It takes a farmer to understand a farmer. And here at Liphatech Ag, we have the farming and ranching backgrounds to know what you’re up against every day. Your dedication, grit and selflessness don’t go unnoticed. Our team is here to support you in every way we can.

WE HAVE YOUR BACKS, BARNS AND BOTTOM LINES.

OCTOBER

OCT 9-11 — POULTRY SYMPOSIUM, Rogers Convention Center, Rogers, Ark. Contact: The Poultry Federation, 321 South Victory Street, Little Rock, Ark. 72201; Ph: 501-375-8131; info@thepoultryfederation.com; www. thepoultryfederation.com.

OCT 16-18 — GLOBAL ETHANOL SUMMIT, Washington, D.C. Contact: U.S. Grains Council, 20 F Street NW, Suite 900, Washington, D.C. 20001; Ph: 202-789-0789; https:// grains.org.

OCT 23-25 — PROCESS EXPO, McCormick Place, Chicago, Ill. Contact: Messe Frankfurt, www.myprocessexpo.com.

POULTRY TIMES PO Box 1338 Gainesville, GA 30503

PH | 770-718-3443

FAX | 770-532-4894

POULTRY TIMES STAFF

CINDY WELLBORN

General Manager, Poultry Times/ PoultryTimes.com

770-718-3443 cwellborn@poultrytimes.com

DAVID B. STRICKLAND

Editor, Poultry Times

770-718-3442 dstrickland@poultrytimes.com

ELIZABETH BOBENHAUSEN

Content Writer, Poultry Times

770-209-3335 cwellborn@poultrytimes.com

RACHEL DANFORD

Digital Specialist, PoultryTimes.com

770-831-8631 rdanford@poultrytimes.com

STACY LOUIS

Senior Sales Executive, Poultry Times/ PoultryTimes.com

770-718-3445

slouis@poultrytimes.com

JANICE SISK

Sales & Administrative Assistant, Poultry Times/PoultryTimes.com

770-718-3439

jsisk@poultrytimes.com

Kim Ewing

Customer Service Representative

770-718-3420

kewing@poultrytimes.com

Be sure to pay a visit to these esteemed sponsors of the Poultry Times, recognizing them as vital contributors to the industry who greatly appreciate your support.

Biosafe Systems | 27 860-290-8890; www.biosafesystems.com

Eagan Mfg. | 19 870-878-6805; www.eaganmfg.com

Farmer Boy Ag | 15 717-866-7565; www.farmerboyag.com

Gas-Fired Products | 18 800-849-7311; www.spaceray.com

Henning Companies | 16 515-253-0943; www.henningcompanies.com

Hog Slat | 31 800-949-4647; www.hogslat.com

Impact Poultry Products | 13 800-448-4723; www.impactpoultryproducts.com

Jones-Hamilton Co. | 3 888-858-4425; https://joneshamiltonag.com

Kelley Mfg. | 20 800-444-5449; www.kelleymfg.com

Kuhl Corp. | 30 908-782-5696; www.kuhlcorp.com

Kunafin (The Insectary) | 30 800-832-1113; www.kunafin.com

Publication Disclaimer

Poultry Times (USPS 217480) ISSN 0885-3371 is published biweekly, 345 Green Street, N.W., Gainesville, GA 30501. Telephone 770-536-2476; Fax 770532-4894. Postage paid at Gainesville, Georgia 30501. Poultry Times assumes responsibility for error in first run of an in-house designed ad only. Advertisers have ten (10) days from publication date to dispute such an advertisement. After ten (10) days, ad will be deemed correct and advertiser will be

L.B. White | 14 608-783-5691; www.lbwhite.com

Liphatech | 2 414-351-1476; https://liphatech.com

Motomco | 23 800-237-6843; www.motomco.com

Neogen | 32 800-234-5333; www.neogen.com

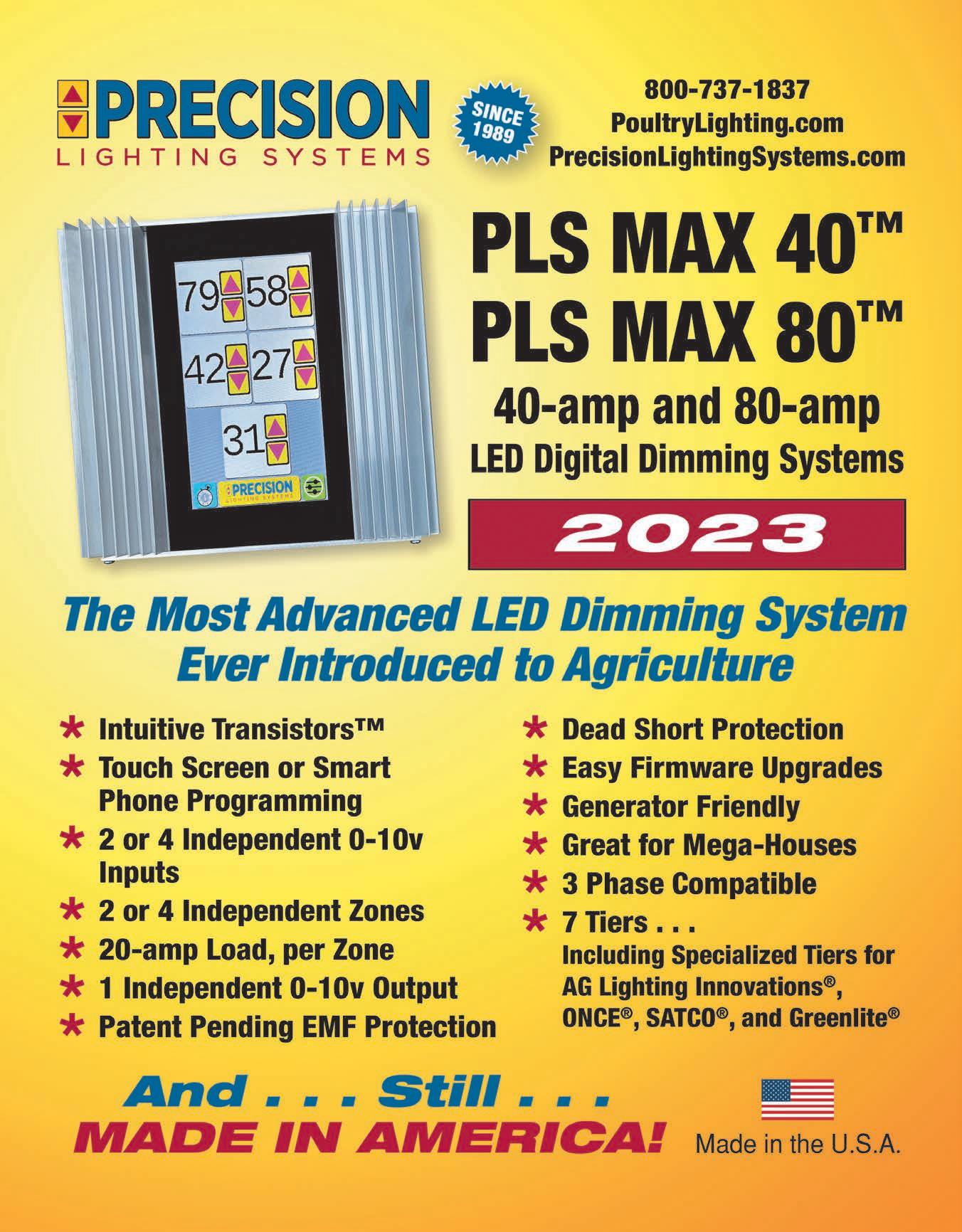

Precision Lighting | 1, 21, 26 800-737-1837; www.poultrylighting.com

S&I Pump Crete | 22 215-687-1342;

http://sipumpcretellc.com

Southwestern Sales | 17 800-636-1975; www.swsales.com

Star Labs | 13 800-894-5396; www.primalac.com

The Egg Carton Store | 30 866-333-1132; www.eggcartonstore.com

Walinga USA | 4 800-466-1197; www.walinga.com

Weightech | 22, 28 800-457-3720; www.weightechinc.com

charged accordingly. Proofs approved by advertiser will always be regarded as correct.

