Top grades forJohn Deere

WITH JOHN DEERE’S INTEGRATED 3D SMARTGRADE CONTROL SYSTEM, USERS CAN ACHIEVE NEW LEVELS OF ACCURACY AND EFFICIENCY IN EARTHMOVING OPERATIONS.

Welcome

Ray Chan Editor

What a year it has been for Caterpillar.

2025 marked a milestone for the global machinery icon, as it celebrated 100 years of engineering excellence, industry leadership, and community impact.

Throughout the past 12 months, we’ve been helping the manufacturer commemorate the centenary by presenting various profiles of satisfied customers, many of whom have stuck with the yellow and black machines from the very beginnings of their businesses.

In this issue, we reflect on those stories, and also on the ways clients and dealers have come together to honour the brand’s legacy and future, building careers and communities with the help of Cat equipment.

Special centennial versions of the machinery were also released to mark the occasion, several of which were used in the company’s Global Operator Challenge heats held across Australian and New Zealand.

These culminated in the Asia-Pacific final held at Japan, with the top three participants winning tickets to the grand final in the US next year.

We were there to observe the rigorous round of challenges, and are able to report on how the contestants performed, along with exclusive photos. Turn to our coverage of the event inside to find out how our local contingent fared.

There is also a bumper number of case studies in this edition, which make for informative reading.

We look at a how a New South Wales-based has leveraged its Kobelco fleet to become one of the sector’s most respected names. In the same state, we travel to two quarry sites spanning more than 122 hectares, where we find Dieci

telehandlers being used exclusively to extract sand and sandstone for construction and civil projects.

Moving north to Queensland, there’s a great piece on how an operations manager with an earthmoving company has gone back to the company he used to work with — CJD Equipment — to source excavators and trucks. Then, in the suburb of Glenwood, a LiuGong excavator has proven to be an eye-opener for a civil business, which bought the model in July this year and has nothing but praise for its combination of power, precision, and compact design.

In Victoria, we interview civil specialist CDL Constructions, responsible for many prominent Melbourne landmarks, such as the Eureka Tower. It’s a business that knows the value of getting the most out of attachments, and that means picking the right brand in the first place.

As well, don’t miss our regular expert articles on machine control, business solutions, dealer profiles, technology updates, and innovative products, along with the regular opinion columns from our partner associations.

As we reach the end of another busy and rewarding year, we must extend our thanks to our readers.

Your engagement, feedback, and continued curiosity are what make this magazine possible. Every story we publish is inspired by a desire to inform, support, and celebrate the earthmoving industry.

Looking ahead, we’re excited for what the next year will bring. We’re committed to bringing you even more insightful features, practical guidance, and stories that showcase the people, innovations and ideas shaping our sector.

Have a safe and happy holiday season.

With a blend of the latest technology and robust design, Neilo’s M7040 grader is helping operators lift their standards on every site, every slope, and every pass. See story on page 64. Image: Neilo

Top grades forJohn Deere

With John Deere’s integrated 3D SmartGrade control system, users can achieve new levels of accuracy and

iciency in earthmoving operations.

An earthmoving contractor says the decision to invest in a LiuGong 909E CR excavator has already paid o , after just six months on the job. Image: Prime Creative Media. See story on page 98.

Earthmoving Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

CEO

Christine Clancy

Head of Sales

Andrew Morrison Editor

Ray Chan ray.chan@primecreative.com.au

Brand Manager

KahChi Liew kahchi.liew@primecreative.com.au 0421 474 407

Production Editor

Michelle Alder

michelle.alder@primecreative.com.au

Design Cat Zappia/Daz Woolley

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website www.earthmovers-magazine.com.au

Copyright Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2025/2026.

Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head O ice 379 Docklands Dr, Docklands VIC 3008 P: +61 3 9690 8766 info@primecreative.com.au www.primecreative.com.au

