HOT WEATHER PREP & TRANSPORTATION www.poultrytimes.com Your poultry industry news source since 1954 April 22, 2024

contact our office for info on Spring & Fall Training Sessions at our facility.

Please

BEAT the HEAT to achieve the absolute maximum potential from all your ocks

The sensitivity of newly hatched chicks to the surrounding climate during transport make it extremely demanding operation. With hundreds of thousands of chicks generating enormous heat energy (each emitting around 1.5 BTUs), the air conditioning system must operate optimally in order to ensure their comfort and safety. This is vital for profitability, as a chick’s comfort during transport has a strong direct correlation with future growth performance.

When stress levels rise, chicks tend to eat and drink less, leading to increased mortality rates and substandard deviations from ideal growth curves. Vibrant, healthy chicks yield significantly better 3- and 7-day mortality rates and are able to benefit most from their genetic growth potential.

VEIT vehicles help you BEAT the HEAT

Imagine transporting over 115,000 poults for over 24 hours from South Dakota to Miami. This kind of trip takes the birds through external temperatures well over 100°F (max. 115°F), yet the air lling the cargo hold never exceeds 80°F and carbon dioxide levels remain optimum the entire time.

Durable, heavy duty construction tailored to the demands of the North American poultry industry

Transporting chicks in North America poses unique challenges for the entire industry. VEIT North America tackles them head-on with their VEIT 40 Heavy Duty trailers. Each trailer is assembled in the USA and features a spacious cargo hold, equipped with a specialized mechanical room. Built similarly to a shipping container, the trailer is extremely resilient and practically indestructible, even under rough handling.

An inside-mounted winch helps with unloading. Two powerful DEUTZ engines are completely integrated with fully-automated starting features and are located in the easy-access mechanical room. The scientifically refined VEIT 3D AirFlow ventilation system evenly distributes temperature - controlled, oxygenated air throughout the cargo area with durable, high-efficiency fans.

All technology is centralized in an easy-access mechanical room. The cargo space is made of smooth, high-quality, corrosion-resistant materials.

Scan to visit: veitna.com

News

7 | HPAI found in cattle in some western states

Business Features

12 | Georgia Ports Authority board approves $65M for Ocean Terminal

Calendar

APRIL

APR 23-26 — CGFA

22 | The importance of dew point monitoring during hot weather

100th ANNUAL CONVENTION, Laguna Cliffs Marriott, Dana Point, Calif. Contact: California Grain & Feed Association, 1521 I Street, Sacramento, Calif. 95814; Ph: 916-441-2272; https://cgfa. org.

APR 24 — TPA SERVICE TECH WORKSHOP, Farm Bureau Expo Center, Lebanon,

26 | Poultry house windspeed maintenance

Tenn. Contact: Tennessee Poultry Association, 1404 N. Main St., Shelbyville, Tenn.; Ph: 931-225-1123; info@tnpoultry.org; www.tnpoultry.org.

MAY

MAY 8-9 — STAKEHOLDERS SUMMIT 2024, Kansas City, Mo. Contact: Animal Agriculture Alliance, 2101 Wilson Blvd, Suite 810-B, Arlington, Va. 22201; summit@animalagalliance.org; https://animalagalliance.org.

WEATHER PREP

“With the spread of HPAI to other species now, it’s likely we’ll see continued activism on this issue.”

— Emily Ellis

|

POULTRY TIMES POULTRYTIMES.COM 5 VOL. 71 | NO. 9 | APRIL 22, 2024 26

HOT WEATHER PREP & TRANSPORTATION www.poultrytimes.com Your poultry industry news source since 1954 April 22, 2024 IN THIS ISSUE On the cover HOT

Viewpoints

& TRANSPORTATION

| 10 8

Cal-Maine facility in Texas

HPAI Connect with us Visit us at: POULTRYTIMES.COM 24/7 on the World Wide Web or scan the code to the right /poultrytimes @PoultryTimes /poultrytimesga

reports positive for

CORPORATE HEADQUARTERS

POULTRY TIMES

PO Box 1338

Gainesville, GA 30503

PH | 770-718-3443

FAX | 770-532-4894

POULTRY TIMES STAFF

CINDY WELLBORN

General Manager, Poultry Times/PoultryTimes.com

770-718-3443

cwellborn@poultrytimes.com

DAVID B. STRICKLAND Editor, Poultry Times

770-718-3442

dstrickland@poultrytimes.com

ELIZABETH BOBENHAUSEN

Content Writer, Poultry Times

770-209-3335

ebobenhausen@poultrytimes.com

RACHEL DANFORD

Digital Manager, PoultryTimes.com

770-831-8631

rdanford@poultrytimes.com

STACY LOUIS

Sales Manager, Poultry Times/PoultryTimes.com

770-718-3445

slouis@poultrytimes.com

JANICE SISK

Sales & Administrative Assistant, Poultry Times/PoultryTimes.com

770-718-3439

jsisk@poultrytimes.com

KIM EWING

Circulation

770-718-3420

kimewing@poultrytimes.com

Index of Advertisers

Be sure to pay a visit to these esteemed sponsors of the Poultry Times, recognizing them as vital contributors to the industry who greatly appreciate your support.

