HUSQVARNA MULTI-BAY CHARGER

HUSQVARNA MULTI-BAY CHARGER

eet

Meet the Husqvarna 40-C1000X4: the ultimate solution for professionals who demand efficient, high-power charging on the go. This smart multi-bay charger powers up to four Husqvarna BLi-X 36V batteries at once, delivering rapid and balanced charging in your workshop, at the job site, or even in your vehicle.

Designed for all-weather use with IPX4 water resistance, it seamlessly combines charger, transport box, and storage for unmatched convenience and portability. Save time, stay productive, and keep your equipment ready—wherever your workday leads. (Batteries sold separately)

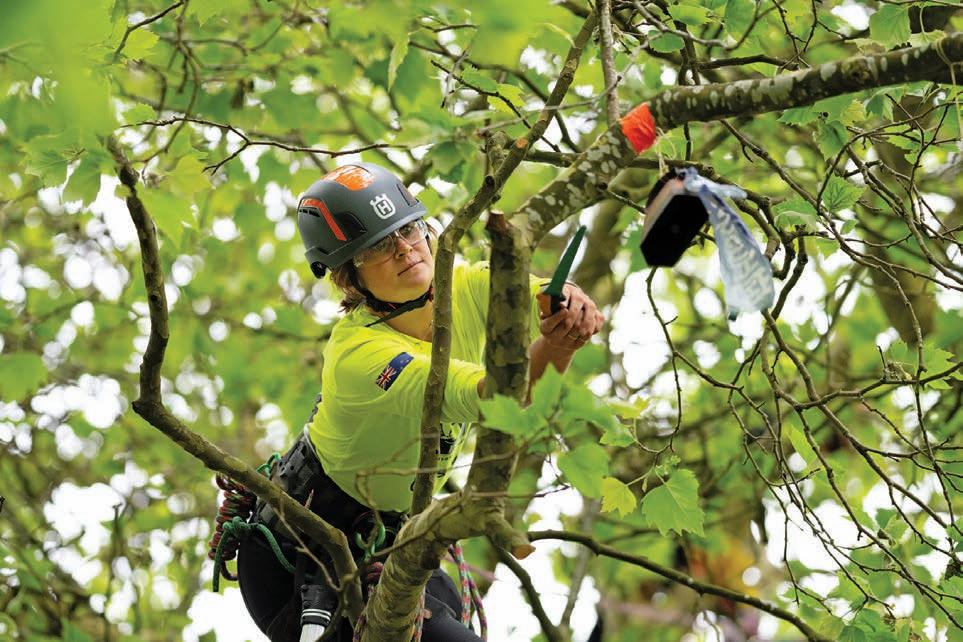

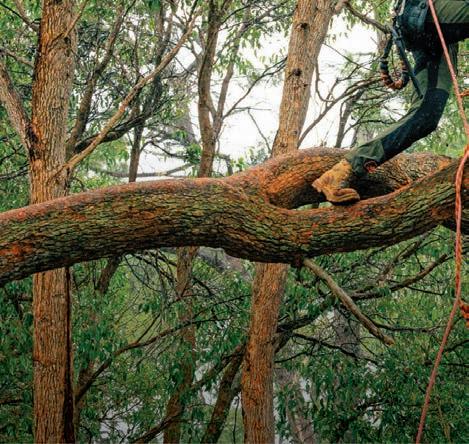

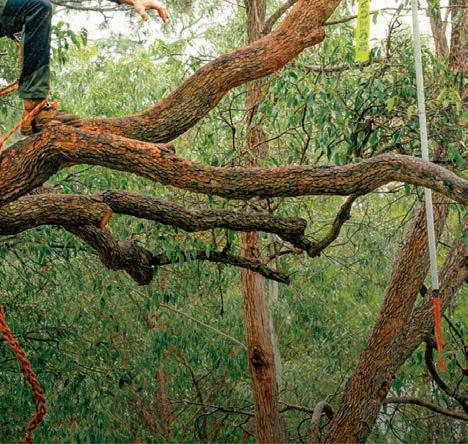

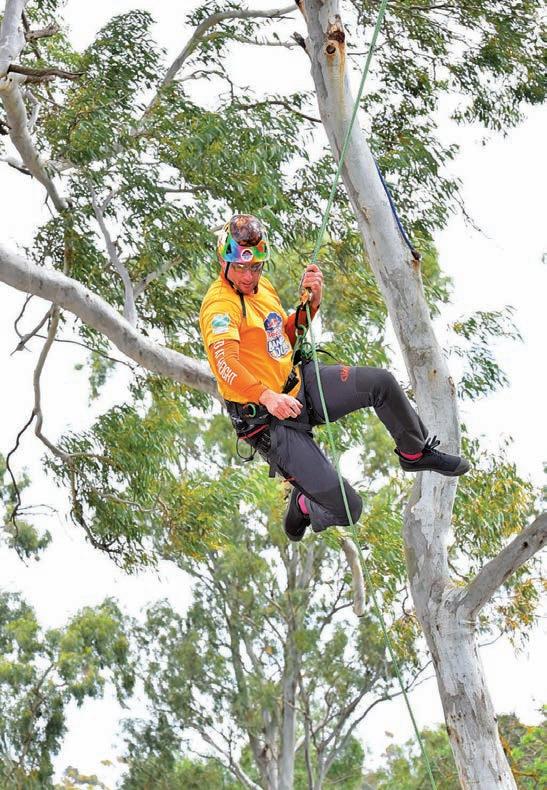

A climbing comp is sure to engage the interest of those looking for a career. Image: TF

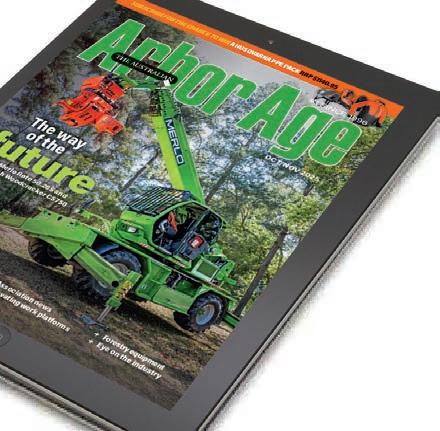

Another year’s own by and, depending on when you’re reading this, a new year is kicking o .

This past year has been a good one for the arbor community, I think. Through the year I’ve chatted to lots of people and attended a few product launches and competitions, and the overall impression I have is of a small industry in good shape. Nobody’s nding it easy and rolling in wealth, but the good operators and sensible businesses are holding their own. Of course, some are doing better than others, but that’s the nature of any industry.

One strong impression from the arbor community has been concern for the future workforce. You’ll see some prominent industry identities have taken the time to chat with The Australian Arbor Age this issue, and all have raised the topic as one needing attention. There are some excellent strategies emerging to try and engage the interest of young adults and get them to consider arboriculture as a career, but we all need to get behind the ideas for them to have e ect.

I, of course, don’t have a de nitive answer to, ‘How can we guarantee an increase in arborist numbers in the future?’ Visiting schools and raising awareness of careers where people can spend their lives in, around, and caring for trees is a good start, and I’m constantly cheering on the associations as they lobby for industry recognition. As one interviewee pointed out, we need people to understand arboriculture isn’t only about cutting down trees.

So maybe that’s something for us all to keep in mind in 2026.

If someone suggests you spend a day manning a stall at a school fete to promote arboriculture, maybe think twice before declining. If there’s a climbing competition nearby, consider taking your children – or a group – to watch. If anything will engage the interest of the younger generation, it’ll be competitive climbing, and word of mouth has to start somewhere. Why not try and get people in your local area talking about climbing or tree care? It’s a start.

Most of all, look for opportunities to introduce people to the tree-care life. Working in and around the amazing world of trees o ers an incredibly ful lling and rewarding lifestyle in a welcoming and supportive community. Does it get any better than that?

I hope your Christmas and New Year are or were awesome, and I’ll look forward to sharing our stories and achievements again in 2026.

Tom Foster Editor

The Australian Arbor Age is published bimonthly by Prime Creative Media Pty Ltd.

Chairman

John Murphy

CEO

Christine Clancy

Head of Sales

Andrew Morrison

Editor

Tom Foster

tom.foster@primecreative.com.au

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design

Jacqueline Buckmaster, Danielle Harris

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website arborage.com.au

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material.

While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2025

Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head O ce

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766

info@primecreative.com.au www.primecreative.com.au

Sydney O ce Suite 11.01, 201 Miller Street North Sydney, NSW. 2060. Australia

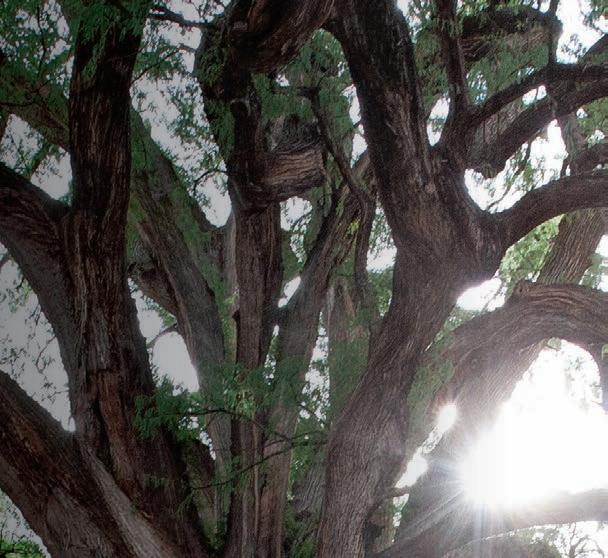

Known as ‘the Tree of Tule’ (El Árbol del Tule in Spanish), this Taxodium mucronatum is thought to have the stoutest trunk in the world.

Growing in a churchyard in Mexico, the trunk circumference – including the heavy buttressing – was measured at 42.0m in 2005. However some killjoys prefer to measure only the inner trunk, which comes in at a paltry 9.38m. Laser measurement in 2005 recorded its height at 35.4m, and one indisputable fact is, contrary to some claims, the Tree of Tule is a single organism, proven by DNA testing.

The age of the grand old Montezuma cypress is unknown, but local legend claims it was planted around 1400 years ago - a theory supported by scienti c estimates.

Aye carumba! After that many years in one spot we’d expect to be getting a little thick around the middle too!

El Árbol del Tule – Spanish for ‘the Tree of Tule’ – is thought to have the largest diameter trunk of the world’s living trees. Image: Pablo/stock.adobe.com

supporting events like the ITCC isn’t just about sponsorship. It’s about

What an incredible weekend in Hagley Park, Christchurch, New Zealand.

