Mega Watt Power is a family-owned Australian business specialising in renewable energy design, installation, construction, and maintenance.

Based in Coffs Harbour, NSW, we operate across three specialist business units:

Utility-scale renewable electrical construction and servicing

Electronics hardware repairs and maintenance

Solar power systems sales, installation and services

We employ a full-time local and remote FIFO workforce of around 50, supported by additional project staff as required. We deliver projects ranging from kilowatt systems to large-scale installations of hundreds of megawatts and bring over 36 years of proven experience in the renewable energy industry.

DC, LV & HV TEST & COMMISSIONING

SOLAR FARM ELECTRICALS

RECTIFICATION & REPAIRS

STATCOM CONSTRUCTION

HV SWITCHING & PLANNING

HV TERMINATIONS

IV-CURVE TESTING

WEATHER STATIONS

O&M SUPPORT

SUBSTATION O&M

TRANSFORMER TESTING

BESS, INSTALLATION & MAINTENANCE

As 2025 draws to a close, Australia’s clean energy sector is entering its next decisive phase – shifting from vision, to investment, to execution. The stories in this edition reflect a national market maturing in real time, evolving alongside global momentum and shifting government priorities.

As Nextracker becomes Nextpower, we see global technology evolving to meet the needs of Australia’s next decade of solar growth. And across the country, companies are solving the practical challenges of a high-renewables grid. At home, the landmark battery system of Consolidated Power Projects Australia Pty Ltd and Eku Energy highlights what community-minded delivery and technical excellence can achieve together.

Specialised Energy Solutions is redefining accountability across the asset lifecycle, driving a new delivery model that is helping close Australia’s engineering, procurement and construction gap.

Enerven’s work on the Eraring and Liddell battery projects also demonstrate what coordinated execution looks like at a utility scale. Meanwhile, RELA is reshaping how the country understands land use by helping developers and farmers plan co-existence through Assess 1.0 and 2.0 – a platform supported by Australian Renewable Energy Council.

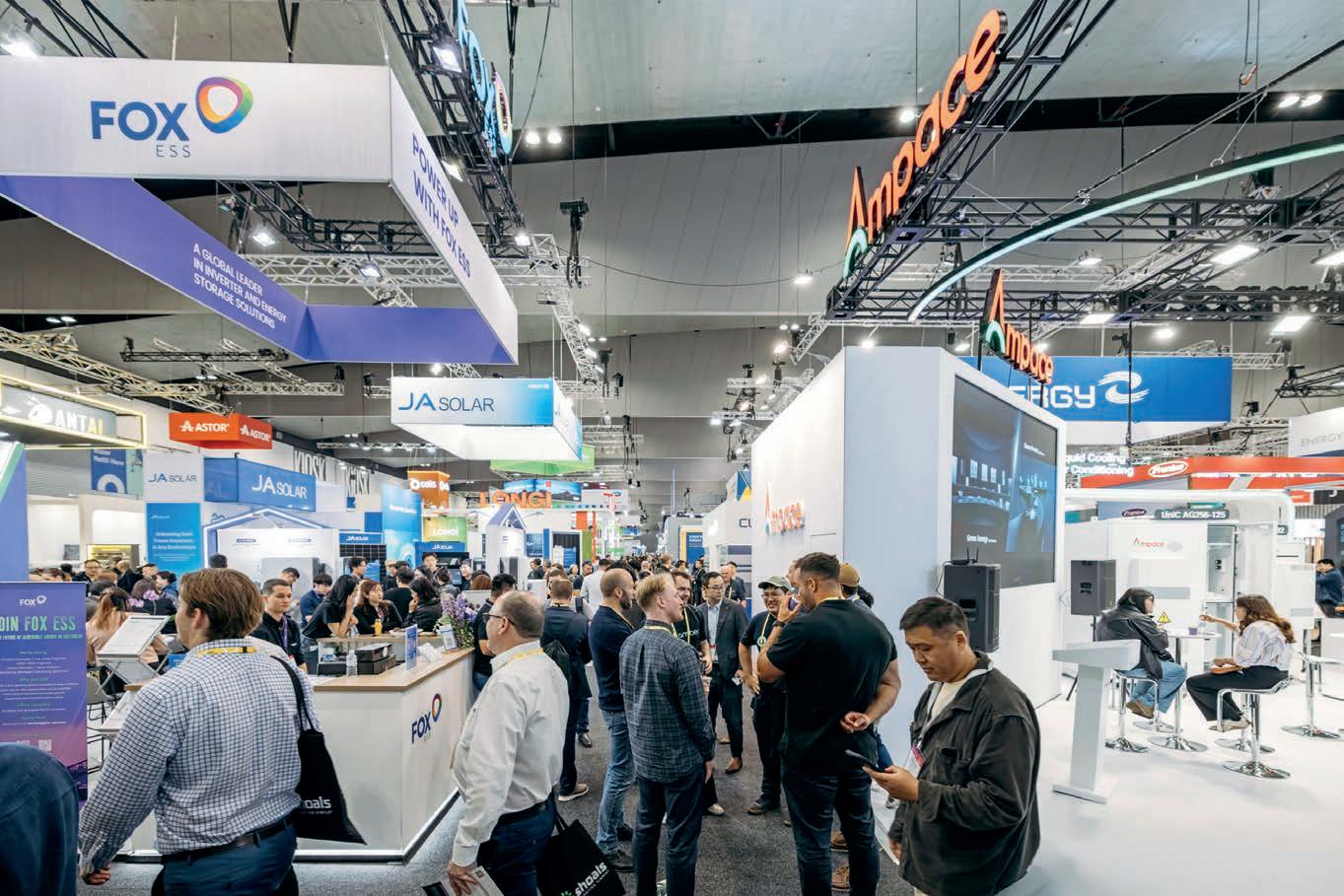

The continued momentum of the sector was unmistakable at All Energy Australia 2025. With over 400 global suppliers in attendance, conversations at the highly anticipated event centred around grid integration, storage scaling, regulatory approvals, flexible demand, and workforce capability. And the recent milestones of large-scale projects, like Transgrid’s Dinawan substation and VicGrid’s Victoria to New South Wales Interconnector West, underline the scale of national progress.

As the sun sets for this year, one message is clear: The energy transition is no longer theoretical. It is happening now in our regions, homes, networks and industries. And in 2026, we will continue to tell the stories of the people and projects powering what is next.

Lavinia Hulley ecogeneration Editor

ecogeneration acknowledges the Cammeraygal people, traditional custodians of the land on which this publication is produced, and we pay our respects to their elders past and present. We extend that respect to all Aboriginal and Torres Strait Islander people today.

Chief Executive Officer: Christine Clancy

Chairman: John Murphy

Editor: Lavinia Hulley

lavinia.hulley@primecreative.com.au

Business Development Manager: Nick Lovering , +61 414 217 190 nick.lovering@primecreative.com.au

Client Success Manager: Karyssa Arendt karyssa.arendt@primecreative.com.au

Head of Design: Blake Storey

Designer : Apostolos Topatsis

Subscriptions : T: +61 3 9690 8766 subscriptions@primecreative.com.au

Published by: PRIME CREATIVE MEDIA PTY LTD

ABN: 51 127 239 212 379 Docklands Drive

Melbourne VIC 3008, Australia T: +61 3 9690 8766 www.primecreativemedia.com.au

www.ecogeneration.com.au

Cover image:

ecogeneration is printed on Lumi paper which is PEFC-certified and manufactured in an ISO 14001-certified mill. Lumi paper also contains premium white waste paper, reducing matter going into landfill. This magazine is available to interested parties throughout Australia and overseas. The magazine is also available by subscription. The publisher welcomes editorial contributions from interested parties, however, the publisher and the Editorial Board accept no responsibility for the content of these contributions and the views contained therein are not necessarily those of the publisher or of the Editorial Board. The publisher and the Editorial Board do not accept responsibility for any claims made by advertisers. Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media, including text and images, you are providing permission for that material to be subsequently used by Prime Creative Media, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by Prime Creative Media and its agents and associates or another party to who Prime Creative Media has provided permission.

Enerven delivers electrical infrastructure and telecommunications solutions that connect communities.

Australia’s solar boom has powered a national transformation toward clean energy – but behind the fields of photovoltaic panels lies a growing challenge.

By 2050, more than one million tonnes of end-of-life solar panels could enter Australia’s waste stream. Now, policymakers, manufacturers and researchers are looking to turn that looming problem into an opportunity for circular innovation.

The Federal Government has set ambitious goals for sustainability in solar, aiming for 82 per cent renewable electricity by 2030 and net-zero emissions by 2050. However, the success of solar uptake has created a parallel challenge: what happens when today’s panels reach the end of their lifecycle? And how do we keep them from landfill?

This year, the cumulative volume of endof-life solar panels in Australia is projected to reach 280,000 tonnes, according to the Australian Energy Council.

“Those panels are full of precious and critical minerals, including silver, copper and silicon,” said Professor Akbar Rhamdhani from Swinburne University of Technology.

The value locked within these panels, particularly high-purity silicon, could be the foundation for a new domestic recycling industry capable of feeding back into the manufacturing supply chain.

“Silicon is a critical mineral, and we need very high-grade versions of it to produce more solar panels, along with many other technologies,” Rhamdhani said.

At Swinburne University of Technology, researchers are developing breakthrough methods to recover and reuse those materials with minimal environmental impact.

For Rhamdhani, the solution is clear: Recycle them to make new panels.

“In a traditional process, we use carbon and extremely high temperatures to reduce raw silica to metallurgical-grade silicon. It is very energy-intensive and takes a lot of time. Recycling can bypass this,” he said.

Professor Rhamdhani’s team is working on “a process that is quite clean, with a no or very low carbon footprint.” Their research program – the first of its kind in the world – brings together international experts to develop zero-carbon processes for recovering high-purity silicon and other valuable materials from end-of-life solar panels.

