$7.95 inc

$7.95 inc

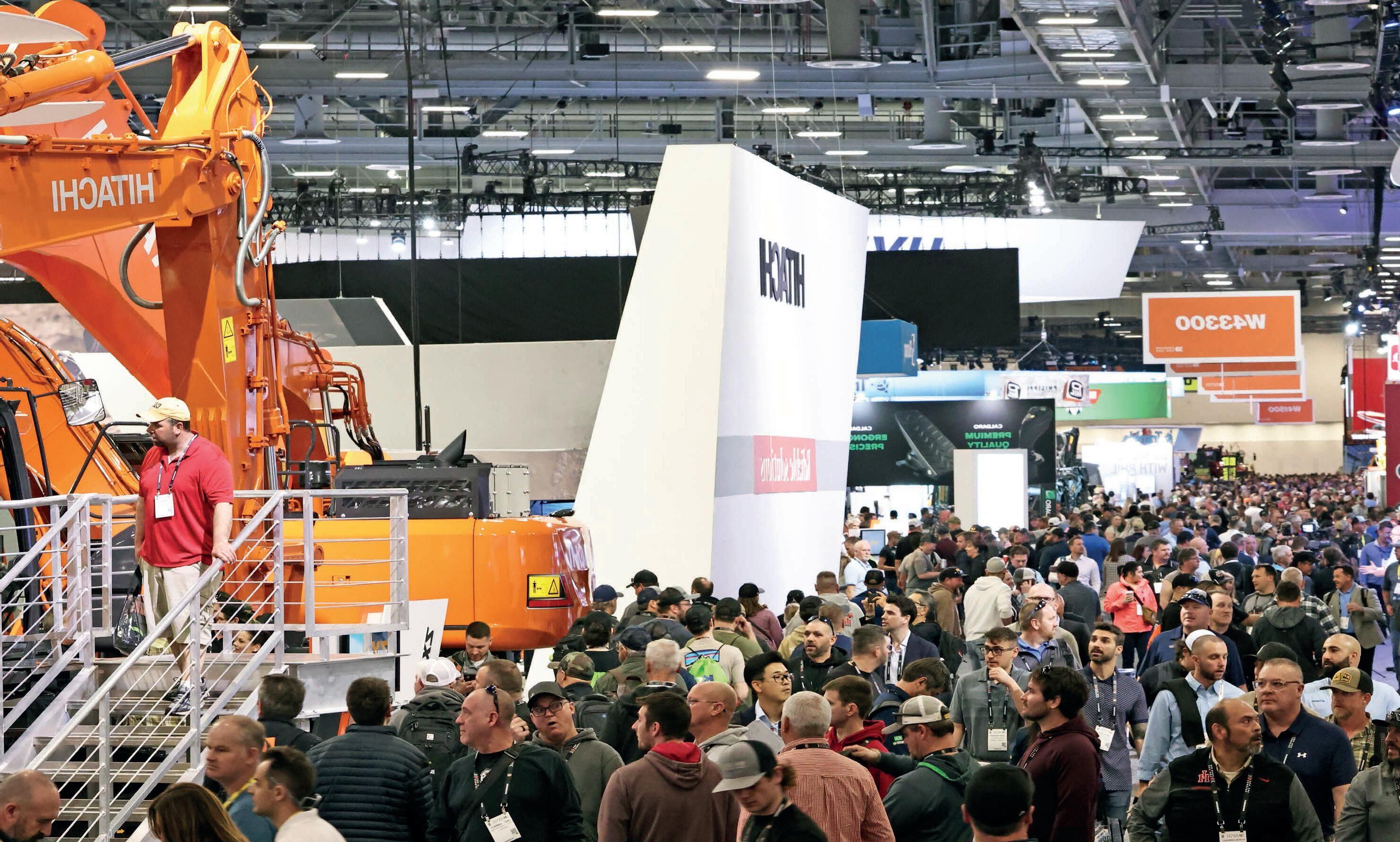

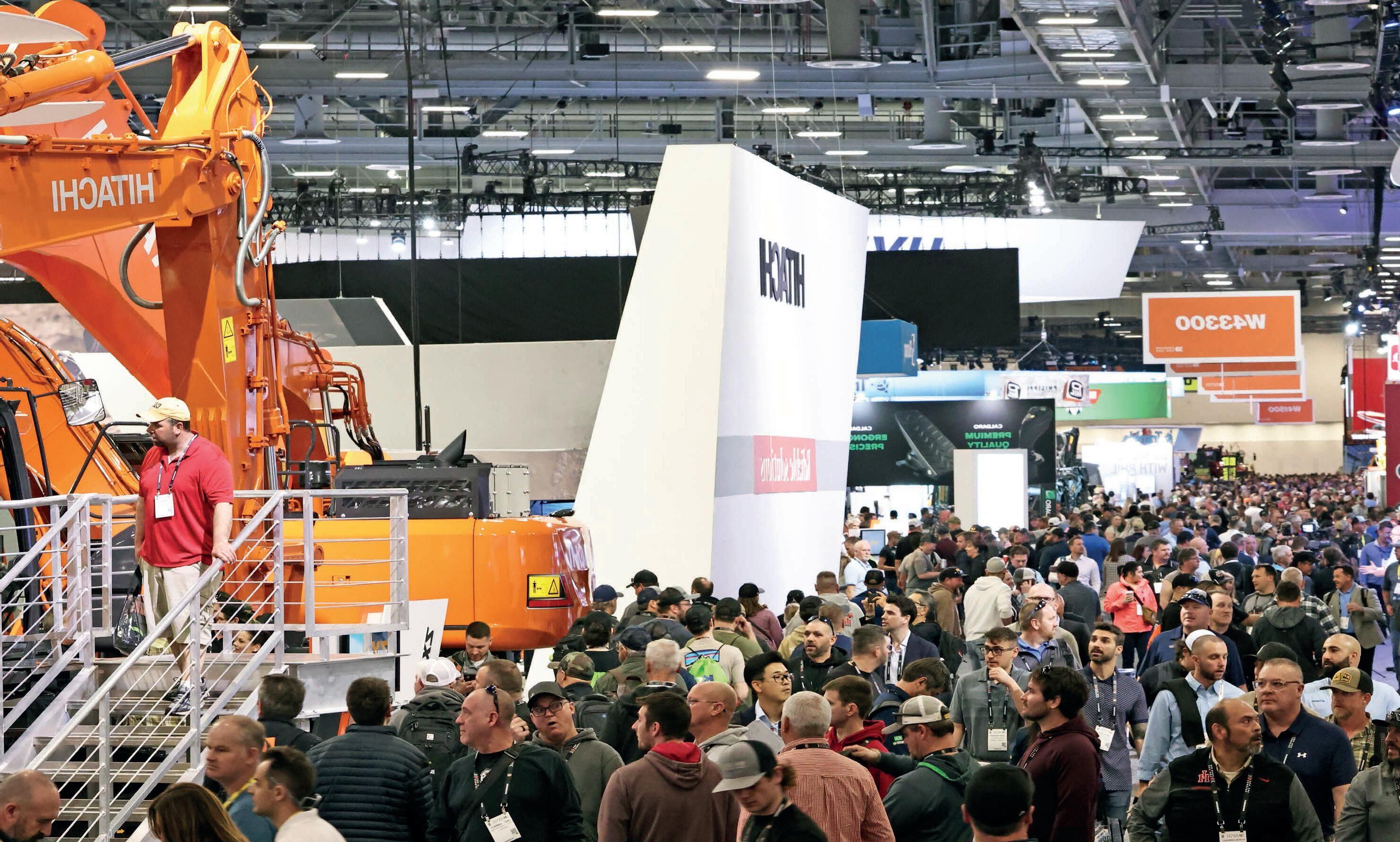

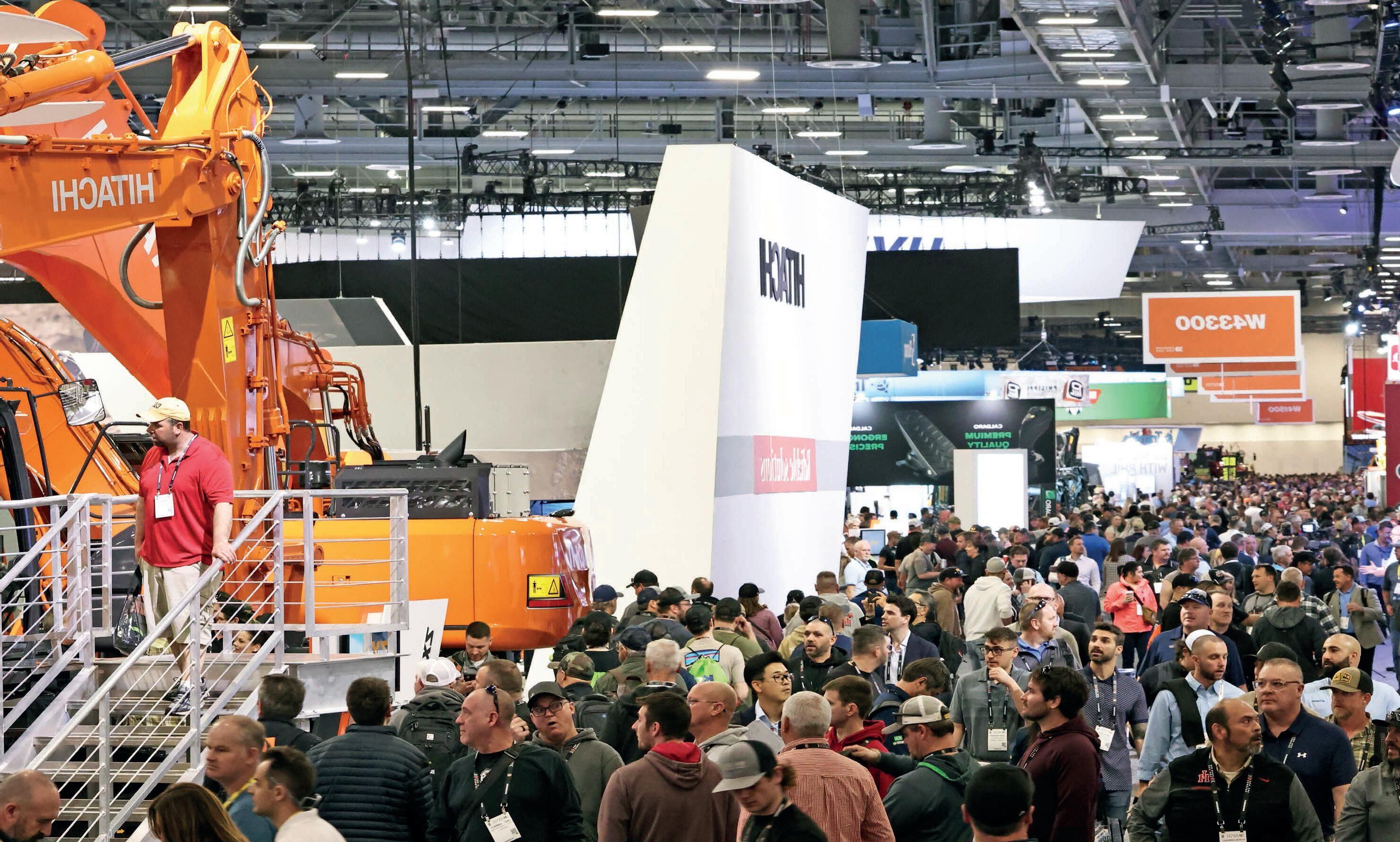

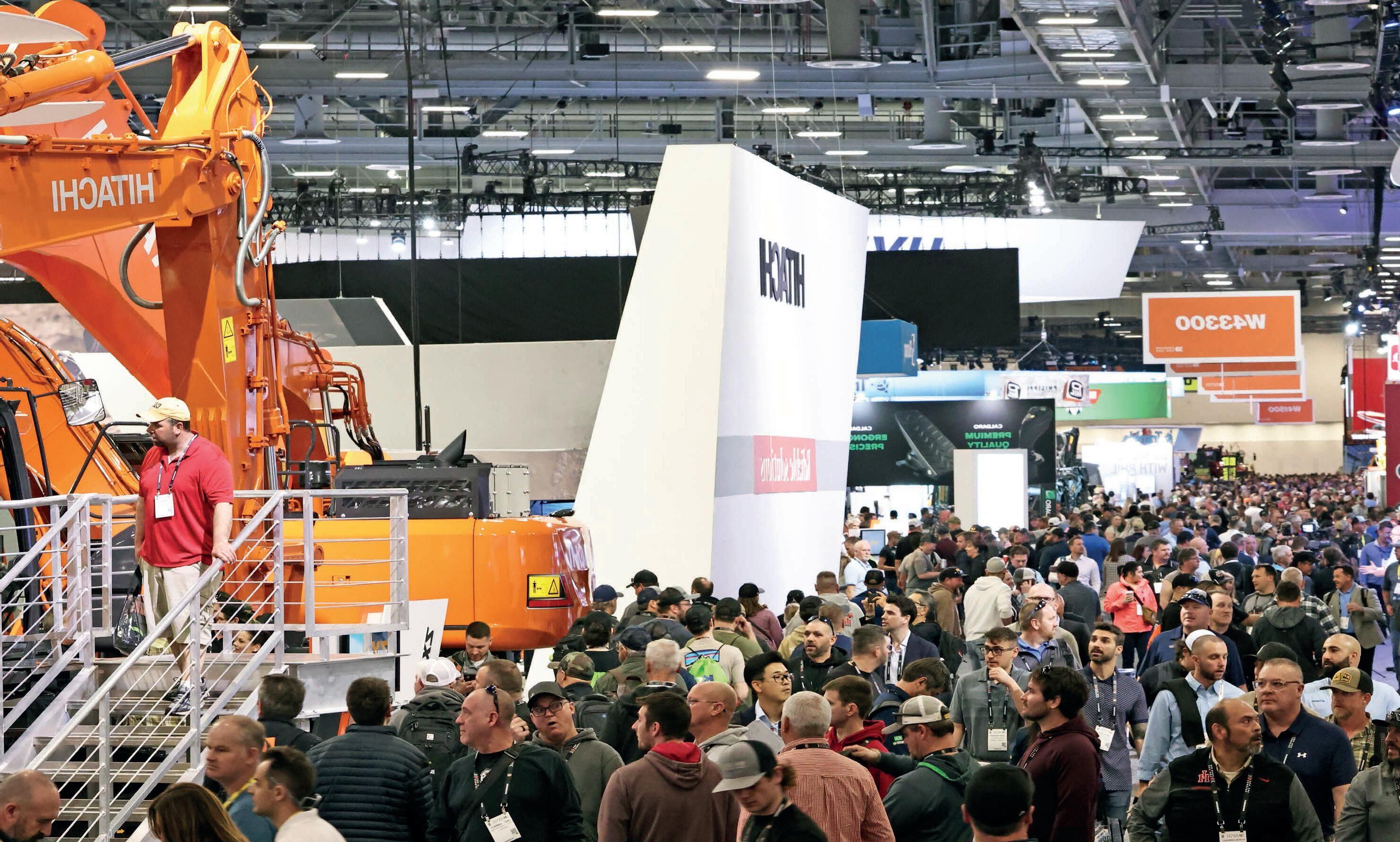

Equipped with integrated payload smart technology, a Cat 972 loader has proven to be indispensable for a Victorian quarry operator.

Ray Chan Editor

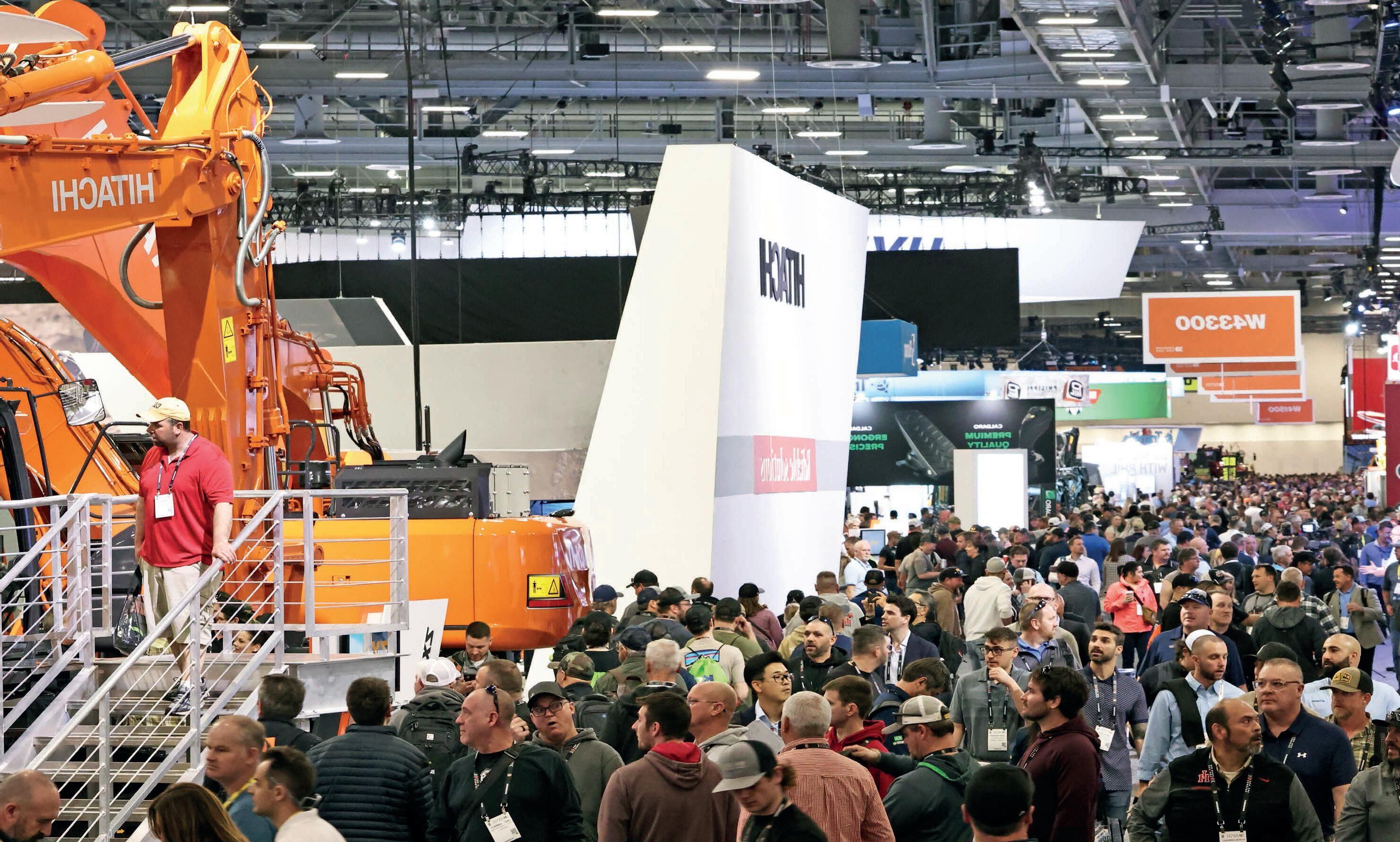

A new year is always seen as an opportune time for reflecting on the past 12 months and looking forward to new challenges.

After weathering a mixed performance in 2025 — bu eted by shifting investment patterns, workforce constraints, and technological transformation — the earthmoving sector seems poised for moderate but meaningful growth in the months ahead.

The industry, essential to mining, infrastructure and construction, continues to reflect the broader Australian economic rhythm: resilient but contending with structural headwinds.

Generally, 2025 was one of stabilisation rather than breakout growth for Australia’s earthmoving and construction equipment markets. Multiple industry analyses paint a picture of modest gains buoyed by public infrastructure pipelines, mining demand, and replacement demand for ageing fleets — juxtaposed against soft private investment.

By year’s end, revenue and order books looked neither booming nor bust — instead reflecting steady demand anchored by public works and mining, counterbalanced by cautious private sector spending.

Looking ahead to 2026, infrastructure investment is likely to remain a key growth driver. The federal and state pipeline of transport, energy, and social infrastructure projects will underpin demand for earthmoving machinery across civil works, roadbuilding, tunnelling, and utility projects.

Zero-emission and low-emission equipment segments are gaining traction as operators seek cost e iciencies and compliance with evolving environmental benchmarks. This year, adoption of electric and hybrid earthmoving machines is expected to rise, driven by government emissions targets and industry readiness to innovate.

This technological shift also dovetails with smart digital integration — telematics, autonomous functions,

and predictive maintenance — which are increasingly di erentiators in customer value and total cost of ownership.

