Volume 61 Number 2

Summer 2020

Published by PITA

5 Frecheville Court, Bury, Lancs BL9 0UF

Tel: 0300 3020 150

Tel: +44 161 746 5858 (from outside the UK)

Fax: 0300 3020 160 email: info@pita.co.uk website: www.pita.co.uk

Editor Daven Chamberlain

St Johns House

Spring Lane

Cookham Dean Berks SL6 9PN

Tel: 0300 3020 159 email: editor@pita.co.uk

UK Advertising Sales

Contact the PITA Office

Tel: 0300 3020 150 Email: info@pita.co.uk

European Representative

Nicolas Pelletier

RNP

16 Rue Bannier – 45000 Orleans, France

Tel: +33 6 82 25 12 06

Fax: +33 2 38 42 29 10 email: europe@pita.co.uk

Designed and typeset by Upstream Ltd, Deepcar, South Yorkshire Printed by Mixam UK Watford, Herts

Regulating Furnish Electrokinetic Parameters

How to Judge Felt Test Trials (Feltest)

Nanoparticle-based Antimicrobial Paper

Biomaster Antimicrobial Range (Addmaster)

Gas Barrier Properties of Coatings (Versaperm)

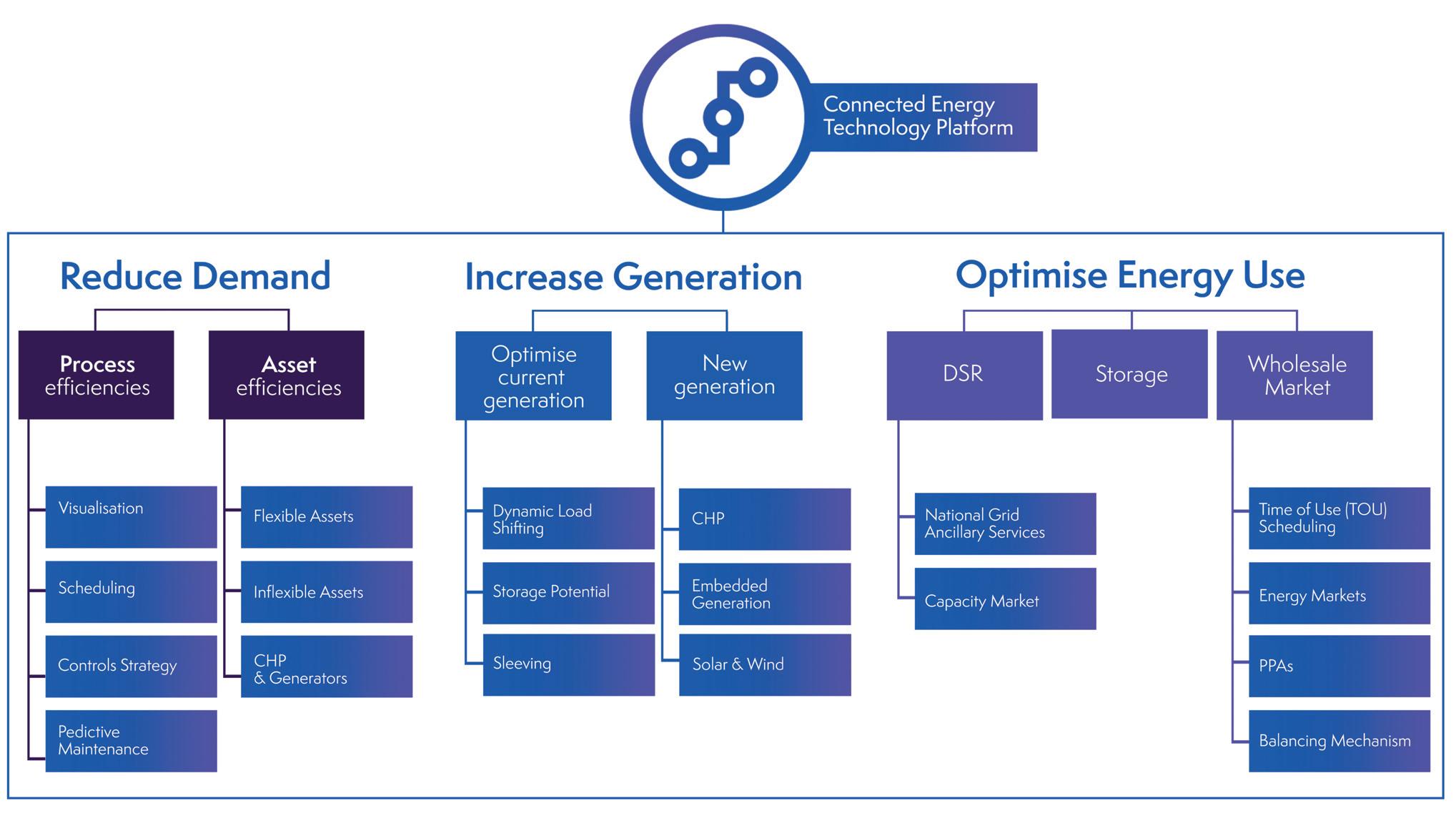

Intelligent Energy Management (GridBeyond)

Paper and Packaging Round-up (APP)

Nanoparticle Binders (EcoSynthetix)

Algae: the Forest in a Flask (PITA)

Millennials and the Circular Economy (DS Smith)

Paper Alternatives to Single Use Plastics (CPI)

Conference / Exhibition / Meeting Reports

Formulation for Sustainable Packaging (Solenis)

To create some much-needed atmosphere, DS Smith has developed its ‘Return to Sport’ range, a series of customisable and fully recyclable options for clubs which can be purchased via its website. Each bespoke ‘fan’ is made from recycled materials and designed to easily slip over existing stadium seating. As a result of DS Smith’s digital print capabilities, the range can be custom printed to celebrate individual fans’ faces or messages of support and represent team colours, sponsors or charitable partnerships.

Right at the start of the current pandemic one main message was pushed above all others – hand hygiene. Washing with warm water and soap for twenty seconds was seen as the biggest single method of preventing infection; failing that, use of alcohol-based hand sanitiser was a secondary measure. What the initial guidance did not mention was the corollary to hand washing – hand drying.

This is a subject we have covered a number of times in the pages of Paper Technology International, and it is worth review ing what has been printed previously. In this it is important to acknowledge the work of ETS – The European Tissue Sympo sium – who has funded a number of research studies over the last decade aimed at highlighting differences between various methods of hand drying systems. These are important because hand washing with soap never removes all microbes from the hands; some will remain, and if hands are not dried, then the mi crobes can transfer to any surfaces touched with wet hands via the liquid water. This is why hand drying is just as important as hand washing.

There are four main methods that are used for hand drying:

Textile towels

Paper towels

Hot-air dryers (low air velocity, high heat)

Jet dryers (high air velocity, low heat)

In our own homes we all probably use textile towels. These are fine to a point, but microbes do build up which means there is cross-contamination between individuals in a household who use the same towel, so they should be changed and laundered regularly (preferably at 60°C or above).

In the commercial world, all four methods are in use, although the textile towel will usually be a roller-towel which each indi vidual pulls to access a fresh (clean and dry) portion. These are very-much in the minority now, and are seldom met with in com mercial rest rooms (the delightful British Library being one no table exception).

By contrast, paper towels were once the mainstay of rest rooms, but by and large have been superseded in recent years by electrically-heated air dryers, the supposed reason being that deal ing with paper waste costs time and money. (Also, there was no danger of dropping an air-dryer down a toilet bowl, whereas dis posing of paper towels in this was a common cause of blockages.)

Before going further, it should be noted that textile and paper towels act both by removing liquid water, and by acting as a ‘sink’ for microbes and surface dirt that are removed by surface contact and abrasion during rubbing with the towel.

So to hot air dryers, of which there are the two sorts noted above. The older style, which can still be met with in many places of ease, use low air velocity and take seemingly ages to

dry hands sufficiently – such that many customers (including me) will often give up and either wipe hands on clothing or sim ply exit the rest room with wet hands – and so the problem of contamination transference noted previously can take place. For this reason, many establishments, when they have upgraded fa cilities, have gone for the most modern approach – high velocity jet driers that blow the liquid water away from the skin surface. There is no doubt that they are highly effective at removing water, which is their primary purpose, but they do this by creat ing an aerosol of water droplets which contaminate surfaces near the dryer.

And herein lies the problem. COVID-19 is known to be trans mitted as an aerosol, which is why we are told to ‘socially dis tance’ when meeting people, because every time we speak, breath, cough or sneeze, we release liquid droplets that could contain the virus. So, if someone infected with COVID-19 is less than diligent at washing their hands, such that the virus particles have not been suitably denatured by the action of soap, the jet drier gives a perfect dispersal mechanism by which surfaces in rest rooms can become contaminated.

Research by ETS has shown many times that jet dryers, which have become the favoured mode of hand drying in many com mercial rest rooms, have significant propensity to cause contam ination due to aerosol dispersion. Now we have a pandemic where a virus is known to spread by exactly the same method. Surely there cannot be a better time for the paper towel and hy giene sector to start promoting their product as a safer alternative to electric hand driers. As Winston Churchill opined, “Never waste a good crisis”, and COVID-19 is nothing if not that!

As the Black Lives Matter protests have shown recently, once you get a head of steam a movement becomes difficult to stop. Conversely, wait and you might just miss the opportunity.

Already, in its guidance to reopening businesses, Preston City Council has issued directions that include, “Instruct employees to clean their hands frequently … provide paper towels and turn off hand dryers to prevent the spread of air borne particles.” In recent months the Daily Mail, Guardian, Metro, Mirror, Wash ington Post and Sky News have all run stories in which people have been urged to ditch “high tech” and go with paper. This has long been known in the NHS, who participated in ETS studies, and this advice has been backed up in The Nursing Times

The Paper Towel business has got a ready-made opportunity to promote its product, positively, and so fight back against its arch-rival of recent years. Let’s hope the hygiene sector makes the most of this opportunity while it is still high in the public consciousness – and also let’s hope we do not see anything like this pandemic happen again!

