Thermo King and BPW

What are the benefits of ePower?

Reliable, independent power supply for fully electric or hybrid refrigeration units

Intelligent energy management and efficient operation

Air-cooled

Saves fuel and CO2

What are the benefits of ePower?

Reliable, independent power supply for fully electric or hybrid refrigeration units

Intelligent energy management and efficient operation

Air-cooled

Saves fuel and CO2

CHAIRMAN

John Murphy

john.murphy@primecreative.com.au

MANAGING

EDITOR

Luke Applebee luke.applebee@primecreative.com.au

EDITOR

Peter White peter.white@primecreative.com.au

JOURNALIST

Sean Gustini sean.gustini@primecreative.com.au

ADVERTISING

Adrian Kos: 0413 777 670 adrian.kos@primecreative.com.au

Ashley Blachford ashley.blachford@primecreative.com.au

DESIGN

Alejandro Molano

HEAD OF DESIGN

Blake Storey

CLIENT SUCCESS MANAGER

Ben Sammartino ben.sammartino@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

O cially endorsed by the VTA

Two thousand and twenty-five has been quite the year for the transport industry. One that has been full of various challenges but also many opportunities.

We kicked January off with a bang when the Australian Government announced that an extra $7.2 billion would be invested into the Bruce Highway – a move aimed at upgrading and fixing the freight route in hopes of turning the tide on its notoriety. Several projects took shape over the remainder of the year, and ongoing developments are still being announced as we approach the end.

In March, aluminium providers and trailer manufacturers were faced with the news that the United States would be implementing tariffs on imports from Australia and trade partners around the world. Higher inflation rates and slower economic growth were general concerns for Australia as a whole, but for the trailer manufacturing industry in particular, it meant the possibility of additional costs being passed onto trailer builders and end users.

Then, Ex-Tropical Cyclone Alfred arrived. Businesses along the east coast were halted and communities were left damaged and affected. But the industry’s resilience and ability to work together in times of need proved to be much more powerful than the natural disaster.

In May, we all geared up for the Brisbane Truck Show. What we witnessed was a record-breaking event which provided OEMs with the perfect opportunity to showcase the latest technologies and equipment our industry has to offer. Manufacturers such as Vawdrey, Haulmark Trailers, Bruce Rock Engineering and JOST took the opportunity to show off new innovations while others like Krueger, GLT and HELLA used it to display their products in their own unique ways. It was a remarkable event to be a part of, and one that truly showcased what transport is all about.

Two thousand and twenty-five was also full of growth for many transport and logistics companies. Industry giants such

as Toll Group, Linfox, Lindsay Australia and Qube continued to expand with record fleet equipment investments, acquisitions, partnerships and yearon-year financial growth. Family and Australian-owned businesses including Followmont Transport, Simon National Carriers, JD Refrigerated Transport, Freight Assist Australia, Tasman Logistics Services, Minus 1 and the many others that have featured in Trailer demonstrated true resilience and development.

As we enter 2026, we inch closer and closer to a reality that could look very different to the one we know now. The Victorian Government’s Victorian Freight Plan, for example, will look to supercharge the state’s $36 billion transport sector with targeted investments in new road, rail and port infrastructure to accommodate higher productivity combinations. Additionally, the Australian Government’s Net Zero Roadmap and Action Plan will work towards reducing national emissions significantly over the next 25 years. But one thing is certain. IF we use 2025 as an example, it’s clear that the heart behind Australian transport will never change.

Trailer Magazine Editor

Peter White

+ No Ubolts

+ More uptime

+ Low maintenance

+ Patented composite rotor

+ Frame bracket symmetry – no shocker bracing needed + SAF drum brake with quick release spherical anchor

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

SAF-HOLLAND (Aust.) Pty. Ltd

+ Long life disc brake technology SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

www.safholland.com.au

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Email: sales@safholland.com.au www.safholland.com.au

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

(Aust.) QLD

(61-7) 3375 7033 Fax: (61-7) 3375 7044

Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044

(Aust.) WA

(Aust.) WA

Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730

December 2025 24

Business partnerships, people movements, developments that bolster freight productivity and more.

22 Economy

The ALRTA believes the Federal Government’s proposal to lower speed limits in rural areas will impact the transport industry if it goes ahead.

24 PBS equipment & engineering

OBrienco Transport dedicates a B-triple road train to epilepsy as Symons Clark Logistics launches the first batch of a massive custom skel order.

28 Tippers

Find out about the latest tipper application developments from E-Plas, Moore Trailers and Bulk Transport Equipment.

36 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

40 Service & maintenance

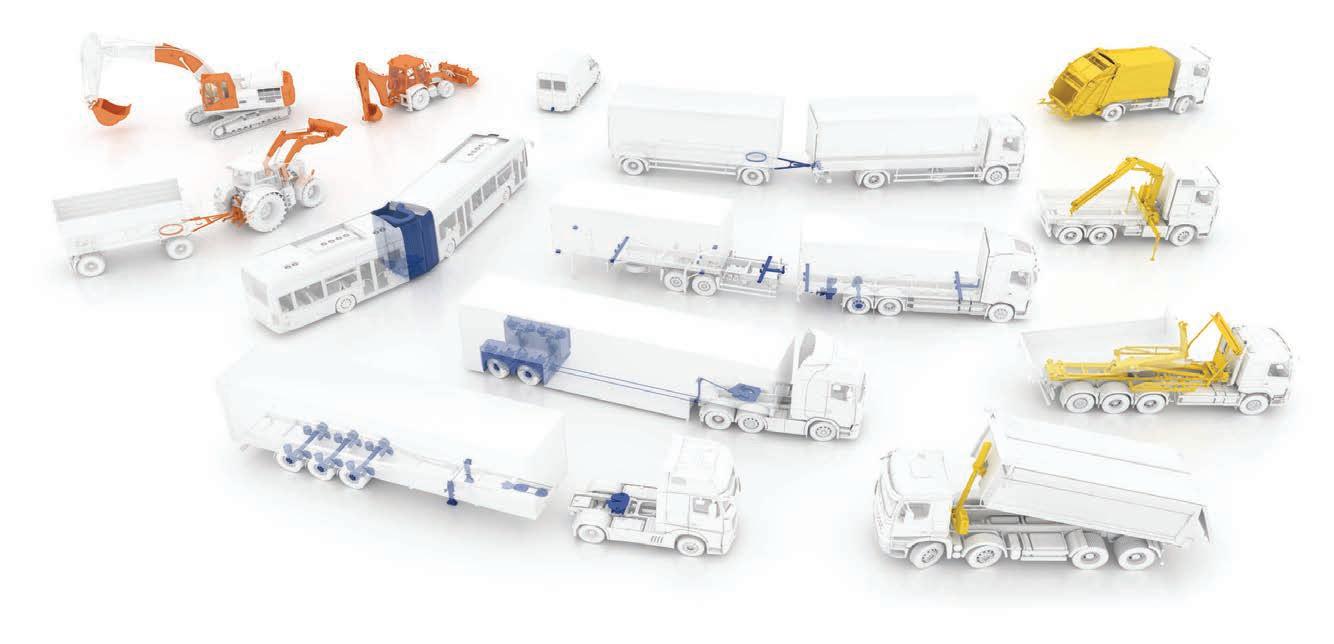

SAF-Holland, JOST and BPW Transpec are making strides with their servicing and aftersales support.

46 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

50 ALRTA

The LRTAV, Department of Transport and Planning and NHVR are championing the development of the High Productivity Livestock Vehicle Network.

52 Infrastructure spotlight

What you need to know about Australia’s biggest road projects this month.

54 World map

DHL’s newly opened Europe Innovation Centre in Germany is a launchpad for the future.

57 Fleet of the month

Multiquip is rolling out 10 custom Performance-Based Standards B-double combinations for Baiada.

58 What’s on Upcoming shows and field days.

National refrigerated transport company, Minus 1, has opened a new facility in Minchinbury, New South Wales.

The 20,000-square-metre purpose-built depot features a 10,200-square-metre cold storage facility and multiple temperature chambers.

Also included is a large refrigerated cross dock, 19 recessed loading docks, a freezer with 10,000-plus pallet capacity and chiller and confectionery rooms with 2,000 temperature-controlled spaces each.

The new Minchinbury location aligns with Minus 1’s clear and aggressive growth strategy which will include several additional national infrastructure projects in the coming years.

Minus 1 CEO and Managing Director, Billy Barba, told Trailer the latest site was developed to accommodate recent growth in NSW and future expansion.

“We’ve seen growing demands as the business shifts from transport only services into the 3PL warehouse and logistics space,” he said.

