www.poultrytimes.com Your poultry industry news source since 1954 June 3, 2024 HOUSING & EQUIPMENT

It’s in our name, and it’s in our craftsmanship. Every American Coolair product is manufactured in our Jacksonville, Florida plant, using American raw materials such as steel sheets and coil, and aluminum sheets, coil and ingot. We produce the most durable ventilation products and evaporative cooling systems for the poultry, dairy, swine, greenhouse, commercial and industrial fan industries. Our fans outlast any other fans, which is why we still carry parts for fans manufactured over 50 years ago. Count on American Coolair for superior, responsive customer service and 100% commitment to quality American design and engineering.

P.O. Box 2300 | Jacksonville, FL | 32203-2300 v: 904/389-3646 | f: 904/387-3449 | agfans@coolair.com | www.coolair.com

REASON #1 ALL-AMERICAN BEST FANS. PERIOD. Value that Stands the Test of Time

News

6 | Four Ga. governors pay tribute to poultry icon Abit Massey

Business Features

12 | Americold breaks ground on cold storage facility

Calendar

19 | Keep ammonia from filling up a poultry house

23 | Benson Hill, Perdue Farms team up on broiler soybean meal

JUN 4 — AFIA/KSU-500, Fundamentals of Feed Manufacturing. Online course runs through July 9, 2024. Contact: American Feed Industry Association, 2101 Wilson Blvd., Suite 810, Arlington, Va. 22201. Ph: 703524-0810; www.afia.org.

JUN 4-6 — AFIA FOOD

SAFETY MODERNIZATION

ACT PREVENTIVE CONTROL

QUALIFIED INDIVIDUAL

TRAINING, The Inn at Opryland,

26 | Report gives insight on future beef, chicken, pork prices

Nashville, Tenn., Contact: American Feed Industry Association, 2101 Wilson Blvd., Suite 810, Arlington, Va. 22201. Ph: 703524-0810; www.afia.org.

JUN 8 — AP&EA ‘EVENING OF FUN’, Birmingham–Jefferson Convention Center, Birmingham, Ala. Featured performer: Kameron Marlowe. Contact: Alabama Poultry & Egg Association, P.O. Box 140, Montgomery, Ala. 36101. Ph: 334-265-2732; www.alabamapoultry.org.

HOUSING & EQUIPMENT

Viewpoints

“Although it has never been a question in my mind that folks in agriculture are there for each other when times are tough, it is wonderful to see the agricultural community support each other in this new way.” — Sarah Covington | 10

7 | USDA unveils efforts to reduce the spread of avian influenze

Connect

Visit us at: POULTRYTIMES.COM 24/7 on the World Wide Web or scan the code to the right /poultrytimes @PoultryTimes /poultrytimesga

POULTRY TIMES POULTRYTIMES.COM 5 VOL. 71 | NO. 11 | JUNE 3, 2024

www.poultrytimes.com Your poultry industry news source since 1954 June 3, 2024 HOUSING & EQUIPMENT IN THIS ISSUE On the cover

with us

24

CORPORATE HEADQUARTERS

POULTRY TIMES PO Box 1338 Gainesville, GA 30503 PH | 770-718-3443 FAX | 770-532-4894

POULTRY TIMES STAFF

CINDY WELLBORN

General Manager, Poultry Times/PoultryTimes.com 770-718-3443 cwellborn@poultrytimes.com

DAVID B. STRICKLAND Editor, Poultry Times 770-718-3442 dstrickland@poultrytimes.com

ELIZABETH BOBENHAUSEN

Content Writer, Poultry Times 770-209-3335 ebobenhausen@poultrytimes.com

RACHEL DANFORD Digital Manager, PoultryTimes.com 770-831-8631 rdanford@poultrytimes.com

STACY LOUIS

Sales Manager, Poultry Times/PoultryTimes.com 770-718-3445 slouis@poultrytimes.com

JANICE SISK

Sales & Administrative Assistant, Poultry Times/PoultryTimes.com 770-718-3439 jsisk@poultrytimes.com

KIM EWING

Circulation 770-718-3420 kimewing@poultrytimes.com

Index of Advertisers

Be sure to pay a visit to these esteemed sponsors of the Poultry Times, recognizing them as vital contributors to the industry who greatly appreciate your support.

Ag Lighting | 17 615-378-0108; www.poultrylights.com

Agralarm | 19 888-968-2802; www.agralarm.com

American Coolair | 2 904-389-3646; www.coolair.com

Big Dutchman | 13 616-582-4000; www.bigdutchmanusa.com

Creekview Mfg. | 32 717-445-4922; creekviewmanufacturing.com

Eagan Mfg. | 20 870-878-6805; www.eaganmfg.com

Farm Alarm | 19 800-407-5455; www.farmalarm.com

Farmer Boy Ag | 26 717-866-7565; www.farmerboyag.com

Flame Engineering | 24 800-255-2469; www.flameengineering.com

FPM Inc. | 16 402-729-2264; www.fpmne.com

Gas-Fired Products | 16 800-849-7311; www.spaceray.com

Henning Companies | 27 515-253-0943; www.henningcompanies.com

Hog Slat | 39 800-949-4647; www.hogslat.com

IMPEX | 18 770-534-1590; www.impex.nl

Publication Disclaimer

Poultry Times (USPS 217480) ISSN 0885-3371 is published biweekly, 345 Green Street, N.W., Gainesville, GA 30501. Telephone 770-536-2476; Fax 770532-4894. Postage paid at Gainesville, Georgia 30501. Poultry Times assumes responsibility for error in first run of an in-house designed ad only. Advertisers have ten (10) days from publication date to dispute such an advertisement. After ten (10) days, ad will be deemed correct and advertiser will be

Kelley Mfg. | 18 800-444-5449; www.kelleymfg.com

Kuhl Corp. | 15 908-782-5696; www.kuhlcorp.com

Kunafin (The Insectary) | 37 800-832-1113; www.kunafin.com

L.B. White | 31 608-783-5691; www.lbwhite.com

Lewis Brothers | 25 912-367-4651; www.lbmfg.com

LVI Enterprises | 32 717-304-1668; www.lvimfg.com

Motomco | 3 800-237-6843; www.motomco.com

National Incinerator | 15 205-589-6720; www.nationalincinerator.com

Newton Crouch | 28 800-241-1350; www.newtoncrouch.com

Overdrive Lighting | 23 800-657-0509; www.aglights.com

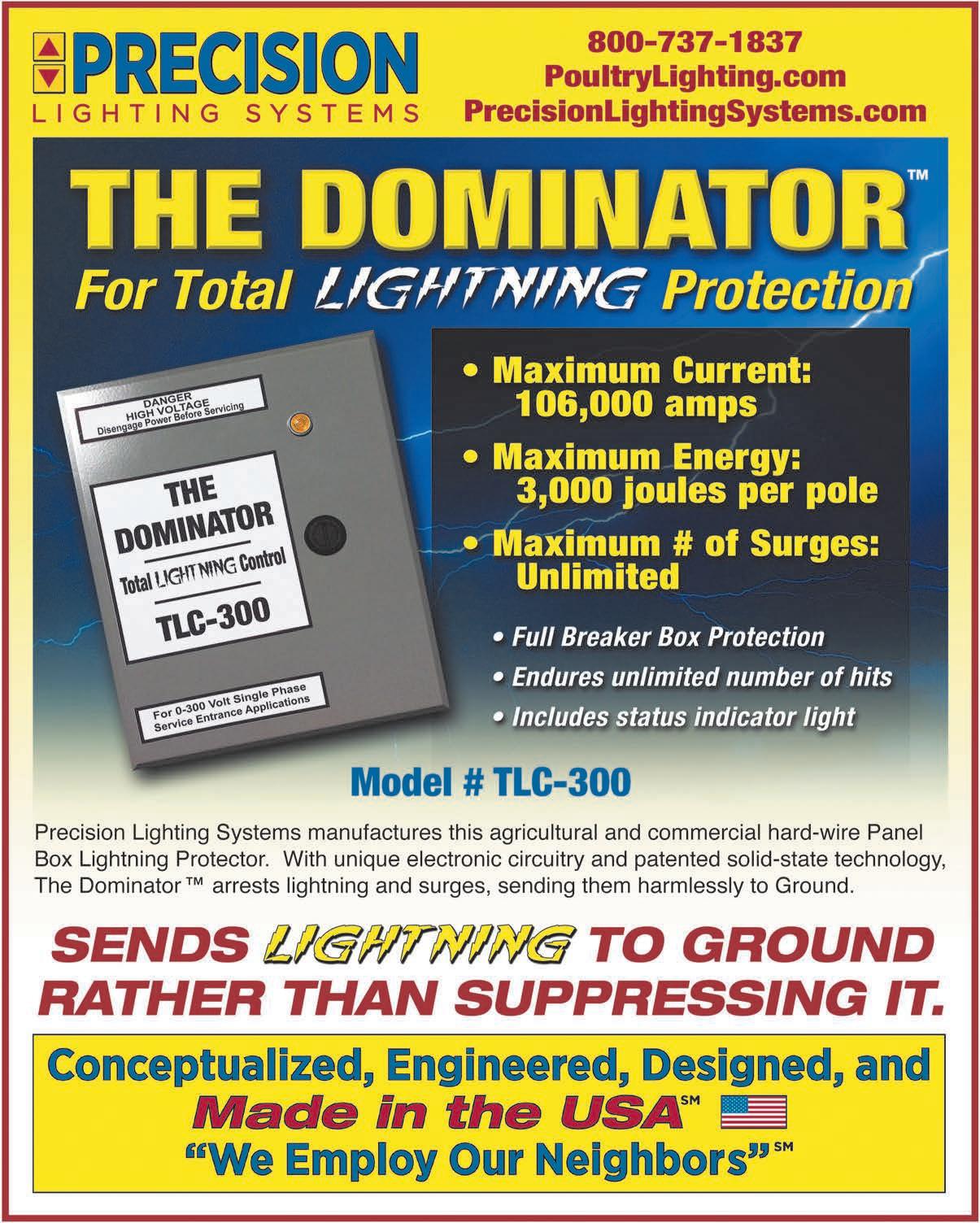

Precision Lighting | 1, 4, 22 800-737-1837; www.poultrylighting.com

The Egg Carton Store | 37 866-333-1132; www.eggcartonstore.com

Walinga USA | 40 800-466-1197; www.walinga.com

Weightech | 21, 28 800-457-3720; www.weightechinc.com

charged accordingly. Proofs approved by advertiser will always be regarded as correct. Subscriptions: Surface mail in U.S., $25.00 for one year, $45 for two years and $65 for three years. Business or occupation information must accompany each subscription order.

