Creekview Mfg., 18

717-445-4922; https://creekviewmanufacturing. com

Eagan Mfg., 14

870-878-6805; www.eaganmfg.com

Farmer Boy Ag, 25

717-866-7565; www.farmerboyag.com

FPM Inc., 24

402-729-2264; www.fpmne.com

Henning Companies, 21 515-253-0943; www.henningcompanies.com

Hog Slat, 31

800-949-4647; www.hogslat.com

Impact Poultry Products, 27

800-448-4723; www.impactpoultryproducts. com

IMPEX, 18

770-534-1590; www.impex.nl

Kelley Mfg., 22 800-444-5449; www.kelleymfg.com

Kuhl Corp., 24 908-782-5696; www.kuhlcorp.com

Kunafin (The Insectary), 24

800-832-1113; www.kunafin.com

L.B. White, 17

608-783-5691; www.lbwhite.com

Lewis Brothers, 27 912-367-4651; www.lbmfg.com

Motomco, 32

800-237-6843; www.motomco.com

Newton Crouch Co., 19 800-241-1350; www.newtoncrouch.com

Overdrive Lighting, 23 800-657-0509; www.aglights.com

Precision Lighting, 1, 2, 30 800-737-1837; www.poultrylighting.com

Star Labs, 26 800-894-5396; www.primalac.com

The Egg Carton Store, 24 866-333-1132; www.eggcartonstore.com

Walinga USA, 3 800-466-1197; www.walinga.com

Weightech, 15, 26 800-457-3720; www.weightechinc.com

General Manager

Cindy Wellborn

770-718-3443

cwellborn@poultrytimes.com

Editor

David B. Strickland

770-718-3442

dstrickland@poultrytimes.com

Digital Manager

Rachel Danford

770-718-3438

rdanford@poultrytimes.com

Senior Sales Executive

Stacy Louis

770-718-3445

slouis@poultrytimes.com

Sales Support

Janice Sisk

770-536-2476

jsisk@poultrytimes.com

Content Writer

Elizabeth Bobenhausen

770-209-3335

ebobenhausen@poultrytimes.com

With a vertical circulation fan system, mixing/circulation tends to occur in zones around each circulation fan, with horizontal circulation fan systems, the circulation fans tend to work together as a single unit to mix the air throughout a house.

dIsclaImer

Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

— By Zippy Duvall vIewpoInt, 10

BUFORD, Ga. — Working through challenges and finding success through the past couple of years has been the goal of many industries across the nation, and the poultry industry as a whole, and the Georgia industry specifically, and was noted during the Georgia Poultry Federation’s recent annual meeting at Lake Lanier Islands, Buford, Ga.

During this annual meeting, GPF elected its new chairman for the upcoming year.

Brad Respess, Tip-Top Poultry, takes the helm as GPF chairman for 2023-2024. John Wright, Fieldale Farms, now becomes the group’s immediate past chair.

“It’s such an honor to be able to be here and to be part of this great state,” Respess said. “This industry is something very special, with all of our great friendships, and it’s a great place to do business. We are looking forward to a great year.”

Respess also expressed thanks to the federation and to the support it gives the state’s poultry industry.

“The real work is done by the federation,” he added. “They do the hard work to make sure we are supported here in this great state to continue our business, our industry and our ability to feed the world.”

The value of the federation’s Georgia Poultry Strong concert event, which will take place this year on Oct. 21, was also noted.

“Everybody recognizes the success of changing our fundraiser from the Night of Knights to the new Georgia Poultry Strong,” Wright said. “It has been a huge undertaking, especially through the COVID pandemic, and we are all looking forward to this fall’s event.”

Mike Giles, GPF president, provided an update on some of the

federation’s activities during the previous year.

During the 2023 Georgia legislative session, he noted that it was a good year with some important bills being passed.

Among them included Georgia House Bill 189, that regarded an increase in truck weights. The bill allows a limit of 88,000 pounds for trucks that are hauling agricultural or forest commodities on local roads and state highways.

“I’m not aware of a single policy that the state could make that

would improve our efficiency on the live production side more so than the increase of truck weights,” Giles said. “We are very fortunate for its passage.”

He also mentioned the success the federation has seen through workforce development.

“This is a program that started, before the pandemic, with a phone call with one of the members who said they were having some trouble finding people,” Giles said. “Automation is going to be increasing more and more, and

we are going to need people who can maintain our equipment and keep it working. We believe that the trend for the future will be producing more chicken with fewer people and that means that the skill set of these people will need to be different.

“They don’t all have to be poultry science graduates, as much as we need them and appreciate them. Through our technical colleges we believe we can give young people a tremendous career path in industrial maintenance. It’s

a great career path, and it’s going to be critically important to us in the future. I don’t know anything more rewarding than seeing a young person set on a career path.”

In looking back and looking ahead, Giles added that, “working through the challenges of the pandemic, this is an amazingly resilient industry, and we are proud to be a part of it.”

Wrapping up the meeting, Abit Massey, GPF president emeritus, noted the importance of the great diversification in industry segments that exist in Georgia.

“What a great place Georgia is with all the strong support we have, it really illustrates that Georgia is the poultry capital of the world in every possible way,” Massey said. “With production, processing, teaching and research, and technical service … I think that it’s so good that we sometimes take it for granted.”

“It’s exciting to be part of the poultry industry in Georgia,” he added. “We are very grateful for all of the strong support.”

GAINESVILLE, Ga. — The House of Representatives is looking to amend the Federal Meat Inspection Act by adding the Processing Revival and Intrastate Meat Exemption Act or the PRIME Act. According to the Institute for Justice, this piece of legislation will permit farmers and ranchers to slaughter their meat at local slaughterhouses. The USDA approved facilities are too far for farmers and ranchers, it was noted. The bill would give states power to regulate slaughterhouses instead of the USDA.

The PRIME Act would permit meat from local slaughterhouses to be retailed in restaurants, grocery stores, hotels and to consumers. The act would not force states to sell meat from local slaughterhouses.

The states that have Meat and Poultry Inspection programs are Alabama, Arizona, Arkansas, Delaware, Georgia, Illinois, Indiana, Iowa, Kansas, Louisiana, Maine, Minnesota, Mississippi, Missouri, Montana, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, South Carolina, South Dakota, Texas, Utah, Vermont, Virginia, West Virginia, Wisconsin and Wyoming. The states that do not have Meat and Poultry Inspection programs are Alaska, California, Colorado, Connecticut, Florida, Georgia, Hawaii, Idaho, Kentucky, Maryland, Massachusetts, Michigan, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, Pennsylvania, Rhode Island, South Dakota, Tennessee and Washington.

The PRIME Act bill was first introduced by U.S. Rep. Thomas Massie (R-Ky.) and U.S. Rep. Chellie Pingree (D-Maine) in the House of Representatives in 2017, however it never made it to the Senate. It was reintroduced in 2020, but never got to the senate. The bill has been reintroduced for a third time by Massie and Pingree in the House of Representatives. This time U.S. Sens. Angus King (I-Maine), Rand Paul (R-Ky.), Mike Braun (R-Ind.), Kevin Cramer (R-N.D.), John Hoeven (R-N.D.), Mike Lee (R-Utah) and Cynthia Lummis (R-Wy.) have a companion bill in the Senate. H.R. 2657 will be amended to the Federal Meat Inspection Act.

The PRIME Act says, “The provisions of this title requiring inspection of the slaughter of animals and the preparation of the carcasses, parts thereof, meat and meat food products at establishments conducting such operations for commerce shall not apply to the slaughtering by any person of animals at a custom slaughter facility, and the preparation at such custom slaughter facility and transportation in commerce of the

carcasses, parts thereof, meat and meat food products of such animals if the slaughtering and preparation carried out at such custom slaughter facility is carried out in accordance with the law of the State in which the custom slaughter facility is located; and the animals are so slaughtered and the carcasses, parts thereof, meat and meat food products of such animals are so prepared exclusively for distribution to household consumers within the State; and restaurants, hotels, boarding houses, grocery stores, or other establishments located in such State that are involved in the preparation of meals served directly to consumers; or offer meat and meat food products for sale directly to consumers in the State.”

