PAPER making!

The e-magazine for the Fibrous Forest Products Sector

Produced by: The Paper Industry Technical Association

Publishers of: Paper Technology International®

Produced by: The Paper Industry Technical Association

Publishers of: Paper Technology International®

FROM THE PUBLISHERS OF PAPER TECHNOLOGY INTERNATIONAL® R T P O P T

Volume 9, Number 2, 2023

FEATURE ARTICLES:

1. Testing: Determining the shape of a paper sample in in-plane compression test.

2. Tissue: The value of data for environmental sustainability assessment.

3. Decarbonisation: High-temperature heat pumps for selected industry sectors.

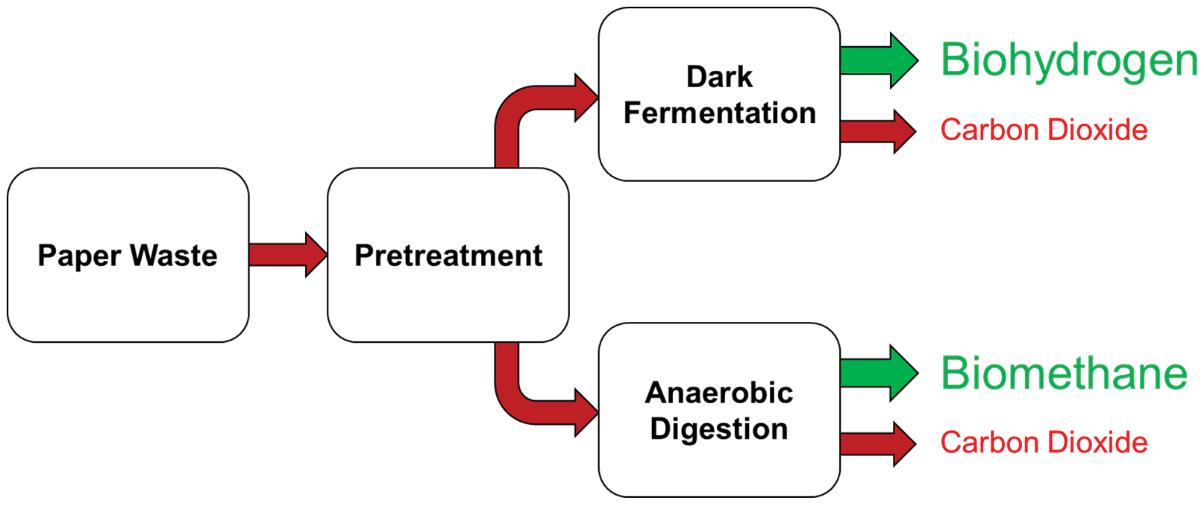

4. Environment: Conversion of paper waste & rejects into materials & energy.

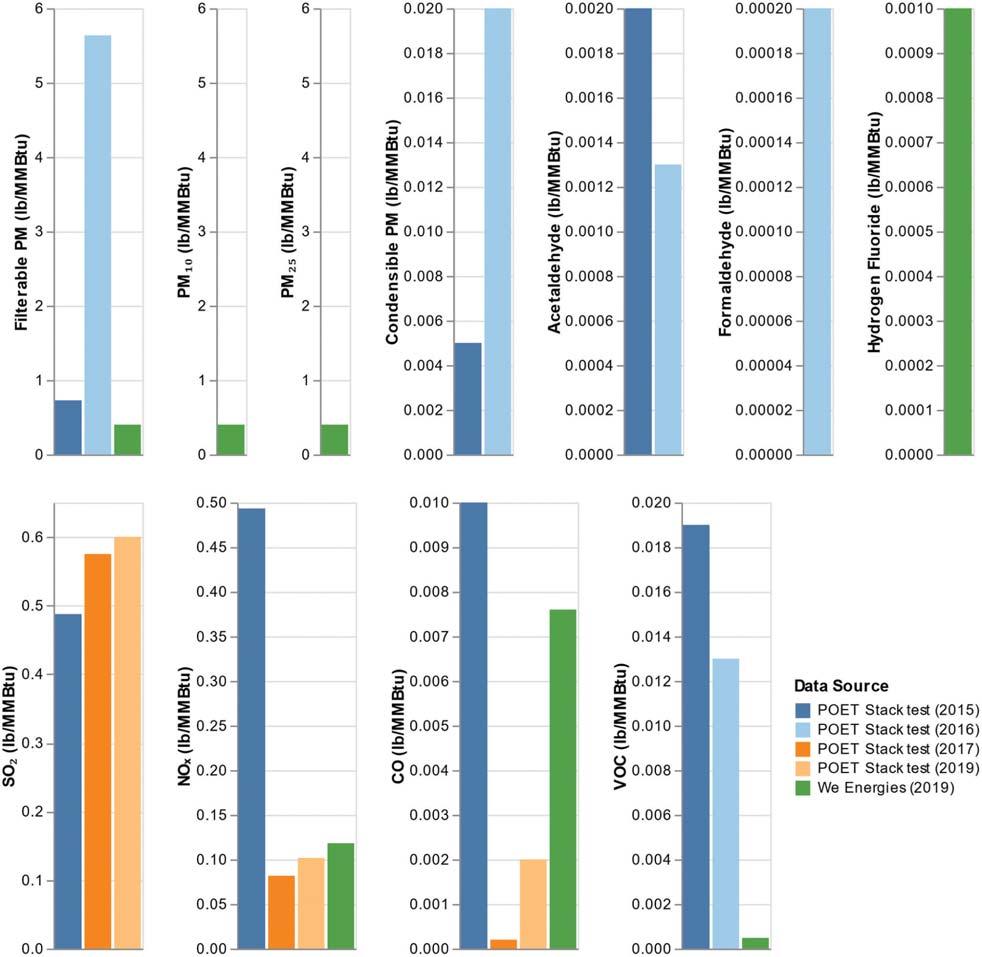

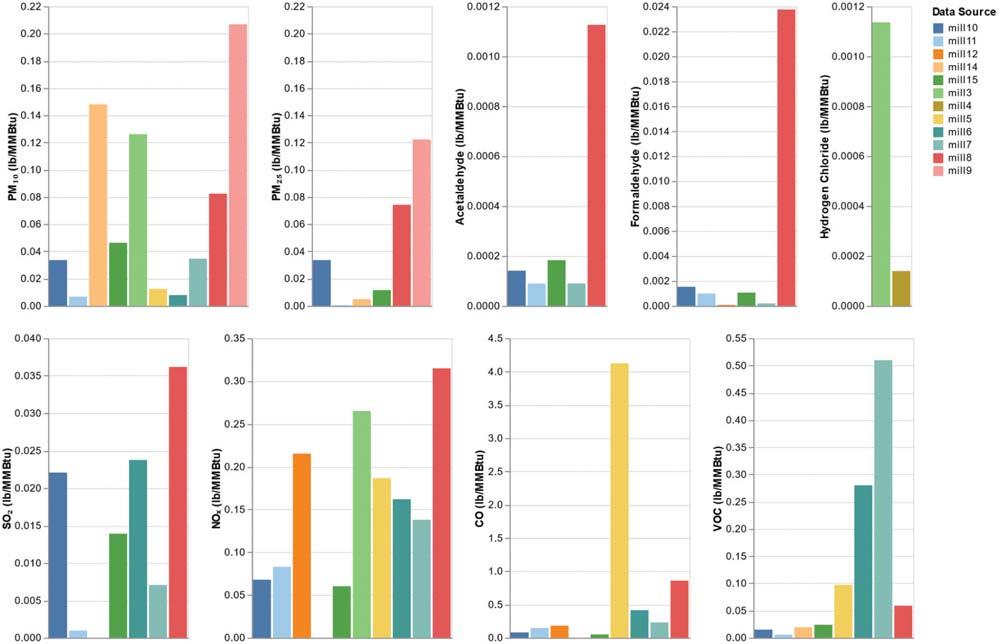

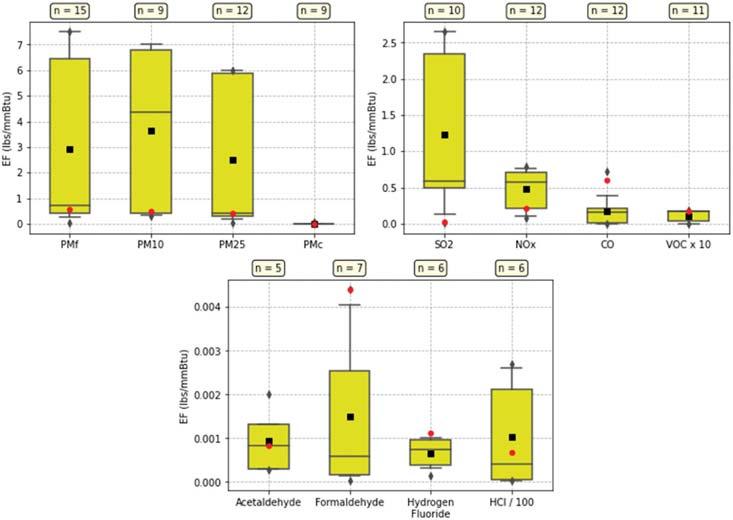

5. Bio-Energy: Emission factors of industrial boilers burning biomass-derived fuels.

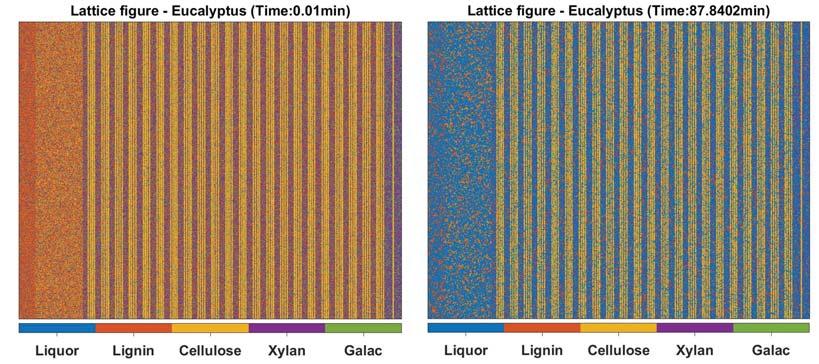

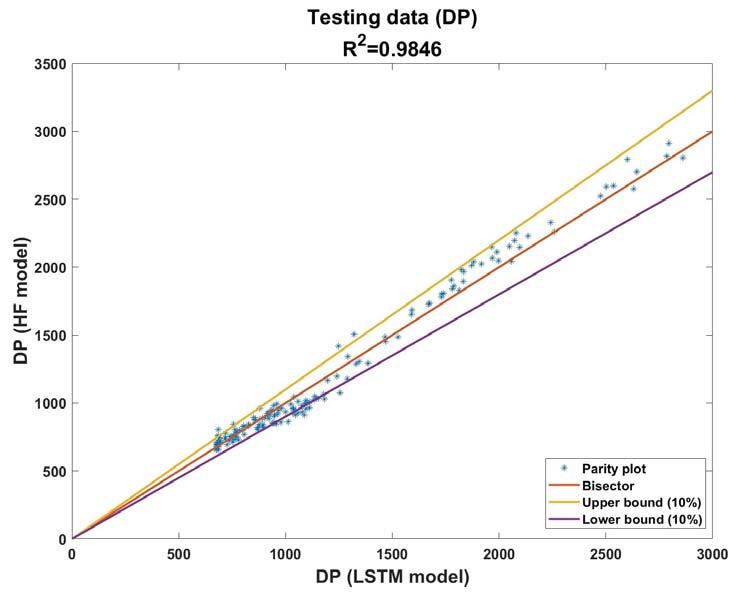

6. Pulping: Achieving optimal paper properties: a new approach for kraft pulping.

7. Wood Panel: Engineered transparent wood composites: a review.

8. Driving: Driving tips for the summer.

9. Proofreading: Tips for effective proofreading.

10. Speed Reading: How to absorb information quickly and effectively.

11. Delegation: How to delegate tasks to your team.

12. Safety Hazards: Prevention of slips, trips and falls.

SUPPLIERS NEWS SECTION:

News / Products / Services:

Section 1 – PITA Corporate Members: ABB / VALMET

Section 2 – PITA Non-Corporate Members

Section 3 – NON-PITA SUPPLIER MEMBERS

mycon GmbH

Advertisers: ABB & VALMET

DATA COMPILATION:

Events: PITA Courses & International Conferences / Exhibitions

Installations: Overview of equipment orders and installations between April and June

Research Articles: Recent peer-reviewed articles from the technical paper press

Technical Abstracts: Recent peer-reviewed articles from the general scientific press

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review , both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

The article presents a new technique for analyzing phenomena occurring during the measurement of the strength properties of paper in the conditions of compression of the tested samples with forces acting in the paper plane. The technique is based on collecting data on the current distance of the clamps holding the tested sample and the force exerted on the sample using a universal testing machine and on the simultaneous recording of image sequence of the sample during the measurement. Next, the resulting images are subjected to processing and analysis, the purpose of which is to extract information about the shape of the sample edge in all phases of the measurement. Its advantage is the ability to determine the deflection arrow of the sample and describe its shape using the selected function given by the analytical parametric formula. It will be helpful in further research on the development of an analytical model describing the phenomena occurring during paper compression, and a method to determine the mechanism of paper destruction and the corresponding maximum force that destroys a paper sample.

