You make it. We pack it. BPA loads your packaged and naked products into cases, master bags and various secondary containers including your hffs machines, wrapper chain in-feeds and indexing thermoform machines.

Plastic- and aluminum-free single-serve coffee pods use an alginate-based primary package material with some barrier properties. The system will employ recyclable secondary packaging with additional barrier, but many packaging details remain to be sorted out.

Faced with an increase in demand driven partly by the pandemic, Oliver Winery now routinely lls 750-mL glass bottles at 12,000 bph as opposed to the 7,000 done formerly.

Glacier gets $7.7M in funding from Amazon among others. The AI-based robotic tech improves sortation at recycling centers, promising actionable insights to companies like Amazon that both package products, and consume recycled materials in their packaging.

The rough and tumble, many-touch world of D2C and e-comm shipping can take a toll on any product, but live house plants were a particular challenge for brand House Plant Box. A sustainable, stylish, and robust pack system with bracing tabs did the trick.

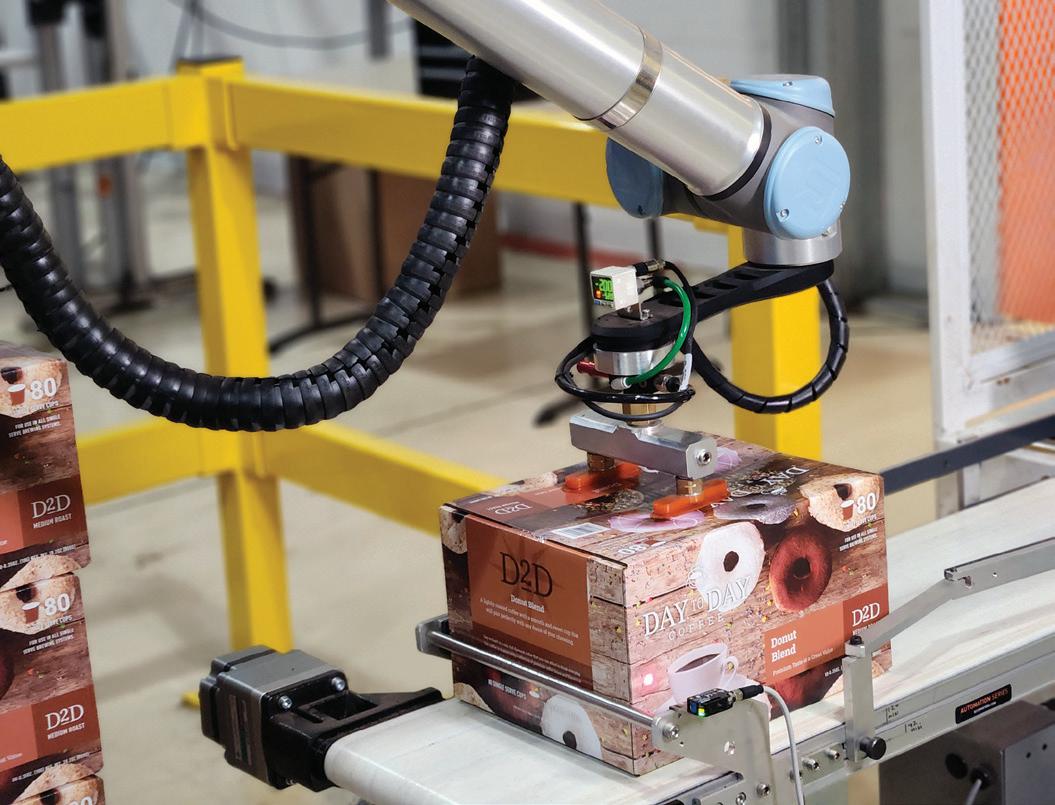

Chicago-area coffee company Napco Brands installs two cobot palletizers, increasing productivity by 15% and freeing up eight operators to handle more specialized tasks.

Organic food delivery service Fresh Harvest supplements its reusable packaging with new compostable produce lm that is also used to fertilize its crops at its end of life.

As its major retailer customers expand their ranges of SKUs with increasingly complex orders, Enterprise CP is using Power Central’s ERP software to all but eliminate human error in packaging inventory management and planning.

Aladin

Jan

M.

Mike

David

Brian

Jasmine

VIDEO

VIDEO

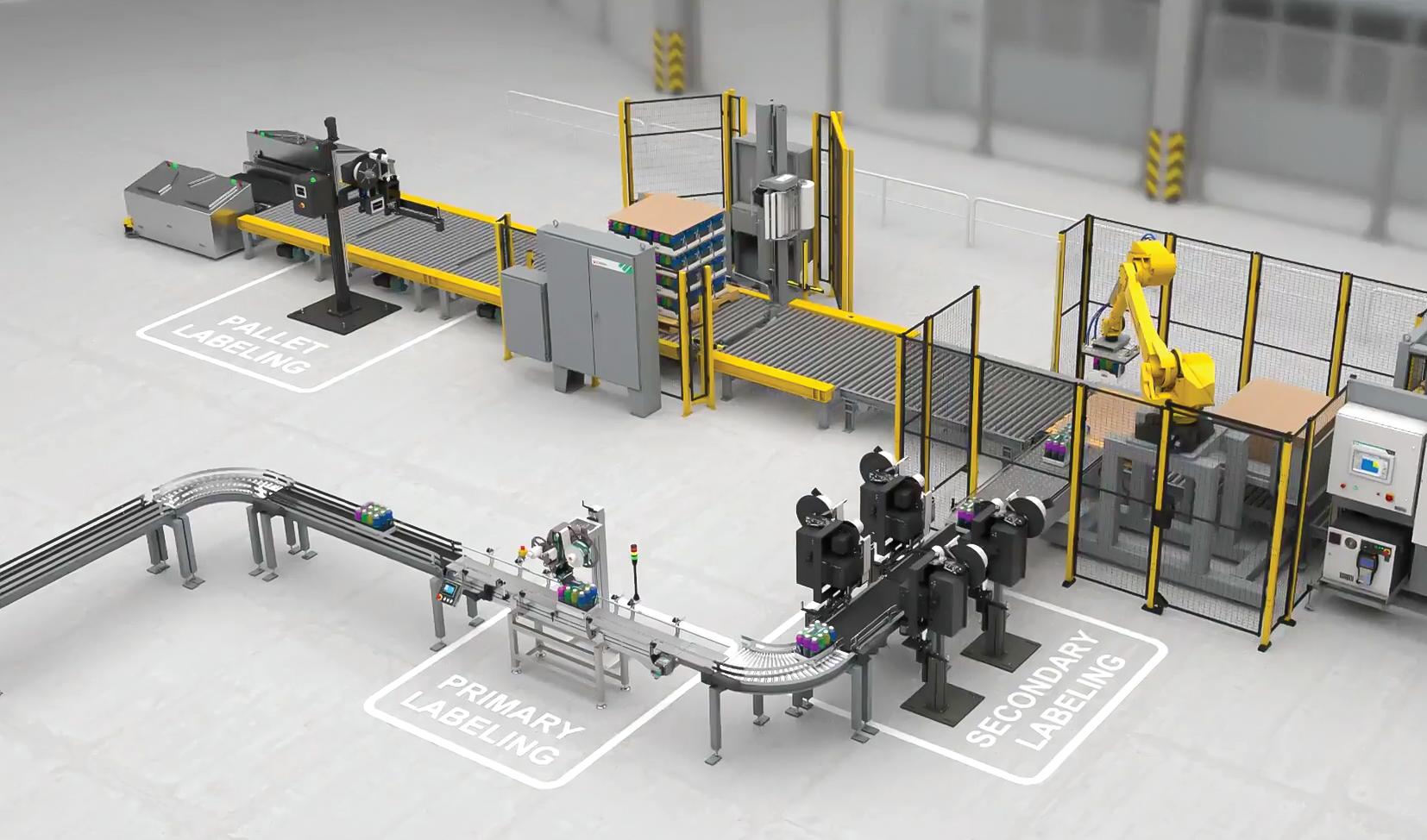

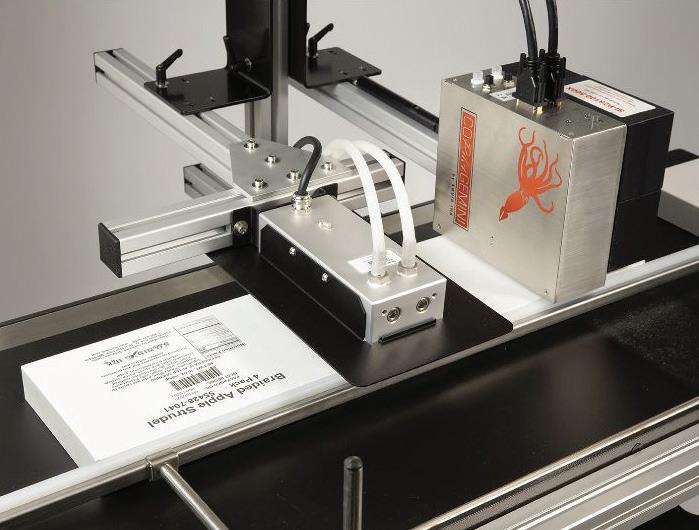

As a leading provider of high-quality labeling, coding, and marking systems, ProMach Labeling & Coding brands like ID Technology design, manufacture, and integrate custom solutions for virtually any primary, secondary, and tertiary packaging. Simply put, we excel at taking information and placing it on your products and packaging to ensure you operate at peak efficiency.

PRIMARY LABELING SOLUTIONS

Pressure-sensitive labeling solutions for various packaging shapes and product types while providing an easy and flexible platform to control and maintain.

SECONDARY LABELING SOLUTIONS

Fast and accurate secondary package labeling that ensures compliance with retailer standards and smooth arrival to your customers, as expected.

TERTIARY LABELING SOLUTIONS

Automating your pallet labeling systems provides safety for your forklift drivers and operators while ensuring the correct label is applied to the pallet every time.

Matt Reynolds

Anne Marie Mohan Senior Editor

Sean Riley Senior News Director

Casey Flanagan Digital Editor

Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors

David Bacho Creative Director

John Schrei Vice President, Sales jschrei@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Media Operations

Jen Krepelka Director, Digital Media

Trey Smith Senior Director, Events

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

It’s the heart of conference season, and the Packaging World team has been on the road in recent months. Here is some of what we’ve found.

I was at PLASTICS Industry Association’s FlexForum recently, where flexible packaging was the main course, and legislation and chemical recycling predictably were the areas of interest. There, Kraft Heinz’s Linda Roman highlighted regulatory challenges around material reduction—legislation that requires significant source reduction doesn’t always recognize the transition from heavier, rigid bottles to lighter, flexible films as a valid form of source reduction. I’m paraphrasing, but she diplomatically emphasized that the discrepancy underscores the need for a more nuanced understanding of sustainability in legislature.

On chemical recycling, PepsiCo’s James Coomes spoke of competing interests. “The challenge as we look at chemical recycling is the mass balance terminology that now has to be put on the package. That creates a hurdle for a marketing team, both in terms of how to talk about it, and with the small amount of real estate that’s on our packaging, [that’s space we need to use to] talk about how good our products are, to drive that consumer appeal and the purchasing decision,” he said. “Despite those challenges, we personally think chemical recycling is a great technology because it’s one of the few right now that actually takes our packaging from a waste recycling stream and gives us food-contact material. We think that needs to continue to develop and bring some of the changes in industry and the recycling infrastructure to help get more of that material.”