“Sydney is our largest market, and

to manage customer demand while maintaining service levels, building a dedicated company-managed site was a must.”

The Minchinbury depot is positioned in a centralised location and within a close proximity to major distribution centres in the area.

It also enables greater access for the fleet’s Performance-Based Standards (PBS) combinations.

“This depot increases our capacity, brand

awareness and footprint in Sydney and NSW,” Barba told Trailer

“Importantly, it provides us with quicker vehicle turnaround times due to the increased number of recessed docks.

Better vehicle utilisation will enable continued growth for our transport division.

“Customers will benefit from an increased service offering, access to a market leading food-grade facility for better productivity, higher capacity and an ability to manage seasonal demand.”

Mondiale VGL has announced the appointment of Matthew Warrington as Group CEO, effective January 2026.

Warrington’s appointment follows an extensive global search and marks an important next phase for the Oceaniabased transport and logistics provider.

He brings more than 30 years of international logistics and supply chain experience to Mondiale VGL and its customers, including senior leadership roles with some of the sector’s most recognised organisations.

Warrington joins Mondiale VGL from Toll Group, where as President of Toll Global Forwarding, he led 2,500 people across 29 countries and managed more than US $2.3 billion (approx. $3.5 billion AUD) in annual revenue.

His earlier career included executive roles with Linfox, Visy Logistics, GrainCorp and BevChain, as well as five years as a Partner and Director with Boston Consulting Group.

Mondiale VGL Chair, Justine Smyth, said

the appointment reflects the company’s continued focus on expansion, innovation and customer success.

“Matthew is a highly respected industry leader with a proven track record of driving growth and delivering customer-focused solutions across large and complex global logistics operations,” she said.

“His commercial insight and deep understanding of what drives performance will further strengthen how we help our customers compete and succeed in today’s market.

“He brings operational discipline and an international perspective that will build on the strong platform already in place and position Mondiale VGL well for the opportunities ahead.”

Warrington said Mondiale VGL had built an impressive global platform and strong reputation across key trade lanes, supported by long-term partnerships with some of Australasia’s and the world’s most recognised brands.

“The company’s progress over the past

several years has been remarkable,” he said.

“I’m looking forward to working with the Board and leadership team to continue building on that success – strengthening our network, expanding our footprint, enhancing our customer offering and creating new opportunities for our people.”

Warrington, based in Australia, will operate from Mondiale VGL’s Sydney office while maintaining a regular presence at Mondiale VGL’s New Zealand headquarters and across the global network.

This leadership transition follows the decision of outgoing CEO, Ray Meade, to move into a senior commercial role within the business.

“Ray’s leadership has been instrumental in shaping Mondiale VGL into the global business it is today,” Smyth said.

“We’re delighted Ray will continue to play an active role in the business and we thank him for his outstanding commitment and leadership over many years.”

We choose Vawdrey because they’re a family business with exceptional values. Their design, quality equipment, back-up support and relationships with customers is what we look

CRL Express has joined forces with Healthy Heads in Trucks and Sheds as a Supporting Level Corporate Partner.

The Victoria-based transport and logistics provider will work with Healthy Heads to drive positive change across the transport and logistics sectors, helping to build a safer, healthier and betterconnected industry.

CRL Express Group General Manager, Brendan Tate, told Trailer Healthy Heads’ mission resonates deeply with its core belief – that people matter most.

“Our business, like every business, is built on people,” he said.

“This partnership is about ensuring no one feels alone. Whether it’s sharing a coffee, offering advice or having a longer conversation, we want to create a culture of support and care across our industry and business.

“Supporting a noble cause that aligns with our values is a small step with a big impact.”

By partnering with Healthy Heads, CRL Express will be able to contribute to the wellbeing of the people keeping industry moving.

Tate sees the partnership as the beginning of a long-term relationship between both organisations.

“As CRL Express grows and evolves, so will our partnership with Healthy Heads,” he told Trailer

“I’d like to extend my sincere thanks to Ben Maguire for championing this partnership. I’m excited about the opportunity to collaborate with Ben, Melissa Weller and the entire team on upcoming initiatives that will make a meaningful impact.

“We’re proud to stand alongside Healthy Heads in promoting mental health and wellbeing in the transport and logistics sector.

“Together, we can make a real difference for the people who keep our industry moving.”

Cahill Transport has completed a major expansion of its Laverton, Victoria, depot.

The project, completed by CMW Design and Construct, primarily delivered an extended warehouse which has significantly increased Cahill Transport’s capacity.

Construction also included building a central workshop and extensive new hardstand areas which have since streamlined yard operations.

Additionally, Cahill Transport invested in a new state office building with modern workspaces, meeting rooms, a staff café and upgraded driver amenities as well as key site infrastructure including drainage, refuelling, truck wash and a new weigh bridge.

CMW Design and Construct said the upgrade has set the foundation for a highperformance logistics hub.

“We are delighted to continue our longstanding partnership with Cahill Transport and deliver a facility that supports their next stage of growth in the transport and logistics industry,” the company said.

“The project was delivered while Cahill Transport remained fully operational, thanks to the seamless collaboration between our team, subcontractors and Cahill’s management.”

We are committed to shaping the future of clean energy transport through cutting-edge technology and Australian-certified solutions. From LPG and LNG to Cryogenics and Hydrogen, our products set the standard for performance, safety, and sustainability. Whether on the road or in stationary applications, we deliver energy solutions that empower industries and communities to thrive in a cleaner, greener world.

Coolway Trans has enlarged its intermodal freight services in a partnership with Pacific National.

The transport company has combined its refrigerated logistics expertise with Pacific National’s extensive rail network to transport freight across Australia in a more affordable, efficient and sustainable way.

By utilising Pacific National’s intermodal services, Coolway Trans now has the capacity to move an additional five to six containers by rail each week.

The fleet’s intermodal freight services have also expanded to cover round trips from Sydney to Perth and Melbourne to Perth.

Coolway Trans CEO, Sunny Ahmed, told Trailer the partnership has enabled the company to maintain reliability and costeffectiveness while expanding its capacity.

“This expansion was primarily led by significant growth in freight volumes to Western Australia and the need to offer

Trans semi-trailer carrying

more competitive transport rates for our customers,” he said.

“As our client base grew, particularly in the food and retail sectors, it became essential to find a scalable, sustainable logistics model.

“Intermodal rail provided exactly that.”

Coolway Trans first opened its WA depot around two years ago, marking a major step in the company’s national growth at the time.

The fleet was initially operating just one B-double per week until increased demand saw it introduce four road trains and several B-triple combinations.

Ahmed told Trailer Coolway Trans later explored the rail option when presented with a strong proposal from Pacific National.

“Pacific National offered a sustainable rate structure and reliable capacity,” he said.

“Their national presence and proven track record made them the ideal partner to support our expansion.”

Western Australian mining company, MLG Oz, has received an extension to its existing contract with Rio Tinto.

The contract is for the provision of bulk haulage site services in support of ongoing activities at the Western Turner Syncline Mine in Pilbara, WA.

It encompasses the provision of offroad bulk ore haulage services, material loading, rock breaking, unloading, stockpile management and road maintenance services.

“We are very pleased to be able to extend our relationship with Rio Tinto for a further three months, which is a positive reflection of the successful commencement and delivery of our services,” said MLG Oz acting CEO, Mark Hatfield.

The extension will provide additional revenues of approximately $5 million through to March 2026.

The original contract revenue is still expected to be approximately $20 million.

The agreement initially targeted two to five containers per week, utilising Pacific National’s equipment and infrastructure while Coolway Trans’ own rail containers were being prepared.

Following a successful trial, the flexible arrangement has allowed Coolway Trans ensure the continuity of its operations during a growth phase.

“The WA expansion has given us greater capacity, more competitive pricing and sustainable transport rates across long-haul lanes for customers who are looking for sustainable and cost-effective rates,” Ahmed told Trailer

“It also strengthens our ability to compete with larger refrigerated transport companies in the Less-Than-Truckload (LTL) segment.

“Importantly, these improvements allow us to pass savings directly to our customers – many of whom are small businesses supplying food across Australia.”

The Pacific National intermodal solution will also allow Coolway Trans to maintain service consistency during peak periods, ensuring products reach markets on time and in optimal condition.

“Our expansion reflects our long-term vision of building a national, sustainable logistics network that supports Australian businesses from coast to coast,” Ahmed said.

“We’re proud of how far we’ve come – from a small family operation to a trusted partner servicing every major state – and we remain committed to innovation, reliability and customer success.”

