First-in-Australia

First-in-Australia

Footprint. Same compact footprint as Übermilk One.

Uncompromised. Consistent microfoam for oat, soy, almond, more.

Trusted. Over 100 trusted venues in Australia & NZ.

Unifying Workflow. Streamlined workflow reduce steps, speed up service.

Reliable. Proven technology, trusted by cafés worldwide.

Evolved. Purpose, built for plant-based milk service.

The all-new Übermilk PB: Barista-trusted engineering, now made for plant-based milk.

With a single touch, Übermilk PB delivers flawless microfoam from oat, soy, almond, and more no workflow disruption, no compromise on quality.

Engineered for reliability and simplicity, Ubermilk PB streamlines your plant-based service so your team can focus on serving, not steaming.

Hundreds of Australia’s best venues trust Übermilk’s technology. Now it‘s ready for your plant-based menu.

Designed for the next generation of café

Book your demo: www.baristagroup.com.au sales@baristagroup.com.au

14 OPPORTUNITY KNOCKS

Inglewood Co ee Roasters Co-Founder Julien Moussi on his journey from co ee cart to café empire.

16 A FRESH COLD FRONT

e new technology that could rede ne cold brew.

74 ESPRESSO YOURSELF

Victor Vu recreates the camel latte-art design.

76 CAFÉ SCENE

Discover new venues across Australia.

78 GET TO KNOW

Karl Lee is taking his co ee knowledge to the world.

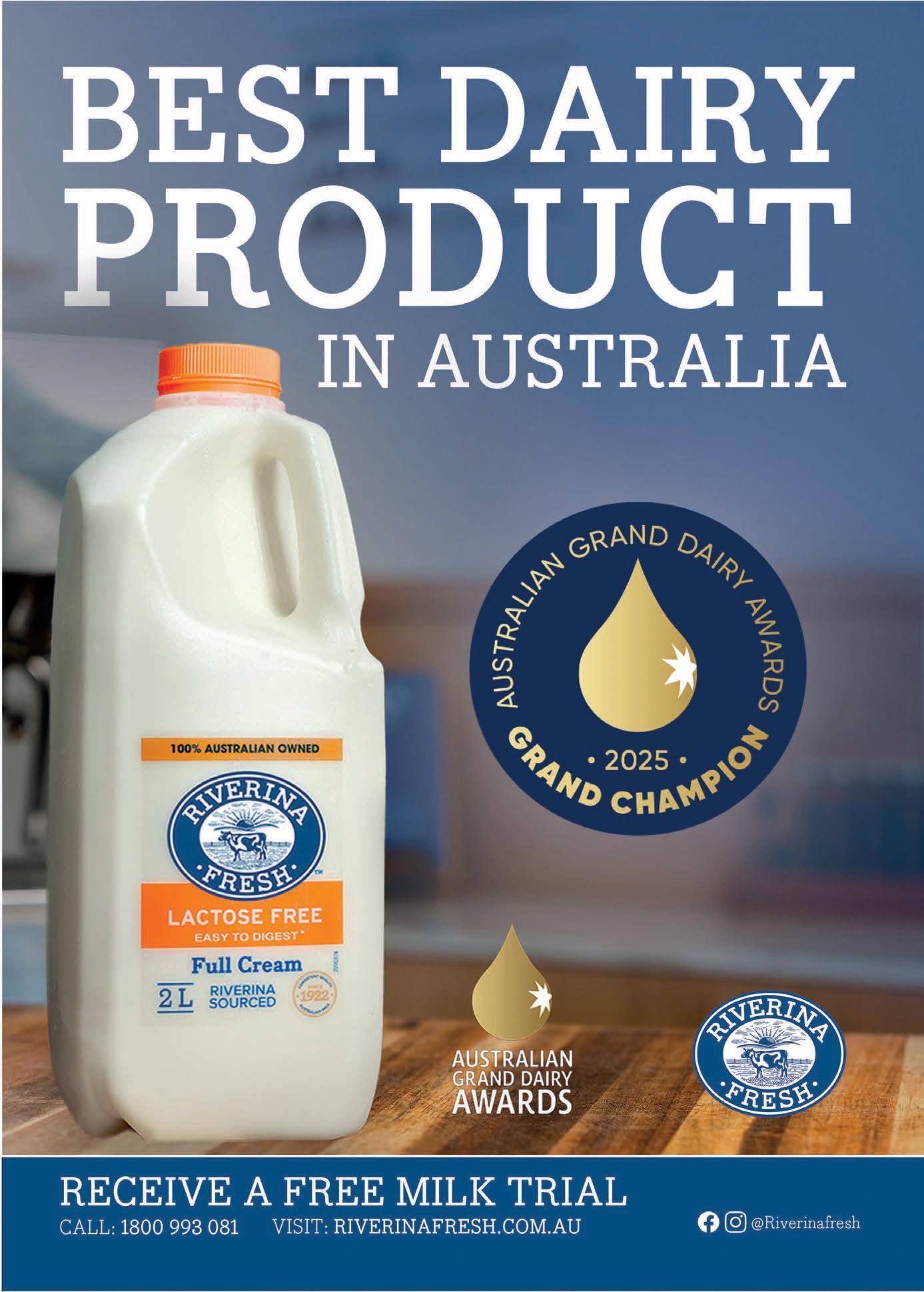

20 AUSTRALIA’S ‘BEST DAIRY PRODUCT’

Riverina Fresh’s historic Grand Dairy Awards win.

22 THE COFFEE PRICE QUESTION

Why now is the time for cafés to raise their prices.

24 KEEPING UP THE MISSION

KeepCup is sharpening its sustainable co ee focus.

27 AT YOUR SERVICE

How cafés can respond when equipment fails.

28 A LOOK AHEAD TO 2026

Keep track of what the NZSCA has planned this year.

30 THE CUP OF COMPETITION

Hany Ezzat on changing the co ee competition game.

32 BEYOND THE TRADE FLOOR

How attendees can make the most of their time at MICE.

34 THE SWEET SPOT

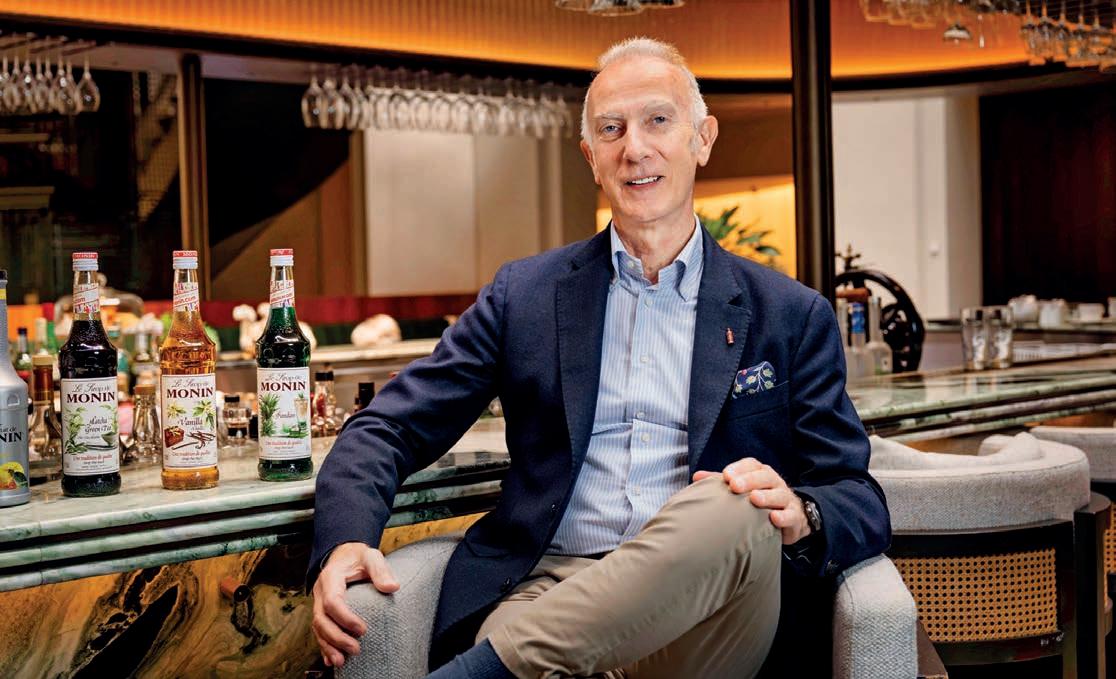

MONIN’s Olivier Monin on the importance of ‘wow’ moments in product creation.

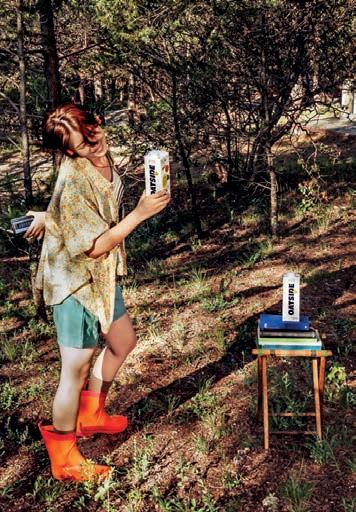

37 G’DAY OATSIDE

Meet the new plant-based milk brand taking on Australia.

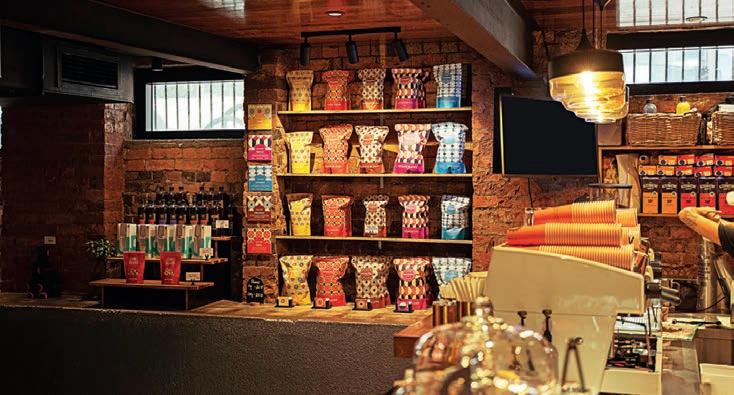

38 TEA’S HOSPITALITY POTENTIAL

At MICE26, T2 will awaken the co ee community to the extraordinary stories, blends, and origins of speciality tea.