Subscriptions: Surface mail in U.S., $25.00 for one year, $45 for two years and $65 for three years. Business or occupation information must accompany each subscription order.

Change of Address: Postmaster, report change of address to Poultry Times, P.O. Box 1338, Gainesville, GA 30503.

Companion Poultry Publications: A Guide to Poultry As-

sociations; Poultry Resource Guide.

The opinions expressed in this publication by authors other than Poultry Times staff are those of the respective author and do not necessarily reflect the opinions of Poultry Times.

Advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

© 2023 Metro Market Media

Gainesville, Georgia 30503

GAINESVILLE, Ga. — Winter weather is right around the corner, and it is important for agriculture producers to know what to expect with the 2023-2024 winter season.

The Farmers’ Almanac mentions the warm winter the United States had in the previous year and this year will bring cold temperatures along with a snowy forecast. The cold temperatures will come from a predicted El Niño. National Geographic defines an El Niño as a climate pattern that describes the unusual warming of surface waters in the eastern equatorial Pacific Ocean. It is part of the “warm stage” of the El Niño-Southern Oscillation (ENSO).

These waters will develop during the later months of 2023 and in the early months of 2024 which could bring icy conditions to the U.S. Just before Christmas, winter will begin on Dec. 21. However, the meteorological winter begins Dec. 1.

The Farmers’ Alamac forecasts “some blizzard conditions blowing snow into areas over northern New England, the North Central States, and northern and central areas of New Mexico, Oklahoma, and Arkansas.” The Alamac uses a mathematical and astronomical method to predict extended weather forecasts. Based on the formula, the Alamac gives this prediction for some parts of the U.S.

In the prediction, it says to expect “belowaverage temperatures and lots of snowstorms, sleet, ice, rain for much of the Great Lakes, Ohio Valley, and Midwest areas of the country, as well as central and northern New England, especially in January and February.”

Also, the Farmers’ Almanac gives this forecast for the upcoming winter season:

• The second week of January will be stormy, snowy, and wet for both the Pacific Coast and the Eastern states.

• Lots of cold temperatures and some storms will keep folks in the South-Central states busy during the middle of January.

• Heavy mountain snows will cover the western U.S. including the mountains on the Pacific Coast during the first week of February.

• An East Coast storm affecting the Northeast and New England states will bring snowfall, cold rain and then frigid temperatures, during the second week of February.

• Unseasonably cold temperatures will blow into the Southeastern states mid-February.

• Potential blizzards for this first week of March will remind folks in the North Central states that winter isn’t over yet.

• Another East Coast storm will bring a wintry mess to this area during the first week of March.

• A possible late-season snowfall over the high terrain of New England during the third week of April.

Ag America Lending suggests that producers use the winter season to look over their finances. Producers should prepare for tax season by gathering up the needed documents for their taxes.

They can also look over their cash flow budget to confirm that all the expenditures line up with the annual budget. For family farms, it is important to look at all the family living expenses and operational expenses.

Ag America Lending recommends that farmers and producers look at the market trends such as:

• How much are input costs expected to increase next year?

• What will commodity prices look like next year?

• What legislation is on the table that could impact my operation?

• How much will farm labor cost next year?

The blog advises that any maintenance that

was not done on equipment during harvest season should be done in the wintertime along with any facilities or barns. It is important that all livestock have a dry and warm place to live during winter months. Calves must maintain their body temperature so they can grow and develop healthy. Kim Clark, dairy Extension educator at the University of Nebraska-Lincoln, gives some tips to keep livestock protected during the cold months:

• Ensure calf hutches are facing away from the wind.

• House animals inside a barn for shelter if possible.

• Provide warm and dry bedding for animals.

• Make sure you have enough feed supply.

The blog hints at growing winter crops. It says that winter crops consist of “broad beans, asparagus, peas and pea shoots, garlic, spinach, onions and winter lettuce” depending on what part of the country a farmer is from. Some others include broccoli, radishes, brussels sprouts, Swiss chard, cauliflower, and kale. If some of the crops are planted, they can assist in avoiding soil erosion.

According to Ag America Lending, other benefits of planting winter crops include:

• Supplying nitrogen

• Reducing weeds

• Providing nectar and pollen for beneficial insects

• Managing soil-borne diseases

GAINESVILLE, Ga. — Many people across the country wonder if poultry receives growth hormones. The answer to this question is “no,” according to a study done by the Poultry Science Department of Mississippi State University. The department explained that hormones have not been used and have been banned since the 1950s.

The poultry industry and the cattle industry follow contrasting regulations. In 1956, the U.S. Food and Drug Administration established that the cattle industry could use growth hormones to promote development, feed productivity and carcass strength.

As of today, there are five hormones implants that are used for cattle, such as progesterone, testosterone, estrogen, zeranol and trenbolone acetate. Zeranol and trenbolone acetate are synthetic hormones that are watched closely by the USDA’s Food Safety Inspection Service. Due to the residue of these products, the FSIS must secure the safety of the beef supply. When beef cattle are under a feedlot, growth hormones implants are necessary. Cattle receive these implants in the form of a pellet. It is surgically placed under the skin and behind the ears. The implants are to not enter the digestive tract; therefore, they are put behind the ears. Over 100 to 120 days, the implant will slowly dissolve and let go of the hormone.

The cattle spend over 100-200 days in the feedlot, as a result these implants are crucial. The study says while growth implants are needed for beef cattle, steroid hormones are not used in chickens, dairy cattle, veal or pigs. If growth hormones were put into the food of poultry, they would not be successful. There is a difference between steroid hormones and protein hormones. Steroid hormones are to be consumed internally because they will stay active through the digestive system. Nevertheless, protein hormones lose their function as they go through the digestive tract. Protein hormones must be injected.

Hypothetically, if chickens were to receive growth hormone injections, they would need them numerous times a day. It is not logical for chickens to receive that many injections because there are too many chickens. Broiler chicken producers have an estimated 20,000 chickens.

The study cites three reasons for the rapid growth of poultry:

1. The success of primary breeder companies in selecting the best birds for growth

and performance.

2. Research related to nutritional requirements of the bird.

3. Academics understand the kind of environment the bird needs to make the most of its genetic and nutritional potential.

Antibiotics are used in poultry and humans to treat infections. In 2019, the National Chicken Council stated in a press release “Much like a companion animal veterinarian would use de-worming compounds to prevent illness in a puppy, chicken producers and veterinarians use compounds to prevent and treat disease in the birds they raise in the field. Waiting until the disease actually takes hold would pose animal welfare issues and likely reduce the effectiveness of antibiotic treatment.”

