Demand

How

Kayasand’s

20 EUROPEAN EVOLUTION

Heidelberg Materials has launched its evoZero range in the European market.

26 MAKING WAVES DOWN UNDER

The new LiuGong 922F excavator has impressed onlookers since its mid-year debut in NSW.

30 A LIFETIME PARTNER

Pinnacle Hire works with quarry operators across the lifecycle of operations.

32 ASTEC UNLEASHES FLEXIBLE CRUSHING SOLUTION

Hopkins Brothers has invested in an Astec GT125 jaw crusher.

34 STRONG FOUNDATIONS

Agile Screening has spent this year building a solid foundation.

36 QUARRY CONVEYOR CHECKUPS

Kinder Australia walking the belt to improve conveyor productivity and safety.

40 EXPERIENCE THE CRUSH

R&M Crushing has turned to Striker Crushing and Screening to support its operational fleet.

42 MAJOR MOVES IN WA

Big shifts are underway in the Western Australian construction materials market.

44 A CRUSHING TRIFECTA

The addition of a Powerscreen Chieftain 1700X screen is a welcome one for R&E Crushing & Plant Hire.

46 MACKAY LOCKED AND LOADED

The Queensland Mining & Engineering Exhibition is set to return in July 2026.

48 CAPPING OFF A BIG YEAR

Komatsu Australia has wrapped up a its year with new machines, partnerships and milestones.

And just like that, we’ve reached the end of another busy year. As we close the books on 2025, now is the perfect time to reflect on what you have achieved this year, and what you hope to do in 2026.

Over the past 12 months, safety has been in the spotlight, with several IQA Safety and Health Conferences taking place across the country. They’ve offered the industry a chance to speak with experts in the field and continue important conversations back on site.

It has also been a year of technological growth and innovation. Original equipment manufacturers have been embracing new digital developments to improve productivity. Whether that’s through the use of drone surveying, artificial intelligence, or smarter machinery, the future is looking bright for quarrying equipment.

The IQA has also jumped on board this digital transformation, launching a new website and mobile app to help connect the

sector. Its new platforms make it easier than ever for members to stay connected with each other, networking and supporting each other’s development.

Next year is shaping up to be even busier than 2025, especially with the 2026 IQA National Conference. The event will take place from 6 to 8 October on the Gold Coast, and will offer attendees more than 50 presentations, 100 exhibitors, local site visits and the IQA National Awards. It’s one event you will not want to miss.

Next month’s Quarry Magazine will be the annual Industry Leaders edition, where key decision makers from across the sector reflect on the year that has come and gone. It will feature interviews, articles, and case studies that highlight what matters to the sector, and what is on the horizon.

If you would like to be involved, please get in touch.

William Arnott Editor

AS WE CLOSE THE BOOKS ON 2025, NOW IS THE PERFECT TIME TO REFLECT ON WHAT YOU HAVE ACHIEVED THIS YEAR, AND WHAT YOU HOPE TO DO IN 2026.

Published by:

379 Docklands Drive

Melbourne VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive Officer

Christine Clancy

christine.clancy@primecreative.com.au

Group Managing Editor Paul Hayes paul.hayes@primecreative.com.au

Editor

William Arnott william.arnott@primecreative.com.au

Assistant Editor

Adam Daunt adam.daunt@primecreative.com.au

Journalist

Daniel Williamson

daniel.williamson@primecreative.com.au

Business Development Manager

Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements

janine.clements@primecreative.com.au

Art Director

Michelle Weston

Cover image: Image: Kayasand

Subscriptions T: 03 9690 8766

subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

As we close out 2025, there’s a real sense of momentum across the IQA. This has been a year where digital innovation, workforce development, and community strengthening came together to reshape how we serve our members.

Our digital transformation reached two significant milestones. In July, we launched our redesigned website at quarry.com.au, providing a modern, mobile-friendly platform for events, training, resources and IQA updates. Building on this foundation, October saw the launch of IQA Connect – our member app putting networking opportunities, our IQA community and new member forums, training notifications, and sector updates directly at your fingertips. These platforms make it easier to stay connected and engaged, whether in the office or on-site.

In May, we launched the inaugural IQA Mentoring Program, pairing 50 participants – 29 mentees with 21 experienced mentors – in a structured six-month program. This initiative came directly from member feedback through our 2024 member survey. Offered free to members, the program filled quickly, creating meaningful connections and knowledge transfer across our sector. The next round kicks off in March 2026.

We are finalising our national awareness campaign, launching early 2026. We’ve filmed members sharing authentic experiences, highlighting what our sector contributes to communities and why people choose this career. This campaign addresses the need to improve public awareness of the vital role of the quarry sector

in every Australian community and to attract and retain workforce. How many times have you told someone you work in quarrying and been met with a blank stare? Yet every road, every building, every piece of infrastructure starts with our sector. Thank you to members who nominated team members to feature, your participation is reshaping how Australia sees quarrying.

Our branches and sub-branches have been exceptionally active, hosting 67 events attracting 2646 attendees – a 9 per cent increase year-on-year. From technical presentations to site visits to social gatherings, these connections strengthen what makes our sector resilient. Combined with our National Conference and education programs, we reached 4198 people – a 27 per cent increase in total engagement. We delivered 63 education courses with 917 participants from 177 organisations. The IQA Learning Hub launched with 115 self-paced enrolments. Membership grew 6 per cent, increasing by 102 members.

COMBINED WITH OUR NATIONAL CONFERENCE AND EDUCATION PROGRAMS, WE REACHED 4198 PEOPLE – A 27 PER CENT INCREASE IN TOTAL ENGAGEMENT.

www.quarry.com.au

The IQA’s Strategic Plan 2023 to 2026 embodies the following vision, values and strategic priorities:

Thriving communities supported by a sustainable industry

Operational Priorities: Deepen industry participation

Sustainable revenue streams apable team echnological innovation ffective engagement

• Great governance

Strategic Priorities: t industry participants with compliance and regulation erse and skilled industry oster strong industry connectivity

IQA Contacts:

For all education, member and branch enquiries:

Phone: 02 9484 0577

Email: iqa@quarry.com.au

Chief Executive Officer Jane Schmitt

President Michael Close

Looking ahead to 2026, the Gold Coast will host our National Conference on 6–8 October with three days of insights, innovation, networking opportunities. The Young Member South African study tour in April will bring emerging leaders from Australia and affiliated Institutes of Quarrying globally together for 14-day professional development, and our member survey will provide input for the 2026–2029 strategic plan.

Thank you to our members, partners, volunteers, branch committees, and staff who made this year possible.

Jane Schmitt Chief Executive Officer Institute of Quarrying Australia

Company Secretary David Cowie

Follow the IQA on our social media pages:

IQAustralia

the-australian-institute-ofquarrying/ iqaus

A new generation of filter press, built to bring proven experience, proficient operation, and progressive ingenuity specifically to the construction and demolition, waste recycling, quarrying, and mining sectors.

ProPress uses a dual feed and plates that are 25% larger, handling more material, producing a dryer cake product, while recycling 95% of its process water.

Find out how CDE ProPress can bring safer operation, reduced costs, and maximized outputs to your plant today.

Michael Close continues his series of conversations with our valued national supporters, exploring their commitment to the quarrying sector and their partnership with the IQA.

Michael Close: Bridgestone Mining Solutions Australia has recently expanded its support from branch sponsorship to becoming a national partner. What motivated Bridgestone to take this next step with the IQA?

Andy Davies, BMSA sales director: We’ve been proud to support the IQA through local branch events for several years, and that involvement has given us a real appreciation for the value the Institute brings to the sector. Becoming a national sponsor felt like a natural progression – it allows us to contribute more broadly and connect with quarrying professionals across the country.

Our business has always been built around long-term partnerships, and the IQA’s focus on education, safety, and professional growth aligns perfectly with our values. It’s about investing in the people who make this sector strong.

Close: Bridgestone Mining Solutions has been part of the Australian landscape for over 40 years. How has that experience shaped your approach to supporting quarrying and mining operations?