One of the risks is persistent labour shortage in skilled trades and plant operators. Surveys indicate that the construction sector — a major earthmoving demand pillar — expects high rates of skilled workforce constraints in 2026, with little relief forecast compared to the preceding period. Whatever the developments, you can rest assured that Earthmoving Equipment Magazine will be there to provide breaking news, innovative updates, and informative case studies of businesses doing their best to achieve maximum e iciencies and profitability.

This issue alone, there is a plethora of compelling reading, as we take you to all points of the country. In Brisbane, we report on how an excavation company’s faith in Kobelco has paid dividends; in the West, we venture to the southern hemisphere’s biggest talc mine to discover which machinery brand makes it tick; and in Victoria, find out how a leading motocross rider has built a world-class practice track at his home.

We round up our coverage of Caterpillar’s celebration of its 100-year milestones with a couple more spotlights on the companies which rely on the yellow machines, as well as visit a NSW four-wheel drive specialist which has taken delivery of the last of the specially-branded Cat Centennial 285 Compact Track Loaders.

There are features on the latest products for skid steers, tracked and wheeled loaders, accessories, and attachments, including an engaging piece on a new single-bevel, single-life bucket cutting edge which does not require mid-life flipping.

And don’t miss our range of contributions from our industry experts, as well as profiles on the dealers and contractors that keep the industry moving forward. All this, plus the popular columns from our team of industry analysts, ensure there’s plenty of material that will keep you engaged.

Happy digging!

Volvo’s new J-Series haulers, such as this A45, have been redesigned to deliver unmatched performance, exceptional power, and cutting-edge technology. Image: CJD Equipment

Earthmoving Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

CEO

Christine Clancy

Head of Sales

Andrew Morrison Editor

Ray Chan ray.chan@primecreative.com.au

Brand Manager

KahChi Liew kahchi.liew@primecreative.com.au 0421 474 407

Production Editor

Michelle Alder

michelle.alder@primecreative.com.au

Design

Daz Woolley

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website www.earthmovers-magazine.com.au

Copyright Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2026.

