VOLUME 118/1 | FEBRUARY 2026

INDUSTRY EVENTS GREEN METALS

VOLUME 118/1 | FEBRUARY 2026

PAUL HAYES

paul.hayes@primecreative.com.au

IN AN ERA OF RISING EXPECTATIONS AND TIGHTER MARGINS, THE QUIET WORK OF CRUSHING AND SCREENING HAS NEVER MATTERED MORE.

Every new year brings a sense of possibility, a chance to recalibrate strategies, and an opportunity to embrace the innovations shaping our industry. And if there’s one area quietly but crucially underpinning operations, it’s crushing and screening. Often overlooked outside the pit, crushing and screening remains the heartbeat of mining. It’s the point at which raw rock becomes a marketable product, where efficiency, safety and reliability intersect in real-time.

Modern mining operations have become more sophisticated, and the equipment and techniques that drive these processes have had to evolve to keep pace. Australian mines now operate under pressures that are both familiar and unprecedented: higher production targets, stricter environmental expectations, tighter margins, and the imperative to adopt more sustainable practices. Crushing and screening sits at the centre of these challenges, and its evolution is critical to success.

We’ve seen advances across the board in recent years. Modern crushers are bigger, smarter and more energy-efficient than ever.

Automation and digital integration are transforming how operators monitor equipment performance, predict maintenance needs, and optimise throughput. Condition-based monitoring and real-time analytics are integral to maximising uptime and productivity. And screening technology has similarly stepped up, with finer control over particle size, enhanced wear resistance and modular designs that allow operators to adapt quickly to changing ore types and production schedules.

But it’s not just about the machines. The real story lies in how mining companies, contractors

CHAIRMAN JOHN MURPHY

CHIEF EXECUTIVE OFFICER CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

Email: paul.hayes@primecreative.com.au

ASSISTANT EDITOR

ENGEL SCHMIDL

Email: engelbert.schmidl@primecreative.com.au

JOURNALISTS

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

BEN CARTWRIGHT

Email: ben.cartwright@primecreative.com.au

and equipment suppliers collaborate to deliver solutions that meet their goals.

Across Australia, the focus is increasingly on reducing energy consumption, limiting dust and noise, and improving worker safety, all while keeping costs manageable. These priorities are shaping the next generation of crushing and screening technology. It’s a period of innovation that mirrors the broader trends: smarter, leaner, greener operations that do more with less.

This issue of Australian Mining takes a closer look at the state of the crushing and screening industry in Australia. We explore the equipment and technologies that are leading the way, highlighting how operators are adopting innovative solutions to improve efficiency, safety, and sustainability across their operations.

As 2026 unfolds, it’s clear that crushing and screening will continue to be more than just a background process. It is, in many ways, a bellwether for how well operations adapt to modern challenges. Companies that embrace innovation in this space will not only improve efficiency and safety but also position themselves to compete on a global stage.

So as we begin the year, it’s worth remembering that even the biggest mines start with the basics: rock, grit and the machines that turn raw materials into opportunity.

In crushing and screening, we see a microcosm of the industry at large; resilient, innovative and ready to take on the future.

Paul Hayes Managing Editor

ETHAN BENEDICTO

Email: ethan.benedicto@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGERS

JAMES PHIPPS

Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN

Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

Front cover

MMD Group is a global leader in material processing equipment for the mining, quarrying and recycling industries. The company is known for innovative technologies, including the Mineral Sizer and Apron Plate Feeder. MMD’s equipment is designed to boost productivity, improve efficiency and reduce operational costs across a range of materials, including coal, iron ore, limestone, bauxite and rare minerals.

The company provides solutions tailored to each client’s needs.

Beyond machinery, MMD offers planning, engineering, installation, training and ongoing support, ensuring clients receive complete service throughout the lifecycle of their operations. With a global network of offices and workshops, MMD is a trusted partner helping mining and processing operations achieve efficiency, safety and sustainability.

Cover image: MMD Group

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00 For subscriptions enquiries please contact (03) 9690 8766 subscriptions@primecreative.com.au

PRIME

Serving the mining industry across Australia. Whether you’re in Western Australia’s iron ore heartland, the coal fields of Queensland, or the mineral-rich regions of New South Wales and South Australia, our regional service centres are ready to support you with expertise, repair and machining services.

FLS’s state-of-the-art Service Centres in Australia are strategically located near major mining regions.

You can be sure our team is ready to meet your needs by providing the most suitable parts and services required to safely and efficiently assist you in keeping your equipment up and running, maximising up time and boosting productivity.

www.fls.com

■ Reduce downtime - mining experts on your doorstep, for planned maintenance or an unplanned outage

■ Local machining facilities - reduce lead time for spare and wear parts, repairs, rebuilds, exchanges

■ One-stop-shop supports performance improvement –training, engineering or onsite support

8 CRITICAL MINERALS

Ring of Fire ignites

From a remote promise to a near-term production opportunity, Australian miner Wyloo is advancing Canada’s Ring of Fire as a critical minerals powerhouse for the clean-tech era.

12 CRUSHING AND SCREENING

The quiet backbone

Always essential, crushing and screening underpins the productivity, efficiency and resilience of Australia’s modern mining operations.

14 CRUSHING AND SCREENING

Sizing up a rare opportunity

Growing demand, complex geology and shifting global supply chains are pushing rare earth miners to rethink their front-end processing.

24 CRUSHING AND SCREENING

Holistic thinking in mineral processing Metso’s history of innovation gives it a unique perspective on mining processes and how every component in a circuit fits together.

56 ASSET MANAGEMENT

Data-driven confidence

A successful air-filter trial has helped Hastings Deering lift operational efficiency at Yancoal’s Cameby Downs mine.

30 CRUSHING AND SCREENING

Global smarts, local knowledge

Opening a new service centre in Mackay was a statement of intent for leading mining equipment specialist FLS.

38 ESG

A renewable transformation at St Ives Gold Fields is undertaking one of Australian mining’s most ambitious renewable energy projects at St Ives, fundamentally changing how the operation will be powered into the future.

62 INDUSTRY INSIGHT

From teething to transformation

With technological, operational and environmental advancements across the sector in the last 12 months, power solutions provider Genus believes greater opportunity is still to come.

70 GREEN METALS

A green opportunity

As the world moves towards net zero, Australia has a key foothold in assisting in the global energy transition.

MINING AND RESOURCES LEADERS FEATURED PROMINENTLY ACROSS THE HIGHEST-PAID EXECUTIVES.

THE STRONG PRESENCE OF MINING LEADERS AMONG AUSTRALIA’S HIGHEST-PAID EXECUTIVES UNDERSCORES THE SECTOR’S GROWING IMPORTANCE TO NATIONAL COMPETITIVENESS AND LONG-TERM ECONOMIC GROWTH.

Mining executives were again well represented among Australia’s highestpaid corporate leaders, highlighting the value creation and risk-taking that underpin the modern resources sector.

Topping the list in 2025 was Develop Global chief executive officer (CEO) Bill Beament, whose remuneration reflected a year of strong commodity markets, long-term incentives coming to fruition and sustained shareholder returns.

According to the Australian Financial Review, using data from OpenDirector, Beament emerged as Australia’s highestpaid CEO after converting 14 million options into shares, lifting his realised earnings to more than $59 million. The conversion, completed at a cost of $9.1 million, boosted Beament’s paper wealth by approximately $58 million and marked the single largest realised windfall for an Australian CEO in 2025.

While eye-catching, the outcome underscores a defining feature of mining leadership remuneration: long-dated incentives tied directly to company performance and commodity cycles.

Beament’s result was not an isolated case. Mining and resources leaders featured prominently across the top 20 highest-paid CEOs, with eight executives from the sector making the list. Among them were Alcoa chief executive William Oplinger, who earned $26.1 million; former Rio Tinto chief Jakob Stausholm on $15.6 million; and BHP chief executive officer Mike Henry with $13.7 million.

Chief executives from WA1 Resources, Genesis Minerals, Northern Star Resources and Yancoal Australia also featured, reinforcing the depth of leadership across Australia’s mining and energy landscape.

The strong showing comes amid a buoyant period for several commodities, particularly gold, which rose by close to 50 per cent over the past year and reached record highs in 2025. For gold producers and developers, rising prices translated into stronger balance sheets, higher share prices and, in some cases, long-term incentives that far exceeded their original valuations.

Analysis by OpenDirector showed that the mining and healthcare sectors stood out for having the

largest gap between statutory reported remuneration and realised pay. The difference reflects executives cashing in on incentives that were granted years earlier, often during periods of uncertainty or pre-production risk.

“Many CEOs in the materials sector received one-off options during their companies’ pre-production phases,” OpenDirector chief executive Donald Hellyer said.

“Their willingness to take risks and invest effort paid off, particularly as rising gold prices and share values boosted returns.”

For the resources industry, the data offers a broader message about growth and global competitiveness. Mining projects are capital-intensive, long-cycle investments that require experienced leadership willing to navigate technical risk, regulatory complexity and volatile commodity markets. Executive incentives are typically structured to align rewards with long-term value creation rather than short-term performance.

and ramp-up before any material value is realised. When projects succeed, the financial outcomes can be significant, but so too are the risks of failure, particularly in developmentstage companies.

The prominence of mining leaders among Australia’s top earners also reflects the sector’s ongoing contribution to national prosperity. Resources companies remain major employers, exporters and taxpayers, supporting regional economies while supplying the minerals and metals required for infrastructure, electrification and decarbonisation.

As demand for commodities such as gold, copper, lithium and iron ore continues to be shaped by global energy transition and population growth, strong leadership will remain central to the sector’s ability to invest, innovate and grow.

Industry observers note that mining CEOs often spend years overseeing exploration, approvals, construction

While headline remuneration figures can attract attention, the broader story is one of an industry that rewards long-term commitment, technical expertise and value creation, and one that continues to play a critical role in Australia’s economic future. AM

FROM A REMOTE PROMISE TO A NEAR-TERM PRODUCTION OPPORTUNITY, AUSTRALIAN MINER WYLOO IS ADVANCING CANADA’S RING OF FIRE AS A CRITICAL MINERALS POWERHOUSE FOR THE CLEAN-TECH ERA.

Once a distant prospect, the Ring of Fire is now moving quickly towards production, as Wyloo combines Australian mining know-how with First Nations partnerships to develop one of Canada’s richest mineral regions.

Three years ago, there was little certainty the infrastructure needed to unlock the Ontario region’s mineral potential would move ahead. But momentum has shifted.

Wyloo, which now owns the highgrade Eagle’s Nest nickel-copper-

executive officer Luca Giacovazzi told Australian Mining. “The First Nationsled all-season road is key to unlocking access to the Eagle’s Nest project and surrounding mineral-rich areas.”

The Ring of Fire covers roughly 5000km2 in northern Ontario and contains nickel, copper, chromite and platinum-group elements, metals increasingly sought after for use in electric vehicles (EVs), energy storage, renewable energy systems, and defence technologies.

Eagle’s Nest is regarded as one of the highest-grade undeveloped nickel

particularly the Yangibana rare earths project in WA.

