It takes a farmer to understand a farmer. And here at Liphatech Ag, we have the farming and ranching backgrounds to know what you’re up against every day. Your dedication, grit and selflessness don’t go unnoticed. Our team is here to support you in every way we can.

WE HAVE YOUR BACKS, BARNS AND BOTTOM LINES.

RODENTICIDE SOLUTIONS FOR ALL YOUR RODENTICIDE NEEDS LIPHATECH.COM

Rats and mice accelerate the spread of at least 35 diseases that plague animal production

Left unchecked, rodent populations will expand rapidly, spreading disease to areas and animals

Rodents cause damage to facilities, increase energy costs and contaminate feed

Titan bait stations are ready-to-go and require no additional securing thanks to a pre-installed custom brick, eliminating the fear of the station blowing away

Weighted stations are less likely to be disturbed by livestock and non-target animals

Removable tray for faster bait replacement: saves time and labor costs

Remember to rotate your bait to prevent resistance to a specific formula

Meet Titan, the Weighted Bait Station from Tomcat designed to make implementing your Rodent Control program simple, fast and effective, without the fear of the station blowing away.

Can use chunks, soft bait, place pacs in bait stations.

One

Poultry Resource Guide.

The opinions expressed in this publication by authors other than Poultry Times staff are those of the respective author and do not necessarily reflect the opinions of Poultry Times.

Advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

Agralarm, 26

888-968-2802; www.agralarm.com

Bird Control Group, 16

844-406-9280; www.birdcontrolgroup.com

Creekview Mfg., 15

717-445-4922; https://creekviewmanufacturing.com

Eagan Mfg., 19

870-878-6805; www.eaganmfg.com

Hog Slat, 30

800-949-4647; www.hogslat.com

Impact Poultry Products, 17

800-448-4723; www.impactpoultryproducts.com

Kelley Mfg., 24

800-444-5449; www.kelleymfg.com

Kuhl Corp., 28

908-782-5696; www.kuhlcorp.com

Kunafin (The Insectary), 28

800-832-1113; www.kunafin.com

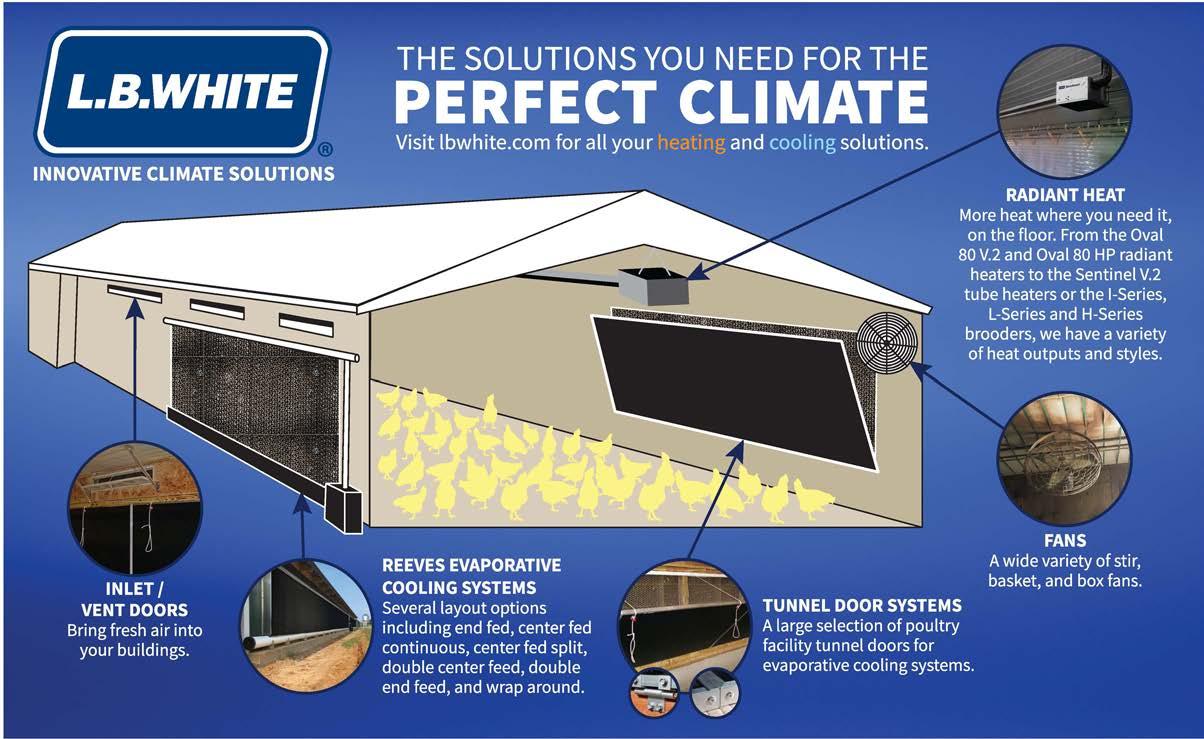

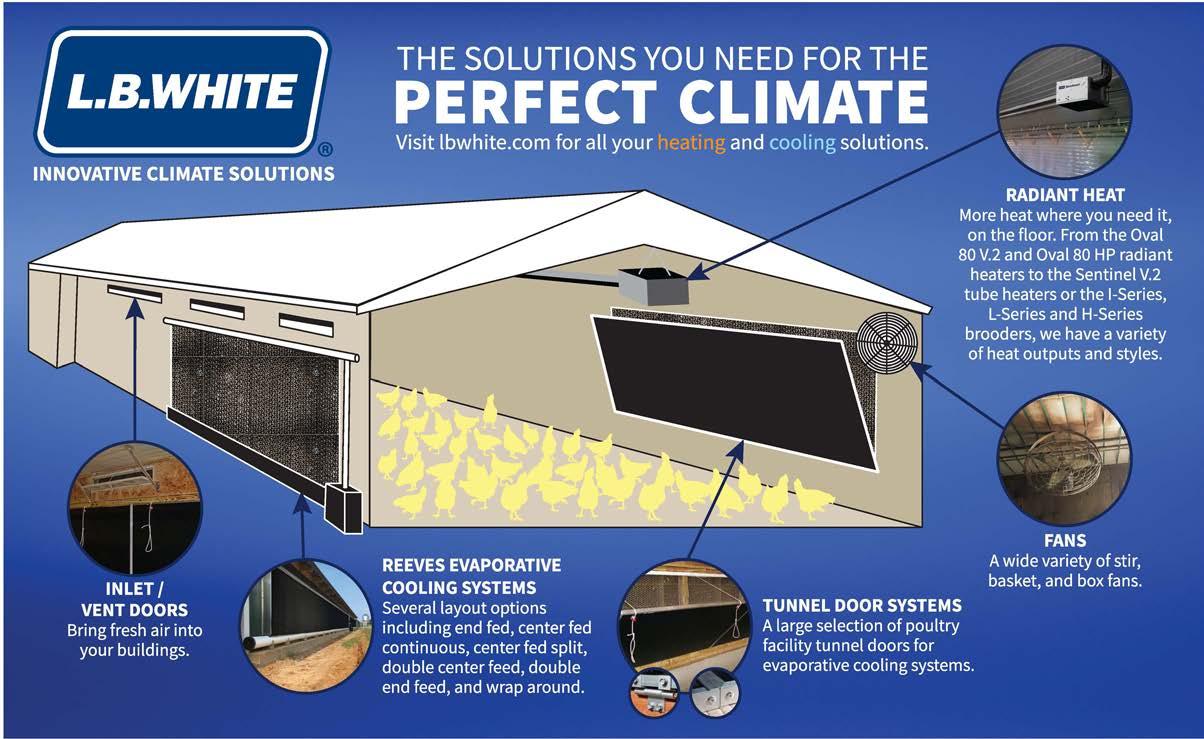

L.B. White, 21 608-783-5691; www.lbwhite.com

Liphatech, 2

414-351-1476; https://liphatech.com

Metzer Farms, 15

831-240-1946; www.metzerfarms.com

Motomco, 4 800-237-6843; www.motomco.com

Neogen, 32

800-234-5333; www.neogen.com

Overdrive Lighting, 14 800-657-0509; www.aglights.com

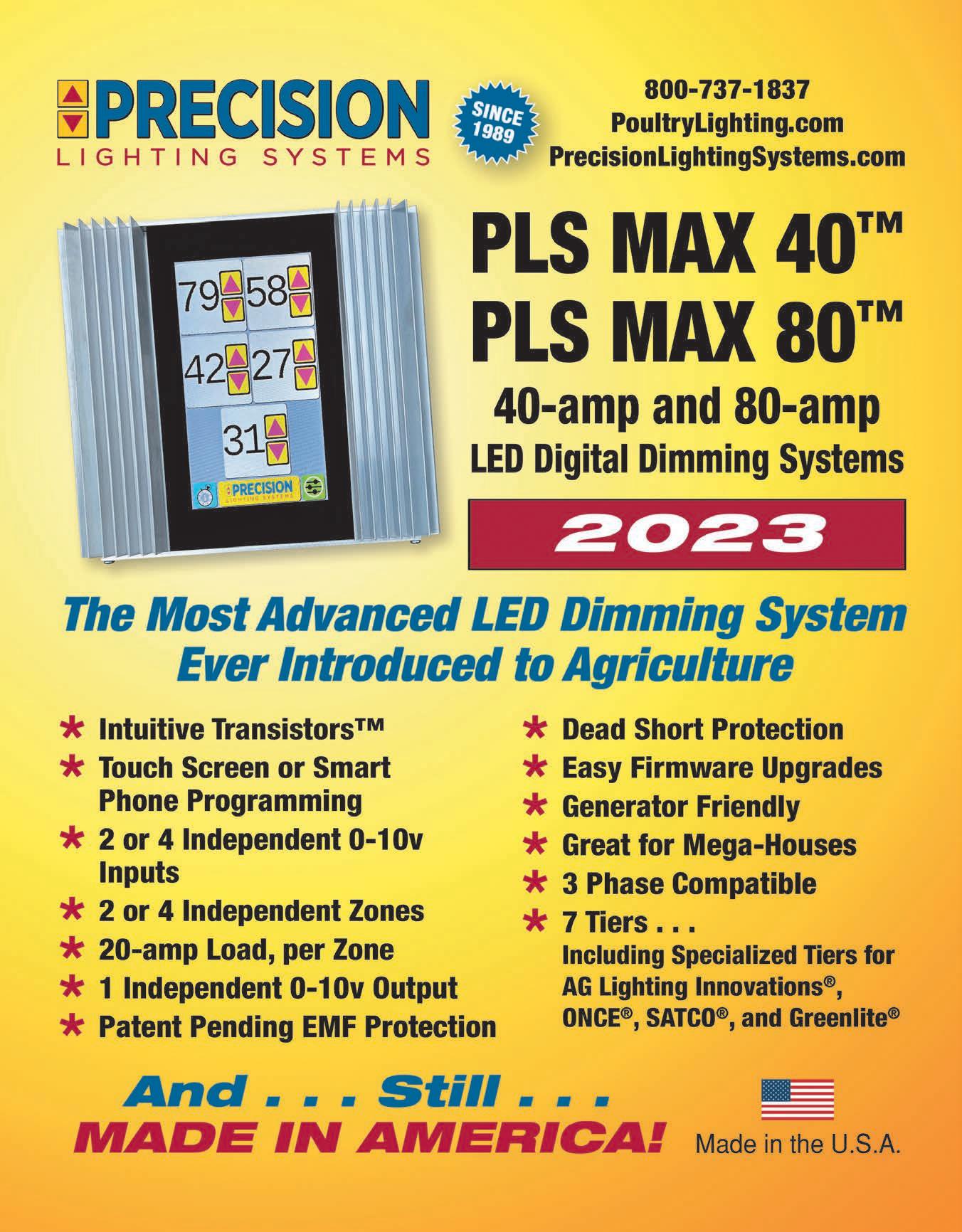

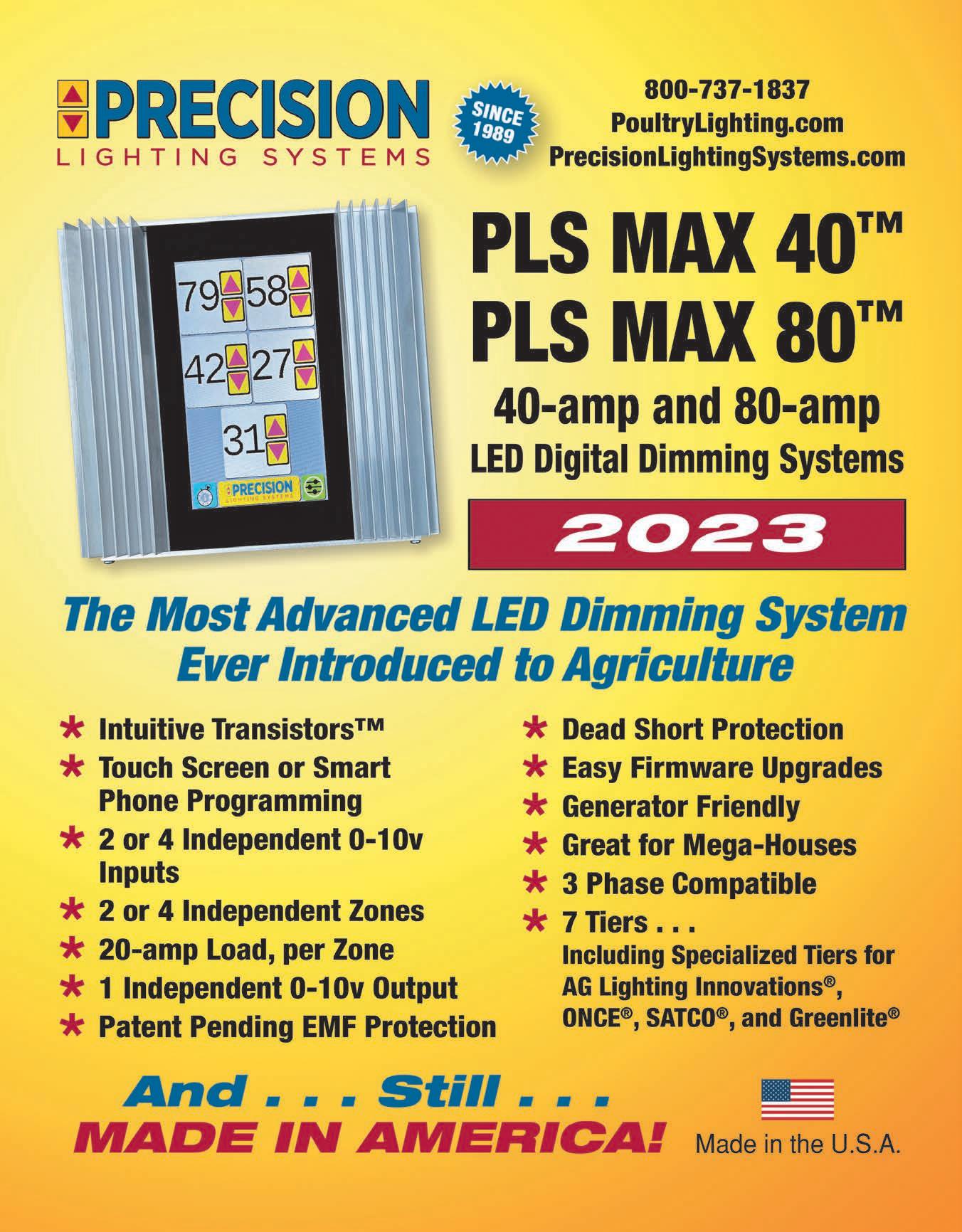

Precision Lighting, 1, 3, 18, 25

800-737-1837; www.poultrylighting.com

Star Labs, 23

800-894-5396; www.primalac.com

The Egg Carton Store, 28 866-333-1132; www.eggcartonstore.com

Walinga USA, 31 800-466-1197; www.walinga.com

Weightech, 23, 27 800-457-3720; www.weightechinc.com

General Manager

Cindy Wellborn

770-718-3443

cwellborn@poultrytimes.com

Editor

David B. Strickland

770-718-3442

dstrickland@poultrytimes.com

Digital Manager

Rachel Danford

770-718-3438

rdanford@poultrytimes.com

Senior Sales Executive

Stacy Louis

770-718-3445

slouis@poultrytimes.com

Sales Support

Janice Sisk

770-536-2476

jsisk@poultrytimes.com

Content Writer

Elizabeth Bobenhausen

770-209-3335

ebobenhausen@poultrytimes.com

Circulation

Kim Ewing

770-535-6395

kimewing@poultrytimes.com

GAINESVILLE, Ga. — The announcement of lab-grown chicken has the taken the United States by storm. The U.S. Food and Drug Administration notes that there are no cultivated meat products on the market. The FDA and the USDA are working are working together to ensure that these products are safe for human consumption and meet all the necessary requirements.

According to Fox Business, “lab-grown meat is created using cells from living animals, such as a fertilized egg, which is incubated and grown into large masses of meat. The product is then cut and restructured into facsimiles of regular, butchered meat products.”

The FDA gives the steps of how lab grown chicken is made:

• Step 1: Manufacturers typically start with a sample of cells from the tissue of an animal, a process that does not require harm to or death of the animal. Some cells from the sample are selected, screened, and grown to make a “bank” of cells to store for later use.

• Step 2: A small number of cells are taken from the cell bank and placed in a tightly controlled and monitored environment (typically, a number of sealed sterile vessels of increasing size) that supports growth and cellular multiplication by supplying appropriate nutrients and other factors.

• Step 3: After the cells have multiplied many times over into billions or trillions of cells, additional substances (for example, protein growth factors, new surfaces for cell attachment, additional nutrients) are added to the controlled environment to enable the cells to differentiate into various cell types and assume characteristics of muscle, fat, or connective tissue cells.

• Step 4: Once the cells have differentiated into the desired type, the cellular material can be harvested from the controlled

environment and prepared using conventional food processing and packaging methods.

In a recent release, UPSIDE Foods notes that it has finished the pre-market regulatory procedure for its lab grown chicken. The company also received a Grant of Inspection from the USDA, which means the company has fulfilled the necessary guidelines for labeling and food safety.

In November 2022, the company became the first in the world to receive the FDA’s permission to start creating lab made meat as they received a “no questions response.” The “no questions response” means that the food is safe to eat. The company has since been cleared of any more regulatory procedures and can start producing their cultivated poultry at the Engineering, Production, and Innovation Center (EPIC). UPSIDE will be placing their chicken product with over 99 percent developed chicken cells on the market.

“I’m thrilled to share that cultivated meat will now be available for consumers in the U.S.,” Dr. Uma Valeti, CEO and founder

of UPSIDE Foods, said. “This approval will fundamentally change how meat makes it to our table. It’s a giant step forward towards a more sustainable future, one that preserves choice and life. We are excited to launch with our signature, wholetextured UPSIDE chicken and can’t wait for consumers to taste the future. UPSIDE has already made one order for Chef threeMichelin-star Chef Dominique Crenn. The poultry will be given out in small quantities to a few restaurants that the company has partnered with.”

