SPARE PARTS?

We have you covered.

BUS&COACHSALES

In a crowded market of bus fleet options, choosing the right partner is essential.

At Bus Stop Sales, we bring over 50 years of family dedication to the industry. We’re not just a supplier—we’re your trusted solutions partner.

Why Partner with Us?

Eco-Friendly Solutions: Award-winning, sustainable options for your fleet.

Comprehensive Range: From Zero Emission Buses (ZEB) to reliable diesel, we cover all your needs.

Local Content, Local Jobs: A mix of world-class imported and locally built solutions, supporting local industry.

Local focus

While many topics concerning the local bus industry are currently before politicians, there’s one in particular that warrants immediate attention and clarification

There’s no shortage of news currently impacting Australasia’s bus and coach industry.

Whether it be a wealth of new deliveries, state government budgets being unveiled, major driver strikes impacting operators and patrons or the announcement of executive appointments, the bus and coach industry in our region is being kept busy.

However, underlining this news is a raft of key issues that remain unanswered.

While they sit wilting away without political progress, they bore more of a hole into an industry that is desperately waiting to react.

The discussion around the zero-emissions bus transition has been subject to the spotlight in recent years, with a wide range of operators, industry experts, association members and suppliers voicing their concerns about the lack of communication on the path forward. In its shadow has been the need to talk about local content. It’s high time that this issue is addressed.

that give manufacturing jobs to locals, is this not a major step forward for local content in our industry?

The fact of the matter is only a handful of bus and coach companies, whether they be on the operations or supply side, are 100 per cent Australian owned and operated nowadays. International influence is well and truly occurring. A clear example of this is Irizar Asia Pacific – a Spanish manufacturer that has made Melbourne its local happy hunting ground in recent years through its newly opened Pakenham facility. From page 28, Irizar discusses how its plan to tackle Australia’s high floor coach market has paid off through a focus on local service and supply.

There’s no shortage of news currently impacting Australasia’s bus and coach industry

The variety that defines local content is on full display in this edition of ABC Magazine, which is tailored to stories on Australasia’s leading bus and coach bodybuilders amid the usual array of current affairs and industry developments.

On the industry front, Bus Industry Confederation (BIC) executive director Varenya Mohan-Ram vows to continue pushing the federal government to discuss what defines local content in Australia. While this happens, bus and coach suppliers continue to do their best with the definitions currently in play.

Our cover is a clear example of this, with Bus Stop Sales deciding to take matters into its own hands. From page 24, Bus Stop director Pete White discusses the brand’s innovations in the local assembly sphere as he prepares to launch both a complete knockdown and a driveable knockdown facility in Brisbane.

While at it, Bus Stop is also expanding its capabilities in New South Wales in a bid to improve its national footprint. It begs the question – if suppliers are pivoting from importing fully built buses and coaches to establishing local assembly sites in Australia

Another example of the benefits of local suppliers being involved in the production of buses and coaches for Australasian operators is with Capral and Volgren. The pair have forged a strong partnership based on Volgren using Capral’s aluminium extrusions in its body design, with the pair highlighting the importance of a local materials supply partnership for bus manufacturing on page 34.

Outside of this, Challenger introduces its first ever general manager to the industry on page 30, while Scania is following the trend of focusing on its aftersales capabilities to enhance its overall product offering.

This edition includes a variety of other news, such as a reflection on the recent BusSA conference for 2025 courtesy of BIC, a breakdown of what the latest seatbelt ADR asks of suppliers and updates on recent bus depot announcements from some of Australasia’s largest operators.

We hope you enjoy the read this month.

Sean Mortell EDITOR, ABC

06. editorial | ignition LOCAL FOCUS

While many topics concerning the local bus industry are currently before politicians, there’s one in particular that warrants immediate attention and clarification

10. news | all aboard

Check out the latest news from around Australia and the world features

23. column | bic TIME TO LEAD

The South Australian bus industry is standing at the crossroads at a defining moment that calls for bold leadership, national collaboration and smarter future-proofing

24. cover story | bus stop sales CUSTOMER CENTRIC

Bus Stop Sales’ rich history is currently evolving, with multiple new developments to enhance its Australian vehicle offerings on the way

28. feature | irizar INVEST FOR SUCCESS

Since entering Australia’s high-floor coach segment, Irizar has carved out a strong reputation by focusing on quality, aftersales support and smart partnerships

30. feature | challenger THE RIGHT FIT

Challenger continues to cement itself as a leader in the Australian bus and coach industry, with its experienced team leading the charge

32. feature | scania PUTTING THE PART IN PARTNER

With a passionate aftersales team and a growing parts network, Scania Australia is committed to keeping buses on the road and in tip-top shape

34. feature | capral aluminium AUSSIE ALUMINIUM

Capral’s ongoing supply partnership with Volgren is allowing the bodybuilder to relish the numerous benefits of having high quality aluminium ready to go from a local source

STAYING SAFE

Keeping safe on the roads is more important than ever, with the BusSAFE program ensuring the right education and warnings are given out

38. feature | father and son A FAMILY AFFAIR

With a combined career of five decades at Volvo, ABC finds out how David and Stuart Woodward are able to successfully mix family and business

40. feature | royans EASY ACCESS

With a spread of locations across both Australia and New Zealand, Royans Group is committed to servicing the bus and coach industry

43. feature | botany smash SAVING GRACE

Damage to a bus or coach is never fun, but Botany Smash Repairs is intent on making a difficult situation easier for operators around the country

45. feature | election review

PLOTTING THE WAY FORWARD

BIC executive director Varenya Mohan-Ram lists the association’s key topics for change that it’s ready to discuss with the latest federal government

46. column | qbic

ROAD SAFETY IS NOT POT LUCK

The Queensland Bus Industry Council discusses why zero limit drug laws for commercial drivers must stay in place

51. competition | best bus TOP DECK TOURER

In a world where new buses grace the road every day, the vintage beauties still manage to catch our eye

departments

54. factory facts | bus deliveries MAY DELIVERIES

Check out the latest bus and coach supplier sales data collected and recorded for you to review and see how the market fared in May

58. back seat | bus restoration TRAVELLING THROUGH TIME

ABC finds out how a group of dedicated people in Western Australia are preserving the history of the state’s public transport system

Head of Customer Experience:

Managing Editor: Geoff Crockett

e-mail: geoff.crockett@primecreative.com.au

e-mail: sean.mortell@primecreative.com.au

Assistant Editor: Tiarna Condren e-mail: tiarna.condren@primecreative.com.au

Designer: Apostolos Topatsis

PRINTING

Brougham Press

ADVERTISING

Sales Manager – South:

Courtney Burton ph: 0481 736 890

e -mail: courtney.walker@primecreative.com.au

Business Development Manager – Bus:

Adrian Kos ph: 0413 777 670

e-mail: adrian.kos@primecreative.com.au

SUBSCRIPTIONS

www.busnews.com.au/subscribe ph: +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST)

e -mail: subscriptions@primecreative.com.au mail: 379 Docklands Drive, Docklands VIC 3008 Australia

Annual subscription rates (12 issues): Australia: $99* Overseas: $A170 (Australian air-mail only) *price includes GST

Cover image: Bus Stop Sales

Image: Capral Aluminium

Melbourne bus driver strike halts network

Over a third of Victoria’s bus network was affected by the work stoppage, with Dysons and CDC Victoria drivers stepping down for 24 hours

In late May, protected industrial action co-ordinated by the Transport Workers’ Union (TWU) occurred after employee negotiations stalled with Dyson Group and CDC Victoria.

According to the TWU, both companies refused decent improvements on rostering, safety and pay, with over 95 per cent of TWU members endorsing the strike when it went to a vote.

Together, the bus companies operate hundreds of bus routes and charter services and together, making up one third of all routes across the state.

The strike lasted a full 24 hours, beginning at 3am on Wednesday May 28 and lasting until 3am Thursday May 29.

The TWU says it was demanding a fair deal that recognises the critical role bus drivers play in keeping the community moving.