Sydney O ice Suite 11.01, 201 Miller St, North Sydney, NSW 2060

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

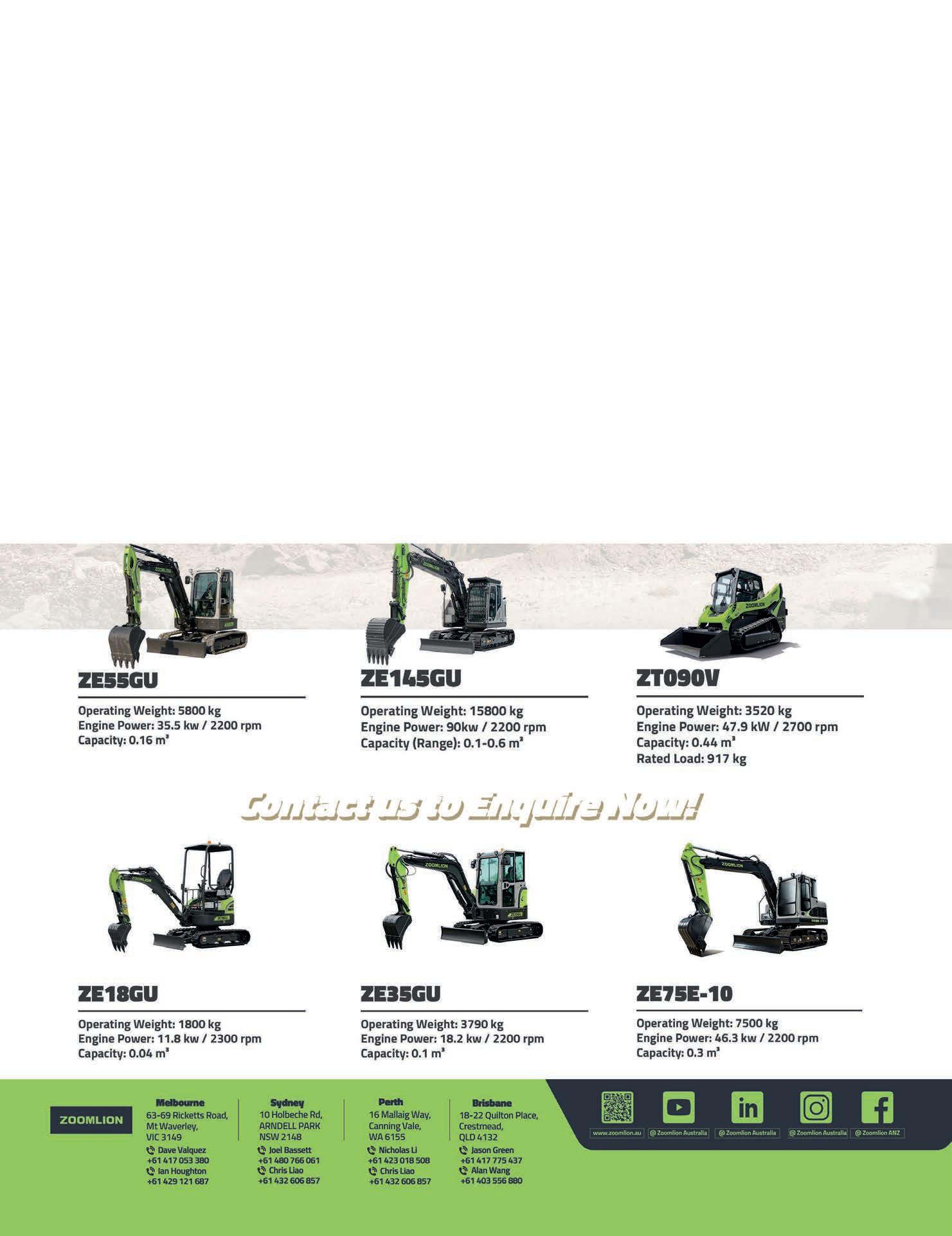

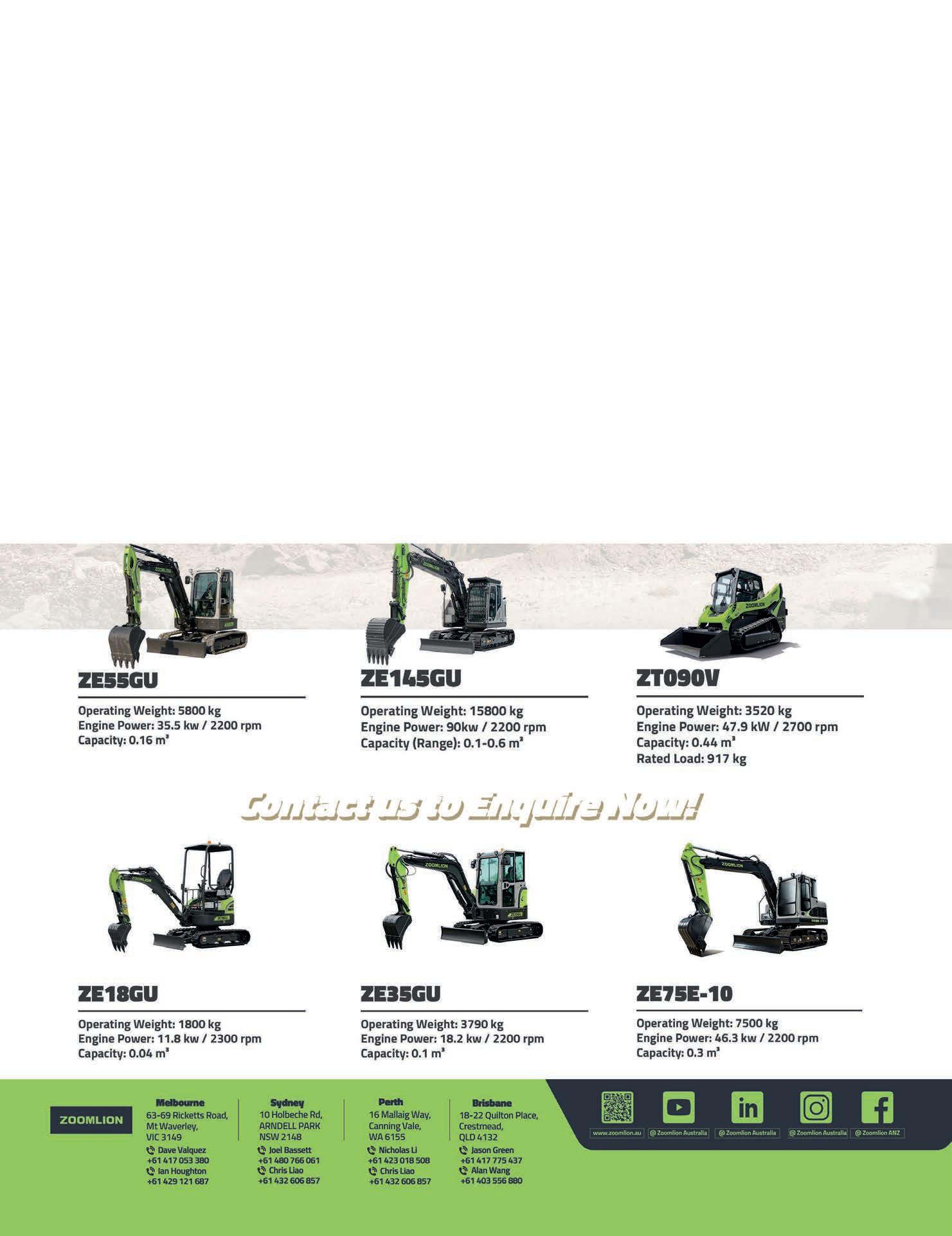

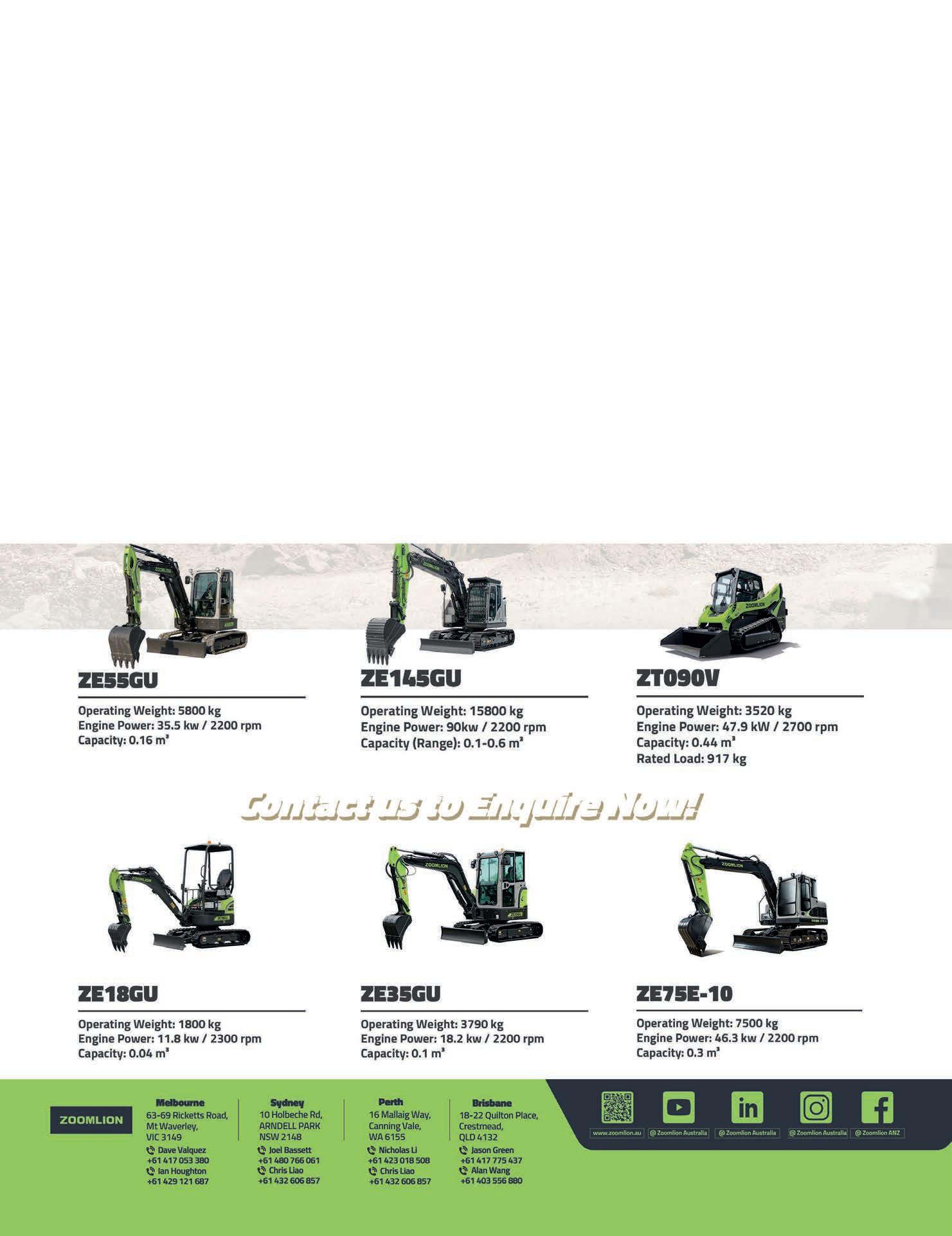

Be in control with the 7 Series excavators and wheel loaders.

With John Deere’s integrated 3D grade control system, users can achieve new levels of accuracy and e iciency in earthmoving operations.

With nearly 60 years of motor grader manufacturing, John Deere graders are known for their blend of precision, power and reliability. Now, with SmartGrade technology — the company’s integrated 3D grade control system — users can achieve new levels of accuracy and e iciency in earthmoving operations.

To tell us more, we spoke with John Deere’s own grader guru, Global Motor Grader Product Manager Matt Costello. Based in the USA, Matt has spent 15 years with John Deere, starting as a factory engineer and later working in fabrication, welding and new product development. He’s also served as a technical instructor, focusing on technician development and readiness.

“In sales, I held the role of Product Consultant, spending a lot of time in the field on customers’ sites. I worked with dealers to help sell the value of John Deere equipment and onboard operators, to ensure they know the features we have to o er,” Matt said.

Given his experience, there’s hardly anything about John Deere equipment that Matt isn’t

eliminates the need for daily greasing, wear inserts or shimming, and there is no need to be constantly adjusting for

John Deere’s graders have, quite literally, made the grade, and even surpassed it.

The Premium Circle

circle wear.

Images: John Deere.

aware of. When it comes to graders, Matt knows each model inside out.

Power, precision and choice

Six-wheel-drive models feature precision mode for consistent speed control, and the powertrain delivers increased horsepower and torque for demanding jobs.

“On-the-go adjustments of the hydrostatic 6WD powertrain let operators tune traction and productivity to ground conditions,” Matt said.

“With eight models available in a combination of tandem and six-wheel drive configurations, two engine sizes and three control options, operators can choose between dual-joystick, fingertip armrest or conventional lever controls, with cross slope standard on all GP models.”

Operator experience and serviceability

All-around visibility is virtually unobstructed, with clear sightlines to the moldboard and beneath the front axle.

The LCD hi-vis monitor provides intuitive access to machine data and displays a highresolution rearview camera image.

Daily service points are grouped for convenient ground-level access and the cooling package is designed for easy cleanout.

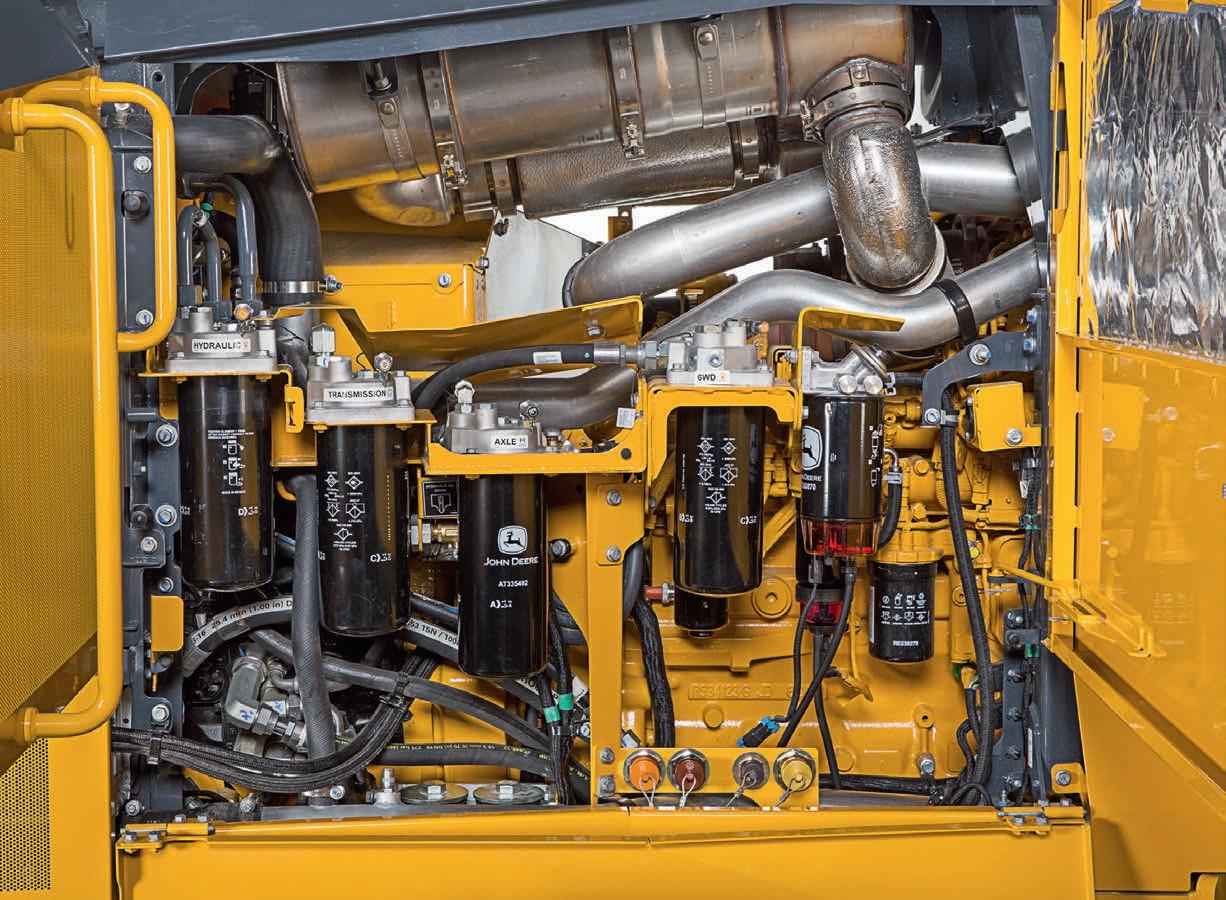

“Ground-level service setup makes daily checks e icient and the same-side filter bank simplifies fluid sampling and filter changes,” Matt said.