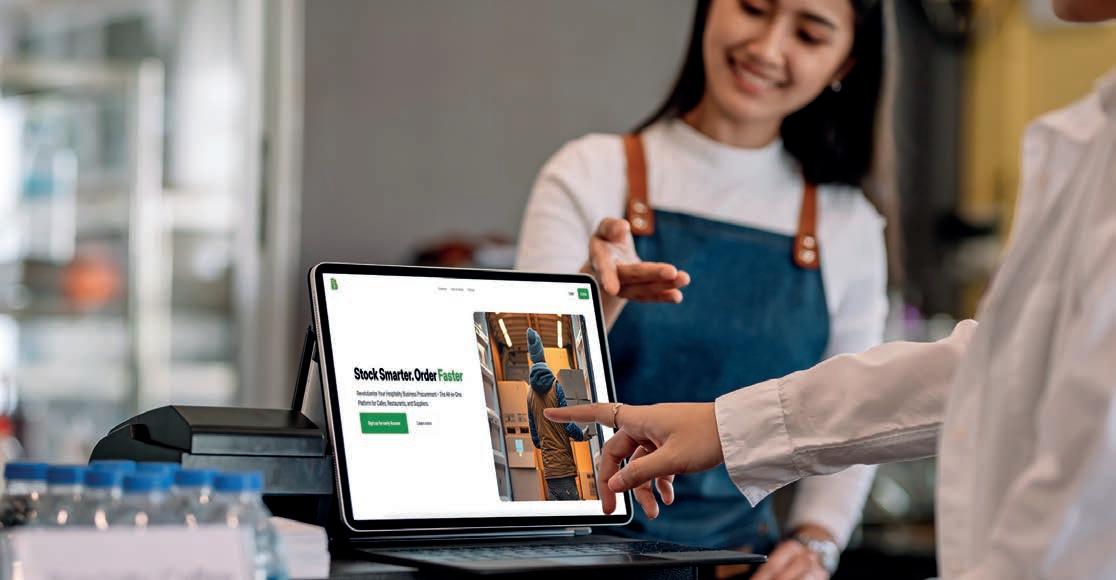

40 SIDE DISH TO SUPERSTAR

Tapping into the potential of potato chips on café menus.

44 EVERY CLICK COUNTS

Simplicity was the north star in the creation of Stokd.

46 BLENDING TRADITION WITH SIMPLICITY

Empowering cafés to jump on the chilled beverage boom.

48 A LINE IN THE SAND

Franke Co ee Systems is bringing the New A Line to Australia – here’s what to expect.

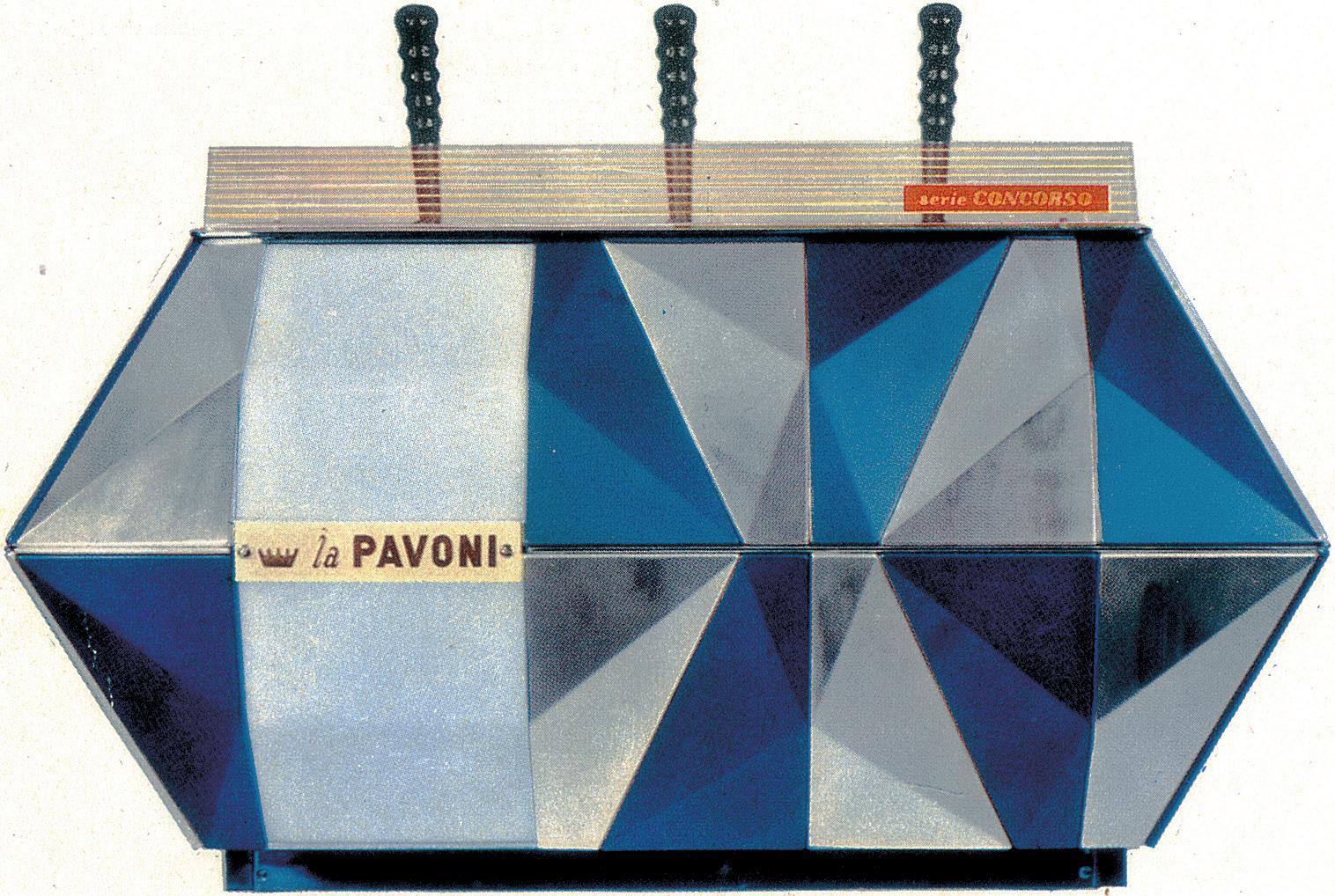

50 THE INVISIBLE INGREDIENT

Why water quality and ltration matters in co ee.

52 WHEN HERITAGE MEETS FUTURE

How history is informing La Pavoni’s new generation of machines.

54 THE GOTO GRINDER

La Marzocco introduces Jay, it’s new grinder innovation.

56 SMART AND SUSTAINABLE

Roasting tech as a lever for boosting co ee’s resilience.

58 TALKING SHOP

Checking out CWE’s new range of products at MICE26.