“The current offers from CDC and Dyson fall short. Our members have been patient, but that patience has run out,” TWU Victorian/Tasmanian director of organising Sam Lynch says.

“It’s time for CDC and Dyson to stop dragging their feet and start listening to workers’ calls for respect and a fair day’s pay.

“We’re standing together to lift the standard across Victoria’s bus network and improve wages, conditions and safety for every driver.”

Commuters were warned of major disruptions in Melbourne’s north and west, as well as in regional cities such as Ballarat, Mildura and Geelong.

“In 2022, more than 300 TWU bus drivers took protected strike action following Dyson’s failure to move on workers’ core demands, including safety and working conditions,” a TWU Facebook post reads.

“If management doesn’t come to the table with a better offer, TWU members will take action again!”

In response, Dysons says the

Below: Commuters were warned of major disruptions in Melbourne’s north and west, as well as

TWU’s decision to initiate industrial action is “disappointing” due to the impact it would have on public transport passengers in Melbourne’s northern corridor.

“Dysons’ proposal for a new Enterprise Bargaining Agreement (EMA) in March will deliver significant wage and benefit outcomes for drivers – including a nine per cent year-one wage increase,” Dysons says in a statement.

“Industrial action causes unnecessary inconvenience to public transport bus passengers. As a family-owned business with over 73 years of delivering quality public transport and charter bus services, we’re committed to maintaining a reliable, high-quality service for our passengers. That’s why we’ve been working constructively to finalise a

Planning to minimise disruption to our passengers and valued customers. Our intention is to operate to a modified timetable during any period of industrial action.”

The operators says it has been negotiating “in good faith” with the TWU since January 2025 to reach a new EBA that benefits employees and the company. It says the TWU has “consistently rejected” the alternative wages and conditions offer that Dysons has presented, with a vote on Friday May 9 revealing roughly 60 per cent of drivers didn’t support the proposed EBA.

“Since the proposed EBA was voted down, we have received no counteroffer from the union,” Dysons says.

“Dysons remains committed to reach agreement on a new EBA within

Love the journey

Discover the ultimate in coach design with our BCI Cruiser bodies, built to fit a variety of European chassis platforms with cutting-edge safety technology, specifically engineered to meet the unique demands of Australian roads. Step into their refined interior designed for maximum comfort, with spacious seating and climate control tailored to enhance every ride. This new generation of BCI coaches sets a new standard of excellence in our industry.

Contact our team for further information on 1300 289 224 or visit bcibus.com.au

Head Office Perth: 08 9353 9000

Melbourne: 03 8787 2100

Brisbane: 07 3275 6900

Adelaide: 08 8182 3888

The end of diesel in WA

Western Australia has officially entered a new era in public transport, with the final diesel bus rolling off the production line at Volgren’s facility and into active service

From this point forward, every new bus built for Western Australia’s public transport network will be fully electric as part of a major step in its transition towards zero-emission transport.

The milestone signals the end of diesel bus manufacturing in Western Australia and the beginning of a clean-energy fleet rollout led by long-term partners Volvo Bus Australia and Volgren.

Volvo, the contracted chassis supplier for the project, says it is proud to support the Public Transport Authority (PTA) in this landmark transition.

“Moving every new PTA bus to electric is a landmark for public transport in Australia,” Volvo Bus Australia general manager Mitch Peden says.

“Our role is to be a dependable, long-term partner – from engineering support to parts and specialised electric bus training – so the PTA can keep communities connected while cutting emissions.”

Under the transition, 130 Volvo BZL

Below:

Under the transition, 130 Volvo BZL Electric buses will be built locally in WA over the coming years. Image: Volvo

WA over the coming years, alongside the installation of high-capacity charging infrastructure at key depots.

Each bus is expected to eliminate around 40 tonnes of CO2 per year and can travel up to 300 kilometres on a single charge, cutting both emissions and operational downtime.

“This milestone is the result of a long-term partnership and a shared commitment to cleaner, more sustainable transport,” Volgren CEO Thiago Deiro says.

“By building these electric buses locally, we’re not only reducing emissions but also supporting Western Australian jobs and developing the next generation of skilled workers.”

Manufacturing of the electric bus bodies remains at Volgren’s Malaga facility, helping secure local jobs and apprenticeships in advanced manufacturing.

WA Premier Roger Cook acknowledged the significance of the moment, confirming that the last diesel bus ever manufactured in

passenger service.

“I want to ensure Western Australia’s economy remains the strongest in the nation. That means diversifying by investing in decarbonisation and supporting local manufacturing so that we can build more things in WA,” Cook says.

“Building electric buses locally is a key part of my government’s vision for a future that is made in WA, complementing our locally built METRONET railcars and historic investment in public transport.

“It won’t just create more than 100 jobs in Perth’s north-eastern suburbs –it will lower our emissions and reduce operating costs across Perth’s public transport network too.”

In the meantime, Perth commuters are already seeing the benefits of electrification with 18 Volvo BZL Electric CAT buses currently in operation across the city, offering quieter and cleaner journeys for passengers.

Upgrades at Malaga and Bayswater depots are also underway to accommodate larger electric fleets as

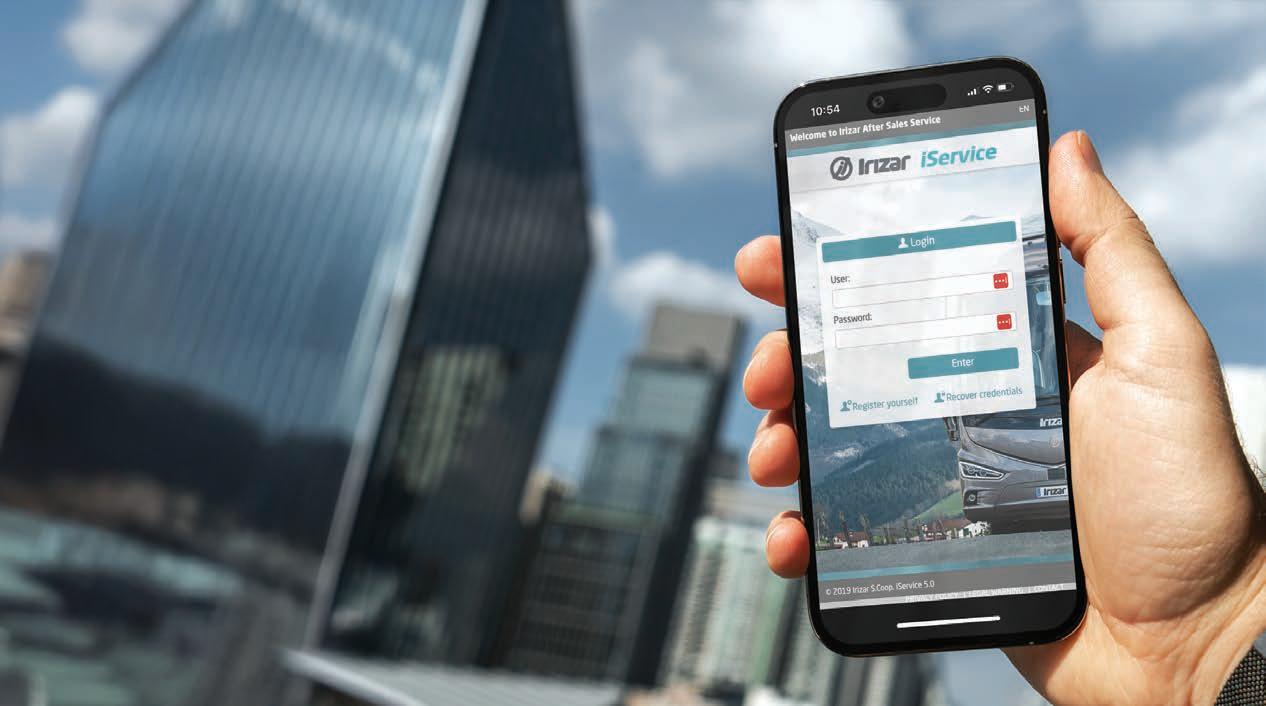

Irizar’s iService Portal is an advanced digital platform with technical data simplifying complex maintenance processes and ensuring fleets remain operational with minimal disruptions.