Change of Address: Postmaster, report change of address to Poultry Times, P.O. Box 1338, Gainesville, GA 30503.

Companion Poultry Publications: A Guide to Poultry As-

sociations; Poultry Resource Guide.

The opinions expressed in this publication by authors other than Poultry Times staff are those of the respective author and do not necessarily reflect the opinions of Poultry Times. Advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement. © 2024 Metro Market Media

POULTRY TIMES POULTRYTIMES.COM 6

Gainesville, Georgia 30503

USDA unveils efforts to reduce the spread of avian influenza

BY ELIZABETH BOBENHAUSEN Poultry Times staff ebobenhausen@

poultrytimes.com

GAINESVILLE, Ga. — In March, the United States saw for the first-time avian influenza jump from avian species to dairy cattle. H5N1, otherwise commonly known as bird flu, was found in cattle in several states in the U.S. After the outbreak began, the authorities at the USDA began taking the necessary precautions to keep the virus from spreading.

According to a statement released by the USDA, the authorities at the USDA began tracing animal movements, sampling herds of cattle for the illness and monitoring milk along with meat coming from cattle. The USDA did not act alone. The agency worked in cooperation with other federal agencies.

In April, the Centers for Disease Control and Prevention confirmed one person contracted bird flu from cattle and to receive attention for pink eye. The USDA issued a warning “to limit the movement of lactating dairy cattle and to collect and aggregate H5N1 test results to better understand the nature of the outbreak.”

The U.S. Department of Health and Human Services is partnering with the U.S. Food and Drug Administration and the CDC for the purpose of initiating new actions such as increased testing and laboratory screenings and testing capacity, genomic sequencing, and other intercessions to slow the spread of avian influenza in food products.

USDA added that it, “is announcing assistance for producers with H5N1 affected premises to improve on-site biosecurity in order to reduce the spread. In addition, USDA is taking steps to make available financial tools for lost milk production in herds affected by H5N1. Building on the Federal Order addressing premovement testing, these steps will further equip producers with tools they can use to keep their affected herds and workers healthy and reduce risk of the virus spreading to additional herds.”

USDA lists the following as its initiatives to limit the spread of avian influenza:

• Protecting against the potential spread between animals and humans.

• Biosecurity planning and implementation support for producers.

• Heat treatment funding to as-

sist in disposing of milk in a biosecure way.

• Producer reimbursement for veterinary costs for premises positive with H5N1.

• Offset shipping costs for flu testing performed at the National Animal Health Laboratory Network (NAHLN).

• Producer compensation for milk production losses.

• Working with the states on limiting lactating cattle movement.

The release added that the HHS, “announced new funding investments through CDC and FDA totaling $101 million to mitigate the risk of H5N1 and continue its work to test, prevent, and treat H5N1. Although the CDC’s assessment of the risk of avian influenza infection for the general public continues to remain low at this time, these investments reflect the department’s commitment to priori-

tizing the health and safety of the American public.”

The HHS noted that it has been preparing for avian influenza outbreaks for the past 20 years, and announced the following as initiatives to assist with public health:

• Ensuring communities are safe, healthy and informed.

• Ensuring that the U.S. food supply remains safe.

• Safeguarding U.S. agriculture and the well-being and livelihood of the nation’s farmers and farmworkers.

• Monitoring all trends to assist with mitigating risk and preventing the spread of H5N1 among both animals and people.

More information about USDA’s dairy cattle H5N1 response can be obtained at www.aphis. usda.gov/livestock-poultrydisease/avian/avian-influenza/ hpai-detections/livestock.

POULTRY TIMES POULTRYTIMES.COM 7 COVER

STORY

PT

Four Georgia governors recently paid tribute to poultry icon Abit Massey

BY JEFF GILL The Times

GAINESVILLE, Ga. — Four Georgia governors, among others, paid tribute May 20, to iconic Hall County poultry pioneer Abit Massey.

“I would suggest that a biography needs to be written about Abit Massey and it needs to be titled ‘The Best Governor the State of Georgia Never Had,’” said former Gov. Nathan Deal, who served from 2011 to 2019.

“He not only recognized those elected individuals who served in both the House and Senate, but he recognized their secretaries and their staff,” he said to a crowd gathered at First Baptist Church Gainesville. “He had a style of what we now call influencers.”

Kind words flowed during the event, which was part of the Rotary Club of Gainesville’s series of “Game Changer” programs.

Massey wasn’t able to attend because of health concerns, which was also mentioned during the event.

“I’ve got news for you,” said former Gov. Roy Barnes, who served from 1999 to 2003. “Cancer is no match for Abit Massey.”

“I’m just so sorry that Abit’s recent health news does not allow him to be here with us today,” Gov. Brian Kemp said. “He would just be tremendously honored and humbled in front of so many of his friends and colleagues.”

Kemp added, “It’s certainly a testament to a life well-lived that so many of our state’s influential leaders, past and present, have taken time to honor (Massey) here today.”

Former Gov. Sonny Perdue, who led Georgia from 2003 to 2011 and served as U.S. secretary of agriculture under President Trump, also lauded Massey in a video.

“Abit Massey, you’re the man,” he said. “I don’t know if you really invented the chicken, but you sure made it famous here in Georgia.”

Massey’s ties to poultry go back decades in Georgia.

The 1949 University of Georgia graduate was president of the Georgia Poultry Federation from 1960 to 2009 and is now the group’s president emeritus.

In addition to advocating for the poultry industry, he has worked to expand research in the field. The Georgia Poultry Laboratory Network sits on Abit Massey Way off Ga. 365 in northeast Hall.

In 2019, he was inducted into the American Poultry Historical Society’s Poultry Hall of Fame.

Massey also has met with U.S. presidents, including Richard Nixon, Gerald Ford, Bill Clinton and Jimmy Carter.

In a November 2023 interview with The Times, he recalled meeting John F. Kennedy

Four Georgia governors paid tribute to Gainesville poultry icon Abit Massey on May 20. Pictured, from left, are Gov. Brian Kemp and his wife, Marty; University of Georgia president Jere Morehead; and former governors Nathan Deal and Roy Barnes. Former Gov. Sonny Perdue spoke in a video presentation.

at the White House in June 1962, along with four governors, to talk about pressing poultry issues.

“Thanks to President Kennedy, we did get relief and were able to expand the export market to the European markets,” Massey said. “That is obviously a great memory.”

He was also remembered on a more personal

level by his son, Lewis Massey, who served as Georgia secretary of state from 1996 to 1999.

He quoted Scripture when describing his father’s attributes.

“Love, joy, peace, patience, goodness, gentleness, kindness, faithfulness and self-control — I think we would all agree that was really the blueprint for dad’s life,” he said.

POULTRY TIMES POULTRYTIMES.COM 8

Jeff Gill The Times

GPF elects officers, highlights successes at annual meeting

DAVID B. STRICKLAND Poultry Times Editor dstrickland@

poultrytimes.com

GAINESVILLE, Ga. — Highlighting successes and working through challenges were all noted during the Georgia Poultry Federation’s recent annual meeting held at the Georgia Poultry Laboratory Network headquarters in Gainesville, Ga.

During this annual meeting, GPF elected its new chairman for the upcoming year.

Blake Wikle, S4 Sanitation Services, takes the helm as GPF chairman for 2024-2025. Brad Respess, Tip-Top Poultry, now becomes the group’s immediate past chairman.

“I have always wanted to be associated with people just like you guys,” Wikle said. “I am honored for it, and I am prepared to serve in any manner that I can.”

And with the changing of the GPF chairman guard, Respess, in speaking about Wikle, said, “we are so thankful for his commitment to the industry … wherever he is needed, he is up to the challenge.”

Also serving as officers for the upcoming year will be Michael Crump, Wayne-Sanderson Farms, senior vice chairman; Vice Chairmen (1-year-terms) Steve Snyder, Claxton Poultry; and Kevin Grindle, Mar-Jac Poultry.

New directors will include Adam Durkin, Fieldale Farms; Steve Schimweg, Tyson Foods; and Jack McMullan. Reelected to a full year term is Dimitry Saknowsky, Harrison Poultry; and carryover directors will be James Bradford, Pilgrim’s; Scott Cochran, Columbia Farms; Lucas Hill, Pilgrim’s; Kelly Horne, Darling Ingredients; Patrick Johnston, Koch Foods; Tim Little, Perdue Farms; Stephen Selman, Sanderson Farms; and Steve

Summer, Cal-Maine Foods.

In his outgoing statements as the previous year’s chairman, Respess said, “It has been really good for me being on the board and as chairman seeing the work that the federation does for our industry. You all work tirelessly throughout the industry to build relationships, to help guide and protect the industry, and I couldn’t be more appreciative of your labor and of your efforts.”

“As we go forward, this year’s (state legislative) session has ended but the federation is going to continue working especially with the Environmental Protection Division here in Georgia as they work on revising the state’s nutrient production strategy through the environmental permitting process,” Respess added. “We are going to make sure that we have our industry represented to support and give voice to what needs we have as an industry.”

Blake Wikle, left, S4 Sanitation Services, is the newly elected chairman of the Georgia Poultry Federation. Mike Giles, center, GPF president, and Brad Respess, Tip-Top Poultry, GPF past chairman, congratulated Wikle during the group’s recent annual meeting in Gainesville, Ga.

Photo by David B. Strickland

“On the local government front, we still see proposed ordinances and other local government actions that limit where poultry houses can be built,” he noted. “The federation is working to oppose these wherever they crop up.”

