Marco Assorati captures Webuild’s vision for an industry that empowers communities, expands opportunity and advances national prosperity.

10 When Webuild, Australia grows

Webuild shows how collaboration with industry and communities is helping build a stronger, more connected Australia.

Rachel Miu: Counting on connection

Rachel Miu, building estimator at Lipman, shares how she approaches construction as both a craft and a community.

54 Build great leaders

Exploring the final chapter of her book, Dr Gretchen Gagel offers advice for construction leaders seeking to elevate their impact.

44 To the EWIT village

Empowered Women in Trades shares highlights from its 2025 Gala Awards.

procurement to lift productivity

The Australian Constructors Association calls for reform to simplify procurement, cut delays and unlock productivity across the industry.

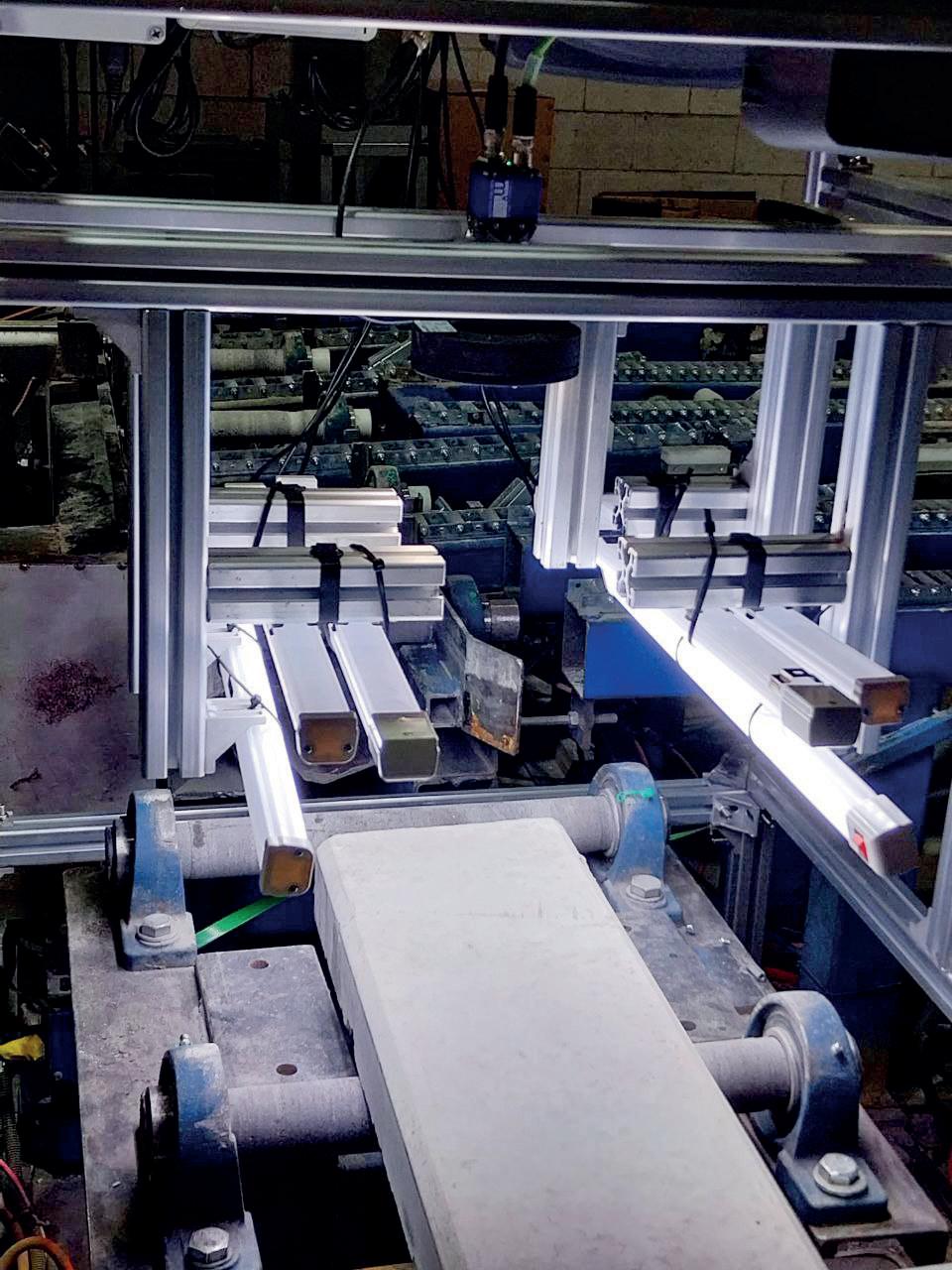

Next-level quality in precast production

National Precast Concrete Association Australia profiles a concrete sleeper manufacturer piloting a new artificial intelligence inspection system.

Ensuring safer and more inclusive workplaces

In its 30th anniversary year, the National Association of Women in Construction shares its latest achievements and efforts to drive culture change. 52 It is time to change the

NexGen closes the reality gap between what young Australians think construction is and what it can be.

Tested strength in steel

FTI Group reveals how its metal tray formwork for high-rise commercial and residential builds delivers assurance on site.

assets and infrastructure integrity

With the holiday season approaching, Hobson Engineering showcases its range of security fasteners.

Building for discovery

Built Environs demonstrates its expertise in Australia’s life sciences sector, constructing environments where research, production and innovation can flourish.

The next step in industrial access

Kattsafe unveils a new modular aluminium stair tower that brings speed, scale and simplicity to industrial access.

The road to autonomy

From project profitability and forecasting to compliance, MYOB explores how artificial intelligence is driving efficiency in the field.

Class of 2025

With its 2025 class confirmed, the Komatsu-Williams Engineering Academy reinforces its commitment to cultivating global engineering talent.

Big builds and bold ideas

If you missed the Major Projects Stage at Converge Expo 2025, we have you covered.

With skill shortages tightening, CONEXPO-CON/AGG 2026 puts careers and capability in the spotlight.

Reflecting on a year marked by endurance and evolution.

The past year has been a study in contrasts for Australian construction. Progress continued at a remarkable pace, even as the sector navigated economic headwinds, supply constraints and shifting policy priorities. Through these challenges, the industry has again demonstrated the resolve that gets the job done.

This year’s progress has been measured less by what was built than by how it was achieved. Contractors have found new ways to collaborate, clients have rethought procurement, and project teams have drawn on data, digital tools and experience to deliver better outcomes.

At the same time, commercial and labour pressures reshaped the way builders worked. Cost escalation has forced companies to refine forecasting, while skill shortages have intensified competition for talent. Many contractors have turned to integrated delivery models and stronger supplier relationships to stabilise performance and maintain quality. These developments signal a maturing industry that is learning to anticipate volatility.

What was once ambition in sustainability is now expectation. Governments, contractors and suppliers alike have made headway toward lower-carbon outcomes, with embodied carbon tracking, renewable power integration and circular economy principles now commonplace across projects.

Equally significant has been the industry’s continued push to build a more inclusive workforce. Initiatives through groups such as the National Association of Women in Construction, Empowered Women in Trades and NexGen have accelerated momentum, creating pathways for women, young people and under-represented groups to step into technical, leadership and on-site roles. Companies are

learning that capability grows from varied experience, backgrounds and perspectives.

Looking forward, 2026 promises both continuity and renewal. Australia’s pipeline remains strong, anchored by transport, energy and defence programs. The projects ahead will call for deeper alignment between design, delivery and digital systems. Collaboration will continue to set the pace for progress.

For Inside Construction, this year has been one of growth, expanding coverage, forging deeper relationships and continuing to share the stories that show the best of the industry. To all who have contributed, collaborated and led, thank you. This magazine exists because of your work, expertise and commitment. And as the year draws to a close, it’s not quite over yet. This edition looks at how far construction has come, and where it’s heading next.

Inside, you’ll find building systems and materials improving delivery and performance; insights into specialised and emerging markets; thought leadership on technology and digital integration; and practical ideas that inform better practice across every level of the industry. From the Inside Construction team, we wish you a safe and well-earned break. See you in 2026.

