Synchronous Motor delivers instant torque and smooth acceleration, taking the U6 EV from 0 to 60km/h in under six seconds.

Having this speed, combined with an impressive travel range of 110km – on a single full charge at consistent speeds of 30-40km/h and under temperatures of 20-25 degrees – means farmers can tackle

the task at hand quickly and e ectively.

The U6 EV is also a highly versatile vehicle, o ering an 800kg tow capacity and a 250kg rear tray capacity, while an 8-inch TFT multifunction display, NFC digital key, and CFMOTO RIDE app integration o er a connected and userfriendly experience.

“Instant torque and the ability to select between two power modes allow for easy towing and slow speed manoeuvring

around the farm,” Carrington says.

“With an 800kg tow capacity, the U6 EV also o ers 120kg more than the UFORCE 600 petrol-powered equivalent.”

Over-the-air updates also ensure the vehicle continues to run with the latest features and improvements.

The ability to fully recharge the vehicle in just six and a half hours – from 0 to 100 per cent under temperatures of 20-25 degrees – is another bene t, allowing

farmers to simply charge it overnight and get back to work the next day.

When purchasing a UFORCE U6 EV, farmers are protected by a two-year vehicle warranty and a ve-year, unlimited kilometre power battery warranty.

Further con dence can be instilled into the purchaser knowing that they will be supported by CFMOTO’s 80-plus national dealer network, serviced by its headquarters in Altona, Melbourne.

Available now at $23,990* ride away, the U6 EV has joined CFMOTO’s growing UFORCE lineup, which began with the UFORCE 1000 in 2018 and most recently expanded with the UFORCE 800 XL and U10 PRO in 2024.

“We continue to o er a growing range of quality UTVs both powered by ICE petrol engines or electric with the new UFORCE U6 EV,” Carrington says.

“From our popular UFORCE 600 range to the all-new 3-cylinder U10 PRO range, CFMOTO has the right UTV for the job.”

For more information on the CFMOTO UFORCE U6 EV, visit www.cfmoto.com.au or contact your local CFMOTO dealer.

*National ride away price is the recommended retail price inclusive of freight to your local dealer and dealer pre-delivery charges. Excludes regional WA and King Island dealers. To confirm the recommended ride away price customers should contact their local dealer, as prices may vary, depending on your location.

From money in a glass jar in a small Dutch country town to now having a global reach, Achmea Farm Insurance’s Ilse van de Meent oultines Achmea’s cooperative legacy and impact across Australian agriculture

When a group of Dutch farmers in the village of Achlum came together in 1811 to protect their livelihoods from haystack res, they founded something extraordinary – they just didn’t know it yet.

They pooled their money into a glass jar and embraced a cooperative insurance model with a greater purpose – reducing the risk of haystack res, minimising nancial loss, and maximising collective strength.

More than two centuries later, that humble beginning has evolved into Achmea, a global nancial services provider serving over 13 million clients, with international operations including Achmea Farm Insurance in Australia.

Despite its global footprint, Achmea’s cooperative heart remains unchanged.

“I love telling our ‘glass jar’ story,” Achmea Farm Insurance marketing and communications general manager Ilse van de Meent says.

“And so do our people – whether they’re sitting at the boardroom table with farm

managers or at a farmer’s kitchen table.

“It’s a story that resonates because it’s about community, resilience, and purpose.”

Since entering the Australian market in 2013, Achmea Farm Insurance has experienced strong growth, serving the needs of Australia’s diverse farming sector, from familyowned farms to complex, large-scale commercial agribusinesses.

The specialist agricultural insurer prides itself on partnering directly with farmers, farm managers, C-suite executives, and investment managers overseeing complex portfolios of properties, machinery, and infrastructure.

“Australia’s farming landscape is incredibly diverse, constantly evolving, and o en unpredictable,” Ilse says.

“We work with a wide range of decision-makers, from multi-generational farmers to CFOs and asset managers, each with their own priorities, whether

it’s protecting critical infrastructure, managing seasonal volatility, or ensuring business continuity across multiple sites.