The Queensland Government has announced a $79.1 million injection into its manufacturing sector.

This investment, part of the State Government’s Transforming Queensland Manufacturing Strategy 2025-2030, was made public at the headquarters of GLT Trailers in Carole Park at the start of October.

Queensland Minister for Natural Resources and Mines, Manufacturing and Regional and Rural Development, Dale Last, met with Mayor of Ipswich City Council, Teresa Harding, to make the announcement.

Harding said the investment and overall manufacturing strategy are vital, with the sector being key to Queensland’s economy.

“The manufacturing industry employs more than 10,000 people in Ipswich and is our third largest employment sector,” she said.

“Manufacturing adds $29 billion to the Queensland economy alongside supporting 175,000 jobs including 83,000 in regional Queensland.

“The Transforming Queensland Manufacturing Strategy 2025-2030 and Action Plan will be investing $79.1 million, which is set to drive Queensland’s manufacturing revival to deliver more jobs, greater productivity and innovation

into the economy, ultimately getting more Queensland products into the hands of global consumers.

“I am looking forward to working with Minister Dale and the Crisafulli Government to bring this strategy to our Queensland manufacturing industry, setting it up for long-term success ultimately boosting our local economy.”

GLT Trailers CEO and Queensland Manufacturing Advisory Council member, Shay Chalmers, expressed her support for the strategy while hosting the meeting between Harding and Last.

“We have some of the world’s leading manufacturers right here in Queensland, and this strategy is a launch pad for longterm success,” she said.

“It’s a plan to help our manufacturers grow, innovate and meet the challenges ahead.”

Norman Carriers has been re-certified to operate under the National Heavy Vehicle Accreditation Scheme’s (NHVAS) Mass Management, Maintenance Management and Performance-Based Standards (PBS) framework.

The re-accreditation confirms that Norman Carriers’ systems for mass, maintenance and fatigue management continue to meet National Heavy Vehicle Regulator (NHVR) standards.

It provides independent recognition of the fleet’s ongoing commitment to safe, compliant and efficient operations, reinforcing its reputation as a trusted operator which takes safety and Chain of Responsibility obligations seriously.

Norman Carriers Safety and Compliance Manager, Richard Wyles, told Trailer the re-accreditation will enable the business to deliver smarter and more efficient logistics solutions.

“The PBS framework allows us to use modern, high-productivity vehicles designed for enhanced safety,

improved manoeuvrability and reduced environmental impact,” he said.

“This capability is particularly important as customer demands evolve, with increasing expectations for reliability, capacity and sustainable transport outcomes.”

Recently, Wyles spoke to Trailer about Norman Carriers’ extensive safety initiatives.

The NHVAS re-accreditation builds on this, reinforcing the business’ commitment to safe operations.

“Ultimately, this re-accreditation reflects

the culture our team lives every day – a focus on safety, efficiency and continuous improvement to deliver dependable logistics solutions our clients and partners can trust,” Wyles told Trailer

“Our recent NHVAS re-accreditation is a direct result of our team’s dedication and discipline.

“Every person across Norman Carriers plays a role in maintaining the standards that keep our fleet safe, compliant and performing at its best. It is something we are genuinely proud of.”

A review into the Tasmanian Freight Equalisation Scheme (TFES) by the Australian Government is now underway.

TFES financially supports Tasmanian freight, including the state’s world-class produce, and passengers to cross the Bass Strait.

The review will consider if the scheme could better support local businesses – including farmers and producers – to compete in domestic and other markets.

It will also consider how the Bass Strait Passenger Vehicle Equalisation Scheme is reducing the cost of moving passenger vehicles across the Bass Strait.

Furthermore, the review will also explore other issues raised by the 2024 Senate Select Committee Inquiry into TFES.

Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, is in favour of improving Tasmania’s freight transport network and the economic

strength that would come with it.

“We know how important these financial support schemes are, as Tasmanians don’t have the interstate road or rail options that their mainland counterparts do,” she said.

“A strong shipping industry means new jobs, supply chain security and economic diversity, which is why we are investing an additional $95 million in the TFES over the next two years.”

Additionally, Federal Member for Lyons, Rebecca White, stressed the importance of this scheme for the farming industry.

“Keeping Tasmania connected across the Bass Strait is vital for our economy and our way of life,” she said.

“This review is about making sure Tasmania’s freight and passenger transport schemes are fit for purpose and delivering the best outcomes for our state.”

Independent reviewers, Dr David

Parmeter and Dr Jenny Gordon, have been appointed to carry out the review.

Parmeter is the former Chair of the Maritime Industry Australia Limited and the current Chair of the Australian Mariners’ Welfare Society.

Meanwhile, Gordon served previously as the Chief Economist at DFAT and currently serves on the Asian Development Bank Institute’s Advisory Council.

The Federal Government is committed to ensuring these critical schemes are fit-for-purpose and best serving Tasmanians, including reducing the red tape for efficient shipping.

Since July 2025, Tasmanian businesses have reportedly been benefitting from a 25 per cent increase in assistance rates under the scheme.

A final review report and recommendations to the government are expected in the first half of 2026.

Tasman Logistics Services CEO and Managing Director, Ivan Vanis, has announced his resignation.

Vanis joined the business in 2010 as General Manager, serving in that role for eight years before moving up to CEO and Managing Director in 2018.

Vanis led Tasman Logistics Services through several growth phases at the helm of its operations.

This was evident when Vanis told Trailer in October that the transport company had tripled in size over the last three years.

This rapid expansion was primarily due to organic growth and various company acquisitions.

Vanis reflected on his time at the business, recognising the opportunity for future achievements.

“After 16 years at Tasman Logistics, I have decided it’s time for a new challenge and have exited the business,” he said.

“My time at Tasman has been amazing in building a great business backed by a sensational team. I have learnt a lot over this time and am proud of what I’ve achieved in conjunction with great people.

“It was my time to move on and pursue other opportunities that kept presenting

themselves and also take some time to spend with my family who have suffered the long hours of logistics for a long time.”

Vanis also took the time to express his gratitude to the people behind Tasman Logistics Services.

“Thank you to the amazing team at Tasman for the support over the years and allowing me to push them to their limits to be their best,” he said.

“I will miss everyone but I’m only a phone call away.”

Riordan Group has purchased Tasmaniabased agricultural company, XLD Commodities.

XLD, established in 2009, is a trusted agribusiness which offers growers and end users a range of contracting options integrated with storage and transport services.

Both XLD and Riordan Group have worked closely together for many years.

Riordan Group manages one of Victoria’s largest grain handling and logistics programs and supports XLD through fully integrated mainland procurement across accumulation, transport, storage, bulk handling and packing.

This partnership has given XLD fast and efficient access to markets in southeast Australia, delivering significant supply

chain efficiencies, cost savings and supply certainty.

As part of the acquisition, all XLD operational staff will be offered roles under the new ownership of Riordan Group.

XLD Commodities CEO, John Tuskin, will work alongside Riordan Group to ensure a smooth transition.

“This acquisition is an exciting investment for us,” said Riordan Group Managing Director, Jim Riordan.

“We are committed to building on XLD’s success and continuing the strong relationships developed with Tasmanian customers and growers.

“We have witnessed the growth of the Tasmanian grain industry as a service provider to XLD for 15 years, and this is an

opportunity to be part of the community and industry development.”

As part of the handover, all existing contracts will be honoured and, under Grain Trade Australia (GTA) provisions, can be assigned to the new counterparty.

Contracts for grain purchases or sales from November onward will be established under Riordan Group in accordance with GTA terms.

“The decision to sell comes with mixed emotions; however, the time is right for the business,” Tuskin said.

“We are very proud of XLD and the relationships we have built, and this change brings opportunities for investment in Tasmania’s grain industry and expanded services for growers and customers.”

Skel trailers

Evolution side tippers

Road train dollies

Flat tops, drop decks

Deck wideners and extendables

Coldcore

ANE and

Walking

PBS

The Australian Livestock and Rural Transporters Association (ALRTA) has refined its governance processes and executive team at its Annual General Meeting (AGM).

ALRTA President, Gerard Johnson, was re-elected for a second year and was warmly endorsed by Council.

Joining Gerard are two new Vice Presidents – Benno Sutherland (Western Australia) and Athol Carter (Queensland).

“Many will know Benno as the face of the ‘Keep the Sheep’ campaign, which made national headlines during the last federal election,” said ALRTA Executive Director, Anthony Boyle.

“Based in Ravensthorpe, WA, Benno runs his own transport business, 5K Livestock and Bulk, with both livestock and bulk grain experience.