Contact information:

1. Centre of Papermaking and Printing, Lodz University of Technology, Wólczanska 221, 95-003 Łódz, Poland.

2. Department of Strength of Materials, Lodz University of Technology, Stefanowskiego 1/15, 90-537 Łódz, Poland.

Appl. Sci. 2023, 13, 1389.

https://doi.org/10.3390/app13031389

Creative Commons Attribution 4.0 License

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review , both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

Article

PawełPełczy´nski

1 CentreofPapermakingandPrinting,LodzUniversityofTechnology,Wólcza´nska221,95-003Łód´z,Poland

2 DepartmentofStrengthofMaterials,LodzUniversityofTechnology,Stefanowskiego1/15, 90-537Łód´z,Poland

* Correspondence:pawel.pelczynski@p.lodz.pl;Tel.:+48-426313816

Abstract: Thearticlepresentsanewtechniqueforanalyzingphenomenaoccurringduringthe measurementofthestrengthpropertiesofpaperintheconditionsofcompressionofthetested sampleswithforcesactinginthepaperplane.Thetechniqueisbasedoncollectingdataonthe currentdistanceoftheclampsholdingthetestedsampleandtheforceexertedonthesampleusing auniversaltestingmachineandonthesimultaneousrecordingofimagesequenceofthesample duringthemeasurement.Next,theresultingimagesaresubjectedtoprocessingandanalysis,the purposeofwhichistoextractinformationabouttheshapeofthesampleedgeinallphasesofthe measurement.Itsadvantageistheabilitytodeterminethedeflectionarrowofthesampleand describeitsshapeusingtheselectedfunctiongivenbytheanalyticalparametricformula.Itwillbe helpfulinfurtherresearchonthedevelopmentofananalyticalmodeldescribingthephenomena occurringduringpapercompression,andamethodtodeterminethemechanismofpaperdestruction andthecorrespondingmaximumforcethatdestroysapapersample.

Keywords: strengthpropertiesofpaper;analysisofdigitalimages;modellingoftheshapeofapaper sample;deflectionarrow

Citation: Pełczy´nski,P.;Szewczyk, W.;Bie´nkowska,M.;Kołakowski,Z. ANewTechniqueforDetermining theShapeofaPaperSamplein

In-PlaneCompressionTestUsing ImageSequenceAnalysis. Appl.Sci. 2023, 13,1389.https://doi.org/ 10.3390/app13031389

AcademicEditor:MilenaPavlíková

Received:21December2022

Revised:11January2023

Accepted:16January2023

Published:20January2023

Paperisanorthotropicmaterialcommonlyusedfortheproductionofcorrugated andcellularcardboard,fromwhichavarietyofpackagingisthenproduced[1,2].Their usefulnessisdeterminedbythestrengthproperties,whichdependtoalargeextenton thepropertiesofthepaperitself[3–9].Atthesametime,itisdesirabletominimizethe weightofthepackagewhilemaintainingtherequiredstrength.Inordertoavoidtimeconsuming,experimentalselectionofthematerialcompositionofthecardboardfrom whichthepackagingismade,itisincreasinglyusedtopredicttheirstrengthproperties bymeansofcalculationsthattakeintoaccountthepropertiesofthepapersusedintheir production[10–14].Oneoftheimportantpropertiesistheresistancetoedgecrushing measuredinthecompressiontestatshortfastening—SCT[15].Duetotheorthotropyofthe paper,resistancetocrushingisdeterminedintwomaindirections,namelyMD(machine direction)andCD(crossdirection).

Copyright: ©2023bytheauthors.

LicenseeMDPI,Basel,Switzerland. Thisarticleisanopenaccessarticle distributedunderthetermsand conditionsoftheCreativeCommons

Attribution(CCBY)license(https:// creativecommons.org/licenses/by/ 4.0/).

However,thetestdoesnottakeintoaccountthephenomenonofbucklingofthetested sample,whichoccurswhenusinglongersampleattachmentlengthsandiscommonlyobservedincorrugatedcardboardpackaging.Analysisofthecompressivestrengthofvarious materialsinthebucklingstatehasbeenofinteresttoresearchersformanyyearsbecause itisofgreatimportanceforestimatingtheloadcapacityofmechanicalstructures[16–19]. However,thestudyofpaperpropertiesinthisareawasusuallylimitedtosimplecompressiontestsandwasnotcombinedwithsimultaneousobservationoftheshapeofthe compressedsamples.

Modernmethodsofprocessingandanalyzingdigitalimagesmakeitpossibleto observechangesintheshapeofbodiessubjectedtoexternalforcesonthebasisofthe

analysisoftheirseriesofimages[20,21].Thankstoadvancesinelectronics,itisnow possibletorecordsequencesofimagesofprocessesoccurringduringstrengthtestsof variousmaterialsinreal-time.Theseriesofimagesobtainedinthiswaycanbereviewedin anyway,focusingonthesignificantphenomenaoccurringduringtheexperiment,andcan alsobesubjectedtoautomaticanalysis,thepurposeofwhichisaquantitativedescription ofagivenprocess.AnexampleofsuchasolutionistheLensovisionsystemforrecording thesurfaceofmaterialssubjectedtomechanicaltesting.ThankstotheuseofDigitalImage Correlation[22,23]inthesquareareasofsuccessiveimagesinthesequence,theyallowfor preciseestimationoflocaldeformationsoftheobservedsurfaces.Visionsystemsarealso usedinpapermakingandprintingtodetectdefectsandassessthequalityofproduced paperorprint[24].Thisispossiblethankstotheuseofadvancedalgorithmsfordetecting defectsvisibleinsubsequentimagesoftherecordedsequence,andoftenalsoalgorithms forautomaticrecognitionofthetypeofdefect.Implementationoftheseoperationsinreal timerequirestheuseofcomputerswithhighcomputingpower.Thisallowstocontrol theproductionlinebasedontheinformationreceivedandimprovetheparametersofthe productionprocessorrejectadefectiveproduct.

Observingtheshapeofpapersamplesduringthecrushingresistancetestallowsfor associatingchangesintheshapeofthesamplewiththemagnitudeoftheforceactingonit duringthetest.Tomakethispossible,itisnecessarytorecordimagesofthesamplebeing testedandsynchronizetheresultingseriesofimageswithdatafromthemachine.

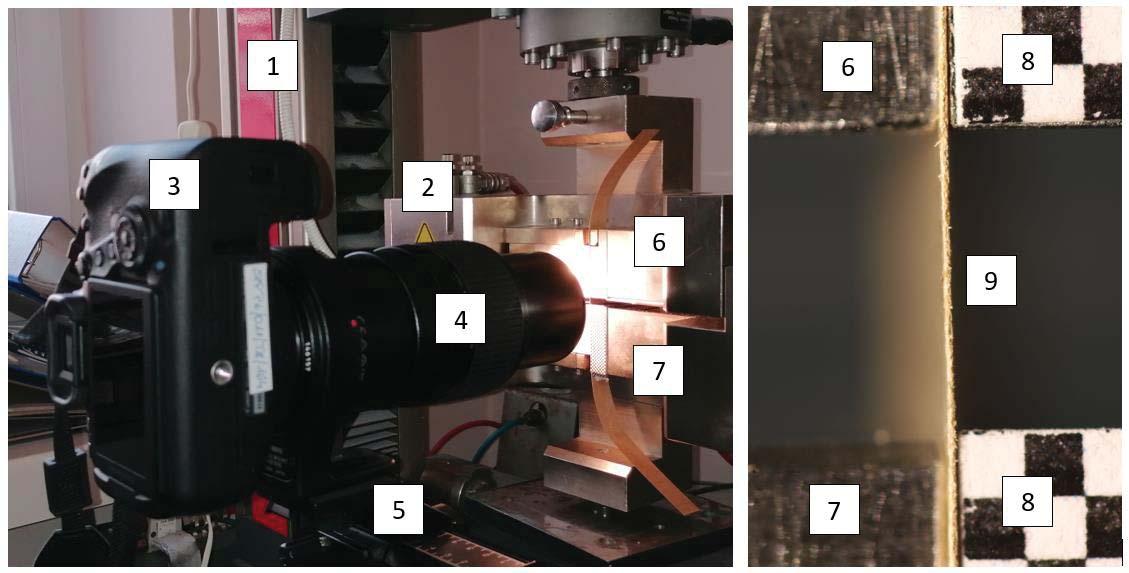

Theuseofdigitalimageanalysismethodsinmeasuringthecrushingresistanceofpaperrequiredsolvingtheproblemofsynchronizationofmeasurementinauniversaltesting machinewiththerecordingofimagesofthetestedsamples.Inordertosimultaneously recordthedisplacementofthemovinghandleofthetestingmachineandtheforceacting onthecompressedsampleandtheimagesofthesampletobetested,themeasuringsetup showninFigure 1awasprepared.

Thestandconsistsofatestingmachine(1)ZwickRoellZ010,anSCTtestholder (2),acameraplacedonatripod(3)—aCanonEOS6DMarkIIfull-frameDSLRwitha CanonMP-E65mmf/2.81–5 × Macrolens(4)andanilluminatorprovidingconstant illuminationwiththepossibilityofadjustingitsdirection(notvisibleinthephoto).This

allowstoachievegoodcontrastbetweentheedgeofthepapersampleunderexamination andthebackground.Inordertoadjustthesharpnessoftheimage,thecameraisattached tothetripodviaasettingsledge(5).Thismakesitpossibletoadjustthepositionofthe cameraintwohorizontalaxes—parallelandperpendiculartotheopticalaxisofthecamera. Thecameralensallowstomanuallychangethescaleofreproductionintherangeof 1to5,whichgivesthesizeoftherecordedfragmentofthepapersampleintherangeof 7.2mm × 5.8mm to36mm × 24mm.Inthepreparedmeasuringsetup,magnificationsin therangeof4to5wereused.

Patternsofcheckerboard(8)withalengthofasinglesquareof1mm(Figure 1b) werestickedtothefixed(6)andmovable(7)clampsofthetestingmachine.Itallowed totrackthemovementofthehandle(6)andtodeterminethespatialresolutionofthe recordedimages.

Themeasurementbeginsbyplacingthetestedpapersample(9)intheSCTholders ofthetestingmachine,settingthedesiredfocallengthofthelensandpositioningthe camerainsuchawaythatthesampleandthecheckerboardfragmentscontainingatleast twointersectionsbetweenitsfieldsareinthefieldofvision.Next,theforcevalueis reset,therecordingofthesequenceofphotosisstartedandafterrecording3–4images,the measurementisinitiatedinthemachine.Themeasurementendswhenthesetdisplacement ofthemovablehandleisreached.Duringtheentiremeasurement,arecordingofthe sequenceofimagesofthesampleisperformedalongwithfragmentsofhandleswith stickedcheckerboards.

Thedevelopedmeasurementtechniqueconsistsofaseriesofoperationsthatmust beperformedinordertoobtaincorrectmeasurementresultsandtheiranalysis.Theflow diagramoftheentiremeasurementisshowninFigure 2.Thetestedmaterialandprocessed dataarepresentedinthefigurebymeansofgrayrectangles.Operationsincludedinthe measurementprocessareshowninlightbluerectangleswithroundedcorners.

Therecordedsequenceofimageswassubjectedtopre-processingandanalysis.Preprocessingconsistedofthefollowingstages:

• conversionofaseriesofRAWimagestoTIFFformatwithoptionalreducingthesize ofadigitalimagetoreducedatavolume,

• extractinginformationabouttherecordingtimeofeachphotointhesequencewithan accuracyof1/100ofasecond,

• conversionofcolorimagestograyscale,

• croppingobtainedimagestothefollowingregions:theexaminedpapersample,the checkerboardonthemovablehandle,andthecheckerboardonthefixedhandle,

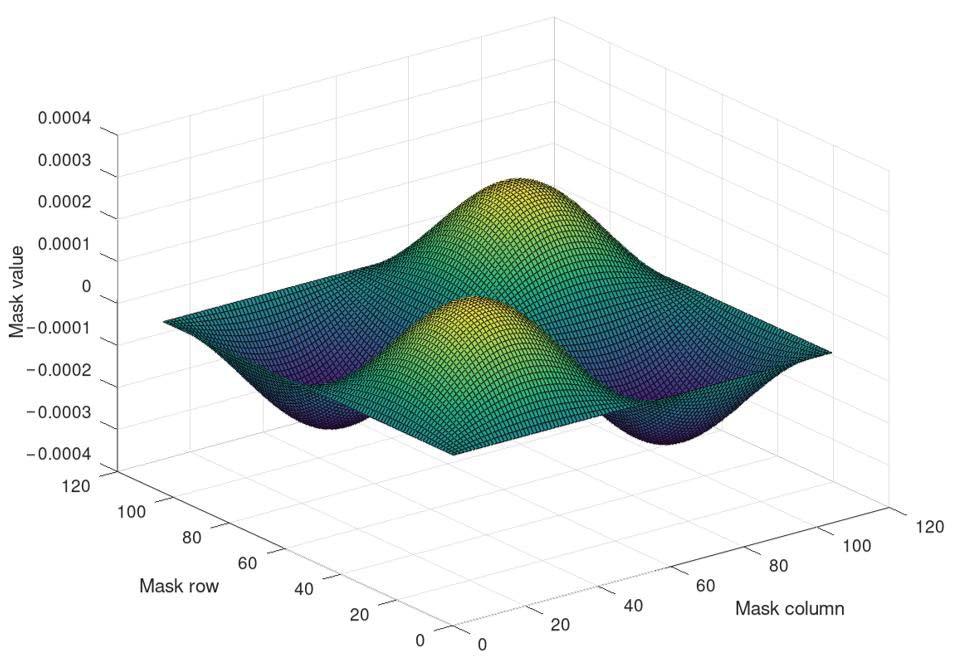

• linearfilteringofthesampleimagebymeansofafilterthatenhancestheverticaledges intheimage;itsmaskisshowninFigure 3,

• linearfilteringofcheckerboardimagesusingafilterthatemphasizesthecornersof thecheckerboardfieldsintheimage;itsmaskisshowninFigure 4.

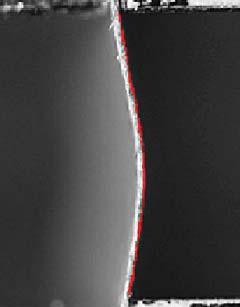

TheresultsoffilteringthesampleimageareshowninFigure 5a.Figure 5bshows theimageofthesampleitselfwiththedetectededgesofthesample:left(green)andright (red).Detectingtheleftedgeisverydifficultduetothelowcontrastintheimage,hencein furtheranalysisitwasdecidedtorelyonthedetectionoftherightedge.Thiscannotbe generalizedtoallcases.Thecontrastdependsonthedirectionandlightingofthesample. Inthefuture,choosingtherightfiltermaskshouldbeanoptionfortheanalysisalgorithm.