The 2025 International Tree Climbing Championship (ITCC), presented by the International Society of Arboriculture (ISA) and hosted by New Zealand Arboriculture, saw over 90 of the world’s best climbers gather for what became the largest ITCC ever held. Across three sun- lled days, the event was a celebration of skill, strength, and passion for trees, with climbers and arborists from every corner of the globe coming together to share knowledge, cheer each other on, and push the limits of what’s possible in the canopy.

This year, Husqvarna proudly continued its role as a major global sponsor, supporting both the ITCC and the ISA Conference. The Husqvarna Australia and New Zealand teams joined forces to ensure a strong presence across both events, connecting with the arborist community, celebrating worldclass talent, and showcasing the brand’s ongoing commitment to those who dedicate their lives to caring for trees.

A standout feature of the weekend was seeing six Husqvarna H-Team ambassadors out in full force, three

Reaching new heights at ITCC 2025 – where skill, focus and passion met the

competing at the highest level, and three volunteering behind the scenes to help make the event a success. Their passion and professionalism captured Husqvarna core beliefs: innovation, community, and a respect for nature. Among the competitors, the

legendary Jo Hedger from the UK – a six-time world champion – brought her trademark precision and power to the trees, inspiring both newcomers and veterans alike. Fellow H-Team climber Krista Strating from Canada, a world champion in her own right, once again

demonstrated the grace and technical mastery that have made her one of the sport’s most admired climbers. Rounding out the trio, Jamie Boston from Australia, currently ranked fth in the world, showed why he continues to be one of the most consistent and exciting

athletes on the circuit. Together, their performances were a reminder of how dedication and love for the craft can elevate the sport to new heights.

Ground support

Supporting them from the ground, and

were three more H-Team ambassadors who volunteered their time to help the event run smoothly: Peter Vergote from Berlin, Scott Forrest from New Zealand, and Kiah Martin from Australia.

From judging events to assisting climbers and helping with setup, these ambassadors embodied the teamwork and community spirit that make the ITCC such a special gathering each year.

Adding to the excitement, Husqvarna showcased two soon-to-be-released chainsaws set to launch globally: the 564 XP® fuel-injected chainsaw, designed for power, e ciency, and reliability; and the 550i XP®, Husqvarna’s largest battery-powered chainsaw to date. Event attendees had the chance to see these machines up close, explore their capabilities, and experience rsthand how Husqvarna continues to push the boundaries of performance for professional arborists.

As the sun set over Christchurch, one thing was clear: this wasn’t just a competition. It was a celebration of everything that makes the arborist world so unique. From breathtaking climbs to the friendships forged between competitors, volunteers, and spectators, the 2025 ITCC was a reminder of how much passion drives this global community.

For Husqvarna, supporting events like the ITCC isn’t just about sponsorship. It’s about standing alongside the people who shape the canopy of the tree-care world.

Scan to view the event showreel. For more information on Husqvarna’s support for climbers visit husqvarna.com/au/.

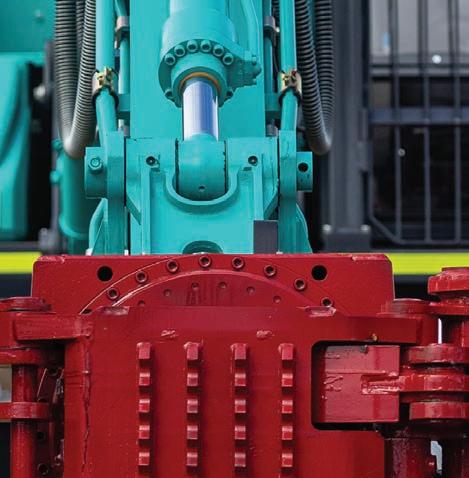

As pressure mounts on operating margins and safety, machinery is playing a larger part in tree care and management. It’s important arborists and timber workers assess equipment based on the tasks it needs to perform.

Spurred on by those before them in allied (or common) industries, arborist and vegetation-management crews alike are rolling out new waves of equipment combinations onto tree-work sites across Australia.

Occasionally referred to as a ‘forestry package’, these units are destined to work anywhere but forestry.

Some of the big hitters, like converted excavators, can look as though they’ve come straight o a harvesting site rather than being designed for their original task of shifting dirt and rock. Heavy protective structures surround the cabin and critical components, while the operator’s vision of the work area is no longer through a basic, slide-open, toughened polycarbonate windshield. Today’s machines feature a thick, xed, ballistic-protection-rated front window.

Fitted with a tree-cutting attachment such as a high-capacity shear or grapple saw, it’s likely that the transformed machine may never swing a digging bucket or rock breaker.

“Machines like this look impressive, perform well, and, with the right attachment, can tick all the boxes for projects with even the strictest of requirements,” said Forest Centre’s Rey Kell. “The journey toward ‘ t-for-

purpose’ for a tree-work machine involves plenty of considered choices behind the scenes, though.”

On a modern commercial timberharvest site, it’s immediately obvious the equipment eet is purpose-built for the job. Base carrier machines and attachments are all designed speci cally for felling, cutting to length, loading, and transporting timber from the forest.

In the tree-care sector, on the other hand, equipment tailored for mechanised tree felling and removals is still a relatively new and niche area in Australia. As one would expect, excavator dealers have the knowledge and experience to steer customers in the right direction for earthmoving tasks, but for more specialised worktool attachment suitability it usually comes down to customer preference. It’s important to kick o with a series of discussions to evaluate what an attachment supplier has to o er.

How does a tree-care business make an educated choice for something like a shear or grapple-saw attachment, or even a complete machine package, for its particular tasks?

• Conduct research. Speak with industry counterparts already on a similar path to the one you’re evaluating. Search online and take note of what reputable crews in other areas or other countries are using for their semi-urban removals, roadside works, or other speci c projects. Are there any common patterns between them or new developments adopted since?

• Identify expectations, limitations or must-haves, and make potential suppliers aware of this during early discussions. Outline the basics of tree types and typical to maximum cut diameters the attachment is expected to tackle in current (and future) jobs, through to site-speci c factors. Do you intend to work in the middle of nowhere, with no one else around? Or will you be on local government or major infrastructure projects, working near to the public, other personnel and property? These parameters should be made clear to help select the correct machinery for the purpose.

• Identify the crossover between operational needs and possible risks. For example, when a hydraulic grapple saw is used, the risk zone for the majority of manufacturers is a 90-metre radius. Is an exclusion zone almost the length of a football eld practical or possible for your

operations? Ask the supplier about chainshot safety, saw speeds, and whether they can o er solutions for reduced chainshot risk and exclusionzone distance.

• Check compliance needs. Clients may request copies of operator manuals and risk assessments for every piece of equipment brought to the job. It may seem obvious, but if you plan to fell or trim trees, the operator manual and risk assessment should contain information that speci cally addresses felling and trimming. Purpose-built

machinery and attachments have all of these items covered from the factory.

“One of the top questions we’re asked is, ‘Can I put a saw on this grapple?’” said Rey.

“Add-on hydraulic grapple-saw cassettes were among the rst products o ered by Forest Centre in the 1980s, and we still supply them today. But if the client request is for tree-facing work, like felling and removals, our answer to that question usually disappoints.”

The stakes are high when taking cuts

There’s a solid range of purpose-built attachments available today.

from a tree in proximity to other people and assets. There’s a solid range of purpose-built attachments available today ,and the manufacturers have done all the hard work for you. It’s just not worth the risk to run something thrown together from a few di erent catalogues when so much is being asked of these tools.

For more information and to see Forest Centre’s range of tree-care attachments, visit forestcentre.com.au or follow on Instagram @forestcentre.

Equipment tailored for mechanised tree felling and removals is still a relatively new and niche area in Australia.

In the demanding eld of arboriculture, safety, e ciency, and precision are non-negotiable. Arborists face unique challenges every day – working at height, navigating from canopy to canopy, and dealing with unpredictable elements. While traditional climbing remains an indispensable skill in tree care, more professionals are turning to tools like the Leguan spider lift to enhance their operations.

Rather than replacing climbing, these versatile machines complement and amplify what skilled arborists do best.

The Leguan spider lift is designed in collaboration with professional arborists. Its compact design, excellent mobility, and safe manoeuvrability in tight or rugged environments make it ideal for tree work. Whether operating on soft lawns, sloped terrain, or in

con ned urban environments, the Leguan can reach even the most di cult worksites without a hassle.

Key features that stand out include:

• All-terrain mobility: a Leguan can handle mud, roots, slopes, and obstacles such as street curbs thanks to its high-pro le track system.

• High reach and precision: with working heights up to 26.5 metres and lateral outreach capabilities, arborists can access di cult branches safely and e ciently.

• Fast setup: saving time increases revenue. With Leguan, there are no manual pre-tasks before operation, just hop on the platform, drive o the trailer and start working.

• Automation and safety: the automatic leveling system, home function and built-in safety features designed to work with the machine ensure Leguan’s e ciency on every jobsite.

Safety is perhaps the most signi cant bene t of a spider lift.

Climbing remains physically demanding and inherently risky. With a spider lift, many tasks – such as pruning, crown reductions, or storm-damage mitigation – can be performed in a more planned and safe manner, reducing fatigue and exposure to fall hazards.

Unexpected breaks of weak branches can happen on any worksite, whether during a storm cleanup or while working on the nal tree after three days without incident. Using a spider lift in co-operation with climbing reduces unexpected hazards bu allowing main lines to be secured and trees to be examined with a lift before climbing begins.

Using a Leguan in co-operation with climbing often translates into increased

productivity. While climbers work on the inner parts, the Leguan operator can simultaneously work the outer sections. This means arborists can take on more work in less time, thanks to greater e ciency and reduced physical strain on the crew.

Larger jobs, such as long passageways with tens or even hundreds of trees, are usually not the most glori ed work for arborists, but still need to be done. This kind of project, with climbing only, could take several days or even weeks. With assistance from a Leguan, these projects can be completed faster.

The spider lift does not replace the climber. There are still countless scenarios where climbing is the best, or only, option. Dense canopies, tall trees, or structural tree inspections deep within the crown usually require the hands-on manoeuvring only a skilled climber can provide.

However, the most e ective arborists are those who combine methods. By using a Leguan spider lift in tandem

with climbing, arborists can handle more work without the increased fatigue. That helps reduce the risk of accidents and maintain the longevity of the tree-care crew. Climbers can focus on the ne-detail work while the heavy lifting is done with a Leguan, and overall, the work can be planned and scheduled with more precision.