Daven ChamberlainA collaborative app that reduces the time to resolution. A service tool that allows field personnel to remotely connect with ABB experts. All backed by cutting-edge augmented reality technology that enables real-time instructions via annotations during live video calls. ABB Ability™ Remote Insights for service will help you troubleshoot faster, improve safety, and increase productivity at your pulp and paper mill. To find out more, contact your Pulp and Paper Account Managers:

Paul

At the beginning of April, Arjowiggins Group Stoneywood Mill undertook an extended maintenance shutdown after the Scottish government stated that non-essential businesses should close unless they were capable of operating in a way that was fully compliant with social distancing advice. Following this early period, new guidelines were issued by Government and the mill started to re-open in early May, and a week later it was fully open, after which it ramped up production rates such that by the end of May it was again in full operation. Part of the process has involved introduction of screens, and moving of some control panels. According to Angus MacSween, the General Manager, “The workforce has come up with some fantastic ingenious de signs to make it happen.” Meanwhile, some of the 420 employ ees continue to work from home.

Corrugated sheet manufacturer CorrBoard UK Ltd has re ceived new investment from two of its major shareholders. VPK Group NV has increased its shareholding to become a 50% shareholder, through a subscription for new shares and the ac quisition of the stake of former shareholder Garthwest; sepa rately, McLaren Packaging, one of CorrBoard’s founding partners, has also subscribed for new shares. VPK produces re cycled paper and paper-based packaging, with markets in food and beverages, consumer goods and e-commerce, tubes and cores. CorrBoard will shortly be installing a new £1.5m auto mated palletisation system at its 320,000 sq. ft. North Lin colnshire plant as well as significant IT control system upgrades.

DS Smith has implemented new measuring technologies across Europe, including Kemsley Mill, with an aim of improv ing the quality of raw materials and increase transparency with suppliers. Initially the technology was employed at both the Rouen paper mill in Northern France and at the Duenas paper mill in Northern Spain. Due to its success at those mills, the tech nology has now been installed at Zărnești mill in Romania and Kemsley mill in the UK, the largest mill for recycled papers in UK and the second largest in Europe. Under the new process, trucks arriving at a mill must pass through a ‘Moisture Gate’ which irradiates the area between the antennas and scans the load using microwave technology. In less than one minute an accurate moisture content readout is delivered, helping to measure the quality of material going into the mill.

Glatfelter in Lydney, Gloucestershire, has now modernised the end section of the PM8 with Bellmer technology. Part of the delivery was a soft nip calender TurboCal; in addition to the paper web and rope guidance system, a TurboReeler pope reel completed the upgrade. Also, it was equipped with the BellDur system, which monitors and controls the winding hardness from the core to the maximum diameter.

Krystals Premier Packaging, based in Lincoln, UK, and Progroup, based in Landau, Germany, will invest jointly to cre ate a packaging park at Progroup’s sheetfeeding site in Ellesmere Port. The packaging park is being constructed over a total area of around 16,000 m² and will be completed in the second half of 2020. Krystals will build a new production site which will be linked to Progroup’s operation via a conveyer bridge for the cor rugated board. IT systems will also be interconnected.

Northwood Hygiene Products Ltd announced the proposed closure of their converting facility in Penygroes, Gwynedd. The

company said: “As part of a strategic review of business opera tions, given the rapidly changing landscape and market condi tions, the directors of Northwood Hygiene Products Ltd regret to announce the proposed closure of the Penygroes manufactur ing facility. As part of the review, various alternative options were considered, but the contraction in market demand as a con sequence of COVID-19, and the subsequent significant fall in current and forecasted sales volumes has led to this very difficult decision being made. Production will be absorbed, and cus tomers will be serviced from other Northwood sites in Telford, Oldham, Birmingham, Lancaster and Bromsgrove.” Meanwhile, questions are being asked by the local MP (Hywel Williams) and MS (Siân Gwenllian), regarding the background to this decision, since at the beginning of the lockdown the factory was operating at “unprecedented order levels”. 94 jobs are affected.

Saica (UK) Ltd has submitted plans to extend its Northamp tonshire facility at Thrapston, and so add a new warehouse/stor age area, with conveyor link between the existing building and extension, a new HGV yard adding 11 HGV parking bays, and an additional car park. Elsewhere, Saica Pack at Telford has taken delivery of a new Lamina 2200 GL gluing and taping machine.

UPM Caledonian extended a planned maintenance shut in mid-March due to the pandemic, but restarted on 20-21 April. A spokesman said: “We can confirm that our Caledonian Paper Mill had been standing still due to extended maintenance which has been prolonged in light of the corona situation.” UPM said it was planning to use shift arrangements, temporary layoffs, or reduced working hours as required to adjust its operations in dif ferent scenarios due to the virus crisis. The mill makes LWC magazine grades with an annual capacity of 250,000 tonnes.

Vernacare has been providing the NHS with infection control products for 50 years, but since the outbreak of Coronavirus the global demand for its single-use disposable containers and mac erators has reached an unprecedented scale. The healthcare com pany, based in Folds Road, Bolton, has increased production by 60%, as healthcare facilities follow WHO advice that ‘single use and disposable’ equipment is needed to minimise the risk of virus transmission.

WEPA has submitted plans for a £100m expansion at their Bridgend site, to include the construction of a second hygiene tissue paper production line along with new pulp storage and bale handling areas, a high-bay warehouse for up to 35,000 pal lets, a shipping area and more. It will enable the company to ex pand capacity to 115,000tpy.

Burgo Ardennes Mill in Belgium took extended downtime (for ten days) amid COVID-19 concerns, “in order to guarantee the health and safety of its employees and in line with the latest indications from the Belgian authorities.” Belgium’s publicbroadcasting organisation RTBF reported on the situation at the mill on different occasions in March amid the growing number of coronavirus cases in the Belgian region bordering France’s Grand Est, and increasing number of illness-related absences at Burgo Ardennes plant, including proven cases of COVID-19. The site restarted operations on 30 March.

DS Smith has partnered with one of the world’s leading man ufacturers of building products to close the loop and solve a short

age of raw materials. Since 2014, staff at the De Hopp Mill in the Netherlands have collaborated on a project with Fermacell, a subsidiary of James Hardie Europe GmbH – an international mar ket leader for fibre cement building materials. Fermacell has tra ditionally used paper for recycling (PfR), such as magazines and newsprint, as a raw material to produce their unique range of gyp sum fibre boards; however, during this project they used fibrous rejects from De Hoop as an alternative raw material – a true ex ample of the Circular Economy in operation. Through this part nership, the De Hoop Paper Mill is diverting 100% of its fibrous rejects from waste into new products, and the parent company is now investigating the viability of extending this innovation across other mills and Fermacell plants across Europe.

A new geothermal heating plant is planned in the municipality of Renkum in the middle of the Netherlands. The plant will allow around 5,000 homes and a paper company to utilise geothermal energy for heat supply. Smurfit Kappa Parenco in Renkum, one of the participants in the project, has been positive about the gen eration of geothermal energy for years; with the help of geother mal energy, the factory can make its steam production fully sustainable.

Stora Enso Langerbrugge Mill in Belgium has successfully undertaken recycling trials with paper cups, verifying a process that will cut the carbon footprint of disposable paper cups by a compelling 50%.

Sappi suspended production on one paper machine at the Lanaken coated woodfree and magazine paper mill, in Belgium, in order to adapt output to falling demand. According to Euwid, production on coated fine paper machine PM 7 was temporarily stopped in reaction to the current lower demand for graphic pa pers caused by the effects of COVID-19.

A fire broke out in the recovered paper yard of the VPK Oudegem plant in Belgium on Monday 27 April, which required the intervention of several surrounding fire brigades. The fire was under control, the fire department reported, the next day, and fire-fighting operations were ended on Wednesday afternoon. At the Oudegem plant, this was the third fire in just one year, ac cording to reports on site. No details have been issued on the ex tent of the damage. The mill produces recovered paper-based corrugated case material on three machines and has a production capacity of approximately 550,000 tonnes per year.

ABB has launched its KPM KC9 Optical Consistency Trans mitter family, a new range of sensors that provide accurate mea surement of total and/or ash consistency for better wet end measurement and control in pulp and paper processes. The sen sors are suitable for pulp, paper, board and tissue manufacturers using virgin or recycled raw materials, particularly those using ash fillers, where only optical sensors are effective to measure ash consistency. Available as either inline or bypass sensors, the entire KPM KC9 Optical Consistency Transmitter family offers the widest range of sensor options currently available and is best suited to measure the lowest consistency ranges.

Kemira has set a target of 30% reduction in combined socalled Scope 1 and Scope 2 greenhouse gas (GHG) emissions by 2030, from the 2018 baseline of 0.93 MTCO2e. The long-term ambition is to be carbon neutral across the whole company by 2045 for combined scope 1 and 2 emissions. The key solutions that will enable emissions reductions include: sourcing zeroemission electricity, switching to renewables for their sites, elec trification of processes, and energy efficiency. Offsetting through nature-based solutions remains a long-term option, but at the lowest level in Kemira’s mitigation hierarchy. For scope 3 emis

sions, Kemira is committed to working with suppliers to decrease the carbon footprint of purchased goods and services.

ABB has launched its newest automated data acquisition and laboratory reporting solution, offering pulp and paper manufac turers rapid analysis of laboratory quality information, with re liable data storage, management and reporting. Purpose-built for paper testing laboratories, the scalable, web-based L&W Lab Management System replaces ABB and other legacy systems, halves procedure times, and tailors laboratory reporting to users’ specific workflow preferences.

