CARTONING, CASE PACKING, AND TRAY FORMING

Proven market leader for low to moderate speed with 70 years of experience

The best value: simple, reliable, and flexible equipment solutions

Impressive customer list who buys repeatedly

Transparent communications with outstanding suppor t

The ascendancy of contract packaging means that once neglected bottling lines are coming back strong. Here’s how Yards Brewing upgraded drop pack operations to pick and place, reducing scrap to the bare minimum, both for its own and its contract customers’ craft brews.

Hawaii’s largest craft brewer installs a new high-speed canning line to complement new cartoning capabilities after a switch from plastic carriers to multipack cartons proves popular with consumers.

A partnership between diagnostic company and yeast supplier strengthens QC programs to detect contaminants in yeast slurries.

Recent front-of-line automation investments are supporting in-house and contract packing growth, with plans for secondary packaging investment to further speed up operations.

As demand for Saint Arnold’s beer grew, so did the need for sustainable solutions to manage excess waste. A new drainage press provided an easy way to dispose of underfilled or damaged cans.

The ascendancy of contract packaging means that once neglected bottling lines are coming back strong. Here’s how Yards Brewing upgraded drop pack operations to pick and place, reducing scrap to the bare minimum, both for its own and its contract customers’ craft brews.

By Matt Reynolds, Chief EditorBack in 1994 when founder Tom Kehoe first hung out a shingle for Philadelphia’s Yards Brewing Co., he was a pioneer to the then-nascent craft brew landscape. The brewery he founded has since grown into a 55,000 barrel/year operation with capacity to grow to 300,000 barrels, producing a balanced mix of everything you’d expect out of a mature craft brew house. What started as a garage-based venture grew into larger facilities and taprooms over the years, with its current home in an 80,0000-sq-ft brewery, event space, and taproom in Philadelphia’s Northern Liberties neighborhood. It’s notable that the brewery has

Scan the QR or visit pwgo.to/8233 to watch a video of Yards Brewing Company’s packaging operations in action.

remained anchored in Philadelphia for its entire existence, serving the four-state area of Pennsylvania, New Jersey, Delaware, and Maryland in retail with a wide swath of beer varieties in all the usual package formats.

For retail and taproom carryout channels, an automated line packs standard 12-oz bottles into 12-pack cases, or into 6-pack cartons in 24-count cases. Designed for the same retail and taproom carryout channels, an automated canning line packs

standard 12-oz and 16-oz multipacks, with a 19-oz specialty format also available. Kegs are filled for foodservice operations and taproom sit-down occasions, and there’s even a variety pack or rainbow pack rework line, though it’s comparatively less automated.

As is becoming more common among established breweries these days, Yards runs a healthy contract manufacturing and packaging (CM/CP) operation—so healthy in fact that it’s currently approaching half of Yards’ business. The brewery just checks all the boxes as a well-diversified operation with a full complement of automated packaging format options, both for its own beers and for its CM/CP customers.

The big trend in craft brew packaging these past few years has been “cans, cans, and more cans,” and Yards is fully on board with the trend. It operates sophisticated automated canning lines that can multipack into PakTech can handles or cartons to accommodate the growing can demand. Still, it was refreshing to hear that Mark Granacki, packaging manager at Yards, is also doubling down on bottling automation. With so much contract packaging business, it only makes sense to offer fast and accurate automation for whatever the format a CM/CP customer might desire: bottle, can, or keg.

A little more than 18 months ago, Granacki identified secondary packaging in its bottling line, namely multipacking, as a weak link. An upgrade was in order.

“Back then, we were doing more traditional drop packing on the bottling line,” Granacki remembers of the legacy equipment. Frequent bottle breakage and other QA issues in multipacking operations were a problem. “But that equipment company had been going out of business, and it was harder to get service and parts for the machine. And in general, drop packing just tends to break a lot of glass, and it’s less efficient.”

The legacy drop packer used a pneumatic lift to raise each case or carton up to meet the bottles. The bottles then indexed into a grid that shifted allowing the bottles, in theory, to fall straight

through a basket into the box. Even under the best conditions bottles can still contact each other and cause breakage. And even when a bottle remained intact at the facility, the transfer shock could result in breakage downstream in the supply chain, perhaps during a temperature change in distribution. Again, the result would be broken bottles and wet cases. Since the 12-pack litholaminated corrugated case format is that of a tight pack with no dividers or inserts, that means glass to glass packaging, making the operation even more tenuous.

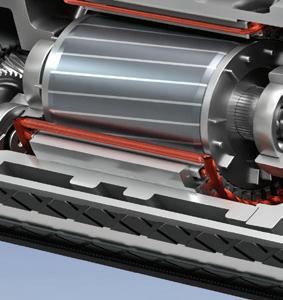

“Meanwhile, as servo motors became more popular in these types of applications, we started looking at some of these pickand-place packers,” says. He and his equipment counterpart Neal Goss, maintenance manager at Yards, visited 2022’s PACK EXPO East in Philadelphia to get a sense of what was available in the gentler pick-and-place case packaging realm.

“We had already decided that we were going to upgrade the asset,” Granacki says. “We had considered some different improvements for the line, and that one was decided to be the

most important, with the greatest potential payback for efficiency and material savings… We saw and liked a few at PACK EXPO East, but we really fell in love with a case packer from Standard-Knapp.”