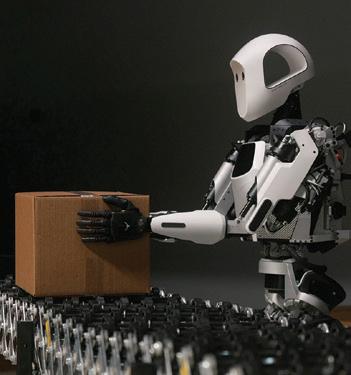

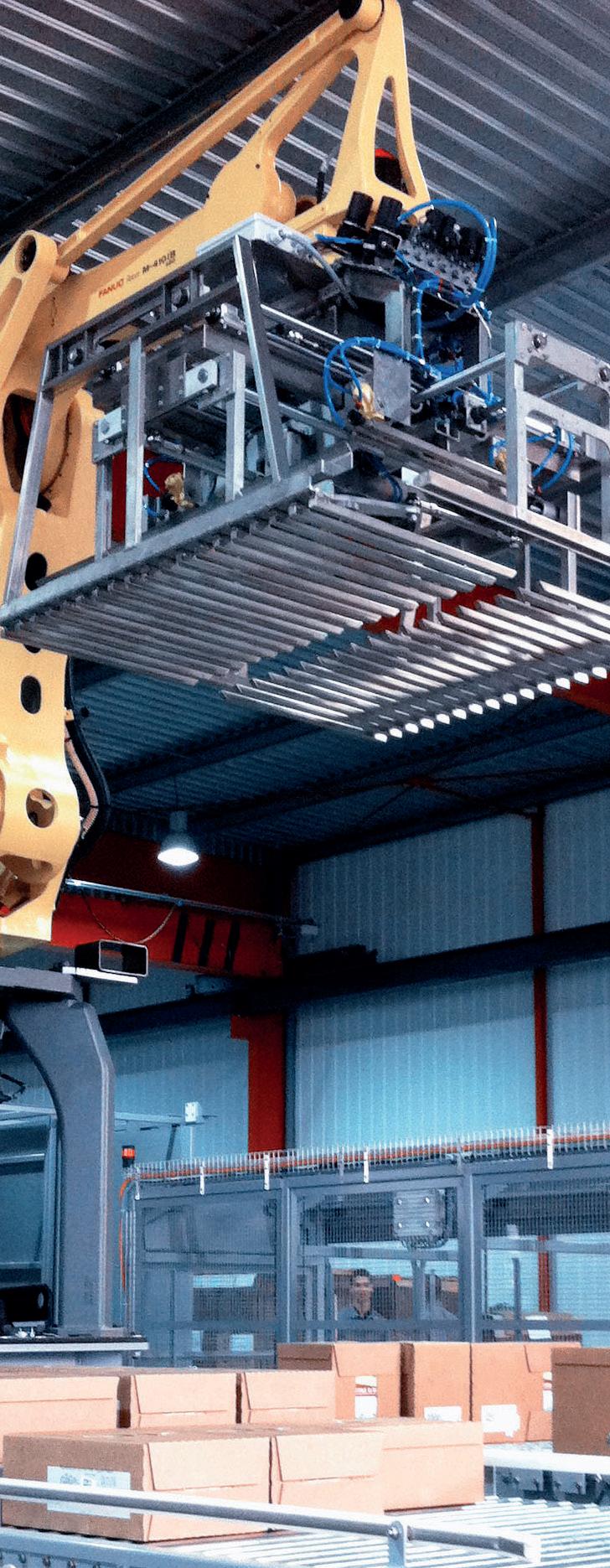

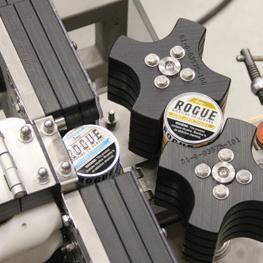

Meanwhile, in Philadelphia, if PACK EXPO East 2024’s record attendance is any indicator, packaging automation is top-of-mind for CPGs and brands. This was particularly evident in the endof-line collaborative robots (and their integrators) that I saw at the show. Flip to page 48 to read about an in-market application, but the show floor was replete with examples of cobot palletizers— Columbia/Okura, Vention, Robotiq, Fanuc, and Patlz were just a few booths I dropped by that had live demos. Palletizing is an especially repetitive and ergonomically unfriendly job. With labor already scarce and workers unwilling to settle, this category is exploding. Integration that offers easy deployment, fast ROI, and remote troubleshooting is a differentiator.

The onset of the AI age was also visible at PACK EXPO East, most evident in inspection and detection. Elementary, for example, showed how AI algorithms monitoring data collected from inspection systems can produce insights about upstream packaging operations. Are more misapplied labels or bad pouch seals coming off of line A than lines B, C or D? AI knows before we do, and possibly before the rejects happen, reducing scrap.

My colleague Anne Marie Mohan was at the Plastics Recycling Conference, and sent this missive from the road: “One takeaway would be the price of recycled materials,” she says. “Price has to come down to make it more palatable as the cost of virgin is low. Legislation is necessary to force brands to use more recycled content; commitments aren’t enough.” Mohan also keeps hearing about the importance of understanding plastics recycling as a system. As such, it requires collaboration among stakeholders. This recurring theme is central to PW’s own Packaging Recycling Conference, coming up in Anaheim in September.

PMMI made news by joining AMERIPEN as an Associate Member, strengthening the relationship between the two. Announcements were made in conjunction with PMMI’s recent Executive Leadership Conference and AMERIPEN’s Annual Summit, both held in mid-April. This will translate into more coordinated work on legislation and other initiatives, many of which related to Extended Producer Responsibility (EPR).

Next up, I’ll be at SPC Impact for packaging circularity, then Waste Expo for the material recovery facility (MRF) point of view, and finally drupa (the first since 2016) in June to see what’s new in digital printing. The retreat of print journalism has been greatly exaggerated in my opinion, but printers that once hung their hats on print and printed collateral like mailers are looking to packaging to expand their reach and ensure their eggs aren’t all in one basket, so packaging is a bigger part of drupa than ever. As always, I’ll report as I go. PW

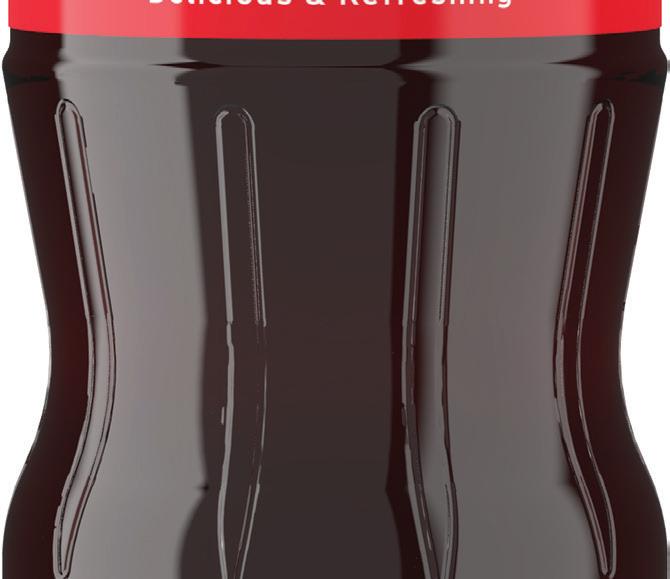

As The Coca-Cola Company continues to make strides towards its goals of reducing PET use by three million metric tons by 2025, the company says this lightweighting innovation will help the company work toward virgin plastic reduction while also helping reduce its overall carbon footprint.

to get below the 21-g mark. From there, we piloted a research lab to develop and test the bottles. As the project got bigger and we entered the more advanced stages, we brought in a design team, suppliers, and more to bring the initiative to life,” he says.

Why now? While this work does have some cost-saving bene ts due to reduction in material inputs, Santamaria says the company is primarily doing this to ensure its packaging is designed ef ciently. Between getting bottling partners on board and product R&D, this all takes time, and he wanted to ensure the company was doing it correctly. Across the value chain, it appeared to be the right time.

The Coca-Cola Company completely redesigned its small PET bottles with its latest lightweighting initiative, changing the shape of and reducing the weight of these bottles. In 2024, all small PET bottles in 12 oz, 16.9 oz and 20 oz will be lightweighted from 21 g to 18.5 g for all The Coca-Cola Company’s sparkling brands, Minute Maid Refreshments, and Minute Maid Aguas Frescas in the U.S. and Canada. Coca-Cola Trademark’s 20-oz 100% recycled PET bottles, excluding caps and labels, will be available in the new lightweighted bottle as well.

It’s been quite some time since the last redesign. For Coca-Cola Trademark’s 20-oz bottle speci cally, that particular bottle design has been in the market since 2006, so it has been nearly two decades. The onthe-go grip design was hip and new when it rst launched in the early 2000s, but it deviated from the original Coke contour.

“Now, we’re bringing back the original contour shape to the North American market but have optimized and modernized it a bit. We’ve been continuously working to ‘right-weight’ our bottles, incrementally going from 27 to 21 grams over the last 10 years. But we’d reached the ‘ oor’ with our previous designs. Our breakthrough innovations in modeling technology, which reduce the weight of our bottles to 18.5 grams, represent a major step in reducing our environmental impact while preserving the durability and functionality of our packaging and, most importantly, the quality and taste standards of our beverages. As The CocaCola Company continues to make strides towards its World Without Waste goals of reducing PET use by three million metric tons by 2025, this lightweighting innovation will help the company work toward this goal, while also helping reduce its overall carbon footprint,” Alejandro Santamaria, senior director, Global Packaging Development & Innovation, The Coca-Cola Company tells Packaging World

“First, we needed to get bottlers throughout the network excited by the idea. We knew some existing bottle designs were not conducive to lightweighting, so we needed to refresh the design completely

since 21 g was the oor weight for the bottle design, it was time

“There had been incremental changes made over the past decade where an infrastructure overhaul was not necessary, but since 21 g was the oor weight for the bottle design, it was time to refresh the design to make even more progress towards lightweighting. We’ve been working on this for a while and it’s no easy feat, but luckily, we have an incredible bottler system that has helped us to accomplish this,” Santamaria says.

There certainly have been some process changes to bring the updated bottle designs to life. Suppliers’ existing preform equipment was re-tooled to produce the new 18.5-g preform design, and bottlers supported the project by investing capital for new molds. Bottlers’ existing blow-molding equipment had to be re-tooled as well to produce the new molds for the updated bottles.

capital for new molds. Bottlers’ existing blow-molding

Downstream of bottle blowing, though, changes to packaging infrastructure are minimal. Filling, capping, labeling, and packaging equipment required minimal adjustments to compensate for the small dimensional differences of the new bottle designs. Other industries, like bottled water, have undergone signi cant lightweighting projects over recent years, and some have noticed the less robust PET bottles don’t perform as well in supply chains or on packaging lines. Coca-Cola doesn’t expect this will be an issue.

“As we are not lightweighting our sparkling bottles to the same extent as water, we don’t anticipate any issues. Our new bottles will still be rigid enough to run through our supply lines without issue,” Santamaria says. “Most things downstream will remain largely the same as the existing packaging is compatible with Coca-Cola and Sprite Trademark, but some tweaks have been made for the sparkling brands in the portfolio.”

There will be no change to any Coca-Cola or Sprite Trademark label size and placement. All other sparkling varieties—like Minute Maid Refreshments and Minute Maid Aguas Frescas—will require new, smaller labels which will follow Coca-Cola and Sprite brands’ label placement format. Previously, Coke’s sparkling offerings were packaged in a straight bottle with a very large label. Now, there will be a similar label size across all brands, which

Santamaria says is a positive change in terms of labeling ef ciency across bottles. There will not be any changes to the cap/closure.