“Achmea Farm Insurance’s “All-in-One Farm Pack” is purposefully designed to be exible and scalable, so clients can tailor it to their speci c risks, operations, and long-term goals, whether they’re running a family farm or managing a national portfolio.”

At the core of Achmea Farm Insurance’s o ering is a simple yet powerful purpose, keeping farmers farming.

“This isn’t just a tagline,” Ilse says.

“It’s a 200-year business ethos that traces back to that glass jar in Achlum.”

Ilse’s passion for promoting the value of insurance is deeply personal. On the due date of her second child, she returned home to nd the family home on re.

“There was smoke everywhere, the walls were burning from the inside. Had I arrived home just a few minutes later, we could’ve lost everything,” she says.

“That experience stays with you. It’s why I believe so strongly in the importance of having the right insurance, and receiving a personal response when it matters most.”

That philosophy – of being close to the client and ready to step up when they need it most – drives Achmea Farm Insurance’s local, direct, and specialist approach to insurance.

“We’re not just serving agricultural and regional communities, we’re a part of them,” Ilse says.

“Clients value our commitment to using local repairers and service providers, which supports local employment and strengthens communities.”

One feature of Achmea Farm Insurance’s All-in-One Farm Pack that Ilse nds especially important is the Guarantee Against Underinsurance – an optional cover available for eligible farm buildings.

“Underinsurance is a genuine concern,” Ilse says.

She explains that underinsurance can occur when the insured sum doesn’t adequately cover the cost of replacing or rebuilding what’s been insured.

“That is why Achmea Farm Insurance o ers an optional Guarantee Against Underinsurance cover for eligible farm buildings,” she says.

“It is designed to give farmers peace of mind if the unexpected happens.”

With rising costs of materials, labour, and energy, replacement costs can quickly outpace insured values. If the insured sum is below the replacement cost at the time of a claim, farmers may need to pay out of pocket to make up the di erence.

With this optional Guarantee Against Underinsurance cover, Achmea Farm Insurance will arrange and pay for the repair or rebuild of the insured building as it was when new or pay the equivalent amount.

“This can be particularly bene cial following major events like the recent oods, where shortages in supplies and builders can push rebuild costs above market level,” Ilse adds.

“At Achmea Farm Insurance, we understand that no two farms are the same,” Ilse says.

“For some, a farm is a multi-generational legacy; for others, it’s a large-scale commercial operation with complex asset

portfolios and supplier relationships.

“Our All-in-One Farm Pack gives clients the exibility to choose what cover they need, where they need it, and how they need it – tailored to their speci c farm, risks and business goals.”

This adaptability allows clients to customise their insurance across a wide range of assets, from homes and machinery to sheds and glasshouses.

Alongside its All-in-One Farm Pack product, the specialist agricultural insurer also o ers Farm Fleet Insurance and Stud Stock Insurance.

Shared vision between nations Ilse grew up in the Netherlands, where Achmea’s roots run deep, but has spent most of her career in Australia, and is proud of the unique and strong ties between the two countries. She recently participated in a Netherlands–Australia

agricultural trade mission focused on collaboration in areas such as sustainability, growing more with less, and prevention-focused farming practices.

“There’s so much we can learn from each other,” she says.

“Whether it’s sustainable farming, innovation in the glasshouse sector, or risk prevention, both countries bring unique strengths to the table. Collaboration between the two is not just bene cial, it’s essential for a sustainable future.”

One area of particular interest is the glasshouse industry, where Achmea Farm Insurance is actively supporting knowledge exchange with its colleagues in the Netherlands to help accelerate growth and innovation in Australia’s emerging protected cropping sector.

In the Netherlands, Achmea, through its vision of Sustainable Living Together, is actively looking for solutions and new

Farm Insurance o ers a Guarantee Against Underinsurance optional cover for eligible farm buildings

perspectives that make society healthier, safer and more sustainable.

For Achmea Farm Insurance in Australia, that same spirit drives local initiatives that support farming communities and promote sustainability.

“From a glass jar in that small Dutch country town to farms across Australia, I think the cooperative foundation is what makes Achmea special,” Ilse says.

“It’s about shared responsibility, longterm thinking, and being there for each other when it matters.”

