Elevate every project with Komatsu’s Smart Construction technology.

Designed to optimise workflows, reduce costs, and boost productivity, our excavators give you the power to build smarter.

Scan the QR code below to explore our range.

*Terms and conditions apply.

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

Komatsu’s new PC88MR-11 excavator

Amarapave

Editorial

Editor Cat Fitzpatrick

catherine.fitzpatrick@primecreative.com.au

Journalist

Jackson Haddad

Contributors

Cathryn Greville, Damian Long, CCF QLD, Trevor Schwenke

Managing Editor Eugene Duffy

Art Director Daz Woolley

Several new Volvo Construction Equipment excavator models will be arriving in Australia

CJD Equipment, the Australian dealer of Volvo Construction Equipment (Volvo CE) has announced that several new Volvo CE excavators will soon be available in Australia.

The EC230, EC260, EC300 and EC360 Tier 3 and Stage 5 excavators integrate engine-pump optimisation technology, delivering up to 15 per cent greater fuel-efficiency compared to previous models.

“These new generation excavators can deliver premium quality and heavy-duty performance,” Volvo CE region international excavator product manager Olle Watz says.

“They mark another way Volvo CE is continuing to understand and adapt to the unique needs of customers and end-users.”

From agriculture and roadwork

to general construction, trenching and quarrying, the four Volvo CE excavator models are designed to provide reliability and performance in a variety of applications.

The new ROPS-certified cab offers improved ergonomics, intuitive controls and advanced humanmachine interface (HMI) systems, providing operators with enhanced visibility and reduced noise levels.

“With the cab, it’s a totally new design with a more intuitive layout,” Watz says.

“Whilst we’ve prioritised productivity and power, it’s not to the expense of operator comfort.”

Aussie Buckets says its new tiltrotator significantly boosts efficiency and performance on excavation sites

Aussie Buckets has announced the launch of a new tiltrotator, designed to offer 360-degree rotation and enhanced tilting capability, which it says significantly improving precision and flexibility in excavation work.

360-degree rotation and tilting allows

for precise manoeuvring, reducing the need for repositioning equipment during excavation tasks.

It has also been designed to integrate with Australian attachments, requiring minimal adjustments when upgrading, particularly with the optional pincer grab.

All models are compatible with Volvo Dig Assist. Operators can utilise tools such as real-time weighing, automated digging and smart monitoring, with Volvo Smart View producing 360° machine visibility. Additional features such as preset depth, height, and swing limits further enhance on-site safety.

“Volvo CE is once again helping customers have the right tools for their specific needs,” Watz says.

Buckets says its tiltrotator can lead to significant operational savings.

A triple mechanical locking system provides a secure connection and an optional pincer grab provides enhanced material handling capabilities without additional complex installations, it says.

“Our tiltrotator combines proven technology from our existing rotating grabs, tilting buckets and hitches,”

Aussie Buckets’ Aidan Kuzmich says.

“We’ve prioritised reliability and ease of integration, eliminating the need for costly fleet replacements.”

Aussie Buckets says early adopters have seen a 30 per cent reduction in excavation time and up to a 40 per cent decrease in fuel consumption compared to traditional equipment. Enhanced precision has also resulted in safer working conditions and reduced manual labour.

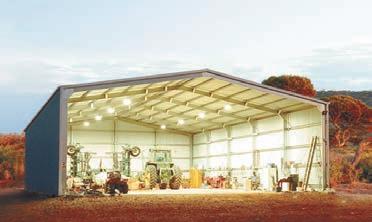

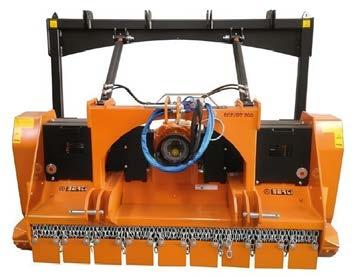

The Mini Brush Cutter Pro X brings a 25 per cent higher cutting capacity

Modeled after Diamond’s Brush Cutter Pro X, the Mini Brush Cutter Pro X is engineered to provide users – from farmers and construction contractors to landscapers and land management professionals – with another tool for their equipment toolbox.

Units are on their way to Australia and will be made available through local Diamond Mowers distributor Colbrook Industries.

This versatile attachment transforms a stand-on or standbehind track loader into a powerful land-clearing tool that tackles trees, cuts through dense brush, and grinds stumps to ground-level, empowering operators to take on a broader range of tasks and jobs.

“This attachment is engineered specifically for the mini skid steer market and adds a new dimension of capability that empowers operators to clear land faster, reduce manual labor, and maximise their equipment investment,”

Diamond Mowers vice president of engineering and product management Nate Cleveringa says.

“It packs all the power and performance of our Brush Cutter Pro X in a streamlined profile designed for those who value relentless durability and optimal versatility.”

The Mini Brush Cutter Pro X

features a spindle-driven blade system with 25 per cent more cutting capacity than standard models, enabling operators to slice through dense brush, thick vegetation, and trees up to 5” (12.7cm) in diameter.

The 42” (106.7cm) cutting width is ideal for tackling everything from landscaping and property reclamation to urban lot clearing and maintaining parks, trails and forest preserves. The direct-drive spindle also delivers smooth and efficient power from the motor to the blades for consistent cutting performance so operators can handle tough materials without compromising on precision.

“The spindle system replaces the more traditional gearbox, which can be prone to wear and tear under heavy loads,” Cleveringa says.

“This design reduces mechanical complexity, resulting in greater durability during heavy duty operations.”

The the offset design of the bolt-on attachment plate allows operators to shift the plate across the front of their carriers to minimise track marks that would normally be left behind. This is particularly useful for precision tasks such as trail clearing or vegetation management near sensitive areas and affords greater flexibility when maneuvering in

tight spaces and working near edges, fences, or other obstacles.

Polycarbonate safety glass shields operators from flying debris and other potential hazards ,while hoses are enclosed in a thin spiral wrap, offering superior safeguarding, an enhanced level of durability, and resistance to wear and tear.

Providing an added layer of protection, the castle nut system locks cutting blades in place and positions them closest to the ground during operation.

Under significant stress or impact, the secure fit reduces vibrations and ensures that, in the event of a blade compromise, failure is isolated to the blade and the attachment continues to operate safely.

“Reliability and performance are crucial for professionals working in challenging environments and were top priorities in the design of this attachment,” Cleveringa says.

“Field testing has shown that the spindle-driven double blades and castle nut system perform well in rigorous conditions. The design handles heavy workloads and minimises downtime by reducing the frequency of maintenance and repairs.”