“This research strengthens the foundation for a sustainable and circular solar industry,” adds Doctor Bintang Nuraeni, Researcher on the project at Swinburne.

For recovering high-purity silicon and other valuable materials from end-of-life solar panels, strengthening the foundation for a sustainable and circular solar industry is key, according to the Australian Renewable Energy Agency.

Although Federal initiatives are beginning to recognise that recycling is the next frontier for renewables, there is still some work to do.

In March 2024, Prime Minister Anthony Albanese launched the Solar Sunshot Program, a $1 billion initiative to supercharge Australia’s ambition to become a renewable energy superpower at home and abroad.

While Sunshot focuses on expanding domestic panel manufacturing, the program is anticipated to eventually address future waste generated by the growth in solar panel use.

The program’s focus on encouraging local capability aims to give industry greater confidence for further investment in the recycling infrastructure that will eventually be essential.

The Swinburne-led consortium extends beyond Australia’s borders.

Partners include IIT Hyderabad and Indonesia’s National Research and Innovation Agency, supported by local industry such as Greenko. Together they are developing advanced methods, including electro-slag refining, to improve the quality of recovered materials and scale regional recycling capability.

“Recycling end-of-life panels can reduce import dependency, cut production costs and lower environmental impact,” said Ashok Kamaraj, Assistant Professor at IIT Hyderabad.

“Establishing silicon recovery infrastructure will support a circular economy, strengthen domestic manufacturing, and aligns with India’s cleanenergy goals.”

Widi Astut, Professor at IIT Hyderabad based in Indonesia sees broader potential.

“Regionally, this initiative positions Indonesia as a hub for PV recycling technology in Southeast Asia, strengthening Indo-Pacific collaboration in renewable material recovery.”

As Gadjah Mada University’s Professor Himawan Tri Bayu Murti Petrus explained, collaboration grants access to frontier knowledge and advanced instrumentation that no single country can achieve alone.

Or as Sadoway Staff Scientist Dr Matthew Humbert puts it: “There is no formula or recipe for generating creative solutions, so we must cast our net as wide as possible. This means bringing together researchers from diverse backgrounds into a collaboration where all are valued,” he said.

Toward a circular solar future

Globally, the solar PV waste stream could reach 78 million tonnes by 2050. The technologies being developed through partnerships like Swinburne’s show that a circular economy for solar is not just possible – it is within reach.

“It is very exciting to be working on such a big project. We have the potential of making significant changes in the industry, and we’re up to the challenge,” Rhamdhani said.

Delivering expert electrical solutions for renewable infrastructure –from Solar PV and BESS to Wind, Hydrogen, VPPs, and next-gen energy systems.

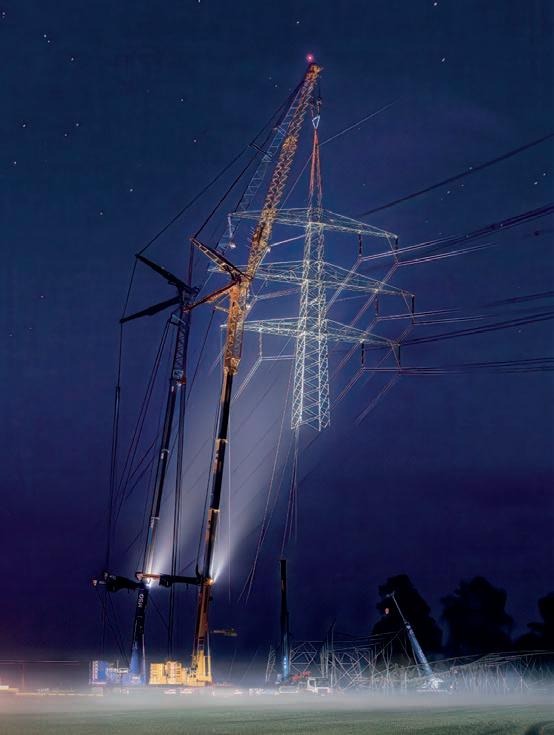

New work has progressed on HumeLink, one of Australia’s most significant transmission infrastructure projects – a $5 billion network upgrade that will connect Snowy Hydro 2.0 and multiple Renewable Energy Zones (REZs) into the National Electricity Market.

Once fully complete, HumeLink will form a critical section of the east-coast transmission backbone, linking generation from South Australia through to northern Queensland and unlocking gigawatts of renewable capacity for Australian homes and businesses.

The joint venture between UGL and CPB Contractors has been delivering the western section of the project, achieving several key milestones in recent months, including:

• Foundation piling for the first transmission tower – establishing the platform for 140 kilometres of new high-voltage lines.

• Construction of access infrastructure –with around 30 access points built and 70 kilometres of new or upgraded access tracks completed to support delivery.

• E stablishment of materials laydown areas – at Gugaa, Ellerslie and near Batlow to streamline tower assembly and logistics.

• Completion of the Tarcutta worker accommodation camp – with the Kunama facility due for completion in November.

• Commencement of two 500 kilovolt substations — one at Maragle to enable the connection to the Snowy Hydro 2.0 grid, and another at Gugaa, which will become a central transmission hub for the Riverina region.

HumeLink is designed to support the rapid integration of renewable energy into the grid, increasing transmission capacity and reliability while reducing network congestion. It represents a major step toward meeting Australia’s 82 per cent renewable-electricity target by 2030.

With work now progressing across multiple construction fronts, Transgrid and its delivery partners are helping to build the backbone of Australia’s clean-energy future. In turn, this will create skilled regional jobs, support local suppliers, and enable the energy transition at scale.

The National Electricity Market (NEM) wholesale market settings review, also known as the Nelson Review, has been handed down, outlining a number of recommendations for reforms to the current industry and market.

This marks the biggest review of the electricity market since the Finkel Review in 2017.

The review, chaired by Associate Professor Tim Nelson, has highlighted recommendations for reforms to the current market settings to help build investment certainty for large-scale renewable clean energy projects, support essential systems services to deliver reliability in the grid and reward consumer participation from home solar and battery systems.

The report aims to prepare recommendations and a roadmap, to support the development and staged implementation of reforms to the NEM wholesale market to support the achievement of Australia’s National Electricity Objectives.

These objectives include the delivery of reliable, competitively priced, safe and secure electricity services, supporting the long-term interests of consumers and prosperity of Australia’s economy.

The Clean Energy Council (CEC) has tabled its submission regarding the report, calling for further analysis and refinement, particularly around design work on Electricity Services Entry Mechanisms (ESEM) and impacts on competition.

The CEC is also calling for more support for longer-term and developing sectors, further engagement with industry on the role of financial derivative markets and specific contract designs.

The CEC is also calling on market development to deliver least-cost essential system services and deliver a reliable system efficiently.

Additional analysis, supported by CEC’s member engagement also points towards a desire for the continuation of working groups and the establishment of new technical working groups to build out the detail needed for final recommendations, with CEC saying transparency and consultation with industry and consumer bodies will be critical for adoption.

An Early Contractor Involvement (ECI) agreement has been signed by Ark Energy with Elecnor Australia, for the delivery of early works on the Richmond Valley Solar and Battery Energy Storage System project, in New South Wales. The Richmond Valley Solar and

Battery Energy Storage System involves a solar farm with a generation capacity of up to 500 megawatts (MW) and a long-duration Battery Energy Storage System with a power capacity of 275 MW and energy storage capacity of up to 2200 MW over eight hours. The BESS

will use LFP (Lithium-iron phosphate technology.

It is expected to play a key role in supporting New South Wales’ transition to renewable energy.

The scope of the agreement includes site studies, detailed engineering design for the solar farm, balance of plant design for the battery energy storage system, structural certification, management plans and permitting support.

The signing of the agreement will enable commencement on detailed engineering, interface planning and overall project delivery timelines.

The work is expected to be completed by Q2 2026, ahead of execution of the full EPC (Engineering, Procurement, and Construction) contract.

The Richmond Valley Solar and Battery Energy Storage System is listed in the Australian Government’s inaugural National Renewable Energy Priority List and was awarded a Long-Term Energy Service Agreement (LTESA) in 2023.

Nextracker becomes Nextpower.

In a global energy landscape defined by accelerating demand, shifting geopolitics and the rapid emergence of artificial intelligence, solar tracking giant Nextracker has evolved into Nextpower. The rebrand marks not just a new name, but also a strategic repositioning of one of the world’s most influential clean energy companies, reflecting the convergence of technology, data and energy systems at a moment when electrification is increasing faster than at any point in modern history.

Founded in 2013, Nextracker – now Nextpower – designs, engineers and supplies technology for utility-scale solar power plants. Headquartered in California in the United States, the company’s reach and innovations in renewable energy has spread across Australasia. This is backed by the recent launch of its NX Earth Truss foundation system in Australia, receiving Federal Government support via the Australian Renewable Energy Agency.

Dan Shugar, Founder and Chief Executive Officer – Nextpower is proud to be leading this new era.

“We are evolving from a tracker company

into a full technology platform, designed to help power the backbone of the global grid right now,” he says.

The statement captures the urgency and ambition behind the transformation. The company, which has led the global solar tracker market for a decade, is now looking well beyond mechanical tracking systems. Nextpower now serves as an integrated technology platform that spans hardware, software and services, connecting the components of modern utility-scale solar generation into intelligent, responsive and resilient power systems.

The timing is not accidental. The world is entering what Shugar calls an “energy demand super cycle.” Electrification across transport, manufacturing and industry, together with the exponential power consumption of data centres and artificial intelligence, is reshaping the global power mix.

“Global electricity demand is surging,” Shugar says.

“Artificial intelligence, electrification and data centres are accelerating faster than anyone predicted. Nextpower is built for this era, connecting intelligent systems that can deliver reliable power at the speed and scale the world now requires.”