“Consumers want to know where their food comes from, what it contains, and how it’s processed,” Massie said. “Yet, federal inspection requirements make it difficult to purchase food from trusted, local farmers. It is time to open our markets to give producers the freedom to succeed and consumers the freedom to choose.”

“More and more, consumers want to know where their food is coming from, especially after the pandemic exposed breakdowns in our supply chains,” Pingree said. “A farmer in Maine shouldn’t have to drive hours to get to a USDAinspected processing facility when other safe options are available. The bipartisan PRIME Act will make it easier for local farms to compete with big meat companies and make locally raised livestock processing more widely avail-

able. This bill will address the needs of communities in a way that supports them by allowing America’s family farms to do what they do best feed their neighbors.”

The North American Meat Institute is not in agreement with the bipartisan bill. The nonprofit trade organization expressed safety concerns because the local slaughterhouses are not regulated by the USDA.

“American consumers rely on rigorous USDA inspection to ensure the safety and quality of their meat and poultry. Allowing meat to enter commerce without inspection and without alerting consumers they are buying uninspected meat jeopardizes food safety and will undermine consumer confidence in all meat products,” Julie Anna Potts, Meat Institute president and CEO, said.

“It is important for the American economy and the entire meat value chain that the safety of our meat and poultry is never taken for granted,” she added. “The meat and poultry industry, and the taxpayer, has invested billions of dollars in food safety protections, research and infrastructure to ensure we have the safest meat in the world. While this bill may be well intentioned, it poses especially unnecessary risks given the many resources available to help new and small facilities gain inspection from FSIS.”

The Meat Institute added that throughout the United States, there are more than 6,500 federally inspected facilities.

By elizabeth Bobenhausen poultry times staff ebobenhausen@poultrytimes.com

By elizabeth Bobenhausen poultry times staff ebobenhausen@poultrytimes.com

This is the first in a small series from Poultry Times regarding the importance of biosecurity.

GAINESVILLE, Ga. — According to USDA, biosecurity is what farmers, or any others do to keep microorganisms, bacteria, fungi, and parasites that cause disease away from their animals.

Structural biosecurity is the maintenance of coops, pens, poultry houses, family farms and commercial farms. Operational biosecurity are the practices people use to maintain biosecurity. The USDA names three illnesses that can be found on poultry farms.

Avian influenza or “bird flu” is a respiratory infection that infects birds. It is brought about by an influenza type A virus infects chickens, turkeys, pheasants, quail, domestic ducks, geese, guinea fowl, waterfowl and wild birds.

There are two types of avian influenza:

1. Extremely pathogenic avian flu cases are very infectious and can easily be spread from flock to flock. This type of strain is deadly to domestic poultry.

2. Low pathogenic avian flu cases are not as infectious and are seen in wild migratory waterfowl. Domestic poultry can still be infected with this strain but will show no signs of being infected.

3. Symptoms of avian influenza include:

• Sudden death without any indication of being ill.

• Loss of appetite

• No energy

• Decline in egg production, soft or warped eggs.

• Inflammation of head, comb, eyelids, wattles and hooks.

• Purple discoloration of comb, legs and wattles.

• Nasal discharge, coughing and sneezing.

• Incoordination or soft fecal matter

Other diseases that biosecurity steps can help against include virulent Newcastle disease which is a virus that harms the respiratory system, the nervous system, and the digestive system in birds. This type of virus is asymptomatic and is fatal. Salmonella is most commonly seen in humans who consume underdone poultry meat and eggs. However, it can be found on live poultry.

Salmonella is a type of bacteria that can cause bowel discomfort, nausea and vomiting. Salmonella is not considered to be fatal, although it can

be extremely harmful to someone who is under the age of five or over the age of 65. The USDA advises someone to wash their hands after dealing with live poultry and to cook poultry meat completely.

The USDA also offers many safety steps to follow regarding farms and how to maintain proper biosecurity.

Among them are:

• Keep visitors to a minimum: People who assist in taking care of poultry should be the only ones allowed near the poultry. If friends and family do not assist with the poultry, they should not be near the poultry. The USDA recommends that if people are to go near live poultry, they should adhere to biosecurity rules.

• Wash your hands before and after coming in contact with live poultry: Bacteria can be spread from birds to humans. To avoid contamination in humans it is important for a person to wash their hands thoroughly. If using hand sanitizer, a person must be sure to eliminate manure and feathers from their hands because hand sanitizer is not strong enough to remove those elements.

• Provide disposable boot covers and/ or disinfectant footbaths for anyone having contact with your flock: It is im-

portant to eliminate any manure, mud or any other waste from a person’s footwear using a long-handled scrub brush before going into a disinfectant foot wash. Be sure that it is clean at all times.

• Change clothes before entering poultry areas and before exiting the property: People visiting farms or facilities should wear protective outer clothing or throwaway boots, coveralls and headgear. They should bathe or at least change their clothes before exiting the farm or facility.

• Clean and disinfect tools or equipment before moving them to a new poultry facility: Before allowing any type of vehicle to leave the farm or poultry facility, be sure that they have been cleaned and disinfected. This also comprises of egg flats that have been around birds and their fecal matter. This prevents any vehicle from transporting diseases. Do not reuse items or items that can’t be cleaned such as egg flats.

• Look for signs of illnesses.

• Report sick birds: The USDA recommends someone not wait if a bird is sick. If someone’s bird has become ill, call a veterinarian, a cooperative extensive service or state veterinarian. Someone can also call the USDA toll-free at 866-536-7593.

WASHINGTON — Three years ago, Farm Bureau launched our #StillFarming campaign. Our goal was simple: reassure Americans that farmers and ranchers were committed to maintaining a steady food supply at a time when many Americans witnessed empty grocery store shelves for the first time in generations and supply chain disruptions made headlines.

Farmers and ranchers take great pride in rising each day to grow the food, fuel and fiber we all depend on, and managing risk on the farm is critical to keeping food on our tables. We are still farming, for our neighbors near and far, thanks to our public investment in U.S. agriculture through the farm bill.

Thanks to risk management programs in the farm bill, farmers can hold on through tough times like high inflation, global market turmoil and natural disasters. We are also building a more sustainable future through conservation programs and agricultural research and helping families facing hunger to keep food on the table

through tough times.

The farm bill matters to all Americans, and 73 percent of adults recognize there would be a significant impact if the farm bill were not reauthorized.

Not many Americans today are very familiar with the farm bill, though. To be fair, it’s a big piece of legislation that comes up just once every five years. Even in Congress, many lawmakers are new to the farm bill as nearly half of them have been elected since the 2018 bill.

The American Farm Bureau recently conducted a survey to better understand where public opinion and awareness stands on the farm bill and funding for key programs. We found that 71 percent of adults had not read or heard much of anything about the farm bill. This was a big reminder that we’ve got a lot of work to do.

The good news is that when it comes to talking about the farm bill, farmers and ranchers are perfect for the job. The American people trust us — nearly 9 out of

we are still farming, for our neighbors near and far, thanks to our public investment in u.s. agriculture through the farm bill.Vincent (Zippy) Duvall, a poultry, cattle and hay producer from Greene County, Ga., is president of the American Farm Bureau Federation headquartered in Washington, D.C.

10, in fact, say they trust farmers. That’s higher than any other profession. Americans have not forgotten those empty shelves, and they are counting on our success on the farm to keep store shelves and pantries full for everyone.

We found there is strong support for risk management programs with the most adults (67 percent) ranking that as one of the top priorities for federal funding in the farm bill. Risk management along with nutrition programs came in as top funding priorities among those surveyed.

This affirms what we have said for a long time across the agriculture community — the farm bill must remain unified. In fact, support for the farm bill dropped by half when we asked folks if they would still support a farm bill that no longer included funding for nutrition programs.

