CONTACT US

Address:

Address:

MOUNTING nancial pressure is pushing more Australian transport and logistics operators to the brink, as insolvencies in the sector accelerate, says a leading business recovery and insolvency rm.

Jirsch Sutherland said a combination of rising costs, labour shortages, regulatory burdens and falling asset values is driving more businesses to restructure or wind down.

The latest ASIC data reveals a sharp upward trend in insolvencies within Australia’s transport, postal and warehousing sector. They rose from 196 in 2021-2022 to 347 in 2022-2023, and 495 in 2023-2024 – a 153 per cent increase in just two years.

Treena

As of April 6 this year, 535 insolvencies had already been recorded, representing a 173 per cent increase compared to 2021-2022 and putting the industry on track for another record year.

Jimmy Trpcevski, Managing Partner of WA Insolvency Solutions (Jirsch Sutherland’s WA division), said the firm has seen a marked increase in insolvency appointments and inquiries from transport operators.

“Businesses are being squeezed from every direction – whether it’s rising operating costs, labour shortages, or compliance pressures. Margins are incredibly thin, and many operators simply can’t absorb the extra costs,” Trpcevski said.

Falling asset values have added to the strain. Ian Hyman, CEO of Hymans Valuers and Auctioneers, said the second-hand truck market has flipped since the pandemic, with some values dropping by as much as 70 per cent.

“Long-haul operators are doing it particularly tough,” Hyman said.

“They have massive investments in equipment and huge ongoing costs, and with interest rates still high, their repayments remain burdensome.”

Hyman also highlights the impact of regulation and compliance.

“Government regulation is getting worse: industry collective bargaining, unrestrained union behaviour, abolition of employee restraint clauses and a myriad of other government-related controls create roadblocks to efficient and well managed operations. It’s all going to make life even harder,” he said.

“These are unprecedented times. I think we’ll see further increases in insolvencies for another couple of years at least.”

Despite the pressures, Trpcevski said that there are options available for viable businesses.

“The Small Business Restructuring [SBR] and Voluntary Administration [VA] regimes are providing much-needed lifelines for operators looking to reset and recover,” he said.

game-changer for eligible small businesses. For those that don’t qualify, VA can provide a path forward – a chance to take control and avoid liquidation. It’s not about shutting the doors, it’s about steering through the crisis.

Jirsch Sutherland is currently handling the liquidation of a national transport and logistics business that grew rapidly but struggled with cash flow as trading costs rose.

“The company had expanded quickly to meet demand but didn’t have the working capital to manage the increased overheads. By the

had already ceased trading,” explained Andrew Mattinson, Principal with Jirsch Sutherland.

“That kind of imbalance in the transport sector can be like trying to accelerate uphill in top gear – you’ll stall if the engine doesn’t have the torque to match.”

The team coordinated the wind-down of the business, which had over 100 prime movers and trailers located across multiple states.

“It was like coordinating a recovery mission across a multi-state depot network,” Mattinson said.

“However, thanks to the di-

rector’s, asset financiers’ and auctioneers’ cooperation and clear records, we were able to recover the assets efficiently and have ensured creditors are in the best position they can be, given the company’s circumstances.”

Mattinson said that while not all transport companies are at risk, pressure points are building across the sector.

“Some businesses are well prepared and are actively reviewing costs, safety regulations, debt levels, and contract structures – but others are leaving it too late.

“That’s why early advice is critical – before the brakes fail entirely.”

PRESIDENT Donald Trump’s controversial executive order that requires commercial truck drivers in the US to be “pro cient” in English is an “overreach” and should not be implemented here, maintains SA trucking boss Steve Shearer.

Shearer, the Executive Director of the South Australian Road Transport Association, was instrumental in making it tougher for most foreign drivers to swap their home licence for the equivalent quali cation in his state.

But he said Trump’s order that states that all commercial vehicle drivers must be be able to “read and speak the English language to converse with the general public”, among other language-related requirements, is unnecessarily harsh.

He said Trump’s directive that reinstates the rule removed under the Obama administration in 2016 has widespread and disastrous rami cations for transport companies already struggling to ll drivers’ seats.

Shearer also fears that Trump’s order will reverberate all the way down the supply chain when it comes into e ect from June 25.

“Trump’s executive order is a short-sighted overreach based on the germ of an idea but without a rm grasp, or any grasp actually, of the realities and implications,” Shearer said.

“Yes, it’s important that heavy vehicle drivers recently arrived from overseas can adequately communicate on the road, and not just with their countrymen, but with all other truck drivers.

“ at is why we and Western Roads Federation [WRF], in particular, keep pushing the need for the licence training and training packages and assessments to include an e ective component on CORE HV driver language and terms.

“Terms so newly immigrant heavy vehicle drivers understand terms like ‘come around’ and ‘hold back’ or ‘back o ’, etc. We know that too many who currently don’t simply tell the heavy vehicle driver in front, ‘I pass’, and around they come regardless of the front driver’s response, which they either don’t understand or choose to ignore.”

Shearer, however, said he’s encouraged by news that the Austroads’ project on the National HV Driver Competen-

cy Framework has a language component.

“We have yet to see that but the fact they have recognised the need is a very positive thing. Now we just need to get it right.

“ en we have to ensure that the assessors, including their fellow countrymen assessors, properly assess the language knowledge component.

“Heavy vehicle drivers do not need to be ‘pro cient’ in English so they could attend an Aussie barbeque and understand everything, but they do need pro ciency in the CORE heavy vehicle driver language.”

WRF CEO Cam Dumesny agrees that teaching overseas drivers the relevant common industry terminology is the best approach in Australia, rather than making English pro ciency a mandatory requirement.

“You may not be able to have a beer with them after work, but they’ll know the terms so you can work with them during the day,” Dumesny said.

“We should be able to communicate on the road, but it doesn’t have to be conversational English – it just has to be common phrases.”

High-pro le heavy vehicle instructor and trainer Andy Hughes said he fully supports language, literacy and numeracy assessments alongside competency requirements.

“But we need to work out how to incorporate it into training standards across the country,” he said.

“I don’t care where you come from, your background, history, culture, age or gender. I care about how well you listen, learn, apply and follow through on your road safety training.”

Hughes said professional trainers already must focus on elevating skills beyond minimum assessment requirements to pass a Practical Driving Assessment regardless of a trainee’s background, culture, identity or belief system.

But any additional compliance or enforcement requirements will only add to the training and assessment burden for training and licensing providers at the front end of a candidate’s career path.

“Any new minimum language rules will raise implementation questions: Who will identify, manage, and support drivers who are found to be struggling with

industry terminology?

“Who will incorporate the new rules across training, assessment and licensing systems in each jurisdiction?

“With Australia’s transport workforce becoming increasingly multicultural, we need coordinated action across all stakeholder groups to address these unique challenges while maintaining safety standards.”

Hughes said enforcement alone cannot help someone understand complicated regulations or navigate highway jargon.

“It takes professional training, specialised assessment experience, and well-developed ‘soft skills’, during training and assessment.”

Transport for NSW said its assessment process includes a computer-based Heavy Vehicle Knowledge Test, which assesses understanding of road rules, safety requirements and signs relevant to trucks.

Applicants then complete a mandatory Heavy Vehicle Competency Based Assessment with a provider to obtain an MC licence.

In Queensland, English prociency is not a legislated requirement for driver licence eligibility, said the Department

of Transport and Main Roads (TMR).

“Applicants for heavy vehicle licences are subject to rigorous testing requirements, including completing training from accredited training providers,” a TMR spokesperson said. For a MC licence, overseas licence holders generally need to transfer to the corresponding lower licence class, then undertake the competency-based training if they wish to upgrade to an MC, the spokesperson added.

LINDSAY Australia is to acquire SRT Logistics, Tasmania’s largest provider of refrigerated supply chain solutions.

e $108.2 million deal, which is expected to be nalised by June 30, will create Australia’s largest refrigerated logistics network.

Under the helm of CEO and majority shareholder Robert Miller, SRT Logistics will continue to operate as a wholly owned subsidiary of Lindsay Australia, with all key management continuing in the combined entity.

SRT Logistics, founded 29 years ago as a small family business in Tasmania, has

grown to employ more than 420 people with operations expanding to Victoria in 2008 and more recently to NSW and Queensland.

Lindsay Australia, established 70 years ago, employs

more than 1500 sta across mainland Australia and o ers specialist services including fumigation, quarantine and import/export services.

Lindsay CEO Clay McDonald said SRT is a quality busi-

ness that has created a compelling position in a market with positive growth characteristics.

“ e acquisition demonstrates disciplined execution of our “Grow the Network” strategy,” McDonald said.

“It will be a transformative event for Lindsay Australia and our shareholders through the creation of a truly national service o ering for our customers. SRT is the clear market leader in the Tasmanian refrigerated transport market.

“Together, both businesses demonstrate strong operational and cultural alignment with the combination

creating compelling opportunities for growth, synergy realisation and competitive advantage.”

Chair of the Lindsay Board of Directors, Ian Williams, added that Robert Miller has successfully built a market-leading business and possesses deep industry connectivity and relationships.

