Green Star

steers the sector

Led by CEO Davina Rooney, the Green Building Council of Australia delivers a record year for Green Star.

FASTENERS SINCE 1935

Upholding our commitment to quality through our NATA-accredited laboratory and close collaboration with key industry partners.

Quality assurance documentation available online at:

REGULAR

4 Editor’s

FEATURE

COVER STORY

GREEN CONSTRUCTION

39 Green Star steers the sector

54 Nina Zundel: Founded on a love of buildings

Aurecon’s Nina Zundel reflects on how an early pull toward buildings set the course for an engineering career spanning multiple states, sectors and structural disciplines.

56 Bojana Zivec: A leader lifting people and outcomes

Bojana Zivec shares how a considered, people-centred approach underpins her work as a project manager at RP Infrastructure.

OPINION

52 Advancing women in the global construction industry

Dr Gretchen Gagel introduces a new global institute dedicated to advancing women in the industry.

ASSOCIATIONS

44 Where culture meets contemporary student living

The National Precast Concrete Association Australia features Wee Hur Y Suites on Margaret, a new addition to Sydney’s student accommodation offering.

46 Webinar ignites global collaboration

The National Association of Women in Construction underscores the importance of male allyship and cultural ambassadorship in the year ahead.

48 We can build it… but we’ll have to work differently

The Australian Constructors Association argues Australia needs to get more productive, and there’s no better place to start than construction.

49 Lifting the next generation of workers

A Women in Cranes and Lifting day held in Campbelltown shows attendees the breadth of opportunity available in the sector.

50 School holiday program raises the bar for workforce inclusion

Empowered Women in Trades profiles a school holiday program easing pressure on working parents at Service Stream.

A year of record certification activity confirms Green Star’s importance to the sustainable evolution of Australia’s built environment.

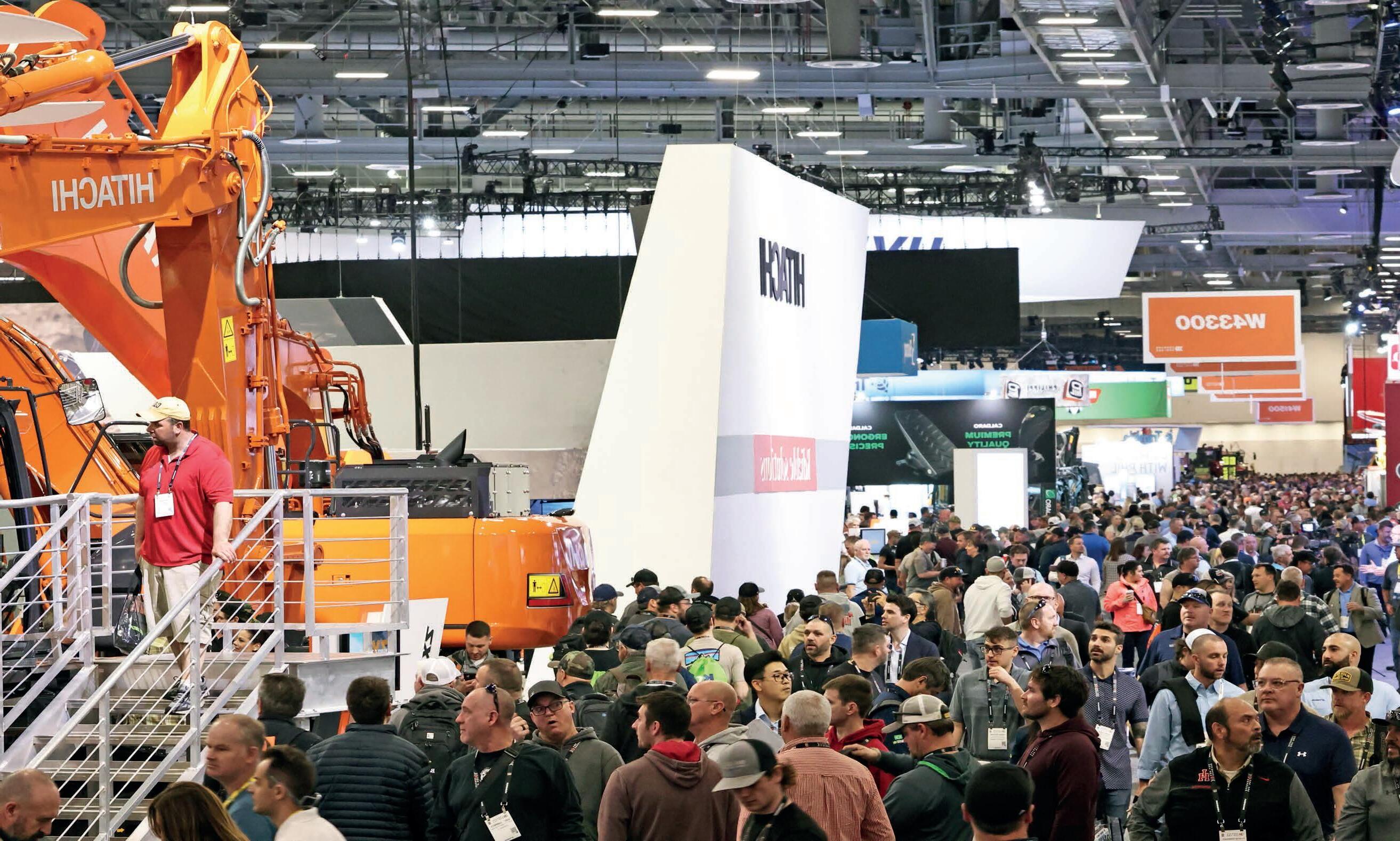

42 It’s a rapidly changing world –be part of the conversation TRANSFORM returns to Sydney in March 2026, uniting sustainability leaders and practitioners from across the built environment.

FOCUS

11 An eye-opening approach to safety

McConnell Dowell unveils how virtual reality is being used to lift safety outcomes across its sites and the wider industry.

14 Lifting the bar

Hobson Engineering details how its lifting hardware range supports safe material movement across complex project sites.

18 Clearing the air on protection

Safety Equipment Australia challenges contractors to consider whether their respiratory protection stands up to real-world conditions.

22 When safety becomes a shared responsibility

Webuild frames safe work as a shared responsibility, embedded across teams and leadership on its projects.

27 Precision without limits

Komatsu Australia brings network-delivered positioning, the newest product in its Smart Construction portfolio, to the local market.

32 Better connected below ground

Powertec Telecommunications calls for in-building connectivity to be treated as essential infrastructure.

From the editorial team

Taking stock and looking forward

Welcome to our first edition of 2026.

The start of a new year invites reflection, but it also brings focus. As 2026 begins, Australian construction carries forward the lessons of recent years, informed by adaptation and hard-won experience. The challenges have not receded, but the sector has become more assured and measured in its response.

This edition looks ahead, focusing less on familiar pressures and more on opportunity across the industry. If the past year is any indication, commercial construction enters 2026 on firm footing. Across the country, project teams have delivered office towers, retail centres, hospitality developments, data centres and life sciences facilities with a level of coordination and technical competence that reflects a sector in good health.

Add to that mixed-use urban renewal precincts, city-fringe commercial hubs and innovation districts, alongside a growing pool of contractors capable of delivering them, and the outlook for commercial construction is encouraging.

Supported by transport, energy, defence, digital and social infrastructure, the forward project pipeline will set the terms of activity for the next decade.

Few milestones carry greater weight than the Brisbane 2032 Olympic and Paralympic Games. The program of venues, transport upgrades and enabling infrastructure now taking form will test construction’s capacity for coordination, legacy planning and long-term thinking. These projects will set benchmarks for how Australia approaches complex, multi-stakeholder programs under global scrutiny.

With all of this opportunity, there is no better time to turn attention to the businesses, solutions and expertise at work across the industry.

Our Green Construction feature considers Green Star certification and its growing role in the sustainable evolution of Australia’s built environment, while also spotlighting a flagship industry event bringing construction and property professionals together to address issues ranging from climate change to nature positive initiatives. This edition covers material handling and lifting hardware, respiratory protection, on-site safety, machine technology and in-building mobile coverage, alongside insights into construction productivity, industry allyship, women in construction programs, cultural change, workforce support initiatives, and projects recently completed and underway. Industry leaders also share career journeys, offer insight into emerging challenges and solutions, and highlight innovation across a range of disciplines. It is an edition that opens 2026 with purpose, and one we hope readers enjoy.

Chairman John Murphy

Chief Executive Officer Christine Clancy

Managing Editor

Mike Wheeler mike.wheeler@primecreative.com.au

Editor Ashley Grogan ashley.grogan@primecreative.com.au

Sales Manager Danny Hernandez danny.hernandez@primecreative.com.au

Design Apostolos Topatsis

Head of Design Blake Storey blake.storey@primecreative.com.au

Business Development Manager Michael Ingram-Casha michael.ingram@primecreative.com.au p: +61 0423 266 991

Client Success Manager Ben Sammartino ben.sammartino@primecreative.com.au

Cover image credit Green Building Council of Australia

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.insideconstruction.com.au

Subscriptions

+61 3 9690 8766 subscriptions@primecreative.com.au Inside Construction is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Construction is owned by Prime Creative Media and published by John Murphy. All material in Inside Construction is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Construction are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Project Picks

This month’s project selection shows how complex, large-scale construction work is being navigated across Western Australia, Queensland and Victoria.

NEXTDC P1 Stage Two, Western Australia

Multiplex

$110 million

Adjacent to the existing P1 data centre at 4 Millrose Drive in Malaga, Stage Two of P1 Perth will double the facility’s current IT capacity. The five-level building represents the fifth data centre Multiplex has been contracted to deliver by NEXTDC. The build is technical, with complexity added by working next to the operational building delivered in Stage One. Sustainable construction practices are driving the project’s delivery, with Multiplex using an electric crane on site to lower emissions. Green concrete has reduced embodied carbon emissions by 65 per cent compared to conventional cement mixes, while prefabricated components – including risers, header pipework and reinforcement cages – are being used to minimise waste and enhance efficiency. The project recently topped out, marking the completion of the structure. Work is now underway on the fit-out of the building’s plantrooms, offices and new data hall.

As part of Stage Two, Multiplex installed the largest satellite antenna array in Western Australia on the roof of the existing P1 building, further boosting its digital infrastructure.