Chairman John Murphy

Chief Executive Officer Christine Clancy

Managing Editor

Mike Wheeler mike.wheeler@primecreative.com.au

Editor

Ashley Grogan ashley.grogan@primecreative.com.au

Sales Manager

Danny Hernandez danny.hernandez@primecreative.com.au

Design Caterina Zappia

Head of Design Blake Storey blake.storey@primecreative.com.au

Business Development Manager Michael Ingram-Casha michael.ingram@primecreative.com.au p: +61 0423 266 991

Client Success Manager Louisa Stocks louisa.stocks@primecreative.com.au

Cover image credit Webuild

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.insideconstruction.com.au

Subscriptions

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Construction is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Construction is owned by Prime Creative Media and published by John Murphy.

All material in Inside Construction is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Construction are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

FASTENERS SINCE 1935

Upholding our commitment to quality through our NATA-accredited laboratory and close collaboration with key industry partners.

Quality assurance documentation available online at:

Major projects across Australia and New Zealand reveal a construction sector building capability, resilience and progress.

Contractor: BESIX Watpac

Current value: $780 million

Details: The new Shellharbour Hospital in Dunmore, New South Wales, marks an advancement in delivering world-class healthcare to the Illawarra region. Designed to reduce the need for residents to travel long distances for treatment, the hospital will provide expanded emergency services, elective surgery, rehabilitation, aged care, acute medical care, mental health support and renal dialysis. BESIX Watpac is

constructing three buildings as part of the development: a six-storey Acute Services Building, a three-storey Ambulatory Care Building and a two-storey Mental Health Building. Each facility is designed to support modern models of care and improve patient outcomes. The project incorporates sustainable design principles and advanced technology and includes a rooftop helipad that will enable air transport for critically ill patients to receive timely and specialised care. Improved public transport links and a

new car park will enhance accessibility for patients, staff and visitors. Approximately 2,000 construction jobs are being created, providing a boost to the local economy and offering opportunities for regional businesses to contribute to the delivery of this vital infrastructure.

Status: Construction commenced in late 2024, with top-out scheduled for Q1 2026. Façade and fit-out works are commencing in December 2025. The project remains on track for completion in 2027.

Contractor: Built, in joint venture with Obayashi Corporation

Current value: $1.45 billion (on completion building value)

Details: Built, in joint venture with Obayashi Corporation (BOJV), is delivering Atlassian’s Australian headquarters adjacent to Sydney’s Central Station on behalf of coowners Dexus and Atlassian. The 39-storey structure, set to become one of the world’s tallest hybridtimber commercial buildings upon completion, represents a milestone in sustainable construction. Through innovative design and deliberate material choice – including mass timber, low-embodied-carbon steel and low-cement concrete – the project is targeting a 50 per cent reduction in upfront embodied carbon across the substructure, superstructure and façades compared to a conventionally constructed tower.

Status: Construction is progressing toward base building completion in 2026.

Initiatives: The BOJV project team developed practical, buildable solutions to address complex construction challenges associated with the site’s heritage-listed elements and proximity to Central Station. Taking a digital-first approach, the team used digital modelling to plan and sequence construction tasks, ensuring precision and efficiency before work began on site. A standout engineering achievement is the diagrid structure, which supports the hybrid-timber superstructure by transferring perimeter loads to a concrete core and two north-facing mega columns. This design minimises the structural footprint while accommodating the site’s constraints.

The centre will be the largest combined aquatic and indoor recreation facility in the country. (Image: Crown Infrastructure Delivery)

CPB Contractors

500 million

he Parakiore Recreation and Sport Centre will serve as a hub for community recreation, aquatic sport and elite training in New Zealand. It combines multiple facilities under one roof to support health, wellbeing and high-performance sport. At more than 30,000 square metres, it will be the largest combined aquatic and indoor recreation facility in the country. The complex features a 10-lane, 50-metre competition pool (with a movable bulkhead and floor), a separate diving pool with a 10-metre tower, five hydroslides (including New Zealand’s first trapdoor waterslide) and an aquatic sensory experience for people with disabilities. On the dry side, it offers nine indoor courts, a central show court with 2,500 retractable spectator seats, fitness and movement studios, and a shared sports administration facility. Structurally, it addresses Christchurch’s earthquake-prone and liquefaction-prone ground conditions with 8,000 stone columns driven 12 metres deep – the largest implementation of its kind in New Zealand. Parakiore is designed not just for elite sport but to be accessible to people of all ages, abilities and community needs. ompletion is expected in December 2025.

ealth and safety were central to every stage of the project. Ongoing project and management safety reviews supported continuous improvement and accountability, with the site achieving MATES in Construction accreditation. Unique site challenges required tailored solutions. Working around large aquatic zones introduced drowning and fall hazards, which were mitigated through scaffold edge protection and exclusion zones. For installation of the fabric ceiling and skylights above the pools, the team designed and constructed New Zealand’s largest birdcage scaffold – a 14-metre-high, full-span engineered access platform providing safe, stable elevated work areas over water.

Contractor: Laing O’Rourke

Details: Laing O’Rourke is the Initial and Early Works Managing Contractor for Suburban Rail Loop (SRL) East. The package of works forms the first stage of construction for SRL East and involves establishing sites for the new underground stations at Box Hill, Burwood, Glen Waverley, Monash, Clayton and Cheltenham as well as the train stabling facility in Heatherton. The first phase of early construction has included site establishment, utility relocation and protection (including gas, water, sewer, telecommunications and electricity), demolition, excavation of a tunnel boring machine (TBM) launch site in Burwood and a tunnel entrance in Heatherton, construction of a new tram terminus and temporary bridging structure at Box Hill, and the delivery of new community spaces at Clayton and Burwood. Laing O’Rourke has also built two network support facilities that will power the TBMs during construction, as well as the SRL East network when trains are running in 2035.

Status: After three years, sites at Box Hill, Burwood, Clayton and Cheltenham will be handed over to tunnelling contractors to commence the next stages of the project, bringing SRL East a step closer to completion.

Status: The project is employing innovative construction methods to improve efficiency. This includes offsite fabrication of 982 bathroom pods, installation of 300 precast panels with integrated brick façades, and prefabrication of column boxes with built-in reinforcement. A heritage building dating back to 1840 is being preserved and structurally upgraded using laboratory-tested timber and a rooftop steel truss. In addition, a modular curtain wall façade has been manufactured off-site to streamline the construction process.

Contractor: Integrate Alliance (Clough, Water Corporation and Jacobs)

Current value: $238.5 million

Details: The Integrate Alliance – comprising Clough (part of the Webuild Group), Water Corporation and Jacobs – is delivering the Engineering, Procurement, Construction and Commissioning (EPCC) contract for the Woodman Point Water Resource Recovery Facility upgrade in Munster, Western Australia. As the state’s largest wastewater treatment plant, the facility is being upgraded to increase sludge treatment capacity, enabling the processing of 120 tonnes of dried solids per day. The project will also support the recovery of biosolids for agricultural use and biogas for renewable energy generation. The scope includes the integration of thermal hydrolysis pre-treatment technology, a new dewatered sludge receival facility, a new solids thickening and dewatering system, and new odour treatment infrastructure.

Status: Work on site is progressing, with engineering design nearing completion. Procurement is now 85 per cent complete, and much of the major equipment has been delivered to site. The concrete framework for the new Pre-watering Building has been completed. This facility will pre-treat sludge from Woodman Point, East Rockingham and Alkimos water resource recovery facilities to achieve a consistent mixture. Equipment on site includes gas engines, sludge silos, conveyors and storage tanks. To date, 200,000 cubic metres of material have been moved on site – equal to nearly 25,000 truck movements – along with 1,185 cubic metres of concrete poured and 100 tonnes of structural steel installed. A dissolved air flotation tank is currently being commissioned.

Webuild partners with industry and communities to deliver the infrastructure that underpins Australia’s economy and social fabric.

“Collaboration is key to success. We succeed together, and if there are challenges, we face them together.”

Construction is a powerful economic engine. It builds the roads that carry trade, the railways that link regions, and the water systems that keep cities alive. It delivers the homes, schools and hospitals that sustain daily life, and the energy networks that power industry. Few sectors contribute more directly to national prosperity.

As Marco Assorati, senior executive vice president operations at Webuild and executive president at Clough, says, “Progress demands infrastructure”.

For Webuild, progress is measured not only by what is constructed but by what continues: the communities it supports, the opportunities it opens and the capability it leaves behind.