The JD 570 was the world’s first frontwheel articulated-frame-steering motor grader when introduced in the 1960s. Since then, John Deere has continued to advance motor grader development.

The foundation: Premium Circle

John Deere’s industry-exclusive Premium Circle is a sealed bearing solution.

“As a fully sealed system that has been in the market for more than five years, it doesn’t need daily greasing — it only requires grease every 500 hours, fitting nicely into your scheduled maintenance,” Matt said.

“It also eliminates the need for wear inserts or shimming, and there is no need to be constantly adjusting for circle wear.

“Achieving grade with 3D grade management solutions is a breeze.

“It also delivers 15 per cent more speed and

40 per cent more torque than traditional circles and reduces maintenance costs.

“Take a look underneath the draft frame and you’ll immediately see the di erence.”

SmartGrade: integrated precision

SmartGrade is Deere’s mastless, integrated 3D grade management system that works on all jobsites.

“The system uses GNSS technology to track the machine’s position, an IMU sensor, and patented in-cylinder position sensing to track slope and blade angle in real time, automatically adjusting the blade based on the 3D site plan,

John Deere motor graders are designed for easy service, with ground-level access of daily service points and a filter bank grouped together on the right side for periodic maintenance.

Various motor grader automations are available, including MachineDamage Avoidance, which prevents blade damage to machine structures.

allowing operators to achieve precise grading with minimal manual input,” Matt said.

“Unlike traditional systems, SmartGrade is fully integrated with no external masts or cables, improving safety, reducing setup time and minimising risk of component damage or theft.

“With the new SmartGrade platform, John Deere has taken more ownership of the hardware, software and display, while still integrating with the GNSS supplier that supports a customer jobsite.

“Touchscreen displays now o er remote display access and wireless data transfer, streamlining updates, troubleshooting and training.”

Automation suite: making grading easier

The John Deere automation suite makes grading easier with less input from the operator, which means long days in the cab are less fatiguing.

The suite includes industry-exclusive features such as Auto-Pass, Auto-Shift PLUS and Auto-Gain for Cross Slope, making it push-button easy to set.

The automations are available from the factory or as an addition to existing GP models and include:

• Machine-Damage Avoidance prevents blade damage to machine structures and tyres.

• Blade Flip mirrors the circle to a preset angle with a double tap.

• Auto-Articulation increases manoeuvrability by coordinating steering and articulation.

• Auto-Pass automates blade placement and grade-control activation at the start of a pass and resets at the end.

• Auto-Shift PLUS allows operators to work without the inching pedal and shifts automatically through roading gears.

• Auto-Gain for Cross Slope adjusts gain settings based on ground speed for optimal performance.

• Machine Presets prepare the machine for transport with one button.

“These features are adjustable and can be overridden, so whether you’re an experienced operator or a novice, automation can enhance your skills,” Matt said.

“John Deere o ers a 500-hour Automation

Demo program, allowing users to experience advanced features in real-world conditions and see how they enhance productivity.”

Connectivity and support

John Deere graders come with in-base connectivity, no subscriptions required.

The John Deere Operations Center — a cloud-based farm and equipment management system — enables remote monitoring, diagnostics and software updates, thanks to John Deere Connected Support. Contractors and fleet managers can track productivity metrics such as fuel consumption, automation usage, machine hours and diagnostics in real time.

SmartGrade is also linked to a telematics system for remote monitoring and diagnostics.

Regular updates ensure the system keeps getting better.

Check out the full range of John Deere Motor Graders at https://www.deere. com.au/en/motor-graders/ or see your local John Deere Dealer.

you’d expect from John Deere - a company with over 50

ROBUST

100% steel bodywork for maximum impact protection and ease of repair

EFFICIENT

Premium, Class-Leading precision hydraulic flow share for ease of use and maximum output

10 integral easily accessible tie-down points make the transportation process safer and quicker COST EFFECTIVE

500-hour Dig-End greasing intervals to reduce regular downtime

Swing-out counterweight provides unrivalled and easy service access

Komatsu’s new PC950-11 excavator moves more tonnes while burning less fuel than its predecessor.

Komatsu has launched its latest hydraulic excavator in Australia, giving quarry and mining operations a powerful new solution to cut costs, improve safety and move more tonnes per hour.

The PC950-11 delivers up to 48 per cent greater productivity while using up to 40 per cent less fuel than the previous model, helping to lower cost per tonne and reduce emissions at a time when fuel costs and sustainability pressures are top of mind for operators.

Komatsu’s National Business Manager for Construction Excavators, Mark Boyes, said customers have been asking for a machine that moves more tonnes, is more fuel-e icient and keeps operators safe and comfortable.

“That’s exactly what the PC950-11 delivers,” he said.

“Our development teams took this customer feedback on board and delivered more power, increased dig forces, greater drawbar pull, superior durability, easy safe access and surround visibility systems, all while maintaining ultra-low fuel consumption.

“It’s designed to handle Australia’s toughest conditions, while helping our customers run more e icient, sustainable operations, whether that be on mine sites or in quarry operations.”

Beyond performance, the PC950-11 has been designed to address two of the industry’s biggest challenges — safety and skilled labour shortages.

Standard features like the KomVision 360-degree camera system, hydraulic access stairway and wide catwalks improve site

safety and make inspection tasks easier.

Inside the cab, operators enjoy a quieter, more comfortable workspace with upgraded seating, climate control and intuitive controls — factors that are often overlooked as a drawcard to retain skilled operators and help reduce fatigue.

Mark said that with its reinforced structures and durable components, the excavator is built to last in demanding quarrying and mining environments.

“Maintenance is simple and safe with ground-level refuelling, extended service intervals and long-life filters,” he said.

“This excavator is not just about power. Every feature has been designed with the operator in mind, from safety and comfort through to lower total cost of ownership.

“We believe the PC950-11 will quickly become the new benchmark for large-scale earthmoving in Australia.”

The PC950-11 is available now through Komatsu’s branch network across Australia, backed by its service and support teams.

For more information, visit: www. komatsu.com.au/equipment/ excavators/13t-to-100t/pc950lc-11

The PC950-11 delivers greater productivity while using up to 40 per cent less fuel than its predecessor. Images: Komatsu

The excavator is built to last in demanding quarrying and mining environments.

Komatsu’s Live Your Dream scheme is helping provide school breakfasts in northern Queensland.

Breakfast is often called the most important meal of the day and for children it can mean the di erence between starting school ready to learn and struggling to focus.

That’s why Komatsu’s Ben Jones chose to spend his Live Your Dream (LYD) grant to support Fuel for Schools, a local North Queensland charity helping more kids begin their mornings with a full stomach and a smile.

Live Your Dream is Komatsu’s initiative that gives employees the chance to support a community project or organisation that they’re passionate about, with a $10,000 grant to help bring their dream to life.

Based in Townsville, Ben has followed Fuel for Schools for several years through his former colleague Paddy Pool, who now works full time with the charity.

“I saw the impact Paddy and the team were having through social media, and it opened my eyes to an issue I never imagined was so common — children in our community going to school without food,” he said.

Through LYD, Ben joined the Fuelling the Future breakfast club at a local primary school, helping prepare and serve meals alongside the team. He also spoke with teachers, who shared how something as simple as breakfast can change a child’s confidence and classroom engagement.

What impressed him most was how the program has grown.

“Supplying kids a piece of toast in the morning is how it started,” Ben said. “But it’s now grown into something that helps build

trust and safe spaces where students feel comfortable opening up to teachers about challenges at home. That enables schools to connect families with further support.”

The numbers show just how big the impact has become. In 2024, Fuel for Schools supported 60 schools across North Queensland, providing almost 7000 meals each week at a cost of $1500–$2000.

“That’s a pretty substantial cost for a charity, so it was amazing to be able to support them through Live Your Dream and extend the program to more children in need,” Ben said.

“The feedback from the charity and the school sta was incredibly positive. For me, it was an eye-opener, seeing how such a simple act can change a child’s day, and maybe even their future.”

Komatsu’s Live Your Dream grant supplied $10,000 to Fuel for Schools. Images: Komatsu

Ben and a teacher prepare slices of toast for breakfast.

Ben serves up breakfast to the school kids.

The market is returning quicker and stronger in January, with used equipment sales growing in this period in both 2024 and 2025. Images: Pickles

Pickles Industrial examines some of the most common factors a ecting buyers and vendors in the used machinery sector.

As 2025 draws to a close, it’s clearer every day that making the right choice in an unpredictable market is particularly di icult.

In the wake of the 2025 Australian election, the civil market has been characterised by a residential sector in recovery, along with increased government support for infrastructure projects.