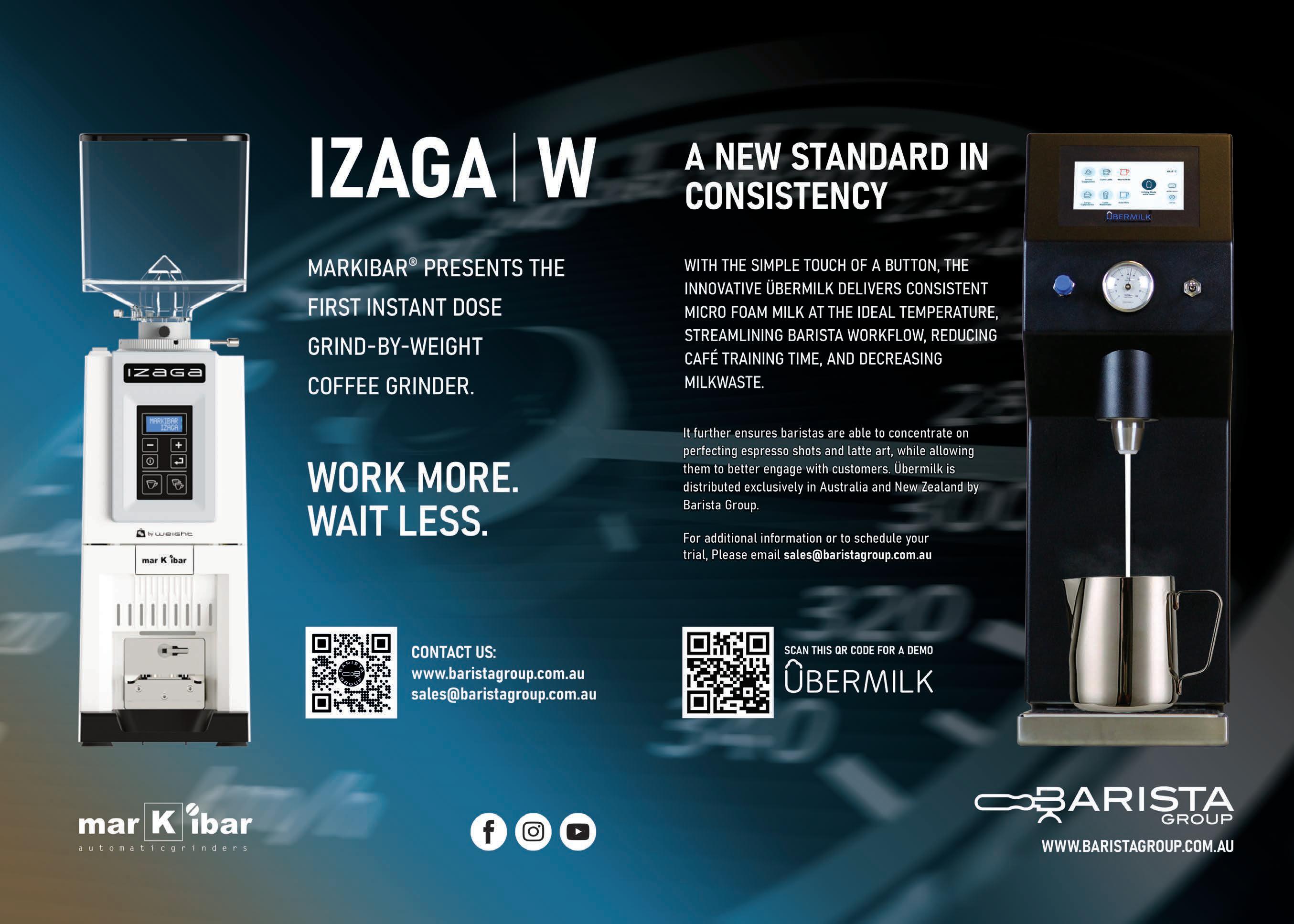

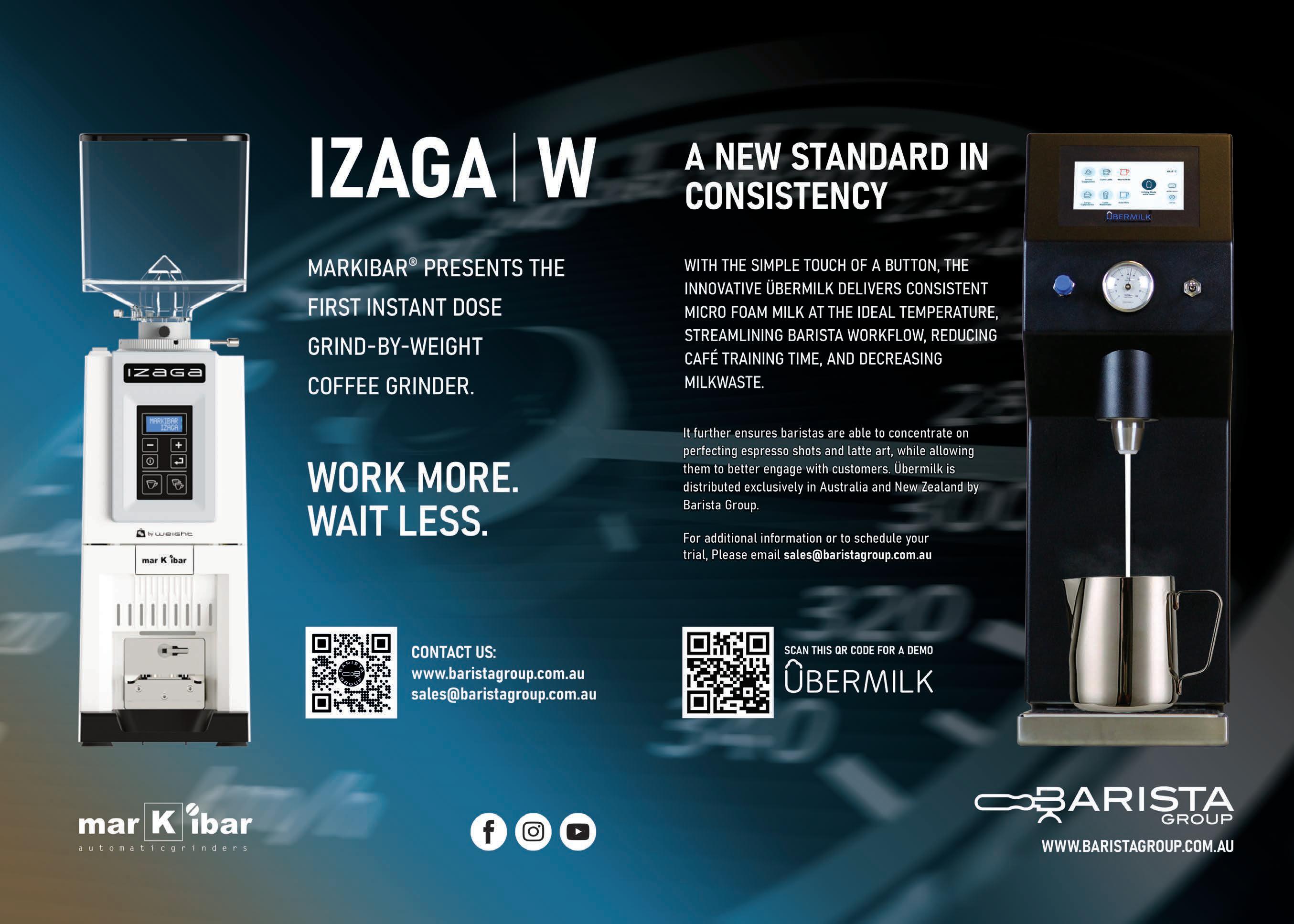

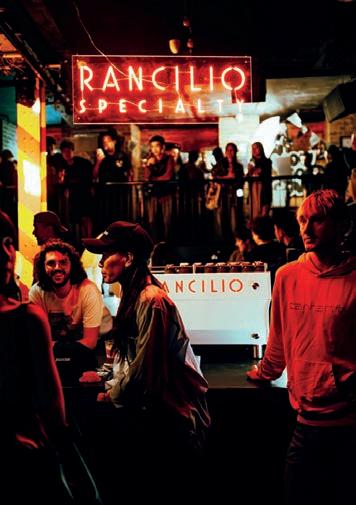

60 BARISTA’S BEST FRIEND

Discover the e ciencies gained at a Sydney café that invested in six Übermilk One liquid dispensers.

62 SCIENCE BEHIND THE SHOT

How Rancilio engineers a perfect harmony inside the cup.

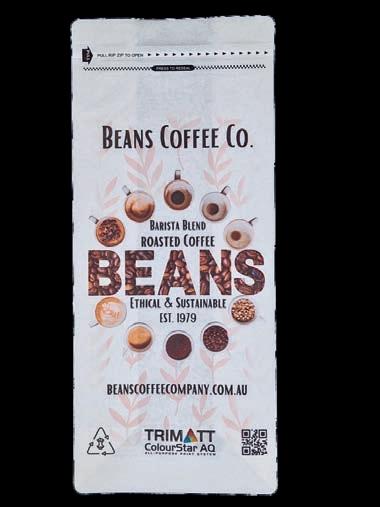

65 PRINTREADY

e packaging printing solution helping Ranges Co ee and other roasters expand their wholesale business.

67 PACKAGED WITH PURPOSE

BioPak Co-Founder Richard Fine on the big themes to come in sustainable foodservice packaging.

68 FOR THE PLANET

How roasters can align ecological consciousness with improving operations.

71 MORE THAN A CUP

Why custom packaging boils down to three key words.

72 POSTROAST PROTECTION

e turnkey solutions ensuring that co ee reaches the retail shelf untainted.

Barista Equip

Unit 4/314 Burleigh Connection Rd

Burleigh Heads

Queensland 4220

For BeanScene’s February cover, the Barista Equip team opened its showroom, just days before Christmas, for a quiet but striking shoot that captured the potential of the Baby Hardtank in action.

With the space emptied for the evening, Showroom & Warehouse Coordinator Darwin Frame showcased his photography skills, producing atmospheric images of two cold brew drinks – one featuring a vanilla cold foam – that highlight both the elegance and brewing power of the compact system.

At the heart of the Baby Hardtank’s appeal is its ability to compress an 18-hour cold-drip cycle into just 40 minutes, transforming what has traditionally been a slow process into a fast, repeatable work ow.

According to Barista Equip CEO Brett Bolwell, the real opportunity lies in reducing labour costs per cup while enabling cafés to expand into boutique, higher-value cold beverages.

Turn inside for the full cover story featuring Adam Wang who was among the rst to install Baby Hardtank at e Maillard Project in Brisbane – and who saw its immediate potential.

“A lot of newer cafés, especially in Melbourne, love using cold brew as the base for signature drinks. If you’re doing a mixed drink with cold brew, consistency is vital,” he says.

“With the Baby Hardtank you can achieve that; it’s not in uenced by factors like humidity, temperature, how much co ee you use –things that can a ect drip tower cold brew.

“With the Hardtank, your cold brew becomes much more replicable.”

For more information, visit baristaequip.com.au

CHIEF EXECUTIVE OFFICER

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

GROUP MANAGING EDITOR

Myles Hume myles.hume@primecreative.com.au

JOURNALIST

Daniel Woods daniel.woods@primecreative.com.au

JOURNALIST

Meg Kennedy meg.kennedy@primecreative.com.au

ART DIRECTOR/DESIGN

Daz Woolley

HEAD OF DESIGN

Blake Storey

BUSINESS DEVELOPMENT MANAGER

Charlotte Murphy charlotte.murphy@primecreative.com.au

CLIENT SUCCESS OFFICER

Caitlin Pillay caitlin.pillay@primecreative.com.au

CONTRIBUTORS

Jessica MacDonald, Victor Vu

HEAD OFFICE

PRIME CREATIVE PTY LTD

379 Docklands Drive, Docklands, Victoria 3008 p: 03 9690 8766 info@primecreative.com.au beanscenemagazine.com.au

SUBSCRIPTIONS 03 9690 8766 subscriptions@primecreative.com.au BeanScene magazine is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Contributors

Victor Vu is the three-time ASCA Australian Latte Art Champion. He placed seventh in the 2024 World Latte Art Championhip (WLAC) in Denmark. Born in Vietnam, Victor worked for three years in hospitality before coming to Australia to perfect his latte art skills. He won the 2018 MILKLAB Barista Battle and the 2020, 2024, and 2025 ASCA Australian Latte Art Championships.

Jessica MacDonald is the General Manager for the NZSCA. Her career has taken her to Auckland, Melbourne, Sydney, and London. She’s worn many hats but remains a roaster at heart. Jessica has volunteered on the Rules and Regulations Committee for World Coffee events and judges in barista competitions and Cup of Excellence programs. Her favourite thing about the industry is the passionate people who care deeply about coffee and the growth of its community.

Once upon a time, I recall searching for a café open during the summer holiday period. Hand-written notes would appear on café doors saying, “closed for January” or “gone shing” for the summer break, but those signs now appear a thing of the past. Granted, café owners are entitled to a well-deserved break and rest over Christmas, but just as so many patrons wind down over the summer months, our desire to connect with friends and socialise in a relaxed manner ramps up – and so does our beverage consumption.

Never before have I seen suburban and city cafés embracing the holiday vibes with such extensive beverage options, from cold co ee concoctions to signature drinks and everything in between, including trending Shanghai Dirty Co ees and reinvented versions of the Mont Blanc. What it means, is that cafés have a smart avenue to charge above the average Australian co ee price at $5.50, and li options above $7.50. When executed well – and adds value to a customer’s experience – it’s not the hip pocket that remembers the price. Instead, it’s the taste that lingers and a higher chance of gaining a repeat customer.

Like us on Facebook @BeanSceneCo eeMag

Making pricing decisions is easier said than done, but when green bean prices are nearly double what they were a year ago – thanks to lower co ee-bean supply from overseas producers, and below average rainfall in Brazil combined with the strength of the Brazilian real – there’s immense pressure on roasters and cafés to pass on those price rises in a climate where so many businesses are already struggling. Fruit and veg prizes are up

2.7 per cent, and meat and seafood prices have risen 3.9 per cent, according to the Australian Bureau of Statistics, further encouraging café operators to work smarter not harder.

One way of achieving this is via the tools cafés embrace. Baby Hardtank, this edition’s feature cover product, is a case in point. It possesses a compact but powerful cold-brew system that can compress an 18-hour cold-drip cycle into just 40 minutes. ere’s also Barista Group’s Übermilk technology.

Both e ciency-creating machines will be on display at the Melbourne International Co ee Expo (MICE).

Speaking of which, MICE is just around the corner (26–28 March). For anyone questioning what equipment can support higher work ow without compromising quality, co ee menu pricing, what drives long-term success, or how to get food products o the ground in the hospitality market – MICE is where you need to be. Explore the latest in co ee equipment, taste some of the country’s best brews from an outstanding lineup of exhibitors, and stay for the insights and knowledge-sharing at the Café Education Stage.

ere really is something for everyone. A er experiencing 13 editions of the expo, which has held two World Barista Championships, seen two venue changes and welcomed hundreds of exhibitors and thousands of visitors, I’m excited to see the show enter another realm and be the expo our industry deserves. I can’t wait to see you there, and wish everyone a prosperous new year, lled with delicious co ee and wonderful experiences that ll you with joy and passion.

SARAH BAKER PUBLISHER

Passion and tradition distinguish la Pavoni. Since 1905, espresso coffee machines, the company’s mission for more than 120 years, identify la Pavoni around the world.

Know-how, creativity, and style: these are the qualities that spring from la Pavoni’s Italian identity and characterise the company’s commitment to bringing coffee machines to life.