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head O ice 379 Docklands Dr, Docklands VIC 3008 P: +61 3 9690 8766 info@primecreative.com.au www.primecreative.com.au

Sydney O ice Suite 11.01, 201 Miller St, North Sydney, NSW 2060

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

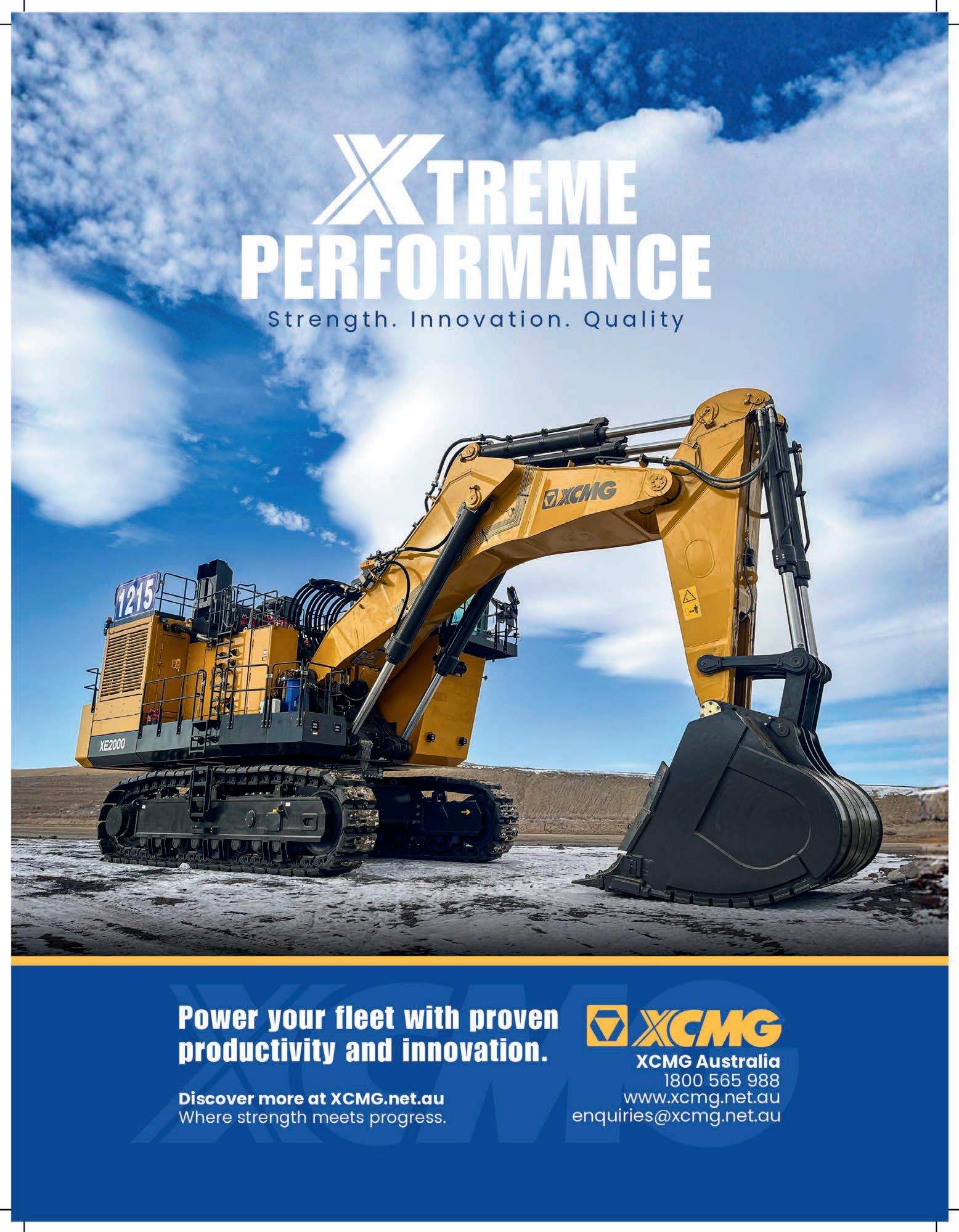

Be in control with the 7 Series excavators and wheel loaders.

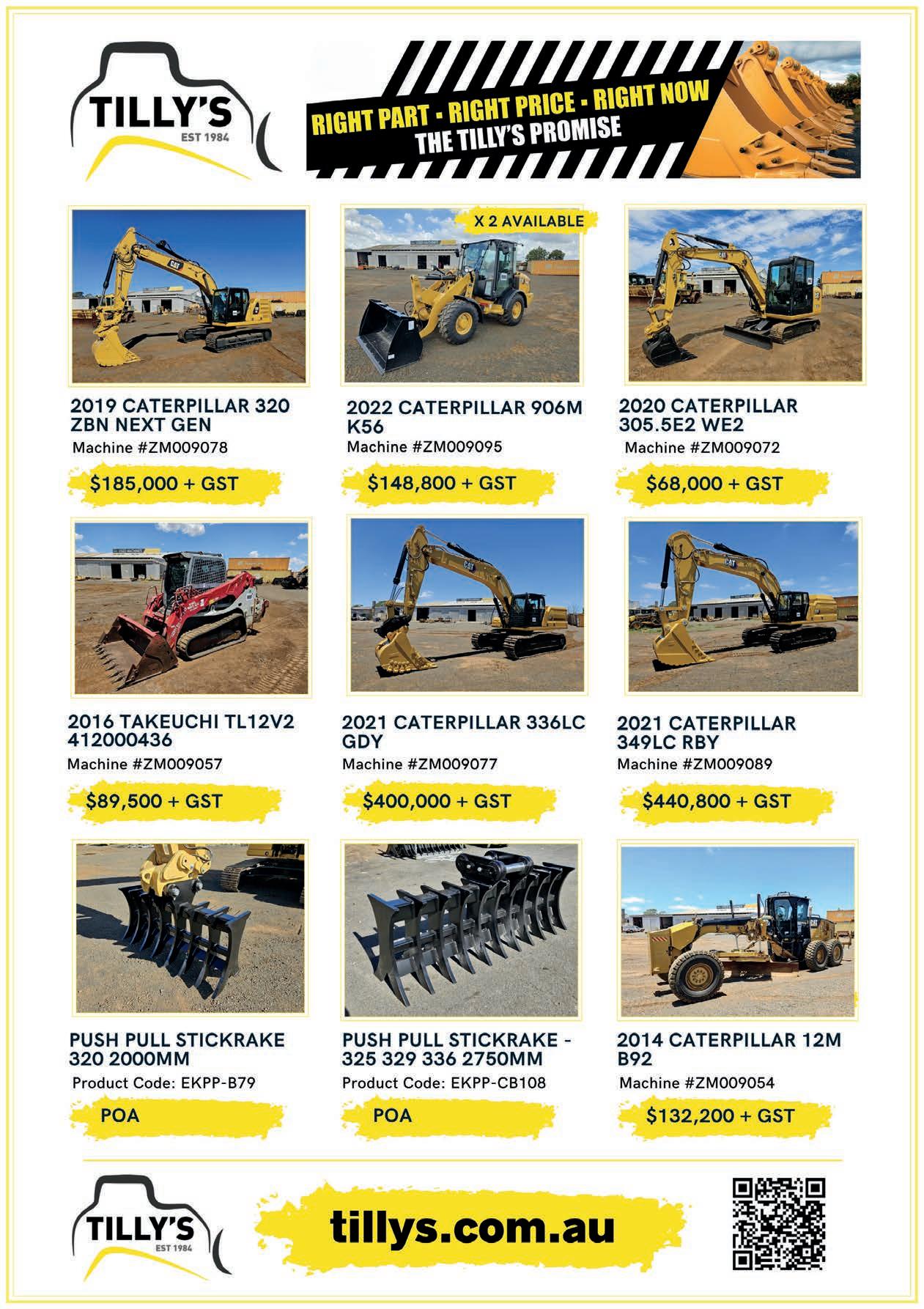

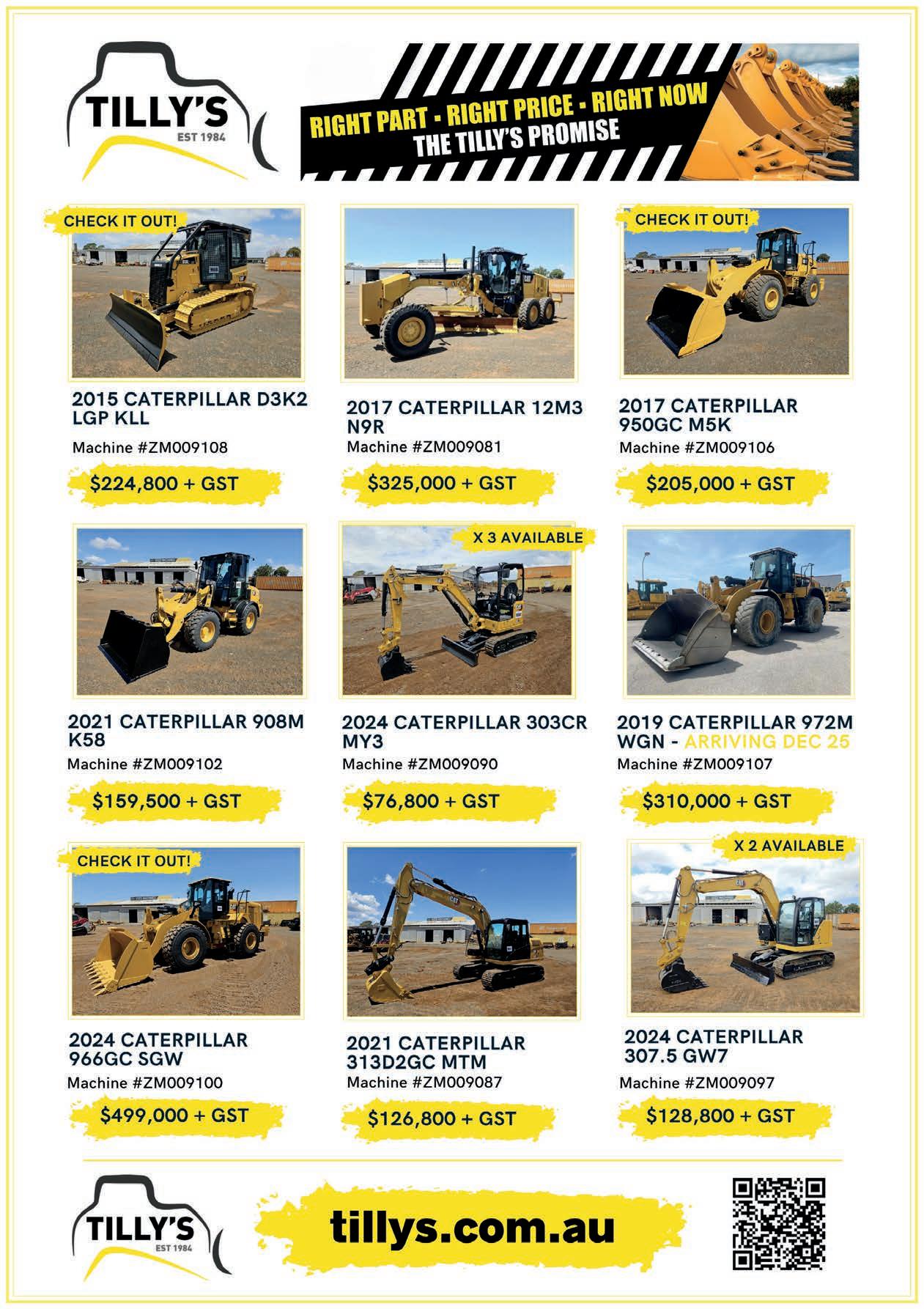

In high-volume, high-stakes environments that quarries face, the role of loaders can’t be underestimated, and getting payloads right is fundamental to the success of the operation.