Two separate trains of thought—Granacki’s operations and daily use perspective, and Goss’ engineering and maintenance mind— converged on the Standard-Knapp 991 Unipack 2.0 case packer.

“On my end, I wanted something that would be produce a relatively minimal amount of motion, to eliminate the amount of stored energy or kinetic energy built up in the machine that would wear on it,” Goss says. “Also, I was looking at the robustness of the travel guides and supported structures above in the gantry system. I then looked at the technology, as far as what controls they were going to use. I just went through it and picked it apart that way. I was shocked that the machine was using all premium products, and I’ll use the term “over-engineering” for the structure, but it was still in the same competitive cost range as the other manufacturers.”

each, so if 20 bottles were to break in a day, and those cases were scrapped, that would start to add up.

“Being able to remove those constraints was a big factor in selecting this equipment,” Granacki says.

The new case packer has been installed at Yards Brewing Co. since October 2023, having briefly served as a showpiece at the Standard-Knapp booth at PACK EXPO Las Vegas ahead of the installation. Beyond the general efficiencies that first attracted Granacki and Goss, the 991 Unipack 2.0 case packer has a few “above and beyond” features.

First, the equipment uses a localized grease system that would allow an operator to hit multiple points from one point of entry into the enclosure. Granacki and Goss took that functionality a step further and added a safety mechanism that prevents the machine

Bottles are cold-glue labeled around the body and neck on a Krones Solomatic. A gentle-handling case packer downstream means very little scrap occurs from label damage.

From Granacki’s point of view, easy changeovers and gentle handling were the twin keys.

“We go back and forth from twelve packs to six packs [in a 24ct master case]. We looked at the basics, asking ourselves, ‘What does the changeover look like? Are the cycle times appropriate to pull product away from that filler in a timely manner, and keep the filler running and operational?’” Granacki says. “We also did a cost benefit analysis on how much we were breaking and what type of material loss that was causing. Seeing a machine that was so gentle with the product, picking them and placing them as opposed to dropping them, made an impact. We also looked at how the Standard-Knapp equipment was were protecting the labels. Since the bottles are being grabbed up top, that also prevented lots of rework and labor for us.”

With the legacy case packing equipment, operators frequently had to keep rags on the conveyors to clean up after bottle breakage. This was especially true of glass-on-glass 12 packs in the drop pack format. Those corrugated 12-pack cases could cost $1.50

from running unless those grease demands are satisfied.

“The machine is automated such that it notifies the operator, and then will shut itself down at some point to force proper maintenance habits. This can be overridden with a code, but it also creates the awareness for the operator,” Goss says.

Another unique feature is a light indication system within the housing of the machine that’s used to notify the operator of status at different phases of the process. And like the souped-up grease system, Granacki and Goss took that capability a step further with Standard-Knapp.

“They installed strip LED light systems on all four corners of the machine that light up in various quadrants that tell the operator different statuses. If there’s a jam in the middle of the machine, the middle machine will light up red and an operator will know to go look in that area,” Goss says. “It speeds up the turnaround time on jams and any errors in the machine. Those are minimal, but when they happen, they’re clearly noted. It gives the machine a cool look overall—our people like to look at this machine with the

Depending on the format, three or four lanes of bottles enter the Unipack 2.0 where they’re picked and placed. Standard formats are 12-pack corrugated cases or 24-count master cases carrying four 6-pack handled multipack cartons.

LEDs on. But it also works as a status light. That’s another great thing that was added and Standard-Knapp ran with it. They did a phenomenal job with the design and programming.”

Adds Granacki, “they even go so far as to color-code the Quick Connect couplings from the air lines to the picker grid, so that you can’t connect it improperly. Everything is intuitive, set up in such a way that it is very poka-yoke [Kaizen mistake proofing], preventing mistakes from happening.”

The new 991 Unipack 2.0 was a drop-in replacement on an existing bottling line. The case packer’s small footprint made a direct swap-out with the legacy drop packer possible, without the need to tear apart the otherwise fully functional line.

Bottling operations begin with a Uni-Pak floor-level depallitizer. Uni-Pak also handles all the conveyance on the line. The depal and conveyance feed an oldie but a goodie, a monoblock rinser, filler, and crowner. Within the monoblock, a nearly 30-year-old, 24-head rinser and 24-head counterpressure filler from GAI is followed by a 6-head Arol crowner. The monoblock is capable of speeds up to 150 bottles/minute for 12-oz bottles, which make up the volume of bottling output, but is flexible enough to handle 750-mL bottles for limited edition or seasonal beers at slower speeds.

“First thing we do out of the filler is we crown with the Arol on the foam after fobbing,” Goss says. “And then as we exit the

A single Columbia palletizer can handle all of these products and more with ease.

crowner, we’ll run through a shower to rinse off the excess foam from the bottle. And then it’ll run through a Heuft x-ray unit that’ll inspect for gross under-fills and reject those.”

Labeling is next, and that’s done on a Krones Solomatic machine that was purchased used from a test facility.

“We essentially geared it down to run with this line. It’s a traditional cold-glue application, putting labels on both necks and bodies,” Granacki says. “We then use a Videojet 1560 black continuous inkjet printer to put on a time stamp and a date code. As we exit the labeler, it’s still single file, but after date coding it opens back up to mass flow and accumulation as conveyance opens up into the three or four lanes to enter the Unipack 2.0 case packer, depending on the pack [12-pack corrugated tightpack cases, or four 6-pack (4x6 drop grid) paperboard cartons, packed 2x2 for 24-count corrugated master case].”