“His passion for advocacy and political insight will be invaluable to the ALRTA leadership team.”

Athol is Frasers Livestock Transport’s Compliance and Central Queensland Manager.

He is also Chair of the Performance-

Based Standards (PBS) subcommittee which is made up of stakeholders from the National Heavy Vehicle Regulator (NHVR), Australian Trucking Association (ATA), grain and livestock carriers and PBS and telematics experts.

“His strong compliance and safety knowledge will be a great asset to the Executive,” Boyle said.

Alan McKenzie from New South Wales is making a return to the ALRTA in the Treasurer role.

McKenzie operates McKenzie Water in Bulla, Victoria, with a fleet of eight prime movers.

His passion for agriculture and its contribution to Australia’s economy, combined with his sharp business acumen, will ensure a steady and wellinformed approach to ALRTA’s financial management.

Meanwhile Ann Ferry is joining the ALRTA executive team for the first time, bringing a wealth of fresh perspective and leadership experience.

“As former ATA Future Leader, Ann brings knowledge in advocacy, government

policy, business development and collaboration,” Boyle said.

“Based in Ballarat and working with GDP Transport in Creswick, Ann’s energy and insight will be a tremendous addition to the team.”

Immediate past President, Scott McDonald, will remain a part of the executive team to ensure valuable continuity.

Boyle said his four years as ALRTA President were marked by enormous dedication, and retaining his guidance will help ensure a smooth transition and steady leadership.

Veteran industry advocate, John Beer, has been appointed as the new Chair of the Driver and Animal Welfare Committee (DAWC).

“Beer is a former National President, ALRTA Life Member and Bruce McIver Award recipient for services to the industry,” Boyle said.

“His leadership, passion, and experience will be a great asset to the committee.”

Outgoing Chair, Graeme Hoare, was warmly thanked by Johnson for his outstanding contributions – including the development of the Truckwash Standards and progress toward a National Effluent Management Plan.

The ALRTA’s executive team has already held its first meeting, laying solid foundations for the year ahead.

The team has committed to meeting fortnightly, strengthening Council engagement and expanding connections across industry stakeholders.

“I’m looking forward to working with the new Executive and welcome everyone’s different skills and passion they bring to the team,” Johnson said.

“I would also like to thank the outgoing Executive – Wade Lewis, David Fyfe, Pete Edmonds and Tamara McArdle – for their tireless work and dedication to our industry.

“The time and sacrifice each person gives is immense and deserves our full appreciation.

“Together with General Manager of Policy and Strategy, Ashley Mackinnon and myself, we look forward to working closely with the new Executive to drive outcomes for all members.”

ZF [pro]Service workshops across Australia provide advanced diagnostic expertise for Trailer Electronic Braking Systems (TEBS)

We understand how complex trailer electronic braking systems can be and servicing them can often be challenging. That’s why we’ve trained workshops across Australia under our next-generation service concept, ZF [pro]Service.

ZF [pro]Service is designed to future-proof commercial vehicle workshops by combining world-class technical expertise and advanced diagnostic training across ZF’s extensive product portfolio.

This program unites the previously separate ZF Service Point and WABCO Service Partner networks into one powerful platform, supporting workshop maintenance for trucks and trailers nationwide. Scan the QR code to find your nearest ZF[pro]Service Workshop

Australian foodservice distributor, PFD Food Services, is doubling the size of its Western Australian operations.

A new flagship facility spanning 22,290 square metres is set to open in the ASCEND Industrial Estate at Jandakot Airport in October 2026.

Marking a major milestone in the company’s growth strategy, the expansion will enhance PFD’s operations, increase capacity and allow it to better serve its growing customer base across WA.

The move will also improve service delivery to meet the changing needs of customers and support regional operations in Geraldton, Bunbury, Albany, Esperance and Kalgoorlie.

“This expansion reflects our commitment to investment in Western Australia, delivering high-quality service and an even more comprehensive product range to our customers,” said PFD Food Services General Manager, Western Australia and Northern Territory, Tony Pascov.

“Over 17 years, we’ve proudly built strong, long-lasting relationships with local businesses and an upgraded facility is needed to meet capacity.

“We’re excited about this next step for PFD as we continue to bring

people together through food across Western Australia.”

The new facility will house state-of-theart infrastructure and equipment – driving efficiency, quality and a greater product range to support PFD’s future growth plans.

This includes energy-efficient refrigerated storage rooms, supported by a modern two-storey office space, truck maintenance

facilities and environmental features including roof-mounted solar panels and refrigeration plant.

The opening of the new facility will also further bolster PFD’s connection to the local community, better position the business to meet increasing demand and reinforce its role as a trusted leader in the foodservices industry.

Border Express has announced an official partnership with PMA Global to provide last mile transport services in Australia.

Established in 1988, PMA Global began as a print management business and has since expanded into a provider of managed services for sourcing print and promotional goods.

The company now supports a diverse range of industries with tailored solutions, including logistics services, to meet unique needs.

Border Express will be PMA Global’s official freight distributor in a collaboration which will strengthen its position as a trusted logistics partner in the

pharmaceutical sector.

“This win reflects our continued dedication to exceeding customer expectations and delivering excellence across all the industries we serve –especially the critical pharmaceutical sector,” Border Express said.

“[The partnership] is especially significant as PMA Global services several major pharmacy chains.

“It also highlights the strength of our broader Border Express team, whose responsiveness and capability were key in winning PMA Global’s trust.”

Border Express was selected by PMA Global due to its ability to deliver

advanced reporting, real-time tracking and exceptional account management.

“With decades of experience in one of the most time-sensitive and compliancedriven sectors, we understand the importance of accuracy, transparency and reliability in every delivery,” Border Express said.

“From meeting strict temperature and handling requirements to ensuring fast, secure distribution, our network and systems are built to meet the unique needs of pharmaceutical logistics.

“We look forward to building a longterm relationship with PMA Global and supporting their success.”

The Australian Livestock and Rural Transporters Association believes the Federal Government’s proposal to lower speed limits in rural areas will impact the transport industry if it goes ahead.

The Australian Livestock and Rural Transporters Association (ALRTA) has condemned the Federal Government’s proposal to reduce default speed limits in rural areas.

The Department of Infrastructure’s Regulatory Impact Analysis (RIA) suggests that lowering the speed limits of sealed and unsealed roads outside built-up areas from 100km/h to 80-70km/h will increase safety and reduce road toll.

The government department is insisting that travelling at up to 100km/h on these roads “may not be safe” and “will increase the risk of crashes, death and serious injuries”.

Therefore, it is vouching that reducing speed limits will help prevent the tragedy of accidents, injuries and deaths.

However, the ALRTA argues that this will harm productivity, compromise animal welfare and “disguise the real issue –

chronic under-investment in rural roads”.

“For regional operators, speed limits directly shape fatigue management, delivery windows and daily productivity,” said ALRTA Executive Director, Anthony Boyle.

“Even a modest reduction of seven km/h equates to an additional 45-60 minutes on a typical full-day run – enough to push drivers into mandated rest breaks or latenight driving under the Heavy Vehicle National Law.”

According to Boyle, this will result in more time spent resting in unsuitable metropolitan zones, greater fatigue exposure during high-risk dusk/ night hours and increased costs and scheduling disruption with “no measurable safety gain”.

He claimed that this will in turn significantly affect transporters and livestock animals.

“In real terms, a driver moving livestock from Dubbo to Melbourne or Brisbane could lose almost an hour in transit, eroding valuable time for unloading and returning to regional rest areas,” Boyle said.

“For livestock transporters, an extra hour on the road carries serious welfare implications. Exposure to sub-zero overnight cold can cause chilling stress, while 40°C daytime heat rapidly increases dehydration risk.”

“The Australian Animal Welfare Standards and Guidelines – Land Transport of Livestock (2012) require journeys to be planned to minimise exposure to extreme weather and ensure contingency arrangements for affected stock.

“The RSPCA also directs transporters to take reasonable steps to reduce the impact of heat or cold during transport, while Agriculture Victoria advises that

if maximum time off water is likely to be exceeded, stock must be spelled or journeys rescheduled.

“An additional hour, particularly in peak summer or winter conditions, is not just a cost to business – it is a genuine animal welfare risk.”

The ALRTA believes reducing default open road speed limits won’t do anything to fix what it feels is the underlying cause of rural road trauma – poor road condition and underfunded maintenance.

“Rural operators already face deteriorating pavements, narrow shoulders and limited overtaking lanes,” Boyle said.