“The secret was nding the right design features that allowed us to lightweight the bottle without compromising the quality of the drink,” Santamaria says. “The new bottles are optimized to reduce weak points in the bottle, preventing CO2 loss and retaining the bubbliness that we all know and love from our favorite drinks. We were able to nd the sweet spot of functionality, while also still retaining the appealing shape of the bottle.”

There was a lot of data collection and consumer research done behindthe-scenes to ensure consumers felt good about the changes being made to the bottles. Santamaria says the response was overwhelmingly positive.

This transition is projected to reduce annual use of new plastic by the equivalent of nearly 800 million bottles in 2025 compared to 2024. Additionally, the packaging shift is estimated to reduce carbon emissions in 2025 compared to 2024 in an amount equivalent of taking more than 17,000 cars off the road for one year. The Coca-Cola Company says it recognizes its responsibility to help solve the global plastic packaging waste

problem, and knows that lightweighting is just one step of the process. In March, Coca-Cola also launched a 100% rPET initiative, where all versions of 20-oz Coca-Cola bottles will be made from 100% recycled plastic (excluding cap and label) in the U.S.

This transition began in March and will be fully rolled out by the end of 2024. All producing bottling partners in The Coca-Cola System in the U.S. and Canada are rolling out the lightweighted bottles at different points this year. In the U.S., the Coca-Cola system consists of 64 independently owned bottlers. To name a few, Coca-Cola Bottling Company United, Liberty Coca-Cola, Coca-Cola Southwest Beverages, Swire Coca-Cola, and Coca-Cola Consolidated Inc. The company has one bottler in Canada, Coke Canada Bottling Limited.

When asked how these bottling partners felt about the move, Santamaria says they’ve been willing and accommodating. “We’re so lucky to have such amazing partners who are committed to reducing use of virgin plastic and driving a circular economy,” he says. “It’s been a true team effort to get this initiative to where we are today.”

—Matt Reynolds

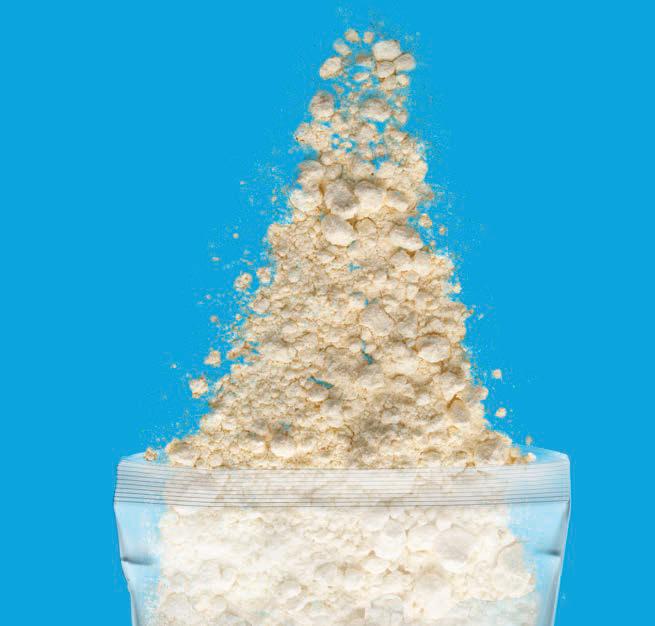

Keurig Dr Pepper (KDP) introduced a new single-serve coffee packaging concept, what it calls its K-Rounds plastic-free pods. K-Rounds pods contain roasted coffee beans that are ground, pressed, and wrapped in a proprietary, protective plant-based coating (primary packaging) preserving the coffee’s flavor and aroma while eliminating the need for plastic or aluminum packaging. A corresponding brewing device called the Keurig Alta brewer is required to brew these specialty K-Rounds.

It’s notable that the plant-based coating doesn’t dissolve into the liquid coffee—it stays intact during the brewing process. So after the KRounds are brewed, consumers must dispose of the remaining pod shell, composed of a food-safe, plant-based material that the company expects will be certified as backyard compostable (certification pending).

The plant-based coating doesn’t dissolve into the coffee—it stays intact during the brewing process. So after the K-Rounds are brewed, consumers will have to dispose of the remaining spent coating. It is expected to be certified compostable. A corresponding brewing device, called the Keurig Alta brewer (inset), is required to brew these specialty K-Rounds.

KDP is acutely aware that coffee, perhaps uniquely among food and beverages, is sacred to consumers. Its aroma and flavor are ritualized such that coffee requires significant barrier layers in packaging to lock in flavor, aroma, and freshness for any stint on a shelf.

So how much of a barrier will this new primary packaging material provide, and how much shelf life can we expect from each individual pod? Will secondary packaging require more barrier to accommodate the compostable material as primary packaging? Packaging World caught up with Phil Drapeau, senior vice president, Future Coffee Systems at KDP to learn more. The bottom line? It’s still a work in progress, but more details will be coming soon as the project moves into beta phases.

Watch a video about Keurig’s compostable pod concept at pwgo.to/8239, or scan the QR code.

Regarding the primary and secondary packaging barrier specifics, “we are working through all of that. I can’t give you an official final shelf life today,” Drapeau says. “Part of us wanting to announce the K-Rounds [before such specifics are defined] is to start the dialogue with our retail partners and consumers and other stakeholders, so we can work through ‘what is a final shelf life going to look like?’”

He indicates that the compostable plant-based coating indeed brings some aroma and flavor protection properties to the table. However, it is likely that the coating’s barrier properties are insufficient—on their own, at least—to provide the extended shelf life that retailers and consumers would prefer. That means that secondary packaging will have to carry some of the barrier load.

“The immediate packaging element for the coffee, that plant-based coating, it does have flavor and aroma protection,” Drapeau confirms. “The secondary packaging will also have some barrier protection within it. We’re working through the dynamics of the secondary packaging materials, exactly how much barrier protection that provides, and then how we package that up in terms of the product counts; the numbers of the pods per secondary pack. Those will be the numbers and the balances that will need to come together. How we match the secondary packaging to the primary packaging, and then pull that through from a final solution standpoint is what comes next, and we’ll be able to share a lot more with you as we get into beta testing and refine the approach.”

Drapeau concedes that there are a lot of different options in front of the company at the moment in this work in progress, but says he and his team are systematically working through them.

“We ask ourselves, ‘what are the things that actually, really work from a true barrier protection standpoint?’ And then we ask, ‘what meets our broader sustainability goals in terms of recyclability?’”

Drapeau was very clear that KDP “certainly doesn’t want to go down a secondary packaging path that is not easily recyclable for consumers. And it has to be something that the municipalities want to recycle, too.” Beyond that, he’s also looking into the broader secondary packaging protections that any product—coffee, durable goods, or otherwise—needs for manufacturing, shipping, and the supply chain.

In a traditional coffee pod or K-Cup, barrier exists exclusively on the primary packaging. In this K-Rounds project, some of that barrier of is moving to the secondary package. The primary and secondary packaging will each have barrier duties, and the secondary packaging still must be easily recyclable. How that’s achieved, and whether the new K-Rounds system is in fact more sustainable than the legacy PP pods, is for an eventual Life Cycle Assessment (LCA) to decide.

“A full LCA is going to have to look at everything, from the full manufacturing process, even the start of life in terms of the coffee itself, its grinding, etc.,” he says. “We’re a little ways off from LCA. It’s clearly on our radar screen, and we know how important that’s going to be to take a holistic look. The focus started with end of life [of the packaging], to meet consumers’ needs, and then working our way back from there.”

As part of the intellectual property portfolio that KDP owns via the larger brewer and coffee round system project, KDP acquired a perpetual license to know-how and technology invented by Delica Switzerland for its CoffeeB system in Europe, including the proprietary plant-based coating and application processes. KDP’s partnership with Delica grants Keurig exclusive rights to use and build upon these technologies for consumers across the U.S., Canada, and Mexico.

“There are four components of the plant-based primary packaging coating, and they all meet the FDA standards for food safety,” Drapeau says. “The primary component in this sealant is alginate, which is typically derived from seaweed. [This project was] accelerated thanks to our partnership with Delica.”

“We fully expect it to be certified compostable, and the certification that we’re going to be working through is TÜV. We have a lot of respect for the approach that they take and what they do,” Drapeau says. “We fully expect the certification, it’s just a matter of the final pods going through that testing. But everything that we know, from what coffee has done in our preliminary testing and onward, this is going to be [certified by TÜV as] completely compostable.”

As with any compostable product, the remaining sealant could be disposed of in the trash, too, though less than ideal for landfill.

As accompanying images indicate, each K-Round is printed with a gold-colored “brew-style code” so consumers can easily identify among different varieties, like espresso (single or double) or dark vs. light roast coffee. This final approach here is also still in the works.

“We’re still looking at a couple of different technologies to get the brew-style codes etched on to the pods themselves. There are technologies that do actual etching, and then there certainly are food-safe inks that can be printed on the K-Rounds,” Drapeau says. “We’re looking at a couple of different technologies, but we have to match that with the brewer [Keurig Alto brewing device] itself, because the brewer has to be able to read that

There’s a wide variety of consumer use preferences, from fourcounts to counts in the hundreds, that must travel different supply chain channels. Beta testing the K-Rounds’ packaging with retailers, both brick and mortar and online, will be varied and complex.

brew-style code. That’s important, which is why we’re kind of experimenting with a few different options right now, while we’re still in kind of this, you know, development stage and tightening these things down.”

Keurig is an omnichannel brand that’s in 45 million homes across the U.S. and Canada. That means there’s a wide variety of consumer use preferences, from four-counts to counts in the hundreds, that must travel different supply chain channels. Beta testing the K-Rounds’ packaging with retailers, both brick and mortar and online, will be varied and complex.

“But that’s also why we’re so excited to get into our beta testing,” Drupeau says. “[Pack counts and sizes] are the things that the beta testing is really going to help us understand as we open up the variety of beverages, from essentially drip coffee in multiple sizes to, now, single-shot espresso, double-shot espresso, drip coffee, or cold coffee that truly comes out cold like at a coffee shop. Understanding how consumers behave and what they drink and the varieties they choose, and then how that manifests in terms of usage patterns over 30, 60, 90 days, that all becomes really, really important to us. And that’s why the beta testing is going to be so critical as we make the final decisions around pack counts and sizes and barrier protections and inks, and all those things.” —Matt Reynolds

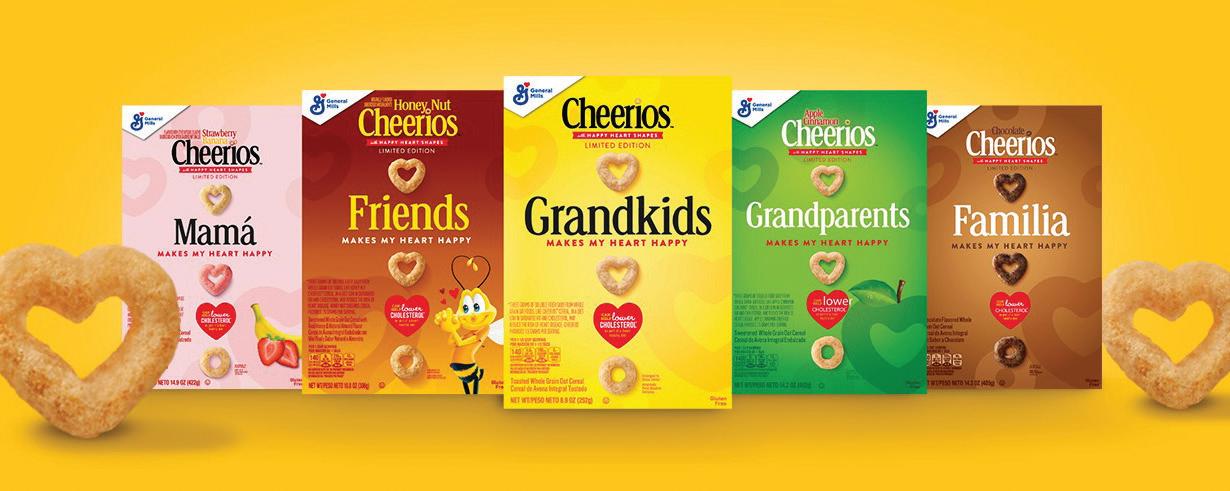

Celebrating its fifth annual “Happy Heart Shapes” campaign, General Mills’ venerable brand Cheerios launched a fun example of digital printing-assisted mass packaging customization. In conjunction with of The American Heart Association’s American Heart Month in February, the cereal known for its iconic “o” shape was once again transformed into a heart shape, reminding consumers of the role good eating habits can play in a heart-healthy lifestyle.