Poultry Strong

It was also announced during the meeting that the federation’s annual outdoor music extravaganza, Georgia Poultry Strong, will be Saturday, Oct. 19, once again at Lake Lanier Islands in Buford, Ga. The “evening under the stars” will feature musical performer Justin Moore.

Mike Giles, GPF president, added that Moore is a multiplatinum, award-winning entertainer with 12 number one hit songs, with his most recent being, “You, Me and Whiskey.”

“It’s going to be a very exciting, lively show,” Giles said, adding that, “we are very excited about this concert; it’s going to be really a lot of fun.”

For more information about this year’s Georgia Poultry Strong event, visit https://gapf.org/ events/.

POULTRY TIMES POULTRYTIMES.COM 9-

PT

VIEWPOINT

Bringing mental health awareness, support to ag.

COMMENTARY

BY

SARAH COVINGTON

American Farm Bureau Federation

Sarah Covington is a Farm Bureau member from North Carolina. She works as a physician associate in oncology, and also owns Hawfields Cattle Co., specializing in registered Scottish Highland cattle. This column is drawn from one presented in the AFBF’s “Focus on Agriculture” series.

WASHINGTON — Throughout the years I have seen our agriculture community come together during times of need. Wildfires, floods, droughts, tornadoes, and hurricanes, for example, all bring the appropriate awareness from news headlines but what about the mental health crisis affecting the people in our industry?

The chronic, sometimes daily struggles of farmers and ranchers, whether financial, family, weather, economic, or regulatory in nature all play a role in our daily lives. Often, we are left to absorb the hardships alone.

That is why I’m thrilled that the American Farm Bureau and the Farm Family Wellness Alliance recently came together to unveil a new resource that can help all of us in agriculture remember we are not alone. It is an electronic platform called Togetherall, a tool developed to bring mental health awareness and support to others.

For my fellow millennials, think Twitter meets Reddit; only so much better. For my older and wiser folks, think of a virtual gathering of peers without nametags or introductions. In this column, I’m sharing my “real time” experience using Togetherall.

Signing up was actually pretty easy. I opened my web browser on my phone and typed in fb.org/farmstateofmind then scrolled to the Togetherall logo. Once I clicked on the logo and was taken to the Togetherall website, I was greeted with a bright yet simple home page where I click ed the join button and filled out my information. A username is autogenerated for me; the name gives me a slight laugh. It is both uplifting and random. “We are off to a good start,” I said to myself.

Next, I was asked to fill out some basic demographic information, although it’s important to note I was allowed to be as specific or vague as I felt comfortable with. After that section was completed, I clicked the community button and looked over my options.

Truthfully, I was impressed! When I first joined, I noticed that there are different communities such as health care professionals, parents, first responders, teachers and, of course, agriculture. Within these communities there are

separate groups. For example, there was a group dedicated to uplifting and positive posts and others specifically for people to vent.

I soon found myself scrolling through posts. The postings found on Togetherall are honest, real and heartfelt. Even today as I continue to browse the platform, I empathize with the members voicing struggles and smile as other anonymous users post supportive reflections. Although it has never been a question in my mind that folks in agriculture are there for each other when times are tough, it is wonderful to see the agricultural community support each other in this new way.

How exciting is it to have a platform where we can talk anonymously with other people in our agricultural family who “get us.” We can go to Togetherall to voice hurt, frustration, or even anger on the hard

POULTRY TIMES POULTRYTIMES.COM 10

POULTRY TIMES

POULTRY TIMES

days and offer fellowship and support on the days we are strong. Having a day that feels like everything is going against you and you just want to quit? Why not take a minute for self-care and scroll Togetherall? Scroll through postings that will make you smile, that will make you laugh. Scroll through postings that make you feel like you are not alone. But most of all, log onto Togetherall to gain hope and support so that the hard days do not stick to us like the beast they can be and rather roll off of us like freshly made hay bales roll out of a bailer onto our fields.

“Although it has never been a question in my mind that folks in agriculture are there for each other when times are tough, it is wonderful to see the agricultural community support each other in this new way.”

POULTRY TIMES POULTRYTIMES.COM 11

example, dedicated postsscrolling postingsthe the andreflections. a folks each iteach a talkfamilyhard

ag.

BUSINESS Americold breaks ground on cold storage facility

KANSAS CITY, Mo. — Americold Realty Trust has officially broken ground on a new $127 million cold storage facility in Kansas City, Mo. State and local leaders recently joined company executives to celebrate the company’s new investment in Missouri.

“Americold is yet another example of an industry-leading employer choosing Missouri due to our economic advantages,” Missouri Gov. Mike Parson said. “This innovative company’s presence in Kansas City is a welcome addition to the region’s thriving logistics sector. We congratulate Americold on its new facility and look forward to the benefits that this investment will provide for Missourians.”

The company plans to create nearly 190 new jobs in the region. The new 335,000-square-foot facility in Kansas City is part of a strategic collaboration with Canadian Pacific Kansas City to colocate Americold warehouse facilities on the CPKC network, the companies noted.

“We are thrilled to break ground on a new cold storage facility in Kansas City,” said George Chappelle, CEO of Americold. “This facility is the first to be built as part of our strategic collaboration with CPKC. By combining our cold storage capabilities with CPKC’s extensive rail network, Americold is poised to deliver a differentiated offering to support more customers across North America.”

“Today’s groundbreaking for this new facility marks the beginning of a significant collaboration that shows what we can achieve with vision and working together for our customers,” said Keith Creel, president and CEO of CPKC. “This project is the first of many across our network and, when combined with our unparalleled cross-border service, will build a new refrigerated supply chain for our customers. Just over one year ago here in Kansas City, when we celebrated the creation of CPKC,

we talked about the unique economic benefits our unrivaled network would bring to Kansas City, Mo., and beyond. We are seeing that happen today.”

The new facility will support CPKC’s Mexico Midwest Express service, North America’s only single-line rail service offering for refrigerated shippers between U.S. Midwest markets and Mexico, the company said, adding that it will also enable more seamless and efficient service for MMX customers.

“I am proud to welcome Americold into our growing and vibrant business community in Kansas City,” Quinton Lucas, Kansas City mayor, said. “With the ability to tap into our talented, highly skilled workforce and our centralized Canadian Pacific Kansas City

transportation system allowing access to more consumers internationally, Kansas City is the prime location for an innovative company like Americold to plant its roots. We look forward to the continued success of Americold in our community and the exciting new opportunities available to Kansas City as a result.”

“We’re thrilled to officially welcome Americold to Kansas City,” said Steven Anthony, vice president of business development for the Economic Development Corp. of Kansas City Mo.“Their presence here, along with the great partnership with CPKC, will further reinforce Kansas City’s deep strength in cold storage warehousing and logistics. The new jobs that will be generated and high-paying wages are icing on the cake.”

“We’re proud to support Americold alongside our partners as the company establishes its first facility in Kansas City,” said Michelle Hataway, director of the Missouri Department of Economic Development.“This exciting project will

help Missourians prosper through its significant investment, job creation, and positive impact on our state’s transportation and logistics industry.”

“It is always exciting when a company breaks ground in Missouri, and we are thrilled to officially welcome Americold to Kansas City,” said Subash Alias, CEO of Missouri Partnership. “Americold is joining more than 20,000 distribution and logistics companies in the state who are benefitting from Missouri’s central location, solid infrastructure, and low business costs. We look forward to watching Americold’s facility take shape and seeing their success unfold here in Missouri.”

Missouri Partnership worked with several partners to attract Americold to Kansas City, including: the City of Kansas City, Economic Development Corporation of Kansas City, Missouri, KC SmartPort, Missouri Department of Economic Development, Missouri One Start, Evergy, and Spire, the group noted.

POULTRY TIMES POULTRYTIMES.COM 12

POULTRY

POULTRY TIMES

Pilgrim’s Pride reports 1Q results with $4.4B net sales

GREELEY, Colo. — Pilgrim’s Pride Corp. has reported its first quarter 2024 financial results. Among the first quarter highlights, includes:

• Net sales of $4.4 billion.

• Consolidated GAAP operating income margin of 5.7 percent.

• GAAP net income of $174.9 million and GAAP EPS of 73 cents. Adjusted net income of $182.9 million or adjusted EPS of 77 cents.

• Adjusted EBITDA of $371.9 million, or an 8.5 percent margin, with adjusted EBITDA margins of 9.4 percent in the U.S., 6.4 percent in Europe, and 9.2 percent in Mexico.

• Diversified U.S. fresh portfolio continues to demonstrate its strength with dynamic market conditions, through increased partnership with key customers in both Case Ready and Small Bird, and improved operational excellence in Big Bird.

• Prepared Foods continues to accelerate its profitable growth through branded fully cooked offerings as Just Bare® and Pilgrim’s® net sales collectively grew 30 percent from prior year and continue to gain distribution across all channels.

• Europe continued its journey to improve through additional distribution with key customers and further optimization of manufacturing and support activities. Diversification through brands continues to grow as net sales for Richmond® and Fridge Raiders® grew 6.5 percent and 9.6 percent respectively.

• Mexico improved results given balanced supply and demand fundamentals in com -

modity markets, deepened relationships with key customers, and expanded presence in differentiated offerings.

• Strong liquidity position and net leverage ratio of less than two times adjusted EBITDA through prudent management of working capital.

• Increased diversification of the portfolio to support profitable growth as protein conversion plant in South Georgia initiated start up in March.

• Completed an external review of our GHG (greenhouse gas) emission intensity levels associated with the sustainability linked bond. Emission intensity declined by 15.6 percent between 2019 and 2022 from improved production efficiencies, capital investments, and energy infrastructure enhancements.

“Although we experienced depressed market conditions and persistent consumer inflation throughout 2023, we saw this as opportunity to enhance our competitive advantage,” Fabio Sandri, Pilgrim’s CEO, said. “To that end, we focused on consistent execution of our strategies, controlling what we can control, and maintaining investment in our operations. These efforts further strengthened our business, accelerating our profitable growth as market conditions evolved.”