To learn more about Achmea Farm Insurance or request a quote, visit www. achmea.com.au or call 1800 724 214.

issued by Achmea Schadeverzekeringen N.V. (Achmea) ABN 86 158 237 702 AFSL 433984. This information is general advice only. Read the PDS & TMD available on www.achmea.com.au to see if this insurance is right for you.

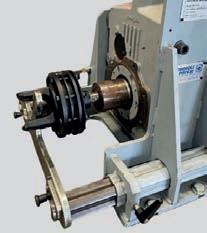

Australia’s No1 locally built mulcher for the last 25 years. Available in Low Body or High Body models in various sizes. Great for clearing up paddocks and bush blocks.

types available

The best value for money Front End Loader mounted post hole digger on the market. Standard with Eurohitch connection with other styles available. Various augers sizes and

Australian made aerators using the Shattertine technology. Great for cracking open hard ground and rejuvenating pastures.

range of

Australian Made slashers with 5 year gearbox warranty. Various sizes and models in single and twin rotor set-up. Great value and strength. Also available in galvanised.

For one Wimmera farmer, cleaning up timber around his property has become a breeze thanks to Rata Equipment’s Power Claw

Around Australia, the list of customers who have not looked back a er purchasing a Power Claw from Rata Equipment is ever-growing.

Its ability to complete multiple jobs around the farm while making light work of tedious and di cult tasks such as removing large logs has made it a winner for farmers across the nation.

Capable of tting on to tractors, skid steers and telehandlers – with size-speci c models available depending on the machine’s power – its versatility and adaptability are among the features cited by local farmers as standouts.

One of these farmers experiencing the bene ts is western Victoria’s Andrew Leslie.

With his farm totalling about 2,500 hectares just outside Horsham in Victoria’s Wimmera region, along with a livestock property about 50km further south, Leslie’s property naturally includes plenty of paddocks that require cleaning up.

When an employee visited the Wimmera Field Days – where Rata Equipment

has a strong presence – the solution to his cleanup needs was found.

“My employee just saw it at the eld days, looked at them all and said ‘I reckon that’s the one to go for’,” Leslie says.

“We bought this as an all-in-one machine to get the job done quickly and e ciently.”

Many farmers across Australia have found uses for the Power Claw beyond what they initially intended – and Leslie foresees himself joining this group – but his primary use of the unit as a cleanup tool is in keeping with how Rata intended it.

Leslie has farmed at his Wimmera property for about 20 years and is also the fourth generation to do so a er his great-grandfather purchased the land about a century ago.

The farm predominantly grows canola, wheat, beans and some barley, along with some hay for the sheep.

It was the acquisition of the livestock property which prompted the purchase

of his Power Claw – a decision which has proven to be a winner.

“We bought the stock farm three years ago and had a lot of timber down there to be cleaned up and a lot of fences that need to be pulled down and repaired,” Leslie says.

“With this, you can quickly and e ciently pull down a fence line by yourself and push it up and clean it up in quick time - so it’s basically a one-man job then.”

For Leslie, a challenge arose when some timber fell just before he was due to start sowing a paddock.

Faced with either sowing around it, or delaying the process until the timber could be cleared, Rata’s Power Claw ensured neither of these scenarios occurred.

“We were able to quickly run around and clean everything up so it’s nice and neat and ready to go it’s been really great that just one person can do that,” he says.

Turning these types of tasks into one-man jobs is where the Power Claw particularly excels.

It brings the same bene ts as the fourin-one buckets traditionally used by a lot of farmers in terms of its strength and usability, but what sets it apart is the ability to grip on to large and heavy items such as logs and rocks to quickly, safely and e ciently move them as required.

Interlocking tines are made from high-tensile steel which helps to further ensure its strength, while the unit’s strength also means even bulky and awkward timber can be handled with ease.

While this is the main use for the Power Claw across Australian farms, its versatility means it has been used to complete everything from clearing overgrown paddocks to being added to a remote-controlled mower by di erent operators.

While many of these uses may only become apparent a er the Power Claw has been purchased, farmers such as Leslie are seeing it as a worthwhile investment due to its adaptability.

“We wanted something that could do as many jobs as possible,” he says.

“If you want to invest in something, you want to be able to do as many things with it as possible.