Legacy runs deep in the company’s Australian story. Through Clough, whose projects have helped shape the nation’s modern landscape, the group’s history spans more than a century. That lineage has become a shared purpose: delivering infrastructure that serves communities and sustains progress.

“Webuild has been part of Australia since the 1970s, delivering projects across Victoria, New South Wales and Queensland. We returned in 2012 and have since been involved in some

of the country’s most iconic and complex infrastructure works,” says Assorati. “With the acquisition of Clough, our combined history in Australia now spans more than 100 years.”

A century of building has given Webuild and Clough both heritage and foresight, with a view to where the next era of investment and innovation will unfold.

That perspective crystallises around three national priorities: transport, water and clean energy.

“ Transport remains the backbone of the nation’s long-term vision,” says Assorati. “Cities must be connected, and as they continue to grow, the road and rail networks must grow with them.”

Connectivity, he believes, is the foundation on which both economic and social opportunity are built. Webuild’s role in this space includes the Suburban Rail Loop and North East Link in Victoria, Sydney Metro in NSW and the Forrestfield–Airport Link in Western Australia. These projects expand mobility, ease congestion and connect regions.

North East Link is a prime example. The project comprises twin three-lane tunnels stretching roughly 6.5 kilometres, together

forming the longest road tunnel in Victoria. Once complete, it will remove 15,000 trucks from local roads each day and cut travel times by up to 35 minutes. It will also improve safety and connectivity across Melbourne’s freeway network.

Water follows transport as the next national imperative. As populations rise and climatic pressures intensify, reliable water infrastructure is critical. From treatment facilities to desalination plants, the systems that sustain supply are central to resilience.

This is illustrated by Clough’s delivery of the Bundeena to Maianbar Water Cycle Management Scheme in NSW, which is providing wastewater services to previously unsewered communities through environmentally sensitive design and construction.

Energy completes the picture, supporting every aspect of daily life, from homes and hospitals to industry and innovation. Webuild’s work on Snowy 2.0 shows its role in advancing clean energy and hydro capability, providing renewable generation that will deliver energy security for decades to come.

“If companies and contractors are to invest with a long-term view, these are the three pillars that will shape the future,” says Assorati.

These priorities reflect Webuild’s strategy, aligning national needs with the company’s global experience. They also encompass social infrastructure, including hospitals and civic assets, as well as sectors such as civil, marine, resources, housing and asset management.

A culture of collaboration

Webuild’s expertise is evident in the scale of its projects, but for Assorati, what matters most is how that knowledge is shared. The company works in concert with clients, contractors and communities. Its reputation rests on trust and cooperation, qualities that turn complex builds into positive outcomes.

“Collaboration is key to success,” he says. “We succeed together, and if there are challenges, we face them together.”

While its projects show capability, its partnerships show character. The group has forged relationships with universities across Victoria, NSW, Queensland and WA to help develop the next generation of engineers and project leaders.

“We do not just create jobs; we create skills,” says Assorati. “We bring knowledge gained from the 50 countries where we currently operate, sharing global expertise and innovation, and adapting it to fit Australia’s environment. This exchange of ideas helps us introduce proven solutions that add real value locally.”

Each project is designed to connect with its community and leave people better equipped for the future. Between July 2024 and June 2025, Webuild spent $4 billion on procurement, of which $3 billion went to local suppliers. Wherever possible, the company prioritises subcontractors located near project sites so that investment stays within the local economy.

The impact of that approach can be seen on Snowy 2.0, where small regional contractors have developed into experienced businesses capable of delivering major works.

“When our partners grow, we grow too,” says Assorati. “It is about creating a cycle of capability.”

Webuild also works with Indigenous enterprises and social procurement programs that open doors for underrepresented groups. Its focus on inclusion has seen women comprise up to 30 per cent of project workforces, above the industry average.

That culture of collaboration runs through every layer of the organisation. Transparency and shared values underpin the way teams operate, fostering trust that lifts both performance and outcomes.

“When collaboration is genuine, it raises standards across the industry,” says Assorati. “We aim to make the construction industry better, not just bigger. What matters to us is the lasting benefit infrastructure brings to communities. That benefit is the ultimate goal, and it defines our vision.”

Ceres is a $6.4 billion

“What matters to us is the lasting benefit infrastructure brings to communities.

That benefit is the ultimate goal, and it defines our vision.”

That same mindset carries across borders.

Operating in more than 50 countries, Webuild brings ideas proven on the world stage and adapts them to Australia’s conditions. The ability to transfer innovation from one region to another is part of what distinguishes the group on complex projects.

It’s an approach grounded in local presence, and the acquisition of Clough has deepened the group’s understanding of Australia’s operating landscape.

This blend of international perspective and local delivery has proved valuable in sustainability. Italy, where Webuild is headquartered, leads Europe in recycling and circular-economy practices. Lessons from that experience are being applied to Australian projects to reduce waste and improve environmental performance.

“Every country is different,” says Assorati. “A common foundation of experience is important, but understanding local expectations is what makes the difference.” Global experience matters when it creates local value, and that is where Webuild’s advantage lies.

Behind this scale of delivery is leadership defined by accountability and a clear sense of direction. Webuild is a global organisation of about 95,000 people, including 7,000 in Australia. In a company of this size, direction

must be consistent and communication precise. Purpose must be shared, so that everyone understands not only what they are

“Our vision can be summarised in one word: integrity,” says Assorati. “We value transparency and collaboration, both in our relationships with clients and stakeholders and within our own teams and supply chain.”

A long-term vision is equally important.

When Webuild delivers a project or guides the organisation, it looks beyond immediate achievements to the positive change its work

Consider Webuild’s delivery of the Western Sydney Airport Line for Sydney Metro. The ability for people to travel easily from one side of the city to the other is a lasting contribution to the community. Snowy 2.0 offers another example, providing renewable energy that will support Australia’s transition to net zero.

“Leadership, for me, means looking beyond the immediate delivery and focusing on the enduring benefits that infrastructure brings to people and the nation,” says Assorati.

His belief in long-term value covers both the infrastructure and the culture that sustains it. Assorati recently took home the Industry Ally Award at the 2025 NAWIC Victoria Awards for Excellence, highlighting that influence.

The award recognises men who champion gender equality and inclusion across construction, reflected in Assorati’s leadership of the Spark North East Link Design and Construct Joint Venture. He and the leadership team set inclusion as a core part of delivery.

The project achieved results across social procurement and female participation. From the outset, the team focused on inclusion, health, safety and overall culture.

“At the start, we did not ask how many positions we needed to fill with women. Instead, we asked what we could do to make this a place where women could succeed. Flexibility was one important factor, but it went further than that,” he says. “We created clear pathways for career growth and ensured that women were represented in senior leadership.”

That environment has produced results, with women now holding key leadership roles across multiple projects.

“When a young woman joins a site and sees women in leadership, she understands she can achieve the same. If we can recreate that environment everywhere, we have achieved something meaningful,” says Assorati.

“What matters is having the best people in the team, regardless of gender. Our responsibility is to ensure that women can enter this industry without fear or hesitation. No one should ever feel that construction is not a place for them or that it is reserved for men. Everyone should feel comfortable and supported.”

The decade ahead

Assorati sees the coming decade shaped by both continuity and change. Transport will stay a national focus, while momentum is building in water, energy and digital infrastructure. Regional development is gaining prominence, with projects such as Snowy 2.0 showing how big projects can renew local economies and lift communities.

Through Clough, Webuild is also extending its reach into maritime and defence, delivering

the Darwin Ship Lift Facility in the Northern Territory and Pilbara Ports’ new Dampier Bulk Handling Facility in WA. Each reflects expertise refined through decades of global delivery.

“We are applying global experience to Australian needs,” says Assorati. “For example, the Women and Babies Hospital in Perth is our first hospital project in Australia, but it builds on experience from more than 200 hospitals across Europe and the Americas.”

As the country’s infrastructure needs evolve, Webuild keeps its focus on people, creating opportunity and progress nationwide.

Together, Webuild and Clough have delivered more than 40 projects across Australia in the past decade. With 13 projects now underway, their work is shaping productivity, connectivity and community outcomes.

“We are ready for what comes next,” says Assorati. “We are confident in our ability to meet the challenges and opportunities of the decade ahead.”

As Australia advances, Webuild advances with it.

“We aim to make the construction industry better, not just bigger.”

From full-scale verification to project-specific support, BlueDeck shows how rigour and responsiveness combine to deliver assurance that carries weight on site.