During the first quarter, the U.S. continued to improve as Big Bird realized significant benefits from enhanced operational efficiencies and market fundamentals, the company said. Case Ready and Small Bird continued to grow from increased distribution with Key Customers, promotional activity, and the value of chicken to consumers. Prepared Foods also drove significant growth in both retail and food service through branded offerings, further diversifying the portfolio.

“Our U.S. portfolio continues to demonstrate an ability to capture market upsides while minimizing downside risk through a diversified set of offerings across multiple bird sizes and valueadded items,” Sandri said. “This approach is further reinforced by our key customer partnerships and relentless focus on operational excellence.”

(Continued on page 15)

The newest addition to Big Dutchman’s line-up of cage-free true aviaries, the NATURA® Visio is a two-tier aviary system that we are excited to introduce into the market. It features our unique “twin belt” design which allows for high visibility of the eggs on both tiers.

Contact your local distributor or sales representative to learn more.

POULTRY TIMES POULTRYTIMES.COM 13 +1-616-582-4000 | bigd@bigdutchmanusa.com WWW.BIGDUTCHMANUSA.COM

Bringing aviary visibility to another level

PATENT PENDING-----

(Continued from previous page)

In Europe, consumer inflation and labor costs continue to be challenging, the company said, adding that its team secured additional business with retail key customers, drove branded growth above category averages, and identified further efficiencies in manufacturing and support activities.

“Over the past year, the Europe team executed a variety of efforts to improve Key Customer partnerships, enhance our operational excellence, and further diversify our portfolio of branded offerings,” Sandri noted. “Our foundation is much stronger today and we will continue to explore ways to accelerate our journey of profitable growth.”

Mexico improved through a combination of enhanced supply and demand fundamentals in the commodity market, increased key customer partnerships, and further momentum of branded offerings. Operational excellence efforts to expand capacity and mitigate risk in live operations remain on track, the company said.

“Our strategies continue to demonstrate their effectiveness as we’ve grown ahead of the markets with our key customers,” Sandri noted. “Similarly, our branded portfolio continues to gain acceptance throughout the market, further diversifying our portfolio. When these efforts are combined with our operational excellence initiatives to expand capacity, we can further drive our profitable growth.”

Pilgrim’s efforts in sustainability continue to drive meaningful progress, the company said, adding that between 2019 and 2022, GHG emissions intensity has fallen by 15.6 percent, translating into an absolute reduction of

216,000 metric tons.

“We are proud of our leadership mindset regarding sustainability,” Sandri said. “Given our continued efforts, we can elevate our performance in GHG intensity reduction, creating a better future for our team members and further reinforcing our vision to become the best and most respected company in our industry.”

For more information, visit www.pilgrims.com.

Chore-Time taps

Shoemaker as associate product engineer

MILFORD, Ind. — Matthew Shoemaker has been named associate product engineer for Chore-Time, according to Todd Martin, engineering manager for the CTB Inc. business unit. In his new position, Shoemaker will design, develop, and create innovative poultry components and equipment to meet customer expectations and business goals, the company announced.

Shoemaker is a recent graduate of Trine University, Angola, Ind., where he obtained a bachelor’s degree in design engineering technology. Throughout his time at Trine University, he completed multiple engineering related internships and held part-time positions in the Warsaw, Ind., area.

Shoemaker is a native of Leesburg, Ind., where he still resides.

IFEEDER board discusses strategic plan and projects

ARLINGTON, Va. — The Institute for Feed Education and Research (IFEEDER) recently held its Board of Trustees meeting to discuss its current projects and install new board leadership and trustees.

“IFEEDER has made great strides in advancing our strategic plan, becoming a trusted resource for the animal food industry and our allied stakeholders, advancing sustainability research, and broadening IFEEDER’s pool of resources,” Lara Moody, IFEEDER executive director, said. “These

collaborations strengthen the industry’s collective efforts toward sustainability and innovation in the feed and pet food sectors.”

In the next year, IFEEDER plans to work on several projects in accordance with its strategic plan, including: adding new resources to the Animal Food Industry Sustainability Toolkit, supporting other research and pursuing education and sustainability projects on the animal food industry’s behalf. IFEEDER will also update its datasets on U.S. feed and pet food ingredient consumption.

As part of its business meeting, the IFEEDER Board of Trustees recognized Mike Gauss, president of Kent Nutrition Group Inc., for

(Continued on next page)

POULTRY TIMES POULTRYTIMES.COM 15

KUHL CORP. FLEMINGTON, NJ 08822 – USA www.kuhlcorp.com hyk@kuhlcorp.com HATCHING EGG WASHERS HATCHER TRAY WASHERS COUNTERS SEPARATORS UNSTACKERS REDUCES BACTERIA COUNT TO NEAR ZERO

Shoemaker

his leadership as board chair for the 2023-24 IFEEDER fiscal year, which ended April 30, and installed Dr. Carlos Gonzalez, vice president of global regulatory affairs at Hill’s Pet Nutrition Inc., as the new chair for the 2024-25 fiscal year, which began May 1. Dr. Stever

Lerner, senior scientific and business advisor of Novonesis Animal and Plant Biosolutions, will serve as vice chair for 2024-25.

With the installation of three new trustees, the IFEEDER Board of Trustees includes: John Akridge, MFA Inc.; Susanna Elliot, Alltech; Gonzalez; Courtney Hall, CHS Inc.; Jamee Krug Blahauvietz,

Elanco Animal Health; Lerner; Scott Lovin, AgState; Paul Phillips, DuraPlas Inc./Maxi-Lift Inc.; Dan Rice, Western Milling; Dr. Chad Risley, Berg+Schmidt America LLC; and Dr. Juan Tricarico, Innovation Center for U.S. Dairy.

IFEEDER also thanks its outgoing trustees for their service: Dr. Leah Dorman, Phibro Animal Health Corp.; Gauss; and Dr. Chris Hostetler, National Pork Board.

Ziggity and Butterfly Concepts appoints EMEA account manager

MIDDLEBURY, Ind. — Earlier this year, Ziggity Systems and Butterfly Concepts welcomed André van Rij, owner of ACPoultry, as their new contracted account manager, specializing in poultry watering and feeding. Van Rij will be serving the EMEA (Europe, Middle East and Africa) territories. In this role, he will be responsible for marketing each company’s concepts, products, and providing

onsite technical services.

For the past 25 years in the poultry industry, van Rij has focused on sharing his knowledge of poultry housing, hatchery and processing equipment, and general poultry management with producers around the world. He has worked with companies of various sizes, educating an industry that helps feed the world. Van Rij will be splitting his responsibilities between Ziggity and Butterfly Concepts supporting producers to achieve the best results and add value to customers’ bird production, the companies said.

“Ziggity has had a presence in the EMEA territory for years,”’ said Ziggity President Robert Hostetler, who also serves as Butterfly Concepts’ managing director, “but this is the first time Butterfly Concepts has had a dedicated team member based in the region.”

Much like Ziggity’s mission for better bird welfare through hygienic water practices, Butterfly Concepts is focused on a more hygienic way to deliver feed through the use of perimeter feed trays, the companies added.

“Bringing André on board only means good things for both companies,” said Rob Steiner, Ziggity’s vice president of sales. “The poultry industry is seeking out unique and better ways to provide water and feed to birds. André shares the same vision and business ethics as we do and is dedicated to helping the end user. His wealth of experience is going to add tremendous value to both companies’ customers.”

Van Rij resides in the Netherlands with his wife, Marga. Together, they also run a bed and breakfast they started during the COVID pandemic.

Motion enters agreement to purchase

BIRMINGHAM, Ala. — Motion Industries Inc. has signed a (Continued from previous page)

Allied Circuits

Van Rij

definitive purchase agreement to acquire Allied Circuits, an electrical and automation company. The transaction is subject to customary closing conditions.

Located in Buffalo, N.Y., Allied Circuits designs, manufactures and services industrial control panels, electro-mechanical assemblies, robotic automation, and integrated solutions. Founded in 1987, the company serves customers in the Western and Upstate New York markets

and into Ontario, Canada, due to its proximity to the border. End markets include aerospace, automotive, filtration, fluid systems & plumbing, food & beverage, oil & gas, pharmaceutical, process industries, semiconductor, and water & wastewater treatment facilities.

The company will join Motion’s business unit, Motion Automation Intelligence (Motion Ai). The addition of Allied Circuits will provide an exceptional work-

force of highly skilled teammates, ATEX certification capabilities and over 20,000 square feet of additional production space to bolster Motion Ai’s existing presence in the area. Motion Ai’s total region size will expand to more than 100,000 square feet of production space and 150 people dedicated to serving existing and new customers, the company said.

“It’s a great match — including the business culture and core values — and we’re very excited about our customers’ expanded access to even more products and services,” Chris Scinta, partner at Allied Circuits, said. “Motion is an industry leader, and we are pleased to integrate employee talents and contribute to the company’s growth.”

“Our customers are growing, and we’re committed to growing with them,” said James Howe, president of Motion. “By combining our engineering teams, we can leverage highly experienced technical resources needed to design, program and support increasing automation needs within the region. This strategic acquisition will create new opportunities for our customers, teammates, and

supplier partners.”

Case Farms facility reaches 1 million hours without lost-time accident

MORGANTON, N.C. — Case Farms achieved a new safety milestone on April 29 after its Morganton processing facility reached 1 million man-hours without experiencing an Occupational Safety and Health Administration (OSHA) recordable lost-time accident.

“Achieving this benchmark is a direct reflection of the employees and supervisors along with the culture here at Case Farms. Together, we will all move in the direction of Case Farms’ commitment to both safety, and a premium product,” said Derrick Caldwell, day shift safety supervisor of the Morganton facility.

“Every member should take

(Continued on next page)

Retro Luminaire Retro Luminaire Retro Luminaire Modeled after our Modeled after our Modeled after our Farm-proven AG25 Farm-proven AG25 Farm-proven AG25 Half the lights Waterproof Low-profile Longer life Better Light. Better Life!----------

How do you keep ammonia from filling up your poultry house?