The FDA and the manufacturers regulate any ionophore, antibiotic and non-antibiotic coccidiostat with strict measures. The USDA closely watches the removal times of medica-

tion that is given to a bird so it can be slaughtered without any medication within its system.

The NCC gives example of some antibiotics that are used:

• Bacitracin: is an antibiotic used to prevent necrotic enteritis in broilers, an infection caused by the bacteria Clostridium. Bacitracin is found most commonly as a topical preparation in human medicine, such as triple antibiotic ointments but is not used for any other purpose in humans. It is not on the list of antibiotics considered by the FDA as medically important in humans.

• Chlortetracycline: is a Tetracycline antibiotic that is primarily used in broilers for preventing and treating diseases. It was phased out for growth promotion purposes in livestock and poultry in 2016 under the FDA’s guidance plan.

• Decoquinate: is not an antibiotic. It is a non-antibiotic coccidiostat used in veterinary (Continued on page 11)

DAVID B. STRICKLAND Poultry Times Editor dstrickland@poultrytimes.com

DAVID B. STRICKLAND Poultry Times Editor dstrickland@poultrytimes.com

GAINESVILLE, Ga. — September was a great month. Do you know why?

College football has started back, sure; I’ll give you that one. But it was also National Chicken Month.

An industry economic impact study noted that the U.S. chicken industry provides more than 1.5 million jobs, almost $95 billion in wages and approximately $417 billion in national economic activity.

Chicken is a big deal.

Both nationally and internationally.

In highlighting this special month, the USDA’s Foreign Agricultural Service provided a special feature on the nation’s chicken exports.

U.S. chicken exports equal about $4.4 billion and 16 percent of global production,

FAS reports, adding that more than 145 different countries imported such items as frozen chicken leg quarters and thighs during the past year.

“As fall approaches, September celebrates the most-consumed meat in the United States: chicken. Two-thirds of U.S. chicken are raised in Alabama, Arkansas, Georgia, Mississippi, North Carolina, and Texas,” FAS said.

What is your favorite type of chicken product?

“While U.S. consumers prefer chicken breast meat, internationally dark meat is widely consumed and desired,” FAS added.

Chicken exports are also viewed by many nations as an affordable protein source.

FAS noted that while, “most U.S. chicken meat exports are often destined for low and middle-income countries which value safe, affordable, tasty, high-protein options – es-

pecially consumers searching for ways to improve their food and nutrition security at a time of rising food prices. In 2022, nearly all (95 percent) of U.S. broiler meat exports were destined for developing economies. Fourteen percent of shipments were exported to least developed countries.”

Chicken exports for the upcoming year are expected to continue to increase according to USDA, with top destinations being Canada, Mexico, China, Cuba, Angola, Guatemala, Taiwan, and the Philippines.

“Looking towards the future, chicken meat exports from the United States are expected to increase by 3 percent in 2024, thanks to increased production,” FAS said, adding that, “… USDA is committed to working with the U.S. poultry industry to ensure unhindered market access and continued success for America’s hardworking poultry producers.”

TUCKER, Ga. — Cold weather means that a poultry house will need special attention to maximize bird performance in an environment that is enclosed with minimal air movement and increased use of fuel to maintain the optimal environment for growth.

Cold weather ventilation is necessary to distribute heat and provide fresh air throughout the poultry house. The goal of cold weather ventilation is to allow cold air to enter the house through the air inlets and mix with the hot and dry air inside the house to maintain a comfortable environment. This requires the structure of the house to be sound in order to prevent air from leaking through openings other than air inlets and fans. This is referred to as house tightness.

Rafael Rivera is director, Food Safety & Production Programs, with the U.S. Poultry & Egg Association based in Tucker, Ga. He can be reached at rrivera@uspoultry. org.

House tightness is necessary to provide the best environment while efficiently using equipment and fuel. A tight house will allow cold air to warm properly and be distributed in a way that keeps the birds warm and dry. Having a house in good repair for proper ventilation and temperature management is important year-round, but certain aspects are more applicable when managing a house during cold weather.

Cold air tends to quickly fall to the floor if it leaks through cracks. Leaks can also cause warm air to escape the house. When cold air enters through cracks, it cannot enter at the necessary speed and height that would allow it to become warm and dry. Air and litter quality decreases with cold air entering the house.

Cold air results in wet litter, chilled birds and increased ammonia levels. Chilled birds will, in turn, eat more feed to keep themselves warm instead of gaining weight and could suffer negative health outcomes because of the increased presence of pathogenic bacteria and ammonia. Also, the added cold air plus the leakage of warm air will require more fuel to maintain the temperature. Increased fuel usage and decreased bird performance will be costly in the long term.

One basic step to check on house tightness is to perform a static pressure test. A static pressure test consists of closing all inlet vents and doors, running a tunnel fan and checking the

static pressure in the house. A static pressure of 0.10” of water column means that the house is tight, and a static pressure of 0.20” of water column means that the house is very tight.

This test will give you a high-level assessment of the condition of the house, but leakage may still be present and malfunctioning equipment could still give you a false sense of security. A smoke test is also a good way to check for leakage and can be used during the negative pressure test to check where air is leaking through the building. In addition, thermal cameras are visual tools that identify temperature differences on surfaces.

To get the best assessment of house tightness, ensure that there is a preventive maintenance program in place. Preventive maintenance programs address common opportunities and help you find overlooked ones. Perform maintenance between flocks as part of your preparedness program for bird placement.

Common maintenance items include cleaning and repairing of equipment. Check that inlet vents are free of dust and debris. Dust buildup on

“Cold weather ventilation is necessary to distribute heat and provide fresh air throughout the poultry house.”

vents can negatively affect air flow and prevent adequate mixing of air inside the house. Adjust vent cables so that they are able to open and close tightly and evenly throughout the house or sections of the house where needed. Side doors and vents should seal tightly around frames when closed. Side curtains or tunnel pad curtains should be in good repair.

Curtains are a significant source of air leakage if they have holes or if not adjusted properly. A good recommendation is to install tunnel curtain pockets to cover any gaps between the side wall and the edge of the curtain. Place insulated fan covers to those that will go unused. House end doors should also seal tightly with polyethylene covers.

Cold air can leak through brooding curtains

(Continued from page 8)

medicine for the control of coccidiosis, a debilitating protozoal infection in poultry. Decoquinate has no human usage.

• Diclazuril: is not an antibiotic. It is a nonantibiotic coccidiostat used in veterinary medicine for the control of coccidiosis, a debilitating protozoal infection in poultry. Diclazuril has no human usage.

• Naracin: is an ionophore used for the prevention of coccidiosis and has no human usage.

• Nicarbazin: is not an antibiotic. It is a non-antibiotic coccidiostat used for prevention and control of coccidiosis in broilers. When combined with naracin, makes the brand name product, “Maxiban.” Nicarbazin

from the non-brooding sections. Brooding curtains should be clean and free of holes, and the ventilation program should include the movement of cold air away through the non-brooding end. Seal drop ceiling gaps and known sidewall cracks.

