CORPORATE HEADQUARTERS

POULTRY TIMES

PO Box 1338

Gainesville, GA 30503

PH | 770-718-3443

FAX | 770-532-4894

POULTRY TIMES STAFF

LAUREN HUNTER

Publisher 770-718-3443 laurenhunter@poultrytimes.com

DAVID B. STRICKLAND

Editor 770-718-3442 dstrickland@poultrytimes.com

GIANNA WILLCOX

Multimedia Journalist 770-718-3421 giannawillcox@poultrytimes.com

STACY LOUIS

Senior Account Executive 770-718-3445 slouis@poultrytimes.com

DEVIN CANTEL

Account Executive 770-535-6394 devincantel@poultrytimes.com

JANICE SISK

Sales Assistant 770-718-3439 jsisk@poultrytimes.com

RACHEL DANFORD

Digital Specialist 678-447-0702 rdanford@poultrytimes.com

Be sure to pay a visit to these esteemed sponsors of the Poultry Times, recognizing them as vital contributors to the industry who greatly appreciate your support.

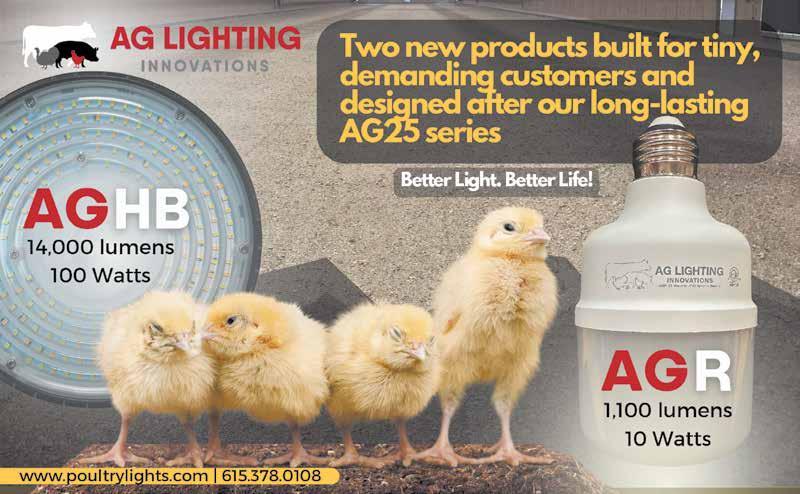

AG Lighting Innovations l 19 615-378-0108; www.poultrylights.com

Big Dutchman l 15 616-582-4000; www.bigdutchmanusa.com

Creekview Mfg. l 18 717-445-4922; https://creekviewmanufacturing.com

Eagan Mfg. l 12 870-878-6805; www.eaganmfg.com

Farmer Boy Ag l 20 717-866-7565; www.farmerboyag.com

FPM Inc. 26 402-729-2264; www.fpmne.com

Gas-Fired Products l 29 800-849-7311; www.spaceray.com

Hog Slat l 3 800-949-4647; www.hogslat.com

IMPEX l 24 770-534-1590; www.impex.nl

Innovative Poultry Products l 22, 24 803-571-3345; www.innovativepoultryproducts.com

Kelley Mfg. l 16 800-444-5449; www.kelleymfg.com

Kuhl Corp. 28 908-782-5696; www.kuhlcorp.com

Publication Disclaimer

Poultry Times (USPS 217-480) ISSN 0885-3371 is published biweekly, 345 Green Street, N.W., Gainesville, GA 30501. Telephone 770-536-2476; Fax 770-532-4894. Postage paid at Gainesville, Georgia 30501. Poultry Times assumes responsibility for error in first run of an in-house designed ad only. Advertisers have ten (10) days from publication date to dispute such an advertisement. After ten (10) days, ad will be deemed correct and advertiser will be

