Through trust, collaboration, and innovation, Alcarail stands as proof that values-led engineering delivers both performance and purpose.

100% SYSTEM AVAILABILITY

Through trust, collaboration, and innovation, Alcarail stands as proof that values-led engineering delivers both performance and purpose.

100% SYSTEM AVAILABILITY

At Siemens Mobility, we value our local manufacturing facilities and engineering teams for their innovative and sustainable ways of working, as they are the key to revitalizing old and new rail technology that will #transformtheeveryday and change the way we travel globally.

Published by:

379 Docklands Drive

Docklands, VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman

John Murphy E: john.murphy@primecreative.com.au

CEO Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor Kayla Walsh

E: kayla.walsh@primecreative.com.au

Business Development Manager

Arron Reed

M: 0466 923 194 E: arron.reed@primecreative.com.au

Client Success Manager Ben Sammartino

E: ben.sammartino@primecreative.com.au

Head of Design Blake Storey

E: blake.storey@primecreative.com.au

Designer Apostolos Topatsis

Subscriptions subscriptions@primecreative.com.au

www.RailExpress.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the Publisher.

Kayla Walsh Editor -

It’s hard to believe it’s the end of 2025 already, and what a year it’s been for the rail industry.

There’s plenty to talk about, including the opening of Melbourne’s much-anticipated Metro Tunnel, set to transform the way residents move around the city.

I was lucky enough to join hundreds of excited members of the public for a sneak peek of State Library Station before its official opening.

In this edition I share my first impressions from the day, as well as an interview with the Executive Project Director of the Metro Tunnel, Ben Ryan, and the Victorian Minister for Transport Infrastructure Gabrielle Williams.

Speaking of city-shaping projects –there’s an update on Auckland’s City Rail Link, which is inching closer to completion in 2026, as well as the Byford Rail Extension Project in Perth, which officially opened to passengers in October.

Our December cover story features Alcarail, a business that was started by engineer Jay Nathella five years ago, and has grown to become a prominent and trusted player in rail systems and signalling across Australia and New Zealand.

Despite everything he has achieved, Jay couldn’t be humbler. He was keen to share the spotlight with Marc Hamameh, Alcarail’s new Chief Executive Officer, whose journey to join the company marks a full circle moment.

Also in this issue, we catch up with some of the team from MTR Australia to discuss the iconic Sydney Metro City & Southwest project, and Siemens Mobility tells us all about its Queensland-based team and the experience it has gained from delivering major projects in the state for more than 100 years.

We hear from KeTech about how the right real-time journey information systems can help Queensland prepare for the Brisbane 2032 Olympic and Paralympic Games, and Downer shares the benefits of working with its expert Engineering Consulting Services team.

All this and much more in the December issue of Rail Express

We hope you have a wonderful Christmas break and come back refreshed and ready for another exciting year for rail!

kayla.walsh@primecreative.com.au

Turning engineering excellence into measurable value.

The engineering powerhouse behind Australia’s largest rollingstock projects is available to deliver smart, valuedriven rail solutions tailored to your needs.

With over 200 highly skilled engineers, Downer’s Engineering team offers unmatched expertise in all aspects of freight and passenger rollingstock design, delivery, and through-life support.

What sets our Engineering Consulting Services apart?

Australia’s largest dedicated rollingstock engineering team.

Deep and scalable technical expertise across all rail modes.

Trusted partner to governments and operators.

Proven success on complex integration and upgrade programs.

Multi-fleet through-life-support with proven track record.

Nationally accredited for safety and quality.

Global OEM relationships and access to global insights.

Trans-Tasman capability, delivering consistent excellence.

Learn more at www.downergroup.com/ecs

Two of the three new bridges to be installed at Broadford, Victoria, as part of the Inland Rail project were lifted into place during a “highly co-ordinated” early morning operation.

Inland Rail is building higher bridges and lowering the railway tracks at Hamilton Street and Short Street in Broadford to create enough clearance for double-stacked freight trains to use the line.

Construction partner John Holland coordinated both bridge lifts during a 15hour closure of the rail corridor in the early hours of Monday October 27.

Made-up of 38 girders and assembled onsite, the new Short Street bridge is 36 metres long, weighs approximately 265 tonnes and was lifted into place by a 650-tonne crawler crane.

The old Short Street bridge will be demolished when the new bridge is completed next year.

At Hamilton Street, five 35-metre girders weighing approximately 40 tonnes each were lifted into place by a 750-tonne mobile crane to form the backbone of the new bridge.

During the track closure, Inland Rail also carried out site establishment and signalling work at the Hume Freeway sites at Tallarook and Seymour. Scott Anderson, Inland Rail

Acting Delivery Director Beveridge to Albury, said the eight remaining Inland Rail sites in Victoria are a “hive of activity” and the bridge lifts at Broadford marked a major milestone for the project.

“There’s still plenty of work to do before we can open the bridges to the community, but it’s a big step forward to have the

girders installed,” he said. “The team carried out the bridge installs in the early hours to minimise the disruption to the local community.

“We thank the community for their patience and cooperation as we carry out the work required to successfully deliver Inland Rail.”

Sydney Metro West has achieved a worldfirst in tunnel construction with a Lining Erector Machine (LEM) being used to line the mined service tunnels that connect to the future stabling and maintenance facility at Clyde.

The LEM was custom-designed to line the two 700-metre tunnels with precast segments, which were made at the project’s Eastern Creek precast yard.

Tunnels excavated by roadheaders usually require cast-in-situ lining, unlike tunnels built using tunnel boring machines (TBMs), which have the capability to both excavate and install tunnel segments to line the tunnel walls as they move.

Lining the service tunnels in the traditional way would have involved assembling large formwork sections, pumping concrete from the surface, and staging multiple pours, which Sydney Metro said is a “slow and labour-intensive process”.

Inspired by TBM technology, project engineers adapted and refined the LEM while on the job, enabling it to complete an entire tunnel ring, built by piecing together four segments, in about an hour.

It took two months to line the final service tunnel, which measures 762 metres

in length and six metres in diameter.

The LEM approach is set to be a gamechanger for the tunnelling industry, speeding up lining while delivering a higher-quality, watertight finish that matches the strength and finish of TBM-built tunnels, and making the job safer for tunnel workers.

The final stage of works to upgrade the Kananook Train Stabling Yard have been completed, with Frankston Line trains now able to be serviced, washed and stabled at the facility.

The upgraded yard comprises a modern new train wash, a new train maintenance facility, staff facilities and increased stabling capacity, from eight trains to 21.

An additional rail connection to the Frankston Line has also been built to enable trains to easily enter and exit the site.

It follows the first stage of upgrade works, completed in May 2020 as part of the Carrum level crossing removal works, and the addition of a new high-tech signal control centre and improved driver facilities in 2022.

Increasing capacity to stable more trains at Kananook near the start of the Frankston Line will allow train services to run more efficiently.

Passengers are also expected to benefit with the introduction of the new X’Trapolis 2.0 trains, currently undergoing testing across the network ahead of their phased rollout on the Frankston, Craigieburn and Upfield lines.

One of the new X’Trapolis 2.0 trains was put through its paces at the Kananook stabling yard recently, testing the new tracks and overhead wiring, finishing with a shiny glow-up in the facility’s new train wash.

The Frankston Line is due to be level crossing free by 2029.

Queensland Rail has started track works on the South West Line, with more than 100,000 ageing timber sleepers being replaced between now and mid-2026.

The project is part of major investment in the line, which predominantly carries grain trains and runs from Toowoomba south to

Warwick and west to Thallon. The line is also used by heritage operators.

Resleepering works have commenced at Thallon, and crews are working their way towards Warwick before heading north to Toowoomba. On average, more than 1000 sleepers are being replaced

per day, with a workforce of about 35 Queensland Rail employees delivering the works using 12 Queensland Rail track machines.

Queensland Rail Head of Regional Scott Cornish said it was great to see the upgrades underway.

“We know how important our regional rail network is in providing a critical link for local supply chains and heritage operators and these works are part of our commitment to improving the existing rail infrastructure,” he said.

He said that with the grain season recently beginning, crews were making the most of off-peak periods to minimise impact to train services.

“A big thanks to all involved in getting this important project for the South West region underway.”

new Maidstone Tram Depot in Melbourne to begin testing.

The depot, which will help maintain, clean and house the new G Class fleet, was officially opened by Minister for Public and Active Transport Gabrielle Williams in October.

The first new tram will undergo a series of tests at the purpose-built facility to assess the braking systems, accessibility features and overall reliability, before it begins planned testing on the light rail network later this year.

A fleet of 100 new low-floor, nextgeneration trams will be rolled out on routes 57, 59 and 82 and will gradually replace the older high-floor trams.

The Victorian Government said the new trams offer more space and better accessibility for up to 150 passengers, which is almost double the size currently operating in Melbourne’s west.

The low floor design will make boarding easier for people with wheelchairs, prams and mobility issues, and the trams will also feature more doors and handrails.

The next-gen trams will also offer modern heating and cooling systems, as well as improved passenger information, with the new design developed in consultation with accessibility groups, passengers and tram drivers.

“This is an exciting milestone for Melbourne’s west – with local workers, local design and local innovation driving the future of our city’s iconic tram network,”

said Member for Footscray Katie Hall. With a 65 per cent local content requirement, the new fleet is being manufactured in Dandenong by Alstom, with the program supporting up to 1900 local jobs across manufacturing, construction and the supply chain.