Yangibana is one of the rare earth developments closest to production in Australia, and Giacovazzi said the company is taking a similar partnershipfirst approach in Canada. He described Wyloo’s co-management model in the Ring of Fire with First Nations communities as a defining feature.

“The communities are very much part of running the mine,” Giacovazzi said.

“What they bring is expertise in operating remote regions – power

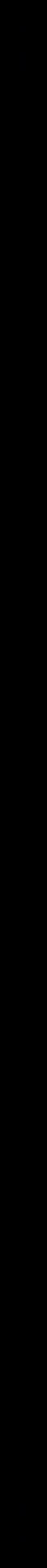

THE EAGLE’S NEST PROJECT IS PART OF WYLOO’S STRATEGY IN CANADA AMID INCREASING AUSTRALIA–CANADA CRITICAL MINERALS COOPERATION.

bring the operations expertise. It’s a strong partnership.”

While mining will benefit from the new road network, Giacovazzi said its value extends far beyond project access.

“It’s about access into their communities, not just mining,” he said. “It’s foundational for long-term development and partnership, and for building sustainable supply chains across both nations.”

Alongside Eagle’s Nest, Wyloo is working to establish downstream capability in Canada.

The company has signed an agreement to pursue a battery materials processing facility in the Ontario city of Sudbury, aiming to fill a major gap in Canada’s midstream EV battery supply chain.

“It had all the right ingredients to be successful and we’re finally starting to see that play out,” Giacovazzi said.

A major turning point for the Ring of Fire came when responsibility for the road projects shifted towards First Nations leadership in 2022–23.

Marten Falls and Webequie First Nations are now the proponents leading key access road proposals through Ontario’s permitting system.

“It’s a First Nation-led piece of infrastructure,” Giacovazzi said. “These communities have been working tirelessly through the Canadian

permitting system, and now we’re finally at the point of construction. That change was a real circuit breaker for the project.”

Wyloo expects the next 12–24 months to be defined by continued road progress, environmental assessment milestones and deeper partnership agreements.

“Beyond that, you’ll start to see first nickel concentrate from Eagle’s Nest,” Giacovazzi said.

International collaboration is another priority. Wyloo sees emerging opportunities linking Australia, Canada and the US as allied nations working to de-risk critical mineral supply chains.

“Ring of Fire has the potential to be an important part of allied countries’ critical mineral supply,” Giacovazzi said. “Australian companies thriving in Canada, and Canadian companies in Australia, shows how strategic these projects are.

“These metals are fundamental, not just for EVs and renewable energy but for AI [artificial intelligence] and advanced defence technologies.”

In Australia, Wyloo’s Yangibana project continues to advance, with the company positioning it as part of the near-term solution to global rare earth shortages.

“The rare earths market is finely balanced, and current prices aren’t enough to incentivise new supply,” Giacovazzi said.

“We’re strategically positioned to be part of the near-term solution, and our project can produce in months, not years. That’s incredibly rare in this space.”

Giacovazzi said demand for minerals is accelerating across every modern technology sector.

“We’re at an exciting point in history. Technology is advancing faster than ever, from EVs to AI and humanoid robots, but underlying all of this is a need for metals and minerals,” he said.

“We simply haven’t done enough exploration to discover the next generation of mines.

“Minerals are the new oil, and the world is waking up to just how critical they are.”

Public interest in the Ring of Fire is also growing. High-profile advertising campaigns promoting the region have run during major sporting broadcasts in Canada, such as the Toronto Blue Jays’ games during the World Series baseball, catching the attention of viewers all over the country.

“People are starting to understand the scale and importance of this project for Ontario, Canada, and the wider allied world,” Giacovazzi said.

As construction advances and partnerships mature, Wyloo believes the Ring of Fire is steadily moving from potential to reality. AM

GOLD BUILT VICTORIA’S MINING LEGACY, BUT A NEW WAVE OF CRITICAL MINERALS IS HELPING TO POSITION THE STATE FOR ITS NEXT RESOURCES CHAPTER.

Victoria’s mining story has always been spun with gold. The discovery of payable gold at Ballarat in the early 1850s reshaped the state forever, triggering a rush that transformed a young colony into one of the world’s mining centres.

But while gold built Victoria’s identity, its future is increasingly linked to a different suite of resources. Critical minerals are emerging as the foundation

for a new era, and Victoria is positioning itself as a key player.

Australian Mining spoke with executive director of the Minerals Council of Australia in Victoria, James Sorahan, who said that while state’s gold sector remains strong, it’s the emerging critical minerals opportunity that is placing it firmly in discussions around national supply chains and global partnerships.

Antimony, in particular, stands out as a mineral of growing significance.

“Victoria is a big part of Australia’s critical minerals future.

We are currently the only state mining antimony,” Sorahan said. “Although antimony has been produced in New South Wales previously, Victoria now holds the country’s active operations and some of its most promising exploration projects.

“Victoria is producing probably four or five per cent of the world’s supply of antimony.”

Strategic demand from partners such as the US, Canada, the UK and the EU has amplified the importance of Victoria’s critical minerals deposits.

The ‘Melbourne Zone’, home to gold and antimony discoveries by Southern Cross Gold, offer a convergence rarely found anywhere in the world.

“The combination is something that is really unique,” Sorahan said.

Beyond antimony, Victoria’s rareearth-rich mineral sands deposits present one of the state’s greatest long-term opportunities. The Murray Basin contains the world’s largest known mineral sands deposits, yet Victoria remains the only basin state not currently mining them.

That, Sorahan believes, is likely to change.

“We can be a real powerhouse in gold, mineral sands, rare earths and antimony,” he said.

Sorahan pointed to how rapidly global markets are evolving.

“The world has changed in the past 10 to 15 years. Rare earths are now really important,” he said.

Proposed mineral sands operations in Victoria hold rare-earth-rich deposits with mine lives of more than 20 years, representing a major opportunity for

VICTORIA IS A BIG PART OF AUSTRALIA’S CRITICAL MINERALS FUTURE. WE ARE CURRENTLY THE ONLY STATE MINING ANTIMONY.”

stable regional employment and longterm economic benefit.

The Victorian Government has also recognised the significance of these emerging industries and increased its support for the sector, with improvements to regulatory pathways a major step forward.

“We have, I think, the best project facilitation office in the country,” Sorahan said, referring to the Resources Victoria Approvals Coordinator introduced in 2023.

“It has helped complex projects navigate multiple acts and regulations and has brought regulators together to support investment.”

In addition, the streamlining of exploration approvals has provided further momentum.

“We are now approaching about 100 per cent within the statutory timeframe of exploration licences being granted,” Sorahan said.

This consistency has been essential as explorers sought to progress advanced drilling and development programs across multiple commodities.

As Victoria prepares for this growth, building a strong skills pipeline is key.

“We need more exposure to earth sciences in schools and universities offering metallurgy, mining engineering and geology,” Sorahan said.

He also emphasised the importance of maintaining strong geoscience capability.

“We need to ensure that we have the right geological knowledge through GeoSurvey Victoria,” he said.

Sorahan believes land access remains central to enabling exploration and future mines.

“Farming and mining can work together,” he said.

“The industry is committed to quality rehabilitation, and we want to ensure everybody benefits.”

Victoria’s golden legacy has created the foundation for a thriving modern sector. But as global demand for critical minerals has accelerated, the state is

poised to contribute much more. With rare-earth-rich mineral sands, highvalue antimony deposits and deeper gold yet to be uncovered, Victoria was entering a new chapter driven by its history and its future potential.

As Sorahan put it, Victoria is “really open for business” and ready to take its place in Australia’s critical minerals landscape.

If the gold rush of the 1800s shaped Victoria’s past, the emerging critical minerals era had the potential to shape its future. And for the first time in decades, Victoria is not only part of Australia’s mining conversation – it is back at the centre of it. AM

WHILE GOLD BUILT VICTORIA’S IDENTITY, ITS FUTURE IS INCREASINGLY LINKED TO A DIFFERENT SUITE OF MINERALS.

ONCE CONSIDERED A NICHE COMMODITY, ANTIMONY HAS RAPIDLY BECOME ONE OF THE WORLD’S MOST STRATEGICALLY IMPORTANT MINERALS. IT IS USED IN DEFENCE APPLICATIONS, ENERGY STORAGE, SEMI-CONDUCTORS AND FLAME-RETARDANT MATERIALS, PLACING IT FIRMLY AT THE CENTRE OF MODERN INDUSTRIAL AND SECURITY SUPPLY CHAINS.

GLOBAL SUPPLY HAS TIGHTENED AS DEMAND FROM ADVANCED ECONOMIES CONTINUES TO RISE, PARTICULARLY ACROSS THE US, UK, EU AND CANADA, ALL OF WHICH ARE SEEKING SECURE, RELIABLE SOURCES OF CRITICAL MINERALS. AGAINST THIS BACKDROP, VICTORIA’S POSITION AS AUSTRALIA’S ONLY ACTIVE ANTIMONY-PRODUCING STATE HAS ELEVATED ITS STRATEGIC IMPORTANCE.

WITH SEVERAL PROMISING EXPLORATION PROJECTS UNDERWAY AND A SUPPORTIVE APPROVALS FRAMEWORK IN PLACE, VICTORIA IS INCREASINGLY BEING VIEWED AS A DEPENDABLE SUPPLIER IN A MARKET WHERE SECURITY OF SUPPLY IS NOW JUST AS IMPORTANT AS VOLUME.