“We are thrilled to have him join the Lindsay Board and believe his almost 30 years’ transport industry operating experience will further strengthen our strategic decision-making.”

Miller, who will become an executive director on the

board, said integrating within Lindsay’s network represents a logical and highly compelling next step.

“I look forward to leveraging the combined expertise to deliver further value to our customers and employees,” he said.

“I have been deeply impressed by the Lindsay team and am excited about the opportunity to work with them in driving continued growth and success.”

Under the agreement, the Miller family will become Lindsay’s largest shareholders with a combined stake of approximately 12.8 per cent.

AFTER a solid start to the year, there was a noticeable dip in new truck sales right across the board in April, reports the peak industry body representing truck manufacturers.

According to the Truck Industry Council (TIC) numbers released earlier this month, a total of 3416 new trucks were delivered, which is a 21.2 per cent decline (709 units) when compared with the same month in 2024.

It’s also the worst month for year-on-year sales so far in 2025 and shows that the market continues to retract in 2025, said TIC.

Year-to-date (YTD), however, the overall Australian truck market is tracking better, though still well down (-10.9 per cent) when compared to the end of April 2024.

“ e April sales numbers in combination with the rst quarter 2025 sales show that the heavy truck and van market is cooling this year,” said TIC CEO Tony McMullan.

“However, at the end of April, overall heavy vehicle sales were the third best on record, only bettered by the record sales years of 2023 and 2024.

McMullan also added that historically new heavy vehicle sales have always slowed in the run-up to a federal

election, with businesses potentially waiting to witness the market reaction to the election result before committing to eet replacements and/or business expansion.

“With the election result now known and with the Labor government returned, Australian businesses have a reasonable insight into the economic environment for the next three years,” he said.

“With that clarity, it will be interesting to watch the Australian economy and business con dence over the next few months.”

McMullan, however, cautioned that “happenings” in the US economy and the possibility of a US recession, may have the potential to weaken Australian business condence in the coming months.

“We are in somewhat unchartered economic times globally and the e ects on the Australian economy are equally unknow.

“It is di cult to predict how new Australian truck sales will perform for the rest of 2025. “However, if we keep tracking at, or above, the third best yearly sales result, 2025 may work out better than some commentators would have you believe.”

TIC said heavy-duty sales took the greatest hit, down a signi cant 28.4 per cent for the month, which equates to 440 less heavies delivered in April 2025 compared with

those delivered in April 2024. Volvo felt the pinch more than most, notching just 183 deliveries in April, down from 353 in the same month last year.

at brings its YTD total to 752 and a market share of 16.7 per cent, a noticeable slide from the same time in 2024 when it was on top with 1141 and 21.4 per cent of the market.

e Swedish giant now sits in third place on the sector table, 45 units adrift of Isuzu which again had a month to celebrate in a sector it’s his torically played second ddle to Kenworth and Volvo.

Isuzu’s 208 units for April moves it to 797 YTD, good enough for a 17.8 per cent market share.

Although falling slightly on its 2024 total for April of 285, Kenworth nished the month with a respectable 271 deliveries and has an early lock on the top sector slot yet. Its YTD total is 1037, good enough for a 23.1 per cent market share, and well up on the 2024 numbers – 986/18.5 per cent market share.

In total 1110 heavy duty trucks were sold in April.

TIC said the segment is fairing a little better YTD, recording a total of 4490 sales to the end of April, down 15.9 per cent (-848) over the same rst four months of 2024. Having started the year in

positive territory, sales in the medium-duty segment have fallen away as the year has progressed. However, in April the sector performed better than any other, though still down on April 2024 sales.

A total of exactly 600 medium trucks were delivered, down 9.0 per cent (-59 trucks) over April 2024.

YTD the sector numbers look a little better, with the segment trailing the same period last year by just 5.7 per cent, or -136 trucks. A total of 2264 medium duty trucks have been sold so far in 2025 with overall leader Isuzu again in a dominant position on top.

TIC said the light truck segment took the bigger hit

with sales of 872 representing a downturn of 25.0 per cent (-291 trucks) over the April 2024 result. Although as seen across the other segments, YTD the segment is tracking better than the April result showed. A total of 3800 lights have been sold so far in 2025, down 12.2 per cent (-526 trucks).

BY DANIELLE GULLACI

AN unfortunate incident on the M1 Paci c Motorway earlier this month made headlines – however the way the company handled the situation has been widely applauded.

For Marulan based bulk haulage business, NJ Ashton, the morning of Friday May 2 will be one that they won’t forget any time soon.

A truck lost part of its load, with around 800kg of scrap metal scattered along a 25km route southbound on the M1, stretching from the NSW Central Coast to Sydney.

It left hundreds of motorists, including emergency service vehicles, with tyre damage and caused signicant delays.

NJ Ashton was quick to take action and assist in any way it could. e company’s General Manager Daniel Falconer issued an apology soon after the incident.

“We’re taking full responsibility for what’s happened and are very sorry for any damage and disruption that’s been caused.”

NJ Ashton sent every quali ed mechanic it had to the site to assist authorities and help get drivers back on the road. Falconer also reassured those a ected that damages resulting from the incident would be covered

by their insurance policy.

reportedly come forward.

ny has established a ho tline, which is looking after claims,” Falconer revealed to Big Rigs

Most of the claims are for damaged tyres, however Falconer said there have also been some claims for windscreens and time o work.

While the vast majority of claims seem to be legitimate, there have been concerns of some trying to lodge claims for damage not caused by

He revealed an estimate of the damage bill. “ ey believe it will be somewhere between $1-2 million but they’ll need to go through all of the claims.”

Falconer also opened up about the driver, who has been with NJ Ashton for just over 12 months.

His truck was parked up for just over week following

the incident, before he got back behind the wheel and returned to his usual run.

“He wasn’t keen to be driving again for the rst few days after this happened, but he’s good now, and back into it.

“He’s been doing this sort of thing for over 20 years.”

Falconer added that he’s had many truckies reach out to show their support too.

“We’ve heard from truckies who’ve said it was an accident, we’ve all had them, we know how you feel.”

And this sentiment was

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

Big readers when the story was shared on our Facebook

John Biondich wrote, “All the very best to the driver. Irrespective of how the in cident happened, it will be sorted and life goes on.”

David Oxley commented, “Will gladly shout that truckie a beer. ese things happen!”

Mathew Carrier added, “Solid move from company and driver, stood up and took responsibility right away.”

NJ Ashton hosted a free community barbeque a week after the incident to apologise face to face to anyone impacted, and as a step towards trying to make things right.

e barbeque took place at 47 Oaks Café at Peats Ridge on Friday May 9, with NJ Ashton covering all costs –treating the community to free sausages, soft drinks, co ees and owers for Mother’s Day. “ ere were 10 of us there from the company. e driver was there and able to chat to a few people. e police were there – about eight of them throughout the day –and someone from the insurance company was there too,” Falconer said.

“We de nitely appreciate all the support we’ve received, including from the media, which has been great. We owned it from the start and for what was a really bad day, we’ve had a reasonable result. e support we’ve received really has been above and beyond.”

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

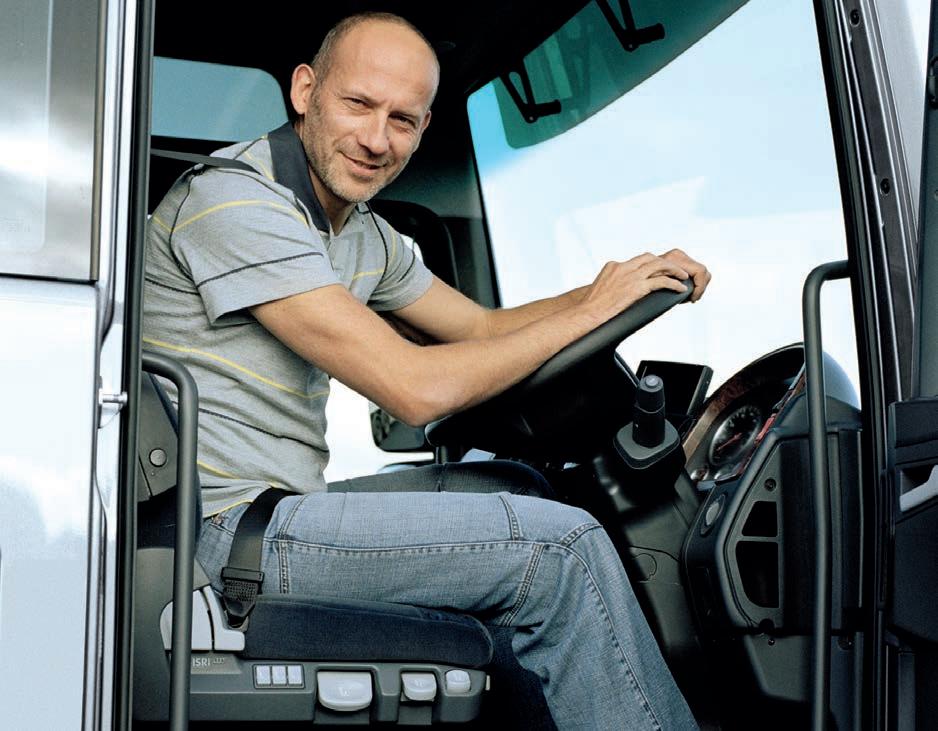

THE covers came o a new line-up of Kenworth wide cab models at the Brisbane Truck Show earlier this month –the T320, T420, T620 and T620SAR.