Construction has little tolerance for untested claims. Steel decks either hold under fire or buckle; composite slabs either act as one or fail. FTI Group’s BlueDeck system, a metal tray formwork for high-rise commercial and residential builds, delivers assurance of structural integrity. It has earned its place on projects because it was subjected to scrutiny that left no room for doubt: structural testing, fire exposure trials, and independent verification by universities and national authorities.

That established compliance. What has sustained trust since is an ecosystem that shapes how BlueDeck is applied in the field. Where many stop at accreditation, FTI built an in-house design team, software tools and project-specific support that make compliance a living practice.

For FTI, establishing an in-house design team stemmed from a commitment to best serving clients. Made up of structural, civil and mechanical engineers, and supported by technical professionals, the team works with project consultants to deliver efficient, assured outcomes.

“Anyone can sell a product, but we wanted to be more than that,” says Tim Nightingale, group design manager at FTI.

“To create a true partnership, you need to have skin in the game. That meant employing professionals in-house who could provide genuine added value.”

Each specialist takes ownership of their projects, ensuring no detail slips through the cracks before steel meets concrete. Rather than applying broad guidance, they generate

project-specific shop drawings and collaborate with architects, engineers and certifiers to resolve issues before they reach site.

“We collaborate with the project team to address any issues upfront, ensuring the project can move smoothly into construction,” says Nightingale. “By capturing potential problems early, we remove delays that would otherwise occur on site. It means our team knows each client’s project as well as the consultants they have engaged to deliver it.”

The design team’s role is to simplify complexity. As architects and engineers push creative boundaries, FTI focuses on providing clear, practical solutions. That commitment extends to product manuals, which have been designed as user-friendly tools to support compliance, clarify details and improve efficiency.

Independent verification

FTI’s in-house expertise has been central to BlueDeck’s evolution. Working closely with consultants and contractors, the team feeds project insights back into development, ensuring the system reflects real-world conditions. Accreditation was the first and most important milestone.

Engineering consultancy Jones Nicholson has been integral to that journey. The firm’s association with FTI began in 2019 on FastTread stairs.

“That project required significant engineering input,” says Alan Hamilton, structural engineer at Jones Nicholson. “It had to be creative, fast, economical and practical for construction. From there, the progression into metal tray formwork for concrete slabs felt natural, given FTI’s capabilities with steel profiles and rolling equipment.”

Initially, BlueDeck was developed as a formwork-only system. It required propping, but it delivered efficiencies by accelerating formwork and construction. The next step was more ambitious: to evolve into a permanent steel deck that could act compositely with concrete, contributing to slab strength.

That shift demanded extensive development, rigorous testing and thorough accreditation. Desktop analysis and engineering codes provided the starting point.

But, as Hamilton notes, “Analysis alone was not enough.”

“We needed to physically test the decking and demonstrate that it performed exactly as designed.”

FTI engaged the University of Technology Sydney (UTS) Tech Lab to conduct largescale structural testing. The key was proving that the steel decking and concrete acted as a single composite slab. Under load, the steel had to behave as reinforcement, taking tension and working integrally with the concrete. Testing confirmed full composite action, validating BlueDeck’s performance and giving it the credibility required for engineers, consultants and builders to adopt it with confidence.

“In many ways, that independent verification was the ‘full stop’ to the compliance journey – proof that BlueDeck works and works effectively,” says Hamilton. Fire performance was the other critical hurdle. With steel decking positioned on the underside of slabs and directly exposed to flame, fire testing was essential. FTI partnered with the CSIRO to carry out trials across a range of slab thicknesses and load conditions. Exposing slabs to flame at the CSIRO’s North Ryde facility was the ultimate trial by fire, and one BlueDeck withstood.

“Just as with the structural testing conducted by UTS, the involvement of such a respected independent body gives BlueDeck credibility,” says Hamilton.

“To create a true partnership, you need to have skin in the game. That meant employing professionals inhouse who could provide genuine added value.”

With easy interconnection, BlueDeck saves time and money on site.

Practical tools for engineers

Proving BlueDeck under fire and load was one milestone; equipping engineers with a digital toolkit to carry that assurance into daily practice was the next.

In collaboration with Jones Nicholson, FTI developed the BlueDeck design app with proprietary Designer Software and supporting resources such as a span calculator and designer manuals.

“The software, calculators and manuals are built from engineering insight, making BlueDeck easier to design, easier to build, and consistently aligned with code requirements,” says Cameron Arkcoll, CEO of FTI.

external partnerships ensuring updates can be developed, tested and deployed without delay.

“FTI’s approach has always been proactive rather than reactive,” says Hamilton.

“From what I have seen, they are already considering how future shifts in the industry will affect their systems and are preparing for those changes.”

“Analysis alone was not enough. We needed to physically test the decking and demonstrate that it performed exactly as designed.”

Hamilton agrees: “We are in a digital age, and engineers naturally gravitate towards software. Manuals are still useful, but having to pull out tabulated documents is far less efficient than being able to access information immediately on a computer. The app makes that possible.”

Engineers can input project-specific data, adjust parameters and see results calculated instantly. Its strength is simplicity: intuitive prompts turn compliance from paperwork into precision on screen, ensuring every requirement is met before construction begins.

“The app has proven to be just as valuable internally,” says Hamilton.

“Our support team picked it up quickly during training sessions and now use it to guide and assist clients.”

Innovation remains a priority. FTI is expanding its engineering capabilities by recruiting product-specific specialists for BlueDeck. For industrial projects requiring higher load capacities, the company’s development and technical teams are already working on product adaptations.

For FTI, everything comes back to tested assurance. Its systems, support and tools are not only meeting today’s standards but are ready for tomorrow’s.

As Hamilton notes, it signals a bright future for the company.

“Their ability to anticipate and respond to change will ensure their products remain reliable and aligned with the expectations of clients and regulators,” he says.

Standards will continue to shift and expectations on materials will rise. Tested under load, proven under fire, and backed by in-house expertise, FTI has shown that reliability is never claimed – only demonstrated.

MYOB Acumatica Construction is a cloud-based Enterprise Resource Planning system that connects your project management, job costing, contracts, payroll, and financials.

“The most valuable thing MYOB Acumatica has given us is confidence. Confidence in our numbers, in our processes, and in our ability to scale.”

Julia Blackman Finance Manager – Camex Civil

Discover why more Australian businesses choose MYOB Acumatica. Watch a product demo.

business across Australia and New Zealand rely on MYOB Acumatica Construction

integrations with third-party applications, including Procore, Autodesk and Hammertech

updates to the platform across 2024

myob.com/au/erp-software

When crews down tools and sites fall quiet over summer, the threat to materials and public assets rises.