A box shop from Pearson feeds erected 12-pack corrugated cases to the Unipack 2.0.

A Pearson box shop feeds the case packer by erecting both corrugated 12- and 24-count cases, and the 6-pack cartons that are then stuffed into the 24-count master cases. These two formats exit the Standard Knapp case packer and run through a Pearson top-sealer to close the boxes. A Videojet laser coder then marks the cases with date and time stamp. Why laser?

“It was something we wanted to try a while back to reduce consumables, like ink,” Granacki says. “We’re happy with it, but we didn’t feel super comfortable at the time etching on bottles or cans necessarily, so we stayed with inkjet on the primary pack.”

What’s next for the brewery? Look for 30th anniversary celebrations like special events, exclusive merchandise drops, tap takeovers around Philadelphia, and more. Plus, with the variety of canning and bottling line automation capacity that Yards has available, using about 55,000 of 300,000 barrel capacity, expect that co-packing business to grow alongside its own homegrown beers, maybe for another 30 years. ●

Whether you are handling cases, trays and packs or bottles and cans in mass or a single file we can help. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Each spiral is built to exact customer specifications, and can even be field modified if needed - thanks to our proprietary modular design.

We also make a full line of Bucket Elevators for your bulk material conveying needs.

For application assistance or additional information, give us a call or visit us at www.ryson.com

Visit us at Pack Expo East Booth 1112

Hawaii’s largest craft brewer installs a new high-speed canning line to complement new cartoning capabilities after a switch from plastic carriers to multipack cartons proves popular with consumers.

By Anne Marie Mohan, Senior EditorIn the 2023 Craft Brew Supplement, Packaging World highlighted Hawaii’s largest craft brewer, Craft ‘Ohana—more widely recognized as Maui Brewing Company (MBC)—and its transition from plastic ring carriers to paperboard cartons for multipacks of its canned beverages (see pwgo.to/8230). The primary driver was sustainability; plastic ring carriers aren’t recycled in Hawaii, whereas paperboard packaging is. The other was the opportunity for enhanced visibility on-shelf. While the 2023 article explored the why of the change, the how is another story.

With its new cartoner, MBC is creating 12- and

packs, a format it learned early on was popular among tourists.

As Craft ‘Ohana Senior Project Engineer David Brendgard shares, MBC’s journey from ring carriers to cartons took several years, a lot of experimentation, and substantial investments not only in cartoning and tray-packing equipment, but also in an entirely new filling line. “We replaced existing equipment to accommodate what we’re trying to achieve today, and moving from plastic carriers into cartons was the driving factor for that,” Brendgard says. “We basically built this line around the idea that we were going to go into cartons.”

Completed in 2023, the new line has streamlined MBC’s operations significantly, both upstream and downstream. Improvements include an 80% increase in MBC’s filling speeds, the flexibility to add new can sizes, quick changeover of different beverage types with automatic CIP (clean-in-place) capabilities, and the ability to produce 4-, 6-, 12-, and 24-ct cartons, including variety packs—a new and very popular product for MBC.

Maui Brewing was founded in 2005 by CEO Garrett Marrero and COO Melanie Oxley in Kahana, Maui, where it operated a 10-barrel brewhouse—in layman’s terms, a brewery with the capacity to produce 10 barrels or 310 gal of beer in a single batch. In 2014, the brewery moved to its current location in Kihei, Maui, where it now makes a range of beverage brands. These include Maui Brewing Co. beer in year-round and limited-edition varieties, Island Soda

craft sodas, Maui Hard Seltzer seltzers and teas, and Kupu Spirits, which include bottled spirits and RTD canned cocktails.

Differentiating MBC’s products is its use of locally sourced ingredients. “One of our most popular beers is our Pineapple Mana Wheat, which uses pineapples grown here on Maui,” shares Brendgard. “A lot of our specialty beers are brewed with local products, whether it’s hibiscus or lilikoi [passion fruit] or limes, that are grown here on the island. We try to do that as much as possible to support our local industry.

“Another thing that distinguishes us is that we are the largest craft brewery in the state of Hawaii. We thrive on providing our beer to the tourist industry by getting it into the resorts, restaurants, chain stores, and C-stores throughout the islands, so when visitors come to Hawaii, our product is in the forefront.”

In addition to being distributed across Hawaii, MBC’s products are also sold throughout most of the continental U.S., as well as in Canada and Japan and to the U.S. military outside the U.S. In late 2022, MBC expanded its portfolio with the acquisition of San Diego-based Modern Times Beer + Coffee, at which time the combined companies joined under the name Craft ‘Ohana.

“Ideally, we’d like to brew our own beer on the mainland, with Modern Times being included in that,” explains Brendgard. “We feel the product is fresher for the consumer and more reliable when it’s brewed closer to the point of consumption.”

In the meantime, Kihei is still the main production hub for MBC’s range of beverages, with a capacity of 70,000 barrels of product per year, which the company is working to grow to 120,000. All of its canned beverages are produced on a single line at the Kihei facility; a separate line handles beer in kegs for draft sales. MBC uses one can size, a 206, or 12-oz, aluminum can, supplied by Ball Corp. out of Honolulu.