Simply enter your VIN for:

Comprehensive Technical Documentation

Precision Spare Parts Ordering

Maintenance Resources

Registering for iService is easy—simply click the “Register Yourself” button on the iService Portal at https://iservice.irizar.com

Buses missing from $5 billion Vic PT blitz

Despite the multi-billion public transport allocation, a Melbourne advocacy group is calling out a lack of funds for buses

The Victorian government has announced the 2025/26 Budget will see $5 billion allocated to public transport across the state, yet with no mention of bus network funding.

With a key focus on Melbourne CBD and surrounds, the multi-billion dollar investment will see $727 million go towards operationalising the Metro Tunnel, delivering turn-up-and-go services for the Sunbury, Cranbourne and Pakenham lines that run through it.

A further $98.7 million will deliver more frequent services for passengers on other lines, making it easier for passengers to get to work and home sooner. These include the Werribee, Sandringham, Craigieburn, Upfield, Gippsland, Bendigo and Seymour lines.

The budget also allocated $4 billion towards the Sunshine Station redevelopment, bringing forward $2 billion of the government’s investment

Above: Sustainable Cities says these positive benefits will not be shared with residents living in suburbs not serviced by trains. Image: Jackie Davies/stock. adobe.com

in Airport Rail to kickstart works as soon as possible.

“We’re focused on what matters most. People just want to get to work and get home sooner, and I’m on their side,” Victorian Premier Jacinta Allan says.

While the opening of the Metro Tunnel and extra rail services will provide some with faster, more connected networks, others are quick to mention the disregard of buses for those in Melbourne’s western suburbs.

Advocacy group Sustainable Cities spokesperson Elyse Cunningham says these positive benefits will not be shared with residents living in suburbs not serviced by trains.

The group is calling for a fast, frequent and connected bus network in Melbourne’s west as the solution for providing commuters with reliable access to stations across the Sunbury line, eliminating the need for extra

car trips or car park upgrades, and to provide ‘a funnel to the Munnel’.

“For the full benefits of the Melbourne Metro Tunnel to be felt, the Sustainable Cities Collective calls on the Victorian state government to reform the bus system in the western suburbs to give residents better access to the Sunbury line,” Cunningham says.

“There is no point spending lots of money on rail upgrades if the access to the station is limited only to those who live within walking distance of the line, or have the means to drive to the station.

“A reformed bus network across the west which is fast, frequent and connected to important destinations such as train stations and shopping centres will ensure the transformational impacts of the Metro Tunnel project are equitably shared across the community.

“Our ultimate message is that we need better buses to provide a ‘funnel to the Metro Tunnel’.”

While increased train capacity helps commuters in and out of the city, most western suburbs residents have no reliable options for getting to local activity centres, the shops or train stations without a car.

“A fast, frequent and connected bus system is what will really get people moving in the west and take cars off the road to reduce congestion,” Cunningham says.

“At the moment, families in the western suburbs need two or more cars to get kids to school and parents to the train station. More train services are great, but a transformed bus network is what will really make the difference in the day-to-day lives of millions of western suburbs families.

“The minister admitted that ‘buses are the poor cousin’ in Melbourne’s public transport, and this announcement proves that Labor still aren’t taking buses seriously as the low cost, high impact transport solution they are.”

Major bus reforms coming for the NT

The reforms will aim to reduce anti-social behaviour and support a more flexible, responsible network

The Northern Territory government has unveiled a major overhaul of the public bus network in Darwin and Palmerston, aimed at reducing anti-social behaviour and improving passenger and driver safety.

Infrastructure and logistics minister Bill Yan announced a Bus Safety Reform Strategy will roll out in multiple stages that will see sweeping changes to the Northern Territory’s public transport system.

“We want every Territorian to feel safe when they catch a bus,” Yan says.

“These reforms are about building a public transport system people can trust and use with confidence.”

A key part of the plan is the closure of the Casuarina interchange by October 2025, with staged closures of the Darwin and Palmerston interchanges to follow. The

government says the closures will reduce crime and allow for a more flexible network design.

Safety measures will also be upgraded, including expanded CCTV at hotspots, direct radio links between drivers and police, and on-board duress alarms.

From August 1, 2025, a new NT Bus Tracker App will launch, providing real-time tracking, journey planning and alerts that factor in walking and cycling times.

The government also confirmed that free bus travel will continue beyond July 1, 2025.

“Since the introduction of free travel, the Transit Safety Unit and bus drivers have reported a decrease in anti-social behaviour on bus services,” Yan says.

“New statistics confirm that our

efforts to improve bus safety are delivering results, with reported assaults on bus drivers down by seven per cent.”

A full review of the Darwin and Palmerston bus network is underway, focusing on reducing wait times, improving routes and trialling on-demand services to replace some low-patronage late-night routes.

“These are real changes that will make a real difference,” Yan says.

“By shutting down outdated interchanges, boosting surveillance and improving real-time communications, we’re creating a network that’s safer and more reliable for everyone.”

The reforms are part of the government’s “year of action,” aimed at reducing crime and improving quality of life for Territorians.

Transdev John Holland Buses appoints new managing director

The new director brings over 30 years of leadership experience and extensive knowledge of the bus sector to the role

Kicking off her role in late May, Daniela Fontana has been named as Transdev John Holland Buses’ new managing director.

Fontana’s long history in the bus industry means she has a deep understanding of network operations alongside the company’s commitment to deliver high standards of safety, service, innovation and recruitment across Transdev John Holland’s region nine contract in Sydney’s CBD and eastern suburbs.

The popular bus network mobilises a rising commuter, tourist and student patronage since the COVID pandemic and sees Transdev John Holland provide over 50 million journeys each year.

As the new managing director, Fontana leads 1,100 staff and oversees three depots and their 470 buses and 48 public and 137 school routes – including the 24-hour 333 circuit between Bondi Beach and the CBD.

Fontana previously led Transit Systems NSW and State Transit Authority NSW. She says she looks forward to stepping into the position to lead a dedicated team of journey makers and a strong internal culture.

“I have always believed buses are a key transport mode,” Fontana says.

“The region nine network is vital in connecting local communities with each other and to the city.

“Having led multiple bus networks and regions across Sydney, I am very excited to drive our people and projects forward that will make great impact to customers in the region.”

Transdev Australia and New Zealand CEO Brian Brennan welcomes the appointment and highlights Fontana’s collaborative approach and operational expertise.

“Daniela brings a strong track record of operational leadership and I’m confident region nine will continue to go from strength to strength under her guidance,” Brennan says.

“She joins a passionate local team of journey makers and, with her history of delivering exceptional results, I’m excited to see what they’ll achieve together.”

Major changes coming to Brisbane bus network

Brisbane’s bus network is set to look very different from the end of June as a wave of changes are set to shake up the current program

Around two-thirds of Brisbane’s bus services will see major changes from the end of the month, as the city is expected to experience “the largest uplift to the bus network in over a decade”.

From Monday June 30, Brisbane City Council will be introducing a new bus network alongside a new Metro route, the M1.

“It will be the biggest change that we have seen in the Brisbane bus networks in decades,” Brisbane Lord Mayor Adrian Schrinner says.

“We’re also adding new bus services, we’re adding extra capacity, we’re boosting frequencies and it’s all about keeping Brisbane moving and getting more people on public transport.”

The upcoming M1 will replace route

111 and 160 bus services, running at five-minute frequencies between Eight Mile Plains and Roma Street. This is the third stage of the Metro roll-out.

About 70 per cent of the bus network will also see changes as the council add five new routes: the 26, 109, 127, 182 and 197.

Four peak-hour services will be extended to all-day operations while 12 combined routes will be launched to eliminate duplicate buses.

Transport chair Ryan Murphy says 30 million additional trips will be available on the network that carried 80 million passengers annually.

“Eighty-five per cent of the trips will be faster or the same, and 15 per cent of trips will be slower, but overall, what we will see is a significant reduction of the buses that

Who is Dyson’s new metro general manager?

are clogging CBD streets during the morning and evening peaks,” he says.