Fox Business reported GOOD Meat also received a “no questions” response from the FDA. GOOD Meat said in a statement that it has cleared “a crucial step in bringing GOOD Meat to restaurants and retail in the U.S.” The statement when on to say that it “is now working with the U.S. Department of Agriculture on necessary approvals.”

GOOD Meat owns the food company Eat Just. Eat Just cofounder and chief executive Josh Tetrick said, “instead of all of that land and all of that water that’s used to feed all of these animals that are slaughtered, we can do it in a different way.”

GOOD Meat has obtained ap -

proval from Singapore to distribute the poultry. They are the first company to get permission on more than one continent. Seventy percent of people in Singapore said that they enjoyed the cultivated poultry and found it to be just as good or better than traditional chicken. Ninety percent of people of Singapore said they would exchange traditional chicken for cultivated chicken.

The GOOD Meat website says, “GOOD Meat is real meat, made without tearing down a forest or taking a life. We’re the first and only company in the world to sell cultivated meat made from cells instead of slaughtered animals.”

Just like UPSIDE Foods, GOOD MEAT will only distribute their chicken products to partnered restaurants. They will begin selling the cultivated poultry to a restaurant in Washington D.C. The owner, Jose Andres, a chef and philanthropist, said “The future of our planet depends on how we feed ourselves … and we have a responsibility to look beyond the horizon for smarter, sustainable ways to eat. GOOD Meat is doing just that, pushing the boundary on innovative new solutions, and I’m excited for everyone to taste the result.”

GAINESVILLE, Ga. — Not just a pesky pest, but a potential costly one, is the darkling beetle. These insects can affect bird health, spread diseases, and cause many problems for producers.

Noted frequently around poultry feed and in house litter, the darkling beetle can migrate during litter clean-out, as well as night flights from fields where they are present and into poultry houses.

The darkling beetle, “originated in the tropics and is well suited for warm humid conditions making the broiler house the perfect habitat for it,” notes Dr. Claudia Dunkley, an Extension poultry scientist with the University of Georgia, in a report. “Inside the houses, beetles can be found under feed pans and feed lines where spilled feed is mixed with litter. The life cycle of darkling beetles takes 40 to 100 days depending on the temperature, as they tend to multiply more quickly as the temperature increases. The adult beetle can live for more than 12 months, with the female beetle laying up to 2,000 eggs during its lifetime.”

A great concern for poultry health is if birds were to consume beetles that are contaminated with diseases. A result of a bird’s inclination to eat insects in the litter and feed.

“Young birds can consume large numbers of beetles which can interfere with feed consumption and can result in pathogen transmission,” Dunkley said. “It has been shown that darkling beetles act as vectors for a number of poultry diseases such as fowl pox and Newcastle and act as a host for E. coli and salmonella. They also act as intermediate hosts for roundworms and tapeworms.”

Beyond the farm, if litter that has a high concentration of darkling beetles is placed on fields near to residential areas and the insects

spread, this could lead to neighbor nuisance complaints.

“Another important problem that can arise from high beetle populations is that of neighbor relations,” Dunkley added. “Litter that has been spread in fields and contains high beetle numbers have resulted in nuisance complaints because these displaced beetles tend to seek refuge in nearby homes.”

In addition to the detrimental effects to poultry, darkling beetles can also cause structural damage to poultry houses.

“While darkling beetles act as vectors that can transmit disease causing organisms to chicken, the most serious impact that these beetles can have on the broiler farm is the structural damage that they can

cause to the houses,” Dunkley said. “The migration of the beetle larvae (the lesser mealworm stage) into the insulation for pupation results in extensive damage. Application of insecticides to structure, including the floor, after cleaning can assist in lowering the beetle survival.”

Control of darkling beetles, as well as other pests such as rodents, flies and waterfowl, should involve a good biosecurity plan and the use of integrated pest management (IPM) procedures.

“An IPM program for a broiler facility must be implemented on a farm-by-farm basis as no set program will fit all situations on all farms,” she added. “Each farm will have to design a program to suit their facility based on a thorough

inspection of the facility and the problems that are identified.”

A rotation of chemical types may be needed to prevent an infestation of beetles that have acquired a resistance to the pesticide being used.

“Over the years the beetles have developed resistance to some insecticides. Effective control of these pests requires rotation of chemicals to reduce the potential development of resistance to active ingredients in the insecticides,” Dunkley said. “Other management practices such as time and mode of application, and monitoring the changes in the beetle population can also help in controlling darkling beetles and reducing their negative impact on the industry.”

By Elizabeth Bobenhausen Poultry Times staff ebobenhausen@poultrytimes.com

By Elizabeth Bobenhausen Poultry Times staff ebobenhausen@poultrytimes.com

GAINESVILLE, Ga. — The University of Georgia poultry science department has assisted with the buildout of new biomapping technology. In information released by UGA, they describe biomapping as, “the practice of sampling at specific points in processing where contamination levels can be assessed, measuring the microbiological status of birds against a specific target organism or a class of organisms.”

Two researchers led the effort at UGA. Manpreet Singh is the head of the Department of Food Science and Technology at UGA as well as a professor. He was joined by Harshavardhan Thippareddi, John Bekkers professor in poultry science at UGA.

This new technology will aid food processors in finding microbial contamination within the plants.

“Our goal was to provide a guidance document for industry to help them understand their facilities from a food safety viewpoint,” Singh said. “We walk through each processing step in the processing plant to identify sampling locations to recognize potential areas of high risk.”

“While data collection in poultry processing plants is not new, the biomapping tool developed by CAES helps processors develop customized evaluation programs for each facility and use the data to better understand risk factors and systematically evaluate processes to improve food safety in processing plants,” Thippareddi added.

“We identify sampling sites, why they should sample those areas, how many samples they should take to understand microbial risks, and how to reduce bacterial contamination,” Thippareddi said.

By finding “hot spots” within the processing plant, it will make

it easier to determine what type of treatment will be needed to eliminate potential diseases.

“This is where creating a biomapping program can prove more effective, depending on the product being processed,” Singh said.

He added that the procedure is alike to the procedure organizations like the USDA use when probing foodborne disease epidemics. In order to establish a proper biomapping system, it is important to conclude what needs to be done in the facility and what pathogens might be present in the building.

UGA gives basic steps to establish the proper biomap procedure.

1. Define the main goal of the biomapping program (efficacy of antimicrobial interventions or the microbiological profile of the process and the impact of process changes).

2. Ident ify the focus of the program, such as foodborne pathogens (prevalence vs. concentrations) or indicator organisms.

3. Establish the microbiological targets at critical processing steps and the implications if those targets are not met.

“Poultry processing is a dynamic

system that must be continuously monitored to minimize potential pathogens in high-risk areas,” Thippareddi said. “The USDA’s Food Safety and Inspection Service is evaluating the poultry production-processing continuum to evaluate locations where control can be put in place to effectively reduce the risk of salmonella from poultry products.”

“Chicken is responsible for 15 to 20 percent of illnesses,” Singh added. “Proper application of biomapping, followed by systematic monitoring and preventive actions, can reduce foodborne illnesses related to poultry and ultimately enhance public health. This can also help producers optimize resources and utilize interventions judiciously to reduce costs, but the main goal is to reduce the incidence of foodborne illness.

“Food safety economics do not matter if public health is compromised.”

“

Food safety economics do not matter if public health is compromised.

ATLANTA — For the Georgia Tech Research Institute’s Agricultural Technology Research Program (ATRP), 2023 marks an incredible milestone as we celebrate 50 years of driving innovation in poultry, agribusiness, and food manufacturing. This past spring, more than 150 attendees gathered at the Historic Academy of Medicine at Georgia Tech to celebrate the people and projects that made the program’s first five decades a success.

What began in 1973 with a $100,000 appropriation from the Georgia General Assembly to involve Georgia Tech in studies supporting the poultry industry has today grown into a multi-million-dollar investment that continues to support Georgia’s number one agribusiness sector.

While the support of the State of Georgia and the University System of Georgia (USG) have certainly made it possible for us to do this work, it is the remarkable people who have been part of the program over the years that have really made it stand out. It was my distinct honor to welcome ATRP past and present team members, program supporters including industry, university, and government partners, and representatives from our state and federal legislative offices to enjoy the anniversary celebration and luncheon.

An especially memorable part of the celebration was our recognition of two very important individuals. F. Abit Massey, president emeritus of the Georgia Poultry Federation, was honored as the ATRP Champion for his unending support and advocacy that have been a major catalyst in the growth and success of the program. J. Craig Wyvill, ATRP director emeritus, was honored as the ATRP Pioneer; it was under his leadership

that ATRP blossomed and grew into a vibrant and internationally recognized program. In recognition of their significant legacies, the program has established the F. Abit Massey Champion Award and the J. Craig Wyvill Pioneer Award. Moving forward, the awards will be presented as deemed appropriate to individuals who exhibit the qualities of each award’s namesake.

In addition to Abit and Craig, it was a privilege to have USG Chancellor Sonny Perdue, Georgia Commissioner of Agriculture Tyler Harper, Harrison Poultry President and CEO David Bleth, Georgia Tech Executive Vice President for Research Chaouki Abdallah, and GTRI Director Jim Hudgens all provide remarks highlighting the importance of technological solutions for the future viability of poultry and Ag. At the conclusion of the celebration event, all attendees had the opportunity to browse the research showcase and demos of

current technologies under development.