Davies: Experience has shown us that every operation is different, but the fundamentals of safety, efficiency, and reliability are always the same. When we started selling directly to customers in 1981, it gave us a unique understanding of what was happening on the ground – the challenges operators face and the practical support they need.

Today, that understanding drives everything we do. We’ve grown beyond supplying tyres to providing integrated solutions – including wheels, hydraulic hoses, rubber tracks, on-site and off-site maintenance, tyre repair, and wheel repair. Our goal is to help operators keep their sites running safely and productively, day in and day out.

Close: What do you see as the key priorities for the quarrying sector in the years ahead?

Davies: The sector is evolving quickly, and technology is playing a big role in improving safety, sustainability, and performance. There’s also a strong focus on developing people - ensuring the next generation of quarry professionals have the skills and confidence to work safely and efficiently.

That’s something we’re passionate about at Bridgestone. We believe training and capability-building go hand in hand with innovation, and it’s where our values really align with the IQA’s purpose.

Close: What are you most looking forward to through this new national partnership?

Davies: The opportunity to connect with a wider network and continue learning from others in the sector. The IQA brings together such a diverse and knowledgeable community, and we’re excited to be part of that conversation on a national scale.

We see this partnership as a way to give back to the sector that’s supported us for more than four decades – to share what we’ve learned and play a part in shaping a strong, sustainable future for quarrying in Australia.

Michael Close, FIQ President Institute of Quarrying Australia

LONG-TERM PARTNERSHIPS, AND THE IQA’S FOCUS ON EDUCATION, SAFETY, AND PROFESSIONAL GROWTH ALIGNS PERFECTLY WITH OUR VALUES.

www.quarry.com.au

The IQA’s Strategic Plan 2023 to 2026 embodies the following vision, values and strategic priorities:

Vision:

Thriving communities supported by a sustainable industry

Operational Priorities:

• Deepen industry participation

• Sustainable revenue streams

• Highly capable team

• Technological innovation

• Effective engagement

• Great governance

Strategic Priorities:

• Support industry participants with compliance and regulation

• Build a diverse and skilled industry workforce

• Foster strong industry connectivity

IQA Contacts:

For all education, member and branch enquiries:

Phone: 02 9484 0577

Email: iqa@quarry.com.au

Chief Executive Officer

Jane Schmitt

President Michael Close

Company Secretary David Cowie

Follow the IQA on our social media pages:

IQAustralia

the-australian-institute-ofquarrying/ iqaus

WA Golf Day 2025:

Rain can’t dampen sector spirit

Despite one of the wettest golf days on record, the Western Australian quarrying community showed up in force to the 2026 IQA WA annual golf day.

Major sponsor CJD Equipment backed the day’s pre-game and post-game functions, while generous hole and team sponsors including WA Limestone, B&F Consolidated Group, Brooks Equipment Sales, and more than industry partners kept the momentum going.

MC Gareth McKean kept spirits high as scores rolled in, with WesTrac Cat ultimately claiming the winner’s trophy after a challenging day on the course.

From drinks carts to massage stations, crossover sponsors to gold team backers, the day showcased what makes WA’s quarrying sector special: connection, community, and the ability to laugh through the rain.

laughs. The relaxed atmosphere provided the perfect opportunity for members to connect with colleagues, customers, and families outside of the usual work environment.

The standout moment? The Haz-Elec Team taking home the coveted Best Dressed Competition prize with their eye-catching tropical team shirts, proving that style counts just as much as skill.

FNQ sub-branch chairperson Darren Caddy and Committee member Keoni Kidner hosted and facilitated the afternoon’s activities.

The FNQ sub-branch continues to demonstrate the value of regional engagement, bringing members together to celebrate the year’s achievements and strengthen professional relationships in a fun, inclusive setting.

Mackay forum sets new standard for sector-regulator collaboration

Queensland’s quarrying sector came together in Mackay on 16 October for a new event that showcased what genuine sector-regulator partnership looks like.

The inaugural Quarry Forum, hosted by Resources Safety and Health Queensland (RSHQ) in partnership with the Institute of Quarrying Australia, drew strong attendance bringing together 76 managers, safety professionals, and future quarry leaders eager to tackle the sector’s most pressing challenges.

IQA’s north Queensland committee member Michelle Lergessner, instrumental in bringing the event to life, said, “the forum provided an excellent

platform for collaboration, and it’s clear that RSHQ’s and the IQA’s commitment to engagement is making a real impact.”

The sentiment was echoed throughout the day. Clayton Hill, past IQA President and Technical Discipline Manager at SLR Consulting, said, “the collaboration between the regulator and sector is unmatched anywhere else in the country with respect to the quarry sector, which we truly value.”

With open dialogue, practical insights, and a room full of engaged professionals, the forum proved that when sector and regulators work together, everyone wins.

The IQA Victorian branch and Victorian subbranch celebrated the achievements of 12 quarrying graduates at their annual Student Presentation Night on 24 October at Novotel Melbourne Preston.

Fifty-four sector professionals gathered to recognise students who completed Certificate III, Certificate IV, and Diploma qualifications, with Kinder Australia generously supplying graduation compendiums.

The evening’s highlight was keynote speaker Daniel Bull, a three-time Guinness World Record-breaking adventurer, who captivated attendees with his insights

on overcoming limitations, embracing discomfort, and the power of asking “what if?” His message that “leadership starts with self-leadership and how you respond to fear” particularly resonated with the graduates embarking on their quarrying careers.

Bull encouraged celebrating achievements along the way using the “summit pose”, a fitting reminder for an industry that values both milestone achievements and continuous improvement.

Congratulations to all graduates on their outstanding achievement and commitment to professional development in the quarrying sector.

An exciting opportunity for profitability and sustainability is emerging in the quarrying sector as operators across Australia face a changing landscape in concrete sand supply.

The demand for concrete in construction continues to rise, as access to natural sand, its key component, is dwindling.

Environmental and regulatory pressures are increasing as infrastructure investment demands more sustainable practices.

Kayasand national sales manager Frank Grech said this creates both a challenge and an opportunity for quarries.

“By rethinking how they manage byproducts, operators can unlock new value streams while reducing environmental impacts,” he told Quarry.

“A great example is at Bass Point Quarry in New South Wales, where Heidelberg Materials Australia has partnered with

In July 2025, Heidelberg announced it would install a new 120 tonnes-per-hour Kayasand V7-120 plant at Bass Point. The plant will process surplus crusher dust, a by-product traditionally considered low-value material, into a consistent, high-quality engineered sand designed for use in concrete.

For Heidelberg Materials, the decision is about more than efficiency. It’s about securing a sustainable, long-term supply of sand for its ready-mixed concrete operations while reducing reliance on natural sand.

“We researched sand manufacturing solutions globally and Kayasand was the only one that met our sustainability and performance criteria,”

“Kayasand aligns with our sustainability goals by reducing waste and balancing sales volumes to production

traditional wet processing, this technology employs a fully dry process that eliminates the need for washing, tailing ponds, and complex water management solutions.

This dramatically reduces a quarry’s environmental footprint and dependence on the local water supply.

These plants precisely control the grading, shaping, and removal of contaminants like clay and silt, producing a quality sand engineered specifically for performance in concrete.

For quarry operators, this means a reliable, consistent product that meets technical specifications and reduces the risks associated with variability in natural sand.

“This is state-of-the-art Japanese technology that replaces the need for natural sand in concrete. In time, it will eliminate that need entirely,” Kayasand chief executive officer Bram Smith said.

“The growth in demand is driven by the construction industry’s drive for sustainable, scalable solutions coupled with quarries’ drive for greater utilisation to drive revenue.”

The Bass Point project shows how profitability and sustainability can go handin-hand. Crusher dust, once stockpiled, can become a revenue stream. At the same time, the switch to engineered sand reduces pressure on finite natural resources and

said. “They give us much better control of the outcome and are more environmentally sustainable than natural sands.”

Australia’s journey toward net zero adds urgency to this transition. According to CSIRO’s Pathways to Net Zero report, the country must reduce emissions by more than 50 per cent from 2020 levels by 2030 to stay aligned with a 1.5°C global warming trajectory. Cement and concrete are among the hardest sectors to decarbonise, yet demand is projected to grow by more than a quarter by 2050.