As Brendgard explains, it was shortly before COVID that MBC began experimenting with the use of cartons rather than plastic carriers for its multipacks. When the pandemic hit, the brewery saw its canned beverage business increase, while sales of its beer in kegs came to a halt. “So we focused entirely on our canning line and how to get those products out,” Brendgard explains.

Throughout the pandemic, MBC used an entry-level cartoner from DMM Packaging to experiment with different carton sizes for its multipacks, including new mix packs, or variety packs, of its beverages. “We found that the mix packs were a very sellable product for us,” says Brendgard. “Visitors to our islands have fewer reservations about buying a case with three or four different varieties than buying a whole case of a single brand.”

It was the success of the mix packs that motivated MBC to upgrade to a more sophisticated cartoner from WestRock, and it was the new cartoner, in turn, that galvanized the brewer to completely replace its existing line, building a new one around the cartoner for maximum ef ciency. It took a year for MBC, with the help of A+E Conveyor, to design the new line, which ultimately required the addition of a mezzanine to accommodate all the new equipment.

The competitive force of craft cocktails is growing, as craft brewers look to reverse a contraction in sales, according to PMMI Business Intelligence’s “2024 Craft Beer and Spirits” report.

Business Intelligence researchers compiled the experiences of 132 craft beer and spirits industry professionals for the report, using an online survey and direct long-form interviews to gauge each category’s current outlook.

One of the most prominent areas where the two categories differ is the overall momentum of sales. While craft beer has struggled to nd avenues of growth in recent years, craft spirits are riding a wave of popularity, propelling the industry to new heights.

“The fact that shipments are down 6.9% over the last year in the craft beer market, our biggest challenges will be to keep costs down, keep people interested in craft beer, and diversify into cider,” said one participating owner of a craft microbrewery.

Visit pwgo.to/8231 to download the report for free. ●

MBC added the new line in three phases. The rst phase involved building the mezzanine and installing the secondary packaging equipment; the second, the installation of a can warmer and overhead conveyance and moving an existing palletizer to accommodate new equipment; and the third, the addition of new depalletizing, lling, and seaming equipment. “Our goal was to incorporate a replacement line with as little downtime as possible,” explains Brendgard.

MBC’s secondary packaging capabilities include the new WestRock cartoner, a WestRock tray former, and a Hamrick Packaging Systems drop-pack case/tray packer. After cans are lled on the ground level, they are transported to the mezzanine level with an overhead conveyor/accumulation system. While the tray former erects the trays, the cartoner loads four, six, 12, or 24 cans into the cartons, after which the cartons are placed into the case trays via the Hamrick drop packer. The lled trays, comprising either six 4 packs, four 6 packs, two 12 packs, or one 24 pack, are

then conveyed back to the ground level on an AmbaFlex spiral conveyor to be palletized.

For mix packs of craft beer and hard seltzer, MBC has a different process. For those products, after the cans are filled, they bypass the cartoner and are placed loose into trays. The trays of loose cans are then conveyed to the main level with a spiral conveyor (also from AmbaFlex) and are palletized. When MBC is

ready to create mix packs, it feeds the trays of loose cans into two robotic cells, each equipped with one Fanuc M410iC/185 four-axis robot (supplied by Hamrick) with two vacuum end effectors. Here, each vacuum tool picks up 24 cans, with all four end effectors picking up a different product variety and placing the cans on conveyors that lead to the cartoner. On the mezzanine, the cartoner creates mix packs of four varieties in 12- or 24-ct cartons. MBC can also create mix packs of three varieties in a 24-ct carton by blocking off one of the four robotic end effectors.

Ever conscious of responsible use of packaging materials, MBC uses the same case trays that hold the loose cans to hold the mix packs. After the robots pick the 24 loose cans from each tray, they move the empty trays to another AmbaFlex spiral conveyor that leads to the mezzanine, where the trays are used for the mix packs. Finished products are transported back to the ground floor by the spiral conveyor and once there, into an FL3000 floor-level palletizer from Columbia, where 100 trays are stacked on a pallet, and the pallet is stretch wrapped.

The cornerstone of the new packaging line is a 44-valve can filler from Krones. In specifying a new filler, MBC was looking for a system that could increase its speed by at least 15%. It also wanted to be able to run different can sizes, such as 16 and 19.2 oz, in the future.

Stand out on the shelf with a label as distinct as your brew.

As Brendgard explains, the only can size Ball offers out of its Honolulu plant is a 206, or a 12-oz, size, so MBC will have to source other sizes from the mainland. In the U.S., a 12-oz can is a 202. “So the requirement we had for the filler was that it could swap out between a 202 and a 206 can size, which is the diameter for the lid, and the different volume sizes.”

We combine advanced technology with ease-of-use, ensuring your bottles and cans embody excellence at first glance.

Our machines are not just equipment; they are the bearers of your brand's story, detailed with the perfect label.

Quick lead times on linear and rotary options from our Stock Machine Program.

Adaptable modular solutions seamlessly integrate into any line.

U.S. support network, anchored in Cincinnati's rich brewing heritage.

Expertise in both pressure-sensitive and cold glue label applications.