Co ee has emerged as one of the strongest in ation drivers in Australia’s latest Consumer Price Index (CPI), with prices for co ee, tea and cocoa surging more than 15 per cent in the year to November 2025, according to new data from the Australian Bureau of Statistics (ABS).

e spike – driven by lower co ee-bean supply from major overseas producers –has helped push non-alcoholic beverages

in ation to 4.7 per cent, well above the broader food and drink category and placing fresh cost pressure on roasters, cafés, and consumers alike.

Overall, Australian household in ation eased slightly in the year to November 2025, with CPI rising 3.4 per cent – down from 3.8 per cent in the year to October – according to the latest ABS data.

e CPI measures changes in the price

of a typical household “basket” of goods and services, including food, transport and housing.

e largest contributors to overall in ation during the past 12 months were housing (+5.2 per cent), food and non-alcoholic beverages (+3.3 per cent), and transport (+2.7 per cent).

Breaking this down further, non-alcoholic beverages prices increased 4.7 per cent in the 12 months to November 2025.

“ e annual rise was driven by co ee, tea and cocoa (+15.3 per cent), due to lower supply of co ee beans from major overseas suppliers,” the ABS says.

A further analysis of categories relevant to café businesses shows:

• Food products prices rose 3.6 per cent in the 12 months to November 2025, driven by snacks and confectionery (+7.1 per cent) due to ongoing cocoa shortages.

• Meals out and takeaway food prices climbed 3.5 per cent, a trend largely attributed to rising wages and ingredient costs

• Meat and seafood prices increased 3.9 per cent, with beef and veal (+11.4 per cent) and lamb (+12.3 per cent) leading the gains, re ecting strong global demand for Australian red meat.

• Fruit and vegetable prices also rose 2.7 per cent, with apples and citrus recording notable increases.

Hospitality Courses Australia has released data indicating the hospitality sector is Australia’s largest employer of young people, with nearly half (45 per cent) of all workers under the age of 25.

e café subsector is indicative of the trend of the industry employing young people, with an average age of just 21.

In total, the accommodation and foodservice industry employs more than

966,000 people, with an 18,700 job growth (two per cent) in the past 12 months.

Director of Hospitality Courses Australia, Samuel Bohr, says demand for hospitality and foodservice workers is at its highest for the year, with November to March serving as the busy period.

“From cafés and restaurants to pubs and hotels, we see a huge uptick in demand for sta over this period – particularly

employees who are well-trained or experienced,” says Samuel.

“Almost half of all hospitality workers are aged under 25. at means for many people, a role in hospitality is there rst job – and it’s a great sector for that, o ering experiences that range from customer service, to fast-paced food preparation, ne dining, and more.”

e average barista’s income is $32,447.

Brisbane-founded café chain Stellarossa will expand its presence out of Queensland and into India following a franchising agreement with the local arm of global consulting rm, Francorp.

Since being founded in 2009 by Phil Cronin and Darren Schulz, Stellarossa has expanded across the Sunshine State with more than 20 locations ranging from the Brisbane region

We’re thrilled to welcome Stellarossa, Australia’s beloved café brand, as they begin their India expansion journey with Francorp,” a Francorp statement reads.

“For 15 years, Stellarossa has proven that great cafés aren’t just about co ee – they’re about creating warm, engaging spaces

people love to return to.

“With beautifully cra ed beverages, premium café menus, and community-driven hospitality, Stellarossa is now ready to partner with passionate entrepreneurs across India.

“Whether it’s a Kiosk, Inline Café, Driveru, or Full Destination Format, the brand brings global standards with exible and scalable models.”

Helping you get your coffee fix!

Committed to innovation and quality to support your success.

Bringing together leading brands in processing, packaging and inspection equipment specifically for the coffee industry. Our solutions set the standard for yield, efficiency and safety. Whatever your product needs, we can meet it with precision and passion.

Australia’s leading specialty co ee professionals have been recognised following a landmark series of competitions hosted by the Australian Specialty Co ee Association (ASCA), with national champions crowned across barista, brewing, latte art, roasting, co ee in good spirits, and cup tasting disciplines.

At the centre of the celebrations was Gabrel Tan, who was crowned Australian Barista Champion a er years of near misses at Big Plans in North Melbourne in late November 2025.

A er nishing runner-up twice and third once over the past four years, Gabrel claimed the top honour, overcoming a strong nalist eld that included Angus Mackie, Liam Pratt, Ziggy Varamulia, Tom Hutchins, and Yeseul Choi. e Veneziano Co ee Roasters Brand Ambassador will now represent Australia at the World Barista Championships at World of Co ee Panama in 2026.

“Every year of not winning gave me great learning experiences,” he says. “Honestly, I just want to shout out my team – especially Craig Dickson. He’s been supporting me ever since I started at Veneziano and he’s believed in me this whole time.

“It took many, many years to get here, but I’m really grateful for everybody who has been part of this journey.”

Big Plans also hosted the Australian Brewers Championship and Australian Latte Art Championship.

Simon Gautherin of Zest Co ee and APAX Lab claimed the Australian Brewers Cup title.

“It’s been 10 years of hard work and dedication,” he says.

“I didn’t compete to win; I removed that from my mind. I wasn’t even too sure if I wanted to be on stage because of the hard work and commitment it takes, so for me it needed to have real meaning.”

In the Australian Latte Art Championship, Amy Zhang returned to the top step of the podium a er a more than two-year sabbatical from competition.

Amy’s victory followed her seventh-place nish at the World Latte Art Championships in Taipei in 2023, and she said revisiting and re ning past designs played a key role in her success.

“When I came in seventh in Taipei, I felt a little bit bad that I couldn’t show everyone my new design in the nal,” she says.

“I kept going to t my design, so when I recreated it and xed it here on stage today, everyone loved it. Now, I have the chance to y to America and show my designs to the world.”

Beyond the barista-focused events,

Australia’s roasting and sensory champions were also crowned late in 2025 and early 2026. e trio will be jetting o around the world to represent Australia at the various World Co ee Championships around the world in 2026.

Amy will be the rst to represent Australia, with the World Latte Art Championship taking place at World of Co ee San Diego in April.

Simon will be travelling to Belgium and World of Co ee Brussels in June, and a trip to Panama City and World of Co ee Panama await Gabrel in October.

Meanwhile, Danny Andrade of Blackboard Co ee Roasters was named winner of the 2026 Australian Co ee Roasters Championship, held at Criteria Co ee in Port Melbourne. He nished ahead of Stitch Co ee’s Peter Lam and Indie Hoop Roasters’ Ik Beom Kim in the three-stage competition, which assessed co ee evaluation, preparation, blending, and roasting skills.

Danny will now represent Australia at the World Co ee Roasting Championships in Belgium at World of Co ee Brussels in June 2026.

ASCA also crowned its 2026 Co ee in Good Spirits and Cup Tasters champions, with Serene Yu of Smay Co ee and Karl Lee taking top honours, respectively.

Serene delivered what judges described as a “performance full of creativity, skill, and air”.

Speaking the day a er his win, Karl said the result was still sinking in.

“Tasting and cupping has become part of my life … I competed rst in 2019, and now I’ve got a trophy, so it’s paid o ,” he says.

Karl will compete at the World Cup Tasters Championship in Bangkok in May 2026, while Serene will join Australia’s other champions on the world stage in Brussels in June.

Opening a new café – or any kind of hospitality venue – is hard work, but what do you learn when you’ve opened more than 40 of them?

Julien Moussi is always on the lookout for new opportunities. In the almost 14 years since opening his rst venue in Fitzroy, Melbourne, he’s created something of an empire with his group of venues, Only Hospitality.

Alongside that, he’s built one of Australia’s fastest growing and best-selling co ee roasters in Inglewood Co ee Roasters.

But it almost never happened.

A er starting his career as a personal trainer, Julien moved back to Melbourne to play VFL football with the Box Hill Hawks, before a severe knee injury changed the trajectory of not only his life, but Australia’s co ee scene.

“I discovered my love for co ee while I was playing footy and working as a personal trainer in Canberra,” says Julien. “I got injured a er coming back to Melbourne – I couldn’t play for a year. In that time, I asked the club if I could make co ees at the ground and, thankfully, they said yes.

“Dimattina Co ee gave me a co ee cart, and I ended up selling at around 10 to 15 other sporting venues. A er about 18 months of juggling I saved around $30,000 to start my rst café, Annoying Brother, in 2012.

“Since then, I’ve opened about 40 venues, around 30 of which have been cafés.”

From inner Melbourne to its outer suburbs and surrounds, and even a successful interstate foray to Burleigh Heads, Queensland, Julien and Only Hospitality have become experts at identifying the best spots for new venues.

When scouring for opportunities, he says it’s important to keep it simple and identify local trends.

“One of the rst things I look at is the housing market and the age demographic of people purchasing in the area. We look for young families in up-and-coming areas where people like to go out for breakfast or lunch and grab a co ee,” he says.

“It’s important to place yourself in areas with high amenities and high activity, like shopping centres or schools.

“Being o the beaten track also isn’t necessarily a bad thing, because you want good parking and for people to have the ability to walk there. ere are a lot of factors involved, but it’s not rocket science.”

A key point of di erence for Julien’s model is many of Only Hospitality’s venues require a new tout, giving him the capacity to reshape them entirely.

“ e more dilapidated the four walls, the better for us,” he says.

“I love seeing people enjoy themselves in

environments we’ve created, curating a vibe and making a venue have an energy to it –creating that soul.”

rough the success of Only Hospitality, Inglewood Co ee Roasters was born. Cory Slater, who was working with Julien as a barista, was key in starting the venture.

Julien says Only Hospitality’s venues were selling about 500 kilograms of co ee a week when Inglewood started roasting in 2017. Now, the business has grown to look internationally for new opportunities.

“Inglewood roasts about 12 tonnes of co ee a week and we supply roughly 350 venues and 250,000 homes around Australia, plus some around the world,” says Julien.

“We’re doing a lot of direct-to-home co ee, even internationally. With the cost of freight and logistics, we’re looking to roast in London and New York. Hopefully we’ll start this year.

“We’re also looking to upgrade our roaster for the second time in three years. We’re looking at a 350kg Brambati. at will increase our volume fourfold, which means we can start having big conversations with many di erent people.”

Despite its size, Inglewood is by no means immune from the past year’s signi cant green bean price rises. But it’s continued to grow, and Julien proudly

expresses its wholesale network has remained strong.

“We’ve really focused on trying to grow our revenue faster than costs have been rising. On a percentage of revenue basis pro tability isn’t what it was, but revenue growth has been able to overcome those barriers for us,” he says.

“Having that direct-to-consumer retail aspect has allowed us to put retail prices up a little. First and foremost, our wholesale partners need to make money, otherwise they’re not sustainable.

“We’ve been more patient with moving our wholesale price compared to retail. We’ve also pulled other levers, o ering free shipping on all online retail orders up until 12 months ago. at’s given us a new way to generate revenue to o set the C-price increase.”