In addition, ongoing challenges such as cost escalation, labour shortages and supply chain disruptions are playing their part, with buyers and vendors navigating the ebbs and flows.

The past decade has seen trends shift drastically, leaving businesses to hope for a reprieve to consider their next moves.

However, the industrial equipment market has always been characterised by a fluctuating nature, meaning that whether you are buying or selling, forecasting the future is a challenge.

Being mindful of the reality of a changing

market allows insiders to be proactive, with practicality proving to be a winning approach for both new and established businesses alike.

To help you steer through the coming months, here are 10 common trends influencing the used industrial equipment market of late.

1. How infrastructure and construction is faring

The activity levels of infrastructure and construction projects have a noticeable e ect on the used industrial equipment market.

Accounting for about 10 per cent of Australia’s Gross Domestic Product (GDP), civil works are the foundation of our economic and social development.

Demand in the used market is driven by the investment into roads, rail, mining and civil works by the government and private sector.

Currently, in post-election Australia,

infrastructure surges prompted by a clearer direction for the sector — with a heavy emphasis on renewables — have led to unique demands for the second-hand market.

2. The state of mining and resources

Similar to infrastructure and construction, the mining and resources sector has a part to play in shifting used equipment prices.

Whether it be through changing commodity prices (such as iron ore, coal, lithium) influencing fleet expansion and contraction, or mining downturns leading to a flood of surplus gear, the status of mining and resources projects drives plenty of supply and demand in the used market.

3. Seasonal disruptions

Seasonality has an influence on Australia’s used industrial equipment market, with agricultural, financial and economic cycles each playing a

OUR NATIONAL FOOTPRINT

With locations across every state and territory, Pickles has local experts on the ground wherever and whenever you need them.

Alongside a vast digital reach and access to an international buyer base, Pickles offers a wealth of remarketing services and Australia’s largest and most trusted marketplace.

With over 850 national employees, including 60 industrial specialists, Pickles is a powerful presence.

Contact a sales expert in your area or scan the QR code to discover more about Pickles Industrial

MEET THE TEAM

Wherever you need support, Pickles has leaders in the field.

Talk to these experts to access dozens of sales executives on the ground nationwide and in your local marketplace.

Grant Barrie 0434 079 653

State Sales Manager, QLD

Brendan Shoemark 0434 265 301

State Sales Manager, Regional NSW & ACT

Levi Silcox 0448 265 301

State Sales Manager, VIC & TAS

Matt Blanch 0428 163 083

State Sales Manager, NSW

Ben Hallam 0407 254 718

State Sales Manager, WA

Andrew Sweetman 0422 005 287

State Sales Manager, SA & NT

Don’t hold on to stock unnecessarily. For businesses considering the decision to retire their fleet, Pickles can guide the process.

part in supply and demand. Seasonal spikes typically occur late in Australia’s summer due to the post-holiday spending lull and in spring when weather improves post-winter.

Natural disruptions (such as wet seasons, floods, bushfires) often lead to delays and an increase in demand for recovery-related equipment.

Furthermore, used agricultural machinery, such as tractors and harvesters, will surge in price during peak harvest periods.

4. January bounceback

Compared with previous years, the market is returning quicker and stronger in January, with used equipment sales growing in this period in both 2024 and 2025.

While the Christmas period still o ers a chance to reset for the industry, the lag in sales post-holidays has reduced.

Customers want solutions faster than ever before, with demand higher in January than it has ever been.

5. Holding onto stock

Since COVID-19, many businesses have opted to hold onto assets that are no longer required. Being slow to make decisions may cost you the opportunity to sell at the best possible price for an asset that could depreciate in value.

This is where maintenance of your assets is crucial, and it is recommended that you spend the money required for professional detailing prior to selling.

For businesses considering the decision to retire their fleet, Pickles can guide the process, having recently assisted Francis Transport in o loading a range of trucks and earning $2.4 million in total sales.

6. Supply chain disruption and OEMs

When new equipment is unavailable due to OEM lead times, supply chain disruptions and delays, businesses naturally seek alternatives and find relief in the used equipment market. This rush to purchase from the used market could be instigated by a variety of factors, including the need to meet contract demands

or comply with regulatory and environmental requirements.

For buyers, shortages will lead to elevated prices and may produce long-term changes in the used market.

7. Environmental considerations

In the wake of net-zero emissions targets, environmental considerations have created demand for compliance, while incentivising innovation and changing how equipment is appraised and valued.

Stricter regulations on emissions and waste management mean that used equipment meeting these standards (such as Tier 4 engines) can increase in value.

For businesses struggling to meet the demands of the market’s push toward greener technologies like hybrid or electric alternatives, upgrading vehicles to ensure they are compliant and able to meet these new standards is recommended.

8. Adapting to changing technology

Our industry is being reshaped every day by the growing role technology is having in our day-today decision-making and functionality.

In the used equipment market, buyers value GPS, grade control and usage data, meaning older machines yet to be upgraded with this tech may be discounted unless retrofitted.

Though older used equipment may not include the latest upgrades, retrofitting means that a used model can be just as e icient at shortening production cycles, reducing costs and improving consistency.

9. The global market

If the unpredictable nature of the Australian market leaves a mark on the used equipment market, then the fluctuations of the global market carry another kind of weight.

Largely driven by supply chain issues, strong overseas demand (from places such as South East Asia or Africa) in the secondhand market can lift prices and reduce domestic availability.

In the case of overseas brands such as CAT,

Komatsu or Hitachi, spikes in resale value are regularly noted when new stock is constrained. Moreover, currency fluctuations also influence export competitiveness.

10. Holding in-person inspections

Being able to inspect and test equipment in person can impact what a buyer is willing to pay.

Seeing an asset’s condition and experiencing its performance face to face enables buyers to determine if it is suitable to their needs.

At Pickles, we pride ourselves on our customer service and transparency, and inspections are a crucial element in finding solutions that suit our customers’ needs.

Though the used market will always fluctuate, buying and selling is less dependent on timing and more about embracing your business’ needs at that time.

Selling enables you to capitalise on generating cash flow and freeing up space, while buying from the second-hand market could be critical to fulfilling your contract obligations or expanding your capabilities.

The reality is that markets will always shift up and down, meaning your e orts to try and play them may be in vain when selling is the most suitable option available to you.

The Pickles expertise

To ensure you are equipped to navigate the used industrial equipment market going forward, we recommend understanding these trends and how Pickles can assist you.

For vendors, knowing what influences the price of used equipment will allow you to gauge an asset’s true value, while buyers can experience greater confidence in your decisionmaking.

Prioritising your needs as a business will enable you to be healthier in the long run, and this is where Pickles is able to step in and guide you.

For more information or to get in contact with a Pickles Industrial expert, please visit pickles.com.au.

CELEBRATING 100 YEARS OF CATERPILLAR

2025 marked a milestone for this global machinery icon, as the world came together to celebrate 100 years of Caterpillar® engineering excellence, industry leadership and community impact.

From its origins in 1925 to its present-day innovations, Caterpillar has helped shape infrastructure, mining, agriculture and energy across continents.

The journey from tracks to triumph began with the merger of the Holt Manufacturing Company and the C.L. Best Tractor Co. in 1925.

Inspired by the movement of its track-type tractors, the name “Caterpillar” was born — symbolising strength, adaptability and progress.

Australasia joins the celebration Across Australia and New Zealand, Cat® dealers hosted a series of events that honoured the brand’s legacy and future.

• WesTrac Cat leads the charge in Western Australia, New South Wales and ACT WesTrac showcased Caterpillar's evolution at major expos like the National Diesel Dirt & Turf Expo in Sydney.

Visitors experienced hands-on demos,

interactive family zones and the unveiling of the all-new Cat 285 — the largest Cat Compact Track Loader to date, with a lift height of 3.7 metres and a lift capacity exceeding three tonnes.

WesTrac also celebrated internally and with customers through storytelling campaigns, video retrospectives and historical displays.

CEO Jarvas Croome highlighted dual milestones: 100 years of Caterpillar and 35 years of WesTrac as a Cat dealer in WA, noting over 20,000 machines delivered and 47,000 customers supported.

• Hastings Deering celebrates in Queensland Queensland’s Cat dealer Hastings Deering marked the centenary with social media tributes, customer events and community engagement, recognising every machine delivery and service call as part of the 100-year journey.

• Cavpower brings history to life in South Australia

Partnering with the History Festival, Cavpower hosted a centenary event in Hartley, featuring live demonstrations of vintage Holt and Caterpillar machines — bringing the brand’s legacy to life for the public.

• William Adams showcases progress in Victoria and Tasmania

William Adams celebrated with historic displays, competitions and community events, including a presence at Agfest 2025.

Antique machines stood beside the latest Cat models, illustrating a century of technological advancement.

A centennial version of a Cat 320 excavator was used for the Big Dig round of the Global Operator Challenge Asia-Pacific final in Japan. Images: Prime Creative Media/Jamie Gray/WesTrac

The commemorative Cat 938 wheel loader used at several of the Australasian rounds of the GOC qualifying heats.

CELEBRATING 100 YEARS OF CATERPILLAR

• Wheels at Wanaka sets a world record with Terra Cat

The 2025 Wheels at Wanaka event aligned perfectly with the Caterpillar 100-year celebrations and featured a world record attempt for the largest parade of Cat Dozers.

Enthusiasts from across New Zealand brought vintage and modern equipment “out of the shed” for a spectacular tribute.

Grassroots gatherings across the regions

From Kingaroy to Kojonup, local communities hosted vintage tractor displays and storytelling events.

Beckett’s Museum in Tasmania featured the largest collection of Cat machinery ever assembled on the island, celebrating Caterpillar’s role in earthmoving, mining, forestry and even Antarctic exploration.