Queen Elizabeth II Jubilee Hospital expansion and new multi-storey carpark, Queensland

Contractor: Built

Current value: $621 million for the hospital expansion and $127.4 million for the multi-storey carpark

Details: Built is delivering the Queen Elizabeth II (QEII) Jubilee Hospital expansion and new multi-storey carpark on behalf of Queensland Health. The project will increase hospital capacity through an additional 112 beds, eight theatres, and expansions and refurbishments of clinical support spaces including medical imaging, pharmacy, pathology and the kitchen. The new eight-storey carpark will deliver an additional 1,379 parking spaces.

Status: Construction is progressing ahead of program and is on track for completion in mid-2027.

Initiatives: Built has leveraged a digital-first approach on this project, using digital modelling from the outset to bring designs to life. This provides clinicians and end-user groups, who typically have limited windows for review and approval, with the ability to immerse themselves in the environment and determine what will and will not work operationally. Using 4D models and virtual reality, rather than presenting drawings on a 2D floorplan, has enabled the team to identify clashes before works start on site, streamline approvals and enhance complex design development, ultimately bringing the project to life efficiently.

Multiplex recently topped out Stage Two of P1 Perth. (Image: Multiplex)

Construction continues on the QEII Jubilee Hospital expansion and new multi-storey carpark in Queensland. (Image: Built)

Community embraces light gauge steel framing.

Extending ‘The Lanes’ precinct, this new 162 place childcare centre will form a cornerstone for Mermaid Waters’ fast-growing community. Intended to build a sense of ‘coming together’, this new state of the art childcare features over 300 individually engineered trusses that were prefabricated from TRUECORE® steel to form the buildings intricate circular shape. Townhouses also marking the banks of the nearby lakeside development have also embraced the benefits of light weight framing for their modern resilient home designs.

Learn more

Project Picks

West Gate Tunnel Project, Victoria

Contractor: A joint venture between CPB Contractors and John Holland

Current value: $10.2 billion (project cost)

Details: The West Gate Tunnel Project in Melbourne was delivered through a partnership between the Victorian Government and Transurban, and the CPB Contractors (a member of CIMIC Group) and John Holland joint venture (CPBJH JV). It involved construction of a new tunnel and new links to the port, the city and CityLink. Work included widening the West Gate Freeway from eight lanes to 12 between the M80 Ring Road and Williamstown Road, as well as construction of a 2.8km eastbound tunnel and a 4km westbound tunnel under Yarraville, a new bridge over the Maribyrnong River, an elevated road along Footscray Road to the Port of Melbourne, CityLink and the city’s north, and new cycling and pedestrian paths.

Status: The West Gate Tunnel opened to traffic in December 2025.

Initiatives: As one of the most technically challenging transport projects undertaken in Victoria, construction required maintaining traffic flows on one of the busiest freight corridors in the country. Beneath Yarraville, the team used some of the largest tunnel boring machines to operate in Australia, navigating complex ground conditions and a densely serviced urban environment. A new bridge and elevated structure were engineered in constrained industrial precincts, requiring precision lifting operations, staged construction over live rail and port interfaces, and continuous stakeholder coordination. The project also delivered new cycling and pedestrian links, threading active-transport infrastructure through established corridors with minimal disruption. Melbourne’s west now benefits from safe, reliable and connected transport infrastructure designed to support long-term growth.

New Women and Babies Hospital Project, Western Australia

Contractor: Webuild

Current value: $1.8 billion

Details: Webuild is the appointed Managing Contractor for the new Women and Babies Hospital and Osborne Park Hospital expansion in Western Australia, as part of the New Women and Babies Hospital Project. Commissioned by the WA Government, the $1.8 billion project will replace the century-old King Edward Memorial Hospital and expand services for women, newborns and families across the state. Located within the Fiona Stanley Hospital precinct in Murdoch, the new Women and Babies Hospital will include inpatient facilities for gynaecology and maternity patients, a neonatology unit, operating theatres, a family birth centre and outpatient clinics. The design places women’s health and wellbeing at its core, creating spaces that support high-quality clinical care, encourage family connection and provide areas for rest and reflection. The expansion of Osborne Park Hospital will deliver enhanced maternity, gynaecology and neonatology services, a mother–baby unit focused on mental health, obstetrics theatres, a family birth centre and additional outpatient clinics. Upgraded support services, including pharmacy, pathology, sterilisation, kitchen and catering, will improve daily operations and ensure a modern, efficient hospital environment for patients, staff and visitors. Status: Construction has commenced for the new Women and Babies Hospital and early site works are underway for the Osborne Park Hospital expansion, with the new facilities scheduled to open in 2029.

The project team used some of the largest tunnel boring machines to operate in Australia.

(Image: Victorian Infrastructure Delivery Authority)

Construction is underway on the new Women and Babies Hospital.

(Image: Webuild)

Both fan units are compatible with Sundström head-tops

SR510 P3 Particle Filter

99.997% filtration efficiency

Wet & dry particle filter

Low breathing resistance 1,300 cm2 filter area

Compatible with Sundstrom filters*

* SR500 can be used with SR510 particle filter and/ or Sundström gas/combination gas filters (organic, inorganic, acid gas, ammonia, mercury)

*SR700 uses SR510 particle filters only

Everything else follows. When Mobile Coverage Fails Indoors,

Carrier-approved in-building mobile coverage, without the cost and complexity of traditional DAS.

Mobile connectivity is critical inside modern buildings. When coverage fails indoors, it disrupts operations, compromises safety and impacts the people who rely on it every day.

Powertec delivers carrier-approved in-building

Powered By

An eye-opening approach to safety

Grounding training in lived experience, McConnell Dowell is using virtual reality to lift safety outcomes across its sites and the wider industry.

university and we have green workers who have never worked around plant before. Our motivation was to increase people’s awareness of blind spots in a meaningful way,” says

“Traditional training methods involve showing pictures on a screen or running through a PowerPoint. Those approaches have value, but they do not give people a real-life experience. We wanted people not only to understand blind spots but also to genuinely

It became apparent that conventional training could take the workforce only so far. Classroom education and toolbox talks could explain concepts, but they could not replicate the pressure of tracking moving plant in a live environment. Even practical exercises had constraints. Crews were invited to sit inside parked machinery to observe the operator’s field of vision, but the logistics were difficult to manage. Machines had to be positioned safely, sessions took time and the approach could not be scaled across large groups or frequent

McConnell Dowell sought a tool that closed the gap between explanation and

McConnell Dowell is using

Greg Evangelakos, health and safety manager for Australia at McConnell Dowell.

FOCUS Safety

“We wanted to elevate the level of respect for operators.”

Participants

lived experience, elevating awareness for all personnel rather than operators alone. The search led to virtual reality (VR).

The team trialled several VR systems, even considering developing one in-house, but none delivered the realism or practicality the company was looking for. Attention turned to Cat Simulators’ SimLite systems.

“There are many options in the VR space and plenty of advertising, but when we found the Cat SimLite unit, we saw something that is highly portable and scalable,” says Evangelakos. “The controls are real Caterpillar controls taken from actual machinery. It is designed by the manufacturer of the plant we use on site, so the cab layout and the blind spots are based on real equipment. It feels like you are in a real machine, and that authenticity matters.”

Cat Simulators systems have long supported operator development, yet McConnell Dowell recognised the potential to extend their value.

“We wanted to increase people’s appreciation for how difficult it is for operators to maintain concentration and remain aware of

After the successful trial of one SimLite unit, McConnell Dowell launched the VR Plant Awareness Training Program, aimed at reducing incidents caused by unsafe or highrisk actions.

The program provides workers with a clearer understanding of the challenges plant operators face, particularly what operators cannot see, which in turn encourages selfresponsibility and safer behaviour around plant. It does this through an experiential learning approach that lets workers view plant operations from the operator’s perspective in a safe virtual environment, while reinforcing the importance of existing control measures such as positive communication.

Using their existing knowledge of typical operating conditions, participants begin with a short online survey accessed via a QR code, rating the percentage of blind spots they believe exist around the machine. They then watch a short instructional video on the simulator controls before starting a pre-set operating task.

After placing the VR headset on and entering the SimLite system, participants sit behind

enter the SimLite system via a VR headset and complete a machinery task from the operator’s seat in a realistic construction environment.

answering questions such as ‘Did the task require more or less concentration than you expected?’ and ‘If you had been operating the machine in real life, would you have been able to identify an approaching person with confidence?’

The training takes about 15 minutes, a duration Evangelakos says is long enough to make an impression yet short enough to maintain focus, particularly for younger workers who enter the industry with different learning preferences.

“Learning has evolved,” he says. “Traditional classroom training, where you sit for an hour staring at slides, just doesn’t work with most new entrants anymore. If participants aren’t actively involved within the first five to ten minutes, they can quickly become disengaged. VR changes that dynamic by gamifying education, making learning interactive and immersive.”

The efficiency gains are compelling. A classroom session might take 20 to 30 workers offline at once, whereas VR rotates participants individually. Up to 30 people can complete the training in a day with minimal disruption to operations.

“It has high educational value and low productivity impact,” says Evangelakos.

McConnell Dowell has taken the program across states and projects, training more than 2,000 employees and subcontractors, including supervisors, engineers, labourers and spotters.

The participant survey found that 96 per cent developed a greater appreciation of the challenges faced by heavy equipment operators, 93 per cent increased their awareness of blind spots, and 91 per cent reported that operating heavy equipment required a higher level of concentration than expected. It also showed that 95 per cent considered the VR plant simulation to be a good learning tool, 83 per cent found it hard, or were unable to keep track of, their surroundings, and 85 per cent found it difficult to notice what was happening around them while operating the simulated equipment.

“Participant feedback has been outstanding,” says Evangelakos.

“We have had people say they will change how they approach plant because they now understand how dangerous it can be.

“We had a planner responsible for designing site compounds who said the experience made them rethink how they design work areas to give operators more space. That is a major impact.

“It means we are not only influencing behaviour around plant but also improving the design of work areas themselves.”

Seeing these positive results and aiming to create broader industry impact, McConnell Dowell purchased two additional units. One was provided to Box Hill Institute TAFE for 24 months to incorporate into training for thirdyear plumbing and carpentry apprentices.