In modern arboriculture, the successful professionals are those who leverage every tool available without compromising skill or safety.

as an essential ally, not a substitute, for climbing arborists. With its ability to improve access, reduce risk, and boost productivity, it allows treecare professionals to perform at their best.

As the industry continues to evolve, one thing is clear: the future of tree work isn’t about choosing between machines and human skill, but about making them work together.

Born from advanced lifting technology, CMC aerial platforms perform in all conditions, o ering solutions and overcoming obstacles di cult for a truck-mounted platform.

Truck and trailer-mounted EWPs have their place and can be cost e ective in many situations, but for versatility, a CMC spider lift is hard to beat.

First among CMC’s features is the ability to access areas otherwise impossible to reach. The lifts can reduce their dimensions to the point of passing through a doorway, slipping under an awning, or traversing a narrow corridor to access a residential yard.

All this is achieved while the lifts move autonomously on tracks controlled by the operator via wire or radio control (depending on the model).

Not even a small operating space poses a problem. CMC aerial platforms

are designed to adapt, achieving the best possible stabilisation, both in open elds and in the tightest and narrowest places.

It’s di cult to nd at terrain in nature, and this can often be an obstacle to the safe use of truck-mounted platforms. However, the hydraulic stabilisers of CMC aerial platforms can level the EWP simply and quickly using the Self Control System by CMC, an autopilot for lifts that forms the basis for working safely on any terrain.

With working heights ranging from 13 to 41 metres, and an above-average lateral reach, CMC spider lifts enable e cient pruning of tall trees. Images: CMC

With working heights ranging from 13 to 41 metres, and an above-average lateral reach, CMC spider platforms are e cient in almost any tree-care task, but especially pruning.

Excellent manoeuvrability and easy and intuitive control features play their part as well, both in full hydraulic versions and in those equipped with guidance systems that include automatic closure of the booms.

Thanks to their low weight and the availability of non-marking tracks, along with special support plates at the base of the stabilisers, CMC aerial platforms are an excellent choice in the most delicate situations, such as public and private gardens, courtyards, or golf courses.

Finally, among CMC’s advantages is its ease of transport.

CMC aerial platforms are self-loading and easily transportable on trailers, thanks to the excellent balance between robustness and low weight.

“For us, this means being The Specialifts, the specialists in spider aerial platforms,” declared Alessandro Mastrogiacomo, CEO of CMC. “We are able to design and manufacture e cient work tools that respond smoothly to the controls and meet the speci c professional needs of our customers.”

CMC lifts are distributed in Australia by Monitor Group. See the range at monitor.net.au.

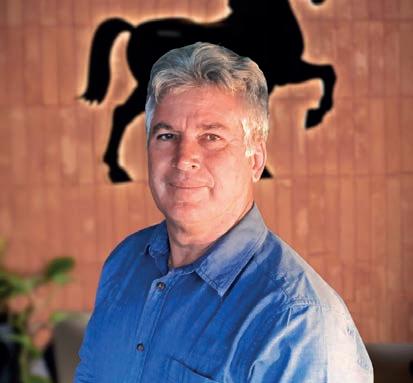

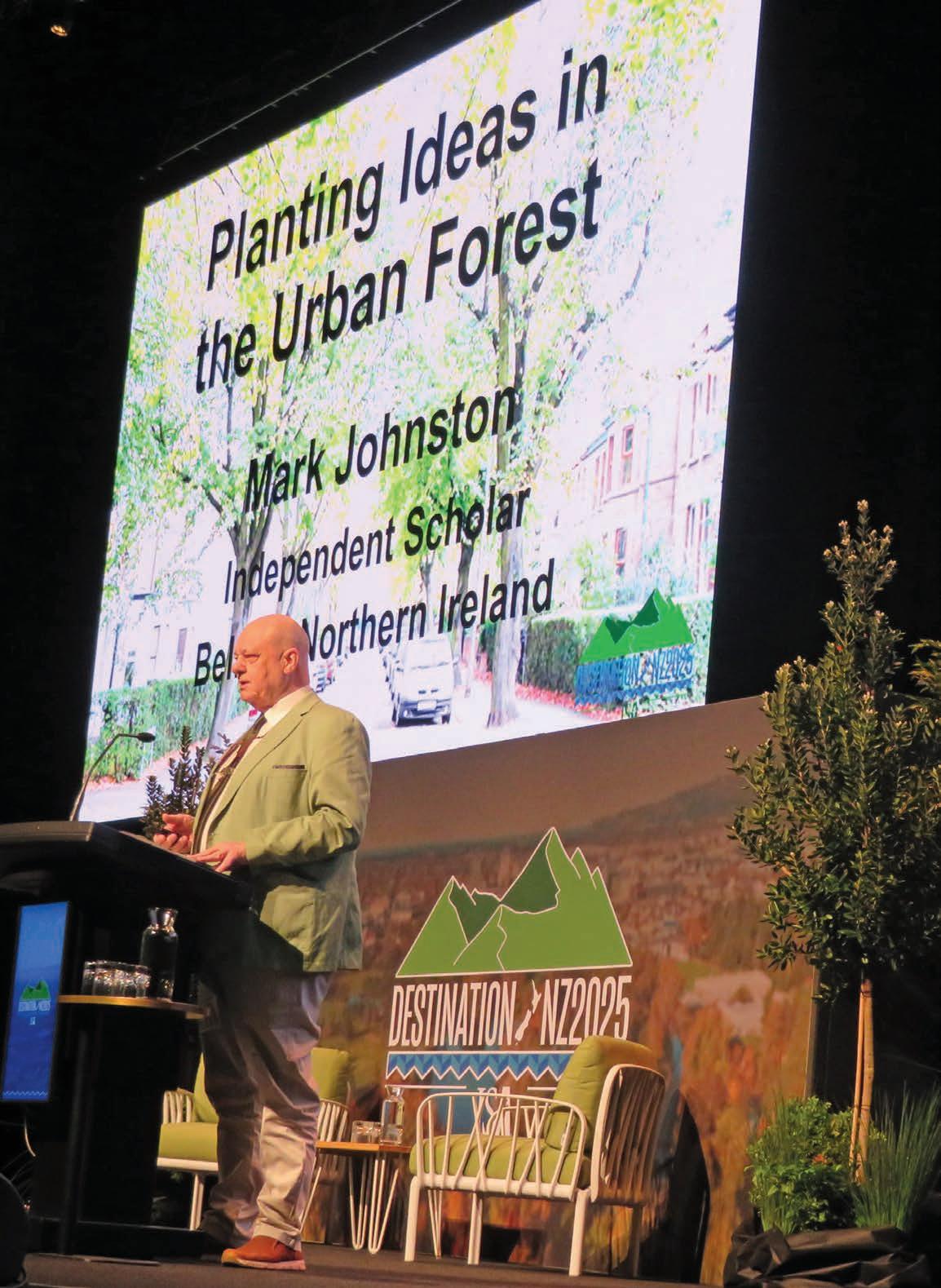

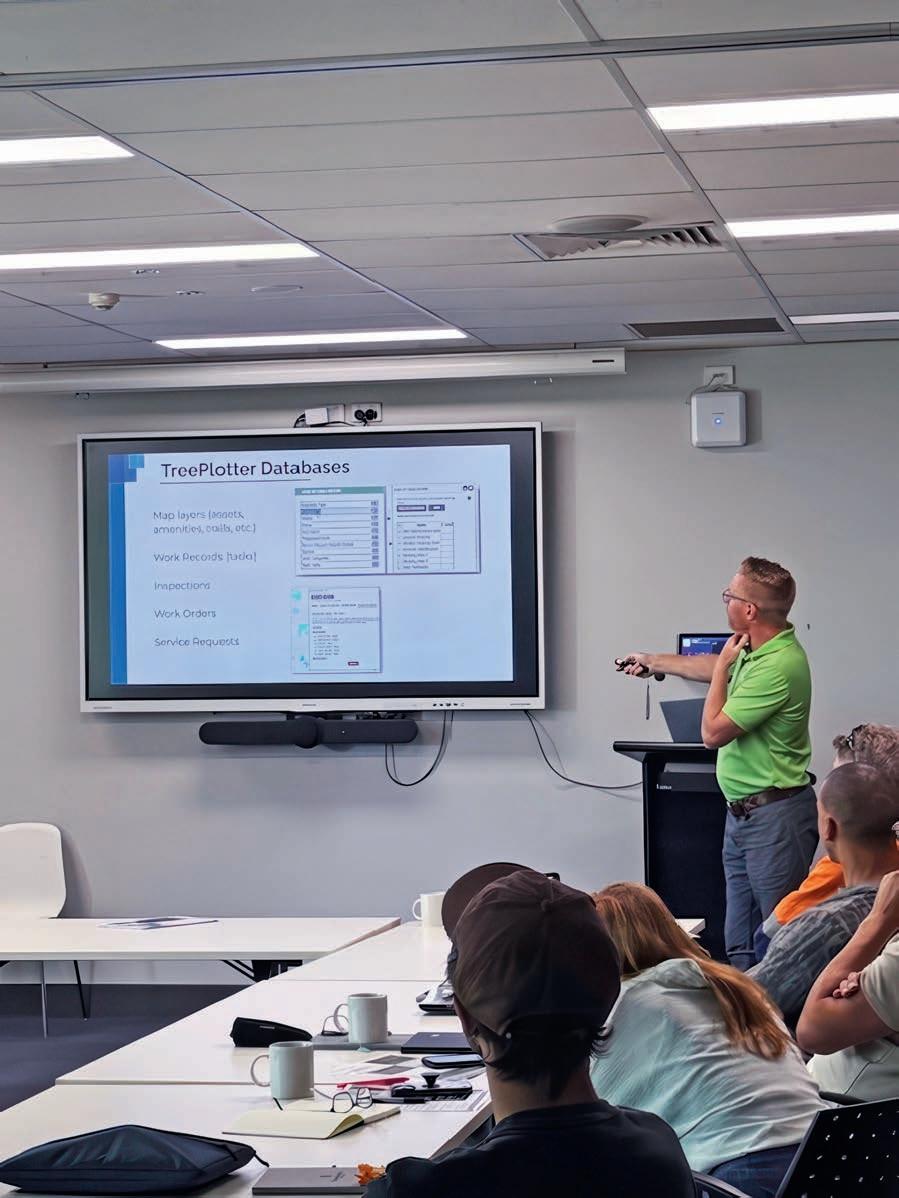

Dr Mark Johnston is an independent scholar of arboriculture, landscape, and urban forestry. He has a PhD in urban forestry and is a fellow of the professional bodies for arboriculture, forestry and horticulture. During a recent visit to New Zealand and Australia, he took time to discuss arboriculture past, present, and future with The Australian Arbor Age magazine.