According to the International Energy Agency, electricity use from data centres alone could double by 2026. That surge places pressure on nations to accelerate new generation capacity. While nuclear and gas face long lead times and permitting hurdles, solar remains the clean energy technology that can be deployed at scale with speed.

Nextpower has positioned itself to occupy this space, acknowledging that solar is no longer a peripheral renewable technology, but now core infrastructure that requires integration, intelligence and reliability.

For over a decade, Nextracker has shipped more than 150 gigawatts (GW) of tracker systems worldwide. Its technology is used on some of the largest and most complex solar projects on record.

But Shugar and his team have long argued

that solar generation must be viewed as a complete system, not a collection of parts.

“Horizon-XTR was our first step in terrain-following tracker systems,” Shugar says. “Now, every layer of our technology works together, converting sunlight into reliable, low-cost, round-the-clock electricity.”

The Nextpower platform extends that system-level philosophy. It integrates trackers, module frames, foundations, electrical balance of system (eBOS), robotics and power electronics. It also brings together digital tools such as TrueCapture and NX Navigator, which optimise energy yield and system performance in real time. The goal is to design and operate solar plants as cohesive, data-driven assets that adapt to the environment, maximise uptime and improve return on investment across their lifespan.

A core principle in the transition is the shift from supplier to partner.

“Our customers have made it clear that they want integrated systems and better control of their generation assets. They want a solutions partner who can apply innovation and optimisation across the entire lifespan of a project,” Shugar says.

This collaborative approach has shaped the company’s success in regions like

Australia, where it has supported more than 7.4 GW of deployments and adapted global technology to the unique demands of local environments and grid dynamics.

If the digital ecosystem is the brain of the Nextpower platform, manufacturing is its backbone. Over recent years, the company has invested in distributed supply chains designed to support localisation, reduce emissions and strengthen resilience.

The company has built manufacturing hubs across North America, India, Latin America and Australia. In Australia, partnerships with BlueScope and Orrcon Steel have delivered locally made torque tubes and structural components, which have strengthened domestic capability.

“Energy generation requires strategic infrastructure. That means building secure, local and low-carbon supply chains is essential,” says Yves Figuerola, Vice President of Supply Chain at Nextpower.

Nextpower’s engineering teams are also expanding innovation into foundations and AgriPV. Faster and more precise foundation systems reduce installation times and material requirements, while

AgriPV allows for dual-use of land, meaning the use of land for both solar energy and agriculture simultaneously.

“We are extending intelligence right down to the ground. Smarter foundations and adaptive designs help deliver clean energy more efficiently and sustainably,” says James Butcher, Director, Engineering Services at Nextpower Australia.

Referred to by Shugar as the “age of electro tech,” the convergence of solar, storage and digital controls will define the next decade of global power. Nextpower’s integrated platform positions the company to lead that shift, connecting hardware, software and data to create smarter, more resilient systems.

“This is about readiness. Nextpower connects technology, manufacturing and innovation to help our customers deliver reliable, affordable and scalable clean power,” Shugar says.

With solar as the foundational pillar of global energy, the Nextpower rebrand signals a broader truth: “The companies building tomorrow’s power systems are no longer renewable specialists. They are the new infrastructure players, reshaping how electricity is generated, managed and delivered,” Shugar adds.

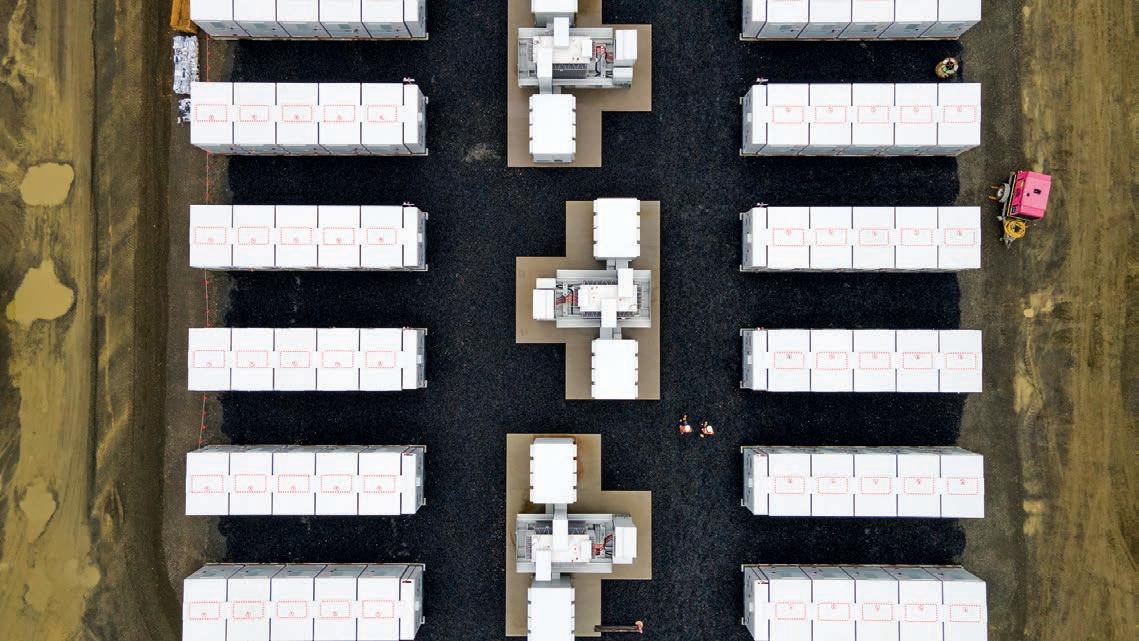

A landmark battery system, capable of supplying a third of Canberra’s peak power, is redefining renewable energy collaboration through engineering excellence, community care and close cooperation.

On the outskirts of Canberra, a nine-metre-high green wall stands as both a visual landmark and a symbol of cooperation. Behind it hums one of Australia’s most ambitious renewable energy assets – a 250-megawatt (MW) / 500 MWh (megawatt-hour) battery energy storage system (BESS) capable of supplying roughly one-third of the Australian Capital Territory’s (ACT) power needs during peak periods.

The project, led by Eku Energy with Consolidated Power Projects Australia Pty Ltd (CPP) as principal delivery partner, is set to become the largest energy storage installation ever built in the ACT.

It is also a textbook example of communication, safety and innovation, demonstrating how well-aligned project partners can accelerate the energy transition without compromising community expectations.

“This project really puts rubber to the road for the ACT. It’s not just about policy rhetoric, it’s a tangible example of what net-zero ambitions look like when they come to life on the ground,” says Tom Best, Chief Operating Officer at Eku Energy.

For both teams, success begins with respect for place. One of the project’s

most distinctive features, a nine-metrehigh acoustic wall, was conceived not for grandeur, but for neighbourliness.

“What is unique here is the sheer scale,” says James Bolton, Project Manager at CPP.

“Most highway noise barriers are around five metres high. Ours reaches nine metres. It has been designed to minimise even the

faint hum of battery-cooling fans during the quiet overnight hours,” Bolton adds.

The wall’s deep-green colour palette was selected in consultation with local council planners to blend with the rural surrounds. Though the system operates quietly, both companies wanted to exceed regulatory expectations.

“We take community impact seriously. The acoustic design came directly out of early planning and consultation work. It was part of making sure nearby residents experienced no disruption from a project that ultimately benefits the whole territory,” says Bjorn Schultz, Global Project Delivery Manager at Eku Energy.

Engineering through the elements

Constructing a major battery facility in Canberra’s crisp winters brought its own challenges. With sub-zero mornings and frozen ground, conventional processes had to adapt.

“It was colder than most of our regional jobs. We even had to warm the water used in our concrete pours to prevent freezing. You would see 80 guys huddled around heaters during pre-start meetings – our typical morning ritual,” Bolton says.

Cold weather was not the only test. The team also introduced advanced drone technology to improve site surveying and progress tracking.

“The drones follow automated flight paths, capturing precise imagery at set points. This allowed us to track progress, share updates with internal and external stakeholders, and reduce the need for on-foot inspections. It was efficiency and safety rolled into one,” Bolton says.

Complementing the drones, CPP used 3D LiDAR surveying to guide the delivery of heavy transformers and high-voltage equipment, ensuring millimetre accuracy onsite.

“These kinds of innovations have moved from nice-to-have to essential on projects of

this scale. They helped us deliver faster, safer, and with less environmental disturbance,” Bolton adds.

While technology enabled progress, people defined success. For both CPP and Eku Energy, the project’s collaborative structure that combined early-works involvement with open communication was key to maintaining momentum.

“We approached this as partners from day one,” says Schultz.

“During the early-works phase, we were developing the design together, ironing out the details before construction kicked off. That early alignment created trust – and that trust carried through every stage of delivery,” he adds.

Bolton agrees, emphasising the value of Eku Energy’s consistent on-site presence.

“Eku struck a great balance for the clientcontractor relationship,” Bolton says.

“They do not just sit in a distant office, but they also do not micromanage either. Their team visits regularly, brings guests through the site, and helps us solve issues on the spot. It is professional but personable – exactly how collaboration should work,” Bolton adds.

The partnership has gone a full year without a single reportable safety incident, a milestone that both organisations attribute to their shared culture and disciplined communication.

“Safety is not just a metric, it is a mindset, driven by a genuine joint effort. Everyone here goes home safely each day, which we’re all proud of,” Schultz reflects.

Community first, always

Even as earthworks and heavy machinery transformed the site, surrounding residents experienced little change in daily life, by design.

“Community consultation started early and never stopped,” says Tom Best, Chief Operating Officer at Eku Energy.

“We have kept lines of communication open so locals know what’s happening, when and why,” he adds.

As part of its community-benefit commitments, Eku Energy established a grant program supporting community initiatives across Canberra.