Centennial collectibles: machinery with meaning

To mark the milestone, Cat dealers o ered limited-edition machines in historic grey — echoing the original colour of early models.

NSW-based Daracon Group added a Centennial Grey 432 Backhoe Loader to its fleet, one of just 25 produced globally.

Daracon’s Cory Hay praised the alignment between the Cat brand and Daracon’s values of quality and e iciency, calling the commemorative machine a symbol of a decades-long partnership.

Special centennial editions of the Cat 938 wheel loader also featured in the Caterpillar Global Operator Challenge across Australia, combining vintage aesthetics with technology like Cat Payload, Cat Detect and advanced cab comfort.

One of the commemorative Cat 938s became a prized possession of Queensland’s Coburn Sand & Gravel, a family business set up 40 years ago by John and David Coburn.

Sister company C&C Civil co-owner Claire Watt said David picked it up himself from the Hastings Deering branch and drove it home.

“That was quite a special moment for David because it’s been his life’s dream to have a big, good-looking loader like that. It was a really nice moment to stand back and look at it and know that it’s ours,” she said.

100 years strong — and just getting started

From global expos to local parades, the centenary celebrations reflected a legacy built on innovation, reliability and community.

With Cat dealers leading the charge, Caterpillar’s next century promises even greater impact across industries and generations.

Voices from the ground: How Cat machinery powers Australia’s earthmovers

As part of the 100-year anniversary celebrations, Earthmoving Equipment Magazine and sister publication Earthmovers and Excavators

spotlighted the stories of customers who’ve built careers, businesses and communities with the help of Cat machinery.

From national parks to quarries, from solo operators to multi-generational businesses, Cat machinery continues to support Australians who build, dig and innovate. These stories are a testament to the brand’s legacy — and its future.

As Caterpillar celebrates 100 years, the legacy remains strong and is set to prosper for the next century.

The Cat 285 — the largest Cat Compact Track Loader to date, with a lift height of 3.7m — was unveiled at the National Diesel Dirt & Turf Expo.

CELEBRATING 100 YEARS OF CATERPILLAR

Western Australia: building roads and legacies

• Proform Civil: tackling steep terrain with precision

In John Forrest National Park, Proform Civil took on its largest project to date — constructing an access road through steep bushland.

Owner Dale Weerts relied on a GPS-equipped Cat 325 excavator to navigate elevation changes and protect native trees.

“I honestly couldn’t have done it without it,” he said. “Everywhere that bucket went, I could see exactly where I needed to be on the screen.”

• Youngs Earthmoving: a 147-strong fleet built on trust

Rodney Young, Founder of Youngs Earthmoving, has built his family business around Cat machinery for nearly five decades.

“Nothing else matches the performance, longevity, reliability and resale value of Cat machines,” he said.

• Kais Hire: premium equipment for remote operations

Dave Kais of Kais Hire calls Cat “the Rolls Royce of the machinery industry”, citing unmatched operator preference and dependable service.

“No one wanted to operate anything that wasn’t Cat when I was younger, because it’s the best,” he said.

Enthusiasts from across New Zealand brought in vintage and modern equipment for a spectacular tribute at the 2025 Wheels at Wanaka event.

David Coburn (left), Claire Watt and Connor Coburn welcome the Cat 938 to their Coburn Sand and Gravel business.

CELEBRATING 100 YEARS OF CATERPILLAR

Queensland: digging deep with confidence

• Crushing Dynamics: powering through hard rock

At a hard rock quarry in Yatala, Crushing Dynamics relies on Cat excavators, loaders and trucks to handle tough terrain.

“They’ve got the power to move that rock, which is great,” Quarry Manager Bob Campbell said.

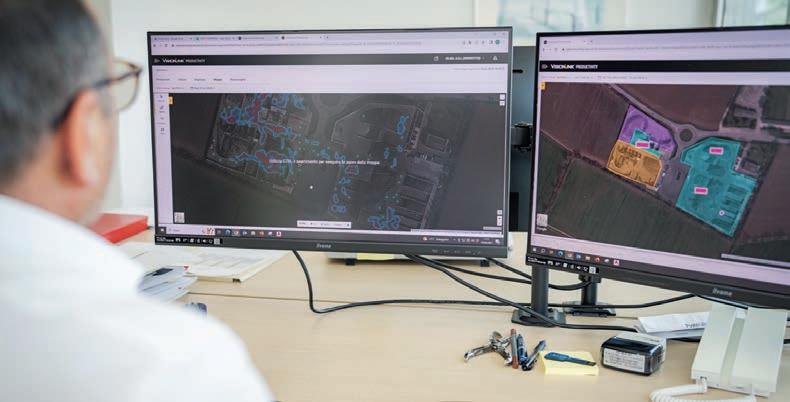

• Kompliance: turning mini excavators into smart monitoring units

Kompliance Founder Tory Ogden has transformed Cat 301.5 Mini Excavators into mobile monitoring systems, using remote controls and VisionLink™ for safe, e icient operation.

“Caterpillar’s Next Gen range has a lot of useful technology we utilise for controlling the system,” he said.

New South Wales: innovation on the road and trail

• Stabilcorp: road repair at scale

From a single Cat RM-250C to a fleet of 200 machines, Stabilcorp has grown into a major player in NSW road rehabilitation. Its Cat RM500Bs and PM310 Cold Planers are key to time-e icient operations.

“When you’re on a square metre rate, it’s all about time e iciency — and Caterpillar is second to none,” Owner Brendan Pinson said.

• O road Advantage: sculpting trails with precision

Former bike racer Josh Green uses a Cat 301.7 Mini Excavator to carve trails into steep terrain.

“With other brands, I couldn’t dig through tough soil. With the Cat excavator, it’s been no problem,” he said.

Victoria: family businesses fuelled by Cat

• Pengelly’s Earthmoving: a legacy that began with a bridge

For nearly 50 years, Pengelly’s Earthmoving has relied on Cat machinery from local Cat dealer William Adams.

Third-generation operator Jack Pengelly recalls the company’s first major job — cleaning up after the West Gate Bridge collapse using a Cat 955K traxcavator.

“The business snowballed from there,” Jack said.

“They started doing estate and road projects all through Werribee.”

With a 1974 Cat 130G grader still in operation, Pengelly’s fleet is a testament to durability.

“To have something that old still running — and still able to get parts — shows how tough Cat machines are.”

• Hutchings Plant Hire: a passion passed down

Hutchings Plant Hire Director Mark Hutchings has been a lifelong fan of Cat bulldozers. His enthusiasm has now been passed on to his two sons, creating a multigenerational connection to the brand.

“We’ve got more than 20 vintage Cat machines, including D2s and D4s,” Mark said. “Some restored, some for parts — but the collection keeps growing.”

Mark also showcases his vintage fleet at events run by the Antique Caterpillar

Pengelly’s Earthmoving uses a 1974 Cat 130G Grader and a 2024 Cat 160 all-wheel drive Next Gen Grader.

Hutchings Plant Hire’s machinery fleet only features Cat equipment, supported by local dealer William Adams.

CELEBRATING 100 YEARS OF CATERPILLAR

Machinery Owners Club, keeping history alive for future generations.

South Australia: from one bulldozer to a fleet of 100

• SC Heinrich: Clare Valley’s earthmoving powerhouse

Based in Stanley Flat, SC Heinrich has grown from a single Cat RD4 bulldozer to a fleet of over 100 machines.

Managing Director Malcolm Heinrich fondly remembers the company’s first new Cat purchase — a 922B wheel loader in 1968.

“We always called it the big loader — until the 936E came along,” Malcolm said. “We still have the 922 and plan to restore it one day.”

Even in community projects, Cat machines are front and centre.

“There’s nothing better than rolling up to a working bee with a Cat machine — usually bigger than the job needs,” he laughed.

Tasmania: mining success in rugged terrain

• Grange Resources: reliability in the wild west

For more than 55 years, Grange Resources has operated the Savage River mine in Tasmania’s rugged West Coast. With more than 50 Cat machines on site — including 20-year-old mining trucks — the operation depends on the reliability of Cat equipment and

support from Cat dealer William Adams.

“Rain, hail, snow or shine — those machines have delivered,” COO Ben Maynard said.

“We’ve used the full suite: diggers, dozers, graders, trucks and excavators.”

The harsh conditions haven’t slowed the fleet down, proving the durability and performance of Cat machinery in even the toughest environments.

A century of impact, a future of possibility

From vintage restorations to large-scale mining operations, these stories reflect the deep connection between Australian businesses and Cat machinery.

As Caterpillar celebrates 100 years, it’s clear that the legacy lives on — not just in machines but in the people who operate them.

With more than 50 Cat machines on the Savage River mine site in Tasmania, Grange Resources depends on the reliability of Cat equipment and support from Cat dealer William Adams.

With his love of Cat machines, the blood of Kais Hire director Dave Kais runs more yellow than red.

REDEFINED SAFETY WITH 3D AVOIDANCE ZONES

The XWSeries creates a total safe working envelope around the machine and operator enabling the control of the machine’s height, slew and rated capacity indication. This comprehensive system covers every eventuality when considering both operator and machine safety, offering complete peace of mind.

Height Control

Slew Control

Rated Capacity Indicator (RCI)

By combining AI-driven human form and object detection with robust hardware and intuitive interfaces, Leica Xsight360 delivers real-time awareness and insights that adapt to the dynamic nature of construction environments.

Staying safe in heavy construction environments is paramount, no matter the site conditions. Artificial intelligence (AI) plays a key part in this. As it continues to transform industries, its application in heavy construction is helping to build a safety-first culture that prioritises people. One such application is the Leica Xsight360 safety awareness solution, due to be released in Australia early next year. It represents a leap forward in how operators and site personnel are protected. Powered by Presien, the system is manufactured by Leica Geosystems, part of Hexagon.

However, as with any emerging technology, it’s crucial for safety professionals to understand not just what the system does, but how it does it.