Julien says the shi ing co ee habits of consumers o er signi cant opportunities in both Inglewood’s wholesale and retail spaces, but it’s a balancing act to keep both sets of customers happy.

“I don’t think co ee volume is dropping in venues, people are choosing to have one or even two co ees at home now, people are drinking more co ee, not less,” he says.

“Having a co ee machine is going to be like having an oven or stove. Within the next decade, there will be a co ee machine in every home, so our balance between retail and wholesale needs to be right.

“We haven’t lost one wholesale customer over anything to do with retail marketing, which shows we’re probably getting that balance right.”

In what is typically a low-margin and hyper-competitive industry, this approach has been a key contributor to its growth.

“We’re a tight knit crew and having that element of being hands-on operators is crucial,” he says. “I’m a barista by trade; I still jump on to pour co ees. Nobody is above jumping on the oor and being at the coalface.

“ at even helps from a team morale perspective when the sta see us help. My

wife was even doing dishes in one of our pubs before Christmas because we had a lot of functions on.

“ ings like that really help the culture, it’s what’s worked for us and is an important part of our make-up.”

It’s one of many lessons Julien took from opening Annoying Brother – almost all of which were learned the hard way – but those insights have held him in good stead.

“I was only 23 and I remember crying very,

very o en in those initial months because it was so stressful,” he says.

“I didn’t make a lot of money, barely enough to pay myself wages, but it was important because I learned to build a model with a cost of goods benchmark, a labour benchmark, and a rent pro le. ose things I learned are what our model is still today. Even things like the way we did payroll and reporting haven’t changed.

“It also taught me a lot of resilience, because that’s when everything was on my shoulders. It helped me learn a lot about who I was and who my people were, and they’re the same people now. It was a lot of fun alongside a lot of hard work and stress, but it shaped us.”

From that co ee cart at Box Hill City Oval to building Only Hospitality and Inglewood, Julien equally embraces opportunity and risk – and this tandem Only Hospitality –Inglewood Co ee Roasters juggernaut shows no signs of slowing down.

While there is an inherent risk starting something new, he says it’s critical to not let caution outweigh the potential.

“It’s human nature to have a negative bias but you must try and steer away from that – a lot of people overestimate risk and underestimate opportunity,” he says. “ ere’s never a perfect time to do something – the ones who just do it eventually come out on top,” he says.

“If you become biased towards the positive, you’ll nd yourself on a path to opening your own venue a lot quicker.”

One of Brisbane’s most reputable specialty coffee venues is putting the Baby Hardtank to the test, compressing cold brew from an 18-hour procedure into a 40-minute extraction that could reshape how Australian cafés approach cold coffee.

The Maillard Project in the heart of Brisbane feels less like a café and more like a co ee laboratory. It’s an environment where light stone, wood and glass create an atmosphere built for experimentation.

At the centre sits a low-set island bar, its espresso machines and pour-over stations arranged like instruments in a controlled study, each designed to showcase the exact avour pro les Adam Wang and his team develop in-house.

e newest exhibit in this co ee lab is the Baby Hardtank, a compact but powerful coldbrew system that’s capturing attention across the Australian café landscape.

Positioned beside the brew bar, it can compress an 18-hour cold-drip cycle into 40 minutes, turning what is traditionally a slow steeping process into high-e ciency, repeatable brewing.

For Adam, whose venues o en serve as testing grounds for innovative equipment, it’s another chance to push extraction into new territory without diluting the purity that de nes co ee at e Maillard Project.

e venue’s philosophy is to celebrate the co ees Adam’s team roast in their most authentic forms. Customers won’t nd decadent signature drinks packed with other ingredients on the menu.

“ e Maillard Project is a pure, co eefocused venue. We serve co ee in its original form,” Adam says, noting the only available cold drinks are iced long blacks or cold brew, which account for 15 to 20 per cent of sales.

“ ere are so many amazing origins, beans, processing methods, roasters… co ee is already pretty incredible on its own – why add more to it?”

When BeanScene spoke to Adam, the Baby Hardtank had been installed earlier that day. It’s now available in Australia through Barista Equip which is importing the machine from Polish cold co ee solutions manufacturer Hardtank – established by a trio of co ee enthusiasts wanting to help businesses of all sizes prepare “amazing cold brew in a fraction of the usual time”.

Adam is putting Baby Hardtank to work in his venue – and providing feedback about its performance in an Australian context. As one of the most in uential gures in the Brisbane specialty scene (his other venue Co ee Anthology was ranked eighth in the World’s 100 Best Co ee Shops in 2025) his endorsement may encourage more venues to diversify into cold brew – or supercharge their existing operations – with Baby Hardtank.

“Cold brew is easy drinking, o ering a cleaner, less bitter taste. We always use lter or lighter-roast co ee, and usually something a bit more interesting – funky, fruity. It’s almost like an iced fruit tea. More mellow, clean. And in warm weather, it’s like drinking a so drink,” he says.

“We ran several batches on the rst day alone with Baby Hardtank – 40 minutes for a cold brew batch is pretty impressive, and a step above the dripping tower we’ve traditionally used that can take anywhere up to 18 hours before we can serve the nal product to a customer.”

Baby Hardtank uses accelerated cold extraction technology based around recirculation. Water is constantly circulated and pushed through the extraction basket meaning the co ee, tea, or infusion ingredients are constantly agitated. It also features a unique basket

design that the company says “creates an extremely clean brew” without the need for additional ltration.

Adam says the Baby Hardtank enables high volume batch-brewing. A busy café can easily sell 10 litres of cold brew a day, but to keep up, this potentially requires four rounds of tower dripping unless multiple towers are in use.

“It can be challenging to keep up with the volume, but with the Baby Hardtank within half an hour you can brew four litres. And if you clean quickly in between batches – which is possible due to a quick and automated cleaning process – you could easily brew 30 to 40 litres a day.”

Hardtank has crunched the numbers itself and says a single Baby Hardtank batch has capacity for up to 350 grams of ground co ee and creates four to ve litres of cold brew.

rough multiple cycles, cafés can serve up to 300 portions per day.

A single Baby Hardtank batch can take 350 grams of ground coffee and creates four to five litres of cold brew.

Adam says this will enable his café to o er cold brew with various origins and blends on any given day. He also expects Baby Hardtank will drive diversi cation for other cafés that invest.

“A lot of newer cafés, especially in Melbourne, love using cold brew as the base for signature drinks. If you’re doing a mixed drink with cold brew, consistency is vital,” he says.

“With the Baby Hardtank you can achieve that; it’s not in uenced by factors like humidity, temperature, how much co ee you use – things that can a ect drip tower cold brew. With the Hardtank, your cold brew becomes much more replicable.”

The big opportunity

It seems Baby Hardtank’s arrival in Australia has been one of the worst kept secrets in the Australian café scene. Without much e ort, Barista Equip CEO Brett Bolwell has elded some 120 inquiries from a range of cafés, roasters, and other venues like golf clubs.

As this edition of BeanScene goes to print,

“Baby Hardtank isn’t influenced by factors like humidity, temperature, how much coffee you use – things that can affect drip tower cold brew. Your cold brew becomes much more replicable.”

THE MAILLARD PROJECT

there will be about a dozen Baby Hardtanks in the national market.

“I consider Adam at e Maillard Project the ‘King of Specialty’. He’s a roaster, a purist,

Riverina Fresh’s Lactose-Free achieved a score of 19.5 out of 20 at the Australian Grand Dairy Awards.

Riverina Fresh’s Lactose-Free Milk recently made history by being named Grand Champion Dairy Product at the Australian Grand Dairy Awards, and it holds the potential to shift the scope of Australia’s café scene.

At most cafés in Australia, the co ee menu reads like a carefully curated story. With discussion around origin, blends, and tasting notes, milk rarely takes the heading – but that’s exactly how Riverina Fresh likes it.

e historic dairy company has grown over more than a century with the philosophy that co ee leads, and milk supports.

Every now and then, though, the quiet achiever in every latte and at white does earn some recognition. In late 2025, Riverina Fresh’s Lactose-Free milk was named the Grand Champion Dairy Product at the Australian Grand Dairy Awards, o cially judged the best dairy product in Australia.

For a brand that sees itself as the backstage crew to the baristas it supports, Riverina Fresh Executive Chairman Craig Shapiro says the recognition is a moment of pride that has been accepted with humility.

“It’s incredibly special,” says Craig. “ is

award re ects the work of our farmers, our team, and the baristas who trust us every day. But ultimately our role is to help cafés serve amazing co ee.”

e Australian Grand Dairy Awards represent the highest recognition in the country. Only gold medal winners from statebased competitions qualify, and products are judged by industry experts across avour, technical excellence, and overall quality.

“ ere are 11 categories,” Craig explains. “Each has its own champion, and then one product across all categories is awarded the overall Grand Champion Dairy Product. To receive that honour with a score of 19.5 out of 20 – as close to perfect as you can get – is incredibly humbling.”

ough the winning product is lactose-free, Craig is quick to point out that its foundation is the same milk the company has produced for generations: fresh, natural dairy from a small group of Riverina based farmers.

“ e lactose-free version starts from our full-cream milk. We simply add lactase to break down the lactose into simpler, more digestible sugars,” says Craig.

“What matters most is the quality of the underlying fresh milk. Without that, nothing works.”

Riverina Fresh’s positioning as a support act to co ee, Craig says, is where the brand shows its true value. Rather than dominating the cup, he says the milk is designed to let the espresso lead to help create balance, sweetness, and texture without overshadowing the roast.

“When baristas talk to us, they don’t ask about awards,” says Craig. “ ey ask if the milk stretches consistently. If it pours cleanly. If it supports the avour of the co ee.

“ e fact our lactose-free milk does all that and has been recognised as the best dairy product in Australia means we’re doing our job.

“Having a high performing fresh lactosefree milk gives cafés another high-quality dairy option that performs beautifully in co ee.”

Behind every bottle of Riverina Fresh milk – Lactose-Free or otherwise – is a supply chain that has been built to prioritise speed, care, and minimal handling. It’s an approach Craig says Riverina Fresh rarely speaks loudly about, but it underpins why the brand has become such a staple in Australia’s specialty co ee scene.

“Our farmers produce exceptional milk every day,” he says.

“From there, our focus is on preserving that quality. We transport quickly, process gently, reduce exposure to heat and light, and get it to our customers as fast as we can.”

e emphasis on strength of supply chain is a practical requirement for producing milk that stretches predictably, froths consistently, and tastes clean and balanced.

Co ee professionals o en talk about consistency and the ability to deliver the same quality cup a er cup. Riverina Fresh’s role in that consistency is recognised across the specialty co ee sector, as the company continues to build strong roaster relationships to ensure it meets the ever-changing needs of co ee lovers.

One of those shi s in consumer behaviour Craig points to is an increasing interest in the role food plays in health and nutrition. e growth of weight loss drugs (GLP-1s) is having a major impact on that narrative, particularly in the United States (US), where upwards of 10 per cent of the population are reportedly now using them.