With emission standards for heavy vehicles being phased in through ADR 80/04 in November, Kenworth has taken the opportunity to continue its long history of evolving its model range.

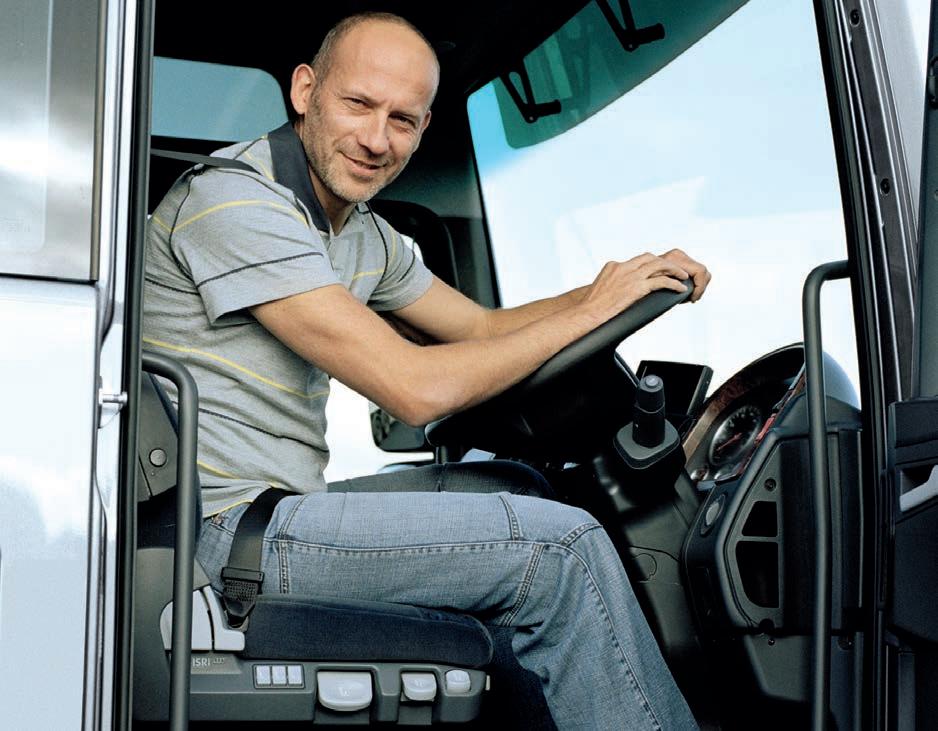

PACCAR Australia Driver

Trainer Brad Crockett told Big Rigs from the show oor the all-new line-up is also the safest Kenworth has put on the road

for a long time with a full standard package – from advanced emergency braking to adaptive cruise control and forward collision warning.

“For a few years now you’ve been able to tick a box and add these systems in but the new rules in Australia have made these standard and it really brings these trucks up to a new level,” explained Crockett.

Crockett said the T620 range is fully adaptable and very versatile, from tipper to the biggest multi-combinations.

Although buyers still have scope for customisation at the

dealership, Crockett said there is an increasing array of PACCAR direct available options.

driving the truck out of the gate with their number plates on, it’s a shorter delivery time,”

Crockett added that some of the most exciting features are those that the driver doesn’t get to see, such as the range’s electrical framework.

“You’re now looking at a faster, smarter decision-making truck. e smarts of the truck are really dialled in.

“When the truck can react quicker to an event and everything kicks o , we’re good to go.”

With a simple press of a button, the new generation Kenworths will also perform a comprehensive systems check. Likewise, at the end of the day

upon shutting down, it will display a detailed trip and vehicle summary. is includes statistics like average fuel economy, idle time, cruise control usage as well as any potential mechanical issues. e T420 is powered by the latest ADR 80/04 compliant PACCAR MX-13 engine, while the T320 and T620s run a Cummins X15 Euro 6 engine, with power ratings up to 625hp and 2050 lb-ft of torque now available from 1000 rpm, making it suitable for a wide range of applications.

THE truck billed as the most powerful conventional product in the market had its rst public showing in Brisbane earlier this month.

Tony O’Donnell, Vice President of Mack Trucks Australia, said the new Mack Super-Liner re ects what the customers have asked for and is designed in Australia, for Australia, and manufactured at Wacol.

He said the new-gen iteration will be ready to roll o the Brisbane production line by the end of 2026 and is a re-

turn to the “heartland” of the Mack brand.

“I think a big thing in that too is driver retention,” O’Donnell said.

“If the drivers are driving a truck that they’re proud of, it’s easier for the owners to retain them as well.”

O’Donnell said there are cues in the truck from the old and the new, from the squarer guard re ecting the more traditional Mack look, to the aero features on the top of the

bonnet for a better air ow.

“We’ve tried to get the best of both worlds, and that’s really what the customers are asking for.”

“We’ve done the same thing with the new Trident. We launched that at our customer dinner last night [May 14] and as soon as we unsilked it we had a crowd around it.”

e new Super-Liner now features the rst-of-its-kind 780hp 17-litre MP11 engine paired with the latest-genera-

tion mDRIVE transmission.

“Realistically, it’s the most powerful conventional production in the market and we’re really proud of that.

“ at will also open some interesting doors for us in mining and we’re really driving to that.”

O’Donnell said driver comfort also takes a giant leap forward with the all-new 70-inch, walk-through sleeper available on both the Super-Liner and Titan models.

e sleeper o ers multiple con gurations, including single and double bunks. e new cab also o ers a full pullout fridge, a feature O’Donnell said is already getting the thumbs up from early users, and also has a TV and microwave option.

“It really is a home-awayfrom home, and with the amount of time they are away, it’s really important the guys are comfortable for their fatigue management.”

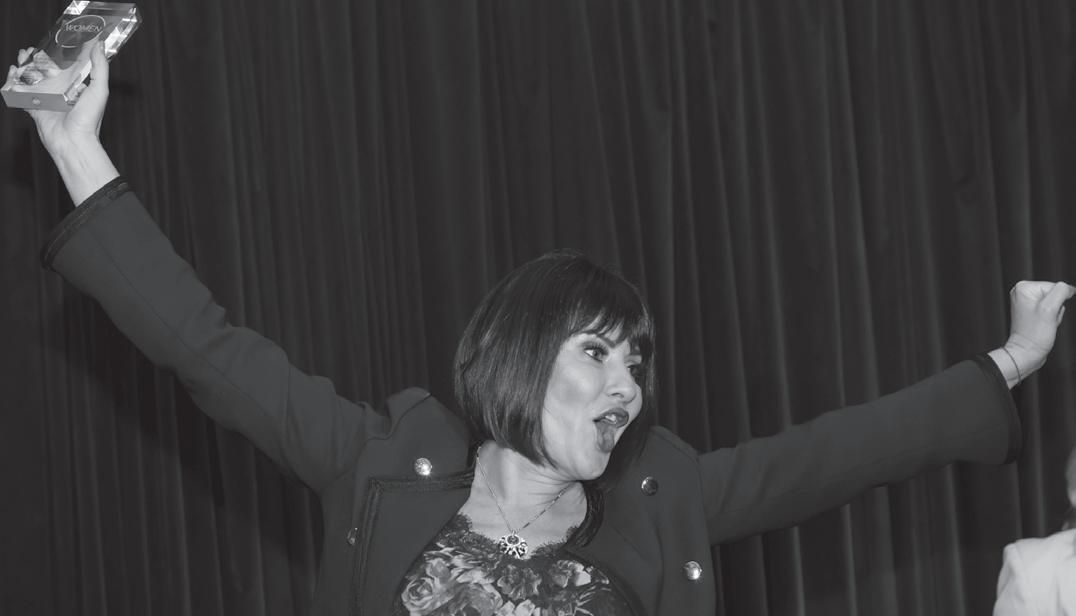

THE Volvo FH16 780 has been named Truck of the Year Australasia (ToYA) 2025 at this month’s Brisbane Truck Show.

e other contenders this year were the Scania Super 500P, the Mercedes Benz eAc tros prime mover and the FAW JT6 550.

“I’m delighted to be here in Australia to see our agship truck receive this award,” said Roger Alm, President Volvo Trucks, at the Brisbane presen tation on May 15.

“Our new FH16 780 is a fan tastic truck to drive, it really is a driver’s dream come true.

“ e new D17 engine gives operators the exibility to gear for e ciency or for heavy haulage while still delivering outstanding durability.

“I’d like to thank the Truck of e Year jury for the award and their recognition of just how signi cant this vehicle is for both our customers and their drivers.”

To be considered for the Truck of the Year Australasia, a truck has to solve problems and issues which trucks elsewhere in the world do not have to deal with.