But in a new packaging twist this year, Cheerios launched special-edition boxes featuring names of those who inspire people to make heart-healthy choices. Special-edition boxes with names like Mom, Friend, Grandparents, and Family, both in English and Spanish, were available at retailers nationwide throughout February. But it got even more custom, bespoke, and made-to-order. Consumers also were able to order personalized yellow boxes online featuring any name (up to 18 characters) at Cheerios.com.

“From being there to cheer on your kids’ activities to laughs across the breakfast table—these are the moments with loved ones that remind us why it’s worth saying, ‘Yes’ to taking care of our heart health,” says Kathy Dixon, senior brand experience manager for Cheerios. “This year, the special-edition Cheerios name boxes and Happy Heart Shapes are a simple reminder for people to take care of their heart so they can be there for all of life’s special moments.”

The brand conducted the campaign with its long-standing partner, global merchandising company Zagwear, who completed the printing and fulfillment of personalized cereal cartons. Pre-printed, filled, and sealed cereal cartons were delivered to Zagwear to be digitally printed with the variable data. Cereal boxes in the campaign have some features of their own that set them apart from traditional Cheerios boxes, such as heart health information and visual references to the heart-shaped cereal pieces. But all those features arrived to Zagwear pre-printed on the box—only that 18 characters-worth of variable data on the front of the carton was digitally printed. That variable data space sat where the Cheerios brandmark would normally reside.

The cartons were printed digitally on an X JET Switch model flatbed UV printer, supplied by Inkcups Now. All the inks had been thoroughly tested for regulatory compliance as well as odor migration to the cereal. Capacity is approximately 150 to 200 cartons per hour.

“Consumers can access the e-commerce shop to order a personalized box via Cheerios.com. We have an integration in which we receive orders, including the variable name data. We print orders as we receive, package the Cheerios boxes up in specially designed and sized shipping cartons and then ship to the individual consumers. All the printing, fulfillment and shipping is taking place under one roof at one of our facilities,” GMI and Zagwear representatives say.

Special-edition boxes were available at retailers nationwide in five delicious flavors: Original yellow-box Cheerios, Honey Nut Cheerios, Chocolate, Strawberry Banana, and Apple Cinnamon. Customized boxes were $20 shipped. —Matt Reynolds

As brands continue to move toward what they see as more sustainable packaging materials, collaboration between CPGs and their equipment suppliers has become an important element in achieving success. One recent example is a partnership between organic mattress company Naturepedic and its roll-packing machinery supplier, C3 Ingenuity, that enabled the company to switch from polyethylene to paper, eliminating 55,000 lb of plastic per year from its roll-packed products.

Based in Chagrin Falls, Ohio, Naturepedic produces certified organic mattresses and bedding, which it sells at its 20-plus retail stores located across North America. Its products can also be found at more than 150 retailers nationwide, including Crate & Barrel, Pottery Barn, and Restoration Hardware, and can be purchased on its website and shipped direct-to-consumer. For all these channels, Naturepedic ships its mattresses, comfort layers, and mattress toppers rolled up and packaged in (until recently) a heavy-gauge PE wrap and placed in a corrugated shipper.

Shares company Vice President of Sales and Marketing Arin Schultz, as a certified organic company committed to supporting an organic, holistic, lifestyle, Naturepedic is always looking for ways to improve its environmental impact. “We especially have an obligation to the planet and to our consumers—and not to be too aspirational—to the world in general to do our part,” he says.

For this switch, Naturepedic enlisted C3 to create a combination paper and machinery solution—a development process that took C3 18 months to complete. One of the challenges was to find a paper that would hold, for example, a king-size mattress compressed into a 76 x 80 x 11-in. circle. “So they were working on formalizing a process to be able to hold all that pressure while using a kraft paper,” explains Schultz.

When it came to the machinery, Naturepedic needed a solution that would allow it to continue to operate its existing CF1396 compression folding system at the same speeds. It also wanted something that wouldn’t add additional manual steps along the way. C3’s response was to engineer an add-on for its existing roll-packing equipment. While Schultz didn’t supply details on the add-on, C3’s website details a new patent-pending hybrid mattress roll cage that can handle paper or plastic. According to C3, the roll cage provides perfect paper tensioning, a reliable paper cutting design for precision, consistency, and durability, a dependable paper feed system, and bead glue application that improves precision and allows for custom patterns. It adds that each bed rolled with paper saves approximately one pound of plastic from landfill.

To deliver on these goals, around two years ago, Naturepedic began exploring alternatives to PE for its roll-packed products. According to Schultz, one option it looked at was biodegradable, compostable films. “It sounds good on paper, but none of them actually breaks down that fast, given the amount of film we end up using,” he says. “So it just made more sense for us, again, an organic company, to shift to kraft paper. It’s recyclable, it’s compostable. It’s literally as natural as we can get in terms of packaging.”

Schultz says Naturepedic is eager to share the technology with other mattress companies. “We’re a very open and honest company,” he says. “We hope the industry goes this way. We get to wear the crown that we were one of the first, if not the first, to do this for a full product line. But if more companies can buy in, and we can help along the way, we’re more than happy to do that.”

Naturepedic began using the new roll cage and paper wrap in fall 2023 and according to Schultz, the new packaging has been a “resounding success” with its customers. —Anne