(a)Theresultoffilteringtheimageofthepapersampleduringthemeasurement,(b)the imageofthesamplewiththedetectedleftedgemarkedingreenandtherightedgeinred.

Figure 6 showstheresultoffilteringthecheckerboardimagesplacedonbothhandles ofthetestingmachineandtheplaceswherethecornersmarkedwithreddotsweredetected. Todetectthecornersbetweenthewhiteandblackfields,regardlessoftheirorder,filtering wasrepeatedtwicewiththefiltermaskrotated90degrees.Next,intheobtainedimages, theplacesofthecornersweredetectedindependentlybydetectingthemaximainthe imagesafterthefilteringandtheresultinginformationfrombothimageswascombined.

Figure6. Theresultoffilteringthecheckerboardimageonthemoving(a,b)andstill(d,e)handle andimagesofthehandlesthemselves(c,f)withthecornerdetectionpointsmarkedinred.Pictures (b,e)showtheresultoffilteringwithafilterwithamaskrotatedby90◦

Thecoordinatesetsofthepointsofthedetectededgesandcornerswereinputinformationtothealgorithmfortheanalysisofimagedata.Theimagecoordinateswereconverted tometriccoordinates(mm)basedoninformationaboutthespatialresolutionoftheimages andthearbitrarilyassumedplaceofthebeginningofthecoordinatesystem(associated withtheplacewherethesampleishandledinastillholder).

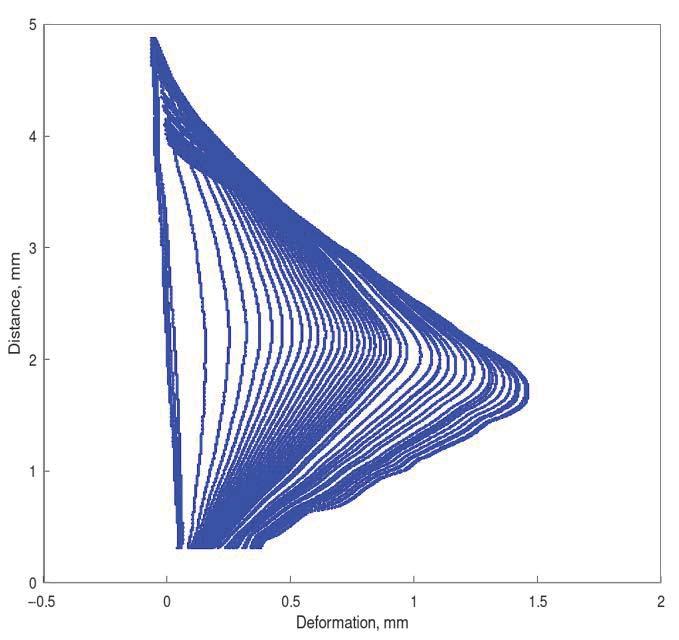

Theshapeoftheedgeofthetestsampleinsubsequentimagesoftherecordedsequence isshowninFigure 7.

Theapparentmovementofthelowerendofthesampleedgeistheresultoflimiting theanalysisfieldtotheareaofcorrectedgedetectionintheimage.Theassumedorigin ofthecoordinatesystem,associatedwiththeedgeofthestillhandle,isbelowthebottom edgeoftheimage.

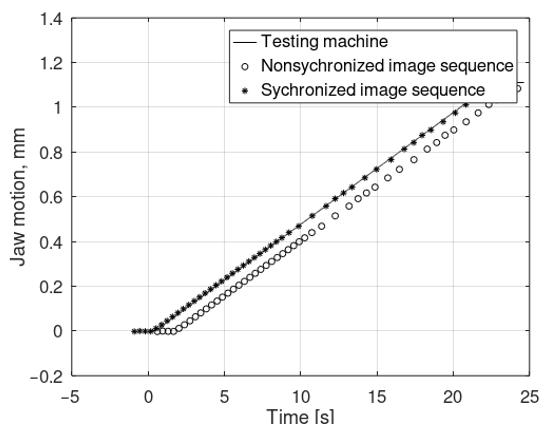

Theaveragevaluesofthecoordinatesofthecornersofthemovableandstationary checkerboardwereusedtodeterminethedisplacementofthehandleatthemomentsof recordingindividualphotos.Basedonthisinformation,thetimeofphotorecordingasa functionofthetimeofmeasurementdataacquisitioninthetestingmachinewasestimated, asshowninFigure 8.Theresultwasthesynchronizationofdatarecordingtimesfromtwo differentsources.

2.5.EstimationofDeformationParametersoftheTestedPaperSample

Themeasurementdataobtainedasaresultofthepre-processingandanalysisofthe imageswerefurtheranalyzedinordertodeterminethevalueofso-calledthedeflection arrowofthepapersampleandtheparametersofthesinusoidalfunctionmodellingthe shapeofthesampleedges.Thisisprecededbyarotationofthecoordinatesystemofthe machinetopositiontheedgeofthesampleatthebeginningofthetestinaverticaldirection. Thisoperationisperformedonthebasisofthecoordinatesofthesamplemountinginthe machineholders.Afterthiscorrection,thedeflectionarrowisdefinedasthedifferencein thehorizontalcoordinateoftheplacesofattachmentofthesampleinthehandlesandthe placeofthegreatestdeflectionofthesample.

Theshapeofthesampleisthenmodelledusingasinusoidalfunctionofimagecoordinates x =f(y):

x = C + A · sin 2 π y Pr + ϕ ,(1)

where:

C-constant—theshiftrelativetothebeginningofthecoordinatesystem(itcanchangein subsequentphotosasaresultof,forexample,cameravibrations,itisnotimportantin measuringthedeflectionofthesample),

A—amplitudeofthesinewavefunctionmodellingthedeflection, Pr—theperiodofthesinewavemodellingthedeflection(attheinitialstageofmeasurement, beforethebucklingofthesample,itcannotbedeterminedaccurately),

ϕ —theinitialphaseofthesinewavemodellingthedeflection(notrelevantfromthepoint ofviewofdeflectionanalysis,butmustbeavariableinordertomatchthemodelwellwith themeasurementdata).

Thedesiredvaluesoftheparametersofthesampleshapemodellingfunctionare searchedintheoptimizationprocedurethatminimizesthe SSESh errorbetweenthemeasurementdataandthemodellingresult.TheerrorisdescribedbyEquation(2):

SSESh = ∑ i x i C A · sin ( 2 · π · y i Pr + ϕ ) 2 ,(2)

where:

i—indexofthepointattheedgeofthetestsample, xi —thehorizontalcoordinateofthe i-thpointattheedgeofthesample, yi —theverticalcoordinateofthe i-thpointontheedgeofthesample.

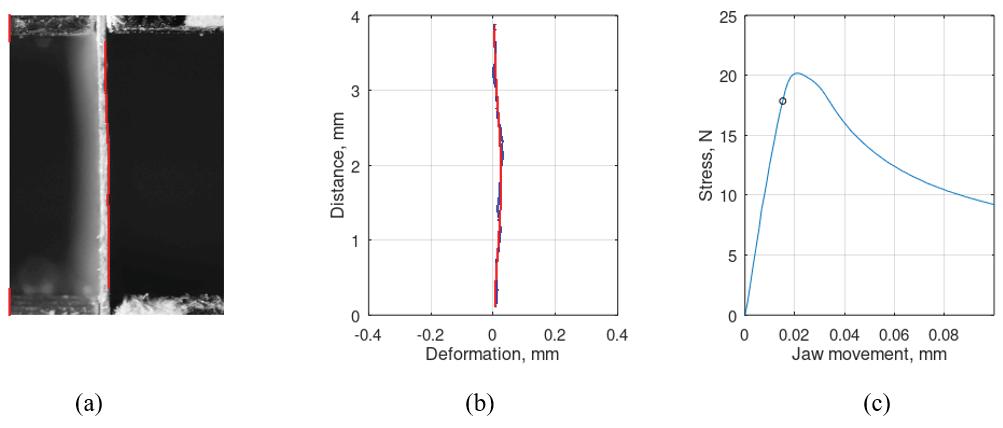

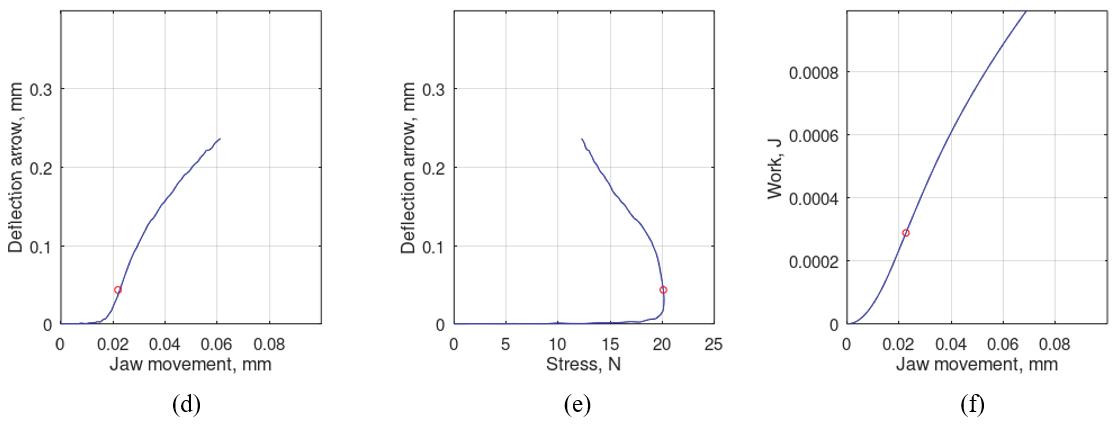

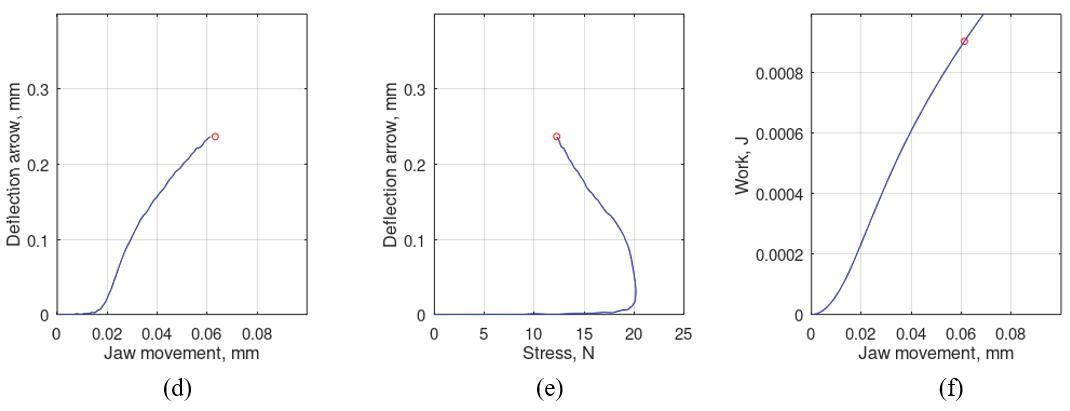

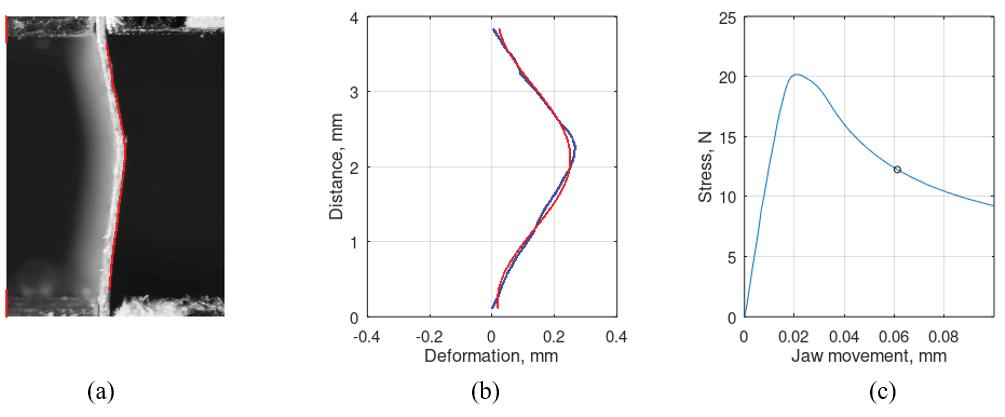

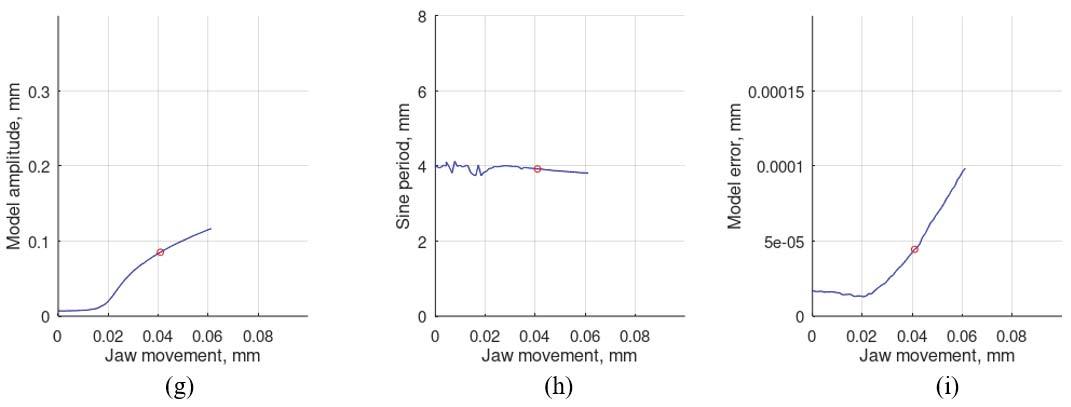

TheresultsofthemeasurementsrecordedduringtheMDcrushingtestofthepackagingpaperandtheanalysisoftheimagesrecordedatthattimeandthemodellingofthe sampleshapeusingthefunctiongivenbytheFormula(1)areshowninFigures 8–10.

appearanceofthesamplebuckling.