“Just the ease of being able to pull out fences and clean up fences in in one machine without taking attachments o was really appealing.”

Further highlighting the Power Claw’s adaptability to individual needs is the size options it is available in.

Rata sells the Power Claw in three broad models – standard, mid-range and compact.

The standard claw is best suited to tractors larger than 75hp, skid steers larger than 2.5 tonnes, along with telehandlers.

The mid-range suits tractors between 45hp and 75hp, skid steers up to 2.5 tonnes and small loaders.

Rata’s compact Power Claw is designed for compact tractors between 25hp and 45hp, plus small stand-on skid steer machines.

Varying widths are available within each model, stretching between 1.35m and 2.6m as standard options depending on size.

Rata has shown a willingness to work with farmers in catering for speci c needs – with a customised 3.4m wide unit for a Queensland farmer providing one example of this.

The ‘o the shelf’ Power Claw is already ticking a lot of boxes for farmers, with everything through to its factory-packag-

ing doubling up as a storage stand for the unit when not in use.

These thoughtful touches mean Australian farmers can be con dent they are getting a product which is tailored to their needs, but Rata’s customer service means other adjustments can be made if needed.

For Leslie, there was only one minor change made and this was done with a potential long-term, heavy-duty use in mind.

“The only thing that we changed was we just went a little bit tighter on the bottom tines,” he says.

“We’ve got a bit of ironstone down there and we’re hoping we might be able to just rake up a few bigger rocks with it so they wouldn’t slip through when we’re doing our pasture renovations.”

Rata’s willingness to help with this is just one of the ways in which Leslie’s customer experience with the company - and Stawell-based dealer Lonsdale Merchants - has been nothing but positive.

“I totally recommend Michael - he was really good to deal with,” he says.

“We did it all over the phone and it was great, he delivered it out and said if there were any dramas to just let him know, which we haven’t had - so it’s great.”

Rata Equipment’s Power Claw range, along with the company’s other attachments, can be viewed online at www.rataequipment.com

When a business has tried numerous brands of the same machine, then chooses to keep investing in a particular brand, the endorsement should be taken seriously.

Such is the story of Queensland fertiliser manufacturer Nathanael Ernst, whose venture into Bobcat telehandlers has yielded three separate purchases, with plans to invest further in the coming year.

Ernst rst bought a 2020 model of Bobcat’s TL38.70HF telehandler, before adding a larger TL43.80HF to his eet last year.

He has since traded in the original TL38.70HF for a newer version of the same model, providing strong evidence of Bobcat’s ongoing success with the business.

Ernst is the manager of Katek Fertilizers, a family-owned business based near Gympie which pelletises about 15,000 tonnes of chicken manure per year.

The vast majority of this heads to Queensland farms further north than its Gympie base, he says, while about a quarter is sent overseas to Vietnam.

Western Australia, Tasmania and the northern Victorian town of Shepparton are other important markets for Katek Fertilizers’ products.

The company also loads out about 3,500 tonnes per year of what Ernst calls ‘loose bulk’, which is pelletised product loaded into grain trucks and sent to sugar cane growers in Far North Queensland or to broadacre farms.

“We probably bring about 18,000 tonnes of manure in to make about 15,000 tonnes

of pellets a year,” he says.

“That also involves moving about 3,000 to 5,000 tonnes of waste product back out to the farms – so the telehandlers do a lot.”

Dealing in such high volumes makes the e ciency of its machinery crucial, particularly when the company only has a small team of 11 people.

When the family bought Katek Fertilizers in 2008, they started with only two older telehandlers, before seeing the merits of maintaining a larger eet.

“Because we were so reliant on them,

when one broke down it was just a headache,” Ernst says.

“If rain was coming and you couldn’t push the manure o the pad, then you lose out.

“That’s basically why we ended up buying more machines, so if one did go down – because any machine can break – you’ve got a backup machine there to jump in and keep going.”

Maintaining consistency between machines was another bene t, Ernst discovered in time, a realisation which inspired him to stick with Bobcat for multiple purchases.

“Before we bought our rst Bobcat, we

always had a mismatch and bought either new machines based on what was good at the time or good second-hand gear from the auctions,” Ernst says.