Marie Mohan

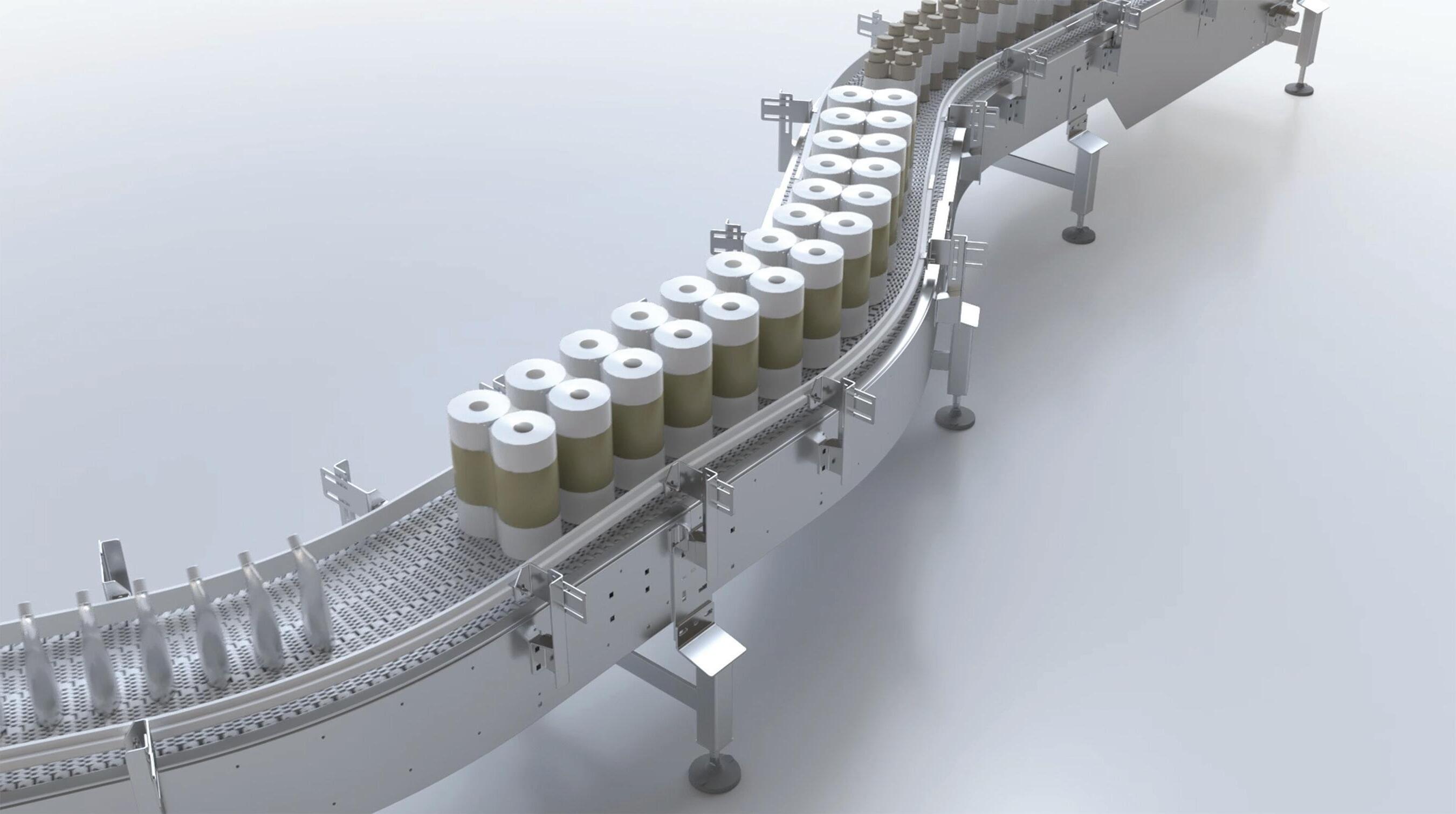

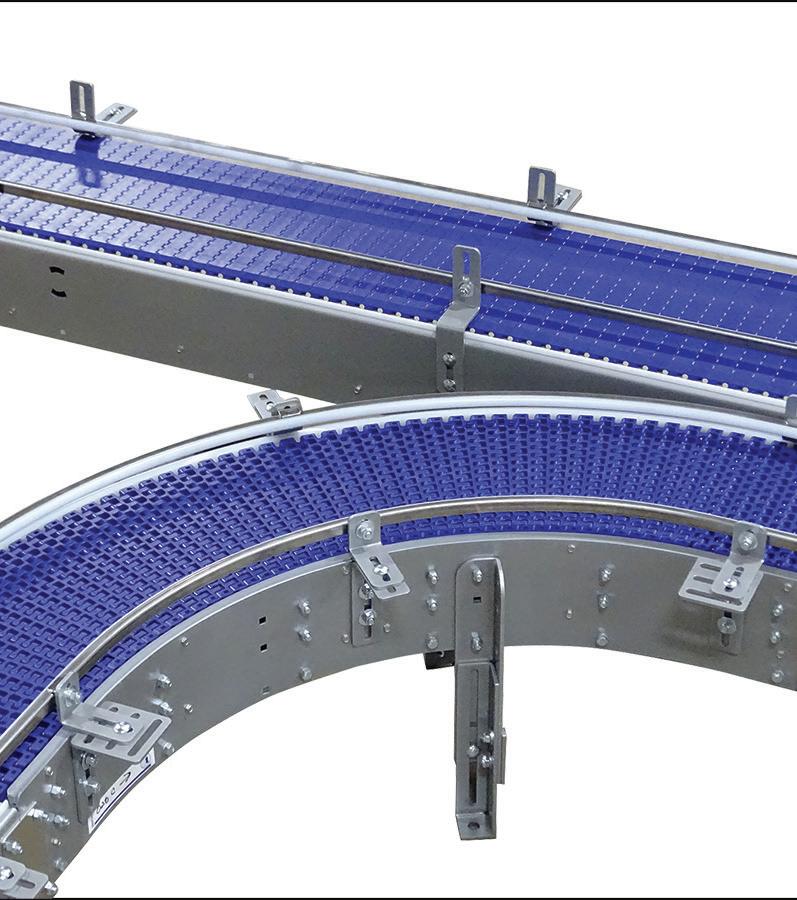

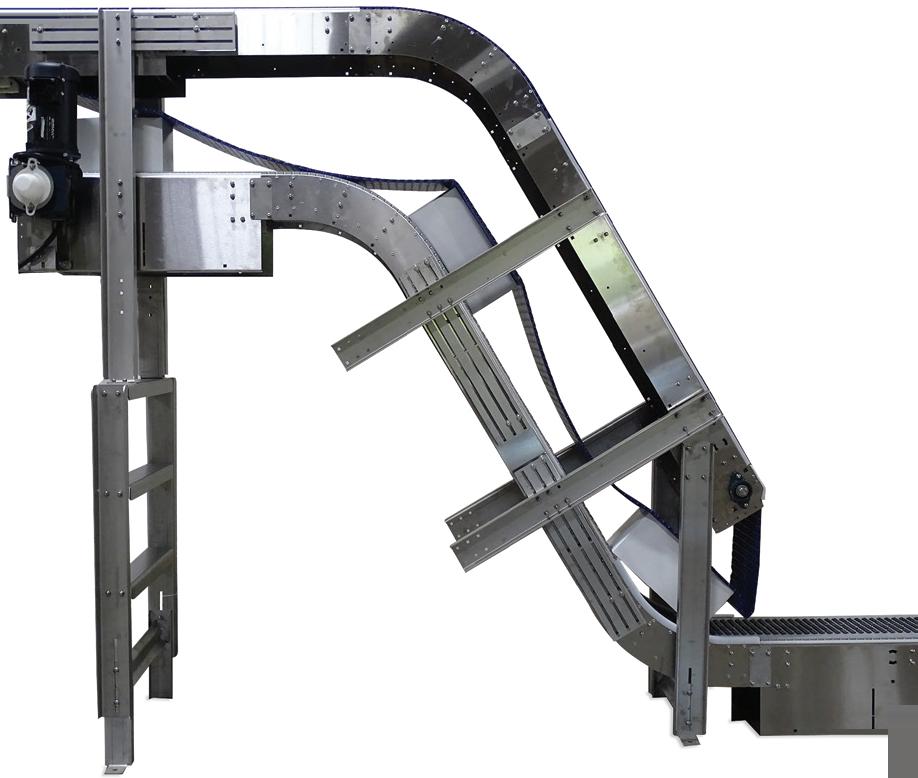

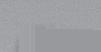

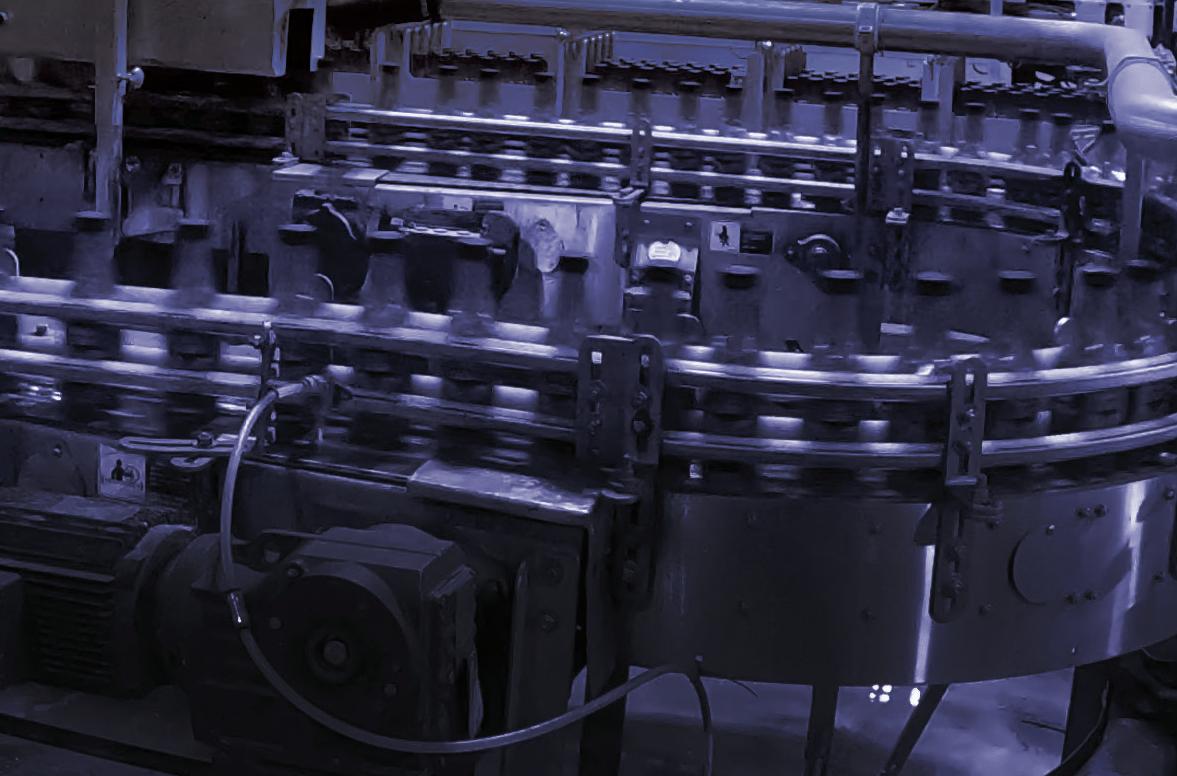

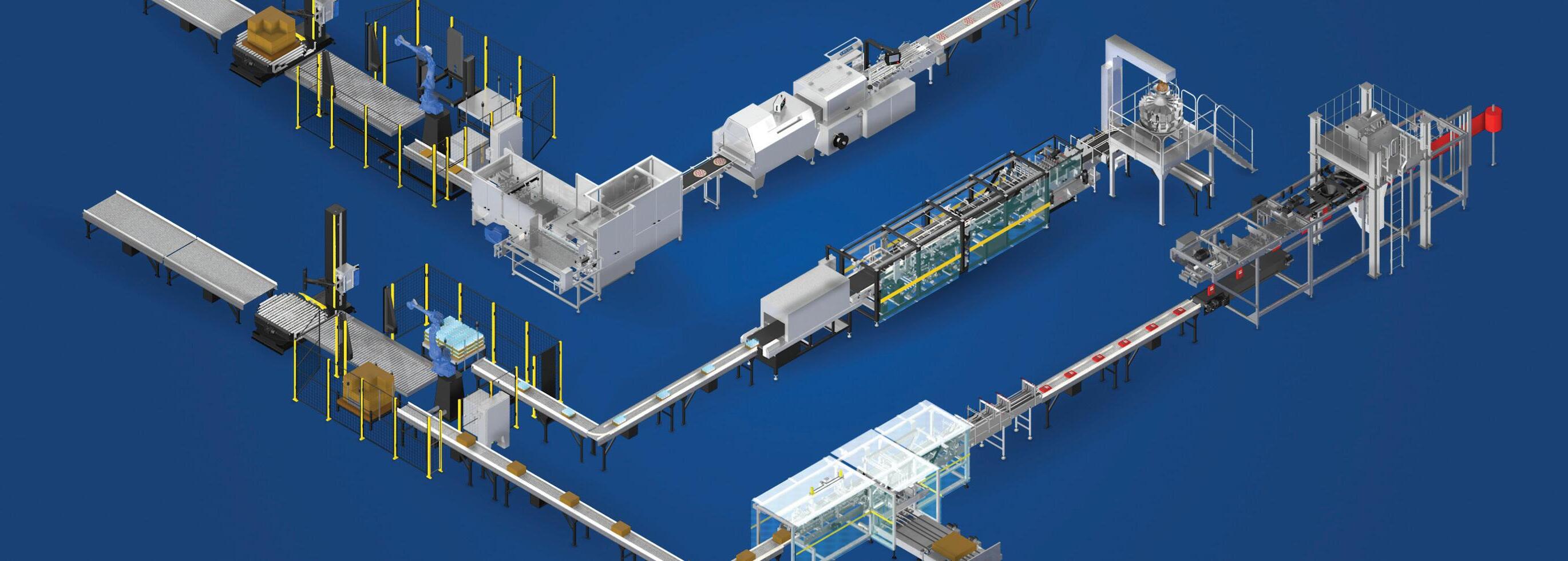

• We make conveyors that will move your product from filling, sealing, inspection, labeling, final packaging to shipment. We’ll take them through every merge, divert, curve, transfer, twist, flip, grip, accumulation, rotation or elevation step along the way.

• Choose from 24/7 workhorse conveyors, standard or custom designed, for simplistic to complex packaging applications. We connect mechanical engineering with electrical so your OEM equipment communicates.

• The goal? Maximize productivity; increase throughput; minimize footprint; factoring next generation expansion and future growth. It’s that simple.

www.multi-conveyor.com

Just as CPGs in the U.S. are reevaluating their packaging in light of EPR policies that will require more sustainable packaging, European CPGs are also facing more stringent requirements through the European Packaging and Packaging Waste Directive. Under PPWD, brand packaging must be 100% recyclable or reusable by 2030. To future-proof its packaging, European table salt producer JOZO has evolved its packaging from a multimaterial canister to a polypropylene shaker with a PP in-mold label that allows for maximum recyclability.

JOZO is no stranger to firsts. In the 1950s, it pioneered the salt-shaker dispenser package in the Netherlands, moving away from the traditional paperboard carton. Until recently, its shaker was made of a mix of materials, with a paperboard and aluminum body, a polyethylene bottom, and a PE and polystyrene cap.

In 2020, JOZO reached out to SFA Packaging to completely redesign its shaker package to comply with PPWD regulations for recyclability. Says SFA Business Development and Marketing Manager Alexander Heinsdijk MBA, the challenge SFA faced was developing a package that was both sustainable and highly attractive. “Switching to a mono-material package was the obvious way to go,” he says.

With recyclability in mind, SFA made the new shaker entirely from PP, including the body and cap. The label was also made

from PP—an in-mold label that fused with the shaker during the injection-molding process. The first iteration was a standard PP IML that, while recyclable, stayed with the package during recycling, resulting in grey, non-food-grade rPP. The next generation of JOZO’s packaging, debuting this year, goes a step beyond with a PP IML that separates from the container during recycling, resulting in high-purity, white rPP.

The label is MCC Verstraete’s NextCycle IML. According to Nico Van de Walle, product and circular economy manager Global IML at MCC, “In the mechanical recycling process, during the grinding stage, the NextCycle IML technology is designed to detach from the container. After the washing and the drying, the light PP label flakes are removed by the air elutriation phase, resulting in clean container flakes that can be recycled and reprocessed into rPP. Through this process, white container flakes result in white rPP. In turn, the higher-yield and high-purity rPP paves the way for a circular economy for PP.”