Meaningoftheindividualchartsineachdrawing:

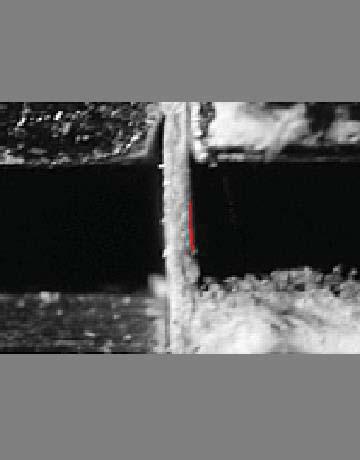

(a)—animageofthesamplewiththeedgedetected,

(b)—theshapeofthedetectededgeinthecoordinatesystemdeterminedonthebasis oftheindicatedpointsofattachmentofthesample,

(c)—theshapeoftheforcecurveasafunctionofdisplacementofthehandlewiththe markedplaceofrecordingoftheshownimage,

(d)—thevalueofthedeflectionarrowasafunctionofdisplacementofthe movablehandle,

(e)—thevalueofthedeflectionarrowasafunctionofforce,

(f)—workondeformationofthesampleasafunctionofdisplacementofthehandle,

(g)—theamplitudevalueofthesinewavefunctionmodellingtheshapeofthesample asafunctionofdisplacementofthehandle,

(h)—theperiodofthesinusoidalfunctionmodellingtheshapeofthesampleasa functionofdisplacementofthehandle,

(i)—thevalueofthesampleshapemodellingerrorasafunctionofthe handledisplacement.

Around,redmarkeronthebackgroundofcurvesrepresentingindividualfunctional dependenciesshowstheobtainedvaluesinthediscussedphaseofthecompressionprocess.

Figure 9 showsthestateofthesampleatthetimeoftransitionfromthepurecompressionphasetothebucklingphaseofthesample.Inthemomentsprecedingthisstate, modellingtheshapeofthesamplewithasinusoidalfunctiondoesnotmakesense.Therefore,graphsfrom(g)to(i)inFigure 9 beginwiththeplacemarkedwithadot.

Figure 10 showsthestateofthesamplewhenthemaximumforceisreached.Upto thispoint,theapproximationoftheshapeofthesampleusingthefunctiondescribedby theFormula(1)ischaracterizedbyasmallerrorvalue,whichmeansthatthebucklingtakes theshapeofasinusoiduntilthemaximumforceisreached.

Figure 11 showstheconditionofthesampleafteritsdestruction.Inthisstate,the approximationofthesampleshapeusingthefunctiondescribedbytheFormula(1)isnot veryaccurate,asindicatedbytheincreasingvalueofthemodellingerror.Thesampletakes ashapesimilartotwosectionsconnectingtheconnectionpoints.

3.Results

Theresultsofmeasurementsmadewithsampleclampinglengthsfrom0.7mmto 5mmarepresented.Ameasurementexperimentwasperformedtostudythebehaviorof samplesofpackagingpapercrushedinthedirectionofMD.Thesamplewas15mmwide, asinatypicalSCTtest.ThestandardclampinglengthintheSCTtestis0.7mm.However, differentvaluesofthesampleconnectionlengthwereused:0.7mm,1.3mm,2mm,3mm, 4mmand5mm.Thethicknessofthepaperwas0.14mm.

Figure 12 showstheshapeofacurverepresentingthedependenceofthecompressive forceofapapersampleonthedisplacementofthemovablehandlewithfasteninglengths from0.7mmto5mm.

Asthelengthofthefasteningincreases,atendencytodecreasethemaximumforce occurringduringthetestisobserved.Curvesforalengthof0.7–5mmincreaserapidlyuntil themaximumvalueisreached,andthenfallsharply,butwithasmallergradient.Table 1 showsthemaximumvaluesofthecompressiveforceasafunctionoftheclampinglength.

Atthesametime,itcanbeseeninFigure 13a–cthatwithfasteninglengthsoflessthan 3mmatthemomentofreachingthemaximumforcenobucklingisobserved.Withlonger lengthsoffastening,thebucklinghastheshapeofasinusoidfragment.

4.Discussion

Theresultsofthemeasurementsmadeitpossibletodrawanumberofconclusions. Foralengthof0.7mm,thepaperfibersdelaminatedandcrushednearthefixedlower handleofthemachine.Inthiscase,theratioofthelengthofthesampletoitsthicknessis L/g=5.Forlengthsof1.3and2.0mm,destructionshallalsooccurnearthelowerhandle withvisiblehorizontaldisplacementofthesamples.Forthesecases,wehaveL/g=9.3 andL/g=14.3,respectively.Forthefasteninglengthsof3.0(L/g=21.4)and4.0mm (L/g=28.5),thedestructionofthesamplestakesplaceinthecentralpartandthesample takestheshapeoftheletterV.Notethatpaperedgesentertangentiallyintobothhandles. However,foralengthof5mm(L/g=35.7),theV-shapeisveryclearlyvisible,inparticular therefractionitself.Thesampleattheplacesofattachmenttobothhandlestakestheshape asforjoint-likesupport.

Inthetheoryofthin-walledstructures,thefollowingclassificationisassumed:when L/g>25–30,whereLisasmalleroveralldimension,theplatesarethin-walled;when 5<L/g<25theplatesareofmediumthickness,whileL/g ≤ 5theplatesarethick[16,17]. Accordingtothisclassification,theclampinglengthL=0.7mmcorrespondstothickplates, andforL=1.3,2.0,3.0,4.0platesofmediumlength,andforL=5.0thinplate.Forplatesof mediumthickness,modificationsaremadeinrelationtothinplates[18,25,26].

Figure 15 showsdiagramsofchangesinthedeflectionarrowofthesampleasa functionofdisplacementofthemovablehandleofthetestingmachinewiththeplace wherethemaximumforceisreached.

Thecorrectnessofdeterminingthedeflectionarrowusingthedevelopedimageanalysistechniquewascheckedbycomparingmeasuredsampleshorteningwiththeanalytically determinedvalueusingtheformulagivenin[16]:

Figure 16 showsacomparisonofthemeasuredandtheoreticallycalculatedshortening ofthepapersamplewithaclampinglengthof4mmand5mmasafunctionofits deflection.Aslightdifferencebetweenthemeasuredandcalculatedvaluesmayresultfrom theadopteddestructionmodel,whichdoesnotreflectallthephenomenaoccurringduring thetest,ortheinaccuracyofdeterminingthedeflectionarrowbyimagingmethods.

approximatingtheshapeofthetestsampleasafunctionofdisplacementofthemovable handleofthetestingmachine.Estimatingtheperioduntilbucklingoccursisnotjustified, sincetheshapeoftheedgeofthesampledoesnotresembleasinusoid.Fromthemoment themaximumforceisreached,thevalueoftheperiodstabilizesatalevelcomparableto thelengthofthefastening.

5.Conclusions

Ameasurementtechniquewasdeveloped,basedonthesimultaneousmeasurement ofthedependenceofthecompressiveforceonthedisplacementofthemovablehandleofa universaltestingmachineandtherecordingofaseriesofimagesofacompressedsample ofthetestedmaterial.Thistechniquehasanumberofadvantagesoverthetraditional approachofrecordingonlyjawmovementandtheforcecurveduringthetest.Itenables non-contactmeasurementofthevalueofthedeflectionarrowofthesampleduringthetest andgivestheopportunitytoobserveitsshape.Thisallowstheshapeofthetestedpaper samplestobemodelledwithdifferentcurves,e.g.,asinusoidalfunction.Thankstothis, itbecomespossibletodeterminetherelationshipbetweenthedeflectionarrowandother variables,e.g.,force,displacementofthehandleofthetestingmachineorworkcarriedout onthesample.

Visualizationofchangesintheshapeofthesampleinsubsequentphasesofthetest togetherwiththequantitiesmeasuredusingauniversaltestingmachinefacilitatesthe predictionofthemodelofdestructionundergivenconditionsandgivesthepossibility ofitsquantitativeverificationbydeterminingthemodellingerroroftheshapeitselfor theparametersdeterminedonitsbasis.Asanexampleofsuchapossibility,theeffectsof approximatingtheshapeofthesampleusingthesinusoidalfunctionandtheerrorgraph ofthisapproximationallowingtoestimatethelimitsofapplicabilityoftheproposedmodel areshown.Thedevelopmentofamodelofpaperdestructionduringcompressionisof greatimportanceforpredictingthestrengthpropertiesofcorrugatedboardandcardboard packagingproducedfromit.Thiswillallowforsavingsintermsofpackagingproducts intransportandreducingtheconsumptionofpaperrawmaterialsfortheproduction ofcardboard.

Inorderforthedevelopedmeasurementtechniquetobefullyusefulintestingthe strengthpropertiesofpaper,theprocessofregistrationandpre-processingofsample imagesmustbeoptimized.Inparticular,theprocedureusedtodetecttheopticaledge ofthesampledoesnotallowforitscorrectdetectioninthevicinityoftheattachmentto

theUTMholder.Itisplannedtomaskthehandlewithblackstickers.Theauthorsare alsolookingforoptimalimagesizesettings,whichwillmaximizethenumberofimages recordedduringtheexamination.Furtherresearchisalsoplannedtodevelopananalytical modeldescribingthephenomenaoccurringduringpapercompressionandmethodsfor determiningthemechanismofpaperdestructionandthecorrespondingmaximumforce thatdestroysapapersample.

AuthorContributions: Conceptualization,W.S.;methodology,W.S.andP.P.;software,P.P.;validation, P.P.andM.B.;formalanalysis,Z.K.;investigation,Z.K.;resources,M.B.;datacuration,M.B.andP.P.; writing—originaldraftpreparation,P.P.,Z.K.andW.S.;writing—reviewandediting,P.P.,W.S.,M.B. andZ.K.;visualization,P.P.;supervision,W.S.;projectadministration,W.S.Allauthorshavereadand agreedtothepublishedversionofthemanuscript.

Funding: Thisresearchreceivednoexternalfunding.

InstitutionalReviewBoardStatement: Notapplicable.

InformedConsentStatement: Notapplicable.

DataAvailabilityStatement: Thedatapresentedinthisstudyareavailableonrequestfromthe correspondingauthor.Thedataisnotpubliclyavailableduetothehighdegreeofcomplexityoftheir organization.Theauthorshavenotyetdevelopedanappropriatestandardfortheirstorage.

ConflictsofInterest: Theauthorsdeclarenoconflictofinterest.

1. Rzepa,S.Parametrypapieru.InProceedingsoftheSympozjumMondiPackaging“FromFibretoCorrugatedBoard”, ´ Swiecie, Poland,1–2December2004.

2. Bai,J.;Wang,J.;Pan,L.;Lu,L.;Lu,G.Quasi-staticaxialcrushingofsinglewallcorrugatedpaperboard. Compos.Struct. 2019, 226,111237.[CrossRef]

3. Czechowski,L.;Bie´nkowska,M.;Szewczyk,W.Paperboardtubesfailureduetolateralcompression—Experimentalandnumerical study. Compos.Struct. 2018, 203,132–141.[CrossRef]

4. Kołakowski,Z.;Szewczyk,W.;Bie´nkowska,M.;Czechowski,L.Newmethodforevaluationofradialcrushstrengthofpaper cores. Mechanika 2018, 24,169–173.[CrossRef]

5. Gajewski,T.;Garbowski,T.;Staszak,N.;Kuca,M.Crushingofdouble-walledcorrugatedboardanditsinfluenceontheload capacityofvariousboxes. Energies 2021, 14,4321.[CrossRef]

6. Yu-Ping,E.;Wang,Z.-W.Plateaustressofpaperhoneycombasresponsetovariousrelativehumidities. Packag.Technol.Sci. 2010, 23,203–216.[CrossRef]

7. Abbès,B.;Guo,Y.Q.Analytichomogenizationfortorsionoforthotropicsandwichplates:Applicationtocorrugatedcardboard. Compos.Struct. 2010, 92,699–706.[CrossRef]

8. Semple,K.E.;Sam-Brew,S.;Deng,J.;Cote,F.;Yanm,N.;Chen,Z.;Smith,G.D.PropertiesofcommercialKraftpaperhoneycomb furniturestockpanelsconditionedunder65and95percentrelativehumidity. For.Prod.J. 2015, 65,106–122.[CrossRef]

9. Kmita-Fudalej,G.;Szewczyk,W.;Kołakowski,Z.Calculationofhoneycombpaperboardresistancetoedgecrushtest. Materials 2020, 13,1706.[CrossRef][PubMed]

10. Fadiji,T.;Ambaw,A.;Coetzee,C.J.;Berry,T.M.;Opara,U.L.Applicationoffiniteelementanalysistopredictthemechanical strengthofventilatedcorrugatedpaperboardpackagingforhandlingfreshproduce. Biosyst.Eng. 2018, 174,260–281.[CrossRef]

11. Li,X.;Wang,J.;Chuang,C.;Gao,D.;Lu,G.;Lu,L.;Wang,Z.Mathematicalmodelsforpredictingthequasi-staticstress characteristicsofcorrugatedpaperboardwithsinusoidalcorealongthelongitudinalcompression. Int.J.Mech.Sci. 2018, 149, 136–149.[CrossRef]

12. Kubiak,T.;Kolakowski,Z.;Swiniarski,J.;Urbaniak,M.;Gliszczynski,A.Localbucklingandpost-bucklingofcomposite channel-sectionbeams—Numericalandexperimentalinvestigations. Compos.PartB 2016, 91,176–188.[CrossRef]

13. Mou,X.-N.;Lu,L.-X.;Zhou,Y.-L.Evaluationofin-planecompressivedensificationstrainofhoneycombpaperboard. Adv.Mech. Eng. 2020, 12,1–11.[CrossRef]

14. Smardzewski,J.;Prekrat,S.Modellingofthinpaperhoneycombpanelsforfurniture.InProceedingsoftheInternational ConferenceAmbienta,WoodisGood—WithKnowledgeandTechnologytoaCompetitiveForestryandWoodTechnologySector, Zagreb,Croatia,12October2012;pp.179–186.