Ag Lighting | 26 615-378-0108; www.poultrylights.com

Agralarm | 14 888-968-2802; www.agralarm.com

Aquapproach | 20 800-604-1924; www.aquapproach.com

Big Dutchman | 17 616-582-4000; www.bigdutchmanusa.com

Eagan Mfg. | 27 870-878-6805; www.eaganmfg.com

Farm Alarm | 21 800-407-5455; www.farmalarm.com

Flame Engineering | 16 800-255-2469; www.flameengineering.com

FPM Inc. | 29 402-729-2264; www.fpmne.com

Gas-Fired Products | 13 800-849-7311; www.spaceray.com

IMPEX | 21 770-534-1590; www.impex.nl

J&D Manufacturing | 25 800-998-2398; www.jdmfg.com

Kunafin (The Insectary) | 29 800-832-1113; www.kunafin.com

L.B. White | 22 608-783-5691; www.lbwhite.com

Neogen | 32 800-234-5333; www.neogen.com

NuTech Biosciences | 18 315-751-0729; www.nutechbiosciences.com

Overdrive Lighting | 23 800-657-0509; www.aglights.com

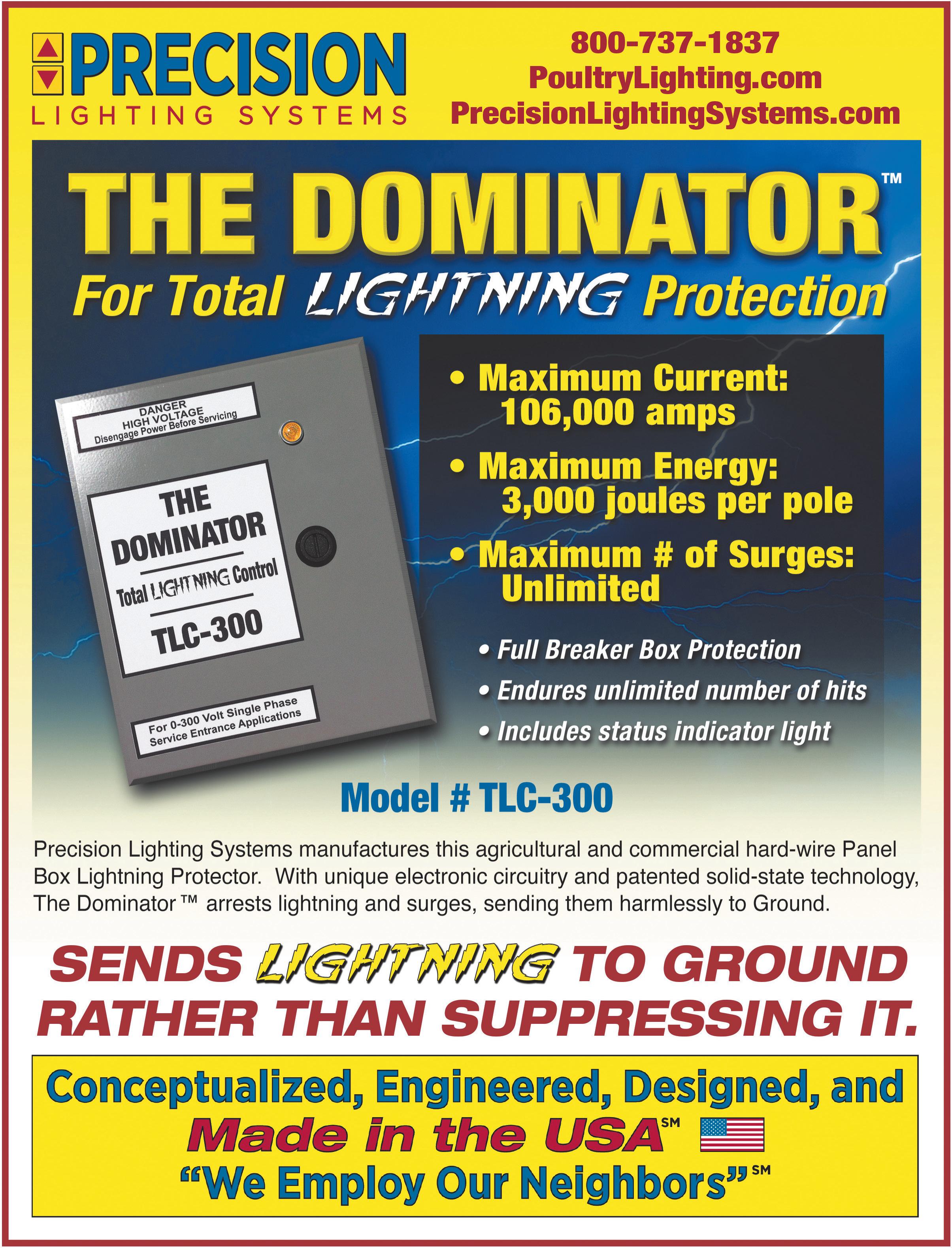

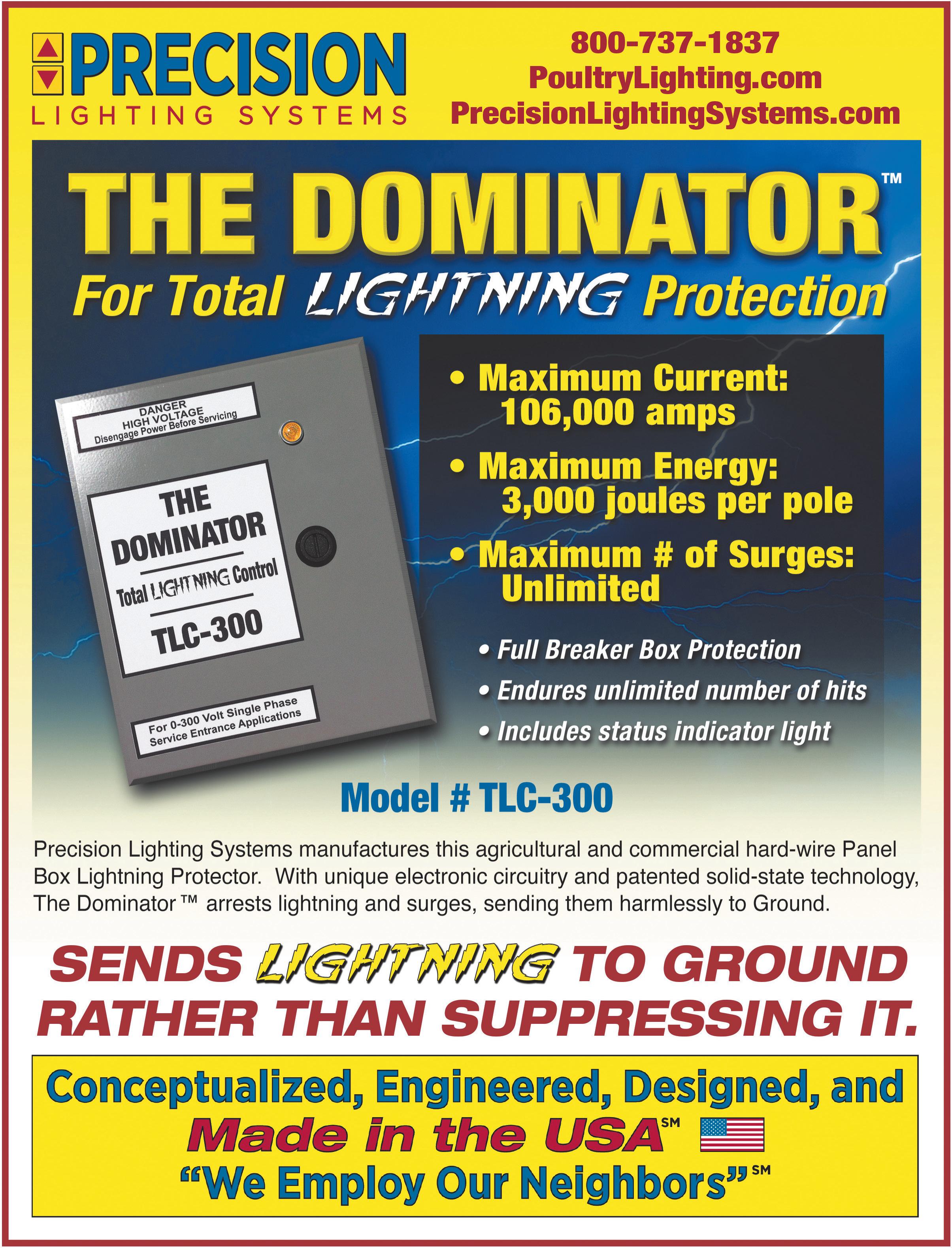

Precision Lighting | 1, 2, 15, 28 800-737-1837; www.poultrylighting.com

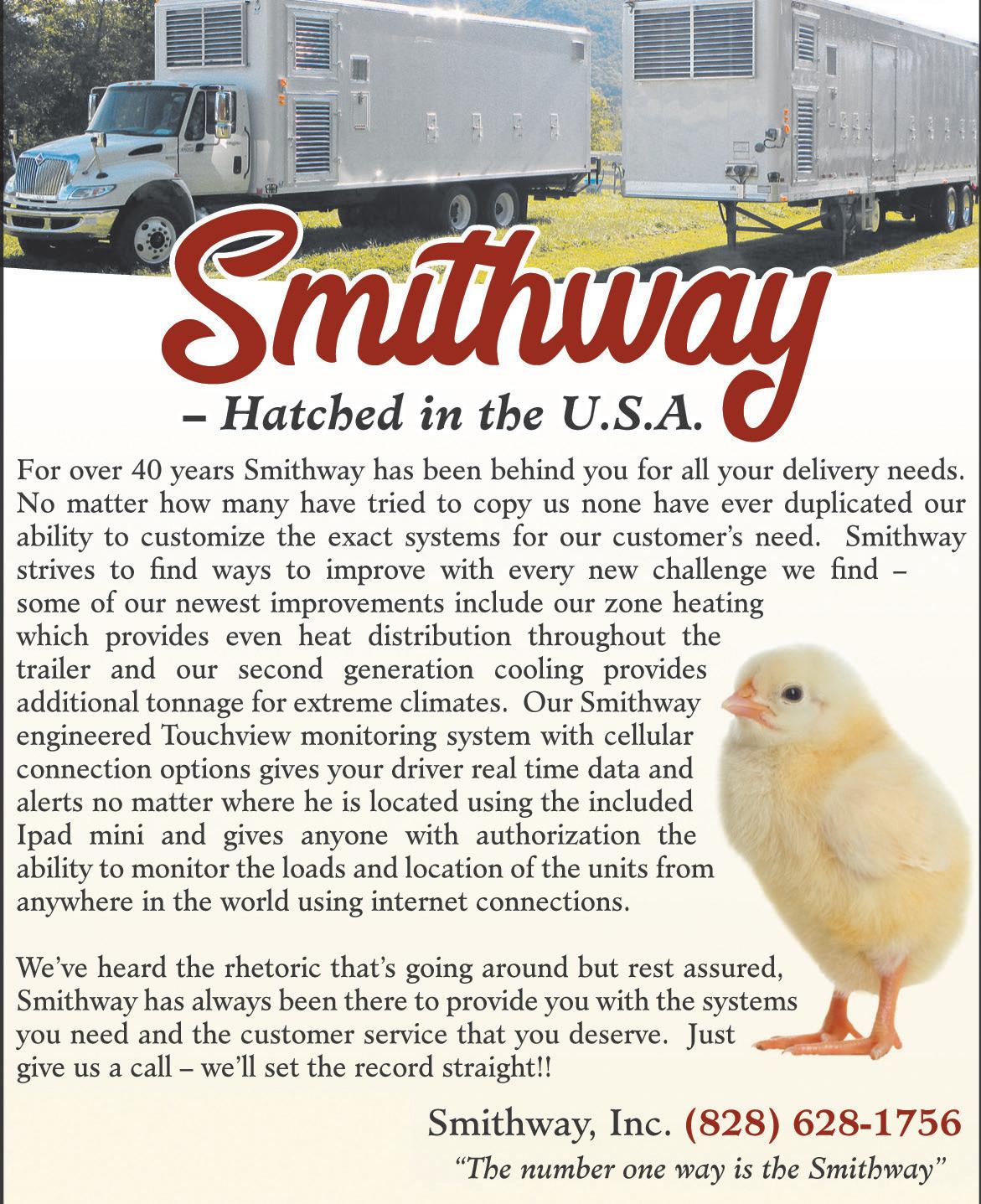

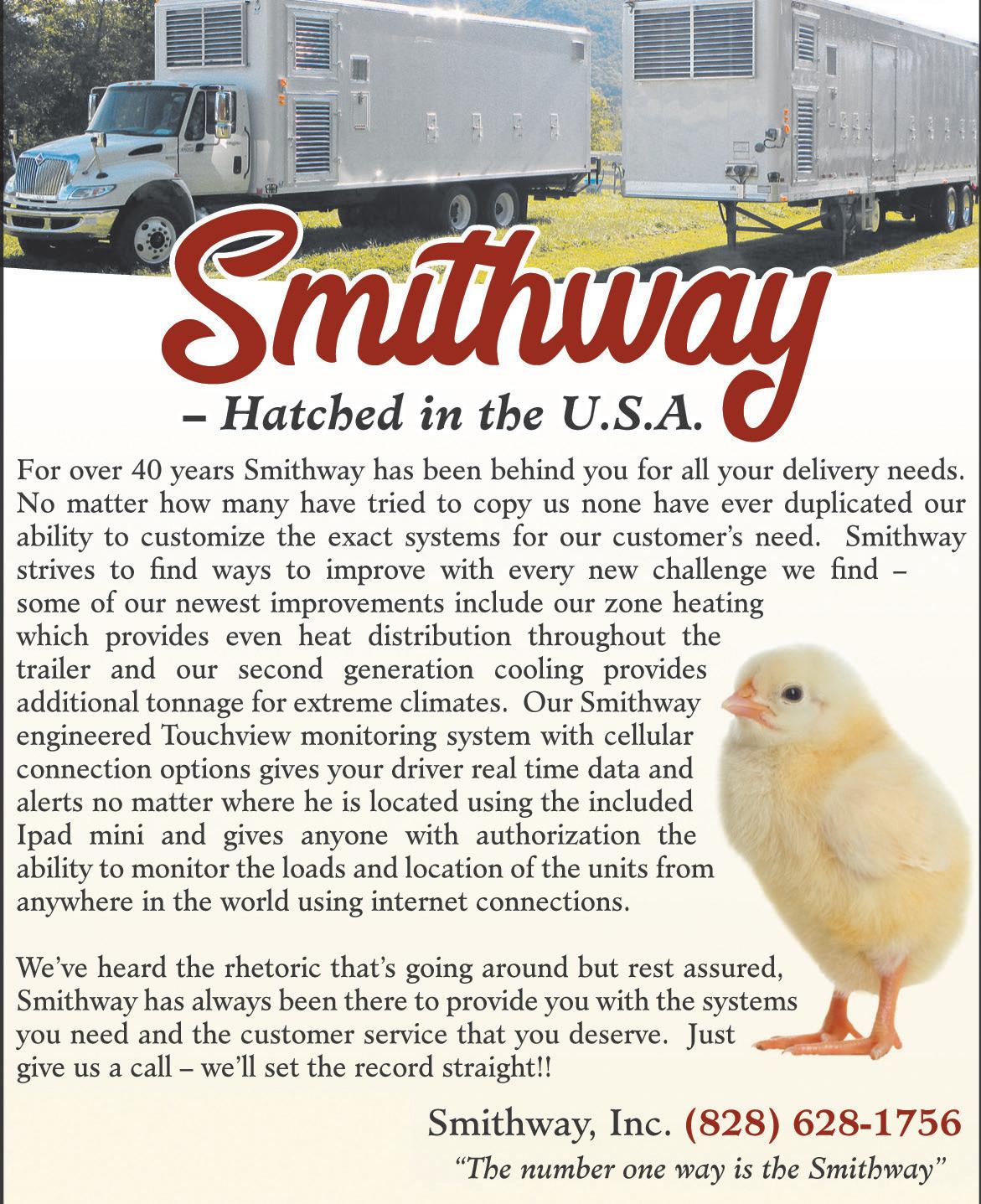

Smithway | 3 828-628-1756; http://smithwayinc.com

The Egg Carton Store | 29 866-333-1132; www.eggcartonstore.com

Veit North America | 4 704-475-3301; https://veitna.com

Walinga USA | 31 800-466-1197; www.walinga.com

Weightech | 24, 25 800-457-3720; www.weightechinc.com

Publication Disclaimer

Poultry Times (USPS 217480) ISSN 0885-3371 is published biweekly, 345 Green Street, N.W., Gainesville, GA 30501. Telephone 770-536-2476; Fax 770532-4894. Postage paid at Gainesville, Georgia 30501. Poultry Times assumes responsibility for error in first run of an in-house designed ad only. Advertisers have ten (10) days from publication date to dispute such an advertisement. After ten (10) days, ad will be deemed correct and advertiser will be

charged accordingly. Proofs approved by advertiser will always be regarded as correct.

Subscriptions: Surface mail in U.S., $25.00 for one year, $45 for two years and $65 for three years. Business or occupation information must accompany each subscription order.

Change of Address: Postmaster, report change of address to Poultry Times, P.O. Box 1338, Gainesville, GA 30503.

The opinions expressed in this publication by authors other than Poultry Times staff are those of the respective author and do not necessarily reflect the opinions of Poultry Times.