With over 50 years’ experience in the tree world, including working as a tree surgery contractor, tree o cer in local government, consultant in private practice, government adviser, and university academic, the likable Mark Johnston has seen some big changes since he rst worked in and around trees in the early 1970s.

“I started in 1973 as a forestry worker,” he said in a voice made husky by recent speaking engagements.

“Then I discovered this thing called ‘tree surgery’. When I left the Forestry Commission, I set myself up as a selfemployed contractor. After dabbling in tree surgery, I had the chance to attend Merrist Wood College in Surrey, England, which was the only place teaching arboriculture and tree surgery at that time.

“That’s when my career really took o . I quali ed as a tree surgeon and went on from there.”

As his studies progressed, Mark found each quali cation he earned set him up to qualify even further, and he pursued an academic career.

“Eventually, after many years,

I did my doctorate,” he said. “I worked pretty much full time on the doctorate research from 1994 to 1998, and I nanced my study by working part-time as a fundraiser for a housing charity and the British Red Cross.”

Mark’s academic career is marked with some considerable milestones.

In the 13 years he spent commuting between his home in Belfast, Northern Ireland, and Myerscough College in Lancashire, England, he was involved in launching the rst Bachelor of Science, and then Masters, degree in arboriculture and forestry. He was also involved in developing the world’s rst online degree courses in arboriculture.

“That was some breakthrough,” he said. “People from all over the world studied remotely with us at degree level.”

During his career, Mark developed several urban greening initiatives in Britain and Ireland, most notably with city-wide projects in London, Dublin, Cardi , Glasgow, and Belfast. He acted as consultant to the Countryside Commission and Forestry Commission in the development of the national

program for the Community Forests Initiative, which created 12 new forests on the fringes of major cities in England. He was the main author of a UK government report on urban trees in England, and went on to lecture or advise on projects in the United States, Canada, China, South Africa, Zimbabwe, and various European countries.

After decades of working with trees and their e ects on society, Mark’s specialty is community engagement with urban greening at a policy or strategic level.

“It’s the nuts and bolts of working with people,” he said.

“I did some pioneering research back in 2008 with a government study called Trees in Towns II. I correlated canopy cover with the indices of multiple deprivation. It was later picked up by American Forests in the US and developed into ‘The Tree Equity Score’ to show local authorities the priority areas, and it’s since been picked up by the Woodland Trust in Britain and developed into the Tree Equity Score UK.

“I think this goes to the roots of urban forestry.

“I’ll quote myself from an early paper: ‘The aim of urban forestry is to improve

Awarding Alice Cowan the Top Student Award for the MSc Arboriculture and Urban Forestry, Myerscough College, in 2009.

The value of Mark’s work has been acknowledged worldwide, but an MBE must’ve been a high point, even for one so awarded.

“The MBE was in recognition of my work in the development of urban forestry in Britain and Northern Ireland,” he said. “But the citation particularly mentioned my cross-community work in Belfast where I managed to bring people together across the community divide.”

With decades of dedication and experience, we asked what developments Mark had been most and least impressed with during his time in arboriculture.

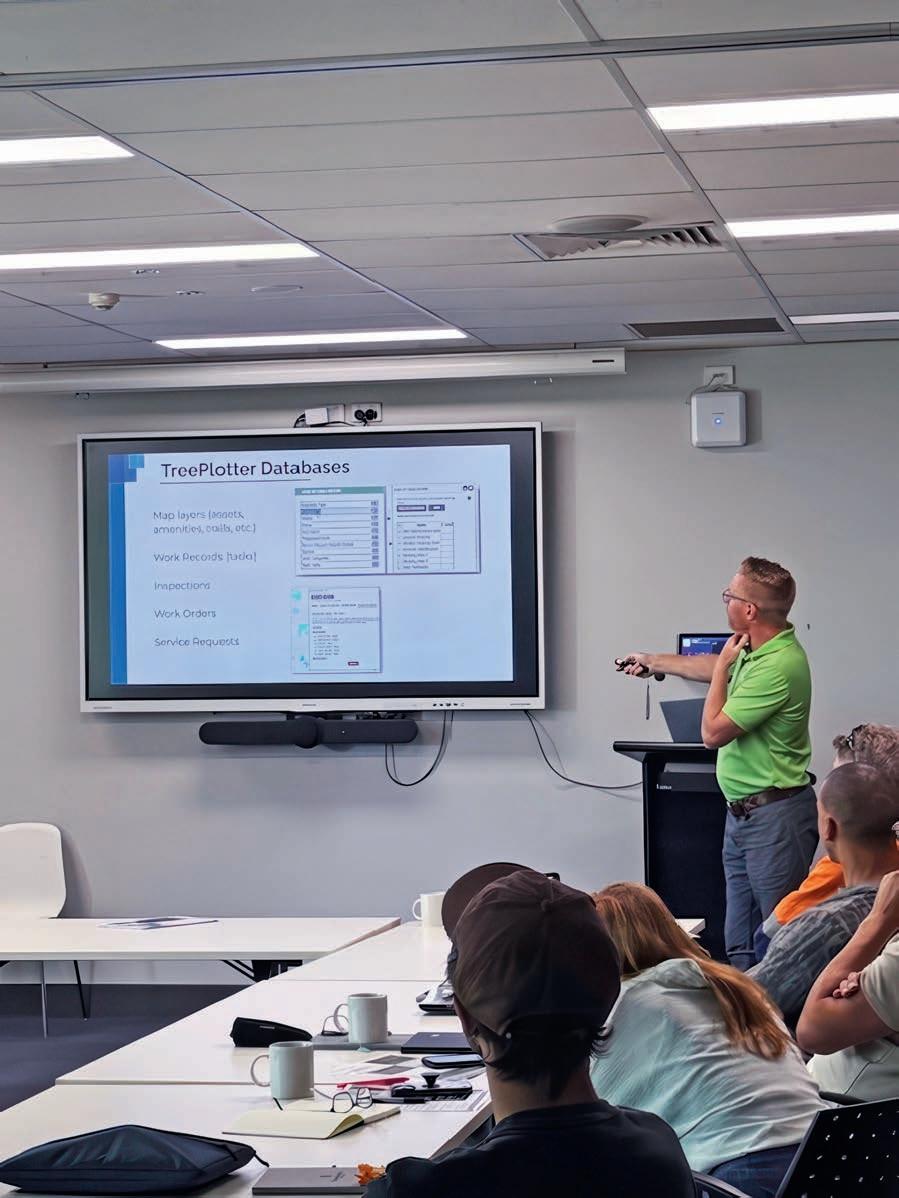

“The good things have included big advances in technology,” he said.

“When I started out it was all pretty basic. But when you look at today’s mapping tools and high-tech gear available in arboriculture, it’s amazing how it’s come on.

“Linked to that has been greater attention to health and safety. I’m quite

more public recognition of our industry. Although the term ‘arboriculture’ isn’t that widely understood, a lot more people are aware of what an arborist is.

“The other thing I think that has catapulted us forward is the concept of urban forestry. Arboriculture tended to focus on the individual tree or small groups of trees, but the idea of the total management of the urban forest resource, and recognition of the environmental, social and economic bene ts of urban trees, has moved to a new level.”

There were also aspects of arboriculture Mark felt hadn’t been so positive.

“We’ve been a bit slow to develop higher-level courses,” he said thoughtfully.

“We do have degree-level courses now. We’ve taken arboriculture from a craft occupation to being a profession. In my area of operation, Britain and Ireland, I wish it had happened a lot sooner. It took a bloody long time and a lot of work to bring it up to that level.

“When I started out there were virtually no women in arboriculture at any level. But as we developed degreelevel courses at Myerscough College, a lot more women signed up. They weren’t required to become pro cient in chainsaw use and tree climbing. They learned an appreciation of those things, but pro ciency wasn’t a requirement for a degree-level quali cation.”

Mark’s visit was his rst to Australia and New Zealand. He was thoroughly enjoying the Blue Mountains of NSW and, as we spoke to him, was eager to visit Tasmania.

We asked if he had any thoughts on arboriculture for Australian practitioners.

“First of all, globally our towns and cities are becoming less green. Various studies are showing that. We need to get our act together, and governments need to get their acts together. If we’re going to be serious about green cities in the future, we need to start working on

Another good thing is there’s a lot more public recognition of our industry “ ”

it, because in many ways we’re going backwards,” he said.

“We also need to work on our industry’s image to show we’re tree experts. We don’t just cut down trees. We’re about urban forestry and urban greening and we link arboriculture to a wider greening agenda. We all need to embrace that as an industry and show we’re part of the solution, not part of the problem.

“Linked to that is we still have a big carbon footprint for what is a relatively small industry. I’m delighted some important strides are being made by many companies in that direction and it has to be encouraged. The use of electric equipment and vehicles should be embraced.”

A highlight

After what has been a rewarding life in arboriculture and academia, we asked Mark for a single high point of which he felt most proud.

The answer came back immediately and without hesitation.

“The promotion of urban forestry.

“I was lucky enough to be on the ground oor in the mid- to late-1970s when the international urban forestry movement was taking o , and I knew some of the key people. I was in touch with Erik Jorgensen, the guy who coined the term around the concept.

“I’ve been pushing urban forestry for 50 years and it’s great. Things like the honour of giving the keynote address at this year’s ISA conference in New Zealand, looking at the past, present, and future of the international urban forestry movement…all that has been wonderful. It really was a buzz.”

Mark’s books and publications, including his free autobiography e-book IdeasintheUrbanForest markjohnstontrees.com.

After a lifetime in and around machinery, and the past three decades catering primarily to the arbor industry, Monitor Group co-founder and Product Manager Tim Joyce can look proudly at the success of the company he helped create.

Tim Joyce and his father had a diesel fuel-injection business, and Tim found himself a dealer for a few di erent equipment brands.

“It was mainly agricultural all-terrain vehicles,” recalled the smiling Joyce in the boardroom of Monitor’s beautifully appointed Tamworth headquarters. “We picked up an agency for the Avant mini loader from Finland, and they had this idea of putting a boom and bucket on one of their little skid-steer mini-loader chassis.

“That was the rst spider lift.”

In 1997 the Joyce business, Diesel Care, imported its rst example of the new machine, and Tim continued to sell machinery ‘on the side’.

