MAR2023 packworld.com 14 Shaping a Pandemic-Era Workforce 20 Soft-Grasp EOATs Gently Grip Potatoes 24 New Twist Wrapper Packs 1,800 Candies/Min 28 Remote Access Streamlines Nutraceuticals 32 Chicken of the Sea’s Fresh Pack Design 11/18 Compostable, Advanced PCR Snack Bar Films Arrive Learn more about our automation solutions at www.westrock.com/ automation

w ©2023 W y ar y W y s r v

T TION SOLUTIONS W ( v or improv L w B

CONNECTED

Many players, one team.

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

www.syntegon.com

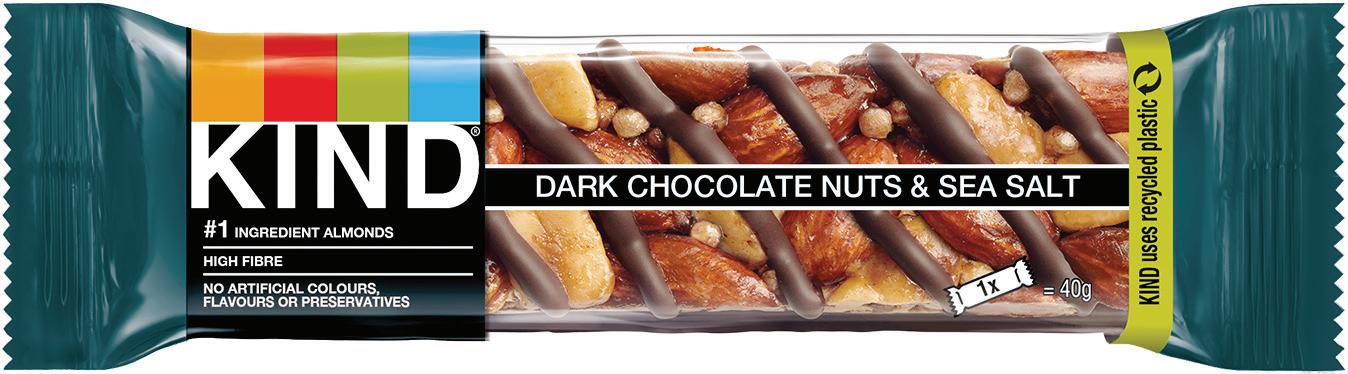

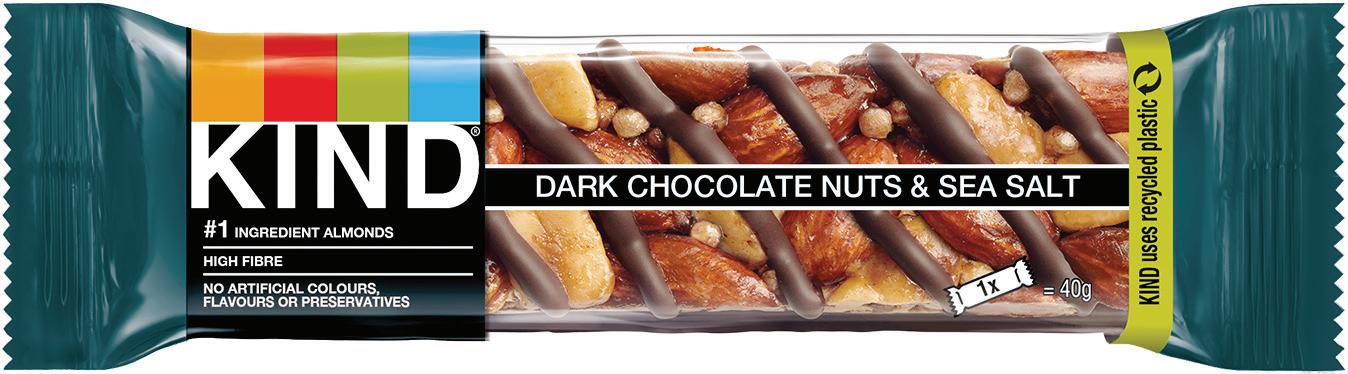

From Mars’ KIND bars’ PCR wrappers made from chemically recycled material (below), to up-andcomer BAR-U-EAT bars’ BPI-certi ed compostable owwrap, the snack bar segment is an early adopter of sustainable new lms.

FEATURES

20 Small Potato Producer Gets a Grip on Growth via Robotics

Using robotics to fuel growth while staying competitive, a leading North American grower, shipper, and packager of bite-sized potatoes is keeping costs down and employment and production up.

24 New System at Orkla Twist Wraps 1,800 Chocolates/Min

Norwegian multinational Orkla tests a new wrapping machine for its chocolate pralines that handily matches the high-speed output of its molding equipment.

PRODUCTS

Aladin Alkhawam Director, Packaging Operations, Par Pharmaceutical

Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé

M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America

Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks

28

HEALTHCARE PACKAGING Remote Access, Monitoring Key to CMO’s Printing Ops

While many manufacturers are hesitant to dive into remote capabilities with their OEM partners, by leasing all printing equipment, this nutraceutical CMO is motivated to make full use of the tech.

Mike Marcinkowski Global R&D Of cer, GPA Global & Hub Folding Box Co.

Paul Schaum Chief Operations Of cer, Pretzels Inc.

David Smith, PhD Principal, David S. Smith & Associates

Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc.

Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

2 PW MAR2023

VOL30 NO3 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing of ce, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing of ces. Copyright 2023 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld.com/subscribe. Free digital edition available to quali ed individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable rms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address.

5 Lead Off 16 The Big Picture 18 Sustainable Packaging

Shelf Impact!

Professional Perspective

News

Quotables/By the Numbers

14 First Person

COLUMNS

32

36

NEWS/EVENTS 6

12

INTERVIEW

34 Technology ADVERTISING 35 Advertiser Index

ADVISORY BOARD

EDITORIAL

DEPARTMENTS

28 20 11 18

ACOPOS 6D

Versatile. Levitating. Adaptive.

• Magnetic levitating shuttles

• Ideal for small-batch production

• Six degrees of motion control freedom

• Fully integrated into the B&R ecosystem

br-automation.com

B&R | A member of the ABB Group

Matt Reynolds Chief Editor

Anne Marie Mohan Senior Editor @PackagingTrends

Iris Zavala Managing Editor

Sean Riley Senior News Director

Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors

David Bacho Creative Director

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Client Success & Media Operations

Jen Krepelka Director, Digital Media

Mike Prokopeak Senior Director, Content & Brand Growth

Trey Smith Senior Director, Events

Sharon Taylor Director, Marketing

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Lloyd Ferguson Founding Partner

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com

CALL 1-877-236-0266 OR SEE VIDEOS OF OUR MACHINES IN ACTION AND MORE AT UNIVERSAL1.COM Break-Away Tamp Systems Flag Labeling Systems Hugger Belt Systems Indexing Roller Systems Interrupted Belt Systems Multi-Panel Systems Split Belt Systems Tamp/Wipe Systems Tamper Seal Systems Vacuum Belt Systems Vertical Trunion Systems Zero Down Time Systems WHEN IT COMES TO LABELING, YOU ONLY NEED TO KNOW ONE THING... OUR NAME. 4 PW MAR2023 Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Phone: 312/222-1010 • Fax: 312/222-1310 E-Mail: info@packworld.com • Web: www.packworld.com PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com ADVERTISING

Sawtell Vice President,

wsawtell@pmmimediagroup.com

Wendy

Sales

Lara Krieger Production Manager lkrieger@pmmimediagroup.com Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com CONTENT

Follow us on twitter @PackagingWorld

Do We Practice What We Preach?

We’re currently in the meatiest portion of the spring conference season. Packaging World editors attend a lot of packaging conferences, expos, and events, and as you would expect, many of them focus on sustainability. Because we’re in packaging, recycling tends to be the biggest topic within the broader sustainability theme.

At these events, I have an admittedly oddball habit of auditing trash bins. My anecdotal findings might be depressing if they weren’t so revealing of the problem we face with recycling. Next time you’re at a sustainable packaging conference, I challenge you to look in the garbage. Try to mask your surprise when you see a mix of PP coffee lids, aluminum Diet Coke cans, PET Coke bottles, and thermoformed PET drink cups, all co-mingled in the trash. This even occurs when there’s a single-stream recycling bin right next to the trash can. It also happens at those wellmarked but still somehow confusing disposal stations that we see in major expo halls. They clearly state where paper, plastic, and aluminum ought to go. In my experience, they’re all like that. No conference or expo is immune; recycling adherence is almost coincidental.

Shouldn’t the speakers and attendees in these halls be among the most adept with materials and recyclability? And given the subject matter floating around the room, shouldn’t recycling at least be top-of-mind?

I suspect a few factors are at play here. One might be that those conference attendees are too smart for their own good. Many folks in the know wouldn’t necessarily be wrong to assume that, at a private hotel conference hall, that Diet Coke can isn’t getting recycled anyway, regardless of which bin it ends up in. Why make the extra effort? And at a basic human level, what’s one Diet Coke can? Of course, extrapolating that piece of human-nature to 8 billion plus folks is a problem.

Also, we’re all traveling out of state to most of these conferences, and waste collection doesn’t always look the same at home as it does where we land. I hail from Chicago, where it’s claimed we have single-stream recycling that’s sorted post-collection (a dubious claim, but that’s another issue). Some states are seeing benefits from dual-stream recycling that asks residents (or for our purposes, attendees at conferences and expos) to do some of the sortation up front, upon disposal. It might make for cleaner bales, but it unavoidably results in confusion and diversion of valuable recyclable material to landfill. Plus, at private hotel exposition halls and conference centers, all bets are off.

I suspect the biggest factor is convenience. Between sessions, attendees are likely off to the restroom and then to respond to that urgent email they received during the aluminum recycling presentation. Proper disposal of that Diet Coke can is an afterthought, and there might not even be a blue bin available. Limited by basic human nature, we can only assure adherence by making recycling effortless, indistinguishable from all other trash disposal.

In Europe, some interesting sensor-laden active and intelligent packaging solutions appear to be on the rise for sortation. Chemical (advanced) recycling plants that represent another potential silver bullet to recycling are popping up all over. And perhaps AI will be doing the sortation for us before long, anyhow.

But between now and then, can anyone tell me what to do with this thermoformed PET tray? I have no idea if whatever MRF or reprocessor ends up receiving it (and in Chicago, even that’s not guaranteed) is equipped to handle thermoformed PET’s more crystalline intrinsic viscosity.