Lowering the cement levels in concrete can significantly reduce emissions. A variety of approaches are being implemented, including using cement substitutes such as fly ash or slag. Well-graded, shaped, and clean sand can significantly lower cement demand in concrete.

“Cement savings of five to 15 per cent are achievable in typical concrete mix designs by using good quality engineered sand made in quarries using Kayasand’s V7 technology,” Smith said.

“Engineered sand provides a practical step forward. By reducing quarry waste, conserving natural sand resources, and supporting more consistent concrete mixes, it helps the sector balance emissions reduction with continued growth.

“For quarry operators, it offers both a sustainability story and a business case:

plants across Australia and New Zealand by 2030, creating a network of facilities capable of transforming quarry byproducts into high-value engineered sand.

For Heidelberg Materials, being among the first to adopt the technology offers strategic benefits: greater control of its sand supply, a pathway to reduced environmental impact, and the ability to meet the expectations of customers seeking more sustainable materials.

Smith said it’s a blueprint for smarter use of every part of the quarry.

“We’re exploring ways to turn every gram of material produced in quarries into something valuable, whether that’s for roads, buildings, or even farming,” he said.

Grech said Kayasand’s deal with Heidelberg Materials Australia at Bass Point signals a broader industry shift.

“Quarries are seeking out opportunities where profitability and sustainability can be achieved from the same investment. They are two sides of the same coin,” he said.

“For quarry operators, engineered sand is proving to be more than a niche product. It’s a scalable solution that strengthens the bottom line, reduces environmental impact, and secures a sustainable sand supply for decades to come.” •

For more information, visit kayasand.com

McLanahan can support its customers at every stage of the journey as demand continues to grow for sandwashing and recycled material products.

McLanahan has seen demand for sand and recycled products grow steadily across several key markets for quarrying and aggregates.

McLanahan business line director for aggregates systems David Hunter told Quarry he expected this trend to continue growing in the coming years.

“As people keep moving to big cities, big cities are going to continue to grow, and as they grow, they’re going to need more civil works, commercial buildings, residential buildings and roads, which will require construction and demolition at the same time,” he said.

“To me, I think the use of construction demolition waste is only going to continue to grow as populations grow. It is one of those areas of the industry that I think will continue to grow globally.

“Especially when you consider logistics, because the further material has to travel, the more economically unviable it becomes. What we typically see is that people want to recycle this material as close to where it comes from as possible to negate this.”

While Europe was an early adopter of recycled materials in the construction sector, other markets, such as the US and Australia, are also showing increased demand.

It is a trend Hunter has witnessed throughout McLanahan’s work with its global customer base.

“The US is starting to get into the notion of construction and demolition waste recycling, and I would say Australia is no further back than the US in that regard. We have some customers actively working in washing and recycling materials,” he said.

“To me, it shows that there is an appetite in Australia for this kind of application. Different states and cities are introducing different taxes and levies to support this, and that’s only going to continue.”

One of McLanahan’s pioneering solutions was established in Townsville, Queensland, where the company worked with familyowned producer Stradacon Penna.

The family operation, owned by David and Vivienne Penna, supplies materials for the Townsville market, including aggregate, recycled concrete products, and sands.

A few years ago, Stradacon Penna approached McLanahan’s Australian dealer Lincom about adding a wash plant for size classification to its site. McLanahan’s UltraWASH Modular Wash Plant was installed quickly and efficiently.

Later, the Townsville-based producers added a McLanahan modular scrubbing system which could accept construction and demolition waste and remove lightweight debris and organic material from the aggregate.

With the new McLanahan Modular Scrubbing System, the family business could reduce the amount of foreign material in its waste feed.

“We first became aware of the McLanahan product range through our long-standing relationship with Lincom. They’ve supplied us pretty much all of our crushing equipment throughout the years, and they maintain a very good relationship with us,” Penna said.

“The whole operation, the scrubber system coupled with the wash plant, enables us to treat this demolition waste and send it back into industry like an as-new state.

“The UltraWASH is allowing us to operate without dust, which is absolutely critical to us. Its reliability is just outstanding.”

Hunter said that the Stradacon Penna solution was an example of how McLanahan can tailor solutions to the

“It is a great example of the uses of our modular sand washing plants, and they have added a coarse material screw washer. It allows them to float out the debris and organics in construction demolition waste material so they can feed that back in cleanly and then trickle it in with their virgin product,” he said.

“They put back in 10 to 15 per cent of recycled material with their virgin material, but it is clean, good quality material going back out the gate again.”

To serve its Australian customer base, McLanahan maintains a strong relationship with Lincom as its Australian dealer.

“I would say there is rarely a day that goes by when someone from our team is not in some discussion with Lincom, they’ve been our dealer for several years. We’re talking to them daily about different sand washing projects,” he said.

“We regularly get on calls with Lincom and the customer to have a discussion, and in some cases, someone from our team will go out to Australia to meet the customer as well.”

The US-headquartered manufacturer is celebrating its 190th year in 2025. It supplies many, if not all, of the key global aggregates markets, including Australia, with solutions from sand washing through to crushing and screening, and much more.

While all of these markets can be highly dynamic as regulations change and production methods are tweaked, Hunter said the company is well-positioned to support customers through its broad product range.

“It helps that we do have a very broad range of equipment for applications like sand washing and processing,” he said.

“A lot of the technology that is used in the sand washing process has been around for quite some time. We have a lot of the equipment that is needed for sand and aggregates washing.

“We also have a very broad range of mineral processing expertise, and I think that is key as well. We have team members with 40 years of experience in minerals processing, and there are very few applications they haven’t seen.

“We can use that industry knowledge to tailor a solution to our quarry customers. The key is that we don’t try to take a one-size-fitsall approach; we take it on a case-by-case basis, and we make sure our teams are working closely with the customer.

“Ultimately, you can’t lose sight of what the customer is trying to achieve and that’s what we’re focused on.” •

For more information, visit mclanahan.com

Bolwarra Enterprises engaged CDE Group for a customised sand washing solution to enhance production capacity.

Bolwarra Enterprises managing director Ian Kidner does not hold back when describing the impact of CDE Group’s sand washing plant at Wongabel Quarry.

With more than 40 years of experience in the quarrying sector, he knows a high-quality product when he sees one.

“CDE are probably the world leader in wash plants. I certainly believe they are,” he told Quarry.

“We did have a look at a few wash plant suppliers, but we went with CDE because they’re known as the best in the world.”

While the business operates several quarries in North Queensland, including Routh Quarry in Georgetown and Jubilee Quarry in Croydon, Wongabel Quarry, located in the Atherton tablelands, plays a key role in supplying materials to the concrete batching plant for Wongabel Concrete and the local market from Cairns to Karrumba.

Bolwarra Enterprises has been run in its current form by Kidner since 2000, after the company was initially founded in 1971,

providing mobile crushing and screening contract work, and acting as a contractor for local councils and government departments.

The company had been purchasing sand materials from two natural sand suppliers for its Wongabel Concrete batching plant, but as those resources began to diminish, a new solution was required.

The North Queensland operation began to look at the potential of manufactured sand for its quarry materials. Given the scale of the investment, the business undertook a thorough due diligence process when evaluating potential suppliers and methods for producing manufactured sand.

Ultimately, CDE Group emerged as the clear choice for the project.

“I consulted with CDE over a period of four to five years. The plant was designed for around 50 tonnes per hour, and it does exactly that,” Kidner said. “They gave us confidence in their product. When you invest your money in these products, that is what you need, and CDE gave us that.

“CDE also sent up a fitter and a couple of guys to help us with the installation of the plant, which was helpful.

“We’re currently operating it at a quarter of its capacity, but we expect that will grow. This plant suits what we needed, and it gives us a lot of room for growth.”

When consulting with CDE, the quarry operator discovered that the sand washing specialists could produce exactly what they needed in a straightforward manner. In contrast, other options were complex and involved multiple companies throughout the process. To meet their requirements, Bolwarra Enterprises purchased an EvoWash, an AquaCycle thickener and an AquaStore water tank. Together, this configuration allows for high-volume processing while keeping the footprint to a minimum. The AquaCycle and AquaStore systems, in particular, are critical to conserving water on-site.