The farm bill’s nutrition programs provide a critical link to families hundreds and thousands of miles from our farms. America’s farmers and ranchers are proud to grow the food that helps supply billions of meals annually to families facing hunger.

With the added pressures of inflation and rising food costs, we found that most people now see the security of our food supply as critical. Not too long ago, I’d say many took it for granted that we have an abundant supply of American grown products. But following supply chain disruptions and global events like the war between Russia and Ukraine, Americans’ eyes have been opened to how fragile our food system is. Eighty-four percent say that, in light of recent disruptions, the U.S. should make our food supply a matter of national security. Simply meaning, we are a stronger country when we can grow our own food.

Farmers and ranchers take great pride in our work — it is truly a calling for us. We show up, rain or shine, to grow and raise safe, sustainable food, fuel and fiber.

We have found our purpose on the farm, and I believe we are still farming because we love the land and this great country. Farmers have America’s back when times are tough, and it’s important for us to know that America has our back and is committed to helping us keep our farms and food supply secure in all seasons. That’s exactly what the farm bill achieves.

Meyn America LLC, a leading poultry processing solutions company, has announced plans to construct an 80,000-square-foot, Green Globes-certified parts distribution facility in the economic development business park of Oconee County, S.C.

The facility is intended to accelerate and improve the accuracy of Meyn’s growing parts business to support customers throughout the U.S., Canada, Mexico and Latin America.

“As part of our continuous improvement effort, we are always exploring opportunities to improve the customer experience,” said Todd Rhodes, vice president and general manager of Meyn Americas. “This new distribution facility will enable us to fulfill our growing customer parts orders more quickly and accurately. In addition, by establishing roots in South Carolina — two hours from our Georgia facility, we will diversify risk caused by any unplanned weather disruptions, allowing us to continue uninterrupted fulfillment of customer orders.”

“When this facility becomes operational, it will harness stateof-the-art automation technology that will significantly improve our OCE (on-time, complete and error-free) shipment to customers,” Michael Otterbach, vice president of Parts Operations for Meyn America, added.

“This move represents a significant milestone in our global supply chain strategy, and we expect it will have the important added benefit of helping us reduce our company’s carbon footprint,” Joost Weel, managing director of Meyn Food Processing Technology B.V., said.

Currently, parts are shipped

via air from distribution centers throughout Europe to Meyn America’s customers — resulting in high CO2 emissions. Meyn’s new South Carolina facility will house a robust parts inventory that will be delivered to customers over land and sea – transportation modes proven to be less carbon

intensive than air.

In addition, the distribution facility’s project managers are pursuing Green Globes building certification, by reducing the project’s environmental impact, identifying opportunities to save energy and minimize future maintenance costs, and fostering

a healthy work environment for employees.

The company is investing $10.8 million in the construction of the warehouse, which it expects to be operational by the third quarter of 2024.

For more information, visit www.meyn.com.

celebrating 60 years

HUNTSVILLE, Ala. — Aviagen® North America welcomed students from around the world as they gathered for the 2023 Production Management School. From May 28-June 24 in Huntsville, Ala., the event united 35 students representing 22 different countries in Asia Pacific; Latin America; North America; and Turkey, Middle East and Africa.

The program is designed to empower participants with the latest knowledge and best practices in the art of successfully managing breeder and broiler operations. As the North American School commemorates its 60th anniversary, the occasion is further distinguished by some notable “firsts” that promise to make this year’s learning journey exceptional.

• Six decades of sharing knowledge and building lifelong relationships.

Initially known as the Arbor Acres Production Management School, the event was first held in 1963 in Connecticut. Since then, it has grown in size and scope, and is now held annually in Huntsville, Ala. Since its inception, the school has nurtured the growth of more than 2,000 students hailing from 100-plus countries, all of whom have successfully completed the program. This legacy exemplifies the school’s commitment to excellence and its global impact in shaping successful poultry professionals, the company noted.

• Comprehensive learning experience.

The Production Management School stands out due to its holistic approach to poultry science. As the industry’s longest-running program of its kind, it offers a comprehensive curriculum covering all aspects of breeder and broiler operations. The curriculum includes

seminars, workshops, and field experiences led by experts who are passionate about helping customers take their expertise to the next level and achieve the most with their Aviagen flocks.

Students benefit from the wealth of experience of Aviagen and guest lecturers specialized in veterinary care, nutrition, genetic research and development, production and farm management, hatchery and incubation and more. Participants are able to reinforce classroom theory with hands-on field experiences at breeder and broiler facilities throughout Alabama.

Outside the classroom, students are provided abundant opportunities to become acquainted and form valuable connections. With a diverse array of instructors and attendees, students gain valuable insights from the varied experiences of their international peers.

The impact is multiplied as students return to their respective operations, armed with newfound knowledge and insights to share with their colleagues, creating a ripple effect that positively impacts the global poultry industry.

• This year’s school enriched with notable “firsts.”

This year the Production Management School returns to in-person instruction for the first time since the COVID pandemic in 2019. Over the past three years, Aviagen transitioned the school online, leveraging innovative technology to pioneer the industry’s first virtual Production Management School.

This year’s attendees will be the first to experience Aviagen’s groundbreaking remote customer service system, featuring augmented-reality smart glasses. The system enables students to virtually tour facilities that were previously closed to visitors due to biosecurity restrictions.

Aviagen has recently implemented this technology to bring their specialists directly to customer facilities, providing realtime and immediate assistance to address challenges and offer expert advice to enhance bird performance, efficiency, and welfare.

This year, the school’s immersive experience is further enhanced through engaging exercises at the Elkmont Veterinary Lab. Additionally, for the very first time,

students will have the opportunity to explore the Aviagen feed mill in Pikeville, Tenn., renowned as one of the world’s most advanced feed processing facilities.

“Our North America Production Management School continues to push boundaries, embracing technology and providing unparalleled practical experiences to ensure students receive a comprehensive education that empowers them to excel in their roles as industry professionals and leaders,” Marc de Beer, president of Aviagen North America, said. “As we prepare to welcome our exceptional students, we eagerly anticipate the opportunity to foster ‘breeding success together,’ forging a path toward a prosperous future.”

For more information, visit https://en.aviagen.com/.

The program gives students invaluable insight into the world of poultry production — a well-established and growing sector across the southeastern United States and across the North American continent. During the course, theory converges with hands-on practice, as Aviagen specialists lead students through the care and expertise that go into raising quality breeding stock. These chicks are then bred to provide families around the world with affordable and sustainable chicken meat.

Poultry breeding insight gained by students includes research and development, planning, the egg depot, the hatchery, and the feed mill. They also learn the importance of animal welfare, biosecurity, health monitoring and diagnostics, and other elements that are vital to health, food safety, and food security. And they receive coaching to help them develop professional skills, such as interviewing and resume creation.

• Learning by doing

Aviagen, local schools celebrate success in Poultry 101 HUNTSVILLE, Ala. — April 24 was a lively day for employees at the Aviagen corporate office in Huntsville, Ala., hosting students from nearby Limestone County Career Technical Center in Athens, Ala. The occasion was to recognize the students’ successful completion of a 12-week Poultry Breeding 101 class sponsored by Aviagen. While celebrating the milestone, Aviagen also took the chance to award the winner of a poultry house model competition. And, in honor of Earth Day, the LCCTC students held their yearly plant sale at the Aviagen headquarters, where employees stocked up on house and yard plants for the spring.

• Learning poultry basics

What started as a learning opportunity for 30-plus students at one school, has grown to encompass three high schools and close to 120 students from LCCTC, as well as Cumberland County and Stone Memorial Schools in Crossville, Tenn. Aviagen started the introductory poultry breeding study at LCCTC in the spring of last year, and this year Cumberland and Stone Memorial have joined in on the unique learning opportunity.

We all learn better by doing, and students were able to put their skills into practice by creating a chicken house model. In doing so, they demonstrated their understanding of biosecurity, and how feed, light, air, and water all play important roles in bird health and welfare. Each school submitted several models, and LCCTC took home the prize for the best chicken house model.