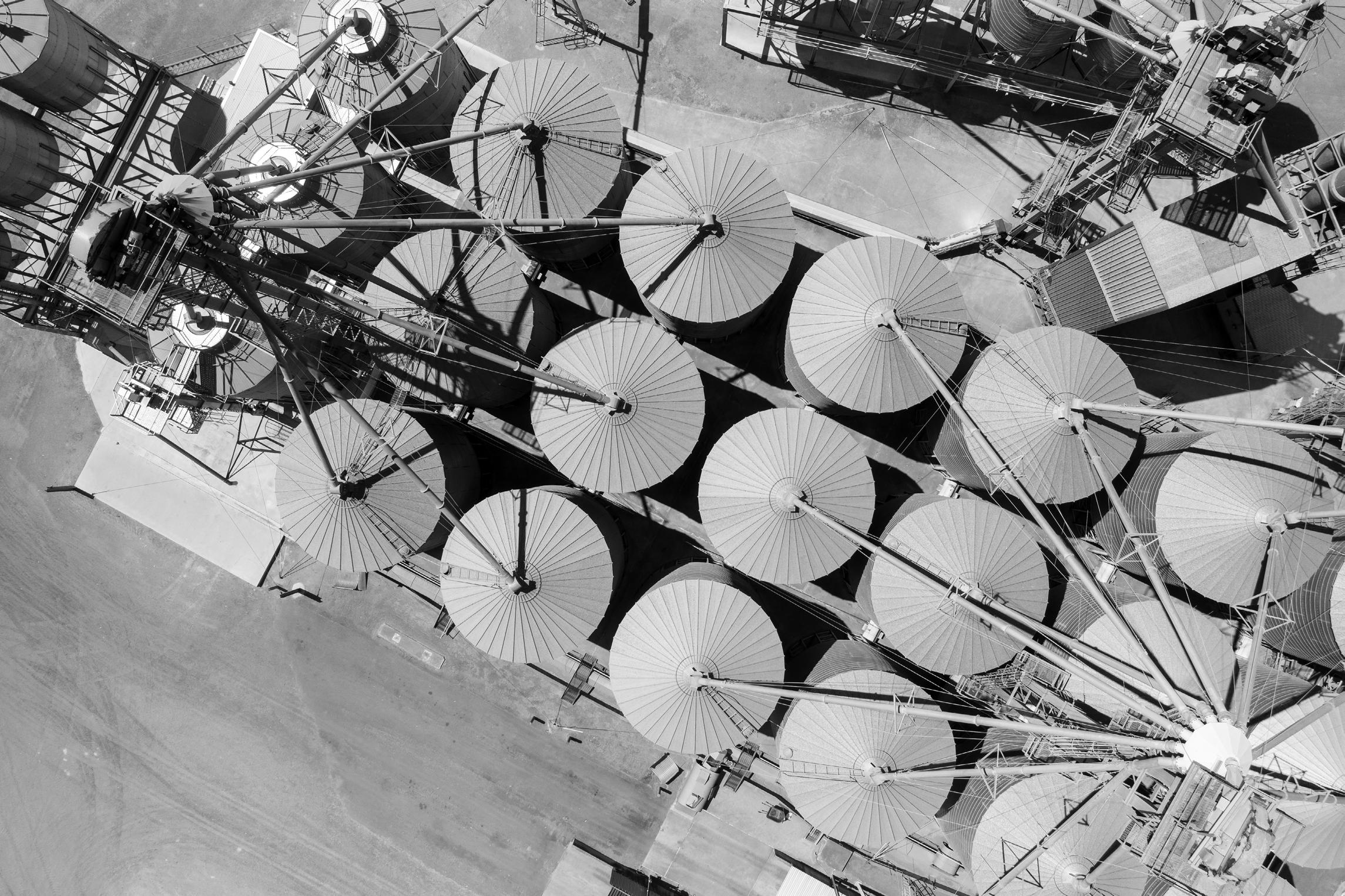

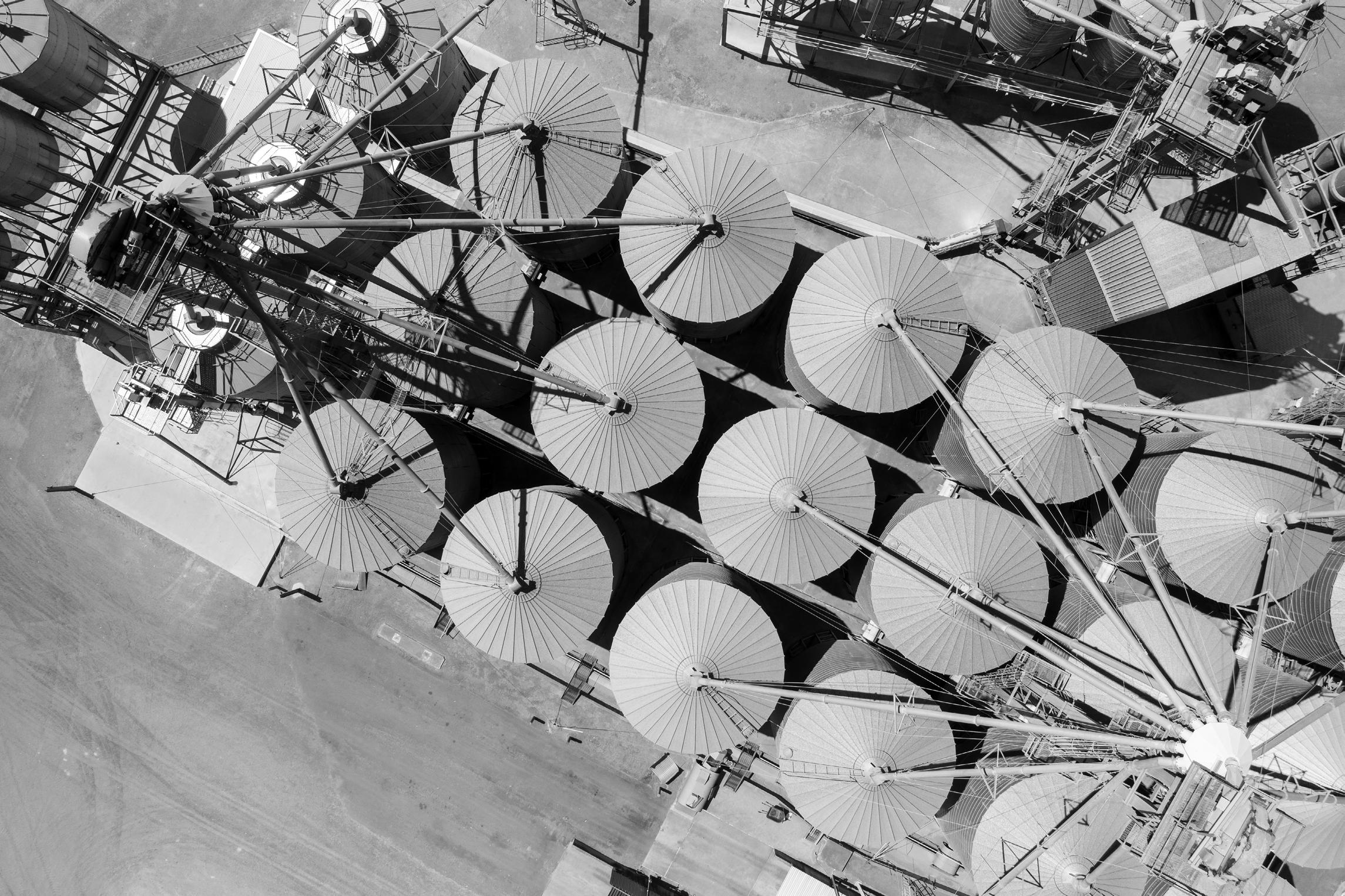

ALWAYS ESSENTIAL, CRUSHING AND SCREENING UNDERPINS THE PRODUCTIVITY, EFFICIENCY AND RESILIENCE OF AUSTRALIA’S MODERN MINING OPERATIONS.

Crushing and screening may not make headlines the way a new mine or a massive project sanction does, but this process sits at the technical and economic heart of today’s resources industry.

From mine throughput and product quality to energy use, emissions and safety, the choices made at the front end of a processing chain determine how efficiently a whole operation runs, and how much value it returns to the balance sheet.

That matters in Australia now because the resources sector remains a major national earner and the industry is under pressure to lift productivity while cutting costs and emissions.

Why it matters

Crushing and screening is among the first stages in most mineral-processing flowsheets: it reduces blasted rock to a range of product sizes, remove fines and oversize material and present a

stable feed to mills, concentrators or direct-shipping stockpiles. The better that front end performs, the more predictable downstream circuits become, which reduces rework, lowers energy consumption, cuts wear on downstream equipment and improves recoveries.

For remote diesel-powered sites, even small improvements in kilowatthours per tonne translate directly into fuel savings and lower fleet emissions, making efficient crushing and screening a lever for cost and sustainability gains.

Good front-end practice also supports resilience. Consistent product sizing reduces conveyor and crusher blockages, shortens maintenance windows and reduces the risk of unplanned stoppages that can ripple through an operation’s schedule and cost model.

In short, crushing and screening is a productivity multiplier. It helps to define the material characteristics the rest of the plant must handle and therefore influence capital planning, operating costs and equipment life.

A modern crushing and screening plant uses a family of machines that are selected and configured to fit geology, throughput and product targets. Typical equipment includes primary crushers (jaw or gyratory crushers) that take blasted rock down to initial sizes; secondary and tertiary units (cone, impact or vertical shaft impactor [VSI] crushers) that refine product size and shape; vibrating screens that separate material into defined size fractions; and conveyors and transfer stations that move material between stages. Mobile crushing and screening plants have become common for short-life pits and satellite deposits because they reduce haulage and speed up project ramp-up.

On the technology side, productivity and control are standout themes. Variable-speed drives and more efficient motors reduce power draw; wearresistant liners, advanced metallurgy and better tooth/impactor designs extend component life; and modern screen media and modular chassis reduce downtime for change-outs.

Condition-monitoring tools – from vibration and bearing-temperature measurement to automated lube systems and online oil analysis –are increasingly standard, helping operations shift from time-based maintenance to condition-based regimes that cut total lifecycle cost. These advances may seem incremental, but in aggregate they shorten payback periods for upgrades and can deliver immediate bottom-line benefits.

Automation is reshaping crushing and screening.

Plant-wide control systems now coordinate feed rates, crusher closed-side settings, screen cut-points and stockpile management to keep material aligned with downstream mill requirements.

Advanced process control (APC) and machine-learning routines analyse throughput, wear and product gradings and recommend setpoint changes to maintain product specifications with

less operator intervention. In practice this translates to steadier ball-mill loads, fewer circulating loads and greater overall plant throughput, outcomes that flow directly to revenue.

Crushers and screens are also a focal point for risk control. Crushing circuits concentrate hazards; moving belts, pinch points, dust generation and highenergy impact zones. Australian mining regulators and guidance materials emphasise engineered guards, remote isolation, clear access protocols and robust pre-start checks for crushing and screening plant.

Proper dust suppression – via cyclones, baghouses, wet suppression or enclosed transfer points – helps to protect worker health and reduce fugitive emissions, while well-designed material flows and

tramp-metal detection protect plant and personnel from unexpected blockages. Integrating safety into equipment specs, rather than retrofitting it later, is a recurring theme in regulatory guidance.

Crushing and screening also plays a role in sustainability beyond energy savings. The right product sizing enables higher value uses for waste and by-products, from aggregates for infrastructure to co-products for downstream processors.

Crushing is key to the construction supply chain, producing road base, rail ballast and concrete aggregates, and careful material segregation reduces waste and creates local supply opportunities. That circularity can make mines more valuable community partners while diversifying revenue streams.

Australian deposits run a wide gamut and each places different demands on crushing technology. Sticky clays can clog cone crushers and block screens; highly abrasive gangue accelerates wear; mixed lithologies demand staged comminution with flexible processing lines. That’s one reason mobile and modular plant designs have grown in popularity: they allow operators to match front-end configurations to local conditions and relocate capacity as project phases evolve.

Environmental approvals for crushing and screening operations increasingly require clear layouts and mitigation plans, so planners must balance throughput with community and environmental expectations.

But the best equipment is only as good as the support model behind it. Operators are prioritising ease of service in areas such as accessible inspection points, standardised spares, sealed bearings, greasing systems that work during operation, and supplier networks capable of servicing remote sites.