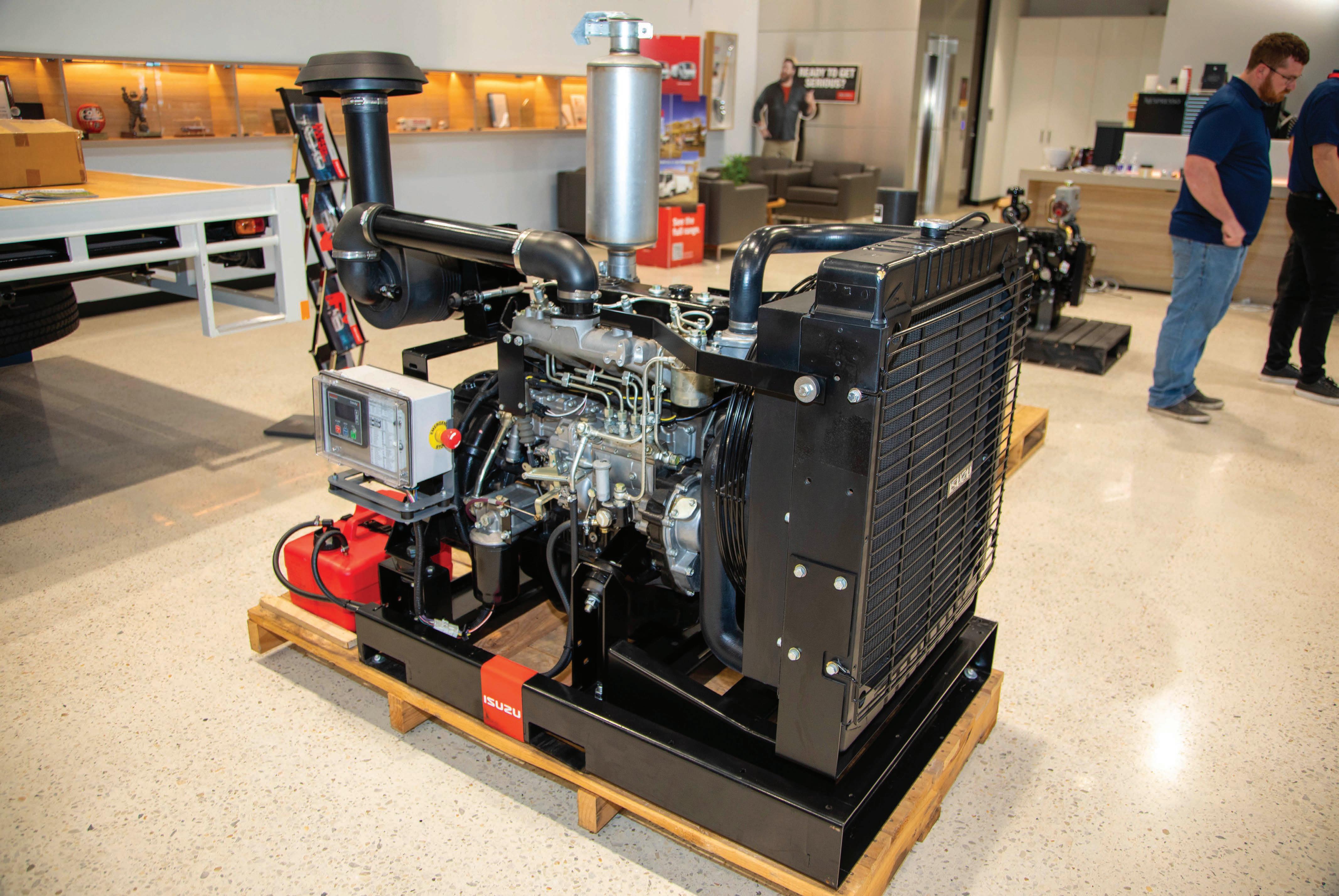

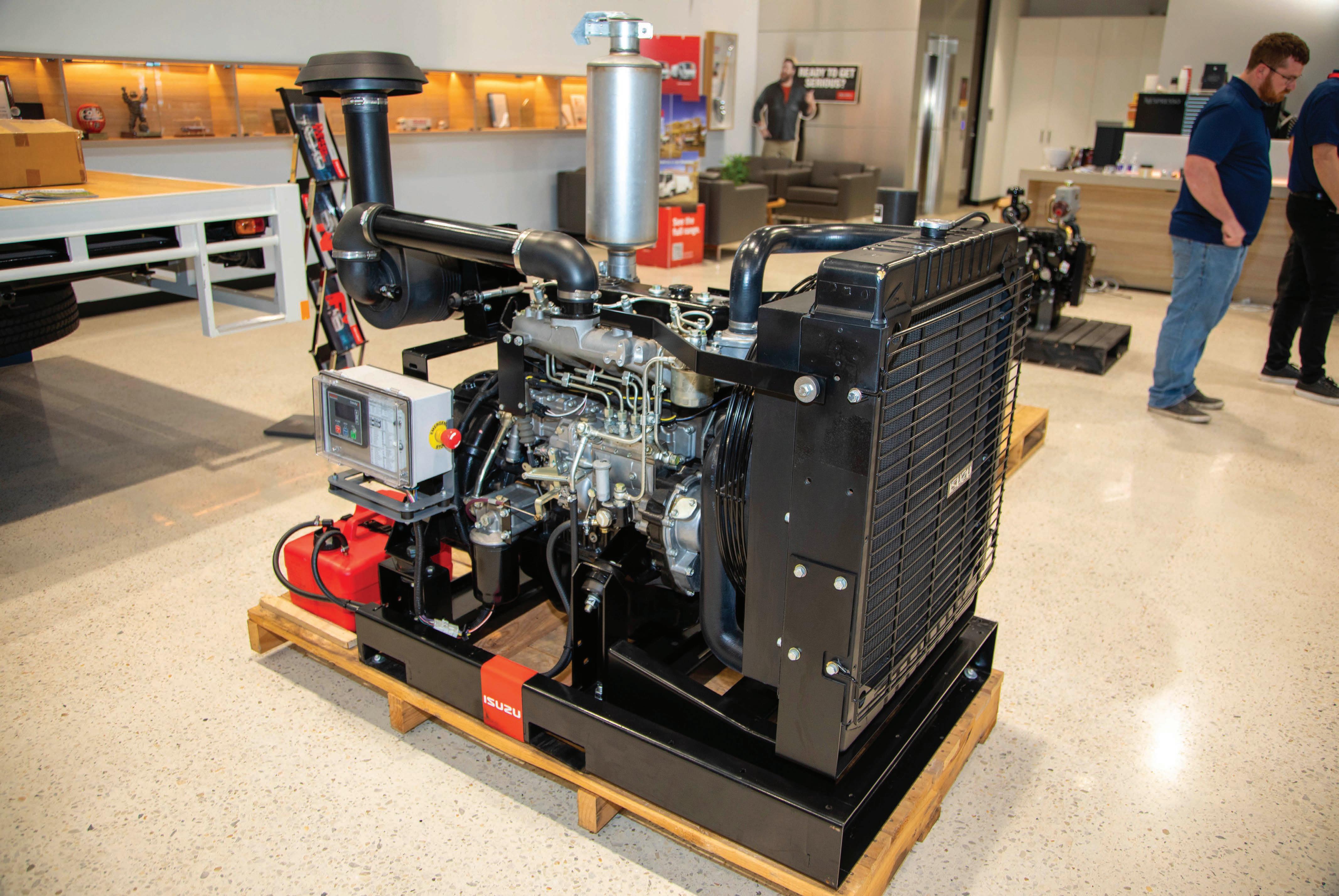

The PC88MR-11 excavator has six working modes

With improved hydraulic flow, the newly-introduced Komatsu PC88MR-11 midi excavator promises a seven per cent productivity boost, making it the idea machine for heavy-duty lifting for simple excavation tasks and tight spaces such as narrow alleys, road construction sites and sewer construction work.

Recently launched in Australia and New Zealand, Komatsu national sales manager – utility Carl Grundy says the PC88MR-11 is compact but doesn’t compromise on performance and efficiency.

“We’ve made upgrades from the previous model, and seen some great improvements in productivity, comfort and serviceability,” he says.

“In particular, we’ve made some improvements to the hydraulic flow that means greater productivity and fuel efficiency for operators. The blade profile has also been

redesigned, which makes backfilling and grading easier with this model.

“This model delivers 12 per cent greater attachment circuit hydraulic flow than the previous model with improvements to the auxiliary hydraulic system, which lets operators get the most out of their attachments for the different types of jobs.”

With an 8.7-tonne operating weight and a bucket capacity of 0.2 cubic metres, the PC88MR-11 is powered by a 65kW (51hp) engine. The short tail swing and swing boom make the PC88MR-11 ideal for tight spaces in residential areas and its compact size means it can be easily transported on equipment trailers from site to site.

“We’ve also looked at the serviceability of the machine and how we can make that easier for customers,” Grundy says.

“This model has three service access doors, including new doors at

the rear of the machine, improving access for maintenance or repair.

“The cab is also designed with the operator in mind, ensuring it’s a quiet and comfortable work environment and all the controls are easy to reach.”

The PC88MR-11 has six working modes that can be switched between by the operator, which match engine speed, pump delivery and system pressure to prioritise speed for greater productivity or fuel consumption for lighter applications.

The Closed Load Sensing System ensures unbeatable speed and control by only using hydraulic fluid when it is needed, which reduces wear and tear on hydraulic components – extending their lifetime and reducing maintenance costs.

Other features include Komatsu fuel-saving technology, Lehnhoff Powertilt available as a factory fit and increased comfort in the cab thanks

to a heated, high-back air-suspended seat with adjustable arm rests.

Sound insulation and the use of sound-absorbing materials means that noise levels are comparable to that of a car.

Inside the cab, a seven-inch multifunction monitor with colour display provides all necessary information for the machine, with a choice of 26 languages.

This touchscreen allows operators to optimise their performance by selecting the optimal oil flow from the hydraulic pump.

On the joystick, proportional controls for auxiliary circuits guarantee precision work with any tool. A rear and side-view camera

system provides visibility all around the machine.

Other safety features include LED working lights as standard, protrusion over the tracks of just 325mm, a neutral position detection system, a secondary engine shutdown switch and a seat belt caution indicator.

Extended maintenance information is also displayed on the monitor and the PC88MR-11 comes standard with Komtrax, Komatsu’s state-of-the-art wireless monitoring system that allows fleet managers to access data from their machinery wherever they are based.

“Komtrax gives owners and operators an easy way to track

their machines, monitor their performance and stay up to date about the status of their equipment, saving time and maximising profits,” Grundy says.

“The machine is backed by the service and support of our widereaching Komatsu branch network, meaning no matter where your jobsite is, our team is available to help with any issues.

“The previous model of the PC88MR was very popular, and we’re looking forward to rolling this newest model out to our customers.”

For more details visit: komatsu.com.au

Jetland’s heavy duty ramps are helping a specialist drilling company safely load and unload its new compact excavator

Rockend Drilling has the capabilities to take on a variety of projects, no matter how challenging, thanks to its skilled team of drilling operators and its expertise in ground engineering, as well as site management.

The Melbourne-based drilling company specialisies in ground anchor and piling services, taking on projects all around Victoria and aiming to provide the best tailored solutions and packages for its clients.

Servicing civil infrastructure, commercial and domestic builds, Rockend Drilling director Geoffrey Torres says the company is committed to ensuring its clients receive the highest quality work, customer service and timeliness.

“We are continually striving to be a market leader in all aspects, including the latest ground engineering education, research and development, and practical innovation,” he says.

As a specialist in both temporary and permanent ground anchors, as well as tailored piling services, the company has extensive experience in constructing strong foundations and support structures.

To help achieve this, Rockend Drilling’s fleet consists of several large excavators, piling rigs and anchor rigs.

A Hitachi 6.5-tonne excavator is the newest edition to the fleet, which has been procured to help with the different projects.

Previously having to transport its larger machines on truck floats – due to the sheer size of the equipment –the new Hitachi excavator is instead transported with a smaller truck.

As a result, Torres needed to find a loading ramp that would help safely load and unload the 6.5-tonne machine at Rockend Drilling’s project sites.

“We needed a ramp that was safe, quick, and easy to use,” Torres says.

Looking online and researching what would be best, Jetland’s range

The competitive price of Jetland’s ramps stood out for Rockend Drilling

Jetland’s loading ramps were purchased for Rockend Drilling’s new Hitachi excavator

of heavy-duty loading ramps ticked all the boxes.

Purchasing a ramp to suit the 6.5tonne machine, Torres says the competitive price of the product was a significant factor as to why Rockend Drilling procured from Jetland. A bonus is the proximity of Jetland’s local warehouse in the south-eastern suburb of Mordialloc.

Another reason Jetland’s range of loading ramps stand out is the way they’re made. All construction and machinery ramps are made from a strong aluminium, making them lightweight and portable.

Rockend Drilling currently has one set of Jetland’s loading ramps, however Torres says there’s potential to purchase more in the future.

“The ramp has performed really well, we haven’t had any problems,” he says.

“If I’m looking to buy more machines that need a ramp, I would 100 per cent be looking to buy some more Jetland ramps.”