Trucks coming to Australasia

have to cope with a very di erent trucking environment to many of their home countries and have to be adapted accordingly. Often, the trucks which are most successful in our markets are those which have been adapted in the best way to make them useful.

e ToYA jury of ve includes Tim Giles, Dave McCoid, Charleen Clarke, Editorial Director of FOCUS on Transport & Logistics and Jury member of the International Truck of the Year In-

novation Award, Randolph Covich, Deals on Wheels NZ Editor and Bob Woodward, Road Transport Engineering Consultant.

e jury assessed the attributes of the four contenders, and after a long discussion decided that this year the FH16 780 embodied the original attributes which have informed the decision of the various global juries involved with the International Truck of the Year since its inception in 1977.

e launch of the FH16 780

by Volvo was a headline mak er from its launch, with Volvo leap-frogging erce rival Sca nia to claim the kudos of pro ducing the highest-powered highway production truck in the world.

According to the jury, the FH16 780 brings a higher lev el of sophisticated engineering and electronics to Austral asia’s toughest road transport tasks.

e power output is gener ated by the Volvo D17 engine, which is based on the current D16 engine with a number of modi cations, including thinner and low drag cylinder liners as well as ‘wave-top’ pistons, which are in the process of being introduced across all of the Volvo truck engines.

achieved at 1700rpm.

e amendments to the design of the engine which enabled the increase up to 780hp saw an increase in the engine’s cylinder bore by 5mm to 149mm. is increased cubic capacity by over a litre, from 16.1 litres to 17.3 litres.

As a result of this increase, the engine is achieving over 600hp all of the way from just over 1000rpm to 1950rpm, with the maximum of 780hp

“ ese numbers become real when the driver puts the truck to work,” said judge and former PowerTorque editor Tim Giles, after driving the FH16 780.

“ is level of power and torque make tough freight tasks a relative breeze and the driver can always feel condent the driveline can handle high masses in di cult conditions.

“ is extra power is coupled with the excellent driver experience which Volvo have developed over the years. ere’s a quiet e ortlessness which

THIS LEVEL OF POWER AND TORQUE MAKE TOUGH FREIGHT TASKS A RELATIVE BREEZE AND THE DRIVER CAN ALWAYS FEEL CONFIDENT THE DRIVELINE CAN HANDLE HIGH MASSES IN DIFFICULT CONDITIONS.”

TIM GILES

the driver feels as they get into a climb at high masses, and the way the driveline copes in an unfussy way with varying gradients is impressive.” is driveline includes the latest version of the I-shift which sees even more integration, electronically, between the engine and the transmission. e changes are imperceptible and very quick, said judges.

For more coverage from this year’s Brisbane Truck Show, make sure you pick up your free copy of the June 6 issue of Big Rigs from the usual outlets.

EDITOR JAMES GRAHAM

foot and owned the mistake.

It instantly punctured – pun intended – most of the flak, although it still didn’t stop the grubs making false insurance claims (see page 5). Oh, and a sausage sizzle to underline how sorry the company was didn’t hurt either. Classy move NJ Ashton. Pity our politicians aren’t as contrite about their blunders. Speaking of pollies, in case you haven’t heard, Minister Catherine King is back in the top job. She was quick to recap her highlights over the last term, citing reformation of commonwealth infrastructure investment and increased funding for local roads, among other achievements.

She’s promising to fix the Bruce Highway this term and “much more”, but to be honest, like you, we’re not really holding our breath.

WHEN will the leaders in this industry get it through their thick heads that we have far more of a driver retention problem than we have a driver shortage problem. ere’s also a driver attraction problem. All these conferences have CEOs, and various executive o cers, senior management placeholders, police head honchos, NHVR and various industry organisations and reps from the unions (perhaps). Virtually none of which have their lives on the line day in day out. Firstly, stop treating those at the coalface as cannon fodder.

Start respecting their knowledge base for what it is.

Stop thinking you know better, simply because you are “higher up the corporate tree” and, for God’s sake stop treating drivers like Neanderthals. Some of the smartest people in the industry sit behind the wheel, not a desk. Value their knowledge and experience.

In addition to paying them well (across-the-board the industry fails) you might consider visiting humanity upon them. Drivers aren’t just scum, verbal punching bags or stupid. Even the least intelligent driv-

ers know when they’re being had a lend of, much to your surprise, I suspect.

We have seen in recent times how “successful” our current systems are for attracting people into the road transport industry, with increasing numbers of crashes, injuries and fatalities particularly this year.

With the amount of scrutiny via the likes of Safe-T-Cam and roadside interceptions, it’s hard to account for it being due to increased time constraint pressures. Especially considering I started in an era when there was real, genuine and ridic-

ulous levels of pressure and pathetically short time frames and when the actual (rather than allowed) speeds were signi cantly quicker. Some factors are better today than in the past like general road network quality (not talking maintenance). We now have so much divided road. Even the Hume Hwy when I started was poor or no shoulders, single lane with a few passing lanes, narrow and rickety bridges.

It seems to me there are a little more “driver distractions”, so it’s hard to justify blaming that. My feeling is that it has

far more to do with the lack of ensuring competency levels and “fast tracking” than almost any other factor.

To retain current although ageing drivers and to attract new drivers you need to pay commensurate with the risks in what is a dangerous occupation as well as competing with industries such as FIFO in the mines. You are directly competing with companies like this and more directly than most executives in this industry realise, I suspect.

Treat your drivers with respect and respect their knowl-

edge. Granted many drivers are opinionated, but most have far more knowledge of their day-to-day experiences than those in the o ce. Dispatch sta in particular should be aware of this and visit their attitude accordingly. When warranted acknowledge excellence, even a “thank you”. You’d be surprised how little courtesy and gratitude is passed onto drivers. You catch a lot more willingness with gratitude than with smart arsed comments.

– Chris Loudon

Driving Hope for SIDS

Women in Trucking Australia (WiTA) has partnered with River’s Gift, a charity dedicated to Sudden Infant Death Syndrome (SIDS) research and prevention.

As part of the ‘Driving Hope’ fundraising campaign, WiTA is encouraging truck drivers to purchase a Hope the Elephant plush toy and place it on their dash, to help share the journey and spread hope to families affected by SIDS.

Karl Waddell and Alex Hamilton established River’s Gift after the sudden loss of their baby son, River, at just 128 days old.

River was gifted an elephant soft toy when he was born so Hope the Elephant became the charity’s mascot.

The Hope the Elephant plush can be purchased on the River’s Gift website.

Roadhouse truck fire

A truck driver who noticed his prime mover had caught fire while he was fuelling up at Barkly Homestead on the Barkly Highway in the NT has been commended for his quick-thinking actions.

The incident occurred at about 7.45pm on Thursday, May 8.

The truckie was able to successfully unhitch the trailers and move the vehicle away from the service station to a safe location on the highway.

“Police commend the truck driver’s actions which prevented any injuries and damage to the trailers or buildings,” said NT Police. Investigations into the cause of the fire are underway.

Minister reappointed

Catherine King has been reappointed as the federal Transport and Infrastructure Minister in Anthony Albanese’s new cabinet – a move welcomed by the Australian Logistics Council (ALC).

ALC CEO and Managing Director, Dr Hermione Parsons, said she looks forward to continuing a strong working relationship focused on lifting the productivity, resilience and sustainability of Australia’s supply chains in metropolitan and regional Australia.

“Freight infrastructure must be recognised as an enabler of national productivity. Minister King is well placed to lead the next phase of reform in collaboration with state and territory governments,” Parsons said.

Eyre Highway blitz

The National Heavy Vehicle Regulator (NHVR) undertook a week-long cross-border blitz targeting heavy vehicle safety on the Eyre Highway.

Operation Compass took place from May 2-9, with results yet to be released at the time of publication. It aimed to address two main areas –driver fatigue and mechanical non-compliance.

The blitz follows numerous serious and fatal crashes along the busy freight route over recent years.

“From January to March this year, we’ve sadly seen 11 lives lost in crashes involving a heavy vehicle across South Australia and Western Australia,” said NHVR Director Southern Region Paul Simionato.

BY RAY HASSALL

IN ‘Enough is Enough: Truckies Deserve a Safe Workplace Too’ [Big Rigs, April 25] Bernard Murphy articulates a frustration familiar to many in the heavy vehicle industry: that the systems regulating road safety unfairly concentrate accountability on professional drivers.

Heavy vehicle operators are subject to increasingly complex compliance expectations while sharing roadways – and, by extension, their working environment – with general motorists who are not held to comparable standards of safety or enforcement.

Murphy highlights several issues. Heavy vehicle drivers are highly scrutinised, yet light vehicle users escape equivalent obligations. Regulatory attention and resources are disproportionately allocated, leaving general motorists inconsistently policed.

Burnout, low morale, and double standards are driving experienced professionals out of the sector. And despite persistent calls for reform, policy has stagnated.

Murphy doesn’t argue this as a lawyer, but the legal question is unavoidable: If a truck is a workplace, what obligations do others have when interacting with it?

e NTARC data suggests the question is urgent: in up to 78 per cent of fatal crashes involving a truck and another vehicle, the other vehicle is at fault.

When is a road a workplace?