Alstom also has the contract to operate the purpose-built Maidstone maintenance depot for the next 15 years, supporting more than 40 full-time employees.

The depot will feature advanced technology, including digital monitoring tools and an automated vehicle inspection system – a tram scanner that captures precise measurements as trams pass through, ensuring safety and performance standards are met in real time.

The premises also incorporates LED lighting, rainwater harvesting, adaptive reuse and recycled materials to reduce environmental impact.

Speaking about the arrival of the first G Class at the depot, Pascal Dupond, Alstom Australia and New Zealand Managing Director said: “Today is about more than opening a facility – it’s about supporting the future of Melbourne’s tram network.

“Maidstone is a state-of-t he-art depot that will keep the G Class fleet running safely and reliably for the next 15 years.

“Built in Dandenong by our skilled local team, these trams combine Alstom’s global technology with Victorian know-how to deliver accessible, energy-e fficient journeys for passengers.”

Pilot testing of contactless payments on public transport in Perth has been expanded to include trains and buses.

Following the success of early trials on Transperth ferries, more than 150 passengers have been chosen to test their credit or debit card, as well as smart phone

A four-week trial across trains, buses and ferries began on October 27 and is intended to ensure the readiness of the new contactless payments before a planned rollout to all passengers by the end of 2025 as part of the SmartRider Upgrade Project.

On November 3, a phased rollout began,

accepted using the Pay-By-Plate option.

The SmartRider cashless public transport ticketing system was first introduced to the Transperth network in 2007.

The upgrade project has included the replacement of more than 4000 SmartRider validators across the bus, train, and ferry network; the replacement of all Add Value Machines with new ‘SmartRider Hubs’; and Pay-By-Plate parking machines upgraded to accept debit and credit cards.

Western Australian Transport Minister Rita Saffioti said in a statement: “With the success of early testing on the ferry network, we’re now ready to expand pilot testing to both buses and trains for the first time, which is a major milestone for the project.

“The project team will be closely monitoring the pilot across all public transport modes, and we remain on track to have these payment options available to the entire community before the end of the year.

“With new payment options and the introduction of one zone fare from 1 January, we’re embarking on an incredibly exciting chapter for public transport in Western Australia.”

the local community has been invited to give feedback on how they move around the area and what’s important to them. This will help to shape the designs for the new underpass.

Expert assessments determined closing the level crossing is the best design solution for Yarraville due to the narrow rail corridor and densely developed area.

gate free by 2029, with a new pedestrian and cyclist underpass built to maintain connection either side of the

The Victorian Government said Anderson Street is one of the most dangerous level crossings on Melbourne’s rail network, registering one fatality and four serious

for almost

a further 26 near misses involving trains, pedestrians and vehicles since 2016.

Boom gates can be down for almost half the morning peak as up to 50 trains travel through the crossing, causing congestion and delays for pedestrians, cyclists and motorists. As part of early planning for the level crossing removal,

The government said it also provides opportunities to enhance the Yarraville Village, making the precinct “quicker, safer and easier for pedestrians and cyclists to get around”, with no more waiting at the boom gates.

Vehicles travelling to Yarraville Village from the west will be able to cross the rail line via nearby Somerville Road and Francis Street.

Five level crossings are being removed in Melbourne’s inner-west, at Newport, Altona, Spotswood and Yarraville.

As part of Victoria's Level Crossing Removal Project, 110 "dangerous and congested" level crossings are being replaced by 2030, with 87 already gone.

With a strong emphasis on trust, collaboration, and innovation, Alcarail stands as proof that values-led engineering delivers both performance and purpose.

Engineer Jay Nathella always dreamed of setting up his own business. Five years ago, he finally made it happen.

He started Alcarail as a small company providing infrastructure delivery management services in Victoria. It has since grown to ten times its original size, with employees spread across Australia, New Zealand and beyond.

“As well as Victoria, we’ve been in Western Australia for the past three years,” said Nathella.

“We are now setting up an office in Brisbane, and we’re trying to negotiate a project in New South Wales as well as in New Zealand.

“We’ve also got our office in India supporting us, and our plan is to expand into the Middle East and the United Kingdom from next year.”

As well as growing its geographical footprint, Alcarail has expanded its services to include project engineering, construction management, system integration, signalling and communication installation, and testing and commissioning management.

In 2023, Alcarail extended its offering to rail systems design as well as signalling and communications design, systems engineering, and safety assurance.

Today, the company operates as a full end-to-end delivery solution in engineering, construction and management, combining hands-on delivery experience with smart, integrated solutions for major rail and infrastructure projects.

It has successfully delivered major signalling projects including the Gippsland Line Upgrade in Victoria and the Armadale Line Upgrade in Perth.

Nathella is particularly proud of delivering the Armadale Line Upgrade on time, on budget, with minimal defects – an outstanding accomplishment for a project of this size and complexity.

“That was a huge win for us,” he said. “Our work was very well recognised by the Armadale Line Upgrade Alliance (ALUA).”

He said one of the keys to Alcarail’s success is its strong relationships, built on collaboration and trust.

“Mutual trust and work ethics are so important – with our people, partners and clients,” he said. “Trust allows people to open up and be honest when they are

struggling, and that really strengthens the relationship and allows for great collaboration. When there’s no trust, that’s when problems start.”

Innovation is another major value that Alcarail is built on, with the company

investing heavily in artificial intelligence (AI) and robotics.

Nathella has set up a sister company to Alcarail, Alca Automation, which specialises in innovative rail solutions. The company has developed projects such as Gravity

AI for rail construction, and Alca-bot, a train maintenance robot that allows for performance and condition monitoring to be carried out on the train at any time.

Other products include a robot on wheels that can lift objects as heavy as seven tonnes and can be used for moving rail, pipes and other heavy objects in tunnels, for example.

“Innovation is something that’s very important to us and we’ve been investing a lot in research and development over the past year,” Nathella said.

Despite the success of Alcarail and achievements over the course of a long career delivering rail projects for major companies, Nathella remains humble.

When pressed more about himself and his accomplishments, he instead defers to a ‘thank you’ card sent from ALUA, which consists of Acciona, BMD, WSP, the Office of Major Transport Infrastructure Delivery (OMTID) and the Public Transport Authority (PTA). The card was full of heartfelt messages of gratitude to Alcarail.

“No matter how big the business gets, I want to stay a company that has authenticity and heart,” he said.

“I want to make a difference in the rail industry through our people-first approach, standing as proof that valuesled engineering delivers both performance and purpose.”

Nathella is also keen to talk about Alcarail’s incoming Chief Executive Officer (CEO), Marc Hamameh.

Nathella and Hamameh go way back – in fact, Hamameh recruited Nathella

during that project,” he said. “A couple of years later, I inherited another project in South Australia and I was looking to hire some people, so I called up Jay and asked him if he wanted to move to Adelaide and step up into a new, challenging role.

“I knew he was smart and able for the job and it was very important for me to see him advancing his career, so I mentored him through his journey.”

Hamameh said it’s very rewarding to see how his friend and colleague’s career has grown over the years, and he’s excited to come on board as CEO of Alcarail.

“We’ve stayed in touch over the years and when I saw the opportunity at Alcarail, we started to seriously talk about me joining the company,” he said. “I’ve spent years working for very large rail organisations, I wanted to experience something new.

“I was looking for the opportunity to work for an agile business where decisions can be made quickly, and we can bring in innovation to directly shape an outcome.”

He said Alcarail’s potential is clear, and he’s keen to help steer the business into

“Alcarail has the right mix of technical credibility, an excellent reputation for delivery, and serious potential for growth.

“It also has passion, integrity, and willingness to push boundaries. I knew it was the right time for me to build something

Hamameh echoed Nathella’s beliefs about the values of innovation, trust and collaboration.

“These aren’t just buzzwords,” he said. “They are defined by how we show up for our customers and for each other.”

His vision for Alcarail is to position the business as a trusted partner of choice for rail system integration and technology in Australia, New Zealand and hopefully beyond.

“I want to build on our existing technical foundations and invest in the people to expand our capabilities,” he said.

“We also want to expand our involvement in digital systems, cyber security, AI and intelligent infrastructure.

“What I envisage for Alcarail is to be recognised not only for what we deliver, but how we deliver it – through collaboration, reliability and innovation.”

Both Nathella and Hamameh said that Alcarail genuinely cares about its people and works hard to foster a culture where everyone feels valued.

Despite being a busy company director, Nathella goes out of his way to connect with

employees at all levels of the business.

“I don’t see differentiation between the leadership team and the working team, we are all valued the same – we just have different responsibilities,” he said. “From day one, I’ve said I want everyone to be treated equally and with the same respect.”

He wants to help all his team to grow their careers, supporting them to take on new challenges.

“I love seeing people’s growth,” he said. “I’m happy to take on young engineers and interns, and I will listen to everyone’s ideas and allow everyone to contribute. If you have big ambitions, you’ll get big opportunities.”

Hamameh’s approach to leadership is similar.

“I’m proud of setting high standards, but I always support my teams to achieve them,” he said. “Leadership is not about being the loudest voice – it’s about enabling the team to succeed. I want the team to feel empowered and trusted, and I hope they see me as someone approachable who listens.”