“Instead of slowing down the very operators keeping regional Australia supplied, governments should be investing in practical safety improvements [such as] sealed shoulders and improved drainage, better line marking and more overtaking opportunities.

“These measures deliver genuine safety outcomes without undermining productivity or welfare.”

The ALRTA is urging governments to:

• retain the current 100km/h sealed road

default and avoid a new unsealed road national limit;

• focus on engineering upgrades and local risk management; and

• measure success by reduced fatigue incidents linked to improved road surfaces.

“Lowering default speed limits is not a

safety strategy; it’s a budget substitute for not fixing the roads,” Boyle said.

“If policymakers want safer outcomes, they must fund the infrastructure, not punish the operators who depend on it.

“If they cancel live export, then they must support rural businesses to transition properly.”

OBrienco Transport has dedicated a new Vawdrey Performance-Based Standards B-triple road train to a cause it holds very close to its heart.

Epilepsy is a chronic neurological disorder which affects around 50 million people worldwide. It’s characterised by recurring seizures and can be accompanied by a loss of consciousness and control of bowel or bladder function. Further temporary symptoms include disturbances of movement, sensation, mood or other cognitive functions.

An estimated five million people are diagnosed with epilepsy each year, and between four and 10 people per 1,000 in the general population have active epilepsy according to the World Health Organization (WHO).

The cause of around 50 per cent of epilepsy cases is unknown. Treatments include anti-seizure medications, brain surgery, dietary therapy and medicinal cannabis, but there is currently no known cure.

On 2 April 2024, Lauren Smith lost her life to Sudden Unexpected Death in Epilepsy (SUDEP). Lauren’s passing brought the entire Queensland community of Clifton together, and highlighted the importance

“I was talking to Lauren’s parents, Craig and Susan, at the funeral about how passionate she was around raising awareness for epilepsy,” says OBrienco Transport Sales Manager and Linehaul Coordinator, Jack O’Brien. “She always put herself out there and shared information around her struggles, seizures and the many near-death experiences she had.

“So, I said to them, ‘Why don’t we continue that legacy? We have some ambitions and I’d love to do something like that, too.’”

This idea very quickly became a reality. OBrienco Transport, with the help of its suppliers and customers, launched a Vawdrey Performance-Based Standards (PBS) B-triple road train for Lauren and Epilepsy Queensland.

“We’ve got two new B-triple sets,” Jack says. “One was branded with our standard OBrienco Transport blue and orange colours and the other in purple for Epilepsy Queensland. We’re using that combination to bring awareness to epilepsy and to share Lauren’s story.”

out to some of our partners, but everyone that I spoke to jumped on board.

“Vawdrey has donated to the charity. Attards provided the curtains and design work for free. The B-triple came with a Mack Super-Liner prime mover and Mack, Western Truck Group and some of our other appliance providers have thrown things in. Our insurance broker, AEI, and one of our main customers, Pacific Seeds, have also come on board.

“The support I received from what could have been considered just a throwaway idea has been amazing. I think it’s going to have a huge impact for Lauren’s family and friends.”

The Epilepsy Queensland Vawdrey Titeliner B-triple combination comprises two 12-pallet drop deck A trailers and a 20-pallet drop deck B trailer. Key features such as mezzanine decks, a Thermo King A-500 fridge unit and SuperStrap load restraint insulated curtains have made the road train extremely versatile.

“It’s a very well-rounded unit to cart almost anything around the country,” Jack

without messing around with permits too much, and the trailers can do that under PBS, Concessional Mass Limits (CML) or even by being deployed as a B-double.”

The B-triple will be involved with a range of freight tasks in 2026. In the first quarter, it will be deployed on a fortnightly basis to move canola and grass seed from Queensland to Western Australia and return with potatoes and onions. Then, in the winter, it will spend time in Moree, New South Wales, and Emerald, Queensland, transporting cotton, produce, general freight and seed around the northern and southern areas of the east coast. From there, the unit will head into South Australia and North Queensland to cart more produce such as pumpkins, onions, potatoes, watermelon before closing out with some general freight.

The Epilepsy Queensland B-triple and its sister road train follow two new Vawdrey B-doubles which arrived in the middle of this year. OBrienco Transport invested in these trailers to accommodate for much heavier freight types such as bricks and construction materials, and the transporter has been in awe with the Vawdrey product ever since.

“Vawdrey is a superior product,” Jack says. “The trailers are fantastic. They perform and they look good on the road. We get compliments on them all of

The rear of the combination showcases all supporting partners.

OBrienco Transport was founded in 2007 by Jack’s father, John. It all began with one truck and an Australia Post contract which grew to nine prime movers, multiple trailer combinations and a range of services including a Full Trailer Load (FTL) division, Less-Than-Truckload (LTL) operations, warehousing, last-mile delivery, general freight and more.

Despite the business’ healthy growth, Jack considers OBrienco Transport an infant in the transport industry’s mindset. He’s always been humble about the company’s position and the journey that will be required to make ‘OBrienco’ a household name. Jack was therefore slightly sceptical when considering purchasing new trailers earlier this year, but he got the assurance he needed after he chose Vawdrey.

“Vawdrey gave us a call a couple weeks after we took delivery of our first trailers to see how they were going, and they did the same for the B-triples,” he says. “Receiving that level of care from Vawdrey was fantastic.

“Vawdrey is just as invested in OBrienco Transport as we are. They want to see us grow to the point that we want to, and they’re going to be a very integral part of that growth. We’ve developed a really good relationship with Vawdrey and we’re very grateful for all of their support –especially with what we’ve achieved for Lauren and epilepsy.”

Contact

Vawdrey Australia

1-53 Quantum Close

Dandenong South, VIC 3175

Ph: 03 9797 3700

Web: www.vawdrey.com.au

Symons Clark Logistics has launched the first of 140 custom Bruce Rock Engineering Performance-Based Standards skels into a transport contract for BHP and Aurizon.

Symons Clark Logistics has become embedded in South Australia’s transport industry over 150 years of operations.

The company was founded in 1875 in the suburb of Rosewater by Cornish blacksmith, Thomas Symons, to service the state’s growing agriculture trade. It then went on to evolve from a small carrier into a leading national logistics provider – a change which was solidified in 1981 when the business was purchased by Alby Clark.

Alby’s sons, Ricky and David, and grandsons, Jason and James, have rebranded Symons Clark Logistics to a diverse logistics operation consisting of more than 300 employees and multiple depots throughout SA. These locations have been established within close proximities to key shipping, intermodal and airport hubs to allow Symons Clark Logistics to provide solutions including wharf cartage, container transport, warehousing, packing and unpacking, heavy haulage, national bulk haulage and project and mining logistics services to customers throughout SA and beyond.

Symons Clark Logistics has most recently

continued its commitment to integrated logistics by forming a partnership with Aurizon. The fleet will service BHP’s Copper SA demand as the network moves to an intermodal solution.

“We have a very unique opportunity to be involved with the operations of BHP and Aurizon in SA’s biggest single logistics supply chain,” says Symons Clark Logistics CEO, Jason Clark. “It’s a generational transformation from road to intermodal.

“This new opportunity sees our businesses servicing the logistics requirements of BHP’s SA operations across three key mines in the state – Carrapateena, Olympic Dam and Prominent Hill.

“Aurizon transports material and equipment via rail from Adelaide to Pimba. That’s where the rail network stops and where we come in.”

Symons Clark Logistics has been commissioned to continue this supply chain by transporting mining support materials such as cement, sand and sulphur from the end of the rail line to the three aforementioned mine sites. In order to ensure ultimate safety and efficiency, an

investment in an array of custom skel trailers built under Performance-Based Standards (PBS) was required.

“We needed custom skel trailers that would be durable enough to traverse the outback roads which run out to the Carrapateena and Prominent Hill mines,” says Symons Clark Logistics General Manager of Regional Mining, Josh Hofmaier. “But we also needed these trailers to support high payloads at the same time. So, we started moving towards a PBS design that was a little more unique.”

This brought the fleet to Bruce Rock Engineering (BRE) for an order which will see a total of 140 units built and delivered by the end of the contract. The ongoing design process, supported by BRE’s in-house engineering team, has been extremely collaborative to ensure all of Symons Clark Logistics’ requirements are fully met.

“We’re having weekly meetings with BRE to discuss the trailers in our order,” Josh explains. “We talk about what additional design tweaks we can make, stress-testing and other relevant diagnostic reports.

“We’re working towards some pretty tight

deadlines, but we’ve been able to utilise BRE’s impressive manufacturing capacity at its Forrestfield and Bruce Rock facilities in Western Australia. BRE has done an excellent job of prioritising what we need in a very short timeframe.”

