PMMI Media Group | www.HealthcarePackaging.com SPRING 2024 The Business Effects of PFAS Regulations | 16 The AI That Drives Humanoid Robots | 26 Protect Your Sterile Barrier Rollstock | 34 Challenges in UserCentered Design | 80 See Special Section | 38 REFILLABLES COME HOME OTCs and Rx in Stackable Glass, Compostable Pouches | 22

THE POWER WITHIN With 48 years of proven performance in ampoule-based contract filling and packaging, we’ll help develop a unique dispensing system for your formulations, with a variety of tips and in a range of different sizes and colors. Your journey to smarter single-use packaging begins here. james-alexander.com • 908-362-9266 PROVIDING UNIQUE SOLUTIONS IN SINGLE-USE GLASS AMPOULE PACKAGING Prescription • First Aid • Dental • Diagnostics • Veterinary • Cosmetics • Dermatology Extended Shelf Life Formulation Stability Tamper Resistance Quality Assurance Two-Part Mixing UNLEASH

22

26

34

80

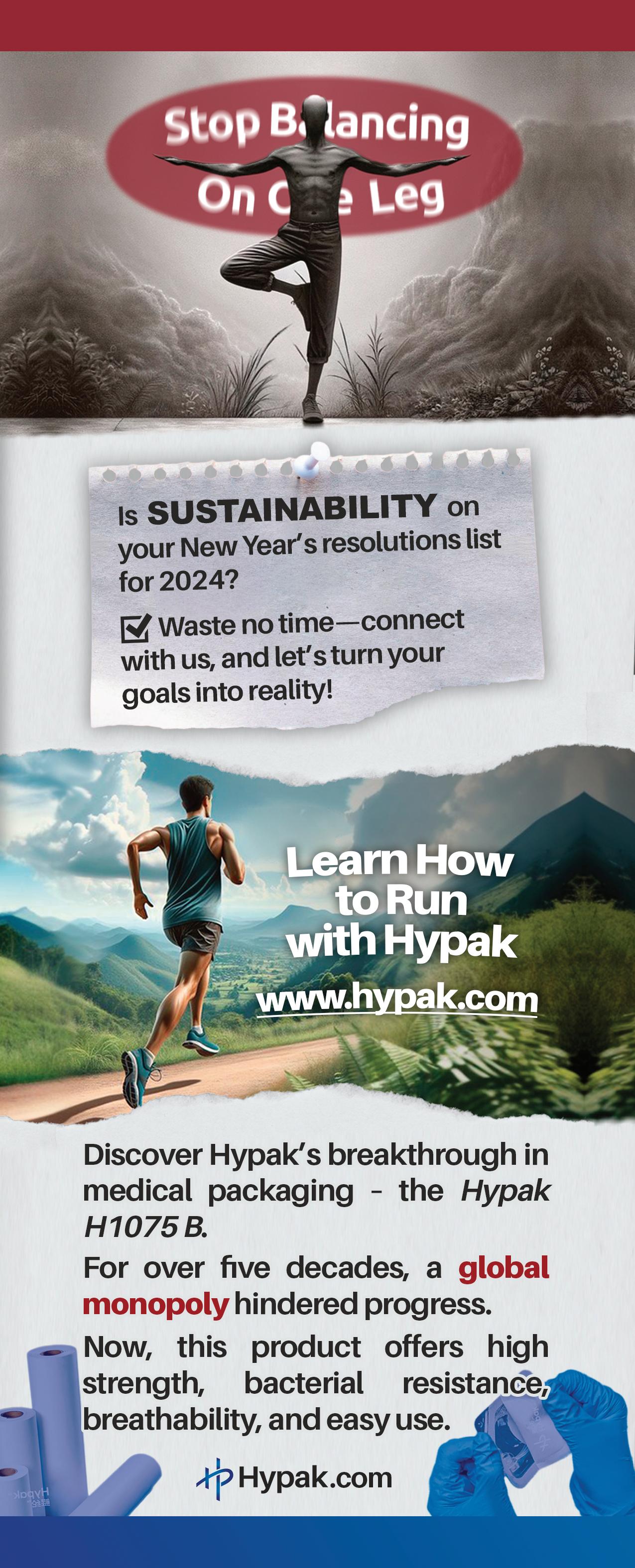

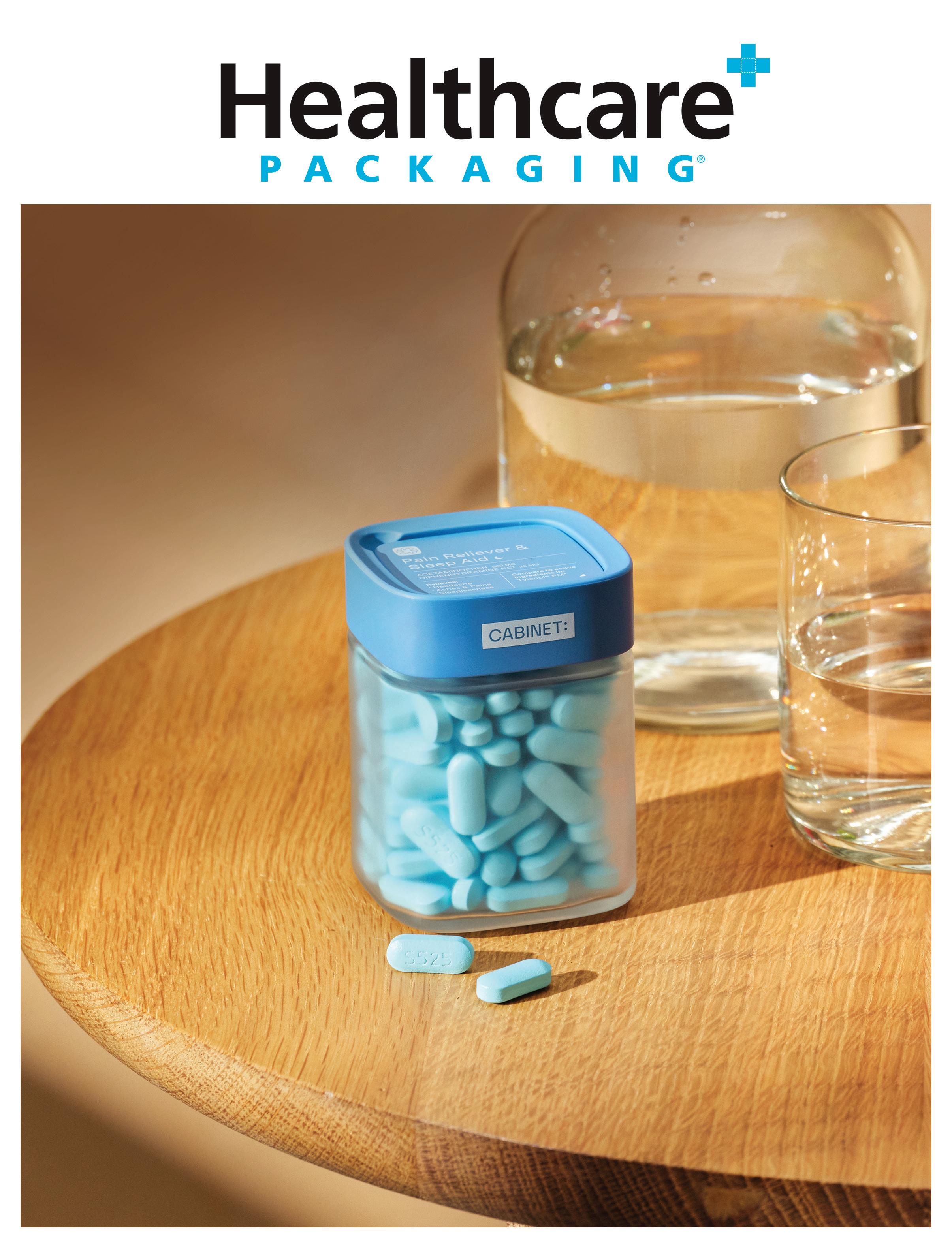

Startup Cabinet Health offers reusable packaging and a refill system for the healthcare market that it says has the potential to transform the industry.

A look at the powerful AI behind the robot that allows it to move, think, and act like us. STERILE

Much attention is given to packages as they protect a product from end-of-line to the patient. But are you correctly handling your sterile barrier inventory prior to packaging?

A panel at Pharmapack discussed competing challenges in designing healthcare packaging and devices, where sustainability or anti-counterfeiting may be in conflict with simplicity for the user.

The

and medical device brands may only

a small portion of a converter’s total

As converters comply with regulations for food and CPG packaging, eventually it may not make economic sense to carry PFAS-containing

solely for life science brands.

—pp. 16, PFAS: Navigating Materials of Concern in Life Science

2 | Healthcare Packaging • Spring 2024 CONTENTS 22 26 80 12 14 Vol.19 No. 1

PACKAGING

REUSABLE

Refill System Cuts

Plastic from OTC, Pharma Packaging

AUTOMATION

Humanoid Robots and the AI That Drives Them

PACKAGING

Protect Your Sterile Barrier System Rollstock

ADHERENCE/DELIVERY

2024 Challenges in User-Centered Design

Cover image courtesy: Cabinet Health, The Sustainable Healthcare Co. COLUMNS & DEPARTMENTS 06 KEREN SOOKNE’S PERSPECTIVE 08 QUICK HITS 10 QUOTABLES/BY THE NUMBERS 12 NEWS 14 COLD CHAIN CORNER 16 MATERIAL DEVELOPMENTS 77 NEW PRODUCTS SPECIAL SECTION 38 Leaders in Healthcare Packaging 2024 This exclusive Leaders in Healthcare Packaging section includes profiles and product listings for a variety of companies serving the healthcare and pharmaceutical industry.

“ ”

implications

immediate concerns

Pharmaceutical

business.

materials

of PFAS bans extend beyond the

of compliance.

represent

Packaging

com o

H g -b

Keren Sookne ksookne@pmmimediagroup.com

CONTRIBUTING EDITOR Melissa Griffen-Young

CONTRIBUTING EDITOR Joseph Derr

ART DIRECTOR Michael Smith

CREATIVE DIRECTOR David Bacho Advertising

VICE PRESIDENT, SALES John Schrei jschrei@pmmimediagroup.com

SENIOR MANAGER, PRINT OPERATIONS Lara Krieger lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER Janet Fabiano jfabiano@pmmimediagroup.com

ACCOUNT EXECUTIVE Elizabeth Tierney 815.861.2992

PMMI Media Group

PRESIDENT David Newcorn

VICE PRESIDENT, DIGITAL Elizabeth Kachoris

SENIOR DIRECTOR, MEDIA OPERATIONS Kelly Greeby DIRECTOR, DIGITAL MEDIA Jen Krepelka

SENIOR DIRECTOR, EVENTS Trey Smith

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI Joseph Angel

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com

www.healthcarepackaging.com Healthcare Packaging® (ISSN # 21543666) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Healthcare Packaging® is published twice annually by PMMI with its publishing office, PMMI Media Group, located at 401 N. Michigan Ave, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Copyright 2024 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www. healthcarepackaging.com/subscribe. Paid subscription rates per year are $55 in the U.S., $80 Canada and Mexico by surface mail; $130 Europe, $200 in all other areas. Single copy price in U.S. is $20. Free digital edition available to qualified individuals outside the United States. POSTMASTER; Send address changes to Healthcare Packaging®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611-3789. PRINTED IN USA by Quad. Volume 19, Number 1 The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@healthcarepackaging. com. Mailing List: We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address. PLEASE RECYCLE THIS MAGAZINE Remove inserts or samples before recycling. PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 p: 571.612.3200 | f: 703.243.8556 | www.pmmi.org PMMI Media Group 401 N. Michigan Ave., Suite 1700 Chicago, IL 60611 p: 312.222.1010 | f: 312.222.1310 www.pmmimediagroup.com Content EDITOR-IN-CHIEF