Kunafin (The Insectary) l 28 800-832-1113; www.kunafin.com

L.B.White l 14 608-783-5691; www.lbwhite.com

Lewis Brothers Mfg. l 11 912-367-4651; www.lbmfg.com

Merck Animal Health 32 800-521-5767; www.merck-animal-health.com

Overdrive Lighting l 23 800-657-0509; www.aglights.com

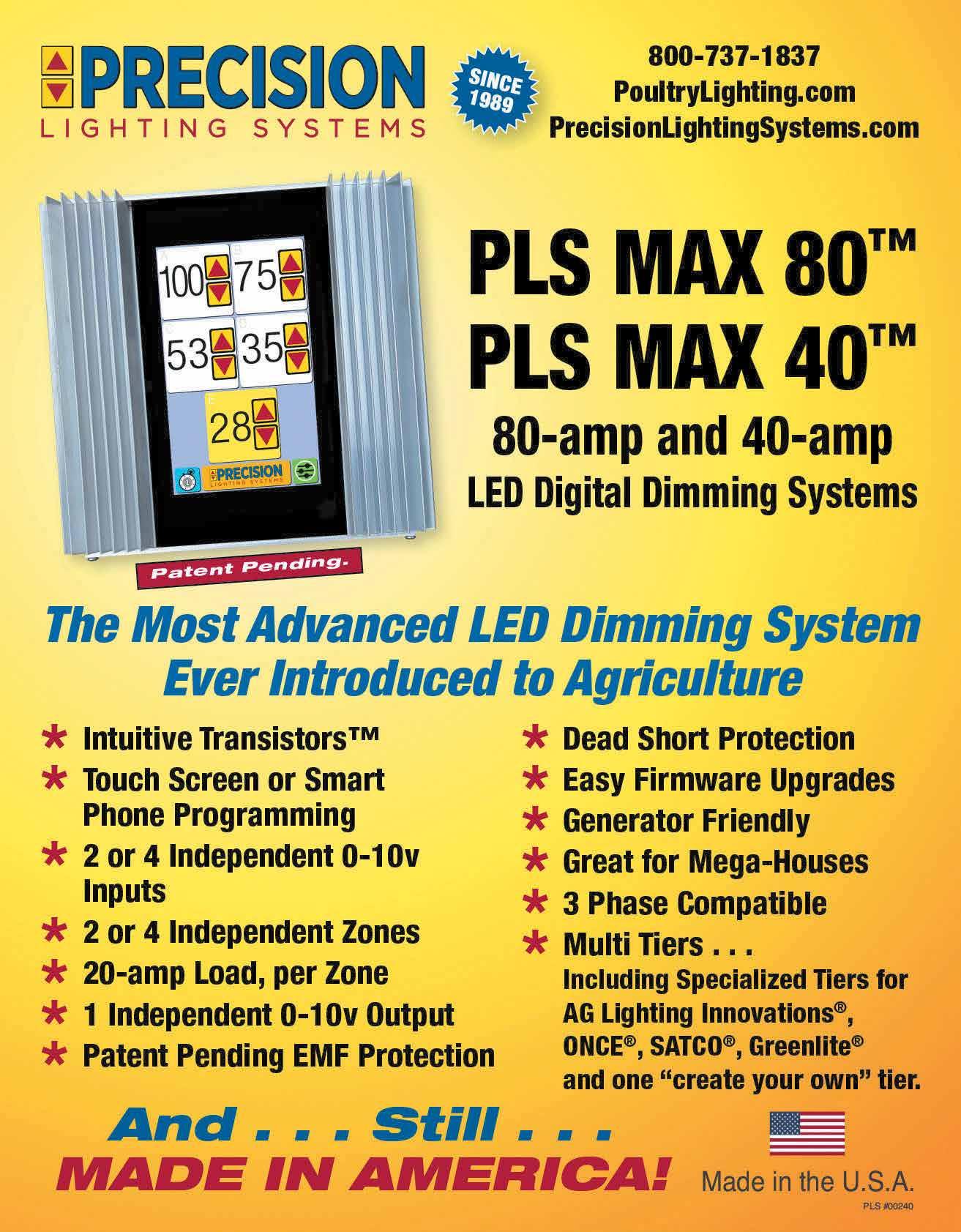

Precision Lighting l 1, 2, 13, 17 800-737-1837; www.poultrylighting.com

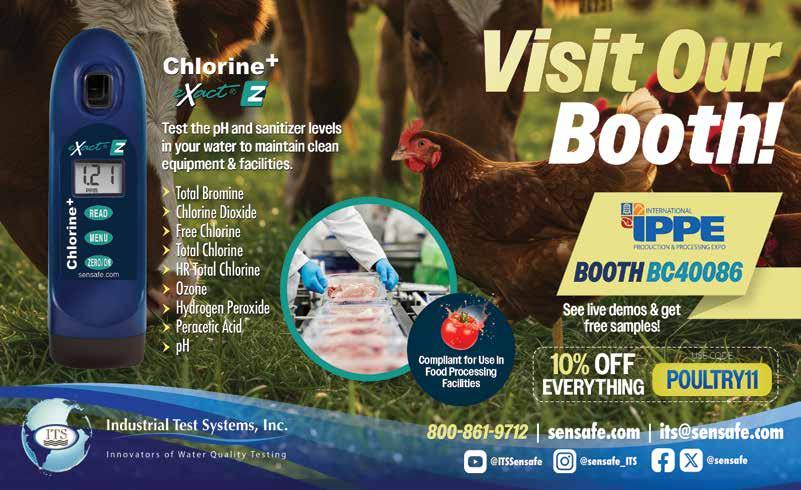

Sensafe l 21 803-329-9712; https://sensafe.com

Stone Bank l 16 833-253-2265; www.stonebank.com

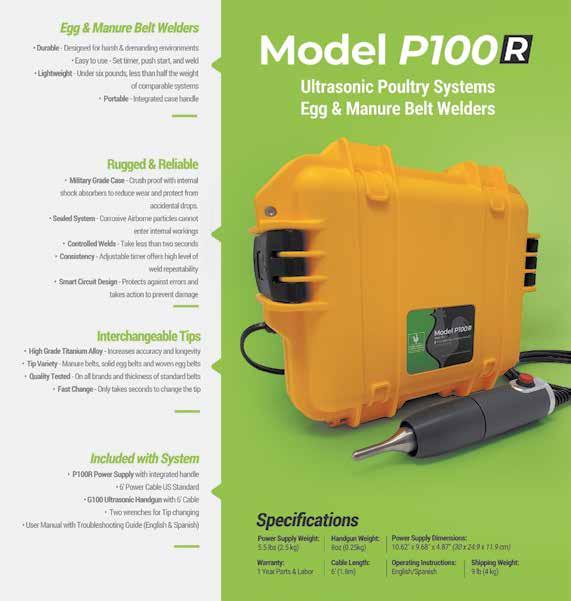

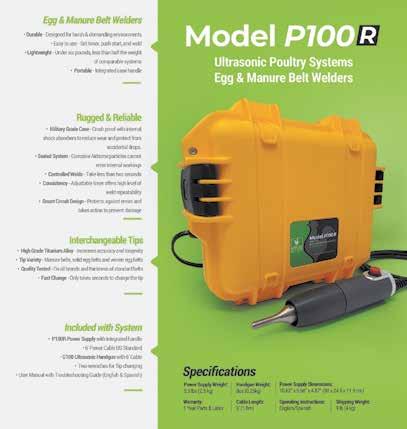

Ultrasonic Poultry Systems l 18 614-549-0627; https://ultrasonicpoultrysystems.com

Uzelac Industries l 25 414-529-0240; www.uzelacind.com

Walinga USA, 31 800-466-1197; www.walinga.com

Weightech, 11 800-457-3720; www.weightechinc.com

charged accordingly. Proofs approved by advertiser will always be regarded as correct.

Subscriptions: Surface mail in U.S., $25.00 for one year, $45 for two years and $65 for three years. Business or occupation information must accompany each subscription order. Change of Address: Postmaster, report change of address to Poultry Times, P.O. Box 1338, Gainesville, GA 30503. Companion Poultry Publications:

A Guide to Poultry Associations; Poultry Resource Guide. The opinions expressed in this publication by authors other than Poultry Times staff are those of the respective author and do not necessarily reflect the opinions of Poultry Times. Advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

© 2025 Metro Market Media Gainesville, Georgia 30503

SEP 9-11 — LIQUID FEED SYMPOSIUM, Hilton Fort Worth, Fort Worth, Texas. Contact: American Feed Industry Association, 2101 Wilson Blvd., Suite 810, Arlington, Va. 22201; Ph: 703-524-0810; www.afia.org.

SEP10-12 — CALIFORNIA POULTRY FEDERATION ANNUAL CONFERENCE, Monterey Plaza Hotel, Monterey, Calif. Contact: California Poultry Federation, 4640 Spyres Way, Suite 4, Modesto, Calif. 95356 Ph: 209-576-6355; Email: info@cpif.org; www.cpif.org

SEP 15-17 — WORLD FERTILIZER CONFERENCE, Marriott Marquis, Washington, D.C. Contact: The Fertilizer Institute, 4201 Wilson Blvd., Suite 700, Arlington, Va. 22203; Ph: 202-962-0490; Email: info@tfi.org. www.tfi.org.

SEP 15-18 — NPFDA FALL MEETING, Omni Providence Hotel, Providence, RI. Contact: National Protein & Food Distributors Association, 2014 Osborne Road, Saint Marys, Ga. 31558; Ph: 912-439-3603; www.npfda.org.

SEP 18-19 — ENVIRONMENTAL MANAGEMENT SEMINAR, Hilton Sandestin Beach Golf Resort & Spa, Destin, Fla. Contact: USPOULTRY, 1530 Cooledge Road, Tucker, Ga. 30084; Ph: 770-493-9401; seminar@uspoultry.org; www.uspoultry.org.

SEP 23-25 — EMI 2025 FALL CONFERENCE (Protein Outlook), Gaylord Texan Resort & Convention Center, Grapevine, Texas. Contact: Express Markets Inc., 6510 Mutual Drive, Fort Wayne, Ind. 46825; Ph: 260-407-2728; E-mail: emi_info@expressmarketsinc.com; www.expressmarketsinc.com/events/.

WASHINGTON — The outlook for U.S. corn production is on track to be at a record level, the most recent World Agricultural Supply and Demand Estimates report indicates.

The market forecasting WASDE report, considered a “gold standard” for agribusiness, is prepared monthly by the World Agricultural Outlook Board and is released by USDA.

“American farmers feed and fuel the world, and this report equips them with the trusted, timely data they need to make informed business decisions,” Brooke L. Rollins, U.S. agriculture secretary, said.

“Corn production for 2025/26 is forecast at a record 16.7 billion bushels, up 1 billion from last month with a 1.9 million-acre increase in harvested area and higher yield,” the report says. “If realized, this total would be 1.4 billion bushels more than the prior record set in 2023/24. The season’s first survey-based corn yield forecast, at a record 188.8 billion bushels per acre, is 7.8 bushels higher than last month’s projection.”

Feed and residual use of corn is estimated in the report at 6.1 billion bushels stemming from a larger crop and lower expected prices, which is an increase of 250 million bushels. Total corn usage for the year is estimated at 16 billion bushels, an increase of 545 million bushels.

“The forecast for 2025 red meat and poul-

try production is reduced from last month,” the WASDE report notes. “Broiler production is raised reflecting recent production and hatchery data. Turkey production is reduced on recent hatchery data indicating lower production in the fourth quarter of the year. Egg production is lowered on reported data through June and slower growth expected in the second half of the year based on recent hatchery data.”

Broiler and turkey exports estimates are increased based on data through June, the report added.

Regarding prices, turkey prices are up, and broiler and egg prices are down, the WASDE says.

“Broiler price forecasts for 2025 are reduced for the second half of the year based on recent price declines through early August, with reduced prices carrying into next year,” the report said. “Turkey prices are raised for the second half of 2025 and 2026 based on recent price strength and support from tight supplies of red meat. The egg price forecast for 2025 is reduced on lower fourth quarter prices reflecting recent prices and improved shell egg inventories. The egg price forecast in 2026 is unchanged.”

For U.S. soybeans the average price for the year is estimated at $10.10 a bushel, and the soybean meal price is forecast in the report at $280 per short ton, which is a decrease of $10.

The National Corn Growers Association is urging Congress and the USDA to increase mar-

kets to assist corn growers who are struggling with the record-low prices noted in the WASDE report.

“Corn growers are already marketing their corn for extremely low corn prices, and this massive projected corn supply without market-based solutions to increasing corn demand is already causing corn prices to fall further,” Kenneth Hartman Jr., NCGA president and an Illinois farmer, said. “Because we need markets fast for this supply, we are redoubling and intensifying our call for Congress to pass pending E15 legislation that will allow for year-round consumer access to higher blends of ethanol and for the Trump administration to quickly broker deals that will open new foreign markets for corn.”

The association adds that an increase to 15 percent ethanol year-round would an immediate boost for corn demand.

“This solution comes at no cost to consumers, requires no additional infrastructure developments and would generate demand for an additional 457 million bushels of corn, according to NCGA estimates,” the group said, adding a push to, “Remove foreign and domestic barriers to corn production, trade, and innovation. U.S. farmers have been promoting these actions for years — they and rural economies need action now.”