“We are extremely proud of the growth and success of this community outreach project. The course is designed to set students on a journey of lifelong learning in the proper care that leads to growing healthy, robust birds,” commented Karri Morton, Aviagen’s human resources project manager and coordinator of the Poultry 101 program. “Our sustainability as an industry depends on our success in attracting our youth and inspiring them to be passionate about poultry. The popularity of the program is proof our efforts are taking root in Alabama and Tennessee.”

De Wet Nortje, Aviagen’s Director of Pedigree and Great Grandparent Operations, is based in Crossville and was instrumental in engaging the Cumberland County and Stone Memorial schools in the program.

(Continued on next page)

“The Aviagen Poultry 101 program has helped forge strong connections between Aviagen and students in our community,” Nortje said. “This program has not only empowered them with handson experience and insights into the poultry industry but has also showcased the vast range of career prospects available at Aviagen and in the poultry industry as a whole. This program is an example of how we live our commitment to fostering a new generation of skilled professionals equipped to shape the future of the industry.”

has been described as the greatest challenge and opportunity of our time. In 2019, Alltech committed its team to a single, shared purpose of Working Together for a Planet of Plenty, viewing it even more broadly as a vision for the global agri-food sector.

As collaboration is essential for the achievement of shared goals, Alltech is inviting the global agriculture and agri-food industry to participate in the company’s inaugural Sustainability Insights Survey to gather insights on the issues that matter most to the agri-food value chain’s stakeholders.

The survey is now open to the global agri-food industry to provide input until June 12, 2023.

The results of this global research will only be presented in aggregate form and responses will not be personally identified in the report. However, the aggregate findings will be shared and available for the benefit of the agri-food industry and its partners later this year.

For more information and to complete the survey, visit www. alltech.com/sustainability-insights-survey.

the company to meet high customer demand for its Hillshire Farm brand products. This $83 million expansion will add 15,000 square feet to its 342,000 square foot facility and state-of-the-art equipment to increase production by 50 percent to better serve customers.

Alltech inviting participation in its first global sustainability insights survey

LEXINGTON, Ky. — Sustainability and the journey it entails

“Given the evolving understanding of sustainability and the complexity of our industry, we believe that there is significant value in exploring and sharing perspectives across the value chain,” said Tara McCarthy, global vice president of ESG at Alltech. “This consultation will better enable us to develop a robust, future-facing perspective and a collaboration strategy that is relevant, ambitious and inclusive. Our aim is to identify tangible actions across the industry and across the value chain, as we seek to deliver a Planet of Plenty.”

CLARYVILLE, Ky. — Tyson Foods Claryville is celebrating its newly expanded cocktail sausage manufacturing capacity, allowing

Hillshire Farm SNACKING! sales are up more than 11 percent over the last year. Hillshire Farm deli meats retail dollar sales are up double digits, supported by the “Oh, Hill Yeah!” campaign that recently debuted nationwide across TV, print, social media, and online, where consumers can view exclusive Hillshire Farm brand content and mouthwatering recipes.

The two plants in Claryville currently produce 130 million pounds of hot dogs, sliced meats, and 70 percent of the world’s cocktail sausages, making Claryville the “Cocktail Sausage Capital of the World.”

The facility employs more than 750 team members and produces more than 120 million pounds of protein yearly. The Claryville plant has been operating since 1984 and producing cocktail sausages since 1991.

Our new Fast Track Wall Vent (Patent Pending) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available either insulated or uninsulated

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

Land O’Lakes: Everyone should care about the global water crisis

LINCOLN, Neb. — “Food security is national security,” said Land O’Lakes President and CEO Beth Ford in a May 8, Heuermann Lecture at Nebraska Innovation Campus in Lincoln, Neb.

To address agricultural challenges, Ford stressed the need for a comprehensive, long-term water sustainability strategy, and shared why water is at the top of her priority list.

“Fresh water demand will outstrip supply by 2030 by 56 percent globally, and water is critical to production agriculture, it’s critical to communities and to life,” Ford said. Water issues and policies are very local but have global implications, especially with agriculture and the food supply.

To meet the grand challenge of feeding 10 billion people by 2050, more agricultural research funding is needed, said Ford. While GMOs

have increased yields by 25 percent, Ford said we’ve nearly maximized the increase in production that they can provide. However, she said research funding is still at 1970s levels, while we simultaneously face an unprecedented challenge of population growth, climate change, water crisis, and food insecurity.

She also addressed the need for more agricultural laborers to ensure all available food is harvested and all available acres are planted.

Land O’Lakes isn’t just a dairy company. Ford referred to the company’s extensive involvement throughout the entire production agriculture value chain. Along with its dairy production, Land O’Lakes business offerings also include animal nutrition through its Purina brand, research-based agronomic products through its Winfield United company, work with smallholder farmers through its non-governmental organization, Venture 37, and sustainable production practices through its Truterra business.

Truterra brings insights into how farmers can make their land more resilient against climate change through practice change, whether

that be carbon capture, cover crops, variable rate application of fertilizer or other things, Ford said. But all that transition costs money. USDA recently awarded the company a $90 million grant to help farmers transition to more sustainable practices.

“We must and we should want the farmer to be profitable. We should want the investment for the farmer to be secure. It is in all of our best interests,” Ford said.

To the students and future farmers and ranchers in the audience, Ford encouraged them to be engaged with local policymakers and help others understand why food security is an immediate issue to ensure national security.

“We need other innovators, other younger folks involved in agriculture and the food supply,” she said.

Dr. Tiffany Heng-Moss, dean of the College of Agricultural and Natural Resources at the University of Nebraska–Lincoln, facilitated the discussion. The fireside chat was part of the 2023 Water for Food Global Conference, which drew more than 400 attendees to focus on solutions to food and water security challenges.

A recording of the lecture can be viewed on the Heuermann Lecture website: https://heuermannlectures.unl.edu/water-stewardshipfood-secure-future.

MILFORD, Ind. — Tim Cantrell has been named key account manager for Chore-Time, according to Kevin Alger, United States & Canada sales manager for the CTB Inc., business unit. In his new position, Cantrell will continue to work with ChoreTime’s existing key accounts as well as broaden Chore-Time’s client base.

Prior to his employment with CTB, Cantrell gained more than 26 years of experience in the poultry (Continued on next page)

processing, raising, feeding, and science industries. He has held positions of sales manager, director of sales and technical services and live operations manager. Cantrell was also previously an owner and operator of a heavy breeder farm.

Cantrell’s other experiences include inventing a method of fertilizing an avian egg in the shell, working directly with the University of Georgia Poultry Science Department, and reopening a hatchery.

A native of Clermont, Ga., Cantrell continues to reside there.

electrical engineering will make it more accessible and affordable.”

House of Raeford congratulates the following 17 recipients of the 2023 House of Raeford Farms Scholarship and announce their plans for the future:

• Katelyn Williams, daughter of Kerry Williams of the Arcadia division attending Northwestern State University.

• Peter Owen, son of Daniel Gay of the Arcadia division attending the University of Alabama – Huntsville.

• Austin Mercer, son of Tim Mercer of the Greenville division attending the University of Georgia.

• Victoria Harris, daughter of Tim Harris of the Greenville division attending Georgia Southern University.

• Kailee Mcilhenney, daughter of Laura Bennefield of the Greenville division attending Brevard College.

House of Raeford Farms awards $42,500 in scholarships

ROSE HILL, N.C. — House of Raeford Farms is pleased to award 17 deserving students with funding for college through its 10th Annual House of Raeford Farms Scholarship Program.

“As we commemorate a decade of scholarship awards, our company recognizes the importance of providing career development opportunities for our youth so they become responsible citizens in the community,” said House of Raeford Farms CEO & Owner Bob Johnson. “This educational assistance program for children of our employees is an investment in their future success.”