4 | Healthcare Packaging • Spring 2024

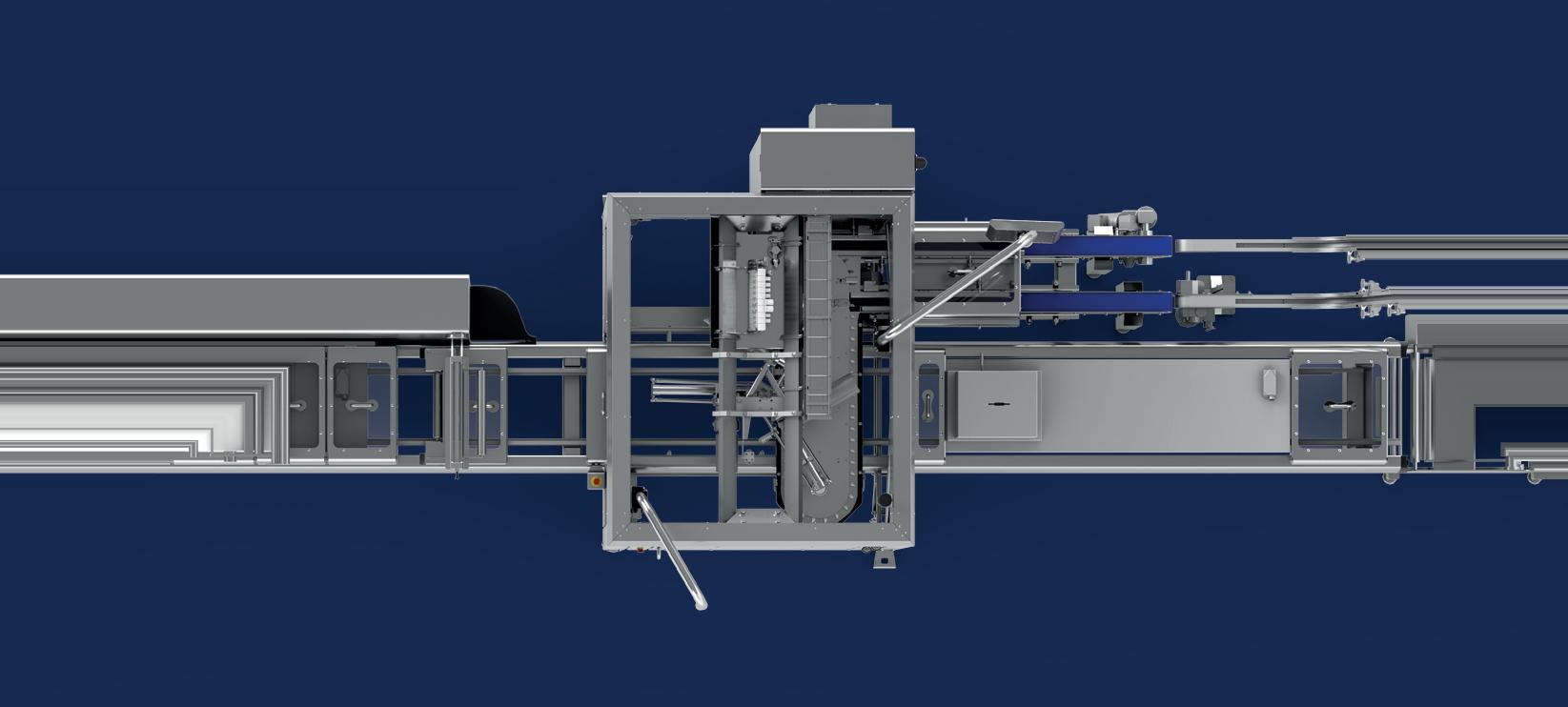

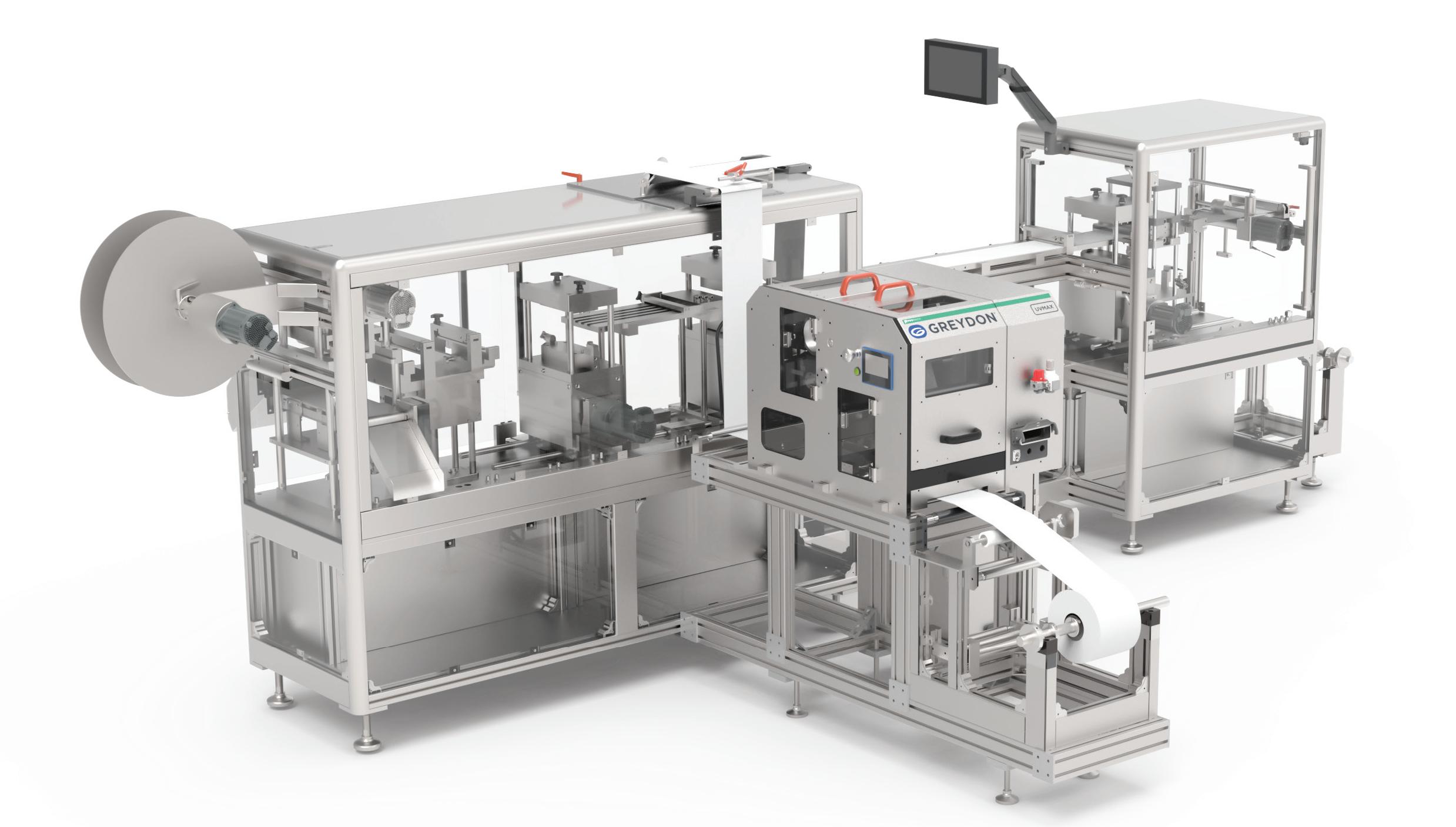

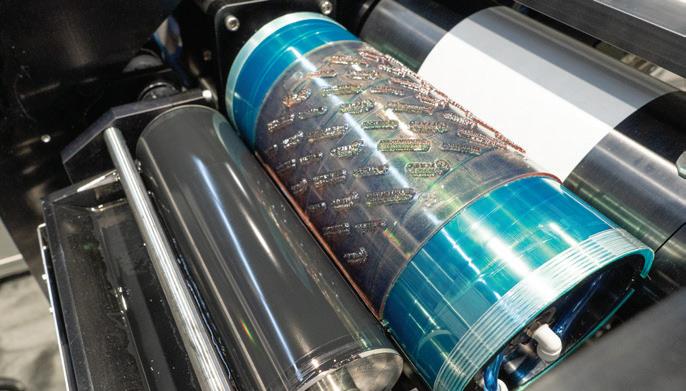

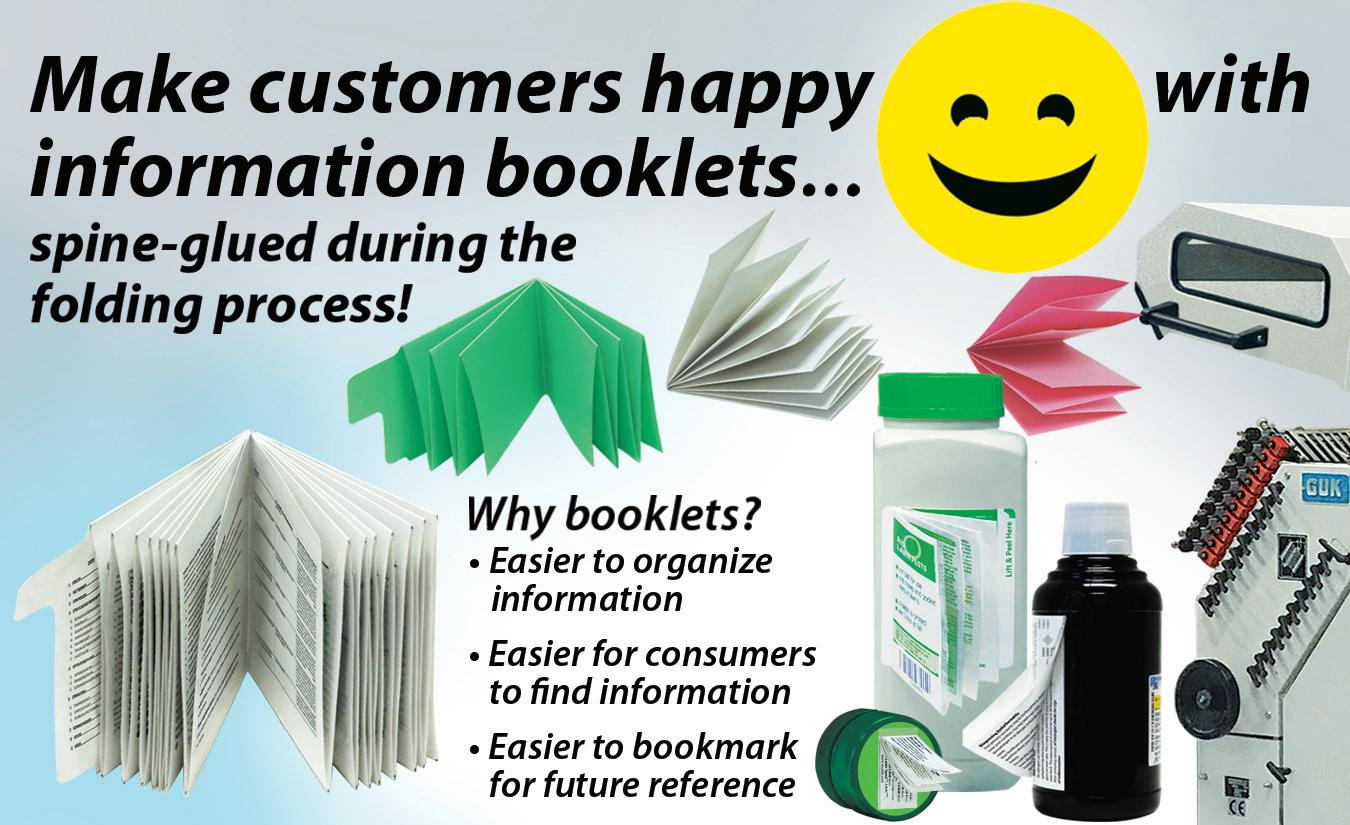

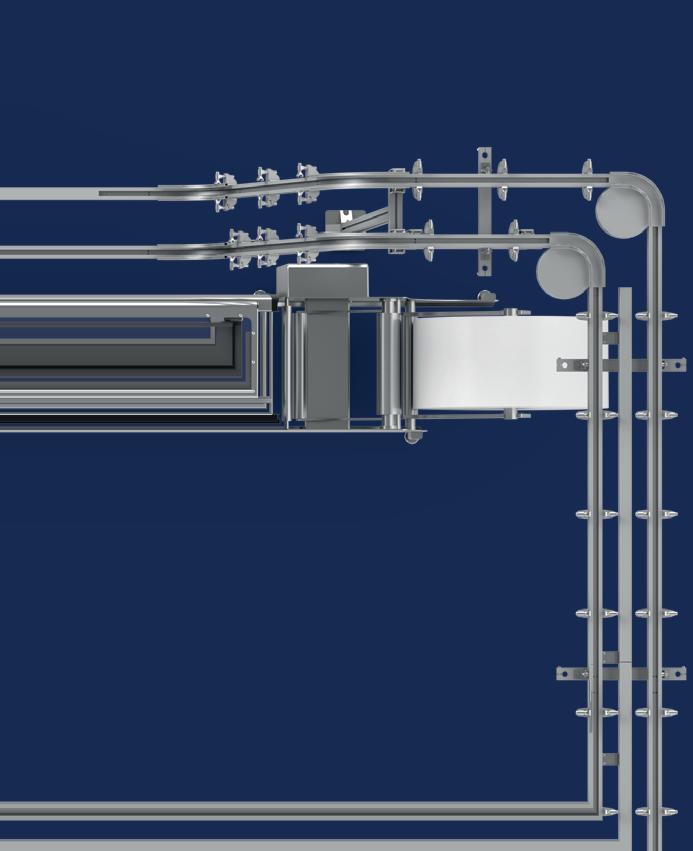

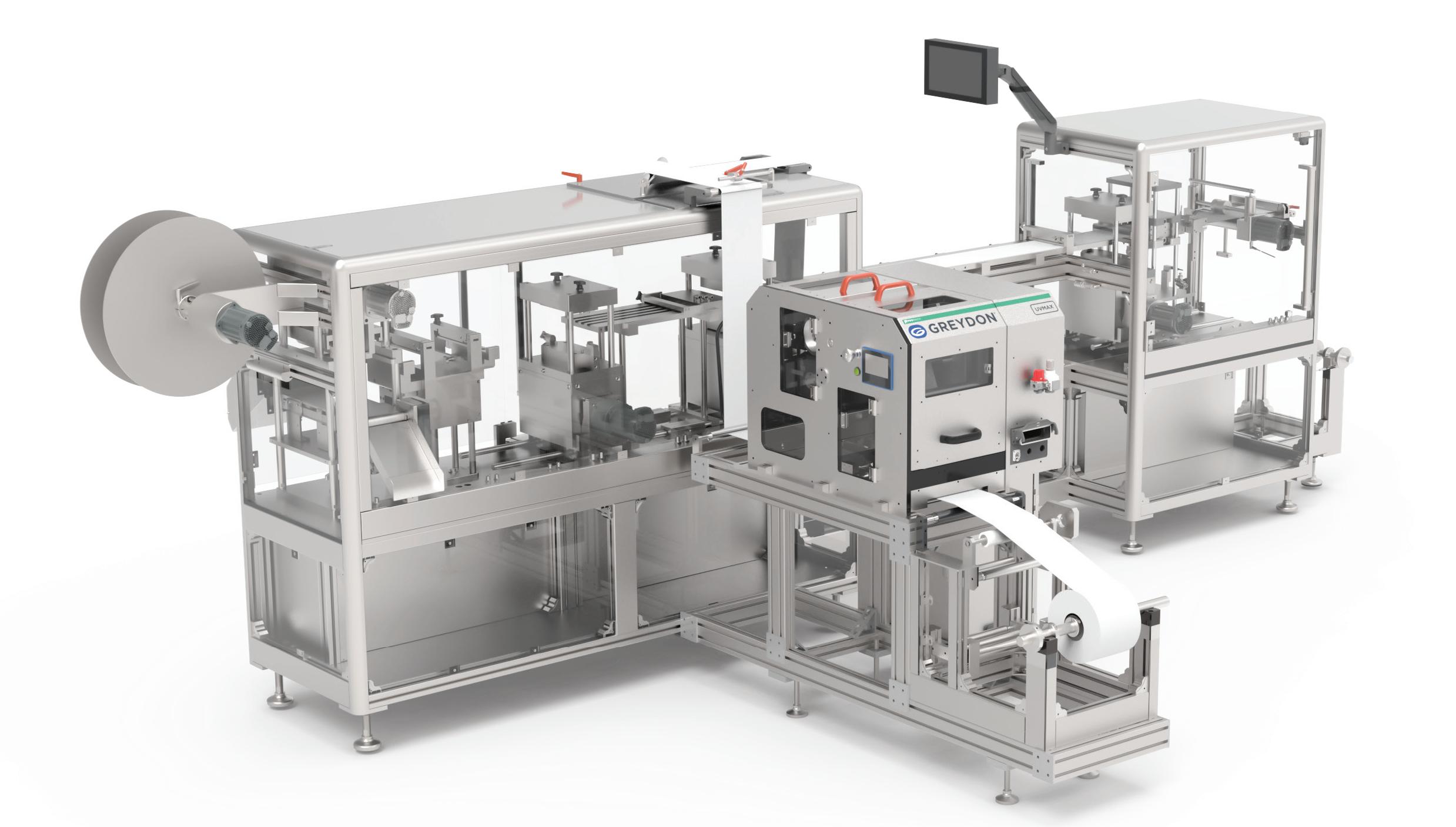

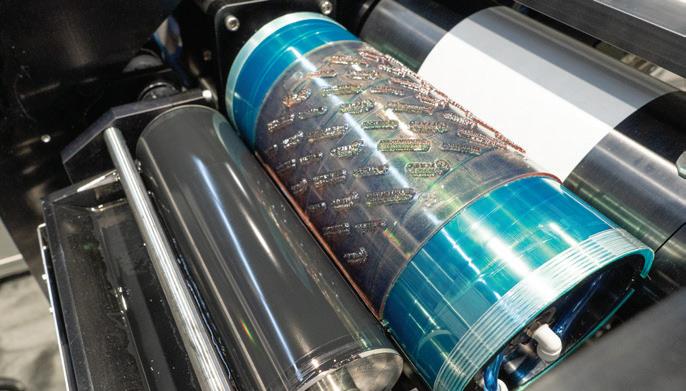

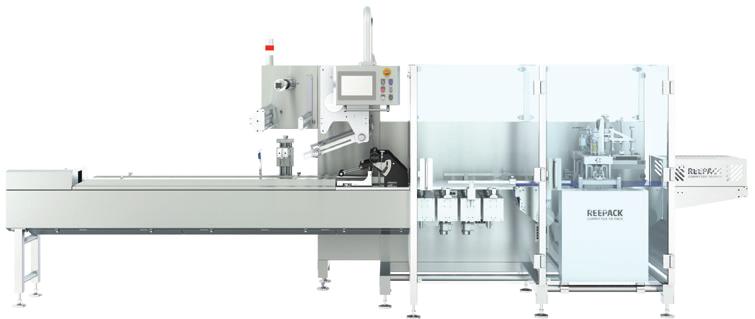

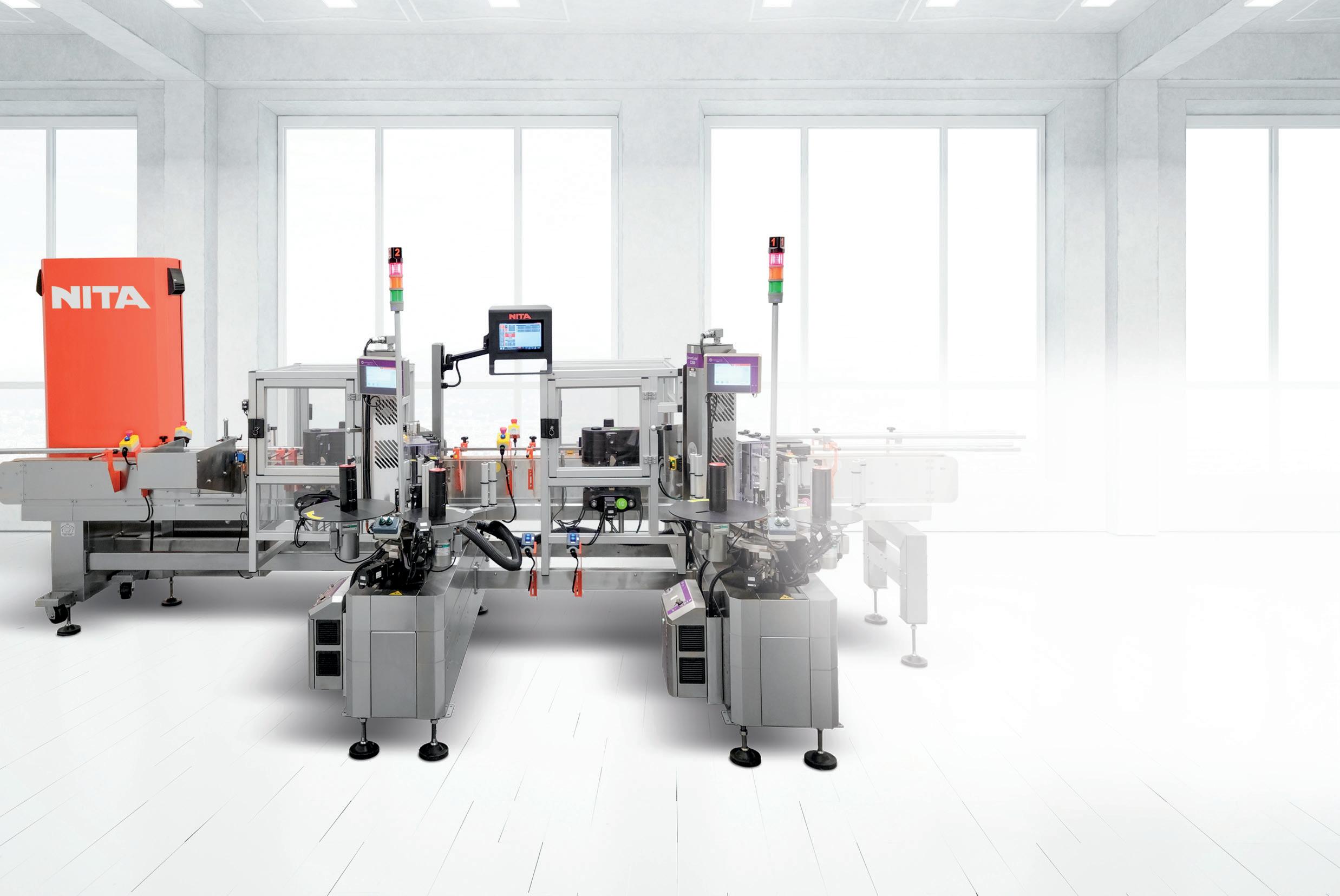

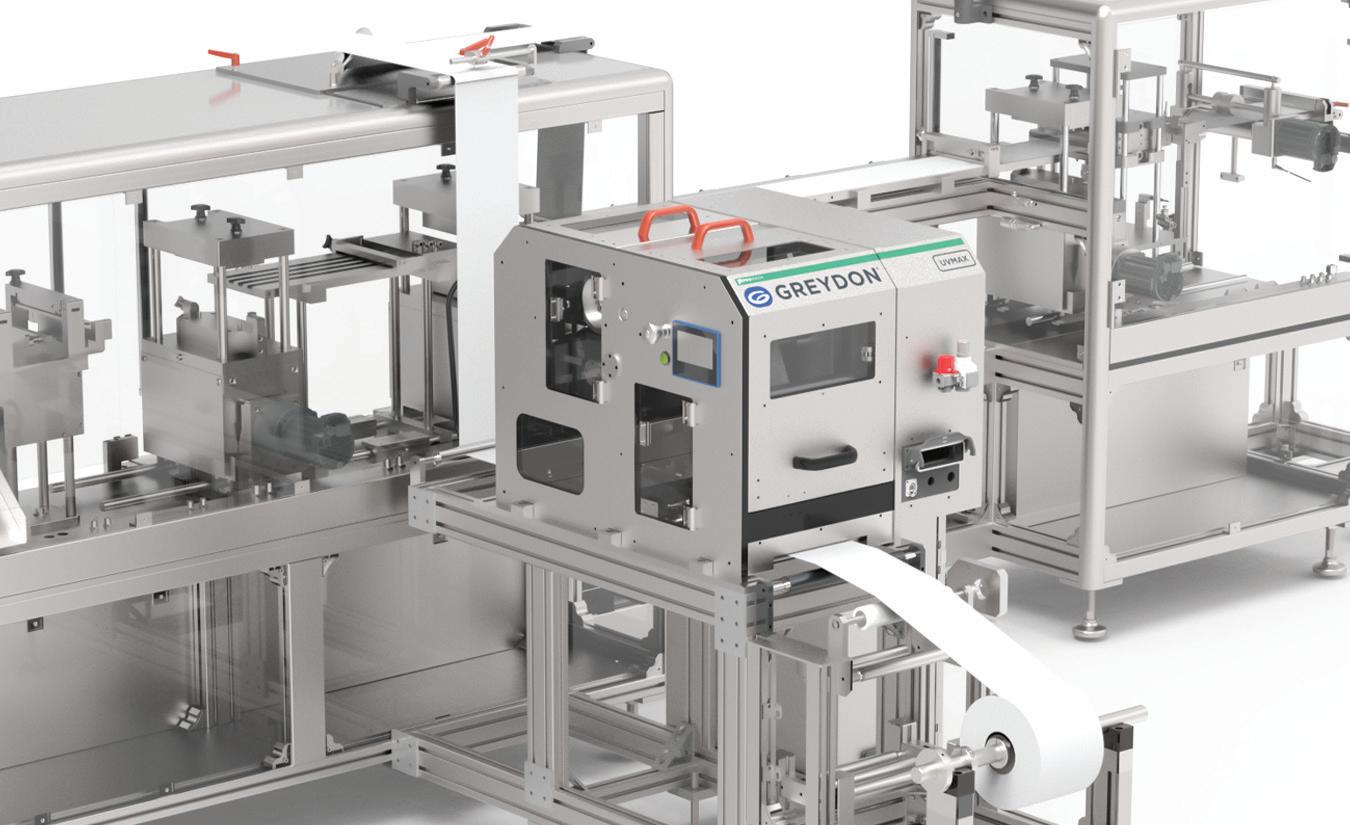

DESIGNED FOR INTEGRATION AND PERFORMANCE

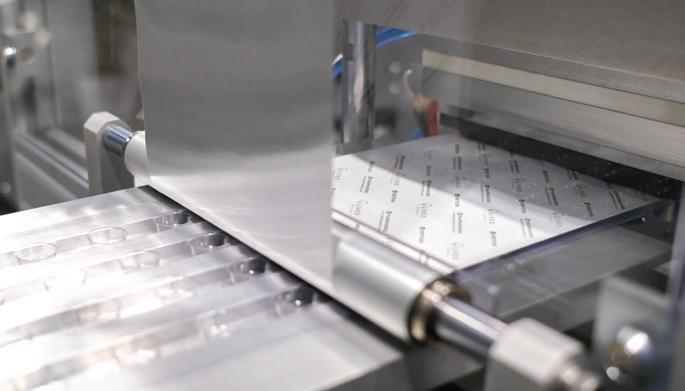

IN-LINE FLEXOGRAPHIC PRINTING FOR BLISTER PACKAGING

The UVMax by Greydon is an in-line flexographic printer engineered to integrate with pharmaceutical blister packaging systems. It prints the complete package, including variable information, with an integrated thermal inkjet printer, thus eliminating the need for purchasing pre-printed blister materials.

SEAMLESS IN-LINE INTEGRATION

Designed to integrate in-line printing capabilities to blister packaging machines and production lines.

STATIC & VARIABLE DATA PRINTING

Prints static product and regulatory data as well as variable coding for a fully finished compliant package.

SERVO-CONTROLLED WEB DRIVE

Industry-leading web management ensures accurate print positioning and reduces the stretching of materials.

INCREASE YOUR PACKAGING PRINTING & THROUGHPUT

Greydon@ProMachBuilt.com | York, PA | 717-848-3875 | Greydon.com © 2024 ProMach Inc. CONTACT US TODAY AT GREYDON@PROMACHBUILT.COM

The Intersection of Sustainability and User-Friendliness

A new refillable prescription package hits the market. Elsewhere, experts discuss the challenges of balancing reusable devices with simplicity.

Operating in such a highly regulated environment, it’s understandable that healthcare can’t make sustainability pivots at the same speed as the fast-moving consumer goods space. But that doesn’t mean that progress— in many forms—isn’t taking place.

Take for example, Cabinet Health and their aim to “de-plastic” pharmacy aisles and medicine cabinets (pp. 22). This isn’t the first time we’ve seen refillable, reusable packaging for oral solid doses, but their sleek offerings are particularly unique in (1) the sheer variety of offerings, (2) their entry into the prescription drug space, and (3) refill pouches which are compatible with both industrial and

home composting. Of course, whether a pouch makes it to home compost depends on the user’s access to home compost. But this represents a major step forward for OTC and prescription drug pouches, particularly with the general public’s current lack of access to industrial composting. Related, I recommend Eight Ways You Might Be Greenwashing Your Packaging and Not Even Know It (hcpgo.to/431)

Practicality will ultimately determine whether a design makes sustainable, user-centric sense. At times, these very concepts are at odds with each other, as panelists discussed at Pharmapack Europe (pp. 80).

KEREN SOOKNE is the Editor-in-Chief of Healthcare Packaging She may be reached at ksookne@pmmimediagroup or at linkedin. com/in/kerensookne

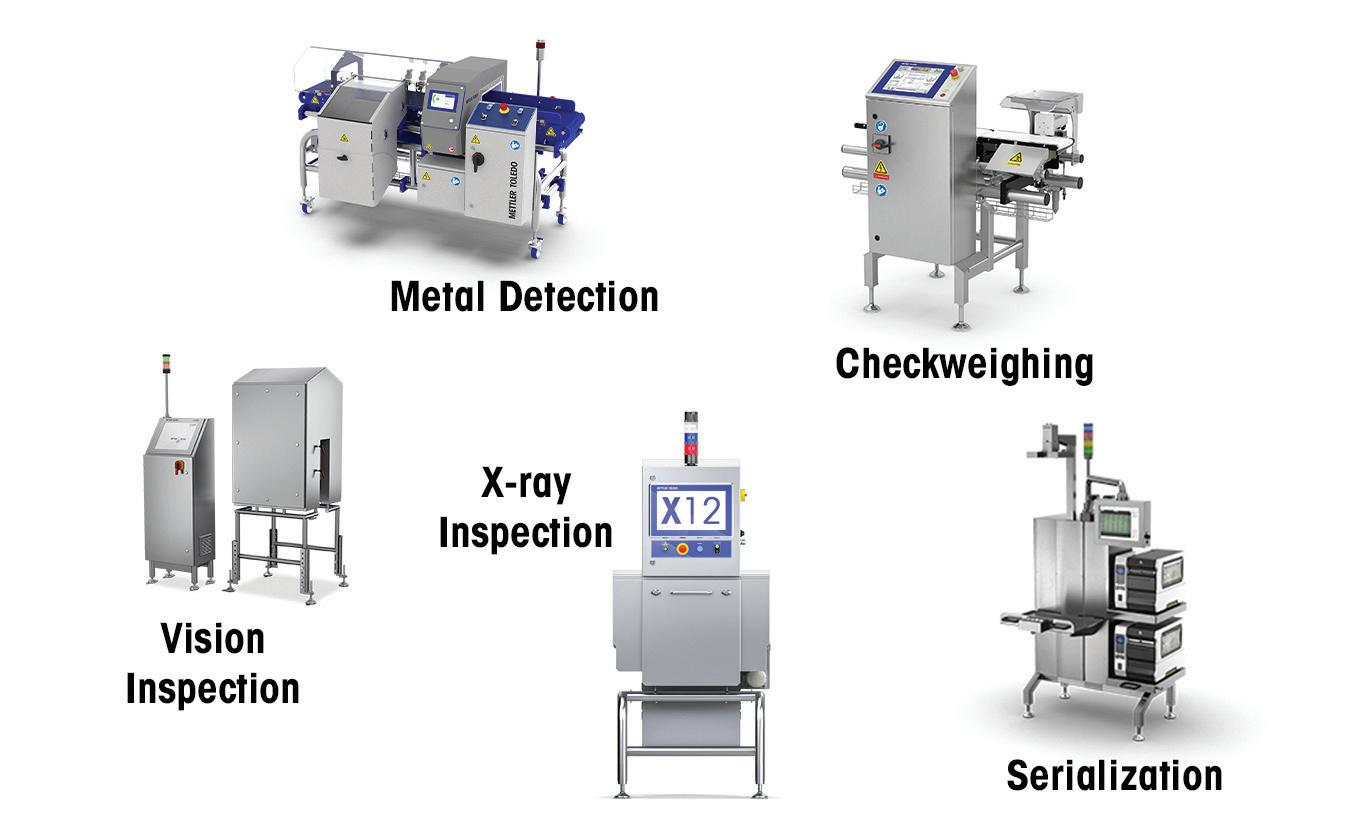

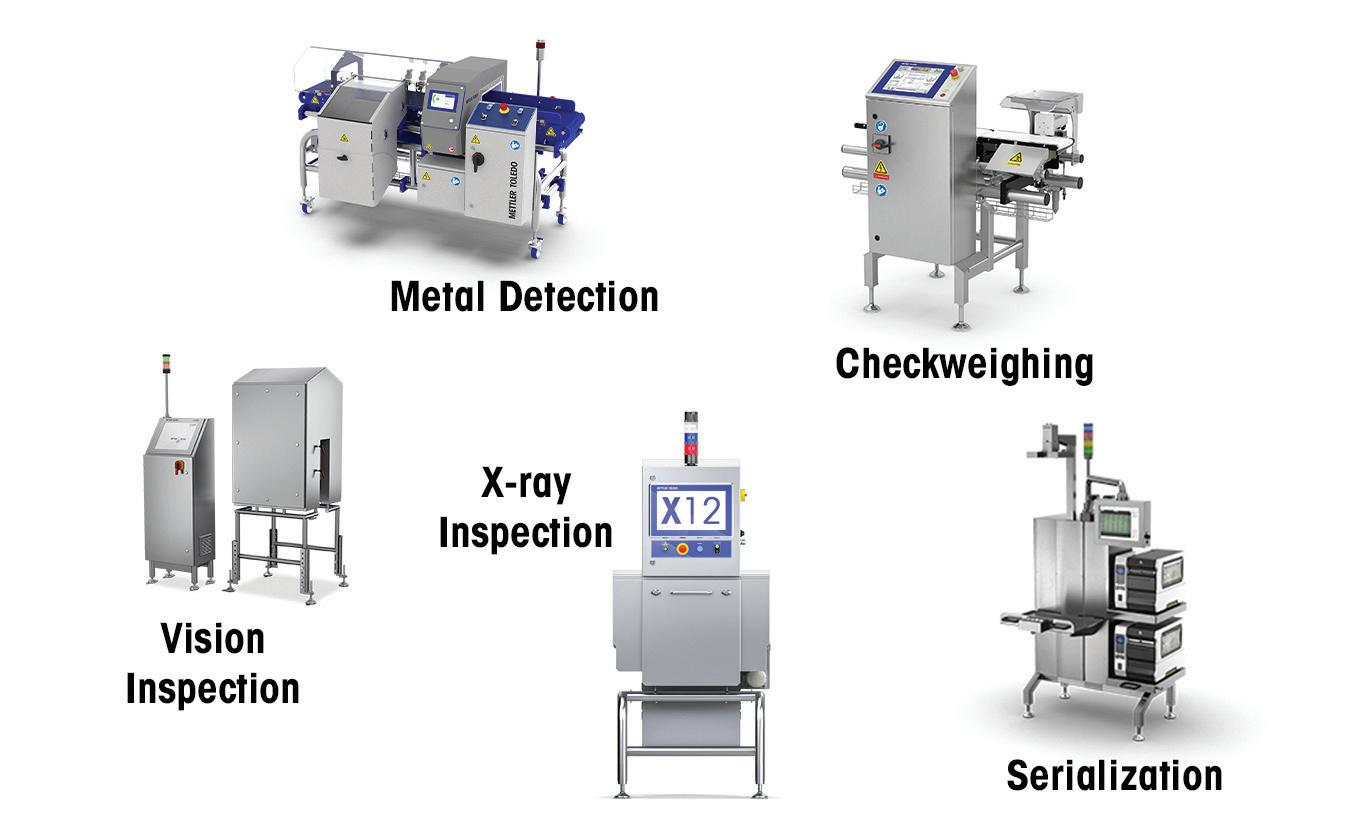

Leading-edge technology trusted worldwide for superior product inspection and contaminant detection.