“Nobody knew what they were,” he said, “so it was an interesting time.

“Ultimately it became a busy enough sideline to become a main line. We sold Diesel Care and put all our resources into the importing of machines. We had Avant mini loaders and Leguan spider lifts. As the spider-lift business evolved we realised there was a business to be had specialising in lifts. We sold the Avant business to my brother-inlaw in Wollongong, who’s been very successful developing it over the years, and we specialised in access equipment, particularly spider lifts.

“We added models, added brands, and grew the range.”

The new business adopted the name

‘Monitor’ – most commonly ‘Monitor Group’ – and Tim enjoyed relating how the brand was chosen.

“That’s a funny story,” he told The Australian Arbor Age.

“Leguan is the spider lift from Finland, and a leguan is a lizard. At the time my brother was wholesaling exhaust systems and had a brand called ‘Goanna’. I was trying to think of a name that didn’t narrow us down to anything in particular because we didn’t know what the future held. I came up with the name Monitor because these other lizards were members of the Monitor family,” he said

“For a long time we called it Monitor Lifts, but as we’ve grown we’ve expanded to include other tree-care products – grinders, woodchippers and

and today employs around 65 people across the country. Ben Joyce, Tim’s brother, joined the company when he nished school and now, as CEO, runs the thriving company with Tim nearby for guidance when its needed.

While Monitor looks – and is – a strong proposition these days, kicking o in 1997 took some commitment.

“It was di cult,” said Tim.

“We could see the spider lift was an amazing concept. Prior to the spider lift you either had a trailer-mounted cherry picker or a truck-mounted boom lift.

“The cherry picker had to be towed with a ute. They were good, and they were an economical product, but they were clunky to use. Every time it had to be moved, it had to be packed up and shoved around.

“The other end of the spectrum was a truck-mounted boom lift or a four-wheel drive boom lift, both of which are big and heavy.

“For so long there was nothing in between. Then, suddenly, the spider lift gave people a product that was like a cross-over machine. It was small, lightweight, and compact – far more compact than a trailer-mounted cherry picker. It could be driven through a doorway and towed behind a ute. It could work on soft, boggy ground, load-

sensitive oors or tennis courts because its footprint was so soft and light.

“But they were self-propelled. You could lift the legs and drive around.

“Apart from the spider lift not being able to drive while elevated, because obviously you have the legs set, it gave people the option of a self-propelled lift. It had the advantage of a bigger, heavier machine in that regard, but it was lightweight, towable and able to t into tight spots.”

All that sounds like the spider lift should’ve been an instant success. But there’s one other consideration.

“It was twice the price of a trailermounted cherry picker,” explained Tim, “so the big pushback at the time was it

being thought too expensive.”

Tim and the Monitor team backed their belief in the product and found, over time, the versatility of the spider lift overcame arborists’ concerns about the higher purchase price. As acceptance grew, so did Monitor.

“When I was rst trying to sell spider lifts, people would say, ‘No. We’re all good. We climb. We might use an EWP once or twice a week’,” Tim said. “They thought they would be useful for trees that were unsafe to climb or inaccessible for di erent reasons. They felt they wouldn’t get the use from an EWP.

“But once they started using a spider lift, they found so much improved e ciency that it became a tool they believed they must have.

“It’s so di erent to the early days

now. Back then, a spider lift was viewed as a bit of a luxury. Now, if someone’s spider lift breaks down for some reason, they’re chasing us and saying, ‘Quick. I need it now. I have to have it on the job’.”

The Australian Arbor Age said it must’ve been interesting to watch that acceptance grow.

“It was interesting for our competitors to watch, too,” said Tim.

“There’s been a lot of spider lifts come on to the market now. Some have come and gone. Some have come and gone a few times.

“We created the spider-lift market in Australia initially, and of all the spider-lift brands we’ve imported since 1997, we still stock, maintain, and support those brands today as exclusive Australian distributors. I think people can see that when they buy a product from Monitor, there’s long-term ongoing support. They won’t be left out in the cold and told parts aren’t available any more.”

These days Monitor has branched out to include brands and equipment like Först, Rayco and Morbark, and to o er its own Monitor-branded spider lifts. The company has also made a big e ort to increase its servicing and hire sectors.

“It’s been an expensive journey,” said Tim.

“I think one lesson we’ve learned the hard way over the years was the need to be careful about straying outside your lane.

“We were careful looking at the wood chippers and stump grinders, which we knew little about. We did know our customers were using both those products, so it was a natural progression for us to include them, and that’s been successful.

“We don’t only do spider lifts. We do scissor lifts, truck-mounted lifts, conventional boom lifts…we do a range of access equipment. But spider lifts are our main game. That’s where we shine. Because so many arborists use spider lifts, its roughly half of our business.”

As The Australian Arbor Age sipped a cappuccino from the Monitor co ee bar, we looked around the hectares of immaculate workshops,

warehousing, and administration o ces – a testament to many years of sound business management. We asked the industry veteran how he felt about the arbor sector and Monitor’s current position.

“Monitor’s in a good place,” he said quietly. “We have good products, good support, and good people. That’s one area where we’re very fortunate. We have an outstanding team and brilliant customers, some of whom have been buying machines o me since I left school.

“Wherever you’ve got machinery, you’ve got breakdowns. Our machines have let people down at times and we might not get it right the rst time, but customers don’t need to worry. Monitor will always be there and will get it right in the end.

“I think arbor is a great industry, and we certainly enjoy being part of it. It’s no y-by-night category and it’s important to Monitor.

“Looking after trees and vegetation is never going away.”

Learn more about Monitor and its range of products and services at monitor.net.au.

Immaculate workshops, warehousing, and administration are testament to many years of sound business management. Image: Monitor

Monitor

Tomcat Chippers have become a top choice for vegetation and utility management contractors who demand equipment that can keep pace with the Australian environment.

If you love your job, you won’t work a day in your life,” said author Mark Twain.

The tree-care industry is all about that. Every day is a di erent puzzle, spurred on by a bit of adrenaline, fun and a sense of accomplishment. Of course, the dangers of tree work can never be underestimated, forgotten, or discredited. That’s why Tomcat builds machines that respect the thrill while prioritising the safety of the men and women who live for the challenge.

In the rugged landscapes of Australia, where bush res rage, storms wreak havoc, and urban sprawl meets untamed wilderness, reliable equipment is a necessity. Across these demanding environments, Tomcat Chippers has been supplying small

and medium-range chippers built for strength, agility and endurance – trusted by arborists and utility management contractors – tackling the nation’s toughest conditions.

From pruning overgrown lots in suburban Sydney to clearing rebreaks in the Perth Hills, Tomcat delivers performance that turns chaos into e ciency.

Tomcat has long been the go-to name for small and medium chippers that dominate the market, with growing interest for the big cats: the formidable 11”, 13”, and 16” capacity chippers. These beasts are designed for contractors tackling the heaviest loads. Engineered with precision in

every weld and component, they withstand the demands of daily operations without skipping a beat. At the heart of the Tomcat range are the proprietary designed chipper drums that produce uniform, high-quality chips ideal for mulch, biomass production, and waste reduction. Unlike less e cient alternatives, Tomcat drum systems chew through branches, logs, and debris with unmatched consistency, minimising downtime and maximising output. When it comes to value, Tomcat o ers the best value for money in the market. You get commercial-grade durability without the premium price tag, ensuring a swift return on investment for large and small eets.

What truly sets Tomcat apart is its commitment to keeping you operational, not sidelined. In a market of faceless corporate suppliers where frustrating service calls are the norm, Tomcat gives you direct, no-nonsense support from people who actually know the machines. O -the-shelf maintenance and wear parts are readily available here in Australia. There’s no endless wait for overseas shipments or exorbitant import fees. Paired with Tomcat’s network of Australianowned dealers and distributors, you’ll nd professional, knowledgeable support at your doorstep. These partners aren’t just sellers. They’re experts who understand the unique challenges of Aussie jobsites, providing hands-on maintenance, training, and troubleshooting to keep your chipper humming.

Power is non-negotiable in this line of work, and Tomcat’s feed capacity proves

it. Tomcat machines boast powerful infeed systems that handle everything from supple eucalypts to gnarled acacia, pulling material through with hydraulic force. Take the Tomcat 4375AFE, for instance – a heavy-duty workhorse ideal for storm cleanups and forestry applications. Whether you’re processing windfall after a cyclone or thinning a harvest-ready stand, this model’s reinforced frame and high-torque drive ensure it thrives under extreme commercial use.

Flexibility comes standard too, with engine options tailored to your needs: reliable Honda petrol engines for lighter, portable setups, or robust Perkins diesel engines for all-day, fuel e cient yakka on remote sites. As for safety, Tomcat doesn’t compromise. Every model adheres to Australian standards, featuring emergency stops, bump bars, forwardreverse controls, autofeed systems, and protective guards and shrouds around all moving parts. These aren’t add-ons.

They’re built-in safeguards that protect operators and crews, letting them focus on the job, not the risks.

Tomcat 4250AFE

The Tomcat 4250AFE 11” capacity wood chipper packs serious power into a compact, lightweight frame ideal for residential tree care, vegetation management, and councils, without unnecessary extras. A massive cutting drum and 85hp Perkins diesel engine deliver optimal power-to-weight performance, and all controls are mounted kerbside. A lift-crush infeed, TRAC autofeed, 360° discharge chute, plus a three-position safety bar with dual e-stops and bump bar provide control and protection. On top of all that, the 2.5t multi-directional hydraulic winch pulls the big branches with ease, and the rugged trailer comes with a spare wheel, toolbox, cone spike, rake holders, and a pole-saw mount. Easy to tow, it’s e cient, essential, and brilliantly built.

In a class of bloated, overpriced chippers, the 13” capacity 4300AFE is a revelation. It o ers high-volume chipping with low running costs and is built for the real grind of utility maintenance, residential tree work, and council eets. Powered by the bulletproof Perkins engine and Parker hydraulics, it devours stubborn branches with ruthless e ciency thanks to Tomcat’s exclusive TRAC reversing autofeed and a hydraulic crush ram. Kerbside controls keep you safe from tra c and the 360° chute directs chips precisely. Safety is ensured: three position bar, dual e-stops, bump bar. Add the 2.5t multidirectional hydraulic winch and rigging or log handling becomes e ortless. With a choice of either tandem or single-axle trailer with all Australian standard parts, Tomcat includes the spare wheel, toolbox, cone spike, rake and pole saw mounts. It means you’re always ready and never stuck. The 4300AFE doesn’t just work hard. It works smart, and it won’t bankrupt you doing it.