Renaissance Chemicals Ltd is supporting AgriFoodX Ltd, by giving access to their laboratory facilities and technical ex pertise. AgriFood X was established to recover high value chem icals from agri-food by-products (AFBPs) for functional food and therapeutic applications, as well as materials for biodegrad able packaging. For certain food and agricultural applications, bioplastics derived from AFBPs offer a more sustainable alter native than non-biodegradable oil-based plastics. Supported by the EIT Food Programme and ERDF FoRTaMP project, Agri FoodX is developing novel bio-based films and scalable produc tion methods. With the aid of Renaissance Chemicals, they hope to accelerate translation from laboratory to production.

ABB has launched a new range of color-coded sensors that makes it easy to choose and manage the optimal pH measure ment solution. The application driven designs are categorised into three groups: the entry-level 100 series for cost-effective measurement in general process applications; the high-perfor mance 500 series for harsh industrial applications; and the 700 series for specialist applications.

The renewed Valmet IQ Quality Management System utilises Valmet’s latest innovations and expertise on pulp and paper qual ity management. It integrates the quality management of the en tire production process and is a step towards an autonomous mill. Valmet IQ consists of all the devices and applications needed to monitor and optimise both process performance and end-product quality: scanners, measurements, profilers, machine vision, and quality control applications. The new quality scanner family is redesigned for even more demanding production environments. All Valmet IQ scanners now consist of stainless-steel exterior, enhanced diagnostics, and a new flexible sensor platform. New IQ Dryness and IQ Multipoint measurements reveal the true dry ness development from the headbox to the reel. The IQ family is completed by the most advanced machine vision system on the market, enabling faster detection of even smaller quality de fects. The renewed Valmet IQ is compatible with the previous generations.

ABB announced its enhanced L&W Autoline automated paper testing system, scalable to fit any laboratory and userfriendly in operation for those new to automated testing. The fast, accurate solution optimises quality control and minimises oper ational costs for all papermaking operations. Building on the legacy of almost 50 years of automatic paper testing, L&W Au toline now comes in two different sizes: L&W Autoline S has a reduced footprint for smaller mills and those new to automated testing. L&W Autoline L is a larger unit, designed for more ex tensive testing requirements.

Finally, PITA welcomes its latest Corporate Member: Carbon Force. The company provides a fully funded, turnkey energy and carbon reduction solution. They build energy centres, powered by renewable energy sources, that replace old fossil fuel powered energy systems. Their turnkey solution includes: Survey, design, procurement, installation, commission and long term mainte nance, all on a fully managed basis. See the PITA website for more information.

work was handled remotely in order to avoid any health and safety risks.

Workers at the Burgo Duino paper mill in Italy walked out on a one-day strike to call attention to the working conditions at the site, after three workers had been in jured the day before – they were working on a platform which collapsed.

Seven workers fell ill, three of them seriously, after inhaling poisonous gas at Shakti Paper Mill in Tetla village, India, following attempts to restart production after the COVID-lockdown.

An explosion occurred at the Verso Corporation paper mill in Jay, Maine, in the pressure digester of the pulp mill; there were no casualties. Also, an accident occurred at the company’s Wisconsin Rapids paper mill, resulting in the death of a contractor.

Waste management company Viridor has been prosecuted and fined following an incident when an employee was crushed by a reversing 22.5 tonne shovel loader driven by an on-site contractor at their Crayford Materials Recycling Facil ity. He suffered very serious internal in juries and multiple serious fractures, both with significant life changing effects.

Recent fires included: Chadha Paper Mill, India, blamed on a short circuit; Es sity Lilla Edet mill, Sweden, on one tissue machine; International Paper, Coosa Mill, Georgia, which caused extensive damage; Mayr-Melnhof paper mill in Hirschwang an der Rax, Austria, blamed on arson by a man on the night shift; Sappi Alfeld paper mill, Germany, PM3; Twin Rivers Paper Company mill in Plaster Rock, USA, contained to chip and bark piles; VPK Oudegem Mill, Belgium, in the waste paper warehouse.

AR Packaging Group is to purchase BSC Drukarnia Opakowań, a Polish cartonboard packaging producer, which will strengthen the strategic position of ARP in Central and Eastern Europe.

FP Kaczory paper mill, located in Poland, took delivery of a steel Yankee supplied by PMP; PM2 is now up and running.

JSC Volga Pulp and Paper Mill in Bal akhna, Russia, engaged Andritz to re build their existing groundwood reject line as a TMP line. Furthermore, due to the corona crisis, the complete start-up

Vajda Papír, Hungary, has been in full operating mode for a few months now, after Andritz installed a new tissue ma chine (capacity 35ktpy).

Following the failure of plans to reopen the Arjowiggins Bessé-sur-Braye coated paper mill in France, the mill, which has stood idle since spring 2019, along with all the machinery, was put up for auction in May.

Baden Board and Baden Packaging, a German recycled board and packaging producer, has ended self-administered in solvency protection proceedings.

The European Commission has re jected a request by the Hansol group to exempt phenol-free thermal paper from the scope of products covered by antidumping measures. The EC has therefore instituted definitive anti-dumping duties on imports of certain lightweight thermal paper from the Republic of South Korea.

Hamburger’s new CCM machine at the Spremberg mill in Germany will start up later than planned; impacts of COVID19 and a recent fire have led to the delay. PM2 is now slated to start in early September.

Iggesund Paperboard’s mill in Work ington, UK, did not have a single accident that led to absence during the whole of 2019; more than 320 people work there.

Klingele Paper and Packaging Group, an independent manufacturer of corrugated base paper and corrugated cardboard packaging based in Germany, has commemorated its centenary this year.

The Koehler Paper Group has joined the 4evergreen alliance, a forum created by CEPI with the aim of increasing the role played by fibre-based packaging in achiev ing a sustainable circular economy.

Papier- und Kartonfabrik Varel PM4 has restarted after a rebuild which raised production capacity for the Jade White Classic and Jade Kraft container board grades by 20% to 360ktpy.

Pro-Gest plans to start the Mantua re cycled containerboard mill, capacity 400ktpy, in September.

Reno De Medici had the Jagenberg sheeter at their Santa Giustina, Italy, re built by Sael.

Sappi announced that its Symbio biocomposite cellulose fibre has been chosen as feedstock for the development of lightweight bio-composite materials, for the Life Biobcompo project. The project aims to reduce vehicle CO2 emissions by 8% through the replacement of conven tional mineral fillers with bio-based fi bres, promoting the use of more sustainable resources and demonstrating these technologies at industrial scale.

Stora Enso and Cordenka GmbH & Co KG have signed a joint agreement to develop precursors for bio-based carbon fibre. The precursor development is car ried out with specialised manufacturing spinning equipment at Cordenka’s Obern burg production site in Germany.

UPM has created a unique concept for release liner recycling, by which they are de-siliconised and used to produce new high-quality release liner base papers. This process will be used on their refur bished PM2 at Nordland, Germany, which is being converted to make a range of fine and speciality paper grades.

WEPA Giershagen has been operating PM19, supplied by Toscotec, since 2015. Recently it has been upgraded with a dou ble press, which has allowed the machine to run faster, enabling it to achieve the steady speed of 2200m/min, a new world record.

Ahlstrom-Munksjö and Metsä Fibre continue their collaboration by focusing on responsible wood sourcing.

AR Packaging aims to be first on the market with dry moulded fibre trays and cutlery. In line with this strategy the group has joined the PulPac Technology Pool. The process, invented by PulPac in 2016, which dry-moulds pulp into solid packag ing and single-use products, is unique and differs from the traditional methods of moulding cellulose and offers a replace ment for single-use plastics at a lower price than previously possible. The project is funded by the European Regional De velopment Fund, VTT and companies.

Many brands and retailers could re duce the climate impact of their packag ing up to 50% and avoid thousands of tonnes of carbon dioxide being emitted to air, according to results based on a large number of life cycle assessments per formed by BillerudKorsnäs using a new

tool that evaluates the environmental im pact of different packaging solutions. The recently introduced digital tool contains an extensive database on different pack aging materials, including data from BillerudKorsnäs’ own production. By se lecting a limited number of parameters re lated to the packaging, such as material, size, production location, transport, and disposal method, it will show the total life cycle impact for carbon dioxide emissions and water consumption.

Lessebo Paper launched Lessebo Re cycled in 2019, an uncoated range of pa pers produced from sorted waste, sourced from Europe. This innovative product made with recycled content is now FSC® certified.

Metsa Board is one of the founding members of the recently established Eu ropean Paper Packaging Alliance. EPPA is a food and food service packaging as sociation whose aim is to promote food safety, circular solutions, and lower car bon emissions as well as call for evi dence-based policy making.

Oppboga Bruk AB, a supplier of multi-ply paperboard for signs, displays and packaging, announced that they had started supplying their FSC-certified prod uct Oppboga Resilient™ for use in the manufacture of face shields to provide ad ditional protection to front line staff in hospitals and care homes in the UK. The face shields are produced by the Swanline Group, a principal merchant of fibrebased materials, print and conversion ser vices to the packaging and POS sectors.

Paper Province, a business cluster within the forest bio-economy in Sweden, has been working on transformation of lignin to enhance properties such as UV and fire protection.

Södra Cell Mönsterås pulp mill in southeastern Sweden, has started the world’s first biomethanol plant using An dritz A-Recovery+ concept which uses a patented extraction process. In addition to biomethanol production, A-Recovery+ also produces sulphuric acid from odor ous gases and recovers lignin for use in advanced bioproducts.