15. PN-ENISO3035:2011;TekturaFalistaOznaczanieOdporno´scinaZgniataniePłaskie.PolskiKomitetNormalizacyjny:Warsaw, Poland,(PolishStandard);2011.

16. Murray,N.W.;Khoo,P.S.Somebasicplasticmechanisminthelocalbucklingofthin-walledsteelstructures. Int.J.Mech.Sci. 1981, 23,703–713.[CrossRef]

17. Królak,M.(Ed.) StanyZakrytyczneiNo´sno´s´cGranicznaCienko´sciennychD´zwigarówo ´ ScianachPłaskich(CriticalStatesandUltimate CapacityofThin-WalledGirderswithFlatWalls);PWN,Warszawa-Łód´z:Daimlera,Poland,1990.

18. Reddy,J.N. MechanicsofLaminatedCompositePlatesandShells:TheoryandAnalysis,2nded.;CRCPress:BocaRaton,FL,USA,2004. [CrossRef]

19. BinKamarudin,M.N.;MohamedAli,J.S.;Aabid,A.;Ibrahim,Y.E.BucklingAnalysisofaThin-WalledStructureUsingFinite ElementMethodandDesignofExperiments. Aerospace 2022, 9,541.[CrossRef]

20. Gonzalez,R.C.;Woods,R.E. DigitalImageProcessing,3rded.;PrenticeHall,SE:Hoboken,NJ,USA,2007;ISBN978-0-13-168728-8.

21. Pełczy´nski,P.;Szewczyk,W.;Bie´nkowska,M.Single-CameraSystemforMeasuringPaperDeformationsBasedonImageAnalysis. Metrol.Meas.Syst. 2021, 28,509–522.[CrossRef]

22. Considine,J.M.;Scott,C.T.;Gleisner,R.;Zhu,J.Y.Useofdigitalimagecorrelationtostudythelocaldeformationfieldofpaperand paperboard.InProceedingsofthe13thFundamentalResearchSymposium,Cambridge,UK,11–16September2005;pp.613–630.

23. Stanier,S.A.;Blaber,J.;Take,W.A.;White,D.J.Improvedimage-baseddeformationmeasurementforgeotechnicalapplications. Can.Geotech.J. 2016, 53,727–739.[CrossRef]

24. Online;ProcemexMachineVisionApplicationsinPulpandPaperIndustryOfferDifferentSolutionsforPulpFurnish,Pulp bale,andRollQualityInspection.Availableonline: https://www.procemex.com/machine-vision-applications (accessedon 7January2023).

25.Volmir,A.S. NonlinearDynamicsofPlatesandShells;SciencePublishingHouse:Moscow,Russia,1972;p.432.(InRussian)

26. Kolakowski,Z.;Jankowski,J.Someinconsistenciesinthenonlinearbucklingplatetheories—FSDT,S-FSDT,HSDT. Materials 2021, 14,2154.[CrossRef]

Disclaimer/Publisher’sNote: Thestatements,opinionsanddatacontainedinallpublicationsaresolelythoseoftheindividual author(s)andcontributor(s)andnotofMDPIand/ortheeditor(s).MDPIand/ortheeditor(s)disclaimresponsibilityforanyinjuryto peopleorpropertyresultingfromanyideas,methods,instructionsorproductsreferredtointhecontent.

To manage their increasingly ambitious environmental agendas successfully, companies need better and more versatile data, yet the elements and mechanisms through which businesses and the environment benefit from data remain poorly understood. A single-case-study setting was designed for examining the perceived value of data for environmental sustainability as seen by the customers of a tissue-paper supplier. The findings, from material collected during interviews with customers in 2022, showcase the multifaceted nature of data's value for business operations and associated ability to support decisions and activities that encourage environment-informed choices and environmental improvements. Also, fully exploiting data's potential for environmental sustainability requires greater volume and detail of product-specific data, transparency of value chains and environmental impacts, and data's better management and sharing. The emerging insight related to the value of data strengthens understanding of how companies could, with data, support their customers' environmental performance.

Contact information:

1 Department of Forest Sciences, University of Helsinki, Helsinki, Finland

2 University of Graz, Institute of Systems Sciences, Innovation and Sustainability Research, Graz, Austria

3 Department of Information and Service Management, Aalto University School of Business, Espoo, Finland

Corp Soc Responsib Environ Manag. 2023;1 –14.

https://doi.org/10.1002/csr.2541

Creative Commons Attribution NonCommercial No Devis License

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review , both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

Received:17November2022Revised:25May2023Accepted:27May2023

DOI:10.1002/csr.2541

1DepartmentofForestSciences,Universityof Helsinki,Helsinki,Finland

2UniversityofGraz,InstituteofSystems Sciences,InnovationandSustainability Research,Graz,Austria

3DepartmentofInformationandService Management,AaltoUniversitySchoolof Business,Espoo,Finland

Correspondence

PäiviLuoma,DepartmentofForestSciences, UniversityofHelsinki,Latokartanonkaari 7,00014Helsinki,Finland.

Email: paivi.luoma@helsinki.fi

Fundinginformation

TheMetsämiestenSäätiöFoundation, Grant/AwardNumber:21VE049KE; Kaute-säätiö,Grant/AwardNumber: 20220113

Abstract

Tomanagetheirincreasinglyambitiousenvironmentalagendassuccessfully, companiesneedbetterandmoreversatiledata,yettheelementsandmechanisms throughwhichbusinessesandtheenvironmentbenefitfromdataremainpoorly understood.Asingle-case-studysettingwasdesignedforexaminingtheperceived valueofdataforenvironmentalsustainabilityasseenbythecustomersofatissuepapersupplier.Thefindings,frommaterialcollectedduringinterviewswithcustomersin2022,showcasethemultifacetednatureofdata'svalueforbusinessoperationsandassociatedabilitytosupportdecisionsandactivitiesthatencourage environment-informedchoicesandenvironmentalimprovements.Also,fullyexploitingdata'spotentialforenvironmentalsustainabilityrequiresgreatervolumeand detailofproduct-specificdata,transparencyofvaluechainsandenvironmental impacts,anddata'sbettermanagementandsharing.Theemerginginsightrelatedto thevalueofdatastrengthensunderstandingofhowcompaniescould,withdata,supporttheircustomers'environmentalperformance.

customervalue,environmentalsustainability,forestindustry,tissuepaper,valueofdata

Companieshaveambitiousinternalobjectivesforenvironmentrelatedsustainability,connectedwithclimate-changemitigation,circulareconomy,andbiodiversityprotection.Atthesametime,they mustcontendwithgrowingdemandsofexternalstakeholdersfor transparentandaccountableactivities(ComasMartí&Seifert, 2013).

Customersdesiretraceabilityofproducts'valuechainsandevidence fortheenvironment-relatedclaimsmade(Ruschetal., 2022),and investorslikewiseaskforbusinesstransparencyanddatathatattest togenuineenvironmentalimprovementsandsustainability(Herzig& Schaltegger, 2006).Regulators,inturn,seekverifiedcomplianceand eliminationofgreenwashing(EuropeanCommission, 2020).

Theseexternalpressures,incombinationwiththeinternallysetobjectives,callforcompanies'bettermanagementoftheirsustainability agendasbyallmeansattheirdisposal,includingversatileuseofdata tosupportsettingtheobjectives,identifyingimprovementopportunities,implementingappropriateactions,andseeingthatobjectivesare met(Buschetal., 2022).

Inthisconnection,dataondiverseaspectsofbusinessactivities, serviceandproductlifecycles,andrelatedenvironmentalimpactscan informenvironment-linkedsustainabilityeffortswhentheintegration, discovery,andexploitationofsaiddata(Miller, 2013)producevaluableinsightinsupportofenvironmentalsustainability(Song etal., 2018).Thisisthecase,forexample,whendatarevealingthe carbonfootprintofaproductareavailableandinfluencecustomers'

Thisisanopenaccessarticleunderthetermsofthe CreativeCommonsAttribution-NonCommercial-NoDerivs License,whichpermitsuseanddistributioninany medium,providedtheoriginalworkisproperlycited,theuseisnon-commercialandnomodificationsoradaptationsaremade.

©2023TheAuthors. CorporateSocialResponsibilityandEnvironmentalManagement publishedbyERPEnvironmentandJohnWiley&SonsLtd. CorpSocResponsibEnvironManag.

purchasedecisions(Pinheiroetal., 2022;Ruschetal., 2022).Other examplesinvolvedatasharingbetweensuppliersandcustomers;for instance,detailingthecontentandoriginoftheproductcanhelpall partiesunderstandandmanagepotentialbiodiversityissuesandother environmentalrisksalongthesupplychain(Contadoretal., 2021).In addition,companiesneeddataforprovingtheirenvironmentalperformancetocustomers,investors,andregulatorswhodemandevidence ofprogressonclearlydefinedpathwaystosignificantreductionin greenhouse-gasemissionsandwhorequirecompliancewiththeEU's newCorporateSustainabilityReportingDirective(ScienceBasedTargetsInitiative, n.d.;EuropeanCommission, 2021).Whencultivated intoinformationand,further,intoknowledge,datacansupportbetter, moreenvironment-awaredecisionsbyincumbentcompaniesandby theircustomersandsuppliers.

Theintersectionofenvironmentalsustainabilityanddigitaltransformation,encompassingincreasingavailabilityandutilizationofdata, hasrecentlycapturedscholars'moreintenseinterest(see,e.g.,Bai etal., 2020;Cardinali&DeGiovanni, 2022).Digitalizationandrelated dataarenowrecognizedasgatewaystosupportingclimate-change mitigation,circulareconomy,andotherenvironment-linkedgoals (DiMariaetal., 2022;Georgeetal., 2021;Liuetal., 2022),withgeneraldiscussionpointingtotheirpotentialroleinashifttoward sustainability – reducedresource-intensity,greaterenergy-efficiency, wastereductions,anddecreasedCO2 emissions(e.g.,Chiarini, 2021; Kerin&Pham, 2020;Niehoff, 2022).Specificdigitaltechnologies facilitatingactivitiessuchascollectionandutilizationofdata,alongsidetheso-calledIndustry4.0ingeneral,arerecognizedasprospectivemeansofsupportingmoresustainablebusinessstrategiesthat incorporatenewbusinessmodels,manufacturingpractices,and supply-chainsolutions(deSousaetal., 2018;Guptaetal., 2021).

Makingdata-drivendecisionsisincreasinglyrelevantnotonlyin companies'internalactivitiesbutalsointheirlargervaluechains, bringinginsuppliersandcustomers(Dubeyetal., 2019;Gebhardt etal., 2021;Goldetal., 2010).Dataneedsaregrowingmoreprecisely elucidated,andgreaterdetailisrequired – thedatamustcover numerousfacetsofproductlifecyclesandvaluenetworks.These requirementsnecessitateconsiderableexpansioninthequantitiesof dataneededbutalsoemphasizetherequisiteofsuccessfullymanagingandutilizingthedata(Gandolfo&Lupi, 2021).Thusfar,though, potentiallyvaluableenvironmentalsustainabilitydatahaveremained scatteredandunder-utilized(Ruschetal., 2022).Efficientmeansof collecting,managing,andutilizingsaiddatainbusinessdecisionmakingarestillemerging,andcommondefinitions,methods,andrules ofthegameforutilizingandsharingdataarelargelyabsent(Busch etal., 2022;EliasMotaetal., 2020).

Inthiscontext,thevaluethatversatileproductlife-cycleand value-networkdataofferforrealizingenvironmentalgainsispoorly understood,andcompanieslackunderstandingofthedata'sultimate valueforbusinessesandtheircustomers.Theseshortcomingsrender itdifficulttoprioritizedata-linkeddevelopmentneedsandarticulate casesforinvestinginrelatedinnovationandcapabilitydevelopment. Itisdifficulteventopointtoempiricalfoundations,sincelittle researchhasexaminedthedetailsoftheelementsandmechanisms

viawhichdataresourcescreatevalueforenvironmentalsustainability. Althoughresearchhaspinpointedcollaborationascrucialtoanymove towardsustainability,ourreviewofpertinentliteratureidentifiedno studiesaimedatsystematicunderstandingofhowacompanycould, withtheuseofdata,serveitscustomers'pursuitoftheirenvironmentalsustainabilitytargets.Inaddition,thereisarecognizedneedfor furtherempiricalresearchspecificallygearedtorevealinghowdigital transformationsupportsreachingenvironmentalgoals(Beltrami etal., 2021;O'Rourke&Lollo, 2021;Ruschetal., 2022).

Thepurposebehindthispaperistohelpfillthatgapbyexamining data'svalueforenvironmentalperformanceasperceivedbythedirect customersofaleadingEuropeantissuepapersupplier.Inastudyfrom theperspectiveofenvironmentalsustainability,weexploredtheterritoryofcustomers'expectations/needsandhowtheyareshifting.Settingouttouncovercriticalelementsandmechanismsofdata'svalue inthiscontext,weaddressedthefollowingresearchquestion: Howis thevalueofdataforenvironmentalsustainabilityperceivedamongbusinesscustomersofatissuepapersupplier?