The 4375AFE reigns as the top 16” woodchipper, combining power, e ciency, and build quality suited to large-scale vegetation management, land clearing, and professional arborists. Its capacity to-weight ratio, driven by a large cutting drum and 125hp Perkins turbo diesel engine, is the result of smart design and precision craftsmanship. Kerbside controls enhance operator convenience and safety. The fully hydraulic 360° discharge chute o ers precise chip direction, and safety includes a three position control bar, dual e-stops, and bump bar. Here too, the optional, unique 2.5t multi-directional hydraulic winch makes hauling heavy trees and branches a breeze.

Dominating machine-fed chippers is the 4375AFE IC con guration, it packs all the power and features of the 4375AFE, with the addition of Tomcat’s patented heavy-duty steel conveyor system. The operator commands hydraulic control over the two-metre steel infeed conveyor and discharge chute, enabling continuous feeding and e ortless

loading of large branches and whole trees. Mounted on a tandem trailer with spare wheel, toolbox, cone spike, rake holders, and pole-saw mount, it’s built to perform, day in, day out. The 4375AFE doesn’t just lead the pack – it de nes it.

As Australia faces environmental pressures, from natural disasters to sustainable land management, Tomcat Chippers is more than a supplier; it’s a partner in progress. Whether you’re out tting a startup crew or expanding a veteran eet, the Tomcat range, from nimble small units to the heavy-hitters, empowers you to work smarter, safer, and better. Discover why contractors nationwide swear by Tomcat. Visit your local dealer today and experience the di erence. The frontier awaits – chip it with con dence.

For more information, visit tomcatchippers.com.au.

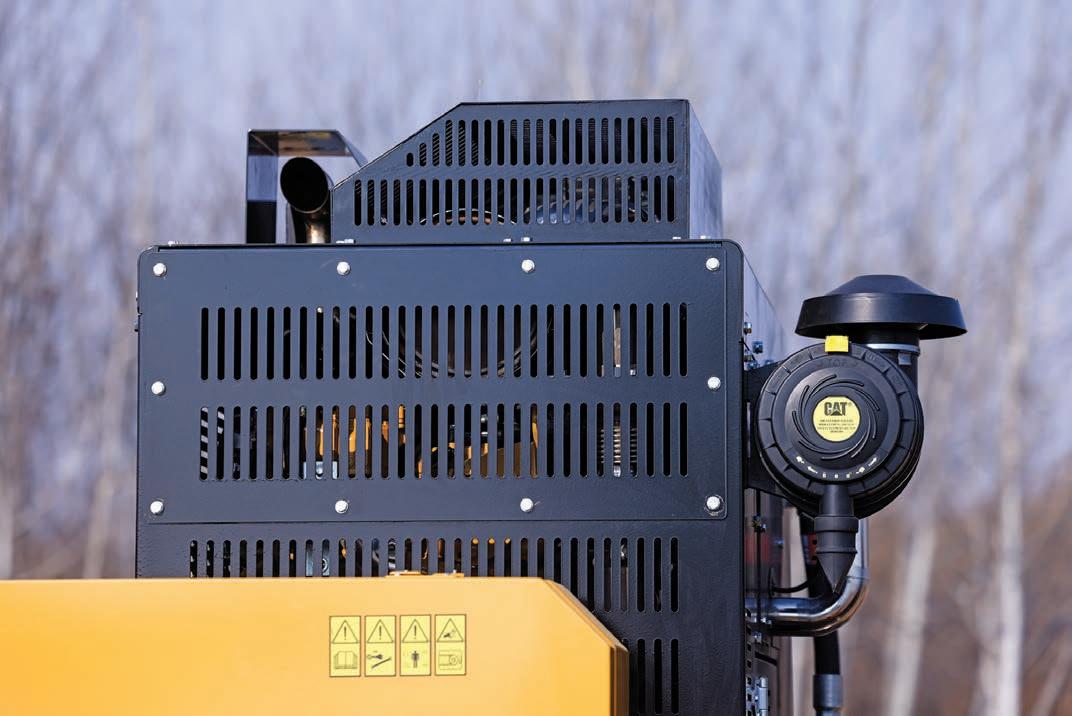

Arborists face a unique set of challenges. From tight residential spaces to environmentally sensitive areas, the demands of tree care and vegetation management require equipment that is both powerful and manoeuvrable. The new Vermeer HG400TX horizontal grinder is designed to meet these needs, o ering a compact, track-driven solution that delivers serious performance without the bulk of larger machines.

The HG400TX is built for access. Its low ground-pressure track system allows it to move con dently across soft, uneven, or landscaped terrain, making it ideal for urban tree contractors, council crews, and vegetation-management teams working in parks, reserves, and residential zones. With a footprint that ts into tight spaces and a design that prioritises mobility, arborists can take this machine where others simply cannot go.

Despite its compact size, the HG400TX does not compromise on capability. Powered by a 170hp CAT engine, it delivers consistent throughput for brush, limbs, and small logs. Arborists can process material quickly and e ciently, reducing time spent on site and improving overall productivity. The machine’s patented duplex drum design ensures smoother operation and helps reduce maintenance intervals, while the SmartFeed system automatically adjusts feed rates to prevent engine stalls and optimise grinding performance.

Transporting the HG400TX is straightforward. It ts easily onto a trailer or truck bed, eliminating the need for oversized load permits and simplifying logistics for contractors moving between multiple job sites. This ease of transport is especially valuable for arborists responding to storm damage or emergency callouts where time and access are critical. Safety and operator control are also features of the HG400TX. The full-

function remote control allows users to manage feed and engine functions from a safe distance, improving visibility and reducing exposure to hazards. This is particularly useful in con ned or high-tra c areas where situational awareness and quick response times are essential.

The HG400TX also supports sustainable practices. By turning green waste into mulch or biomass, arborists can reduce land ll contributions and promote circular resource use. This aligns with the growing emphasis on environmentally responsible operations across the industry, especially in council and government contracts where sustainability targets are increasingly common.

For arborists working across Australia, the HG400TX o ers a rare combination of compact design, reliable performance, and operational exibility. Equally suited to small-scale treemaintenance and larger vegetationmanagement projects, it’s a versatile addition to any eet. Whether clearing storm debris in Queensland, managing roadside vegetation in Victoria, or maintaining parklands in South Australia, the HG400TX is ready to work.

Vermeer Australia continues to support arborists with equipment built for real-world conditions. The HG400TX is a re ection of that commitment: a machine designed and built for the terrain, tasks, and time pressures arborists face every day.

In the eld, performance matters. But so does access, safety, and support. The HG400TX delivers all four, helping arborists get the job done faster, safer, and with less downtime. It is not just a grinder. It is a compact solution for a complex industry.

To learn more about Vermeer’s range of tree-care solutions, or to speak with your local specialist, visit vermeeraustralia. com.au or contact your nearest branch.

A 170hp CAT engine delivers consistent throughput for brush, limbs, and small logs.

The full-function remote control allows users to manage feed and engine functions from a safe distance.

The BT300 is a serious 15-inch capacity chipper with plenty of horsepower to get the job done, and it’s 100 per cent designed and made in Melbourne, Australia.

The Piranha BT300 is powered by the 4HK1 Isuzu turbo-diesel engine delivering 197hp.

Power is sent to the 400kg, 650mmdiameter cutter drum with four staggered knives, while the chipper features a 380mmH Xx500mmW (15” x 20”) direct opening into the cutter-drum housing (no step-downs).

Features

As an electronically controlled, common-rail direct-injection diesel motor, the 4HK delivers excellent fuel economy and is also very quiet when running. Dual horizontal infeed wheels o er strong pulling power and, with the assistance of the hydraulic winch (which quickly folds away during loading), di cult trees and branches are handled quickly with minimal physical e ort from the operators.

Other features that ensure ease of use include the hydraulic auto-engage clutch, hydraulic discharge-chute swivel and the hydraulic tailgate-raise-andlower functions. Chippers,

The BT310 o ers 500mm of ground clearance.

The design team paid attention to the ner details of the BT300, making servicing quick, easy and low e ort.

Starting at the front with the engine, the Isuzu 4HK1 o ers 500-hour service intervals, allowing longer operating periods between scheduled oil and lter changes. And with many operators already running Isuzu trucks in their eets, the shared stockholdings of lters and essential engine parts and spares can be kept to a minimum.

When the engine compartment door is opened, all lters and service points are right there, making oil and lter changes simple. A remote oil drain hose makes draining the old engine oil out of the sump quick, easy and mess-free. An access door at the top of the engine cover ensures new oil is easily lled back into the motor.

There’s even a work light mounted inside the engine bay which improves visibility when checking the essentials in dark conditions.

The other major service requirement for any chipper is attending to the chipper knives, and on a Piranha BT300 this is done with convenient access via the side walkway ramp. When the chipper housing hood is opened, the top part of the cutter drum is completely exposed, making knife changes easy and safe.

Chipper blades are torqued up tight, as everyone knows, and when access requires reaching down into a door, the job becomes di cult. That’s all changed with the Piranha BT300.

Piranha Chippers are 100 per cent Australian made and owned, and with a class-leading ve-year/3000-hour warranty they’re a good choice for anyone serious about chipping wood.

Contact the Piranha team today. They’d love to show you just how good the BT300 is in real life. Call 1300 406 171, or log on to piranhachippers.com.au.

Morbark lls the gap for larger-scale arborist operations.

When it comes to turning timber into chips, Morbark has been a global powerhouse for more than 65 years.

Known for strength, reliability, and output that doesn’t quit, Morbark machines have become the backbone of forestry, arboriculture, and landmanagement operations around the world.

Now, through its exclusive partnership with Monitor Industries, Morbark’s chippers are available across Australia, backed by Monitor’s national network of branches, service teams, and aftersales expertise. It’s a collaboration that combines American engineering excellence with Australian service and support, delivering productivity and peace of mind for the country’s hardestworking arborists.

Big machines for big jobs

Morbark’s range of industrial drum and whole-tree chippers is designed to keep up with the demands of professional operators who can’t a ord downtime. Built in Winn, Michigan, each machine is engineered for maximum throughput, simpli ed maintenance, and longevity in the eld.

The Morbark 2230 is one of the largest models now available through Monitor Industries. Compact enough for simple transport between urban and regional

worksites, yet powerful enough to handle large timber, the 2230 features a 365hp diesel engine and a 22” x 30” infeed opening. It’s ideal for councils, contractors, and arborists managing high-volume vegetation or land-clearing projects.

For operators who need a versatile, mid-range unit that balances capacity and manoeuvrability, the Morbark 1621 is a reliable performer. Featuring an 18” x 20.5” infeed opening and powered by a robust diesel engine, it’s purposebuilt for arborists and vegetationmanagement crews tackling substantial pruning, line clearing, or removal work. The 1621 delivers strong pulling power, consistent chip quality, and ease of maintenance, all in a transport-friendly footprint.

When workloads demand greater throughput, the Morbark 1821 steps up with added capacity and 170hp of engine power. With an 18” x 20.5” infeed and upgraded feed system, it handles bigger timber with less need for chainsaw prep. A larger drum and enhanced feed rollers ensure smooth, high-volume processing ideal for contractors, councils, and utility arborists working in demanding environments.

For the average arborist, productivity comes down to time, mobility, and reliability. That’s where the Morbark range really shines.

While many contractors rely on compact tow-behind or tracked chippers for day-to-day pruning and removals, the Morbark series lls the gap for larger-scale arborist operations – tree services that handle high-volume clearing, line-management work, or storm clean-ups.

For example:

• The Morbark 2230 suits multi-crew operations that need to chip whole limbs or multiple trunks at once.

• The 1621X provides a balance between portability and output, making it a favourite among regional and council contractors.

• The 1821 is ideal for dedicated vegetation management, roadside clearing, or larger-scale arborist operations where power and throughput are critical.

Monitor Industries’ product specialists work closely with operators to identify which chipper best ts their work volume, towing requirements, and

budget, ensuring each purchase is practical and pro table from day one.

For Monitor Industries, partnering with Morbark was a natural t. Both companies share a heritage of engineering excellence, customer focus, and long-term reliability.

Monitor has been supporting Australia’s arbor industry since 1997 and was the rst to bring spider lifts into the country. Today, with branches in Tamworth, Sydney, Melbourne, Brisbane, Caboolture, and Perth, Monitor provides nationwide coverage with factorytrained service technicians and stocked parts warehouses, ensuring Morbark owners have the same con dence and continuity of support that has made Monitor a household name.

Each Morbark chipper sold by Monitor is backed by:

• Comprehensive handover and training for operators;

• scheduled servicing and maintenance programs;

The Morbark 2230 features a 365hp diesel engine and is ideal for councils, contractors, and arborists managing high-volume vegetation or land-clearing projects. Images: Monitor

• readily available genuine parts; and • local after-sales support via Monitor’s technical team.

It’s this level of end-to-end service that gives arborists, councils, and contractors the con dence to invest in Morbark equipment for the long haul.

As the Australian arboriculture and vegetation-management sectors continue to evolve, both Monitor and Morbark are committed to helping operators work smarter, safer, and more e ciently.

“Morbark machines are built to last and to perform day in and day

out, even in harsh conditions,” said Chad Firth, National Sales Manager at Monitor Industries. “By pairing them with our national support network, we’re ensuring arborists have access to world-class equipment backed by local service and knowledge. It’s a partnership that’s strengthening Australia’s professional tree-care industry.”

Monitor Industries – powering productivity, nationwide.

When you choose the BVR Brush Chippers from Morbark, LLC, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and cra smanship. ese chippers are designed to stand the test of time and make your toughest jobs easier and more pro table.

Don’t settle for less. Choose the chipping power of the BVR Brush Chippers and experience the di erence that Morbark’s legendary performance can bring to your business.

Unlock Powerful Performance with the BVR Line of Wood Chippers from Morbark.

When you choose a BVR Wood Chippers, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and craftsmanship. These chippers are designed to stand the test of time and make your toughest jobs easier and more profitable. Don’t settle for less. Choose the chipping power of BVR Wood Chippers and experience the difference that Morbark’s legendary performance can bring to your business. To find a Dealer in your neck of the woods, go to https://dealers.morbark.com.

Monitor Industries - Australia

Ph: +61 1800 025 024 www.monitor.net.au

Stevens Group - New Zealand

Ph: +64 09 275 0443

www.stevensgroup.co.nz

For more information or to view the full range of Morbark chippers available in Australia, visit monitor.net.au or contact your local Monitor branch. ®

To learn more about the complete line of BVR Wood Chippers, scan the QR Code with your mobile camera

The experts at Diamond Mowers have a few tips for e ective post- re cleanup and future re defence.

In a re-prone country, land-care professionals are often faced with the daunting task of cleanup and recovery. When res a ect landscapes, the immediate focus for operators must be on clearing hazardous debris, stabilising the land, and ensuring damaged areas don’t become more vulnerable to erosion and invasive species.

Mulching stands out as a critical part of this process, o ering a controlled and eco-conscious approach to rehabilitating re-damaged areas and making them more resilient. With the right equipment, properties can be e ciently restored while reinforcing landscapes against imminent risks.

Types of res

Fires a ect landscapes di erently depending on the region. Understanding these distinctions can help contractors choose the right methods and equipment for recovery.

• Forest res typically involve dense, woody debris. An open drum mulcher is best for removing large trees in forested areas.

• “Our new Drum Mulcher OD Pro X2 features durable carbide teeth to handle thick vegetation, making it ideal for forest re recovery where clearing large remnants quickly is essential for land restoration,” said Nate Cleveringa, Vice President of

Engineering and Product Management at Diamond Mowers.

• Brush res tend to occur in scrubland environments and leave behind tangled, low-lying greenery. The sharp, powerful blades of a brushcutter enable it to e ciently cut through weeds and shrubs a regular mower or trimmer might struggle with. A brushcutter in this situation can help restore land to its natural state.

• Grass res move quickly across grasslands and can leave debris that contributes to erosion and invasive plant growth. Here, again, a drum mulcher is the best choice for

processing thick patches of tough vegetation. Diamond’s Drum Mulcher DC Pro X2 features proprietary Edge™ Hardened Steel Teeth, which have taller ‘paddles’ to ingest more material for a more comprehensive and cleaner mulch on the rst pass. Meanwhile, a brushcutter o ers thorough treatment for more delicate areas. Together, these attachments can help maintain the soil and promote healthy regrowth of native plants.

Post- re landscapes present unique dangers and hazardous conditions that need to be addressed carefully. Taking the right precautions helps to ensure the safety of workers and the e ectiveness of cleanup e orts. Look for hidden hazards like unstable trees and smouldering vegetation that can compromise operator safety or cause further damage if left unattended. Always use appropriate protective gear. Operators should be equipped with helmets, gloves, and safety glasses to protect against ying debris, sharp objects, or accidental contact with machinery, and work in stages. Address high-risk areas rst, especially near buildings or infrastructure, to eliminate immediate threats. Prioritising these zones will also allow for emergency repairs or access to critical areas sooner.

When tackling post- re cleanup, it’s important to start with more perilous areas where erosion or regrowth pose risks.

• Stabilise slopes vulnerable to landslides or soil erosion. That can lead to long-term land integrity. With its extended reach, an excavator drum mulcher is an ideal option for accessing burnt vegetation in hard-toreach areas and creating a protective layer over the soil on steep terrains.

Taking the right precautions helps to ensure the safety of workers and the

e ectiveness of cleanup e orts.

• Protect waterways from burnt debris and loose soil that can wash into streams or rivers, impacting water quality and local ecosystems. A brushcutter excels at clearing smaller vegetation around tight waterways, which contributes to a reduction in runo contamination.

• Create and maintain defensible spaces by thinning vegetation to create rebreaks and protective bu ers around homes, businesses, utility poles, and other infrastructure.

An important aspect of post- re recovery is preparing for future disasters and cultivating long-term resilience. Landowners can support these goals by incorporating mulching as part of their ongoing land management e orts and tracking regrowth, incorporating rebreaks, enhancing soil health and biodiversity. Mulching returns organic material to the soil, enriching it with nutrients that promote native plant regrowth.

The sharp, powerful blades of a brushcutter enable it to e ciently cut through weeds and shrubs a regular mower or trimmer might struggle with.

Recovering from wild res is as much about rebuilding the land as it is about preparing it for what’s ahead. By integrating mulching into routine maintenance, contractors and land-care professionals can strengthen ecosystems, reduce long-term risks, and turn vulnerable terrain into resilient landscapes.

Learn more about Diamond Mowers at colbrookindustries.com.au.

Arcadia Tree Care, based in Albany in WA, handles all types of tree work, from a prune or safety check right through to the removal of towering eucalypts in close proximity to structures.

Four years into its journey, Arcadia Tree Care is owned and run by Leon Fry, who recently took delivery of Monitor 1890 spider lift.

If Leon’s opinions are typical of 1890 owners and operators, we’re not surprised it’s such a popular machine.

“This is the rst EWP we’ve bought through the business,” said the cheerful Leon, “but I have a long history of using them through past companies I’ve worked for.

“The largest EWP I’ve used was a 65-metre truck-mounted unit, but I regularly worked with 24-metre EWPs. That was back in my 20s, working in Kings Park and Botanic Garden in Perth. I also used truck-mounted EWPs in London in the UK.”

Leon rst struck out on his own about four years ago, and initially worked mostly with hire equipment – mainly trailer-mounted and truck-mounted EWPs. The purchase of the Monitor 1890 was a carefully considered one, but Leon has only bene t from the decision.

“About 12 months ago we started a contract with the Department of Housing and Works where we do a lot of work at the schools in the region,”

Leon told The Australian Arbor Age magazine. “I found that with the play equipment, and the way trees were located throughout the school, and with the rise of nature playgrounds and similar features, there wasn’t the access for truck-mounted or trailer-mounted EWPs. Those machines can’t get into the places spider lifts can.

“On top of that, a lot of the work is deadwooding and ne pruning on trees where it’s impossible for a climber to access the outer parts of the canopy.”

Leon didn’t mince his words when we asked if the 1890 had been a good purchase.

“It’s become a huge asset for our business,” he said. “It’s allowed us to take on work we couldn’t previously bid on or didn’t have the capability to do. It’s also

on a winner.

“Second to none. Just fantastic,” he said when asked about Monitor.

“Steve at the WA branch has been a huge help, and we’ve dealt with people from Monitor all around the country. We’ve dealt with the hire department, the spare parts department, and sales.

“We also chose Monitor because it’s a one-stop solution for modern arboriculture companies. It has truckmounted EWPs, the largest range of spider lifts available, good-quality wood chippers from Först and Morbark, and they have Rayco stump grinders.

“As far as arbor machinery goes, you can deal with just the one company. In this day and age when there’s so much to do, it’s made buying and running machines really easy.

“All in all, it’s just a fantastic company to deal with.”

For more information, visit monitor.net.au.

Rain didn’t dampen spirits at October’s 2025 WA State Tree Climbing Championships, held at the Perth Hills Discovery Centre. Despite bouts of drizzle, 25 climbers took to the trees in an unforgettable weekend of skill, speed, and community spirit.

Preliminary events saw competitors tackle ve disciplines: Aerial Rescue, Work Climb, Ascent, Belayed Speed Climb, and Throwline, testing every aspect of technical ability and physical endurance.

After climbing all day on wet and slippery trees, only three climbers advanced to the Masters Challenge – the ultimate test of speed, accuracy, and skill.

When the ropes nally came down, Luke Osborne emerged as the new 2025 WA State Champion, claiming top honours with strength, nesse, and focus.

“I have been climbing since I was 18,” said Luke. “I knew I had one more good day in me and I’m thrilled it was this one.” He now sets his sights on representing WA at the Australian Tree Climbing Championships in Tasmania in 2026.

Seasoned competitor Pascal Oosterik

took second place, also winning the Aerial Rescue and Ascent events. Re ecting on the competition, he said, “Keeping your head calm is just as important as technique. I was happy with second place.”

His advice to novice climbers? “Have passion and ask for support. We’re a great community of climbers.”

Rounding out the podium was rsttime competitor Lucas Burt, whose determination and athleticism earned him third place overall and thunderous applause from the crowd. “It was hard!” he admitted. “It was a big day, and I was stoked to get through to the Masters.”

Despite the unpredictable weather, the crowds came out in full force – families wrapped in raincoats, kids jumping in puddles, dogs tugging on leashes, and the smell of barbecue in the air. Spectators gathered to watch the action, cheer on competitors, and explore the

machinery and equipment on display.

The championships were hosted by ArbWest, supported by a dedicated committee and an incredible group of volunteers.

“A lot of work went into organising this event, from securing the venue and council permits to coordinating competitors, judges, exhibitors and volunteers,” said Jolyon Elliott, ArbWest committee member and competition judge. “We’re so proud of what we achieved, and we can’t wait to host an even bigger event next year.”

The event wouldn’t have been possible without the generous support of sponsors and exhibitors.

WA TreeWorks was one of the major sponsors and had team members competing.

“We see the championships as a fantastic opportunity for our industry to come together,” said Steven Barker,

Masters Challenge

1. Luke Osborne – State Champion 2025

2. Pascal Oosterik

3. Lucas Burt

Event winners

• Aerial Rescue – Pascal Oosterik

• Belayed Speed Climb – Riki Peterson

• Ascent – Pascal Oosterik

WA TreeWorks General Manager and ArbWest committee member. “It’s not just about competition. It’s about safety, innovation, and community spirit.”

Ellenby Tree Farm, an ArbWest Silver Corporate Partner, was also proud to lend its support by providing a selection of native trees for the winners.

“Sponsoring the championships aligns with our core value of supporting the community,” said Craig Woodro e, General Manager. “This event represents the strength and resilience that de nes our profession.”

Kimberley Tree Care made its mark on the event, not only as a sponsor but with several team members stepping up to compete.

“We’re proud to support an event that celebrates the professionalism and passion of arborists,” said owners Marco Morgado and Marta Rodrigues. “It’s about sharing knowledge, building connections, and inspiring the next generation.” Marco also served as a judge on the day and is a dedicated ArbWest committee member.

For Hayes Tree Care, sponsoring the adrenaline- lled Aerial Rescue event was a perfect t.

“It’s great to support something

• Throwline – Luke Osborne

• Work Climb – Kye Nordine

Sponsors

• Coastline Mowers

• Ellenby Tree Farm

• ETS Infrastructure Management

• Hayes Tree Care

• Husqvarna

• Kimberley Tree Care

• Marlow Ropes by CSP Distribution

• Pete’s Treeworx

• Stihl Shop Osborne Park

• Treeswest

• WA TreeWorks

that brings together skilled arborists who share our love for trees and the outdoors,” said owner and ArbWest committee member Nick Hayes. “The championships celebrate talent, safety, and professionalism – everything our industry stands for.”

Coastline Mowers sponsored the Masters Challenge and had an exhibition

stall, continuing over 20 years of support to the local arborist community.

“We’ve added a huge range of arborist climbing and safety gear to our lineup,” said Store Manager Tim Stuart. “It’s great to see our equipment being used by the best climbers in WA.”

And from Treeswest, General Manager Dave Crispin summed up the feeling

despite the weather. We’re proud to support such an important event that brings our community together.”

Dave Crispin, who also serves as ArbWest’s Acting President, played a key role in organising the event.

CSP Distribution and Stihl Shop Osborne Park donated prizes for the winners, as did Husqvarna Australia.

CSP Distribution Director Alex Witt commented: “We’ve been part of the arboriculture community for over 30 years, and it’s always a pleasure to support events like the WATCC. It’s a wonderful family day out and a great chance to showcase the talent of our WA climbers. We’re proud to be involved and look forward to continuing that partnership well into the future.”

There was also a large exhibition of arborist equipment and machinery on display at the Perth Hills Discovery Centre.

Vermeer Equipment of WA & NT, an ArbWest Gold Corporate Partner, was one of the exhibitors. Tree Care Specialist Sam Hayes said: “We decided to exhibit

at the Tree Climbing Competition because it’s a great opportunity to be among other members and businesses in the arboriculture industry, and to showcase some of our machinery in a hands-on setting.”

Another ArbWest Gold Sponsor with a stall at the event was training specialists RelyOn.

“At RelyOn, we see this event as a vibrant celebration of talent, passion, and community,” said Martha Waterson, Senior Arboriculture Quali cations Manager. “We’re proud to support the climbers who are setting the standard for excellence in our industry.”

Other exhibitors included ArbWest’s

Silver Corporate Partner Tree Care

Machinery; Bronze Corporate Partners Scha er Loaders and Avant Equipment, who all showcased their arborist equipment; and Kask Helmets, who displayed their arborist helmets for the rst time in WA.

When all the prizes and presentations were nally over and the crowd drifted away through the damp forest paths, one thing was certain – the 2025 WA State Tree Climbing Championships had once again shown the best of WA’s arboriculture community.

For more information on ArbWest and its activities, visit arbwest.com.au

Queensland’s Jamie Boston

There would be very few in Australia’s arbor scene who haven’t at least heard of Jamie Boston.

A successful climber at international level, his credits include ve Queensland championships, one NSW title, and one Asia Paci c win. The Australian Arbor Age caught up with the Queenslander shortly after his return from the recent International Tree Climbing Championships in New Zealand, where he nished fth in the world. The interview came only days after he completed his two-year term as president of the Queensland Arboricultural Association (QAA).

A quick career overview

“We started out in Mullumbimby, NSW,” said Jamie. “That’s where my family’s

has a wealth of arboricultural experience.

from. My brother and I started there working powerlines for ETS.

“We travelled to the Northern Territory, and in 2014 I moved to Brisbane to work at Treescape Australia. I was Foreman or Team Leader of the commercial division and then became a Training Manager.

“It was around that time, it must’ve been 2017, I started doing some work for QAA. I had a passion for climbing competitions so I thought I’d help out where I could.”

In 2020, Jamie and his brother, Terry, started Boston Tree Care, which continues today. Meanwhile, Jamie’s work with QAA ramped up until, in 2024, he took on the presidency.

“I did two years as president and stood down just recently,” he said. “Two years

is all that’s allowed as president, and I wanted to focus more on family, so it suited me. I’m still on the committee and will continue to help with the associations and climbing competitions.”

Another reason Jamie is known to most in Australia’s arbor fraternity is his association with Husqvarna.

“In 2023, I partnered up with Husqvarna as Australia’s second H-Team ambassador, along with Kiah Martin,” said Jamie. “I’m pretty proud of that.”

While it seems there can’t be enough time in a day to allow Jamie to meet all his commitments, he gets it done somehow, and especially enjoys his work with Husqvarna.

“There are some real perks to being

an H-Team Ambassador,” he said. “We get to travel to Europe with the rest of the H-Team and test prototypes and new products. We give our feedback, particularly on where we see the industry going. We also share how, as arborists in the eld, we can help to develop the product.

“I think for both myself and Husqvarna it’s a good partnership. I’m still climbing and working at the highest level, and Husqvarna is getting real product feedback from a professional, while the company supports me in my climbingcompetition endeavours.

Jamie explained one of the facets of H-Team activities he enjoys most is that Husqvarna listens.

“When we’re all in Europe with the H-Team, the lead engineers for each of the products are locked into everything we say. They write down everything. They want to hear what we all think about the product and translate that into the nished product. It’s really cool,” he said.

Jamie and his brother have a healthy business, and the competition climbing has proven a successful pursuit for Jamie, but he has concerns about the future of arboriculture in Australia.

“I think we’ve had a drop o in people wanting to be part of the arbor industry,” he said.

“I see it in a couple of ways. As a climber I see less and less in the next group coming through in competitions. We’re trying to do what we can to encourage more people by running amateur comps and training days.

“As a business owner it’s becoming harder to nd sta – not only quali ed sta , but apprentices willing to do the work. Maybe generations are changing and people don’t want to work outside as much as my generation did. I mentioned a decline in climbing arborists and I’m not 100 per cent sure why that is. I know at QAA we have some initiatives where we visit schools and career days to showcase what arbor’s about. Let’s hope others will do the same and that will raise some interest.

“I don’t have the solution, but it’s de nitely something I’m passionate about trying to make happen.”

While every day may not be perfect in the arbor world, Jamie’s happy with his time as part of the tree-care community.

“It’s been pretty special,” he said.

“I’ve been able to travel the world climbing trees, and I have lifelong friends all around the globe who I’ve met through the industry – people with a similar passion. I’d love other people to experience that.”

Nominations are open for the 2026 UAAA Industry Awards, recognising excellence, innovation, and safety in the eld of utility arboriculture.

Every year the Utility Arborist Association of Australia (UAAA) hosts its Industry Awards, shining a light on individuals and teams who go above and beyond to make the arboriculture industry safer, stronger, and more sustainable. It’s an opportunity to recognise those who lead by example, whether through technical excellence, leadership, mentoring, innovation, or community spirit.

If you know someone who inspires others, demonstrates exceptional professionalism, or contributes meaningfully to the industry, now is the time to nominate them.

Nominating a colleague, mentor, or rising star helps showcase the talent and passion that drives Australian arboriculture forward. Recognition not only honours their e orts but strengthens a shared commitment to