Hexagon’s Machine Control Division Product Manager Brad Mullis takes a deep dive into the main components of the Leica Xsight360 solution. He explains how, by combining AI-driven human form and object detection with robust hardware and intuitive interfaces, the product delivers real-time awareness and insights that adapt to the dynamic nature of construction environments.

“The Leica Xsight360 solution leverages industry-leading edge-AI models to deliver real-time object detection and operator alerting,” Brad said. “In addition, occupational health and safety managers benefit from its AI-powered incident auditing and reporting capabilities, which support the development of proactive and data-driven safety strategies.”

The system comprises a set of hardware components that can be installed on any vehicle. These include the Leica CRS360 AI processing unit, the Leica CRS214 in-cabin display, the Leica CRS240 Automotive Ethernet camera and the Leica CR50 connectivity module.

Every detection is geolocated to identify danger zones and high-risk areas on site, enabling the implementation of appropriate measures to prevent future incidents.

Visual alert architecture and operator experience

Brad said that the Leica Xsight360 system indicates all visual alerts through an interface via the Leica CRS214 CAN-based operator display.

“Leica Xsight360 visual alerts are fully

configurable to suit di erent site requirements and operator needs. This includes customising alert colour, flashing pattern and buzzer settings separately for general and critical detections,” he said.

“Configurations are managed through the Leica Xsight360 setup app on the online customer platform by an authorised user. Operators cannot change alert settings directly from the in-cab display. Access may be granted to operators or limited to designated personnel such as safety o icers or site engineers.”

The Leica Xsight360 system supports flexible camera configurations tailored to di erent machine types. Using up to six 120° wide-angle cameras, the system can deliver 360° awareness. Machines may be configured with partial coverage, depending on the operational risk zones and application.

Brad said the Leica CRS214 in-cabin display presented a sector-based alert layout that corresponds to the actual camera coverage installed on the machine.

“The display provides real-time illuminated segments that indicate both the direction and

The Leica Xsight360 system enables operators to stay safe in heavy construction environments, no matter the site conditions.

Images: Leica Geosystems

severity of detections, aligned precisely with the configured fields of view. This ensures the operator is only alerted to activity in zones that are actively monitored,” he said.

“For enhanced situational awareness, the system can be integrated with the Leica MC1 machine control solution, enabling operators to view live camera feeds on their Leica Geosystems machine control display.

“These feeds are not stitched into a composite view but can be cycled or displayed in parallel. Upon detection, the Leica MC1 interface can be configured to automatically switch to the relevant camera stream, providing immediate visual context.”

Camera mounting stability options

Leica Xsight360 supports a wide range of camera mounting options designed for ease of use and flexibility on all machine types, including:

• Magnetic/adhesive mounts — high-strength magnetic bases with adhesive backing, suitable for metal, plastic or glass surfaces, originally developed and tested in vibrationprone machine control sensors;

• rail mounts — clamping brackets compatible with rail diameters from 17 to 50mm, o ering 360° camera rotation; and

• flat base plates — bolt-on or weldable plates with multi-orientation hole patterns.

“Camera brackets support vertical, horizontal, side and inverted orientations with adjustable tilt angles,” Brad said.

“A dual screw locking mechanism ensures stability under vibration. All cameras use automotive Ethernet cables with M12 connectors, and optional extension cables allow for placement of disconnect points in safe and accessible areas.”

Brad said that Leica Xsight360 on-machine components have been engineered for machines that undergo frequent assembly and disassembly cycles.

“The camera's quick-connect/disconnect rear plugs enable easy removal and reinstallation without tools,” he said.

“Brackets are designed to maintain alignment under vibration and resist degradation from repeated handling. Cable systems support colour-coded labelling (from a local installer) to simplify reinstallation, while the stress-relief loops and dust caps protect connectors during frequent connection/disconnection routines.”

Installation, calibration and configuration

Leica Xsight360 eliminates the need for traditional calibration tools such as checkerboards. Cameras are pre-calibrated at the factory, and IP addresses are automatically assigned upon connection.

System calibration is performed during setup using a wizard-driven interface on a standard laptop or tablet over the system’s internal Wi-Fi or over-the-air through the online platform. It is designed to be simple, with no advanced technical skills required.

The calibration process includes:

• Camera alignment;

• zone definition using physical markers (e.g. cones); and

• detection validation.

“The AI engine does not require calibration. Users simply select the operating environment from predefined options, and the system adjusts detection parameters accordingly,” Brad said.

“If a camera is moved or replaced, the system compares the current view to a stored reference image and prompts recalibration if needed.

“Following the configuration, a walk-around test is conducted to verify detection zones and system functionality. Detection zones can be adjusted via the Manual Sensor Configuration, as required.

“The installer will need to verify that the Alert Trigger is behaving as expected. It is important to note that the system will be inactive in safe mode (e.g. hydraulic lock engaged) and activate only in working mode.

“Detection events are uploaded to the cloud, and a calibration certificate is generated and can be stored in the vehicle.”

Fail-safe mechanisms and fault handling

Leica Xsight360 includes multiple fail-safe mechanisms to ensure operational integrity:

• Camera disconnection or damage triggers a camera failure icon on the in-cab display and disables the a ected sector, while the rest of the system remains active.

• Obscured or dirty lenses are flagged with a ‘camera obscured’ icon, flagging that detection in the sector is unavailable.

• Low-light conditions prompt a low-light warning for the a ected zone.

• Startup diagnostics verify firmware versions, image quality, frame rate and detection capability.

• Software failure results in an error icon and halts detections until resolved.

• Alert trigger signal failure defaults the system to active detection mode to prevent unsafe silence.

All faults are logged locally and to the cloud. The Device Maintenance dashboard provides real-time visibility into system health, and alerts can be escalated via email or SMS.

“Operators cannot disable the system without physically tampering with the wiring,” Brad said.

“Any wiring modifications are time-stamped and logged in the cloud. If the system is unplugged or the fuse is removed, the machine will be flagged as inactive during expected operating hours.

“Alert deactivation muting can only be performed remotely by authorised personnel via the cloud interface. The system’s input trigger ensures alerts are only active when the machine is in a hazardous state.”

C.R. Kennedy

The Xsight360 safety awareness solution will be available in Australia through spatial technology specialist and distributor C.R. Kennedy (CRK).

CRK National Manager for Machine Control Nick Leith said the system’s visual AI models are trained for heavy construction operations and continuously improve performance through machine learning.

“The Leica CRS360 AI processor runs Presien’s most advanced model to date — refined over 700,000 hours of real-world operation on construction sites — delivering low-latency operator alerts with minimal false alarms,” he said.

“Utilising proven AI detection technology, purpose-built for construction environments, Leica Xsight360 mitigates risks in real time by detecting hazards to keep people safe on site. The system supports up to six cameras, providing coverage on any construction vehicle to detect people, other vehicles and construction cones to reduce the likelihood of accidents.

“We want to get innovations such as these to key players in the market to test for spatial awareness and safety reporting.

“It will be a fantastic application for toolbox meetings and just general reporting for overall operations as well.”

More information: www.crkennedy.com.au/

The components of the Leica Xsight360 system.

During the holiday break, while operators are away, work sites and machinery can be at greater risk.

The end of the year is a chance to pause, recharge and enjoy some much-needed time with family and friends. But it is during these breaks that incidents of theft, damage and even public injury can have lasting consequences for the bottom line.

Owners should ensure they take practical steps to protect both their assets and the community during downtime.

Australian crime data shows the issue is ongoing:

• A recent report from the ABS revealed 2024 saw theft reach a 21-year high, with over 595,000 incidents recorded nationally.

• Around 0.7 per cent of households experienced motor theft, inclusive of heavy vehicles and machinery.

• Serious and organised crime now costs the Australian economy up to $68.7 billion annually.

NTI’s National Product Manager for Mobile Plant, David Kidd, said that beyond theft, unsecured sites also presented a business risk, as well as risk to the wider community.

“From recently excavated sites to partially built structures that could collapse in summer storms or high winds, there are many exposures that could lead to liability issues arising for members of the public,” he said.

“If anything goes wrong onsite during downtime, you may still be liable, and the liability costs can be detrimental to your business. Before you knock o for the holidays, leave enough time for a thorough clean-up and safety check.”

Simple, practical steps for operators

Reducing exposure doesn’t always require costly measures. Many of the most e ective safeguards come down to preparation and diligence.

Here are practical actions to consider before closing the site:

1. Maintain a clear inventory by recording serial numbers, photos and GPS locations of all machinery.

2. Use motion-sensor lights and audible alarms to help deter intruders.

3. Mark equipment using forensic identifiers like microdots or etching.

4. Secure controls and fluids using vandal covers, lockable fuel caps and hydraulic system locks.

5. Consider GPS tracking devices and remote immobilisers for visibility and control even when o site.

6. Check fences, repair gates, and close o any gaps that could allow unauthorised access.

8. Remove hazards like waste, chemicals and surplus equipment.

9. Cover excavations to help prevent accidents.

10. Notify local police about extended shutdowns or arrange occasional patrols.

11. Shut down mains power and lock the switchboard to eliminate electrical risks.

12. Review your insurance cover. Check that your mobile plant and equipment is insured through a specialist provider like NTI.

Why extra vigilance matters

While the holiday break has always been a vulnerable period, current trends make security even more important.

Many incidents are no longer opportunistic. Instead, organised groups deliberately target machinery and attachments with high resale value.

With theft rates climbing, insurers are increasingly looking for evidence of proactive security measures when assessing claims or renewing cover.

From a safety perspective, there are greater expectations from the public.

Communities and regulators alike are less tolerant of poorly secured sites, particularly

Make sure machinery is adequately insured, as equipment and attachments with high resale value are often targeted for theft. Image: NTI/iStock: ewg3D

around high tra ic areas like parks and schools.

David said that prevention is always preferable to dealing with the aftermath of a serious incident.