Stora Enso has begun testing an auto mated truck in its Uimaharju mill area in Joensuu, Finland. The objective is to find out to what extent automated transporta tion using a self-driving vehicle can re duce emissions and improve safety. The maximum speed of the automated vehicle moving between the sawmill and the pulp mill is 20kmh. The truck transports wood chips from the sawmill to the pulp mill, travelling the distance of some 1.4 kilo metres about 15 times a day.

UPM has newly adopted the target of doubling the amount of broadleaved trees growing in company-owned forests in Finland. In the light of current research data, increasing the proportion of broadleaved trees improves the forest’s growth and yield as well as its species di versity and resistance to climate change. UPM plans to increase the proportion of broadleaved trees to one fifth of all tree species growing in habitats that are suit able for birch. The dominant tree species growing in Finnish forests are typically pine and spruce.

Canfor Corporation announced it will be closing the Isle Pierre sawmill, located near Prince George, British Columbia, Canada, in Q3 2020.

Cascades Inc is to close the Brown Containerboard Packaging facility located in Burlington, Ontario, as part of the Cor poration’s continuing optimisation initia tives for its Containerboard Packaging business.

Domtar Corporation has completed its purchase of the Point of Sale paper business from Appvion Operations, Inc. The business includes the coater and re lated equipment located at the West Car rollton, Ohio, facility as well as a license for all corresponding intellectual property. With this acquisition, Domtar will be come a large-scale, integrated producer of POS paper.

DS Smith has opened its first recy cling facility in the United States. The Reading facility is unique in the region as it is alongside the company’s paper mill and within a mile of its packaging plant, creating a closed loop manufacturing model. Capacity is 36ktpy.

FPC Tissue in Chile has installed a Web Monitoring System on their new 2000mpm, 5.6m tissue machine, supplied by Procemex.

Graphic Packaging announced the planned closure of the White Pigeon, Michigan, coated recycled board mill (70ktpy) and PM1 containerboard ma chine in West Monroe, Louisiana (120ktpy). Both closures will be effective June 30, 2020.

Greif Inc. announced the closure of its La Palma, California, plastics and fibre facility. The fibre drum business will be redirected and serviced from their Morgan Hill, California, location.

Grupo Corporativo Papelera in Mexico started a new tissue production line (capacity 100tpd), supplied by A.Celli Paper.

Hamrick Engineering has success

fully and economically extracted arabino galactan and taxifolin from larch (tama rack) wood chips, and been granted patents for this technique in the countries with the most larch trees – the USA, Canada and Russia. This technique im proves the quality of the pulp, and the ex tracts have been shown to have significant probiotic effects in both people and ani mals, and can aid in producing animal feed without antibiotics that can be la belled as ‘organic’.

International Paper has committed to donating two million corrugated boxes to hunger-relief organisations during the COVID-19 pandemic. Also, the company is to sell its Brazillian corrugated packag ing business, which includes three con tainerboard mills and four box plants, to Klabin S.A

LD Celulose S.A., a joint venture be tween Lenzing AG and Duratex S.A., is to build one of the largest dissolving wood pulp plants in the world, in Minas Gerais State, Brazil.

New-Indy Containerboard, a 50/50 joint venture between the Kraft Group and Schwarz Partners, has acquired Shoreline Container, a Michigan-based paper and packaging company. With this acquisition, New-Indy will optimise Shoreline’s two manufacturing facilities: one at Holland, Michigan, which pro duces corrugated packaging products, and another at Zeeland, Michigan, which dis tributes protective and specialty packag ing materials.

Northern Pulp Nova Scotia, which is owned by Pulp Excellence Canada, plans to upgrade the pulp mill and has re quested that Nova Scotia Environment issue an Environmental Assessment pro cess for its proposed Effluent Treatment Facility (ETF) modernisation.

Sonoco has approved an $83 million investment to strengthen its uncoated re cycled paperboard (URB) mill system in the United States and Canada. The major ity of the investment includes transform ing its Hartsville, S.C., corrugated medium machine (No.10) into a state-ofthe-art URB machine with annual produc tion capacity of approximately 180ktpy. The machine conversion should be com pleted and on-line by early 2022. As part of the mill system optimisation program, Sonoco will also increase capacity of its Wisconsin Rapids, WI, mill. Finally, the company is permanently closing its No.3 URB paper machine in Hartsville and its Trent Valley, Ontario, Canada paper mill due to market conditions.

Sun Paper, a Chinese company, has abandoned its plan to build a huge paper

mill in Arkadelphia, Arkansas. The com pany cited “continued political friction and economic instability,” and the coronavirus outbreak as reasons for walking away from the project. The $1.8 billion mill was announced in 2016 but has faced uncer tainty since then because of trade tensions.

The Arab Company For Paper Products Ltd. (Arapepco) successfully started PM1 at Khan Al-Asal paper mill, near Aleppo, Syria, after a major rebuild sup plied by Toscotec.

Gulf Paper Manufacturing in Kuwait has restarted PM1, which pro duces packaging (mainly corrugating medium) after Toscotec completed a major rebuild of its dryer section.

Kimberly Clark Products Malaysia, Kluang Johor Mill, employed A.Celli to upgrade the TM2 Tissue Line with a new off-line shaft puller and a new set of ex pandable spools, in combination with the upgrade of the rewinder slitting unit.

Japan’s paper distribution group Kokusai Pulp & Paper Co. Ltd, Se quana SA and Bpifrance have entered into binding agreements for the potential acquisition of Sequana and Bpifrance’s 83.7% in Antalis by KPP. The transac tions are expected to create a world mar ket leader in the distribution of paper, packaging and visual communication in Asia, Europe, Australia and Latin Amer ica (capacity 3.3Mt).

Picknik Marketing Pty Ltd in South Africa started a Toscotec tissue machine at its Johannesburg mill. The new line, ca pacity 75tpd, produced high quality tissue from day one.

Sunshine New Material for Hygiene and Health Care Jiangyin Co. Ltd started two spunlace machines, a winder and a rewinder at their plant in Jiangyin, China, installed by A.Celli.

ABB has introduced the next-generation L&W Autoline; launched its KPM KC9

Optical Consistency Transmitter family; introduced its newest automated data ac quisition and laboratory reporting solu tion; and finally launched a new range of colour-coded pH sensors.

A.Celli has developed the Doctor Rewinder for a fast and effective removal of any defects in nonwoven reels and to obtain small format reels through longi tudinal cutting.

Andritz Diatec has developed a fully automatic, high-speed face mask convert ing line for the production of disposable face masks.

BTG launched CONTROLsuite, its in tuitive, user-friendly and comprehensive solution to optimise loop performance. Also, Pulp 4.0, an integrated solution to improve overall fibreline performance; it can be implemented for the entire fibre line, or by process area – the three process areas are: MACScook, MACSwash and MACSbleach. Finally, the company has continued to implement its new-genera tion Yankee Performance Monitoring sys tem (VigilancePRO).

Clyde Industries, a provider of boiler efficiency solutions, has successfully es tablished a new office, Clyde Industries India Private Limited, located in Bale wadi, Pune, India.

Evonik has launched HYDREX® P, a silica with an optimised particle size dis tribution, high optical efficiency and unique internal structure, aimed as an ex tender to Titanium Dioxide

Spreader roll manufacturer and service provider Finbow has invested in capacity expansion in Pirkkala, Finland, where new workshop area has been opened ded icated to handling spool assemblies of ser viced rolls.

Kadant Inc., reached a milestone in nanotechnology-enhanced composite doctor blades sales. Since the launch a few years ago these blades now represent Kadant’s largest volume composite doctor blade type.

Metso Corporation has demerged its flow control solutions and services busi ness focussed on the oil and gas refining,

pulp, paper and bioproducts industries, chemicals and other process industries; the new company will be known as Neles Corporation

PMP opened a new engineering office in Łódź, Poland, dedicated mainly to sup port its tissue business. The employment target of the new office is 40 engineers.

The new RunEco EP650 Turbo Blower developed by Runtech Systems features an ABB motor, leading to reduced rotor losses and higher load capacity.

By combining SKF and SMT’s techni cal analysis and optimisation capabilities, engineers can now have a seamless expe rience when designing transmission sys tems. The SMT MASTA software helps engineers to accurately and rapidly design and predict performance characteristics.

SKF has released a compact and costeffective vibration and temperature sensor for monitoring the condition of rotating parts on heavy industrial machinery –called the SKF Enlight Collect IMx-1.

Solenis has completed the acquisition of the paper business of ChemSystems Also, Solenis is expanding production at its Ankleshwar facility in India to manu facture its next-generation Pergafast™ 425 colour developer for the thermal paper market.

TietoEVRY is partnering with Turck Vilant Systems, a leading RFID solutions provider in the pulp and paper industry, to generate more value for data in the logis tics ecosystem. The co-operation includes co-innovation in solution development, technology sharing, as well as sales and marketing.

Valmet introduced a renewed Valmet IQ Quality Management System for pulp, tissue, paper, board, and converting indus tries.

Voith introduced the new TwinDrive double unwind, which ensures a winding capacity that is up to 20% higher com pared to the use of conventional unwind ing systems.

PRESS Page 31.

M. Wroe

M. Wroe

Today’s main goals for the global paper manufactures are to achieve higher efficiencies, improving quality at the same time as lowering production costs. It could be done using state-of-the art paper stock preparation and wet end technologies and better studying and understanding of the processes.

In papermaking we also need to implement the papermakers rule “stable production process is a guarantee of high paper ma chine productivity”.

Since paper stock, in the whole, is a complex colloid system with dispersed and dissolved particles in a liquid, different forces and processes take place. This includes balancing interactions and repulsions following reversible adsorption of particles on fibre surfaces and other furnish components that have, for ex ample, high concentration of non-productive substances, mainly the carriers of anionic charge (“anionic trash”) [1].