Wechosetofocusonthevaluechainbehindtissuepaper becauseofitsassociatedcomplexdemandsforenvironmentalsustainability,fromarangeofstakeholders:customers,investors,regulators,andothers(Ghosal, 2015;Toppinenetal., 2017).Thesedemands casttherapidlygrowingneedforenvironmental-performance-related dataintohighreliefalso.Thebodyofdatarequiredcomprisesmyriad detailsthatacompanymaycollect,produce,process,andsharein relationtoitsactivities,products,andvaluechains(alltheway throughtocustomersanddisposal)thatcouldshedlightontheirenvironmentalimpactsandtheimprovementopportunities.Inpreviousliteratureontheforestcompanies(Mäkelä, 2017)itisfoundthatthese companiesreportontheenvironmentalperformanceoftheirsupply chainonlyverylittle.Hence,relyingonsecondarysourcesavailablein reportingdatafromthecompaniesthemselvesisnotlikelytoproduce sufficientlyin-depthinsightsfromthecustomerinterfacetofacilitate solidanalysis,callingforcollectionofprimarydata.Thecasecompany, MetsäTissue,hadrecognizedaneedtomakebetteruseofdatato enhanceitsenvironment-relatedperformanceinthebusinessof tissue-papermanufacture,anditsoughttounderstandhow,alongside itscustomers,itcouldenhanceitsutilizationofdataforenvironmental sustainability.ThefindingspresentedhereareoutputfromajointprojectwithMetsäTissuecarriedoutinJanuarytoJune2022that includedeightinterviewswithdirectcustomersofMetsäTissue engagedinretailandprofessionalsales.

Thisempiricallyunderpinnedstudy'scontributiontotheoryis twofold.First,weidentifiedthediscreteelementsoftheenvironmentalsustainabilityvaluethatcustomersperceiveindata,and,second, ourworkmakesthemultifacetednatureofdata'svalueinsupportof environment-informeddecisionsandenvironmentalimprovements explicit.Theresultingsenseofthevalueheldbydatacontentandthe possibleusespointstothenecessityofreliableproduct-specificand environment-relateddatatosupportbetterinformeddecisionswithin companiesandalongtheirvaluechains.Thework'scentralcontributiontopracticeisinstrengtheningourunderstandingofhowcompaniescouldseizedata'spowertoenhancetheircustomers'

environmentalperformance.Thefindingsofthisempiricalstudyprovidein-depthinsights,whichsofarwereonlyrarelypresentedinliterature.Thearticleisstructuredtopresenttheconceptualbackground oftheresearch,thenoutlinetheresearchdesignandapresentation ofthemostimportantfindings.Wethendelveintotheirimplications withthediscussionsectionandarticulationofourgeneral conclusions.

Consideringenvironmentalsustainabilityhasbecomeaprerequisite foranybusinessthatwantstomeetstakeholderexpectationsand guaranteeitsoperations'long-termsuccess.Fromabusinessperspective,themainaiminstrivingforenvironmentalsustainabilityisto reducethenegativeenvironmentalimpactsofcorporateactivities whilestrengtheningone'seconomicperformanceandalsofactoringin socialeffects(Khanetal., 2021).Pursuitofsustainabilitymaybemotivatedbydemandsfromregulators,owners,markets,andotherstakeholdersjustasmuchastheexpectedeconomicbenefitsandthe organization'sethicscommitments(Baumgartner&Rauter, 2017). Simultaneously,corporatesustainabilityhasbecomeamorestrategylinkedissue,involvingnotonlylegalcompliancebutalsogaininga competitiveedgeandmanagingthebusiness'sreputation(Engert etal., 2016).Companiesaimtointegrateenvironmentalconsiderationsintotheiractivitiesacrossbusiness-functionboundaries,from productdesignandsupply-chainmanagementtobusinessdevelopmentandsales(Meueretal., 2020).Inaddition,somestakeholders demandthatcompaniestakeresponsibilityforsustainablepractices throughoutthesupplychain(Sarkisetal., 2021;Sodhi&Tang, 2019).

Increasingavailabilityofdata,enabledbydigitalization,ischanginghowbusinessesoperate,thusaffectingopportunitiestoinfluence environmentalsustainability.Datacanbedefinedasobjectivefacts abouteventsandobservationsofthestateoftheworld(Davenport& Prusak, 1998)orassymbolsthatrepresentpropertiesofobjects, events,andtheirenvironments(Ackoff, 1989).Itisonlyafterthe transformationofdataintoknowledgebymeansofunderstanding saiddataincontextandelaboratingonthevaluablepatternsuncoveredthattherelevantdatacanfunctionmaximallyforenvironmental sustainability(Ackoff, 1989;Rowley, 2007).

Datacanaddvaluebydrivingtransparency,optimization,learning,anddeeperunderstandingofsuchfactorsascustomerneeds (Chenetal., 2015).Data'svaluewithspecificregardtoenvironmental sustainabilityliesintheabilitytobringenvironmentalconsiderations intostrategicandoperativedecision-makinginanevidence-based mannerforbusinessfunctionssuchasproductdesign,production planning,supply-chainmanagement,andbusinessmodels'development(deSousaetal., 2019;Langley, 2022).Dataaffordinnovative waystoimproveefficiencyand,furthermore,monitorandoptimize processesandproductperformances(Niehoff, 2022).Thissourceof informationisrecognizedalsoforitspotentialinbuildingtransparency amongstakeholders(Ruschetal., 2022).Theabilityofdatatoaidin settingplausibleenvironmentaltargets,identifyingimprovement

opportunities,carryingoutactions,andmonitoringthedevelopment onvariousfrontsmakesdata-informedoperationshighlyattractivein conjunctionwithorganizations'worktowardambitiousobjectives theyhavesetforthemselvesinrelationtoenvironmentalsustainability,whichaddressclimate-changemitigation,circulareconomy,and biodiversityprotection.Forcompanies,theuseofdataoffersparticularvalueforbringingenvironmentalconsiderationsintostrategicand operativedecision-makingacrossabroadspanofbusinessfunctions, fromproductdesigntosupply-chainmanagement(deSousa etal., 2019;Langley, 2022).

Inthisconnection,abodyofdatathatcoversdiverseaspectsof businessactivitiesandofproductandservicelifecycles,including relatedenvironmentalimpacts,canyieldknowledgeforenvironmental sustainability.Varietyofdatacouldsupportbusinessesintheirenvironmentaleffortsbyilluminatingmultipleaspectsofthoselifecycles andtherelatedmaterialflowsandemissions,suchthattheycanbetterassessenvironmentalimpactsandidentifyimprovementopportunities(Nascimentoetal., 2019;Tsengetal., 2018).Inaddition,data thatrevealpatternsinhumanbehaviorandneedscouldfacilitate effortstopinpointopportunitiesforsustainableconsumption,sound procurementchoices,andnewbusinessmodels,whilealsoproviding technicalinputonthesystems'performancethatmayaidinsystemic improvements(Guptaetal., 2021;Luomaetal., 2021).Possibledata sourcesrangefromcompanies'internalprocessestoexternalsupplychainpartnersandcustomers(Hartmann, 2016;Rantaetal., 2021). New,bettermeansofaccessingandapplyingenvironment-related dataarebeingdevelopedconstantly.Forinstance,smartalgorithms, connecteddevices,andBigDatacansupportresource-andenergyefficientproductionandconsumption(Bohnsacketal., 2022);blockchaintechnologiesservetrackingofmaterials'paththroughsupply chains;waste-to-resourcemarketplacesmaybeestablished;anddigitaltwinsanddigitalproductpassportsassistintracingproductlife cycles.

Creatingcustomervalue – withdata'spotentiallycrucialcontributiontothis – isaprerequisiteforbusinesssuccess(Flintetal., 1997; Graf&Maas, 2008;Porter, 1996).RobertWoodruff(1997,p.142) definescustomervalueasthe “customer'sperceivedpreferencefor andevaluationofthoseproductattributes,attributeperformance,and consequencesarisingfromusethatfacilitate(orblock)achievingthe customer'sgoalsandpurposesinusesituations.” Whichattributes, consequences,andgoals/purposesaredesiredgetsaffectedbythe product-usesituationandcanchangeovertime.Forinstance,users' accumulatedexperiences,perceptions,preferences,andevaluations (bothindividual-levelandsocial)affectvaluecreation(Helkkula etal., 2012;Woodruff, 1997).Also,customersassessvaluerelativeto theirownresourcesandprocesses,andtheyconsiderresources'integrationandsharingbetweenprovidersandcustomers(Rintamäki& Saarijärvi, 2021).Thisfactorisespeciallytopicalinthecaseofdata: thevaluecreationisadynamicprocess(Grönroos, 2008;Tzokas& Saren, 1999)whereinproviderandcustomercreatevaluetogether throughtheirinteraction(Ballantyne, 2004;Grönroos&Voima, 2013). Muchhingesoncombinationsofforces.Customers'strategicfocus andoperationprocessesaswellasregulationandtechnology,for

example,maytriggerchangesincustomer-experiencedvalue(Flint etal., 1997).Anticipatingwhatcustomerswillperceiveasvaluable,in theircontextandintheirterms,isseenascriticaltomaintainingcustomervalueinacontinuouslychangingworld(Huretal., 2013; Rantalaetal., 2019;Rintamäki&Saarijärvi, 2021).

Thepulpandpaperindustry,withthetissue-paperindustrybeingno exception,facescomplexdemandsforenvironmentalsustainability, fromawiderangeofdirections.Thesedemandsaredrivenbymore extensiveawarenessofsustainabilitybycustomersandotherstakeholders,tighteningregulatorylimits,andglobalizationoftheindustry itself(Ghosal, 2015;Toppinenetal., 2017).Themulti-tiersupply chains,whichfeatureforestmanagementandharvesting,manufacturing,logistics,retailsales,anduseoftheproducts,havecrucialimplicationsforenvironmentalsustainability(Vidaletal., 2010).Thisindustry useswood-basedfiber,water,energy,andchemicals,allinsignificant amounts(Lipiäinenetal., 2022).Hence,climatechange,resourceefficiency,andsustainableforestmanagementhavebeenamongthe topicsprioritizedontheindustry'senvironmentalagenda(Ranängen& Zobel, 2014;Tuppuraetal., 2016).

Tissue-typepapers,suchas(forhomeandaway-from-homeuse) papertowelsandtoiletpaper,areputtocleaning-relatedandpersonal useinhouseholds'day-to-daylifeandprofessional-salescustomers' routineoperations(e.g.,cleaningandfacilitymanagement,industrial production,andpublic-sectorwork).Demandforthemisrising steadilyinresponsetochangesinconsumptionpatterns.Bothvirgin andrecycledfibersareamongthemainraw-materialinputs,andthe goodsaretypicallyproducedrelativelyclosetotheconsumptionsites, forshorttransportationdistances.Thetissue-paperindustry'sturnoverinEuropecomestoroughly10billioneurosannually,accounting for25%oftheglobalmarketforthesepapers(EuropeanTissue Symposium, n.d.).About75%ofthevaluearisesthroughretailsales, andtherestcomesfromaway-from-homeandB-to-Bmarketssuch ashotelandrestaurant,hospital,andofficeuse(EuropeanTissue Symposium, n.d.).

Againstthisbackground,wechoseonecompanytorepresent firmswithinthisexpandingindustryofferinguniqueandin-depth insightsintovaluecreationbasedondata.Thecasecompanychosen forstudyincombinationwithitsretail-andprofessional-salescustomerswasMetsäTissue,oneofthelargesttissue-papersuppliersin Europe(EuropeanTissueSymposium, n.d.),whichhasnineproduction units,inFinland,Sweden,Germany,Poland,andSlovakia.With1.2billioneurosin2022sales,MetsäTissuealoneemploysapproximately 2500people.ThecompanyispartofMetsäGroup,aFinnishforestindustryentitythatprovidesabroadrangeofwood-basedproducts toglobalmarkets.ThemanagementteamatMetsäTissuerecognized aneedtomakebetteruseofdatainsupportofenvironmentalsustainability,andthecompany'smanagerswerereadytoworkwiththeir

customerstounderstandthepotentialvalueofdatamorefully.Therefore,thecasecompanywasreceptivetotheideaofthistimelyanalysis(Gray, 2018).Wesawgreatvalueinanon-anonymouscaseofthis nature,fortheopportunity – rareinforest-businessresearch – to afforddeeperunderstandingoftheemergingconvergenceof environmental-sustainabilityanddatawork.Thisisespeciallyvaluable sincebothoftenareperceivedascomplexandabstractareaswithlittlesoundempiricalresearch.

AmongMetsäTissue'scustomersareretailersbutalsovariousclientsengagedinprofessionalsales(suchasdistributorsofofficesupplies).Improvingenvironmentalperformanceisnotonlyatoppriority forMetsäTissuebutalsocrucialforitscustomers,whichfacemountingpressureforenvironmentalsustainabilityfromtheirownstakeholdersand,hence,seekproofofenvironmentalimprovementsinthe associatedsupplychains.ExplicitdemandsforMetsäTissuearise from,forexample,customers'commitmentstoreducingtheir greenhouse-gasemissionsinlinewithspecificscience-basedtargets (ScienceBasedTargetsInitiative, n.d.).Inaddition,thecompanyhas directlycommittedtovariedsustainabilitytargets,amongthemhaving entirelyfossil-freemillsandproductsby2030(MetsäTissue, n.d.). OperatingprimarilyinEurope,italsomusthonorEU-levelregulatory requirementsforcorporateenvironment-relatedreportingandtransparency(e.g.,EuropeanCommission, 2022).

Toadvanceunderstandingofthecustomer-perceivedvalueofdatafor environmentalsustainability,wechosetoconductaninductivesinglecasestudy,foraqualitativedesignwhereintheanalysisisstrongly groundedinempiricaldata(Gioiaetal., 2013).Casestudiesareattuned todevelopingconceptualcontributionsandnuancedaccountsofthe phenomenoninareal-worldcontext(Gray, 2018;Vossetal., 2002), especiallyinfieldswithrelativelylittlepriorattentionfromempirical science(Bansaletal., 2018).Theexploratoryapproachweapplied (Gray, 2018)enabledustounpackthecomplexphenomenonofthe perceivedvaluefromtheangleofthecasecompanyanditscustomers byuncoveringitsuniquefeaturesandpatterns(Bernardetal., 2017). Theapproachaddedvaluefortheparticipantstoo,astheprocess unfolded:sparkingofinsightinrealtimestrengthenedscholarlyunderstandingofthecontextfurther(Bansaletal., 2018).Furthermore,this wayofengagingenabledscientificandpracticalunderstandingofthe phenomenontoinformeachother(Bansaletal., 2018).Withitscollaborativemethod,thestudygenuinelystrengthenedMetsäTissue's environment-relateddatacapabilitiesasrelevantindividualsfromits sustainability,marketing,data-management,andcorporatefunctions werebroughtintotheproject.