The program is called Powering Big Dreams and channels project benefits directly into local entities; including, notfor-profits, charities, environmental groups, and similar services that offer community support and empowerment. This ensures energy transition delivers social value alongside economic and environmental returns.

“The ACT Government have made it clear that clean energy should create shared prosperity. We are proud that this project reflects that vision, not only through jobs and emissions reduction, but through tangible investment in the community,” Best explains.

CPP’s national footprint means many of its crews are seasoned veterans of regional construction.

Bolton explains that experience shaped the project’s onsite culture.

“There is a family feel onsite. A lot of our site team have been with CPP for years, and they bring newer local workers into that culture. It is a mix of regional pride and professional discipline,” Bolton says.

He credits the strong work ethic of regional tradespeople and the continuity of experienced supervisors for keeping morale and productivity high through the colder months.

“They really care about what they build. For most of them, it’s their own backyard and so they want to see it done right,” Bolton adds.

At full operation, the 250 MW / / 500 MWh system will store surplus renewable power from the ACT’s solar farms and rooftop arrays and dispatch it during evening peaks, helping to balance supply and demand. In doing so, it directly advances the ACT’s

target of achieving net-zero by 2045.

“The system acts as a reliability anchor. It soaks up excess renewable generation (those green electrons) and releases them when the grid needs it most. This strengthens stability without adding emissions,” Best says.

Bolton agrees that battery storage represents the next frontier in Australia’s renewable integration.

“Batteries are enabling technology. They make more wind and solar viable by bridging the gap between generation and use. The batteries do not just act as storage, they enable flexibility and are future-proofing the grid,” he says.

With construction milestones being reached and commissioning on the horizon, both companies are already reflecting on what comes next.

“Every project teaches you something new,” Bolton says.

“We have solved challenges here that will make future projects even smoother. The key

takeaway is how effective joint problem-solving can be when trust is established early,” he adds.

For Schultz, the focus is on continuous collaboration and innovation.

“We are already planning the next wave of projects with CPP. This one proved that we could deliver large-scale infrastructure safely, efficiently and with genuine community engagement. The next challenge is scaling that model,” Schultz says.

Both agree that the legacy of Canberra’s flagship battery will extend far beyond its physical footprint.

“For us, it is about demonstrating that the transition to renewables can be orderly, safe and beneficial for everyone. We have shown that with the right partners, you can build big and still build responsibly,” Best says.

The promise of power stored, and shared

As Australia’s appetite for electricity grows – fuelled by data centres, electrification and industry decarbonisation – projects like the Williamsdale BESS will play an increasingly

vital role.

The Williamsdale BESS is not just a technical achievement, it is a statement about what coordinated, forwardlooking energy development looks like.

“The Williamsdale BESS would not have been possible without the Australian National University’s Battery Storage and Grid Integration program – a collaboration between science and academia, government and the private sector to support the ACT energy transition,” Schultz says.

“Going green does not mean using less power, it means using it smarter. Batteries like this are the bridge between ambition and action,” Best concludes.

With its blend of engineering ingenuity, community focus and collaborative spirit, the ACT’s largest battery project offers a blueprint for the clean-energy decade ahead, one built not only on megawatts and megawatt-hours, but on trust and shared purpose.

The LR 1700-1.0 combines the transport advantages of the 600-ton crawler crane class with the performance of the 750-ton class. It has the latest innovations of the Liebherr crawler crane portfolio. The high performance level is based on the statically new base machine with up to 15 percent more load capacity. The modern derrick system comes with V-frame, VarioTray and modular M-Wagon ballast trailer. Perfect for wind power, infrastructure and industry. www.liebherr.com

As the country races to expand its renewable capacity, Specialised Energy Solutions is closing the Engineering, Procurement and Construction (EPC) gap with a partnerfor-life model that redefines accountability across the lifecycle of clean energy assets.

Australia’s clean energy build-out is accelerating at an unprecedented pace, but for many asset owners, the challenge begins long after the ribboncutting ceremony.

Behind every gigawatt of new solar and storage capacity lies a long-term question of performance, reliability and risk. In an industry where most Engineering, Procurement and Construction (EPC) contractors step away after practical completion, one Australian company is rewriting the rulebook on lifecycle accountability.

Founded in 2022, Specialised Energy Solutions (SES) has quickly earned its reputation as a trusted partner across the nation’s renewable energy sector.

Aaron Mulhall, Chief Executive Officer at SES says the young but growing organisation is built around a simple, yet radical idea that companies that design and build energy assets should also remain responsible for their long-term performance.

“Most EPCs stay for just 2.5 per cent of your asset’s life, while SES stays for 100 per cent,” says Mulhall.

“When the same partner builds, maintains, and services your asset, interests are fully aligned. Cutting corners upfront only creates future risk for SES itself. So, we invest in quality that endures.”

A three-pillar model long game SES’s integrated model combines three core business divisions: EPC, operations

and maintenance (O&M), and technical support aligned with Original Equipment Manufacturer (OEM), to deliver what the company calls its ‘three-in-one EPC approach.’

This full-spectrum of service covers every phase of a renewable energy project’s life –from civil construction and grid-connected installation to decades-long O&M.

O&M sits at the heart of SES’s offering. The team provides electrical, mechanical, civil and operational support across existing assets, with tailored contracts that extend far beyond the warranty period. Their technicians are the same specialists who helped design and install the original systems – giving asset owners continuity of knowledge and accountability rarely seen in the industry.

Complementing O&M is Technical Product Support, a division dedicated to root-cause analysis and remedial work. Drawing on SES’s background in heavyindustry and fixed-plant maintenance, the team investigates installation or product failures to identify and resolve underlying issues – not just the symptoms. This results in improved asset output, reduced downtime, and confidence that performance problems are being solved at the source.

Finally, SES’s Development Division manages the early stages of new clean energy projects, from civil construction through to turnkey mechanical and electrical installation. Together, these arms create a seamless bridge between short-term project delivery and long-term operational success.

To understand SES’s philosophy, Mulhall points to what he calls the “EPC gap.”

Traditional EPC contractors are typically engaged for the design, procurement, construction, and commissioning of a project – a process that lasts less than a year. On a utility-scale solar or Battery Energy Storage System (BESS) asset with a projected 35-year lifespan, that represents just 2.5 per cent of the journey.

Once practical completion is achieved, most EPCs hand over the keys and move on to the next project. Their contractual interest ends, leaving asset owners to navigate the remaining 97.5 per cent of the asset’s life alone.

“Too often EPCs choose equipment on lowest upfront cost, not long-term performance,” says Alba Ruiz Leon, NonExecutive Director at SES.

“They overlook equipment reliability and fail to ensure true compatibility across all moving parts over time. This leaves owners exposed to hidden ‘iceberg risks’ – where only a fraction is visible, while most remain hidden until it is too late,” she adds. These hidden risks can emerge years after the EPC departs. For BESS in particular, warranty conditions hinge on strict adherence to Original Equipment Manufacturer (OEM) maintenance schedules. Yet, few EPCs maintain Service Level Agreements (SLAs) with OEMs, forcing owners to contract manufacturers directly at high cost. Without these agreements, preventive maintenance can slip, warranties can lapse, and failures may only surface once the coverage period has expired – leaving owners to foot the bill.

Even with a generous two-year warranty

period, it still represents just 5.5 per cent of an asset’s overall life. The remaining 92 per cent is the O&M phase, where the real financial and performance risks lay.

Battery Storage: Promise and pitfalls

As the renewable transition deepens, BESS are rapidly becoming the backbone of a flexible, reliable grid. But their complexity introduces new layers of risk. Unlike solar photovoltaic (PV) modules, which are largely passive, BESS assets involve dynamic electrical, thermal and software interfaces between multiple OEMs. A minor calibration fault or firmware mismatch can cascade into system-wide failures.

SES has aimed to position itself at the forefront of this frontier. Its engineers are trained and accredited by leading OEMs to deliver warranty-compliant maintenance and repairs, ensuring every intervention safeguards both performance and warranty status. By maintaining formal partnerships and SLAs with OEMs, SES gives asset owners confidence that their equipment will continue to operate within manufacturer specifications – without the need for costly third-party callouts.

“At SES our combined EPC, O&M, OEM

term KPIs, it’s about designing projects that can stand the test of time,” Ruiz Leon says.

For SES, staying involved beyond practical completion is not a contractual obligation – it is a strategic advantage. Because the company remains responsible for performance over the long term, it designs and constructs assets with lifecycle reliability as the starting point, not an afterthought.

This philosophy has become known internally as #theSESstandard, which is a guiding set of principles that informs every project, process and partnership.

“#theSESstandard is more than a slogan. It is the blueprint of our identity. It reflects our commitment to excellence and integrity – and it is why asset owners trust us not just to deliver projects, but to stand behind them for life,” Ruiz Leon says.

Under this ethos, SES prioritises quality at every stage – from component selection and cable management, to commissioning documentation and operator training. The organisation’s technical teams are equally adept at fault diagnosis as it is at design validation, providing a rare edge to its

From construction to custodianship

SES’s “partner-for-life” model is redefining what being an EPC means in the clean energy era. Rather than viewing project delivery as the end point, SES sees it as the beginning of a decades-long custodianship. By integrating EPC, O&M and OEM partnerships, SES reduces lifecycle risks, safeguards warranties, and maximises asset uptime. This approach delivers measurable benefits for investors and operators alike:

• Long-term reliability – Assets are engineered for maintainability, reducing future failure rates.

• Warranty security – OEM-compliant maintenance protects warranties without excessive cost.

• Operational continuity –The same partner who built the asset maintains institutional knowledge through its operational life.

• Financial certainty – Reduced downtime and fault frequency translate directly into

In less than three years, SES has expanded from a start-up to a key player across multiple renewable technology streams –solar PV, wind, and increasingly, hybrid PV and BESS systems.

Mulhall says the organisation’s fast growth reflects national demand and a cultural shift.