The AquaCycle recycles up to 90 per cent of water used, sending it to the AquaStore

for immediate reuse. This avoids the use of settling ponds – a key win in a landconstrained environment. Adding to the mix is the EvoWash system. Compact and modular, it handles high-frequency dewatering and integrates cyclonic separation to control silt cut points. This means less loss of valuable fines and more consistency in the final sand and gravel products.

Kidner and his team elected to operate the plant off their own power supply. The 50-tonne-per-hour plant has also opened up new opportunities for the business. Using the plant, Wongabel Concrete has been able to

redesign its concrete mix designs due to the quality of the manufactured sand product.

Alongside the 25,000 tonnes of concrete sand the quarry produces annually using the CDE plant, the quarry has been able to produce clean fill sand for backfilling, sand for the septic system, as well as fill sand for local golf clubs.

“It is a superior product to the natural sand product. There was a transition period, but it has been financially beneficial for us as well,” Kidner said. “We still use some natural fine sand due to our concrete colour mix designs and the colour difference between the natural sand and manufactured sand.

“But overall, moving to manufactured sand with the CDE wash plant has been very beneficial because we can do more inhouse. The quality control we have received as a result of this is excellent, giving us peace of mind.

“We haven’t had any dramas with it. CDE helped us set it up, and it works really well.”

As access to natural sand reserves becomes increasingly difficult and the reserves themselves diminish, by transitioning to manufactured sand with CDE’s help, Bolwarra Enterprises has futureproofed its operations.

“Because we manufacture the sand and the CDE plant washes it, it’s all in-house now,” Kidner said.

“Our wash plant is of very good quality because it is all built in-house by CDE, and it has helped us keep the quarry and keep the concrete plant busy.” •

For more information, visit cdegroup.com

Heidelberg Materials has launched its evoZero range in the European market after a long journey to manufacture carbon-captured cement.

Heidelberg Materials has continued to forge ahead with carbon capture technology after the global construction materials producer debuted its evoZero product in Europe.

“I am proud and excited to announce that the entire process chain is now established, and our Brevik CCS facility is directly contributing to the reduction of carbon emissions in the

The evoZero leverages Heidelberg Materials’ carbon capture and storage (CCS) project in Brevik, Norway, which was officially opened earlier this year. The product has been recognised with a low Global Warming Potential designation and is thirdparty verified by DNV Business Assurance Germany GmbH. The DREIHAUS project is the first in Germany to use evoZero cement. The project, which KRAUSGRUPPE is leading in collaboration with PERI 3D Construction and Korte-Hoffmann Gebäudedruck, is under construction in the German town of Heidelberg and when finished, will result in a three-storey apartment that is optimised for 3D printing.

Two of the project’s three buildings will be built using an evoBuild 3D printing product that, according to Heidelberg Materials, is “a fully recyclable construction material.” It features a binder that, compared to Portland cement, has a 50 per cent lower carbon footprint. The third building is planned to use Heidelberg Materials’ evoZero product. The CO₂ reduction is achieved in the carboncaptured cement through the use of carbon capture technology at Heidelberg Materials’ Brevik CCS plant.

“DREIHAUS, built with CO₂-reduced, circular building materials from Heidelberg Materials, exemplifies the transformation underway in the German construction industry,” Heidelberg Materials Germany general manager Christoph Streicher said.

“Here, we are demonstrating how the continuous expansion of our sustainable product portfolio enables us to offer our customers not only highly innovative, but also customised solutions that provide optimal support for the successful realisation of diverse construction projects.”

Von Atchen said the product would help customers achieve significant progress toward their sustainability goals.

“We are committed to creating real solutions for decarbonising the built environment and advancing sustainable innovation together with our partners,” he said.

“With the German premiere of evoZero, the world’s first carbon-captured cement,

we are ringing in a new era of sustainable construction today in Heidelberg and across the country.”

A similar milestone is underway in the Norwegian construction sector, as Skanska builds the Skøyen Station in Oslo. The project is seen as fundamental to improving transport links between the western region of Oslo and the city centre, with the new station providing two tracks and modern infrastructure while being situated 45m underground.

“Our first deliveries are destined for true flagship projects in sustainable construction across Europe, with work on some of these projects set to begin imminently,” Heidelberg Materials managing board member Jon Morrish said.

“By adopting evoZero, our customers can turn sustainability into a real competitive advantage and demonstrate leadership in the transition to CO₂-reduced construction.”

The launch of evoZero was made possible by Heidelberg Materials’ flagship site in Brevik, which was launched in June 2025.

After years of construction, the CCS facility was unveiled to more than 300 guests, including Norwegian energy minister Terje Aasland and Norwegian crown prince Haakon Magnus.

The company estimated that the Brevik CCS plant will capture 400,000 tonnes of CO2 annually, which equates to around half of the site’s annual emissions. Once captured, the CO₂ is liquefied and shipped to an onshore terminal on the west coast of Norway, from which it is transported via pipeline to be permanently stored in the North Sea.

The first volumes of CO₂ were captured, liquefied, and temporarily stored in June as part of the site’s operational start-up process, which included the first shipments of the liquefied CO₂ to Øygarden.

“Brevik CCS is a powerful example of how businesses and government can work hand in hand to pave the way for a more sustainable future,” Norwegian energy minister Terje Aasland said.

The launch of the Brevik CCS has been closely followed by a final investment decision on Heidelberg Materials’ CCS facility in Padeswood, North Wales, which is currently in progress. The company secured a funding agreement with the UK Government, which effectively provided the green light for construction to begin on the project.

Set to be Heidelberg Materials’ second CCS facility, the Padeswood site is expected to expand the company’s evoZero production capabilities in Europe.

The facility is estimated to be capable of capturing 800,000 tonnes of CO₂ annually, which is close to 100 per cent of the site’s annual emissions.

The captured CO2 will be transported via an underground pipeline and stored securely and permanently under the seabed of Liverpool Bay, which is part of the HyNet North West project.

With construction set to begin before the end of 2025 on the North Wales facility, the

company estimated it will be commissioned in 2029 and create 50 new jobs.

“Padeswood CCS represents a transformative leap for the entire hard-toabate sector, both from a technological and a sustainability perspective,”

Heidelberg Materials chief sustainability and new technologies officer Katharina Beumelburg said.

“With evoZero from Padeswood, we will enable ambitious sustainable construction projects with measurable and verifiable CO₂ reductions – driving real change and shaping the future of our built environment.” •

Eltirus founder Steve Franklin explains how the company has grown from a boutique consultancy into a leading force in quarry resource optimisation, digital transformation, and sustainable practices.

Eltirus was born out of a simple but powerful idea: that quarry operators needed more than just technical advice – they needed partners who could help them understand what’s in the ground, extract it sustainably, and ensure compliance with both operational and statutory requirements.

From the outset, its mission has been to bridge the gap between traditional quarrying practices and the emerging possibilities of digital transformation.

The company’s team comprises surveyors, geologists, geotechnical and mining engineers, and software developers. It has built a culture that values curiosity,

collaboration, and continuous improvement.

Eltirus founder Steve Franklin said the company has always believed that innovation should serve a purpose – not just to impress, but to solve real problems and add tangible value.

Eltirus has delivered hundreds of projects across Australia and New Zealand, ranging from implementation of drone programs, exploration programs, resource assessments, scheduling, resource optimisation, rehabilitation planning and due diligence assessments.

“Our work is grounded in rigorous technical standards, with a strong focus and

on quality, repeatability and professional competence, including compliance with the JORC Code and the Registered Professional Engineers of Queensland legislation to ensure that we meet and exceed industry requirements,” Franklin said.

Some of its most notable contributions include:

• Increasing the life of an inner-city quarry by an additional seven years through effective geotechnical and mining engineering.

• D etermining how to develop a new quarry that had no effective haul truck access in extremely steep terrain (and in

an earthquake prone area) and working with the site on the deigns, schedule and operation plan to bring it into production.