Creating a cleaner, whiter recyclate was important to JOZO in order to receive the highest score for recyclability. According to de Walle, in the past, RecyClass—the cross-industry initiative that advances plastic packaging circularity in Europe—categorized white packaging in the same class as colored packaging, in which case IML received the maximum recyclability score. However, due to a recent change, white packaging is now subjected to the same guidelines as transparent packaging. Following an assessment by third-party certification body CIRCPACK by Veolia, JOZO’s new container received a “B” classification from RecyClass, meaning the quality of the recyclate is good enough to be used in closedloop or cascade open-loop applications.

JOZO offers its Sea Salt and Himalaya Salt in 300-g, 100% PP shakers in markets that include Benelux, Scandinavian countries, and the Middle East. Shares JOZO Product Portfolio and Sustainability Manager Florence Ruellan du Créhu, since it was launched in Q1-24, the new package has received a positive response from consumers. —Anne Marie Mohan

Our mobile exhibition will come to you exclusively and free of charge!

Our show truck demonstrates our latest products. Take advantage of this unique opportunity to discuss solutions to your problems with our specialists and experts on-board our show truck.

In response to consumer pushback against single-use plastic packaging, brand owners are increasingly finding ways to replace plastic packaging with paper. The biggest challenge to making the switch, however, has been finding an alternative to the non-recyclable polymer coatings traditionally used with paper packaging to provide a barrier against moisture for food and beverage applications.

One category that has had some recent success in this area is microwavable noodle cups. Last year, Nissin Foods U.S. replaced the nearly five-decades-old polystyrene cup for its Cup Noodle ramen noodle soup line with a proprietary double-wall fiber cup from Graphic Packaging Intl. (see pwgo.to/8236). Following Nissin’s paperization lead, in January, South Korean C-store chain CU, part of BGF Retail, introduced its own microwavable paper cup—in this case compostable—for a new own-brand noodle line, New Today’s Chicken Noodle.

CU’s solution to the plastic coating conundrum was a custom-developed bio-based coating from CJ Biomaterials, a division of South Korea-based CJ CheilJedang and a producer of polyhydroxyalkanoate (PHA) biopolymers. CJ BIO found a way to combine amorphous PHA (aPHA) with polylactic acid (PLA) bioplastic for a microwavable coating that reduces petroleum-based plastic and increases bio-based content without compromising the functionality and quality of the paper cup. The coating also allows the package to be both home- and indus trially compostable.

In Korea, awareness of composting is not high, and the infrastructure is not universally available. Nevertheless, shares Hwang-Bo Min, merchandising department professional, BGF Daily Food Grocery team, PHA was applied to the inner surface of the Noodle Cup to improve sustainability by using bio-based coating.

Arrange a visit at your location today!

Scan to learn about our wide range of first-class Technical Services.

Visit us at Pack Expo East Philadelphia, PA

March 18-20, 2024

Booth # 721

PHA is one of the newest biopolymers to be produced at scale and is created through microbial metabolic processes. “Many bacteria produce and use PHAs as an energy storage material in nature,” says the company. “CJ Biomaterials’ PHAs are produced through aerobic fermentation, converting natural sugars [from feedstock such as corn and sugarcane] into PHA polymers directly inside microbial bio-factories comprising standard stirred, aerated fermentation tanks. Each fermentation consists of a growth phase, during which empty cells—the ‘bio-factories’—are grown to target concentrations, followed by a production phase, during which the cells fill up with PHA.”

According to the company, PHAs work well as modifiers to other polymers or biopolymers and can increase bio-based content, accelerate biodegradation, and improve the functional properties of resins and finished products. When compared with more widely used semi-crystalline PHA, aPHA (branded PHACT A1000P by CJ BIO) is a softer, more rubbery biopolymer that offers fundamentally different performance characteristics.

In the case of the coating for CU’s noodle cups, using aPHA with PLA enhanced the processability of PLA by providing flexibility and allowing for more stable use across a wide range of temperatures. “It also exhibits good oil barrier properties, surpassing conventional polypropylene coating while providing a 100% bio-based solution,” says Max Senechal, executive vice president and chief commercial officer at CJ Biomaterials.

The final package was manufactured in December 2023 and introduced in CU stores Jan. 3, 2024. The cup and lid are printed with the PHACT brand name and copy detailing the composition of the biodegradable coating used inside the cup. “CU wanted to show that this is a product that uses PHACT,” says Min. “We wanted to show customers that CU develops a variety of eco-friendly products.

Despite consumers inexperience with compostable packaging, Min adds that they are interested in the development of new products. “Although the eco-friendly concept may seem unfamiliar when it comes to Noodle Cup, customers believe that they are contributing to the environment by purchasing those eco-friendly products,” she says. —Anne Marie Mohan

The portion of composters’ operating costs spent addressing contamination, 85% of which is from conventional plastic, according to a report from Closed Loop Partners’ Center for the Circular Economy

3

The number of consumers who filed a lawsuit against Colgate-Palmolive, arguing that labeling on its Tom’s of Maine and Colgate brand toothpaste tubes designating them as recyclable is “false and misleading” because only a “miniscule” number of recycling facilities actually accept them for recycling

20-30%

The average increase in sales experienced by brands that have adopted connected packaging experiences, according to Jenny Mora Stanley of creative agency Appetite Creative 12.5M

The number of paperboard rolls that will be eliminated per year with Tesco’s launch of the “UK’s first-ever” tubeless kitchen foil, made possible by a new state-of-the-art rolling machine

“Though plastic remains the dominant material [for beverage packaging], it will face stronger headwinds going forward as the green movement stays strong and past efforts to improve the material’s image like lightweighting have run their course. Plastic packaging manufacturers must innovate on sustainability, either through improvements in the material itself or through commitments to plastic neutrality and circular economies through improved collection and recycling.”

–Joseph El-Hage, lead analyst, in a release from The Freedonia Group, “Plastic is Still King in Beverage Packaging Landscape despite Emerging Paper, Aluminum, and Molded Fiber Alternatives”

“The growth in bioplastics production capacity should be understood in the broader global context of a climate crisis, escalating energy costs, and disrupted value chains. Despite these challenges, the capacity for bioplastics production is on the rise, underscoring the resilience and significance of our industry.”

–Hasso von Pogrell, managing director of European Bioplastics (EUBP), in an article from the association, “EUBP unveils the results of the 2023 Market Data Report”

“Multipacks and secondary packaging are key to creating a sustainable alcohol brand. The key is to combine functionality and consumer convenience with sustainability. Paperboard packaging has come a long way in terms of its functionality, with barrier coatings available to increase durability in moist or chilled environments, for example. Packaging still has to be desirable as well as sustainable, especially in highly competitive categories. If the packaging isn’t desirable or functional, it won’t sell, which adds up to more waste.”

–Renan Joel, managing director of packaging at event company Easyfairs, in an article from The Spirits Business, “Can paper packaging be premium?”

“We will support thoughtful packaging EPR proposals that properly balance the needs of all stakeholders. We will not support poorly designed packaging EPR proposals that we believe are not based in reality and will not result in positive environmental change and greater packaging recovery and recycling.”

–Dan Felton, executive director of AMERIPEN, in a press release from the association, “AMERIPEN Testifies at U.S. Senate Committee Hearing on Extended Producer Responsibility Policies for Packaging”

Helping you bring your best products to market.

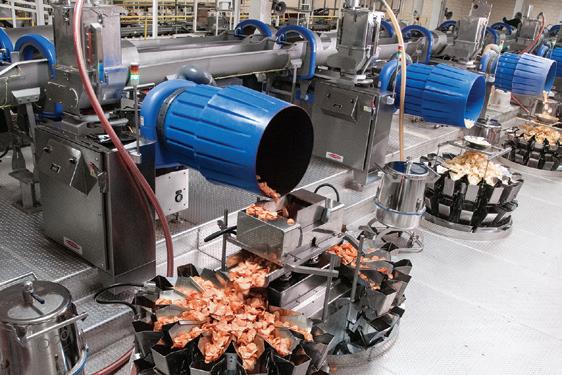

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

PROCESSING AND PACKAGING SOLUTIONS

• Food processing systems

98

17

• On-machine and process area seasoning application

• Conveying and product handling

• Multihead/combination scale weighing and filling

33 32

• Snack bagmaking and case packing

• Metal detection and x-ray

34

• Check weighing and seal checking

• Controls and information systems

116

94

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

99

36 26

108

42 0842 2 ~2~ ~2

107

20

The largest recycler in North America, WM, is making critical investments in AI, automation, and innovative technology to modernize its recycling facilities and expand recycling access to communities in a more than $1 billion planned investment through 2026. How is that money being distributed?

Brent Bell:

First, we’re going into new markets where there are not really a lot of recycling processors today. We know that there’s a demand for more consumers to get access to recycling, so we want to give them the processing infrastructure to do that. One great example is Fort Walton Beach in the Florida panhandle. During COVID, there were a lot of folks that relocated to that part of the country because they could work remotely. They came from areas that had strong recycling programs and arrived to find there was little recycling infrastructure there. So WM is there and in other new markets to unlock supply material that is currently going to the landfill.

Brent Bell, VP of recycling, WM

Brent Bell, VP of recycling, WM

WM just announced a billion-dollar investment in recycling infrastructure. We sat down with Brent Bell, VP of recycling, to see how the money will be spent (hint: AI optical sorters and new facilities), and what it means for pack design and PCR supply.

Then in our existing facilities and markets, we’re automating with the latest technology, including AI. What that new automation does for existing facilities is make a much higher quality bale of material. A lot of the brands want to use recycled plastic in a bottle-tobottle fashion, or they want to get their own recycled materials back into their packaging. Whether that’s because of minimum [recycled] content laws or because of their own sustainability goals, they want it. We’re able to make a higher quality material because we’re able to sort this optically and with AI technology. A side effect is we’re able to reduce labor, which a nice tradeoff because labor in those [material recover] facilities is often hard to get. We’re also upgrading our labor staff with more modern technology. The folks at these recycling facilities are now using tablets, and they’re programming the optical sorters with computers these days. And the biggest benefit is that it increases our capacity. In the same footprint where we may have processed 20 to 25 tons per hour, we’re now able to process 40, 45 tons per hour with the latest optical tech.

Where in your facilities is AI making this difference?

It’s predominantly being applied to the optical systems, on the near infrared (NIR). Those opticals are sorting at a thousand picks per minute. The quicker they can identify material and those objects, the better.

There also have been some great cases where we were using it to identify different compositions on certain lines. Or from a safety perspective, we’re looking to use AI to identify propane tanks, batteries, or other items that could be dangerous at a facility. We could use AI in the future to look at the material streams and learn what kinds of products are we seeing. We could go back to certain brands and let them know if we’re seeing one of their products or classes of products, or if we’re not seeing it in our recycling streams.

And if you think about extended producer responsibility (EPR) and some of those programs in the future, think that data’s going to be more relevant. It will help us learn how much of [a given brand’s] material actually gets recycled. That’s why WM is working with brands to make sure the packaging they’re putting on the shelves is recycling-friendly, and designed in such a way that this AI can account for it, so that the optical scanners can recognize these materials and properly put them in the right buckets.

Just yesterday I was with a major brand, and we had this exact discussion. Because we’re designing this equipment that hopefully lasts in these communities for five or 10 years to come, we need their input up front. The beauty of some of the new technology is we can adapt it to changing packaging, but it’s only helpful if we’re working with the brand from day-one. When they invent that product and to start designing their packages, we need to make sure that we can accommodate those; that they will be recycling-friendly at the end of their life. We’ve always had this open door, if you will. We’re happy to either test or otherwise help identify whether your new product or package is going to be recovered. We’d love to be involved on day-one

Protect your brand with inspection solutions that enhance food safety and weight compliance for packaging lines.