Project Engineer Bhuvana Kunamneni has been with Alcarail for more than three years and said she’s learned a lot in that time.

“Jay took me on when I was a fresh graduate with zero knowledge of the rail industry,” she said. “I have a civil engineering background, so I never thought I would end up in rail, but I love it.

“I started out working on the Gippsland Line Upgrade as a site engineer, then I became a project engineer, and now I’m leading one of the teams performing the works on-site. The career growth at Alcarail is fantastic.”

Kunamneni said Nathella has been a supportive employer, encouraging her to take on new challenges.

“He’s always open to us trying new things and pushing us to get involved with different types of projects and teams,” she said. “Despite my on-site role, he gave me the opportunity to work closely with the design teams for several months.

“This not only grows our skills but helps us to figure out where we’re happiest and most comfortable.”

Kunamneni added that Nathella calls her weekly to check in.

“He asks how I am, whether I need any help from him or the company – he even personally helped me with getting my visa organised,” she said. “From my perspective, he’s really down to earth and looks after his employees very well.”

“Alcarail is a great place to work – a place where people can grow, contribute and belong.”

MARTIN BEALES

RAIL MANAGER – WEST (NORTHERN TERRITORY, SOUTH AUSTRALIA AND WESTERN AUSTRALIA), MCCONNELL DOWELL

“Alcarail, led by Jay, has demonstrated dependable delivery performance.

“The team consistently exhibits accountability, professional discipline, and pragmatic problem-solving.

“Across all stages of the engagement, they have honoured commitments, communicated proactively with stakeholders, and maintained workmanship to specification.

“On the strength of these outcomes, we look forward to continuing our relationship on future projects.”

JEFF TYLOO

ALLIANCE MANAGER, ARMADALE LINE UPGRADE ALLIANCE

“Working with Alcarail on the Armadale Line Upgrade Alliance has been an exceptional experience.

“The Alcarail team brings a rare combination of deep technical expertise,

collaboration, and reliability – qualities that truly set them apart in the rail industry.

“From design through delivery, they’ve demonstrated a strong commitment to quality, proactive communication, and a genuine partnership mindset.

“Alcarail’s professionalism and ability to integrate seamlessly within a complex project environment make them a trusted partner we look forward to working with again."

ANTHONY HODGE

GENERAL MANAGER OF RAIL AND TECHNOLOGY SYSTEMS, UGL PROPRIETARY LIMITED

“Alcarail has been a reliable and dependable partner across our complex systems projects.

“Their team integrated seamlessly with ours, demonstrating strong technical capability and a genuine commitment to delivering high quality outcomes and getting the job done right.

“What stood out most was their responsiveness and ability to adapt quickly to project needs while maintaining a high standard of quality and collaboration.

“Their contribution has been a key part of delivering a successful outcome for the project.”

We chat to some of the team from MTR Australia about the iconic Sydney

Sydney Metro City & Southwest is one of the world’s most pioneering engineering projects.

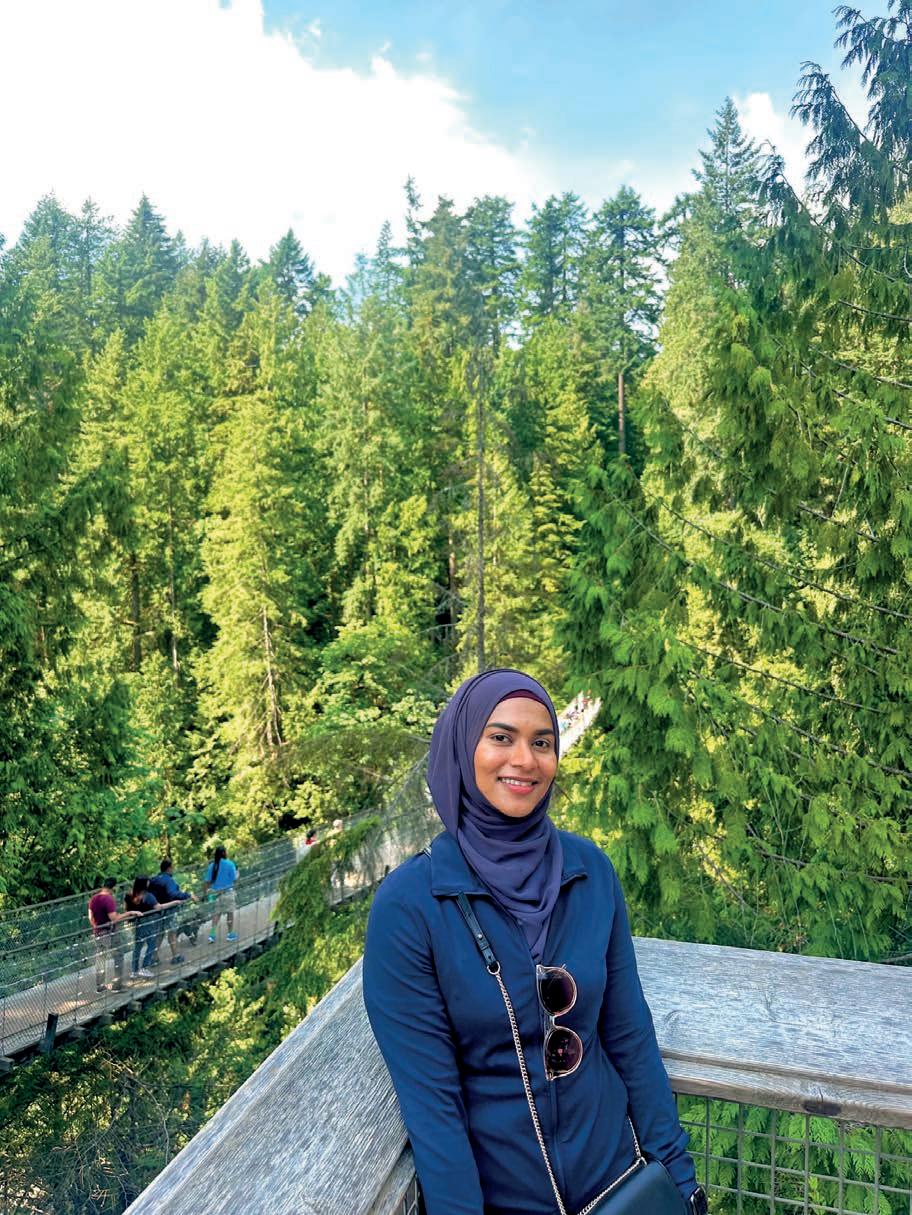

New fast, easy and reliable metro rail services started in May 2019 in Sydney’s North West and extended to Sydenham in August 2024 as part of the City & Southwest project.

The City & Southwest project extended the Sydney Metro Northwest Line by 15.5 kilometres and involved automating the existing line with Communicationsbased Train Control (CBTC) and Grade of Automation 4 (GoA 4) – which means the trains can run without any staff on board.

Sydney Metro City extends from Chatswood on the North Shore through new stations at Crows Nest, Victoria Cross, Barangaroo, Martin Place, Gadigal and Waterloo, with new platforms at Central

and Sydenham stations making travel easier for passengers.

The extended line opened in August 2024 and recently celebrated a record-breaking first year, racking up more than 66.8 million journeys.

The remaining portion of the converted Bankstown Line between Sydenham and Bankstown will open in 2026.

As the integrator of the new line, MTR Australia collaborated with all the different interfaces across the project to help deliver the new railway as one team.

MTR Australia is very proud of the role it played in the successful completion of Sydney Metro City and is now hard at work on the next phase of the project.

On a recent trip to Sydney, we caught up with some of the MTR Australia team to find out more.

Paul Gill, General Manager of Trains, Systems, Operations and Maintenance (TSOM) at MTR Australia for Sydney Metro City & Southwest, said he’s very proud of what the company has achieved on the

“We’re very fortunate to have worked on Sydney Metro City & Southwest, and have achieved some fantastic outcomes,” he said.

“We achieved something that's never been done before in automating an existing railway with CBTC and GoA4

Gill’s large team covers all aspects of the rail systems that they deliver for MTR, while also integrating them with the other services that are provided by civil contractors, such as the stations, track,

“That has to be brought together as one complete system and we have a lot of responsibility in making that happen and

“I try to create an environment so my team can deliver the design and products and test and commission those assets.

“I find ways to deliver outcomes we can be proud of – a fully integrated system that

He said MTR has been proactive and innovative in finding solutions.

“We got this amazing project up and running, very successfully and reliably.”

Gill has enjoyed seeing members of the community using the M1 metro line.

“It's incredible to see how many people are using the railway that we've built together as a team to go to work, to go to school, and to really change the way that they manoeuvre and carry out their day-today business in Sydney and the surrounding suburbs,” he said.

“That, for me, was the most inspiring part of this project.”

When asked what stands out when he thinks about MTR Australia’s values, Gill said it’s all about trust.

“There’s a lot of trust that you have to put into the people, the technology, the solutions,” he said.

“These aren’t run-of-the-mill projects, these are iconic, and once-in-a-lifetime.

“We trust in each other and we trust in our work to deliver the right outputs.”

“One day I will proudly tell my grandchildren about being part of this project.”