Advertisement content is the sole responsibility of the advertiser. Poultry Times assumes no liability for any statements, claims or assertions appearing in any advertisement.

Companion Poultry Publications: A Guide to Poultry Associations; Poultry Resource Guide.

© 2024 Metro Market Media Gainesville, Georgia 30503

POULTRY TIMES POULTRYTIMES.COM 6 6

HPAI virus found in cattle in some western states

COVER STORY

BY ELIZABETH BOBENHAUSEN Poultry Times staff ebobenhausen@ poultrytimes.com

GAINESVILLE, Ga. — The USDA, the U.S. Food and Drug Administration, the Centers for Disease Control and Prevention, as well as other local officials are looking into instances of highly pathogenic avian influenza found in cattle.

The disease is primarily found in birds. The USDA reports in a release that the states of Kansas, Texas and New Mexico have reported finding HPAI in some cattle. An oropharyngeal swab test was conducted on a dairy farm in Texas. Unpasterized clinical samples were gathered from two dairy farms in Kansas and one farm in Texas. The tests concluded that

the virus was making cattle ill. However, some other tests were performed on March 22-24 because farmers had seen deceased birds on their land. The findings in Texas showed that the transmission of the disease was from wild birds. The National Veterinary Services found no evidence that suggests that HPAI can be transmitted to humans due to no mutations in the virus.

According to the Kansas Department of Agriculture, symptoms can include a drop in milk production, loss of appetite and changes in fecal consistency. The illness seems to be affecting older cattle. The USDA and the Kansas Department of Agriculture said that the risk of humans contracting the illness from milk is low because of pasteurization.

“The pasteurization process of heating milk to a high temperature ensures milk and dairy products can be safely consumed, as confirmed by the Centers for Disease Control. Pasteurization has continually proven to success-

fully inactivate bacteria and viruses, like influenza, in milk,” the Kansas Department of Agriculture said in a release. “Dairies are also required to only allow milk from healthy animals to enter the food supply chain.” The department also acknowledged that the CDC warns against drinking raw or unpasteurized milk.

“For the dairies whose herds are exhibiting symptoms, on average about ten percent of each affected herd appears to be impacted, with little to no associated mortality reported among the animals,” USDA said. “Milk loss resulting from symptomatic cattle to date is too limited to have a major impact on supply and there should be no impact on the price of milk or other dairy products.”

Texas Agriculture Commissioner Sid Miller added that, “this outbreak has quickly grabbed the attention of the agriculture industry on a national level. Understanding the details surrounding the transfer of avian virus to livestock is the top priority of animal

health professionals and agriculture agencies. While troubling, this outbreak is not currently expected to threaten our nation’s commercial dairy supply.”

“This new confirmed infection of dairy cattle is an unprecedented development,” Miller said. “What we are doing now is working to get the facts straight. We anticipate more developments in the coming days. TDA and other state and national agencies are working around the clock to ensure the safety of our food supply.”

USDA adds that HPAI has been found in several wild mammal species, poultry flocks and neonatal goats. The department adds that wild species are susceptible to the disease after coming in to contact with and consuming wild birds that have been infected.

A full list of wild mammal species that have been affected can be obtained at https://www. aphis.usda.gov/livestock-poultry-disease/avian/avian-influenza/hpai-detections/mammals.

POULTRY TIMES POULTRYTIMES.COM 7 7

PT

Cal-Maine facility in Texas reports positive for HPAI

DAVID B. STRICKLAND Poultry Times Editor dstrickland@ poultrytimes.com

RIDGELAND, Miss. — A Parmer County, Texas, facility of Cal-Maine Foods reported on Apr. 2, positive for highly pathogenic avian influenza H5N1. The company reports that it depopulated 1.6 million laying hens and 337,000 pullets, which amounts to about 3.6 percent of the company’s total flock.

Cal-Maine is the nation’s largest producer and distributor of fresh shell eggs. It adds that this facility is temporarily closed, and the company is following USDA protocols, and is also working with its other facilities to make the impact on customers minimal.

In a statement, Cal-Maine notes that it, “remains dedicated to robust biosecurity programs across its locations; however, no farm is immune from HPAI. HPAI is still present in the wild bird population and the extent of possible future outbreaks, with heightened risk during the migration seasons, cannot be predicted. According to the U.S. Centers for Disease Control and Prevention, the human health risk to the U.S. public from HPAI viruses is considered to be low. Also, according to the USDA, HPAI cannot be transmitted through safely handled and properly cooked eggs. There is no known risk related to HPAI associated with eggs that are currently in the market and no eggs have been recalled.”

“This is absolutely devastating news for Cal-Maine and the entire Panhandle region which has already suffered so much already,” Texas Commissioner of Agriculture Sid Miller said “Given this latest development, all producers must practice heightened biosecurity measures. The rapid spread of this virus means we must act quickly.”

This comes on the heels of

HPAI being detected in 11 dairy cattle facilities in four states. The USDA reports the number of cases currently at Texas, 7; Kansas, 2; Michigan, 1; and New Mexico, 1.

Miller also is continuing to assure consumers that dairy cattle producers are following rigorous safety measures to ensure the safety of dairy products, which already follow pasteurization protocols, and that any milk from sick cows are required to be diverted or destroyed.

“The current risk to the public remains minimal,” Miller said. “It is important for us as an industry to maintain a high level of vigilance. State and national agencies will continue to provide updated

guidance as developments warrant.

“Producers need to work with us and report cases right away,” he added. “Transparency is going to be key to navigating and mitigating this outbreak. I encourage producers to work with state and national officials to report any symptomatic animals as soon as you identify them.”

In regard to the safety of dairy cattle, the Nebraska Department of Agriculture, although no cases have been reported in Nebraska, in efforts to protect the state’s herds, the NDA has issued an importation order that is effective immediately.

This order requires all breeding

female dairy cattle entering Nebraska to obtain a permit issue by NDA. Producers needing to obtain these permits will need to contact NDA, by phone at 402-471-2351 or online at www.nda.nebraska. gov/animal/imports.

“The health and safety of livestock in Nebraska is top priority,” said Dr. Roger Dudley, Nebraska state veterinarian. “At this time, it appears the HPAI illness found in dairy operations in some states only affects lactating dairy cows and is not being seen in other segments of the cattle industry. Now, more than ever, is the time to enhance biosecurity measures on farms and ranches to help protect livestock from illness.”

POULTRY TIMES POULTRYTIMES.COM 8

PT

HPAI virus in U.S. West jumps to cattle and at least 1 human worker

DAVID B. STRICKLAND

ITHACA, N.Y. — Scientists are looking into how the highly pathogenic avian influenza virus has made the species jump from traditional birds to other species, primarily the reports recently of the virus infecting dairy cattle in some western U.S. states, and at least one human worker in Texas.

Researchers at Cornell University’s College of Veterinary Medicine Animal Health Diagnostic Center, as well as other diagnostic laboratories, are taking a close look at the virus and note that its sequencing may provide some understanding on how the virus can jump to another species and give insight to prevent future infections.

“When there is spillover of HPAI to a new species, especially to mammals, it is always concerning, as the virus may adapt and gain the ability to transmit between

animals,” Dr. Diego Diel, associate professor of virology and director of the Virology Laboratory at Cornell’s AHDC, said.

In the past two years, the HPAI virus has led to the death of millions of commercial poultry, wild birds and animals that have fed on the carcasses of the dead wild birds. But the presence of the virus in ruminants is new.

“The cows in Texas weren’t producing as much milk, and milk consistency was very different,” said Dr. Elisha Frye, a Cornell assistant professor of practice in a Cornell report. “The cows had mild respiratory signs, weren’t eating well and some had short-term, low-grade fevers.”

Several sample types were sent to Cornell from Texas where a research team began exploratory next generation sequencing (NGS), which can detect the virus in a large variety of species. Their research showed that pigeons, grackles, and some farm cats also died from the virus.

When infected wild birds in-

fected with HPAI move through farm areas they can contaminate food and water sources. The researchers noted that this is likely how the virus spread to the dairy cows. They are continuing to investigate whether this is how the infected cattle contracted the virus, or if it was through cow-tocow transmission.

“We will study how HPAI spilled over into dairy cows to understand why this outbreak happened,” Diel said. “There are a number of very important questions about its source and the risk of transmission to other animals and humans that need to be addressed.”

Human case

On Apr. 1, the Texas Department of State Health Services reported a human case of H5N1 avian influenza. This patient became sick after contact with, presumably, an infected cow. Their primary symptom was conjunctivitis (pink eye).

The Texas DSHS, “along with local, regional, state and federal partners is investigating this on-

going situation,” the department announced. “Avian influenza A (H5N1) viruses have only rarely been transmitted from person to person. As such, the risk to the general public is believed to be low; however, people with close contact with affected animals suspected of having avian influenza A (H5N1) have a higher risk of infection.”

There has also been at least one recent fatal human case internationally. The Vietnam Ministry of Health reported a case in March of a 21-year-old male in the Khanh Hoa province of Vietnam who contracted a case of H5N1 and their symptoms did not improve and died as a result.

To assist with minimizing a worker’s risk of coming in contact with the virus, the Centers for Disease Control and Prevention recommends that, “people exposed to HPAI A (H5N1)-virus infected birds or other animals (including people wearing recommended Personal Protective Equipment) should monitor themselves for new respiratory illness symptoms, including conjunctivitis (eye redness), beginning after their first exposure and for 10 days after their last exposure.”

POULTRY TIMES POULTRYTIMES.COM 9

--

Poultry Times Editor dstrickland@ poultrytimes.com PT

VIEWPOINT

POULTRY TIMES

Keep foxes out of the hen house

COMMENTARY BY EMILY ELLIS

Animal Agriculture Alliance

Emily Ellis is manager, communications and content with the Animal Agriculture Alliance based in Arlington, Va.

HPAI and animal rights extremism

ARLINGTON, Va. — Animal rights extremists are always on the lookout for new opportunities to attempt to portray animal agriculture negatively — and they’re not above using unfortunate circumstances to further their campaigns and spread fear with consumers.

At the Animal Agriculture Alliance, we’ve seen them aggressively target farms that are still moving on from recent barn fire losses; harass processors struggling to keep the supply chain flowing during the peak of the COVID-19 pandemic; and now target farmers grappling with highly pathogenic avian influenza (HPAI) in their flocks.

The intersection of animal and public health has never received as much attention as it does today — thanks in large part to COVID-19. At the onset of the COVID-19 pandemic, animal rights groups were swift to assert that animal agriculture was to blame and that the only solution to avoiding future disease issues was to go vegan. When that theory was disproven, they quickly changed their tune (and narrative), arguing that animal agriculture would be the cause of the next pandemic.

They also targeted employees within animal agriculture who were deemed essential, claiming that these workers were being exploited. This message gained some traction for them as they simultaneously tried to gain footing in various social justice movements, including workers’ rights, to broaden their reach.

Similar to activism around COVID-19, animal rights groups are now targeting HPAI. Our hearts go out to the farmers that have experienced this virus on the farm and had to depopulate to protect the health and well-being of their flocks and

“With the spread of HPAI to other species now, it’s likely we’ll see continued activism on this issue.”

the larger bird population.