When inspection equipment is at the forefront of food safet y and qualit y, downtime is not an option. We understand the impor tance of preventative maintenance and technical suppor t that ensure your equipment, and your brand, continue to thrive

Dont miss us this fall at Pack Expo International! Find out more about our inspection equipment and see live demonstrations at BOOTH 1758!

sales@fortresstechnology.com | (416) 754-2898

LEARN MORE ABOUT OUR EQUIPMENT ONLINE

to determine if our new automation sites can handle that package, to recognize and properly sort it.

But WM’s high-efficiency facilities with high-tech AI optical sorters aren’t the only ones out there. You have to account for older recycling infrastructure, too, right?

Right. If we can handle it, then that’s great. But we are also pragmatic, knowing that there’s a lot of recycling facilities that we don’t process material for. We have to consider the average MRF or recycling facility in the U.S. Would they be able to process it as well? Because, for a brand, they’re not just going to go forward if WM can process a package at their new facilities, but all the other older facilities can’t. So we want to make sure we approach that as, ‘Hey, listen, while we may be able to process this, others may have a challenge. So why don’t you just try to make that bottle out of clear plastic instead.’

and the brand and the marketing team what they want, but also make it recycling-friendly at the end of the lifecycle? We want to see what those packs are up front, maybe before going to market, so we can offer some suggestions that might have a negligible impact cosmetically, but a major impact on the backend, on the recyclability.

What about small format packaging recovery?

What we call small is less than three by three inches. The small stuff, quite frankly, is always going to be somewhat of an issue with curbside recycling. We’re looking at other solutions, like home channels where consumers can put all their plastics in a bag that then goes into the bin. But those aren’t ideal for automated facilities because the scanner is going scan on the outside of the bag, and we don’t have enough employees to spend on handpicking these bags.

How do you talk to brands about colored vs. clear bottles?

Bottles are the classic example. Every bottler wants clear back, they don’t want the greens and they don’t want the blues. Colored PET typically ends up the textile industry. And that’s fine, and that’s a great market for. But if a brand truly wants to be bottle-to-bottle, you can’t be packaging your product in green or blue bottles, expecting to get back clear. That’s just not a realistic tradeoff. At some point, a brand has to get marketing and sustainability teams to work together to balance between a bottle that’s still attractive on a store shelf, but also recycling-friendly. We’re here to help to make sure that it’s designed properly from the get-go.

What other sorts of advice do you find yourself giving brands to make their package designs both more recoverable and valuable to end markets?

Some of the new PET bottles you’ve seen on the shelves have a full shrink wrap on top of them. If that shrink wrap is polypropylene, but the bottle is HDPE or PET, the first optical or AI is going to recognize that as being polypropylene. So we advise brands try to make the grade of resin consistent throughout that bottle. And from a flexible packaging perspective, the multilayers and the different layers of commodities, that doesn’t make it recycling-friendly because it’s impossible to separate all the different layers in there. The big question is, how can we still give your consumers what they want,

So we don’t have a perfect answer for the small, three- by threeinch or less packaging, and it’s not accepted in our programs today. But as we’re looking at EPR, and everyone wants to get materials back, maybe a non-curbside solution can address the small format.

When making this investment, what kind of brand or CPG input did you receive?

The one thing we heard loud and clear when we were making these investments was that there was going to be demand for recycled material. That could be the result of internal sustainability goals, or of legislated minimum content requirements, or both. If you go down the list of every major brand, see what they’re doing today, and then see what they want to do tomorrow, it’s a massive, massive ramp up on reusing recycled materials in packaging. Let’s take plastics as an example. It has a relatively low recycling rate today, so we’re going to need five to 10 times as much plastic to get recycled to even become close to meeting these brands’ goals. We asked ourselves, ‘how do we unlock more supply, and not just take market share away, but how do we go and get markets, and capture and supply material that’s going to the landfill today?’

Our portfolio of new capacity, plus new markets, is about 2.8 million, almost 3 million tons of new capacity that we’re going to open that will unlock supply that’s going to the landfill today, and put that back into the recycling facilities that we’re investing in. That said, plastics is about 5% of what we deal with. That 3 million tons, it’s all grades. It’s just a blended, single-stream pile. But we are doing education campaigns specifically around plastics because it’s one of the highest value materials we collect. And because of the way we share our commodity values with the inbound customer—typically a municipality—then if they can increase the amount of plastics in their bin, that helps out their economics as well. We’re trying to promote good recycling practices to make these curbside programs successful, and increasing the recycling of plastics is a key to doing that. Inevitably that will create more material that we can get in the curbside programs, which will make more material available for these brands to hit their sustainability goals and minimum content requirements that are coming in a few years as well.

When you need mission-critical labeling systems that will be reliable, cost-effective, and easy to use, you need a partner that you can trust.

Weber Packaging Solutions is a family-owned label solutions company that has been helping customers look their best for over 90 years.

We provide turn-key labeling solutions, like the new Model

modular print-apply labeling system or the ELF-50 front/back label applicator. With experience in just about every industry, we make sure you succeed in getting your product labeled correctly.

Visit us at www.weberpackaging.com and see how we can ensure your next project is successful.

Polypropylene is emerging as a more valuable, desirable recycled material in the U.S. Where is WM on that stream?

Ten years ago, polypropylene was just hidden in the [plastic recycling symbol] three through seven bales. For the most part, people that were buying three through seven bales were buying them to try to get the remaining ones and twos out, since some would sneak through. The irony to it all was that anybody that was making a three through seven bale, the real value was just what got left over. We started working with KW Plastics nearly 15 years ago, that was their first polypropylene order from us. That’s obviously a business that’s grown. It’s been a great story for them because we’re collecting polypropylene, and KW turns it into paint cans that are now on the shelves of Home Depot, Lowe’s, and all the retailers.

We’ve increased our polypropylene over the last few years by 40%. Most or all recycling facilities now sort polypropylene. The economics are just too good to pass up. We see that as growing for more and more recyclers to actually process it separately. But also more importantly, we’re seeing that being a go-to grade to use for brands who had been using a generic number seven grade. We’ve seen a lot of them switch over to polypropylene to use their materials because they see it’s recycling-friendly. It’s a good packaging grade to use, and now if you go down the store shelves, there’s way more polypropylene—yogurt, butter dishes, etc.—a lot more than in year’s past. As long as the size is greater than three by three, it’s a valuable material.

I’ve heard you say that plastics is only about 5% of the material you collect, but it creates something like 90% of the conversations. Will that always be the case?

It shocks people is when we say that, but it’s true. In the average stream today, if you look at anybody’s average bin, it’s got cardboard, mixed paper, aluminum, steel, and plastics, but plastics are only 5%. And that’s a pretty small piece for us to deal with, but it’s a big part of the conversation because that’s what’s in the newspapers. Whether it’s ocean plastics or plastic pollution or single-use plastics, people want to know what else we can do with it. We’re trying to do our share to make sure that there’s an infrastructure in place to increase the recycling rate of all commodities. But specifically, if you can increase it on plastics, then it helps out the economics with everyone in that recycling value chain.

Consumer recycling remains voluntary. Does that need to change to get to the volumes of PCR that brands say they’ll need?

That’s the most amazing thing that I think people overlook. They don’t realize that, for the most part, curbside recycling is completely a volunteer program. There’s nothing to force someone to recycle at a curbside program. I get that in California, there’s some laws with commercial, but for residential, no one’s forcing you to recycle. It’s the right thing to do, but it’s a volunteer effort. That’s where we’re really trying to share that message, ‘Hey, the economics work if you don’t put this stuff in a landfill. It’s way too valuable. Let’s make sure that it gets recycled.’

But even more surprising, this voluntary program is one that big chunks of the supply chain rely on. During COVID, we had a lot of communities that were short on drivers, so they had to stop their recycling routes. We got notifications from our plastics vendors, from our cardboard folks, because there are certain parts of the value chain that can’t use virgin material anymore. They have committed their whole process to using recycled content. We sent these communities letters back saying that we knew there’s a shortage of toilet paper and tissue supplies for hospitals. Those all get delivered in boxes, and those boxes are made from paper mills that can only use recycled material. That means we can’t have a disruption in the recycled material supply chain, or else it’s going to really impact your grocery store shelves and your hospitals. I don’t think that the average community is aware that recycling is a necessity in the supply chain now.

What’s on the horizon in terms of recycling films? Are we going to evolve beyond store drop-off and get to curbside film recycling?

There’s a place just outside of Chicago called Hickory Hills where we’re doing a curbside film recycling pilot. We started another one in the Salt Lake City area as well to unlock that stream. Meanwhile, we’re automating our MRFs to be ready for films. In some cases, we’re initially

putting in the whole film system. And in other cases, we’re just making sure that it’s engineered so that we can put a film system in place in the future. Once we get done with these pilots—at some point, and we’re not there yet—the goal is that we can tell consumers to put all their plastics in the bin. Because people get confused with recycling, and when you ask them what they’re confused about, they generally say plastics. So we hope to eventually tell them to always recycle plastic. They can put it all in there and then we can sort it, whether it’s film or rigids, at these automated recycling facilities. We didn’t know initially, until we did the pilots, if we were even capable of doing this. And interestingly enough, even without accepting it, film represents about one to 2% of our materials in the bin to begin with. It’s a pretty high percentage to begin with, even though it’s not accepted in any of these programs. That’s where these pilots’ results will be fascinating, in part to see how much more material we can actually collect. But we’re starting with film pilots now, and then if those go well, we’ll scale them.

How are these pilots in Hickory Hills, Ill., and Salt Lake City performing so far?

In a way, we’re kind of forcing it to work because we’re pretty committed to it. Even if we don’t officially accept film in our curbside programs, we can still take the 2% out that we’re getting today, and make sure that we have good end markets for this material. That’s going to be the next big step in film recycling—making sure that we’ve got good, secure end markets that are sustainable. Then, we can start going into communities and putting films on their acceptable items list. Not all communities at once, we’ll phase it in. That’ll be the next step of that process.

From a mechanical recycling perspective, how do you view the advent of chemical or advanced recycling?

There are like $8 billion in projects related to chemical recycling going on today. I don’t know how many will get finished. We’ve already talked about brands’ demand for PCR materials to go back into their products. The demand for material for chemical recycling in a few years, with all these new plants, is going to be huge. So we’re trying to unlock more supply. Our view is that mechanical recycling will always take a precedent over chemical, but chemical is going to be absolutely needed for what I’ll call the non-mechanical recycling-friendly plastic grades. It definitely has a home in the recycling infrastructure. We’re excited for those folks to come online and start taking some material that isn’t really all that easy to mechanically recycle today.

Are you keeping an eye on HolyGrail 2.0, digital watermarking tech, and digital passports as pilots begin to scale in Europe?

It’s really interesting, but the viewpoint I have on that is kind of simplistic. They can put all these digital codes on the packaging if they want, but if people are still putting in it the trash bin and not recycling it, it doesn’t matter because none of my machines are ever going to read it. I have to get the material out of the trash bin and into the recycling bin. My view is that we’re a long way away from [digital watermarks and passports] being a benefit. I need just people to recycle. Everybody knows that a plastic bottle is recyclable, but we’re only getting three out of every 10 of these in the right bin. We just need to get folks to put the right materials in the right bin first. If machines can read that material at some point, and that adds to better sortation, that’ll be great. But if it goes in the trash bin, it’s not going to do anybody any good.