And if those of us who blather about this everyday are completely lost in the weeds, what can we expect from the average consumer? PW

mreynolds@pmmimediagroup.com

5 700+ Modular Technologies Ideal for: Industries: • Difficult-to-handle products • High-speed collation • Advanced automation • CPG • Contract Packaging • Food and Confectionary • Personal Care • Household Goods • And many more... To find out more, see www.pmikyoto.com or email us at sales@pmikyoto.com

LEAD OFF

Real Packaging World photo of a trash bin at a sustainable packaging conference held last year.

Paper Packaging Expands to Reckitt’s Dishwasher Tablets

Innovation that enables a switch from plastic to paper packaging for a range of Consumer Packaged Goods products having challenging barrier requirements has been on a tear of late. This includes paper bottles for liquids, flow wraps for confectionery, and cups for yogurt. Among the latest is a new stand-up pouch for multinational Reckitt’s Finish dishwasher tablets, a particularly difficult application given the product’s water-soluble nature.

Introduced in Carrefour retail stores in France in the fall of last year, the paper-based pouch is the culmination of a multi-step process by Reckitt to “achieve the ultimate pack in terms of sustainability.” That’s according to Krzysztof Krajewski, director of packaging sustainability hygiene at Reckitt, who says the innovation around the Finish package first gained momentum in 2018, when the company developed a long-term plan to reach its goal.

“In 2019, Finish replaced the non-recyclable plastic laminate from its stand-up pouch with a recyclable film,” he says. “Later in 2021, we incorporated a minimum of 30% recycled plastic into its recycled pouch and rigid packaging, eventually leading to the paper-based packaging that launched in November 2022.”

Top 5 Robot Trends for 2023

New data from the International Federation of Robotics shows that in 2022, the stock of operational robots around the globe hit a new record of about 3.5 million units, while the value of installations reached an estimated $15.7 billion. Looking to 2023, IFR has identified five trends that will shape automation and robotics in the coming year. These include:

The new pouch was developed by Reckitt and longstanding supplier Mondi, whose tactic is to “use paper where possible, plastic when useful,” says Olivier Seux, head of global key accounts at Mondi. Seux explains that Mondi used its EcoSolutions approach, whereby it jointly evaluated the requirements of the product packaging—sealability, durability, and water-resistance—along with Reckitt’s sustainability goals to design and manufacture the new pouch.

“The paper-based packaging is replacing 75% of plastic with responsibly sourced paper and works towards Reckitt’s sustainability target of

1.Energy efficiency: Energy efficiency is key to improving companies’ competitiveness amid rising energy costs; the adoption of robotics can in many ways help lower energy consumption in manufacturing. Compared to traditional assembly lines, significant energy savings can be achieved through reduced heating, while at the same time, the high speed of robots increases production rates, making manufacturing more time- and energyefficient.

Today’s robots are also designed to consume less energy, which leads to lower operating costs. To meet sustainability targets for their production, companies are using industrial robots equipped with energy-saving technology such as robot controls that can convert kinetic energy into electricity, feeding it back into the power grid, and smart power-saving mode technology that controls the

robot’s energy supply on-demand throughout the workday. Since industrial facilities need to monitor their energy consumption, such connected power sensors are likely to become an industry standard for robotic solutions.

2. Reshoring: Resilience has become an important driver for reshoring in various industries. For example, car manufacturers are investing heavily in short supply lines to bring processes closer to their customers. These manufacturers use robot automation to manufacture powerful batteries cost-effectively and in large quantities to support their electric vehicle projects, making the shipment of heavy batteries redundant.

Relocating microchip production back to the U.S. and Europe is another example of a reshoring trend. Since most industrial products nowadays require a semiconductor chip to function, their supply close to the customer is crucial. Robots play a vital role in chip manufacturing, as they meet the requirements for extreme precision. Specially designed robots can now automate silicon wafer fabrication, perform cleaning and cleansing tasks, or test integrated circuits.

3. Ease of use: The emergence of new automation platforms is making it easier for nonexperts to program industrial robots, as OEMs work with low-code or no-code technology partners to enable users of all skill levels to program robots. New, easy-to-use software with intuitive user experiences is replacing extensive robotics programming and opening up new robotics automation opportunities. For example, a traditional heavyweight industrial robot can now be equipped with sensors

6 PW MAR2023 NEWS

halving the amount of virgin plastic used by 2030,” Seux explains. “At the same time, the sealable packaging provides excellent barrier properties, protecting the dishwasher tabs from moisture, making the packaging sustainable by design.”

According to Krajewski, Reckitt chose to focus its sustainable packaging efforts on the Finish package due to the plastic-reduction potential of the product—the world’s largest automatic dishwashing brand. While the new bag is currently only available in Carrefour in France, Reckitt plans to launch the new packaging across Europe once it has made adaptations to the structure to make it recyclable in those markets as well. When the launch is complete, Reckitt estimates the new paper-based pouch will help eliminate more than 2,000 metric tons of plastic annually as well have a notable impact on CO2 emissions.

As Krajewski explains, Reckitt used the company’s Sustainable Innovation Calculator (SIC), which measures the sustainability of plastic and packaging inputs of every new product, in the development of the paper pouch. “Using the SIC and an external Life Cycle Assessment, we were able to understand the innovation’s impact across countries with different recycling regulations and facilities,” he says. “It also allowed us to get a detailed understanding of its impact on CO2 emissions. We expect this packaging will generate 15% less CO2 emissions across the packaging lifecycle versus previous versions.”

The technical details on the pouch construction are proprietary, but Seux shares that a polyethylene zipper is used for the package. The pouch is gravure-printed in up to 10 colors, depending on the product variety. According to Krajewski, the new construction did require some adjustments to Reckitt’s packaging equipment, with changes ranging from relatively small to larger improvements in the process.

As for the cost of the new package, Krajewski says that Reckitt always ensures that its innovations are cost-effective for the company and for its customers. He adds, “As we continue to scale up production of the new packaging, we expect to see its cost reduce.” —Anne

Marie Mohan

and software that allow for collaborative setup operation. This makes it easy for workers to adjust heavy machinery to different tasks.

Easy-to-use programming interfaces that allow customers to set up the robots themselves are also driving a new segment of low-cost robotics. Many manufacturing customers reacted to the pandemic in 2020 by experimenting with robotic solutions. Robot suppliers acknowledged this demand, making improvements to their equipment for easy setup and installation, with preconfigured software to handle grippers, sensors, or controllers that support lower-cost robot deployment.

4. Artificial Intelligence (AI) and digital automation: Connected robots are transforming manufacturing. Robots will increasingly operate as part of a connected digital ecosystem, with cloud computing, big data analytics, or 5G mobile networks providing the technological base for optimized performance.

AI also holds great potential for robotics, enabling a range of benefits in manufacturing. The main aim of AI in robotics is to better manage variability and unpredictability in the external environment, either in real time or offline. AI-supported machine learning will thus play an increasing role in areas such as optimizing processes and predictive maintenance. This technology will also help manufacturers, logistics providers, and retailers deal with frequently changing products, orders, and stock. The greater the variability and unpredictability of the environment, the more likely AI algorithms will provide a costeffective and fast solution.

5. Second life for industrial robots: Since an industrial robot has a service lifetime of up to 30 years, new technology is giving old robots a second life. Industrial robot manufacturers are now running specialized repair centers close to their customers to refurbish or upgrade used units in a resource-efficient way. This prepare-to-repair strategy for robot manufacturers and their customers also saves costs and resources. Offering long-term repair to customers is an important contribution to the circular economy.

—Anne Marie Mohan

• Process Flexibility: Modular conveyor systems with standard designs

• Cost Flexibility: Quote solutions with options for every project blueprint

7

build your best conveyor business DISTRIBUTORS modularconveyor.com 844.293.2816

new

• Product Flexibility: Quickly introduce

products into inventory

represent Modular Conveyor Express and get your conveyor systems and equipment in

weeks! Conveyors designed by Nercon 18” SPIREXTM

3-4

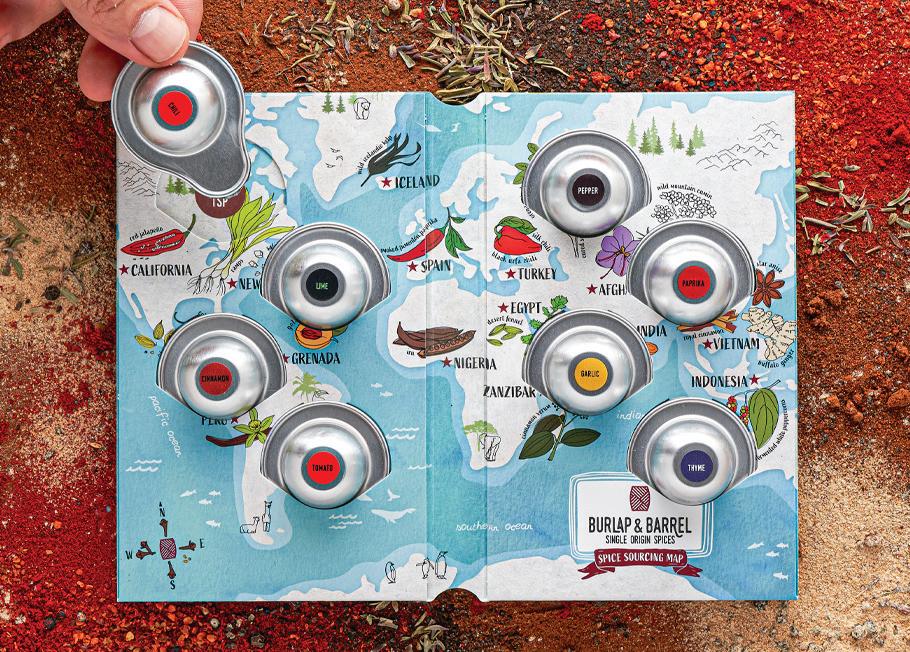

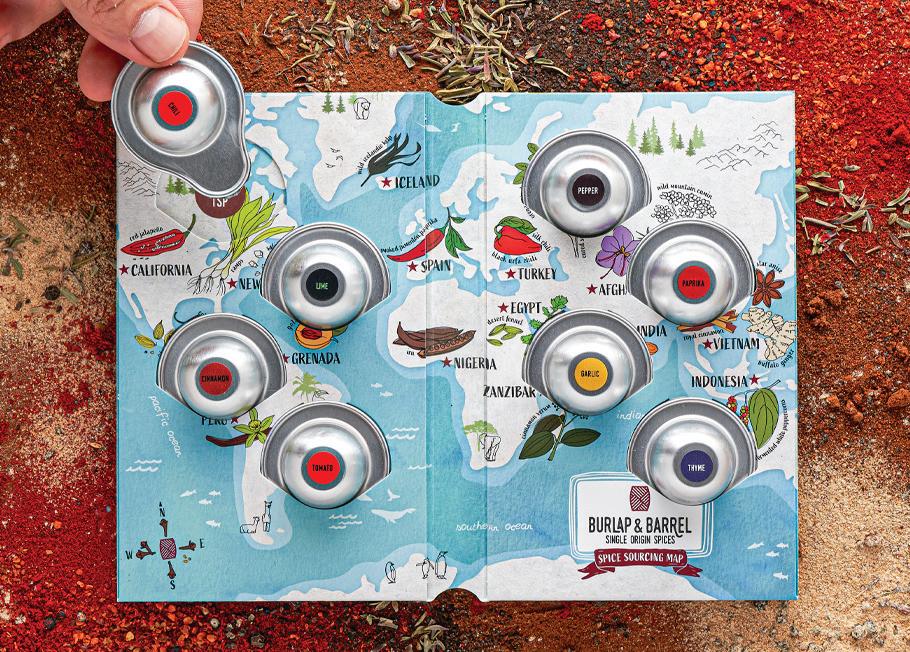

Aluminum Pods Are Just the Ticket for Clever ‘Spice Passport’