“Dealing with theft or an accident isn’t on anyone’s holiday wish list. But with some forward planning and extra vigilance, operators can go into the shutdown with peace of mind,” he said.

For expert support in protecting mobile plant and machinery, speak with your broker or visit NTI, Australia’s trusted specialist insurance provider for the transport, logistics and construction industries.

Limits and exclusions apply. This information is general only and does not take into account your objectives, financial situation or needs. When making decisions about our insurance, consider the Product Disclosure Statement and Target Market Determinations at www. nti.com.au. Insurance products are provided by National Transport Insurance, a joint venture of the insurers CGU Australia Pty Ltd trading as CGU Insurance ABN 62 004 478 960 AFSL 700014 and AAI Limited trading as Vero Insurance ABN 48 005 297 807 AFSL 230859 each holding a 50% share. National Transport Insurance is administered on behalf of the insurers by its manager NTI Limited ABN 84 000 746 109 AFSL 237246.

7. Brace temporary structures.

At NTI we’ve always been successful in finding new ways to keep our customers truckin’, shippin’ and diggin’.

With specialist insurance and roadside assistance products designed to protect Australian businesses and families, NTI is the specialist our customers can count on in their time of need.

Liebherr Generation 8 crawler dozers let operators use their skills and capabilities to the full.

Earthmoving equipment operators are often responsible for the success of projects, knowing they have to fulfil the specified requirements on time and always find appropriate solutions.

On site, they call the shots, where every tonne makes a di erence, and cost-e ective operations are crucial.

The contribution of dozer operators, in particular, can be significant: from supply of material, to site and storage capacity management.

In this regard, the new generation Liebherr crawler dozers are a godsend, literally enabling those inside the cab to make the earth move.

Full powered multifunctional tool

Whether in heavy dozing or in precise levelling, the new Generation 8s keep the users “in the fast lane”.

The hydrostatic drive always delivers the optimum pushing speed, while the Operator Assistance Systems guarantee maximum grading quality and e iciency.

The Liebherr crawler dozer also lets users choose the highest possible speed for their operating conditions and directly call up full thrust at any time via the joystick.

It o ers full automation without compromise: perfect breakout force on any terrain. Use the Quick Drop for rapid lowering of the blade, and the Auto Blade for automatic raising and lowering of the blade.

Through the Liebherr hydrostatic drive, the machine automatically and continuously delivers the correct traction when ripping –without any gear changes.

At the end of ripping the first strip, the rear ripper is raised automatically at the push of a button.

The undercarriage design also gives the added benefit of a low centre of gravity. Ready to tackle any stony or steep terrain, the fixed ripper control with mini-joystick always ensures a stable hold.

If the ground is loose, simply select a higher speed range. Due to the electronic pilot control, not only can operators set the speed of the machine, they can also select the reactivity and speed of the operating hydraulics in the display.

They can also equip their Generation 8 crawler dozer with the proven Liebherr quality heavy duty blade.

Users can rehabilitate the site after extracting the materials of value, by switching to the environmentally friendly eco mode for light work and material transfer.

This lets them achieve both the required pushing performance and maximum fuel economy.

The machines are safe on slopes at top speed. When driving on embankments, the machine assists with automatic speed monitoring.

The Hill Assist function, with automatic parking brake, makes hill starts simple. The modern Liebherr drive system completely

dispenses with the need for a wear-intensive foot brake.

Meanwhile, the standard Liebherr “Free Grade” provides active blade stabilisation when grading surfaces, ramps and embankments with longitudinal and transverse slopes.

Liebherr primarily uses its own diesel engines in the crawler dozers – specifically designed for heavy construction machinery.

In combination with the hydrostatic drive, the machine generates the maximum tractive power at any speed.

Cost-e ective construction

Profitable crawler dozer operation is much more than just cutting the cost of moving material.

When developing the new Generation 8, Liebherr focused attention on the entire construction site process: from simple transport, through cost-e ective operation for both light and heavy applications, with the aid of intelligent assistance systems, right up to service logistics.

Liebherr focuses development on the overall process – because cost-e ective crawler dozer use is determined by all the processes in daily operations.

So, for example, the new Liebherr machine, with a six-way folding blade, can be transported without the use of special tools or a special transport permit.

In addition, the operation of a hydrostatically

The new crawler dozers o er full automation without compromise, with perfect breakout force on any terrain. Images: Liebherr

controlled machine is so simple and intuitive that every truck driver can load it safely. And with the optional reversing camera, manoeuvring is even easier.

Users can decide how much “power” the Liebherr crawler dozer will give. If large quantities of material are to be moved, the hydrostatic drive works at constant engine speed to save resources and keep costs down.

The larger blade capacities of the Generation 8 machines give additional reserves of power. For light work, operators can give priority economy with the eco mode.

And every time, the environment always benefits. Generation 8 ranks particularly well in heavily built-up commercial areas due to its low noise emissions.

Machine intelligence

Within level 2 of the new Liebherr Operator Assistance Systems, “Definition Grade” allows operators to model a 2D surface without a rotating laser. All they need is a reference point from the site surveyor.

With the blade automatically lowering to the reference measurement, the creation of a precise 2D surface is child’s play – even over large distances and in di erent pushing directions, all without the need for a laser or complex machine controls with satellite connection.

And at the same time, Liebherr technology now enables grading speeds that previously could not be achieved.

With the Liebherr Connect fleet management, businesses can plan the next service and always keep an eye on upcoming maintenance work. If the worst comes to the worst, simply notify the service partner and order the right spare part including express delivery via MyLiebherr on the mobile phone.

Users can program dozers to precisely match working conditions and be fully reliant on the professional equipment from Liebherr.

The high quality engineering concept of Generation 8 extends across the entire life of the machine. Starting from initial development of the sturdy construction machines, it covers all factors of safety for daily operation.

Safety without compromise

Demanding tasks require full attention. With a single glance at the new 9-inch touch display drivers can be certain that all operating parameters are in the green range.

Whether it's for the UHF radio or phone

charging, the full 12V and 24V power supply, along with two USB sockets, ensures everyone can connect to the right outlet.

The continuously variable hydrostatic Liebherr drive particularly shows its strengths when driving on extremely soft ground: with permanent traction on both drive tracks, the machine can be manoeuvred, without changing gear, completely free from jerking.

In combination with the good weight distribution, this means the crawler dozer is always safe and sure on the move.

Due to the compact design of the hydrostatic drive components, the centre of gravity of the machine remains very low.

Normal drive (low drive) has been ideally designed and operates particularly well on softer ground, whereby noise levels also remain exceptionally low.

In addition, the Liebherr dozer has a large wading depth. The demand-driven hydrostatic fan saves energy and lowers the noise levels even further.

Build for operators

Crawler dozer operators depend fully on all of their senses. Through e ective shock absorption, the latest Generation 8 dozer filters out vibrations, but you still have the full feedback to form the perfect level. The reassuring Operator Assistance Systems help you to exceed your demands for productivity and precision. Through the digital display interface, users always keep an eye on their objective.

Crawler dozer operators play a leading role on the construction site and are frequently one of the first into action.

For this reason, the new Liebherr machine is

ready and waiting with lighting for access and exit as well as for the engine compartment, and there are centralised maintenance points to simplify early morning inspection.

Right from the start, operators can feel at home in the spacious driver’s cabin and adjust the seat and joysticks to match their own ergonomic needs.

Their presence is immediately detected by the seat contact switch, leaving them free to belt up and get started right away.

The advanced lighting layout illuminates even the outermost corners around the machine. With large glass surfaces, sloping shapes for containers and ideal positioning of exhaust pipe and driver’s seat, the design is optimised for visibility to give a clear overview even in tight spaces. The windscreen wipers can be regulated separately for perfect visibility in every direction.

At a glance

• PR 716 G8 Litronic

Operating weight: 13,300–15,800kg

Engine rating: 97kW/132HP

Stage V/Tier 4 Final

Blade capacity: 2.92–3.3 m3

• PR 726 G8 Litronic

Operating weight 17,500–20,800kg

Engine rating: 125 kW/170HP

Stage V/Tier 4 Final Blade capacity: 3.33–3.87 m3

• PR 736 G8 Litronic

Operating weight: 21,200–25,500kg

Engine rating: 160kW/217HP

Stage V/Tier 4 Final

Blade capacity: 4.1–5.57 m3

• PR 746 G8 Litronic

Operating weight: 25,900 - 31,500 kg

Engine rating: 190kW/258 HP

Stage V/Tier 4 Final

Blade capacity: 6.00-7.20 m3

• PR 756 G8 Litronic

Operating weight: 35,400 - 43,000 kg

Engine rating: 260 kW/349HP

Tier 4 Final

Blade capacity: 8.92-11.80 m3

For more information, visit www.liebherr.com.au

The larger blade capacities of the Generation 8 machines give additional reserves of power.

Liebherr focuses development on the overall process – because cost-e ective crawler dozer use is determined by all the processes in daily operations.

Beat the heat this summer with Alemlube’s Automotive Premium range of energy-e icient evaporative coolers and industrial ceiling fans, which provide high-volume, low-speed air distribution safely at minimal cost.

factories and workshops where cooling methods such as air-conditioning are not feasible and are environmentally harmful.

Mobile

evaporative

air coolers

Alemlube's two Automotive Premium mobile evaporative cooling units are perfectly suited to warehouses and workshops, providing the most energy-e icient temperature relief for commercial or industrial environments of any scale.

use of chemicals or refrigerants and use less electricity.

Known to be an extremely energy-e icient cooling method, these water evaporation units are highly suited for workspaces where the ambient air is hot and the humidity is low.

They work by combining the natural cooling properties of water with a steady and variable airflow to lower indoor temperatures overall.