“I’ve always been a big fan of using just one brand and, with all my machinery that I’ve ever bought, one of the things I’ve had to have is a good dealership that’s under an hour away.

“They’re on the Sunshine Coast so they’re about an hour away from us and the service is really good.”

Bobcat machinery – including the telehandlers – is distributed and serviced nationwide by Bobcat Australia, which is a division of Clark Equipment.

This means customers can be con dent in the a ersales support from a company which has a strong footprint across the entire country.

Ernst would not have stuck with the Bobcat telehandlers if they were not meeting his daily needs for the factory, and if the di erent models did not work in harmony with each other to complete contrasting jobs.

The TL38.70HF is the smaller of the two telehandlers, providing a 7m li height and 3,800kg li capacity, and being powered by a 130hp (97kW) engine.

The engine size and auxiliary standard ow of 150L/min is identical on the TL43.80HF, however the larger model provides a 4,300kg li capacity and 7.5m li height, as well as weighing about 600kg more.

Ernst further highlights the hydrostatic gearboxes which the Bobcats o er – and particularly the TL38.70HF – as being “like

little race cars”, describing this as one of the standout features compared to other brands he has used.

“That’s the main reason I bought the TL43.80HF about 12 months ago, because I didn’t like the gearbox elsewhere,” he says.

“It’s just fast and it’s good. It’s not quite as fuel e cient as a mechanical drive gearbox or power shi gearbox, but it has a lot more power and for what we do it’s just better.”

Having the two Bobcat telehandlers with di ering li capacities – and overall

machine weight – means that Ernst can tailor their individual workloads.

Broadly speaking, the TL43.80HF’s slightly larger li capacity and overall weight means it is used for more of the grunt work, whereas the “zippiness” of the TL38.70HF means it has found its place completing other important daily processes.

“For the TL38.70HF, its main job is making a mix, but to run the manure through the plant we’ve got to get the moisture level right,” Ernst says.

“Depending on what blend we’re running through the plant, it will get certain amounts of wet and dry chicken manure or composted chicken manure, mix it to the right mix and then other telehandlers will feed it through the plant.

“Its main job is mixing that, but we’ve also got a hectare pad and we lay the manure out about 100mm thick and then we turn it with a big tractor with a plough.

“Then, when it’s dry, we push it up and put it into the sheds so that when it rains we can still operate the plant.

“Our site is about 10 acres between com-

posting pad and factory, so it’s also ideal for speeding us around.

“The operator on the TL38.70HF is my production manager and he just likes the zippiness. They’ve got the same engine, same gearbox and same di s in but he just likes the manoeuvrability, slightly shorter wheelbase and it’s just better for him.”

When it comes to the larger TL43.80HF, the addition of a three cubic metre bucket means it can pick up about three tonnes of product at a time with ease, enabling trucks to be loaded quickly.

Growing appreciation

Ernst is steadfast about one thing – his next telehandler purchase will be a Bobcat.

The success of both models means the more di cult decision will be whether to purchase another TL38.70HF or a TL43.80HF.

“They complement each other well and that’s why we’re a bit unsure which size we’ll buy next,” he says.

“There’s nothing to make me think I wouldn’t buy another Bobcat, because there’s nothing I could buy that I think would come close.

“Everything has been thought out about where things are placed - the starter motors and alternators are all easy to get to, the ergonomics are good and the batter supports are good.”

Ernst was full of praise for the service received from Clark Equipment’s Sunshine Coast branch, also citing the e ciency of having multiple machines serviced at the same time by sticking with Bobcat.

“The more we get through them, it means rather than just servicing one, they can just look at all of them, which is always better,” he says.

“We’re very happy with the support of Bobcat on the Sunshine Coast, and unless something goes wrong, I won’t buy another brand of telehandler.”

Bobcat’s full telehandler range, along with other agricultural machinery such as tractors, mowers and utility vehicles, can be viewed at www.bobcatofaustralia.com.au

AVR potato harvesters are backed by a long history and form a key part of Vin Rowe Farm Machinery’s range

Vegetable harvesting requires specialised machinery, usually tailored to that particular product.