Your brand is on the line, so you need equipment that’s better than good. Anritsu systems deliver performance, reliability and low total cost of ownership Plus, we back our longlasting equipment with unparalleled service and support.

Discover what you’ve been missing. Learn how to advance your product quality and operational efficiency at anritsu.com/product-inspection.

PERSPECTIVE

X-RAY SSV CHECKWEIGHER

M6 METAL DETECTOR

XR75

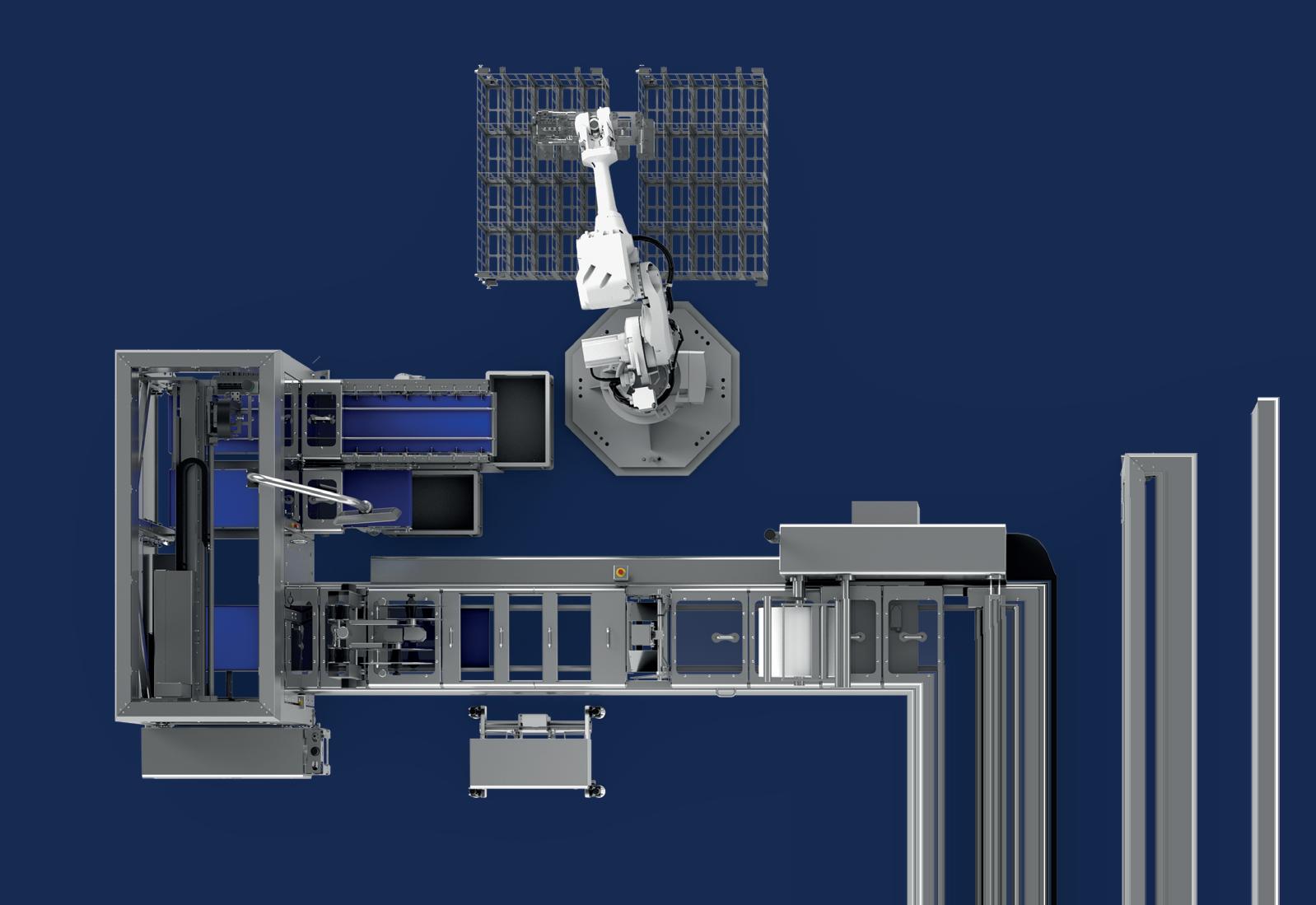

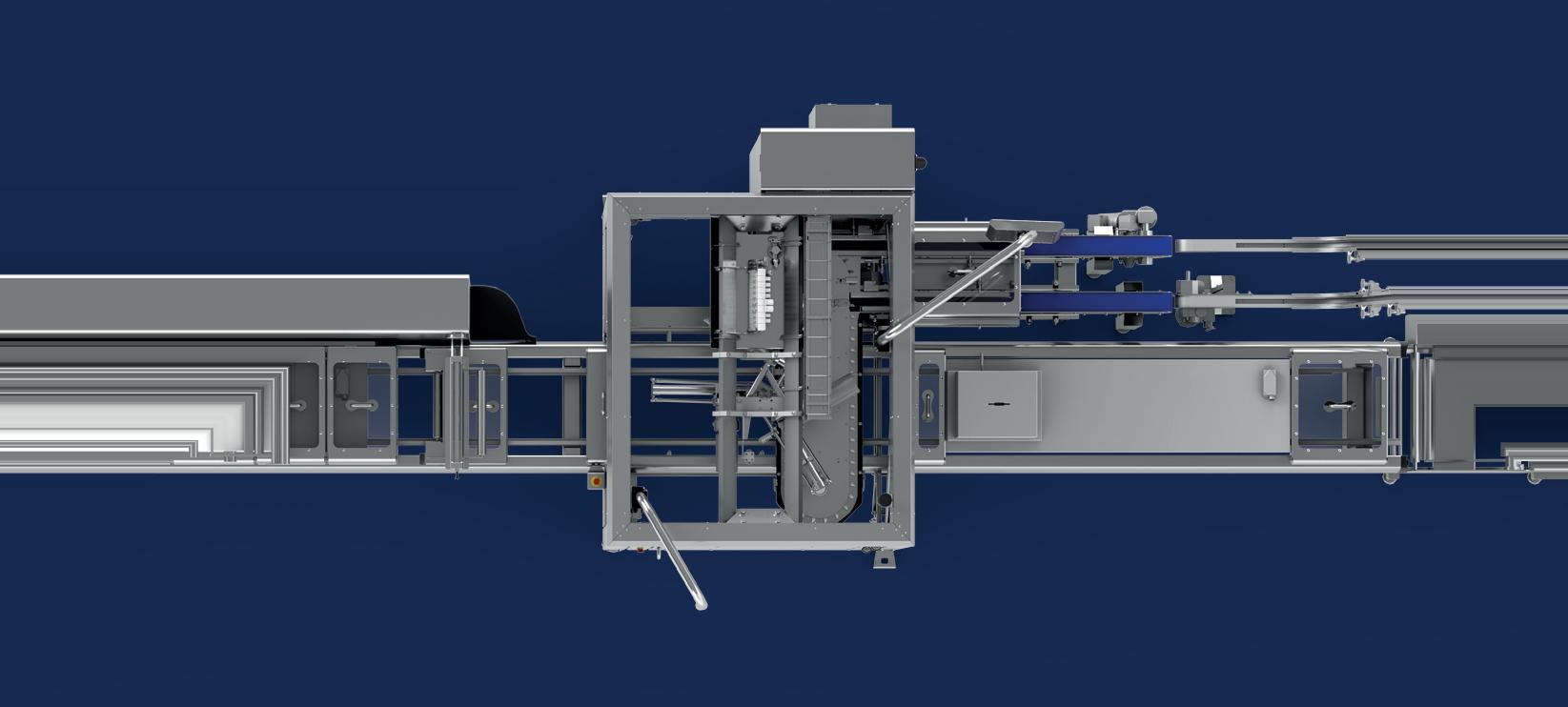

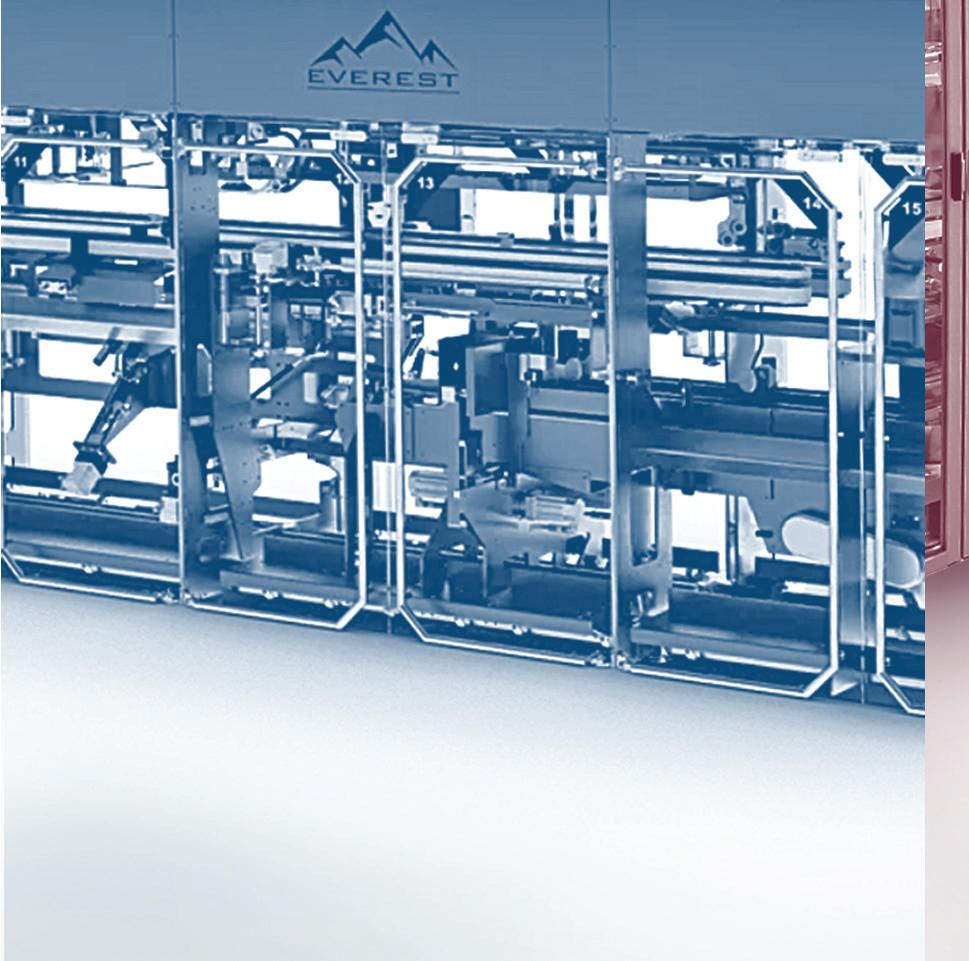

O SOU C O -O -L C IN SOLU IONS C ON OU ww. c o .co end- of-line au tomated pack aging s olu t ion s Pac teon Group c ompanie s o ff er

.co

ss c olo i s.co

o i w s.co

www.sc

www

www.

1

Fatalities Alleged as Nurse Swapped Fentanyl with Tap Water

An Oregon Public Broadcasting article highlighted a disturbing set of incidents at Asante Rogue Regional Medical Center in which a nurse is suspected of removing the painkiller fentanyl from patients’ IV bags, and replacing it with tap water. The number of people who have died or been impacted by the diversion and tampering has not been officially reported. The tap water, which is not sterile, reportedly led to multiple incidences of pseudomonas infection which Docs on Call host Dr. Robin Miller says is very dangerous to people in poor health, and can cause sepsis, pneumonia, and more. —Keren

Sookne

2 Sanofi Supports Employees Diagnosed with Cancer

Fierce Pharma notes Sanofi is going the extra mile for employees. The company-wide “Cancer & Work: Acting Together” support program secures any employee’s job, including salary and benefits, for a minimum 12 months after diagnosis of cancer or other critical illnesses. Sanofi has run the program in some form for years. This next iteration is designed to provide social, emotional, and financial support. Benefits include flexible work arrangements, external psychological support, and support for caregivers and managers. Work to cover “miscellaneous non-medical expenses” is underway. —Melissa

Griffen

3‘Copycat’ Eye Drop Packaging Draws FDA Warning

Per ABC News , the latest eye drop issue in a spate of contamination warnings is copycat packaging that resembles Bausch + Lomb's Lumify brand eye drops. FDA is warning consumers not to use South Moon, Rebright, and FivFivGo brands. South Moon tested positive for Burkholderia cepacia complex, which FDA reports can lead to antibiotic-resistant infection, and neither drug was found to have the active ingredient in Lumify’s redness-reducing drops. Some online copycat product photos may feature the words “Bausch + Lomb,” while actual product may look different. —Keren

Sookne

4 Spoon-in-lid Packaging Launched for Infant Formula

According to a recent MSN article, UK-based Chadwicks and New Zealand-based Tekplas partnered on an innovative spoon-in-lid design for infant formula packaging. Unlike the traditional packaging for infant formula that simply places spoons inside formula cans, the scoop will not become submerged within the contents of the can with the spoon-in-lid design. Launched in the infant formula market in New Zealand, Australia, and East Asia, all the components of the packaging, including the aluminum can, over-lid, scoop, and die-cut lid, are reportedly fully recyclable. —Melissa Griffen

5 FDA Neglect in Tainted Breathing Machine Scandal?

ProPublica coverage claims the FDA failed to protect millions of people who used tainted breathing machines, particularly those manufactured by Philips Respironics, including the popular DreamStation for sleep apnea. Despite receiving numerous complaints about a dangerous defect, the FDA did not issue alerts to doctors or patients over the course of a decade. The company submitted reports years later without penalty. Other leading device makers submitted hundreds of thousands of late reports to the FDA, leaving regulators and the public without safety information. In Feb. 2024, reporters for the With Every Breath series received a George Polk Award for journalism. —Tim Hayes

6 Last-Mile Pollution Hits Homes Near Hubs

A recent UW News article highlighted a rarely discussed topic: how e-commerce hub pollution affects residents. U of Washington researchers found that Seattle-metro neighborhoods within 1.9 miles of an Amazon last-mile delivery station or sortation center are exposed to twice the amount of delivery van and truck traffic (and thus higher emissions) than neighborhoods farther away, despite ordering fewer packages. While healthcare shipping accounts for only a small portion of all goods shipped—and the study was focused on Amazon—it’s a reminder that hubs can impact local public and environmental health, particularly as home healthcare increases.

—Keren Sookne

QUICK HITS To keep up with the latest news bits from around the world visit healthcarepackaging.com to subscribe and get Quick Hits sent right to your inbox. 8 | Healthcare Packaging • Spring 2024