For more information on Jetland’s range of heavy-duty loading ramps, visit jetlandramps.com.au

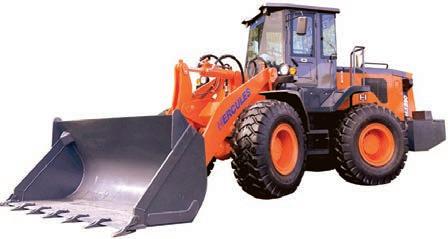

LiuGong’s R&D facilities are further reinforcing the OEM’s market lead for the introduction of a wide range of electric equipment

Australian distributor of LiuGong equipment, McIntosh Distribution, recently visited the OEM’s Global Research and Development Centre in southern China.

Based in Liuzhou, within the Guangxi region, the site left a lasting impression on McIntosh Distribution general manager Digby Moullin

“The sheer scale of the facilities is highly impressive and the level of automation and speed in which equipment is manufactured due to the automated assembly lines feeding from the sides, above and

below is world class,” he says.

Moullin adds the technical processes and systems operating at the facility were also amazing.

“LiuGong’s research and development work is quite incredible. They run every test imaginable, from acoustics through to dirt, dust and water ingress, plus stress testing of steel items, thermally stressing components and assessing electrical circuit durability,” he says.

Having seen the facility up close and in person, Moullin says it further reinforced his belief that LiuGong

is well placed to have a significant impact across numerous Australian industries with its electric equipment line-up.

“LiuGong has been at the forefront of battery electric machines for over 15 years and has amassed over 11 million hours on BEV products around the world,” he says.

“It now has a very broad range of equipment, and we have seen first-hand that LiuGong has an extensive product development road map to further complement its existing range.”

As one of the first OEMs to identify the potential of battery electric vehicle (BEV) technology, LiuGong has since launched more than 90 products, offering solutions for almost every application and segment, including mining machinery, industrial and port equipment, agricultural machinery and various other products.

It has 11 electric product lines, including loaders, excavators, mining trucks, aerial work platforms, industrial vehicles and agricultural equipment.

Wheel loaders were the first electric machine to be released by

LiuGong offers different sizes in its electric wheel loader range

LiuGong in 2018 and there are now more than 6,000 operating globally through Asia-Pacific, Europe, North America and Latin America.

The first green loaders delivered energy savings of around 20 per cent thanks to the optimised electric drive, hydraulic and transmission systems, whilst variable hydraulic and energy recovery systems added a further 15–20 per cent energy boost.

These machines have already

helped to save hundreds of thousands of tonnes of greenhouse gas emissions, LiuGong says.

Moullin says the potential for LiuGong’s wide range of commercially available equipment in Australia is enormous, with several key factors set to drive its adoption.

“The upfront capital cost of the machines is invariably lower than most competitors’ equivalent diesel options,” he says.

“The fact they are electric means

they are more responsive; the absence of any engine noise and diesel fumes makes them ideal for indoor and night-time applications, and the operational costs are significantly cheaper than diesel machines.”

Organisations looking to decarbonise have typically been some of the early users of LiuGong’s electric machines in Australia, Moullin says, however the favourable economic and operational benefits is now increasing the adoption of the BEV technology across a range of industries.

“BEV machines create a fraction of the CO2 emissions from diesel machines, but the cost savings also are now becoming just as attractive,” he says.

“The operational cost savings are significant. Based on a 20-tonne operating weight loader being used for 2,000 hours per annum, the savings are upward of $50,000pa.

“The transition to electric machines in Australia is progressing and once industry realises the full range of equipment now commercially available and its significant benefits, the speed of the transition will increase exponentially.”

For more information on LiuGong’s BEV technology, visit liugongaustralia.com.au

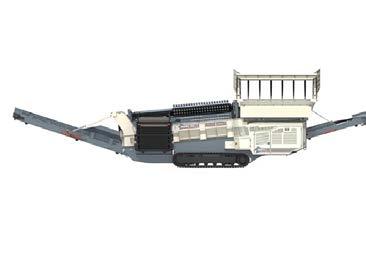

A granite quarry in Western Australia is putting McCloskey crushing and screening equipment from 888CSE through its paces – and it hasn’t missed a step

For North West Quarries, a Western Australian producer of road base and other rock products, McCloskey machinery from 888 Crushing and Screening Equipment (888CSE) has not just met the needs of the quarry operator, but exceeded them.

With a main rock quarry in Port Headland called Pippingarra, North West Quarries is part of a family-run group of companies that own and operate quarries and transport operations in WA and the Northern Territory.

From Pippingarra, North West Quarries is one of the largest suppliers of roadbase and subbase materials in the Port Headland area and the wider Pilbara region. Working with granite, quarry manager Craig Bridgman says the hard material is challenging for machinery to process. As the company’s previous crusher began

to show wear, the time came to look for a more heavy-duty upgrade.

This is when North West Quarries turned to 888CSE, which supplied a McCloskey J6 jaw crusher.

“We use the J6 as a primary crusher in our operation,” Bridgman says.

“So, we get the rock out of the pit, and then that’s the first stage of crushing. We’ll make everything down to -150mm material through that jaw. The reason we chose this particular machine was because the rock in the pit was too hard and abrasive for our previous crusher to handle, so it was starting to show signs of wearing out.”

He says the J6 jaw crusher has been a significant upgrade for the business, handling the granite with ease.

“It has a much bigger chamber, and with McCloskey being a Metso brand, they’re lot more suited to hard rock mining applications.

“We went with the McCloskey machine because of their durability and reputation. They’re tried and tested products, so we had the confidence that it was going to meet our needs for the future.”

Having operated the J6 jaw crusher since 2023, Bridgman says the site comfortably processes around 3,000 tonnes of rock a day.

“It can easily do more than that –probably up to 500 tonnes an hour if you wanted to push it hard,” he says.

“We’ve been very happy with its performance – it’s been flawless. It’s been very reliable and definitely a big upgrade on the previous equipment that we’ve had. It’s met and exceeded all of our needs, and it’s basically transformed the operation. We’ve been able to expand our product range and expand our stock on ground to get ahead with what we’ve been able to supply the local market.”

Having such an efficient jaw chamber in a mobile machine is a big plus for the quarry’s operations, says Bridgman.

“Being a tracked machine makes it a lot more versatile,” he says.

“It makes it a lot more flexible than a fixed plant. With fixed you’re restricted to one location, and you have to feed it in a certain way all the time. With the J6 we’re able to move it between different products around the quarry and off-site if needed.”

Accompanying the jaw crusher is a McCloskey R230 reclaimer screen that North West Quarries purchased after having such a great experience with the J6.

“We chose this model as it was the biggest one on the market that McCloskey had,” Bridgman says.

“We’re using that to feed into a McCloskey C4 cone crusher that we use to take the -150mm material from the jaw crusher down to -40mm product.

“We’ve set up the reclaimer with a two-way split and it is able to integrate with the jaw crusher, so it fits that size of machine perfectly.

“It’s been a big step up for us

and the engineering that goes into the McCloskey equipment is second to none. They’re a lot more durable and heavy-duty than many of their competitors.”

He says the simplicity of McCloskey machinery is a major plus with regards to keeping the machinery up and running.

“McCloskey has taken out a lot of the complications involved in running a diesel hydraulic machine,” he says.

“Other brands have more technical components and it’s harder to work on them – you have a lot more problems with downtime. With these McCloskeys, we have had very few issues with downtime.

“If we have anything that fails, it’s simple to figure out what’s wrong, and then they are basically up and running again within a few hours.”

Bridgman says the aftersales support from 888CSE has been ‘incredible’ and says the crushing and screening specialist has been vital for the smooth running of the McCloskey machinery.

“888CSE are always on the phone if you need them and they will go

out of their way to supply parts out of Perth that day when we have an urgent breakdown,” he says.

With the support of 888CSE and the quality of McCloskey machinery, Bridgman says the relationship between North West Quarries and 888CSE will continue strong into the future as the business looks to expand.

“We’re a family business, so building long lasting relationships with our suppliers is our main point of difference in business,” he says.

“We’re pushing the Northern Territory side of our business a lot at the moment, with more contracting work, so having McCloskey machines that we can rely on will be essential for that. When you’re running a contracting business, it’s all about how quickly you can put the material on the ground and to make sure that you’re producing for a client.

“We enjoy working with 888CSE, so we’ll look to use them as much as possible as they continue to bring new machines into the country.”

For more information on the McCloskey range of machinery available from 888CSE, visit: 888cse.com.au

The CASE Minotaur™ DL550 has already changed jobsites across Australia — combining the strength of a dozer with the precision of a loader in one compact, unstoppable machine. It’s built to do more, with less, and it’s earning serious respect where it matters most: on the ground. Ready to see what it can do for you?

Scan the QR code to learn more.