Packaging World readers are brand owners, CPGs, FMCGs, and food, beverage, and pharma companies who rely on packaging to deliver their products to consumers. Do you have any parting thoughts for them?

I would say that we hear their message loud and clear. Whether it’s through your own sustainability goals or through regulation, there’s a big and growing demand for recycled material and a need for companies like WM to unlock more material. We’re making investments in infrastructure to do just that. Any help we can provide on education or help on making sure your packaging designs and materials are recycling-friendly, our doors are open for that. Because we want this to be successful for everybody, and to increase the recycling rate. The overall goal is to get more material in this circular economy backing the right hands. We’re excited to be a part of that. PW

With our state-of-art Feeders, Prefeeders, and Assembly Systems, quality isn’t just a feature, it’s our standard.

Highly qualified technicians available for on-site repairs.

training.

spare-parts department.

By Sterling Anthony, CPP, Contributing Editor

By Sterling Anthony, CPP, Contributing Editor

All brand owners know whether their products are vulnerable to the spoiling effects of oxygen. But not all know how to systematically manage that vulnerability with packaging. Brand owners who include the oxygen transmission rate (OTR) in their decision-making need a solid understanding of its capabilities and its limitations.

OTR measures the steady-state diffusion of oxygen through a permeable material. Diffusion occurs at different rates at different conditions of temperature and relative humidity (RH). That’s why testing is done under standardized conditions and the results expressed in standardized terms, for example cc/100 in2/24 hours (or a metric version).

This article is not about packaging that has undergone a change to its internal oxygen content. Exempted, therefore, is modifiedatmosphere packaging (MAP), which purges oxygen and replaces it with an inert gas. Also exempted is vacuum packaging, which removes oxygen, causing the packaging film to tighten to the contours of the product. Those exemptions notwithstanding, the packaging still must provide adequate barrier.

The term, “barrier flexible packaging,” clouds the fact that all flexible packaging provides barrier, some just better than others. An OTR is useful for comparing options under identical ambient conditions. The OTR, conversely, might not correlate with the ambient conditions that the packaged product will encounter throughout its supply chain. Standardized test conditions of 73°F and 0% RH, for example, might not be consistently encountered throughout a regional supply chain, and even less so throughout a national one.

ethylene ratios yield better barrier and improved processing. On a different but related note, recycled polymers are not as chemically homogenous as virgin polymers. The respective OTRs will be different, in favor of virgin, even if not by much.

In the United States, laboratories cite ASTM D3985 Standard Test Method for Oxygen Transmission Rate. Some film suppliers also provide testing, but laboratories can claim to be disinterested parties. That said, laboratories are known to be less objective about their testing equipment. Whether evaluating a laboratory or a film supplier, a brand owner should be wary of a party who promotes a standard uncritically. Wariness also is warranted if a party tries to dissuade a brand owner from modifying a test so that results correlate better with anticipated conditions.

In addition to oxygen, barrier might have to be provided against moisture and light. A generalization is that the more types of barrier needed, the more the structure is likely to incorporate foil or a metallized substrate. If, however, light is not a concern and there is a marketing advantage to a clear (transparent) package, consideration can be given to structures that incorporate PVDC (polyvinylidene chloride).

There are data that compare the OTRs of the various films, at the same gauge, from poorest to best. There’s no need to start from square-one in identifying plausible candidates.

There are data that compare the OTRs of the various films, at the same gauge, from poorest to best. There’s no need to start from square-one in identifying plausible candidates. But no matter how reliable the data and how application-suited the barrier flexible packaging, it can be all for naught if the brand owner’s facility lacks certain quality-assurance (QA) measures.

An OTR less-than-or-equal-to 1 cc/100 in2/24 hours is considered high barrier. Its relevance should be evaluated by asking, “Is that much barrier needed? What structures can provide it? What is the cost? What are the involved technologies? And how can that barrier be leveraged for a competitive advantage?”

OTR is affected by various factors. One is the thickness of the structure, especially for a monolayer film. There are practical limits— costs and machinability among them—as to how thick a film should be. Thickness also is a limiting factor for multilayer structures, particularly laminations and coextrusions. There, the barrier layer typically is the most expensive, so there is a cost incentive to use it in the thinnest layer suitable for the application. The same frugality should extend to materials used as barrier coatings.

OTR also is affected by the chemical composition of a film. A case-in-point is the copolymer EVOH (ethylene vinyl alcohol). Higher

One such QA measure concerns incoming supplies, making sure that what’s received meets specification. A manufacturer of prosthetics (e.g., knee replacements) failed in that regard. The oxygensensitive polymer component of those devices was supposed to be protected by the packaging. For years, the manufacturer received packaging that was missing its oxygen barrier. This was discovered after implanted prosthetics prematurely degraded, necessitating replacement surgeries. It triggered a bevy of lawsuits, still being litigated at the publication date of this article.

Another QA concern is the integrity of the sealing operations. Barrier flexible packaging can be perfect in terms of its construction yet be sabotaged by poor seals. Entrance of oxygen through a poor seal is easier than diffusion. The sealing station needs to remain calibrated at the correct combination of temperature, pressure, and dwell time.

In conclusion, achieving flexible packaging that has the requisite oxygen barrier is a multi-faceted undertaking, but the correct approach clears the air and lets the brand owner breathe easier. PW

By Anne Marie Mohan, Senior Editor

By Anne Marie Mohan, Senior Editor

Reduce. Reuse. Recycle. It’s not just a catchy slogan; it’s actually a waste hierarchy that starts with the most preferable strategy and works its way down the list. Therefore, after reducing—or eliminating— packaging material, reuse is the next best strategy for tackling plastic packaging waste, yet it’s the one that’s used the least. According to the Ellen MacArthur Foundation, just 2% of the packaging used by its New Plastics Economy Global Commitment signatories is reusable, and that number has remained constant since the program launched in 2018.

As two recent reports illuminate, the widespread adoption of reusable packaging can result in substantial environmental benefits and is “critical to tackling the plastic waste and pollution crisis.”

That’s according to EMF, whose 2023 report, “Unlocking a Reuse Revolution: Scaling Reusable Packaging” (see pwgo.to/8237), outlines the challenges and opportunities to scaling up reusable systems and what’s needed for a complete system change. The second report, “Refill Again” (see pwgo.to/8238), from non-profit ocean conservation organization Oceana, describes the scale of the plastic pollution problem and the impact reusable packaging offers.

Both reports are based on a reuse model where consumers purchase products at retail in reusable packaging that they then return to the store for subsequent sorting, cleaning, and refilling. While EMF’s report focuses on a variety of single-use plastic packaging applications, i.e., food, beverage, personal care, etc., Oceana’s centers on single-use plastic beverage cups and bottles, the latter of which, it says, is the second most common litter item across seven aquatic environments.

Although the reports differ in scope, they offer many similar conclusions. The most notable is that “returnable plastic packaging has better environmental outcomes than single-use plastic packaging across almost all scenarios, applications, and performance indicators” (EMF). Another is that recycling is a false solution to the plastic crisis. Reports Oceana, “It has been estimated that only 9% of all plastic produced since the 1950s has been recycled, with the remaining 91% incinerated, sent to landfills, or lost to the environment.”

Furthermore, Oceana says that recycling could actually be exacerbating pollution by releasing huge quantities of microplastics into wastewater. It also notes that the use of more recycled content—a goal of nearly every major CPG—does not make it more likely that a bottle will be collected and not become pollution in the ocean.

Another point made by both reports is the importance of collaboration. States EMF, “To reach the scale necessary to tackle plastic pollution, reuse urgently needs to be scaled; to make the economics work, collaboration is essential.”

One group identified as essential to this transformation is CPG brands; Oceana’s conclusions note that the beverage industry in particular holds the key to substantially reducing aquatic pollution

from plastic bottles and cups. Other groups tapped as being crucial to scaling up these systems are policymakers, including state, federal, and global, who have a crucial role in creating the enabling conditions, and financial institutions, which are needed to support and invest in new infrastructure.

EMF’s report models three different theoretical reuse scenarios: a fragmented effort, a collaborative approach, and complete system change. It concludes that the greatest impact can be achieved with a complete system change, which it defines as “a visionary scaled, shared, and standardized return system.” This will require a highly shared infrastructure, where sorting and cleaning centers and transport to and from the centers is shared, and all parties operate under the same rules and standards. It also relies on standardized, pooled packaging.

If the infrastructure is put in place for a total system change, EMF estimates that moving to reuse can result in a 20%-plus reduction in annual plastic leakage to the ocean by 2040. Other environmental wins include (not surprisingly) a reduction in the use of virgin plastic, and—depending on the reuse scenario—a decrease of 35% to 69% in GHGs related to rigid-to-rigid packaging and a reduction of up to 30% to 70% in water consumption. It will also result in a significant drop in plastics volumes, up to 54% to 76%, and a decrease in waste generation of up to 90%.

Another notable finding by EMF is that even when a single-use plastic package uses 100% recycled content, reusable packaging still outperforms single-use packaging in terms of environmental impact. This excludes single-use flexible packaging, whose light weight results in lower GHGs versus reusable packaging.

Oceana’s findings are similarly compelling. It reports that a 10-percentage point increase in reusable packaging by 2030 could eliminate the equivalent of over 1 trillion single-use plastic bottles and cups and prevent up to 153 billion of these containers from entering our world’s oceans and waterways.

Given the tortoise-like speed of adoption until now, reusable packaging has a long journey ahead before achieving such results. To speed this transition, in “Refill Again,” Oceana urges all beverage and bottling companies to set targets to increase reusable packaging by at least 10% and allocate appropriate involvement and marketing resources to ensure these targets are achieved.

In “Unlocking a Reuse Revolution,” EMF advises stakeholders on three concrete actions they can take to realize the full benefits of return systems. These include adopting a fundamentally new approach, kickstarting the transition by deploying collaborative multi-brand and multi-retailer systems, and following through by enlarging these systems across a greater range of products, sectors, and geographies. PW

Rockstar Energy kicked off 2024 with a dynamic new look and feel. The brand unveiled the latest visual identity refresh across its full product range, its first in more than four years since its acquisition by PepsiCo in 2020. During the intervening years the brand had transitioned and progressed into a lively, vibrant, and refreshing aesthetic. The latest move is evidence of Rockstar’s progressive approach to continuously evolve the brand to appeal to more diverse and modern energy drink fans.

The refresh is timed with a new strategic evolution towards a future focused on Rockstar’s zero-sugar range. It’s also part of its wider “Press Play” platform launched last year, which the company says encourages consumers “to say yes to the things they love to do.”

“The refresh is the visual complement to this, with every touchpoint of the identity oriented towards Rockstar’s evolved brand positioning,” Marie-Therese Cassidy, VP of design, PepsiCo Europe, says.

The new look retains its iconic star logo but departs from the previous design by introducing a simpler, more universal appeal. The idea is to cater to a broader, more modern audience of energy drink consumers across the portfolio.

“First and foremost, our new visual identity provides greater accessibility and inclusivity by differentiating Rockstar from traditional energy drink norms,” Cassidy says. “Rockstar has a wide variety of flavors, including both full-sugar and no-sugar variants, and we wanted the visual identity to reflect how these extensive offerings cater to a broader audience.”

While the new design is a departure from its predecessor, some elements were too infused into the brand’s identity to abandon. When asked what was kept, “Definitely the gold star, which is synonymous with the Rockstar brand,” Cassidy says. “We optimized the size and positioning a bit in the refresh, but the shape and color remain the same in the new design.”

The star logo’s placement on the can, however, changed to be more consistent across the flavor range. A single gold star logo is now centered on the can, providing a singular visual gateway into Rockstar’s full range of flavors.