One of the most enjoyable aspects of my role with ATRP has been the opportunity to develop so many lifelong friendships. While I have said it before, the 50th celebration really cemented for me how special the people of ATRP really are. This includes

all of the past and present researchers, staff, and students who have and continue to contribute to the program, as well as all of our external industry, academic, and federal lab partners, without whom the program would not have the impact that it does today. As I look toward the future, I am very excited, as the

next generation of bright and energetic people continue to build on the incredible ATRP legacy and drive forward the innovation needed to keep poultry and Ag a viable industry for years to come.

So, here’s to the next 50 years of ATRP, and thank you for being a key part of our future success!

Also, for a glimpse into the program’s history and to listen to a special podcast series commemorating the anniversary, visit the 50th anniversary webpage at atrp.gatech.edu/atrp50.

This article is reprinted from PoultryTech, a publication of ATRP of the Georgia Tech Research Institute, a program conducted in cooperation with the Georgia Poultry Federation with funding from the Georgia legis -

As I look toward the future, I am very excited, as the next generation of bright and energetic people continue to build on the incredible ATRP legacy …ATRP photo The Georgia Tech Research Institute’s Agricultural Technology Research Program has established the F. Abit Massey Champion Award and the J. Craig Wyvill Pioneer Award as part of the continuing legacy of the program and in recognition of each individual’s contribution to the development, growth and sustainment of ATRP. Pictured are, left to right, Jim Hudgens, GTRI director; F. Abit Massey, president emeritus of the Georgia Poultry Federation; J. Craig Wyvill, ATRP director emeritus; and Doug Britton, ATRP program manager.

cent year-over-year, with E-commerce remaining a driving force in their growth as sales increased 125 percent year-over-year.

protein availability and lingering inflation.”

GREELEY, Colo. — Pilgrim’s Pride Corp. has recently released its second quarter 2023 financial results.

Among the second quarter highlights include:

• Net sales of $4.3 billion.

• GAAP net income of $60.9 million and GAAP EPS of 25 cents. Adjusted net income of $105.3 million and adjusted EPS of 44 cents. Consolidated GAAP operating income margin of 2.3 percent.

• Adjusted EBITDA of $248.7 million, or a 5.8 percent margin, with adjusted EBITDA margins of 4.6 percent in the U.S., 5.2 percent in the U.K. & Europe, and 12.2 percent in Mexico.

• All regions improved financial performance relative to the prior quarter given operational excellence efforts, portfolio diversification, higher attribute programs and branded offerings, in partnership with key customers.

• The diversification across bird sizes and our operational excellence efforts enabled margin growth in U.S. Fresh business relative to prior quarter, despite continuing challenging market conditions in the commodity Big Bird business.

• U.S. Prepared Foods business momentum continued in branded fully cooked products as Just Bare® and Pilgrim’s® collectively grew more than 56 per-

• U.K. and Europe business continue its margin growth trajectory, given benefits from our ongoing manufacturing network optimization program, growth with key customers, and synergies from back-office integration.

• Mexico improved as supply and demand fundamentals became increasingly balanced and challenges from live operations are reduced, while the company continued to grow value-added programs and brands.

• Organic growth programs to support our key customers and the strategy of portfolio diversification remain on track. Both expansion project at the Athens, Ga., facility and new protein conversion plant in South Georgia remain on track to be fully operational by the beginning of 2024.

• The company’s leadership journey in Sustainability continued as it completed an inventory of GHG emissions footprint for the global supply chain and implemented a variety of programs and systems to reduce energy usage which will be highlighted in the 2022 Sustainability Report to be published in the third quarter.

“Throughout the past 12 months, our consistent execution and focus on portfolio diversification, growth with key customers, and operational excellence has been instrumental in our ability to navigate extremely volatile market conditions,” said Fabio Sandri, Pilgrim’s CEO. “Our business profitability increased quarter over quarter yet again despite challenges in overall

“In the U.S., margins significantly improved from the first quarter despite continuing challenges in the market conditions of the commodity Big Bird segment, given an intense focus on our operational excellence efforts,” Sandri said. “Case Ready and Small Bird maintained steady performance while cultivating promotional activity and growth with key customers. Prepared Foods continues its branded momentum as Just Bare® and Pilgrim’s® sales collectively grew over 56 percent from last year.”

“Q2 was still challenging for the commodity segment. Although market conditions have recently improved, the team is in the process of executing a variety of action items to further drive operational excellence,” Sandri added. “We maintain our commitment to profitable growth through our continued investment in automation, expansion at our Athens, Ga., facility, and construction of a new protein conversion plant in South Georgia.”

As for the U.K. and Europe business, momentum continued as profitability grew for the fifth straight quarter given benefits from recent network optimization, continued cost recovery efforts, and growth with key customers through innovation and strong service levels, Pilgrim’s noted.

“Throughout the past year, the team has been exceptionally diligent in driving cost efficiencies throughout our manufacturing network, recovery of inflationary impacts, and synergies from back-office integration,” Sandri

said. “We are pleased with the remarkable progress over the past year, we will continue to explore opportunities to profitably grow our business.”

Mexico results improved relative to both first quarter and prior year as supply and demand fundamentals became progressively balanced, overall live performance improved, and interest in our branded offerings increased, the company added.

“Throughout the past several quarters, Mexico maintained strong service levels to Key Customers and grew its branded presence despite challenges in live operations,” Sandri said. “We commend the team for their rapid response and operational excellence efforts to alleviate these issues. Our continued investments in this region will further lessen future potential concerns and provide the foundation for additional profitable growth.”

Pilgrim’s continues to make progress in Sustainability as it recently completed an inventory of its GHG emissions footprint, the company reported. These efforts have been further amplified by energy audits, installation of metering systems, and training at its U.S. locations.

“The completion of our GHG inventory strengthens the foundation to reduce our emissions footprint throughout our supply chain,” Sandri said. “Equally important, we have implemented a variety of tools and management processes to evaluate our progress and identify additional opportunities in our production facilities.”

BUFFALO, Minn. — Since 1958, Minnesota’s turkey farmers have served crowd-pleasing turkey to the masses at the Minnesota State Fair, continuing the tradition into their 65th year.

Even though the name has changed over the years, “Turkeyteria,” “The Turkey House,” and “Pilgrim Tom’s Takeout Turkey,” the high-quality turkey menu items at Turkey to Go continue to exceed the expectations of turkey lovers everywhere, the Minnesota Turkey Growers Association notes.

The Giant Juicy Turkey Sandwich and Slow-Roasted Drumsticks remain fan favorites that celebrate the versatility of turkey as a meal. With 40,000 people (about twice the seating capacity of Madison Square Garden) served in 2022, there is no question that turkey is ready to headline the Great Minnesota GetTogether once again in 2023.

“The Giant Juicy Turkey Sandwich is a top-secret recipe,” said MTGA Board President Jake Vlaminck. “Once you’ve tried it, you’ll understand why it has been voted best in fair food.”

In addition to celebrating 65 years at the fair, Minnesota Turkey also

celebrates 15 years of donating a portion of Turkey to Go proceeds to Hunger Solutions Minnesota.

Last year, Minnesota hit a record high number of visits to food shelves, more than 5.5 million visits. That is almost 2 million more than 2021 and 1.7 million more than the previous record set in 2020. Hunger Solutions Minnesota connects families and individuals experiencing food insecurities to long term solutions to hunger.

The Minnesota State Fair runs Aug. 24-Sept. 4 in St. Paul, Minn. Turkey lovers can find Turkey to Go conveniently located across from the poultry building and next to the GotMilk stand. Also, keep up to date with Turkey to Go on Facebook (@ TurkeyToGo) and all things Minnesota Turkey @DiscoverMinnesotaTurkey.

ALEXANDRIA, Minn. — The Minnesota Turkey Growers Association Board of Directors is comprised of turkey producers and allied industry members. Each year, during the Annual Summit and annual meeting, members vote to fill expiring seats on the board.

This year, MTGA members elected R.J. Orsten, a turkey grower near Willimar, Minn., to the board to replace Paul Kvistad, a turkey grower from Wood Lake, Minn. Kvistad served MTGA for nine years and was termed out of his position on the board.

The 2023 board election included two additional seats up for election. Nate Van Beck, director of production accounting at Jennie-O Turkey Store; and Barry Koppen, director of poultry sales at Kindstrom-Schmoll, were both successful in their bids for re-election and remain on the board.

The board met after the annual meeting to elect new officers. Jake Vlaminck will take over as board president and Shane Wilhelm will become the new vice president. Corey Nelson will continue his position as treasurer.

Also during the summit, the Minnesota Turkey Research and Promotion Council, the farmer-led entity responsible for overseeing the Minnesota turkey check-off, announced its new board members and elected its 2023-24 leadership team.

Joining the MTRPC board in 2023 for three-year terms are Jon Klaphake and Sharleen Whittenburg. Klaphake and his wife Ashley own and operate Meadowlark Turkey LLC near Melrose, Minn. Whittenburg, and her husband Carl, grow turkeys and operate Protein Alliance LLC near Alexandira, Minn.

The board and members thanked retiring board member Ashley Klaphake, for the years of service and dedication she has provided to the MTRPC.

Following the annual meeting, the board met to elect officers for the coming year. Loren (Butch) Brey, who formerly served as vice president, will take over as board president. Tim Miller will assume the vice president role, and Peter Gruhl will be the next treasurer.

With this new leadership, the continued success of the Minnesota Turkey Research and Promotion Council is assured, the council noted, adding that the board is committed to continuing the mission of the MTRPC, which is to discover and share healthy practices for its members and consumers by advancing strong research and public education.

CHICAGO — Nutrition science experts from the American Egg Board’s Egg Nutrition Center (ENC) recently submitted public comments to the 2025 Dietary Guidelines Advisory Committee in response to elements of its proposed scientific review protocol to help achieve a complete and accurate picture of the current body of research around the relationship between diets and cardiovascular health.

The scientific review protocol establishes guidelines and requirements for the methodology the DGAC will use to assess nutrition research studies to inform its recommendations to the U.S. Departments of Health and Human Services and USDA in developing the 2025-2030 Dietary Guidelines for Americans.

“Eggs play an increasingly important role in American diets, and what we know about the benefits of eggs has grown exponentially as nutrition science has evolved. The American Egg Board and our highly credentialed scientists at the Egg Nutrition Center are committed to supporting the crucial work of the Dietary Guidelines Advisory Committee to ensure its esteemed members can make fully informed recommendations based on the breadth of current science,” said Emily Metz, president and CEO of the American Egg Board.

Specifically, the ENC submitted scientific comments related to the

(Continued on next page)

proposed review protocol for the question “What is the relationship between dietary patterns consumed and risk of cardiovascular disease?”:

• Consider expanding the current study duration criteria—currently limited to studies that ran for 12 weeks or more—to allow for studies of shorter duration, which comprise a significant portion of relevant scientific literature on the topic.

• Consider including additional biomarkers for cardiovascular health that have become generally recognized by the scientific community as valid and important to evaluating cardiovascular risk.

“There are important considerations not currently accounted for in the proposed scientific review protocol that will help ensure that the Committee has a complete and accurate understanding of what the current science says,” said Dr. Mickey Rubin, executive director of the AEB’s Egg Nutrition Center. “First, it is widely accepted that studies of shorter duration are sufficient in assessing the impact of diet on cardiovascular risk markers like blood cholesterol. The data from

those studies are potentially important and relevant to include in their review. Second, the science around cardiovascular health has advanced, and there are important biomarkers for cardiovascular risk that would not be captured in the current protocol.”

Full, detailed comments submitted to the DGAC as part of the public comments process are available at https://www. regulations.gov/comment/HHSOASH-2022-0021-0386.

As a research and promotion organization, the AEB does not and cannot attempt to influence policy. The AEB’s Egg Nutrition Center will continue to support and participate in the DGAC process by submitting scientific information that may be relevant to the current request for comments on behalf of America’s egg farmers when the public is invited to do so, the association noted.

The 2025 DGAC consists of 20 nationally recognized nutrition and public health experts appointed by HHS and USDA to review the current body of nutrition science and develop a scientific report with in-

dependent, science-based advice for HHS and USDA to consider as they develop the 2025-2030 Dietary Guidelines for Americans.

DOBSON, N.C. — Illegal drug trafficking just became a little harder in the western North Carolina mountain town of Dobson thanks to a donation from Wayne-Sanderson Farms. “Rowdy,” the small community’s first drug detection dog, is now patrolling the streets and taking a bite out of drug crime, the company announced.

Dobson, N.C., police Chief Shawn Myers and the city commission recently recognized the company for its contribution, which helped purchase and train the town’s new K-9 officer. Recent stops have sniffed out ever-larger shipments of illegal narcotics, some of it bound for Dobson and Surry County users.

Rowdy is an 18-month-old German shorthair pointer, a breed known for its strong olfactory capa-

bilities and its penchant for drug detection, as well as human and article searches. Myers said the K-9 officer’s deployment is timely. In only a few weeks on the job, Rowdy has already sniffed out methamphetamine and fentanyl in six different stops, leading to four arrests.

“People are excited that we have a new tool in this fight against drugs — we’ve received invitations from community groups and local schools to come down and show off the dog, and the word is spreading,” Myers said. “We have a message for drug dealers — stay clear of this community. Rowdy is out there with our officers, and we’ll sniff you out eventually.”

Interstate 77 runs through Surry County and nearby Dobson as it bisects the state, serving as an illicit drug supply line for the area, officials noted. The interstate is also a primary drug corridor for rural regions of Appalachia to the north and major drug markets in northeastern U.S. cities. Local law enforcement has seen major spikes in the trafficking of fentanyl, heroin, methamphetamine and other deadly narcotics.

Wayne-Sanderson Farms Dob-

Needing

Needing

The QUALITY, DESIGN, WARRANTY and PRICE you have come to expect.

The QUALITY, DESIGN, WARRANTY and PRICE you have come to expect.

Overdrive 16 watt EH80 50K competes with Floor light levels of other 25 watt models.

9 watts saved at every socket. Money in your pocket.

Overdrive 16 watt EH80 50K competes with Floor light levels of other 25 watt models. 9

Other models available in Dim and Non Dim models

*Available

Other models available in Dim and Non Dim models

www.aglights.com/800-657-0509

www.aglights.com/800-657-0509

*

*Energy

*IP66

*Constant

*Available with Junction Boxes.

*CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

*Constant

*CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

*5 YEAR WARRANTY!

son Complex Manager Matthew Wooten championed the company’s funding of the dog and its training.

“We knew we could help, and we wanted to because we can’t take a passive position on illegal drugs — drug use affects every family in this county, one way or the other,” Wooten said. “The lives lost, the impact on people, the crime and addiction — it’s not acceptable, and we wanted to do our part to make a difference.”

MTRPC recognizes the value the PHC program brings to farmers, farm workers, and industry partners. The goal of the scholarship fund is to expand participation in the PHC program and foster career growth in the turkey industry.

“The certificate program will help employees and managers get that extra boost, encouraging them to stay and grow in their turkey industry career,” said MTRPC Board President Loren Brey. “I would love to see more farm managers and employees take this course.”

BUFFALO, Minn. — Applications are now open for three full scholarships to the University of Minnesota’s Poultry Health Certificate (PHC) program, funded by Minnesota Turkey Research and Promotion Council.

The UMN course is designed to be flexible, with most courses offered online, the council noted, adding that the 12-credit program covers the underlying principles of poultry production and higher-level training in poultry health and disease. Students will also learn about farm finances, business management, and data collection focused on improving farm production and operation.

“The University of Minnesota Poultry Health Certificate is a program designed specifically for poultry professionals at all career stages,” (Continued on next page)

said Dr. Tim Johnson, UMN professor. “This scholarship is an excellent opportunity to fully fund the student’s education, building the steppingstones for career advancement and personal growth.”

A bachelor’s degree or prior college experience is not required for the PHC program nor the MTRPC scholarships, but a high school diploma is.

For more information about the PHC program and a link to the online MTRPC scholarship application, visit poultrytraining.umn.edu.

ensuring that education, research and training is conducted under a single umbrella.

The new foundation will bring the work of the Fluid Fertilizer Foundation, Foundation for Agronomic Research, and Nutrients for Life Foundation together and ensure that the industry’s resources are used for maximum impact.

The three pillars of the new FERT Foundation are fertilizer education, research, and training. Fertilizer education will continue under the Nutrients for Life program name. Training will operate under the Ford West Leadership Academy. Research will combine priorities of the Fluid Fertilizer Foundation and the Foundation for Agronomic Research. The new Foundation will be a separate 501(c)3 organization, and will be a private foundation, serving the needs of the fertilizer industry. TFI members will direct its activity.

ARLINGTON, Va. — The Fertilizer Institute has announced the consolidation of industry-supported organizations into the FERT Foundation, which will be dedicated to

It’s noted that the goals of the FERT Foundation include:

• Building greater understanding of the tremendous benefits afforded by using fertilizers, including an understanding of the industry’s commitment to sustainability.

• Developing easily digestible re-

search summaries for dissemination to retail agronomists.

• Building a body of research that is being used in education and with regulatory agencies.

• Spearheading a leadership program designed specifically for fertilizer industry members.

• Fostering and promoting careers in nutrient science and education –including 4R Nutrient Stewardship to a diverse audience of learners and educators.

The first annual Ford West Leadership Academy will be held January 15-18, 2024, in Houston, Texas. Further details, including a preliminary schedule and registration information are available at https://www.tfi. org/content/ford-west-leadershipacademy.

“The aim of the FERT Foundation is a world in which fertilizers are understood and appreciated, scientific research supports advocacy for sustainable fertilizer use, and an engaged, informed and diverse workforce serves a thriving industry,” Corey Rosenbusch, TFI president and CEO, said. “By leveraging economies of scale and more closely aligning objectives, these organizations will better serve the industry

than could the existing patchwork of stand-alone organizations.”

Further information on the FERT Foundation, visit https://www.tfi. org/content/fert-foundation.

ARLINGTON, Va. — The American Feed Industry Association is now accepting nominations through Aug. 28 for its annual Friend of Pet Food Award, to be recognized at the AFIA Pet Food Conference on Jan. 30, 2024. Launched in 2019, the award recognizes individuals who have made significant contributions to support the growth of the pet food industry.

“The AFIA Friend of Pet Food Award celebrates the unwavering dedication and pioneering spirit of those who contribute to the advancement of pet food research and

innovation,” said Louise Calderwood, AFIA’s director of regulatory affairs. “It recognizes the tireless efforts of those committed to ensuring the well-being and happiness of our furry friends through cutting-edge nutritional discoveries. Their passion and commitment shape the future of pet nutrition, strengthening the bond between humans and their beloved animal companions.”

An ideal nominee will be currently employed and active in the pet food industry or an associated area, such as new product development, transportation, regulatory, academia, media or promotion, the associated noted. There is no restriction by company or industry affiliation, or the function performed by the nominee.

The award winner will be invited to attend the 2024 AFIA Pet Food Conference which is being held in conjunction with the International Production & Processing Expo in Atlanta, Ga., happening Jan. 30-Feb. 1, 2024, where they will be publicly recognized with a plaque.

For more information on the award or to nominate someone, visit www.afia.org/friendofpetfoodaward.

Zaxby’s welcomes Lau as new chief financial officer

ATHENS, Ga. — Zaxby’s® is welcoming Donny Lau as chief financial officer effective as of July 25. With more than 20 years of experience, Lau comes to Zaxby’s most recently from Dollar General, where he served as senior vice president, finance & chief strategy officer. Prior to his Dollar General tenure, Lau held numerous roles at Yum! Brands. At Zaxby’s, Lau will lead the finance function, including financial strategy, planning and analytics, accounting and treasury.

“Donny’s proven track record in driving financial growth in QSR and retail organizations, implementing effective strategies and navigating complex financial landscapes makes

him a perfect fit for Zaxby’s as we embark on our next phase of growth and expansion,” said Bernard Acoca, Zaxby’s CEO. “I am confident that his expertise and leadership will further elevate our organization’s financial performance and position us for continued success.”

Lau joins Zaxby’s from Dollar General where he served as the senior vice president, finance & chief strategy officer. Since joining Dollar General in 2017, Lau held a variety of leadership positions overseeing many of the company’s key corporate finance functions including strategy, corporate development, investor relations, financial planning & analysis (FP&A) and strategic planning.

While at Yum! Brands, Lau held numerous roles of increasing responsibility, including mergers and acquisitions, FP&A, investor relations, corporate strategy and corporate planning. He also helped architect and played a lead role in the 2016 spin-off of Yum! China into a separate publicly traded company and the subsequent financial refranchising strategy to transform Yum! Brands into a capital-light pure-play franchisor.

Lau received his bachelor’s degree from the University of Kentucky and holds an MBA in finance and strategy from Vanderbilt University.

“I am very excited to join Zaxby’s and work alongside this talented team, including our team members and franchisees, to drive the next chapter of growth,” Lau said. “I look forward to helping build on the company’s strong foundation and positive momentum as we continue to capitalize on growth opportunities we see ahead, while delivering meaningful value creation for all stakeholders.”

GREELEY, Colo. — According to a recent report, Americans eat more than 28 million chicken wings per year. That’s a lot of wings! Pilgrim’s is helping wing lovers “Get Lost in Flavor, Not Sauce” with the introduction of its new no-sauce, full-flavor Garlic Parm Chicken wing to shake up your summer menu.

These new “mega meaty” wings

will be available at Costco locations throughout the northeast United States. The wings are marinated and seasoned with a blend of rubbed spices and can be baked, microwaved, or prepared in an air fryer.

“Mixing things up is a great way to add a little excitement and variety to your summer menu. It’s also a great way to add flavor without the mess, and that’s always a plus!” said Rizwan Akbar, head of commerce, Pilgrim’s.

Founded in Texas in 1946, Pilgrim’s is one of America’s largest chicken companies and works with more than 4,000 family farm part-

ners. Garlic Parm Wings join the Pilgrim’s® prepared chicken portfolio, adding a welcome addition to their diverse flavor profile offerings. This includes their Popcorn Chicken, Original and Hot & Spicy Nuggets, Fillets, Strips, and other delicious products.

Pilgrim’s Garlic Parm Chicken Wings are sold in four-pound bags and made with all-natural chicken with no hormones, or steroids. The chicken is minimally processed and uses no artificial ingredients. For more information, visit https:// www.pilgrimsusa.com/product/ garlic-parm-wings.

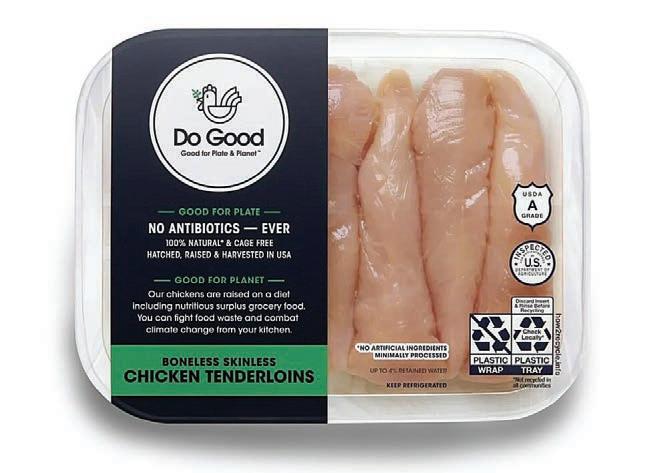

Do Good Foods receives Environment + Energy’s ‘Top Product’ award BEDMINSTER, N.J. — Do Good Foods has announced that its flagship product, Do Good Chicken®, has won the prestigious Top Product of the Year Award in the 2023 Environment + Energy Leader Awards program. This award recognizes Do Good Foods as an exemplary leader in the sustainable food

(Continued on page 19)

space and its positive impact in energy or environmental management.

What makes Do Good Chicken award winning? First, Do Good Foods takes healthy surplus food from grocery stores and upcycles it into nutrient-dense chicken feed, the company said, adding that its upcycled animal feed provides chickens with a more natural diet. Do Good Chickens are then fed this feed and sold at grocery stores, restaurants, or cafeterias. The company notes that every purchase of Do Good Chicken empowers consumers to now be a part of a climate change solution, while simply enjoying a delicious chicken on their plate.

This unique “closed loop” process reduces the food waste and greenhouse gas emissions typically associated with poultry production, Do Good Foods said.

It was Do Good’s that gained the attention of the award program’s panel of judges, the company said. One judge noted, “Do Good Foods is producing a better tasting chicken while at the same time promoting a model for food sustainability. That’s a win-win for all of us.”

Each Do Good Chicken saves surplus grocery food from being thrown away, thereby preventing the release of 3 lbs. of greenhouse gases (CO2e) from entering the atmosphere, the company said.

“I’m exceptionally proud of the Do Good Foods team, and this important award affirms that our efforts are both having an impact and getting noticed by the industry,” said Justin Kamine, the co-CEO of

Do Good Foods. “We’re making a difference. Since its launch, Do Good Foods has diverted more than 32 million pounds of surplus grocery food from the landfill to date, saving more than 4,300 metric tons of greenhouse gases ( CO2e ) from entering the atmosphere.”

The Environment + Energy Leader Awards program aims to commend excellence in products and projects that deliver significant

energy and environmental benefits.

Sarah Roberts, co-president of E+E Leader, emphasized the rigorous selection process, stating, “This year’s entrants had to surpass an exceptionally high bar to qualify for an award, thanks to a seasoned and discerning judging panel as well as stringent judging criteria.”

For more information about Do Good Chicken, visit: http://www. DoGoodFoods.com.

Our new Fast Track Wall Vent (Patent Pending) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available either insulated or uninsulated

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

ATLANTA — The R. Harold and Patsy Harrison Research Faculty Fellowship recognizes innovative, promising early-career research faculty interested in exploring breakthrough applied engineering and science research to address poultry industry challenges. The three-year fellowship, within the Georgia Tech Research Institute’s Agricultural Technology Research Program (ATRP), is awarded to an entry-level researcher through a competitive application process.

The fellowship’s first recipient, Dr. Konrad Ahlin, recently completed his tenure, and in the following questions and answers, shares his thoughts on the experience.

Q: What drove you to apply for the fellowship?

A: I was driven to apply for the fellowship so that I could learn more about the poultry industry. I have a background in robotics and mechanical systems, and I wanted to help apply these skills to food processing. The dexterity and coordination required to emulate manual

labor is beyond the capacity for machines to replicate, so I believe that food processing and agriculture will be the next frontier of robotics. This fellowship was an amazing opportunity to learn more about how poultry products are made in this country and where the challenges are.

Q: What was the focus of your research?

A: The focus of my research was on manipulation of products. One of the crucial and most challenging aspects of robotics is the boundary where machines meet the real world. Understanding the nuances of grasping, lifting, and manipulating is crucial if we want robots to interact with manufacturing. Within the poultry industry, strategies for handling the product change with every step of the process, compounding the complexity of introducing mechanical labor.

Q: What was the most rewarding aspect of your fellowship experience?

A: The most rewarding aspect of the fellowship was the opportunity to meet people. I spoke last year at the RMC (American Meat Science Association’s Reciprocal Meat Conference), and, at that event and others, I have talked with people from every stage of poultry processing.

From farmers who raise the birds, to the operators who debone the product, to the owners who run the processing facilities. Also, learning about how poultry is processed has been extremely rewarding. The infrastructure is amazingly complex, with hundreds of nuances threaded through each task.

Q: Did the fellowship provide you with any insights that you hadn’t anticipated?

A: I have a philosophy when it comes to robotics: if you want to automate a task, you first have to do it yourself. The insight that most impressed itself on me through this process is how far robotics still has to go before it can compete with the dexterity and subtle artistry of a person. Often, if a person performs a task for long enough, they will find the most efficient means of performing the task. As a roboticist, I strive to learn from people so that I can apply those methods to machinery. What I hadn’t expected was just how optimized these tasks have become under human-powered labor. People always find the best, most efficient way to do something within their constraints.

Q: Were there any opportunities the fellowship provided that you may not have had otherwise?

A: This fellowship was an opportunity for me to learn. Before the fellowship, I had some limited insights into the poultry industry. However,

during the fellowship, I had the freedom to explore and experiment with different ideas to gain a better understanding of how the poultry industry operated.

Q: How has the fellowship influenced your research path and career goals?

A: This fellowship has pushed me out of my comfort areas. I don’t know that my research will drastically change the industry, but I do know that nothing will be changed by tame questions or timid ideas.

Q: What advice would you give to other early-career researchers who may be interested in applying for the fellowship?

A: I would suggest that any researcher who is interested in applying for the fellowship should go into the experience with questions rather than answers. Researchers want to find solutions; it’s the nature of the job. However, take the time to listen to those in industry. Observe how it’s done. Find out what the needs are. Only then should you find the questions that interest you and pursue them. Take risks, be bold, and see what you can discover.

Reprinted from PoultryTech, a publication of the Agricultural Technology Research Program of the Georgia Tech Research Institute, a program conducted in cooperation with the Georgia Poultry Federation with funding from the Georgia Legislature.

University of Missouri

COLUMBIA, Mo. — One of the main reasons plants use water is to allow them to absorb carbon dioxide from the atmosphere. This means that, in plants, the water and carbon cycles are tightly linked. In a new study, researchers from the University of Missouri and the USDA used this foundational prin-

ciple to identify sustainable farming practices aimed at helping staple crops like corn and soybeans thrive during extreme weather conditions that have become more common in the Midwest.

This study examined how farming practices affect crop resilience to climate change by examining water and carbon fluxes in three contrast-

ing ecosystems: A business-as-usual tilled cropping system, an aspirational no-till cropping system with cover crops, and a native tallgrass prairie ecosystem.

“One of the big goals is what we call climate-smart agriculture, which can mean using crops to absorb carbon out of the air, but it also means trying to adopt farming

practices that help farms adapt to the changing climate,” USDA research hydrologist Adam Schreiner-McGraw said. “As it gets hotter, plants get more stressed, and that means they often have lower yields. This research is focused on understanding adaptation and how to work toward more resilient agro-ecosystems.”

A comparison of rates of evapotranspiration — when water transfers from the land to the atmosphere— and carbon dioxide exchange revealed interesting patterns among ecosystems. In an analysis of data collected over the past fouryear cycle, the native prairie ecosystem had higher rates of evapotranspiration than the tilled cropping system. In comparison, however, the prairie’s rate of evapotranspiration didn’t differ much from that of the no-till cropping system. Further, both cropping systems had higher amounts of plant growth (i.e., carbon uptake) than the native prairie.

From these findings, the tilled cropping site appears the most sensitive to environmental changes compared to the native prairie, which is most resilient to extreme weather, Schreiner-McGraw, who works in the USDA’s Cropping Systems and Water Quality Research Unit on MU’s campus, said. Moreover, because the no-till system has the most crop diversity, including corn, soybeans, wheat, and hay, it had the most variable rates of evapotranspiration. This phenomenon SchreinerMcGraw attributes to agricultural management strategies.

Understanding variable rates of evapotranspiration help scientists weigh if the ‘planned’ management has a bigger impact on the water and carbon budgets than the ‘unplanned’ weather variability, which can help with predictions for crop water and carbon uptake as extreme weather gets worse.

Another way to build environmental resistance is to plant a diversified rotation of crops over the long term, said Jeffrey Wood, an assistant professor in the MU School of Natural Resources. As climate fluctua-

tions intensify — for Missouri, that’s warmer, wetter winters and drier summers with less frequent rain — understanding how best to support crop adaptation and which crops to plant at what times of the year has become increasingly necessary.

“The type of work we do lends itself to collaboration because we all share data in a community-based network,” Wood said. “People are always willing to share ideas, which makes it easy to work together and contribute to research that expands in scope from the problems one re-

An eddy covariance tower, a tool which measures the breathing capacity of an ecosystem, sits in Tucker Prairie, Missouri’s largest remaining virgin tall-grass prairie.

searcher might be working on locally to those another might face on a bigger scale.”

“Agriculture accentuates interannual variability in water fluxes but not carbon fluxes, relative to native prairie, in the U.S. Corn Belt” was published in Agriculture and Forest Meteorology. Co-authors include Megan E. Metz, John Sadler and Kenneth Sudduth. This research is a contribution from the Long-Term Agroecosystem Research (LTAR) network, which is supported by the USDA.

WEST LAFAYETTE, Ind. — Christian Krupke, professor of entomology at Purdue University, has been named the Dean’s Fellow for Resilient Agriculture to provide research leadership aimed at making agriculture more productive and durable.

Krupke will lead a multiyear initiative that brings together research faculty from different disciplines in the College of Agriculture. Their goal is twofold: to conduct longterm research that helps farmers make decisions based on reliable, field-scale data and to demonstrate practices that bolster the durability of the entire agricultural system.

“There’s an incredible amount of federal and private industry funding going into this broad field, but some of the practices either are not being tested in a rigorous and systematic way, or the results are not being clearly communicated to growers,”

Krupke said. “This is an area where Purdue research and extension can have influence.”

Working on dedicated land owned by the university, the researchers will describe what resilient agriculture looks like in practice using

a systems approach that includes their collective specialty areas. Experiments incorporating these techniques will occur at field scale over several years to compare traditional and resilient farming practices, and the approaches will change as new

information comes to light.

“Dr. Krupke’s research and extension programs in pest management of corn and soybeans over nearly 20 years make him an ideal person to lead this effort,” said Karen Plaut, executive vice president for research and former dean of the College of Agriculture. “His program in field crops entomology continues to track the leading edge of the discipline through groundbreaking discovery research and the delivery of highimpact integrated pest management solutions for stakeholders.”

Krupke defines resilient agriculture as “considering the needs of the present without sacrificing system durability for the future.”

“Many people in Purdue Agriculture are working to improve the sustainability and profitability of Indiana farms,” said Ken Foster, interim dean of the College of Agriculture. “Now, their efforts to develop new practices and methods that create a more resilient food supply can be better integrated across disciplines and demonstrated directly to our state’s farmers.”

Krupke also is currently seeking

The Associated Press

PHOENIX — The summer of 2023 is behaving like a broken record about broken records.

Nearly every major climate-tracking organization proclaimed June the hottest June ever. Then July 4 became the globe’s hottest day, albeit unofficially, according to the University of Maine’s Climate Reanalyzer. It was quickly overtaken by July 5 and July 6. Next came the hottest week, a tad more official, stamped into the books

(Continued from page 23)

input from growers, commodity organizations, conservation groups and industry representatives to ensure that the approaches selected are realistic and viable for a range of practitioners.

Baseline data collection in this inaugural year will occur on 102 acres at the Agronomy Center for Research and Education and on additional acreage at two of eight

by the World Meteorological Organization and the Japanese Meteorological Agency.

With a summer of extreme weather records dominating the news, meteorologists and scientists say records like these give a glimpse of the big picture: a warming planet caused by climate change. It’s a picture that comes in the vibrant reds and purples representing heat on daily weather maps online, in newspapers and on television.

Purdue Agricultural Centers. The study design will compare paired, adjacent fields: one farmed using common, traditional methods and the other with techniques that researchers, farmers and conservation groups collectively characterize as resilient. Researchers will measure such parameters as soil health, beneficial and pest insects, pathogens, weed and yield per acre over time.

“Purdue entomology is dedicated

Beyond the maps and the numbers are real harms that kill. More than 100 people have died in heat waves in the United States and India so far this summer.

Records are crucial for people designing infrastructure and working in agriculture because they need to plan for the worst scenarios, said Russell Vose, climate analysis group director for the National Oceanic and Atmospheric Administration. He also chairs a committee on national

to addressing challenges in agricultural production and the preservation of natural resources,” said Cate Hill, department head. “Christian is involving disciplines beyond our own in this systems-wide approach to strengthening agricultural resilience.”

“Currently, if you’re a farmer and you say you want to get involved in resilient agriculture and implement some novel approaches, it’s very

records.

In the past 30 days, nearly 5,000 heat and rainfall records were broken or tied in the U.S. and more than 10,000 records set globally, according to NOAA. Texas cities and towns alone have set 369 daily high temperature records since June 1.

Since 2000, the U.S. has set about twice as many records for heat as those for cold.

“Records go back to the late 19th century and we can see that there has been a decade-on-decade increase in

(Continued on page 27)

difficult to find out — clearly and definitively — what your next steps should be and what the relative pros and cons of different approaches may be,” Krupke said.

He hopes results from the study will help growers make informed decisions on their own land, but he already has a sense of its overriding theme: “We have to be more judicious about everything we do.”

SAN MARCOS, Texas —

The USDA has awarded Texas State University a $5 million grant to encourage non-traditional agricultural audiences to consider potential careers in the agricultural, natural resources and human sciences (FANH) workforce.

The five-year grant will support the Research Through Agriculture Internships, Scholarships and Experiential Learning (RAISE) program, overseen by project director Doug Morrish, a professor in the Department of Agricultural Sciences. Eryn Pierdolla, a lecturer in the Department of Agricultural Sciences, Nicole Wagner, an assistant professor in the Department of Agricultural Sciences, and Pratheesh Omana Sudhakaran, an assistant professor in the Department of Agricultural Sci -

ences, will serve as co-PDs.

Texas A&M University AgriLife Extension, Houston Community College, Palo Alto College, Laredo College and Austin Community College are partner institutions on the project.

The program will address the challenge by creating a one-of-akind internship hub to annually provide 55 paid internships for the fall, spring and summer semesters. These internships will partner students with the USDA, Texas A&M AgriLife Extension and Texas State’s Bobcat Farm. RAISE will specifically target urban counties to raise awareness of USDA opportunities among a wider, non-traditional agriculture audience that may not otherwise consider a FANH career due to lack of exposure.

Community college students participating in RAISE will directly benefit by being enrolled in the courses “Careers in Agriculture” and “Ag Internship,” both counting toward their fouryear degree upon transfer to Texas State. The revised curriculum for “Careers in Agriculture” will help develop the career and leadership skills of more than 1,500 students.

RAISE will also utilize a number of other strategies to reach the program’s goals. RAISE will provide an on-boarding process to include families in students’ career choice journey and also implement a mentoring program using former USDA fellows that have already participated in an internship and have employment in USDA or government agencies. The program will also initiate outreach for FANH majors other than agriculture, including nutrition, family and consumer science, engineering, biology and chemistry.