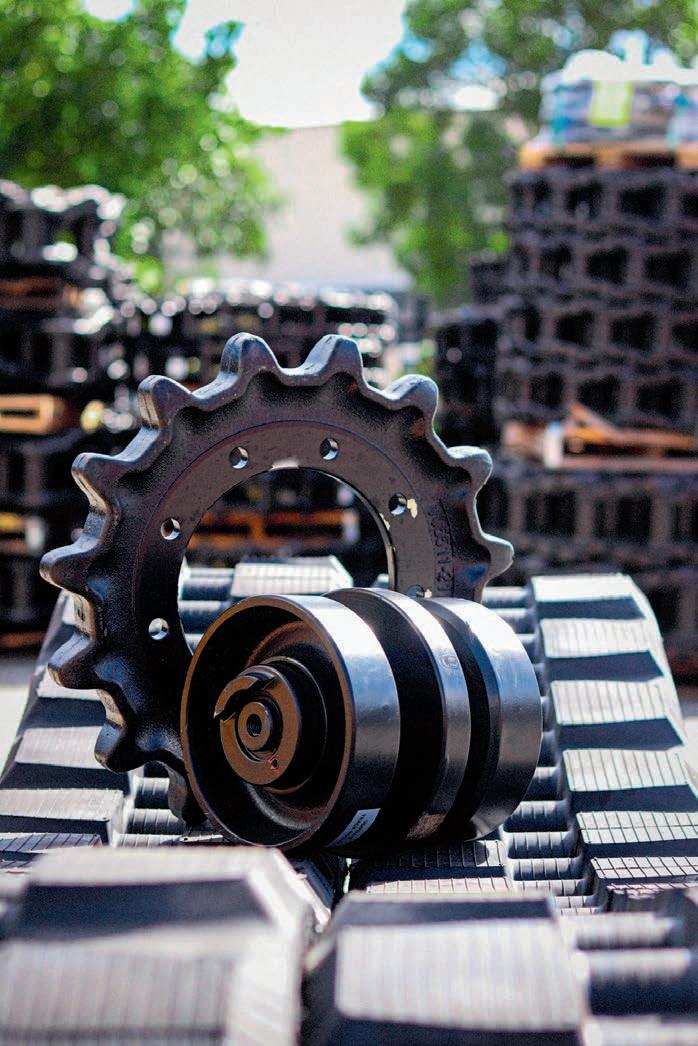

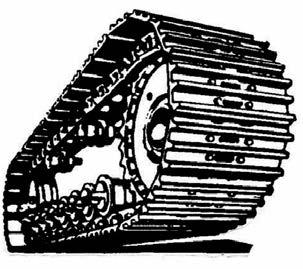

ITR Pacific is your one-stop parts and service solution

In the dynamic landscape of the Australian earthmoving industry, one name stands out for its commitment to quality, performance and customer satisfaction: ITR.

The world-renowned Italian brand, best known for its complete range of aftermarket earthmoving machinery parts, is one of the fastestgrowing companies in the industry, providing a one-stop solution for most makes and models of earthmoving equipment.

With an expansive network of branches, warehouses and workshops strategically positioned throughout the Australian market, alongside industry experts stationed in every region, ITR Pacific is uniquely positioned to deliver an exceptional customer experience.

Offering a comprehensive range of undercarriage parts, rubber tracks and pads, ground engaging tools, repair parts, tyres, and more, ITR Pacific provides unparalleled stock accessibility and support.

This extensive local inventory, coupled with the backing of the broader group, empowers ITR Pacific to confidently cater to a diverse array of sectors within the Australian market, spanning mining, construction, plant hire, agricultural, and forestry industries alike.

Range

From rubber tracks and undercarriage components to

ground-engaging tools and repair parts to OTR tyres and diesel engine parts, every product bearing the ITR name is designed for performance and quality.

ITR parts are designed and engineered by the group’s inhouse R&D department in Italy and manufactured in ISO-certified production facilities with stringent quality control measures, resulting in a consistent and reliable product that has attracted the business of numerous OEM and other aftermarket companies globally.

The range covers parts suitable for most makes and models of dozers, excavators, graders, loaders, scrapers, dump trucks, drill rigs, harvesters, apron feeders and more, ranging in size from 0.5 tonnes up to 800 tonnes.

What truly sets ITR apart from the competition in an industry where performance and downtime are not an option is its servicing capabilities. With two undercarriage track shops located in Brisbane and Sydney, an on-site rubber track and OTR tyre installation team in Southeast Queensland, a robotic welder for hardfacing ground engaging tools and track shoes, as well as a team of specialists in the field performing undercarriage and bucket inspections country-wide, ITR Pacific can provide end-to-end

ITR offers a huge array of parts for earthmoving machinery.

Image: ITR Pacific

solutions for its customers beyond just the parts.

Just as ITR does not compromise on the quality of its parts, it has certainly not compromised on the quality of its track shop equipment.

Heavy-duty track beds and track winders, custom-made for Australian conditions, are capable of handling chains up to 10 tonnes in weight, comfortably covering the large Cat D11 and Komatsu D475 track groups. The services on offer include:

• t rack bolt-ups and track plate swaps

• t rack lengthening and shortening

• complete track frame refurbishments, track frame crack repairs, and modifications

• robotic, abrasive-resistant tungsten-carbide hard facing of ground engaging tools, such as bucket teeth and cutting edges

• hardfacing of dozer track plates with tungsten-carbide grit for added wear resistance.

Looking to the future, ITR remains steadfast in its ongoing commitment to providing its customers with streamlined and efficient services and parts with quick turnaround times.

The company is continuously expanding its presence in the Australian market through industry acquisitions and new developments, allowing it to build its product range and service offering with additional locations and industry experts.

The substantial growth ITR has seen over the last 12 months reflects the strength of the Australian earthmoving industry and the ongoing demand for services and parts.

To find out more about ITR’s full product offering and services, call 1300 820 214 or visit www.itrpacific.com.au.

CATERPILLAR303-CCR 2007,zeroswing,fitted withbackfillbladeand450widediggingbucket, hashammerpiping,steeltrackswithrubber inserts.Goodstrongdiggerworked6000hours. S486.

TOROSTPF-30 2024,Forkliftbrandnew,3tonlifting capacity,powershifttransmission,dieselpowered, containermast,sideshift,lights,beacon,3mlift, runningaroundouryardshowing5hoursonly.S462. TA1221932.

$25,000+GST

CATERPILLAR303CR ExcavatorwithMagnet,fitted withsteeltrackswithrubberpads,canopy,2speed tracks,backfillblade,comeswith500dia.verystrong magnetalso450wideGPbucket.Worked3400hours, runswell.S473.

$35,000+GST

DOOSAN12-56 2012,AirCompressor,IngersolRand 12-56,200 cfm capacity,4cylinderturbodiesel, operatingpressure2000psi,4airoutlets,allmounted onsilencedtrailer,onlyworked1730hours.S463. TA1223429. $19,000+GST

$22,500+GST

CATERPILLAR910LOADERMOUNTED AGT-SSFM81 ForestryMulchernew,2024mountedon Caterpillar910loader,4in1bucket.Mulcherisquick hitchmounted,hasownrearmountedpowerpack withDeutz4cylinderengine,60hp100litresper minute.Runswell.S464. $60,000+GST

KOMATSUD21A-8 2006,Bulldozer,fittedwithROPS andFOPSframe,hasangleandtiltblade,2speed powershifttransmission,comeswithTrimble automaticbladelasercontrol,weighs4ton,strong dozeronlyworked3,300hours.S476. TA1238570. $35,000+GST

REXSOILSTABILISERGRINDERHDS-PULVI fittedwithcabwithcertifiedROPSframe,Detroit engine,hydrostaticdrive,drumhasbulletteeth andcuts1.2mwide,has1200litrewaterorlime tankwithhydraulicpumptosprays.Runswell. S438.

DYNAPACCC102 2005,RollerDynapacCC102,2005 year,tandemsmoothdrumvibratingroller,Deutz engine,hydrostaticdrive,ROPSframe,worked2,200 hours,runswell.S479. $14,500+GST

$38,000+GST

CATERPILLAR303.5CCRWITHHYDRAULICSAW 2010year,ROPScanopy,2speedrubbertracks, backfillblade,comeswithhydraulictimbersawhead and600mmmudbucket.Sawwillcut100mmtimber easily,versatileunitworked2980hours.S474.

CASE480-E fittedwith4in1bucketwithnew edge,ROPScabin,poweredbyCummins4cylinder engine,powershiftforwardandreverse,6,000 hours.Goodloader.S429. $18,000+GST

AGTKTT23 2024,Minibobcat,new,fittedwith rubbertracks,hasauxiliarypiping,weighs900kg, lifts375kg,23hpelectricstartmotor,brandnew. S475. TA1237057. $10,800+GST

JCB520-50TELEHANDLER Farmspecial,4wheel drive,4wheelsteer,liftsto2ton,5mmaxlift,Perkins diesel,4speedpowershifttransmission,comeswith quickhitchhydraulicgrabandGPbucket,hasrear hydraulics,weighs4.5ton,verymaneuverable, worked2400hours,runsverywell.S485. TA1260703.

CATERPILLAR321DLCR 2013,Fittedwithhammer piping,2wayflow,heavycabguarding,quickhitch, 1200widebucket,verygoodzeroswing excavator, onlyworked5100hours.S447.

VERMEERBC1800XL 2011,Woodchipperpowered byCummins170hpengine,hassmartfeedsystem, hydraulicwinch,rotarychute,materialcapacityupto 480mmdiameter.Worked4,590hours,runswell,job completed.S478. TA1252593. $35,000+GST

YANMARC10R minidumper,dieselpowered, hydrostaticforwardandreverse,1ton capacity,isonly950wide for tightsites, workedonly550hours,runswell.S481. TA1255779.

$9,000+GST

KOMATSUPC800-6FINALDRIVES 1990,Komatsu finaldrives,tosuitKomatsuPC800-6excavator,one hashydraulicmotor,onewithout,workingwhen removedfromexcavator.A466.

CATERPILLAR302CCR6.5TON 2007,Caterpillar 302-CCRzeroswingexcavator,2007year,canopy,has steeltracksbutcomeswithsetofrubbertracks,has hammerpiping,fittedwithbackfillbladeand450 diggingbucket,worked2000hours.Goodstrong2ton digger.S482. $24,000+GST

CATERPILLAR950-960SIZE BulldozerbladesuitCat 950-960sizemachine,3800wide,hastwinvariable angleplussideshift,reversablecuttingedge,good strongblade.A472. $10,000+GST

AUSAD100AHA 2017,articulatedhighlift dumper, 4wd,hasROPS,3cylinderKubotadiesel, hydrostaticdrive,1toncapacity,1.1mwide,willtip

CATERPILLAR9104 IN 1BUCKET FrontEnd Loader, articulated,3speedpowershifttransmission,Cat3204 engine,opencab,goodtyres,newhydraulichoses, hasextravalve for rippers,weighs7.5ton.Strongwell maintainedloader.S453. TA1206819. $31,000+GST

ATLASCOPCOXAS350GD aircompressor,700 cfm capacity,125psiworkingpressure,6cylinderdiesel powered,allmountedonsteerable4wheeltrailer. Runswell.S407.

