Address:

Email:

BY KAYLA WALSH

A Queensland woman has extended her thanks to two truckies who kept her mum safe after she was “harassed” on the road recently.

EDITOR

james.graham@primecreative.com.au

REPORTERS

GENERAL

BUSINESS

Treena

treena.heit@primecreative.com.au

Linda Wilkinson told Big Rigs that her mother Karen was travelling from Stanthorpe to Innisfail in her ute and trailer when a Ford Sedan started driving in an intimidating manner.

“My mother is in her 60s and was helping my sister move house,” she said.

“There was a white Ford Sedan that was tailgating her, then it would overtake her and pull up on the side of the road.

“Then when Mum drove past, the car would pull out behind her again, before overtaking and then putting its indicator on, trying to get her

to pull over.”

Linda said the Ford driver’s behaviour, which started when her mother was travelling through Miles and continued towards Toowoomba, was “very worrying”.

Thankfully, two helpful truckies stepped up to shield Karen’s ute from the car.

“Mum was chatting to two truckies via the UHF and they too were watching this car.

“Mum used to be a truck driver and asked if they could put her in the ‘rocking chair’, so they boxed her in.

“They kept chatting on the UHF and kept her safe all the way through to Toowoomba.”

Karen is not sure of the full names of the drivers, but said their first names are Ray and Peter.

“It was late at night but mum thinks Ray was driving a semi

for Wickham’s,” Linda added.

“She’s not sure about the other truck but it had a ship-

ping container on the back and his name was Peter. “We just wanted to say a

big thank you to them. Well

and keep it sunnyside up.”

*12

AS part of a $46 million spend to install rumble strips on key regional and rural routes over the next three years, over 100 kilometres have been added to this major highway. The Audio Tactile Line Marking (ATLM) – or rumble strips – are located between Bathurst and Cowra on the Mid-Western Highway.

The idea of rumble strips is to give an audible warning to

the driver if they drift out of their lane.

According to Transport for NSW regional director west Alistair Lunn, these rumble strips are a proven safety treatment in reducing the number of crashes by 15 to 25 per cent.

“The Mid-Western Highway is used by thousands of motorists each day including freight operators and travellers

who are often on long trips,” Lunn said.

“If their vehicle leaves its lane for any reason such as fatigue, distraction or inattention, the rumble strips will cause a vibration effect to alert the driver to correct their path and avoid a serious accident.

“Our crews have been working along this corridor since April 15 installing the ATLM along the edge and centre

lines and have now completed the task, so there’s 147 kilometres of rumble strips between Bathurst and Cowra – a journey of just over 100 kilometres.”

Crews have also been installing rumble strips along hundreds of kilometres through the central and north-west of the state.

Work will soon begin to install more of these on the

Mid-Western Highway between Cowra and West Wyalong, and the Great Western Highway between Mount Victoria and Bathurst.

“Safety is our number one priority and installing ATLM along some of our key regional and rural routes is a proven, effective measure we can apply to increase the likelihood that all of our road users get home safely.”

BY DANIELLE GULLACI

FOR well-known truck driver and outback farm owner Danyelle Haigh, a recent health scare has shone further light on the issues those in remote areas face when requiring medical care. Now she’s calling on governments to fix the nation’s broken rural and remote healthcare system.

Danyelle and her husband Anthony Haigh, who many would recognise from popular television show Outback Truckers and more recently their show Outback Farm, moved to a remote 5000-acre property, about 200km north of Alice Springs over two years ago – where their primary business is producing and de-

livering hay for the cattle industry.

That’s all the while continuing to run Murranji Water Drilling, which sees them on the road travelling to some of the most remote locations, together with their two young sons Heath, 10, and Theo, 5. It was around 18 months ago that Danyelle found a small lump in her breast. She was told it was benign but to come back and get it checked if it grew or changed.

A few months ago, she realised that lump had tripled in size, so presented to Alice Springs Hospital – a two-hour drive from home – only to be told it could be months before she could even get an ultrasound or a mammogram, as

a physician would need to be flown in.

“I was actually supposed to get checked again after 6-12 months. But it was such a mission last time that I just put it on the back burner,” she said. With breast cancer running in the family – her grandmother battled breast cancer and had to have a mastectomy – Danyelle didn’t want to take any chances.

Her only option was to fly interstate so she could receive the medical attention she needed.

As she revealed, “I rang my mum pretty upset, because it was quite scary and I didn’t know what to do. I didn’t realise my mum had spoken to Anthony that night and they organised flights for me to the Gold Coast. I saw a GP there a couple of days later, had an ultrasound that afternoon and then a mammogram straight after.”

Danyelle returned home to the Northern Territory while awaiting the results before having to get back on a plane to the Gold Coast to undergo surgery and have tumours removed from both of her breasts.

Thankfully they were benign but turned out to be fast, aggressive tumours. “They take these sorts of tumours out all the time, because eventually they can turn into cancer. It’s

more common than people know. But the early detection is what stops it from turning into breast cancer, whether that be in six months or five years down the track.”

Danyelle says she’s thankful that her husband and her mother pushed so hard for her to go to the Gold Coast to do what was needed for her health. Yet there are many

others who aren’t so lucky. “There are people who can’t afford to go interstate to see a doctor, so they just leave it. And there’s the time factor too that makes it hard for people. With all that’s been going on, we’ve only been out drilling for two weeks of the year so far.”

According to the Cancer Council, a mammogram ev-

ery two years is the best way to detect breast cancer early and improve survival. For people living in remote areas, unfortunately that’s sometimes easier said than done.

“Alice Springs is quite a big town and it’s appalling really that it’s so difficult to get an appointment for something like a mammogram. They don’t have the staff so sometimes they have someone there once a month, sometimes even less – and even then, appointments are really hard to get.”

Along with an ultrasound, mammogram and biopsy, Danyelle used the trip interstate to get her health in check. While there, she says she also had blood tests, a colonoscopy and gastroscopy, which found a large ulcer in her stomach that had been causing issues for months and she discovered she needed a double iron infusion too.

“In remote, rural Australia, the health system is really struggling. They can’t get staff. The closest clinic we have is about 60km away and they have FIFO nurses and doctors. They’re being paid really good money, so the incentive is there, they just can’t get the staff,” added Danyelle.

“Something has to change, because the current government is talking the talk but isn’t walking the walk.”

ALTHOUGH the main focus was on record social housing investment, there were still wins for the trucking industry to celebrate in the 2024-25 NSW budget.

One of the features of the spend in the regions was an extra $28.6 million allocated towards building and upgrading 13 heavy vehicle rest stops in the state.

Most of those are still under wraps at deadline for this issue, pending approval from the feds that they would stump up with their share of the builds.

Transport for NSW (TfNSW) could, however, confirm that $2.4 million would be coming from the state as part of its 20 per cent share in the $12 million upgrades to the Tycannah northbound and southbound rest areas that are due to start construction next year.

“The remainder of this NSW budget funding is for future funding submissions under the heavy vehicle rest area program (HVRAP), which would require matching Australian Government contributions,” said a TfNSW spokesperson.

As earlier reported by Big Rigs, Hay is also to benefit from increased rest area investment with a total of $3.8 million allocated to design and construct a new 200m x 70m rest area on the Sturt Highway. There will also be dedicated slip and turning lanes off the Sturt and Cobb highways, creation of a truck parking area with protection for existing services, and adding shelters, landscaping, and connecting footpaths.

The budget also contains $44.5 billion for regional transport and roads, as part of various NSW and Australian Government funded projects, which include:

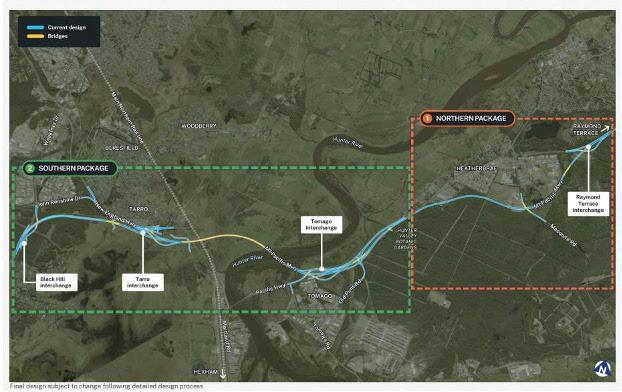

• $1.4 billion for construction of the M1 to Raymond Terrace extension and Hexham Straight widening projects.

• $1.1 billion to progress Princes Highway projects including construction of the Milton Ulladulla bypass, Jervis Bay Road intersection upgrade and Jervis Bay Road to Hawken Road upgrade.

• $926 million for construction of the Coffs Harbour Bypass.

• $868.4 million for New England Highway upgrades

including construction of the Singleton bypass, planning work for the Goonoo Goonoo Road upgrade in Tamworth and further planning for Muswellbrook Bypass.