Murphy is correct that a heavy vehicle is legally recognised as a workplace under Section 8 of the Work Health and Safety Act 2011 (NSW). e de nition has been judicially extended to cover areas a ected by the work undertaken in that space, as established in Inspector Campbell v James Gordon Hitchcock. However, this does not mean that the road becomes a workplace for all users.

Section 29 of the Act sets out duties for “other persons at the workplace,” such as visitors or contractors. ese obligations apply only where a person is physically present at a workplace and engaged in activities under the direction or control of a PCBU (Person Conducting a Business or Undertaking).

public road is not in a work place relationship with the truck or its driver. ey have

SOME AGENCIES PROVIDE STRUCTURED GUIDANCE, CAMERA ACCESS, AND FATIGUE MODELLING TOOLS, WHILE OTHERS OPERATE WITH MINIMAL SUPPORT. THE RESULT IS A FRACTURED SYSTEM WITH SIGNIFICANT VARIATION IN ENFORCEMENT CONSISTENCY, CAPABILITY, AND INTENT.”

no employment, contractual, or visitor connection, nor are they subject to lawful instruction by the PCBU. ere is no practical or legal mechanism by which a truck driver could issue enforceable directions to surrounding road users. WHS duties therefore do not extend to members of the public operating in a shared roadway. WHS law is not a general public safety law. Applying strict liability o ences designed for work environments to general road users would introduce incoherence and enforcement risk.

Dangerous or negligent light vehicle behaviour around trucks should continue to be regulated under transport legislation, not workplace law.

Road safety duties lie elsewhere

Statutes such as the Road Transport Act 2013 (NSW) and its equivalents de ne and penalise dangerous driving behaviour: tailgating, unsafe overtaking, failing to maintain control, and driving while fatigued or distracted. ese frameworks are proportionate to their public safety purpose. ey incorporate evidentiary standards and procedural safeguards that WHS law was never designed to provide in this context.

Murphy’s instincts are correct – light vehicle behaviour around trucks is under-regulated – but the correct response is better road enforcement, not stretching workplace legislation beyond its mandate.

The enforcement

cy in Truck Driver Fatigue Management con rm many of Murphy’s concerns. eir study, based on interviews with law enforcement o cers (LEOs) and transport regulation agents (TRAs), identies key systemic weaknesses in how truck driver fatigue (TDF) laws are enforced.

Training for LEOs is inconsistent and often insu cient. Many o cers receive only minimal or outdated training in TDF enforcement, sometimes no more than a few hours, and frequently with no structured follow-up.

In the absence of con dence, some o cers use discretion to avoid fatigue-related enforcement altogether. ey may choose not to stop trucks, avoid checking logbooks, or refrain from asking relevant questions.

Operational priorities also interfere. O cers are routinely reassigned from fatigue enforcement to higher-pro le or time-critical tasks, such as tra c collisions or general policing duties. is deprioritisation of fatigue undermines the law’s deterrent potential. Compounding this is the lack of direct exposure: o cers who have not witnessed fatigue-related crashes often fail to see the issue as a priority.

Professional development is also patchy. O cers frequently rely on informal learning, shadowing colleagues or self-study rather than consistent, agency-wide training. Enforcement outcomes vary

tools, while others operate with minimal support. e result is a fractured system with signi cant variation in enforcement consistency, capability, and intent.

Despite these capability and consistency problems, amendments to the HVNL now propose to add a new o ence: a duty not to drive unless “ t.” is reframes the current prohibition on driving while fatigued into a broader requirement modelled on section 28 of the Model WHS Act.

According to the National Transport Commission (NTC), the provision aims to empower drivers to assess and act on their own tness to drive.

But criminalising an individual’s self-assessment does not constitute empowerment. Ironically, if the creation of a duty would establish the right to stop driving when unwell, section 28 of the WHS legislation would already provide it. Adding a prosecutable offence does not support that right; it turns it into a potential liability.

e proposed o ence would further concentrate regulatory pressure on drivers, who already account for nearly 90 per cent of HVNL prosecutions. e standard of “ tness” is conceptually vague and legally unde ned.

criminalising un tness will make drivers more likely to stop or feel safer in doing so?

What this amendment introduces is a symbolic provision, unsupported by enforcement practice.

Where next?

Murphy’s conclusion – that responsibility for road safety cannot rest solely on drivers – is backed by evidence. Enforcement systems are stretched. Regulatory coverage is uneven. e supply chain and general public remain under-scrutinised. Fixing these issues does not require more o ences. It requires clarity in legislative scope, so that WHS laws remain focused on workplaces and so that road laws govern road use.

It also requires investment in enforcement capacity, with consistent fatigue training and access to supporting tools.

e regulatory burden should be better distributed, holding upstream supply chain actors and high-risk motorists to account. Above all, reform should be cautious and precise: legal obligations must be clear, enforceable, and proportionate to the risks they seek to address.

Shared roads require shared responsibility. But responsibility must be legally coherent, operationally realistic, and enforced fairly. at is the next frontier for road safety reform.

Some agencies provide structured guidance, camera access, and fatigue modelling

Unlike fatigue, which has prescriptive limits, tness could refer to anything from illness or medication use to emotional wellbeing. Without clear evidentiary thresholds or investigative protocols, enforcement becomes subjective and inconsistent.

ere is also no existing enforcement infrastructure to support such a duty. O cers already struggle to enforce existing fatigue rules, as evidenced by the Casey study. Creating a broader, vaguer o ence will only deepen enforcement confusion.

Even the NTC’s rationale – that the o ence empowers drivers to make safety-based decisions – fails on its own terms.

Empowerment does not require criminal sanction. Where is the evidence that

About the author: Ray Hassall is the former Executive Director Statutory Compliance at the NHVR. He left that role at the end of 2024 after 11 years and now heads up Lincoln Regulatory Consulting which tries to help people work out which parts of the regulatory system matter and how they can best build their safety and compliance responses. Hassall believes that improving how serious incidents are investigated can support both safety and fairness. He has worked with operators, investigators, and frontline regulators, and brings a grounded understanding of how the system works – and where it can improve.

The all-new range of Isuzu trucks is almost here. And with it, comes a whole new definition of reliability. Class-leading safety features. Increased driver comfort and a sleek new cab design. It all adds up to a truck you can depend on like never before. Visit isuzu.com.au to register your interest and keep up to date on the new range. The all-new Isuzu truck range.

From humble beginnings, this legendary transport operator has celebrated a huge milestone, taking the keys to his 700th truck.

IT was over 60 years ago that a young Neil Mansell began his business with just one truck, a 1956 Ford F600. Back then, he never could have imagined what was to come.

From such humble beginnings, the Toowoomba-headquartered Neil Mansell Group (NMG) has grown into a vast family-owned group of businesses that provide transport and specialised services across the country.

e group covers a diversied range of specialised operations including engineering, steel fabrication, heavy transport, concrete, panel and paint, metal supplies, welding, crane hire, mining, and quarrying and landscaping.

To this day, Neil remains at the helm of the business he founded all those years ago, with his son Robert Mansell serving as Assistant Managing Director, alongside running Mansell Bulk Haulage and the other coastal businesses from his base at the Sunshine Coast.

NMG now operates over 1350 registered pieces of equipment and employs approximately 700 sta across a range of roles.

As Neil takes the keys to his 700th truck purchase – in the form of a highly customised ‘Big Bonnet’ Mack Titan –the family has yet another reason to celebrate.

When it came time to order the 700th truck, it was always going to be something special.

One of the company’s longest-serving employees had met with the boys from Mack and Western Truck Group (WTG) in late 2023, when he realised Neil was about to purchase his 700th truck.

Both Mack and WTG knew this momentous occasion was one they didn’t want to miss.

“ ey saw there was an opportunity to do something for Dad, a surprise to mark the triumph if you like,” said Robert Mansell, adding that a highly customised Mack Titan t the bill.

“Mack along with WTG

THIS IS THE FIRST MACK EVER TO HAVE IT, WHICH MAKES IT EXTRA SPECIAL.”

ROBERT MANSELL

ent. I mean, Dad still paid for it,” laughed Robert. “But it’s the thought that counts!”

In consultation with Mack and WTG sales rep Ben Dare, they came up with a plan and Mack brought something new to the table.

“ ey had this new Big Bonnet becoming available direct from the production line that was going to become an option on a Titan,” revealed Robert.

“ is is the rst Mack ever to have it, which makes it extra special. It’s a big square bonnet in the old style, with a massive grille and bigger lights. It looks more old school and it looks tough.”

Powered by a 685hp MP10 engine and tted with a 76inch sleeper, the truck also includes mDRIVE automated manual transmission and a host of customised features to re ect its signi cance.

“Our drivers love the mDRIVE auto transmission.

ere’s no doubt that there’s a driver shortage in this coun-

Neil can be di cult to pin down, so Robert revealed it took a bit of hard work and reminders to arrange for him to come to the Mack plant at Wacol for the unveiling.

“We’ve bought about 25 Mack Super-Liners in the last few years, so he knew there was something about to come o the line,” said Robert.