$18,000+GST

NPKS24XL Pulveriserprocessorshear,hasmanual rotatinghead,pickuphas100bossespinnedto80, 370betweenearswith520pincentres,weighs2ton, suit25-30tonexcavator,goodcondition.A468. TA1231469.

C.W.E.ROCKTUNGSTONCOREDRILLS Rock drillingbits,largecorebarreltungstentippedbits, C.W.E.brand,1x1100diameterrockbit,1x1050 diameterrockbitand1x900diameterdiggingbit.3 bitsallingoodorder,have200mmsquaredrive,price for $11,000+GST

RAMMAX1404F Compactor,TrenchRoller,820mm wide,hascableremotecontrol,poweredby2cylinder diesel,weighs1.4ton,runswell.S470. TA1231476.

$14,000+GST

CATERPILLAR910 Loaderordozerhydraulic angleblade,25-30wide,hasquickhitchpick up,suitCat910sizemachine.Goodorder. A477. TA1248986. $5,000+GST

CATERPILLAR312D 2024,Longreachboom,unused, suit12tonexcavators,will fit Caterpillar312-D,comes withGPbucketandbucketram,reaches13.8m,new boom.A474. TA1237064. $21,000+GST

JEC2T concreteprocessorcrusher,hasmanualrotating head,reobarcutter,opensto800wide,headplatehas80 pins,centresare500,distancebetweenears320to340. Unitweighs2ton.A341. TA1035074. $18,000+GST

4TEFCP3061 2021,platecompactorvibrating,brandnew 900wide,headhas80pins,460centresand335between ears.Weightis1060kg,newcompactorplatereadytogo. A426.

TAG40-50TON bucketstosuit40to50ton excavators,suitHitachiEX450,strongwellbuilt buckets.A306. TA960182. $7,500+GST

HITACHIZX450-H SuperDemolitionBoom,fits HitachiZX-450-HExcavator,reaches25.5m,comes completewithrams,hoses,pinsetc,wouldsuit mostexcavatorsinthe45-60tonclass,hashad littleuse.A461. TA1209975. $41,000+GST

CATERPILLAR950-966SIZE Dozerblade,suit Caterpillar950966sizemachine,hasquickhitch pickup,bladeis3450wide,hasanglebothways andsideshift.Verygoodorder.A459. TA1209973. $10,500+GST

CAPTOKSBO5 2024,Rockbreakerunused,suit1.5 tonexcavator,modelSB05,oilflow10-20LPMat 100-120BAR,headhas45bossespinnedto25,95 pincentres,120betweenears.Brandnew.A471. TA1237059.

$2,500+GST

PALSONIC7B7B 1999,piledriver,99yearofmanuafacture,

LABOUNTYMDS-112R steelshear,jawopeningis545mm, hasheadtosuitCaterpillar345excavator,120pins,585pin centreswith490betweenears.Comeswithowncarryframe, weightis3ton.Strongshear.A429.

USEDMAGNETIC pulverisermagneticusedsuit22-28 tondigger,80mmpinsat500mmcentresand330mm to370mmbetweenears.Magnetneedsgensettorun. A194.

$21,000+GST

WIZARD2000320D 2000,SteelShear,hasmanual rotatinghead,bigblades,headhas100mmbosses, 360betweenearswith500mmpincentres,weighs2.2 ton,willsuit25-30tonexcavator.Strongshear..A475. TA1238569. $19,000+GST

NPKSTEELSHEAR SteelShear,hasmanualrotating head,hastips for concretedemolition,headhas80 pin,570centres,315to370ears,weighs2.2ton. Goodshear.A457. $19,000+GST

JEC1800 pulveriser,suitableforconcreteorrock,head has90bossespinnedto80mm,distancebetweenears 330to410,reobarcutter.Crusherwillcrushmaterial downto40mmminus,weighs1.8ton.A340.

Bulldozerblade,suitCat 950-966sizemachine,hashydraulicangle,bladeis 3700wideand1240high,reversablecuttingedge, $10,000+GST

NIPPONSHARYONP-70 1990,PileDriver Hammer,hydraulic,doubleactingimpact,ram weight7ton,willdrive300-800diameterpiles. Unitweighs14.3ton,goodorder.A465. TA1221938. $35,000+GST

OKADAPULVERISER opens900wide,hasreo barcutter,headhas80pinat440centreswith 370betweenears.Strongrobustpulverisersuit 20-25tonexcavator.A456. TA1209970.

CATERPILLAR303CCR 2008,Zeroswing Excavator,has2speedrubbertracks,canopy,fitted with600bucket,hammerpiping,backfillblade, worked4000hours,3tondiggerrunsverywell. S484. $28,500+GST

$23,000+GST

SUMITOMOLECH-20F7-S6.5TON 2008,Magnet excavator,large,20082mdiameter,weighs6.5ton, headhas130and120pins,530betweenears,710pin centres,suit50-65tonclassexcavator.Bigmagnet. A485. TA1255778.

TROMMELLTROMMEX TrommelBucket, Trommexbrand,hydraulicrotating,bucketis 1500long,1250highwith55mmgrids,headhas 80pins,450centreswith330ears.Willsuit20-25 tonexcavator,goodorder.A483. TA1255173. $7,000+GST

Amarapave is transforming workforce diversity and inclusion for women, non-binary individuals and other minorities hoping to enter the construction and asphalt sectors. Managing director and Converge 2025 speaker Jenika Stubelj explains

The infrastructure and construction sectors have placed a great importance on the development of diverse workforces.

While the industry is working to address cultural reform, only three per cent of tradespeople are women, per SBS Online, highlighting the industry’s need to attract a more diverse cohort to battle workforce shortages.

Amarapave, a social enterprise that specialises in asphalt paving services within the construction industry, has a mission to transform workforce diversity and inclusion.

Amarapave managing director Jenika Stubelj says that while creating meaningful employment opportunities across different backgrounds and identities is a priority for the company, so too is the quality of its projects.

“We can deliver an asphalt paving job just as well as every other company with regards to quality. But we’re also showcasing that there’s a different way of thinking,” Stubelj says.

“Ash [MacMahon, field director –Amarapave], who identifies as nonbinary, runs our crew. I don’t think that’s been seen before in the asphalt industry.

“We’re very much about breaking

stereotypes and empowering people. The best way to do that is to actually get out there and showcase our work.”

The Converge Expo 2025, which is taking place in Melbourne in September, is doing just that, by providing a platform for industry changers and leaders to showcase and exchange ideas and solutions, in the hope of improving the industry across the board.

“We work in a field where we’re always innovating, and we’re always looking for a better way to do things,” Stubelj says.

“At trade shows like Converge, you go along with the intention to learn and see what the rest of the industry is doing.

“They’re a great collection of innovations, whether that’s in human resources, technology or people, there’s usually something new to learn.”

Stubelj, along with four other speakers of note, will be presenting as part of Converge expo’s Championing Change panel, focusing on ‘building a workforce that reflects our communities’.

She says the panel will encourage attendees to consider diversity, reflect on their own experiences, and potentially drive change in their own organisations, through

Amarapave fosters diversity by recruiting and training females and non-binary people in the asphalt sector

shared perspectives and stories.

“I think it’s really cool that there’s a whole selection of really inspirational, powerful female role models that are going to be talking at this event,” she says.

“When you have these opportunities and you can tell your story, quite often there’s going to be people in the audience that resonate.

“Ideally, it’s those people who can share our insights within their own organisations. Then, hopefully we’ll see more ripple effects.”

The Championing Change panel will also aim to provide more understanding around the benefits of a diverse workforces, explore the challenges faced by underrepresented groups, as well as showcase innovative approaches to breaking down traditional stereotypes.

“People entering the workforce these days are looking at organisations through a cultural lens, and looking for workplaces that are serious about equality,” she says.

“Are there equitable opportunities for training and development? Do people feel like they can contribute their opinions? If they speak up about something, are they going to be heard, or are they going to be discriminated against for trying to go against maybe the status quo?

“People naturally are drawn to that feeling and sense of purpose at work. You want to go to work and feel like you’re valued and you’re contributing to something, regardless of the financial compensation.”

Converge will take place on September 17-18, 2025, at the Melbourne Convention and Exhibition Centre.