“We will take buses out of the CBD and reallocate them into the suburbs. Metro has always been about replacing large numbers of those smaller buses that carry 70 people with mega buses that carry 170 people.

“We expect that we’ll be one of the first cities in the world to have public transport patronage now exceed its pre-COVID levels.”

Changes to the Brisbane bus network may include new route paths, stop changes, bus number changes, transfers or routes being merged with another route. Timetables may also be adjusted.

Brisbane City Council is urging passengers to plan ahead.

The new general manager is stepping up from his current role as regional planning manager, leading the operator towards a zero-emission future

Australian bus operator Dyson Group has announced Brad Dyson as its newest metropolitan general manager, leading the Metropolitan Zero Emission Bus Franchise (MZF) division.

With over 25 years of experience in the bus and coach industry, Brad brings a wealth of knowledge and expertise to the role. His extensive career within Dyson Group has seen him take on various roles, most recently serving as regional planning manager.

As a fourth-generation member of the Dyson family, his appointment continues the family’s longstanding involvement in the company’s operations, which began in 1952

when Laurie Dyson founded the business with just four buses.

company’s operations and strategic vision positions him well to lead the MZF division as it embarks on a transformative journey towards zero-emission public transport.

“I’m incredibly excited to take on this role and lead our team as we contribute to the decarbonisation

opportunity to shape the future of transport in Victoria.

“I’m proud to be part of a team that’s not only building on Dyson’s rich history but also leading the way in reducing emissions and creating a better environment for future generations.”

Right: Brad brings a wealth of knowledge and expertise to the role. Image: Transport for NSW.

Queensland bus industry questions tender

In April, the Queensland government outlined a new contract tender that veered away from its usual way of business. Sean Mortell reports the industry is seeking clarification on what this means for its future

April 1 is usually a day for pranks. For laughter. Smiles. Mischief. The Queensland bus industry can be forgiven for thinking they were part of an intricate April Fool’s Day this year when a new tender was dropped by Queensland’s Department of Transport and Main Roads (TMR).

But it wasn’t. To kickstart April, the department released a new invitation to offer (ITO) for nine new routes devised for the Queensland towns of Ipswich and Logan. These new routes had been advocated for by both the community and operators supplying bus services to the region for quite some time.

Instead of giving these operators the first right of offer, the ITO signalled a change in approach from TMR for the nine routes. However, a 10th route was handed out to an existing operator.

“We thought it was interesting that the TMR offered first right of offer to an operator for one route, but put the other nine routes out to a public tender,” Queensland Bus Industry

Above: O’Dwyer says “the whole project seems rushed and not well thought out”. Image: Queensland government

Council (QBIC) executive director Jason O’Dwyer told ABC

“Operators in the area and QBIC were not given the courtesy of a phone call regarding going to open tender.

“One might expect that after 40-plus years of successful partnership with successive governments, the department and services to the public, that these operators may have deserved a call from Translink explaining the decision, not to mention QBIC as well given our 100 years of history in representing operators in Queensland.”

It’s a concerning moment in time for all of the state’s bus industry. Pre-existing arrangements were thrown out the window as operators who have forged up to 50 year histories of Queensland owned and operated business now ponder what the future holds if Translink awards the nine new routes to operators from outside the area. Will they then start stripping more contracts from existing companies? Or is it just a one-off

move to inspire more competition in the region?

O’Dwyer was left pondering how TMR reached its decision to “have a new operator in an area that already has operators”.

O’Dwyer went on to question the impact on layover facilities, passenger interchanges and driver rest areas which are already congested with three current operators, including Brisbane City Council.

“How it could be a more efficient use of government money to have a fourth operator at these sites? It doesn’t pass the lunchroom test,” he says.

“Some operators have been advocating for these routes for the best part of 10 to 15 years, they’ve identified the need, done the modelling and advocated for it both locally and with the department – it’s well within their expertise to deliver.”

Adding to the confusion is a provision in the ITO that stipulates a new depot is included as part of the contracts. O’Dwyer says the most recent discussions with TMR is that it wishes to own depots. However, he says that he sees from the ITO that the land is being leased seemingly in contradiction to what’s been advised to industry.

Part of the contract is the chance to run an estimated 37 state-managed buses and depot infrastructure that will be allocated by the government. An initial government investment would see more than $24 million poured into the network to grow it and reduce congestion. The depot mentioned in this ITO would be the first to be owned by the government.

“The suggested depot will be in the middle of nowhere, so there’ll be significant dead running for the successful operator on some routes,” O’Dwyer says.

“From a network planning, attraction and retention perspective, the industry is left scratching its head. Will the new operator will be given a flat block of land with demountable buildings, running on generators, servicing new routes with little to no accessible bus stops, appropriate street furniture or accessible footpaths for those with disabilities?

“The industry finds it hard to recruit drivers, let alone in a depot with at best temporary buildings – you need decent facilities to attract and retain drivers. The whole project seems rushed and not well thought out.”

The opportunity to submit for the ITO will close on June 11 after having been through two deadline extensions.

In response, a spokesperson from TMR told ABC it has commenced the ITO process as part of the state’s plan to provide a “frequent, accessible, reliable and safe public transport network”.

“The ITO was open since Tuesday April 1, 2025 and closed on Wednesday June 11, 2025,” the spokesperson says.

“To date there has been significant interest from the industry and we look forward to further announcements following the tender evaluation process.”

The spokesperson didn’t comment on why TMR has changed its process to make it an open tender except for the 10th route that has already been awarded, nor how the depot will work between the government and operators.

Like many modern metro bus

service contracts in Australia, zero-emissions bus technology is also built into the contract. ABC reported that Translink had revealed more details on how the power sourcing for running zero-emissions buses would be arranged at the Ipswich depot.

“The state will ensure the New Chum depot has access to power from day one,” Translink says on updated documents for the contract’s Invitation to Offer (ITO) process.

“This may be in the form of diesel generators until such time as an electrical connection can be arranged. As such, the State Electricity Procurement Arrangement does not currently exist for the purposes of sharing.

“The state will also supply diesel fuel and AdBlue for the diesel buses from day one. As such, the offeror does not need to cost depot electricity and diesel/AdBlue bus fuel costs in their offer.”

Once the depot has been upgraded to accommodate battery electric buses, Translink says the state will review this arrangement to consider additional electricity requirements for charging.

“At this point, the state will be happy to share relevant extracts of the State Electricity Procurement Arrangement as it relates to the charging KPI,” Translink says.

“For clarity, the offeror does not need to cost electricity supply in their offer.”

This has led to more head-scratching on the bus industry’s side, with O’Dwyer saying this change in

PROFESSIONAL REFINISHING

approach limits operators from being able to trade power and off-set costs.

“My understanding of interstate ZEB operations is that they have the ability to trade power with retailers and generators to significantly off-set costs to make electric depots more financially viable,” he says.

“By locking operators into a power sharing deal with the government, it ties the hands of operators behind their backs.

“This just leaves operators with the operation of the contract, but even then, the government has approved the routes and set the timing, so the profit margin isn’t that great.”

O’Dwyer says the industry is voicing its concerns about what precedent this sets for future contracts in the state. O’Dwyer’s main goal is to ensure Queensland avoids following other Australian states that have tendered networks to new operators who have no experience in the area, namely New South Wales and its Sydney bus contracts, and found issues with service delay, cancellations, passenger complaints and driver shortages.

“We’re in discussions with the department and listing our concerns – we’ve said this model is a failed playbook,” he says.

“We don’t want our state making the same mistakes, so government needs to better engage with our industry. We cannot have a race to the bottom on price, as it will be the passengers and taxpayers that will ultimately suffer.”

Branches across Australia & New Zealand When back on the road means back to business. Choose Royans.

First electric bus hits the road on Mosgiel route

Another dozen buses are expected to hit the roads before mid-year, ushering in a new era of public transport in New Zealand

Passengers on Dunedin’s public transport will soon be enjoying smoother, quieter rides as the first electric buses begin filtering into the depot’s.