The selection criteria for each $2,500 House of Raeford Farms Scholarship includes academic record, demonstrated leadership, participation in school and community activities, honors, work experience, and a statement of goals and aspirations.

One of the 2023 applicants shared the importance of the award to her educational aspirations, saying, “Receiving this scholarship is consequential to me because I am from a low-income family, and it will equip me with the financial support I need to get through college. Having the funds to pursue my dream career in

• Sydney Paul, daughter of Tammie Baxley of the Hemingway division attending Florence-Darlington Technical College.

• Gabriela Morales, daughter of Jacinto Morales of the Johnson Breeders division attending Western Carolina University.

• Nancy Morales, daughter of Jacinto Morales of the Johnson Breeders division attending Southwestern University.

• Andrew Reynolds, son of Nicole Reynolds of the Rose Hill division attending UNCChapel Hill.

• Mariah Mckiver, daughter of Jakiya Chasten of the Wallace division attending East Carolina University.

• Haydan Crapps, son of Randy Crapps of the West Columbia division attending Midlands Technical College.

• Harman Crapps, son of Randy Crapps of the West Columbia division attending Midlands Technical College.

• Patrick Swygert, son of Chris Swygert of the West Columbia division attending Clemson University.

• Taylor Herring, daughter of Fayth Herring of the Corporate division attending N. C.

State University.

• Jackson Stampe, stepson of Michelle Stampe of the Corporate division attending Cape Fear Community College.

• Marshall Windham, son of Chan Windham of the Corporate division attending the University of South Carolina.

• Sophie Windham, daughter of Chan Windham of the Corporate division attending the College of Charleston.

The House of Raeford Farms Scholarship fund has helped students pursue their academic and professional goals by awarding a total of $375,000 during the last 10 years to 150 students across six states. House of Raeford is grateful to be able to offer this benefit to the dependents of our associates, the company said, adding that it is rewarding to see the impact the program is having on the lives of young people and their families.

Employees and their families are encouraged to visit the Scholarship Page on House of Raeford’s website for more information on next year’s scholarships, which will open in January 2024 — https://houseofraeford.com/responsibility/community-involvement/scholarships/.

Motion Industries

announces executive officer promotions

BIRMINGHAM, Ala. — Motion Industries Inc., a leading distributor of maintenance, repair and operation replacement parts, and a premier provider of industrial technology solutions, announces the promotions of Joe Limbaugh to executive vice president–chief operations officer; and James Howe to executive vice president–chief commercial officer/chief technology officer, effective as of June 1. Both will continue to report to Motion’s President Randy Breaux.

This year, Limbaugh will celebrate 40 years with Motion. In 2021, he was promoted to executive vice president, leading strategic initiatives to improve customer service levels and increase Motion’s productivity. In addition to his current responsibilities leading marketing, supply chain, DC/FC operations, real estate and enterprise excellence, he will assume responsibility for operations in all

of the Mi solutions businesses. This includes Mi Conveyance Solutions, Mi Fluid Power Solutions, Motion Ai and Mi Repair & Services.

Howe recently celebrated 30 years with Motion and was promoted to executive vice president in 2021 with responsibility for eCommerce, strategic pricing, sales excellence and corporate accounts. He will continue to lead in these areas with the added responsibility of human resources.

“These are two richly deserved executive promotions,” Breaux said. “Over the years, both Joe and James have proven to be exceptional leaders for Motion in their respective areas of the business. In addition, they play vital roles in defining the strategic direction of the company and continue to take on additional responsibilities to improve our value proposition. Joe and James have built great supporting teams and have done an outstanding job producing fantastic results for Motion and Genuine Parts Company. These changes will certainly enhance the value Motion delivers to our customers, employees and stakeholders.”

For more information, visit www.motion.com.

Women MAKE Awards. This national awards program honors women who have demonstrated excellence and leadership in their careers across all levels of the manufacturing industry, from the factory floor to the executive level.

BASF’s 2023 award winners include:

• Women MAKE Honoree: Carol Easley, Operations Director, Polyol North America

• Women MAKE Honoree: Cara Madzy, Vice President Operations, Coatings Americas

• Women MAKE Emerging Leader: Lindsey Daniels, Process Safety Specialist

“We are proud to celebrate the 2023 Women MAKE Award recipients who are making a difference at BASF and shaping the future of manufacturing,” said Marc Ehrhardt, president, BASF North America. “It is role models like you, who drive innovation, and at the same time inspire the next generation of female talent in our industry. At BASF we know the value of different perspectives and experiences, and we stay commit-

ted to attracting, developing, and retaining great female talent.”

The Women MAKE Awards are part of the MI’s Women MAKE America initiative, which is the nation’s marquee program to close the gender gap in manufacturing. Women account for about half of the U.S. labor force but represent less than one-third of the manufacturing workforce. Women MAKE America aims to create a 21st-century manufacturing workforce by empowering and inspiring women in the industry.

“The biggest challenge facing manufacturers continues to be the growing workforce crisis, and women are the industry’s largest talent opportunity; bringing just 6% more women into manufacturing would fill all open jobs in the sector today,” said MI President and Executive Director Carolyn Lee. “That is exactly why the Women MAKE Awards are so important and powerful. These are the women who will inspire our next generation of female talent to pursue a career in this industry.”

BASF sponsored the annual awards ceremony, which was held recently in Washington, D.C. For

more information about BASF careers and efforts that promote women in manufacturing, visit www.basf.us/women.

Chick-fil-A launching bottled salad dressings nationwide

ATLANTA — Attention all salad lovers, meal preppers and athome cooks: started in May, Chickfil-A expanded its retail footprint with the nationwide launch of its bottled salad dressings. Following a successful pilot in Ohio and Tennessee last fall, 12 fluid ounce bottles of Chick-fil-A’s most popular salad dressings will now be available at participating grocery and Walmart stores across the U.S.

Chick-fil-A® Bottled Salad Dressings will begin rolling out in stores during the next few weeks. The retail offerings include:

• Avocado Lime Ranch

Dressing

Chick-fil-A’s most popular salad dressing, the Avocado Lime Ranch is a twist on the Garden Herb Ranch Dressing. With creamy avocado, spices and lime, this southweststyle dressing can liven up any

salad or wrap.

• Garden Herb Ranch Dressing

The classic Garden Herb Ranch mixes buttermilk with savory garlic, onion and herb flavors, giving it a traditional, creamy taste reminiscent of delicious homemade dressing.

• Creamy Salsa Dressing

The Creamy Salsa Dressing was originally developed by Chick-filA’s culinary team to pair with the Spicy Southwest Salad and blends southwest flavors of cumin, hot peppers, tomatoes and garlic.

• Zesty Apple Cider Vinaigrette Dressing

The lightest of the four dressings, this vinaigrette is made with apple cider vinegar, fruit juices, spices and honey for a robust yet sweet flavor.

“From Boston to Sacramento, customers who heard about our pilot let us know they are eager to buy bottles of their favorite Chick-fil-A salad dressing at their local grocery stores,” said Michael Garrison, senior director of innovation and new ventures at Chick-fil-A. “These

(Continued on next page)

(Continued from previous page)

salad dressings will join four of the brand’s most popular sauces available in participating grocery stores: bottled Barbeque, Polynesian, Sweet & Spicy Sriracha and Chick-fil-A Sauce.”

To celebrate the national retail launch of Chick-fil-A salad dressings, Chick-fil-A culinary experts are sharing their favorite meals to prepare at home with Chickfil-A dressings. Recipes include Avocado Lime Ranch Scrambled

Whether it be windrowing to produce a pathogen & insect reduced bedding to grow a top performing flock of BIRDS, or pulverizing litter to make a soft fluffy bedding without the need to decake or add shavings, we have the equipment to fit your operation. We have various models, sizes and options to fit your needs. Keep in mind, our goal is customer service, quality equipment and of course the BIRDS.

Eggs, Southwest Creamy Salsa

Corn Salad, Cheddar Ranch Biscuits with Ham and Zesty Bacon

Potato Salad.