For more information on exhibiting and attending, visit convergeexpo. com.au to download the prospectus, or contact our team directly on +61 3 9690 8766 or converge@primecreative.com.au

CATERPILLAR

140M3

2015,AccugradeReady, AirConditioner,Air SuspensionSeat, Beacon,Lighting, Mirrors,MoldboardSize -14',OnlineOwner's Manual,ProductLink, Pushblock,Radio-AM FMRadio,RipperMulti-Shank,ROPSEnclosed,Scarifier. N9D00466. TA1232534. $381,700

CATERPILLAR

972M

2021,AirConditioner, AutoLube,Beacon, Bucket,Fire Extinguisher,Lighting, Mirrors,OnlineOwner's Manual,ProductLink, Protection12Months 1500HrsEPP,RadioAMFMRadio,Ride Control,ROPSEnclosed,Weight MonitoringSystem. M8W20255. TA1213828. $456,500

CATERPILLAR

AP600FLRC

CATERPILLAR

730-04LRC

2020,AirConditioner,Air SuspensionSeat,Am FmRadio,AutoLube, CustomerValue Agreement(Cva)24 MonthsHDAdvantage, EROPS,Lighting,Online Owner'sManual, ProductLink,Protection 12Months1500hrsEpp. RearView Camera,Tailgate. 3F300510. TA1173354. $577,500

CATERPILLAR

930K

2019,AirConditioner, AutoLube,Beacon, Bucket,Hydraulic Coupler-Quick,Fire Extinguisher,ForksPallet,Lighting,Mirrors, OnlineOwner'sManual, Protection12Months 1500HrsEPP,Ride Control,ROPSEnclosed,Weight MonitoringSystem. P3K00732. TA1232292. $324,500

2018,3DGradeControl -Capable Beacon Generator

OnlineOwner'sManual ProductLink

Screed,ExtensionsHydraulic SonicGradeSensors WashdownTank. JA600105. TA1205008. $183,700

962M

2017,AirConditioner Counterweight Lighting Mirrors

OnlineOwner'sManual ProductLink Radio-AMFMRadio RideControl ROPS

SteeringType-Wheel. EJB00947. TA1223308. $313,500

CATERPILLAR AP300FLRC

2021,CustomerValue Agreement(CVA)24 MONTHSHD ADVANTAGE HEATEDENDGATE OnlineOwner'sManual PRODUCTLINK ProtectionREMAINING FACTORYWARRANT 36/3000PREMIER. YES00126. TA1186026. $247,500

CATERPILLAR

326-07

2019,3DTopCon System AirConditioner AuxiliaryHydraulics BoomCheckValve IncludesTiltMudAnd1 GPBucket OnlineOwner'sManual Protection12Months 1500hrsEPP StickCheckValve. MFJ00134. TA1185595. $275,000

For a huge range of new and used Cat® parts visit CatUsed.com today.

Western Australian contractor Proform Civil has recently used Cat® machinery to undertake its largest job yet – building an access road through the bush that showcased the versatility and technical capabilities that Caterpillar is known for

For Proform Civil owner Dale Weerts, Cat® machinery purchased through local dealer WesTrac has provided the comfort, accuracy and reliability he needs to undertake road building, car park construction and bulk earthworks in WA.

Having set up his family business in 2013, and with the support of the dealer, Weerts has built up a fleet of Cat machinery that has allowed the business to take on challenging bulk earthworks to a tight schedule and with minimal disruption to a National Park site.

Earthmovers & Excavators spoke with Weerts after the recent completion of a major road build and car park project for the state government, to learn more about Proform Civil and how Caterpillar’s machinery design and cutting-edge technology has helped him grow his business.

From design to digging

“I started out doing civil design work,” Weerts says.

“I worked with local governments and ended up working with Rio Tinto for a bit as well, doing a lot of design work on roads, railways and culverts. It got to the point where, as I was sat there designing projects at my computer, I wondered how I would go about building it.”

This, he says, led him to project management where he managed contractors for building projects and saw his passion grow for getting involved at the ground level.

“I always had some small machinery to do yard work,” Weerts says.

“Then, when I moved to a fiveacre block, there was a lot of hard ground that needed digging and I ended up buying a little five-tonne excavator. Even before it arrived I

had people asking me to do jobs and I ended up doing our neighbour’s asphalt driveway. So that’s how the contracting side started out.

“When I first started Proform Civil it was largely consulting work, so I was designing roads and culverts, and a lot of the work was for shires out in the Wheatbelt. When I got this excavator, I ended up doing a lot of work for them as well. Before you know it, I had a team, and then a truck and a 15-tonne excavator, then a 25-tonne excavator. It just kept on growing.

“It wasn’t easy to set up the business, but I just love it and that’s what keeps driving me every day.”

Proform Civil’s ability to both cover both the design and construction sets the business apart, with Weerts saying that it allows him to make design suggestions for his clients.

“There’s passion there to be shaping

up pads and building things, seeing it come to life. I especially like the design and construction type work. We actually do a lot of that now because a lot of the clients that we did design work for loved it when they found out we can build it too,” he says.

“We do a lot of council submissions because I used to work for a lot of the councils around here. So, we submit building permits and try and make it a bit easier for our clients, especially homeowners doing house pads for example.

“Even for one of our latest projects, which was for the state government’s Department of Biodiversity, Conservation and Attractions [DBCA], we ended up doing a lot of the drainage design, and it really helped the project.”

Precision and skill

Among its many projects, Proform Civil undertook the delivery of a $1.1 million 730m-long access road to a new day use area in John Forrest National Park in the Perth Hills.

The business also built the West

Ridge car park at the site, with the day use area now fully completed and open to the public.

Weerts says that this was the largest bulk earthworks project that Proform Civil has undertaken to date, and one that presented various challenges for the team.

“The access road was straight through the bush, so involved clearing a corridor,” he says.

“It’s also very steep, it had a 25 per cent crossfall, and we had to lift this road up in some areas by four and a half metres. This was logistically a challenging project because, with it being a National Park, we had to be very careful around how we cleared it and rehabilitated the areas scarred by the earthworks.

“When we finished it, we were commended on our quality of work. We saved a lot of trees in the process and ensured that we didn’t damage the trees that were retained.”

Weerts says that his Cat fleet, particularly a 25-tonne Cat 325 fitted with grade assist technology developed by Caterpillar in partnership with Trimble,

was essential in achieving the precision needed to quickly build the road with minimal impact on surrounding vegetation.

“Once we’d won the job, I knew that I wasn’t going to be able to use a laser level or just rely on conventional techniques to build up the height differences we were dealing with, and I didn’t want to be running out onto the ground doing checks all the time,” he said.

“So, I decided on the biggest excavator I could afford with GPS, and that was the Cat 325. I honestly couldn’t have done it without it. I put about 1,500 hours on the machine on that job and everywhere that bucket went, I could see exactly where I needed to be on the screen.

“It definitely helped me with timeframes and reduced the surveying costs massively as very little had to be pegged out.

“For me, coming from the civil design background, I’m used to seeing cross sections and long sections on the screen. Now, I’m actually looking at it in the cab, but instead of my mouse, it’s my bucket

or other attachment that I can see in relation to it.

“It improves the workflow 10-fold. Where we used to have a lot of set out pegs, you’d have to get out and use the laser level, so you’d be in and out of your digger 10 times a day. Now, I can see it all on the screen, and it’s hard to describe how much time that saves you. I can see exactly what level I’ve got to work to. The technology now is amazing

– you can literally press a button and the digger will screed off a flat area for you automatically.”

Caterpillar collection

Proform Civil currently has a fleet of six Cat machines – two loaders, a roller, two excavators and the compact track loader that kicked off Weerts’ love for the brand.

“I bought a 259 compact track loader as I was getting sick of being

Dale Weerts with his daughter

bumped around in the machine I had and Caterpillar is well known for building comfortable equipment,” he says.

“It’s a really reliable, robust machine that gets the job done, so we ordered a 15-tonne Cat 315GC excavator after that and I was blown away by how nice it was inside. The air con is great and they’re quiet inside with no vibration. Compared to other brands, you feel a bit more refreshed after a day’s work in a Cat machine.

“They also put a lot of thought into the design. On the 15t excavator, you can access everything from the ground for your checks, you don’t have to get up on top of the machine to do it.”

Another significant benefit he adds is the breadth of information that Caterpillar provides through its apps such as VisionLink®, which provides remote telemetric data for

Cat machinery was integral to the success of

The Cat 325 excavator with GPS removed the need for pegging out the site, improving productivity

his machines no matter where they are located.

“Having access to everything on my phone is really handy,” Weerts says.

“I can book in servicing, see how the hours are on each machine and how productive each machine has been in a day. In a morning I can check to see how much fuel a machine has in it, so when we go out to a site we know whether we need to take fuel. Caterpillar also puts barcodes on their parts, which I can scan with my phone and order it via the Cat central app. All of this reduces my downtime on site.”

A vital component is the ongoing aftersales support provided by WesTrac, which Weerts says is one of the reasons why he keeps returning to the brand.

“If I’ve got an urgent issue, they’ll come out that day and fix it, which is really good support,” he says.

“I was recently on a job where the machine was getting moved out to the Wheatbelt the next day, and I

bumped one of the GPS cables. I called WesTrac and they fixed a new cable and it was ready to go, easy as that.

“Another example of how good their service is was when I took my 15t excavator on a float out to Hyden to build a car park, and when I got there I realised a stone had gone through the back window and smashed it.

“So we were out in Hyden, in the middle of nowhere, yet three days later WesTrac had a new window for me at the post office next door to where I was working. I was amazed. All I had to do was give them a call and they sorted it out for me. They keep you moving.”

For Weerts and Proform Civil, a high level of customer service and going the extra mile for clients is core to the business, and his Cat machinery plays a significant role in allowing him to deliver fast and efficient work even in the depths of a National Park.

“We are a family business, we’re very honest, and we communicate

with our clients every step of the way,” he said.

“We try to help our clients where we can, and honesty and hard work is why our clients keep coming back, we try and make it easy for them to work with us and get their job completed.”

As for what will be the next Cat machine joining the fleet, it seems a grader won’t be far off.

“We’re definitely looking for more machinery as we take on new jobs,” Weerts says, “and if we continue getting into the larger bulk earthworks we’ll be looking at bigger equipment too.

“I want jobs that present a challenge to me, because that’s how you grow. I’m not too worried if, in 10 years’ time, we’ve got five pieces of equipment or 50, as long as we’re happy doing what we’re doing, we’re still enjoying it, and our clients are happy. That’s good growth for me and my family.” © 2025 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

CASE Construction Equipment’s extensive product offering ensures customers have the right equipment for any job

Since its inception in 1842, CASE Construction Equipment has been a cornerstone of the industry.

With over 180 years of experience, CASE has built durable and reliable equipment that thrives on the toughest job sites.

CASE says that its suite of products reflects a commitment to power, efficiency and versatility, ensuring customers have the right equipment for any job.

The all-new CASE Minotaur DL550 is a groundbreaking addition to the construction equipment industry, establishing an entirely new category – the compact dozer loader.

Merging the robust performance of a dozer with the agility of a loader, this new machine creates a versatile and powerful tool designed to transform the job site.