“My family survived the 1980s farm crisis,” Hartman added. “I don’t want my daughter to be talking about the 2020s farm crisis in 40 years. The situation is dire, and new market demand is the only way we are going to dig out of this.”

“We are pleased that the court has acknowledged EPA’s deliberate determination that the EPCRA reporting exemption is appropriate. This common-sense ruling settles an issue that has spanned more than 20 years

Nath Morris,

USPOULTRY president

WASHINGTON — The U.S. District Court for the District of Columbia recently issued an order that confirms the air emission reporting exemption for the natural breakdown of farm animal waste. The exemption was affirmed under EPCRA (the Emergency Planning and Community Right-to-Know Act) and issued in June 2019 by the U.S. Environmental Protection Agency.

The court added that the exemption is appropriate because of the connection of EPCRA and the CERCLA (the Comprehensive Emergency Response, Compensation and Liability Act).

This decision comes more than 20 years since the U.S. Poultry & Egg Association, the National Chicken Council and the National Turkey Federation sent a formal request to EPA regarding the emission reporting requirement of ammonia emissions under EPCRA and CERCLA. This request noted that the programs were not meant to cover naturally occurring releases into the air from animal waste breakdown.

USPOULTRY, the National Cattlemen’s

Beef Association, the American Farm Bureau Federation and the National Pork Producers Council intervened after an environmental group coalition filed a motion that challenged the exemptions.

“We are pleased that the court has acknowledged EPA’s deliberate determination that the EPCRA reporting exemption is appropriate,” Nath Morris, USPOULTRY president said in an announcement. “This common-sense ruling settles an issue that has spanned more than 20 years and rightfully removes what would be nothing more than an unnecessary paperwork exercise for farmers and ranchers across the U.S.”

The National Cattlemen’s Beef Association also commented on the court’s ruling on what it describes as affirming protections “from onerous and unnecessary air emissions reporting requirements.”

“CERCLA and EPCRA were intended to address the worst industrial and toxic chemicals, not govern family farms and ranches,”

Kaitlynn Glover, NCBA executive director of natural resources, said. “This decision affirms that family cattle producers should not have to file reports for a natural, biological process under a law meant for significant chemical contaminants.”

“NCBA stepped up to protect family farms and ranches through this litigation and we are pleased that the federal district court has brought clarity to this decades-long discussion,” Glover added.

The NCBA also noted that the laws were intended to “address massive, severe chemical spills and environmental contaminants. Unfortunately, these laws have been weaponized by animal rights activists seeking to target family farms and ranches.”

The National Pork Producers Council adds that this ruling is a “significant victory in its long-running efforts.”

“NPPC and other livestock groups have been fighting activists over this issue since January 2009 when the Bush administration required livestock farms to file reports to emergency authorities over the routine emissions from livestock farms,” the council said. “The debate over these emissions dates back far earlier — when activist groups such as the Waterkeeper Alliance made them a centerpiece of its campaign against the U.S. pork industry.”

Regarding this most recent court decision, the NPPC notes that the court agrees with it and the EPA, “that since Congress passed the Farm Act, no reporting was necessary, making this a huge win for U.S. pork producers.”

DAVID B. STRICKLAND

ATLANTA — The 2026 International Production & Processing Expo is setting a record pace to become the largest in the trade show’s history.

The trade show floor is currently at more than 629,000 square feet, with more than 1,130 exhibitors scheduled, with approximately five months remaining until “show time.” This is already a gain over last year’s 598,000-plus square feet of exhibit space.

“Ninety-five percent of the show floor has been booked, and we are excited about all that will be available for attendees to see and experience at the 2026 IPPE,” show organizers noted.

Next year’s Expo will mark the U.S. Poultry & Egg Association’s 78th annual International Poultry Expo; and it will also be the 14th annual event where the American Feed Industry Association’s International Feed Expo, and the Meat Institute’s International Meat Expo, all join together to form the IPPE.

The annual exposition is the premier event for those involved in the poultry, egg, animal feed, and meat industries.

“IPPE attendees will discover real-world solu-

tions, watch cutting-edge equipment in action and network with top decision-makers from every corner of the supply chain,” show organizers added.

In addition to the exhibit halls, more than 80 hours of educational session programming will be available to attendees with topics that run the gamut from safety to technology to market trends.

The Expo also continues to expand its international attendee representation. Last year, of the more than 30,500 registered attendees, more than 8,900 were from 129 different countries.

The 2026 IPPE will be at the Georgia World Congress Center in Atlanta, Ga. Show dates and hours will be:

• Tuesday, Jan. 27: 10 a.m.-5 p.m.

• Wednesday, Jan. 28: 9 a.m.-5 p.m.

• Thursday, Jan. 29: 9 a.m.-3 p.m.

Registration opens Oct. 6. For more information, visit www.ippexpo.org.

Ninety-five percent of the show floor has been booked, and we are excited...

GIANNA WILLCOX

MULTIMEDIA JOURNALIST

GIANNAWILLCOX@POULTRYTIMES.COM

TUCKER, Ga — Biosecurity is the first line of defense in poultry production, and in a world where disease threats are rising — it’s no longer optional. It helps protect bird health, human safety, and farm profitability. However, implementing biosecurity protocols on poultry farms is challenging because of human behavior, facility design, and resource limitations. To strengthen on-farm practices, the U.S. Poultry & Egg Association is offering producers information on “Infectious Disease Risk Management: Practical Biosecurity Resources for Commercial Poultry Producers” through its Learning Management System. Producers will get an overview of comprehensive biosecurity practices, cleaning and disinfection, pest control, and so much more. The information is meant to help with the development of effective biosecurity practices and can be used as a tool for program creation, personnel training and education.

The “Infectious Disease Risk Management: Practical Biosecurity Resources for Commercial Poultry Producers” is available to USPOULTRY members under the “Featured” tab of the Learning Management System. For more information and to gain access to the Learning Management System, contact Matt Spencer at mspencer@uspoultry. org.

ZIPPY DUVALL American Farm Bureau Federation

WASHINGTON — U.S. farmers and ranchers are committed to growing high-quality agricultural products and safe, nutritious food for families near and far. Here in the U.S. and abroad, Americangrown means high quality and value. We know that our products can compete anywhere in the world, when barriers are removed. That’s why we are eager to see a boost in trade opportunities for U.S. farmers and ranchers with new and existing markets. Trade matters to farmers and ranchers because we need export markets to help us remain competitive and economically sustainable.

If we’re going to keep growing the food, fiber, and renewable fuel that our country needs for national security, we need to ensure that farms of all sizes have opportunities for growth. Agricultural trade can maximize the value of our products. For example, some cuts of meat are more popular in other countries, and a variety of fresh produce is grown for both consumers in the U.S. and abroad. When farmers have this variety of market opportunities, they can keep their businesses running and support jobs across our nation’s economy. Our agricultural trade helps to create jobs right here on American soil.

urging the administration to finalize new deals and to reach agreements with large agricultural markets like China.

The stakes are high when it comes to trade negotiations, and unfortunately, farmers and ranchers are often first to bear the brunt of retaliatory tariffs.

Did you know that more than 1 million full-time jobs are supported by U.S. agricultural exports?

According to USDA data from 2023, about half of those jobs were on the farm and the remaining half were across related industries like shipping, processing and storage. If we look at trade as a return on investment, agricultural exports double our returns, with every $1 of farm products sold overseas bringing back more than $2 in economic activity here in the U.S.

At Farm Bureau, we are grateful for the administration’s focus on achieving new trade deals with a commitment to making agriculture a priority. With the recently announced framework deals in the European Union, Japan, Indonesia, South Korea and the Philippines, in addition to recent deals with Vietnam and the United Kingdom, we see real opportunities for U.S. farmers and ranchers. We are

That’s why we consistently urge the administration to limit trade disruptions and work to resolve disagreements quickly. Farmers and ranchers, our employees, our families, our rural communities, and our fellow Americans across the country cannot afford to lose markets or the trading relationships we have built with our businesses over the years. One-fifth of U.S. agricultural products are exported, and behind those products are hundreds of thousands of hardworking Americans.

Let’s keep working to open new markets and strengthen our existing partnerships so that U.S. farmers and ranchers can keep leading the world in growing safe and sustainable food for families at home and around the world.

Let’s keep working to open new markets and strengthen our existing partnerships so that U.S. farmers and ranchers can keep leading the world in growing safe and sustainable food for families at home and around the world.

SILOAM SPRINGS, Ark. — CobbVantress LLC announces the appointment of three accomplished executives to its leadership team, adding that these strategic moves underscore its commitment to innovation, operational excellence, and sustainable global growth.