Diets are rapidly changing because of their

popularity, and this is impacting portion sizes and the type of food being ordered in cafés and restaurants. A focus on fresh food and reduced consumption of ultra-processed foods has taken grip in the US.

While lactose-free milk is far from a new product, it’s gaining traction due to the continuing shi away from ultraprocessed food and back towards fresh, natural products.

Craig says the impact will be similar in Australia once GLP-1s become more accessible.

“ ere’s a paradigm shi that is coming for the specialty co ee and café sector in Australia, because of weight loss drugs,” he says.

“People are going to be eating less, so they need to eat smarter. ere’s de nitely momentum back toward fresh, natural dairy.

“People want food that’s simple and nutritious. With cafés being such a part of daily life, the milk they choose really matters.”

But even as dietary habits change, the company doesn’t pitch lactose-free milk as the star. It’s one option within the broader rise of high-quality dairy.

“ e award shows that you don’t need to compromise,” Craig says. “Cafés can o er something for people who avoid lactose while still serving the best dairy product in Australia.”

Because lactose-free milk has a slightly higher cost to produce, cafés o en treat it similarly to plant-based alternatives – o ering it as a small premium option.

e natural sweetness created when lactose breaks down into glucose and galactose has a genuine impact on avour. Glucose is

naturally sweeter than lactose, which leads to a change in avour pro le. is added sweetness o ers greater avour balance in milk-based drinks, unlocking a point of di erence for iced co ees and signature beverages.

“ ere’s de nitely an opportunity for cafés to think di erently about lactose-free dairy,” Craig notes. “People who usually add sugar might not need to. And if the milk helps create a better-tasting drink, it’s something the café can be proud to stand behind.”

But again, Riverina Fresh stresses that milk should enhance the cup, not dictate it.

“Ultimately, cafés know their customers best, we’re just here to support them,” says Craig.

For Riverina Fresh, the Grand Champion Dairy Award is a company milestone – and a moment shared with baristas, café owners, and roasters around the country who use its milk to bring the best co ees to life.

“ e award belongs to the whole community: our farmers, our team, the cafés who trust us, and the baristas who work magic behind the counter,” says Craig.

“We just provide an ingredient. ey create the experience.”

For Craig, that is the simple way of summing up Riverina Fresh’s role in Australia’s specialty co ee scene. Not the headline act, but a trusted support act – a humble partner helping create the best cups in Australia.

And, now, the producer of Australia’s best dairy product.

For more information, visit riverinafresh.com.au

Cafés raising coffee prices has long been a topic of discussion in Australia. Dean Merlo details why it’s time for operators to bite the bullet.

Co ee is one of the world’s most heavily traded and valuable commodities, but as global demand has increased and green co ee production has stalled, price rises have shown little sign of slowing down in recent times.

e average price of green co ee almost doubled across 2025, and the early signs in 2026 indicate similar pressures. e consistent jumps have had Australian cafés and roasters feeling the squeeze in what Dean Merlo, founder of Merlo Co ee Roasters that supplies to more than 1500 venues, describes as the most tumultuous period he’s witnessed.

“It’s a tough time for roasters right now, the co ee prices aren’t just unprecedented, they’re ridiculous. ey’re closing in on double what they were a year ago. It’s incredibly hard to pass that onto cafés who are already struggling with rising costs,” says Dean.

“Co ee is basically a traded commodity now, I don’t believe this is just a spike – if you look at the history of the past 12 months, it’s kept rising. is is the greatest turmoil I’ve seen in the co ee market in my time.”

Merlo, under Dean’s stewardship, has grown to become one of Australia’s largest familyowned co ee roasters since being founded more than three decades ago. In that time, it has also opened 16 cafés in its home market of Queensland, from Brisbane to Toowoomba.

Dean has seen some roasters look to o set rising prices by changing their blends, a move he believes would send a negative message to Merlo’s loyal customer base.

“What I’ve explained to our people is everyone likes to buy cheap co ee, but no one wants to sell cheap co ee,” he says.

“We could have used cheaper origins or cheaper blends in the past year, but we refuse to do that and compromise the quality of the co ee. It doesn’t send the right message to customers, as well as culturally throughout our organisation.

“I simply will not do it. We use the same blend now as we did 33 years ago, and that’s important to us.”

What, then, is the tipping point? What levers can be pulled to ensure Australia’s roasters and cafés continue to not only survive, but thrive? e simple answer, according to Dean, is pricing changes in cafés.

According to the La Marzocco Future of Australian Co ee Report, the average co ee price in an Australian café in 2025 was $5.50 – which is signi cantly lower than other developed markets around the world. at

gure rises to $6 to $7 in major metropolitan hubs like Sydney and Melbourne and drops to under $4 in some regional areas and budget options.

e average price of a co ee in Brisbane sat at around $6 last year, and Dean believes raising prices to match the rest of the market doesn’t have to be as scary as it seems. In fact, Merlo’s own locations increased prices from

$4.90 to $5.50 in one fell swoop and felt next to no blowback from customers.

“We knew we just had to charge that price, otherwise it’s a question of when you go broke,” says Dean. “It’s tough when you’re talking to cafés out there and they’re nervous since their costs are going up and they’re getting strangled in their own business, and they’re too worried that the café across the

road isn’t putting their prices up,” Dean says.

“We’ve explained our pricing to all our customers. We charge $5.50 for a basic at white with $1 for extras. We only charge once for extras, so say if you have a double shot with soy and a shot of syrup, that’s still just $1 more.”

is approach is reasonable for both the café and the customer, he says. Dean discovered it’s di cult to individually charge for each addition on top of the co ee itself.

“We explain to our wholesale customers that’s what our cafés charge, and we’re in their business so it’s di cult – in some respects it’s hard to be a wholesaler and a retailer at the same time, because you’re e ectively selling wholesale to your competitors, but we don’t see any of the cafés we sell to as competitors as there are so many things that di erentiate the customer experience.”

Dean says that end consumers are willing to accept – or won’t notice – price increases as long as the other aspects of the café experience remain up to scratch.

“ e thing we’ve tried to impart onto our customers is that if you’re charging ve bucks for a co ee, you’re going broke. It’s as simple as that,” he says.

“If you have a quality product and o er a quality service, the food’s good, and you’re just doing all the right things as good retailers, people won’t even blink – they won’t even look at the price.

“We proved that with our stores in that the increases barely got a mention from our customers when it happened.”

Despite the external pressures, Merlo’s café locations did not stand still in 2025. e opening of a wholesale bakery at its Bowen Hills Roastery looks set to expand further in 2026.

“2025 was so big for us, we opened a bakery, and it’s a full-on wholesale bakery and we sell retail at our shop. It’s in our Bowen Hill Roastery and it’s been going incredibly well,” says Dean.

“It’s not easy to produce both in the same spot, but we’re excited about it, and we feel it’s an investment that makes us stand out.”

“It’s crucial to diversify, you can’t just stand still. If you’re trading exactly as you were last year, it’s not going to work,” says Dean.

“It could be as simple as a change in menu where you’re showcasing that you’re now making iced drinks or adding cold foams, but you must be up on all of that. I believe a big warning sign for a café is if they haven’t changed anything in the past 12 months. It doesn’t have to be something as large scale as switching up the entire t-out, but even small changes help step things up.”

For more information, visit merlo.com.au

As trailblazers in sustainable coffee culture, KeepCup is returning to the Melbourne International Coffee Expo in a big way.

Aer 15 years at the forefront of reusable co ee culture, KeepCup is sharpening its focus on younger drinkers.

Its Sip Check campaign, unveiled in December 2025, will take the stage at MICE in March 2026, positioning reusable cups as equal parts sustainability tool and style statement.

For MICE26, Co-Founder and Managing Director Abigail Forsyth says the KeepCup stand will focus on personalisation and everyday reuse, with Sip Check brought to life through an interactive mirror moment.

“I’ll just say that you’ll need to bring your phone along to our booth … it speaks to KeepCup as an accessory to your life … I can’t say much more than that.”

Alongside this, there will be a customisation-led element showing how cafés can merchandise multiple products and colourways together, as well as “playful opportunities” for visitors to personalise their cups on the trade oor.

It’ll also be a key chance for KeepCup to present its expanded range, as well as new co ee accessories, to potential wholesale customers and general co ee enthusiasts.

“We haven’t exhibited at MICE for a couple of years, so it’s an opportunity for us to showcase the whole range of new products we have online that cater to all the di erent styles and ways people are using the brand,” Abigail says.

Products that have experienced signi cant growth in the last few years include the Cold

and

reuse.

More are expected to be added to this list, to be unveiled at MICE.

With the expo serving as a signi cant gathering space for the co ee industry, Abigail is aware of its importance in forming connections and sharing innovations.

“ e support of the speciality co ee

industry has always been absolutely foundational to KeepCup – it’s where we got our start all those years ago,” says Abigail.

“It’s about nding that next generation of roasters, cafés, baristas, and people who are interested in the industry, and being able to get them all in one place and have those conversations.

“It’s very energising and we’re excited to be there.”

Working in the sustainability space for more than a decade, she has seen many changes in the industry.

She’s also seen a stronger appetite for local manufacturing, with consumers looking at supporting homegrown suppliers – KeepCup’s own Cold Cup is “100 per cent made in Australia”.

“It goes to who we are as a brand and to sustainability. Many cafés are about community, so there’s a ow-on e ect of supporting the businesses that surround that community,” she says.

Abigail also points to the signi cant shi toward making high quality co ee at home – and how the Australian industry is tapping into that.

At the same time, cafés are doubling as a retail space for companies like KeepCup, where consumers can purchase its re-usable cups and limit the environmental impact of takeaway co ee consumption.

“ e nice thing about KeepCup now is we’ve got a lot of breadth in our product range, where we can have a number of products that appeal to di erent customer types, di erent co ee drinking preferences. In that sense, we can become a one-stop shop for a café to purchase their reusables,” she says.

“It’s a way to connect people – you’re buying the beans; you buy the cup – it creates a sense of community.”

As MICE approaches, Abigail reiterates that word – connection – is front of mind.

“Having the chance to connect at MICE is essential. It allows us to establish our presence within the specialty co ee industry while engaging directly with the community,” she says.

“Whether that’s through a great experience of coming to visit the stand, showcasing our product range and the new items we have on o er, meeting new and existing customers, or even talking with industry peers: those moments – when you meet someone face-to-face – become so vital to building relationships … a er that, everything ows so much more e ortlessly.”

For more information, visit au.keepcup.com

At this year’s International Coffee Expo, Coffee Works Express is unveiling the newest gear from the world’s most trusted names — Astoria, Wega, Mazzer, and Franke.

From the Astoria AB200 to the Wega Polar, from Mazzer’s Mini Series to Franke’s sleek new A-Line systems, you’ll find the tools that shape the future of coffee.

Don’t just hear about the latest in coffee tech. See it, taste it, try it. Only at CWE.

activations

When coffee equipment fails at the worst possible time, Coffee Machine Technologies is ready to step in and ensure cafés are back trading in time for service.