With over 10,000 hours of field testing and 29 patents, CASE says the Minotaur DL550 is engineered to dominate job sites with impressive power and hydraulics.

The Minotaur’s fully integratedchassis C-frame, equipped with the same blade featured on the CASE 650M dozer, boasts 25,826 pounds (11.7 tonnes) of drawbar pull.

This ensures smooth and efficient dozing, while its impressive vertical lift path and 5,500-pound (2.5-tonne) rated operating capacity make it the ultimate site loader.

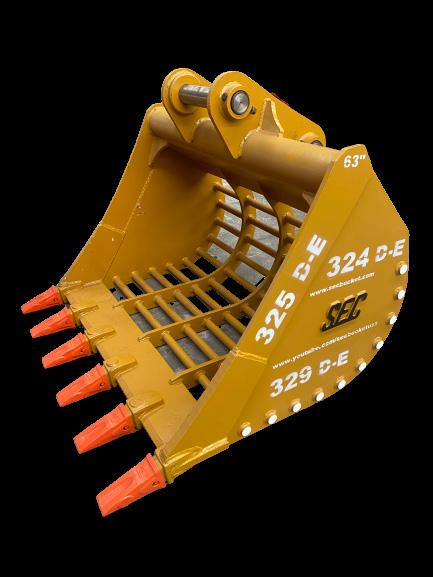

Another notable addition to CASE’s offering is the D-Series mini-excavators, with models ranging from one to six tonnes.

This new range includes true zero tail-swing models that allow operators to work confidently in confined spaces.

Manufactured in Italy, each model is equipped with hydraulic and mechanical quick couplers, up to three auxiliary circuits, and advanced electro-hydraulic and load-sensing systems, for maximum adaptability with a wide range of attachments.

Customisable controls and optional amenities, such as DAB Radio, position the D-Series as a comfortable, safe and productive choice for operators.

CASE says that its B-Series compact track loaders (CTLs) redefine operator comfort and efficiency, delivering a reimagined interface and environment designed to simplify operation and enhance machine control.

Models range from the TR270B to the TV620B, with the CASE TV620B being the largest CTL on the market, boasting an operating weight of 7.3 tonnes and engine power of 114hp (83.8kW).

The spacious, easy-to-enter cab is equipped with an 8-inch

The CASE Minotaur DL550 (above left) combines the performance of a dozer with the agility of a loader. CASE’s true zero tail-swing D-Series mini-excavators (above right) range from one to six tonnes

LCD multifunction display and simple electro-hydraulic controls, allowing operators to dial in and save machine settings tailored to specific applications or preferences.

This advanced interface ensures a smooth and efficient operation, reducing operator fatigue and increasing productivity.

These CTLs retain the robust strength and styling of the previous series while incorporating re-engineered critical inner workings to withstand the toughest environments.

Maintenance-free Tier 4 Final emissions solutions ensure compliance with environmental standards while reducing the need for frequent maintenance, allowing operators to focus on the job at hand.

CASE understands the unique demands of the construction industry and provides everything from the biggest compact track loader on the market to dozers, mini-excavators, wheel loaders, skid steer loaders, Minotaur DL550, crawler excavators, graders, and the original workhorse – the backhoe loader.

Reach out to your local CASE dealer to explore the full range and discover how CASE can transform your construction operations. Visit www.casece.com for more information.

$384,000 Plus GST

With a significant amount of instability in the market, it’s a challenging time to plan future infrastructure spending

The Trump World Tariff Wars are creating extreme volatility in our stock markets.

Confidence is down, uncertainty is up, and we wait for some stabilisation so businesses can plot their direction. On top of that, us Queenslanders are facing our own uncertainty as well.

Since the LNP government came to power, it has been airing the dirty laundry of the previous Labor government. In particular, it highlighted the lack of planning over the Olympic infrastructure and the cost blowouts of current and planned infrastructure projects.

The scale of the problem has made the LNP reconsider current projects and even pre-election commitments.

The Pioneer-Burdekin Pumped Hydro Project was dumped prior the election based on escalating costs – with the LNP labelling it “unachievable”. The Sunshine Coast Rail link, which was promised from Beerwah to Maroochydore by 2032, has been drastically rescoped by terminating the rail line at Birtinya. The extension instead being replaced with a metro-style alternative that will connect to the Sunshine Coast Airport. There has also been the consideration of rescoping some of the hospital projects.

The Olympic infrastructure plan was rolled out to positive reviews.

The Premier acknowledged that his pre-election commitment of ‘no new stadiums’ was wrong and that it was right to put the interest of Queenslanders ahead of any political

Damian Long, CEO CCF QLD

decisions. In addition, there is some significant Olympic infrastructure that will now be built in the Victoria Park precent.

Whilst the new Queensland government was busy establishing its plan for the state, Queensland was hit with two major flood events and a tropical cyclone. The full damage is still being assessed and whilst it is known the damage bill is high, we still don’t know how high.

Add into the mix a federal election where infrastructure announcements are king and both sides of government are mirroring each other’s commitments. A major announcement is the $7.2 billion in Bruce Highway safety improvements on an 80/20 split between the federal and state governments. That’s yet another $1.8 billion that the state government needs to finance.

The uncertainty now lies around the upcoming Quensland State Budget due to be handed down on June 24. It is too early for leaks, but the Treasurer did forecast that the LNP’s assessment of the finances show that the state’s debt could reach $217.8 billion by 2028. Coal royalty revenues are projected to be lower and Queensland’s GST allocation has been reduced by $2.4 billion.

Victoria Park will be one site seeing Olympic infrastructure built. Image: Falko Göthel/stock.adobe.com

These events have put enormous pressure on Queensland’s finances. The Crisafulli government promised that there would not be any reduction in infrastructure spending.

There is no reason to doubt this commitment, but it is becoming urgent to understand how the commitments will be financed in the short term and to ensure that there is a continued strong pipeline of projects beyond 2032.

We do know that the Commonwealth government will aid with disaster recovery, Olympic infrastructure, and the Bruce Highway – but we do not know the timing nor the overlap of the funding. It is prudent to ensure efficiency of spending to ensure flood reconstruction, safety improvements and betterment are done at the same time to maximise output for the funds available. However, this needs to be understood very quickly so that companies can make decisions regarding staffing and capital expenditure.

The delay in handing down an Olympic Infrastructure Plan, coupled with changes of government and associated priorities, has slowed the roll-out of new projects. It is reported that some companies are laying off people.

Infrastructure forecast reports and associated profiling on labour demands show peaks around 2026–2027 and a return to current levels at the end of the decade. We need to retain our workforce and have the confidence to build the stocks through recruitment and training to ensure we can meet the forecast program.

Two elections in the one financial year and, when you add in the Trump phenomenon, the industry is naturally nervous.

The positive is that the Queensland government is collaborating with industry and understands that we need to invest in infrastructure to grow this state.

The budget will come around quickly, and I expect the new financial year will kick off with clarity and confidence.

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

As we approach our upcoming National Awards for Excellence event next month during our 30th Anniversary year, it’s important to pause and look at how far we have come since the National Association of Women in Construction (NAWIC) was formed in 1995.

The peak body for women and those who support women in the construction sector, NAWIC is led by a team of passionate staff and volunteers who all strive to help champion and empower women in the construction and related industries to reach their full potential. With Chapters in every state and territory, we are also part of a global network of NAWIC organisations, including those in the United States, United Kingdom, New Zealand and Canada.

Professor Paula Gerber, who is now is part of the Law Faculty at Monash University specialising in construction law and human rights, established NAWIC in Australia 30 years ago, after returning from five years working as an attorney in Los Angeles.

Paula, always strong advocate for increasing female participation in the construction industry, was a member of NAWIC in the US and saw the need to establish the organisation here. As was headlined in The Age’ s article ‘Not a woman on site’ in June 1995, the building industry in Australia at that time largely remained a male bastion, and NAWIC began to change all that. Through helping women network with others in the construction industry, providing education and improvements to attract more women into the industry

NAWIC is celebrating 30 years of supporting and advocating for women in construction. Image: NAWIC

ensure women have successful careers in construction.

Any culture change comes back to people. And people are at the heart of what makes construction tick. We are all working together to achieve cultural change and create fair, inclusive and respectful workplaces where individuals, businesses and the community enjoy from the myriad of benefits that equitable and inclusive environments bring.

Cathryn Greville, CEO, NAWIC

at both trades and professional levels, NAWIC has long led the charge in addressing the gender imbalance in the construction sector.

For that we are truly grateful, and I know that Paula is very proud that NAWIC continues to be a thriving industry organisation with around 15,000 members nationally. We continue to build on both Paula’s legacy and our history of dedicated volunteer contributions to grow NAWIC’s reach and impact.

Our National Awards for Excellence is one way of honouring the outstanding achievements of the visionaries, the collaborators, and the trailblazers who continue to shape the future of construction.

The national awards showcase and recognise the outstanding achievements of those driving excellence and innovation in construction in the following categories:

• Crystal Vision Award

• P resident’s Choice Award

• Business Award

• Male Ally Award

While NAWIC has been at the forefront of driving positive changes to enable and benefit women and underrepresented groups for the past 30 years, these awards recognise the people and organisations who are also doing the hard work on the ground to

These benefits include improved financial returns, greater innovation, a positive reputation, achievement of work health and safety imperatives, improved compliance, better ways of working, reduced workforce shortages, lower risk and construction that meets the needs of the population.

So, my sincere thanks and congratulations go to all of our national award finalists who are playing their part in helping to create a fair, inclusive and respectful culture where all workers can reach their full potential.

Please follow us on social media and our website as we celebrate our award winners and NAWIC’s 30th Anniversary. The National Awards for Excellence ceremony is being held in Sydney on 9 May 2025. Get awards info at nawic.com.au.