BY MICHAEL CZARICK, DR. BRIAN FAIRCHILD, GARRET ASHABRANNER & WILLIAM STRICTLAND University of Georgia

ATHENS, Ga. — You are frying eggs for breakfast. You get distracted and the next thing you know your eggs are burning and your kitchen is filling with smoke. What do you do first? Open the window to get rid of the smoke or remove the skillet from the stove to stop the generation of the smoke? You of course, remove the skillet from the stove, then open windows because opening the windows in itself doesn’t solve the problem, because your eggs are still burning and filling the kitchen with smoke.

Controlling ammonia in poultry houses presents a very similar situation. How do you keep your house from filling with ammonia? Sure, you can turn on exhaust fans to re -

move the ammonia, but to actually solve the problem you need to stop or at least slow the generation of ammonia.

At the beginning of a flock, producers with built-up litter typically control the generation of ammonia through the use of a litter treatment. But, for long-term ammonia generation control, producers need to limit the amount of moisture in the litter because moisture is one of the key building blocks of ammonia.

The fact is even at the beginning of a flock, ammonia control is tied to litter moisture control. This is because one of the most important factors determining litter treatment life is litter moisture. If the litter is not properly dried between flocks the resulting high ammonia generation rate will quickly overwhelm the litter treatment’s limited ammonia neutralizing

(Continued on next page)

POULTRY TIMES POULTRYTIMES.COM 19 Peace of mind is now wireless!! No Monthly/Annual Fees to pay! No wires to install and maintain between buildings! Remote call in to check temperature and all conditions! Farm Alarm Systems T: 800.407.5455 • F: 704.753.5205 www.FarmAlarm.com Monitor: ➤ Power ➤ Temperature ➤ Water ➤ Ventilation ➤ Controller ➤ Curtain ➤ Feed over run ➤ Generator ➤ Customized settings by owner Wyr-LS 4.0

scrubbers

1

Ammonia

Figure

ability.

Another method of removing ammonia from a poultry house is through the use of a scrubber. An ammonia scrubber works by pulling air from a poultry house through a filter/media, typically containing some type of acid, which chemically scrubs/ removes the ammonia from the air. Though this may sound like a great idea, there are a couple of significant issues with this method of ammonia removal.

First, though a scrubber can potentially remove ammonia from the air in a poultry house, it scrubber does not remove moisture from the air or litter. If minimum ventilation rates are lowered in response to lower house ammonia concentrations, litter moisture levels will tend to increase, resulting in increased ammonia generation rates, which could easily overwhelm the ammonia-removing capacity of the scrubber.

Another important consideration is that since a scrubber’s ability to remove ammonia from the air requires a chemical reac-

tion, there is a limited amount of time before the chemicals will need to be replenished. This challenge is not that different from controlling ammonia early on during a flock through the use of a litter treatment. The litter generates ammonia. We apply a litter treatment to the litter, and the acid in the litter treatment neutralizes the ammonia, and ammonia levels are reduced until all the chemical is used up.

The greater the amount of ammonia being generated, the greater the amount of chemicals/litter treatment required and the shorter the life of the litter treatment. In either case, there is a limit to how long ammonia can be chemically removed from the air in a poultry house.

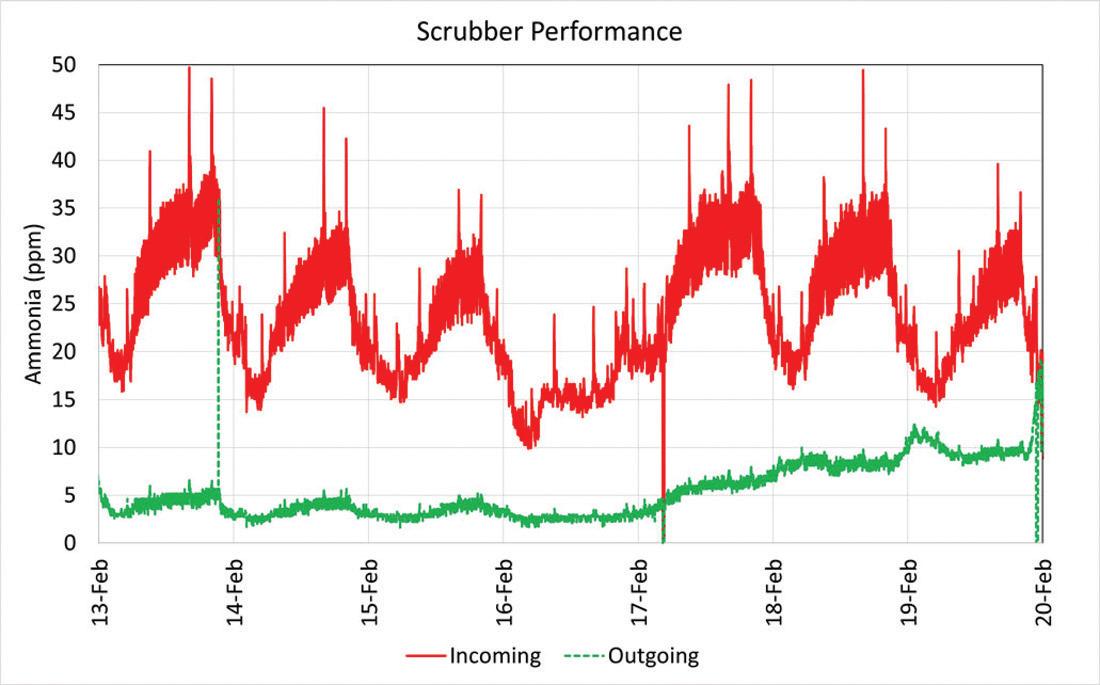

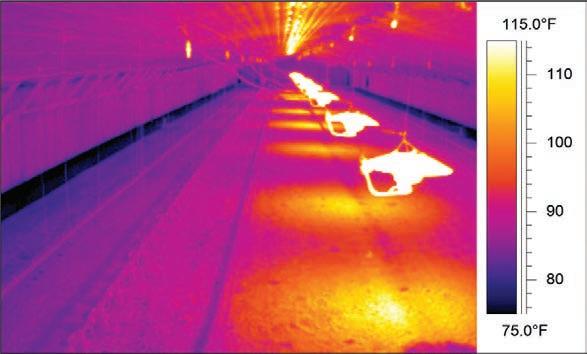

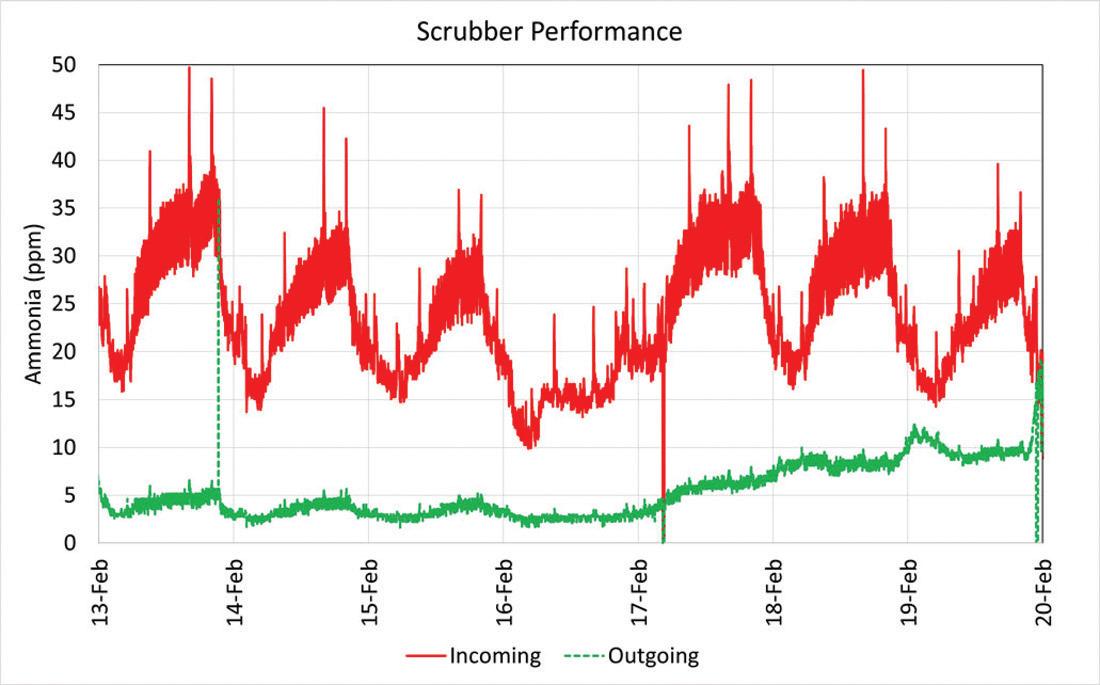

During the winter of 2023, a commercially available scrubber was installed in a broiler house and operated continuously for the last three weeks of a flock (Figure 1). The scrubber’s air exchange rate was measured and determined to be 300 cfm. Ammonia meters were installed on the intake and exhaust sides

Introducing EAGAN FAST TRACK Wall Vents

of the unit, along with temperature and RH sensors and measurements were recorded every minute.

The scrubber was found to be effective at lowering the concentration of ammonia of the air flowing through the unit. Ammonia concentrations were reduced by between 5 and 30 ppm with the greatest reductions corresponding with the highest incoming ammonia concentrations (Figure 2). One minor weakness of the scrubber was that it did not remove all the ammonia from the air. Ammonia concentrations leaving the scrubber were typically between 5 and 10 ppm with the higher concentrations typically being associated with higher house ammonia levels.

A much more significant weakness was that only 300 cubic feet of air each minute (or 18,000 cubic feet of air each hour) was “scrubbed” of ammonia; 18,000 cubic feet of air may seem like a lot, but it is important to realize that there were at least four 36” fans operating a minimum of two minutes out of five, providing 864,000 cubic feet of

ammonia-free air each hour. To provide that same ammonia removal rate would have required approximately 48 scrubbers of the design tested. Another way to look at it is that the scrubber was essentially only capable of removing the same amount of ammonia as two 36” fans operating five seconds out of five minutes.