Not a weekend goes by without Co ee Machine Technologies (CMT) receiving a phone call from a panicked café owner about malfunctioning equipment. It’s a high stakes moment: weekends are the busiest trading period, and the downtime can quickly spiral into lost sales and disappointed customers.

For more than 20 years, CMT has built its reputation on being the lifeline cafés call in these moments of crisis. With 24/7 support, the Victorian company’s nationwide network of trained technicians can diagnose issues and respond immediately to get machines back online – o en within a matter of hours and in time for peak service.

It’s this combination of speed, expertise, and reliability that’s made CMT one of Australia’s most recognised independent co ee machine service providers, says Founder John Colangeli.

It’s why the company is also trusted by everyone – from boutique cafés and roasters to national chains – businesses that have all been impacted by rising operational costs and green bean prices during the past 12 months.

“Downtime due to a machine fault, or grinder for that matter, is the last thing venues need,” John says.

“Across Australia, there are many good service providers, but what really sets us apart is our depth of knowledge across a wide range of equipment. Rather than being limited to a handful of manufacturers, we have the knowledge and capability to work across multiple brands, including the early models through to the latest technologies.

“Responsiveness is another key point of di erence. It’s an around-the-clock service, including weekends and a er hours. It’s not easy, but it’s vital we can respond quickly for our customers.”

CMT has intimate knowledge of almost every aspect of the co ee industry. Beyond its service department, it supplies equipment from some of the most reputable overseas manufacturers, runs a café out of its Lygon

Street, Carlton, showroom, and even manufactures its own Viper steamer, boiler and hot water systems.

e importance of a responsive service team therefore isn’t lost on John.

at’s why CMT operates an in-house service team of 12 technicians that work out of hubs in Victoria’s Tullamarine, Lygon Street, Mornington Peninsula, and Geelong, and Sydney – each on the road with their own van. at’s in addition to four technicians who work in CMT service centres refurbishing or xing equipment.

But the company’s reach extends nationally through a network of handpicked partner companies in each state.

“ ese partnerships allow us to support national businesses – cafés, restaurants, and multi-site chains – wherever they operate,”

John says. “ rough our preferred third-party technicians, we can deliver a consistent level of service nationwide.”

When a café calls with a problem, CMT works quickly to resolve it. In metropolitan areas, technicians are usually on-site within the hour, aiming to x the issue the same day. Nationally, around 90 per cent of the time, the company can maintain that response speed.

Finding and supporting skilled technicians is another key ingredient. So is keeping up with ever-more sophisticated electrical components in co ee equipment.

“All our techs are trained in-house across all equipment and where manufacturers o er training or technical support, we take advantage of it. Each van is stocked with a large range of parts. We don’t want them turning up only to nd they don’t have the right part to get the job done,” John says.

He believes cafés can minimise or even avoid downtime in the event of equipment meltdown.

“Maintenance is the most important thing. I’ve always said that even though café owners and sta aren’t technicians, they know their machines well and o en better than we do,” he says.

“If something doesn’t feel right or isn’t behaving normally, they’ll o en notice it early. at’s the point where they should call us in, so we can assess what’s wrong – or what could potentially go wrong – before it turns into a bigger issue.

“Sometimes it’s something simple like a leak, but leaks can quickly turn into bigger problems, especially if water reaches electronic components. Many modern machines are heavily reliant on electronics, so small issues can escalate if they’re not addressed quickly.”

Some cafés mitigate risk by running backup machines or grinders – a philosophy John supports.

“Bench space doesn’t always allow for that, but in our own café in Carlton, for example, we run two machines. In the unlikely event one fails, you’ve got a backup ready to go.”

As operational pressures mount, cafés can take comfort knowing CMT is just a phone call away, stopping small faults from turning into major disruptions.

“For customers using CMT as a national service provider, they really see the di erence – not just in their own operations, but in the experience they’re able to then deliver to their customers,” John says.

2025 turned out to be an incredible year for specialty coffee in New Zealand, but with 2026 now well underway, the next few months are filled with unmissable events, competitions, and opportunities.

2026 is shaping up to be an amazing year for New Zealand’s specialty co ee community. From competitions that spark creativity to gatherings that deepen connections, the New Zealand Specialty Co ee Association (NZSCA) is brewing up a full calendar of events designed to inspire, educate, and unite co ee lovers across Aotearoa. Here’s your rst look at what’s coming.

Mark your calendars for our Annual General Meeting, which will take place in Christchurch – also known as the Garden City. O ering a vibrant co ee scene and a welcoming atmosphere, it’s perfect for re ecting on the year that was and shaping our future together.

e AGM is more than a meeting; it’s a chance to connect with the Board and other members, share ideas, and enjoy a couple of days of co ee culture. We’re planning a fun lineup around the AGM, so stay tuned for details and make the most of what the city has to o er.

Regional competitions return in 2026 with a fresh, accessible format designed the celebrate local talent and encourage new faces to step into the spotlight. ese stripped-back events focus on connection and creativity, and also act as a so launch into Nationals for those who might feel intimidated by the big stage. Our goal? To remove barriers and create a space where more people feel con dent to

‘just give it a go’. Less pressure, more fun, and plenty of opportunities to learn and grow.

Two big weekends of national competition in Auckland means more spectators, more energy, and even a few friends from across the ditch.

e Cup Tasters Championship and Brewers Championship kick o the year in early May, and we’re thrilled to welcome the Brewers Cup back into the calendar for the rst time in years.

Late September will bring the artistry and precision of barista cra and latte art. ese competitions are about more than titles –they’re about skill development, community

connection, and creating pathways for co ee professionals at every stage.

We can’t wait to see fresh faces from the Regionals stepping up to the challenge.

In August we will be bringing back a past crowd favourite with the return of Symposium.

Designed as a space for learning, discussion, and professional development, Symposium has long been valued for bringing the co ee community together beyond competition.

More details will be shared in the coming months, but we can say now that we are looking forward to creating a meaningful and engaging experience for attendees.

With a full year of events on the horizon, 2026 is set to be a strong year for the specialty co ee community. Stay connected through our newsletter and social channels as we share more information and open registrations across the year.

For more information on the New Zealand Specialty Co ee Association, or to join, visit nzsca.org

Hany Ezzat started a movement in the world of coffee competition with a side hustle that has since become a major influence on the international scene.

People who compete in co ee competitions are always looking for an extra edge. From novel roasting processes to new water mineral concentrates, it’s the one-percenters that determine whether you make the nal round, li the title, or head home empty-handed.

Hany Ezzat knows all about what it takes to compete at these high levels. As an Australian Brewer’s Cup nalist every year between 2020 and 2025, and coach of 2024 Australian Roasting Champion and seventh-place winner at the 2025 World Roasting Championship, Sangchul Lee, he has seen how little changes can equal big results.

at desire to nd an extra edge inspired Hany to create Ni Wares cups. Over the past ve years his vessels have gained traction all over the world.

“I’ve been doing co ee competitions since 2017. Competitions were what inspired me to join the industry in the rst place, and I’m really lucky to work around a lot of inspiring people that have created a lot of incredible co ee tools,” says Hany.

“Working with the likes of Saša Šestić at Ona Co ee enabled me to see these things that changed the game, and it inspired me to nd my own way. When I was prepping for the 2020 Brewer’s Cup I was testing a bunch of vessels, and I ended up really liking two of them for my competition co ee.

“One of my co-workers had made his own cups for a competition before, and I thought I could try and make a hybrid between the two I really liked. e biggest features were the thick and thin elements of the rim which had a profound di erence on the way the co ee was perceived. I was connected with a renowned local ceramicist, Madeline Cardone, and I ended up nishing second in Australia.”

Ni Wares cups, on the surface, look like a perfectly smooth, pastel pink cup that, from the top down, look slightly asymmetrical with a small dimple poking up through the bottom. Every aspect, however, has been deliberately cra ed with the perfect delivery of co ee in mind. e speci c shade of pink has been scienti cally proven to make things taste up to 20 per cent sweeter, while the smooth texture has also been designed to positively in uence the experience of the user.

e di erent thickness of the two sides has also been carefully considered. e thinner, sharper lip promotes a thinner layer of liquid on the palate to support delicate notes like orality and brightness. On the other side a thicker, rounder lip supports more intensity, texture and sweetness.

Finally, the small, protruding dimple has

Ni Wares.

been designed to promote swirling in the liquid and prevent sediment from settling.

Hany says the current versions of the di erent Ni Wares vessels are the result of years of research.

“I ended up sending my rst handmade cups to someone in ailand and he ended up winning a competition with them, fast forward a couple of years of R&D where we slightly changed the shape, the colours, the weights, and I got really inspired,” says Hany.

“I found scienti c papers that proved things taste sweeter out of a pink cup, and that weight and shape all in uence the way co ee tastes. I started on my mission to design the perfect cup and started connecting with local

designers in Canberra, FORMSWELL, to start mass producing in 2021/22.

“ e rst prototypes from the factory came out in 2023 and I gave them to Kristóf Maróy for the World Brewer’s Cup, and he made the semi- nals using them. Since we fully launched in early 2024 it’s just been gangbusters.”

Currently, there are four di erent cups in the Ni Ware catalogue. e original Bouba, the thinner Kiki, and the Espresso and Milk Toto variants.

“ e Bouba cup is designed speci cally for co ee competitions, but the more I learned and developed I realised we had to make di erent cups for di erent co ees,

just like we do for wine,” says Hany.

“Bouba and Kiki are our lter options.

ey’re e ectively a red wine glass and a champagne ute – the thin shape and small surface area of the Kiki is going to intensify the sweetness and body of a co ee, so things like washed co ees taste amazing in thinner and more delicate cups.

“Big, natural co ee and co-fermented co ees taste better when you open them up, so that’s what the Bouba is perfect for. We want people to hold and swirl it like a wine glass. I was super lucky to work with Hugh Kelly who is a three-time Australian Barista Champion who made the world nals three times to create an espresso cup for his competition.” e espresso cup used by Hugh has also been used by the likes of recently crowned World Barista Champion Jack Simpson alongside a range of national champions from all over the world.

“I can’t even count how many champions have used them, but at least 13 di erent national champions used this at this year’s World Brewers Cup,” says Hany. “We’ve also had World Barista Championship nalists, and Jack won with them this year. We’ve even had them in latte art nals, and runner-up at the World Ibrik Championships Paul Ungureanu used them.

“ e espresso cup has become a bit of a staple in the world competitions. e goal is to put our cups in the hands of the best athletes

in the game, and they’ve been my biggest supporters and advocates.

“It’s amazing to know we’re changing the way people look at co ee. Having all these champions engage with it around the world,

it’s like a big family that extends across the globe. It’s super nice.”

Hany has become a leading voice in how each of the ve senses combine to alter the co ee experience. In 2025 he embarked on tours to the likes of South Korea, Kazakhstan, Kyrgyzstan, Japan, Qatar, and Indonesia, and demand for Ni Wares products continues to skyrocket.