For home chefs on the go, single-origin spice company Burlap & Barrel has created a clever and compact travel sampler kit, the Spice Passport, that features a selection of its bestselling products from around the globe in a handy, portable booklet-style package. The kit craftily mimics a passport in appearance that,

upon opening, displays a playfully illustrated world map, with spice samples packaged in recyclable aluminum pods slotted into the card according to their country of origin.

“We created the Spice Passport as a travel sampler kit, so you never have to eat bland food on the road again,” says Burlap & Barrel co-founder Ethan Frisch. “It’s perfect for spicing up your meals when you’re visiting relatives, cooking in other people’s kitchens, and camping expeditions. A mix of sweet, savory, and hot spices, the kit includes eight of our most popular spices and will set you up to cook thousands of different cuisines.”

Based in New York City, Burlap & Barrel was established in fall 2016 as a purveyor of singleorigin spices and a Public Benefit Corporation. The company works directly with smallholder farmers in 23 countries, many of whom have never exported their products before. According to Frisch, the company differentiates itself through the high quality of its spices—a result of its thoughtful sourcing, small farmer partners, and the speed of its supply chain. “We’re buying right at the point of harvest and importing immediately,” explains Frisch. “So our spices are just that much fresher.”

Eighty percent of Burlap & Barrel’s spice products are sold direct-to-consumer through its own website as well as via other online retailers and at retail in a number of regional specialty chains and independent specialty stores around the country. One long-time customer of the company is its “spice buddy,” Occo Spices, which uses Burlap & Barrel’s products for its premeasured, single-serve spice collections in aluminum pods.

Occo is also based in New York City and was formed in 2018. Whereas Burlap & Barrel is focused on the sourcing of spices, Occo’s strategy is around offering spices in a packaging format that allows consumers to experiment with new recipes and flavors while the spices are at their peak flavor, without having to invest in a full bottle that may thereafter sit unused in a cupboard.

“The idea is to give you just enough of what you need to try something new once, and then you can

8 PW MAR2023 NEWS

move on to whatever you want to cook the next night,” says Occo co-founder Connie Wang. “One part of our mission is to find new ways to show the value of the packaging to consumers, helping them to realize that they can access really high-quality ingredients that may be off the beaten path without having to worry about cost or quality or sourcing. Because Occo and our partners can do a lot of that heavy lifting for them.”

To develop the patented aluminum pod it uses for its spice selections, Occo worked with industrial design firm Fuseneo. The pod is modeled on those used by coffee companies for their Keurig-style capsules, but is much smaller, holding just 1∕2 teaspoon of spice. The pod is bowl shaped with a flat bottom, allowing it to sit on a countertop, and features a wide rim and a tab that acts as a handle. An aluminum lidding film covers the pod and can be easily peeled back for access to the spice.

According to Wang, while Occo considered a plastic blister-style package, the aluminum pod better met its requirements for sustainability and product freshness. “We were making a single-serving product, so we didn’t want it to be plastic; that just felt like we were putting more trash into the world,” she says. “Instead, we thought aluminum was a great solution, A, because it’s the most recycled and recyclable food packaging material, and also B, because it offers an impermeable gas barrier.”

The aluminum package, coupled with equipment custom-built for Occo that provides modified atmosphere packaging, allows for a shelf life far beyond that of the three- to six-month shelf life of traditionally packaged spices. “The nice thing about the Occo packaging is that the spices don’t expire, because they’re protected from oxygen, light, and humidity,” says Wang. “We are still doing testing on the oxidation rate of the spices inside the packaging, but we can confidently say [the shelf life is] at least three years with the packaging we have. And it’s most likely longer.”

According to Frisch, he and Occo co-founder Lisa Carson had talked for some time about collaborating on a product for Burlap & Barrel before beginning development of the Spice Passport in 2021. The passport concept, he shares, serves two purposes: “What do we carry with us when we travel? We travel with a passport,” he says. “So the passport idea reminds consumers that they can take it with them when they travel, and it also ties back to our travels to work with famers all over the world to source our spices.”

Independent designer and illustrator Seton Rossini conquered the task of translating this dual concept through the engaging and colorful artwork on the passport, which is offset printed. The paperboard sleeve, supplied by Curtis Packaging, measures 6.25 in. tall x 4 in. wide x 1 in. thick and is made of 18-pt SBS.

Since its launch in November 2022, Burlap & Barrel’s Spice Passport has been so popular that, at press time, Frisch says the company had nearly run out of the product. The kit is priced at $9.99 (no shipping fee) for a single passport and at $54.99 for a six-pack. —Anne Marie Mohan

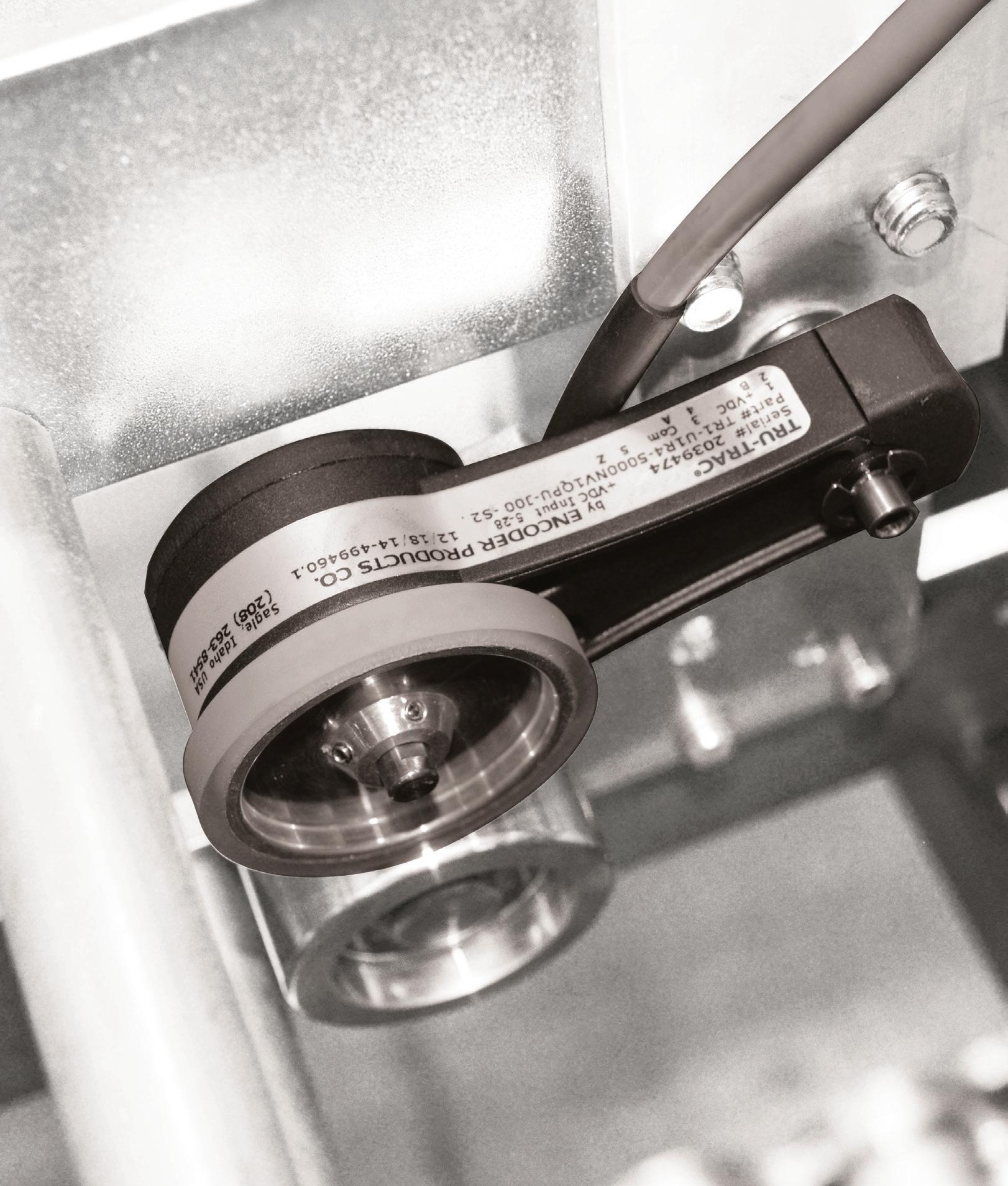

1-800-366-5412 · encoder.com Your Yo Responsive Experts p p IN MOTION CONTROL EPC encoders provide motion feedback designed for printing, marking, and product inspection, and are manufactured in Idaho, USA. Contact EPC Contac t TO LEARN MORE 9

PMMI Welcomes First Female Board Chair

PMMI, The Association for Packaging and Processing Technologies, announces Patty Andersen from Delkor Systems as the 2023 Chairperson of the Board, the first time a woman has held the position at the association.

As co-owner and vice president of human resources and aftermarket services at Delkor Systems, Andersen plays a pivotal role in guiding the company’s strategic vision and direction and she brings this expertise to her role as PMMI chairperson.