Another significant weakness is that, as noted previously, scrubbers have a limited amount of ammonia they can react with. For instance, it takes around 1 lb. of most acid-based litter treatments to react with 0.14 lbs. of ammonia. The scrubber tested contained approximately 50 lbs. of an acid-impregnated carbon … essentially 50 lbs. of litter treatment, which meant that it theoretically could only neutralize roughly 7 lbs. of ammonia.

Figure 2. shows the ammonia concentration entering and leaving the scrubber over the last seven days of the study flock. As expected, the highest ammonia concentration occurred at night when the only the minimumventilation fans were operating off a timer, and the lowest during

FAST TRACK Wall Vents

Our new Fast Track Wall Vent (U.S. Patent No. 11,33,392) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available with an Aluminum or UV stabilized PVC frame

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

POULTRY TIMES POULTRYTIMES.COM 20

602 EAGAN ROAD, P.O. BOX 620 BLACK ROCK, AR 72415

Aluminum

UV Stabilized PVC

Cord Guide Installation Tool

Framed Fast Track Wall Vent

Framed Wall Vent

the minimum-ventilation continuously tain the levels flowing 3 of during slightly week similar, scrubber’s the house caught, later and ously was from tration decreased was 100 eration any based Zeolite. the of

(Continued from previous page)

the day when outside temperatures rose and minimum-ventilation fans were operating continuously along with other fans to maintain the proper house temperatures. During the last week of the flock, house ammonia levels varied between 10 and 35 ppm. Air flowing out of the scrubber varied between 3 and 12 ppm.

It was observed that the concentration of ammonia flowing out of the scrubber during the last three days of the flock were slightly higher than they were earlier in the week when ammonia concentrations were similar, indicating a slight reduction in the scrubber’s ability to remove ammonia from the air. The scrubber was removed from the house prior to catching. After the birds were caught, the litter was decaked, and five days later the scrubber was returned to the house and turned on. A 54” fan, operating continuously in conjunction with the sidewall inlets, was used to remove ammonia and moisture from the house. The initial ammonia concentration was over 100 ppm and after three days decreased to 40 ppm. Though the scrubber was initially able to decrease the incoming 100 ppm air to 40 ppm, after two days of operation the scrubber was unable to eliminate any ammonia from the air.

During the following flock the carbonbased scrubber media was replaced with Zeolite. Though the initial performance of the Zeolite material was very similar to that of the acid-impregnated carbon, its life was

significantly less, approximately a week. These studies demonstrate the difficulty of trying to control ammonia using scrubbers. Though it is theoretically possible, they don’t address the core problem, ammonia generation. As with the case of a smoke-filled kitchen, if you don’t focus your efforts on the generation of the thing causing your problem, you will never solve the problem.

Michael Czarick is an Extension engineer; Dr. Brian Fairchild is an Extension poultry scientist; Garret Ashabranner, is a PhD UGA graduate; and William Strictland is a MS candidate, all with the University of Georgia College of Agricultural and Environmental Sciences Cooperative Extension. More information can be obtained at www.poultryventilation.com.

Serving the Meat, Poultry and Seafood Industries

POULTRY TIMES POULTRYTIMES.COM 21 Paid Advertorial

WeighTech...

---

Ammonia scrubbers Figure 2

Benson Hill and Perdue Farms team up on broiler soybean meal

BY ELIZABETH BOBENHAUSEN Poultry Times staff

ebobenhausen@ poultrytimes.com

ST. LOUIS, Mo. — Benson Hill has been working on cracking the genetic code in a variety of plants, the company announces. Perdue Farms and Benson Hill have been working together to show how impactful a soybean-based meal made up of Benson Hill’s Ultra-High Protein, Low Oligosaccharide (UHP-LO) soybeans could affect broiler diets.

After completing food assessments, the results demonstrated that the use of the UHP-LO soybean throughout all phases of broiler production decreases feed costs and still upholds performance levels, the companies noted, adding that the tests also indicated a high protein and metabolizable momentum in the soybeans.

Have shortened

hours? Face greater lumen depreciation than you expected?

A company release says, “as previously announced, Benson Hill’s UHP-LO soybean varieties demonstrate novel attributes for

animal feed rations, enabling broadacre expansion of Benson Hill’s proprietary soybeans. Previous research identified three key product attributes of UHP-LO soy that uniquely position it for adoption by animal companies, soybean processors, and farmers. These key attributes are higher protein levels, lower anti-nutritional factors, and competitive yields.”

“Our ongoing work with Perdue and other

leading poultry producers opens up opportunities for diversifying soy options in animal feed and shows the benefits our seed innovations can deliver,” Deanie Elsner, CEO of Benson Hill said. “These positive results validate more than 20 years of soybean breeding for quality traits, further enhanced by our CropOS technology platform, enabling us to offer an innovative soybean meal option to an already established market.”

Randy Mitchell, vice president of nutrition and research with Perdue Farms, added, “we’re encouraged by these latest results. We look forward to partnering with Benson Hill to further evaluate this value-added soybean meal derived from their proprietary soybean genetics in our commercial operations.”

“Trial results indicate there is enough value in soybean meal derived from Benson Hill UHP-LO soybeans to drive large-scale adoption by poultry producers,” Dr. Roy Brister, an independent animal nutrition and strategic poultry advisor, said. “Now is the time for the industry to build on this exciting innovation.”

LED by Innovation

It’s time to look at what’s controlling your light bulbs.

Have shortened life hours?

Face greater lumen depreciation than you expected?

Face greater lumen depreciation than you expected?

Flickering at different lighting levels

Flickering at different lighting levels especially low light levels?

6/10/15W

Directional

- Directional Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs.

- Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

www.aglights.com/800-657-0509

Dim/ 14/26W Non Dim models 10/16/25W Dimm models

*Energy Star Approved for rebates

*Constant Current Driver delivers full current/wattage with minimal lumen loss at low voltages.

*CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

POULTRY TIMES POULTRYTIMES.COM 23 LED by Innovation 100% PURE TRAILING EDGE

Silicone Protection Gasket

of Dimmable

TIRED Poultry Dimmer

LED Lamp that

LED by Innovation 100% PURE TRAILING EDGE

light

Silicone Protection Gasket

It’s time to look at what’s controlling your

bulbs.

10/16/25W Dimm models of Dimmable LED Lamps that TIRED Poultry Dimmer www.aglights.com/800-657-0509

shortened life hours?

6/10/15W Directional Dim/ Non-Dim

Have

especially low light levels?

Star Approved for rebates

Current Driver delivers full current/wattage with minimal lumen loss at low voltages. CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

*Energy

*Constant

LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs.

Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%. LED by Innovation 100% PURE TRAILING

for:

us

problem!!! BEST LED control Full LED Life Low Level Dim Opstion Silicone Protection Gasket 6/10/15W Directional Dim/ Non-Dim 14/26W Non Dim 10/16/25W Dimm of Dimmable LED Lamp TIRED The ONE & ONLY Poultry www.aglights.com/800-657-0509

Flickering at different lighting levels especially low light levels? *Available with Junction *Energy StarApproved *IP66 Wet located *Constant Current with minimal lumen *CONSTANT ARE A FEATURE COMPETITORS -Directional Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs. - Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%. 100% PURE TRAILING EDGE ‘Trailing Edge’ Dimmer design is the only option for: It’s time to look at what’s controlling your light bulbs. Let us help you solve the problem!!! BEST LED control Full LED Life Low Level Dim Opstion Silicone Protection Gasket 6/10/15W Directional Dim/ Non-Dim 14/26W Non Dim models 10/16/25W Dimm models AskusaboutourNEWFeederlights The ONE & ONLY Poultry Dimmer www.aglights.com/800-657-0509 *Available with Junction Boxes. *Energy Star Approved for rebates *IP66 Wet located rated *Constant Current Driver delivers full current/wattage with minimal lumen loss at low voltages. *CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER! - Directional Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs. - Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

- Directional Beam Angled

-

‘Trailing Edge’ Dimmer design is the only option

It’s time to look at what’s controlling Let

help you solve the

life

of Dimmable LED Lamps that TIRED Have shortened life hours? Face greater lumen depreciation than you expected?

PT

Boehringer Ingelheim opens R&D lab in Mo.

BY ELIZABETH BOBENHAUSEN Poultry Times staff ebobenhausen@ poultrytimes.com

ST. JOSEPH, Mo. — Boehringer Ingelheim has established a new research and development laboratory in St. Joseph Mo. The company recently hosted a ribbon cutting ceremony to demonstrate its new facility and stated that the laboratory will “revolutionize the development of future products, including biotherapeutics.”

Boehringer Ingelheim explained, “this unique late-stage R&D laboratory, the only one of its kind in the U.S., is designed to streamline the process of transitioning products from development to manufacturing, enhancing our ability to serve animals better. The lab’s flexible design and proprietary equipment, which allows scientists to mimic operations, removes hurdles of transfers and maximizes efficiency.”

“As we venture into exciting new areas of innovation, this facility will play a pivotal role and will be instrumental in driving R&D for future products,” said Caroline Belmont, vice presi -

dent of U.S. global innovation, Boehringer Ingelheim.

The location is ideal because it is inside the business’s global operations, the company said, adding that it primarily will be

dedicated to developing livestock and horse products.

“Boehringer has a strong presence in the Midwest, with key facilities and operations contributing significantly to its global operations,” Belmont added. “This region is a crucial hub for the global animal health industry due to its rich agricultural heritage and extensive livestock farming. Boehringer’s strategic positioning in this community allows it to leverage local resources and expertise, playing a pivotal role in advancing the global animal health industry.”

Kim Young, president of the Kansas City Animal Health Corridor, said, “Boehringer Ingelheim is not just a global leader in animal health — they are a part of the fabric of our community. This facility underscores Boehringer’s dedication to leading the industry in research, development and manufacturing. The heart of the corridor are the companies choosing to invest in the region.”