Will Sawyer has been promoted to vice president, global business operations and strategy. Since joining Cobb in December 2024 as managing director of global supply chain and strategy, Sawyer has been instrumental in advancing key initiatives across the organization. In his expanded role, he will lead global planning, marketing, communications, and IT — driving alignment and innovation across these critical business functions, Cobb said.

Sawyer brings industry expertise, having held senior leadership roles at Tyson Foods, most recently as senior director of strategy for the Poultry segment. His background also includes serving as lead industry analyst for animal porotein at CoBank and holding leadership roles at Rabobank. He began his career as a research analyst at Credit Suisse, building a strong foundation in financial and strategic analysis.

Dr. Matilde Alfonso joins Cobb as vice president, sales and technical services, bringing more than 25 years of strategic and technical leadership in the poultry industry. Most recently, she served as manager of veterinary technical services at Ceva Animal Health LLC. Her prior experience includes key leadership roles at Tyson Foods, including director of breeder and hatchery operations.

Alfonso’s extensive operational knowledge and global perspective will be pivotal in leading Cobb’s sales, technical services, quality assurance, and veterinary functions, the company added.

As Chris Lewellen, current vice president of finance and accounting, prepares to retire after 27 years of dedicated service, Leandro Farias will assume the role of managing director, finance and accounting.

Farias brings more than two decades of finance experience across the chemicals, automotive, food, and poultry genetics sectors. He joined Tyson in 2009 and later transitioned to Cobb-Vantress Brazil in 2015, where he has served as director of finance for operations in Brazil, Peru, and Colombia since 2019.

“I am excited to announce Will and Leandro’s new roles and also welcome Matilde to our leadership team,” Shelby Watkins, Cobb president, said. “Their combined experience, strategic vision, and leadership will be vital as we continue to scale our global operations and deliver exceptional value to our customers and partners around the world.”

Cobb Research Initiative

Cobb-Vantress also announces the recipients of the 2025 Cobb Research Initiative (CRI) grants. This year, seven innovative

KANSAS CITY, Mo. — State and local leaders joined Americold and CPKC executives recently to celebrate the grand opening of Americold’s new Import-Export Hub in Kansas City. The $100 million-plus investment marks a major milestone in Missouri’s growing logistics sector and reflects the state’s strategic advantage in supporting global food supply chains, the companies announced.

“Americold’s new facility is an exciting development for the Kansas City area and its thriving logistics sector,” Missouri Gov. Mike Kehoe, said. “Missouri’s affordability, strategic location, and access to infrastructure continue to encourage investment and job creation. We’re proud to see an industry leader like Americold choose our state while further strengthening the local economy.”

The 335,000-square-foot facility, developed in collaboration

with Canadian Pacific Kansas City (CPKC), is expected to create nearly 190 new jobs and will serve as a key hub for CPKC’s Mexico Midwest Express (MMX) service, North America’s only single-line rail service for refrigerated shippers between the U.S. Midwest and Mexico.

“This is more than infrastructure — it’s a fully integrated solution that connects food producers to consumers faster and more efficiently,” George Chappelle, Americold CEO, said. “By combining our cold storage capabilities

and food flow expertise with CPKC’s rail network through Kansas City, we’re creating a new North American cold chain that delivers real value to our customers. Simply put, we’ve unlocked a better way to move food.”

“This grand opening marks the realization of a shared vision,”

Keith Creel, CPKC president and CEO, said.“This facility is the first of many across our unrivaled North American network. By combining Americold with our secure, singleline cross-border service, we have created a new refrigerated supply

chain for our customers shipping food and other temperature-controlled products across Canada, the United States and Mexico.”

“Kansas City proudly welcomes Americold to our thriving business landscape,” Kansas City Mayor Quinton Lucas added.“With direct rail connectivity through CPKC and a talented local workforce, this new facility highlights how strategic partnerships can reshape industries and accelerate innovation. We’re excited to be at the center of that transformation.”

The project was supported by Missouri Partnership, the City of Kansas City, Economic Development Corporation of Kansas City, Missouri, KC SmartPort, the Missouri Department of Economic Development, Missouri One Start, Evergy, and Spire.

“Americold’s investment in Kansas City not only brings new jobs — it brings opportunity,” Tracey Lewis, president and CEO of the Economic Development Corporation of Kansas City, Mo., said.“This project strengthens our logistics infrastructure and creates path -

projects have been selected for funding.

The CRI is designed to advance the science of poultry genetics by fostering crossdisciplinary collaboration. These partnerships play a critical role in addressing key challenges — ranging from disease prevention and animal welfare to production efficiency and product quality, the company noted.

“This year marked a milestone for the CRI, with a record number of proposals submitted,” Dr. William Herring, Cobb vice president of research and development, said. “By combining cutting-edge technology with deep scientific expertise, we’re addressing the most pressing challenges in poultry production and advancing the future of genetics. We’re excited to see the impact these

ways for local talent to thrive in a fast-growing sector. It’s the kind of momentum we love to see for our city and our people.”

“Americold’s grand opening represents an exciting step forward for our transportation sector,” Michelle Hataway, director of the Missouri Department of Economic Development, noted. “We’re excited to see how this company’s investment will create new opportunities across the state.”

“It is always exciting when a company opens its doors in Missouri,” Subash Alias, Missouri Partnership CEO, added. “Americold is joining nearly 20,000 distribution and logistics companies in the state who are benefitting from Missouri’s central location, solid infrastructure, and low business costs.”

Lombardo as its first chief strategy officer

RIDGELAND, Miss. — Cal-Maine Foods Inc. announces the appointment of Keira Lombardo as the company’s first-ever chief strategy officer.

The creation of this role underscores CalMaine Food’s commitment to delivering longterm value through operational excellence, innovation, and deeper stakeholder engage-

ment, the company notes, adding that, as CSO, Lombardo will work with the senior leadership team to further accelerate and shape enterprise priorities — building on Cal-Maine Food’s leadership role in a rapidly changing marketplace.

where she played a key role in repositioning the company from a commodity protein producer to a branded, purpose-driven CPG business — leading functions across corporate affairs, people and culture, and stakeholder strategy.

Lombardo is a seasoned food and agriculture executive with more than two decades of experience leading transformation and growth across complex, multi-stakeholder food systems. She brings a performancedriven mindset grounded in purpose and a deep commitment to the people and principles that power a resilient, sustainable food supply — today and for the future, CalMaine said.

Lombardo most recently served as CEO of Dairy MAX, a large-scale dairy organization representing approximately 700 farm families across eight states. Under her leadership, Dairy MAX implemented an ROI-focused operating model, aligned its structure, talent, and strategic focus, and elevated dairy as a smart, affordable choice rooted in wellness, trust, and sustainability, the company added. Before joining Dairy MAX, she was a senior executive at Smithfield Foods,

Lombardo’s responsibilities at Cal-Maine Foods will include partnering on enterprise strategy, stakeholder engagement, corporate affairs, public relations, and digital integration. She will work to align the company’s internal vision with external priorities, ensuring that purpose, performance, and culture reinforce one another.

“Keira brings a rare combination of strategic discipline, stakeholder fluency, and food system insight to Cal-Maine Foods,” Sherman Miller, Cal-Maine Foods president and CEO, said.“Her leadership will support our ability to continue to execute our long-term strategy and leverage our disciplined capital allocation into meaningful stakeholder returns — partnering with the team to unlock new growth opportunities, navigate complexity, and strengthen our performance in a dynamic environment.”

“Cal-Maine Foods leads with scale and operational strength — and continues to evolve through innovation, discipline, and strategic focus,” Lombardo said. “I look forward to collaborating with the leadership team to build on that momentum and help drive long-term value across the business.”

ARLINGTON,Va. — Registration is now open for the American Feed Industry Association’s annual Equipment Manufacturers Conference, to be held Nov. 5-7 in Rancho Mirage, Calif. This year’s theme is “Winning Strategies for Workforce Protection and Management.”

“EMC is a unique forum for feed industry professionals to come together to discuss opportunities and challenges, foster camaraderie among the industry and support the next generation of leaders.We welcome attendees from all sectors of the animal food industry to join these important conversations,” Gary Huddleston, AFIA’s director of feed manufacturing and regulatory affairs, said. “This year’s theme of workforce protection and management is important and timely given workforce challenges in today’s manufacturing environment.”

This annual conference, hosted by AFIA’s Equipment Manufacturers Committee, focuses on updating the equipment sector of the feed industry on current issues and trends, providing an environment for learning from educational speakers and industry leaders and bringing the industry together to network. The conference

will also feature educational sessions on industry safety standards, updates from Washington, D.C., employee expectations and constraints and a panel discussion on today’s business opportunities.

The three-day event kicks off with an annual golf tournament, which raises money for the EMC Scholarship Fund, the association added.