“Patty has provided PMMI with valuable guidance as a leader and a Board member. We are excited as she takes on a larger role in the strategic direction of PMMI as our first female chair,” says Jim Pittas, president and CEO, PMMI. “Her more than 20 years of packaging industry experience coupled with her ability to inspire others to work together and think creatively to solve problems, makes her an incredible asset to the association.”

At PMMI, Andersen has held several leadership positions beginning with joining the Education & Workforce Development Committee in 2010 and taking over the chairperson role of the committee in 2015. She has a long history of service to both the industry and association. Andersen served as a member and chair of the Employee Development Committee (2012-2019), vice chair and chair of the Strategic Planning Committee (2020-2023) and founding member of the Packaging and Processing Women’s Leadership Network (PPWLN), serving on the Executive Council since 2016. She has served as a member of the PMMI Board of Directors since 2017 and joined the Executive Committee as vice chair in 2020. Education and the development of the packaging and processing workforce has been a passion for Andersen throughout her career. Beyond her commitment to PMMI, Andersen has served on the Board of Directors of Hennepin Technical College

The Packaging and Processing Women’s Leadership Network is hosting a new quarterly Learning Circle webinar series. These interactive 30-minute webinars will cover key skills and guidance for career advancement and from subject-matter experts and women leaders in the industry. The first Learning Circle, held on March 21, 2023, focuses on business acumen and the importance of understanding the financial side of manufacturing. Visit pmmi.org/ppwln to view the webinar and to learn more.

Foundation, been a member of the Central Lakes College Robotics/Automated Systems Technology Advisory Council, St. Paul College Electromechanical Automation Systems Advisory Council, and Northwood Technical College Automated Packaging Systems Advisory Council.

She has extensive experience in capital equipment manufacturing and provides expertise in organizational needs analysis, root cause analysis, and lean manufacturing processes. Andersen’s real strength lies in her depth of understanding in each of her respective areas of management and her ability to inspire others to work as a team to execute initiatives with a high degree of quality and innovative problem solving.

Andersen succeeds PMMI’s prior Board of Directors Chair, Emmanuel Cerf, vice president at PolyPack, Inc. Cerf will continue to serve on the PMMI Executive Committee as Immediate Past Chair. —Casey Flanagan

Scan to learn more 10 PW MAR2023 NEWS

Patty Anderson

BAR-U-EAT First to Offer BPI-Certified Compostable Bar Wrappers

Colo.-based natural, energy-dense bar brand and 1% for the Planet member BAR-U-EAT unveiled new Biodegradable Products Institute (BPI)-certified compostable packaging for its individually wrapped bars. The brand says this makes it the first bar company in the world to offer packaging carrying this certification for the entire package. The move ensures that the packaging will break down properly in commercial compost systems, and not contaminate the environment. It also steps leaps beyond the industry standard of single-use plastics, according to the company.

Every year more than two billion pre-packaged snack, protein, and energy bars are consumed, almost all of which come in single-use plastics or multi-layered wrappers. This creates millions of pounds of waste from a non-renewable, non-biodegradable resource. BAR-U-EAT’s new packaging are made from renewable, sustainably sourced materials can break down to become nutrient-rich soil. This type of packaging is at the forefront of where sustainable packaging technology is headed and where it needs to go to combat waste and the use of finite resources. The company claims it is is a full 10 years ahead of the curve and is already compliant with California’s SB 54 legislation, which requires all packaging in the state to be third-party verified to be recyclable or compostable by 2032.

The new packaging is composed of plant-based materials from FSC Certified sustainably managed forests. The brand’s material supplier Elk Packaging uses a combination of films from Futamura and other suppliers. It additionally complies with the specifications established in the American Society for Testing and Materials (ASTM) D6400 to be aerobically composted and is biodegradable.

“The film structure is a lamination of a cellulosic-based film and a compostable sealant web with LLDPE properties. The plant-based materials come from a wood cellulose from FSC-certified, sustainably managed forests and corn,” says Jason Friday, BAR-U-EAT’s co-founder, further confirming that the film material is not PLA-, PHA-, or Braskem-related.

The film material is flexographically printed in five colors total, one for each of four SKUs plus white, and provided as rollstock to the brand for flow wrapping. Notably, this film material runs on traditional flow-wrap equipment.

Since compostable packaging is quite new to most consumers, Packaging World asked Friday about how he handles consumer education and proper disposal, to ensure the film doesn’t end up in landfill or worse, contaminating an existing recycling stream.

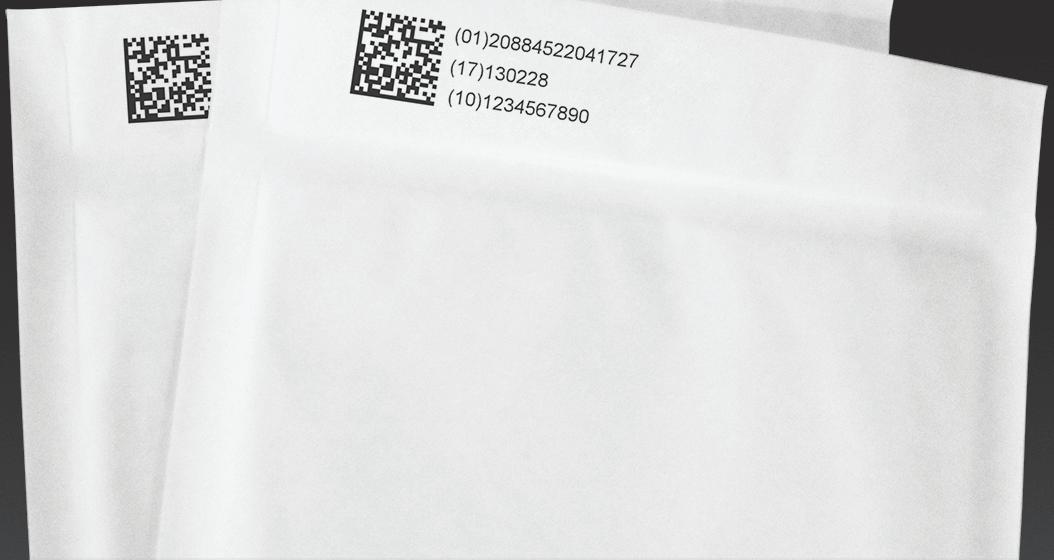

“On the packaging there is a section which says, ‘BPI Compostable Commercially Compostable Only.’ There is also a QR code on the side of every box which directs them to a link on the BAR-U-EAT website that outlines how to properly dispose of our packaging and compost. This is also bolstered by marketing efforts in email, social, and SMS,” he says. “The consumer is expected to commercially compost our packaging. This is the best route for the consumer to take so that it can turn into usable compost. If a consumer doesn’t have access to commercial composting, the appropriate place to dispose of the wrapper is in a landfill. These wrappers are not recyclable but are biodegradable.”

According to the company, BAR-U-EAT’s longstanding mission is to change the way we think about the food that we eat and how it’s packaged. Founders believe that packaged food should be simple, free from oils and preservatives, and packaged in a way that is less wasteful and regenerative to our planet. With BAR-U-EAT’s new plant-based packaging, the wrapper your food comes in will now become food for our planet, the company says. —Matt Reynolds

11

www.nerconconveyors.com 844-293-2814 SpirexTM Contact Us for Details New 18” Design CONVEYOR EQUIPMENT IN 6 - 8 WEEKS

Occupies minimal floor space

No changeover needed

Modular design for easy modifications

Configured for various in-feed and discharge height combinations

of multiple

•

•

•

•

• Options

slope angles and chain widths

BY THE NUMBERS

3,000

The number of U.S. residents that will be selected to provide answers to an online questionnaire on the most effective way to communicate nutritional information on the front of food packaging as part of an FDA consumer study

6M

tonnes

The increase in units of single-use plastics produced globally per year from 2019 to 2021, despite tougher worldwide regulations, according to Reuters

$10M

The amount Keurig Green Mountain has agreed to pay in a class-action settlement with a consumer who sued over coffee pod recyclability claims; Keurig will also add on-pack language indicating the cups are “not recycled in many communities”

4.6%

The CAGR of the global packaging machinery market, reaching $66.14 billion by 2030, driven by the increase in demand for convenience food products, according to ResearchAndMarkets.com

“A standardized methodology for product climate footprints doesn’t exist yet, but in the meantime, we hope this launch [of on-pack labeling] empowers consumers to learn more about climate footprint labeling and encourages other companies to disclose this information so that consumers are able to make informed decisions right from the grocery aisle.”

–Julie Kunen, director of sustainability, Oatly North America, as reported by Food Dive in an article, “Oatly debuts carbon footprint labeling on U.S. products”

“EPA recently developed guidelines regarding empty pharmaceutical containers and determine[d] that any residue is nominal and is not considered hazardous. Recycling HDPE has benefits. Studies have shown it is more cost effective to produce from recycled HDPE than it is to manufacture virgin HDPE plastic. One kilogram of HDPE requires 1.75 kilograms of oil to manufacture.”

“The packaging ecosystem has not advanced at the pace that organizations setting targets back in 2017 and 2018 had hoped for. Organizations face operational and financial challenges that were discovered only through the attempt to deliver their goals, but meaningful progress on sustainability can still be made with more realistic frameworks in place.”

–John Blake, senior director analyst with the Gartner Supply Chain practice, in a press release, “Gartner Predicts 20% of Organizations with Sustainable Packaging Goals Will Shift Their Focus from Recycling and Eliminating Plastics to Reducing the Carbon Footprint of Their Packaging by 2026”

“Danone is trudging ahead without a serious plan to deal with plastics, despite clear concern from climate and health experts and consumers, and a legal obligation to face up to the issue. It continues to rely on single-use plastic packaging in the hopes that recycling will miraculously deal with the flood of plastics it puts on the market. But recycling is a limited solution as only 9% of plastics ever made have been recycled. It’s unrealistic for food giants like Danone to pretend recycling is the silver bullet.”