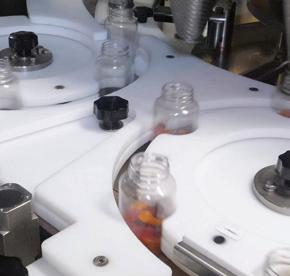

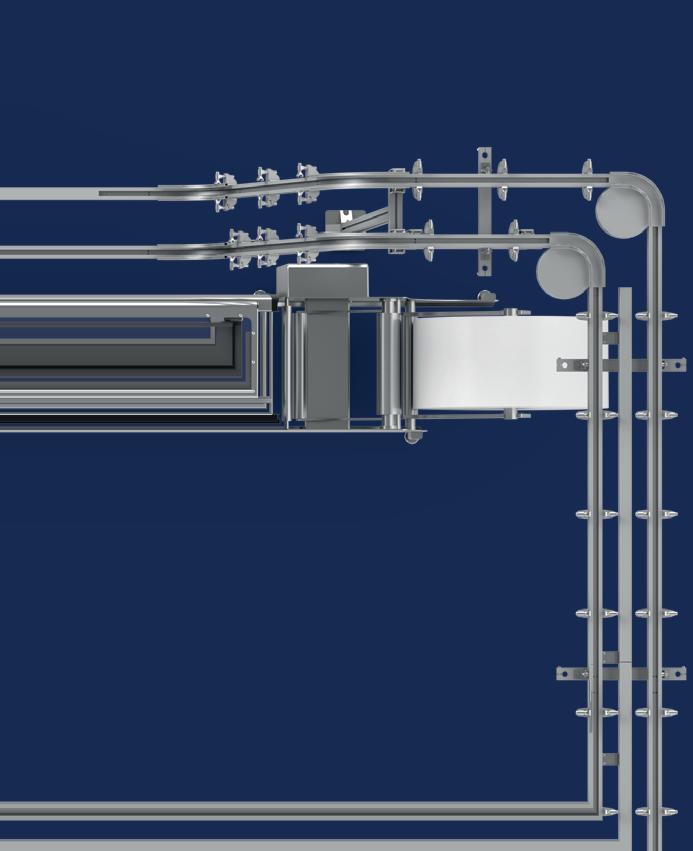

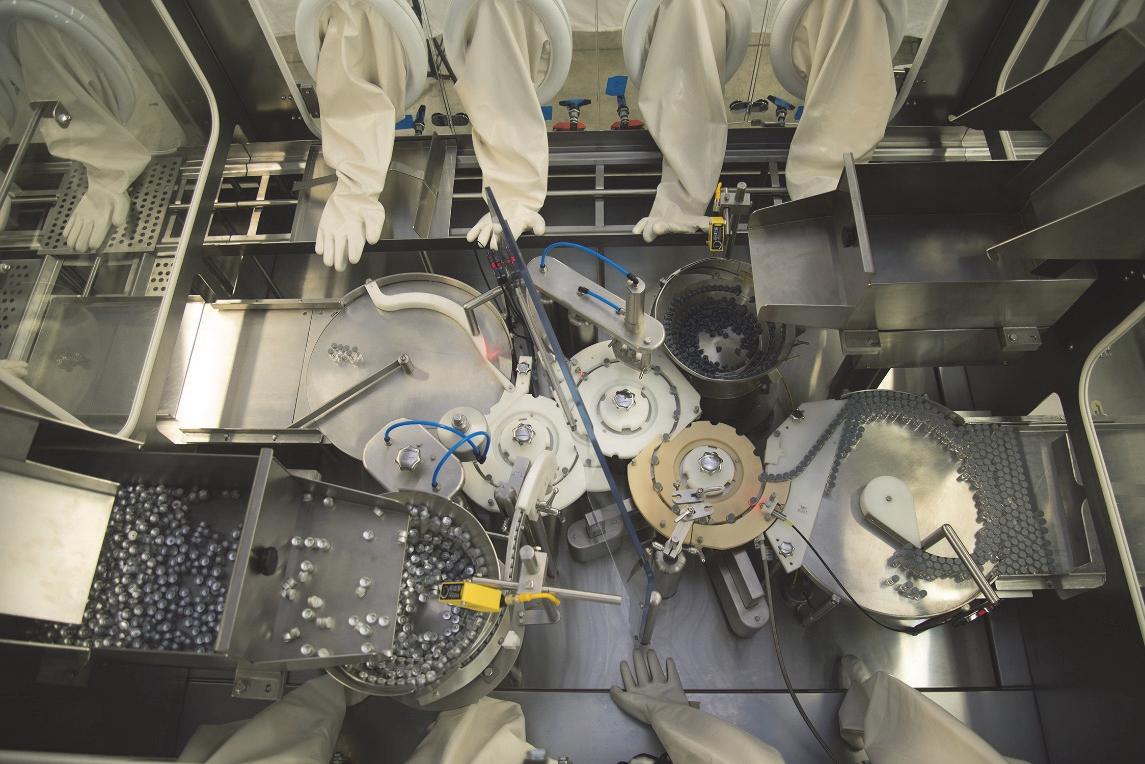

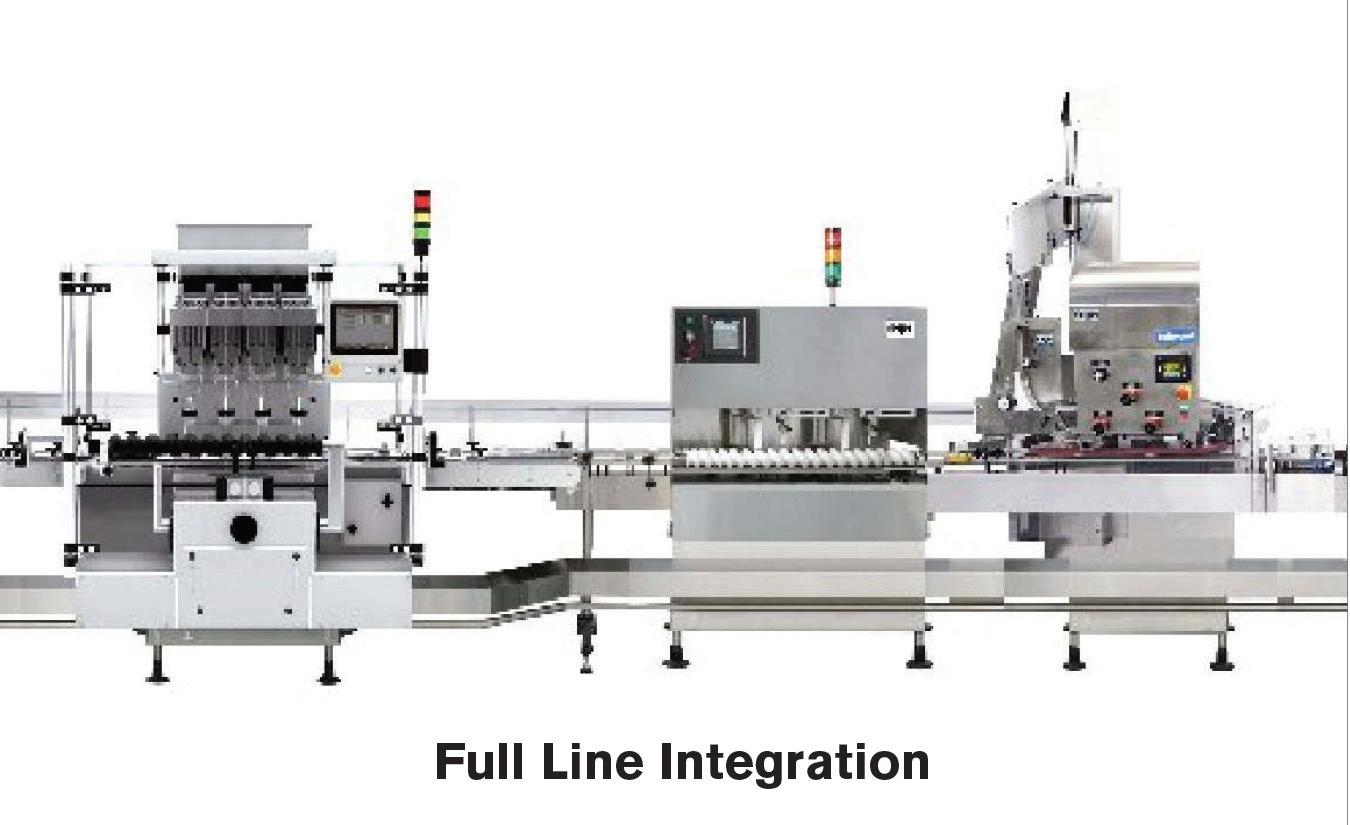

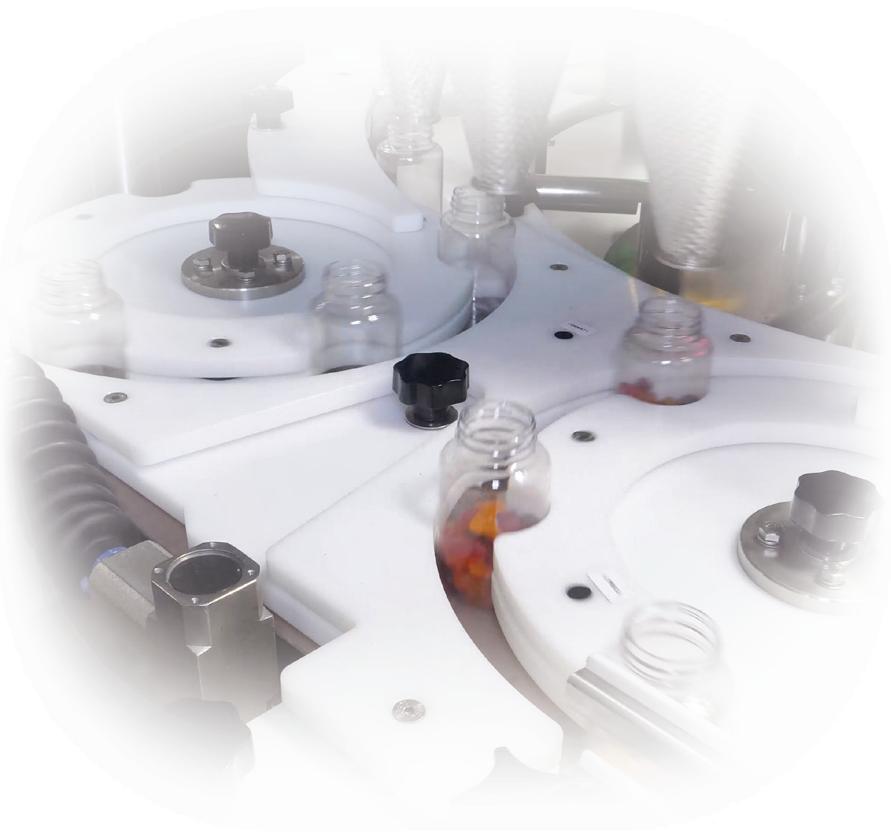

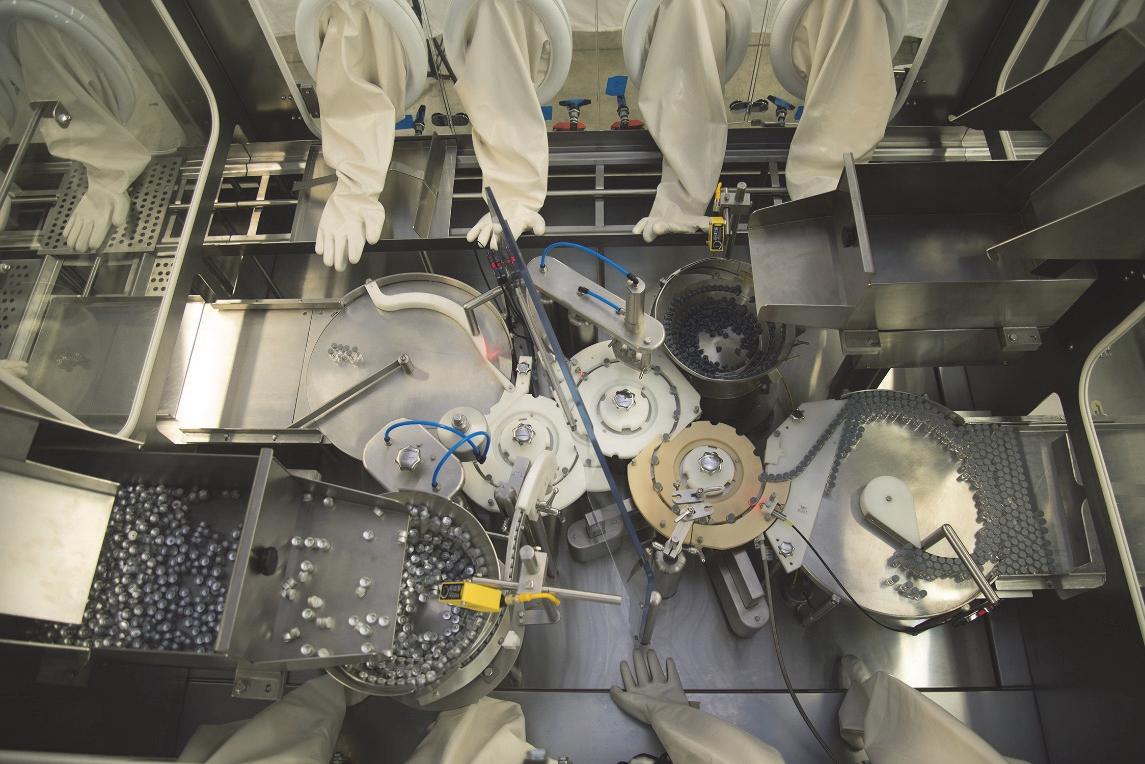

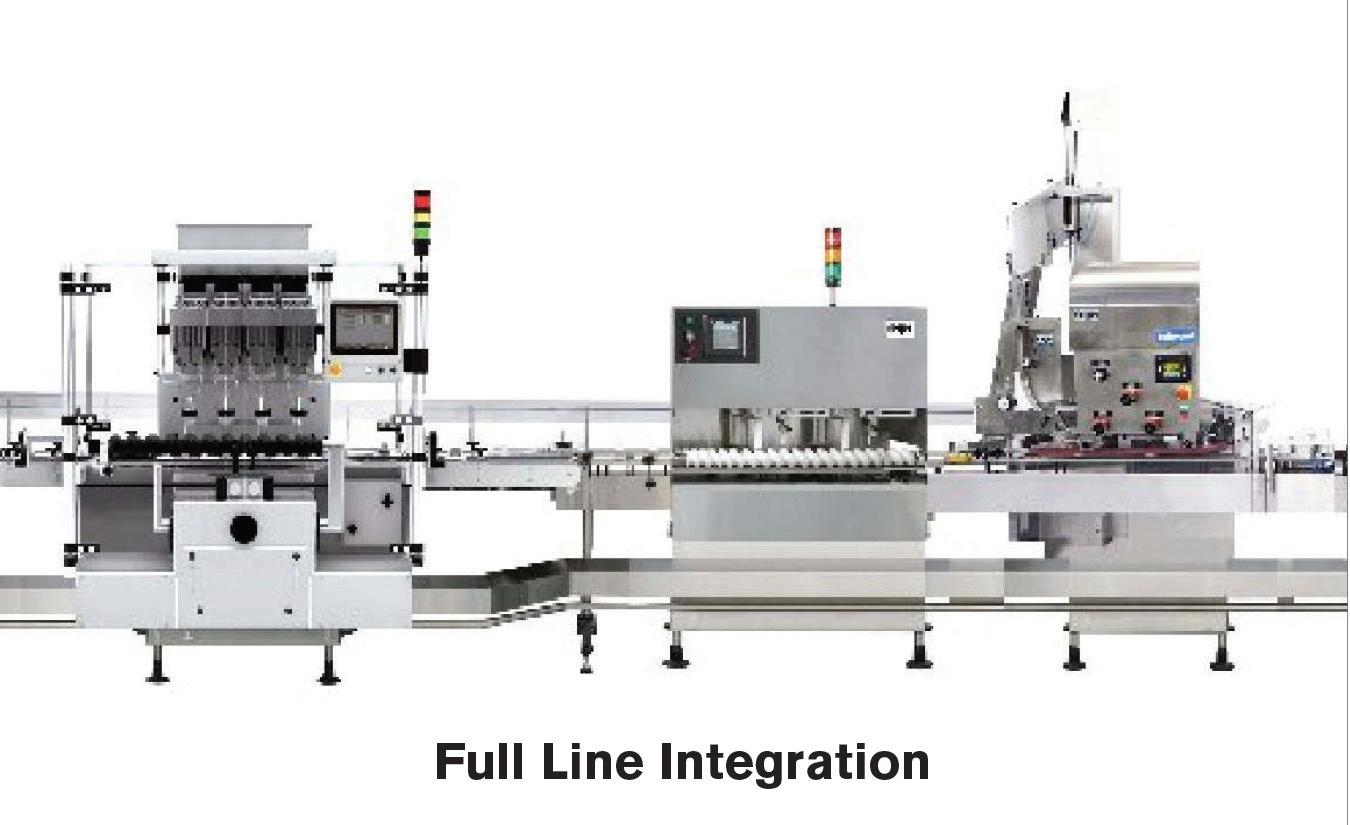

Monoblock Filling and Closing

From our headquarters in North Carolina, Chase-Logeman Corporation has been designing and building monoblock style filling and finishing equipment trusted by the healthcare industry for over 63 years. To meet your exacting process needs, ChaseLogeman integrates production processes for a sanitary process package.

Whether you are using vials with stoppers and crimps, or bottles with plugs and caps, Chase-Logeman has decades of experience to integrate the complete filling line.

Contact us at:

Chase-Logeman Corporation

303 Friendship Drive Greensboro, NC 27409

336.665.0754

info@chaselogeman.com

https://www.chaselogeman.com

“We’re moving into a kind of ‘post-technical challenge’ world—10 to 15 years ago, a lot of the challenge was technical. Can we make things small enough, last long enough for the battery, etc? The technical problems have largely been solved… people can have pulse oximeters on their wrists with ECGs, you can measure blood glucose in real time and have it connected. The technology is not the problem anymore. The problem now is, will the payers pay for these? Will the regulators approve it? Will the users use it?”

—TOM OAKLEY, VP OF DESIGN AND DEVELOPMENT, SPRINGBOARD

On Unregulated and Counterfeit Medicines:

“ I'm taking four generic drugs for my hypertension and elevated cholesterol... and if I got a drug that was half as potent as I thought it was, I could have a heart attack, never knowing that I didn't get the treatment that I thought I was getting.”

—FDA COMMISSIONER ROBERT CALIFF IN A HOUSE APPROPRIATIONS SUBCOMMITTEE HEARING (VIA REUTERS, FEB. 28, 2024)

“At the beginning of the twentieth century, anthropogenic mass was equal to only 3% of global biomass. ... About 120 years later, in 2020, anthropogenic mass is exceeding overall biomass in the world.”

—EMILY ELHACHAM ET AL., “GLOBAL HUMAN-MADE MASS EXCEEDS ALL LIVING BIOMASS,” NATURE, DEC. 9, 2020

$22 MILLION

THE FIGURE allegedly paid to hackers as a result of the ransomware attack targeting medical firm Change Healthcare. The transaction was publicly visible on Bitcoin’s blockchain.

Source: Wired

50%

IN EVERY SECTOR SURVEYED, an hour’s unplanned downtime now costs the manufacturer at least 50% more than it did two years prior.

Source: Siemens, The True Cost of Downtime 2022

$2.5 MILLION

THE AMOUNT of funding raised by Scotland-based drug delivery device developer 1nhaler to develop its paperbased, single-use dry powder inhaler (DPI), which integrates a breathable membrane.

Source: Archangels

47%

THE PERCENTAGE of Americans surveyed that falsely believe only safe, verified websites selling prescription drugs appear at the top of search results. 60% of online pharmacy users would consider purchasing from an unapproved source for convenience.

Source: ASOP Global, Americans’ Perception and Use of Online Pharmacies Survey

Q 10 | Healthcare Packaging • Spring 2024 QUOTABLES BY THE NUMBERS

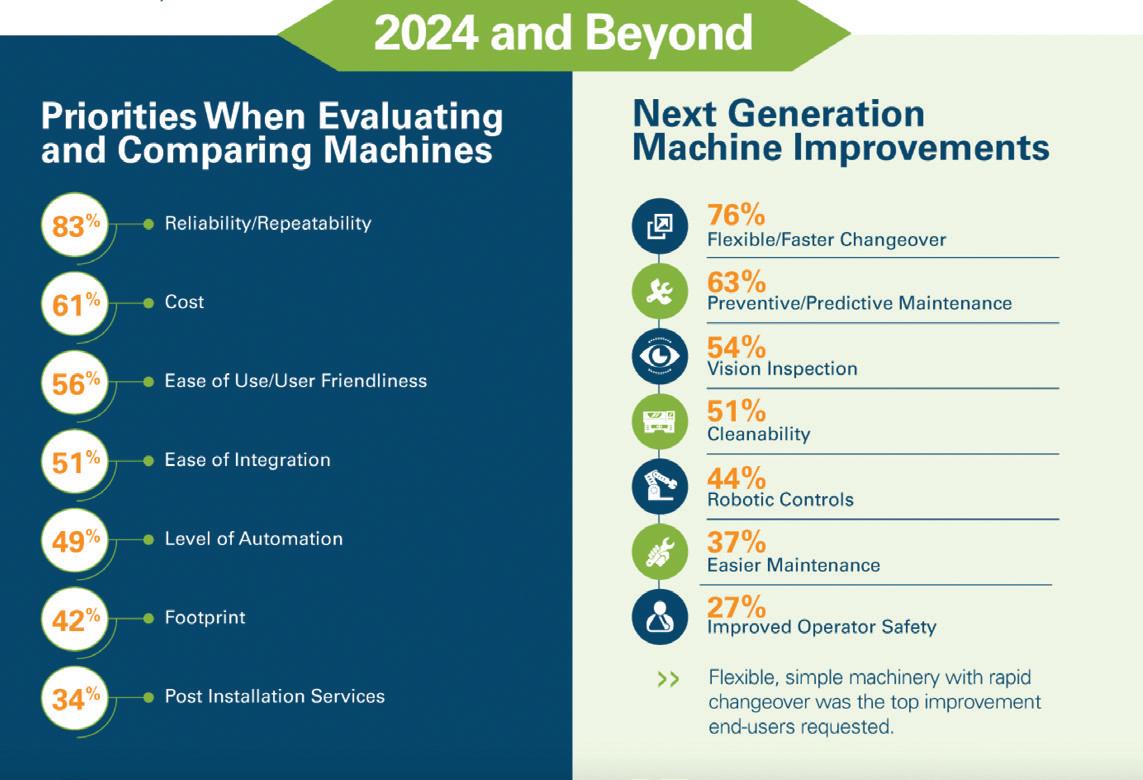

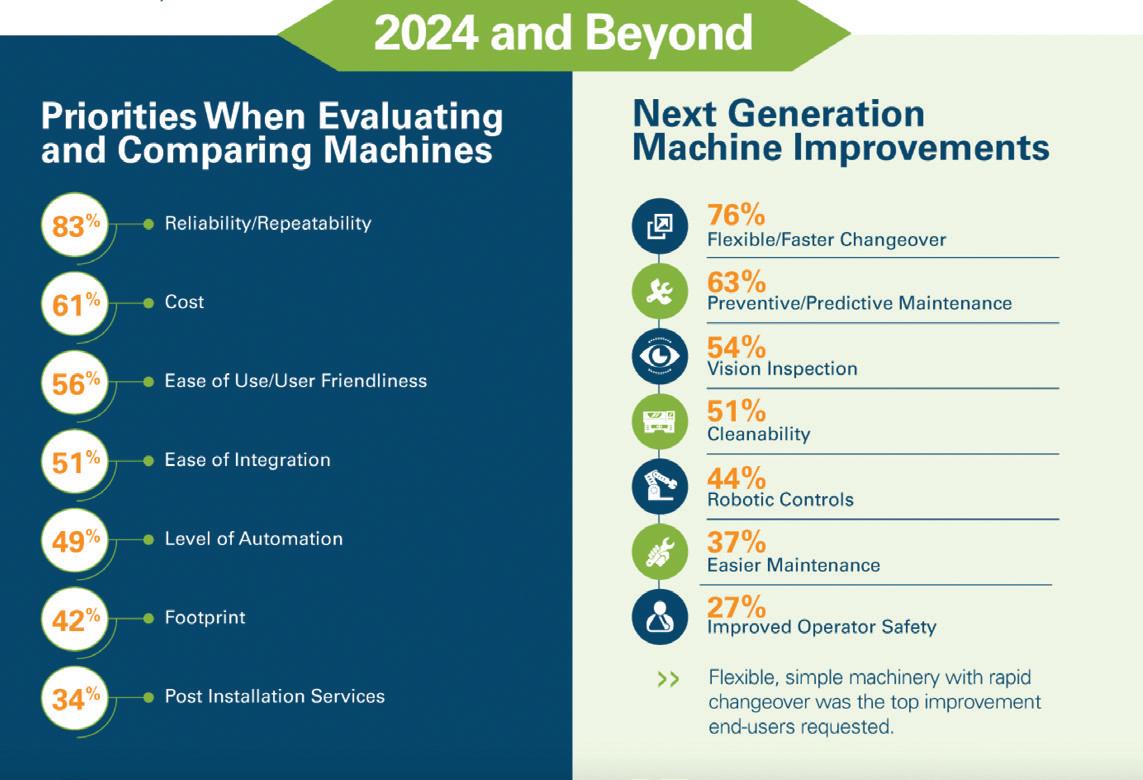

Pharma Machinery Market Growth

Outpaces Larger Industries

A forecasted expansion of the pharmaceutical machinery market is driven by enhancements in technology, automation, sustainability, and supply chain challenges, as highlighted in a recent infographic, Pharmaceutical Manufacturing: The Future Ahead, released by PMMI (view the infographic at hcpgo.to/430). “A large portion of the biggest pharmaceutical manufacturers have announced capacity expansion in the billions, with the majority of investment going toward expanding capacity in North Carolina,” says Rebecca Marquez, director, custom research, PMMI. “This has pushed forecasted growth of packaging machine shipments to the pharmaceutical sector up for 2023 and 2024 compared to other industries.” Both e-commerce and central pharmacies, which sit between the retail pharmacy and wholesaler and serve multiple pharmacies, were cited as major reasons for this growth. Increasingly, central pharmacies are being used to serve mail-order prescriptions in the growing e-commerce landscape.

Going into 2024, manufacturers identified reliability/repeatability (83%) as a top priority when evaluating and comparing

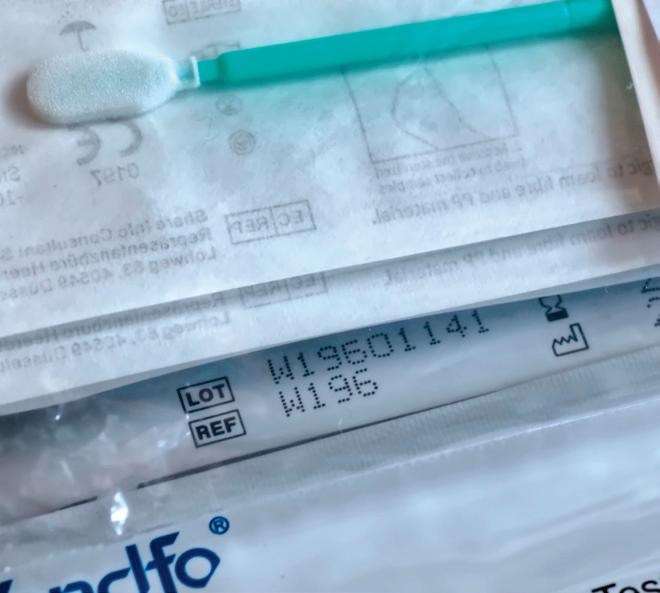

EU: Proposed Compliance Delay for IVDs

In January, the European Council (EC) proposed more time for companies to become compliant with the In Vitro Diagnostic Medical Devices Regulation (IVDR), under certain conditions, to ensure availability of safe devices. The EC reports that a considerable number of legacy in vitro diagnostics (IVDs) currently on the market do not comply with the rules, nor have they been replaced by new devices. The proposed new transition periods include (1) a shorter transition period for high risk IVDs (Dec. 31, 2027) and (2) longer periods for medium and lower risk IVDs (Dec. 31, 2028, and Dec. 31, 2029, respectively). The proposal is advancing to review by the European Parliament and Council for adoption.