A move toward “service sells equipment” is visible in procurement choices. Operators often prefer vendors who offer local parts holdings, condition-monitoring platforms and rapid field response, all of which reduce the downtime that erodes key performance indicators and profitability. Regulators’ maintenance checklists underscore the value of daily checks and structured defect-reporting systems for crushers and screens.

Upgrading to higher-efficiency motors, improving control systems, investing in wear-resistant components and adding condition monitoring often have attractive returns because they reduce ongoing operating costs. Those returns are amplified on diesel-powered remote sites: a kilowatthour saved is a litre of diesel conserved, with immediate flow-through to margins and emissions accounting.

Crushing and screening may not be glamorous, but this processes is central to the resources industry’s ability to meet global demand reliably, cost-effectively and responsibly. For Australian operations navigating tighter margins, decarbonisation goals and community expectations, smart investment in the front-end equipment – control systems, safety design and service models – can unlock productivity and environmental benefits simultaneously.

That combination is precisely what will help the industry grow sustainably in the decade ahead. AM

DEMAND, COMPLEX GEOLOGY AND SHIFTING GLOBAL SUPPLY CHAINS ARE PUSHING RARE EARTH MINERS TO RETHINK THEIR FRONT-END PROCESSING.

Demand for rare earths has doubled over the past decade, with the International Energy Agency forecasting that it could double again by 2050.

That demand is being driven by the central role rare earth elements (REE) play in the manufacture of clean energy technologies such as wind turbines, renewable batteries and electric vehicles. A renewed effort by Western nations to secure supply chains by sourcing REEs outside of China, which has increased export controls on several critical minerals, has further intensified the focus on diversified production.

Australia holds at least four per cent of the world’s rare earth reserves, positioning it strongly for growth. The recent US–Australia Critical Minerals Framework added further momentum to the development of exploration, production and processing capabilities across the country.

However, accessing REEs is not always straightforward.

While traditional processing flowsheets for REEs rely heavily on multiple stages of crushing, screening and grinding, many operations are now investigating alternative front-end

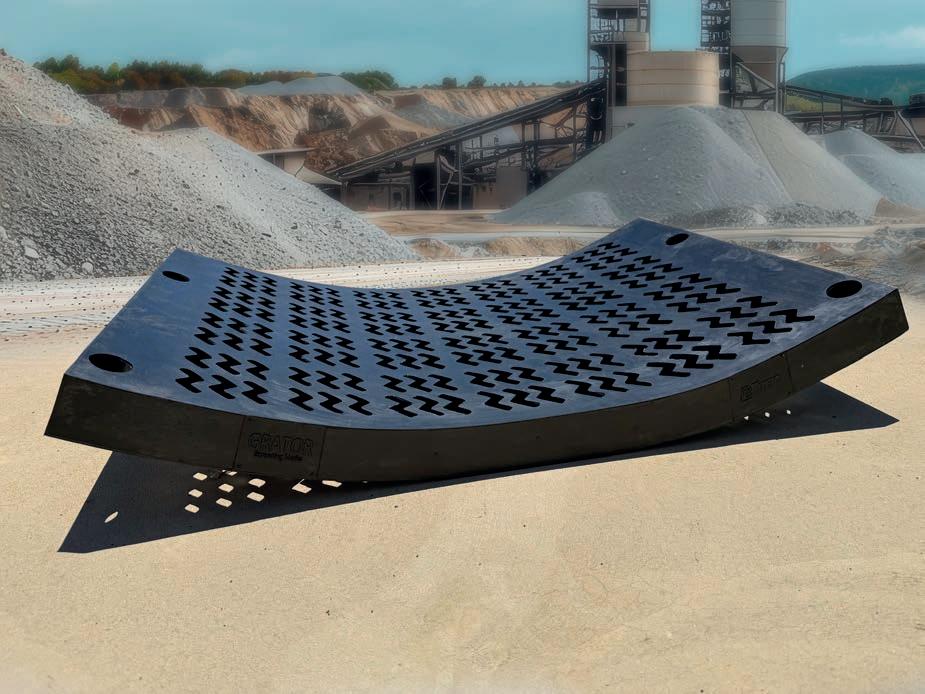

One such approach is in-pit sizing – the use of a Sizer within or near the mining face to condition ore before it leaves the pit.

For rare earth projects, which often occur in complex geological settings with variable textures, weathered profiles and highly abrasive gangue minerals, in-pit sizing offers compelling advantages. These include reducing haulage requirements, stabilising feed to downstream plants and minimising

MMD Group, a leading provider of mineral processing technologies for the mining, quarrying and recycling sectors, is helping REE miners explore this approach.

Established in 1978 to serve the underground UK coal industry, MMD began by designing and manufacturing inline breakers. Early in its history, the company invented and patented the twin-shaft Mineral Sizer, launching the first 500 Series model in 1980.

Today, the company produces a wide range of Sizers, Sizer stations and feeders suited to varied operating conditions.

A Sizer-first alternative

According to MMD Australia West director Morné Coetzee, conventional rare earth comminution circuits in Australia tend to follow a familiar pattern: primary jaw crushers, secondary cone crushers and, depending on the desired product size, tertiary crushing or milling.

While well understood, she said, these circuits require significant structural and civil works, multiple conveyors and transfer stations, and fixed plant locations with limited flexibility. They also generate high levels of dust and fines and demand substantial power in downstream milling.

“Rare earth deposits in Australia, such as monazite- and bastnäsite-dominated systems, often contain a mix of clays, weathered saprolite and harder fresh rock,” Coetzee told Australian Mining

“In traditional crushers, this variability drives fluctuating performance, unstable throughput and inconsistent product size.”

In-pit sizing provides an alternative by conditioning ore to a consistent, conveyable size early in the materialhandling chain.

Selecting the right Sizer begins with evaluating the material properties of the ore being mined and loaded.

Coetzee said REE deposits often present unique challenges because of their complex geology.

“REE deposits, especially lateritic and weathered granitoid-hosted ore bodies, may contain fines and clays that become plastic under moisture,” she said. “Moisture fluctuations, especially in Australian climates, affect material cohesion, stickiness and throughput reliability. Wet or sticky ore can bind traditional crushing equipment, reducing production. A Sizer is designed to process wet and sticky material with a self-cleaning design.

“REE mine designs also have many satellite pits, so equipment still needs to process effectively while remaining mobile. The MMD equipment is perfect for this application.”

MMD works closely with its customers to gather engineering, operational and material-specific data to determine the appropriate Sizer model and configuration.

“It involves identifying the physical properties of the material including, but not limited to, size distribution, MPa [megapascal], abrasion index, moisture content, bulk density, plasticity, oversize frequency and contaminants,” Coetzee said.

“We then consider throughput and production targets, including peak surges and feed consistency. The required product size, combined with the material properties, determines the Sizer model, tooth configuration and speed.

“Other considerations include upstream and downstream processes such as interface heights, discharge angles and transfer points. The initial evaluation also factors in site integration requirements, including footprint restrictions, structural limitations, energy supply and environmental constraints.”

Whether a project is brownfield or greenfield also influences the commissioning process.

“For greenfields, our engineering team can assist with any design, suggesting the best upstream and downstream processing solutions, including feed methodology and transfer point designs,” Coetzee said.

“Brownfields have other considerations. After an on-site evaluation, we determine the best replacement methodology and assess constraints such as pit location, feed consistency, structural limits, footprint, equipment mobility and environmental factors.”

MMD Sizers are available with a range of tooth configurations and purpose-designed gearboxes that cater to a wide spectrum of project needs. But REE operations often require additional customisation.

“While many customers adopt standard options, rare earth operations tend to require more specific modification – especially for tooth

packages, or when oversize frequency or lump shape is atypical and calls for modified tooth height, pitch or breaker bar arrangements. Coetzee said Sizers deliver an advantage over cone or impact crushers when dealing with the sticky or plastic clays common in REE environments, with custom options providing further adaptability.

“Sizers are well-suited to highmoisture environments, and selecting the right tooth configuration depends on the material’s moisture characteristics,” she said.

Other site-specific factors include power-train or footprint restrictions, unusual loading angles and non-standard hopper integration.

With offices and workshop facilities in Brisbane, Perth the Hunter Valley and Mackay, MMD maintains extensive spare-part holdings to support its customers.

“Our technicians are all longterm employees who intimately understand the equipment. We offer service contracts and take pride in our responsiveness,” Coetzee said.

“On-site performance monitoring and optimisation, wear-part supply and planning, operator training,

maintenance support and lifecycle upgrades are all key elements of the service we provide.”

With many Australian REE projects still refining their geometallurgical models, early-stage decisions remain critical. To help de-risk those early commitments, MMD offers flexible commercial pathways that allow customers to validate performance and build confidence before committing to a capital purchase.

With demand for rare earths only set to increase, Australian REE operations can rest assured that MMD Group has a legacy of innovation and implementation that can help unlock rare earths opportunities in all kinds of environments. AM