The new Chinese-built Geely C13E 75-passenger electric bus is the first to start plying the route between Mosgiel and Dunedin, delivered and operated by Kinetic-owned Go Bus.

By July, six of these high-capacity electric buses will be on the road as part of a new 13-vehicle electric fleet transforming public transport for the growing Mosgiel community.

The Kinetic fleet will include six large buses, six standard-size EVs and a smaller 22-seat, wheelchair-accessible vehicle for a new On Demand service.

Below: The introduction of electric buses to Dunedin’s network builds on Kinetic’s broader commitment to sustainability across New Zealand. Image: Kinetic

“This is an exciting milestone for our team in Dunedin,” Go Bus COO Ben Barlow says.

“The arrival of our first zero-emission, 75-passenger electric bus marks a major step forward in delivering cleaner, more sustainable public transport for the region.”

The first large EV entered service in early April, with more arriving throughout May and June. Delivering the vehicle early allowed local drivers to undertake comprehensive training and gain valuable experience operating the new model across varied terrain — from highways to residential streets.

“The feedback so far has been fantastic,” Barlow says.

“Passengers are loving the quieter,

more comfortable ride, while our drivers appreciate how smooth and responsive the vehicle is to operate.”

To support the new fleet, Kinetic has upgraded its depot on Dukes Road in Mosgiel with state-of-theart charging infrastructure that was completed ahead of schedule. The depot will serve as the primary hub for the electric vehicles.

The introduction of electric buses to Dunedin’s network builds on Kinetic’s broader commitment to sustainability across New Zealand.

Over the next several years, diesel buses will continue to be progressively phased out as contracts renew, supporting long-term emissions reduction goals for public transport.

Electric double-decker buses launch in West Auckland

A new fleet of 44 electric buses have hit the roads in West Auckland

The new buses, including 26 double-deckers, will run every 10 minutes on AT’s WX1 Western Express frequent service from Westgate to the city centre via the Lincoln and Te Atatū bus interchanges.

The new buses will also replace current diesel buses on the 11T, 11W and 12 routes in the coming months.

Auckland Transport (AT) fleet specification manager Edward Wright says Auckland is now well on its way to hitting its 2030 target for the electric transition.

Auckland now has 224 electric buses, with AT saying it operates more electric buses than any other city in Australasia.

“Each of these new double-decker electric buses can fit 100 passengers, and we have boosted capacity on the WX1 service by an additional 7,333 seats every weekday, and 51,000 seats every week,” Wright says.

“We’re adding another 31 electric

buses to our fleet by the end of June. By August next year, we will have a fleet of 450 electric buses, which is around a third of the 1,350 buses that

operates AT’s services.

“Longer term, we have plans in place for Auckland’s bus fleet to be fully electric by 2035.”

Above: The new doubledecker taking off. Image: Auckland Transport

Time to lead, not lag

The South Australian bus industry is standing at the crossroads at a defining moment that calls for bold leadership, national collaboration and smarter future-proofing

BIC executive director

Varenya Mohan-Ram delivered an inspiring call to arms for all stakeholders to embrace regulatory reform, harmonisation and practical pathways to decarbonisation at the BusSA conference in May.

“We’re not just running buses,” he said, “we’re shaping the future of public mobility.”

Fixing regulatory patchwork

A key theme of the keynote address was the urgent need for national consistency in rules and standards: Australian bus operators face a fragmented compliance regime, particularly around fatigue management, vehicle maintenance and emerging low-emission technologies, oftentimes resulting in confusion and inefficiency.

“Clarity and consistency are not luxuries – they are necessities,” Varenya reminded the audience.

“A harmonised national approach is essential if we’re to meet growing expectations while keeping our operations sustainable.”

Varenya also took the opportunity to welcome the appointment of Nicole Rosie as the incoming CEO of the National Heavy Vehicle Regulator (NHVR), expressing strong support for deeper engagement between the NHVR and the bus sector, especially on long-standing compliance issues.

Closing the accreditation gap

South Australia currently lags behind other states in its operator

accreditation framework — a space that undermines both public confidence and industry standards. Varenya made it clear that this must change for progress to be made.

“There’s a choice to be made. Either South Australia lifts its own accreditation standards or we empower the NHVR to manage national accreditation directly. Either way, we need action,” he said.

And this isn’t about burdening operators with red tape. It’s more about ensuring that all operators — especially those already going above and beyond — operate on a level playing field.

Zero emission ambitions, diesel-era contracts

The transition to zero-emission buses (ZEBs) has been underway for quite some time, yet existing contract frameworks remain a major barrier. Many of the current agreements are tailored to diesel fleets, leaving operators to absorb additional costs associated with depot upgrades, charging infrastructure and updating safety protocols.

One insurer, for instance, recommended that a 20-metre buffer zone be implemented between electric buses and buildings or the construction of thermal barriers. These are all requirements that few existing depots can meet without significant capital investment.

“These aren’t fringe issues — they go to the heart of operational viability,” Varenya said.

“If we’re serious about a green

transition, we need contract structures that reflect today’s reality — not yesterday’s.”

A seat at the table

What operators want is to be heard over funding and frameworks. The sector is calling for early, frequent engagement with regulators and governments to co-design the systems that will shape the future of transport.

Varenya weighed in: “We’re ready to lead, but we must be included in the planning because we know what works and we care deeply about getting it right — for our passengers, our people and our planet.”

Unification across the industry

The address concluded with a heartfelt thank you to the operators, suppliers and advocates who keep the sector moving — often behind the scenes and under increasing pressure.

The message was clear: with unity, accountability and smarter policy settings, South Australia can move from lagging to leading the national conversation.

“We’re not asking for handouts,” Varenya said.

“We’re asking for fairness and the tools to deliver the world-class bus network South Australians deserve.”

Varenya went on to congratulate BusSA on a fantastic conference, stating, “BusSA members are well represented”, giving kudos to BIC colleagues Kirsten Jongsma and Dean Moule on their own presentations.

Above: BusSA executive director Craig Spurr at the conference. Image: BIC

Customer centric

Bus Stop Sales’ rich history is currently evolving, with the bus and coach supplier telling Tiarna Condren about its multiple new developments to enhance its Australian vehicle offerings

The Australasian bus and coach industry is continuously changing. A key issue that suppliers face is the level of local content expected for long term supply contracts.

Bus Stop Sales is intent on creating leading solutions for its customer base and being flexible when it comes to supply and delivery to set a benchmark for new bus and coach models in Australia. For operators delivering contracted services across city networks and remote mining operations, this represents a compelling proposition.

“We offer our customers arguably the most extensive range of options when it comes to various stages of bus assembly,” Bus Stop Sales director

Pete White told ABC

“Options include fully assembled in Australia or fully imported for value. We then offer a range of hybrid options in between.

“The focus for us is collaboration and clarity with the customer base to all agree and transparently communicate the level of content needed and delivered.”

While King Long remains one of the flagship brands of Bus Stop Sales, the company’s real strength now lies outside of just the one badge. The ability for Bus Stop to deliver a complete range of vehicles that are tailored to operator and government needs is at the forefront of its value offering to the local market.

From electric school buses to diesel

coaches, 4WD and 2WD options, I-BUS (powered by Isuzu) and even mid-sized alternatives, White says Bus Stop Sales is offering superior flexibility across its product portfolio.

With infrastructure available to support full vehicle manufacturing, CKD (complete knockdown) and DKD (driveable knockdown) assembly, as well as fully built imports, Bus Stop Sales is a supplier capable of responding to the Australian bus and coach industry’s needs. White says the key to success is transparency between the supplier and the customer on what the required local content needs to be.

In collaboration with King Long, the company’s technical and compliance team has played a key role in co-developing a versatile hybrid bus

Above: Operators can choose the right assembly package that works for them

platform designed to support a range of build options.

Whether it be starting with a driveable chassis and frame, integrating pre-assembled components or delivering a fully built solution, the combinations are designed to be flexible. From zero local content through to a local ‘hero’ configuration, Bus Stop Sales can tailor the build to meet each customer’s specific operational and compliance needs.