“I just suggested we go and see the latest truck in person, and if he twigged to what was going on, he didn’t let on. He was very surprised and pleased when they took the

trucks cover huge distances. It’s pretty standard for our trucks to do a million kilometres in their rst ve years, after that we move to shorter distance jobs but often in harsher conditions like the desert,” he said.

With working lives like that, reliability and fuel economy are high on Robert’s list of requirements.

e new Titan will be on the Brisbane to Darwin run taking groceries and general freight in a triple road train con guration.

“We’ll keep it on the bitumen, but even so, those distances mount up pretty quickly, so fuel economy is paramount, and this is an area where the Macks excel,” Robert added.

“Reliability is fundamental, and we’ve got all our new Macks on service agreements with Mack, which really takes the pressure o our workshop. It also means the people who know the trucks best are the ones working on them. Knowing your costs upfront is a bonus, but we’re very happy with the contract maintenance Mack provide.”

As Robert revealed, his father has always had a bit of a soft spot for Macks.

“When I was about eight

and when he bought his rst brand-new truck in the mid1960s, it was a Mack, so the decision of what truck we would get to celebrate reaching 700 was a bit of a no-brainer really.”

e new Titan is now the agship of the NMG eet and has two slogans emblazoned on its anks.

‘Outback Titan’ features on the bonnet and ‘New Dog, Old Tricks’ can be seen on the 76-inch sleeper cab.

“One of my sons came up with the sleeper cab slogan,” said Robert, whose daughter and two sons all work in the business. “I reckon it sums things up nicely.

ness become what it is, and they’ve really got behind us to help us celebrate Dad’s success. is Mack embodies the kind of determination that made this company what it is.”

Vice President of Mack Trucks Australia, Tony O’Connell added it was an honour to celebrate this milestone with NMG. “Neil’s story re ects the spirit of hard work, loyalty, and innovation that Mack stands for,” he said.

“To see a Titan with our new Big Bonnet mark the 700th truck in their eet – it’s a testament to a legacy built over decades and a partnership we’re proud to be part of.”

It’s been quite the year for this passionate truckie who’s been recognised not once, but twice with prestigious awards for the dedication and professionalism he brings to his work.

BY DANIELLE GULLACI

UNLIKE many trucking families, 50-year-old Brad Train and his brothers didn’t grow up around trucks, yet they all ended up following the same path – inspired by a man who showed them the ropes and helped them get their foot in the door almost 30 years ago.

“My cousin had a boyfriend at the time, Sam Giufre, who was involved with trucks. ey got married and they’ve been together 34 years now,” said Brad.

“We started hanging out with him and his mates and that’s how me and my brothers Darren and Michael got into trucks. ey used to call us the hangers, because we used to always hang around,” he laughed.

At the time, Brad had been building horse oats. “I wanted to get out of the factory – I just wanted to drive,” he said. e brothers all learnt to drive in Sam’s Ford LTS 9000 and an old International Acco.

“Once we started going with Sam in the truck, it just snowballed. Every chance we could we were in the truck with him, then on the weekends, he showed us how to work on them too.

“I got my licence at 21. Once we got the feel for it, Sam and his mates recommended us to a couple of blokes they knew and that’s how we got into it. My mum reckons if we didn’t have trucks in our life, we wouldn’t have anything to talk about!”

Just as Sam inspired the Train brothers, they’re now inspiring the next generation too.

“My niece is about to turn 18. She’s joined the army to get into the transport side there, and now my nephews are wanting to get into trucks too. ey’ve all been brought up around trucks.”

Based in Ipswich, Queensland, Brad now works for VE Group, transporting wide and oversize loads right across the country.

He’s behind the wheel of the pride of the eet – a 2024 Kenworth T909.

It’s a very special truck, done up as a tribute to Kenworth’s 100-year anniversary – so special in fact, it’s featured on Kenworth’s 2025 truck calendar for the month of May.

“I got that truck brand new and it’s all specced up. It has a mural on the back of Kenworth’s Seattle factory, representing the 100-year anniversary of Kenworth and has panels they imported from America, that they don’t have here.”

VE Group is a Queenslandbased bulk haulage, earthmoving and civil construction company with o ces in Moura, Rockhampton, Gladstone and Ipswich.

e company is owned by husband and wife team Nathan and Bronwen Howell, who started out in 2006 with a skid steer. Eventually they bought their rst truck, an ex-K&S 4864 Western Star, and from there, the business has continued to grow.

For Brad, the past three decades have seen him hone his skills as a truck driver, working his way up from rigids to road trains and oversize loads.

As Brad recalled, “ e rst truck I ever drove was an S-Line body truck, working for a man named Tim O’Carroll, who at the time had three trucks. I’d put the front end loader in the back of the truck and head to concrete plants to clear out all the waste. He gave me an opportunity to drive trucks as a young fella and I rolled with it. I was there for four years.

“ en an opportunity came up where my brother was working, to drive a truck and dog for Bastow’s Earthmoving. I did pretty much everything there, rst in the truck and dog, then road trains and oat work, carrying oversize loads. I was there for about 19 years. en I worked at Blands Sand and Gravel for just under four years, driving their AB triple road trains, before starting with VE Group.”

When Brad began working at VE Group six years ago, he was pulling grain tippers. “ en they bought some additional oats and that gave me the opportunity to go back to doing oversize work. As the company got bigger, they’ve purchased more and more machines and oats,” he explained.

“VE Group mainly has truck and dogs, as well as road trains and four oat trailers.

I do all the bigger stu . It’s mainly civil work, including for a lot of government jobs like building roads, as well as mining work.

“I go wherever the work is – it’s a lot of transport for external customers too, not just transporting our own machines. It’s mostly up and down the east coast.”

According to Brad, with VE Group being a family business, it means he can maintain a great work/life balance too, despite the long distances he travels.

“I’ll come to work Monday morning and I’m usually home on a Friday night. If I can’t get home and want to get back, they’ll y me back. And if I do need to work a Saturday, they’ll give me three days o the following week. ey’re a really good company to work for and the type of people who always say g’day to you.”

rough all his years in the industry, Brad has maintained an unblemished and exemplary driving record.

is led to him being named Professional Driver of the Year at the National Trucking Industry Awards, announced during a gala dinner event at the Australian Trucking Association’s (ATA) Trucking Australia Conference in Adelaide on Wednesday April 30.

Brad’s recent win follows another a huge accolade last September, where he also received the state-based award for Professional Driver of the Year at the Queensland Trucking Association’s (QTA) Road

Freight Industry Awards.

Humble in his achievements, when asked about his most recent win, Brad said, “I’m just one of many professional drivers out there and I was lucky to even be nominated. All of the nalists are such top operators.”

Speaking with Brad, his passion for the industry shines through. “I just love being in this industry and the freedom that comes with it. In my job you get to see a lot of the countryside. I love waking up in a di erent spot every morning.

“I reckon I’ll be doing this until the day they take my licence o me.”

Owners of VE Group, Nathan and Bronwen Howell are exceptionally proud of Brad’s achievements to date. “Brad is a remarkable role model and a very humble professional for our transport industry and it is fantastic to see him being recognised on a national level,” they told Big Rigs

For those considering a career in trucking, his advice is simple. “Just do it, you’ll love it!” he said.

“ ere were people who gave me a chance when I was younger. We need to nd more people out there willing to give the younger people a go. Unless you know someone, it can be hard. A lot of people just need someone who is willing to give them a chance.”

Outstanding Contribution to the Australian Trucking Industry:

Tobin, Followmont Transport (Eagle Farm, Queensland)

National Professional Driver of the Year: Brad Train, VE Group (Ipswich, Queensland)

National Trucking Industry Woman of the Year: Ann Lopez, Lopez Bros Transport (Enfield, NSW)

National Trucking Industry Workforce Award: Border Crane Consultants (Wodonga, Victoria)

TruckSafe John Kelly Memorial Award: Jim Pearson Transport (Port Macquarie, NSW)

Doug Young has meticulously documented every kilometre of his driving career – now, at 8.4 million and counting, he’s mentoring the next generation.

BY JAMES GRAHAM

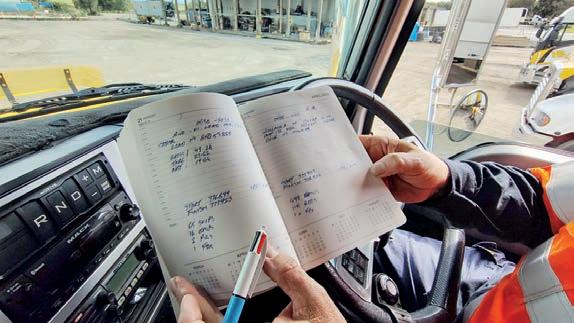

WHEN Hannah’s Haulage truckie Doug Young, 58, says he’s clocked up 8.4 million ki lometres behind the wheel in more than 30 years of driving, you can take it to the bank.

It’s all there in black and white, meticulously record ed in a career-long series of handwritten diaries, doc umenting loads, locations, hours worked, load weights and daily kilometres.

Doug said the habit start ed when he worked in the healthcare industry up until the age of 26, rst as an or derly and then later as a house manager in the disability ser vices sector.