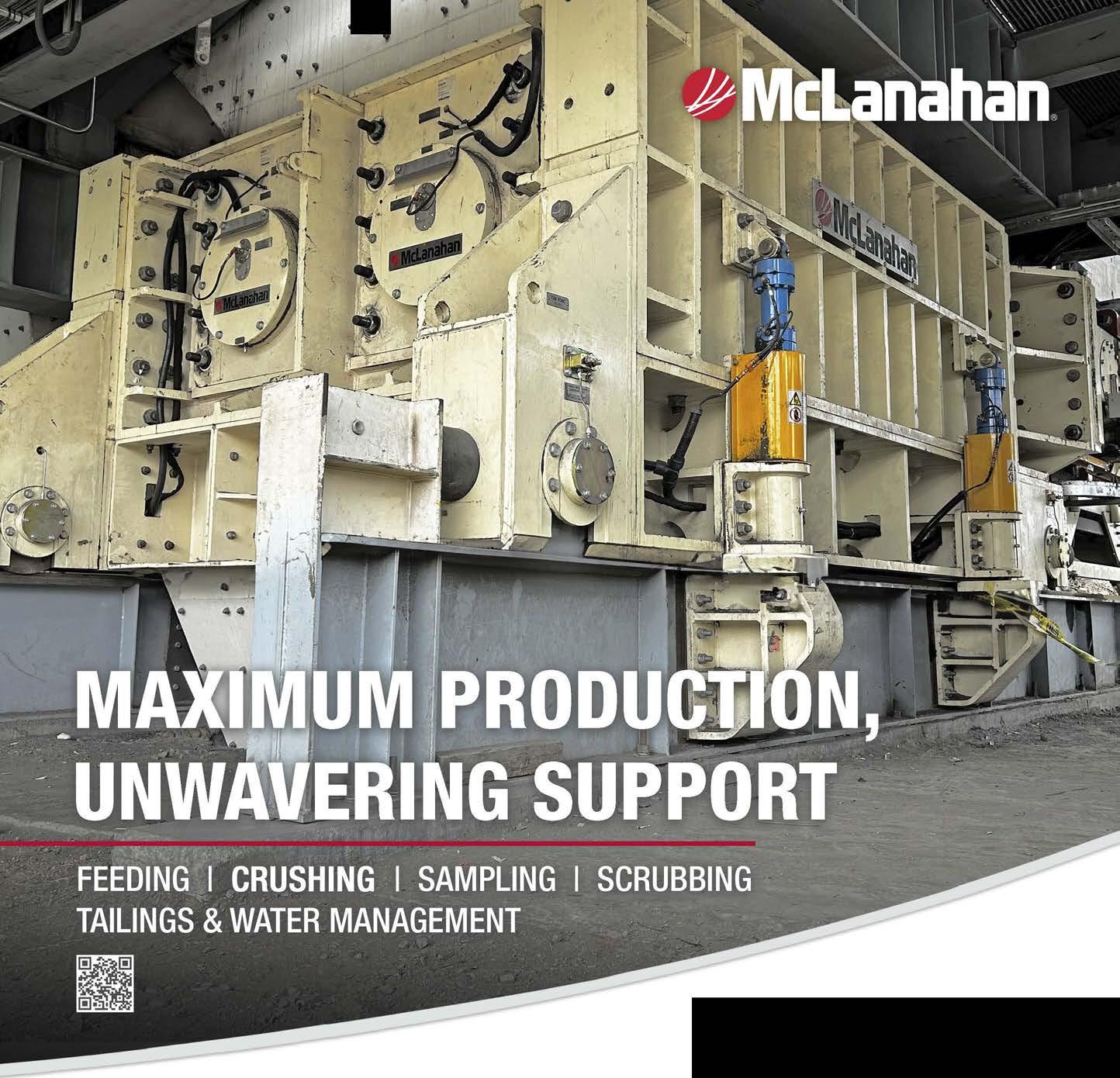

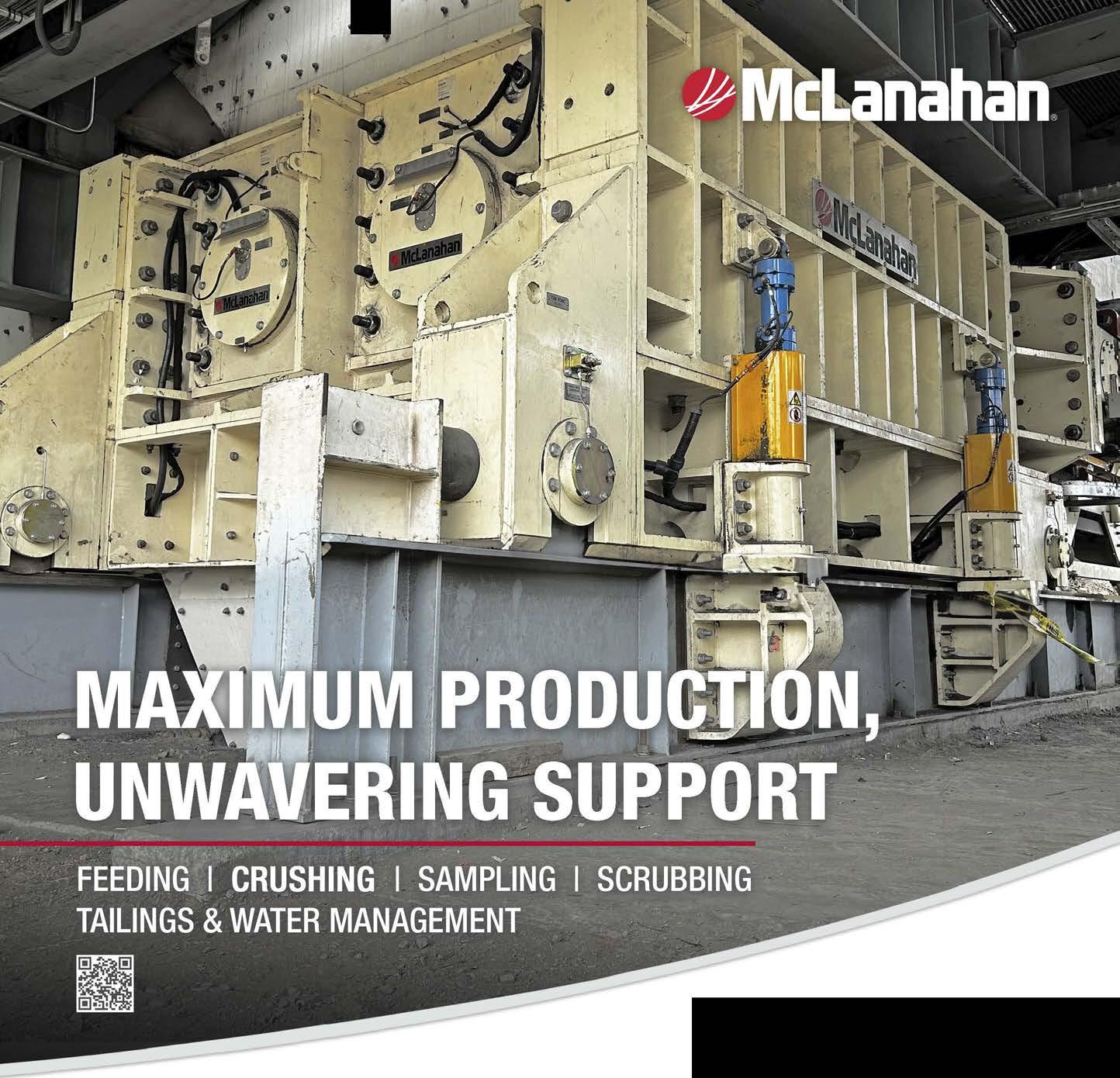

FEEDER BREAKERS ARE BUILT TO TAKE PUNISHMENT, BUT THEIR RELIABILITY IS NEVER ACCIDENTAL. LEARN HOW TO OPTIMISE PERFORMANCE WITH MCLANAHAN.

By breaking down both the engineering principles and the maintenance steps behind reliable performance, McLanahan is helping operators turn everyday upkeep into measurable gains in machine life and production uptime.

Speaking during a recent webinar, McLanahan global product engineering specialist Dave Imler guided miners through the inner workings of feeder breakers, sharing insights that could save downtime and extend machine life.

“Feeder breakers might look straightforward, but these machines are far more complex than they might seem,” Imler said.

“Their performance, reliability and longevity all hinge on operators

understanding the engineering behind them and applying disciplined maintenance practices.”

Feeder breakers are used to break down large lumps of ore or coal and feed them into the processing plant at a controlled rate. And at the heart of every feeder breaker is the chain and flight bar system.

Operators may encounter slip-fit bars, bolted bars, or a combination of both, while most installations rely on engineering-class push-link chains designed to withstand constant impact.

Chain tension is one of the simplest yet most important factors in preventing failures: too tight and shafts, sprockets and bearings are overstressed; too loose and the chain can skip teeth or even drop flight bars.

For ideal chain tension, a slight droop under the head shaft on the return side should be visible through inspection ports, giving operators a clear guide to proper tension.

Adjusting tension is straightforward when done correctly, according to McLanahan. Most machines use hydraulic cylinders and shim packs at the tail shaft, allowing controlled adjustments.

Symmetry is essential. Both sides must be evenly set to prevent misalignment, which can quickly lead to costly damage. Planning for chain replacement is equally important.

Sites that keep full chain and flight assemblies on hand can proactively schedule change-outs, turning what could be a drawn-out downtime event into a controlled, one-day task.

Imler suggests using the right tools that are designed to make the job easier, but stresses the importance of safety.

“Hydraulic jigs and custom fixtures can simplify the process, but safety is paramount,” he said. “Locking out and tagging out before the adjustments keeps operators clear of high-force areas and careful preparation prevents injuries during high-pressure maintenance tasks.”

The drives that power feeder breakers are another critical area requiring attention.

These machines typically use one of three coupling types: safety couplings that shear under extreme torque to instantly decouple the drive; fluid couplings that transmit torque through hydraulic oil like a car’s torque converter; and friction-plate clutches that rely

BREAKER PICKS ARE ENGINEERED TO WITHSTAND HIGH IMPACT WHILE DELIVERING CONSISTENT MATERIAL SIZING.

on spring tension and pad condition, slipping when overloaded.

Each system behaves differently under stress and requires specific maintenance routines to maintain reliability.

Hydraulic conveyor drives introduce another layer of engineering. Variabledisplacement axial-piston pumps control conveyor speed by adjusting the swash plate, while charge pumps maintain system pressure and cooling.

Operators who understand normal pressure ranges, oil flow and

temperature – ideally around 120°F (49°C) – can detect emerging issues before they become major problems.

Mechanical connections also demand careful attention.

Shrink-disc locks, taper-bushing connections and bearings all require precise installation and regular inspection to prevent wear, misalignment or premature failure.

Daily and weekly checks, such as verifying chain tension, monitoring bearings for heat and cleaning dust from

DROP-DOWN ACCESS PLATFORMS ALLOW SAFER, MORE EFFICIENT INSPECTION AND MAINTENANCE.

critical areas, help maintain efficiency and prevent small issues from escalating.

Over time, predictable wear appears on breaker bits, liners around the roll shaft, top-deck plates and chain transition zones. Annual inspections allow teams to plan component replacements before failures interrupt production, turning maintenance from a reactive task into a proactive strategy.

Imler said audits and proactive inspections help to save production and reduce costs.

“We know these machines inside and out,” he said. “Mines should identify emerging wear patterns before they turn into critical problems.”

The feeder breaker, often operating quietly in the background, is a decisive piece of machinery in mining operations.

With the right understanding, regular maintenance and careful planning, these machines can deliver years of reliable performance, even in the harshest conditions. AM

FT2650

MOBILE JAW CRUSHER

•Up to 25% more capacity

•Production rates up to 400TPH

•Optional hydraulic relief

•Aggregate & recycling applications

FT3055

MOBILE JAW CRUSHER

•Production rates up to 700TPH

•50” x 18” pan feeder

•23.6” tracks with dual drive

•Largest crushing stroke in class

BME IS LIFTING BLASTING PERFORMANCE ACROSS AUSTRALIA’S MINING INDUSTRY, DEBUTING A NEW ELECTRONIC DETONATOR PLANT IN KALGOORLIE.

BME’s decision to set up an electronic detonator assembly plant in Kalgoorlie is an exciting milestone that promises big benefits for Australia’s mining industry.

By moving beyond overseas suppliers, the company is investing in local manufacturing that promises supply chain resilience, faster response times and closer support for miners across Western Australia. The new facility positions BME as the first electronic detonator manufacturer in the state, addressing a long-standing industry need.

BME global manager strategic partnerships Rakhi Pathak told Australian Mining the facility will play a central role in meeting growing demand.

“The Kalgoorlie region is strategically located to serve as a key supply hub for iron ore, gold, nickel, lithium and other critical mineral mining customers,” Pathak said.

“Local mining companies have expressed keen interest, as the location gives them significant supply chain security and definite logistical benefits.”

The project has progressed quickly, harnessing BME’s strong international experience.

“This plant utilises proven equipment from our South African operations, including a semi-automated line from our Losberg plant,” Pathak said.

“BME has considerable experience in establishing and operating these facilities, and we have already established a similar facility in Canada as part of our globalisation drive.”