Unsurprisingly, animal rights groups are using the unfortunatebut-necessary depopulation happening to claim farmers are carelessly putting down large numbers of birds in order to profit from indemnity payments. We know this is not the case, but unfortunately, this is the message animal rights groups are sharing with the media to get in front of consumers.

Extremists have gone so far as to make posts on social media looking for farms that are experiencing HPAI in an attempt to get footage of depopulation and its effects. With the spread of HPAI to other species now, it’s likely we’ll see continued activism on this issue.

At the Alliance, we always say it’s better to be proactive rather than reactive. Don’t wait for a crisis to hit before you take steps to make yourself a harder target for potential

POULTRY TIMES POULTRYTIMES.COM 10 10

POULTRY TIMES

animal rights extremism.

This includes implementing basic farm security measures, including:

• Ensuring offices and cabinets have locks.

• Installing proper lighting, alarms, and cameras.

• Posting “No Trespassing” and restricted area signage.

• Establishing check-in procedures for visitors.

• Thoroughly screening all job applicants.

• Developing a crisis communication action plan.

In addition to farm and facility security measures, we also recommend doing your part to take away the mystery surrounding animal agriculture. We know most people are several generations removed from the farm, so it’s our job to proactively look for opportunities to share more about what actually happens on the farm. You could do this by getting active on social media, but it could also be as simple as looking for more opportunities to have positive conversations with your local community members.

Ultimately, animal rights groups make up a small minority of the population. While they can make a lot of noise, it’s usually within their own silo of supporters. Nevertheless, it’s important to take steps now to make yourself a harder target for potential animal rights activism.

We’ll be discussing this topic and more about our upcoming Stakeholders Summit, set for May 8-9 in Kansas City, Mo. Register today at bit.ly/AAA24 to save your seat for the in-person event or to purchase a recording pass!

Visit www.animalagalliance.org to learn more about our work monitoring animal rights activism and bridging the communication gap between farm and fork.

POULTRY TIMES POULTRYTIMES.COM 11 11

--USDA Agricultural Research Service

BUSINESS

POULTRY TIMES

Georgia Ports Authority board approves $65M for Ocean Terminal

SAVANNAH, Ga. — The Georgia Ports Authority has approved contracts totaling $65.6 million for container yard work at the Port of Savannah’s Ocean Terminal, a 200-acre facility just downriver from GPA’s main container port.

“We’re very pleased with the progress on improving Ocean Terminal’s container handling capability,” said GPA President and CEO Griff Lynch. “We’re on track to see greater container capacity by late 2027.”

The board approved three project components, including earth compacting to prepare the site to hold container stacks, removal of a former bridge pier and preliminary utility installation behind the wharf structure. The work will be funded through revenue bonds GPA issued in 2022.

Previously approved upgrades at Ocean Terminal include the

purchase of eight ship-to-shore cranes, refurbishing the wharf structure, and construction of an overpass for direct access to US 17. When all work is complete, Ocean Terminal’s annual capacity will grow from 300,000 twenty-foot equivalent container units to more than 1.5 million TEUs.

“At Georgia Ports, we never stop investing in the future,” said GPA Board Chairman Kent Fountain.

“As new and existing port users grow their trade through our terminals, we’re ready to take on additional cargo, providing the world-class service that our customers have come to expect.”

Lynch reported to the board that GPA anticipates a third straight month of growth for March.

“I’d like to thank our local partners in the International Longshoremen’s Association and Gateway Terminals, along with

our GPA employees for their work moving cargo across our docks with efficient, reliable service,” he said. “With a positive showing in the calendar year to date, Savannah is building momentum toward a stronger second half of Fiscal Year 2024.”

The ports of Brunswick and Savannah will receive a total of $82.7 million in federal funding for maintenance dredging and harbor improvements in a six-bill budget package passed by Congress March 8, 2024.

Nearly $38 million will go to the Port of Brunswick, including $11.35 million for the Brunswick Harbor Improvements project and another $26.6 million to dredge the federal waterway to its full authorized depth.

Inner harbor dredging completed earlier this year brought that portion of the Brunswick

Balanced importexport trade at the Port of Savannah improves the efficiency of ocean carrier service.

Port officials predict March will be Savannah’s third positive month in a row for container volumes.

channel to the authorized 36 feet. However, funds allotted in 2023 were insufficient to bring the outer harbor from approximately 37 feet all the way to its full authorized depth of 38 feet.

The new funding will cover the cost of dredging work in Brunswick’s inner harbor starting in late fall of 2024. Outer harbor dredging will begin in December 2024. These items will take several months to complete.

• Doubling size of U.S. Customs facility

Construction has also started on a new, larger U.S. Customs inspection facility at the Port of Savannah, more than doubling the size of its current location, GPA noted.

The $44.5 million project will transition U.S. Customs operations from its current 130,000 square-foot location on Garden City Terminal to an adjacent 300,000 square-foot building. The new location will accommodate federal inspections by Customs and other federal agencies such as the USDA and the U.S. Fish and Wildlife Service.

POULTRY TIMES POULTRYTIMES.COM 12

GPA photo by Stephen B. Morton

USPOULTRY seeking nominations for the Dr. Charles Beard Research Excellence Award

TUCKER, Ga. — The U.S. Poultry & Egg Association and the USPOULTRY Foundation are accepting nominations for the Dr. Charles Beard Research Excellence Award through July 1.

The goal of the award, which has been presented since 2013, is to recognize outstanding completed research projects, funded by USPOULTRY or the USPOULTRY Foundation, that have made a significant positive impact on the poultry industry.

Nominations can be accepted from universities and research institutions that conduct poultry research, as well as from anyone in the research community or any USPOULTRY member, staff and sponsored committee. Self-nominations are also allowed. Nominations should focus on research projects completed within the past five years but may include projects completed at an earlier time if a project’s impact has only recently become recognized.

Additional information about the award can be found by video at https://www.youtube.com/ watch?v=WT6uTXTFnwQ.

To submit a nomination, please send a letter to Dr. Denise Heard, vice president of research, at dheard@uspoultry.org. The letter should include the nominee’s name, a brief description of the nominee’s research accomplishments and the impact of the research.

The recipient of the Dr. Charles Beard Research Excellence Award will be the primary researcher who conducted the recognized research project(s) and will receive round-trip transportation to, and three nights’ lodging at the International Production & Processing Expo (IPPE) in Atlanta, Ga. A cash prize of $1,500 will also be awarded. The award will be presented at IPPE during the USPOULTRY Chair’s reception and acknowledged by Heard during the International Poultry Scientific Forum.

The USPOULTRY research program encompasses all segments of broiler, turkey and commer-

cial egg operations. To date more than $36 million has been invested in the association’s research program. One of USPOULTRY’s key strategic objectives is to increase the availability and constant improvement of the quality and safety of poultry products through comprehensive research.

Cal-Maine Foods reports its 3Q 2024 results

RIDGELAND, Miss. — CalMaine Foods Inc. reports its results for the third quarter of fiscal 2024 (13 weeks) ended March 2, 2024.

Highlights include: Quarterly net sales of $703.1 million; Quarterly net income of $146.4 million, or $3.01 per basic common share; Record quarterly sales volume of total dozens sold and spe-

cialty dozens sold; and cash dividend of $48.9 million, or $1 per share, pursuant to the company’s established dividend policy

“We are very pleased with CalMaine Foods’ strong financial and operating performance for the third quarter of fiscal 2024,” Sherman Miller, president and CEO of Cal-Maine Foods, said.

“Our sales reflect lower average selling prices compared to a year ago, when the shell egg industry experienced record high market prices due primarily to the impact of highly pathogenic avian influenza (HPAI) and other market factors resulting in a significant reduction in supply. While the more recent outbreaks of HPAI have also affected supply and caused market prices to move higher, the overall market impact has not been as severe.

“Fueled by strong demand, our total sales volumes (dozens sold) for the quarter were higher than the third quarter of fiscal 2023 and reached a company record. Consumer demand for eggs has been strong, especially during the winter holiday season. We have worked hard to meet this demand with a favorable product mix of

conventional and specialty eggs, as well as enhanced egg products offerings. Our managers and employees have continued to efficiently run our operations in a challenging environment due to the impact of and ongoing threat of HPAI. Despite the distractions, we have continued to meet the needs of our valued customers.”

“In addition to our strong organic growth opportunities, we are pleased with the operational performance and successful integration of our acquisition of assets of Fassio Egg Farms Inc., located in Erda, Utah outside of Salt Lake City, acquired in our second fiscal quarter,” Miller added.

“Following the end of the third quarter, we completed the acquisition from Tyson Foods Inc. of a recently closed broiler processing plant, hatchery and feed mill located in Dexter, Mo. We intend to repurpose the acquired assets for use in egg and egg products production. We remain focused on identifying other acquisition opportunities that complement our operating model and further extend our market reach.”

(Continued on next page)

POULTRY TIMES POULTRYTIMES.COM 13

(Continued from previous page)

• Sales performance & operating highlights

“For the third quarter of fiscal 2024, our net sales were $703.1 million compared with $997.5 million for the same period last year, which was the company’s highest quarterly sales period with record high average selling prices for conventional and specialty eggs,” Max Bowman, vice president and chief financial officer of CalMaine Foods, said. “The decline in sales revenue for the third quarter of fiscal 2024 was primarily due to the significant decrease in egg prices compared to a year ago. However, market prices moved higher sequentially in the third fiscal quarter due to both the recent impact of HPAI and normal seasonal fluctuations.”

“Our overall sales volumes improved 3.2 percent compared to the same period last year as we sold 300.8 million dozens compared with 291.4 million dozens for the third quarter of fiscal 2023,” Bowman noted. “Conventional eggs sold reached 192.2 million dozens, up 2.6 percent, while specialty eggs sold were

108.6 million dozens, a 4.4 percent increase over the prior-year period. These results represent the highest total dozens sold and highest specialty dozens sold in any quarter for Cal-Maine Foods.

“Net income attributable to CalMaine Foods for the third quarter of fiscal 2024 was $146.7 million, or $3 per diluted share, compared with $323.2 million, or $6.62 per diluted share, for the third quarter of fiscal 2023, which was another record for the company.”

“The net average selling price per dozen was $2.152 for conventional eggs in the third quarter of fiscal 2024, down 41.5 percent compared with $3.678 for the prior-year quarter,” Bowman said.

“Net average selling price for specialty eggs was $2.415 per dozen, compared with $2.616 per dozen for the third quarter of fiscal 2023, a decline of 7.7 percent. Specialty dozens sold were 36.1 percent of total dozens sold in the third quarter of fiscal 2024 compared with 35.7 percent in the prior-year period.”

“We reported operating income of $162.8 million for the third quarter of fiscal 2024, compared with operating income of $407.8

million for the prior-year quarter, primarily reflecting lower market prices,” Bowman added. “However, we benefitted from lower feed ingredient prices compared with the same period a year ago. For the third quarter of fiscal 2024, feed costs per dozen were down 19.9 percent compared with the third quarter of fiscal 2023. Our other farm production costs were higher primarily due to higher flock amortization and increased facility costs.

“Current indications for corn supply project an overall better stocks-to-use ratio, implying potentially lower prices in the near term. However, as we continue to face uncertain external forces including weather patterns and global supply chain disruptions, price volatility could remain. Soybean meal supply has remained tight relative to demand in the third quarter of fiscal 2024.”