• $432.2 million for Newell Highway upgrade projects including construction of the Parkes Bypass and new Dubbo Bridge.

• $216.3 million for planning and early works on the Wyong Town Centre upgrade.

• $200.3 million to complete Great Western Highway upgrades at Medlow Bath and Coxs River Road.

• $138.7 million for safety and reliability improvements on the Barton Highway.

• $35.0 million towards duplication of Nelson Bay Road from Bobs Farm to Williamtown.

• $59.4 million towards continued planning of the Mandalong Road upgrade.

• $47.3 million for the Jindabyne Education Campus project to provide. improved access to the new school facilities for the local community.

• $38.9 million for Tumbi Road Central Coast High-

way intersection upgrade construction.

• $97.5 million to help reduce congestion as part of the Avoca Drive upgrade.

• $36.4 million for safety upgrades on the Bells Line of Road.

• $22.5 million for pavement surface upgrades on Hume Highway at Marulan.

• $21.3 million for safety improvements on Waterfall Way.

• $20.9 million towards widening of the Marshalls Creek bridge in Wagga Wagga.

The budget also contained a further $332.2 million to transform Parkes into a national freight and logistics hub Road Freight NSW (RFNSW) CEO Simon O’Hara said he was pleased with the investment in the M7 and M12 and praised NSW Roads Minister John Graham’s office for assuring that the federal infrastructure spend would continue on those projects.

“Given the pivot of government priorities, roads and infrastructure haven’t been left out either. There are positive aspects to it,” O’Hara said.

A total of $1.0 billion has been allocated for Sydney roads in 2024-25, bringing the total program to $5.2 billion, including matched funding from the Australian Government.

The program will:

• Upgrade Mamre Road Stage 2 between Erskine Park and Kemps Creek for $1.0 billion.

• Widen Elizabeth Drive with four lanes connecting Mamre Road and The Northern Road to the airport for $800 million.

• Widen Richmond Road –M7 to Townson Road for $520 million.

• Upgrade Garfield Road East for $276.3 million.

• Upgrade Memorial Avenue

• Add a separated four-lane dual carriageway on Mulgoa Road Stage 2 between Glenmore Park and Jeanette Street for $230 million.

• Upgrade the intersection at St Johns Road and Appin Road for $45 million.

O’Hara also welcomed the $5.7 billion for disaster-stricken communities. That includes more than $632.4 million for the Northern Rivers and Central West for funding voluntary buybacks, raisings, repairs and retrofits.

O’Hara was also pleased to see $3.3 billion to fix flood and fire-damaged roads.

BY KAYLA WALSH

A proposed truck stop on the Warrego Highway at Helidon Spa in Queensland is still on the market, five years after a development application was approved.

Back in 2019, Lockyer Valley Regional Council gave the go-ahead for a service centre with three food drivethrough facilities and an internal restaurant.

The plans also include a large truck parking area and a grassy seating area.

Unfortunately, the development approval has now lapsed, and there hasn’t been any serious interest from a buyer in months.

The real estate agent in charge of the listing, Paul Schmidt-Lee from Ray White Commercial Toowoomba, told Big Rigs: “We’ve been pushing left, right and centre to the larger players in regards to service stations, but nothing has come of it yet.

“You never know though; you can never predict what will happen tomorrow.”

The original developer is said to have pulled out of the project before construction could begin, and SchmidtLee said there was some interest when it initially went on the market.

“There was a little bit of in-

terest but when Covid came along, it went quiet,” he said.

“Then it came back, there was some enquiry on it.

“Moving forward, I think it will be interesting to see what happens come the lat ter part of the year.”

Whoever takes up the project will have to reapply for development approv al, which Schmidt-Lee says could take between six and 12 months.

“What they’ll normally do is put a contract down sub ject to [approval] and then they’ll go away and do their due diligence.

“It normally takes between six and 12 months but that all depends on what they are trying to do, the relation ship with the council and all those type of things that can play out.”

In the years since the Helidon Spa development was approved, several competitor outlets have sprung up in the Lockyer Valley region, including the Mobil service station at Plainland.

However, Schmidt-Lee said that the $2.3m site is still in a prime spot along the Warrego Highway.

“The overall interest in that property is the size and location,” he said.

“There isn’t anything between the likes of Gatton and Toowoomba that would

accommodate that size of development.”

A second proposed truck stop, not too far away, is also showing no signs of progress years after getting the green light.

A mega service centre, complete with service station and shop, five fast food outlets, two cafes/restaurants, a 50-room motel, a truck wash and truck depot/truck parking bay was approved for a site at Haiglsea on the War-

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

rego Highway back in 2019.

“Given the Warrego Highway is a key trucking route this will be an easy stopping point where trucks can access amenities, but also where trucks/trailers can be parked/ stored for extended periods without having these parked by drivers within suburban areas,” the application noted.

“There is parking for caravans as part of the motel. This is to allow people with caravans to stop and stay at

the motel. It is not intended to operate as a caravan park.”

A total of 392 parking spaces had been planned over the entire site, including 25 spots at the proposed truck depot.

Later that year, however, developer EMAAAS Pty Ltd lodged a “minor change” to its application which has not yet been approved by Ipswich City Council.

Ispwich City Council confirmed to Big Rigs that the

development application is still “in progress” five years after it was first approved. At time of press, they could not provide a reason for the delay.

During the pandemic, an extension was granted to development approval, which is now valid until April 30, 2027.

Big Rigs has attempted, without success, to contact EMAAAS Pty Ltd for comment.

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

BY KAYLA WALSH

FIXES for a raft of heavy vehicle driver licensing issues plaguing the industry are expected to be debated at the Australian Trucking Association’s General Council meeting this month.

Licensing was a hot topic, along with driver shortages, training issues and unsafe driver behaviour, at the 2024 Workforce and Driver Training Summit, which took place in Melbourne last month in response to growing industry concerns.

ATA’s chief of staff Bill McKinley told Big Rigs he couldn’t reveal what the summit’s “priority outcomes” were before the council had a chance to discuss them on July 10 and offer its solutions.

But Ross Transport driver Joshua Ulbrich, the only current full-time truckie invited to speak at the recent two-day summit, confirmed to Big Rigs that one of the biggest issues brought up by participants was licensing regulation.

“It was suggested that there be more of an in-depth look into people’s background when they come to Australia from

overseas and want to transfer their international licences,” said Ulbrich, the ATA’s 2024 Professional Driver of the Year award winner.

“If you had a truck licence overseas, you shouldn’t automatically be able to drive a truck over here.

“You should have to physically demonstrate that you can drive, that you can restrain a load, that you can reverse a truck and trailer. It all comes down to safety.”

Ulbrich also gave a speech which addressed driver retention and what should be expected from both employers and employees.

“We need employers to be up-front with new employees about everything, from the freight tasks you will be doing to the state of the equipment you have, to what your work week will look like,” he said.

“I think sometimes they skim over these things, and if you want to retain drivers you’ve got to be honest from the start.

“Then on the other side, drivers have got to present themselves well, they’ve got to have a good attitude.

“They don’t necessarily have

to know everything, but they have got to be honest about what skills and experience they have.”

Ulbrich also spoke about how the government can help improve safety in the transport industry and address the driver shortage.

“We need more funded training packages for the industry, whether you want to be a mechanic or a driver or in administration,” he said.

“Some people don’t have the ability to outlay money for training courses, but it is something that they want to do.

“One of the things I suggested was a HECS (Higher Education Contribution Scheme) for those people, where you only have to pay back the loan once you are earning a certain amount.”

He was happy to be invited to the summit, to give his input from a driver’s perspective.

“There were some important people there – the head of Mainfreight, the head of K&S Freighters, the head of Simon’s.

“No matter what company we were from or what experience we had, we were all fighting for the same things.

“These things need to be changed, to make the transport industry a safer and more enticing industry to be part of.”

Steve Broadbent, who was a truckie for 40 years but has recently stepped out from behind the wheel to run his own safety and compliance business with his wife Jodie, gave a speech about safety culture at the summit.

He told Big Rigs: “This industry has changed a lot since I first came into it back in the ‘80s, and the culture has got to change with it.

“We need to drive that culture of safety and make sure all processes are followed, there are no shortcuts, and communication about safety doesn’t get lost between upper management, middle management and the floor

“If you see something that’s wrong, you shouldn’t be frightened to speak up.”

He also shared his thoughts on minimum training hours – a hot button topic at the summit.

“I don’t think the hours required at the moment are anywhere near high enough,” he said.

“I think we should look at the industry and the way they do things themselves and go

from there.

“Simon’s, for example, do 200 hours with their road train drivers.”

Broadbent thought the summit was productive and is looking forward to hearing what the ATA General Council decides.

“There were a lot of good ideas and smart people there, and I think the recommendations are heading in the right direction.”

EDITOR JAMES GRAHAM

ration.

