PAPER making!

The e-magazine for the Fibrous Forest Products Sector

Produced by: The Paper Industry Technical Association

Publishers of: Paper Technology International®

Volume 10, Number 1, 2024

CONTENTS:

FEATURE ARTICLES:

1. Corrugated: Deciphering Double-Walled Corrugated Board Geometry.

2. Tissue: Eco-friendly Sanitary Napkins made from Natural Fibres.

3. Chemistry: Spherical Polyelectrolyte Brushes as Flocculants and Retention Aids.

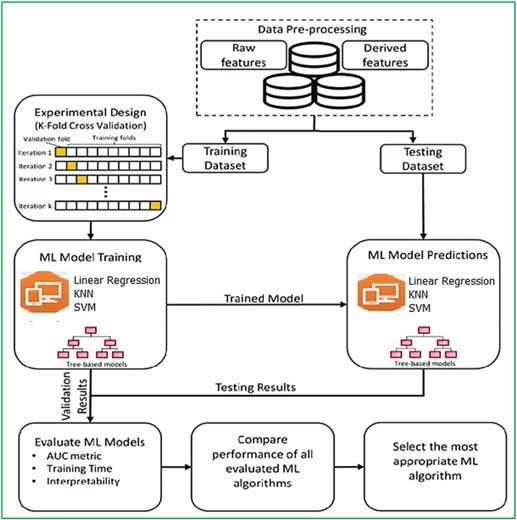

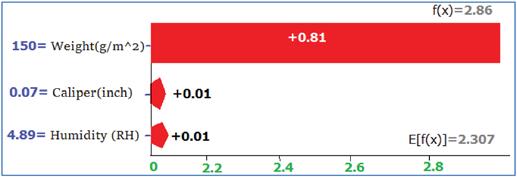

4. Artificial Intelligence: Paper Quality Enhancement using Machine Learning.

5. Water Treatment: Catalytic Ozonation for Pulp / Paper Mill Wastewater Treatment.

6. Sustainabililty: Sustainable Operations in Paper and Pulp Industry.

7. Wood Panel: Challenges for Recycling Medium-Density Fibreboard (MDF).

8. Packaging: Evaluating Hemp Bast Fibres in the Production of Packaging Paper.

9. LinkedIn Tips: 10 Time-Saving and Effective LinkedIn Hacks.

10. Packing a Suitcase: 12 Proven Packing Tips for Smarter and Lighter Packing.

11. Word Hacks: 6 Microsoft Word Hacks You Need to Know in 2024.

12. Working at Height: 10 Working at Height Tips that might Save a Life.

SUPPLIERS NEWS SECTION:

News / Products / Services:

Section 1 – PITA CORPORATE MEMBERS

ABB / KEMIRA / VALMET

Section 2 – PITA NON-CORPORATE MEMBERS

VOITH

Section 3 – NON-PITA SUPPLIER MEMBERS

PULPAC / TOSCOTEC

Advertisers: ABB / BLACKBURN CHEMICALS / PAPERMACHINE CONSULTANCY SERVICES LTD. / SPRAYING SYSTEMS / VAKUO / VALMET

DATA COMPILATION:

Events: PITA Courses & International Conferences / Exhibitions

Installations: Overview of equipment orders and installations between Nov. and Feb.

Research Articles: Recent peer-reviewed articles from the technical paper press.

Technical Abstracts: Recent peer-reviewed articles from the general scientific press.

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review , both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

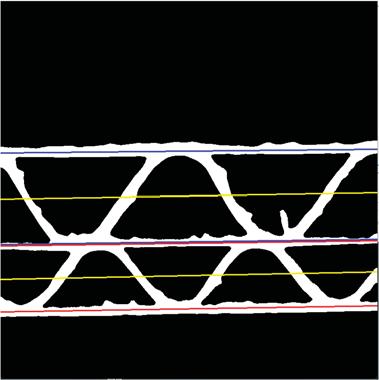

Deciphering Double-Walled Corrugated Board Geometry Using Image Analysis and Genetic Algorithm

MACIEJ ROGALKA1, JAKUB KRZYSZTOF GRABSKI1 & TOMASZ GARBOWSKI2Corrugated board, widely used in the packing industry, is a recyclable and durable material. Its strength and cushioning, influenced by geometry, environmental conditions like humidity and temperature, and paper quality, make it versatile. Double-walled (or five-ply) corrugated board, comprising two flutes and three liners, enhances these properties. This study introduces a novel approach to analyze 5-layered corrugated board, extending a previously published algorithm for single-walled boards. Our method focuses on measuring layer and overall board thickness, flute height, and center lines of each layer. Integrating image processing and genetic algorithms, the research successfully developed an algorithm for precise geometric feature identification of double-walled boards. Images were recorded using a special device with a sophisticated camera and image sensor for detailed corrugated board cross-sections. Demonstrating high accuracy, the method faced limitations only with very deformed or damaged samples. This research contributes significantly to quality control in the packaging industry and paves the way for further automated material analysis using advanced machine learning and image sensors. It emphasizes the importance of sample quality and suggests areas for algorithm refinement to enhance robustness and accuracy.

Contact information:

1 Institute of Applied Mechanics, Poznan University of Technology, Jana Pawla II 24, 60-965 Poznań, Poland

2 Department of Biosystems Engineering, Poznan University of Life Sciences, Wojska Polskiego 50, 60-627 Poznań, Poland

Preprints.org (www.preprints.org) – not peer-reviewed.

doi: 10.20944/preprints202401.1721.v1

Creative Commons CC BY License,

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

Improvements to Eco-Friendly Sanitary Napkins made from Natural Fibres: Development and Characterization

M. MAHALAKSHMIA & V. MAHESHWARI

Three sanitary napkin types produced from natural fibers were put through a rigorous evaluation process to determine their performance attributes in this study. In order to give a thorough understanding of their absorbency, retention, rewet resistance, and leakage prevention capabilities, these napkins had different core compositions and top layers. The outcomes showed that although all the variations had different advantages and disadvantages, Sample S3, which had a bamboo-flax-hemp core, was the best performer. It had remarkable absorbency and retention, even though it slightly rewet under load. Sample S1 excelled in absorbency and dryness, while Sample S2 showed balanced performance. These results highlight the significance of customizing the composition of sanitary napkins to individual user preferences while maintaining an environmentally and biodegradably sound framework. Textiles play an essential role in assisting women in their struggle against numerous barriers. Women's health and hygiene are supported by absorbent hygiene, an essential type of medical textiles, particularly during the menstrual cycle, which presents several challenges for women. In order to make sanitary napkins more affordable, this research focuses on changing natural fibres to make them appropriate for use in them. This aids in breaking into the rural women's market, assisting the women in adapting to the physiological changes occurring during these vulnerable days, allowing them to make their vitalizing contributions to society with greater flair.

Contact information:

Department of Costume Design and Fashion, PSG College of Arts and Science, Coimbatore, Tamil Nadu, India.

Migration Letters, Volume: 21, No: S1 (2024), pp. 1053-1059

Open Source

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

Volume: 21, No: S1 (2024), pp. 1053-1059

ISSN: 1741-8984 (Print) ISSN: 1741-8992 (Online)

www.migrationletters.com

Improvements to Eco-Friendly Sanitary Napkins made from Natural Fibres: Development and Characterization

M. Mahalakshmia1, V. Maheshwari2

Abstract:

Three sanitary napkin types produced from natural fibers were put through a rigorous evaluation process to determine their performance attributes in this study. In order to give a thorough understanding of their absorbency, retention, rewet resistance, and leakage prevention capabilities, these napkins had different core compositions and top layers. The outcomes showed that although all the variations had different advantages and disadvantages, Sample S3, which had a bamboo-flax-hemp core, was the best performer. It had remarkable absorbency and retention, even though it slightly rewet under load. Sample S1 excelled in absorbency and dryness, while Sample S2 showed balanced performance. These results highlight the significance of customizing the composition of sanitary napkins to individual user preferences while maintaining an environmentally and biodegradably sound framework. Textiles play an essential role in assisting women in their struggle against numerous barriers. Women's health and hygiene are supported by absorbent hygiene, an essential type of medical textiles, particularly during the menstrual cycle, which presents several challenges for women. In order to make sanitary napkins more affordable, this research focuses on changing natural fibres to make them appropriate for use in them. This aids in breaking into the rural women's market, assisting the women in adapting to the physiological changes occurring during these vulnerable days, allowing them to make their vitalizing contributions to society with greater flair.

Keywords: bamboo, flax, hemp, eco-friendly, hygienic, sanitary napkins, Super absorbent polymer.

1. Introduction:

This study on improving the eco-friendliness of this disposable sanitary product was initiated because to the increased consumer awareness of environmental friendliness and the need for disposable goods to maintain a healthy atmosphere. The prepared sanitary napkins are made up of an absorbent core, a super absorbent polymer, and a leak-proof substance, all of which are enclosed in cover stock [1].

People now expect more from textiles in terms of providing this sanitary functionality as consumer awareness of hygienic lifestyles grows. Research in the textile and garment industries has been heavily focused on developing novel fibres, textiles, finishes, and apparel items that will provide the wearer with this level of comfort. There are several synthetic commercial items on the market. But safer raw materials that can provide our fabrics with a wide range of applications are now flooding the market in an

1 Department of Costume Design and Fashion, PSG College of Arts and Science, Coimbatore, Tamil Nadu, India.

2 Department of Costume Design and Fashion, PSG College of Arts and Science, Coimbatore, Tamil Nadu, India.

effort to meet the demands of sustainability and eco-friendliness on a global scale [2-4]. The revival of interest in products made from renewable resources is a result of ecological concerns. Natural fibres, agro-waste fibers and biodegradable polymers might be thought of as an environmentally safe option because of this [5]. All natural fibres and agro-waste fibers are low density, less harmful to technology used for processing them, economically viable, and biodegradable [6].

A unique aspect of female development is the use of sanitary napkins during the menstrual cycle, when a woman's body is most vulnerable and she needs to take the necessary safety steps to protect herself. A wear study conducted to assess the comfort of sanitary napkins revealed that a highly humid microclimate developed in the area between the napkin and the skin, which led to subjective pain. Inconvenience related to sultriness was reported by more than 60% of the individuals [7]. This discomfort is brought on by the increase in temperature inside the napkins, and adults who use diapers have also reported feeling it [8].