“For too long, we have waited until workers arrive on site, then tried to pair them with a mentor,” says Evangelakos. “By engaging with TAFE, we reach people before they enter the workforce. That is where the next generation of workers are coming from.”

The other unit was made available for other construction companies to loan at no cost.

“Improving how McConnell Dowell operates is one thing, but we also have a responsibility to give back to the industry,” says Evangelakos. “We did not want to internalise a tool that can improve safety outcomes. Making it available to the industry allows others to benefit, and the uptake has been impressive.”

The program’s expansion reflects McConnell Dowell’s commitment to lifting safety standards across the sector. By improving understanding of plant operations at every stage of a career, from apprenticeship through to site leadership, the company is contributing to a workforce that is more aware, better prepared and committed to safer behaviour.

Information on the VR Plant Awareness Training Program, including booking enquiries, is available via McConnell Dowell’s website.

“Improving how McConnell Dowell operates is one thing, but we also have a responsibility to give back to the industry.”

The Cat SimLite unit features genuine Caterpillar controls.

Material handling and lifting

Lifting the bar

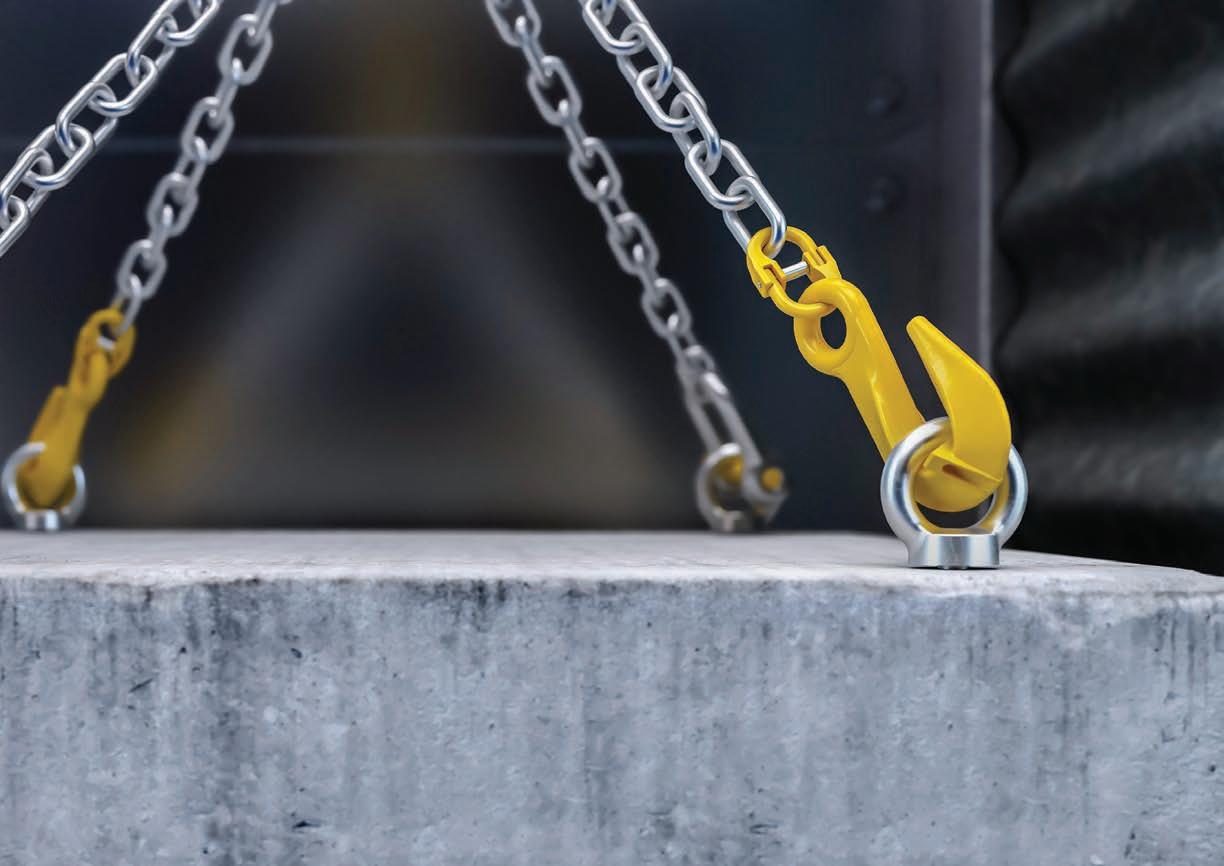

Hobson Engineering’s lifting hardware underpins the safe movement of materials on complex project sites.

Material handling and lifting now sit at the centre of modern construction delivery.

High-rise developments, industrial builds and infrastructure projects are compressing staging areas and accelerating programs, forcing cranes, hoists and rigging systems to work closer to their limits. The connection points – eye bolts, hooks, shackles and lifting points – often dictate how a lift behaves once it is under load. That increased pressure has made the performance of individual lifting components far more consequential.

With the scale and frequency of lifts increasing, the risks tied to low-grade or undocumented hardware have multiplied. These vulnerabilities remain embedded across many sites, prompting Hobson Engineering to focus on the relationship between specification, documented performance and real-world use.

A tightening lifting landscape

Alan Washburn, national product and market development manager at Hobson Engineering, describes a market that is “steady but under pressure”.

“Construction activity is strong in many regions, and that naturally feeds ongoing demand for lifting components,” says Washburn. “At the same time, there is more scrutiny around safety, specification and compliance than ever before. It is a market that rewards quality and exposes shortcuts quickly.”

Shrinking budgets and stretched labour have increased the temptation for project teams to substitute lower-grade hardware.

“Across our range, and lifting is a significant part of that, we are seeing a tightening environment. Material costs soared after the COVID-19 pandemic, and some companies

Hobson Engineering tests lifting components to the required standards and adds further assurance with magnetic particle inspection. (Image: Hobson Engineering)

have struggled. That creates pressure on procurement teams and builders to save money wherever possible,” says Washburn.

“The problem is that compliance cannot be trimmed. The biggest risk we see is an assumption that all lifting components are created equal. They absolutely are not.”

Non-compliant hardware often mirrors certified components in appearance yet behaves unpredictably under load. These are safety-critical parts carrying weight above crews and equipment, and the margin for error is thin. A single failure can result in severe injury or loss of life and cause project delays, investigations and extensive rectification work. In many cases, the rectification cost of replacing undocumented or unsuitable hardware exceeds the initial saving.

Recent incidents have highlighted how easily lifting risks escalate when connection components fall outside the specification. Regulators and asset owners have responded with firmer procurement controls, more detailed inspections and stronger documentation requirements. Contractors are now expected to demonstrate not only that hardware is certified, but that it can be traced directly to its batch and test report.

Suppliers with transparent documentation and stable manufacturing controls are becoming essential partners as reliability rises to the top of procurement criteria. Hobson Engineering has aligned its lifting portfolio with these expectations through disciplined testing and traceability.

Products that hold the load

Hobson Engineering’s lifting range includes eye bolts and nuts, slings, shackles, hooks, weld-on lift points, and chain connectors and master links. These products sit at the core of day-to-day lifting activity on highrise, industrial and civil projects, where loads are constantly being moved, positioned and secured.

In construction, this hardware is relied on for structural steel erection, precast placement, mechanical services installation and the handling of formwork and reinforcement. In fabrication yards and staging areas, weld-on lift points and shackles support repetitive lifting tasks, while slings, hooks and chain

connectors form the assemblies required for heavier or more complex movements. Together, these components form the connection systems that determine how material is managed safely across a project.

“By supplying compliant products suited to these demanding tasks, we provide hardware that sits at the centre of safe and reliable materials movement,” says Washburn.

Standards, testing and traceability

Lifting components are governed by standards that outline how they must be manufactured, tested, marked and applied on site. These requirements govern material properties, load behaviour and performance under stress.

“Standards guide everything we do. We know exactly what requirements each product must meet,” says Washburn. “Some suppliers might claim full testing when only batch testing has been done, or they may not test to the correct load. It is easy to make broad claims, but much harder to invest in proper testing.”

Hobson Engineering tests its lifting components in accordance with the relevant

“Certification

and traceability – they go hand in hand.”

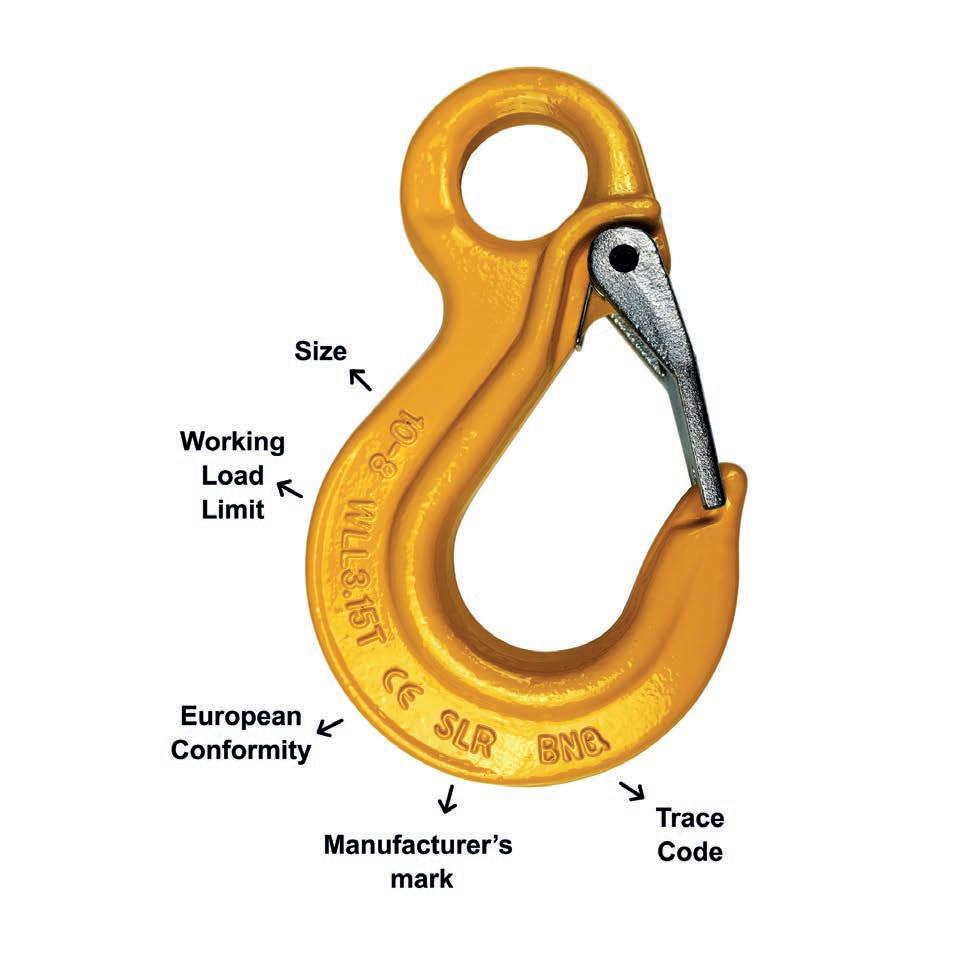

Every mark matters. Find all safety markings on Hobson Engineering lifting components. (Image: Hobson Engineering)

FOCUS Material handling and lifting

Lifting components differ in design and strength. Assuming they are all the same is dangerous. (Image: InWay/ stock.adobe.com)

“It is a market that rewards quality and exposes shortcuts quickly.”

standard and applies an additional layer of inspection through magnetic particle testing.