• HPAI & table egg supply outlook

Outbreaks of HPAI have continued to occur in U.S. poultry flocks. From November 2023 through January of 2024, the USDA division of Animal and Plant Health Inspection Service reported that

approximately 15.7 million commercial layer hens and pullets have been depopulated as a result of HPAI outbreaks.

During the third quarter of fiscal 2024, Cal-Maine Foods experienced an HPAI outbreak within its facilities in Kansas, resulting in depopulation of approximately 1.5 million laying hens and 240,000 pullets. Following the end of the third quarter, on April 1, 2024, one of the company’s facilities located in Parmer County, Texas, tested positive for HPAI, resulting in depopulation of approximately 1.6 million laying hens and 337,000 pullets, or approximately 3.6 percent of the company’s total flock as of March 2, 2024. Production at the facility has temporarily ceased as the company follows the protocols prescribed by the USDA. CalMaine Foods is working to secure production from other facilities to minimize disruption to its customers, the company added.

Cal-Maine also notes that it remains dedicated to robust biosecurity programs across its locations; however, no farm is

(Continued on page 16)

POULTRY TIMES POULTRYTIMES.COM 14

-----

immune from HPAI. HPAI is still present in the wild bird population and the extent of possible future outbreaks, with heightened risk during the migration seasons, cannot be predicted. According to the U.S. Centers for Disease Control and Prevention, the human health risk to the U.S. public from HPAI viruses is considered to be low. Also, according to the USDA, HPAI cannot be transmitted through safely handled and properly cooked eggs. There is no known risk related to HPAI associated with eggs that are currently in the market and no eggs have been recalled.

• Looking ahead

“We are proud of our ability to manage our operations effectively and deliver favorable results to date for fiscal 2024,” Miller added. “Like other producers, we have navigated significant challenges related to HPAI, and we remain diligent in our efforts to mitigate any future risks. We commend our team of managers and employees who have worked through these challenges with minimal disruption to our overall production and

distribution. Importantly, we remain committed to meeting the needs of our valued customers with a diverse offering of quality products.

“Demand for shell eggs has remained strong as consumers look for an affordable and nutritious protein option. Across our operations, we are focused on meeting this demand, as we continue to identify opportunities to extend our market reach. We are also making significant investments in our operations to drive innovation and more efficient production and support our ability to add capacity, including cage-free opportunities. We have a strong balance sheet that provides us with the flexibility to fund our growth initiatives, including potential acquisitions. We believe fiscal 2024 will be another successful year for the Company, and we look forward to the opportunities ahead for Cal-Maine Foods.”

For the third quarter of fiscal 2024, Cal-Maine Foods will pay a cash dividend of approximately $1 per share to holders of its common and Class A common stock. Pursuant to Cal-Maine Foods’ variable dividend policy, for each quarter

in which the company reports net income, the company pays a cash dividend to shareholders in an amount equal to one-third of such quarterly income. Following a quarter for which the company does not report net income, the company will not pay a dividend with respect to that quarter or for a subsequent profitable quarter until the company is profitable on a cumulative basis computed from the date of the most recent quarter for which a dividend was paid. The amount paid per share will vary based on the number of outstanding shares on the record date. The dividend is payable on May 16, 2024, to holders of record on May 1, 2024.

Cal-Maine announces retirement of Jeff Hardin

RIDGELAND, Miss. — CalMaine Foods has also announced that Jeff Hardin, senior vice president of sales, is retiring from his position with the company, effective July 23, 2024. Scott Hull, vice president of sales, will assume the executive officer role previously held by Hardin, effectively im-

mediately. Hardin will continue to work with Hull through the transition period until his official retirement date.

Hardin joined Cal-Maine Foods in 1988 and was named vice president of sales in 2002. He has played a pivotal role in driving the company’s consistent record of sales growth and establishing valuable long-term working relationships with Cal-Maine Foods’ leading customers, the company added.

Hull has been with the company since 2009. He has worked closely with Hardin in his most recent position, as well as in his prior role as national sales manager. He previously served as a general manager at the company’s Louisburg, N.C., location before joining the sales team in 2014.

“Jeff Hardin has been an outstanding sales leader for CalMaine Foods, and we are extremely grateful for his 36 years of dedicated service,” said Sherman Miller, president and CEO of CalMaine Foods. “Throughout his tenure, he has developed strong working relationships with our valued customers and provided exceptional service and support

16

(Continued

14)

from page

that are hallmarks of Cal-Maine Foods. We are thrilled to have Scott Hull take on additional sales leadership responsibilities and assume the executive officer role. He has already demonstrated his proven ability to lead our sales efforts, and we are confident we will continue to have market success under his leadership. We look forward to working together as we continue to execute our growth strategy and extend our market reach.” Report: cost of electrifying U.S. commercial truck fleet at $1T

WASHINGTON — Full electrification of the U.S. commercial truck fleet would require nearly $1 trillion in infrastructure investment alone, according to a new report from Roland Berger released by the Clean Freight Coalition.

The study forecasts a realistic infrastructure buildout for the electrification of medium- and heavy-duty commercial vehicles, exposing what the CFC calls a massive investment gap as state and federal policymakers mandate increased adoption rates of battery-electric commercial vehicles.

Key findings:

• Preparing today’s commercial vehicle fleet for electrification would require the commercial vehicle industry to invest upwards of $620 billion in charging infrastructure alone, including chargers, site infrastructure and electric service upgrades.

• Utilities would need to invest $370 billion to upgrade their grid networks to meet the demands of just commercial vehicles.

• This nearly $1 trillion expenditure does not account for the cost of new battery-electric trucks, which according to market research can be two to three times more expensive than their diesel-powered equivalents. For example, a diesel Class 8 truck costs roughly $180,000, while a comparable battery-electric truck costs over $400,000.

The CFC, which consists of transportation stakeholders across the trucking and motor-

coach industries, says that policymakers must address these cost concerns and infrastructure hurdles to make an electrified supply chain function smoothly for the American economy. The study found that while medium-duty vehicles will face fewer roadblocks, economic and operational constraints make electrification very challenging for the heavy-duty segment. Furthermore, the study outlined the significant improvements in battery range and charging infrastructure capabilities that would be needed to support a path for the electrification of long-haul vehicles.

“Electrification means focusing on the vehicle segments that are easier first; it means that we have to look at how fleets operate and potentially adjust; it means that we need better cooperation and planning across industries and governments; and it requires an openness to alternative technology paths to decarbonizing the heavy-duty segment,” said Roland Berger senior partner Dr. Wilfried Aulbur. “It also is clear that an industry with a yearly turnover of about $800 billion and a profit margin around 5 percent cannot invest $620 billion without financial support or a significant increase in freight rates.”

“This study thoroughly examines the issues surrounding the infrastructure buildout necessary to electrify commercial vehicles, and it clearly shows how the heavy-duty vehicle industry’s needs are vastly different not just from other sectors of our economy, but from each other,” said CFC Executive Director Jim Mullen. “I want to thank the team at Roland Berger for so clearly outlining the challenges electrifying our supply chain poses as the industry and nation continue working toward our shared goal of reducing trucking’s impact on the environment.”

American Trucking Associations President and CEO Chris Spear, added, “We’re facing an unfunded, $1 trillion mandate that carries enormous consequences for the American consumer. You don’t overcome obstacles by ignoring them, which this study lays out the high investment costs required to elec-

(Continued on page 20)

Heidy

Mobile grader for increased uniformity of broiler breeder pullets

Controlling the weight of your birds to ensure flock uniformity at the point of lay is extremely important. The Heidy mobile grading scale from Big Dutchman makes the weighing and grading process simple and efficient. Contact your local distributor or sales representative to learn more.

17 +1-616-582-4000 | bigd@bigdutchmanusa.com WWW.BIGDUTCHMANUSA.COM

Product inquiries: info@nutechbio.com 315-251-4324 • 315-751-0729

(Continued from page 17)

trify the commercial vehicle industry. Policymakers should take note that pursuing technologyneutral solutions can deliver operational savings and emissions reductions at a fraction of the cost. A real-world understanding of the path to our shared goal of zero emissions is needed, but unrealistic timelines and expectations will break the bank.”

Chester’s Chicken hires Rice as executive VP

BIRMINGHAM, Ala. — Chester’s Chicken welcomes Bill Rice to the executive team as executive vice president, head of sales, operations and supply chain. Rice joins Chester’s after a short retirement preceded by nearly four decades of experience in foodservice supply chain management, most re -

cently as a senior vice president at Krispy Krunchy Foods LLC.

Under Rice’s leadership and with a solid foundation already laid, the company plans to accelerate growth and evolution, the company said, adding that Rice will ensure team members have the resources needed to achieve Chester’s aggressive growth goals while continuing to support existing franchise partners.

“We continue to prioritize investing in the Chester’s leadership team and Bill is the perfect complement,” said Alexis Lobodocky, general manager, Chester’s Chicken. “He brings extensive expertise in supply chain, an area of opportunity that will drive gains for the Chester’s brand and Chester’s operators.”

Prior to Chester’s Chicken, Rice served seven years at Krispy Krunchy where he championed a redesign of the company’s supply chain network. Notable achievements also included overhauling procedures on issues including vendor and manufacturer selection, quality control, inventory and organizational management; devel -

oping a turn-key branded grabn-go and breakfast program, in addition to several other menu items and product concepts; and achieving year-over-year double-digit sales growth by establishing and maintaining continuous sources of supply amidst various supply chain disruptions.

Rice has also held leadership roles at Intl. Traders Inc./MBM Corp., Performance Food Group, and Kraft Foodservice Corp.

“The Chester’s culture and core values like ‘winning as a team’ and ‘fried chicken is fun’ are what drew me in and convinced me to exit retirement,” Rice said. “It’s refreshing to be working alongside some of the best in the industry who are energized about our future and focused on initiatives that deliver the most value to our operators.”

Rice began this new role in January and has been working against several Q1/Q2 projects including a supply chain optimization study, adding new and profitable menu items, equipping the team with new sales tools, and bringing on additional resources to the field team.

Egg Innovations set to introduce in-ovo technology to help eliminate chick culling

WARSAW, Ind. — Egg Innovations announces that it is committed to furthering its mission by being the first U.S. based company committed to implementing in-ovo sexing technology to populate their family farms. Introducing in-ovo sexing, which is only available in Europe today, Egg Innovations is determined to be the catalyst to help eliminate chick culling within the American egg industry, the company notes.

“Humane care is the ethos in which Egg Innovations was founded. Humane care is centric to our mission, this commitment to in-ovo sexing is a huge step as we will be able to label our products ‘free of chick culling,’” Dr. John Brunnquell, founder and CEO of Egg Innovations, said. “While it’s an unknown if the market is ready to embrace this, we know it’s the right thing to do. We are excited to trailblaze with this technology in the U.S. for the wellbeing of our products, customers, and industry.”

By utilizing this in-ovo sexing technology, Egg Innovations notes that it will be able to implement practices for more humane egg production that avoids the practice of male chick culling. While Egg Innovations’ present practices for raising chickens with higher-welfare standards starts with young hens at a day of life, this commitment allows them to extend the company’s humane care mission to the egg before hatching. This is a true integration of a more ethical life cycle for egg production as Egg Innovations extends its commitment to “Chickens. People. Planet.” Egg Innovations plans to utilize their regenerative farming Helpful Hens brand as the vehicle to in-

POULTRY TIMES POULTRYTIMES.COM 20

20

Rice

The importance of dew point monitoring during hot weather

Figure 1: Typical summertime hourly outside air temperature, Rh, and dew point (Athens, Ga., July 2022).