Step into the future of labeling

The new Krones filler operates at 550 cans/min, which is 80% faster than MBC’s previous equipment, and can accommodate can sizes other than the 202 12-oz. It also includes a CIP system that cleans both the interior and the exterior of the machine. Foaming heads on the filling valves ensure sanitation when changing between beverage types. “If you’re going from beer to soda, or vice versa, depending on the sugar content or the alcohol content, you have to make sure the filler is 100% clean so you won’t cross contaminate the next product,” says Brendgard.

“Our previous system required a lot more manual cleaning, for sure. You really had to get in there with the hand brush and scrub,” he adds. “We’ll still need to do that, that never goes away, but it will make it a lot easier for the operator at the end of the day with CIP to make sure the machine is 100% clean.”

Another feature of Krones’ equipment that made it the best choice for MBC was its ease of use, which is particularly important due to the brewery’s island location. Bringing a technician from Krones to the plant either from Germany or the U.S. mainland causes numerous days of shutdowns.

“Krones fillers are remarkably easy to use,” says Brendgard. “The complexity comes down to changeparts and repair and maintenance.” For this, he explains, MBC has trained its operators and maintenance department on valve rebuilding and on preventative maintenance for the filler and seamer. “We want to train our maintenance department and our operators to be highly specialized, so we don’t have to bring in techs from outside,” he says. “So training is very important to us, not only for the education of our employees, but also so that we have on-site service.”

The Krones filler is housed along with a six-head Ferrum sealer in a cleanroom enclosure on the ground floor. One option MBC added to the new line is a CSW (Can Systems Worldwide) lid feeder. “With our previous machine, every one and a half minutes we’d have to add a new roll of lids,” says Brendgard. “With the CSW lid feeder, we can run the machine a full hour without having to add more lids. This allows the operator to pay more attention to the actual filling process, rather than stocking up on lids.”

CSW also added a Filtec inspection and sampling system. The system provides valve monitoring to advise the operator when a valve is constantly hitting a low fill or an overfill, for example.

“It also makes sampling much more convenient,” Brendgard says. “If you have a rebuilt valve, you can say, ‘Give me the next 10 cans off this specific valve,’ and it will pop those off for you.”

Rounding out the new packaging line are a number of other new machines. At the beginning of the line is a depalletizer from Ska Fabricating that removes the preprinted aluminum cans from bulk pallets onto a conveyor. The cans are then flipped upside down and rinsed with an ion air rinser before they are filled and seamed.

Following filling and seaming, MBC installed a can warmer. As Brendgard explains, cans are filled at 33°F, so when they exit the filler, they begin to sweat immediately due to the high heat and humidity of Maui. “We found that if we place them directly into the cartons, the cartons get ruined,” he says. “So we installed a PRO Engineering can warmer to bring those cans just above dew point so they don’t sweat as they’re going into the cartons.”

MBC also added an Accutek labeler, which is used when the brewery creates short-run limited-edition offerings using blank cans. “But the majority of our product will be printed cans,” Brendgard notes.

Using a phased approach to installing the new cartoning capabilities and filling line, MBC’s new packaging line was completely up and running by year-end 2023. According to Brendgard, the new line has met all of MBC’s expectations. ●

It is relatively uncommon for craft brewers to produce their own yeast, instead sourcing this very sensitive process to third parties. The integrity of that yeast is essential to creating the right flavor profile for the beer. But by the time a brewer is likely to test for any contaminants that might be present in the yeast, it’s further down the line when the batch of beer has already been produced—at which point the brewmaster might find that the taste is off.

By the time a brewer is able to test for contaminants in yeast slurries, the impact might already be noticeable in the flavor profile of the beer.

Traditional quality control test kits for the brewing industry are designed to detect potential spoilers in the finished product rather than in the yeast itself. But these are what the brewing industry has been using—the yeast suppliers as well as brewers producing their own yeast—to test for unwanted bacteria throughout the harvesting and yeast propagation processes.

This presents issues on several levels, including the time required and the inability to get the sensitivity needed in what is itself a living organism, notes Neva Parker, director of operations for White Labs, a San Diego-based manufacturer of liquid yeast cultures used primarily for fermentation in beer and other fermented beverages.

“There hasn’t been a lot of innovation in microbiology over the decades, particularly in craft beer microbiology. We have used very traditional microbiological techniques to detect contaminants,” Parker says, adding that the technology is very “old school,” with culture plates designed to detect very specific organisms. “We would make our product, we would test it multiple times for quality, and we would have to wait three to five days in order to release the product from a QC hold.”

A few years ago, White Labs embarked on a collaborative development project with bioMérieux to develop a test geared specifically toward the yeast slurries themselves, which have a whole set of their own demands. “We really wanted to find a way that was not only more rapid but had a higher level of sensitivity when it came to detecting unwanted organisms in our cultures,” Parker says.

Though bioMérieux has a history of creating easy-to-use rapid assays for diagnostics in the beer and wine space, those tests were not focused specifically on yeast slurries. “We had a nice suite of several assays for different spoilage organisms in the brewing process. But it was very difficult for those brewers to test for the wide panels of organisms that could potentially be contaminating the yeast. It’s a very difficult matrix to work with,” says Adam Joelsson, senior director of assay development for bioMérieux. “There was a clear and evident need—with feedback from the market—for something compatible with yeast slurries.”