The results speak for themselves. Symons Clark Logistics recently took delivery of its first batch of 26 PBS and Dangerous Goods (DG) compliant custom skel trailers which included a combination of five super quad road trains, six super A-triples and 15 A-triple drop decks. According to Josh, these units have already made the BHP and Aurizon supply chain contract extremely efficient.

“These combinations are highly efficient and can move significant weight,” he says.

Gross Combination Mass (GCM) ratings of 187 tonnes allow the quad road trains to move freight such as copper concentrate, cement and other products to BHP’s mining sites with ease. This is also applicable to the super A-triples and A-triple drop decks which boast 142-tonne and 130-tonne GCMs respectively.

These capacities are also bolstered by extremely low tare weights throughout all of the trailers. Josh says extensive testing was required to achieve these specs.

“Keeping the height of the trailers down to cater for taller container heights and maintaining the structural integrity of the trailers was key,” he explains. “We also wanted to make sure that the trailers could be hooked up to bogey-drive and tri-drive prime movers for full flexibility within the supply chain.”

Symons Clark Logistics’ operations also required certain access benefits. These were delivered by BRE via PBS in a significant way.

“PBS has given us much greater flexibility with getting units of different lengths into certain locations,” Josh says. “We needed to meet more requirements to achieve this, but it’s made our combinations on the road much safer.

“Greater access is particularly important to us. We want our trailers to be flexible to the point where we can be short enough to travel around Adelaide through Port Adelaide and load at various supplier locations. So, a lot of work was involved to get them right.”

The single drop deck skels also went through various iterations to ensure maximum performance. Built with lower deck heights than the super triples and quads while maintaining a similar strength, they can be connected with tri-axle dollies in a gooseneck configuration to maintain stability when transiting in larger combinations.

“We ended up working through 11 versions of the drop decks in the span of two weeks,” Josh says. “We needed to get the payloads for the container weight correct on every trailer to reduce the risk of lighter and heavier containers on the trailer combinations.

“Standard drop decks will typically only offer a maximum container weight of 28.5 tonnes. We didn’t want to have any

restrictions, so we used a spread-axle setup on the front which gave us a higher payload.

“The trailers are DG compliant too, which is highly unique in the industry.”

Symons Clark Logistics is now experiencing increased productivity by being able to move a variety of heavy freight across both rough mining terrain and the extensive PBS road network.

“Our trailers have been going non-stop since the contract started in October, and we haven’t found anything wrong with them,” Josh says. “The different GCM and payload figures provide versatility in what we can move which gets the job done faster.”

These capabilities have become a point of pride for the logistics operator’s team.

“Our drivers and workers are proud to be operating such solid products,” Josh adds. “It has made the start of the operation a lot easier than it could have been.

“We haven’t had to worry about any mechanical issues, and coming from BRE, we’re not surprised. We’re incredibly proud to have BRE as a partner and look forward to doing more business with them in the future. The experience has been fantastic.”

Contact

Bruce Rock Engineering

15 Swan Street, WA 6418

Ph: 08 9061 1253

Web: www.brucerockengineering.com.au

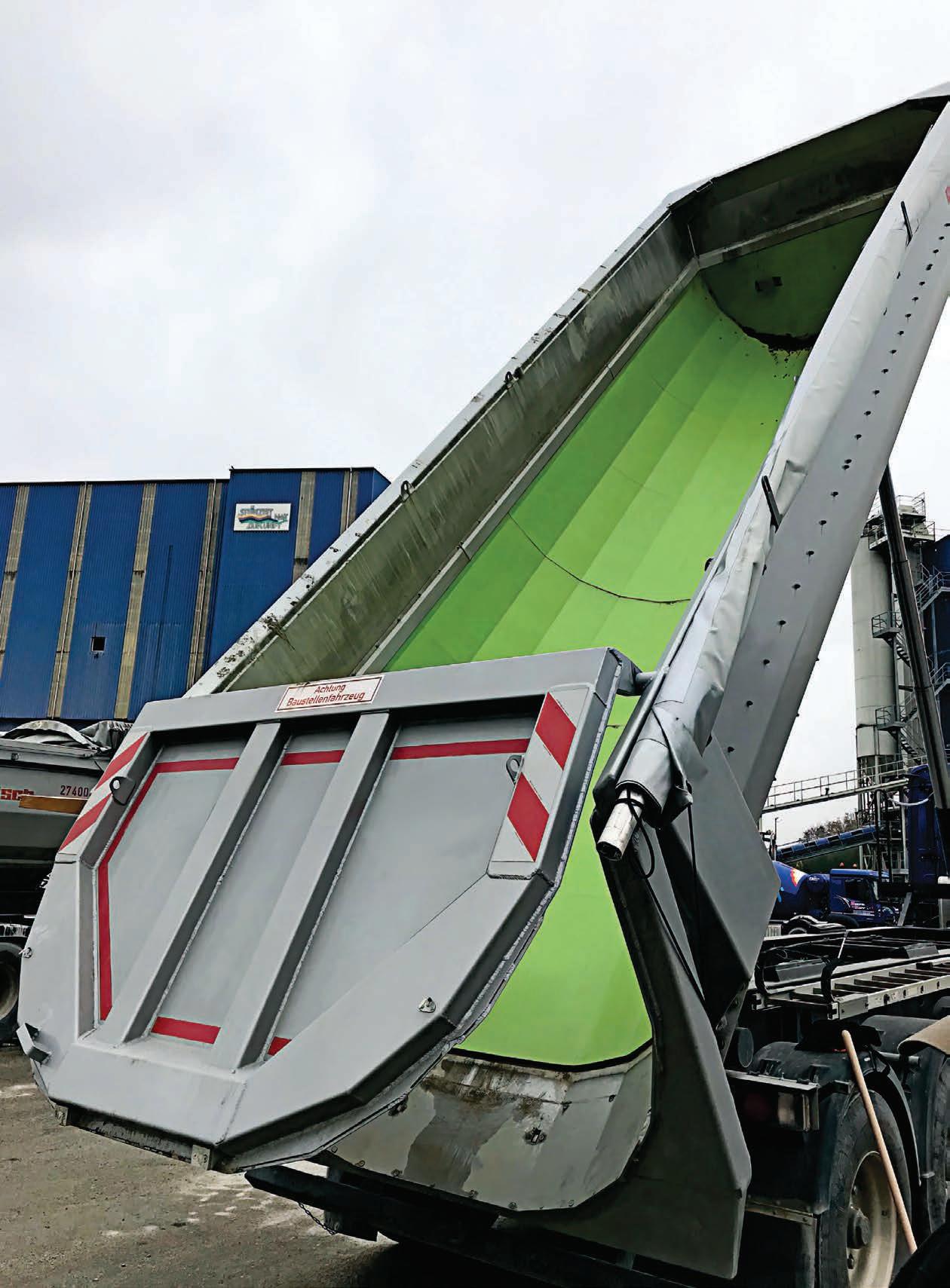

E-Plas’ QuickSilver and Heavy Duty liners offer a full suite of operational advantages in tipping applications.

E-Plas’ QuickSilver and QuickSilver Heavy Duty tipper liners are two premier options within the transport industry which have demonstrated their worth in realworld applications. Each come with their own unique benefits depending on the application and freight task at hand.

The classic QuickSilver variant has long been renowned as an ultimate stateof-the-art industrial strength UHMW-PE continuous liner for truck and trailer combinations. Generally used in end tippers, side tippers and quick-release applications across the transport, bulk handling, minerals, agriculture and grain sectors, it diminishes a number of core issues upon implementation including hang-up, tipper body abrasion and corrosion, unnecessary service

and maintenance, downtime and increased expenses.

On the other hand, QuickSilver Heavy Duty has quickly emerged as a top-tier solution since launching in the Australian market just over a year ago. It was developed specifically for extreme abrasion under high intensity and can withstand applications such as sand, gravel, rock, recycled glass and construction rubble which require eight or more trips per day – while still flexing increased wear capacity and flow improvements.

Side by side, QuickSilver and QuickSilver Heavy Duty can cater to the varying demands of tipper combinations while ultimately increasing safety.

“Safety is a very big aspect of QuickSilver

and Heavy Duty,” says E-Plas National Operations Manager, Rupin Joshi. “These liners are the perfect products to have because they can handle multiple different materials with very low maintenance and cleaning required.”