For a farmer to get the best outcome from all their hard work, it requires carefully selecting both their machinery brand and choice of dealer.

AVR potato harvesters and Vin Rowe Farm Machinery are both experienced operators who specialise in the sector and are well equipped to give Australian farmers what they need.

Founded in Belgium in 1849, AVR started by producing hand tools for agriculture before various stages of development culminated in the company moving into potato harvester manufacturing in 1970. Its range can be broadly separated into single and two-row trailed bunker harvesters along with two and four-row self-propelled harvesters.

AVR is represented on mainland Australia by Vin Rowe Farm Machinery,

a company which has been based in the Victorian town of Warragul since 1961 and is well equipped to serve all parts of the nation quickly.

An important part of the AVR range is its selection of Spirit trailed bunker harvesters.

This product range begins with the Spirit 6100, which is a single row unit, before stepping up to the two-row 6200, 7200 and 9200 models.

Built for precision and protecting the potatoes during harvest, the Spirit range has been designed to provide a smooth product ow with minimal drop heights, as few directional changes as possible and a at picking-o table.

The 6100 and 6200 each have six tonne capacities, which steps up to seven tonnes on the 7200 and eight tonnes on the 9200.

The 6100 is driven by a CAN-bus system, which enables operation via a joystick and screen with the ability to add control functions and self-diagnostics.

Wide channels and a large platform around the picking-o table increases both safety and e ciency, while large wheels and wide tyres helps with easy machine pulling while minimising impact on the soil.

AVR describes the Spirit 6200 as being “highly reliable because of its simple design and performs spectacularly at the same time”.

Soil separation immediately commences on the digging and sieving web, while a three-row rotary comb removes any stones and clumps from the ow.

Once the bunker is full, AVR says it can be unloaded in under a minute using the quick unloading oor.

The Spirit 7200 integrates an additional haulm separation system through a roller just upstream of the in-line potato belt, while a trash web under the haulm

web ensures any late dropping potatoes remain in the machine.

This unit is also compatible with AVR Connect, which allows machine data to be accessed online.

Stepping up to the Spirit 9200 introduces AVR’s patented Varioweb cleaning module, which allows for exible and customised cleaning, being able to adjust to any soil conditions, and consists of a pintle belt and axial roller combination.

It is a fully hydraulically driven machine which has the option of a Clean and Go bunker that provides a bu er for eight tonnes of potatoes, additional sieving capacity and no need to stop the machine while unloading the bunker.

Another popular model within AVR’s range is its Puma 4.0 self-propelled fourrow harvester.

Described as being heavy-duty, reliable and easy to operate, it is also tted with AVR Connect along with a touchscreen, joystick and quick-select rotating button. Its compact and lightweight construction means it is extremely manoeuvrable, boasting a 50-degree steering radius at the front and 20 degrees at the rear.

The harvest channels are 1.45m wide for the model with four lots of 75cm rows – or 1.55m with four lots of 90cm rows – and the ridge pressure can be adjusted under all circumstances to remove the potatoes from the soil.

It also o ers the Varioweb cleaning module, along with AVR Comfort Drive that means the machine can be operated with

maximum stability and ensure increased driver comfort.

This unit is powered by a 12.8L engine that produces 469hp (350hp) which provides increased power to both the front and rear wheels.

It also has an eight tonne bunker capacity but despite its size and strength, the Puma 4.0 retains a light footprint thanks to its very high exion tyres.

Another crucial feature across the AVR potato harvester range is automated depth control.

Vin Rowe has specialised in European brands which are well suited to speci c horticulture tasks, such as potato harvesting.

Having operated for more than 60 years, the company is well versed in what Australian farmers need and showcased its national presence by travelling from Victoria’s Gippsland region to Brisbane for this year’s Hort Connections event.

The company says its central location means there are only a few remote parts of Australia which it cannot guarantee 24hour service to.

As a family-owned business, Vin Rowe Farm Machinery says it cares passionately about the brands which it represents and remains the exclusive mainland distributor for the AVR range.