Licensing and compliance were key milestones. BME secured approval to commission and store substantial quantities of class one explosives, including detonators and boosters, following a detailed regulatory process that emphasised safety and transparency.

“We undertook this process with the same diligence as we adopt during all our operations, prioritising engagement with stakeholders such as government regulators and communities,” Pathak said.

The company has spent more than a decade building its Australian presence, primarily through the uptake of its AXXIS electronic initiation system. Growth has been organic, driven by direct engagement with key mining customers, contractors and service providers seeking high-performance, easy-to-use blasting technology.

BME believes the Kalgoorlie plant deepens its commitment, marking the next phase in supporting customers across the country.

“The detonator plant is part of our continued evolution in this primary market,” Pathak said. “We are building infrastructure to support safe, reliable and cost-efficient supply of electronic detonators, high explosives, and a full basket of goods and services for surface and underground customers.”

The shift toward electronic initiation is accelerating in Australia, with mining operations seeking greater control, improved fragmentation and better energy efficiency. As sites move away from shock tube systems, BME’s AXXIS product has gained strong traction.

“As in other markets, mining companies are increasingly recognising the benefits of electronic initiation, driving demand for our detonators as operations transition away from shock tube systems,” Pathak said.

“BME takes pride in the AXXIS product’s market-leading robustness, ease of use, safety and flexibility, qualities that continue to set the benchmark for electronic blasting technology.”

BME has conducted trials across WA mines to demonstrate these benefits, while investing heavily in software and digital tools to further enhance blasting performance.

“Electronic detonation systems are well aligned with the ongoing advancements of the digital age, enabling continuous innovation and improved blasting efficiency,” Pathak said.

“Our BLASTMAP blast design application allows for complex designs to be rigorously trialled and simulated for best results.”

Integration of BME’s in-house blast timing and blast loading software allows for the safe application of advanced timing methods, achieving more useful work from the same explosives without risking vibration or other environmental exceedances.

For example, tools like XPLOLOG provide the data mining teams need for day-to-day performance improvements. Meanwhile, BME’s XPLOSMART

– an artificial intelligence (AI)enabled, comprehensive mine-to-mill software – provides a more holistic and predictive solution by integrating AI-driven insights and advanced geospatial tools across the entire mining value chain.

“This streamlines workflow and ensures continuity of data across the mining operation, optimising not just the blast itself but downstream processes like milling efficiency and resource utilisation, and linking these to financial and environmental, social and governance [ESG] imperatives,” Pathak said.

With the debut of the Kalgoorlie plant, BME is entering a new era in its Australian business, combining local manufacturing capability with digital innovation. AM

Electrification. Critical minerals. Data centres. Fleet transition. Transmission builds. Australia’s mining and resources sector is ramping up fast. To keep pace, you’ll need a delivery partner that’s collaborative, agile, and forward-looking. That’s where Genus comes in.

With hands-on experience from major transmission upgrades like Pilbara EnergyConnect and the Hunter-Central Coast REZ, we know how to bring your project online and into the grid, quickly, safely, and seamlessly.

If you’re looking for a delivery partner who can move as fast as the market demands, trust Genus.

genus.com.au

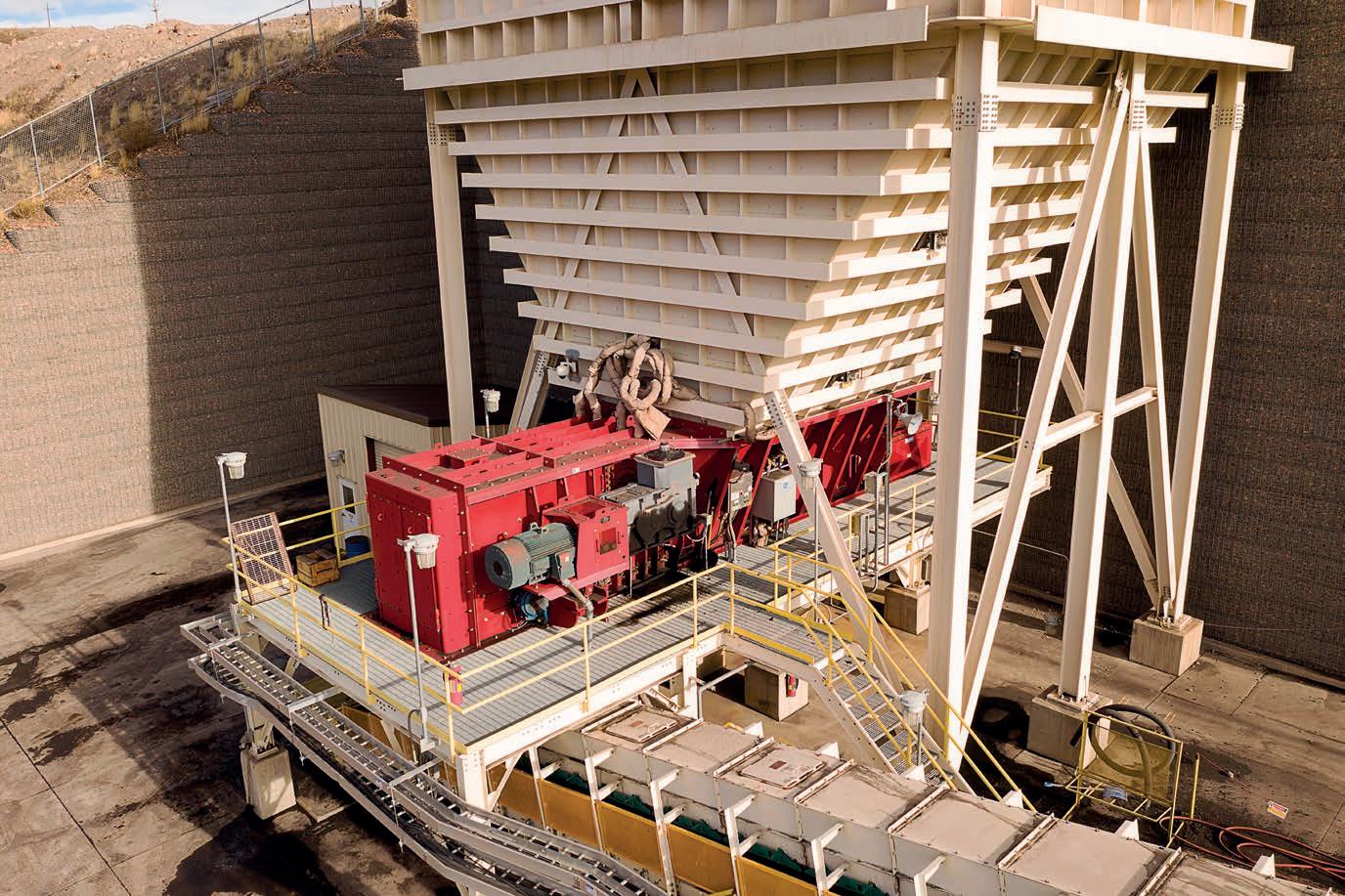

FROM DIESEL-POWERED REMOTE SITES TO HIGH-DUTY CRUSHING CIRCUITS, TECO’S MAXE3 MINING MOTORS PROVIDE EFFICIENCY, RUGGED CONSTRUCTION AND LOW-MAINTENANCE RELIABILITY.

Electric motors account for a large portion of a site’s electrical demand in mining operations, and energy consumption accounts for most of a motor’s cost. That means efficiency is critical.

TECO’s MAXe3 Mining range offers a premium-efficiency solution that can deliver real long-term savings.

“From experience, the cost for a motor when installed is 95 per cent energy consumption throughout its lifetime, so it makes sense that when you select motors that they should be of the energy-efficient type,” TECO Australia sales director Wilfred Krog told Australian Mining

The TECO MAXe3 series, including the larger AFJN series, has a premium IE3 efficiency standard, with many sizes exceeding the minimum efficiency performance standard (MEPS) levels.

Between reduced load demands and efficient operation under full load, the payback period for upgrading from a less efficient motor to a TECO MAXe3, according to the company, often proves to be very short.

“Once the difference is paid back between a less efficient motor to a premium efficient motor, the savings

On remote mine sites powered by diesel generators, every kilowatthour saved translates into lower fuel consumption, fewer emissions and reduced operating cost.

industry, overall consuming costs are becoming more important,” Krog said. “If remote mines sites rely on diesel generators to provide their power, then this energy conversation is even more critical [as] most mine sites have targets to reach with becoming greener.”

The TECO AFJN MAXe3 Mining electric motor is built around a rugged cast-iron, squirrel-cage frame and designed for compactness and strength. According to TECO, the AFJN series offers a 15 per cent increase in power density and a 20 per cent reduction in weight, which helps to maximise space and simplify installation.

Designed for power and resilience, the TECO AFJN MAXe3 is built to handle the extreme conditions typical of mining operations. Those operating conditions often present dust, moisture, high ambient temperatures, vibration, and variable load demands.

TECO has engineered the MAXe3 Mining series to endure these challenges by excluding dust, spray and moisture with its high IP66 rating. Krog said the motors can also “withstand arduous load demands”, whether from vibration or thermal cycling, which is typically experienced on crushers and screens.

“The heavy-duty cast-iron frame with cast cooling fins is one of the heaviest on

the market and is most suitable for these applications,” he said.

Additional thermal protection is also built in. The motors include two sets of thermistors as standard, with one for alarm and the other for tripping. For larger motors, resistance temperature devices (RTD) can also be installed in the stator windings or bearings to provide real-time condition-monitoring.

“Reliability is probably the most important issue that TECO addresses, with a patented grease relief system fitted for bearing maintenance,” Krog said. “This allows the motor to be maintained whilst in operation, whether that’s manually or with auto lubricators.

The motors’ additional rotating labyrinth seals also help to eliminate dust and moisture, which is a significant gain when it comes to extending service life.

With TECO motors designed, improved and innovated over the last four decades, the TECO MAXe3 Mining series delivers a proven blend of efficiency, durability and low maintenance.

These motors are a reliable route to cut energy use, reduce emissions and improve performance while also offering a practical, future-ready choice for modern mine sites. AM

For over 45 years, we have successfully provided pioneering Sizer technology to many industries worldwide. Our tailored mobile, semi-mobile and fixed Sizer stations as well as our latest in-pit innovations, are reliable and efficient answers to reduce the complexity of today’s modern mining challenges.

As a turnkey provider, we have the specialist knowledge and equipment to offer comprehensive services and support. From conceptual planning and design through to manufacture, installation and aftersales service. We are your partner throughout your sustainable journey.

Crushers are the beating heart of any mining operation, working around the clock to break down rock and ore in some of the harshest conditions imaginable.

But with shock loads, vibration and contamination all taking their toll, crusher bearings are often the first components to fail. Timken’s engineering expertise is helping operators change that.

of engineered-surface (ES) coated spherical roller bearings and solidhousing solutions.