Its range of powerful cooling units, comprising two evaporative coolers and four industrial ceiling fans, is perfectly suited to warehouses,

The easy-to-operate AAPKA30 and AAPKA24 models produce high volumes of airflow, both featuring an oscillating fan with adjustable swing louvres. They are fully mobile with sturdy lockable wheels and are fitted with robust, onepiece moulded polyethylene housing that does not crack or leak, resulting in low-maintenance capabilities.

Importantly, the cooling units are environmentally friendly, as they cool without the

These evaporative cooling systems therefore provide substantial energy savings compared to refrigerated air units.

The AAPKA30 evaporative cooler generates an impressive airflow of up to 23,000m3 per hour, while the AAPKA24 unit produces up to 12,000m3 of airflow per hour. Additionally, the units can detect the relative humidity in the workspace and adjust their water consumption to meet preferred and optimal working conditions.

The AAPKA24 mobile evaporative air cooler used in a workshop. Images: Alemlube.

Industrial ceiling fans

Alemlube's Automotive Premium range of four industrial ceiling fans quietly moves large amounts of non-turbulent airflow over long distances, vertically or horizontally, using low amounts of electricity.

The four ceiling fan models come with variable blade sizes, from four metres to up to 7.3m in diameter. They can therefore be used in a variety of work conditions to ensure optimal airflow, in isolation for workstation spot cooling, or as a multi-fan system across large floor areas with high ceilings. They can also be used to displace fumes and other workshop odours.

At the top of the ceiling fan range is the AAP-CF-7E model with six blades, each 7.3m in diameter, suitable for cooling areas up to 1800 square metres and producing airflow of 13,800 cubic metres per minute.

E ective simplicity is at the heart of Alemlube's ceiling fan designs, as they feature three-phase motor power supply which is ideal for plug-and-play installation.

The AAP-CF-6E features 6.1m diameter blades which are ideal for areas of 1380m2, as it produces airflow of 12,000m3 per minute. The 5.5-metre blade diameter AAP-CF-5E has an application area of 1050m2, while the AAP-SF4E comes with five 4m blades that are suitable for an application area of 450m2.

Powerful and maintenance-free, the fans' motors and blades move significant high volumes of air at a low speed, providing superior performance and e iciency, combining maximum airflow with long-term reliability. Enhancing their durability, the industrial ceiling fans' blades are made from high-strength aircraft aluminium alloy and are coated in PVDF.

The patented airfoil design, with its special reinforcing rib support system, increases the strength of the fan blades and avoids the fantail from sagging and fatigue of connecting components.

For peace of mind, all models comply with the Australian and European CE Standards, ensuring safety and quality.

With Australia enduring long, hot summers, Alemlube's Automotive Premium evaporative air coolers and industrial ceiling fans provide e icient solutions to beat the heat in warehouses and workshops across the country.

More information: www.alemlube.com.au

The AAP-CF-5E High Volume Low Speed

Industrial Ceiling Fan has 5.5m diameter blades and is suitable for cooling areas up to 1050m2

The AAPKA24 mobile evaporative cooler produces airflow of up to 12,000m3 per hour.

Alemlube industrial ceiling fans

AAP-CF-7E:

• 7.3m blade diameter

• Six blades

• Application area: 1800m2

• Airflow: 13,800 m3/minute

AAP-CF-6E:

• 6.1m blade diameter

• Six blades

• Application area: 1380m2

• Airflow: 12,000 m3/minute

AAP-CF-5E:

• 5.5m blade diameter

• Six blades

• Application area: 1050m2

• Airflow: 10,500 m3/minute

AAP-SF-4E:

• 4m blade diameter

• Five blades

• Application area: 450m2

• Airflow: 8000 m3/minute

The AAPKA30 mobile evaporative air cooler generates an impressive airflow of up to 23,000m3 per hour.

Alemlube mobile evaporative coolers

AAPKA24

• 240V/50HZ 650W three-speed motor

• Fan diameter: 24"/60cm

• Oscillating fan, adjustable swing louvre

• Airflow: 12,000 m3/hour

• Maximum cooling area: 150m2

• Tank capacity: 70L

AAPKA30

• 240V/50HZ 1,100W three-speed motor

• Fan diameter: 30"/76cm

• Oscillating fan, adjustable swing louvre

• Airflow: 23,000 m3/hour

• Maximum cooling area: 220m2

• Tank capacity: 130L

In heavy equipment applications, hoses often dictate the margin between productivity and downtime.

For hydraulic hose specialist BOA Hydraulics, the commitment is simple: to supply products that enable freedom of control. That means partnering only with hose system manufacturers it trusts to deliver.

An example of this is BOA’s collaboration with Yokohama Hydraulic Hose, a connection that stands out in the Australian market.

As BOA Marketing Head Jorge Boakes explains, Yokohama isn’t just a hose manufacturer.

“It’s a global brand built on more than a century of innovation and quality,” he said.

“Since opening its doors in 1917, Yokohama has earned a worldwide reputation for producing high-performance rubber products trusted across various industries, from automotive to mining and heavy machinery.”

Why Yokohama hoses matter

Yokohama’s hydraulic hoses are engineered for mobile machinery working under extreme pressure and conditions. Every hose is built with top-grade rubber and high-tensile steel, and they’re tested well beyond industry minimums.

Here’s what makes the di erence:

• Precision manufacturing for consistent quality;

• impulse testing of over 1.2 million cycles, more than double the industry standard;

• certified constant-pressure performance (ISO 18752);

• tighter bend radius and smaller outer diameter for easier routing;

• abrasion-resistant cover that handles tough environments; and

• roughly 25 per cent lighter than conventional spiral hoses, making it easier to handle and improving fuel e iciency.

“It’s a hydraulic hose system built for hard work and long service life,” Jorge said.

Why BOA Hydraulics chose Yokohama Jorge said BOA doesn’t just sell parts.

“We deliver integrated hydraulic systems designed to put users in control,” he said.

“Our team visited Yokohama’s factory in Japan to see the company’s process firsthand. We saw the same diligence in their testing and manufacturing that we bring to every customer relationship.

“We now o er matched hose and fitting systems engineered to OEM standards. That

includes crimp specifications, assembly support and full traceability.

“It’s everything you need to install with confidence and keep machines moving.”

Tested to

perform

Jorge said that when it comes to hose testing, not all methods are equal.

“Yokohama goes further, pushing its hoses beyond standard industry protocols to make sure they’re ready for real-world punishment,” he said.

“While typical SAE and EN standard tests use a square pressure wave and max out at around 400,000 to 500,000 impulse cycles, Yokohama hoses are tested using a much tougher peak pressure method.

“This is known as the Komatsu and Hitachi spike testing standard — simulating the hammering conditions of heavy machinery under load.”

Here’s how Yokohama’s hoses are tested:

• Impulse tested to 1.2 million cycles — more than double SAE/EN standards;

• pressure testing at 150 per cent of Max Operating Pressure (MOP) — most SAE hoses are tested at only 120-133 per cent MOP;

• test oil temperatures of up to 120°C — ensuring performance in extreme heat; and

• peak wave pressure cycles — replicating the real surges and stress that equipment generates in tough jobs.

“This rigorous testing is why BOA trusts Yokohama to stand up in the harshest environments. It’s more than numbers on a spec sheet — it’s performance you can rely on when it counts,” Jorge said.

The Yokohama Boom Arch hoses used at Cloncurry. Images: BOA Hydraulics

Yokohama hoses provide fewer breakdowns, longer hose life and more hydraulic uptime.

Field-proven over 7000 hours

Jorge said that Yokohama hoses have proven themselves “out in the field”.

“We installed a full set of 2-inch Yokohama Boom Arch hoses on two Hitachi EX1900 excavators — one at Rocklands Mine in Cloncurry in Queensland, the other at Osborne Mine, 200km south,” he said.

“Both machines had previously run other brands of hose. These showed vertical cracks near the crimp within 1000 hours and had already started to rust internally.

“The Yokohama hose at Rocklands ran for 4200 hours before the mine ceased operations. The hoses were still in great condition.

“The other machine at Osborne is still running with the same Yokohama hose after 7455 hours.

“There’s no visible damage or wear. Even under clamp contact, the hose holds up better than anything else on the market.

“That’s why we recommend running Yokohama hoses throughout the system. It prevents uneven wear, keeps clamps tight and extends the life of your setup.

“Some businesses even use Yokohama on their flow meters when tuning hydraulic pumps, demonstrating complete confidence in the product.”

Built for hydraulic uptime

For operators in mining, construction, forestry and beyond, the hose they choose matters.

“BOA’s partnership with Yokohama gives them a hydraulic solution that’s built to last and backed by experience. They provide fewer breakdowns, longer hose life and more hydraulic uptime,” Jorge said.

“If you’re ready to upgrade your hose setup, talk to us. With Yokohama and BOA, you’re

not just buying a hose. You’re getting the confidence to take control.”

More than just hoses

Jorge said that the Yokohama partnership was just one part of the BOA solution.

“From the ground up, we’ve built a fully integrated hydraulic management system, designed to give total control over repairs, maintenance and fleet performance,” he said.

“With the BOApod mobile workshop, the

BOAhub app for digital job and asset tracking, and our end-to-end training and service support, we go well beyond hose and fittings.

“Whether you’re an owner-operator or servicing a full fleet, BOA delivers a smarter, faster way to stay on top of your hydraulics.

“Quality hoses are important, but hydraulic uptime comes from a fully integrated solution.

When you’re ready to move from patch-ups to proactive control, we’ve got the tools, the tech and the team to help you do it.”

The Yokohama product is about 25 per cent lighter than conventional spiral hoses.

Yokohama hoses have shown consistent performance in field conditions.

The true value of insurance lies far beyond the policy paperwork: it lives in day-to-day business confidence and in the assurance that if things go wrong, they won’t stay down for long.

The earthmoving sector’s scale and speed mean a single incident, whether an accident, an equipment failure or a theft, can halt operations and put investments at risk.