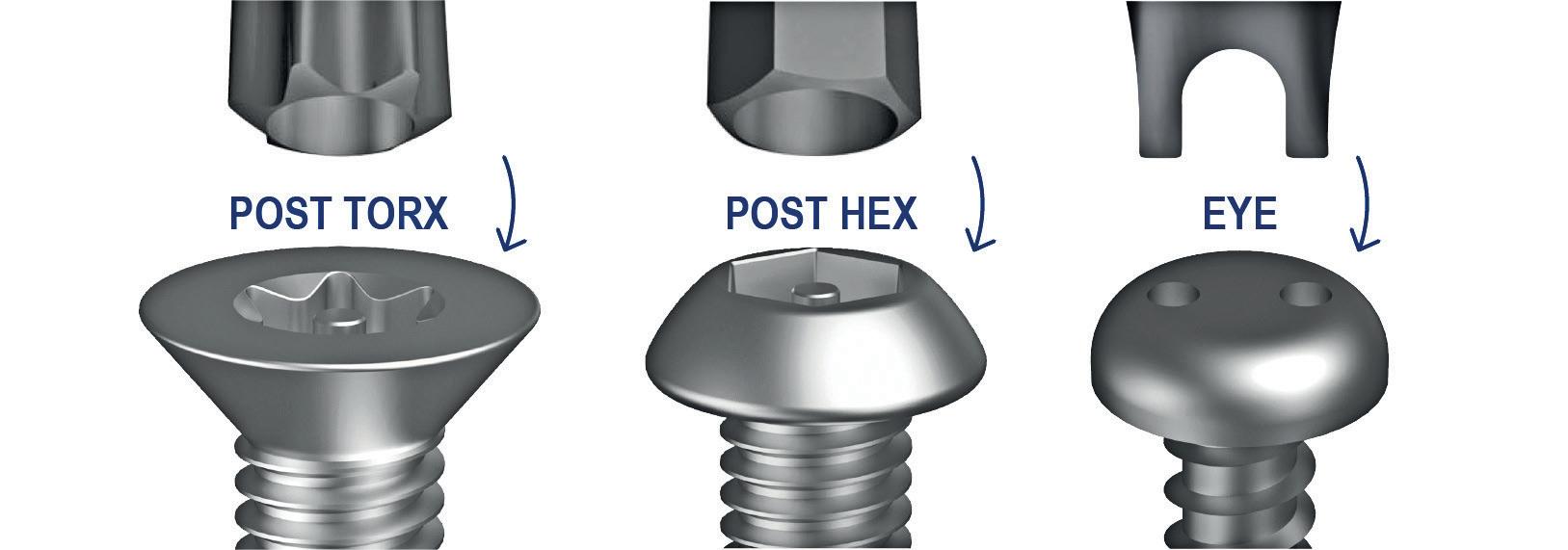

With nearly a century of history, Hobson Engineering’s fastening solutions feature in some of the nation’s most critical structures. Among the most specialised of these are security fasteners, designed to deter tampering and safeguard the built environment.

With the end of the year approaching, idle equipment and exposed assets heighten the need for vigilance. For Hobson Engineering, this is when security fasteners demonstrate their worth.

Alan Washburn, national product and market development manager at Hobson Engineering, says this time of year is a reminder of why protection should be considered from the earliest stages of project design.

“While security fasteners have been part of the construction vocabulary for decades, awareness remains uneven,” says Washburn. “Many projects still overlook their value until a theft, failure or safety incident occurs. Education is key.

“We want to ensure contractors, asset owners and councils understand that these solutions are available and can be incorporated easily into design and procurement processes. Then, they can enjoy these holiday periods with peace of mind.”

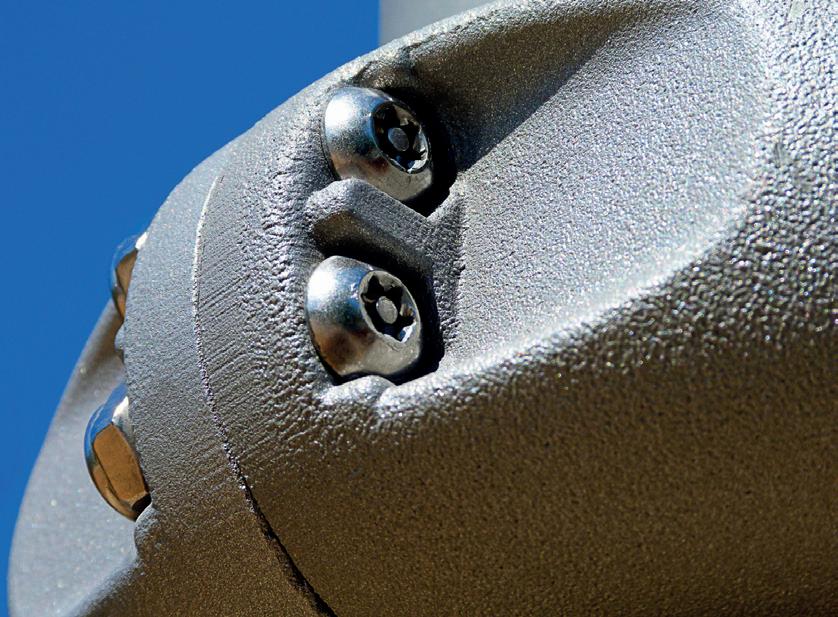

A security fastener is a screw, bolt or nut engineered to resist unauthorised removal. Unlike conventional fixings that use common Phillips or hex drives, these fasteners feature unique head designs that can only be engaged with matching driver bits. Some allow controlled removal with the correct tool, while others are permanent, creating a secure connection that cannot be undone without damage.

Among the permanent types are shear nuts and secure rings. A shear nut tightens like a standard hex nut until it reaches a specific torque, at which point the outer section snaps off, leaving a smooth, rounded surface that cannot be gripped with standard tools. A secure ring takes a different approach, fitting over a bolt or nut to lock it in place and prevent removal without destruction. These deceptively simple mechanisms provide

durable, tamper-resistant protection suited to everything from public amenities to highsecurity installations.

Washburn says adoption of these fixings has risen across Australia’s construction sector in recent years. The growth of complex and sensitive assets has driven demand for higher levels of protection.

In Defence environments, security fasteners are a mainstay in perimeters, access points and equipment enclosures. They secure fencing, gates, lighting systems and communications infrastructure, reducing the risk of tampering or forced entry. Within facilities, they protect control panels, armouries and restricted storage areas where reliability and controlled access are required.

“They are essential in reducing the risks of vandalism and trespass that can cause service disruptions or safety incidents.”

Security fasteners require specialised tools, ensuring that critical machinery, safety barriers and protective enclosures remain intact. (Image: Andrew Berezovsky/shutterstock.com)

“More contractors are recognising that while these fasteners might cost a little more initially, the investment pays off through extended asset lifespan and reduced replacement costs.”

“The appeal lies in permanence and accountability,” says Washburn. “Once installed, a fastener’s integrity cannot be compromised without clear evidence of interference. For Defence contractors, this provides assurance that every physical barrier performs as intended.”

Inside data centres, where digital security often dominates attention, physical protection remains equally critical. Security fasteners are used to lock fencing and perimeter barriers, as well as internal racks, equipment mounts and enclosures housing sensitive hardware. These facilities operate under strict access protocols, and tamper-resistant connections prevent unauthorised entry or component removal. Washburn explains that while alarms and surveillance are the primary deterrents, physical barriers reinforced with secure fixings provide an additional safeguard.

Along rail networks, these fasteners play a role in protecting both people and infrastructure. They are used to secure fencing, barriers and trackside equipment, preventing unauthorised access to live rail environments.

“They are essential in reducing the risks of vandalism and trespass that can cause service disruptions or safety incidents. For asset owners and contractors, their value lies in longevity,” says Washburn.

“Once installed, these fasteners retain their performance through vibration, weather and constant operational pressure, ensuring rail infrastructure remains protected over time.”

They are similarly vital across public infrastructure – from playgrounds, lighting columns and transport shelters to utilities, treatment plants and community facilities – supporting safety, reliability and longterm asset performance. In settings like playgrounds, safety is paramount. A missing fastener can lead to serious injuries, making secure connections critical.

“The cost of a playground may not compare to that of a transformer or rail corridor, but the potential human cost from an accident makes these fixings just as important,” says Washburn.

The construction market is shifting focus from the upfront price of a project to its long-term cost of ownership. Asset protection has become a key consideration, with maintenance, vandalism and theft now influencing design decisions. Security fasteners play a decisive role in minimising those risks.

“More contractors are recognising that while these fasteners might cost a little more initially, the investment pays off through extended asset lifespan and reduced replacement costs,” says Washburn.

In public spaces such as transit stations, parks and retail displays, security fasteners help prevent casual vandalism. (Image: Blue Corner Studio/ shutterstock.com)

Hobson Engineering continues to refine and expand its range, guided by collaboration with customers who present specific challenges for the engineering team to solve. The goal is always to achieve the right balance between strength, durability, practicality and security.

“Every project brings its own challenges, whether it is environmental conditions, accessibility or security classification,” says Washburn. “Our role is to match the right fastener to the right application so performance is never compromised.”

Innovation continues to drive development. The challenge, he says, is that the technology must evolve as quickly as those attempting to defeat it. This ongoing contest of engineering progress has produced a growing variety in driver bit designs and sophisticated approaches to restricting tool access.

“In the future, it could become similar to locksmithing, where only qualified professionals with verified credentials are authorised to purchase or use certain driver types,” says Washburn. “That would further guarantee these products are handled responsibly and kept out of the wrong hands.”

To ensure quality, the company oversees its products’ journey from warehouse to worksite.

As a national distributor, each stockist must meet standards covering product handling, technical knowledge and customer service.

This framework sustains both consistency and accountability. It also reinforces the company’s philosophy that technical products require technical support. Stockists form the connection between Hobson Engineering’s expertise and the market’s practical

requirements, ensuring products are applied correctly and maintained to specification.