Traceability is now an expectation across lifting activity. Hardware that once relied on packaging for identification is now required to carry permanent markings that remain visible throughout its service life. Hobson Engineering stamps the trace number directly onto each component, giving installers, supervisors and inspectors an immediate link

“Our test reports are publicly accessible,” says Washburn. “Anyone can enter the trace number on our website and retrieve the certification immediately. We want traceability to support on-site checks, not complicate them.” Markings also help distinguish certified hardware from lookalike alternatives. Safe working loads, batch trace numbers and CE identification provide visible indicators of how and where a component has been manufactured. CE identification, while not required in Australia, confirms that the component has been produced under recognised European quality controls.

Awareness on the ground

Although lifting hardware is critical, it is often selected on site rather than specified in detail during design. This creates added exposure,

shackles and eye bolts should be treated like lives depend on them. Because they do. (Image: wanfahmy/ stock.adobe.com)

Hooks,

Contractors must now prove that hardware is not only certified but also traceable to its batch and test report. (Image: APchanel/stock.adobe.com)

“Welders require formal training before they can work on a project, but there is no equivalent for lifting hardware or even general fasteners,” says Washburn. “A carpenter, bricklayer or electrician might be incredibly skilled in their trade but may not know the correct installation method for a nut and bolt or lifting eye. Incorrect installation of lifting hardware can cause catastrophic failure even when the product itself is completely compliant.”

Without structured training pathways, much of the knowledge required for safe lifting practice is absorbed informally on site. Clear documentation, visible markings and easily accessible reports are becoming key tools that help crews make informed decisions on the job.

A maturing lifting environment Washburn notes that compliance continues to be the strongest force shaping the material handling and lifting sector.

“When incidents occur, there is always public discussion and promise of action, but ongoing enforcement is limited,” he says. “We would like to see more routine testing requirements and more oversight, similar to what exists for fire systems or other regulated components.”

Construction teams increasingly seek supply chains they can verify. They want components that can be linked to their test reports, documentation that is accessible on site and hardware that has been tested to the relevant standard’s requirements.

Hobson Engineering contributes to this maturing environment by combining testing discipline, permanent traceability and transparent documentation to support safer lifting practice.

Asked for the main message he wants contractors to take from this, Washburn says, “Certification and traceability – they go hand in hand. A test report is only valuable if you can match it to the product in service. That is why the stamped trace code is essential. Combine that with the CE marking and you have confidence that the hardware will perform as required.”

As lifting tasks grow in complexity, the sector is moving towards hardware that can be verified quickly and trusted without hesitation. The focus on specification, compliance and traceability is now driving more informed on-site decisions, and connection hardware is recognised as a key control point in managing lifting risk across Australian construction.

“We provide hardware that

sits at the centre of safe and reliable materials movement.”

Clearing the air on protection

Australia is challenging contractors to consider whether their respiratory protection stands up to real-world conditions.

deeper digs to increasingly hazardous materials, are pushing contractors to reconsider what constitutes ‘adequate’ respiratory protection under live site conditions. The challenge is that compliance is easily mistaken for safety, as though meeting the minimum standard equates to genuine protection, when in reality their workforce is less shielded than they believe.

For Safety Equipment Australia (SEA), that’s not good enough.

Respiratory protection in construction refers to the equipment and practices used to prevent workers from inhaling hazardous airborne contaminants created during common tasks such as cutting concrete, grinding, drilling, welding, spraying and demolition. These activities can release fine particulates, silica dust, fumes, vapours and other substances that travel into the lungs and contribute to long-term illness.

Effective respiratory protection involves selecting the right type of respirator for the task, ensuring it fits and performs correctly, and using it consistently whenever a worker

as tunnelling, demolition and enclosed spaces, respiratory protection becomes a critical measure that sits alongside ventilation, engineering controls and safe work systems to reduce exposure to acceptable levels.

Airborne hazards have always been part of construction work. What has changed is the clarity with which those risks are now understood. Silica, in particular, has pushed respiratory protection higher on the agenda for large-scale projects, demolition jobs and tunnelling works.

Yet there are still shortcomings in how respiratory protection is understood and applied. That gap between ‘baseline compliance’ and ‘best-available protection’ is where SEA managing director Graham Powe believes the sector still has ground to cover.

The risks behind minimum standards

“Most reputable companies are taking a serious approach to respiratory protection. Many implement a respiratory protection program, which is required in the Australian standards,” says Powe.

The SR500 offers both gas and particle respiratory protection. (Images: Safety Equipment Australia)

“There are also companies that are just looking to tick the box. If you have a small team of people working for an employer and they all need respiratory protection, but they have beards and do not want to shave, then the company has to go to a loose-fitting head-top.

“The temptation for a small company is to buy the cheapest product that fits that design concept. There are products on the market that, in real terms, give a lower level of protection.”

Loose-fitting head-tops differ fundamentally from tight-fitting face pieces, which rely on an airtight seal and require the wearer to be clean-shaven and fit-tested. Loose-fitting head-tops, by contrast, do not form a facial seal. Instead, they create positive pressure inside the hood by delivering a constant flow of filtered air from a powered-air purifying respirator (PAPR) unit. This makes them suitable for workers with facial hair, but it also means the protection level depends on airflow performance rather than a physical seal.

“When people are working hard, their breathing rate increases, and when the breathing rate increases, the speed of the air moving in and out of the lungs is much higher,” says Powe.

“If someone is consuming 40 litres of air a minute in volume during heavy work, they could have instantaneous air flows of 160 to 180 litres a minute on an inward breath. If your fan unit only delivers 120 litres a minute, you will outbreathe it and the pressure will go negative. As soon as it goes negative, there is a high chance of inward leakage of contaminant.

“A tight-fitting full-face piece connected to a PAPR gives a much higher level of protection. But you have to be clean shaven, otherwise you can have inward leakage if you are not careful.”

The issue, he says, is that the Australian standard test requirements for PAPRs set a relatively low bar. AS/NZS 1716 specifies the baseline requirements for manufacturing and performance of respirators used to protect against harmful or oxygen-deficient atmospheres. If the only question asked in procurement is “does it have AS/NZS 1716 approval?”, then differences in performance can go unnoticed.

originally with half and full-face masks and entering the PAPR market in the early 2000s. What distinguishes Sundström, Powe explains, is engineering designed to reduce exposure as far as practicable, not just to the occupational exposure limit.

“Their objective for respiratory protection is to bring the user’s exposure to contaminants as close to zero as possible,” says Powe.

“Some other brands aim to get the wearer down to what is considered the occupational exposure level. The difference is that, over the past 20 years or more, occupational exposure levels have been reduced for different gases, chemicals and particulates. What was considered safe 10 years ago might not be safe now.

SR700 is designed for use with tight-fitting and loosefitting head-tops, providing protection in wet and dry particle environments.

“With Sundström, end users can be rest assured they are getting the highest quality and highest protection levels on the market.”

The

FOCUS Safety

“There are products on the market that, in real terms, give a lower level of protection.”

“When Sundström works with its engineering team, the project is not just to manufacture a product that meets the European, Australian and US standard requirements, but one that exceeds those requirements in terms of material quality, performance, service and technical back up.”

Inside the SR500 and SR700

To illustrate that focus on protection, Powe points to the Sundström SR500 and SR700 PAPRs.

The SR700 is the lighter of the two systems, designed for loose-fitting head-tops used across wet and dry particle environments. It pairs with Sundström’s SR510 P3 particulate filter – a unit engineered to capture 99.997 per cent of particulates – and offers airflow settings of 175 and 225 litres per minute that maintain positive pressure inside loose-fitting hoods, shields and helmets. By removing the need for gas filtration components, the SR700 reduces weight on the body and simplifies operation for workers engaged in grinding, cutting, sanding or other dust-generating tasks.

The SR500 is configured for more complex exposure conditions, offering both gas and particle respiratory protection. It uses the same P3 particle filter as the SR700, but can also be fitted with a range of threaded gas and combination filters to manage

combinations. With airflow settings designed for higher-demand tasks – 175 and 240 litres per minute – the SR500 allows contractors to move between silica dust, solvent-based products and mixed hazards across a shift without changing blower platforms.

“Both units are compatible with all Sundström head-tops,” says Powe. “A lot of people do multiple job types where they might be exposed to gas and particulates on one job and then only particulates on the next. They might buy the SR500 so they do not need to worry about having different units.”

The SR500 and SR700 are also built around sustained airflow performance, an area that separates minimum-standard equipment from systems that genuinely safeguard workers. Each blower continuously monitors resistance in the hose, filters and pre-filters, and alerts the wearer through sound, light and vibration if the unit can no longer maintain safe flow. This becomes critical during heavy physical work, when rising breathing rates increase air demand and raise the risk of inward leakage.

Comfort, wearability and flexibility

Respiratory protection is rarely associated with comfort, yet Sundström continues to refine wearability without diluting protection.

A PAPR is comfortable to wear because

The SR700 with the tight-fitting SR200 full-face mask is ideal for environments with high levels of dust concentration, such as asbestos.

and the use of loose-fitting hoods or helmets eliminates the need for a tight face seal. The blower fan pulls air through the filter, reducing the effort required to breathe.