You can’t miss the pits and terraced walls of the quarries on the outskirts of Ballarat in Western Victoria. The operations — one in Moyston, the other in Napoleons — have been run by familyowned business Log Hut Quarries for more than 20 years.

Moyston is a sand quarry excavated for a product used in sports ovals and concrete, while the Napoleons location is a source of Types A and B fill, gravel, bluestone, sand, red dredge, and topsoil.

The materials support everything from road and rail construction to house slabs, structural fill, drainage, and landscaping.

Earthmoving Equipment Magazine visited the quarries to find out more about the company from Managing Director Timothy Porter and his daughter Jessica, who serves as General Manager.

The Porters don’t shy away from their a ection for Caterpillar equipment.

“Log Hut has a large variety of Caterpillar machinery, including excavators, loaders, and dozers,” Tim said. “We have 14 pieces of Cat equipment in total, and a fleet of eight truck and trailer set-ups to deliver our products.”

Tim boasts several decades of industry experience, having been the previous owner of a plant and equipment hire business named Porter Plant, which provided machinery and vehicles for short and long-term hire.

During that time, he built a relationship with William Adams, the business becoming one of the dealer’s biggest customers.

“I started Porter Plant in 1994 with my father, and we worked solely in the gas industry,” Tim said.

“We bought our first Caterpillar machine, a backhoe, in 1995. In about 1997, we bought our first excavator, a seven-tonner, and we built up from that.

“In 2000, we were lucky enough to enter a plant hire agreement with Victorian government road agency VicRoads, supplying its fleet.

“Our fleet of Caterpillar equipment grew quickly. I bought more than 200 pieces of equipment through William Adams before I sold the company in 2020.

“When I focused on Log Hut Quarries, I continued to buy more Cat equipment from William Adams.”

For quarries the size of Log Hut’s, loaders play an essential part, as they are practically the mainstay, used for material handling,

Log Hut’s Cat 972 loader has demonstrated strong productivity, fuel e iciency, reliability, and safety benefits, largely due to integrated smart technologies and durable design.

Caterpillar Payload for Trade (CPFT) accurately measures material in the bucket as it's being loaded.

transportation over short distances, and loading trucks.

As such, the accuracy of payload information used in quarry loaders can’t be underestimated, as it a ects safety, operational e iciency, cost control, and overall profitability.

“Precise data eliminates guesswork, ensuring every load is optimised,” Jess said.

“Overloaded trucks are unstable, have reduced braking performance, and are at greater risk of rollovers and tyre blowouts, especially on uneven terrain. Accurate data helps mitigate these risks and comply with safety regulations.

“Proper weight distribution, which is guided by accurate payload data, keeps the truck stable during transport, protecting operators and preventing material spillage.”

Jess said that accurate information allowed operators to hit the target payload every time, maximising the material moved per cycle and eliminating time-consuming re-weighing.

“Optimising each load the first time reduces the number of passes required and minimises delays caused by having to adjust an incorrect load, streamlining the load and haul process,” she said.

Then there’s reduced equipment wear. Both underloading and overloading cause unnecessary strain on the equipment's structure, engine, brakes, and tyres. Accurate payloads reduce this stress, extending the lifespan of machinery and lowering maintenance costs.

For quarries the size of Log Hut’s, loaders play an essential part, used for material handling, transportation over short distances, and loading trucks.

Overloaded trucks also burn more fuel, while underloaded trucks require more trips to move the same amount of material, wasting fuel in both scenarios.

For Tim and Jess, their Cat 972 loader has been a solid addition to the fleet.

The medium-sized workhorse has demonstrated strong productivity, fuel e iciency, reliability, and safety benefits, largely due to integrated smart technologies and durable design.

The even better news is that the machine has been equipped with Caterpillar Payload for Trade (CPFT), an on-board weighing technology for Cat machines that accurately measures material in the bucket as it's being loaded. It’s the first loader in Victoria to have this upgrade installed.

William Adams Major Account Sales Manager Guy Rigoni explains more about the innovation.

“The machines already come with the Cat Payload system from the factory, but now they have the option of having CPFT installed as required,” he said.

While standard Cat Payload helps operators hit load targets for e iciency (not for sales), CPFT is a certified, legally approved version of the system, allowing its weight data to be used for commercial transactions, reducing paperwork, and integrating with business systems for billing and tracking.

“CPFT allows the customer to charge for

product straight out of the bucket without the need for a weighbridge on site, improving the machines’ versatility,” Guy said. “This will definitely achieve accuracy as the scales are calibrated with precise weights and verified by an independent body.”

As an added benefit, the technology can be paired with Caterpillar’s cloud-based fleet management software VisionLink, allowing payload data to be captured by the customer with the use of E-Tickets and daily, weekly, monthly, and yearly detailed reports.

“Tim first approached me asking for more

information about the payload systems on wheel loaders for use in the quarries,” Guy said.

“When Caterpillar launched the CPFT option, it was a perfect fit for their business because Log Hut does a lot of mobile crushing.”

Jess said for operations that sell material by weight, such as Log Hut, trade-approved weighing systems ensured every load is accurately recorded, guaranteeing correct invoicing and maximising revenue.

“Having the CPFT system on is a massive plus for our business,” she said.

“It gives more reliability on site and gives

our customers security that our weights are accurate when we're loading out.

“We're dealing with Tier 1 clients all the time and we need to have that surety that everything is right, and that all boxes are ticked.

“When you're loading into the truck, there’s a green light system on it that tells the operator when the correct weight is achieved.

“You can target your weights, and you can tell the system how much you want to put on the truck, which saves overloading, which in turn improves on-road safety.”

Jess was also happy with the loader’s reverse

With CPFT, users dictate how much they want to put on the truck, which saves overloading and improves on-road safety.

management system, which alerts the driver of obstacles or people within the work area.

“We love how the 972 has been working with CPFT. We will be taking delivery of another 972 this year with the tech installed,” Jess said.

Tim was e usive about the connection with Guy and William Adams.

“I was one of his first clients and we've worked together in the industry for quite a few years, and we've got a great relationship,” he said.

“We couldn't be happier with the service we get from William Adams. The backup support we've received has been great.

“Since we had this machine delivered, they've come out and given us numerous training sessions on how to use the system.

“If something goes wrong, they're first on the phone to help us out.

“They also can do a lot online, so if we have a fault, they're usually able to fix it within an hour. They can log into the machine electronically and help us with anything we need.”

Tim said the availability of parts was exceptional.

“All parts are on hand, and they're an hour away from us. So we have no downtime,” he said.

A Queensland quarry is improving e iciency by making strategic investments in equipment, technology, and site performance.

With more than a century of rock reserves, Fulton Hogan’s Blue Rock Quarry, based in South East Queensland, is focused on investment in technology, safety, and e iciency.

Over the past year, the site has transitioned to a full Komatsu rental load-and-haul fleet, completing the line-up with the arrival of a PC950LC-11 excavator.

Within weeks, the impact has been clear, with faster loading cycles and productivity gains across the operation.

Fulton Hogan Divisional Manager Quarries, Carl Buckland, said the move wasn’t about upgrading machinery, but reshaping how the quarry is managed, monitored, and supported.

“The PC950 is giving us e iciency gains. We’re loading our dump truck in six passes, which is an improvement on what we had

prior,” he said.

“Our operators love the new gear, and keeping people happy goes a long way to having a safe and productive operation.”

A rental partnership built on support

Komatsu’s rental partnership with Fulton Hogan was designed to address the site’s operating constraints and production goals. However, Komatsu Australia’s Rental Manager Craig Marsden said that providing a machine was only one part of the solution.

“Rental is more than putting a machine on a job site; it’s the back-up that keeps those machines operating, so the customer can meet their obligations and their commitments,” he said. “That support can include rapid on-site response, ongoing optimisation, and

a fully scalable fleet model to grow with the customer’s quarry.”

Along with the rental support, the fleet solution includes Komatsu’s Smart Quarry Site (SQS), which delivers e iciency gains through realtime visibility across safety events, production cycles, fuel use, emissions, and machine health.

Komatsu Business Development Manager for Smart Construction, James Kelly, said the first priority was understanding Fulton Hogan’s constraints and tailoring an SQS solution to best accommodate the company.

“The vision was clear: safety, visibility, quality, reliability, and the ability to scale the fleet without large upfront capital outlay,” he said.

Blue Rock now receives automated daily

reporting, enabling the team to understand what’s happening on the site before the day begins through the SQS platform. GPS tracking, geofencing, and machine analytics give managers the insights needed to lift utilisation and plan proactively.

“Machine e iciency, emissions, fuel usage, and production capabilities are all reviewed daily. Analysing that data allows them to make informed, proactive decisions that impact their next day’s operations,” James said.

The combined fleet and technology approach has already delivered results, improving safety, operator performance, and workflow transparency. System insights are now used in training, planning, and continuous improvement.

“Komatsu’s rental solution, combined with SQS, gives the quarry flexibility and financial certainty, allowing the team to focus on growth while preserving cash flow, and accessing the latest technology as it evolves,” Craig said.

For more information, visit: www.komatsu.com.au/equipment/ excavators/13t-to-100t/pc950lc-11

Drive your 2026 results with Pickles

2025 was a record year for Pickles; discover why when you partner with Australia’s auction leaders. Gain access to an extensive network of competitive buyers built through our expansive digital presence. Whether you’re offloading excess assets or looking to maximise your returns, Pickles has the industry expertise to help power your sales to success.

Auction and sale results for the past year have shown that the second-hand market remains vital to the earthmoving industries.

2025 will be remembered as a year when continued trust in Australia’s used market rewarded buyers and vendors with consistent results.

With the extreme highs of the post-pandemic boom long gone, the industrial market experienced a re-balancing and achieved stability over the previous 12 months.

Despite early projections forecasting a softer year for industrial activity — in part due to the uncertainty around the Federal Election — the market experienced a steady year in 2025. Prior to this, concerns were raised around how the market would behave once Australia returned to business as usual. However, the drastic decline in turnover anticipated for buyers and vendors never eventuated.

Pickles experienced a record year of results in 2025, with $600 million secured in industrial equipment sold across the past 12 months. Now, with the industrial market set to break new ground in 2026, it’s important to reflect on the trends and fluctuations of the previous year to help inform and steer our shared industry future.

The industry overall saw a return to stability in the first quarter of 2025, as an increase in market activity defined the January to March period with results outperforming those of Q4 in 2024.

A stronger interest in used machinery over new equipment acquisitions signalled a shift in preference that, combined with increased buyer activity, led to higher bids per asset and fostered a steadier market.

The introduction of Euro 6 standards — which are designed to reduce vehicle emissions and help meet targets — had a major impact. Historically, there is a hesitation to adapt to newer models, and this continued over the course of 2025.