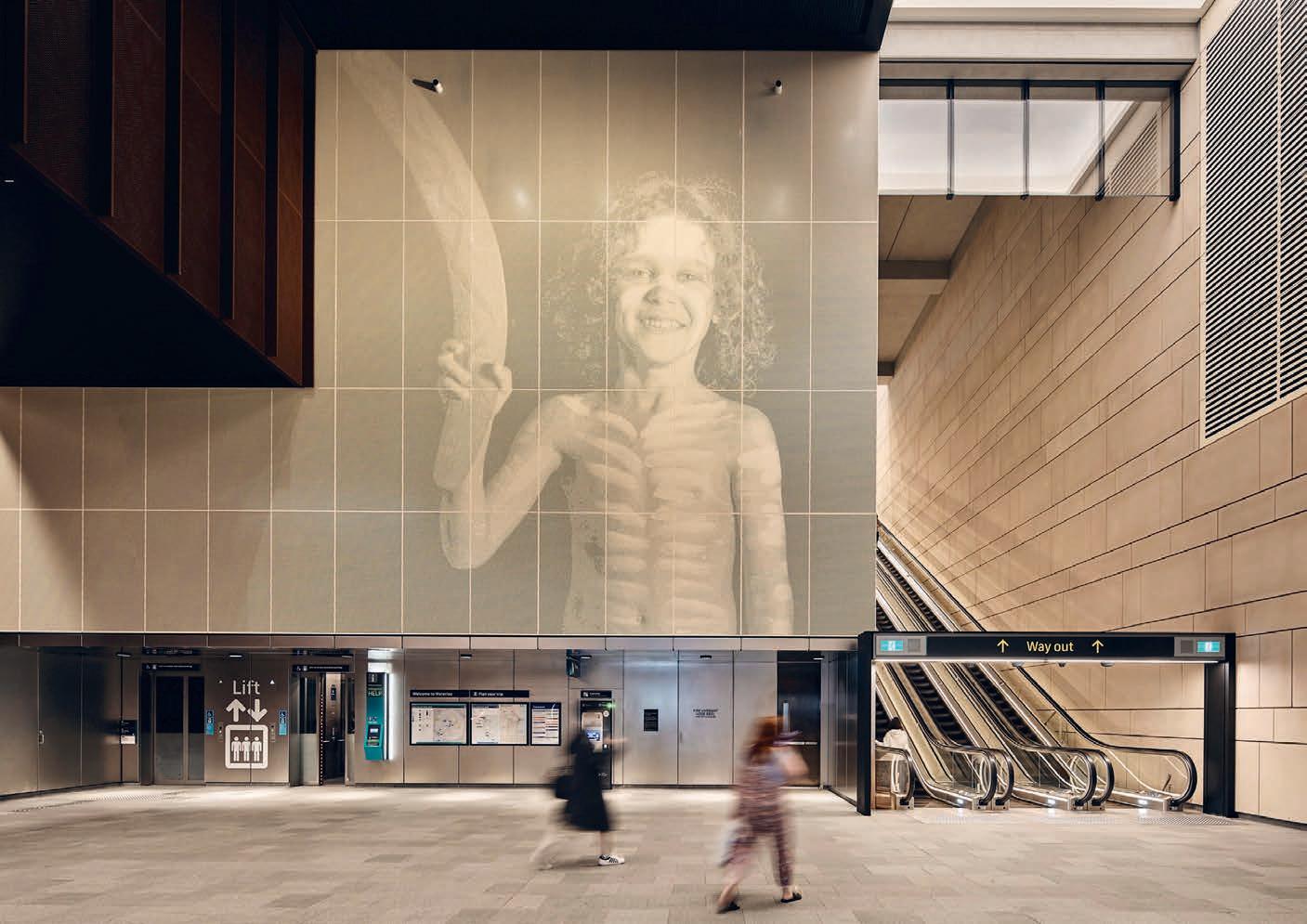

Evangeline Pablo, Senior Commercial Manager at MTR Australia

Looking to the future, Gill said he’s excited about the potential in Sydney and beyond.

“I think we're very well placed to expand our capabilities on other metro projects in the future, as well as other rail systems like high-speed rail.

“We’ve got a great team that has a strong success rate, and we’ve set the bar very high.”

Evan Koltsis, a project engineer with MTR Australia, said he’s grateful to have had plenty of opportunities to grow professionally in his role.

“I’ve been able to work in a variety of teams, not just contributing but leading,” he said. “I’ve been able to develop leadership skills and build relationships in the industry, which has been great for my career.”

He added that the company has a fantastic culture, where everyone is treated with respect.

“The people I work with are great to deal with and very approachable,” he said. “We’re like a work family.

“I think this is so important when delivering a project at the scale of Sydney Metro City & Southwest – not just for the success of the project, but for your own health and wellbeing.”

He said safety is a top priority for MTR Australia, from general site inspections to pre-starts.

“We all feel safe and comfortable working here and look out for one another. It’s a great place to work.”

Carmela Pelaez is a senior project engineer within the MTR construction team, working on the Sydney Metro City & Southwest project.

After successful delivery of the City section, Pelaez and her team are now working on the Sydenham to Bankstown line.

“Day to day, we’re co-ordinating and ensuring things are installed to program,” she said.

“We’re interfacing with other contractors and making sure everything runs smoothly.”

She said working on the project has challenged her in new ways.

“The job has a lot of different stakeholders involved, and we’re

dealing with many different interfaces. Communication is so important and knowing the right person to speak to.”

Pelaez enjoys her fast-paced role and said MTR takes great pride in the quality of its work and its culture of collaboration.

“I love working with our team, our client and our interfaces,” she said.

“There are a lot of smart people around, all willing to get the job done.

“My colleagues clearly care a lot about the work they are doing, and everyone is willing to help out.”

She said the diverse team all bring something different to the table.

“We all have different experiences and viewpoints, and we come together to think of new solutions. Our managers are also very supportive.”

She said MTR’s international experience, especially its success in Hong Kong, gives it an advantage in Australia.

“We have a unique niche,” she said. “It’s great to see how we’ve taken our international learnings and applied them to the metro project.”

As someone who has lived in Sydney all her life, Pelaez is delighted to be involved in a project that’s having such a positive impact on the city.

“It’s a major public transport transformation,” she said. “I love working on projects that are giving back to the community.

“Helping to deliver the City section of the Metro from Chatswood to Sydenham was

MTR Australia is proud to have been instrumental in a project that has changed Sydney residents’ lives for the better.

a huge career highlight for me. My friends have all been raving about how great it is

and the wider community,” she said. As a working mother, Pablo is grateful that MTR

being part of the Sydney Metro City & Southwest project.”

September 2026

EXHIBIT IN 2026. BE SEEN. BE HEARD. BE CHOSEN.

Siemens Mobility has more than 100 years of experience delivering major projects in Queensland, with a highly skilled team that has both specialised local knowledge and strong customer relationships.

Siemens Mobility has been delivering transport solutions in Australia for over 150 years.

Its rich history in Queensland dates back to 1890, when Toombul Iron Interlocking Works was established in Brisbane to manufacture McKenzie & Holland signalling equipment. It was later acquired by Westinghouse and Invensys, that eventually became part of Siemens Mobility in 2013.

As the only trackside railway company to have achieved an Australian Made recognition, Siemens Mobility also has an abundant history of interlocking systems, signalling solutions, and point machines in Queensland. There have been more than 130 installations since the late 1970s across the North Coast line to the west of Brisbane,

with many maintained and replaced as models have evolved.

In 2016, with the supply of locomotives to Queensland freight customers, a regional locomotive service centre was established in Mackay to provide dedicated service close to its freight and mining customers, and ensure that they have the local, reliable support they need.

The regional team has progressively grown thanks to a strong focus on customer engagement and service delivery. Within the past year, Siemens Mobility invested in a wheel press that has localised a critical maintenance activity for customers, which has resulted in eliminating the need for long-haul transport from Mackay to Brisbane, saving tens of thousands of

kilometres in truck travel and significantly reducing carbon dioxide emissions and costs.

The team has continued to grow to meet the rail infrastructure needs for a growing state. From beginning the first implementation of the European Train Control System (ETCS) Level 2 in Australia with the added complexity in a freight network, powering Stage 2 of the new Gold Coast Light Rail and being awarded a contract for the delivery of Hacon software to optimise passenger experience via a new intermodal journey planner by Transport and Main Roads in 2024, Siemens Mobility has established a firm base to support the rail industry in Queensland. This vast experience means Siemens Mobility’s Queensland team

has the expertise, specialised skills and industry connections needed to successfully deliver projects in the state.

We spoke to two key members of that team – Craig Ackroyd, Solution Engineering Manager, and Stephanie Lautier, Regional Project Manager, to find out more.

Craig Ackroyd’s career in the rail industry started back in 1982, working for Westinghouse Rail Systems and Invensys Rail, and continued with Siemens after the acquisition.

He’s been involved in countless major projects in various roles including principle design engineering, and engineering management, with his favourite being Roma Street station’s signalling transformation in the 1990s.

“Roma Street was the first Solid State Interlocking (SSI) application in Queensland,” he explained. “Eight interlockings got commissioned and were delivered over the course of a few years.

“As the designer, checker, panel tester and team manager for the Roma Street project, I did the walk out across the bridge and through the tunnels, and a lot of the planning that led to that final moment.

“To be there at the end when it was all commissioned and handed over, to see what we had achieved in action, was very satisfying.”