“Asset owners are demanding partners who can think beyond construction schedules and contract milestones,” he says.

Mulhall’s own background helps explain the organisation’s success. A seasoned electrical professional with more than 15 years of experience in utility-scale power-station installation and integration, he understands the technical and operational nuances that separate a successful project from a costly one. His team blends hands-on field experience with systems-level insight, uniting

team called in to fix them – a role that has cemented its credibility and informed its proactive approach to new builds.

“We see the full picture, that’s our goal,” explains Mulhall.

“When you are the one called to diagnose and repair other people’s failures, you learn exactly where shortcuts were taken. We apply those lessons from day one.”

The future of accountability

As Australia scales up its clean-energy capacity, the industry’s focus is shifting from megawatts installed, to megawatts sustained. Reliability, warranty integrity and operational excellence will define the next phase of the transition.

For asset owners, the takeaway is clear: the best way to reduce lifecycle risk is to partner with an EPC that stays for the whole journey. SES’s integrated model, where engineering precision meets

Enerven’s role in delivering the Eraring and Liddell Battery projects has highlighted the organisation’s ability to collaborate, plan and deliver on major battery energy storage technology, which is expected to benefit the nation for generations to come.

EEraring and Liddell

energy transition. The proudly South Australian company – with sites in Adelaide, Sydney, Brisbane, and Perth – delivers integrated design, construction and maintenance services across electrical, renewable-energy and telecommunications infrastructure.

“Our roots in South Australia are a core part of who we are as a business,” says Enerven CEO Richard Amato.

“From delivering the Torrens Island to the Bungama battery energy storage systems, these projects have helped build the expertise that underpin our national capability today. The lessons we’ve learned through years of local delivery are what now enable us to operate confidently and successfully across the country. Enerven’s role in shaping Australia’s future energy system is just beginning; it’s a future built on

transmission lines, substations and battery energy storage systems – the essential backbone linking modern renewable generation to the national grid.

With ambitions that reach beyond technical delivery, the organisation’s evolution from a utilities contractor into a national clean-energy partner reflects both industry change and an internal culture built on collaboration, community engagement and end-to-end capability.

Connecting energy networks to a renewable future Enerven’s roots began in building substations and transmission infrastructure for the South Australian market.

“South Australia has always been at the forefront of renewable innovation, and Enerven has grown alongside that

established the technical depth and project discipline that we now bring to large-scale projects such as Eraring and Liddell.”

To meet the national consumer demand shift from fossil fuels to distributed renewables, the organisation saw an opportunity to extend its expertise. Project Delivery Director for New South Wales and Queensland, Simon Valencia says Enerven’s distinctive DNA sets it apart.

“We have been focused on getting into the emerging markets of wind, solar and batteries, to complement our strengths in substations and lines to connect the existing network – what we do well,” Valencia says.

Those origins underpin Enerven’s claim as a “one-stop shop” – capable of designing, constructing, integrating and maintaining every component required to bring new generation online.

A true end-to-end partner

In a sector often fragmented between developers, equipment suppliers and engineering firms, Enerven’s integrated model is a rarity.

“Traditionally, a solar farm might engage one contractor to build the array, another to deliver the substation, and someone else again to connect the transmission line,” says Valencia.

“Our proposition to our clients is give us the whole lot, and we will manage the entire process for you, end to end.”

That full-service capability stems from a workforce fluent in both electrical engineering and project management.

Mechanical and electrical engineers work alongside onsite supervisors and logistics specialists to coordinate road access, heavy transport and complex commissioning schedules.

“It is really about process and control,” Valencia says.

“Our teams understand each component – the substations, the roads, the battery blocks – and how they interconnect. We capture everything in our engineering and quality-management systems so we can deliver efficiently and safely.”

The Eraring Battery Project: Scale and ambition

The Eraring Battery Project, beside the Eraring Power Station near Lake Macquarie in New South Wales, is a flagship project transforming the site of Australia’s largest coal-fired power station into one of the biggest batteries in the Southern Hemisphere.

“As a project manager, my first impression was just the scale of it,” says Valencia.

“The team had to prepare challenging ground, such as dug up old car bodies and other remnants from decades past and turn it into a massive pad covered in battery banks.”

Enerven is delivering both the civil and electrical scope, including new substations, transmission extensions, and integration works that allow the battery to connect seamlessly into the grid. The project uses Wärtsilä batteries, selected by Origin Energy as the principal contractor.

“They have done the first part and are commissioning it now. The second part is starting earthworks again, installing new blocks and bringing them online. It is incredible to see the vision come together,” Valencia says.

Commissioning requires precision timing with the Australian Energy Market Operator

Both projects exemplify Enerven’s ability to work as a project

(AEMO) to ensure power-quality and frequency compliance.

“There is always pressure because each commissioning window is tight. But I always say – pressure is for tyres, not for humans. The key is planning, coordination and communication.”

By mid-December, the Eraring project will be progressing through its commissioning phase, preparing additional battery blocks for energisation and grid export.

Enerven has been chosen to design and construct all three stages of Origin Energy’s Eraring Battery Energy Storage System (BESS). Enerven’s role spans all three stages of the project:

• Stage 1: 460 megawatt (MW) / 1070 megawatt hours (MWh) two-hour duration battery, expected online in late 2025.

• Stage 2: 240 MW/1030 MWh two-hour duration grid-forming battery, expected online in early 2027.

• Stage 3: 700 MWh expansion, increasing the Stage One battery’s dispatch duration to approximately four-hours, also expected online in late 2025.

The Liddell Battery Energy Storage System is a landmark renewable energy project essential to seamless integration of the battery into the grid, enhancing energy reliability.

Enerven’s role encompasses the design and construction of critical infrastructure to connect the battery to the National Electricity Market. This includes:

• The construction of a 330/33 kilovolt (kV) battery substation.

• A 450-metre 330 kV overhead transmission line.

• An extension to the existing 330 kV switchyard.

Just a few hundred kilometres north lies the Liddell Battery Project, another former coalgeneration site being reborn as renewable infrastructure. For Enerven, the project represents both continuity and complexity.

“The Liddell project is almost exactly the same as Eraring,” Valencia says.

“There is a new substation, brownfield tieins, roads, warehousing – the full suite. The main difference is the battery technology.”

While Eraring uses Wärtsilä systems,

Liddell deploys Fluence batteries, a joint venture between Siemens and AES.

“At Liddell we are subcontracting to Fluence, who are the principal contractor for AGL. Each client chooses a different supplier for technical reasons, so our job is to be adaptable – to design and integrate whatever technology is specified.”

By the end of the year, Enerven expects Liddell’s second stage of battery blocks to be handed over to Fluence for commissioning. That is when they will start energising and feeding power back into the grid.

Managing multi-partner projects of this scale demands more than engineering expertise. It requires trust and communication.

“It all comes down to relationships,” Valencia says.

“You have got to make sure everyone is aligned with common goals, from contractors, clients, suppliers, to regulators. As the lead, it is our job to set the flag post: ‘here is where we are going, and here is what we need from each of you to get there’.”

He credits Enerven’s solution-focused culture for its success.

“There is a real willingness to be client-pleasing. Our contract might sit in the drawer, but what matters is delivering outcomes. That approach resonates – it is why we are winning work in New South Wales and Queensland,” Valencia says.

Beyond technical delivery, Enerven’s leadership recognises that these projects reshape the communities they inhabit. Many regional towns once centred around coalfired power generation are now adjusting to a new economic identity built on renewables.

“Both Eraring and Liddell encompass communities that have been in limbo. People worked at those stations for decades. Now, with the batteries and new infrastructure, there are opportunities for them to stay involved through operations and maintenance,” says Valencia.

He recounts one story that captures this generational handover.

“We met a gentleman named Pete, our electrical supervisor at Liddell. He started

are not genuine about what it means to be inclusive in this industry. At Enerven, we are wholeheartedly focused on building local capability and diversity of thinking – that’s how you get the best outcomes.”

Valencia sees further opportunity for Enerven to lead on data-driven quality systems.

“When you show clients real data, it builds trust,” says Valencia. “Quality is not just compliance, it is about demonstrating control, progress and accountability. Enerven already does a great job, but as we refine those systems, we can accelerate.”

“You will get found out quickly if you

For Enerven, the dual delivery of the Eraring and Liddell batteries represents more than two projects – it symbolises the organisation’s role in bridging the country’s past and future energy systems.

“These sites once powered the nation through coal. Now they are powering it through storage. It is a tangible demonstration of transition,” says Richard Amato, Chief Executive Officer at Enerven.

For Enerven, engineering excellence through investment in people, partnerships and purpose is how it strives to build its future success.

“Projects are exciting, but without people, they cannot succeed. That is what really drives us: building infrastructure that lasts, and a workforce that grows with it,” Amato says.

“As we expand our footprint in Australia’s growing energy storage market, we remain committed to providing solutions that enhance energy resilience and accelerate the path to a cleaner, more sustainable future.”