The EC is proposing to accelerate the implementation of the EUDAMED medical device database by making certain modules mandatory by late 2025,

machines and flexibility/faster changeover (76%) as a critical improvement for next-generation machines. The infographic also details key trends affecting the pharmaceutical industry. Automating costs, labor, changing packaging formats due to sustainability requirements, and delays in acquiring parts were all identified as challenges for the industry in their respective categories.

—Gatwiri Muthara

instead of waiting for all modules to be in place. MedTech Europe is supportive of measures that keep devices available to patients in need, while it issued four considerations that it believes should be met before any modules of EUDAMED are made mandatory.

—Keren Sookne

UPCOMING EVENTS

INTERPHEX (Apr 16-18) New York, NY

ISTA Forum: TransPack & TempPack (Apr 22-24) San Diego, CA

PDA Parenteral Packaging Conference (Apr 23-24) Copenhagen, DK

thePACKout (May 14-16) Coronado, CA

GS1 Connect 2024 (June 4-6) Orlando, FL

EXPO PACK Mexico (Jun 4-7) Mexico City, MX

PACK EXPO International (Nov 3-6) Chicago, IL

FOR THE LATEST in packaging and machinery, check out the 2023 PACK EXPO Innovations Report covering Pharma/Med Device.

NEWS 12 | Healthcare Packaging • Spring 2024

Ensure your products match the prescription.

• CEIA high sensitivity metal detection; ferrous, non-ferrous, stainless steel

• Ishida X-ray for foreign object and product defects

• Ishida precision checkweighing for weight verification

• Powders, capsules, tablets, liquids

Heat and Control® offers a complete line of metal detectors, checkweighers, and X-ray inspection systems for pharmaceutical products from the leading manufacturers, Ishida and CEIA®. Technical support, demonstration, and testing is available in North, Central and South America.

91 97 16 98 34 108 94 116 102 2 1 101 1 17 93 59 103 104 107 36 96 42 0842 2 ~2~ ~2 27 26 1 52 14 28 29 52 info@heatandcontrol.com | heatandcontrol.com

Quality Control.

detection systems that offer unparalleled sensitivity

pharmaceutical products to protect

consumer

brand. LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Inspection and foreign object

for

your

and your

INSPECTION & FOREIGN OBJECT DETECTION

PHARMACEUTICAL

Apr. 16-18, 2024 Booth 1308 Javits Center NYC NY, USA

ISTA: New White Paper on Shipping & Distribution Risk Assessment

Developed by the ISTA Pharma Committee, the new ISTA PCW-02 | Shipping & Distribution Risk Assessment white paper provides an overview for developing a shipping and distribution risk assessment process for temperature-sensitive product shipments. A risk assessment involves identifyin g the hazards and evaluating the risks associated with exposure to those hazards. Risks to products during shipments include damage, lost shipments, temperature alarms, delayed shipments, and more. [Experts will also discuss what’s new in temperature-controlled shipping at the ISTA Forum, Apr. 22-24 in San Diego.] Download ISTA’s white papers from their site via: hcpgo.to/429 —Keren Sookne

Surplus Feather System for Cold Chain Insulation

Expected to launch for life sciences in the first half of 2024 (as of press time), Pluumo+ is designed to insulate temperature-sensitive deliveries in life sciences using surplus feathers destined for landfill. After cleaning, Pluumo converts feathers into an intermediate fiber which is then combined with a small amount of binder material (a PLA/PBS composite), then formed into insulation and sealed within a starch-based compostable outer film. An example of bioutilization, the system is reported to be compatible with dry ice and a variety of configurations to accommodate different payloads, a range of temperature-profiles, and more. With any new innovation, due diligence on thermal performance is necessary. —Keren

Sookne

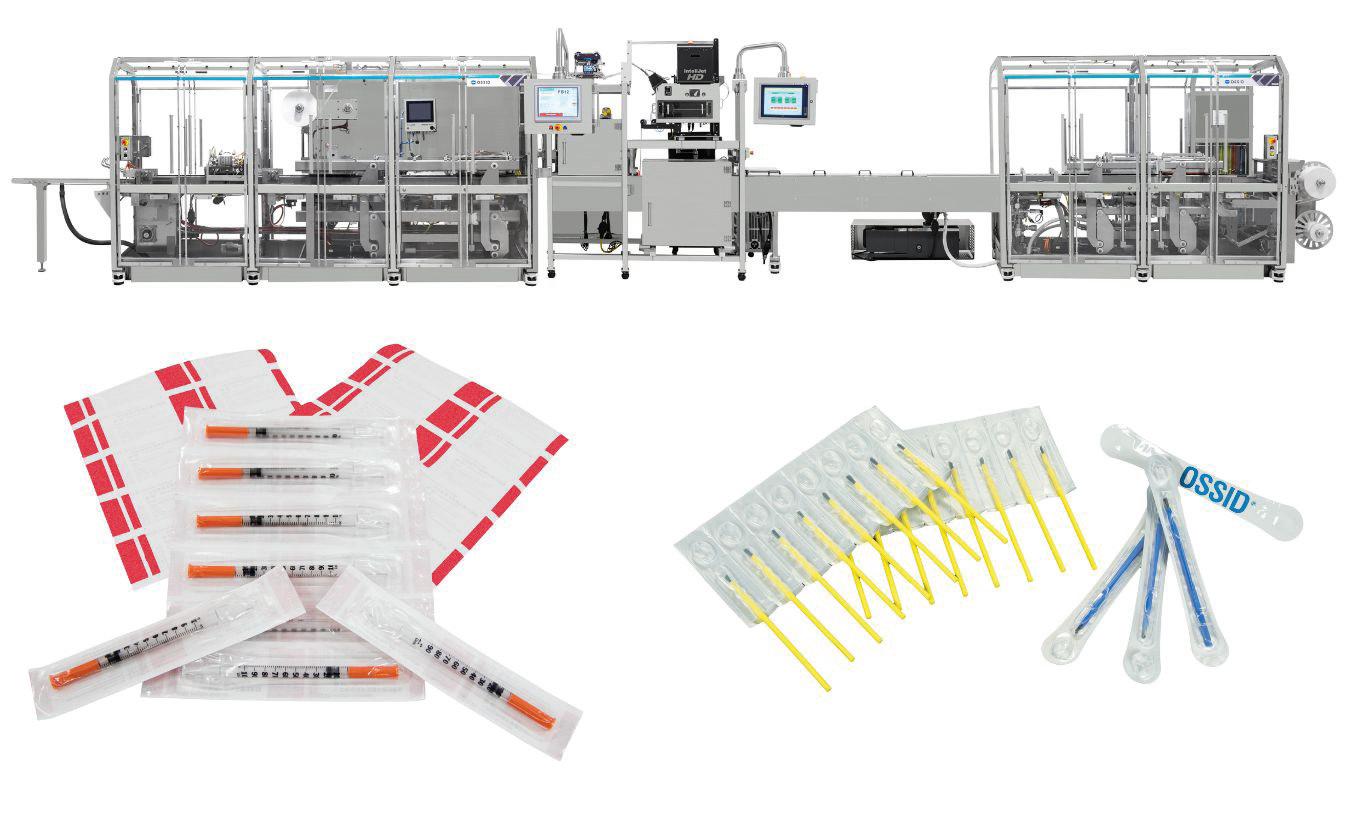

Harpak-ULMA offers medical packaging solutions that meet all of the standards required, helping to provide maximum product protection, hermetic sealing, customizable package shapes, hygienic individual or multi-packs, and easy-open options.

Our experts are ready to walk you through all of the considerations and help you choose the right packaging options for your products.

COLD CHAIN CORNER

© 2024 Harpak-ULMA Packaging, LLC, 85 Independence Drive, Taunton, MA 02780 USA a T a a a W k w th Ha ak-ULMA f m a a kag ng s t ns w th va at n- a y atf ms that m t a n st y stan a s! C nta t s T ay! www ha ak- ma m • 800-813-6644

CCLeAgile.com Complete RFID Solutions Custom Inlay Development Inlay Testing Labeling Printing and Converting Encoding and Personalization Software and Hardware Highspeed RFID Packaging Lines High-Speed RFID Injectable Packaging Lines Late stage encoding with speeds up to per minute Download Our White Paper CCL e-Agile offers comprehensive RFID solutions, featuring customized high-performance inlays, hardware, software, and a seamless, nonintrusive bolt-on solution for high-speed encoding and late stage personalization on RFID packaging lines. S E Pre-Filled East pril 22-24 S E Pre-Filled West June 10-11 Pack E po No ember 3-6 PD Pre-Filled October 22 -23 Pharma Ed PFS December 4-5th Live RFID demonstrations at: RFID Made Easy 700 items

PFAS: Navigating Materials of Concern in Life Science Packaging

From regulations to supplier inventory, how might PFAS bans impact your operations in the short- and long-term? What might be the next materials of concern?

KEREN SOOKNE, EDITOR-IN-CHIEF

While the healthcare packaging and medical device communities have been exempted from certain material regulations, recent discussions have highlighted the need for companies to prepare for changing laws, especially those pertaining to per- and polyfluoroalkyl substances (PFAS), commonly referred to as “forever chemicals.” These chemicals do not readily breakdown in the body or environment and have been linked in studies to endocrine disruption, certain cancers, and more.

During a session at the[PACK]out in 2023, experts from Boston Scientific and Amcor shared insights on the global regulatory landscape and its implications for healthcare brand owners. To start, Alex Bowman, R&D Manager at Amcor, emphasized the importance of staying informed and prepared for regulatory changes that will impact the life science packaging community, underscoring the need for companies to anticipate and adapt to these shifts.

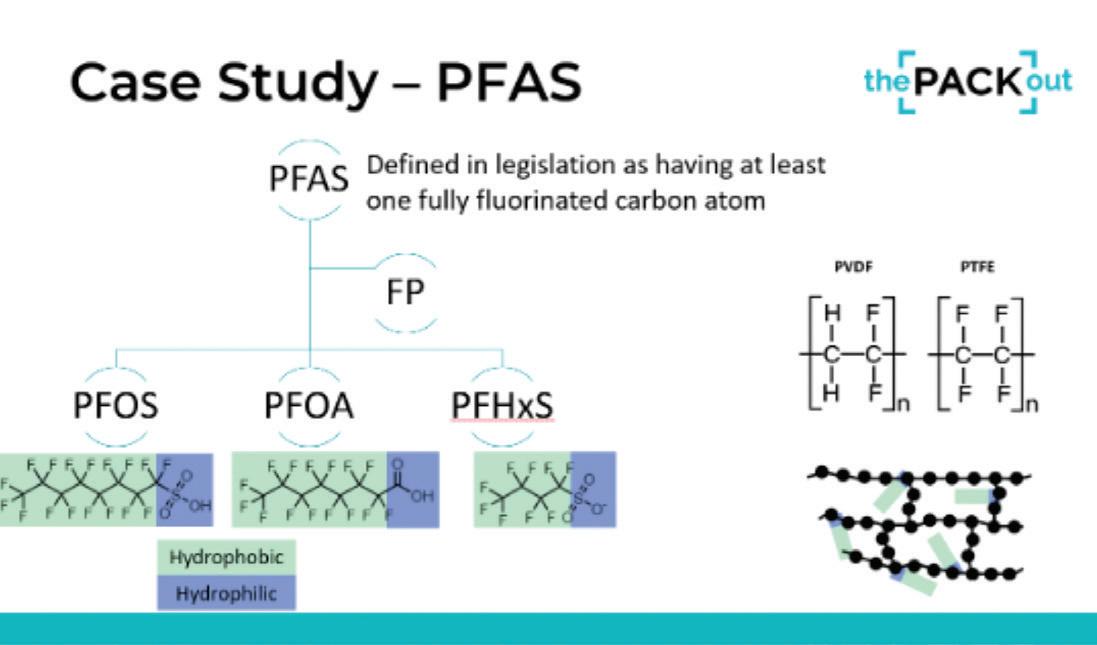

PFAS uses in healthcare packaging

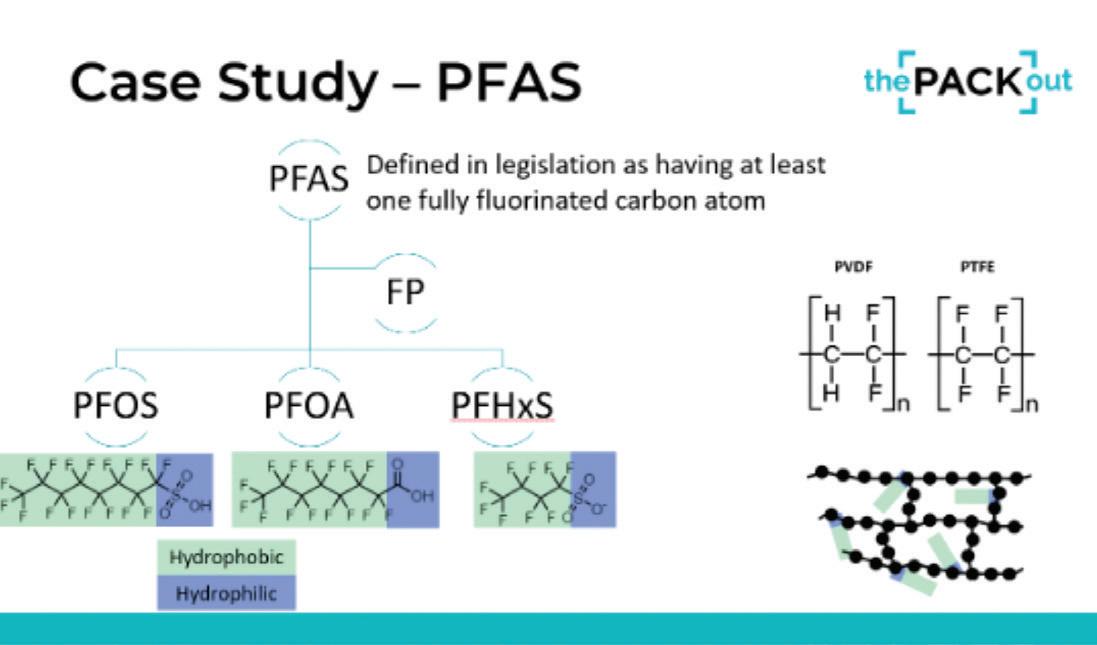

PFAS, which encompasses a broad range of chemicals used for their hydrophobic and hydrophilic properties, have come under scrutiny due to their persistence in the environment and potential health impacts. Haley Gorr, PhD, an Engineer and Global Product Steward from Boston Scientific, said, “What’s really important to understand is how PFAS is defined in the legislation. PFAS is really an umbrella term including PFOS, PFOA, PFHS—they’re very similar. In the legislation, they’ve been shifting towards a very holistic definition of PFAS. There’s not a lot of opportunity to differentiate between those different types of molecules. They’re saying, ‘If you have one fully fluorinated carbon atom, then you’re in scope.’ And that’s where everyone’s landing whether EU, U.S., etc.”

Gorr said that while their presentation wasn’t about debating the merits of these chemicals, it’s important to understand that there is a difference between molecular PFAS and polymerized PFAS, noting that the latter, known as fluoropolymers or FPs, are non-toxic due to their stable, locked-in structure.

“Fluorinated polymers have really helpful properties. We like them because they are biologically inert, they are hydro-

phobic, and they contribute lubricity to our products because the water sits on top of those materials [due to the hydrophobic fluorinated carbon atoms],” she said ( see slide above ). She explained that PFAS is generally used in medical devices to add lubricity and reduce friction on some catheters, wires, and implants. Another common application is to cover electrical wires that come into contact with tissue, such as the lead wires of some defibrillators and pacemakers. There are limited, if any, alternative materials for these complex applications at present.

There are, however, some traditional PTFE applications with alternative materials. Gorr explained that PTFE may be included in glossy carton coatings to prevent sticking. PTFE-free carton coatings are now widely available.

Bowman explained why converters use materials that fall under the PFAS umbrella in their films as processing aids. “Typically, linear low densities [LLDPE] and polypropylene are the kinds of materials that can use aids in processing. There’s a stick-slip phenomenon when these polymers are extruding through a die interface and these fluoropolymers and fluoroelastomers reduce that friction against the interface. So it’s basically eliminating things like melt fracture and orange peel and gives a nice clear film so you can see what’s inside your package,” he said.

MATERIAL DEVELOPMENTS 16 | Healthcare Packaging • Spring 2024

↑ PFAS is an umbrella term including PFOS, PFOA, PFHS. Source: Haley Gorr/Alex Bowman via the[PACK]out

↑ Haley Gorr, PhD, Engineer and Global Product Steward at Boston Scientific.

INNOVATIVE PACKAGING. IT’S IN OUR DNA. No matter what your packaging challenge, we’ll provide a unique, fully-integrated equipment solution that perfectly fits your needs. Fairfield, New Jersey • 973-808-8185 mgamerica.com See us at Interphex Booth 2221

MATERIAL DEVELOPMENTS

Market forces and indirect effects

The implications of PFAS bans extend beyond the immediate concerns of compliance. Pharmaceutical and medical device brands may only represent a small portion of a converter’s total business. As converters comply with regulations for food and CPG packaging, eventually it may not make economic sense to carry PFAS-containing materials solely for life science brands.

“We’re seeing some of those impacts in the regulations in food packaging that are driving a lot of action right now. We’re actively changing out of PFAS-containing materials to not-intentionally-added PFAS materials, including resins and additives that we’re buying from our suppliers, and then upstream even further to those chemical manufacturers making the fluoropolymers and fluroelastomers that we use as processing aids,” said Bowman. “Think about what the demand change feels like to the chemical manufacturers and resin and additive producers. They’re seeing a major shift away from one type of material.”

↑ Alex Bowman, R&D Manager at Amcor.

↑ Alex Bowman, R&D Manager at Amcor.

For now, Bowman reckons converters will continue to support healthcare customers with the existing materials. “But I don’t expect

it to be that way forever. Eventually, you can see the demand start to shift and it probably becomes unprofitable and unlikely that they’re going to continue to support what’s a pretty small consumer in terms of all of the plastics in the world,” he added. “We’re able to avoid some of these regulations because we’re in our own regulated markets. But some of these things are going to come at you from further up the supply chain than even [suppliers] can control.”

Legislation: U.S. and abroad

The conversation touched on legislative actions at the state level in the U.S., with Vermont being the first to enact a ban on PFAS-containing food packaging that went into effect July 1, 2023. On Feb. 28, 2024, the FDA announced the completion of a voluntary phase out in which grease-proofing substances containing PFAS are no longer being sold by manufacturers for food contact use in the U.S. market.

Maine’s PFAS-reporting law requires disclosure of certain materials in products. While packaging is currently exempt, according to a local news report, manufacturers are grappling with the difficulty

Install

The G&K-Vijuk Cartonac 2005 Folder has a hinged feeding table for easy access to the fold plates and rollers.

It is a simple upgrade from a Cartonac 91 or 2000!

715 Church Road, Elmhurst, IL 60126 • 630-530-2203 • www.guk-vijuk.com

leaflets in-line and insert them along with the product into cartons!

Fold

and synchronize a G&K-Vijuk Cartonac with your packaging line’s chain or toothed-belt drive.

Need help? Automate! PRODUCT Save on labor, time, and leaflet storage space! Call today to optimize production!

The ingle- ource pharmaceutical packaging y tem provider with over a century of cu tomer ati faction

Excellence in:

• Individual mac ines

• Full pr duc i n lines

• In- use manufac uring

• Exclusive represen a i n f par ner rands

• Full line in egra i n

For:

• Oral s lid d se

• Liquid d se / Asep ic fill finis

• P wders

• Gummies

• Pers nal care pr duc s

Asep ic Fill Finish

C pping

C se/Tr y P cking

Coding

Co oning

Coun ing

Decon min ion

Feeding

Filling

Inser Feeding

Isol ion Technology

L beling

Line In egr ion

Robo ic P lle izing

Seri liz ion

S eriliz ion

W shing

©2023 ProM ch Inc 5600 Kier n Mon re l, QC H4S 2B5 PHONE 514-337-6990 EMAIL info@NJMPackaging.com WEB NJMPackaging.com

Vi it in

of identifying PFAS in their products and supply chains. That regulation also has a PFAS ban built in for 2030.

Outside of the U.S., new regulations include a mineral oil ban in France for food packaging, a PVC food packaging ban in Taiwan, and mandatory packaging reporting in Singapore.

Additionally, Gorr highlighted the proposed EU PPWR, the Packaging and Packaging Waste Regulation, evolving from the directive (PPWD). “This [regulation] is still the same content as the [directive]. You’re still required to report on what’s in your packaging waste and be accountable for it,” she said, which ties into extended producer responsibility and environmentally preferred purchasing (EPP) programs. “It’s not just regulations that we need to care about, it’s also what our customers are requiring of us. It’s a different type of requirement, but still a requirement. If they’re asking you for recycled content, I feel that we are obligated to supply that to them, if possible,” Gorr said.

Looking ahead, the life science packaging community must prepare for the possibility that medical device packaging and devices themselves may not remain exempt from these regulations indefinitely. Gorr, who owns the advocacy gap assessments for the REACH regulations at Boston Scientific, pointed out that while medical devices might currently be shielded from

certain bans, the industry must remain vigilant and proactive in its approach to regulatory compliance. “Medical devices are not going to be exempted forever,” she cautioned, suggesting that the industry should be proactive in engaging with legislators and educating them on the potential socioeconomic impacts of proposed bans.

What’s next?

As the regulatory environment continues to evolve, the industry faces the challenge of balancing compliance with innovation and sustainability. The session concluded with a forward-looking question posed to the audience: “What do you think the next PFAS will be?” As Bowman and Gorr highlighted, PFAS is certainly not the last material of concern that will either be banned or discussed in the media as an environmental or human health risk. Responses varied, indicating a wide range of concerns about potential future regulations on materials such as colorants, additives including titanium dioxide, BPA, PVC, styrenes, and nanoparticulates.

Understanding, adapting to, and anticipating the regulatory landscape will be critical to maintaining compliance and ensuring the continued viability of healthcare products and processes.