The Texas State grant is part of the larger “From Learning to Leading: Cultivating the Next Generation of Diverse Food and Agriculture Professionals Program” (NextGen) initiative from the USDA’s National Institute of Food and Agriculture. The $262 million NextGen investment in institutions of higher education is intended to foster the next generation of diverse agricultural professionals across the nation.

temperatures,” said Gavin Schmidt, director of NASA’s Goddard Institute for Space Studies, keeper of the agency’s climate records. “What’s happening now is certainly increasing the chances that 2023 will be the warmest year on record. My calculations suggest that there’s, right now, a 50-50 chance.”

The larger the geographic area and the longer stretch of time during which records are set, the more likely the conditions represent climate change rather than daily weather. So the hottest global June is “extremely unlikely” to happen without climate change, as opposed to one city’s daily record, Texas state climatologist John Nielsen-Gammon said.

Still, some specifics are striking: Death Valley flirted this summer with the hottest temperature in modern history, though that 134 degree F record is in dispute.

Phoenix grabbed headlines among major U.S. cities on July 18 when it marked a 19th consecutive day of unrelenting mega heat: 110 degrees F or more. It kept going, reaching a 22nd straight day on July 21. The daytime heat was accompanied by a

record stretch of nights that never fell below 90 degrees F.

“Everybody’s drawn to extremes,” Vose said. “It’s like the Guinness Book of World Records. Human nature is just drawn to the extreme things out of curiosity.”

But the numbers can be flawed in what they portray.

Think of the individual statistics as brush strokes in a painting of the world’s climate, Cornell University climate scientist Natalie Mahowald said. Don’t fixate on any specific number.

She and other climate scientists say long-term warming from burning coal, oil and natural gas is the chief cause of rising temperatures,

along with occasional boosts from natural El Nino warmings across parts of the Pacific, like the planet is experiencing this year.

El Nino is a natural temporary warming of parts of the Pacific that changes weather patterns worldwide and adds an extra warm boost. An El Nino formed in June and scientists say this one looks strong. For the previous three years El Nino’s cool flip side, La Nina, dampened a bit of the heat humans are causing.

A super El Nino spiked global temperatures in 1998, then was followed by less warming and even some flat temperatures for a few years until the next big El Nino, Mahowald said.

Weather won’t worsen each year and that should not become a common expectation, but it will intensify over the long run, she said.

The University of Michigan’s Richard Rood used to blog about climate records for Weather Underground, but in 2014 he got sick of continuously new extremes and stopped.

“I think we need to get away from that sort of record-setting sensationalism at some level and really be getting down to the hard work,: he said, addressing the need for people

to adapt to a warmer world and get serious about slashing emissions that cause hotter, more extreme weather.

NOAA tracks weather observations from tens of thousands of stations throughout the U.S. and its global calculations incorporate data from more than 100,000 stations, Vose said.

When those records come in, the agency checks their quality and calculates where the numbers fit historically. NOAA’s National Center for Environmental Information in North Carolina is the arbiter of national records, while the local National Weather Service offices handle those for individual cities, Vose said.

A special international committee deals with world records and, at times, scientists disagree on the reliability of 100-year-old data.

Validating records takes time. Because of a backlog of extreme weather events to analyze, officials haven’t finished approving 130-degree F records from 2020 and 2021 at Death Valley, Vose said.

“Our primary job is keeping score, meaning what happened? How unusual was it?” he asked. “It’s not like we take great joy in saying it was the warmest year on record. Again.”

WASHINGTON — The National Aeronautics and Space Administration has announced eight winning teams and awarded $750,000 in prizes in the second phase of the agency’s Deep Space Food Challenge. The winning teams will move on to compete in the third and final phase of the challenge.

As NASA prepares to send astronauts farther into the solar system than ever before, the agency needs food systems that can fortify future crews in deep space for years at a time. The Deep Space Food Challenge calls on solvers from around the world to create technologies to help feed astronauts on future long-term space missions.

“These creative winning solutions come from teams made up of business, universities, and individual solvers, showcasing how NASA can benefit from everyone’s expertise to solve crucial

challenges,” said Amy Kaminski, program executive for Prizes, Challenges, and Crowdsourcing in NASA’s Space Technology Mission Directorate (STMD) at NASA Headquarters in Washington. “We’re excited to announce Phase 3 of the challenge to see where these teams can take their technologies next.”

Phase 2 tasked dozens of teams with building and demonstrating small-scale prototypes of technologies that use minimal resources

and create little waste while producing safe, healthy, and appetizing foods for astronauts. A panel of judges selected eight winners to build and demonstrate full-scale food technologies over the next year in Phase 3.

The following U.S. teams will each receive $150,000 in prizes from NASA and advance to compete for up to $1.5 million in total prizes from NASA in Phase 3:

• Air Company of Brooklyn, N.Y., developed a system and processes for turning air, water, electricity, and yeast into food.

• Interstellar Lab of Merritt Island, Fla., created a modular bioregenerative system for producing fresh microgreens, vegetables, mushrooms, and insects.

• Kernel Deltech USA of Cape Canaveral, Fla., developed a system for cultivating mushroombased ingredients.

• Nolux of Riverside, Calif., created a solution that mimics the photosynthesis that happens in nature to produce plant- and mushroom-based ingredients.

• SATED (Safe Appliance, Tidy, Efficient, and Delicious) of Boulder, Colo., developed a space cooking appliance that would allow astronauts to prepare a variety of meals from ingredients with long shelf lives.

NASA and the Canadian Space

Agency also jointly selected three international teams as Phase 2 winners. These three teams are invited to advance their technologies in Phase 3:

• Enigma of the Cosmos of Melbourne, Australia, created an adaptive growing system to increase the efficiency of plants’ natural growth cycles.

• Mycorena of Gothenburg, Sweden, developed a system that uses a combination of microalgae and fungi to produce a microprotein.

• Solar Foods of Lappeenranta, Finland, created a system that uses gas fermentation to produce single-cell proteins.

“Astronauts will tell you that tasty and nutritious food is a critical part of any successful human space exploration mission,” said Denise Morris, program manager of NASA Centennial Challenges at NASA’s Marshall Space Flight Center in Huntsville, Ala. “The possibilities presented in this challenge could help sustain our explorers on future missions, and even have the potential to help out right here on Earth in areas where food is scarce or hard to produce.”

The competition is a first-of-itskind collaboration between NASA and CSA. In April, CSA awarded prizes to the teams advancing to the final stage of the Canadian challenge, which runs in parallel with NASA’s.

The Deep Space Food Challenge is one of NASA’s Centennial Challenges, which are part of the Prizes, Challenges, and Crowdsourcing program within STMD. NASA Marshall manages Centennial Challenges. Subject matter experts at NASA’s Johnson Space Center in Houston and NASA’s Kennedy Space Center in Florida support the competition. NASA, in partnership with the Methuselah Foundation, manages the U.S. and international competitors.

For more information on NASA’s Deep Space Food Challenge, visit https://www.nasa.gov/spacefoodchallenge.

(Aug. 1): New York eggs were unchanged on all sizes. Regional and California eggs were steady. The undertone is steady. The national shell egg inventory was up 1.1 percent when compared to the previous week. Demand was moderate to fairly good. Offerings were light to moderate. Supplies were moderate. Market activity was moderate. Breaking stock offerings were light to very light for the light to moderate demand. The national breaking stock inventory was down 6 percent from previous week. Light type fowl offerings were fully sufficient; processing schedules were normal to less than normal, the USDA Agricultural Marketing Service reports.

Shell egg demand indicator (July 26): Consumer demand for shell eggs continues to track at an average level as a consistent wholesale market is bringing a reassuring stability to the shopper experience. Wholesale prices for cartoned eggs remain steady on a light to moderate offerings and moderate supplies. Interest is moderate to good on moderate trading. Prices on the loose egg market remain steady on light to moderate offerings and moderate supplies and interest. Trading is moderate. Wholesale breaking stock prices are steady with light to moderate demand, light offerings, and moderate supplies. Schedules vary and trading is slow to moderate. The preliminary survey of retail outlets indicates a slowdown in the recent active pace of promotions with a slightly lower average ad price.

Broiler: Estimated slaughter for week ending July 29 was 158,563,000. Actual slaughter for the week ending July 22 was 158,358,000.

Heavy-type hen: Estimated slaughter for the week ending July 29 was 2,022,000.

Actual slaughter for the week ending July 22 was 1,911,000.

Light-type hen: Estimated slaughter for the week ending July 29 was 732,000. Actual slaughter for the week ending July 22 was 756,000.

Total: July 29: 161,317,000; July 22: 161,025,000. The estimated number available for the week ending July 29 is 167.6 million.

Negotiated prices in trucklot and less-than-trucklot quantities of ready-to-cook whole body broiler/fryers delivere d to first receivers; prices in cents per pound

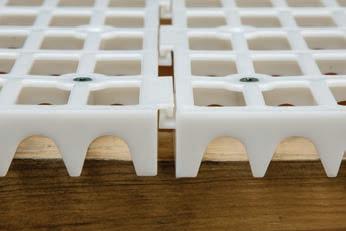

Rectangle slots create 58.5% of total opening to reduce manure buildup resulting in a cleaner floor.

Each 2’ x 4’ panel weighs 6.7 pounds...over 3/4 of a pound more than competitive brands. 21 longitudinal ribs compared to others with only 17 ribs provides a level slat surface with only three support runners.

Multiple interlocking edge tabs reduce flexing to promote a flat, stable walking surface. Arch latitudinal ribs furnish greater support to the longitudinal ribs.