“We do not sell directly to the public, so our distribution network represents our brand in the market,” says Washburn.

“It is important that our stockists uphold Hobson Engineering’s reputation for reliability and safety.”

As construction pauses over the holiday season and the nation’s assets stand still, protection depends on preparation.

Security fasteners help keep Australia’s built environment secure, functional and safe, and Hobson Engineering continues to champion their quality and availability throughout the industry.

In playgrounds, security fasteners cannot be removed by curious children or vandals with a standard wrench or screwdriver. (Image: Jhovan Ngapak/shutterstock.com)

Built Environs brings expertise and insight to Australia’s life sciences sector, constructing environments where research, production and innovation can flourish.

Australia’s capacity to produce vaccines and medicines at home depends on the buildings where science takes place. Such facilities are intricate, highly regulated and fundamental to the nation’s health resilience. As investment in life sciences accelerates, so does the need for builders who understand how to create environments that protect both people and research.

Built Environs has decades of experience and technical command of this specialised field. The company’s expertise spans design, construction and, most critically, the testing, commissioning and qualification/verification of two distinct facility types.

The first supports scientific research into pathogens such as bacteria, viruses and other microorganisms that cause disease.

The second enables the development of therapeutic medications, including vaccines, drugs and clinical trials.

science of construction

Goce Causevski, general manager for Victoria at Built Environs, says projects in the life sciences sector demand a different way of thinking about construction, beginning with the end.

“The complexity comes from the fact that you are effectively creating a machine that people work within to produce vaccines or conduct research,” explains Causevski.

“Every element, from the airlocks and pressure regimes to how each part interacts with the science or manufacturing process, is critical.

“Construction must link closely to commissioning and qualification/verification. With traditional projects, the process tends to move sequentially towards practical completion. In life sciences, we begin with the end in mind.”

Built Environs starts with regulatory certification and compliance, then works backwards through the program, defining each stage with intent. The approach mirrors the complexity of these projects and the discipline required to deliver them.

It also speaks to their importance. These facilities form Australia’s first line of defence against pathogens and play a crucial role in research, public health and scientific progress.

With increasing investment from government and pharmaceutical companies, the sector is entering a period of expansion that aligns with Built Environs’ strengths.

“Much of our capability comes down to the experience of our people,” says Causevski. “We have senior team members who have spent more than 30 years working in this space, both in Australia and overseas in locations such as China, Puerto Rico and the United States, where many of the large pharmaceutical companies have a strong presence.”

This in-house expertise is centred on understanding Therapeutic Goods Administration requirements and Good Manufacturing Practice (GMP) standards. Together, these frameworks govern Australia’s regulatory environment for life sciences construction, an area in which Built Environs operates with fluency and confidence. That same attention to detail applies to physical containment. In Australia, these environments are classified as Physical Containment Level 2, 3 and 4, setting strict parameters for the control of security, access, airflow, pressure and materials handling (sterilisation and decontamination processes).

“When dealing with live viruses, there can be no risk of escape into the atmosphere or the surrounding workspace,” says Causevski. “Managing that containment barrier is vital, and our people have extensive experience designing, constructing and validating those systems.”

With an established life sciences portfolio, Built Environs has delivered many projects that demonstrate its reliability and professionalism. Its clients include some of the largest pharmaceutical manufacturers in Australia and globally, with one recently completed build standing out for the challenges overcome.

Located in Victoria, the project involved expanding a production facility and a therapeutic production line within a live environment. As the team retrofitted the existing building, pharmaceutical production continued next door.

“That meant we had to manage not only the normal construction process but also create containment within containment to ensure the facility remained compliant and could maintain production targets while we worked alongside their operations,” says Causevski.

The complexity lay in prefabricating certain elements while minimising dust, noise and vibration. Those are standard considerations in construction, but in such tightly regulated environments, tolerance for disruption is effectively zero.

“The regulations exist for good reason, as these products are ultimately used in humans and play a role in protecting the community. We cannot jeopardise that,” says Causevski.

“Our processes, systems, quality assurance (QA) and subcontractor selection are critical in this space. Everything must be managed with absolute precision to avoid exposing the client or their facility to contamination risks.”

Another development under construction focuses on mRNA vaccine production. Previously, Built Environs worked on facilities using cell culture technologies with live viruses, but mRNA production involves a different process and operational setting.

“We are seeing differences in how these facilities are designed, commissioned and brought to life, and that is creating new opportunities for learning and innovation within our teams,” says Causevski.

Built Environs’ methodology of working backwards centres on one principle: commissioning and verification define everything that comes before.

“The complexity comes from the fact that you are effectively creating a machine that people work within to produce vaccines or conduct research.”

A new pharmaceutical heating, cooling and clean-in-place process services system.

From there, everything hinges on robust quality controls. That includes inspection and test plans more stringent than those used on a standard commercial project. The team maps the design into those plans, communicates them to subcontractors, and traces and validates every step, from shop drawings to the procurement of materials and plant.

A hallmark of these projects is clean building practice, involving checks well above standard, such as confirming all wall cavities are clean before closure to ensure no live organisms or construction debris remain.

“We inspect everything thoroughly to ensure nothing could compromise the integrity of the facility months or even years down the track,” says Causevski.

He attributes that consistency to meticulous commissioning, assurance measures and a clear understanding of the full sequence from design through to verification. Built Environs applies those principles through its trade selections and on-site management, ensuring quality is embedded long before handover.

Pre-commissioning checks are equally important, with prototyping used to test and refine systems ahead of installation. The team prototypes connection details, joints and seals to confirm airtight performance and compliance with required standards.

“These checks allow us to work through the QA process so that when the building or clean room is finished and we begin the final verification through enhanced commissioning, we already know it will perform as intended,” says Causevski. “These are not the types of facilities where you reach the end and uncover an issue. Testing must reveal potential flaws early, because problems are not easily fixed later.”

Digital engineering has made that possible. Within Built Environs, and across the wider McConnell Dowell Group, modelling tools now underpin every stage from design to delivery.

Where drawings were once two-dimensional and manually transferred between stages, the process is now entirely digital. This in-house capability allows the team to coordinate complex services from the outset, track every component and assign unique identifiers to equipment that can then be installed and verified at completion.

On the Victoria build, that digital integration proved essential. Working within an existing live plant would otherwise have been challenging.

“We were able to model the existing facility, verify that model and adapt it to the refurbishment requirements,” says Causevski.

“That allowed us to prefabricate many of the services off site, which reduced the amount of work required during the shutdown period and shortened the overall timeframe compared to undertaking all works in situ.”

The future of life sciences construction, Causevski says, will be defined by the convergence of technology and research. Artificial intelligence (AI) is emerging as a powerful tool, with potential to accelerate clinical trials and shape how vaccine technologies such as mRNA evolve. Australia, he believes, is well positioned to lead that intersection.

The country’s universities already have the skills and appetite to integrate AI into specialised research, from developing firstline defences against pathogens to advancing vaccine production. With continued investment and support from government, Causevski says Australia could become a global centre for this type of innovation rather than watching it migrate offshore.

For Built Environs, opportunity lies in building both capability and capacity as the sector expands. Attracting and developing the specialist skills needed to deliver tightly controlled environments remains a strategic focus.

“Like most other builders, we have graduate programs and structured onboarding processes, but we also rotate people across different projects, so they gain exposure to a variety of sectors such as life sciences, education and sport and recreation,” says Causevski.

“We plan that intentionally so they can build a broad foundation of experience.”

This depth is strengthened through partnerships with industry bodies at the trade level, enabling teams to learn the technical aspects of the systems they are helping to deliver, whether that be mechanical engineering or plumbing.

“That type of engagement is not something most builders are doing, but we believe it is essential because the services and commissioning components of these facilities are so critical,” says Causevski.

Knowledge sharing is embedded across teams. Regular training sessions led by

in-house experts ensure lessons are carried between projects and regions, including Victoria, South Australia and New Zealand.

Built Environs also maintains a global view of the life sciences sector, with team members participating in study tours of highcontainment facilities overseas. Observing international best practice and bringing those insights home helps the business stay connected to the latest thinking in both design and delivery.

As interest in life sciences continues to grow internally, Causevski sees that curiosity as a sign of strength. Many of the company’s engineers and project managers actively seek assignments in the sector, drawn by the complexity and challenge.