Additional equipment maintenance includes fan and heater care. Fan blades and louvres need to be clean of dust and be able to open and close. Fan motors should run at capacity. Replace and adjust fan belts according to specifications. Clean and service heaters to the arrival of cold weather.

Perform preventive maintenance on water lines to prevent freezing and leaks that add extra moisture to the litter.

Last, but not least, always check the sup-

has no human usage.

• Monensin: is an ionophore used for the prevention of coccidiosis and has no human usage.

• Penicillin: is an antibiotic that is used very infrequently in broiler production. Its only use is to treat flocks that succumb to gangrenous dermatitis, another clostridial disease – which is uncommon, but has occurred at a low rate. Penicillin use has not been a standard practice for the purposes of growth promotion in broilers, but it was phased out for growth promotion purposes in livestock and poultry in 2016 under the FDA’s guidance plan.

• Robenedine Hydrochloride: is not an antibiotic. It is a non-antibiotic coccidiostat used in veterinary medicine for the control of coccidiosis, a debilitating protozoal infection

plemental power generators so that they are ready in case of emergency. Keep replacement parts for all equipment available in case of mechanical breakdown.

A thorough preventive maintenance program will allow you to find additional leaks, and you will be able to address them with minimal investment and time. Once repairs are completed, pre-heat the house to check how well the structure can keep temperature while achieving the proper mix of air for the birds.

Cold weather preparation includes structural and equipment soundness. Preventive maintenance will keep you ready with minimal investments and avoid loss in bird performance and welfare.

in poultry. Robenedine has no human usage.

• Tylosin: is a Macrolide antibiotic that is used in veterinary medicine to prevent necrotic enteritis in broilers, an infection caused by the bacteria Clostridium. It is a medically important antibiotic, and it was phased out for growth promotion purposes in livestock and poultry in 2016 under the FDA’s guidance plan.

• Virginiamycin: is a Streptogramin antibiotic used strategically to prevent necrotic enteritis, an infection caused by the bacteria Clostridium. It is a medically important antibiotic, and it was phased out for growth promotion purposes in livestock and poultry in 2016 under the FDA’s guidance plan.

There are no antibiotics within chicken meat. The USDA ensures that all chickens must be clean of antibiotics before being processed.

BERKELEY, Calif. — Upside Foods has selected the greater Chicagoland region for its first large-scale cultivated meat production plant. The 187,000 square foot plant, based in Glenview, Ill., will start by producing ground cultivated chicken products, with plans to expand to other species and whole-textured formats in the future.

With an initial capacity to produce millions of pounds of cultivated meat products per year and the potential to expand to more than 30 million pounds, the plant represents a significant step forward in achieving the company’s vision of creating a more humane, sustainable, and resilient food system, the company said.

“On behalf of the State of Illinois, we are excited to welcome Upside Foods to the Land of Lincoln and are committed to supporting their growth in the cultivated meat industry,” said Illinois Gov. JB Pritzker. “Here in Illinois, we are a hub for tech and innovation, thanks to our talented workforce and prime location in the heart of the Midwest. This new facility is a significant investment in our communities — creating new good-paying jobs while advancing our ambitious clean energy goals to create a more sustainable future. We also congratulate Upside Foods on their recent milestone of being the inaugural company to commercially sell cultivated meat in the United States. Their pioneering leadership makes them a perfect fit for the region.”

The state-of-the-art plant, designed to house cultivators with capacities of up to 100,000 liters, will stand as one of the world’s largest and most advanced commercial cultivated meat facilities, the company added. Building upon the knowledge gained

from Upside’s Engineering, Production, and Innovation Center (EPIC) in California, Upside’s new plant will cultivate meat at commercial scales and serve as a guiding force for the company’s future endeavors in scaling up its operations to the next level.

“We’re excited that the next chapter of our journey towards building a more sustainable, humane, and abundant future will be in Illinois,” said Dr. Uma Valeti, CEO and founder of Upside Foods. “Establishing our plant in this region allows us to tap into a remarkable talent pool, a thriving innovation ecosystem, and a notable history of meat production. We are grateful for the collaboration and partnership that we have built at the state, county, and local levels in our site selection process.”

The company notes that its selection of Glenview was driven by the region’s esteemed legacy in meat production, a shared commitment to innovation and sustainability, and strategic geographical advantages. Located at major transportation crossroads, the plant will serve as an ideal hub for large-scale production,

distribution, and sale of cultivated meat products.

Following its acquisition of Wisconsin-based cultivated seafood company Cultured Decadence, Upside Foods is furthering its commitment to the Midwest with a planned investment of more than $140 million in the region, along with the creation of more than 75 new jobs, from warehousing and logistics positions to bioprocessing and food production, as well as other commercial functions.

“We are proud to partner with Upside Foods as they make the strategic decision to harness the unparalleled strengths of the greater Chicagoland region,” said Kyle Schulz, executive vice president, World Business Chicago. “Their groundbreaking work in growing meat, poultry, and seafood directly from animal cells aligns with our region’s commitment to innovation, sustainability, and the future of food. We are excited to support Upside Foods in their journey and work together to promote the greater Chicagoland region as a hub for innovative and sustainable solutions that address

the challenges of our time and continue the Chicagoland legacy in protein production.”

Upside has selected Jacobs as its design and manufacturing partner for its facility.

“Jacobs has extensive experience working with disruptive, innovative partners,” said Bob Pragada, CEO of Jacobs. “This project aligns with our Boldly Moving Forward strategy in challenging the status quo in the food industry. The meat industry is water- and land-intensive and a significant source of greenhouse gases, and yet global demand for meat continues to grow. This facility will enable Upside to produce cultivated meat at a commercial scale, a key milestone in the company’s mission to create a more humane, sustainable and resilient food system.”

Upside selected the name “Rubicon” for its first large-scale cultivated meat production plant with an appreciation for its historical significance as a point of no return. The company added that this choice reflects its commitment to redefine the future of food.

Upside Foods

Mechanical Solutions Inc., a U.S.based manufacturer of food and further processing equipment, and millwright services, has moved into its new 93,000-square-foot headquarters campus located in Gainesville, Ga.

The expansion is due directly to the company’s fast growth in its first seven years of operation, the company noted. The complete campus, which has six times more square footage than its previous location, houses its business offices, manufacturing, warehousing, R&D, and training center.

“This move was a significant next step to support current customer and manufacturing

needs, our recent diversification into additional vertical markets, and future expansion plans into Latin America,” Heath Jarrett, CMS president, said. “Our new 7,700-square-foot office facility brings together our management, engineering, design, and administrative staff to foster collaboration and greater production efficiencies.”

The modern business offices feature a team-inspired open floorplan with glass walls to allow natural light throughout the building, and spacious individual offices.

CMS also made large capital investments in its state-of-theart manufacturing facilities. They have added a new laser with an auto-loading system, CNC press

(Continued on next page )

brake, CNC plate roller, two new manual lathes, two new mills, new table band saw, sand blasting room, nitrogen generator, water jet and two 150-horsepower air compressors.

“The investment in production equipment was a key part of our expansion plan to further broaden our manufacturing capabilities, meet our customers’ needs with greater efficiencies and improve delivery lead-times,” Jarrett said. “All of our manufacturing facilities buildings have been updated and are now climate controlled.”