The EMC scholarship fund provides scholarships for students pursuing a career in feed or grain sciences at seven universities.

Early-bird registration runs through Oct. 3, with a discounted rate for AFIA members. For more information and registration, visit www. afia.org/events/emc/.

SALISBURY, Md. — On Maryland’s Lower Eastern Shore, more than 47 percent of households struggle to afford the state’s high cost of living and don’t earn enough to afford necessities, according to the 2025 ALICE Report.

As part of a commitment to help ease that burden for its Lower Shore neighbors, Perdue Farms and its associates have delivered $302,955 to the United Way of the Lower Eastern Shore since December 2024.The con-

tribution includes associate campaign pledges, investments from the company, and the Franklin P. and Arthur W. Perdue Foundation, the charitable giving partner of Perdue Farms.

throughout the United Way network, helping deliver opportunities for all neighbors to thrive.”

Give every hen a seat at the dinner table

“Our associates are the heart of our company, and they care deeply about the well-being of their neighbors,” Kevin McAdams, Perdue Farms CEO, said. “We have been long-time supporters of the United Way mission. I’m proud of the impact our associates have made through their generous support of local organizations making lasting positive change in the communities where our associates call home.”

Perdue’s support of the United Way of the Lower Eastern Shore aligns with its “Delivering Hope To Our Neighbors®” outreach, which focuses on improving quality of life and strengthening communities where its associates live, work, and raise their families.

Perdue employs more than 2,220 associates on the Lower Eastern Shore, the company added.

“We are honored and thankful for the leadership Perdue demonstrates in helping the local community through our partnership, especially in our most recent 80th anniversary year,” Pam Gregory, United Way of the Lower Eastern Shore president and CEO, said. “Thousands of our neighbors are living paycheck to paycheck and making tough choices every month. Perdue’s commitment to supporting us is seen all year and inspires others to get involved. Perdue is a respected leader

Perdue remains the number one contributor to the annual United Way of the Lower Eastern Shore campaign, which allows associates to deduct funds from their paychecks to support United Way partner agencies, the company said, adding that it and its associates have contributed more than $5 million to the United Way of the Lower Eastern Shore since 1994. Perdue’s entire donation remains on the Lower Shore to support crucial programs and services provided by 43 local agencies through nearly 80 programs annually.

SILOAM SPRINGS, Ark.

— Simmons Foods announces a new record for the M.H. (Bill) Simmons Memorial Scholarship program. In 2025, 118 students were awarded a total of $215,800 in scholarships — the largest class and highest amount in the program’s 46-year history. These scholarships support the children of Simmons team members and growers as they pursue vocational, technical, and college degree programs, the company said, adding that the program was established in 1979 by Mark

The patented DuoChain system increases feed space for female breeders, improving flock uniformity and performance. Its efficient design allows more birds to have feed space, providing better production results for more aggressive eaters.

Contact one of our authorized distributors today provide a more uniform feeding solution for your breeder flock.

Simmons in memory of his father and company founder, M.H. (Bill) Simmons, and has since become a cornerstone of Simmons’ commitment to education and opportunity.

“This year marks an exciting milestone,” Mark Simmons, Simmons Foods chairman of the board, said. “Each scholarship represents an investment in the future – not just of these students, but of the families and communities we serve. We’re incredibly proud of this year’s record-setting class and the potential they carry forward.”

Since its inception, the M.H. (Bill) Simmons Memorial Scholarship has awarded more than $1.8 million to over 1,400 students.The 2025 class of high school graduates includes many first-generation college students.

To help celebrate their achievements, each scholarship recipient received a personal note from Mark Simmons and Todd Simmons, CEO, a yard sign to proudly display, and recognition on banners at Simmons facilities that feature their names and the names of their par-

ents, the company added. Beyond the scholarship, Simmons Foods offers a variety of educational and professional development opportunities, including paid internships, tuition reimbursement, on-the-job training, Career Leadership, and the People First Leadership Experience.

as part of Microsoft’s global $23 billion gaming business, the company said, adding that her portfolio also includes strategy, product and engineering, marketing, and commercial planning and operations. She joined Microsoft in 2017 as a corporate vice president and prior to Microsoft held multiple leadership roles at T-Mobile and McKinsey & Co.

SPRINGDALE, Ark. — Tyson Foods Inc. announces the appointment of Sarah Bond as a new independent director on its board, effective immediately.

As Xbox president, Bond leads the organization driving Xbox’s innovation and growth across hardware, software and services

Foods,” John H. Tyson, company chairman, said. “We are confident that her unique expertise will help us continue to grow and serve our customers, our team members, and our shareholders.”

With deep consumer technology experience, Bond sits on the board of the University of Southern California School of Cinematic Arts and is vice chair of the board of the Entertainment Software Association, the company added. Bond has a bachelor of arts in economics from Yale University and a master of business administration from Harvard Business School.

“Sarah is dynamic and passionate, with proven management strength, and her energy and personality are a wonderful fit for our culture. As our management team, members of the board and the Tyson family got to know Sarah, we immediately felt that she would be a tremendous addition to Tyson

“Tyson Foods is a world-class food company with iconic brands, and I am delighted to join the board and support the company as it continues to execute its long-term growth strategy with customers and consumers,” Bond said.

The appointment of Bond increases the number of directors on the Tyson Foods board to 16, with 10 independent directors.

In addition to Tyson and Bond, others currently serving on the Tyson Foods Board of Directors are Les R. Baledge, Mike Beebe, Maria Claudia Borras, David J. Bronczek, Donnie King, Maria Martinez, Kevin M. McNamara, Cheryl S. Miller, Kate B. Quinn, Jeffrey K. Schomburger, Barbara A. Tyson, John R. Tyson, Olivia Tyson and Noel White.

CoBank: Can largescale solar installations coexist with ag in rural U.S.?

DENVER — Local opposition to utility-scale solar installations in rural areas is growing following the rapid pace of new solar developments in recent years. Concerns about land use in areas largely dominated by agricultural production are fueling much of the community-level resistance, analysts with CoBank noted, adding that, with crop production revenue currently under intense pressure and subject to annual volatility, some landowners are welcoming the more consistent revenue advantages of solar land-lease payments. But wider opposition could stymie additional solar developments in rural areas, slowing growth in the U.S. energy supply.

According to a new report from CoBank’s Knowledge Exchange, solar expansion could deliver the fastest, most affordable means for increasing the nation’s razor-thin

energy reserves while driving new revenue streams for rural communities. However, success will be dependent on regional policy and site planning guidelines that ensure the local communities’ needs and interests are prioritized. The report is the first in a series of upcoming research articles and part of “The New Golden Age of Electricity” digital hub about rising energy scarcity and securing future power supply for rural America.

“Concerns surrounding the pace of solar developments in rural areas and the implications for land use in agricultural regions are warranted,” Teri Viswanath, CoBank lead power, energy and water economist, said. “But there are guardrails to reduce the risk of land use tensions and other conflicts that would enable landowners and rural communities to capture the financial benefits of solar projects without displacing or disturbing agriculture farmland.”

Growing resistance to solar installations in rural communities is likely in response to the speedy development that has already taken

Whether it be windrowing to produce a pathogen & insect reduced bedding to grow a top performing flock of BIRDS soft fluffy bedding without the need to decake or add shavings, the equipment to fit your operation. We have various models, sizes and options to fit your needs. Keep in mind, our goal is customer service, quality equipment and of course the BIRDS.

place and concerns about what future construction might look like, CoBank added. More than one-half of all U.S. solar installations have materialized since 2020, with 25% of that development occurring since the passage of the Inflation Reduction Act in 2022.

Solar energy generation can be installed at a rate five times faster than all other new electricity sources combined and remains the lowest cost solution to expanding energy supplies, even without government subsidies, CoBank noted. While federal policy has recently become much less supportive of renewable energy and tax credits are now limited, the costs of solar development remain favorable. The biggest headwind for expanding solar energy production is local opposition.

A recent analysis by USA TODAY found that around 15 percent of counties in the U.S. have some form of restriction on building new

utility-scale solar energy projects. This includes outright bans, zoning restrictions, specialized land-use rules or political stonewalls. At least 395 local restrictions across 41 states, in addition to 19 statelevel restrictions, are so severe that they effectively block renewable development in these areas. In rural areas, solar development occurring on prime farmland has had an outsized negative influence from the community perspective, CoBank noted. To rectify that trend, American Farmland Trust and the American Farm Bureau have recommended a set of guardrails that would prevent the solar industry from siting developments on prime agricultural land. Those recommendations include prioritizing solar power on shared agricultural land or marginal and brownfield sites, offering a more acceptable pathway for rural communities and landowners to capture the benefits of tax revenue and lease payments. The report also notes that economies of scale and high costs are major reasons why simply installing solar on exist-

ing rooftops is not a feasible answer. Successful efforts to balance local community interests with solar development have the potential to pay off handsomely. According to data collected by the American Clean Power Association, a recurring $739 million came back to communities last year in the form of state and local taxes and land-lease payments.