Another Queensland project that stands out to Ackroyd is the delivery of WESTECT ATP (Automatic Train Protection).

WESTECT ATP was delivered by Siemens Mobility (at the time, Invensys Rail Australia) across the whole of the North Coast Line from Brisbane to Cairns in 1994, to protect 2500 kilometres of the regional rail network, including the Tilt Train – Australia’s fastest train. And while the WESTECT ATP system has reached its end-of-life, the technology remains sturdy.

“That ATP was really before its time, and it’s still current today, so it’s been very reliable and great value for money,” said Ackroyd.

Ackroyd’s colleague Stephanie Lautier agreed that this project was very advanced in terms of safety.

“It was nearly a European Train Control System (ETCS) Level 2, which didn’t exist anywhere else in the Southern Hemisphere at the time,” she said.

After WESTECT was commissioned, it remained operational for more than two decades. Onboard hardware started to be upgraded from 2006 to enable the system to continue working for another 20 years.

Lautier, like Ackroyd, has enjoyed a long career with Siemens, starting out more than 20 years ago in software engineering at Siemens France before moving to Westinghouse Rail Systems and Invensys Rail in Australia.

She has been a project manager with Siemens Mobility for the past 11 years and said one of her career highlights is the first time she travelled in the Tilt Train after helping to deliver WESTECT II, just a couple of years after she moved to Australia.

After upgrading the onboard hardware, a Design Acceptance Test (DAT) needed to be executed with an independent tester.

The test was done on the Tilt Train, running north out of Townsville in the middle of the night.

“I was on the train in the middle of nowhere with the tester and my tools, sitting down in the cab and trying to measure things,” she said.

“One of the tests was to check whether the system would stop the train in front of a

red signal, as it was programmed to do. The tester was asking the driver to accelerate towards the red signal and he didn’t want to because he was scared and he didn’t trust the system.

“We had to make a few phone calls to convince the driver that he was allowed to do this, then when he was ready to do it and accelerated towards the red signal, the system intervened to stop the train 20 metres in front of the signal. He couldn't believe it!”

Ackroyd and Lautier both said that one of Siemens Mobility’s advantages is the strength of its relationships with customers and across Queensland’s rail industry.

“Siemens’ Queensland project management office and the entire engineering team have fantastic working relationships with our customers,” said Lautier.

“We have strong communication, and it really helps our projects to flow smoothly.”

Mobility has many highly experienced engineers based in Queensland.

She added that knowing a customer well means the team understands what they are looking for, even when they don’t explicitly say it.

“Experience also teaches us to ask the right questions, and to never assume,” she said.

Ackroyd agreed, saying Siemens’ longestablished presence in the state has helped to build those industry connections.

“I’ve been working with Queensland Rail since the 1990s and that longevity puts you in good stead and allows you to become closer with the customer because you have that history,” he said.

“The rail industry here isn’t gigantic, and a lot of engineers that have worked for Siemens now work for the customer, and vice versa. We all know each other.”

He highlighted the importance of maintaining a positive attitude and listening to the customer’s needs.

“We want these projects to be fulfilling and even fun to work on,” he said. “You’re not going to get anywhere bashing heads.”

Ackroyd said that when it comes to rail projects in Queensland, Siemens Mobility is always part of the puzzle.

“Sometimes we’ll get queries from competitors or from customers about a project that we’ve worked on previously, and because we did the original install, oftentimes we have to provide that consultation anyway.

“It’s one of the benefits of having such a long-term, historical base in the state. We have such a deep knowledge of the rail network here.”

Siemens Mobility boasts a highly experienced team based out of its Brisbane office, from communications engineers to onboard signalling engineers to cybersecurity and ETCS specialists.

Lautier said the team has a low turnover, which means valuable experience and local knowledge stays within the company.

“People love working here, so they stick around,” she said. “That means when new people come in, they learn from the experience of staff who have been with us for years.

“Craig’s team has a great mix of interns, graduates and very experienced employees, which provides a perfect environment

for mentoring. We’ve also got a fantastic internal training department to train people in all our products and processes.”

Ackroyd said one of the factors that encourages staff to stay with Siemens long-term is the opportunities that the company offers.

“As Siemens is a global company, there are great opportunities to travel all over Australia and the world and gain knowledge from projects in other countries,” he said.

“I’ve probably done about 10 jobs in the United Kingdom, one in Spain, one in Portugal, one in Malaysia, one in Thailand, and several in Indonesia and New Zealand.

“We’ve worked everywhere, and that means our young people get to travel around the world to see and experience some great stuff.”

Both Ackroyd and Lautier continue to see a future in Queensland and Siemens Mobility, because of the people.

“The people are great,” Lautier said. “I just had a year’s sabbatical, and when I came back to Siemens eight weeks ago I didn’t even consider going anywhere else.”

Major Projects and Infrastructure, Operations and Maintenance, Technology, Plant and Equipment, Rolling Stock and Manufacturing, Passenger Rail, Freight Rail and more.

FEBRUARY

High Speed Rail and Light Rail

MARCH Manufacturing

APRIL

Heavy Haul and Signalling & turnouts

MAY

Intermodal and Safety

JUNE

Passenger Rail

JULY

Workforce and Decarbonisation

AUGUST

Digitalisation and Digital twins

SEPTEMBER

Condition monitoring and Maintenance

OCTOBER

Plant & Equipment

NOVEMBER

AusRAIL

DECEMBER

Sustainability and Innovation

For

KeTech shares how the right real-time passenger information systems could make a difference when it comes to Queensland’s rail network –not just for the Brisbane 2032 Olympics, but today and into the future.

The Brisbane 2032 Olympic and Paralympic Games will place Queensland on the world stage, with millions of visitors and global media attention.

The event is not just about two weeks of sport. It holds significance in terms of the state's economy, global profile, and legacy.

With all eyes on Queensland, it has to get it right – and that means having the appropriate infrastructure and technology in place to get people where they need to go to efficiently, without it resulting in chaos.

It also means investing in transport solutions that are going to serve Queensland’s growing population before, during and after the games – and the time for action is now.

We spoke to Paul Warren, Sales Director at real-time passenger information company KeTech, for his insights.

To adequately serve the needs of passengers at the Olympics and beyond, Brisbane’s rail network is going to need to be as smart and connected as possible.

KeTech’s solutions support the passenger journey – not just at stations and on-board trains, but as early as when they step off a flight, or into their hotel lobby and see a screen informing them of when and where they can catch the next train to

their destination. Its Customer Information Systems (CIS) turn stations into intelligent hubs that keep passengers connected, but it’s also available as a web version that can be shown on any device with access to the internet.

“For an event like the Olympics, the whole environment needs to be considered,” said Warren.

“That means stations as well as trains, bus and tram interchanges and airports, but also event venues, hotels, bars and cafes.

“Having real-time information readily available to customers means there’s less crowding and people waiting around at stations long before they need to be there.”

Meanwhile, KeTech’s Passenger Information Systems (PIS) transform a train from a mode of transport into a real-time, enhanced travel experience.

It provides passengers with accurate, up-to-the-second information, on seat availability, station stops, service changes, and onward multimodal connections so they can make better informed decisions, faster and easier.

When it comes to the Olympics, Warren said the benefits of reliable real-time information extend far beyond managing overcrowding.

“Reliable real-time passenger information means passengers get where they need

to go as smoothly as possible, improving the customer experience,” he said. “It also boosts operational efficiency, requiring minimal input from station staff and train crew.

“With reducing crowding, there also comes safety and security benefits –especially when navigating unfamiliar journeys, allowing everyone to get back home or to their accommodation safely.

“If you achieve all the above, it’s great PR (public relations) for operators and the event organisers.”

Accessibility is always paramount in transport, but even more so for an event such as the Olympic and Paralympic games.

Warren said it’s critical to take a broad view of accessibility considerations at a high level in the planning stages of an event, applying these individually to each station.

“It’s so important for everyone to be included and be able to make the most of the games,” he said. “Accessibility means different things for everyone. It's as broad as the operators or transport authorities want to play it.”

Warren said KeTech has vast experience tailoring customer information to different contexts, so once a client decides on the outcomes they want, it can deploy its

technology to realise those outcomes in the smartest way.

“That might be digital signage for more accessible routes, or using icons to overcome multilingual variances,” he said.

“Using a consistent approach to digital signage across multiple routes and stations allows both travellers and station staff to interpret key points of information ‘at a glance’ to support journeys.”

For the best outcome for all passengers, Warren said different information systems should be integrated across the rail environment, which is where KeTech’s Universal Information System (UIS) comes in.

“We are very passionate about joining all these information assets and technologies together with a single control system,” he said.

“That’s a good reason why our Universal Information System was designed to be modular, to adopt different and new technologies and data feeds for a richer information outcome.

“This unification is so critical to enabling operators to provide accurate, consistent, real-time information in context of wherever or whenever it is required.”

Warren said it’s essential that Queensland starts the planning process for the Olympics as early as possible, to ensure a smooth and successful event.

“While 2032 seems like a while away, there will be a lot of stations, routes and multimodal interchanges that will all need to be reviewed and planning for how they will support the flow of people for the games,” he explained.

“There will be pressure to pull everything together in time for such a prestigious event.”

Another key pressure will be budget constraints – and operators and transport authorities will need to ensure they are investing in solutions that will support passengers before, during and long after the games.