The company’s range can be viewed online at www.vinrowe.com.au

A seven-tonne bunker capacity features on the Spirit 7200. Image: Prime Creative Media

Available at dealerships nationwide, Maxam tyres are giving farmers the performance they need with the bene t of considerable cost savings

When seeking out new pieces of agricultural machinery, Australian farmers are always looking for the durability and toughness to handle local conditions, along with a brand they can trust and value for money.

This same logic also applies to the crucial pieces of equipment which keep this machinery running: their tyres.

The long distances travelled in an average day, particularly by broadacre growers, along with managing variable soils and maximising operating e ciency through controlling fuel and other output costs, makes the choice of tyre crucial.

Maxam knows the importance of providing a reliable and durable tyre for Australian farmers, who work in harsh conditions and need products that will not let them down.

The company says its tyres are available at between 50 and 60 per cent of the cost of traditional premium tyre brands, without compromising on advanced technology and durability within the product.

“This is particularly signi cant for Australian farmers, who o en manage large eets and cover extensive ground, making

tyre costs a primary operational consideration,” Maxam APAC representative Dewald Welman says.

“With margins tight and machinery working longer hours, the cost-per-hour of tyres is a critical metric for Australian operations.”

The lower upfront cost of Maxam tyres combined with their “robust durability and performance” means farmers can reduce their capital outlay without sacri cing reliability.

They can also extend tyre life even under heavy workloads and long transport runs, reduce fuel consumption due to optimised rolling resistance and improved traction, and support their long-term farm sustainability by protecting soil structure.

A ordability does not come at the expense of performance or technology with Maxam tyres.

They boast a wide, low-pressure footprint that minimises soil compaction and protects the long-term productivity of paddocks.

A 45-degree lug pro le delivers reliable

traction on soils as diverse as the red loam found in Queensland and the heavy clay of Victoria.

Radial and very high exion construction o ers exibility and comfort on rough terrain to reduce operator fatigue during long days in the eld, while self-cleaning tread maintains grip and e ciency even in sticky or variable soil conditions.

An eight-year warranty on Maxam radial tyres provides peace of mind for farmers.

This warranty also includes support for stubble and eld hazard damage along with scraper applications and reinforces the local support which Maxam provides.

Maxam’s AgriXtra XL VF tyres were also independently tested by the German Agricultural Society (DLG) last year.

The tyres achieved the lowest fuel consumption for both eld and transport tests among all tyres tested, while delivering above-average results in terms of area performance. They also delivered high tractive force, reduced soil compaction and strong durability.

“Our tyres delivered critical advantages during the comparative testing, earning them the DLG Seal of Approval,” Maxam’s vice president

of global agriculture Greg Gilland says.

“This con rms that we o er a superior product that delivers exceptional value on all comparative measures at a more competitive price.

“By reducing soil compaction, enhancing fuel savings, and improving traction, our AgriXtra XL tyres help farmers achieve greater pro tability while promoting sustainable farming practices.”

Locally, farmers have also experienced the bene ts. Improved traction and reduced slippage in variable soils have been reported, along with noticeable fuel savings especially during mixed eld and road operations.

One Victorian farmer, who was using Maxam tyres for the rst time, highlighted “the good, strong sidewalls, wide bead areas and strong rim guard”.

For another Victorian broadacre grower, it was the overall performance and support which was most impressive.

“We’ve found Maxam tyres give us the grip and durability we need, without the premium price tag,” the farmer says.

“The local dealer support makes a real di erence during harvest.”

Maxam tyres are backed by more than half a century of experience and have built a strong reputation and global recognition during that time.

Its parent company – Sailun Group – sells its tyres in more than 160 countries around the world and has established research and development centres across three continents.

In late 2022, Maxam’s AgriXtra tyres were fully approved for original equipment tment to various tractor models manufactured by global giants Case IH and New Holland.

These AgriXtra tyres are the core of Max-

am’s range, being speci cally designed for high-horsepower tractors and harvesters.

Maxam also produces VF (very high exion) tyres, which the company says provides up to 40 per cent higher load capacity or can operate at 40 per cent lower air pressure without compromising speed or performance, therefore enabling them to reduce soil compaction and improve fuel e ciency.

Introducing these VF tyres was relatively recent, only arriving in Australia in late 2023, but was described as a “significant change” to tyre technology at the time. It provides another example of Maxam

adapting its products to changing needs, while having a strong eye on what Australian customers require.