Now, the brand has partnered with Co eeTools to help more co ee enthusiasts get their hands on the cups.

With a host of brands that prioritise the best possible co ee experience in its stable, Co eeTools Director Curtis Arnold says he’s excited to help Ni Wares continue to grow.

“Competition breeds technology and innovation, and that ends up trickling down to the consumer. is is the perfect example of that,” says Curtis. “Hany’s cups have been used in so many competitions at global and local levels all over the world.

“At that level of competition, you’re always looking for that small point of di erence, but this is also an opportunity for less sophisticated co ee drinkers to experience some of this competition-level equipment and experiment with these high-level concepts.

“Apart from the pleasure of working with someone like Hany, Ni Wares aligns really well with some of our other brands like Barista Hustle and xBloom, where the focus is on true specialty co ee and the attention to detail that comes along with it.

“ e Ni Wares cups are also beautiful and feel lovely in your hand, they’re appealing on a number of levels. You don’t have to have a world-class palate to appreciate the di erence they make and to enjoy using them.”

For more information, visit coffeetools.au or ni-wares.com

Following a record-breaking year in 2025, how can attendees make the most of their time at this year’s Melbourne International Coffee Expo?

While the Melbourne International Co ee Expo (MICE) trade

oor alone is a treasure trove of discovery, organisers of the 2026 event are building in plenty of golden opportunities outside of the con nes of the main expo.

An exciting line-up of activations are set to celebrate, educate, and connect the industry, including the BeanScene Café Owners Education Series; Co ee Industry Heroes Awards; the return of the Roaster’s Playground and Trip to Origin; and the inaugural MICE at Night.

Although attendees are spoilt for choice when it comes to curating their own MICE

experience, each of these initiatives operate with the same goal in mind: creating opportunities for connection.

“For some, it’s going to be the connections made through engaging with Trip to Origin, for others it’s going to be celebrating the industry at the o cial MICE a erparty and awards,” says Siobhan Rocks, General Manager – Events at Prime Creative Media, which organises MICE.

“It’s important to us that we are able to facilitate attendees creating di erent points of connection in their own way.”

e BeanScene Café Owners Education Series, sponsored by Grounded Packaging,

Representatives from the world’s origin hot spots will share their knowledge of coffee at its source.

will allow for café owners to step back from their day-to-day to obtain a stronger grasp of the industry in 2026, while providing actionable tips to ensure their businesses aren’t just existing, but thriving.

Topics to be covered include café management, the future of Australiangrown co ee, and navigating the cold co ee revolution.

“MICE is where the café community comes together, and the BeanScene stage is a place where owners can connect on shared industry topics,” says Siobhan.

“Our goal is to create an environment where owners feel empowered, inspired, and ready to take their business to the next level.”

e event will also feature the Global Co ee Report (GCR) Leaders Symposium, aiming to bring together leading roasters, business operators, and industry decision makers to unpack the trends, opportunities, and challenges shaping the global co ee landscape.

Attendees can expect a dynamic schedule from an extended panel of experts, and the opportunity to network and connect directly with industry leaders in the co ee industry.

MICE also marks the second year of the Co ee Industry Heroes Awards, which Siobhan says are “a real celebration of the trailblazers, the legends, and the newcomers within the co ee and café industry”.

“We’re putting people who are in the industry in the middle and shining a light on them as part of that,” she says.

is year will also see the expansion of four awards: the Sustainability champion, Co ee Educator, Best new café, and Home grown hero.

Following a record-breaking 2025, MICE organisers are harnessing that momentum, including the return of the highly successful Roaster’s Playground. It’s also the must-see event Siobhan recommends for MICE rsttime attendees.

“It’s the best representation of the Australian co ee scene: it’s a celebration of the diversity of di erent roasters, and it’s a cost-e ective way of getting their product out there. If there’s any argument on how good co ee is in Australia, it’s because of these people.”

e event will also see the expo’s rst extended-hours event, MICE at Night, which will turn the exhibition oor into an industry party for one night only.

Siobhan says it will allow key members of the co ee industry even greater access to the show.

“Although MICE typically runs across three action- lled days at the Melbourne Convention and Exhibition Centre, we have found café owners and operators can sometimes struggle to engage with the show as it falls during peak business times,” says Siobhan.

“We know how hard baristas, managers, and café owners work, so MICE at Night will

be an opportunity for them to let o steam while they network.”

She says the most exciting part of putting together this year’s event is the number of new exhibitors who’ve never attended MICE before, allowing the expo to continue to grow alongside the vibrant industry it serves.

“It’s really great to see a show that’s been

around for 13 years go through a phase of reinvention.”

MICE will be held from 26 – 28 March 2026 at Melbourne Convention and Exhibition Centre.

For more information, visit internationalcoffeeexpo.com/attend

TURNKEY SOLUTIONS BUILT TO ENHANCE YOUR COFFEE PERFORMANCE

INTEGRATED TECHNOLOGIES, SUPERIOR SUSTAINABILITY

Imagine a complete turnkey processing and packaging line for your coffee. From beans reception to end-of-line solutions, each machine is interconnected in a digital ecosystem, maximising performance, production efficiency, and ensuring superior sustainability through monitored processing, reduced energy consumption, lower emissions, and with the ability to handle all compostable and recyclable packaging materials. Imagine being able to have all this from one single source. IMA Coffee Hub. Look no further.

ima.it/coffee

More than five years since his last trip to Australia, MONIN CEO Olivier Monin sat down with BeanScene to discuss product advancement and sustainability driving his global gourmet flavour company.

From humble beginnings in France to a global industry leader, MONIN is no stranger to growth and innovation.

e fact the company now operates in over 160 countries and produces more than 200 avours is undeniable proof of this.

Distributed in Australia through Stuart Alexander since 2012, MONIN’s product line has become a staple for creative beverage makers in bars, hotels, and cafés – from premium syrups, frappe powders, gourmet sauces, fruit purees, to liqueurs and cocktail mixers.

Starting out as a liquor company before pivoting into its core business of syrups –family is the common thread throughout MONIN’s history. Its roots stem back to 1912, when Olivier’s grandfather, Georges Monin, founded the company in Bourges, central France, and passed it on to Paul, Olivier’s father.

Olivier later took the helm as president in 1993 – leaving his Chicago banking job and challenging himself to take the company to the next level. He achieved that and has been at the forefront ever since.

at family heritage still holds true, with Olivier’s 28-year-old daughter recently joining the company. He’s tasked her with visiting each of the company’s global plants,

located in the Americas, Asia, and Europe, to understand the di erences between each.

But he reiterates that whether a company representative carries the Monin last name or not, customers are treated with the exact same mentality: “nice people always want to help”.

“Every one of our plants and subsidiaries has a managing director, and they’re all easy to talk to. For us, that’s essential. We now have more than 1,400 MONIN employees, and any one of them can call me or send me an email. It’s important we keep that essence of the company, so we can continue to support our many customers across the world.”

Even with a 113-year history, Olivier recognises the need for MONIN to continually improve. A mindset shi in the way its products are presented to the market is an example of this, as well as its investment in sustainability initiatives (more on this soon).

On the rst point, he highlights the need for MONIN to evolve the way it serves its customers. One of those developments is an emphasis on “selling solutions”.

“We always say we are not selling the product, but the solution instead, because behind the scenes we have the skilled people who do that – so MONIN, and our distributors, are investing in a very high-level of professionalism,” he says.

“ e solution should be di erent for each venue, even if they are just a few metres apart. Most times, their customers are di erent, and so the expectation will be di erent.”

With MONIN products available in 165 countries, the company is privy to an array of trends across the co ee and café industries – the matcha explosion saw the company release a Green Tea Matcha syrup.

Olivier says the company hears from those on the ground in every country, including Australia. If the idea has merit, the company’s R&D team seek to understand how to maximise this opportunity so customers can bring new avours into their drinks menu.

“New trends are very di cult to de ne, but one trend we’re really working on is to now concentrate on avours that aren’t as sweet.

ere’s a global trend worldwide towards this, consumers are demanding it,” he says.

Before launching products, the company ensures the recipe matches the intended avour. Olivier o en gets the nal say on any new product.

“I always believe with every new syrup, if I don’t get that ‘wow’ moment, then we need to go back to work,” he says.

MONIN currently has more than 200 syrup recipes, thanks to access to variety of fruits from around the world. Olivier says

one of the most recent editions is jabuticaba, a Brazilian fruit that’s become a “very popular” avour.

“In every region where MONIN operates a manufacturing plant, we try to also develop a new syrup close to the local food,” he says. e company has recently established its own plantations, planting yuzu – a citrus plant – ve years ago in Europe and vanilla in Madagascar.

“Yuzu was the rst because we saw that there was going to be a decrease in production, mainly in South Korea, where 80 per cent of the production is coming from … we’ve done this beautiful plantation, but we think we should multiply by 10 because the global production is decreasing, and the demand is increasing.”

e company’s Madagascar operations started not long a er. e country itself produces at least 80 per cent of the worldwide vanilla supply.

Olivier says the company bought land in a small village, employing 80 locals, and has built a school classroom. e farm sits 1000 kilometres from the main production area and partners with local business for the production.

He says the way the farm has been set up “enables us to take care of each tree”.

“We take care of our environment, and I think very few companies can do that, especially in the syrups industry,” he says.

“It’s so important to take care of nature, because if you don’t teach your kids, then you will lose it. So it’s very important for us to be part of it.”

Olivier puts a strong focus on the increased naturality of ingredients, noting the trend’s rise in Australia. Currently, 98 per cent of MONIN products are made with 100 per cent natural ingredients.

“When I came on 40 years ago, there were just a few ingredients – around three, four or ve – in the recipes. Now it’s more like 15 to 25, and much more complex. To make it self-preserved, you need to add a lot more smaller types of spices, and di erent types of ingredients,” he says.

“Before [the change], we were producing new avours in almost a few days in the lab. Now it’s more like a few months, because we want to keep it stable, without using any preservatives,” he says.

On the sustainability front, each new MONIN plant aims to improve upon its environmental impact, with Olivier highlighting the company uses solar panels in Bourges that can save 80 per cent of its water waste.

“ e more people that use that system, the better for the planet,” he says.

Other goals include using 100 per cent recycled glass, and the company is looking to

overhaul each plant with water sustainability in mind, realising downstream models to target zero waste in the coming years.

Elsewhere, MONIN purchased a 13th generation orchard in France with more than 340 fruit varieties that was closing down. Although this farm doesn’t grow fruit for MONIN products per se, the company is selling the trees to ensure they get another lease on life.

On what advice he would give to MONIN customers, including cafés, Olivier says there’s an opportunity for cafés and other venues to avoid “cheap product, made the arti cial way” and lean into more natural ingredients that consumers are increasingly demanding.

“ at’s our advantage, and why we play at the premium end of the market. We may be a bit more expensive … that’s because our products contain high quality ingredients but it’s better for everyone.”