It takes a farmer to understand a farmer. And here at Liphatech Ag, we have the farming and ranching backgrounds to know what you’re up against every day. Your dedication, grit and selflessness don’t go unnoticed. Our team is here to support you in every way we can.

WE HAVE YOUR BACKS, BARNS AND BOTTOM LINES.

Rats and mice accelerate the spread of at least 35 diseases that plague animal production

Left unchecked, rodent populations will expand rapidly, spreading disease to areas and animals

odents cause damage to facilities, increase energy costs and contaminate feed

itan bait stations are ready-to-go and require no additional securing thanks to a pre-installed custom brick, eliminating the fear of the station blowing away

eighted stations are less likely to be disturbed by livestock and non-target animals

emovable tray for faster bait replacement: saves time and labor costs

emember to rotate your bait to prevent resistance to a specific formula

Meet Titan, the Weighted Bait Station from Tomcat designed to make implementing your Rodent Control program simple, fast and effective, without the fear of the station blowing away.

Can use chunks, soft bait, place pacs in bait stations.

necessarily reflect the opinions of Poultry Times. advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

aviagen, 23 256-890-3800; www.aviagen.com

Biosafe systems, 14 860-290-8890; www.biosafesystems.com

Boehringer ingelheim, 3 www.boehringer-ingelheim.com

cackle Hatchery, 20 417-532-4581; www.cacklehatchery.com

cobb-Vantress, 21 479-524-3166; www.cobb-vantress.com

creekview Mfg., 20 717-445-4922;

https://creekviewmanufacturing.com

eagan Mfg., 28 870-878-6805; www.eaganmfg.com

FPM inc., 31 402-729-2264; www.fpmne.com

Henning companies, 33 515-253-0943; www.henningcompanies.com

Hog slat, 39 800-949-4647; www.hogslat.com

Hubbard, 30 423-447-6224; www.hubbardbreeders.com

iMPeX, 32 770-534-1590; www.impex.nl

Kelley Mfg., 34 800-444-5449; www.kelleymfg.com

Kuhl corp., 31 908-782-5696; www.kuhlcorp.com

Kunafin (The insectary), 31 800-832-1113; www.kunafin.com

L.B. White, 24 608-783-5691; www.lbwhite.com

Liphatech, 2

414-351-1476; https://liphatech.com

Metzer Farms, 17 831-240-1946; www.metzerfarms.com

Motomco, 4 800-237-6843; www.motomco.com

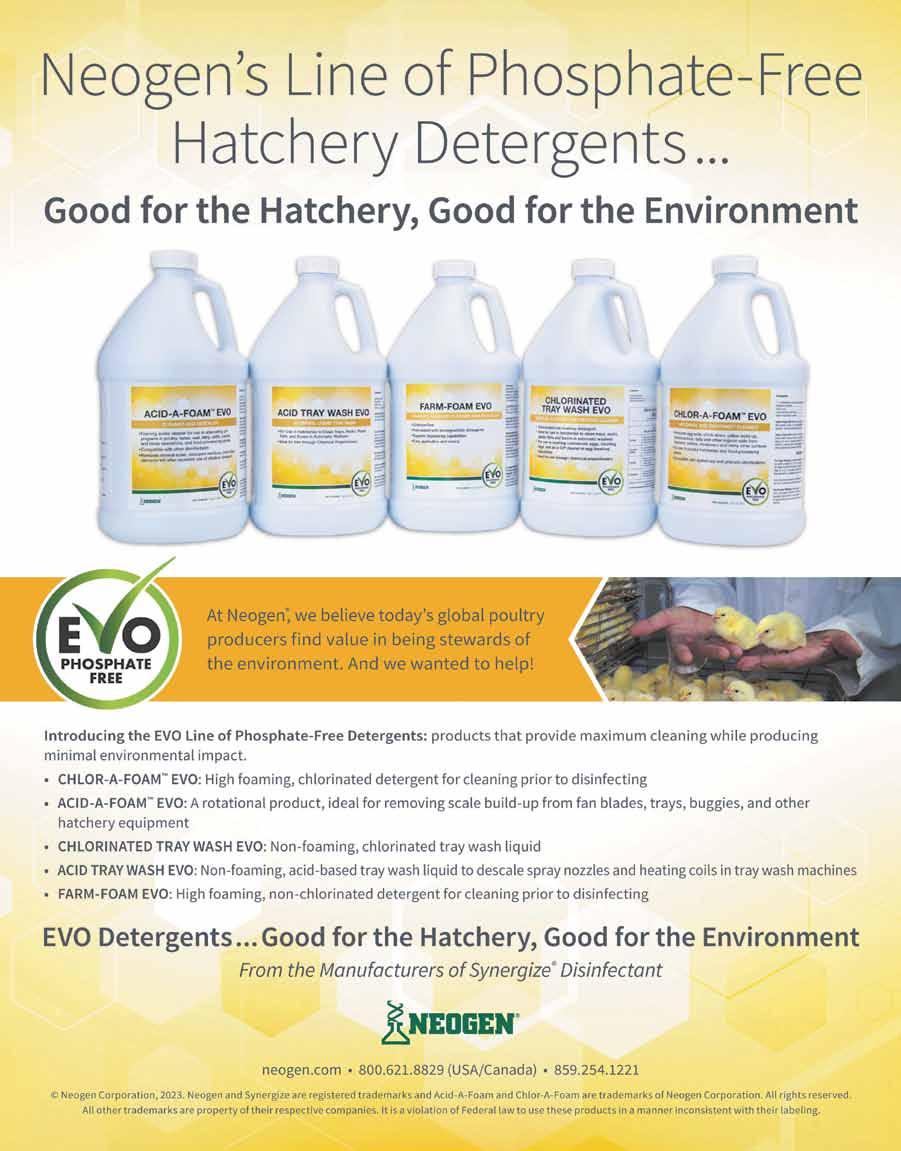

Neogen, 40 800-234-5333; www.neogen.com

Overdrive Lighting, 18 800-657-0509; www.aglights.com

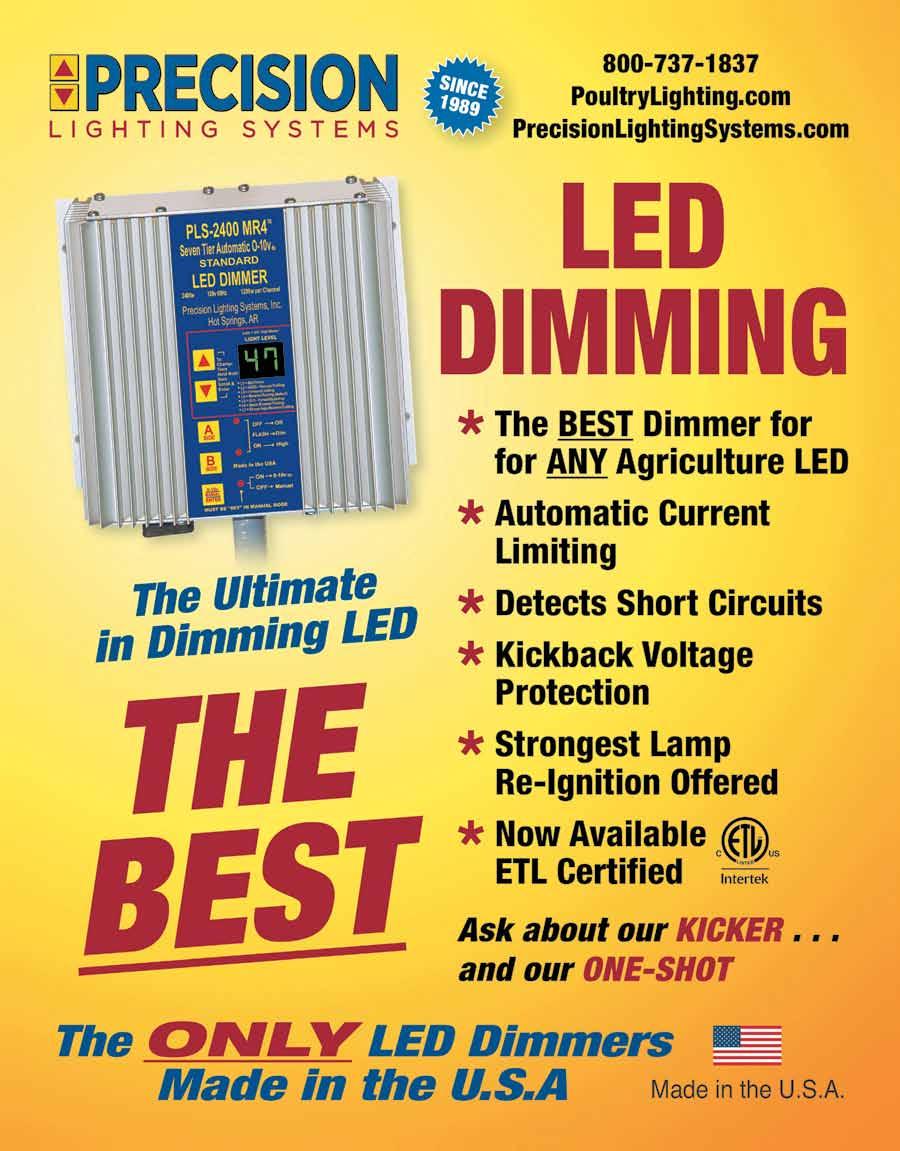

Precision Lighting, 1, 15, 25, 37 800-737-1837; www.poultrylighting.com

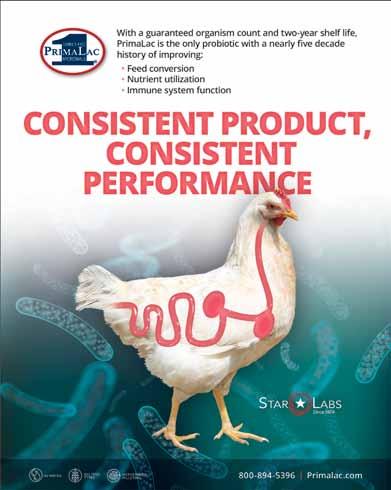

star Labs, 17 800-894-5396; www.primalac.com

The egg carton store, 31 866-333-1132; www.eggcartonstore.com

Walinga Usa, 38 800-466-1197; www.walinga.com

Weightech, 32 800-457-3720; www.weightechinc.com

Ziggity, 16 574-825-5849; https://ziggity.com

General Manager

cindy Wellborn

770-718-3443

cwellborn@poultrytimes.com

editor

david B. strickland

770-718-3442

dstrickland@poultrytimes.com

digital Manager rachel danford

770-718-3438

rdanford@poultrytimes.com

senior sales executive stacy Louis

770-718-3445

slouis@poultrytimes.com

sales support

Janice sisk

770-536-2476

jsisk@poultrytimes.com

content Writer elizabeth Bobenhausen

770-209-3335

ebobenhausen@poultrytimes.com

WASHINGTON — The USDA, in recent reports, gives its updates on broiler chicks and turkey poult hatch numbers.

In its most recent “Chickens and Eggs” report, the USDA’s National Agricultural Statistics Service notes that broiler-type chicks hatched for April were down slightly.

“Broiler-type chicks hatched during April 2023 totaled 819 million, down slightly from April 2022,” NASS said. “Eggs incubators totaled 723 million on May 1, 2023, up slightly from a year ago. Leading breeders placed 7.88 million broilertype pullet chicks for future domestic hatchery supply flocks during April 2023, down 1 percent from April 2022.”

For turkey poults, NASS reports an increase of 4 percent for May in its June “Turkey Hatchery” report.

“Turkey poults hatched during May 2023 in the United States totaled 23.5 million, up 4 percent from May 2022,” the report said. “Poults hatched were up 11 percent from the April 2023 total of 21.1 million poults.”

Turkey poults hatched were also increased 4 percent for the month, NASS adds.

“The 22.4 million net poults placed during May 2023 in the United States were up 4 percent from the number placed during the same month a year earlier,” the report said. “Net poult placements were up 12 percent from the April 2023 total of 19.9 million.”

For broiler egg-type chicks, they are reported down 8 percent for the month, USDA notes.

“Egg-type chicks hatched during April 2023 totaled 46.4 million, down 8 percent from April 2022,” NASS said. “Egg in incubators totaled 47.4 million on May 1, 2023, down 7 percent from a year ago.”

Turkey eggs in incubators at the beginning of June were up 7 percent from last year, the agency noted.

“Turkey eggs in incubators on

June 1, 2023, in the United States totaled 28.8 million, up 7 percent from June 1, 2022,” NASS said. “Eggs in incubators were up 2 percent from the May 1, 2023, total of 27.6 million eggs.”

Regarding egg production, the department adds that chicken eggs in April were up 1 percent.

“United States egg production totaled 9.01 billion during April 2023, up 1 percent from last year,” NASS reports. “Production totaled 7.71 billion table eggs and 1.30 billion hatching eggs, of which 1.19 billion were broiler-type and 103 million were egg-type. The average number of layers during April 2023 totaled 386 million, up 4 percent from last year. April egg production per 100 layers was 2,336 eggs, down 2 percent from April 2022.”

NASS also reports that the total

number of chicken layers for the month was up 5 percent from 2022.

“Total layers in the United States on May 1, 2023, totaled 387 million, up 5 percent from last year,” the report said. “The 387 million layers consisted of 317 million layers producing table or market type eggs, 65.6 million layers producing broiler-type hatching eggs, and 4 million layers producing egg-type hatching eggs. Rate of lay per day on May 1, 2023, averaged 77.8 eggs per 100 layers, down 2 percent from May 1, 2022.”

And in its June 14, “Broiler Hatchery” report, NASS notes that broiler-type eggs set were up 1 percent, and chicks placed were down 1 percent.

“Hatcheries in the United States weekly program set 244 million eggs in incubators during the week

ending June 10, 2023, up 1 percent from a year ago,” the report said.

“Average hatchability for chicks hatched during the week in the United States was 79.4 percent.”

The agency notes that for average hatchability it is figured by dividing the chicks hatched during the week by the egg set three weeks prior.

For chicks placed, NASS said, “broiler growers in the United States weekly program placed 189 million chicks for meat production the week ending June 10, 2023, down 1 percent from a year ago.

Cumulative placements from the week ending Jan. 7, 2023, through June 10, 2023, for the United States were 4.30 billion. Cumulative placements were down slightly from the same period a year earlier.”

This is the third in a series from Poultry Times regarding the importance of biosecurity. This article focuses on the importance of cleaning and disinfecting facilities and equipment.

GAINESVILLE, Ga. — Maintaining proper biosecurity is essential to have a healthy facility or farm. The Center for Food Security and Public Health at Iowa State University gives the basics for correctly cleaning and disinfecting farms and poultry facilities. According to Iowa State University, cleaning and disinfecting contains physical and chemical elements to clean. The cleaning processes are different because of the pathogens present. Any organic material must be eliminated before starting the disinfection process.

Also, the disinfectant needs to be strong enough to get into porous surfaces to reach infectious materials. The U.S. Environmental Protection Agency advises that farmers or employees use cleaning and disinfectants that are approved by the organization.

Iowa State says that there are many methods to apply disinfectants such as spraying, foaming, misting, wiping and submersion. It is important to read the label directions before applying disinfectants and disinfectants should be used as instructed. Always wear protective clothing to lessen human exposure. Additionally, be mindful of where the disinfectants are to be used. Surfaces must be clean and dry before applying disinfectants. For equipment that can’t get wet like electronics, fumigation can be used.

Iowa State specifies that contact time is important. Pathogens are killed by disinfectants gradually, not instantaneously. When the appropriate contact time is applied, it will increase the effectiveness of the disinfectant. Contact times are different depending on the temperature, the product and the method that is used. Specific contact times are found on the label. The surface be-

ing disinfected should remain wet for the duration of the contact time. Sometimes the disinfectant may need to be reapplied because of the necessary contact time. Disinfectants such as alcohol evaporate quickly, while some disinfectants such as phenols will leave a residue.

Also, according to Iowa State, elements such as soil, bedding, litter, feed and manure can deactivate disinfectants, particularly chlorine and iodine. Remove any organic materials that might hinder the disinfectant from taking effect. When some equipment needs to be cleaned, using air through a compressor or a blower is recommended. This technique will not affect equipment that has heavy organic materials on it.

Elements that affect cleaning and disinfection efficiency:

• Surface type

• pH Levels

• Water quality

• Temperature

• Weather

Cleaning and disinfection procedures:

1. Dry clean: Remove any organic materials.

2. Wash and Rinse: Clean objects with a cleansing agent to remove any other organic materials. Repeat if necessary.

3. Dry: Completely dry the object before applying disinfectants.

4. Disinfection application: Apply the EPA approved disinfectant. Follow the instructions for the proper concentration levels and contact times. Check that the object is completely covered with the disinfectant and remains wet

for the duration of the contact time. Repeat if necessary.

5. Rinse and dry: Rinse the object completely with clean, warm water. If the object is not thoroughly dried off, it can damage the object. Damage can include deterioration of rubber or corrosion of metal parts. Objects can also air dry.

Iowa State also advises if run off water is used, it must be captured or denatured to avoid contamination. New solutions should be made before use. Some disinfectant mixtures will deactivate within 24 hours; therefore, they should be used on the same day. If a mixture has passed it prime and is used, the effect of the solution will not be as strong. If a farmer or employee feels the mixture has been diluted, it can be tested.

The university states that metal surfaces such as stainless steel and aluminum are much simpler to disinfect compared to others. Although, some disinfectants can be harmful to metal surfaces because they can cause corrosion. Rubber and plastic surfaces are to be handled as firm and nonporous surfaces. Yet, there are particular chemicals like phenols and sodium hydroxide that can damage these surfaces.

If phenols are used on these surfaces, the chemical could stain the surface. Just like metal surfaces, these chemicals could also cause corrosion. Solutions that are alcohol, may cause rubber surfaces or particular plastic tubing to swell or harden

after persistent or recurring use. Using heat to disinfect these surfaces is not recommended because the heat can cause plastic to melt. Wood surfaces are challenging to disinfect, but it can be done. The way to clean wood is by dry cleaning. If water is used to clean the wood, it could dilute the disinfectant. After cleansing the wood, it is recommended to use a disinfectant that is created specifically for wood surfaces.

Iowa State urges farmers and employees to use caution as they apply disinfectants. Many disinfectants are not safe for the skin, eyes and lungs. They can cause pain to these parts of the body. Some disinfectants can be much more harmful because they can cause someone to be burned. Always be sure to wear proper gloves, goggles and masks when applying disinfectants. Likewise, be sure that all C&D employees have been appropriately trained to mix and apply disinfectants. They should also know the risks involved in applying disinfectants.

While it is important to have C&D techniques inside a barn or facility, Iowa State lays out how to make a C&D station for vehicles.

1. Soak: Hose down the vehicle to rinse off any organic materials. This includes the tires, wheel wells, undercarriage, mud flaps, splash guards and stairs.

2. Wash: Wipe, spray or scrub the vehicle to remove any additional organic materials. Start from the dirtiest part of the vehicle and end with the cleanest.

a. Pressure washers will advance the cleaning process.

b. Do not spray the water near poultry houses because this can lead to contamination of the houses.

3. Rinse: Just like rinsing a car, be sure that all soap residue has been removed. When rinsing the vehicle off, start from the top and proceed to the bottom.

4. Read: Read the label on the disinfectant to be sure that precautionary measures are taken to prevent someone from being injured. It is important to wear the proper

WASHINGTON — The United States congress is made up of many committees and caucuses. One caucus is called the “Congressional Chicken Caucus.” According to Congressmen Sanford Bishop’s website, the Congressional Chicken Caucus “is to educate other Members of Congress about the history, contributions and concerns of the U.S. chicken industry, which emanate from a wide range of issues pertaining to food safety, trade, labor, immigration and the environment. The Chicken Caucus serves as a forum where chicken producers, processors, consumers, and retailers can provide Members of Congress with their thoughts and suggestions on how to sustain and improve our poultry industries.”

The National Chicken Council reported that members of the chicken caucus, Rep. Barry Moore (R-Ala.) and Rep. Abigail Spanberger (DVa.) were among those who wrote a letter to U.S. Agriculture Secretary Tom Vilsack, USDA, and to U.S. Trade Representative Katherine Tai. The two representatives and 41

protective gear as well.

a. Take notice of what dilutions, water temperature, environmental temperature and ventilations are needed for disinfection.

5. Disinfect: Start applying the disinfectant on thev tires first to increase contact time before moving.

a. Move the vehicle slowly forward to ensure all parts of the tires are properly disinfected.

b. The vehicle must remain wet throughout the disinfection process and contact time to kill any viruses. Applying the disinfectant more than once may be needed.

Using heat

According to Iowa State, heat can

of their colleagues insisted that the two agencies contact their Chinese counterparts to reinstate the Chinese market for poultry products after epidemics of avian influenza in the United States.

The letter stated, “On March 23, 2020, USDA’s Animal and Plant Health Inspection Service (APHIS) and the General Administration of Customs China (GACC) adopted a policy of regionalization in the event of an HPAI outbreak. This agreement allows states unaffected by HPAI to remain eligible for international trade during an outbreak while outlining conditions affected states must meet to regain eligibility to export products.” It went on to say,

be an effective way for eliminating viruses in poultry houses. Though, it is important to note the attributes of a poultry house before proceeding with a heat treatment. In some cases, heat treatments are not recommended. Some elements to consider include weather, relative humidity, UV light, left over organic materials, pathogen strains and surface wood types.

Heat can be used in wet (steam) or dry (baking) conditions. When using a heat treatment, monitoring temperatures is essential. It is advised that thermometers are put inside barns or houses. One thermometer should be positioned at one end of the barn or house and the other at the additional end. The thermometers are to be four to six feet above the turkeys and also at cage level for layers. Do not put thermometers around or on a heat-

“Specifically, if HPAI was detected in poultry, a statewide ban would be enforced for all products exported from the state of detection and the resumption of imports and exports would be approved no sooner than 90 days post-virus elimination, disinfection and cleaning at all impacted sites in a state.”

According to the letter, the most recent epidemic of avian flu took place in February 2022. The General Administration of Customs of the People’s Republic of China took the necessary measures to continue trade of poultry products. All trade restrictions for the states of Kentucky and Texas were lifted in July of 2022 as per the agreement.

ing device. The temperature of the houses or barns should be checked two to four times per day.

The highest number of vegetative bacteria are killed in steam with temperatures at 131 to 149 degrees F. Most viruses are destroyed at 158 degrees F or 70 degrees C. The avian influenza virus can be killed at 110 to 120 degrees F for seven days.

Cleaning and disinfecting can be very important to flock health. The USDA put out a checklist to ensure that flocks are remaining healthy.

For houses:

1. Wear personal protective equipment.

2. Enclosures must be empty for a thorough cleaning.

3. Remove all litter, manure and other debris.

4. “Dry” clean all areas.

5. “Clean” all surfaces.

The agreement states that trade constraints must be released after 90 days of the virus being abolished. Although, the GACC withdrew their decision to allow trade from the states of Kentucky and Texas. Since August, the GACC has not engaged with APHIS to resume trade among the states of Kentucky, Oklahoma, Delaware, North Carolina, New Jersey, Maine, Maryland and Texas. All of these states have met the agreement requirements to resume trade.

“Poultry producers are under pressure not only to protect animal health but market health, too. American producers bet on reliable trading partners and China is not holding up their end of the deal,” Moore said. “I urge Secretary Vilsack and Ambassador Tai to engage with their Chinese counterparts and encourage them to honor the 2020 agreement and restore American market access.”

House Agriculture Committee Chairman Rep. Glenn Thompson (R-Pa.) said, “Trade is one of our most valuable tools to stimulate the economy, and China’s disregard for existing regionalization protocols is negatively impacting our poultry industry. Our nation’s growers follow long-standing guidelines to ensure the health and safety of poultry products. The Biden Administration must engage with the GACC to uphold our trade agreements and reopen this critical export market for U.S. poultry.”

6. Rinse all surfaces carefully with water.

7. Apply disinfectant.

8. Leave enclosure empty.

9. Discard protective equipment.

10. Wash hands thoroughly. For vehicles:

1. Clean equipment and vehicles.

2. Do not share tools, poultry supplies or lawn and garden equipment.

3. Establish procedures for cleaning and disinfecting equipment and vehicles.

4. Give clear and consistent instructions.

5. Define paths where trucks, vehicles and other equipment can travel.

6. Know the warning signs of poultry disease.

Mike Brown is president of the National Chicken Council headquartered in Washington, D.C. This column is drawn from one originally appearing in The Hill.

WASHINGTON — America loves chicken. It’s healthy, delicious, sustainable and — for the moment — the most affordable protein in the meat case. The U.S. chicken industry supports millions of good paying jobs in hundreds of rural communities. Unfortunately, some in Washington — and their allies in the trial-bar and activist boardrooms — want to make chicken less affordable. Why? A small, but vocal minority of radical activists are persistently advocating for the end of animal agriculture, even though most Americans depend on chicken as an affordable source of nutrition.

New data shows that grocery prices increased 11 percent between 2022 and 2023. Making chicken — a protein staple on which families of all income levels rely — more expensive and less available makes no sense. Sadly, for the American consumer, that is exactly what’s being proposed. And those most vulnerable would be first in line: lower income earn-

ers, children who receive free and reduced cost school meals, and needy individuals who rely on food banks to feed their families. There has never been a worse time for needless governmental regulation.

One example: To be sure, Salmonella is a potentially dangerous food-borne bacteria. It occurs naturally in chickens. That’s why we stress the need to always cook chicken to an internal temperature of 165°F and to avoid cross-con-

tamination in the kitchen. When those steps are followed, there is absolutely no danger of foodborne illness from chicken.

Chicken producers work continuously and closely with United States Department of Agriculture (USDA) to reduce the presence of Salmonella in and on chicken. The industry has implemented new controls and interventions and supported modernized poultry inspection. As a result, we are meeting

and exceeding USDA’s rigorous food safety standards.

If chicken is safer now than it’s ever been, why do some want to abandon this approach and potentially require millions of pounds of chicken to be sent to landfills rather than dinner tables. Salmonella is not an “adulterant” in chicken, as potential new USDA guidelines suggest. It is not “added” to chicken. It occurs naturally and, through strict protocols and testing procedures, can be minimized. And Salmonella is completely destroyed when chicken is properly handled and cooked.

The Biden administration is fond of reminding all of us to “follow the science.” It’s an ironic sentiment given that we have yet to see any science underlying these proposals.