There are many publications dedicated to the electrokinetic state of fibre suspensions as well as the effects of different chemical products on several electrokinetic parameters of the paper stock, Z-potential and flow potential or on drainage and retention of fibre, fillers and non-productive substances. The modern pulp and paper mills control the following electrokinetic parameters [2]: Electrokinetic Z-potential as a characteristic of fibre sur face charge with “static” ions, Streaming potential as an evaluation of ion concentration in diffusive layer where the ions move along a so-called “sliding surface” of static ions, Cationic demand of paper stock as a measure of anionic charged particle concentration in the paper stock, Electrical conductivity of stock as a measure of conductive ion concentra tion depending on stock temperature and affecting the potential values, Stock filtrate turbidity characterising colloid particles of different dimen sions in the liquid phase.

A relationship between cationic demand and Z-potential of stock from the headbox of a newsprint paper machine (PM) is shown in Figure 1. The parameters vary so much that it is difficult to speak about PM efficiency. If we consider the total paper production line ef ficiency from woodchips for Thermal Me chanical Pulp (TMP) production to the winder, for paper with higher brightness, brightness losses are 5-6% (Figure 2) due to technological drawbacks in the paper ma

chine system as compared to a reasonable expectation of not more than 2%.

A three-component chemical system included fixing and re tention agents was used previously, which was actually more efficient. We can compare the efficiency of the old system and current one from the relationship between fibre and fines re tention and the Z-potential of stock from the headbox shown in Figure 3. If we proceed from the current 50% retention level Z-potential would have been approximately -19mV, but now it is in the range of -8 and -12mV. Also, a retention level based on the actual cationic demand of the PM headbox stock would have been 57-58% (Figure 4). However, fines, extractives, and chemicals infiltrate into white water due to the drawbacks of the new chemical system and therefore the anionic contaminant concentration rises. That is why the chemicals designated to act as a fixative neutralise anionic charge in the liquid phase more and more which have a negative impact on Z-potential and retention levels. In this case retention agents lose their ef fect. It is therefore necessary to find (a) the right dosages of flocculants and (b) a correct ratio between flocculants and co agulants. It should be noted that although stability of electroki netic parameters are important factors, it does not mean that the whole PM efficiency reaches a maximum. It could be done only in case of the correct process control and application of the best available technologies. But, in this case study, these measures were not used. The technological conditions and chemical systems should be changed with updating of the pro

duction processes. Regulating electrokinetic parameters together with advanced control methods and modern laboratory equipment will contribute to improving PM runnability. This goal was earlier discussed and success fully implemented [1,4,7,8]. In principle it is a matter of adaptability of the chemical technology to specific production conditions that can result in maximum profitability. On the other hand, many offers from different chemical suppliers and distributors without up-to-date servicing tools can create numer ous difficulties for papermakers. They don’t know how to select the optimum technolog ical conditions or chemical systems. More over, laboratory trials can’t simulate a real PM processes; they can only determine the tendencies.

An appropriate choice could be made de pending on surface anionic charge, fibre mor phology variations and presence of non-productive substances in paper stock from virgin pulp or recycled fibre. Only after thoroughly planned multistage experiments on the basis of the following factors can a choice be made:

Preliminary selection of chemicals on the base of current production targets, Primary evaluation of chemical effi ciency in laboratory by measurement of electrokinetic potential, streaming potential, electrical conductivity, cationic demand of stock filtrate, tur bidity of filtrated and non-filtrated samples as well as pulp drainage rate, concentration and dimensions of pitch particles. (The conditions of the mill needs to be simulated, i.e. include the characteristics of original fibre and paper furnish, the time interval be tween chemicals dosage and techno logical processes, stages of stock dilution with recycled or white water before flocculant addition. It allows to detect how the chemicals are ad sorbed onto the fibre surface or on other stock components and/or inter act with non-productive substances [1, 2, 3].)

Determination of the maximum possi ble dosage of cationic chemicals such as polyelectrolytes or PolyDADMAC amounts required to clear up the specifics of adsorption capacities of fi bres relating to polymers with various charge density, chemical structure and molecular weights. This enables plot ting of titration curves to form a true idea of adsorbed and diffused ion lay ers in the fibre field while taking into account real stock conductivity and temperature,

of real fibre charge after its careful washing with deionised water

purities.

Further stages of evaluation include: Balancing of chemical dosages, Laboratory testing of technology with handsheets to evaluate trends, Production trials and technology correction on-line or in the following testing periods.

In contemporary scientific literature there are some articles detailing analysis of Z- and streaming potentials measuring methods. One can conclude that every measuring device has some advantages and disadvantages, but its application always requires highly clean and careful handling. A rather wide database of parameters needs to be collected during a rather long testing period (weeks, months, etc.) to make credible conclusions about the functioning of a highly productive PM.

The authors used “SZP 04” and Mütec’s “PCD 03, PCD 04” devices to determine pulp potentials (mV) and conductivity (µS/cm), cationic demand (mg PolyDADMAC/l) and Dr Lange’s “Dr 2800” and “HACH” for fil trate turbidity measuring (FAU and NTU units, respectively). Furthermore, the param eters were analysed from various sampling points of the stock preparation system and PM headbox to determine the effects and consumption of chemicals that are important to correctly apply the technology and optimi sation of chemicals dosage.

With increasing paper stock’s cationic demand, fixing and neutralising processes of non-productive substances start to play a more considerable role. In the first case it is fixation of the anionic substances onto the fibre allowing it to be removed from the white water circuit together with paper prod ucts (retention); in the second case, its bind ing in liquid phase that not absolutely excludes its further fixation even in a “clean” virgin pulp furnish. Anionic contam inant neutralisation in the stock is illustrated in Figure 5 , where one can see that well-

founded increasing of low molecular poly mer (from polyamine assortment) dosage re duces an absolute value of streaming potential at constant Z-potential of material surface [3].

Successful fixation is guaranteed by ap proximately equal or weaker bonding extent of the fixing agent with non-productive sub stances comparing with fibres.

Figure

Figure

Selection principle of fixing chemicals depending on cationic demand of original pulp is shown in Figure 6 [5]. The logarith mic trend of this relationship allows the con clusion that with increasing cationic demand as well as the filtrate turbidity and COD higher than 500 to 600mg, PolyDADMAC/l fixative charge density won’t be the same as compared with lower concentrations of an ionic trash. Also, evidential variety of nonproductive substances hampers fixing chemical effect. As mentioned above, speci ficity of fixing agent selection is stipulated by the fact that if charge density at its dosage point is lower than the required level, neu tralisation of anionic contaminants in liquid phase could occur without its fixation. The results of filtrate titration would be wrong, since cationic titrate PolyDADMAC with charge +6.5µeq/g would balance them. When this chemical dosage increases, it gradually accumulates in the liquid with step-by-step enlargement of anionic impurity particle di mensions (a) before its settlement, and (b) recharging of negatively charged fibre. Note that high level of furnish cationic demand can be from excess or overdosing of chemi cals with anionic charge; for example, an ionic dyes or optical brighteners, dispersants, micro particles of silica and bentonite. Addi tion of micro particles to above mentioned situation led to an imbalance between dosages and charges of cationic component and anionic reagent for formation or the lack of cationic com ponent totally in PM short circulation system. From experience, for such furnish composition very effective balancing method is the application of so called ”Carrier System” technology in cluding combinations with micro particles [5,9]. This technol ogy is successfully being used in tissue production where there can be a need for some wet strength quality. High cationic PVAm-component fully shows wet web properties and in com bination with anionic product effectively improves wet strength resin application with lower dosage without secondary deposits in wet end and fibres re-charging [7]. In high porosity base paper production technology for laminating base paper pro duced from 100% waste paper the “Carrier System” success fully replaced 0.8% of cationic starch with some correction of regime for the whole assortment (Figure 7). Concerning high porosity qualities similar positive results were obtained in sack paper and gypsum board base production. Below is outlined a practical example of liner production where a partner for ben tonite resulted in a homopolymer of polyvinylamine (PVAm) in a system were problems occurred from excess usage of chemi cals with positive charges.

Paper furnishes from unbleached pulp and high yield (semichemical) pulps (NSSC) with high contamination levels are spe cific for chemical application because of very poor degree of

cationic demand

mg PolyDADMAC/l

demand

pulp washing. In laboratory tests with PolyDADMAC an abso lute value of streaming potential firstly grows as anionic sub stances are neutralised. But then the titration curve takes the usual form (Figure 8) as in the case of recycled fibre furnish with medium cationic demand (Figure 9). Addition of a fixative to gether with a retention agent does not alter the curve character on the whole. It can be assumed that the adsorbed layer of static ions and diffused layer are rather thick and the well-known Helmholtz-Smoluchowski equation becomes not completely ap plicable to calculate the potentials. In this case the most nega tively charged ions displace nearer to adsorbed layer and the Z-potential absolute value is higher than that of real fibre. Com bined application of chemicals for neutralising of such kind of substances as aluminium sulphate or polyaluminiumchloride (PAC) together with low molecular, highly cationic fixing agent and low cationic, low molecular weight flocculant, could be ef fective in practice.

The following principles should be considered, to maintain PM efficiency and runnability [2]:

Preliminary stock treatment with fixing agent specifically adjusted for given production conditions and deposit control, Application of adapted retention and filler system, sizing and strengthening agents, providing stable formation and drainage conditions, electrokinetic parameters of paper stock before web forming,

Providing an increase in web dryness after sheet forma tion and improved wet web strength of the sheet before the drying section.

Selection of chemical dosage point, taking into account the specificity of technological line, Providing chemical compatibility and synergy of their ef fects.

In the case study presented below all above principles were ob served that resulted in an improvement of the PM runnability (the whole efficiency, material and time saving, improved quality).