For more information about CMS Mechanical Solutions, visit www.cmssolutions.com.

approved $330,000 for five new research grants at four institutions through the comprehensive research program. The research funding was approved by the boards of directors of both organizations, based on recommendations from the Foundation Research Advisory Committee.

The committee evaluates research proposals to determine their value to the industry and then makes recommendations to the boards for funding. Committee members are professional specialists from different segments of the poultry and egg industry who represent a variety of disciplines.

“Providing funding for research in areas of critical need to the industry remains a vital role in USPOULTRY’s and the Foundation’s service to the poultry industry,” said Jarod Morrison, Farbest Foods Inc., and USPOULTRY chairman. “The Foundation Research Advisory Committee members volunteer numerous hours to review and evaluate research proposals before making recommendations for funding. We sincerely appreciate their work.”

The research grants for each institution include:

mance and Inhouse Environment of Commercial Broiler Barns; Mississippi State University.

• Can Colony Nests Also Function as Floor Space for Cage-free Layers? Assessing Animal Welfare and Egg Quality Outcomes; North Carolina State University.

TUCKER, Ga. — The U.S. Poultry and Egg Association and the USPOULTRY Foundation have

The association’s comprehensive research program dates to the early 1960s when funds were first approved for poultry disease research. It gradually grew into an all-inclusive program incorporating all phases of poultry and egg production and processing. Since the inception of the research program, USPOULTRY has reinvested more than $35,700,000 into the industry in the form of research grants. More than 50 universities and federal and state facilities have received grants over the years.

• Virus Isolation, Serological Surveillance and Mechanical Transmission of Egg Drop Syndrome; University of Georgia.

• Identifying Virulent Avian Enterococcus Faecalis Isolates by Using Matrix-Assisted Laser Desorption/Ionization — Time of Flight (MALDI-TOF) Mass Spectroscopy; University of Nebraska-Lincoln.

• Development of a Web-Based Artificial Intelligence System for Analyzing Broiler Activity Index; University of Georgia.

• Effects of Combined Sprinkler and Cool Cell Systems on Cooling Water Usage, Water and Feed Consumption Rates, Bird Perfor-

SPRINGDALE, Ark. — Tyson Foods is reinforcing its commitment to help end hunger with a $2.5 million donation to Feeding America partner food banks. Additionally, in honor of Hunger Action Month®, Tyson is donating 2.5 million pounds of protein, the equivalent of 10 million servings of protein, to ensure equitable ac-

cess for communities experiencing the highest rates of food insecurity.

“People are working hard to provide for themselves and their families, yet one in 10 Americans experience food insecurity, including nine million children,” said Erika Thiem, chief supply chain officer at Feeding America. “Tyson’s continued partnership, and their focus on equitable access, brings us one step closer to an America where no one is hungry.”

Tyson Foods will allocate $800,000 of its donation to support Equitable Food Access grants which aim to improve access to nutritious food among people experiencing the highest rates of food insecurity.

The remaining $1.7 million donation will support efforts to maintain and expand capacity of eight protein “pack rooms” across the Feeding America network of local food banks.

Primarily used to repack bulk or private label protein products into family size quantities, protein pack rooms increase the types of protein that can easily be donated and distributed. Considering the

high demand for perishable items, such as high-quality meat, food banks need the proper infrastructure to fulfill the food safety and temperature requirements for storing, repacking, and shipping fresh and frozen products.

“At a time when millions of people across America face hunger, we’re proud to continue our partnership with Feeding America to help provide families and communities with access to nutritious, quality foods,” said Tim Grailer, senior director of social impact at Tyson Foods. “Hunger doesn’t have a season, but in September, we’re taking extra steps to raise awareness of food insecurity and show how much good food can do.”

Since 2020, Tyson Foods has donated more than 41 million pounds of protein valued at approximately $82 million to the Feeding America network of 200-member food banks, and 60,000 partner agencies, food pantries and meal programs. In the last year alone, the company has donated nearly 22 million pounds of protein — the equivalent of more than 85 million servings of protein — to the Feeding America network. Donation

events are scheduled throughout Hunger Action Month.

into the 21st century and steps the industry is taking to better protect animal and human health while producing safer, more sustainable food.

ARLINGTON, Va. — The American Feed Industry Association has released its annual “Our Industry, Our Promise” report, detailing the operational challenges facing today’s animal feed and pet food manufacturers and actions the AFIA is taking to address them.

The report provides an analysis of the animal food industry’s contribution to the U.S. and global economies and the forces making it difficult to conduct business. It also provides an inside look at efforts underway to usher the federal regulation of animal food

“In recent years, the importance of advanced animal nutrition in ensuring the well-being of animals and human health has gained increased awareness,” said Mike Gauss, AFIA Board chair (2022-23) and president of Kent Nutrition Group Inc. “As consumers become more discerning about the origin and quality of the food they consume, the demand for healthier and more sustainably produced animal products has significantly risen. Our association plays a crucial role in meeting these demands.”

The report focuses on work completed during AFIA’s fiscal year from May 1, 2022, through April 30, 2023, with sections on:

• The business climate for U.S. animal food manufacturers, including managing domestic supply chain challenges, resolving discrepancies between state and federal regulations, and advocating for modernized pet food label requirements.

(Continued on next page )

(Continued

• Animal food safety, including preparing manufacturing facilities for routine U.S. Food and Drug Administration inspections, safeguarding against potential animal disease outbreaks, protecting worker health and calling for the continued safe use of formaldehyde in swine and poultry feed.

• Global policy challenges, including averting a potentially catastrophic trade crisis with U.S. exports in the event of a foreign animal disease outbreak, advocating for sound international policy at the national level and within global fora, holding U.S. trading partners accountable and opening new markets for U.S. animal food exporters in key countries.

• Industry progress in sustainability, including standing up for the animal food industry in international dialogues as a solution to global food security and climate challenges as well as equipping members with resources needed to meet their customers’ and stakeholders’ sustainability pledges.

The report also provides an up-

date on AFIA’s professional networking and educational offerings, recognizes several industry award winners and acknowledges the ways the AFIA has given back to local communities and engaged in social media.

For more information, visit www.afia.org/news/state-of-industry-report.

MILFORD, Ind. — Nicholas Murphy has been named product design engineer for Chore-Time, according to Todd Martin, engineering manager for the CTB Inc. business unit. In his new role, Murphy will design, develop, and create innovative poultry components and equipment to meet customer expectations and business goals.

Prior to joining CTB, Murphy worked as an engineering intern

in the engineered component process industry where he conducted tests of the atomization process, collected data to analyze efficiency and spot errors and completed work independently and with other engineers.

A graduate of Purdue University, Murphy received his bachelor of science degree in aeronautical and astronautical engineering in the spring of this year. Murphy is a native of Leesburg, Ind., where he still resides.

EDEN PRAIRIE, Minn. — Zinpro Corp. served as presenting sponsor for the 17th annual NAMIWalks Minnesota on Sept. 23, at Minnehaha Park in Minneapolis.

“At Zinpro, our mission is centered on health and wellness, and that includes

mental health,” said Rob Sheffer, Zinpro president and CEO. “Each year, I’m proud that our employees here in Minnesota and around the world take part in this walk as a way of demonstrating our support for removing the stigma around mental illness and for the important advocacy work being done by NAMI Minnesota.”

NAMIWalks supports the efforts of NAMI Minnesota (National Alliance on Mental Illness) to provide education, support and advocacy for children and adults with mental illnesses and their families.

“This year the U.S. Surgeon General issued a report on the impact of loneliness and isolation,” said Sue Abderholden, executive director of NAMI Minnesota. “NAMI’s programs connect people and lets them know they are not alone. No one gets through a serious mental illness by themselves.”

NAMIWalks is a transformative opportunity in which participants reduce stress, build community, and find local support and services that can make a difference.

WITH A NAME LIKE OURS POULTRY HAD TO BE OUR PASSION

WASHINGTON — The U.S. Department of Labor has announced that its Occupational Safety and Health Administration has awarded approximately $12.7 million in grants to 100 non-profit organizations across the nation to support education and training to help workers and employers recognize serious workplace hazards, employ injury prevention and understand workers’ rights and employers’ responsibilities under federal law.

Funded through the Susan Harwood Training Grant Program, the grants are being awarded in three categories, namely Targeted Topic Training, Training and Educational Materials Development and Capacity Building grants.

“The award of Susan Harwood Training Grants remind us of Dr. Harwood’s important contributions to making our nation’s workplaces safer and healthier for countless U.S. workers,” said Acting Secretary of Labor Julie Su. “Dr. Harwood’s dedication to educating workers and employers continues to inspire those of us at the Department of Labor and those whose organizations will use these grants to help save lives.”

The program’s name and purpose reflect the legacy of the former director of OSHA’s Office of Risk Assessment. In 17 years with OSHA, the late Harwood was instrumental in developing federal standards that today protect people from workplace hazards, including asbestos, benzene, bloodborne pathogens, cotton dust, formaldehyde and lead, the department noted.

“These grants are one of our most effective resources for providing training and education to hard-to-reach workers in highhazard industries. More than a third of the awardees will be conducting training in the south, improving our training footprint in an area with a large, underserved

workforce,” said Assistant Secretary for Occupational Safety and Health Doug Parker. “Training should be a key part of ensuring vulnerable workers are in safe and healthy environments and that they feel safe at work.”

OSHA awards grants to nonprofit organizations, including community and faith-based groups, employer associations, labor unions, joint labor-management associations, Native American tribes and local and state-sponsored colleges and universities. Target trainees include small-business employers and underserved vulnerable workers in high-hazard industries.

DENVER — Prolonged drought and record heat are threatening soybean yields in several key growing states across the Midwest. With most of the soybean

crop still in the critical pod-setting phase that depends on moisture in August, persistent dry conditions are lowering yield projections and raising concerns about the availability of supplies.

Scouts participating in the recent Pro Framer Crop Tour found sporadic and highly variable yields for both corn and soybeans, especially across the western Corn Belt. Record high temperatures and dry conditions in August have negatively impacted both crops. At this stage of the growing season, yield loss due to ongoing heat stress is a much greater risk for soybeans than for corn.

According to a new research brief from CoBank’s Knowledge Exchange, soybeans have a much tighter supply situation than corn due to the loss of planted acres. USDA estimates soybean planted acreage fell 4.6 percent year-overyear this spring to the lowest level since 2020.

“If hot and dry conditions in the Midwest continue and yield loss for soybeans increases, the U.S. soybean supply will tighten further, resulting in stronger interior cash basis and lower exports,” said Tanner Ehmke, lead grains and

oilseeds economist for CoBank.

Ehmke was among the scouts participating in the crop tour who observed soybean pods being aborted in the triple-digit heat. Although pod counts were higher in many states compared to last year and the three-year average, more pods will likely be aborted if hot and dry conditions continue. In addition to drought and heat stress, sudden death syndrome was widely noticed by scouts, as was white mold.

However, high temperatures late in the growing season are associated with a higher soybean oil content, according to the United States Soybean Quality Annual Report. This coincides with historically strong soybean oil prices relative to soybean meal prices, driven by the expansion in demand for renewable diesel.

“While hot temperatures during the growing season tend to cause lower protein levels in soybeans and lower soybean meal values, the combination of higher oil extraction and higher soybean oil prices will benefit processors,” Ehmke said. “Buy basis for co-ops and processors will be higher in

the forthcoming crop year for soybeans, but processor margins are expected to remain strong.”

Stung Chicken Bites, and the new challenger, Sweet Chili Chicken Bites.

Chester’s Chicken Bites Combo features eight chicken bites, the choice of two sauce flavors, a small side, and a honey butter biscuit. This Chicken Bites Combo introduces Chester’s new marinated breast chunks along with a new sauce. Guests can choose chicken bites sauced and tossed in Frank’s RedHot® Stingin’ Honey Garlic or the new sauce, Frank’s RedHot® Sweet Chili – or mix and match.

dia pages, with the winner being crowned in January.

Additionally, in time for tailgating season, Chester’s is offering a Mix-N-Match Flavor Pack, which includes 24 chicken bites with the choice of three sauce flavors, along with three dipping sauces on the side.

For more information on Chester’s Chicken, visit www.chesterschicken.com.

and innovative retailers conference that features expert leaders, new product offerings, and more.

This year’s event took place at the Georgia World Congress Center in Atlanta, Ga., Oct. 3-6. With heavy attendance expected at the c-store industry’s premier event, Krispy Krunchy showcased its operator resources, new, more effective menu and support materials, as well as its leadership team, the company said.

Chester’s Chicken pits its honey chicken bites against its sweet chili

BIRMINGHAM, Ala. — It’s a Battle of the Bites! Guests who stop in Chester’s Chicken this fall should be prepared for a flavor showdown between the restaurant’s reigning champ, Honey

“Our Honey Stung Chicken Bites made with Frank’s RedHot Stingin’ Honey Garlic Sauce are a popular menu item, so it’s time we gave it a little competition with another delicious flavor from Frank’s RedHot,” said William Culpepper, vice president of marketing, Chester’s Chicken. “Guests will vote with their tastebuds, and we can’t wait to see which flavor will wind up on top.”

Customers will be able to vote multiple ways – via QR code found on the packaging, the Chester’s Club, and the brand’s social media pages. Updates on how each flavor is performing will be shared monthly on Chester’s social me-

ALEXANDRIA, La. — Building on a year of wins for the brand, Krispy Krunchy Chicken® showed up big at this year’s National Association of Convenience Stores (NACS) Trade Show, a convenience

Krispy Krunchy Chicken is expanding and expects to hit 3,000 stores in the next few months. The hot food concept has opened more than 350 locations year-to-date and continues to grow as a leading c-store fried chicken brand and foodservice solution for retailers, the company added.

“For years, NACS has been a flagship event for our team, and we are excited to share with retailers all the new things we’ve developed to help them be successful with our program,” said Jim Norberg, president of Krispy Krunchy Chicken. “The foodservice sector of convenience stores continues to grow at rates far higher than QSR, with average margins that exceed most everything else in the merchandise assortment. We’re proud to be a part of that momentum for the retailers with whom we already work — and for those new potential licensees who we’ll be meeting at the show.”

In addition to having a presence at the show, Krispy Krunchy stepped up for a great cause during its time in Atlanta. The company donated its signature hand-breaded, Cajun-spiced fried chicken and other hot foods to Goodr, a national initiative that is committed to lowering food waste for the greater good, and the Atlanta Community Food Bank, a leader in the fight against hunger in the greater Atlanta and North Georgia areas.

For more information, visit www.krispykrunchy.com.

FRANKLIN, Tenn. — Hardee’s® is turning up the heat, and welcoming a new Nashville Hot Chicken to the menu. It will be joining Hardee’s Hand-Breaded Chicken platform to include kicked-up versions of Hardee’s favorites like Nashville Hot Hand-

Breaded Chicken Sandwich, Nashville Hot Hand-Breaded Chicken Tenders, and Nashville Hot HandBreaded Chicken Biscuit at participating locations.

“At Hardee’s, we’re all about offering the homestyle foods our guests crave. We’re expanding our famous chicken lineup with just the right amount of spice,” said Mallory Jones, director of brand marketing for Hardee’s. “The flavors speak for themselves. While there’s a nod to our Tennessee headquarters, we know guests

across the country will love this new flavor.”

The new menu items began on Sept. 13 and are available both in store and in the Hardee’s App, where My Rewards members can redeem an in-app only offer for BOGO for $2 hand-breaded chicken sandwiches (regular, BLT or Nashville Hot). The Nashville Hot Chicken platform will be a permanent fixture on the Hardee’s menu, the company said.

For more information, visit www.hardees.com.

OAKWOOD, Ga. — WayneSanderson Farms was recently recognized for stellar safety performance as industry leaders and peers joined company safety and leadership staff at the recent annual National Safety Conference for the Poultry Industry. The company received 13 separate facility awards during the industry’s largest annual safety-focused event.

The company added that the awards validate the company’s approach to employee safety and health under the leadership of Reggie McLee, Wayne-Sanderson vice president, health and safety,

who launched the Zero Accident Culture initiative in 2015 to emphasize personal responsibility for safe workplace practices.

“Making sure our workforce knows the importance of a safe working environment is only part of it,” McLee said. “But showing we care enough about each other to require safe practices from everyone on the team is how we make it happen.”

His team went on to develop a proprietary Supervisors Safety Matrix, with tools and processes supervisors could use to analyze and improve workplace behaviors and map out best practices to improve safety. The initiative was later incorporated into the com-

(Continued on next page )

Our new Fast Track Wall Vent (Patent Pending) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available either insulated or uninsulated

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

(Continued from previous page)

pany’s Amazing Starts With Me corporate culture platform.

Clint Rivers, Wayne-Sanderson Farms president and CEO, commented on the safety awards and the company’s continuous improvement strategy for safety, health and employee welfare.

“We’re proud of the awards, but we’re even prouder of the performance,” Rivers said. “The best way to get improvement in DART rates and reductions in injuries is by making sure our emphasis is always on our people.”

Awards were based on injury statistics over a three-year span in tandem with judge’s program evaluations.

Awards of Distinction

• Wayne-Sanderson Farms Adel, Ga.: hatchery

• Wayne-Sanderson Farms Elkin, N.C.: hatchery

Awards of Honor

• Wayne-Sanderson Farms Albertville, Ala.: hatchery

• Wayne-Sanderson Farms Collins, Miss.: hatchery

• Wayne-Sanderson Farms Danville, Ark.: fresh processing facility

• Wayne-Sanderson Farms Dob-

son, N.C.: fresh processing facility

• Wayne-Sanderson Farms Hazlehurst, Miss.: feed mill

• Wayne-Sanderson Farms Laurel, Miss.: feed mill

• Wayne-Sanderson Farms Newton, N.C.: feed mill

• Wayne-Sanderson Farms Troy, Ala.: hatchery

• Wayne-Sanderson Farms Tyler, Texas: hatchery

Awards of Merit

• Wayne-Sanderson Farms Albertville, Ala.: fresh processing facility

• Wayne Farms Pendergrass, Ga.: fresh processing facility

VERONA, Mo. — Kemin Industries has opened a new manufacturing facility in Verona, Mo., to produce its Proteus® line of clean-label functional proteins that are used to increase yield and enhance the quality of meat and poultry products within the food industry.

Kemin broke ground on the new building in November 2021, and recently hosted a ribbon-cutting ceremony to officially open the 38,000-square-foot facility. The operation is a $70 million investment that employs nearly 30 full-time workers in the Verona community.

The facility, which will run under FSSC 22000 Certification and completed its first run

under USDA inspection on July 25, 2023, will manufacture Kemin Food Technologies – North America’s patented Proteus line of clean-label, functional protein ingredients for a variety of meat and poultry applications. The Proteus portfolio of musclebased protein ingredients can help food processors naturally

(Continued on page 22 )

retain moisture typically lost in processing, which translates to processing efficiencies with improved quality.

The state-of-the-art Proteus production plant will have an initial capacity to produce enough functional protein to treat more than a billion pounds of meat, poultry and protein-based applications.

“Since acquiring Proteus in April 2021, we’ve been eager to open this site and serve customers, who continue to demand sustainably sourced, technologically advanced solutions,” said Marc Scantlin, president, Kemin Food Technologies – North America. “Opening our first-ever Proteus dry production plant provides the opportunity to partner with more meat and poultry manufacturers, positively impacting the quality of our global food supply.”

Prior to construction of its Food Technologies site, Kemin established a presence in Southwest Missouri in 2011, with a manufacturing location for Kemin Nutrisurance, the company’s pet food and rendering technolo-

gies business unit. Today, Kemin has three locations in Missouri: Kemin Nutrisurance facilities in Verona and Sarcoxie and the new Proteus production plant.

“We’ve found a great pipeline of talent in Verona and the surrounding area that has successfully grown our manufacturing capabilities for our pet food business, and we believe this community will offer the same support for our Proteus production plant to meet the high interest of our customers,” said Dr. Chris Nelson, president and CEO, Kemin Industries. “I’ve been impressed with all our team members in Southwest Missouri, and I know even more potential employees are here to help us bring better meals to families around the world.”

Kemin anticipates yield-enhancing Proteus solutions will further expand the global reach of its Food Technologies business, with plans for additional production capacity in Latin America beginning in 2024.

For more information, visit https://www.kemin.com/na/enus/markets/food/products/proteus.

SALEM, N.H. — Pete & Gerry’s Pasture-Raised Eggs, part of the Pete & Gerry’s family of egg brands, including Pete & Gerry’s Organic and Nellie’s Free Range, today announced the launch of their latest campaign, “(Almost) The Wildest Eggs You Can Get.”

The announcement comes hot off the heels of securing national distribution for its Certified Humane® Pasture-Raised Eggs — now available from coast to coast at major retailers including Whole Foods, Kroger, Stop & Shop, Shaws, Hannaford, and The Giant Co. This significant distribution milestone comes just months after the new item’s introduction, the company noted.

Pete & Gerry’s Pasture-Raised Eggs hit the market earlier this year, offering eggs from hens raised to Certified Humane Pasture-Raised welfare standards, which guarantee that each hen enjoys at least 108 square feet of pastures with room to roam,

forage, and explore under sunny skies, the company adds.

Pete & Gerry’s Pasture-Raised Eggs has launched a “wild” new national advertising campaign, in partnership with creative agency Humanaut, featuring streaming TV, YouTube, and social media ad placements, as well as digital out of home. The advertising campaign will be inmarket through the end of the year.

The new ads depict shoppers going to dangerous lengths to source wild eggs from eagle, ostrich, and even alligator nests. But thanks to Pete & Gerry’s Pasture-Raised, consumers don’t have to brave the actual wilderness to get the freshest, highest-quality eggs; they can simply buy them straight from the supermarket shelf

“As the industry pioneer in better production practices, Pete & Gerry’s has the credibility and brand equity to win in Pasture-Raised, and our latest distribution milestone shows that we are well on our way to achieving that goal,” Phyllis

(Continued on page 28 )

Rats and mice accelerate the spread of at least 35 diseases that plague animal production

Left unchecked, rodent populations will expand rapidly, spreading disease to areas and animals

Rodents cause damage to facilities, increase energy costs and contaminate feed

Excellent for burrow baiting, clean out, or any indoor baiting (when animals aren’t present)

Meal bait is an exclusive oat and grain formula designed for maximum rodent acceptance

MEAL BAIT is specifically formulated for livestock producers, especially poultry facilities where rodent populations are high and biosecurity is critical

(Continued from page 22)

Rothschild, chief marketing officer at Pete & Gerry’s, said. “We feel the time is right to launch this campaign to build on our success so far this year. The story we’re telling is fun and memorable, but also resonates with consumers who care about animal welfare and high- quality foods.”

“The egg category is rife with quaint pastoral imagery and beautifully cracked eggs, regard-

ATHENS, Ga. — A properly designed circulation fan system can provide a grower with a variety of benefits. During cold weather, circulation fans can transfer hot air collecting near the ceiling to bird level, increasing floor temperatures and decreasing heating costs. Circulation fans can also help move warm air from the center of a house

towards the cooler areas near the side and end walls, thereby improving house temperature uniformity

and again potentially lowering heating costs. Last but not least, a well-designed circulation fan

less of whether or not the eggs came from hens that actually lived such an idyllic life,” Bethany Maxfield, Humanaut creative director, said. “By creating tension between the kinds of images consumers are used to and the overthe-top wild animals in the campaign, we were able to create an unexpected splash of humor for the brand and show how well Pete & Gerry’s Pasture-Raised hens actually live.”

system can increase air movement at floor level resulting in drier litter, lower ammonia levels, and overall improved bird performance and health.

As is the case with a tunnel ventilation system design, there is more to designing an effective circulation fan system than scattering a few nondescript circulation fans around a house. For instance, a tunnel ventilation system needs to be able to exchange a specific amount of air each minute. Likewise, a circulation fan system needs to be able to mix a specific volume of air each minute.

A tunnel ventilation system requires tunnel fans that have a

(Continued on page 30)

(Continued from page 28)

number of important characteristics (i.e., discharge cone, 54”+ diameter air moving capacity). Likewise, a circulation fan system requires fans that meet a number of equally important characteristics (i.e., size, air moving capacity, construction, wide guard spacing). Both systems require the fans to be installed in a specific area of a house and in a specific fashion in order to generate the desired air flow pattern within the house. Finally, as is the case with a tunnel ventilation system, a circulation fan system needs to be designed to be able to generate a specific air velocity at floor level if benefits are to be maximized.

Numerous field studies conducted by the University of Georgia Poultry Science Department have documented that circulation fan system benefits appear to be maximized if it can move least 20 percent of a house’s volume each minute. For example, a 40’ X 500’ house with an average ceiling height of 9 ½’ has a

volume of 190,000 cubic feet. To be able to mix 20 percent of the house volume each minute, a circulation fan system should be capable of moving at least 38,000 cubic feet of air each minute. For a 60’ X 600’ house with an average ceiling height of 9 ½’ (342,000 cubic feet) a circulation fan system should be capable of circulating at least 68,400 cubic feet of air each minute (Figure 1).

The required number of circulation fans can be calculated by dividing the total circulation fan system capacity by the air moving capacity of an individual circulation fan at a static pressure of 0.00”. For instance, if a circulation fan moves 5,600 cfm @ 0.00”, at least seven would be required in the 40’ X 500’ house and at least 12 in the 60’ X 600’ house.

For most houses, the most appropriate circulation fan is a 24”, 1/3 hp fan that moves approximately 6,000 cfm (Figure 2). The fan should have an orifice around the prop which helps to produce a narrower air jet which maximizes the distance the fan will move air along the ceiling.

In addition, a narrow jet of air moving along the ceiling at the center of a house helps to create a return air flow pattern along the side walls and floor (Figure 3). To minimize power usage, circulation fans

should have an energy efficiency rating of 16 cfm/watt or greater.

Circulation fans should generally be evenly spaced along the center line of a house, within few inches of the ceiling, directed to blow air towards the end walls of the house. The circulation fans should be installed so that they are held in a position where they are blowing air parallel to the ceiling and prevented from blowing air towards the floor. In most circumstances, circulation fans will need to be installed between 40’ to 60’ on center. It is generally recommended against installing circulation fans in a “racetrack” pattern where the fans are installed in two rows, positioned near the side walls, blowing air in opposite directions. Positioning circulation fans near the side walls tends to create excessive air movement near the side walls, potentially creating drafty conditions for the birds near the side walls. In addition, generating excessive air movement near the side wall disrupts inlet air flow patterns, thus preventing the cool incoming air to be fully warmed before moving down to floor level. Last but not least, placing circulation fans near the side may not result in the hot air collecting near the ceiling peak being fully mixed with the rest of the air in the house.

In houses utilizing partial house brooding, the circulation fans in the brooding area should be installed so that half the circulation fans are directed to blow air towards the end wall and the other half towards the brooding curtain. The circulation fans that are near the center of the brooding area, blowing in opposite directions, should be positioned approximately 20’ apart (Figure 4). Ideally, circulation fans would be positioned within 40’ of the end wall and brooding curtain. On the non-brooding end all the circulation fans should be directed to blow air toward the non-brooding/tunnel fan endwall. The first circulation fan should be positioned within 20’ of the brooding curtain to encourage the movement of warm air from the brooding end to the non-brooding end of the house.

The goal when designing a circulation fan system is to create a continuous high-velocity air stream along the peak of the ceiling moving air from the center of the house to the ends where it reverses direction and moves back towards the center of the house along the side walls and the floor at much lower velocity (100 - 150 ft/min). By creating a “whole house” circulation pattern, variations in house temperature and air quality tend to be minimized. In addition, the air movement over the litter created by a well-designed circulation fan system will lead to drier litter, reduced ammonia levels, and in turn an overall improvement in bird performance and health.

Michael Czarick is an Extension engineer and senior public service associate with the University of Georgia College of Agricultural and Environmental Sciences Cooperative Extension.

At Neogen®, we believe today’s global poultry producers find value in being stewards of the environment. And we wanted to help!

Introducing the New EVO Line of Phosphate-Free Detergents: products that provide maximum cleaning while producing minimal environmental impact.

• CHLOR-A-FOAM™ EVO: High foaming, chlorinated detergent for cleaning prior to disinfecting

• ACID-A-FOAM™ EVO: A rotational product, ideal for removing scale build-up from fan blades, trays, buggies, and other hatchery equipment

• CHLORINATED TRAY WASH EVO: Non-foaming, chlorinated tray wash liquid

• ACID TRAY WASH EVO: Non-foaming, acid-based tray wash liquid to descale spray nozzles and heating coils in tray wash machines

• FARM-FOAM EVO: High foaming, non-chlorinated detergent for cleaning prior to disinfecting