POULTRY TIMES POULTRYTIMES.COM 24

PT

CDC seeks PPE usage for ag employees as HPAI protection

BY ELIZABETH BOBENHAUSEN Poultry Times staff

ebobenhausen@ poultrytimes.com

GAINESVILLE, Ga. — The Centers for Disease Control and Prevention have stated that the agency has spoken to state health executives and is asking health officials to disperse personal protective equipment to local farmers to stop the transmission of avian influenza.

In a recent Reuters report, CDC Principal Deputy Director Nirav Shah said, “while the risk to the U.S. public remains low, states should act to protect people with work exposures including people on dairy farms, poultry farms and in slaughterhouses.”

The CDC has insisted that farmers, employees, and emergency respondents wear PPE as they may be at risk when around sick animals, livestock, feces, raw milk, or contaminated surfaces.

The CDC is also giving information on how a person can pro-

tect themselves around animals that have contracted avian influenza. The organization says poultry farmers, livestock farmers, backyard bird flock owners, veterinarians and veterinary staff, animal health responders, public health responders and slaughterhouse workers are the most at risk for contracting bird flu. To avoid catching the dis-

ease recommends that a person stay within six feet of sick birds, livestock, Carcasses of birds or livestock, raw milk, udders from lactating cows, fecal matter, litter, surfaces, and pools of water.

The proper protective gear includes coveralls, NIOSH (National Institute for Occupational Safety and Health) particulate respirators, safety goggles, rub-

ber boots, rubber boot covers, a head or hair covering and gloves.

CDC says while wearing PPE a person should:

• Avoid touching yourself above your chest, especially your eyes, mouth, or nose, after touching any contaminated material.

• Do not eat, drink, smoke, vape, chew gum, dip tobacco, or use the bathroom.

• Use separate designated clean areas, one for putting on PPE and another for taking it off. When training employees to wear PPE, topics to cover include:

• Proper fit-testing, wearing, and use of respirators.

• Safe removal of respirators

• Safe disposal of disposable respirators

• Cleaning and disinfection of, and recommended respirator cartridge change-out schedule for, reusable respirators

• Medical contraindications to respirator use

• Use of only NIOSH approved respirators.

Complete l ine of l itter m anagement e quipment Industry Leader in Litter Management for over 50 years 912-367-4651 www.lbmfg.com sales@lbmfg.com Lewis Litter BLade dump Body Housekeeper tHe pouLtry House BLower Lewis windrower #5 Housekeeper “de-caking” pouLtry HousecLeaner the Lewis Crustbuster AerAte And Condition litter. New Product!

PT

Organic products topped record sales in 2023

BY ELIZABETH BOBENHAUSEN Poultry Times staff

ebobenhausen@ poultrytimes.com

GAINESVILLE, Ga. — The Organic Trade Association has released its 2024 Organic Industry Survey. In the report it states that the sales of certified organic items surpassed a record setting $70 billion in 2023 and the marketplace sales of organic items exceeded $69.7 billion.

That is an increase of 3.4 percent, OTA notes, adding that the organic market modified their supply chain and redoubled their efforts to cover the costs of doing business from increasing costs at the grocery store. With the industry expanding, the total cost of organic foods for 2023 was $63.8 billion and the total cost of organic non-food items was $5.9 billion.

“It is encouraging to see that organic is growing at basically the same rate as the total market. In the face of inflation and considering organic is already seen as a premium category, the cur-

rent growth shows that consumers continue to choose organic amidst economic challenges and price increases,” Tom Chapman, co-CEO of OTA, said. “Although organic is now a maturing sector in the marketplace, we still have plenty of room to grow.”

“It is essential to educate consumers that choosing organic is a straightforward way to tackle some of the greatest challenges we face,” Matthew Dillon, co-CEO

of OTA, said. “Whether it’s accessing healthy foods, improving transparency in supply chains, mitigating climate change, supporting rural economic resilience, protecting natural resources, or realizing the multitude of other benefits, effectively communicating and delivering on these promises is the key to expanding organic’s share of our dinner plate.”

In the organic market, dairy and eggs are the fourth largest group.

Last year, organic dairy and egg sales increased by 5.5 percent, around $8.2 billion. The sale of organic eggs and dairy grew an estimated 8 percent over all dairy and egg products. Milk and cream sales rose by 5 percent, approximately $4.2 billion. Dairy free or plant based dairy products increased by 14 percent, about $700 million. Meat, poultry and seafood goods account for 8.5 percent of all organic sales.

The OTA survey also states, “In 2023, the increase in dollar sales in the organic market was driven more by pricing than unit sales. But that said, consumers boosted their purchases of many organic products. Increases in unit sales were reported for up to 40 percent of the products tracked in this year’s survey. The survey also showed that prices for many non-organic products climbed at a faster rate than organic products. This means the price gap between conventional and organic is closing, which should help fuel growth for organic products in 2024.”

Better Airflow = Happier Flocks

POULTRY TIMES POULTRYTIMES.COM 26 • Tight Sealing • Rigid Design • Quality Components Mega Flow 58C 800-845-3374 FarmerBoyAg.com

Upgrade Your Fans Today!

PT

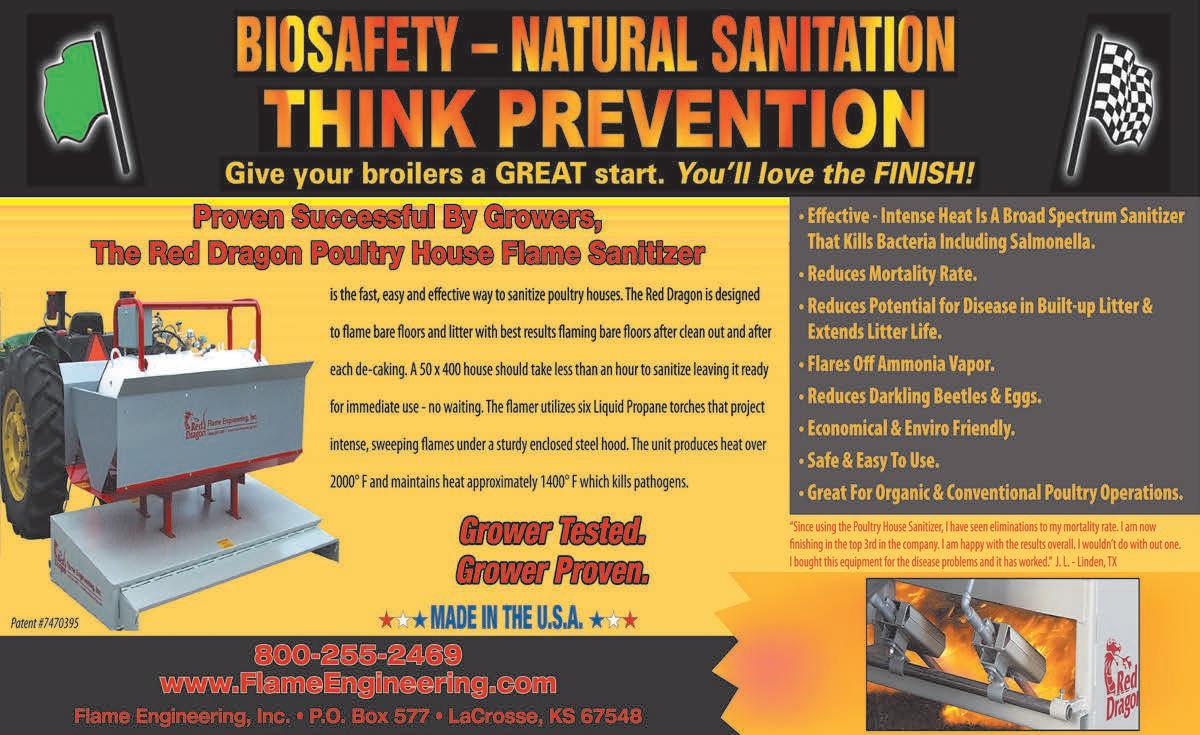

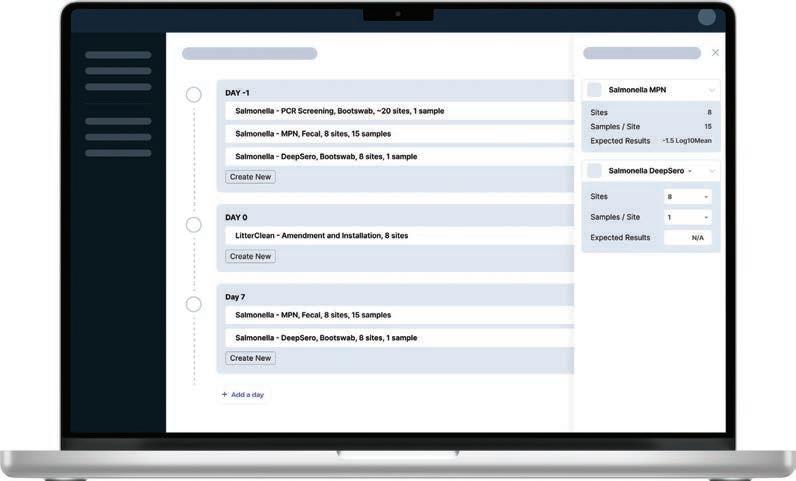

Ancera releases monitoring tools for poultry companies

BY ELIZABETH BOBENHAUSEN Poultry Times staff ebobenhausen@poultrytimes.com

BRANFORD, Conn. — Ancera, which it notes is a leading business in innovation for supply chain intelligence, is announcing new products such as monitoring tools. According to the company, these tools will enable poultry companies to see from third parties in real time their product’s efficiency.

Some companies that would benefit from this new technology would be makers of vaccines, feed additives, litter amendments, antimicrobials, sanitation supplies and quality control equipment, Ancera said, adding that these companies can keep track of the progressions of products and measure their influence on performance and food security. Also, it will lessen their costs and increase margins.

“Poultry production relies on many partners, and Ancera’s combined hardware-software monitoring system brings real-world evidence to improve the development, trials, and sales support of products that power the food supply chain,” Arjun Ganesan, CEO of Ancera, said. “As an objective third party source, we bring a new level of trust when data shows the effectiveness of their products, like vaccines, which translates into more business won for poultry industry allied companies and a more produc-

tive, safer food supply for consumers.”