“But for me, it is also personal. Some of the products made in the facilities we build are used by family and friends,” he says. “When you see someone close to you relying on a product that exists because of a facility you helped construct, it has real meaning. It reinforces that what we do has a genuine community impact.”

For Causevski and the Built Environs team, the reward lies in knowing their work advances both science and society, building the foundations for discoveries that protect and improve lives.

“Every element, from the airlocks and pressure regimes to how each part interacts with the science or manufacturing process, is critical.”

A purpose-built, state-of-the-art admissions area.

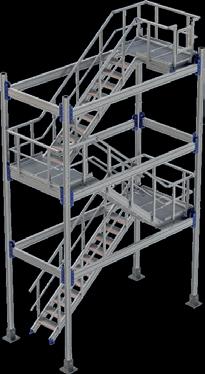

A modular rethink of industrial access, Kattsafe’s new aluminium stair tower unites speed, scale and simplicity.

Steel gave industrial access its form and, for a time, its authority, symbolising stability even as its weight and rigidity slowed those who built with it. Kattsafe recognised that endurance need not come at the expense of efficiency.

For more than 20 years, this Australian heightsafety specialist has sought to make access simpler. With the introduction of its modular range 10 years ago, the company showed how systems could be lighter, faster and more adaptable by design. Its latest development, the Industrial Modular Access Stair Tower, brings those qualities to an industrial scale, demonstrating how modularity delivers both structural integrity and operational agility.

Launched in November 2025 as the first product in Kattsafe’s industrial range, it marks a shift in how large facilities design, assemble and maintain access requirements.

Keeta Voss, marketing coordinator at Kattsafe, says traditional steel stair towers remain prevalent less through merit than through convention.

“Traditional steel systems are still used because it is what people are familiar with. It is seen as the default choice, but there are downsides,” says Voss. “Steel is heavy and difficult to install, particularly when you are dealing with large stair towers that require heavy-duty cranes. The lead times can also be quite long because the systems are not modular. Every part must be pre-fabricated and pre-engineered in a factory before it leaves the floor, which can extend the timeline by weeks or even months.”

The company’s new stair tower is fabricated from high-strength aluminium. It arrives on site as a flat-packed system that assembles through Kattsafe’s proprietary T-bolt and T-slot connection method, converting what was once a labour-intensive process into fast installation.

“Components can be stacked module by module, similar to Lego,” says Voss. “It is lightweight, clean and far easier to handle.”

Efficiency is built in and visible before the first component is assembled on site. Because the structure is proprietary and engineered, design cycles shrink from weeks to days, compressing lead times while maintaining compliance and quality. For project managers negotiating schedules and crane allocations, those gains translate into cost and time savings.

Aluminium also removes one of steel’s age-old problems: rust. It resists corrosion, extending lifespan and sustaining performance in demanding environments. It remains recyclable while eliminating the maintenance burden and weight that can complicate largescale installations.

In practice, the stair tower recognises that projects seldom unfold exactly as drawn.

Even minor variations in site dimensions or tolerances can impose delays and redesigns, yet Kattsafe’s modular composition accommodates deviation with ease.

“Modularity is the key,” explains Voss. “Our designs can be configured in countless ways. If a wall ends up higher than planned or a structure is out by a few millimetres, contractors can make on-site adjustments without returning for redesign. With steel, major changes would essentially mean starting over.”

Each module contains a single flight and platform, pre-fitted with adjustable brackets that allow calibration during installation. Subsequent modules interlock to form a continuous structure, balancing stability and flexibility.

“Contractors crane each section into place and secure it,” says Voss. “If the system needs to be reconfigured, it can easily be pulled apart and adjusted, much like Lego.”

Those practical benefits have already drawn interest from the industry, with Kattsafe trialling the stair tower with select clients and showcasing it at recent events to positive response. Long-time customers who had been seeking taller access solutions can now deliver those projects without the complexity associated with steel. Installers, too, have welcomed the change, finding aluminium easier to handle than fabricated steel. The result is a system that streamlines work for contractors and installers alike.

The design reflects the scale and complexity of today’s industrial builds. Kattsafe’s assemblies have been installed in distribution centres approaching 30 metres where roof access is required, and they are equally suited to data centres and water infrastructure. The modular architecture adapts to irregular geometries, enabling stair runs to follow forms that would challenge traditional steel fabrication.

it in the field and understands how it works, adoption will grow quickly.”

Digital integration further strengthens this efficiency. The company’s online configurator, Kattsafe Builda, enables engineers and clients to model designs, refine configurations in real time and generate instant compliant drawings and pricing.

“Traditionally, a steel fabricator would need engineers and drafters working for days or weeks to create the same design,” says Voss. “Builda handles much of that automatically, with built-in compliance constraints to ensure accuracy. It saves considerable time and streamlines the process.”

Builda captures Kattsafe’s focus on simplification, aligning designs with Australian Standards and reducing friction between concept and construction.

For Kattsafe, the launch of the Industrial Modular Access Stair Tower signifies a turning point in industrial access design.

“It shows that steel is no longer the only option and that access systems can be faster, cleaner and more adaptable,” says Voss.

“If we can encourage more architects, specifiers and builders to see what modular aluminium systems can do, it will change the industry completely. Education is the biggest part of it. Once the industry has seen

To accelerate that adoption, Kattsafe provides engineering support, installation manuals, digital resources and forthcoming case studies detailing performance in varied conditions.

The system also lends itself to future adaptation, ready to address emerging challenges across infrastructure and industry.

“Right now, our focus is on the stair tower, which is a straight vertical system. But because it is modular, we can do much more with it –for example, linking stairs with platforms or extending access horizontally. The flexibility is almost limitless,” says Voss.

“Many of our products evolve because a project pushes us to create something new that proves to be valuable for the wider market. That is how our current modular system gained so many configurations. Innovation for us always starts with listening to the customer.”

From its early access systems to the industrialscale assemblies that now define its range, Kattsafe’s trajectory is one of continuous refinement. What began as an idea to make access safer and more flexible has matured into an ecosystem of configurable, engineered products elevating efficiency to new heights.

“It really changes the height access space and remains one of the only systems with this level of modularity and flexibility,” says Voss. “It’s going to make some waves.”

Assembly is streamlined using Kattsafe’s proprietary T-bolt and T-slot connection method.

“Components can be stacked module by module, similar to Lego.”

From project profitability and forecasting to compliance, MYOB explores how artificial intelligence is driving efficiency in the field.

Few topics spark as much debate on construction sites and in boardrooms as artificial intelligence (AI). Across the globe, progressive teams are already utilising AIdriven tools to analyse site data, predict cost overruns, detect safety risks and streamline scheduling. But is now the time for mid-sized construction firms to act?

That question is front of mind for Valantis Vais, head of product and product marketing at MYOB, who says the answer lies in practicality: focusing on what AI can deliver for construction businesses today and how leaders can prepare their teams to use it wisely.

Through MYOB Acumatica, the company is helping construction businesses connect field operations with financials, turning real-time data into faster, smarter decisions.

“There are wide interpretations and applications when it comes to AI,” says Vais. “It can range from a simple chatbot that saves a firm five minutes on basic day-to-day tasks to something as complex as predictive analytics that identify a bottleneck in a project schedule and save millions of dollars.”

AI, he adds, already ranges from simple assistance tools to intelligent systems that make decisions and handle complex objectives.

The term now covers a broad spectrum, from traditional machine learning to generative models and the emerging field of agentic AI.

marketing at MYOB.

Imagine an AI procurement agent that tracks material usage, predicts shortages and automatically places orders at the best price, or a workforce allocation agent that monitors worker availability, certifications and productivity before reassigning crews or booking subcontractors. These are not far-off possibilities, says Vais, but early glimpses of what is already taking shape.

“This shows how far-reaching the implications of AI can be,” he says. “At the moment, the only real limit is our imagination.”

The journey

Vais compares the journey of AI in construction to the automotive industry’s path to self-driving vehicles, from level zero with no automation to level five with full autonomy where a car drives itself completely.

In the construction industry, he sees the journey progressing from basic digitisation to autonomous back-office systems.

At level one, AI automates simple tasks such as invoicing and record-keeping, while people still make key decisions. Level two introduces automated workflows and order-to-cash processes, streamlining routine approvals and preventing delays. Low-code or no-code technology has helped businesses reach this stage, although it still depends on rule-based instructions such as “if this, then that”.