–Rosa Pritchard, plastics lawyer for ClientEarth, as quoted in an article from BeverageDaily.com, “‘We are very surprised by this accusation’: Danone sued over plastic pollution”

12 PW MAR2023 QUOTABLES

–Thomas Pizzuto, founder of DecomRX Corp., in an article from Plastics News, “Maine begins writing packaging EPR rules”

Multi-Head Combination Weighers

• Available in 10, 14, 16, 20 & 24 Head Models

• 10.4” Color Touch Screen

• Fully Enclosed Radial Feeder

• Wash-Down Models Available

• Easy Access to Breaker for –Lock Out Tag Out

• Achievable Speeds of up to 150 BPM

• Load Cell Technology for ln-Feed Detection

• Easy Removal of All Parts for Cleaning

• Optional Timing Hoppers & Diverting Hoppers

800.504.7120

Our MULTI-HEAD COMBINATION WEIGHERS deliver a high-quality build backed by our industry leading customer service. High Tek USA knows that the food industry needs the best performance, with the best options all in one reliable and lasting solution. .

Tackling the Challenges of a New Workforce

made it difficult because the wage factors had not caught up to those benefits. And so we had to raise wages, as did a lot of the companies we compete with for labor. Once people started coming back to work, it was a very competitive market, and it wasn’t as easy to find employees.

Are you finding it more challenging to find skilled labor or unskilled employees?

We have really focused on technology and on finding ways to increase production without adding a lot of headcount. So the labor force we’re desiring is a more technical, more skilled workforce. That makes finding employees more difficult too. Even today, the areas we struggle with are in mechanical roles—so maintenance, engineering, more of the technical operators who understand how to run and adjust and skillfully operate equipment.

Packaging World:

When we last spoke, you mentioned that at the beginning of the pandemic, you had plenty of workers, but then during and after, your labor force was smaller. What drove that change?

Nolan Wolkow:

As we look at the time during the pandemic, there was a shift in the worker’s thought process. The main thing we saw was that there wasn’t a desire to go back to work right away. There were a lot of incentives from the government to actually stay out of work, which

We still can find individuals for more of the general labor roles; it’s the skilled labor that’s a challenge, and the reason for that is twofold. First, everybody’s looking for skilled labor, so there is a competitive aspect to finding that labor, and second, there aren’t a lot of people going into the manufacturing industry anymore. We’ve seen more of the younger generations gravitate toward work-from-home jobs with a flexible schedule. And so you don’t see as many individuals, the newer high school graduates, looking at manufacturing as where they want to go.

Do you see other changes in the new workforce that you’ve had to adjust to?

There are a lot of individuals who want to work Monday through Friday—they do not want to work on the weekend. And there’s enough available work out there for them that if they look around,

POSITIONING SYSTEMS FOR PACKAGING MACHINES

Electronic, bus-compatible position indicators with target / actual value comparison and intuitive operation

Automated fieldbus-/Ethernet compact actuators: easy commissioning, fast amortization

Mechanically compatible: SIKO positioning systems are mechanically interchangeable

IO-Link in the most compact position indicator

SIKO Products Inc., www.siko-global.com

14 PW MAR2023 FIRST PERSON

Nolan Wolkow, president of CPG and co-man/co-pack Enterprise CP, featured for its new equipment in a previous issue of Packaging World (see pwgo.to/7908), describes how his company has adjusted to the new, ‘post-pandemic’ workforce.

they can find jobs that will be Monday through Friday.

One of the roadblocks we run into in manufacturing is you typically run around the clock. At my previous job with SunOpta, we ran 24 hours a day, seven days a week, 365 days a year. For someone coming out of high school, a lot of the highly desirable jobs start on the back shift [late afternoon through midnight]; they don’t start Monday through Friday, 8 to 5. And so, getting someone to say, “Yeah, I’m willing to work that back shift,” has been a harder sell than probably the job itself, because you can’t have 12 people in a maintenance group on days and none on nights. You have to build positions that you need to be successful, which includes back shifts.

What strategies have you used to address these challenges?

One of the things we’ve focused on is how can we be competitive and still be family-friendly from a work schedule standpoint. So a lot of the decisions that we’ve made in the last six months to a year have really been focused around how do we stay on a four-day schedule, flexing to five, staying away from Saturday and Sunday—that’s family time— while at the same time being able to complete our production cycles and take on new growth over the course of the next one to five years.

We’ve done that with technology, through bigger, faster, more automated equipment that requires fewer people and that can increase our production 30%, 40%, 50%, without having to add a Saturday workday or a weekend shift. And in the last year, we’ve gone from producing probably an average of 350,000 units a day to, I think in the last three months we’ve averaged about 550,000. And we did that without really adding a lot of equipment; we’ve done that more with how well our equipment has run. We’ve added tools like Redzone [connected worker platform] to be able to watch our OEE and downtime and trend our performance. As a result, we’ve seen 10-point improvements across all of our lines in the last year just in OEE, which has been probably the biggest improvement we’ve seen because now we’re producing more with the same exact labor.

We also have a pretty good work environment as far as it’s not overly noisy and we keep the temperature around 70 degrees [Fahrenheit] in our packaging department because we have to control humidity, and the machines operate the best in a fairly standard environment. So it’s not a bad environment to be in. A lot of our competition within the community consists of meat plants, and that’s a very different environment to work in than ours. So we’ve tried to make our environment, our workdays, and our schedule better and more friendly for families.

The good news is, as we sit here today, we’re actually pretty good on labor—not without a lot of work and effort—but we’re sitting about where we need to be from a labor standpoint. We’d love to continue to increase our skillset, but that’s one of those areas where we know we’ll have some struggles, and we’re trying to be creative in how we go after and help promote more skilled labor as we go forward. —Anne Marie Mohan

15

By Sterling Anthony, CPP, Contributing Editor

Reflections on the Simply Tropical Lawsuit

A class-action lawsuit alleges that Simply Tropical juice drink contains synthetic chemicals. If true, it contradicts the brand’s claim, arched top-central on the label, that the product is “ALL NATURAL.” As of this writing, the Defendants—the Simply Orange Company and its parent, the CocaCola Company—have not made a public response, nor has there been any announced rulings by the Southern District of New York Court. This article does not take a position as to the merits of the lawsuit. The position taken herein is that the lawsuit should be of interest to all companies seeking to leverage packaging as a marketing tool.

Communication is one of the functions of packaging (along with containment, protection, convenience, and utility). Communications can be implicit in utilizing structural elements, such as material, shape, and size. Communications can also be implicit in utilizing graphics elements, such as brand name, colors, depictions, and fonts. Communications, however, become explicit with the use of text. The packaging’s written words, just like spoken words, can be evaluated for their truthfulness.

The Federal Trade Commission Act empowers the Federal Trade Commission (FTC) to regulate what’s collectively known as truth-in-advertising. The FTC operates under a sweeping mandate as to medium, whether print, electronic, internet, billboards—and, yes, packaging and labeling. The FTC’s powers of enforcement range from warnings to crippling fines. Consumers need not rely solely on the FTC’s initiatives. An individual can bring a class-action suit, as was done in the subject matter.

Companies make claims expecting that consumers regard those claims as credible. But beyond being credible, the claims need to be truthful, neither deceitful nor misleading. Without that quid pro quo, companies will undeservingly benefit at the expense of consumers. That’s not to say that every violation of truth-in-advertising is intentional. Besides, intent mostly factors in determining the severity of the enforcement.

To use packaging as a medium for untruthful claims is a misuse of an otherwise potent and versatile tool. Therefore, the question is how to avoid misuse. The answer resides in recognizing the role of promotion and how it is introduced into the broader framework of marketing packaged products. Although there is no universal template for that framework, it should follow a logical sequence.

The framework starts with research aimed at identifying consumers’ wants and needs that can be profitably satisfied, in other words a matching of opportunities and capabilities. Then

comes the concept stage, wherein ideas take shape as to specific product offerings. Whenever practical, concepts (at minimum) should include the structural packaging, e.g., types and materials. Product characteristics are not the same as consumer benefits. The former needs to be communicated in terms of the latter, which is the role of advertising and its media, including packaging. The determination of product characteristics, consumer benefits, and their linking claims should precede and direct the product development stage.

Regulatory oversight of this framework is a constant. What is not always a constant, however, is adequate oversight by a given company. The various intra-company departments have the same goal of a successful product, but they have different, sometimes conflicting responsibilities. Checks and balances with requisite signoffs are needed. What restraints keep the marketing department from crossing the line from puffery to untruths? What restraints keep the product development department from including undeclared ingredients/components? To say that the legal department needs to make sure that the decisions by other departments pass muster is necessary, but not sufficient. There needs to be a corporate culture that is simultaneously committed to competitive verve and to ethical operations.

Class-action lawsuits of the type herein discussed can have packaging-related ramifications, starting with a public announcement. Not all lawsuits make national news, as the Simply Tropical case did. Still, the prospect of doing so increases for well-heeled Defendants. The Simply Orange Company is a major player in the fruit drink industry, in its own right. But its iconic co-Defendant, the Coca-Cola Company, makes for an even more arresting headline. The point is that a company and its subsidiaries are linked, for better or for worse.

As noted, Simply Tropical is the alleged violator, not Simply Orange (the original and the flagship variety). All the varieties comprising the Simply product line, however, are sold in the same type of packaging, caring the same shaped labels, with brand name Simply rendered in the same font. Packaging is a tool unmatched for its effectiveness in giving a product line a shared look. The downside is that what negatively impacts one variety can negatively impact the other varieties by mere association.

Especially at retail, and regardless of whether a product is supported by mainstream advertising, the packaging is the point-of-purchase closer. The consumer relies on the packaging’s communications to make an informed decision. The communications need to be conspicuous, quick, convincing, and truthful. PW

16 PW MAR2023

THE BIG

PICTURE

Companies make claims expecting that consumers regard those claims as credible. But beyond being credible, the claims need to be truthful, neither deceitful nor misleading.

Innovation Through Integration

nVenia, through our legacy brands, has a long history of quality, durability and service. Whether you need primary, secondary, or end-of-line packaging equipment, nVenia will provide innovative integrated solutions.

www.nVenia.com CONTACT US info@nVenia c o m 8 0 0 2 53 5103

ARPAC HAMER OHLSON FISCHBEIN

By Anne Marie Mohan, Senior Editor

KIND Bar Wrap Closes the Loop

After the successful debut last year of a exible lm retort pouch made from advanced-recycled materials for its Sheba wet cat food (see pwgo. to/7909), Mars has expanded the use of this emerging technology to its KIND snack bar line in the U.K and Ireland. A complement to mechanical recycling, advanced recycling is a process that breaks down hard-to-recycle, mixed-waste plastic into its chemical components, which can then be used to produce virgin-quality, foodgrade plastic resins for a range of packaging applications.

conversion (TAC) technology, which involves the thermal degradation of plastic waste at different temperatures in the absence of oxygen to produce liquid oil, or pyrolysis oil. Plastic Energy’s branded “pyoil” is known as Tacoil.