“ ey tell you in healthcare the best form of self-defence is documentation, so I’ve just learned very early on to document everything,” explained Doug as he re ected on a special driving milestone that few could match.

“It’s mainly for myself, but it’s actually helped when they’ve lost job information on computers. I can go back through any day and tell them exactly what they need to know.”

Although he’s had a passion for trucks since he was a young boy growing up in Sydney’s Liverpool, Doug credits his late father, who was also named Doug, for the inspiration behind the switch from healthcare to the cab.

“ e only other thing I knew how to do was drive because my father was a driving instructor in the army. He taught all us boys how to drive.

“He taught us how to drive an old Diamond Reo with a Spicer gearbox. en he taught us Road Ranger before I moved away from home.”

e bulk of Doug’s 8.4 million kilometres have been with three companies, the rst of which was the Wetherill Park-based DTM Transport, which was later bought out by K&S Freight in 2006. He spent 17 enjoyable years with them, carting gases all over Australia. After that Doug moved to Toll Express for six or seven years, carrying liquid gas and fuel to regional NSW before taking a break from the dangerous goods sector for a stint with Woolworths.

e installation of in-cab cameras ended that partnership, a move that Doug still has strong feelings about today: “ ey say it’s for safety reasons, but I don’t think it is. It’s more about big bosses micro-managing sta and I don’t think it’s needed.”

Doug tried his hand at a handful of other driving roles after Woolworths – none of which he says are worth a mention here – before landing on his feet two years ago driving liquid ammonia for Hannah’s Haulage, which is owned by Scott Hannah and based at Riverstone in Sydney’s north-west.

“I love Scott’s, they’re a very good company and they leave me alone – I wish I’d come here 20 years ago,” Doug said. “ ey know what I know and I’m very good on gases, I’ve done gases for most of my life. I helped Scotty set up the trucks to do the stu that we’ve got to do and I love it.”

Scott, who was quick to let Big Rigs know about Doug’s remarkable driving milestone, said it’s the veteran driver’s ‘old school’ and ‘can-do’ at titude that helps make him stand out from the pack.

“Most younger people today seem to have a ‘I can’t do’ ap proach, but if we’ve got a fair bit on, Doug will work it out with his hours and always say, ‘Yeah, no worries, I’ll get it done. I’ll start early, nish late, whatever we’ve got to do to get the job done’.

“It doesn’t matter whether it’s here, or in the middle of South Australia.”

“Having the experience he’s got, especially in the DG, makes him second-to-none.”

As a measure of that respect, Scott didn’t hesitate in throwing Doug the keys to a new Mack Super-Liner a little over a year or so back and Doug’s already clocked up more than 330,000 blemish-free kilometres in the pride of Hannah’s 40-strong eet.

“ at’s the hard part today – some blokes say they can drive them, but whether you drive them without bending them is something di erent,” Scott said.

“ e young blokes [seem to] know more than Doug and I know. When Doug was young, and the same with me, you spoke to the older blokes and listened and watched, whereas now the young blokes try to tell us we’re doing it wrong.”

Scott, however, is sticking to his guns on the mentoring pathway as the best way to prepare younger drivers for bigger combinations and has assigned Doug the job of teaching a handful of youngsters the ropes, a role he’s thriving on.

“If there’s one thing I can get into someone’s head it’s that the only dumb question is the one you don’t ask,” said

Doug when asked what his best advice would be to newcomers today.

“An old-timer taught me that when I was starting out and I’ve never forgotten it.

“Any question in this game is not a stupid question. If it’s going to save your life, ask it.”

Doug, who started in a 3-tonne truck and had to slowly work his way up, does worry about the training shortcuts that some in the industry now seem to be taking.

“Some of the drivers I see –and I do a lot of kilometres –they scare the shit out of me, and I’ve been driving a long time.

“I see blokes driving semi-trailers and they’re watching a DVD – while they’re driving.”

Still, Doug sees more than just a glimmer of hope in the youngsters he’s mentoring at Hannah’s – and in his son Josh, who at just 24 is about

to follow in the old man’s footsteps, driving road trains up in Roma, Queensland.

“He’s already got far more experience than the old man, you just ask him,” laughs Doug.

“I’ve never pushed him into it. It’s just something he’s really wanted to do and it’s the best thing he’s done.

“I’d put him on tomorrow –he’s a very good operator.”

Doug is on a 24-hour break when Big Rigs stops by Hannah’s Riverstone yard to get some pictures for this story.

He’s o again to load ammonia at Kooragang Island in Newcastle the next day before the 800km haul down to Mulwala on the Victorian border – a routine he’ll repeat three times that same week.

At more than 5000km a week, it’s not going take Doug long to reach the coveted 10-million-kilometre mark, a target he’s determined to log

sion for the industry as he did when he rst started – and his health has never been better since ditching the soft drinks and crap food for healthier choices he buys himself before spending four or ve nights away from home at a time.

“My wife is a bit of a gym junkie, and so she always ate healthy, so yeah, she just really trained me into eating healthier.”

When we ask him to reel o some career highlights, he said every day there’s something new to add, he just loves the job that much.

“I’ve done two-up to Perth multiple, multiple times, and that’s just sensational…some of the country I’ve seen.

“In the gas industry, I’m taking liquid oxygen to mines out in the middle of nowhere, other gasses out to the wharves where they put it on the top of fuel for protection – just a vast range of stu that I didn’t realise was involved in the dangerous goods business, it’s just incredible.

“My wife and I want to go travelling eventually, but at the moment I’m enjoying what I’m doing, and I’ll keep doing it for as long as I can.

“Trucking’s given me a very, very good life.”

Our test driver takes the new Mercedes-Benz workhorse for a spin on the Gold Coast to see for himself if it really is as tough as it looks.

BY GRAHAM HARSANT

RECENTLY Big Rigs vited to the Gold Coast to ex perience a rather special truck, a new Mercedes-Benz Arocs –now available from the factory in tipper spec.

e guys at Daimler Truck Brisbane saw an opportuni ty to go the Full Monty and deliver a vocational truck with all the bells and whistles that will withstand anything a mud/rock/and in this in stance, a fertiliser carter could possibly throw at it.

Yes, the Arocs is a tipper and dog combination and it is de signed from the factory to not only be tough-as, but to make life easy for body-builders to do their thing.

To this end Daimler Bris bane got trailer specialist, Hercules involved.

From wheelbase and overall combinations, to placement of the oil tank, PTO and everything else needed to make bodybuilding more e cient, the collaboration has resulted in a tough as nails, quarry-spec truck with everything you could want on it, and which will carry a 40-tonne payload.

Modern trucks, as you all know, have a myriad of electronic systems built in to meet environmental and safety laws. All these systems talk to each other via CAN bus.

For those not in the know, CAN bus stands for Controller Area Network and is a communication protocol that allows ECUs (Electronic Control Units) to communicate with each other – and in any modern truck there are lots of them.

ey allow e cient data transfer between the ECUs with reduced wiring, improved reliability and control everything from engine control to brakes, steering and lighting. It’s like your brain, with its neuron pathways all talking to each other.

Now, if you were silly enough to stick a probe in your noggin you are in all likelihood going to do a serious amount of damage to yourself. It’s the same with a modern truck.

We’ve heard horror stories of body builders cutting into a wiring loom and someone’s brand new pride and joy instantly turns into an oversized paperweight. To trace and x the problem can be very time consuming and very expensive.

So, Mercedes-Benz have produced the Arocs, which has to be the easiest truck on which to add a tipper/trailer as any truck could possibly be. How have they done it?

Simply put, Daimler has put everything in the truck from factory, so that the body builder has no need to get into the cabin to do the work – no cutting or splicing of wires, no adding tipper controls – it’s already there.

Under the multimedia screen

are a series of electric switches pre-installed for the tipper controls. ere is everything from PTO through to tarps open or close to dolly lock, that is all wired in and down through the back of the cab to the chassis, ready for the body builder to pick up on. ere is a quick reference guide in the truck with a QR code so the body builder can get information online, should they need it. is is in addition to help from their friendly Daimler dealer.

To illustrate the lengths Mercedes-Benz has gone to, there is prewiring for spotlights and extra lighting. ere’s even wiring in the roof for the tment of rotating beacon lights. e body builder simply has to cut holes in the roof, pick up the wiring and t the beacons. e truck is designed to make it easier to t the body with less work to be done before the truck hits the road. at equates to both time and money savings and minimal risk of something going wrong in the process.

With the Arocs, Mercedes has made a truck that is easier for the bodybuilder, to put a tow hitch and body on, and to get it PBS certi ed. As well as the aforementioned, there are many other changes to the truck to cater for the environments in which it will work.

Ground clearance is higher with fuel and AdBlue tanks placed higher as well, along with the front bumper (underneath the distinctive grill) – all

designed with the o -road nature of the truck in mind.

ere’s a straight front axle which also gives more ground clearance. And there are different front shock absorbers to take some harshness out of the ride often associated with o -road trucks.