“The design of Sundström head-tops focuses on making them as light as possible without compromising the protection levels. They have a good head harness, Sundström’s own design, not something bought in,” says Powe.

“The direction of airflow inside the head-top is designed so it is not blowing into the user’s eyes. The flexibility of the hose between the head-top and the fan unit, and the way the fan unit is supported on the body, are all carefully considered.

“Ergonomic design is very important. There is still some weight, it is still extra equipment, but Sundström has a strong focus on minimising the impact the wearer feels from the unit.”

Standards, fit testing and frameworks

Behind the hardware sits the architecture of respiratory programs: standards, frameworks and the guidance that ties them together.

AS/NZS 1716 is the familiar reference on product approval, however Powe is careful to point out that while it is essential, it does not tell contractors how to choose and use products in context.

“It does not do as much for the end user as people might think. It is the standard that the products themselves have to be approved to, so it is still important and everybody should look for it,” says Powe.

“The standard that end users should refer to is AS/NZS 1715. That is the one for the user. It has many guides on how to make a selection and what protection levels you get for different contaminants.

“In that standard, fit testing is compulsory for people using tight-fitting face pieces, and it is expected to be done annually or if there is any change to the person wearing it, such as teeth being removed or scars or other changes to the face.”

SEA has been involved in fit testing since the late 1980s and participated in the development of the RESP-FIT program, the accreditation framework under the Australian Institute of Occupational Hygienists (AIOH). As a sponsor of the program, the company now steers end users towards RESP-FIT accredited fit testers

while continuing to train distributors across its national network.

At the same time, international standards are shifting. Australia has adopted new ISO standards for respiratory protection that will run alongside existing Australian and New Zealand standards before taking effect in 2027.

The incoming ISO frameworks will create more defined performance tiers for different respirator classes, including PAPRs, making it easier for contractors to align equipment selection with the conditions on site.

“If we just talk about PAPRs for instance, at the moment they all have the same protection levels in the standards, no matter how much flow rate they provide,” says Powe.

He explains that the new standard provides guidance for end users on aligning protection with exposure levels, while creating an incentive for manufacturers to develop equipment that satisfies the four designated protection tiers.

“In the future, the standard will position existing products like Sundström at a higher level and help people make a more informed choice,” he adds.

The next frontier

If there is one message Powe wants the industry to absorb, it is that loose-fitting PAPRs are not a catch-all solution.

“I would like them to better understand that loose-fitting head-tops have limitations, particularly where hard work is involved on hot days. They need to reconsider that and, in certain situations, they need to use tightfitting face pieces,” he says.

“Not all PAPRs perform the same. They have different flow rates, and some do not even meet the flow rate they claim. With Sundström, end users can be rest assured they are getting the highest quality and highest protection levels on the market.”

SEA’s challenge to contractors is to look beyond the approval sticker and treat realworld performance as the measure that should guide their decisions.

With nearly half a century of respiratory protection experience, 140 distributors nationwide, educational resources and a trained support team, the company is well placed to help drive a more informed approach across the industry.

“A tight-fitting full-face piece connected to a PAPR gives a much higher level of protection.”

FOCUS Safety

When safety becomes a shared responsibility

Across Australia, Webuild grounds its projects in a culture that connects every team member and all levels of leadership to a shared understanding of safe work.

“Safety is the foundation of everything we do.”

In the words of Shannon Spark, vice president of QHSE at Webuild in Australia, it functions less as a slogan and more as an operating framework that shapes decisions, interactions and expectations across the company’s international footprint.

“It is integrated into our core processes, training, competency frameworks and the values that guide the business. We have a commitment to target zero, which means we hold a clear position that even one accident is unacceptable,” says Spark.

“We empower every person on our projects to speak up, intervene and stop work if something is unsafe. Safety for us is not only compliance; it is fundamental to how we plan, execute and deliver work. It is our DNA.”

Safety is treated as intrinsic to Webuild’s culture. Across its projects, safe work is a shared responsibility, achievable only when it becomes instinctive on site rather than an exercise in compliance.

This thinking underpinned the introduction of the Safety Builders program in 2017, now embedded in all new projects globally. It provides a stable structure aimed at fostering a safety culture that elevates leadership capabilities at all management levels, but its strength lies in the way it is adapted to the conditions and realities of each project.

In Australia, that means delivering the program in a form aligned with local construction settings and the way work is planned and carried out on site. It also addresses the cultural dynamics present across diverse teams and considers how consistent messages, effective conversations and shared expectations can support a pathway toward zero harm.

More than that, Safety Builders is an ecosystem, with what Spark calls a “cascade” of sub-programs – including the Senior Leader program, the Frontline Leader program and training on the Safer tool – each designed for a different tier of the workforce.

“It begins with leadership engagement,” she says. “We bring together senior leaders, clients, joint venture partners and other key decision makers. We take them through what Safety Builders is, why it matters and how it works. From there, the group defines an agreed safety vision for that specific project.”

The Frontline Leader initiative engages those making decisions and overseeing the planning and execution of work on site. First implemented in Australia on the North East Link in Melbourne, which is still underway, it considers cultural sensitivities, the combined surface and underground construction environments, the dynamics of a city-based workforce and the measurable indicators of safety climate and on-site behaviour. It continues to be refined through these insights, supported by feedback and assessed throughout the life of the project.

Since its implementation, notable shifts have emerged on site, including changes in the language used by crews.

“People began referring to themselves as Safety Builders. They would talk about their safety vision. They would place their personal commitments on a dedicated wall. That visibility turned accountability into something shared and tangible,” says Spark. “We also saw strong support from senior and project

The Frontline Leader program was created to address the unique challenges faced by frontline supervisors in Australia’s construction industry. (Images: Webuild)

leadership to ensure every worker participated, including subcontractors. Full participation is a core part of making the culture consistent across the team.”

Safer, a practical engagement tool that brings the culture to life on site, is central to the program. It is a small card that sets out how to start an interaction, address the focus of the conversation, frame the safety context, encourage safe actions and reflect on consequences.

In all of these programs, cultural sensitivity is prioritised. Webuild’s workforce brings different ethnicities, education levels, skill sets and understandings of how they fit into a project structure. Cultural sensitivity requires the safety content, facilitation style and tools to be understood and used across all of those groups. That inclusivity is essential in a diverse construction environment.

They also help cultivate psychological safety, opening the way for candid, constructive conversations. Those discussions may be about positive behaviours, unsafe behaviours, or simply trying to understand why a task is being performed a certain way. They create space for honesty, clarity and change.

Spark says psychological safety is especially important during periods of rapid change, which are common on construction projects.

“These exchanges help leaders understand how crews are coping, what pressures they are experiencing and how accessible support feels,” she adds.

Central to this environment is the Stop Work Authority. Every person, whether a staff member or subcontractor, has the authority to intervene. Webuild supports that responsibility with a structured reporting and review process to assess what activity was stopped and what changes may be required.

“We have a commitment to target zero, which means we hold a clear position that even one accident is unacceptable.”

Shannon Spark, vice president of QHSE at Webuild in Australia.

Since its launch, Safety Builders has engaged more than 20,450 participants.

FOCUS

Webuild’s safety tools and systems are designed to engage a diverse workforce through inclusive training and empowerment.

“Safety is the foundation of everything we do.”

“People will not speak up unless they feel psychologically safe and believe their voice has value. If nothing happens after they raise a concern, the culture deteriorates. We want the opposite. We recognise and reward people who exercise their authority and we reinforce the importance of intervention in pre-starts, toolboxes, inductions and training,” says Spark.

“Positive recognition is equally important. Understanding what is working well helps us drive improvement across all projects and reinforce the behaviours that lead to success.”

Since its launch, Safety Builders has delivered 1,175 workshops and more than 73,300 hours of training across 81 projects globally, engaging more than 20,450 participants. Speaking to its impact, Spark says having a unified safety culture and leadership approach across global operations gives Webuild a reliable footing for project delivery. It aligns diverse groups of workers around shared expectations and behaviours.

But Webuild does not measure success solely by the number of programs delivered. While improvements in safety outcomes are consistently tracked, the company also seeks feedback from participants on site, inviting their observations and suggestions for improvement. Responses so far have shown a 97 per cent satisfaction rate for the Safety Builders program in Australia.

“We engage specialist facilitators who work with our project teams. After each workshop we seek feedback on how meaningful and empowering the experience was, and whether participants feel confident in applying the

“The consistent message is that the workshops give people clarity, confidence and a sense of ownership. That is what drives

It is being recognised by the wider industry as well. Safety Builders received a Gold Stevie Award at the 2025 International Business Awards for its cultural sensitivity, measurable impact and relevance to modern construction practice. The award highlighted Webuild’s commitment to embedding a global safety culture in local contexts.

“It is one of several awards Safety Builders has received globally, but it is significant for Australia because it recognises the adapted Australian version. The award underscored the value of tailoring global safety culture to local conditions,” says Spark.

“Our facilitators work closely with each project to understand the scope, workforce and challenges, and tailor safety content accordingly. That relevance is what makes the program powerful.”

For contractors, clients, communities and the wider industry, Safety Builders acknowledges the realities of a fast-paced, mobile sector. Thousands of workers may pass through a project and change is constant. To manage that environment, the framework establishes common language, consistent systems and capable safety leadership.

Its initiatives influence more than Webuild’s own delivery, reducing disruption, supporting project continuity and offering an approach that partners and clients can adopt. For communities, safer worksites mean fewer interruptions and greater confidence in the infrastructure being delivered.

The common language created through the program is what differentiates it, Spark explains.

“When everyone understands the risks, required controls and expectations, you can adapt the program to any setting, whether it is a remote project, a FIFO workforce, a city environment, a night shift or extreme weather conditions,” she adds.

“The intent, tools and values remain consistent, but the conversations in the workshops draw on the lived experiences of the participants. That is why the impact is so strong and why satisfaction rates are so high. It’s a personal experience.”

Your Lifesaving Rules consolidate this shared language and are being rolled out on all Australian projects. The 20 non-negotiable safety behaviours draw on real incidents and set out the high-risk construction activities and the minimum controls required.

“The Critical Risk Control program verifies those controls. Together, they provide clear structure for how we talk about risk and how we manage it,” says Spark. “It is an education tool, a system tool and a behavioural reinforcement tool. We verify that the critical controls are in place to protect life, ensure expectations match behaviour and use conversations to recognise good practice and correct unsafe behaviour.”