NAWIC is the peak membership body for women working in the construction industry and supporting sectors across the built environment. A national notfor-profit association dedicated to the attraction, development and retention of women in the construction industry, NAWIC has local chapters in every state and territory, and forms part of a global NAWIC network of like-minded people focused on driving gender equity. You can find out more about NAWIC through its social media channels @nawicau or website nawic.com.au

MSCHYDRASCREW100 hydraulicorelectricdive.W71.

MCCLOSKEYJ50V2

2020,1270x735jawopening,Catengine,magnet,sidebelt 54tonne.KM100. TA999690.

$575,000+GSTEXDepot

MCCLOSKEYS130

14'x5'twodeck,100mmremotetippinggrid,Cat130hpInstocknow.SM248. TA908181. POA

MCCLOSKEYJ50V2

2019,1270x735jawopening,Catengine,wellmaintained andregularlyserviced.KM91. TA1232332.

$590,000+GSTExKingIsland

MCCLOSKEYS130

2020,14'x5'doubledeck,Catengine,15'hopper.SM238. TA1198773.

$280,000+GSTExMSCdepot

MCCLOSKEYS190

2020,20'x5'twodeck,100mmgrid,readyforwork condition.SM237. TA1203702.

$345,000+GSTExMSCdepot

MCCLOSKEYI3CR diesel/hydraulicpowered,adjustableimpactapron 27,500kg.KM138. TA859307. POA

MCCLOSKEYJ40

1016x610mmjawopening,Catengine,magnet,sidebelt 37tonne.S167. TA1227406. POA

PROGRAM WELCOME TO THE of the 2025

Thanks to naming sponsor

8AM - 4PM DAILY 15TH - 17TH MAY 2025

BRISBANE SHOWGROUNDS

On behalf of the Civil Contractors Federation Queensland (CCF QLD) – the event organiser – I’m proud to welcome you to the 2025 Heavy Equipment & Machinery Show (HEMS) at the Brisbane Showgrounds.

Now in its fourth edition, HEMS continues to grow in stature as a premier event for our industry – bringing together contractors, suppliers, manufacturers and service providers from across Queensland and beyond. This year’s show features a record number of exhibitors, new networking spaces such as the CCF Marquee, and exciting activations

the Queensland civil construction industry. We also welcome the return of our valued partnership with the Brisbane Truck Show (BTS), allowing all HEMS attendees to enter BTS for free.

Damian Long, CEO CCF QLD

like the Hard Hat Hunt, offering daily prizes for participants.

HEMS wouldn’t be what it is today without the invaluable support of our long-term Naming Sponsor, Pickles, who have been with us since the very beginning in 2019.

We thank them –and all our sponsors – for their ongoing commitment to

Running alongside the show once again is the annual CCF QLD State Conference, which brings industry leaders together to share insights on productivity, innovation and policies that impact the future of civil construction in Queensland. It’s a vital conversation at a pivotal time for our sector.

Whether you’re here to explore the latest equipment, attend the conference, or make new connections; we’re thrilled to have you join us for what promises to be another standout event.

Thank you for your support – and enjoy the show. I look forward to seeing you there.

Damian Long Chief Executive Officer Civil Contractors

Federation Queensland Organisers of the Heavy Equipment & Machinery Show

Once again, Earthmovers & Excavators magazine is proud to be the Media Partner of CCF QLD and the Heavy Equipment & Machinery Show 2025.

Events such as HEMS form a vital role in bringing industry together to not only showcase the latest machinery, equipment and technology on the market but to renew existing relationships and create new connections.

With Queensland looking ahead to hosting the Olympic Games in 2032 as well as seeing ongoing population growth, the infrastructure pipeline will see the state be the focus of significant construction growth in coming years. Vital to this will be machinery and equipment that can

Cat Fitzpatrick Editor, Earthmovers & Excavators

increase productivity, reduce rework and ensure high standards of safety on work sites.

HEMS brings together some of the largest names in civil construction to be a platform for advancements in machine control, operator assistance, zero-emission technology, fuel efficiency, telematics and more. Whether you are looking for

information on current market trends, high quality parts or new attachments, HEMS 2025 is at the forefront of what is happening in the civil construction landscape.

With the free shuttle bus running between HEMS and the Brisbane Truck Show this is the perfect opportunity to see some great machinery, speak to the experts and explore the potential benefits to your business.

Have a great show!

Cat Fitzpatrick Editor, Earthmovers & Excavators Media Partner of the Heavy Equipment & Machinery Show 2025

Celebrating four editions – proudly presented by Pickles

Australia’s largest civil construction machinery event is back! The Heavy Equipment & Machinery Show (HEMS) returns to the Brisbane Showgrounds from 15–17 May 2025 for its 4th biennial edition – and it’s shaping up to be the most powerful one yet. Since humble beginnings in 2019 –launched at the Pickles Archerfield yard – HEMS has grown into a nationally recognised event for contractors, suppliers and industry professionals. At the heart of this

Be sure to enter via O’Connell Terrace!

Shuttle buses: Free return transfers between HEMS and BTS

Train: Fortitude Valley Station is a short 10-minute walk away

Driving? Paid onsite parking is available at the Brisbane Showgrounds and surrounds

From the airport: Less than 20 minutes by car or train

growth has been Pickles, who return as the Naming Sponsor for 2025. Their continued support is not just appreciated – it’s essential. Quite simply, the event wouldn’t happen without them. Don’t miss the Pickles Auction, a show highlight with machinery and gear up for grabs across the show’s weekend.

Wake up and join SENQ Breakfast hosts Corey Parker and Ian Healy for a live on-site broadcast at our OFFICIAL OPENING from 6:00am

Proudly sponsored by SITECH Construction Systems & Trimble, this new dedicated space provides a welcoming area for CCF QLD members to relax, network and recharge during the show. Members will enjoy drinks, nibbles and networking daily from 2pm–4pm each show day. On Friday and Saturday afternoons during happy hours, they will also enjoy live entertainment by the terrific Steph Long Duo. Not a member yet? Come and chat to our team to find out how you can get involved with CCF QLD.

Hard Hat Hunt

Get ready to explore! Scan QR codes hidden around the site for your chance to win daily prizes, including:

– 9:00am on Thursday 15th May. Grab a free barista coffee, participate in activations like ‘pass the footy’, run by Pickles, and enter our giveaway to be in the running to win a range of fantastic prizes –including signed sports memorabilia and much more. Plus, don’t miss the official ribbon cutting ceremony by Deputy Premier, Jarrod Bliejie MP. It’s the perfect way to kick-off three epic days at HEMS! Come on down, we’re open 8:00am – 4:00pm. Buy your tickets now via heavyequipmentshow.com.au for quick entry to the show. Please note ticket sales and food vendors on-site at the show are cashless.

Each edition of HEMS has brought bigger crowds and bolder displays:

• 2019: Inaugural event at Pickles Archerfield – 900 attendees

• 2021: First partnership with BTS in Hamilton – 3,500 attendees

• 2023: Move to Brisbane Showgrounds – 5,500 attendees Now, in 2025, the show returns with more exhibitors, experiences, and innovations – cementing its place as the go-to event for the civil construction industry.

• V IP AFL and NRL tickets for the weekend of the show

• Cricket bats signed by the legendary Lord Ian Botham OBE

• A signed Brisbane Lions AFLW guernsey, thanks to Hastings Deering

• A luxury K’gari (Fraser Island) getaway, courtesy of Mitsubishi Motors Australia

• Plus other awesome surprises!

Thursday 15 May – RICC, Brisbane Showgrounds

Running alongside the show, the 2025 CCF QLD State Conference brings together the brightest minds and boldest voices in the sector. Held at the Royal International Convention Centre, it features a packed program of economic insights, workforce development and productivity strategies, followed by networking drinks and entertainment.

Speakers include:

• T he Hon. Jarrod Bleijie MP, Deputy Premier

• Matthew Peter, Chief Economist, QIC

• Kevin Walters, Former Brisbane Broncos Player & Coach, over a plated lunch

Conference tickets include complimentary access to HEMS and BTS.

HEMS proudly partners once again with the Brisbane Truck Show (BTS) – taking place simultaneously at the Brisbane Convention & Exhibition Centre (BCEC). Thanks to reciprocal ticketing, your pass gives you access to both events, combining the best of construction and transport in one unforgettable week.

Free shuttle buses will run regularly between the Showgrounds and BCEC, so you can move effortlessly between events and take in everything the combined offering has to offer.

Whether you’re flying in or just travelling across town, take some time to enjoy Brisbane – a growing capital known for its sunshine, food and relaxed vibe.

King Street Precinct

Located right next to the Showgrounds, King Street is bursting with restaurants, wine bars and cafes – perfect for postshow catchups or team dinners.

South Bank

Chill out riverside or check out QAGOMA, the State Library and the Queensland Museum.

Accommodation deals

Head to heavyequipmentshow.com.au to explore exclusive accommodation packages via OzAccomm, plus discounts on food, drink and experiences nearby.

James Street

Shop boutique labels, sip on specialty coffee and explore one of Brisbane’s most stylish strips.

This year’s show wouldn’t be possible without the generous support of our sponsors:

Naming Sponsor: Pickles

Uniform Sponsor: Hip Pocket Workwear & Safety

CCF Marquee Sponsors: SITECH Construction Systems & Trimble

Hard Hat Hunt prize contributors: Hastings Deering, Mitsubishi Motors Australia, & CCF QLD

Lanyard Sponsors: MCJ Maintenance & Repairs and Vision Intelligence

Visit HEMS online at www.heavyequipment show.com.au to buy tickets and view the current exhibitor listing!

SIDESHOW ALLEY, BRISBANE SHOWGROUNDS ENTRY VIA GATE 5, O’CONNELL TERRACE

ENTRY / EXIT

TOILETS

PARKING

FOOTPATH

FOOD TRUCK

BAR

FIRST AID

FREE BUS TO BRISBANE TRUCK SHOW

MARQUEE 1

MARQUEE 2

CCF QLD MEMBER

MARQUEE

ACTIVATIONS