• Using numerical modelling techniques to build a model of a major sand deposit that has proven accurate over some six years and changed how the business is run.

• Working with a cement plant to help them optimise the material blend from their two quarries and test the correctives they are using to determine the best production outcomes for the business and provide certainty for planning purposes.

These projects exemplify our approach: start with a clear scope, engage deeply with the client’s needs, innovate and deliver practical, actionable outcomes.

Innovation is at the heart of Eltirus, but not for its own sake. Franklin said it innovates to solve problems, reduce risk, and improve performance.

Recognising the need for good operational data to make better decisions about what is happening in the field, Eltirus embarked on developing a system (Eltirus Enable) specifically for the quarry industry.

Field proven with Stevenson in New Zealand, it is used across the business, from its largest operation, Drury in Auckland and across the smaller operations as well.

Enable is now also in the US market and we look forward to rolling it out to more of our clients in 2026.

Another key target for Eltirus is resource optimisation. Franklin said many cases, the shape, extent and size of quarry design, especially at the consenting stage was often quite arbitrary.

“We started research into how you could optimise a resource to maximise the net present value (NPV), reduce CO2 emissions and accurately predict development requirements for budgeting purposes,” he said.

“This work, centred on a linear programming approach can optimise not just a single resource, but multiple resources simultaneously, providing management and technical insights never previously envisaged.”

Eltirus has also worked with drone software platforms for the past eight years, actively promoting the value of this type of software not just for stock management, but for whole-of-site survey, vital to engineering and planning processes.

Franklin said recently the company had noted that the primary market player had stopped innovating.

“We started looking for a platform that could provide not only drone survey results but also improved site safety performance through AI haul road and bund wall assessment, geotechnical assessment and compliance to design checks,” he said.

“We found such a platform in Strayos, out of the US and are very impressed with both the product they have some up with and the incredible service they provide. It is very heartening to see the take-up of it by our clients across the country and we see great potential for this, and the partner AI real time fragmentation device called Netra.

“These innovations are not theoretical. They’re deployed in real quarries, delivering measurable improvements in efficiency, safety, and sustainability.”

Over the years, Eltirus learned some critical lessons that continue to shape its work.

Every project must deliver value, whether it’s improving NPV, reducing CO₂ emissions, or enhancing compliance. For example, in one hard rock quarry, Eltirus’ optimisation work led to a 43 per cent uplift in NPV and a significant reduction in the stripping ratio, making the project viable.

In another case, its digital transformation efforts reduced diesel consumption and CO₂ emissions by 19 per cent, saving $600,000 in extraction costs.

“These are not just numbers,” Franklin said. “They represent real improvements in profitability and environmental impact.”

A well-defined scope is the foundation of success. The company has seen projects falter due to vague objectives or shifting expectations. That’s why it works closely with clients to clarify their goals, the scope of the work, and what they hope to get from it, right from the outset, with a specific focus on ensuring that it can be practically applied in the field and with an eye to the value it will create.

Whether it’s a resource assessment or a rehabilitation plan, clarity ensures alignment and accountability. Franklin said theory is important, but practicality wins the day.

“Our work is designed to be implemented rather than be a drawing to be admired on an office wall,” he said.

“We produce geological and scheduling

models that integrate with operational systems, resulting in plans that guide real-world actions, and tools, such as user-friendly GPS rovers and 3D machine guidance systems that empower teams on the ground to get results.

“By way of example, our rolling Quarry Operating Plans are not static documents. They’re living tools that align strategic goals with daily operations and are appreciated by operational teams, auditors and regulators alike for their ability to ensure safe, productive and effective action in the field.”

Knowledge transfer is a core part of Eltirus’ approach. By becoming part of the client’s team, it actively works to upskill client personnel, embedding methods, skills and knowledge into their workflows, and ensure that the value Eltirus creates continues to grow and endures.

Through its partnerships with software providers such as Deswik (mining engineering software), Seequent (geological software) and Strayos (drone AI software), Eltirus works with some of the brightest minds in the geomining software industry, enabling it to keep at the forefront of innovation and new methods.

The company’s relationship with leading quarry planning consultancies such as Hetherington in Australia and Boffa Miskel in New Zealand also allow it to bring an integrated approach to every project.

Eltirus is committed to advancing the quarrying industry. It contributes through magazine articles with a specific focus on raising awareness of new technologies, methodologies and systems, conference presentations, industry awards (such as the IQA Innovation award) and outreach programs across Australia and New Zealand.

“We’ve supported initiatives alongside our industry bodies to engage school leavers, promote technical understanding, showcase the career opportunities in quarrying and its broad value and necessity to our communities,” Franklin said.

The company’s focus remains on innovation, sustainability, and practical excellence.

Franklin said he sees enormous potential in the Strayos AI-driven drone survey platform, operational data management using Enable, autonomous equipment, and integrated resource optimisation.

“Our goal is to help clients do more with less – minimising resource risk, reducing costs, improving safety, and enhancing environmental outcomes,” he said.

“We’re proud of what we’ve achieved in our first nine years, but we’re even more excited about 2026.

“The quarry industry is evolving, and Eltirus, in conjunction with our customers and partners is leading the way.” •

For more information, visit eltirus.com

The new LiuGong 922F excavator has impressed onlookers in the quarrying and earthmoving sectors since its mid-year debut in New South Wales.

The Liugong 922F excavator made its debut at the prestigious National Diesel Dirt & Turf expo held in Sydney earlier this year.

The impressive 22-tonne model attracted a lot of attention from industry professionals, enthusiasts, and media representatives alike, showcasing Liugong’s commitment to innovation and excellence in construction equipment.

As part of the showcase, the 922F excavator was tested in the event’s dig pit, demonstrating its capabilities to attendees. Since then, Liugong’s trusted dealer for New South Wales, Victoria, and Queensland, Construction Distribution Australia (CDA), has conducted demonstrations for key customers in Queensland.

These demonstrations have allowed professionals from the quarrying and earthmoving sectors to test the 922F excavator in real-world conditions and see how Liugong’s latest machine can support their daily tasks, with the initial feedback being positive.

“It’s given us the opportunity to provide greater exposure to LiuGong, the new model and the various new features over the previous E-series,” CDA Brisbane sales member Joe Plater said.

“They’ve all had the chance to utilise the machine, track it and have a dig with it as well.

“Feedback has been positive. Demo attendees have remarked how smooth the hydraulics are and how beneficial it is to have

programs that suit the operator and what tasks they’re doing at the time.”

In designing the F-Series, Liugong completely redesigned the cabin to be larger than its predecessor, and it is equipped with an air suspension seat and silicon oil shock absorbers to support smoother operations. Operators can also use the eight-inch LCD colour touchscreen, which is easy to operate with the control dial located in the armrest.

The new electro-hydraulic system provides pinpoint precision to the operator while also helping maximise the engine power. The new boom float technology prevents excessive pressure during braking applications and further reduces fuel consumption as the boom can fall under its own mass.

The 922F excavator is powered by a Cummins Stage III 124kW engine with three working models available to operators including power, economy and standard, which can reduce fuel costs.

Operators can use these modes to customise the excavator’s performance for their application, with power mode excelling

fuel economy, providing savings while still delivering strong output.

“Operators can adjust the hydraulics speed or cycle times if they want to make them quicker, or if their final trimming, they can suit it to that as well,” Plater said.

“The slew control has also improved to be smoother and more responsive, and it now feels like you’re one with the machine. The E-series and F-series both have quite a quick cycle time when digging, but the F-series gives you a better feel for the machine when you’re working.

The 922F excavator comes standard with a factory-fitted quick hitch and a 1.1 cubic metre general purpose bucket. Since its debut earlier in 2025, customers from various sectors, including quarrying, civil construction, and agriculture, have expressed interest in Liugong’s latest machine.

“We’re making sure potential customers know that this model is a premium machine,” Plater said. “It is well-suited to Tier-1 companies in all aspects.” •

Australian Earth Training founder Scott Lidster shares his experiences operating a Volvo EC950 fitted with a 6.6m³ heavy duty XMOR High Production bucket from ONTRAC Group.