Operators faced di iculties gaining access to new models in the Euro 6 specification, leading to a spike in the second-hand market where used models are a known quantity. This led to established brands such as Isuzu and Hino experiencing a 10-15 per cent price rise for branded trucks that were ready and available. As the economic direction for the rest of the year became clearer post-election, Pickles

flourished in Q2, with more than $60m in sales in June alone. Once May concluded and the Federal Election passed, operators began making critical moves for their businesses, whether that be to buy, sell, retire, or liquidate.

This change in atmosphere led to more movement in the industry and an increase in clearance rates, which had slumped in Q2, but lifted by the end of September.

The status of the market in Q3 and Q4 favoured those who accepted the fluctuating nature of the industrial market. Large event auctions picked up, courtesy of insolvency and retirements, with sales remaining strong up until the Christmas period.

There was a departure from caution as Pickles saw a large number of sellers enter the market, and buyers who were decisive and in need of ready, available, and quality equipment.

In addition, there were a number of insolvency-driven sales, particularly in the line haul transport space. With the Australian market levelling out over the past year, it’s expected that this momentum will continue to build into the new year.

As a major Australian auction house, Pickles possesses the knowledge and expertise to secure businesses the most bang for their buck at auction. The benefit of taking your fleet to auction is that, historically, auctions can draw a premium when there's a larger consolidation of assets, as it creates selling motivations that appeal to buyers.

This surge in available assets encourages competitive bidding, with buyers feeling a greater chance of securing what they want when there are more items for sale. Feature and event auctions are e ective for vendors looking to sell large quantities of assets in one go, as it helps to clear their inventory in a timely fashion and at a premium price.

Businesses looking to restructure, retire, or downsize larger amounts of equipment can capitalise on standalone event sales with Pickles. By prioritising the quality and story of not only the equipment but the business as well, Pickles drives a premium price by o ering equipment to an exclusive marketplace of eager buyers.

Among many auction highlights, two retirement sales from 2025 reflect Pickles’ ability to maximise results and to work e ectively to achieve a satisfying result for two historic Australian businesses.

Following the retirement of Templemichael Constructions, Pickles was entrusted to sell the company’s fleet of civil construction equipment.

The goal was clear: maximise the fleet’s value and secure an outcome that reflected the legacy of Templemichael.

Late-model Volvo articulated dump trucks, a range of excavators, crushing and screening equipment, Drake floats, Kenworth prime movers, and more than 100 attachments were o ered. Plenty of enthusiastic buyers showed interest in buying from a selection of mostly single-use and ownership assets, leading to a 100 per cent clearance rate and more than $5.2m in total sales.

Held in September, the Francis Transport Retirement Sale bid farewell to a historic Australian company following over 115 years of service.

Pickles was proud to guide this process for Francis Transport and to help o load a range of transport assets, including curtain side trailers, prime movers, and rigids from Kenworth.

The sale enabled buyers to own a piece of Australian trucking history and attracted an eager volume of bidders, ensuring a strong result with $2.4m accrued in total sales.

Ultimately, 2025 was a year of market normalisation in the Australian industrial sector, characterised by the ongoing appeal of construction, agriculture, mining, transport, and logistics.

Rising operational costs for industrial businesses led to an increased interest in the used industrial market, which is where Pickles

continues to prove its worth. Looking ahead, the industry will be boosted by the experience of enduring the market’s fluctuations in 2025.

From a digital viewpoint, Pickles has levelled up in the last few years, with 2025 marking a period when customers searched more than ever. Search activity jumped 36.8 per cent and organic search sessions grew by 23.4 per cent, a sign of stronger intent and engagement.

With technology continuing to evolve from both an asset valuation and equipment standpoint, Pickles’ digital marketplace is set to unveil further resources to assist buyers and vendors in 2026, with customer service and innovation remaining at the forefront.

With hundreds of industry experts located across the country, a wealth of sales data at its disposal, and a large range of used industrial equipment, Pickles remains a major name in auctioneering for a reason.

To speak with a Pickles Industrial expert or to find what you need, visit pickles.com.au.

REBUILDS Cat ® Flexible Component Rebuilds give you the power to choose what to rebuild based on your budget and business needs. Choose to rebuild or replace just the engine or engine plus other major components. And with Cat ® Equipment Protection Plans and 0% 24-month* secured or unsecured finance, your rebuild is both affordable and fully protected. Ready to customise a rebuild that works for you? Talk to your local Cat dealer or visit cat.com/rebuildoptions-au

A four-wheel-drive accessory specialist has just taken delivery of its first earthmoving machine, a Cat® Centennial 285 Compact Track Loader, which also happens to be the last Centennial machine delivered in 2025.

The Cat 285 is Caterpillar’s largest compact track loader, released last year to acclaim, thanks to features such as a lift height of 3.7 metres and an operating capacity of more than three tonnes.

Because 2025 was also Caterpillar’s 100th anniversary, a number of special Centennial models were made available, which boasted unique livery and branding. The last of them –#12 of 21 limited edition Centennial models –was recently snapped up by New South Wales four-wheel-drive business GMF4X4.

We spoke with company founder Greg Moore about his business and why he plumped for the Cat 285.

4x4 corners

Based in Bathurst, GMF4X4 has grown from a one-man operation into an Australian manufacturer whose products are trusted by four-wheel-drive (4WD) owners locally and internationally.

Central to that growth has been a focus on quality, practical design, and investment in equipment that supports e iciency without compromise — an approach that led the business to acquire the Cat 285.

Founded in 2011 by Greg Moore, GMF4X4 was born not out of a desire to chase trends, but from first-hand experience. Like many successful niche manufacturers, the company’s origins lay in identifying shortcomings in the market and addressing them through thoughtful design and robust engineering.

“We set out to create accessories that were strong and functional — products designed by someone who understood how 4WDs are actually used rather than how they look in a catalogue,” he said.

From the outset, GMF4X4’s philosophy was to build accessories that last. That meant using quality materials, manufacturing locally, and refining designs through hands-on problem solving.

What began as a small operation grew as

word spread among 4WD owners looking for equipment they could rely on in harsh conditions. Rather than expanding too quickly, the business evolved organically, guided by customer feedback and real-world performance.

“Today, GMF4X4 designs and manufactures a growing range of 4WD accessories, including front bars, under-body protection, UHF bonnet brackets, and other critical components,” Greg said.

“While Bathurst remains the heart of the operation and the centre of our manufacturing capability, GMF4X4 products are used beyond regional NSW. Customers across Australia —

and increasingly overseas — choose GMF4X4 for its reputation for strength, reliability, and engineering integrity.”

Greg said that manufacturing in-house has allowed GMF4X4 to maintain quality control while remaining agile. Designs can be refined, processes improved, and production adjusted without reliance on external suppliers.

As the business has grown, so too has the complexity of day-to-day operations. Material handling, yard maintenance, site works, and infrastructure tasks all play a role in keeping manufacturing flowing smoothly.

It was this reality that prompted GMF4X4 to reassess how work was being done on site — and to look closely at the role a compact machine could play.

“The decision to purchase a Caterpillar 285 skid steer was driven by necessity rather than novelty,” Greg said.

“GMF4X4 needed a machine that could perform reliably across a wide range of tasks, both within the manufacturing environment, and across associated farm and property operations. Precision, durability, and e iciency were non-negotiable requirements. In that context, Caterpillar emerged as a natural fit.

“CAT equipment is known for its quality, durability and consistent performance, aligning directly with our own standards.”

For GMF4X4, the Cat 285 is far more than a piece of yard equipment. It has become a core operational asset, used daily for material handling and logistics, moving steel and components safely and e iciently around the workshop and storage areas.

In a manufacturing environment where downtime has a direct impact on productivity, the ability to move materials quickly and accurately is critical.

Beyond logistics, the machine plays an important role in yard and site maintenance, as well as earthworks and property improvements.

With both business and farm operations to support, versatility was essential.

“The Cat 285’s compact size, lifting capability, and attachment compatibility allow it to transition between tasks, reducing the need for external contractors, and giving GMF4X4 control over scheduling and costs,” Greg said. That independence is valuable in regional areas where contractor availability can be limited and delays can quickly compound. By having a dependable machine on site, GMF4X4 has improved e iciency and reduced downtime across daily operations — benefits that flow into manufacturing output and delivery timelines.

The purchasing experience itself reinforced

GMF4X4’s confidence in the Caterpillar brand. The machine was supplied through the Bathurst branch of WesTrac, with the dealer involvement playing a role in the decision.

From the initial enquiry through to delivery, Greg said the process was seamless and professional. Upon delivery, Moore was welcomed by the WesTrac team and quickly established a working rapport with key sta , including sales representatives Luke Hession, Michael Webster and Peter Smith.

WesTrac provided on-going support and follow-ups to Greg, which demonstrated the highest level of commitment to the business.

“That backup matters,” Greg said. “They went above and beyond to help kick o the relationship, and that gives confidence that the support will be there when you need it.”

The WesTrac team also encouraged Greg to take out a FitFleet Premium Customer Value Agreement (CVA), a move he has not regretted.

FitFleet CVAs are designed to remove uncertainty from fleet maintenance by bundling genuine Cat parts, expert labour and essentials such as required fluids into a single, planned agreement. By covering these core maintenance essentials upfront, customers gain greater visibility over operating costs while ensuring their machines are maintained to Caterpillar’s exacting standards.

Shortly after placing a deposit on the Cat 285, GMF4X4 expanded its Caterpillar fleet with the purchase of a Cat TH414C telehandler — evidence that the initial investment delivered on expectations.

Greg said the Cat 285 also carried additional significance as part of Caterpillar’s 100th Anniversary Centennial Edition range.

“While the limited-edition status was not the primary driver behind the purchase, it resonates strongly with GMF4X4’s own values,” Greg said.

“Caterpillar’s century-long legacy of innovation, durability, and hard work closely mirrors the philosophy behind GMF4X4’s products.

“Taking delivery of one of the Centennial machines was a point of pride for the business, made even more memorable by GMF4X4’s involvement in filming and promotional content associated with the anniversary release. For a company that places such importance on longevity and craftsmanship, the symbolism was fitting.”

Support and back-up were also considerations. In a manufacturing environment, equipment downtime can halt production entirely.

GMF4X4 expects strong parts availability, servicing, and technical support from Caterpillar and WesTrac, ensuring the machine remains productive and reliable over the long term.

“That expectation of support is not optional, but fundamental to maintaining consistent output and meeting customer demand,” Greg said.

Looking ahead, GMF4X4 sees Caterpillar remaining a leading choice as both the business and its associated operations continue to grow.

Greg said the positive experience with the Cat 285 and subsequent telehandler purchase has set a benchmark for future equipment decisions, reinforcing the value of investing in machinery that aligns with the company’s standards rather than simply meeting minimum requirements.

“GMF4X4 is Australian-owned and Australianmade. By sourcing local materials and manufacturing in-house, the business delivers quality while supporting local industry and skills,” Greg said.

“The addition of high-quality equipment like the Cat 285 ensures that as demand increases, those standards are maintained.”

• The Cat 285 features a vertical lift arm that delivers a maximum lift height of about 146 inches, providing excellent reach and easier truck loading.

• Equipped with a standard E-Bar undercarriage, the 285 combines the lifting strength of a rigid frame with the terrainfollowing flexibility of an oscillating system.

• Powered by a Cat C3.6TA turbocharged, after-cooled engine, it supports three auxiliary hydraulic flow options — Standard, High Flow, and High Flow XPS.