“When it comes to our customers, one size does not fit all – that is what sets us apart,” White says.

“This approach can accelerate local assembly timelines and reduces build risk while also allowing us to maximise Australian labour content.

“This can include the actual body build, panels, glass and paint right through to electrical integration, complete interior fit-out and compliance testing.”

Operators all around Australia choose the ideal vehicle package based on factors such as price, operational requirements, expected lifespan, local content preferences, manufacturer support and procurement policies. It signals an evolution of choice and preferences for operators to consider and include in their latest models that they order.

White says the program reflects Bus Stop Sales’ broader mission to deliver buses that are locally supported, operationally practical and engineered for the real-world needs of Australian operators and content requirements.

current realities of bus manufacturing – it says no suppliers are able to deliver a 100 per cent Australi

an-made bus, with new assembly options bringing flexibility to local manufacturing and supply.

“All manufacturers rely on globally sourced components from China, Europe and elsewhere. However, our focus is on transparency and balance, identifying what can genuinely be sourced and assembled locally,” White says.

“What we can offer is clarity, collaboration and the right local content for each contract.”

Through its partnership with King Long, Bus Stop Sales accesses a deep well of international research and billions of kilometres of operational trials, in addition to development and

with a driveable chassis and frame, integrating pre-assembled components or delivering a fully built solution

to partner with its battery supplier with tier one aftersales support, offering superior and unmatched Australian aftersales support, for example,” White says.

“We focus on searching for the best components globally with the best support to ensure the product is world class. This is a win/win for all as bus assets need to be on the road to generate a return for the operator.

“In key ZEB drive battery and components, for example, there are no viable and reliable Australian solutions available today, and so we have to be looking at sourcing them overseas.

cuses on searching components globally

“Our approach is to maximise local skills, support Australian manufacturing and ensure that the end result is compliant in addition to being commercially and operationally viable.”

As is seen across most industries in Australia, the current skills shortage in the bus and coach industry and elsewhere is proving to be a hinderance. With driver shortages leaving operators short-changed, and with a drop in apprentices picking up the tools, the question on a lot of people’s minds is how these important people can be brought back onboard.

For Bus Stop Sales, who has seen a shortage in fabrication and mechanical expertise, the company has looked outside traditional

channels to try and find a solution.

Launching its own ‘Future Leaders’ program back in 2022, the company is committing to bringing on more apprentices to find “the next generation of tradesmen and women”.

“Future leaders is about providing career pathways that are supported and attractive to candidates,” White says.

“Attracting talent to our industry is crucial and encouraging non-traditional candidates is important for us.

“Today, we have a diverse range of apprentices including women, Indigenous Australians and mature age staff.”

This focus on skills development is closely aligned with the company’s ambitious expansion plans. With cutting-edge facilities already operating in Brisbane, Sydney and Melbourne, and new expansion planned for both South Australia and Western Australia, Bus Stop Sales is positioning itself to meet growing demand nationwide while also creating local jobs.

“Our investment in people and infrastructure goes hand-in-hand,” White says.

“By growing our facilities and expanding our reach, we provide more opportunities for apprentices to gain hands-on experience and

become an integral part of the industry’s future.”

While plans for SA and WA are well underway, the company has also been making moves in New South Wales. White recently announced that a larger site is on the way to better serve the state and its operators.

The new facility will support Bus Stop Sales’ growing local assembly program and further enhance its ability to offer “genuine Australian content”, something the company says sets it apart in a competitive market.

It is only the start of an ambitious scheme to develop and evolve the

of international research

Bus Stop Sales name in Australia so that it can entrench itself as the go-to bus and coach supplier in the country.

“With our local assembly program and genuine Australian content options, we’re delivering real value, not smoke and mirrors,” White says.

“My family has been manufacturing buses for over 40 years and that experience is built into everything we do.

“This new site is just phase one of an exciting plan to increase support for bus operators and the industry partners we’ve proudly worked

Below: Bus Stop Sales has plans to expand to

Above: Through its partnership with King Long, Bus Stop Sales accesses a deep well

Invest for success

Since entering Australia’s high-floor coach segment, Irizar has carved out a strong reputation by focusing on quality, aftersales support and smart partnerships

When Irizar first stepped into Australia’s high-floor coach segment, it saw an opportunity to do things a bit differently.

Focusing on quality, aftersales support and building solid relationships, the internally renowned body builder laid the foundations for what’s become a steady and

Starting with a clear goal to offer something tailored to the local market, Irizar has gone from a new face in the segment to a trusted name for operators looking for something reliable, well-finished and built for the long haul.

Irizar Asia Pacific managing director Steve Heanes says a lot of the brand’s success can be credited to establishing the right framework internally.

Below: Irizar opts to prioritise service delivery vehicles over acquiring real estate close to

early on, putting the right people in the right management roles and making sure everyone had ownership of their areas,” Heanes told ABC

“It’s not just about selling a vehicle but about how we deliver it, the quality behind it and the aftersales support.

“It’s truly a real team effort and I think that’s allowed us to push ahead.”

While this foundation laid the groundwork for growth, sustaining it in such a competitive market demanded a different way of thinking and a unique product offering.

“The bus market in Australia is largely contract-based and, due to the often-high specifications, doesn’t always leave a lot of room for operators to grow,” he says.

“We wanted to ensure that our products were multi-purpose, allowing operators to use their vehicles more flexibly for charter work or transport services outside of their normal runs.

“That’s what’s helped us gain traction.”

After offering higher spec vehicles like the V/Line and TransWA coaches, Irizar began standing out in the local body builder market. And as demand grew, so did the company’s investment in local operations from parts support to field service teams.

“We’ve really increased our parts

Above: The Irizar Pakenham facility

offerings to ensure our customers can access whatever they need,” Heanes says.

“We’ve gone from having $1.2 million in parts inventory three years ago to over $5 million.”

Relocating to Pakenham, Melbourne just over 12 months ago was also a significant investment for the OEM and its aftersales capabilities. When moving, Heanes says Irizar put its own spin on customer support, opting to prioritise service delivery vehicles over acquiring real estate close to operators.

“Our philosophy is that most of the time the customer wants us to come to them, so there is no point investing in real estate if you’ve still got to drive to the customer,” he says.

“I’d rather spend the extra money in our service vans and our people, creating an aftersales support network that can adequately support our customers.

Irizar is also establishing key partnerships in the parts warehousing area and setting up key satellite operations not only to support large customers but also feed the demand of the medium to single bus operator.

“Our service vans are state-of-theart, and we’re building a team that goes to the customer, not the other way around. That’s the difference.”

Parts Supply Solutions and Hanover Displays director Fiona Watson told ABC the relationship between the partner companies and Irizar began organically.

Irizar has worked hard to cement themselves in the Australian bus and coach industry, recognising that Australia is one of the toughest markets and has unique requirements.

“They’re not just boxes on wheels anymore. Australian operators want style, comfort and performance, and that’s what we’re delivering. The buses are tailored to their unique operating environments,” Heanes says.

Heanes says the tailoring isn’t just cosmetic – it’s functional. Whether it’s adjusting to dusty regional roads or transitioning to camera mirrors to reduce vibration, Irizar takes local conditions seriously.

“It’s about listening to feedback and improving every time,” he says.

While Irizar has been charging ahead, companies like Parts Supply Solutions and its partner company Hanover Displays have been riding

“Our customers were buying Irizar buses and requesting our equipment, destination signs, roller blinds, spare parts and CCTV. That’s how it started, and it’s just kept growing,” Watson says.

These days, the companies supply both destination signs and CCTV systems – two of the most requested integrations on Irizar coaches.

“We’re down there almost every week doing installations,” Watson says. “They’re one of our key partners.

“Irizar are easy to work with, we just get things done together. If they need a sign or an install, we sort it. The relationship is proactive and really local. That’s what makes it seamless.”

The blossoming partnership has had a flow-on effect for both parties. As Irizar has grown, so has Hanover and Parts Supply.