Mars’ transition from a petroleum-based polypropylene film wrap to one made of advanced-recycled, recyclable materials for its KIND snack bar is the culmination of a collaboration between Mars, Landbell Group, and SABIC, among other supply chain partners. It also represents another step toward Mars’ sustainable packaging goals, which include a reduction in its use of new virgin plastic by 25% and the incorporation of 30% recycled content into its plastic packaging by 2025, as well as the redesign of more than 12,000 packaging components across its diverse portfolio to fit within the recycling infrastructure that exists today or is likely to exist in the future.

“At Mars, we want to contribute to a circular economy where packaging material never becomes waste, but is recycled, reused, or composted,” says Barry Parkin, chief procurement and sustainability officer at Mars, Inc. “For this to happen, we need new solutions and infrastructure to change the recycling landscape and to complement mechanical recycling.”

The first step in the advanced recycling supply chain is the collection and sorting of post-consumer mixed-waste plastic, including materials such as multilayer film, that would typically be downcycled or incinerated. This part of the Mars project is being coordinated by Landbell, a provider of environmental and chemical compliance services in Germany, Austria, and Switzerland. Landbell works with recycler Hündgen Entersorgung to sort the mixed-waste plastics and deliver them to the provider of the next step in the process, advanced recycling, which is done by Plastic Energy. At Plastic Energy’s plant, the materials undergo the company’s patented thermal anaerobic

SABIC, a Saudi Arabia-based petrochemical company that has led many pioneering packaging applications using advanced-recycled materials, is next in line. At its manufacturing facility in Geleen, The Netherlands, SABIC uses the Tacoil as feedstock to produce virginquality, food contact-approved PP via its TRUCIRCLE initiative. The PP is then pelletized and supplied to Tagleef Industries, which uses the resin to create a biaxially oriented PP film. The BOPP is then converted by flexible plastic packaging supplier SIT Group into printed, roll-fed packaging film that is used by Mars to flow wrap its KIND bars. What ultimately makes the solution a closed-loop one is that, after use, Mars’ KIND bar wraps can be collected for recycling—at curbside in Ireland and through store drop-off in the U.K.—launching the circular process all over again.

SABIC’s PP is certified circular and is verified and authenticated in a mass balancing approach under the International Sustainability and Carbon Certification (ISCC) PLUS scheme. According to SABIC, its TRUCIRCLE products offer a carbon footprint reduction in the range of 2 kg of CO2 per each kilogram of polymer produced, based on the diversion of post-consumer, used plastic from incineration.

News of the new packaging was announced by the parties in fall 2022. Said Peter Morris, general manager at KIND Snacks UK, “At KIND, we are committed to making our packaging as sustainable as it can be. This announcement marks the latest milestone towards achieving this vision, and we look forward to driving positive and long-lasting changes to our packaging in the future.” PW

FREE DOWNLOAD

Interested in sustainable packaging such as the new lm wrap used for Mars’ KIND bar? Download the free report, “Future of Packaging and Sustainability,” by PMMI and Euromonitor Intl. Visit pwgo.to/7910 to access the full report. PW

18 PW MAR2023 SUSTAINABLE PACKAGING

YOU’LL LEARN

Small Potato Producer Gets a Grip on Growth via Robotics

Using robotics to fuel growth while staying competitive, a leading North American grower, shipper, and packager of bite-sized potatoes is keeping costs down and employment and production up.

Gentle handling EOAT Automating ergonomically hard labor

By Aaron Hand, Editor-in-Chief, ProFood World

The multi-generational potato farmers of Tasteful Selections began in Nebraska, relocating to Arvin, Calif., to take advantage of the rich farmland and year-round growing season. The journey since has been not only geographical but one of innovation as well. Always searching for business growth opportunities, the company pioneered the category of bite-sized potatoes to offer consumers a simpler and more convenient source of nutritious potatoes.

“We are constantly planting, harvesting, and picking the freshest product for our customers,” says Nathan Bender, chief operating officer for Tasteful Selections. “We’re growing so fast that without automation, we can’t keep up.”

Fanuc robots have been a big part of Tasteful Selections’ journey, including 11 Fanuc M-410iB palletizing robots and five Fanuc M-3iA delta robots for case packing. “What we’re trying to do is flatten our curve of our costs, so we can provide a great service to our customers and keep our pricing down,” says Ernie Waldo, plant manager for Tasteful Selections. “As we’ve rolled out automation, it has been a real blessing to our employees to bring consistency to the line and bring consistency to our costs.”

Tasteful Selections got its start in robotics with the help of Schneider Packaging Equipment, a Fanuc Authorized Systems Integrator. The potato company liked Schneider’s OptiStak, which creates recipes for the layers of boxes to be stacked on the pallets. Based on Fanuc software, OptiStak quickly optimizes pallet configurations and enables operators to change patterns on the fly.

“They have been turnkey, out of the box, minimal programming that we needed to do on our end, and super, super successful on creating consistencies throughout our plant,” Waldo says.

Tasteful Selections also employs state-of-the-art production technology. To maintain high standards of quality, flavor, freshness, size uniformity, and best practices for sustainability, the company owns the entire planting, growing, harvesting, and packaging process. And when it wanted to expand and optimize its potato production, robotic automation was seen as the key.

In just a few years, Tasteful Selections has grown from 100 workers to close to 900. The robotic palletizers have also made a difference in employee accidents and injuries. Previously, workers stacked 50-lb boxes onto pallets up to 92 in. high, but now the robotic palletizers perform that task. “We were able to come up with a very modular, unique design for our palletizers,” says Justin McHenry, vice president of plant operations for Tasteful Selections. “It’s capable of picking up any one of our boxes in this facility, stacking a pallet as high as will fit in the back of any refrigerated truck, and does all that without requiring any tooling change.”

20 PW MAR2023

WHAT

Shifting mesh bags of small potatoes presented handling challenges, ultimately tackled by Soft Robotics’ mGrip soft gripper.

DAK Americas, an Alpek Polyester Business, is the to Count On.

PET&rPETProducer

We are growing our recycling initiatives and offerings to meet the needs of today’s consumers and brand companies who are demanding PET products with a recycle content. We actively participate in circular economies to foster increased sustainability and reduced impact on the environment.

We are expanding our capability and capacity to offer more RPET solutions to allow for bottleto-bottle recycling applications, including the innovative Single Pellet Technology® (SPT). SPT provides an integrated recycle content (up to 25% recycle content) in virgin production operations in select PET resin offerings.

Linking innovative products to our customers’ unique requirements is what we do best.

The broad line of Laser+® PET Resins continues to be engineered to meet the changing needs of the bottling / packaging markets, while our R&D and Technical Service experts maximize the benefits that Laser+® PET can bring to your business.

At Alpek Polyester / DAK Americas we are always committed to providing environmentally conscious solutions.

ENABLING A PET CIRCULAR ECONOMY.

Alpekpolyester.com 1.888.738.2002 oC n v e r t e r s /B ottl ers

Recycler Consumers / C o l l e c t o sr

Finding the right robotic gripper

As the company increased the speed of the processing lines, manually packing the bags of potatoes in boxes became an issue. The packing space did not allow for additional line staff. Additionally, the company wanted to minimize the human touch points to ensure the best food safety and quality practices.

“We want to make sure our potatoes are the safest they can be from

farm to fork,” says Lindsey Mebane, food safety manager for Tasteful Selections. “Before we had the robotics, everything was done by hand. For food safety, that is a little bit of a concern because there are more hands touching the product. Granted, they are wearing gloves, but there’s still human contact.”

Robots handling the potatoes, however, was cause for concern as well, since they could potentially cause more bumps and bruises than human handling. Having not only a food-safe but also gentle robotic solution was of utmost importance.

Helping you bring your best products to market.

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

PROCESSING AND PACKAGING SOLUTIONS

• Food processing systems

• On-machine and process area seasoning application

• Conveying and product handling

• Multihead/combination scale weighing and filling

• Snack bagmaking and case packing

• Metal detection and x-ray

• Check weighing and seal checking

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Tasteful Selections approached Soft Robotics which makes advanced technologies that enable automation of a wide variety of products—to nd a robotic gripper that could reliably grab a shifting bag of potatoes while easing the positioning tolerance requirements of the robot and the machine vision imaging system guiding it. The solution was Soft Robotics’ mGrip soft gripper.

“The end-of-arm tooling for this application needed to be able to handle a lot of variability,” explains Ben Gibson, applications engineering manager of packaging solutions for Soft Robotics. “These are mesh bags of baby potatoes. Depending on how the product settles on the belt, it can end up in lots of different shapes or sizes. We were able to handle all of this with a single end-of-arm tool.”

Free Download: Robots And CobotsAn Automated Future

The PMMI Robots and Cobots Report presents emerging technologies and compiles predicted growth in the years ahead. It examines the predictions made four years ago in the 2019 Robotics Report— which predictions have been fulfilled, and which have yet to materialize? It also explores the key trends underpinning the robotics industry and how those trends are likely to impact deployments and manufacturing strategies into the future.

92 91 97 98 34 108 94 116 17 20 107 32 99 36 42 0842 2 ~2~ ~2 26

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING. info@heatandcontrol.com

heatandcontrol.com Apr. 04-06, 2023 Booth 304 Portland, Oregon USA 22 PW MAR2023

|

Visit pwgo.to/7657 to download an executive summary of the report for free.

Plus, the unique gripper material allows the bags to be grabbed without any concern of damaging the product by applying too much force or using a rigid gripping tool. “We chose Soft Robotics because of the softness of the plastic and its integration with the Fanuc robot,” says Emilio Lemus, automation manager for Tasteful Selections. “It speeds up the process a lot, and at the same time, takes care of our product the way we want it.”

The pneumatic actuated tool allows the operators to control the air

pressure to either tighten or loosen the grip on the bags of potatoes. It also knows exactly the correct number of bags to fill a box as well as where to place them in the box.

“It helps with the quality—hands aren’t being harsh on them—and it helps with the overall efficiency because we are sending what we are supposed to be sending out, so it eliminates a lot of human error,” Mebane says.

Innovation gets results

As a result of the mGrip-enabled robotic work cell, Tasteful Selections was able to exceed 45 bags per minute and increase its packaging line’s overall equipment effectiveness (OEE) by 15%, achieving 100% return on investment (ROI) within nine months.