As the industry evolves, so does Safety Builders. Spark describes it as a live program that Webuild continues to evolve and improve.

In 2026, new modules focused on psychological safety will be released, reflecting the growing need for clarity around what psychological safety entails and what

productive conversations in that space involve. Technology now plays an active role in how the program is applied, particularly through the use of digital monitoring.

“We harness digital monitoring to analyse safety performance, interactions in the field and both leading and lagging indicators. We also use digital monitoring for occupational health exposures,” says Spark.

“We have artificial intelligence embedded in plant and equipment, particularly where there are people and plant interaction risks. This includes our tunnel boring machines (TBMs) and heavy equipment. These tools introduce an additional layer of control.”

Collaboration remains a driver. Webuild works with joint venture partners, clients and industry bodies, while also engaging with regulators who play an important role in sharing lessons and connecting industry practice.

“The aim is to leverage each other’s innovation and experience so we can lift safety performance across the sector,” says Spark.

Through ongoing refinement and shared commitment, Webuild is contributing to a construction industry that is safe, resilient and equipped for the demands ahead.

“Understanding what is working well helps us drive improvement across all projects and reinforce the behaviours that lead to success.”

The Safety Builders program supports a zeroharm culture, embedding safe behaviours across all levels of the workforce.

Precision without limits

Komatsu Australia is bringing network-delivered positioning into the Smart Construction ecosystem with the launch of K-RTK for the Australian market.

Australian earthmoving projects are operating with less tolerance for positioning failure than at any point in the past decade. Live models, concurrent work fronts and compressed

programs mean accuracy issues now surface immediately. When positioning breaks down, production slows, rework follows and confidence across the site erodes.

K-RTK is a subscription-based network service delivering high-accuracy corrections to GNSS-enabled equipment via the mobile data network. (Image: Komatsu)

FOCUS Machine technology

“K-RTK operates through more than 900 reference station sites across Australia, which places it among the highest coverage services currently available in the market.”

For many contractors, the choice has already been made. Network real-time kinematic (RTK) is now the preferred positioning approach on complex earthmoving projects, particularly where site-based base stations struggle to keep pace with program and scale. Komatsu Australia’s data shows adoption rising from about 64 per cent in 2024 to 73 per cent by the end of 2025.

That operating environment has driven Komatsu Australia to introduce K-RTK, a subscription-based network service delivering high-accuracy corrections to GNSS-enabled equipment via the mobile data network. Corrections are drawn from a distributed network of reference stations rather than a single site-based base station and delivered in real time using NTRIP. The requirement to install, manage and protect base-station hardware no longer sits with site teams.

Marc Brook, product manager for Smart Construction at Komatsu Australia, says it is regarded as a reliable way to achieve centimetre-level accuracy.

“With network RTK now the dominant approach compared to traditional site-based base stations, now was the right time to launch K-RTK,” he says.

With reliable centimetre-level accuracy, operators can start work immediately.

(Image: IndustriArc)

Traditionally, establishing RTK capability required purchasing and managing a base station for each site, often at high upfront cost. This subscription-based service removes the need for contractors to purchase, maintain or configure base stations each time work fronts relocate.

Traditional radio-based base stations are prone to signal dropouts, black spots and interference, interrupting work and eroding productivity. K-RTK removes those constraints, keeping coverage consistent across active worksites.

“K-RTK operates through more than 900 reference station sites across Australia, which places it among the highest coverage services currently available in the market,” says Brook.

“As a result, in most areas where construction activity is taking place, K-RTK is accessible.”

He adds that because corrections are delivered via the mobile data network rather than private radio transmission, there is no requirement for radio frequency licences from government regulators.

Corrections are drawn from a distributed network of reference stations rather than a single site-based base station and delivered in real time. (Image: Harvepino/shutterstock.com)

Marc Brook, product manager for Smart Construction at Komatsu Australia. (Image: Komatsu)

FOCUS Machine technology

“With machine guidance supported by accurate RTK corrections, operators can work more independently and efficiently.”

Accuracy becomes critical once work is tied to a digital design, whether that is an engineered model supplied by surveyors and designers or a simpler design created by an operator on the machine. With reliable centimetre-level accuracy, operators can start work immediately. They power up the machine, load or create the design, connect to K-RTK and begin work with confidence that the finished result will meet specification.

“GNSS technology has replaced many traditional methods such as grade lasers and manual set-out,” says Brook. “In the past, contractors would spend time establishing position and height references and manually checking levels. With machine guidance supported by accurate RTK corrections, operators can work more independently and efficiently.”

That immediacy only holds if positioning systems can move with the job. On most Australian construction sites, that means working across mixed fleets and a range of positioning devices. K-RTK is compatible across the common GNSS products used locally, from survey rovers and RTKenabled drones through to machine control, guidance and autosteering systems.

While the technical benefits of network RTK are implicit, confidence on site ultimately depends on the capability behind the service.

K-RTK is supported through Komatsu’s Smart Construction Support Centre in Australia, providing both remote and on-site support.

“Our support team includes specialists with backgrounds across surveying, construction, machine control and mixed-fleet environments. That breadth of experience allows us to provide practical, informed advice that reflects site conditions,” says Brook. “The service is monitored 24 hours a day, seven days a week to ensure maximum uptime and performance.”

He adds reliable positioning is now the starting condition for guidance, control and automation to function consistently on site.

“You can add capability to machines, but without stable corrections, the benefit is

lost,” he says. “Many Smart Construction products address specific challenges, such as machine guidance, machine control and data management. K-RTK provides the positioning accuracy those systems rely on.”

To learn more about K-RTK, call 1300 566 287 and ask for your local Komatsu representative.

K-RTK at a glance

Flexible RTK corrections

K-RTK delivers RTK corrections suited to a range of project requirements and equipment configurations. It supports network RTK solutions including VRS and iMAX as well as Nearest Base and Single Base connection methods.

Broad hardware compatibility

The service is available across common GNSS hardware that supports NTRIP, including machine control systems, survey rovers, RTK-enabled drones and autosteering platforms.

Formats and datums supported

K-RTK supports standard correction formats including RTCM 3.0, RTCM 3.2 MSM and CMR+ as standard, with compatibility across both GDA2020 and GDA94 datums.

Reliable positioning

Corrections are delivered via the mobile data network, eliminating basestation interference while improving coverage, uptime and compliance with government communications requirements.

Wide coverage footprint

With an expanding reference-station network, K-RTK is typically accessible wherever good mobile internet connectivity is available.

Local technical support

K-RTK is supported by Komatsu’s technology specialists, with 24-hour service monitoring, and local phone and on-site support available.

•

•

•

FOCUS Building technology

Better connected below ground

Below ground, Powertec Telecommunications is treating inbuilding connectivity as essential infrastructure for safety, emergency communication and modern building systems.

Mobile connectivity is assumed as standard in today’s buildings, yet it consistently breaks down in one of the most intensively used parts of the built environment: basements and car parks. Too often dismissed as a post-construction technical oversight, the consequences surface in long-term asset performance and, in some cases, user safety.

As commercial operations manager at Powertec Telecommunications, Tom Bolton sees the pattern repeated across residential towers, commercial offices and retail developments. He says builders and developers need to treat in-building coverage as a core building service, particularly in underground environments.

“Basements and car parks continue to be mobile coverage black spots. At a very basic level, signal is coming from external towers, and once a building starts to go below ground, that signal becomes harder to access. Modern construction is also working

harder to maximise available space, which means deeper basements and more complex structures,” he explains.

“The challenge is twofold. First, the materials used in construction make it difficult for signal to penetrate the building envelope. Second, once below ground level, mobile signal is similar to light – it often does not travel through solid structures or underground.”

Without an integrated in-building mobile coverage solution, basements, stairwells and car parks are left with unreliable or unavailable signal, with implications that are not limited to convenience.

During construction, underground areas are active work zones that depend on continuous communication for coordination and safety. Once operational, those same spaces serve residents, visitors, maintenance teams and contractors who expect uninterrupted access to emergency services.

In-building mobile coverage in basements and car parks supports the safety of maintenance and inspection personnel. (Image: Yuliia/ stock.adobe.com)

Bolton notes that underground car parks today are generally well designed and safer than in previous decades, yet the inability to call Triple Zero during a medical event or accident introduces a risk that no amount of lighting or ventilation can offset.

Powertec has been engaged on projects prompted by incidents involving users who could not exit their vehicles or summon assistance, scenarios that quickly reframe mobile coverage as a core safety requirement.

Lone worker exposure adds another layer of risk. Maintenance and inspection tasks in basements and plant areas frequently occur in isolation, often outside normal operating hours. While man-down systems and emergency alert devices are increasingly specified, they rely on mobile connectivity to function. Without coverage, these systems offer compliance comfort without practical protection, leaving workers exposed and asset owners vulnerable.

While safety alone is sufficient to prioritise in-building mobile coverage in car parks and basements, underground connectivity also supports more than basic communications. It enables modern building systems and services that are now being digitised into IoT platforms.

Bolton notes that manufacturers favour cellular connectivity for its simplicity, eliminating the need for WiFi configuration

and credential management. HVAC controls, environmental monitoring, electricity meters and lift emergency phones are now routinely reliant on mobile networks, as are parking payment systems and access controls.

The rise of electric vehicles and charging infrastructure further reinforces the requirement. Chargers depend on connectivity for monitoring, billing and fault reporting, yet many are installed in basements never designed with mobile coverage in mind. Without in-building solutions, reliability suffers and operational risk sits with owners and operators.

“Further, mobile broadband modems, emergency pendants and security systems often rely on cellular connectivity,” says Bolton. “Connectivity enables smarter buildings and safer environments.”

Regulation is beginning to respond. In 2024, the Australian Government introduced telecommunications requirements for new housing developments of 50 lots or more to consider mobile coverage during planning, signalling an expectation that connectivity should be treated as an essential service alongside water, electricity and gas. Bolton sees similar expectations emerging for high-rise residential developments of comparable scale.

“All of this reinforces that mobile connectivity underpins safety, compliance and the future functionality of modern buildings,” he says. Despite its importance, responsibility for in-building mobile coverage is poorly defined, which is why Powertec is often engaged late in the project lifecycle or after construction is complete.