SCOTT, TELL US ABOUT YOUR BACKGROUND – WHERE YOU COME FROM AND HOW YOU FIT INTO THE QUARRY INDUSTRY.

I’m an operator. I’ve been operating equipment for more than 35 years now, in a lot of facets, construction, quarrying, mining, etc. In the past 15 years, I’ve been in the training side of our industry and for the past seven or eight years, I’ve had my own company, Australian Earth Training. We support the quarrying industry with proficiency-based training, both here in in Queensland and other parts around Australia.

IS THIS THE FIRST TIME YOU’VE OPERATED A VOLVO EC950?

It’s the first time I’ve operated the 950. I’ve done about 20 minutes on a Volvo previously, and I spent a couple hours on this 950 the other day. I was pleasantly surprised. It offered a lot in breakout. It offered a lot in comfortability, it was super stable, and I really enjoyed the two or three hours that I sat on it.

TELL US ABOUT WHEN YOU FIRST COME ACROSS XMOR AND WHAT YOU THOUGHT OF IT AS A BUCKET AND A CONCEPT.

It would have been four or five years ago. Came through on the socials and straight away it blew my mind because they were taking a bucket somewhere that I’d never seen a bucket be taken before. I’ve been a fan of this bucket from afar for a lot of years.

WERE YOU SCEPTICAL WHEN YOU FIRST SAW IT?

I don’t know if sceptical the right word. I was definitely bloody curious for obvious reasons. It’s a cool design. I was super super curious.

WHAT WAS YOUR INITIAL REACTION TO USING THE XMOR BUCKET?

The initial reaction actually took me probably half an hour. When I came down the other day and started loading the trucks, I was focused on loading the trucks. Then I had

a moment where I went, “oh, hang on – I’m actually using one of these XMOR buckets.”

It was it was seamless. I had this preconceived idea in my head from the shape of it that it was going to react differently in the material. That certainly was not the case. It just felt like business as usual which I found really cool.

COMPARING THE XMOR TO A TRADITIONAL BUCKET, WHAT WERE THE BIGGEST THINGS YOU FOUND THAT WERE DIFFERENT IN THE OPERATION?

I think it seemed easier. The inconsistencies of blasted material – there’s material in these shots is going to stop any bucket, any machine. Right? All things being equal, when the dig was good, it just peeled through like it was nobody’s business.

So yeah, probably that speed aspect of what it what it gave me during those couple of hours was pretty noticeable.

HOW ABOUT THE FILL FACTOR OF THE BUCKET?

Yeah, fill factor was there. Again, you know, fragmentation is important on any bucket. The fragmentation that that I had during those couple of hours was a little bit all over the place but when we’re in a position to get a good bucket the XMOR certainly enabled that to happen.

BUCKET KEEPING UP WITH CRITICAL MAINTENANCE OF A BUCKET?

Maintenance is critical to anything in our game. If it’s lacking, things are going to slip and I’d suggest that the XMOR bucket is no different in that manner.

WHAT WILL BE THE TOP THREE THINGS YOU WOULD SAY WAS GOOD ABOUT THE XMOR? Ease of use, the bucket fill capability and its agility. Particularly in quarrying you have to sort the oversize out, otherwise it blocks the jaw. I found the bucket really nimble to pick out oversize and that really surprised me. You look at that bucket and it’s a deep design, it’s wide, it’s a lot of things, and I just thought it’d be a little bit arduous, and it surprised me on how agile it was just to pick out the rocks and leave fines behind.

WHAT ARE THE HANG UPS WITH AN XMOR BUCKET THAT YOU SEE AS A NEGATIVE?

I honestly couldn’t see a negative with the bucket. Again, fragmentation is going to be cruel for any bucket or any method of moving material right. All things being equal, I feel as if this XMOR bucket is only going to add value, to an operation. I honestly, hand on heart, couldn’t tell you a negative from operating it. •

For more information, visit ontracgroup.com.au

September 2026

EXHIBIT IN 2026. BE SEEN. BE HEARD. BE CHOSEN.

Pinnacle Hire is not just a hire business. It is a full-service contractor delivering turnkey solutions across advanced dewatering, pumping, water treatment and dredging.

Pinnacle Hire is much more than a rental company for water management solutions. Since its establishment in 2021, Pinnacle Hire has rapidly grown into a company that supports quarry operators at every stage of their projects.

In the four years since opening, Pinnacle Hire has completed more than 1000 projects, leveraging its extensive range of rental solutions and the knowledge of its expert team to handle everything from small-scale pumping to large-scale tailings dams. Its custom dewatering solutions are supported by its in-house engineers and consultants, as well as professional site assessments, ensuring each solution is tailored to the customer’s exact application and pain point. Once commissioned, Pinnacle Hire supports its solutions with 24/7 service across 13 locations nationwide.

“When water challenges threaten your project timeline in the quarrying sector, you need a partner with proven expertise,” Pinnacle Hire marketing manager Philipp Sharma-Jansen said.

“Our philosophy is straightforward: proactive planning with the right expertise

and equipment makes all the difference so that our customers can keep moving forward.

“The result is that our customers can access advanced technology that is backed by expert solutions and get the right solution for their business.”

Water management issues often start small but can develop into major problems for quarry operators. The ripple effects may include disrupted production, which affects delivery schedules, waterlogged site conditions that raise safety concerns, the risk of equipment damage from exposure, and complicated compliance issues around discharge requirements.

The quarry industry has high operational compliance standards and faces daily pressures, with tight margins that can illafford unscheduled downtime.

Since each quarrying operation has its own quirks and considerations, Pinnacle Hire’s expert team of consultants and engineers perform on-site inspections to understand the scope of the customer’s issues.

They will assess the site’s water management requirements, evaluate the current dewatering equipment, establish

early-failure detection system and a clear protocol for future issues.

“We have been able to grow as a business because we do more than just rent equipment,” Sharma-Jansen said.

“We partner with all our customers, whether they’re in quarrying or civil works or elsewhere, and work with them across the entire lifecycle of their project.”

Customers across Australia have been impressed by Pinnacle Hire’s holistic approach to developing water management solutions.

“The team was prompt, professional and got the job done quickly, which minimised disruption to our project,” one Pinnacle Hire customer said.

Sharma-Jansen said the company prided itself on its customer service.

“This rapid, high-level support is our standard. We don’t just rent equipment, we are a full-service water management contractor,” he said.

“Our in-house engineers conduct a rapid site assessment and immediately deploy a turnkey solution for your challenge.

“Whether it is a large-scale construction dewatering project or a complex creek bypass pumping operation, we use advanced pumps and integrated water treatment systems to ensure compliance with EPA discharge requirements.

“This focused approach ensures certainty in performance and minimises downtime on our customer’s project.”

Pinnacle Hire offers a range of solutions from internationally recognised equipment suppliers, which have been used to address

pumping issues, water treatment, and water storage. Pinnacle Hire’s range includes Tsurumi Pumps, Sulzer, Selwood, BBA Pumps, Elementz, Fortress, OrbSolar, FloKwip, Aggressor, Dominator and Atlas Copco.

To further enhance this product, Pinnacle Hire offers its Eagle Eye monitoring system, which enables its team to provide customers with technical support and

real-time monitoring from across Australia.

The company’s strategic locations in major cities like Perth, Brisbane, and Sydney, allow it to deliver efficient support to its customers whenever they need it.

“When you work with Pinnacle Hire, you are accessing a team that includes environmental engineers, environmental scientists, dewatering technicians, civil

Pinnacle Hire supports many sectors, including quarrying, mining, civil works and more.

engineers, and hydraulic engineers with extensive real-world experience,” SharmaJansen said.

“Water management is not just about pumps – it is about partnership and that’s what is at the heart of our business’s approach to the quarry sector.” •

For more information, visit pinnaclehire.com.au

Unleash the power of productivity, don’t let tough applications hold you back any longer.