Large language models then push businesses toward level three, enabling conditional autonomy where AI can complete end-to-end processes such as accounts receivable with minimal human input. It recognises when an invoice is late, determines how to follow up, and manages the communication – much like a car that can detect lanes and correct its course but still needs a driver.

Level four emerges when multiple AI agents begin working together, sharing information across functions such as accounts and sales to manage risk and cash flow – akin to a vehicle that can navigate and overtake autonomously. Level five, though still aspirational, represents an autonomous enterprise that runs its operations while people focus on strategy, vision and value creation. In the car analogy, the driver steps inside, sets the destination and the vehicle takes them there.

“This is a useful framework for understanding where your organisation sits on the autonomy spectrum and what is needed to progress,” says Vais. “The question is not just what AI is capable of, but where each business stands on that journey and how far it wants to go.”

For now, technology is capable of supporting most organisations up to level two, he explains. Yet many construction firms remain at level zero or one, still relying on manual processes and disconnected spreadsheets.

Those ahead of the curve are increasingly using AI to enhance how work is planned, delivered and managed across the construction lifecycle, from pre-construction through to delivery and maintenance.

“Right now, the most visible benefits are in cost reduction, safer job sites, quality control and extending the lifespan of equipment,” says Vais.

“One of the most promising areas is in improving the connection between the office and the field in real time.

“Traditionally, project managers prepare a weekly report that summarises site activities and then email it to the team. With AI, that process can become almost instantaneous.

“The system can analyse site activity data and automatically generate a written summary of what occurred each day or week. The project manager simply reviews it, confirms the details are correct and shares it.

“This gives the back office an immediate understanding of what is happening on site, closing the communication gap that often exists between the field and the office.”

Another use case involves estimators and project managers who receive constant scope changes, client requests and email updates.

“Managing that information manually can be overwhelming,” says Vais. “AI can process those emails, compare new information against the existing project scope, and identify what has changed. This helps teams manage variations more efficiently and reduces the risk of something being overlooked.”

A further example of AI in practice, already built into MYOB Acumatica, is anomaly detection. Vais explains that the technology analyses data sets such as materials purchased from specific vendors, comparing prices and flagging possible overcharging.

“Pricing discrepancies can occur due to errors or outdated rates and identifying them manually would take hours of review. With anomaly detection, managers no longer need to sift through hundreds or thousands of records. AI highlights just the few that need attention,” he says.

“This kind of functionality makes activities that were once impractical due to time constraints now entirely achievable. It helps construction firms manage costs, increase transparency, and improve decision-making. That is the kind of value AI can deliver today.”

Across Australia, mid-sized construction businesses are starting to see measurable gains.

In MYOB’s recent study, the top benefit reported from AI use was improved decision-making (46 per cent), followed by increased productivity (39 per cent).

“What I find most interesting about the improved decision-making result is that, even though we are not yet operating at levels three or four of autonomy, AI is already helping teams make better calls,” says Vais.

By interpreting schedules, analysing data and synthesising large volumes of information, AI is enabling project managers and business leaders to understand and act faster.

“AI can collate huge amounts of information and present it in a way that aligns with how people think and work,” says Vais. “That accessibility is what makes it powerful.”

He often hears construction described as “data-rich” – an industry with vast stores of historical information but little clarity on how to use it. MYOB calls this data overload, and AI can help close that gap. By turning data into actionable insight, it simplifies complex decision-making and puts information to work. Predictive analytics, for instance, can deliver faster and more accurate cost estimates while helping control labour, material and compliance expenses.

“At the moment, the only real limit is our imagination.”

“Right now, the most visible benefits are in cost reduction, safer job sites, quality control and extending the lifespan of equipment.”

Turning data into value

On the value front, MYOB frames AI across three experiences: assist, automate and advise.

The “assist” layer acts as a digital helper, allowing users to query their systems conversationally. For instance, a manager could ask which projects are most profitable or which suppliers rank highest by spend. It makes it easier to access and interpret information without manual effort.

The “automate” layer streamlines repetitive processes such as invoice handling and approvals, saving time while maintaining oversight. For example, when an email with an invoice arrives, AI can read it, extract the information, and generate the bill directly in the system, linking it to the correct project. By the time the user opens it, the work is done and ready for review.

The “advise” layer provides deeper insights that guide better decision-making. Through anomaly detection and predictive analytics, AI highlights cost variations or irregularities before they escalate, without requiring someone to manually analyse lines of data. The system surfaces what matters most, enabling managers to act faster and more confidently.

“Through these three lenses, AI transforms how construction firms use the data they already have,” says Vais. “It takes them from being data-rich but insight-poor to being insight-driven and more agile in every aspect of their operations.”

Technology alone will not carry a business up the autonomy curve. Many construction businesses still need to get their foundations in place before they can benefit from AI. Large language models and AI systems rely on information being accurate and, to some extent, structured in a way that allows them to interact with it and make informed decisions. That data readiness is one of the biggest barriers to adoption.

Data security, privacy and compliance are another concern. Sensitive project and financial information must be protected, yet AI systems need context to generate meaningful insights. This tension often slows adoption.

“At MYOB, we tackle this challenge head-on,” says Vais. “Privacy and security are built into the core of how we integrate AI into our platform.”

The platform, MYOB Acumatica, is a cloudbased enterprise resource planning (ERP) system that brings financial, customer, project and reporting management together in one environment. In the way it assists businesses, automates workflows and delivers insights, privacy remains fundamental. At its core is a secure gateway that anonymises business data before prompts are sent to large language models. This ensures context is retained for accuracy, while sensitive information never leaves the protected system.

“This gateway delivers both power and control,” says Vais. “It allows businesses to access the full capability of AI while maintaining confidence that their data remains secure and compliant.”

But the biggest barrier, Vais argues, is change management, and it starts at the top. While technology is exciting to talk about, what really determines success is how leaders use it.

At MYOB, leaders embrace large language models openly, showing teams that experimentation is not just acceptable but essential. By modelling curiosity and new approaches, they have turned experimentation into a core part of how the company works.

“What changed for us, and what I believe needs to happen in construction, is that leaders must actively use and normalise these technologies,” says Vais. “They need to demonstrate that AI tools are legitimate and valuable, creating an environment where their teams feel comfortable experimenting.”

This shift, Vais adds, highlights a broader truth for every industry: adoption starts at the top. If leaders are not modelling the behaviour, their teams are unlikely to follow.

He describes MYOB’s approach to AI as deliberate and grounded in practicality. Rather than adding AI features for the sake of it, the focus is on where the technology can genuinely improve workflows and deliver value. Privacy remains central to that philosophy, as evidenced by MYOB Acumatica’s secure gateway. Equally important is trust and local relevance. MYOB designs its platform to meet the regulatory and compliance standards of Australia and New Zealand.

Looking ahead, the goal is to ensure customers can adapt without disruption.

“We are designing MYOB Acumatica to be open and flexible, with the gateway connecting

to multiple AI models rather than locking users into a single provider. Businesses can choose the model that best suits their needs in terms of cost, efficiency and speed,” says Vais.

“That openness ensures longevity. When you commit to our platform, you are not confined to today’s technology. You are positioned to benefit from the next generation of advancements as they emerge in the months and years ahead.”

Vais emphasises that MYOB’s approach to AI is practical first. He says success depends on how people use it in their day-to-day work rather than on simply acquiring new technology.

For mid-sized firms ready to explore AI, Vais recommends starting with small pilot projects that prove the use case and build confidence.

“Allow teams to test the technology within a specific workflow and see how it can support their day-to-day operations,” he says.

“For example, take an upcoming request for proposal (RFP) and feed it into a large language model to extract key information, such as opportunities for the business to participate. Observe how the AI interprets the data and what insights it provides.”

Vais cautions against rushing into technology purchases without a clear plan. Too often, he says, organisations treat new systems as “all-in” investments, handing them to their teams and expecting results. That approach rarely works. The key is to create an environment where teams can test, learn and refine while ensuring data quality and accessibility are in place.

He recalls a business that used a large language model to help complete an RFP when a vendor was slow to provide technical input. The team was able to finalise its proposal faster and with greater accuracy.

“These small pilots help spark creativity and imagination within the organisation,” he says. “They show people what is possible.”

The no-regret move