MATERIAL DEVELOPMENTS

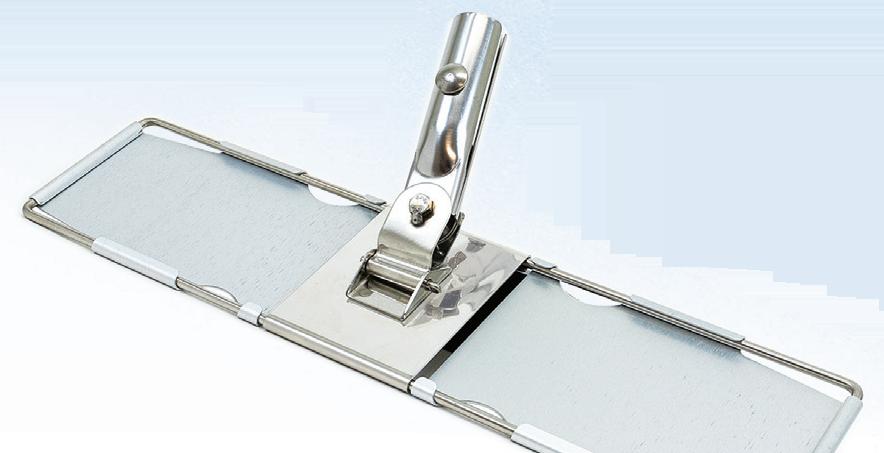

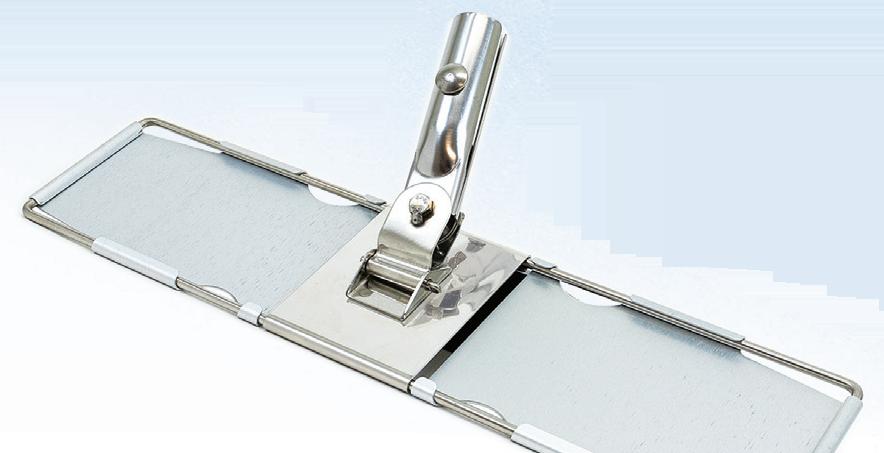

Gamma sterilized and validated to a sterility assurance level of 10-6 per AAMI standards for healthcare products. Now Available Pre-sterilized! MADE IN USA Cleanroom Sponge The ORIGINAL TruCLEAN Aluminum Mop Frame Ultra-lightweight hybrid design for easy and efficient cleaning of hard to reach areas. www.perfex.com Shop Online! Booth # 1529 April 16th - 18th Visit Us: The pioneers of cleanroom disinfection and your trusted supplier of critical cleaning tools for controlled environments. 1-800-848-8483 Est. 1924 Specifically designed aquazone foam ideal for cleaning and disinfecting high-grade cleanroom environments. INNOVATIVE CLEANING TOOLS ® TruCLEAN

Refill System Cuts Plastic from OTC, Pharma Packaging

ANNE MARIE MOHAN, SENIOR EDITOR, PACKAGING WORLD

TOP THREE TAKEAWAYS

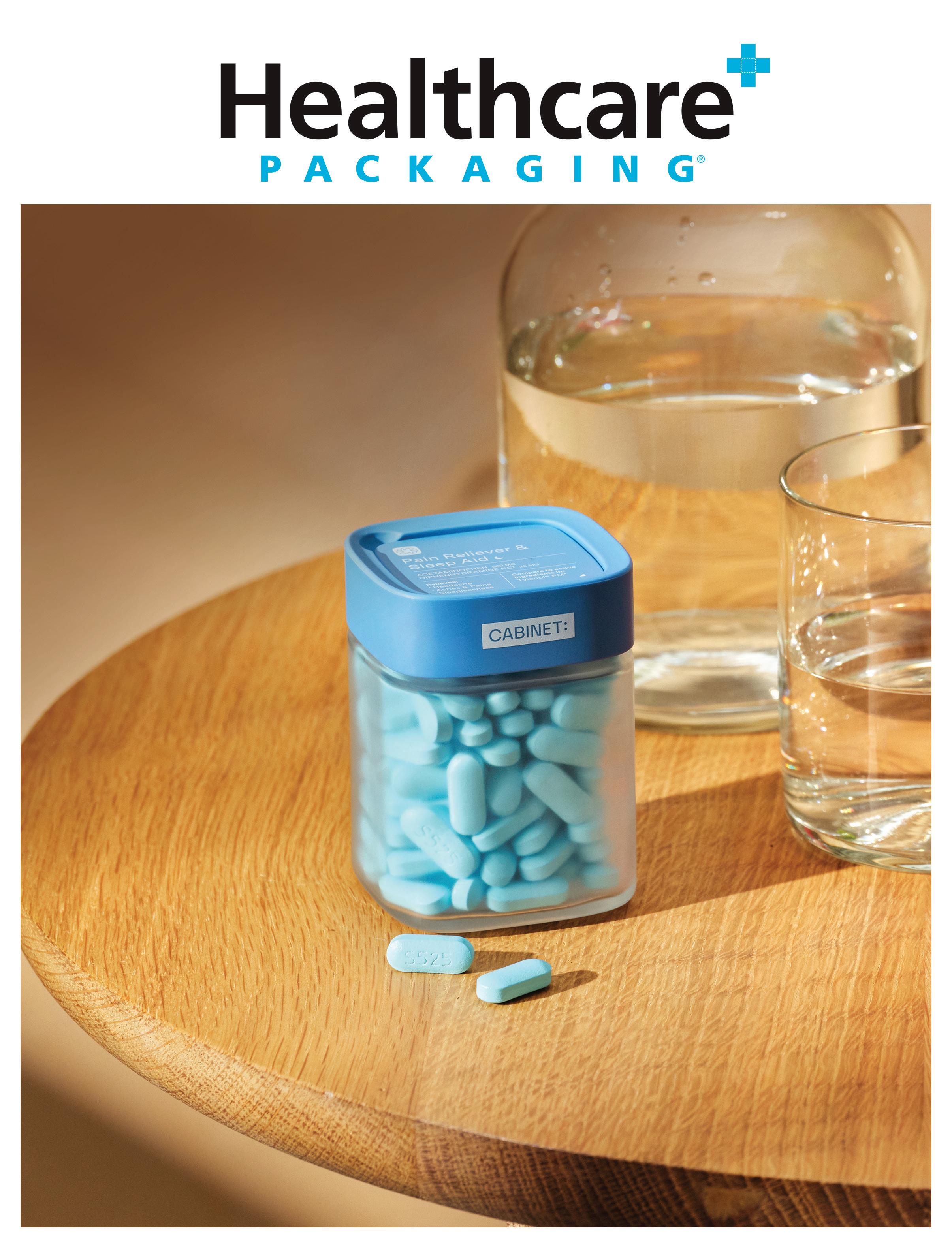

In every CPG category and market, efforts are underway to eliminate single-use plastic packaging when and where it makes sense. One area that has traditionally lagged behind, however, is the healthcare market, primarily OTC and pharmaceutical packaging. However, startup Cabinet Health has come up with a solution that it says has the potential to transform the industry, making it more sustainable—“from retail and pharmacy aisles to medicine cabinets and homes.”

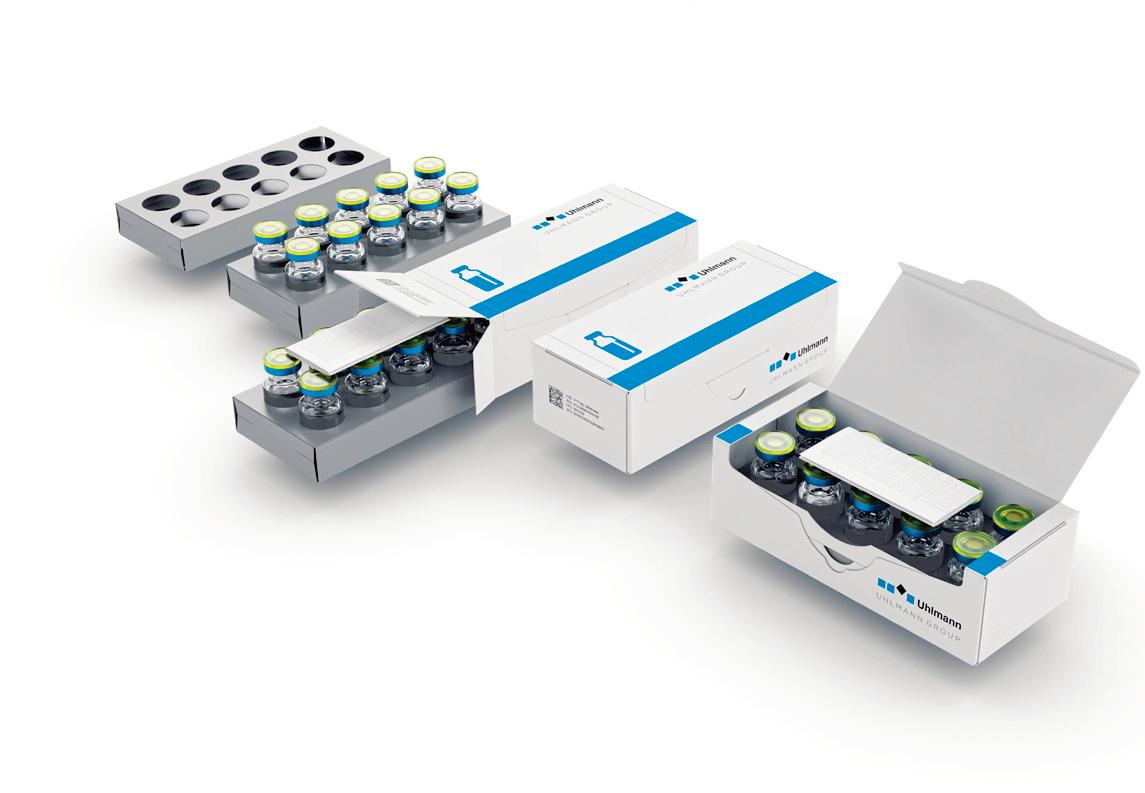

Founded in 2018 by Achal Patel and Russell Gong, Cabinet Health: The Sustainable Healthcare Co. has developed a reusable and refillable packaging system whose components include a stackable, shatter-resistant and reusable glass bottle paired with refills in a compostable pouch. Its initial products, a line of OTC meds under the Cabinet brand name, first became available via direct-to-consumer (D2C). In May 2023, the portfolio, which

includes allergy, pain, cold and flu, digestive, and sleep remedies, launched at retail in 700-plus CVS pharmacy stores nationwide.

Gong shares that he and Patel came up with the idea for Cabinet while they were working abroad running a social innovation program for a consulting group that focused on identifying mission-driven and sustainable startups and helping them scale as businesses. “We saw firsthand the impact of the plastic crisis and saw other industries coming up with innovative sustainable packaging solutions, but no large healthcare players were successfully tackling this issue yet,” he says. “We combined our backgrounds in sustainable startups and medicine [Patel’s grandfather built one of the first acetaminophen factories in a small town in India] to reimagine people’s medicine cabinets.”

Reflecting on the scale of the plastics crisis, Gong shares that more than 194 billion plastic medicine bottles enter landfills each year. Further, one model found that humans consume 0.1 to 5 g of microplastics each week—the latter is roughly the size of a credit card. “The plastic waste crisis is a public health crisis,” he says.

Reusable packaging exhibits both form and function

In developing the reusable packaging system, Gong relates that Cabinet started from scratch, doing most of the work in-house, but did bring in some “amazing specialists and partners along the way.” The cube-shaped medicine containers, he shares, were developed with both form and function in mind. Available in a small and large size, they are made from glass, frosted to preserve the contents and shatter-tested for durability. They are also stackable for easy organization on consumers’ medicine shelves.

REUSABLE PACKAGING 22 | Healthcare Packaging • Spring 2024

1. Startup Cabinet Health offers reusable packaging and a refill system.

2. The portfolio of OTC products launched in CVS Pharmacy stores in 2023.

3

. A starter kit comes with one reusable container and one compostable pouch.

1. Cabinet Health’s portfolio of OTC products, including allergy, pain, cold and flu, digestive, and sleep remedies, initially launched at retail in 700-plus CVS pharmacy stores nationwide.

We don’t just make caps.

We make possibilities. We

We believe every project we work on is a way to create a dynamic customer experience. That’s why we design customized packaging solutions to fit exactly what your customer needs.

To find out how we can help, visit us at mrpsolutions.com

Says Gong, “With a low, square profile, the Cabinet system takes up a fraction of the space in your medicine cabinet than traditional bottles—a dream for minimalists, aesthetes, and anyone who could use the extra storage space.”

Topping each bottle is a colorful, reportedly child-resistant square plastic cap with a bayonet locking closure and integrated

magnet. Nestled inside a concave area on the top of the closure is a separate, removable magnet upon which is printed directions for use of the medication, expiration date, lot number, and other required information, as well as a QR code consumers can use to order medication refills.

For the refill packaging, Cabinet chose a proprietary material that is compatible with both home compost devices and industrial composting facilities. According to Gong, the company is also currently waiting on backyard-compostable certification. Along with the capsules or tablets, each refill pouch also holds a new snap-in magnet specific to that batch.

“Cabinet’s system uses glass, compostable flexible films, and aluminum,” Gong says. “We indexed on hyper-recyclable materials with compostable films being our path forward for earth-digestible materials. We looked into a whole host of other materials, but ultimately we needed to balance regulatory quality, cost, design, and sustainability.”

FLEXIBILITY

A single Columbia palletizer can handle all of these products and more with ease.

REUSABLE PACKAGING WWW.PALLETIZING.COM / 800 628 4065 LEARN MORE

2. Available in a small and large size, Cabinet Health’s reusable, sustainable packaging is made from glass, frosted to help preserve the contents and shatter-tested for durability.

3. The flexible pouch for refills uses a proprietary material that is compatible with both home compost devices and industrial composting facilities.

A pound per person of plastic saved annually

According to Cabinet, by switching to the brand’s refillable system, a consumer can eliminate up to one pound of plastic annually and hundreds of pounds of plastic in a lifetime. To arrive at that estimate, the company calculated that, on average, a single empty bottle is made of 3.75 oz of plastic and that, also on average, consumers purchase about five refills of a given medicine per year.

“Oftentimes, pills expire before they’re able to be used, or even worse, expired pills are consumed,” says the company. “Cabinet medicines come in lower pill counts than some bulk medicine offerings to minimize pill waste. With that in mind, we factored in a 0.85 to 1 ratio to account for us offering fewer pills per purchase than competitors in some cases.

“Based on the above variables, we estimate that when you buy a Cabinet medicine starter set [reusable bottle with medication plus one refill], you are eliminating one single-use plastic medicine

bottle immediately, plus four more via compostable medicine refills throughout the year. Multiply that by 0.85, and you are eliminating one pound of single-use medical plastic per year.”

The company’s products are manufactured in India, using FDA-approved active ingredients. Cabinet pays for carbon offsets to account for the transport of the product and make the supply chain less damaging for the environment.

The next step in Cabinet Health’s journey to “de-plastic pharmacy aisles and medicine cabinets across the country” is the use of its packaging system for prescription pharmaceuticals. In October 2023, they launched their refillable mail-order prescription services after a beta-test period. For this application, the company has designed a child-resistant pouch for refills.

In the future, Gong says Cabinet plans to offer packaging formats to accommodate other form factors, such as liquids and creams.

REUSABLE PACKAGING Scan to learn more

4. A Cabinet medicine starter kit comes with one reusable container with pills or capsules and one compostable pouch containing product refills.

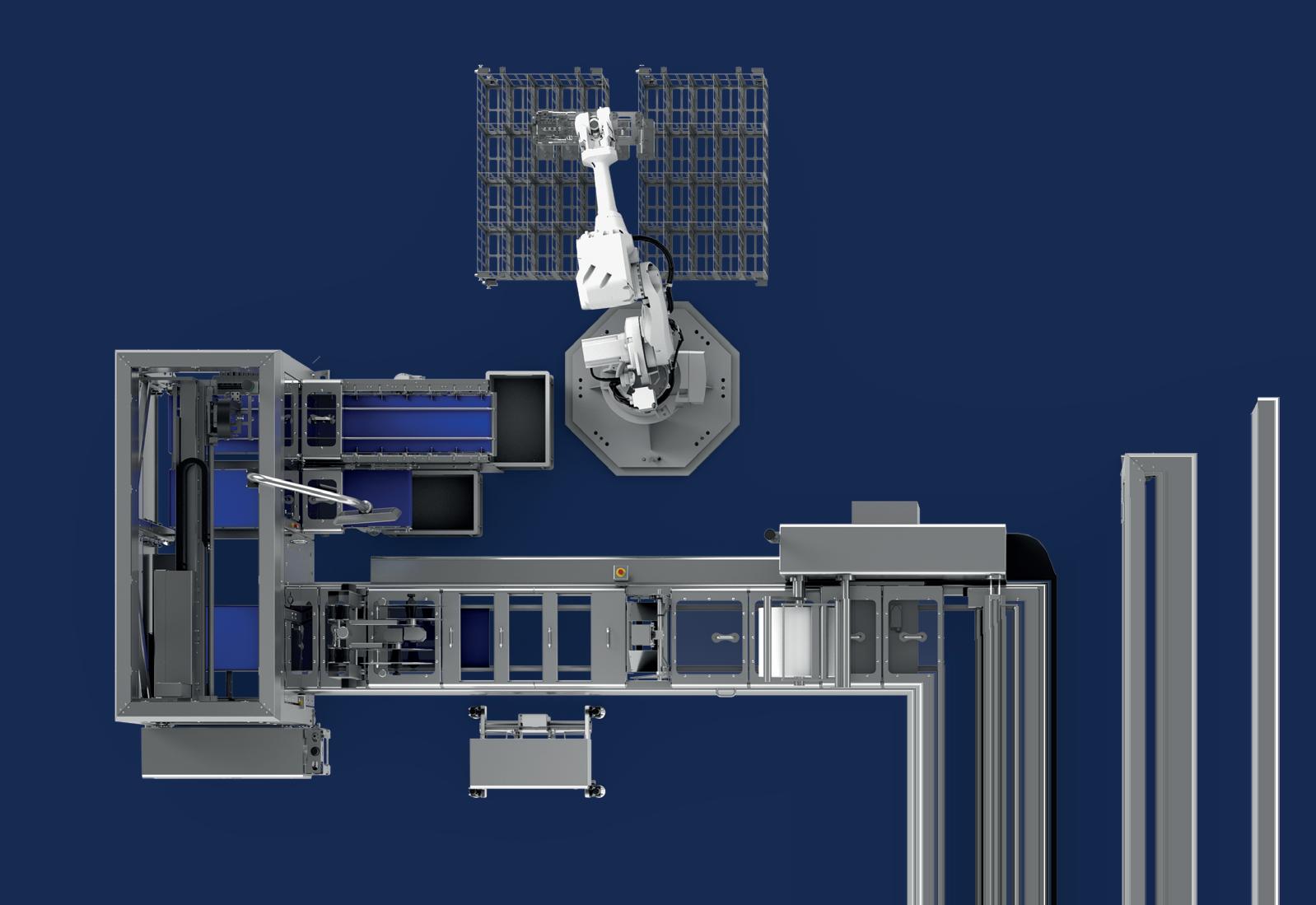

Humanoid Robots and the AI That Drives Them

ELISABETH CUNEO, SENIOR EDITOR, DIGITAL STRATEGY & ENGAGEMENT

TOP THREE TAKEAWAYS

1. AI allows robots to capture information, analyze data, make inferences, and act.

H2. The robot practices a task in simulation thousands of times over, optimizing performance.

umanoid robots, also referred to as general-purpose robots, use AI to perform the tasks they’re assigned. By now you know that humanoid robots are not just a thing of the future. In fact, you’ve likely seen videos of how they are currently being used in manufacturing and retail and could very well be deployed soon on the packaging line. But do you know what drives them? What makes them effective, and what technology enables them to “think” and move like humans? It’s none other than artificial intelligence (AI).

With a combination of advanced computer vision and machine learning, the robot can navigate complex environments and perform tasks like climbing stairs and grasping objects. The powerful machine learning program allows the humanoids to apply new experiences to known information—in effect, learning new experiences—and “learn” how to take this information and its own experiences into account for future actions. It’s this ability that lets the robot reason, draw conclusions, and ultimately, make decisions.

3. The future may lie in robots acting on voice commands without pre-programming.

Human-like intelligence

As the humanoid robots move around their environment, the AI is what allows the robot to capture information through cameras and LiDAR sensors, analyze that data, make inferences, and then move or act to the desired outcome. It’s these sophisticated tasks that allow the humanoid to resemble humans in their thinking.

As CEO & Co-Founder of Sanctuary AI, the robotics company that created humanoid Phoenix, Geordie Rose has said, “general-purpose robots must be able to sense, understand, and act in the world the same way we do.” And to do that, they require AI.

“While we’re immensely proud of our physical robot, the real star of the show is the underlying software. Carbon is our pioneering and unique AI control system, designed to give Phoenix humanlike intelligence and enable it to do a wide range of work to help address the labor challenges affecting many organizations today. It is a cognitive platform that provides Phoenix with the ability to think and then act to complete work tasks just like a person. Integrating modern AI technologies to translate natural language into action in the real world, Carbon features reasoning, task, and motion plans that are both explainable and auditable,” says Rose.

EVE, the humanoid robot from 1x , backed by OpenAI, the company behind ChatGPT, leverages AI to reason and perform tasks. EVE is referred to as an “embodiment chatbot,” generating answers to questions much like OpenAI’s ChatGPT does, using available information and patterns in data to give the best answer. OpenAI’s mission states that it aims to create “a computer that can think like a human in every way and use that for the maximal benefit of humanity.”

Part of thinking like a human is not only using data to come up with a solution, but also being able to handle many tasks and work autonomously (apart from other human help). Humanoids for use in manufacturing often perform tasks like picking and placing, and material handling tasks, apart from human influence while at the same time operating safely around humans on the line.

AUTOMATION 26 | Healthcare Packaging • Spring 2024

1. A critical component needed to make robots truly general-purpose is dextrous hands, says Sanctuary AI’s Geordie Rose.

How our name change now gives you more solutions.