Because yeast has a very different matrix than finished beer, for example, bioMérieux needed to tap into outside expertise. “The natural thing to do was to reach out to the yeast manufacturers themselves,” Joelsson adds.

Before long, bioMérieux developed the partnership with White Labs and ultimately launched the Gene-Up Brewpro Yeast Slurry, a PCR (polymerase chain reaction) test designed to detect contaminants in raw yeast materials and yeast propagations in order to ensure high-quality fermentations.

Often used for testing yeast slurries are quality control tests designed to detect potential spoilers in finished beers. But the fact that there’s already a live organism in the yeast culture makes this problematic, Parker explains. “It’s really hard to test for other organisms when you’ve already got a huge population of one

organism that you’re testing within,” she says.

“Some of these organisms are quite fastidious,” Joelsson adds. “They require specialized plates and enrichment broths to selectively grow them in this really difficult high-concentration background of yeast. To find one CFU (colony forming unit) of contaminating organism in there is quite a difficult task. Traditional agar-based or culture-based methods can do that, but it requires some significant expertise, and it takes quite a long time to get the results—five to 10 days for some of these yeasts.”

In quality control tests of finished beer products, the yeast level is so low, it’s not difficult to exclude it from the testing. But in tests of yeast itself, this becomes much trickier to parse out the unwanted yeasts and other bacteria. “It’s really hard to pick through all the different organisms and find the ones that you don’t want vs. the ones you do want,” Parker explains.

The goal of the collaboration, therefore, was to take that testing time down to two days and also provide testing in a simple-to-use format that gives a clear indication of contamination.

“It was a multi-year project to develop this. The goal was to have a really highly multiplexed panel against these various yeast and bacterial targets that may contaminate yeast and then subsequently contaminate the fermentation at a brewer,” Joelsson says.

White Labs is focused heavily on the craft brew space.

It’s not every day a brewery breaks onto a scene unoccupied since before prohibition. But that was the case for Lazy Magnolia Brewing Company in Kiln, Miss.

Opening in 2005 as a small family brewery, Lazy Magnolia was the first in Mississippi to enter the packaged beer space after the state repealed a slew of old regulations that had prevented this type of business.

Fast forward to late 2022, when the brand was sold to investors out of Utah. Lazy Magnolia’s name and character stayed the same, but its packaging horizons widened significantly.

The new owners have made significant investments in new equipment, “upgrading our packaging equipment, upgrading our fillers, upgrading our depal,” says Christopher Maros, general manager at Lazy Magnolia. “And we’ve picked up a lot of business due to getting to the fully automated stage.”

Both canning and bottling operations were treated to equipment investments, but the new can filling equipment has been the biggest game changer for the brewery. A twin set of rotary fillers now sends triple the product down the line every hour, with quality control leaps ahead of the legacy equipment.

Lazy Magnolia’s focus on cans keeps the brand in line with the growing popularity of cans as a packaging format. “Cans don’t take up as much real estate, they’re lighter to ship, and they’re easier to package in my mind,” Maros says.

All that extra canning capacity and convenience has driven Lazy Magnolia’s own portfolio growth, paving the way for plans to introduce eight new styles of beer in 2024.

Lazy Magnolia is far from the only brand benefitting from the new equipment, though. Contract packaging makes up most of the company’s operations.

About 80% of Lazy Magnolia’s packaging

operations are done for Richard’s Rainwater, a water brand whose product runs perfectly well on craft brewery equipment. Another 5% of the business is for contract brewing and packaging of craft beers, leaving about 15% of packaging operations for the brewer’s own beer. The new equipment has allowed Lazy Magnolia to take on even more contract packing work, with two new contracts to package for other brewers set to begin by the end of March.

“The co-packing in world of craft brew is heating up. Everybody’s wanting to come up with some kind of new innovative product,” says Maros. “Being a primarily co-packing facility, [the investors] saw the opportunity in co-packing, that is most of the drive to put the capital into this facility.”

Overlooking packaging operations, where can and bottle depalletizers from Ska feed respective can and bottle lling operations, all by GAI. Both lines—all three really since there are two canning lines—reunite as they pass through a pasteurization tunnel ahead of accumulation and secondary packaging.

Lazy Magnolia’s upgraded canning line begins with the unloading of Ardagh brightstock cans with a new full-height CIB automatic depalletizer from Ska Fabricating, which replaced an older Ska depalletizer. Maros says the new machine has no trouble keeping up with the recently increased speeds further down the line.

“It’s fully automated, that’s what I love about it,” Maros says. “You throw the pallet of cans in there, cut the straps, take the top frame off, and the depal does all the work itself. It’s pretty much hands-off, so I don’t need to have an operator there.”

A single- ler organizes the depalletized cans into a Ska S-Grip straight lowerator, and a GRX ionic air blade rinses the empty cans as they drop down to the lower level. A Videojet inkjet coder also date-codes the bottom of each can during the lowerating process.

The ion-rinsed and coded cans are split into two lines via Ska-supplied, Modular Convey Express (MCE)-manufactured conveyance to the most impactful upgrade on the line so far—a duo of parallel GAI 3621 monoblock 10-head rotary can llers, each with single-head seamers.