• A high-performance powertrain includes two-speed travel and an optional SpeedSensitive Ride Control system.

• The redesigned operator station o ers a spacious cab with options like a sealed-andpressurised enclosure, ventilated/heated airride seats, and seat-mounted joysticks. The 8″ touchscreen monitor includes Bluetooth, integrated radio, camera feeds, and multilanguage support, delivering top-tier user comfort and e iciency.

The XWSeries creates a total safe working envelope around the machine and operator enabling the control of the machine’s height, slew and rated capacity indication. This comprehensive system covers every eventuality when considering both operator and machine safety, offering complete peace of mind.

Height Control

Slew Control

Rated Capacity Indicator (RCI)

The Xwatch system creates a defined working area around the excavator, monitoring and restricting the machine’s height, slew, and lifting capacity. Images: Xwatch.

An innovative safety solution is now protecting all new equipment in JN Bentley’s UK fleet.

Xwatch has emerged as an influential safety solution in the mining, transport, and civil construction sectors, reshaping how contractors manage risk around high-energy machinery.

Designed to give operators greater control while reducing exposure to hazards, the system has become a benchmark for modern, technology-led safety practices.

That reputation has been reinforced by UK-based JN Bentley, part of the global Mott MacDonald Group, which last year added 13 new Komatsu excavators to its fleet, each fitted with the Xwatch XW5 system.

The delivery represented the next phase of the contractor’s broader investment program and signalled a shift in its approach to plant safety, with new excavators entering the fleet equipped with Xwatch as standard.

Supplied by Marubeni-Komatsu, the UK distributor for Komatsu, the machines followed JN Bentley’s 2024 decision to move away from a competing safety system in favour of a solution that o ered greater capability, practicality, and operator acceptance.

That phase of the rollout saw 20 Komatsu machines fitted with an integrated Xwatch and Leica Geosystems 3D Collision Avoidance system, a combination well-suited to the high-

risk, congested environments typical of utilities work.

With a workforce of more than 2500 people and annual project values exceeding £500 million, JN Bentley has long been recognised for embedding safety into every aspect of its operations.

Technology plays a role in that culture, with

the decision to standardise on Xwatch driven by a combination of operator feedback and the need for intuitive, dependable systems that reduce exposure to high-energy hazards on site.

JN Bentley Director Dean Holmes said the business favoured opportunities to invest in equipment and technology that not only

protected its people, but also made day-to-day tasks simpler and safer for operators and site teams.

“We identified that the Xwatch system would significantly improve our current o erings compared to our then-incumbent supplier and other available systems,” Holmes said.

“We are installing the Xwatch system on all new excavators entering our fleet, as we believe XW5 provides a robust direct control to help minimise our workforce’s exposure to highenergy hazards.”

How Xwatch works

At the core of the system is its ability to create a clearly defined working envelope around the excavator. Xwatch continuously monitors and controls key machine functions such as height, slew, and lifting capacity, ensuring the excavator remains within safe operating limits at all times.

This level of control is particularly valuable when working near overhead services, in confined spaces, or while handling heavy loads, helping to protect both operators and the surrounding worksite.

The system o ers a suite of safety functions. Its height control operates in an automatic, fail-safe manner, with function selection never more than two key presses away.

All potential machine high points are monitored, with full power always available to move away from a limit. Approaches to limits are managed through ramped slowdown and soft-stop control, eliminating bounce, overshoot, or undershoot. An optional chassis sensor can also be installed to compensate for terrain slope.

Slew control is equally sophisticated, o ering single or dual parallel wall and angular limitation. When wall limits are active, the front-end equipment is also monitored to prevent breaches.

Limits can be manually entered or set by positioning the machine, and if multiple limits are active, the system automatically switches displays as hazards are approached. Set-up is quick and straightforward, with optional access key protection and all settings retained on start-up.

The Rated Capacity Indicator (RCI) function further enhances safety by ensuring lifting operations remain within the machine’s safe working load. By measuring height, radius, and load, the system allows operators to work at maximum capacity while staying safely within defined limits.

Flexibility is another feature of the XW5. The system can be configured to suit a range of project types and operating environments, making it adaptable across JN Bentley’s civil and utility portfolio.

Using electric-over-hydraulic integration and feather-touch proportionality, XW5 delivers smooth, accurate control in real time, allowing movement restrictions to be set for each job without compromising productivity.

The installations were completed by Xwatch engineer Tom Dacosta, with all new machines now commissioned and ready for deployment on live sites. With further units expected this

Above: The XW5 uses electric-overhydraulic integration and feather-touch proportionality to deliver accurate control in real-time.

Below: The home screen is easy to use and provides information on the machine height, slew, and lifting capacity.

year, JN Bentley is setting a benchmark for safety-led procurement, underpinned by trusted partnerships and proven, practical technology.

Australian availability

In Australia, the XW5 is distributed by Xwatch Safety Australia, operating under the safety banner of geospatial solutions specialist C.R. Kennedy.

The partnership combines Xwatch’s

machinery safety technologies with C.R. Kennedy’s expertise in positioning and spatial solutions, delivering enhanced safety outcomes, improved operational e iciency, and national support.

Xwatch Australia General Manager Nick Leith said the collaboration reflected a shared commitment to raising safety standards across the construction and civil industries.

“This partnership integrates Xwatch’s advanced safety systems with C.R. Kennedy’s expertise in geospatial technology, o ering comprehensive solutions for construction,” he said.

With o ices and warehouses located in Melbourne, Adelaide, Brisbane, Cairns, Perth, Hobart, Darwin, and Sydney, Xwatch Safety Australia is well-placed to provide training, service and technical support nationwide, ensuring contractors have access to the tools and expertise needed to make safer worksites a reality.

As Australia’s mobile plant and equipment sector grows in response to demand across construction, infrastructure, and mining industries, businesses are turning to flexible equipment solutions to keep projects moving.

Recent forecasts show the construction machinery market is on track for expansion, with analysts projecting annual growth of about four to five per cent through to 2030, driven by road, rail, energy, and resource developments (source: Australia Construction Machinery Market Report 2025-2034).

This growth creates opportunities on both sides of the hire market: for operators looking to manage rising business costs and for owners seeking to maximise the return on their investment by hiring out their fleet.

It’s important to be reminded of the key considerations when hiring out mobile plant and equipment (MPE). NTI’s National Product Manager for Mobile Plant, David Kidd, explains why it’s critical to understand what you’re entering into when it comes to hire arrangements and insurance.

Hire agreements are central to any hire business and a critical risk management tool. Engage a lawyer experienced in preparing hire agreements for the mobile plant industry to draft an agreement tailored to you.

The one-o expense is negligible compared to the risk exposure from a contract that’s poorly worded or doesn’t cover the relevant risks and conditions.

David said this was one area where shortcuts shouldn’t be taken.

“Hire agreements are civil agreements. A high-quality hire agreement can provide

years of contract certainty and clarity,” he said.

“A poorly-worded one can lead to complications like obtaining adequate insurance, conflicts around who is responsible for damage, accusations of unfair contract terms, and delayed or declined insurance claims.”

Preparing your hire agreement with transparent terms and conditions is a critical step to work through with your lawyer.

“There is a lot to consider, and obtaining legal expertise to craft a hire agreement can serve the business and customers well into the future,” David said.

“Delivering a positive customer experience can protect your reputation and boost your brand, leading to repeat business and referrals. Clarity of obligations can protect both owner and hirer.”

Damage waivers are not insurance policies: they are conditions or clauses in a hire agreement that — when included or purchased as an option — will often remove the hirer company’s rights of subrogation for recoveries or costs if the item has succumbed to an unforeseen event while on hire.

“Poorly constructed damage waivers have the potential for disputes and other di iculties,” David said.

“Communication and clarity on what the

It’s important to have strong hire agreements in place when hiring out mobile plant and equipment. Image: NTI

damage waiver does and doesn’t cover is critical, so the hirer can identify and make suitable arrangements to deal with any gaps, including opting out of the damage waiver and insuring themselves if they prefer under standard dry hire conditions.”

Alternatively, equipment can be comprehensively insured while in the hirer’s possession and use.

“You can attach conditions, such as hirer responsible for an elevated level of excess to force their skin in the game, and other appropriate and reasonable terms to ensure accountability,” David said.

“This is where legal advice is recommended, to ensure that your hire agreement and conditions of hire are clear and not subject to any ambiguity.”

David said a sound hire agreement clearly describes the insurance you’re providing and the risks the hirer must manage or cover.

“I recommend working with your broker and making the most of their experience and expertise,” he said.

“Experienced brokers are experts in their field, so be guided by them.

“Their input on how insurance arrangements comply with hire agreement requirements is invaluable. The goal is to avoid uninsured losses for you or your customer, ensure the customer understands their liabilities, and that they have a positive experience.”

It’s important to ensure that your insurer is legally entitled to manage any insurance claims per the hire agreements’ terms, conditions, exclusions, and limitations, including pursuing recoveries (legal action) directly from the hirer (your customer).

Hiring out your MPE can be a great way to generate revenue from all your assets. If you’re thinking of hiring out some of your MPE, it’s important to obtain the right expert advice and insurance. Speak to your lawyer and insurance broker.

National Transport Insurance is an equal joint venture administered on behalf of the insurers CGU Australia Pty Ltd trading as CGU Insurance ABN 62 004 478 960 AFSL 700014 and AAI Limited Trading as Vero Insurance ABN 48 005 297 807 AFSL 230859 by its manager NTI Limited ABN 84 000 746 109 AFSL 237246. This article contains general information only and you should obtain your own professional advice based on your personal and business circumstances. NTI bears no responsibility, and shall not be held liable, for any loss, damage or injury arising directly or indirectly from your use of or reliance on the information in this article.

At NTI we’ve always been successful in finding new ways to keep our customers truckin’, shippin’ and diggin’.

With specialist insurance and roadside assistance products designed to protect Australian businesses and families, NTI is the specialist our customers can count on in their time of need.

Specialist logistics partner Kenter is known for turning di icult jobs into controlled, repeatable processes that protect project timelines and deliver operational value for equipment dealers, overseas buyers, and infrastructure contractors.

Kenter International Logistics is focused on complex, high-stakes freight movements where heavy machinery, deadlines, and compliance requirements leave no room for error.

Rather than operating as a general freight forwarder, the business positions itself as an end-to-end project logistics provider. It combines planning, dismantling, biosecurity preparation, multi-mode transport, documentation, and 24/7 coordination into a single managed solution for clients across Australia and international destinations.

In each project, Kenter is responsible not just for booking freight, but for designing and orchestrating the chain of activities from equipment preparation to final shipping documentation.

The company’s expertise is demonstrated by an assignment that required the transport of 16 35-tonne forklifts to overseas clients, who had bought them from an Australian dealer.

Kenter managed the dismantling, cleaning, and export process from Queensland and New South Wales — coordinating multiple providers and meeting vessel and biosecurity requirements.

Some of the forklifts were also at di erent sites, each with unique access, dismantling, and timing requirements. Some locations had easy crane access, while others required detailed planning to manage equipment movement and compliance.

In their assembled state, these forklifts were too large for standard containers and could not be accepted as RORO (roll-on, roll-o ) cargo until they met export-cleaning and biosecurity criteria. This meant the project could not be executed with simple, o -the-shelf freight arrangements.

The job required a carefully engineered combination of dismantling, heavy-lift handling, containerisation of components, and shipment of the cleaned main units to the destination.