Having an o cial Australian distributor means Maxam customers have access to responsive a er-sales support and warranty service, something which is critical for minimising downtime during peak seasons.

Maxam tyres are also readily available through local tyre dealers across the nation, with product availability, tment advice and support available for farmers by contacting their nearest dealer.

Maxam’s full product range can be viewed online at www.maxamtyres.com.au

John Berends Implements continues to y the ag for Australian manufacturing, producing high quality products at its Melbourne factory

In the south-eastern Melbourne suburb of Dandenong, there remains a shining example of Australian agricultural manufacturing.

Leading farm machinery manufacturer John Berends Implements has operated since 1966 and is still family owned.

The company continues to service the agricultural sector with Australian-made, high quality and well-priced farm implements, something it has done for nearly 60 years.

Boasting more than 8,000sqm of factory area, almost all aspects of production are done at John Berends Implements’ site, encompassing everything from steel processing and welding to painting and nal assembly.

The only external processing is some local machining and laser cutting.

It is an extensive operation, and one which the company has invested in the long-term viability of by adding the likes of a high-speed plasma cutter and welding robots.

John Berends Implements is not a onetrick pony either, also priding itself on the large range of products it builds to suit a variety of agricultural applications.

The selection includes everything from large twin rotor slashers, trailing road graders and broadacre disc ploughs through to aerators, rippers, rakes and post hole diggers for smaller acreages.

Having built these products over many decades, and re ning the production

process along the way, it means John Berends Implements can remain a welloiled machine that manufactures proven, high-quality products that consistently do the job.

The philosophy behind most new designs is how can it be built strong enough for Australian conditions and the intended job but simple enough to keep it a ordable for farmers.

“We could charge the same as other manufacturers and probably still sell similar numbers at a higher pro t, but our company policy is to always provide Australian farmers with value for money,” general manager Derrick Berends says.

“If the farmer goes away happy with their machine, then they are more than likely to consider Berends for future machinery purchases.”

Australian-made products have always been associated with strength and quality, while also giving farmers the con dence they were developed for local conditions and needs.

Maintaining this local manufacturing presence, and ensuring farmers can access Australian-made agricultural implements, is what motivates John Berends Implements to keep developing.

“There has been a growing number of cheap imports coming out of Asia and we have already seen several local manufacturers take the path of importing these low-quality products instead of manufacturing them locally,” Derrick says.

“We believe it is very important that Australia maintains a strong local manufacturing sector just as it is important that consumers should buy Australian grown produce at the supermarkets.

“Although we can never match the sort of pricing coming out of places like China, we also know that the quality and a ermarket service of these products o en lets them down and it is this aspect which we can use to our advantage.

“We frequently get asked if we can repair gearboxes on cheap imported machines which are barely over a year old yet out of warranty.

“Unfortunately, there is not much which can be done in most cases as they are designed as a throw away item once they break down.”

John Berends Implements aims to build its products to the required strength for Australian conditions – using the speci -

cations they would like to have as buyers – without adding too many complex features which add unnecessary cost.

In addition to its products being built for local conditions, they are backed up by an extensive national dealer network.

Both of these are traits which Derrick says many of the cheap imported alternatives do not provide.

“The other big issue that is occurring is that customers are being sold machinery which is too light and not t for purpose,” he says.

“This is where having a good dealer net-

work who can o er the right advice, and back up the product they sell, is important.

“When you are looking at buying new machinery, always consider Berends as an option and compare the features and prices against other brands. You may be pleasantly surprised.”

John Berends Implements is located at 130 Frankston-Dandenong Road, Dandenong South.

The company can be contacted on (03) 9791 2494 or by visiting www. johnberendsimplements.com.au

Tractor sales have stabilised in the month of June, the Tractor and Machinery Association says, with two states and two size categories seeing a welcome boost

June saw national tractor sales become somewhat steadier, in the face of continuing climate challenges and general conservative sentiment from farmers.

There were around 1,300 tractors sold for the month, which is down about 4 per cent on the same month last year, and means overall sales are about 10 per cent behind for the year to date.