Hang-up, one of the most prevalent issues in tipping, is eliminated with QuickSilver and QuickSilver Heavy Duty. The liners’ flow rates prevent bulk material from sticking to the surface of the tipper tray, allowing materials to flow much easier at a lower tipping angle and increasing safety for heavy vehicle operators. This increases productivity while eliminating the potential for injuries to occur.

“Having an empty trailer when returning after each trip is key for a lot of operators,” Rupin explains. “This is one of the biggest

benefits of QuickSilver and Heavy Duty.

“Bins are always left empty, meaning drivers can load them with more cubic metres and get more money per trip. It also decreases the chances of injuries occurring because people aren’t spending as much time manually cleaning their trucks out.”

Both QuickSilver liners were developed in the United States by Mitsubishi Chemical Advanced Materials (MCAM). They quickly gained traction throughout the international market before arriving in Australia.

To compare the effectiveness of each, E-Plas and MCAM recently conducted a case study which put both liners through the applications of a customer that was transporting a very abrasive material. The results found that Heavy Duty lasted approximately 30 per cent longer than the standard QuickSilver – proving the claims behind its durability to be true. In another study, E-Plas and MCAM compared QuickSilver Heavy Duty and a wear resistant steel liner with a customer that was looking to reduce weight and achieve a similar product lifespan. Heavy Duty lasted twice as long as the wear resistant steel liner material did.

“Aluminium liners don’t tend to help with the release, flow and elimination of carryback,” says MCAM Linings Business Manager for Asia Pacific, Orson Yong. “This can cause damage to the trailer body itself, leading to unnecessary repair costs and downtime.”

Elimination is what QuickSilver Heavy Duty in particular specialises in. The product also has a distinctive green colour which allows operators to easily identify whether a tipper is empty or if there is still product in the trailer.

“There has been a very positive trend for Heavy Duty, especially in Europe,” Orson adds. “We launched Heavy Duty internationally around six years ago and the uptake has been very encouraging.

“The growth of Heavy Duty over the classic QuickSilver grade has been around 15 per cent. That says a lot about its performance considering the original QuickSilver product has been in the market for over 20 years.”

QuickSilver Heavy Duty has been performing exceptionally in Australia so far. According to Rupin, feedback has been extremely positive.

“In terms of its performance, the initial response has been very good,” he says. “The product has met all of the standards and requirements that we expected it to.

“Our customer base has been very open to Heavy Duty. There has been a great reaction from the market, and we haven’t received any negative feedback from all of the people currently using it.

“A lot of customers have also been interested in upgrading from QuickSilver to Heavy Duty too. Australia seems to be loving it.”

The classic QuickSilver liner remains the perfect choice for transport companies

and operators outside of the mining realm. The fact that it has been available in a competitive and ever-expanding market for more than 20 years speaks for itself.

“QuickSilver is a great long-term investment,” Rupin says. “We know that it can be installed in a day based off the feedback received from the operators we work with. Our customers have been able to keep their trailers on the road for longer and get a great return on investment.”

E-Plas plans to further investigate the long-term benefits of QuickSilver Heavy Duty in the near future. Simultaneously, it will continue the legacy of QuickSilver.

“We are currently having discussions with our installers to see if QuickSilver Heavy Duty will work in hot mix applications,” Rupin reveals. “We’re also exploring a mine site application with automated trucks.

“We’re always looking to take on an application that others might not want to touch. That’s the key thing about our partnership with MCAM – we have the freedom to explore different sizes of rolls and kits without being restricted to one thickness or size. We’re always watching out for different opportunities and we’ll continue to do so.”

Contact E-Plas

Ph: 03 8361 1791

Web: www.eplas.com.au

From quarry contractors to Harvest operators to Road Train work. BTE is earning its keep everyday. Hard work demands the best Equipment.

Chassis warranty across the whole trailer range.

Chassis warranty across the whole trailer range.

40 TONNE Ballraces on all Dog Trailers.

90MM Diameter pivot bar.

Moore Trailers is expanding to bring a wide range of additional manufacturing capabilities and efficiencies to its operation.

Lionel Moore had spent over a quarter of a century building trailers with other manufacturers in the rural town of Pittsworth, Queensland, when he decided he could channel his expertise into an enterprise of his own. So, in 1988, he partnered with his sons, Shayne and Grahame, to establish Lionel Moore Trailers.

The business operated out of the corner of a rented shed in its early days, mainly repairing attachments for old trailers. But, following the commission of its first new trailer build in 1992, its operations changed significantly. Lionel Moore Trailers quickly relocated to an upgraded facility and then extended its value proposition extended over time.

Moore Trailers soon boasted an extensive portfolio of combinations ranging from tippers, flat tops, drop decks, tilt trays and extendables to livestock trailers, fibreglass and steel tankers, conveyor floor units, convertible trailers and dollies. This vast offering grew the business’ customer base significantly.

This concept of growth has always

remained integral to Moore Trailers’ operations. Now, the company is expanding its facility complex even further as part of a new business strategy.

“We are thrilled to have entered a new age in our company’s journey with an expansion of our operations,” Shayne says. “This is a strategic move which will create a more efficient flow for our production.”

The project involves consolidating all of Moore Trailers’ divisions into two new state-of-the-art facilities in Pittsworth.

The first location, at a size of 3,500 square metres, will serve as a dedicated blast, prep and paint shed with two fully enclosed blast booths (22 metres and 15 metres in length respectively) including dual blast heads and dust suppression and extraction features.

The blast booths will be joined by two prep areas and three paint booths. The latter will provide internal mechanical platforms for trailers as well as full downdraft vapor extraction capabilities.

Moore Trailers’ second building will be a 2,750-square-metre finish and repair facility. Complementing the

company’s existing finishing section, it will include a variety of amenities such as multiple internal pits with hydraulic floors to suit the business’ broad range of products and many overhead gantry cranes. These will further be supported by a repair section with access to pits, brake testing area and drive-through for quick turnaround.

Shayne says the combination of these two sites will have a great impact on the Moore Trailers business.

“The consolidation of these sites will enable us to reduce production time, deliver high-quality products and services more efficiently, strengthen our industry presence and foster community growth and development,” he says. “This move also represents a significant step towards achieving our long-term vision of operational excellence and industry leadership.

“We want to thank our dedicated team, loyal customers, and partners for their unwavering support.”

Moore Trailers’ two new facilities are expected to be operational in the first quarter of 2026.

HELL A’s DuraLED range with integrated DT connectors provide ultimate reliability and efficiency that

• Highly resistant to impact and vibrations

• Corrosion-resistant

• Broad temperature range

• High-performance silicone seals

• Tight line insulation sheathing (reliable environmental sealing)

• Resistant to most substances used in industry and engine compartments

• Compatible with a range of cable cross-sections

Hallett Group isn’t just an ordinary, vanilla transport company. It’s much more like a Neopolitan option with several flavours which customers can enjoy at the same time. The organisation is the largest integrated supplier of building, construction and mining materials in South Australia with the ability to transport bulk freight throughout the entire country, source and supply its own products to end users and support major infrastructure projects simultaneously.

“We have a solution for everything,” says Hallett Group General Manager – Transport and Logistics, Joshua Macfarlane. “Being agile and solutionbased is one of our key pillars.”

In Joshua’s view, Hallett Group is a company that was born out of necessity.

The family-owned business started from one single business stream, Hallett Concrete, but demand from the market called for more coverage.

“We have evolved significantly over almost 50 years by listening to the market and taking the next steps,” he says. “That’s why we’re so integrated and in control of what we do.”

Hallett Group’s outreach spans all across Australia. Although its operations are headquarted in SA, the many parts of its business extend its services into Victoria, Northern Territory, Western Australia and more.

Transporting more than seven million tonnes of heavy construction materials a year is a powerhouse fleet consisting of around 200 prime movers and 50 Bulk Transport Equipment (BTE) tipper bodies and trailers. Joshua says the trailers in particular are very versatile due to their ability to be deployed in various configurations – an essential factor in achieving the seven million figure each annum.

“We’ve got a mix of everything”, he explains, “from tandem and twin-steer prime movers to five- and six-axle truck and dogs, Performance-Based Standards (PBS) combinations, A-triples, B-doubles and A-doubles. It’s a very agile fleet.”

Hallett Group recently bolstered this fleet even further with the addition of three PBS A-triple tri-axle tri-drive end tipper combinations from BTE. The investment was made following major organic growth and demand from the market.

“We’re doing a lot of internal development work on our low carbon cement product range, including Enviro Construct,” Joshua reveals. “There’s been a lot of natural growth of the business and our mining operations through Central Australia.”