For more information, visit enerven.com.au

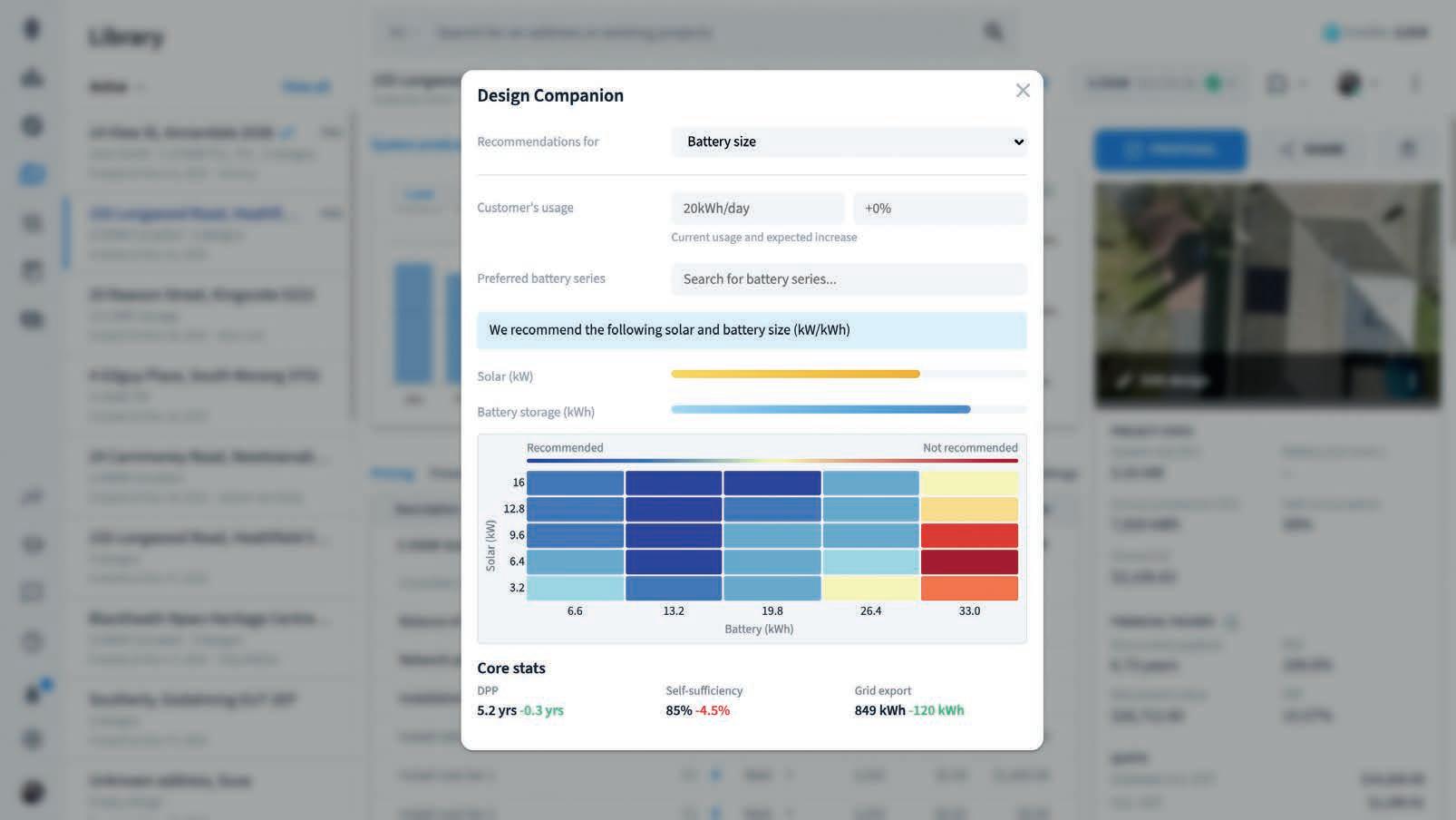

Pylon’s Co-Founder sheds light on how the company’s new tool ‘Battery Adviser’ is helping solar retailers design a smarter solar-plus-storage system.

Australia’s solar retailers are entering a new phase of complexity. The sector is being reshaped by sharper consumer expectations, changing retailer obligations and the rising importance of behind-the-metre storage.

Against this backdrop, Pylon, a solar design platform, has introduced a new digital tool called ‘Battery Adviser,’ with a promise to give installers a technical leg up.

One of its biggest advantages is the ability to calculate the ideal battery size for any home-based on real usage patterns and household energy goals.

Battery Adviser helps to take the guesswork out of storage sizing.

For a platform already relied upon by hundreds of retailers and installers to produce fast, high-resolution proposals, Battery Adviser marks a meaningful progression toward data-driven, tailored solar-plus-storage design.

“Battery storage is one of the fastestgrowing segments in solar, but sizing it correctly has always been a major hurdle for solar installers,” says Nelson Zheng, CoFounder of Pylon.

“Because households can now shift major loads into that free power window, the rightsized battery becomes even more critical.

Battery Adviser gives solar retailers a datadriven way to design systems that deliver real value for homeowners with the changing energy offer landscape,” he adds.

Battery Adviser arrives as the Federal Government prepares to launch the Solar Sharer initiative, which will require energy retailers from July 2026 to offer households in New South Wales, South-East Queensland and South Australia with a free three-hour daytime electricity window.

This policy shift will reshape household energy use to encourage people to run appliances during the free power period and rely on storage for the remainder of the day. For retailers and installers, the challenge will be configuring systems that suit those new behaviours.

Battery Adviser automates this process. It analyses a home’s existing solar system, consumption patterns, load-shifting opportunities, and homeowner goals like maximising bill savings. It then provides a tailored recommendation for the ideal battery size, helping avoid over or undersizing by matching capacity precisely to real household behaviour and the emerging policy landscape.

Pylon’s success in meeting the needs of solar installers is a credit to their communityfirst approach. The team regularly attends global solar conferences and speaks with installers across Australia and New Zealand. This theme was explored in Pylon’s recent appearance on the ‘Tassie Solar Man’ podcast hosted by George Auchterlonie of REST Energy Tasmania.

In the episode, Zheng revealed that it was only after speaking directly with installers that Pylon recognised the glaring gap in the industry when it came to the offering of design tools for installers to do their job more effectively and accurately.

Many of Pylon’s most popular features

have come directly from installer requests to solve everyday workflow frustrations. From smarter drawing tools to streamlined proposals, the platform has evolved through thousands of conversations held on rooftops, at trade expos and in workshop training sessions.

“Honestly, Pylon wouldn’t even exist if we hadn’t chatted with a bunch of installers first. You really have to be obsessed with your users’ problems and really listen. Everyone has a different way of providing feedback, so we try to meet them wherever they are,” Zheng says.

“One installer told me he was working on an install next door when a curious neighbour called him over. He ended up

kitchen table using Pylon’s all-in-one platform – he designed the system on the spot, got the e-signature, and even collected a deposit then and there. When I heard that, I knew we’d built something that truly streamlines the whole process,” he adds.

The podcast also touches on the shift away from near-map-only design workflows, as well as the seasonal nature of solar sales –highlighting why many retailers prefer not to commit to fixed software fees or long-term contracts. Pylon’s pay-as-you-go credit model means businesses only pay for what they use, a structure Zheng describes as a “no-brainer” in a competitive market where efficiency and fast proposal turnaround times can determine a sale.

Pylon’s global conference calendar remains central to its success, giving the team concentrated, face-to-face time with installers and early visibility of emerging trends.

In the recent podcast, Nelson also discussed the sharp contrast between the Australia and New Zealand market. Australia is one of the

For installers working across both countries, Zheng notes that policy frameworks, incentives and consumer behaviour can significantly influence technology adoption.

He also comments on the residential versus commercial market.

“Right now, we’re seeing battery installs really take off. It’s probably the biggest trend in residential solar. At the same time, feed-in tariffs have dwindled, so the old ‘solar-only’ model is fading. Homeowners care more about self-consumption and storage now than ever before,” Zheng says.

“Selling to a homeowner versus a business is a whole different ball game. Homeowners might be swayed by a neighbour’s install or a rebate, while businesses pore over the investment numbers. Both markets are booming, but you have to approach them very differently,” Zheng added.

Zheng also highlights what makes the Australia market particularly dynamic.

“Australia has always been the home of solar innovation going back to the 1980s. In recent years, we have benefited from a remarkably stable regulatory environment for rooftop installations. We’re seeing that

As energy retailers, consumers and policymakers continue shifting toward more dynamic models of consumption and storage, tools like Battery Adviser will become more essential. With Battery Adviser now integrated into Pylon’s workflow, more retailers will have the opportunity to produce richer, accurate and future-ready proposals in minutes.

Battery sizing – once a mix of guesswork and generic assumptions – can now be determined through precise and household-specific modelling. According to Pylon, this shift will accelerate battery adoption and reduce mismatched systems across Australasia.

As Zheng emphasises throughout the podcast: “The future of solar design lies in listening closely to installers, understanding local market nuances, and building tools that evolve fast.”

With Battery Adviser, Zheng believes Pylon is putting that philosophy into practice.

Building on the success of this year, the Clean Energy Council’s 2026 events will continue to unite Australia’s renewable energy community - featuring the flagship Australian Clean Energy Summit, regionally focused summits and a combined technical wind forum, driving even greater impact and collaboration.

Designed by industry for industry, these events offer powerful opportunities to connect, share insights and be part of the conversations shaping Australia’s clean energy future.