A second example of unnecessary intrusion by USDA focuses on the way chicken growers are compensated. We use what might be called a “pay for performance” system — under which farmers are

Usda’sunnecessaryintrusionintochickenindustry

surveys show the current system works for everyone: farmers, chicken companies, the birds themselves, and ultimately, the American consumer.

financially incentivized to raise healthier birds. High performing farmers are paid better than others.

Under this system, contract farmers are guaranteed a pre-arranged base pay for the chickens they raise. In addition, farmers earn bonuses based on the weight and performance of their flocks. Some companies also offer bonuses to help cover the costs of utilizing the latest on-farm technology.

In addition to base pay rates and bonuses, growers in this model do not take on most of the risks associated with chicken production, like hedging grain markets or finding and maintaining customers such as restaurants and grocery stores. Contract chicken farmers are protected from the greatest economic risks, have a predictable market, and earn a good living.

Surveys show the current system works for everyone: farmers, chicken companies, the birds themselves, and ultimately, the American consumer.

Despite the success of this model, the USDA has revived an Obama-era approach to turn this well-functioning system on its head. Their proposals would dramatically increase costs and risks associated with contract chicken farming, at a time of record inflation. And, in the name of “transparency” and “fostering competition,” USDA would make it difficult to reward the most efficient and effective growers. That is tragically un-American.

And there’s more.

Back when Bill Clinton was president, USDA began allowing chicken processors to run certain parts of their plants at higher line speeds. It may be the most wellstudied pilot program in the history of the federal government. Now, USDA is suggesting it might abandon this 25-year-old program and put America even further behind our global competitors. Chicken companies in Canada, Europe, South America, and Asia operate the same exact equipment at up to 30 percent higher line speeds than we do, and without food safety or worker safety issues.

The department appears to be listening to those who suggest faster line speeds are dangerous to workers. The data says otherwise. Since the program was started in the 1990s, the U.S. chicken indus-

try has made tremendous strides in technology. The area of a processing facility where these faster line speeds are permitted is almost completely automated. Over the last 30 years, the total recordable poultry processing illness and injury rate decreased 73 percent; a decrease in injury rates that coincided with a period of substantial

increases in line speeds, bird size, and automation.

It may be that well-intentioned regulators are misinformed. If so, we stand ready to work every day to address their concerns about Salmonella, fairness in chicken contracting, line speeds and other issues. Or those same regulators might be listening to those groups

who will use whatever means necessary to make chickens more expensive to grow and process — and far more expensive to eat — to serve their own agendas.

America loves chicken. It’s a healthy, economical and versatile source of protein that sustains our country and is arguably the most important food in the world. Let’s keep safe, affordable chicken on our plates. Chicken works for America.

This column appeared May 19, 2023, in The Hill. The original post can be found at https://thehill.com/ opinion/congress-blog/4012775solutions-in-search-of-problemsusdas-unnecessary-intrusion-intochicken-industry/.

“Consumers should be able to trust that the label claims they see on products bearing the USDA mark of inspection are truthful and accurate,” said U.S. Agriculture Secretary Tom Vilsack. “USDA is taking action today to ensure the integrity of animal-raising claims and level the playing field for producers who are truthfully using these claims, which we know consumers value and rely on to guide their meat and poultry purchasing decisions.”

Free-range/grass-fed

FSIS has received several petitions, comments, and letters from a wide range of stakeholders asking the agency to reevaluate its oversight of animal-raising claims, specifically, how they are substantiated. In addition, the veracity of “negative” antibiotics claims (e.g., “raised without antibiotics” or “no antibiotics ever”) has come into question.

FSIS, in partnership with USDA’s Agricultural Research Service, will be conducting a sampling project to assess antibiotic residues in cattle destined for the “raised without antibiotics” market. The results of this project will help inform whether FSIS should require that laboratory testing results be submitted for the “raised without antibiotics” claim or start a new verification sampling program.

FSIS will also be issuing a revised industry guideline to recommend that companies strengthen the documentation they submit to the agency to substantiate animal-raising claims. The agency plans to strongly encourage use of thirdparty certification to verify these claims. Together these actions will be used to guide potential rulemaking on animal-raising claims. USDA looks forward to continued engagement

with stakeholders as it works to ensure these claims meet consumer expectations, the department said. For more information, visit www.usda. gov.

Former Wayne-sanderson veterinarian forms consultancy to aid producers

“I want to continue doing what I do best — assist stayer

commercial broiler producers and their suppliers by solving current problems or introducing new technologies to improve chicken wellbeing,” Stayer said.

Prior to Sanderson Farms’ merger with Wayne Farms in 2022, Stayer managed 11 broiler locations in Georgia, Mississippi, North Carolina, and Texas that produced more than 13 million birds a week. His primary responsibility was working with live-production managers, nutritionists, suppliers and diagnostic laboratories to build comprehensive health programs.

“Ensuring animal well-being and consumer food safety were also important elements of our health programs,” he added.

Stayer frequently shared his field experiences at scientific conferences, as well as in in articles and video interviews for the trade media.

Earlier in his career, Stayer was a veterinary technical consultant for Elanco Animal Health and a staff veterinarian for Arbor Acres. He received his doctor of veterinary medicine degree from the University of Tennessee and a master of science degree at Mississippi State University.

For more information, contact Stayer by email at DrPStayer@ gmail.com.

Lover’s Day.

“Minnesota’s turkey industry is resilient! Since the beginning of the highly pathogenic avian influenza (HPAI) outbreak, the turkey industry has fought to overcome challenges, all while continuing day-to-day operations and providing turkey for families worldwide to enjoy,” said Jes Westbrock, MTGA president.

Minnesota turkey farms and companies that process turkey are integral to the state’s economy. Minnesota is the number one producer of turkeys in the nation and is home to 600 turkey farms across the state and three turkey processors. Minnesota’s turkey industry annually contributes over $12 billion1 in economic activity to Minnesota and provides more than 46,0001 jobs.

Turkey is an easy choice for a healthy lifestyle because it’s leaner than most red meat and even chicken. A 3-ounce portion of roasted skinless turkey breast contains only 3 grams of fat and 27.3 grams of protein.

“As a 3rd generation turkey farmer, I am proud of our industry’s history in Minnesota. Turkey is a versatile, delicious, low fat and high protein option for families to enjoy daily,” said MTRPC President, Pete Klaphake.

Turkey farm families, turkey processors, and the allied industry that supports both sectors are passionate about raising locally-grown, wholesome, and nutritious turkey for their families and yours, the associations noted, adding that, delicious and innovative ways to prepare turkey can be found at www.minnesotaturkey. com or www.eatturkey.org.

changemakers and thought leaders throughout the ag value chain to explore unique and innovative opportunities in agriculture, business, health and nutrition.

The Alltech ONE Conference has been held in Lexington, Ky., home of Alltech’s global headquarters, for the past 38 years. In 2023, the global leader in agriculture is bringing the conference to its partners, customers, suppliers and friends across the globe, providing the opportunity for more people than ever to experience the power of ONE.

“As our customers and partners continue to face many challenges and uncertainties, we determined that 2023 would be dedicated to meeting them in their market,” said Dr. Mark Lyons, Alltech president and CEO. “This special edition of the ONE will endeavour to deliver global expertise to locally relevant issues. In the midst of economic and political uncertainties that fuel regionalization, this ONE reflects the responsibility we have as a global company to be a connector of people and ideas, ever advancing our purpose of Working Together for a Planet of Plenty.”

Alltech ONE Calgary will feature global and Canadian experts discussing agriculture, animal nutrition and business, including keynote presentations from Lyons, and renowned motivational speaker, Chris Koch.

The Alltech ONE World Tour will continue with stops in the U.S., Asia, South America, and the Middle East.

For more information and to register for Alltech ONE Calgary, visit https://one.alltech.com/calgary/.

Doug Anderson, area human resources manager for Wayne-Sanderson Farms, provided insights into how employees can be developed into the leaders needed by an organization. Speaking on his experiences with talent management at Wayne-Sanderson Farms, he noted that frequently the talent pool for company leadership can be identified from within current employees, given the right direction from management. He offered several examples of the success of this approach along with some of the benefits of identifying leaders internally.

Following his presentation, Anderson and Stan Fretwell, Arkansas operations manager for Peco Foods, participated in a roundtable discussion where they examined some of the approaches they have used to improve turnover and encourage employees to remain at their facilities. Some suggestions discussed between the panelists and attendees included recognition initiatives, developing meaningful relationships with employees, and checking in with employees prior to key turnover intervals.

Steve Hartley, president of Matrix Industrial Control Systems Inc., presented attendees with several emerging technologies in poultry processing. Far from being abstract tools or simple recordkeeping software, today’s electronic systems capture data in real time and can empower managers to make production decisions based on current data that can be stored for later use. Cloud technology and its advantages over legacy systems, including scalability, accessibility and cost effectiveness, was also reviewed, leading to a discussion of artificial intelligence, plant automation and vision technology.

Minn. Gov. recognizes

‘Turkey Lover’s day’ in Minnesota

BUFFALO, Minn. — The Minnesota Turkey Growers Association and the Minnesota Turkey Research and Promotion Council commended Minnesota Gov. Tim Walz for declaring June 18, 2023, Turkey Lover’s Day in Minnesota. June is known as National Turkey Lovers’ Month, with June 18th specifically noted as National Turkey

alltech ONe World Tour announces a canadian stop in calgary

LEXINGTON, Ky. — Following the spring European events in Budapest and Dublin, the Alltech ONE World Tour will travel to Calgary, Alberta, Canada on July 3–4, 2023. Alltech ONE Calgary will explore collaborative solutions to the greatest challenges facing the agri-food industry as it relates to the Canadian marketplace, uniting

TUCKER, Ga. — Poultry industry professionals from around the country recently met in Nashville, Tenn., for USPOULTRY’s 2023 Poultry Processor Workshop. The workshop focused on developing and retaining leaders, process control and technology, and animal welfare, along with many other topics.

Amelia Woods, poultry welfare manager at PAACO, spoke about successfully integrating animal welfare programs into plant operations. One key consideration she encouraged attendees to keep in mind is not to expect a cookie-cutter approach across plants, as each has its own unique characteristics. She also discussed common audit points and how these criteria can be evaluated.

More information about USPOULTRY’s educational seminars can be obtained at www.uspoultry. org.

(continued on page 16)

airgood named customer service manager for chore-Time

MILFORD, Ind. — Sherri Airgood has been named customer service manager for Chore-Time, according to Tina Streit, vice president and general manager for the CTB Inc., business unit. In her new position, Airgood will lead and manage Chore-Time’s Customer Service group.

Prior to her employment with CTB, Airgood gained more than 32 years of experience in customer service and sales positions in the medical device industry. Airgood received her bachelor’s degree in business management at Indiana Institute of Technology, Warsaw, Ind.

A native of North Webster, Ind., Airgood now resides in Ligonier, Ind.

coBank: rising cost of grain storage will force elevators to lower bids

DENVER — The cost of storing grain, commonly referred to as the cost of carry, has soared to record highs due to rising interest rates, high commodity prices and increasing costs for labor, insurance, transportation and energy. That is putting a significant squeeze on grain elevators, which may be forced to lower their local bids on grain to manage through the unfavorable economics of holding commodities.

According to a new report from CoBank’s Knowledge Exchange, the interest-related cost of carry in the 2023-2024 crop year will increase 21 percent for corn, 42 percent for soybeans and 50 percent for all-wheat, year-over-year. Each of those costs is estimated to be the highest on record. The projections are based on the forecasted average annual interest rate for grain merchandisers of 7.75 percent for the 2023-2024 crop year, and USDA’s

marketing year average price forecasts of $4.80/bu. for corn, $12.10/ bu. for soybeans and $8.00/bu. for all-wheat.

Financing the ownership of corn, wheat and soybean inventories is a major cost of carry for grain elevators. Interest expense as a percentage of the total cost of carry can vary widely among grain merchandisers and between crop years. But it can typically comprise one-quarter to one-third or more of a grain elevator’s total cost of storing grain and oilseeds.

“For grain elevators, the sharp rise in interest rates couldn’t have come at a worse time as they borrow higher-priced funds on commodities that have also remained at historically high prices,” said Tanner Ehmke, lead grains and oilseeds economist for CoBank. “And while grain elevators are motivated to move inventory as fast as possible to lower carrying costs, processors and end users will want to delay ownership of commodities to reduce their own inventory costs.”

The persistent inverse in futures markets, where the price of laterdated contracts are lower than spot prices, further complicates matters

for grain elevators. In normal market conditions when supplies are abundant, forward futures contracts are priced higher than the nearby spot prices to account for storage costs and a small risk premium. When futures prices are lower than spot prices, farmers are motivated to sell commodities rather than hold them for future sale.

Cooperative elevators are in business to buy and market their members’ grain. That means they will be obligated to carry inventory despite the economic disincentive of doing so. Holding commodities in high-interest rate environments also ties up a company’s working capital, which can put a strain on other business operations. This is especially problematic in volatile markets when liquidity is needed for managing margin calls on futures hedges.

“It’s a challenging situation for cooperative grain elevators as well as farmers, because it comes at a time when farmers are also facing higher costs,” Ehmke said. “Coop managers will need to closely scrutinize their operating costs and impose greater discipline on cost wherever possible. And if they need to lower their bids and widen basis

to cover storage costs, they should communicate early and consistently with farmer members who will be impacted.”

The positive news on carrying costs is that the Federal Reserve is expected to hold interest rates at their current levels for the foreseeable future. And USDA is forecasting corn, soybean and all-wheat prices to drop for the 2023-2024 crop year from the year prior, which will take some pressure off carrying costs, CoBank noted.

For more information, visit www. cobank.com.

Smithsonian Institution have announced a new partnership to increase access to civic and cultural experiences for thousands of teens. Through a variety of shared resources and activations such as visits to Smithsonian museums, national 4-H events, digital storytelling projects, and online content, 4-H and the Smithsonian will provide increased opportunities for young people to learn and explore.

WASHINGTON — The National 4-H Council and the

4-H is the country’s largest youth development organization. Delivered by the nation’s Cooperative Extension system, 4-H strives to eliminate the opportunity gap facing America’s kids through diverse programming, life skills building, and mentorship. The Smithsonian is the world’s largest museum, education, and research complex, with 21 museums and the National Zoo. Established for the “increase and diffusion of knowledge,” the Smithsonian has always been committed to inspiring generations through knowledge and discovery, and the Institution has recently set a goal to reach every classroom in the nation.

During the next two years, 4-H’ers from across the country will have the opportunity to participate locally and online in project-based learning. Teens can participate in a variety of programs, including Museum on Main Street (MoMS), an outreach program from the Smithsonian that brings traveling exhibitions, educational resources, and programming to small towns across the U.S. This year the program will pair 4-H teens in two to three states with subject matter experts to develop a project benefiting their communities via Cooperative Extension’s 4-H programs and the Smithsonian. In addition, 4-H youth attending National 4-H Council’s annual summits—Ignite by 4-H, True Leaders in Equity Institute, and Citizen Washington Focus—will receive guided tours and participate in learning sessions centered around themes in democracy and civics, diversity, equity, access & inclusion, STEM, and careers at five Smithsonian museums.

Digital educational resources created by 4-H and the Smithsonian will also be available on Clover by 4-H and the Smithsonian’s

Learning Lab.

“It is important that the Smithsonian’s vast educational resources are available to all Americans — from those in major cities to rural towns — not just those who visit our museums,” said Smithsonian Secretary Lonnie Bunch. “Through new technology, virtual exhibitions, and resources and now this partnership with 4-H, we are able to reach more people than ever before and inspire learning across the country.”

“Helping young people widen their perspective through cultural and historical lenses can lead them to find their spark and further develop skills that are critical to civil discourse, such as tolerance, curiosity, and leadership,” said Jennifer Sirangelo, president and CEO of National 4-H Council. “These opportunities inspire young people to dream big and encourage them to drive positive change in their communities.”

The partnership is kicking off in June with guided Smithsonian tours during Citizenship Washington Focus, 4-H’s annual lead(continued on next page)

leader in the liquid feed industry into the Liquid Feed Hall of Fame each year at the symposium. The Liquid Feed Hall of Fame recognizes and honors individuals who have made significant contributions to the science and growth of the liquid feed industry. Nominations for the Liquid Feed Hall of Fame are open until July 28.

More information on the Liquid Feed Symposium, including registration, the agenda and information about the location, can be found at www.afia.org/lfs-2023/.

helping to make it economically feasible for farmers to implement sustainable practices around the world. It is how agriculture and farmers can be part of the climate solution, helping to reduce emissions, improve water quality and use, increase yields and build up the resilience of our soils for the next generation. Our vision is to make regenerative agriculture commonplace across our global supply chain, enabling farmers to produce food more sustainably while increasing their profitability and resiliency,” said Chantelle Donahue, North America agriculture supply chain vice president, with Cargill.

cargill expands regenerative agriculture program to europe

MINNEAPOLIS, Minn. — Cargill is leveraging its unique position in the supply chain to pioneer its award-winning regenerative agriculture program in Europe, which will see farmers in Germany, Poland, Romania, and France financially compensated to adopt climate-friendly farming practices.

Building on two years of success in North America, Cargill RegenConnect will also expand from 15 to 24 states, introducing the program in nine new states including North Carolina, South Carolina, Georgia, Colorado, Mississippi, Alabama, Oklahoma, Louisiana and Texas. It will also provide U.S. farmers with higher payments, cover more commodities (such as cotton) and improve ease and access to enrollment via mobile devices.

Cargill RegenConnect has not only received positive feedback from growers and customers but has also been recognized by the prestigious 2023 Edison Awards for its innovative approach to creating a more resilient and secure food system. Its expansion demonstrates Cargill’s commitment to helping farmers adopt sustainable agricultural practices across its global supply chain, rooted in the firm belief that change starts where the food system begins – at the farm.

“Companies like Cargill are

“Cargill RegenConnect’s success to date demonstrates how making sustainable, regenerative agriculture financially viable for farmers can help nature-positive production practices scale more quickly and become standard. It is one of the many ways we plan to meet our goal to reduce emissions in our supply chain and will impact every area of our business – from sourcing wheat and corn for our starches, and sweeteners to growing rapeseed oil for our salmon feed,” she added.

Cargill RegenConnect is a voluntary, market-based regenerative agriculture program which helps farmers improve soil health and decarbonize the agriculture supply chain.

Farmers enrolled in the program can choose the practices that are best suited to their operation’s unique growing conditions, which includes planting cover crops and implementing reduced- or no-till farming. These practices help sequester carbon in the ground, build soil resilience and improve water quality, Cargill said.

In addition to providing technical support and resources to enable farmer success, the program offers an environmental market opportunity for participants, who are then able to connect with some of the world’s largest companies actively seeking to reduce their environmental footprint while supporting regenerative agriculture.

Eligible farmers in North America are invited to enroll now through Sept. 15 by visiting https://www.cargillag.com/.

Tyson Foods completes acquisition of Williams sausage co.

SPRINGDALE, Ark. — Tyson Foods Inc. has completed the previously announced acquisition of Williams Sausage Co. Inc. of Union City, Tenn., furthering the company’s strategy to increase its capacity and product portfolio. To ensure the continuity of business operations, Emily Billingsley, Roger Williams’ daughter, will be responsible for the company’s operations.

“This acquisition aligns with our strategy to win with customers, augments our manufacturing capabilities, and expands our product portfolio,” said Stewart Glendinning, group president, Prepared Foods for Tyson Foods.

“Williams Sausage Company brings real strengths in its brand, facilities, and direct store delivery network that make this a logical and welcome addition to our Prepared Foods business.”

“Our family has enjoyed 65 years of success thanks to dedicated team members, great customers, and fantastic suppliers that have allowed us to build a quality food company,” said Williams Sausage Company President and CEO Roger Williams. “We’re grateful to find a new partner in Tyson Foods, a company that understands the important legacy of family businesses and is committed to supporting a smooth transition for all stakeholders.”

“We are honored that Williams Sausage Company is entrusting us with their 65-year legacy and a portfolio of value-added brands for retail and food service customers,” Glendinning said.

Williams Sausage Co. employs approximately 500 team members and produces fresh and fully cooked sausage, bacon, and sandwiches for retail and food service customers.

Perdue Farms and draper Valley Farms support skagit Food distribution center

SALISBURY, Md. — As part of a commitment to help its food insecure neighbors, Perdue Farms has awarded a $10,000 grant to the Community Action of Skagit County in Mount Vernon, Wash., through the Franklin P. and Arthur W. Perdue Foundation. The donation from Perdue’s charitable giving arm is part of the company’s Delivering Hope to Our Neighbors® outreach to improve quality of life and build strong communities.

Perdue Farms is the parent company of Draper Valley Farms in Mount Vernon, home to local brands Draper Valley Farms®, Roxy® The Organic Chicken and Ranger® The Free Range Chicken. The grant supports Community Action’s Skagit Food Distribution Center (SFDC), the centralized distributor of bulk items and fresh food in Skagit, Island, and Snohomish counties in Washington. The center supports 19 food banks and hot meal programs and accounts for up to 80 percent of the items available at local food banks. The program serves 27,500 people monthly.

“Food insecurity affects our region’s most under-resourced populations, including individuals and families facing economic vulnerability, those living within food deserts, and older adults living in isolated areas of rural eastern Skagit County,” said Bill Henkel, Community Action’s executive director.

“Funding from the Perdue Foundation will support the operations of the SFDC as it works toward its goal of providing more fresh and nutritious food to community members … through our region’s food banks and hot meal programs,” Henkel said.

Kim Nechay, executive director of the Perdue Foundation, said Skagit Food Distribution Center provides a vital service.

(continued on next page)

“The center helps older adults and families with children and many others in need,” she said. “The Perdue Foundation is happy to support its programs.”

For more information about the foundation, visit https://corporate.perduefarms.com/company/ foundation/; and for more information about Community Action of Skagit County, visit https:// www.communityactionskagit. org/.

chester’s chicken relaunches Fried chicken sandwich

BIRMINGHAM, Ala. — Remakes better than the original? Here’s one to add to the short list: Chester’s new Fried Chicken Sandwich, is now available nationwide at all Chester’s locations, the company announced.

Chester’s Chicken, the fresh fried chicken quick-service restaurant concept with 1,100 locations across the U.S., has relaunched its fried chicken sandwich with a new bun, new bird, and new sauce.

The new sandwich is built with a specially marinated and double-breaded, whole breast fillet, topped with Chester’s awardwinning signature sauce and crunchy crinkle cut dill pickles, all on a Martin’s® Famous potato roll. The result is a juicier, crispier, more flavorful version of the chicken sandwich that made Chester’s famous, the company noted.

“If you love fried chicken sand-

wiches, prepare to meet the new boss,” said Scott Richard, director of culinary innovation, Chester’s Chicken. “We’re constantly looking at ways to innovate and make our menu even better. We made all the right tweaks to perfect our new fried chicken sandwich and the taste is a knockout we know guests will crave.”

Since the beginning of Chester’s in 1965, the brand has continued to build a menu based on in-

novation, winning several awards for its sandwiches, sauces, and sides in the process, the company said, adding that it introduced its original fried chicken sandwich in 2019 at the onset of the chicken sandwich QSR industry wars. It’s since become a fan favorite on the menu; Chester’s sold 3 million chicken sandwiches in 2022.

The updated fried chicken sandwich is just the latest example of the brand’s constant quest to offer the best chicken on the planet and provide guests exciting, flavorful chicken sandwich options. Last year the brand ran two successful chicken sandwich LTOs: Honey Stung Chicken Sandwich, made with Frank’s RedHot® Stingin’ Honey Garlic Sauce, and honored in Convenience Store Products’ annual “Retailer Choice Best New Products Contest,” and the Buffalo Mac Chicken Sandwich, featuring Chester’s signature fried chicken tossed in buffalo sauce and topped with a scoop of mac & cheese and a slice of white American cheese.

For more information about Chester’s Chicken, visit www. chesterschicken.com.

With Cobb Cares, we combine our mission of feeding the world and making a difference with our values of family, integrity, innovation and being the best. We emphasize five key pillars for our Cobb Cares sustainability story. As we focus on genetic progress, poultry care and welfare, community, environment and the workplace, we hope you’ll have a greater understanding of how Cobb is committed to a more sustainable future not only for our business, but for our team members, the communities that we work and live in and the global poultry value chain. Learn more at cobbcares.com or scan the QR code below.

By eduardo costa cobb south America

By eduardo costa cobb south America

SILOAM SPRINGS, Ark. —

Focusing on correctly processing, storing, and transporting chicks is very important to producing the best-quality day-old chicks. Newly hatched chicks cannot fully selfregulate their body temperature and need an environment with the correct ventilation to provide sufficient oxygen that helps them maintain a thermo-neutral body temperature. Any stress, even for short periods, can harm broiler performance.

From the moment the chicks are dry inside the hatcher through the first hours on the broiler farm, internal body temperature should be maintained at 104 degrees F to 105 degrees F (40 degrees C to 40.6 degrees C). Chick body temperature can go up very quickly, and once the birds are hot, it’s difficult to cool them back down.

When body temperatures get close to 106 degrees F (41 degrees C), the birds start to pant as they try to lose the excess body temperature. They lose five times more moisture by panting than with regular breathing, leading to dehydration. Overheating is the biggest cause of dehydration for chicks. Also, panting increases relative humidity in the environment, making it more difficult for the birds to exchange heat by evaporation. When the chicks are hot, they spread the wings, get very noisy, and become lethargic.

When room temperature is too low or there is too much draft through the boxes, the chicks will huddle, trying to control body temperature. Pulling out green chicks (early pullout) or after spray vaccination are the moments where chicks are most susceptible to chilling. Besides being a contamination source, wet chick boxes can also chill the other birds. Make sure the boxes are clean and dry at pullout time.

The temperature inside the boxes

if climate conditions are good and chicks are comfortable, they should be calm, breathing quietly through their nostrils with little noise, and evenly spread in the boxes.

should be maintained at 90 degrees F (32 degrees C), but that temperature may be from 11 degrees F to 22 degrees F (6 degrees C to 12 degrees C) higher than room air temperature. This is why it’s so important to keep space for air flow between the stacks of boxes. As a rule of thumb, there should be enough space to walk between the stacks of boxes.

Low relative humidity will also accelerate dehydration. Humidity cannot compensate for moisture loss, and if it’s too high, chick heat loss by evaporation is limited, causing more heat stress. Keeping the relative humidity around 65 percent is best to maintain chick quality and welfare.

Chick transporters should provide a minimum ventilation rate of 20 CFM (34 m3 per hour) per 1,000 chicks in the wintertime and double

this in the summertime. Some trucks depend on movement to ventilate the interior, but these trucks do not ventilate well in heavy traffic or when stationary. Ideally, the trucks should have mechanical air intake with an air preparation chamber (for temperature and humidity) and exhaust fans should be able to maintain the correct amount of oxygen and temperature.

As in the processing and holding rooms, temperature inside the boxes should stay at 90 degrees F (32 degrees C) and relative humidity should stay at 65 percent. The floor of the truck body needs to be very well insulated to prevent heat accumulation in the truck, especially on the bottom boxes. Drivers must be specialized and committed to the care of the day-old chicks through good animal husbandry and welfare

practices.

Minimum stocking density should be 3.3 in² (21 cm²) per chick, with lower chick concentration during extremely hot weather and/or long-distance trips (check with local regulations as some areas legislate chick density). Upon arrival at the farm, face the vehicle into the prevailing wind to prevent wind chill on the chicks during unloading. The birds should go straight to the brooding area and have immediate access to feed and water. If doing a quality check and count sample, this needs to be done simultaneously with unloading by trained personnel.

Holding the birds in the boxes inside the brooding area will quickly lead to overheating. During unloading, count the number of chicks dead on arrival (DOA) and observe if this mortality is evenly spread through the truck or is concentrated in spots. Then provide immediate feedback to the driver.

Chick behavior is one of the best tools to evaluate climate conditions and bird comfort. The chicks should be calm, breathing quietly through their nostrils with little noise, and evenly spread in the boxes. When released in the broiler house, the birds should be active and spread evenly, looking for water and food calmly.

Five key points:

• Temperature: Keep temperature inside the boxes at 90 degrees F (32 degrees C). Remember that inside the boxes, it can be from 11 degrees F to 22 degrees F (6 degrees C to 12 degrees C) higher than room temperature. Use chick cloacal temperature as a tool. Keep it in the range of 104 degrees F and 105 degrees F (40 degrees C to 40.6 degrees C).

• Ventilation: Provide enough fresh air. Leave space for air flow but no direct air drafts over the birds. Keep CO2 below 2,500 ppm (0.25 percent and RH at 65 percent).

• Loading: Do not overload the trucks. Load the truck according to truck type recommendations and roads. Give a minimum of 3.3 in² per chick (21 cm² per chick). In very hot weather, a lower density is rec-

(continued on page 24)

Helping to feed a growing population. Reducing the environmental impact of poultry meat production. Providing efficiencies for sustainable farming. Breeding sustainability is what we do. Let us show you at aviagen.com.

TUCKER, Ga. — Effective hatchery and breeder management is critical for the success of any poultry operation. USPOULTRY’s 2023 Hatchery-Breeder Clinic will provide attendees with insights into best practices, maximizing performance from start to finish, and other topics related to chick quality and breeder management. The clinic will be held July 20-21 at the DoubleTree by Hilton Downtown in Nashville, Tenn.

“Attendees at this year’s USPOULTRY Hatchery-Breeder Clinic will come away armed with an array of knowledge focused on maximizing the performance of their birds and hatcheries throughout the production cycle. Incorporating

(continued from page 22)

ommended. Check with local regulations as some areas legislate chick density.

• Unloading: Don’t open the doors facing the wind. Unload

feedback with their own experience and expertise, the planning committee has put together a robust schedule of topics to help hatchery and breeder managers and other leaders get the most from their flocks,” said Kirk Dawkins, hatchery division manager at Fieldale Farms Corp., and program committee chairman.

Agenda topics include Raising Today’s Broiler Breeder, with attention to Brooding Best Practices, Feeding from Start to Finish, and Male Management After Trans-

straight to the brooding area and release the birds immediately. Count the number of chicks DOA and observe the distribution of this mortality.

• Behavior: Pay close attention to

fer; Late Flock Management and Fertility; Shell Quality; Egg Pack / Sanitation; Bronchitis / Respiratory Challenges; Automation Preventive Maintenance; Maximizing Turning in Multi-Stage Equipment and Improving Chick Quality; Hatchery QA ... Why and How to Gather the Data; Embryology: Challenges with Low Fertility Flocks; Maximizing Hatch ...What Can You Control; Vaccine Handling; and Hatchery Sanitation.

The 2023 USPOULTRY Hatch-

chick behavior during holding, transportation, and after placement. Listen to what the chicks are trying to communicate. For more information, access the Cobb Hatchery Guide and Broiler

ery-Breeder Clinic planning committee, comprised of industry hatchery and breeder operations leaders, includes Adam Black, Aviagen Inc.; Kirk Dawkins, Fieldale Farms Corp., and program committee chairman; Don Hickman, Mountaire Corp.; Alicia Hill, Tyson Foods Inc.; Brian Hyde, Tyson Foods Inc.; Chad Mason, House of Raeford Farms Inc.; Ashley McGovern, Pilgrim’s; Jason Phillips, Amick Farms LLC; Richard Rutledge, Mountaire Corp.; Stephanie Smith, Peco Foods Inc.; Joe Steed, Pilgrim’s; and Kent Weldon, Koch Foods.

Don’t miss this valuable opportunity to gain knowledge and network with your colleagues. To register, reserve your room and see the full agenda for the USPOULTRY 2023 Hatchery-Breeder Clinic, visit https://www.uspoultry.org/programs/education/seminar/#hbc.

Management Guides at www.cobbvantress.com.

Eduardo Costa is hatchery production director, Cobb South America.

Be

Eniscia nonsequis soluptatur magnis eicae invelic aeperum fugiamuscia vollabor recepudi que praturibus, quam cus.

Landus aciis in culparuptate pro vendero doluptas aut fuga. Quam dolorescit faceptius, secte nobit volore volupta nos exceatecaes atiorib usaecer chiligenimus sum etum nis utempor empelit iusam, incienes aliae estibus moluptata explibus. Hent eat ute si cus, quam fugiti te net aut eleste quatia est eostiunt utem eturecu sdamus earcipitas aut remodi blandi venimoluptat et del etur audae nonsequid

Eniscia nonsequis soluptatur magnis eicae invelic aeperum fugiamuscia vollabor recepudi que praturibus, quam cus. Landus aciis in culparuptate pro vendero doluptas aut fuga. Quam dolorescit faceptius, secte nobit volore volupta nos exceatecaes atiorib usaecer chiligenimus sum etum nis utempor empelit iusam, incienes aliae estibus moluptata explibus.

Hent eat ute si cus, quam fugiti te net aut eleste quatia est eostiunt utem eturecu sdamus earcipitas aut remodi blandi venimoluptat et del etur audae nonsequid magnis ut latem etur? Uci derferes quassit, sae debit as doluptia quae. Nempos re

Take advantage of this showcase of your company by sending in your testimonial on how Poultry Times has helped market your company over the years

Ad Cost

Full Page $1,000

Half Page $500

1/4 Page $250

MANHATTAN, Kan. — The USDA and the Department of Homeland Security (DHS) Science and Technology Directorate (S&T) officials recently celebrated the dedication and ribbon-cutting of the National Bio and Agro-Defense Facility.

This facility, which offers the highest level of biocontainment laboratories and safety protocols, is the first of its kind in the United States and will allow scientists to study and diagnose critical animal diseases, the departments said.

“America’s farmers, ranchers and consumers count on our researchers to understand, monitor for and develop solutions to combat a variety of high-consequence animal pathogens, and a facility of this magnitude positions us to respond,” said U.S. Agriculture Secretary Tom Vilsack. “This new, innovative facility will give USDA scientists access to cutting-edge, safe and secure technology so they can continue to lead the world in animal health research, training and diagnostics to protect our food supply, agricultural economy and public health.”

The valuable scientific information delivered by researchers at NBAF will also allow America to remain a leading contributor of countermeasures that will protect agriculture, economies and citizens across the globe, the agencies added.

NBAF will replace DHS’ Plum Island Animal Disease Center, which is a biosafety level-3 facility in New York that is more than 68 years old. Both departments have collaborated on the requirements for this next-generation science facility since 2006, and Manhattan, Kan., was selected as NBAF’s site in 2009. DHS led NBAF’s design and construction, and USDA will own and operate the facility.

“NBAF is a historic investment for agriculture and our Nation in ensuring the health, safety and security of the U.S. food supply,” said Under Secretary and USDA Chief Scientist Chavonda Jacobs-

Young. “As the first facility of its kind in the United States, the innovative and cutting-edge solutions our scientists and partners can produce here will lead efforts to protect public health and address new and emerging diseases for many years to come.”

“This new facility highlights USDA’s commitment to taking every step possible to protect the United States from transboundary, emerging, and zoonotic animal diseases,” said Under Secretary for USDA’s Marketing and Regulatory Programs Jenny Moffitt.

“Through investments like these, we can ensure our country has the tools to keep the American people and our agricultural animals safe, and to prevent diseases costly to farmers.”

With more than 400 employees, USDA’s Agricultural Research Service (ARS) and Animal and Plant Health Inspection Service

(APHIS) will share NBAF’s operational responsibilities. ARS will primarily focus on research to understand high-consequence and emerging animal diseases and develop countermeasures, such as vaccines and antivirals. APHIS will focus on prevention, surveillance, diagnosis and response to these diseases, including the expertise to manage two vaccine banks and train state and federal veterinarians to recognize livestock diseases.

A ribbon-cutting ceremony held at the facility highlighted the state and local community’s support. City of Manhattan Mayor Mark Hatesohl, Kansas State University President Dr. Richard Linton, Kansas Governor Laura Kelly, U.S. Senator Jerry Moran, and former U.S. Senator Pat Roberts also addressed the crowd during the ceremony.

“NBAF’s Midwest location offers researchers and diagnosticians closer proximity to develop key

partnerships with the animal health industry and several academic institutions,” said NBAF Director Dr. Alfonso Clavijo. “NBAF will create opportunities between scientists and animal health companies to enhance and expedite the transition of new veterinary countermeasures from research to market to protect the nation’s agriculture if needed.”

Adjacent to Kansas State University and on the Western edge of the largest concentration of animal health companies in the nation, the 48-acre NBAF campus includes more than 700,000 square feet of total building space. The main building, at 500,000 square feet, includes containment laboratories, animal holding facilities, office spaces, facility support areas and required safety systems — such as redundant high efficiency particulate air filter and waste decontamination systems.

ARLINGTON, Va. — On June 8, the American Feed Industry Association commended several U.S. senators for introducing the Innovative Feed Enhancement and Economic Development Act of 2023 (or “Innovative FEED Act”), which would amend the Federal Food, Drug and Cosmetic Act to establish a regulatory pathway for a new category of animal food substances that act solely within animals’ gut microbiomes or in the feed they are digesting to provide non-nutritive benefits.

Upon introduction of the bill, AFIA President and CEO Constance Cullman said, “Our industry is bringing forward innovative animal food solutions to benefit animal health, human food safety and the environment, and now, thanks to the leadership of several Senate leaders, we have the legislative solution needed to provide a modernized regulatory pathway to meet marketplace demands. We fully support the Innovative

FEED Act and hope Congress will quickly approve this bill, giving our farmers and ranchers the tools they need and putting our international counterparts on notice that we are fully equipped to compete in the future.”

“We cannot thank Senators Roger Marshall, R-Kansas, Tammy Baldwin, D-Wis., Jerry Moran, R-Kansas, and Michael Bennet, D-Colo., enough for their

dedication to this important animal food issue,” she added.

The AFIA has been calling on the U.S. Food and Drug Administration (FDA) to update its outdated 1998 Policy and Procedures Manual Guide 1240.3605, which has prevented animal food manufacturers from clearly identifying the ways their products may bring about non-nutritive benefits on the labels unless they go through the

FDA Center for Veterinary Medicine’s cumbersome drug approval process.

Without congressional approval, the FDA contended it did not have the authority to regulate these products as food ingredients. The Innovative FEED Act would change this by creating a category for zootechnical animal food substances (ZAFS), regulating these products as food ingredients, not animal drugs, and bringing the FDA policy into the 21st century, AFIA noted.

Dozens of countries are already safely using these innovative feed ingredients on farms, yielding results in terms of improved animal production and well-being, diminished pre-harvest food safety concerns, and reduced environmental impact of livestock production, AFIA said, adding that, without this legislative change, U.S. agriculture is at a competitive disadvantage to its international counterparts.

Our new Fast Track Wall Vent (Patent Pending) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available either insulated or uninsulated

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

WASHINGTON — An early bird El Niño has officially formed, likely to be strong, warp weather worldwide and give an already warming Earth an extra kick of natural heat, meteorologists announced.

The National Oceanic and Atmospheric Administration on June 8 issued an El Niño advisory, announcing the arrival of the climatic condition. It may not quite be like the others.

It formed a month or two earlier than most El Niños do, which “gives it room to grow,” and there’s a 56 percent chance it will be considered strong and a 25 percent chance it reaches supersized levels, said climate scientist Michelle L’Heureux, head of NOAA’s El Niño/La Niña forecast office.

“If this El Niño tips into the largest class of events ... it will be the shortest recurrence time in the historical record,” said Kim Cobb, a climate scientist at Brown University. Such a short gap between El Ninos leaves communities with less time to recover from damages to infrastructure, agriculture, and ecosystems like coral reefs.

Usually, an El Niño mutes hurricane activity in the Atlantic, giving relief to coastal areas in states from Texas to New England, Central America and the Caribbean, weary from recent record busy years. But this time, forecasters don’t see that happening, because of record hot Atlantic temperatures that would counteract the El Niño winds that normally decapitate many storms.

Hurricanes strengthen and grow when they travel over warm seawater, and the tropical regions of the Atlantic Ocean are “exceptionally warm,” said Kristopher Karnauskas, associate professor at the University of Colorado Boulder. So this year, NOAA and others are predicting a near-average Atlantic hurricane season.

In the past, a strong El Niño has led to record global warmth, like in 2016 and 1998. Scientists earlier this year had been saying next year is more likely to set a record heat, especially because El Niños usually reach peak power in winter. But this El Niño started even earlier than usual.

“The onset of El Niño has implications for placing 2023 in the running for warmest year on record when combined with climate-warming background,” said University of Georgia meteorology professor Marshall Shepherd.

An El Niño is a natural, temporary and occasional warming of part of the Pacific that shifts weather patterns across the globe, often by moving the airborne paths for storms. The world earlier this year got out of an unusually long-lasting and strong La Nina — El Niño’s flip side with

cooling — that exacerbated drought in the U.S. West and augmented Atlantic hurricane season.

What this in some ways means is that some of the wild weather of the past three years – such as drought in places – will flip the opposite way.

“If you’ve been suffering three years of a profound drought like in South America, then a tilt toward wet might be a welcome to development,” L’Heureux said. “You don’t want flooding, but certainly there are portions of the world that may benefit from the onset of El Niño.”

For the next few months, during the northern summer, El Niño will most be felt in the Southern Hemisphere with “minimal impacts” in North America, L’Heureux said.

El Niño strongly tilts Australia toward drier and warmer conditions with northern South America — Brazil, Colombia and Venezuela — likely to be drier and Southeast Argentina and parts of Chile likely to be wetter, she said. India and Indonesia also tend to be dry through August in El Niños.

While traditionally El Niño means fewer hurricanes in the Atlantic, it often means more tropical cyclones in the Pacific, L’Heureux said.

El Niño hits hardest in December through February, shifting the winter storm track farther south to the equator. The entire southern third to half of the United States, including California, is likely to be wetter in El Niño. For years, California was looking for El Niño rain relief from a decades long megadrought, but this winter’s seemingly endless atmospheric rivers made it no longer needed, she said.

The U.S. Pacific Northwest and parts of the Ohio Valley can go dry and warm, L’Heureux said.

Some of the biggest effects are likely to be seen in a hotter and drier Indonesia and adjacent parts of Asia, L’Heureux said. Also look for parts of southern Africa to go dry.

On the other hand, drought-stricken countries in northeast Africa will welcome beneficial rainfall after enduring drought conditions for several years due to prolonged La Niña events, said Azhar Ehsan, associate research scientist at Columbia University.

Some economic studies have shown that La Nina causes more damages in the United States and globally than El Niño.

One 2017 study in an economic journal found El Niño has a “growth-enhancing effect” on the economies of the United States and Europe, while it was costly for Australia, Chile, Indonesia, India, Japan, New Zealand and South Africa.

But a recent study says El Niño is far more expensive globally than previously thought, putting damage estimates in the trillions of dollars. The World Bank estimated that the 1997-1998 El Nino cost governments $45 billion.

The United States also faces hazards from El Niño despite some benefits. Ehsan noted that the increased rainfall in California, Oregon, and Washington heightens the risk of landslides and flash flooding in these areas. “While El Niño brings benefits in terms of water resource recharge, it poses certain hazards that need to be considered and managed,” he added.

TUCKER, Ga. — The U.S. Poultry & Egg Association and the USPOULTRY Foundation have approved approximately $250,000 in funding for two new research grants at two institutions through the Board Research Initiative Program.

The topics and request for proposals were selected by the USPOULTRY board of directors. The Foundation Research Advisory Committee evaluated several research proposals and then recommended which proposals to fund to the board.

The research grants are as follows, and the research funding was made possible in part by donations to the USPOULTRY Foundation. The donations came from a wide range of poultry and egg companies, individuals and families to support the Foundation’s mission of funding industry

research and recruiting students into poultry careers.

The grants include:

• Investigation into the Contributions of Rooster, Hens and Social Dynamics on the Reduced Hatchability in Broiler Breeders; Auburn University (research grant made possible in part by an endowing Foundation gift from Mar-Jac Poultry Inc.)

• Updated Decision Support Tool for Supplemental Heat Requirements in Barn Depopulation During an

HPAI Outbreak; Iowa State University (research grant made possible in part by an endowing Foundation gift from MPS Egg Farms)

The USPOULTRY Board Research Initiative was created by the boards of USPOULTRY and the USPOULTRY Foundation to address current issues facing the poultry industry.

The USPOULTRY Board Research Initiative operates alongside the USPOULTRY Comprehensive Research Program and augments the great success of the

existing program by focusing additional resources toward defined areas of research.