Joshua claims the A-triples are the heaviest combinations south of Port Augusta in SA. Measuring in at 46.5 metres in length, they boast Gross Combination

Masses of up to 150 tonnes and payloads of around 100 tonnes.

The trailers have been deployed in Hallett Group’s internal business and are travelling to various clients in SA as well as to mining customers in Central Australia, the Northern Territory, WA in the Pilbara and the northern parts of Queensland. Joshua says the fleet was built with a purpose to go anywhere and to do anything.

“The trailers are predominantly transporting mining materials like aggregates and sands, complemented by our cementitious products for our mine development work,” he says. “We’re moving anything from the rocks out of the ground at quarries all the way through to the kitchen sink and everything in between. It’s an end-to-end supply chain.”

Increased productivity has been one of the standout advantages of the road trains so far. Their PBS capabilities and payload figures have allowed Hallett Group to transport bulk materials much more efficiently with fewer trucks and therefore less fuel and additional operational costs.

“The 100-tonne payload figure is pretty important to us,” Joshua says. “We can do more for less while keeping the industries and communities that we’re deeply connected with satisfied.”

The second advantage has been more prevalent in the fleet’s long-term use of the BTE product.

“Our uptime is really critical,” Joshua explains. “Our combinations are doing up to 250,000 kilometres or more a year, working in the middle of the outback in very remote areas. We can’t afford to have mechanical breakdowns, body failures and downtime in these isolated parts, and that’s why BTE’s trailers are so critical to us.

“We have BTE trailers that have done more than two million kilometres without any cracks or major faults. That’s almost unheard of for an aluminium body truck.

“BTE also offers an extensive chassis warranty, but not once have we needed to make a claim.”

Overall, Joshua says the new A-triples have been performing excellently. He believes the trailers are built for the challenges Hallett Group is presented with because they turn up and go straight to work from the word ‘go’. This, he explains, is testament to Hallett Group’s ongoing relationship with BTE.

“BTE is very clever, and they do a lot of due diligence on their products. I can call Alan Griffiths at any time and say, ‘I’ve got this wild idea about how we’re going to do more with less’. He’s always open to having that conversation.

“I’ve never worked with another company that is as willing to innovate as BTE. I love to live and breathe trucks, design and productivity, and it’s great to see someone with that same energy and enthusiasm to want to drive change in the industry.”

This close-working relationship has made trailer deliveries aplenty. Hallett Group has launched eight combinations in the last year alone which have included a mix of end tippers, side tippers, truck and dogs and rigid bodies in addition to the latest three A-triples.

“I can pick the phone up and talk to the guys at BTE at any time,” Joshua says. “They’re not salesmen trying to jam a product down your throat. They’re trailer builders and real people. That personal piece means a lot.

to get, I know the people face to face and I can have the Director of the business call me if I need anything.

“Hallett Group has a great relationship with BTE, and when you have great relationships and products, you both achieve really good things together.”

Hallett Group is now in the midst of another expansion phase. The business is currently tendering for major infrastructure work in the metropolitan areas of Adelaide which could require a significant amount of BTE trailer orders to be made if successful.

“SA is going through a really interesting time with its infrastructure spends, and it’s really exciting for a SA business like us to be part of a once in a lifetime project,” Joshua says. “By having BTE in our corner, we know that we can build a product that will go to the project, but a product that is also versatile and can secure the future needs of our business.”

“We’ve partnered with BTE for close to 10 years now,” he says. “We run a pretty critical supply chain and we can’t have a business like ours without reliable partners. Contact Bulk

“So, I’m quite excited about working with BTE because I know what I’m going

Web: www.bte.net.au

Ph: (03) 9794 0313

AAA Comet Gas has become the first to take delivery of Marshall Lethlean’s next-generation liquefied petroleum gas tanker.

Australia’s liquefied petroleum gas (LPG) sector operates as a prominent piece of the country’s economy and is essential for a variety of consumers. According to a 2017 report from Gas Energy Australia, LPG is consumed by nearly two million Australian households and provided to more than 160,000 businesses.

Furthermore, a report published by Grand View Research in 2023 found that the sector has experienced year-onyear revenue growth since 2020 – with a projected compound annual growth rate (CAGR) of 4.1 per cent between 2024 and 2030.

Among the providers contributing to the growing LPG sector is AAA Comet Gas, a proud family-owned enterprise operating out of the heart of Australia’s east coast. Founded in 2002 and headquartered in Tweed Heads, New South Wales, the business has spent over two decades specialising in the transport of 45kg LPG cylinders throughout NSW and parts of Queensland.

AAA Comet Gas caters to the LPG’s wide range of customers, from homeowners with barbecues to major commercial clients with forklifts and heating systems. Major servicing is

bolstered by a competitive, same-day delivery capability.

AAA Comet Gas Managing Director, Mick Taylor, says it is this quality that makes the business stand out in the industry.

“We’ve refined our process to make ordering easy,” he says. “Whether it’s done online or over the phone, we make sure customers never run out of gas when they need it most.”

Another key aspect of AAA Comet Gas’ operations is its utilisation of different modern technologies. While some of these technologies are used to help customers manage their orders, track deliveries and make payments online, many come in the form of complex equipment to assist in the safe transport of LPG altogether.

“Safety is always our top priority,” Mick says. “It is essential that we ensure safety for our customers, our team and the wider communities that we serve.”

AAA Comet Gas recently became the first fleet to take delivery of Marshal Lethlean’s brand-new trailer model, a 53,000-litre LPG tanker. The product, developed in close collaboration with Air Brake Corporation and Acme Fluid

Handling, represents a shared vision of safety, operational, performance and durability standards.

“This delivery marks the beginning of a new chapter,” says Marshall Lethlean Sales Manager, Garry Brennan. “We’re setting a new benchmark for what LPG tankers can achieve with Air Brake Corporation, Acme Fluid Handling and AAA Comet Gas.”

All parties contributed to this new standard in their own ways. Air Brake Corporation’s involvement included the designing and manufacturing of the intelligent Electronic Braking System (i-EBS) brake kit and system which was specifically designed for this tanker.

The i-EBS spec has equipped the tanker with various safety features. One of these is an adaptive braking response which can automatically adjust itself to load weight, terrain and driving conditions. Rollover mitigation is also included which provides advanced stability control and reduces rollover risk during emergency manoeuvres. In addition, the i-EBS comes with predictive diagnostics such as real-time alerts for brake wear, air pressure anomalies and system faults, while being fully compatible with

telematics platforms for live monitoring and compliance reporting.

Mick, who personally delivered the new LPG road tanker from Marshall Lethlean to AAA Comet Gas’ headquarters, praised the i-EBS’ handling.

“This braking system is just one of the qualities that makes this tanker a game changer,” he says. “It gives you confidence on the road, especially when you’re hauling full loads through unpredictable terrain. It’s the kind of innovation we’ve been waiting for.”

The LPG tanker’s capabilities are further bolstered by fuel pumping and metering components from Acme Fluid Handling. The Corken Z3500 pump and ZV 200 bypass valve in particular provide optimum performance across many fuel delivery options such as bulk-metering, unmetered bulk, hose reel delivery, self-filling and compressor unloading. These systems are

combined with Acme Fluid Handling’s own VTM 200A flow metering system to give high accuracy and efficiency over the fuel delivery process.

Marshall Lethlean’s new LPG tanker was designed in Australia to maximise its durability and minimise maintenance across a mix of road and weather conditions. Its standout benefits include payload efficiency, reduced tare weight for fuel savings, Australian Design Rules (ADR) compliance, Dangerous Goods (DG) certification and configuration customisation for fleet needs.

“This new road tanker is the first Marshall Lethlean unit to join the AAA Comet Gas fleet, and we couldn’t be happier with how it’s been performing,” Mick says. “Its build quality and engineering are first-class, and the lighter tare weight, improved payload capacity and upgraded safety systems fit perfectly with the way we run our operation.

“We take pride in maintaining a modern, reliable fleet that reflects the professionalism and safety standards our customers expect. This new tanker gives us the reliability to keep LPG supplies moving to our loyal customers and the flexibility to support future growth and expansion.”

With the delivery of Marshall Lethlean’s new LPG tanker now in the rear view mirror, Mick sees an exciting future with the OEM.

“This delivery opens the door for more collaboration down the line,” he says. “It gives us continuity as we plan for the next phase of our fleet’s growth.”

Contact

Marshall Lethlean

20 Whitfield Blvd, Cranbourne West VIC 3977

Ph: 03 9797 2100

Web: www.mli.com.au

Gippsland Body Builders has reached its 50th anniversary with a new captain at the helm and new horizons to match.