Kenter Managing Director Emily Jackman

said that the company’s involvement began with a detailed assessment and planning phase conducted by its operations lead to determine the best combination of shipping methods for the machines.

“This step illustrates the company’s emphasis on technical evaluation before any physical work begins, ensuring that choices around containers, cranes, and vessel types are driven by dimensional and regulatory realities rather than convenience,” she said.

“By designing the project holistically from the outset, Kenter set up a pathway where dismantling, washing, and transport all aligned with vessel schedules and port requirements.” A technical challenge lay in reducing the forklift dimensions so components could travel in 40-foot open-top containers without compromising the integrity of the machines.

Kenter oversaw the removal of the mast and side-pick frame from each unit, creating a configuration in which the drivable main body could remain mobile while the tallest and

widest structures were separated for container shipping.

“This approach allowed the project to take advantage of containerised freight for bulky components while still utilising RORO loading

for the main units, optimising both space usage and handling e iciency,” Emily said.

“Once dismantled, each main unit still needed to pass biosecurity checks to be accepted as RORO cargo. Kenter arranged for the drivable

bodies to be transported to a specialist wash facility where they were cleaned to export standards, ensuring they were free from soil, plant matter, or contaminants that could breach quarantine rules at destination.

“Only after this process were the units delivered to port, where they could be driven directly onto the vessel bound for Ho Chi Minh City, while the mast assemblies and sidepick frames were loaded into the open-top containers for concurrent shipment.”

Throughout this operation, coordination and documentation were critical. Kenter managed communications between fitters carrying out dismantling, crane operators responsible for heavy lifts, road transport providers moving the various components, and the shipping lines booking both containers and RORO slots.

The company also prepared Bills of Lading and export paperwork, keeping the regulatory and commercial documentation in line with the physical movements so the shipments flowed through the system without delays.

“Kenter successfully exported all forklifts from Brisbane and Sydney to the destinations in compliance with export and biosecurity regulations,” Emily said.

“The project demonstrates Kenter’s ability to bridge the gap between machinery dealers and international buyers by e ectively turning

Kenter arranged for the drivable bodies to be transported to a specialist wash facility where they were cleaned to export standards.

an oversized, non-standard cargo profile into a compliant, multi-mode export solution.”

Emily said the project emphasised engineering-led planning. The company did not treat these forklifts as generic pieces of cargo, but instead worked from their weight, dimensions, and operational characteristics to design an appropriate dismantling and shipping strategy.

“Secondly was the seamless integration of multiple logistics modes, combining open-top containerisation with RORO shipping and road transfers between sites, wash facilities, and ports,” she said.

Another theme is compliance as a central design constraint rather than an afterthought.

“The need to meet biosecurity and export regulations shapes the sequence of work, from when and where cleaning occurs to how the units are presented at the port gate,” Emily said.

“Kenter’s handling of documentation and close coordination between all stakeholders ensures that these compliance requirements are built into the workflow and not left to chance, reducing risk for both the dealer and the overseas buyer.”

In summary

• The challenge

Fully assembled, each forklift was too large for standard container shipping and ineligible for RORO loading unless cleaned to export

standards. The project required dismantling, specialist handling, and multi-mode coordination to meet both container and RORO shipping requirements.

• The solutions

> Assessment and planning: Initial project scope reviewed by Kenter’s operations led to determine the best combination of shipping methods.

> Dismantling: The mast and side-pick frame were removed so each unit could fit into 4-foot open top containers.

> Export wash: The drivable main units were transported to a wash facility and cleaned to meet strict RORO vessel biosecurity standards.

> Transport and loading: Cleaned units were delivered to port and driven directly onto the RORO vessels, while dismantled parts were shipped in containers.

> Coordination and documentation: Kenter’s operations team handled all communication between fitters, crane operators, transport providers, and shipping lines, and prepared Bills of Lading and export documents.

> Multi-site management: Kenter executed a coordinated, multi-state operation with precision,overseeing units in two states simultaneously.

> Custom handling: Adjusted dismantling, transport, and shipping for each site.

> Compliance: Ensured every unit met export standards through seamless teamwork across fitters, crane crews, transporters, and wash facilities.

“By delivering these complex exports across two states in record time, Kenter continues to prove its capability as a trusted partner for machinery dealers and international buyers — o ering true end-to-end project management beyond what general freight forwarders can provide,” Emily said.

Quickly & easily serviced due to the modular design

Heavy duty steel swivel allows the reel to swivel up to 180 degrees

Sliding guide system ensures that the hose returns neatly and evenly

Gen3 hose offering ultimate flexibility is kink free under pressure

Speed rewind control system ensures that the hose retracts at a safe & steady speed

Ergonomic & streamlined the reel is easy to work with & adds both to the efficiency and aesthetics of your workshop

Creating a more e icient and better-organised workplace has become a top priority across modern workshops, manufacturing facilities, and industrial environments.

Loose hoses and tangled cables on the work floor, along with poorly defined work zones, are ine icient and pose safety risks. Recognising this, Alemlube has introduced Rewinda, a new generation of hose, cable, and barrier reels designed to raise the standard of work site safety, organisation, and productivity.

The Australian-owned company understands the daily pressures faced by workshops and industrial operators. Time is valuable, space is often limited, and compliance with workplace health and safety requirements is nonnegotiable.

The Rewinda Series has been engineered to address these challenges head-on, delivering a retractable reel solution that simplifies hose and cable management while enhancing workplace safety.

Developed in partnership with a longstanding reel manufacturer, the Rewinda range combines functional engineering with a modern, professional appearance.

Featuring proprietary mouldings, advanced tooling, and a serviceable modular design, every Rewinda reel is built for long-term performance. Backed by a 10-year warranty on materials and workmanship, plus a noexclusions two-year warranty on wearing parts, Rewinda provides peace of mind.

The relevance of retractable reels

Retractable hose and cable reels have become a must-have in workshops, mine sites, transport depots, and production facilities. By keeping hoses and cables o the floor and neatly stored when not in use, reels reduce trip hazards, prevent damage to equipment, and improve workflow e iciency.

The Rewinda Series has been designed as a family of reels, covering common workshop applications. The range includes compressed air reels, high-pressure water reels, hot wash reels, chemical and pesticide reels, welding reels, grease reels, electrical cable reels, and highly visible barrier reels — all sharing the same design philosophy, safety features, and durability.

Replacing Alemlube’s original S Series released in 2008, Rewinda represents the next evolution in retractable reel technology. Every model has been researched, designed, and engineered to meet current market needs and exceed industry expectations across Australia, New Zealand, and Papua New Guinea.

Core design features

At the heart of the Rewinda Series is a suite of patented and user-focused design features that make everyday operation safer and more e icient.

All hose and cable reels are fitted with a speed rewind control system, ensuring hoses retract smoothly and at a controlled pace. This prevents sudden snapback, reducing the risk of injury, damage to tools, and accidental contact with vehicles or equipment.

Complementing this is the stop-at-any-point latching system, allowing users to lock the hose or cable at the length required every time. This eliminates frustration, improves ergonomics, and enhances control during operation.

A sliding hose guide system ensures hoses return evenly onto the barrel assembly, preventing bunching on one side of the reel. This feature not only improves reliability but also extends hose life and ensures consistent retraction over time.

The reels are protected by UV-stabilised, next-generation polymer covers that resist fading and degradation, even in harsh environments. Heavy-duty steel swivels allow up to 180 degrees of movement, providing excellent working flexibility whether mounted on walls and ceilings or in vehicles.

Compressed air is essential in almost every workshop, and the Rewinda compressed air hose reels are designed to deliver consistent, uninterrupted airflow with maximum durability.

Models such as the Alemlube AR1020CAB Rewinda Compressed Air Hose Reel feature Gen3 hybrid polymer hose assemblies, o ering flexibility while remaining kink-free under

pressure. Integrated hose bend restrictors further protect the hose at high-stress points, extending service life and reducing maintenance costs.

These reels are suited for use with tyre inflators, pneumatic drills, impact wrenches, angle grinders, and ratchets. They are used across automotive workshops, transport depots, mine sites, manufacturing facilities, agricultural workshops, and civil contractor operations.

For demanding washdown applications, the Alemlube AR1020HPWR Rewinda High Pressure Hot Water Washdown Hose Reel delivers industrial-grade performance where heat, pressure, and reliability are critical.

Designed as a robust hose storage and retrieval system, this reel is fitted with a high heat-resistant wire braid hose capable of handling hot water up to 90°C, making it ideal for food processing, manufacturing, mining, transport depots, and other high-pressure washdown environments.

Crimped hose ends ensure secure, leak-free operation, while an integral carry handle and detachable mounting bracket provide added flexibility during installation and maintenance. Manufactured with impact-resistant, UV-stabilised polypropylene covers, the AR1020HPWR is engineered to withstand corrosive conditions and harsh climates. A heavy-duty internal spring assembly, combined

with the Rewinda speed control brake system, delivers smooth, controlled retraction whether the hose is partially or fully extended.

Serviceable and compatible with updated mounting brackets that suit Alemlube S Series and other brands, this reel can be wall-, floor- or ceiling-mounted, and is built to perform reliably in the challenging operating environments commonly encountered across Australia and New Zealand.

E icient lubrication is critical in heavy-duty industries, and the Rewinda grease hose reels are engineered to provide reliable, cost-e ective grease delivery in demanding environments.

The Alemlube AR615GB Rewinda Grease Hose Reel features a high-pressure wire braid hose designed to handle the rigours of grease applications. Suitable for workshops requiring dependable lubrication solutions, this reel supports cleaner operations by keeping grease hoses o the floor and neatly stored.

Like all Rewinda reels, the grease hose reel incorporates speed-controlled retraction, a stop-at-any-point latch and an even hose layering system. These features improve operator control, reduce hose wear and enhance overall workplace cleanliness and safety.

Welding environments demand the highest levels of safety, and the Rewinda Oxy Acetylene Twin Hose Reel has been developed to meet these requirements.

The Alemlube AR615OAR Rewinda Oxy Acetylene Twin Hose Reel is an industrialquality hose storage and retrieval system featuring flexible, heat-resistant Grade R welding hoses. Designed for oxy acetylene applications, this serviceable reel complies with workplace health and safety standards.

Suitable for gas welding and gas cutting applications, the reel is used by contractors, fabricators and professionals in construction,

mining and industrial sectors. By keeping twin welding hoses properly managed and evenly retracted, the reel reduces trip hazards, prevents hose damage and supports safer welding operations.

Electrical safety and cable management are critical in busy workshops and production facilities. Rewinda electrical cable reels provide a practical solution by keeping power cables organised, protected and easy to deploy.

The Alemlube AR1024020CRR Rewinda Electrical Cable Reel is supplied with 20 metres of heavy-duty rubber electrical cable (threecore x 1.5 square millimetres), rated at 240V and

10 amps. It delivers up to 1000W when coiled and 2000W when uncoiled, making it suitable for a range of workshop equipment.

Approved and compliant with AS/NZS 3000 standards, this reel is ideal for powering column lifts, TIG and MIG welders, refrigeration units, air conditioning equipment and other electrical tools. Smooth retraction prevents tangling, minimises cable damage, and reduces trip hazards.

In addition to hose and cable reels, the Rewinda family includes high-visibility barrier reels designed to improve site safety through e ective zone management.