The seamers can be adjusted for a maximum of three seam sizes, and Lazy Flamingo standardizes around 200 mm, 202 mm, and 206 mm. This range of can end/lid diameters allows Lazy Magnolia to seam seven different can varieties; an 8-oz sleek, a 12-oz sleek, 12-oz standard, 16-oz standard, 19.2-oz standard, a 21-oz “Arizonastyle” can, and an 8.4-oz “Red Bull-style” can, Maros explains.

Each seamer can be changed over within about 30 minutes to run whichever can size Lazy Magnolia needs on a given day, with functionality to pull product from a single tank into two different sizes at once, one on each line.

“With both of those llers behind one depal, we’re able to feed both of them consistently at speeds of 4,000 per ller, or 8,000

an hour total,” Maros says. That’s 133 cans/min, compared to the roughly 40 cans/min Lazy Magnolia produced with its legacy filler.

These fillers have been not only faster, but “very high quality, they’re very well put together, very user-friendly,” Maros says.

Just before lids are placed on each can, an undercover gasser injects CO2 inside. The lidded cans are sent to the seamer within two to three seconds from there, limiting trapped oxygen in the cans to virtually zero. That translates to low dissolved oxygen in the beer, meaning high quality and shelf life.

Once seamed, the cans are transported and combined via MCE conveyors into a single, foot-wide mass flow-style conveyor. The belt sends the cans through a Hermis TP-HRW 5 pasteurizer for a 42-minute dwell time.

The pasteurizer ramps up to a temperature capable of killing any potential pathogens or spoilage organisms before cooling the cans back down to room temperature on exit. It can also be used simply as a warmer, Maros explains, “so the cans come out the other end dry. It’s very humid here in Mississippi, so we usually have to run it at a certain temperature just so the cans don’t sweat.”

The pasteurized cans are then single filed and sent through a series of in-house-fabricated air jets to further ensure removal of any moisture.

Once past the air jets, the cans can either be sent to a CVC Technologies Inc. labeler, or to an accumulation table if the cans are pre-printed.

Lazy Magnolia uses pressure-sensitive labels for its own cans, but also accommodates printed and sleeved cans for its contract packing customers. The brand aims to switch to printed cans for its own products once volumes are high enough though, “just because there’s gigantic money savings there,” Maros says.

Secondary packaging for cans is currently done by hand,

with plans for automation soon. The brand’s current setup for beer products includes PakTech 4-pack can carriers for 16-oz products, and 6-pack carriers for 12-oz products. Trays are handfolded, and multipacks placed in them by hand.

Not to be outdone by the canning line, Lazy Magnolia’s bottling line received its own upgrades to help scale operations and provide more options for contract packaging customers.

Lazy Magnolia can run 12-oz bottles of various shapes, as well as a 750-mL bottle usually reserved for specialty beers. The bottles are amber for in-house beers and most contract packing customers, and clear for Richard’s Rainwater. Bottles for the brewer’s own product are supplied by Colorado-based Owens Rockway Glass.

The bottling line starts with another Ska depalletizer, this one a bit older with an infeed at the filler level instead of overhead. From there, the bottles are sent to a GAI 16-head rotary filler with a three-head capper/crowner, which runs up to 5,000 bottles/hour, or 83 bottles/min.

The GAI filler is new to Lazy Magnolia, but it’s not the first time it’s been on a packaging line, as Maros explains, “our old [filler] was just very neglected, so we actually found this used one from a brewery out of New York.”

After filling and capping, the bottles are sent through the same pasteurizer that services the two canning lines, allowing the brand to pasteurize bottles and cans at the same time. “We run everything through the pasteurizer and pick off the cans after the pasteurizer at the accumulation table,” Maros says.

Bottles run through the same CVC Technologies labeler as the cans, where they are also date coded before heading to secondary packaging.

Now that front-of-line operations have been automated to allow for new business, Lazy Magnolia’s eyes are on its secondary packaging optimization, keeping a similarly quick pace as with earlier upgrades.

That starts with automating case packing for bottles, with the brand now waiting for upgrades to arrive.

Currently, an offline master case erector from Eagle starts the process by assembling 24-count master cases for bottles. Six-pack carton carriers need to be manually erected and placed into the master cases. The cases with cartons inside are then manually added to an APE drop packer, which picks and places 24 bottles at a time.

That process will be taken out of workers’ hands soon though, explains Maros, “we’re waiting on one new piece that’s going to be able to erect the six-pack carrier, put the four six-pack carriers into the master case, drop the bottles into the six-packs [with the APE drop packer], and then tape the cases as well.”

The master cases are palletized by hand, but the brewer plans to purchase a palletizer in 2025.

The canning line has its own automation upgrades in the pipeline as well. “Toward the end of the year, we’re going to get a PakTech machine that automatically puts [can carriers] on. We’re either going to get that or a Hi-Cone machine, the plastic ring applicators,” Maros says.

This year’s plans also include a “continuous motion packer that makes the tray and then places the six-packs or loose pack in the tray,” Maros says. The brewer is speci cally installing a DMM Packaging T300 tray former packer, as well as a DMM CTC 40 can carton packer, in about a year.

The brand’s 12-oz and 16-oz standard cans require trays with a different footprint than its 8-oz and 12-oz sleek cans, so its focus is on exible equipment to accommodate the different sizes.

A bit further down the road in 2025, Maros also aims to have shrink bundling capability for cans.