Adding robotics also enabled the company to achieve another advantage in 2020—a way to easily social distance employees on the production line. “Because of the robotics, we had less people on the line, so that really helped with the social distancing,” Mebane says. “It allows the people to be farther apart because the person putting the bags in boxes isn’t standing right next to the person putting boxes on the pallet.”

With the investment in automation, Tasteful Selections has been able to grow very quickly as well as maintain the quality of its small potatoes for customers. And it’s all been done at an attractive price point.

“If we don’t innovate, we’re not going to be competitive. Our prices will go up,” McHenry says. “We haven’t taken a price increase in 10 years on our product. We’re able to maintain that through automation.” PW

PRODUCTS THAT SHINE 1-800-295-5510 uline.com ORDER B M FOR SAME DA HIPPING π

23

Tasteful Selections began its robotics journey with Fanuc palletizers from Schneider Packaging Equipment.

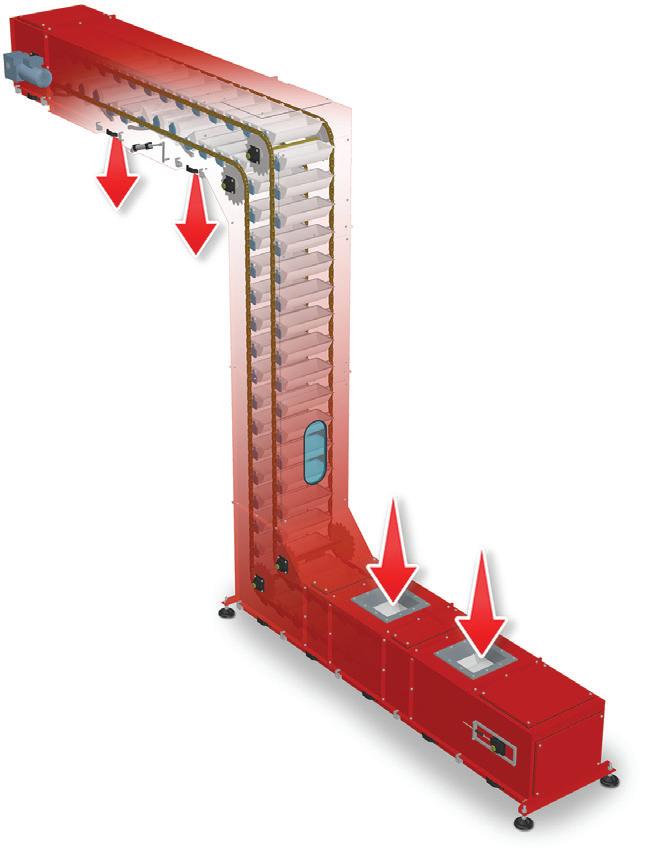

New System at Orkla Twist Wraps 1,800 Chocolates/Min

Norwegian multinational Orkla tests a new wrapping machine for its chocolate pralines that handily matches the high-speed output of its molding equipment.

By Anne Marie Mohan, Senior Editor

Founded in 1654 as a Norwegian mining company, Orkla is now one of the leading brand manufacturers in the Nordic and Baltic states, with product distribution in 100 countries and 114 factories around the world. The conglomerate has changed its focus over the decades and now operates in a range of Consumer Packaged Goods markets, including hygiene and personal care, baking, food, and confectionery. Around 15% of Orkla’s total operating income is generated by its Confectionery & Snacks business. Among its popular confectionery brands are Göteborgs Kex, Kalev, Laima, Nidar, and Panda.

It is at its plant in Vaajakoski, Finland, that Orkla produces its line of Panda chocolate products. Several years ago, the plant was experiencing challenges with the two packaging machines it was using to wrap its chocolate pralines. The machines had long since reached the limits of their performance and could no longer keep up with the high output of the chocolate molding line that fed them. The equipment was only able to wrap one third of the products coming off the production line. Two thirds were placed in temporary storage due to the lack of packaging capacity and were only transferred to the packaging process after production of the rst batch was complete. Since 2015, Orkla had been in discussions with equipment supplier Theegarten-Pactec about acquiring new equipment; in 2018, it was time to make a move.

Initially, Orkla planned to replace its two lower-performing packaging machines with two of Theegarten-Pactec’s MCC wrapping machines for molded chocolates. The MCC can handle double-twist and foil-wrap packs at 1,200 products/min. The machines would be able to accommodate the entire output of Orkla’s molding line, thus the confectioner would no longer require intermediate storage, and delayed packing would become a thing of the past. However, a lucky coincidence—and a leap of faith on Orkla’s part—resulted in a change of plans.

Orkla becomes test site for new wrapper

Not long after Orkla made the decision to acquire the two MCC wrappers, Theegarten-Pactec told the company about its latest customized solution for the confectionery industry: the CHS packaging machine, designed speci cally to handle chocolate products with various wrapping styles at speeds to 1,800 products/min. The machine had already been through intensive tests at Theegarten-Pactec’s Dresden, Germany, headquarters in a development process that lasted several years.

“At this time, Theegarten-Pactec was looking for a partner to put the CHS through industrial trials,” recalls Arto Liimatainen, technical manager at Orkla. “We were excited about the prospect of getting an even more powerful packaging machine and agreed in late 2019 to set up one MCC and one CHS machine in our premises instead of two MCC machines.”

24 PW MAR2023

Chocolate wrapping machines

WHAT YOU’LL LEARN

Among Orkla’s wide range of confectionery products is its Panda brand of chocolates, produced at its plant in Vaajakoski, Finland.

Adds Daniel Schibur, head of sales at Theegarten-Pactec, “This was the perfect opportunity for us to test the CHS under real-life conditions in confectionery production. A continuous product flow, continuous operation, different packaging materials and product qualities, cleaning and maintenance work during operation or even difficulties such as process equipment downtimes—there are lots of things that cannot be simulated. Ultimately, tests like these are essential to put the finishing touch to a new development and get it ready for the market.”

Steffen Hamelmann, marketing/public relations at Theegarten-Pactec, explains the differences between the MCC and the CHS: “The MCC is also a high-performance packaging machine that can be converted to other types of packaging. To be honest, however, it must be said that certain combinations of packaging styles are excluded on the machine due to its design. In other words, when buying the machine, one must already consider which types of packaging might also run on the machine in a few years’ time. This is different with the CHS. Regardless of how the machine was originally configured at the time of delivery, further packaging styles can be easily retrofit later in any combination.”

In addition to the improvement in flexibility, the CHS also increases the maximum output rate of the machine by 600 products/min. According to Hamelmann, the CHS can reach 1,800 products/min, while at the same time gently handling the delicate chocolate products, using continuous motion. With other machines, the product is slowed down before each packaging step and then accelerated again. With each of these multiple acceleration and braking processes, the products are subjected to forces that limit the possible output per minute. “On the other hand, the continuous principle means that the products pass through the packaging process at almost the same speed,” he explains. “This means that there are almost no acceleration forces acting on the products, and a higher number of units can be packaged.”

Two-lane infeed assists in high-speed operation

The modular CHS was installed and commissioned at Orkla in early 2021. In addition to the general functional tests, the machine’s twolane infeed—a unique feature of the CHS—was tested in depth. One of the main challenges was the separation of products from the continuous product flow on the main belt into the CHS’s two-lane infeed while ensuring a constant balance between the two lanes. Each of the two infeed lanes has to be supplied continuously with 900 products/min. In the wrapping process, both lanes are merged into a single-lane flow of 1,800 products/min.

The CHS solves this problem with an integrated camera system and sensors that constantly check the incoming products on their way from the main conveyor to the two-lane infeed and then into the packaging machine. This enables the control system to determine exactly how many products are on the two-lane infeed at any time, ensuring that the difference between both lanes is never more than five products. This, along with the continuous motion of the machine, allows the CHS to achieve an output of up to 1,800 products/min for the doubletwist wrapping style used by Orkla.

After the products are fed into the machine on two lanes, a gripper head takes the chocolates from the infeed belt and transfers them to the packing head. During this step, the two-lane infeed process is converted into a single-lane packing process. Meanwhile the machine unwinds the film rollstock, and pieces are cut from the roll and fed into the packaging process. In the next step, within the rotating packing head, the cut-to-size film wrap is fed to the product. The product is then wrapped with the packaging material, and the two ends are twisted in by the rotary grippers, creating the typical double twist wrap. Finally, the products are discharged from the machine via a chute or belt and transported automatically to the secondary packaging process to be loaded into cartons or pouches.

25

The modular CHS packaging machine, developed specifically to wrap chocolate products gently at high speeds, was installed and commissioned at Orkla’s Vaajokoski plant in early 2021.

Watch a video of the CHS machine in operation at pwgo.to/7866

Machine adapts to market requirements

Although double-twist wrapping is currently the only packaging style being used to wrap chocolate products at Orkla in Vaajakoski, as Hamelmann explains, the CHS can be adjusted to handle a number of different packaging types, nine in fact: double twist, protected twist, top twist, side twist, foil wrap, bottom fold, side fold, Vienna fruit fold, and envelope fold. The machine allows the fold type and format to be

YOU DESIGNED, TESTED, PRODUCED.

WE’LL PROTECT IT FROM HERE.

Your focus is your business. What’s ours? Solutions that get your pro uct to your customers well protecte an efficiently. Working with us means spending less time on transit packaging and more time perfecting your products.

Discover Signode and explore our transit packaging solutions.

www.signode.com

changed in four hours, with most of these changes requiring only one person. Also, as Hamelmann shares, the machine can be easily retrofit to handle new package types, regardless of how the CHS was originally configured at the time of delivery.

Since customers have to respond quickly to new market requirements, such as resized chocolate products, Theegarten-Pactec has also increased the range of product sizes that the CHS can handle. Whereas

existing machines could wrap products 16 to 45 mm long, the new system offers a range of lengths between 16 and 60 mm. The company has also made adjustments to the width; previously it was 12 to 25 mm, now it’s 12 to 35 mm.

According to Liimatainen, Orkla is very happy with its new wrapping equipment. “The packaging machines have given us outstanding results all along the line,” he says. “We’ve finally been able to increase our packaging capacities. It was this that prompted us to purchase the whole packaging system, comprising the CHS, the MCC, and the feeding system, in October 2021.” PW

/ bundle / unitize / warehouse /

pack

transport

26 PW MAR2023

According to Orkla Technical Manager Arto Liimatainen, Orkla was excited to test the CHS, a more powerful wrapping machine than the MCC.

The packaging machines have given us outstanding results all along the line. We’ve finally been able to increase our packaging capacities.