Due to the fact that vaginal bacteria like Candida albicans thrive in warm, moist environments and cause infections, women become more vulnerable to vulvo-vaginal infections as a result. A free flow of water vapor could lessen the pain caused by napkins [9]. The vulva region, which is made up of epithelial tissues, surrounds the vaginal opening. This tissue's structure, occlusion, moisture, and susceptibility to friction set it apart from other bodily parts. The vulva, like other epithelial tissues, defends the vagina from hazardous bacteria through the use of defense cells. However, inadequate ventilation, heated settings, and minor wounds brought on by friction between clothing and skin encourage the growth of microorganisms. This worsens if the user wears underwear, pantyliners, or sanitary napkins made of synthetic materials, which raise the temperature and pH of the vulva region and lead to a variety of skin infections that manifest as itchiness, soreness, redness, and swelling in the vaginal area [10]. The polypropylene (PP) spunbond nonwoven is used as the outer cover material for the majority of sanitary napkins, which are the absorbent pads worn externally by women during menstruation to absorb the menstrual flow [11]. This outer cover stock is better suited for sanitary napkins because it is in close contact with the skin of the vulva region [12]. This article discusses the various styles of sanitary napkins that have been produced from a variety of raw materials that have been improved and developed through earlier research.

2. Materials and Methods

2.1 Methods for Preparation of Sanitary Napkins from Natural Fibres

2.1.1 Assembly of sanitary napkins with prepared absorbent core layer

Absorbent core - 25 cm in length and 7.5 cm in width

Leak proof polyethylene sheet - 25 cm in length and 7.5 cm in width

+ (2 * Thickness of prepared absorbent core)

Cover stock polypropylene sheet - length-27 cm and width-18 cm

Polypropylene sheet was used to cover the absorbent core and leak-proof polyethylene sheet at the bottom. They are joined by a seal. The sanitary napkin is subsequently manufactured and sealed.

2.1.2 Top Layer

The top layer is made entirely of spun bamboo, which is hypoallergenic, soft, and biodegradable, by nature. A non-woven fabric with a web-like structure is produced by the spun lacing process, offering a soft and smooth surface.

1054 Improvements to Eco-Friendly Sanitary Napkins made from Natural Fibres: Development and Characterization2.1.3 Middle Layer

Super Absorbent Polymer (SAP) is a highly absorbent material that can hold many times its weight in liquid in the middle layer (B). Menstrual fluids can be quickly absorbed and retained with the help of sanitary napkins.

2.1.4 Core Layer

Bamboo Fiber: Gives the inner layer comfort and softness.

Flax Fiber: Provides the core with extra strength and absorbency.

Hemp Fiber: Boosts the absorbency of the core and adds to its environmental friendliness.

2.2. Testing methods for sanitary napkins

Table 1 lists the tests that were done to gauge sanitary napkin performance.

Table 1 Tests carried out to gauge sanitary serviette performance qualities

S.No. Performance Properties To Be Tested Testing Standards Remarks

1 Absorbency% IS:5405-1980 A-1.2

2 Retention% IS: 5405-1980 5.1

3 Rewet under load Modified IS: 5405-1980 5.1

4 Leak Factor Modified IS: 5405-1980 5.1

5 Fibre Absorbency

These tests were done in 2 ways:

1. In-house method

2. performance tester method

MA001-1-diapersworldwide.com

2.2.1 Absorbency test for sanitary napkins

A burette, a glass plate, a sample stand, a weighing device, a stopwatch, goat blood with anticoagulant, or test fluid—both of which represented menstrual blood—were used in this experiment. After the napkin's dry weight (IN) was determined, it was set on a level, flat glass plate so that its underside could be observed. Liquid was dripped onto the centre of a sanitary napkin at a rate of 15 ml per minute at a height of approximately 1-2 mm away from the burette. The sanitary napkin's capability to absorb liquid was tested until it reached its limit and started to leak (as seen by the pad leaking on the sides), at which point it lost its ability to absorb liquid. The amount of liquid absorbed up to the end point was measured in millilitres (ml) and the values were tabulated based on the burette readings.

The absorbency percent of the sanitary napkin was determined by measuring its capacity to absorb blood up until the point of leakage.

The absorbency% was calculated using the formula:

Absorbency% = ((FA-IN)/ (IN))*100

IN - Initial weight of the whole napkin

FA - Final weight of napkin

2.2.2 Retention%, leak factor and rewet under load

Menstrual blood with an anticoagulant or test fluid, which approximated menstrual blood, a burette, a glass plate, a stand to hold the sample, one kilogramme of weight, blotting

paper, a weighing machine, and a stopwatch were needed for this test. Blotting papers with known beginning weights were inserted on top and bottom of the pad, respectively, after weighing the sanitary napkin and identifying the leak's position. A standard weight of 1 kg was placed across this fluid-absorbed area for 1 minute. At the end of the loading time, the top and bottom of the pad are taken out in order to calculate the ultimate weight of the serviette and blotting sheets.The retention percentage measured how much blood the sanitary napkin could hold after absorbing it when 1 kg of weight was applied.

The retention% was calculated using the formula:

Retention% = ((FR-IN)/ (IN))*100

Where IN- napkin Initial weight

FR- napkin final weight

The sanitary napkin's ability to contain absorbed blood from its sides and bottom when one kilogramme of weight is applied is known as the leak factor. The leak factor was calculated using the formula:

Leak factor% = ((FTB-ITB)/ (ITB))*100

Where ITB- top blotting paper Initial weight

FTB- top blotting paper Final weight

The rewet under load is the ability of the sanitary napkin to resist leaking of the absorbed blood from the top of the sanitary napkin on application of 1 Kg weight. The Rewet under load was calculated using the formula:

Rewet under load% = ((FBB-IBB)/ (ITB))*100

Where IBB- bottom blotting paper Initial weight

FBB- bottom blotting paper Final weight

2.2.3 Techniques for evaluating the performance of the sanitary napkins in the made-up performance tester

A performance tester, test fluid, and a stop clock were used to conduct the testing. The aforementioned procedures were followed in order to utilise the fictitious performance tester. The integrated load cell made it unnecessary to take out the sanitary napkins from the apparatus each time the weight of the apparatus needed to be measured, making the process easier and more precise than with the previously mentioned internal approach.

Initially, the load cell controller is nullified to guarantee the accurate measurement. The exact centering of the burette was confirmed. The glass plate was placed on top of the sample sanitary napkin. The liquid was released from the burette at a rate of 15 drops per minute, with a distance of 1 to 2 millimetres from the sanitary napkin. Furthermore, there is a reservoir that will provide the liquid to the burette during the testing procedure, removing the need to empty the burette and add more liquid. The electronic weighing balance will show the weight of the sample. The stop clock was configured to run each time the time component required to be measured and reported. The weighing lever was skewed inward to the top of the napkin's centre, and the liquid reservoir holder was turned sideways to measure the fluid retention capacity. The sanitary napkin's rewet under load and leak factor might be measured by placing blotting paper over and below it before adding weight. To calculate weight, sanitary napkins and blotting sheets were weighed separately before being placed on the base plate. The sanitary napkin's performances were computed.

1056 Improvements to Eco-Friendly Sanitary Napkins made from Natural Fibres: Development and Characterization2.3 Performance tests for sanitary napkins developed from the natural fibres

The performance of sanitary napkins made from natural fibers was evaluated using the fabricated performance tester and tested according to the tests listed in Table 2.

Table 2 Dimensional and performance characteristics done for the developed sanitary napkins

Experiment Standard

Strike through rate

STN2: 138/90

Absorbency% IS:5405-1980 A-1.2

Retention% IS: 5405-1980 5.1

Rewet under load

Leak Factor

3. Results and Discussion

Modified IS: 5405-1980 5.1

Modified IS: 5405-1980 5.1

3.1 Varieties of Sanitary Napkins made from the natural fibres

Table 3 Varieties of Sanitary Napkins

Tables 3 and 4, respectively, provide information on the different sanitary napkins manufactured with different natural fibers as well as the results of their performance analysis. The information supplied shows the extent of spread of goat blood for three distinct samples (S1, S2, and S3), each of which represents distinct properties of absorbent materials, as well as the absorbency, retention, rewet under load, strike-through rate, and leak factor. Sample S3 is the best of all the napkin samples because of its good absorbency, retention, and leak factor—even though it rewets under load more than the other samples.

With an absorbency percentage of 142.48%, Sample S1 exhibits good absorbency and can hold a significant volume of fluid. In addition, it has a high retention percentage of 138.65%, which indicates that the majority of the liquid that is absorbed is retained.

Interestingly, S1 does not rewet under load, indicating that it keeps its dryness under pressure. Its relatively high leak factor of 2 could, however, suggest that it is less successful in keeping liquid from passing through. The 14 second strike-through rate suggests that it absorbs quickly. Goat blood has spread quite a bit, measuring 55 mm in length and 40 mm in width, which suggests good coverage.

In spite having lower retention and absorbency percentages than sample S1, sample S2 still performs well. It shows some wetness under pressure with a minor rewet under load of 0.71. Effective liquid containment is suggested by the low leak factor of 0. The comparatively quick absorption is indicated by the strike-through rate of 5.99 seconds. Goat blood has spread less widely than S1, measuring 35 mm in length and 30 mm in width.

Sample S3 exhibits superior fluid absorption and retention capacity, as evidenced by its highest absorbency and retention percentages. Its notable rewet under 6.9 load, however, could compromise its dryness under pressure. At 0.65, the leak factor is comparatively low. An acceptable absorption speed is indicated by the strike-through rate of 8.78 seconds. With measurements of 50 mm in length and 45 mm in width, the goat blood spread is likewise significant, indicating good coverage.

As a result of their various strengths and weaknesses, these samples are suitable for a variety of applications depending on the particular requirements of absorbency, retention, rewet resistance, and leakage prevention.

4. Conclusion

Three different types of sanitary napkins made of natural fibers, each with specific performance characteristics, were thoroughly analyzed in the study. A number of standards, such as absorbency, retention, rewet under load, leak factor, strike-through rate, and the degree of goat blood spread, were carefully examined in order to evaluate these sanitary napkins. Important information about the effectiveness of these environmentally friendly and biodegradable menstrual products was provided by the results. With an absorbency percentage of 142.48%, Sample S1, which was made up of a core layer made of a blend of bamboo and flax and a top layer spunlaced entirely of bamboo, showed excellent absorbency, with a retention percentage of 138.65%, it effectively held onto liquid, and when under load, it showed no signs of rewetting, demonstrating its resilience to pressure. S1, which comparatively high leak factor of 2, indicating that there is still potential for improvement in stopping liquid seepage. At 14 seconds, the strike-through rate was rapid and the spread of goat blood was wide.

In comparison to Sample S1, Sample S2, which had a core layer made of a bamboo-hemp blend, showed slightly less absorbency and retention. It performed well with a leak factor of 0, ensuring efficient liquid containment, but it also displayed a low rewet under load of 0.71, indicating some wetness under pressure. The rate of strike-through was 5.99 seconds, and the spread of goat blood was marginally smaller than S1. With the highest absorbency and retention rates out of the three samples, Sample S3 remained out as the top performer. It was exceptional at absorbing and holding onto fluids. Its notable rewet under 6.9 load,

however, may have an impact on its dryness under pressure. With a leak factor of 0.65, it was evident that liquid leakage was effectively prevented. Goat blood was widely dispersed, and the strike-through rate was 8.78 seconds.