Lee spent five days with Jon Kelly and his Heavy Haulage Assets crew as they transported her prized $14 million sculpture from Brisbane to its new home at the National Gallery of Australia in Canberra (see full story on page 12).

To say that Lee was blown away by the professionalism and skills of the crew, is arguably the understatement of the year so far.

In two effusive minutes on Instagram, she did more to change the image of trucking to a non-industry audience than I’ve seen any organisation, or well-funded third-party do in six years in this role.

We need to bottle that up and start a social media campaign using similar messaging with a varity of non-industry faces.

NEWS that the National Heavy Vehicle Regulator (NHVR) would be inspecting approximately 8500 heavy vehicles over 12 weeks – beginning this month – was met with some scepticism from readers.

The checks are being conducted as part of the regulator’s National Roadworthiness Survey, taking about 45 minutes to complete.

Big Rigs reader Graeme Kelly said: “Just another blitz on a transport industry already losing drivers. What other industry would put up with all the fines, the poor

road conditions…”

Roger Develder added: “Fix the bloody roads first. I’m sick of losing hub covers.”

Trent Yendall wrote: “Just a thought, maybe ease up a little bit with handing out fines. Ed

wants to drive now.”

While Kylie McDonald questioned: “How is a 45min inspection going to help truckers with their ‘fatigue’ when they have to remain on work hours for the full 45mins, or longer if the NHVR choose to

TRANSPORT and Main Roads Queensland has confirmed there will be no amenities provided for truckies at a new rest area being constructed along the Gregory Developmental Road in Queensland.

A revamp of the existing northbound rest area is also in progress, with both areas ready for use within the next six months. However, there will be no toilets, showers, shaded areas or other facilities provided for truck drivers at either rest area –which left readers puzzled.

Leanne Dyer commented, “These politicians and desk jockeys have no idea. It should

be mandatory that parking bays and heavy vehicle rest areas have a minimum of toilets. Saying there’s a roadhouse nearby is ridiculous.”

Bruce Skelton agreed:

“What a joke. Should take toilets out of parliament house as

McDonald’s down the road has facilities.”

Shane Bills added, “Maybe these pen pushers should venture out into the world of truck driving and see how they like the conditions they have imposed on drivers.”

WITH 40 years of success under their belt, the founders of Clark Windows – Craig and Sandra Clark –have called time on their career, ready to hand the reins over to new owners as they step into retirement. Started in 1984, the Tasmanian based company specialises in windows and doors, with a trusty fleet of nine trucks allowing them to offer their services to all parts

of the island state.

From modest beginnings, the past four decades have seen the company transform into a thriving state-wide business that incorporates three factories with showrooms, a loyal

team of staff and a fleet of Isuzu trucks for the company’s transport operations.

Craig and Sandra have a people-first approach, building relationships with their retail and wholesale customers.

Their desire to form strong bonds extends to suppliers, including Webster Trucks, where they purchased their first Isuzu over 20 years ago –an Isuzu NLR 200.

When Clark Windows opened its first manufacturing facility in the coastal town of Smithton, in north-western Tasmania, it was all hands-on deck, with Craig pulling double-duty as director and salesman on the floor.

They now rely on a team of 70 employees and tradespeople to deliver their products and services on time to customers across the state.

Reflecting on those early days in the 80s, Craig says there were many lessons that he’s kept close to his heart. And as his time at the business draws to a close, he’s keen to share some of that wisdom.

“The major factor is that you have to commit to delivering

the product on time,” he said.

“You have to try to make it the best possible quality, and if anything doesn’t turn out absolutely correct, rectify it as fast as possible to keep your customer happy.

“Thankfully we learned the hard lessons early, met the right people, and now we’re proud to produce thousands of windows every year.”

Ensuring those products get to where they’re needed, Clark Windows has a modern fleet of nine medium-duty Isuzu trucks: five FRR 110-240s, an FRR 107-210, an NQR 87190, an NPR 65-190, and an NPR 300.

Each model was chosen for safety and comfort and specified for the task of window and door installation.

“Once we graduated past utes and into trucks, we always went with the Isuzu brand… they’ve never put a foot wrong so there was never any need to go anywhere else,” said Craig.

“The first truck was the NLR 200, then we went with the 300, 450, 500, all the way up to our current fleet.”

Sandra also spoke about the evolution of the fleet. “We can’t believe the difference in comfort over the years,” she said.

“I almost feel like the drivers are almost spoiled these days, which is a good thing as they work so hard!”

The company’s 40-year milestone is a fitting send-off for Craig and Sandra as they reflect on the final stretch of their careers.

They say that all that remains now is a comprehensive handover to the new owners, a pair of brothers who have worked within the company for many years.

“We’re definitely leaving the place in the safest of hands,” assured Craig, a sentiment which is echoed by Sandra.

“There’s so much about the place that we’ll miss – the customer interactions, the people, and the development of our young individuals.

“We’ve had some amazing apprentices turn into long-running employees… We’ve been very lucky that way, it’s been an amazing journey.”

MELBOURNE-based C&C

Express Refrigerated Transport is winding up its operations after 15 years in business.

Owners Craig Griffin and Cam Saddington (C&C) made the announcement on social media in May, but plan to continue to make deliveries until all the equipment is sold off.

“When they sell the last piece of equipment, then they’ll close the doors,” said a source familiar with the Laverton North fleet.

“There are little pieces of the puzzle going every week.”

Craig and Cam built up the business from one “old” exBooth Transport cabover in

2009 to 13 Kenworth prime movers and 19 trailers.

They prided themselves on being the ‘go-to guys’ for chilled and frozen interstate transport to Melbourne, Sydney, Brisbane and Adelaide.

“We have made this decision ourselves and feel now is the perfect time to leave while we are still somewhat on top,” Cam posted on the company Facebook page.

“I am sure the rumour mill has gone into overload already which was to be expected but our drivers and those close to us know the real deal, which is all that matters to us.

“Thank you to everyone that has been a part of this journey

including some great customers, some not so great customers, some awesome guys at Kenworth and Cummins (they know who they are) but most of all our team of awesome drivers.

“We would have nothing if not for the guy’s that drive these things every day and give up so much.”

Big Rigs understands that all the drivers have since found new roles, and been paid their entitlements, but Craig and Cam have not decided where they’ll land next.

Our source told us that the pair are happy with their decision, particularly with the many challenges facing operators today.

“They didn’t want to work for nothing and we’re in hard times at the moment. It’s hard to get drivers, fuel’s up, wages are up, everything’s up. But the customers out there aren’t putting their rates up; if anything they want to put them down.

“They have some of the best rigs on the highway and best maintained, and the way they operate at C&C, people don’t want to pay for that quality anymore.

“They’d rather have a two-dollar shit-heap running up and down the highway with their food in the back and pay nothing to get it done, that’s if it gets done, and they [C&C] don’t want to be part of that.

“They’ve probably got one of the best names in the business on the highway.

“So, while they’re on top of their game, this is how they have decided to finish.”

Artist Lindy Lee sings the praises of this elite heavy haulage team after a fiveday journey carrying the biggest load of its kind ever seen on Australian roads.

BY JAMES GRAHAM

LINDY Lee’s new favourite superheroes don’t wear capes – they’re the trucking team responsible for successfully hauling her prized sculpture from Brisbane to the National Gallery of Australia (NGA) in Canberra.

The renowned artist travelled every step of the fiveday, 1200km journey with the 13-tonne Ouroboros, a $14 million immersive sculpture that took her four years to complete and says the trip was one of the highlights of her life.

Thanks to meticulous planning by project boss Jon Kelly, from Heavy Haulage Assets, and the calm-under-pressure skills of his truckies Liam Khan and his dad Ray, and their project pilot, the legendary ‘Nick the Greek’, Lindy’s precious cargo arrived on June 19 without a scratch.

Instagram account.

“Every cliche about them being uncouth louts is wrong, wrong, wrong. They are the salt of the earth. They were so cour teous, caring and kind.

“They were curious about art, life and the universe. We had great chats. And they were so dedicated to the cargo they were carrying. Liam and Nick’s steadiness was stellar.

“It’s been the most amazing trip of my life. You have no idea of the logistics. Liam has to ne gotiate 36 gear changes coming down the range – it’s insane.

“The pilot, Nick the Greek, I’m in love with him. He’s such a gorgeous guy, and oh my god, the skill. I had no idea of the amount of skill there is in all of this.”

The haul, however, wasn’t without its share of “hairy ride” moments that were out of the crew’s control, admits Lindy.

“Truckies are superheroes,” an exuberant Lindy writes on her

Thick fog grounded the team at Goondiwindi, and Lindy says the winds were so fierce near Dubbo that it was only the “Freddy Mercury” netting that kept the sculpture sheeting in place.

“There were two incidents involving f*cking dickheads,” Lindy adds on Instagram.