“More Irizar coaches means more of our products are being specified. It’s part of our broader growth for sure, but Irizar’s success has absolutely

having $1.2 million in parts inventory three years ago to over $5 million

Heanes says the partnership is a “win-win” for all involved.

“When we grow, they grow. That’s the reality,” he says.

As Heanes looks to the future, Irizar’s next chapter includes diversifying beyond coaches and doubling down on aftersales support.

“When it comes to aftersales support, we are still not at the level I want us to be at yet,” he says.

“There is always room for growth and always a way for us to provide better for our customers.”

In the product department, Heanes teased a possible launch for the second half of 2026.

“I hope the bus show next year will serve as the host for an exciting launch for some new vehicles,” he says.

“In order to keep up with the trends and the needs of operators, you have to diversify your offerings. Would we look at city buses or BRT? Is there more to do in the electric space? These are all conversations we are having internally.”

With a stable framework in place and a plan moving forward, Heanes has lofty goals for the future of Irizar in Australia and New Zealand.

The right fit

Challenger continues to cement itself as a leader in the Australian bus and coach industry, with its experienced team leading the charge

Building a great bus is a bit like putting on a stage show. You might have a star performer out front in the shiny finished vehicle, but it takes a whole cast and crew behind the scenes to make it all happen.

From the designers sketching the first lines, to the engineers fine-tuning every component, to the sales and support teams keeping customers happy long after the keys are handed over, success in bus manufacturing is always a team effort.

Challenger Bus and Coach has spent the better part of a decade building its team, bringing in industry veterans, technical experts and fresh eyes to its operations.

While it may seem time-consuming and cumbersome to some, Challenger prides itself on its ability to source the very best the industry has to offer. And its newest hire is no exception.

Kicking off his role in July, Challenger has hired long-time transport stalwart Paul Fagg as its first ever general manager.

“I started out as a mechanic, did my apprenticeship with Subaru, then moved into the truck world with

Kenworth, working on the production line and in a range of technical roles,” Fagg told ABC.

“After about five years there, I joined Daimler in 2007 and, apart from a short stint elsewhere, I’ve been with them ever since.

“Over the years I’ve done everything from product management to technical support, regional sales and even helped launch new products from the ground up.”

Despite spending the majority of his nearly 30-year career in trucks, Fagg says he’s been lucky in some of

his roles to spend time around buses and is keen to dive head-first into the industry.

“I’m lucky to have a pretty broad experience across the whole automotive industry, which gives me a unique advantage that others may not have,” he says.

“When Challenger called, I said that I have a lot to learn about buses and about the industry, but I am more than happy to take on the challenge.

“I can see that Challenger has a great team and friendly people, but it’s also very focused on quality products, reliability and customer service. From my point of view, that’s really what builds a good business and good product.

“I couldn’t be happier with my decision.”

Joining Challenger as its very first general manager, Fagg says he is excited to work with CEO Greg Sloan and the broader team to “build towards a bright future” for the company.

“I’m keen to combine not only mine but the owner’s vision for the company, and build it around supporting the customers, building

Above: The Callibar and V10 ready for a day’s work

Left: Challenger’s new general manager Paul Fagg

Images: Challenger Bus and Coach

the parts distribution network, support systems and everything involved that goes along with supplying products,” he says.

“The priority for me is setting up the foundations to ensure that we can react and support quickly if there are any problems or breakdowns and we can minimise the downtime to support the customers.

“The second aspect would be looking at where the industry is going, looking at the trends and adapting accordingly.”

Fagg’s first port of call upon starting next month will be heading out across the country to make introductions to staff and customers – something he says he is very excited for.

“I’ve heard amazing things about the team, and their work has been what has made Challenger what it is today. It’ll be great to pick their brains,” he says.

As Fagg says, behind every successful bus delivery is not just a production line, but a well-oiled machine of people, trust and shared purpose.

At Challenger, that team-first mindset is already paying off, highlighted by a recent delivery to Hintercoast Transport.

For the Gympie-based operator, choosing the right vehicles is about practical reliability, service support and long-term simplicity. That’s why owner and diesel mechanic Dennis Smith turned to Challenger for his most recent fleet additions.

Hintercoast recently took delivery of two models, the V10 and the new Callibar.

“What stood out about Challenger was the build quality, especially the steel frame, and the support from the team,” Smith told ABC.

“We’re only a small company, but the Challenger team have been great from day one, both with purchasing and aftersales. Anything we’ve needed, they’ve been quick to respond. That goes a long way.”

Smith says there’s already been positive feedback from both drivers and passengers, with the team eager to jump onboard once they arrived.

“The V10 has been a hit. It drives well and accessibility is spot on. The

Callibar is still pretty new to us, but so far so good,” he says.

“The drivers are still getting used to the electric mirrors, but that’s just part of moving with the times.”

With his mechanical background, Smith places a high value on standardisation and ease of maintenance, something he’s hopeful Challenger will stick with as the brand evolves.

“One of the big reasons we’re considering replacing the rest of our fleet with Challengers is because they’ve kept things simple,” he says.

“If they can maintain that, same filters, same bearings, same layout, it just makes everything so much easier. You don’t want four different types of buses in the shed with different parts on every shelf.”

part in the company’s decision-mak ing, saying that especially for regional and small operators, aftersales support is crucial.

“Aftersales support is very important for regional operators because of not only the terrain we sometimes come across, but because of the size of our fleets,” Hintercoast co-owner Sandi Smith told ABC.

“We have quotes and jobs coming in every day and we can’t afford to have a bus be down. We can’t be without them.

“If we have any drama, we just ring Challenger and they are pretty much straight up here to try and sort things out for us.

“We are incredibly happy with the service that we’re getting from them, and that’s why we’ve decided to go and order another two.”

The Challenger team’s support, combined with a smart, practical

Putting the part in partner

With a passionate aftersales team and a growing parts network, Scania Australia is committed to keeping buses on the road and in tip-top shape

When running a bus fleet, the need to maximise reliability and uptime is critical. When any unplanned downtime occurs, it impacts the entire business, from financial bottom lines to customer satisfaction and brand reputation.

For Scania Australia, ensuring its customers maintain operator profitability and keep buses running is of the upmost importance.

Once a Scania bus or coach is in service, maintaining it in full working order is made possible by a team of passionate Scania aftersales people working in the national parts warehouse in Campbellfield, Victoria.

Here, in a giant new warehouse, Scania keeps significant stocks of service parts as well as crash repair and exchange parts to reduce vehicle off road time to a minimum.

With predictive servicing parameters now in place and a sophisticated vehicle monitoring system up and running, ensuring the right parts are in

the right place at the right time is the aim of national parts logistics inventory manager Matthew Pol.

“Efficient processing and dispatch of parts is one of our core values, as we strive to reduce downtime for customers who may be waiting on repair parts from an unplanned event. Maintaining customer uptime is what drives us,” Pol told ABC.

This month, the national parts team will add a second string to its bow with the opening of a new national parts warehouse in Hope Valley, south of Perth, which will be more than twice the size of the company’s previous WA warehouse.

Able to hold the parts to service the growing number of Scania buses, coaches and trucks now on the road in the west, the warehouse will boast a state-of-the-art processing system and greater floorspace for faster unloading of containers, leading to quicker in/out times for parts, helping to reduce delivery times to customers.

“We outgrew our Welshpool parts warehouse far more quickly than

Above:

With the success of the Scania Touring, the company has significantly increased the number of parts it keeps on hand in Australia. Image: Scania Australia

we anticipated so the new facility in Hope Valley will give us enough capacity for the next decade’s worth of anticipated growth across our truck and bus lines,” Pol says

“With the success of the Scania-Higer A30 and the Scania Touring, the ‘bumper-to-bumper’ Scania coach, we have increased significantly the number of part numbers we keep on hand in Australia.”

The arrival of the new three-axle Scania Touring however will not add greatly to the parts holding due to the modular nature of Scania’s chassis engineering.

“We’re simply adding another axle and a set of brakes to the chassis, so there’s a high level of commonality, which makes servicing easier,” he says.

“The part numbers and stock holding required for regular maintenance should not increase unduly for customers who run their own workshops.