“For larger buildings above certain size thresholds, there is usually a requirement to install a distributed antenna system, or DAS, to bring mobile signal from outside and propagate it throughout the building and down into car park and basement areas,” says Bolton.

“In many tender processes, that requirement is either overlooked or loosely bundled into the electrical scope. Electrical contractors then find themselves needing to retrofit a solution late in the build.

“Historically, systems were sometimes installed without proper engagement with mobile carriers. The infrastructure would be there, but without carrier agreements in place, activation would be deferred to the building owner, often with substantial and unexpected fees.”

Bolton says identifying the need for a DAS early and engaging a communications specialist avoids those outcomes.

“It removes hidden costs and surprises and allows the most suitable and cost-effective solution to be selected,” he says. “The key is collaboration between builders, approved electrical contractors and communications experts from the outset.”

When in-building mobile coverage is considered during planning and design, Bolton explains, project teams can establish realistic performance objectives, align solutions with budget constraints and prioritise critical areas. Indicative pricing can be developed early, followed by detailed design and site surveys that integrate into the construction sequence. Installation occurs at appropriate stages, commissioning is completed with full documentation, and the

Mobile connectivity supports the operation of modern cities, linking buildings, systems and services across the urban environment.

(Image: paisan1leo/ stock.adobe.com)

“Addressed

early,

it

integrates cleanly into design and construction, supports safety obligations and underpins the functionality of modern building systems.”

FOCUS Building technology

“Connectivity enables smarter buildings and safer environments.”

finished system operates as intended from occupation.

“While we can come in after construction, early involvement reduces disruption and costs,” says Bolton.

There are also architectural and aesthetic considerations. As buildings incorporate higher-end finishes and more complex forms, retrofitting communications infrastructure introduces compromises that undermine design intent. Early integration avoids surface mounted solutions and visual disruption, delivering outcomes that are effectively invisible to occupants while remaining robust in performance.

Powertec’s role in this process draws on long-standing expertise in radio frequency (RF) communications, a discipline Bolton describes as a “highly nuanced field” that requires experience to perfect. The company’s solutions draw on Nextivity CEL-FI cellular repeaters, including the QUATRA variant, which supports Power over Ethernet, multi-carrier 4G–5G coverage and remote system management.

As the largest distributor of this technology in the Asia-Pacific region, Powertec has been involved in some of the earliest applications of these systems. The company operates with an entirely onshore team based on the Gold

Coast, supported by satellite offices across Australia and operations in New Zealand.

“Our systems are carrier agnostic, meaning we are not aligned to one provider. Property ratings increasingly consider ubiquitous multi-carrier connectivity as a marker of building quality, potentially increasing building value,” says Bolton.

“Deployment speed is another point of difference. While traditional DAS systems can take six months or more to deliver, our solutions can typically be deployed within two months from start to finish. They also allow targeted coverage and can be delivered at a fraction of the cost of legacy systems.”

Beyond the technical case, Powertec is focused on positioning mobile coverage as essential infrastructure. For contractors and developers delivering car park and basement works, Bolton is clear that mobile connectivity must be addressed during delivery, not after the build is complete.

“Mobile connectivity in basements and car parks cannot be treated as an afterthought,” he says. “Addressed early, it integrates cleanly into design and construction, supports safety obligations and underpins the functionality of modern building systems. Deferred, it introduces risk, cost and compromise.”

Electric vehicle charging stations depend on connectivity for monitoring, billing and fault reporting.

(Image: InfiniteFlow/ stock.adobe.com)