“The police had pulled over oncoming traffic to the road shoulder. The idiots decided to queue jump, so they were driving at us at 100km/h, we were driving at 80km/h and we took up both sides of the road.

“It was only Liam’s and Nick’s steadiness that avoided a headlong and fatal collision. Cool as cucumbers. I hope they all make it to the opening in October. I love them so much.”

Jon Kelly tells Big Rigs that you can count on him being in Canberra for the formalities later this year, along with his trucking-mad sons James and Josh, both of whom were on hand to help Dad with logistics out of Brisbane.

Jon has been the brains behind some of the biggest and heaviest loads ever moved on Australian roads.

But the Ouroboros project, commissioned by the NGA to commemorate its 40th anniversary this year, would have to go down as one of his highlights.

“We’re used to doing things of this dimension and they’re between 120- and 200 tonnes so it was nice to do something that was large but not heavy,”

Jon said.

“But it’s not often that we pull an article of this size out of suburbia. It was hard getting it out, and as I always say, the first and last kilometre of the journey is the hardest, and that was very evident with this move.”

Firstly, however, Jon had to convince the UAP (Urban Arts Project) Foundry to let him transport the sculpture in one load.

When they first called to commission Jon for the job, the foundry wanted a price to move it to Canberra in four

separate pieces.

But when the drawing came through of the finished sculp ture, which was 11m long, 8m wide, and 4.5m high, Jon quickly came back to tell them it could be done “holus-bolus”.

“Then they nearly shit them selves. When you’re dealing with people in the art world, they’re very cautious people who haven’t had exposure to transport. I had to go and prove to them at a desk-point level that we could do it.”

advantage. Then we had the ability to lower the cargo to under 5.1m if we had to.”

Even so, there was a fair amount of satisfaction as he watched his crew safely negotiate those final few kilometres through the Canberra CBD.

That involved route surveys, and the massive task of conditional approvals from the National Heavy Vehicle Regulator for a mountain of road permits.

“This was a very, very high stakes, high-profile job, and the job was won before we even loaded the trailer because the hardest part was getting the approvals.

“The final permit went on and on. Canberra gave us some resistance because it’s the largest load to ever come into the Canberra CBD in history and it doesn’t get any more CBD than the National Gallery on King George Terrace, right next to the old Parliament House.”

Choosing the truck was an easy choice – a 2023 Kenworth T659, 155-tonne rated – and so was its driver.

Liam is Jon’s main full-time truck operator. He’s been with Jon for over 10 years and used to be head of his oil and gas division at Heavy Haulage Australia.

“He’s a great operator, super-meticulous, super-professional; he’s just a really good advocate for the transport industry, to be honest.

“His old man Ray [in the back-up truck]; I’ve known him since I was 10 years old. He used to run Darwin for my grandfather [Frank ‘Smiler’ Nilon].

“I never thought that when I met Ray as a kid I’d ever have the opportunity to both employ him and his son.”

With an added drop-bed on the trailer, Jon was able to extend the MTE, five rows of

“I’m very proud of the fact that not only were we successful winning the job, but very successful in delivering a Canberra first and a National Gallery of Australia first, and also a UAP-first, who’s one of the largest art manufacturers in the world.

Ouroboros is based on the ancient image of a snake eating its own tail, and it is the symbol of eternal return, of cycles of birth, death, and renewal.

Located at the entrance of the National Gallery, people will be able enter the ‘mouth’ of the sculpture and walk into the curved space to experience darkness that is illuminated by

“This is their largest commissioned piece of artwork to ever hit the road.

“It was a very interesting to get exposure to the art world. They’re just as passionate as us truckers, so it was really nice to have Lindy Lee travel with us as well.”

Jon thought that being an artist she’d tag along for the first couple of hours, watch the Ouroboros come out of Brisbane and maybe fly to Canberra to reconnect for the last couple

light beams emanating from the hundreds of perforations on its surface.

Lindy said she hopes when people see the sculpture, particularly when they go inside it, they will experience a “deep connection to something which is much larger than just this little, individual body”.

“[I hope it helps people feel] that we are a part

of hours as it crawled to its final resting spot in front of the NGA.

“But she didn’t leave its side. She was 100 per cent there the whole way through. It opened her eyes.

“She fell in love with the crew and said it was the trip of a lifetime and that’s a big deal coming from a person like that.

“She’s seen a lot of things –and done a lot of things – so that’s a massive feather in our cap.”

of this greatness, we’re intrinsic to it as much as this greatness is intrinsic to us,” she said.

“I actually want people to really feel that in their hearts and their souls.”

More than 400 people had worked on the sculpture over 60,000 hours that included 2km of welding and the handcutting of 45,000 holes. It is designed to last for at least 500 years.

From the humblest of beginnings, Followmont Transport has flourished into one of Australia’s most successful trucking operations.

BY DANIELLE GULLACI

THE story of Followmont Transport started in much the same way as many other transport businesses did, with just the one truck. It was an eight tonne Hino flat top FF. Today that’s grown to a fleet of over 170 prime movers, around 250 rigids, 430 trailers and 181 forklifts operating from its 24 depots – and travelling a combined total of 130,000 kilometres each day.

It was way back in 1984 that Bernie Tobin and Alan Salpietro laid the foundations for this transport success story.

“They started the business off the back of a rail strike. They had just the one truck and drove it from Brisbane to Cairns, delivering magazines to newsagents,” said Mark Tobin, who took the reins as CEO of Followmont in 2013, before purchasing the business together with his brother Ben Tobin in June 2016, to carry on the legacy of their father and his business partner.

“A big thing we always say at Followmont is never forget how we got here. We show and work with respect and that is what drives us forward. My father and Alan worked very hard to build the business up,” Mark added.

“Those first 10 years were really hard work. It wasn’t until about five years in that they were able to construct their first building. Before that they were working from beneath a house.”

Now 48, Mark has been with the business for 33 years, however it’s been part of his life for even longer. “I was only eight years old when they started Followmont. I’d ride my push bike here after school and be in the trucks every weekend. I worked in every aspect of

the business before becoming CEO.”

The house Bernie and Alan originally worked from was located at Stones Corner in Brisbane, before they moved to a depot in Geebung, where the business stayed for many years until moving to the current location at Eagle Farm in 2009, which brought with it exponential growth.

“From there, we just exploded. We’ve done two renovations to double the size, including a massive reno eight years ago. In the last 10 years we’ve had massive growth,” explained Mark.

“I’ve been running the business for 15 years now but it’s the effort dad and Alan put in at the beginning. Their philosophy was that we never don’t move something because the truck isn’t full.

“One of the biggest things I’m proud of is that we still do the small deliveries for the mums and dads. They can drop something off here and we will take it. We have accounts that spend millions with us, and then others that just need something small delivered.

“To this day, our philosophy is all around service to the customer no matter the obstacle. We go to every town in Queensland and New South Wales daily, no matter how big or small it is. At Followmont, we look after each other, your word is your word.”

Of Followmont’s 24 depots, 20 are located in Queensland and four are in New South Wales, ranging from as far north as Cairns all the way down to Sydney.

“We have a number of different revenue streams off the back of that – including 3PL, our specialised logistics business and a large refrigeration

A BIG THING WE ALWAYS SAY AT FOLLOWMONT IS NEVER FORGET HOW WE GOT HERE.” MARK TOBIN

business,” explained Mark.

a truck all goes back into the business. That secures us for growth and sustainability.”

Adding to that, Followmont builds all of its own sites through its building arm called Bootooloo Property, which was launched in 2017 –though Mark revealed they’ve been building all of their own depots for the past 20 years. Currently, the company’s property portfolio is valued at approximately $95 million.

“We own everything here – we have all our own workshops, our own sites, trucks and recruit our people, we don’t use many sub-contractors. That means we can con

“From bricks and mortar to workshops and fuel. Everything is in-house.”

Regardless of how big it’s grown, at Followmont, its people have always been at the heart of the business and are what keeps the wheels turning. The company now employs approximately 1000 people.

“It’s been an amazing journey, but at the end of the day we don’t own the business, our people do,” said Mark.

“I’m big around open communication to all people in our business. Everyone knows how we’re going and where we’re heading.

ple, the values and empowerment. I have a very good team around me that I reckon are the best in their fields and our industry.

“Bernie and Alan worked really hard, now I want to get the best out of our people. So we have our own training and development business for our people, a future leadership program and an intern program. That’s all run internally. It gives our people the opportunity to develop and grow.

“It’s about leadership and empowerment and creating a true family business, where we’re using our values in training and development.

flourish. It’s our relationships and values that set us apart from our competitors. One of the main things for our family is that we put a lot of time and effort in making sure that mine and my brother’s relationship is number one. We will not let anything happen to that.

“I’ve had great mentors, but I’ve mostly been self-taught. I’ve really worked hard on leadership and how to be the best version of you. You’ve got to put the business first, the team second and yourself third. You never put yourself first.”