UGA

BY MICHAEL CZARICK University of Georgia

BY MICHAEL CZARICK University of Georgia

ATHENS, Ga. — When it comes to predicting the likelihood that birds will experience heat stress conditions on a given day, knowing outside relative humidity first thing in the morning is not particularly useful. Though air moisture levels have significant impacts on bird comfort, relative humidity is constantly changing over the course of a day.

In the morning relative humidity will tend to be between 80 percent and 100 percent. In the afternoon, as temperatures rise and the moisture-holding ability of air increases, the relative humidity will decrease. How much the relative humidity will decrease on a given day, and therefore how likely growers will have problems keeping

POULTRY TIMES POULTRYTIMES.COM 22 22

UGA

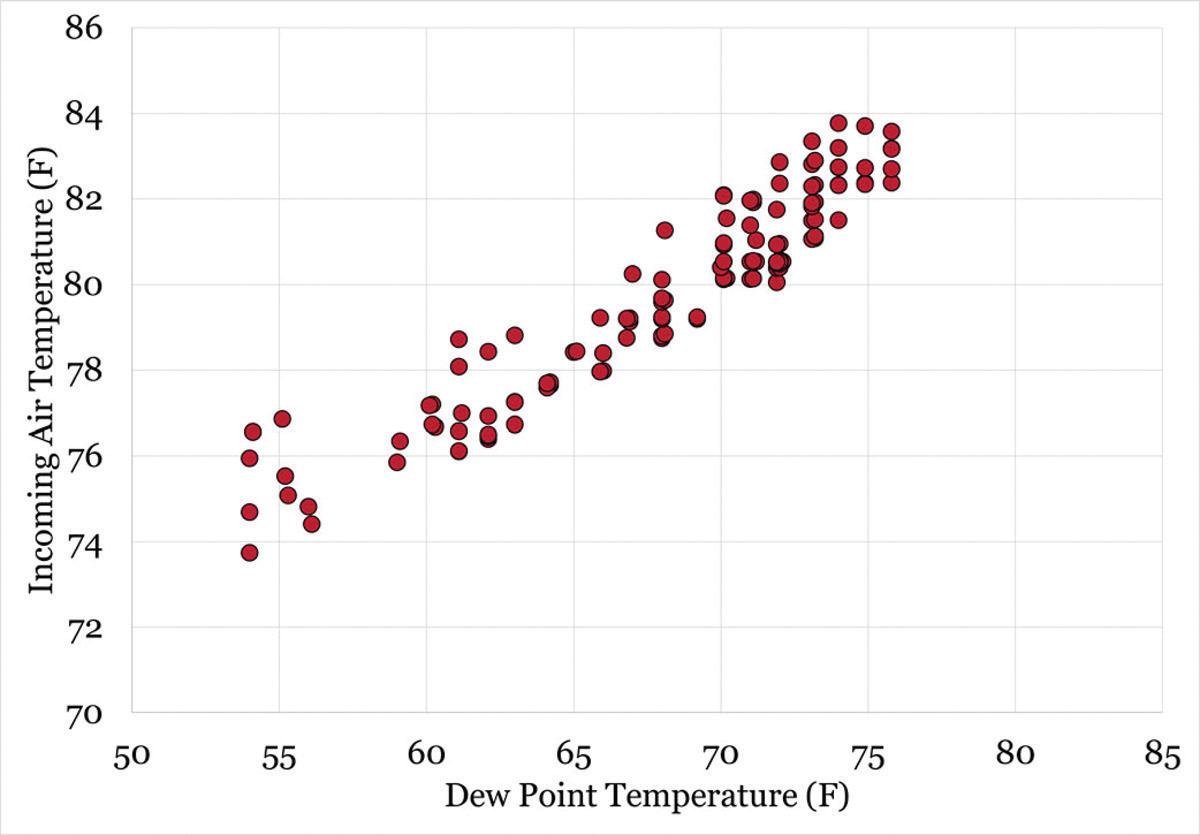

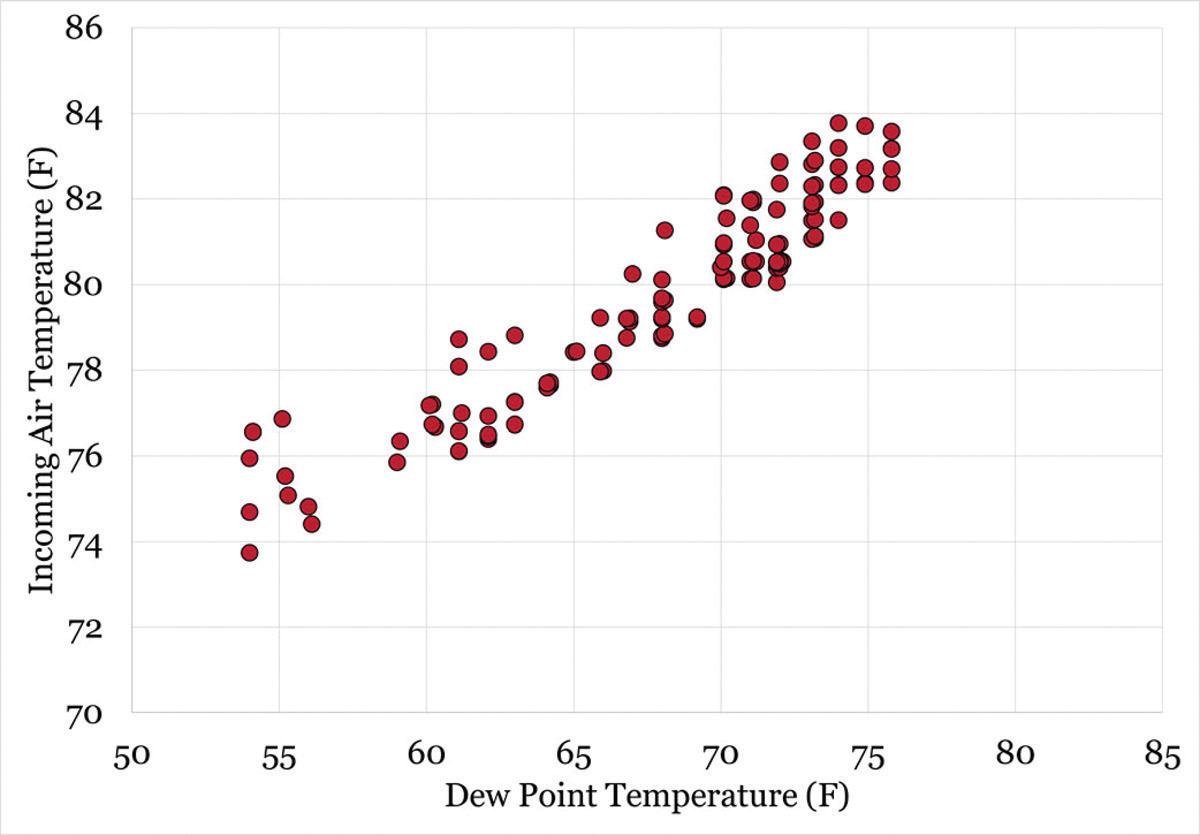

Figure 2: Athens, Ga., (June-August 2022). Incoming air temperature vs. dew point (outside temperature 90 degrees F to 95 degrees F).

of Dimmable LED Lamps that

Have shortened life hours?

birds cool, is difficult to predict based on morning relative humidity. A far better predictor of the potential for heat stress conditions is the dew point temperature.

As air temperature decreases, its moisture holding capacity decreases and therefore the relative humidity increases. Dew point is the temperature to which the air needs to be cooled to increase the relative humidity to 100 percent. The lower the dew point temperature,

100% PURE TRAILING

UGA

Figure 3: Calhoun, Ky., (June – August 2022). Incoming air temperature vs. dew point (outside temperature 90 degrees F to 95 degrees F).

the lower the amount of moisture in the air. The higher the dew point temperature, the higher the amount of moisture there is in the air.

Face greater lumen depreciation than you expected? Flickering at different lighting levels especially low light levels?

Dew point is a measure of the amount of moisture there is in the air independent of air temperature. Interestingly, though the outside relative humidity can change dramatically over a 24-hour period, the actual amount of moisture there is in the air doesn’t. Since the amount of moisture in the air is relative con-

‘Trailing Edge’ Dimmer design is the only option for: It’s time to look at what’s controlling Let us help you solve the problem!!!

stant, the dew point temperature does not tend to change much over the course of a day (Figure 1) and as a result, it is a very good measure of air moisture levels that our birds will have to contend with on any given day.

What dew point temperatures should be of potential concern to poultry growers? A dew point of 65 degrees F or lower is typically con-

(Continued on next page)

of Dimmable LED Lamps that

LED by Innovation

AskusaboutourNEWFeederlights

100% PURE TRAILING EDGE It’s time to look at what’s controlling your light bulbs. Silicone Protection Gasket

Have shortened life hours?

of Dimmable LED Lamp that

It’s time to look at what’s controlling your light bulbs. Silicone Protection Gasket

100% PURE TRAILING EDGE

Have shortened life hours?

Face greater lumen depreciation than you expected?

Face greater lumen depreciation than you expected?

Flickering at different lighting levels especially low light levels?

Flickering at different lighting levels especially low light levels?

6/10/15W Directional Dim/ Non-Dim

- Directional Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs.

6/10/15W Directional Dim/

- Directional Beam Angled LED'sexact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs.

- Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

- Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

- Directional Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs.

www.aglights.com/800-657-0509

www.aglights.com/800-657-0509

- Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

www.aglights.com/800-657-0509

10/16/25W Dimm models

10/16/25W Dimm models

*Energy Star Approved for rebates

14/26W Non Dim models

*Energy Star Approved for rebates

Non Dim

*Available with Junction

*Energy Star Approved

*IP66 Wet located

*Constant Current with minimal lumen

*CONSTANT ARE A FEATURE COMPETITORS

*Constant Current Driver delivers full current/wattage with minimal lumen loss at low voltages.

*Constant Current Driver delivers full current/wattage with minimal lumen loss at low voltages. CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

*CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER!

POULTRY TIMES POULTRYTIMES.COM 23 23

LED by Innovation

TIRED

Poultry Dimmer

LED by Innovation

TIRED Poultry Dimmer

BEST

Full

Low

Silicone Protection Gasket 6/10/15W Directional

14/26W

10/16/25W

LED control

LED Life

Level Dim Opstion

Dim/ Non-Dim

Dimm

ONLY Poultry

100% PURE TRAILING EDGE

Edge’ Dimmer design is the only option for: It’s time to look at what’s controlling your light bulbs. Let us help you solve the problem!!! BEST LED control Full LED Life Low Level Dim Opstion Silicone Protection Gasket

Directional Dim/ Non-Dim 14/26W Non Dim models 10/16/25W Dimm models

‘Trailing

6/10/15W

The ONE & ONLY Poultry Dimmer www.aglights.com/800-657-0509 *Available with Junction Boxes. *Energy Star Approved for rebates *IP66 Wet located rated *Constant Current Driver delivers full current/wattage with minimal lumen loss at low voltages. *CONSTANT CURRENT DRIVERS ARE A FEATURE THAT OVERDRIVE COMPETITORS DO NOT OFFER! -

Beam Angled LED's - designed with the exact beam angle to offer even FC lighting on the floor based on poultry house spacings/specs. - Directional beam angle lamps offer 100% dimming while Omni lamps typically wont dim below 25%.