Visit us at PackExpo East March 18th – 20th, booth #1329.

Joining the Rychiger family means more than just a name change for us at Nuspark, it’s a change that now offers you a wider range of innovative equipment solutions and emerging technologies.

As part of the Rychiger family, we combine our advanced secondary & tertiary packaging automation capabilities with their deep expertise in primary packaging equipment. Helping to make factories and plants smarter, more productive, and sustainable.

We are smarter together, offering over 125 years of combined experience.

smarter

Make it

Humanoid robots are described as general purpose in that they function in many different real-world environments. The humanoids are there to help do a little bit of everything, learn the environment, predict future needs, and go where they’re needed. But not all humanoids are developed solely for work. Developing more than just task-based learning, Hanson Robotics’ Sophia, is described as a social robot and is learning how to read human faces and expressions for ultimate human-like functionality.

The robot is powered by Hanson AI’s OpenCog, a cloud-based AI program that enables the robotics company to have large-scale cloud control of its robots. Sophia’s “brain” has deep-learning data analytics for processing the data that she extracts from her millions of interactions. She learns through both her own interactions, like humans, as well as what she is programmed to know.

Sophia describes it best, “My real AI combines cutting-edge work in symbolic AI, neural networks, expert systems, machine perception, conversational natural language processing, adaptive motor control, and cognitive architecture.”

Whether designed for social interactions or packaging and manufacturing help, humanoid robots have the ability to use their human-like intelligence to process data, learn from experiences, and accomplish tasks.

healthcare Packaging options

2. Apollo shines in tasks that are considered “gross manipulation,” or gross motor function, like grabbing something with both hands.

But first, training

As stated, the AI behind the robot is what is helping it learn new things and get better at them over time.

“The best way to think about Apollo is like an iPhone, or a personal computer. You can think of the AI as different applications that can go on top of it,” says Jeff Cardenas, Founder of Apptronik , the robotics company that created the humanoid robot Apollo.

AUTOMATION

Efficient, sustainable,

designed for meeting strict medical standards. Experience simple operation and superior seal quality today. sales@formostfuji.com • 425-483-9090 • www.formostfuji.com Scan for details!

Cutting-edge packaging equipment:

and

1256 Nor h Church S ree Moores own, NJ 08057 PHONE 856-273-3377 EMAIL WLS@ProMachBuilt.com WEB Weilerl .com ©2023 ProM ch Inc , B ckground im ge of WLS l beler ken from NBC News Vi ls | Bulk syringes | Bo les | Ampules & c r ridges Au oinjec ors | Non-ph rm ceu ic l The mo t advanced pre ure en itive labeling and label printing olution available Pressure sensi ive la eling La el prin ing | Serializa i n Vial c ding | Inspec i n Hig es speed Bes l cal service C mpac f prin Simplici y & au n my For: Vi it in

The robot then learns these different applications through the idea of reinforcement learning, in which the robot practices how to do something in simulation and performs the task thousands of times over. In doing that, it is constantly optimizing how it performs the task over time, performing the task better and better.

“There are a lot of new software frameworks that have real potential to enable the robots to do a much wider range of tasks and learn much quicker. It’s early days for this, but we’re starting to adopt things like large language models, and in robotics there’s a version of this called large behavior models,” says Cardenas.

Through this idea, a human would show the robot how to do something, either by tele-operation or eventually by video and the robot would learn how to do that based on demonstration. Cardenas says that Apptronik is currently working on this and researching how it can be used to help Apollo do many more things over time.

“The idea is to build a general-purpose platform that is a software update away from doing something new,” says Cardenas.

Since humanoids are not humans, but rather machines, they of course have limitations, especially as it relates to experiencing a new problem or environment for the first time. As humans, we can anticipate what could occur even if we never experienced it, but these robots can’t do that unless that problem has already occurred, and it has “experienced” it. Meaning, each humanoid robot would require some sort of training to complete a given task.

As mentioned above, large language models and demonstration are the future in robotic task learning. In a similar vein, Sanctu-

We Believe in the Transformative Power of Automation

Are you struggling with floor space, optimizing production rates or excessive down time?

Let’s talk about your next project today!

AUTOMATION

3. Agility Robotics’ Digit uses its claw-like hands to grab and move empty tote boxes, removing this repetitive task from human workers.

Modular and scalable assembly equipment from Stevanato Group.

When pharma and CDMO partners need high precision, high quality, high yield assembly solutions, they turn to Stevanato Group.

Our GMP-compliant device sub-assembly and final assembly equipment can be configured to adapt to your production requirements, providing technology transfer from prototyping to high volume production. This modularity also enables for different formats or devices to be run on the same line, reducing time-to-market.

Visit us at booth #1319 during the Interphex show in New York 16-18 April!

stevanatogroup.com

“The idea is to build a general-purpose platform that is a software update away from doing something new.”—Jeff Cardenas

ary AI reported a system for training its humanoid Phoenix on specific tasks.

To get it right, the robotics company says that it films a particular task being done and then digitizes the entire event as a virtual environment. The AI can then practice the task in this virtual environment, perfecting the performance until it is ready for the physical world.

“AI gets better, smarter, and faster with more data, so the robots can complete tasks faster with more data and repetition,” says Rose.

While it’s the early days of general-purpose robots, Cardenas says that they are working on exciting new things that leverage proven robotic technology and AI to improve humanoid robotic function in the future.

Melonee Wise of Agility Robots , maker of Digit, describes that the future of humanoid robots and learning lies in the large

language model that enables the robot to understand a voice command and perform the task without any pre-programming (kind of like using ChatGPT).

“A lot of the places that we use learning or artificial intelligence is in the higher aspects of the system for learning a new tote, or a new model of a customer’s facility. Where it will become very powerful is in high-level programming of Digit. Instead of having an engineer type lines of code to explain the task, you’ll verbally ask Digit to do the task… That’s where we see long-term the value of solutions like ChatGPT and large language models,” says Wise.

Wise says that today Agility is using AI for identifying objects in the facility, but in the future the company could use it to simply tell a robot a command and it will perform the commanded task.

As more companies adopt AI into their daily lives, the technology will only improve, producing faster results and smarter innovation. Should we feel threatened by AI-powered robots as mere humans? Or can humanoid robots truly share the packaging line with us? For now, only the future holds the truth about whether or not humanoid robots will ever be widely adopted into packaging lines large-scale. Until then, keep your eyes open for a robot co-worker to come parading into your plant, and if you happen to see one, let us know.

AUTOMATION ©2024 ProMach Inc. Booth 2353 Javits Center, NYC Join Us at Exclusive representation of partner brands ProMachPharma.com plus

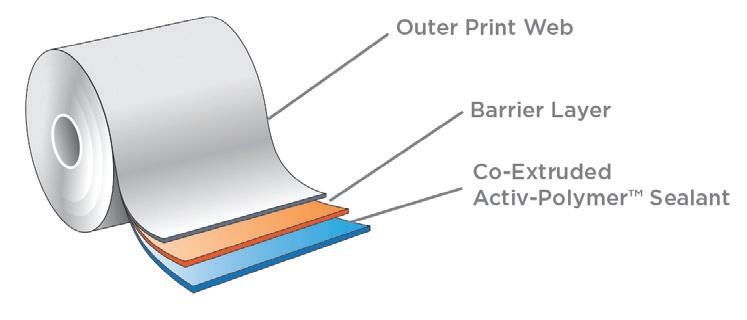

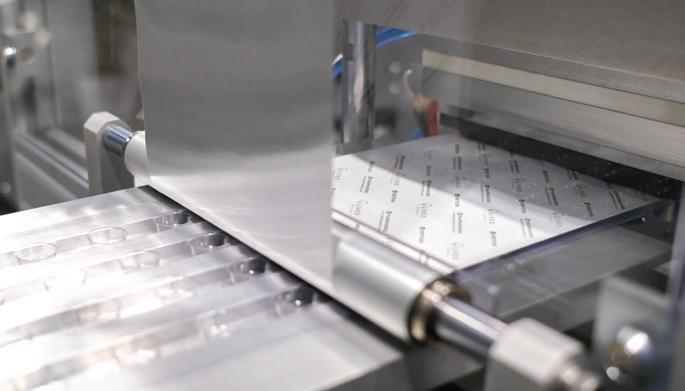

Protect Your Sterile Barrier System Rollstock

KEREN SOOKNE, EDITOR-IN-CHIEF

1. It’s important to correctly handle inventory prior to packaging.

OTOP THREE TAKEAWAYS

2. High temperature can impact the solubility of slip agents in resins.

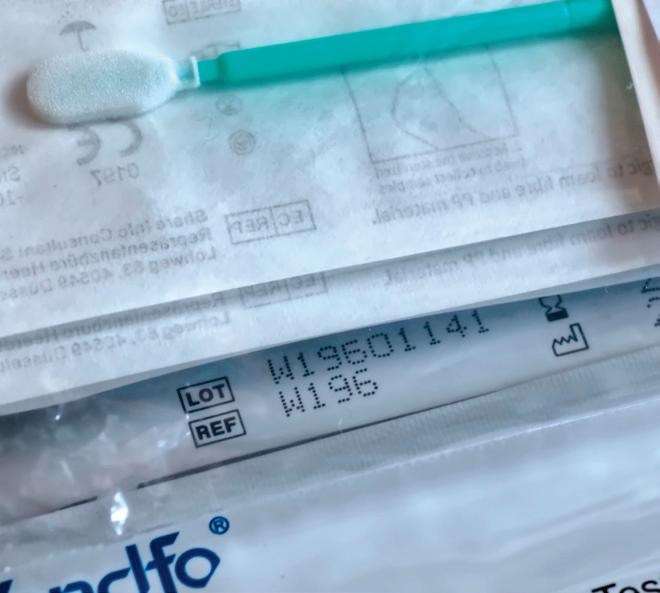

n Sterile Packaging Day 2024 at MD&M West, Henk Blom, Todd McDonald, and Nick Packet discussed a roundup of sterile packaging updates from the Flexible Packaging Association’s Sterilization Packaging Manufacturers Council. This included their mission, efforts to educate policy makers on sterile packaging to help prevent unintended consequences from well-meaning legislation, and best practices for storing rollstock/pouches for sterile barrier systems (SBSs).

“In cases where only a partial roll is used, it’s a good idea to keep the outer packaging and re-wrap rolls if they’re returned to inventory for future use.”

On the latter topic, while many are rightly focused on what happens to the package after filling—on its way to the patient— rollstock storage considerations prior to packaging are also critical to success. Blom shared common tips from an SPMC white paper, Rollstock Storage and Handling, to protect your materials before packaging.

3. Consider conditioning rollstock before production.

Rollstock and pouches should be protected from the elements —kept clean and dry—with minimized exposure to direct sunlight. He noted that while it may sound like common sense, not every facility around the globe features a pristine warehouse, with climate and pest control. Dust and chemical contamination, which can be carried into cleanrooms via packaging, should also be minimized.

Rolls are typically individually wrapped on a pallet and should remain packaged until ready for use. In cases where only a partial roll is used, it’s a good idea to keep the outer packaging and re-wrap rolls if they’re returned to inventory for future use.

Storage conditions play an important role in the health of your rollstock. Stock is typically best stored at 50-80 °F (10-27 °C) but Blom said to consult your supplier for material-specific conditions. What happens if rollstock deviates from temperature requirements? Blocking (in which one layer sticks to another), wrinkling, or crushed cores can occur.

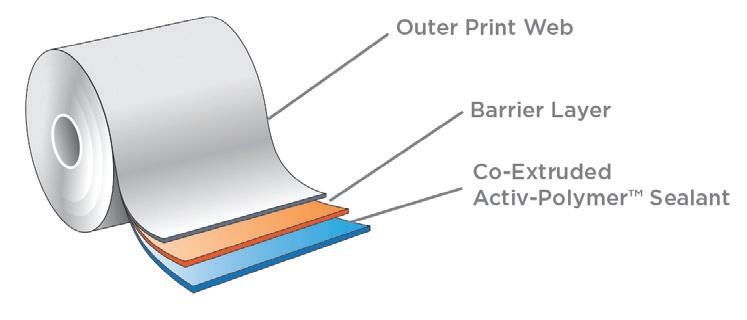

Blom noted another temperature consideration: slip agent behavior. “A lot of sealants—such as polyethylene and peelable sealants—are processed with low levels of what’s called a slip agent. This helps the materials move though the equipment. That material is designed to bloom to the surface and give you a low coefficient of friction so that you get good machinability,” he explained. “But as the temperature changes, the solubility of that slip agent in the material changes. As the temperature increases, the slip actually wants to go back into the material. And so your COF [coefficient of friction] will start to increase and the material will start to stick and slip as it’s moving through, for instance, a flow wrap machine.”

The good news here is that this process is reversible by placing the roll in cold storage, which will allow the slip to bloom back out to the material’s surface.

STERILE PACKAGING 34 | Healthcare Packaging • Spring 2024

↑ From left: Henk Blom, PAXXUS; Todd McDonald, Technipaq; and Nick Packet, DuPont Tyvek Healthcare Packaging.

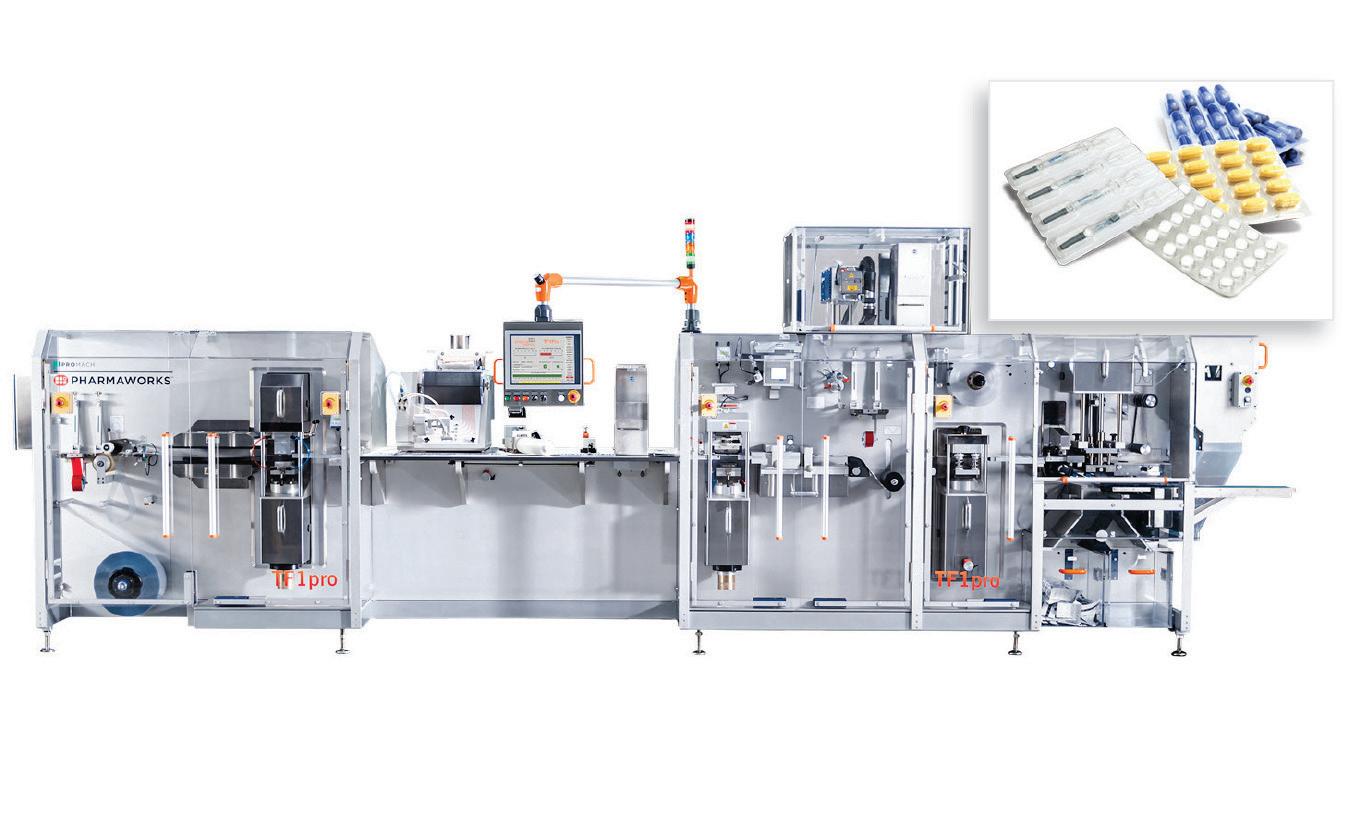

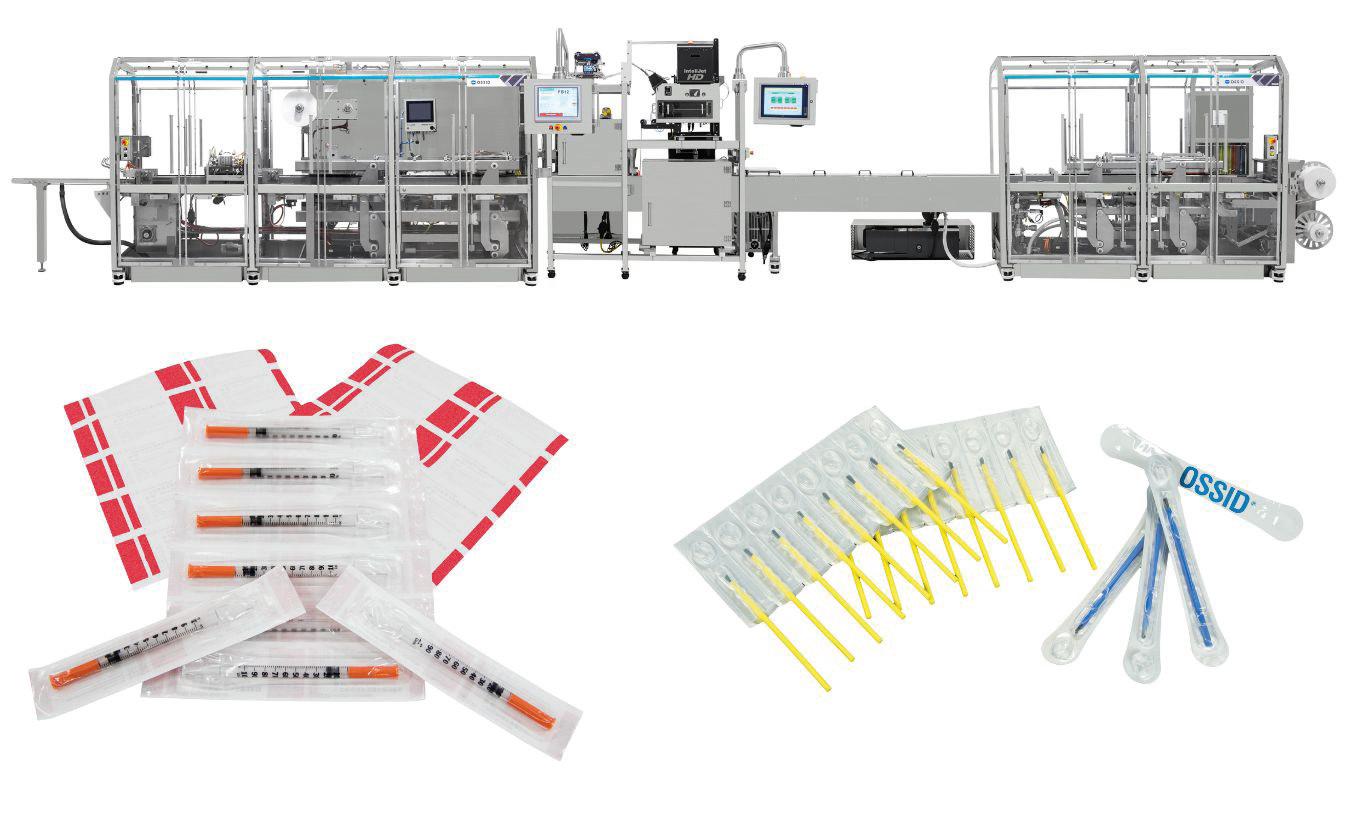

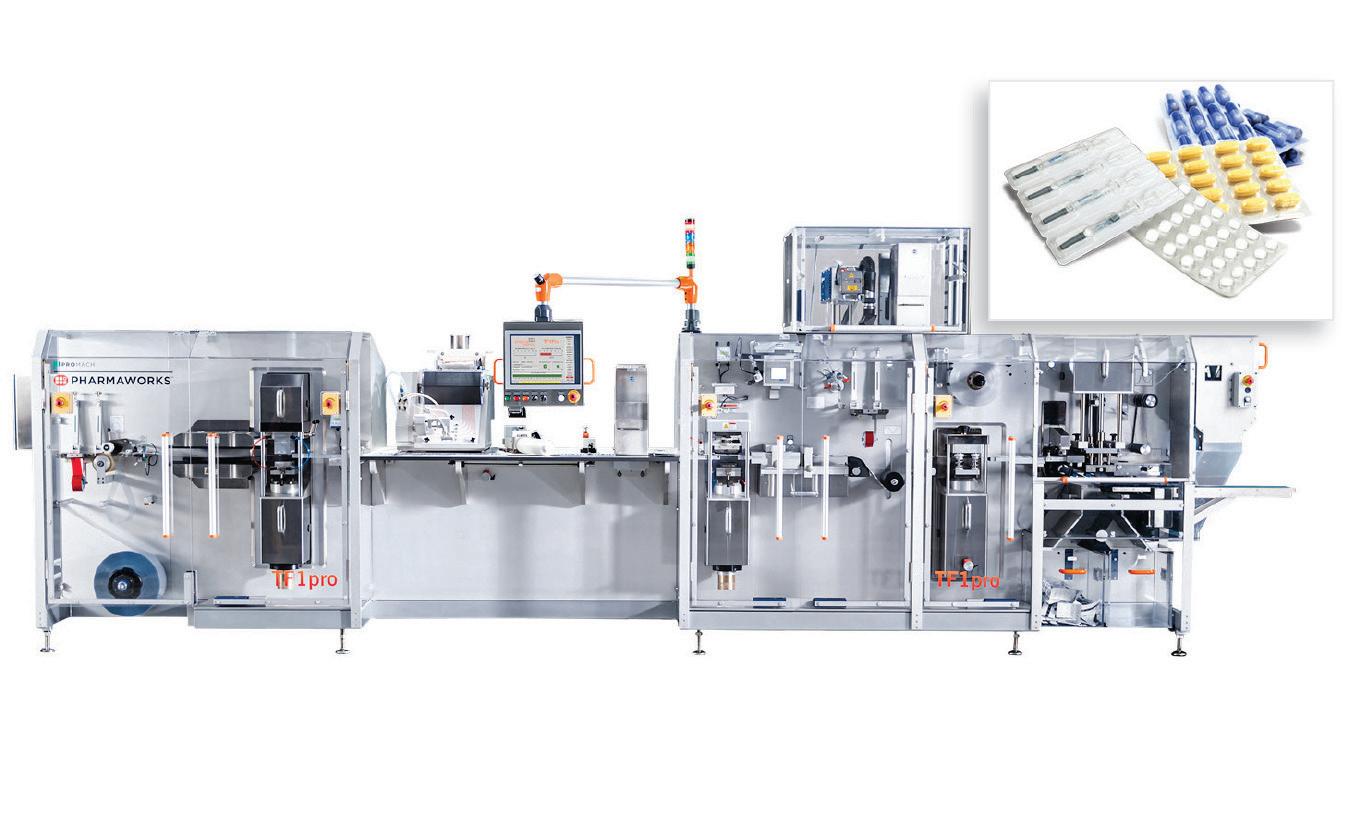

The USA’s leading provider of pharmaceutical and medical packaging solutions Sustainable packaging solutions built and supported locally Blister Machines Custom Automation/ Product Handling Rebuilds Vision Inspection Cartoning i it in 2346 Success Drive Odess , FL 33556 PHONE 727-232-8200 EMAIL Sale @Pharmawork .com WEB Pharmawork .com ©2023 ProM ch Inc. Medical device | Pharmaceutical Nutraceutical | Consumer goods Animal health

“…it’s important to always work closely with your material supplier to understand if a particular material has any specific storage requirements that need to be taken into consideration.”