“The investments made for the Olympics will need to remain current and adapt to the day-to-day needs of the commuter and leisure travellers,” said Warren.

“We have all walked past sad-looking assets around travel hubs that are either displaying out of date or out of context information or are just switched off.

“This is generally about ease of management, as they are remote assets, then they become an effort to control and update.”

Warren said having a central point of control for disparate assets is a core benefit of deploying KeTech’s UIS.

“Once accessibility is part of the system, maintaining this becomes easier when it’s a key part of the operational process, and having UIS underpins this.”

He added that while Brisbane 2032 is a significant event for Queensland, there are major events happening across Australia all the while, and the principles of KeTech’s vision can and should ripple through to all operators.

“I hope that the Brisbane Olympic Games are executed so effectively that they create model operating processes that other areas will aspire and adapt to.”

There’s no guesswork when it comes to Downer’s Engineering Consulting Services, thanks to its team of more than 200 experienced engineers working in the rail industry every single day.

With over 155 years of experience in the rail industry, Downer is a leading provider of end-to-end transport solutions across Australia and New Zealand.

Through its Rail and Transit Systems (RTS) business, the company is a trusted supplier of rollingstock asset management services, with proven capability in the design, manufacture, maintenance, and overhaul of both passenger and freight fleets.

Its team of more than 200 engineers partners with operators, governments, and industry leaders to deliver smarter, safer, and more sustainable transport networks.

These engineers are problem-solving, innovating and delivering every single day, with up-to-date knowledge of time to supply and cost of supply thanks to Downer’s

With so much knowledge to share, Downer decided to offer its expertise to the wider rail industry via its Engineering Consulting Services.

To find out more, we spoke to Julian Tullett, Executive General Manager of Engineering and Technology with Downer’s Rail & Transit Systems.

As someone who has worked in rail for 38 years and spent 25 years in consulting, Tullett knows the industry inside out.

He has held lead roles on several major global projects, becoming a trusted advisor to clients, and has a passion for customer satisfaction, technical excellence and delivering complex programs with

professional engineering team delivering specialised technical and assurance services across heavy rail, light rail, and freight applications.

His team is responsible for supplying engineering expertise to Downer’s Rail & Transit Systems, which is in turn responsible for the daily operations and maintenance of some of Australia’s largest passenger fleets, as well as delivering Downer’s rapidly growing Engineering Consulting Services to the wider rail industry.

He said Downer has a distinct advantage over other consulting businesses in Australia and New Zealand because its engineers are on the ground, working in the rail industry daily.

“We don’t just advise a solution,” he said. “We know what a solution will take to actually implement, because we do it.

“We also manufacture rollingstock within our sites, so our engineers speak with operations, commercial and safety every day.

“We thrive on complex integration projects and technical challenges.”

By contrast, he said a consultancy that is not directly involved in the industry is at more of a distance from what’s happening day-to-day.

“It’s totally different for us,” he said. “Everything we do, we remain current. Our team is at the forefront. At any point in time, we are tendering, designing, manufacturing, maintaining and operating rollingstock, and that’s either existing or brand-new.”

According to Tullett, this means that there’s no guesswork with Downer.

“Say a client wants to know how much a project would cost – we’re not making estimates based on work we did ten years ago,” he said.

“We are running trains, and we stand behind our costs for 30 years. We really do know the cost and value of projects and how to bring them into service with budget certainty.

“We keep winning major contracts, and that’s because we are the best – technically and competitively.”

Another factor that Tullett said sets Downer apart is its scale, with more than 26,000 employees in total, including 200 experts in rollingstock engineering.

“The breadth and depth of our knowledge of the trans-Tasman rail network is unmatched,” he added.

He said the way the company is structured also helps when it comes to consultancy. Nationally accredited, its employees work as a matrix, agnostic to boundaries and siloes.

“We can pull people in from various areas of the business that have transferable skills when needed, and a lot of our work, even internally, is almost on a consultancy basis,” he explained.

“If we are coming up with a solution, we know we have to do all the engineering, the testing, the paperwork, and get the final sign-off.

“There are not many organisations that will let you into that entire process, whereas our people know that coming up with an idea here means someone else getting that cleared under Rail Safety National Law.

“Other consultancy companies don’t necessarily think about how much ideas will cost or how they might be implemented safely.”

Tullett said Downer is on the cutting edge when it comes to new technologies, with its XDNA company specialising in Artificial Intelligence (AI) solutions.

“We really are on the verge of a step change in the rail industry, and Downer has fully embraced this,” he said.

“We’ve had great success with AI and augmented reality, and we’re using generative AI on our consultancy projects to drive and speed up the overall systems engineering process.”

Downer is also a big supporter of decarbonisation initiatives and is working with global technology partners to bring innovative solutions to the market.

“We will be at the forefront of rail decarbonisation technology in the coming months and years,” he said.

battery suppliers, and we’ve got some pretty impressive projects in the pipeline. Watch this space.”

Tullett said Downer has built strong connections across the rail industry over the past 155 years – from operators to regulators to suppliers and partners.

“Our relationships with international technology partners have taken us decades to build, and they really help us stand out from the competition,” he said.

“When a client asks us about their options around new technology, how much it will cost and how long it will take, we know the answers.

“Our knowledge of the supply chain and our partnerships allow us to bring technologies into Australia, but also to give a wider consultancy approach and offering.”

With thriving operations across multiple states in Australia as well as in New Zealand, Tullett said Downer also has a deep understanding of what governments want when it comes to rail.

“We’re tuned into political and wider aspirations,” he said. “One of the major ones in Victoria – and other states seem to be following this – is local content.

“That means we’re thinking about how we ensure we buy Australian goods and services, getting our supply chains focused on what state governments want to achieve, how they want to spend their money and how they want to develop locally.”

He said Downer is proud to be investing in developing its Australian workforce and supporting local suppliers.

“A great example of this was Victoria’s High Capacity Metro Train (HCMT) fleet,

has a team of more than 200 expert rollingstock engineers.

which Downer designed, built and maintains, as part of the Evolution Rail Consortium.

“We managed to achieve 60 per cent local content. It’s so important to have that local touch.”

FROM PAPER TO PHYSICAL NETWORKS

Downer’s Engineering Consulting Services has shared insights and advice with teams across many major projects.

“We’ve got a team of people assisting with the introduction of new light rail, because the only new rollingstock that has been introduced under the new Office of the National Rail Safety Regulator (ONRSR) framework for bringing trains into revenue service was HCMT, which we did successfully,” Tullett shared as an example.

“We also designed and developed a battery electric locomotive for different applications across rail operations and we’ve got a team in Auckland, New Zealand using our unique experience in assurance and requirements compliance and pulling the evidence together to get that verified and certified in the rail industry.”

He explained that in rail, as much work goes into the “paper network” as the physical train network.

“The paperwork side is very much our wheelhouse as well as the physical network – we’re experts at getting appropriate safety cases and external signoffs.”

Although Downer is a large company, Tullett said there’s no job too small.

“We’re happy to support the rail industry, even if it’s just a few hours of advice,” he said.

“Varied work gives our team exposure to different types of scenarios, allowing them to upskill and become better engineers.

“So it helps us, and it helps the industry –it’s a win-win.”

ENGINEERING CONSULTING SERVICES CAN HELP WITH:

• Feasibility and concept studies (including concept designs, maintenance strategies and whole-of-life costings)

• Decarbonisation (engineering design and delivery of decarbonisation projects)

• Rollingstock engineering and design (whole life capability across passenger, freight and light rail)

• O perations and asset management (through-life support for rollingstock fleets)

• Turnkey solutions (end-to-end project management, delivery and support)

• Digital and data (digital consulting, software and services including maintenance, asset intelligence, sustainability and robotics)

Progress is being made in Queensland, with a new train station opening on the Gold Coast and a major upgrade announced for a historic station in Brisbane.

South East Queensland recently celebrated its first new train station in nearly a decade, and the first on the Gold Coast in 16 years.

Pimpama Station features 380 car parking spaces, a 40-bicycle lock-up enclosure, a pedestrian overpass with lifts on each platform, and lighting and CCTV throughout.

Accessibility is a key part of the station’s design, with ten accessible car parking spaces, braille and tactile station maps, hearing aid loop coverage, lifts and seating.

More than 90 train services will run through Pimpama each weekday, and at least 70 services each Saturday and Sunday.

A community event took place on opening day, with a free sausage sizzle provided by Pimpama Men’s Shed, as well as free cookies and merchandise being handed out by Queensland Rail employees.

Queensland Rail Chief Executive Officer Kat Stapleton welcomed customers to the new station.

“There will be a train at this station approximately every 10 minutes during peak times and then every 30 minutes during off peak times, every day of the week,” she said.

“We are so proud to continue the Queensland Rail tradition of connecting communities, as we have done for the past 160 years.”

The opening of the station has meant minor timetable changes for some parts of the Gold Coast Line.

For stations between Varsity Lakes and Coomera, trains travelling inbound (towards Brisbane) now arrive up to two minutes earlier and leave up to two minutes later travelling outbound (towards the Gold Coast).

Bus routes in the area have also been adjusted to align with the new station and updated rail timetables.

Pimpama Station is the first new station to open in South East Queensland since the Redcliffe Peninsula Line opened in 2016.

It was delivered by the Cross River Rail Delivery Authority, to help connect South East Queensland’s growing population.

Two other stations on the Gold Coast Line are also being built at Hope Island and Merrimac.

Design has been completed for the Hope Island Station and Acciona Georgiou Joint Venture (AGJV) is now carrying out major construction.

As AGJV is the head contractor delivering the Coomera Connector Stage 1 North package, which is immediately adjacent to the station, the integration and delivery of both projects by the one contractor was

determined to be the best solution. Major construction is expected to be completed in 2026 and will be followed by a testing and commissioning phase.

Fulton Hogan has completed design of Merrimac Station and major construction is currently underway within the eastern and western rail reserves and Gooding Drive. Further construction work is also continuing within the rail corridor.

Meanwhile the historic Shorncliffe train station in Brisbane is undergoing a “oncein-a-generation” revamp after a seven-year journey to protect its rich rail history.

The renovation will involve preservation works, including restoring the old station buildings to their 1914 footprint.

The existing World War II-era air raid shelter will also be preserved, and the existing heritage awning will undergo a restoration process.

Accessibility improvements will be made, including a new entrance ramp to the station, two new accessible seats, an accessible ticket window and accessible toilets.

Other accessibility works will include 90 metres of high-level platform raising (including at the boarding points), upgraded hearing augmentation loops and tactile ground surface indicators.

New CCTV will also be installed, as well as new customer information screens, new wayfinding and platform signage, and improved lighting.

This stage of the upgrade follows the meticulous excavation of the ticket office subfloor in 2019, where more than 400 historical items from the last century were discovered.

These discoveries have been catalogued by a third-party heritage specialist and included 100-year-old train tickets,

newspaper clippings, bottles, and clothes.

A 1940s sailor’s cap was also found and returned to its owner’s family seven decades after it was lost, in a heartwarming reunion.

Queensland Rail said that while the archaeological process affected timeframes for the Shorncliffe upgrade, subsequent reviews of the project scope have ensured it will deliver “meaningful benefit to the community with responsible use of taxpayer funds”. With that process finished and necessary bracing works for the ticket

office also complete, Shorncliffe Station will be closed for construction from November 29, 2025.

A shuttle bus loop service will connect passengers to Sandgate Station, which is a three-minute drive away from Shorncliffe.

St Patrick’s College at Shorncliffe will also be serviced by a separate, dedicated bus for students, which will run to and from Sandgate Station direct to the school.

Stapleton said Shorncliffe’s main construction milestone was a long time coming.

“Preserving and celebrating historic Shorncliffe Station is a key focus for Queensland Rail, and this upgrade will enhance our rich rail history while delivering safer, modern and more accessible public transport for all customers,” she said.

“We have taken the time to review the project for value for money and now we’re delivering a station upgrade with benefits for the community, while taking care with taxpayer funds, and we’re excited to start on the major works.

“We want to reassure the community and our customers that works will be undertaken as efficiently and safely as possible, with careful consideration of the historic and heritage elements of Shorncliffe Station.”

Shorncliffe train station was built in 1897 and was originally a resort station for turnof-the-century holidaymakers.

It is one of the few surviving works by famous Queensland Railways architect Henrik Hansen.

Melbourne’s Metro Tunnel marks the biggest transformation of the city’s rail network since the City Loop opened in 1981.

The big moment has arrived – Melbourne’s long-awaited Metro Tunnel is finally opening to passengers.

Offering hundreds of new services per week, the "Summer Start" will mark a soft launch for the new network.

Metro Tunnel services will run seven days a week and stop at all five new underground stations: Arden, Parkville, State Library, Town Hall and Anzac.

The Metro Tunnel consists of twin nine-kilometre tunnels running underneath the CBD, from St Kilda Road to North Melbourne.

It will mean faster travel across the city – about 12 minutes from Arden in North Melbourne to Anzac on St Kilda Road.

Trains will run every 20 minutes between Westall and West Footscray from 10am until 3pm on weekdays and 10am and 7pm on weekends. Weekend services will depart East Pakenham every 40 minutes and Sunbury every 60 minutes.

This will give passengers, train drivers, station staff and everyone else involved the opportunity to get familiar with the new systems and stations.

During the Summer Start, passengers on the Cranbourne/Pakenham and Sunbury lines will continue their journeys as normal through the City Loop and connect to

Metro Tunnel services at interchange locations, including Footscray and Caulfield stations.

On 1 February 2026, the Metro Tunnel will be fully integrated into the wider transport network. This is when all services on the Sunbury and Cranbourne/Pakenham lines will travel exclusively through the new tunnel.

The Frankston Line will also return to the City Loop, improving access to the CBD

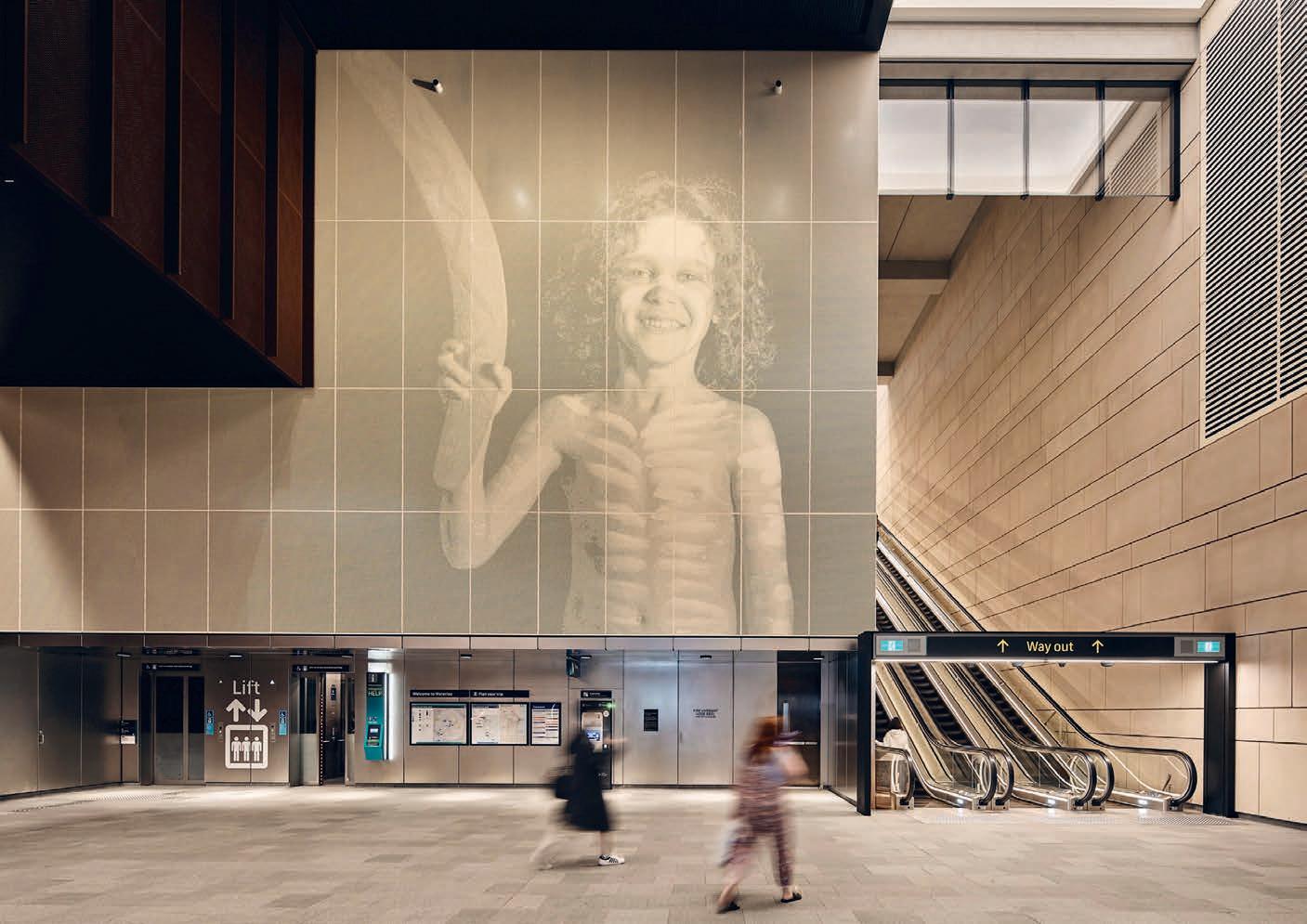

Members of the public enjoying a sneak peek of the new State Library Station before its official opening.

for thousands of passengers on one of Melbourne’s busiest lines.

To celebrate the opening of the Metro Tunnel, public transport users will have access to free weekend travel, providing an opportunity to see Melbourne’s five new underground train stations.

Free Saturday and Sunday travel will apply from early December 2025 to 1 February 2026 and extend across all modes of public transport across Victoria.