A new range of environmentally friendly polymers based on vinylamine was originally presented as a class of universal chem icals that integrate fixing properties, strengthening of web in PM wet end as well as the final product, retention and drainage agents for fibre suspensions, and strength improvement of paper and board in dry conditions as well as under moisturising. Pa permakers are often sceptical about chemical universality. How ever, in this case, taking into account the specifics of a liner PM with 1000t/d capacity, carefully selected dosage points and se lecting the correct strategy of new chemical implementation, suc cessfully helped to reveal PVAm-product advantages. Laboratory tests of three polymers from this product range with different charge densities enabled choice of a suitable product for liner production. The handsheets for laboratory tests were made using a “Rapid Köthen” sheet forming apparatus. In Table 1 average test results (as percentage change) are presented.

No. PVAmamphoteric PVAm - low cationic charge PVAm - medium cationic

1 Burst, % + 11.0 + 15.0 + 20.0

2 Tensile, % + 4.0 + 9.0 + 9.0

3 Double folding test, % + 32.0 + 18.0 + 3.0

4 SCT, % + 2.0 + 14.0 + 10.0

1. Strength property changes of liner using three different PVAm’s.

The conclusion about an illogical, unsystematic chemical ap plication approach appeared from discussing the current liner tech nology which used seven chemicals and nine dosage points (Figure 10). Originally, unbleached hardwood pulp was treated

with highly cationic PAC and polyamine (PAm), followed by cationic starch and additional dosage of polyamine was then in troduced into the kraft pulp suspension. After the adsorption of PAC particles and with increased consumption of polyamine, the molecules remained on fibres mainly in liquid phase, where they neutralise agglomerating anionic contaminants. In this case there was no expected incremental effect of starch retention on the fibres since low molecular polymer cationic particles have already ad sorbed on active zones of the fibre surface. Sizing agent was in troduced a little later, practically in low consistency pulp, along with a portion of PAC, probably to help with sizing agent retention. Also, biocides were introduced before stock discharge onto the wire, to avoid pitch problems. Finally, before the headbox, ben tonite was dosed that did not have any chemical partner to provide proper formation with the use of a cationic polyacrylamide or at least with a starch. On the contrary, worsening of drainage oc curred in the wire part with increased bentonite consumption.

It should be noted that bentonites are the general term for a large mineral class based on montmorillonite, a composite with crystal and non-crystalline structure. At dissolution in water pos itively charged metal ions such as Al3+, Mg2+, Si4+, Na+, Fe3+ due to its insufficient quantity inside crystal structure of product dif fuse to the liquid phase. So, mineral particles with dimensions about 300nm but thickness less than 1nm get a significantly neg ative charge. Metal ions become available to react with anionic impurities in the liquid phase that result in secondary pitch trou ble in the wet end as well as in the drying section. If bentonite is used alone, without a cationic partner, stock dispersing could take place that leads to the detriment of fixing-retention pro cesses. The same situation could happen with the use of silica sols in the known two-component combinations; a balance in the system is hardly achieved even at minimum concentration of non-productive substances, taking into account the high speed of modern PMs. The references to the results of intensive drainage have not been confirmed, since optimal drainage is a complicated target including a complex of processes such as fibre and filler retention, web formation, etc.

Coming back to our practice, it seems to be that fibre surface saturation with cationic chemicals before final dilution pro vides favourable conditions for effective retention of sizing agent for internal sizing at electrokinetic potential in the range between -2.3 and -7.8mV. However, the variations of cationic starch retention led to the variations of sizing agent retention rates, to secondary deposits and unrea sonable biocide application. Moreover, excess of 0.2% to 0.4% PAC intensified fibre surface charge neutralisation up to Z-potential value of the stock from the PM headbox between -1.5 to -3.8mV, even after bentonite suspension addi tion. This example disproves the postu lates of early electrokinetic theory which stated that the best formation con ditions can be reached at Z-potential values coming to 0 or a little higher, up to + 5mV. PAC, PAm and 1.2% cationic starch were totally excluded from the filler ply pulp loop in the modernised technology with 0.35% to 0.40% PVAm. PAC was also eliminated from the short circulation system, and 0.12% of the PVAm quantity was dosed before the screens. Thus, bentonite received its “long-expected” partner with protection against anionic trash particles and reten

tion-drainage properties with fibre micro flocculation. As a re sult of the balance the new combination drainage improved with increased PM speed (Figure 11). The bentonite consumption was reduced by 27% and the internal sizing agent by 9-10%. With a decrease in the initial concentration of anionic trash, the PVAm main role shifted to strengthening of paper web structure

that enabled the complete exclusion of starch and resulted in the formation of smaller pulp flocs and improved formation.

Finally, the technological flow sheet has been significantly simplified with increased anionicity of furnish and purity level of PM white water circuit (Figure 12). Cationic de mand of non-filtered pulp sample from the PM headbox rose which indicated that high amount of residual chemicals such as PAm and cationic starch fragments in the liquid phase was due to the current production tech nology. Simultaneously, the simplification of this chemical system easily allows adjustable control of further issues relating to produc tion. No pitch problem, easy regulation of re tention and drainage in parallel with strengthening. Table 2 indicates, besides chemical savings, other advantages of the new technology, which in part stem from im proved sheet formation.

As a general conclusion we can say that using modern laboratory equipment together with advanced anal ysis, the correct interpretation and management of electrokinetic parameters of a furnish will help to improve chemical selection and total technology, which in time improve PM’s productivity for various paper grades.

W.E.Scott, Principles of Wet End Chemistry, Atlanta, TAPPI Press, 1996, 185pp.

P.V. Osipov, T.A. von Vadkerthy & D. Mönch, “Optimization of paper and board production by means fixation and retention additives application”, SPb, 1996, 4th ISTC “PAP-FOR-1996”, pp.115-130.

P.V. Osipov & D. Mönch, “Memories about future: electrokinetic potential of paper furnishes”, Pulp. Paper. Board, 2001, No.34, pp.16-20.

P.V. Osipov & S.P. Osipov, “Evaluation of drainage, effective ness of polymeric additives in wet end of paper machines”, Pulp. Paper. Board, 2007, No.2 (Part 1), pp.62-68. P.V. Osipov, “Effective use of chemical auxiliary substances in paper and board production”, DSc (Tech) dissertation, SPb., SPbSTUPP, 2007, 295pp.

P.V. Osipov & V.V. Sokolov, “Colloid – chemical aspects of solve pitch problems and improvement of paper machine pro ductivity”, Pulp. Paper. Board, 2011, No.8, pp.74-78. P.V. Osipov, “Improvement of paper production with wet strength properties”, Pulp. Paper. Board, 2012, No.7, pp.56-59. P.V. Osipov, “Modern chemical nanotechnologies for high speed paper machines. Pulp. Paper. Board, 2013, No.10, pp.64-72. P.V. Osipov. “Modern chemical technology in test-liner and flut ing production productivity improvement”, Pulp. Paper. Board, 2012, No.8, pp.84-88.

A. Esser, M. Rübenacker, N. Schall, R. Haffke & O. Truppner, “Synthetic dry strength agents on a polyvinylamine basis”, International Paper World, 2005, No.10, pp.25-28.

Many papermakers have a love-hate relationship with their Paper Machine Clothing (PMC), and their press felts in partic ular. This paper aims to give you the insights you need as a pa permaker to judge press felt trials effectively, so that you can increase the machines bottom-line through better performing felts.

Press felts are probably the mechanical components that change the most over the course of their life in the machine, typ ically a number of weeks. By connecting output data of the ma chine with the life of each felt – and the changing felt properties per day – new insights are gained.

These insights, presented as fact-based charts, give both the papermaker and the felt supplier an objective reference to judge the performance of trials, making the process to better press felts faster and more worthwhile.

Many papermakers have a love-hate relationship with their Paper Machine Clothing (PMC), and their press felts in particu lar. But what makes optimising the performance of press felts a ‘special class’ challenge?

A combination of many factors.

First of all, the complexity of press felts as a product. The de signer has to make a selection from several base designs, choose the numbers of batt layers with the appropriate fineness’s. To needle the batt on the base, the designer must choose the best of many different needling procedures and different types of nee dles. After needling, several finishing procedures can be com bined to create the best result. All-in-all the felt designer has to make decisions from roughly a hundred million theoretical vari ants.

Another factor is the significant change that press felt prop erties undergo over the course of their few weeks of life. We be lieve that the press felt is probably the single most changing mechanical component in a running paper machine with already thousands of variables. That makes press felts what we call a true variable!

What can a paper maker do to improve press felt performance?

You will discover that dealing with the assessment and improve ment of press felts is a real science … but it’s not rocket science.

Knowledge is power | Take control

Step one in successfully improving the performance of your press felts is understanding how your current felts change over the course of their lifetime. And how these changes affect (the output of) your total machine.

This understanding comes from monitoring the felt properties on a daily basis, and this is not a task you can delegate to your PMC supplier. A papermaker can only create a consistent basis for judging his current and future press felts when the paper maker himself takes control of his best interest.

And it is in a papermaker’s best interest to know his own ma chine better than anyone else.

I like to stress the importance of doing measurements at reg ular intervals for establishing a culture of structural improve ment. Later on you will learn about which data to monitor and how to support your suppliers to come with continuously better felts and fabrics for your machine.

The pickup felts of supplier A are connected to a 1% higher production output per day, compared to supplier B. Because of the complexity of the machine, you cannot make 100% conclu sive statements based on these data, but you do need to record this information as an important signal of the relation between pickup felt A and the overall performance of your paper machine.

If you measure and record chemical use as a variable, you may notice that the consumption of felt cleaning agents for felts supplied by supplier B is 5% lower per ton output.

As you see in both examples, the differences in measured variables can be small, but if you add all differences they can re sult in significant production gains or losses. And because the variations are small, it is important to use accurate data, either from your machine control systems or high precision measuring instruments.

We recommend collecting data for a minimum of 12 months to determine how the performance of your felt relates to the per formance of your machine.