“Regardless of the pace of solar development ahead, future installations will inevitably affect local communities so more engagement from the solar industry is needed,” Viswanath said. “Strengthening partnerships with agricultural stakeholders and implementing effective land management strategies will be critical to mitigating challenges and gaining acceptance. Solar power is essential for meeting near-term demand growth, and rural America can play a key role in this while diversifying farm income and benefiting local communities through additional tax revenue.”

TUCKER, Ga. — The U.S. Poultry & Egg Association has released the second edition of its North America Commercial Waterfowl Animal Welfare Guidelines for Ducks and Geese,

reflecting the organization’s ongoing commitment to sustainable duck population management and effective conservation practices.

To protect both wildlife and industry interests, the USPOULTRY Duck Council reviews and updates these guidelines every two years.

The updated edition outlines recommended practices in four key areas: food safety, animal welfare, environmental stewardship and biosecurity.While not intended as a comprehensive animal well-being manual, these guidelines are designed to be adaptable across diverse production systems and industry scenarios.

The Duck Council is composed of member companies dedicated to producing and processing premium duck and goose products.

Serving as a unified voice for the industry, the council works to establish best practices, address regulatory matters, and, when needed, sponsor research aimed at expanding duck and goose consumption.These efforts also drive innovation and continuous improvement in both live production and processing technologies.

“Regularly updating our guidelines ensures that we are not only safeguarding the health and sustainability of duck production, but also supporting the industry with the latest best practices,” Drey Frey, Culver Duck Farms, Duck Council chair, said. “By working together as a council, we can address emerging challenges, adapt to evolving science and strengthen our

commitment to the industry.”

For more information, visit https://www.uspoultry.org/duck-council/.

JBS USA enters agreement to build its largest U.S. bacon and sausage site in Iowa

GREELEY, Colo. — JBS USA announces it has reached an agreement to purchase a production facility in Ankeny, Iowa, with plans to build out the largest ready-to-eat bacon and ready-to-eat sausage plant in the company’s U.S. portfolio.The facility was previously owned and operated by Hy-Vee.

The 186,000 square-foot facility will be transformed to produce fully cooked bacon and sausage products. The location previously

Tips for Manure,

and

produced other types of food for Hy-Vee stores. Due to the type of work involved, JBS is looking to hire former employees who previously worked at the facility for the retailer. After the initial capital investments and construction are complete, the plant is expected to be operational by mid-2026 and to create approximately 400 jobs when all phases of the project are finished, the company announced.

“Today’s announcement aligns with our long-term strategy of offering more value-added and prepared foods products to meet the needs of our customers and consumers,” said Wesley Batista Filho, JBS USA Chief Executive Officer.

“We are proud to grow our operations in Iowa, where we already operate four production facilities, with another expected to break ground later this year.”

In May, the company announced its intention to build a state-ofthe-art fresh sausage production facility in Perry, Iowa. JBS also operates plants in Council Bluffs, Marshalltown and Ottumwa.

“This facility in Ankeny will not

only expand our prepared foods business in the U.S., it will also benefit from synergies and strategic supply of product from our other plants in the region,” Rick Foster, head of JBS USA Prepared Foods, said.

In 2021, JBS USA opened a fully cooked bacon facility in Moberly, Mo., which has already been through an expansion. In Perry, the fresh sausage plant will provide raw material to this new facility, allowing the company to produce fully cooked sausage items in addition to bacon, supporting ongoing

efforts to meet increasing customer demand for these types of products.

With a focus on supporting rural America and investing in its team members, JBS USA will offer its signature Hometown Strong and Better Futures programs in Ankeny, the company added.Through Hometown Strong, the company is investing significantly in rural communities across the U.S. and Canada, supporting infrastructure, childcare, housing, schools and more.The Better Futures program provides tuition-free community

college for team members and their children.

The transaction is subject to customary closing conditions.

its first Phoenix

ATLANTA — Zaxbys® is continuing its expansion into the western U.S. with the opening of its first-ever Phoenix, Ariz. location. Located at 37756 N. Gantzel Rd., the new Zaxbys is owned and operated by Brian and Jessica Nelson of Bockbock LLC. It will be open for dine-in and drive-thru service starting on Aug. 13.

In celebration of the opening, on Aug. 19 from 10 a.m. to 2 p.m. local time, there will be a ribbon cutting ceremony featuring opening remarks from Zaxbys Chief Operating Officer Sharlene Smith, as well as franchisee owner and operator, Brian Nelson. The first 100 guests to visit the new Phoenix Zaxbys

location will receive free Zaxbys for 6 months, guests will also be able to enjoy Zaxbys fan-favorite menu items, a special 360-degree photo booth experience and selfie photo ops with Zaxbys props, a live DJ and a spin the Zaxbys prize wheel for the chance to win items.

“Following the tremendous success of our Las Vegas opening, we’re proud to announce Zaxbys newest location in Phoenix, Arizona,” Sharlene Smith, Zaxbys chief operating officer, said.“Thanks to the dedication of our franchise partners, Brian and Jessica Nelson, we’re accelerating our growth out West and continuing to introduce the Zaxbys famous Fingerz and signature sauces to new fans across the country.”

On the heels of a successful Las Vegas opening this past spring, the brand is excited to bring its fan-favorite crispy Chicken Fingerz, signature sauces and full line-up of menu items to an entirely new western market in Phoenix with an already vibrant and evolving food scene, the company said, adding that Arizona marks the second new state entry for Zaxbys in 2025 as the brand continues to build awareness amongst new consumers and attract more franchisee partners. Zaxbys is on track to eclipse its 1,000th new store opening in 2025.

Spanning 3,000 square feet, the new location is equipped with 56 seats for dine-in guests, as well as a dual drive-thru and curbside pickup door for expedited service.The new location’s

Modern Farmhouse design features prominent branding with Zaxbys signature colors, logo, and sauce medallions, as well as a cohesive brand story showcased through vibrant elements and sauce-inspired art, the company added.

“We are thrilled to introduce Zaxbys to Arizona!” Brian Nelson, owner and operator, said.

“While we may represent a trusted national brand with craveable, high-quality chicken and

sauces, we are truly just regular people, determined to bring smiles to our guest’s faces and help create meaningful lasting memories with our food and hospitality at the center.”

The Nelsons are working to open additional locations in Phoenix in the coming years. To help build this first location, they contracted local contractor Marsh Development Inc. The new restaurant is expected to provide up to 70 new employment opportunities.

collaborations will have across the industry and beyond.”

With a focus on enhancing the performance and resilience of Cobb breeding stock, the CRI aims to strengthen the global poultry supply chain and deliver long-term value to producers and consumers alike, the company said. By engaging researchers from diverse fields, the initiative continues to uncover new insights and develop tools that support genetic innovation.

“At Cobb, our commitment to progress is rooted in strategic partnerships,” Watkins added.

“By supporting these forwardthinking projects, we’re accelerating discovery, driving genetic progress, and helping provide more innovative solutions for our customers.”

For more information about the CRI, and the full list of recipients, visit www.cobbgenetics.com/cri. from Page 10 PT

BY JESS CAMPBELL, JEREMIAH DAVIS, CODY SMITH & KELLY GRIGGS

NATIONAL POULTRY TECHNOLOGY CENTER

Auburn

University

AUBURN, Ala. — Ten minutes could save you $350 or more per pump (and about $27/pad) by cleaning all evaporative cooling system troughs, headers, and sumps now!

A grower can significantly increase the life of an evaporative cooling pump(s) by regularly dumping the dirty water from the system and maintaining fresh water in the recirculation system during use. These cooling system pumps are not designed to operate under harsh conditions that we commonly see out in the field.

Maintaining fresh water will extend the life of pumps and pads. Cleaning these systems reduces the frequency of dry pads, algae

growth, scale buildup, and most importantly emergency situations like dead pumps, which may cause birds stress this summer.

Here is a “sneak peek” of what you might find if you have not done this recently. Watch out for snakes, spiders, and wasps!

Photo 1 shows a sump and cooling pump covered with grass and leaves. Photo 2 shows the end of an evaporative cooling trough that is full of grass. Both of these systems need a quick cleaning and debris removal to prevent a malfunction.