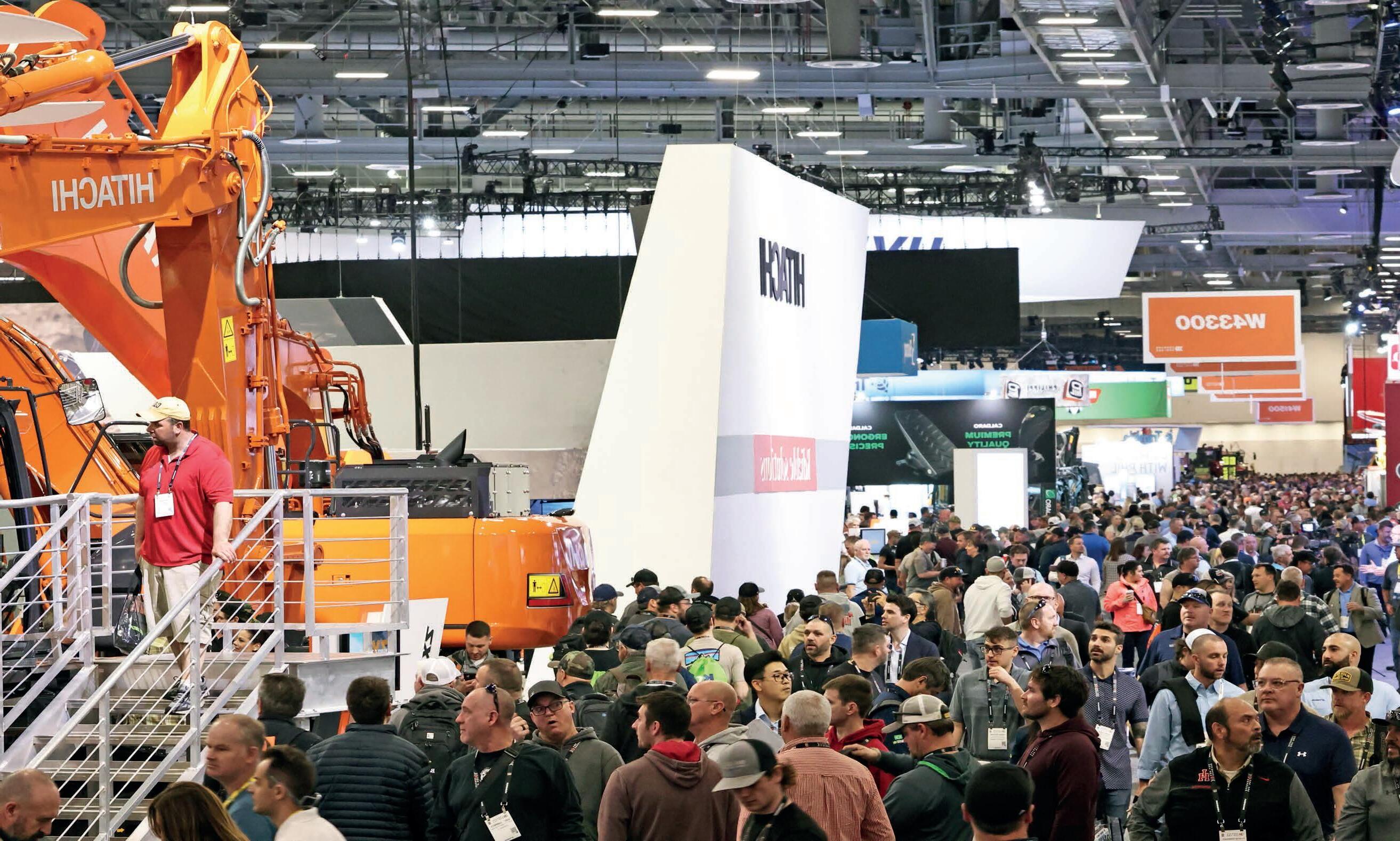

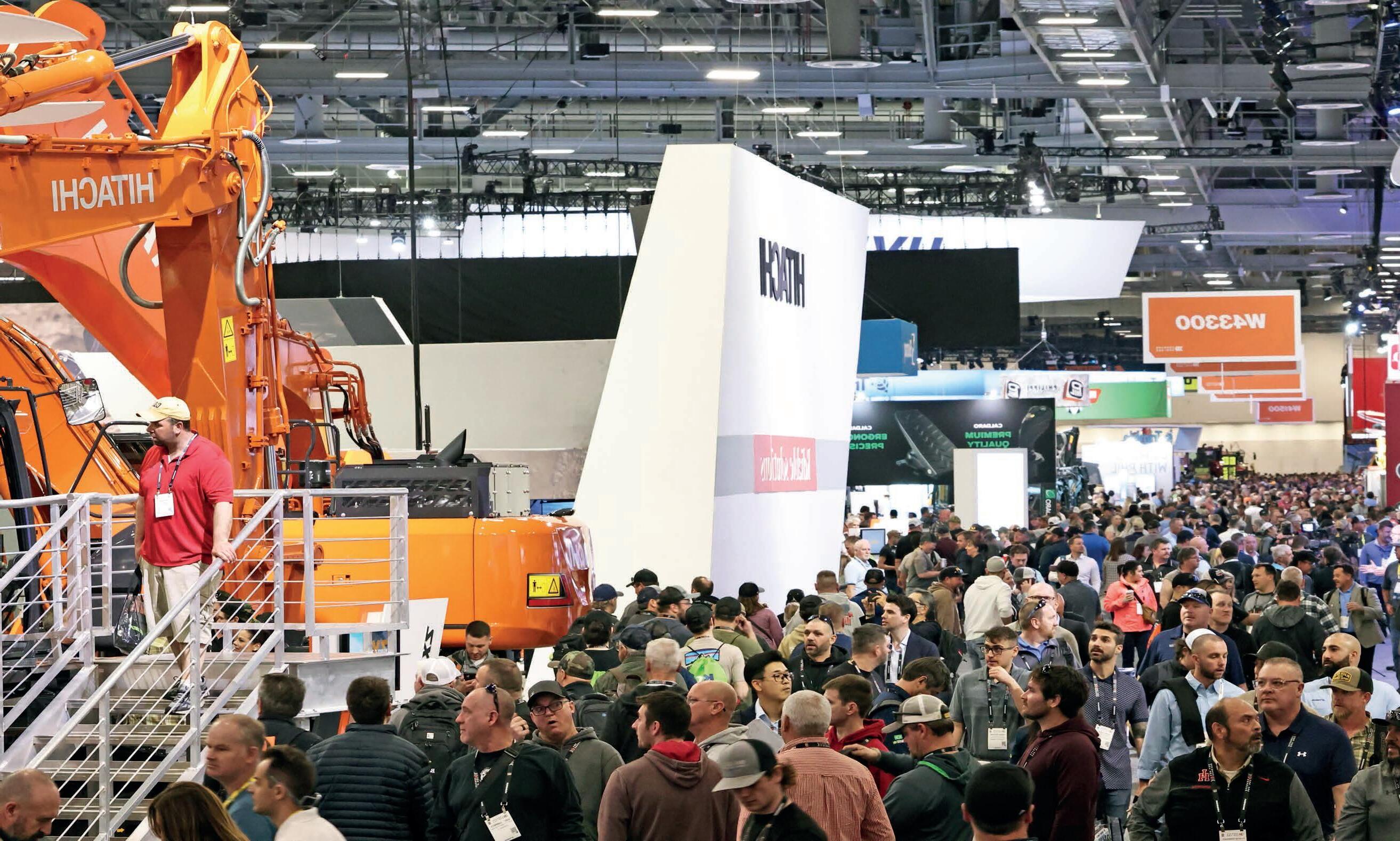

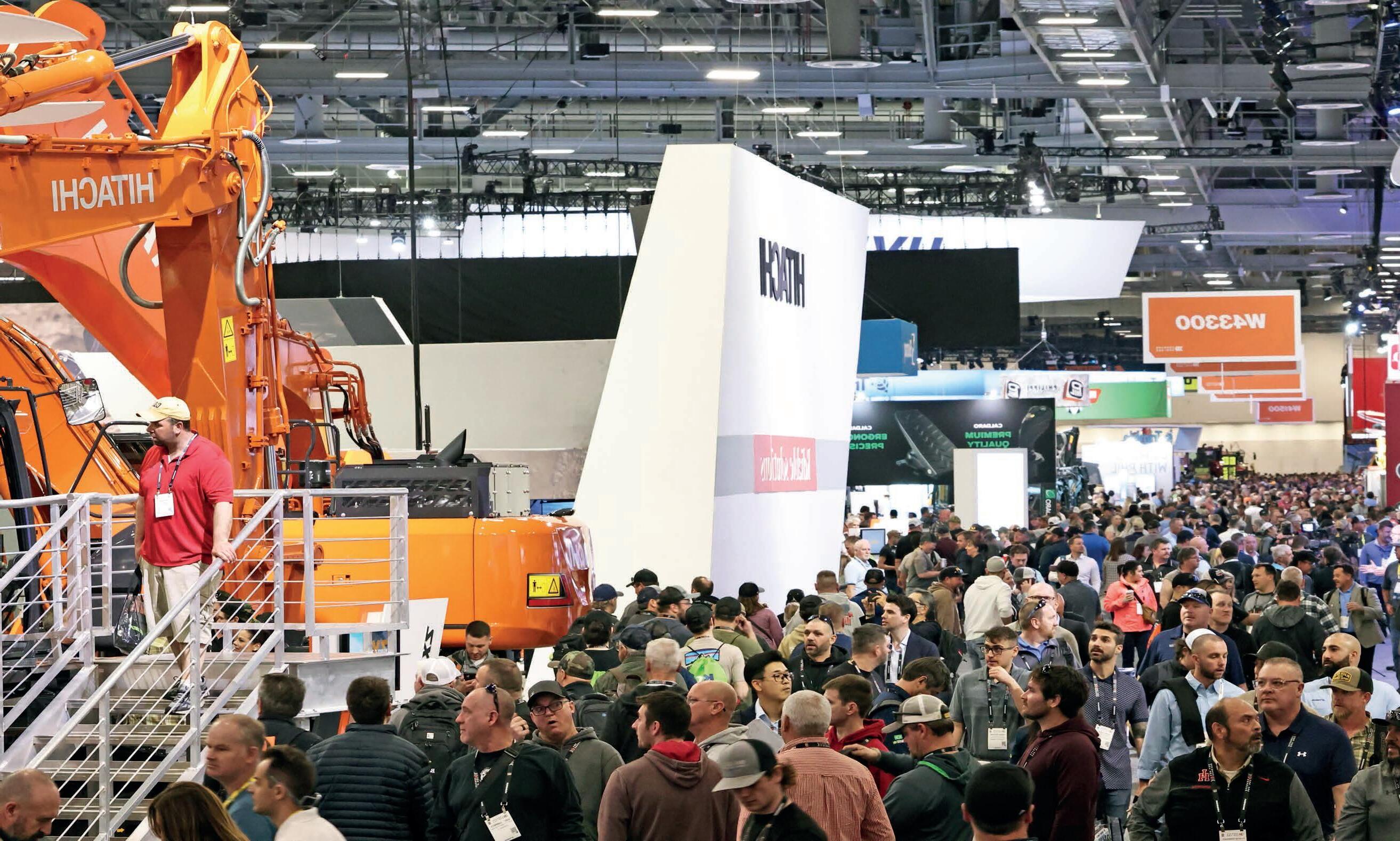

BeyondthispageliesanessentialresourceforAustraliansattending CONEXPO-CON/AGG2026,oneoftheworld’slargestconstruction tradeshows,takingplace3-7March2026inLasVegas,UnitedStates. Planyourvisitaroundthiscomprehensivelistingofcompanies exhibitingatCONEXPOwithconfirmeddistributioninAustralia.

TO CONEXPO

YOUR AUSTRALIAN GUIDE TO CONEXPO

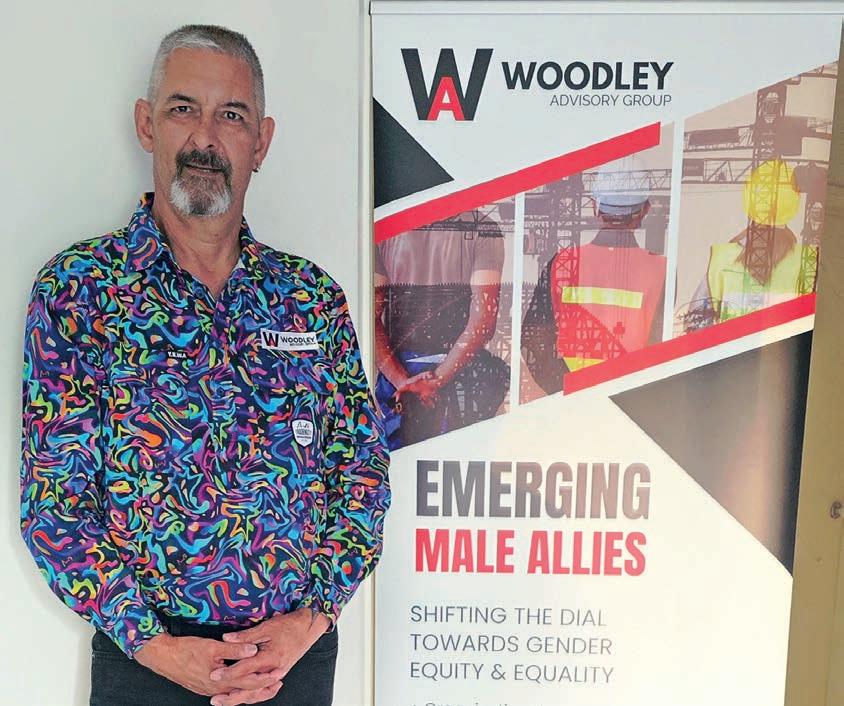

Green Star steers the sector

A year of record certification activity has confirmed Green Star’s importance to the sustainable evolution of Australia’s built environment.

Green Star certification is stepping into new territory across the built environment. What began as a voluntary commitment to healthier and more efficient buildings has evolved into a marker of quality relied upon by government, investors, developers and occupiers.

The Green Building Council of Australia’s (GBCA) Green Star: A Year in Focus FY2024–25 report shows the scale of progress, with almost 2,000 certifications achieved across Green Star’s core areas of application, including buildings, communities, fit-outs and operational performance. The breadth of that activity reflects a sector that recognises the value of independent verification and is acting accordingly.

The momentum has carried through a period of global uncertainty and cost pressures. Instead of slowing, uptake has continued to grow across all building types, from commercial towers and mixed-use buildings to industrial facilities and sports venues. Demand is also strong in government projects, with more than 140 public assets now using Green Star Buildings to assess long-term performance. This trajectory is supported by policy settings, finance frameworks and community expectations.

Jorge Chapa, chief impact officer at GBCA, says this year’s report findings point to sustainability becoming embedded in the built environment – a new norm for the industry and the community.

“Whether it’s the certification of an allelectric aquatic centre or a community that highlights the best of adaptive reuse and highperforming homes, industry has taken the challenge of creating systemic change in the built environment, head on,” he says. That willingness is evident in the range of projects certified this year.

The Brimbank Aquatic and Wellness Centre demonstrates what can be achieved when operational performance is treated as a design priority. As Australia’s first 100 per cent renewable-energy-powered, zerogreenhouse-gas-emitting aquatic centre, it achieved a 6 Star Green Star Design and As Built rating. It also speaks to a long-standing challenge for councils managing aquatic assets, which are typically among the highest energy users in municipal portfolios.

Drew Hildebrandt, manager of Brimbank Leisure Centres, explains the thinking behind the project.

The Brimbank Aquatic and Wellness Centre achieved a 6 Star Green Star Design and As Built rating. (Image: Dianna Snape)

GBCA CEO Davina Rooney. (Image: GBCA)

COVER STORY

Green Construction

“The certifications that we are seeing are a result of industry valuing Green Star for all the benefits it brings to them.”

“Brimbank Council declared a climate emergency in 2019, and we have strong requirements for our facilities to meet highest possible sustainable design standards,” says Hildebrandt. “Our Climate Emergency Plan outlined a commitment to ‘assess the feasibility of electric alternatives to building new, or upgrading old, gas infrastructure in council buildings’. Council was determined to exceed this commitment by bringing this all-electric centre to fruition.”

Cultural projects are demonstrating ambition of the same calibre. Powerhouse Parramatta, delivered by Infrastructure NSW with Lendlease, is on track to become the first public institution in the country to reach a 6 Star Green Star Buildings v1 rating. Its design incorporates climate resilience, low-impact materials and an all-electric operational model supported by renewable energy. The museum’s submission gained more than 70 points across the rating categories and provides a reference for civic buildings seeking to demonstrate credibility, transparency and measurable outcomes.

As Carmel Reyes, head of climate action and sustainability at Powerhouse, says, “At Powerhouse Parramatta, we made a deliberate – and at the time, considered bold – choice to completely exclude gas and fossil fuels from our building operations.”