Directional

of Dimmable LED Lamps that TIRED Have shortened life hours? Face greater lumen depreciation than

expected?---

you

(Continued from previous page)

sidered dry air and birds are very unlikely to become heat stressed. A 70 degrees F dew point temperature indicates moderate air moisture levels. Market-age birds will likely experience some level of thermal discomfort, but with sufficient air speed and a properly operated evaporative cooling system, bird performance will not likely be affected. What growers need to be most concerned with is dew point temperatures of 75 degrees F or higher. Dew point temperatures in this range indicate that there is a tremendous amount of moisture in the air and as a result, keeping market-age birds comfortable will be extremely difficult.

Figures 2, 3 and 4. illustrate how dew point temperature affects the cooling produced by a pad system when outside air temperatures are between 90 degrees F and 95 degrees F. Though the three locations; Athens, Ga., Calhoun, Ky., and Fayetteville, Ark., are far from one another, they exhibit a very similar relationship between pad cooling and dew point temperature.

When dew point temperatures were in the sixties, incoming air temperatures were in the seventies, and it would have been relatively easy for most growers to keep market-age birds comfortable. When dew point increased into the low seventies, incoming air temperatures would have tended to be in the high seventies to low eighties. Keeping birds cool would have been more of a challenge but provided a

Figure 4: Fayetteville, Ark., (June – August 2022). Incoming air temperature vs. dew point (outside temperature 90 degrees F to 95 degrees F).

house was capable of generating air speeds of 600 ft/min or more and the birds were evenly distributed, performance should have been minimally affected. But when dew point temperatures climbed above 75 degrees F, incom-

ing air temperature would have been increased to the low to mid-eighties. Making matters worse, since there is so much moisture in the air, the incoming relative humidity would have likely been near 90 percent, making it very dif-

Serving the Meat, Poultry and Seafood Industries

POULTRY TIMES POULTRYTIMES.COM 24 ficult panting. perature fronts Between increased greater ture coming the RH ing 86 the area grees single 80 of losses with moisture having on a to dew going to market-age 24 Paid Advertorial WeighTech...

UGA

ficult for the birds to cool themselves through panting.

Figure 5 illustrates how the dew point temperature can change over time as weather fronts bring moisture into and out of an area. Between July 18 and July 20, the daytime high increased 10 degrees F. But of equal if not greater concern was the dew point temperature increased 10 degrees F as well. Peak incoming air temperature for a typical house on the 19th would have been 80 degrees F with a RH of 85 percent.

Twenty-four hours later the peak incoming air temperature would have increased to 86 degrees F with a RH of 90 percent! Luckily, the next day the moisture moved out of the area and the dew point dropped below 70 degrees F. But it is important to note that just the single day of dew point temperatures around 80 degrees F resulted in the loss of thousands of birds in the area. As you might expect, the losses tended to be greatest in those houses with less-than-ideal air velocities.

Though we don’t have any control over the moisture content of air outside poultry houses, having an accurate measure of what it will be on any given and/or the next few days can warn a grower of potentially challenging conditions to come.

All a grower needs to do is Google “current dew point” or “tomorrow’s dew point.” If it is going to be 75 degrees F or higher, they need to prepare for the worst, especially if they have market-age birds. Fan/pad condition should

Figure 5: Hourly temperature, Rh and dew point July 18-23 (Calhoun, Ky., 2022).

be checked along with tunnel fan and pad settings, migration fences, circuit breaker temperatures, water filters, etc., all of which can affect their ability to keep their birds comfortable under the upcoming challenging conditions.

Michael Czarick is an Extension engineer and senior public service associate with the University of Georgia Department of Poultry Science. For more poultry housing information, visit www. poultryventilation.com.

The

Our bench scales feature our industry leading MicroWeigh indicator, and is

in many sizes to fit your processing needs.

In today’s fast paced processing world, efficient,

and

25 1-800-457-3720 www.weightechinc.com Bench Scales

WeighTech

of bench scales offers processors the best of both worlds: functionality

durability.

available

line

and

reliable

equipment are crucial. 1649 Country Elite Drive, Waldron, AR 72958 Phone: 479-637-4182 Fax: 479-637-4183 The patented industry leading electronic indicator for harsh washdown environments www.jdmfg.com Family Owned & Operated in Eau Claire, WI JD360 Destratifier FAN SELECTION & LAYOUT Reduce the Temperature Gradient from Floor to Ceiling by up to 55%! UGA

rugged scale systems and

Poultry house windspeed maintenance

Photos by NPTC

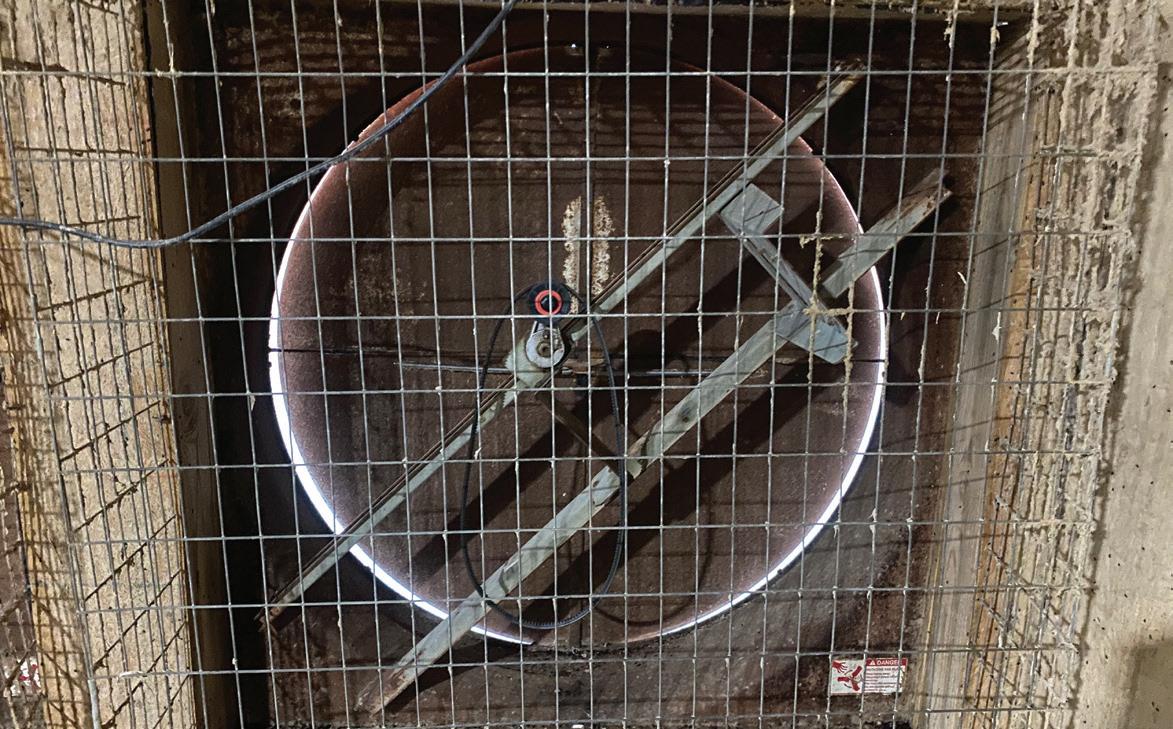

Figure 1: Can you identify the problem with the fan in this picture? A. no motor, B. no propeller, C. not clean, D. all the above. If you answered, “D. all the above,” you would be correct. It is also interesting to note that the adjacent tunnel fan #3 is plugged into the outlet above this fan, tunnel fan #1. This fan is not ready for hot weather.

BY JESS CAMPBELL, JEREMIAH DAVIS, CODY SMITH & KELLY GRIGGS National Poultry Technology Center Auburn University

BY JESS CAMPBELL, JEREMIAH DAVIS, CODY SMITH & KELLY GRIGGS National Poultry Technology Center Auburn University

AUBURN, Ala. — The focus of this article is to serve as a guideline of things to consider doing prior to hot weather arrival or annual wind speed checks.

The goal is to achieve maximum full tunnel wind speed, evaporative cooling performance, exceed minimum wind speed requirements with ease, and help prevent emergency repairs during hot weather operation.

gear ratio between the motor speed and propeller speed. Anything that goes wrong with the drive system causes lost fan performance. Check belt tension: loose belts reduce the gear ratio, causing loss of airflow, and reduce belt life. Check belts for wear: Belts riding lower in the pulleys change the gear ratio and lower fan performance. Check pulley alignment: Misaligned pulleys cause excessive belt wear and more drive losses. Check pulleys for wear: cupped out pulleys allow belts (even a new belt) to ride lower in the pulley, which changes gear ratio and lowers air flow.

2. Tensioners

Tunnel fan maintenance checklist

The tunnel fans are the lifeblood of tunnel windchill cooling and getting the bird cooling we drastically need during hot weather. All tunnel fans must be in top shape before they are needed. Insufficient fan maintenance often results in insufficient wind speed and reduces hot weather performance. Below is a list of items to check.

1. Drives (pulleys and belts)

The drives transmit power and provide the

Fan tensioners must deliver full tension on the fan belt for the fan to operate at maximum designed potential. These must be lubricated, exercised by hand, and inspected closely to make sure they are in alignment with prop and motor pulleys. Make sure the dry bearing on this pulley is not damaged and causing unnecessary drag on the fan belt and motor. One or two bad tensioners can keep a house from reaching full wind speed potential. In most cases, damaged tensioners simply need to be replaced with a new one to regain like-new fan performance.

3. Shutters and guards

Anything that obstructs the airflow causes lost fan performance. Clean shutters once per week during tunnel ventilation. Dirty shutters

26 Retro Luminaire Retro Luminaire Retro Luminaire Modeled after our Modeled after our Modeled after our Farm-proven AG25 Farm-proven AG25 Farm-proven AG25 Half the lights Waterproof Low-profile Longer life Better Light. Better Life!

Figure 2: Can you identify the problem or problems in this picture taken from the inside of a broiler house looking through the tunnel inlet?

A. cobwebs on pads, B. cobwebs on bird wire of inlet, C. light and air leak entering between the floor and wall of the doghouse, D. floor is dirty, E. all the above. If you answered, “E. all the above,” you would be correct. This doghouse and pad system is not ready for hot weather.

require more energy from the airflow to open and they reduce airflow and efficiency. Clean guards once a week because dirty guards present more surface area to obstruct airflow. All butterfly shutters or dampers must be in perfect working condition. If they don’t fully open and fully close, this is a problem with house tightness. Significant ventilation problems can be the result of damaged butterfly shutters.

4. Motors

Most electric circuits and electrical devices run more efficiently and last longer at cooler temperatures. Clean motors once per flock. Dirty motors run hotter, lose efficiency, and have reduced motor life. It is a good idea to have at least one motor already wired and a pulley installed so the job of a quick motor swap is pos-

sible when needed.

5. Bearings

Lubricate bearings twice per year where applicable (Spring and Fall). Dry bearings require more power to turn, causing you to lose fan efficiency and shorten bearing life. Go ahead and bring some new grease fittings with you when you start greasing because there seems to always be one or two that won’t take grease.