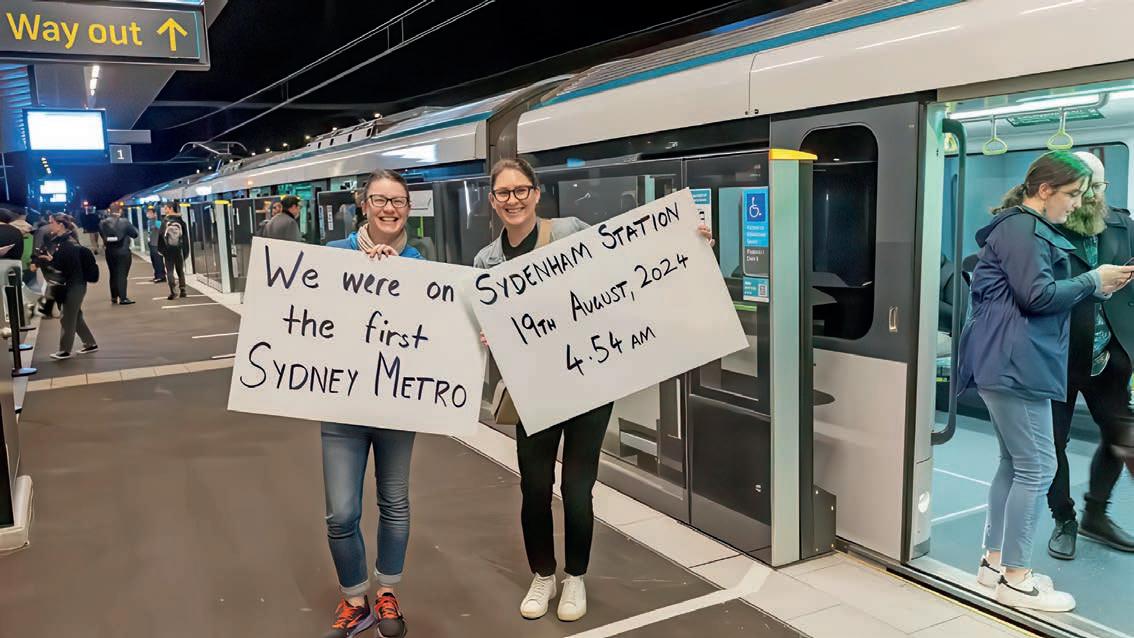

Before the Metro Tunnel opened to passengers, I was lucky enough to join 7000 enthusiastic Victorians for a sneak peek of the new State Library station before it was fully completed.

In the heart of Melbourne CBD, where La Trobe Street meets Swanston Street, State Library Station has a shared concourse with Melbourne Central Station, where passengers can change between Metro Tunnel and City Loop services without tapping off with their myki cards.

It was a quick tram ride away from my apartment in the Docklands early on a Saturday morning – and boy was it worth the trip.

Before you even go inside, you can see this is no ordinary station.

A striking artwork, Forever by Australian artist Danie Mellor, is printed on the glass panels that make up the station’s glazed facade on La Trobe Street. It depicts historical photographs of Wurundjeri Woi Wurrung women, layered against modern landscape images taken by Mellor in Wurundjeri Country using infrared photography.

The portraits of Indigenous women were sourced from the archives of the neighbouring State Library Victoria, with help from the library’s curatorial team. The artwork acknowledges Victoria’s First Peoples, especially women – honouring their social, familial and cultural contributions to Melbourne.

There are nods to culture, history and the State Library all around the station, in fact. After picking up my lanyard and information booklet on my way into the station, I was greeted by an imposing main entrance featuring 12 metre-high columns topped

with massive beams, reflecting the classical architecture of the station’s namesake. The beams measure 18 metres long and more than three metres wide, and each weigh about 80 tonnes.

Hopping on an incredibly grand escalator and heading underground, I was in for more surprises. The station’s platforms are more than 35 metres below street level and 18 metres wide – among the widest underground metro platforms in the world. It's the deepest of the new stations, and being that far underground, you almost forget about the hustle and bustle far above you as the city goes about its day.

There are also little Easter eggs scattered around the station – from fittings designed to mimic Australian insects, to nods to Australian animal footprints on the platforms.

Look up, and you'll see a spectacular 10 metre-high arched ceiling featuring vivid orange beams, inspired by the Australian sunset, as well as chandelier lights designed and made in Melbourne.

The longest escalator at the station is 42 metres long – 12 metres longer than the escalators at Parliament Station, making it the longest escalator in Melbourne.

I was impressed, and the public seemed to agree, with a lot of ooh-ing and aahing, selfies and excited chatter happening around me.

The crowd was a broad mix – parents with young children, groups of teenagers, professional-looking couples, older people – a reflection of the community who will be using this service.

Entertainment was provided, adding to the lively atmosphere on the day – with an accordionist at the station entrance reminding me of my semester living in Paris and getting the Metro to university, and kids jumping up and down as they posed for a photo with women dressed up as huge flowers.

I spoke to Ben Ryan, Executive Project Director of the Metro Tunnel Project, who said it was fantastic to see so many smiling faces at the open day.

“We’re incredibly proud of this new station, and it was wonderful to welcome so many people through the doors,” he said.

“I want to recognise the whole team who have been working hard to deliver this project. My thanks go to everyone who has contributed to the Metro Tunnel. I’ve been involved for two-and-a-half years, but some people have been part of this journey for almost a decade.”

Work first started on State Library Station in 2017. Since then, thousands of crew

members have built the two entrances, poured concrete for the station platform and pedestrian underpass, installed 27 escalators, 19 lifts and platform screen doors.

Ryan said many lessons have been learned from the delivery of the Metro Tunnel project, which will serve Victoria into the future.

“This is a massive project for Melbourne –we’ve had 7000 workers involved in this, and with that comes a maturity of local skills,” he said.

“In my view, the government has created the certainty of a rail project pipeline, so people will be able to go on to work on projects like the Suburban Rail Loop – growing their careers while building important infrastructure.”

Speaking to the media ahead of the official opening of the Metro Tunnel, Victorian Minister for Transport Infrastructure Gabrielle Williams said this project has been a long time coming.

“I’m sure many of you have noticed the disruption that’s been happening above ground while this work has been undertaken, but we’ve done it all for a reason,” she said.

“The reality is that the City Loop, despite serving our city well for over 40 years, is

She said the City Loop now has a sister who is going to “help her out”, with tunnels connecting the two rail links at State Library station as well as Town Hall.

“The two sisters hold hands, to help carry Melbourne’s load for a long time to come,” she said. “What the tunnel has effectively done is taken three of our busiest lines, from the Cranbourne/Pakenham corridor to the Sunbury corridor, out of the City Loop, and given them their own dedicated corridor.

“This allows for turn up and go services

Williams said the Metro Tunnel is a “future-proofing” project that will cater to Melbourne’s growing population and make it easier for people to live and work in the city and surrounding areas.

“It’s not just about what we can deliver from day one, or from the timetable change,” she said.

“It’s about what we can deliver for many, many years to come, to cater to a growing community.”

She said the Metro Tunnel has given

Melbourne and Women’s Hospitals and the Peter Doherty Institute for Infection and Immunity.

“Having that medical precinct accessible by rail is huge, not only for people in the metropolitan area of Melbourne but also from our regions,” she said.

“About 70 per cent of V/line services hit that Cranbourne/Pakenham to Sunbury corridor, so it ends up being a big connecting point.

“If you’re a cancer patient coming from Bendigo, for instance, you will now be able to interchange and use the Metro Tunnel to get to the medical precinct. And if you’re a university student or

someone working at the hospitals or university, your daily commute will be easier too.”

Speaking about State Library Station, she said constructing an underground station of such huge scale right in the heart of the city was an impressive display of engineering “keyhole surgery”.

She continued: “This is a really neat site – we’re about a metre-and-a-half under the City Loop here, which meant that when these guys were constructing it they could hear the train announcements from the City Loop while they were tunnelling!

“To be able to build something of this size under the CBD and still ensure that the city

above ground was still able to move was quite an engineering feat.”

She thanked the community for its patience over the best part of a decade, while the project was being delivered.

“We’ve asked people to change the way they move, we’ve disrupted their travel, and we want to say thank you,” she said.

“That’s part of the reason why we have committed to free weekend travel from early December 2025 to 1 February 2026.

“We want people to get out there and check this out.”

The Monash Institute of Railway Technology will expand its capabilities with the opening of its new workshop on the university campus.

The Monash Institute of Railway Technology (Monash IRT) in Melbourne is celebrating the opening of its new railway manufacturing workshop, which will further enhance its capabilities in research and innovation.

The new workshop contains a large, three-axis CNC (computer numerical control) machine, a precision welding table, laser cutting grinders, lathes, guillotines, benders and other equipment that will enable the team at IRT to manufacture components, carry out research and more.

“We recently bought a brand-new, unique laser cutter that has an upgraded sixkilowatt laser head,” said Professor Ravi Ravitharan, Director of Monash IRT.

“It can cut up to 25-millimetre-thick mild steel sheets all at once, which is significant for railway research activities, saving time and costs whilst supporting greater precision and protecting the structural integrity of materials.”

Professor Ravitharan said Monash IRT always starts with an initial idea for an innovation that could improve rail operations. The team of engineers, scientists and technicians working at IRT will research and test these concepts, as well as manufacturing components and even entire solutions which can be implemented on railway systems.

“To deliver solutions to the rail industry, Monash IRT has 3D printing, digital twin and modelling capabilities, design and testing capabilities, and we now have our own additional manufacturing capability,” he said.

“This railway manufacturing workshop can manufacture components to the highest standards for us to deliver services to the railway industry.

“In-house manufacturing capability allows Monash IRT to provide a quick turnout from concept design to prototyping and production. This allows us to deliver critical advanced solutions to the local and international railway industry.”