The study's conclusions imply that sanitary napkins' performance can be greatly impacted by the type of natural fibers used in their development. The bamboo-flax-hemp core of Sample S3 showed excellent absorbency and retention, but it also had a minor rewet resistance issue. Sample S2, which combined hemp and bamboo, showed balanced performance traits. With a bamboo-flax core, Sample S1 was the most absorbent and driest, but its ability to prevent leaks could be strengthened. Because of these differences in performance, these sanitary napkins can be used for a variety of purposes. Women can select products that meet their unique needs, whether they are for absorbency, dryness, or leak prevention, and they are also biodegradable and environmentally friendly. This research opens the door for environmentally friendly sanitary napkin alternatives that put performance and sustainability.

References:

J. Saranya, C. Prakash, and S. Kubera Sampath Kumar, “Menstrual Hygiene Practices among Adolescent Girls”, International Journal of Innovative Technology and Exploring Engineering, vol. 8, no. 12, pp. 364-366, 2019.

M.P. Sathianarayanan, N.V. Bhat, S.S. Kokate, and V.E. Walunj, “Antibacterial finish for cotton fabric from herbal products”, Indian Journal of Fibre and Textile Research, vol. 35, no. 1, pp. 5058, 2010.

T.M. Choi, and T.E. Cheng, “Sustainable Fashion Supply Chain Management”, New York; Springer: 2015, pp. 15-25.

Y. Song, Q. Zheng, and C. Liu, “Green biocomposites from wheat gluten and hydroxyethyl cellulose: processing and properties”, Industrial Crops and Products, vol. 28, no. 1, pp. 56-62, 2008.

H.D. Rozman, K.R. Ahmadhilmi, and A. Abubakar, “Polyurethane (PU)-oil palm empty fruit bunch (EFB) composites: the effect of EFBG reinforcement in mat form and isocyanate treatment on the mechanical properties”, Polymer Testing, vol. 23, no. 5, pp. 559-565, 2004.

Y. Habibi, W.K. El-Zawawy, M.M. Ibrahim, and A. Dufresne, “Processing and characterization of reinforced polyethylene composites made with lignocellulosic fibres from Egyptian agroindustrial residues”, Composites Science and Technology, vol. 68, no. 7, pp. 1877-1885, 2008.

A.M.Z. Jukic, C.R. Weinberg, D.D. Baird, P.P. Hornsby, and A.J. Wilcox, “Measuring menstrual discomfort: a comparison of interview and diary data”, Epidemiology, vol. 19, no. 6, pp. 846850, 2008.

W. Audra, and A. Frank, “Comfort Perception of Breathable and Nonbreathable Diapers”, International Nonwovens Journal, vol. 14, no. 3, pp. 19-22, 2005.

I. Parkova, & A. Vilumsone, “Microclimate of Smart Garment”, Material Science, vol. 6, pp. 99103, 2011.

G.B. Marcela, G.G. Paulo, and L.B.P. Cristina, “Association of sanitary pads and clothing with Vulvo vaginitis”, Jornal Brasileiro De Doenças Sexualmente Transmissiveis, vol. 25, no. 3, pp. 123-127, 2013.

H.S. Mohapatra, A. Chatterjee, and P. Kumar, “New Generation Application of Polypropylene”, International Journal of Advanced Engineering and Nano Technology, vol. 1, no. 1, pp. 1-9, 2013.

G.M. Ingo, and S. Scarlet. 1987. Copper-Modified Carboxyalkyl-cellulose Fiber. US Patent US4637820A, filed March 4, 1987, and issued March 4, 2005.

Spherical Polyelectrolyte Brushes as Flocculants and Retention Aids in WetEnd Papermaking

NA SUAs the criteria of energy conservation, emission reduction, and environmental protection become more important, and with the development of wet-end papermaking, developing excellent retention aids is of great significance. Spherical polyelectrolyte brushes (SPBs) bearing polyelectrolyte chains grafted densely to the surface of core particle have the potential to be novel retention aids in wet-end papermaking not only because of their spherical structure, but also due to controllable grafting density and molecular weight. Such characteristics are crucial in order to design multi-functional retention aids in sophisticated papermaking systems. This review presents some important recent advances with respect to retention aids, including singlecomponent system and dual-component systems. Then, basic theory in papermaking is also briefly reviewed. Based on these advances, it emphatically describes spherical polyelectrolyte brushes, focused on their preparation methods, characterization, conformation, and applications in papermaking. This work is expected to contribute to improve a comprehensive understanding on the composition, properties, and function mechanisms of retention aids, which helps in the further investigation on the design of novel retention aids with excellent performance.

Contact information:

Department of Printing and Packaging Engineering, Shanghai Publishing and Printing College, Shanghai 200093, China;.

Molecules 2023, 28, 7984.

https://doi.org/10.3390/molecules28247984

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

molecules

Review

SphericalPolyelectrolyteBrushesasFlocculantsandRetention AidsinWet-EndPapermaking

NaSu

Citation: Su,N.Spherical PolyelectrolyteBrushesas FlocculantsandRetentionAidsin Wet-EndPapermaking. Molecules 2023, 28,7984.https://doi.org/ 10.3390/molecules28247984

AcademicEditor:Ecaterina

StelaDragan

Received:6November2023

Revised:2December2023

Accepted:5December2023

Published:7December2023

Copyright: ©2023bytheauthor. LicenseeMDPI,Basel,Switzerland. Thisarticleisanopenaccessarticle distributedunderthetermsand conditionsoftheCreativeCommons Attribution(CCBY)license(https:// creativecommons.org/licenses/by/ 4.0/).

DepartmentofPrintingandPackagingEngineering,ShanghaiPublishingandPrintingCollege, Shanghai200093,China;suna@whu.edu.cn

Abstract: Asthecriteriaofenergyconservation,emissionreduction,andenvironmentalprotection becomemoreimportant,andwiththedevelopmentofwet-endpapermaking,developingexcellent retentionaidsisofgreatsignificance.Sphericalpolyelectrolytebrushes(SPBs)bearingpolyelectrolyte chainsgrafteddenselytothesurfaceofcoreparticlehavethepotentialtobenovelretentionaidsin wet-endpapermakingnotonlybecauseoftheirsphericalstructure,butalsoduetocontrollablegraftingdensityandmolecularweight.Suchcharacteristicsarecrucialinordertodesignmulti-functional retentionaidsinsophisticatedpapermakingsystems.Thisreviewpresentssomeimportantrecent advanceswithrespecttoretentionaids,includingsingle-componentsystemanddual-component systems.Then,basictheoryinpapermakingisalsobrieflyreviewed.Basedontheseadvances, itemphaticallydescribessphericalpolyelectrolytebrushes,focusedontheirpreparationmethods, characterization,conformation,andapplicationsinpapermaking.Thisworkisexpectedtocontribute toimproveacomprehensiveunderstandingonthecomposition,properties,andfunctionmechanisms ofretentionaids,whichhelpsinthefurtherinvestigationonthedesignofnovelretentionaidswith excellentperformance.

Keywords: sphericalpolyelectrolytebrushes;flocculation;retentionaids;wet-endpapermaking

1.Introduction

Thewet-endofpapermakingisaverycomplexsystem,wherepaperstockisasuspensionbasedonfiberswithwaterasthemedium.Thecomponentsofpaperstockare relativelycomplex[1],mainlyincludingthefollowingcomponents:(a)Fibers.Based onthesourceofrawmaterials,thesecanbedividedintowoodpulp,reedpulp,straw pulp,etc.Thechemicalcomponentsmainlyincludecellulose,hemicellulose,andlignin. (b)Granularfillers.Theseconsistofinorganicfillerssuchasgroundcalciumcarbonate (GCC),precipitatedcalciumcarbonate(PCC),kaolinite,talcpowder,titaniumdioxide, etc.,andorganicpolymerfillerssuchaspolyethylenefillers,fiberfillers,etc.Thefiller particlesizeisgenerallylessthan10 μm[2].(c)Variousadditives.Thesecanbedivided intotwocategories[3]:processadditivesandfunctionaladditives.Theformerincludes retentionaids,filteraids,defoamers,fungicides,etc.,withafocusonimprovingeconomic benefits[4,5].Thelatterismainlydesignedtoimprovetheend-usepropertiesofpapers, involvingsizingagents[6],drystrengthagents[7],wetstrengthagents,whiteningagents, etc.(d)Solubleinorganicsaltsandotherimpurities.

Thedevelopmentofthepapermakingindustryhasputforwardhigherrequirements fortheapplicationofwet-endchemicalsinpapermaking.Twoapplicationpurposesof wet-endchemicalsaremainlyinvolved.Oneistogainaccesstovariouspropertiesof paper.Theotheristoincreaseproductionefficiencyandimprovetheoperationofthe papermachine.Accordingly,wet-endadditivesaremainlydividedintotwocategories: functionaladditivesandprocessadditives.Theclassificationofwet-endchemicalsin papermakingisshowninFigure 1.

Overthepastseveralyears,intenseresearchonnewtypesofretentionaidshasresulted inanenormousnumberoffundamental[8–11]andappliedstudies[12–15]duetotheir significanteffectonpaperstockquality,andtheoperationefficiencyofpapermachines.The retentionefficienciesofretentionaidsareofgreatsignificance,especiallyunderhighshear condition.Theappropriateuseofretentionaidsisaneffectivewaytoreduceenvironmental pollutionandsaveresourcesviatheretentionoffinesandfillers.

Sphericalpolyelectrolytebrushes(SPBs)refertothesystemthatlongpolyelectrolyte chainsaregraftedtocolloidalspheres[16].Recently,ithasattractedmuchattentiondueto itsexcellentretentionperformanceinpapermakingoriginatingfromitscore–shellstructure[17].Itnotonlytakestheadvantageoftheionizationsurfaceandthree-dimensional nanostructures,butalsohasthecontrollablechargedensityandmolecularweightofgraftingpolymerchains[18–20].Moreover,itssphericalsymmetryorquasi-symmetricstructure hastheabilityofshearresistance.Sotheflocsflocculationwouldbeeasiertobeinducedby SPBsthoughthebridgingeffect,thusmakingtheflocsstrongerinturbulence.Consequently, consideredasaneffectiveretentionaid,SPBshaveapromisingapplicationprospectin wet-endpapermaking.

Todate,aseriesofreviewsaboutretentionaidsinwet-endpapermakinghavefocused onchitosan[21],cellulose[22],andpolymer[23].AsforSPBs,sincethefirstreview reportedbyBallauff,M.,2007[24],manypublishedreviewshavemainlyconcentrated ontheconstructionofnanocomposites[25],ioniceffects[26]andtheirapplicationin sustainableenergy[27],andnanoreactors[28].However,thereisnoreviewrelatedto SPBsasaretentionaidinwet-endpapermaking,whichisstillneeded.Inthisarticle, recentstudiesontheretentionaidsandbasictheoryofwet-endpapermakingarereviewed firstly,includingsingle-componentsystemsanddual-componentsystemsaswellastheir applicationonpapermaking.Furthermore,thesynthesisandapplicationofSPBsinwet-end papermaking,andtheinteractionofSPBswithcalciumcarbonateandfibers,aredescribed. Throughthisreview,anewdirectioninretentionaidsinwet-endpapermaking,wherewe seegreatpotentialforSPBs,ishighlighted,emphasizingthestructure–functionrelationship withrespecttoretentionperformance.Finally,theexistingchallengesanddevelopment trendsofhighperformanceretentionaidsareproposedandprospected.

2.RetentionSystems

Theretentionoffinecolloidalparticles(e.g.,finefibersandfillerparticles)onthe meshintheslurrywithoutadditivesiscausedbymechanicalinterception.Therefore, theretentionrateismainlydeterminedbythesizeoftheinterstitialspaceinfibers.In practicalindustrialproduction,alargeamountoffillerandfinefibersarelostinwhitewater throughthemeshduetohighturbulenceandhighshearforces,resultinginarelatively lowretentionrate.Therefore,itisoftennecessarytoaddretentionaidstoimprovethe retentionrateoffinecolloidalparticlesintheslurryonthemesh.Retentionaidscanchange theaggregationbehaviorofhydrophobiccolloidal.Withthecontinuousdevelopmentof wet-endpapermakingsystems,retentionaidsarealsoconstantlyimproved.Accordingto thecompositionofretentionaids,commonlyusedretentionsystemsaresingle-component systemsanddual-componentsystems.

2.1.Single-ComponentSystems

Classicalsingle-componentsystemsareinorganicandorganic,amongwhichorganic retentionaidscanbefurtherdividedintotwocategories:naturalpolymersandsynthetic polymers.

CommonlyusedinorganicretentionaidsincludeAl2 (SO4 )3 [29,30],polyaluminium chloride(PAC)[31,32],andFeCl3 [33,34].Duetotheexistenceofanegativechargeonthe surfaceofpaperpulp,theelectroneutralizationofmultivalentmetalionsresultsinflocculation[35,36].Aluminumsaltsinwaterhavecomplexstructuresandioncharacteristicswith changesinpHvaluesandchangingconditions,resultingindifferentadsorptionproperties onthesurfaceofpaperpulp[37].MasatoKatoetal.[38]investigatedtheretentionperformanceofAl2 (SO4 )3 inbleachedwoodpulp.ItwasfoundthatoxalicacidorMg2+ reduced thecontentofaluminum,whichwashardlyaffectedbyionicstrength.However,theshear resistanceoftheflocsinturbulenceislimited,makingitdifficultforinorganicflocculants tomeetthedevelopmentneedsofmodernpapermaking[39,40].

Naturalpolymersarewidelyusedbecauseoftheircharacteristicsofbeingcheap, renewable,andenvironmentallyfriendly.Thecommonlyusednaturalpolymersinpapermakingarestarch,chitosan,guargum,andcellulose.Amongthesenaturalpolymers, naturestarchisbyfarthemostusedpolymerduetoitswidesourceandlowprice[41,42]. However,starchwithlowcationicdegree( ≤ 0.2)[43],whichisavailableinmanycommercialareas,cannotprovidesufficientattractiontostabilizeadsorbedsubstances,resultingin itslowretention[44].Sostarchisusuallymodifiedphysicallyorchemicallytoextendits usefulness.SvetlanaBratskayaetal.[45]reportedacationicstarchwithacationicdegree rangingfrom0.25to1.54.Theyfoundthatthecationicdegreehadasignificantimpact onretentionperformance,andtheretentionwassignificantlyimprovedwithincreased cationicdegree.Chitosan,asanothertypeofnaturalpolymer,hasalsobeenwidelyappliedinpapermaking[46–49].Lietal.[50]studiedtheretentionofmodifiedchitosanin reedpulp/CaCO3 ,indicatingthatthemaximumretentionrateofCaCO3 couldreach80%. However,thelowchargedensityanduncontrollablestructureofnaturalpolymerslimit theirapplicationinpapermaking.Soeffortstoovercomethesedrawbackshaveledtoa largeamountofresearchattentionfocusingonthesyntheticpolymers.

Currently,polyacrylamide(PAM)andpolyethyleneimine(PEI)arethemostwidely usedsyntheticpolymersinpapermaking,suchaslinearpolyacrylamide[51],hyperbranchedpolyacrylamide[52],dendriticorstar-shapedpolyacrylamide[53],branched polyethyleneimine[54],etc.ThestructureofpolymerretentionaidsisshowninFigure 2.

PEIisamulti-branchedpolymerwithdifferentweightandchargedensity.However, PEIunmodifiedbycationicactivationisnotsuitableforalkalinepapermaking[55–57]. ItisbecauseitloseschargewhenthepHisabove5.5.Carrascoetal.[58]studiedthe performanceofcationicPEIinbleachedwoodpulpusingzetapotentialmeasurementand colloidaltitrationmethod.Itwasfoundthatthepresenceofelectrolyteshadanegativeeffect onflocculation.Betterretentioneffectofpapermaterialwasachievedwhenzetapotential fluctuatedbetween 5mVand5mV,buttheshearresistanceofPEIwasnotimproved.

Basedonchargecharacteristics,polyacrylamide(PAM)isdividedintofourtypes: cationicpolyacrylamide(CPAM),anionicpolyacrylamide(APAM),amphotericpolyacrylamide(ACPAM),andnonionicpolyacrylamide(NPAM).APAMandNPAMaremainly usedinacidicpapermakingprocess,sotheirapplicationscopeisrestricted[59].Dueto thefactthatpaperpulpsaregenerallynegativelycharged,CPAMhasbeenappliedin single-componentretentionsystems[60–63].TheretentioneffectofCPAMisinfluenced byitschargedensityandmolecularweight.ACPAMiswidelyusedinpapermaking owingtoitsanti-polyelectrolyteeffect[64–67],whichmeansitsviscosityincreaseswiththe increaseinsaltionconcentration.Luetal.[68]preparedACPAMwithdifferentstructures byinverseemulsionpolymerizationandfoundthatfavorableretentionoffillersinthe pulpwasobtainedwhentheanionicdegreewas5%,thecationicdegreewas20%,andthe molecularweightwas200,000–300,000.

Recently,hyperbranchedpolyacrylamidehasattractedconsiderableinterestbecause ofitscharacteristicsasacoagulantaidoriginatingfromitshighcationicdensityandlow molecularweight[69–73].Theformedflocshavetheadvantageofsmallvolume,dense structure,andstrongshearresistance.Furtherstudieshighlightedthatbranchedpolymers havehigherretentionandshearresistancethanthoseoflinearpolymers[74–76].Angeles Blancoetal.[77]studiedtheflocculationprocessofhyperbranchedPAMonpaperpulps usingfocusedbeamreflectancemeasurement(FBRM).Itwasnotedthatthechargedensity hadasignificantimpactonthepropertiesoftheflocs.Lowchargedensityhadanegative impactonthegrowthofpolyelectrolytechain,therebyaffectingtheflocculationprocess, whilehighchargedensitymayreducetheproportionofbridgingmechanismandincrease theproportionofpatchingmechanism.Polyacrylamidewithahighmolecularweightand hyperbranchedstructurehasgoodapplicationprospectsinpapermaking.

Additionally,dendrimerorstarpolymershavegraduallybecomeresearchhotspotsas retentionaidsinpapermakingduetotheirhighlybranchedthree-dimensionalmorphology[78–81].Comparedwithlinearpolymers,theyusuallyexhibithighsolubility,lowsolutionviscosity,smallhydrodynamicradius,highshearresistance,smallmolecularvolumes, andhigh-densityfunctionalgroups[82].Shanetal.[83]synthesizedstar-shapedCPAM

byreversibleaddition–fragmentationchaintransferpolymerization,whichisamethodof acrylamideandmethacryloyloxyethyltrimethylammoniumchloridecopolymerizion.The retentionrateoffillersandfinefiberswasimprovedthroughbridgingmechanism.

Forcationicmicroparticles,whetherorganicorinorganicparticles,fewconformational changesincelluloseflocculationoccurbecauseoftheirrigidstructure[84–86].ZeguiYan etal.[87]exploredtheretentionperformanceofcationicSiO2 particlesandcationicorganic polymerparticlesinunwashedbleachedkraftsoftwoodpulp/PCCandfoundasignificant improvementinretentionrate.XiaohongPengetal.[88]preparedcopolymerparticlesof acrylamide,acyloyloxyethyltrimethylammoniumchloride(DAC),andpolyethyleneoxide (PEO)throughinverseemulsionpolymerization,andstudiedtheretentioneffectofDAC andPEOonthefiber.ResultsindicatedthattheincreaseintheratioofDACandthechain lengthofPEOisbeneficialtobridging,therebyimprovingtheretentionrate.

Insummary,thereareseveraltheoreticalmodels,namely“Electricneutralization”, “Patching”,and“Bridging”,thatdescriberetentionmechanismofretentionaids.The neutralizationeffectismainlycausedbysimpleelectrolytesandlow-molecular-weight polyelectrolytes,suchasAl2 (SO4 )3 ,FeCl3 ,andPEI.Thepatchingeffectismainlycausedby cationicpolyelectrolyteswithhighchargedensityandmediummolecularweight(100,000 to1million)(e.g.,PEIandPAM).Forhigh-molecular-weightpolyelectrolytes,bridging effectshavehigherpossibilitythanthatoflow-molecular-weightones.

2.2.Dual-ComponentSystems

Withthecontinuousdevelopmentofpapermaking,existingsingle-componentsystemshavebeenincreasinglyunabletomeettheneedsofretentionaidsunderhighshear conditions.Inordertoobtainflocswithhighershearresistance,greatattentionhasbeen paidtodevelopdual-componentsystems.Theprocessofdual-retentionsystemsgenerally refertotheadditionofcationicadditivesfirst,followedbytheadditionofanionicadditives.

Ingeneral,dual-componentsystemsmainlyinvolvetwodifferentsystems:“dual polymericretentionsystem”and“microparticleretention-aidsystem”.Theformeris composedoffixativeswithalowmolecularweightandhighchargedensity,andflocculants withahighmolecularweightandlowchargedensity.Thissystemcanachievearelatively goodretentioneffect,butthepaperformingperformanceislimitedbyforminglarge andlooseflocs.Thelattersystem,theso-called“microparticleretention-aidsystem”,has developedintooneofthemostsuccessfullycommerciallyavailableproducts.Compared totraditionalretentionsystems,itnotonlyhasexcellentretentioneffectsonwet-end chemicaladditives,finefibers,andfillers,butalsoreducestheconcentrationofwhitewater andincreasesthepapermachinespeed,thusgeneratingenvironmentalandeconomic benefits[89,90].Interestingly,eveniftheaddingorderofbinarycomponentsisreversed, thereisalmostnodifferenceinitsflocculationindex.Classicalmicroparticleretentionaids areanionicparticlesandcationicparticles.

TypicalanionicparticlesarecomposedoftheCompzilsystem(starch-colloidalsilicon)[91]andtheHydrocolsystem(CPAM-bentonite)[92].B.Alinceetal.[93]studied thedepositionbehaviorofcalciumcarbonate(PCC)onpaperfibersinCPAM-bentonite systems.BychangingthedosageofCPAM,itwasfoundthatCPAMprovidedananchor pointforbentonitetofunctiononthefibersandPCC.Bentoniteplayedabridgingrole betweenthefibersandPCC.ExcessivedosageofCPAMwouldweakenthebridgingeffect ofbentonite.TheinteractionforcebetweenfibersandPCCobtainedthroughtheCPAMBentonitesystemwasstrongerthanthatoftheCPAMsystem.NorlitoCezaretal.[94] reportedcationicparticlesbymodifyingthesurfaceofSiO2 with2,3-epoxypropylHmethylammoniumchloride.Resultsshowedthatitsignificantlyimprovedtheflocculation efficiencyofclay.Theoptimaldosageratioofcationic(SiO2 )toanionic(APAM)wasinthe rangeof2:1and5:1.Moreover,therigidityofSiO2 improvedtheefficiencyofbridging. Cationicmagnesiumaluminumhydroxide/APAMwasusedbyWangSonglinetal.to studyitsretentionperformanceontalcpowder/reedpulp.Theretentioneffectimproved withthedecreaseincolloidalparticlesizeofmagnesiumaluminumhydroxideparticles.

Theretentionratewashighestattheconditionsoftheamountofmagnesiumaluminum hydroxide0.6%andtheamountofAPAM0.06%.

Inaddition,organicpolymerparticlesnotonlyhavethethree-dimensionalnanostructureoftheionizedsurfaceofinorganicparticles,butalsopossessthecontrollablecharge densityandflexiblechainsoforganicpolymers,whichisexpectedtobeanovelretention aid[95–98].Takingcationicorganicpolymerparticlesasanexample, XiaoHetal.[99] preparedcationicorganicparticlesbyemulsifier-freeemulsifierpolymerizationandstudied theirflocculationonfineclay.Itwasfoundthatthedosageratioofcationicparticlesand anionswas8:1attheoptimalflocculationpoint,andthedosageofanionsaccountedfor 0.06wt%ofclay.Thesebinarycomponentsplayedasynergisticroleintheflocculation process.OnoHiroshietal.[100]synthesizedcationicpolymerparticles(CPMP)with differentchargedensitiesandsizesbyemulsionandmicroemulsionmethods,andstudied theeffectofCPMPonpositivelychargedandnegativelychargedcalciumcarbonate.It wasfoundthatCPMPhadnoobviouseffectonpositivelychargedcalciumcarbonate.For negativelychargedcarbonate,however,theoppositeistrue.TheadditionofAPAMcould improvetheflocculationeffect.

3.EvaluationMethodsofRetentionAids

Forsingle-componentsystemanddual-componentsystem,thereareavarietyof waystomeasuretheretentionefficiency,suchasfluorescencemicroscopy,fieldemission electronmicroscopy(FE-SEM),transmission(TEM),focusedbeamreflectancemeasuring instrument(FBRM),flocculationturbidity,zetapotential,anddynamicretention.The DynamicDrainageJar(DDJ)isawidelyusedreliableinstrumentfortestingtheretention efficiencyofsingleormultipleretentionaids.Thefirst-passretention(FPR)ofpulp suspensionandPCCcanbecalculatedbasedonEquation(1):

FPR = Ci C0 Ci × 100%(1)

where Ci and C0 aretheconcentrationsofcolloidalparticlesinslurryandinfiltrate,respectively.

4.BasicTheoryinWet-EndPapermaking

Wet-endchemistryofpapermakingmainlystudiestheinteractionamongvariouscomponentsofpaperstockduringretention,filtration,forming,andwhitewatercirculation,as wellastheireffectsontheoperationalperformanceofpapermachinesandproductquality. Interfacechemistryisanimportanttheoryinwet-endchemistryofpapermaking.Dueto thecomplexcompositionofcolloidsinpapermaking,althoughmostfibersizesarebeyond thescopeofcolloids,thegapsinfibersbelongtothecolloidsize.Therefore,papermaking processcanbestudiedbythetheoriesrelatedtocolloidandinterfacechemistry.

4.1.MainForces

Thewet-endpapermakingisacomplexanddiversepolydispersesystem,inwhich therearevariousforcesinvolved[101].Intermsofmacroscopiccomponents,itcanbe mainlysummarizedintofollowingseventypes:(l)adsorptionofvariousadditiveson fibers,finefibers,andfillers;(2)aggregationoffibers,fillers,andfinefibers;(3)aggregationamongvariousadditives;(4)interactionwithwaterbetweenfibers,finefibers, andadditives;(5)neutralizationofsurfacechargesofsuspendedandsolubleanionicsubstances;(6)formationanddevelopmentofmicellesthatcomprisesurfactantmolecules; (7)establishmentofdynamicequilibriumbetweensolubleinorganicsaltsandinsoluble electrolytes.

Fromtheperspectiveofmicro-force,theforcesamongmaincomponentsmentioned abovearemanifestedasvanderWaalsforces,hydrogenbonds,ionicbonds,andcovalentbonds.Asfordryingpaper,thestrengthoftheforcesamongfibersvaries:the hydrogenbondis8.81KJ/mol,theionicbondis41.8–54.34KJ/mol,thecovalentbondis 292.6–351.12KJ/mol[102],andthevanderWaalsstrengthisweakerthantheothers.

4.2.MachinismofInterfaceInteraction

4.2.1.TheConformationofPolyelectrolytes

Theconformationoflinearpolyelectrolytesinsolutionchangescontinuously.Numerousstudieshaveshownthatpolyelectrolytesmainlyexistintheconfigurationofcircular adsorptionorflat[103–106].Forhigh-levelpotentialenergysurface‚polyelectrolyteshave asmallmolecularweight,highchargedensity,andstrongelectrostaticinteractions.Sopolyelectrolytesarepronetoexistonsolidsurfacesinaflatconfiguration.Figure 3 displaysthe adsorbedpolyelectrolytes,whichwasdividedintothreesegmentsby Böhmeretal.[107]: train,loop,andtails.Thelengthofeachsegmentdependsonitschargedensity,molecular weight,negativechargeonthesolidsurface,etc.Forexample,thestrongertheelectrostatic effect,thesmallerthemolecule‚thusresultinginmoretrains‚andfewerloopsandtails. Theoretically,itispredictedthatwhenpolyelectrolytechainsdrivenbystrongelectrostatic forcesareabsorbedonthesolidsurface,theyarecomposedof80%trains‚20%loops‚and raretails.

4.2.2.AdsorptionbetweenPolyelectrolytesandFibers

Generallyspeaking‚theadsorptionprocessbetweencationicpolyelectrolytesand fiberscanbedividedintothreestages[108]:adsorption,reconstruction,anddiffusion, asshowninFigure 4.Forcationicpolyelectrolyteswithdifferentstructures,thestages willvary.

Forpolyelectrolyteswithlowmolecularweightandhighchargedensity‚theyrapidly adsorbonthefibersurfaceinaflatconfigurationbyion-exchangemechanism.Anditalmost immediatelydiffusesintothefiberwithoutanymolecularreconstructionprocess.Cationic polyelectrolyteswithmediummolecularweightdisplayaflatconfigurationduringinitial adsorption‚resultinginlowpositivechargedensityonthesurfaceofpulps.Subsequently, onlyminorreconstructiononthesurfaceofpulpshappens.Therefore,thechargedecayat thesecondstageisalsosmallerthanthatofpolyelectrolyteswithhighmolecularweight. Afteradsorptionofcationicpolyelectrolyteswithhighlybranchedstructuresandhigh molecularweightonpulpfibers‚thesurfacechargeoffibersrarelydecays.Thisisbecause itisdifficultforthereconstructionanddiffusionprocessofpolyelectrolytesonthesurface ofpulpfiberstooccur.

4.2.3.RetentionMechanism

(a) Single-componentsystems

Accordingtothetheoryofcolloidalaggregation‚theretentionmechanismcanbe dividedintothreemodes:coagulation,flocculation,andagglomeration.

Coagulationimpliesthatfornegativelychargedcolloidalparticlessuchasfinefibers, talcpowder,calciumcarbonate,titaniumdioxideetal.,thedoublelayerbecomesthinner andzetapotentialfallsundertheactionofelectrolytes.Therefore,theelectrostaticrepulsion forceswhichcommonlyexistbetweencolloidparticlesdecrease‚resultingintheinstability ofcolloidparticles.Theretentionisproducedbytheformationofsmallaggregates(also knownas“softaggregates”).

Colloidalparticlesarebondedtogetherbypolymerswithahighmolecularweight (greaterthan100,000)duetotheinstabilityphenomenon[109].Thecoagulantadsorbsonto thesurfaceofcolloidalparticlesinarandomcoilconformationthroughelectrostaticor non-electrostaticforces.Theseadsorbedpolymersformso-called“hardaggregates”by reactingwithanothercolloidalparticle.Wecallthisprocessflocculation.

Agglomerationreferstotheinstabilityphenomenonofcolloidalsuspensionscaused bytheactionofpolymerswithlowmolecularweight(lessthan100,000)andhighcharge density.Duetothehighpositivechargedensityofretentionaids‚theyadsorbedonthe surfaceofnegativelychargedparticlesthroughionbonds‚formingso-called‘patch’[110]. Thesepositivechargepatcheswillagglomeratewiththenegativechargeofanotherparticle by“bridging”(seeFigure 5).

(b) Dual-polymericretentionsystem

Therearesomedefectsinsingle-componentsystems.Theformedflocsaresensitiveto hydrodynamicforces,leadingtoflocsfragmentexposedtoturbulentshearforces.While theshearforceslowsdownordisappears,thesedispersedflocswillnotberestored,making itsretentionabilitygreatlyreduced.Anovelretentionsystemhasemerged,whichisso thatthatthesynergisticeffectisgenerallyachievedthroughdualcomponents[111].

Researchhasfoundthathardandtoughflocscanbegeneratedbycombiningtwo typesofpolyelectrolyteswithdifferentchargesandcontrollingaddingorder.Ifacationic polyelectrolyteisaddedbeforeaddingananionicpolyelectrolyte‚theretentioneffectis farbetterthanthatofsingle-componentsystems[112].Theactingmechanismmaybe explainedasfollows:

Afteraddingcationicpolyelectrolyteswithlowmolecularweightandhighchargedensity‚polyelectrolytesareadsorbedbynegativelychargedparticlesinaflatconfiguration‚ causingcationicpatches.Theseadsorbedpolyelectrolytesonlyhaveveryfewloopandtails extendingintotheaqueoussolution‚butprovidinganchoringpointsforanionicpolyelectrolytes.Anionicpolyelectrolyteswithhighmolecularweightandlowchargedensityare thenbondedontocationicpatches.However,manysegmentsofanionicpolyelectrolytes willextendintoaqueoussolutionsduetotherepulsiveforceofnegativechargesonthe

particlesurface.Theybindwithcationicpatches‚justlikeabridge‚agglomeratingsmall particlesintolargeflocs.

(c) Microparticleretention-aidsystem

Aspreviouslymentioned,thedual-microparticleretention-aidsystemiscurrently recognizedasthemostadvancedandeffectiveretentionsystem.Itcanbeusedinhighspeedsprayformingmachinesandfullyenclosedcirculationsystems.

TheCompzilsystemwasdevelopedandappliedinpapermakingbyaSwedishcompany.ItisacontrolsystemcomposedofcationicstarchandSiO2 nanoparticles(3–5nm) withhighspecificsurfaceareaandhighnegativechargedensity.Theretentionmechanismoffillerisgenerallybelievedtobethatfinefibersandfillerparticlesareaggregated bycationicstarch,thusgeneratingflocculent.WhenSiO2 nanoparticlesareadded,this flocculentmaybetornapartintosmallflocs.Forlow-charge-densitypolyelectrolytes,the flocculationmechanismseemstobemainlythebridgingeffect[113].Asforpolyelectrolytes withahighchargedensity,electrostaticattractionplaysamajorrole.Obviously,dueto themigrationofSiO2 nanoparticlesintotheadsorbedcationicstarch,thepulpandsilicon particlesformanetworkflocthathasatendencytoreaggregateaftershearing.Therefore, theuniformityofpaperwillnotdeteriorateevenunderhighretentionrate.Inaddition,the structureoffinishedpaperwillbecomeloose,resultinginincreasedporosityandimproved waterfiltrationperformance.

TheHydrocolsystemisatypicalduplexcontrolsystemwhichwasdevelopedinthe UnitedKingdom.Theworkingprinciplemaybethatrelativelycoarseflocsareformed whencationicelectrolyteswithahighmolecularweightareaddedintothepulp.However, theseflocswillbecutintosmallflocswhenitissubjectedtotheactionofamixingpump andascreeningmachine.Thesetinyflocs,undertheactionofHeidelbergpigments,will reaggregateintoauniformnetworkflocculent.Sofillerparticlesorfinefibersareretained inthepaperpulptoachievethepurposeofretention.

5.SphericalPolyelectrolyteBrushes

Polymerbrushes[114]withuniquepropertiessuchasahighchargedensity,high symmetryorquasi-symmetricstructure,andlowmolecularweightprovidegreatpotential andlimitlesspossibilitiesforitsapplicationsinbiomedicalapplications[115–117],nanoreactors[118–120],durableprotectiveclothing[121,122],etc.Thebrushconformationis influencedbythecurvatureofgraftedsurface.Figure 6 displaysthestructureofpolymer brushesondifferentgraftingsurface.Whentheradiusofcolloidalparticlesismuchgreater thanthethicknessofthegraftedbrushlayer,planarbrushesform(seeFigure 6a).The colloidalparticlesizeismuchlessthanthethicknessofgraftedbrushlayer,resultingin theformationofastar-polymer(seeFigure 6c).Ifthepolyelectrolytechainsaffixtothe spheresurface,then,e.g.,sphericalpolyelectrolytebrushes(SPBs)result[25].Asshownin Figure 6b,thecoreradiusRc denotesinitiator-immobilizedspheressurface,fromwhich polyelectrolytechainsaregrafted.Lreferstothethicknessofthebrushlayer,Rh isthe hydrodynamicradius,and ζ isthezetapotential.SPBsnotonlypossessmanyadvantagesoriginatingfromtheirspecialmolecularstructure,butalsohasasimplesynthesis process[123,124]andeasy-to-controlmolecularweight[125,126].Therefore,SPBshave recentlyattractedworldwideresearchinterest[127–132].

5.1.SynthesisMethods

5.1.1.Physisorption

Physisorptionisareversibleprocess,whichistheself-assemblyprocessofmacromoleculeswithsurfaceactivityorpolymerswithendgroupfunctionalgroups[133],as showninFigure 7A.Bothgraftcopolymersandblockcopolymerscanbeformedbyphysisorption.Theessenceoftheprocessisbasedonselectivesolvation.Theinsoluble segmentssettledownandaffixonthematrix,whilethedissolvedsegmentsstretch,formingapolymerbrush.Additionally,polymerbrushescanalsobeformedwhenselective adsorptionofgraftcopolymersoccursonthesubstratesurface.

Takingtolueneasaselectivesolvent,ParsonageEetal.[134]studiedthepolymer brushformedbytheadsorptionofaPS-b-PVPcopolymerwithdifferentmolecularweight onthesubstrate.PVPwasaffixedtothesubstratesurfaceandPSformedapolymerbrush. MotschmanHetal.[135]discussedtheadsorptionkineticsandadsorptionisothermsof PS-b-PEOcopolymeronthesurfaceofsilicagelintoluenesolvent.Theresultsindicated thatapparenttwo-rateprocesseswereshowedinadsorptionkineticsinacertaintime range.Atfirst,weakinteractionsliedinthegraftingchainsduetotheeffectofsurface diffusion.Subsequently,denselypolymerbrushesformedbyosmosisbehavioramong graftingchains.

Intheprocessofphysisorption,desorbingoftheadsorbedmacromoleculeshappens easilyduetotheweakhydrogenbondorvanderWaalsforce.

5.1.2.CovalentAttachment

Covalentattachmentisanirreversibleprocess.Thatis,thepolymerchainsareconnectedbychemicalbondsonsubstratesurface.Thisprocesscanberealizedbytwo technologies,namely“graftingto”and“graftingfrom”,asshowninFigure 7B.

“Graftingto”meansthatunderappropriatereactionconditions,thesynthesized polymerswithfunctionalend-groupswillreactwithmodifiedsubstratesurface,andthen polymerscovalentlybondedtosubstratesurfacetoformapolymerbrush[136,137].Auroy Petal.[138]synthesizedaPSSbrushonthesubstratesurfaceofsilicagelbyatwo-step method.Firstly,PSchainwithtrichlorosilaneend-groupswasgraftedonthesubstrate surfacebyusingthe“graftingto”technology,andthenthePSSbrushwasobtainedby insitusulfonationreactiononsubstratesurface.Theshortcomingofthe“graftingto” techniqueisthatonlyafewkindsofpolymershavebeengraftedtothesubstratesurface. Oncethepolymerchainsonsubstratesurfacehavereachedacertainamount,theremaining chainscouldnolongerbegraftedduetosterichindrance.Inparticular,asforthegrafted polyelectrolytechains,electrostaticrepulsionshouldbeconsidered.Therefore,thismethod hasanegativeinfluenceonthegraftingdensityofpolymerbrushes.

The“graftingfrom”techniqueisbasedonthesurfacebeingmodifiedbypolymerizationinitiatorsunderlightorheat[139–142].Thepolymerbrushpreparedbythismethodis firmlybondedbecauseofbearinginitiatorfunctionalitiesonsubstratesurface,thusleading toadenselayerofbrush.Bothconventionalfreeradicalpolymerizationandactivefree radicalpolymerizationareemployedtopreparepolymerbrushwithhighgraftingdensity.

Conventionalfreeradicalpolymerization,bywhichthelinearpolymersareformed,is suitableformostvinylmonomers.Sothismethodisthemostwidelyusedinthepolymer industry.HandJ[143]reportedapoly(4-vinylpyridine)polymerbrushcreatedbyfree radicalpolymerization,andthenthequaternizationwascommencedbyaddingCH3 Ito prepareapolyelectrolytebrush.Whenpreparingbrushesusingacrylicacidasthemonomer, itwasfoundthatincreasingthereactiontimeandthesolidcontentofthemonomerwere beneficialforincreasingthelengthofbrush.Itisasimpleandeffectivemethodforthe synthesisofpolymerbrush,butlowmonomerutilizationisaproblem.Itismainlybecause thatthetwofreeradicalsdecomposedbyaninitiatorareonthesubstratesurfaceandin thecontinuousphase,respectively,leadingtoalowmonomerconversionrate(41.48%).

Activeradicalpolymerizationmainlyincludestwostrategies:atomtransferradical polymerization(ATRP)[144–147]andreversibleaddition–fragmentationchaintransfer (RAFT)[148–151].ZhaoBetal.[152]synthesizedmixedpolymerbrushesofPSand PMMAusingATRPtechnologyandnitroxide-mediatedradicalpolymerizationtechnology. Thegraftingdensity,molecularweight,anddistributionofthemixedpolymerbrushare controllable.BaumMetal.[153]synthesizedPS,PMMA,andPAA-coPMMApolymer brushesusingRAFTtechnologybybondingnitrogen-containinginitiatorsontothesurface ofsilicon.Duetothelowconcentrationofsurfaceinitiators,additionalinitiatorsare requiredtoincreasepolymerizationrate.

5.2.CharacterizationandConformation

Sofar,variousexperimentalmethodshavebeenadoptedtocharacterizetheSPBs.For example,themorphologyofSPBscanbecharacterizedbycryogenictransmissionelectron microscopy(Cryo-TEM)[154–157],small-angleneutronandX-rayscattering[158–161].The particlesizecanbemeasuredbyatomicforcemicroscopy(AFM)[162–164]anddynamic lightscattering(DLS)[165–168].Themolecularweightanddistributionofpolymerbrushes canbecharacterizedbygelpermeationchromatography(GPC)[169–171],andthensurface graftingdensityiscalculated[172,173].CurieEPKetal.[174]studiedthepolymerbrush ofhydrogenatedPS-b-PEOdiblockcopolymerbytheneutronreflectiontechnique.Itwas foundthatchaindensitychangedfromstepdistributiontoparaboladistributionwith theincreaseingraftingdensity.Guoxetal.[175]studiedthehydrodynamicradiusRH ofmicellarpolyelectrolytebrushconsistingofPScore(50~100nm)andPAAbrushes atdifferentKClconcentration(10 3 ~3m)byDLS.ItwasfoundthatRH wasinversely proportionaltotheionicstrength,whichwasconsistentwiththeDaoud–Cottonmodel. PruckerOetal.[176]studiedaPSbrushwithdifferentgraftingdensitiesgraftedonsilicon waferbyAFM.Theresultsshowedthatthestructureofthebrushwasdependentonthe graftingdensity.Whenthegraftingdensitywaslow,thesurfacewasunevenbecauseof theaggregationofPSchain.Onthecontrary,thecollapseofthePSchaincouldforma uniformcoating.

InordertoexploretheconformationofSPBs,manytheoreticalmodelshavebeen explored[177].Accordingtothecomplexityofmodels,itcanbedividedintothefollowing categories:scaletheory[178–180],numericalself-consistentfieldtheory(NSCFT)[181–183], analyticalself-consistentfieldtheory(ASCFT)[184,185],moleculardynamics(MD)[186], Browniandynamics(BD)[187,188],andsoon.HariharanRetal.[189]studiedanSPB systemusingtheDaoud–Cottonmodel.UsingtheMonteCarlomodel,LuoMB[190] studiedtherelationshipbetweentheconformationalparametersofpolymerbrushesand thestretchingvolumeofrandomandrestrictedchains.Theresultsshowedthattheeffects oftheextendedvolume(EV)oftwotypesofchainsonthemeansquareenddistance<R2 > andthemeansquareradiusofrotation<S2 >arebasicallyidentical.

Inaddition,researchonthefundamentalnatureofSPBshasbeenreported.ConsideringthespecialconstitutionofSPBs,theinfluenceofexternalfactors(ionicstrength, pH)ontheconformationalparametersofpolyelectrolytebrushcanalsobemonitoredby physicaltestmethods.Forexample,BallauffM[191]investigatedtheinfluenceofpH valueandionicstrengthonbrushthicknessinaPS-PAAsystem.TheyfoundthatthepH valueofthesystemaffectedthedissociationdegreeofpolyacrylicacidbrush.Intheacid condition,acrylicacidwasdifficulttodissociate.WhenNaOHwasaddedtothesystem, OH- wasneutralizedwithH+ ,causingthepresenceofcarboxylateanionontheacrylic acidchain.Duetotheincreaseintheelectrostaticrepulsionforce,theswellingofchains happens.Moreover,theeffectofelectrolyteconcentrationonthemorphologyofPAA brushonmicrosphereswasmainlyduetotheelectrostaticeffect.Thehigherelectrolyte concentrationwas,themoreobvioustheelectrostaticshieldingeffectwas,whichledto theshrinkageofthepolymerbrush.Yu[192]foundthatthebrushchaininthespherical PSSbrushcouldfullyswellinthewaterphase,andthebrushcollapsedafteraddingLa3+ , whichmaybecausedbythedecreaseinosmoticpressure.

5.3.ApplicationinPapermaking

Asinourpreviouswork(seeFigure 8),cationicsphericalpolyacrylamide(CSPAM) brushesweresynthesizedbygraftingmannichedpolyacrylamide(PAM)fromthesurfaceof γ-methacryloxypropyltrimethoxy-silane-modifiedSiO2 nanoparticles[193].Theretention effectofCSPAMrevealedthatthehighestfirst-passretentionwas71.1%whenthedosage ofCSPAMwas3.5mg · g 1

SchematicrepresentationsofsynthesisprocessofSPBs(A)andcationizationprocessof SPAM(B).CopiedfromDeGruyter[193].

Cationicsphericalpolyelectrolytebrushes(CSPBs),withpoly(2-(acryloyloxy) ethyltrimethylammo-niumchloride)chainsweregraftedfromthesurfacesofcolloidalsilica particlesbyZhangXiongzhietal.[194].TheCSPBswerecharacterizedbyvariouscharacterizationmethodsinvolvingFourier-transforminfraredspectrometry,thermo-gravimetric analysis,transmissionelectronmicroscopy,andX-rayphotoelectronspectroscopy,asdisplayedinFigure 9.Andthen,theCSPBswereinvestigatedasflocculationandretention-aids forbleachedeucalyptuskraftpulpandkaolin/pulpparticles.Theresultssuggestedthat theflocculationandretention-aidpropertieswereimproved.

HuangYuetal.[195]reportedadual-componentsystemconsistingofCSPBsand anionicpolyacrylamide(APAM)toimprovetheretentionanddrainagepropertiesof bleachedeucalyptuskraftpulpandprecipitatedcalciumcarbonate(PCC).CSPBscomprised asilicacoreandashellofcopolymerofacrylamide(AM)and[2-(methacryloyloxy)ethyl] trimethylammoniumchloride(METAC).TheCSPB/APAMsystemshowedbetterretention efficiencythanthecationicstarch/APAMsystemunderdifferentturbulentconditions.As illustratedinFigure 10,theCSPB/APAMdual-componentsysteminteractedwithfibers andPCCthroughapatchingandbridgingmechanism.

Figure9. FTIR(A),XPS(B)(“*”denotesthesignalpositionofnitrogenatomsinthespectrumofSiO2 ), andTGA(C)ofCSPBs;TEM(D)ofSiO2 (a)andCSPBs(b);meanchordlengthofpulpsuspension inducedbycationicadditives(E).Reprintedwithpermissionfrom[194].Copyright:2016,Elsevier.

Figure10. FSEMimagesofPCCflocsadheringtothesurfaceoffibers(A):(a)Withoutanyadditives, (b)withcationicstarch/APAM(cationicstarch=35mg/g,APAM=0.03wt%),and(c,d)withCSPB3/APAM(CSPB-3=18mg/g,APAM=0.03wt%);FlocculationmechanismoftheCSPB/APAM dual-componentsystem(B).Reprintedwithpermissionfrom[195].Copyright:2015,Elsevier.

Y.Meietal.[196]presentedacomprehensivestudyoftheinteractionofSPBswith cationicmodifiedpolyacrylamide(CPAM),calciumcarbonate(CaCO3 )particles,and cellulosefibers.Intheirwork,italsoelaboratedthissystemasamodelforretentionaidsin thepapermakingprocess.Theresultssuggestedthatthedualflocculationsystemusing anionicSPBsworkedsoefficientlycomparedtobentonite,whichcanbeattributedtothe highcationexchangecapacity(CEC)ofSPBs.AnionicSPBsactedasaparticlebridge betweenfibersandCaCO3 .

6.ConclusionsandOutlook

Asfollowsfromtheaboveoverview,numerousretentionaidshavebeenutilizedin wet-endpapermaking.Itcanalsobenoticedthatcurrentstudiesaremainlyfocusedona basicdescriptionofsingle-componentsystemsanddual-componentsystems,whilemuch lessattentionispaidtothecorrelationofstructureparametersinvolvingchargedensity, molecularweight,andtheretentionperformancesofretentionaids.Therefore,theprospect ofdevelopingnovelretentionaidswithhighlybranchedstructuresandcontrollablecharge densityandmolecularweightisanexcitingdirectionthathasyettoberealized.Previous studieshavefoundthatsphericalpolyelectrolytebrushescanadapttothecurrentdemand forpapermaking.

Lookingforwardtothefuture,however,awidescopeofchallengeswillcontinueto createexcellentperformanceretentionaidsduetothecomplexityofwet-endpapermaking. Firstly,therearelimitedpublicationsfocusingonSPBsasretentionaidsinpapermaking. InadditiontoCSandSiO2 ,othertypesofnanoparticlesastemplatesshouldbefurther studied.Moreimportantly,furtherdevelopmentofSPBswithdifferentgraftingdensities, molecularweights,andchargedensitieswillbeakeytorealizetheapplicationsinwet-end papermaking.Secondly,currentanalysisinvolvingtheinteractionforcebetweenCSPBs andfibershasbeenrestrictedtomacroscopicanalysis.Thatistosay,thespecificinteraction force,whethervanderWaalsorelectrostaticforces,hasnotbeenclearlyunderstood.Finally, thefractaldimensionofflocsinwet-endpapermakingandtheretentionmechanismof SPBscanalsobefurtherstudied.

Interestingly,furtherresearchwillcontinuetofocusonmulti-componentadditives.

Funding: ThisworkissponsoredbyNaturalScienceFoundationofShanghai(21ZR1422100).

InstitutionalReviewBoardStatement: Notapplicable.

InformedConsentStatement: Notapplicable.

DataAvailabilityStatement: Dataarecontainedwithinthearticle.

Acknowledgments: KeyLabofIntelligentandGreenFlexographicPrinting(KLIGFP-01)technical support.

ConflictsofInterest: Theauthordeclaresnoconflictofinterest.

Abbreviations

AbbreviationsName

GCCGroundcalciumcarbonate

PCCPrecipitatedcalciumcarbonate

SPBsSphericalpolyelectrolytebrushes

PACPolyaluminiumchloride

PAMPolyacrylamide

PEIPolyethylene

CPAMCationicpolyacrylamide

APAMAnionicpolyacrylamide

ACPAMAmphotericpolyacrylamide

NPAMNonionicpolyacrylamide

FBRMFocusedbeamreflectancemeasurement

DACAcyloyloxyethyltrimethylammoniumchloride

PEOPolyethyleneoxide

DDJDynamicDrainageJar

CPMPCationicPolymerMicroparticle

ATRPAtomtransferradicalpolymerization

RAFTReversibleaddition–fragmentationchaintransfer PSPolystyrene

PMMAPolymethylmethacrylate

PAAPolyacrylicacid

Cryo-TEMCryogenictransmissionelectronmicroscopy

DLSDynamiclightscattering

AFMAtomicforcemicroscopy

GPCGelpermeationchromatography

NSCFTNumericalself-consistentfieldtheory

ASCFTAnalyticalself-consistentfieldtheory

MDMoleculardynamics

BDBrowniandynamics

EVExtendedvolume

CSPAMCationicsphericalpolyacrylamide

CSPBsCationicsphericalpolyelectrolytebrushes

AMAcrylamide

METAC2-(methacryloyloxy)ethyltrimethylammoniumchloride

CECCationicexchangecapacity

References

1. Ma,H.Areviewofwaystoadjustpapermakingwet-endchemistry:Manipulationofcellulosiccolloidalbehavior. Lignocellulose 2014, 3,69–107.

2. Gibbs,A.;Pelton,R.;Cong,R.Theinfluenceofdextranderivativesonpolyethyleneoxideandpolyacrylamide-inducedcalcium carbonateflocculationandflocstrength. ColloidsSurf.A 1999, 159,31–35.[CrossRef]

3. Lima,D.U.;Oliveira,R.C.;Buckeridge,M.C.Seedstoragehemicellulosesaswet-endadditivesinpapermaking. Carbohydr.Polym. 2003, 52,367–373.[CrossRef]

4. Fatemeh,N.;Hamidreza,R.;Hossein,R.;Hossein,J.T.Applicationofbio-basedmodifiedkaolinclayengineeredaspapermaking additiveforimprovingthepropertiesoffilledrecycledpapers. Appl.ClaySci. 2019, 182,105258.

5. Boufi,S.;González,I.;Delgado-Aguilar,M.;Tarrès,Q.;Pèlach,M.À.;Mutjé,P.Nanofibrillatedcelluloseasanadditivein papermakingprocess:Areview. Carbohydr.Polym. 2016, 154,151–166.[CrossRef][PubMed]

6. Ibrahim,M.M.;Mobarak,F.;El-Din,E.I.;Ebaid,A.E.;Youssef,M.A.ModifiedEgyptiantalcasinternalsizingagentforpapermaking. Carbohydr.Polym. 2009, 75,130–134.[CrossRef]

7. Lourenco,A.F.;Gamelas,J.A.F.;Sarmento,P.;Ferreira,P.J.T.Enzymaticnanocelluloseinpapermaking—Thekeyroleasfiller flocculantandstrengtheningagent. Carbohydr.Polym. 2019, 224,115200.[CrossRef][PubMed]

8. Koshani,R.;Tavakolian,M.;vandeVen,T.G.Cellulose-baseddispersantsandflocculants. J.Mater.Chem.B 2020, 8,10502–10526. [CrossRef]

9. Huang,C.;Li,H.;Liu,W.;Zhan,H.Theretention-anddrainage-aidbehaviorofquaternarychitosaninpapermakingsystem. ColloidsSurf.A 2007, 297,147–153.

10. Malik,S.;Rana,V.;Joshi,G.;Gupta,P.K.;Sharma,A.ValorizationofWheatStrawforthePaperIndustry:Pre-extractionof ReducingSugarsandItsEffectonPulpingandPapermakingProperties. ACSOmega 2020, 5,30704–30715.[CrossRef]

11. Lossmann,K.;Hecht,R.;Saame,J.;Heering,A.;Leito,I.;Kipper,K.Retentionmechanismsofacidicandbasicanalytesonthe Pentafluorophenylstationaryphaseusingfluorinatedeluentadditives. J.Chromatogr.A 2022, 1666,462850.[CrossRef][PubMed]

12. You,Y.;Zhang,J.;Sun,X.Fabricationofanovelhigh-performanceleatherwaste-basedcompositeretentionaid. RSCAdv. 2019, 9, 16271–16277.[CrossRef][PubMed]

13. Karim,Z.;Svedberg,A.Controlledretentionanddrainageofmicrofibrillatedcelluloseincontinuouspaperproduction. NewJ. Chem. 2020, 44,13796–13806.[CrossRef]

14. Dichiara,A.B.;Song,A.;Goodman,S.M.;He,D.;Bai,J.Smartpaperscomprisingcarbonnanotubesandcellulosemicrofibersfor multifunctionalsensingapplications. J.Mater.Chem.A 2017, 5,20161–20169.[CrossRef]

15. Xu,Q.;Kong,Q.;Liu,Z.;Zhang,J.;Wang,X.;Liu,R.;Yue,L.;Cui,G.Polydopamine-coatedcellulosemicrofibrillatedmembrane ashighperformancelithium-ionbatteryseparator. RSCAdv. 2014, 4,7845–7850.[CrossRef]

16. Baharvand,H.;Rabiee,A.Synthesisofpolyelectrolytebrushesonsphericalmagneticpolymerparticles. J.Polym.Res. 2014, 21, 596.[CrossRef]

17. Huang,Y.;Xue,X.;Fu,K.Applicationofsphericalpolyelectrolytebrushesmicroparticlesysteminflocculationandretention. Polymers 2020, 12,746.[CrossRef][PubMed]

18. Li,Y.;Hao,Q.H.;Xia,S.Y.;Yan,D.X.;Tan,H.G.Morphologiesofsphericalbidispersepolyelectrolytebrushesinthepresenceof trivalentcounterions. Chem.Phys. 2020, 539,110941.[CrossRef]

19. Wang,W.;Li,L.;Henzler,K.;Lu,Y.;Wang,J.;Han,H.;Tian,Y.;Wang,Y.;Zhou,Z.;Lotze,G.;etal.ProteinImmobilization ontoCationicSphericalPolyelectrolyteBrushesStudiedbySmallAngleX-rayScattering. Biomacromolecules 2017, 18,1574–1581. [CrossRef]

20. Lqbal,D.;Yan,J.;Matyjaszewski,K.;Tilton,R.D.Swellingofmuti-responsivesphericalpolyelectrolytebrushacrossawiderange ofgraftingdensities. ColloidPolym.Sci. 2019, 298,35–49.

21. Azmana,M.;Mahmood,S.;Hilles,A.R.;Rahman,A.;Arifin,M.A.B.;Ahmed,S.Areviewonchitosanandchitosan-based bionanocomposites:Promisingmaterialforcombattingglobalissuesanditsapplications. Int.J.Biol.Macromol. 2021, 185,832–848. [CrossRef]

22. Lenze,C.J.;Peksa,C.A.;Sun,W.;Hoeger,I.C.;Salas,C.;Hubbe,M.A.Intactandbrokencellulosenanocrystalsasmodel nanoparticlestopromotedewateringandfine-particleretentionduringpapermaking. Cellulose 2016, 23,3951–3962.[CrossRef]

23. Moud,A.A.Polymerbasedflocculants:Reviewofwaterpurificationapplications. J.WaterProcessEng. 2022, 48,102938. [CrossRef]

24.Ballauff,M.Sphericalpolyelectrolytebrushes. Prog.Polym.Sci. 2007, 32,1135–1151.[CrossRef]

25. Nie,G.;Li,G.;Wang,L.;Zhang,X.Nanocompositesofpolymerbrushandinorganicnanoparticles:Preparation,characterization andapplication. Polym.Chem. 2016, 7,753–769.[CrossRef]

26. Yuan,H.;Liu,G.Ioniceffectsonsyntheticpolymers:Fromsolutionstobrushesandgels. SoftMatter 2020, 16,4087–4104. [CrossRef][PubMed]

27. Giussi,J.M.;Cortez,L.;Marmisollé andAzzaroni,O.Practicaluseofpolymerbrushesinsustainableenergyapplications: Interfacialnanoarchitectonicsforhigh-efficiencydevices. Chem.Soc.Rev. 2019, 48,814–849.[CrossRef][PubMed]

28. Lu,Y.;Ballauff,M.Sphericalpolyelectrolytebrushesasnanoreactorsforthegenerationofmetallicandoxidicnanoparticles: Synthesisandapplicationincatalysis. Prog.Polym.Sci. 2016, 59,86–90.[CrossRef]

29. Bajza,E.;Hitrec,P.;Muic,M.InfluenceofdifferentconcentrationsofAl2 (SO4 )3 andanionicpolyelectrolytesontannery wastewaterflocculation. Desalination 2005, 171,13–20.[CrossRef]

30. Dong,Y.;Shen,Y.;Ge,D.;Bian,C.;Yuan,H.;Zhu,N.Asodiumdichloroisocyanurate-basedconditioningprocessforthe improvementofsludgedewaterabilityandmechanismstudies. J.Environ.Manag. 2021, 284,112020.[CrossRef]

31. Zhao,C.;Shao,S.;Zhou,Y.;Yang,Y.;Shao,Y.;Zhang,L.;Zhou,Y.;Xie,L.;Luo,L.Optimizationofflocculationconditions forsolublecadmiumremovalusingthecompositeflocculantofgreenanionpolyacrylamideandPACbyresponsesurface methodology. Sci.TotalEnviron. 2018, 645,267–276.[CrossRef][PubMed]

32. Huang,J.;Yang,Z.H.;Zeng,G.M.;Ruan,M.;Xu,H.Y.;Gao,W.C.;Luo,Y.L.;Xie,H.M.InfluenceofcompositeflocculantofPAC andMBFGA1onresidualaluminumspeciesdistribution. Chem.Eng.J. 2012, 191,269–277.[CrossRef]

33. Ren,J.;Wei,H.;Li,A.;Yang,H.EfficientremovalofphosphorusfromturbidwaterusingchemicalsedimentationbyFeCl3 in conjunctionwithastarch-basedflocculant. WaterRes. 2020, 170,115361.[CrossRef][PubMed]

34. Chen,Y.;Yang,C.;Hu,J.;Huang,M.;Zhao,L.;He,J.;Zhang,S.;Shen,F.;Tian,D.Cascadeutilizationofcropstrawthrough aFeCl3 -mediateddeepeutecticsolventbiorefinery:Lignin-containingcellulosenanofibersflocculantfabricationfollowedby fertilizerproduction. Chem.Eng.J. 2023, 472,144823.[CrossRef]

35. Verma,A.K.;Dash,R.R.;Bhunia,P.Areviewonchemicalcoagulation/flocculationtechnologiesforremovalofcolorfromtextile wastewaters. J.Environ.Manag. 2012, 93,154–168.[CrossRef]

36. Li,Z.;Zhang,Y.;Wei,X.;Huang,L.;Zhang,J.;Wu,Y.;Zhang,Y.;Xiang,Y.Acomprehensivestudyontheperformanceand mechanismofmicroplasticsremovalbyenhancedcoagulationmethods. J.WaterProcessEng. 2023, 56,104238.[CrossRef]

37. Rong,H.;Gao,B.;Dong,M.;Zhao,Y.;Sun,S.;Yue,Q.;Li,Q.Characterizationofsize,strengthandstructureofaluminum-polymer dual-coagulantflocsunderdifferentpHandhydraulicconditions. J.Hazard.Mater. 2013, 252–253,330–337.[CrossRef]

38. Kato,M.;Isogai,A.;Onabe,F.Adsorptionbehaviorofaluminumcompoundsonpulpfibersatwet-end. J.FoodSci. 1998, 44, 361–368.[CrossRef]

39. Dai,Q.;Ren,N.;Ning,P.;Ma,L.;Guo,Z.;Xie,L.;Yang,J.;Cai,Y.Inorganicflocculantforsludgetreatment:Characterization, sludgeproperties,interactionmechanismsandheavymetalsvariations. J.Environ.Manag. 2020, 275,111255.[CrossRef]