Label Applicators Built For Speed and Endurance

Your business runs better with a state-of-the-art labeling solution that can really perform. With the Label-Aire® Model 3115-TS Wipe-On Applicator, you’ll discover the power and profitability of precise, easy, and fast labeling you can count on. Under the hood of the 3115 is its stepper motor drive which delivers reliable operation and incredible labeling speeds up to 2,000 inches of web per minute with our optional powered rewind. All this power is easily controlled by our new touch screen interface for simple setup and configuration.

Contact

label-aire.com | 888.664.8111

time you put our wipe-on pressure-sensitive technology to the test with the Model 3115-TS.

It’s

us for your nearest authorized distributor. LABELING

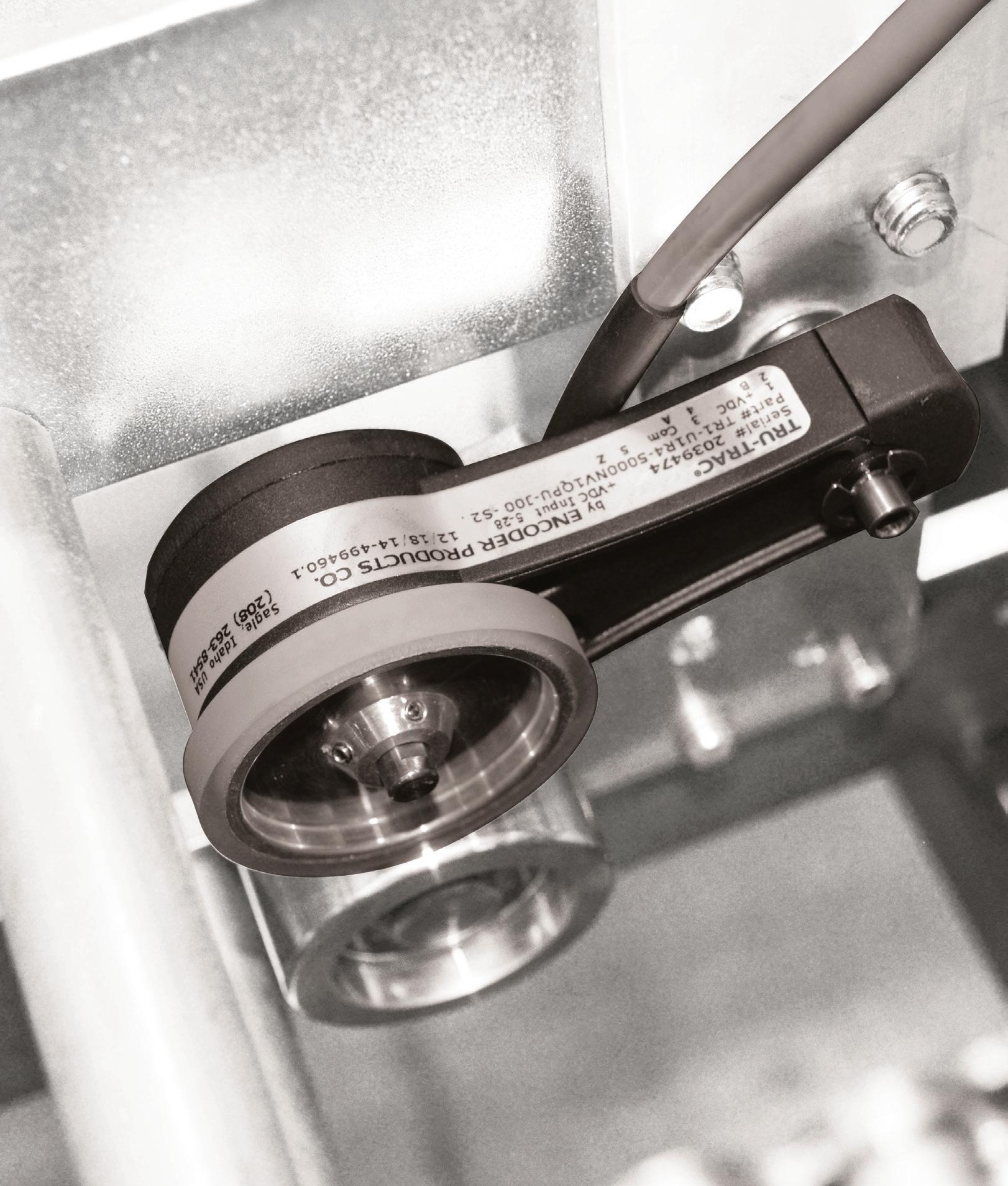

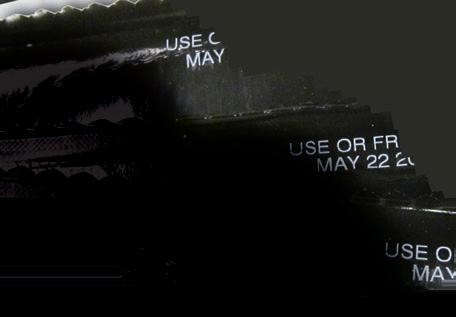

Remote Access, Monitoring Key to CMO’s Printing Ops

While many manufacturers are hesitant to dive into remote capabilities with their OEM partners, by leasing all printing equipment, this nutraceutical CMO is motivated to make full use of the tech.

By Matt Reynolds, Chief Editor

Ion Labs is a full-service turnkey contract manufacturer (CMO) of nutraceutical products. Common capabilities and equipment categories at the Largo, Fla. facility include blending, encapsulation, tableting, coating, packaging for powders/solid dose, secondary packaging, and cartoning, along with blister packs, liquid encapsulation, stick packs, and gummies.

“We’re a very scalable contract manufacturer with a diverse range of capabilities requiring us to be flexible with our equipment,” says Matt Keib, senior VP of operations at Ion Labs. “We have blending capabilities, equipment capabilities, and packaging capabilities that can that allow us to be efficient and optimal, for both an MOQ of 5,000 bottles, all the way up to 100,000 bottles or more.”

Notably, Ion Labs is an early adopter and champion of remote access and remote monitoring in partnership with its OEM vendors. Even at the tail end of the pandemic, after having seen remote technology

vault to the forefront, we still often hear about the IT/OT divide, and the difficulty operations folks have in convincing IT and company leadership of the merits of remote access tech. But Ion Labs takes a different tack. The company is always looking for equipment that it can network together and remotely monitor to better understand predictive maintenance and hours of usage.

“It’s an entire philosophy that, with any new equipment that we bring into the plant, we want it to have remote monitoring and reporting capability, versus having a mechanic log hours manually or inspect the equipment to see how it’s performing. I would say it’s more of a new practice, a new business model, as far as demanding that capability for anything that we acquire, moving forward,” Keib says. “Now, one of the critical decision points for us with OEMs is whether they have the ability to remote in, monitor the equipment, and provide that real time information, utilizing the cloud or proprietary platform.”

Even among those vanguard CPGs and CM/CPs who are all-in on remote access, the question of who owns and manages the data often remains fraught. Many companies try to manage their own data, only tapping the OEM in an emergency. Again, Ion Labs is the exception. It happily uses its OEMs’ platforms and lets them manage the data. It’s not developing its own, in-house platform for equipment. Nor does Keib want to. He prefers to focus on core competencies of manufacturing and packaging nutraceuticals.

“We don’t have all the experts, in-house, on all the equipment that we have,” Keib says. “In order to run the equipment as efficiently as possible, and to get the most out of it, we need experts to help us. And if we’re troubleshooting or if we have an error, the best way to do that is to quickly connect, via a portal that our IT controls, so that we can have them remote in, or continually monitor. I think you need to have a strong IT department that knows how to understand the risk and build the correct securities in place to manage it.”

28 PW MAR2023

Connected printers

WHAT

Equipment lease model

YOU’LL LEARN

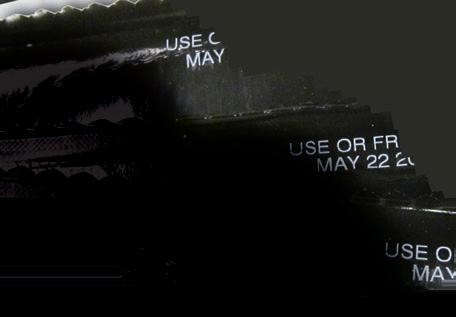

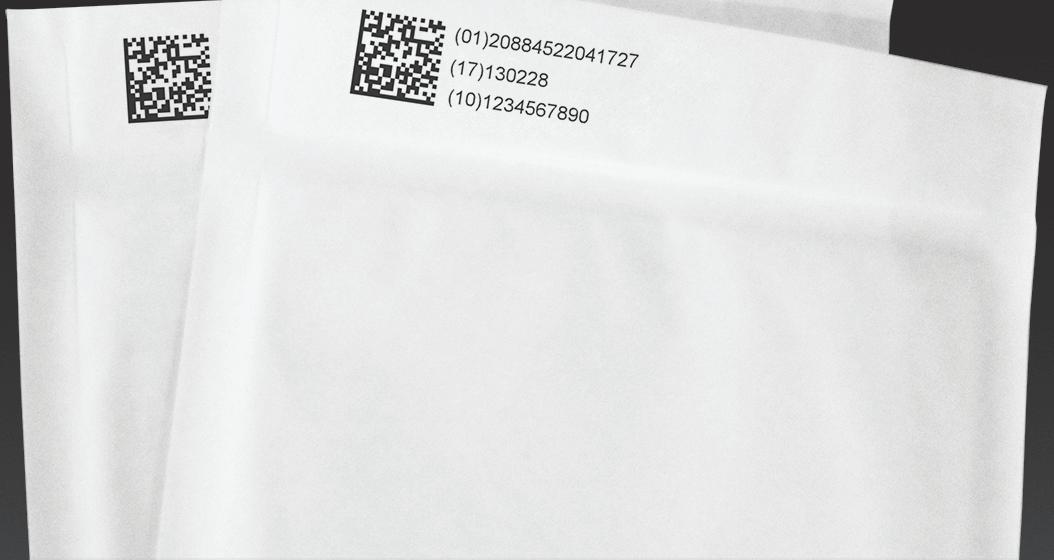

Maintenance manager monitoring Videojet equipment via the VideojetConnect Remote Service (VRS).

Remote access to coding and marking

Having 11 different finished goods packaging lines in a facility makes for a lot of connected equipment. One equipment category that appears on every line, and stands to benefit most from remote monitoring, is coding and marking.