Continued page 18

BY KAYLA WALSH

BEN Butch never planned to be TikTok famous, but the interstate truckie now has 100k followers on the social media platform – and counting.

The Wollongong native, 33, said he’s an “idiot” when it comes to technology, but started a TikTok account as part of a bet with a friend two years ago.

“My mate’s partner said to me, ‘Let’s have a competition,’” he told Big Rigs.

“‘We’ll start a TikTok, and the first to get to 1000 followers wins.’

“I didn’t know much about this sort of s**t at all, but she put the app on my phone and away I went anyway.

“I woke up the next morning and I had 5000 followers.

I couldn’t believe it.”

Ben’s content is a mix of funny videos and music, with an impressive singing voice that has won him plenty of fans.

But his page has really blown up in the past few months, since he released his first original song – Highway Addiction.

The tune, which describes

how Ben can never escape the call of the open road, has racked up over 70k views on TikTok and 15,000 streams on Spotify.

“I was at the traffic lights a couple of weeks ago and I could hear this song, so I put my window down,” he said.

“The car next to me was playing Highway Addiction.

“I just wanted to shout out,

‘That’s my song!’

“I just never expected anything like this.”

Ben wrote the country music song about five years ago but didn’t do anything with it until a musically minded friend encouraged him to put it out into the world.

“The song is about being addicted to the highway, and it really is an addiction,” he said.

“Once you’ve had that freedom, you can’t get away from it.”

Ben, who has worked for Boland Transport for the past six years, said he has tried to switch from interstate to local work several times, but he gets itchy feet.

“I’ve got three beautiful children at home and walking away from them is the

hardest thing I have to do every Sunday.

“But at the end of the day, I’m doing it all for my kids.”

Truck drivers make up the majority of Ben’s followers, and he said most of them are supportive – though he does get the odd negative comment.

“You’re always going to get people saying stuff like ‘New age truck drivers make you sick’,” he said.

“I can’t get fuel now without someone saying ‘Hey, you’re that TikTok idiot.’

“I worry that people will think I’m arrogant, but I’m not like that at all.

“Thankfully I don’t get too much hate, it’s mostly positive.”

Ben, who transports steel up and down the East Coast, said he “didn’t care” if no-one ever listened to his song.

This is partly because he just wanted to get it out of his system, and partly because it contains a tribute to someone very special who has passed away.

“The reference to the person who has passed away is very meaningful to me,” he said.

“That person, he ran the highways for 40 years and taught me everything I know.

“I don’t want to name him because the family are quite private, but he was an amazing person who changed my whole outlook on life.

“I hope he would be proud of me now.”

Ben has no ambitions to become a world-famous country music star or influencer.

“I don’t need millions of dollars - I’m happy being a truck driver,” he said.

“I love it and I hate it, and I could never give it up.”

From page 16 acquisition of Bradco Trans-

or so. But my brother

is much younger than me

time yet, he’s already looking well into the future. “I plan to be here another 20 years

32 – so because of that generation gap, Ben is the future of our business.”

Our writer gets a second chance to take two of Western Star’s X-Series trucks for a spin and is impressed with what he discovers.

BY GRAHAM HARSANT

THE Star is that 1: The X-Series was recently voted Australasian Truck of the Year by industry experts and, 2: Supply lines are now strong, both good rea sons to reacquaint myself with the product.

Western Star had the misfor tune of launching their new range of trucks – the X Series – here in Australia in 2021, as Covid raged around us.

As we all know, this caused world-wide shortages of just about everything and truck supply lines were as much af fected as everything else. At that launch I did a series of quick laps around Mount Cotton, outside Brisbane.

Although the drives were short, I was impressed with the product and the efforts to which Western Star had gone to bring their trucks up to spec, and even surpass some of their competitors.

There are three models in the range: the 47X, 48X (de signed specifically for Austra lia and NZ) and 49X, and all are available in a multitude of specification so I’d suggest going online or talking with a WS dealer to discuss your specific needs.

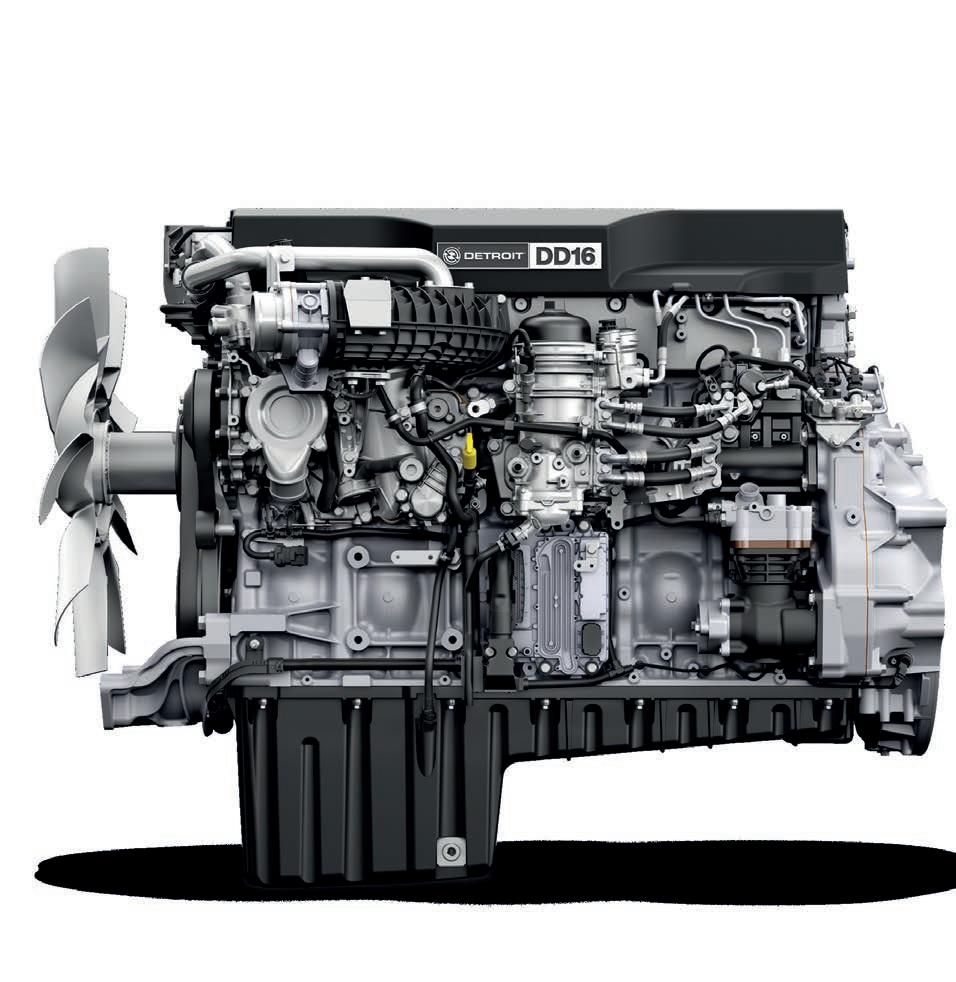

In a nutshell, the 47X with its shorter hood and set back axle gives it a great turning radius. Detroit 13-litre or Cummins 9-litre power is available, along with Auto or manual trannies.

The 48X is 6x4 only, and available with either the Detroit Diesel DD13 or DD16 engines, with power output ranging from 450hp through to 600hp. The model features a set forward axle and suits a range of applications right up to B-double work.

The 49X is the big banger in every respect, from cabin size through to road train application.

This time around I have a full day to play and have chosen the 49X for the morning and the 47X in the arvo, from Papa bear to Baby bear if you will. Not only that but I’ve elected to drive manuals in both versions!

The above exclamation mark is there because in the 15 years I’ve been test driving new truck product (as in prime movers), every one has been an automatic.

The last time I drove a manual was a trip to Sydney to Haulin’ the Hume with a couple of mates some five years ago. I’m a bit nervous that I’ll do an ACL on the clutch, but I’m confident in the knowledge every other truck journo there is in the same boat.

The 49X bonnet is wide but not overly long – certainly

shorter than the Constellation is replaces – so forward vision is good. A big tick to the mirrors on their C mounts. Electrically operated and rock solid. Strong enough to hang off (I did), they offer good vision and are great to see around.

The bonnets are injected resin and use WS’s ISO Tech suspension system to isolate it from the worst road conditions. Strong and lighter by around 45kg, the bonnet can be opened and closed with one hand with secure latches hidden behind the Western Star logos on the flanks.

The front is adorned with Western Star’s new signature, stainless steel grill. The design seems to be a bit polarising, but personally I reckon it looks great. There’s no mistaking this for any other brand.