“Our ES coatings cover the rollers with a special layer that extends operating life and can handle poor lubrication,” Davies said. “When you combine ES coatings with Timken’s caststeel solid block housing, which is twice as strong as cast-iron alternatives, you get a much more resilient unit for impact crushers and similar applications.”

“Crusher bearings face a combination of contamination ingress, like rock dust and water, and high-impact loading that’s inherent to the application,” Timken national mining manager Mark Davies told Australian Mining “That leads to indentation and material wear from fine ingress, plus additional stress from high-impact loading. Short bearing life is a common outcome.”

To tackle these issues, Timken has developed a range

From primary jaw crushers in hardrock mines to cone crushers in mineralprocessing circuits to impact crushers in coal or aggregate plants, each machine subjects its bearings to unique stresses. Timken’s ES-coated bearings and sealed bearing housing assemblies are designed to handle those variables across the full crushing circuit.

Davies said while failure modes don’t differ dramatically between sites, whether it’s a quarry or a gold operation, the combination of heavy impact and contamination remains constant.

“Every site has crushers and they all face the same enemy: dust,” he said. “Keeping that dust and debris out of the bearing is key to long life.”

Timken’s sealed solid-block housings provide multiple layers of protection.

“We use very efficient primary seals, plus secondary covers, purely to keep the lubricant clean inside the bearing,” Davies said. “That cleanliness gives longer life and minimises wear.”

The ES coating also proves its worth when lubrication conditions are less than ideal, a frequent reality on remote mine sites.

“If we’ve identified indentation from hard-particle ingress as a damage mode, applying an ES coating can extend bearing life dramatically,” Davies said. “It’s particularly good for poorlubrication conditions.”

Proper fit and lubrication are recurring themes in Timken’s guidance for crushing applications. As one of the company’s technical white papers stated, improper fits and poor lubrication are leading causes of premature bearing failure.

“Getting the shaft and housing fits correct is critical,” Davies said. “That’s one of the key areas we can help with; assisting in calculating the right fits for different crushers and vibrating screens.”

Lubrication serves several functions: reducing friction, dissipating heat and ensuring a consistent film between rolling elements.

“[When] using a suitable lubricant, the right type, quantity

and replenishment frequency, is really key,” Davies said. “We’ve got calculators and global experience to help operators determine that.

“Poor lubrication is one of the biggest mistakes people make.”

Timken’s white paper also cautioned that over-greasing can be as damaging as under-greasing, causing excess heat and lubricant breakdown.

Mixing incompatible greases can also lead to premature failure.

Regular inspection, correct viscosity and adherence to original equipment manufacturer (OEM) schedules all play vital roles in maintaining bearing health.

While crushing applications are front of mind, Timken also has its eye on the screening side of the circuit.

“Vibrating screens and feeders are another key application where we do a lot of work,” Davies said. “They predominantly use spherical roller bearings, but they have to be built to a

vibrating spec, with specific tolerances and internal clearances to make sure they operate successfully.”

Brass cages have proven particularly reliable for these applications.

“Other manufacturers sometimes use steel, but we get better results out of the brass cage, so we’ve stuck with that,” Davies said.

Timken’s approach combines advanced materials with field-based engineering support.

“We’re always engaging with operators to identify the real-world failure modes and adapt our solutions,” Davies said. “Every site is different, so it’s about tailoring what we’ve learned globally to what’s happening locally.”

Knowledge is another component of bearing performance. Timken offers training and maintenance programs that focus on correct bearing fitting, sealing and re-lubrication. Its white paper noted that even seasoned technicians benefit from refresher sessions to reinforce best practice and ensure new staff are up to speed.

“Maintenance teams are under pressure to keep production running, but preventive care saves far more in the long run,” Davies said. “If we can help them avoid just one unplanned shutdown, that’s already paid for itself.”

With crushers working at the heart of mining and aggregate production, every hour of uptime counts. Timken’s engineered bearings, coatings and solid-housing systems are proving that careful design and maintenance expertise can make a measurable difference to reliability.

“As the industry pushes for more efficiency and less downtime, our role is to keep machines turning longer and harder,” Davies said.

“The right bearing solution can be the difference between a costly shutdown and smooth, continuous production.” AM

METSO’S HISTORY OF INNOVATION

GIVES

IT A UNIQUE PERSPECTIVE ON MINING PROCESSES AND HOW EVERY COMPONENT IN A CIRCUIT FITS TOGETHER.

Metso’s expertise is grounded in a history of innovation that spans more than a century.

From the steamage inventions of Bruno Nordberg through to artificial intelligence (AI)-driven technologies such as RockSense 3D, the company draws on a lineage of mining innovation with few peers in the industry.

These breakthroughs have made Metso a name synonymous with core mining processes, including feeding, screening and crushing.

Alongside its extensive product portfolio, Metso prides itself on supporting customers throughout the design, establishment and operation of a project. For Metso, the whole is always greater than the sum of its parts.

Metso technology manager –midsize and mobile crushers Asia Pacific – Mustafa Pardawala said a holistic approach to circuit design is essential when consulting on new or existing projects.

“One of the most valuable things Metso provides is process design,” Pardawala told Australian Mining

“We look at the entire flowsheet and simulate the whole circuit rather than treating equipment as standalone.

“Our simulation tools and expertise spans across crushing, screening and feeding, which allows us to ensure that the entire circuit performs as intended. One of the most crucial parts of this is getting the process input information as accurate as possible.”

Early consultation allows Metso to design the crushing, screening and feeding stages as a single system. By engaging at the design stage and using tools like Bruno, Metso can match equipment to ore properties, rightsize crushers and screens and balance loads across the flowsheet, reducing bottlenecks, unnecessary recirculation and downstream issues.

It also gives Metso the opportunity to educate customers, test options through simulation and apply lessons from its large installed base.

Pardawala’s colleagues agree that thinking about the circuit as an integrated whole is essential.

Metso technology manager –screening Asia Pacific – Peter Lundberg

said inefficiency in one area quickly compounds across the system.

“Variability in crusher feed, whether due to fluctuating ore fragmentation, inconsistent particle size distribution, or poor choke feeding, can lead to nonuniform product shape,” Lundberg said.

“Irregular shape and size distribution compromise downstream comminution efficiency, particularly in milling circuits, where predictable grindability and throughput depend on consistent feed characteristics.”

Technology manager – crushing Asia Pacific – Jason Perrella noted similar effects from poor screening performance.

“If we’re not getting the separation we designed for, too much undersize goes to the crusher,” he said.

“Excessive fines in the crushing chamber can cause packing, force spikes and high power draw. Fines don’t need crushing, but they still wear the chamber and decrease efficiency.”

Perrella said poor feeding can also create a force imbalance in the crusher.

“If we’re not maintaining a proper material level in the crushing chamber, slabby and long particles get through and then affect the screen, and so on,” he said.

Perrella believes one of Metso’s biggest strengths is its breadth across the flowsheet.

“We’re not just a crushing, screening or feeding company; we cover the entire mineral processing flowsheet,” he said.

“Our team has shared expertise across all technologies.”

The scale of Metso’s installed base is another major advantage.

“We’ve got well over 100 years of experience designing circuits with these machines, and a huge global installed base,” Perrella said.

“That real-world data feeds into our modelling tools – including Bruno – and into our knowledge bank. It allows us to deliver advanced consultation and

Perrella said one of the most impactful recent technologies has been Metso’s RockSense belt analyser products, which enables particle size distribution measurement.

“With tools like RockSense – using 2D or 3D particle-size analysis on the belt – operators can constantly track what’s coming into and out of each part of the plant ,” he said.

“That enables on-the-fly adjustments to balance the circuit.”

While technologies like RockSense seem far removed from the steam-age innovations of Bruno Nordberg, they share a lineage that has made Metso a trusted name for more than a century. AM

Certified repair / rebuild options 1. RELIABLE REBUILD COMPLETION – ON TIME COMMITMENT*

On-time completion

All variations finalised within 21 days from agreed commencement date

Price

TALK TO YOUR LOCAL REPRESENTATIVE TO SCHEDULE YOUR REBUILD TODAY.

Securing mining contracts has proven a strong pathway to growth for Cooper Civil & Crushing.

After a career in earthmoving, Daniel Cooper started the New South Wales business in 2017. He quickly realised he needed a trusted relationship with a quality equipment supplier for the business to prosper. That’s when Tutt Bryant Equipment entered the picture.

Tutt Bryant Equipment national business development manager –crushing and screening – Paul Doran told Australian Mining that he and his team have worked closely with Cooper over the past five years, developing a relationship that has helped the company go from strength to strength.

“Daniel’s business has continued to enjoy strong growth by taking on opportunities that relate closely to its core disciplines. One example is the processing of ore at a gold mine in central New South Wales,” Doran said.

“The project involved providing supplementary feed to the mine’s primary crushing station using mobile crushing and screening equipment. The start of this project coincided with the arrival of Cooper’s latest acquisition from Tutt Bryant Equipment, the L120330 double crusher from Jonsson.”

With Tutt Bryant’s guidance, Cooper chose the Jonsson model after considering several options.

“I had seen the Jonsson equipment operate in Finland and was impressed enough to buy one,” Cooper said.

The diesel–electric unit combines a two-deck scalper, C120 jaw crusher, 330GP (420hp) cone crusher and three-deck product screen on a single chassis. It can plug into main site power or a dedicated generator, or run off its on-board generator. This flexibility lets operators optimise production using the lowest energy costs available. It turns 500mm run-of-mine (ROM) feed into a 10mm product.

It was Cooper’s 14th purchase of a mobile crusher or screen from Tutt Bryant, a testament to the strength of the customer–supplier relationship.

Doran said the ‘Tutt Bryant way’ emphasises supporting long-term customer growth.

“We don’t want to sell our customers one piece of equipment; we want them coming back to us for all their equipment,” he said.

Cooper’s acquisition of the Jonsson L120-330 highlights Tutt Bryant’s premium range of mobile crushing and screening products, but Doran said the goal is not to sell the biggest or most expensive machine.

Instead, the focus is on understanding how a machine will fit a project and support future work.

“If someone rings up and says, ‘I want a jaw crusher’, we don’t just give them a quote for whatever we

have in stock,” Doran said. “We talk through their options and try to understand their business.

“Once we know all that, we can scope out the best solution.”

Tutt Bryant’s account managers pride themselves on understanding operational challenges and project requirements.

“They’re operational people,” Doran said. “Most of them have run equipment and run sites, and customers know our team understands their challenges.”

Cooper agrees that a relationship with Tutt Bryant extends well beyond the initial sale.

“Tutt Bryant look after me for parts, service work and the occasional tech support requirement,” he said.

Tutt Bryant assists customers during commissioning by preparing each machine at its facility and shipping it to site.

Field service technicians set up the equipment, conduct operator familiarisation and safety training, and ensure users understand controls and maintenance routines.

Technicians stay on site for several days during first operation, overseeing the process and answering questions. They also advise customers on recommended spare parts – especially for remote sites – and provide ongoing support, including remote monitoring through Tutt Bryant’s fleet management system, to ensure reliable performance.

For Doran, working to make sure customers like Cooper Civil & Crushing receive support throughout the entire equipment lifecycle is central to the company’s ethos.