According to Ancera, the new products are, “built upon a standardized and scalable framework, Ancera’s system allows companies to design, test, and price product field trials before ever deploying resources to the field. This enables all parties to agree on common success criteria, scope, and cost, followed by robust advanced analytics to assess product

effectiveness.

“Field trials executed under real-world conditions better represent their performance in a production system and allow allied companies to better quantify their value. Following a successful field trial, the system can remotely monitor the entire product deployment to predict product performance issues and proactively schedule technical services.”

POULTRY TIMES POULTRYTIMES.COM 27

WITH A NAME LIKE OURS POULTRY HAD TO BE OUR PASSION EXPERTS IN POULTRY CONSTRUCTION SINCE 1924. HENNINGCOMPANIES.COM HENNING

PT

Bench Scales

The WeighTech line of bench scales offers processors the best of both worlds: functionality and durability. Our bench scales feature our industry leading MicroWeigh indicator, and is available in many sizes to fit your processing needs.

2026 is declared International Year of the Woman Farmer

BY ELIZABETH BOBENHAUSEN

Poultry Times staff

ebobenhausen@ poultrytimes.com

GAINESVILLE, Ga. — U.S. Ambassador to the United Nations Linda Thomas-Greenfield, and USDA Deputy Secretary Xochitl Torres Small were in attendance as the UN announced that 2026 will be the International Year of the Woman Farmer.

The USDA led efforts to acknowledge the importance of women in farming. The resolution had more than 100 co-sponsors. The agency stated that women are accountable for approximately 50 percent

of the world’s food production. In some countries women manufacture between 60 and 80 percent of the food.

“The worldwide observance will call attention to the vital role that women play in global food and agricultural production,” USDA said. “It will also raise global awareness of the unique challenges women in agriculture face, catalyze action to help address those challenges, and support many of the UN Sustainable Development Goals, including those focused on gender equity, food security and poverty.”

Torres Small added, “from the field to the factory, from the classroom to the boardroom, women are fundamental to the future of agriculture. As leaders, it is our responsibility to make sure the next generation of women farmers have equal access to economic, educational and leadership opportunities, and that we dismantle the unique barriers they face so they can continue to take on the challenges of meeting the world’s growing food, fuel and fiber needs. USDA is proud to have led the U.S. government’s efforts in support of declaring 2026 as the International Year of the Woman Farmer, and we thank the many nations that signed on in support. We look forward to working with partners worldwide to scale up efforts that empower and advance women farmers while tackling global food security in 2026 and beyond.”

The USDA also noted that, “by shining a spotlight on women’s role in farming across the world, the International Year of the Woman Farmer will also raise awareness of constraints women face in areas including property rights and land tenure, access to credit and markets, and lack of technical and educational support. It will emphasize, as well, the importance of women in leadership roles to better ensure representation at the highest levels of decision-making.”

POULTRY HOUSE SOLUTIONS • Poultry Litter Admendment Spreader • Acid Alum Sprayer • Boric Acid Spreader • Litter Spreader newtoncrouch.com • 800.241.1350 1-800-457-3720 www.weightechinc.com

1649 Country Elite Drive, Waldron, AR 72958 Phone: 479-637-4182 Fax: 479-637-4183 The patented industry leading electronic indicator for harsh washdown environments

In today’s fast paced processing world, efficient, reliable and rugged scale systems and equipment are crucial.

PT

Brent Fielder, Chick-fil-A director of corporate social responsibility, speaks to the 2024 Community Scholar recipients at Chick-fil-A Dwarf House in Hapeville, Ga.

Chick-fil-A awards scholarships to this year’s ‘Community Scholars’

BY ELIZABETH BOBENHAUSEN Poultry

Times staff

ebobenhausen@ poultrytimes.com

GAINESVILLE, Ga. — Chickfil-A has given $25,000 in scholarship funds to 12 students that are a part of its Chick-fil-A Community Scholars.

These students were not affiliated with the Chick-fil-A franchise or restaurants. According to a statement released by Chick-filA, “the Chick-fil-A Community Scholars program is an expansion of Chick-fil-A’s existing education initiatives and an extension of Chick-fil-A’s corporate social responsibility commitment to care for people and communities. This year, an additional $26.4 million in scholarships was also awarded to Restaurant team members.”

The first scholarships to be awarded to students occurred

“Scholars are paired with a Chick-fil-A staff leader to mentor them. Scholars also have the chance to meet together virtually each month, creating an environment of collaboration, growth and fun.”

in 1973 at the fast-food chain’s first location, the Dwarf House in Hapeville, Ga. S. Truett Cathy awarded the first class with their scholarship funds.

Funds are still given at the Dwarf house, and awardees for this class is comprised of students that have finished extensive community service and some who have even established their own nonprofit organizations.

“The Chick-fil-A Community Scholars program is unlike other scholarship programs because it comes with the opportunity

for students to participate in a year-long leadership development and mentorship program,”

Brent Fielder, senior director of corporate social responsibility for Chick-fil-A, said. “Scholars are paired with a Chick-fil-A staff leader to mentor them.

Scholars also have the chance to meet together virtually each month, creating an environment of collaboration, growth and fun.”

Taylor Peterson, a 2023 Chickfil-A Community Scholar who attends the University of Michigan,

said “The Chick-fil-A Community Scholars program provides a national network of incredibly talented and hardworking peers, and each student has something different that drives them. Being surrounded by these accomplished students is inspiring. The community you build throughout this program are people you can rely on, ask questions to, and collaborate with for years to come.”

For more information about the Community Scholar program, visit www.chick-fil-a.com/community-scholars.

POULTRY TIMES POULTRYTIMES.COM 29

PT

Chick-fil-A photo

Inof will thatsaid. awareness in to andincluding equity, thewomen of our theeconomic,dismantle so the world’s needs. U.S. supportFarmer, nations look partners that women food “by women’s the Woman awareness areas landemphasize, women ensure -

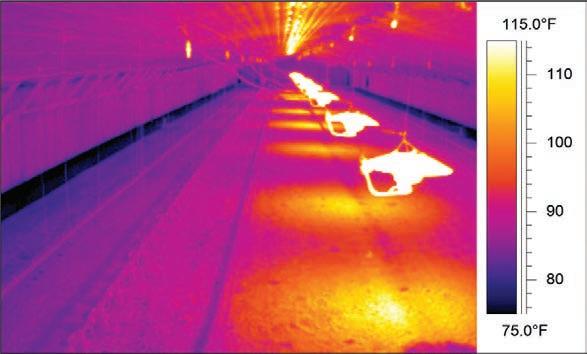

Common mistakes when installing controller temperature sensors in your poultry house

BY MICHAEL CZARICK & DR. BRIAN FAIRCHILD University of Georgia

ATHENS, Ga. — A poultry house controller’s temperature sensors are, in a sense, its “eyes” enabling it to “observe” what is happening throughout a poultry house so it can accurately determine what equipment it needs to operate to maintain the proper environmental conditions throughout a house. As a result, a controller’s ability to maintain proper growing conditions for the birds is only as good as the information it receives from its eyes/temperature sensors.

In today’s large poultry houses, it is not uncommon for there to be significant variations in temperature from the center of the house to the sidewalls, as well as between the center of the house and the end walls/brooding curtain as well as from floor to ceiling. If a controller is unaware of hot or cold spots within a house, due to improper temperature sensor location, it cannot take the necessary corrective actions to address these hot and cold spots and bird performance, health and welfare can suffer.

The following is a list of mistakes commonly made when positioning controller temperature sensors within a house that can harm a grower’s ability to provide the proper growing conditions for birds throughout their houses:

1. Installing temperature sensors along the centerline of a house.

Temperature sensors positioned along the center of the house tend to paint the prettiest picture of house conditions because this is where temperatures tend to be most stable. The problem is that conditions nearer the side walls can be very different during both summer and winter.

During hot weather, the centerline of the house tends to be the coolest area of a house. But on a hot summer day, a controller needs to be aware of what is happening in the warmest locations to make sure those birds near the side wall are not becoming heat stressed due to naturally lower air velocities and heat entering through side wall curtains and/or poorly insulated concrete stem walls. Conversely, during cold weather, it tends to be cooler near the sidewall than along the centerline of a house due to excessive heat loss from poorly insulated stem walls, side wall curtains, leakage and poorly performing side wall inlets.

Lower air temperatures near the sidewall can not only result in chilled birds but can result in not only chilled birds but also increased litter moisture due to the fact that

cool air does a poor job of removing moisture from the litter. Higher litter moisture levels will in turn result in higher house ammonia concentrations and subsequent potential bird health and performance issues.

The controller needs to see these cooler areas of a house so it can take corrective actions (i.e., turn on heaters) before bird performance and health suffer. The thing to keep in mind is that in general if the birds near the sidewall are comfortable then most likely the birds toward the center of the house are comfortable as well. The converse is far less likely to hold true. As a result, to help ensure the maximum number of birds have optimal growing conditions, it is generally recommended to install temperature sensors within five to ten feet from the sidewalls (alternating sides of a house), ideally attached to either a feeder or drinker line.

2. Installing temperature sensors too far from house end walls and/or brood curtain(s) of a house. Often temperature sensors are positioned 40’ or more from the endwalls and/or brooding curtain(s) of a house. The problem with this is that these areas will tend to run cooler than they should during cold weather simply because the controller is unaware these traditionally leaky areas of a house are cool. As is the case with low air temperatures near the sidewalls during cold weather, low air temperatures near the end walls/brooding curtain tend to result in increased problems with caked litter, ammonia and chilled birds.

In addition, feeder control pans are typically located near the endwalls, and if it is too cool (or hot for that matter) there may not be enough birds in the area to eat enough feed from the control pan to trigger it to operate. To ensure that the areas near the endwall of a house remain warm and dry during cold weather, and there are sufficient number of birds to trigger feeder control pans, temperature sensors should be placed within 15’ of the endwalls/brood curtain(s).

3. Placing temperature sensors too close to a radiant heater.