“Our dressings bring versatile flavors to the table making them perfect for marinating chicken,

drizzling on tacos or whipping up a pasta salad,” said Chick-fil-A Chef Christy Cook. “We love seeing the culinary creations our customers already make with their favorite Chick-fil-A dressings, like Creamy Salsa Waffle Fries. Now, we can’t

wait to see what they create with our Bottled Salad Dressings in their own kitchens.”

For more information about Chick-fil-A and stories about the company’s food, people and customers across the country, visit www.chick-fil-a.com/stories.

Chick-fil-A bottled salad dressings will not be sold in restaurants. Customers are encouraged to contact their local grocery and Walmart locations to confirm availability and pricing. Chick-fil-A salad dressings can be found in the refrigerated section of each participating retail location.

Perdue Farms debuts new seasoning just in time for grilling season

SALISBURY, Md. — Perdue Farms, the fourth-generation, family-owned, U.S. food and agriculture company, has provided consumers with high-quality, premium protein for more than 100 years and has recently announced the debut of its first-ever custom in-house seasoning: The Farmhouse Blend.

Featuring a proprietary blend of herbs and spices, the company’s newest offering is all consumers need to elevate their fresh chicken dishes to a whole new level this grilling season, the company notes.

As experts in protein, Perdue Farms knows exactly what it takes to make favorites like grilled chicken taste delicious — and that there is no better way to show off one’s cooking skills in the summer than on the grill. The all-in-one blend combines the flavors of roasted garlic and herbs with the savory essence of umami to deepen the flavor and perfectly complement the protein so that no other seasonings are needed to serve up flavorful chicken this summer. Suffice to say, friends and family will have high praise for the grill master.

“At Perdue Farms, we pride ourselves on providing customers with solutions in the kitchen – whether that is in the form of high-quality, premium protein raised with no antibiotics ever, or this new seasoning blend, which was developed fully in-house,” said Chris Perdue, vice president of direct-to-consumer marketing at Perdue Farms and fourthgeneration Perdue family member.

“Our Farmhouse Blend Seasoning takes the guessing game out of the perfect combination of spices and herbs to enhance the flavors of fresh

chicken and will be a delicious staple for your meals this grilling season.”

Farmhouse Blend Seasoning is available now in 3.25-oz. bottles for $6.99 on www.PerdueFarms.

com, alongside items from Perdue’s premium protein portfolio including chicken, beef, and pork, as well as seafood, side dish, and dessert options.

Visit

Uniform Uniform Easy-Install Easy-Install IP-65 Rated IP-65 Rated Long Lasting Long Lasting Brighter at 2165 lumens Brighter at 2165 lumens

Uniform Uniform Easy-Install Easy-Install IP-65 Rated IP-65 Rated Long Lasting Long Lasting Brighter at 2165 lumens Brighter at 2165 lumens

Efficient But NOT Overdriven

Efficient But NOT Overdriven

Efficient But NOT Overdriven

Efficient But NOT Overdriven

By Jess campbell, Jeremiah davis, Kelly Griggs & cody smith

National poultry technology center Auburn university

By Jess campbell, Jeremiah davis, Kelly Griggs & cody smith

National poultry technology center Auburn university

AUBURN, Ala. — Many companies and producers have already started to check poultry house wind speeds for adequate hot weather bird cooling ability. During these times we are often asked the question, “what can I do to ensure the houses will pull maximum wind speed”?

The simple answer is to make sure every tunnel fan is operating at maximum potential. The most common answer we get for fan maintenance is, “change the belt”. Yes, fan belts made the list but, not first in the process of proper and complete fan maintenance! Please read below to find out why we think belt replacement should come last when conducting complete fan maintenance.

1. Motors

The most important and expensive item on the Fan 5 list is the fan motor. Every tunnel fan motor should be clean, have an uncompromised power connection, and bolted firmly to the fan. Any motor that intermittently stops working, is slow to start, or makes a humming noise, should be repaired, or replaced immediately! We recommend having at least one replacement tunnel fan motor of each size on the farm. A new belt will not fix a blown motor!

• Fan motor capacitors

We received this motor (see photo) from a local producer that was having issues with fan motors going out. The issue with some motors might not be the motor itself, but with the start or run capacitors that are designed to help the motor operate properly. If you have a fan that is slow to start, it is likely a capacitor. Notice the top of the capacitor is bulging out and corroded. In-

stead of replacing the motor a qualified electrician or capable producer or equipment maintenance technician could troubleshoot and fix this problem without replacing the motor. This would save costs and time for the producer. Adding a new v-belt to a fan with a bad start capacitor will not fix the fan and certainly will not improve the house wind speed.

We recommend a close inspection of the fan belt tensioner (if applicable) next. The tensioners’ job is to keep adequate tension on the fan belt so that the motor delivers the horsepower to the fan pulley with minimal slippage. These tensioners are notorious for making loud noises when the bearings are dry and adding friction instead of tension. If you can hear the tensioner from over 250’ away, it is time to take action and replace those noisy tensioners.

They are robbing your fans of CFM’s and working against your efficient tunnel ventilation system. These should be greased (if applicable), lubricated, and exercised at

least twice a year to make sure you get full life expectancy from each fan. They must be replaced if the pulley doesn’t spin freely or makes a noise, doesn’t maintain belt tension, or is out of alignment. A new belt will not fix a bad tensioner!

Every fan bearing should be inspected for dry bearings, noise, or wear that will not allow the fan prop to spin as freely as possible with minimum friction. It doesn’t work that way.

These can be expensive, labor intensive to replace, and cause a fan to be down for an extended period if neglected. Get those bearings tuned up ASAP! A new belt will not fix a bad bearing!

Pulleys

Fan motor pulleys and fan prop pulleys must be aligned, in likenew shape, and not scrubbing on the fan frame. Worn or “cupped” pulleys must be replaced. We recommend replacing pulleys with the exact fit and size as what you have for optimum performance.

Increasing size can increase fan

power but will also increase power bills and may shorten the life of the fan motor if this isn’t engineered. If you are considering this, please consult the fan manufacturer prior to implementation. A new belt will not fix a worn pulley!

• Fan pulley issue

Can you identify the problem in the picture below with this fan pulley? Would a new belt fix this problem? If you guessed the pulley is in contact with the fan motor frame, is causing substantial noise and friction on the fan motor, and wearing the belt out prematurely, then you would be correct! A new belt would not fix this fan problem!

5. Belts

New fan belts won’t fix most fan problems! Consider the following questions before you just slap on new fan belts and move onto the next task on the list! New belts are often not the correct fan maintenance repair!

• Would you put new tires on your vehicle if you knew the front wheels were out of alignment (vibrates as you travel down road) and you noticed the existing tires

were severely worn only on one side of the tires?

No, you should get an alignment done prior to installing new tires! Installing a new v-belt on a fan that has pulleys on the motor, tensioner, or fan out of alignment will only result in a prematurely worn belt. The corrective action would be to realign all the pulleys and then install the new belt.

• Would you install new tires on a vehicle with a slipping transmission?

No, you would need to have the transmission repaired or replaced, because installing new tires would not overcome the bad transmission. Similarly installing a new v-belt on a fan with a damaged tensioner will only result in poor fan performance and a prematurely worn belt. Don’t waste your time and money on a belt when it really needs a new tensioner.

• Would you install new tires on a vehicle with an engine that is overheating?

No, new tires will not keep the engine from overheating and forcing the vehicle to shut down during hot weather use! Installing a new

ATHENS, Ga. — There are essentially two types of poultry house circulation fan systems: vertical and horizontal. In a vertical circulation fan system, fans are located in the center of the house, typically near the ceiling, and are oriented to blow straight down towards the floor. The air then moves across the floor, up the side walls, and back along the ceiling to the center of the house, creating a vertical air circu-

lation pattern.

In some instances, the circulation fans are directed to blow air upward towards the ceiling, creating a circular air flow pattern in the opposite direction. In either case, air circulation tends to be localized around each circulation fan.