The DD16 sits high but has everything you should check daily within easy reach. The radiator is huge, sits between the chassis rails and is over 800mm from the ground. If you hit a Roo (and you will) it’s not going to damage the cooler, and you’ll be able to

drag Skippy’s remains out easily.

The cabin is aluminium with steel strengthening in all the right places to make it the toughest and most rigid WS has produced, including extra cross beams in the floor for the Aussie market.

The cab is raised high above the tanks to aid air flow and cooling of both motor and cab. Some may think it looks a bit ‘tacked on’ but I didn’t mind it, and it’s designed like that for good reason.

This 49X has the 72-inch bunk. If you’re doing ‘The Paddock’, or similar, this is the one to have.

There’s enough room to party all night long back there and it’s a breeze to walk past the gear shift protruding from the totally flat floor, which interestingly was covered in squishy thick rubber, like those mats made for standing on all day.

I loved the feel and no doubt it adds to the effective isolation of engine noise from the cabin. There’s everything back there to provide for week/s

lice siren goes off. In front of you is an American-style dash layout with lots of dials and room for plenty more.

The rows of switches are all plug and play, so you can move the most commonly used to a favoured position.

away from home. Shut the door, and then shut it again because the triple rubber sealing around it is so airtight that I reckon this truck would float if you ran it into a dam.

You’ll know if it’s not shut properly because a warning that sounds like a German Po-

Western Star, by their own admission had a bit of catching up to do on the safety front and the X Series is now right up there with the best of them. It’s got ABS, EBS, Lane Departure Warning and every other safety device out there.

Time to drive and I snick the shift into first and idle away. Thankfully the clutch is light so the ACL remains intact.

From a shaky start and tak-

ing a few burrs off the cogs to make life easier for the next journo, I soon get used to the ubiquitous 18-speed Road Ranger and am having a lot of fun.

For me, if I was a professional and had to do a lot of the city/suburban driving I’d go for the Detroit DT12 Auto, which I know to be a terrific ‘box, but here at ‘Playschool’ I’m loving renewing the acquaintance with a manual.

This is an easy truck to drive and, although set up for the heaviest applications – and me with only a single trailer behind me - the ride is very comfortable.

Continued on page 22

At Capricorn, we’ve done the hard work for you. With one consolidated trading account across thousands of suppliers, we’ve got all the parts and services you need to run a successful heavy vehicle business. It takes the hassle out of managing multiple payments – plus you’ll earn Capricorn Rewards Points for every dollar you spend, putting cash in your back

Find out more about the benefits of belonging to Australia’s largest coop for automotive.

One trade account Quick access to parts & services

Generous Rewards Program No joining fee

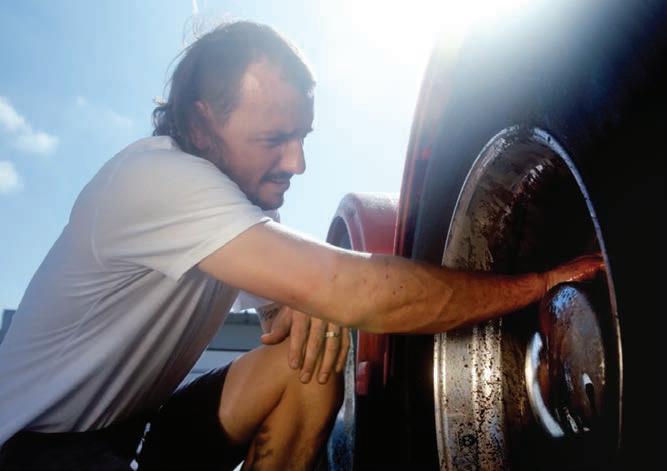

This one-of-a-kind, customised 2019 Trident helps with rail maintenance across a wide part of southern Australia.

BY DAVID VILE

IT could be widely agreed that road and rail transport have been in fierce competition against each other throughout Australia for the better part of the last century.

However, some innovative planning and building, such as that which has gone into Matt Tennant’s Mack Trident Hi-Rail Tipper, combines both road and rail componentry into a flexible and versatile transport solution.

Matt oversees the operation of Tenex Rail, which undertakes rail maintenance works across a wide part of southern Australia from its base at Seymour.

The 2019 Trident has been custom-built with rail gear behind the axles to operate on railway lines hauling sleepers and railway ballast and is the only one of its kind in Australia. Matt had the Trident loaded up on the back of another Tenex Rail Mack and on show at the Kyabram Mack Muster earlier this year, with the dual-purpose vehicle drawing plenty of attention.

Looking for versatility and a rail-road vehicle capable of taking on heavier payloads in his operation, Matt conceived the development and build of the Trident with the co-operation of the Mack factory and Aries Rail in Perth.

“It was designed by myself and built in collaboration with Aries Rail,” Matt explained.

“Mack came to the party and designed the cab - chassis to how we wanted to accommodate the rail equipment. The

exhaust, transmission airlines and electricals were all modified or moved in-house on the production line by Mack.

“To get them up clear of the chassis rails, Mack also predrilled holes in the chassis to Aries requirements so everything would fit straight on.”

While the progression from concept to reality was around a 12-month undertaking, the process of getting the Mack work-ready was fairly quick, even with the truck having to be shipped across to Perth to be fitted out at the Aries Rail factory.

“Mack worked pretty closely with Aries sharing the designs

and so forth. The rail system was pretty much 90 per cent built on the floor in Perth, the truck was sent over there and fitted out in around two weeks, so it was under three weeks getting it over there and back to Victoria for delivery,” Matt said.

The rail gear is gauge convertible so it can run on both the Victorian broad gauge and NSW standard gauge networks. Along with the rail gear, Aries fitted the Trident with a tipper body which is designed to manage a variety of material, particularly ballast and sleepers, and has a three-way tip function (left/right and rear) along

with a several chutes in the rear tailgate to place the ballast right where it is needed.

Given its ability to ‘ride the rails’ makes for an interesting driving experience in a few different ways and as Matt explained it requires a different mindset to operate as opposed to driving ‘on road’.

“On rail the steer tyres are elevated about 300mm above the rail head, you put the truck into gear and off you go, you don’t steer and don’t touch the steering wheel, the bonnet sits up pretty high and proud, you go along doing the regulated speed.

“It is a weird sensation to just be going where the rails take you – your brain is saying ‘I need to be steering’ but you just can’t touch the steering wheel. If you run through a road crossing with a bit of high asphalt or something and you’re holding the wheel it might grip and potentially derail you, so it’s a matter of keeping the wheels straight.”

Another point to consider is the fact that doing this type of work the Trident spends as much time going backwards at a steady speed as it does travelling forwards between stockpiles and work sites.

“You get loaded at a crossing with ballast, and you may have to back in a kilometre or may have to do ten k’s to the tip-off point and then drive back out to reload, so virtually 50 per cent of the kilometres showing on the odometer have been done in reverse!” Matt said.

“The M-Drive transmission offers four gears in reverse so you can do your mid 30s

[km/h] quite easily without revving the guts out of it. Out on the road with 535hp we can tow a tag trailer behind it with a bit more weight on it and get around the countryside - it can tackle the hills with ease.”

While the project may have been a costly one to get off the ground Matt reckons the savings add up given the other machinery and equipment he runs as part of his business.

“Previously, we were using an Hydrema articulated dump truck which have their place, but the beauty of this is it can haul a 20-tonne payload which is double that of a Hydrema, and you can drive this to site with a Hydrema on a trailer behind and have two vehicles doing the work of three. Or you could be doing little ballast jobs and head out in this with a loader on the trailer and pretty much be self-sufficient and not needing a float to shift a loader and articulated tipper from site to site.”

The Tenex Rail operation works throughout Victoria, up into NSW and across to South

Australia and has a strong connection to the Bulldog breed, with the Trident being hauled to Kyabram behind a 2019 Super-Liner.

“That one is build #86 of the 100-year Mack Anniversary specials, before that we had another 685hp Super-Liner,” Matt said.

“Prior to that we had a ‘98 model CH Fleetliner, so have been with Macks for a while. I’m currently restoring a 1987 Super-Liner at home which is in the rebuild phase at the moment - I’m finding my feet with it, but people have been really helpful with advice and parts and so forth.”

Needless to say, the Trident is proving its worth, and the vehicle is an example of turning an idea into a successful outcome and Matt is justifiably proud of the result.

“It’s the only one built by Mack and delivered as a ‘railready’ so it’s a one of one. Both Mack and Aries entertained my crazy ideas and they have pretty much knocked it out of the park - it ticks all the boxes.”