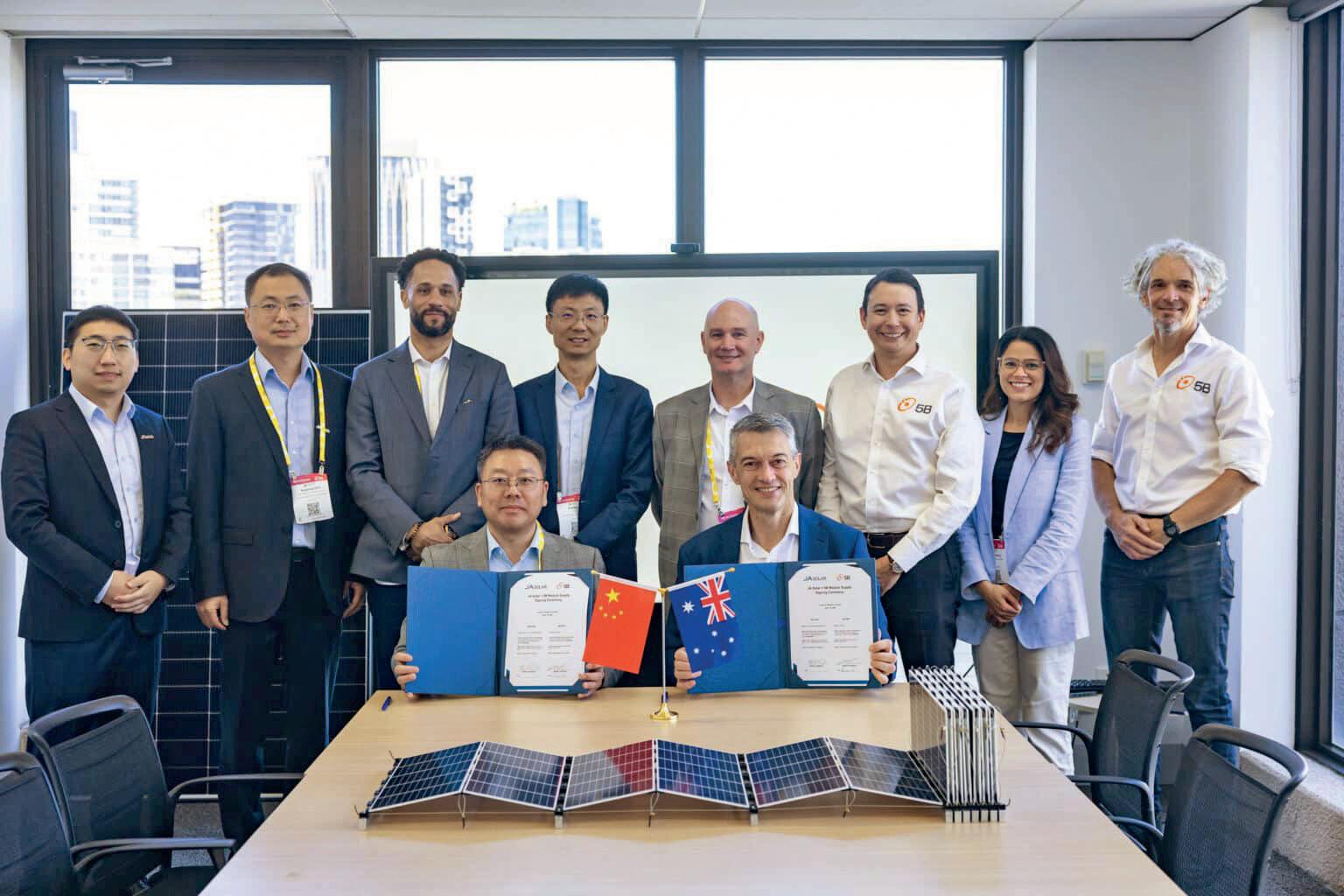

A monumental agreement has been signed by two of the industry’s biggest providers.

Global energy technology developer Trina Storage, a division of Trinasolar, has signed a Memorandum of Understanding (MoU) with Pacific Green Energy Group (Pacific Green) to deliver up to five gigawatt-hours (GWh) of battery energy storage systems (BESS) between 2026 and 2028.

The MoU represents one of the largest energy storage collaborations. When completed, the projects will be capable of storing and dispatching up to five billion watts per hour into the grid, strengthening reliability and accelerating the clean energy transition toward a low-carbon future.

Under the MoU, Trina Storage will supply its advanced grid-scale battery systems, integrating industry-leading technology designed for safety, efficiency and longevity.

Pacific Green will oversee development and project delivery across multiple sites in Australia and other international markets.

Helena Li, President of Trinasolar, said the partnership underscores Trinasolar’s ongoing commitment to advancing global clean energy goals.

“This MoU marks a major milestone for both Trina Storage and Pacific Green in the global renewable energy landscape, including

Australia. A five GWh supply commitment demonstrates the scale and confidence driving our partnership with Pacific Green. Together, we are combining innovation, global expertise, and local execution to enable a more resilient and sustainable energy future,” Li said.

“This partnership enables us to deliver our growing global pipeline efficiently and at scale,” said Scott Poulter, CEO of Pacific Green.

“Together, we’re accelerating the deployment of projects that support the clean energy transition,” Poulter said.

The collaboration builds on Trinasolar’s established footprint in Australia, following earlier partnerships such as the 1.5 GW (gigawatt) Vertex N module supply agreement with Marubeni Australia, and the Limestone Coast North Energy Park Project announced earlier this year in South Australia, a pivotal project for Pacific Green with an enterprise value of AUD $460 million and a planned installed capacity of 250 MW(megawatt)/500 MWh (megawatt hours).

These projects reinforce Trinasolar’s strategic role in delivering integrated solar and storage solutions across the Asia-Pacific region.

Pacific Green currently manages a global storage pipeline of 11 GWh, including seven GWh in Australia and four GWh across Europe, highlighting the strong and expanding partnership between the two companies.

Trina Storage, a business unit of Trinasolar established in 2015, provides energy storage products and solutions and is committed to reshaping the energy landscape. The company is also dedicated to lead the way in all-round smart solar energy solutions driven by customers and scenario needs, and facilitating the transformation of new power systems for a net-zero future.

As a vertically integrated battery technology provider, Trina Storage’s comprehensive capabilities, covering battery cell research & development (R&D), manufacturing, and seamless integration are helping to advance the industry overall.

Its diverse portfolio spans energy storage batteries, battery energy storage cabinets, energy storage converters, residential energy storage solutions, and integrated intelligent energy management systems. While its primary focus centres on utility-scale projects, specifically in solar and storage, as well as standalone application scenarios.

The International Energy Agency (IEA) has released findings from its flagship World Energy Outlook (WEO) report.

Updated annually to reflect the latest data and geopolitical conditions, the latest edition of the flagship World Energy Outlook (WEO) report has arrived at a moment defined by profound uncertainty. Covering the global energy system, the WEO uses multiple scenarios to show how today’s decision-makers, including governments, could reshape global energy security, supply chains and emissions trajectories. Rather than forecasting a single outcome, the report highlights the consequences, trade-offs and contingencies that flow from different policy choices.

The 2024 report places heightened emphasis on critical mineral supply security, reflecting mounting concerns about the materials needed for batteries, solar panels,

electric vehicles (EVs) and other clean energy technologies.

According to the IEA (International Energy Agency), escalating threats and long-term structural hazards have pushed energy to the centre of national and economic security debates. Traditional risks to fuel supply remain, but they now intersect with tightening restrictions on critical mineral exports, intensifying geopolitical rivalries and an electricity system increasingly exposed to cyberattacks, operational failures and extreme weather.

These challenges unfold against a complex backdrop. Global oil markets currently show a substantial supply surplus despite ongoing

conflicts, while countries adopt divergent strategies to pursue energy security and affordability. Many fuel-importing economies are accelerating renewables and efficiency as core solutions. Others continue to prioritise reliable access to traditional fuels, reinforcing fractures in the international energy system.

Even as geopolitical uncertainty clouds the outlook for global trade, the WEO notes that international energy trade remains indispensable. Vast supplies of oil, solar panels, batteries and liquefied natural gas (LNG) create strong incentives for producers to continue seeking global markets. At the same time, differing national priorities and fragmented policy environments add complexity to future supply-chain dynamics.

The IEA highlights an uncomfortable tension: momentum behind emissions reduction efforts has softened, even as climate risks accelerate.

The year of 2024 was officially the hottest on record, marking the first time global temperatures exceeded 1.5°C above preindustrial levels. While renewables achieved their 23rd consecutive annual deployment record, consumption of oil, gas, coal and nuclear power also reached historic highs.

The IEA reinforces that there is no single storyline for the future of global energy. Instead, the WEO provides a suite of exploratory and normative scenarios built on rigorous modelling and the most current policy, market and technology data. These pathways allow governments, investors and industry to understand how choices made today could either deepen or strengthen the global energy system.

ADVERTISE IN

EXPERT COVERAGE OF THE PROJECTS AND DEVELOPMENTS THAT ARE RESHAPING THE AUSTRALIAN ENERGY MARKET.

23,000+ COMBINED CIRCULATION

Our magazine, e-newsletters and website are valued at all levels of the industry, from financiers and developers to installers and suppliers. As the energy market transitions to renewables, our readers look to ecogeneration.

ecogeneration is the only title in Australia to cover all aspects of the clean energy industry; delivered across print, online and email. The bi-monthly magazine, officially endorsed by the Clean Energy Council, keeps the industry informed from the boardroom to the work van.

The print and digital magazine, and pass on rate, has a combined circulation of more than 23,0000, as well as receiving extra distribution at important industry events.