You are in this for the long haul, so after these 12 months you can start reaping the benefits by working on improving the per formance of your PMC by basing your decisions on fact-based information, instead of supplier based benchmarks or your own gut feeling.

Picture yourself monitoring one of the relevant variables for a felt (for instance: compaction). Unless there is a huge deviation from the benchmark values, you can’t possibly know if the com paction value you measure is of positive or negative influence on the overall performance. You need more information.

To get a clear picture of the performance of each of your felts we suggest to collect two types of data: machine data and felt data.

Machine data covers the output of the machine and factors that affect the cost price of your product. We look for machine data that can be measured per day or per tonne. The aim of col lecting machine data is to show how the performance of your press section relates to the overall performance (output) of your machine.

Examples of relevant machine data: Production in tonne/day Felt washing chemicals in kg/tonne

Number of breaks per day (better than “time lost due to breaks”)

Steam consumption in the pre-dryer section in tonne/tonne

Power consumption in kWh/day for the press section’s vacuum pump

Of course there is much more. Important to realise is that we choose to focus on data that is measured per day or per tonne, because it allows us to start comparing the machine performance per day with the life of each individual piece of Paper Machine Clothing.

Although you can’t allocate the general output data point to a specific part of the paper machine, this data does provide a signal about how the individual parts of the complex system work together.

Normally all the machine output data is already recorded and saved in the paper machine’s control system. Extracting relevant machine data should not be a problem for mills with a qualified IT staff. The trick is to organise the data in such a way that it can be used easily for comparison with data from the felts that are running in the machine.

The second type of data we need is the felt data. When we monitor how felt properties change over time, we get signals on how these properties influence the total machine performance, which is directly related to the bottom line results.

If we want to structurally improve the performance of press felts, we have to take into account that felts have a very wide range of properties. The difference between felt weights for one position can be up to 50% (e.g. a 1200 - 1800g/m2 range). There fore it is better to monitor “relative data” than “absolute data”.

A papermaker monitors the felt caliper and measures a value of 1.66mm. This measured value in itself doesn’t provide much useful information (which is the case for any stand-alone mea surements that are within the benchmark value range). So we need to put the measured caliper value into perspective by knowing if the felt weight is for example 1200g/m2 or 1800g/m2. Calculating the compaction percentage is the solution to this challenge.

Figure 1: Wet press felt showing volume of water and volume of felt material.

When the felt goes into the nip it will be compressed and at the nip exit it will expand back. During the lifetime of the felt, this expansion will decrease and the felt becomes compacted. Compacted felts absorb less water than non-compacted felts. Therefore the caliper of the felt should be judged in conjunction with the felt weight.

Figure 1 is a simplified picture of 1m2 of running press felt. Normally, felt material and water are distributed over the full volume, but for easy understanding all the felt material is pro jected on the bottom and all the water is projected on top.

h = measured caliper (height) of the wet felt [mm] s = solid (non-absorbing) part of the felt [mm] v = void (absorbing) part of the felt [mm]

The “solid” part of the felt can be calculated, as we know the density of the felt material (being PA) and the surface (being 1m2).

F = actual weight of 1m2 felt [g/m2] ρ = density of press felt (approx. 1.14 for PA) [g/cm3]

This makes s = F * 103

1.14 * 106

Now the compaction of a felt can be defined as percentage of the solid felt part in the total measured height, or in a formula:

COMPACTION [%] = s h * 100%

This formula is easier to calculate (if you work in the metric system) when you use the adjusted formula:

COMPACTION = F [%] or in words:

11.4 * h

Compaction is felt weight F (in g/m2) divided by 11.4 times the measured caliper h (in mm).

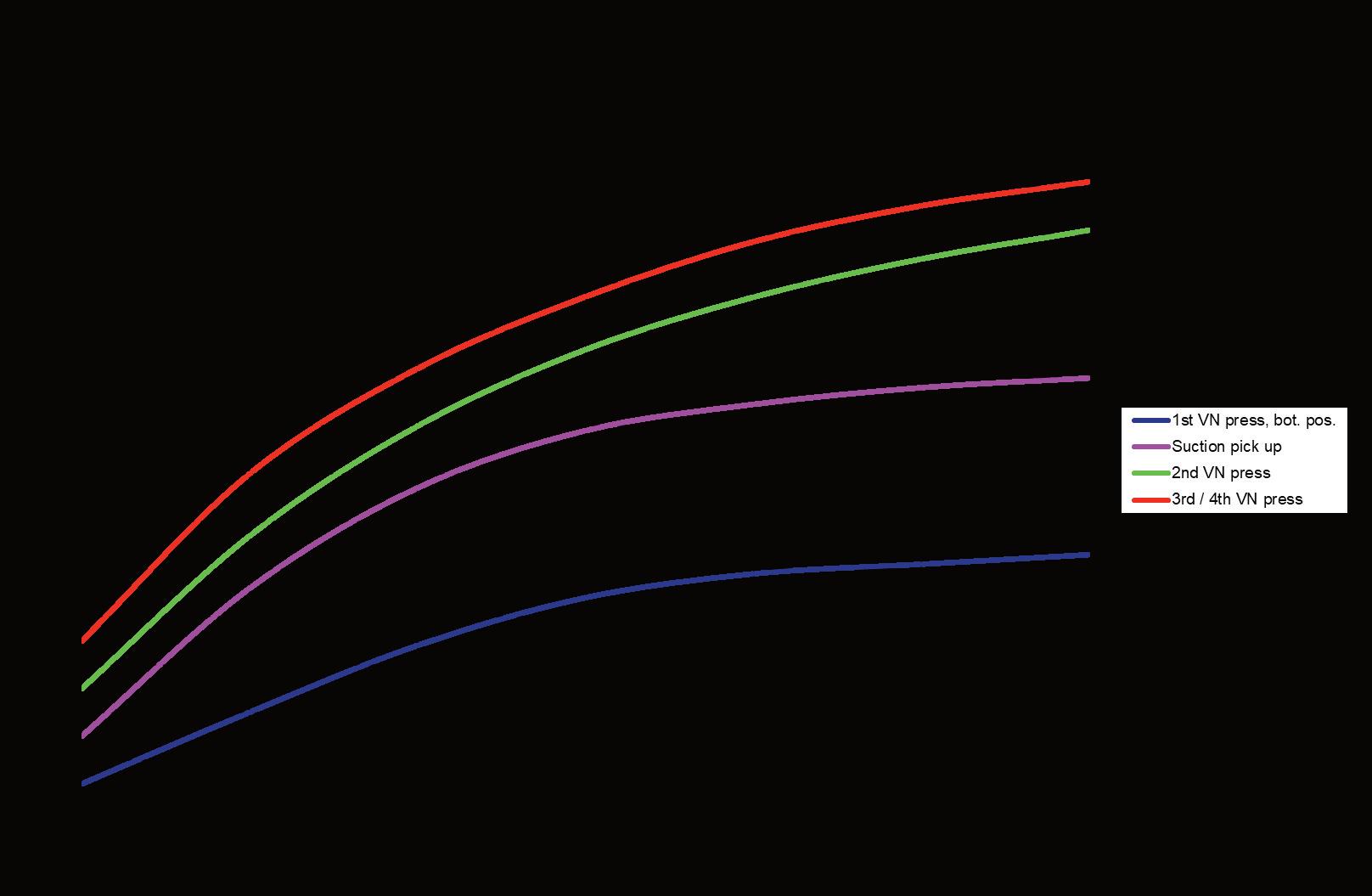

Figure 2 shows an example of compaction curves for a nip dewatering machine.

Another important and well known parameter is the felt per meability. A good and affordable indicator for felt permeability is the metric for airflow through the felt at the Uhle boxes.

However, the airflow is not only determined by the perme ability of the felt. The applied vacuum plays a major role. There fore, it is smart practice to convert the measured airflow value to a standardised vacuum level.

For instance, if you measure an airflow of 8m/s over the Uhle box with an applied vacuum of 40kPa, you can standardise by anticipating the value of the airflow at a vacuum level of 10kPa. This is the Dynamic Felt Permeability (DFP). In this example the DFP is 2m/s @ 10kPa.

“NEVER forget that your press felts do not perform in a laboratory environment or at somebody else’s mill. They perform in YOUR machine” Marcel Lensvelt

Collect both machine and the felt data, on a daily basis.

Table 1 shows an example set of data for the felt life of every position in the paper machine.

For each PMC we know the installation dates and removal dates. This knowledge allows us to connect the running days of each felt with the output performance data you collected earlier.

Make charts for every press position. On the X axis the day’s life, starting at 1 until as long as you have data. On the Y axis you put your machine and felt data. Take the average of all daily productions when felt 1 was 1 day old, then when it was 2 days old, etc.

After some time you get the insight into how specific cloths influence the overall performance of the entire paper machine.

The longer the period, the better the quality of your chart. It is best practice to use the collected data/averages for a period of at least 12 up to 24 or 36 months as a rolling average. By using such a long period, your averages will be statistically reliable without being influenced by totally different machine setups or other ghosts of the past.

The first and third press felt have a life of four weeks, but they are never installed at the same time.

The number of daily breaks (the red bars in the chart) seems somewhat correlated to the steam consumption, the green line in the chart. The blue line shows the daily production. It is clear to see that after a shutdown the machine does not immediately get to maximum output. Just before a shutdown, daily output drops a bit and the number of breaks go up.

When you watch closely, you will see that at the end of the first cycle the machine has up to 6 breaks per day. At the end of the second cycle you also have more breaks, but ‘only’ 4 per day.

Now after collecting machine data of several days with “pickup felt life = 1”, “pickup felt life = 2” etc. and combining that with the felt data, we can make a chart for every press felt in the machine as the example in Figure 4.