From page 22

THE morning flies by and after lunch it’s time to hop in the ‘tiddler’ of the range, the 47X prime mover with single trailer attached. This is the day cab version and at the outset let me say that I reckon it’s the best looking day cab on the market, from any angle. WS

have got the proportions of the design just right. This model is powered by the DD 13 with 525 horses and 2500Nm so makes light work of the fully laden trailer. By now I’m so confident with the manual that, with apologies to Eaton, I decide to forego the clutch…and have trouble getting into the

next gear. Ray Vella, my companion on this trip advises me to change cogs faster as the Detroit drops revs quickly. I do so and, again having smoothed out the edges of these cogs as well, the rest of the drive is relatively smooth. If I had to come up with one word to describe the

47X, it would be ‘Chuckable’. That shortened wheelbase allows for tight turns in city/port applications but there no wallowing. The view over and around the sloped bonnet is great. As with the 49X the Jake brake is quiet compared to old school and will haul you up in no time.

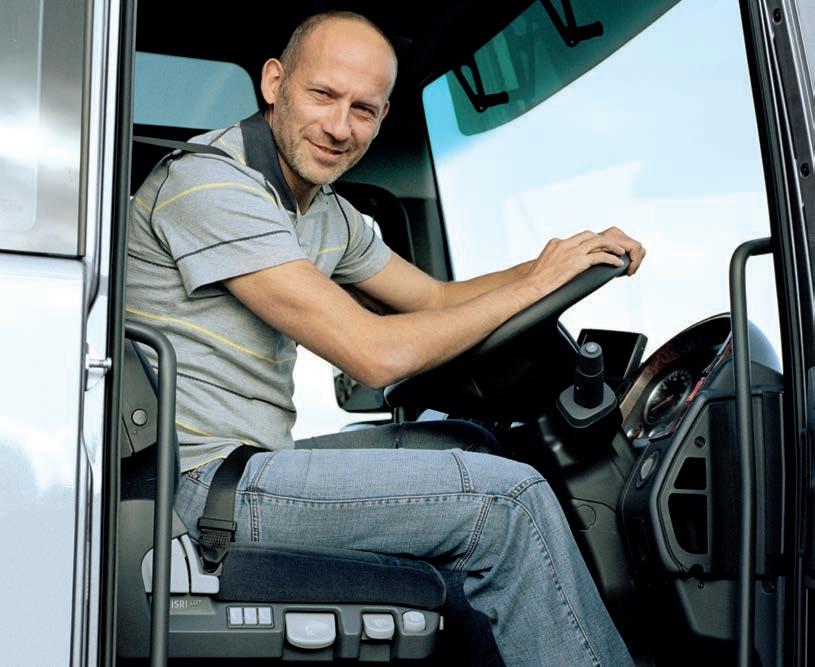

The Isri seats are nice and wide and together with plenty of steering adjustment, everyone will find their perfect driving position with the Stick in just the right place. I loved my time in the Big Banger 49X and if driving and living in a truck it is right up there. On the other hand, for day

work and driving anywhere, particularly in built up areas, the 47X is a hoot! I think I actually loved that truck even more. These trucks have come a long way on every front from their revered predecessors. Go get in one and try it for yourself. If you don’t, you are doing yourself a disservice.

Scan QR code for more details.

Having found her calling behind the wheel, this second-generation truckie is taking over 76,000 Instagram followers along for the ride.

BY DANIELLE GULLACI

FOR Casuarina Smith – better known as Trucking with CJ –social media has become a way to share what she does with the masses. From providing insight into the day-to-day life of a truckie, to spreading important safety messages and working to attract more people into the industry, which has been calling out for more truck drivers for years.

In the two years since she started her Trucking with CJ Instagram page, it’s amassed over 76,800 followers – a feat she never could have imagined. While 44.8 per cent of those followers are from Australia, the remaining 55.2 per cent of her followers come from overseas, with the lion’s share being from the United States.

Based in South Australia, 34-year-old CJ works for Merkanooka Haulage in Western

A It’s fly-in fly-out work, on a two week on and two week off roster, which has been the per fect fit, allowing CJ to continue wor too.

in January,” she said, “When I’m on a mine site, I haul the raw unprocessed gold ore from the mine to a processing plant. Some of that is within the mine site and some is on public roads.

“We’re hauling around 300 tonne when loaded, so are really heavy.”

A family owned and operated company, Merkanooka Haulage specialises in both mining and agricultural transport services.

That means there’s a fair amount of diversity in CJ’s role too. For example, when CJ spoke with Big Rigs she was on her way to the Forrestania mine site, located around 400km east of Perth, to pick up a drill rig and bring it back to Marble Bar in the Pilbara. “Sometimes I’ll do that sort of work as well. Then in October I’ll be coming off the mine work and will go and do the grain harvest, driving a C-train.”

But for CJ, despite being around trucks her entire life thanks to her truck driver father, following in his footsteps wasn’t always on the cards.chard in the Adelaide Hills. “I e on that property and Ition on the land doing cherries I continued with that; but there’s not much money there more, so we’ve mostly had to uit trees out which is super devastating. Now my dad and I are both driving trucks,”

here at Merkanooka in November last year. I wasn’t looking for another job but this opportunity presented itself.

“Although I had held my unrestricted licence from 10 years prior, I wasn’t sure if I’d be able to do the work – and I was honest about that with my boss. I knew I could pick it up easily though and I did. Within a week, I was driving a triple road train, at about triple the weight of the fuel tankers I was in.”

For CJ, she’s taken to the role like a duck to water. “One of the great things here is the variety. I ask people all the time, can you teach me this or teach me that. I’ve learned to identify punctures, change tyres – because you’re working so remote, you can’t just call a mechanic; so that’s been really good for me, it’s what I always wanted.

follow her other dream – motorcross. She found work in a motorbike store with dreams of pursuing a career in racing, but it wasn’t to be.

“I raced motorcross for a few years. I don’t have much time to ride anymore but I still have my Harley and Husqvarna for when I go home.”

When CJ first finished high school, the initial plan was to

Looking for a long-term career, CJ got her diploma of financial services and moved into insurance broking, where she spent seven years successfully climbing the corporate ladder. As she quickly found out though, being chained to a

and where she was going,” recalled CJ.

“I loved Queensland but my sister said there’s no point in staying in a place you love if you’re doing something that makes you miserable five days of the week!”

CJ applied for a Canadian Visa. “But I had zero dollars in my account. So I came home and worked for seven months driving concrete agitators to save money. I bought a oneway ticket and headed over for just under two years.

As she explained, “I worked on a cattle ranch in Alberta, at

of it because I’d worked so hard to get there. You can’t drive a truck and dog unless you really have the skills because some of the sites are so tight.”

When an opportunity presented itself to drive fuel tankers, CJ got her dangerous goods ticket and secured work as a driver for Liberty Fuels. In the meantime, she progressed to her MC licence and eventually moved into fuel road trains.

“In the beginning people were hesitant to give me a go,” said CJ. “Throughout my driving career, it’s been other people’s fears that have outweighed

“So many people have tried to tell me I wouldn’t be able to do this or do that. But what I’ve found here is that people will always find a way for you to learn to do it, so I’m eternally grateful for that.

“There are some beautiful people I’ve met too. I feel like I have all these older experienced uncles I can learn from!”

As for CJ’s social media and online presence, she says her boss has been very supportive. “He sees the power of what I’m doing online and encourages it.

“I really love doing the safety videos to try and help educate everyday road users. My plan now is to build up my YouTube channel, where I can do more of the informational, longer

It’s CJ’s hope that by sharing the work she does, it might just encourage other people to take the leap and join the transport

“I’ve been up against it a fair bit with people who didn’t think I was capable. But I’ve persisted and people can see the benefit and the power of that. For now I’m just trying to be the best and most skilled truck

SHELL Rimula has partnered with Big Rigs in a big way – so there are even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs National Road Transport Newspaper Facebook page, calling

for your best truck photos and add yours in the comments, or email them to kayla.walsh@ primecreative.com.au.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each edition of Big Rigs Newspaper, with one win ner announced each month. Keep those amazing truck pics coming!

When the going gets tough, truckies keep everyone going

‘It’s always interesting and always different’

Having spent three decades in the industry, this WA-based road train operator says once transport gets in your system, it’s pretty hard to shake.

BY DANIELLE GULLACI

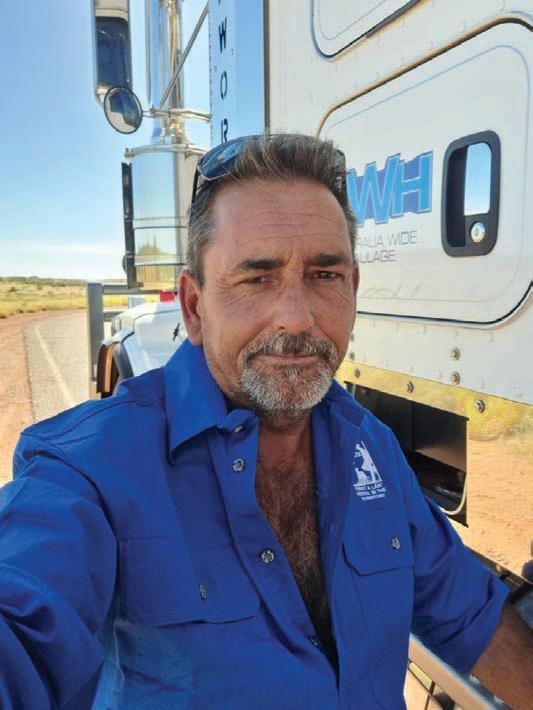

SOMETIMES spending up to five or six weeks out on the road at a time, for Gary Morton, his truck really is a home away from home.