Thefullprocesswasdesignedasasix-month(January–June 2022)collaborativeresearchprojectwithaworkinggroupthatcomprisedfivemembersofthesustainability,marketing,anddatamanagementfunctionsandasteeringgroupwithfourcorporate-level managers.Inaddition,theregionalvice-presidentsforsalesand selectedkey-accountmanagerswereinvolvedintheprocess,bothvia

thesales-groupmeetingsandwhenthecustomerinterviewswere beingpreparedforandconducted.

Theprojectfollowedathree-stageprocess(showninFigure 1)in whichthefirststagefocusedonsettingobjectivesfortheworkand obtainingcommitmentfrominformants/researchparticipantsat MetsäTissue.Thisphase'sproblemformulationincludedninebackgrounddiscussionswithkeyinternalinformants,twoworking-group meetings,andameetingofthesteeringgroup.Phase2broughtcustomersintothepicture,toengageingeneratingjointunderstanding ofdata'svalueforenvironmentalsustainabilitybymeansofinterviews.Additionally,thatphaseutilized,forpreparationforthecustomerinterviews,twoworking-groupmeetings,asales-group meeting,andonesteering-groupmeetingaswellas,forreflectionon theinterimresults,ajointmeetingoftheworkinggroupandthesales group.Theworkinthefinalphaseassessedtheopportunitiesand challengesidentifiedinthecustomerinterviews,sharedthefindings withcustomers,andarticulatedlessonsfromtheprocessforfuture businessdevelopmentandcustomerengagement.Phase3featured twofurtherworking-groupmeetingsandonemeetingeachofthe salesandthesteeringgroup.Inaddition,aninternalworkshopwas held,andtheteamsolicitedtheinternalparticipants'anonymousinput onthelessonsfromtheprocess.

MetsäTissue'scustomersdifferedintheircommitmenttoenvironmentalsustainability,notallhadsofarspecificallyprioritized developingtheirdatasourcesanddatamanagement,andsomelacked resourcesatthetimeofthestudytodevotetosuchmatters.We directedourattentiontothesetofcustomersthatseemedprepared todiscussthetopic.Focusingonthosecustomercompaniesreadyto discussthecoretopicfacilitatedcollectingvalid,reliablefutureorientedinsightastorapidlyevolvingneeds,thusenablingthecompanytotackletheseneedsproactivelyanddevelopthecapabilities required.Thetechniquefacilitateddelvingbeyondcommonlycited factors(e.g.,carbon-footprintdata)andformingvitalknowledgefor thefuture.

Potentialintervieweeswerechosenonthebasisoftheirsystematic workonsustainabilityandforhavingexpressedinterestindiscussing theutilizationofdataforenvironmentalsustainabilitywiththeirsuppliers.Prospectiveinterviewees(involvedinretailandprofessional sales)wereidentifiedincooperationwithMetsäTissue'svicepresidentsresponsibleforregionalsalesanditskey-account

Interviewee Roleatthe companyCompany'ssalestype

AManaging director

BSustainability manager

Professional(cleaning-and hygiene-productsupplier)

Professional(supplierofcleaning, hygiene,andofficeproducts)

CSustainability director Retail

DSalesdirectorProfessional(cleaning-and hygiene-productsupplier)

ESustainability director

Professional(officesupplier)

FSustainability director Retail

GSustainability manager

Professional(officesupplier)

H1a Sustainability manager Retail

H2a Sustainability specialist

Sameasabove aInformantsH1andH2,fromthesamecustomercompany,participatedin ajointinterview.

managers.Attentionwasgiventoinvolvingcustomersfromallsix regionswherethecompanydoesbusiness(Europeanmarkets),forelicitingviewsfrommultiplemarkets.Potentialintervieweeswerethen contactedbythecorrespondingkey-accountmanagers,andtheir interestinparticipatingwasconfirmed.Theindividualscontacted representedthecustomerentity'sbusiness-managementorsustainabilityfunction(thisdependedonthesizeofthecompany).Somecustomers,facingpressuresfrominflationandsupply-chaindisturbances atthetimeofthestudy,couldnotprioritizethetopicatthetimeof thestudy.Intheend,nineinformants,fromeightcustomercompanies,participatedintheinterviews.TheyarelistedinTable 1

Allextractsreproducedbelowarefromtheinterviewsheldwith customersinphase2(inApriltoMay2022),whichwereaudiorecordedandtranscribed(yieldingaround50,000wordsoftext).They werecarriedoutintheformofinteractiveMicrosoftTeamssessions adheringtoaprotocoldevelopedforpurposesofsystematicdatacollection.Toenhancecomparabilityfurther,oneoftheresearchersfacilitatedtheinterviews,encouragingparticipantstoexpresstheir thoughtsonthethreemainopenquestionsguidingtheconversation. Accordingly,theprocess,whichwascarriedoutineitherEnglishor Finnishandtook38–58minperinterview,focusedonthesecentral

FIGURE1 Atimelineoftheworkand itsphases. TABLE1 Theinformantsofthestudyandtheirroles.issues:(1)whichdriverswereshapingtheneedforanduseofdataat thecompanies;(2)whatkindofspecificdata,forwhatspecificneed, wasperceivedtobethemostvaluable;and(3)whatpotentialbusinessvaluesaiddatarepresented.

Inadditiontotheleadresearcher,oneortworepresentativesof MetsäTissuewerepresentforallinterviews:thecustomer'skeyaccountmanagerandasustainabilityspecialist.Theyweretherenot toparticipateactivelybuttohearthecustomer'sneedsandthoughts. Beforeallsessions,wemadethebackgroundandrationaleforthe interviewexplicitinrelationtoservingbothresearchinterestsand thecompany'seffortstoimproveintherelevantarea,andweassured theparticipantsofconfidentiality,togiveroomforopendialogalso addressingsensitiveissuesandpossiblycontroversialtopics.We madesuretoaddressanyquestionsorconcernstheinformantsmight havehadabouttheprocedureortheuseoftheresults.Ourdataset comprisesoneinterviewpercompany,withthemaindecision-maker whodealtwiththedemandsimposedonsuppliersforenvironmental sustainability.Foroneoftheinterviews,tworepresentativesofthe customerfirmwerepresent,andtheresthadoneinterviewee.

OurempiricalresearchemployedinductivelyorientedandcontentdrivendatastructuringandanalysisinformedbytheGioiamethodology(Gioiaetal., 2013;Magnani&Gioia, 2023).Aninductivemethod forsystematicallyanalyzingqualitativedatainamannerthatmaintainsopennesstodiscoveringnewconceptsandideas,itoffersthe furtherbenefitofenablingtheinformants'voicestofeatureprominentlyinthereportingontheresearch(Fontana, 2020;Fontana etal., 2021;Gioiaetal., 2013).Thistechniqueissuitedwelltoexploringtheconstructsandthemesassociatedwithdata'sperceivedvalue forenvironmentalsustainability,anditsupportsrichresultselucidatingtheconceptsidentifiedfromthedata.Asourresearchobjective wastoprobetheinterviewees'perceptionsaboutthevalueofdata, ourempiricaldatacorpuscontainsonlyprimarydatafromtheinterviewsconductedinphase2.Anyfurtherdatasources,likepublicly availablereports,werenotconsideredsincethecontentspresentedin thereareunfitforthisresearchproject.

Ourcodingandanalysisyieldednotadefinitivelistoraranking ofvalueattributesbutasetofexamplesthathighlightinterestingperceptionsgroundedinempiricaldatafromanevolvingfieldwherein severalkeyconceptsarestilltobedefined.Weusedfeaturesofthe MicrosoftOfficesuitethatfacilitatedataanalysisbyallowingthe wordingusedbytheinformantstoguidehowweorganizedand codedthedata.Thistoolsupportedtheteam'seasyiterationoverthe originaldata,therebyhelpingguaranteedeepinsightastothecharacteristicsofthedata.

Thefirststagebuiltondevelopingfirst-ordercodes(concepts) fromtheresearchdatawhilestayingrelativelyclosetotheoriginal material.Thesecondstageledtoprocessingtheseintosecond-order codes(themes)and,further,intoacoherentsetofaggregatedimensions.Forthefirst-ordercoding,thefullbodyofresearchdatawas

assessed,suchthatwecouldidentifyvalue-relatedaspectsbyusing opencodingthatreliedontheinformants'discourse.Here,one researcherperformedtheanalysis,andanothercheckedthecodingto verifythereliabilityoftheassessment.Similaraspectsthatemerged werecombinedtoconstitutethesetofconcepts,orfirst-ordercodes. Inthesecondphase,theresearchersstartedgroupingthosecodesby themeinaccordancewiththeirsimilaritiesbyiteratingbetweenthe first-ordercodesandtherawinterviewtranscripts;thisallowedusto identifythemesthatwerefirmlygroundedinthedata.Viaseveral iterations,asetofthemesdeveloped.Finally,thelatter,oursecondorderconstructs,wereorganizedintomoreabstractaggregatedimensionsusefulforexplainingthephenomenon.Forfullerunderstanding oftheperceivedvalueofdataforenvironmentalsustainability,we examinedtherelationshipsamongtheelementsidentifiedandconsultedtheliteraturetosupportfurtherreflectiononthefindings (Gioiaetal., 2013).Wecouldthenemploythisstructurefordescribing thefindingsindetailandstrengthentheresultingdescriptionwithfurtherquotesfromtheinformants.

Ourfindings,presentedbelowinlinewiththestructureoftheGioia analysisdepictedinFigure 2,shedlightonhowthestudy'sinformants perceivedthevalueofdataforenvironmentalsustainability.The viewsoftheinformantsrevealthatdata'sperceivedvalueforenvironmentalperformancehastwofundamentalelements:First,theintervieweescalledattentiontospecifictraitsofthedataandrelateddata managementrequired:availabilityofreliabledetail-levelproductspecificdataandincreasedtransparencyofproductvaluechains, coupledwiththeestablishmentofviablesystemsfordatamanagementandintegrationsolutionsthatsupportmanagingandsharingthe relateddata.Second,theyidentifiedvarioususesfordatathatshould encourageenvironment-associatedimprovements.Amongtheseuses arethecreationofaddedvalueforthecustomers'owncustomers (i.e.,thesecondtier)andforconsumers,contributiontobetterbusinessdecisions,andguaranteedcompliancewithregulations(also strengtheningstakeholdertrust).Thesectionsbelowexamineinformants'viewsofthesevariouselementsindetail.

Informantsstressedthecustomers'needfordetailedproduct-specific dataandincreasingtransparencyofthefullproductvaluechainsand theirenvironmentalimpacts.Whileasignificantportionofthevarious environmentalimpactsiscreatedoutsidethecustomer'sactivities,the customercompaniesare,toanincreasingextent,deemedresponsible forthevaluechainsintheirentirety.Suchdatawouldequipthemto

choosemoresustainableproductalternatives,setenvironmentrelatedpoliciesfortheirproductportfolio,complywithregulations thatareinthepipeline,andeducatetheirowncustomersinmoresustainablepurchasing.Therefore,theparticipantsneedaccesstocomprehensivedata,withfinergranularity,pertainingtotheproducts' materialsandtheiroriginespecially,asinformantF,aretailer'ssustainabilitydirector,noted: “Thereisaneedforincreasinglydetaileddata [ ]thescope,quantity,andthemesofdataareexpandingallthetime;all thetime,therearenewdatathatneedtobecollected. ” Forinstance, awarenessofthemanufacturingconditionscanrevealopportunities forenvironment-relatedimprovements.

Inthecaseofthetissue-papermarket,thetransparencyenvisionedwouldentailsomeabilitytotracethejourneyofthepaper fromtheforestandthemilltouse – andeventothesecondandthird cyclesintheproduct's “life,” whendoingsoisfeasible.Thissupports understandingtheproduct'ssustainabilityalongitsentirejourney. However,theinformantsrecognizedhowtrickyitistomakecomprehensiveproduct-specificdataavailable.Acknowledgingthechallenges,oneinformantpointedout, “Itismoreaboutstartingthe process[thanhaving100%correctnumbers].Juststartaskingandnudgingthenextlevelofcompanies[beforeyouinthechain]togatherthat data” (B,asustainabilitymanagerforacustomersellingto professionals).

Pertheinterviewees,thedataavailableforeachproductshould notbegeneraloraveragesbutthatproduct'sactualcontext-specific data,enablingcomparisonbetweendistinctproductsandfindingof sustainablealternatives.InformantC,workingasthesustainability directorforacustomercarryingoutretailsales,stressed, “Iwouldlike tohavedataontheproductandacomprehensiveview[of]itsvarious sustainabilityimpacts:theproductinthecenter,andthenithasdata attributes ” Morespecifically,theintervieweesexpressedadesirefor products'contentdetails,datarelatedtotheirorigin,andquantificationofenvironmentalimpacts.Relevantproduct-contentdatawould covertheproduct'smaterialsandcomposition(e.g.,anyrecycled material),correspondingdetailsforthepackaging,andeven “product recipes” revealingthechemicalsused.Theorigindatashouldidentify thesourcesofatleasttheproduct'smostcriticalmaterials,sothat issuessuchaspossiblebiodiversityriskscanbeidentified.Finally,the environmental-impactdatashouldaddresscarbonfootprintsatthe veryleast,buttheinformantsdetectincreasingfocusalsoon biodiversity-relateddata.Circular-economydatatooareofinterest, thoughtheywerenotemphasizedintheinterviews(therewasprobablyasenseoflimitedapplicabilityofcircularityinthetissue-paper domain).