• Output potential of up to 750tph - depending on material type and crusher settings

• Terex Jaques JW55 HD jaw chamber with hydraulic CSS adjustment

• Direct drive chamber via Transfluid KPTO21

• 10m3 hopper capacity with pan feeder and pre-screen (additional capacity available with the optional side extensions)

• An optional bypass conveyor is available, or material can run under the jaw to the product conveyor

Astec offers a broad range of tracked equipment for Australian quarry operators that are versatile enough to handle many applications, from recycled materials to paddock rock crushing and more.

Australian quarry operators of all shapes, sizes and applications are set to reap the benefits from Astec’s major investment in its production capacity.

The manufacturer has invested heavily in its production capacity in Omagh, Northern Ireland. The site expansion, funded by a multi-million-dollar investment, enabled Astec to meet the global distribution demand for its tracked crushing and screening equipment.

Now, the benefits of those upgrades are being fully realised as more of Astec’s wellregarded tracked crushing and screening equipment is available to its global customer base and applicable to many quarrying and aggregates applications.

“Our manufacturing base has greatly increased due to this investment,” Astec business line manager Adam Gordon told Quarry. “As a result, we can offer more of our customers access to our leading crushing and screening equipment.”

Now, thanks to its expanded production capacity, Astec is offering several models of crushing and screening equipment to Australian quarry operators, contractors, recyclers and miners as part of its end-ofyear sale. The run-out sale means more Australian operators can access the original equipment manufacturer’s high-quality equipment for their operations. With Astec’s tracked units, Australian customers can access well-designed tracked crushers and screens featuring the well-regarded Kodiak cone crushers, Kolberg-Pioneer jaw crushers and tracked high-frequency screens. The Kolberg jaw crushers feature an innovative mass momentum flywheel design to generate more crushing force. While conventional jaw crushers generate more force by increasing fuel consumption and horsepower, the Kolberg jaw crusher uses momentum to deliver most of the crushing action. This results in less fuel consumption which helps

reduce the quarry’s overall operating costs. Gordon said that fuel usage is a factor that can unlock major savings for operators dealing with tight margins.

“It is something that is coming into play because all operators of tracked crushing equipment are facing pressure on their margins,” he said. “There is always going to be pressure and competition on your selling price but whatever you can do to reduce your operating costs it helps every businesses’ bottom line.”

The range of Astec tracked equipment includes several models including the GT440CC. Astec has brought the tracked close-circuit impactor plant to Australia for the first time having arrived at its Acacia Ridge facility in early November.

“We’ve brought in the larger units before, but this is now a versatile crusher for those operators who are regularly going from site to site,” Gordon said.

“It is well suited to smaller crushing contracts and is very easy to relocate.”

The robust design of all Astec’s tracked equipment means it will be durable and dependable for years of service. A number of Astec’s clients have used its FT300 Cone Crushers for close to a decade. Powered by a CAT C13B engine and featuring a Kodiak Plus design, it offers efficiency and low operating costs while the PLC controls the crusher and a hydraulic cone brake ensures safe operation. The fuel consumption on the machine is particularly impressive.

“Our relationship with Astec’s tracked equipment started about ten years ago with the FT300. It’s served us well and while it has a few hours on it now, it still does a great job,” an Astec customer said.

Astec’s Australian team, led by Gordon, are ready to help customers get the right equipment for their application.

“We have a very versatile range of equipment. Whether you’re a large quarry, on the asphalt-side of the business, a small quarry, a recycled materials producer, a contractor, or an earthmoving operation, we have a machine that can suit your application,” he said.

“With our jaw crushers, cone crushers and screens, we can work with the customer to find a machine that is not only good quality but performs at a high level.” •

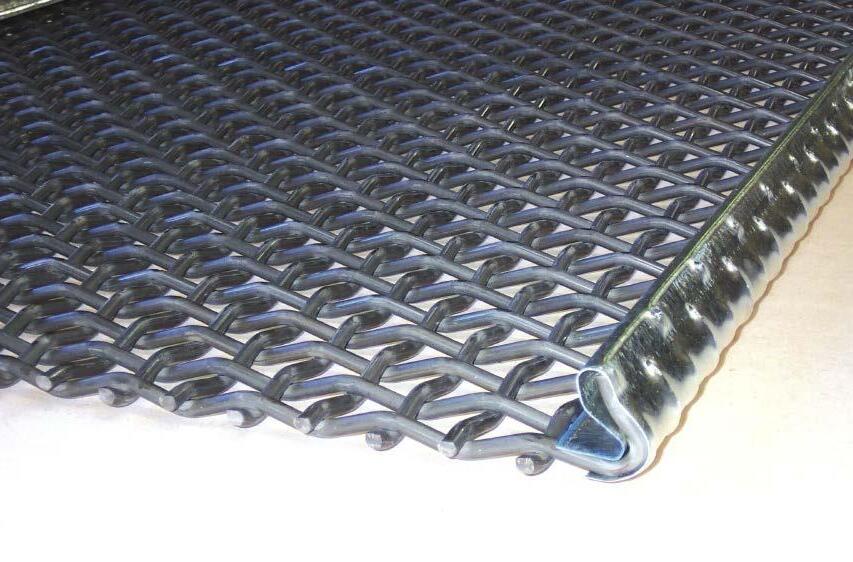

A year is a long time in the quarrying industry, and Agile Screening has used

Wfirm Trinity Capital purchased the Australian and New Zealand screen media business of Locker, they were making a long-term play.

Locker’s origins can be traced decades back to when Thomas Locker started weaving wire for the coalfields in England. Over the year, it had expanded to the extent it had a reputable presence in Oceania throughout Australia and New Zealand.

Sill and his firm saw an opportunity to elevate the company to new heights within the Australian and New Zealand quarrying sector.

“When we looked at the business, we were really impressed by the team members who all had real industry experience within the quarrying and mining sector. Collectively, there was hundreds of years of experience within the team,” he told Quarry

“We knew we had an exceptional team so the next steps for us as a business was to surround them with highclass manufacturing facilities and we wanted to connect with our customers so

“As a company, we’re on a journey with our customers and we want to establish ourselves as a screen media expert who can help them with their screening requirements.”

Behind the scenes Agile Screening has been working feverishly to set-up strong foundations for the business’ future.

The company has moved four manufacturing facilities, and they are fully operational. It has also invested significant time in strengthening its international supply chain including site visits and quality testing to ensure the product meets Agile Screening’s standards.

By having an extensive supply chain, Agile Screening can provide a flexible approach to manufacturing products for its customers. For example, longer lead time projects can be serviced through its international supply chain partners while projects with a sharper deadline may be serviced through its local facilities. So far, the behind-the-scenes work has paid off with a tick of approval from its quarrying and mining customers.

“We’ve worked really closely with all our customers this year to understand exactly how their business operates, what lead times they require and what their annual usage rates are,” Sill said.

“With that information, we can work with our international supply chain and our trusted supply partners to delivers a product that is high-quality, low cost and benefits our customers.

“It is an intensive process but we want to connect with our customers and understand their business so we can advise them properly as a screen media expert and come up with the right solutions for their business.

“Since we have taken over the business we have found many of our customers have stayed with us and have wanted to engage with us in this process so that has been a great tick for the business.”

As a brand-agnostic manufacturer, Agile Screening has the flexibility to devise screen

Agile Screening has a wide range of screen media solutions.

media solutions that suit the customer’s applications. It has an expansive range of options including Poly Ripple (polyurethane screening media), Tufflex (polyurethanecoated wire and synthetic rope), Poly Modular, Rubber Modular and wire screening media.

This means Agile Screening can work with both end-user customers and original equipment manufacturers on a case-by-case basis without bias and with the customer’s best interests in mind.

“When we’re looking at the quarrying industry in particular, we know our customers need solutions that are delivered fast and efficiently,” Sill said.

“Because we specialise and focus on screen media and are independent in the sense we’re brand-agnostic, we are able to provide our customers with direct and honest feedback in a timely manner,” Sill said.

“No quarry wants downtime, especially when it can be avoided. By understanding their pain points, we provide them the tools to screen successfully within their applications and run the most efficient operation at the lowest cost per tonne.”

Sill and his team have spent parts of 2025 embedding themselves in the local and

international quarrying and aggregates markets. This market research will help the company bring the latest screen media trends and innovations to its clients in Australia and New Zealand.