For more information, please contact: Nick Lovering Business

Development Manager

nick.lovering@primecreative.com.au 0414 217 190

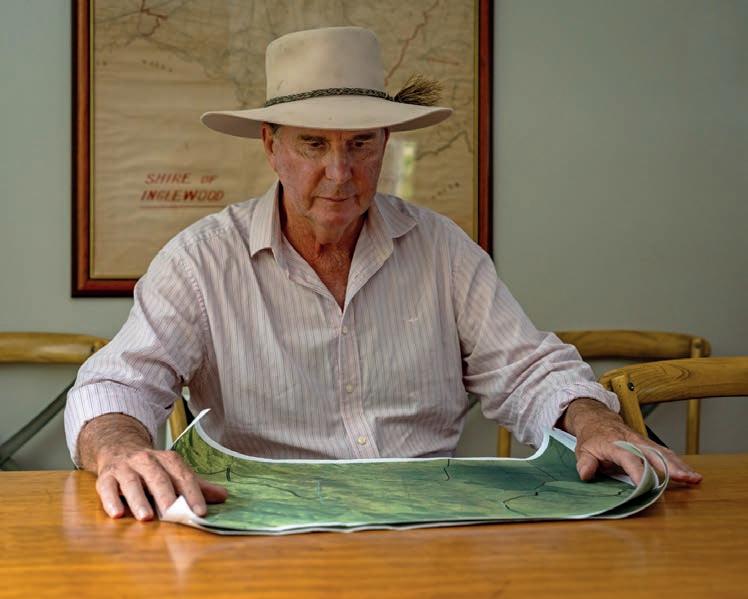

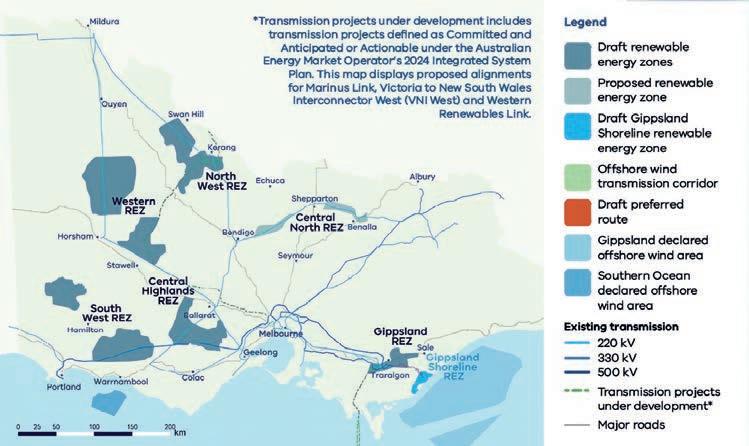

RELA is supporting landowners and developers to optimise coexistence between food production and renewable energy through their Assess 1.0 and Assess 2.0 platform – with funding support by the Australian Renewable Energy Agency in 2025 to ensure energy, agriculture and ecosystems can work in synergy by being fully informed about both land use.

In simple terms, coexistence refers to how renewable energy infrastructure, such as wind turbines, solar panels, battery storage, roads and wires, can operate alongside existing land uses and industries in a way that minimises conflict and maximises shared benefit.

In Australia’s race toward net zero, regional land is increasingly being asked to serve multiple purposes. For generations, its value was measured in food and fibre; now societal demands and associated opportunities include energy, carbon offsets and biodiversity outcomes.

“Regional land has historically fulfilled one global demand – food and fibre,” says Michael Katz, Chief Executive Officer at RELA.

“But over the last decade, and particularly in the past five years, we have seen new macro-demand for energy, decarbonisation and biodiversity emerge. Land productivity in this new paradigm is about coexistence between these uses.”

Wind turbines on farms are perhaps the clearest illustration. Across the country, farmers are leasing parts of their properties for wind projects while continuing to grow crops and graze livestock.

“If you can understand how to layer food production with an energy or carbon project, you can optimise productivity and the benefits for the landholder as well as the wider region,” says Katz.

Lessons from the paddock Wind-farm projects have shown that coexistence is possible – but it’s not automatic. RELA’s experience suggests that the biggest challenges arise when

communication breaks down and knowledge is unevenly distributed.

“There is a lot of information sitting in people’s heads – landholders, developers, lawyers, engineers – and the only way to achieve a balanced negotiation is to give everyone access to that knowledge,” says Katz.

That philosophy underpinned RELA Assess 1.0, the company’s first-generation land assessment platform. Developed to help landowners evaluate the suitability of a site for utility-scale wind or solar, Assess 1.0 provides a desktop assessment of factors such as grid proximity, land availability, topography, and environmental constraints.

For landholders, the tool offers independent, fact-based insights into the potential value of land and its compatibility with renewable infrastructure – information that was once difficult to obtain.

“Our goal is to reduce information asymmetry. We provide landowners the facts so they can engage on an equal footing,” says Katz.

Catching early recognition, the Australian Renewable Energy Agency (ARENA) supported the RELA Assess 1.0 project’s expansion, providing funding towards the development of RELA Assess 2.0 – the next-generation of the online portal that automates and scales the process.

Running from February 2025 to March 2026, the project is designed to give

landowners, farmers and rural communities easy digital access to insights that were once available only through consultants or developers.

“Assess 2.0 builds on our earlier manual process and turns it into a self-service platform. It brings together geospatial data, grid mapping and land-suitability modelling to provide rapid, data-driven assessments of renewable potential,” says Katz.

The tool will include new features, such as a Land Plan Builder that enables landholders to upload or outline their existing agricultural systems, as well as a Social Licence Index which highlights community and environmental considerations, such as neighbouring density, biodiversity values and competing land uses.

At its core, the Assess 2.0 platform is designed to build trust.

By providing transparent data and a shared evidence base to facilitate informed negotiations, RELA’s intention is to build trust through those interactions.

“The only way to achieve coexistence is through collaboration. The only way to collaborate effectively is for all sides to be fully informed about their own interests and those of the other stakeholders,” says Katz.

Developers, too, stand to benefit.

“Developers told us they wanted the data layers that only landholders could provide – things like soil conditions, water access or seasonal movement patterns. They also

asked that the social-licence indicator use a simple traffic-light format – a high-level guide rather than a prescription – and we have incorporated that,” says Katz.

Co-existence beyond infrastructure

For RELA, coexistence extends well past physical infrastructure. The company is also focused on financial and contractual alignment to ensure the long-term lease agreements underpinning projects are structured to meet both developer and farmer needs.

“A developer wants a 30-year linear, inflation-indexed lease linked to revenue,” says Katz.

“But a farmer’s financial needs are often non-linear – affected by drought, expansion opportunities or succession planning. So we have built a prepayment product that lets landholders access value upfront without selling their land.”

The mechanism allows developers to maintain their preferred long-term lease structures while giving farmers the flexibility to manage cashflow for operational or family needs.

It is a financial reflection of the same principle driving the technology platform –alignment through understanding.

Building capacity across the sector

Rather than chasing isolated showcase projects, RELA is investing in lifting capability across the entire ecosystem.

Katz believes this is essential if

Co-existence is a reality that many will need to adjust to, with increased urbanisation and population growth placing strain on land availability.

coexistence is to become standard practice rather than an exception.

“There is probably no project that’s perfect and no project that’s doing it all wrong. Everyone is operating with the capabilities and templates available at the time. What we are seeking to do is find the best outcome available at any given time, and to raise overall capability,” says Katz.

That effort includes knowledge-sharing for regional lawyers and advisers through Continuing Legal Education sessions, exemplified by RELA General Counsel Jess Salvato’s recent presentation at the Rural Issues Conference in Sydney.

“We share what we have learned so others can apply it. Obviously, it’s great when they call us to implement the knowledge, but even if they don’t, the sector benefits.”

RELA has also convened a Stakeholder Reference Group to guide Assess 2.0’s development; comprising 17 representatives across seven categories, those being Landholders, Landholder Advisers, Government, Agricultural Peak Bodies, First Nations representatives, AgTech specialists,

“Every perspective is responded to. It might be included, deferred or marked as out of scope, but nothing is ignored. That process is central to building a platform that truly reflects the range of voices involved in coexistence,” says Katz.

Beyond renewables, regional land faces mounting pressure from urban expansion. Katz says that this is not part of their business scope, but urbanisation is both a challenge and an opportunity like other land use changes.

“Decarbonisation, energy, regulation, biodiversity and urban growth – they are all new pressures on land, but they are also opportunities. What matters is understanding the trade-offs and giving landholders the tools to make informed decisions,” says Katz.

RELA’s Social Licence Index helps flag potential friction points early.

“If the index shows red or orange, that

doesn’t mean you can’t proceed – just that you will need to invest into the management of those issues,” adds Katz.

For landowners on city fringes, where future rezoning could lift property values, the organisation’s financial products also offer a way to participate in renewables now, without losing long-term upside.

“Landowners can maintain ownership and still access the value of their lease,” says Katz.

Ultimately, RELA’s mission is to make landowners active participants in the energy transition rather than passive hosts.

“No one party has all the answers, but we remain focused on making sure every stakeholder is fully informed and that the process is transparent and balanced,” says Katz.

This approach directly supports national goals.

According to the Australian Energy Market Operator’s 2024 Integrated System Plan, the National Electricity Market will require a six-fold increase in grid-scale wind and solar by 2050 under its Step Change scenario – equivalent to three-to-six gigawatts of new capacity every year for the next decade.

Meeting that target will depend on community confidence and cooperation. By helping landholders and developers communicate on equal terms, RELA’s technology and frameworks address one of the transition’s most persistent bottlenecks, that being social licence.

Katz believes this transformation could redefine Australia’s regional economy.

“We are going through one of the biggest transitions in modern history,” says Katz.

“From a regional perspective, it is similar to the industrial revolution – a change in the fundamentals of land economics,” he adds.

For rural communities, that shift carries enormous promise.

“If landholders approach this transition fully informed, it has a chance to redefine productivity. And with that comes decentralisation of wealth and opportunity that could last for generations,” says Katz.

“In RELA’s view, coexistence is not just about technology or land use, it is about designing a future where energy, agriculture and nature all belong and thrive together,” concludes Katz.

As Mariano Martínez Larcuen, Country Manager – Solarig Australia writes, the level of domestic opportunity when it comes to battery energy storage systems and other renewable energy sources has rarely been higher. So, how can we make the most of it?

Australia has become one of the world’s most dynamic markets for large-scale battery energy storage systems (BESS), with more than 30 assets and 7.5 GWh (gigawatt-hours) currently operational.

The sector’s growth is driven by ambitious renewable targets and a robust regulatory framework under the Australian Energy Market Operator (AEMO). The recent Capacity Investment Scheme (CIS) tender marked a major milestone, awarding over 24 GWh of new storage capacity.

The country has rapidly become the global testbed for BESS development and innovation, which has positioned Australia at the forefront of large-scale BESS development. It also brings new technical and operational challenges.

Meeting these requires a simple yet hard-toachieve formula: boots on the ground, a local AEMO compliance data-driven control centre, and strong partnerships with OEMs through Long-Term Service Agreements (LTSAs) that guarantee performance, reliability, and longterm value for asset owners.

In Australia’s rapidly evolving yet still