Even as Lazy Magnolia nds itself in the middle of an upgrade plan, Maros sees major bene ts to operations from the brand’s current progress. “Going to full automation, where you take the human factor out of it, you can literally cut your labor costs in half, especially on the packaging side,” he says.

As front-of-line productivity boosts are coupled with plans for further end-of-line automation, Lazy Magnolia continues to cement its legacy as Mississippi’s pioneering packaged beer brand, poised for growth in its own portfolio alongside its contract packing partnerships. ●

As demand for Saint Arnold’s beer grew, so did the need for sustainable solutions to manage excess waste. The Weima E.200 drainage press provided an easy way to dispose of underfilled or damaged cans.

By Aaron Hand, Editor-in-Chief, ProFood WorldWhen Saint Arnold Brewing shipped its first keg of beer in 1994, it launched itself as Houston’s first craft brewer. Almost 40 years later, as Texas’s oldest craft brewer, Saint Arnold is still finding new ways to reinvent itself.

Faced with challenges posed by excess waste, the brewer was on the search for sustainable solutions when the team ran across game-changing equipment at the Craft Brewers Conference in Denver a few years ago. They had been dutifully recycling cans that had never been used—for discontinued brands, for example—but crushing reject cans that had already been filled was another matter and not something they could handle in-house.

But Saint Arnold, the patron saint of brewers and the company’s namesake,

smiled down on them when they discovered the Weima E.200 drainage press. It enables the brewer to much more easily recycle aluminum cans that are unsaleable.

The brewer had been grappling with an abundance of underfilled or damaged cans that were accumulating within its facility, occupying precious storage space and hindering efficient operations. “What this piece of equipment did for

us is now we can recycle low-fill cans or out-of-date cans,” says Phil Dagger, Saint Arnold’s packaging manager. “It used to be that anything out of date, we’d have to save it up, ship it out to a recycling company, and pay them to do that in order to recycle it correctly.”

With the drainage press from Weima, Saint Arnold is easily able to empty and crush a load of cans into 3 to 4 lb pucks, with full pallets shipped off to recycling.

Instead of paying for that service, Saint Arnold is reaping the benefits in the money it gets back for that crushed aluminum, providing a quick ROI on the E.200. “Just the amount of money we’re getting back for being able to recycle those cans pays it off in about a year and a half,” Dagger says. Factoring in the other benefits the brewer receives, the ROI is more like nine months, he estimates.

The Weima E.200 is a universal hopper with a sizable infeed capacity. The machine drains underfilled or out-of-spec product in one easy step. Rejected cans can be ejected directly into the machine’s hopper, which punctures them so the contents can be drained into a collection bin. All rejected cans are then easily compressed into 200 mm discs for recycling.

The machine can also be hand-fed in the case of loose cans that need crushing. In Saint Arnold’s case, they weren’t able to make use of the inline version of the drainage press because of line space, Dagger says. Instead, rejected cans are collected in a bucket to the side of the processing line, and that bucket is dumped into the drainage press.

Workers empty the bucket of cans daily typically, though sometimes twice a day, Dagger says, noting that the bucket is easier to dump if it’s not quite full. Dagger and his team have hooked up a pipe to existing fittings on the press to the drain to keep the flow of drained beer cleaner.

Despite space constraints in its brewing facility, Saint Arnold was still able to strategically place the free-standing Weima machine on-site. The damaged cans are manually loaded into the hopper, which swiftly compresses them, reducing volume and liberating much-needed space.

Instead of storing damaged cans in bulk in its warehouse

How are e-commerce, sustainability, and premiumization, among other topics, affecting the needs of CPGs in craft brew and spirits? How are your peers and competitors among CPGs evaluating new packaging machinery? Learn all of this and more in “Operational Trends: Craft Beer and Spirits” webinar. Visit pwgo.to/8232 to view it for free. ●

before shipping to recycling, Saint Arnold is now able to take up much less space by storing tightly compressed discs of aluminum instead of partially filled cans. Not only does this maximize floor space between trips to the recycler, but it also increases the value of the aluminum due to its compressed form. The new system also significantly reduces the frequency of shipments to the recycler, streamlining logistics and minimizing transportation emissions.

Crafting beer sold in distinctive, colorful cans has set Saint Arnold Brewing apart. As part of the craft brewing community, there’s also a strong tradition of environmental responsibility. Saint Arnold’s Recycle Rewards program, for example, incentivizes customers to return printed cardboard 6-pack carriers for reuse— not only to reduce waste but also to save costs by repurposing the expensive carriers.

The move to the Weima E.200 has been huge for Saint Arnold’s recycling efforts, Dagger says. “We were dumping our used cans in the garbage can,” he concedes, pointing to the added cost savings they’re now seeing with fewer garbage pickups. Recalls and out-of-date product that was already palletized was going to the recycler, but that wasn’t true of the individual rejects. “For daily low-fills, the time it took for somebody to open each can, dump it, and make sure it’s dried out—we just couldn’t sustain that.” ●

From complete brewhouses to individual solutions that enhance brewery performance and sustainability, we work hard to meet your every goal. Found in over 500 breweries throughout North America, our latest innovations have been specially developed for high efficiency and fast ROI. Couple our range of products with experienced technical service professionals available 24/7, and you have a partner truly committed to your success.

gea.com/unitedstates

sales.northamerica@gea.com