“His success helps our success,” he said. “And that’s a satisfying thing to be part of.” AM

We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency. Our industry leading expertise in crushing, screening, feeding, loading and wear protection allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

MATERIALS AND PROCESSING SOLUTIONS THAT HELP WA MINING OPERATIONS HIT EVERY TARGET.

In an industry often measured by sheer production volume, B&F Consolidated Group (BFCG) is showing that precision and engineering are just as vital to success as the tonnes of ore that are extracted.

Across Western Australia’s mining sector, demand for high-specification materials – from gold processing to aggregates and infrastructure rock for mine sites – has never been greater.

BFCG has capitalised on this demand, positioning itself as a turnkey partner that manages projects from feasibility studies through to production and processing.

Founded in 2017 in partnership with the WA Limestone Group, BFCG combines decades of expertise in crushing and screening with a flexible contract model tailored to client needs.

The company doesn’t simply supply materials; it oversees the entire mining value chain, from drill and blast planning to processing and final product delivery. This integration brings cohesion and consistency to technically complex, high-stakes projects.

“What sets BFCG apart is our dedication to high-end materials with uncompromising quality requirements,” BFCG operations director Johan Barnard told Australian Mining.

“We manage the entire process, using bespoke blast designs, selective mining, customised blending and tailored

crushing solutions to ensure exceptional quality management right up to the final product leaving the weighbridge.”

For clients, this level of control is critical. BFCG produces highspecification aggregates and processed ore for gold and other resource operations, helping to ensure materials meet strict metallurgical and engineering standards.

Aviation-grade pavement aggregates, rip-rap for civil works and bulk process materials are all delivered on spec.

“Our clients don’t just need material; they need confidence that every tonne will meet spec,” Barnard said.

“Every project is meticulously planned, from initial layout to ongoing quality checks throughout production. This precision allows us to deliver on time, on spec and often under budget.”

BFCG’s success also relies on purpose-built crushing plants and advanced software that monitors drill and blast operations, haul logistics, processing metrics and internal quality control in real-time.

Flexible fleet solutions allow the company to scale resources according to operational demands, whether maintaining baseline throughput or ramping up for peak production.

Centrally located in Western Australia, BFCG leverages WA Limestone’s supply chains and local knowledge to navigate the logistical challenges of remote mining sites.

“We’re not just delivering materials,” Barnard said. “We’re shaping the mining industry, mentoring the next generation, and setting higher standards for quality and sustainability.”

By integrating precision-led processes, advanced technology and end-to-end project management, BFCG transforms traditional mining and quarrying operations into strategic advantages for clients.

“We focus on delivering complete solutions that unlock maximum value, particularly on technically complex and cost-sensitive projects,” Barnard said.

“Our goal is long-term sustainability and reliability over the life of the project, not just short-term gains.”

BFCG is redefining how mining materials are produced and delivered, turning precision into a competitive edge for WA’s resource sector. AM

ueensland has seen its share of exciting mining developments over the 12 months. From coal through to critical minerals, the state’s resources sector is firing on all cylinders.

Of course, a world-class resources sector would quickly come to a halt without the support of similarly worldclass mining services suppliers.

As part of its commitment to Queensland’s mining industry, FLS opened a new service centre in Mackay last year to address that very need.

FLS head of site sales, Indonesia and eastern Australia Karl Spaleck said the new centre has been established to play a key role in supporting the state’s mining industry, with a particular focus on north Queensland, including the Mount Isa region.

“We’ve always had plans to grow in north Queensland,” Spaleck said. “It was really just a matter of where we could provide the best service and be closest to our customers.”

Despite already operating centres in Mackay and Rockhampton, there was a recognition from FLS that a larger

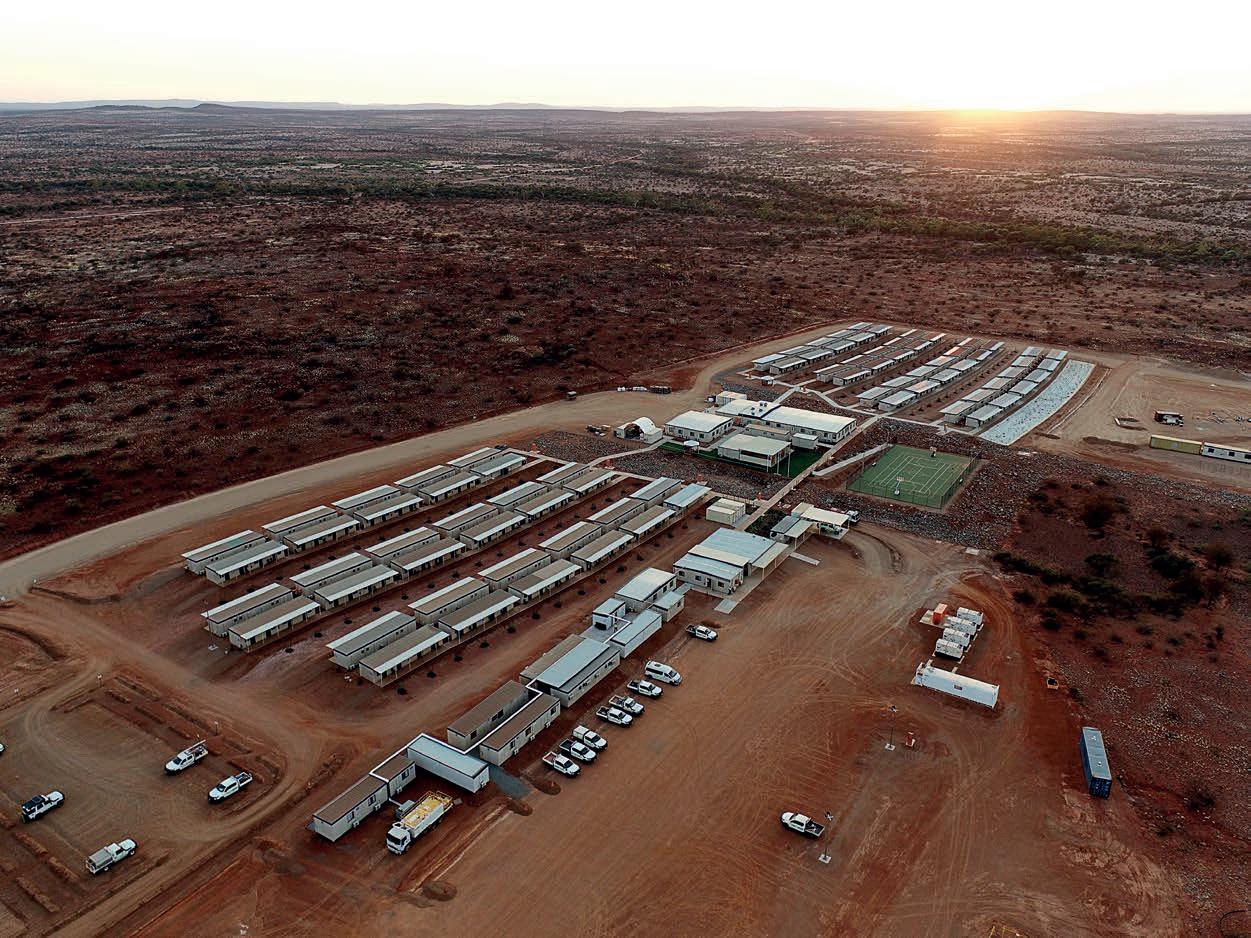

is supplying the gyratory crusher, to coal operations in the Bowen Basin.

To service that growth, FLS had to consider exactly what a new centre should look like and where it should be located.

Spaleck said the smaller centres had reached their limits in size and expansion, which prompted a search for the right site in the best location.

It turned out that Mackay – which sits in the heart of Queensland’s busiest mining provinces, making it a central and easily accessible hub for customers –offered the ideal location.

The new site is also large enough to take on some of the warehousing duties previously carried out at FLS’s Pinkenba service centre, enabling equipment and machinery to be stored closer to operational sites.

“We don’t have to keep everything in Pinkenba now. That has cut down delivery times by about 19 hours, which means a lot less downtime for customers,” Spaleck said.

In addition to being closer to customers, the Mackay facility is designed to handle a broader range of equipment than the company’s previous smaller locations in the region, including major rebuilds of gyratory crushers.

“There’s no problem working on the ABON sizers in there, as well. You can have a workshop, but if the concrete flooring is not up to standard you can’t put an ABON sizer in it.”

FLS carries out extensive work for coal customers, and the new centre provided an opportunity to rethink the best way to service those operations.

“It’s close to our service exchange program, we’re able to do the ABON sizers, and we’re able to do the rebuilds for the owner-operated equipment in the Mackay workshop,” Spaleck said.

Starting with a fresh slate, FLS has built a modern centre engineered to deliver faster access to critical spare parts, complete major equipment rebuilds and broaden the technical support available to miners across the state.

The Mackay centre was one of seven FLS service centres expanded or opened in strategic locations around the globe as part of the company’s renewed focus on mining services and its CORE’26 mining strategy.

Spaleck said the successful establishment of the new centre was helped by being able to draw upon the experiences of the four other major service centres FLS has around Australia. Importantly, it was also shaped by the input and requirements of local customers.

“We knew what we wanted to do with our customers here,” Spaleck said. “We know the region well, and we know Queensland mining well. We feel that this is a service centre that can support our customers well.” AM

The Jonsson L120-330 delivers exceptional performance through its compact yet heavyduty design, offering outstanding capacity built on a proven engineering concept. Equipped with the powerful pairing of the Nordberg® C120 jaw crusher and GP330 cone crusher, this model consistently meets, and often exceeds, customer expectations across demanding applications. Its dual electric-powered crushers not only reduce operating and maintenance costs but also contribute to lower environmental impact. With both crushers mounted on a single chassis, the L 120-330 eliminates the need for reloading between stages and significantly reduces the footprint required for setup, making it an efficient and space-saving solution for highcapacity crushing operations.

COPCO RENTAL AUSTRALIA’S DRILLAIR Y1260 IS PROVING HOW A SINGLE COMPRESSOR CAN LIFT PERFORMANCE FROM THE DRILL PAD TO THE PROCESSING PLANT.

In the mining industry, every piece of equipment must earn its place on site. Compressed air has always been an essential part of drilling and processing activities, yet the methods of delivering this vital resource are changing.

The DrillAir Y1260 from Atlas Copco Rental Australia is more than just a compressor.

“It’s a versatile rental solution, designed to provide mining operations with the exact power you need, when you need it, without the obligations that come with ownership,” Atlas Copco marketing manager David Irwin told Australian Mining

“The Y1260 is purpose-built for drilling applications, offering a substantial flow range of 1126 to 1431 CFM [cubic feet per minute] and pressures reaching up to 35 bar.

“This level of performance makes it a natural fit for deep-hole drilling operations. However, the value of the Y1260 extends beyond the drill rig.”

Once raw material is extracted, it must go through crushing, screening and transport processes, and this is where the Y1260’s adaptability shines.