Each barrier reel stores and retrieves 30 metres of durable barrier fabric, making them ideal for temporarily restricting access to hazardous areas or managing foot tra ic. These reels are used in freight depots, mine and quarry sites, workshops, construction zones, and large residential or commercial facilities. Fitted with hooks and reinforced eyelets, Rewinda barrier reels can be easily attached to existing fixtures or securely mounted to masonry or timber surfaces. Clear demarcation helps prevent accidents and ensures compliance with safety procedures.

The Alemlube Rewinda Series has been designed with space e iciency in mind. Reels can be wall-mounted, ceiling-mounted, or vehicle-mounted, freeing up valuable floor space and keeping work areas uncluttered. For mobile applications, sturdy locking pins ensure reels remain securely in place during transport. A modular, serviceable design makes inspection, maintenance, and component replacement simple and cost-e ective.

With sustainability becoming increasingly important, Alemlube has incorporated ecoconscious design into the Rewinda range. Reel covers are manufactured from recyclable polypropylene, and the durable construction reduces the need for frequent replacement. By minimising hose wear and improving storage practices, Rewinda reels reduce waste while delivering long service life. This commitment to quality and sustainability is reinforced by Alemlube’s warranty coverage.

From compressed air and grease delivery to welding gases, electrical power and safety barriers, the Alemlube Rewinda Series o ers a complete hose, cable, and barrier management solution.

Designed for performance, safety, and durability, Rewinda helps workshops operate e iciently while maintaining best-practice safety standards.

When quality, reliability, and long-term value matter, Rewinda is the smart choice for modern industrial environments.

For more information, visit www.alemlube.com.au

Liebherr continues to build on its national service capability, reinforcing its commitment to customer support, technical excellence and workforce development across Australia.

Justin's roles include coordinating field operations, mentoring team members and ensuring projects meet

At the heart of the Liebherr Earthmoving division is a tight knit team of passionate and accomplished service technicians.

Their deep product knowledge and understanding of local operating conditions enable precise diagnostics, reliable repairs and e icient service delivery even in the most challenging environments.

Across the country, Liebherr’s service teams have achieved several milestones, demonstrating a continued focus on operational excellence and customer satisfaction.

Through close collaboration and dependable service delivery, Liebherr has strengthened its partnerships with key customers across large-scale infrastructure and resource projects.

These relationships underscore Liebherr’s ability to deliver under pressure and maintain fleet reliability in critical operations.

Strategic expansions in key regions have also improved Liebherr’s ability to provide localised expertise and faster response times.

These initiatives ensure that customers benefit from consistent service no matter where their operations are located.

Meanwhile, Liebherr’s teams continue to provide tailored maintenance and support solutions to customers operating in remote and demanding environments.

Investing in the next generation

Liebherr remains committed to developing skilled technicians through its national apprenticeship and training programs.

Apprentices gain hands-on experience, receive structured mentoring and access practical learning resources — preparing them for long-term careers in heavy equipment service and maintenance.

Recent achievements across the apprenticeship program highlight Liebherr’s investment in people development, with several

apprentices recognised for their technical skill, dedication and contribution to their teams.

These accomplishments reflect a service culture that values growth, knowledge sharing and professional excellence.

Liebherr continues to invest in modern facilities designed to enhance operational capacity and customer service delivery.

New developments include expanded workshop bays, dedicated paint and

sandblasting facilities, and increased parts storage to improve e iciency and turnaround times.

These upgrades are part of Liebherr’s ongoing commitment to ensuring customers experience the highest level of service, support and reliability.

Customer satisfaction remains at the core of Liebherr’s operations. Initiatives focused on “first-time fix” rates, diagnostic precision and streamlined repair processes are being implemented nationally to minimise downtime and further strengthen customer confidence.

Team profiles

• Daniel (New South Wales)

When Daniel joined Liebherr in 2024 as a muchneeded Vehicle Preparation Technician, he didn’t just fill a gap; he lifted the standard across the board.

From the moment he stepped into the role, Daniel’s dedication, precision and pride in his work have set a new benchmark for what exceptional preparation looks like at the company.

Whether it’s ensuring each machine leaves the workshop in flawless condition or helping coordinate the smooth delivery of major projects like the Western Harbour Tunnel in Sydney, Daniel’s commitment to doing things right and doing them well has made him an indispensable part of Liebherr’s Aftermarket Parts Team.

But Daniel’s impact doesn’t stop at the tools. He’s also become a mentor to apprentices, leading by example and passing on the values that define Liebherr’s success: safety, quality, integrity and professionalism. His approachable nature and willingness to share his knowledge have helped shape the next generation of skilled technicians.

Daniel has been recognised as a future leader in the Liebherr business.

• Daryl (Western Australia)

With four years of experience across the Liebherr Group — two in Scotland and two in Western Australia — Daryl has consistently

demonstrated technical capability, leadership and commitment to excellence.

A recent career highlight was assembling and commissioning the first-ever LH60 material handling machine in WA — a milestone achievement that showcased his technical skill and attention to detail.

Daryl takes great pride in mentoring the next generation of technicians and in setting high standards for safety, quality and customer satisfaction.

For Daryl, Liebherr’s value of “One Passion. Many Opportunities.” perfectly captures his journey.

Other notable achievements include playing a key role supporting some of Liebherr’s more remote clients, providing critical on-site support and ensuring the reliable performance of Liebherr equipment across remote operations.

• Justin (South Australia)

With more than eight years of experience in the heavy equipment industry, Justin has

earned a reputation for technical expertise and leadership.

His time with Liebherr began as a Field Service Technician, where his problemsolving skills, reliability and unwavering commitment to customer satisfaction quickly set him apart.

Today, as a Leading Hand Service Technician, Justin plays a pivotal role in coordinating field operations, mentoring team members and ensuring every project meets Liebherr’s standards.

His notable achievements include assisting and overseeing the Ferris Metals LH60 highrise build, showcasing precision and technical master; delivering a custom one-o build for SA Water, tailored to unique operational needs; and contributing across multiple divisions, including mobile cranes, maritime cranes and the mining division, reinforcing Liebherr’s versatility and commitment to excellence.

• Thomas (Victoria)

Thomas was formerly Liebherr’s authorised service agent in Switzerland, where he spent the past six years refining his skills as a Field Service Technician.

During his time there, Thomas developed technical expertise across complex diagnostics, hydraulic systems and customer support.

A natural leader and mentor, Thomas is passionate about sharing his experience with local technicians and apprentices, supporting their development, and helping to elevate the overall standard of service delivery.

Thomas’ arrival further strengthens Liebherr’s service capability and its commitment to providing exceptional support and streamlined processes to customers across Victoria.

His addition also opens opportunities for future technician exchanges across the global Liebherr network, continuing to share a collective passion for quality and excellence worldwide.

Built for serious performance, the Dieci DP 7000 Dump Truck delivers power, payload and precision where it matters most. With a 12,000 kg maximum payload, 125 hp FPT engine and compact, highly manoeuvrable design, it moves heavy material efficiently through demanding and confined worksites. A ROPS-FOPS approved cab enhances operator safety and comfort, while the large load volume reduces cycle times - keeping productivity high on every shift.

Max Capacity: 12,000 kg

Dump Capacity: 7.5 m

3

Max Speed: 27 km/h

Max Power: 93 kW (125 hp)

Businesses need to be more mindful of proactive hose maintenance, and not wait for a problem to occur, which often leads to lost time and money. Images: BOA Hydraulics

When it comes to hose care and maintenance, users need to be less reactive and more proactive.

More than one-third of all breakdowns that stop operations, delay jobs, and blow out budgets come down to a single failed hose.

It’s not just a maintenance issue. It’s a risk to productivity and profit. When a hose bursts, everything stops. Projects fall behind. Crews go idle. Replacement parts need to be sourced. And if you’re working remotely, support might be hours away. Meanwhile, your machinery is costing money without making any.

The kicker? Most of it’s preventable.

The problem is that too many businesses are stuck in reactive mode. They’re waiting for something to break before acting. It’s common, but it’s costing them. There’s no plan, no warning, and no control.

BOA Hydraulics was built to change that. It’s a smarter system that lets operators take control before failures happen.

The shift starts with mindset: from reacting to planning; from hoping to knowing; from firefighting to control.

The old way was generally waiting, wasting, and losing.

Traditionally, hydraulic repairs have been an afterthought. A hose blows, the job stops, and you start chasing help. You wait for parts, pay emergency rates, and lose time and money in the process.

This reactive approach leaves operators exposed. There’s no room to plan, no visibility, and definitely no control.

That’s where BOA comes in.

BOA’s integrated approach flips the model on its head. Its rugged all-terrain mobile repair

unit, the BOApod, brings the workshop to the worksite. No more hauling gear back to base.

No more waiting on third parties.

But it’s the BOAhub app that truly powers the proactive shift. This digital control centre does more than track jobs. It logs every hose and fitting, and flags service needs before failures happen. Think of it as predictive maintenance but built for real-world conditions.

You can schedule work in advance, track asset histories, and keep things moving without the constant stress.

• Hose fails;

• machine stops;

• you call around for help;

• parts are sourced manually;

• downtime stretches into hours; and

• you pay the bill and hope it doesn’t happen again.

• BOAhub flags potential failure early;

• you schedule repair before failure;

• BOApod is on site and stocked;

• technician completes the job in minutes; and

• system logs everything automatically.

That’s not just maintenance. That’s an operational upgrade.

Here’s a quick cost reality check.

If one hose failure idles a $300/hr machine for four hours, that’s $1200 gone. Now multiply that across your fleet for the year. Add in emergency call-out charges, delays, and administration time, and the cost of reactive maintenance adds up fast.

BOA customers are turning that equation around. They’re cutting downtime by up to 70 per cent, avoiding after-hours callouts, reducing

The BOA system lets users schedule work in advance, track asset histories, and keep things moving without constant stress.

parts waste, and saving time on invoicing and job tracking.

That kind of shift doesn’t just save money. It frees up resources to grow the business.

Whether you’re an owner-operator or running a national fleet, BOA adapts to your size and set-up.

Some customers begin with a basic workshop arrangement. Others scale fast, running multiple BOApods, bulk storage containers, and BOAhub Premium features like digital scheduling, live stock tracking, and tailored on-site training.

The goal is the same: full control over your hydraulic maintenance, wherever and however you work.

Need help training a new tech? BOA has you covered.

Looking to streamline multiple crews? Easy. Want to customise your setup to match specific machines? Done.

This is what scalability looks like when it’s designed from the ground up.

The future of hydraulic uptime BOA isn’t just selling gear. It’s building a smarter way forward.

The BOAhub platform continues to evolve with smarter job management, automated reordering, and detailed asset tracking.

New BOApods are rolling out across Australia, stocked and ready to keep crews moving. And the team is growing too, doubling down on service and support across every region.

From mining contractors in WA to earthmoving crews in Queensland, operators are making the shift from reactive to proactive processes and they’re not looking back.

Hydraulic downtime doesn’t have to be a given. You don’t have to keep putting out fires. You don’t need to rely on luck and late-night callouts.

With BOA, you get a system that puts you in control — one that gives you visibility, predictability, and peace of mind.

When your equipment runs better, so does your business. Enjoy the freedom of total control.

Learn more at boahydraulics.com

NATIONAL SUPPORT

Cat tiltrotators attach to a range of fabricated and hydraulic attachments, enabling more work to be done.

A new tiltrotator system introduced by Caterpillar® will enable its excavators to improve machine utilisation.