Front quarter panels are steel rather than plastic and the bottom step is made out of a rubber compound to allow ex should you hit a rock in the quarry. It is also heavily dimpled to scrape muddy boots.

e air intake is di erent from the roof down to the air cleaner, having a twin cyclonic feature which will take the heavier particles out of the air and drop them out before it gets into the air lter, giving longer life from the air cleaner. We had a look at the build order for this truck and there are dozens of speci c changes: heavy-duty everything, cover plates for the (all round) disc brakes, splash guard, front underride guard, pre-install for UHF, changed frame overhang – the list goes on and on.

Should you get stuck in mud, the Arocs features a “rock free” system where the electronics work with the gearbox to rock the truck backwards and forwards to help get you out of the shtick – only to be used o -road!

We know it works because at one stage we got stuck in a muddy quagmire. Ahh, Queensland. Sunny one day –muddy the next.

So we have one tough truck but what’s it like to drive?

Loaded close to 50 tonne GCM, I take hold of the (safety yellow) grab rails and climb into the cab. Having driven the Actros I’m familiar with the layout – the smart interactive Multimedia Cockpit sitting on the two-tone dashboard, the superbly comfortable seats, fridge under the quality bunk mattress.

ere are those preinstalled switches on the dash but otherwise it’s pretty much Old Home Street.

I lay my phone on the charger, check the axle loadings, set the auto climate control, twist the column mounted gearshift into drive, the brakes release automatically, and we are away.

First up, this truck has a steel sprung front axle, and the cabin is also on springs – unlike the all-airbag Actros. e difference? Absolutely minimal. It rides well, it corners well

and it is oh so quiet.

Underneath me is M-B’s OM471 litre engine putting out 530hp and 2600Nm through their proven 12-speed AMT gearbox, which has been tweaked to hold onto the gears slightly longer.

It is plenty to pull these 50 tonnes uphill and keep up with the tra c. Coming out of roundabouts and up decent inclines, the truck was happy to drop back to 8th gear then move through 9th and 10th in short order while keeping the speed up.

e three-stage engine brake works a treat in conjunction with the all-round disc brakes on the truck and trailer, with

After some hours travelling over back roads, freeways and muddy terrain we end up back at Rocky Point Fertilisers who graciously allowed the photo shoot and loaded the truck with their product – as well as giving a fascinating tour of their facility.

I drive the truck up to a mountain (literally) of fertiliser in the making, hit the appropriate buttons on the dash, the trailer gate unlocks, the trailer rises and job done! As I’ve found with the Actros product, the Arocs is point and go with no fuss. e steering is great, the cabin is superbly insulated, the ride is positively cosseting. Rain sensing wipers, autoer small touches make the Arocs a Rolls Royce of tough tippers. Don’t believe me? Go

SHELL Rimula has partnered with Big Rigs in a big way – so there are even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs Facebook page, calling for your best truck photos and add yours in

the comments, or email them direct to danielle.gullaci@ primecreative.com.au for your chance to win the main prize.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each print edition of Big Rigs, with one winner announced each month.

Keep those amazing truck pics coming!

ALTHOUGH Neil MacDonald had been held up for ve days, he was in a happy frame of mind when I saw him.

e 71-year-old truckie drives a Kenworth K200 for Pilon Transport which has its base at Dubbo, NSW.

Neil was sitting in the driver’s seat of his rig at the BP Cluden Roadhouse and was delighted to yarn to Big Rigs

“I am waiting for the place to open where I have to deliver to tomorrow,” he said.

A very friendly driver, Neil has been with Pilon for the past nine years.

“I think I am their oldest driver,” he said.

His roadhouse of choice when in the area is the Gilgandra Shell in NSW.

“ ey make the best egg and bacon sandwiches I have ever tasted and they are so

big,” he said. Neil said the worst highway he gets on is the Gore between Goondiwindi and Millmerran. “I call it 40 kilometres of hell. You travel slow and it still is so rough that loads shift.”

Even though Neil drives all around the country, he lives at Port Douglas in far north Queensland.

“It is absolute paradise there. I have a 50 foot yacht and cruise around when I get time

o ,” he said.

A connoisseur of seafood, Neil has a wonderful way to obtain prawns and sh.

“When I go cruising I take supplies of cartons of alcohol which I don’t drink but barter with trawlers to get the freshest prawns and sh,” he said.

Neil has been driving for 50 years and was carrying steel when I saw him.

“It has come from Brisbane for Townsville and sometimes I take cars back south,” he added.

Neil may be in his seventies but I told him he looks a lot younger. “I don’t feel younger when I load or unload,” he laughed.

As for his current Kenworth, Neil raves about it. “It has a 650hp Cummins motor and an automatic gearbox and is a bit old but I just enjoy driving it!”

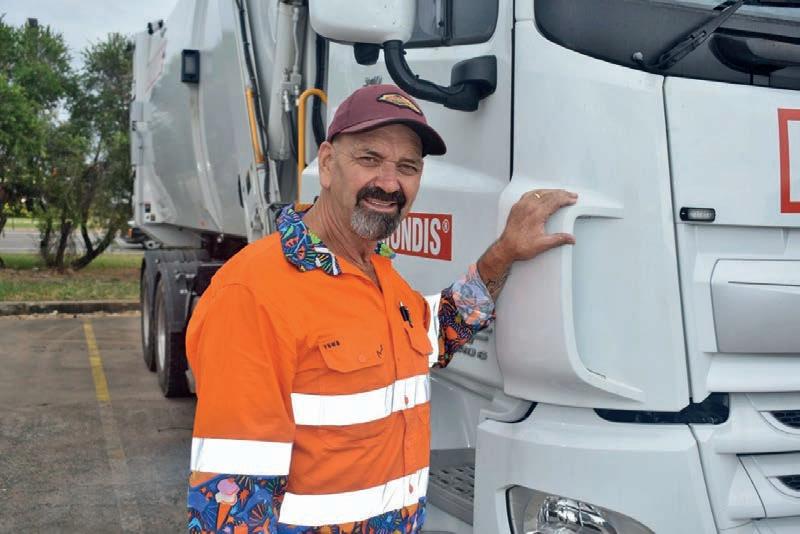

VETERAN driver Rob Smith describes himself as a ‘garbo’, driving a DAF for Remondis, based at Townsville.

e 59-year-old is the local branch manager and picks up general waste and cardboard.

“I mainly do my work around the city and have been with Remondis for two years and a truckie for more than two decades,” he said.

Rob said the DAF was an excellent vehicle for the work for one main reason.

“It has a compactor and does most of the work for me. In the old days garbos would have to handle lots of the waste and get dirty,” he said.

A keen motorbike rider, Rob told Big Rigs of a Hogs

Harley Memorial Ride he and others would be going on two days from when I saw him.

“It is in honour of my late son Brendan who died from a motorbike accident back in April 2022 when he was aged 28,” Rob said.

Rob likes the Bohle Little Acre Roadhouse and his fa vourite food is ai dishes.

Asked about the roads, he said that parts of the ring road between the north of Townsville connecting with the south and west needed xing.

Remondis boasts 35-plus branches, depots, transfer stations, disposal and pro cessing facilities, stretching from Perth to Weipa to Dan denong and most places in between.

WHEN Big Rigs saw Peter Collie, he was picking up scrap metal from the driveway of a mechanical workshop located in Townsville.

Peter, 50, was driving an Isuzu for Sims Metal which purchases scrap from businesses of all sizes, as well as individuals in the Townsville region.

“We have three such trucks and I have been doing this job for a couple of months,”

Peter said.

But Peter has over 20 years experience driving trucks for other companies too.

“Some have been earth-

“I really love doing this and hope to for many years,” he

Queensland, which he said serves good food.

moving businesses,” he said, “I really love what I do.”

Outside work Peter enjoys time in the bush and gets to a property near Tully which is 200km north of Townsville.

“I ride motorbikes and just enjoy life,” he said.

Having said that, Peter acknowledged that Tully was one of the wettest places in Australia.

“It does rain a lot there,” he said.

Peter continues to maintain his tness which is crucial for his job. “I work out a fair bit,” he said.

FRIENDLY driver Brett Woodbridge drives a modern Kenworth for Lindsay Transport and had delivered avocados when he stopped to chat.

Aged 57, Brett has been with Lindsay Transport for two years. “But I have been a truck driver for 25 years and I like it,” he said.

Brett added that the near new Kenworth was comfortable to travel in.

“It has a 610hp motor and an automatic gearbox,” he

Brett lives in Townsville and most of his work is a shuttle run between there and Mackay, about 390km south.

“ e Bruce Highway between the Burdekin and Bowen is really bad in spots,” he said.

He added that there were ample rest areas for drivers

along his run but that this wasn’t the case further south of Mackay.

Two of the places he likes stopping at when he gets to travel north are at Cardwell.

“ e pub there serves a good meal and the café with the big replica mud crab out the front has delicious sh. ey look after me whenever I pull up there,” he said.

A Sydney Roosters supporter in the NRL, Brett is originally from NSW.

“I was from around the Riverina area of NSW and we came here to Townsville so my son and daughter could go to James Cook University. ey both now have good jobs,” he said.

As for recreation, Brett enjoys going shing at the seaside suburb of Pallarenda which is in sight of Magnetic Island.

His favourite roadhouse is the BP Charlton in