Gary, 53, has been working for Australia Wide Haulage for the past 18 months, driving a Kenworth T659, which he’s had since brand new – after being given the keys to the rig in January last year.

“I jumped out of another T659 and straight into this one. It’s a new truck and I absolutely love it. It’s a pleasure to drive and has everything in there – a tv, microwave, a big bunk. She’s very comfortable on the road,” Gary said. His work generally takes him throughout Western Australia and into the Northern Territory, delivering general freight and stock feed. “There are no set runs, it’s wherever the freight takes us. We do a lot of work into Darwin and Kununurra, delivering into the stations and the mines.

“It’s always interesting and always different. In transport the years just go by so quickly. For me, I’ve been driving most of my life, so I’m a veteran of the road, but you never stop learning.”

Gary grew up in Perth and spent time living in Darwin around 20 years ago.

Though he got his HR licence at the age of 19, Gary

started his working life working on boats out at sea, before the road came calling. “Even back then, I knew I’d get into trucks at some point in my life. I loved the look of the Kenworths, the road trains, and had a love of travelling,” he said.

After a stint spent sea diving for a living, Gary returned to land, buying a house and getting into transport at the age of 23. “And I’ve done it ever since.

“My first gig was doing overnight express up to Port Hedland, which was two trips a week. I’ve done a bit of everything since then – whatever will go on a trailer really. I’m a bit of an all-rounder I suppose.

“Once transport gets in your system it’s pretty hard to shake – it’s like a bad addiction. You can try to walk away from it but it always draws you back. And it’s something you have to have a strong passion for too,” added Gary.

“But that passion also comes with a lot of responsibility. A responsibility to the general public, to yourself, to your employers and to your clients. Ultimately when you are out on the road, the buck stops with you.

“You need to have thick skin and a bloody good sense of humour too!”

As he chatted with Big Rigs – while dropping in and out

of service – Gary had just left Darwin on his way back home to Perth.

After working across various roles behind the wheel, Gary has been in road trains full time for the past five years.

As he reflected on what’s changed in trucking over the last 30 years, Gary explained, “I worked my way up like the old guys. You had to be competent in every combination you were operating in back in the day, before you could move into something bigger.

“Now everyone is screaming out for drivers – and it’s getting a bit dangerous out there, when you’ve got people coming at you at 100 kilometres an hour

“You’ve still got the mateship to a degree but everyone is in such a hurry. No one has the time like they used to back in the day.

“Times have changed but I still enjoy a roadside barbeque or feed occasionally. I’ve done that a few times with some mates but you don’t see it much anymore.”

Gary says Australia Wide Haulage has been a great company to work for – including when a health scare saw him off the road for about two months late last year. Though he’s thankfully back to good health, it resulted in a new nickname.

legs but I just kept going for a few months as you do, until it got to a point where I really had to stop. I was out of action for about two months, in and out of hospital.

“I spent my last Christmas at a hospital in Broome. I could hardly walk, let alone drive. I came close to losing my feet.

But being a truck driver you just keep going. I don’t even know how it started – it could have been a dodgy shower or something. But I’m back to 100 per cent now.

“My mates started calling me Happy Feet – and that name has stuck. We have a laugh about it now.”

And as for Australia Wide Haulage – a family business which has depots in Perth, Port Hedland, Broome and Karratha – Gary couldn’t speak more highly.

“They had my back through all the hospital stays and everything – that was really refreshing to see.”

In his work, while Gary does the occasional shorter runs, he usually heads further afield. “I have some family in Darwin too, so if I ask for some time off when I’m up that way, they’ll give me a few days off. They’re really good like that.

“And if there’s freight to go out, so long as I’m within my

out again after I return.”

He says many of the roads he travels on are fairly quiet. “It’s not like in the Pilbara where you have all the quads and mining traffic.”

When asked about the most challenging roads he gets along, he nominates Victoria Highway, which he says is pretty rough; and the Great Northern Highway between Kumarina and Newman.

“That stretch of the Great Northern is a really narrow bit of road with a lot of traffic.

Although they are starting to widen a lot of these sorts of roads now.

“When you look at it, the roads are our workplace as well as being for use by the public, so the government needs to have that duty of care and get these roads fixed.” Gary adds that he enjoys the fact that no two days are the same in his current role. “My work takes me through the mining areas and into Darwin, so that mixes it up a bit and gives you that variety.

“I enjoy the lifestyle and getting to meet people in the regional areas, who are fantastic. I enjoy camping by the side of the road when I can too.

“This company looks after me – I’ve got this great new truck and I’m left alone to do

YOUNG Cody Hansen, who works in the wash bay of a large road transport company, is non-verbal. He is a genuine inspiration to everybody who knows him.

Aged 21, Cody is employed one day a week by Blenners at their large depot beside the Bruce Highway at Tully in north Queensland.

His proud father Glen is also employed at Blenners as a jack of all trades from driving excavators to trucks on local deliveries.

“Cody just loves trucks and started going into Blenners with his carer and doing volunteer work, and they have put him on the payroll one day a week. He always has a smile on his face and while he is non-verbal, he knows what is said to him and responds,” Glen said.

“We are very lucky to have a great team at Blenners who have the time and consideration for Cody, and in doing so, it makes him comfortable at the workplace.”

Because of his disability Cody will never obtain a

driver’s licence so that rules him out of ever being a truckie.

But with such a love of trucks Cody is relishing his role at Blenners where scores of rigs come into the washing bay.

It is his third year there with many more years ahead of him.

Two of the recent highlights for Cody was being a passenger in a Blenners trucks during the Townsville Convoy for a Cure and also the street parade on June 8 which was part of the celebrations for Tully’s 100th year.

“Cody just loved honking the horn during the convoy and during the Tully Street parade hundreds of people waved to him. Lots of people know him,” Glen said.

Around 60 floats or trucks took part in the popular Tully event.

The driver of the Townsville Convoy truck was a long time Blenners driver Dippy Southern.

“Cody is a top young

man and a hard worker who everybody likes,” Dippy said.

It was the second Townsville Convoy Cody had participated in.

Glen said that Blenners owners Les and Judy Blennerhassett were very good to Cody.

“When he turned 21 there was a post on the Facebook page and it got responses from many companies and people in the road transport industry,” Glen said.

Cody, who will turn 22 in September, also recently got to ride in a local collection truck in the area.

The Hansen family live at Mission Beach near Tully after spending many years on Magnetic Island which is a suburb across Cleveland Bay from Townsville.

Cody attended Mission Beach State Primary School and later the Diverse Learning Centre in Innisfail for high school.

He can’t wait until each Wednesday comes around so he can be doing what he enjoys – being around trucks.

A truckie for 15 years, Rob Moon has worked for S&L Transport for the past four and loves it.

Ron, 47, was parked up in his 2012 Western Star in Townsville ready to hook up a trailer when Big Rigs saw him.

“I have brought up general freight from Brisbane to here and have a similar load to take back,” he said.

The Western Star is powered by a 500hp motor with an 18-speed gearbox and Ron said it was comfortable.

An experienced driver,

Rob used to do a run from Brisbane to Darwin and also another to Adelaide.

“I like the freedom on the road and all of the people I get to meet. Many characters included,” he said.

The worst roads he gets along are sections of the Bruce Highway and others near Miles and Goondiwindi.

“I came along the Bruce south of Townsville yesterday and it was terrible,” he said.

While Ron said he feels there are enough rest areas in Queensland, he qualified that remark.

“We need more with good facilities for us drivers,” he said.

His three favourite roadhouses are the BP Cluden where I saw him, and two in the NT – Threeways and Renner Springs.

As for hobbies, Rob said he didn’t have time for many these days.

“I am not into football but did used to enjoy V8 racing. But I have six sons with the youngest aged 16 and three still live at home and I love spending time with them,” he said.

WHEN I saw a veteran driver sitting in the cabin of his Western Star 4900 the first thing I noticed was the large rubber thongs on his feet.

Nothing unusual about that because many of our drivers don the same footwear.

But the difference here is that this driver is named John Thong. He works for Singh Transport based at Dalby.

“I am carrying scrap metal from Townsville to Brisbane,” he said.

I asked John, 60, what the scrap metal was from.

“It is all from old washing

machines,” he said.

The B-double, powered by a 600hp motor and with an 18-speed road ranger gearbox, was parked at a Townsville roadhouse.