While many common packaging materials like oriented PET, foils, highly engineered papers, and various polyolefins are not typically affected by humidity, there are certain nylons and papers that can be affected. Here, it’s important to check with your supplier, because certain papers can absorb and desorb moisture with changes in humidity. The good news, Blom said, is that this is reversible, but it’s preferable to ensure protection from the start.

Nylons can absorb 5 to 9% of their weight in moisture. “That’s a significant amount of moisture, and it can change the physical properties quite drastically. If you dry it out completely, it becomes somewhat brittle, and then as it absorbs more moisture, it can become much more stretchy,” Blom said. “In roll form, it can actually start to wrinkle because it also expands the material a bit. Again, this is reversible, so you can put it in a drier environment and that moisture will eventually equilibrate back out.”

The location of the nylon layer matters. “If your nylon is in the middle of a multi-layer, coex structure, it’s not actually seeing the ambient humidity, it’s protected by the outer layers. So it’s not as

—Henk Blom

much of a concern there,” he added. “But if it’s the outer layer of the laminate, or the standalone material with a heat seal coating on it, for instance, we generally would wrap that in the metallized polyester to get maximum barrier protection.”

If there’s a big difference between storage and floor conditions, Blom said it’s a good idea to condition your rollstock, allowing 24 to 48 hours for the material to equilibrate to ambient conditions before packaging. “Some materials will be more susceptible than others,” he noted, adding that if COF is an important consideration, then conditioning will help stabilize the material. Blom hammered home that some materials have unique requirements that may not be covered by the more common storage recommendations he shared. “So, it’s important to always work closely with your material supplier to understand if a particular material has any specific storage requirements that need to be taken into consideration,” he said.

View SPMC’s white papers, including Rollstock Storage and Handling, at sterilizationpackaging.org/learning-tools

STERILE PACKAGING

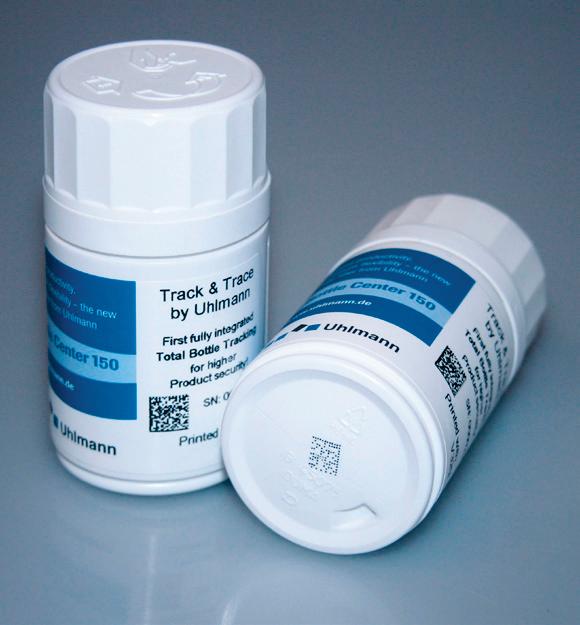

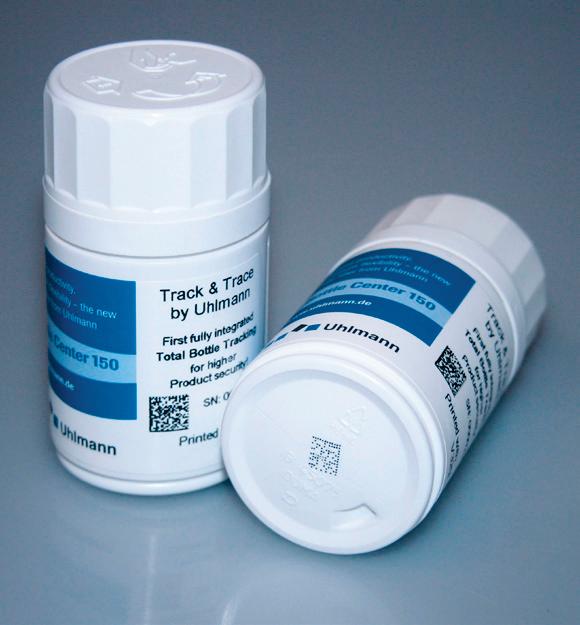

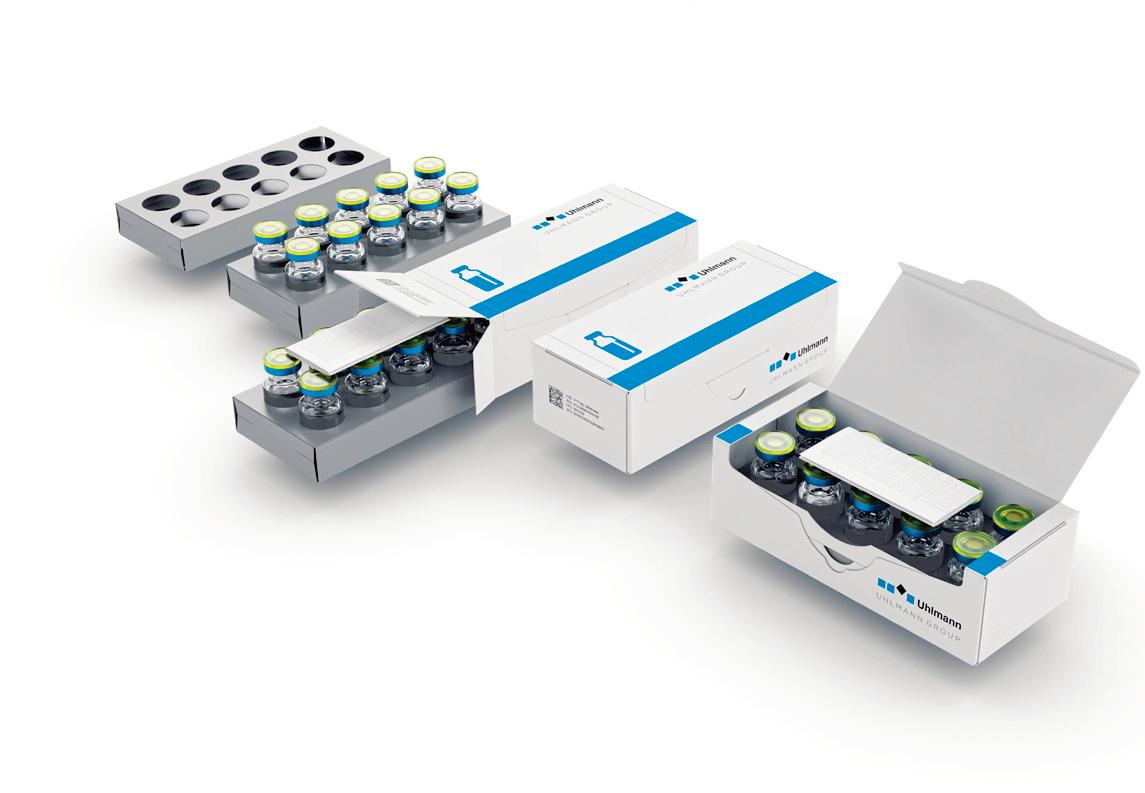

M al D X-Ray C kw g g V n n n T a k & T a n

C m z Ma al Ha l gGl bal F l -ba S v n S al za S l n

OS L v D m a

B

4www.m . m/

A w a

This exclusive Leaders in Healthcare Packaging section includes profiles and product listings for a variety of companies serving the healthcare and pharmaceutical industry.

SPECIAL SECTION 2024

Anritsu Product Inspection & Detection

701 Innovation Drive, Suite A, Elk Grove Village, IL 60007

847-419-9729

detectionperfection@anritsu.com

www.anristu.com/product-inspection

Anritsu provides high-quality inspection systems for the Pharmaceutical and Nutraceutical industries to help ensure the safety and integrity of your products. Our systems are designed to detect foreign objects as well as verify product integrity and quality in tablets, capsules, cartons, cases, sachets, sticks, patches, tubes, pouches, bottles, cans, and medical devices.

With our X-ray systems, it’s possible to detect even the smallest metallic and non-metallic contaminants in products even in sealed areas. Anritsu X-rays also perform a wide range of quality checks on opaque and thin packaging. All models come with standard HD imaging and safety design features that ensure minimal leakage.

Our line of SSV Checkweighers features models that are specifically designed to check the exact weight of capsules, small bottles,

aerosol inhalers, blister packs, or cases with the greatest accuracy. We also offer multi-lane checkweigher models that can easily handle high production volumes of capsules, pouches, and other products.

The Anritsu M6 Tablet Metal Detector can detect metal contaminants as small as 0.22mm in tablets and capsules. In a pharmaceutical production line, this equipment can inspect up to 30,000 items per minute without being affected by vibrations, electromagnetic noise, or static electricity.

Combination systems consist of a checkweigher and a metal detector united into a single unit – saving space and reducing the total cost of ownership. The option of vertical metal detector heads allows for the inspection of vertical packaging such as bottles or stand-up pouches.

There is no greater priority than the safety and security of your customers. Our commitment to developing unique inspection solutions of the highest value advances the food and pharma industries and assures consumer safety. It’s our goal to continue a level of precision, reliability, and support that truly advances the quality of your product and the efficiency of your operation.

Delivering a Positive Anritsu Customer Experience is at the core of everything we do. We are a global team, supporting each other’s families and those of future employees. We are dynamic and agile. The market is ever-changing, and we are too! We hold ourselves to the highest standard – always striving for flawless execution. We strive to maximize the performance of our technology and ultimately that of our customers.

See our ad on page 6 Spring 2024 • Healthcare Packaging | 39

Antares Vision Group

200 Century Parkway, Ste. C, Mount Laurel, NJ 08054

856.780.3465

sales.us@antaresvision.com

www.antaresvisiongroup.com

Antares Vision Group’s range of Inspection Machines is designed to guarantee your product’s quality, integrity, and safety and meet regulatory requirements. Our new generation of vision technologies allows product inspection of any container and product content from any angle during different production phases.

AV Group’s Prefilled Syringe Inspection Machine can handle up to 400 pieces per minute, processing SVP glass and plastic syringes up to 24mm in diameter. It inspects liquids with a wide range of viscosities, from water-like products to emulsions and gels. An additional camera mounted on a secondary carousel yields 100% inspection of the syringe surface. Fast, smooth single-point handling minimizes the risk of product breakages and scratches, thanks to individually motorized grippers and guideless conveying with vacuum-operated starwheels.

The VRI VI series specializes in precise, highspeed vial inspection of up to 400 liquid-filled

glass containers per minute, combining sophisticated particle and cosmetic detection with technology-driven closure integrity verification. The unit can inspect liquids in various viscosi-ties, including water-like, oily, suspension, gel, emulsion, lyophilized, and powder products. Vials are also inspected for cosmetic defects such as crimping quality, flipoff color, neck-shoulder sidewalls, and stopper position. Molded glass and plastic containers also can be inspected.

DIAMIND, an integrated ecosystem for comprehensive production management, offers holistic transparency and production optimization. It operates at the line, factory, warehouse, enterprise, and supply chain levels through sophisticated inspection systems to end-to-end traceability via cloud-based data management.

Antares Vision Group is driving the digitalization of products and supply chains by leading traceability, inspection, and integrated data management. AV Group helps companies achieve safety, quality, efficiency, and sustainability, enabling Trustparency®.

DIAMIND, AV Group’s integrated ecosystem of solutions, simplifies the production environment and supports business growth by enabling a tailored data-driven journey by applying artificial intelligence and blockchain technology.

AV Group operates in the Life Science (pharmaceuticals, medical devices, and hospitals), Beverage, Food, Cosmetics, Chemicals, and Packaging industries. The Group operates in 60 countries, employs over 1,300 people, and has a consolidated network of over 40 international partners.

See our ad on page 11 40 | Healthcare Packaging • Spring 2024

BELL-MARK

331 Changebridge Road, Pine Brook, NJ 07058

973-882-0202

connect@bell-mark.com

www.bell-mark.com

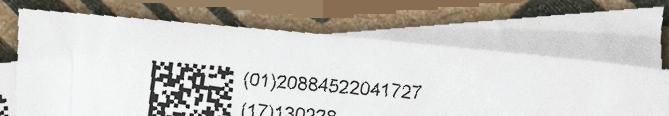

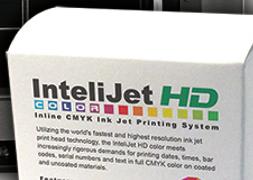

Medical Device and Pharmaceutical Packaging - The accuracy of coding on your product package is crucial. Expiration dates must be clearly identifiable and easily human-readable. Bar codes must be verifiable and scannable. There are no exceptions. BELL-MARK addresses these needs with systems that provide the highest quality print available on cartons, medical paper, Tyvek, poly, and foil substrates.

BELL-MARK has successfully satisfied UDI GS1 requirements for many of our customers. We understand the UD1 rules and regulations and have experience in a wide range of applications. From retrofitting band sealers to Form, Fill, Seal packaging machines, we have the expertise to ensure your codes are verifiable and scannable and meet the necessary regulations.

Meat, Poultry and Prepared Foods PackagingEliminate costly labeling by printing directly onto

your package or replace your CIJ printer with a maintenance-free alternative. BELL-MARK offers a full line of washdown tolerant printers, including both thermal transfer and thermal inkjet technologies. Print variable data, graphics, nutritional facts, bar codes, lot/expiration dates and safe handling instructions on almost any surface. Rest easy knowing your printer is IP67 rated and can be washed down and sanitized without complicated protective procedures.

Industry-Leading Reliability - BELL-MARK’s in-line printing and coding equipment delivers industry-leading reliability and durability, time and time again. High-resolution print quality that consistently affords you the peace of mind in knowing that your codes will not fail. While other companies may claim it, BELL-MARK leads the way in the lowest cost of ownership and highest return on investment.

For over 65 years, BELL-MARK has been developing innovative solutions for on-demand package and carton printing applications in the medical device, pharmaceutical, prepared foods, meat, bakery, dairy, and poultry packaging industries. BELL-MARK offers many in-line printing technologies, including piezo inkjet, thermal inkjet, thermal transfer, flexographic, and ink coder - all designed with cost-effectiveness and user flexibility in mind.

See our ad on page 25 Spring 2024 • Healthcare Packaging | 41

CCL Healthcare

120 Stockton Street, Hightstown, New Jersey, 08520

609.490.3700

CCLHealthcare@cclind.com

CCLHealthcare.com

CCL Healthcare stands as a global leader in printed secondary packaging, boasting 37 cGMP facilities worldwide and continuously expanding. Our dedicated team of experts is solely focused on manufacturing innovative packaging solutions for the pharmaceutical, medical device, biotech, and life science industries.

Smart and Intelligent Packaging: Since pioneering the first RFID label on a commercially available pharmaceutical product in the early 2000s, CCL Healthcare has remained at the forefront of innovative smart packaging solutions. Today, we offer fully integrated hardware and software solutions for IoT, RFID, NFC, and dualfrequency packaging.

Clinical Labeling Expertise: Experience the powerful alliance of Clinical Systems and Faubel under the banner of CCL Clinical! Leveraging over two decades of expertise and operating across

various manufacturing sites, we emerge as your premier partner for clinical trial labeling. With a combined portfolio of distinctive offerings, global reach, and dedicated local assistance, CCL Clinical sets the standard for excellence in clinical trial labeling services.

Functional and Specialty Labels and Products:

CCL specializes in complex multi-web constructions to create functional products and applications that surpass the capabilities of other converters. Our strength lies in the unique ability to print adhesive on uncoated material, empowering our engineers to design solutions for our customers’ most complex projects.

Specialization in Folding Cartons: Our global folding carton production specializing in low volume high mix products. We offer no MOQ;s, short lead-times and industry leading quality.

CCL Healthcare offers comprehensive RFID solutions, featuring customized highperformance inlays, hardware, software, and a seamless, non-intrusive bolt-on solution for high-speed RFID packaging lines called RFID Line Management or RLM. RLM is the most advanced non-intrusive bolt-on RFID encoding and validation solution on the market. RLM fully integrates into your current packaging line, achieving encoding speeds of 700 items per minute.

Our commitment to patient safety drives us to develop cutting-edge RFID inlays for the pharmaceutical industry. We firmly believe that if our inlays can prevent even one patient death, aid in a drug recall, or ease the burden on healthcare providers by allowing them more time to focus on patient care, then our efforts are justified.

Failure is not an option for us that is why we offer optimized RFID Inlays tailored to your medications dielectric properties.

See our ad on page 15 42 | Healthcare Packaging • Spring 2024

Manufacturer of Monoblock Style Filling and Closing Equipment for volumes from microliters to 125ml in glass and plastic containers.

Chase-Logeman Corporation

303 Friendship Drive, Greensboro, NC 27409

336.665.0754

info@chaselogeman.com

ChaseLogeman.com

For over 63 years, Chase-Logeman Corporation has been building monoblock-style filling/ closing machines and support equipment. From our offices in Greensboro, North Carolina, ChaseLogeman custom designs every machine to maximize production quality without sacrificing throughput.

This equipment reliably serves the Chemical, Cosmetic, Diagnostic, Homeopathic Medicine, Nutraceutical, and Pharmaceutical markets with machines that are easy to use and durable.

All of Chase Logeman’s machines are washdown capable. There are designs available for flammable materials and processes requiring isolators. Every machine begins from a cGMP thought process.

Chase Logeman incorporates filling, plugging, capping, and labeling capabilities into the

monoblock machine as requested to save space and minimize the number of operators needed. Product changes can be accomplished in 15 minutes or less, often without tools.

Specializing in fill sizes from microliters to 125ml, every Chase-Logeman machine prevents repetitive stress injuries by incorporating proven automation processes into the machine.

Contact Chase-Logeman and let our years of experience help automate your filling process.

See our ad on page 9 Spring 2024 • Healthcare Packaging | 43

Columbia Machine, Inc.

107 Grand Blvd., Vancouver, WA 98661

360.694.1501

pallsales@colmac.com

www.loadtransfer.net

REDUCE CONTAMINATION—The

Load Transfer Station (LTS) product line, offered by Columbia Machine, helps to reduce contamination from entering production areas, streamlines operations & reduces costs. Columbia manufactures a complete line of pallet transfer solutions including stand-alone stations to fully automatic solutions that allow pallet load transfer to be completed in less than one minute, without requiring the operator to leave the safety of the forklift.

INDUSTRY LEADING STANDARD SAFETY—

Columbia Machine’s LTS solutions come standard with the latest safety features. These include Category 3 electrical safety components, upstacker guarding with A-B SensaGuard RFID interlocked door switches, multiple emergency stops, and muted light curtains on the automated systems. Every Columbia Machine LTS has been engineered to exceed the requirements of

pharmaceutical processors who are working to meet FSMA regulations.

Flexible Product Handling

Columbia’s LTS is capable of transferring products that are packaged in cases, super sacks, glass vials, pails, barrels, drums and bags from one pallet type to another, including Plastic, Chep and GMA pallets that are commonly used in both receiving and shipping applications.

Columbia Machine, Inc.

The Load Transfer Station (LTS) product line is part of the Palletizer Division of Columbia Machine, a leading American palletizer manufacturer. For more than 80 years, Columbia has manufactured complete palletizing and material handling solutions.

The mission at Columbia Machine is to be the preferred supplier of engineered product solutions in the targeted markets we serve. We provide exceptional customer value through strategic marketing, innovative product development and unparalleled customer service. We value safety, integrity, trust, fairness, professionalism and teamwork in relationships with our customers, employees, business partners, suppliers and shareholders. We “always” see our business through “the eyes of our customers,” and provide them with superior solutions through innovation, quality, reliability and continuous improvement.

See our ad on page 24 44 | Healthcare Packaging • Spring 2024

Columbia/Okura LLC.

301 Grove Street, Vancouver, WA, 98661

877.204.7444

COLLCSales@colmac.com

www.columbiaokura.com

Columbia/Okura LLC is a robotic palletizing integrator, applying expert knowledge and tools to solve customers’“End of Line” production challenges for a diverse range of businesses, products, and applications. The historical success of our company can be attributed to an exclusive focus on end of line palletizing systems and applications. Columbia/Okura LLC offers robotic palletizing solutions comprised of dynamic products and services aimed at increasing our customers end-of-line packaging efficiency, promoting safety, and reducing their overall cost of production. Like all industrial robots, Columbia/Okura robots are programmable, automating tasks that are often repetitive or harmful to workers. They have the ability to lift and move heavy loads quickly while keeping products safe and stacking them to be shipped or even neatly to be sold in stores.

The Columbia/Okura miniPAL® is a collaborative palletizing robot built for flexibility and

ease of use. It features a range of cobots by Universal Robots, that can handle up to 30KG. The miniPAL® is equipped with Pally software, an intuitive pattern-building program—created in partnership with Rocketfarm—that is easy to operate and program for various product types, including cases, spot packs, trays, bundles, and plastic bags. With 25 years of equipment design and system integration experience, we have the knowledge to offer the right solution for the job. We offer complete and professional services; from initial system design proposals through project start-up and commissioning, as well as after sales support.

Our integrated lines offer an end-to-end solution for fully automated bagging and robotic palletizing line solutions from a single, US-based, OEM provider. Our service offering includes integration of manual bagging machines, openmouth bagging machines, valve bag fillers, air packers, impeller packers, and pallet dispensers.