Informantssoughtreliabilityandcomparabilityofproduct-specific andenvironment-relateddataboth,tosupportgreaterenvironmental sustainability.Incurrentconditions,thedata'sreliability,particularlyin thecaseofproduct-specificdetails,isseenasachallenge.Whilesome standardsforlife-cycleassessmentandmethodsofcalculatingcarbon footprintshavebeendeveloped,theproduct-relatedenvironmental dataavailabletodayaretypicallynotcomparable;thebackground assumptions,definitionofboundaries,andothervariationsrenderthe datapracticallyunusable.Informantsalsocitedaneedfor

transparencyofthedatasources(e.g.,clearstatementsofwhether thecalculationsappliedproduct-specificstandardizedimpactassessmentswithrealdataversusaveragedataforalargerproductgroup), andtheysawanincreasingneedforthirdpartiestoverifyand improvethequalityoftheenvironment-relateddata.

Theintervieweesstressedthatpracticaldata-managementsystems andintegrationmechanismsformanagingandsharingenvironmentrelatedproductandbusinessdataarerequiredforefficientcollection, management,anduseofdatatosupportenvironmentalsustainability. Theyconcludedthattheirrespectivecompanies'existingdatamanagementsystemsarenotsuitedtomanagingtheburgeoningvolumesofproduct-specificdataorservingsolidmanagementdecisions rootedinup-to-dateenvironment-relateddata.Theaim,asoneinformantdescribedit,shouldbe “thedata[comingoutof]thesystemwith thepushofabutton,suchasthefinancialdata,sothatwecouldcheck withthemanagementteamonceaquarterwherewearegoinginterms ofouremissiontargetsforthisyear” (H1,sustainabilitymanagerfora retail-salescustomer).Informantspointedoutthattheirproductmanagementsystemswerecreatedforpurposesverydifferentfrom workingwithsustainabilitydata;therefore,managingenvironmentrelateddatarequireslargeamountsofmanualeffort: “Itisveryprecise datathatisneeded,butourinformationsystemsdonotnecessarilysupportthatdata;[forthatreason]wehavetodoalotofmanualwork” (F, theretail-entitysustainabilitydirectorquotedabove).Theinformants articulatedaneedextendingbeyondtheircompany'sboundaries,for effortlesssharingofdataalongtheirsupplychains.InplaceofthecurrentpracticeinvolvingquestionnairesandExcelsheetssharedby e-mail,establishmentofjointdataplatformsandinterfacesbetween data-managementsystemswerecitedasopportunitiesforefficiently sharingofdata,decreasingtheduplicationofwork,andimprovingthe data'squality.

Informantssawthedatadescribedaboveasapromisingtoolfor respondingefficientlytotheirowncustomers'andtoconsumers' environment-relatedquestionsanddatarequests:consumers “keep askingmorequestionsanddemand[ ]transparency – theywantto knowwheretheproductscomefrom,whereandhowtheyaremanufacturedandunderwhatconditions,andhowtheenvironmenthasbeen takenintoaccount” (H1,speakingfromtheperspectiveofaretailcustomer'ssustainabilitymanager).Asthingsstand,addressingthese questionsandrequestsistime-consumingsincethedataarescattered acrossvarioussystems,mustbespecificallyrequestedfromsuppliers,

ormightnotbeavailableatall.Someinformantsstatedthat,rather thanrespondtotheserequestsonanadhocbasis,theymustproactivelypreparethemselvesforimpendingdataneeds.Forinstance, informantB(theprofessionalcustomer'ssustainabilitymanager) stated, “We'retryingtolookintoourcrystalballs,tryingtobelooking aheadandseethecustomerdemands[ ]sothatwhen[our]customers ask[for]somedata,wecansay, ‘Yes,wehavethat ’” Informantsalso sawthepowerofenvironment-relatedperformancedataforbringing relatedattributesintothesalesdiscussionswithsecond-tiercustomersalongsidepriceanddirectlybroadeningtheperspectivebehind consumers'purchasedecisions.Severalintervieweesclaimedtohave noticedashiftintheircustomers'focus,frompricetowardsustainability,andthatvendorsarebringingenvironmentaldatatothetable tosupportsalespitches:forinstance,theinformantquotedabove emphasizedthat “salesrepswouldlovenothaving[pricebe]theonly focusinacustomermeeting, ” stressingthat “wehaveothervaluesto bringtothetable ” E-commercewasrecognizedasenhancingthe opportunitiestobringenvironmentaldataintocustomers'andconsumers'decisionprocess.Itwasidentifiedequallyasapotential sourceofdataonconsumerbehavior/preferencesandasarouteto encouragingenvironment-friendlypurchasingpatterns.

Armedwithenvironmental-performance-relateddata,vendorscan alsobetterservetheircustomers'worktowardsustainability-basedbusinessgoals,suchasmeetingemission-andpackaging-relatedtargets. Oneinformantmentionedinfographicsasanespeciallyimpactfulwayto concretizehowmuchsingle-useplasticacustomercouldavoidby switchingtoamoresustainablealternative.Byactivelyidentifying, recommending,andprovidingsustainableproductalternatives,vendors canhelptheircustomersreducetheiremissionsandimprovetheir engagementwiththeenvironment.InformantBofferedtheexampleof “lookingtoacustomer'scompanymissionandsay[ing], ‘I'veseenthatyou haveagoalhere – youwanttoreducethis.IknowhowIcanhelpyouwith that ’” Thistiesinwiththepreviouspoint:grantingone'sowncustomers andtheendconsumersaccesstothedataissaidtopromotelearning thatfavorsmoreenvironmentallyinformeddecisions.Theinformants recognizedthemselvesasplayinganimportantroleineducatingtheir owncustomers,andtheyacknowledgedthatthemoreenvironmentally awarethosecustomersare,thebetterthedecisionsthatarelikelytofollow. “Ifthey[customers]haddataabouttheirhandtowelsortheirtoilet roll,andtheexactconsumptionandtheexactcarbonfootprintandanythingelsethatwouldreinforcethatdecision,Ionlythinkitcreatesamuch morecompellingargument,whichthenadecisionwillbemadefrom, ” statedinformantD(salesdirectorforaprofessional-salesentity).Via data,thewaytheythinkaboutproductsmightchange,andtheycould benudgedtowardmoresustainablepurchasingdecisions.

Additionally,theintervieweessawdataasvaluableforstrengtheningcredibilityincustomers'eyes.Datatransparencyincommunication withcustomersandendusersisperceivedasbuildingmutualtrustand helpingconvincebothestablishedandnewclients.Avendorthatprovidesenvironmentaldataforitsproductsandoperationsislikelytogain thestatusofatrustedadvisertoitscustomers.Also,customersdeeming anygivenvendorcommittedtoenvironmentalissueshingesonactive provisionofdata,asinformantAnoted: “Themorewecandemonstrate

topotentialclientsourenvironmentalcredibility,themorewecangrowour business” (managingdirector,professional-salescustomer).

Theparticipantsregardedavailabilityofreliableproduct-specificand otherenvironment-relateddataasabletodrivebetterbusinessdecisionsandtarget-settingrelatedtotheircompanies'environmental sustainability.Theyrecognizedsaiddataasnecessaryinputtoviable businesstargets(whetherforcarbonreductionorproduct-portfolio improvements)andtocompanypolicies(e.g.,onpackagingandrawmaterialpurchases).Thesedataarerequiredalsoforawell-reasoned foundationforinvestmentlogicandtoaidinassessingbusinessdecisions: “Decisionsmustbebasedondatasothatweknowwhattherelevantissuesareandwhatkindofstrictbutappropriategoalsweshould aimfor” (informantH1).

Inaddition,dataaidinsteeringtheworktowardtheenvironmentaltargetssetandsupporttrackingofprogress.Measuringhowwell thetargetsaremetandreportingtothemanagementonthecompany'senvironmentalperformancecallsforreadilyavailable,up-todate,andverifiableenvironment-relateddata.Informantsexplained thatdataarecrucialforgenuinelyguidingbusinessactivitiestoward thetargetsand,furthermore,enablingleaderstomakeachangeof coursewhenneeded.IntervieweeH1providedanillustrationhere too: “Wehavescience-basedclimategoalsandacarbon-neutralitytarget year,sodataisessentialsothatwecanmonitorandseewhereweare going[ ].Ifwedon'thavedata,orifweonlygetdataonceayear,it's verydifficulttoleadthatworkintherightdirection ”

Datathataregenuinelyproduct-specificandclearlyconnectedto environmentfactorsalsoassistinenrichingunderstandingofthe company'ssupplychains,andtheinformantsidentifiedsupply-chain transparencyasanincreasinglyimportanttopic.Commitment toscience-basedclimatetargets,forexample,obligescompaniesto makesuretheirsuppliersarecommittedtoclimate-relatedimprovements.Theysawdataasdemonstrablyenablingnotonlybetterrisk managementbutalsoidentificationofimprovementandcollaboration opportunitiesinthesupplychains: “Whenwehavebetterdataonwhat kindofpartnerAisinrelationtopartnerB,thenwecouldmoveforward withthatpartner,A,becauseithastriedtodothingsbetter” (C,the aforementionedsustainabilitydirectorforaretailcustomer).

Datamayalsosupportcompany-internalinnovationandlearning. Someinformantscitedthisfacetoftheirapproachtosustainabilityas especiallyimportant.Theydidnotspecifywhatinnovationemerging viathedatamightlooklike,however,andtheynotedthatbuildingon thedataishardestforpioneers.

Participantsreadilyacknowledgedenvironment-relateddata'svalue forsupportingtheirabilitytorespondtoregulatoryrequirements,

helpingthemtocomplymoreeasilywithstricterrequirementsfor datacollectionandreporting.Inthemarketswheretheoperationsof theinformants'companieswereconcentrated,EUregulationisimpellingever-increasingrequirementsforproduct-andenvironmentrelateddata: “It'sahugeregulatorytsunami[fromtheEU]andtheneed fornewdataandreporting” (informantF).AmongthetopicalregulatoryinstrumentsmentionedarethenewCorporateSocialResponsibilityDirective,expandingthereportingrequirements;theproposed directiveoncorporate-sustainabilityduediligence,callingforcompaniestotakeresponsibilityfortheirglobalvaluechains;andacirculareconomypackagetighteningtherestrictionsappliedtoenvironmental claims,tolimitgreenwashing.

Theinformantssawhigh-qualitydataasalsoaffordingacoherent andcrediblepictureofthecompany'senvironmentalperformance.At listedcompaniesespecially,gainingthetrustofinvestorsdemands this: “Idon'tseeitaspossibletogetveryfarbyrepeatingsetphrases [relatedtothecompany'senvironmentalperformance].Thedatareally needtobeoutthereforinvestorstoo,sothattheybelievethatyourstory iscoherentandcredible” (H1).Partofthecommunicationwithinvestorsisparticipationinthird-partysystemsforratingcorporateresponsibilityperformance,suchasEcoVadis's.Thistoocallsfor extensiveprovisionofdata.

Insum,theintervieweesperceivedenvironment-relateddataof consistentlyhighqualityashelpingconcretizethingsandavoid greenwashinginsustainabilitycommunications.Dataattesttothe legitimacyofwhatthecompanyissayingandarenecessaryfor avoidingamarketfloodedwithgreenwashing: “ It'sgoodtohave somereallygoodstrongdatasothatpeoplecanseeit'snotgreenwashing ” (A,fromtheperspectiveofamanagingdirector).Informants recognizedaneedfordigestible,simplecustomer-facingcommunicationaboutdatathatmaintainsafocusedmessage: “ Whenyouget specificwithpeople'sexactusage,thenthat'swhenitbecomesreally powerful ” (D,thesalesdirectorquotedabove).Notonlycustomers butalsoemployeesaskforconcreteexamplesofwhatthecompany hasdonefortheenvironment(forexample,howmuchplasticwaste hasbeenavoided).Inaddition,someinformantslistedattractingtalentasanotherpotentialsourceofvaluecultivatedviathedata: “ Employeesalsostarttoexpectacertainlevelfromtheiremployer, suchthattheytooneedtogetdatatoprovethat – notjustsentences likewhatisbeingdonebutthekindofdatathatmakesthembelieve thatweareactuallydoingthings ” (H2,asustainabilityspecialistwith aretail-salescustomer).Inaddition,datacanexertaneffectonpublicopinion.Thisdovetailswiththefindingsrelatedtodata'spower todrivelearning.Oneinformantstressedtheimportanceofbringingtherightinformationtothepublicsothat,forinstance,old assumptionscanbedismantled.

Whenaskedaboutthemonetaryvalueofdatasupportiveofenvironmentalsustainability,theinformantswereunabletoquantify it.Thistypeofdatawasaddressedsimplyinqualitativeterms,asthe futureofthebusiness,crucialforbusinessgoals,keytocreatingnew clientrelationships,andthedifferencebetweengainingandlosing business.

Theprojectparticipantsfoundthatsuccessfullysupportingbusinesses'environmentalsustainabilitynecessitatesmeetingseveralconditionsrelatedtothecontentandreliabilityofdataandhowthedata aremanagedandshared.Thepresenceofthesecharacteristics enablesutilizingthedatainawiderangeofdecisionsand activities – inthebusinessitself,initsvaluechains,andamong stakeholders – thatsupportenvironmental-consideration-based choicesandoperationsthatentailimprovements.Thespectrum extendsfromintroducingenvironment-linkedattributesforpurchasingchoicestotrackingprogresstowardsetenvironmentaltargets.We canconnecttheseelementstotwolevelsinthehierarchyofperceivedcustomervaluethatWoodruff(1997)identifiesasessential whencustomersareassessingthevalueofproducts:thecharacteristics,whichhecalls “attributesandattributeperformances,” andthe usesofdata,whichhedescribesas “desiredconsequencesinusesituations.” Whilethathierarchywasdevelopedprimarilywithregardto products,ourfindingsindicatethatitmesheswellalsowithassessing thevalueofdataforcustomers.