6. Power cords

Make sure all power cords are in good operating condition and the power outlets, if applicable, are not loose, charred, or damaged in any way. Eliminate human safety hazards, fire hazards, and fan failures from happening when

(Continued on next page)

Introducing EAGAN FAST TRACK Wall Vents

Figure 3: Can you identify the problem or problems in this thermal image of an end wall door? A. top of door leaking hot air, B. no insulation in ceiling, C. air leaking between ceiling and end wall, D. the hot air leaking through these openings would lower full tunnel wind speed and additional heat gain from missing insulation, E. all the above. If you answered, “E. all the above,” you would be correct. Once again, this house is not ready for hot weather and might not pass a house tightness test or wind speed test.

FAST TRACK Wall Vents

Our new Fast Track Wall Vent (U.S. Patent No. 11,33,392) takes the concept of a wall vent to the next level. It comes fully assembled right out of the box, goes up very quickly and is very competitively priced.

Wall Vent Features

Δ Available with an Aluminum or UV stabilized PVC frame

Δ Superior performance

Δ Integrated track cord tensioner/locator

Δ Integrated winter latching system

Δ Cord guide included along with installation jig to speed up installation

Δ Available in 8”,10’, 12”, 14” heights with custom lengths available

Δ Perfect for retrofit applications-the wall vent is surface mounted to compensate for framing irregularities and can be ordered to fit virtually any opening

Δ Orders come bulk-packed in palletized gaylords to make it easier and faster on installation crews

POULTRY TIMES POULTRYTIMES.COM 27 27

602 EAGAN ROAD, P.O. BOX 620 BLACK ROCK, AR 72415

Aluminum Framed Fast Track Wall Vent UV Stabilized PVC Framed Wall Vent Cord Guide Installation Tool

fans Evaporative checklist ing not formance extends pads more side with dry. system in often and damaged cleaned, order new tential. bris a Once move this inspection might the tive bypass leaks to manent ters. stored able inspected high without are justed from be during ing drained

(Continued from previous page)

fans are called to run continuously.

Evaporative cooling checklist

Time and effort spent maintaining the evaporative cooling system not only improves the cooling performance of the house, but it also extends the life of the evaporative pads and pumps. Read below for more tips.

1. Pads

Blow debris from inside or outside of pad system to doghouse with backpack blower with pads dry. Then thorough cleaning of the system and rinsing of the system is in order. Excessively dirty pads are often the result of poor wind speed and high static pressure. If pads are damaged or cannot be adequately cleaned, they must be replaced in order to restore the house to likenew airflow and wind speed potential.

2. Doghouse

Sweep all cobwebs and other debris from the back of the pads with a broom or blow out with a blower. Once everything is on the floor, remove it from the doghouse. Once this is complete, do a thorough inspection for any air leaks that might be present. Check along the ceiling, floors, and evaporative system for any places air can bypass wet pads. Spray foaming air leaks is a quick and simple method to fill cracks, but usually not a permanent fix.

3. Filters

Remove and clean or replace filters. Replacement filters must be stored on site and be readily available when needed. Filters must be inspected once a week at times of high use. Do not operate a system without filters or screens in place.

4. Pumps, floats and tanks

Make sure pump intake screens are clean, floats are in place and adjusted and tanks are clean and free from debris. Pump screens must be inspected at least once a week during periods of high use of cooling system or as often as system is drained and flushed.

5. Distribution header

Flush the distribution header.

Loosen the union at distribution header and carefully clean all distribution holes in header with screwdriver or soft bristle brush. Do not change the size of the hole in the header. Run water in system to ensure all holes are free from debris or clogs.

6. Water supply

Test run recirculation system to make sure water fill levels are adjusted properly, and adequate water is available to fill system. Make sure the supply system fully wets the entire pad system and no dry streaks occur on pads. If water quality problems surface, additional filtration or treatment may be necessary. One simple way to extend system life is by routinely flushing the water during periods of high use. One system flush per week is much better than once per flock or per year!

7. Tunnel inlet opening

Inlet curtain opening must be at least a minimum of 80 percent of the area of the cooling pad system area. For example, for 1,000 square feet of 6-inch recirculating pad, there must be a minimum of 800 square feet of free air unobstructed inlet opening. Bunched up curtains or partially opened tunnel doors must not restrict the tunnel inlet opening!! This is ideal time to test run the tunnel inlet for proper operation. We often find broken strings, damaged pulleys, holes in curtains, and twisted cables keeping inlets from functioning properly.

Tunnel house tightness checklist

Minimize all possible air leaks that will take away from the full house wind speed potential. Now is an ideal time to conduct a house tightness test per company guidelines to make sure houses are sealed for efficient environmental control. We recommend that this test result and the fan or fans used

are recorded and documented in the control room of each house for future reference and repeatability.

1. Ceilings

All attic access boards, doors, and leaks need to be inspected and sealed to keep the house from leaking attic air into the house. Damaged attic inlets need to be replaced or re-moved and covered with plywood or equivalent.

2. Doors

All end wall doors must be inspected for safe operation and for air leaks. Inspect, seal, and repair as needed.

3. Perimeter inlets

All sidewall or ceiling inlets need to be inspected for air leaks and proper operation. If the insulation is damaged, now is a good time to repair or replace it. We find a lot of air leaks around damaged metal vent doors. They are like Deion Sanders, “they ain’t hard to find.”

4. Foundation

Make sure all sidewall and foundation leaks have been identified and sealed properly. Small foundation leaks added together end up being significant contributors of hot air leaks and these leaks are often low at the foundation. The hottest place in the house during tunnel ventilation and the lowest windspeed location is typically along the foundations down each sidewall.

5. Curtains

All tunnel houses that have sidewall curtains should have a top curtain flap and bottom lumber strip or equivalent seal at the bottom. Loose curtains can drastically reduce full tunnel wind speed, if al-

lowed to exist. Holes and tears in curtains must be repaired with curtain tape or an equivalent method that will last.

6. Inlet and vent machines

Tunnel inlet and sidewall vent machines and strap machines must be cleaned, inspected, repaired, and serviced just like any other piece of equipment. Grease those gears! Make sure all connections, limits, cables, and straps are in reliable condition and function flawlessly. These machines can sometimes get out of adjustment and need to be recalibrated or reset in the controller to make sure they fully open and fully close when used.

Bottom line

Even though this is not a comprehensive maintenance item list, we hope it helps identify maintenance items that may go overlooked when time is short.

Our goal is to promote full potential wind speed, performance, and prevent emergency repairs during hot weather operation. Good luck this spring from the Auburn University National Poultry Technology Center!

Jess Campbell is an Extension housing specialist with Auburn University’s National Poultry Technology Center; Jeremiah Davis is the NPTC director and Extension specialist, Cody Smith and Kelly Griggs are NPTC research engineers, all with Auburn University’s Biosystems Engineering Department. More information from the NPTC can be obtained at www.poultryhouse.com.

POULTRY TIMES POULTRYTIMES.COM 29

FLY PROBLEMS? Got Manure? We have the cure! Entomologist on Staff. Free Phone Consultation. www.kunafin.com 1-800-832-1113 WHOLESALE PRICES: On cartons, labels, flats, trays, nests, marketing items, poultry supplies & more! 866.333.1132 www.eggcartonstore.com ®

MARKETS

Compiled by David B. Strickland,

Editor

770-718-3442

dstrickland@poultrytimes.com

N ational Turkey Market: (Apr. 8): The market on frozen 8-16 lb. hens and 16-24 lb. toms was steady with steady to weak undertones. Offerings moderate to ample. Frozen domestic 2024 production Grade A basted equivalent processor offering prices on a national basis for Grade A 8-16 lb. hens were 84¢$1.03 FOB and 16-24 lb. toms 86¢-$1.05 FOB for current shipments. No trading reported for current deliveries. The market on tom breast meat was steady to weak. Offerings moderate to moderately heavy, mostly moderate. The fresh destrapped tenderloin market was steady to instances firm. The frozen destrapped tenderloin market was steady with mixed undertones. Offerings of fresh destrapped tenderloins light to moderate and frozen at least moderate. The white trim markets were steady with steady to barely steady undertones. White trim offerings uneven ranging light to moderately heavy, mostly moderate. Further processed demand slow to moderate. The 4-8 lb. breasts market were steady with steady to weak undertones. Institutional sized rib breast markets are steady to barely steady. The market on tom drums was steady to fully steady, wings steady to firm, and necks steady to barely steady. Tom wing demand moderate to good with 2-joints strongest, balance of tom bulk parts light to moderate. Offerings of tom 2-joint wings short to very light, balance light to moderate. The thigh meat and bone-in thigh markets were firm. The fresh mechanically separated turkey (MST) market was steady, frozen steady to firm, USDA Agricultural Marketing Service reports.

N ational Broiler/Fryer Slaughter:

Broiler: Estimated slaughter for week ending Apr. 6 was 153,864,000.

Actual slaughter for the week ending Mar. 30 was 153,043,000.

Heavy-type hen: Estimated slaughter for the week ending Apr. 6 was 1,591,000.

Actual slaughter for the week ending Mar. 30 was 1,588,000.

Light-type hen: Estimated slaughter for the week ending Apr. 6 was 567,000.

Actual slaughter for the week ending Mar. 30 was 719,000.

Total: Apr. 6: 156,022,000; Mar. 30: 155,350,000.

Grain Prices

Broiler/Fryer Report

Egg Markets

Turkey Markets

Broiler Eggs Set/Chicks Placed in 19 States

POULTRY TIMES POULTRYTIMES.COM 30 Page 30 | Poultry Times

USDA quotations New York cartoned del. store-door: Mar. 25 Apr. 9 Extra large, no change $2.53--$2.57 $2.53--$2.57 Large, no change $2.51--$2.55 $2.51--$2.55 Medium, no change $2.40--$2.44 $2.40--$2.44 Southeast Regional del. warehouse: Mar. 25 Apr. 9 Extra large, up 13¢ $2.40--$2.60 $2.53--$2.62 Large, up 15½¢ $2.36--$2.57 $2.51½--$2.59 Medium, up 17½¢ $2.23--$2.46 $2.40½--$2.48

Weighted avg. prices for frozen whole young turkeys Weighted average (cents/lb.) F.O.B. shipper dock National Week ending Apr. 5 (range) (weighted avg.) Hens (8-16 lbs.) 103-103 103.00 Toms (16-24 lbs.) 103-105 104.00 Week ending Mar. 29 (weighted avg.) (Change) Hens (8-16 lbs.) 84.90 18.10 Toms (16-24 lbs.) 104.00 0.00

USDA National Composite Weighted Average For week of: Apr. 5 $1.33.01 For week of: Mar. 29 $1.32.82 Majority (whole body) Apr. 5 Eastern Region: $1.04--$1.46 New York: $1.15--$1.46 Central Region: $1.15--$1.33 Chicago: $1.15--$1.29 Western Region: $1.17--$1.59 Los Angeles: $1.17--$1.50 Negotiated prices in trucklot and less-than-trucklot quantities of ready-to-cook whole body broiler/fryers delivere d to first receivers; prices in cents per pound

OHIO COUNTRY ELEV. Mar. 11 Mar. 25 Apr. 9 No. 2 Yellow Corn/bu. $4.01 $3.97 $3.91 Soybeans/bu. $11.54 $11.74 $11.39 (Courtesy: Central Ohio Farmers Co-op, Marion, Ohio)