In a horizontal circulation fan system, the circulation fans are

placed along the center of the house, next to the ceiling, moving air horizontally along the ceiling toward the house’s end walls. Upon reaching the end walls, the air then changes direction and moves back along the side walls as well as along the floor underneath the circulation fans. Whereas with a vertical circulation fan system, mixing/ circulation tends to occur in zones around each circulation fan, with

horizontal circulation fan systems, the circulation fans tend to work together as a single unit to mix the air throughout a house and in the process create uniform conditions throughout a house.

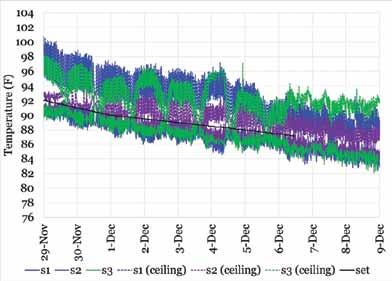

A study was conducted on a broiler farm in North Georgia comparing a vertical circulation fan system to a horizontal circulation fan system. The vertical circulation fan system consisted of eight Cubo

vertical circulation fans evenly spaced along a 40’ X 500’ dropped ceiling broiler house (Figure 1). Each Cubo unit consisted of a 1/3 hp motor powering a centrifugal blower, located 18” above the floor. The fan pulls air off the ceiling via a flexible duct then blows it out in a 360-degree pattern horizontally across the floor.

The horizontal circulation fan system consisted of eight 24”, 1/3

hp fans (Multifan 24” - approximately 6,500 cfm @ 0.00”) positioned next to the ceiling along the centerline of the house, blowing air towards the end walls. The same target temperatures and relative humidity (40 – 60 percent) were used in both houses.

Though the vertical circulation fan system reduced temperature stratification during brooding to

(Continued on next page)

(Continued from previous page)

five degrees or less, the horizontal circulation fan system did a better job reducing it to two degrees or lessen (Figures 2 and 3). The biggest differences observed between the two types of circulation fan systems were their abilities to create uniform temperatures throughout the brooding area/house and to generate air movement over the litter, thus promoting litter drying.

With the horizontal circulation fan system, the air within the brooding area/house was mixed from end to end, moving cool air near the brooding curtain/end walls to the center of the house and warmer air near the center of the house to the end walls/brooding curtain. The thorough mixing of the air in the house resulted in consistent house temperatures, which was reflected in more uniform heater runtimes

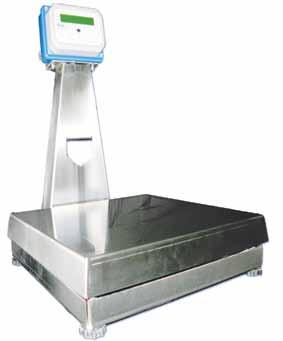

The WeighTech line of bench scales offers processors the best of both worlds: functionality and durability. Our bench scales feature our industry leading MicroWeigh indicator, and is available in many sizes to fit your processing needs.

In today’s fast paced processing world, efficient, reliable and rugged scale systems and equipment are crucial.

(Figure 4 and 5).

Furthermore, a horizontal circulation fan system’s ability to move excessive bird heat from the center of the house towards the end walls, where extra heat is often needed due to tunnel fan and tunnel door leakage, could result in significant fuel savings.

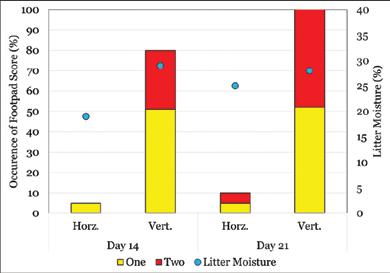

The study also found that a horizontal circulation fan system was able to produce significantly

more air movement over the litter throughout a house than the vertical circulation fan system. With the vertical circulation fans, air movement was limited to within 15’ to 20’ of each fan, while the horizontal circulation fans worked together as a system, creating air speeds of between 100 - 150 ft/min over most of the house’s floor area, which in turn resulted in overall drier litter and

(Continued on page 28)

The patented industry leading electronic indicator for harsh washdown environmentsFigure 6: Paw scores and litter moisture (Trial 1). Figure 7: Paw scores and litter moisture (Trial 2).

BUFFALO, Minn. — The 2023 Minnesota Turkey Summer Summit, June 29-30, hosted by the Minnesota Turkey Growers Association (MTGA), is an event that connects all sectors of the turkey industry — from Minnesota and beyond. The summit is an occasion for turkey industry stakeholders to gather for premier educational opportunities, policy discussion, and a poultryfocused vendor fair. The event is being held at Arrowwood Resort & Conference Center, Alexandria, Minn.

2023 agenda highlights include:

• Interactive learning panels featuring media professionals and wild bird population managers.

• Department of Homeland Security featuring cybersecurity and food security issues and efforts.

• Minnesota Turkey Grow-

ers Association and Minnesota Turkey Research and Promotion Council Annual Meetings.

• Turkey 101 — Featuring feed and grain market management, Next Nest, and engineering for bird health and energy efficiency.

• Turkey Taste-off returns — submit your recipes for consideration today. (info@ minnesotaturkey.com)

• HPAI status update and response review session.

• U.S. Roundtable for Sustainable Poultry and Eggs.

• Exceptional networking opportunities and poultry-focused allied industry showcase/ tradeshow.

National turkey industry leaders, state and regional agriculture leaders, and legislative and regulatory leaders will make special guest appearances.

New to Summer Summit in 2023 is the “Turkey Toss” — a cornhole tournament to raise funds for leadership development. Summit education opportunities have been expanded to feature consumerfocused panels and HPAI conversations beyond the commercial turkey industry. Turkey 101 has something for everyone, with the latest and greatest for each sector of the on-farm turkey industry. Come

for world-class educational opportunities and excellent networking opportunities with legislators, government agencies, turkey industry partners and fellow turkey growers. Registration is now open; sign up by visiting www.minnesotaturkey.org. Make room reservations by calling the Arrowwood Resort directly at 866-386-5263. The Summer Summit block will be held until June 7, 2023. Interested in making a weekend of it? MTGA has negotiated special weekend rates for those wishing to stay the weekend.

MTGA exhibitors and vendors are welcome and encouraged to attend. Sponsorship opportunity details are available at www.minnesotaturkey.com or call Brandon Severns at 763-682-2171 with questions. The deadline to register for an exhibit booth and sponsorship opportunities is June 7, 2023.

WASHINGTON — The USDA’s Animal and Plant Health Inspection Service is taking emergency action to help protect the critically endangered California condors after several have died from highly pathogenic avian influenza (HPAI).

APHIS has approved the emergency use of HPAI vaccine in an attempt to prevent additional deaths of these birds.

The U.S. Fish and Wildlife Service approached APHIS about vaccination after a California condor was found dead in late March and then confirmed positive for HPAI at APHIS’ National Veterinary Services Laboratories. Since then, 13 condors have died and were confirmed to have HPAI, and two others are in recovery at a rehabilitation center.

The authorized vaccine is a killed, inactivated product conditionally licensed by APHIS’ Center for Veterinary Biologics in 2016. Since the vaccine has not previously been tested against this strain of the virus in these species, the first step in the vaccination program is a pilot safety study in North American vultures, a similar species, to investigate if there are any adverse effects before giving the vaccine to the endangered condors.

This trial is funded by the U.S Fish and Wildlife Service and will be carried out with the surrogate vultures in North Carolina and began in May.

APHIS grants emergency use approvals, which exempt products from one or more regulatory requirements normally applied to licensed vaccines, to prevent, control, or eradicate animal diseases in connection with an official USDA program and/or an emergency animal disease situation.

APHIS approved this emergency vaccination of the condors because these birds are critically endangered, closely monitored, and their population is very small which allows close monitoring of the vaccine to ensure it is administered only to the approved population.