A lot can happen during two weeks of down time. Birds and rodents can move in quickly to places you never thought possible! At the very least each cooling system needs pads blown out, water fully drained, sump and trough cleaned out (if needed) and refilled with fresh water each summer flock.

Photos 3 and 4 are before and after cleaning a dirty evaporative cooling system trough.

A little routine water flushing,

water counts when the temperature hits high and evaporative cooling is needed to reduce bird stress. Good luck out there for the rest of this summer from the National Poultry Technology Center!

Side note: The young man in photo 4 is Jake Campbell, Jess Campbell’s son, and he still loves working on farms every time he gets a chance. Good luck, be a bird chiller and not a pump killer!

Jess Campbell is an Extension housing specialist with Auburn University’s National Poultry Technology Center; Jeremiah Davis is the NPTC director and Extension specialist, Cody Smith and Kelly Griggs are NPTC research engineers, all with Auburn University’s Biosystems Engineering Department. More information from the NPTC can be obtained at www.poultryhouse.com.

maintenance, and fresh water replacement can prolong and possibly prevent the need to disassemble the system (as shown) to clean it the hard way.

We know growers that get 3 years out of pads and some that get more than 10 years out of pads. You may ask, what is the difference? Water quality has a lot to do with pad/pump life expectancy, but you cannot forget the importance of fresh water replacement, routine maintenance, and evaporative cooling system cleanliness.

• Fresh perspective: The total replacement cost on a 66 x 600 broiler house. About 250 pads (about $27/each) and 6 pumps (about $350/each) on this one house would be about $8,850 per house. Add some PVC glue, miscellaneous fittings, and some cleaner to the list and this grower has about 9,000 reasons to make sure this system is well taken care of.

• Bottom line: Every pad counts, every pump counts, and every clean gallon of

DAVID B. STRICKLAND

RICHMOND, Va. — The closed, former Tyson Foods plant in Glen Allen, Va., has been sold for $5 million.

Cushman & Wakefield/ Thalimer, a real estate services firm, announces that the 208,000 square foot facility, located on Mountain Road in Glen Allen has been acquired by Hanoverlovestheproperty LLC, from Tyson. The manufacturing building sits on more than 53 acres.

This facility’s closure was announced in the spring of

GIANNA WILLCOX MULTIMEDIA JOURNALIST GIANNAWILLCOX@POULTRYTIMES.COM

WAYZATA, Minn. — Cargill’s Animal Nutrition and Health announces the opening of its new retail feed facility in Granger, Wash. The company notes this expansion as a milestone investment in the Pacific Northwest region.

This new facility modernizes production using innovative technology, such as automated bag check weighing and pedestrian sensing mobile powered equipment, to ensure the safety of Cargill’s feed and people.

“Our presence in Granger is in response to the

growing demand for animal feed in the west, as the trend of ranching and farming continues to rise,” Phil Graham, Cargill Animal Nutrition and Health managing director, said. “We look forward to partnering with current and future ag retailers as the industry continues to grow.”

In addition to meeting the growing needs of farmers, the Granger retail feed facility:

• Has the capacity to produce and package 120,000 tons of animal feed annually,

• Brings 21 new jobs to the local community,

• And serves multiple species, such as poultry, equine, sheep, rabbits, and wildlife.

The new feed operation is a standalone facility that shares the same site as Cargill’s bulk dairy

feed mill. It will hold pellet mills, packaging lines, a spacious warehouse, and so much more for employees.

The Granger team will work to increase the number of Cargill’s trusted brands, including Nutrena, Loyall Life, and Black Gold, on store shelves across the region.

“Cargill has consistently shown up as a true partner to Mid States and our members — never hesitating to lean in, listen, and take action,” Mark Schmitt, D&B Supply president and CEO, said. “This new facility in Granger isn’t just an investment in infrastructure — it’s an investment in our future.”

Uzelac Industries is a major supplier of Rotary Drying Systems to the poultry industry, including for such notable clients as Herbruck’s Poultry Ranch, Michael Foods, Foster Farms and Tyson, building custom equipment for over 30 years.

EGGSHELLS can become calcium for layer chickens.

FEATHER MEAL can become protein for animal feed.

MANURE can become fertilizer.

Thanks To Uzelac Industries Rotary Drying Systems

BY MICHAEL CZARICK & DR. BRIAN FAIRCHILD

University of Georgia

ATHENS, Ga. — A study was conducted to investigate the impact of sudden increases in air temperature on the body temperatures of broiler chickens. Sevenweek-old broilers were monitored using micro temperature data loggers that they ingested.

The birds were placed in a 4’ x 5’ floor pen, and additional birds were placed in the pens without data loggers to create a starting density of approximately 6 pounds per square foot of floor space.

The room temperature was generally maintained at approxi-

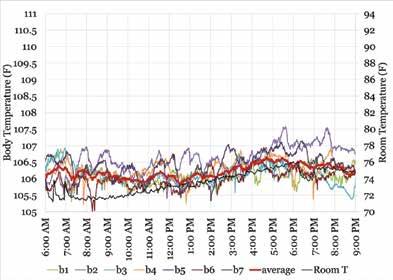

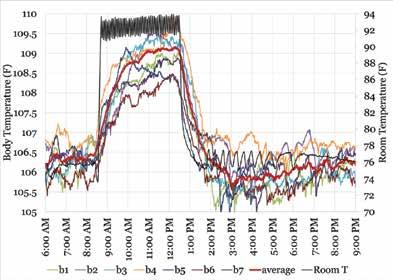

mately 74 degrees F, except during specific 2- to 6-hour intervals when it was raised to 82 degrees F, 87 degrees F, or 92 degrees F. Throughout the seven-day study, room temperature, relative humidity, and bird body temperatures were recorded every minute. Figure 1 shows the body temperatures of the seven broilers on the first day of the study (6:00 a.m. to 9:00 p.m.), where an air temperature of 74 degrees F – 76 degrees F was maintained. During this period, body temperatures remained relatively stable, ranging from 106 degrees F to 106.5 degrees F — within the normal range for broilers, as reported in previous research.

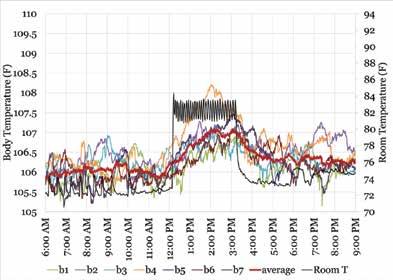

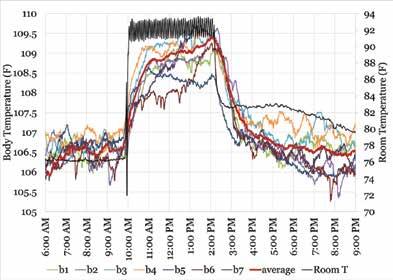

On the second day, the room

temperature was increased to 82 degrees F from 12:00 p.m. to 3:00 p.m. (Figure 2). During this period, the average body temperature of the birds gradually rose to 107 degrees F over the first two hours and then plateaued for the remainder of the three-hour test period. Although elevated, a body temperature of this level is typically not considered problematic. Within an hour of the room temperature returning to 74 degrees F, the birds’ body temperatures returned to normal levels.

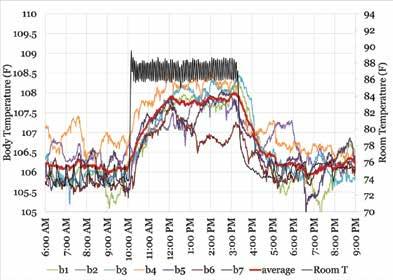

On the third day of the study, the room temperature was raised to 87 degrees F between 10 a.m. and 3:30 p.m. (Figure 3). This time, the average bird body tem-

perature plateaued at approximately 108 degrees F within the first two hours, after the room temperature reached 87 degrees F. A body temperature of 108 degrees F has been shown to reduce broiler feed consumption and weight gain dramatically. Bird body temperatures returned to normal within two hours after the room temperature was restored to 74 degrees F.

On the fourth day, the room temperature was increased to 92 degrees F from 10:30 a.m. to 12:30 p.m. (Figure 4). As expected, the higher room temperature resulted in a greater increase in body temperature (109 degrees F). A body temperature of 109 degrees F would likely have a

We have learned that relevant, actionable news and information are absolutely critical to every aspect of the poultry industry as we all navigate very challenging times. With a focus on current industry trends and concise content delivery, The Poultry Report is designed to provide you with a single source of industry insight in an easy-to-digest format.

Delivered free to your email inbox Monday through Friday. To subscribe, visit

https://www.poultrytimes.com/thepoultryreport

more negative impact on broiler performance.

How much broiler performance would be impacted would depend to a large extent on how long a bird’s body temperature remained elevated. As with previous days, body temperatures returned to normal within two hours of the room temperature returning to 74 degrees F.

On the final day of the study, the room temperature was again raised to 92 degrees F, this time for a duration of four hours. As in the previous day’s trial, the average body temperature plateaued at approximately 109 degrees F within the two hours of the room temperature reaching 92 degrees F. Notably, unlike the earlier trial, in this trial it took over five hours for the birds’ body temperatures to return to approximately 106 degrees F.

There were two differences on this day. First, the room temperature could not be quickly lowered back to 74 degrees F due to the temperature of the incoming air, which was significantly higher (80 – 82 degrees F). Secondly, the humidity was approximately 20 percent higher during the second trial. The combination of these factors made it more difficult for the birds to quickly rid themselves of excess heat, thereby increasing the time required for their body temperature to return to normal. Although this should not be surprising, it does reinforce the importance of cooling the birds at the end of the day when they are exhibiting signs of

heat stress.

Bottom line: the quicker a bird’s body temperature can be brought back to normal, the less likely its performance will suffer. Here are a few things to consider when you are looking to bring near-market age birds’ body temperatures quickly back to normal after a stressful hot summer afternoon:

1. Make sure that all the tunnel fans operate throughout the night.

2. Consider keeping the lights on at night. During dark periods, bird movement is minimal, resulting in reduced heat loss from the undersides of the birds due to the insulating properties of the litter on which they sit.

3. Double check to make sure your tunnel fans are properly maintained (belts are tight and not overly worn, shutters and screens are clean).

4. Do not operate evaporative cooling pads late at night. Outside humidity tends to climb above 80 percent as the outside temperature drops below 80 degrees F. Operating evaporative cooling under these conditions tends to produce little temperature reduction and brings the relative humidity of the incoming air to near saturation, thereby actually reducing heat loss from the birds.

Michael Czarick is an Extension engineer; and Dr. Brian Fairchild is an Extension poultry scientist, both with the University of Georgia College of Agricultural and Environmental

GAINESVILLE, Ga. — Poultry Times’ new podcast, The Coop Scoop, had the distinct honor this week of its first live, in-studio participant — Kevin McDaniel, Wayne-Sanderson Farms president and CEO.

McDaniel provided an in-depth insight into the poultry business, as well as the latest news regarding his company. And there has been a variety of Wayne-Sanderson news in recent weeks. The company has acquired fellow Georgia company, Harrison Poultry; announced it will be a Southeastern Conference (SEC) sponsor; and it has also celebrated the grand opening of a new $43 million feed mill in Danville, Ark. Wayne-Sanderson Farms is certainly reporting some recent successes, but as McDaniel notes, for business success there needs to be a consistent focus on the processes.

“We strive at Wayne-Sanderson to continue to strive for excellence, to get better at what we do every day,” he said. “We have a concept that we call process focus, and it’s basically our continuous improvement effort.”

“In my philosophy … if everyone in the organization incorporates a process-focused mindset, if they focus on their processes and the things they can control, the overall outcome; it’s better for the company, better for the product, better for everything,” McDaniel said. “Everybody has a role in it, like quality and safety. It’s not just a department; it’s everybody’s job to worry about quality and safety. It’s the same way with continuous improvement process focus, saying that we will continue to build on our strengths. We’ll solidify ourselves where have weaknesses and

do better at that.”

Looking at broiler production industry-wide, McDaniel added that things are looking good, especially from a grain input perspective.

“There are, however, a lot of negotiations that are going on globally that may influence grain and the trading of grain … but right now, everything is looking bright from a grain standpoint and if demand keeps on, it looks like we’re in a good spot,” he said.

“We’ve also seen a little bit of a shift of some of our items into fast food channels,” McDaniel added. “You’re seeing more and more restaurants adding and taking more

Got Manure? We have the cure! Entomologist on Staff. Free Phone Consultation.

2023, along with a site in Van Buren, Ark.

Poultry Times has reached out to Tyson Foods for comment.

In early 2024, after the Glen Allen plant closure was reported the prior year, Virginia Gov. Glenn Youngkin and the Virginia Department of Agriculture and Consumer Services announced the formation of the Central Virginia Poultry Cooperative Inc., which switched focus to eggs from broilers. The farmer-owned co-op produces and sells cagefree table eggs to Dutch Country Organics of Indiana.

“When we learned … that poultry farmers in Central Virginia needed our help, I directed our Secretary of Agriculture and Forestry to bring a team together and find a way forward for the family-owned farms of the region,” Youngkin said in an announcement at that time. “I am thrilled to share that less than a year later; the Commonwealth is supporting many of these growers in making a bold step forward to a brighter future in the fast-growing market for cage-free eggs.”

space in the menu for chicken-type items. Some chains that are primarily thought of as burger restaurants, hamburger restaurants, are shifting to chicken items and some are actually selling more chicken than they are beef. So, that’s exciting for us. It’s become a standard menu item, so that speaks well for our space.”

• The nation’s third-largest poultry producer, Wayne-Sanderson Farms’ headquarters in Oakwood, Ga., is very near the Poultry Times office, and it was an honor to have Kevin McDaniel as an in-studio guest. To hear the complete podcast, visit www.PoultryTimes.com and follow the link to The Coop Scoop

Through its contracts, Dutch

“We look forward to our new relationship with the Central Virginia Poultry Cooperative and its family farm members. The family farm is our story. It’s what we support. It’s what we encourage. The family farm, where fresh, natural eggs come from fresh, clean environments.”

Country’s eggs are sold to national retailers such as Walmart, Kroger, Costco, Aldi and Target.

In the 2024 announcement, Lamar Bontrager, Dutch Country Organics CEO, said, “We look forward to our new relationship with the Central Virginia Poultry Cooperative and its family farm members. The family farm is our story. It’s what we support. It’s what we

encourage. The family farm, where fresh, natural eggs come from fresh, clean environments.”

In Virgina, Tyson Foods, also in 2023, announced the opening of a $300 million fully-cooked production plant in Danville. The company notes that this 325,000 square foot facility produces about 4 million pounds of fully-cooked poultry a week.

“Danville represents a sig-

nificant commitment to the region and we take our responsibility to enhance the communities where we live and work seriously,” Donnie King, Tyson Foods president and CEO said in the 2023 announcement. “This plant is also a significant step toward our ongoing goal of operational excellence by investing in innovative technology and automation.”

National Turkey Market:

(Aug. 18): The market on fresh and frozen 8-16 lb. hens and 16-24 lb. toms was steady to firm. Fresh and frozen Grade A 8-16 lb. hens and 16-24 lb. toms demand was light to moderate. Offerings short to light on frozen commodity 8-16 lb. hens and 16-24 lb. toms at $1.49-$1.72 fob for current shipments. Fresh hen and tom November offerings light. Trading slow. November fresh 8-16 lb. hens and 16-24 lb. toms *$1.49-$1.59 fob. No frozen trading reported. The market on tom breast meat and destrapped tenderloins was firm. Demand good. Offerings short to light. The market on white trims was steady to firm. Demand moderate to good. Offerings short to light. Further processed demand moderate to good. The consumer sized breast market was steady with a firm undertone. Demand and offerings light. Institutional sized breast markets were steady with a firm undertone. Demand light to moderate. Offerings light. The frozen tom necks market was steady with a firm undertone while fresh were steady with a weak undertone. The balance of frozen tom bulk parts markets were steady to firm while fresh was steady. The hen neck market was steady to barely steady, balance of hen bulk parts at least steady. Demand light to good, mostly moderate to good with drums and wings the most active. The thigh meat market was steady to firm. Mechanically separated turkey market was steady with mixed undertones, USDA’s Agricultural Marketing Service reports.

Broiler: Estimated slaughter for week ending Aug. 14 was 171,784,000. Actual slaughter for the week ending Aug. 1 was 171,719,000. To-date 2025: 5,309,535,000.

Heavy-type hen: Estimated slaughter for the week ending Aug. 14 was 1,915,000. Actual slaughter for the week ending Aug. 1 was 1,799,000. To-date 2025: 55,073,000.

Light-type hen: Estimated slaughter for the week ending Aug. 14 was 627,000. Actual slaughter for the week ending Aug. 1 was 810,000. To-date 2025: 21,202,000.

Negotiated

ExzoltTM, new from Merck Animal Health, wipes out over 99% of Northern Fowl Mites in two easy to administer doses. And because it’s simply applied through your poultry drinking water system, there’s no special training or new equipment needed, meaning one person can treat all your birds faster than ever. For serious mite control that keeps your birds and bottom line healthy, visit US.Exzolt.com.