“Historically we used to supply

mostly chassis components to bus and coach customers who did their own servicing, so service parts and some crash parts took up most of our bus and coach holdings.”

Since offering a total package of body and chassis, Scania has switched to holding body panels as well as crash parts such as head and tail lamps and mirrors. Naturally, holding body parts requires more space, which is partly why the company has expanded its warehousing.

“A smashed windscreen means you have a bus off the road, and that leads to all sorts of issues for operators, so we do everything we can to have replacement screens in place and ready for when a customer calls,” Pol says.

“As we move into the battery electric vehicle age, we will see a range of new and different parts coming into the warehouse. But thanks to the new technology, there will be fewer fast turnover parts,

given the reduced number of service items, though we will be keeping replacement battery modules on hand.

“Irrespective of the pace of BEV adoption, though, with city bus working lives remaining at 25 years, there will be plenty of demand for internal combustion engine service parts for quite some time to come.”

For regular replacement parts, Scania has an advanced and automated parts ordering system that ensure supplies of fast-moving parts are always in stock or on your Scania dealer’s shelf.

“We’re using optimised purchasing parameters to ensure the right stock is on hand, and we’re constantly reviewing product and what parts we need to support the product. There’s a continual review and development of what we need and when,” Pol says. One of the elements that helps Scania to accurately predict parts requirements is the data drawn from

tens of thousands of connected Scania buses and coaches operating worldwide. This real time data allows visibility of wear rates across a variety of components, prompting preventative servicing to reduce the potential for unplanned vehicle off-road inconveniences, as well as ensuring replacement parts are in place in good time.

“The Scania parts supply chain and distribution network is an integral part of the Scania bus and coach success story in Australia,” Scania national sales and contracts manager Jamie Atkinson says.

“Customers locked into performance contracts for route services, for example, cannot afford to wait for parts. We work hard to ensure their maintenance programmes can function seamlessly to keep their vehicles on the road, and this is highly valued as part of the Scania partnership promise between us.”

Aussie aluminium

Capral’s ongoing supply partnership with Volgren is allowing the bodybuilder to relish the numerous benefits of having high quality aluminium ready to go from a local source, Sean Mortell reports

As Australia’s largest bus body builder, Volgren has enlisted Capral Aluminium as one of its main material suppliers for its body builds.

Over time, Capral’s aluminium has become so integral that it now forms the basis of Volgren’s body structure. Volgren chief commercial officer and head of strategy Yuri Tessari told ABC that there has previously been confusion around the bodybuilder’s use of materials and that Capral has always remained pivotal to Volgren’s Australian bodies.

“There’s been a misunderstanding in some parts of the industry that, because we use the Co-Bolt gussets from Hess, all aluminium used in our buses comes from Switzerland, but our aluminium is all locally sourced from Capral,” he told ABC

“We only use HESS’ Co-Bolt technology that helps us to bolt and screw our structure together without the need to weld.”

What makes Volgren unique in the local market isn’t its local sourcing of such an important material, but the choice of material that it has made.

Since Volgren was first founded in the 1970s in Dandenong, Victoria, steel has been globally the most popular selection for constructing a bus body.

However, Volgren hasn’t sought to follow the status quo. Its enduring partnership with Capral is all about using aluminium instead of steel, and it started in 1979 when Swedish OEM Volvo partnered with Volgren founder George Grenda to create Volgren and introduce extruded aluminium for bus body construction rather than steel. The bold decision is continuing to have wide-ranging benefits for the growing bodybuilder.

“Aluminium overall is a better raw material to use – it is lighter and has anti-corrosion properties,” Tessari says.

“You can build a body with aluminium that will last longer, regardless of operational conditions.

Above: Capral and Volgren have forged a long-lasting supply partnership for bus manufacturing

Especially when we are venturing into zero-emissions technologies at Volgren, having a lighter body structure provides us with way better fuel or energy efficiency than what we’d get with steel.”

The use of aluminium in Volgren’s Co-Bolt assembly system has been a particular highlight of the bodybuilder’s manufacturing success in Australia. The technology means the Volgren body frame using Capral aluminium requires no welding to assemble – instead, it can all be bolted on, keeping the quality of each Volgren body consistently impressive.

With the use of bolted gusseted joints, Volgren uses Capral’s custom designed aluminium extrusions to avoid the risk of continuous bus vibrations fracturing welds and creates a better quality bus for local customers.

“Welding a bus structure requires lots of welds, so you rely too much on the quality of the work – which is often manual – faulty welds could easily lead

Images:

Capral

to structural breaks,” Tessari says.

“However, with custom aluminium extrusions, it’ll always be bolted to the right tension in the same spot, so we know our bodies are going to last.”

This security in build quality has allowed Volgren to push the limits with its warranty offerings for customers around Australia. By using aluminium on all of its body builds, Volgren has been able to secure key contracts by offering a warranty that in some cases has surpassed 20 years on its models.

“We’ve been able to commit to long warranty periods because we use aluminium that we know is going to last us for a long period of time,” Tessari says.

“It gives us the peace of mind to take a risk in contracts, as we have to consolidate thousands of components into a single bus, so if a critical part like the aluminium isn’t performing, then we can have a lot of issues.”

In a market that is increasingly being influenced by international brands and manufacturers, Tessari says the ability to use locally sourced key materials is a great source of pride for Volgren. Although running a business often means using the cheapest price is best, Tessari says this must be balanced with the priority of engaging with local suppliers to create a high quality product that is also uniquely Australian.

“These are the differences when it comes to local manufacturing and supply – it’s not just about local assembly,” he says.

“We want to buy key components from local manufacturers – it may cost more than importing it from overseas, but we want to invest in the local supply chain and our local partnerships.

“Sometimes local suppliers are taken for granted as just a percentage of local content on a spreadsheet, but to us they mean so much to what we do.”

While Capral and Volgren’s partnership has been enduring, it’s also been enhanced by Capral’s evolving product offer. In 2023, Capral released LocAl®, a lower carbon aluminium option available across extruded and rolled products.

The LocAl offer uses primary aluminium produced with significantly lower embodied carbon.

Most people understand that aluminium is an excellent material for sustainability and circularity due to its ability to be infinitely recycled. What is not well understood is that the production of primary aluminium often carries a high carbon footprint as the process is very energy-intensive.

“In 2025, approximately 30 per cent of the primary aluminium billet Capral uses in its eight local extrusion presses has a carbon content lower than eight kilograms CO2e per kilogram of aluminium,” Capral general manager of supply and industrial solutions Luke Hawkins told ABC

“Approximately 300 tonnes have a certified carbon content lower than four kilograms of CO2e per kilogram of aluminium. This is a strategic change for Capral, driven by our desire to make lower carbon aluminium accessible to Australian manufacturers. The market is looking for this product, and as Australia’s largest extruder of aluminium, we must make it available.”

The carbon emissions in primary aluminium production range from under four kg CO2e/kg Al to over 20kg CO2e/kg Al, largely dependent upon the energy sources used.

The current global average carbon emission for primary aluminium is approximately 12.4 kg CO2e/kg Al.

“At eight kilograms of carbon emissions per kilogram of aluminium, the LocAl Green offer has significantly lower carbon emissions than the current global average for primary aluminium,” Hawkins says.

“It gives Australian manufacturers like Volgren an important opportunity to make more responsible

Above: Volgren has incorporated some of Capral’s newer sustainable aluminium products on its zero-emissions bus builds

procurement decisions when they source extruded aluminium.”

In addition to lower carbon emissions, the primary aluminium offered under the LocAl® brand is sourced exclusively from Aluminium Stewardship Initiative (ASI) certified smelters.

LocAl Green aluminium has become part of Volgren’s material arsenal as the bodybuilder makes innovations in the zero-emissions bus body space, focusing development on efficiency improvements, weight reduction and more responsible material sourcing.

“We’ve been able to achieve up to 350 kilograms of weight reductions on our bodies when compared to an equivalent steel body structure,” Tessari says.

“This gives us better fuel and battery consumption on all bus body models that we produce.”