Vultures and California condors are wild birds, not poultry as defined by the World Organization of Animal Health (WOAH), and APHIS does not expect their vaccination to result in impacts to poultry trade.

This emergency use approval is limited to the endangered California condors. USDA Agricultural Research Service scientists continue to research vaccine options that could protect U.S. poultry from HPAI, should vaccination be necessary for additional birds in the United States.

JUN 6 — AFIA/KSU-500, Fundamentals of Feed Manufacturing. Online course runs through July 11, 2023. Contact: American Feed Industry Association, 2101 Wilson Blvd., Suite 810, Arlington, Va. 22201. Ph: 703-524-0810; www.afia.org.

JUN 6-8 — USAPEEC ANNUAL MEETING, San Antonio, Texas Contact: USA Poultry & Egg Export Council, 1532 Cooledge Road, Tucker, Ga. 30084; 770-413-0006; www.usapeec.org.

JUN 7 — DCA BOOSTER BBq, Harrington, Del. Contact: Delmarva Chicken Association, 16686 County Seat Hwy. Georgetown, Del. 19947; Ph: 302-856-9037; www.dcachicken.com.

JUN 7 — TPA SERVICE TECH WORKSHOP, Farm Bureau Expo Center, Lebanon, Tenn. Contact: Tennessee Poultry Association, P.O. Box 1525, 1404 N. Main St., Shelbyville, Tenn. 37162-1525; Ph: 931-225-1123; info@tnpoultry.org; www.tnpoultry.org.

JUN 7-8 — ADVANCED LISTERIA INTERVENTION & CONTROL WORKSHOP, Kansas City, Mo. Contact: North American Meat Institute, 1150 Connecticut Ave. NW, Washington, D.C. 20036; Ph: 202-587-4200; www.meatinstitute.org.

JUN 7-9 — CORN UTILIZATION & TECHNOLOGy

CONFERENCE (Virtual), Contact: National Corn Growers Association, P.O. Box 407, Chesterfield,

Currently, biosecurity measures remain the best, most effective tool for mitigating the virus in commercial flocks, and improved biosecurity measures by the commercial industry have vastly reduced the number of detections compared to previous outbreaks. For example, in March 2022, there were a total of 51 commercial poultry HPAI detections. In March 2023, there were 7 commercial poultry detections, a decrease of 85 percent from the previous year.

In April 2023, there were just two commercial cases of HPAI, compared to 106 cases in April 2022. More information about APHIS’ efforts to work with industry as well as state and other federal partners to manage the outbreak can be found www.aphis.usda.gov.

Mo. 63005; Ph: 636-733-9004; https://ncga.com.

JUN 9-10 — 63RD ANNUAL POULTRy FESTIVAL, Rogers Convention Center, Rogers, Ark. Contact: The Poultry Federation, 321 South Victory Street, Little Rock, Ark. 72201; Ph: 501-375-8131; info@thepoultryfederation.com; www.thepoultryfederation.com.

JUN 11-14 — AAAP ANNUAL MEETING, Sawgrass Marriott, Jacksonville, Fla. Contact: American Association of Avian Pathologists, 12627 San Jose Blvd., Suite 202, Jacksonville, Fla. 32223; Ph: 904-425-5735; aaap@aaap.info; www.aaap.info.

JUN 12-13 — CPF SUMMER MEETING, The Cliffs Resort & Spa, Pismo Beach, Calif. Contact: California Poultry Federation, 4640 Spyres Way, Suite 4, Modesto, Calif. 95356; Ph: 209-576-6366; https://cpif.org.

JUN 13-15 — IOWA TURKEy FEDERATION SUMMER MEETING, Honey Creek Resort, Moravia, Iowa. Contact: Iowa Turkey Federation, 535 East Lincoln Way, Ames, Iowa 50010; Ph: 515-232-7492; https://iowaturkey.org.

JUN 20-22 — 2023 SOUTHEAST EGG INDUSTRy REGIONAL CONFERENCE, Hosted by the Florida Poultry Federation. Hammock Beach Golf Resort & Spa, Palm Coast, Fla. Contact: Swartz & Associates, 2522 Capital Circle NE, Suite 14, Tallahassee, Fla. 32308; E-mail: pat@saameetings.com; www.southeastegg.com.

JUN 26-28 — FINANCIAL MANAGEMENT SEMINAR, Omni Amelia Island Resort, Fernandina Beach, Fla. Contact: USPOULTRy, 1530 Cooledge Road, Tucker, Ga. 30084; Ph: 770-493-9401; seminar@uspoultry.org; www.uspoultry.org.

(Continued from page 26)

improved paw health. Though there was more air movement, no adverse chick reactions were observed.

The study illustrated that there is much more to be gained from a circulation fan system than simply moving hot air off the ceiling. A proper circulation fan system can not only break up temperature stratification, but also promote more uniform house conditions, drier litter, and improved foot pad health as well (Figures 6 and 7).

Michael Czarick is an Extension engineer, Dr. Brian Fairchild is an Extension poultry scientist, and Connie Mou was 2020 Ph.D. student, with the University of Georgia College of Agricultural & Environmental Sciences Cooperative Extension in Athens, Ga. More information can be obtained at www. poultryventilation.com.

N ational Broiler Market: (May 23): Whole broiler/fryer prices were steady to firm for wogs; steady for whole birds. Supplies were light to moderate and moving well. Demand was moderate to good. Processing schedules were normal. Floor stocks were balanced. Market activity was moderate. In the parts structure, prices for jumbo boneless were steady, other white meat items steady to firm. Wings were steady and dark meat was steady to firm. Thigh meat was moving well. Demand was moderate to good. Market activity was moderate. In production areas, live supplies were moderate. Weights were mostly desirable, the USDA Agricultural Marketing Service reports.

Retail chicken report (May 19): National summary indicators climb higher, incentives to purchase increase, the middle of the month ad cycle leaves no excuse to the invitation to take home a pack. Bagged and cut-up fryers take a slight drop in volume but increase price levels. B/S breast in bulk and wings racket up the volume, pricing is mostly higher. Thighs and drums also push bulk packs, smaller pack will lay idle on clearances. IQF parts take the week off. The deli holds its ground, fried/baked 8 piece and finger foods pick up the pace. Specialty items and organics inch slightly higher on volumes. A week of the “twos” leads into the Memorial Day weekend, normally a hamburger and hotdog holiday. Poultry had better get its party hat on this ad cycle or risk being left behind in the weeks to come, the AMS reported.

Broiler: Estimated slaughter for week ending May 20 was 160,673,000. Actual slaughter for the week ending May 13 was 159,335,000.

Heavy-type hen: Estimated slaughter for the week ending May 20 was 1,797,000.

Actual slaughter for the week ending May 13 was 1,762,000.

Negotiated prices in trucklot and less-than-trucklot quantities of ready-to-cook whole body broiler/fryers delivere d to first receivers; prices in cents per pound

Weighted

(Courtesy:

For the week of May

Light-type hen: Estimated slaughter for the week ending May 20 was 792,000. Actual slaughter for the week ending May 13 was 727,000. Total: May

Rectangle slots create 58.5% of total opening to reduce manure buildup resulting in a cleaner floor.

Each 2’ x 4’ panel weighs 6.7 pounds...over 3/4 of a pound more than competitive brands. 21 longitudinal ribs compared to others with only 17 ribs provides a level slat surface with only three support runners.

Multiple interlocking edge tabs reduce flexing to promote a flat, stable walking surface. Arch latitudinal ribs furnish greater support to the longitudinal ribs.

MOTOMCO's #1 selling formula worldwide

Use Hawk Baits in a rotational program for up to 6 months, especially for regular maintenance baiting during spring & summer

Available in 9lb and 18lb Chunx Pails, 86ct and 150 ct Place Pacs, 12lb Bulk Pellets, 25lb and 50lb Bulk Meal, 86 ct Meal Place Pacs, and 8lb and 16lb Soft Bait

Supported by Motomco Territory Managers across the U.S For more information contact: