PAPERmaking!

The e-magazine for the Fibrous Forest Products Sector

Produced by: The Paper Industry Technical Association

Publishers of: Paper Technology International®

PAPERmaking!

FROM THE PUBLISHERS OF PAPER TECHNOLOGY INTERNATIONAL® Volume10, Number2, 2024

CONTENTS:

FEATURE ARTICLES:

1. Paperboard: Relating papermaking process parameters to paperboard properties.

2. Tissue: Simulation of sheet moulding during TAD processing

3. Chemistry: ASA for better sizing – a review

4. Environment: CO2 emissions accounting of Chinese paper industry.

5. Water Treatment: Quality evaluation of water disclosure of Chinese paper mills

6. Sustainabililty: Recycling various papermaking wastes as eco-friendly slurry.

7. Wood Panel: Antibacterial Medium-Density Fibreboard (MDF) production.

8. Packaging: Barrier coating and tray forming of paperboard

9. Social Media: Using X (Twitter) for business.

10.Eye Health: Easy steps to keep your eyes healthy

11.Sitting Posture: Tips for improving posture at your computer desk.

12.AI in the Office: Possible uses of AI to improve the office environment.

SUPPLIERS NEWS SECTION:

News / Products / Services:

• Section 1 – PITA CORPORATE MEMBERS AFT / ARCHROMA / VALMET

• Section 2 – PITA NON-CORPORATE MEMBERS ANDRITZ / VOITH

• Section 3 – NON-PITA SUPPLIER MEMBERS KADANT / KONECRANES / SICK

Advertisers: ABB

DATA COMPILATION:

Events: PITA Courses & International Conferences / Exhibitions

Installations: Overview of equipment orders and installations between Feb and June

Research Articles: Recent peer-reviewed articles from the technical paper press

Technical Abstracts: Recent peer-reviewed articles from the general scientific press

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

1 of 1

PAPERmaking!

FROM THE PUBLISHERS OF PAPER TECHNOLOGY INTERNATIONAL®

Volume10, Number2, 2024

Relating papermaking process parameters to properties of paperboard with special attention to through‑ thickness design

MIKAEL NYGÅRDS1,2

A biaxial stress state has been proposed to formulate a failure criterion for paperboard during bending. About 100 paperboards have been splitted, such that top, middle, and bottom plies have been free-laid and tested in the machine direction, cross-machine direction as well as in out-of-plane direction (ZD). The purpose was to determine the failure stresses and its dependency of papermaking parameters: density, degree of orientation, and fiber length for each layer. A linear model to predict the geometrical strength of a plies was suggested. Analytically simulations of different paperboard structures behavior during bending were performed. The density of the middle ply affected the location of the failure position in ZD, as well as the maximum bending moment. The impact of orientation and degree of anisotropy was simulated, which can be used to optimize the ZD property gradient by tweaking the properties, and hence optimize paperboard performance.

Contact information:

1 BillerudKorsnäs, 801 81 Gävle, Sweden

2 Solid Mechanics, Department of Engineering Mechanics, KTH, 100 44 Stockholm, Sweden

MRS Advances (2022) 7:789–798 https://doi.org/10.1557/s43580-022-00282-7

Creative Commons Attribution 4.0 International License

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

MRS Advances (2022) 7:789–798

https://doi.org/10.1557/s43580-022-00282-7

Relating papermaking process parameters to properties of paperboard with special attention to through‑thickness design

Mikael Nygårds1,2

Received: 23 March 2022 / Accepted: 26 April 2022 / Published online: 6 May 2022

© The Author(s) 2022

Abstract

A biaxial stress state has been proposed to formulate a failure criterion for paperboard during bending. About 100 paperboards have been splitted, such that top, middle, and bottom plies have been free-laid and tested in the machine direction, cross-machine direction as well as in out-of-plane direction (ZD). The purpose was to determine the failure stresses and its dependency of papermaking parameters: density, degree of orientation, and fber length for each layer. A linear model to predict the geometrical strength of a plies was suggested. Analytically simulations of diferent paperboard structures behavior during bending were performed. The density of the middle ply afected the location of the failure position in ZD, as well as the maximum bending moment. The impact of orientation and degree of anisotropy was simulated, which can be used to optimize the ZD property gradient by tweaking the properties, and hence optimize paperboard performance.

Introduction

In the papermaking process, fbers with diferent fber length are mixed into a pulp. In the process, it is possible to steer a paperboard machine to control the density by refning and by chemical additives in diferent plies in a paperboard. It is also possible to steer the orientation of the fber by controlling the headbox outlet speed in relation to the moving web. Hence, by utilizing papermaking parameters paperboards can be engineered to have diferent properties in the plies of a multiply paperboard.

The product paperboard is characterized with respect to its bending stifness, thickness, or grammage. To optimize these properties and the paperboard functionality the through-thickness (ZD) profle can be engineered. The straightforward path to optimize the bending stifness would be to make a paperboard with and I-beam structure. However, when a paperboard is folded an I-beam structure might not be optimal to comply with the stress state that arise. One complicating factor is that the in-plane tensile and compression behavior is diferent for paperboard [1]. Depending on

* Mikael Nygårds Mikael.nygards@billerudkorsnas.com

1 BillerudKorsnäs, 801 81 Gävle, Sweden

2 Solid Mechanics, Department of Engineering Mechanics, KTH, 100 44 Stockholm, Sweden

how the ZD profle is engineered diferent failure mechanisms can be activated when a paperboard is folded.

Before a paperboard becomes a package, it needs to be converted; creasing is used to score the paperboard such that it will fold along pre-defned lines [2]. For optimal converting behavior it is important to control where the intentional damage created during creasing develops. This put additional requirements on the paperboard design that can be considered for optimal folding performance.

The key element to design paperboard properties in the ZD is to utilize multiply board structures, such that at least three plies can have diferent properties. To evaluate how the efect of the papermaking process in each ply, it is necessary to freelay the plies and perform testing, where the intention is to isolate the constituent plies, and test each of them separately. While multiply paperboard has been available for a long time, efective and rigorous methods to free-lay (or isolate) the plies have not been available until recently. Initially surface grinding was used [3], and the technique has also successfully been used to determine properties of top, middle, and bottom plies [4–7]. The technique works to determine properties, but is dependent on good calibration of the machinery, and is very time consuming. A more time efcient machine has been developed by Fortuna Gmbh [8], where a rotating knife is placed after a nip. With this technique top, middle, and bottom plies can be free-laid in a very time efcient procedure. The machine has also been used to characterize properties of plies [9–11].

The aim of this work would be to implement analytical models that can be used to predict the performance of paperboards. It will be based on how it is constructed in the thickness direction using the properties of three plies in the paperboard structures. This will be done by utilizing laminate theory Fellers and Carlsson [12] and Fellers [13], and Timoshenko beam bending [14] to construct a model that can predict the maximal bending moment for paperboards based on papermaking variables such as density, fber orientation, and fber length.

Theoretical background

In the analysis, we will assume that in-plane tensile and outof-plane shear stresses will contribute to failure during folding. With laminate theory, it is possible to calculate how a multilayer structure respond to external forces, which helps us to develop a ZD structure with accurate bending stifness.

Elastic bending

Bending stifness of paperboard is normally measured by twopoint bending, when the bending arm is L = 50 mm [15]. With this confguration the shear stress component is negligible. Bending of a homogenous cantilever beam with a rectangular cross section will be performed with a bending moment Mb per unit width. A tensile stress will arise on the convex side of the beam, and compressive stresses on the concave side.

The theoretical framework for evaluation of the bending stifness for multiply paperboards have been derived by Fellers and Carlsson [12] and Fellers [13]. By using the defnition of bending moment, integrating the elastic stress in the beam and by utilizing strain compatibility the bending moment for a homogenous beam with thickness, t, and rectangular cross section the bending moment becomes

If the angle, θ, is measured in degrees the bending stifness is given by

In the two-point bending setup, one end of the paperboard is clamped, and the other end is loaded by a concentrated load. The bending moment then decreases linearly as the distance x from the clamped end increase. If small deformations are assumed during the bending stifness measurements, then the maximum defection δ becomes

The two-point bending is commonly used as a quality control in industry. Then w = 38 mm wide samples are bent, and L = 50 mm is used. For this test, the force, PSb, that is read on the testing device is often interpreted as the bending moment of the paperboard

Multi-ply paperboards consist of several plies, which can represent layers in a laminate. With a multi-ply model, it would be possible to calculate the bending stifness. The model can be used to make predictions, and hence extend the design space for multi-ply paperboards. The ability to make calculations is benefcial for optimization, since it can give an indication of the choice of raw material, grammage, and ply layout. For multi-ply paperboard the same strategy as for homogenous plies are applied. However, it needs to be accounted for that the plies are not located along the neutral line. Then bending stifness for a multi-ply structure can then be expressed as where

Then bending stifness which is evaluated as the steepest slope of a F − δ plot, becomes

where Ek is the elastic modulus of ply k, which might be in either MD or CD. The ply coordinates zk (Fig. 9) (k = 0, 1, 2, …., N) where N is the number of plies, are calculated as

where t is the total thickness of the paperboard. The bending stifness is dependent of the thickness and grammage of the diferent plies.

Relating papermaking process parameters to properties of paperboard with special attention…

Maximum bending moment during folding

Two-point bending, or a cantilever confguration is often used to measure the bending stifness of paper and paperboard. Folding of a paperboard will give an initial linear response associated with the bending stifness. Thereafter, a peak bending moment will be reached, which is followed by a non-linear response as the paperboard is folded 90°.

To evaluate bending stiffness the standard span is L = 50 mm. This ensures that the shear component during folding is small. On the other hand, a span of only L = 10 mm is used when folding both uncreased and creased paperboards. To analyze the stress state in the paperboard during folding a Timoshenko beam analysis [14] can be applied to uncreased paperboard samples, see further Nygårds [16]. The stress state then consists of two components, an in-plane tensile/compressive stress, σx, and an out-of-plane shear stress, τxz, which is expressed as

stress state. Here the diference is however smaller than a factor 2 in density, hence the efect should be neglectable compared to other assumptions. It also has a large dependency of thickness. In thick paperboard, and paperboards with low τ f or high σ f the shear stress component will become larger than the normal stress component. This means that it will contribute to failure, basically the paperboard will shear and cause failure. L = 10 m is an idealized lab setting, bending of paperboards can occur, with shorter bending arm, L, the shear component will be even more important. The conclusion from this is that the out-of-plane shear properties afect the folding behavior for paperboard grades, yet it can be disregarded for nonpaper materials.

Because of the biaxial stress state, a failure criterion needs to be formulated. The idea here is to keep it simple to enable predictions of failure. It should also cover the simple mechanisms that have been observed, which are:

• Normalized stress components should be used.

• If the normal stress is positive, shearing will be more difcult since the fbers are stretched.

and where t is the sample thickness, w the width, and z the distance from the neutral line of the specimen. For most materials, the shear component will be small, and can be neglected. However, due to the orthotropy in paper materials, where the in-plane stifness and strength are much greater than the out-of-plane stifness and strength, the shear component will impact the behavior. For this purpose, it will be of interest to evaluate the stress components in relation to its measured failure stresses, σ f and τf, accordingly

• If the normal stress is negative, shearing will be easier since the paperboard ply can buckle.

• For simplicity no mixed terms are accounted for.

Using the assumptions above it was assumed that

where σf(z) and τf(z) are the failure stresses that are diferent in the diferent plies. Out-of-plane shear strength is needed to evaluate the folding behavior. Normally out-of-plane shear strength can be associated with breaking of bonds within the sheets. In the literature out-of-plane shear properties are often lacking. Instead, ZD strength is most often measured strength value. A fair approximation base on the work by Stenberg et al. [17] is

and In the analysis, it was assumed that the failure stress is homogenous in the thickness direction, hence the paperboard does not have a property gradient. This is an obvious simplifcation in the case of multiply paperboard, which will not have a homogeneous stress distribution in the thickness direction. It shows that within the normal limit of failure properties there is shift of dominating stress component. However, it should also be emphasized that if there is large diference in properties of the outer plies and the middle ply, this will also afect the parabolic shear

Hence, the failure criterion can be express as

The failure criterion has been plotted in Fig. 1 for some diferent combinations of uniform failure stresses σ f and 𝜎 f ZD . This show that as 𝜎 f ZD decreases the failure mechanism is changing from in-plane tension/compression, i.e., failure close to the outer surfaces, that is dominated by the network structure to out-of-plane shear, i.e., failure within the paperboard, that is dominated by bond strength.

Fig. 1 The failure criterion plotted for a 400 μm paperboard with diferent normal and shear failure stresses. In bending the paperboards will fail in the z-position, where the normalized stress is maximal

Results

Properties of free‑laid plies

Paperboards from a series of trial productions have been splitted (Fortuna [8] to free-lay the top, middle, and bottom plies. About 100 paperboards with various properties was used in the study. The paperboards were selected to have variation in the diferent plies to represent the limits with respect to density, fber orientation etc. within each layer. The plies have been characterized with respect to physical properties and tensile tests to measure density, degree of anisotropy, strength, and stifness within each layer. The in-plane tensile properties were measured using ISO 1924-2, while the ZD tensile test was measured using ISO 15754. Normally the variation of strength is about 10% when whole paperboard is tested, which is due to the inhomogeneous fber structure that can have density variations. When free-laid plies are tested, the strength variation is about the same. However, the splitting procedure is also a source of variation, since thickness of the free-laid plies can vary between splits. The aim here has been to try to position the splitting position to the middle of the interface. However, the interface has a thickness of 10–20 mm, hence some fbers from the neighboring ply will still be found on the free-laid ply. The variation of strength properties would then be about 10% and is the main reason to the variations seen in Figs. 2, 3, 4, 5. The data will be used to formulate simplifed models that can be used to make qualitative analytical predictions, in these we will not consider variation at this time. Of interest will be to identify the importance of papermaking parameters

such as density, fber orientation, and fber length to predict strength and stifness.

Since paperboard is orthotropic the geometrical mean strength is often calculated from the strength in the machine direction (MD) and cross-machine direction (CD) [18],

In this work several paperboards have been tested, a diferent feature between the paperboards was the fber orientation. From tensile testing of paperboards with diferent fber orientation it was established that as the MD/CD strength ratio varied; in fact, the tensile strengths in MD and CD were invariant, see Fig. 2, where the top, middle, bottom plies have the same behavior as the whole paperboard.

The strength of a paperboard in arbitrary direction was expressed as

where A is the degree of anisotropy, which by rearranging Eq. (19) the strengths in MD and CD can be expressed as

MD forCD,where

CD < 1 ,

where σ0 is the strength of an isotropic sheet, at

b CD = 1. At this stage it can be concluded that the Eqs. (20–21) can be (19)

Relating papermaking process parameters to properties of paperboard with special attention…

2 Tensile strength as function degree of anisotropy for the whole paperboard and the free-laid plies

of anisotropy, A

3 Strength of free-laid plies as function of density

4 The geometrical mean in MD and CD elastic modulus normalized with fber length show a liner relation with density

used to make fair approximations about the fber orientation efect on the plies.

The density of the paperboard plies as well as the fber length will afect the strength properties. If the strength σ0

was plotted versus density one can see that the strengths of the three plies became grouped into diferent clusters. The diference could be explained by the diference in fber length of the fbers used in the diferent plies. Here, we

Fig.

Degree

Fig.

Fig.

assume that the following average fber lengths apply to the diferent plies:

• Bottom ply Lfiber = 2.0 mm,

• Middle ply Lfiber = 1.3 mm,

• Top ply Lfiber = 1.5 mm.

This is essentially a curve-ftting of the data, but it has a physical relevance. The bottom plies were made of softwood fbers, the top plies had diferent mixtures of hardwood and softwood fbers, while the middle plies had mixtures of softwood, hardwood, broke, and CTMP. All these measurements were also in agreement with measurement of average fber length for headbox pulp samples. However, due to the large number of paperboards tested, there are samples the deviate from these fber lengths. Then one gets the plot in Fig. 3, where the ration σ0/Lfber has been plotted for three plies. In Fig. 3 it was obvious that the density and σ0/Lfber were different for the diferent plies. By doing a linear regression it became evident that the failure stress, 𝜎0 , of the ply data in Fig. 3 can be simplifed into a simple equation

The aim of plotting the tensile properties of the free-laid plies was to fnd relations to diferent parameters that easily can be controlled during machine trials. This was identifed to be density, fber length, and fber orientation (here expressed as a function of the MD/CD strength ratio). Based on this, simple expression was found that can be implemented in the derived stress state during folding. Here we found that the tensile strength can be expressed as:

Normally the tensile strength and tensile stifness is correlated in paper materials. In Fig. 4, it should be noted

that the ratio tensile stifness/fber length also has almost a linear correlation with density for the free-lied plies. There is a deviation for the top ply at high densities. This should be due to the long fber length that cause greater entanglement between the fbers, and lead to fber failure rather than bond failure where the fbers are torn out of the fber network. To make a simple model of stifness in relation to strength it can be assumed that

Typically, ZD tensile tests are performed on the whole paperboard. This is since testing on free-laid middle plies can show smaller ZD strength values, because damage can be initiated during the splitting operation. Therefore, we will present ZD strength tested on whole paperboard, but it will be presented against the middle ply density, since this is most physically relevant since the ZD tensile failures occurs in the middle ply. In Fig. 5, the ZD strength density can be seen, and a linear trend can be observed, yet there is variation. A linear trend would be expected since ZD tensile strength correlates with the number of bonds in the fber network. Formations efects that give local variation of density, as well of ply strength in relation to interface strength will, however, contribute to the observed variation. For the modeling purpose it will however be relevant to assume that denser middle plies give higher ZD strength, that based on the data in Fig. 5 can be assumed to follow

Based on properties of the free-laid sheets it has been possible to develop models that express the failure stresses as function of the papermaking parameters: density, fber orientation, and fber length, which are parameters that can be altered during the papermaking process. The derived

Fig.

Relating papermaking process parameters to properties of paperboard with special attention…

models are now inserted in the failure envelope (Eq. 18), hence Or expressed in MD and CD

of anisotropy, A = 1 in all plies. In the simulations the efect of diferent grammage in the plies was investigated, and the impact of density of the middle ply as well as fber length in the middle ply. When the density of the middle ply is low the paperboard thickness is high (Fig. 6).

Modeling of bending of paperboard structures

Paperboard structures do not have uniform through-thickness (ZD) profles, instead the idea is to have a ZD- profle to optimize performance. In papermaking one can easily change the density, fber length, and orientation of each ply, which was also observed in Figs. 2, 3, 4. Based on this information some artifcial paperboard structures will be constructed to visualize potential problems that can arise during bending. For this purpose, the laminate theory and bending analysis equations were implemented in an Excel sheet. To show how the concept works, the laminate theory was frst used to optimize the bending stifness of an artifcial symmetric paperboard with grammage 250 g/m2, degree

When Lfber = 1.0 mm was used, a rather weak middle ply was simulated; a local maximum was found, where the bending stifness can be optimized with respect to grammage in the outer plies. The simulations showed that the maximum bending stifness have about 25–30% of the grammage in the outer plies. However, simulations with Lfber = 2.0 mm, which represent a middle ply with high elastic modulus. For this case, it was observed that the middle ply contributes considerably to the bending stifness of the paperboard, and therefore the bending stifness increase with increasing grammage in the middle plies. Hence, the efect of the increased thickness due to more grammage in the middle ply was larger than the efect of separating the denser outer plies. This was an interesting observation since many paperboard products are within the property range used. It is hence not necessarily true that maximum bending stifness is achieved with 30% outer plies.

The bending stifness analysis showed that the bending stifness can be optimized by altering the grammages of outer plies, and the maximum ratio between bending stifness and grammage of the paperboard can be found. However, there are also other parameters that depend on the grammage of the outer plies, such as printing and surface properties. Therefore, other parameters than bending stifness also contribute to optimal paperboard performance. For the upcoming simulation of paperboard folding, we have

Fig. 6 Optimization of bending stifness simulating paperboards with diferent densities in the middle ply, as well as diferent fber lengths Lfber = 1 mm (solid lines) corresponding to EMP = 900 MPa and Lfber = 2 mm (dotted lines) corresponding to EMP = 1800 MPa

constructed a paperboard, where data was taken from Fig. 3 This is a asymmetric paperboard with diferent densities 600, 500, and 750 kg/m3 for the bottom, middle, and top plies, respectively, and fber lengths 2, 1.3, and 1.5 mm in the plies. The grammages (83, 250, and 50 g/m2) were chosen such that the paperboard thickness became h = 400 μm and based on the properties of the plies the failure stress during bending was estimated and put into the stress state Eqs. (14–15). With the chosen material parameters, the normal stress is still dominating, but it should be seen that the largest normalized stress can be found in the middle ply, close to the interfaces. This indicates that tensile failure can occur in the middle ply before it can be seen in the outer plies. The normalized shear stress was smaller than the normal stress, but it was not neglectable. This can be seen when the proposed failure criterion was plotted (Fig. 7) it was noted that the fmax is located along the bottom interface, where we hence expect failure to occur when the maximum bending moment has been reached. If a higher bending moment is desired for the paperboard, then the highest prioritization should be to increase the strength of the bottom interface, thereafter the top interface should be strengthened.

The fact that the failure criterion f is largest in the middle ply suggest that the failure will occur there during bending, and that modifcations of the middle ply will alter the value and position of the failure criterion. In paperboard making, it is common to work with the middle ply to alter the properties of the paperboard. If the density of

the middle ply is changed the in-plane and ZD strength of the middle ply will change, which will alter the failure criterion. In Fig. 8, the middle ply density has been varied from 250 to 750 kg/m3. It should be noted when the density is around 500 kg/m3 the failure criterion is roughly the same in the middle ply and the outer plies with this parameter set. This must be optimal; the middle ply has then been made bulkier without compromising the maximum bending moment. As the density is decreased the risk of failure in the middle ply increases, which will also lower the maximum bending moment. And when the middle ply is denser the largest risk of failure is within the outer plies and dominated by the normal component.

In the previous plots (Figs. 7, 8) the failure criterion has been shown for A = 1, i.e., when the paperboard is in-plane isotropic. At a paperboard machine more fbers are often oriented in MD. This will alter the shape of the failure criterion. In fact, the orientation of diferent plies can be altered to minimize the risk of failure, and hence increase the maximum bending moment. If the orientation of the outer plies varies from A = 1 to A = 2 one can see that it is the CD direction that will have the largest risk of failure, see Fig. 9. This is since the failure stress in MD will increase more when the fbers are oriented in MD. In Fig. 9, it can also be seen that a similar efect occurs when the orientation of the middle ply is changed, the risk of failure during folding increase with increased MD orientation.

Fig. 7 Failure criterion based on the unsymmetrical paperboard that was constructed

Discussion and conclusion

The development of analytical models can help us to better understand how paperboards behave under diferent loading conditions. One alternative approach would be to develop fnite element models to do the same kind of analysis. Both methods have their respective advantages and drawbacks. The main advantage with the model presented

here is that it quickly can correlate papermaking parameters to potential risks and do simple parameter studies; this by utilizing Excel.

Splitting and free laying of the top, middle, and bottom plies of paperboards that had been produced during diferent trial gave us a good database to develop phenomenological models of strength that was dependent on density, degree of anisotropy, and fber length. Typical values from this data set were used to perform simulation of folding of paperboard.

Fig. 8 Efect on the failure envelope of having diferent density in the middle ply

Fig. 9 Efect on the failure envelope of orientation: (left) bottom and top plies, (right) middle ply

It was evident the greatest risk for failure often was within the middle ply. Moreover, if the density is lowered, the risk of failure due to insufcient middle ply density increases. Hence by having good control of the densities in the diferent plies it would be possible to balance where the weakest point in the through-thickness direction should be located, and how much stronger the outer plies need to be for optimal performance. Hence, it is not the strength of the individual ply that is important, it is the relation to the other plies that gives optimal performance.

While it could be concluded that an efficient way to increase the bending stiffness of a paperboard was to decrease the density of the middle ply. When the density is decreased from 500 to 400 kg/m3 the bending stifness increase about 50%. However, the analysis also show that this will result in a 20% drop in ZD strength. The drop in ZD strength will also afect the maximum bending moment that the paperboard can carry, which in turn will afect the box compression. Hence, lightweight will reduce quality of the paperboard, which is not acceptable.

An alternative approach is then to work with the strength profle in the through-thickness direction. Instead, it would be possible to work with the density gradient in the paperboard, which can be controlled by drainage of the paperboard during production. The analysis done here showed that it would be advantageous to increase the strength of the lower part of the middle ply to increase the maximum bending moment of the paperboard. In addition, the orientation of the diferent plies can be utilized to optimize the paperboard performance; the plies can be oriented more or less in the MD to minimize the largest stresses that arise in the through-thickness direction.

Acknowledgements The work has been fnanced by internal resources from BillerudKorsnäs, for which the author is grateful. BillerudKorsnäs acknowledge the possibility ofered to publish results within the scientifc community.

Funding Open access funding provided by Royal Institute of Technology.

Data availability This manuscript has no additional data available.

Declarations

Conflict of interest There are not potential conficts of interest behind the work presented here.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes

were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/

References

1. M. Nygårds, J. Sundström, Comparison and analysis of in-plane compression and bending failure in paperboard. Nord. Pulp Pap. Res. J. 31(3), 432–440 (2016)

2. D.W. Coffin, M. Nygårds, Creasing and folding, Advances in Paper Science and Technology: Trans. 16th Fundamental Research Symposium (2018)

3. M. Östlund, S. Östlund, C. Fellers, Experimental determination of residual stresses in paperboard. Exp. Mech. 45, 493–497 (2005)

4. M. Nygårds, Experimental techniques for characterization of elasticplastic material properties in paperboard. Nord. Pulp Pap. Res. J. 23(4) (2008)

5. A. Hagman, M. Nygårds, Short compression testing of multi-ply paperboard, infuence from shear strength. Nord. Pulp Pap. Res. J. 31(1), 123–134 (2016)

6. H. Huang, M. Nygårds, A simplifed material model for fnite element analysis of paperboard creasing. Nord. Pulp Pap. Res. J. 25(4), 502–509 (2010)

7. H. Huang, M. Nygårds, Numerical and experimental investigation of paperboard folding. Nord. Pulp Pap. Res. J. 26(4), 452–467 (2011)

8. Fortuna GmbH, Splitting Machine AB 320 P, Fortuna GmbH, Eisenbahnstraße 15, D-71263 Weil der Stadt (2004)

9. G. Marin, In-plane fracture of paperboard, Master thesis, KTH Royal Institute of Technology, Solid Mechanics, Stockholm (2014)

10. J. Tryding, G. Marin, M. Nygårds, P. Mäkelä, G. Ferrari, Experimental and theoretical analysis of in-plane cohesive testing of paperboard. Int. J. Damage Mech. 26(6), 895–918 (2016)

11. A.N. Giashi, T. Gereke, T. Mbarek, C. Cherif, Novel dynamic test methods for paperboard composite structures. Exp. Tech. (2021). https://doi.org/10.1007/s40799-021-00496-8

12. Fellers, Carlsson, Bending stifness, with special reference to paperboard. In: Handbook of Physical Testing of Paper, Vol 1, Chapter 5: 233–256 (1983)

13. C. Fellers, Laminate theory for papermakers, in Paper Products Physics and Technology (Walter de Gruyter, 2009), pp. 287–314

14. S. Timoshenko, Theory of Elasticity. Engineering Societies Monographs, ed. by H. W. Craver (McGraw-Hill, New York, 1934)

15. ISO 2493-2, Paper and board—determination of bending resistance—part 2: Taber-type tester, Technical Committee: ISO/TC 6/ SC 2 (2011)

16. M. Nygårds, Behavior of corners in carton board boxes, in Mechanics of Paper Products, 2nd edn. ed. by S. Östlund (Walter de Gruyer GmbH, Berlin, 2021)

17. N. Stenberg, C. Fellers, S. Östlund, Plasticity in the thickness direction of paperboard under combined shear and normal loading. Trans. ASME 123, 184–190 (2001)

18. Htun, Fellers, The invariant mechanical properties of oriented handsheets. Tappi 65(4), 113–117 (1982)

PAPERmaking!

FROM THE PUBLISHERS OF PAPER TECHNOLOGY

Volume10, Number2,2024

Simulation of Sheet Molding during Through Air Drying of Tissue Paper within a Papermaking Framework

K. REZK & B. SJÖSTRAND

A way to improve product performance of tissue grade paper products is to replace the press section with a Through Air Drying (TAD) section which is a technique where paper sheets are moulded into a structured fabric by vacuum boxes and transferred over one or more TAD cylinders with steam heated displacement drying. The process of sheet molding is modelled with Comsol Multiphysics where the computational model is setup with a 2-dimensional representation of the paper sheet. The tissue sample with randomly distributed fibre positions is generated using a MATLAB script written in the Livelink interface with Comsol. The process is simulated with the Moisture Flow multiphysics interface. The comprising physical modules are the Laminar Flow and the Moisture Transport in Air modules. Respectively, these modules calculate the velocity and pressure field of the moist air as well as the relative humidity, which is a rewrite of the concentration of water in air. The fibres in the sheet are modelled as porous media where the fibres contain both moist air and liquid water in equilibrium. In this paper, a basis weight at roughly 20 g/m2 is simulated and compared to laboratory data. The aim of the model is to estimate solid content in the paper sheet over vacuum time as well as energy demand and required airflow through the structure.

Contact information:

Pro2BE, the research environment for Processes and products for a circular forest-based bioeconomy, Department of engineering and chemical sciences, Karlstad University, Karlstad, Sweden.

COMSOL Conference 2023, Munich Open Source

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

SimulationofSheetMoldingduringThroughAirDryingofTissue PaperwithinaPapermakingFramework

K. Rezk1, B. Sjöstrand1

1. Pro2BE, the research environment for Processes and products for a circular forest-based bioeconomy, Department of engineering and chemical sciences, Karlstad University, Karlstad, Sweden

Abstract

A way to improve product performance of tissue grade paper products is to replace the press section with a Through Air Drying (TAD) section which is a technique where paper sheets are moulded into a structured fabric by vacuum boxes and transferred over one or more TAD cylinderswithsteamheated displacementdrying.Theprocessofsheetmolding ismodelledwith Comsol Multiphysics where the computational model is setup with a 2-dimensional representation of the paper sheet. The tissue sample with randomly distributed fibre positions is generated using a MATLAB script written in the Livelink interface with Comsol The process is simulated with the Moisture Flow multiphysics interface. The comprising physical modules are the Laminar Flow and the Moisture Transport in Air modules. Respectively, these modules calculate the velocity and pressure field of the moist air as well as the relative humidity, which is a rewrite of the concentration of water in air. The fibres in the sheet are modelled as porous media where the fibres contain both moist air and liquid water in equilibrium. In this paper, a basis weight at roughly 20 g/m2 is simulated and compared to laboratory data. The aim of the model isto estimate solid content in the paper sheet over vacuum time as well as energydemand and required airflow through the structure

Keywords: CFD, Dewatering, Moisture transport, tissue paper, through air dying.

Introduction

Water removal during paper and board manufacturing is an energy intensive process. The dewatering process in paper and board manufacturing generally consists of four stages with progressively high energy demand [1, 2]. The first stage comprises water removal with gravity or centrifugal forces where water escapes without additional energy input and then with help of static elements in the geometry of the paper machine, followed by low and high vacuum pressure. In the second stage of vacuum exposure, where higher levels of vacuum pressure are applied through suction boxes [2-8]. Most of the suspended water is removed during gravitational and vacuum dewatering [9]. The third stage is performed in the press section by compressing the paper in one or more press nips [10] The last stage, which far exceeds the other stages in energy demand, is comprised by thermaldryingwhere remaining water in fibres are evaporated on steam-heated cylinders [9, 11]. Hence, improving the mechanical dewateringprocessespriortothethermalstagecould reduce major production cost.

A number of researchers have studied vacuum dewatering experimentally using laboratory equipment as well using pilot scale machines [2-8, 12-21] Process parameters that influence sheet dryness such as applied vacuum, dwell time and basis weight have been analysed.[4, 6, 13, 22-25]

These studies show that a prolonged dwell time would increase dryness to a certain level. To reach a higher dryness level, increased vacuum pressure is necessary.

Numerous researchers have conducted theoretical and numerical analysis on various aspects on vacuum dewatering such as single-flow mechanics in fibrous porous media where permeation through compressible fiber beds, permeability in various representative fiber structures were studied as well as penetrated air volume calculated and compared to experimental data [26-30] Some attempts on simulating the two-phase flow behavior during the early stage of dewatering of the unbound water where progression on estimating the dwell time and dry content with varying pressure pulses has been conducted in [16, 31, 32]. While there are improvements that need to me made on the estimation of the dewatering rate, the penetrated air volume showed excellent agreement with experimental data.

Fluidinertiaaswellasspatialheterogeneityhasbeen studied for moderate Reynolds number in various fiber arrangements by [33-37]. Moreover, the influence on the permeability based on sample size, boundary conditions, homogeneity and isotropy were studied. The relations are used to predict permeability for various fiber arrangements and porosity levels.

A way to improve product performance of tissue grade paper products is to replace the press section with a Through Air Drying (TAD) section which is a technique where paper sheets are moulded into a structured fabric by vacuum boxes and transferred over one or more TAD cylinders with steam heated displacement drying (Tysén 2018, Tysén et al. 2015; 2018) Much like conventional papermaking machines, where the Yankee cylinder is the most energyrequiringstep,theTADcylindershavebyfar the highest energy demand. Hence, improving the drying rate in the molding process is necessary from an energy demand standpoint. The process of sheet molding is modelled with Comsol Multiphysics where the computational model is setup with a 2dimensional representation of the paper sheet. The tissue sample with randomly distributed fibre positions is generated using a MATLAB script written in the Livelink interface with Comsol. The process is simulated with the Moisture Flow multiphysics interface. The comprising physical modules are the Laminar Flow and the Moisture Transport in Air modules. The purpose of this paper isto gain a better understanding ofdriving as well as limiting mechanisms of moisture transport in porous media concept of TAD molding system. The aim is to develop a first draft ofa computational model that can simulate the change in solid content

Theory / Numerical Set Up

Wood fibres for papermaking and paper sheets are both hygroscopic materials and, as such, contain bound water within the sheet network structure and within fibre walls. The network of fibres in a sheet as well as the fibres themselves can be viewed as porous media and understanding the physics and characteristics of fluid transport is key in numerically assessing water removal rate. Physical effects such as fluid flow and transport of fluids in different phases is considered. Heat transfer is excluded from these simulations at this stage as evaporative cooling is assumed to have neglectable effects on the drying process.

Computational domain

The computational model is setup with a 2dimensional representation of the paper sheet. The tissue sample with randomly distributed fibre positions is generated using a MATLAB script written in the Livelink interface with Comsol. The script creates fibres and randomly position them throughout the domain, which represents the paper, see Fig. 1. The code can be set to create fibres comprising of various basis weights and paper sheet porosities Inthispaper,asheetcomprisingofabasis weight at 18 g/m2 and a porosity at approximately 0.7 were simulated and analysed Ten different structureswerecreatedin theLivelink Matlabscript

Figure 1 2-dimensional representation of paper sheet model in Comsol. The upper SEM image is from the study [20]

The basis weight (g/m2) is a standard measurement inpapermanufacturinganditrepresenttheweightof the paper in relation to a standard size. More specifically, it is the ratio between the mass of dry substance and the surface area of the sample.

Where ���� coarseness or length density (kg/m) of a fibre,�� isthenumberoffibres,whereas �� (m)isthe height of the sample

Modelling continua in porous media

Porous materials such as networks of wood fibres has a complex solid structure and is highly discontinues from a continuum theory perspective, see Fig. (2). This is resolved by viewing the modelled structure as a porous media in several layers, that is, the wood fibres are interpreted as a mixtureofdifferentmaterials(solidsandfluids)with measurable quantities in a macroscopic field.

Figure 2 A 2-dimensional schematic representation of the structure of a single wood fibre and, on smaller scales, bundles of microfibrils.

Governing Equations / Numerical Model

At the start of the simulation process, the fibres are saturated with water, although surrounded by moist air. As air flows through the paper sheet, the fibres are dried due to moisture mitigation from the core of the fibre to the surface through convection and capillary forces. At the surface, water is evaporated though forced convection and vapour diffusion. The process is simulated with the Moisture Flow Multiphysics interface. The comprising physical modules are the Laminar Flow and the Moisture Transport in Air modules.

Pore space in the paper model

The penetrating airflow is modelled with the continuity and Navier stokes equations in COMSOL Multiphysics 6.1, see Eqs. (2) and (3),

=0 (2)

(3)

where ������ is the deviatoric stress tensor which includes the bulk viscosity due to compressibility in the air, see Eq. (4).

(4)

Turbulence modelling was excluded from the simulationsdue to small length scalesin the order of 10e-6 m and, hence, leading to low Reynolds numbers.

The moisture transport in the air is described with a modified advection diffusion model shown in Eq. (5),

(5)

where ���� (kg/mol) is the molar mass of water vapour, ���� (m2/s) is the vapor diffusion in air coefficient and �� (kg/m3s) is the moisture source or sink term. The concertation term in in Eq. (5) is related to the relative humidity with the vapor saturation concentration. ��

(6)

Porous media modelling in wood fibre

The wood fibres are typically hygroscopic materials and, as such, should be modelled as a porous media. The fibres contain two phases in equilibrium, which is the liquid water and the moist air. The driving force for transportation of each phase is vapor diffusion and convection in air, as well as capillary flow and convection for water. Assuming that the inertial forces in the fibres are neglectable, Darcy’s correction model is used to relate pressure gradients to the volume averaged superficial velocity

contain the maximum amount of water. The relative permeability varies between zero and one for each phase depending on the water content within the fibre walls. The total permeability is, hence, the product of the intrinsic and relative permeability.

where ������ (m2) is permeability coefficient and �� (Pa·s) is the dynamic viscosity. The permeability is typicallydecomposedintointrinsicpermeabilityand relative permeability for multiphase flow in porous media according to [38]. The intrinsic parameter represents the permeability of liquid or gas in an entirely saturated state, i.e. the pores in the fibre

The equations that describe the relative permeability for eachphase aredescribedinEq. (9) and (10).[38]

The intrinsic permeability for wood fibres are used from [38]

Fluid transport in and between wood fibres is described with the following equation

where ���� (kg/(m·s)), see Eq. (12), is the vapor transport in the gaseous phase in the wood fibre. As the Millington and Quirk equation is used calculate theeffectivediffusivityinseeEq.(12).Thecapillary flux term ������ (kg/(m·s)),seeEq.(13),isdescribed as the relative humidity gradient of the moisture contentandanadded diffusivityterm ���� (m2/s),see Eq. (14). [38] The moisture content, ��(����), is a function of the relative humidity, see Eq. (15)

The liquid saturation, ����, is a dimensionless parameter and it describes the amount of water left withinthepores, ���� istheporosityofthewoodfibres and ���� is vapour mass fraction.

Model simplifications

Some of the major assumptions this model relies on is:

• Aligned fibre positions due to 2dimensional representation of the paper sheet

• The forming and deformation of the fibre web during the TAD molding process is excluded

• Zero unbound water remaining in the paper sheet model.

Initial and boundary conditions

Initially, the fibres are saturated with water and the pore structure of the paper sheet contains air. The boundary conditions of the 2-dimensional representation is presented in Fig. (3)

Figure 3 The properties of the computational domain and boundary conditions.

Pressure was applied at the inlet and outlet boundary in which the vacuum level was set at 30 kPa at the outlet and reference pressure at 0 Pa was set at the inlet. Symmetry was set at thevertical boundaries as the fibre structure of the domain which was considered characteristic. Key input parameters for the simulation model are presented in Table (1)

Table 1: Key input data to the simulation model

Parameter data

Permeability

Porosity

Vapor-air diffusion

Vacuum pressure

Density fibre

Mesh setup and solver settings

Size

4.8e-8 [m2]

0.55 [-]

2.6e-5 [m2/s]

-30 [kPa]

1340 [kg/m3]

An unstructured mesh grid containing triangle elements was created for the paper models, see Fig. (4).Thegridissolvedinafiniteelementspacewhere a set of basis functions are used to create piecewise linear relations between the mesh elements and convert them to weak formulations for them to be solved. Moreover, geometrical features such as the

diameter of a single fibre as well as typical gap distance between adjacent fibres

A direct linear system solver was used coupled with an implicit second order backward differentiation formula (BDF) solver. The direct solver is called PARDISO which handles sparse linear systems using LU factorization to compute a solution. More information on the solver is found in COMSOL documentation. The BDF solver performs time stepping using a backward differentiation with a maximumorderofaccuracyof2,whichisthedegree of the interpolating polynomial.

Figure 4 Grid resolution and geometrical properties of the paper sheet model.

Results and Discussion

The results are comprised by presenting the solid content of the fibre web over time Fig. (5) presents four snapshots of the solid content at times 0, 5, 10 and 20 ms. Local variations of the solid content are observedat20mswhichisaresultofadjacentfibres blocking the airflow and hence, reducing the influence of convective mass transport. Considering that the fibre web is viewed in two dimensions, the air blockage should be overrepresented and thus, causing larger variations of the airflow. This notion is supported in [33] which concluded that flow resistance in the isotropic fibrearrangement in space is lower than the in-plane isotropic orientation and disordered unidirectional fibre arrangements at creeping flow conditions for low to moderate

Figure 5 Colour plot representing solid content in in the fibre structure

The averaged solid content for the entire fibre web is presented in Fig. (5)

Figure 6 Solid content comparison to laboratory trials performed by [20]

The solid content from the simulation model is compared to lab-scale data from [20], for early TAD molding the simulation model show great coherence with the laboratory results. After some time, the laboratory results deviate from the linear behaviour and display diminishing returns. A few additions need to be added to the models to capture the diminishing returns. In a first approach to establish a numerical model of the TAD molding process, the influence of web deformation was excluded which eliminates both compressibility of the sheet which leads to decreasing permeability and also the rewettingphenomena,whichareimportantfactorsto consider for a comprehensive model [39, 40]. The TAD fabric is likewise excluded from the simulations According to [12] machine clothing such as forming fabrics affects the dewatering rate andmagnitudethroughthreemainparameters,fabric caliper, void volume and air permeability. Similar dependence on the process is assumed to be influenced by TAD fabrics. Adding some of these to the numerical models, it is hypothesized to better simulate both laboratory and pilot scale results.

Conclusions

The first draft of the simulation model shows promising results in terms estimating average solid content over dwell time. At least that is the case up until roughly 15 ms. Based in laboratory results, the solidcontentrateseemstoconvergetoanupperlimit value,whichisnotthecaseforthesimulationmodel. Hence, experiments indicate that there is a physical limit on the dewatering rate The surface moisture vaporization needs to by analysed further as theory suggest that there should be an increased resistance to surface vaporization as the moisture level decreases in the porous media. However, since the dryness levels during the TAD molding process rangesabout5-6%fromstarttofinish,itshouldhave a neglectable affect as there is still a lot of bound water in the fibre. Other limiting factors that are not considered at the moment are:

• Including the TAD wire which add blockage to the airflow as well as absorbs water from the fibres

• AnalysingtheTAD molding processina3dimensional space which should have an overall reduction in blockage due to an addeddimension where theflow can travel.

• Including the deformation of the fibre web during the molding process. Perhaps the poroelastic physics interface could be utilized to analyse both the deformation of the fibre web as the fluid transport of the porous media simultaneously.

Acknowledgements

The authors are grateful for the financial support of the Knowledge foundation,Grant No.2022-0024, as well as generous in-kind contributions from Albany International Inc., Karlstad University and Valmet AB.

References

[1] Hubbe MA, Sjostrand B, Nilsson L, Koponen A, McDonald JD. Rate-limiting Mechanisms of Water Removal during the Formation, Vacuum Dewatering, and Wet-pressing of Paper Webs: A Review. Bioresources. 15(4) (2020) 9672-755, [2] Ramaswamy S. Vacuum dewatering during paper manufacturing. Dry Technol. 21(4) (2003) 685-717, https://doi.org/10.1081/Drt-120019058 [3] Attwood BW. A study of vacuum box operation.PaperTechnology.3(5)(1962)T144-T53, [4] Neun JA. Performance of High-Vacuum Dewatering Elements in the Forming Section. Tappi J. 77(9) (1994) 133-8, [5] Neun JA. High-vacuum dewatering of newsprint. Tappi J. 79(9) (1996) 153-7,

[6] Räisänen K, Karrila, S., Maijala, A. Vacuum dewatering optimization with different furnishes. Pap Puu-Pap Tim. 78(8) (1996) 455-,

[7] BaldwinL.Highvacuumdewatering.Paper Technology. 38(4) (1997) 23-8,

[8] Räisänen KO. Vacuum systems. In: Gullichsen HPJ, editor. Papermaking part 1: Stock preparation and wet end 2000. p. 417-30.

[9] Sjöstrand B. Vacuum Dewatering of Cellulosic Materials: Karlstad University; 2020.

[10] Wahlstrom B. Wet pressing in the 20th century: Evolution, understanding and future. Pulp Pap-Canada. 102(12) (2001) 81-8,

[11] Kuhasalo A, Niskanen, J., Paltakari, J., Karlsson, M. Introduction to paper drying and principles and structure of a dryer section. In: Gullichsen PJ, editor. Papermaking part 2, Drying 2000. p. 16-53.

[12] Granevald R, Nilsson LS, Stenstrom S. Impact of different forming fabric parameters on sheet solids content during vacuum dewatering. Nord Pulp Pap Res J. 19(4) (2004) 428-33, https://doi.org/DOI 10.3183/npprj-2004-19-04p428-433

[13] Pujara J, Siddiqui MA, Liu Z, Bjegovic P, TakagakiSS,LiPY,etal.Methodtocharacterizethe air flow and water removal characteristics during vacuum dewatering. Part I - Experimental method. Dry Technol. 26(3) (2008) 334-40, https://doi.org/10.1080/07373930801898091

[14] AslundP,VomhoffH.Methodforstudying the deformation of a fibre web during a suction pulse. Nord Pulp Pap Res J. 23(4) (2008) 398-402, https://doi.org/DOI 10.3183/npprj-2008-23-04p398-402

[15] Sjöstrand B, Barbier, C., & Nilsson, L. . Influence on sheet dewatering by structural differences in forming fabrics. Paper Conference andTradeShowCincinnati,Ohio,USA2016.p.76776.

[16] Sjostrand B, Barbier C, Nilsson L. Modeling the influence of forming fabric structure on vacuum box dewatering. Tappi J. 16(8) (2017) 477-83, https://doi.org/Doi 10.32964/Tj16.8.477

[17] Sjostrand B, Barbier C, Ullsten H, Nilsson L. Dewatering of Softwood Kraft Pulp with Additives of Microfibrillated Cellulose and Dialcohol Cellulose. Bioresources. 14(3) (2019) 6370-83, https://doi.org/10.15376/biores.14.3.63706383

[18] Rahman H, Engstrand P, Sandstrom P, Sjostrand B. Dewatering properties of low grammage handsheets of softwood kraft pulps modified to minimize the need for refining. Nord Pulp Pap Res J. 33(3) (2018) 397-403, https://doi.org/10.1515/npprj-2018-3037

[19] Sjostrand B, Brolinson A. Addition of Polyvinylamine in Chemi-thermomechanical Pulp and Kraft Pulp and the Effects on Dewatering, Strength, and Air Permeance. Bioresources. 17(3) (2022) 4098-115, https://doi.org/10.15376/biores.17.3.4098-4115

[20] Sjostrand B, Danielsson M, Lestelius M. Method for Studying Water Removal and Air Penetration during Through Air Drying of Tissue in Laboratory Scale. Bioresources. 18(2) (2023) 307388, https://doi.org/10.15376/biores.18.2.3073-3088

[21] Sjostrand B. Progression of Vacuum Level in Successive Vacuum Suction Boxes in a Paper Machine-Impact on Dewatering Efficiency and Energy Demand-A Laboratory Study. Bioresources. 18(2) (2023) 3642-53, https://doi.org/10.15376/biores.18.2.3642-3653

[22] Britt KW, Unbehend JE. Water Removal during Paper Formation. Tappi J. 68(4) (1985) 1047,

[23] Granevald R. Vacuum dewatering of lowgrammage paper webs and fabrics.: Karlstad University; 2005.

[24] Aslund P, Vomhoff H, Waljanson A. The deformation of chemical and mechanical pulp webs duringsuctionboxdewatering.NordPulpPapResJ. 23(4) (2008) 403-8, https://doi.org/DOI 10.3183/npprj-2008-23-04-p403-408

[25] Pujara J, Siddiqui MA, Liu Z, Bjegovic P, TakagakiSS,LiPY,etal.Methodtocharacterizethe air flow and water removal characteristics during vacuum dewatering. Part II - Analysis and characterization. Dry Technol. 26(3) (2008) 341-8, https://doi.org/10.1080/07373930801898125

[26] Jackson GW, James DF. The Permeability of Fibrous Porous-Media. Can J Chem Eng. 64(3) (1986) 364-74, https://doi.org/DOI 10.1002/cjce.5450640302

[27] Zhu S, Pelton RH, Collver K. Mechanistic Modeling of Fluid Permeation through Compressible Fiber Beds. Chem Eng Sci. 50(22) (1995) 3557-72, https://doi.org/Doi 10.1016/00092509(95)00205-J

[28] Nilsson L, Stenstrom S. A study of the permeability of pulp and paper. Int J Multiphas Flow. 23(1) (1997) 131-53, https://doi.org/Doi 10.1016/S0301-9322(96)00064-X

[29] Matthews GP. Computer modelling offluid permeation in porous coatings and paper - an overview. Nord Pulp Pap Res J. 15(5) (2000) 47685, https://doi.org/DOI 10.3183/npprj-2000-15-05p476-485

[30] Nilsson L. Stepwise Development of a Mathematical Model for Air Flow in Vacuum Dewatering of Paper. Dry Technol. 32(13) (2014) 1587-97, https://doi.org/10.1080/07373937.2014.909844

[31] Rezk K, Nilsson L, Forsberg J, Berghel J. Modelling of water removal during a paper vacuum dewateringprocessusinga Level-Set method. Chem Eng Sci. 101 (2013) 543-53, https://doi.org/10.1016/j.ces.2013.07.005

[32] Rezk K, Nilsson L, Forsberg J, Berghel J. Simulation of Water Removal in Paper Based on a 2D Level-Set Model Coupled with Volume Forces Representing Fluid Resistance in 3D Fiber Distribution. Dry Technol. 33(5) (2015) 605-15, https://doi.org/10.1080/07373937.2014.967401

[33] Rezk K, Forsberg J, Nilsson L, Berghel J. Characterizing flow resistance in 3-dimensional disordered fibrous structures based on Forchheimer coefficients for a wide range of Reynolds numbers. Appl Math Model. 40(21-22) (2016) 8898-911, https://doi.org/10.1016/j.apm.2016.05.036

[34] YazdchiK,LudingS.Towardsunifieddrag laws for inertial flow through fibrous materials. Chem Eng J. 207 (2012) 35-48, https://doi.org/10.1016/j.cej.2012.06.140

[35] Koch DL, Ladd AJC. Moderate Reynolds numberflowsthroughperiodicandrandomarraysof aligned cylinders. J Fluid Mech. 349 (1997) 31-66, https://doi.org/Doi 10.1017/S002211209700671x

[36] Yazdchi K, Srivastava S, Luding S. Microstructural effects on the permeability of periodicfibrousporousmedia.IntJMultiphasFlow. 37(8) (2011) 956-66, https://doi.org/10.1016/j.ijmultiphaseflow.2011.05. 003

[37] Yazdchi K, Srivastava S, Luding S. Micromacro relations for flow through random arrays of cylinders. Compos Part a-Appl S. 43(11) (2012) 2007-20, https://doi.org/10.1016/j.compositesa.2012.07.020

[38] Datta AK. Porous media approaches to studyingsimultaneousheatandmasstransferinfood processes. II: Property data and representative results. J Food Eng. 80(1) (2007) 96-110, https://doi.org/10.1016/j.jfoodeng.2006.05.012

[39] Mcdonald JD, Kerekes RJ. Estimating limits of wet pressing on paper machines. Tappi J. 16(2) (2017) 81-7, https://doi.org/Doi 10.32964/Tj16.2.81

[40] Sjostrand B, Barbier C, Nilsson L. Rewettingafterhighvacuumsuctionboxesinapilot paper machine. Nord Pulp Pap Res J. 30(4) (2015) 667-72, https://doi.org/DOI 10.3183/npprj-2015-3004-p667-672

PAPERmaking!

FROM THE PUBLISHERS OF PAPER TECHNOLOGY INTERNATIONAL®

Volume10,Number2,2024

Alkenyl Succinic Anhydride: The Question of Covalent Bonding and Chemistry Considerations for Better Sizing—Review

YAO NTIFAFA1, LEBO XU1, SARA BOLLINGER1, YUN JI2 , & PETER W. HART1

Alkenyl Succinic Anhydride (ASA) is a sizing agent used in papermaking to increase the water repellency of paper. Almost 60 years after the introduction of the chemical in papermaking, scientists still have differing views on how ASA interacts with cellulose. Several experiments were conducted to bring more clarity to the ASA sizing mechanism, especially on the contentious question of ASA-cellulose covalent bonding or the esterification reaction between ASA and cellulose during papermaking. Herein, research papers and patents, including experiments and results, from the 1960s to 2020 were reviewed. Our investigation revealed that the ester bond formation between ASA and cellulose is insignificant and is not a prerequisite for sizing effectiveness; the main ASA-related material found in sized paper is hydrolyzed ASA or both hydrolyzed ASA and ASA salt. In addition, ASA emulsion stability and ASA emulsion retention are important for sizing efficiency improvement

Contact information:

1 WestRock, 2742 Charles City Road, Richmond, VA 23231, USA

2 Department of Chemical Engineering, University of North Dakota, Grand Forks, ND 58202, USA.

Polymers 2023, 15, 2876 https://www.mdpi.com/2073-4360/15/13/2876

Creative Commons Attribution 4.0 International License

The Paper Industry Technical Association (PITA) is an independent organisation which operates for the general benefit of its members – both individual and corporate – dedicated to promoting and improving the technical and scientific knowledge of those working in the UK pulp and paper industry. Formed in 1960, it serves the Industry, both manufacturers and suppliers, by providing a forum for members to meet and network; it organises visits, conferences and training seminars that cover all aspects of papermaking science. It also publishes the prestigious journal Paper Technology International® and the PITA Annual Review, both sent free to members, and a range of other technical publications which include conference proceedings and the acclaimed Essential Guide to Aqueous Coating.

polymers

Review

AlkenylSuccinicAnhydride:TheQuestionofCovalent BondingandChemistryConsiderationsforBetter Sizing—Review

YaoNtifafa 1,*,† ,LeboXu 1,†,SaraBollinger 1,†,YunJi 2,† andPeterW.Hart 1,†

1 WestRock,2742CharlesCityRoad,Richmond,VA23231,USA;peter.hart@westrock.com(P.W.H.)

2 DepartmentofChemicalEngineering,UniversityofNorthDakota,GrandForks,ND58202,USA

* Correspondence:yao.ntifafa@westrock.com

†Theseauthorscontributedequallytothiswork.

Abstract: AlkenylSuccinicAnhydride(ASA)isasizingagentusedinpapermakingtoincreasethe waterrepellencyofpaper.Almost60yearsaftertheintroductionofthechemicalinpapermaking, scientistsstillhavedifferingviewsonhowASAinteractswithcellulose.Severalexperimentswere conductedtobringmoreclaritytotheASAsizingmechanism,especiallyonthecontentiousquestion ofASA-cellulosecovalentbondingortheesterificationreactionbetweenASAandcelluloseduring papermaking.Herein,researchpapersandpatents,includingexperimentsandresults,fromthe 1960sto2020werereviewed.OurinvestigationrevealedthattheesterbondformationbetweenASA andcelluloseisinsignificantandisnotaprerequisiteforsizingeffectiveness;themainASA-related materialfoundinsizedpaperishydrolyzedASAorbothhydrolyzedASAandASAsalt.Inaddition, ASAemulsionstabilityandASAemulsionretentionareimportantforsizingefficiencyimprovement.

Keywords: AlkenylSuccinicAnhydride(ASA);cellulose;papersizing;covalentbonding;sizing agentstability;sizingagentretention

Citation: Ntifafa,Y.;Xu,L.; Bollinger,S.;Ji,Y.;Hart,P.W.Alkenyl SuccinicAnhydride:TheQuestionof CovalentBondingandChemistry ConsiderationsforBetter Sizing—Review. Polymers 2023, 15, 2876. https://doi.org/10.3390/ polym15132876

AcademicEditor:LiliWang

Received:13June2023

Revised:23June2023

Accepted:25June2023

Published:29June2023

Copyright: ©2023bytheauthors. LicenseeMDPI,Basel,Switzerland. Thisarticleisanopenaccessarticle distributedunderthetermsand conditionsoftheCreativeCommons Attribution(CCBY)license(https:// creativecommons.org/licenses/by/ 4.0/).

1.Introduction

Theobjectiveofpapersizingistodelaywettingbyreducingthefiberabsorbency. AlkenylSuccinicAnhydride(ASA)wasintroducedasasizingagentinpapermakingin1963 byWurzburgandMazzarella[1].ASAisanorganiccompoundwithcyclicdicarboxylic anhydrideandatetrafurandione(Figure 1).Thechemicalislightyellowcolor,oil-like, non-solubleinwater,andliquidatroomtemperature[2,3].

emulsion particles are retained in the forming paper sheet at the wet end and forming section. Sizing development mostly happens in the dryer section, where the particles break down to release ASA in contact with the fibers [9,10].

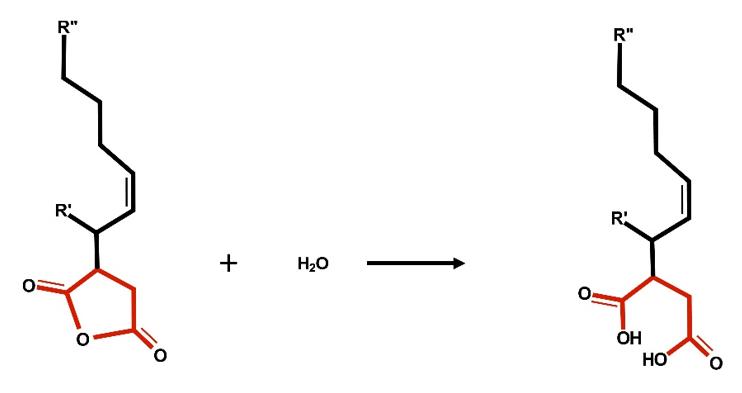

Figure1. SchemeofesterbondformationbetweenASAandcellulose.

Today,commoninternalsizingchemicals(e.g.,alum/rosin,AKD[Alkylketenedimer] andASA)areintroducedintoapulpslurryatthewetendduringthepapermakingprocess.

Polymers 2023, 15,2876. https://doi.org/10.3390/polym15132876

The proposed and widely cited ASA sizing mechanism is the formation of an ester or covalent bond between ASA molecules and fibers. Figure 1 illustrates the ester bond formation between ASA and fiber (cellulose). However, during the last 60 years of papermaking research, this popular mechanism has been questioned. Several scientists are still uncertain about the binding mechanism between ASA and cellulose. In addition, most scientists agree that ASA hydrolyzes in water during the papermaking process (Figure 2) [7,11–13].

, 15, x

Figure 1. Scheme of ester bond formation between ASA and cellulose.

Alum/rosinsizingiscommonlyusedforacidicpapermakingwithatypicalpHrangefrom 4.0to5.5.InthispHrange,alumformstherightaluminumspeciestoeitherreactwith soaprosinortoretaindispersedrosin(DRS)forsizingdevelopment.AKDandASAare usedinalkalinepapermakingprocesses,whereASAhasahigherreactivitytocellulosic fibercomparedtoAKD.Moreover,ASAhasalsobeenreportedtobeappliedinacidic

DuetotheinsolubilityofASAinwater,ASAoilneedstobeemulsifiedbeforeadding tothewetendforhomogenousdistributioninpulpslurries.Theemulsifiercanbestarchbased(cationicstarch)orpolymer-based(polyacrylamide).TypicalASAemulsionparticle sizeisaround1 µm.TheASAemulsionhasashortshelflife,andthusthechemicalis typicallyemulsifiedon-siteinthemillanddosedtothewetendassoonaspossible.The emulsionparticlesareretainedintheformingpapersheetatthewetendandforming section.Sizingdevelopmentmostlyhappensinthedryersection,wheretheparticlesbreak downtoreleaseASAincontactwiththefibers[9,10].

Scheme of ester bond formation between ASA and cellulose.

The proposed and widely cited ASA sizing mechanism is the formation of an ester covalent bond between ASA molecules and fibers. Figure 1 illustrates the ester bond mation between ASA and fiber (cellulose). However, during the last 60 years of papermaking research, this popular mechanism has been questioned. Several scientists are still certain about the binding mechanism between ASA and cellulose. In addition, most entists agree that ASA hydrolyzes in water during the papermaking process (Figure [7,11–13].

TheproposedandwidelycitedASAsizingmechanismistheformationofanesteror covalentbondbetweenASAmoleculesandfibers.Figure 1 illustratestheesterbondformationbetweenASAandfiber(cellulose).However,duringthelast60yearsofpapermaking research,thispopularmechanismhasbeenquestioned.Severalscientistsarestilluncertain aboutthebindingmechanismbetweenASAandcellulose.Inaddition,mostscientists agreethatASAhydrolyzesinwaterduringthepapermakingprocess(Figure 2)[7,11–13].

Figure2. SchemeoftheformationofhydrolyzedASA.

Figure 2. Scheme of the formation of hydrolyzed ASA.

Thecovalentbondingquestionbecomesaheateddebatebetweenscientistswhosupporttheesterbondformationastheprimarysizingmechanismandscientistswhobelieve esterbondingisalmostnonexistentanddoesnotplayamajorroleinpapersizing.Dueto theconfusionaroundthecovalentbondingquestions,manyauthorsprefertousetheexpressions“widelyaccepted”,“generallyaccepted”,“generallyunderstood”,“traditionally”, or“assume”inreferencetotheASA-cellulosecovalentbondformation[7,12,14–19].

The covalent bonding question becomes a heated debate between scientists who port the ester bond formation as the primary sizing mechanism and scientists who believe ester bonding is almost nonexistent and does not play a major role in paper sizing. the confusion around the covalent bonding questions, many authors prefer to use pressions “widely accepted”, “generally accepted”, “generally understood”, “traditionally”, or “assume” in reference to the ASA-cellulose covalent bond formation [7,12,14–19].

Inthisreview,patentsandresearchpaperswithexperimentaldatawerereviewedto understandtheASAsizingmechanismsince1963.Inaddition,chemistryconsiderations forbetterapplicationofASAarebrieflydiscussed.

In this review, patents and research papers with experimental data were reviewed understand the ASA sizing mechanism since 1963. In addition, chemistry considerations for better application of ASA are briefly discussed.

2.DebateonASASizingMechanisminPapermaking

PriortotheintroductionofASAtothepapermakingprocessinthe1960s,theadditive wasusedinthetextileindustrytoimpartwaterrepellencytocellulosicfabrics.Patent 2,903,382byRobertBerls[20]in1959provideddetailsonhowtomakehydrophobic cellulosicfabricusingASA.DifferenttypesofASAwithchainsfrom19to35carbon atomsweredissolvedinsolventsuchasisopropanol,benzene,toluene,chloroform,carbon tetrachloride,ammonia,morpholine,andwateremulsions.Thefabricwasdippedintothe resultingsolutionthenheatcured.TherecommendedASAconcentrationwasfrom0.7%

Figure 1.

to2.5%(14to50lb/t)oftheweightofthefabric.ThespraytestmethodoftheAmerican AssociationofTextileChemistsandColoristsA.S.T.M.Designation:D583-54wasusedto evaluatewaterrepellency.Therewasnomentionofesterificationreactionnorcovalent bondingintheclaim.Inaddition,theASAapplicationislikewaxapplicationtotextile fiberforhydrophobicity,asclaimedinpatent2,759,851in1956byFluck,Pluckemin,and Logan[21].

In1963,WurzburgandMazzarella[1]mixedASAwithdifferentderivativesofstarch toformanemulsion.ItwasclaimedthattheapplicationoftheASAemulsiononfiber madethesheethydrophobic.Thepatentdemonstratedthesizingprocesswiththeuseof theASAemulsionandtheadditionofalum,aluminumchloride,longchainfattyamines, sodiumaluminate,polyacrylamide,animalglue,polyamidepolymers,primaryamine starchderivatives,secondaryaminestarchderivatives,tertiaryaminestarchderivatives, andquaternaryaminestarchderivatives.

Theauthorrecommendedtouse0.5to2partsbyweightofcationicstarchper1part ofthesizingagenttoobtainadequateresults.Differentdosagesfrom0.25%to2%(5to 40lb/t)ofthesizingagentwereusedin14differentexamplestosupporttheclaim.Uranine dyeandinkdiptestswereusedtoprovethehydrophobicityofthesheets.Therewasno disclosureofcovalentoresterbondingbetweenASAandcelluloseinthepatentdocument. Cuculo[22]atNCStateUniversitytriedtoesterifysuccinicanhydridewithcellulose in1971.First,successfulresultswereobtainedfromthereactionbetweenviscoserayon celluloseandsuccinamicacid.Thesampleswerebakedinsuccinamicacidat136 ◦C, 183 ◦C,and207 ◦C,water-washed,andthentreatedwith3%sodiumsulfatetoformsodium cellulose-hemisuccinate.Thedegreeofsubstitutionsforthereactionswere,respectively, 0.03,0.24,and0.25.Theauthorconcludedthatthedegreeofthesubstitutionofreaction dependsstronglyonthereactiontemperature.Second,whensuccinicanhydrideinwater wasusedundercomparableconditionstothoseofthesuccinamicacid,theauthorstated thattherewasnoevidenceofesterformation.Thereportedreactionyieldwithsuccinamic acidwas36%,andtheauthormentionedthatammoniacopiouslyevolvedduringthe reaction.Therecommendedtemperatureusingthesuccinamicacidisabove150 ◦C.

McCarthyandStratton[23]studiedthereactionbetweencottonlinterspulpandASA in1986.Inonestudy,thecottonlintersandASAwerereactedinN,N-dimethylformamide withtriethylamineasacatalyst.Inanotherstudy,thecottonlinterpulp(washedin chloroform-ethanolsolutionfor48handairdryforseveralhours)andahighconcentration ofASA(1.5%or30lb/ton)werereacted.Poly(1,2-dimethyl-5-vinylpyridiniumbromide),or DMVPB,wasusedasASAretentionaid.Inbothstudies,FTIRdatashowedtheformation ofesterbonds,howevertheefficiencyofthesereactionswasnotreported.InMcCarthy’s thesisin1987[24],theauthorshowedbyFTIRthatASAreactedwithethanoltoformester bonds.ItisnotknownifpartoftheASAformedesterbondswithethanolratherthan cellulosesincethepulpwaswashed48hwithchloroform-ethanolsolution.

Wan[25]studiedthemechanismofASAsizingin1988usingC14-labelledtetradecenylsuccinicanhydride(TDSA)andtetradecenylsuccinicacid(TDSAcid).TDSAand TDSAcidemulsionsweremadeusingstarchasanemulsifierata1:3ratio.Theemulsions containing1.3%totalsolidwaschargedtothepulptomake60g/m2 hand-sheets.TheC14labelledtechniquewasusedtoquantifytheASAcomponentinthesheetsafterchloroform extraction.TheresultsshowedthatunreactedASAispredominantlyfoundinthesheet andabout25%ofASAcanproducesizingandisnotextractablewithchloroform.

Accordingtotheauthor,theretainedASAcouldbeexplainedbycovalentbondingdue tothreereasons.First,thecontinuousincreasinginsizingatroomtemperaturesuggests thereductioninmoistureallowstheASAtoreactwiththehydroxylsofcellulose.Second, theASAmolecule,whichisunderconstantreorientationduringthesizingprocess,would undergohydrolysisifatanytimethehydrophilicpartofthemoleculeisexposedto moisture.Theretainedmoleculecanbeassumedtobeheldbystrongerirreversiblebond forces.Third,theinabilityoftheASAcid(hydrolyzedformofASAinthedicarboxylicacid form)tosizehand-sheetsdemonstratesthathydrogenbondingisnotthemechanismof