The team were able to get hands-on with the latest screen media technology from international supply partners and see how these new innovations could be applied in the local market.

Sill said it is all part of making sure that Agile Screening’s customers received the best solutions in 2026 and beyond.

“We want to make sure we’re at the forefront of any advancements in screen media so that we can bring those to our customers through our product offering,” he said.

“Although we are a growing company, our commitment to quality and our local expertise will always remain at the heart of how we support our customers in Australia and New Zealand.

“We have made significant investments in our operations this year, and we are excited that these will support our customers’ success going forward.” •

For more information, visit agilescreening.com.au

Simex TF Drum Cutters combine low vibration with consistent cutting performance, making them ideal for controlled excavation in quarries when conventional excavation or percussive systems have little effect.

The dual-drum design enables precise, selective removal of the rock mass while maintaining wall integrity. The resulting fragmented material typically achieves a grading that eliminates the need for further volume reduction.

• Precise cutting

• Low noise and vibration

• Maintenance-free operation

Compatible with excavators from 2.5 to 70t, TF Drum Cutters deliver reliable productivity across a broad range of applications.

Use Simex online tool to estimate hourly production and identify the most suitable TF model for your excavator and material type.

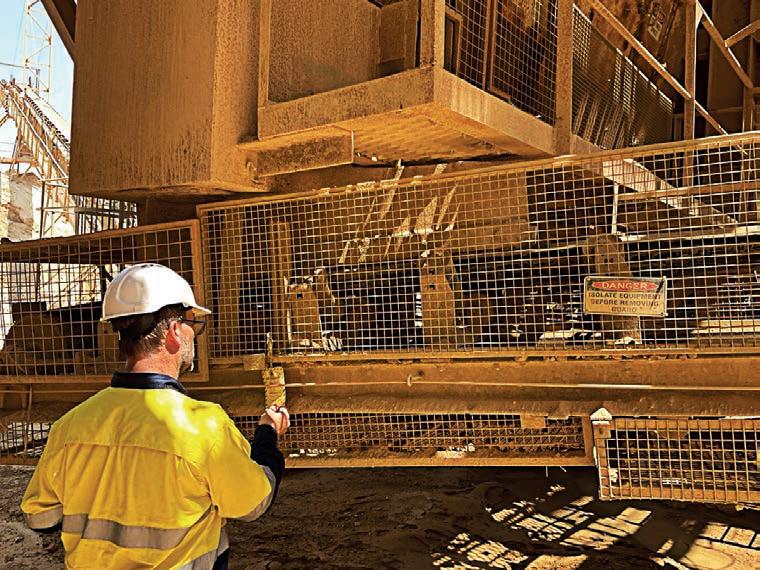

Kinder Australia is “walking the belt” to help spot ways quarries can improve conveyor productivity, safety, and longevity.

Afresh pair of eyes on a quarry site can reveal things that quarry staff may have normalised or overlooked.

This is the basis of Kinder Australia’s conveyor health checks.

“When someone sees the site for the first time, they can spot the areas of improvement or potential hazards,” Kinder Australia field application specialist Jason Whitwell told Quarry.

Tailored to each quarry’s specific requirements, each health check aims to improve performance and minimise risks through a comprehensive site visit.

Starting with a pre-consultation, Kinder Australia’s field application specialists work closely with quarries to discuss their specific problems, needs and expectations.

Whitwell said Kinder Australia’s team will then “walk the belt”, inspecting its operation and noting down problems for later attention.

“We go along the length of the conveyor, taking photos and measurements, looking for any potential problem areas,” he said.

“We cover the conveyor from top to bottom, using an iPad to document everything we come across. This means looking at the standard components, making sure there’s no structural damage, spillage, or anything that is not up to standard.

“Sometimes, the issues we find are sitewide, while others could be tracking issues on an individual conveyor.”

The photographs, videos, and other information are then collated into a report that helps form the basis for future reporting. It provides a summary of what issues the site is facing, highlights where the site is performing well, and provides a conveyor-byconveyor breakdown.

Whitwell said one of the most common issues that Kinder’s specialists find in quarries is poor belt condition.

“Quarries are looking for increased volumes and conveyor capacities around the country, which requires equipment to be in peak condition,” he said.

“Conveyor health checks identify immediate and future wear, plus, we provide a detailed performance analysis.”

Often, poor belt condition is the result of mistracking. Kinder Australia’s team checks to make sure each belt has the right type of tracking system to suit the conveyor belt’s speed, direction, trough angle, and

material loading. Specialists also look for any alignment problems and can provide solutions to promote the correct conveyor alignment. Kinder’s range of idler frames can support this effort.

The K-Retractable Idler/Impact Frames range are suitable for all bulk material handling applications, while the K-HD Retractable Impact Frames are applicable for the toughest quarrying and mining applications.

They allow conveyor rollers to be changed out under transfer loading chutes without requiring the frames to be removed.

Kinder’s check-up reports help site managers plan their maintenance processes and can assist with budgeting.

Whitwell said it helps quarry management understand what problems need a simple solution and what ones require a more comprehensive approach.

“For example, some customers think that fixing belt tracking could be hard or an expensive thing to fix, when it is probably a lot more affordable than they would think,” he said.

“The report breaks down what is the highest priority, so site management can gradually roll out improvements over the coming months to keep expenses low.

“We also educate sites on the importance of including belt cleaners and the importance of removing carryback. One major benefit is that carryback on pulleys and return rollers can affect their performance, which leads to a flow on effect. By installing a belt cleaner, the

conveyor becomes safer, more reliable, and more productive.”

Carryback can also lead to belt and structural damage as fugitive material can build up to bury idlers, conveyor components, or structural supports, furthermore, requiring clean-up labour or even the replacement of parts. Primary belt cleaners, like Kinder’s Micro Eraser Primary Belt Cleaner can play a vital role in reducing carryback and keeping conveyor belts running smoothly and efficiently.

Many of the sites that Kinder Australia’s field application specialists visit are located in Australia’s remote or regional areas.

For these sites, minimising downtime and maintenance is even more important than usual, as it can take longer to get things up and running again if something goes wrong.

Whitwell said these clients often appreciate Kinder Australia putting in the effort to see the site in person.

“Clients are usually grateful for the report,” he said. “The proactive ones get started on finding ways to improve their plant.

“Anyone can reach out to us to organise a conveyor health check. Our team of field application specialists are ready and eager to help.” •

For more information, visit kinder.com.au

The Bulk Handling Technical Conference and Expo will return in 2026, providing opportunities for Australia’s quarrying sector.

On 16-17 September at the Melbourne Convention and Exhibition Centre, the Bulk Handling Technical Conference and Expo (BULK2026) will once again bring the biggest names, brightest minds, and the most innovative technologies under the same roof.

“BULK2026 is all about bringing the industry together, showcasing innovation, sharing knowledge, and celebrating the people and projects driving bulk handling forward,” Prime Creative Media general manager of events, Siobhan Rocks, said.

“Whether you’re an engineer, operator, or supplier, BULK2026 offers insights and

BULK2026 brings together Australia’s bulk handling and quarrying industries, offering a unique platform to connect with a wide audience, meet new clients, and explore the latest technologies in the sector. The event also highlights critical industry topics, including sustainability, workforce safety, and supply chain resilience.

Quarry decision makers will have the opportunity to engage directly with peers, suppliers, industry leaders, and potential partners. Attendees can gain market insights, discover innovations, explore business opportunities, and advance their professional development, all while building meaningful

Rocks said BULK2026 is an engaging, hands-on, and practical way for people gain valuable insight into the sector.

“Discover, discuss, and witness in-person the latest equipment. From conveyors to dust control, to robotics and AI-powered maintenance tools, it’s a useful way to explore how new and innovative technologies, automation, and digitalisation are impacting the sector.”

Attendees will be given a chance to increase brand exposure to a large, industrial audience, and generate leads by connecting with potential clients that you might not meet elsewhere.

your brand the ability to shine in front of one of Australia’s largest industrial audiences,” Rocks said.

“Companies can expect real leads and projects and connect directly with professionals who are actively seeking bulk handling solutions.”