From this chart can be deducted that only from day 5 the ma chine reaches its maximum output. The first 2-3 days the steam consumption is relatively high, as are the number of breaks. After day 10 the end-of-life becomes noticeable: the steam consump tion goes up – indicating less dewatering by this felt and so does the number of breaks. This could have two possible (feIt related) causes: maybe the felt compaction has a maximum value of approx. 63%, or this position has a critical dynamic felt per meability of approx. 1.7m/s @ 10kPa.

In Figure 3 we have made a chart of machine data during seven weeks. This imaginary machine runs in a two week shutdown cycle and with every shutdown a new pickup felt is installed.

Looking at the chart, most can be won by reducing the breakin period of the pickup felt. This should be the target for a new trial felt. It is up to the felt supplier to decide how; he can play with the permeability, the level of pre-compaction, the felt sur face with other batt layers and different needling procedures…

“If you work with true data, your improvements will be real

Marcel Lensvelt

correlation

machine data

as long as the machine achieves more daily output during the first 5 days.

When the trial felt is on the machine, just plot the trial felt’s data into the chart above and the supplier and the papermaker have an excellent baseline to judge the performance of the trial.

When a papermaker has recorded sufficient and solid “nor mal” performance data for his machine, he can use this valuable information as the reference to work with his PMC supplier in developing new and better performing press felt designs.

In closing this paper … you are invited to open your eyes and actually SEE your felts’ performance.

showing machine data and felt properties over pickup felt life.

make visual charts

show

felt properties change over time and their effects on

total paper machine performance. Visual charts are a pow erful tool for communicating with your PMC suppliers.

Keep things as simple as possible. As a papermaker you’ll want to pick one goal to improve (and ONE goal only, that should be clear from this paper).

your PMC suppliers to develop better felts for you

sharing your data with them. Show PMC suppliers

visual charts

are seriously empowered to im prove and help them kick-start innovative press felt trial processes.

they will SEE that

Dr Mahendra Patel, industrypaper@yahoo.co.uk (www.industrypaper.net)

Dr Mahendra Patel, industrypaper@yahoo.co.uk (www.industrypaper.net)

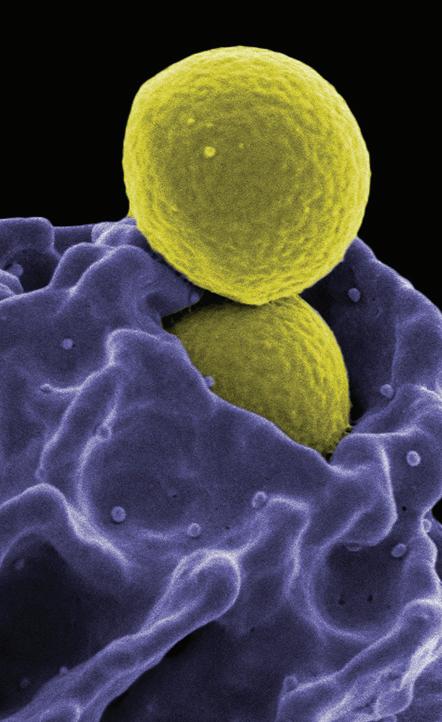

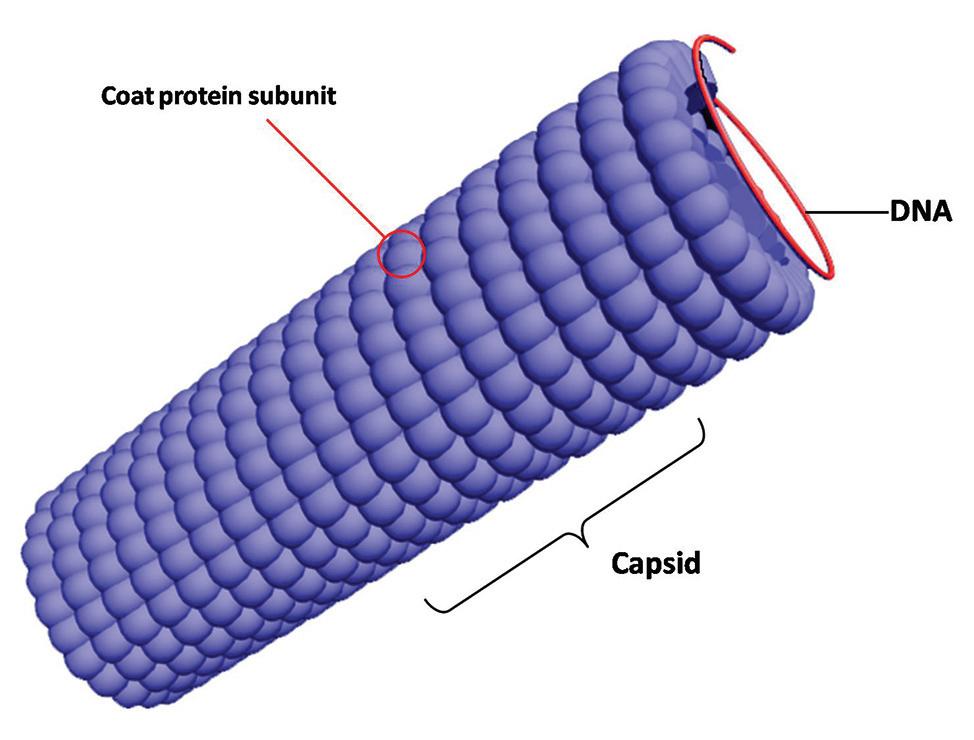

Paper, Packaging and Tissue industries are already indoctri nated with the antibacterial and antimicrobial concepts, produc ing special packaging materials to preserve food and fruits and antibacterial tissue papers. These are mostly based on antimi crobial organic compounds and inorganic materials. In the meantime, lots of advancements have taken place in nanotech nology with production of a number of nano materials which have antibacterial properties. In fact, the antimicrobial efficiency of some of the nanoparticles is many times more than that of tra ditional antimicrobial additives.

For combatting the sub-microscopic bacteria and viruses, an timicrobial paper incorporating nanoparticles, can be very ef fective. It is particularly appropriate at the present juncture to use such papers and products to arrest spread and kill the deadly coronavirus. The key technologies available now in use for pro duction of antimicrobial paper and products, are reviewed, along with test results in reducing the percentage of virus on the an timicrobial paper surface and thus spread of the virus.

Finally, the impact of the coronavirus epidemic on the paper industry has been forecast, and techniques for formulating the nanoparticle-based antimicrobial composite and its addition during paper manufacturing are discussed.

We have witnessed the horror of the coronavirus epidemic since the beginning of this year, causing deaths of almost half a million and infection of several millions of people throughout the world. Governments, hospitals, testing laboratories and se curity staff members, doctors and scientists are all playing their roles to arrest infections due to this epidemic. Some industries are also working hard to meet the rapid production and supply of testing and personal protective equipment to combat the spread of the virus. In this challenging time, we are all looking to do everything we can to reduce the spread of infection, to pro tect ourselves and others, and this includes broadening the avail

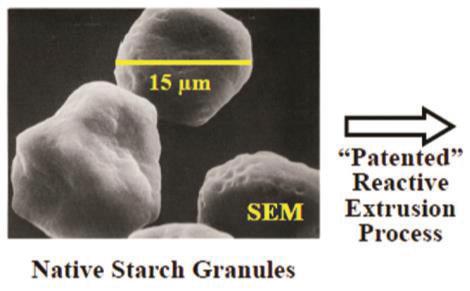

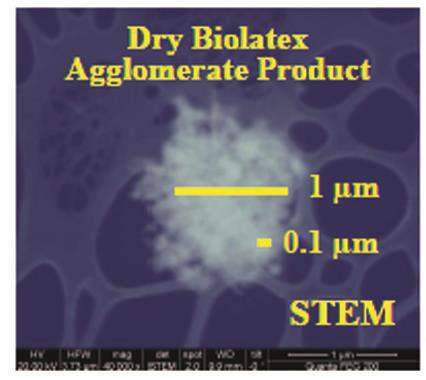

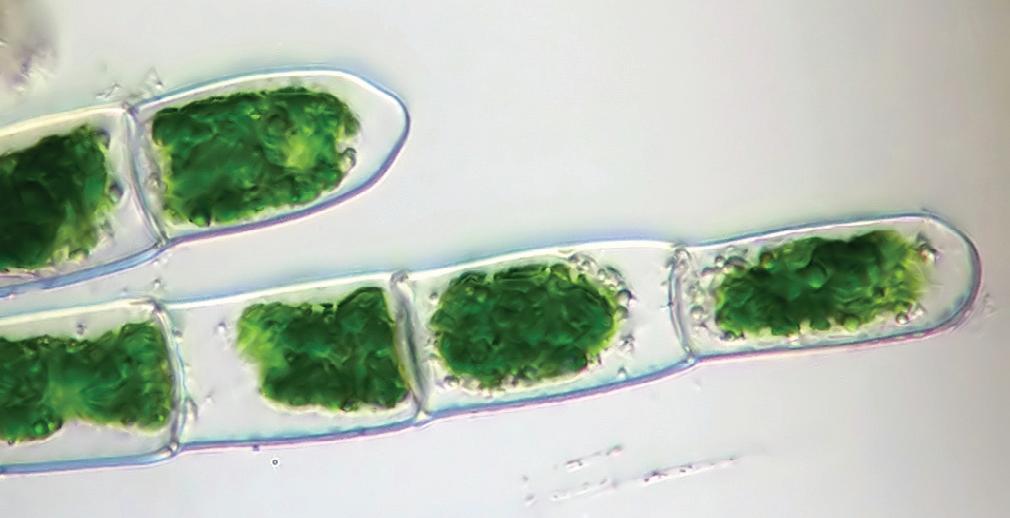

ability of antimicrobial papers to all sectors.